Patents

Literature

199results about How to "Reduce brake noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

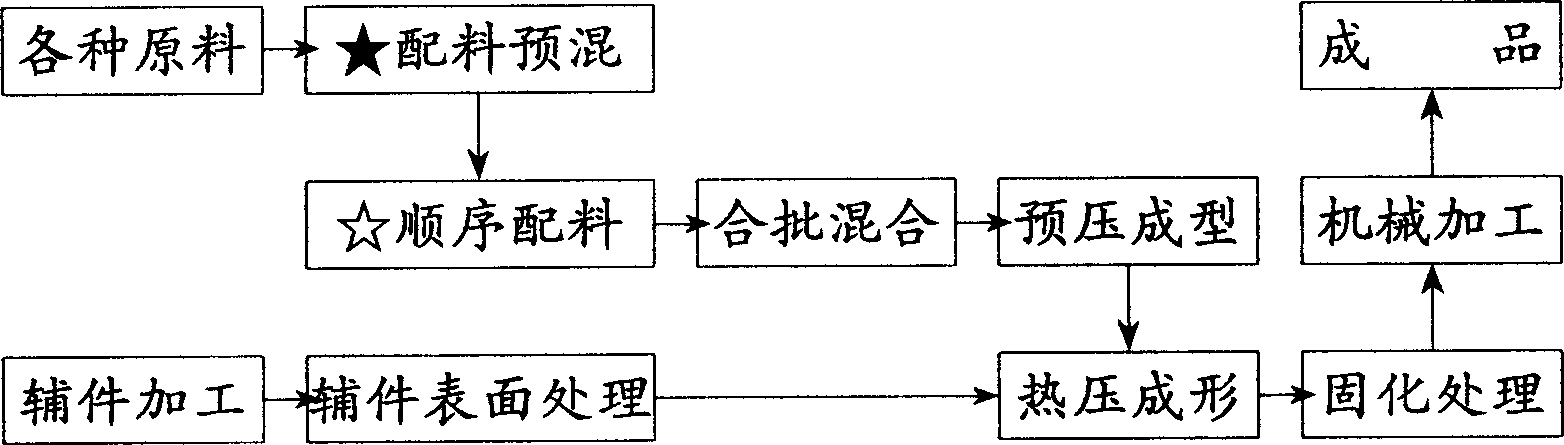

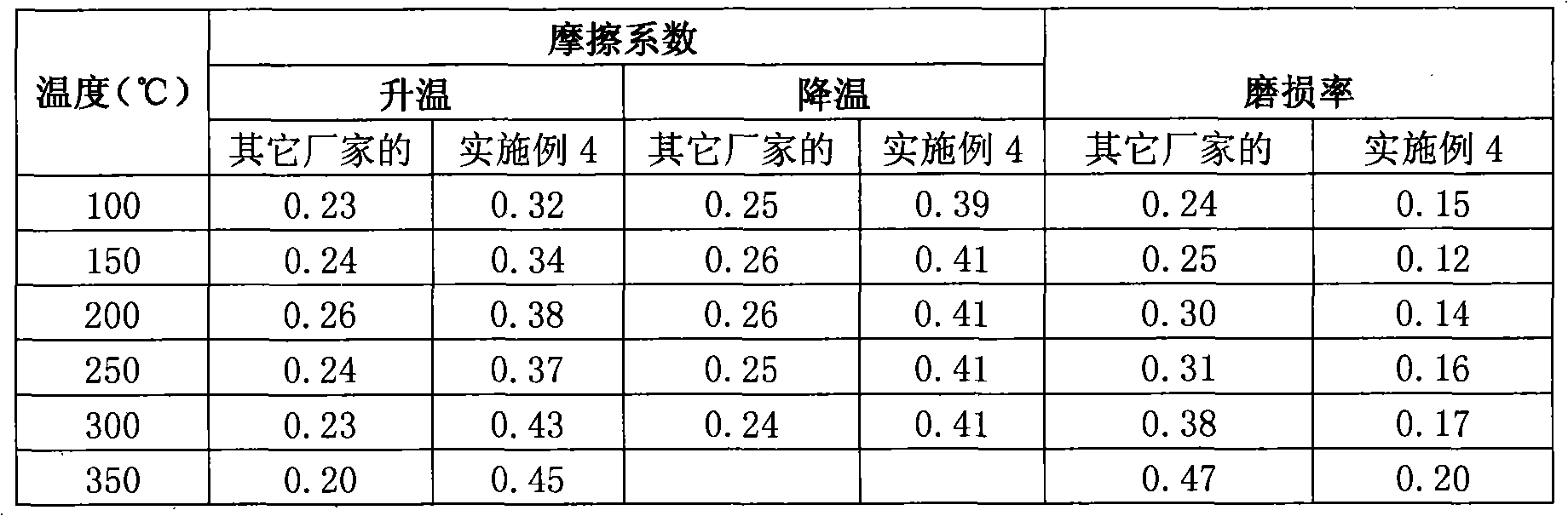

Environment-protection type high-performance automobile braking piece and making method

InactiveCN1814657AIncrease frictionOvercoming high temperature recession defectsFriction liningFiberAdhesive

This invention relates to a preparation technology for producing special products with plastic substances characterizing in mixing an adhesive agent, strengthened fibers, a regulator for friction performance and inorganic fillers in good match to process the surfaces of them with an anti-high temperature coupler to be hot-pressed to a format to get a high performance car brake plate of environmental protection, which replaces that made of asbestos fiber and overcomes the shortcoming of declining at high temperature of the asbestos car brake plates.

Owner:CENT SOUTH UNIV +1

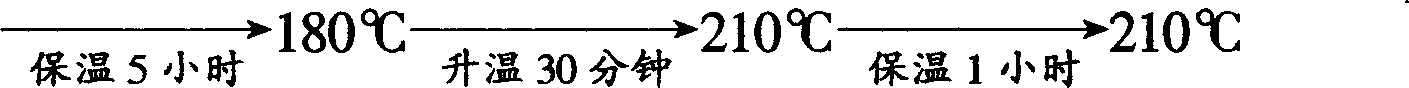

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

Disc brake for vehicle

Owner:HITACHI ASTEMO LTD

High-performance semi-metallic brake pad

ActiveCN101555915ASensitive brakesReduce brake noiseFriction liningGraphite particleAluminium silicate

A high-performance semi-metallic brake pad comprises the following components according to weight percentages: 4-6% of nitrile rubber powder, 2-4% of tyre powder, 3-5% of crystalline flake graphite, 6-9% of foam iron powder, 9-13% of boron containing phenolic resin, 8-12% of chopped steel fibre, 2-4% of alumina fibre, 8-11% of red copper fibre, 2-5% of cashew nut oil friction powder, 2-3% of graphite particle, 2-3% of calcined petroleum coke, 7-13% of barite, 3-4% of chromite, 2-3% of magnetite, 2-4% of diatomite, 7-10% of glued aluminium silicate fibre, 3-5% of flake aluminium powder, 2-4% of molybdenum disulfide, 0.2-0.5% of zinc stearate, 0.7-1% of antimony sulphide, 0.5-1% of copper sulphide, and 0.3-0.5% of tungsten carbide. After the brake pad is used, the car brake is sensitive, brake noise is low and comfort performance is good. The brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

Method for preparing brake pad friction material by using rice and wheat straws

InactiveCN103820078AAbundant resourcesReduce recycling costsOther chemical processesFriction liningFiberAtmospheric pollution

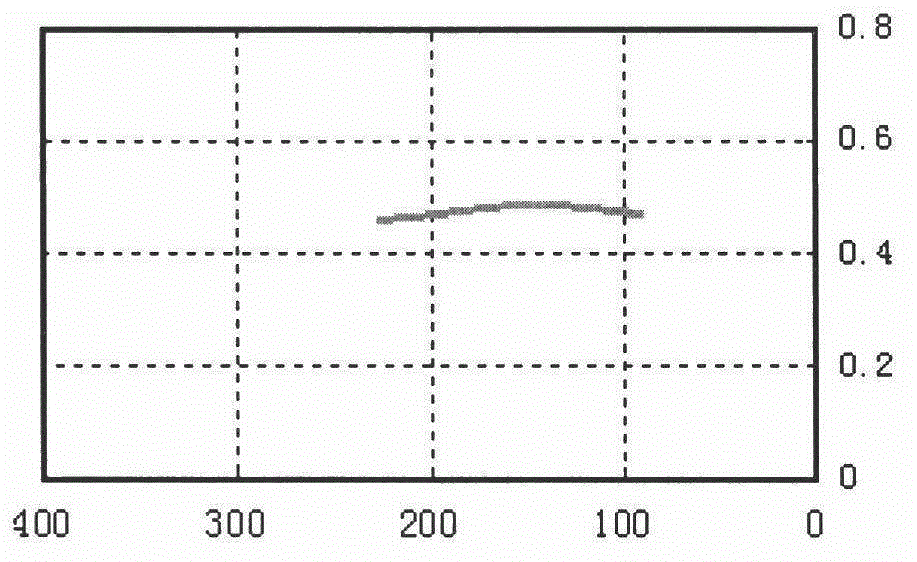

The invention discloses a method for preparing a brake pad friction material by using rice and wheat straws and relates to the technical field of composite materials. The brake pad friction material has the following formula: 15 percent of toughened fibers, 16 percent of modified resin, 14 percent of a friction increase agent, 9 percent of sulfur and tin powder, 1.6 percent of carbon black, 2.5 percent of zinc oxide, 8.9 percent of barium sulfate, 10 percent of rice and wheat straw carbon powder, 6 percent of aluminum hydroxide, 14 percent of modified li beads and 3 percent of zinc stearate. The materials are uniformly mixed and stirred, pressed in a mold and subjected to machining such as grinding and chamfering according to a technical requirement to obtain a braking pad. According to the method, the rice and wheat straws are used as raw materials to prepare carbon powder which replaces graphite in a friction material formula, so that the atmospheric pollution caused by severe combustion of straws in each year is alleviated, the production cost of the brake pad is reduced, and the brake performance and the braking effect are enhanced; the friction coefficient is stable; the brake pad is simple in structure, low in brake noise, environment-friendly and pollution-free.

Owner:YANCHENG XINHAO MACHINERY

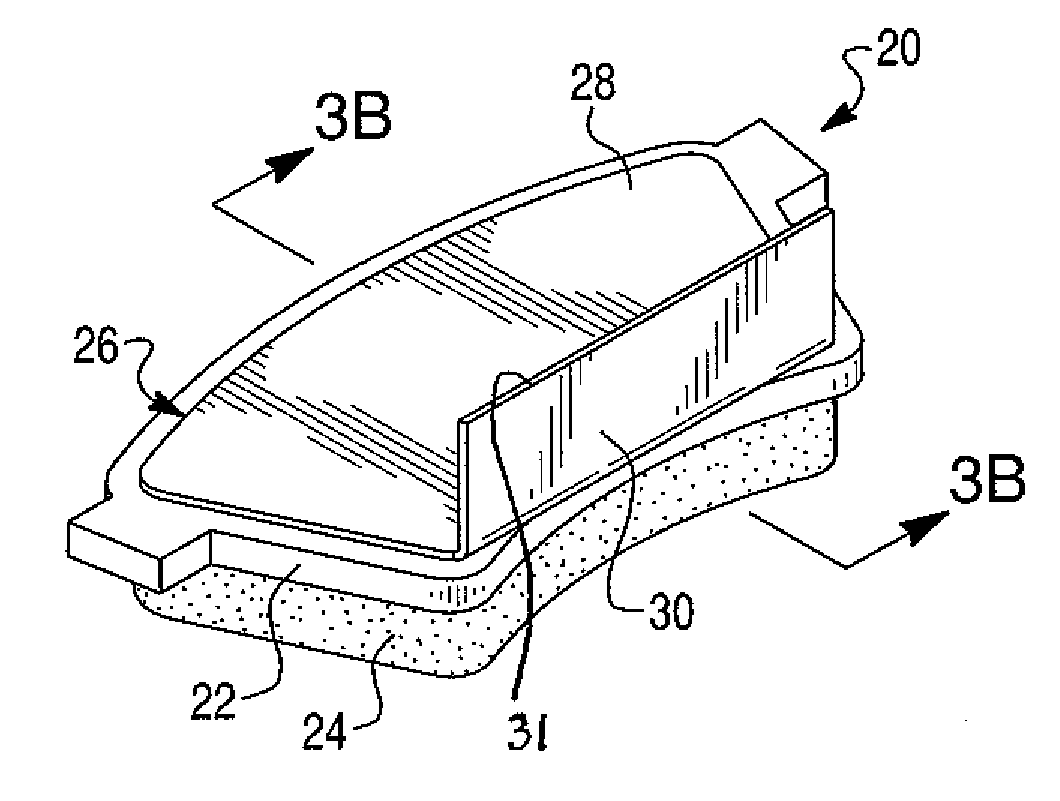

Flanged shim for disc brake squeal attenuation

ActiveUS20090223753A1Large dampingArea maximizationFluid actuated brakesNoise/vibration controlUltrasound attenuationEngineering

A brake pad assembly provided for a disc brake apparatus. The brake pad assembly comprises a backing plate having a flat inner face and a flat outer face oriented opposite to the inner face, a friction member fixed to the inner face of the backing plate, and an anti-squeal shim attached to the outer face of the backing plate. The anti-squeal shim includes a flat support plate attached to the outer face of the backing plate and a straight flat flange plate. The support plate of the anti-squeal shim has a peripheral edge including opposite outer and inner edges and opposite side edges. The flange plate is in the form of a flexible cantilever formed integrally with the support plate of the anti-squeal shim and extends away from one of the outer, inner and opposite side edges of the support plate of the anti-squeal shim.

