Patents

Literature

71results about How to "Prevent blowback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

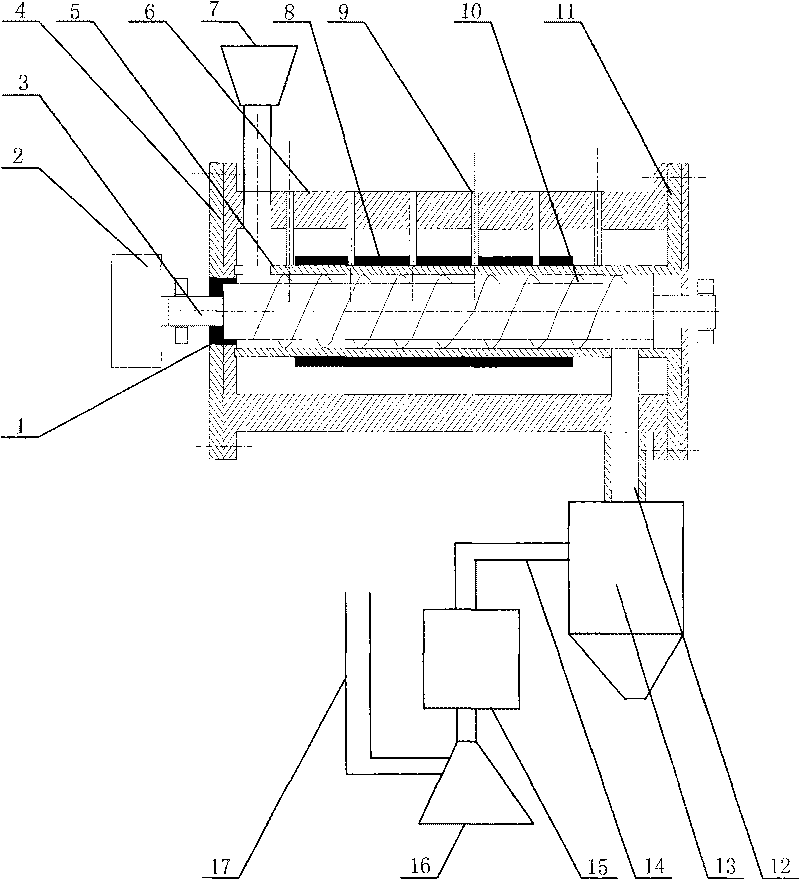

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

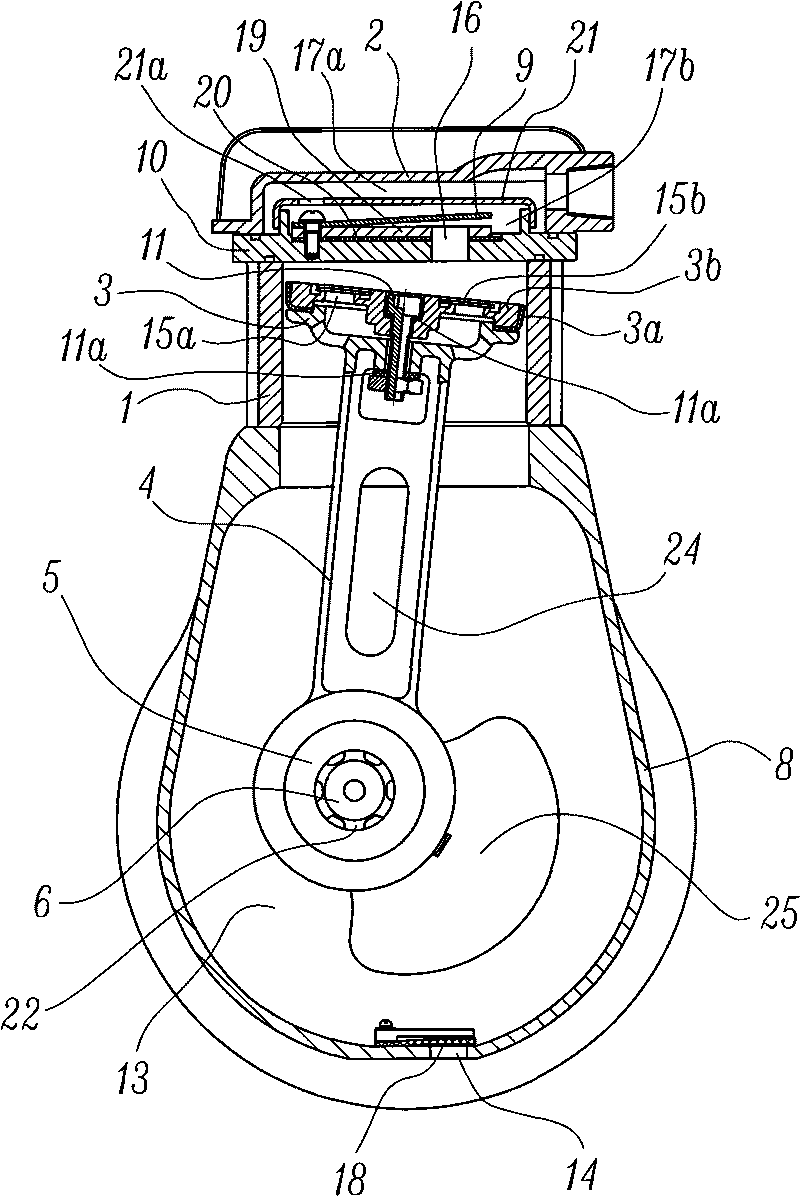

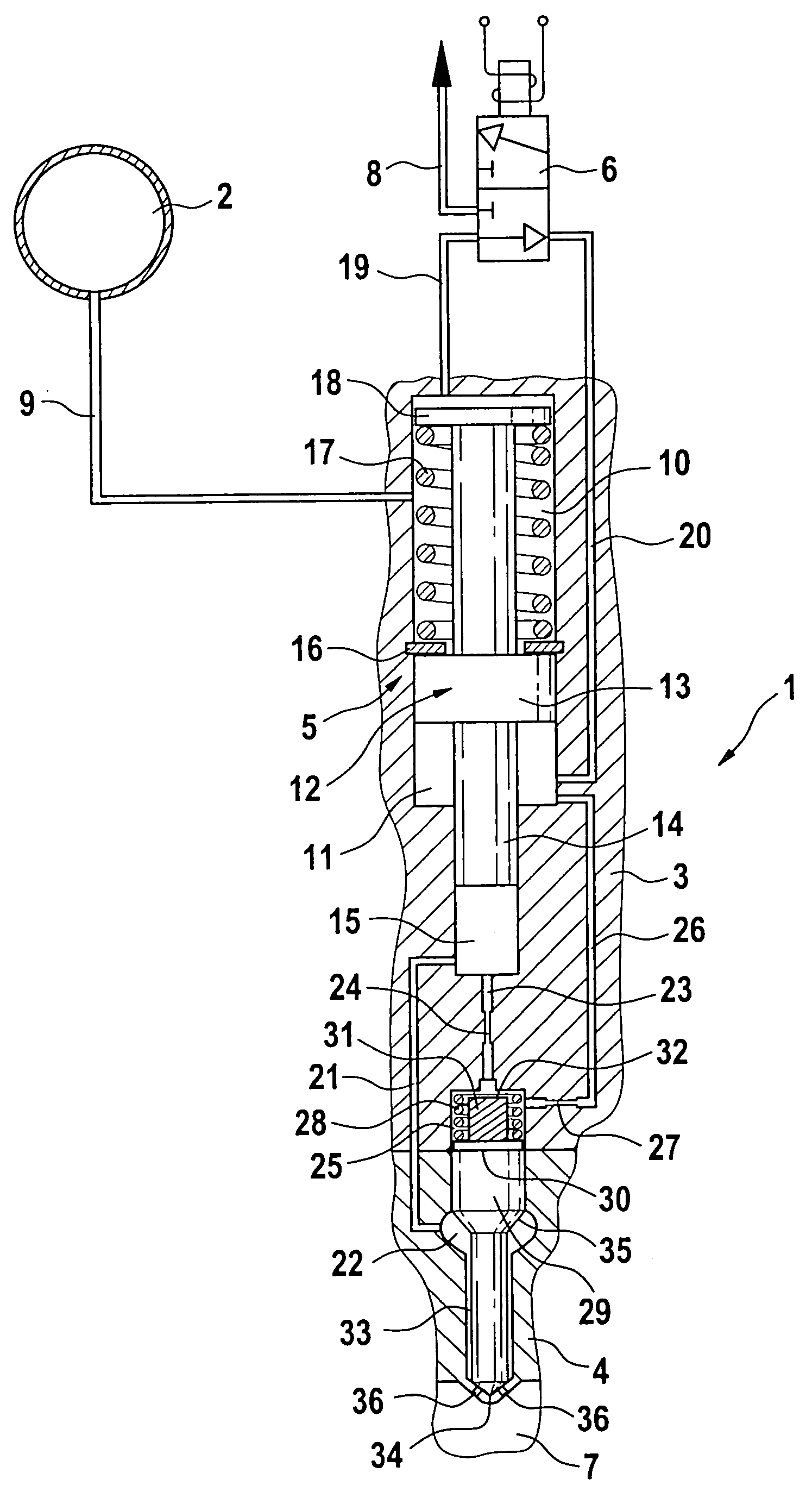

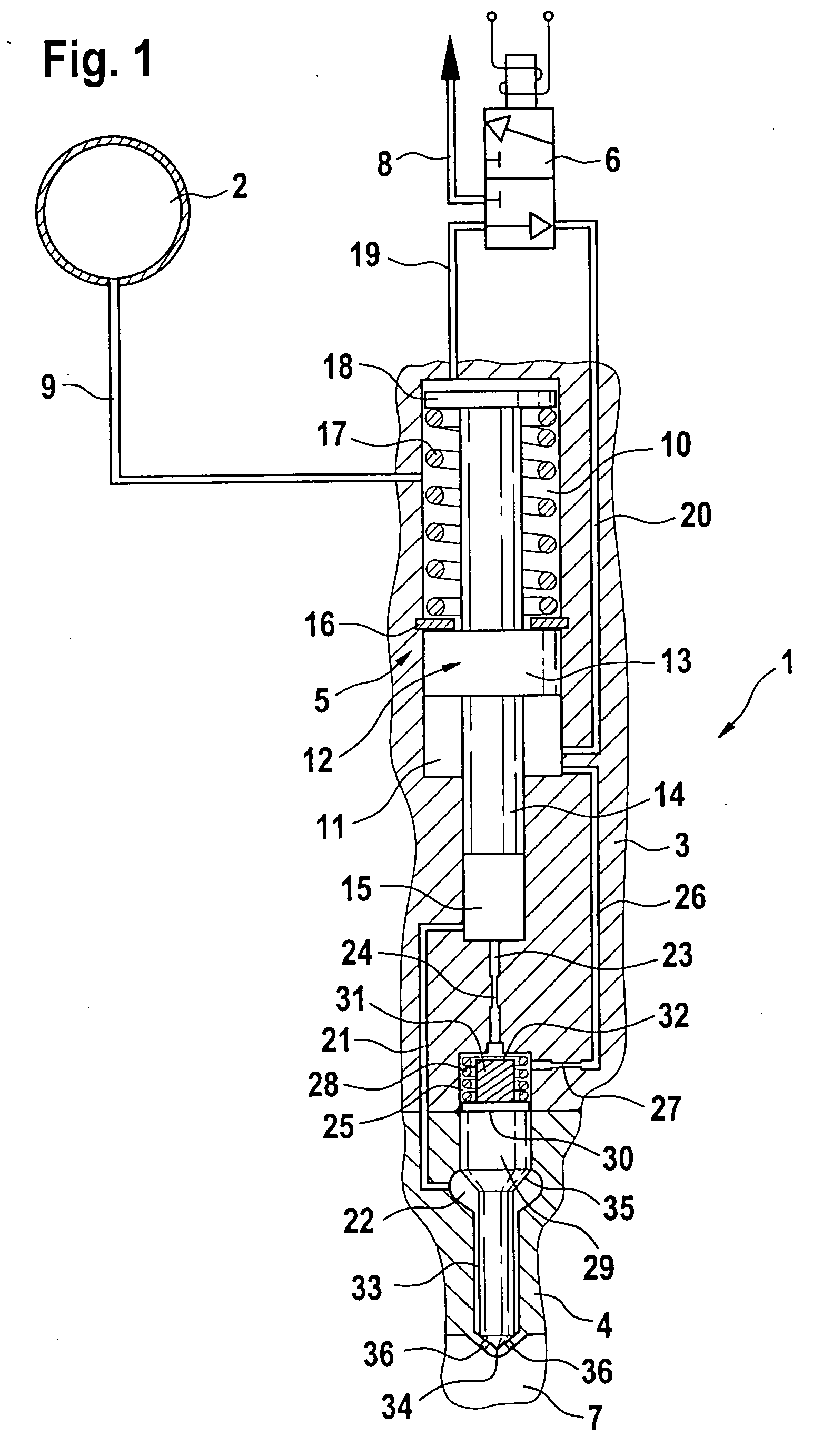

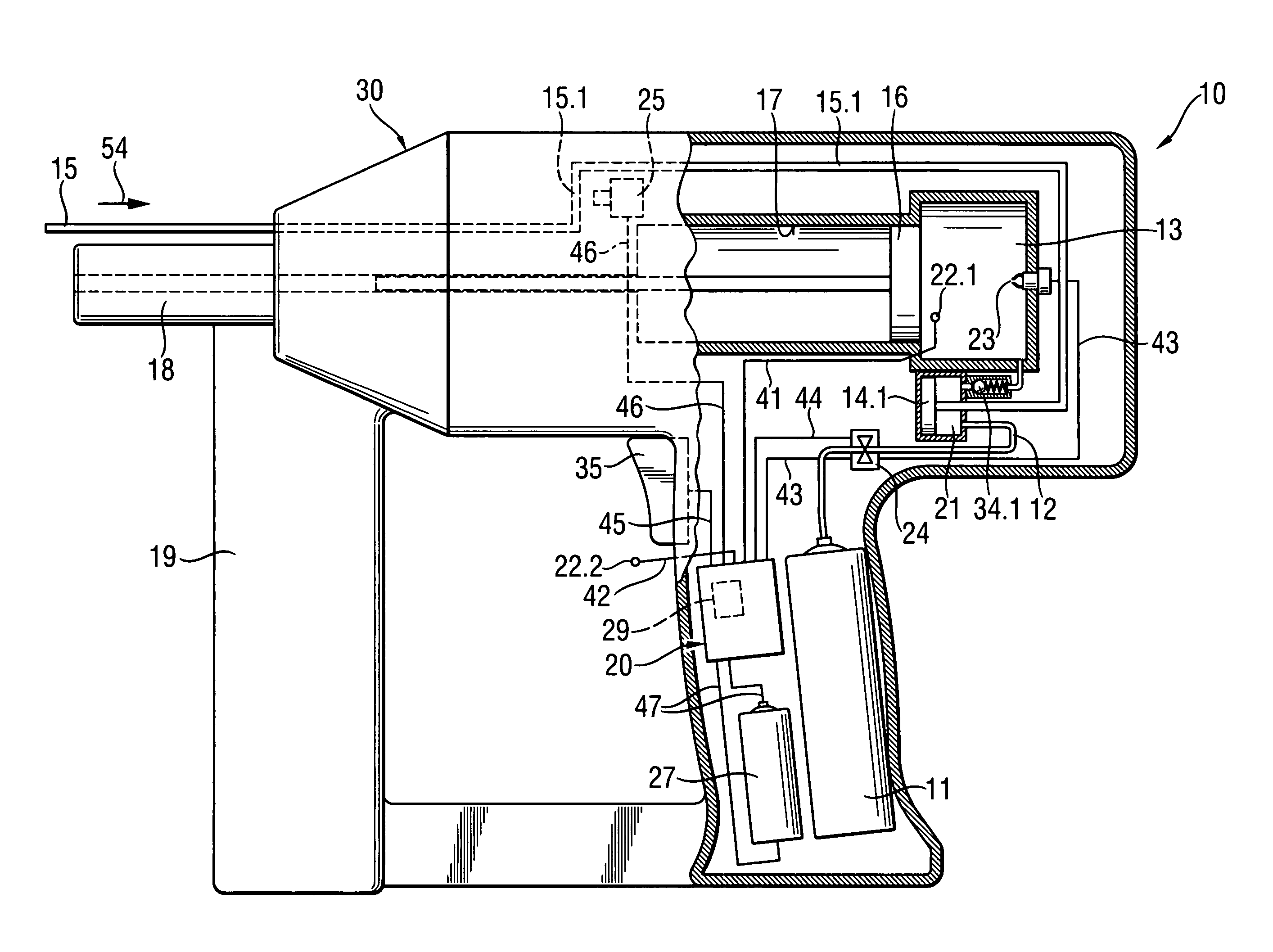

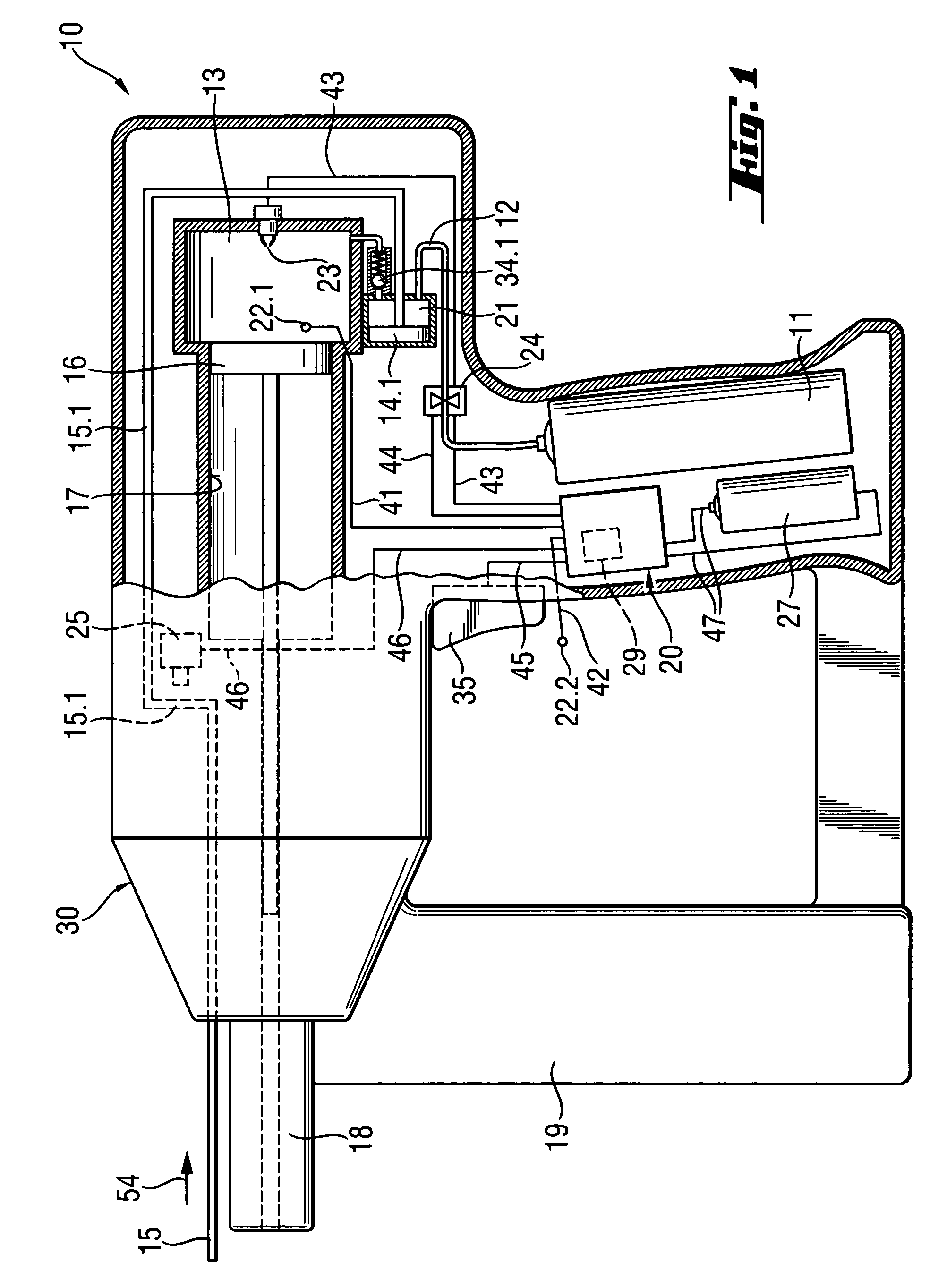

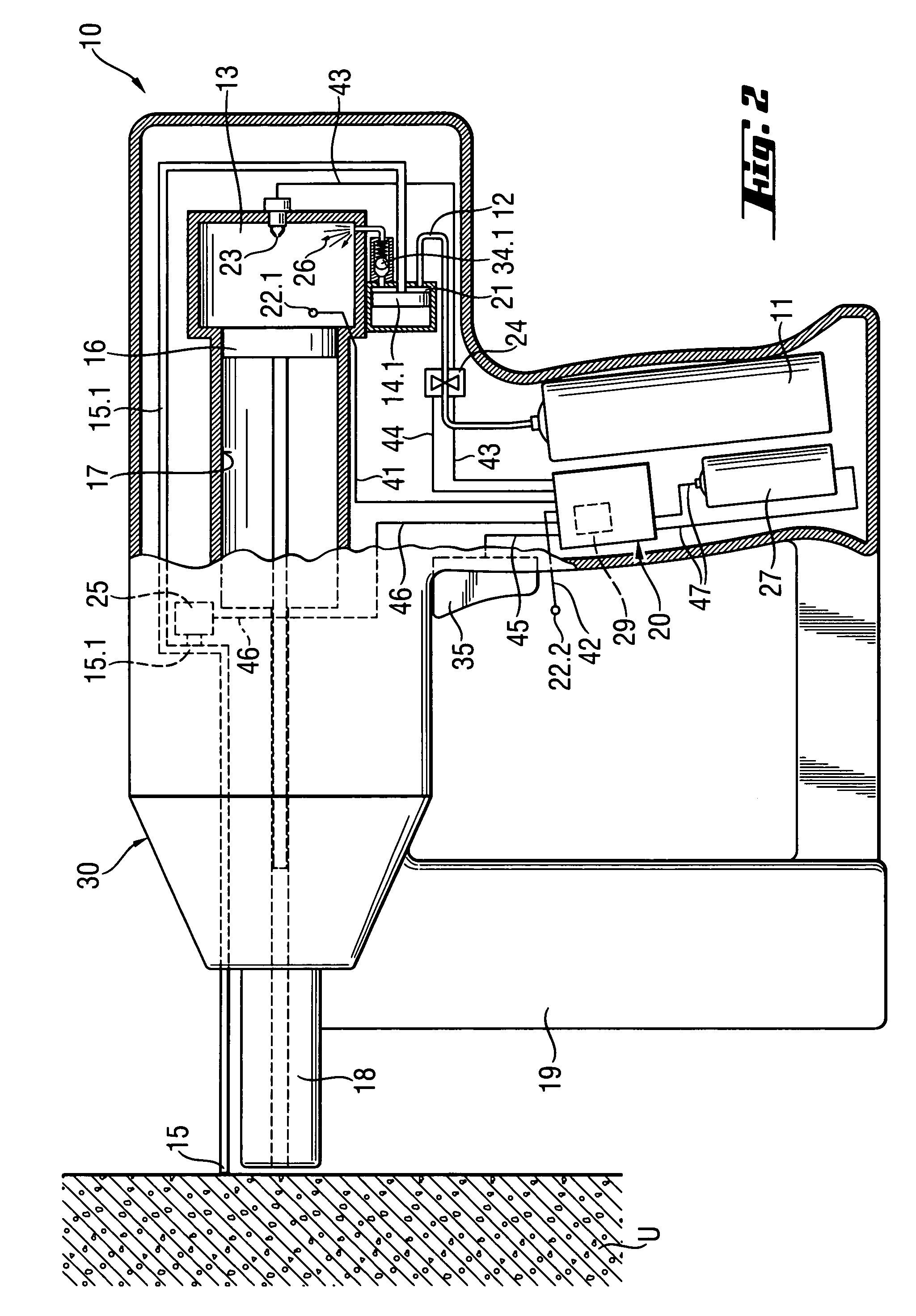

Combustion-engined setting tool

InactiveUS20050001002A1Accurate measurementIncrease productionStapling toolsNailing toolsCombustion chamberEngineering

A combustion-engined setting tool for driving fastening elements includes a fuel guide (12) connecting a fuel source (11) with a combustion chamber (13), at least one electronically controlled valve (24) arranged in the fuel guide (12) between the fuel source (11) an the combustion chamber (13), a control unit (20) for opening the electronically control valve (24) for a predetermined, by the control unit (20) time period, and a storage chamber (21) arranged between the electronically controlled valve (24) and the combustion chamber (13).

Owner:HILTI AG

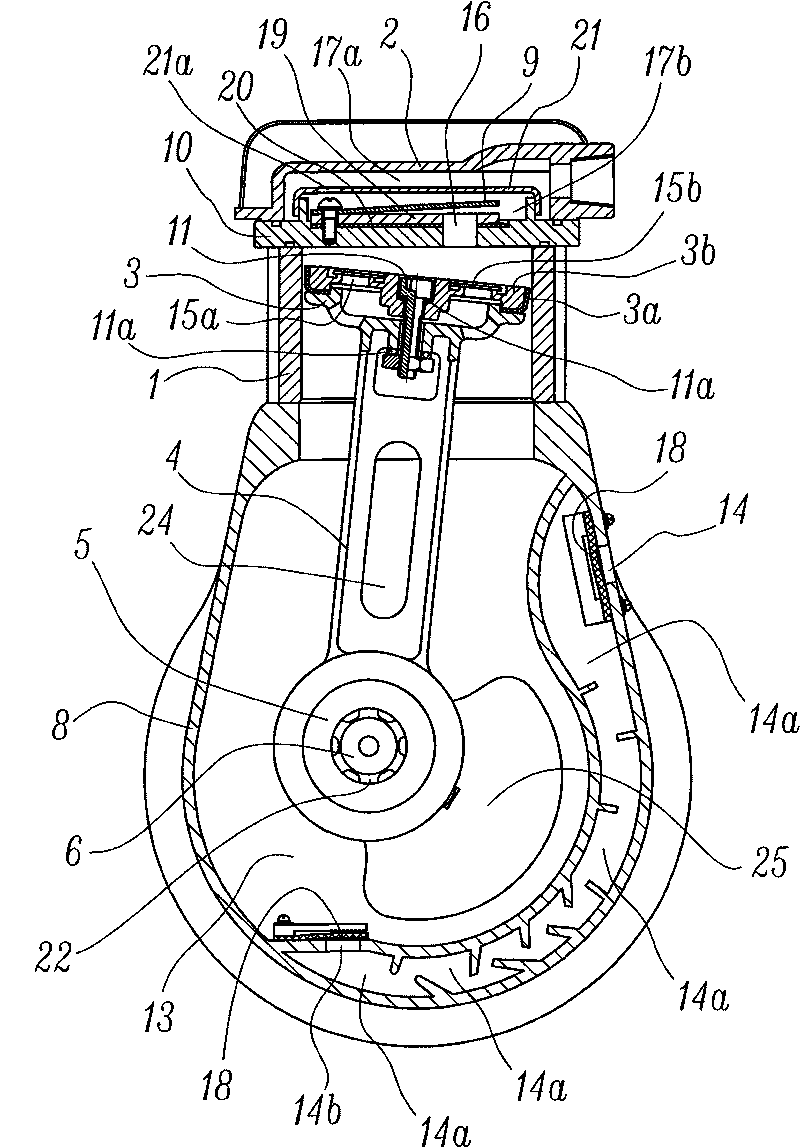

Low-noise structural oilless air compressor

InactiveCN101737296APrevent blowbackEasy to absorbPositive displacement pump componentsPiston pumpsLow noiseVibration amplitude

The invention belongs to the technical field of air compressors, and relates to a low-noise structural oilless air compressor which comprises a cylinder, a cylinder cover and a piston, wherein the piston is provided with a sealing ring or a sealing leather cup made of a self-lubricating material, a crankcase is tightly connected with a crankcase cover plate and forms a crankcase intake muffler, an air intake one-way valve is arranged at an air intake or an air intake passage of the crankcase intake muffler communicated with the outside atmosphere, a damping pad is arranged between an exhaust valve plate and a valve seat, the valve seat is connected with a silencing cap, a crank pin is made into the shape of a spline or similar to the spline, a heat insulation hole or a heat insulation slot is arranged on a connecting rod body, and a heat insulation pad is arranged at the joint of a fastening bolt and the piston or a connecting rod. The low-noise structural oilless air compressor has the advantages that the air intake noise is low, the working temperature and the mechanical noise of a bearing are low, and an auxiliary balance block is arranged on a cooling fan, thereby reducing the vibration amplitude of the compressors, and effectively reducing the body vibration noise.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

