Patents

Literature

1441results about How to "Reduce vibration and noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

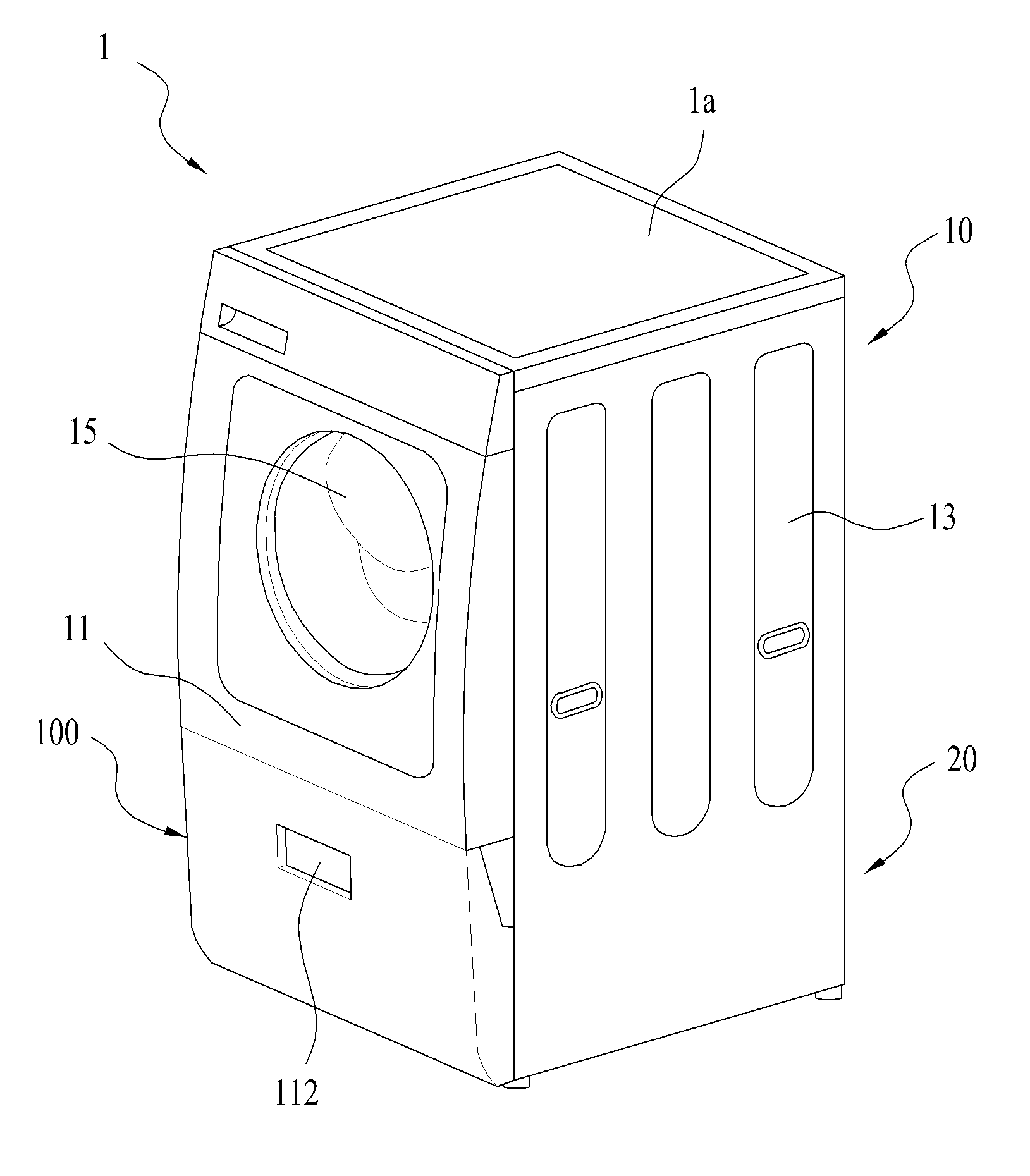

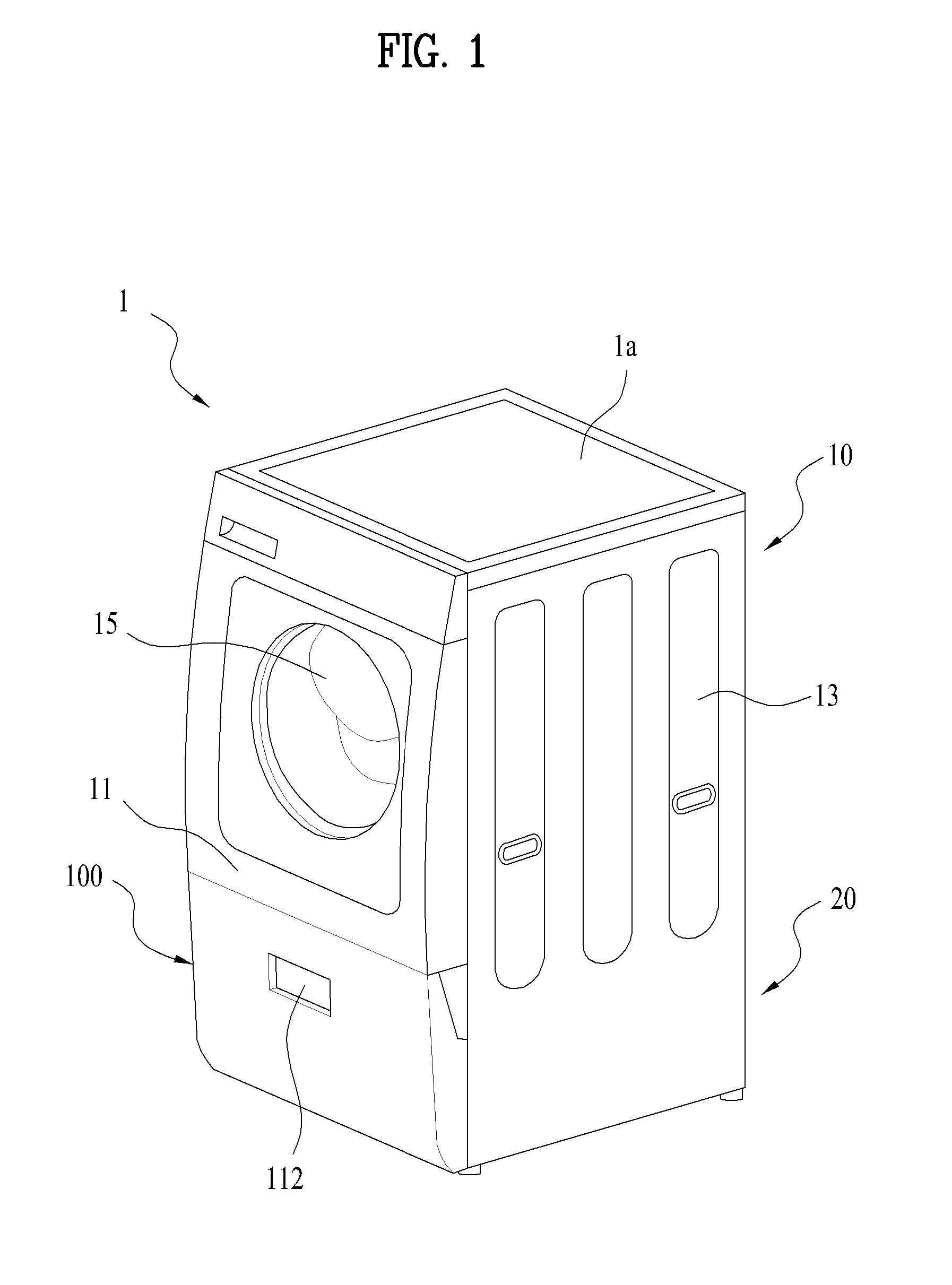

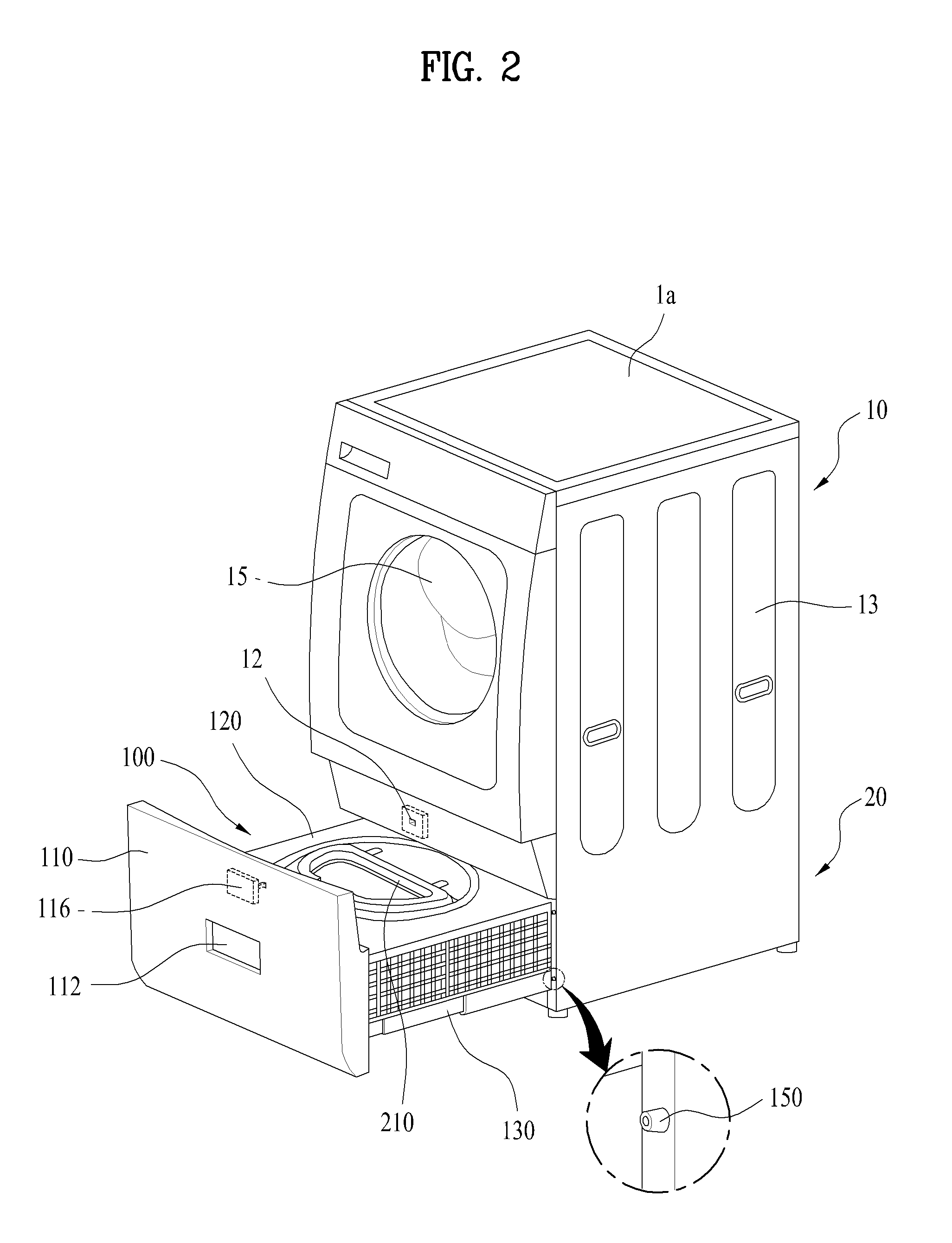

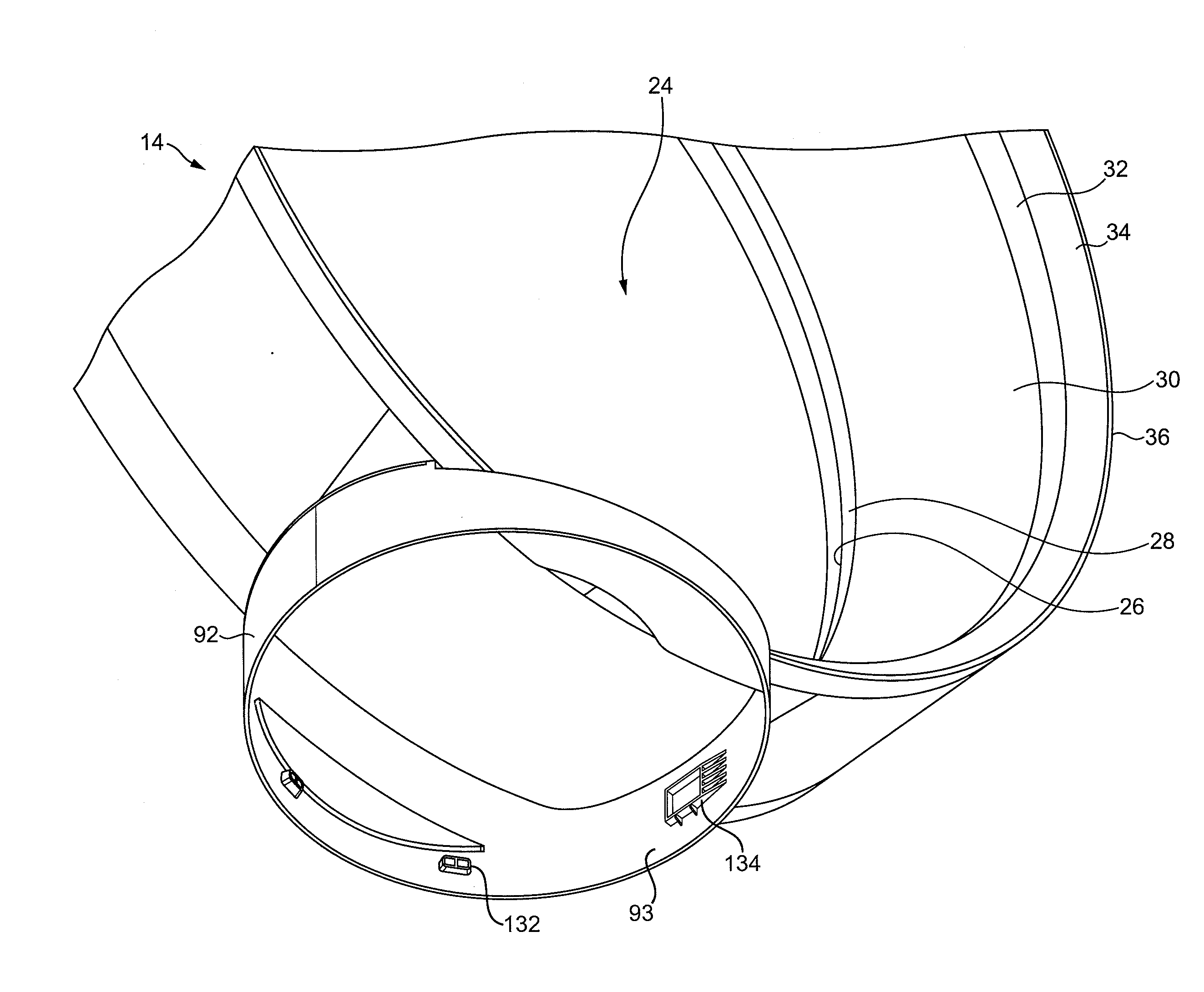

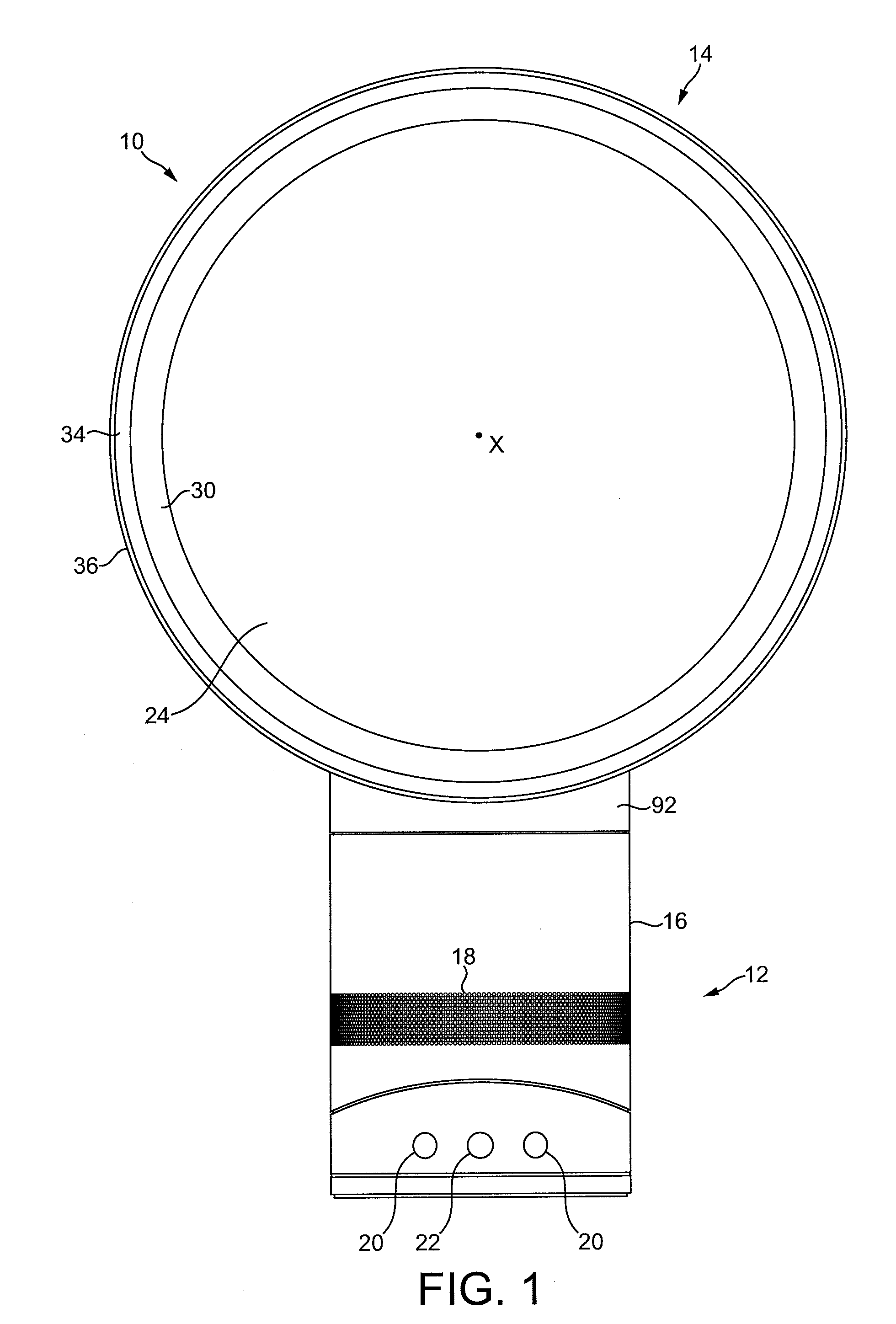

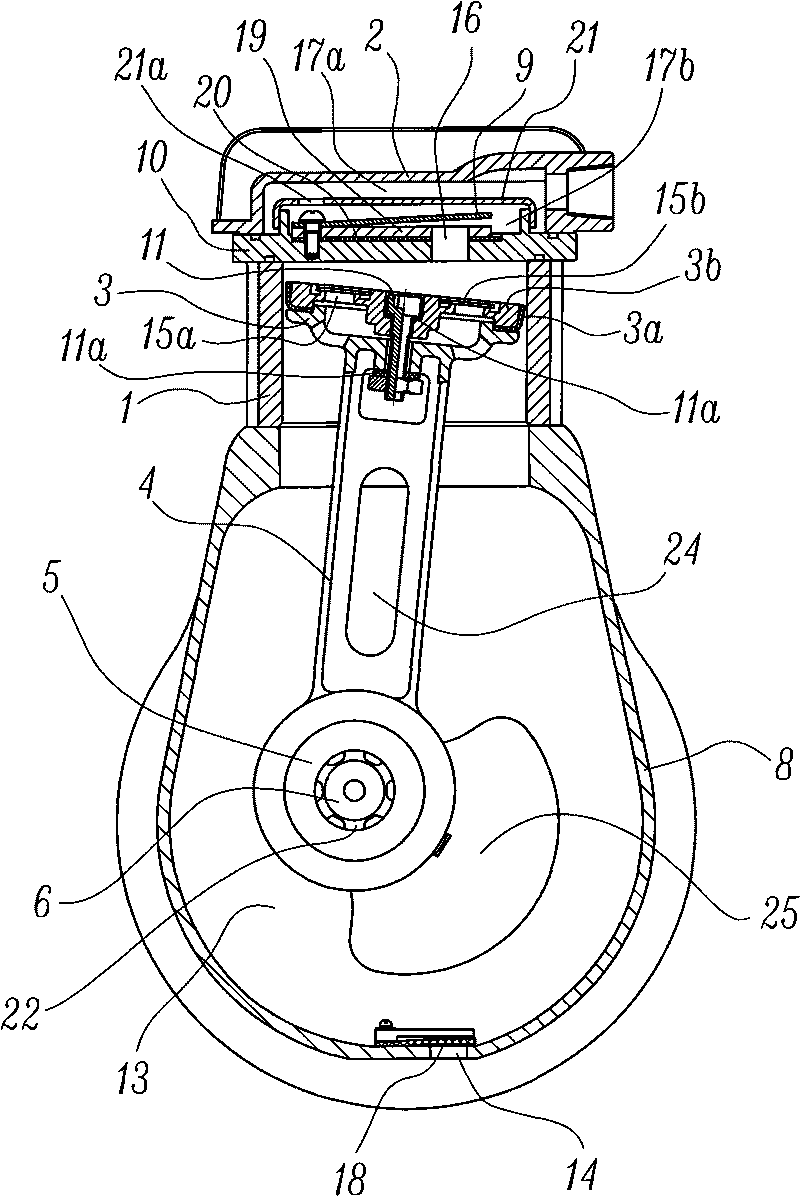

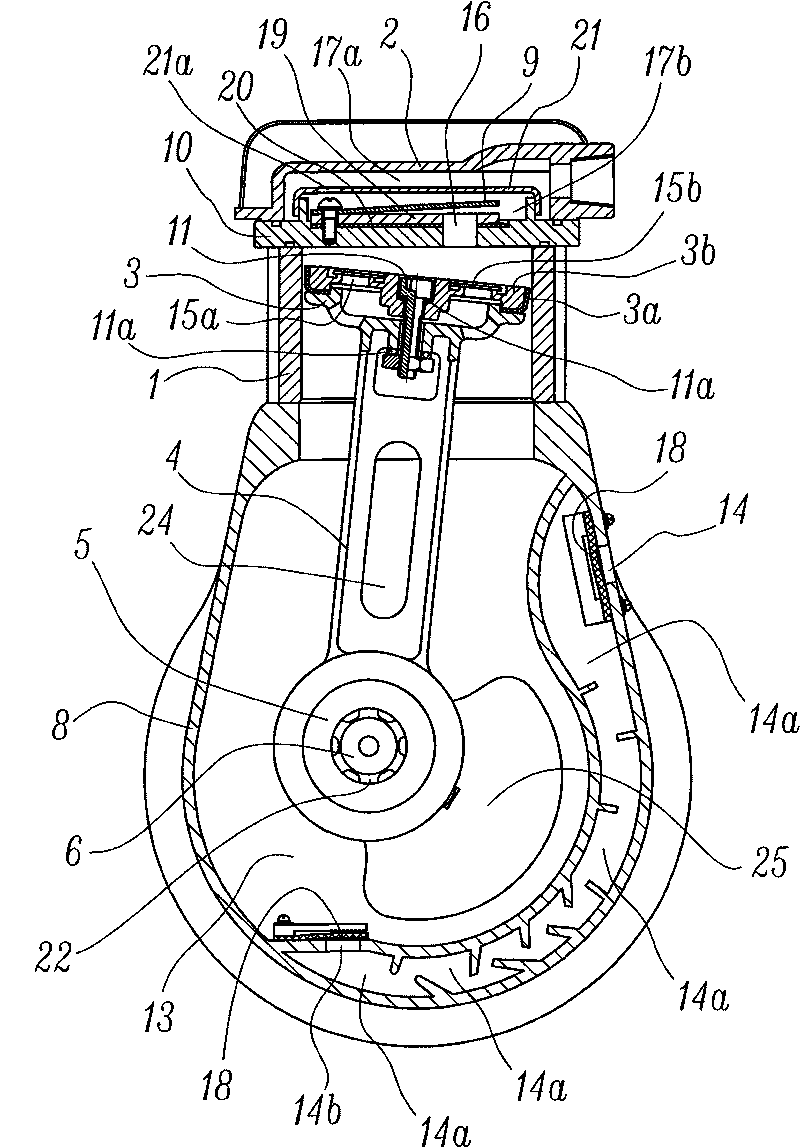

Laundry apparatus

ActiveUS20110265524A1Improve productivityEnhance the imageOther washing machinesTextiles and paperEngineeringLaundry

A laundry apparatus including a cabinet; a first space provided in the cabinet, in which a first treating part provided to treat laundry is installed; a second space provided in the cabinet, in which a second treating part provided to treat laundry is installed; a drawer movably provided in the second space, in which the second treating part is installed; and a rail unit configured to limit vertical and horizontal movement of the drawer with respect to the second space and to guide the outward movement of the drawer. Therefore, laundry may be treated by using the first and second treating parts and vibration and noise generated in the second treating part may be reduced.

Owner:LG ELECTRONICS INC

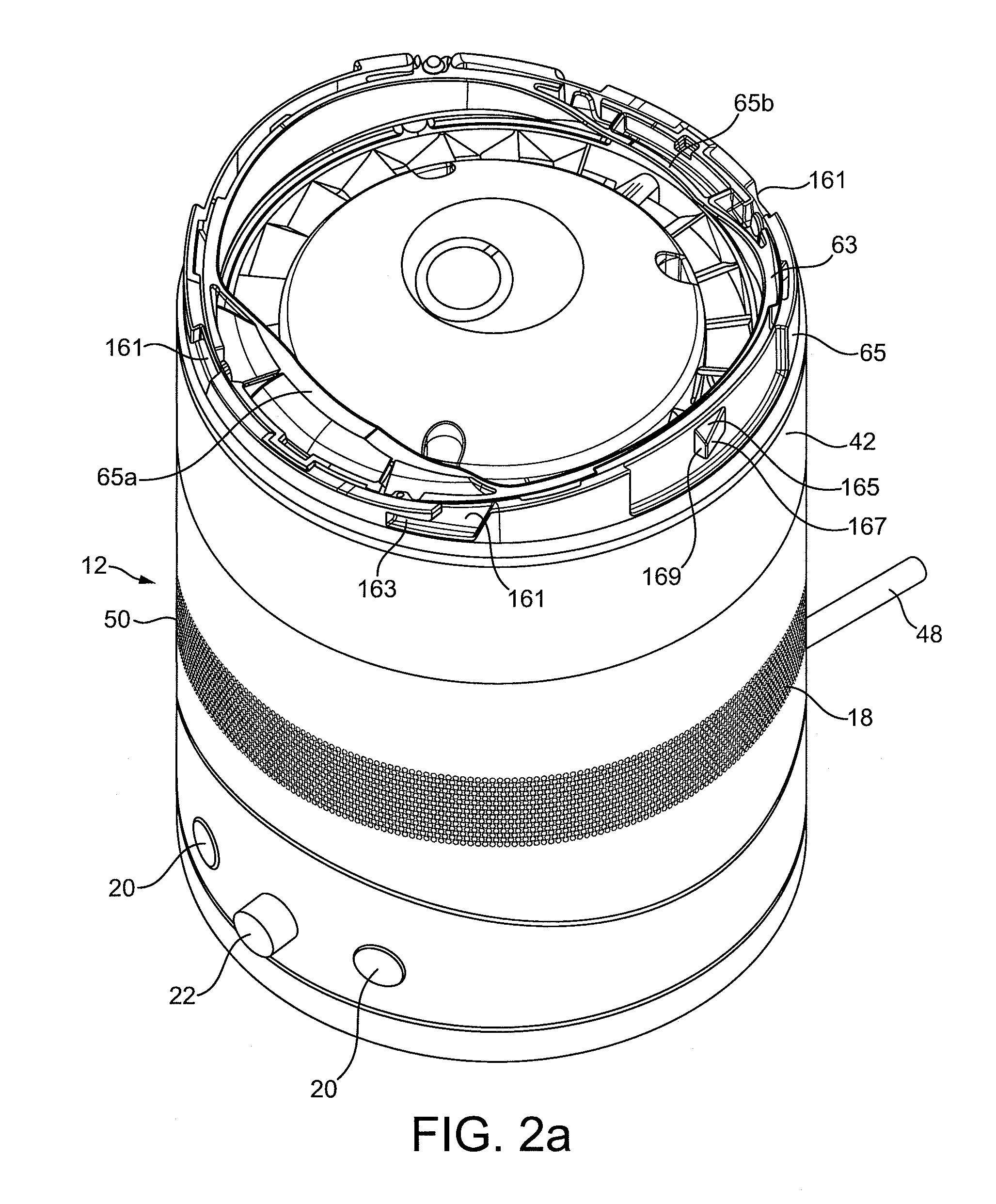

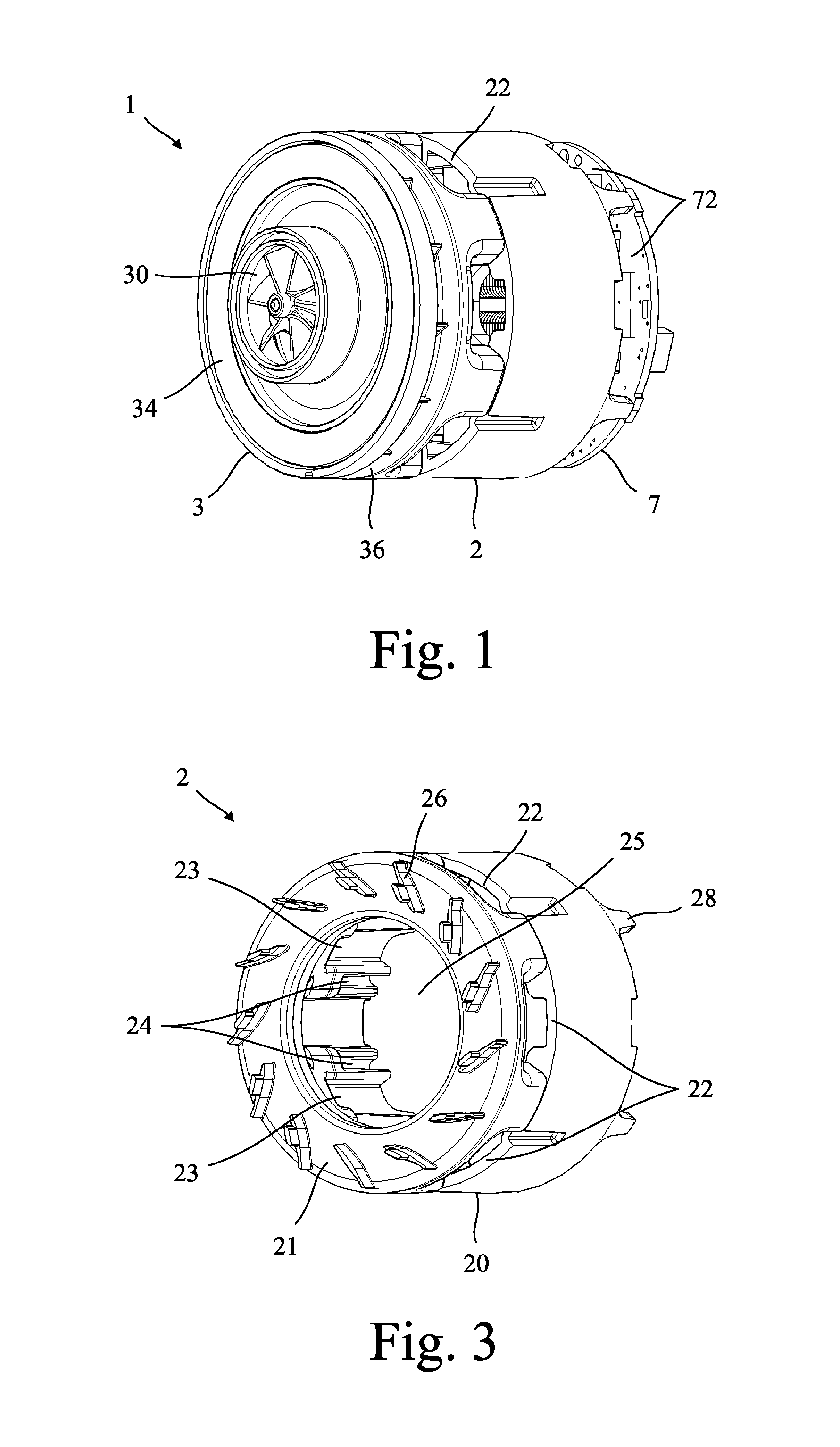

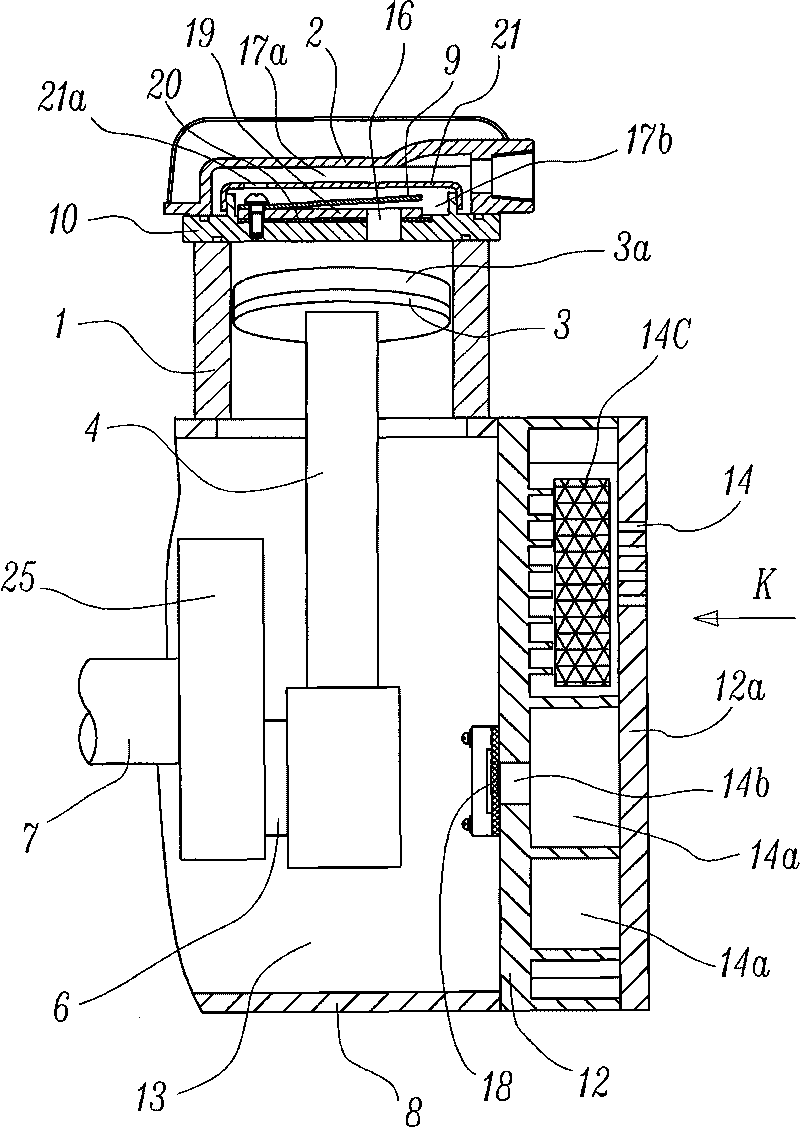

Fan assembly

ActiveUS20100226763A1Emission reductionWide operating speed rangePump componentsJet pumpsEngineeringAirflow

A bladeless fan assembly for creating an air current includes a nozzle mounted on a base. The nozzle comprises an interior passage and a mouth for receiving the air flow from the interior passage and through which the air flow is emitted from the fan assembly. The nozzle defines an opening through which air from outside the fan assembly is drawn by the air flow emitted from the mouth. The nozzle is detachable from the base, which is preferably sized to be accommodated within the opening of the nozzle for transportation.