Owner:WOLVERINE ADVANCED MATERIALS

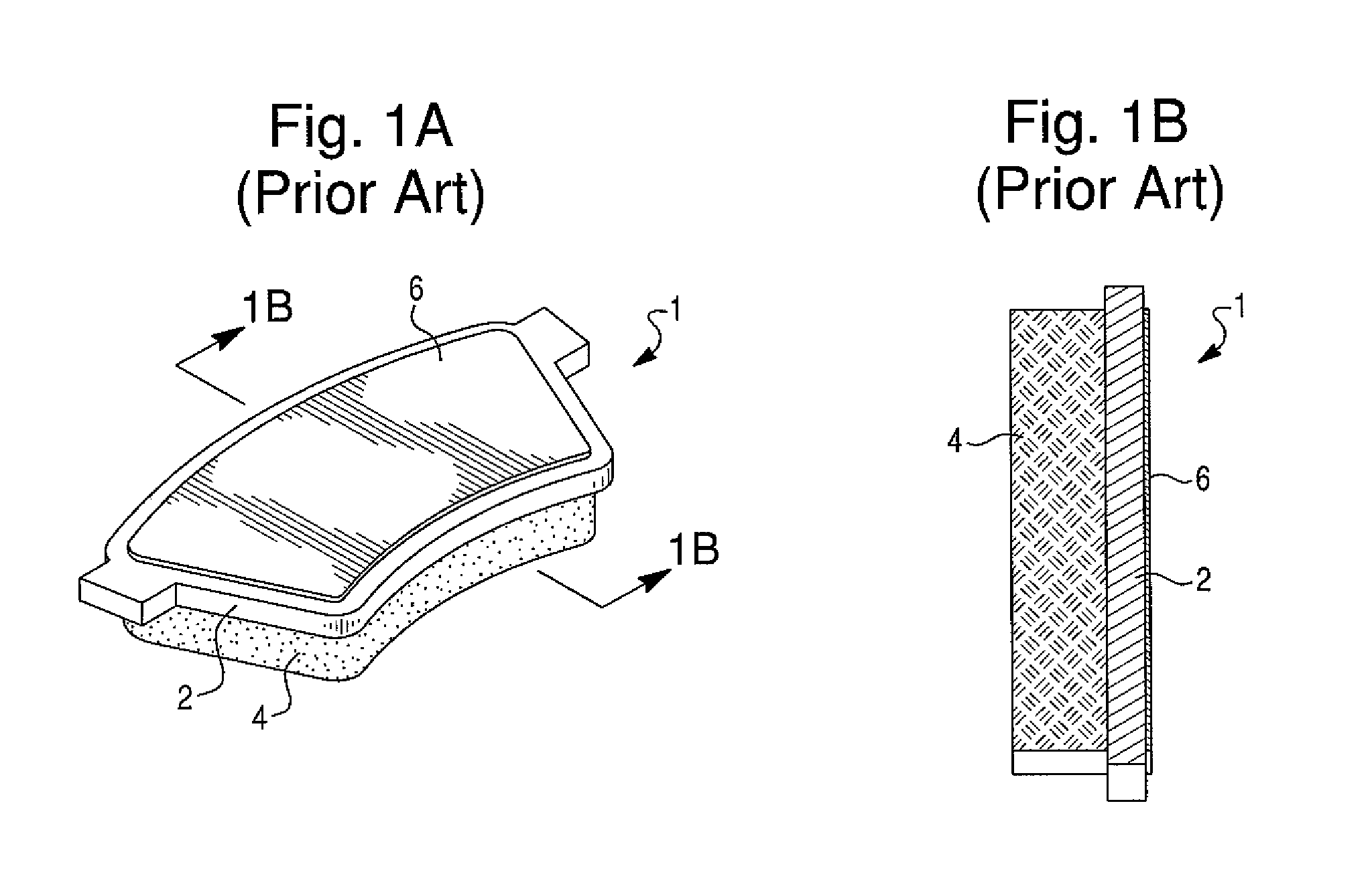

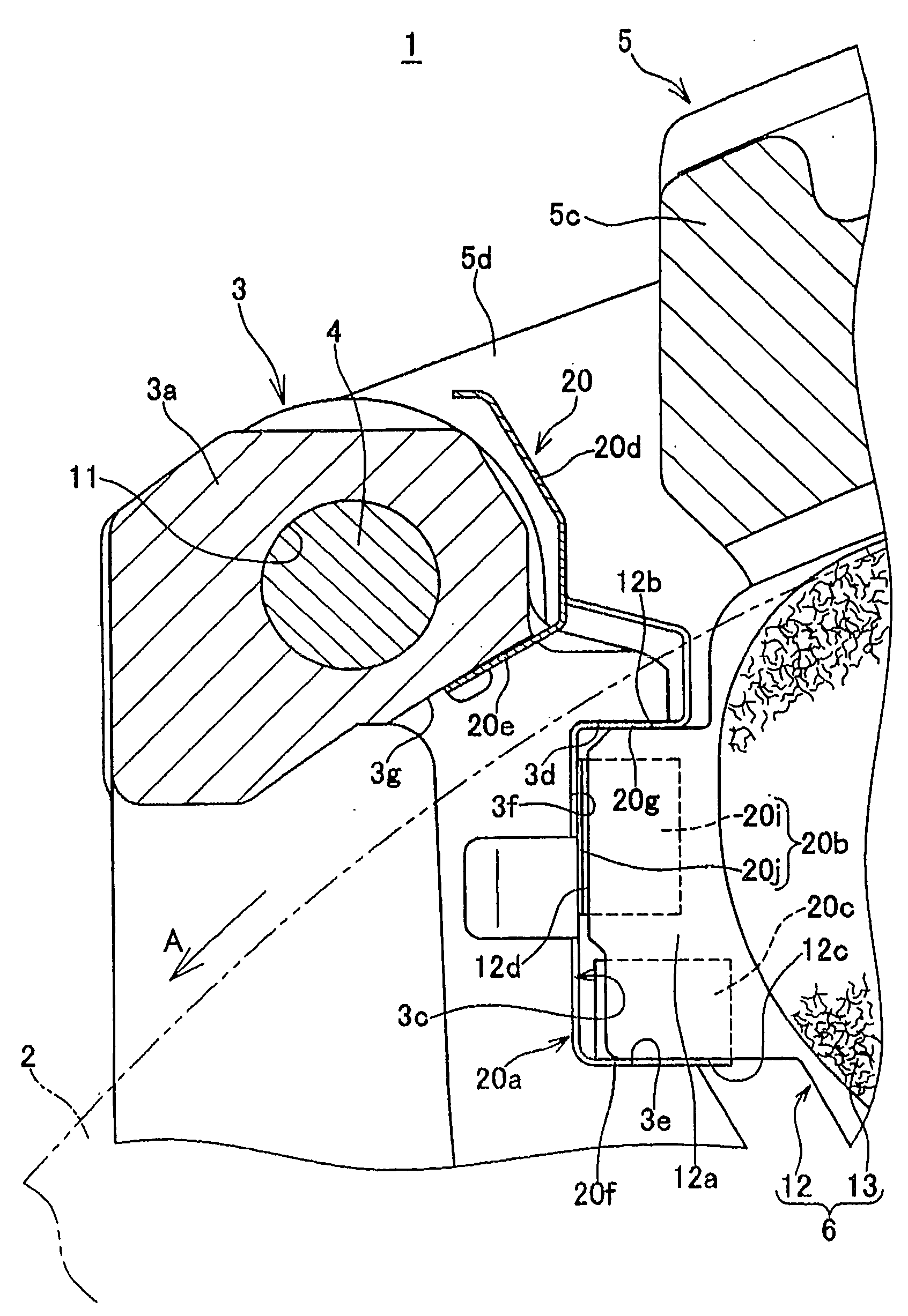

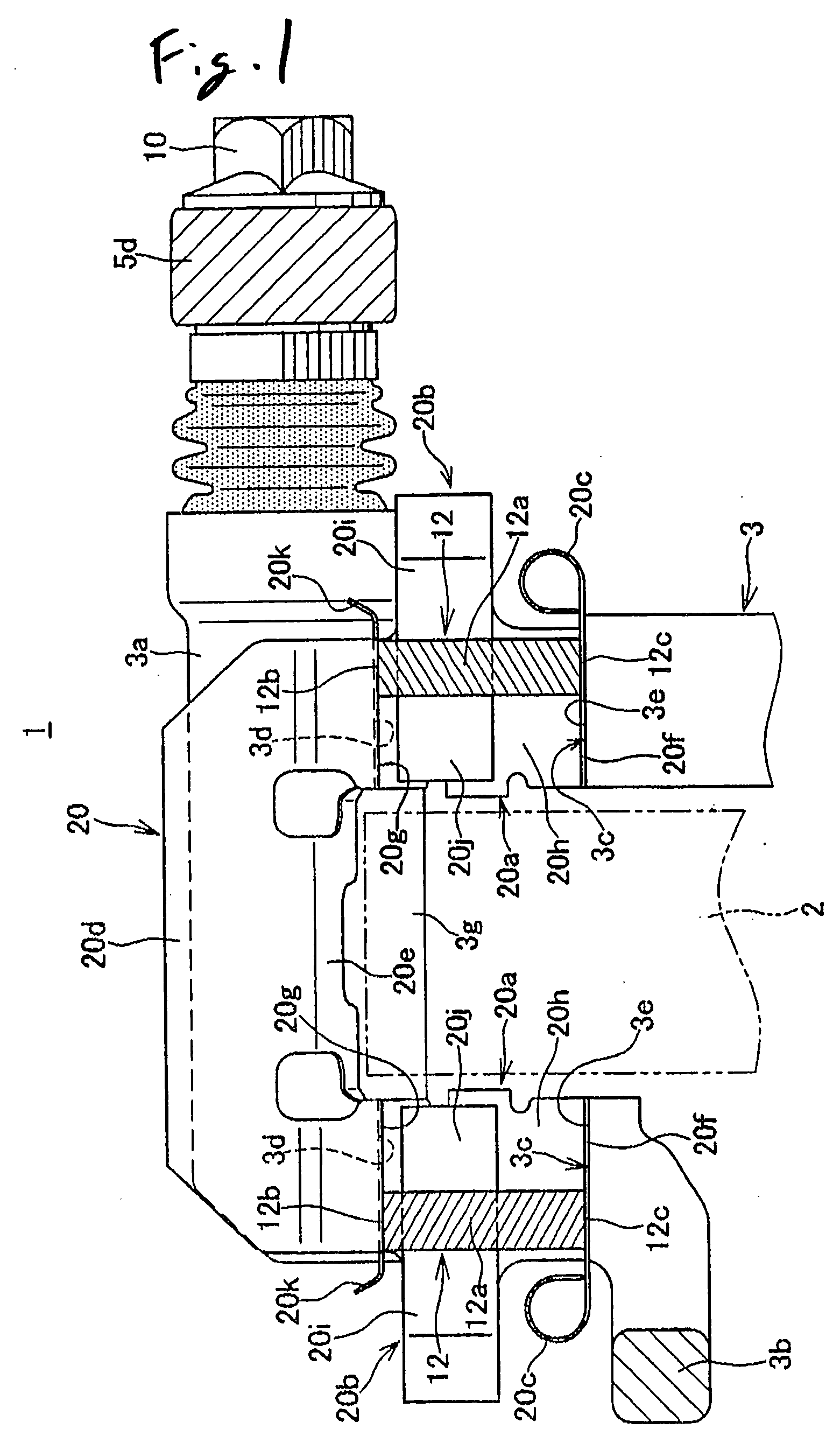

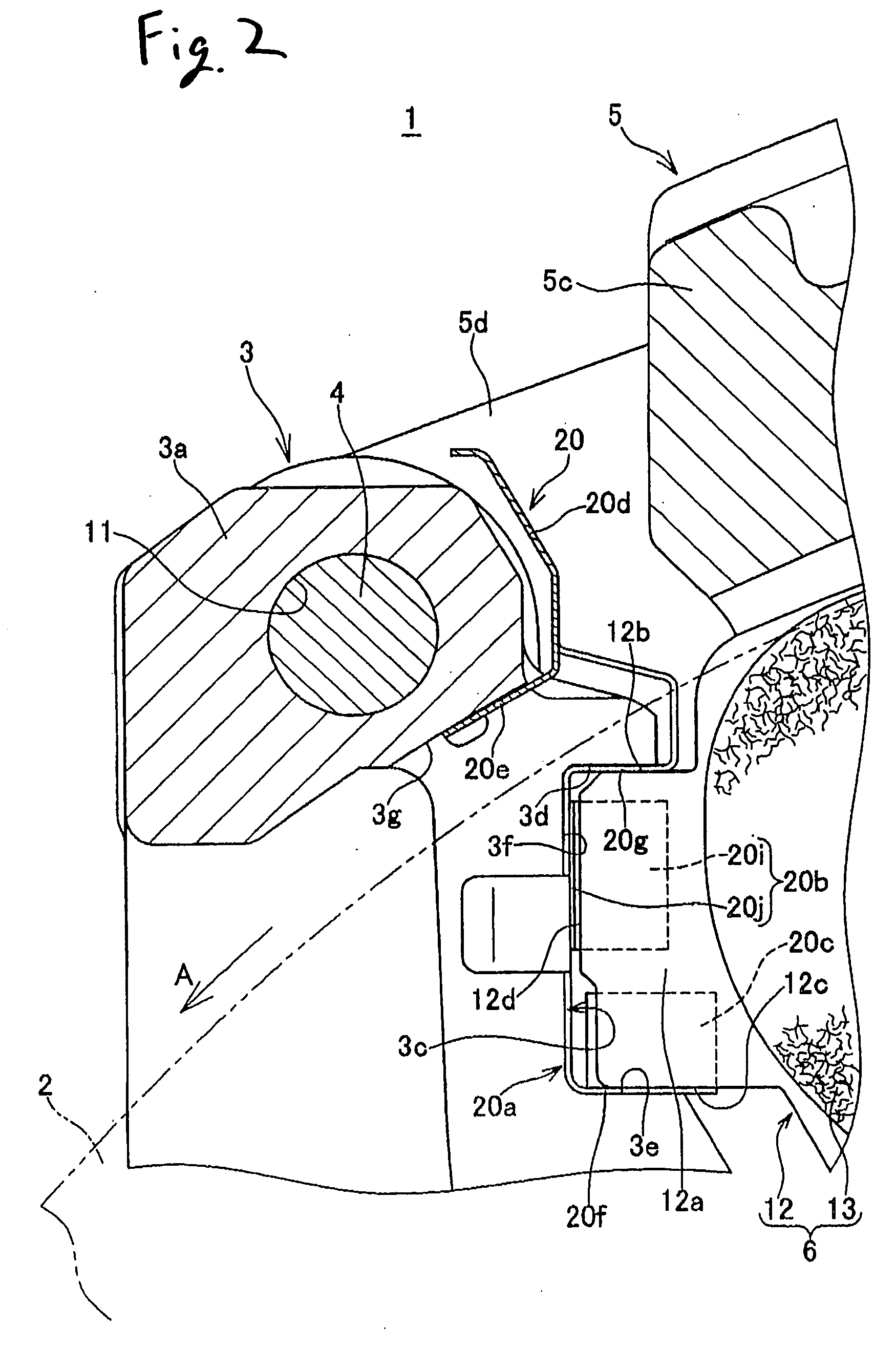

Disc brake for vehicle

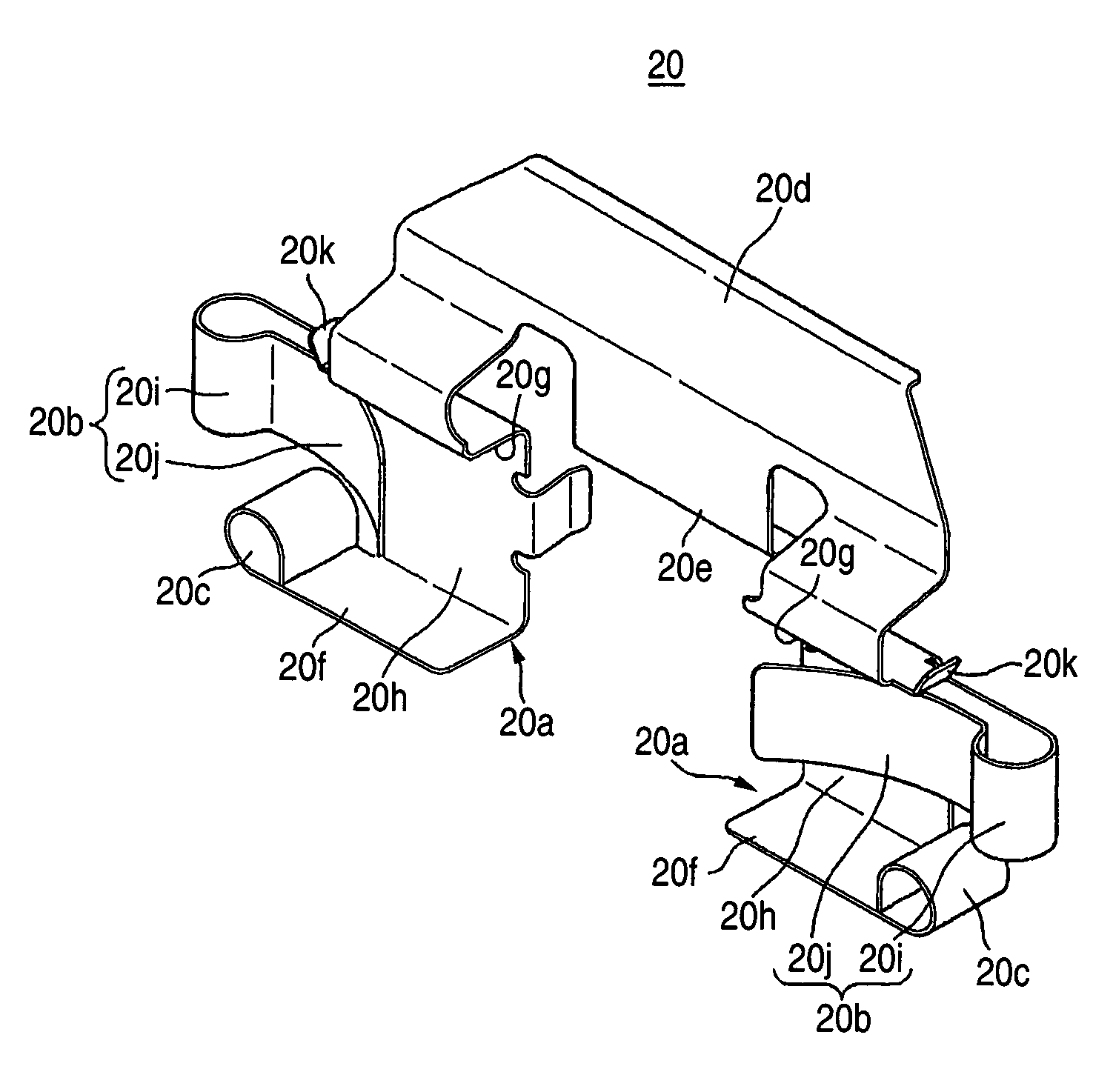

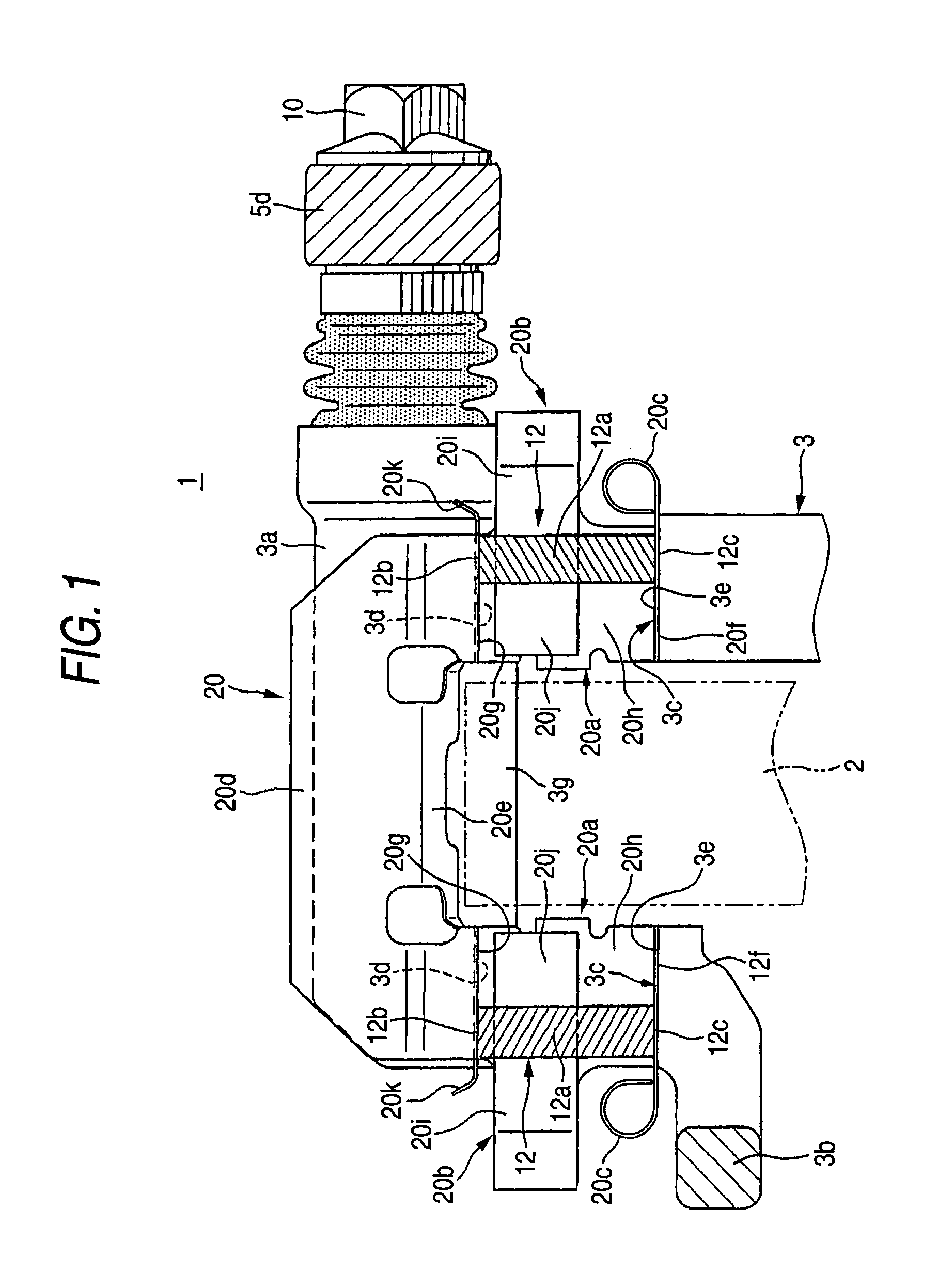

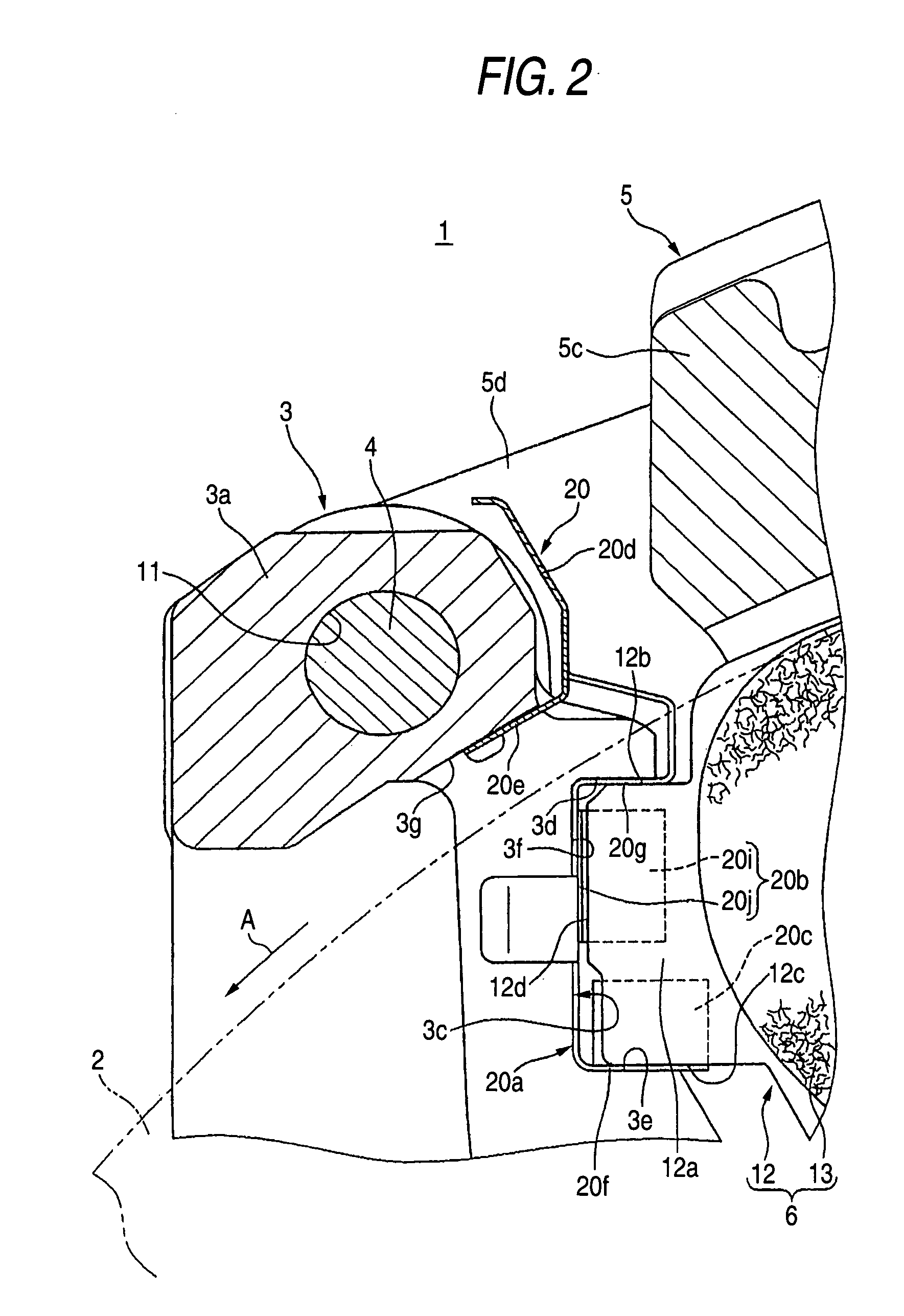

ActiveUS20040144602A1Reduce brake noiseSuppress tremorAxially engaging brakesSlack adjustersEngineeringCalipers

A disc brake for a vehicle has a caliper bracket fixed to a vehicle body, a pair of caliper support arms striding an outer periphery of a disc rotor in a disc axial direction, pad guide grooves formed in the caliper support arms so as to be opposed to each other, friction