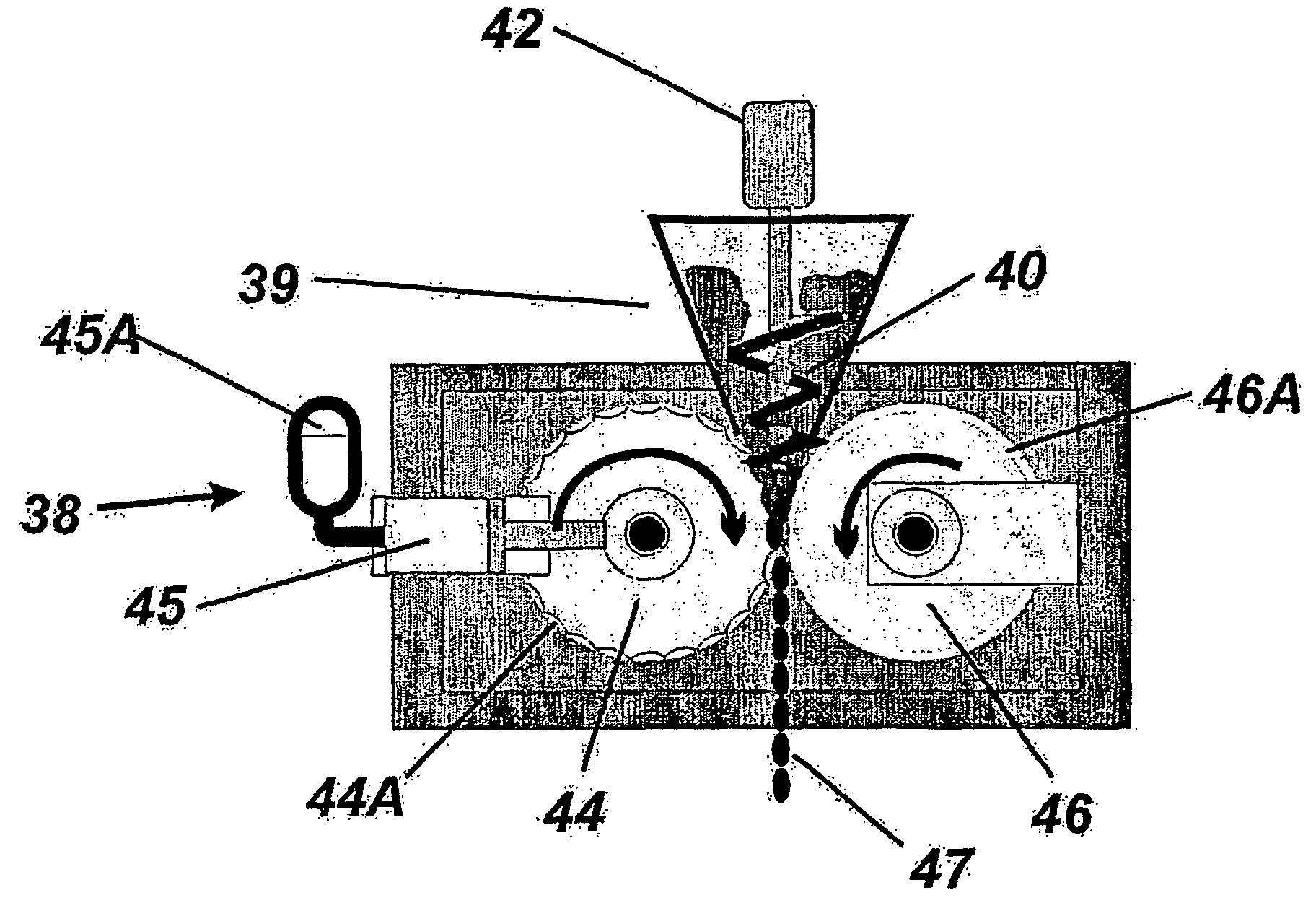

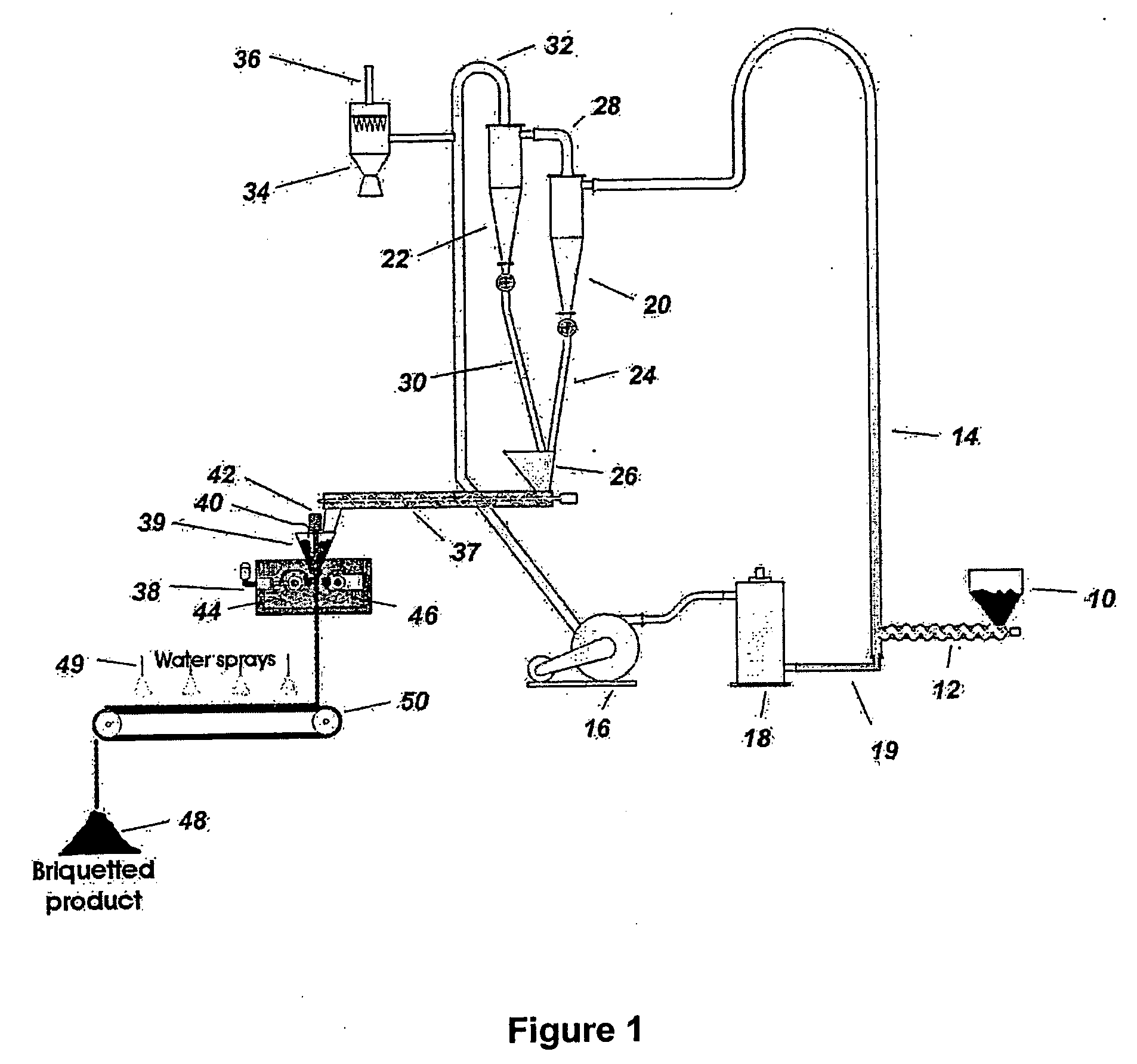

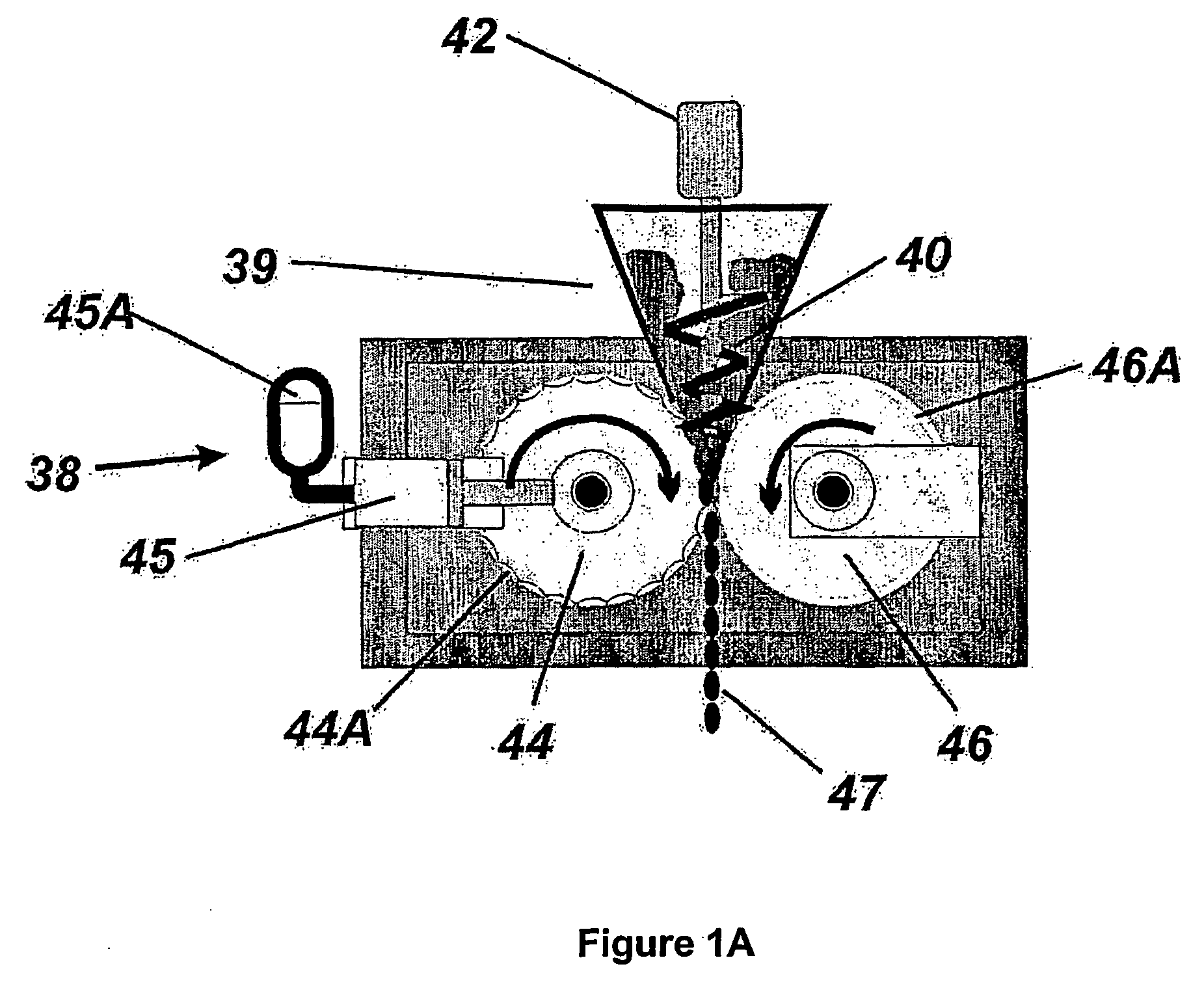

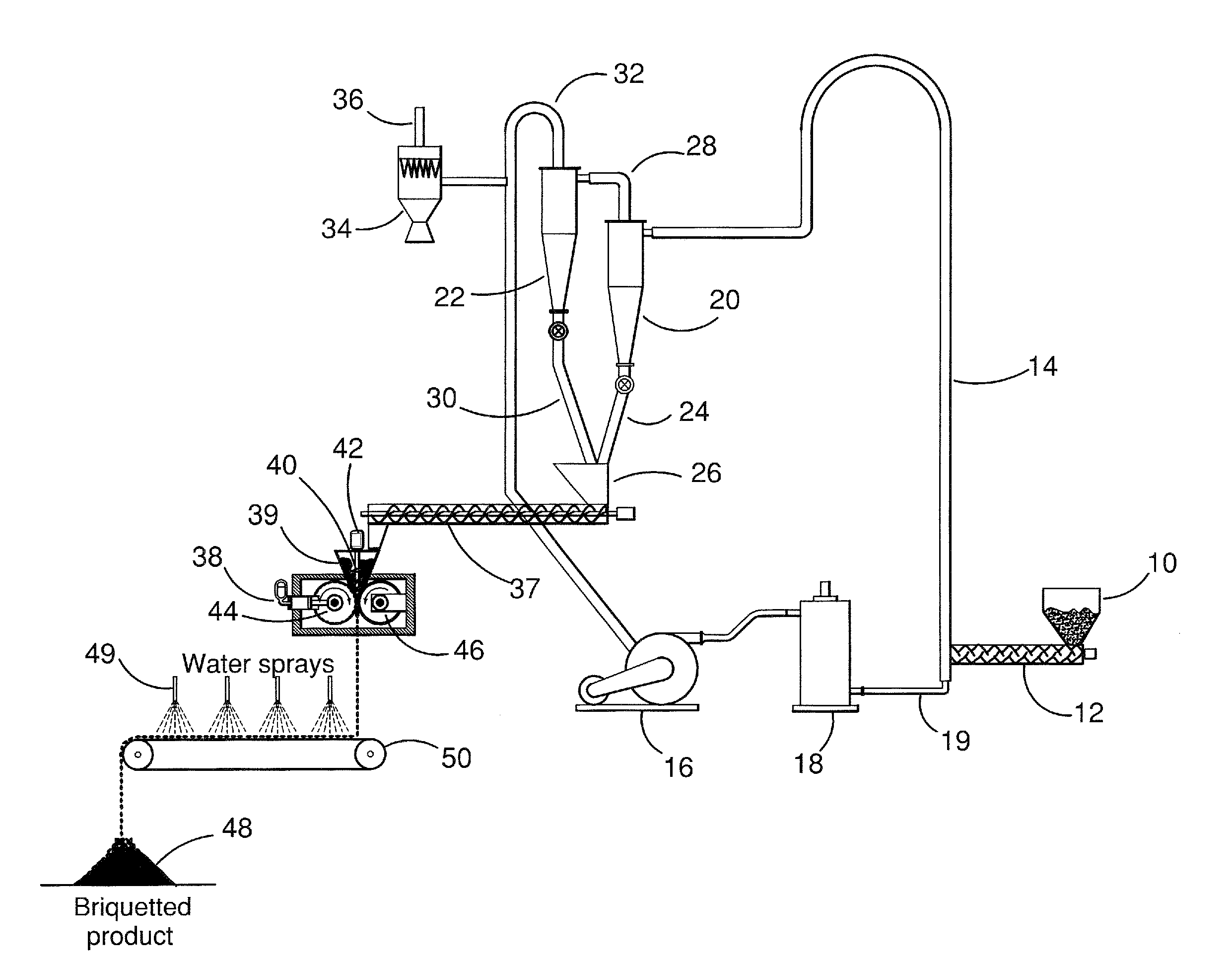

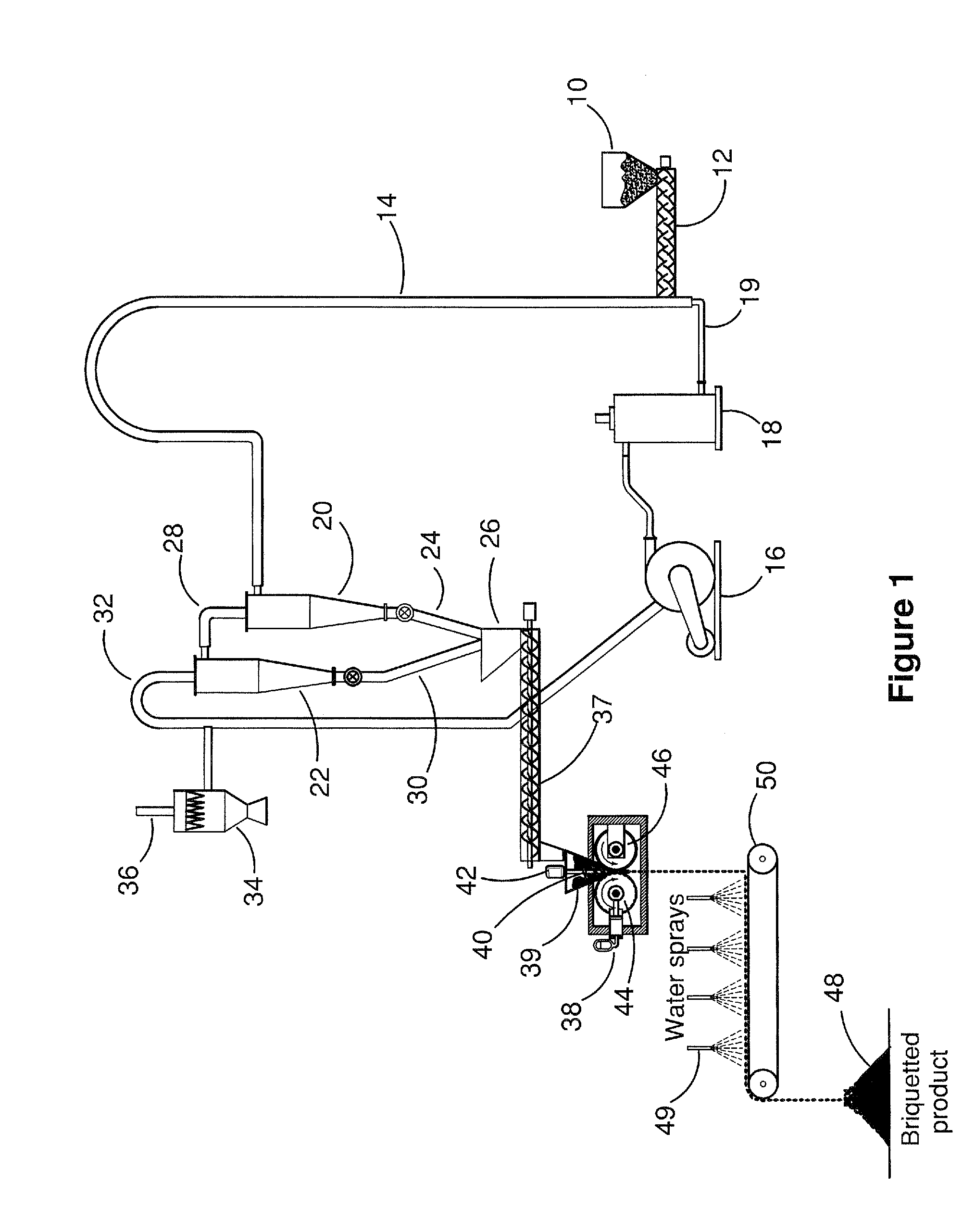

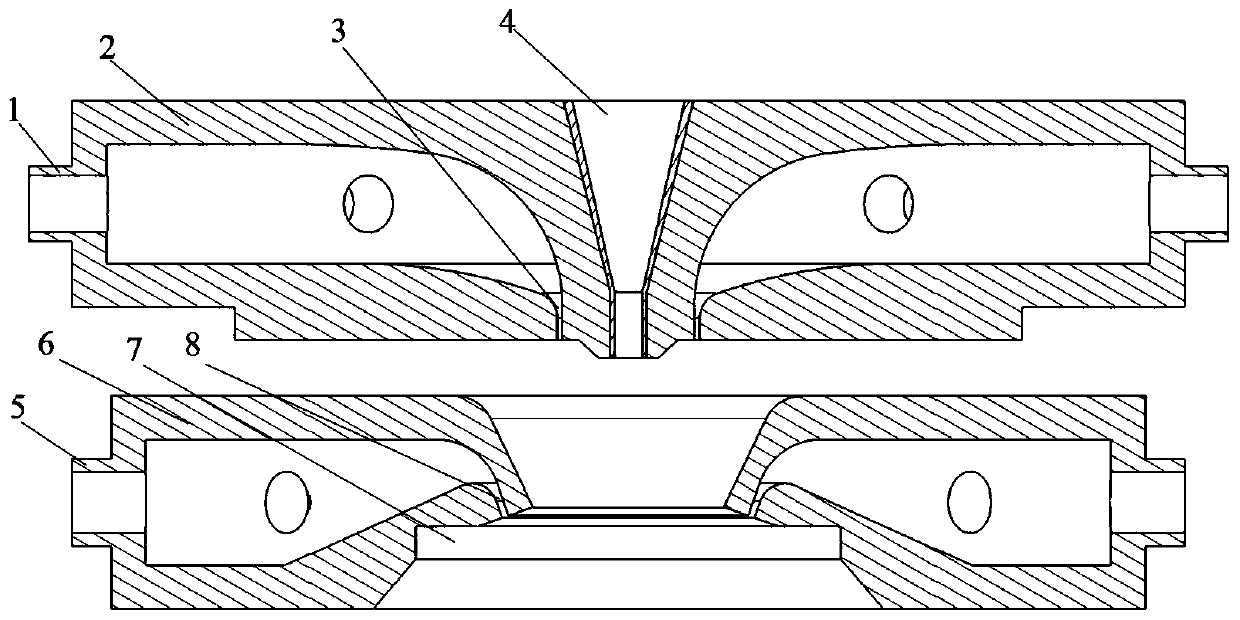

Briquetting process

ActiveUS20060112617A1Reducing pressure buildupLower the volumeConfectioneryBiofuelsParticulatesWater vapor

A process and system is provided for briquetting particulate matter such as moisture-containing bituminous and sub-bituminous coal. This process includes partially drying the particulate matter and feeding, the partially dried particulate matter to a briquetting apparatus under conditions such that water vapour is released from the particulate matter during feeding. The particulate matter is passed through briquette forming rollers to form briquettes. The released water vapour substantially displaces or prevents the ingress of a large proportion of other gaseous components from the atmosphere surrounding an / or intermixed with the particulate matter. The particulate matter that is fed to the briquetting apparatus is surrounded by and intermixed with a gaseous component containing 70 to 100% by volume of water vapour at the point where it enters the briquette-forming part of the briquetting apparatus, such that when the particulate matter is compressed during briquette formation, the water vapour liquefies and the pressure buildup of gaseous material in the thus-formed briquettes is minimised. This reduction in the pressure buildup of gaseous components also acts to reduce blow-back of gases as the coal fines are being formed into briquettes.

Owner:K R KOMAREK +3

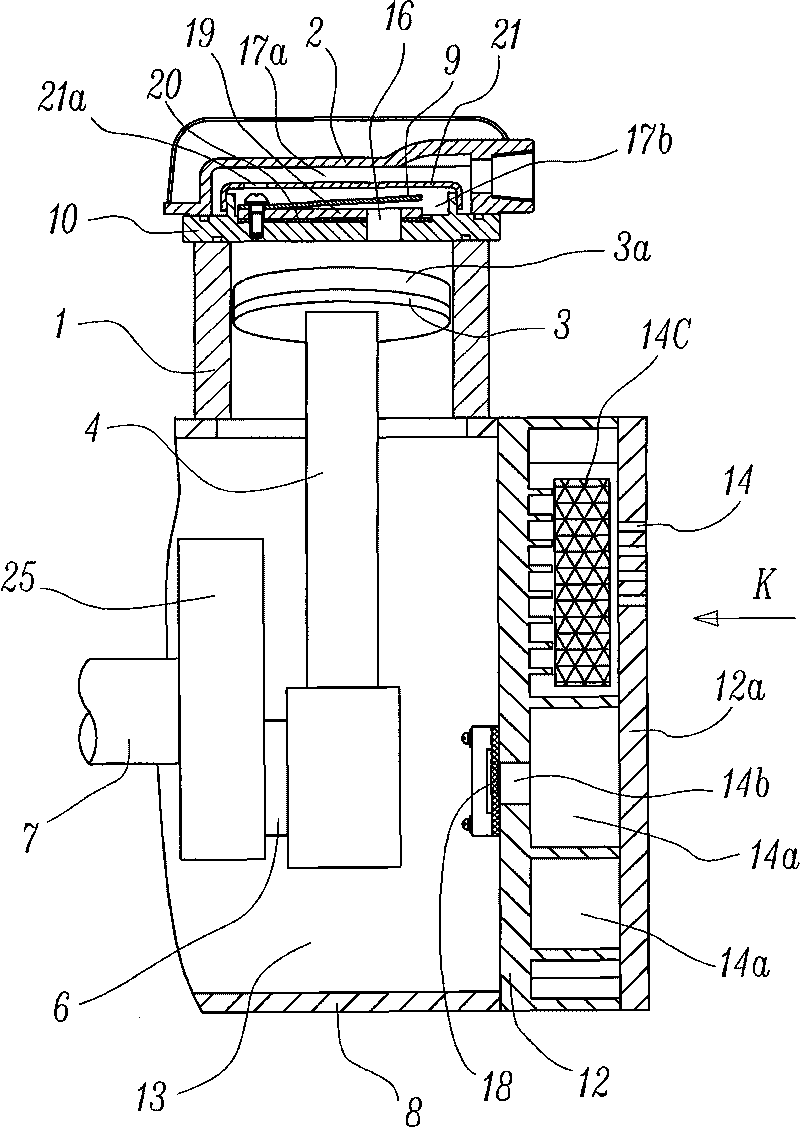

Device for damping the needle lift in fuel injectors

InactiveUS20050077378A1Quick closeRaise emission levelsMachines/enginesFuel injecting pumpsCombustion chamberPiston

A fuel injection apparatus for injecting fuel into the combustion chambers of an internal combustion engine includes a high pressure accumulator, a pressure booster, and a metering valve. The pressure booster includes a working chamber and a control chamber that are separated from each other by an axially movable piston. A pressure change in the control chamber produces a pressure change in a compression chamber that acts on a nozzle chamber via a fuel inlet. The nozzle chamber encampasses a nozzle needle. A nozzle spring chamber that acts on the injection valve element can be filled on the high-pressure side via a line that leads from the compression chamber and contains an inlet throttle restriction. On the outlet side, the nozzle spring chamber is connected to a chamber of the pressure booster via a line that contains an outlet throttle restriction.