Owner:DYSON TECH LTD

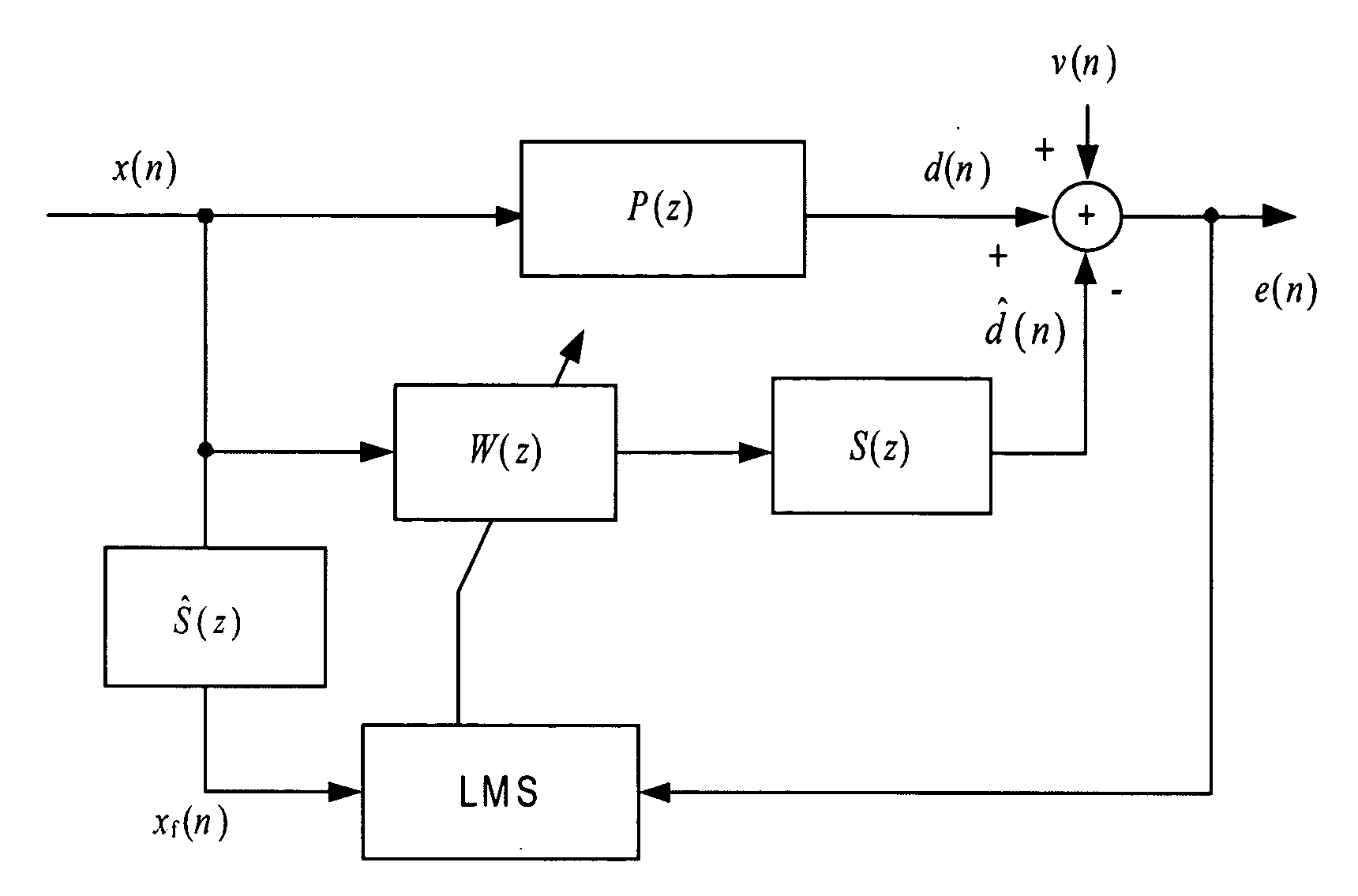

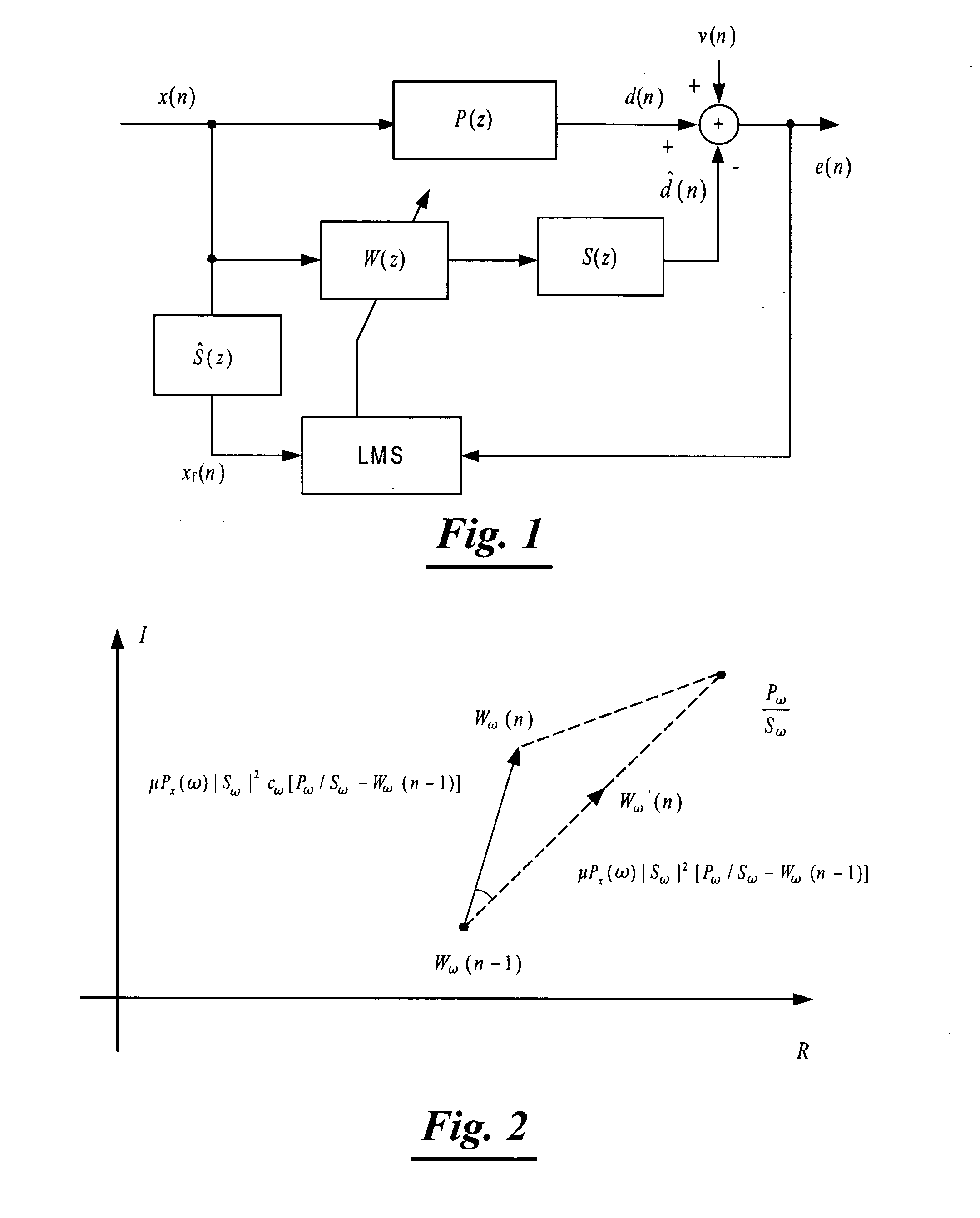

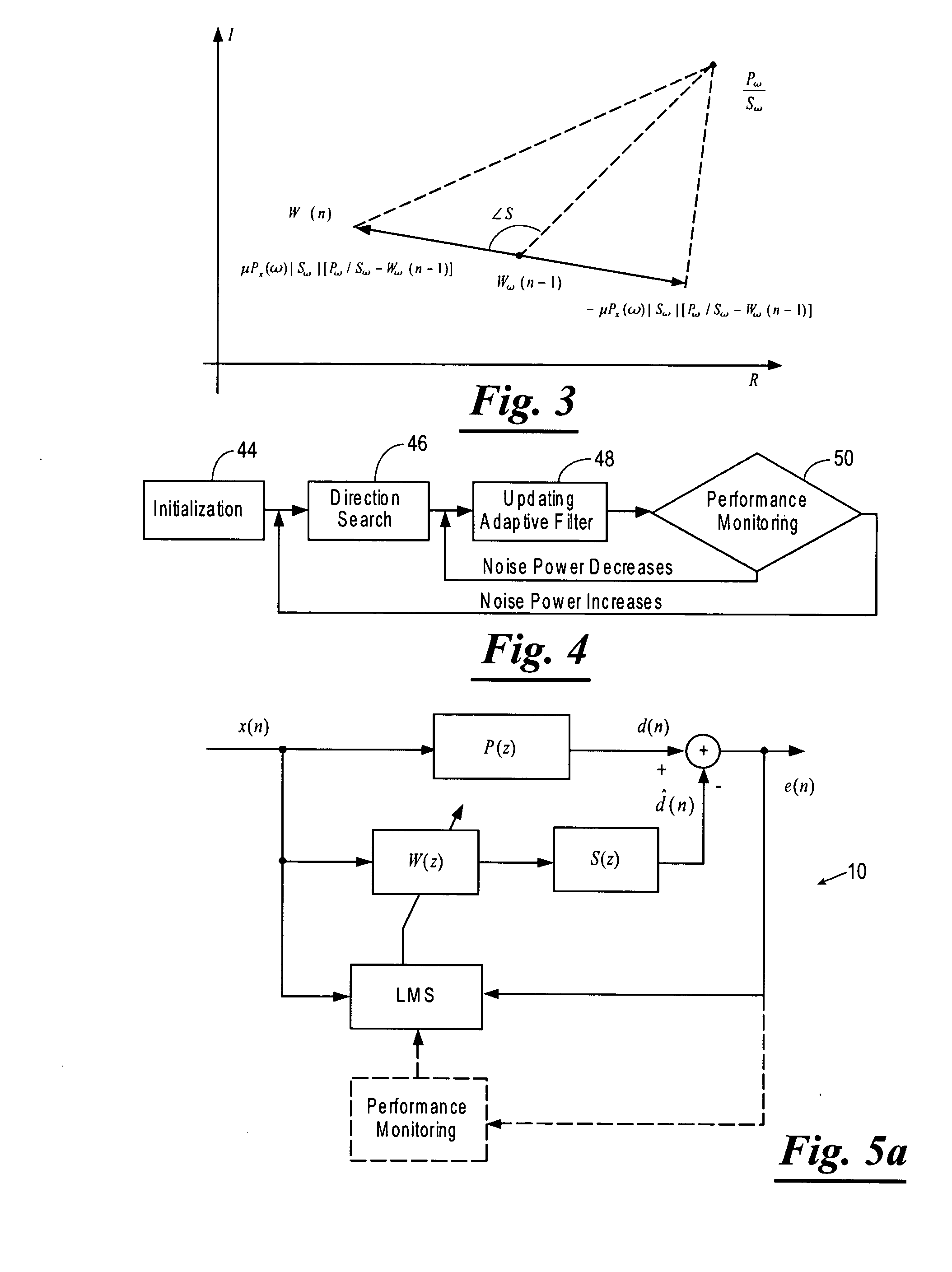

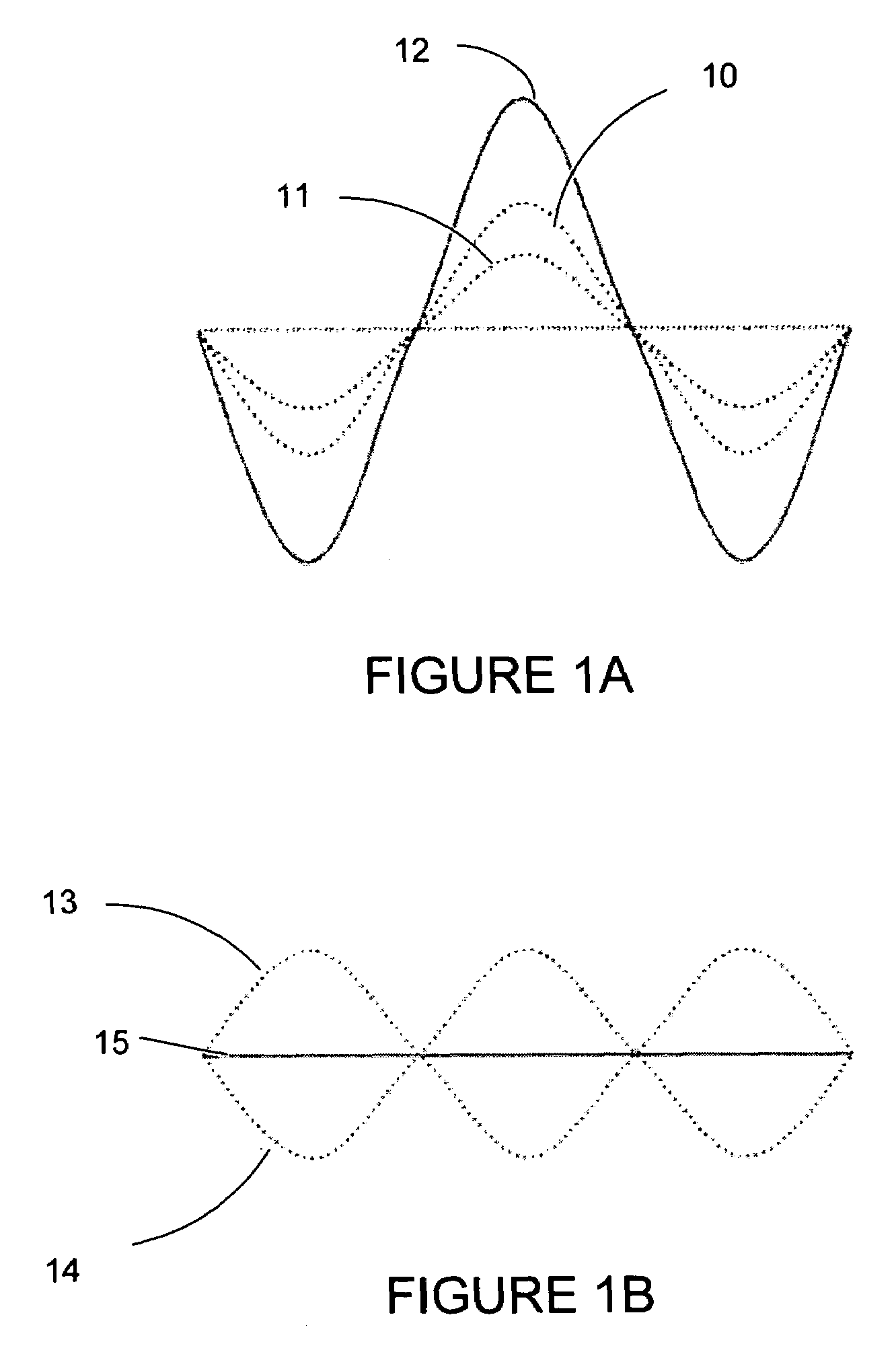

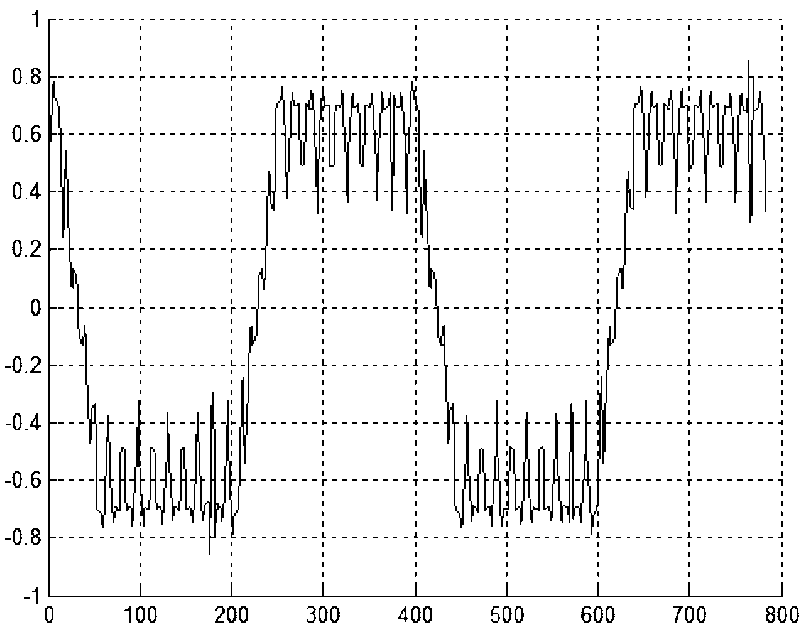

Active noise control algorithm that requires no secondary path identification based on the SPR property

InactiveUS20100284546A1Reduce vibration and noiseReduce residual noise powerEar treatmentNoise generationNoise controlControl system

A control system for reducing noise or vibration in a target zone. The noise or vibration is produced by a source and transferred to the target zone by a main path. The control system is provided with an actuator, at least one error sensor and a controller. The actuator is positioned to deliver actuated signals into at least a portion of the target zone. The at least one error sensor monitors the residual noise or vibration power in the target zone and produces an error signal representative thereof. The controller receives a reference signal representative of noise or vibration produced by the source, and the error signal representative of the residual noise power in the target zone. The controller analyzes sub-bands of the reference signal and the error signal without identification of a secondary path, and provides drive signals to the actuator to cause the actuator to deliver the actuated signals into the target zone so as to reduce the residual noise power in the target zone.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

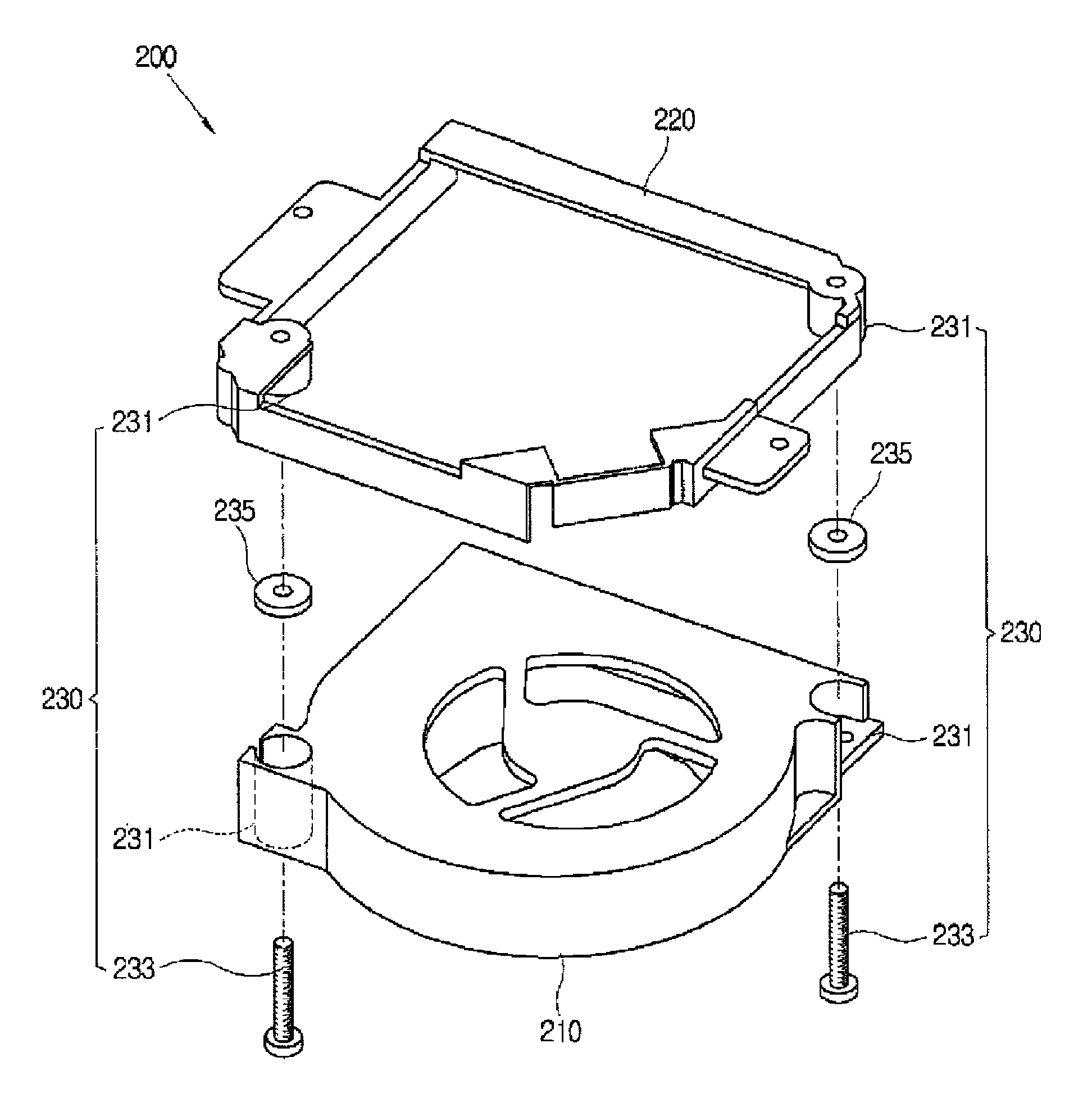

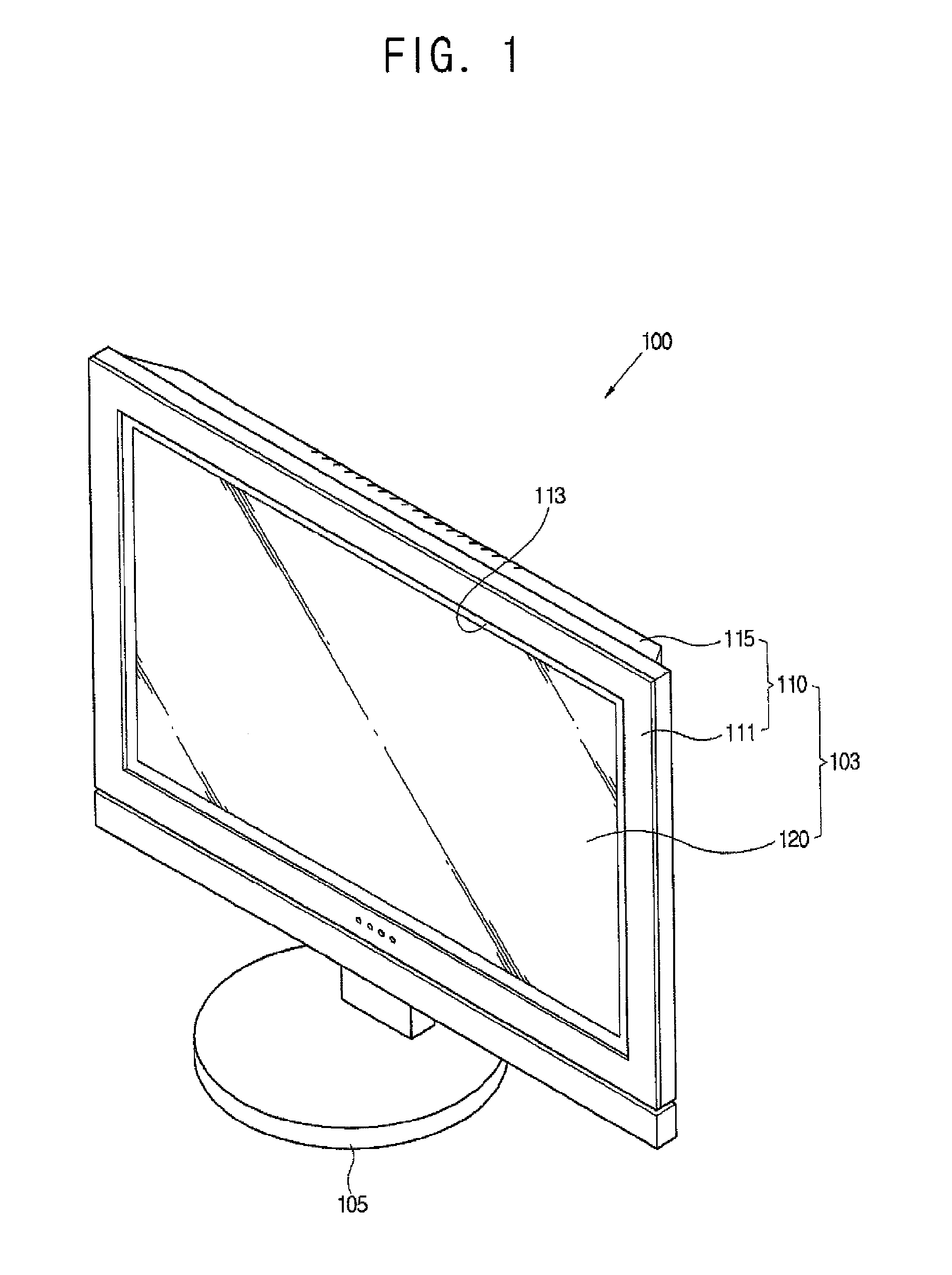

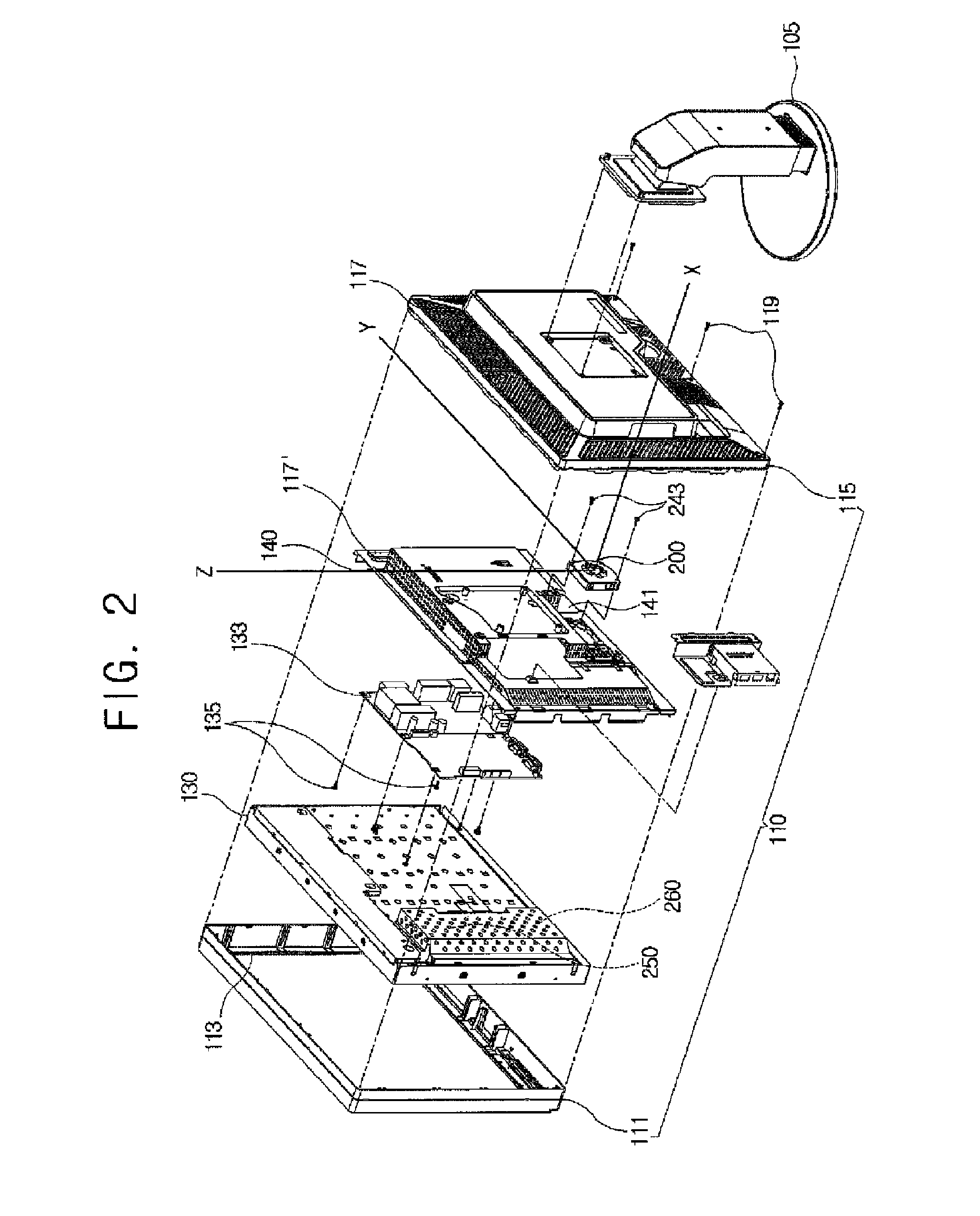

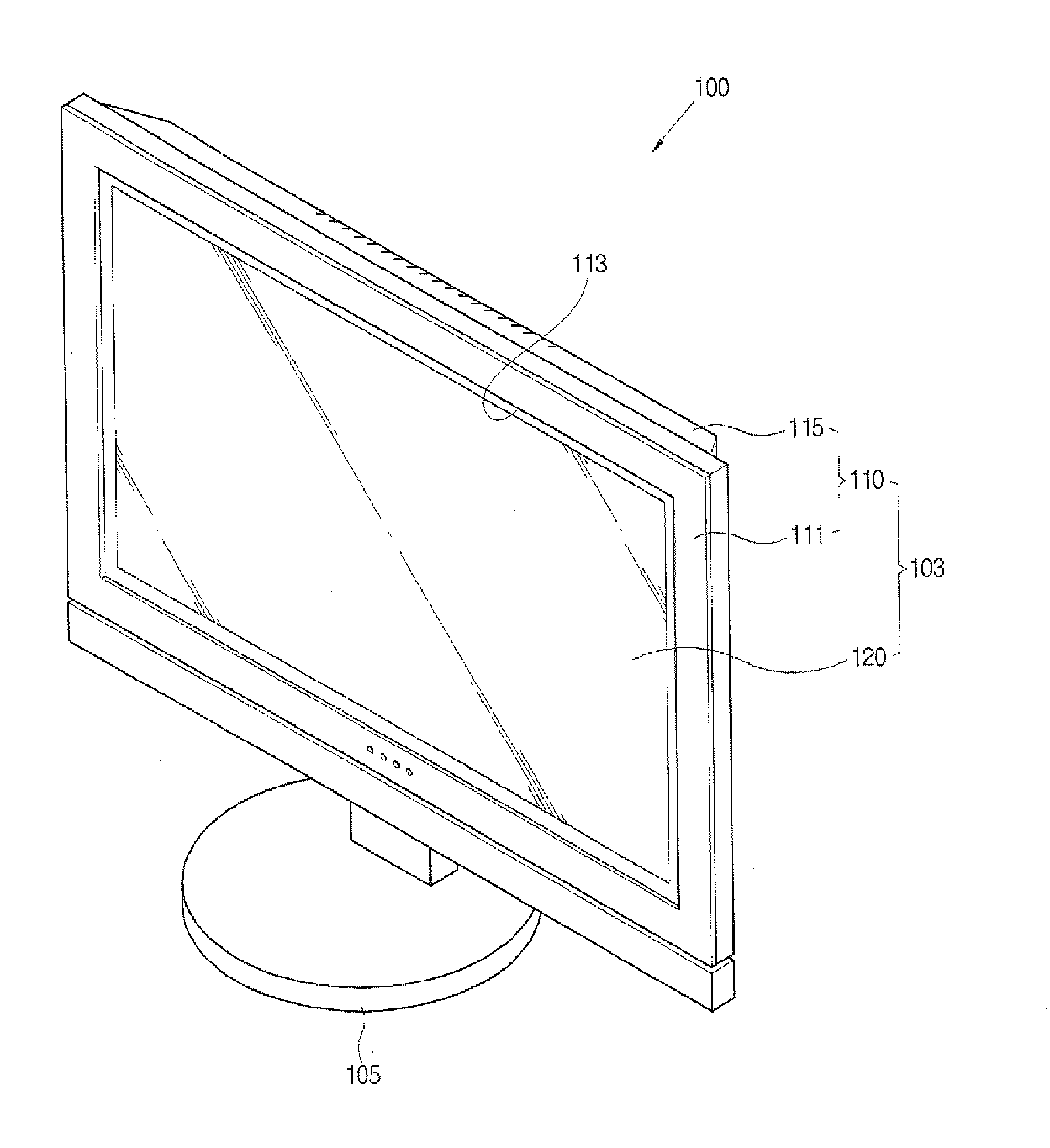

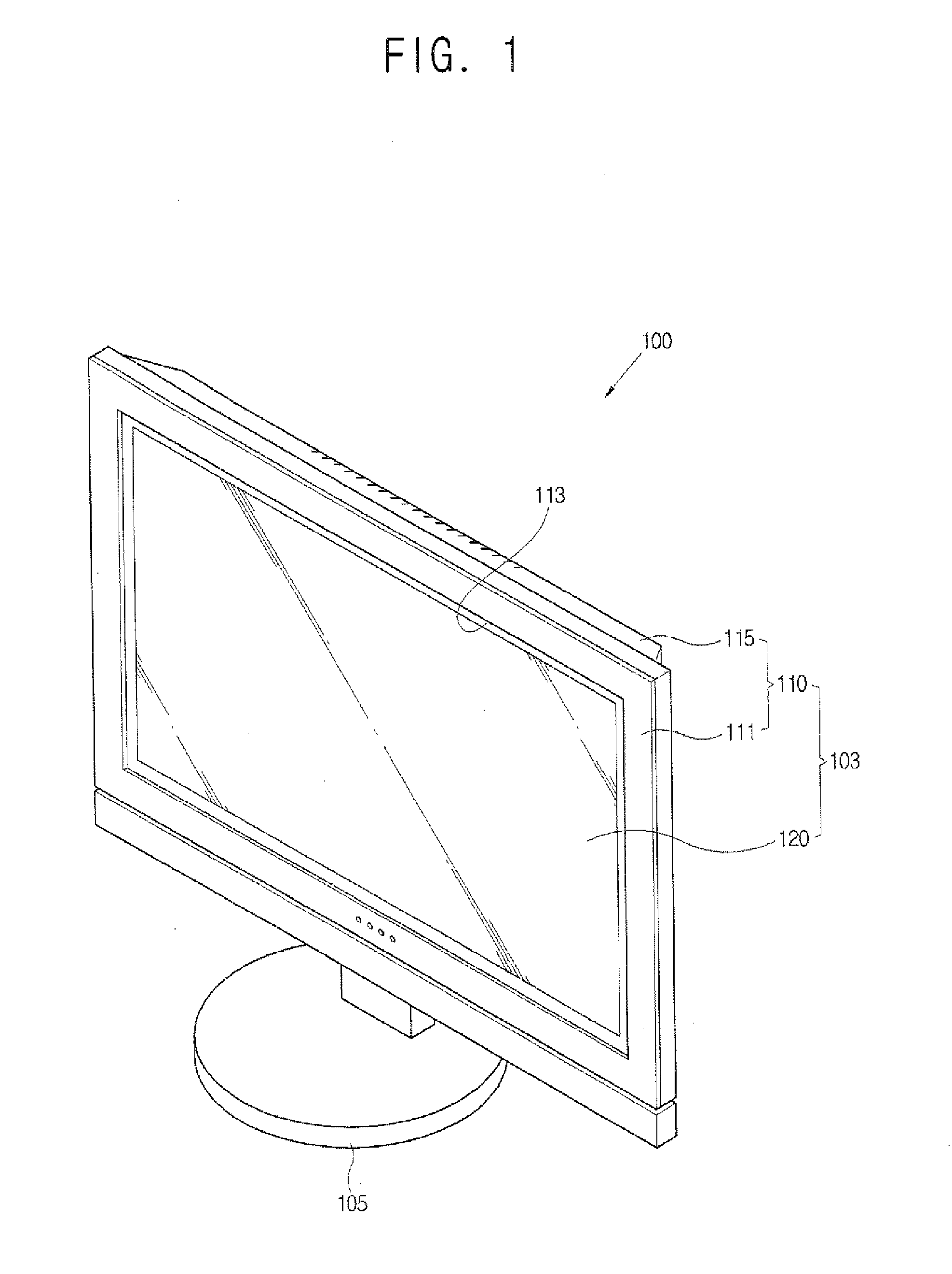

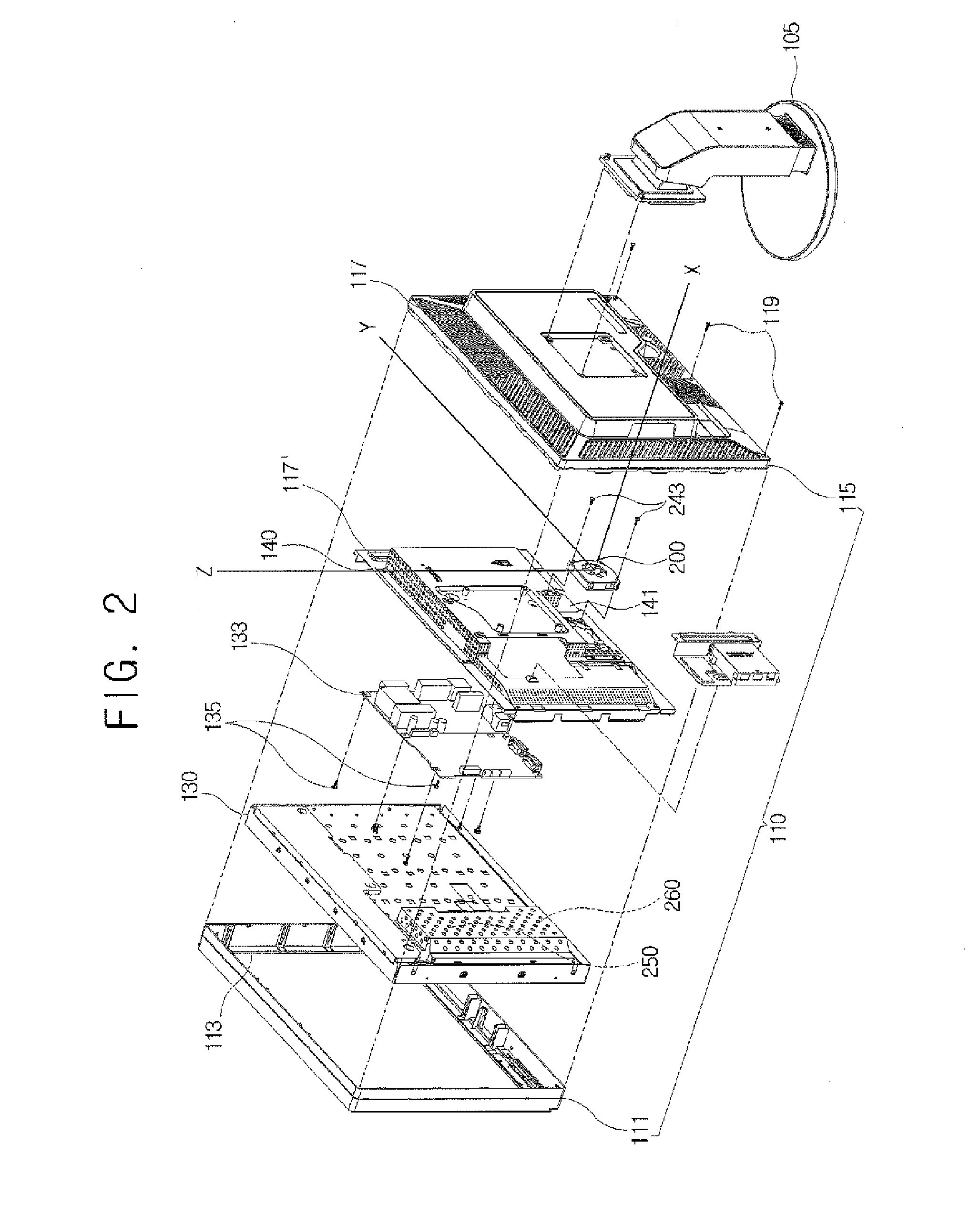

Cooling fan unit and display apparatus having the same

ActiveUS7800706B2Improve cooling efficiencyEfficient heatingStatic indicating devicesDigital data processing detailsLiquid-crystal displayEngineering

A display apparatus having a casing in which an opening part is formed, includes: a liquid crystal display panel that is supported by the casing so that an image can be displayed through an opening part; a backlight unit that is provided behind the liquid crystal display panel and has a light source that emits light; a shield cover that is provided behind the backlight unit and is supported by at least one of the backlight unit and the casing; and a cooling fan unit that is combined to the shield cover and supplies cooling air to the backlight unit.