pads disposed on both sides of the disc rotor, the friction pads having ears projected from both side portions of a back plate thereof, and pad retainers disposed on the pad guide grooves, the ears of the friction pads being movably supported by the pad guide grooves via the pad retainers, wherein pad retainers each has pad returning portions for urging the friction pads away from the disc rotor.

Owner:HITACHI ASTEMO LTD

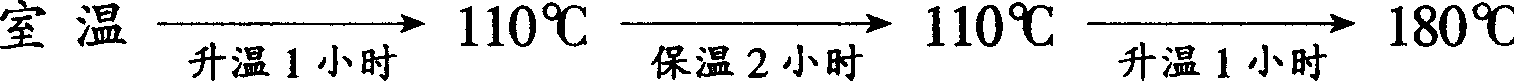

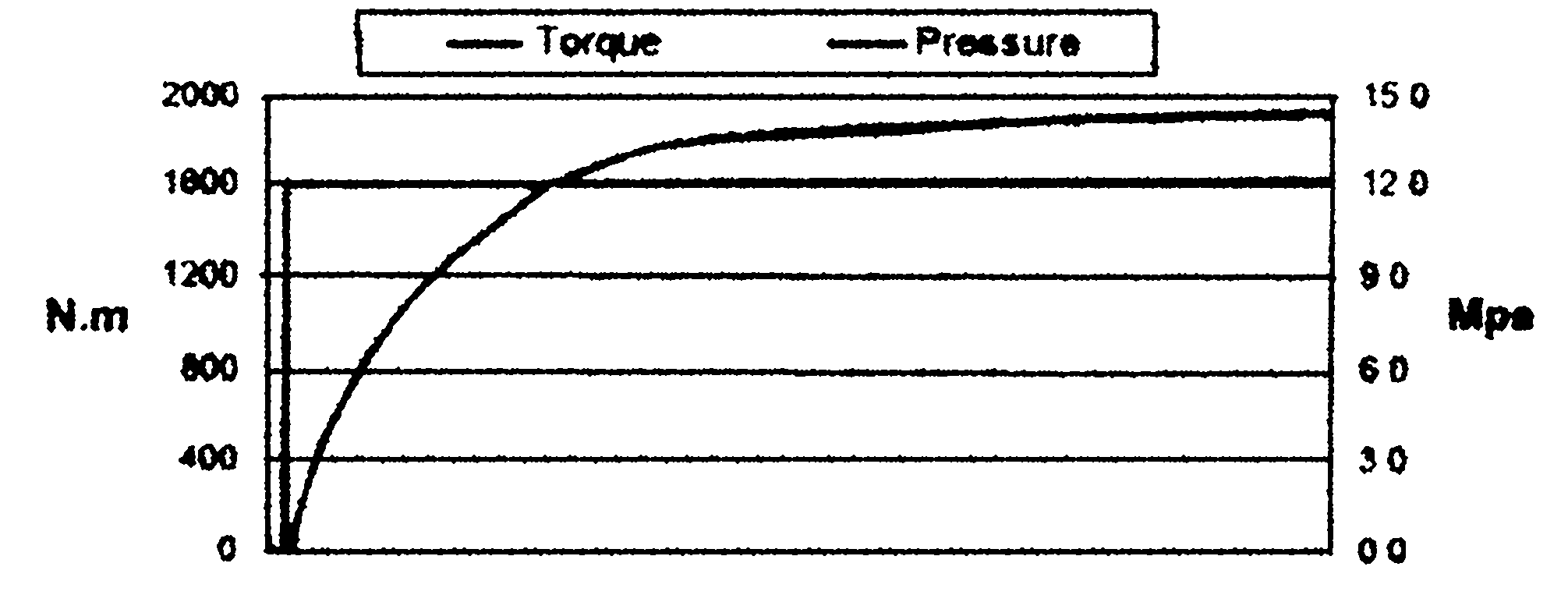

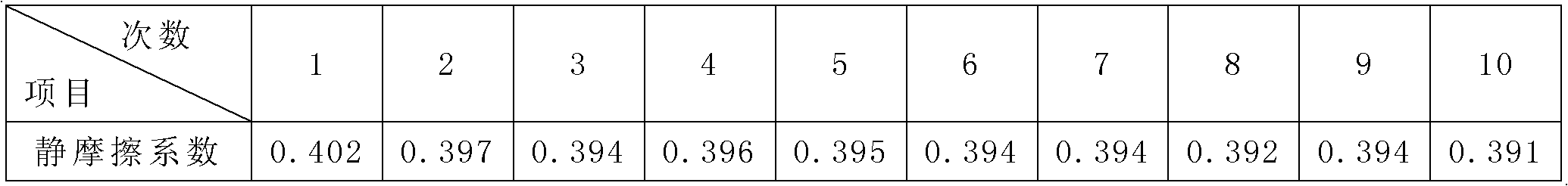

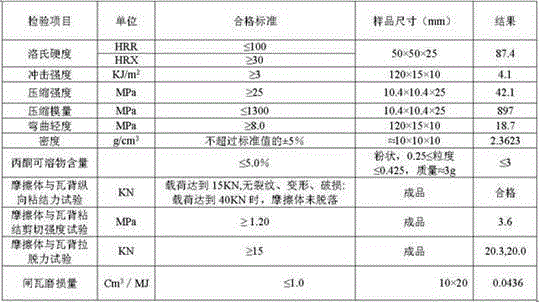

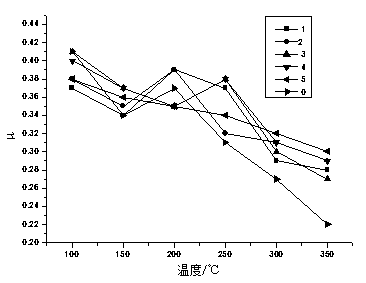

Resin-based yawing brake pad for wind-generated generator and preparation method thereof

