Patents

Literature

1399 results about "Low temperature curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low Temperature Heat Cure Epoxy Adhesives. Low temperature heat curing one part epoxy systems are formulated to cure at temperatures from 175 to 210°F (80° to 100°C). These systems are well suited for bonding heat sensitive substrates and engineered to fit other application requirements, such as: Bonding similar/dissimilar substrates with CTE differences.

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

Modified epoxy resin composition, production process for the same and solvent-free coating comprising the same

InactiveUS6677426B2Satisfactory curabilityImprove mechanical propertiesEpoxy resin coatingsAcetoacetatesEpoxy

There is provided a modified epoxy resin composition including a reaction product of an epoxy resin and an alkyl-substituted acetoacetate and a reaction product of an alcohol having at least one hydroxyl group in one molecule and an alkyl-substituted acetoacetate; a production process for the same; and a solvent-free coating using the same. The composition provides a solvent-free epoxy resin composition which has a low viscosity and excellent low-temperature curability.

Owner:WESTLAKE EPOXY INC

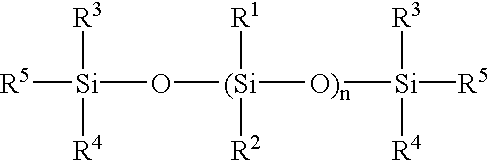

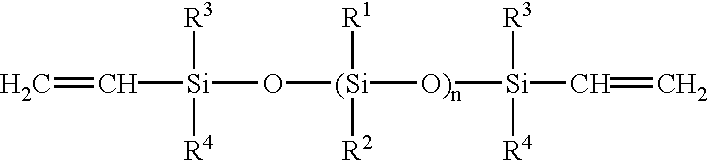

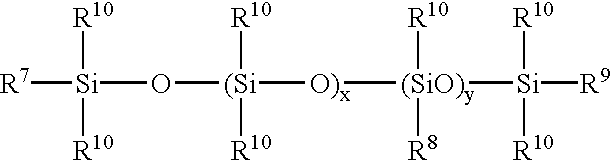

Low temperature, fast curing silicone compositions

InactiveUS6573328B2Low curing temperatureImproves of curedLayered productsSolid-state devicesPolymer sciencePtru catalyst

Heat-curable silicone compositions employing a reactive silicone, a silicone hydride crosslinker and a catalyst system which includes a rhodium-based catalyst, a stabilizing system are disclosed. A combination of rhodium and platinum-based catalysts are employed as well. The compositions are low temperature curing and are capable of providing low coefficient of thermal expansion compositions. A stabilizer system which includes in combination a peroxide and an acetylenic compound is also disclosed.

Owner:HENKEL LOCTITE CORP

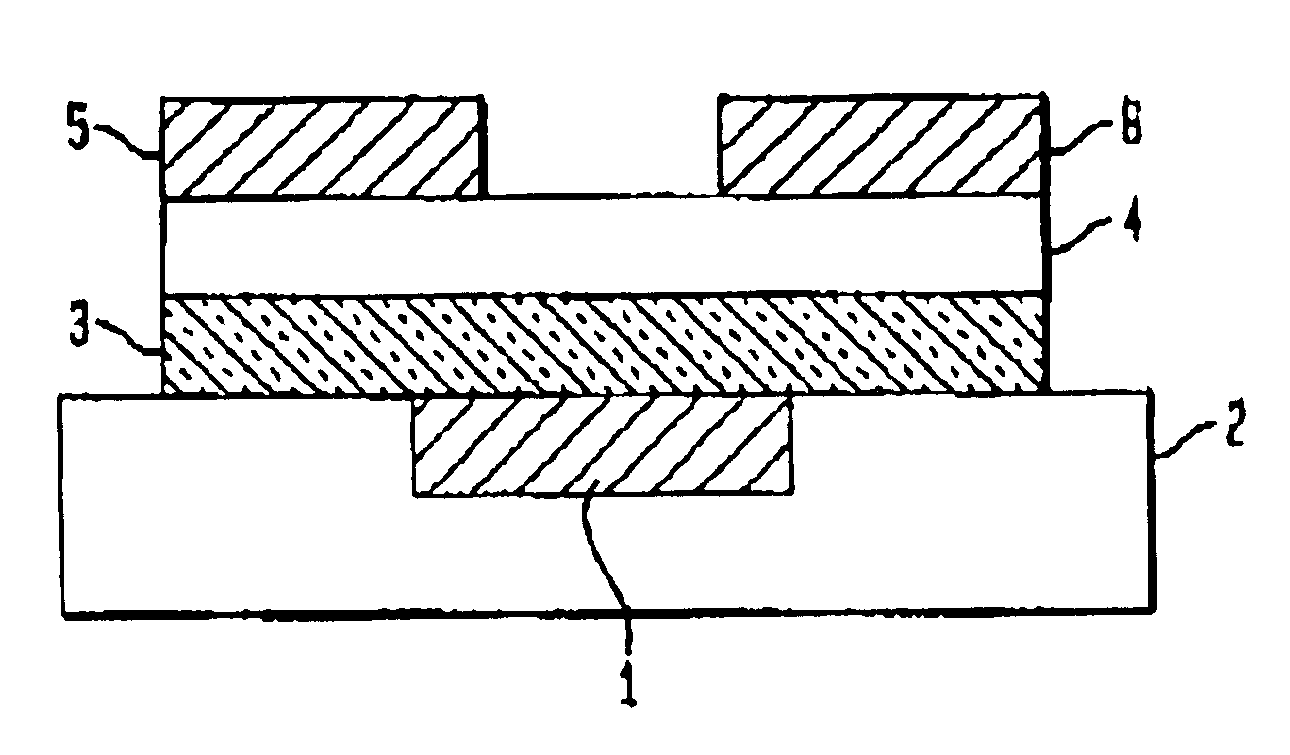

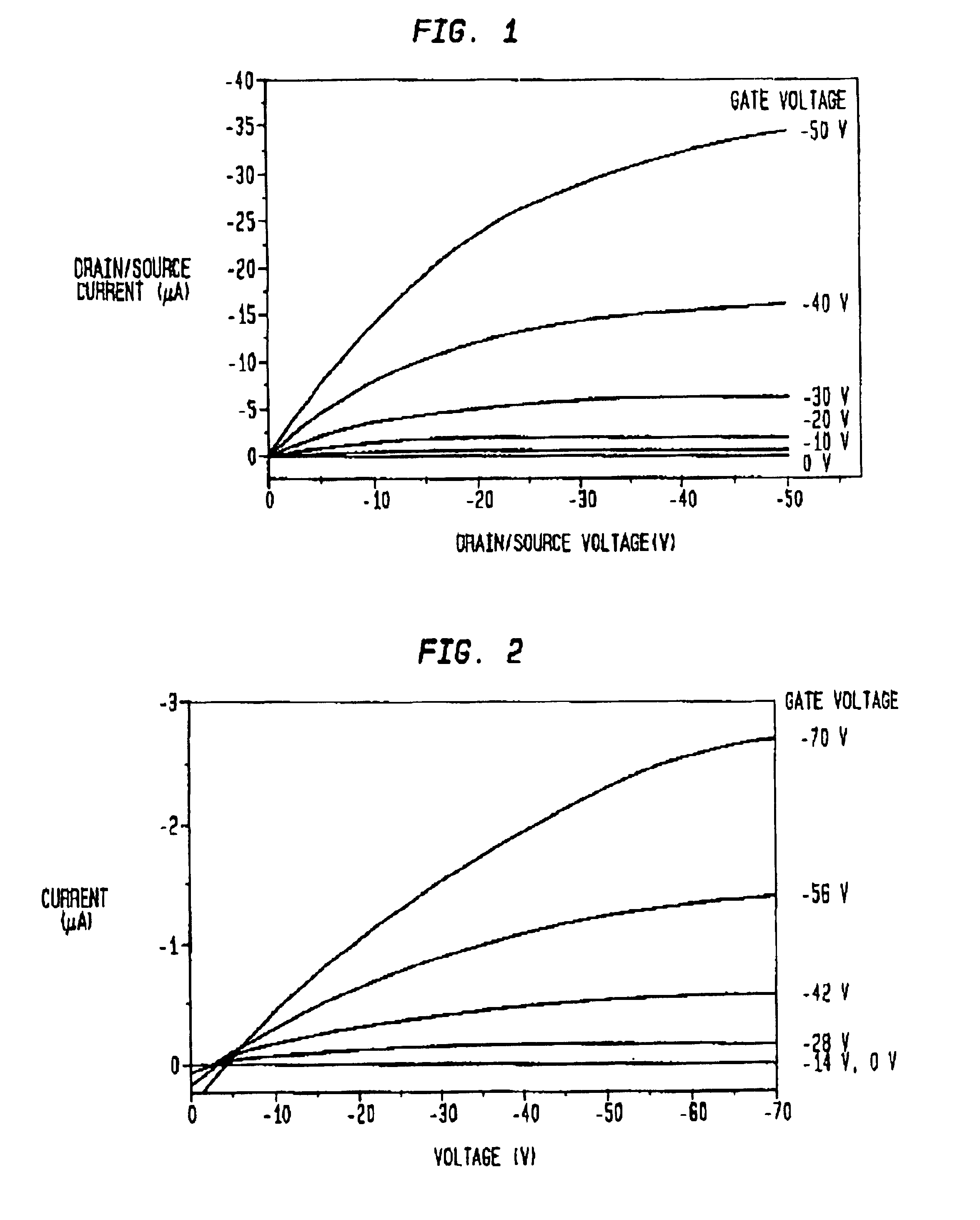

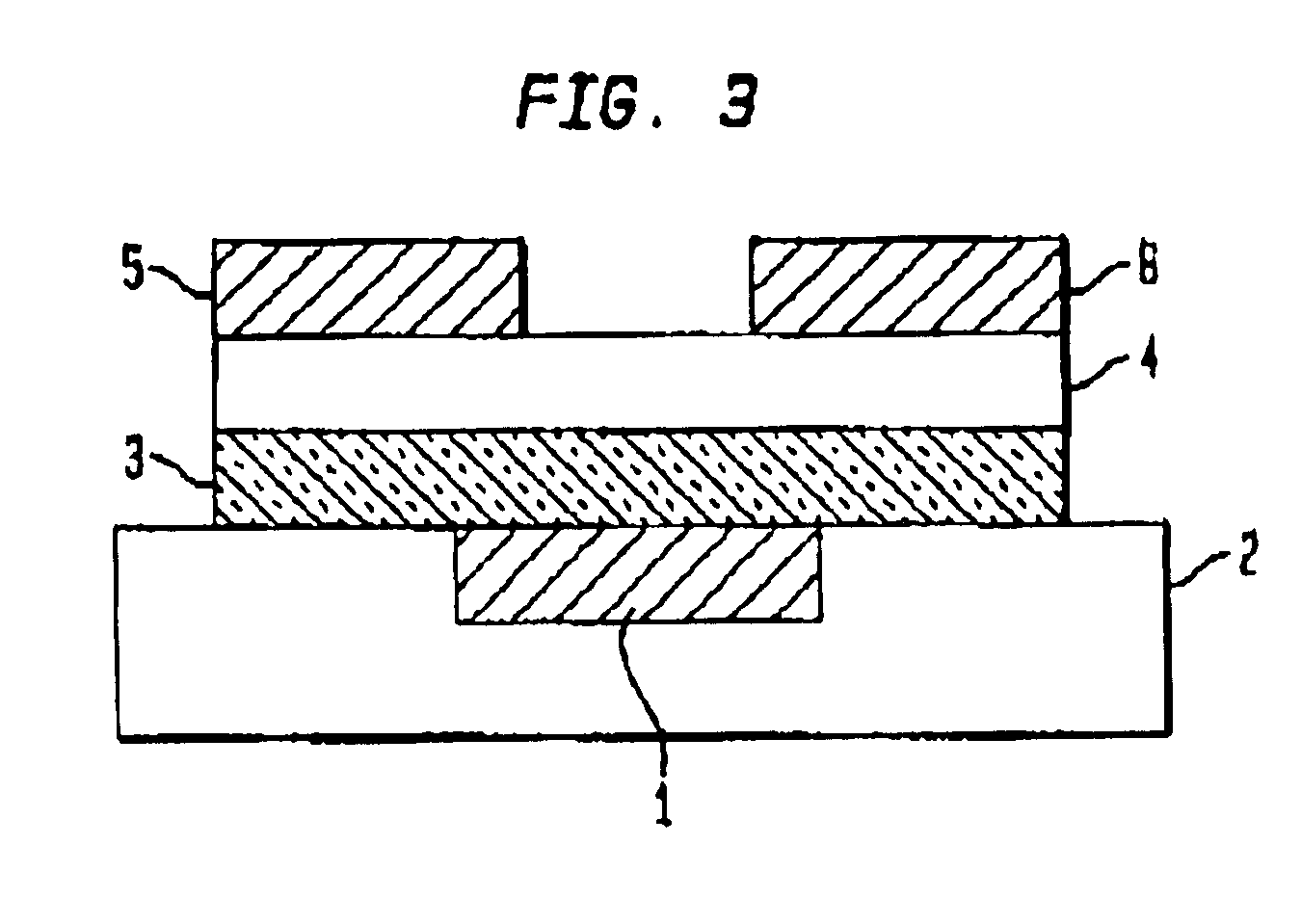

Organic semiconductor device having an active dielectric layer comprising silsesquioxanes

InactiveUS6891237B1Solid-state devicesPretreated surfacesOrganic field-effect transistorLow temperature curing

An organic field effect transistor (FET) is described with an active dielectric layer comprising a low-temperature cured dielectric film of a liquid-deposited silsesquioxane precursor. The dielectric film comprises a silsesquioxane having a dielectric constant of greater than 2. The silsesquioxane dielectric film is advantageously prepared by curing oligomers having alkyl(methyl) and / or alkyl(methyl) pendant groups. The invention also embraces a process for making an organic FET comprising providing a substrate suitable for an organic FET; applying a liquid-phase solution of silsesquioxane precursors over the surface of the substrate; and curing the solution to form a silsesquioxane active dielectric layer. The organic FET thus produced has a high-dielectric, silsesquioxane film with a dielectric constant of greater than about 2, and advantageously, the substrate comprises an indium-tin oxide coated plastic substrate.

