Patents

Literature

89results about How to "Raise emission levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

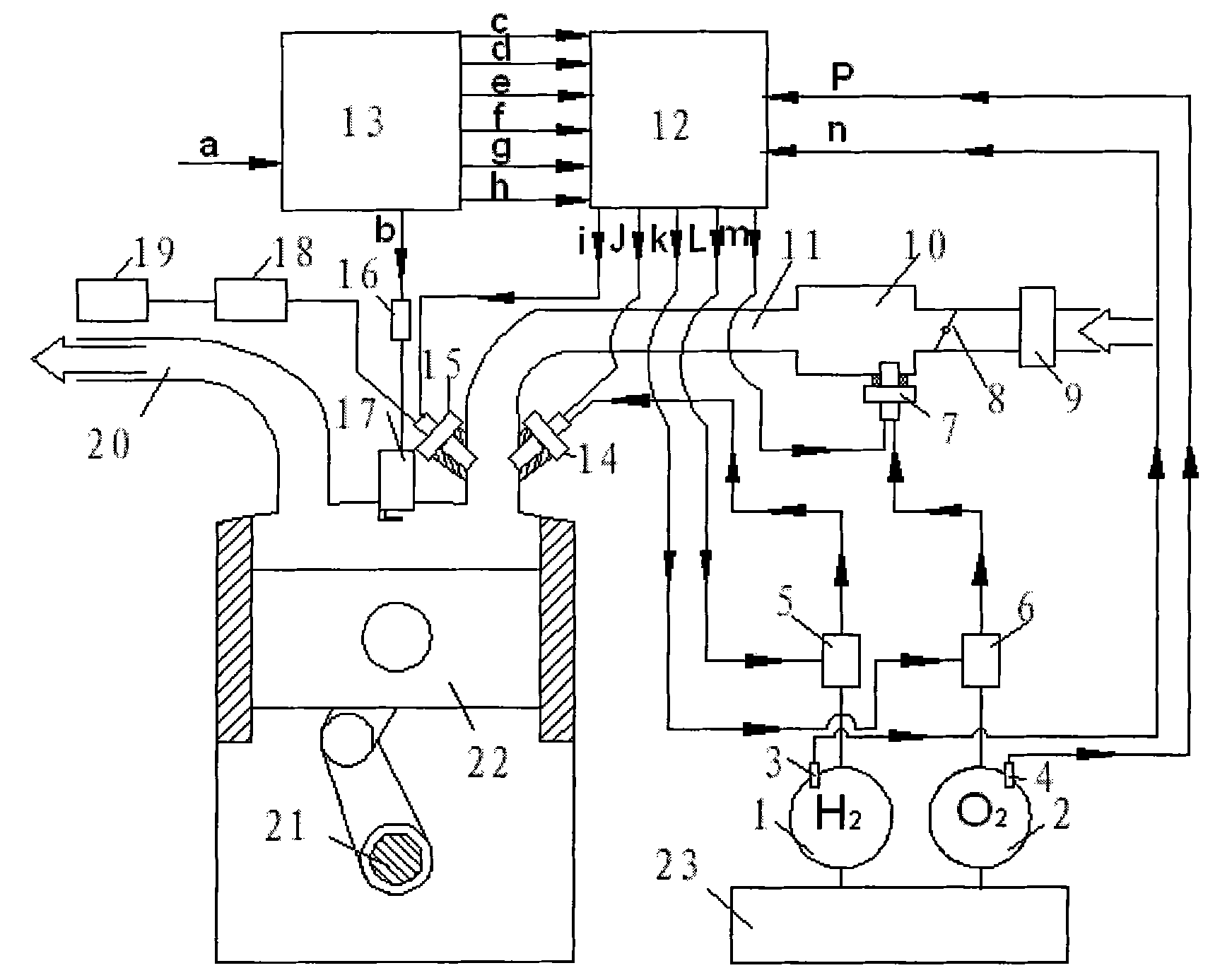

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

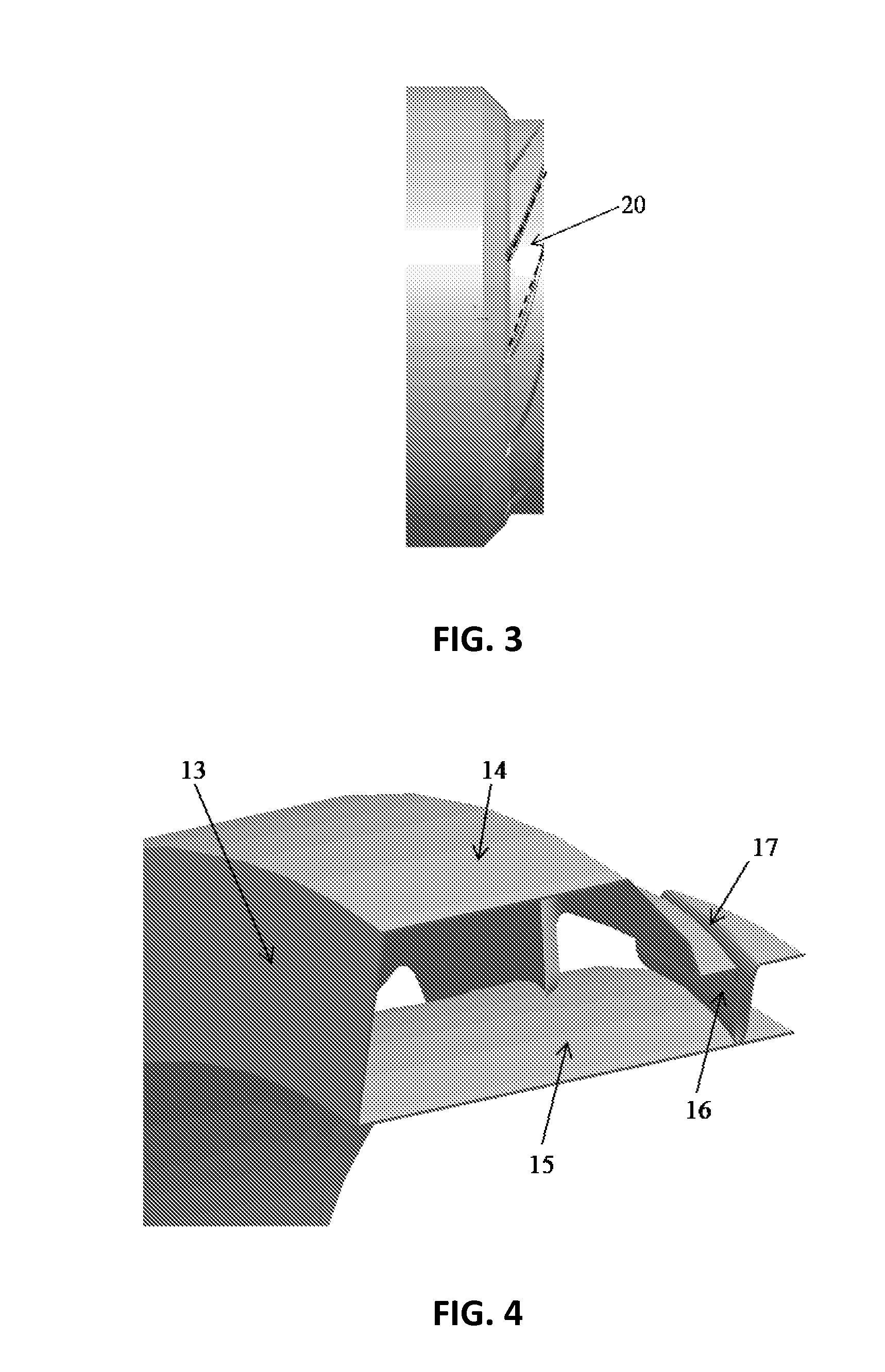