InactiveCN101956775AMeet the requirements of yaw low speed brakingHigh coefficient of static frictionFriction liningLow speedAluminum silicate

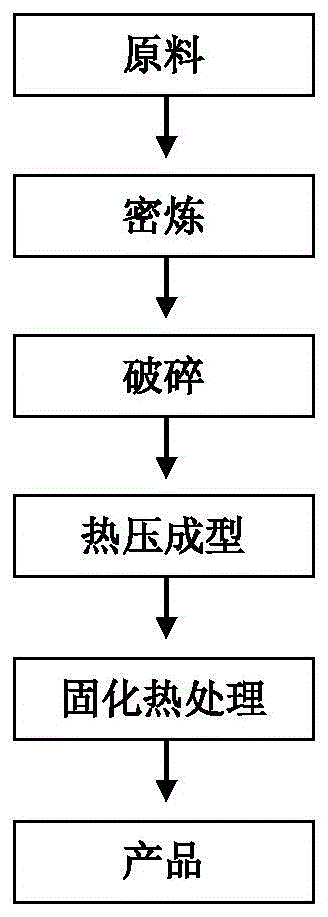

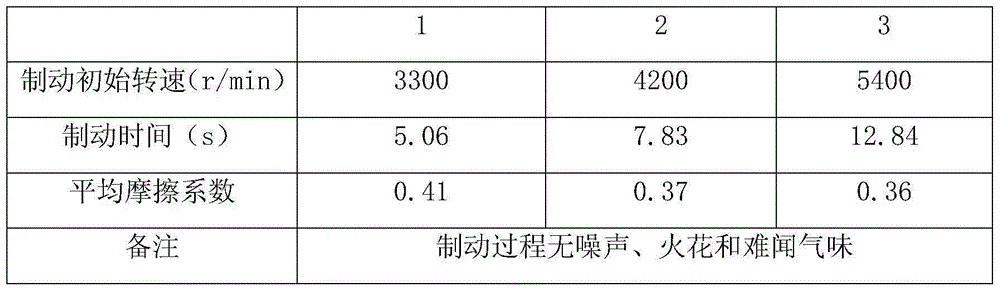

The invention discloses a resin-based yawing brake pad for a wind-generated generator and a preparation method thereof. The resin-based yawing brake pad comprises phenolic resin, nitrile butadiene rubber, organic friction powder, chopped steel fiber, red copper fiber, aramid fiber, aluminum silicate / KFK fiber, graphite, barite and the like. The preparation method comprises the following steps of: weighing various components according to the formula; mixing the components by a plow harrow type blender mixer at high speed; ensuring that each fiber is fully dispersed uniformly; hot pressing forming at the temperature of 160-200DEG C; carrying out heat treatment in a heat treatment tank; cooling to the room temperature along the temperature of the furnace; and finally, machining to obtain the resin-based yawing brake pad. Compared with the general powder metallurgy brake pad, the yawing brake pad has the advantages of proper static friction coefficient, stable friction coefficient, low brake noise, smaller antithesis wear and lower manufacturing cost and can fully meet the yawing low-speed brake of the wind-generated generator.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Low copper-containing friction material composition used as brake pad

A low copper-containing friction material composition used for brake pad is provided, which consists of the following components by weight parts: 4˜6 parts of aramid fiber, 2˜2.5 parts of tyre powder, 5˜6 parts of heavy magnesia, 5˜6 parts of red vermiculite, 8˜10 parts of ceramic fiber, 3.5˜5 parts of magnetite, 7˜8 parts of boron-containing phenolic resin, 15˜17 parts of calcium sulfate crystal whisker, 16-18 parts of potassium titanate, 15˜17 parts of barite, 5.5˜7 parts of flake graphite, 6˜8 parts of friction powder of cashew nut oil, 6˜8 parts of calcined petroleum coke, 1.5˜2 parts of boron nitride, 5˜7 parts of flake aluminum powder, 0.4˜0.5 parts of pure copper fiber, 0.4˜0.6 parts of black silicon carbide. Said friction material composition is highly environmental friendly and has low content of heavy metal, wherein the content of copper is lower than 0.5%, and an excellent friction layer and transfer membrane can be formed when using said friction material composition. Said friction material composition has a satisfactory high temperature and thermal decay resistant performance, long service life, good abrasion resistance and stable friction coefficient.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

High-friction coefficient composition brake shoe and production method thereof

The invention relates to a high-friction coefficient composition brake shoe. The high-friction coefficient composition brake shoe comprises a steel backing and a friction material, the friction material comprises the following raw materials including, by weight, 1-5 parts of aramid fiber, 8-12 parts of butadiene-acrylonitrile rubber, 0.5-1 part of stearic acid, 0.3-1 part of an accelerant, 0.6-1 part of sulphur, 0.5-1 part of zinc oxide, 4-7 parts of phenolic resin, 10-20 parts of inorganic composite fiber, 8-15 parts of iron powder, 10-20 parts of barium sulfate, 7-15 parts of kibdelophane powder, 5-10 parts of steel wool fiber, 1-3 parts of bauxite, 8-15 parts of potassium feldspar powder, 2-5 parts of mica, 2-5 parts of flake graphite, 5-10 parts of sepiolite fiber and 2-5 parts of molybdenum disulfide. By means of the high-friction coefficient composition brake shoe, the change of the speed of the wear rate of the high-friction coefficient composition brake shoe can be basically identical to the change of the adhesion coefficient of a wheel track, the abrasion loss when a vehicle is braked is less, failure can not occur in braking, and the traffic safety is guaranteed. The invention provides a production method of the high-friction coefficient composition brake shoe at the same time.

Owner:HEBEI XINJI TENGYUE INDAL

Low-noise heat-fade-resistant resin-base friction material

InactiveCN104109342AStable coefficient of frictionReduce noiseOther chemical processesLow noisePolymer science

The invention discloses a l-noise heat-fade-resistant resin-base friction material which is prepared from the following components in percentage by mass: 10-15% of nano aluminum oxide modified phenol aldehyde resin, 3-6% of aramid fiber pulp, 12-18% of mineral fiber, 5-7% of graphite, 3-5% of antimony trisulfide, 5-7% of coke, 0.5-1.5% of aluminum oxide, 3-5% of ferric oxide, 5-7% of cashew oil friction powder, 3-9% of expanded vermiculite, 2-6% of kieselguhr, 3-9% of nitrile-butadiene rubber and the balance of barium sulfate. The material has the advantages of appropriate and stable friction factor, favorable heat fade resistance, low abrasion ratio, low braking noise, high plastic deformation resistance, high shock resistance and the like, and conforms to the operating requirements.

Owner:YANCHENG INST OF TECH

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

Copper-free organic ceramic brake pad

InactiveCN104179860AImprove heat resistanceImprove recession resistanceFriction liningAdhesiveHeat resistance

The invention discloses a copper-free organic ceramic brake pad which comprises an adhesive, a reinforcing material, a friction performance modifier and filler. Modified sulfide, modified graphite, the friction material reinforcing agent and the friction performance modifier are adopted in the formula of a friction material, so that the heat resistance, anti-declining performance, noise reduction property and impact resistance of the friction material are improved, the service life can be prolonged, and the corresponding comprehensive usability of the friction material can be improved. The advantages of stable compression performance, excellent flexibility and lubrication property and the like of the modified sulfide and the modified graphite are used for the formula design of the friction material, so that high-temperature friction performance is guaranteed, high-temperature wear of a product is smaller, friction couple is not damaged, brake noise is reduced, high-temperature cracks are avoided, environmental pollution is reduced, and the like.

Owner:东营宝丰汽车配件有限公司

Potassium hexatitanate/sodium hexatitanate whisker composite ceramic frication material and preparation method thereof

The invention relates to a composite ceramic fiction material of potassium hexatitanate / sodium hexatitanate whisker belonging to the material technical field, wherein the composite ceramic fiction material comprises 5-20 parts of organic resin, 1-10 parts of rubber powder, 10-40 parts of potassium hexatitanate and sodium hexatitanate whisker, 0-5 parts of aramid fiber, 10-20 parts of graphite and 20-40 parts of filler. The composite ceramic fiction material of the invention doesn't contain asbestos without harming the human body and polluting the environment, which has superiorities in eliminating braking noise and heat degeneracy, improving using life of the product, overcoming adhesive occlusion among friction couples and the like.

Owner:SHANDONG UNIV

Thermal decay resistant composite fiber reinforced type brake pad

InactiveCN107489717AImprove thermal stabilityStrong resistance to heat decayOther chemical processesFriction liningFiberFrictional coefficient

The invention belongs to the technical field of brake pads and particularly discloses a thermal decay resistant composite fiber reinforced type brake pad. The thermal decay resistant composite fiber reinforced type brake pad is prepared from the components of, by weight, 7-23 parts of phenolic resin, 5-15 parts of reinforced composite fibers, 3-17 parts of mineral fibers, 2-8 parts of glass fibers, 3-8 parts of montmorillonite nano-powder, 0.3-0.9 part of 2,4,6-tris(dimethylaminomethyl)phenol, 5-15 parts of barium sulfate, 3-12 parts of butyronitrile powder, 4-11 parts of coke powder, 5-15 parts of frictional powder, 5-15 parts of graphite, 5-15 parts of tire powder, 3-7 parts of carbon black, 4-10 parts of nano fluorite powder, 2-7 parts of sepiolite, 3-9 parts of nano silicon dioxide aerogel powder, 2-6 parts of ground calcium carbonate and 5-15 parts of silane coupling agents. The metal-free brake pad is high in thermal stability, thermal decomposition resistant capacity and thermal decay resistant capacity, stable in frictional coefficient, high in abrasion resistant performance and low in brake noise.

Owner:杭州西湖摩擦材料有限公司

Metallic matrix spindle brake pad for wind driven generator and preparation method thereof

InactiveCN101660581AMeet the requirements of high-speed brakingImprove mechanical propertiesFriction liningFiberWind driven

The invention relates to a metallic matrix spindle brake pad for a wind driven generator and a preparation method thereof. The material comprises iron powder, copper powder, tin powder, sulphur, shortcut steel fiber, copper fiber, high alumina ceramic fiber, inorganic oxide, graphite, etc. The preparation method comprises: weighing the components of the material according to the formulation, stirring and mixing the components in a special dry-type mixer, and ensuring the fibers to be fully dispersed and even; pressing the mixture for molding at the normal temperature, then sintering at the certain pressure and temperature, and cooling along with a furnace; finally, machining to obtain the metallic matrix spindle brake pad. Compared with the common powder metallurgy brake pad, the frictionmaterial prepared by the method is added with metals and the ceramic fiber, so as to remarkably improve the mechanical properties of the material and the static friction torque; meanwhile, the product has the advantages of moderate and stable coefficient of dynamic friction, better wear resistance, low brake noise and less dual wear, can completely meet the requirement of the wind driven generator for high speed brake of a spindle, and realizes environmental protection in deed.

Owner:CENT SOUTH UNIV +1

Environment-friendly noise-free brake block and processing method thereof

InactiveCN103351844ANo pollutionSuitable for useOther chemical processesFriction liningFiberEnvironmental resistance

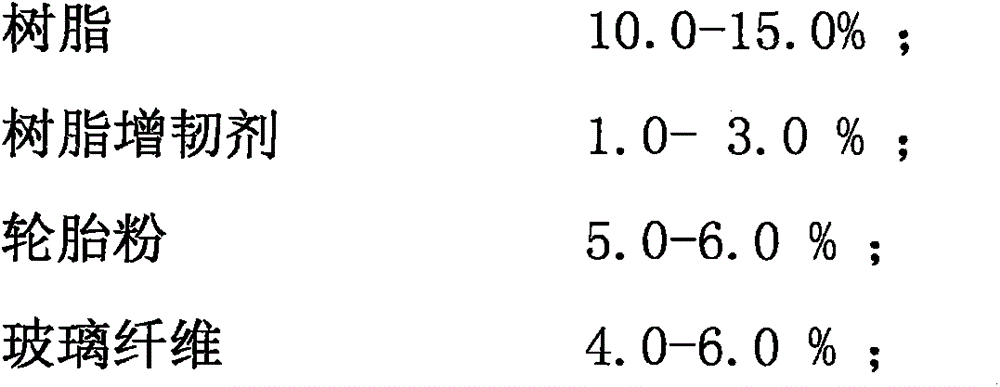

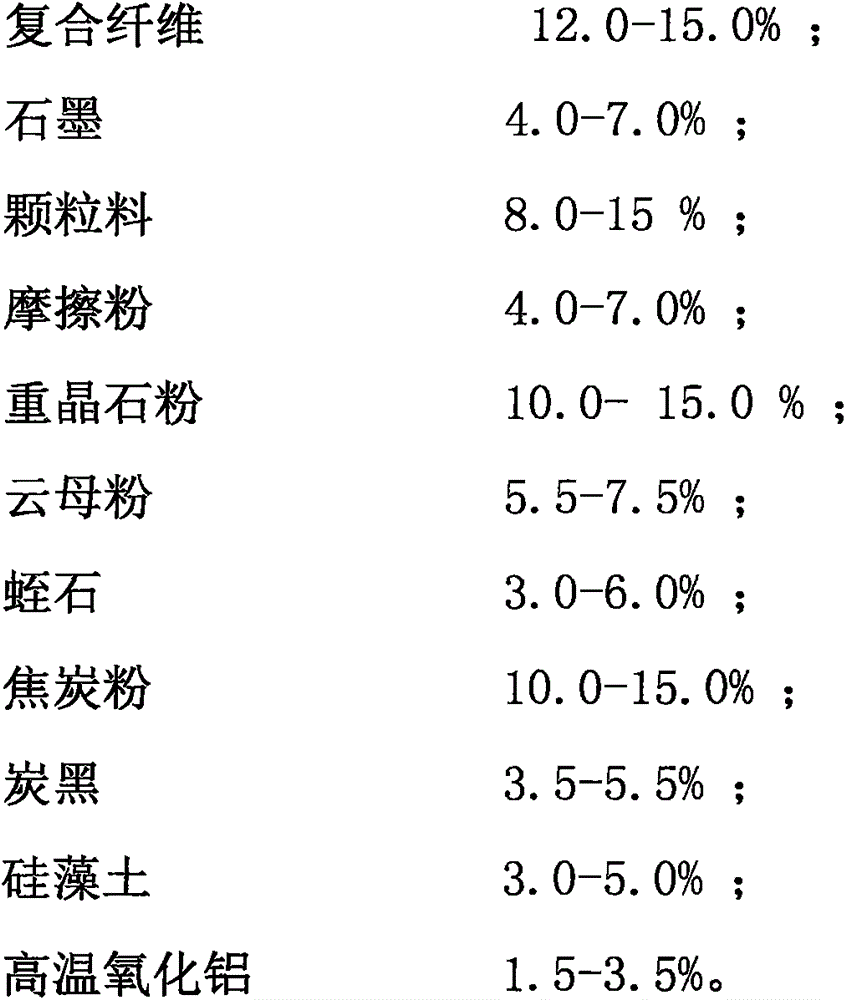

The invention discloses an environment-friendly noise-free brake block and a processing method thereof. The brake block is produced from resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, frictional powder, baryte powder, mica powder, vermiculite, coke blacking, carbon black, diatomite and high-temperature aluminium oxide. The environment-friendly noise-free brake block has the advantages that no asbestos, heavy metals and compounds are contained so that no dust falls after braking and no asbestos dust is generated to pollute environment and result in cancer, lots of soft raw materials such as flexible granules, and moreover, organic frictional powder and organic rubber powder are added, and simultaneously, inorganic packing such as coke and vermiculite of porous loose structure is added, so that the brake block is comfortable to brake without noise and thereby especially suitable for urban buses.