Owner:ALCATEL-LUCENT USA INC +1

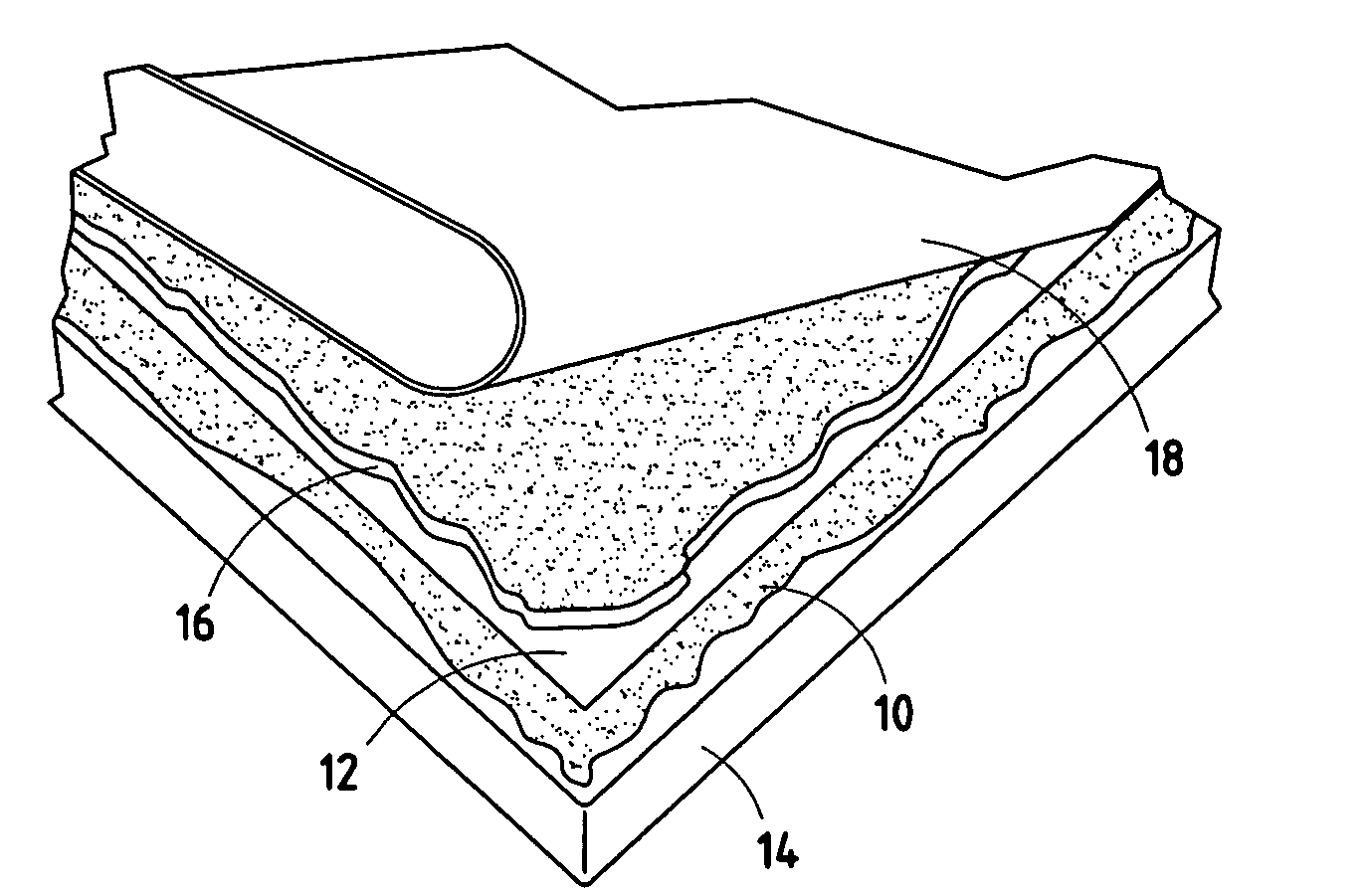

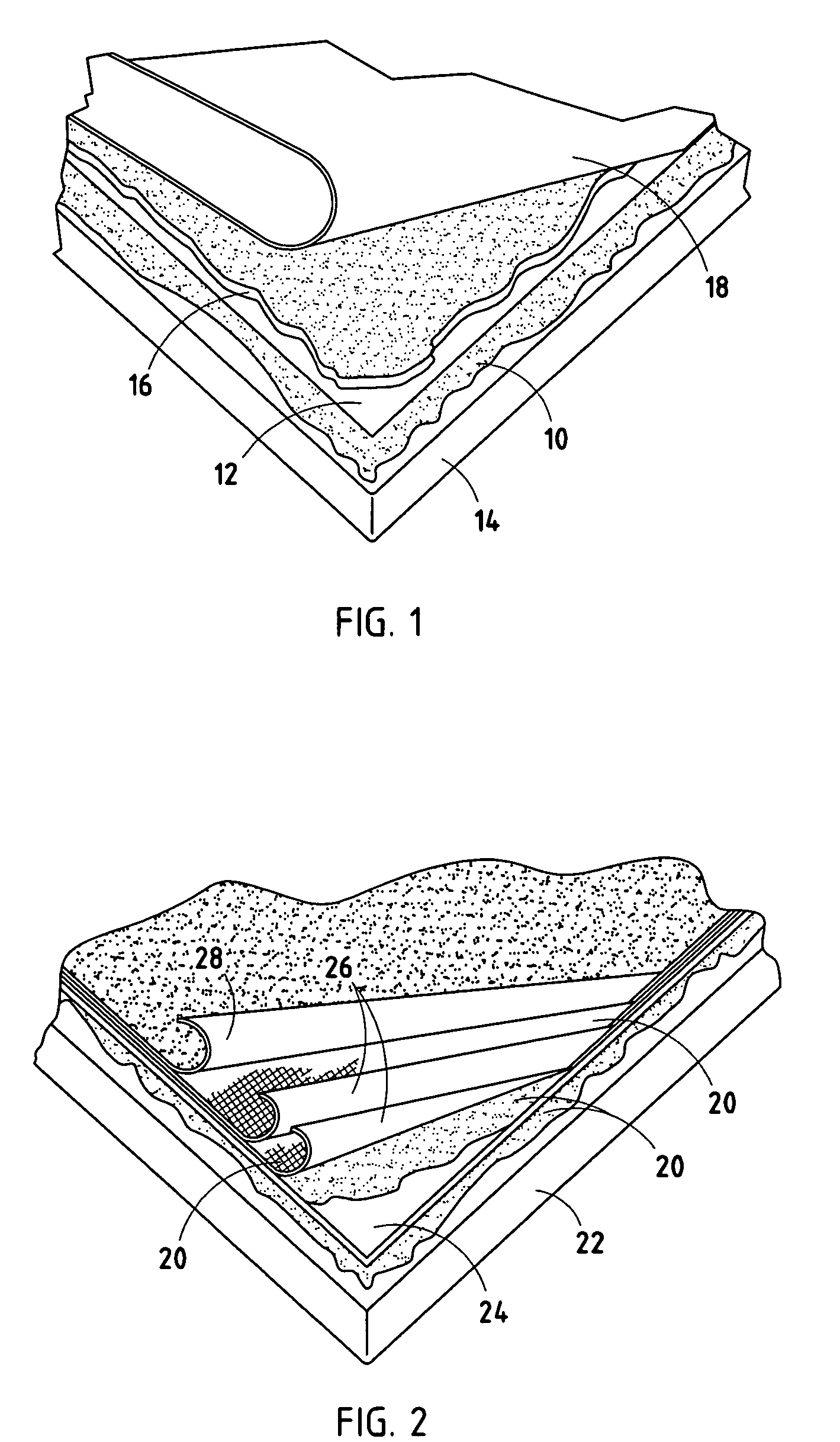

Fast line maintenance repair method and system for composite structures

InactiveUS20070095457A1Minimum skillQuick fixLighting and heating apparatusLayered productsAdhesiveRepair material

A fast line maintenance repair process for damaged composite structures includes the application of a pre-cured patch that uses a quick curing paste adhesive to bond the patch to the structure. The adhesive is cured at relatively low elevated temperatures provided by a chemical heat pack. The low temperature cure eliminates the need to dry out the part and permits the application of the repair in a hazardous environment. In a typical commercial airline application, airline maintenance personnel can install the repair at the flight gate. The repair is intended to restore the structure to a desired load capability in approximately one hour. The repair can be removed if need be with less overall damage than would occur upon removal of typical mechanically fastened repairs. All or some of the repair materials and tools can be provided in a portable kit.

Owner:THE BOEING CO

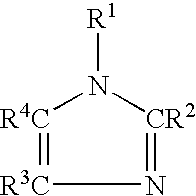

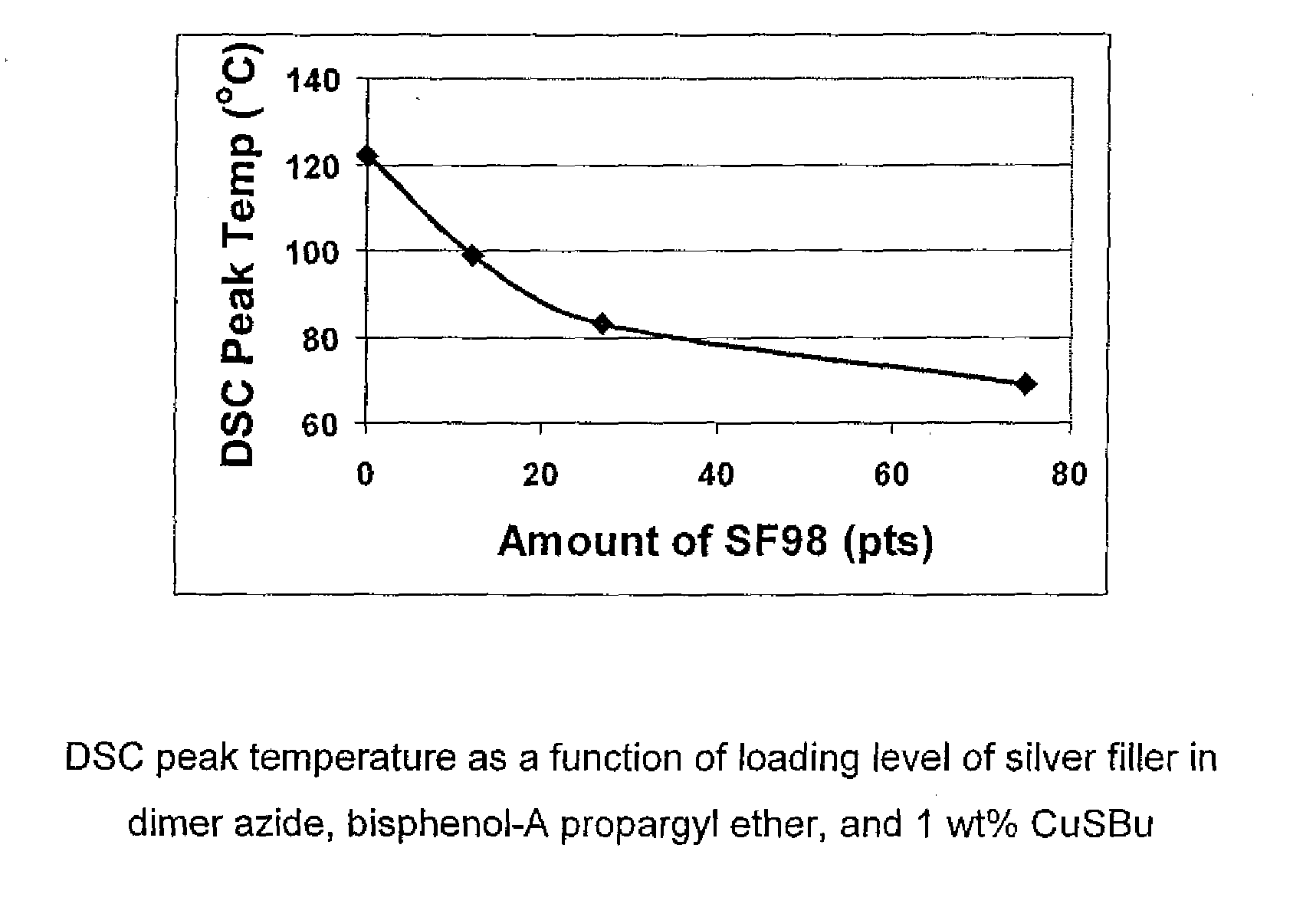

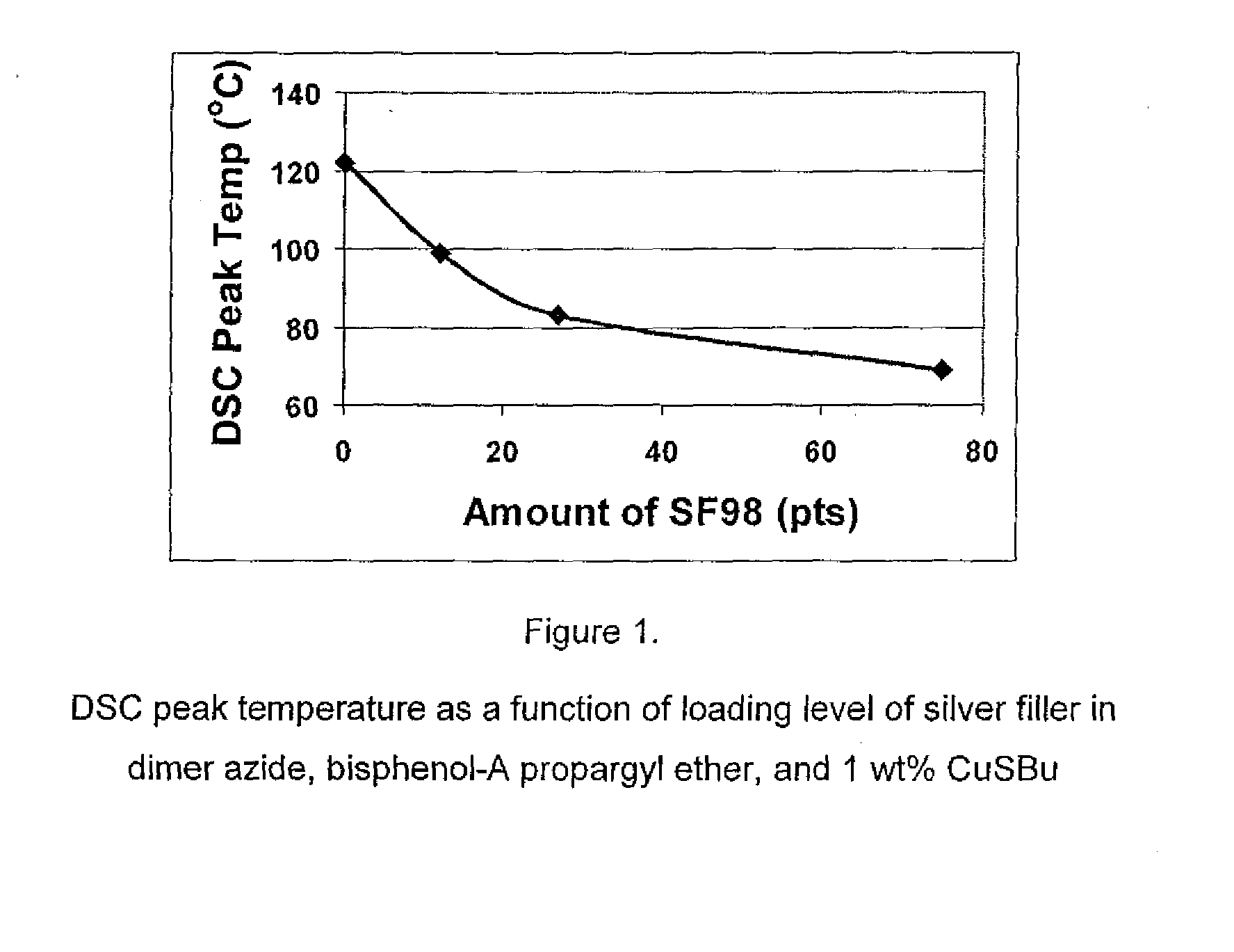

1,3-dipolar cycloaddition of azides to alkynes

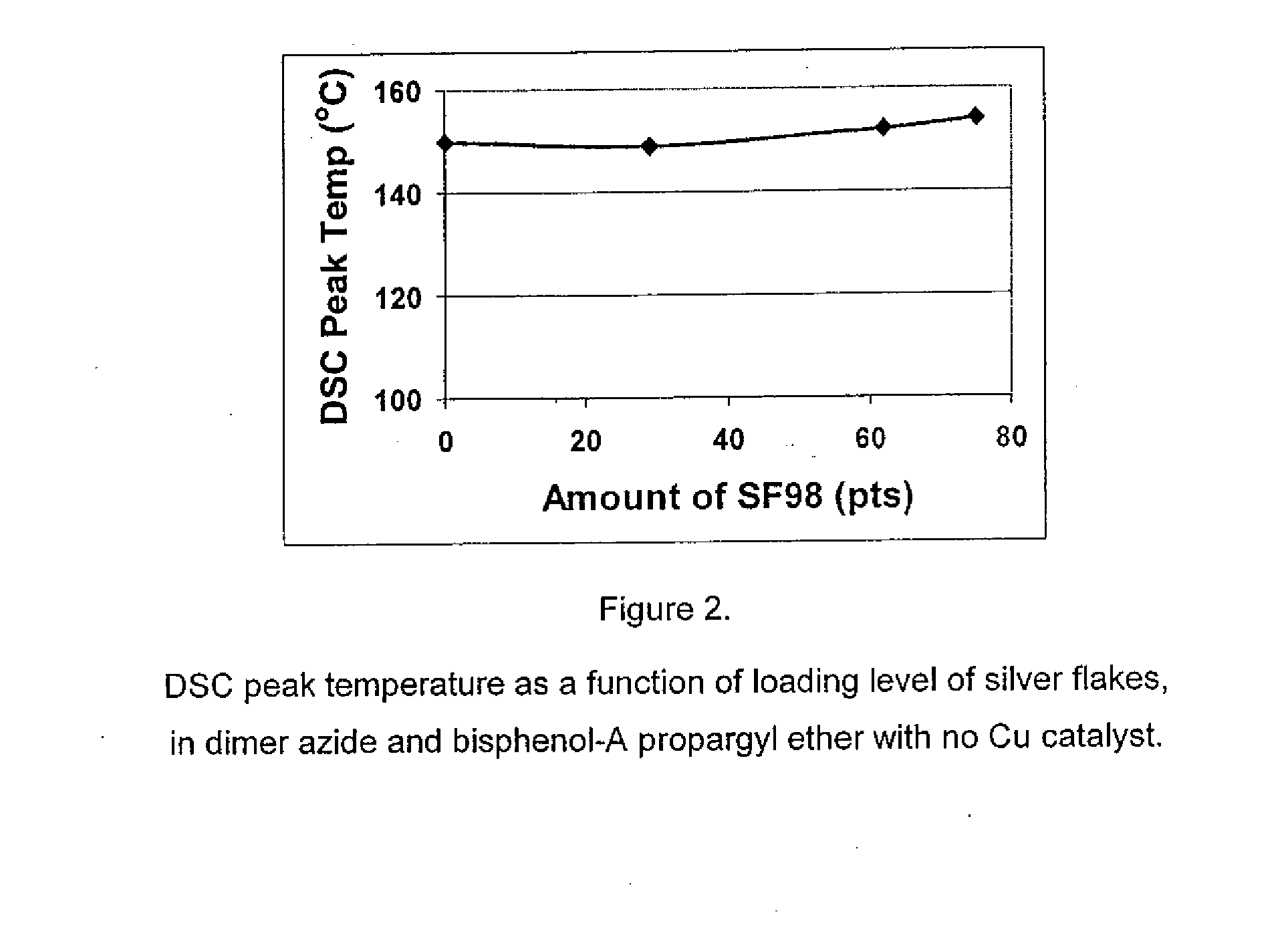

InactiveUS20100121022A1Decreased DSC peak temperatureIncrease loadAdhesivesOligomer1,3-Dipolar cycloaddition

