Oil filling pipe assembly of passenger vehicle

A technology for fueling pipes and passenger cars, applied in the field of fueling pipe assembly, can solve the problems of fueling jumping guns in advance, and achieve the effects of delaying collisions, reducing force, avoiding jumping guns in advance and anti-spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

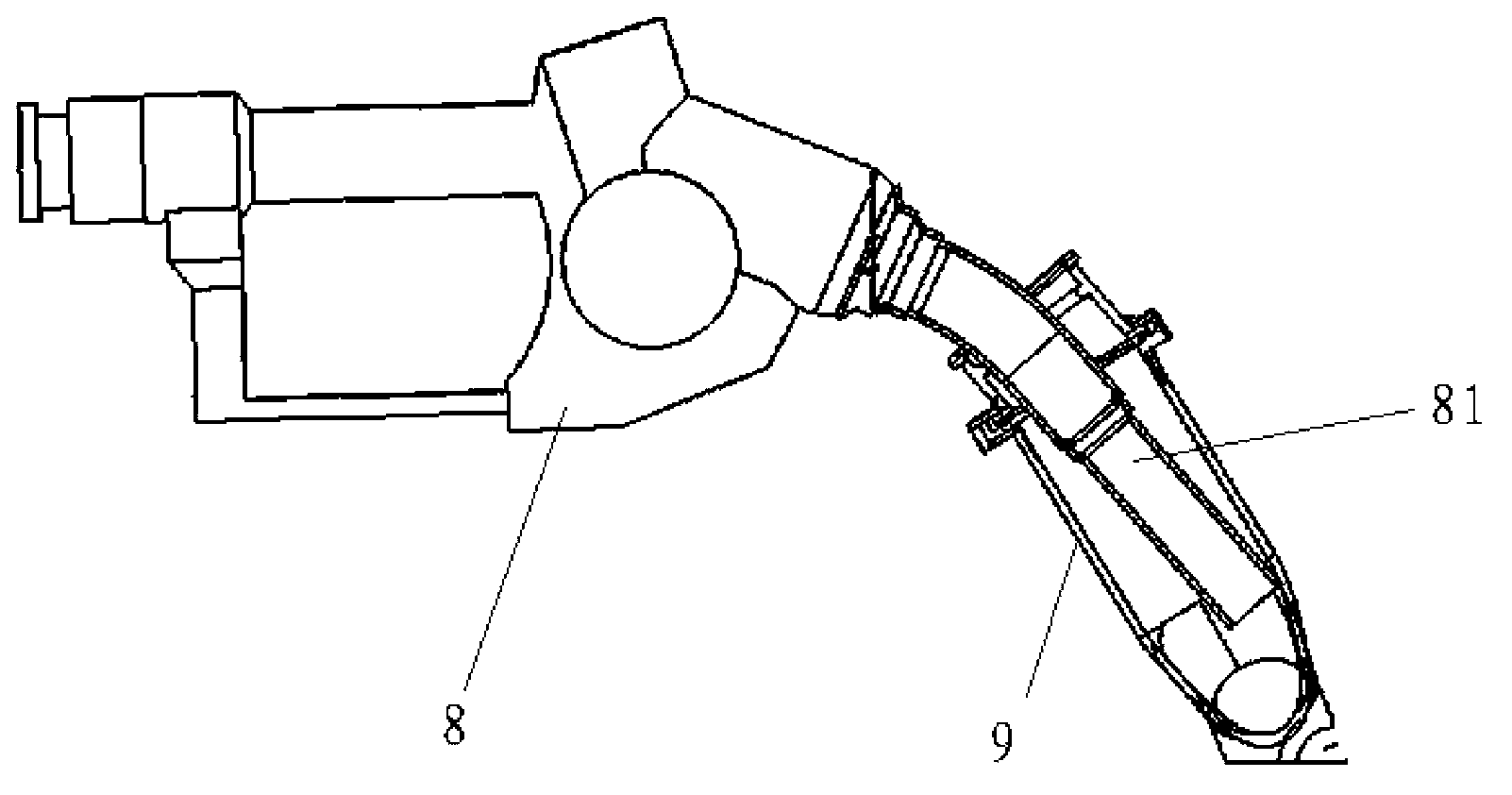

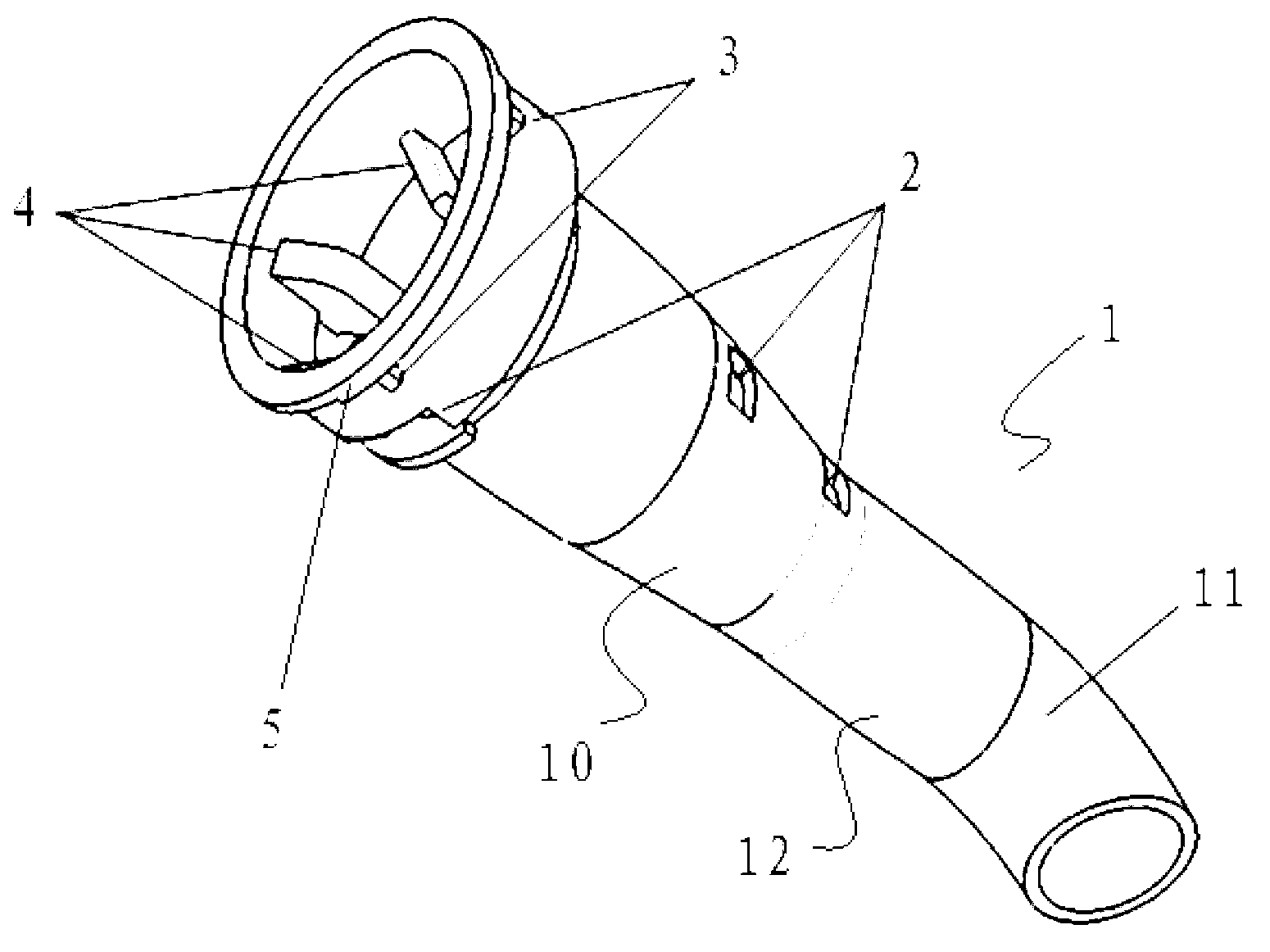