Owner:耿琪国

Little-dust and low-metal friction material and preparation method thereof

InactiveCN105041926AReduce ashLess ash falling, low brake heat fadingOther chemical processesFriction liningPolymer scienceCellulose fiber

The invention discloses a little-dust and low-metal friction material and a preparation method thereof. The friction material is composed of, by weight, binding agents, reinforced fibers, lubricating agents and filler, wherein the binding agents are composed of butyronitrile modified phenolic resin and butyronitrile rubber powder, the reinforced fibers are composed of aramid fibers, cellulosic fibers and steel fibers, the lubricating agents are composed of crystalline flake graphite and synthetic graphite, and the filler is composed of barite, friction powder, zircon powder and expanded vermiculite. The preparation method comprises the steps of batching, mixing, pressing, heat treating and machining. The little-dust and low-metal friction material and the preparation method thereof have the advantages that rusting does not occur easily, the braking noise is low, braking heat fading is reduced, wear resistance is higher and fall dust is little.

Owner:江苏普华力拓摩擦材料有限公司

Test bed for brake noise of high-speed train brake disc

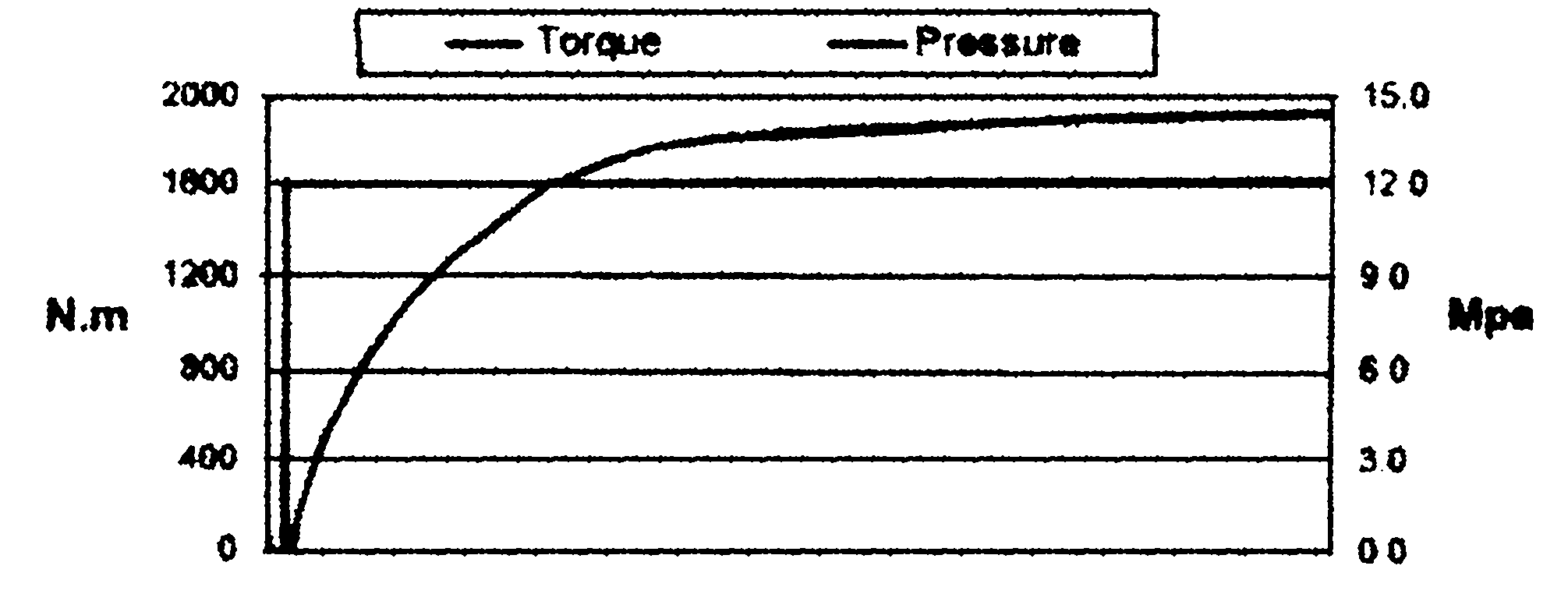

InactiveCN104535342AReduce brake noiseSimple structureRailway vehicle testingTorque sensorAutomotive engineering

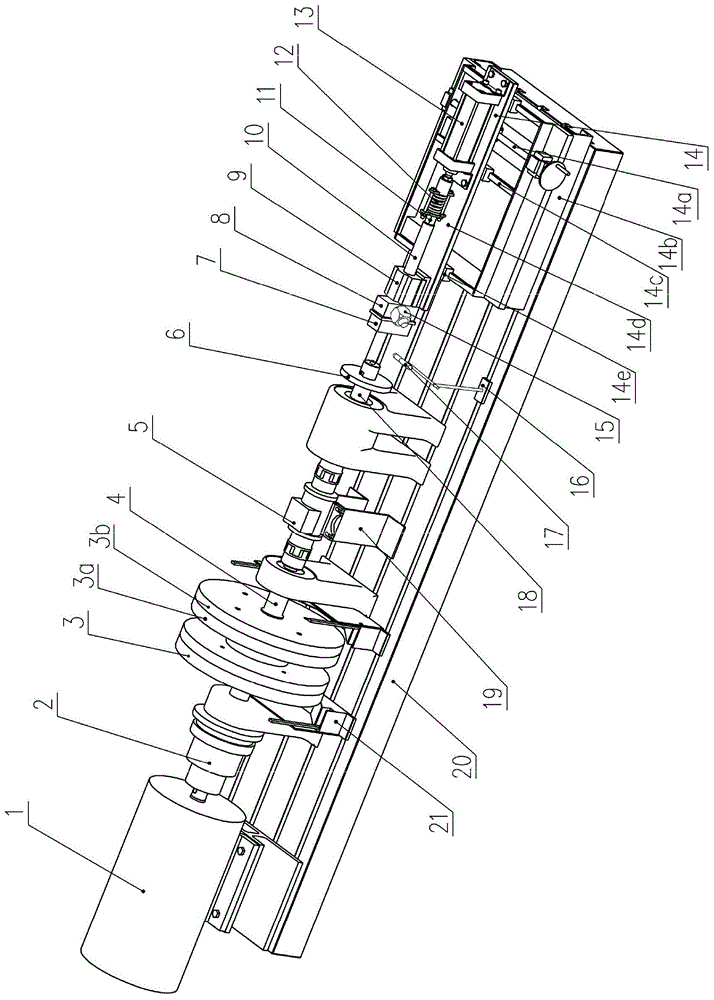

The invention relates to a test bed for brake noise of a high-speed train brake disc. According to constitution of the test bed, an output shaft of a variable frequency motor on the left side of a base is connected with a brake shaft sequentially through an electromagnetic clutch, a fly wheel shaft and a torque sensor, the brake disc is connected with the right end of the brake shaft, and a fly wheel set is fixed to the fly wheel shaft; a sliding table capable of moving front and back is arranged on the right side of the base, an air cylinder is installed on the right side of the sliding table, an output shaft at the left end of the air cylinder is connected with a clamp for clamping a brake pad sequentially through a spring, a piezoelectric type one-way force sensor and a guide rod, and the middle of the guide rod is supported on the sliding table through a linear bearing; a three-dimensional acceleration sensor is installed on the side face of the clamp, the left face of the brake pad is opposite to the right face of the brake disc, the induction end of a sound sensor is located nearby the brake disc, and the variable frequency motor, the electromagnetic clutch and the air cylinder are electrically connected with a control system. The test bed can simulate the brake working condition of the high-speed train brake disc to carry out brake noise tests, find out the relationship among the brake working condition, brake materials and the brake noise and provide a test basis for reducing the brake noise of the high-speed train brake disc.

Owner:SOUTHWEST JIAOTONG UNIV

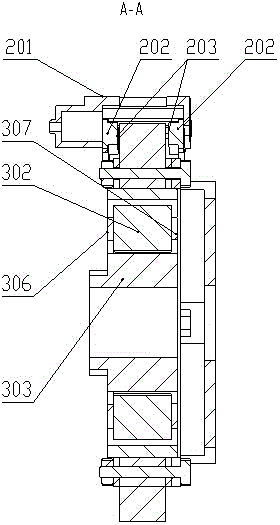

Brake integrating rotary barrel type eddy current retarder and drum brake

ActiveCN103089857AReduce generationIncreased braking safetyElectrodynamic brake systemsDrum brakesEddy currentElectromagnetic brake

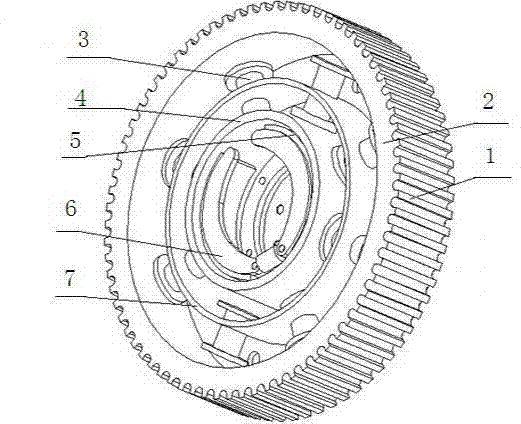

The invention discloses a brake integrating a rotary barrel type eddy current retarder and a drum brake, wherein the brake is used for braking and speed reduction of an automobile. A retarder outer rotor, a brake drum and a coil support are coaxial, and the coil support is located between the retarder outer rotor and the brake drum. A plurality of magnet exciting coils provided with iron cores are fixed on the coil support and are evenly distributed along the circumferential direction of the outer circle of the brake drum, the axial leads of the magnet exciting coils are located in the radial direction of the brake drum, and first gas intervals are formed between the magnet exciting coils and the retarder outer rotor, and second gas intervals are formed between the magnet exciting coils and the brake drum. Two adjacent magnet exciting coils provided with the iron cores, facing to the same gas interval, are opposite in polarity. When the automobile speed is low, a brake shoe enables a friction liner to be pressed towards the brake drum to achieve friction braking; when the automobile runs at a normal automobile speed, the magnet exciting coils are powered on to produce electromagnetic braking torque to reduce the automobile speed, and then the automobile is braked through friction. When the automobile speed is high, electromagnetic braking and friction braking act in a combined mode. Braking thermal failure is avoided, and safety performance of automobile braking is improved.

Owner:BAOHUA SEMI TRAILER FITTINGS CO LTD ZHENJIANG CITY

Novel environment-friendly noise-free brake pad and machining method thereof

InactiveCN105387107ANo pollutionSuitable for useOther chemical processesFriction liningFiberUrban bus

The invention discloses a novel environment-friendly noise-free brake pad and a machining method thereof. The brake pad is made of resin, a resin flexibilizer, tire powder, glass fibers, composite fibers, graphite, granules, friction powder, baryta powder, mica powder, vermiculite, powdered coke, carbon black, kieselguhr and high-temperature aluminum oxide. The novel environment-friendly noise-free brake pad has the beneficial effects that the brake pad does not contain asbestos or heavy metal or compounds, fallen dust is avoided after braking, and environment pollution and cancers are avoided as no asbestos powder is generated; a large quantity of the soft materials such as the flexible granules, the organic friction powder and the organic rubber powder are added, and the inorganic filler such as the porous coke of a loose structure and the vermiculite is also added, so that a user feels comfortable during braking, noise is avoided, and the brake pad is particularly suitable for urban buses.