Owner:HENKEL KGAA

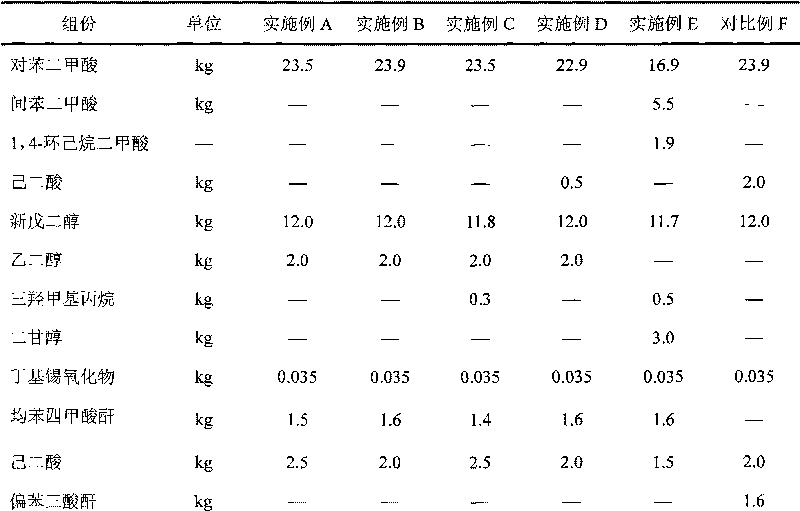

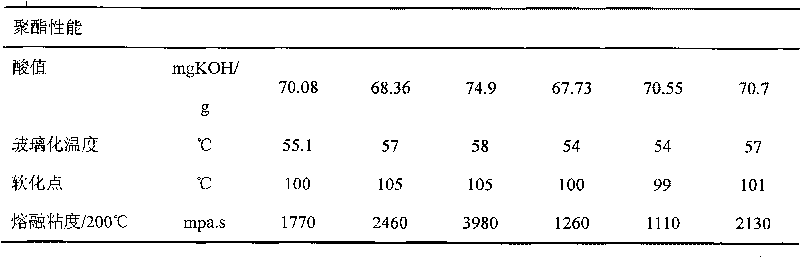

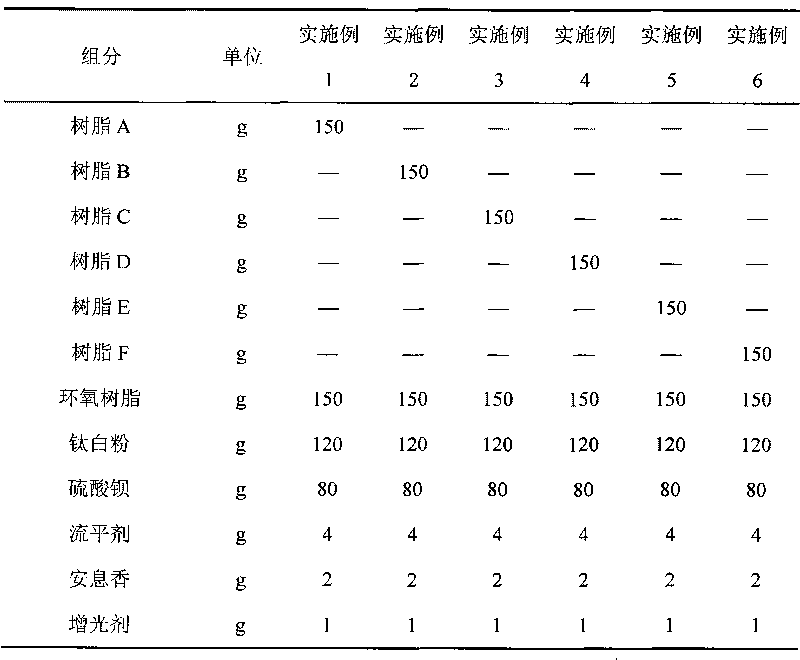

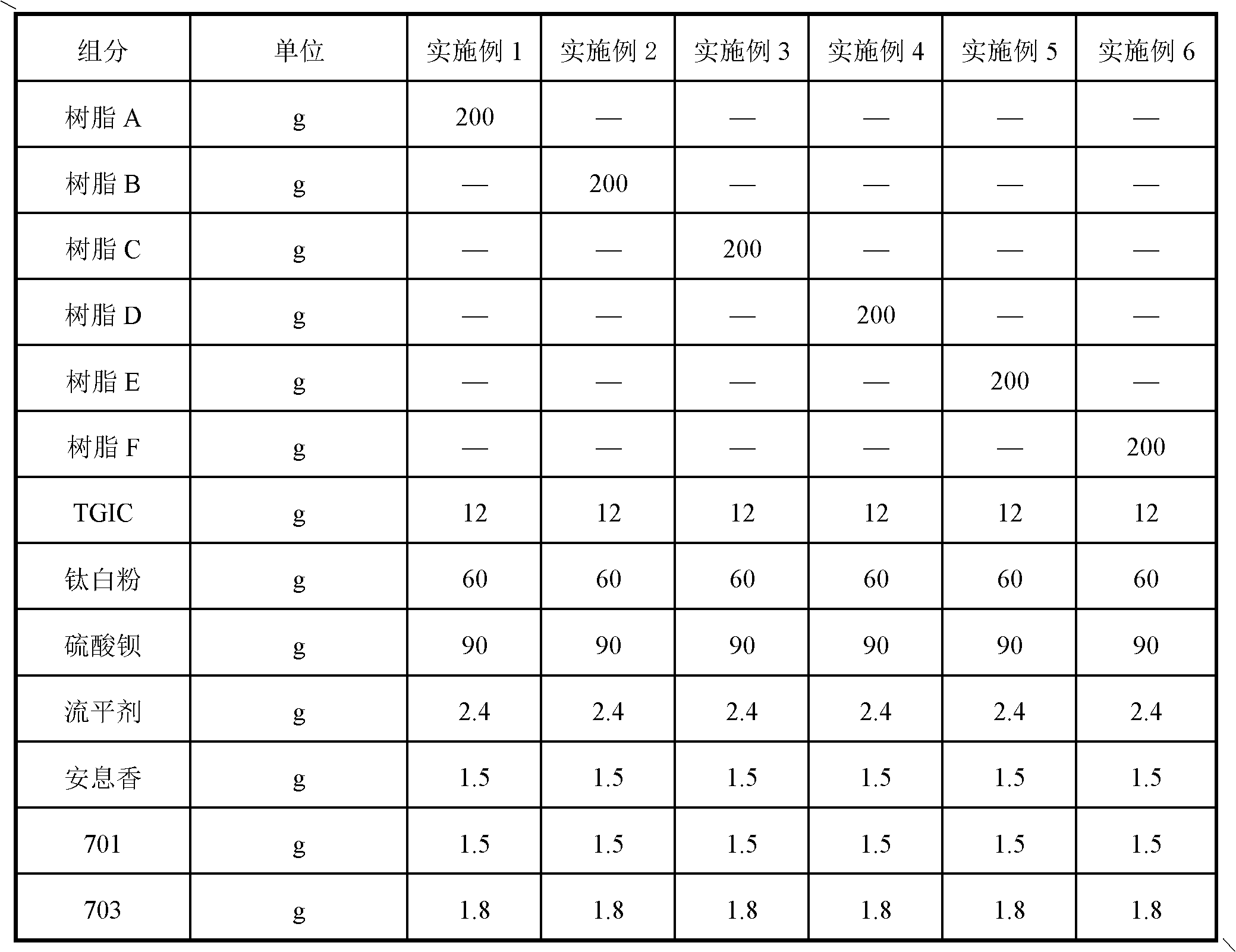

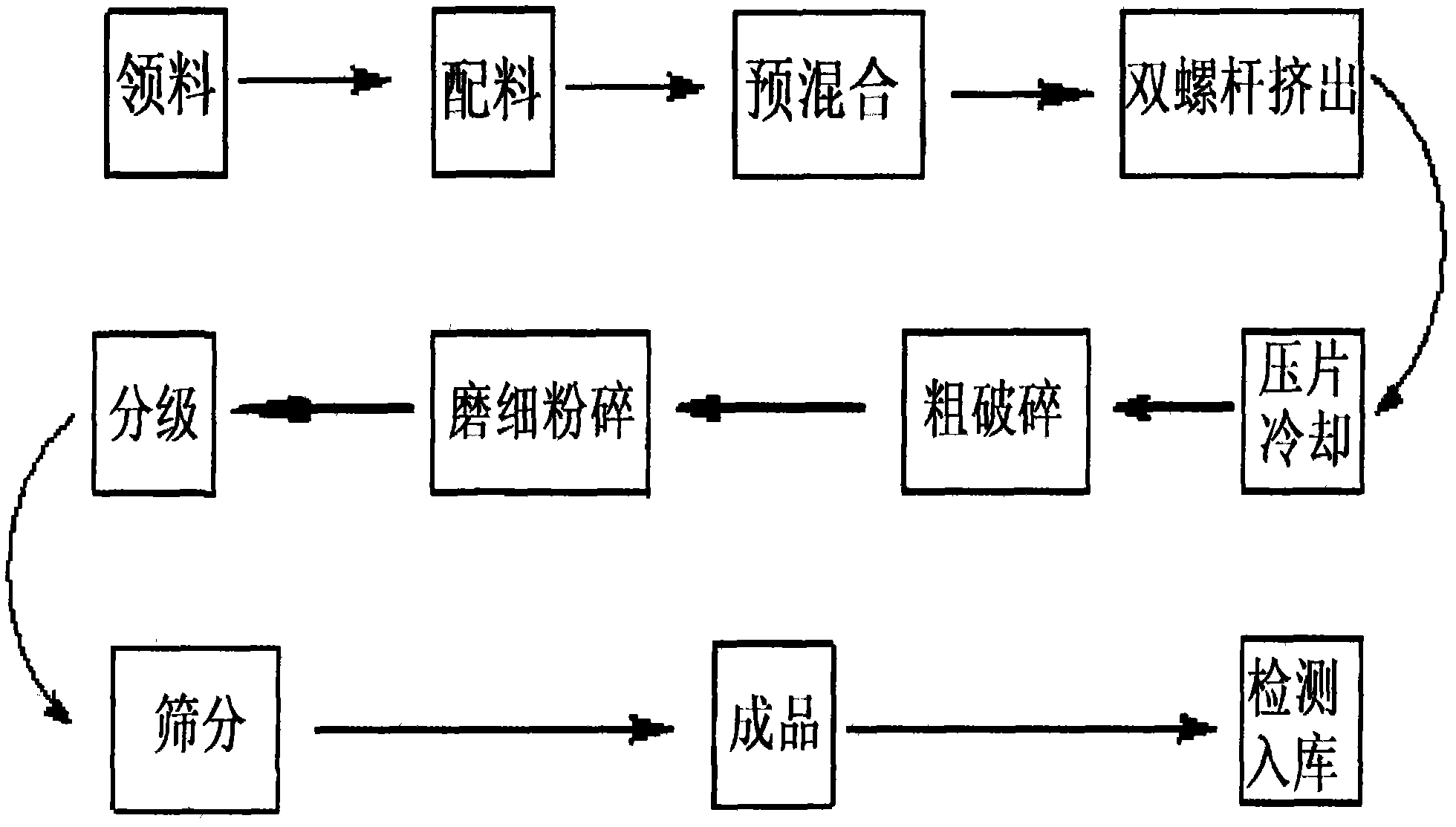

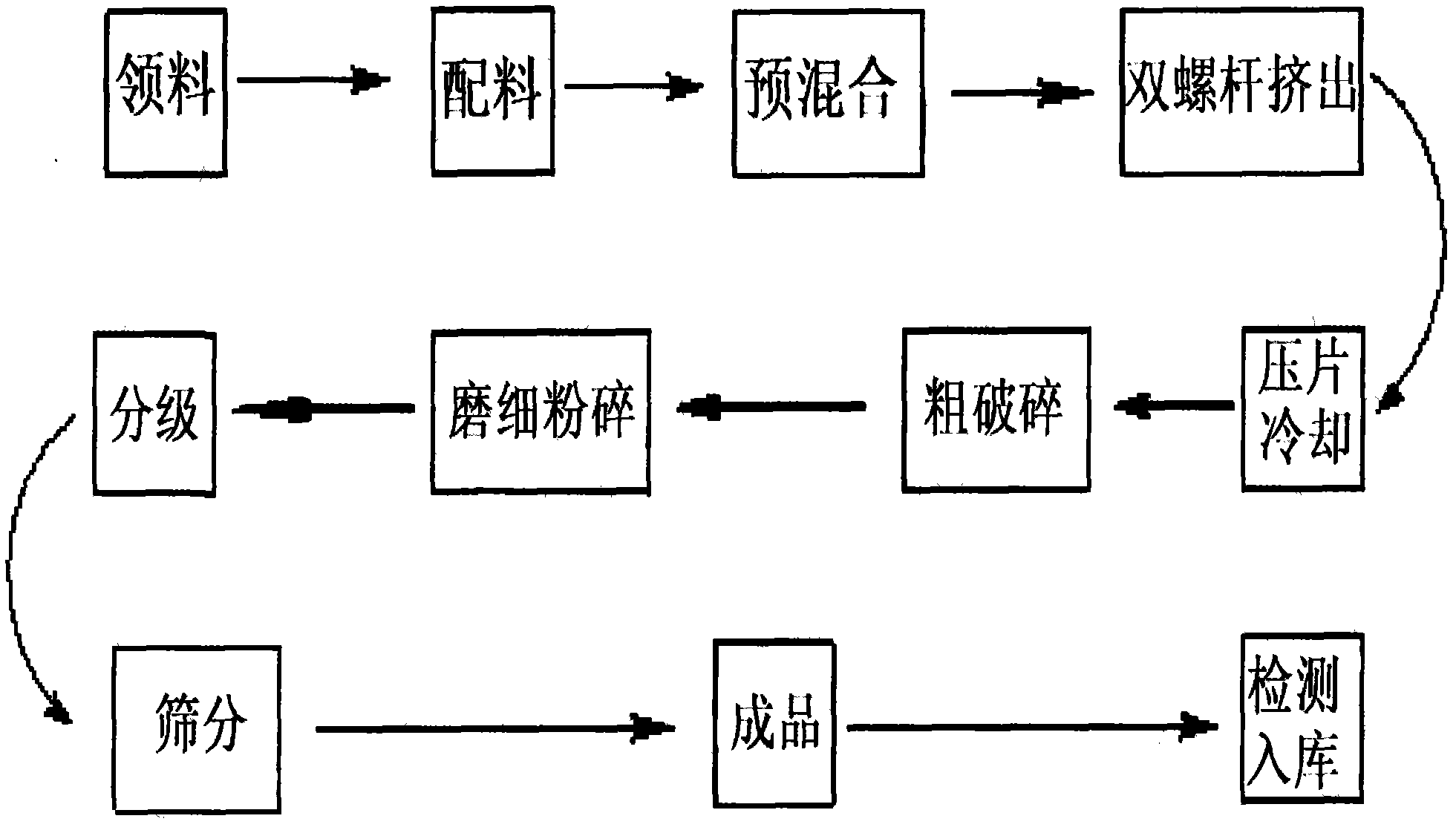

Low-temperature cured terminal carboxyl polyester resin for mixed powder coating and preparation method thereof

ActiveCN101735432ASuitable glass transition temperatureGood storage stabilityPowdery paintsEpoxy resin coatingsHybrid typeEpoxy

The invention discloses a low-temperature cured terminal carboxyl polyester resin for mixed powder coating. The polyester resin is prepared by performing melt polycondensation reaction on the following components in percentage by weight: 25 to 45 percent of polyalcohol, 35 to 65 percent of aromatic polyatomic acid, 0 to 10 percent of fat polyatomic acid, 0 to 2 percent of branching agent, 6 to 15 percent of acid hydrolysis agent, and 0.01 to 0.15 percent of esterification catalyst. The invention also discloses a method for preparing the low-temperature cured terminal carboxyl polyester resin. The prepared polyester resin has the characteristics of proper glass-transition temperature, softening point, good storage stability, and the like; the polyester resin, epoxy resin, filler and assistant in a certain proportion are mixed, and the mixture is prepared into powder through melt extrusion mixing, cooling, crushing and sieving; and the prepared powder can be cured at the temperature of 160 DEG C, and has the advantages of excellent leveling performance, good impact performance, and the like.