Owner:SAMSUNG ELECTRONICS CO LTD

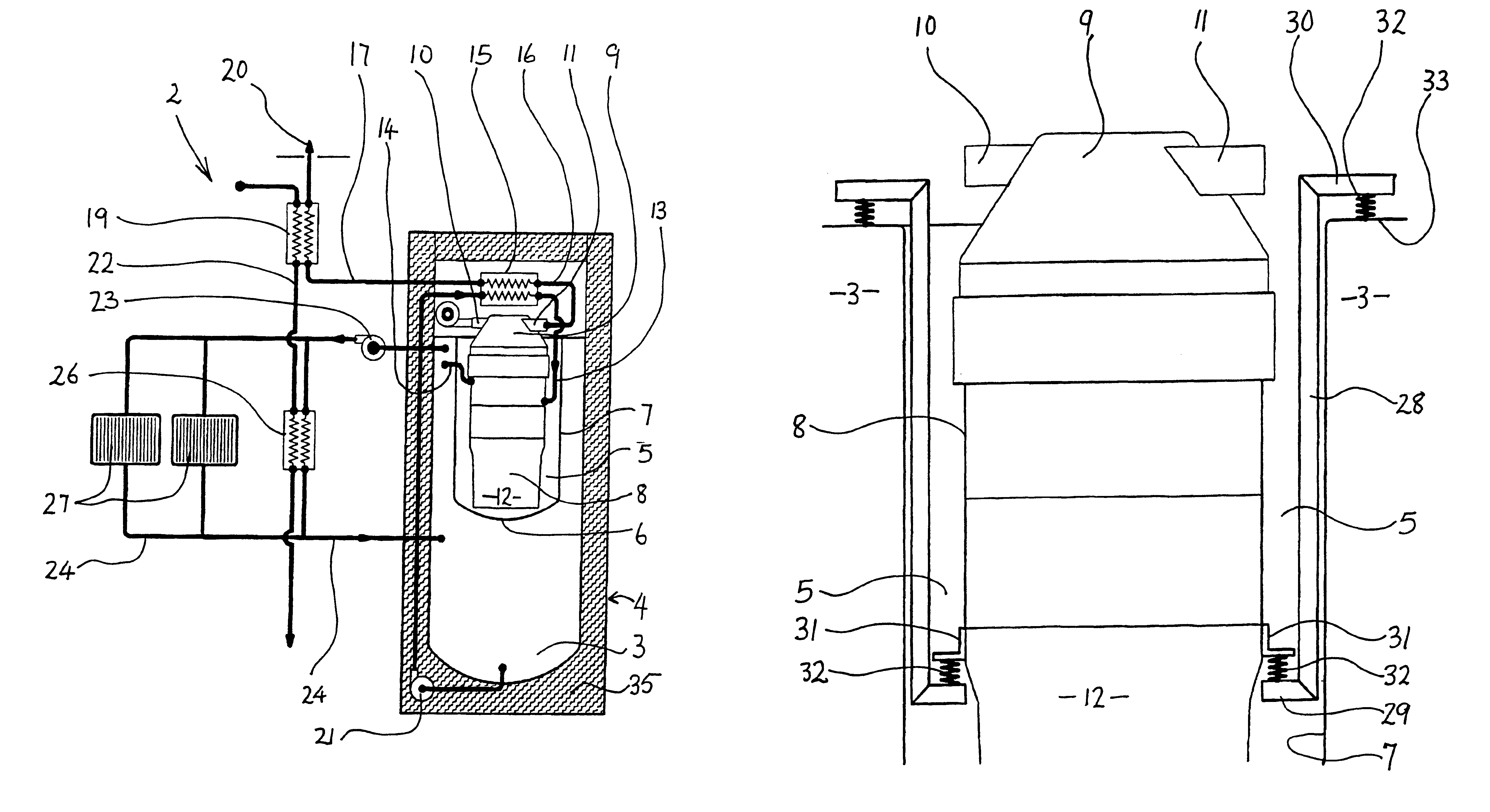

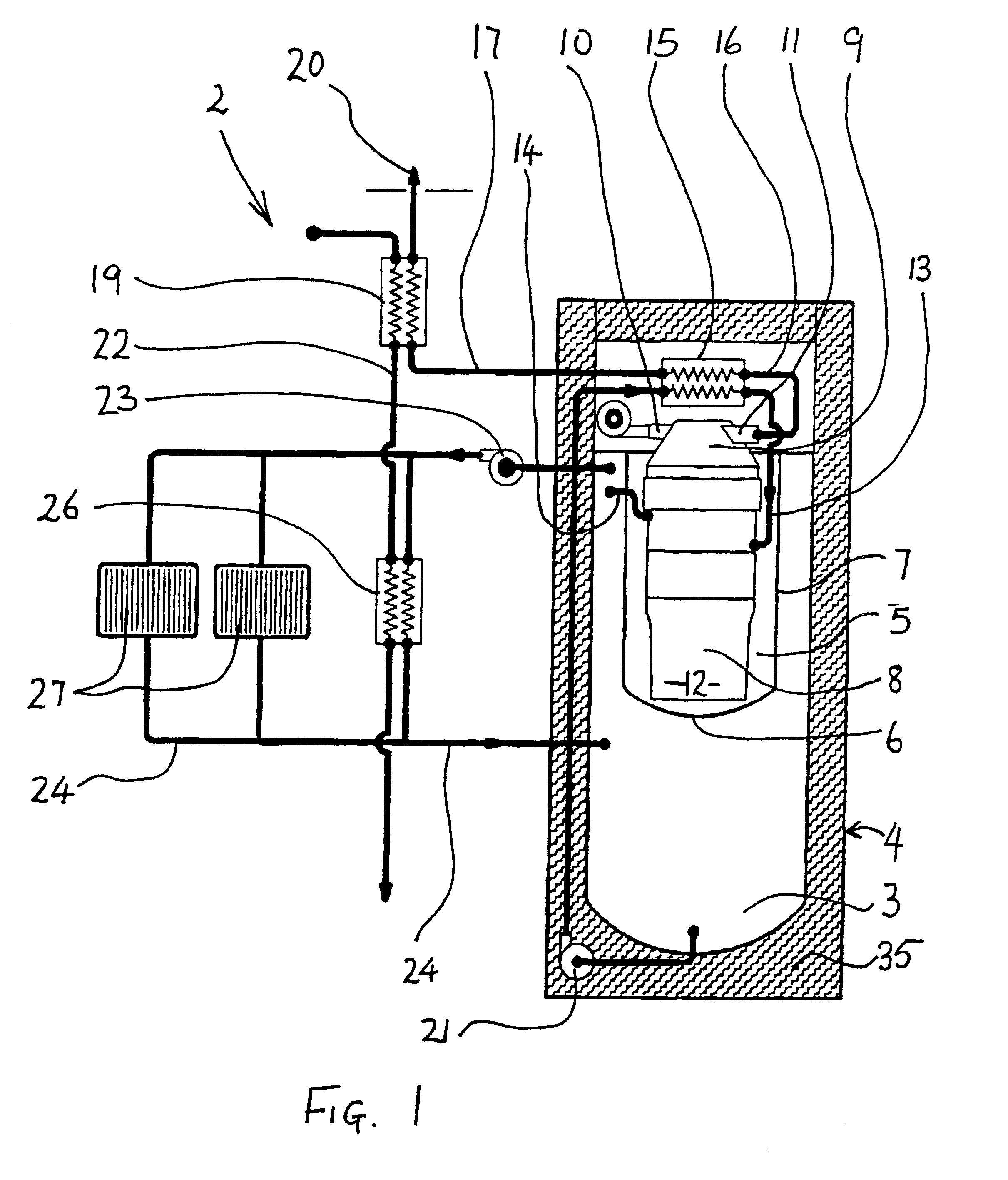

Co-generation system employing a stirling engine

InactiveUS6525431B1Reduce noise and vibrationReduce vibration and noiseInternal combustion piston enginesHeat storage plantsExhaust gasCogeneration

A co-generation system for producing heat, hot water and electricity for a building is provided while generating a minimum of noise and vibration within the building. The system includes an engine and burner with a generation; a storage tank, for storage of primary water, which is adapted to contain therein the engine and generator; apparatus for circulating and heating the primary water, and apparatus for venting exhaust gases to the outside of the building. The hot water may also be secondary water and either or both water may be potable. The engine optimally operates on a Stirling cycle. The building may be a commercial or domestic dwelling which is free standing or part of a larger structure or may be mobile.

Owner:WHISPER TECH

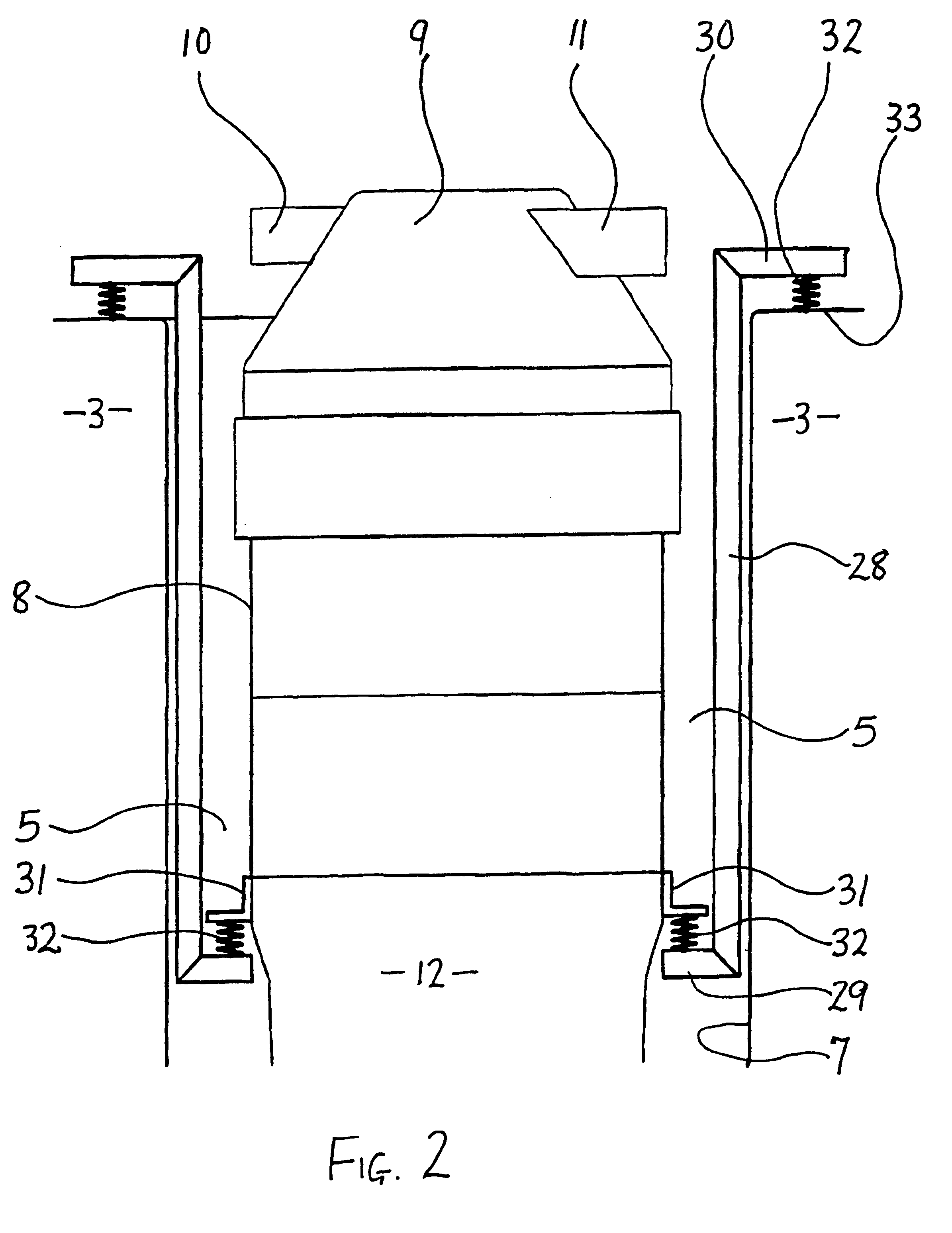

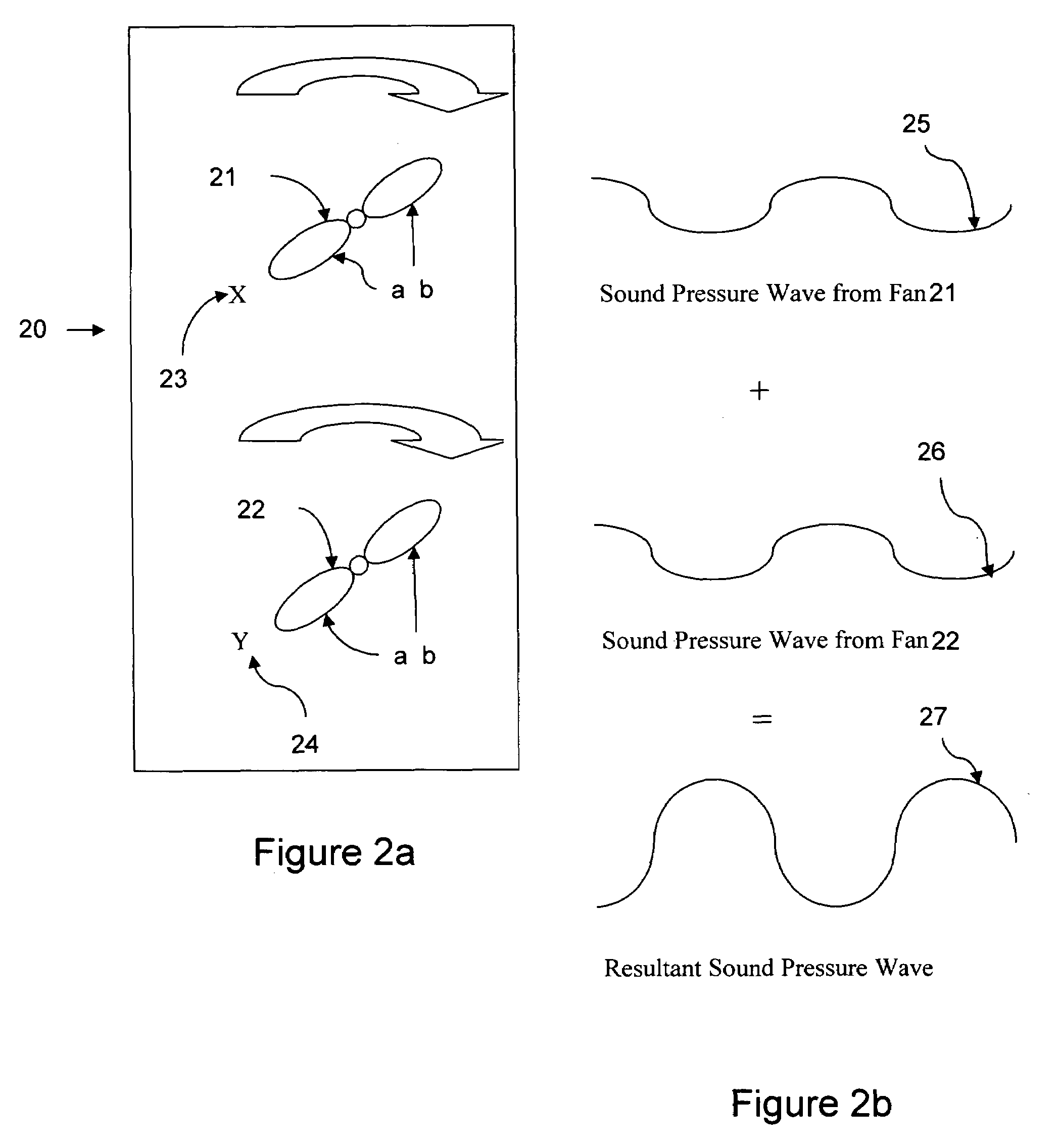

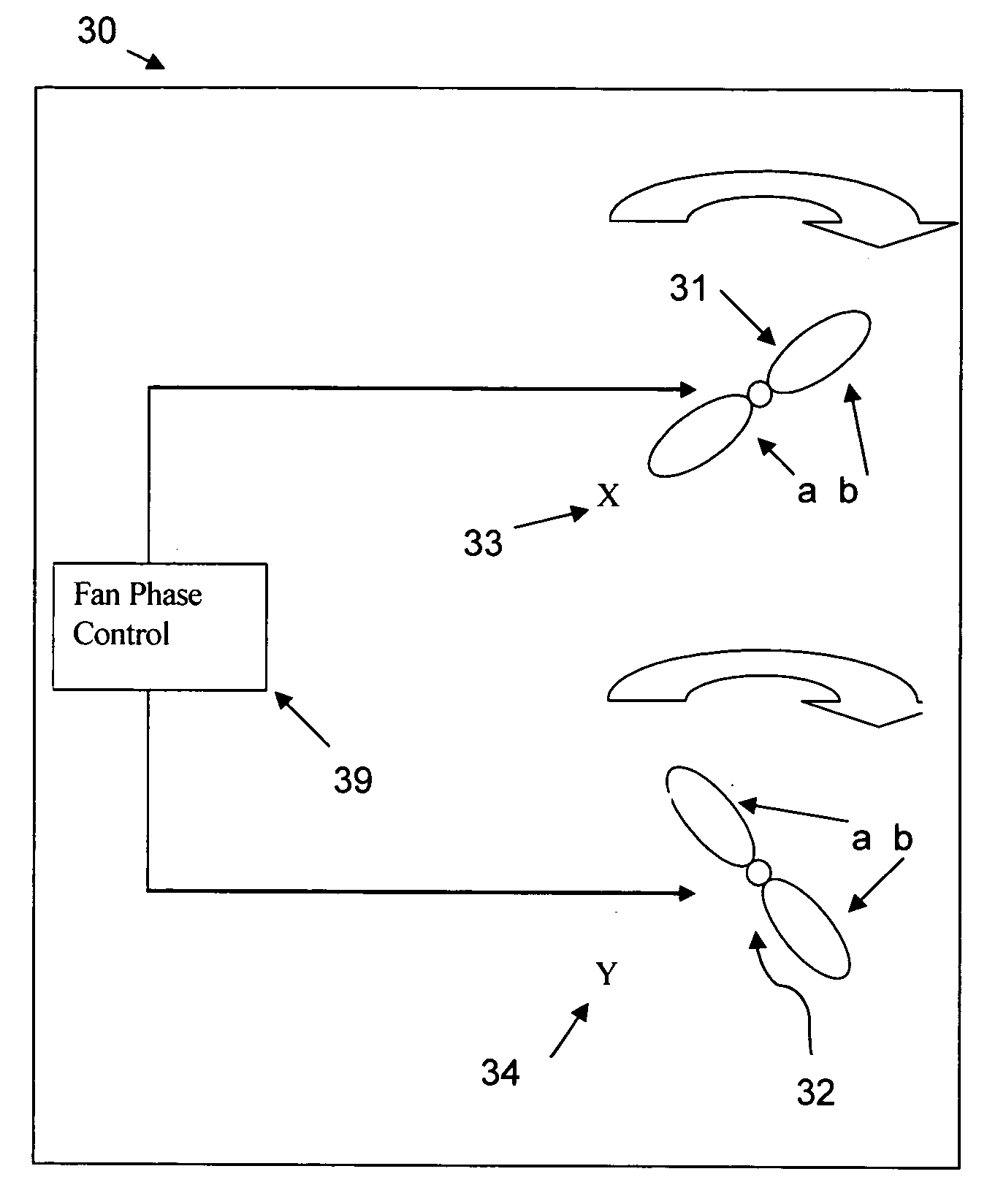

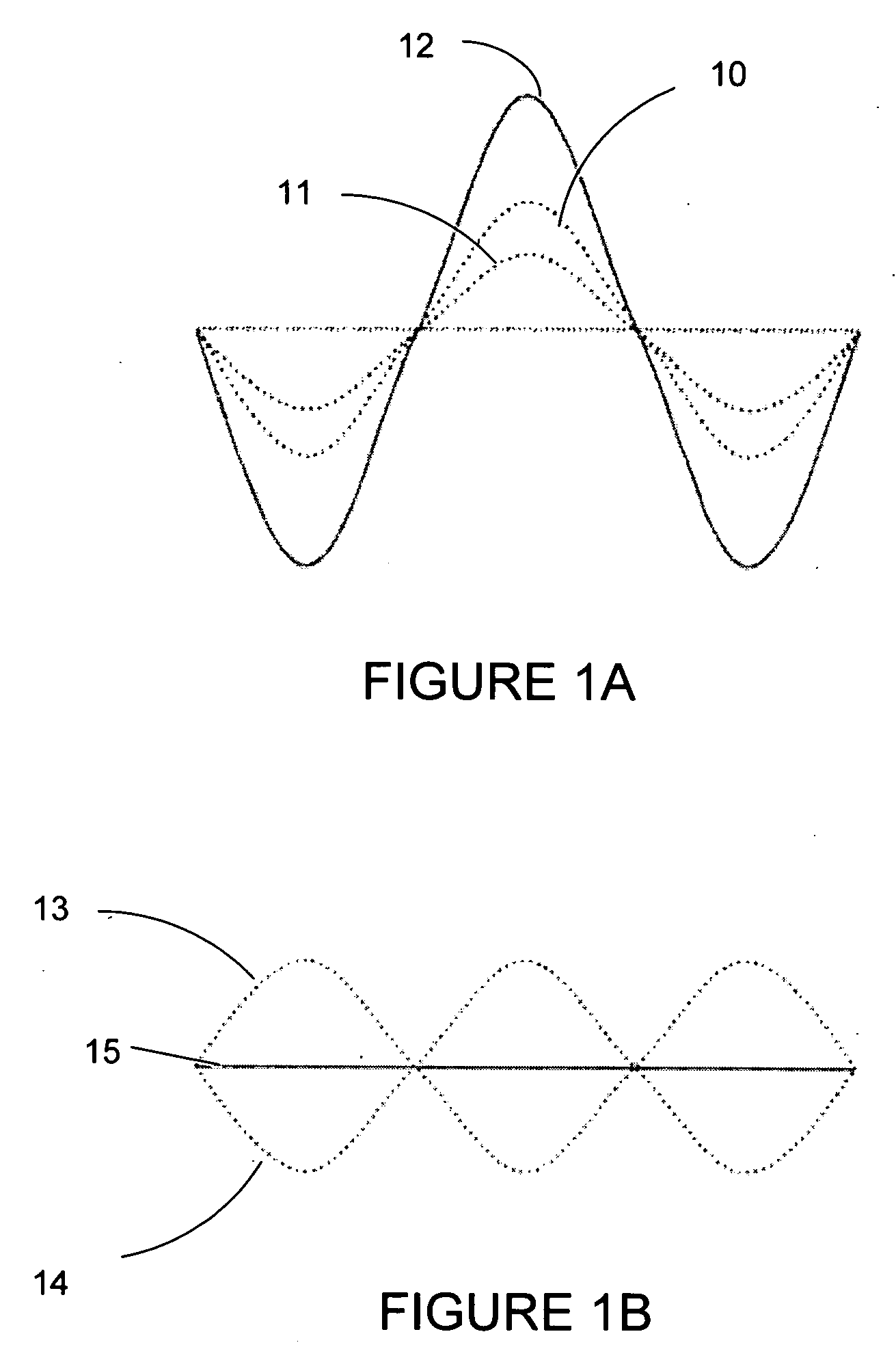

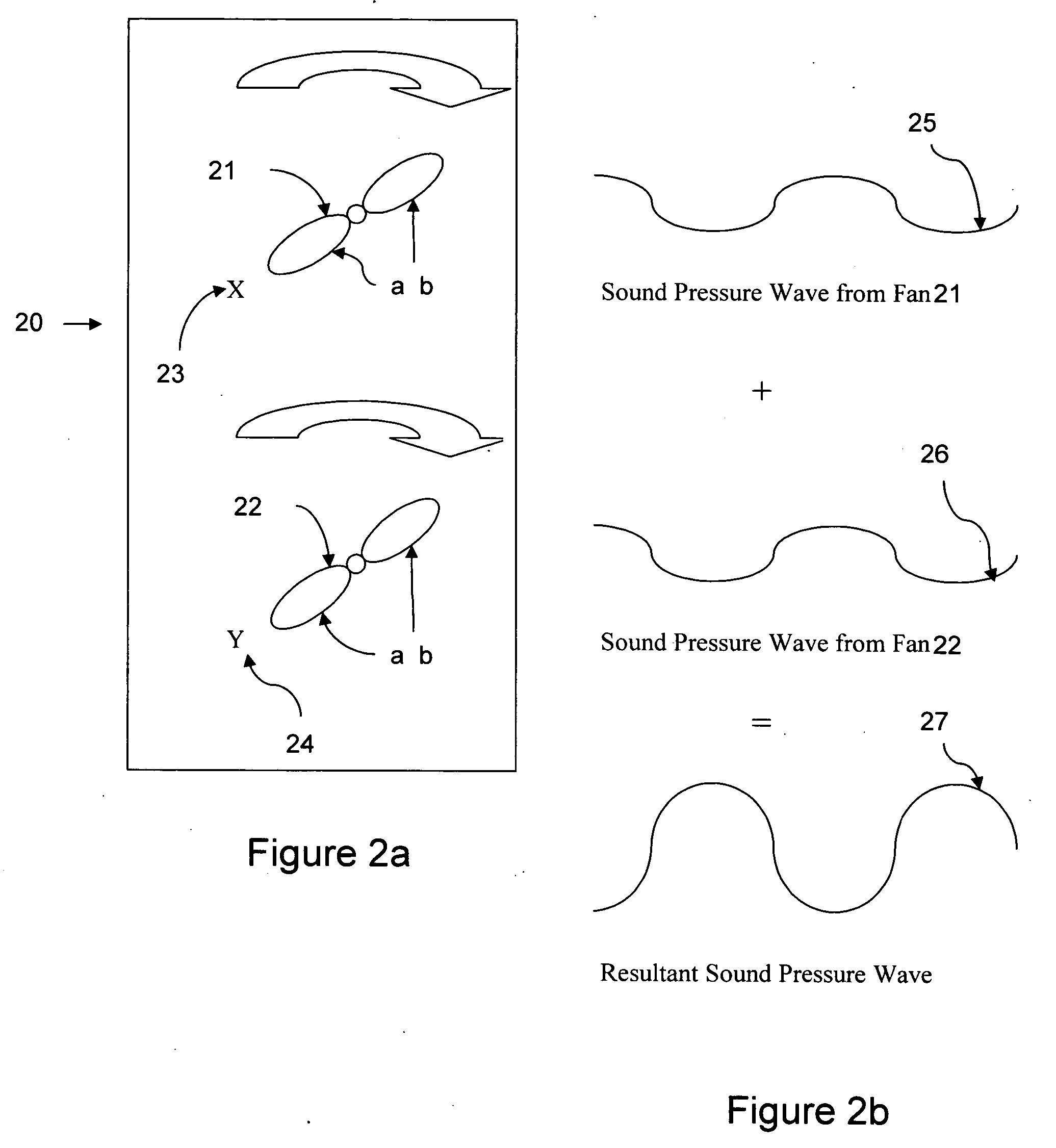

Mutual active cancellation of fan noise and vibration

ActiveUS7282873B2Reduce vibration and noiseReduce noiseDC motor speed/torque controlMultiple dynamo-motor startersPhase differenceEngineering

A multi-fan apparatus and method incorporates mutual active cancellation of fan noise and / or vibrations. The multi-fan apparatus includes two or more fans circuits, each comprising a fan, a fan speed controller and a separate tachometer, and a fan phase controller. The phase controller is connected to at least one fan speed controller and to each tachometer. Each fan's speed is independently and dynamically maintained at the same set speed by the fan speed controllers using an independent control loops. A noise and / or vibration cancellation phase difference between fans is determined in order to achieve destructive interference of pressure waves and, thus, noise and / or vibration reduction, in pre-determined region of a system incorporating the multi-fan apparatus. The phase controller establishes and maintains this cancellation phase difference between the fans based upon feedback from the tachometers.

Owner:LENOVO PC INT

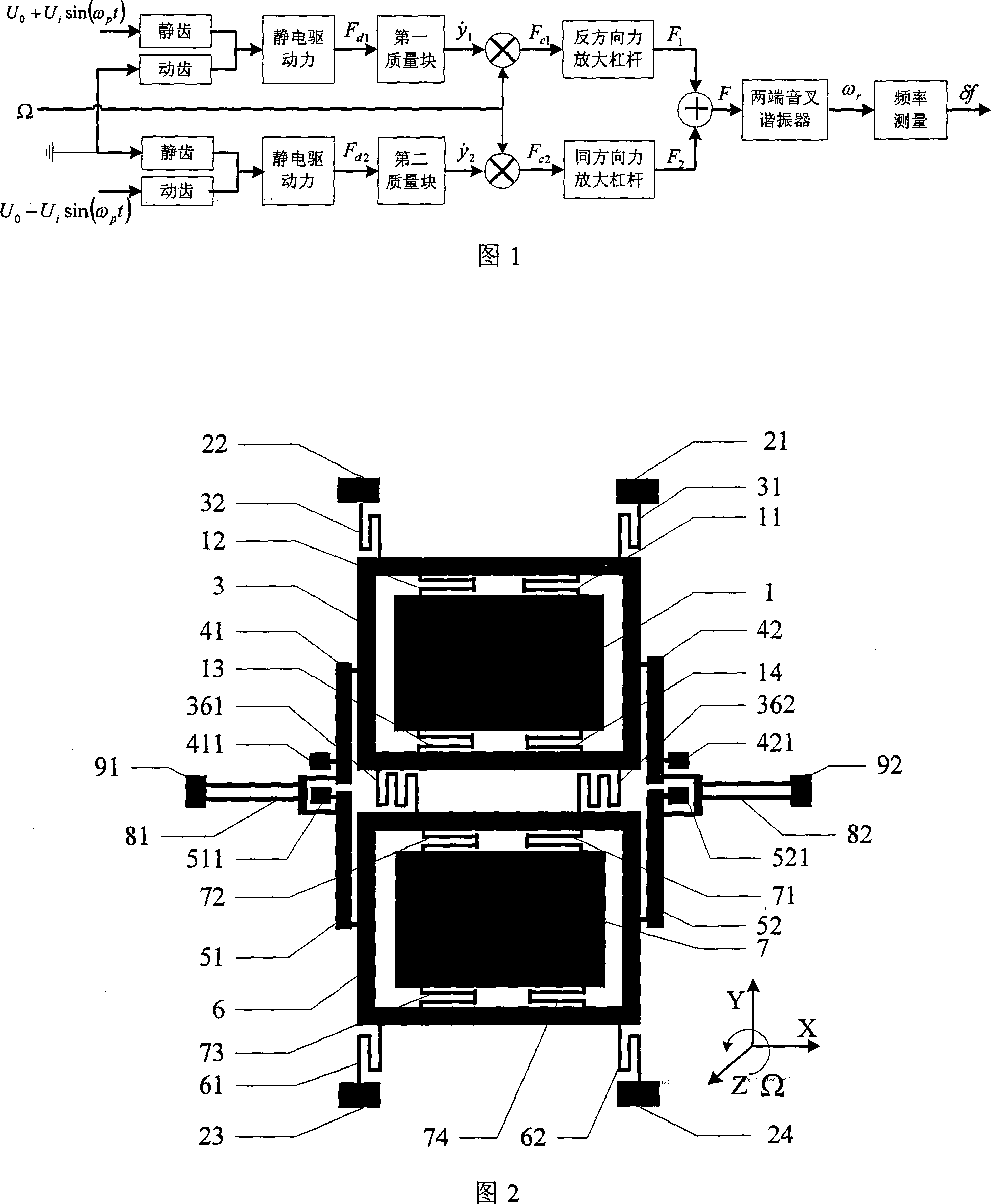

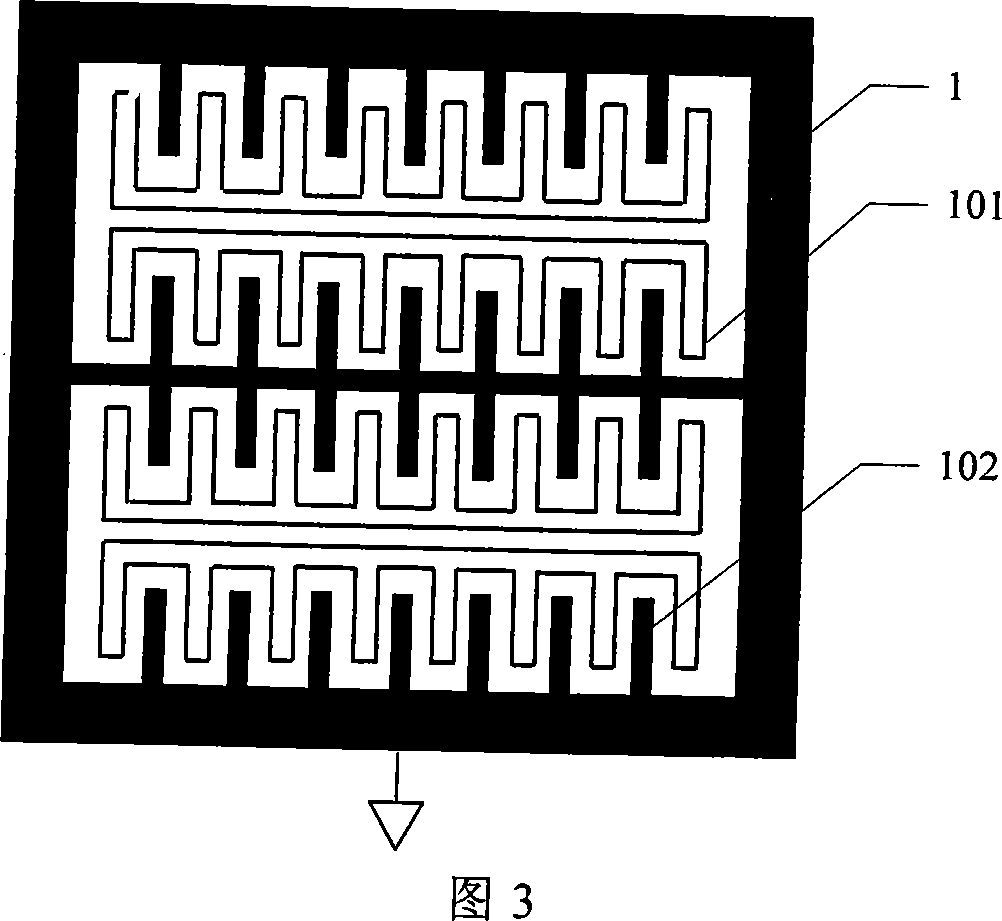

Double quality blocks attune output type silicon MEMS gyroscopes

ActiveCN101135563AReduce vibration and noiseReduce energy lossTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesGyroscopeResonance

The gyroscope comprises: fixed teeth, movable teeth, two mass blocks, two outer frames, two pairs of leavers and two tuning fork resonators. The first mass block and second mass block are respectively connected to the first outer frame and second outer frame through four infolding beams; two outer frames are respectively secured on the anchor point through the outer supporting beam; two outer frames are connected through a pair of folding beams; both right and left sides of the first outer frame are connected to the free end of two tuning fork resonators via the opposite direction force amplifying leaver; the both right and left sides of the outer frame are connected to the free end of two tuning fork resonators via the same direction force amplifying leaver; by testing the resonance frequency of tuning fork resonator at both ends, calculating the rotating speed inputted from outside.

