Carbon nitride photocatalytic material doped with heterogeneous elements and its preparation method and application

A technology of heterogeneous elements and catalytic materials, applied in chemical instruments and methods, physical/chemical process catalysts, non-metallic elements, etc., to achieve the effects of increasing porosity, simplifying the process, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

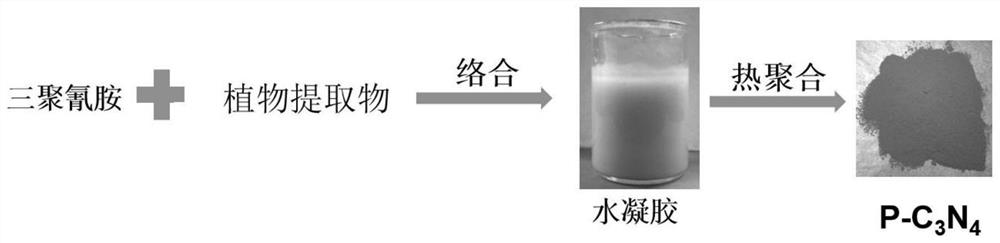

[0031] The first aspect of the present invention provides a method for preparing a carbon nitride photocatalytic material doped with heterogeneous elements, comprising the following steps:

[0032] (1) reacting the graphite-phase carbon nitride precursor and the plant extract in a solution to obtain a gel material, wherein the plant extract is a mixture containing phosphorus-containing compounds and inositol extracted from plants;

[0033] (2) Calcining the gel material by temperature programming under the protection of an inert gas to prepare a carbon nitride photocatalytic material doped with heterogeneous elements.

[0034] step 1)

[0035] Specifically, the graphitic carbon nitride precursor in step (1) of the present invention is generally a C-rich and N-rich compound, examples of which include but are not limited to melamine, dicyandiamide, cyanamide, thiourea and urea. The plant extract of the present invention is a mixture obtained by extracting plants as raw materi...

Embodiment 1

[0044] This embodiment is an exemplary extraction and detection process of plant extracts used in the preparation process of heterogeneous element-doped carbon nitride photocatalytic materials. The specific steps are as follows:

[0045] a. use sodium sulfate and acetic acid solution to soak the selected rapeseed meal to obtain the soaking liquid, and use a pH meter to adjust the pH value of the solution at 2.5;

[0046] b. filter the resulting soaking solution, then neutralize it with a 10% sodium hydroxide solution to obtain a neutralizing solution, and use a pH meter to adjust the pH value of the solution to 7.5;

[0047] c. Filtrating the neutralization solution to obtain a precipitate, and performing secondary acidification of the obtained precipitate with 1 mol / l hydrochloric acid, and using a pH meter to adjust the pH value of the solution to 1.5 to obtain a plant extract.

Embodiment 2

[0049] This embodiment is another exemplary extraction and detection process of the plant extract used in the preparation process of the heterogeneous element-doped carbon nitride photocatalytic material. The specific steps are as follows:

[0050] a. use sodium sulfate and acetic acid solution to soak the selected rapeseed meal to obtain the soaking liquid, and use a pH meter to adjust the pH value of the solution at 2.5;

[0051] b. filter the resulting soaking solution, then neutralize it with a solution containing 10% sodium hydroxide and 5% ammonium sulfate to obtain a neutralizing solution, and use a pH meter to adjust the pH value of the solution to 7.5;

[0052] c. Filtrating the neutralization solution to obtain a precipitate, and performing secondary acidification of the obtained precipitate with 1 mol / l hydrochloric acid, and using a pH meter to adjust the pH value of the solution to 1.5 to obtain a plant extract.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com