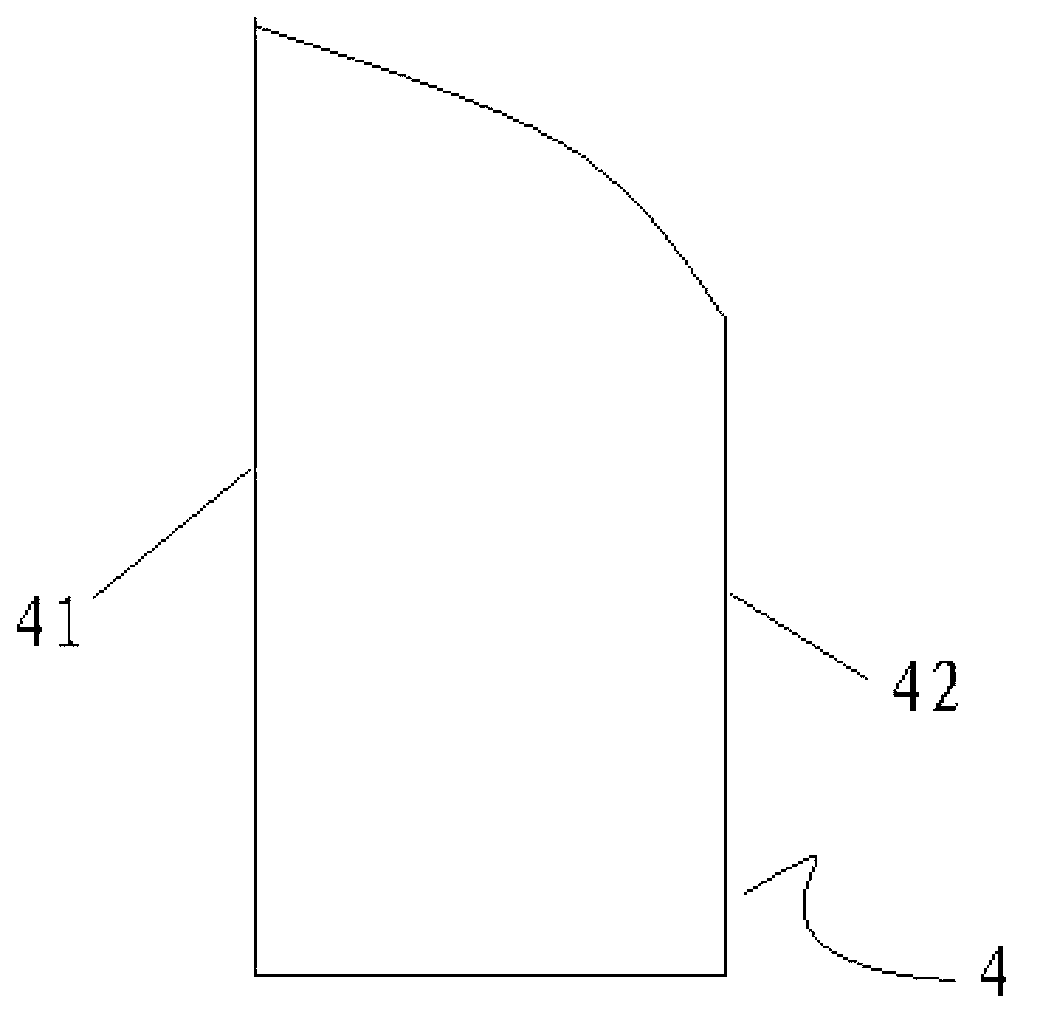

[0020] refer to Figure 2 to Figure 5 , a fuel filler pipe assembly for a passenger car of the present invention includes a fuel filler pipe 9, a guide device 1 is fixed on the fuel filler pipe 9, and the guide device 1 includes a straight-through pipe 10 for the gun barrel 81 to penetrate, A plurality of barrel stoppers 4 are arranged at intervals along the circumferential direction of the inner wall above the straight-through pipe 10 , preferably the plurality of barrel stoppers 4 are equidistantly arranged on the circumferential direction of the inner wall of the straight-through pipe 10 . refer to image 3 , the barrel stop block 4 includes a connection end 41 for fixing the inner wall of the straight-through pipe 10, and the opposite end 42 of the connection end of the plurality of barrel stop blocks 4 surrounds a hole for the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com