Owner:BEIHANG UNIV

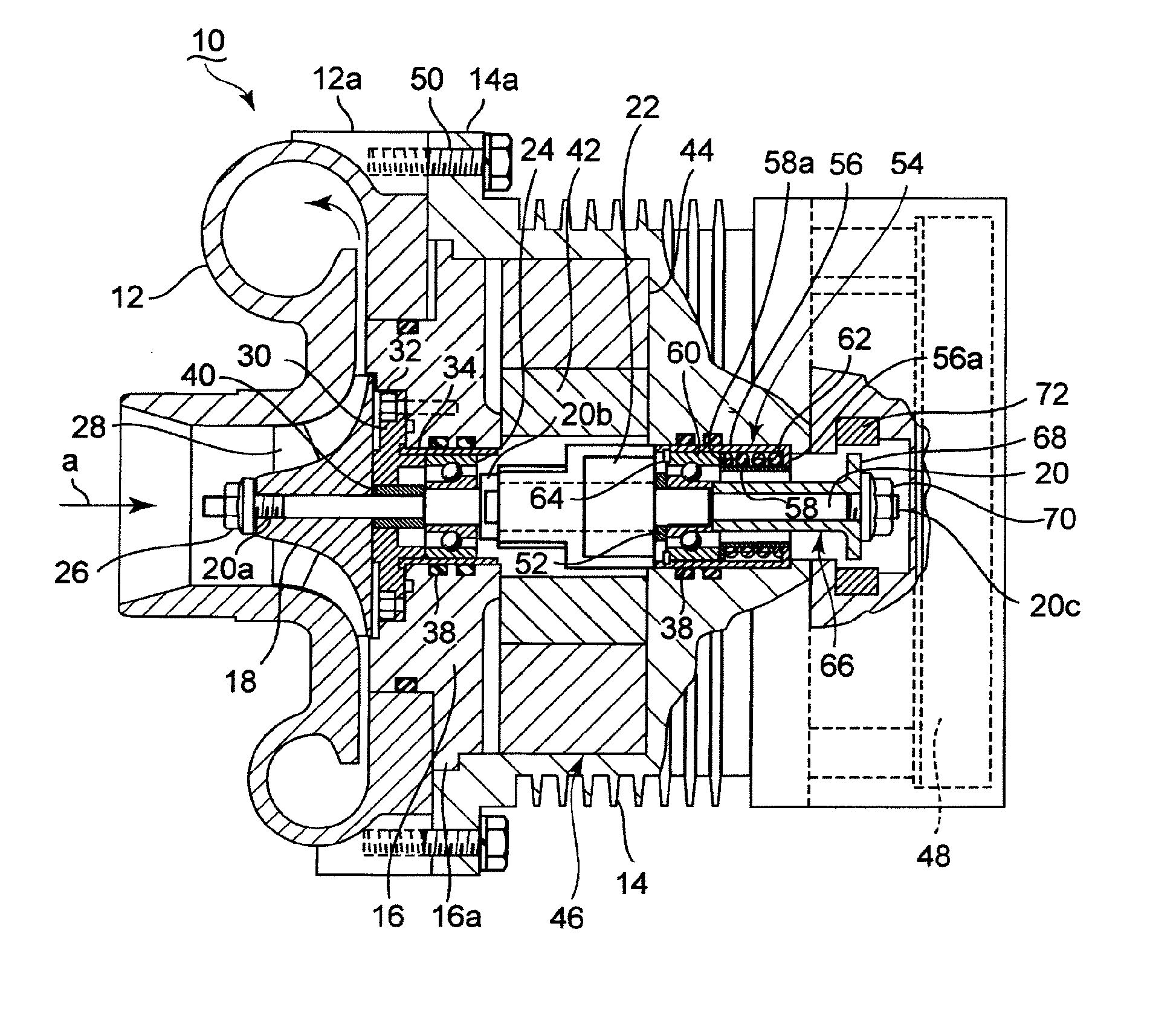

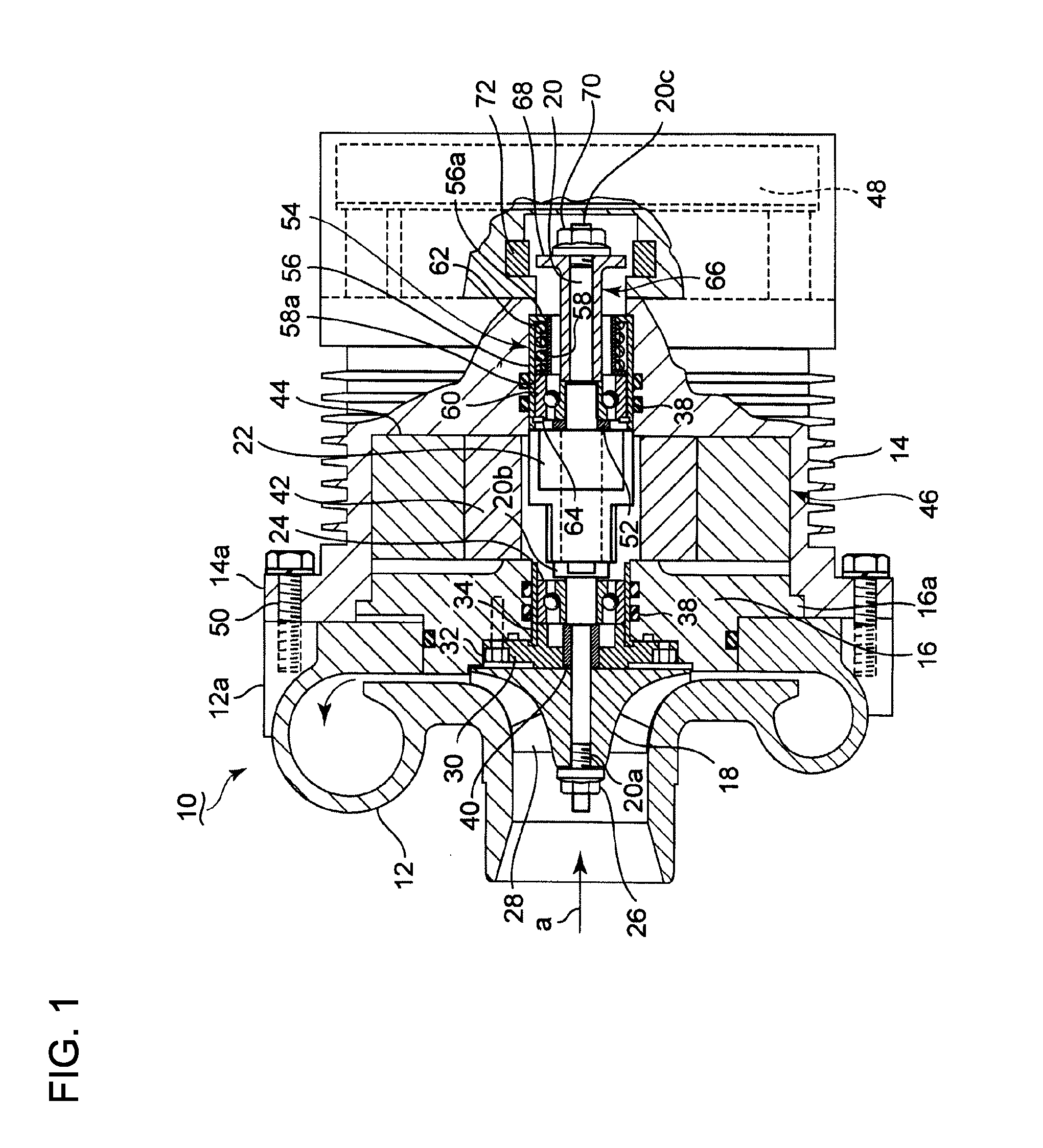

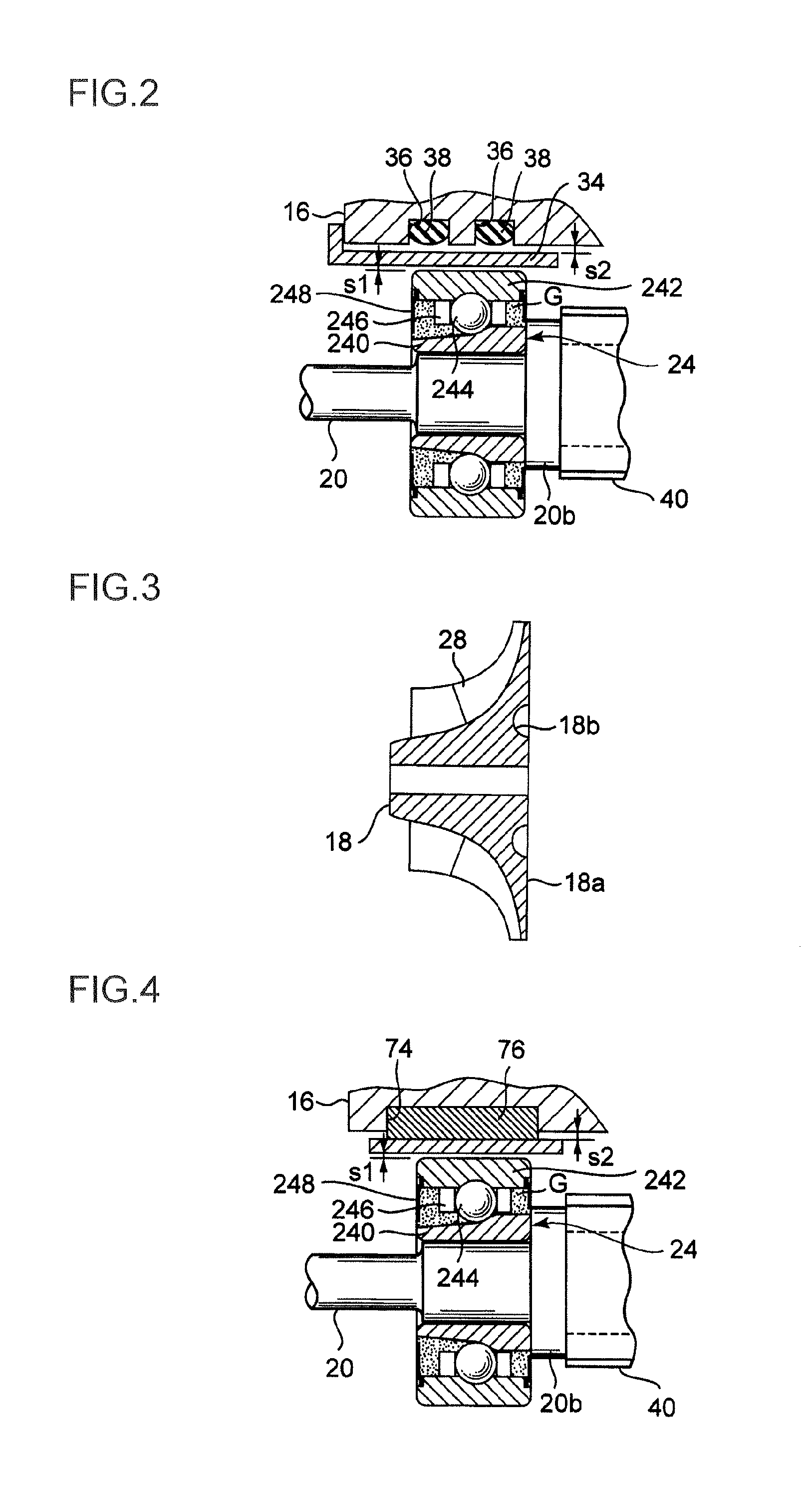

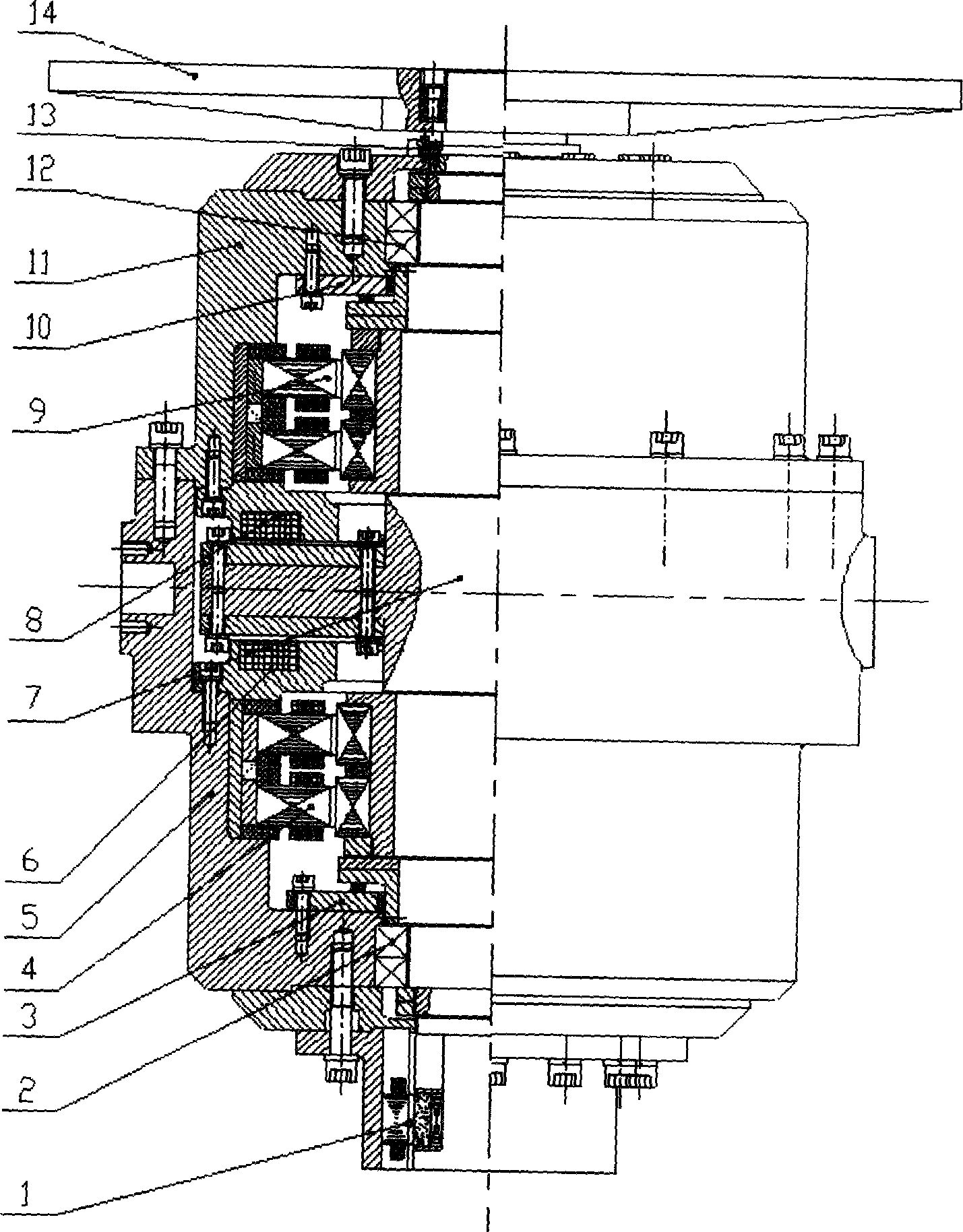

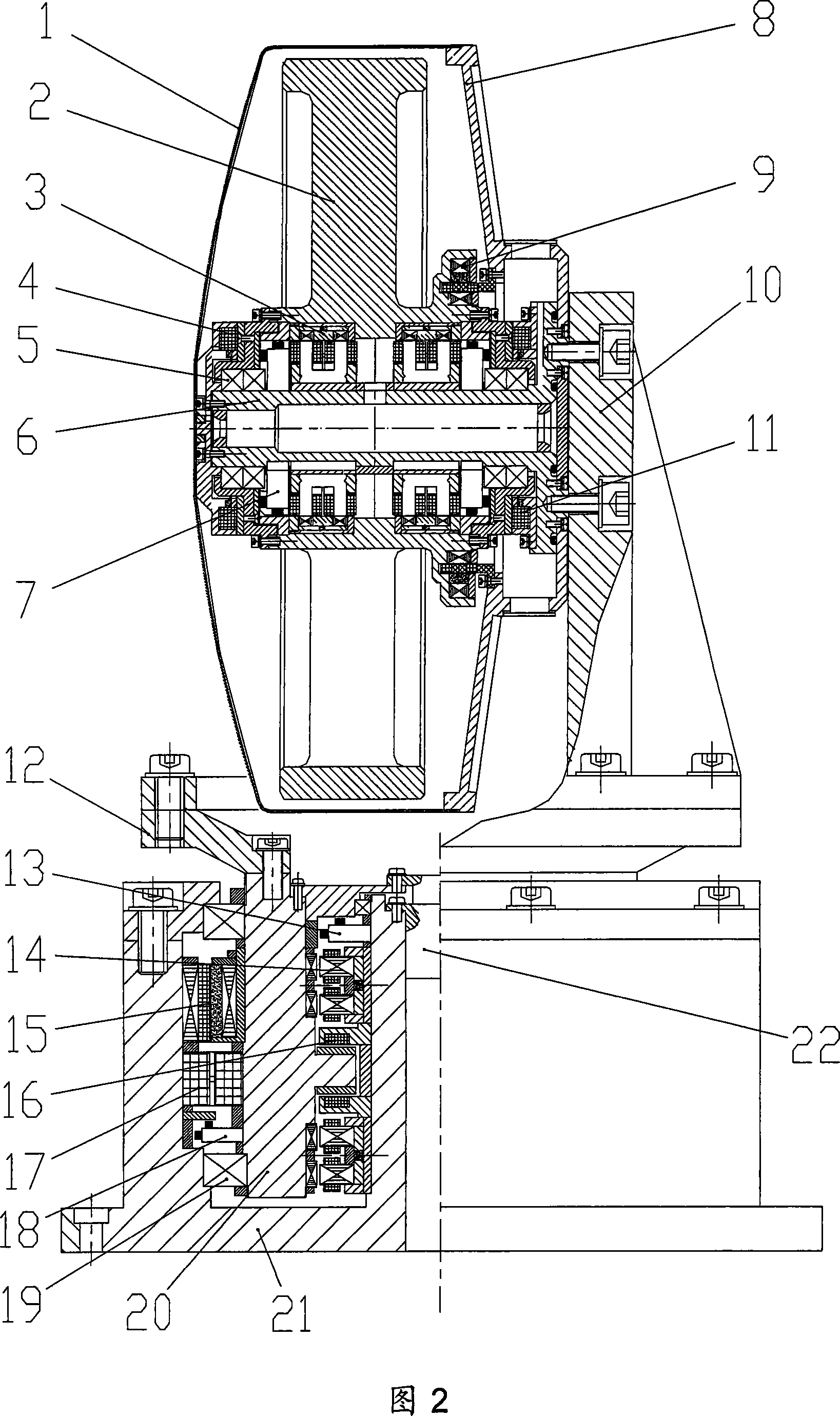

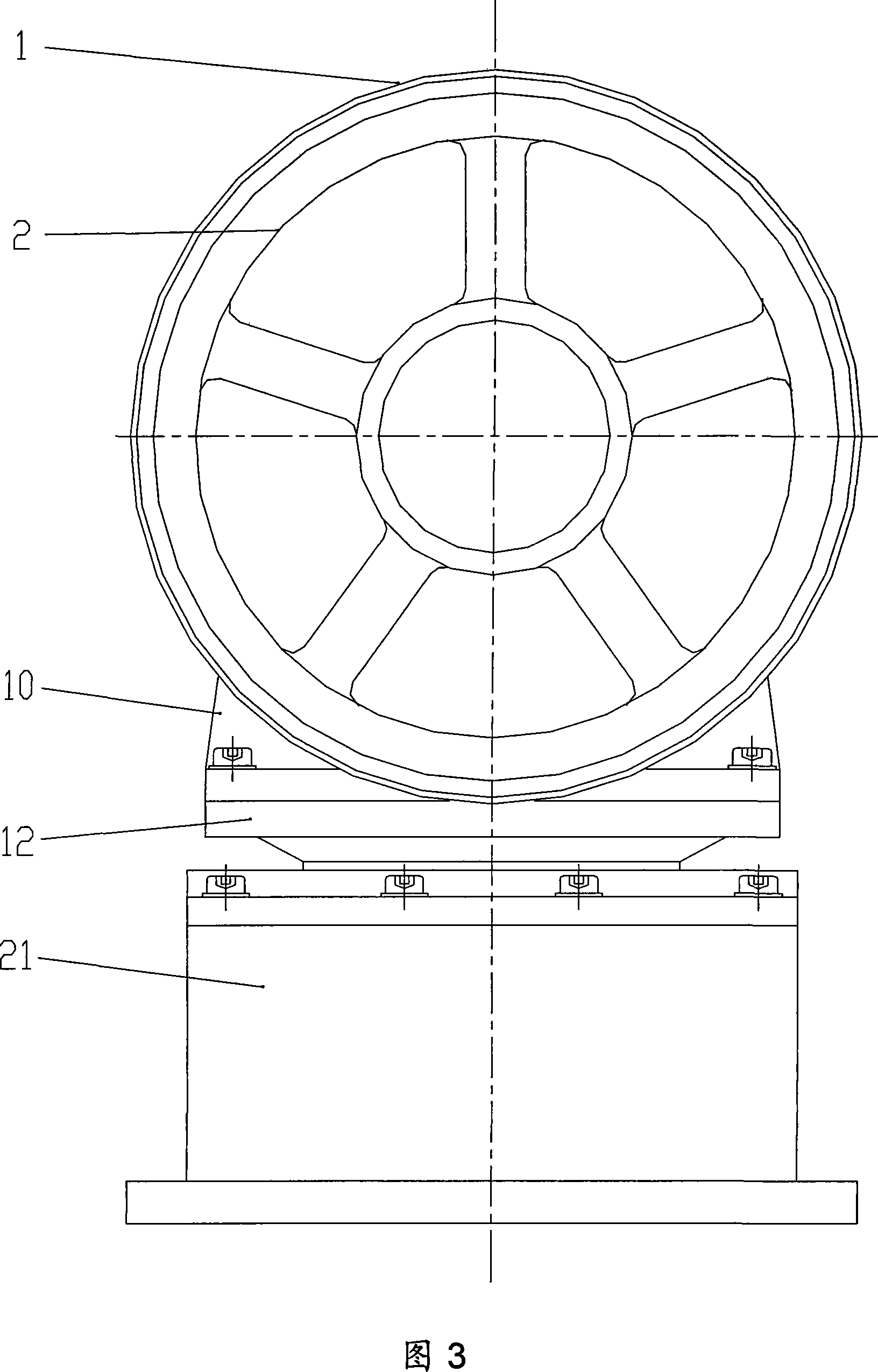

Electric supercharger, assembling method of the same, and internal combustion engine

ActiveUS20140090626A1Reduce vibrationSuppress reduction in output of rotationPump componentsBall bearingsBall bearingExternal combustion engine

It is intended to implement an electric supercharger that has a simplified architecture, is easy to assemble, produces reduced vibration and noise, and has a motor inverter, making it possible to minimize losses in motor output and rotary-shaft output. The electric supercharger is provided with the following: an integrated housing with a built-in electric motor and motor inverter; and a ball bearing and damper-sleeve structure arranged on both sides of the electric motor. The damper-sleeve structure comprises a large-diameter sleeve, a spring guide, a coil spring, and a ball bearing. A gap is formed between the ball bearings and a sleeve and the large-diameter sleeve. The inner ring or outer ring of the ball bearings are supported by various support members disposed on both sides. An elastic O-ring that elastically supports the sleeve and large-diameter sleeve is provided on the outside of the sleeves.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

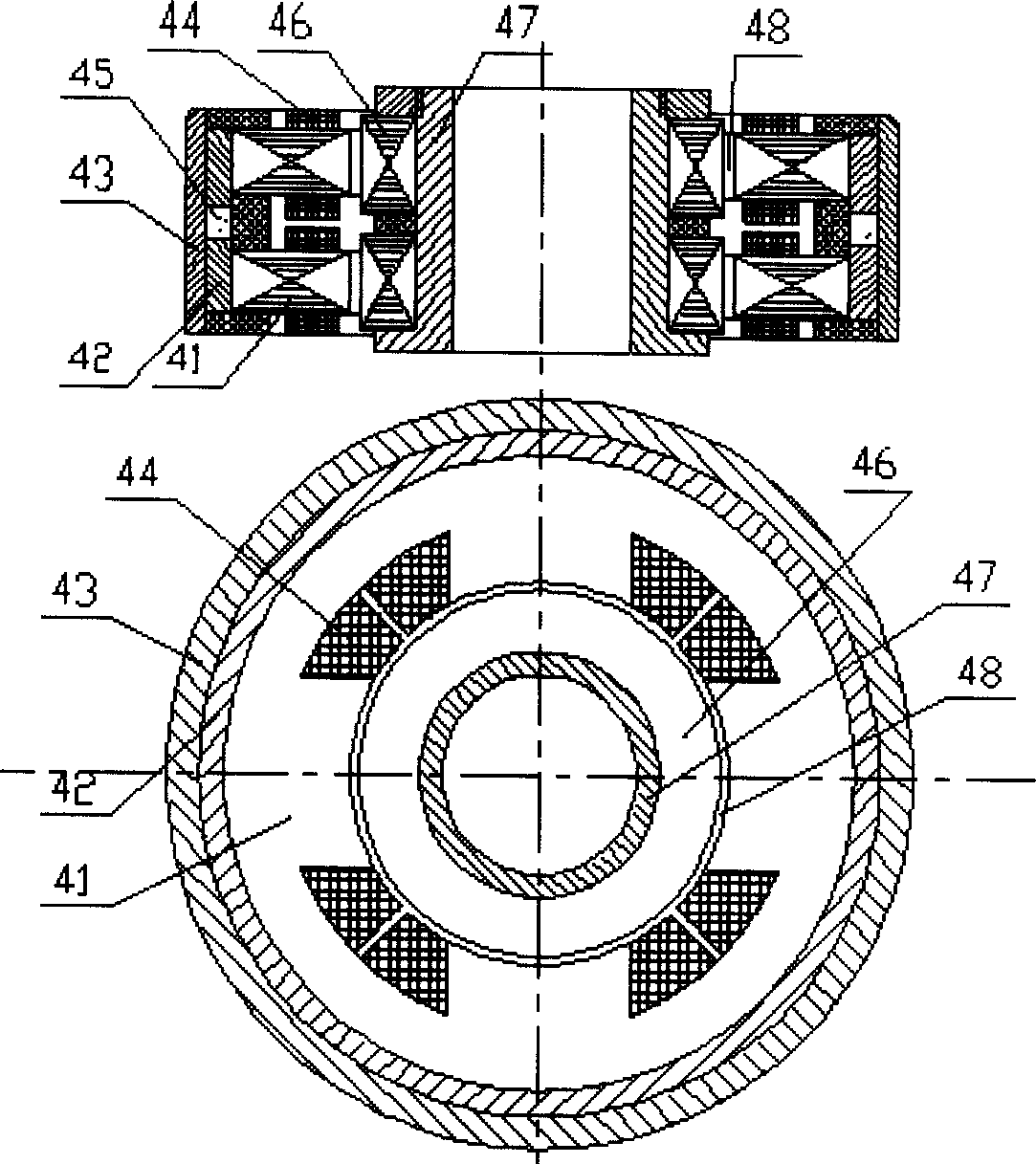

Single end support type magnetic suspension control moment gyro of single framework

InactiveCN101049860AEliminate frictional momentIncrease speedSpacecraft guiding apparatusUltra high speedAxial displacement

A single end supported single-frame magnetic-levitation torque-controlling gyro is composed of magnetically levitated rotor system and frame system. Said magnetically levitated rotor system consists of gyro rotor, axial and radial magnetic bearings, and axial and radial displacement sensors, protecting bearing, drive motor and gyro room. Said frame system comprises frame jointer, end covers, mandrel, torque motor, angular position sensor, electrically conductive slide ring, mechanical bearing, and base. It has high rotation speed and long service life.

Owner:BEIHANG UNIV

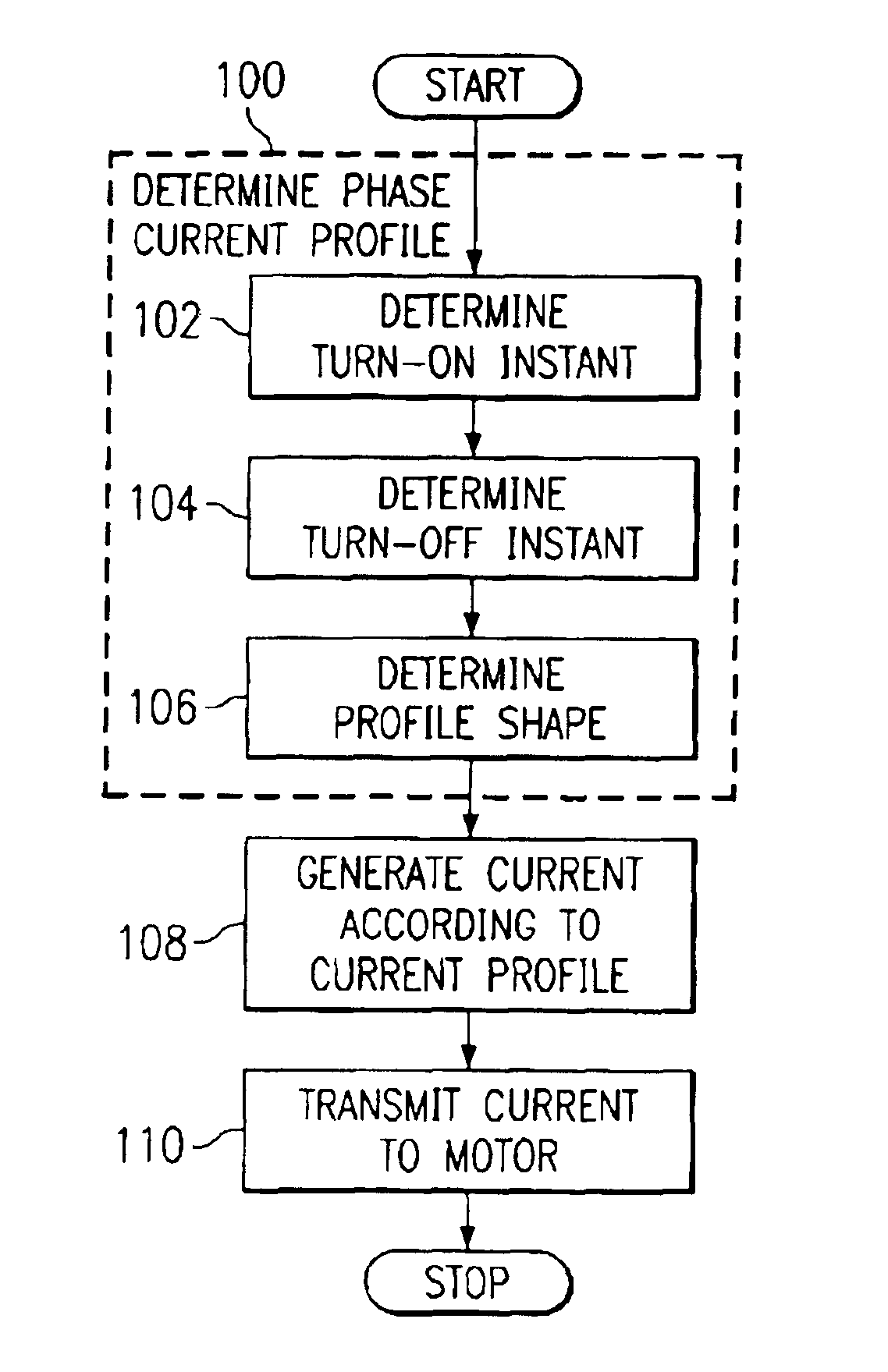

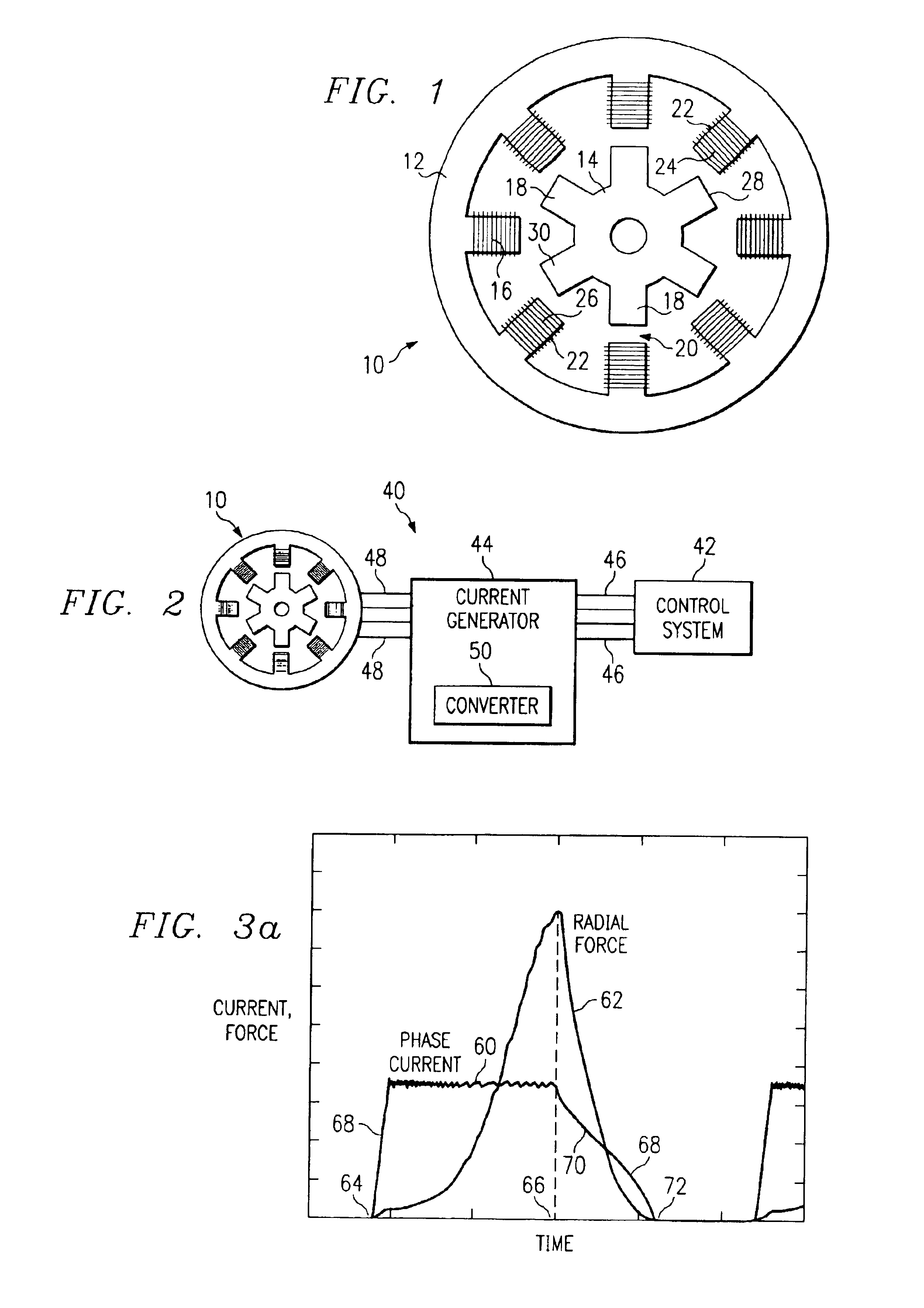

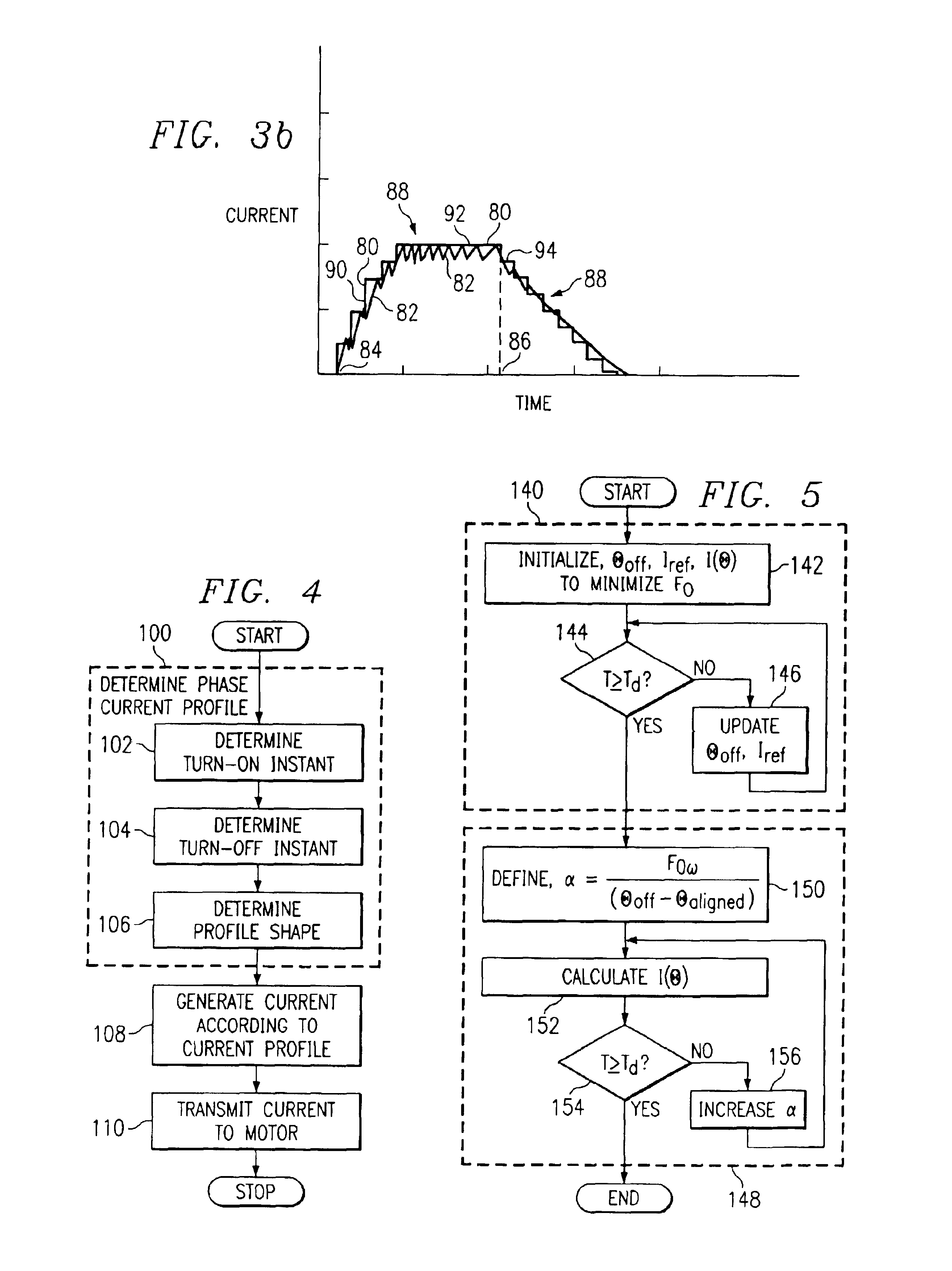

Method and apparatus for reducing noise and vibration in switched reluctance motor drives

InactiveUS6922036B1Reduce noiseReduce vibrationElectronic commutation motor controlMotor/generator/converter stoppersPhase currentsEngineering

According to one embodiment of the invention, a method includes generating, by a computer, a phase current profile, generating a phase current according to the phase current profile, and applying the phase current to the switched reluctance motor drive. Generating the phase current profile includes initializing one or more first profile parameters which define at least a first portion of the phase current profile. Generating the phase current profile also includes determining whether a first performance criterion is satisfied based on operation of the switched reluctance motor drive using the first profile parameters. Generating the phase current profile also includes updating at least one the first profile parameters if the first performance criterion is not satisfied.

Owner:TEXAS A&M UNIVERSITY

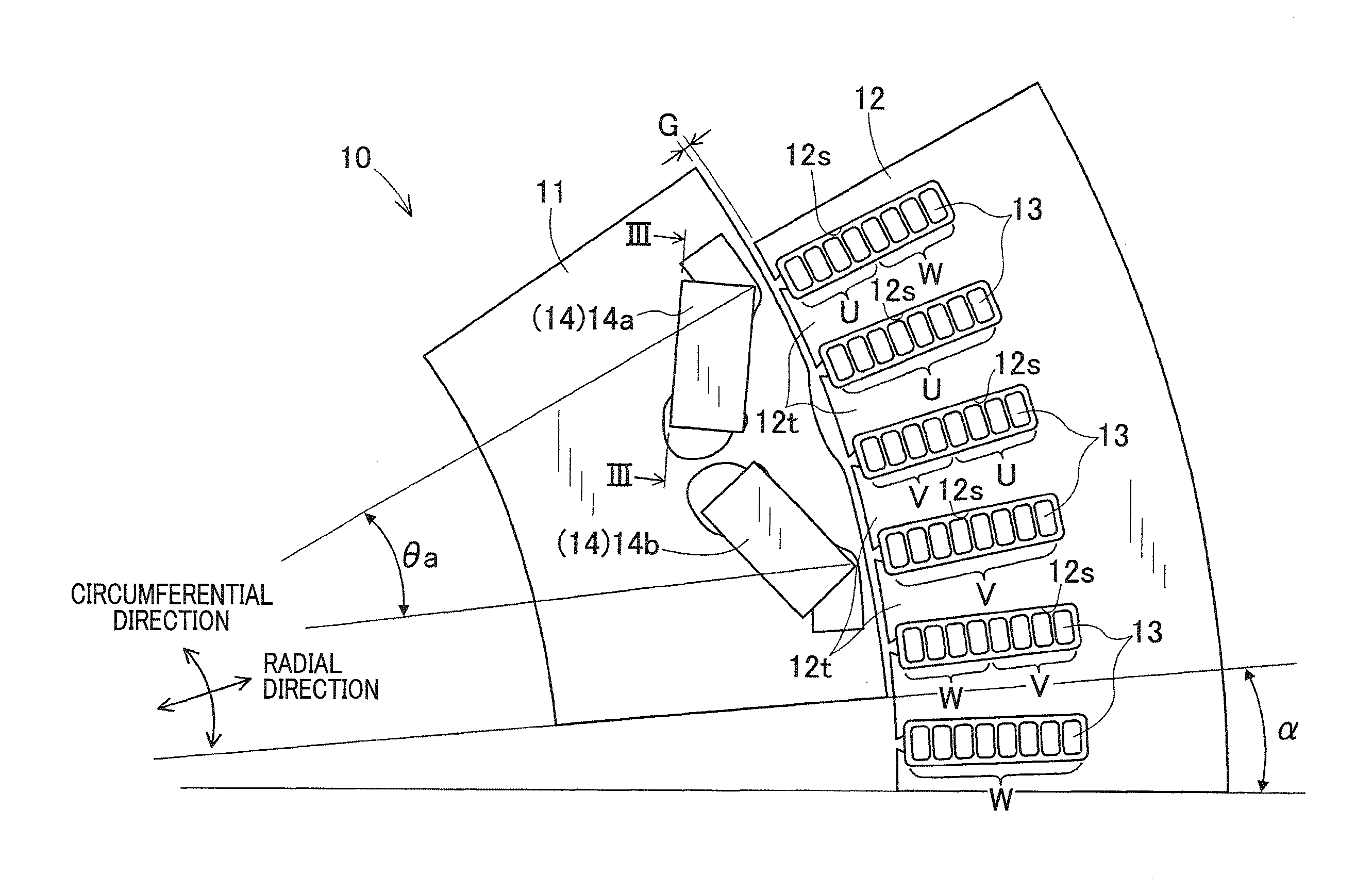

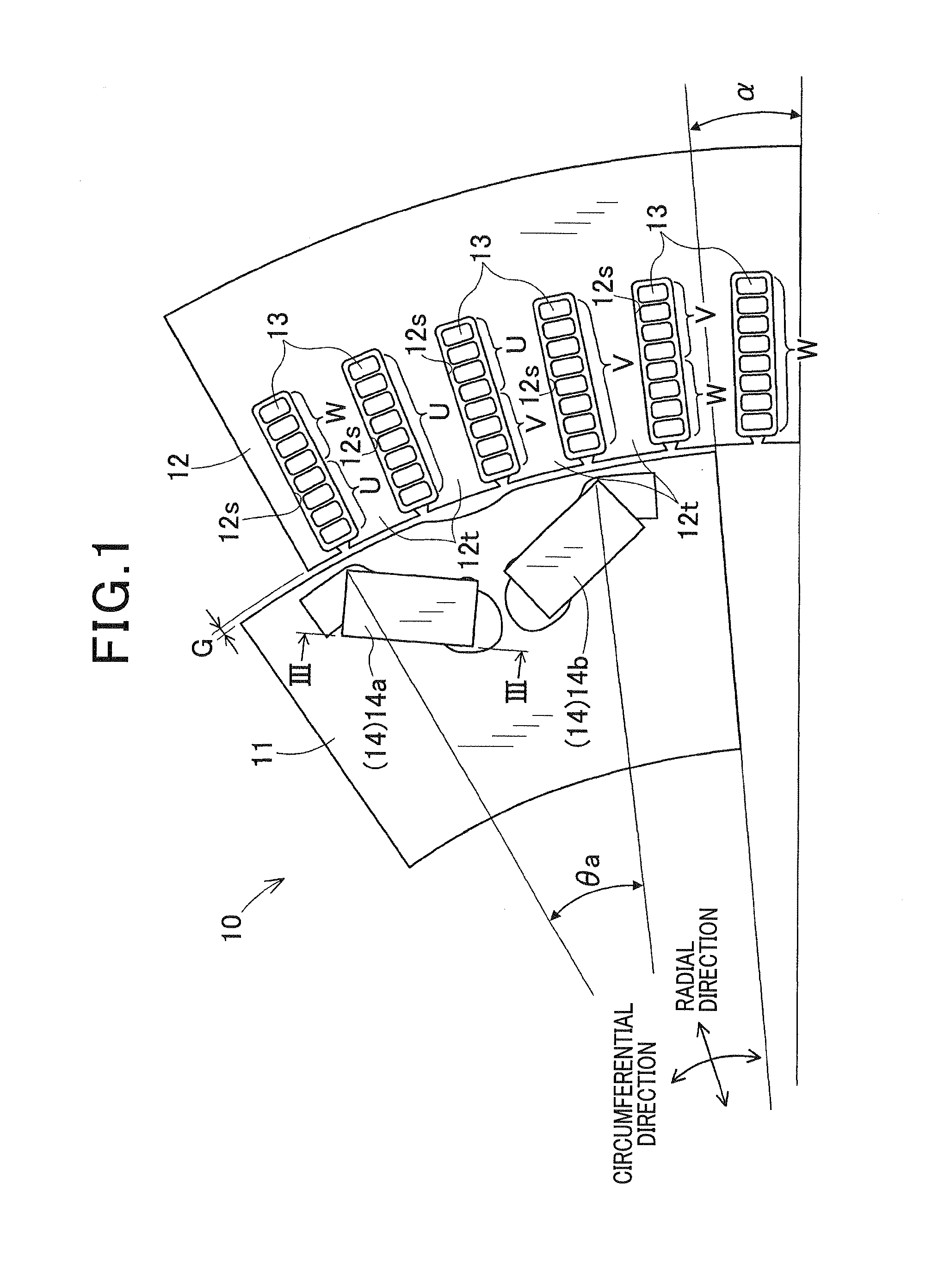

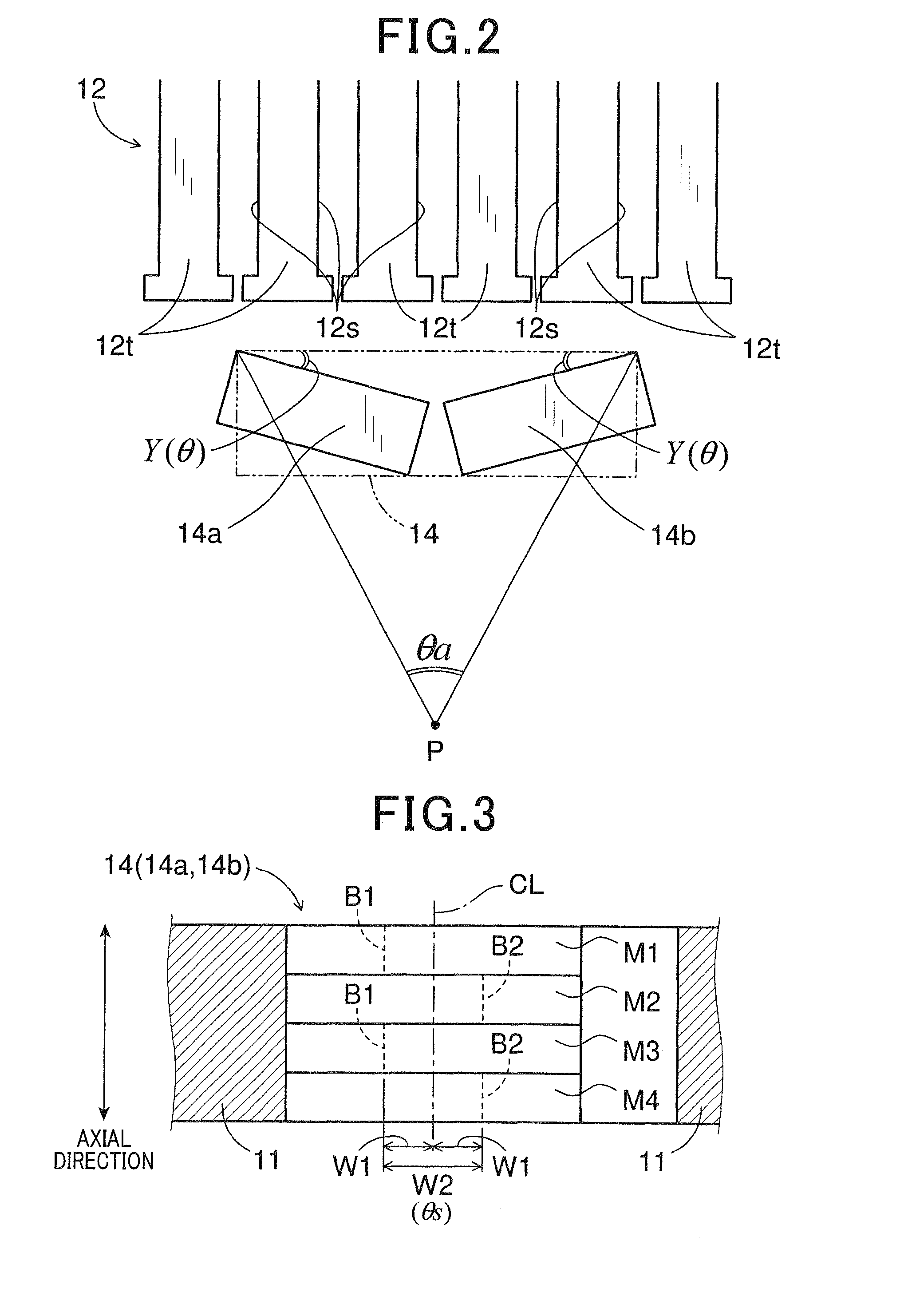

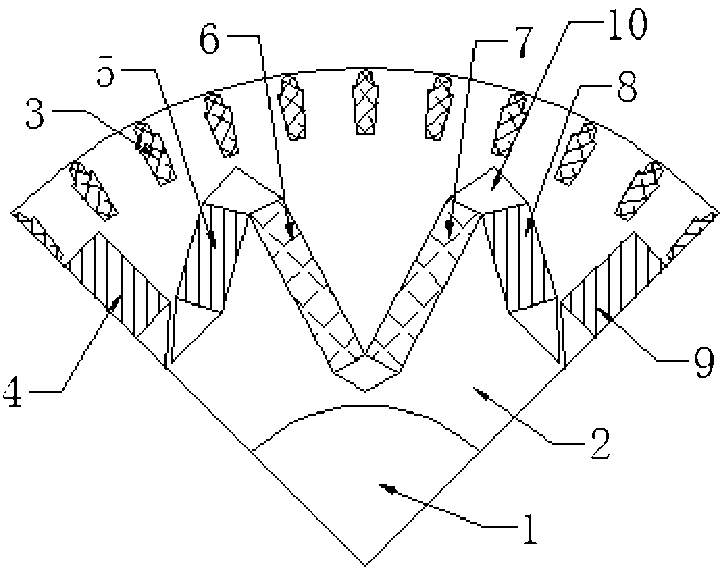

Rotary electric machine

ActiveUS20130270958A1Low component requirementsReduce vibration and noiseMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machineSoftware engineering

A rotary electric machine includes a stator and a rotor located in a rotatable manner relative to the stator via a gap. The stator includes a multi-phase stator winding that is held in a plurality of slots formed in the stator. The rotor includes at least one magnet section embedded therein so as to face the slots. The magnet section includes a plurality of axially laminated magnets with a skew angle which is an angle of a positional difference between the magnets. This skew angle θs is set so as to satisfy θs=kα / 2 where α is a slot pitch which is an angle between the slots, and k is a coefficient set based on: an arc ratio θa being an angle covering an area in which magnetic flux radially flows from the magnetic section; and a slot factor S being a ratio of the slots relative to the magnet section.