Owner:QINGDAO LIBO AUTO PARTS PRECISION CASTING

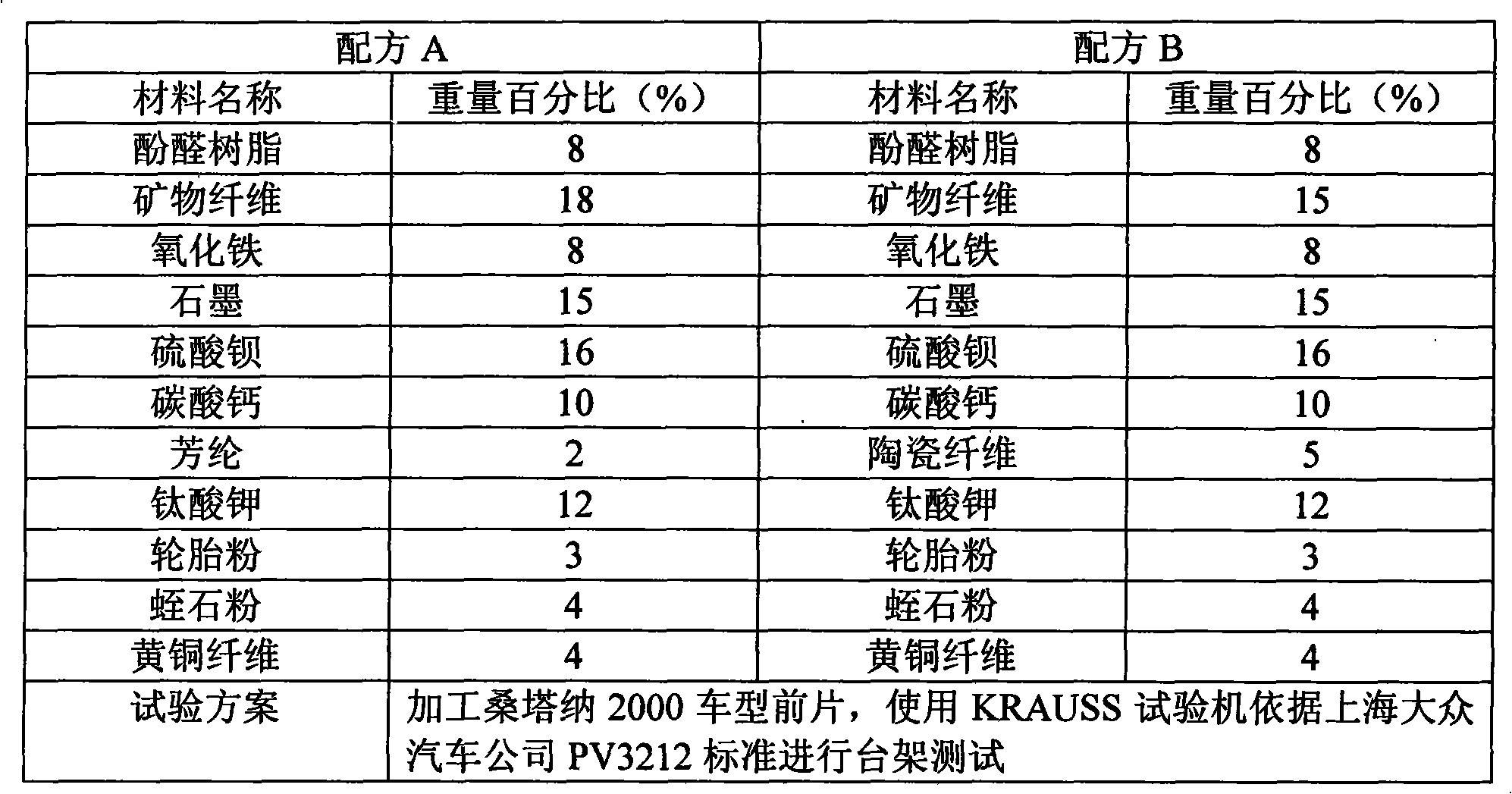

Method for producing friction material with ceramic fibre

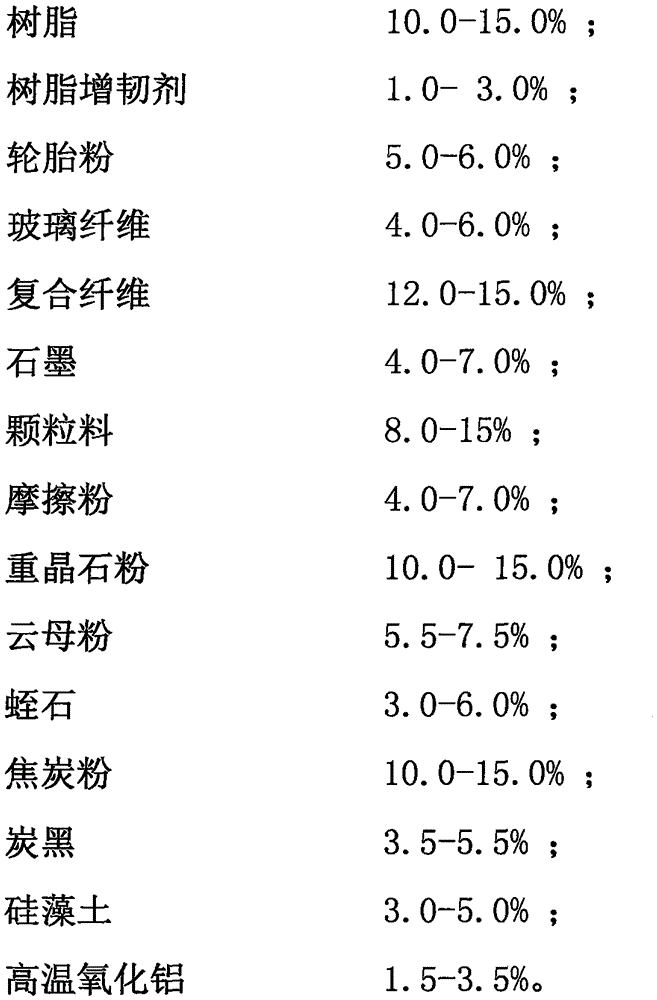

The invention relates to a method for preparing a friction material by using ceramic fiber in the friction material field. The technical proposal is characterized in that resin, fiber, an abrasive, a lubricant and filler are provided with such processing steps as batch mixing, molding and hot briquetting, heat treatment, grinding and inspection to obtain the friction material. The resin used is nano-copper modified phenolic resin; the fiber is a combination of ceramic fiber and aramid fiber or mineral fiber, wherein, the dosage of the ceramic fiber is 2 portions to 5 portions by weight; the abrasive comprises aluminum oxide, iron oxide or magnesium oxide; and the lubricant comprises graphite, molybdenum disulfide or mica, the filler comprises barium sulfate, calcium carbonate, potassium titanate or vermiculite powder. The method aims at utilizing the advantages of ceramic fiber, such as high melting point, high molar quantity, stable compression property and excellent chemical resistance stability and good flexibility in the design of friction material formula. The friction material does not incur heat fading at high temperature and has stable friction factor, little abrasion and impact strength improved by approximately 30 percent. The friction material leads to a comfortable braking when being used without producing noises and the service life is more than 70 thousand kilometers.

Owner:信义集团公司

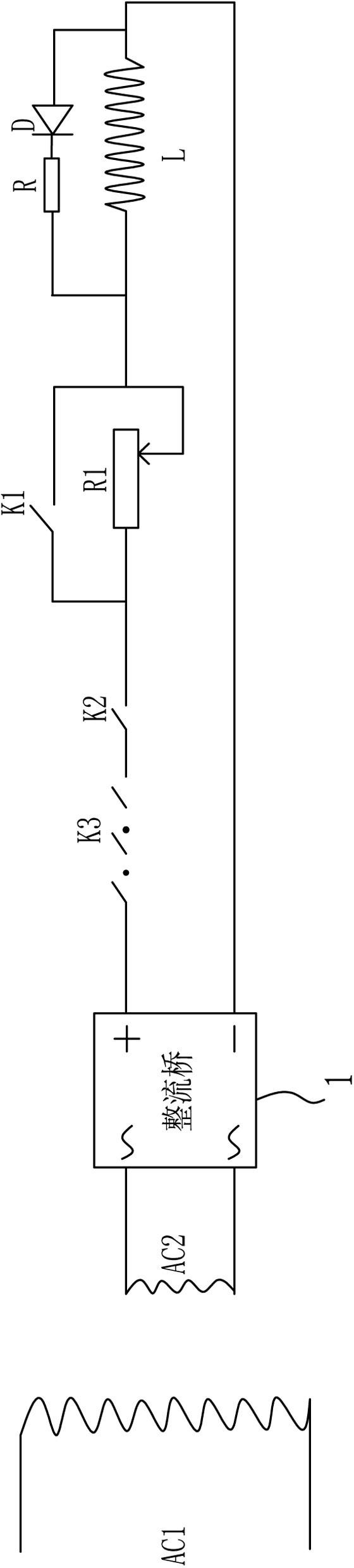

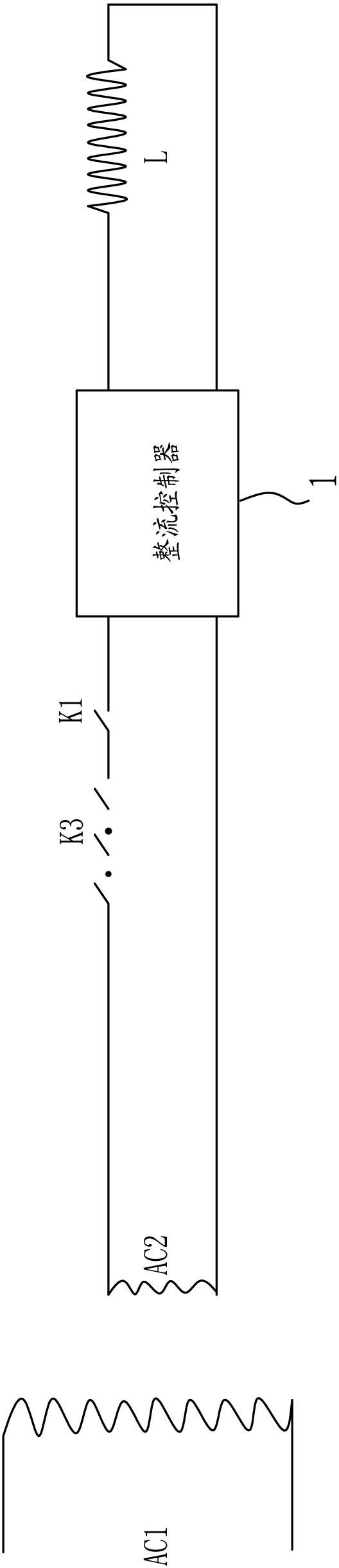

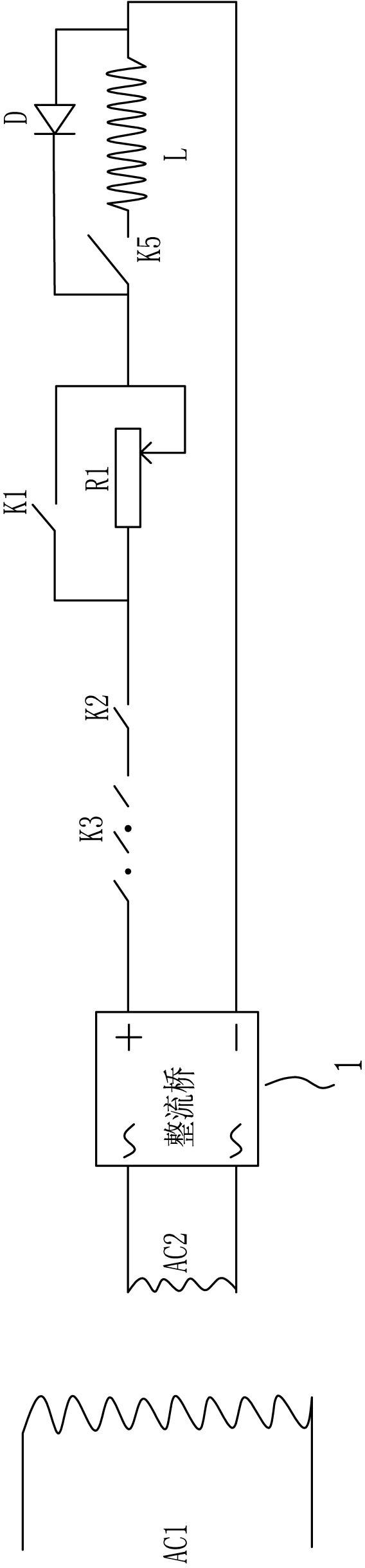

Control circuit of elevator brake

InactiveCN102674194ASafe and reliable brakingReduce brake noiseElevatorsHoisting equipmentsLow noiseTransformer

The invention relates to a control circuit of a fast and low-noise brake and belongs to the technical field of an elevator for a permanent-magnet synchronous traction machine. The control circuit comprises a transformer, a safety switch, a band-type brake switch and a brake coil, wherein the input end or output end of the brake coil is connected with an emergency stop switch in series. Since the overall circuit control is not changed, and just one emergency stop switch is added in the control circuit, and the switch is fully controlled by an elevator control system. The emergency stop switch does not act when the elevator normally runs, and the emergency stop switch acts only when the elevator needs emergency braking. The emergency braking of the elevator happens in a few circumstances, so the damage of the brake coil can be neglected; and due to the existence of the emergency stop switch, the brake braking can be divided into two modes, one braking is braking when the elevator normally runs, and the other braking is braking when the elevator is in an emergency situation. Not only can braking noise of the brake be greatly reduced, but also the stopping of the elevator is safer by adopting the control mode.

Owner:KINETEK DE SHENG SHUNDE MOTOR CO LTD

Carbon-based friction material for automobile disc brake and preparation method thereof

The invention relates to a composition and a preparation method of an asbestos-free friction material taking carbon fibre or other carbon materials as a main body, and in particular to a carbon-based friction material for an automobile disc brake and a preparation method of the carbon-based friction material. The friction material and the preparation method of the friction material mainly aim at solving the technical performance problems that a brake pad is high in the heat fading of friction coefficient and wear rate and is easy in the production of brake noises, and as a formulation of the brake pad often contains asbestoid fibre, the brake pad does not meet the requirement of environment-friendliness, etc. The friction material is a novel friction material with a carbon base between a carbon-carbon base and an NAO or ceramic base. The friction material mainly comprises carbon materials such as the carbon fibre and graphite, and comprises accessories such as a resin binder and a small number of inorganic or organic fillers. The friction material is produced by hot press moulding. Compared with a friction material with an NAO or ceramic base, the carbon-based friction material for the automobile disc brake disclosed by the invention has the advantages of being reliable in brake performance, low in brake noises and long in service life, and preventing friction coupling from being damaged.

Owner:杭州吉成汽车零部件有限公司

Few-metal-content low-density noise-free resin based composite friction material and preparation method

InactiveCN106701018AHigh strengthLow densityOther chemical processesFriction liningLow noiseFrictional coefficient

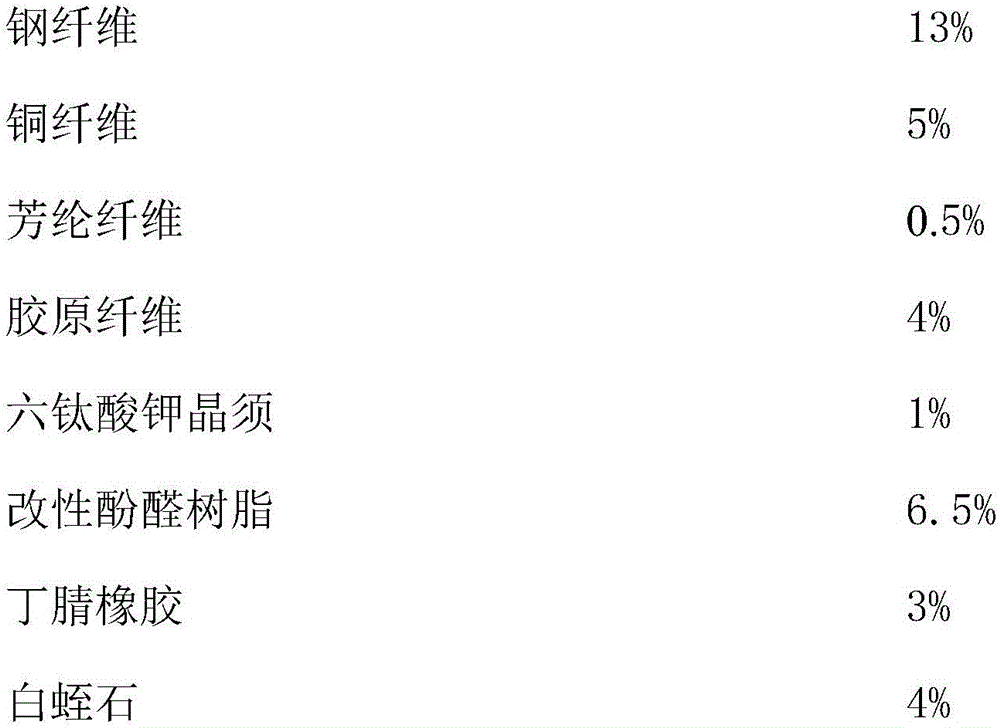

The invention discloses a few-metal-content low-density noise-free resin based composite friction material, which is prepared from the following components: a reinforced fiber, a binder, flaky graphite, a filling material, precipitated barium sulfate, frictional powder, coke, a complexing agent, copper sulfide, molybdenum disulfide, chromite powder, alumina, expanded graphite, natural graphite and granular graphite. The invention also further provides a preparation method of the few-metal-content low-density noise-free resin based composite friction material. The few-metal-content low-density noise-free resin based composite friction material provided by the invention has characteristics of low noise, low density, a stable frictional coefficient, low wear rate and the like.

