Preparation method of cobalt electro-catalysis oxygen reduction material wrapping nitrogen-doped carbon nanotube

A nitrogen-doped carbon and nanotube technology, applied in the fields of materials and energy, can solve the problems of reduced catalytic activity and poor stability, and achieve the effects of high product purity, improved performance, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

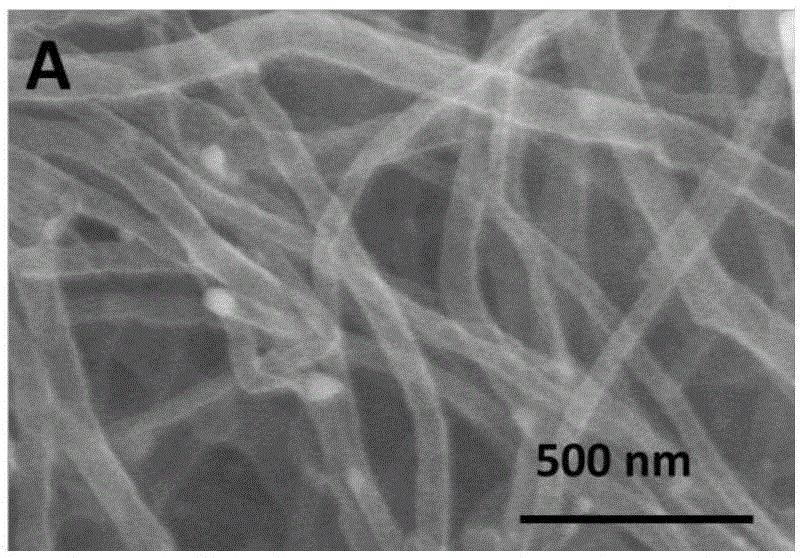

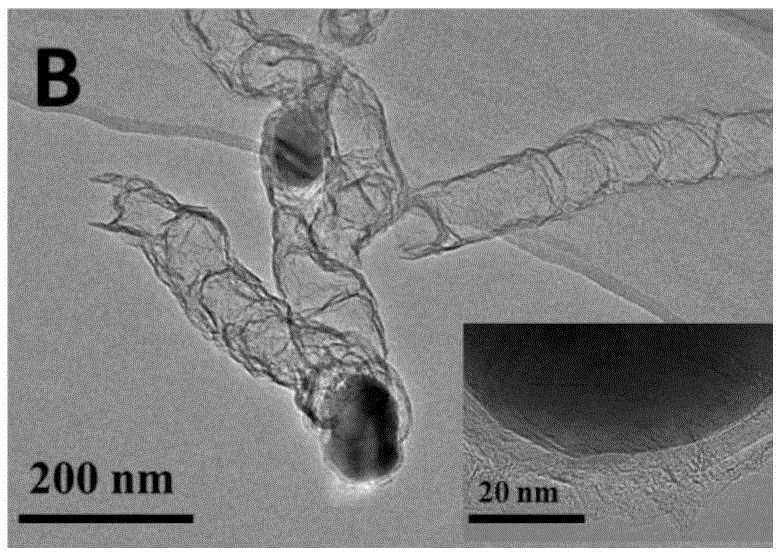

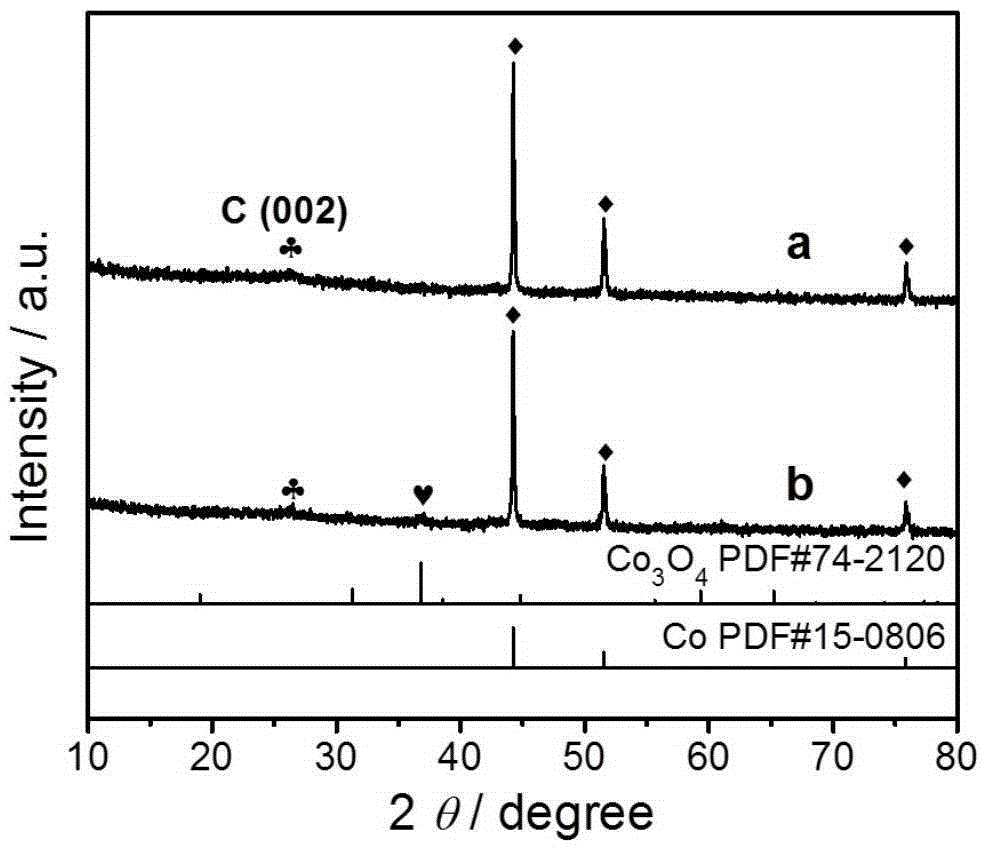

[0039] A method for preparing a nitrogen-doped carbon nanotube-wrapped cobalt electrocatalytic oxygen reduction material, comprising the following steps:

[0040] 1) Preparation of self-assembled melamine precursor: Weigh 9 mmol each of melamine and cobalt nitrate hexahydrate, 6 mmol of glucose, add 10 ml of water, after stirring evenly, adjust the pH to 2.5 with 1M hydrochloric acid, and continue stirring for 30 min. The product was centrifuged at 6000r / min, and the supernatant was removed and freeze-dried for use. The resulting product was pink in shape as a rod-like structure 4-10 μm long.

[0041] 2) Preparation of nitrogen-doped carbon nanotube-wrapped cobalt electrocatalytic oxygen reduction catalysts (Co-N-CNTs): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, and raise the temperature to 550 °C under an argon atmosphere. ℃ for 3h, then continue to heat up to 900°C for 3h, the heating rate is 5°C / min, the roasted product will be mixed...

Embodiment 2

[0052] A method for preparing a nitrogen-doped carbon nanotube-wrapped cobalt electrocatalytic oxygen reduction material, comprising the following steps:

[0053] 1) Preparation of self-assembled melamine precursor: Weigh 9mmol melamine, 4.5mmol cobalt chloride hexahydrate and 3mmol glucose, add 10ml water, after stirring evenly, adjust the pH to 4 with 1M nitric acid, and continue stirring for 30min. The product was centrifuged at 6000r / min, and the supernatant was removed and freeze-dried for use.

[0054] 2) Preparation of nitrogen-doped carbon nanotube-wrapped cobalt nanoparticle hybrid material electrocatalytic oxygen reduction catalysts (Co-N-CNTs): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, argon Under the atmosphere, the temperature was raised to 550°C for 3h, and then the temperature was continued to 800°C for 3h, the heating rate was 2°C / min, and the obtained roasted product was mixed with 0.1MH 2 SO 4 Mix and stir for 1 h to...

Embodiment 3

[0056] A method for preparing a nitrogen-doped carbon nanotube-wrapped cobalt electrocatalytic oxygen reduction material, comprising the following steps:

[0057] 1) Preparation of self-assembled melamine precursor: Weigh 9mmol melamine, 18mmol cobalt acetate tetrahydrate and 9mmol glucose, add 10ml water, after stirring evenly, adjust the pH to 5 with 1M nitric acid, and continue stirring for 30min. The product was centrifuged at 6000r / min, and the supernatant was removed and freeze-dried for use.

[0058] 2) Preparation of nitrogen-doped carbon nanotube-wrapped cobalt nanoparticle hybrid material electrocatalytic oxygen reduction catalysts (Co-N-CNTs): put the self-assembled melamine precursor prepared in step 1) into a tube furnace, argon Under the atmosphere, the temperature was raised to 550 ° C for 3 h, and then the temperature was continued to 700 ° C for 3 h, the heating rate was 10 ° C / min, and the obtained roasted product was mixed with 0.1 MH 2 SO 4 Mix and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com