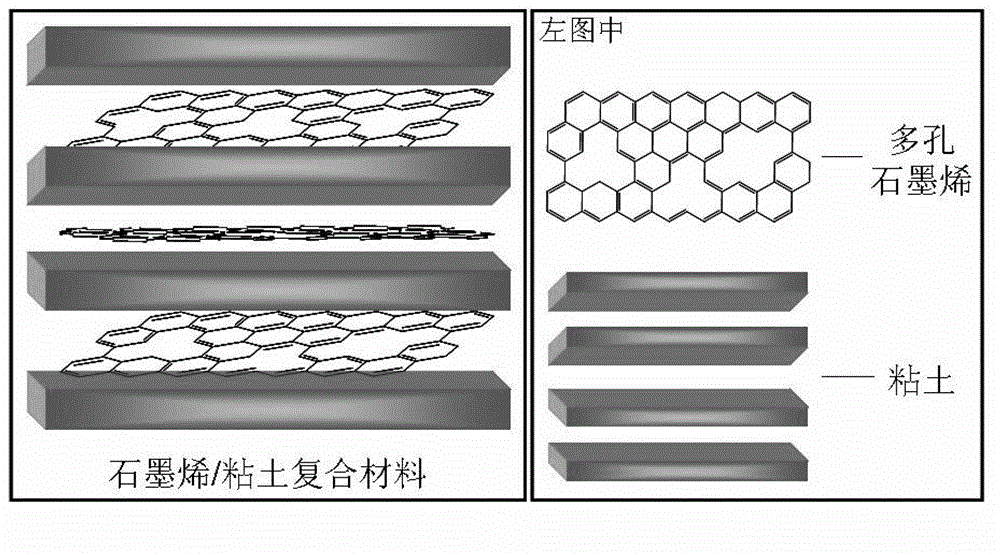

Graphene/clay composite material, and preparation method and application thereof

A composite material and graphene technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve problems such as research and application limitations, easy agglomeration, etc., to achieve improved adsorption performance, good dispersion, and reduced small reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

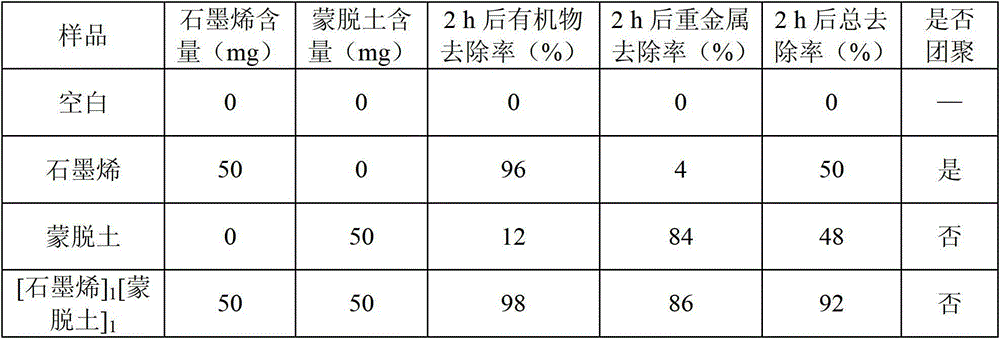

Examples

Embodiment 1

[0045] (1) Add 1g of graphite powder (Tianjin Kemiou Chemical Reagent Co., Ltd.) into 25mL of 98wt% concentrated sulfuric acid, cool to 0°C in an ice-salt bath, and slowly add 2.5g of KMnO 4 , then heated up to 30°C, stirred at 20rpm for 6h, added 200mL of water after the reaction, and then added 2mL of 30wt% hydrogen peroxide to react until the solution was bright yellow, centrifuged at 600rpm, washed with water, and put the obtained solid into 200mL of water. , treatment at a frequency of 40Hz for 2h, and then treatment at a microwave power of 700W and a frequency of 2KHz for 1h to obtain graphene oxide; adding 3g of NaOH, heating in a tube furnace at 760°C for 1h under nitrogen protection to obtain porous graphene; porous graphite The specific surface area of ene is 350m 2 / g, the weight loss at 900°C is 3wt%.