Owner:HANGZHOU KEBO TECH

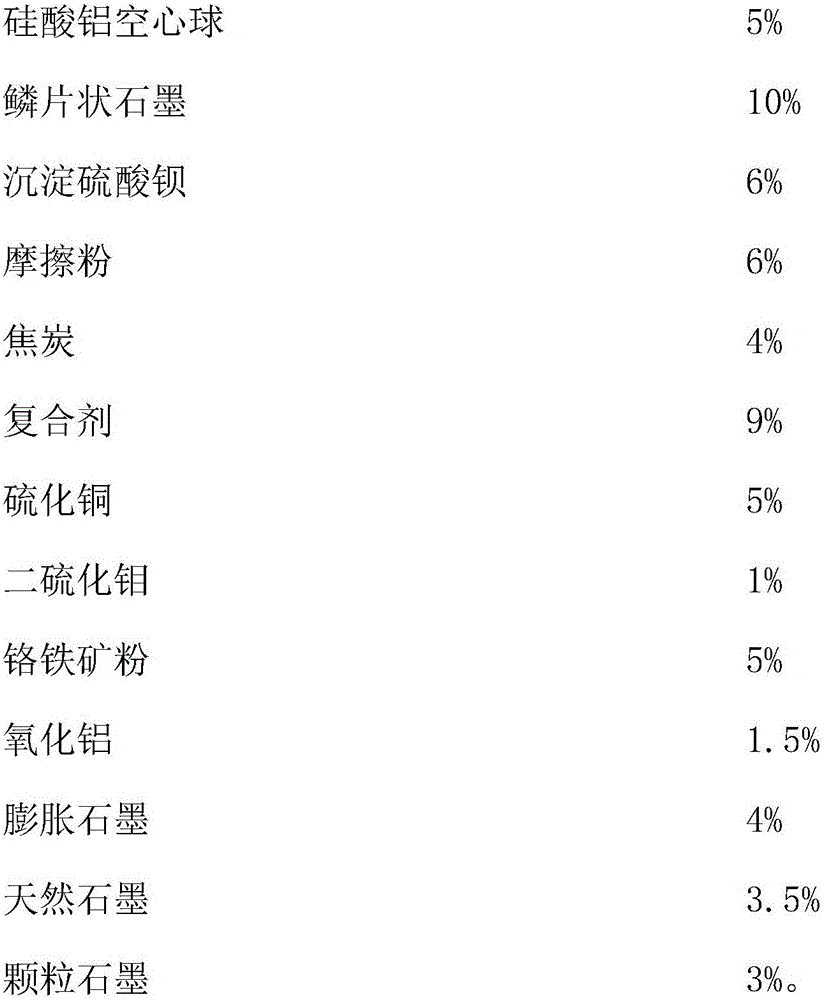

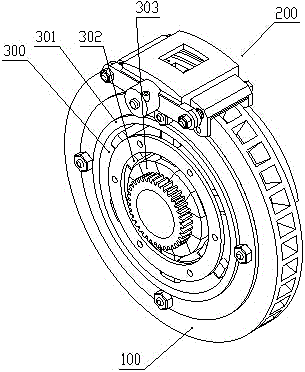

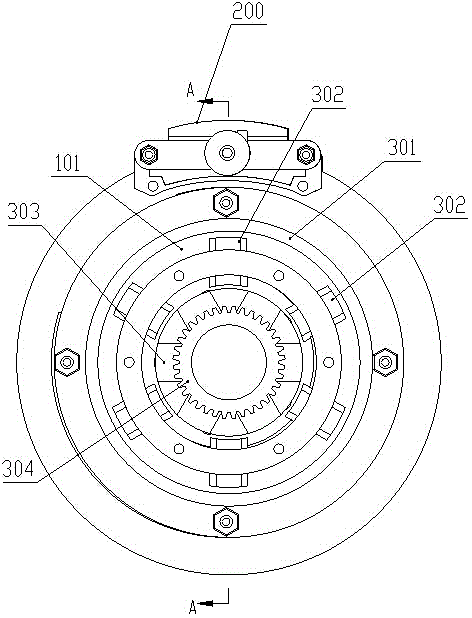

Outside-disc inside-magnet disc brake

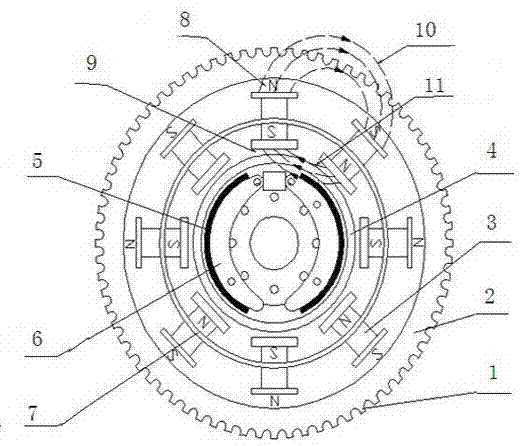

InactiveCN104632954AGood solution to frictionSolve the problem of high magnetic permeability and low remanenceAxially engaging brakesBrake actuating mechanismsForce linesBrake torque

The invention discloses an outside-disc inside-magnet disc brake. The outside-disc inside-magnet disc brake comprises a brake disc, a friction braking device and an electromagnetic braking device, wherein the brake disc is mounted on a rotary shaft, the friction braking device exerts contact braking torque on the brake disc, a round hole which is concentric with the brake disc is designed in the middle of the brake disc, the electromagnetic braking device exerts non-contact braking torque on the brake disc, the electromagnetic braking device comprises a rotor ring and a magnetic field generating body, the rotor ring is mounted on the round hole and rotates with the brake disc, the magnetic field generating body is located in the rotor ring, and a magnetic force line that is generated by the magnetic field generating body is cut when the rotor ring rotates with the brake disc. An electromagnetic braking area and a friction braking area on the brake disc are separated so that the problem that good friction rate, high magnetic permeability and low residual magnetism rate can not be simultaneously achieved is solved, moreover, the electromagnetic area is in a non-friction mode without abrasion, a friction disc is merely required to be replaced when replacing is required, resources are saved, and maintaining costs are lowered.