Owner:GUANGZHOU KINTE IND

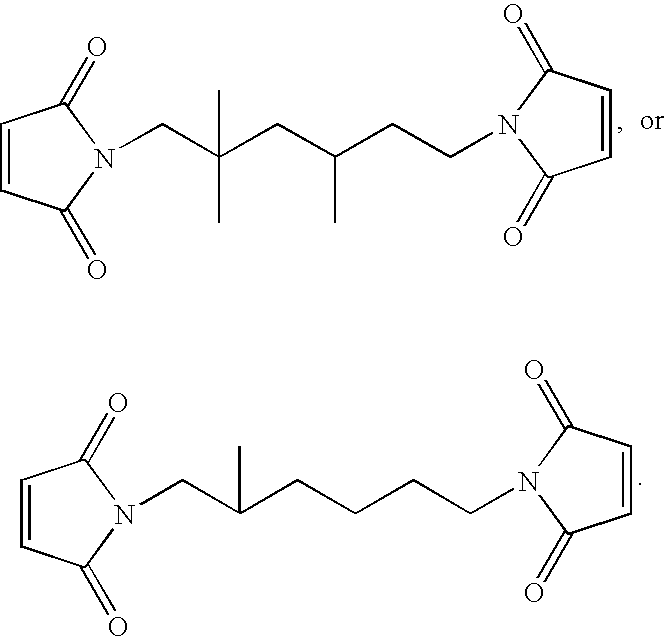

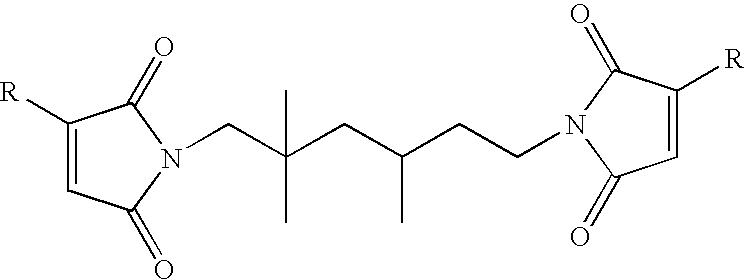

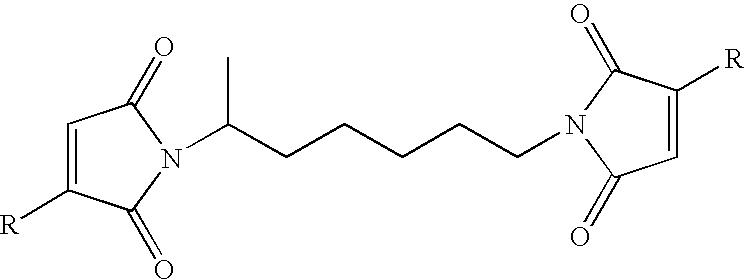

Low temperature curing acrylate and maleimide based formulations and methods for use thereof

ActiveUS20100063184A1Non-fibrous pulp additionFilm/foil adhesivesLow temperature curingElectronic packaging

The present invention is based on the discovery that certain electron poor olefins combined with nucleophiles and a base catalyst are useful as adhesive compositions for the electronic packaging industry. In particular, the adhesive formulations set forth herein are useful as low temperature curing formulations with high adhesion to a variety of substrates. Invention formulations typically cure at about 80° C. and have a potlife of about 24 hours. The formulations cure by the well-known Michael addition reaction.

Owner:DESIGNER MOLECULES

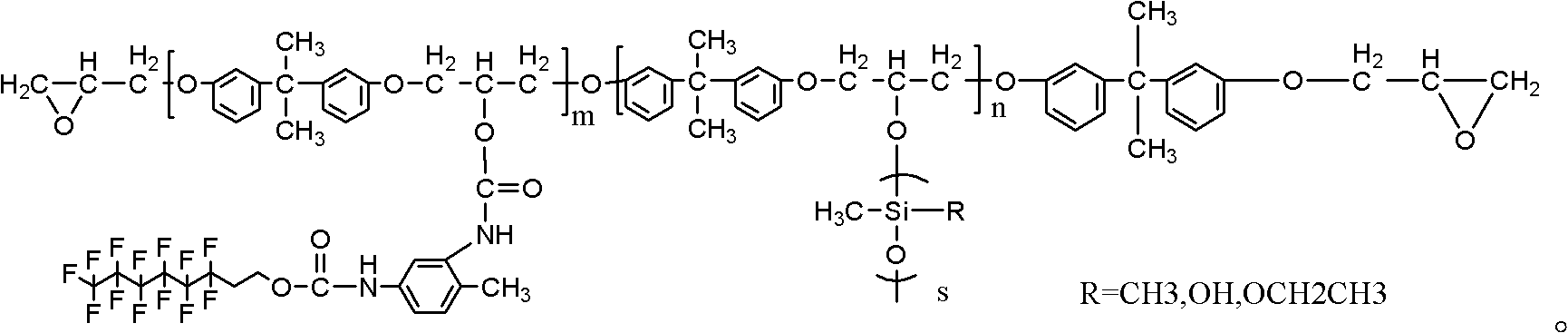

Low temperature curing high temperature resistant inorganic / organic hybridization epoxy adhesive and preparation thereof

InactiveCN101440268AImprove brittlenessImprove high temperature heat aging resistanceInorganic adhesivesEpoxy resin adhesivesCouplingLow temperature curing

The invention discloses a low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive and a preparation method thereof, which relate to an inorganic / organic hybrid epoxy adhesive and a preparation method thereof. The invention solves the problems that inorganic / organic hybrid epoxy adhesive prepared by the prior art has poor high-temperature thermal aging resistance and needs high curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive is prepared by an epoxy resin, an epoxy resin low-temperature curing agent, a coupling agent, an inorganic active hybrid material and a dispersant. The preparation method comprises the following steps: the epoxy resin, the epoxy resin low-temperature curing agent and the coupling agent are mixed and stirred evenly, and then the inorganic active hybrid material and the dispersant are added into the mixture to be stirred evenly to obtain the low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has high high-temperature bonding strength, good high-temperature thermal aging performance and low curing temperature. The low-temperature curing high temperature-resistant inorganic / organic hybrid epoxy adhesive has the advantages of simple production technology, convenient operation and broad application.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

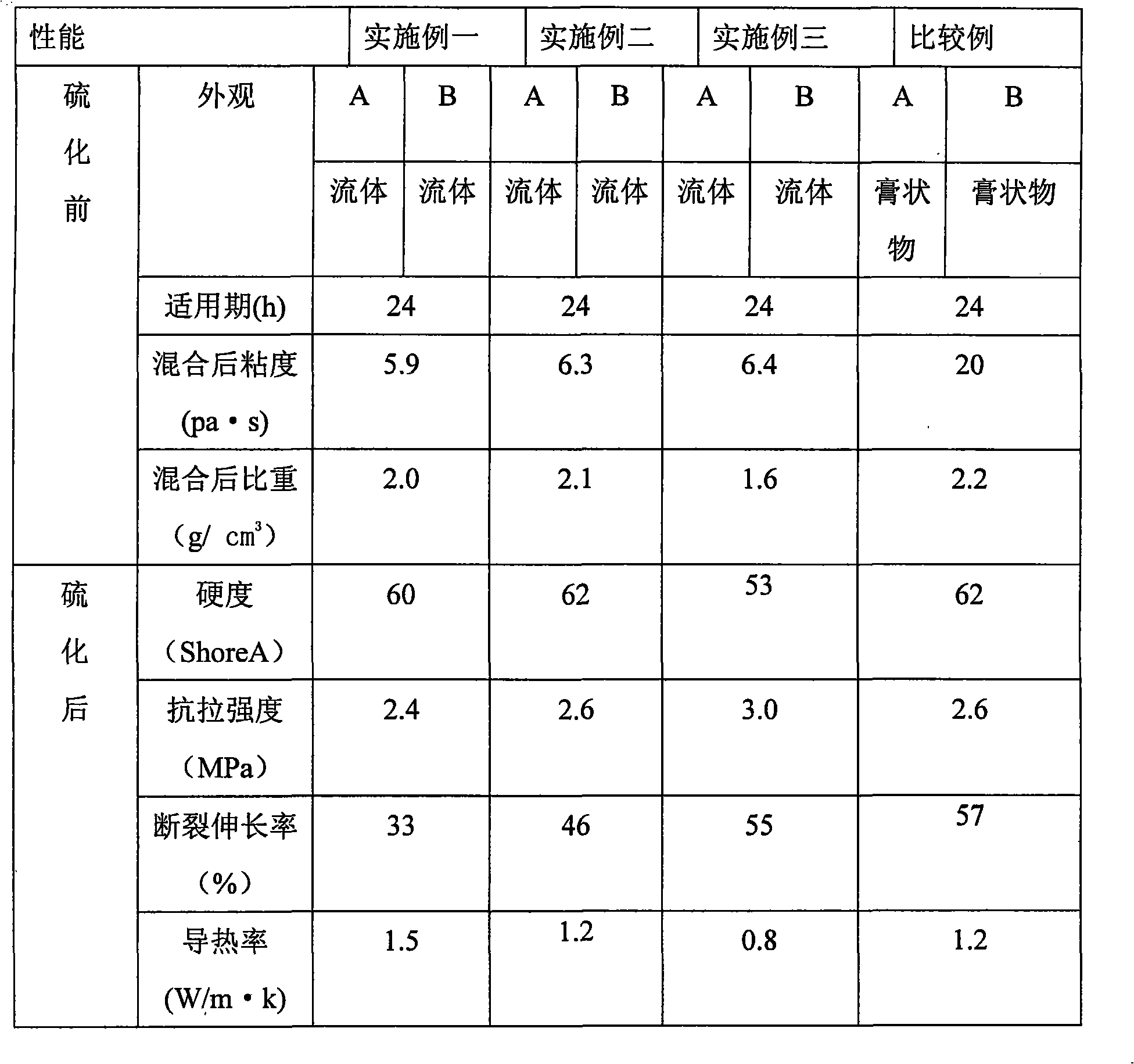

Addition type heat conducting silicon rubber and manufacturing method thereof

Owner:CHENGDU GUIBAO SCI & TECH

Polyurethane resin mortar for cement base material repairing

The invention relates to a polyurethane resin mortar composition for cement base material repairing, which comprises raw materials A, B and C, wherein the raw material A comprises the following materials in parts by weight: 100 parts of polyalcohol, 5-60 parts of plasticizer, 0.01-3 parts of catalyst, 0-2 parts of defoaming agent, 0-30 parts of chain extender or crosslinking agent, 0-3 parts of coupling agent and 0-10 parts of stabilizer; the raw material B is isocyanate or prepolymer thereof; the raw material C is solid filler; and the mass ratio of the three raw materials A, B and C is 10:(1-30):(10-200). The composition is used as the repairing material for concrete structures of ballastless tracks and cement asphalt mortar, and has the advantages of high curing speed, good low-temperature curing property, high ductility and the like.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +2

Method of preparing low temperature solidifying environment protection type cathode electrophoresis coating

InactiveCN101054487AImprove stabilityLow curing temperaturePaints for electrolytic applicationsPolyamide coatingsEpoxyLow temperature curing

The invention discloses an environment-friendly cathode electrophoretic coating with a low heating loss and low solvent content which can be cold cured. The method includes following steps and craft conditions: (1) preparation of curing agent and modification of mainbody resin. The curing agent is prepared by reaction of isocyanate, ketoximes solvent and trimethylolpropane so as to produce multifunctional group for closing the isocyanate curing agent. The whole reaction of mainbody resin modification includes chain extension reaction of epoxide resin, ring-opening reaction of amine and polyamide to the epoxide resin, the preparation of semi enclosed isocyanate and grafting reaction steps; (2) preparation of the catalytic curing agent slurry; (3) preparation of cathode electrophoretic coating latex and color paste. The invention improves the epoxide resin stability, reduces the resin curing temperature, and declines the heating loss of the dope and the discharge of the solvent. It applies extracting method in the latex producing process to reduce the solvent content so as to produce a environment-friendly cathode electrophoretic coating which can be cold cured.

Owner:佛山科富科技有限公司

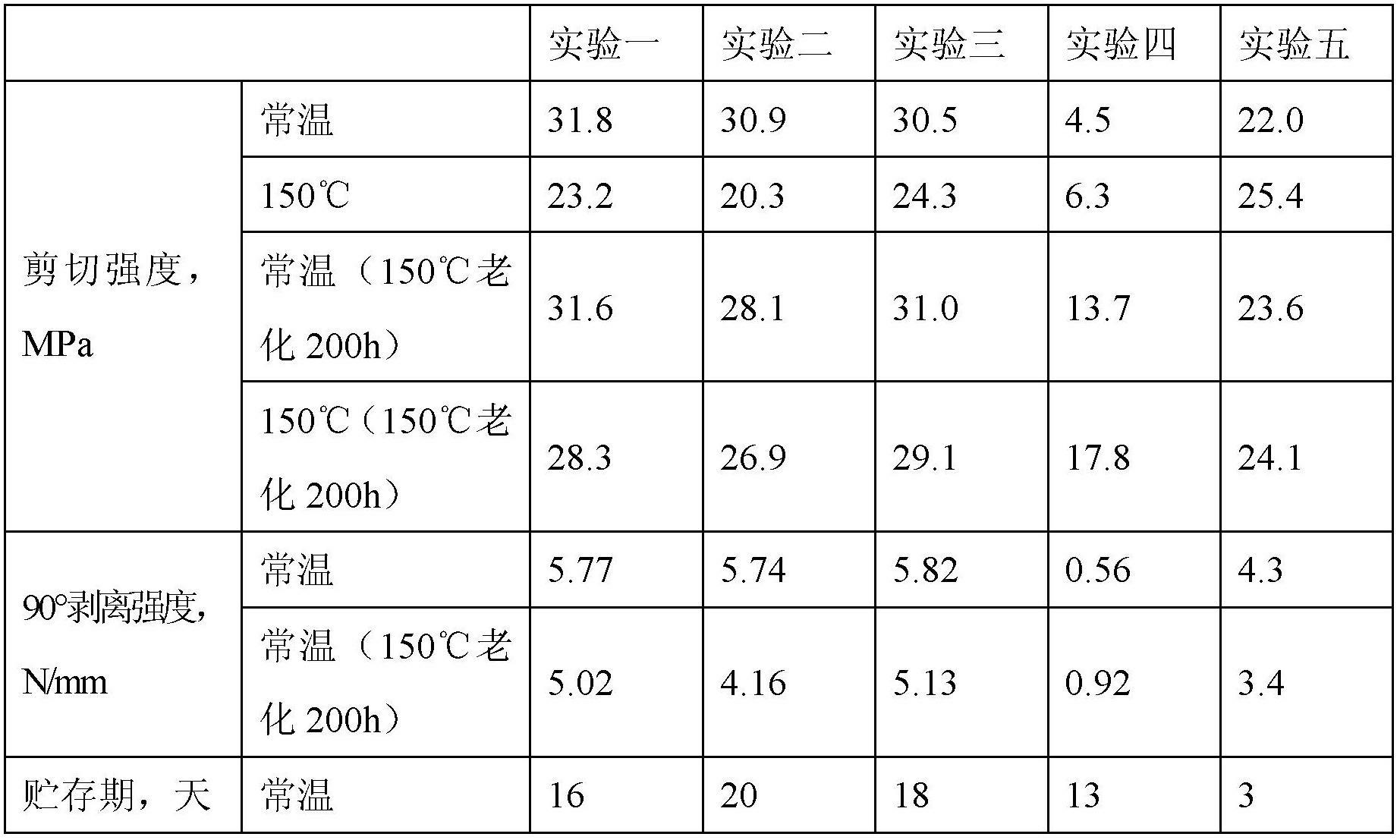

Low-temperature curing cyanate ester adhesive and preparation method thereof

InactiveCN102676112ALow curing temperatureHigh bonding strengthFilm/foil adhesivesEpoxy resin adhesivesPolymer scienceAdhesive

The invention discloses a low-temperature curing cyanate ester adhesive and a preparation method thereof, which relate to an adhesive and a preparation method thereof and solve the technical problems of high curing temperature and short room-temperature storage period of the existing cyanate ester adhesive. The adhesive disclosed by the invention is manufactured by adopting cyanate ester resin, a catalyst, modified resin, organic nano particles, inorganic nano particles, a thinning agent and a toughening agent. The preparation method comprises the following steps that: firstly, a mixture A is prepared; secondly, the toughening agent is added into the mixture A to obtain a mixture B; thirdly, the modified resin and the thinning agent are added into the mixture B and are stirred and mixed uniformly, the catalyst is added into the mixture to obtain a substrate, and then the substrate and quartz fiber fabric are subjected to hot melting to be combined into a low-temperature curing cyanate ester carrier adhesive film, so the low-temperature curing cyanate ester adhesive is obtained. The curing temperature of the low-temperature curing cyanate ester adhesive prepared by the preparation method provided by the invention is low, the low-temperature curing cyanate ester adhesive can be cured at a temperature of 120-140 DEG C, and the room-temperature storage period of the low-temperature curing cyanate ester adhesive is as long as 20 days, and meanwhile, the low-temperature curing cyanate ester adhesive has high bonding strength and excellent heat-resistant performance and is suitable for bonded materials which cannot resist to high temperature.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Solvent-free polyaspartate polyurea paint, and preparation method and application thereof

ActiveCN105670475AExcellent low temperature curingImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingSolvent free

The invention provides a solvent-free polyaspartate polyurea paint, and a preparation method and application thereof. The solvent-free polyaspartate polyurea paint comprises a component A and a component B. The component A comprises the following ingredients in percentage by weight: 60-80% of hexamethylene diisocyanate and 20-40% of urethano modified HDI (hexamethylene diisocyanate) tripolymer. The component B comprises the following ingredients in percentage by weight: 60-70% of polyaspartate, 5-10% of pigment and filler, 10-20% of modified silicon micropowder, 1-3% of defoaming agent, 1-3% of leveling agent, 2-5% of adhesion promoter and 1-3% of coupling agent. The mass ratio of the component A to the component B is (3-5):1. The technical scheme provided by the invention greatly improves the low-temperature curing performance of the product and enhances the binding strength with the nonpolar material polyethylene; and the solvent-free polyaspartate polyurea paint has the advantages of high flexibility, high mechanical strength and high chemical corrosion resistance.