Owner:DENSO CORP

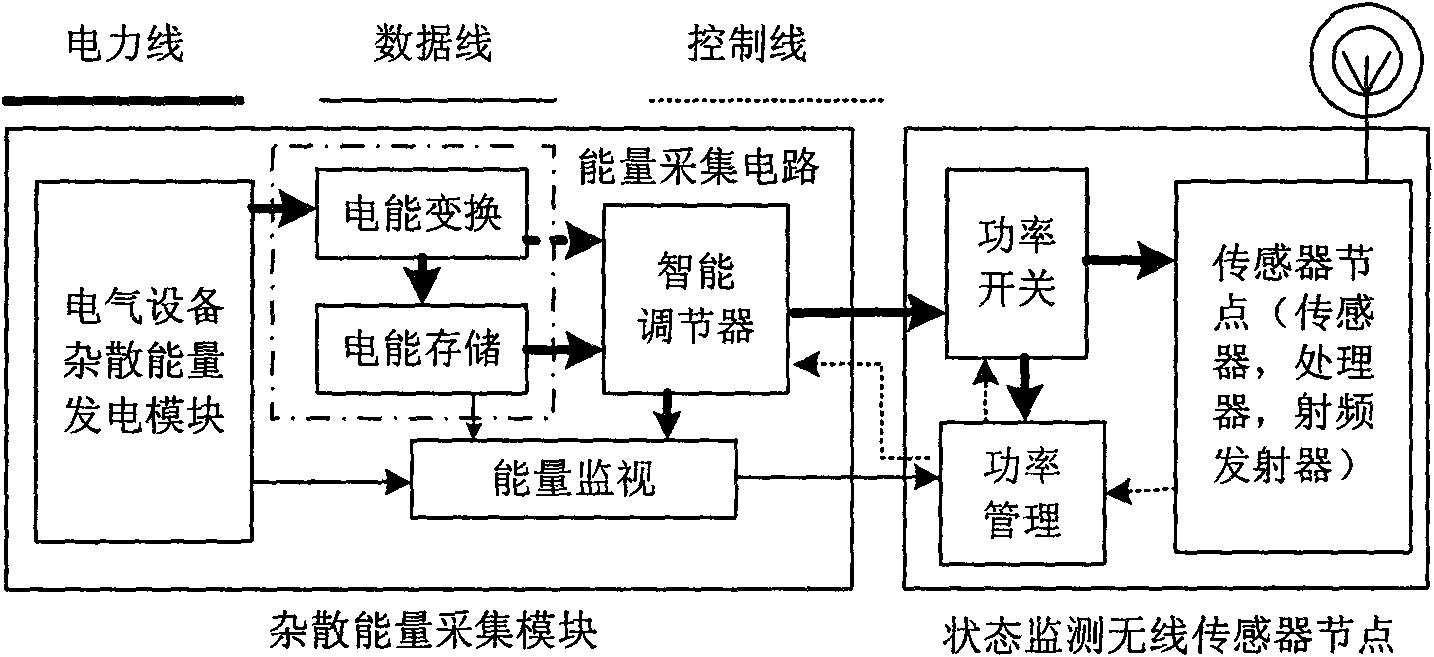

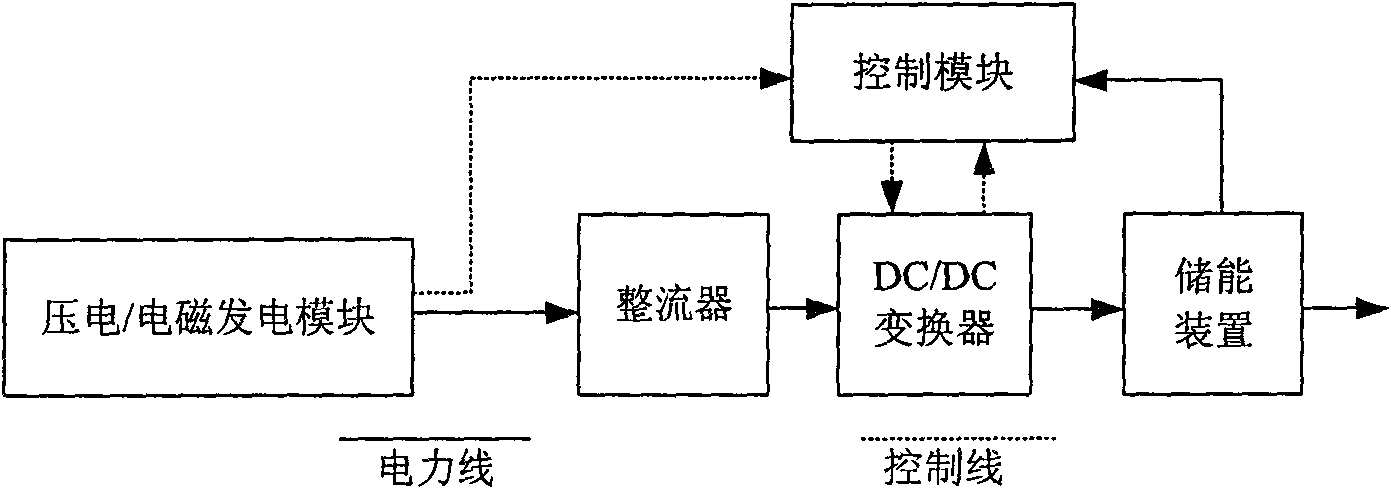

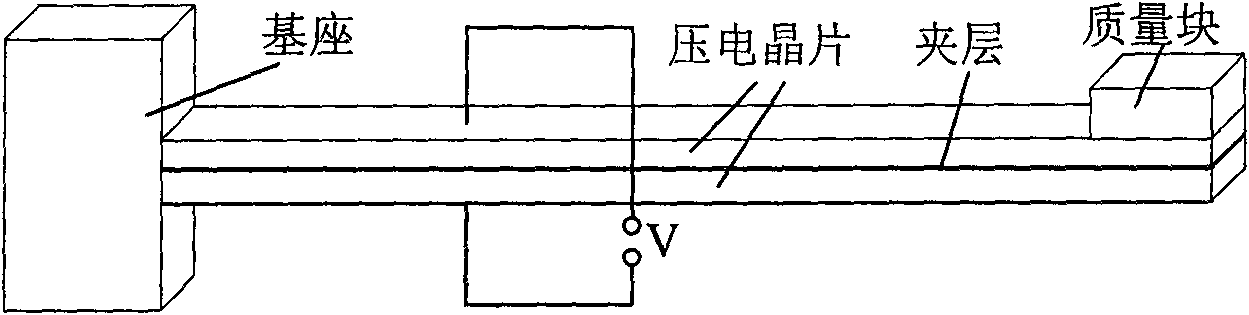

Stray energy power supplying method of electrical equipment status monitoring wireless sensing system and device thereof

InactiveCN101656492ASolve power problemsMeet the requirements of energy saving and environmental protectionBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectrical devicesEngineering

The invention relates to a stray energy power supplying method of an electrical equipment status monitoring wireless sensing system; a vibration power-generating device, or a temperature difference power-generating device or a flux leakage power-generating deice is adopted to lead mechanical vibration energy or heat energy or flux leakage energy which is generated in the operating process of the electrical equipment to be converted into electrical energy, and the electrical energy is transformed and adjusted by a transformation module, and the transformed electrical energy is stored in an energy storage device such as a rechargeable battery, a capacitor and the like, so as to supply power for the node of the electrical equipment status monitoring wireless sensor. A device applied to the stray energy power supplying method comprises a stray energy power-generating module such as vibration power generation, temperature difference power generation or flux leakage power generation, an electrical energy conversion module and an electrical energy storage module which are arranged on the electrical equipment. The invention can effectively utilize stray energy generated in the operating process of the electrical equipment to supply power for the node of the wireless sensor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Mutual active cancellation of fan noise and vibration

ActiveUS20060103334A1Reduce vibration and noiseReduce noisePump componentsMultiple dynamo-motor startersVelocity controllerActive cancellation

A multi-fan apparatus and method incorporates mutual active cancellation of fan noise and / or vibrations. The multi-fan apparatus includes two or more fans circuits, each comprising a fan, a fan speed controller and a separate tachometer, and a fan phase controller. The phase controller is connected to at least one fan speed controller and to each tachometer. Each fan's speed is independently and dynamically maintained at the same set speed by the fan speed controllers using an independent control loops. A noise and / or vibration cancellation phase difference between fans is determined in order to achieve destructive interference of pressure waves and, thus, noise and / or vibration reduction, in pre-determined region of a system incorporating the multi-fan apparatus. The phase controller establishes and maintains this cancellation phase difference between the fans based upon feedback from the tachometers.

Owner:LENOVO PC INT

Cooling fan unit and display apparatus having the same

ActiveUS20080089028A1Improve cooling efficiencyEfficient cooling and heatingStatic indicating devicesDigital data processing detailsLiquid-crystal displayEngineering

A display apparatus having a casing in which an opening part is formed, includes: a liquid crystal display panel that is supported by the casing so that an image can be displayed through an opening part; a backlight unit that is provided behind the liquid crystal display panel and has a light source that emits light; a shield cover that is provided behind the backlight unit and is supported by at least one of the backlight unit and the casing; and a cooling fan unit that is combined to the shield cover and supplies cooling air to the backlight unit.

Owner:SAMSUNG ELECTRONICS CO LTD

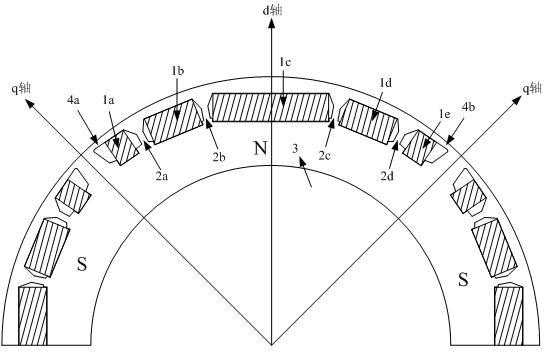

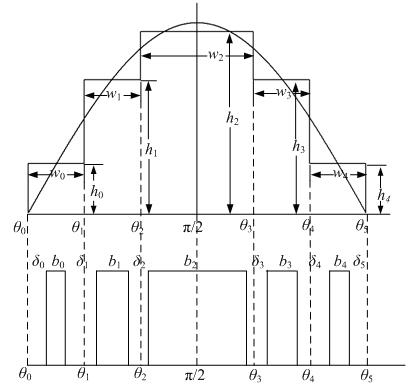

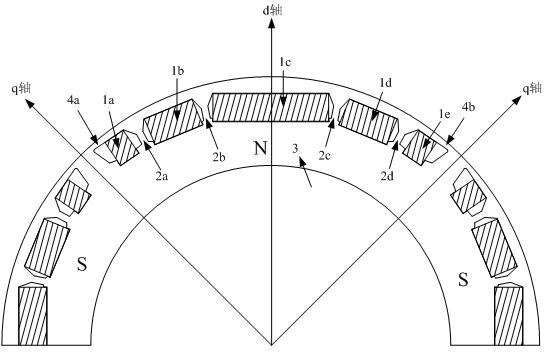

Rotor of built-in permanent magnet motor and magnetic steel structural parameter determining method thereof

InactiveCN102157998AHigh mechanical strengthIncrease stiffnessMagnetic circuit rotating partsElectric machinePermanent magnet motor

The invention relates to a rotor of a high-quality and high-speed built-in permanent magnet motor and a magnetic steel structural parameter determining method thereof. In the invention, the whole section magnetic steel of each electrode of the rotor of a conventional built-in permanent magnet motor is divided into multiple sections of magnetic steel which have the same polarity and different widths; the multiple sections of the magnetic steel are respectively arranged in a rotor core; and reinforcing ribs with the function of magnetic isolation are arranged among the multiple sections of the magnetic steel. By reasonably modulating and determining the width and distribution of each section of the magnetic steel, the air gap magnetic density waveform approaches sine distribution; harmonic components are reduced to the greatest extent; the eddy current loss of the magnetic steel and the torque pulsation of the motor are simultaneously reduced; and the electromagnetic performance of the motor is enhanced. Furthermore, the multiple sections of the magnetic steel are arranged in the circumference along the rotor; the highest rotating speed of the safe operation of the rotor is greatly enhanced on machinery; the radial thickness which is needed by the magnetic circuit of the rotor is obviously reduced on the structure; the rotational inertia and weight of the rotor are reduced; the dynamic response of the motor is improved; and the requirements of a high-speed driving system on the performance of the motor are met.

Owner:SHANGHAI UNIV

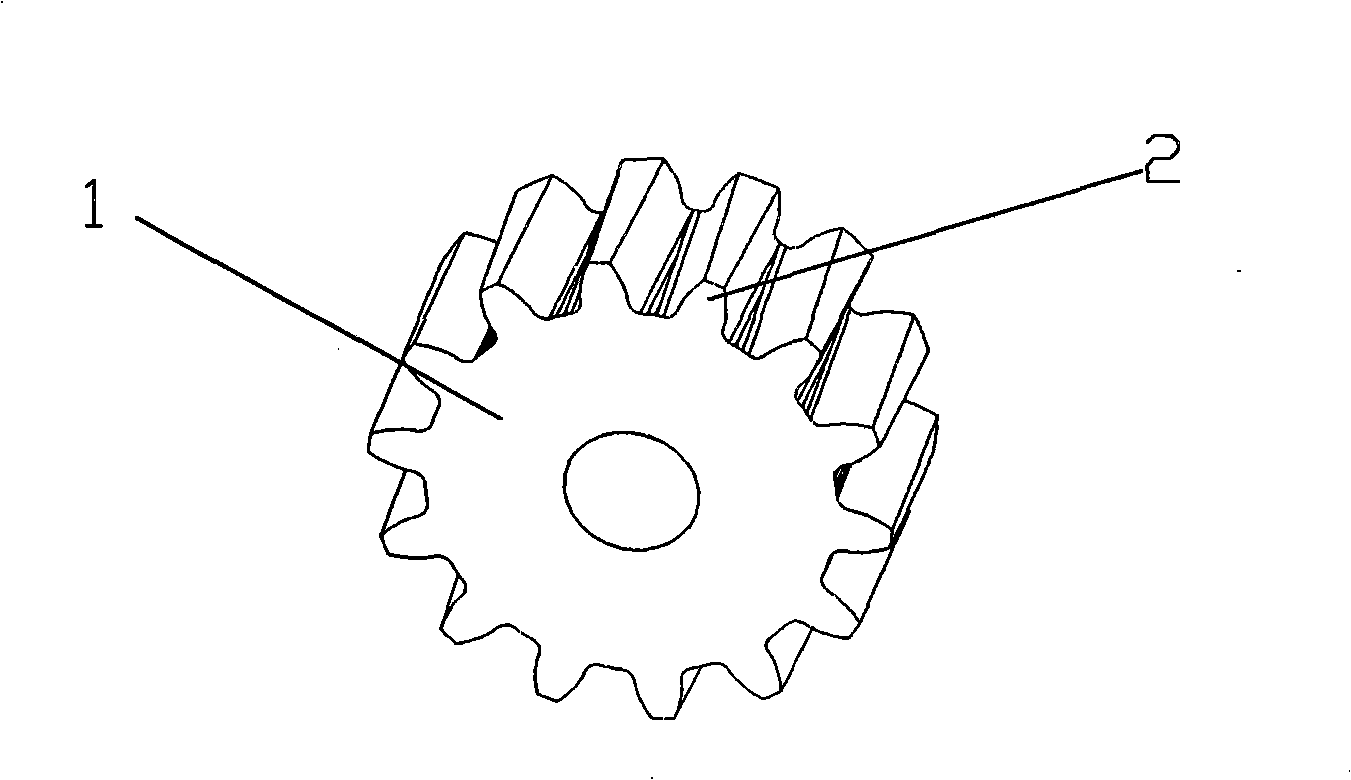

Tooth thickness variable cylinder profile modified gear and gearing device using same

InactiveCN101285520AEliminate or reduce backlash and backlashReduce vibration and noisePortable liftingToothed gearingsGear transmissionEngineering

The invention discloses a variable tooth thickness profile shifted cylindrical gear and a transmission device using the same. The transmission device comprises a gear disk and a gear tooth; the gear adopts the tangential modification mode, and tangential modification coefficients change according to the order from small to big along the gear disk shaft, and becoming-bigger directions of tangential modification coefficients of two tooth faces of the gear tooth are the same; an included angle is formed between the two tooth faces of the gear tooth of the gear, and the meshing backlash can be adjusted by adjusting the axial relative position of gears meshed with each other, thereby effectively eliminating or reducing the backlash and return difference, reducing the vibration and noise and prolonging the service life; compared with the addendum modified variable thickness gear transmission used in the prior art, the transmission device of the invention has the advantages of smaller sliding ratio, good manufacturability of gear processing and low cost, etc.; compared with other clearance adjusting modes, the transmission device has the advantages of simple structure and small volume, etc.

Owner:CHONGQING UNIV

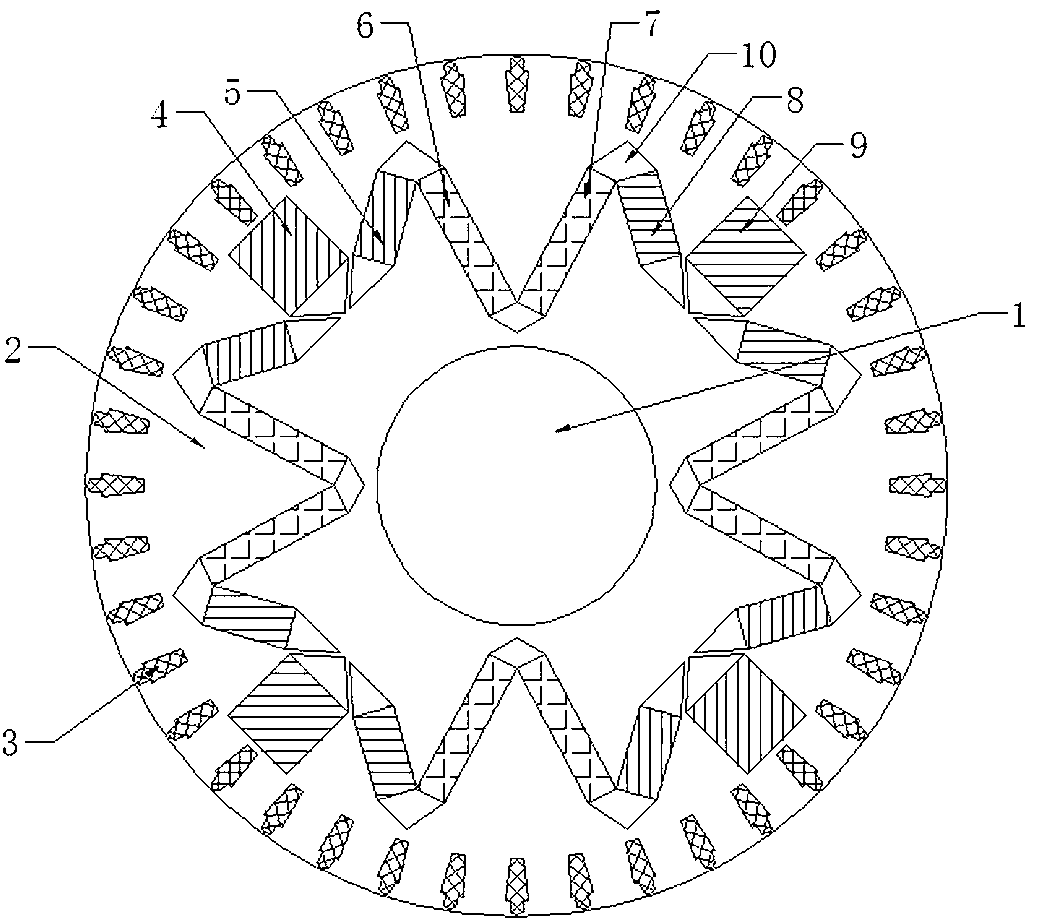

Asynchronous starting permanent magnet synchronous motor rotor based on permanent magnets with different residual magnetic densities

ActiveCN103219814ALow costReduce dosageMagnetic circuit rotating partsElectric machinePermanent magnet synchronous motor

The invention relates to an asynchronous starting permanent magnet synchronous motor rotor based on permanent magnets with different residual magnetic densities, and belongs to the field of permanent magnet motors. The asynchronous starting permanent magnet synchronous motor rotor comprises a rotating shaft, a starting cage, a rotor iron core and the permanent magnets, wherein 2p VVV-shaped permanent magnet slots encircling the rotating shaft are uniformly formed in the rotor iron core; a first permanent magnet and a second permanent magnet are arranged in a first V-shaped slot; a third permanent magnet and a fourth permanent magnet are arranged in a second V-shaped slot; a fifth permanent magnet and a sixth permanent magnet are arranged in a third V-shaped slot; and magnetism isolation slots are reserved between the permanent magnets. On the premise that the stable-state running performance is not reduced, the cost of an asynchronous starting permanent magnet synchronous motor is effectively reduced, and the no-load air gap magnetic density waveform sine distortion rate is reduced; harmonic waves are effectively suppressed; the efficiency of the motor is improved; the torque ripple is reduced; and the vibration noise is reduced.

Owner:SHENYANG POLYTECHNIC UNIV

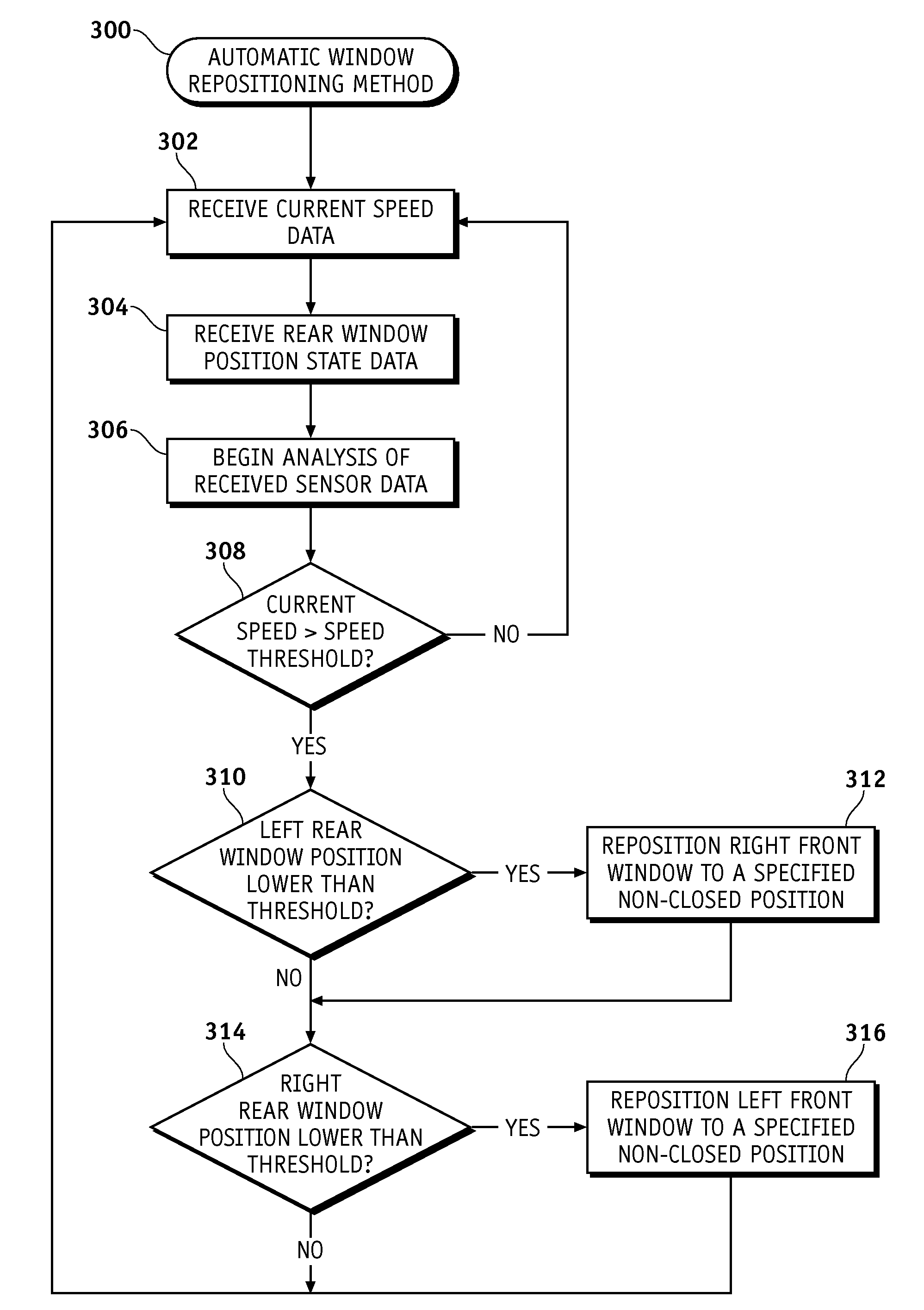

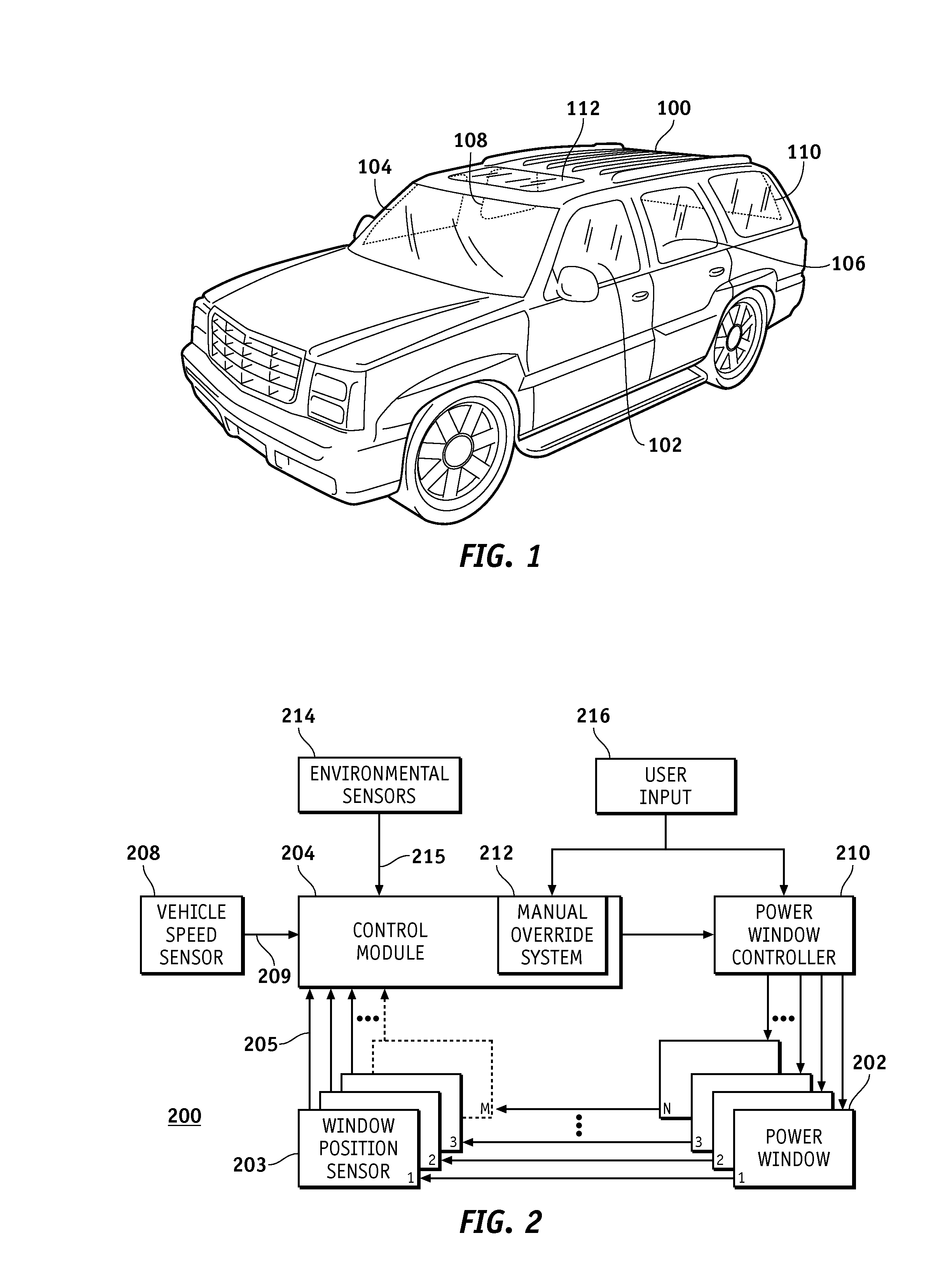

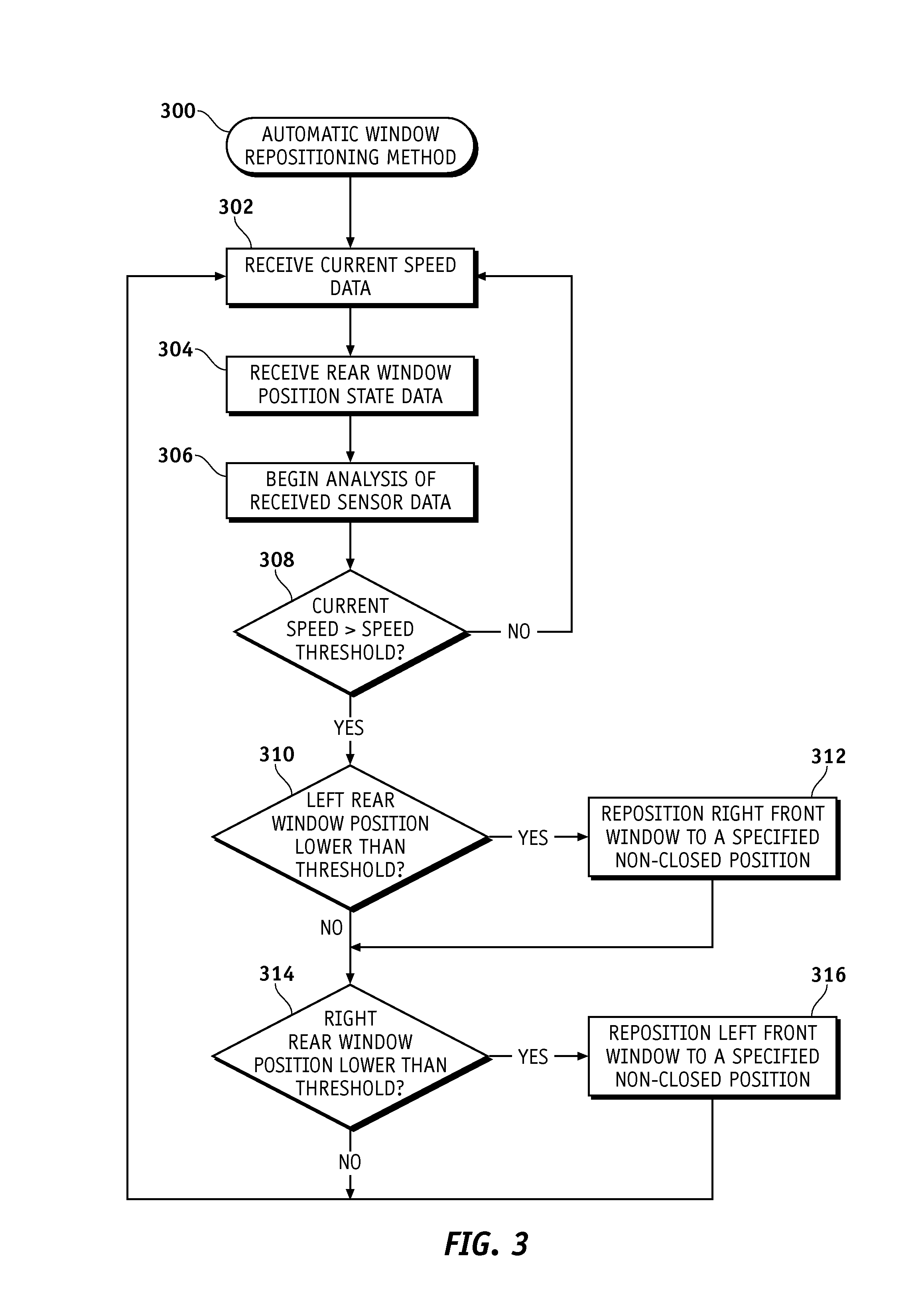

Automatic window repositioning to relieve vehicle passenger cabin wind pressure pulsation

InactiveUS20090069984A1Reduce vibration and noiseReduce intensityDC motor speed/torque controlDigital data processing detailsAutomotive engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

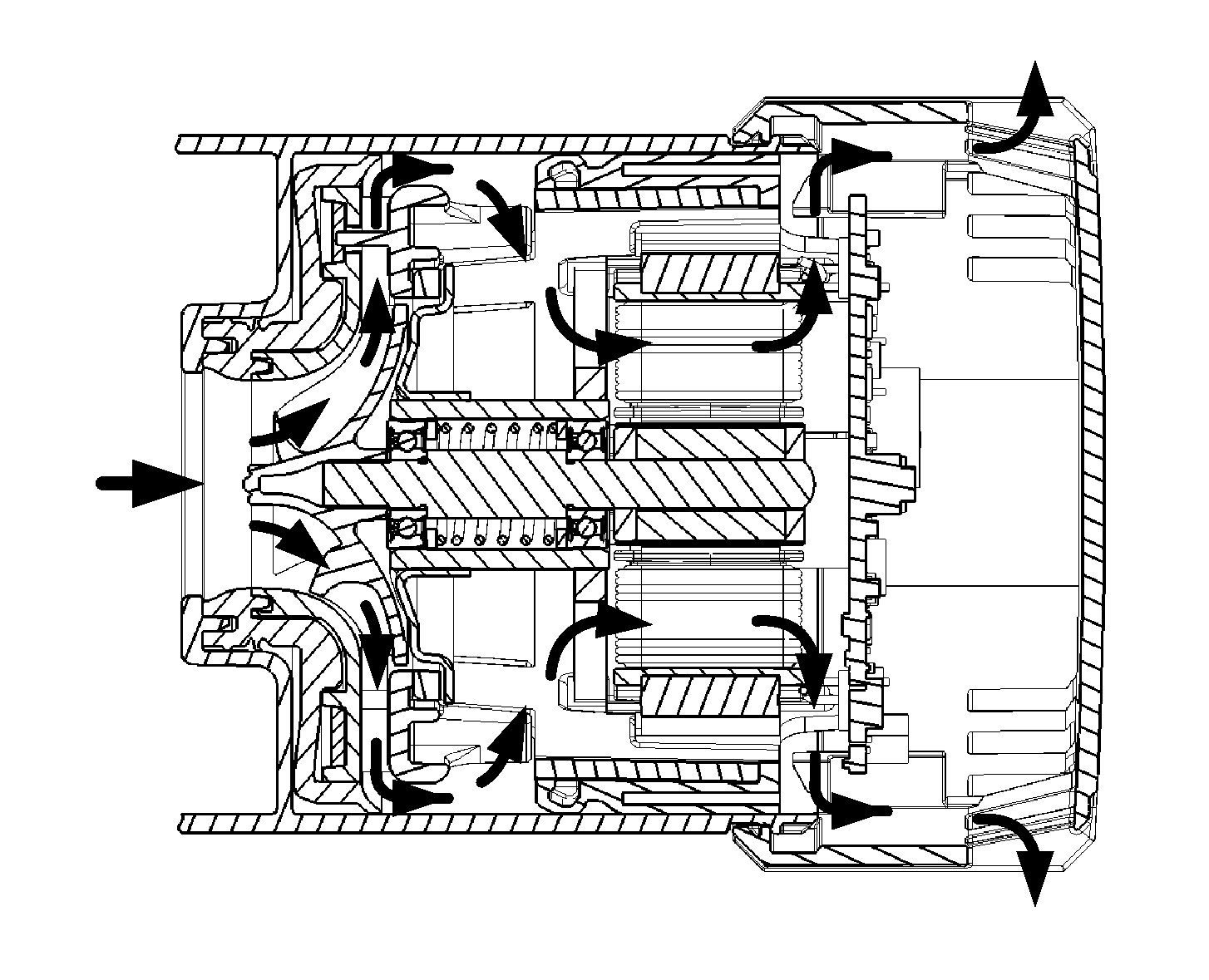

Compressor

A compressor that includes a frame, a rotor assembly, and a heat sink assembly. The rotor assembly includes a bearing assembly to which the heat sink assembly is secured. The compressor is configured such that, during use, air is drawn through the interior of the frame. The heat sink assembly then extends radially from the bearing assembly into the air path through the frame such that the air flows over the heat sink assembly.