Owner:ROBERT BOSCH GMBH

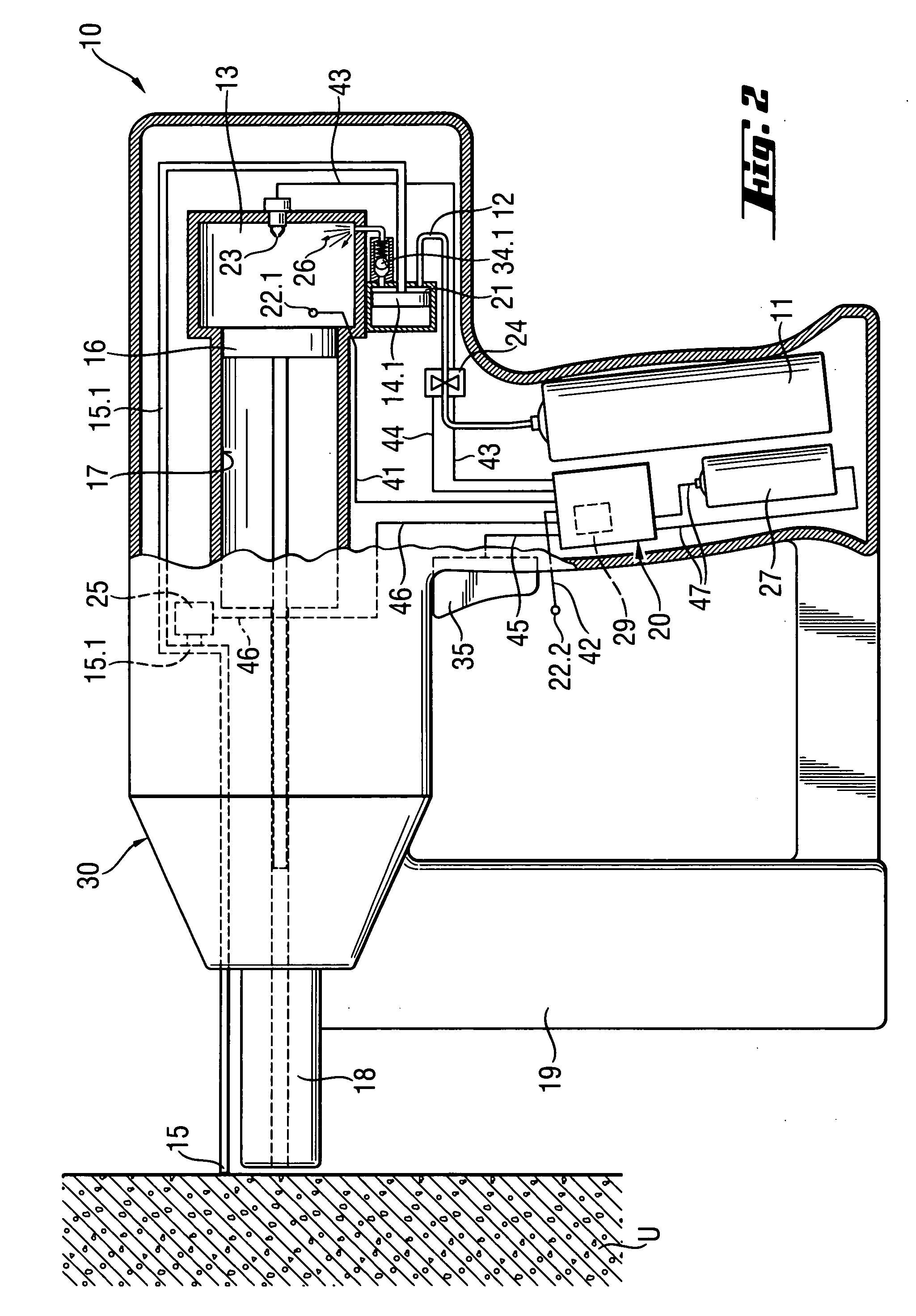

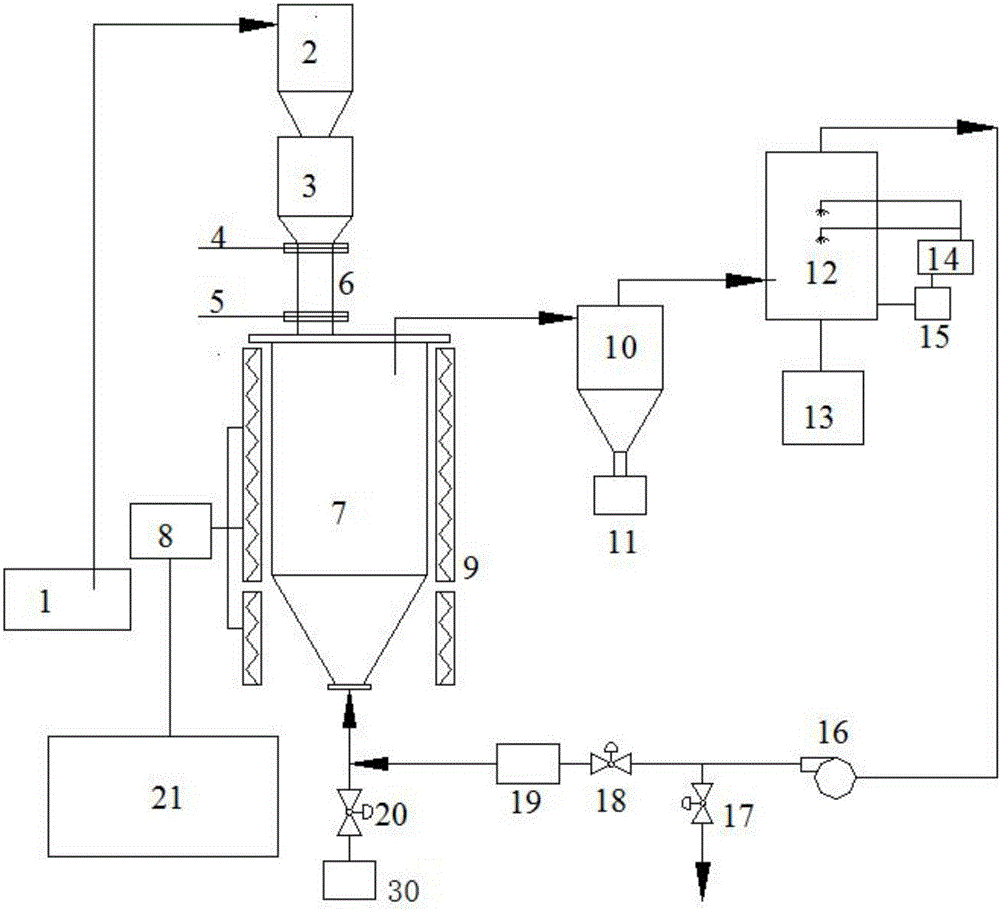

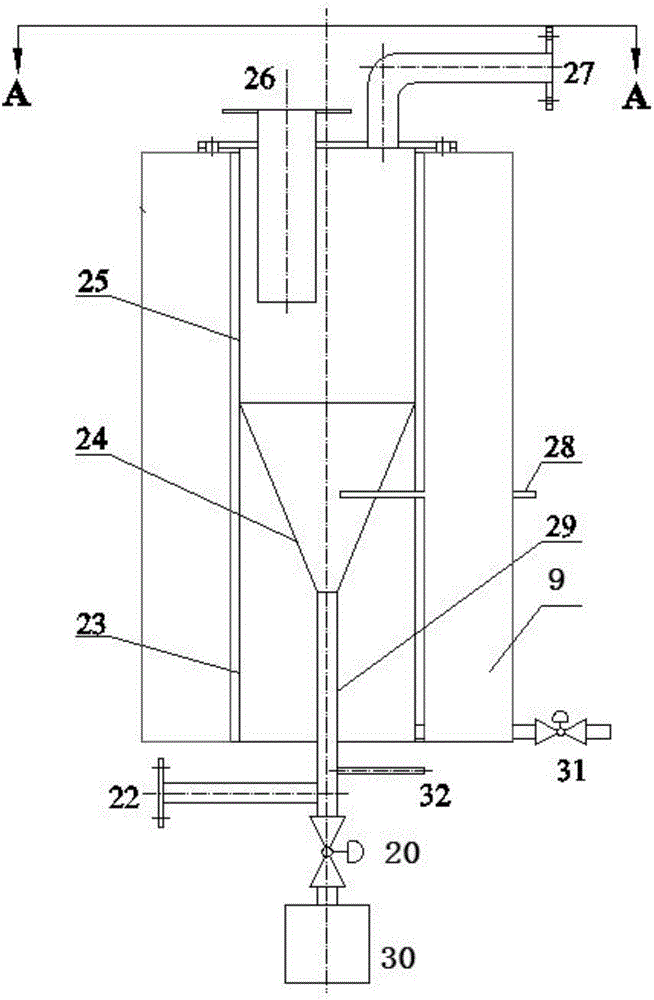

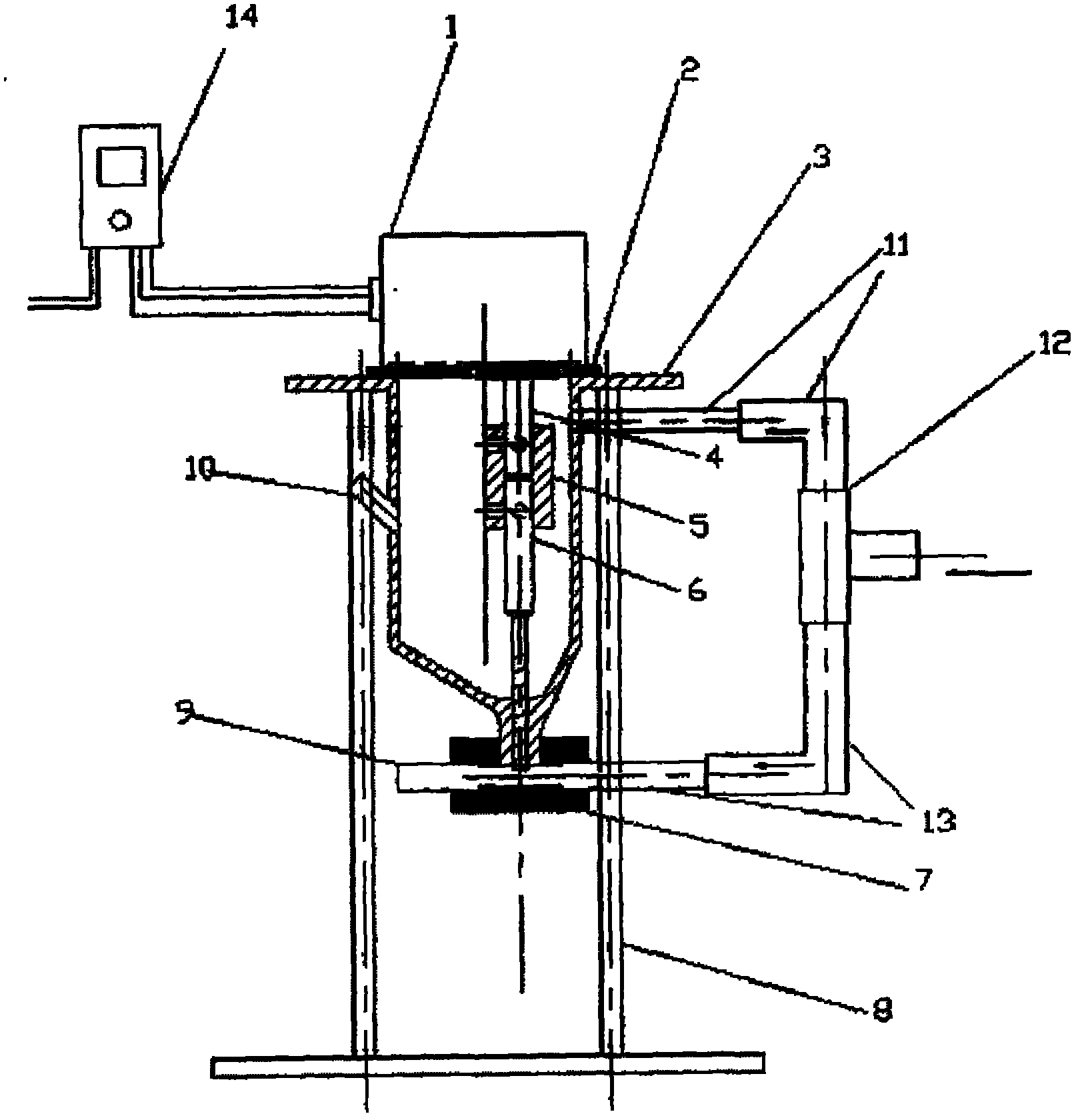

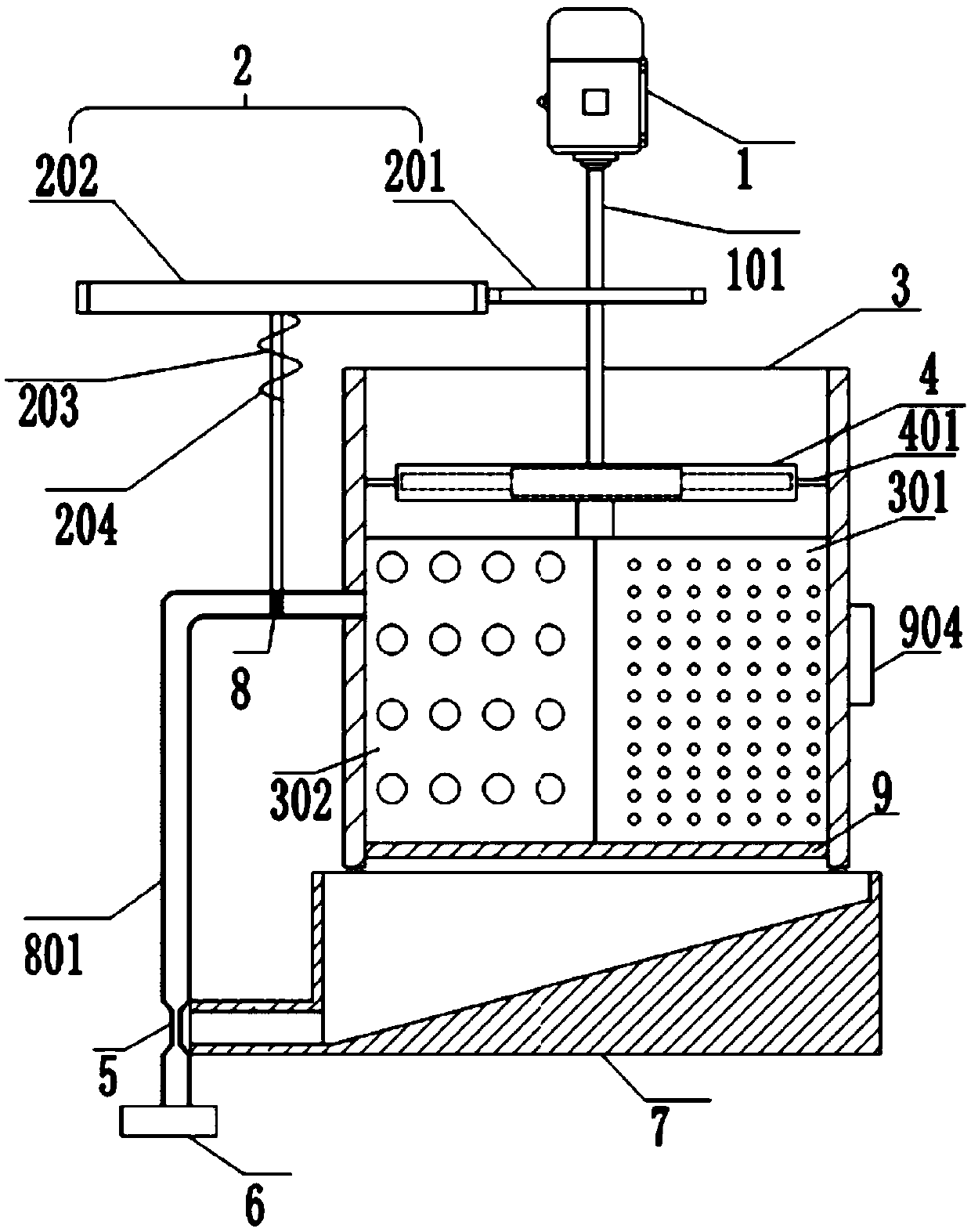

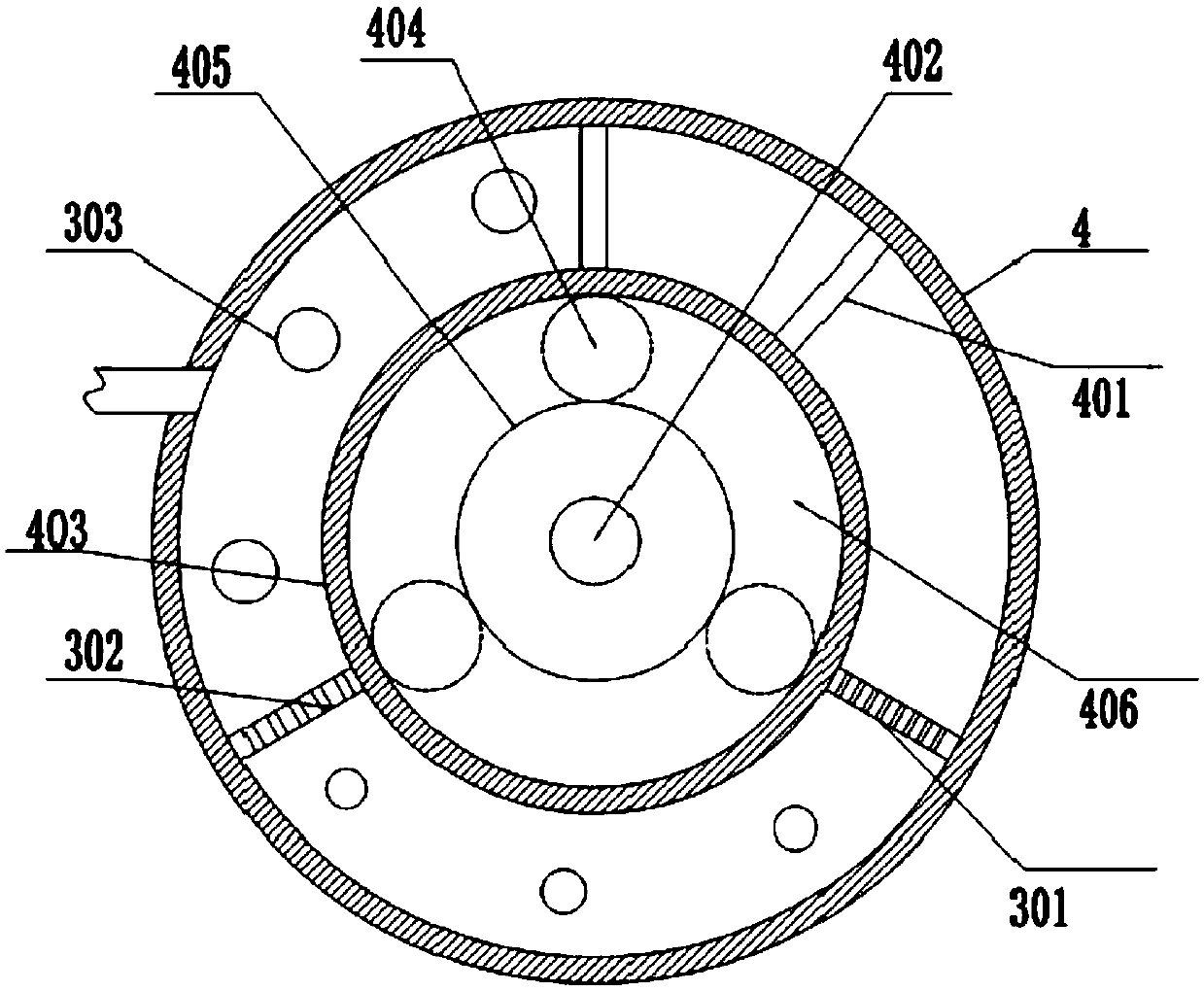

System for preparing activated carbon or bio-oil by fast activation or fast pyrolysis of biomass

ActiveCN106336885APrevent blowbackAchieve preactivationCarbon compoundsBiofuelsActivated carbonControl system

The invention relates to a system for preparing activated carbon or bio-oil by fast activation or fast pyrolysis of biomass. The system comprises a feeding system, a pyrolysis reactor and a heating device thereof, an activated carbon / biochar collecting system, a spraying condensation system, a fluidization gas circulation system and a control system which are connected in sequence. The feeding system comprises a vacuum material-sucking machine, a weighing device and a material storage tank which are communicated with each other in sequence. The activated carbon / biochar collecting system comprises a cyclone separator and a carbon collecting box. A discharging outlet of the pyrolysis reactor is connected with a feeding port of the cyclone separator. The spraying condensation system comprises a spraying condenser, a heat exchanger and a circulating pump. An outlet of the cyclone separator is connected with an air inlet of the spraying condenser, and the fluidization gas circulation system comprises a circulating fan, a control valve and a flowmeter. The system for preparing activated carbon or bio-oil by fast activation or fast pyrolysis of biomass can be applied to fast activation of biomass to prepare the activated carbon, and the activated carbon with a high specific surface area is prepared; the system for preparing activated carbon or bio-oil by fast activation or fast pyrolysis of biomass can also be used for fast pyrolysis of the biomass to prepare the bio-oil, and the production cost is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

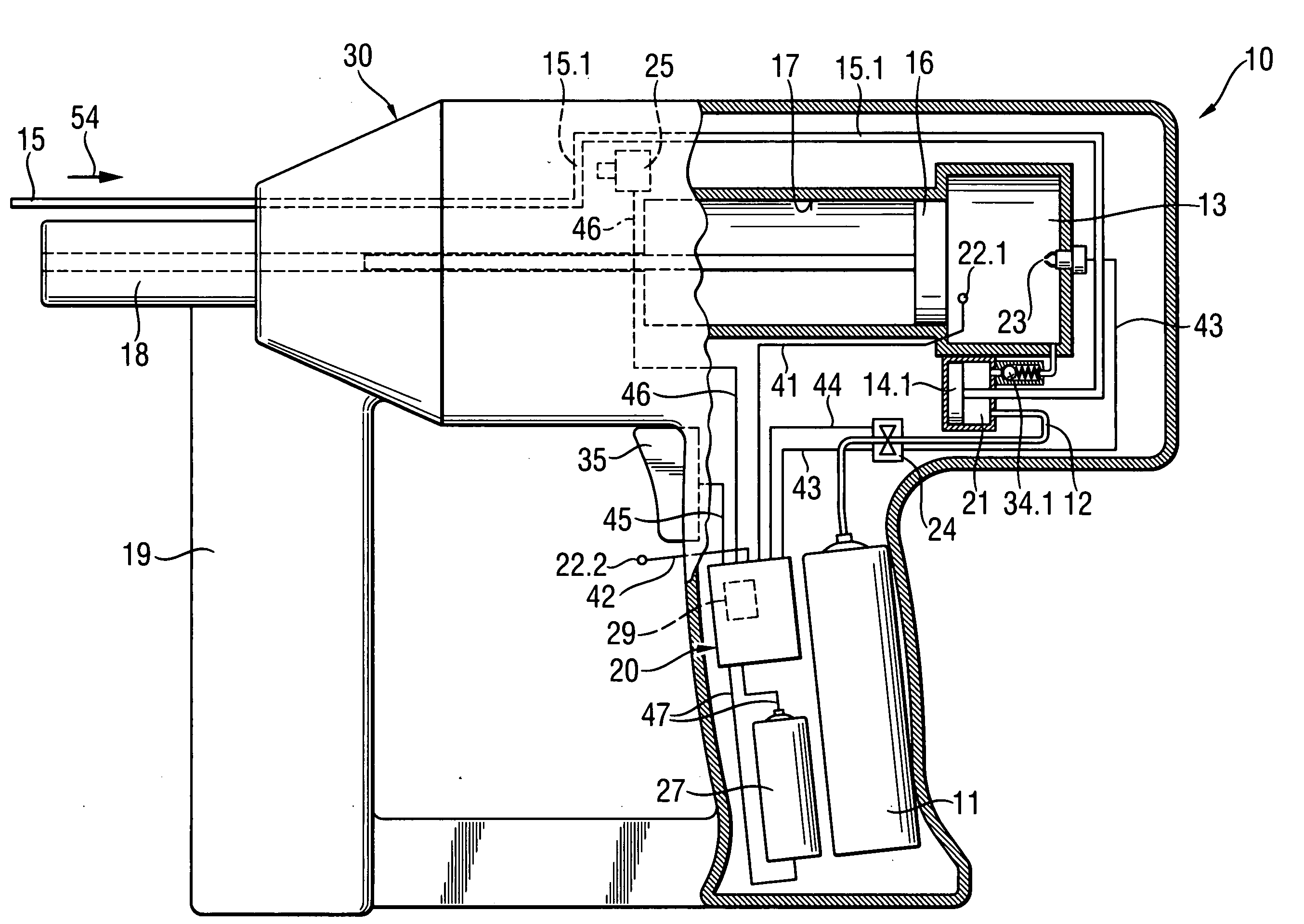

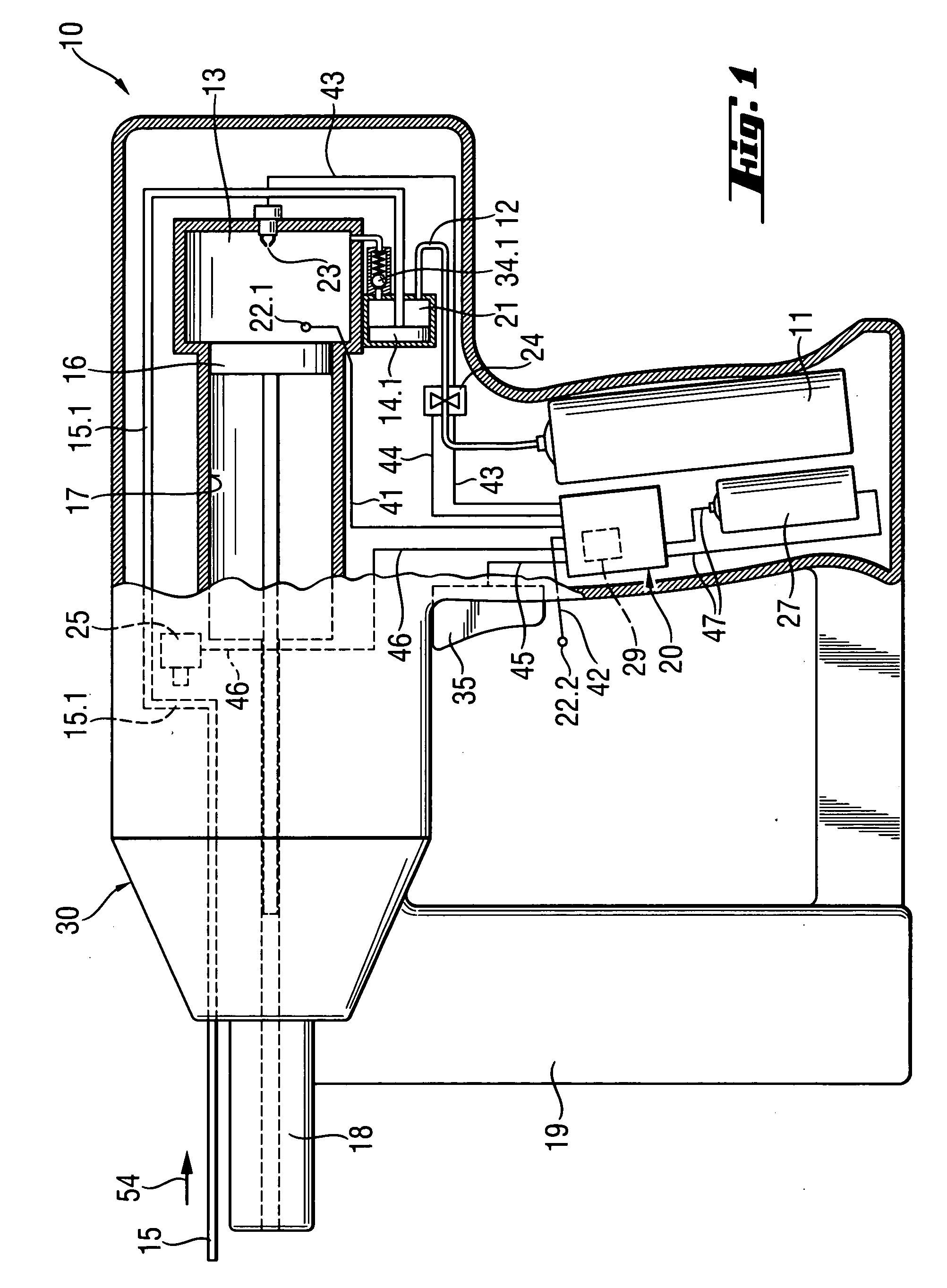

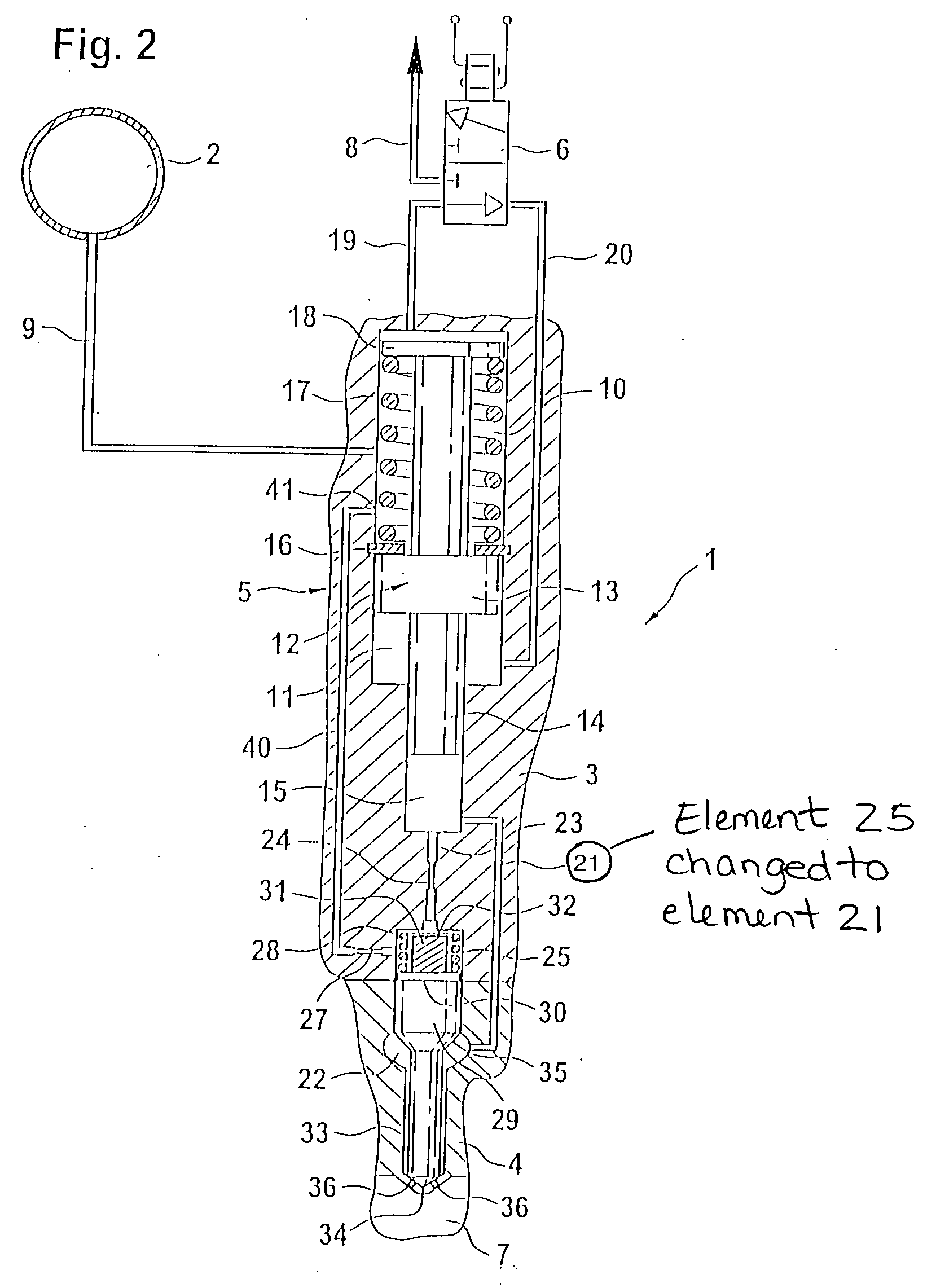

Combustion-engined setting tool

InactiveUS6974063B2Accurate measurementIncrease productionStapling toolsNailing toolsCombustion chamberNuclear engineering

The present invention relates to a combustion-engined setting tool for driving fastening elements, such as nails, bolts, pins in a constructional component, with a fuel guide (12) extending from a fuel source (11) to a combustion chamber (13) and with at least on electronically controlled valve (24) which is arranged in the fuel guide (12) between the fuel source (11) and the combustion chamber (13), and with a control unit (20), including at least one actuation means (25) with which the valve (24) is opened for a predetermined time period. For improving, it is proposed to arranged in the fuel guide (12) a storage chamber (21) between the electronically controlled valve (24) and the combustion chamber (13). The storage chamber becomes filled with fuel through the electronically controlled valve already before the setting tool is pressed against a constructional component, enabling rapid, following one after another, setting processes.