Owner:CYG CHANGTONG NEW MATERIAL

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

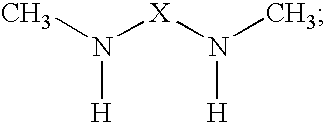

Curing agent for low temperature cure applications

InactiveUS20080194776A1Extended drying timeRapid hardness developmentThin material handlingEpoxyLow temperature curing

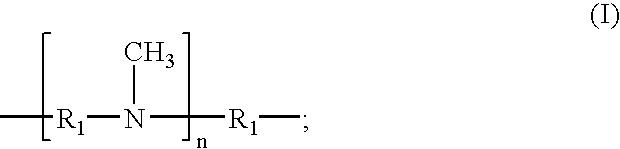

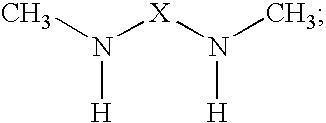

The present invention provides N,N′-dimethyl secondary diamine polymers including methylamine-terminated poly-(N-methylazetidine) and methylamine-terminated poly-(N-methylazacycloheptane). Amine compositions and amine-epoxy compositions comprising N,N′-dimethyl secondary diamine polymers are also disclosed.

Owner:EVONIK DEGUSSA GMBH

High-conductivity silver paste and preparation method thereof

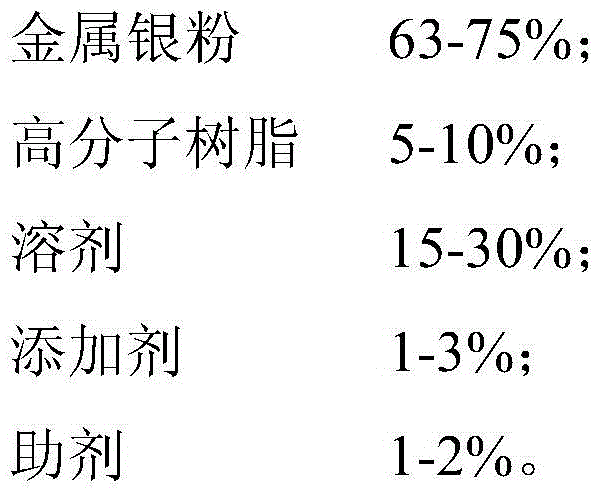

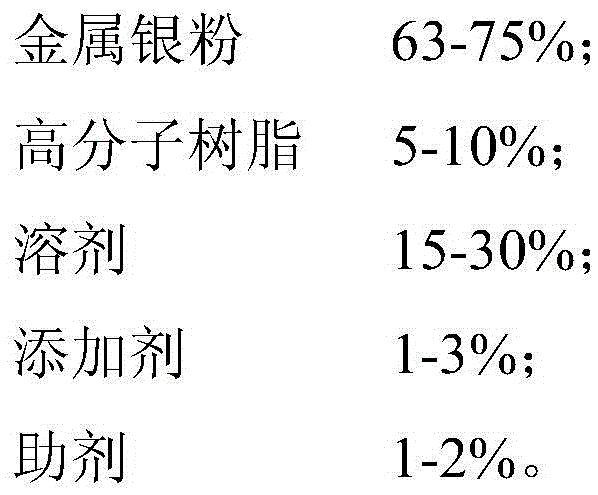

ActiveCN105632588AImprove conductivityGood stacking densityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteLow temperature curing

The invention provides a high-conductivity silver paste and a preparation method thereof. The high-conductivity silver paste comprises metal silver powder, wherein the metal silver powder is a mixture of micro-order sheet-shaped silver powder, submicron-order spherical silver powder and nanometer silver powder. The high-conductivity silver paste has the advantages that silver powders with different grain sizes and morphological structures are fully utilized and mutually matched, so that the silver powder can form a more compact status on the structure, and the low-temperature sintered nanometer silver powder is added to be further connected with the conductive silver powder; after mixing the silver paste with macromolecule resin, a solvent, an additive and an assistant agent, the paste can acquire relatively high conductivity under a condition of low-temperature curing (less than or equal to 150 DEG C); and meanwhile, the paste has favorable printing adaptability and favorable attachment performance, and can be applied to the fields of a printed conductive circuit, a radio frequency identification (RFID) label antenna and the like.

Owner:KUSN HISENSE ELECTRONICS

Moisture curable sealer and adhesive composition

ActiveUS7317051B2Low costMaintain good propertiesRoof covering using flexible materialsBituminous material adhesivesPolymer scienceCarcinogen

A low cost moisture curable sealer and adhesive composition containing a polymer having reactive silyl groups and a bituminous material and having many advantages over conventional moisture cure sealer compositions, including greater elastomeric properties, improved flexibility and pliability, lower durometer, faster and deeper cure, low temperature cure. The composition is also free of carcinogens such as coal tar, toxic isocyanates, and volatile solvents.

Owner:CHEMLINK

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

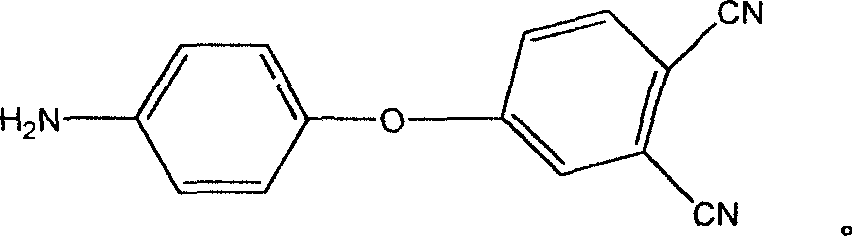

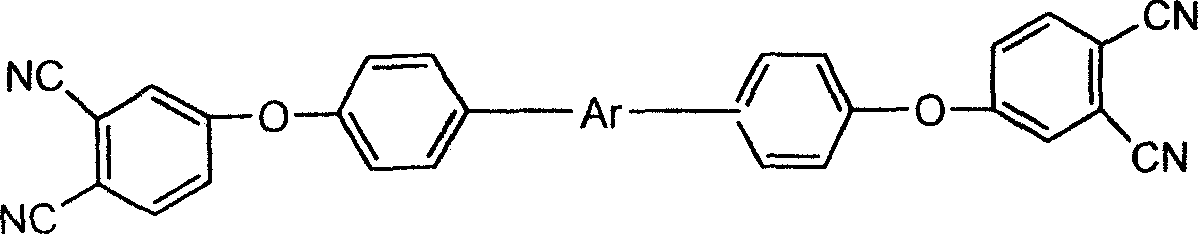

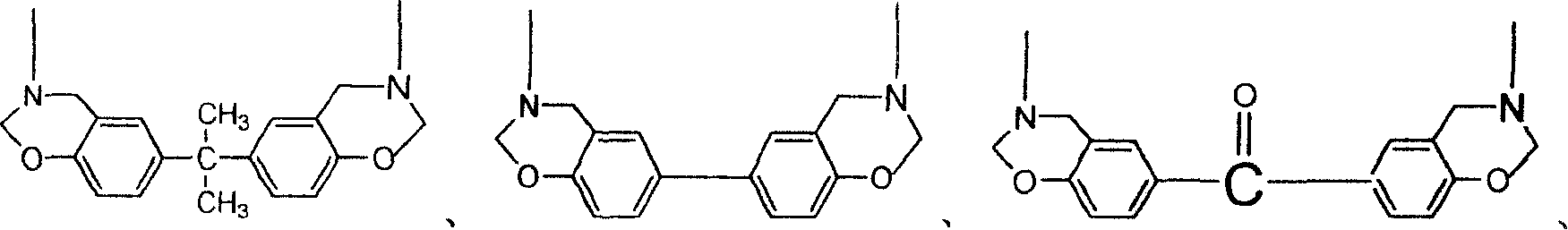

Double end group ortho-benzene dimethyl nitrile-benzo oxazine resin, solidified substance and its preparing method and use

InactiveCN1944400ARegulating and Controlling Control StructuresRegulating and Controlling Control PerformanceCarboxylic acid nitrile preparationOrganic compound preparationBenzeneHeat resistance

The present invention belongs to the field of high molecular synthetic material, and is especially one kind of double end group o-phthalonitrile-benzo oxazine resin, and its solidified substance and preparation process. The present invention provides one kind of 4-aminophenoxyl-o-phthalonitrile monomer and the double end group o-phthalonitrile-benzo oxazine resin therewith. The double end group o-phthalonitrile-benzo oxazine resin has excellent curing reaction activity, low temperature curing performance similar to that of benzo oxazine resin, heat resistance similar to that of o-phthalonitrile resin, greatly lowered curing temperature and capacity of use in high temperature condition. The preparation process is simple and controllable, and the product has excellent application foreground.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

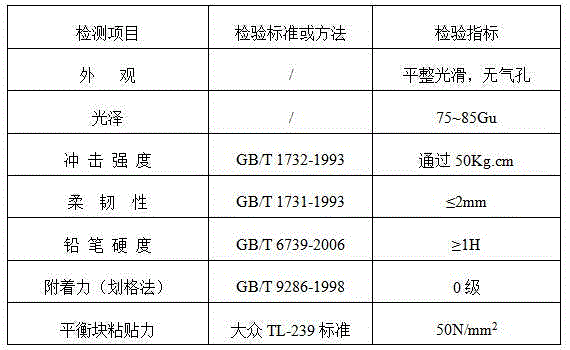

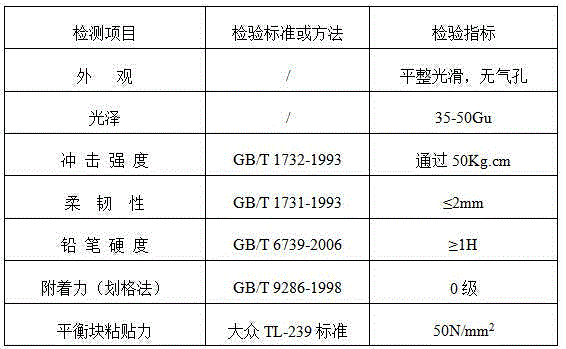

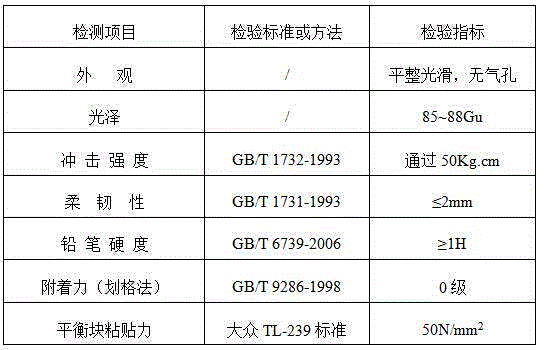

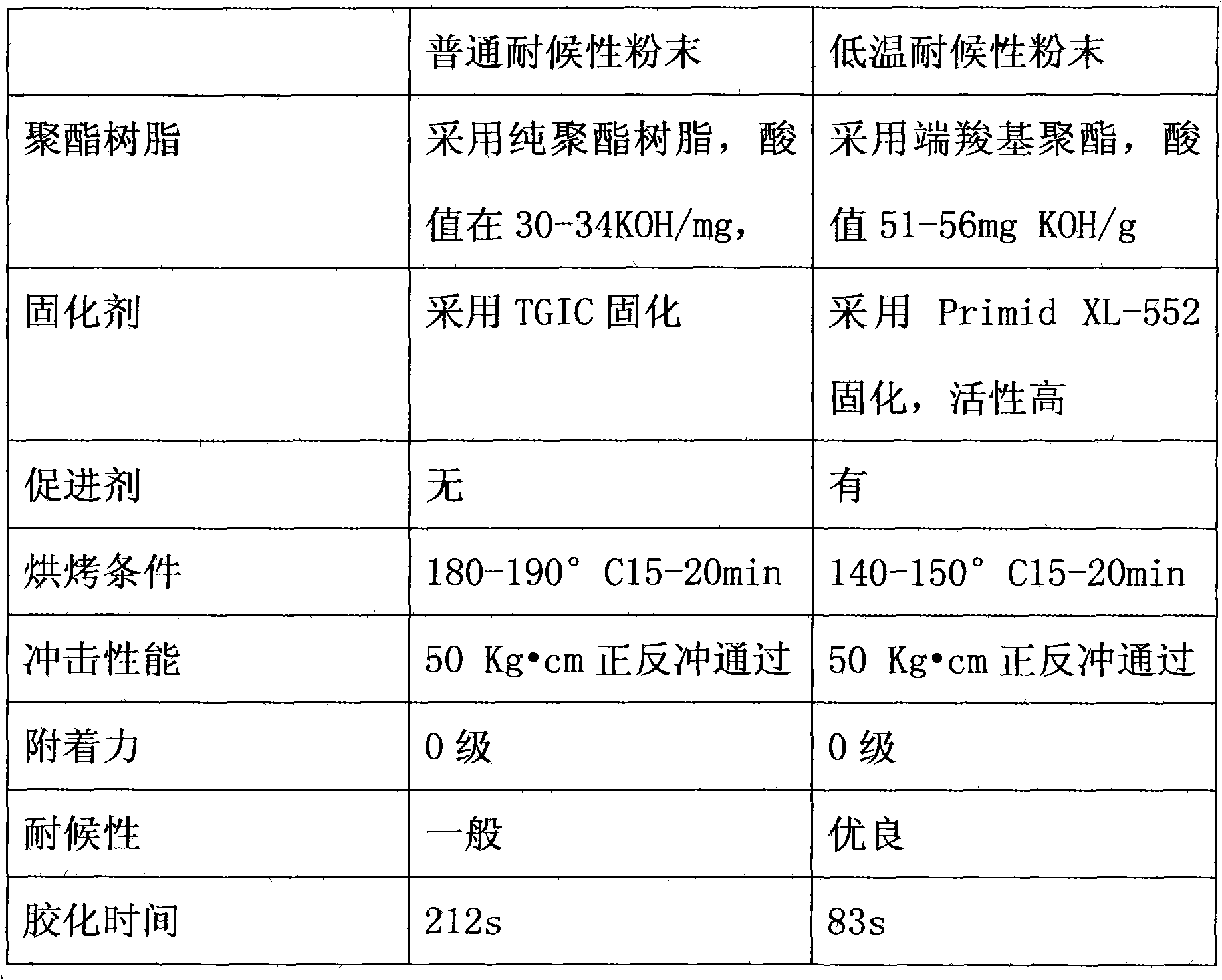

Special low-temperature cured body powder coating for aluminum wheel of automobile and preparation method thereof

ActiveCN104449268ALower the initial reaction temperatureAchieving Low Temperature CuringAnti-corrosive paintsPowdery paintsEpoxyLow temperature curing

The invention discloses a special low-temperature cured body powder coating for an aluminum wheel of an automobile, which consists of low-temperature cured polyester resin, epoxy resin and a latent accelerator. The invention further discloses a preparation method of the powder coating. The powder coating can be cured at 150-160 DEG C and extremely good levelling property and anti-caking performance are ensured, so that requirement for the mirror surface effect of aluminum wheel coating of the automobile is satisfied. Moreover, the coating has excellent counterbalance adhering performance and air permeability; low-temperature curing is achieved, the energy consumption for coating the aluminum wheel is reduced, and the toughness of the aluminum wheel is increased.