Owner:DYSON TECH LTD

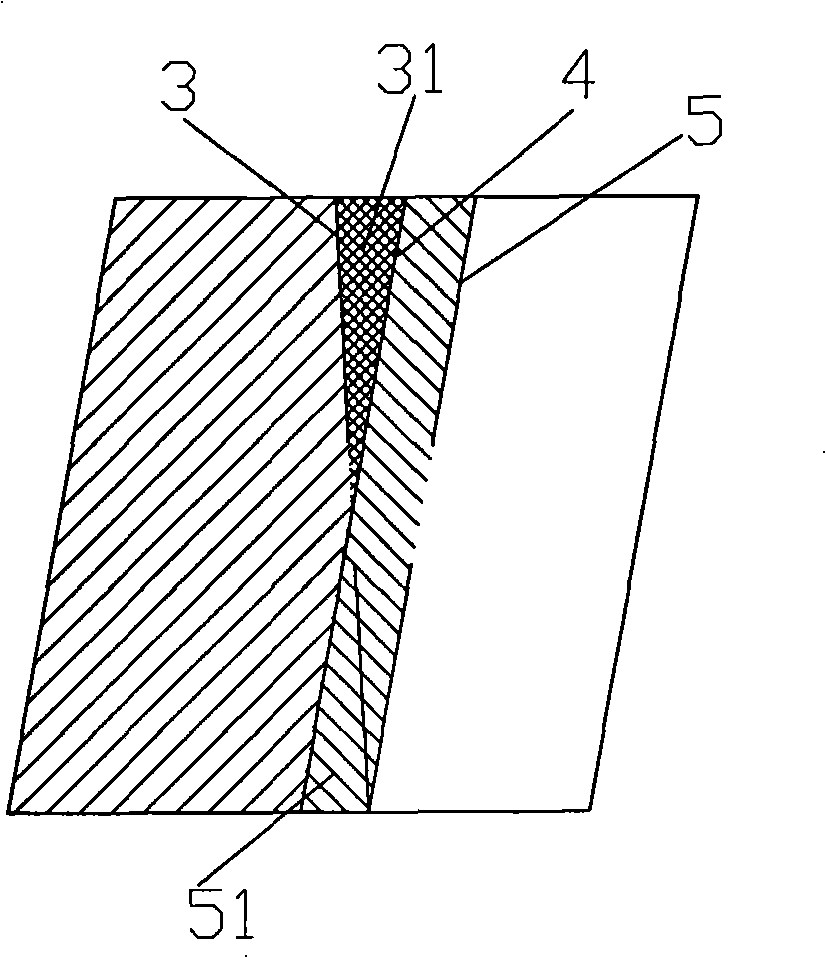

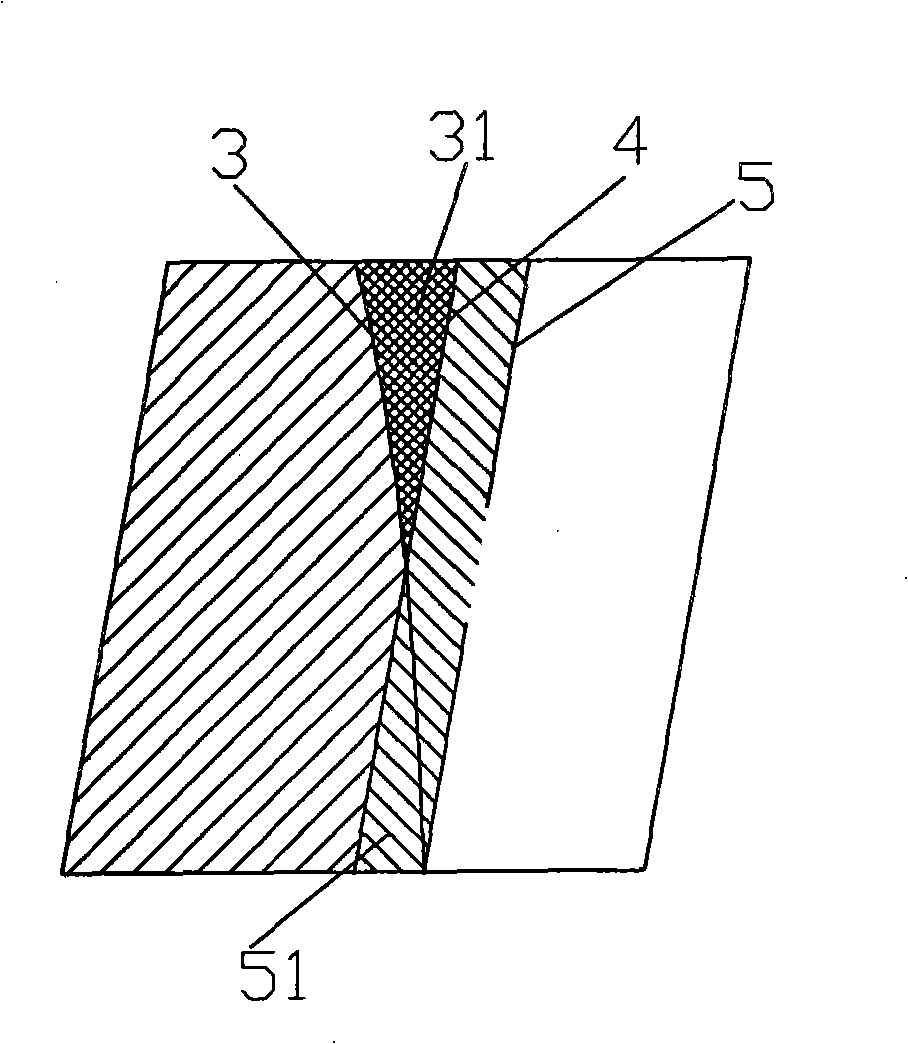

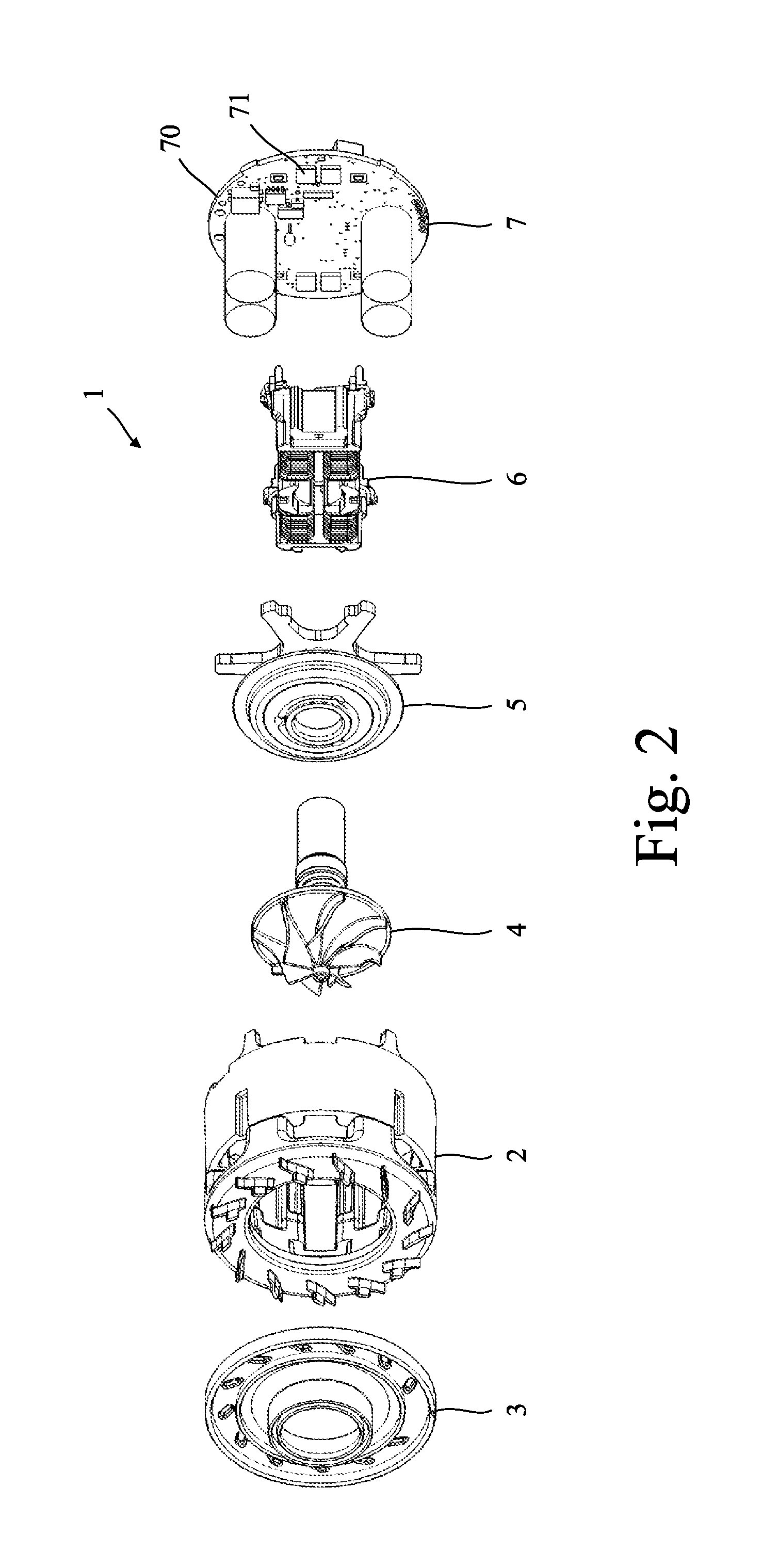

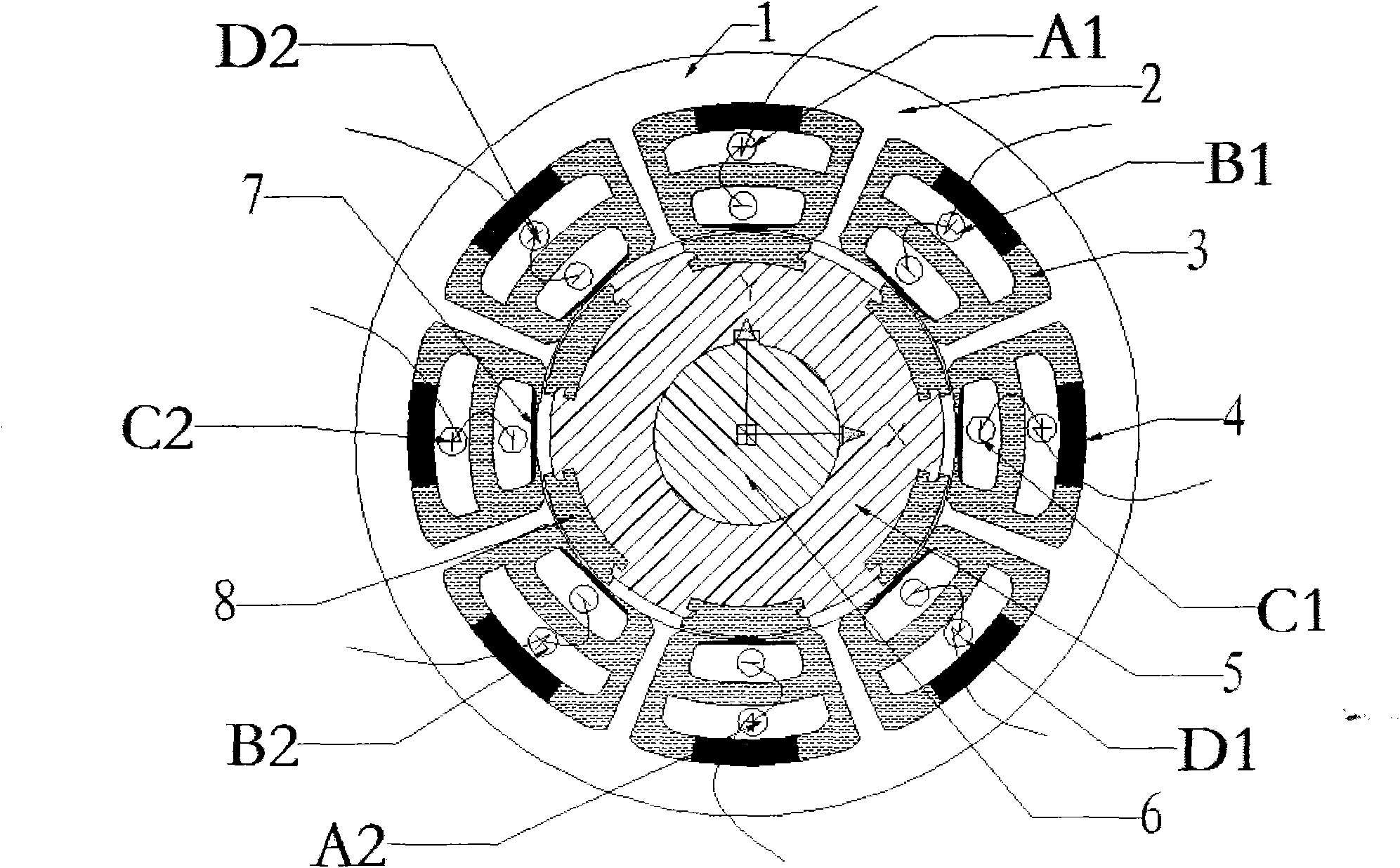

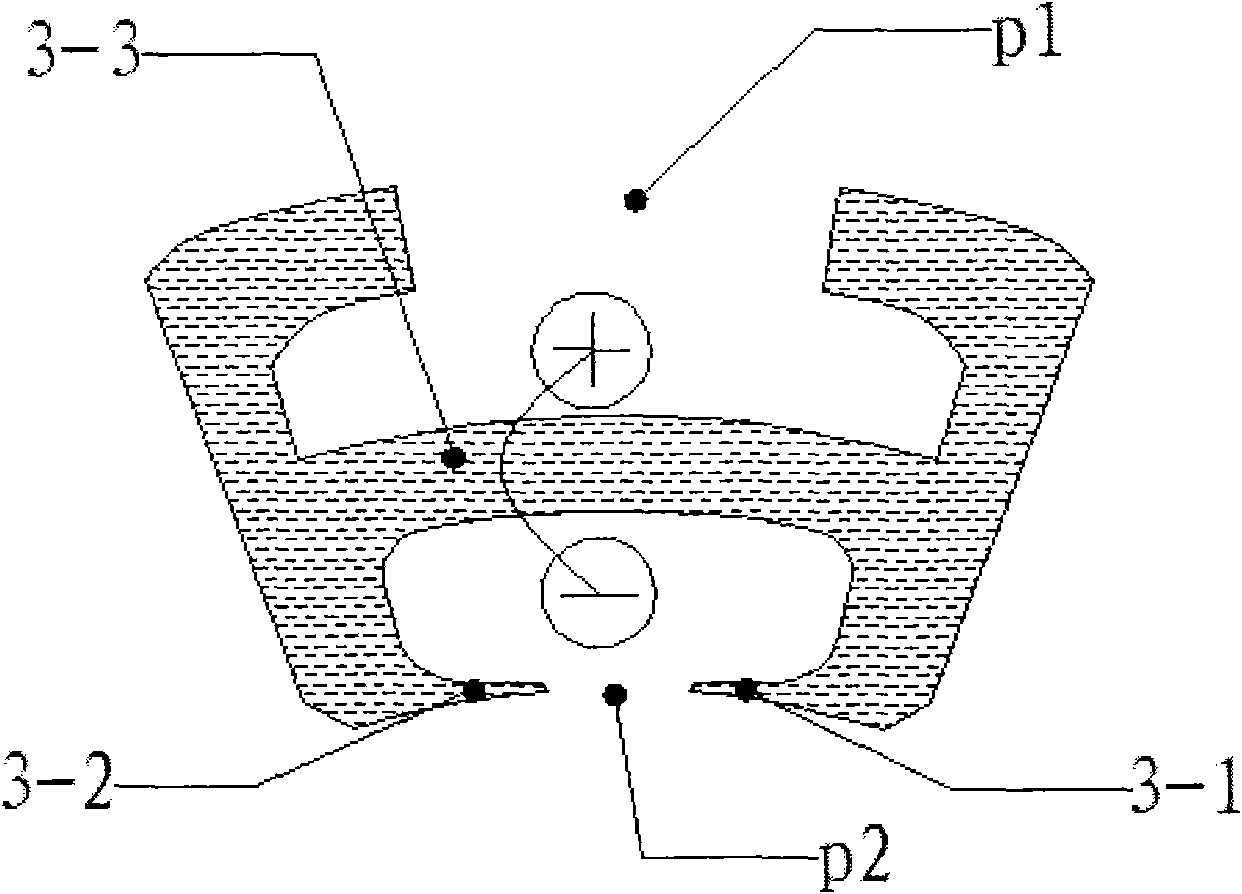

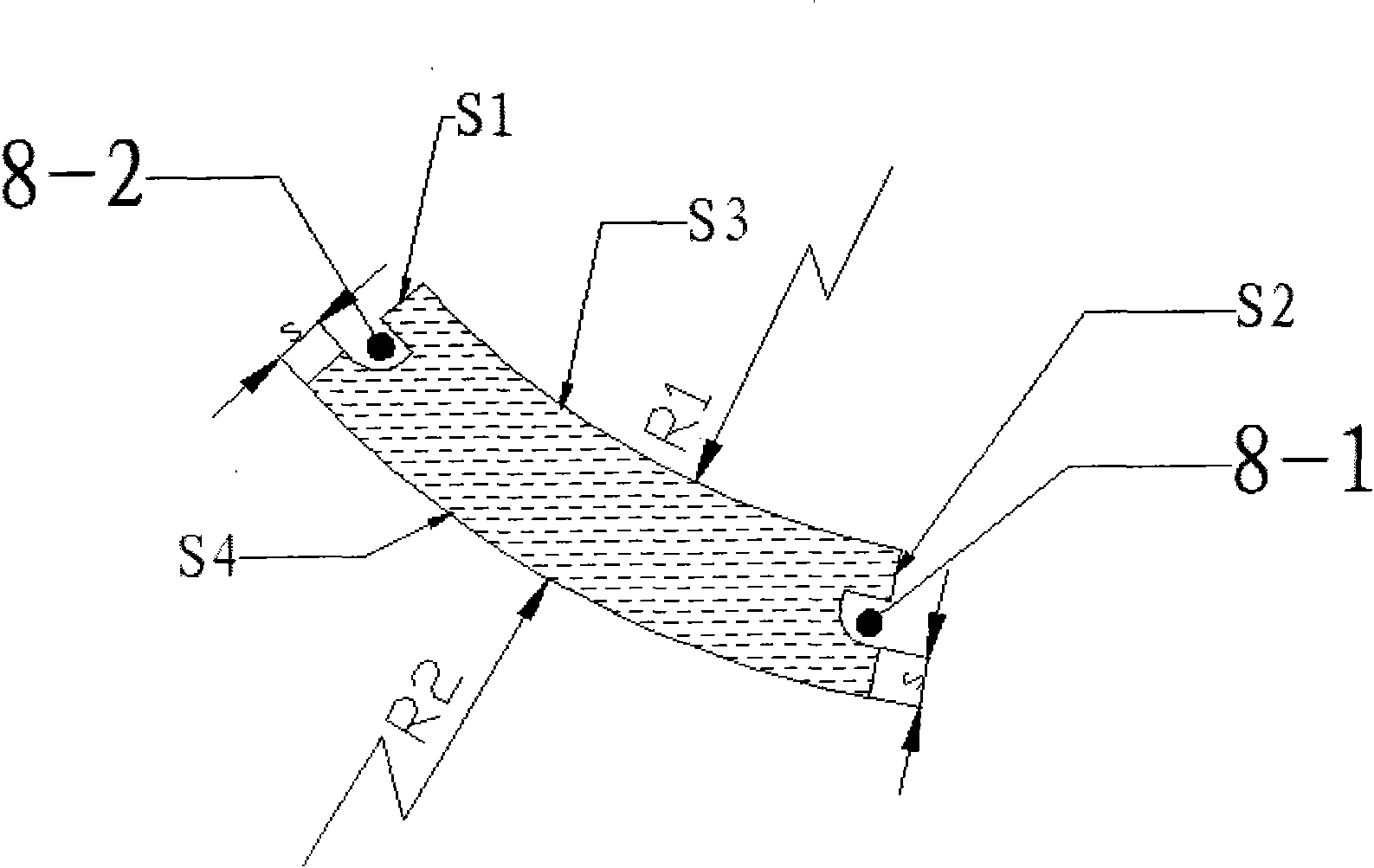

Mixed excitation short-magnetic-circuit variable-reluctance motor

InactiveCN102315746AEasy to installFlexibleMagnetic circuit rotating partsMagnetic circuit stationary partsNoise levelElectrical polarity

The invention discloses a mixed excitation short-magnetic-circuit variable-reluctance motor 1 as well as a stator structure and a rotor structure thereof. An inner circular face t of a base part 2 of the mixed excitation short-magnetic-circuit variable-reluctance motor is provided with modules 2-1 which protrude inwards in a preset interval angle; the stator part comprises a plurality of H-shaped stator sections 3 and first permanent magnets 4 (1) arranged at all the H-shaped stator sections p1, and the polarities of the permanent magnets of the stator sections are opposite; an exciting winding coil is embedded into two stator slots of each H-shaped stator section 3; and the rotor part comprises a rotor body 5 and a plurality of annular body rotor sections 8 arranged on the rotor body and / or second permanent magnets 4 (2), wherein the second permanent magnets are arranged on the s3 surfaces of the annular body rotor sections, and open grooves 8-1 and 8-2 are arranged on the lateral surfaces of the annular body rotor sections. According to the invention, the rotating force of the variable-reluctance motor can be increased, the energy density is improved, the torque ripple and the vibration and noise level are reduced, the performance is stable, and the size is smaller under the requirement of same output torque.

Owner:SOUTH CHINA UNIV OF TECH

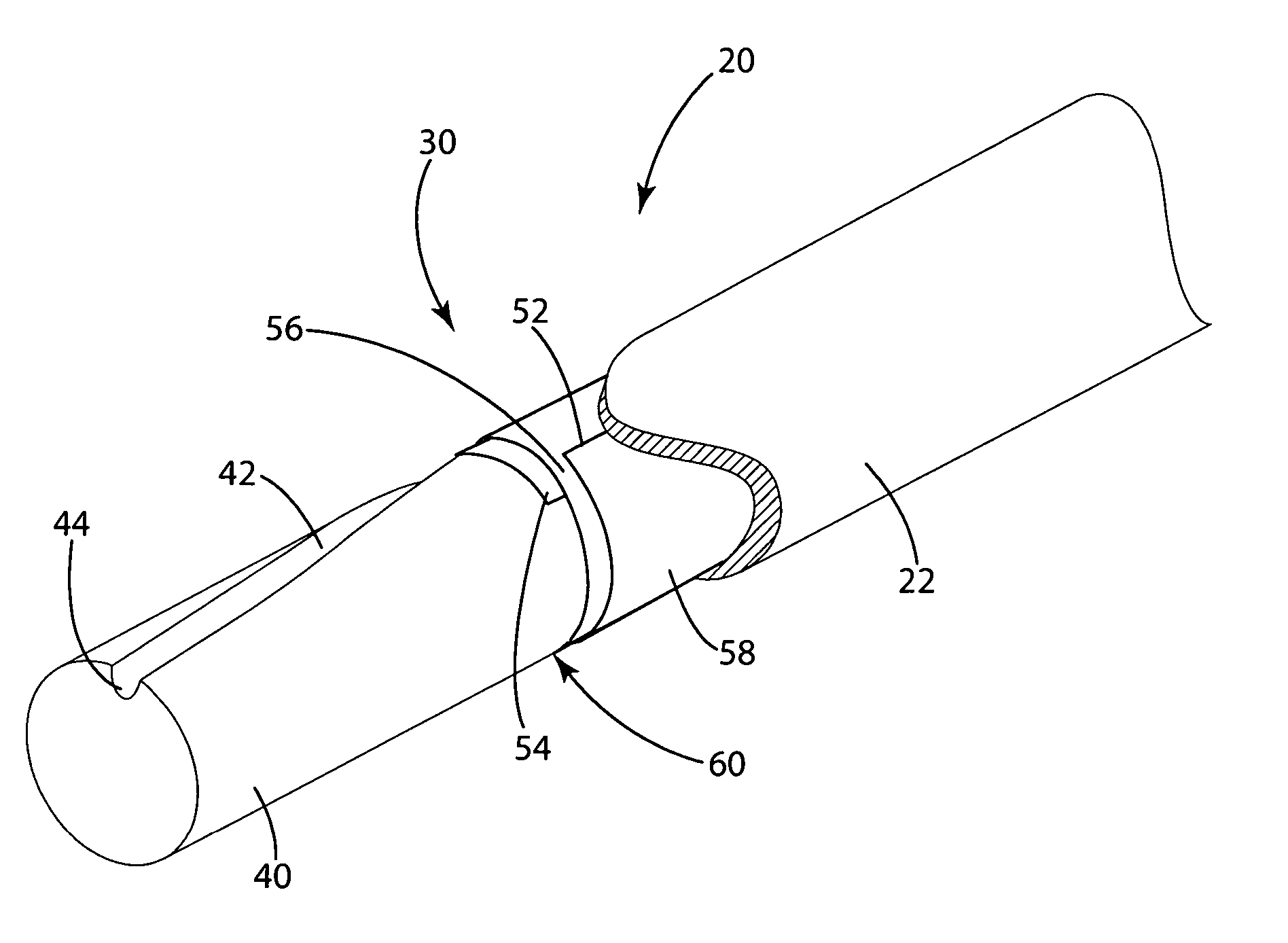

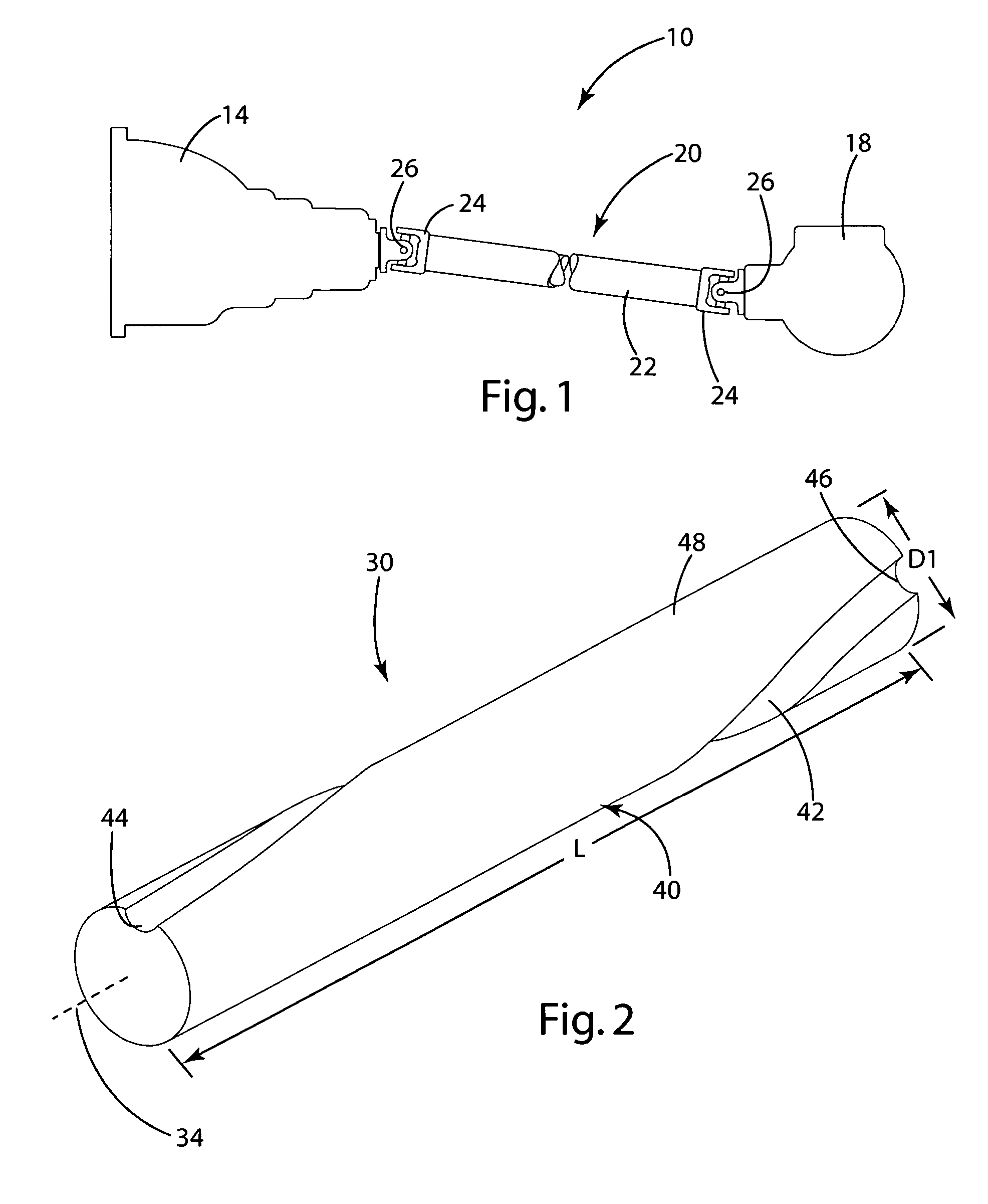

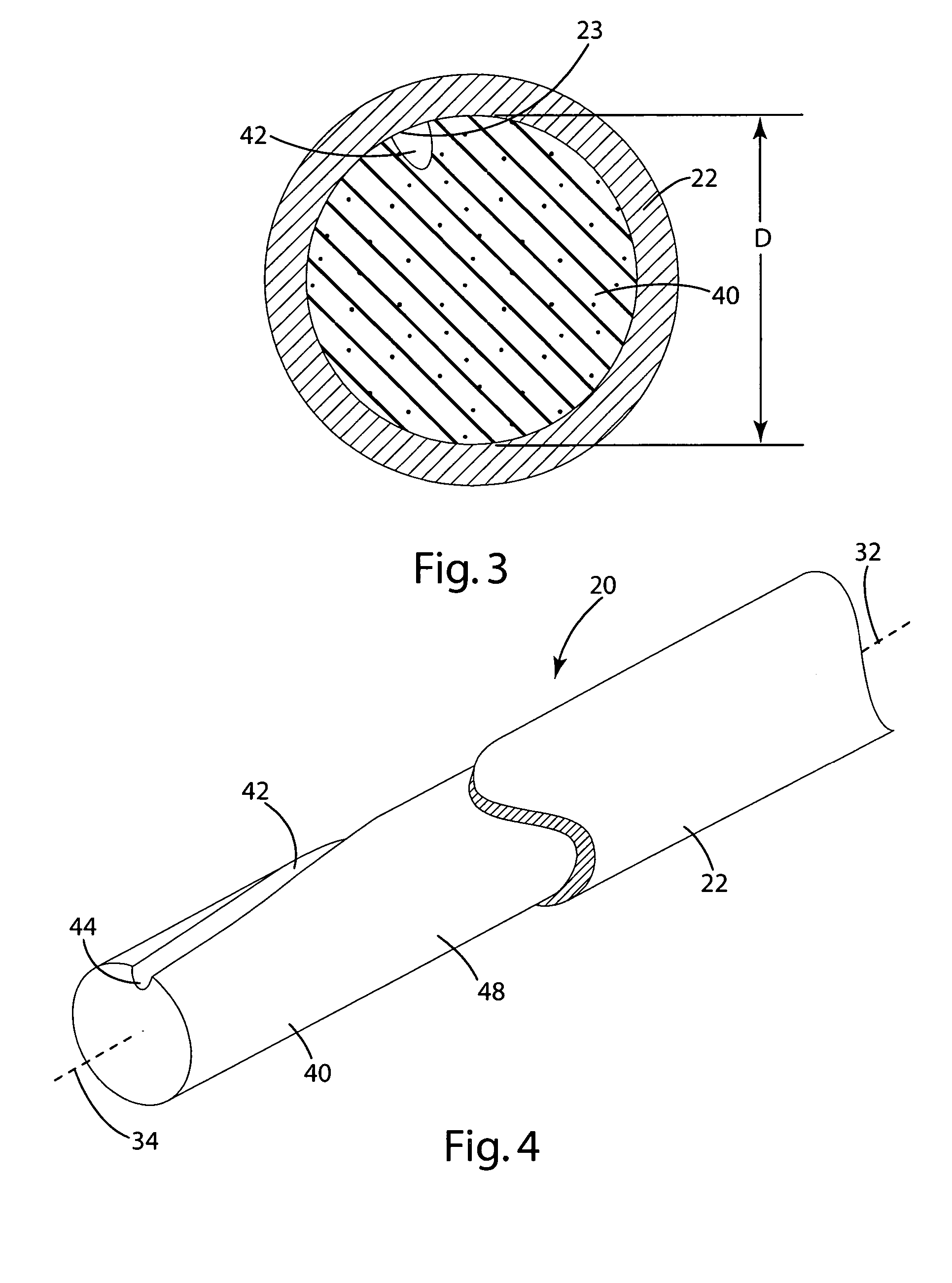

Damper for a vehicle torque transferring assembly

InactiveUS7083523B2Reduce vibration and noiseEasy to assembleRotating vibration suppressionShaftsCost effectivenessEngineering

A lightweight damper for reducing noise and vibration in torque transferring assemblies that is easily assembled and cost efficient. The damper may be formed from a foam material having a density less than 1.4 lb / ft3, and includes an outer surface that is resiliently biased against the inner surface of a tubular shaft when installed. In a second embodiment, the damper is formed from a sheet of material that dissipates energy such as noises and vibrations through movement of the layers relative to each other. In third embodiment, the dampening sheet and foam damper are combined to provide a damper that dampens noises and vibrations across a large frequency range.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

Low-noise structural oilless air compressor

InactiveCN101737296APrevent blowbackEasy to absorbPositive displacement pump componentsPiston pumpsLow noiseVibration amplitude

The invention belongs to the technical field of air compressors, and relates to a low-noise structural oilless air compressor which comprises a cylinder, a cylinder cover and a piston, wherein the piston is provided with a sealing ring or a sealing leather cup made of a self-lubricating material, a crankcase is tightly connected with a crankcase cover plate and forms a crankcase intake muffler, an air intake one-way valve is arranged at an air intake or an air intake passage of the crankcase intake muffler communicated with the outside atmosphere, a damping pad is arranged between an exhaust valve plate and a valve seat, the valve seat is connected with a silencing cap, a crank pin is made into the shape of a spline or similar to the spline, a heat insulation hole or a heat insulation slot is arranged on a connecting rod body, and a heat insulation pad is arranged at the joint of a fastening bolt and the piston or a connecting rod. The low-noise structural oilless air compressor has the advantages that the air intake noise is low, the working temperature and the mechanical noise of a bearing are low, and an auxiliary balance block is arranged on a cooling fan, thereby reducing the vibration amplitude of the compressors, and effectively reducing the body vibration noise.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

Vibration and noise abatement pad

InactiveUS7300032B2Reduce vibration and noiseEfficient drainingSpringsVibration dampersNoise removalEngineering

A base pad for supporting mechanical machines and equipment and which is configured such that it reduces the noise and vibration emanating from these machines. The pad is constructed entirely from shredded and comminuted rubber tires and is configured such that it provides for the efficient run-off and / or draining of any moisture generated from under the machine unit.