Owner:HILTI AG

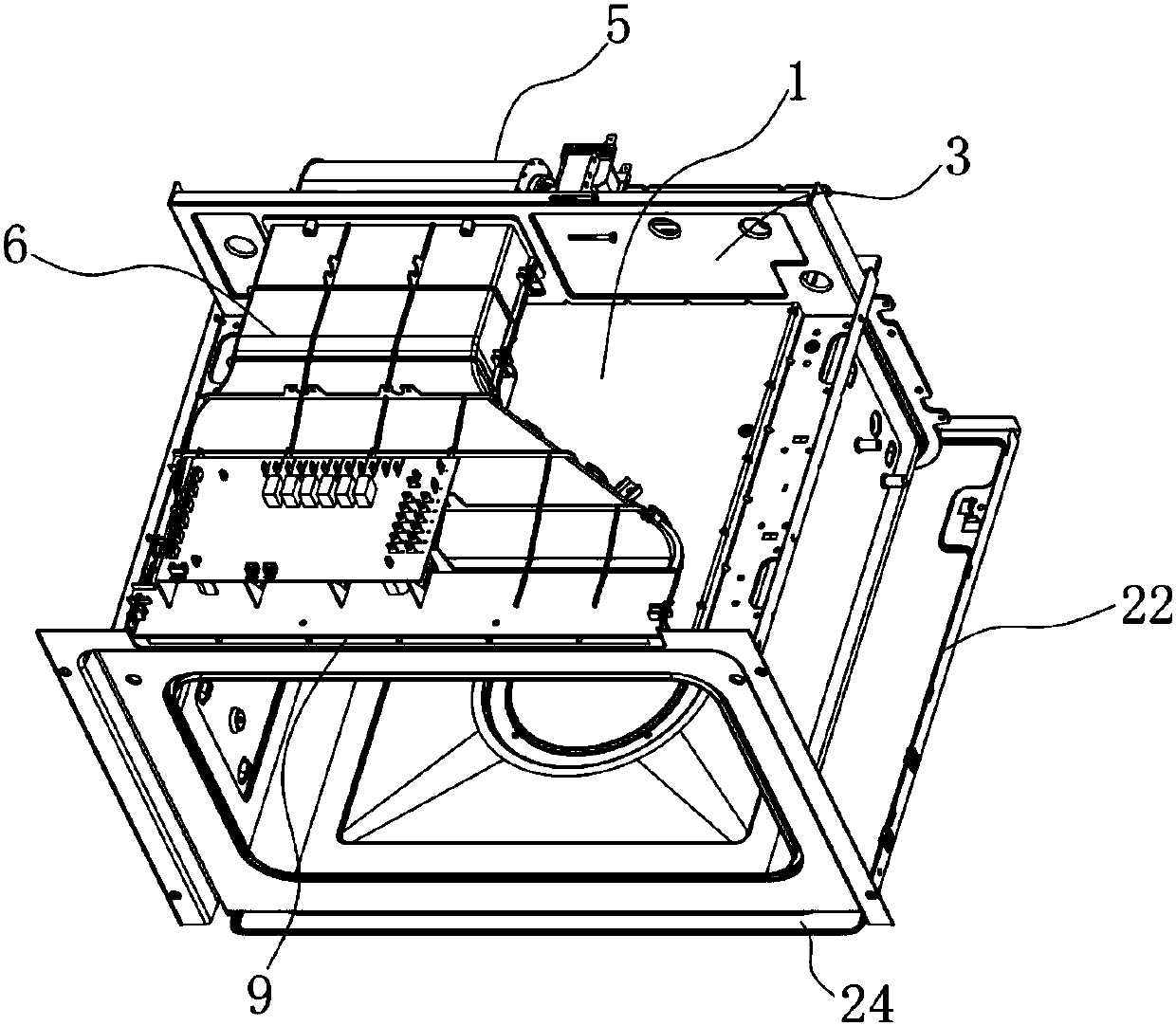

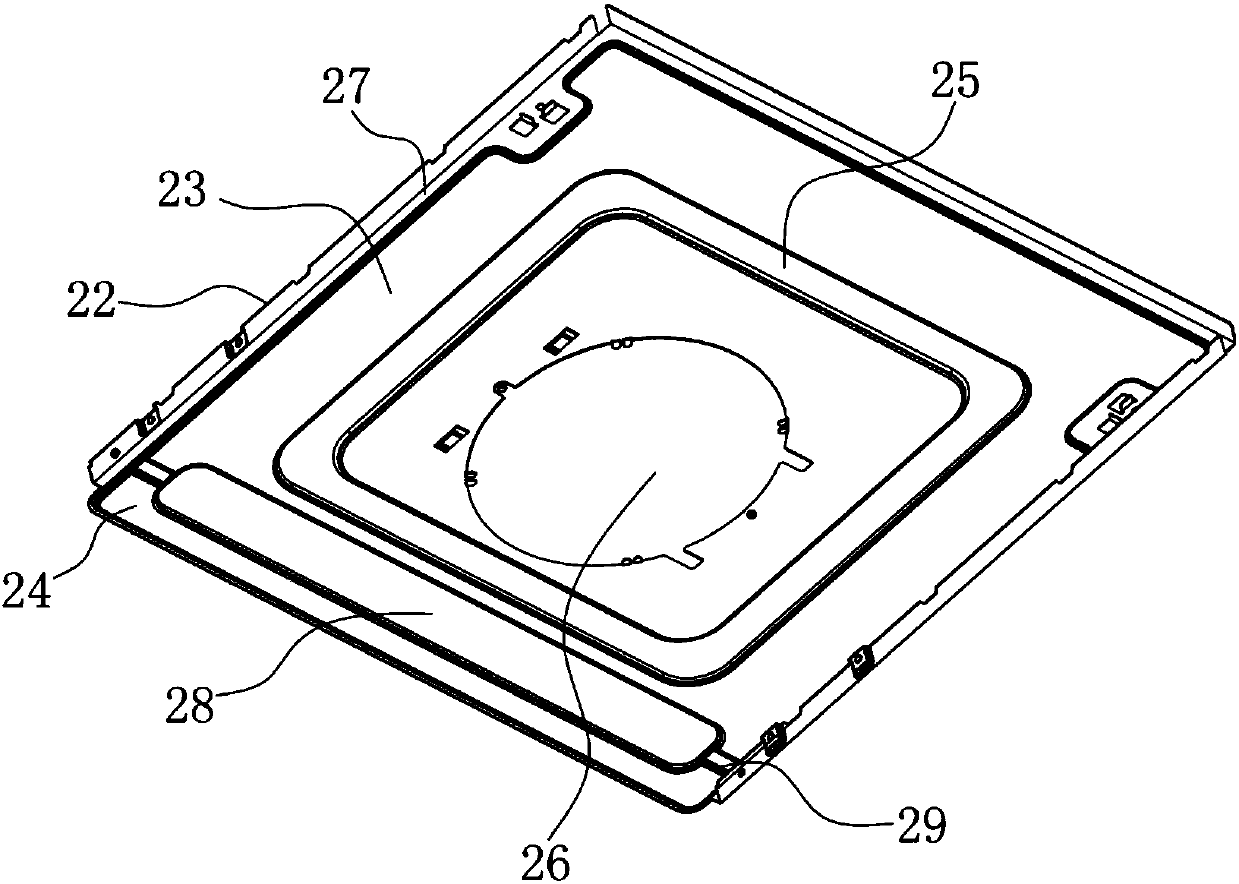

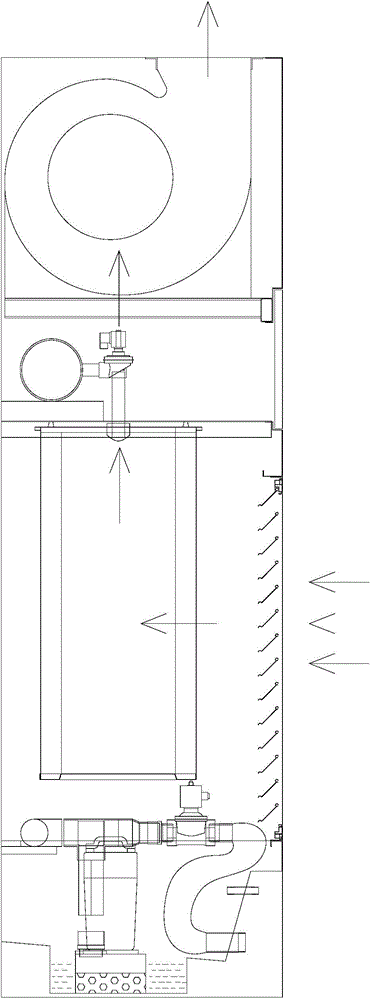

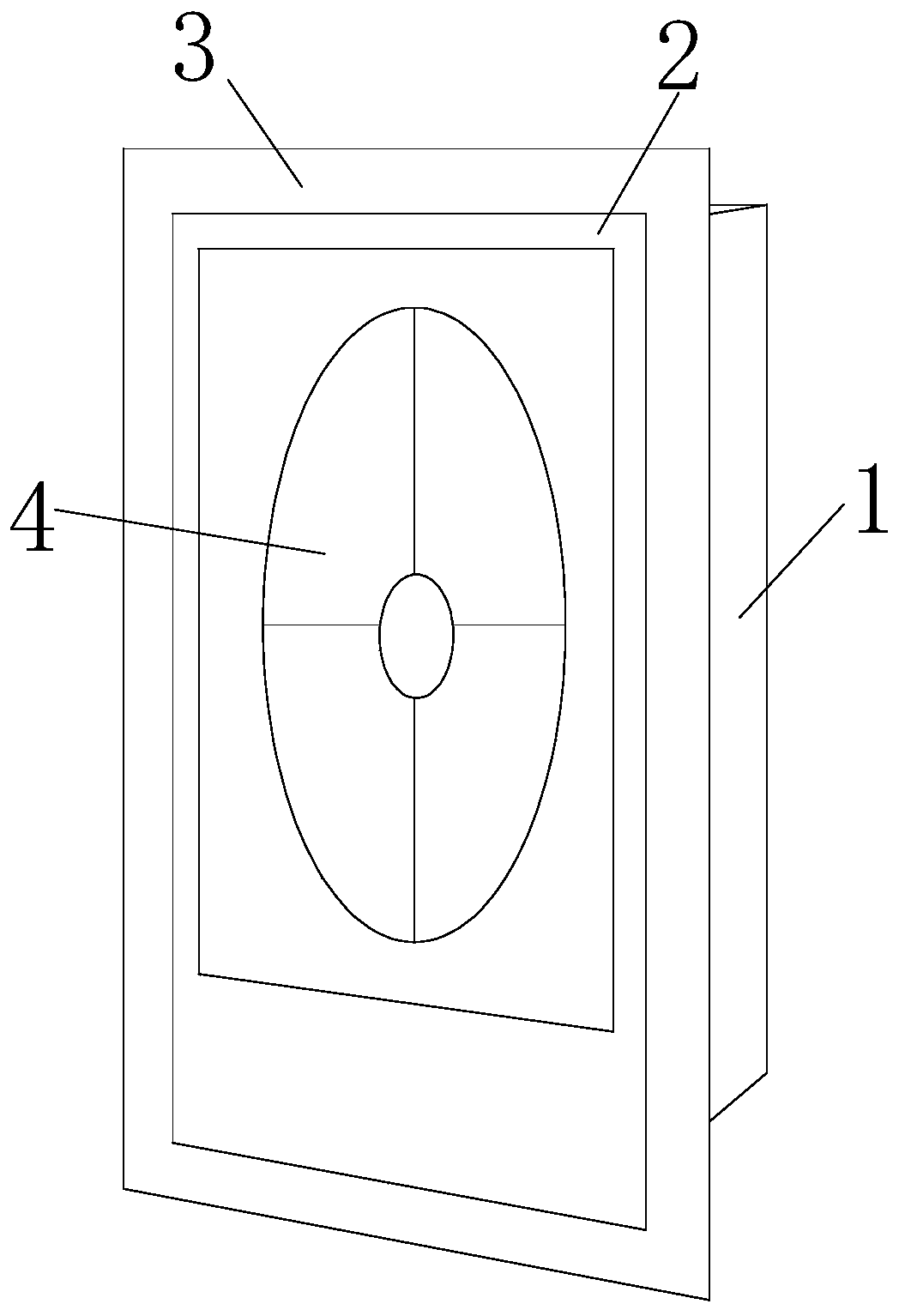

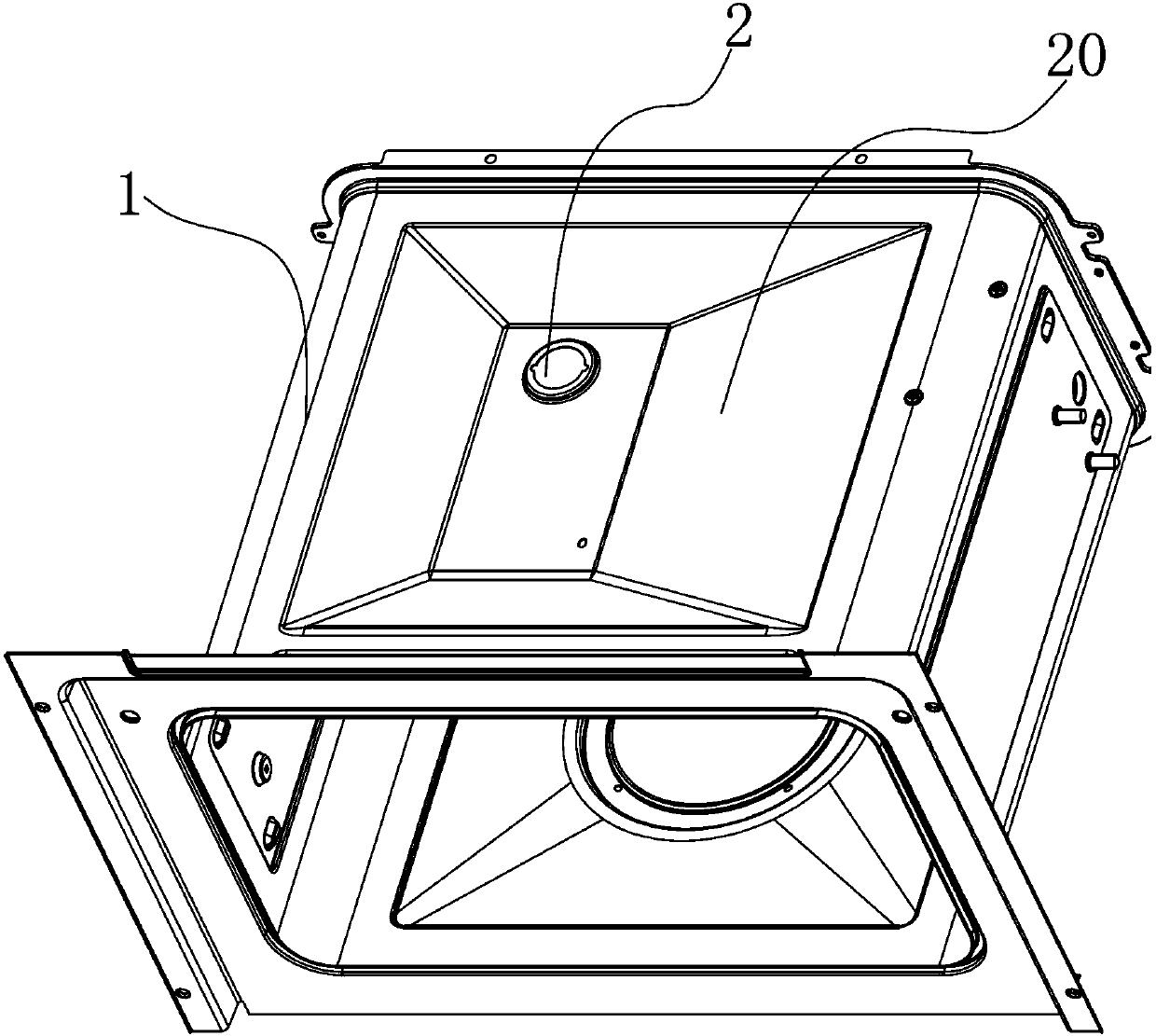

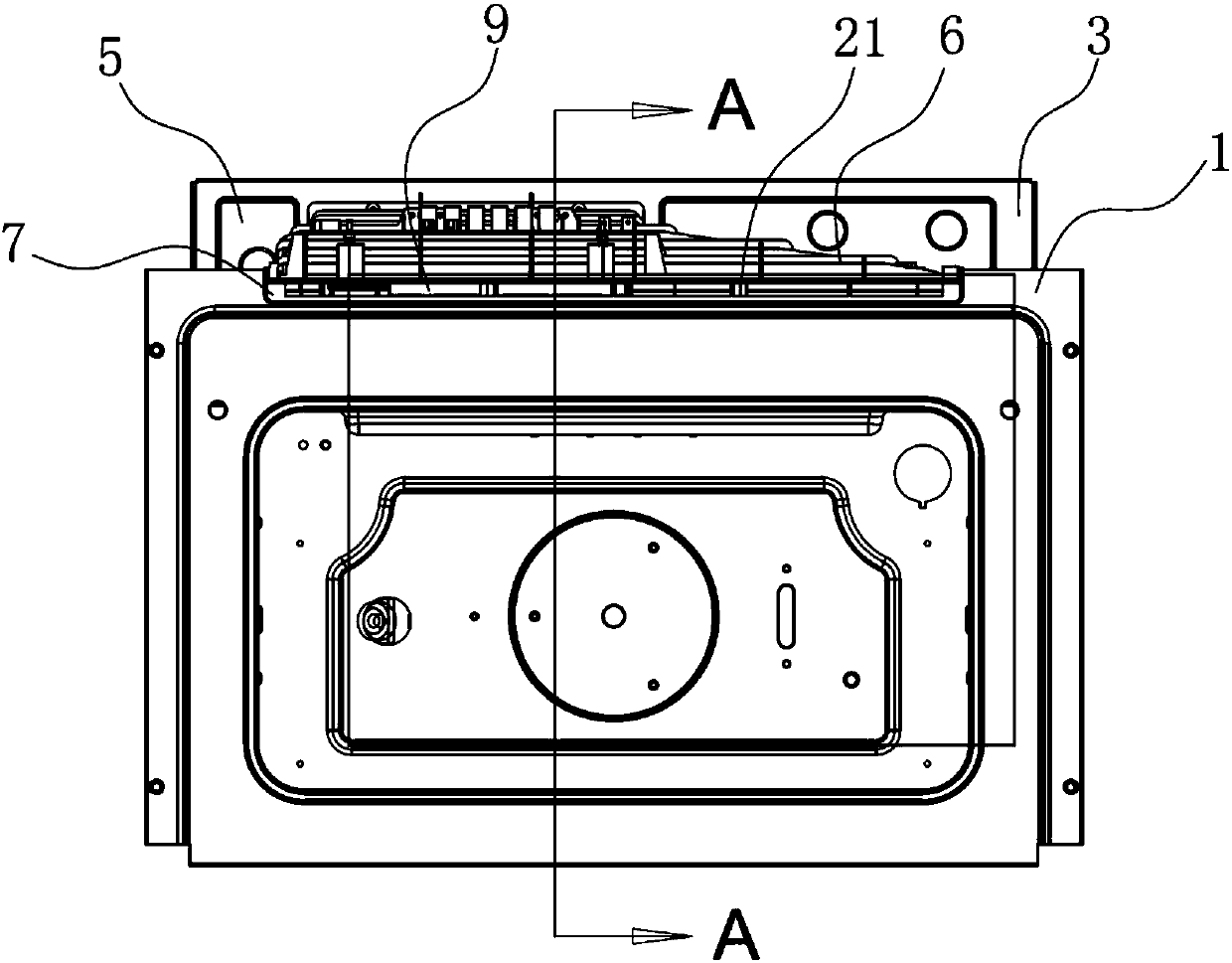

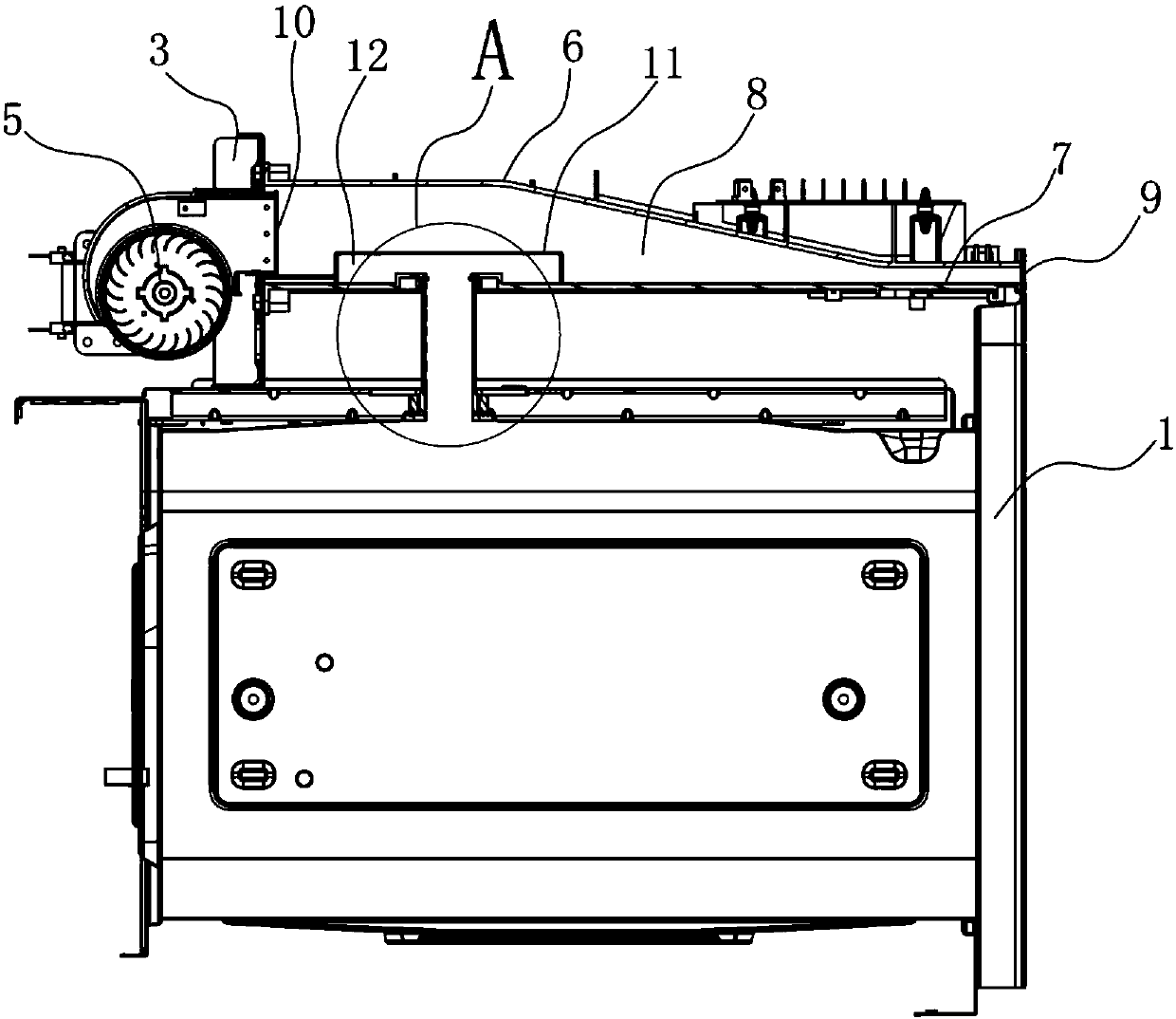

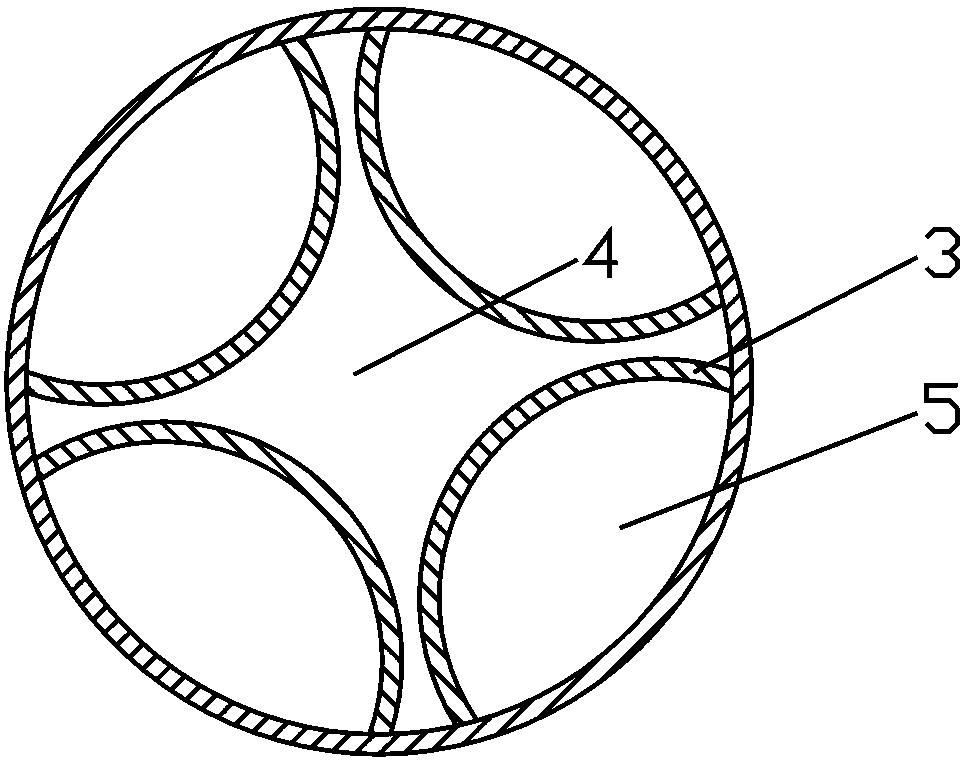

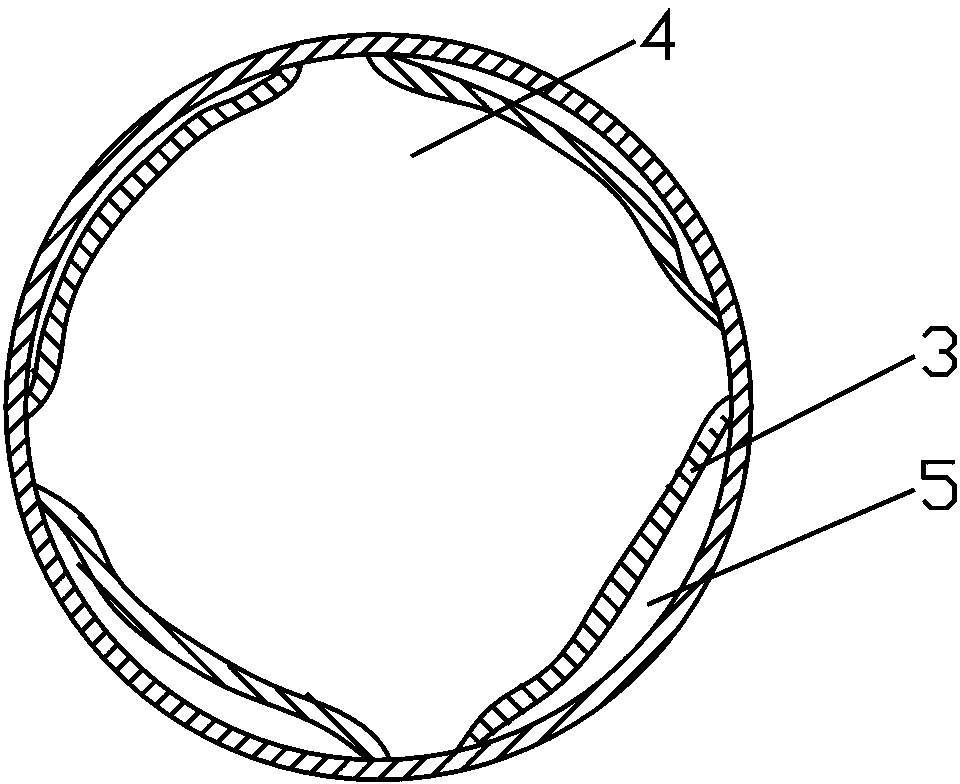

Embedded electric steaming box

PendingCN107898302AImprove the safety of useSimple structureBoiling over preventionSteam cooking vesselsElectricityEngineering

The invention discloses an embedded electric steaming box. The embedded electric steaming box comprises an electric steaming box inner container, a base plate, an insulation board, a gas guide tube, an exhaust hood, a cover base plate and a cooling fan; a water collecting groove and an overflow groove are formed in the base plate, a steam outlet is formed in the top surface of the electric steaming box inner container, an exhaust passage is formed in the space between the exhaust hood and the cover base plate, an opening, at the side of a door of the electric steaming box inner container, of the exhaust passage forms an exhaust port, an opening relative to the other side of the exhaust port forms an air inlet, the cooling fan is arranged on the outer side of the insulation board, an air outlet pipe of the cooling fan is connected with the air inlet, a metal deflector cover is arranged on the cover base plate, a steam cavity is formed in the space between the metal deflector cover and the cover base plate, a steam outlet with the air-out direction perpendicular to the air-out direction of the cooling fan is formed in the side wall of the steam cavity, a steam hole is formed in cavity top of the steam cavity, a steam inlet is formed in the cavity bottom of the steam cavity, and the gas guide tube is located between the electric steaming box inner container and the cover base plate and communicated with the steam inlet and the steam outlet. The embedded electric steaming box has the advantages of being convenient to install, good in sealing effect, capable of discharging steamto lower the temperature rapidly and the like.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

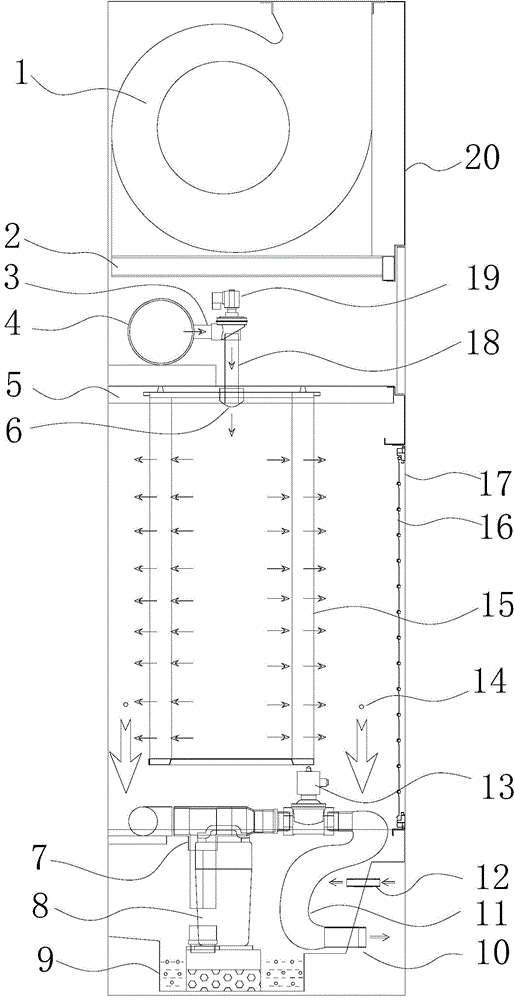

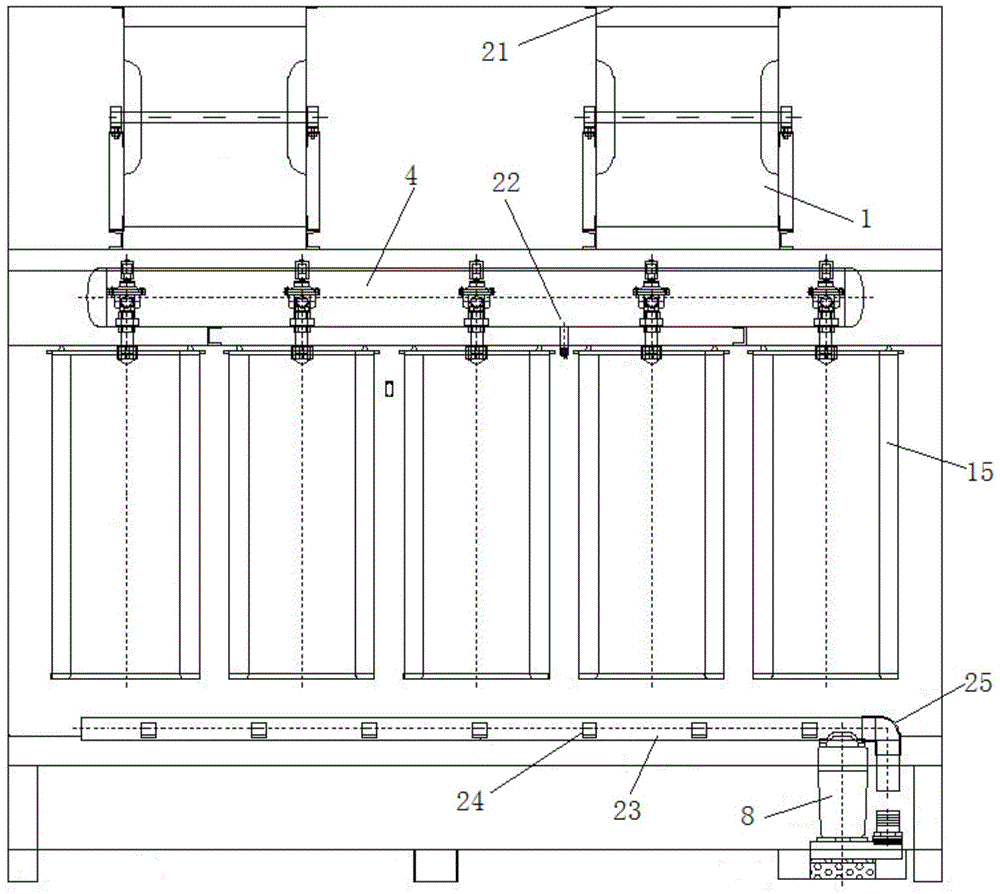

Filter core type deduster and control method thereof

InactiveCN104083974APrevent blowbackHigh precisionCombination devicesDispersed particle filtrationWaste managementDirt

The invention relates to a filter core type deduster and a control method thereof. The filter core type deduster comprises a cabinet, a fan and a dirt accumulating tank, wherein the fan is arranged on the top of the cabinet through a fan support plate, the dirt accumulating tank is arranged at the bottom of the cabinet, a filter core is arranged between the fan and the dirt accumulating tank and is fixed in the cabinet through a filter core installing plate, the bottom end of the filter core is enclosed, the top end of the filter core is provided with a through hole, a blowing blasting head is installed in the through hole and is connected with a pulse valve through a blowing pipe, a cylinder is arranged between the filter core installing plate and the fan support plate and is connected with the pulse valve through a cylinder air outlet pipe, one side of the cabinet is provided with a dust absorbing port, and the dust absorbing port is provided with, from interior to exterior, an air inlet gauze and an air inlet shutter. The filter core type deduster can completely remove dust in dust-containing air and allows dust filtering to be more thorough, ash in the filter core can be easily removed, the filter core is hardly to obstruct and has high filtering efficiency, so the filter core type deduster can be widely applied to removal of industrial dust.

Owner:柏司得环保科技(上海)有限公司

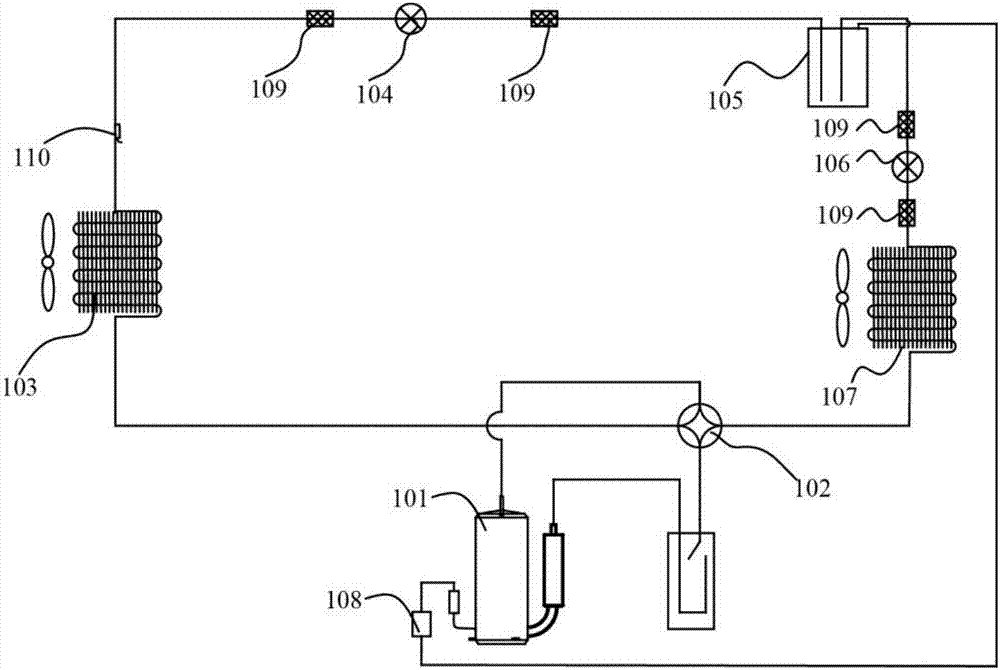

Gas replenishing and enthalpy increasing heat pump system and heating control method thereof

PendingCN106918161APrevent blowbackImprove heating effectMechanical apparatusFluid circulation arrangementProcess engineeringCheck valve

The invention relates to the technical field of heat pump systems, in particular to a gas replenishing and enthalpy increasing heat pump system and a heating control method thereof. The gas replenishing and enthalpy increasing heat pump system comprises a compressor, an indoor heat exchanger, a flash evaporator and an outdoor heat exchanger which are connected into a heating loop. A first throttling device is arranged between the indoor heat exchanger and the flash evaporator. A second throttling device is arranged between the outdoor heat exchanger and the flash evaporator. The compressor is provided with a gas replenishing port, and the flash evaporator is provided with a gas exhaust port. The gas exhaust port of the flash evaporator communicates with the gas replenishing port of the compressor through a check valve. The gas replenishing and enthalpy increasing heat pump system further comprises a controller. The controller is connected with the first throttling device and used for adjusting the opening degree of the first throttling device. By the adoption of the heat pump system, opposed injection of the compressor is avoided, and the heating capacity and energy efficiency of the system are improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

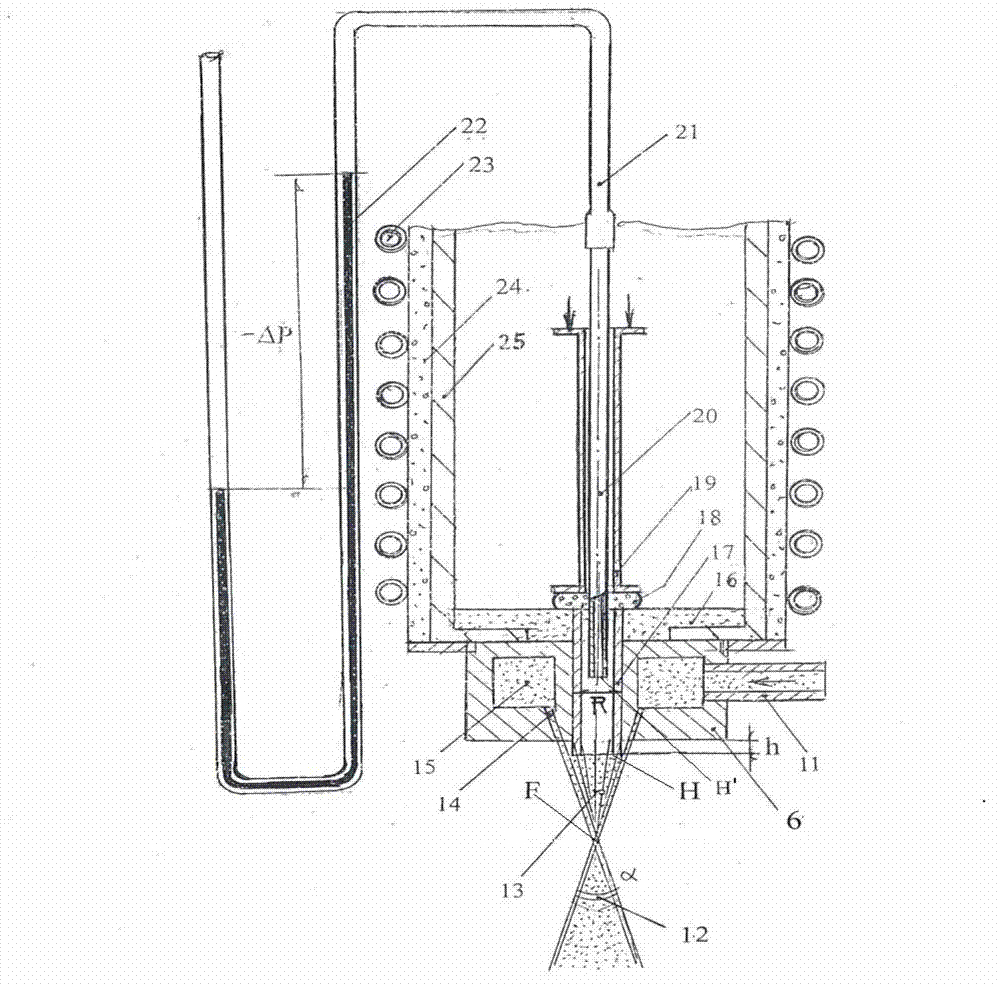

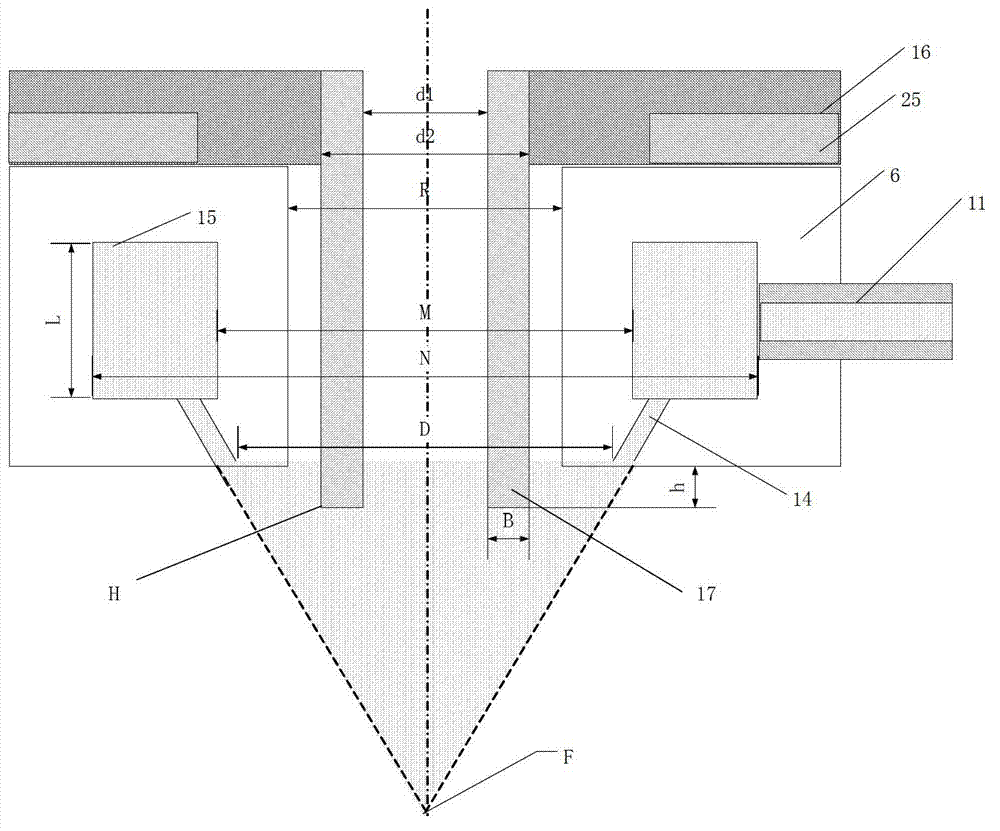

Method and device for spray forming of high-speed solid phase particles

The invention relates to a method and a device for spray forming of high-speed solid phase particles. The device comprises a high-speed solid phase particle generating device and an induction smelting furnace. The high-speed solid phase particle generating device comprises a focus nozzle and a pipe body. The pipe body comprises a material pipe, a conical pipe and a sealed gas reversing chamber. A stainless steel gas pipe is inserted into the pipe body in axial direction, the front end of the stainless steel gas pipe is arranged inside the conical pipe, high-pressure gas led from a high-pressure gas leading pipe passes through the gas reversing chamber and enters the stainless steel gas pipe from small vent holes on the surface of the stainless steel gas pipe, negative pressure is formed inside the conical pipe, solid powder generates high-speed solid particles fast and the high-speed solid particles are sprayed out from the nozzle. The nozzle is arranged below the induction smelting furnace and provided with a vertical inner through hole, and the lower end of a molten metal conveying guide pipe at the bottom of the induction smelting furnace penetrates out from an inner hole of the nozzle. By means of the novel spray forming technology, cooling speed of the molten metal is increased to 104.5-106 DEG C / S, and various multi-phase metastable phase composite phase materials can be directly produced.