Owner:GUANGZHOU KINTE IND

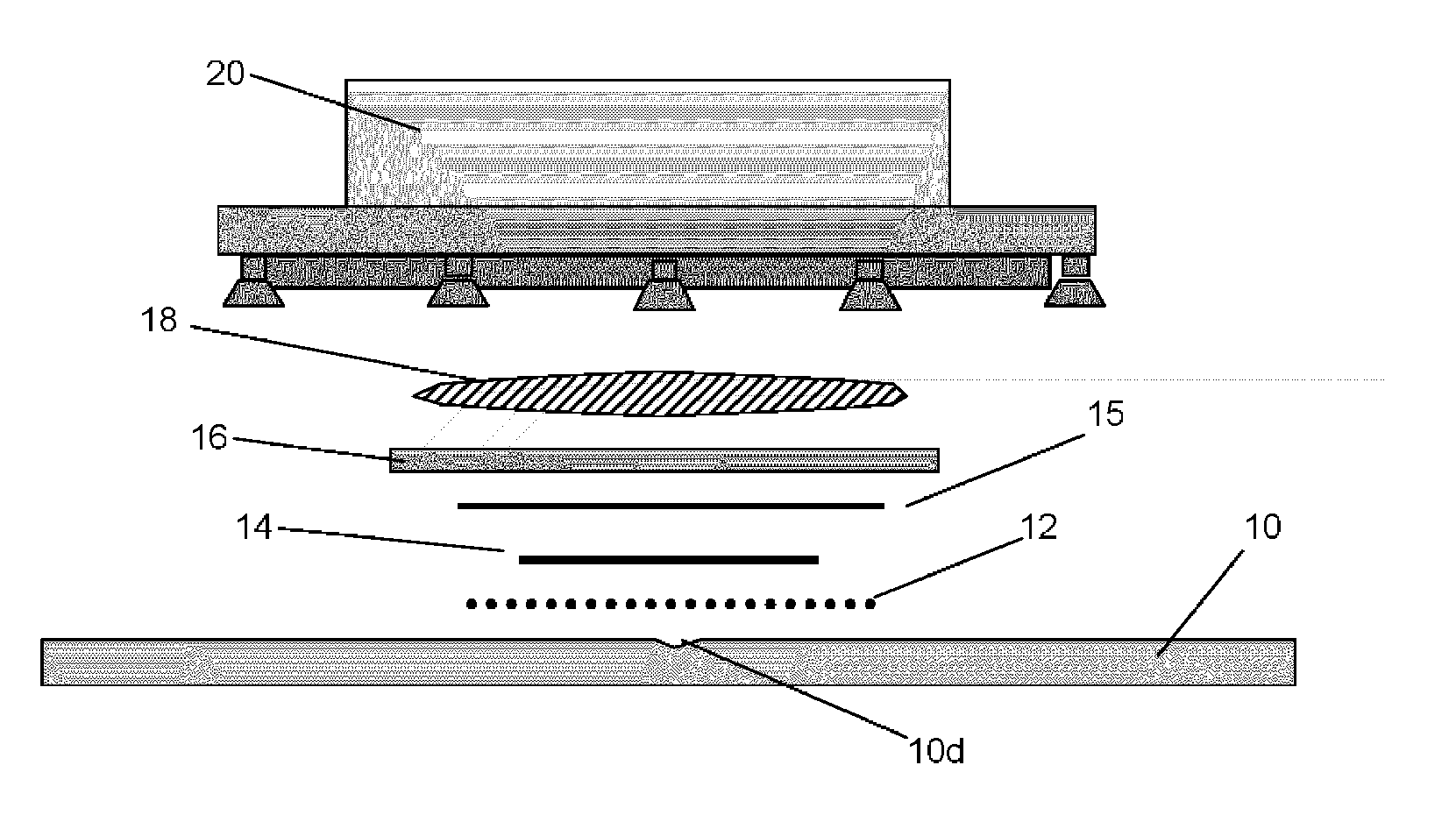

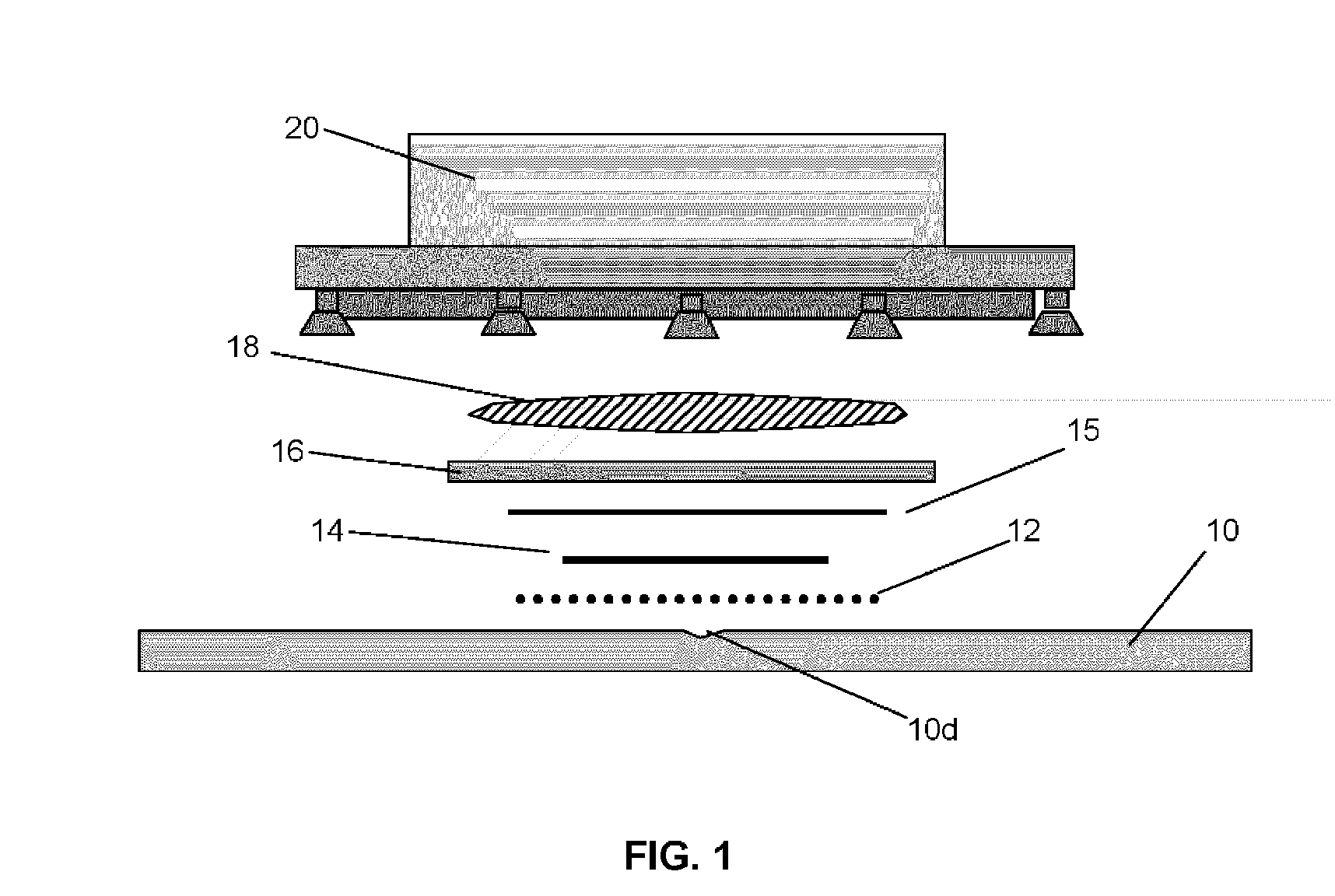

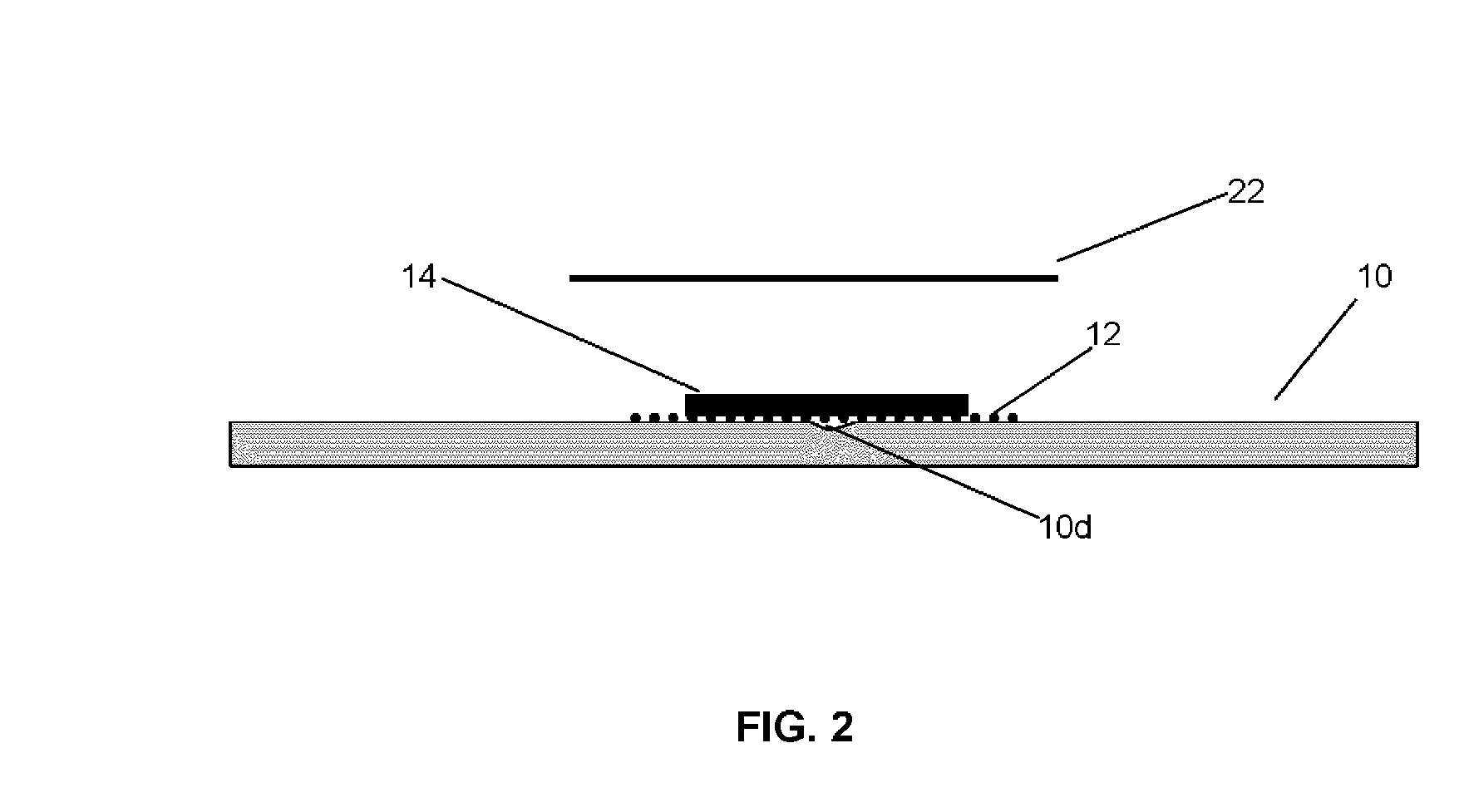

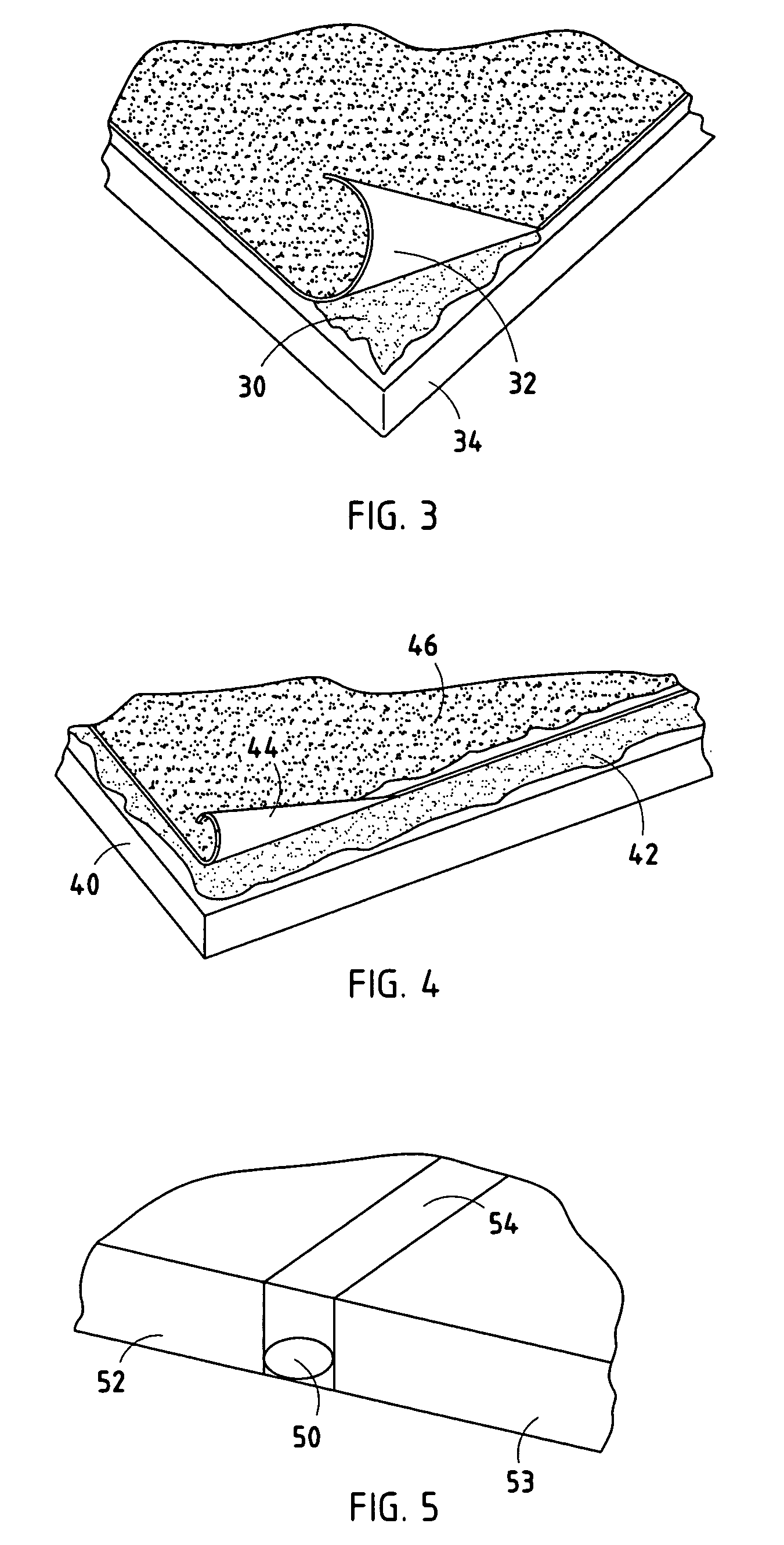

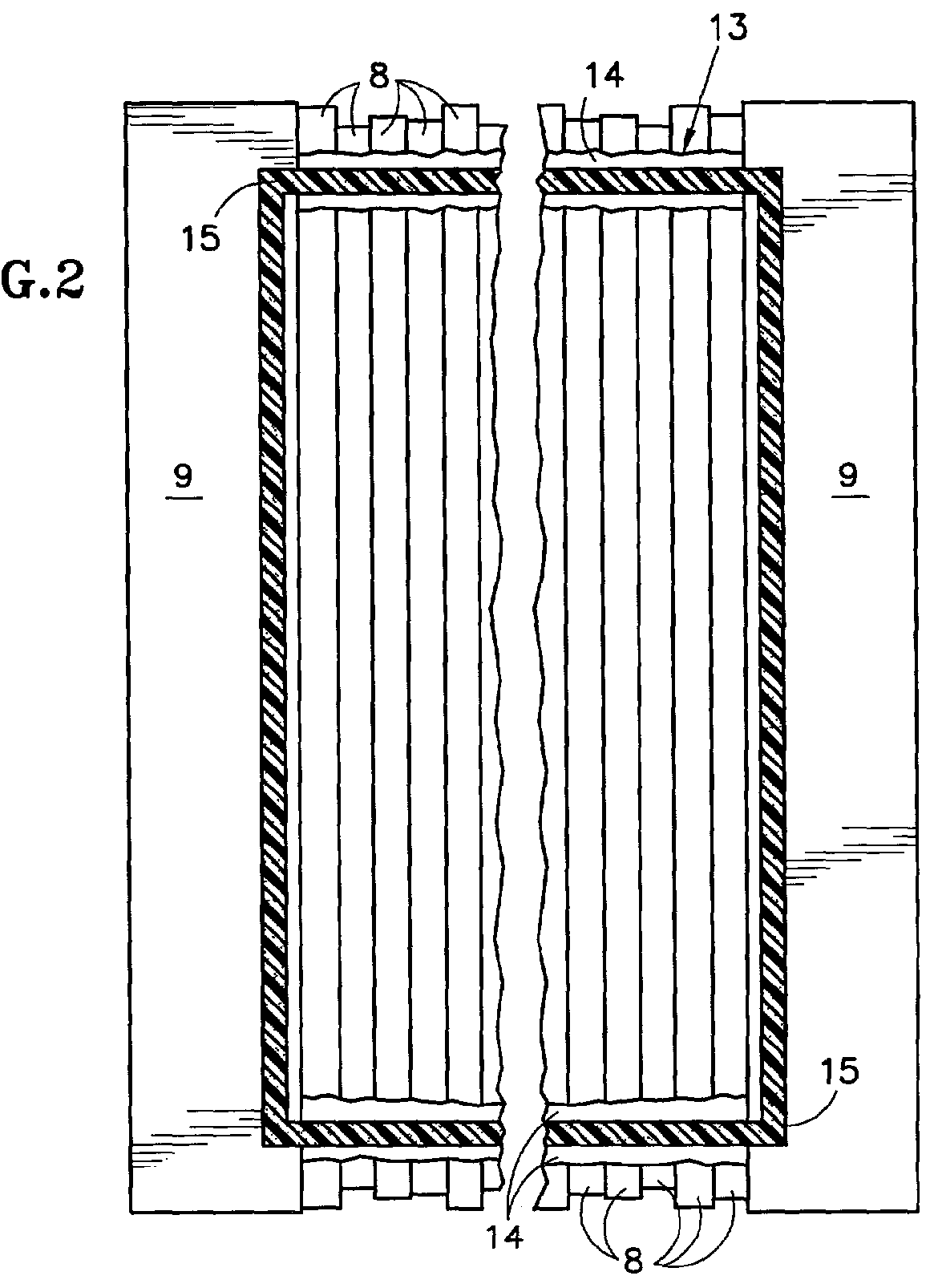

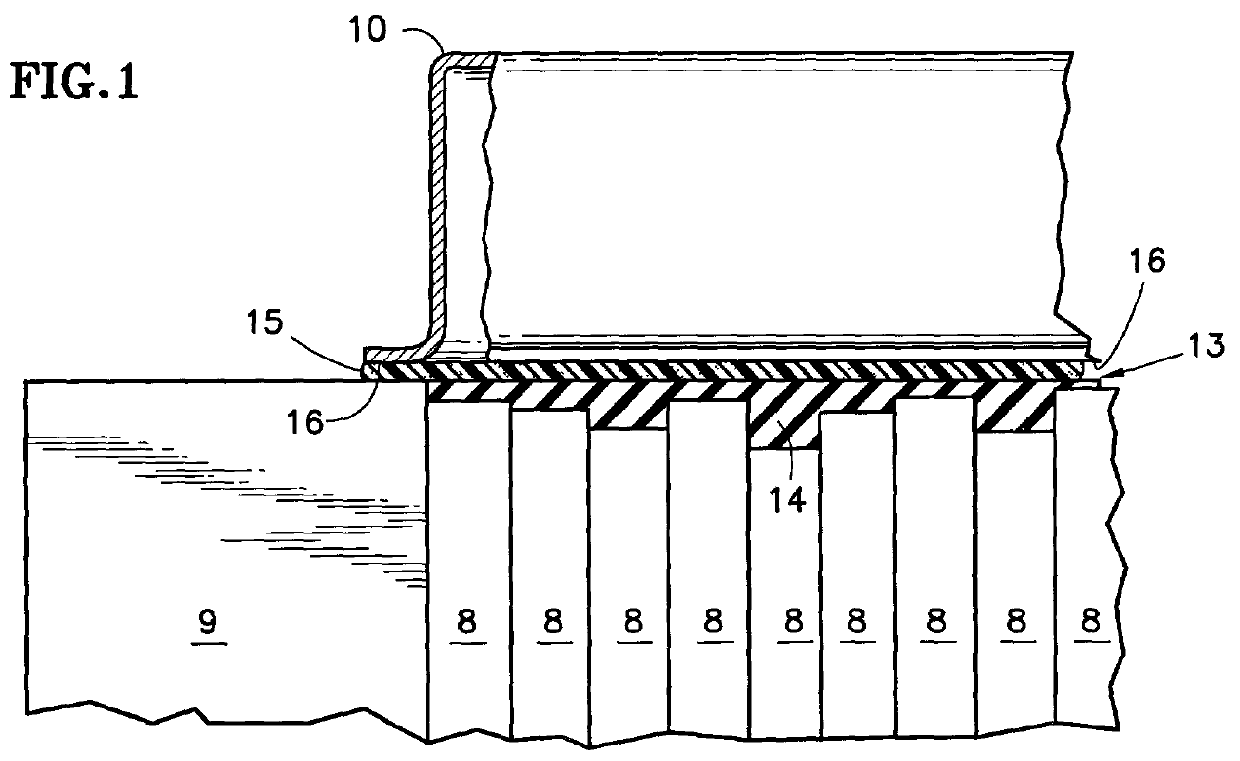

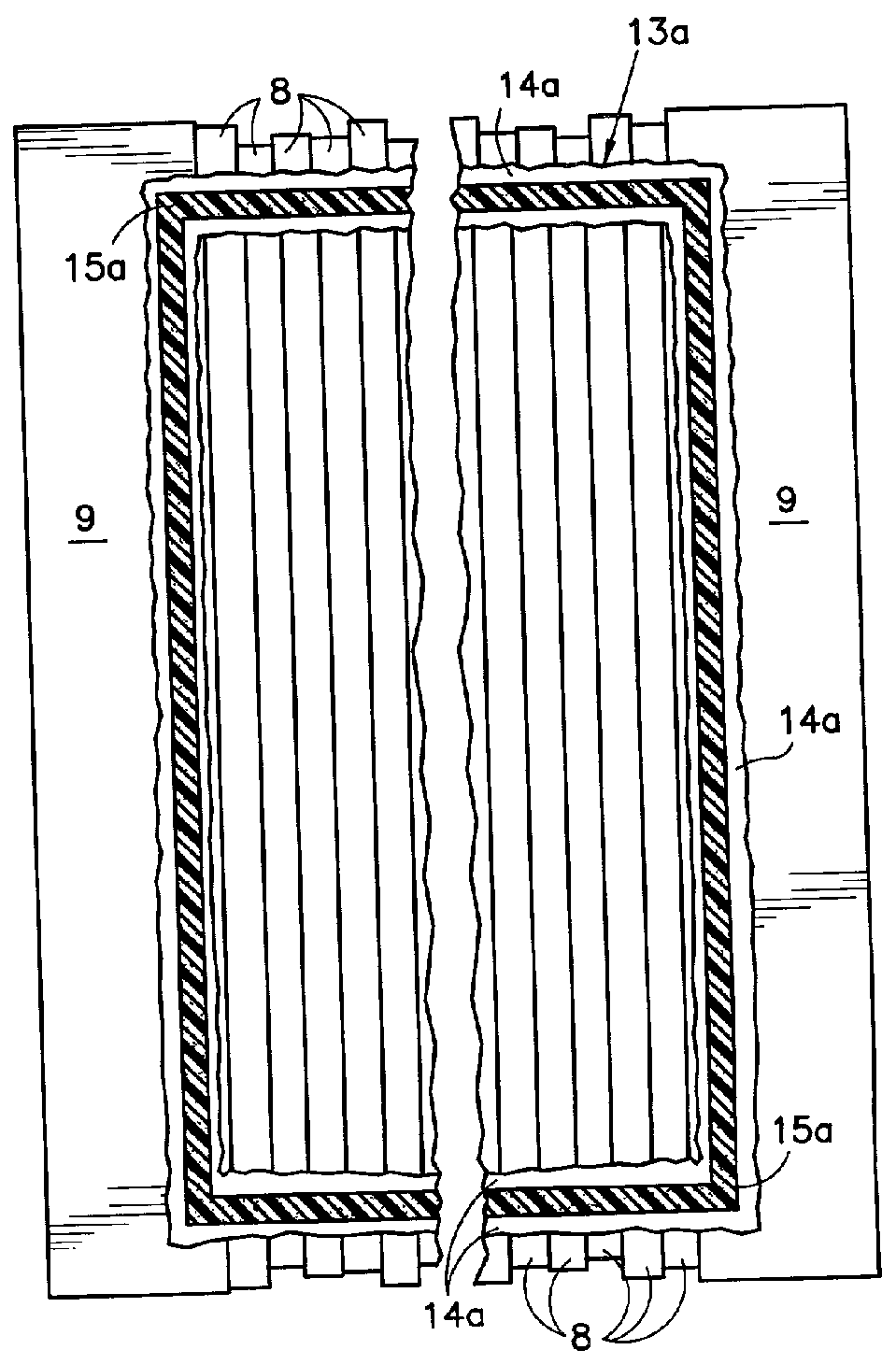

Proton exchange membrane fuel cell external manifold seal

InactiveUS20010055708A1Low creepCompressibleSolid electrolytesFuel cells groupingLow temperature curingEngineering

A sealant system 13 for a manifold 10 of a proton exchange membrane fuel cell includes low temperature cured or heat cured silicone rubber bridges 14, 14a, 14c between the end plates 9 to compensate for the uneven edges of various fuel cell component layers, and a layer 15 of silicone rubber foam or sponge, or a molded silicone rubber gasket 15a, extending across the bridges and along the end plates, around the entire contact perimeter surfaces of the manifold, to seal the manifold to the fuel cell. The cured silicone rubber may extend along the end plates between the bridges. A rubber strip 20 may be adhered to the silicone rubber bridges and end plates. The bridges may comprise a first layer 22 of low shrinkage self-leveling RTV liquid rubber with viscosity in the range of 10,000-20,000 cps and a second layer 14 of RTV liquid rubber.

