Method for producing low temperature cured ceramic friction plate

A production method and technology of friction linings, which are applied in the direction of friction linings, base materials, mechanical equipment, etc., can solve problems such as fluctuations in brake performance, brake failure, and poor high temperature resistance of brake pads, and achieve a balance of friction coefficient and braking noise. Small and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

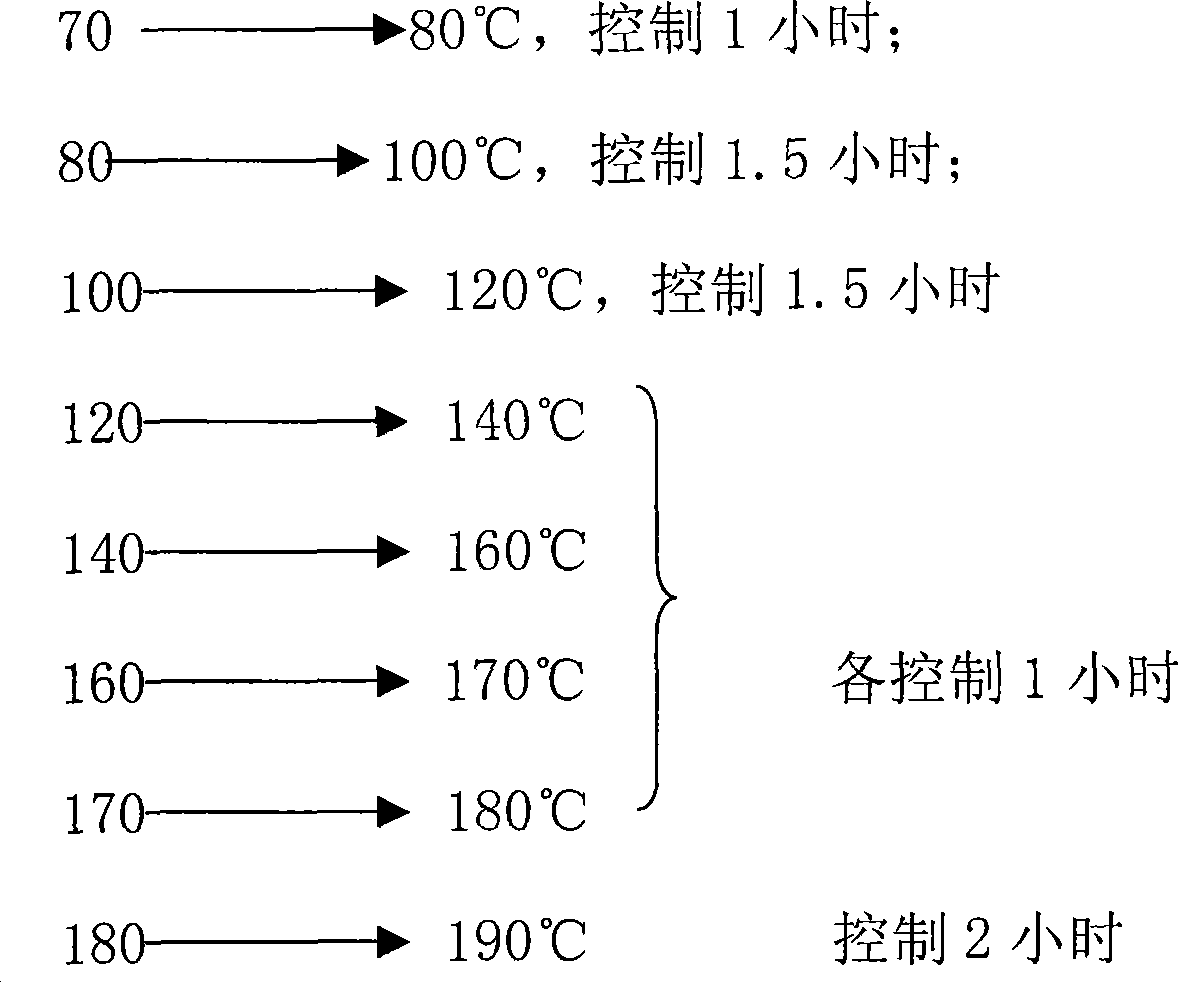

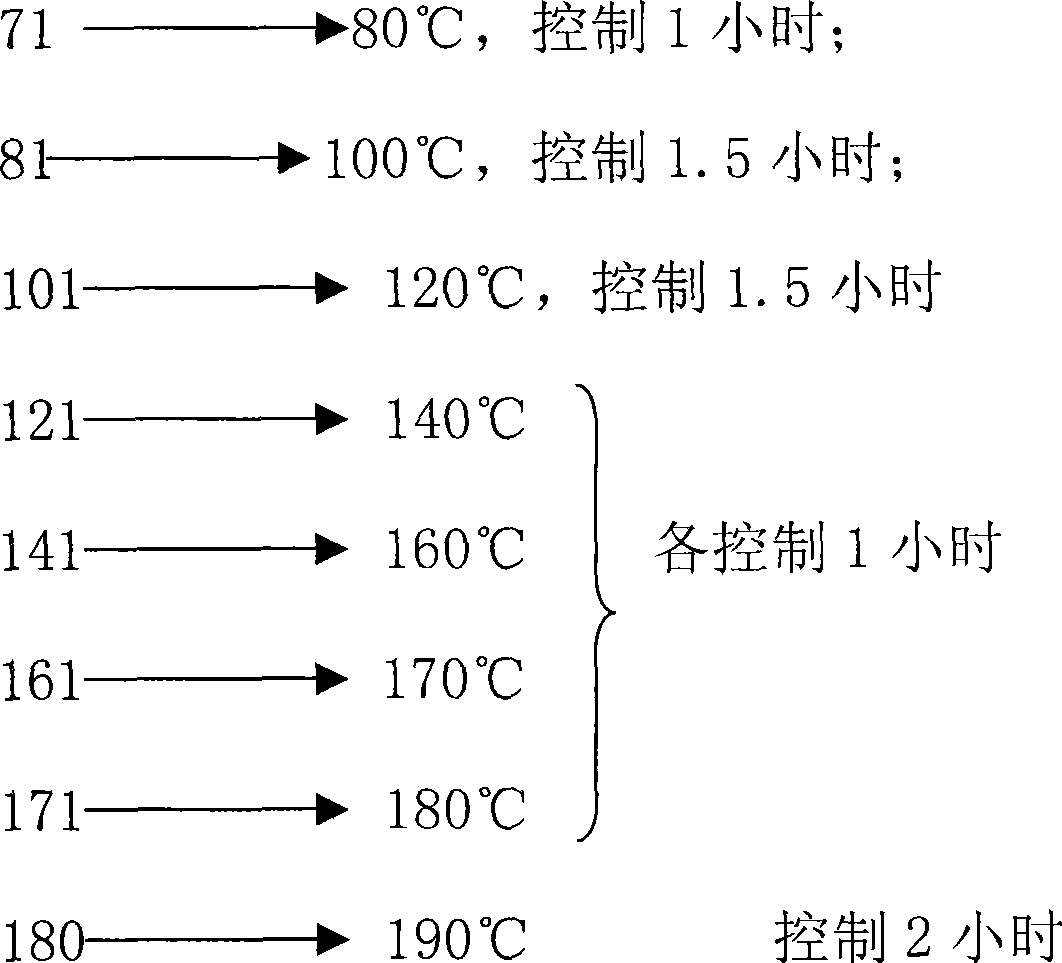

Method used

Image

Examples

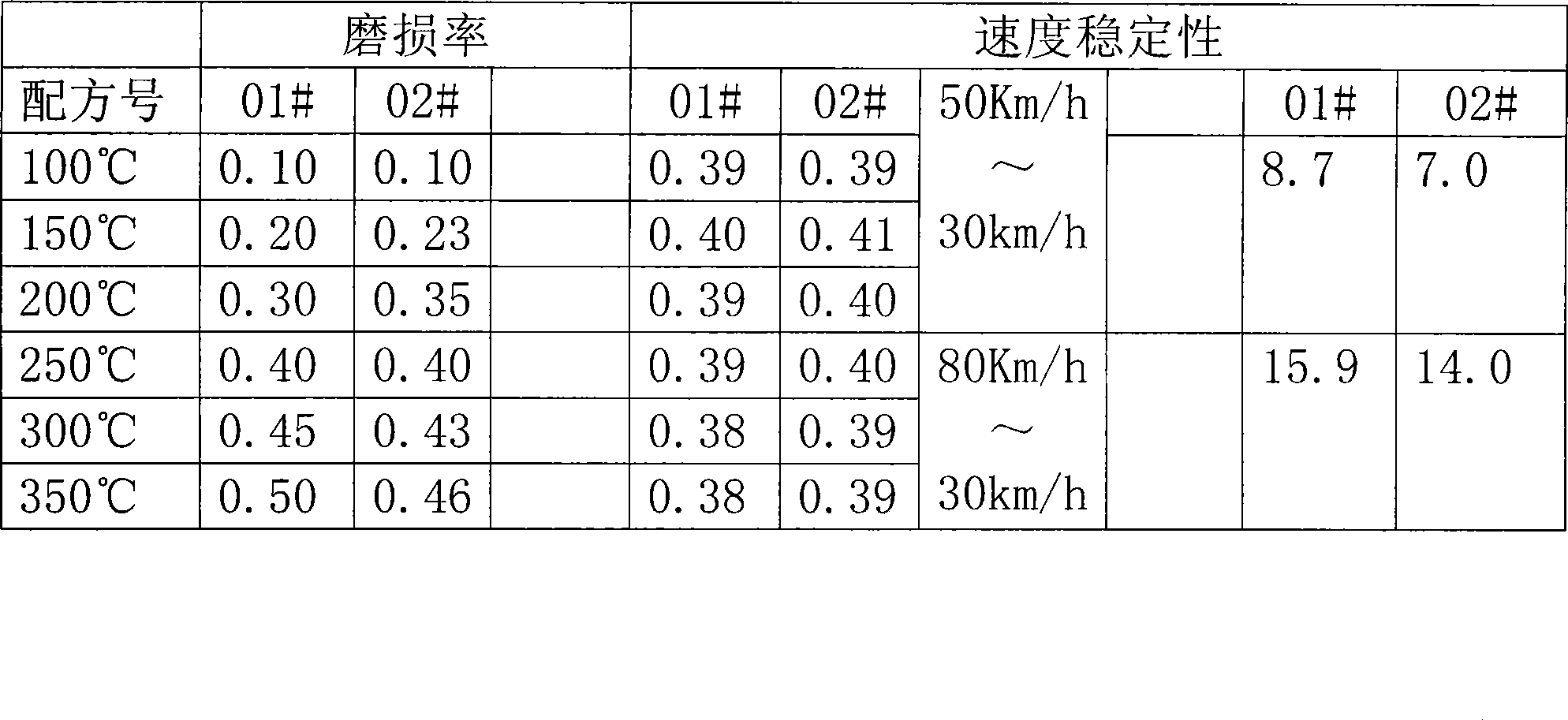

Embodiment 1

[0035] When making automobile brake pads, the specific weight percentages are: high temperature resistant adhesive accounts for 20%, reinforcing agent accounts for 28%, friction increasing agent accounts for 10%, friction reducing agent accounts for 