Owner:UNIV OF SCI & TECH BEIJING

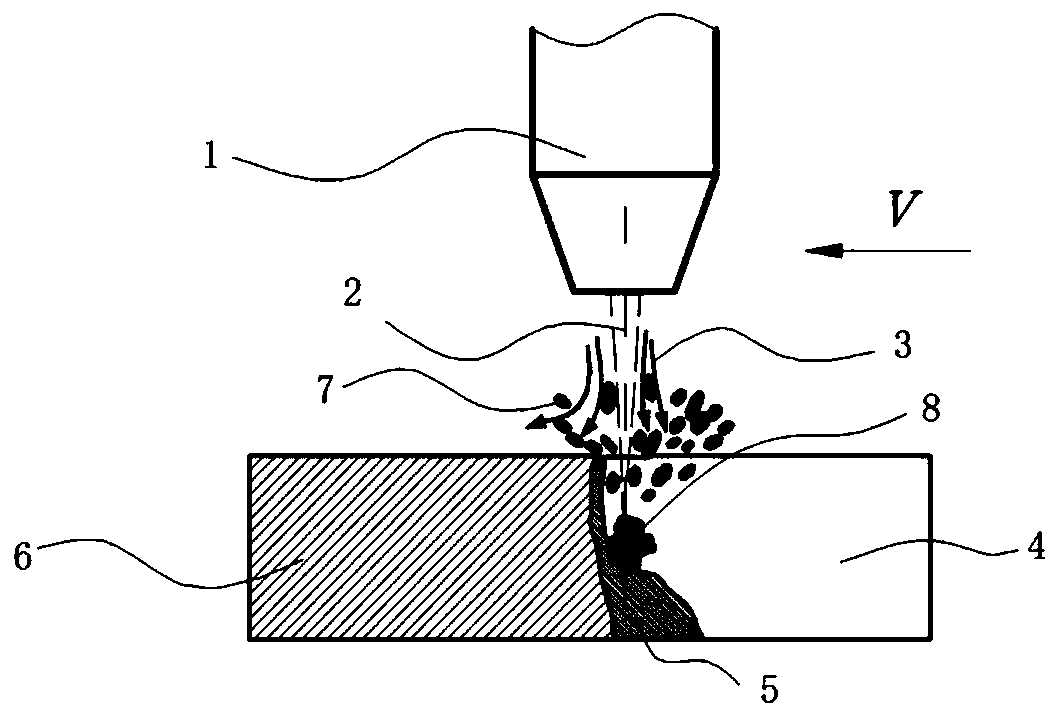

Electromagnetic field-assisting laser cutting method

ActiveCN110293324AAvoid "reverse spray" phenomenonImprove cutting effectLaser beam welding apparatusShielding gasEngineering

The invention relates to an electromagnetic field-assisting laser cutting method which is characterized by comprising the steps of (1) fixing an electromagnetic coil onto a laser cutting head, and moving along with the laser cutting head; (2) arranging a gas heating device into a cutting assisting gas circuit; (3) arranging a bottom shielding gas device under a corner part of a workpiece to be cut; (4) defining a corner cutting lead-in section and a corner cutting lead-out section in a laser cutting track; (5) starting a laser cutting system, turning on a cutting assisting gas heating device when a laser beam moves to a starting point of the corner cutting lead-in section, starting an electromagnetic field, and starting the cutting of a corner area; (6) when the laser beam moves to a termination point of the corner cutting lead-out section, turning off the cutting assisting gas heating device, closing the electromagnetic field, and finishing the cutting of the corner area; and (7) whenarriving at the cutting tail end point, turning off a laser generator, turning off a cutting assisting gas switch, and accomplishing a cutting process. Compared with the prior art, the electromagnetic field-assisting laser cutting method provided by the invention has a favorable cutting effect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

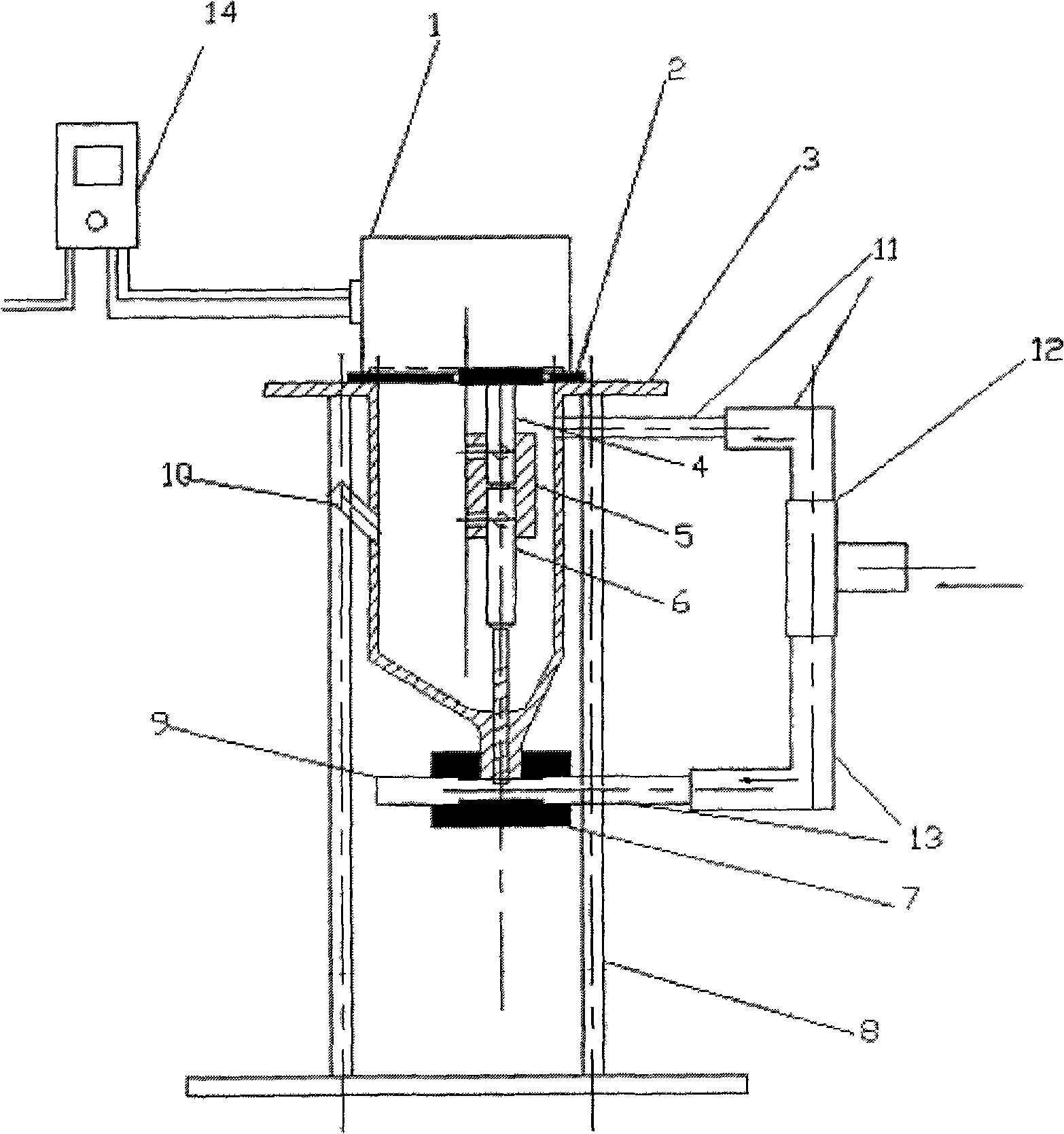

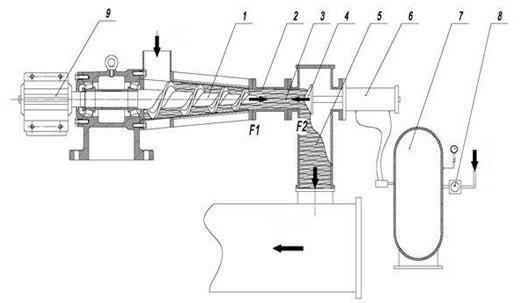

Vertical spiral powder conveyer

The invention discloses a vertical spiral powder conveyer. A motor (1) is arranged on a material cabin (3) and is connected with a speed adjuster (14); a sealing pad (2) is arranged between the motor (1) and the material cabin (3); a supporting seat (8) is arranged at the lower part of the material cabin (3); a shaft coupler (5) is arranged in the interior of the material cabin (3) and is connected with a motor spindle (4) and a spiral rod (6); the lower end of the spiral rod (6) extends into a material conveying tee joint (7), and the spiral rod is rotated to convey powders into the material conveying tee joint (7); a material inlet pipe (10) is arranged on one side of the wall of the material cabin (3); one end of the material conveying tee joint (7) is connected with the lower part of the material cabin (3), and the other two ends of the material conveying tee joint (7) are respectively connected with an air inlet pipe (13) and a material outlet pipe (9); one end of an air distribution tee joint (12) is connected with a pipeline of the air bottle, and the two other ends of the air distribution tee joint are respectively connected with the air inlet pipe (13) and a balance air pipe (11) for dividing air into two air paths; and the material outlet pipe (9) is connected with the material conveying tee joint (7) for outputting the powders from the powder conveyer.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

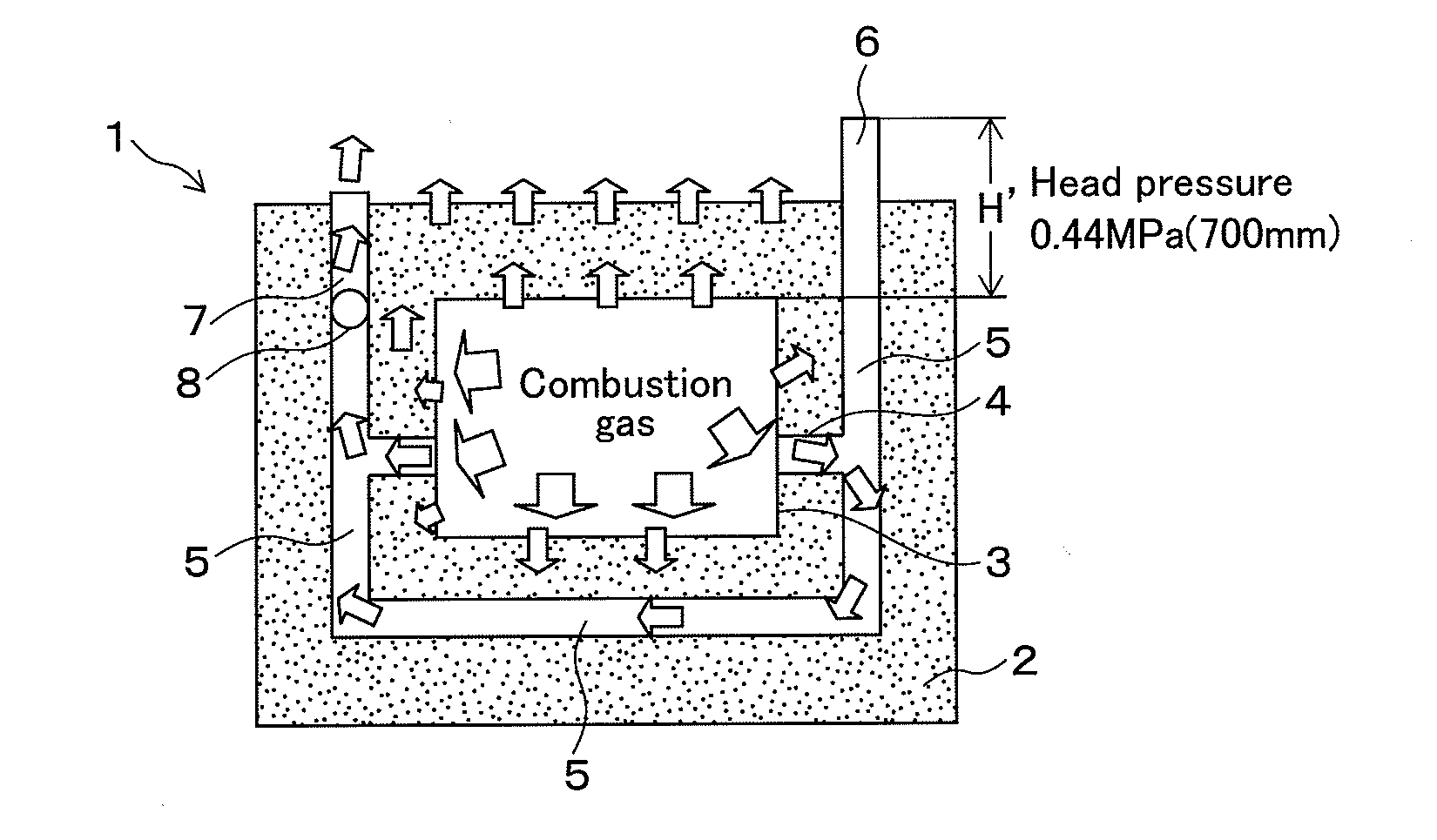

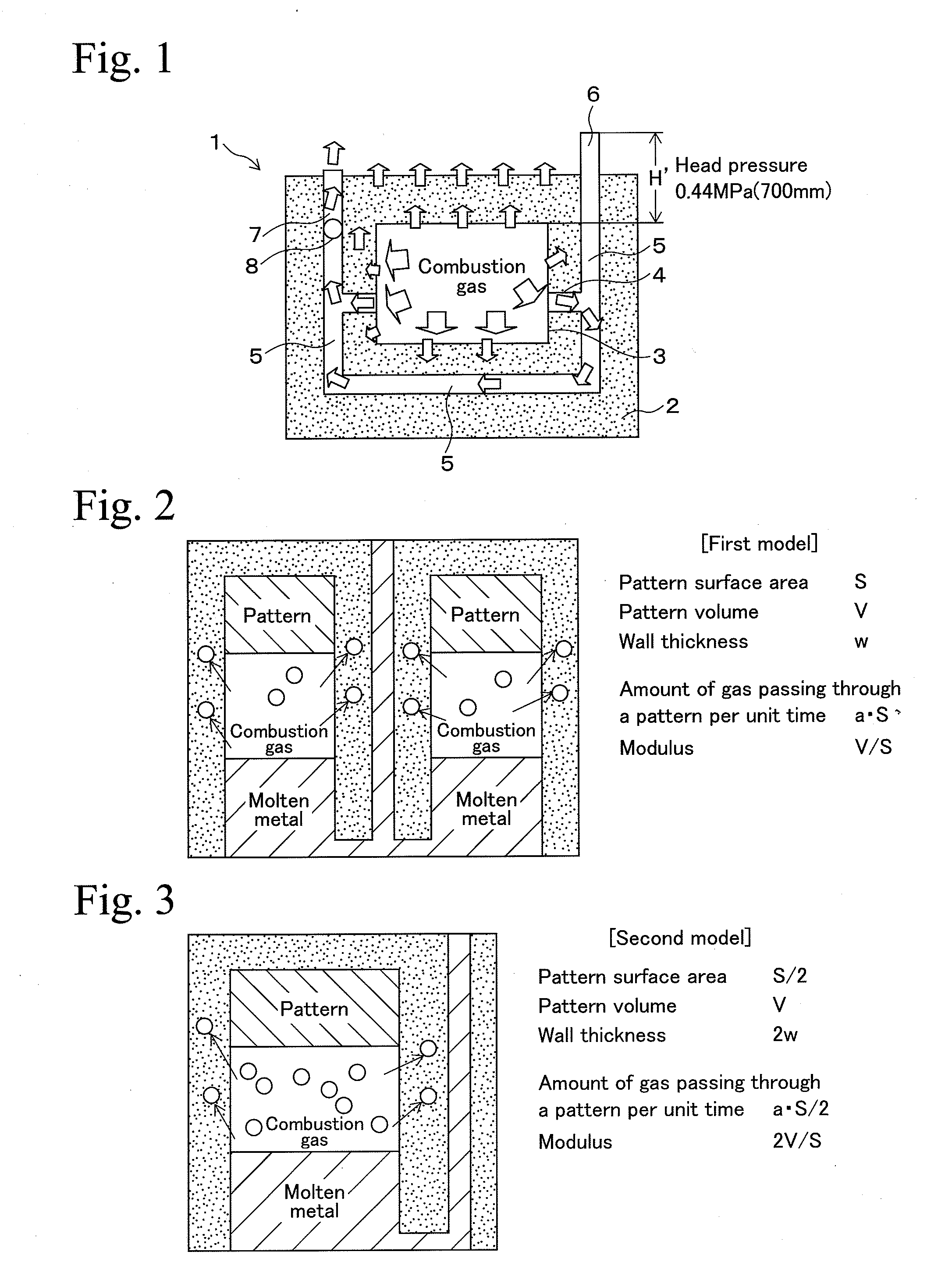

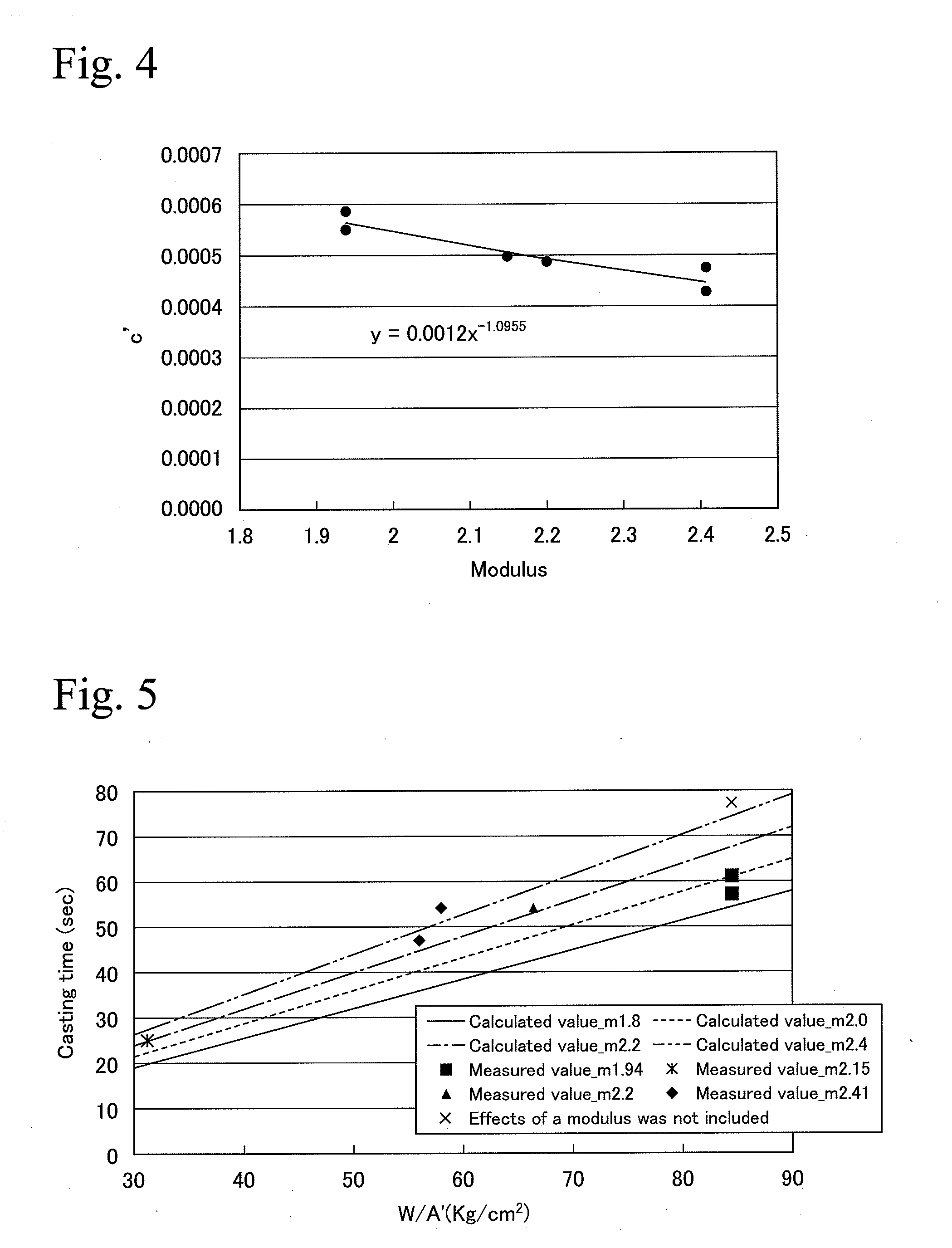

Evaporative pattern casting process

ActiveUS20120273151A1Accurate settingQuality improvementFoundry mouldsFoundry coresMetallurgyMaterials science

An evaporative pattern casting process includes forming a mold by burying a pattern made of resin foam in casting sand, pouring molten metal into the mold, and evaporating the pattern with the molten metal and thereby casting a product. In the evaporative pattern casting process, casting time during founding is set according to a modulus (pattern volume÷pattern surface area) of the pattern. Accordingly, the casting time in the evaporative pattern casting process is accurately set with high precision.

Owner:HONDA MOTOR CO LTD

Dust clearing device for computer host

InactiveCN109013563AIncrease the dust removal areaExpand the range of dust removalCleaning using toolsCleaning using gasesArchitectural engineeringHost machine

The invention discloses a dust clearing device for a computer host. The dust clearing device comprises a host shell, and a motor is arranged at the bottom end of the host shell and fixed to a mountingplate through bolts. An output shaft is arranged at the right end of the motor, and the left side of the output shaft is fixedly connected with the motor. The right side of the output shaft penetrates through the mounting plate and is fixedly connected with a lead screw. A movable platform is movably connected to the lead screw, and an air cylinder is arranged on the left side of the upper end ofthe movable platform and is vertically fixed to the movable platform through bolts. A telescopic rod is arranged at the upper end of the air cylinder, and the top end of the telescopic rod is fixedlyconnected with the lower surface of a flat plate in a welded mode. A compression piece is arranged on the right side of the air cylinder, and a linear guide rail is arranged in the middle of the upper end of the flat plate. A dust clearing mechanism is slidably connected to the linear guide rail. Left-right moving in the horizontal direction is achieved by arranging the lead screw, and thus the dust removing area of a cleaning brush is increased; and a second fixing block is fixedly connected with a motor, the dust removing range of the cleaning brush is further enlarged, and thus dust removing is more thorough.

Owner:合肥超必达网络技术服务有限公司

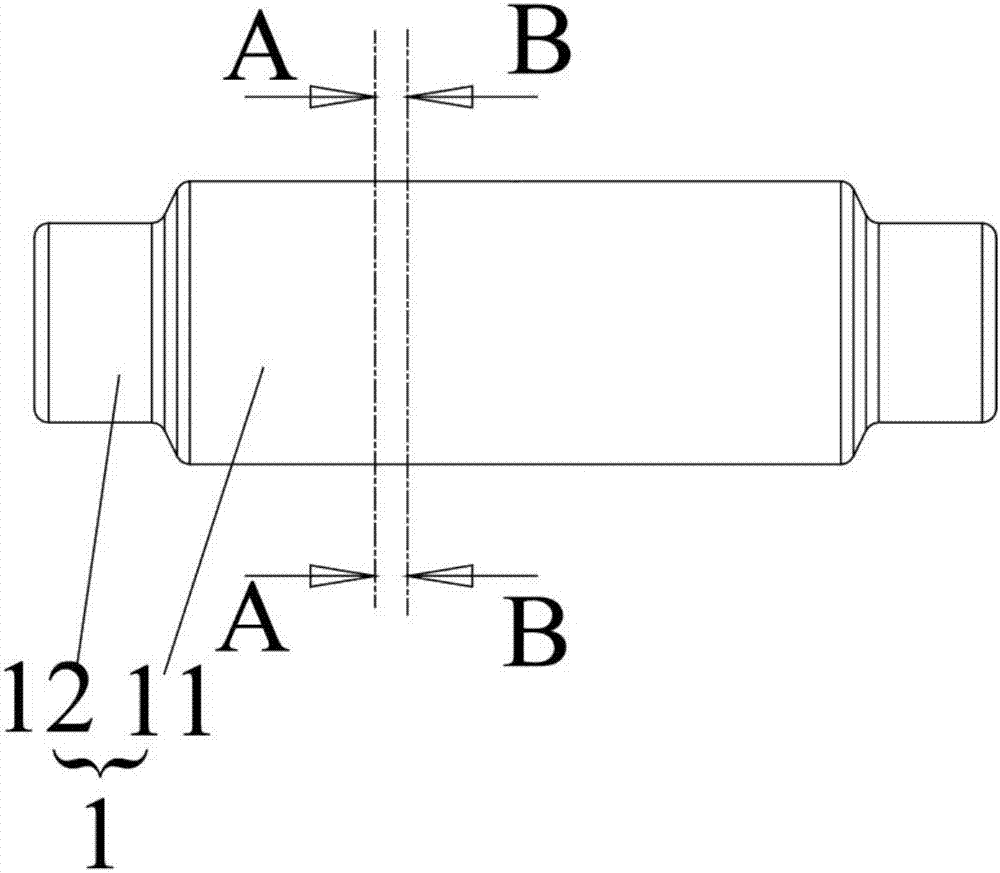

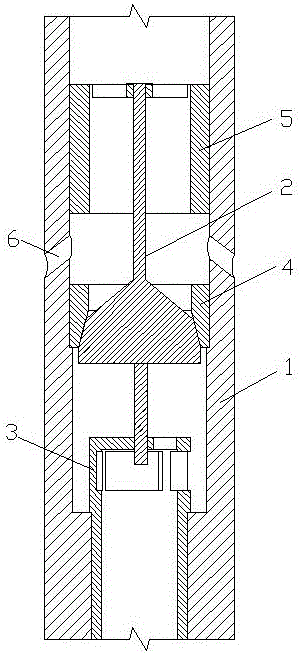

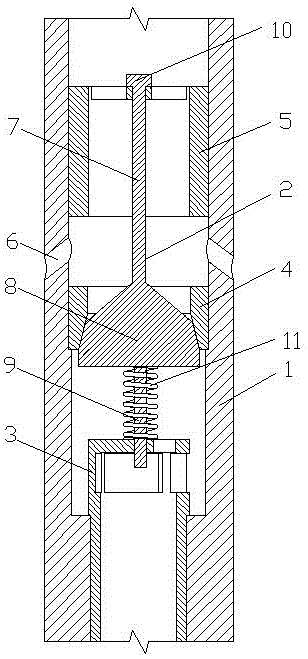

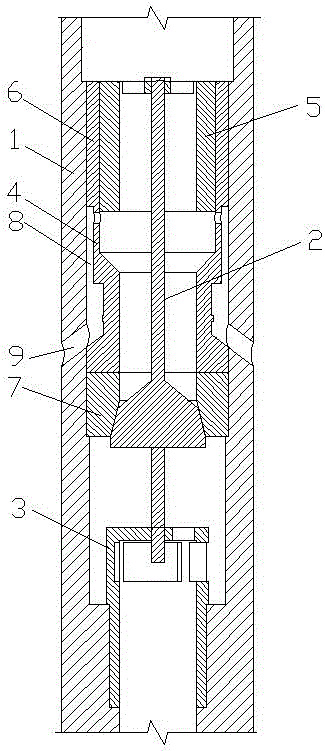

Back pressure valve

InactiveCN106481295AEliminate potential safety hazardsSmall amount of workFlushingWell drillingSlurry

The invention discloses a back pressure valve and belongs to the technical field of drilling equipment. The back pressure valve comprises a valve body, a valve element, a bearing seat and a valve seat and is characterized in that the bearing seat and the valve seat are arranged in the valve body, the bearing seat is located below the valve seat, a piston is arranged in the valve body and sleeves the valve element, a slurry return hole is formed in the valve body and located between the valve seat and the piston, and the slurry return hole is communicated with the inner cavity of the valve body. The back pressure valve has the advantages that slurry in a well can be automatically filled into a drill pipe, a slurry filling device needs not to be connected to fill the slurry into the drill pipe after each drill pipe part is descended, work amount is reduced greatly, time and labor are saved, slurry filing cost is lowered effectively, the slurry in the well can be prevented from being reversely sprayed into drill pipe through the inner cavity of the valve body, and safety accidents are avoided.