Owner:AUDI AG

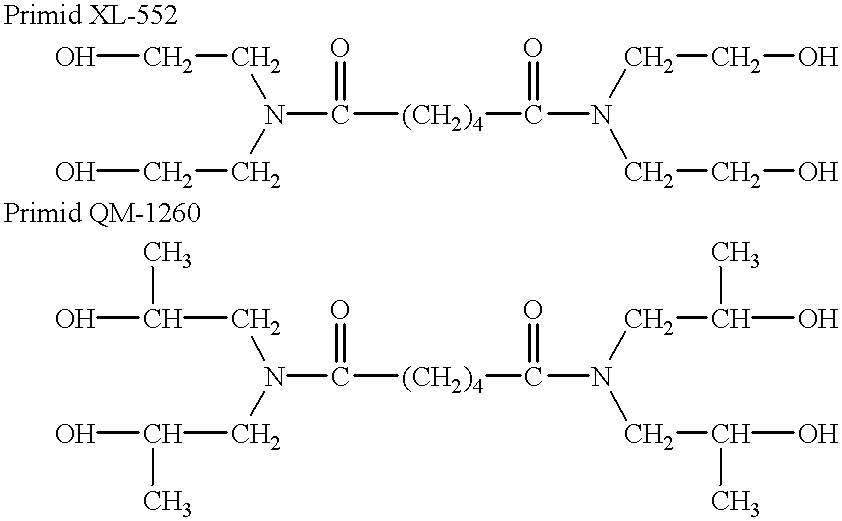

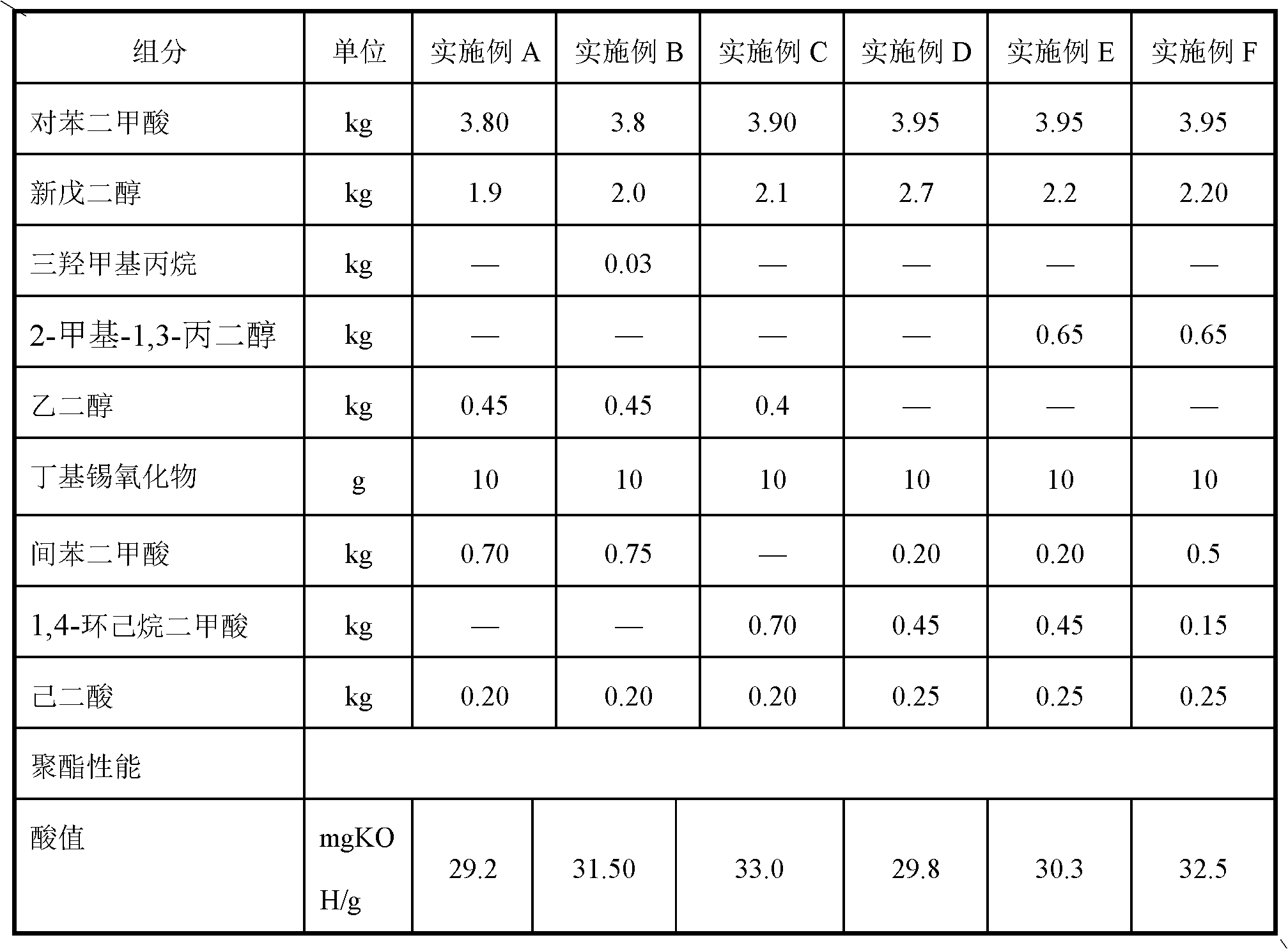

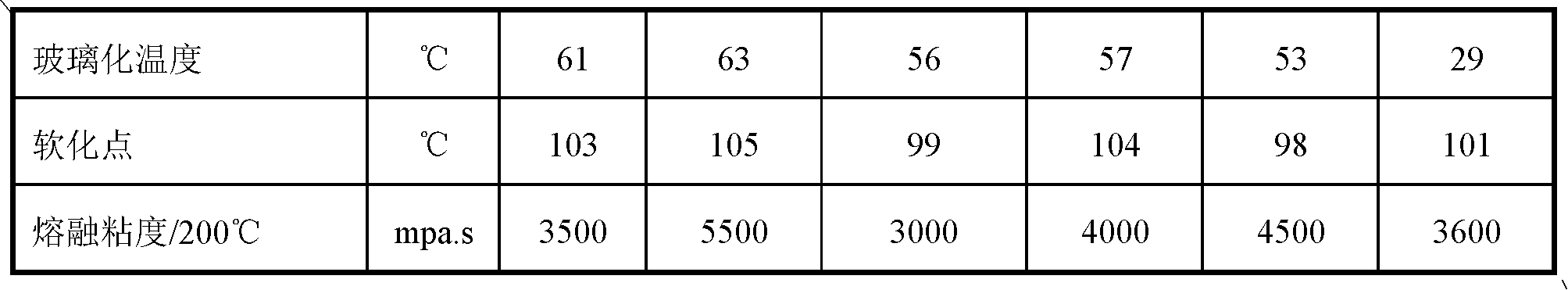

Polyester resin for beta-hydroxyalkylamide low temperature curing weather-resistant powder paint and preparation method thereof

ActiveCN102010501AHigh glass transition temperatureHigh softening pointPowdery paintsPolyester coatingsPolyolLow temperature curing

The invention discloses polyester resin for a beta-hydroxyalkylamide low temperature curing weather-resistant powder paint. The polyester resin is prepared from the following components by weight percent through melt polycondensation reaction: 25-45% of polyol, 40-55% of aromatic polybasic acid, 0-8% of aliphatic polybasic acid, 0-5% of branching agent, 5-15% of acidolysis agent and 0.01-0.15% ofesterification catalyst. The invention also discloses a preparation method of the polyester resin. The polyester resin prepared by the method disclosed in the invention has the advantages of higher glass transition temperature and softening point and proper melt viscosity and storage stability; and the powder paint prepared from the polyester resin has the advantages of excellent levelling property and mechanical properties, good thick-film pinhole resistance and the like.

