Brake integrating rotary barrel type eddy current retarder and drum brake

An eddy current retarder, drum brake technology, applied in drum brakes, brake types, electric braking systems, etc., can solve the problems of safety hazards in drum brakes, avoid brake thermal failure, reduce harmful Dust and brake noise, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

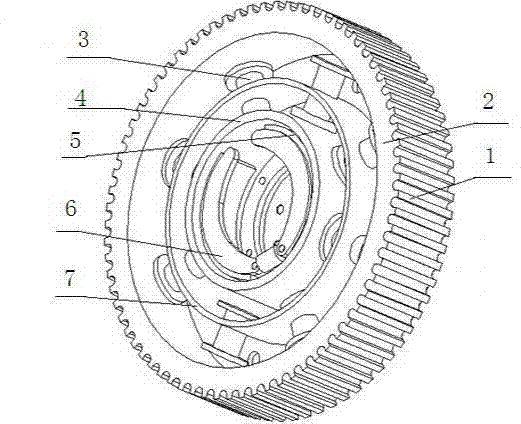

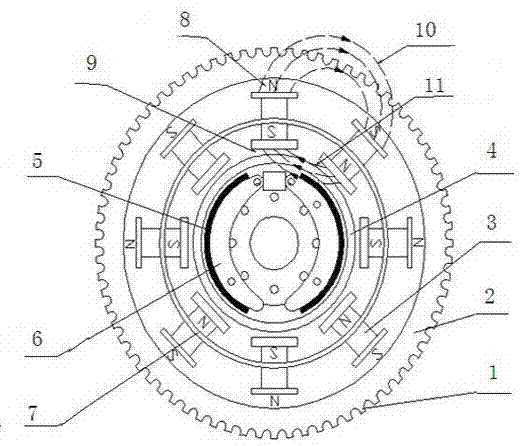

[0015] see Figure 1-2 As shown, the present invention integrates the eddy current retarder on the traditional drum brake. Keep the original friction brake assembly (including brake drum, brake shoe, etc.). The invention consists of a friction brake part and an eddy current retarder part. The friction braking part includes a brake drum 4 , a friction lining 5 and a brake shoe 6 . The eddy current retarder part includes heat sink 1 , retarder outer rotor 2 , excitation coil 3 with iron core and coil support 7 . Wherein, the brake drum 4 of the friction braking part is also the retarder inner rotor of the eddy current retarder part.

[0016] The outer rotor 2 of the retarder, the brake drum 4 and the coil support 7 with a circular cross section are coaxial, and the coil support 7 is located between the outer rotor 2 of the retarder and the brake drum 4 . The outer surface of the retarder outer rotor 2 is the retarder cooling fin 1, and the retarder cooling fin 1 and the reta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com