Owner:CHENGDU ZHUOXIN IND

Grinding device for silica gel production

The invention relates to the field of silica gel grinding, in particular to a grinding device for silica gel production. The grinding device for the silica gel production comprises a machine frame, wherein a motor, an operation cylinder and a collection chamber are sequentially fixed to the machine frame from top to bottom. A planetary gear train, a filtering and screening part and a partition plate are sequentially arranged in the operation cylinder from top to bottom. A material pipe fixed to the motor and a blower positioned at the lower side of the material pipe are arranged on one side ofthe operation cylinder, an output shaft of the motor is coaxially connected with a gear reduction mechanism, a baffle plate is rotatably arranged in the material pipe in a matched mode, the gear reduction mechanism is connected with the baffle plate, and grinding balls are placed in the filtering and screening part. The grinding device for the silica gel production is applied to basic material grinding, the grinding degree of the base material can be sufficient, and the utilization rate of the base material can be improved.

Owner:重庆君诚硅胶有限公司

Oil filling pipe assembly of passenger vehicle

InactiveCN103057402AAvoid early jumping the gun and backsprayImprove flow spacePipe supportsFlexible pipesFuel oilBackflow

The invention discloses an oil filling pipe assembly of a passenger vehicle. A guide device is also arranged in an oil filling pipe; a plurality of gun barrel limiting blocks are arranged at intervals in the circumferential direction of the inner wall above a direct connection pipe; the gun barrel limiting blocks comprise connection ends used for fixing the inner wall of the direct connection pipe; and the relative ends of the connection ends of the gun barrel limiting blocks define a guide space which is provided for a gun barrel to penetrate into and is coaxial with the direct connection pipe. When an oil gun is inserted for filling oil, the guide device can be used for limiting the gun inserting position to avoid the problems of advance gun jumping and reverse spraying caused by incorrect operation; at the same time, the oil filling length at the straight end of the oil filling pipe is increased, so that the flowing space of oil liquid in the oil filling process is enlarged, the time of collision between the oil liquid and the inner wall of the oil filling pipe is delayed, and the possibility of backflow of fuel oil is reduced; and due to the design of a bent pipe, the impact force of the oil liquid on the pipe wall due to the change of the flowing direction of the oil liquid is effectively reduced, and the possibility of backflow of the fuel oil is further reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Device for opening and closing air conditioner air duct through support rotating clamping and filter screen opening and closing

ActiveCN109916075APrevent blowbackAvoid damageLighting and heating apparatusAir-flow control membersEngineeringAirflow

The invention discloses a device for opening and closing an air conditioner air duct through support rotating clamping and filter screen opening and closing. The device structurally comprises a protective shell, a movable frame, a baffle block and an opening and closing rotating device. The baffle block is positioned on the front end surface of the protective shell and is fixedly welded with the protective shell through a right-angled plate body to form an integrated structure. A front support rod is driven by an inner rotating plate to be overturned and movably rotated inside under the limitof a roller frame; a front folding frame can be overturned in a sliding groove in an annular manner through a support rod; and the opening and closing of a filter screen, arranged inside a concave block, of a threaded plate are movably adjusted through the threaded plate, so that the air conditioner air duct can be opened and closed through the bidirectional opening and closing of the filter screen, and the damage of airflow to an opening and closing structure can be prevented.

Owner:嘉兴市新中软计算机系统工程有限公司

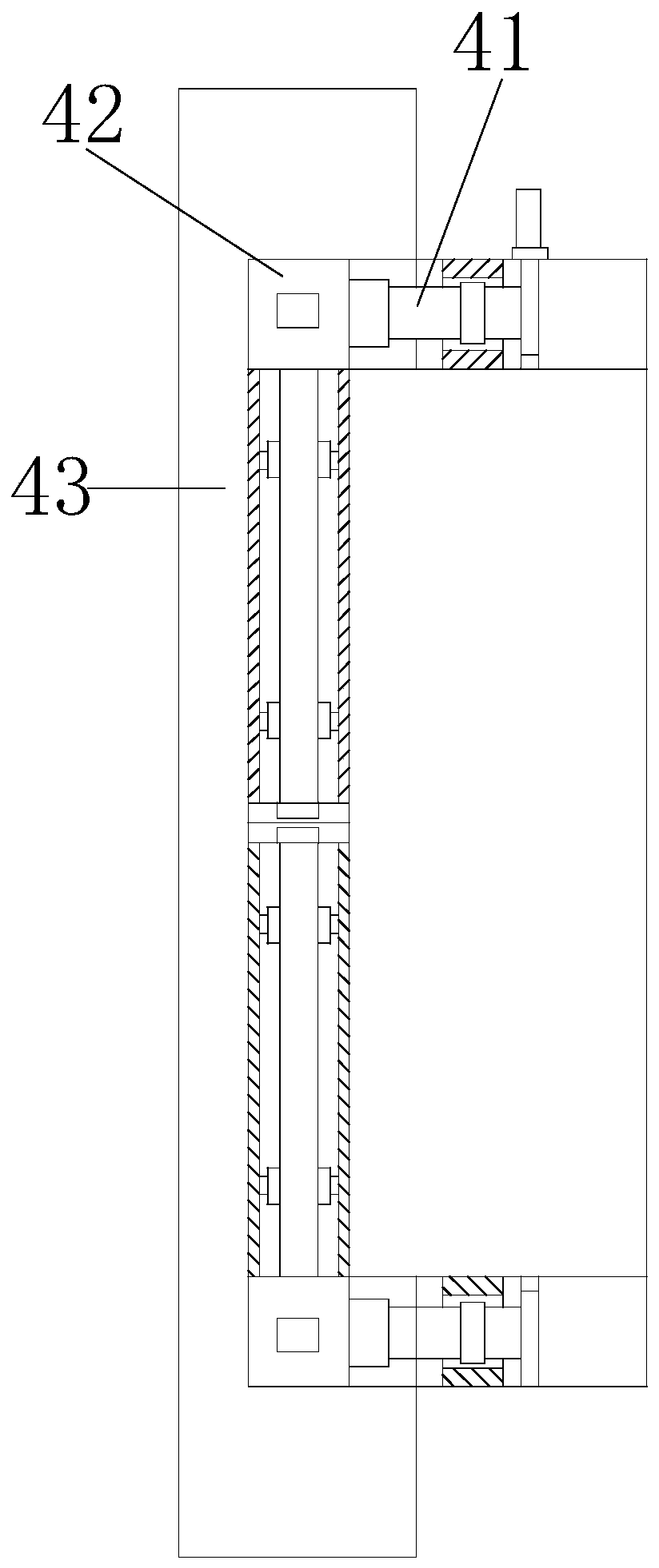

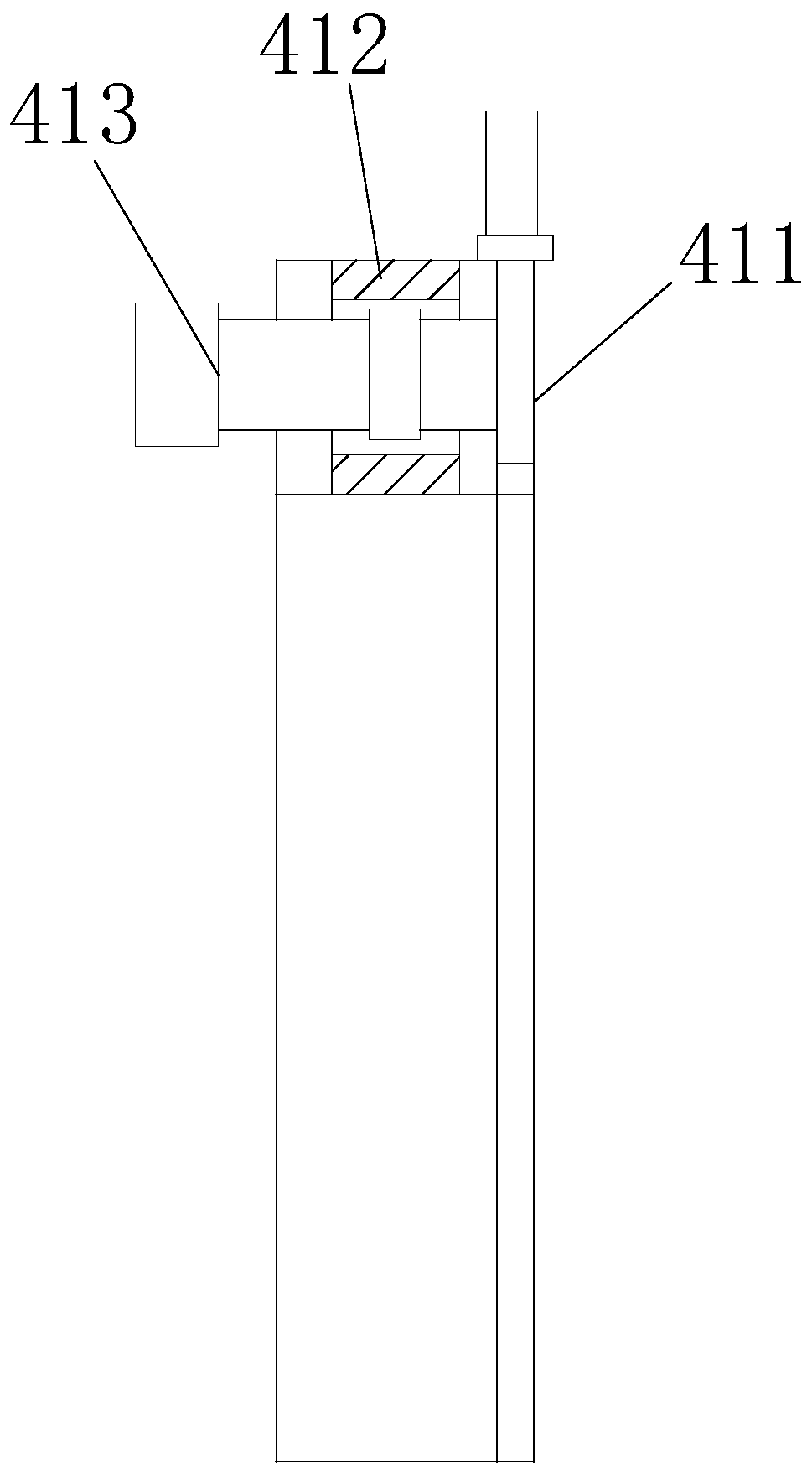

Continuous cooking anti-reverse spraying device

ActiveCN102182092ASolve the blowback problemReduce speedDigestersPaper material treatmentMechanical engineeringStreamflow

The invention discloses a continuous cooking anti-reverse spraying device. The device mainly comprises a frequency-variable transmission system, a feeding spiral shaft, a throat pipe, a push-stopping valve, a pressure-stabilizing tank and an air source stabilizer. The device is mainly characterized in that: the rotation speed of the feeding spiral shaft can be automatically adjusted according to the flow change of materials, so a pushing force is kept stable. The working pressure of an air source is not affected by external environment and is kept constant through the air source stabilizer, so that 'material plug' is not damaged by the fluctuation of flow pressure in a feeding process, and the aim of preventing reverse spraying in a continuous cooking and feeding process is fulfilled.