Owner:GUANGZHOU KINTE IND

Thermosetting weather-resistant low-temperature curing powder

InactiveCN102277067ALow curing temperatureShort curing timePretreated surfacesPowdery paintsWeather resistancePlastic materials

The invention discloses thermosetting weather-resistant low-temperature curing powder, which belongs to the technical field of new materials. 0.3%-0.6% of accelerator, 15%-25% of filler, 3%-15% of pigment, 0.5%-2% of auxiliary agent after mixing, the invention has the beneficial effect of curing the coating film The required baking conditions are only 140-150 ℃, 20min, the curing temperature is lower, the curing time can be shortened by 2 to 3 times compared with ordinary products, the mechanical properties are not affected, and it has good weather resistance, which can meet the needs of production and life. , can be used in wood processing, engineering plastics and some metal alloy materials and other fields, expanding the application field of traditional powder.

Owner:SHANGHAI YUANFANG PAINT CO LTD

Modified acrylic resin mortar composition and preparation method thereof

ActiveCN102491680AThe composition ratio is scientific and reasonableImprove performanceCombustionAntioxidant

The invention provides a modified acrylic resin mortar composition and a preparation method thereof. The composition consists of component materials A, B and C, wherein the component material A comprises modified acrylic resin, a flexibilizer, a plasticizer, a crosslinking agent, a coupling agent, a polymerization inhibitor, an accelerating agent, a thickening agent, a combustion improver, an antioxidant and a defoaming agent; the component material B is an initiator; the component material C is an aggregate, wherein the mass ratio of component A to component B to component C is (100-300): (0.5-3): (50-2500). The composition has the advantages of simple preparation method, easy and simple field construction operation process, good low temperature solidification property, adjustable solidification speed, high mechanical strength, good toughness and good ageing resistance and low temperature resistance.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Low-temperature curing temperature-resistant heavy-duty anticorrosive paint

ActiveCN101698754AGood physical and mechanical propertiesImprove adhesionAnti-corrosive paintsPolyamide coatingsEpoxyLow temperature curing

The invention provides low-temperature curing temperature-resistant heavy-duty anticorrosive paint, which comprises a component A and a component B, wherein the component A takes epoxy modified silicone resin as main raw material combined with other pigment fillers and additives; the component B is modified polyamide; and the component A and the component B in use are mixed in a certain ratio. The low-temperature curing temperature-resistant heavy-duty anticorrosive paint is characterized in: 1, two components cured to be film at low temperature, no need for high-temperature baking, simple convenient construction, cost saving and capability of resisting a high temperature of 200 DEG C for a long period of time; 2, excellent physical and mechanical properties, adhesion, good flexibility and high anti-impact strength; and 3, excellent chemical stability, boiling resistance, oil resistance and anti-aging performance.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Low-temperature cured cathode electrophoretic coating, and preparation method and use method thereof

ActiveCN103031038ASolve the three major problems of practical applicationPaints for electrolytic applicationsEpoxy resin coatingsLow temperature curingSurface smoothness

The invention relates to a low-temperature cured cathode electrophoretic coating. The coating comprises cathode electrophoretic coating emulsion and color paste which are stored independently, wherein the composition ratio of cathode electrophoretic coating emulsion to color paste is 1:4. The cathode electrophoretic coating emulsion is prepared in such a way that 30-40 parts of matrix resin, 10-15 parts of low-deblocking curing agent, 1-2 parts of high boiling point alcohol ether cosolvent, and 0.5-1 part of organic acid and / or mineral acid are added into an emulsifying disperser in sequence for stirring and mixing uniformly, and the temperature is controlled under 40 DEG C; and then 40-50 parts of deionized water is added into the emulsifying disperser in twice or more times for high-speed emulsification for one hour. The coating and the preparation method thereof have the advantages as follows: low-temperature dissociation of blocked isocyanate is realized; low-temperature curing performance and coating stability are combined; low-temperature curing performance and coating surface smoothness are combined; and the curing temperature is as low as 140 DEG C.

Owner:GUANGDONG KODEST EP SC CO LTD

Resin mixture and glass reinforced plastic section bar prepared thereby

InactiveCN101157795ALightweight and high strengthThermal insulationPolymer scienceLow temperature curing

The invention relates to a resin mixture used for producing FRP (fiberglass-reinforced plastics) profile, the FRP profile made from the mixture and a preparation method thereof. The resin mixture comprises the following materials according to weight proportion: 10 of resin, 0.4 to 3 of low shrinkage agent, 2 to 15 of fillers, 0.05 to 0.2 of low temperature curing agent, 0.05 to 0.2 of high temperature curing agent, 0.05 to 0.2 of parting agent, 0.02 to 0.5 of pigment and appropriate amount of coupling agent and ultraviolet absorbent. The preparation method of the FRP profile by using the mixture is that: a reinforcing material is immersed into the resin mixture. The obtained material is extruded to get forming under high temperature and high pressure through a die; during the extrusion forming, the die is heated after being separated into three segments, and the temperature of the three segments is respectively 60 DEG C to 100 DEG C of a first segment, 100 DEG C to 150 DEG C of a second segment, 100 DEG C to 148 DEG C of a third segment; the haulage speed is 320 mm / min.

Owner:潘锦荣

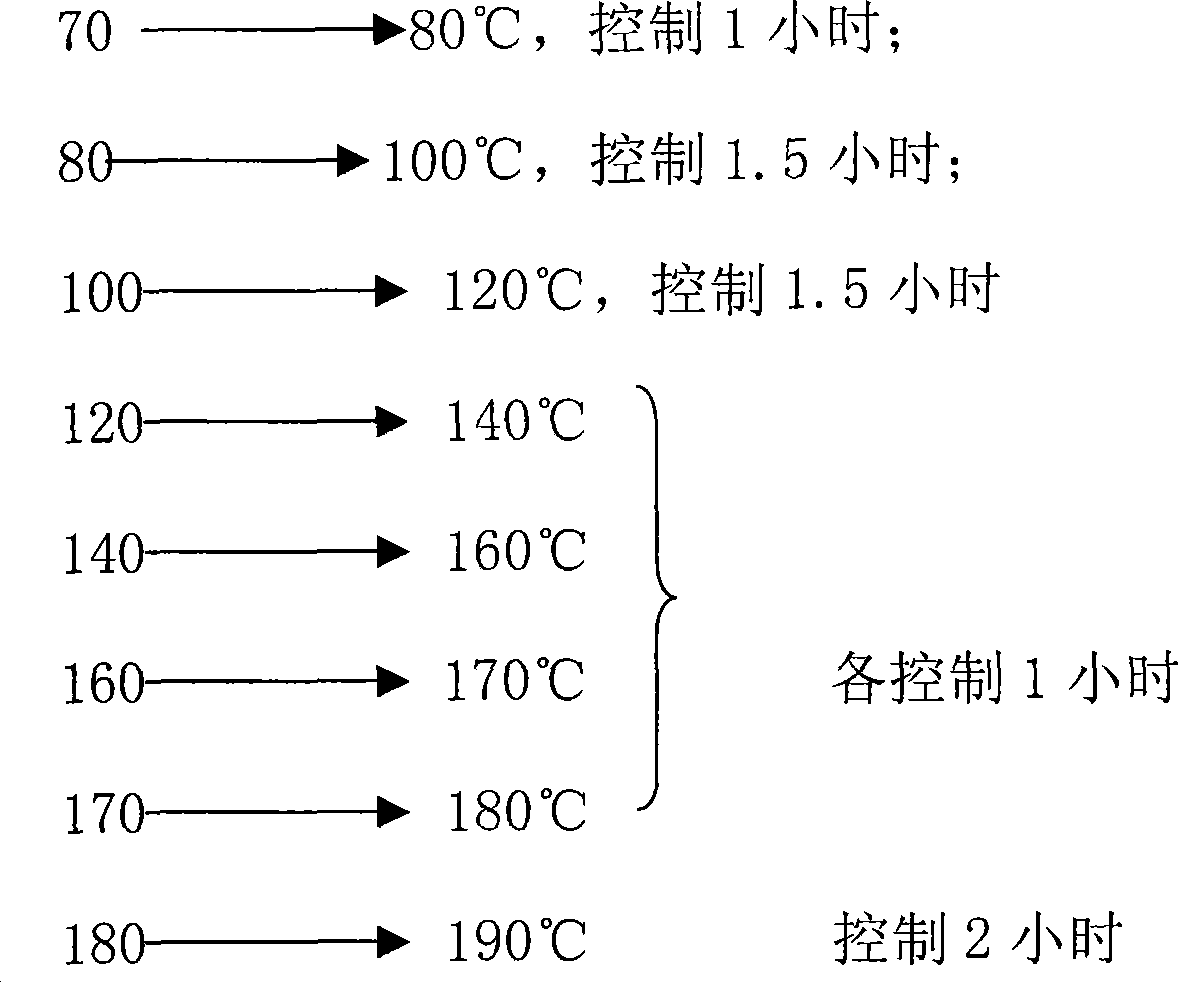

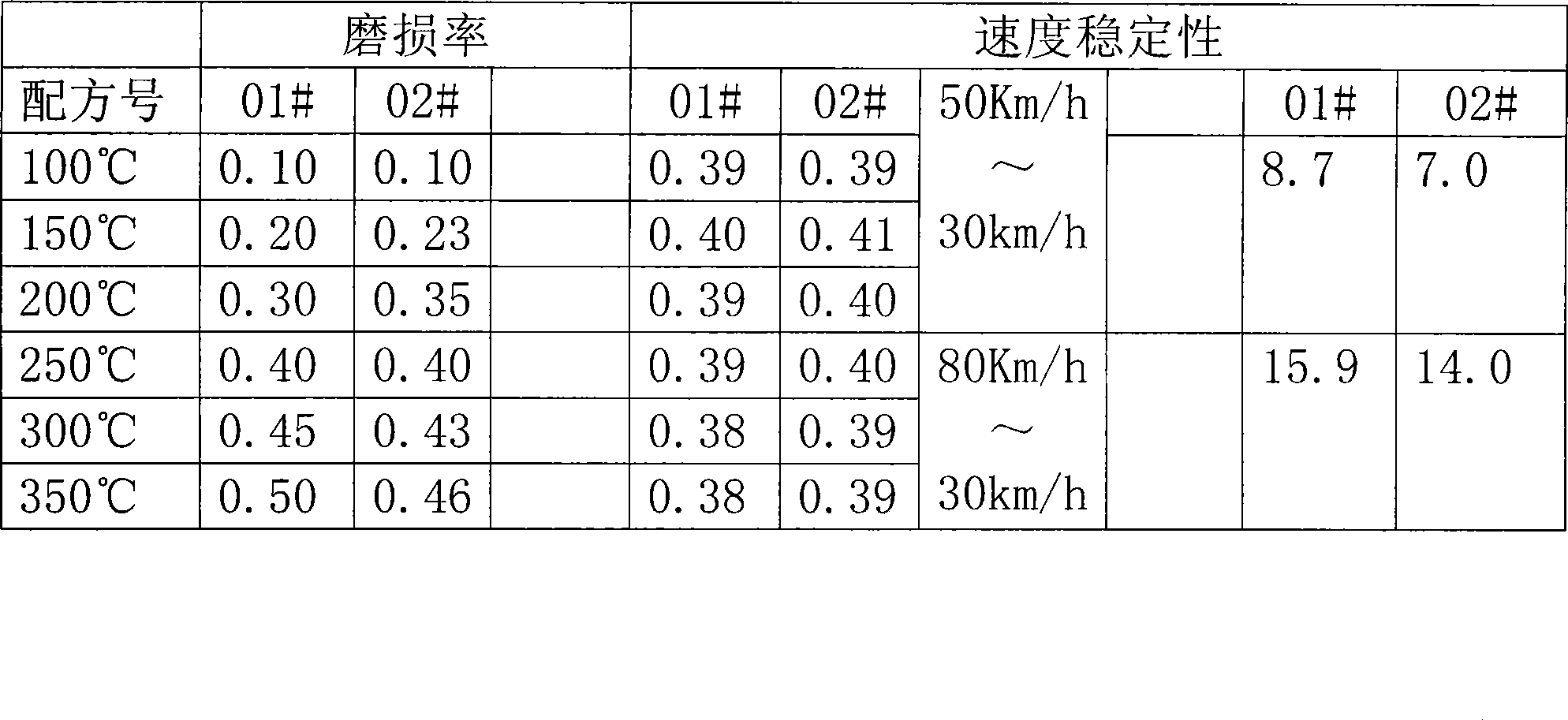

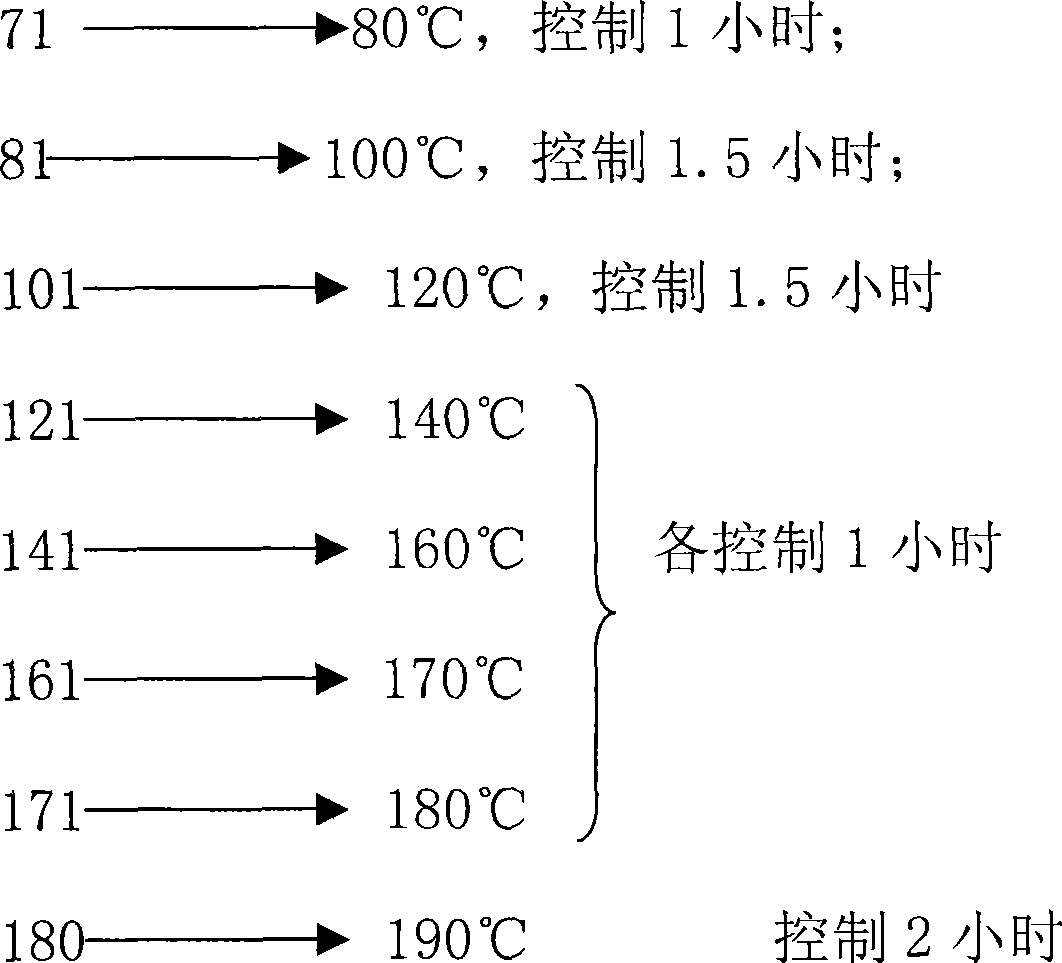

Method for producing low temperature cured ceramic friction plate

The invention discloses a method for producing friction plates of low temperature solidified ceramics, which is characterized in that the friction plates are produced by the following raw materials based on the weight percentage: 15-25% of high temperature resistance adhesives, 20-35% of reinforcing agents, 5-15% of friction adding agents, 10-25% of anti-friction and 20-30% of filling agents. The method has the advantages of no metal or little metal, low density, no pollution, low cost and long service life, etc. As ceramic fibers and ceramic powders are adopted, the high temperature resistance, dispersivity, adsorptivity, wearing resistance and stability are good and the density and price are low, thus ensuring balanced friction coefficient, little fading, no damage to coupling, low brake noise and light weight. The overall performance can reach the level of the same international products.

Owner:济南市腾晟汽车配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com