Owner:ATIRE TECH

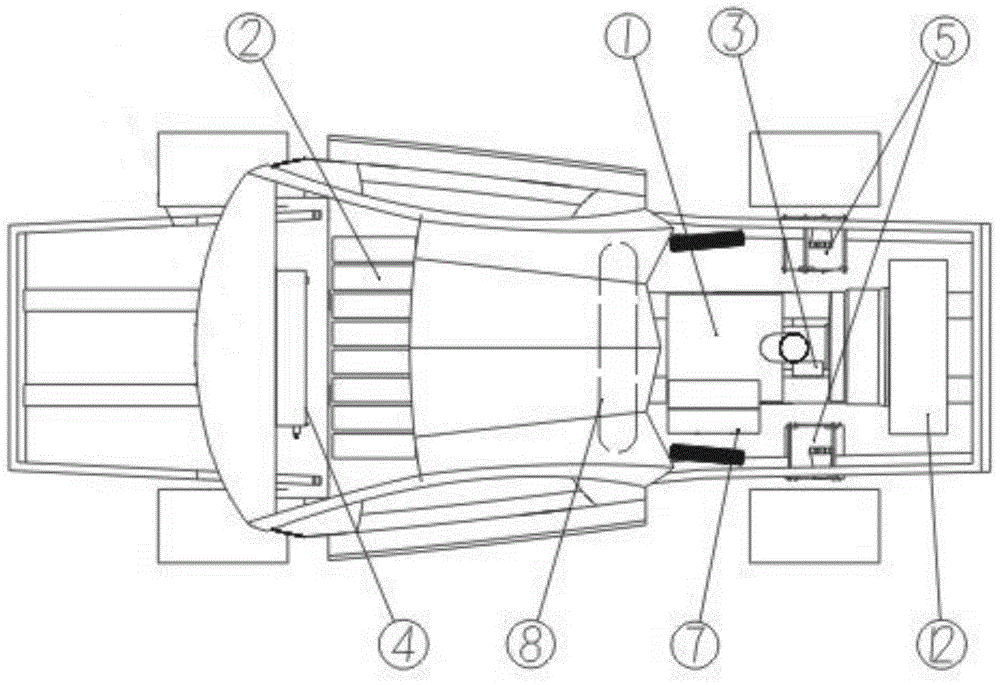

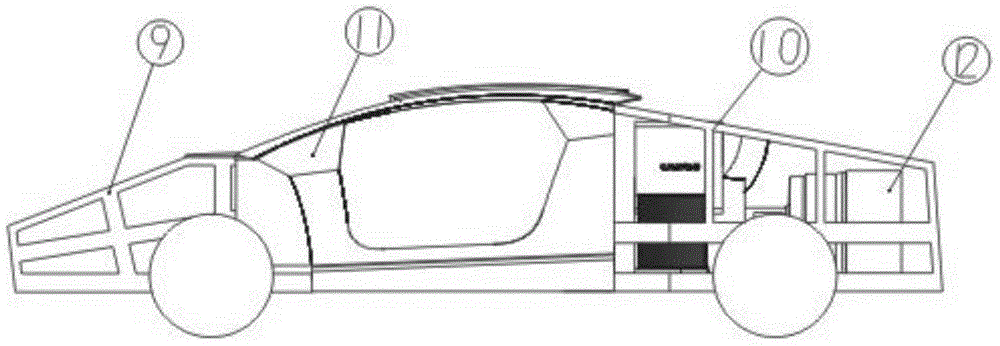

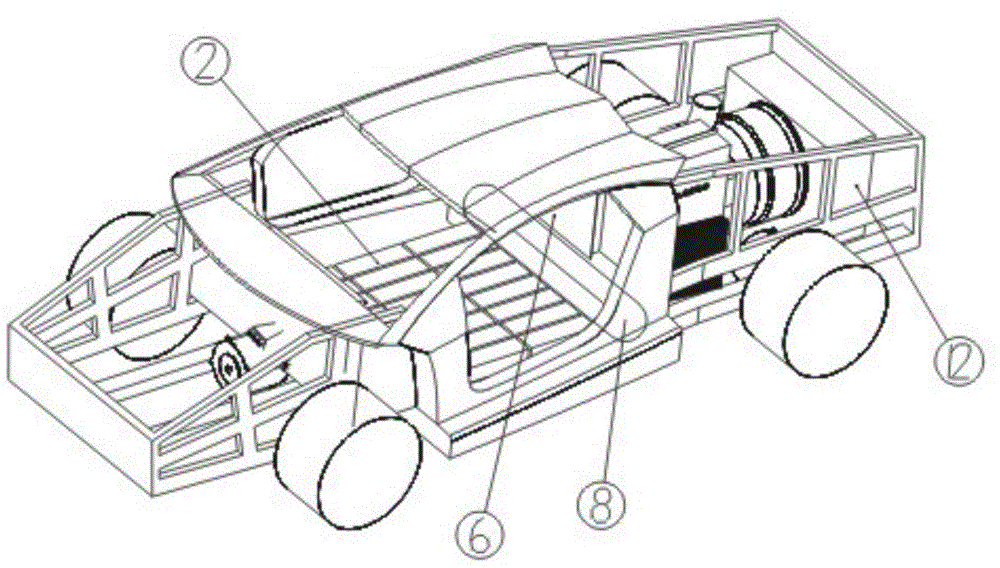

Mid-engine incremental stroke electric vehicle

ActiveCN104802629ASimple structureAvoid pollutionHybrid vehiclesSpeed controllerVehicle frameElectric machine

The invention provides a mid-engine incremental stroke electric vehicle. The electric vehicle comprises a vehicle body, a turbo shaft engine (1), a battery pack (2), a generator (3), a whole vehicle controller (4), a driving motor (5), a gas controller (6), a battery controller (7), a gas holder (8) and a gas inlet tank (12), and is characterized in that the vehicle body comprises a vehicle main body, wherein the bottom structure of the vehicle main body forms a vehicle frame; the turbo shaft engine (1) is distributed between a front axle and a rear axle and is close to the vehicle frame of the rear axle; the axis of the output shaft of the turbo shaft engine (1) is positioned on the symmetry planes of the vehicle body; the air inlet of the turbo shaft engine (1) faces towards the tail of the vehicle; the gas inlet tank (12) is communicated with the air inlet of the turbo shaft engine (1); the gas inlet tank (12) is communicated with a gas inlet grille on a vehicle covering piece. The electric vehicle has the characteristics of high energy conversion efficiency, good operating performance, long driving mileage and high vehicle body structural strength.

Owner:刘慕华

High-precise uniaxial magnetic-levitation revolving table

InactiveCN1865897AEliminate frictional momentHigh control precisionWork measurementStructural/machines measurementStatorElectrical and Electronics engineering

The related high-precise single-axis magnetic levitation turntable comprises: a moment motor, a lower protective bearing, a lower / upper radial / axial integrated displacement sensor, a lower / upper radial magnetic levitation, an angular position coder, and a work platform. Wherein, it uses radial / axial magnetic levitation bearing to realize non-mechanical contact stable suspension between stator and rotator. This invention reduces friction moment and total volume greatly, and improves control precision and system security.

Owner:BEIHANG UNIV

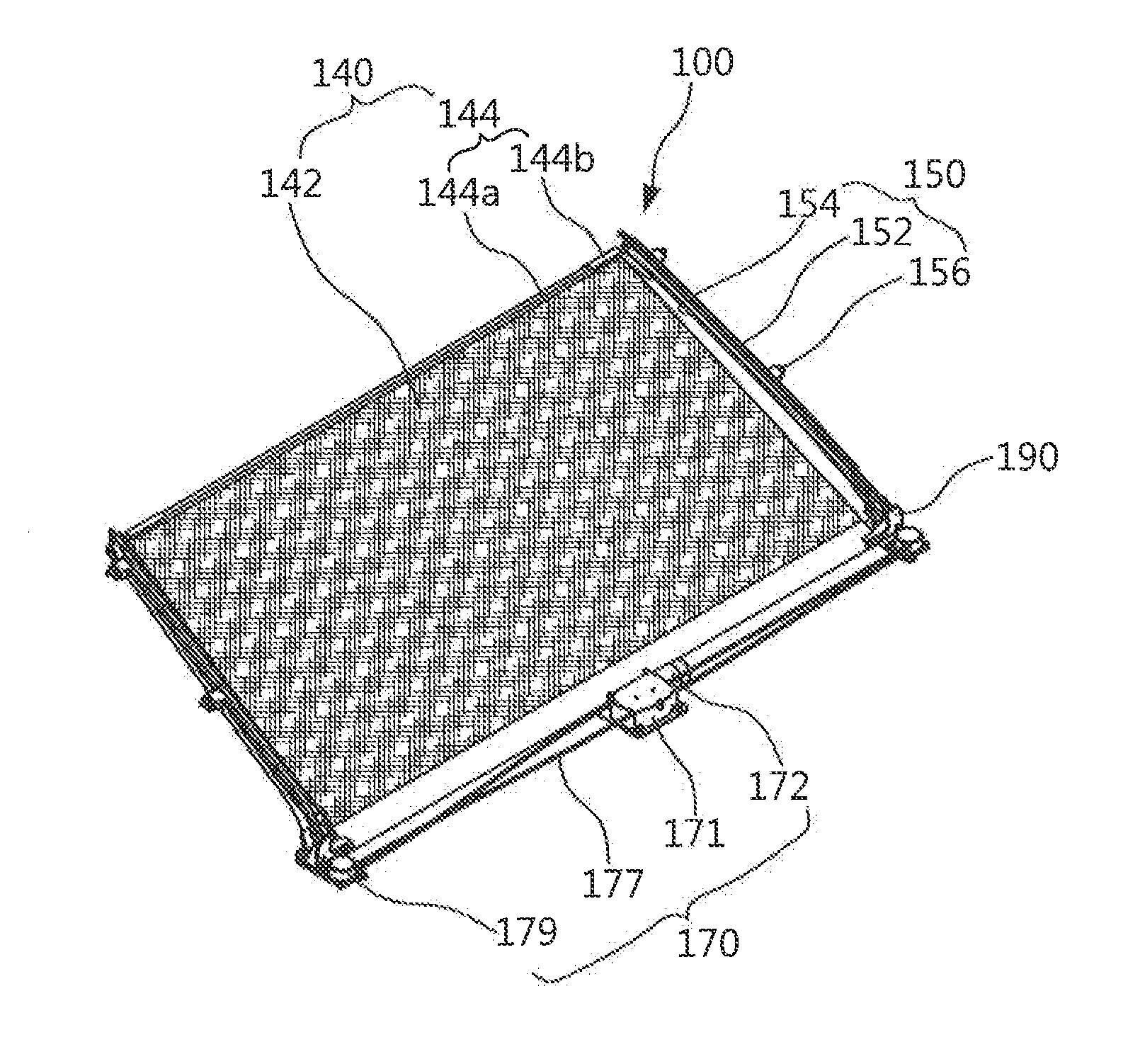

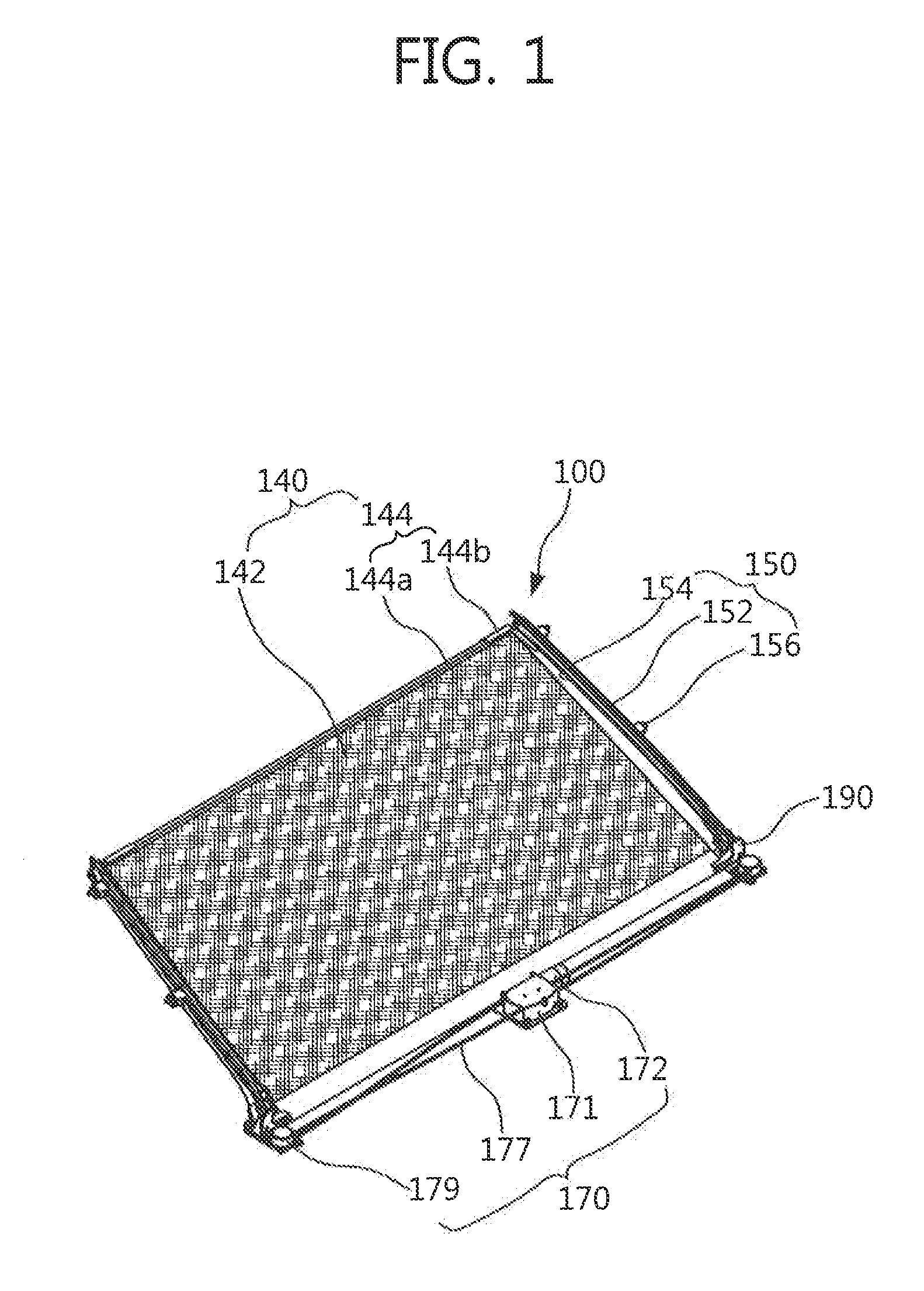

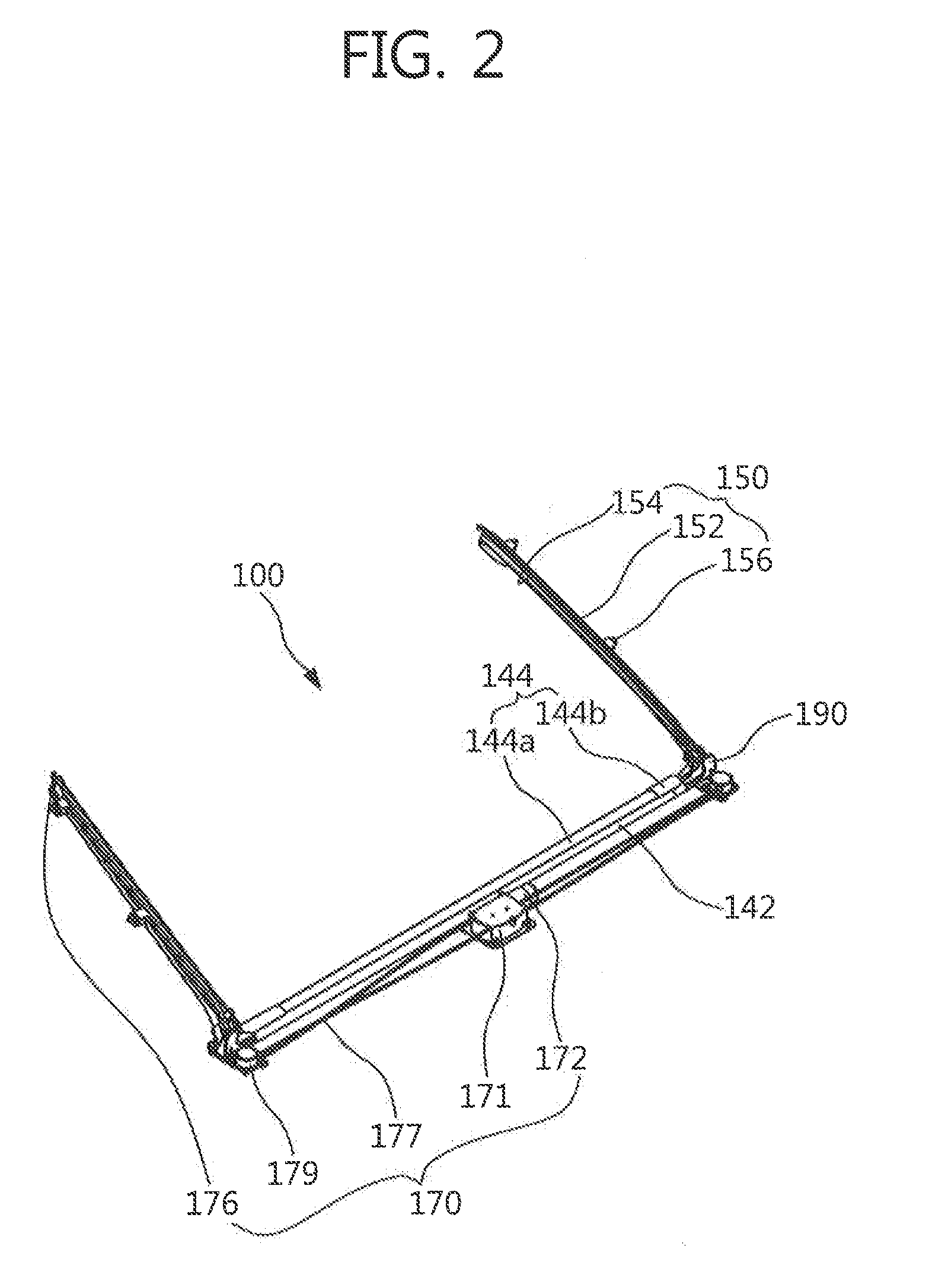

Window blind assembly for vehicle

ActiveUS20120048489A1Conveniently transportedReduce vibration and noiseWindowsAntiglare equipmentEngineeringWindow shutter

There is a need for a window blind assembly for a vehicle, in which vibration and noise are reduced when a shade curtain moves and which is convenient to be transported. The window blind assembly tor a vehicle includes: a main frame; a pair of connection units arranged in the main frame; a rotary shaft rotationally arranged in the connection units; a pair of guide rails rotationally arranged in the connection units and formed with guide grooves; a shade curtain supporter movably coupled to the guide grooves of the pair of guide rails; a shade curtain including one side end portion connected to the rotary shaft and rolled into the rotary shaft, and the other side end portion connected to the shade curtain supporter and unrolled as the shade curtain supporter becomes apart from the rotary shaft; and a driving unit providing driving force to move the shade curtain supporter along the guide rail.

Owner:KOREA FUEL TECH

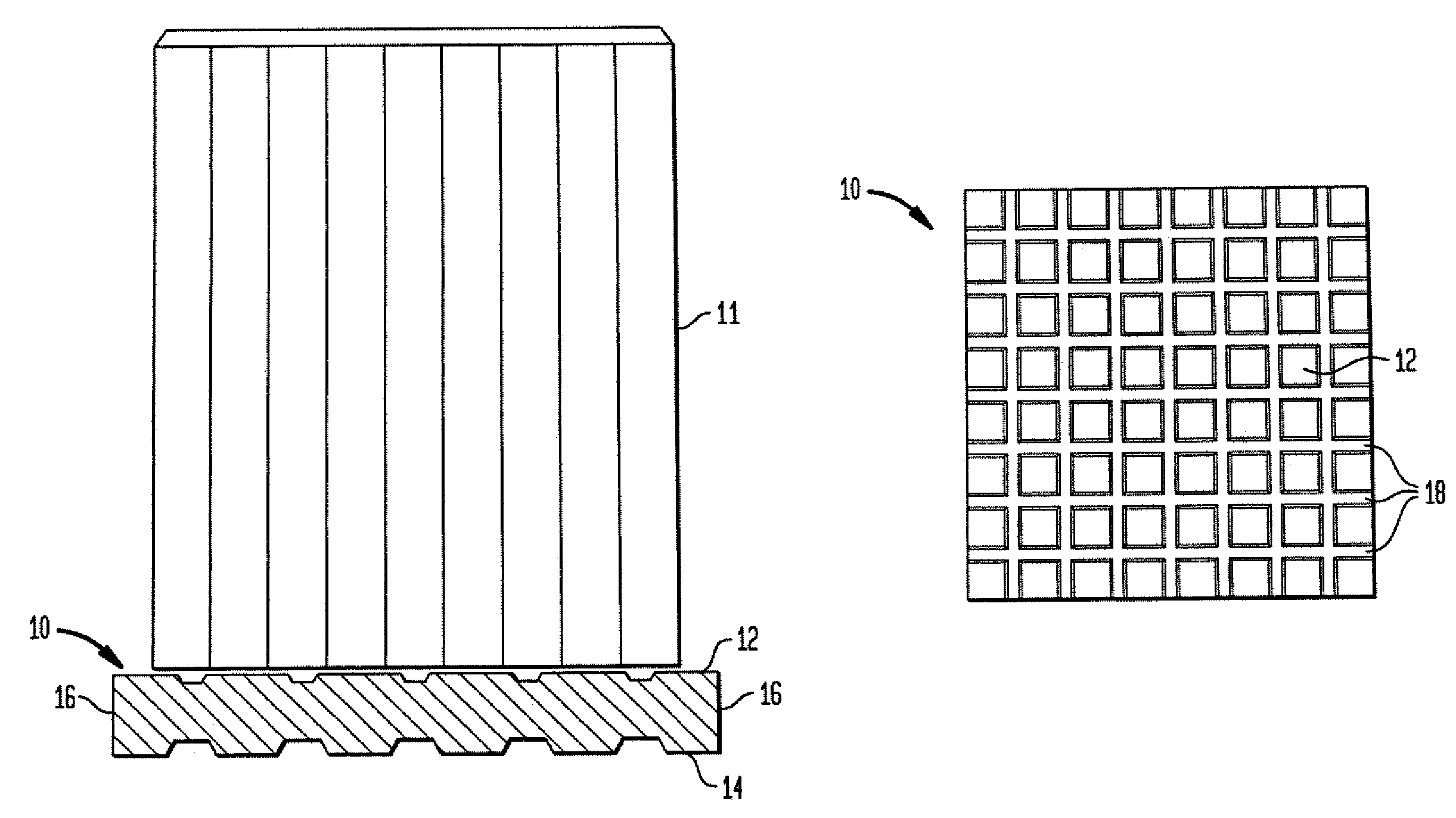

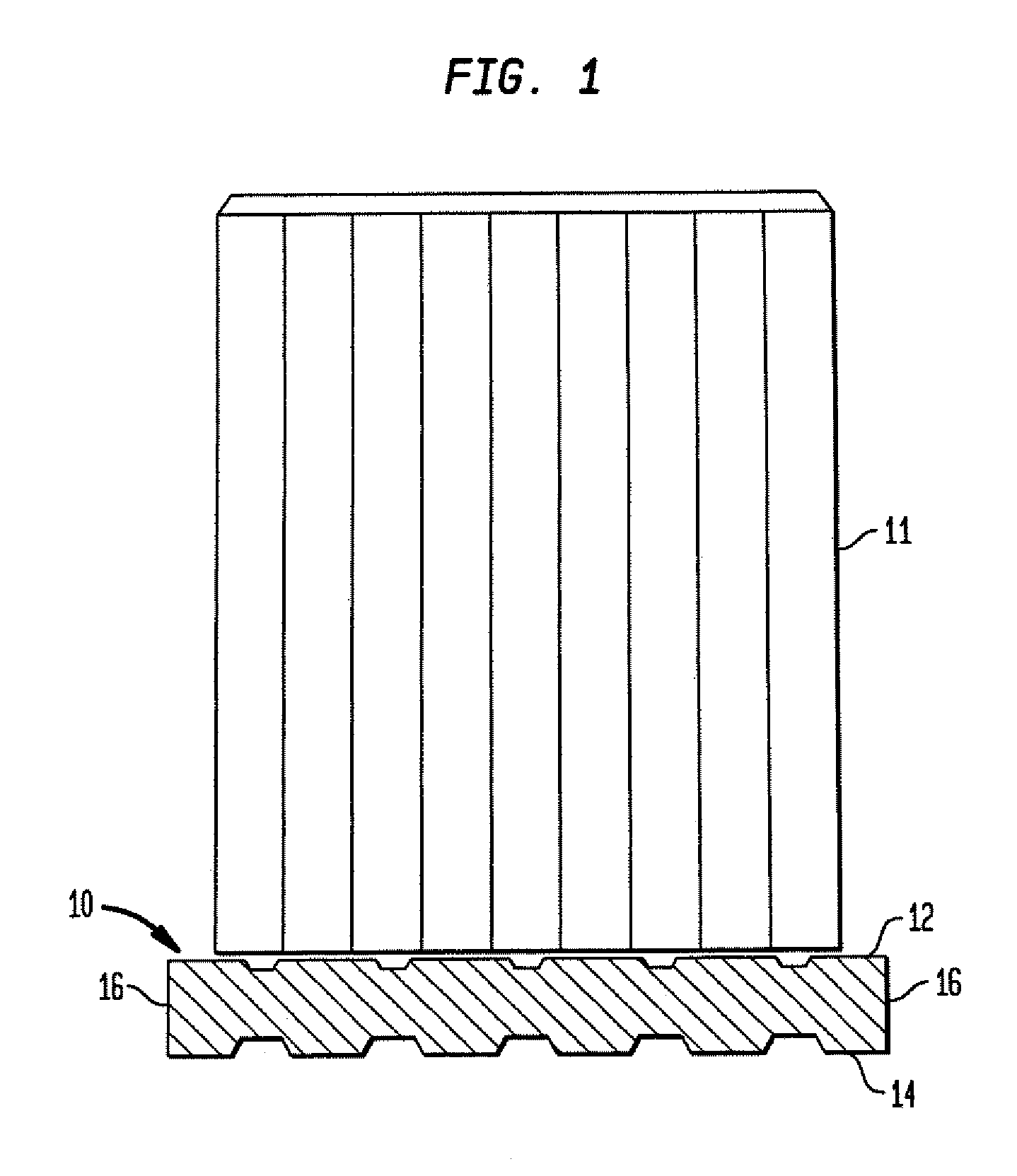

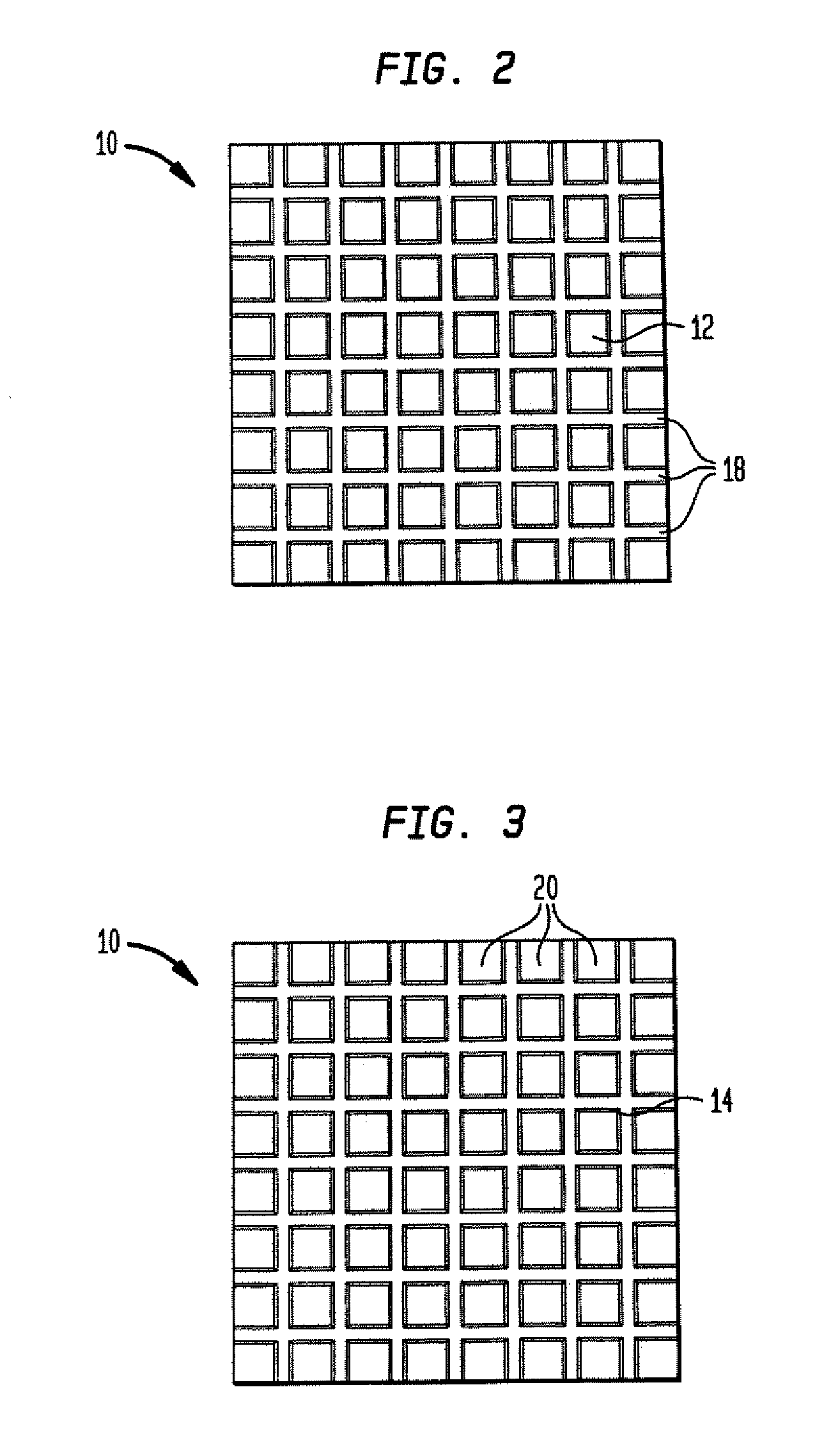

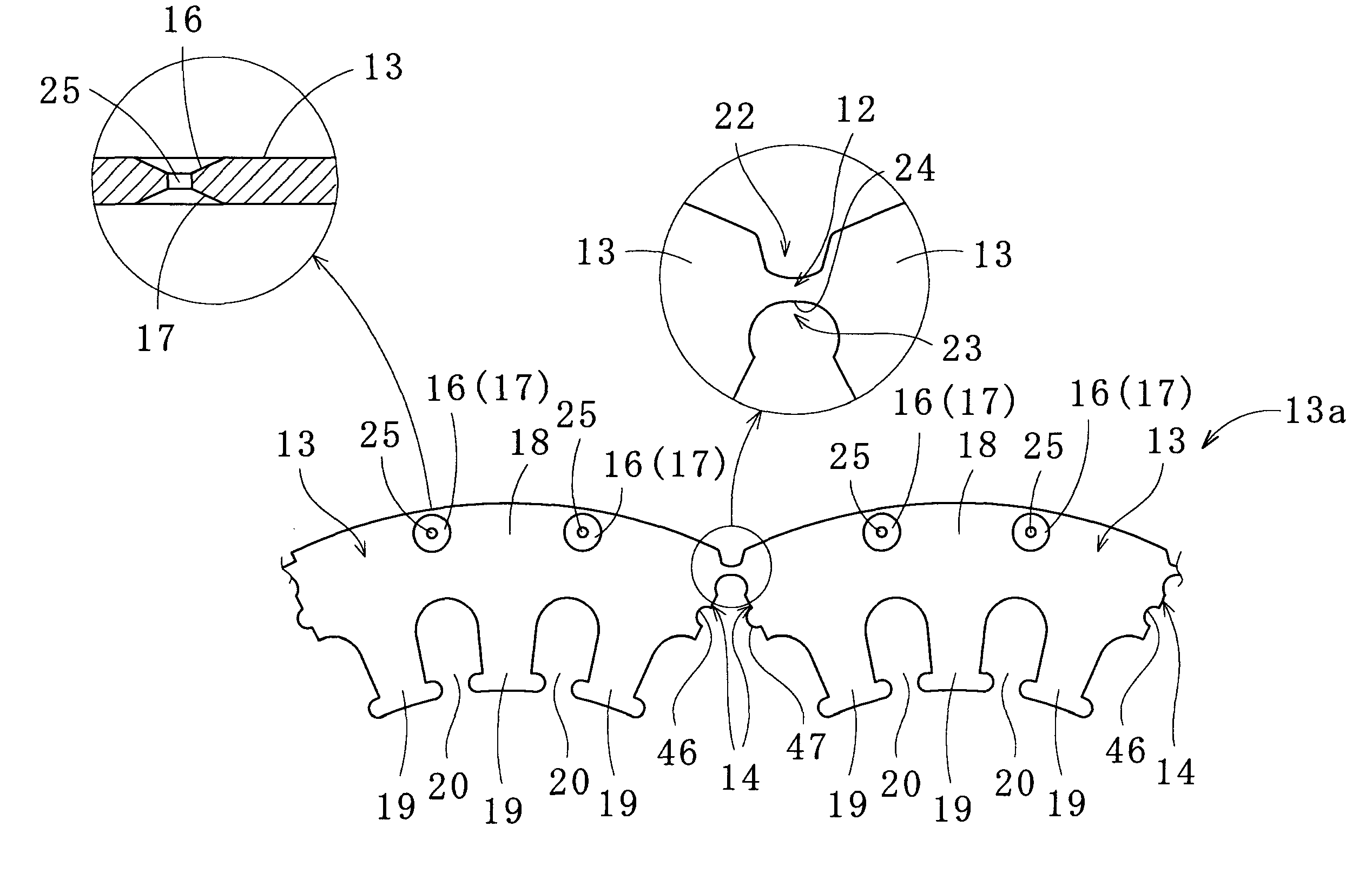

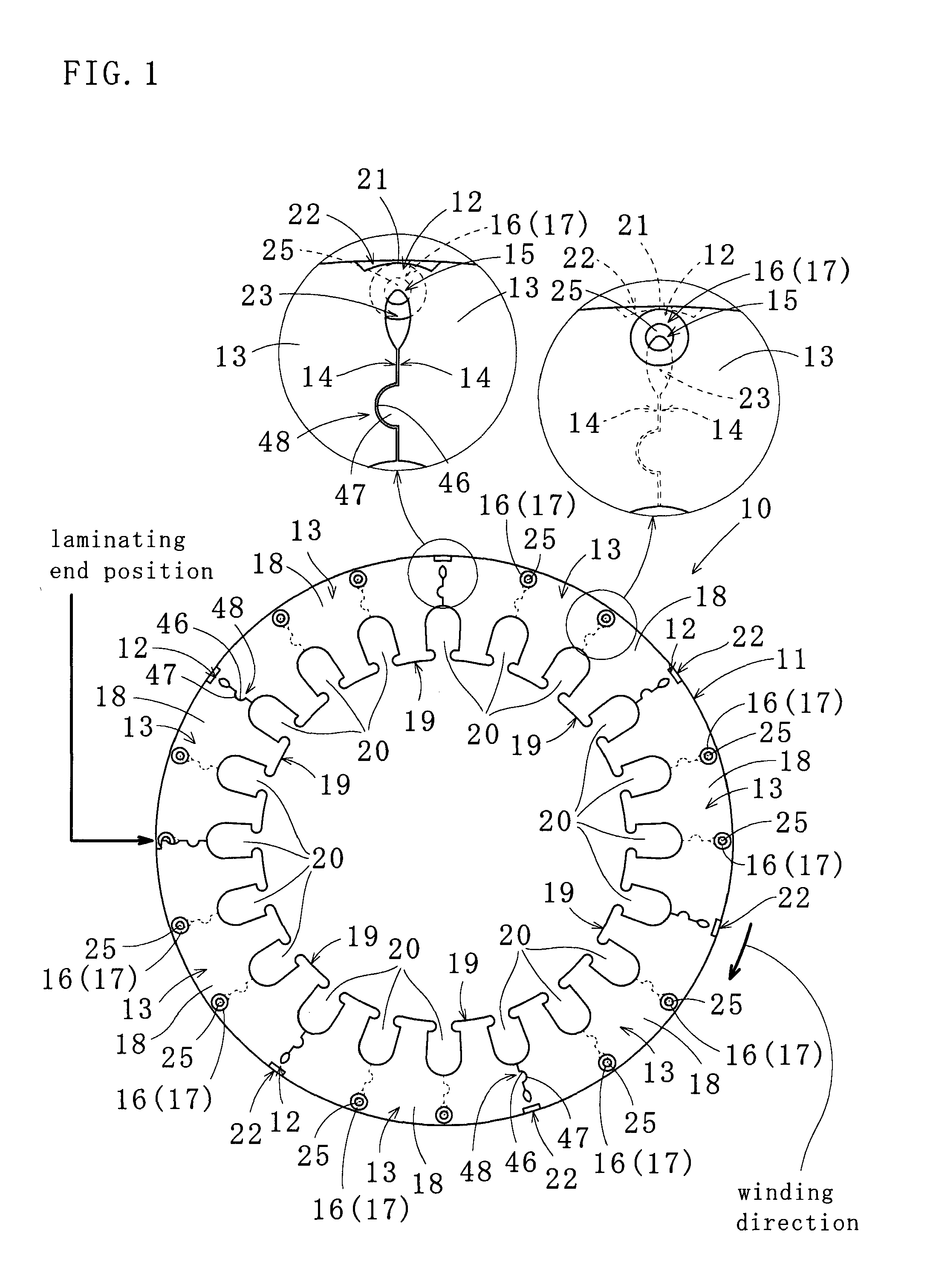

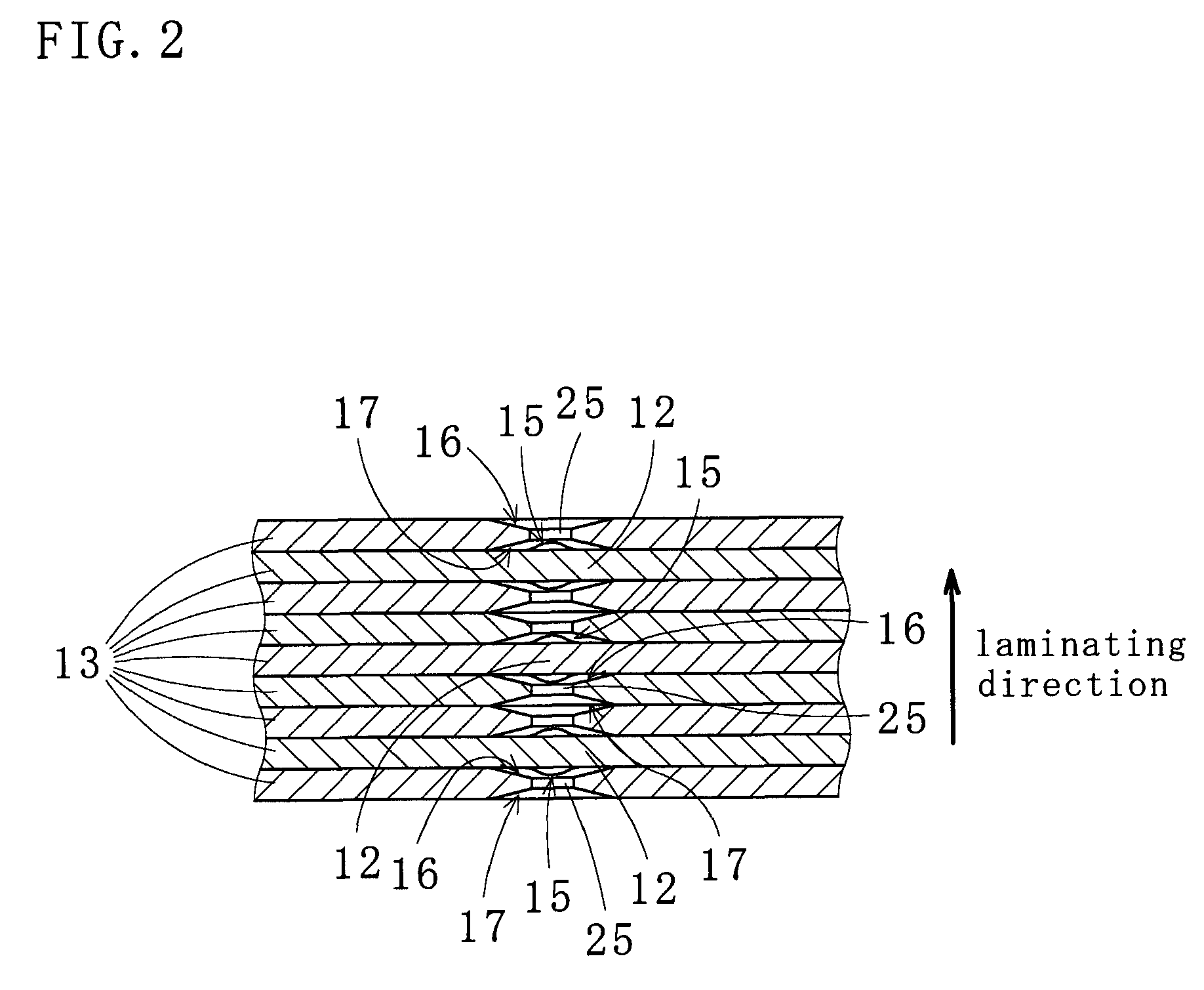

Laminated core and method for manufacturing the same

InactiveUS20100090560A1Avoid clearingReduce vibrationMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectrical and Electronics engineering

A laminated core 10 including a plurality of segment core sheets 13 spirally wound and laminated in layers while connecting portions 12 connecting the adjacent segment core sheets 13 are bent, ends of the segment core sheets 13 are aligned with each other and the connecting portions 12 in the adjacent layers are circumferentially displaced relative to each other, the connecting portions 12 located in outer peripheral areas 11 of the segment core sheets 13, the laminated core 10 comprising:a concave cutout 22 formed on a radially outward side of the connecting portion 12, the concave cutout 22 accommodating a radially expanded part 21 within an outer circle of the laminated core 10, the radially expanded part 21 formed in the connecting portion 12 radially outward at the bending of the connecting portion 12; an interior cutout 23 formed on a radially inward side of the connecting portion 12, the interior cutout 23 defining a bent position of the connecting portion 12; anddepressed receptacles 16, 17 respectively formed on a top side and a bottom side of a radially outward area of the segment core sheet 13 except for the connecting portions 12, the depressed receptacles 16, 17 each receiving a thickness-direction expanded part 15 formed in the connecting portion 12 in a thickness direction thereof at the bending of the connecting portion 12.