Owner:YUEYANG FOREST & PAPER CO LTD

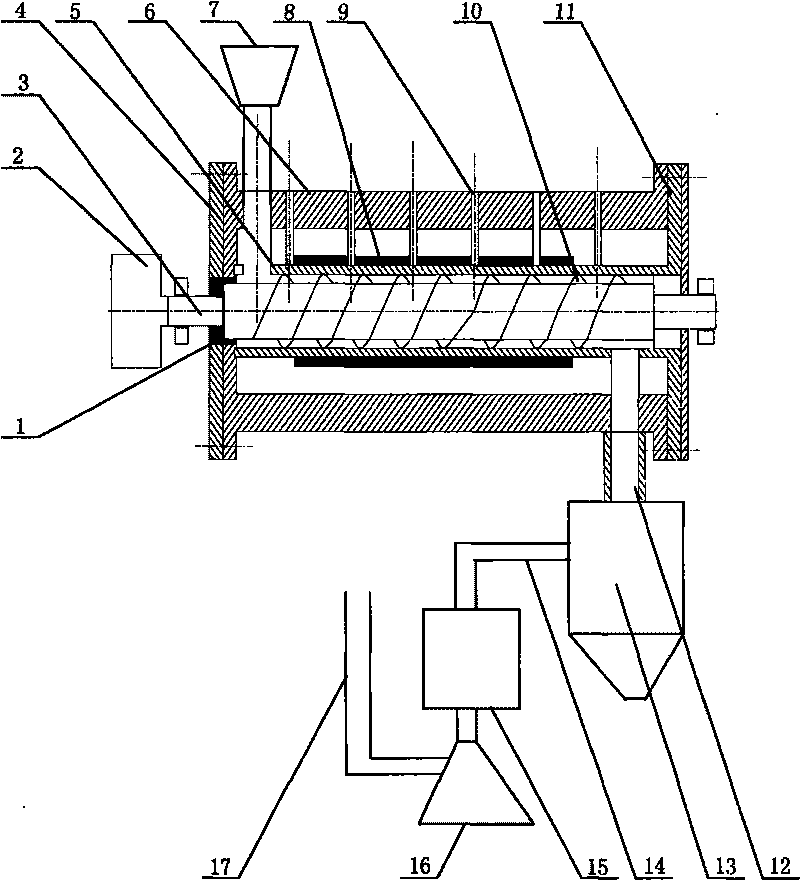

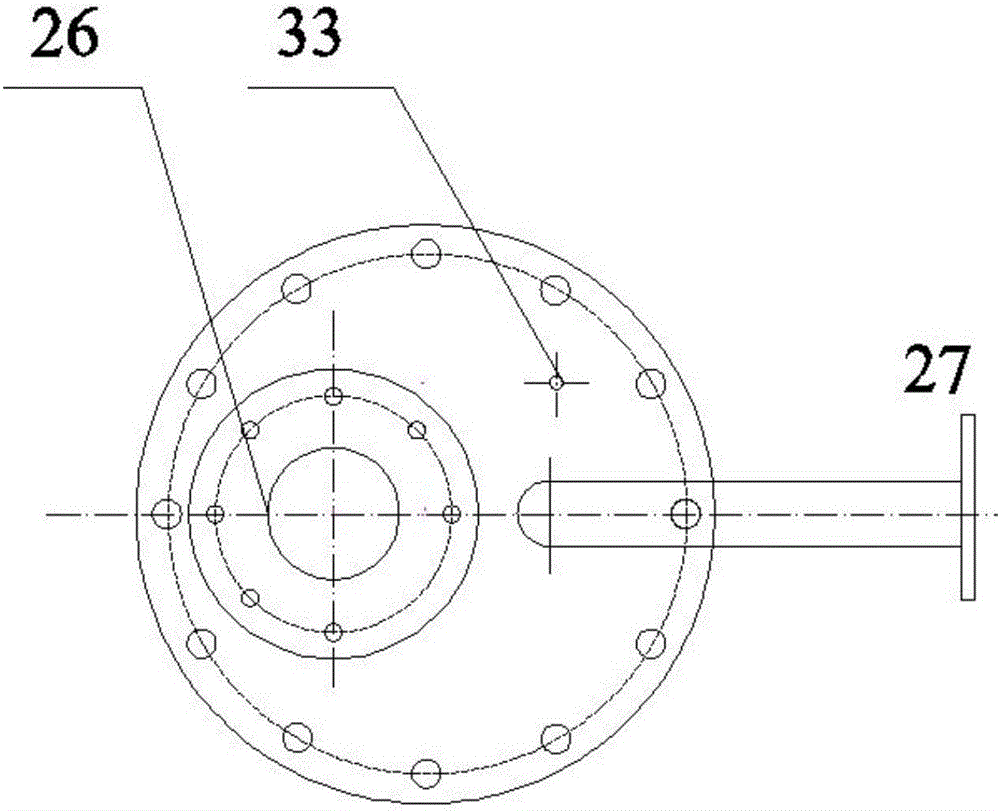

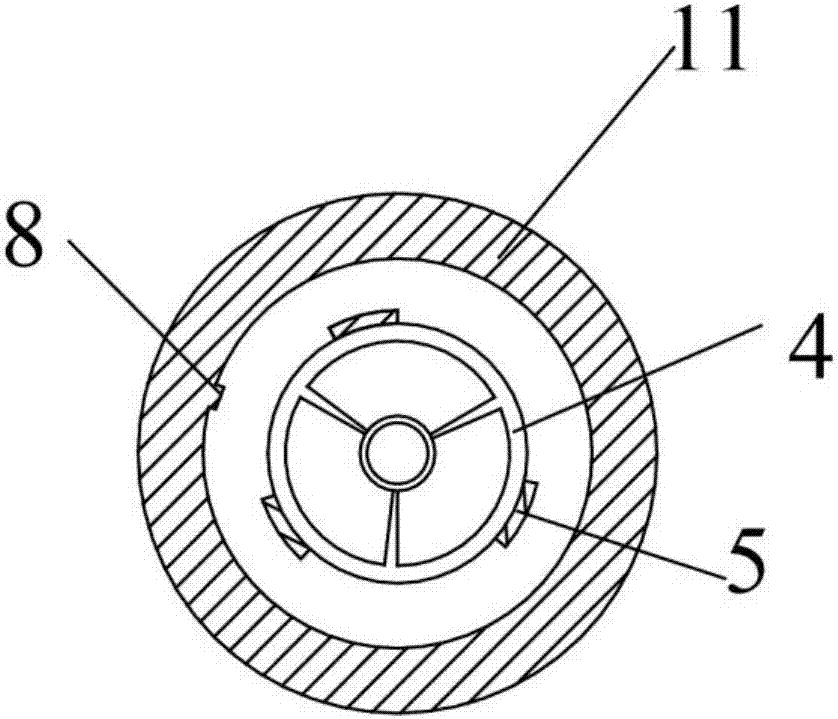

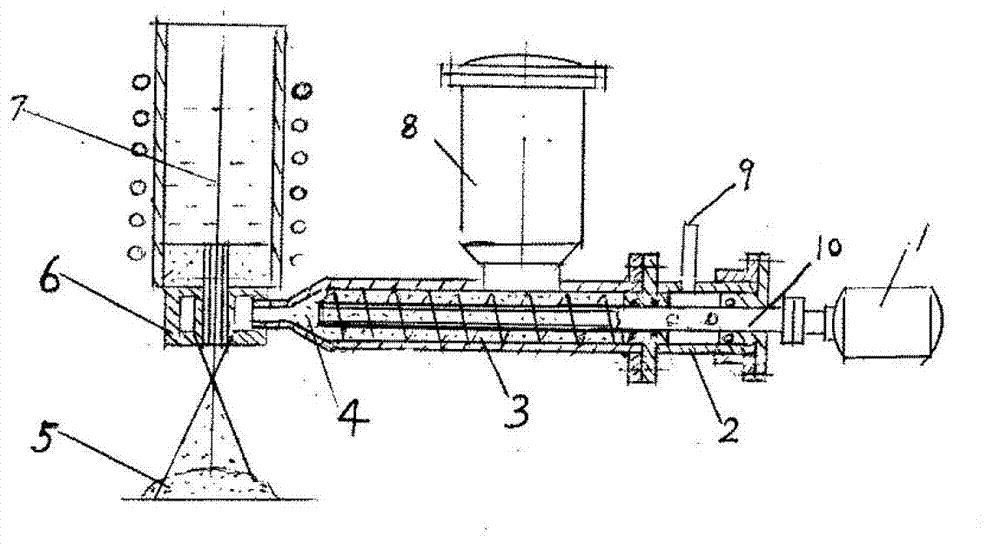

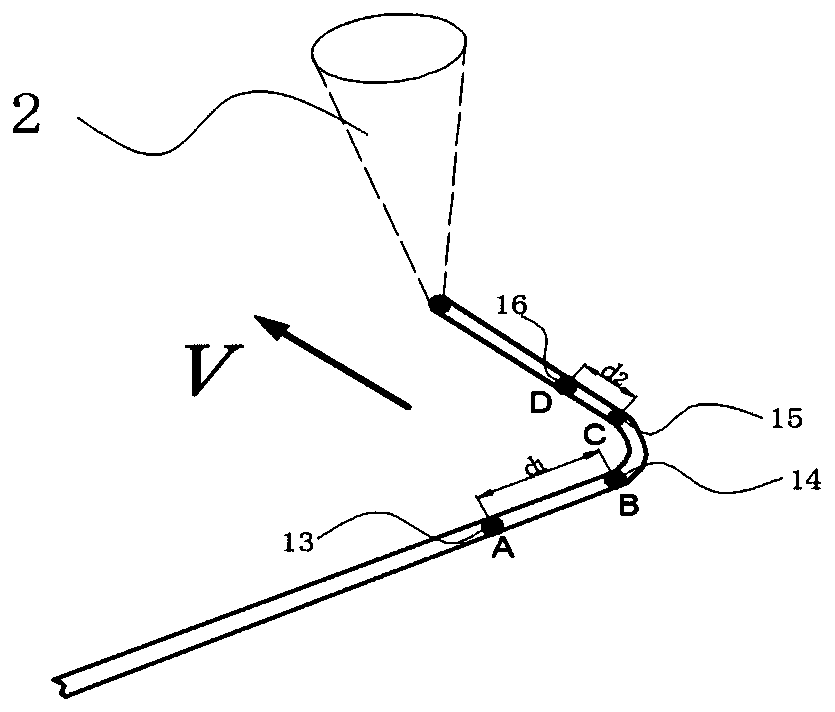

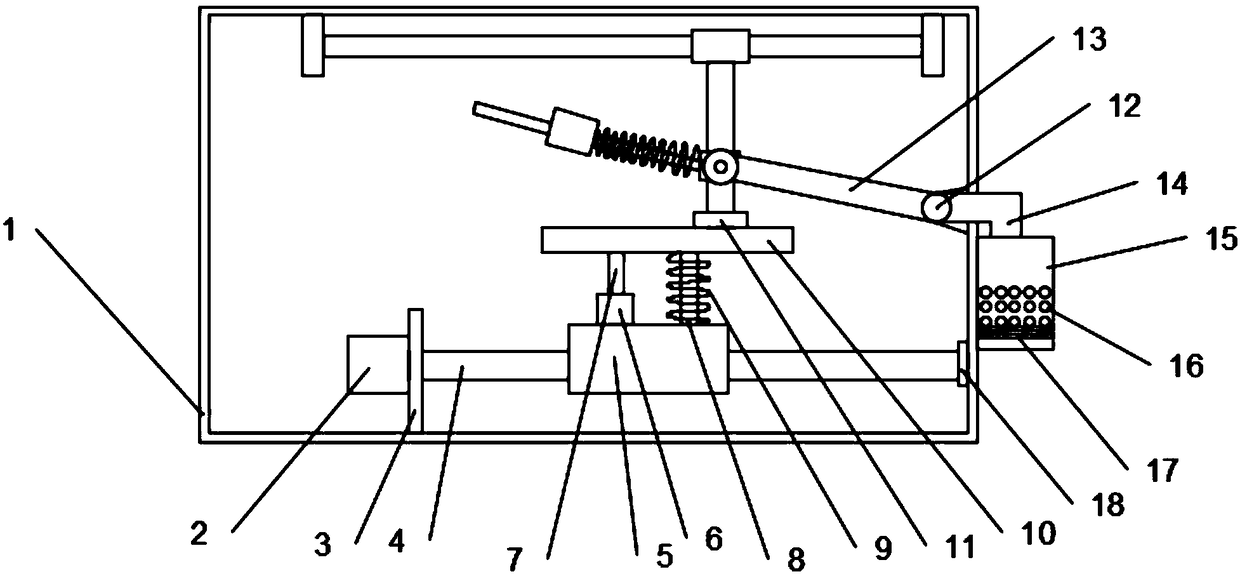

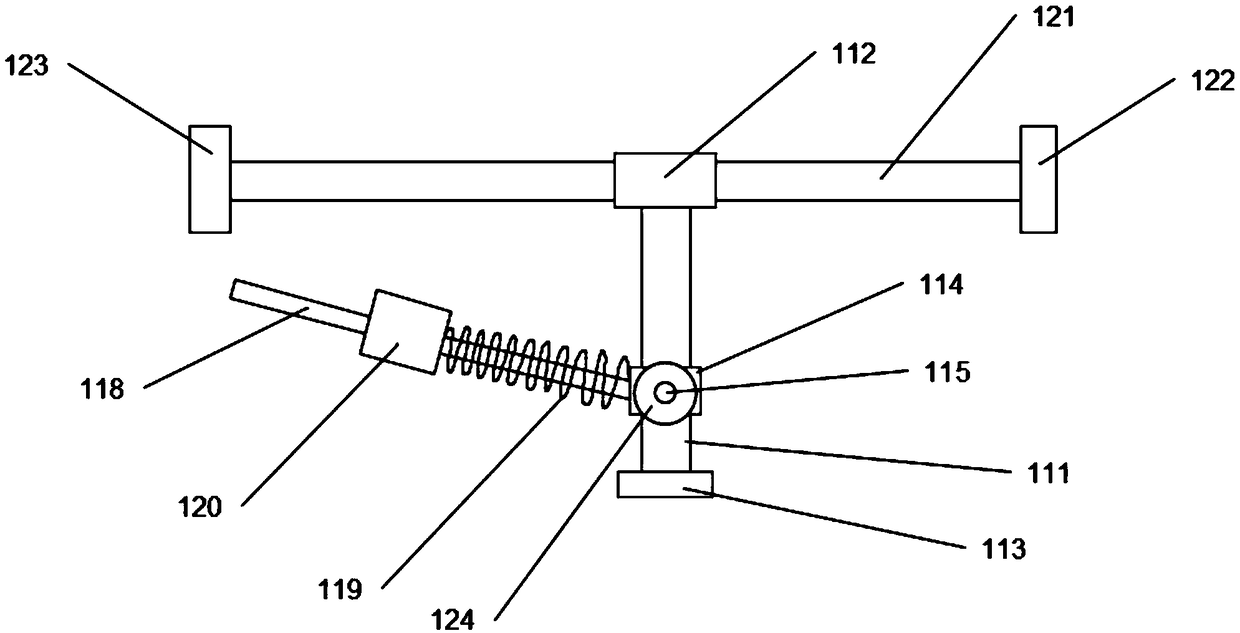

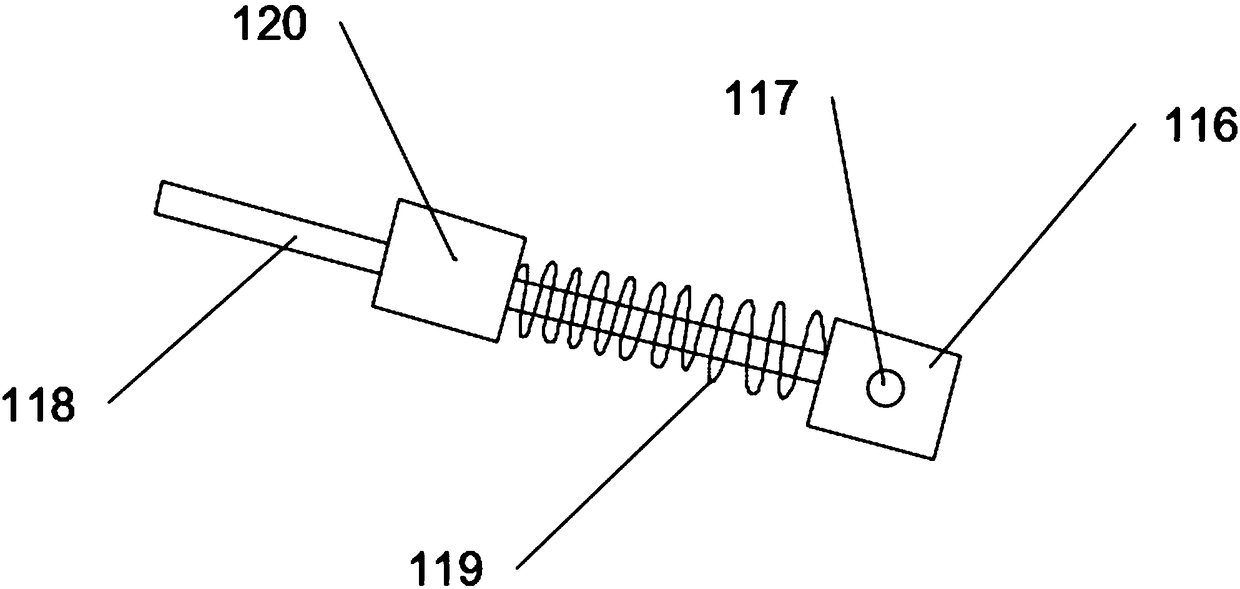

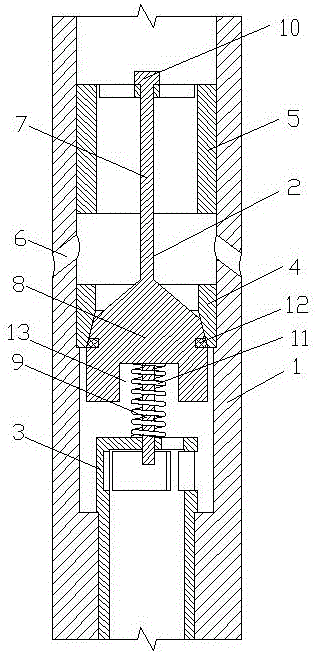

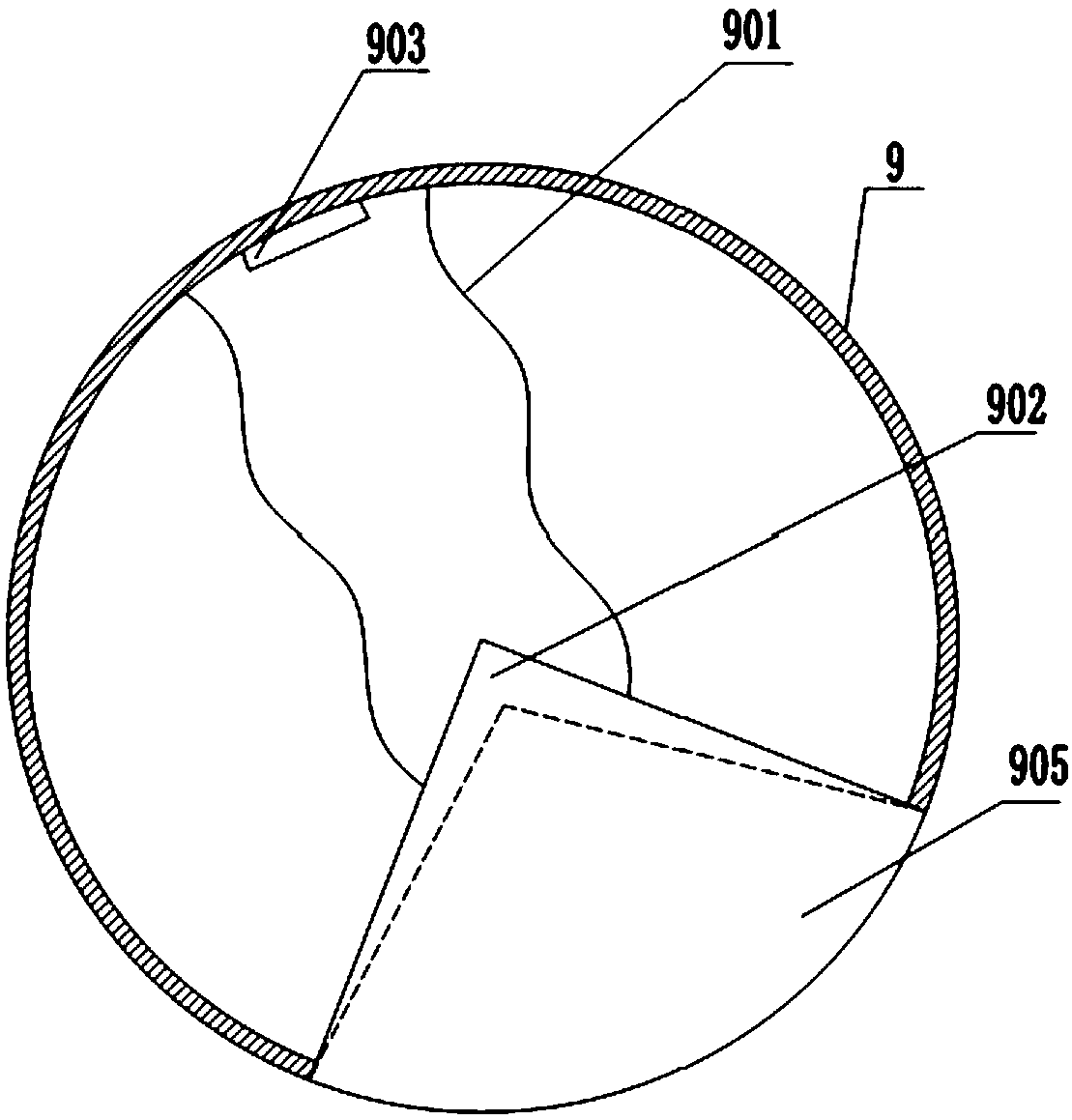

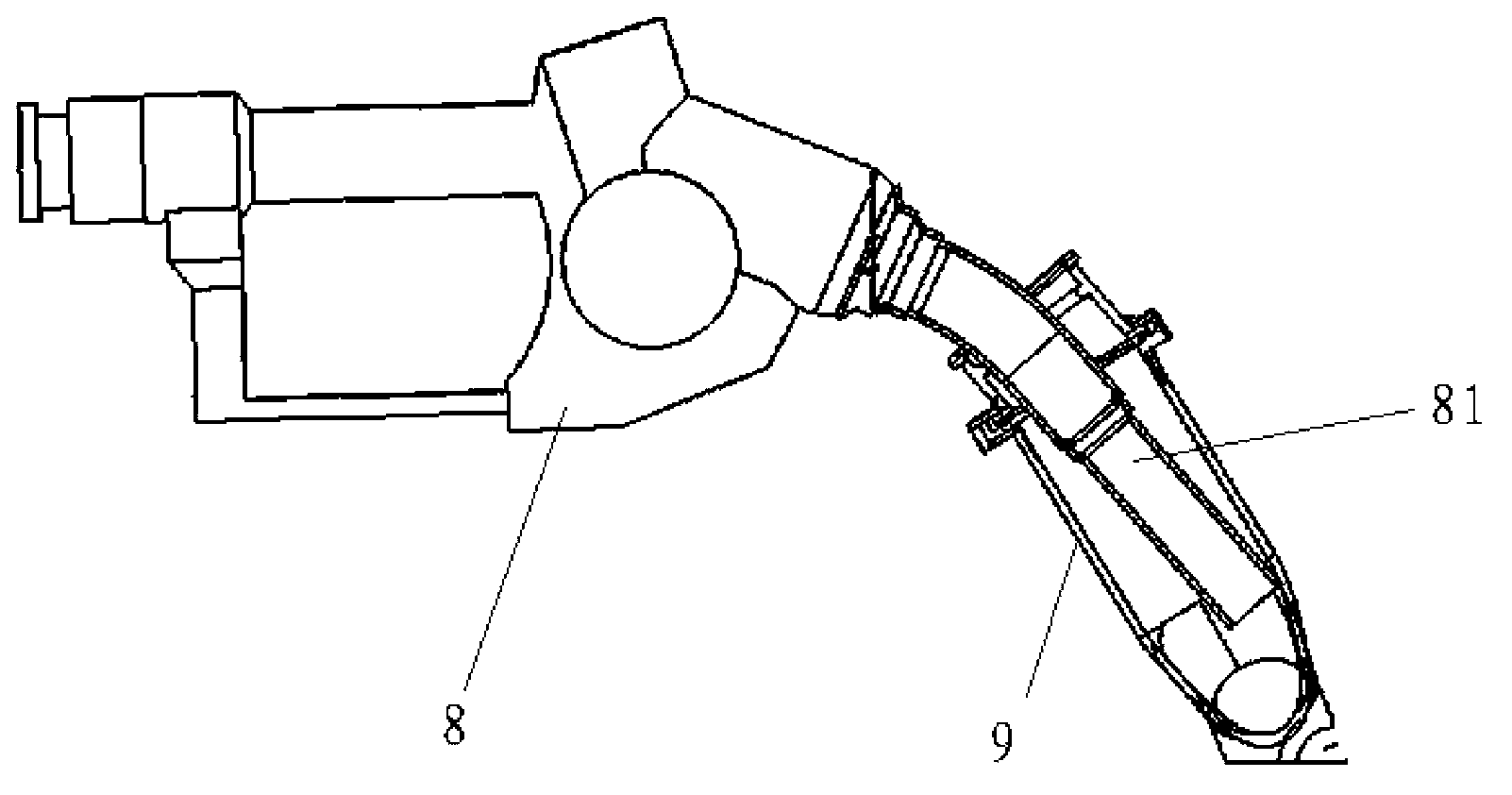

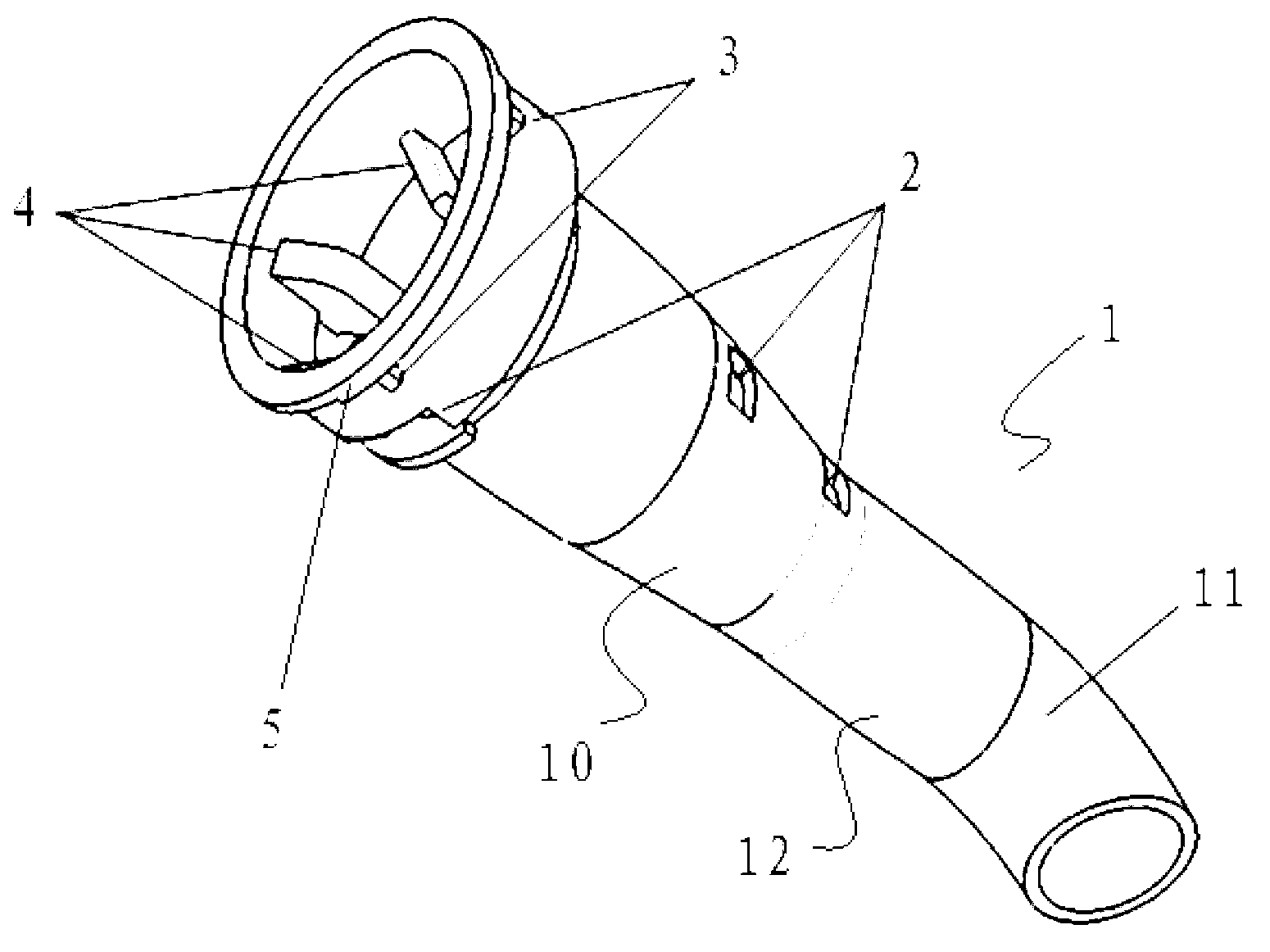

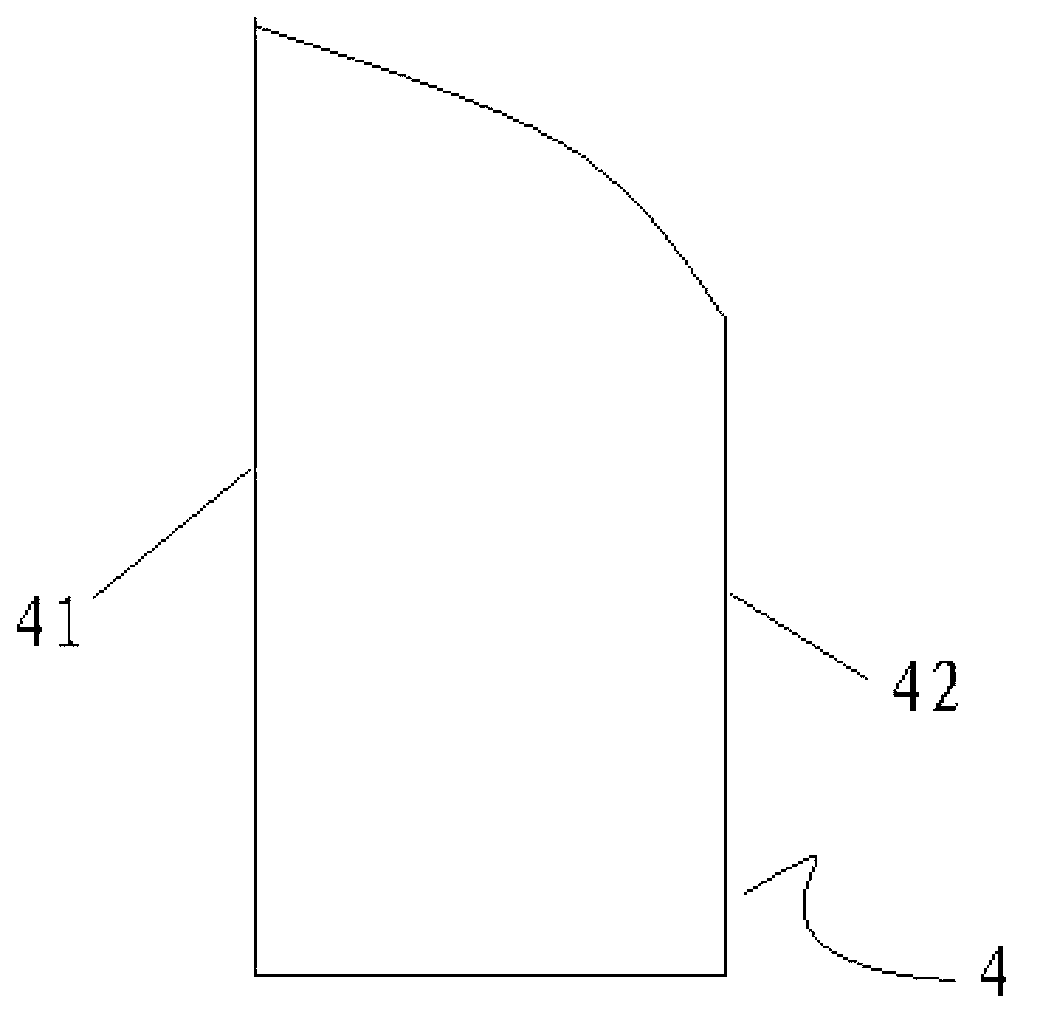

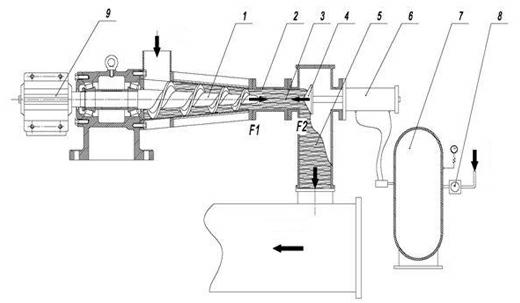

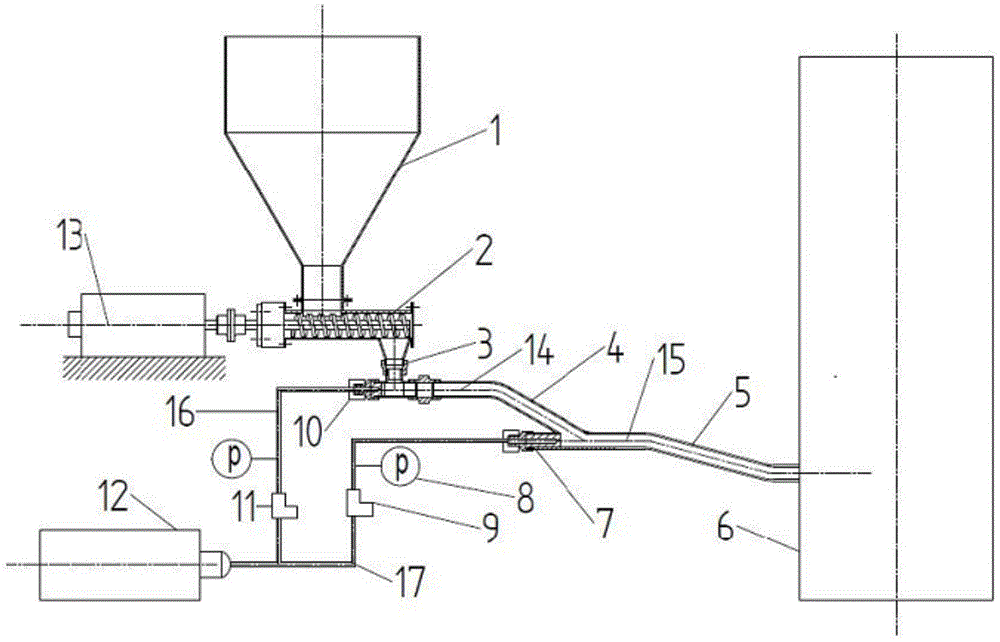

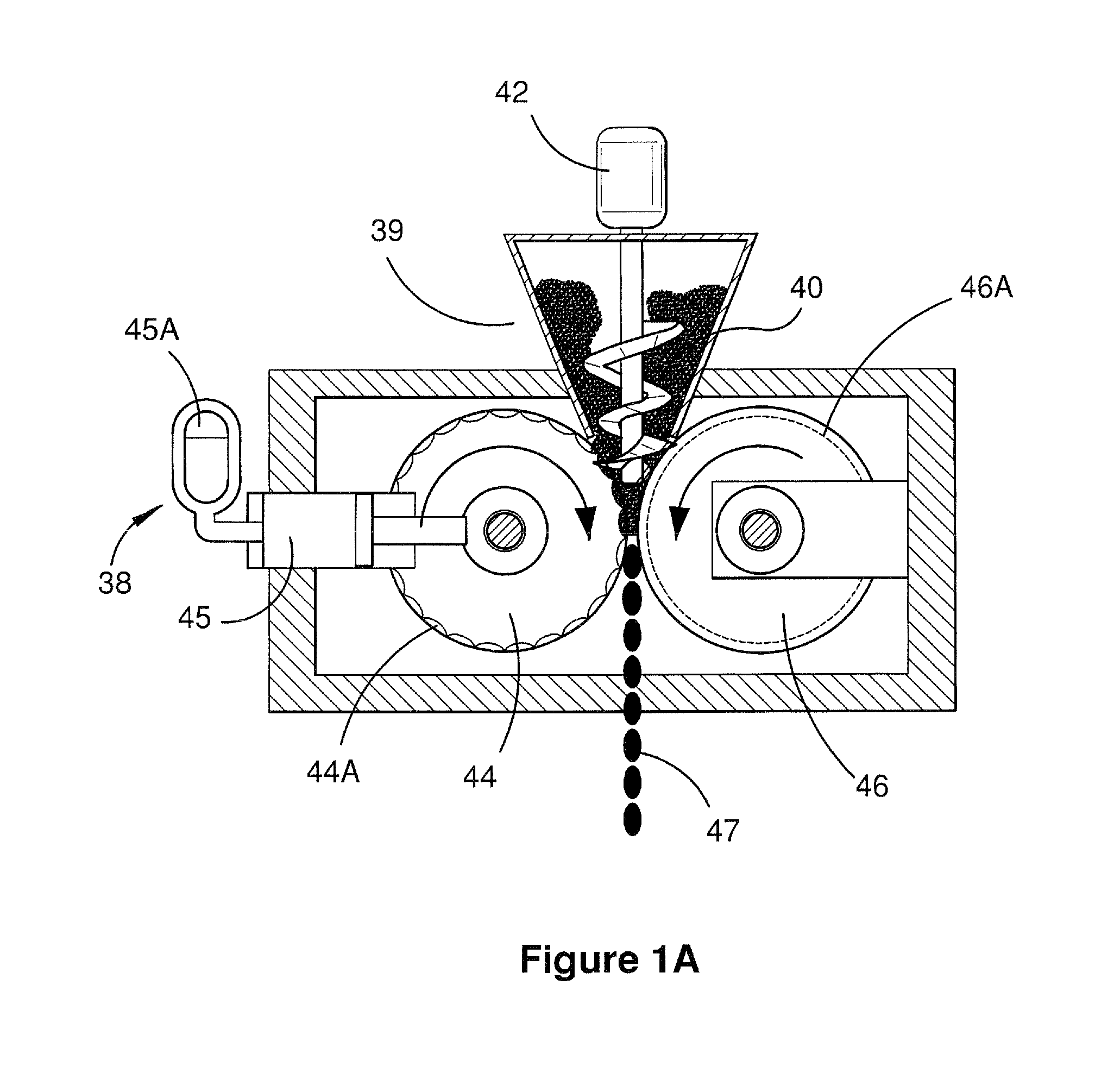

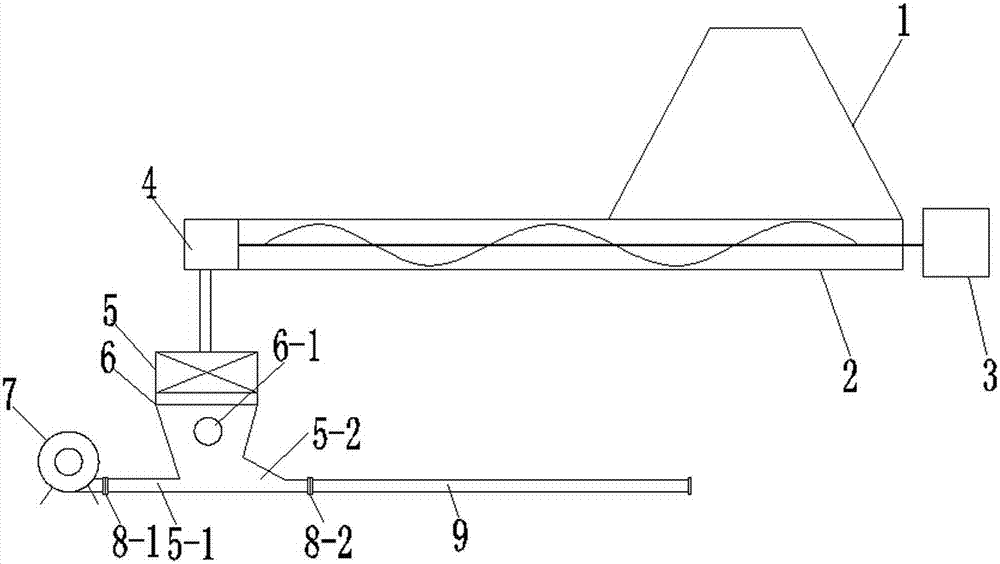

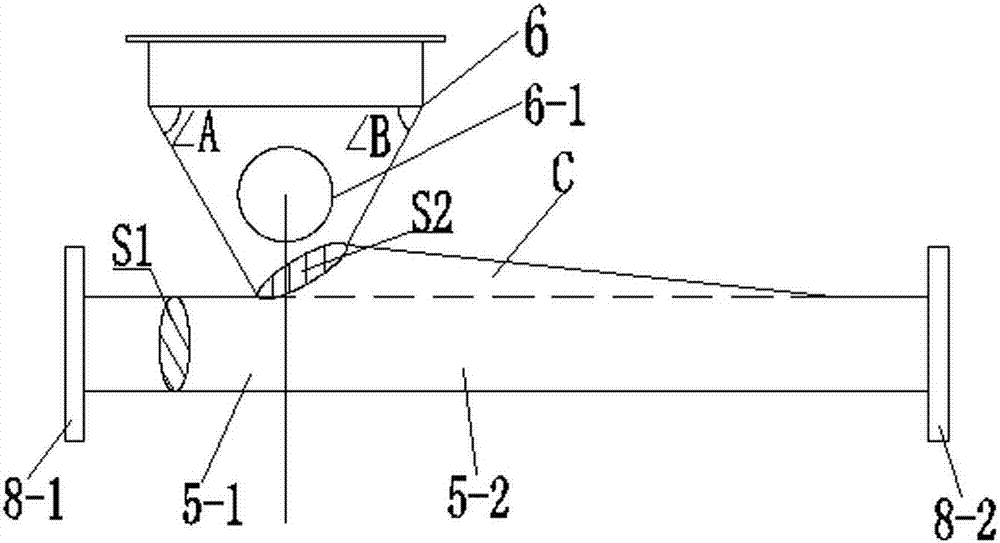

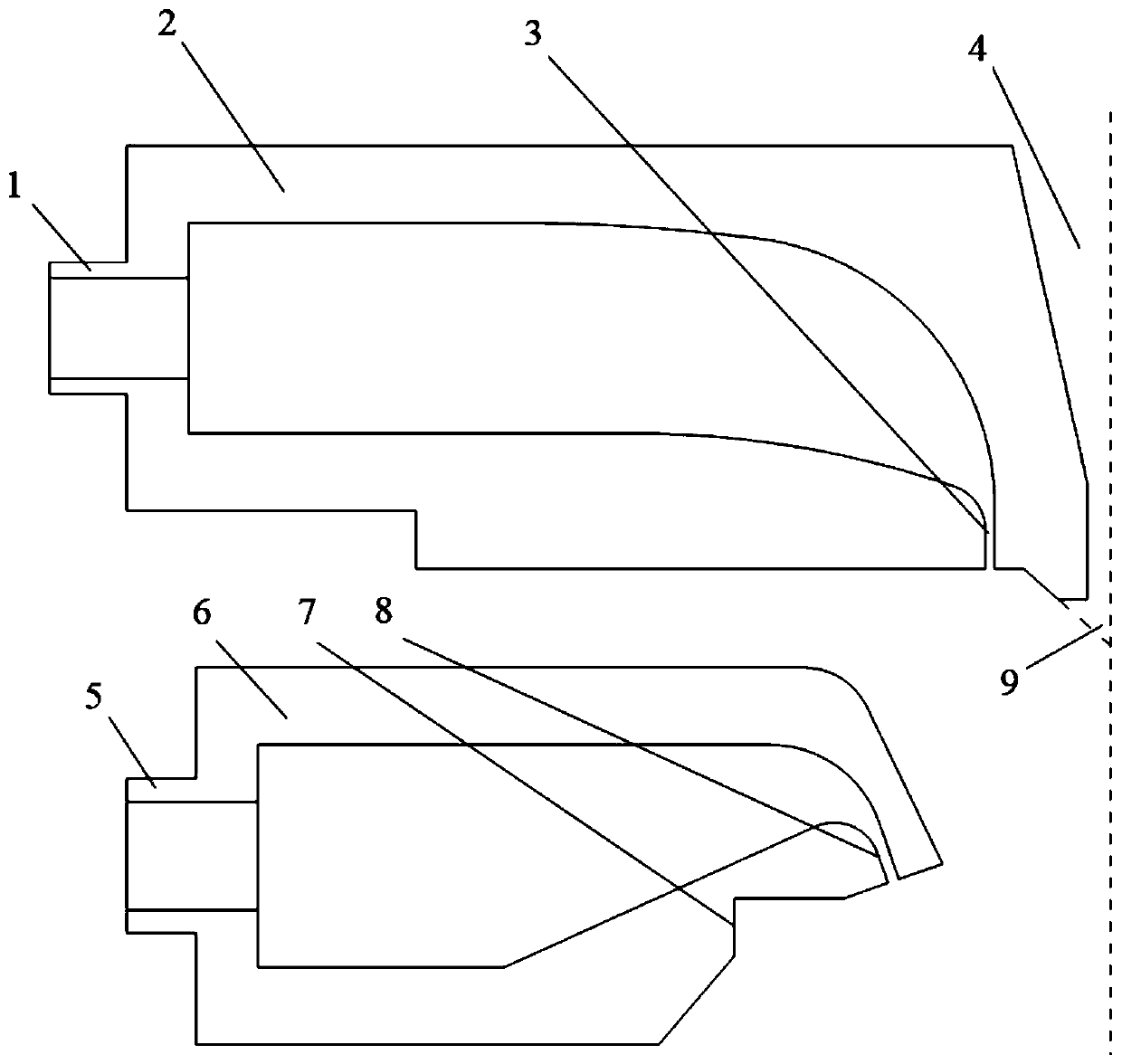

Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

InactiveCN104877694AAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveGas cylinder

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

Briquetting process

ActiveUS20090025285A1Reducing pressure buildupLower the volumeBiofuelsSolid fuelsParticulatesWater vapor

A process and system is provided for briquetting particulate matter such as moisture-containing bituminous and sub-bituminous coal. This process includes partially drying the particulate matter and feeding, the partially dried particulate matter to a briquetting apparatus under conditions such that water vapor is released from the particulate matter during feeding. The particulate matter is passed through briquette forming rollers to form briquettes. The released water vapor substantially displaces or prevents the ingress of a large proportion of other gaseous components from the atmosphere surrounding an / or intermixed with the particulate matter. The particulate matter that is fed to the briquetting apparatus is surrounded by and intermixed with a gaseous component containing 70% to 100% by volume of water vapor at the point where it enters the briquette-forming part of the briquetting apparatus, such that when the particulate matter is compressed during briquette formation, the water vapor liquefies and the pressure buildup of gaseous material in the thus-formed briquettes is minimised. This reduction in the pressure buildup of gaseous components also acts to reduce blow-back of gases as the coal fines are being formed into briquettes.

Owner:COMMONWEALTH SCI & IND RES ORG +3

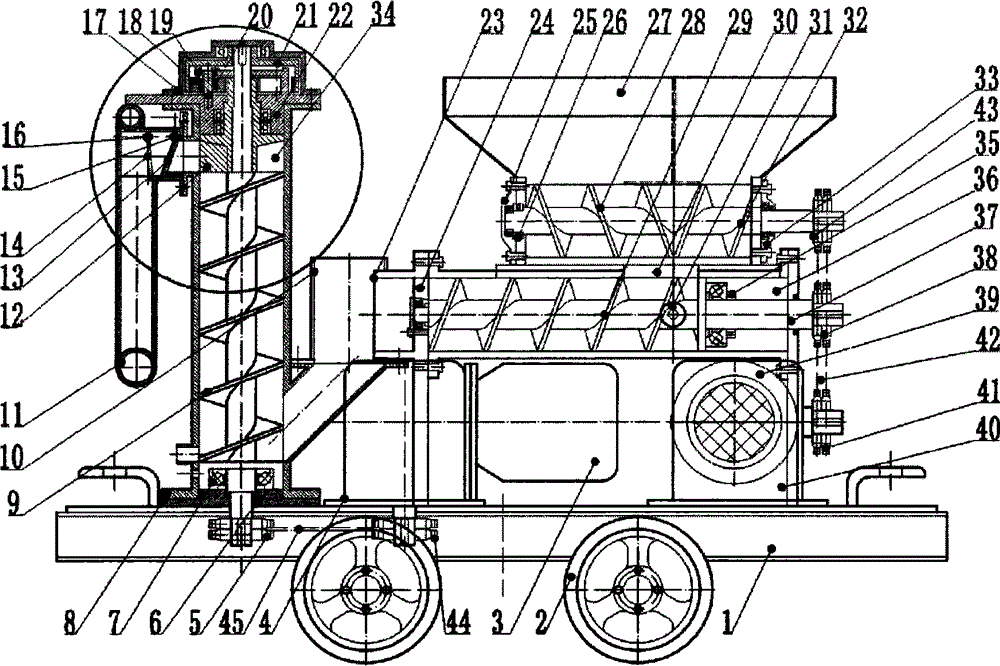

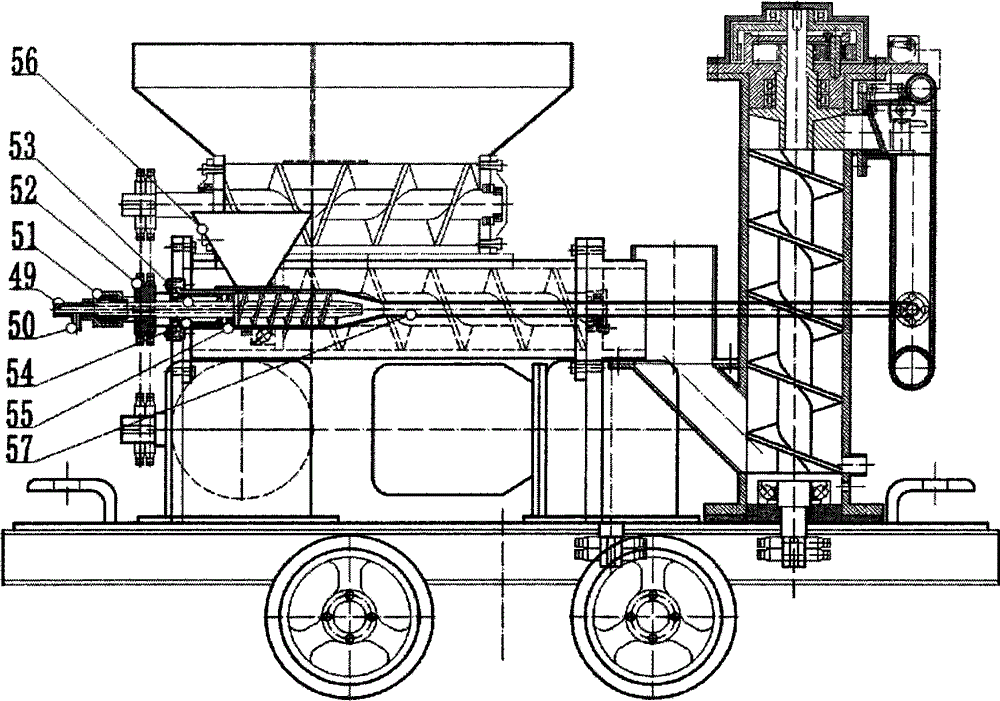

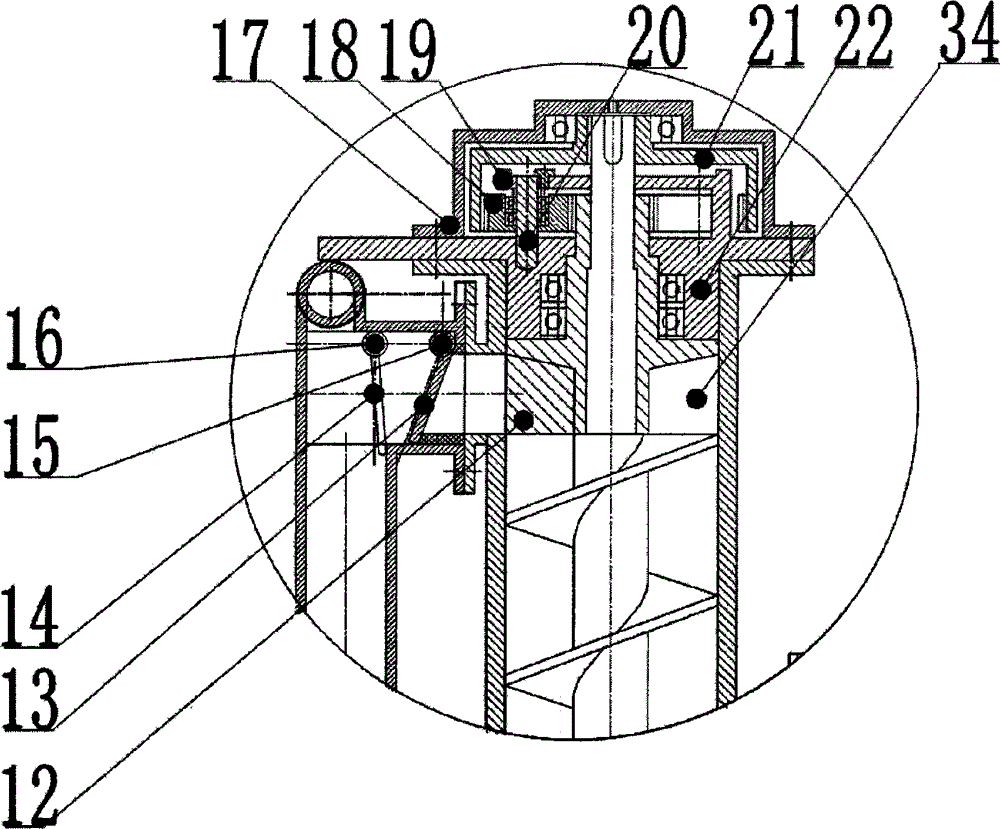

Wet type concrete spraying machine

InactiveCN105298512AImprove protectionPrevent blowbackUnderground chambersTunnel liningEngineeringSlurry

The invention discloses a wet type concrete spraying machine which comprises an undercarriage. The undercarriage is provided with a material conveying mechanism, a slurry conveying mechanism, a spraying mechanism and an accelerating admixture device; the slurry conveying mechanism is arranged above the undercarriage in parallel; the material conveying mechanism is arranged above the slurry conveying mechanism; the accelerating admixture device is arranged on a side surface of the slurry conveying mechanism; and the spraying mechanism is arranged at an outputting end of the slurry conveying mechanism, communicates with the slurry conveying mechanism, and is perpendicularly arranged on the undercarriage. Through the technical scheme, functions of small size, complete function, zero pollution, simple structure, high reliability and long service life are fulfilled.