[0046] (2) Add 1g of the porous graphene prepared in step (1) to 100mL of ethanol (chemically pure, 99v / v%), disperse for 0.5h at an ultrasonic power of 300W, an...

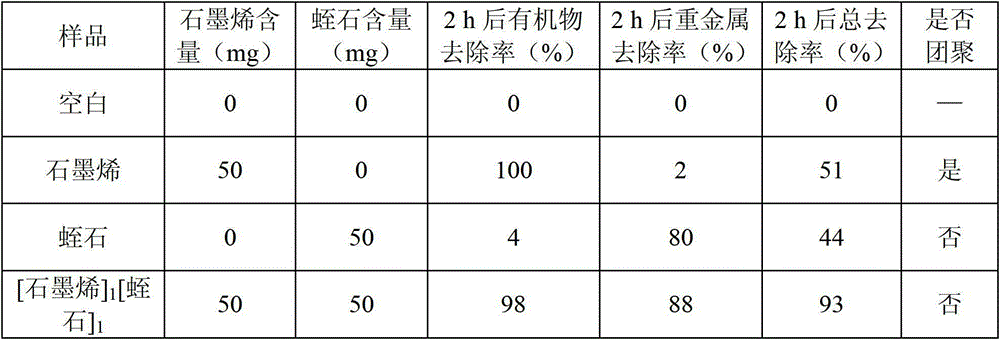

Embodiment 2

[0048] (1) Add 1g of graphite powder (Tianjin Kemiou Chemical Reagent Co., Ltd.) into 25mL of 98wt% concentrated sulfuric acid, cool to 0°C in an ice-salt bath, and slowly add 3g of KMnO 4 , then heated up to 60°C, stirred at 30rpm for 5h, added 200mL of water after the reaction, and then added 3mL of 30wt% hydrogen peroxide to react until the solution was bright yellow, centrifuged at 800rpm, washed with water, and put the obtained solid into 200mL of water. 1 h at a frequency of 40 Hz, then 1.2 h at a microwave power of 700 W and a frequency of 2 KHz to obtain graphene oxide; add 4 g of KOH, and heat at 760 ° C in a tube furnace for 2 h under nitrogen protection to obtain porous graphene; porous The specific surface area of graphene is 370m 2 / g, the weight loss at 900°C is 6wt%.

[0049] (2) Add 1g of the porous graphene prepared in step (1) into 100mL of water, disperse for 0.4h at an ultrasonic power of 300W and a frequency of 40Hz, then add 1g of vermiculite, heat to ...

Embodiment 3

[0051] (1) Add 1g of graphite powder (Tianjin Kemiou Chemical Reagent Co., Ltd.) into 25mL of 98wt% concentrated sulfuric acid, cool to 0°C in an ice-salt bath, and slowly add 2.5g of KMnO 4 , and then heated to 50°C, stirred at 40rpm for 4h, after the reaction was completed, 200mL of water was added, and then 2mL of 30wt% hydrogen peroxide was added to react until the solution was bright yellow. 1. Process at a frequency of 40 Hz for 2 hours, then process at a microwave power of 700 W and a frequency of 2 KHz for 1.4 hours to obtain graphene oxide, then add 5 g of NaOH, and heat in a tube furnace at 760 ° C for 1 hour under nitrogen protection to obtain porous graphene; The specific surface area of porous graphene is 390m 2 / g, the weight loss at 900°C is 5wt%.

[0052] (2) Add 1 g of the porous graphene prepared in step (1) to 100 mL of acetone (chemically pure, 99%), disperse for 0.3 h at an ultrasonic power of 300 W, and a frequency of 40 Hz, then add 1 g of illite, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com