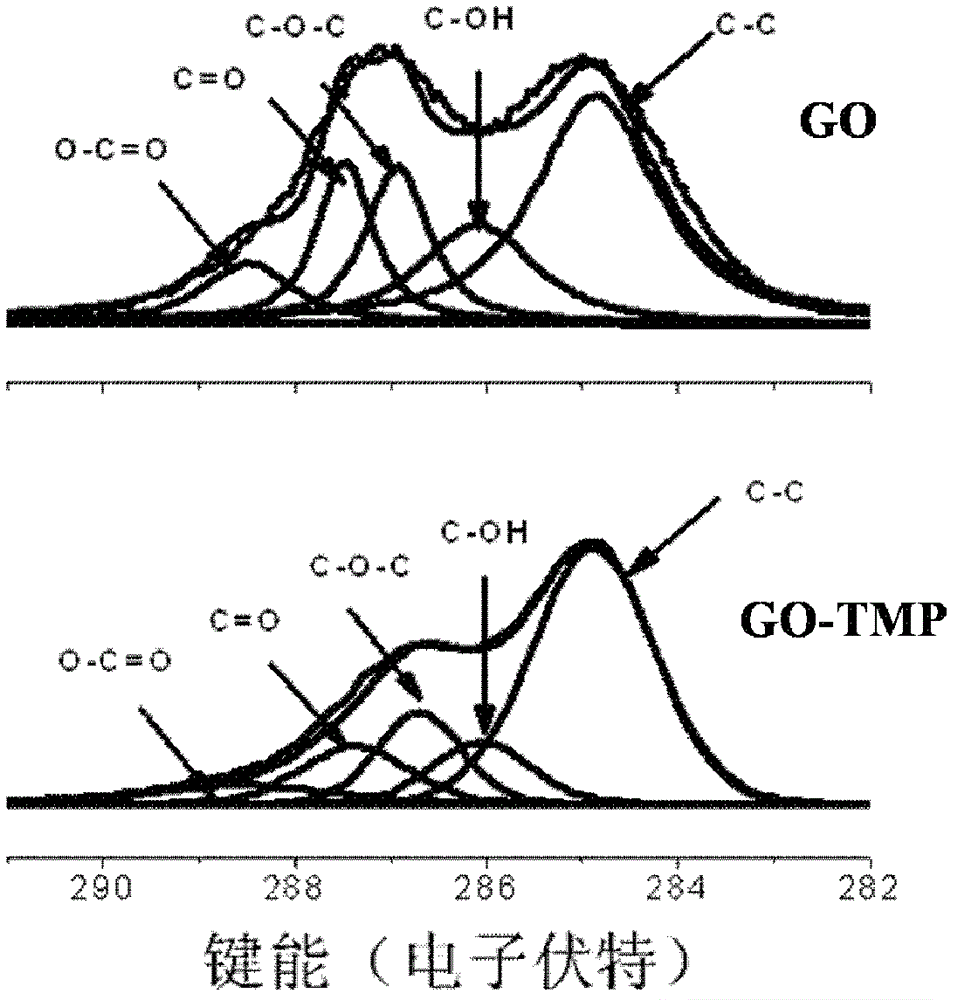

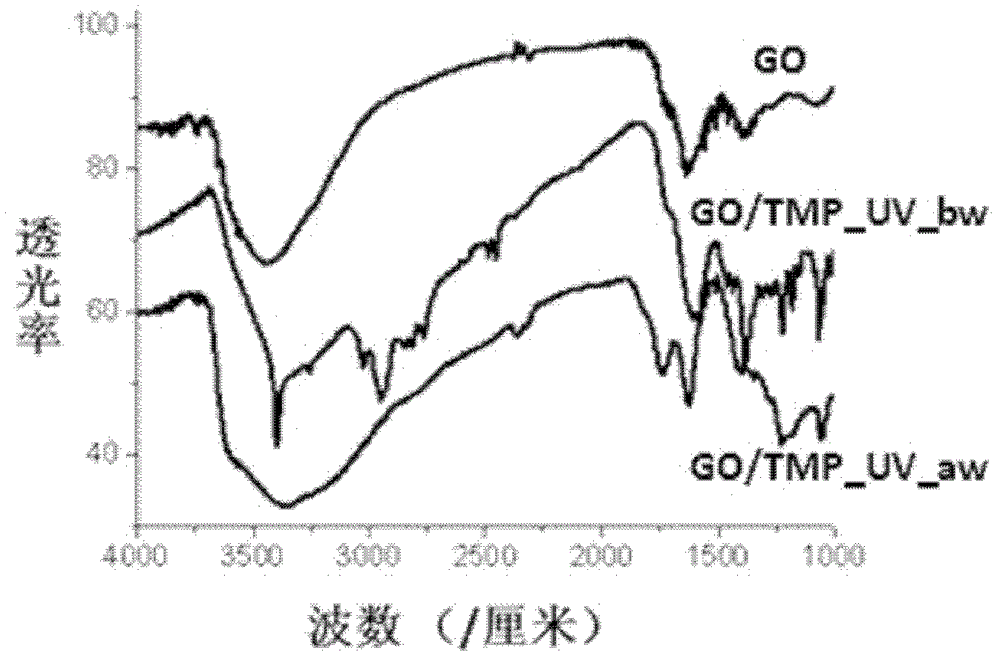

Method for selectively reducing graphene oxide by using hindered amine light stabilizer

A technology of light stabilizers and hindered amines, which is applied in the field of nanomaterials chemical technology, can solve the problems of blending materials that limit graphene, and achieve the effects of energy saving and environmental protection, simple operation methods, and high group selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] Example: preparation of redispersible graphene semiconductor material by catalysis of small molecular hindered amines.

[0036] Graphene oxide powder preparation: 2.5g graphite, 1.9g NaNO 3 , 11.5g KMnO 4 and 85ml concentrated H 2 SO 4 After mixing, stir in an ice bath for 1 hour, then stir at room temperature for 2 days, and finally add 250ml of 5wt% concentrated sulfuric acid and 20ml of 30wt% H 2 o 2 Continue to stir for 2 days, centrifuge, and wash with deionized water, repeating this 8 times to obtain graphene oxide.

[0037]Preparation of graphene oxide solution: First, the prepared graphene oxide is ultrasonically dispersed to obtain a dispersed graphene oxide solution, and a very small amount of unexfoliated particles is removed by centrifugation at 3000 rpm for 30 minutes. Secondly, the centrifuged upper layer solution was centrifuged again at a speed of 4000 rpm for 30 minutes to obtain a sediment containing graphene oxide with a relatively uniform size, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com