Control circuit of elevator brake

A technology of elevator brakes and control circuits, applied in elevators, hoisting devices, transportation and packaging, etc., can solve the problems of only one type of brakes, increasing the difficulty of design, manufacture and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

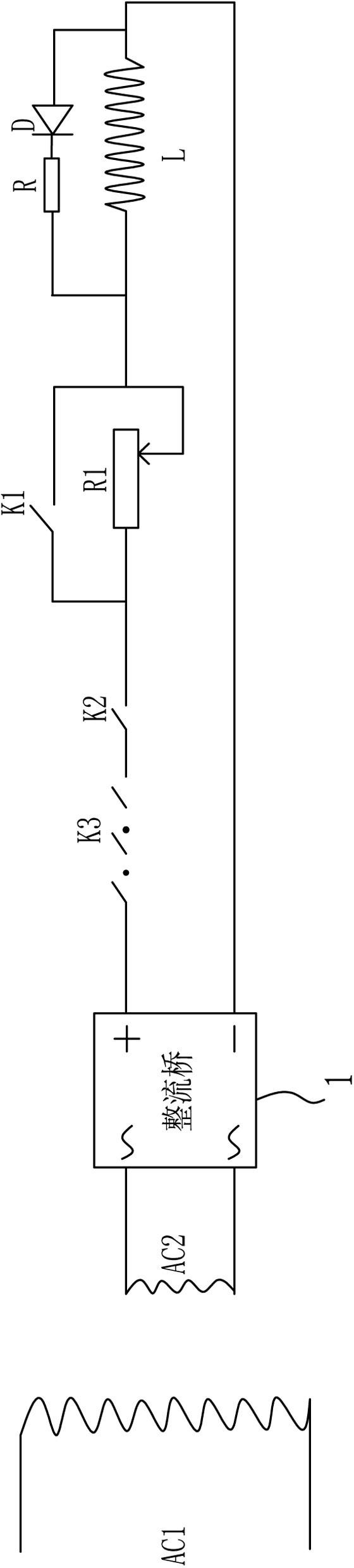

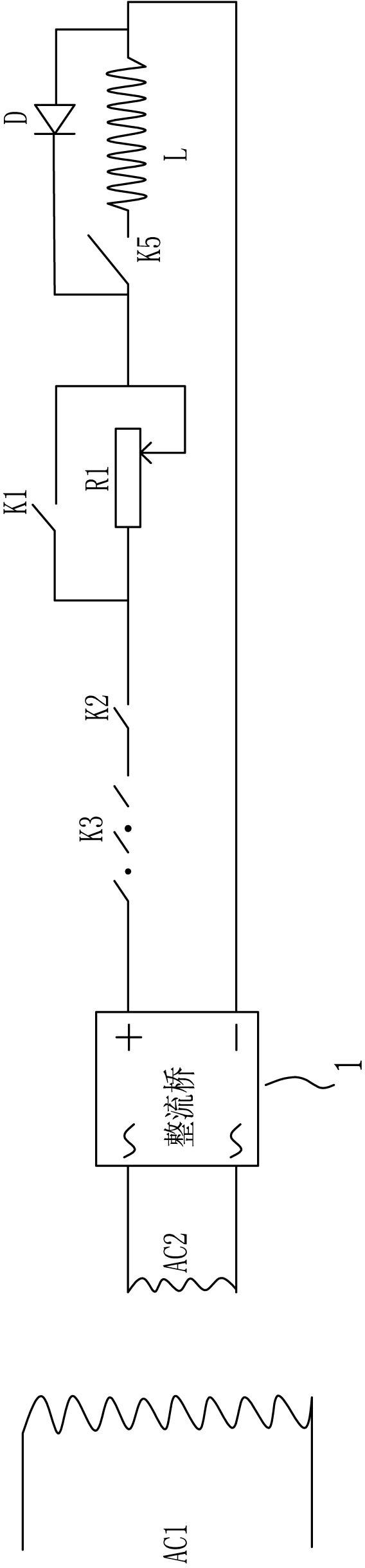

Embodiment 1

[0016] Embodiment 1, combining image 3 , a control circuit for an elevator brake, including a transformer, a safety switch K3, a brake switch K2, an economic variable resistor R1, an emergency stop switch K5 and a brake coil L, and the transformer includes a primary winding AC1 and a secondary winding AC2, the secondary The two output ends of the winding are respectively connected to the rectifier circuit 1, the safety switch K3, the brake switch K2, the economic variable resistor R1, the emergency stop switch K5 and the brake coil L are connected in series between the positive pole and the negative pole of the rectifier circuit 1, and the brake coil L A reverse diode D is connected in parallel between the input terminal and output terminal of the reverse diode D, and the output terminal of the reverse diode D faces the anode of the rectifier circuit 1, and the emergency stop switch K5 is set at the input terminal of the brake coil L. The emergency stop switch K5 and the reve...

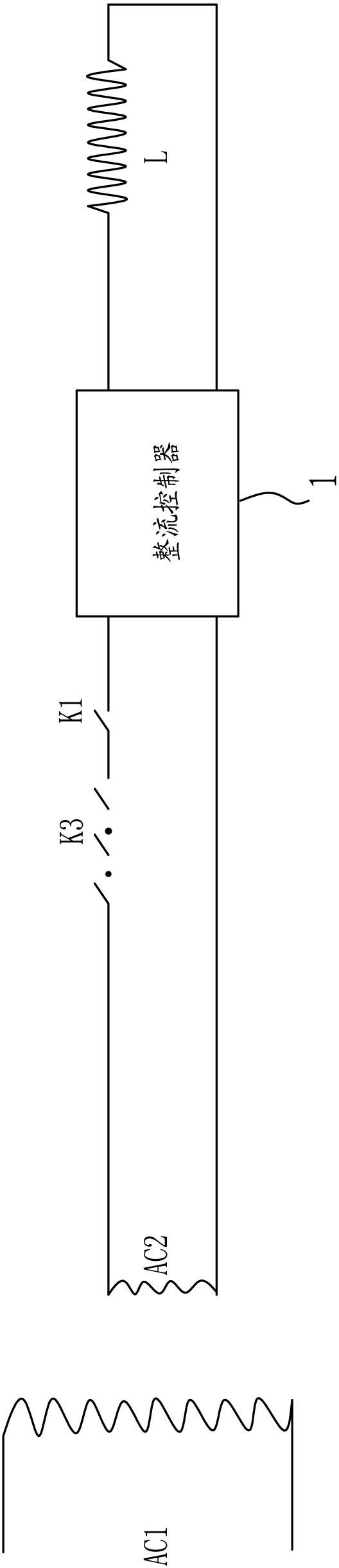

Embodiment 2

[0017] Example 2, combined with Figure 4 , a control circuit for an elevator brake, including a transformer, a safety switch K3, a brake switch K2, an emergency stop switch K5 and a brake coil L, the transformer includes a primary winding AC1 and a secondary winding AC2, and the two output ends of the secondary winding AC2 The rectifier controller 1 is connected in series between them, the safety switch K3 and the brake switch K2 are connected in series between the two output terminals of the secondary winding AC2, the brake coil L and the emergency stop switch K5 are connected in series between the positive pole and the negative pole of the rectifier controller 1. The rectification controller (which is the prior art) includes a rectification circuit, a step-down circuit and a voltage stabilization circuit. When the elevator is in the normal standby state, the emergency stop switch K5 and the safety switch K3 are both closed. When the elevator receives a running command, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com