Owner:MITSUI HIGH TEC INC

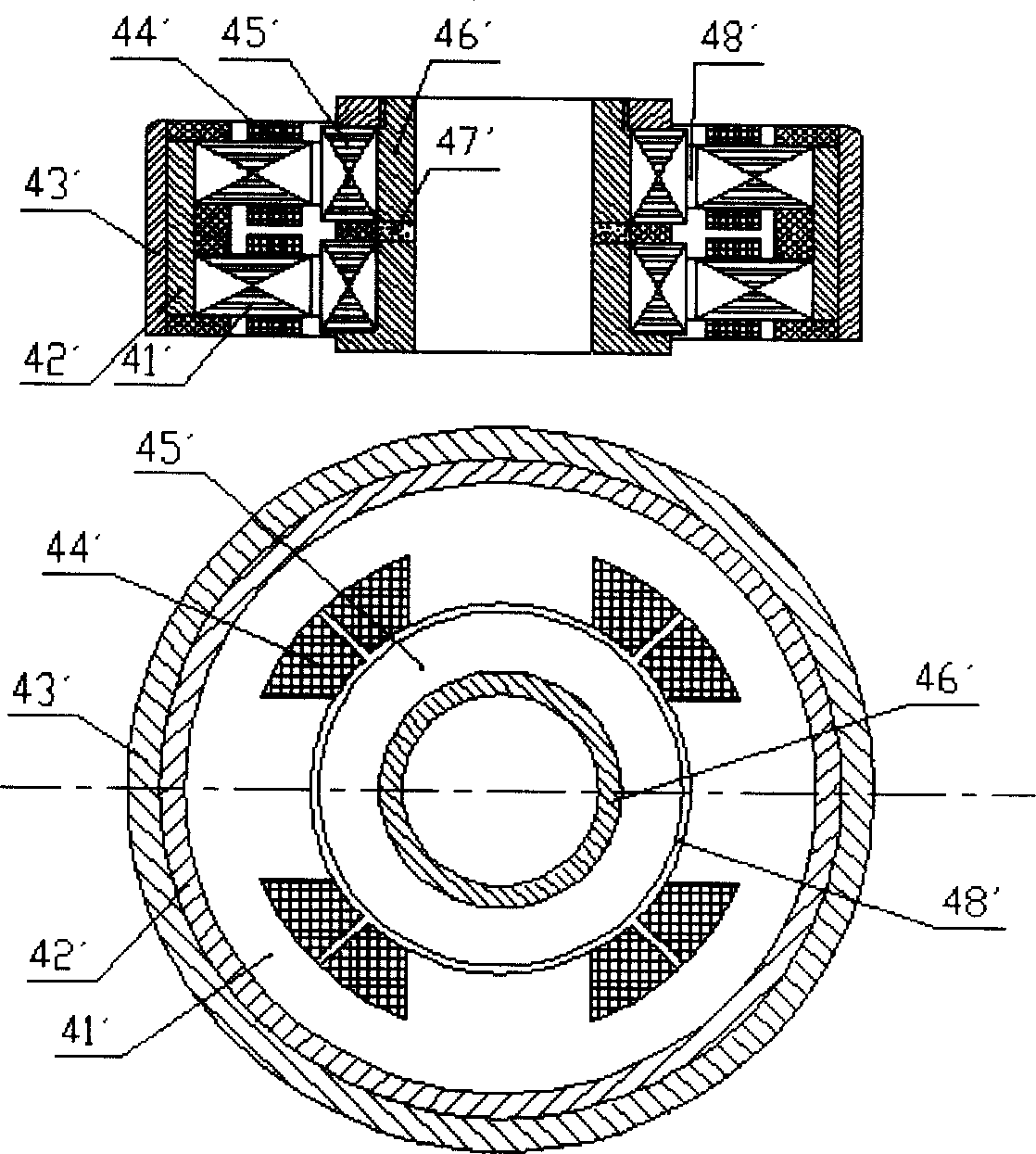

Completely non - contacting magnetic suspension control moment gyro of single framework

InactiveCN101049861AEliminate frictional momentIncrease speedSpacecraft guiding apparatusElectrically conductiveDrive motor

A fully non-contact single-frame magnetic- levitation torque-controlling gyro is composed of magnetically levitated frame system and magnetically levitated rotor system. Said magnetically levitated frame system consists of frame jointer, protecting bearing, mandrel, torque motor, angular position sensor, radial and axial magnetic bearings, integrated radial / axial displacement sensor, electrically conductive slide ring and base. Said magnetically levitated rotor system comprises gyro rotor, axle holder, axial and radial magnetic bearings, integrated radial / axial displacement sensor, protecting bearing, drive motor, sealing cover, base and jointer.

Owner:BEIHANG UNIV

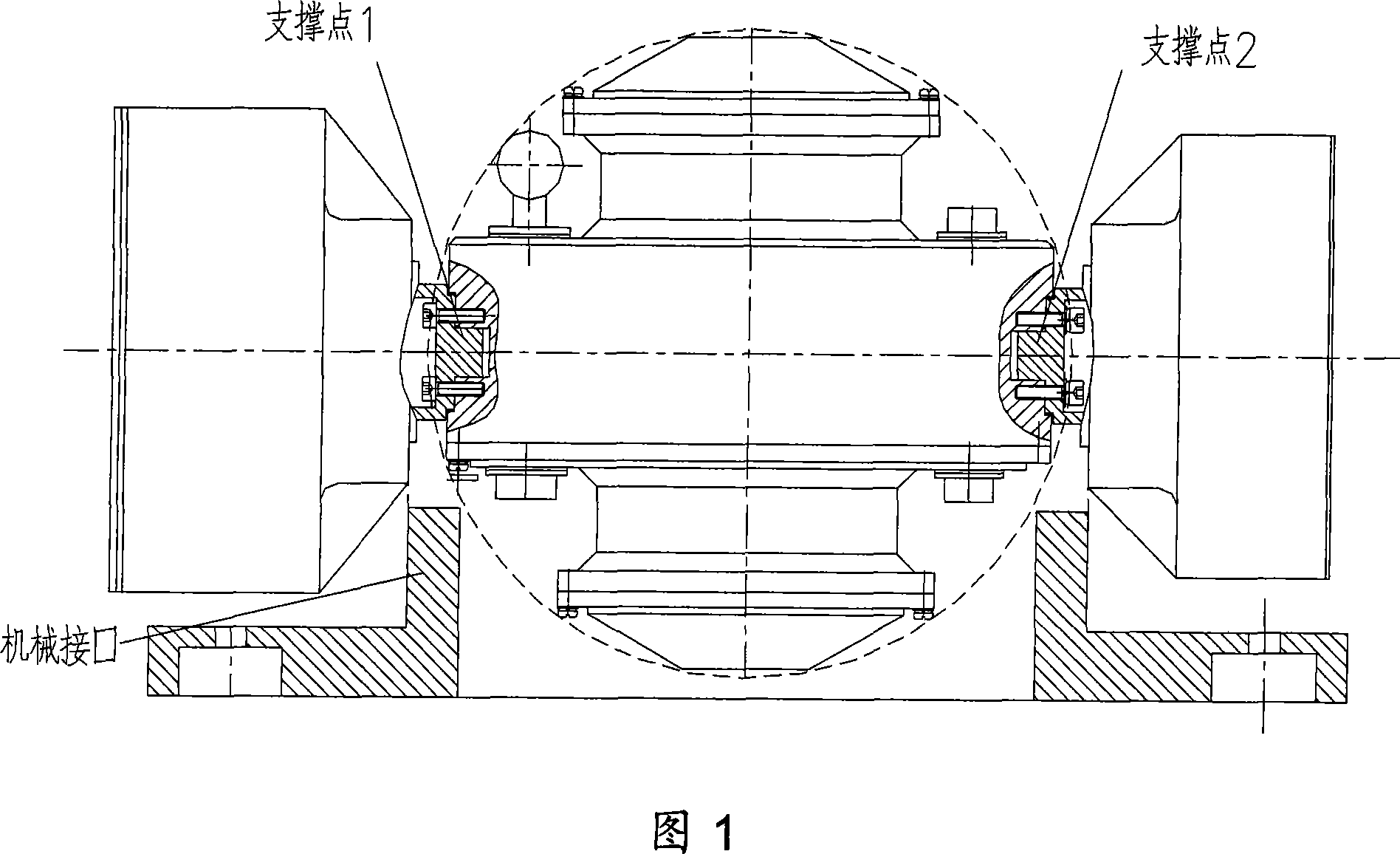

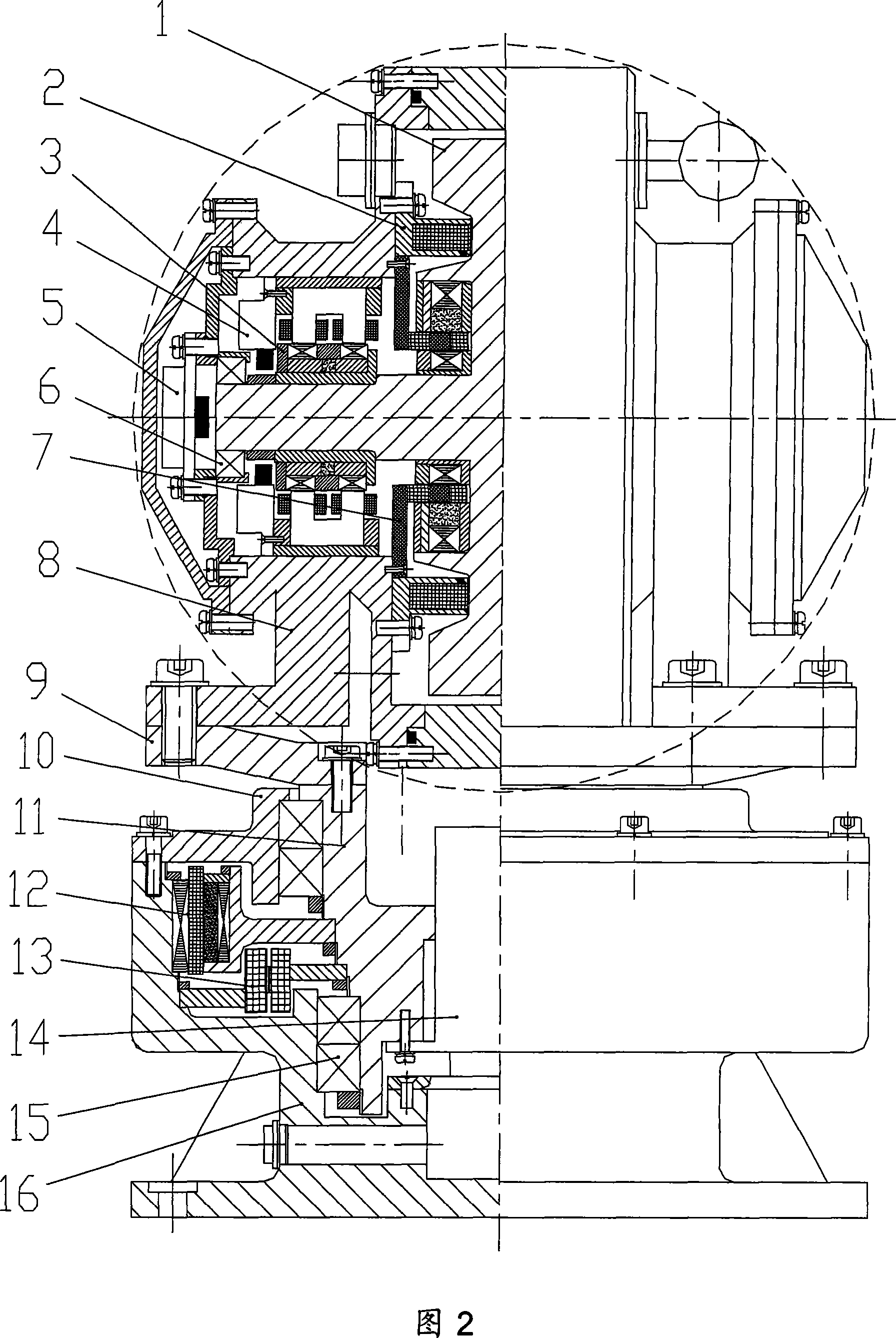

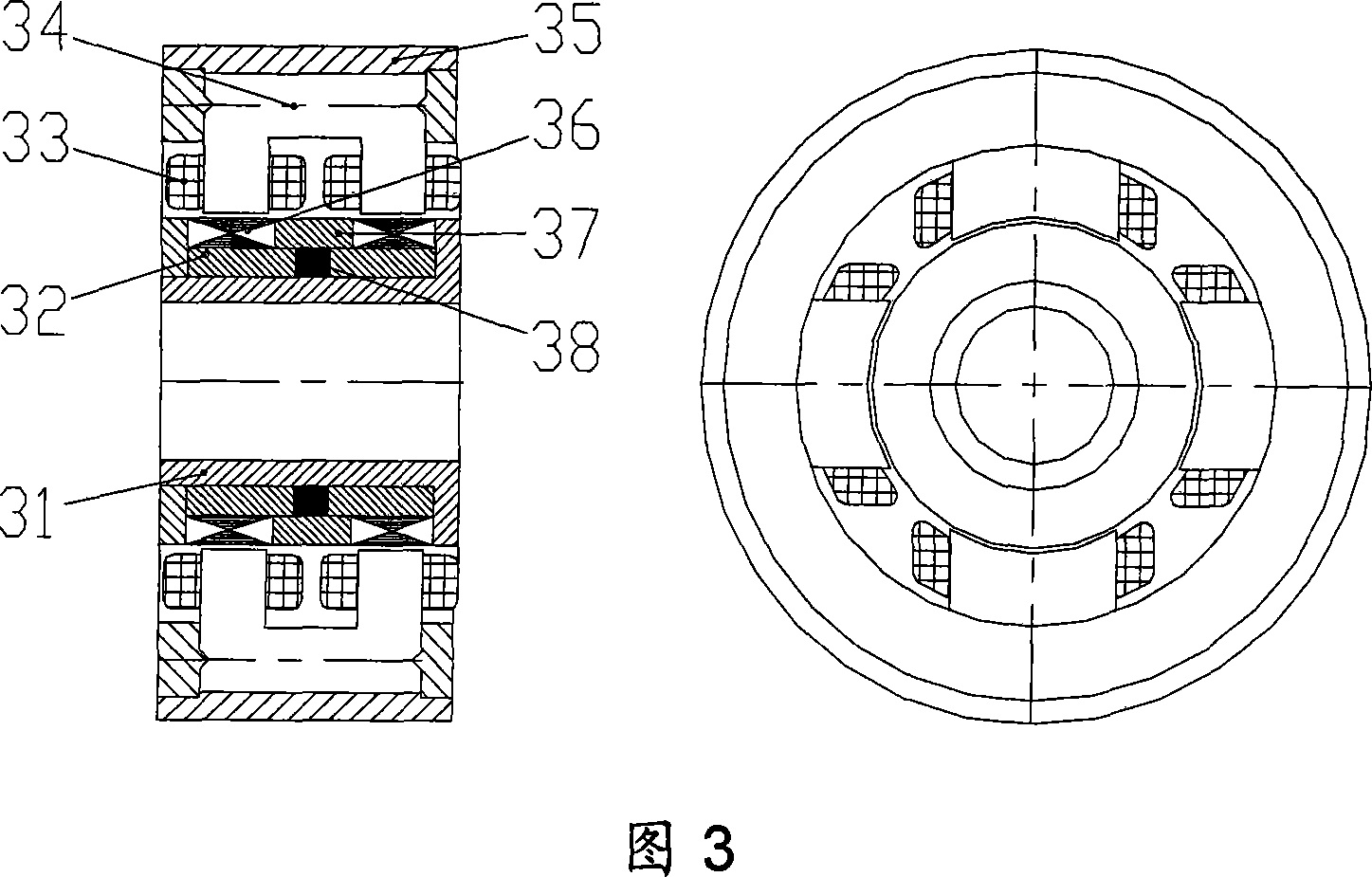

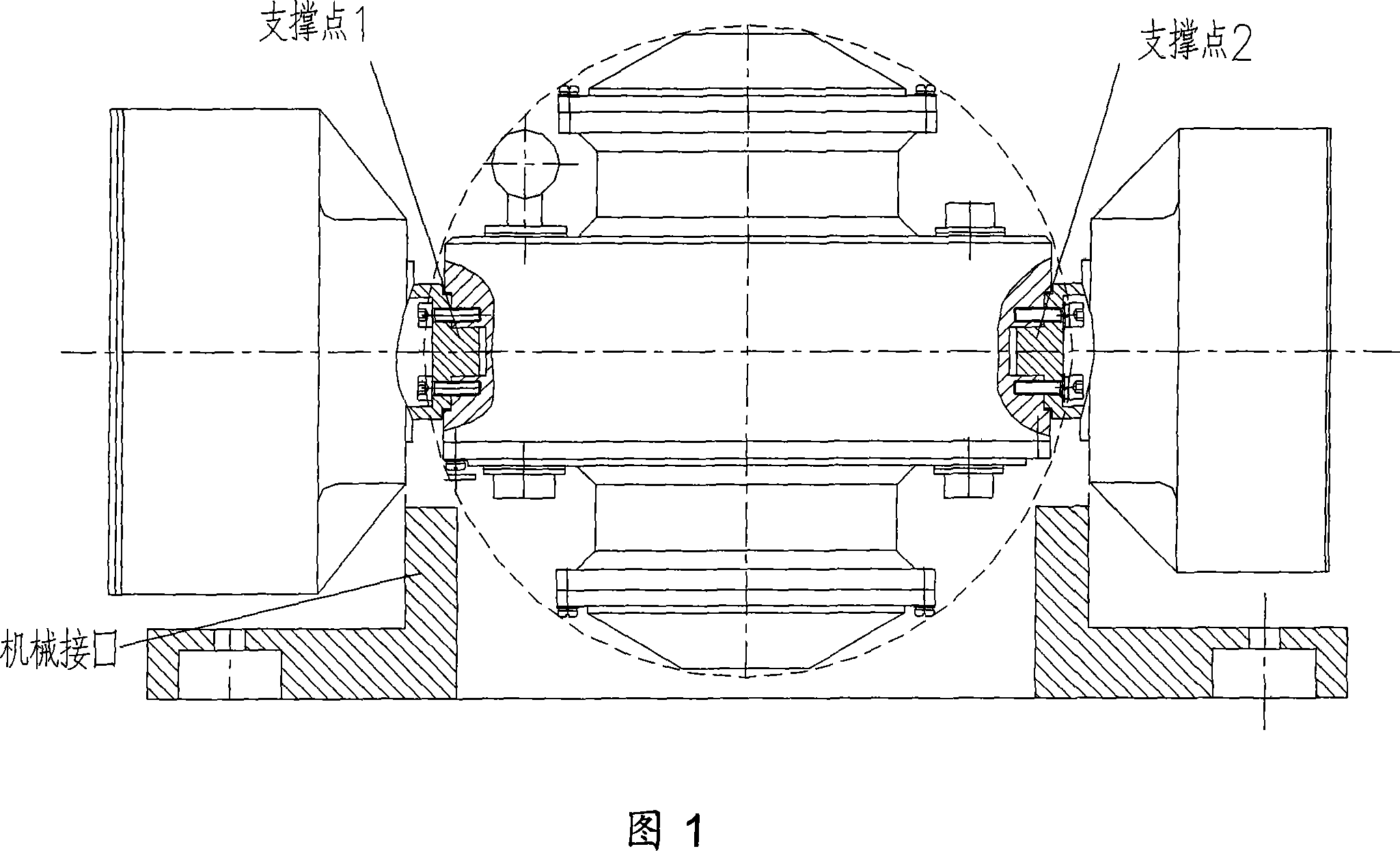

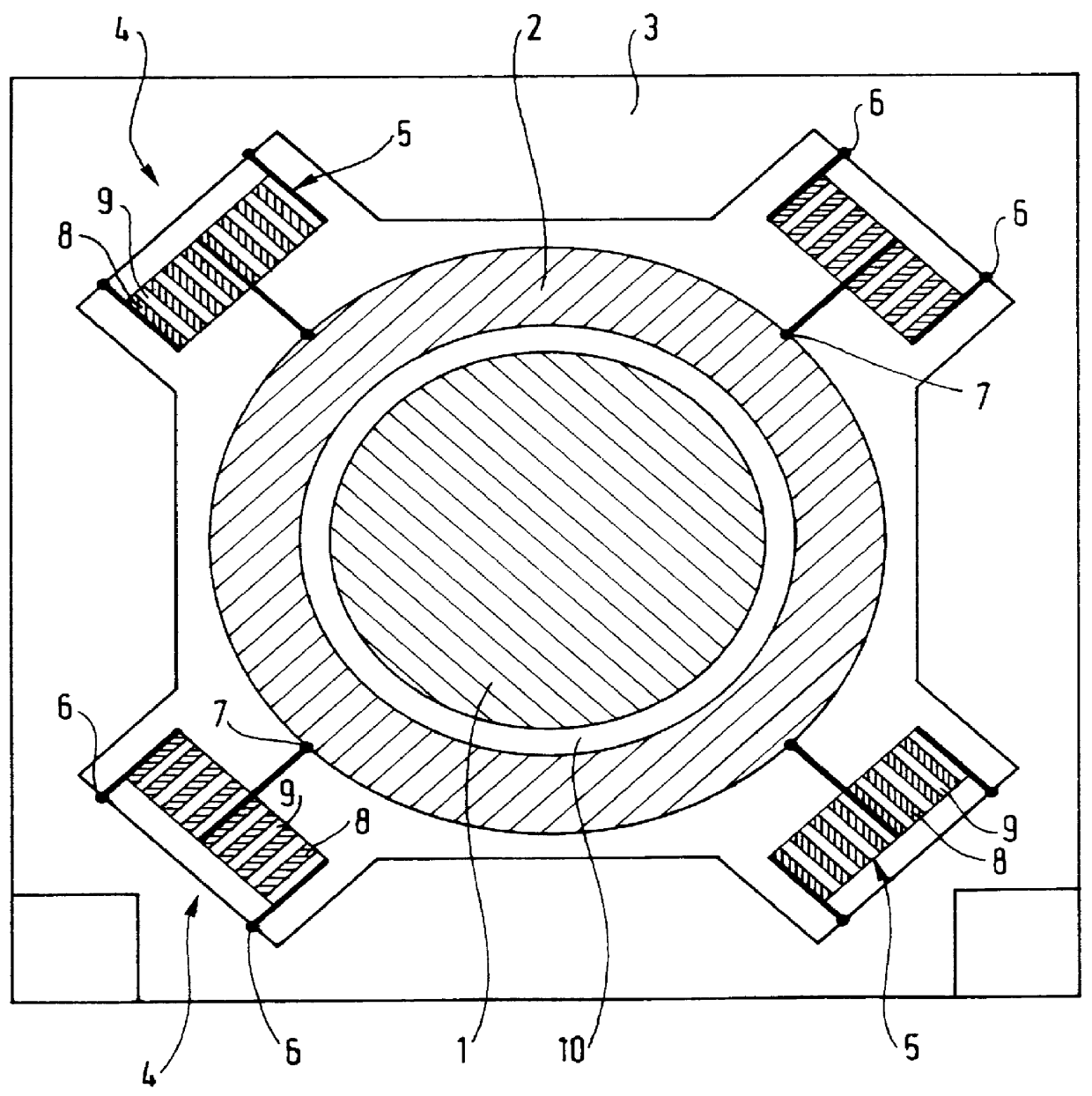

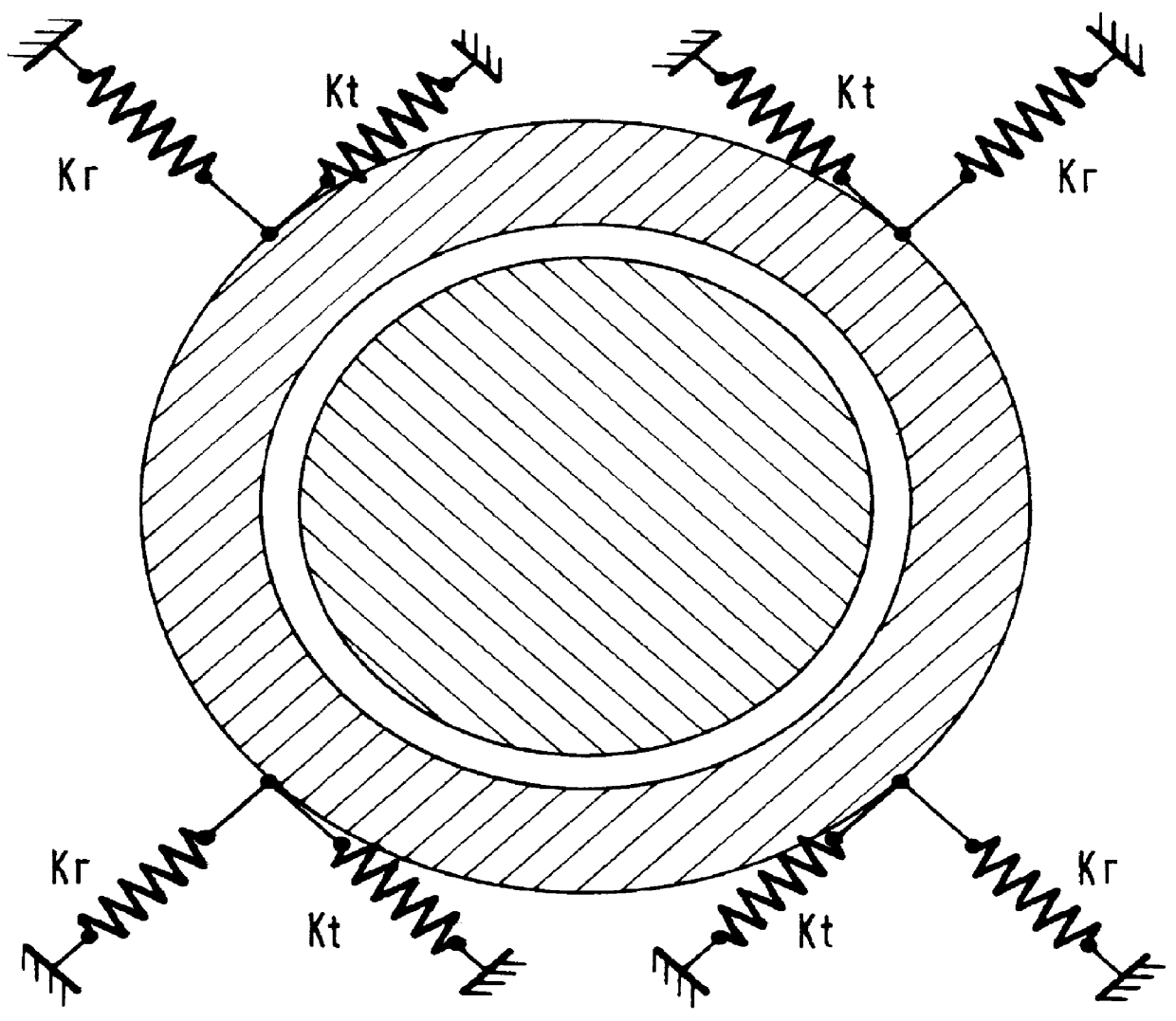

Method of reducing noise in a rotary electric machine, attachment apparatus for attaching the stator of a rotary electric machine and for implementing the method, and a rotary electric machine provided with such apparatus

InactiveUS6107705ASolve excessive vibrationReduce vibration and noiseFinal product manufactureNon-rotating vibration suppressionAxial displacementElectric machine

The invention concerns attachment apparatus for a stator of a rotary electric machine, said machine comprising a rotor, a stator coaxial with the rotor, an airgap between the stator and the rotor, and a casing provided with attachment points for attaching the stator; according to the invention, the attachment apparatus comprises attachment elements mounted between the attachment points and the stator; each attachment element having an anisotropic stiffness comprising a tangential component Kt for taking up in part the static forces of the machine, and a radial component Kr for relieving in part the dynamic forces of the stator relative to the casing; the resultant of the tangential components Kt taking up the static forces of the rotary electric machine with an axial displacement or a radial displacement of the stator that is less than or equal to a predetermined value that is less than the airgap; and the resultant of the radial components Kr relieves the dynamic forces of the stator with a predetermined coefficient of transmission to the casing.

Owner:GEC ALSTHOM MOTEURS

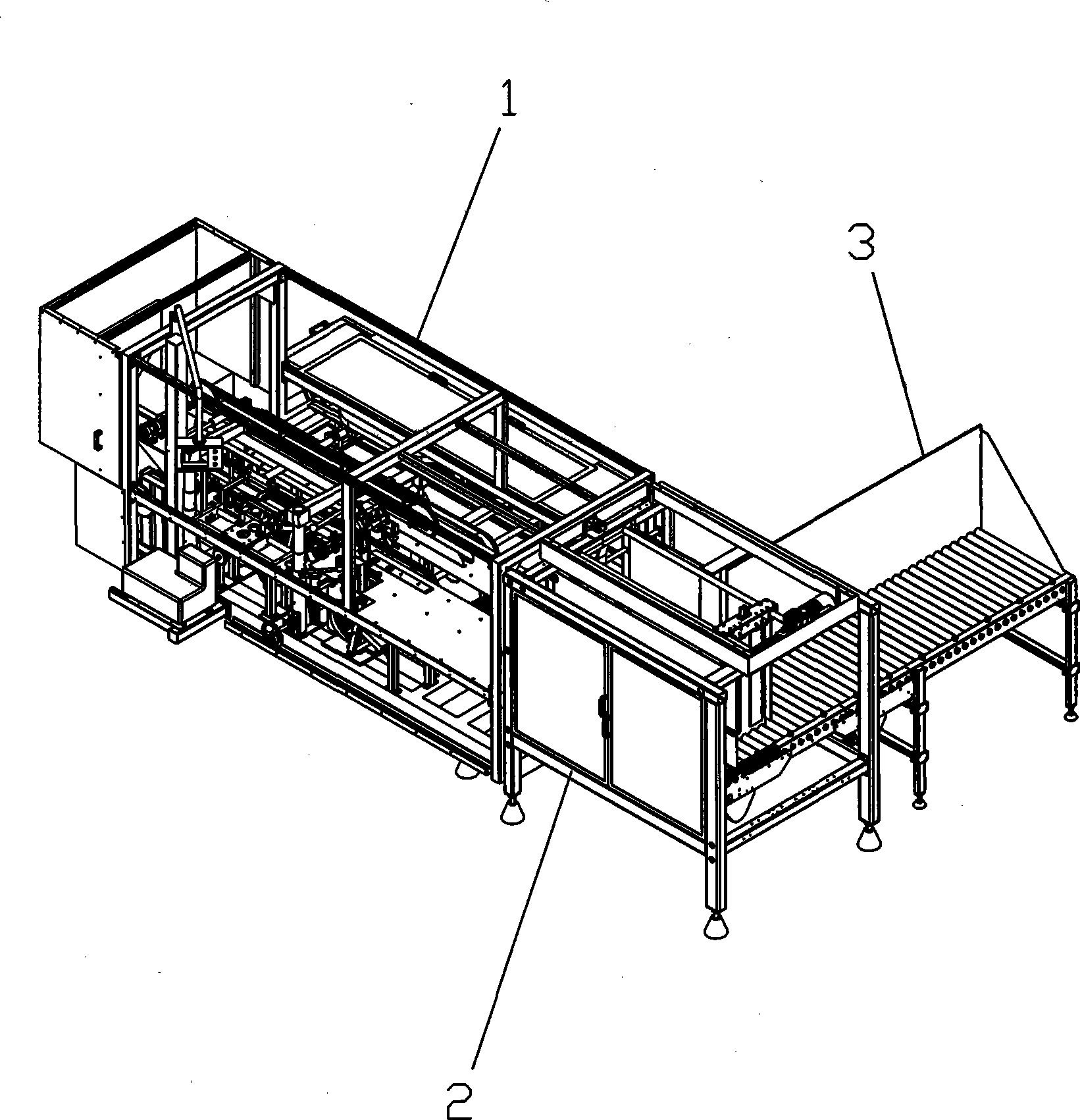

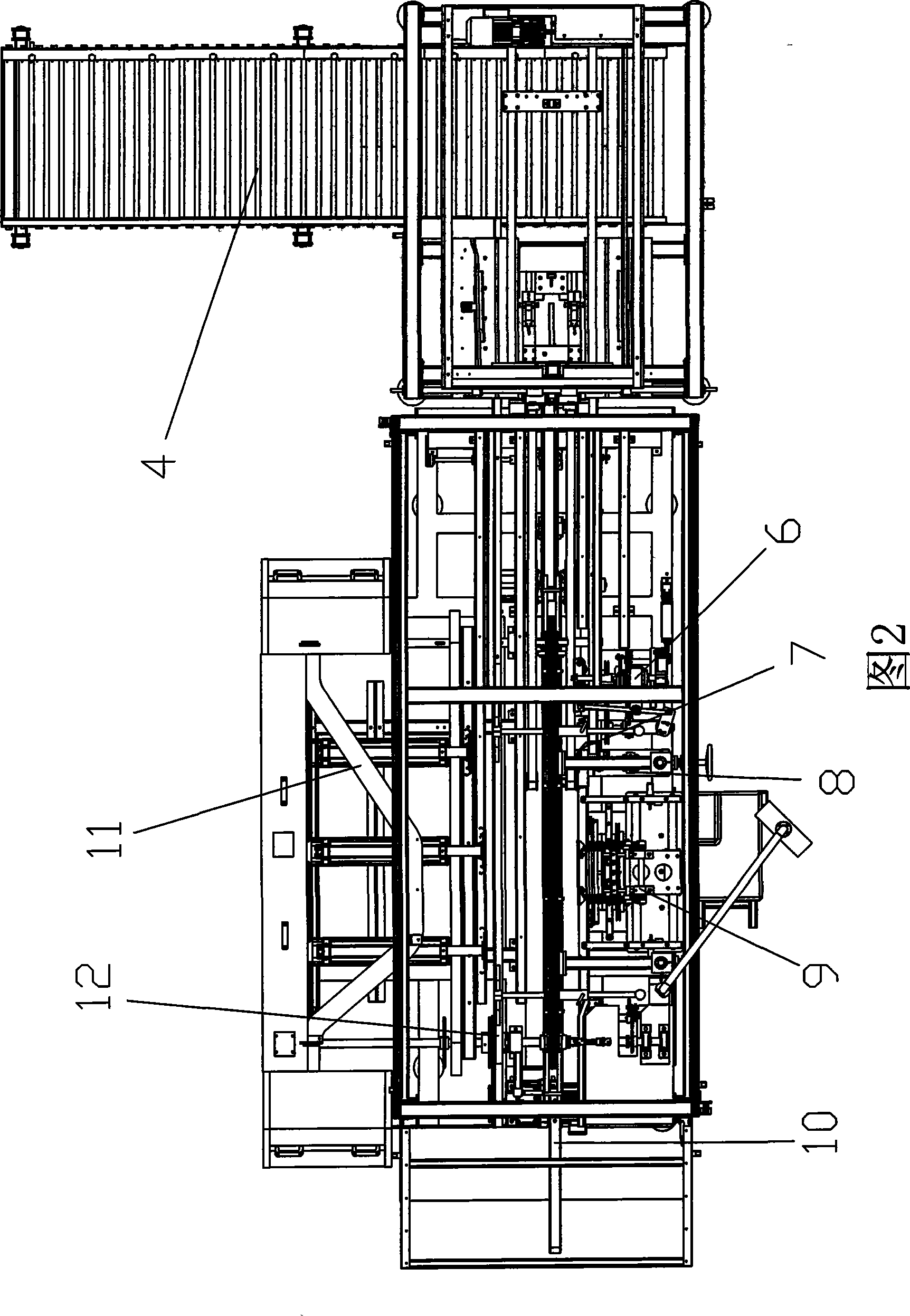

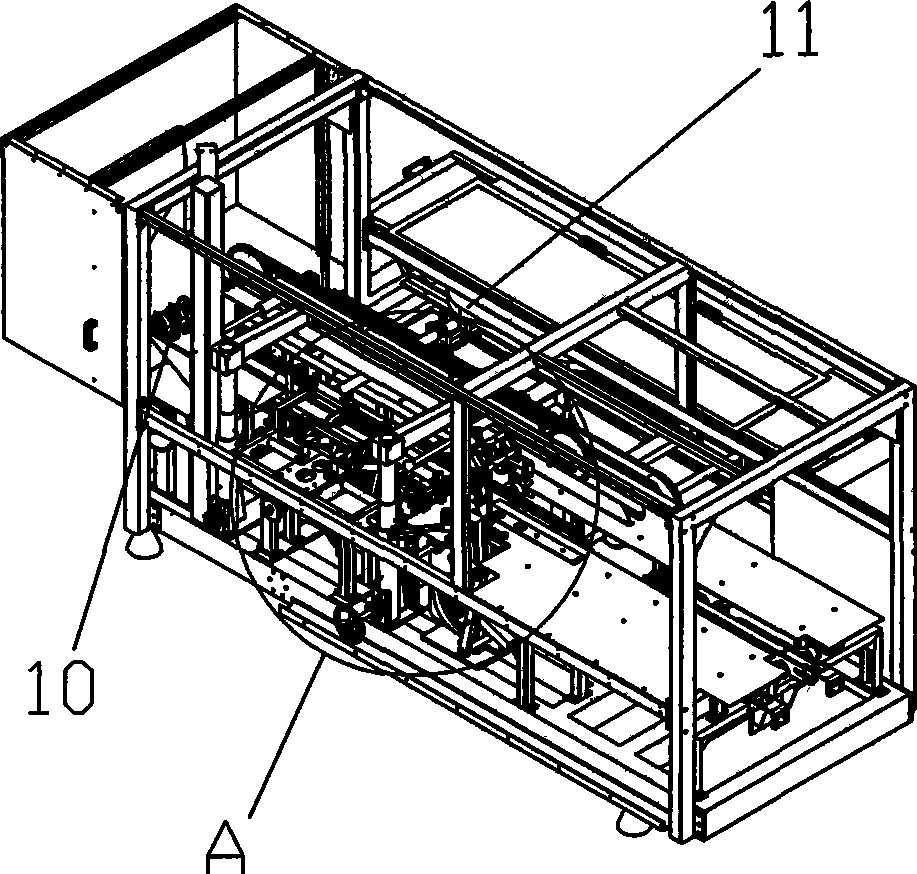

High-speed paper carton forming device

InactiveCN101450539AReduce vibration intensityReduce vibration and noiseBoxes/cartons making machineryMolding machineCarton

The invention relates to a high-speed carton molding machine. The high-speed carton molding machine comprises a mainframe part, a pusher part and a stacking supply part; the mainframe part comprises a cut paper transporting component, an unpacking molding component, a box retaining and positioning component, a gelatinization component, an outer foldout component, a box discharging and dropping component, a box pressing and molding component relatively arranged at one side and an upper box poking and adjusting component; the box pressing and molding component comprises two small circulating guide rails in parallel arrangement, a circulating transmission chain, a sliding guide rail, a box pressing component and a large circulating guide rail; the sliding guide rail is vertically arranged between two small circulating guide rails and is connected with the circulating transmission chain; two ends of the sliding guide rail are connected with tracks of two small circulating guide rails through slide blocks respectively; the bottom end of the box pressing component is arranged on the sliding guide rail through a sliding sleeve; the upper side of the box pressing component is connected with a track of the large circulating guide rail through an idler wheel; and the large circulating guide rail is provided with a section of a bended convex track. The high-speed carton molding machine has a compact structure, high carton molding speed, small vibrating strength and noise and large carton storage capacity.

Owner:广州市万世德智能装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com