Owner:CHONGQING JIAOTONG UNIVERSITY

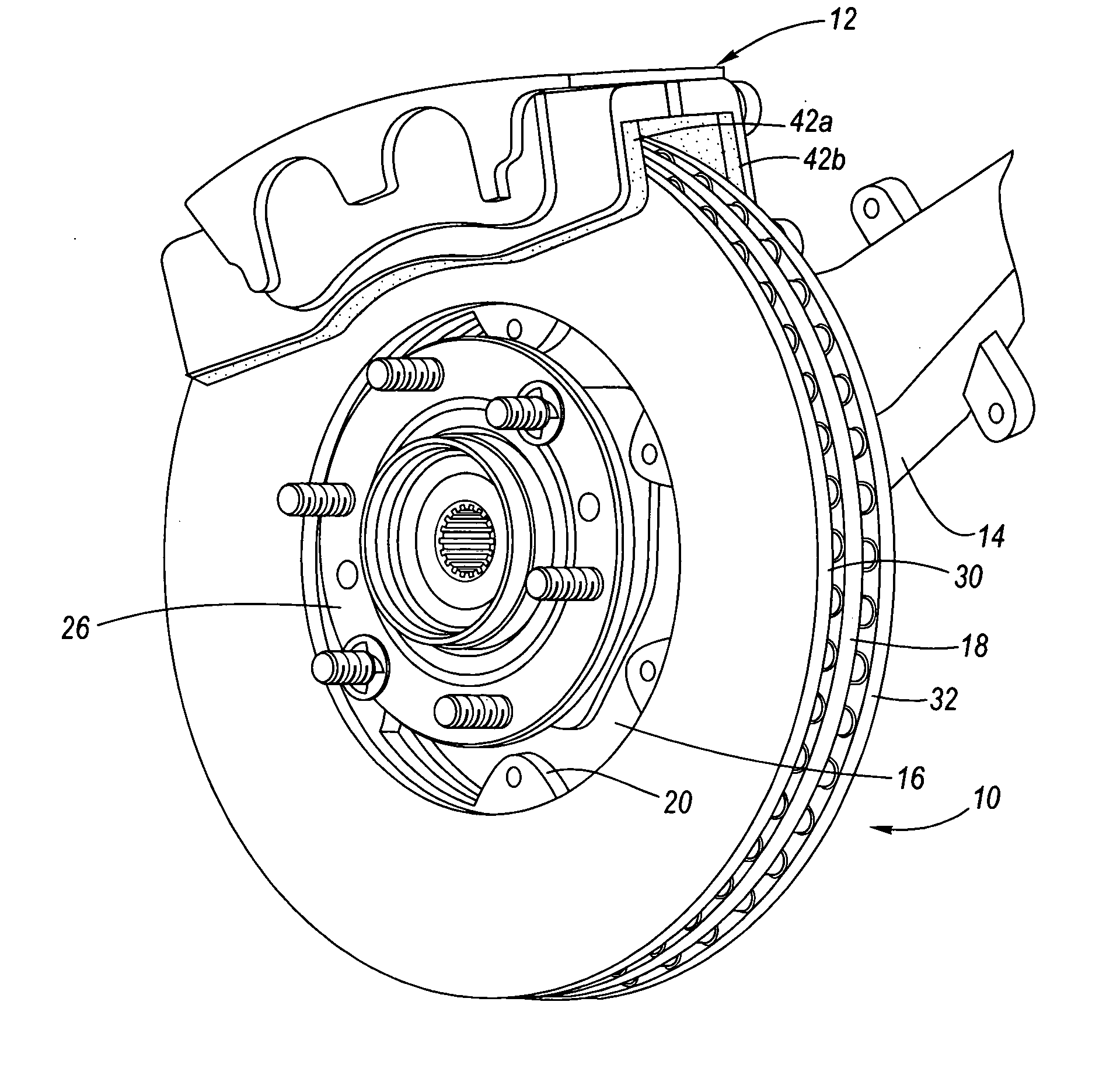

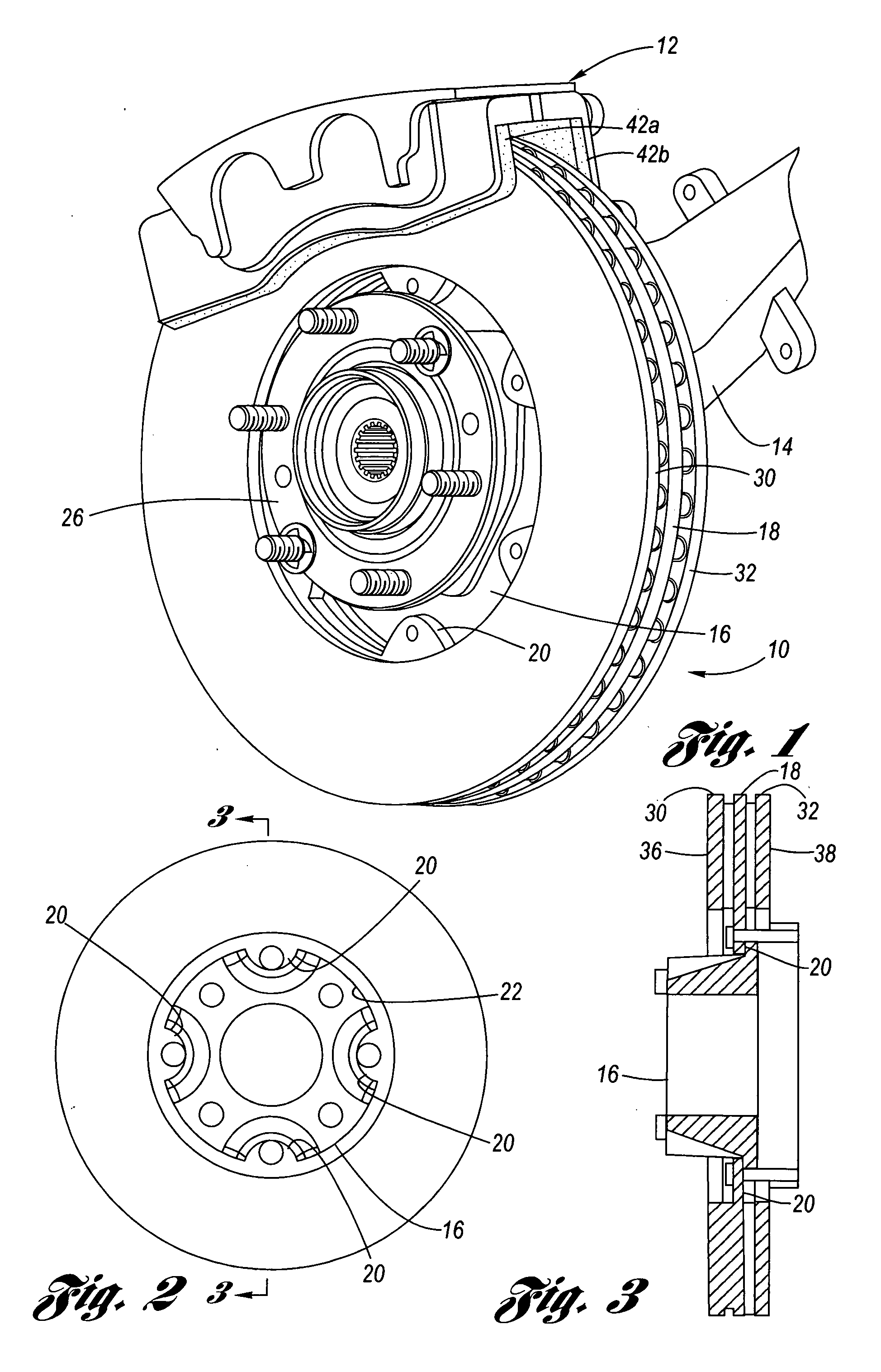

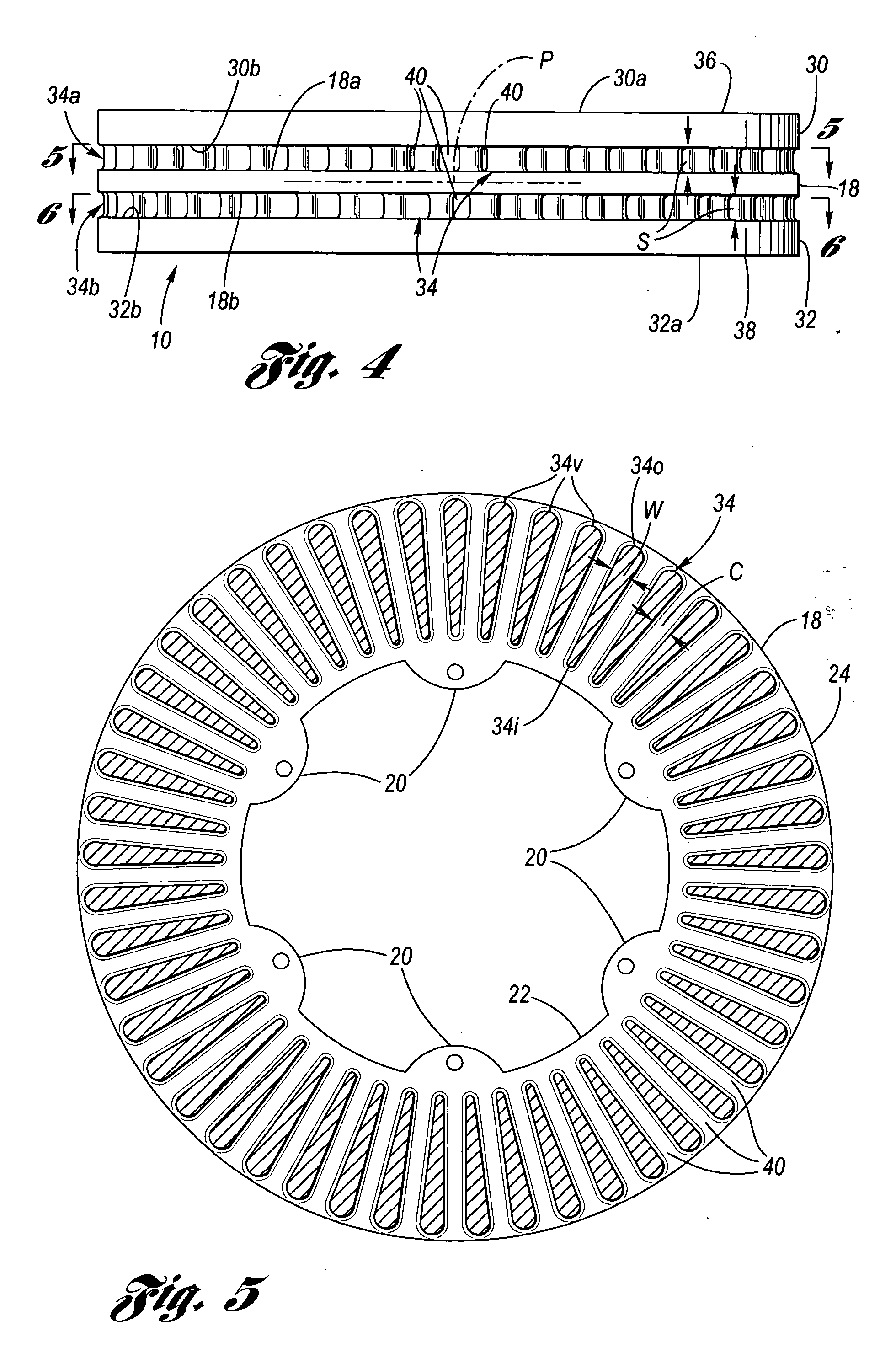

Hatless brake rotor

InactiveUS20050263358A1Reduce brake noiseReduce pulsationBraking element arrangementsNoise/vibration controlAir cycleAir movement

A hatless rotor for an automotive disk brake system, wherein the following improvements are realized over known disk brake systems: reduced braking noise, improved air cooling, decoupling of wheel to rotor cross-talk, reduced brake pulsation, reduced mass, reduced rotor cheeks temperature during braking, and better air movement access for improved cooling of the rotor cheeks. The hatless rotor includes a first rotor cheek, a second rotor cheek and a central disk, wherein the first and second rotor cheeks are spaced from, and mutually interconnected to, the central disk by first and second sets of vanes, staggered relative to each other, and configured to provide optimal air circulation. The central rotor disk is connected directly to the motor vehicle axle hub via a suitable rotor hub connected thereto.

Owner:GENERAL MOTORS COMPANY

Stator fixed type eddy current retarder

ActiveCN103259386AAvoid failureIncreased braking safetyAsynchronous induction clutches/brakesBrake torqueEddy current

The invention discloses a stator fixed type eddy current retarder which conducts braking and speed reducing on an automobile. The stator fixed type eddy current retarder comprises an outer rotor, an inner stator and a stator shaft, wherein the outer rotor is of a hollow-cylinder-shaped structure, a plurality of U-shaped stator magnet yokes are fixedly arranged on the outer ring surface of the inner stator, the bottom faces of all the U-shaped stator magnet yokes are fixedly arranged on the outer ring surface of the inner stator in the axial direction of the inner stator, a U-shaped opening of each U-shaped stator magnet yoke faces toward the inner surface of the outer rotor, and a gap is arranged between each U-shaped opening of each U-shaped stator magnet yoke and the inner surface of the outer rotor. The plurality of U-shaped stator magnet yokes are divided into m sets, the m sets of U-shaped stator magnet yokes are distributed at equal intervals in the axial direction of the inner stator, each set of U-shaped stator magnet yokes are composed of n U-shaped stator magnet yokes, the n U-shaped stator magnet yokes in each set are arranged in an equal-angle mode in the outer ring peripheral direction of the inner stator, and a magnet exciting coil is wound on each U-shaped opening of each U-shaped stator magnet yoke in each set. The magnetic field usage rate is high, under the condition that the same current is switched on, produced braking torque is large, and braking safety performance is good.

Owner:江阴智产汇知识产权运营有限公司

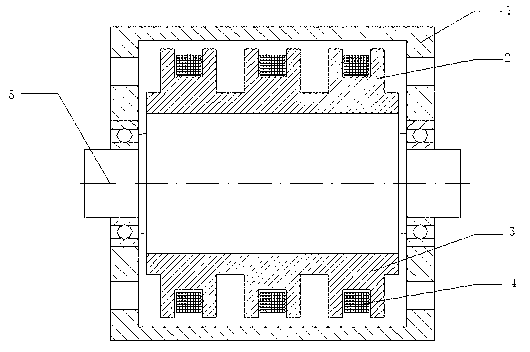

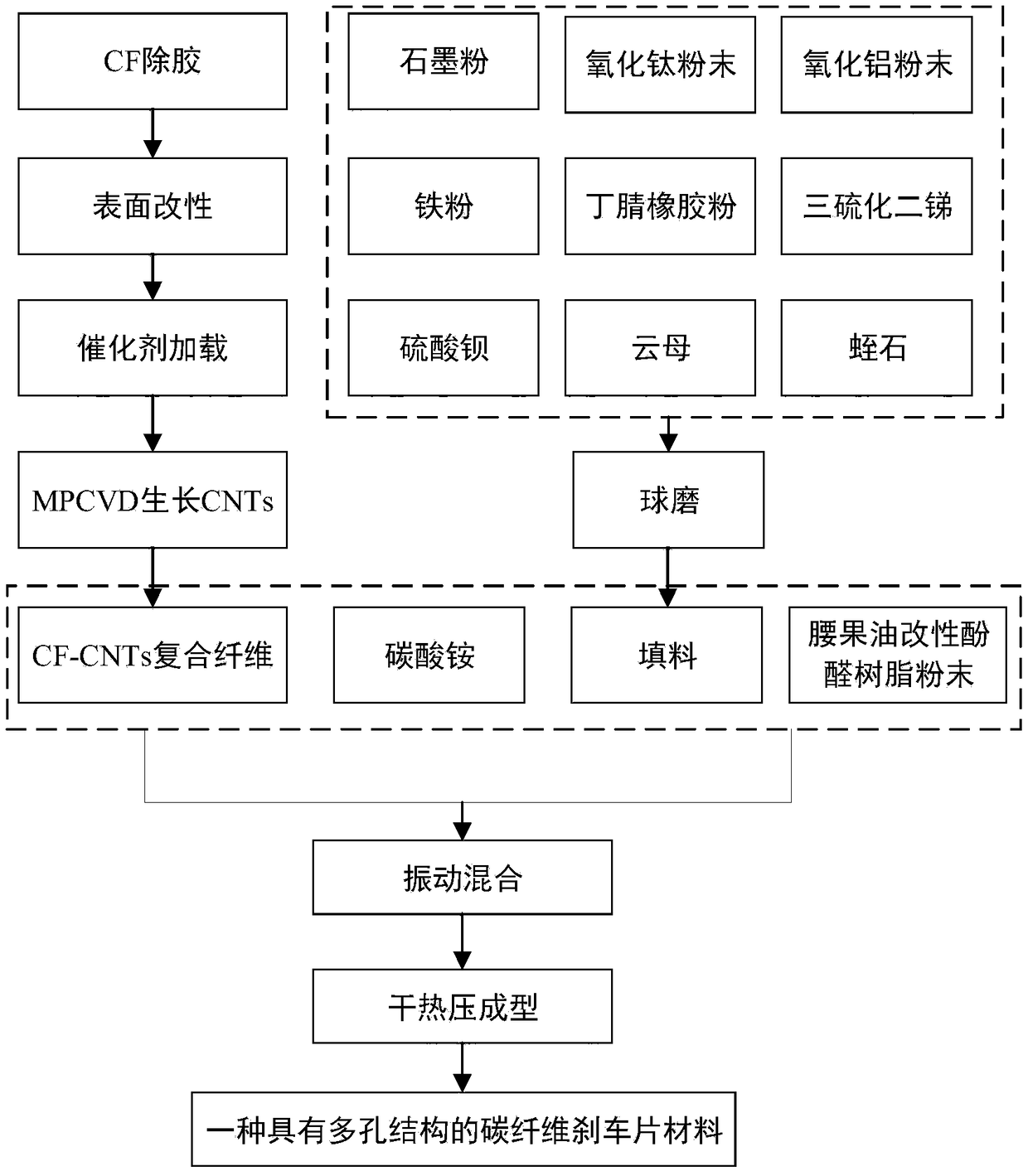

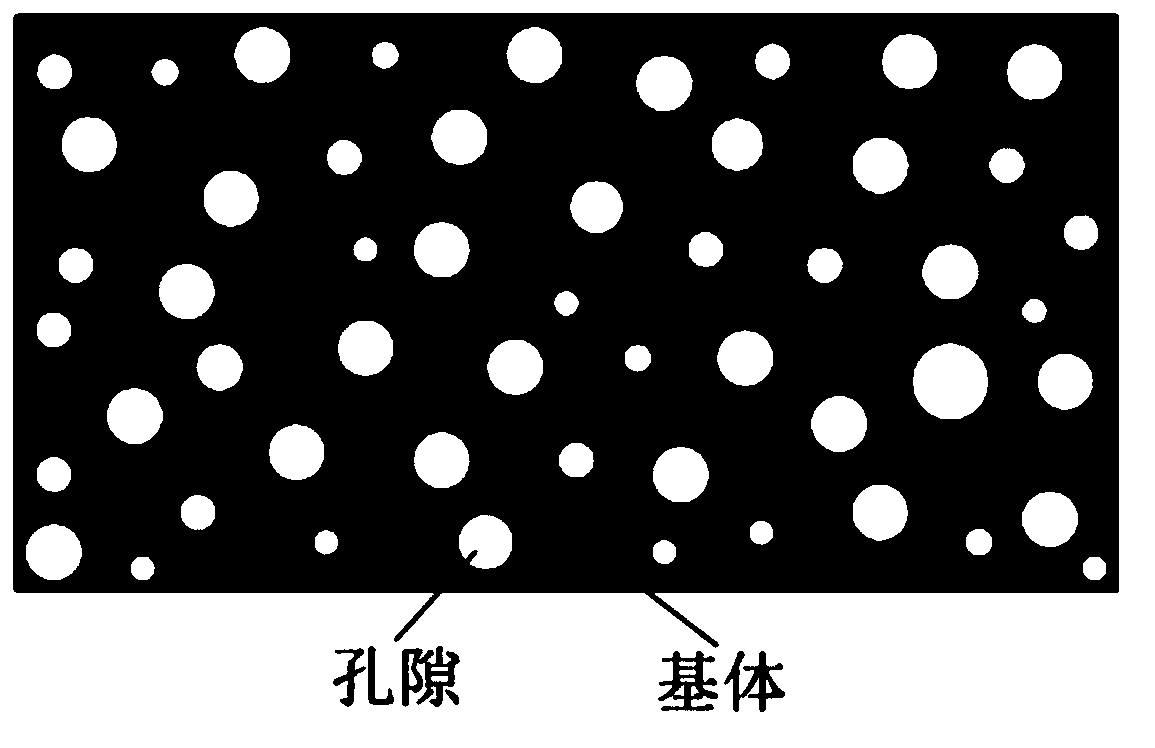

Carbon fiber brake pad material with porous structure and preparation method of carbon fiber brake pad material

ActiveCN108662050AAvoid damageLow densityOther chemical processesFriction liningAdhesiveWear resistance

The invention discloses a carbon fiber brake pad material with a porous structure and a preparation method of the carbon fiber brake pad material. The preparation method is characterized in that a composite fiber of carbon fiber-carbon nanotubes (CF-CNTs) and a filler serve as a matrix, cashew nut oil modified phenolic resin is taken as an adhesive, a pore forming agent is added to obtain the porous structure, and the carbon fiber brake pad material is prepared by adopting a dry hot press molding technology. The carbon fiber brake pad material with the porous structure has the advantages of being simple in formula, low in density, low in braking noise, excellent in heat dissipation performance, good in strength and wear resistance and the like; and in addition, a pore structure of a brakepad can contain certain grinding scraps, so that damage to a brake disc or a brake drum caused by the grinding scraps is reduced.

Owner:WUHAN UNIV OF TECH

Low-metal ceramic-based drum-type brake pad and preparation method thereof

The invention discloses a low-metal ceramic-based drum-type brake pad and a preparation method thereof. The low-metal ceramic-based drum-type brake pad comprises the following raw materials by weight percent: 20 to 30 of ceramic adhesive, 10 to 20 of steel fibre, 15 to 30 of composite fibre, 0 to 5 of calcium carbonate crystal whisker, 2 to 5 of glass fibre, 0 to 5 of artificial graphite, 5 to 10 of crystalline flake graphite, 0 to 5 of chromium chromite, 2 to 5 of friction powder and 0 to 15 of composite filler. The preparation method comprises the steps of mixing, cold pressing, hot pressing, heat treatment, machining and ceramic treatment. The brake pad prepared by the invention has the characteristics of high-temperature resistance, high-pressure resistance, impact resistance and the like. Compared with a traditional product, the service life is enhanced by more than 2 times.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com