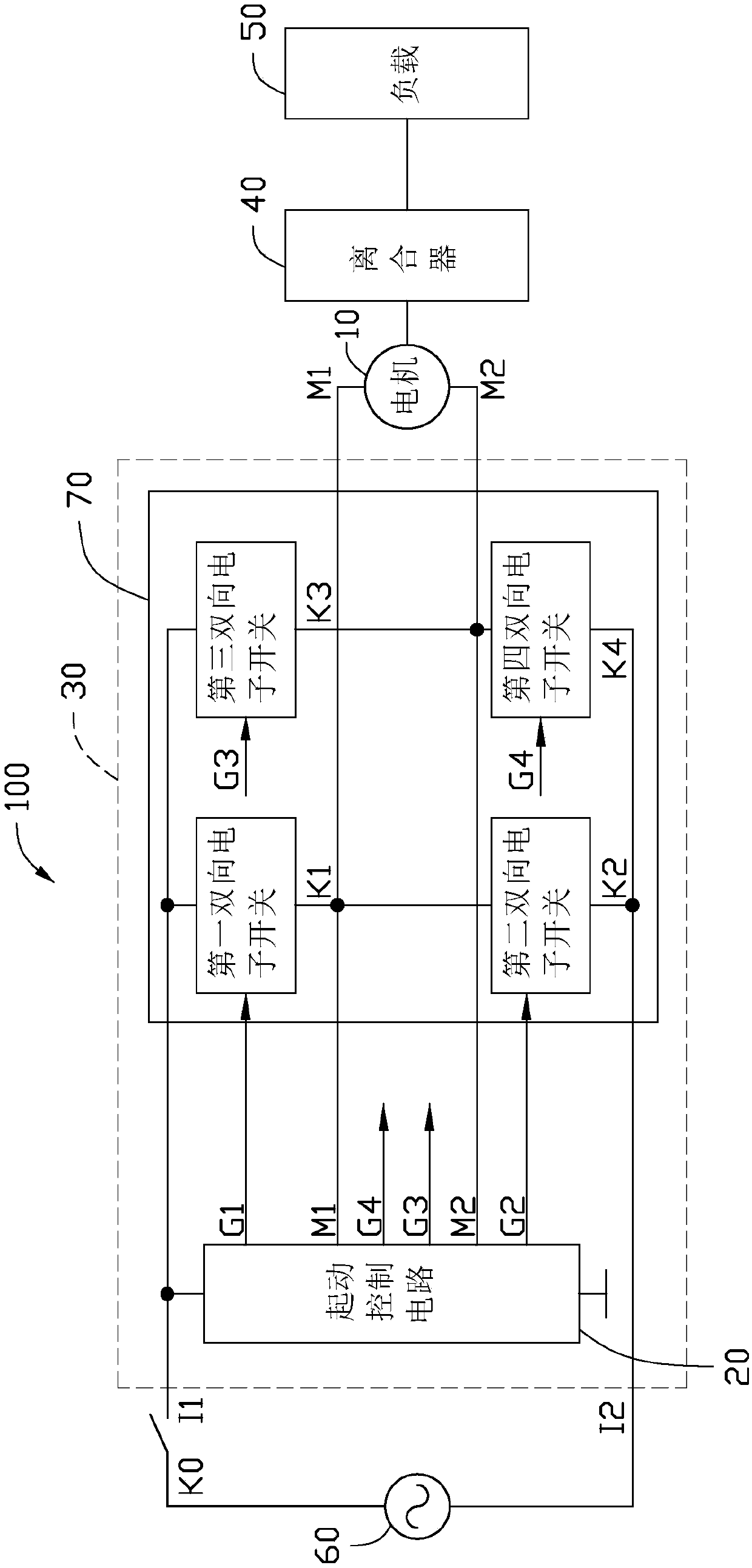

Motor drive device, motor assembly and load drive device

A motor drive and circuit technology, applied in the direction of starting devices, etc., can solve the problems of small starting torque of the motor, inconsistent torque, unsuitable for starting, etc., to achieve neat motor voltage waveform, consistent torque, reduce starting failure and The effect of vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

[0068] In other embodiments, part of the logic circuit can be integrated into the integrated circuit according to actual conditions. For example, only the start-up control circuit 20 can be integrated in the integrated circuit, and the bridge circuit 70 can be provided outside the integrated circuit. For another example, according to design requirements, all the motor driving devices 30 may be arranged on a printed circuit board with discrete components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com