Owner:SHENZHEN FRIENDSHIP SHEN TECH CO LTD

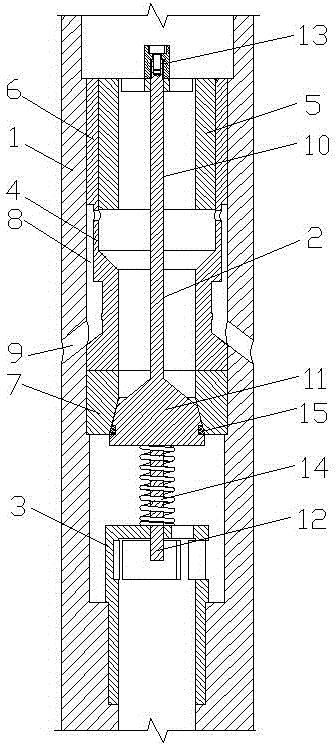

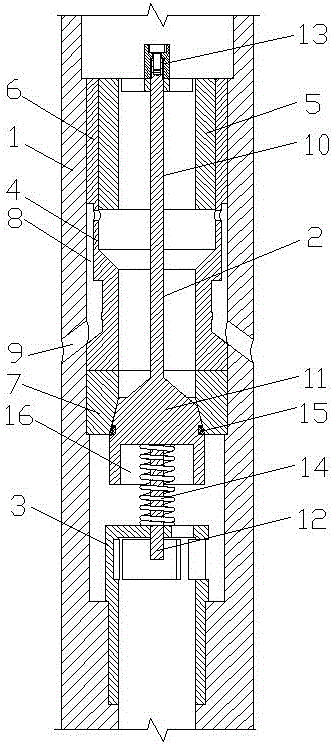

Backpressure valve capable of achieving automatic slurry injecting

The invention discloses a backpressure valve capable of achieving automatic slurry injecting, and belongs to the technical field of drilling equipment. The backpressure valve comprises a valve body, a valve element and a support base and a valve base which are arranged in the valve body, wherein the support base is located under the valve base. The backpressure valve is characterized in that a piston is arranged in the valve body and arranged on the valve element in a sleeving mode, the valve base comprises an upper valve base body and a lower valve base body, the upper valve base body is located between the piston and the valve body, a slurry reflux tank hole is formed in the upper valve base body and communicated with an inner cavity of the valve body, and a slurry reflux hole is formed in the valve body and communicated with the slurry reflux tank hole. According to the backpressure valve, due to the fact that slurry in a well can be automatically injected into a drill pipe and does not need to be injected into the drill pipe by connecting a slurry injection device to the drill pipe whenever a part of the drill pipe is put down, the work amount is greatly decreased, the slurry injecting cost is effectively reduced, the condition that the slurry in the well is reversely sprayed into the drill pipe through an inner cavity of the valve body is effectively prevented, and then well drilling safety is guaranteed.

Owner:CHENGDU ZHUOXIN IND

Novel Roots blower material conveying device

PendingCN107499940APrevent blowbackSmall pressure lossBulk conveyorsPackagingSocial benefitsElectric machine

The invention aims to provide a novel Roots blower material conveying device comprising a material storage bin, a spiral propeller, a receiving hopper and a Roots blower. A material outlet in the lower portion of the material storage bin communicates with a feeding port of the spiral propeller; a rotating shaft of the spiral propeller is connected with a rotating shaft of a motor to form a material propelling structure; a discharging port of the spiral propeller communicates with a rotary valve through a pipeline, wherein the rotary valve is mounted at an upper opening of the receiving hopper and used for material adding; an air inlet pipeline on the lower portion of the receiving hopper communicates with an air outlet of the Roots blower, and a pipeline, with an inclined-surface-shaped outlet, on the lower portion of the receiving hopper communicates with a positive pressure conveying pipeline; and the bottoms of the air inlet pipeline, the pipeline with the inclined-surface-shaped outlet and the positive pressure conveying pipeline are on the same plane. The novel Roots blower material conveying device is simple in structure, novel, unique and convenient to mount and use, material reverse injection caused by pipeline blockage is effectively solved, the pressure loss of the positive pressure pipeline is reduced, energy consumption is reduced, the working efficiency is high, and the economic and social benefits are remarkable.

Owner:佳诺威集团(河南)新材料有限公司

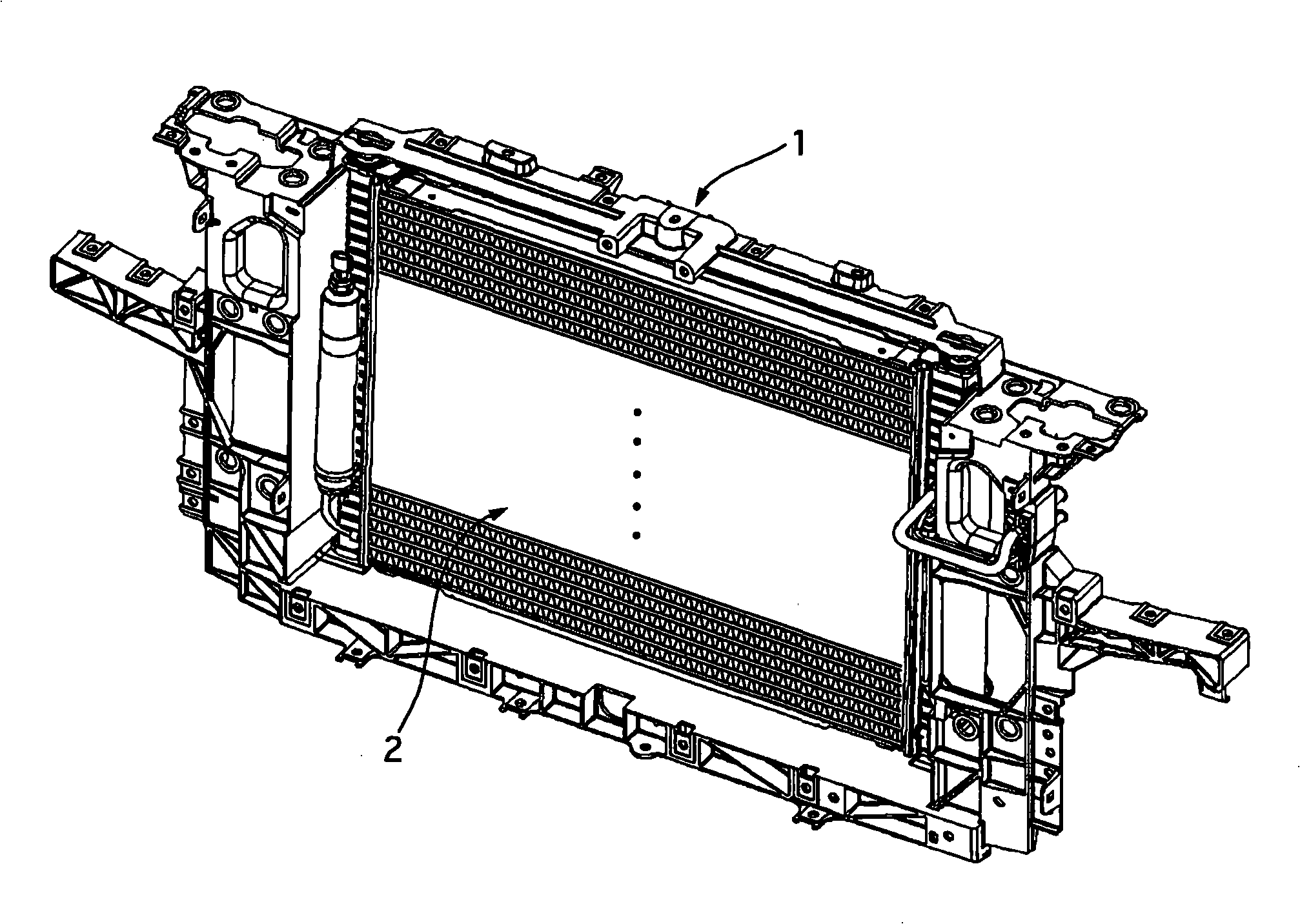

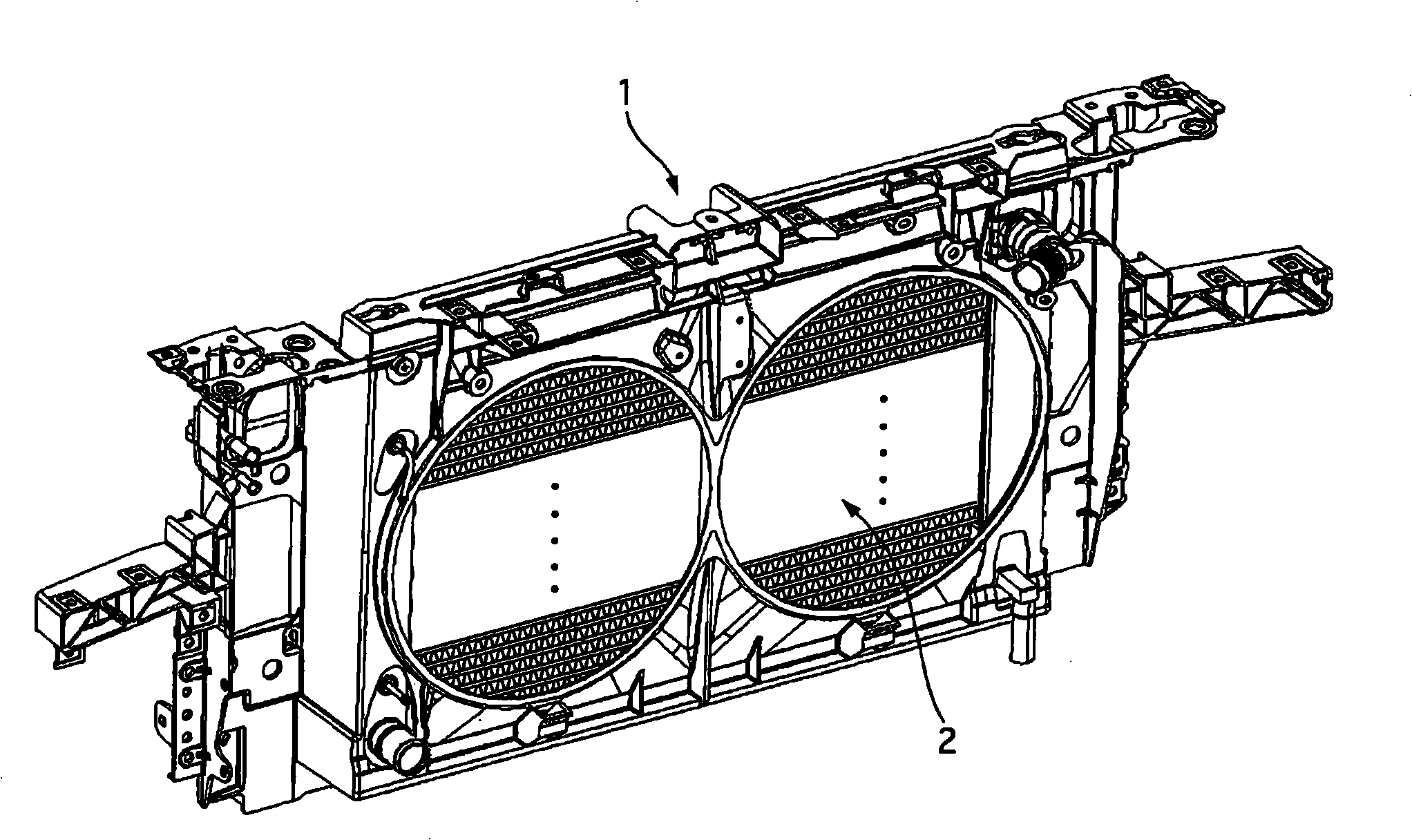

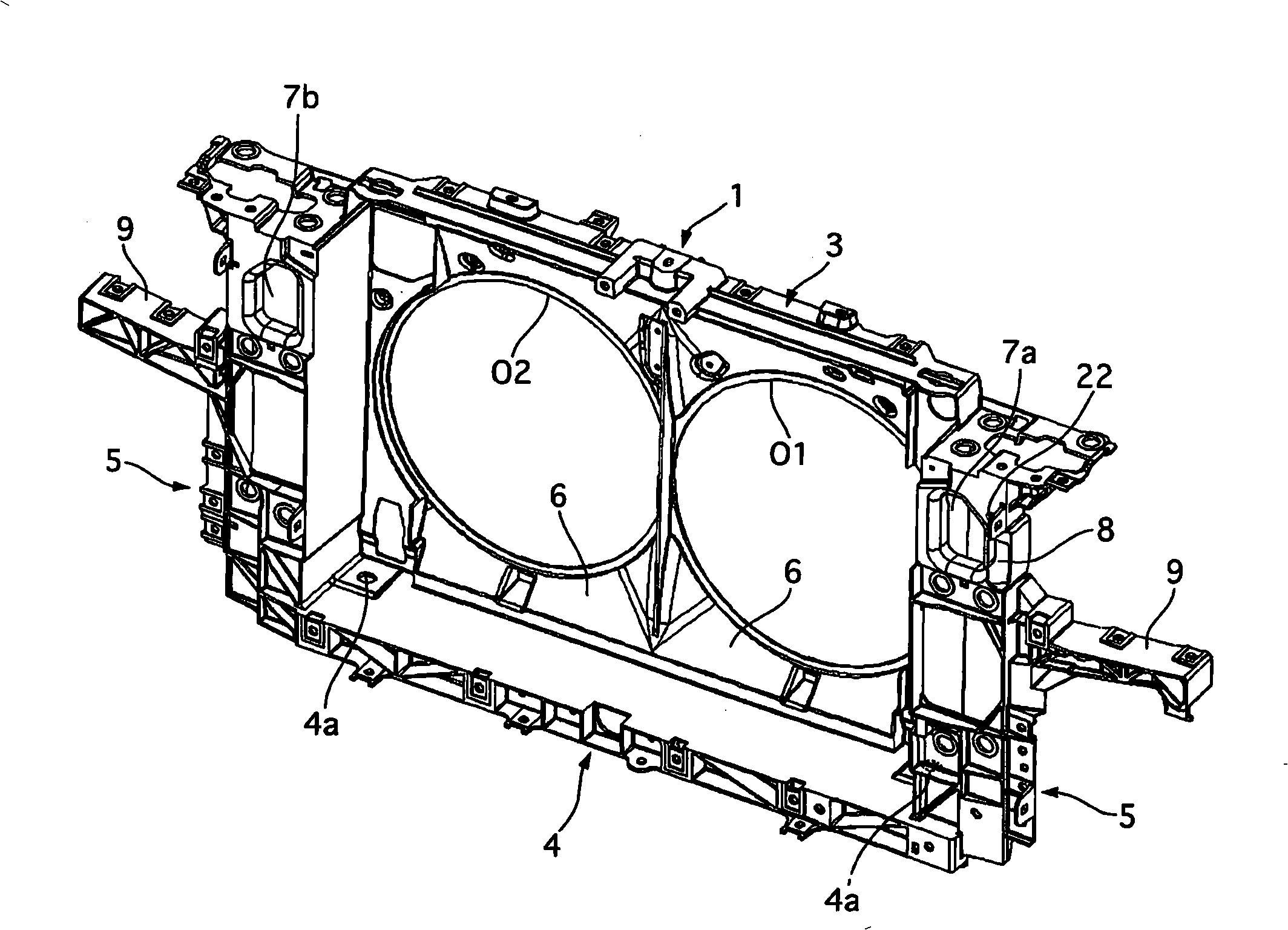

Radiator core support

InactiveCN101300149ASmooth connectionPrevent blowbackAir-treating devicesEvaporators/condensersEngineeringHeat spreader

The invention provides a radiator core support. A condenser (10) is placed in front, relative to the vehicle, of a radiator core support (1). Also, connection ends, for connection to the vehicle, of piping (30, 31) of the condenser (10) are placed penetrated through through-holes (8) and projected to the rear side of the vehicle, the through-holes being formed in the radiator core support (1). A bracket (40) is provided at the radiator core support (1), and the bracket (40) is capable of fixedly supporting the piping (30, 31) with gaps between the piping (30, 31) and the through-holes (8) closed.

Owner:CALSONIC KANSEI CORP

Double-layer gas atomizing nozzle suitable for field of metal powder preparation

The invention relates to a double-layer gas atomizing nozzle suitable for the field of metal powder preparation. The double-layer gas atomizing nozzle mainly comprises a straight air inlet, an upper atomizing nozzle, a liquid guiding pipe and a lower atomizing nozzle; during the atomization process of the metal powder, the upper nozzle and the lower nozzle are used for atomizing the molten metal flowing out of the liquid guide pipe at the same time, the lower-layer nozzle provides high-speed jet flow for melt-liquid atomization, the upper-layer nozzle is used for preventing backflow generatedby atomization of the lower-layer nozzle, and providing an appropriate outlet suction negative pressure for the outlet of the diversion pipe. The double-layer gas atomizing nozzle solves the problem of obstruction of metal melt flow in a traditional restricted nozzle reflux area and has the characteristics of being simple in structure, convenient to adjust and high in reliability.

Owner:BEIHANG UNIV +1

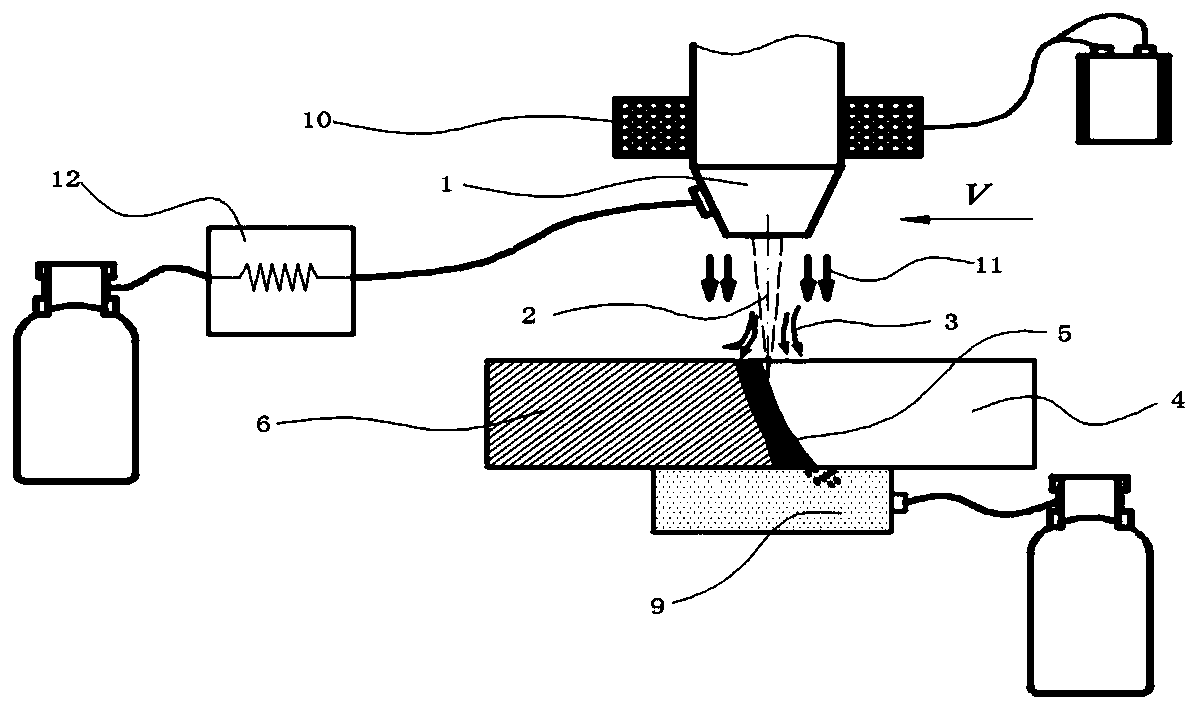

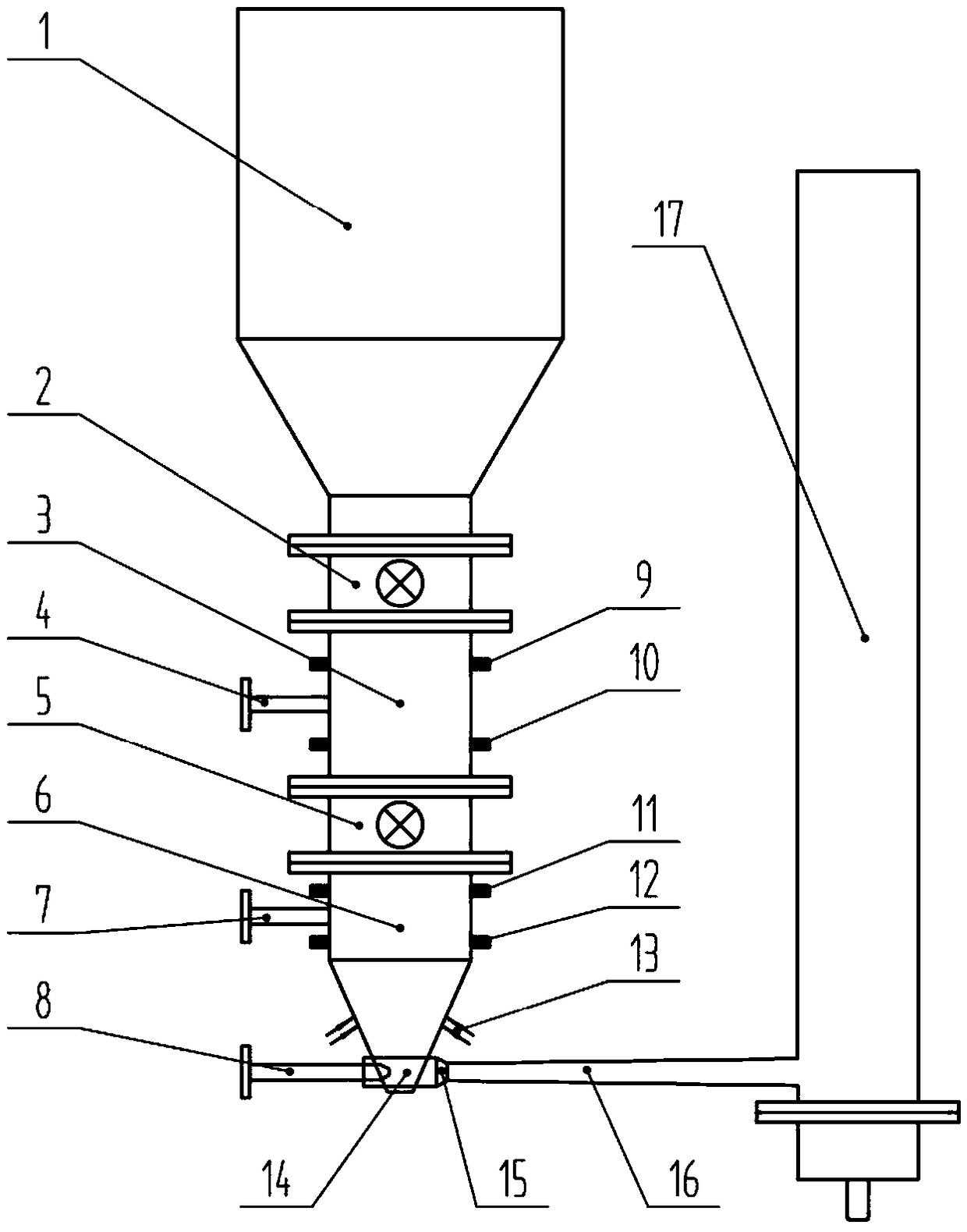

Voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking

ActiveCN109305564AThe feeding process is controllablePrevent blowbackBulk conveyorsAutomatic controlBiomass

The invention relates to a voltage stabilization-continuous pneumatic conveying feeding system for biomass thermal cracking, and belongs to the technical field of biomass thermal cracking. The voltagestabilization-continuous pneumatic conveying feeding system comprises a material transition bin, a conical pressure bin, a material receiving chamber and the like. A dual-material bin and a double butterfly valve design are adopted by the feeding system, so that the effects of pressure isolation, air locking and environment sealing are achieved, the feeding process is controllable, the phenomenonthat materials are reversely sprayed is avoided, and the reliability and the stability of the thermal cracking process are improved. A laser-photosensitive sensor and a PLC are used as an automatic control system, a two-stage electric butterfly valve is adopted as an execution component, and the materials automatically fall into the conical pressure bin from the material transition bin. Aerationair is added into the conical section of the conical pressure bin, and the materials in the conical pressure bin are fluidized, so that the phenomena of bridging, wall hanging and material bursting are avoided. Thermal cracking by-product non-condensable gas generated by biomass rapid thermal cracking which serves as spraying, pressurization and pressure maintaining gas is adopted by the feeding system, so that resources can be saved, self-powered energy is achieved, and pollution is avoided.

Owner:BEIJING FORESTRY UNIVERSITY

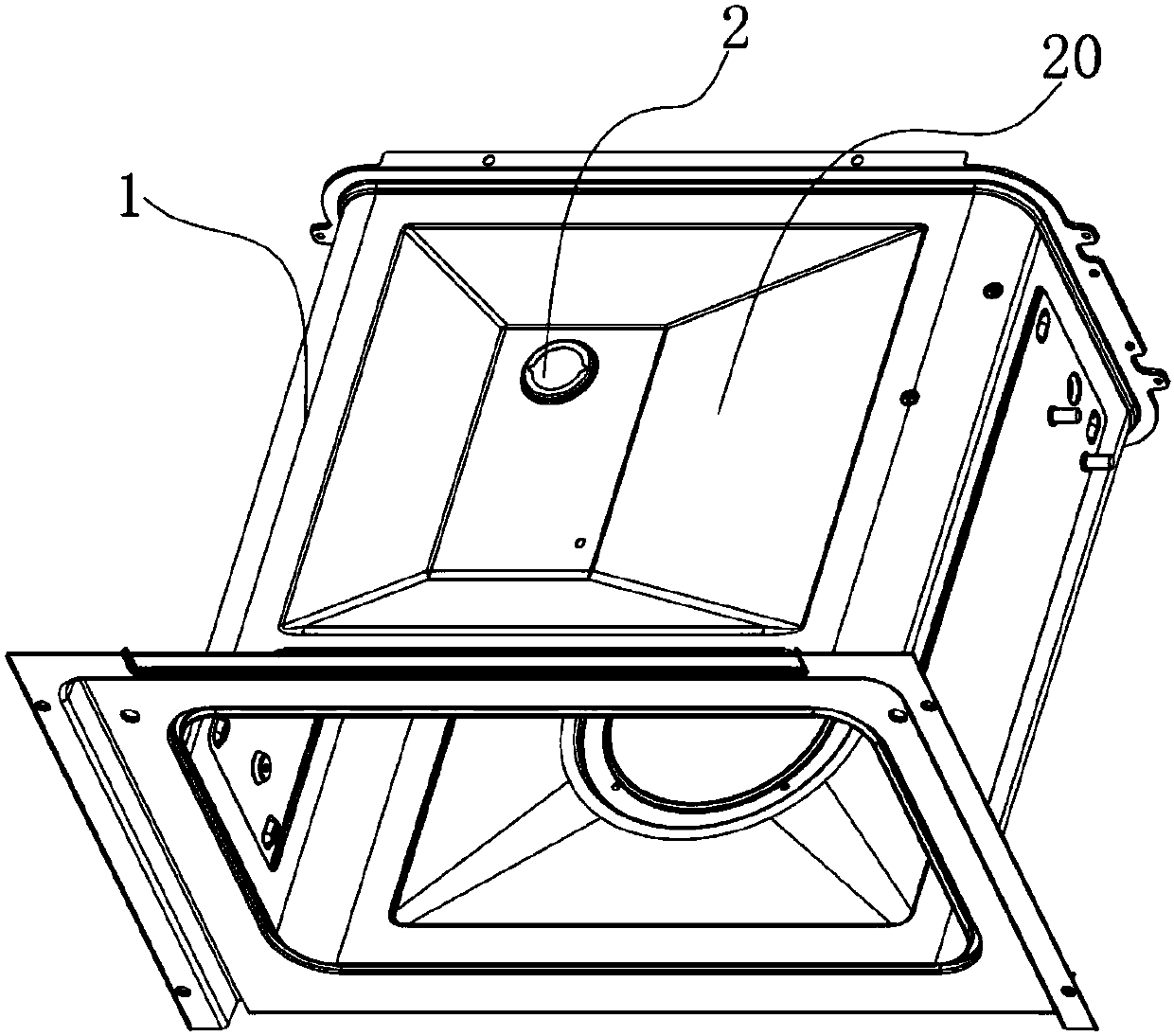

Embedded electric-steamer steam discharge system

InactiveCN107912966AImprove structural stabilityReduce the temperatureSteam cooking vesselsElectricityThermal insulation

The invention discloses an embedded electric-steamer steam discharge system. The embedded electric-steamer steam discharge system comprises an electric-steamer inner container, a thermal-insulation plate, a steam guide tube, a steam discharge cover, a cover base plate and a cooling fan and is characterized in that the top surface of the electric-steamer inner container is provided with a steam outlet, a steam discharge channel is formed between the steam discharge cover and the cover base plate, one side, located at the gate of the electric-steamer inner container, of the steam discharge channel is open to form a steam discharge outlet, the other side, opposite to the steam discharge outlet, of the steam discharge channel is open to form an air inlet, the cooling fan is fixed outside the thermal-insulation plate, the air outlet tube of the cooling fan is connected with the air inlet, the cover base plate is provided with a metal flow-guide cover, a steam cavity is formed between the metal flow-guide cover and the cover base plate, the lateral wall of the steam cavity is provided with a steam guide outlet, the steam discharge direction of the steam guide outlet is vertical to the air discharge direction of the cooling fan, the top of the steam cavity is provided with a steam hole, the bottom of the steam cavity is provided with a steam inlet, the steam guide tube is located between the electric-steamer inner container and the cover base plate, and the steam inlet and the steam outlet are communicated with each other through the steam guide tube. The embedded electric-steamersteam discharge system is convenient to mount, good in sealing effect, capable of sufficiently cooling discharge steam, high in use safety and the like.

Owner:HANGZHOU DE&E ELECTRICAL CO LTD

Blowdown pipe for defecation nursing machine

The invention relates to the field of cleaning and nursing, and discloses a blowdown pipe for a defecation nursing machine. The blowdown pipe comprises a blowdown pipe wall and an interlayer, wherein an inner cavity of the blowdown pipe is arranged in the blowdown pipe; the interlayer is adhered to the inner side of the blowdown pipe wall; the inner cavity of the blowdown pipe is divided by the interlayer so as to form a closed inner cavity of the interlayer; the interlayer protrudes towards the center of the blowdown pipe and extends along the length direction of the blowdown pipe; the blowdown pipe wall is a waterproof rigid layer; and the interlayer is an airtight elastic layer. The blowdown pipe has the advantages of unobstructed blowdown, difficulty in blockage and water conservation.

Owner:HANGZHOU YINAO INTELLIGENT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com