Parking pallet transverse moving drive device

A technology of parking tray and driving device, applied in the field of car parking, can solve the problems of inconvenient use and maintenance, hidden dangers, and high occurrence rate of power line failure, and achieve the effect of good safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

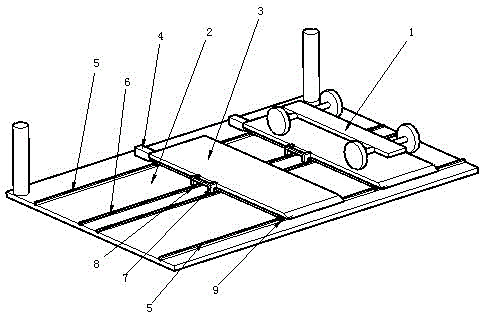

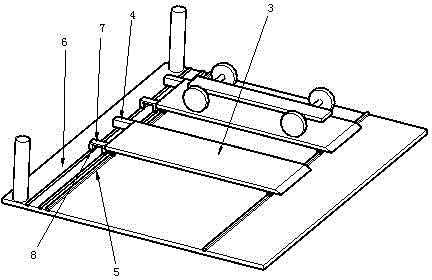

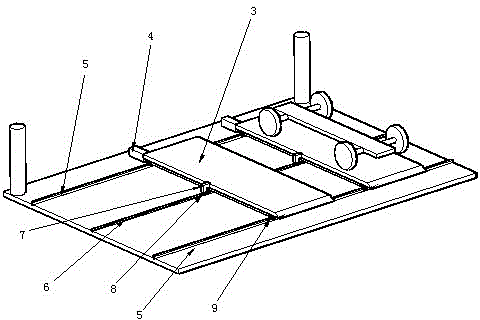

[0022] In the embodiment, there are three parking spaces (2) between the two concrete pillars, on which two traversing parking pallets (3) are arranged, and the DC motor (4) is installed on one side of the parking pallet (3) the end of the conductive track (6), the installation height of the conductive track (6) is lower than the height of the front and rear track (5), the conductive track (6) is insulated from the ground, and the brush holder (7) elastically connects the brush (8) to the conductive On the track (6), the output shaft of the DC motor (4) is connected to two rollers (9) on one side of the parking tray (3) through the transmission shaft, and the conductive track (6) is arranged on the parking space (2), and the conductive track The power supply voltage of (6) is a low-voltage direct current, and the direct current motor (4) is a brushed motor.

[0023] Such as figure 1 The schematic diagram of the double conductive rail drive device between the front and rear ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com