20%, filler accounts for 22%. The high-temperature-resistant binder is a suspension resin; in the reinforcing agent, ceramic fiber 8%, ceramic powder 4%, mineral fiber 5%, glass fiber 5%, sepiolite 3%, wollastonite 3%; the ceramic fiber is a high-purity fine ceramic fiber produced by Shandong Luyang Group; in the friction-increasing agent, 3% of silicon dioxide, 3% of aluminum oxide, 2% of iron oxide, zirconium Quartz 2%; in the described friction reducer, graphite 4%, petroleum coke 3%, copper powder 3%, aluminum powder 4%, talcum powder 3%, molybdenum disulfide 3%; in the described filler, 6% barite, 6% limestone, 6% vermiculite, 4% mica; the percentages are all percentages of the total weight.

[0036] (two), mixing

[0037] P...

Embodiment 2

[0060] Make the brake friction plate, its specific weight percentage: high temperature resistant adhesive accounts for 18%, reinforcing agent accounts for 22%, friction increasing agent accounts for 12%, friction reducing agent accounts for 18%, filler accounts for 30%. The high-temperature-resistant adhesive is nano-modified double-horse resin, in which graphite fluoride and molybdenum dioxide are used to replace flake graphite, and nano-scale styrene-butadiene rubber powder is used to replace tire powder. Sulfide is used as a secondary binder to improve temperature resistance, and carbonaceous porous soft materials are used to reduce product hardness, increase porosity, and reduce noise; in the reinforcing agent, 5% of steel fiber and 1% of copper fiber , ceramic fiber 5%, ceramic powder 3%, mineral fiber 2%, glass fiber 2%, sepiolite 2%, wollastonite 2%; Produced; in the friction-increasing agent, 3% of silicon dioxide, 3% of aluminum oxide, 4% of iron oxide, and 2% of zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com