Mouse-cage type tapered rotor electromotor

A conical rotor and motor technology, applied in the field of motors, can solve the problems of increasing the cost of motor materials, increasing the size of the motor, and consuming energy, and achieve the effects of compact structure, high starting torque, and high economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

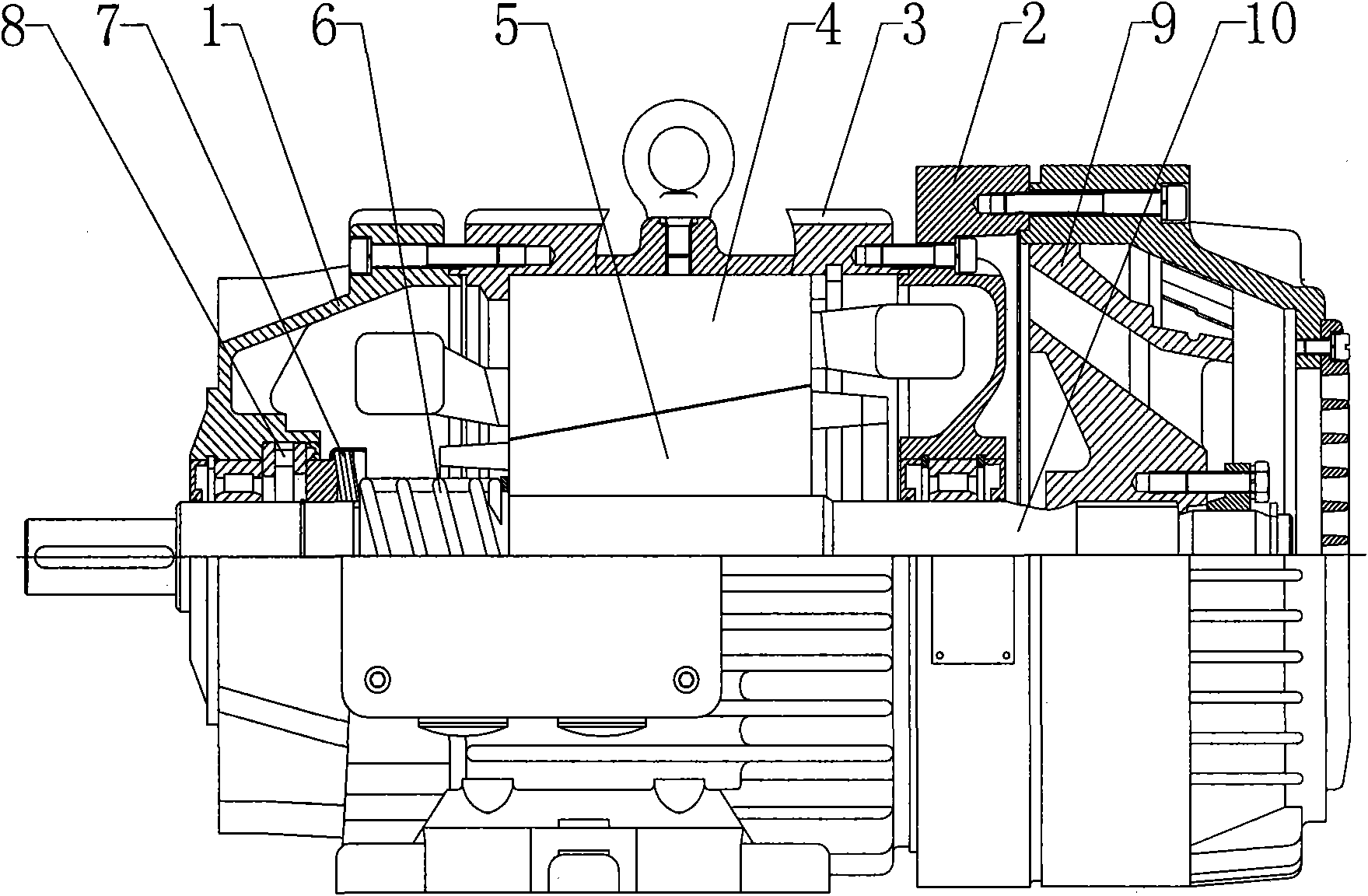

[0014] like figure 1 As shown, a squirrel-cage conical rotor motor described in the embodiment of the present invention includes a front end cover 1, a rear end cover 2, a casing 3 and a main shaft 10 passing through the casing 3, and a The stator 4 and the rotor 5, the rotor 5 is installed on the main shaft 10, the rotor 5 is conical, and the stator 4 is also matched with the rotor 5 to form a conical inner cavity, and the mating surface of the rotor 5 and the stator 4 is made into a friction surface .

[0015] A further design of the motor is that a brake spring 6 is provided on the motor shaft 10 at the front end of the rotor 5 , and the other end of the brake spring 6 is connected to the front end cover 1 .

[0016] The further design of the motor is that the brake spring 6 is connected to the front end cover 1 through a butterfly spring group 7, and a thrust cylindrical roller bearing 8 is arranged in the middle.

[0017] A further design of the electric motor is that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com