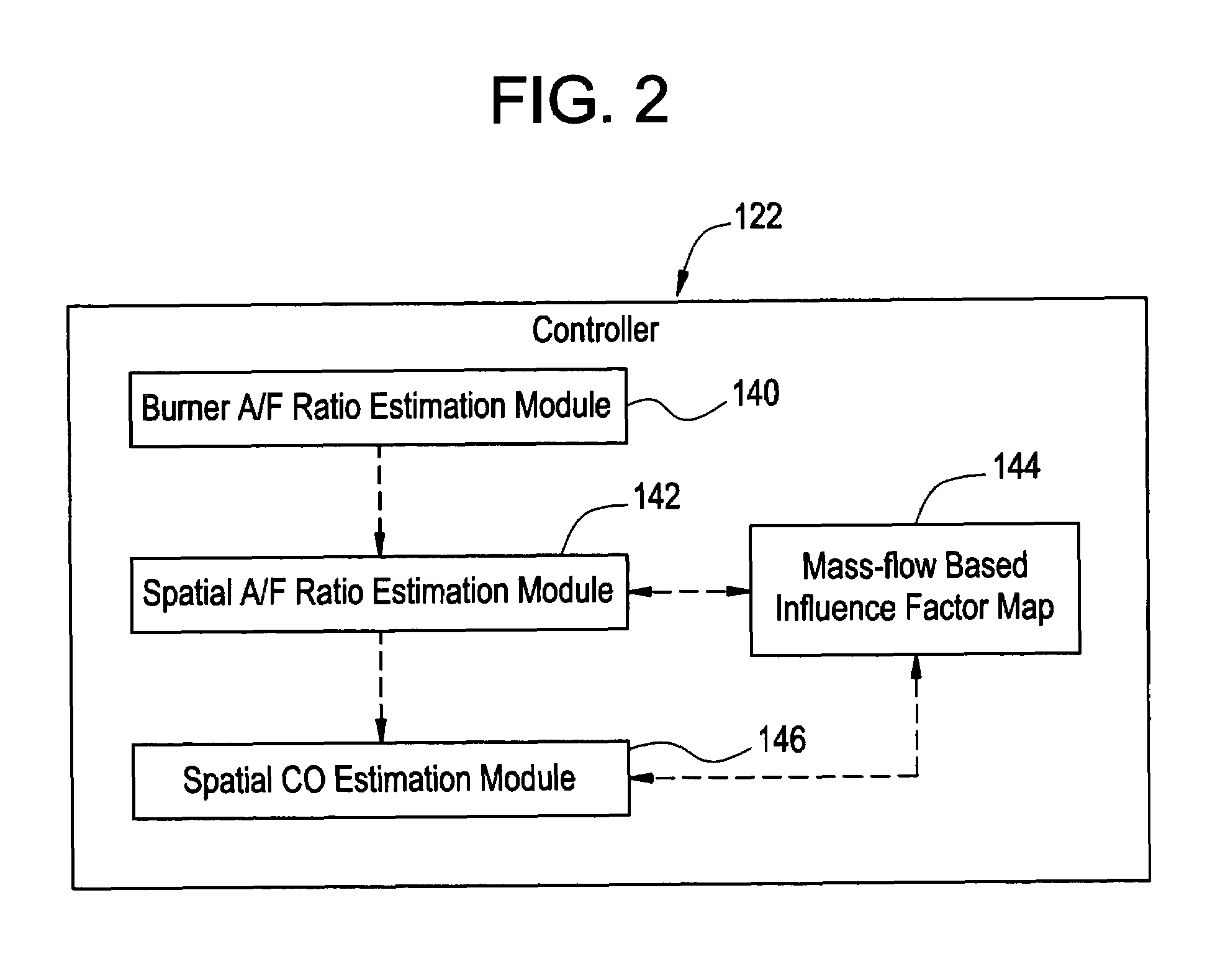

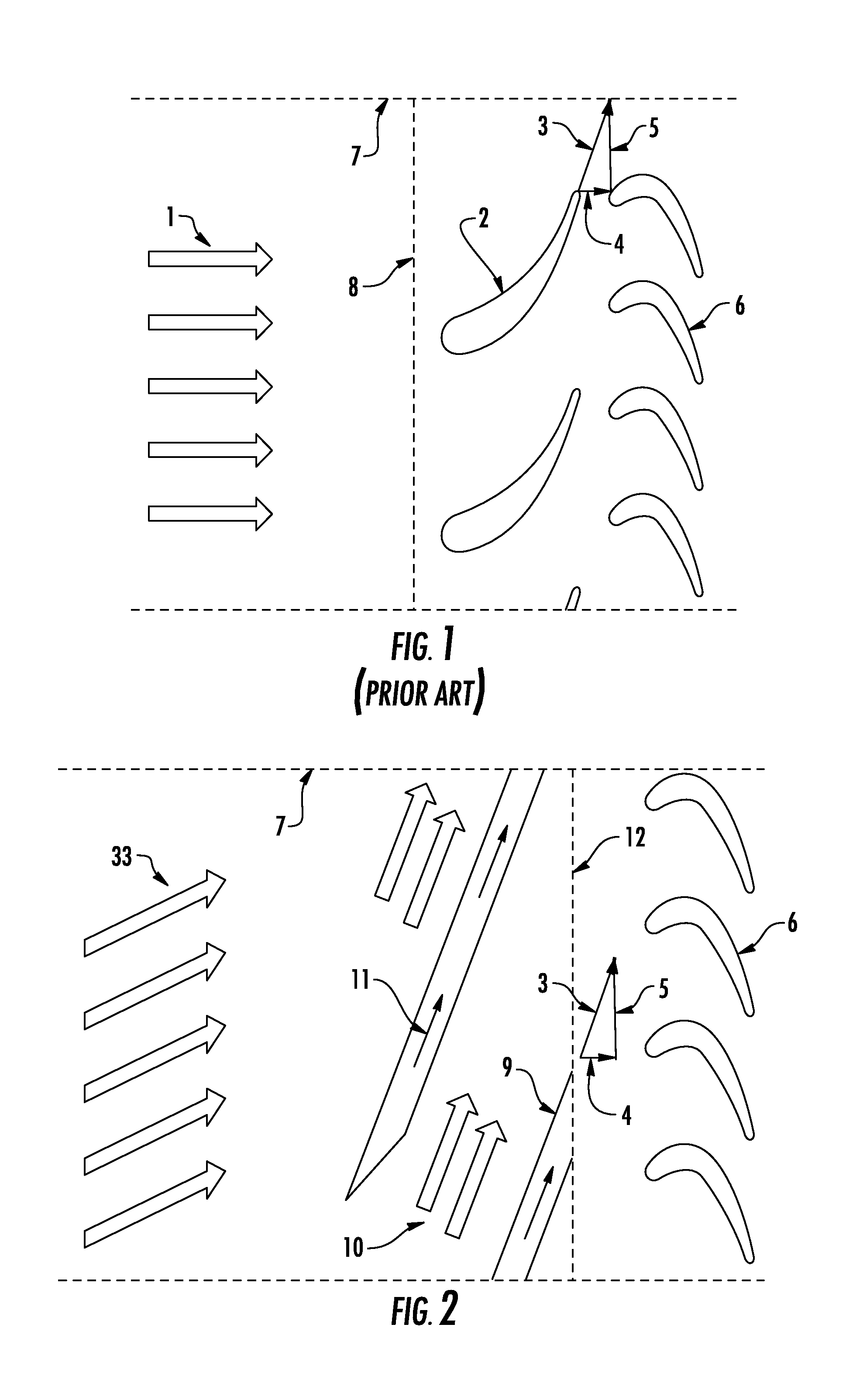

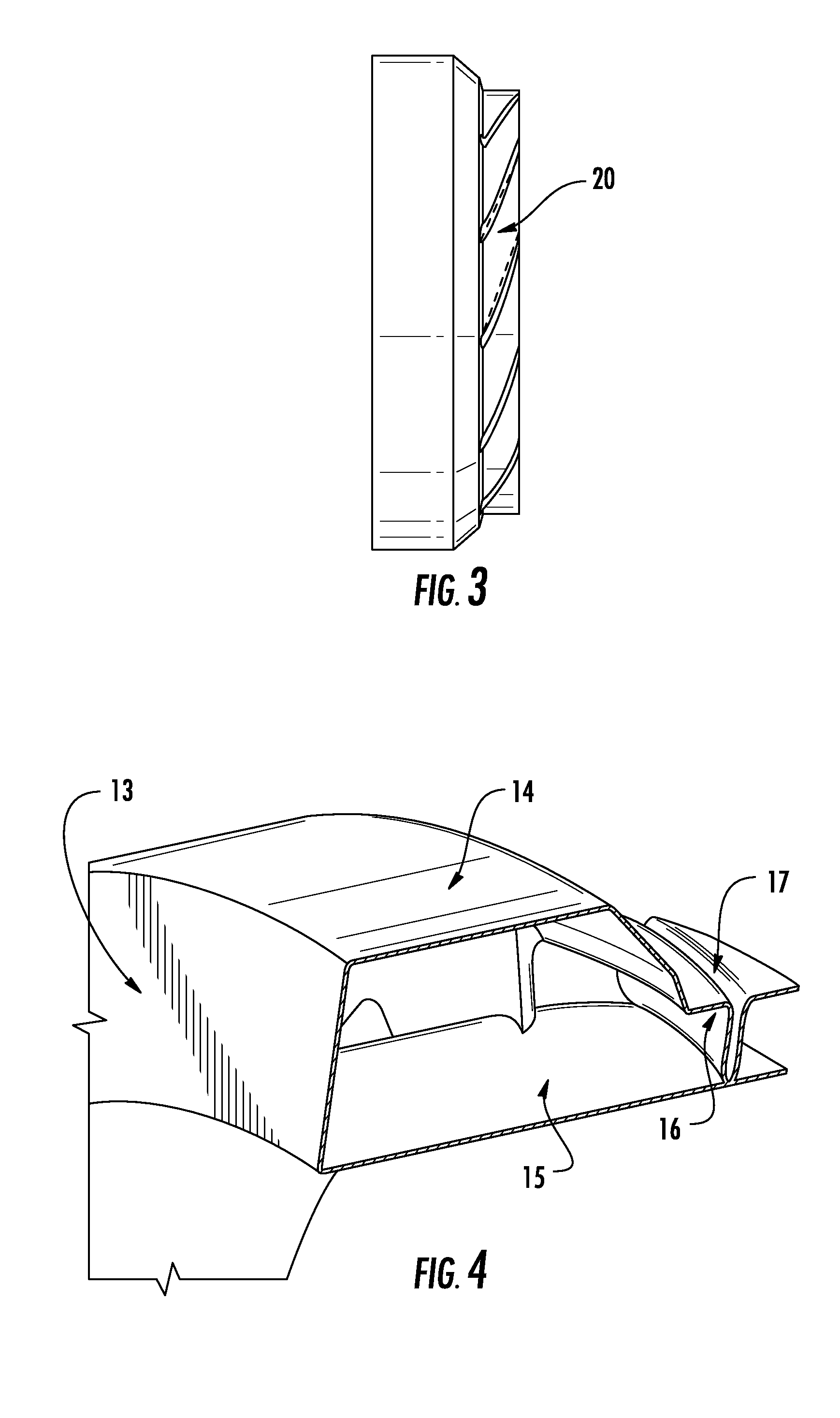

Tangential combustor with vaneless turbine for use on gas turbine engines

ActiveUS20110209482A1Shorten the lengthReduce manufacturing costContinuous combustion chamberGas turbine plantsTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

Pollution control system for kiln exhaust

InactiveUS20140170046A1Reduction of organic compound and other emissionAvoid cloggingGas treatmentOrganic chemistryPtru catalystPorous medium

Disclosed is a method and apparatus for the reduction of organic compounds and other emissions from an industrial plant utilizing a cement or minerals kiln that has a high level of organic compound emissions. The invention consists of a filter for the control of particulate emissions which has been treated with a catalyst to provide catalytic destruction of gaseous emissions as process gases are passed through the porous medium of the filter.

Owner:F L SMIDTH & CO AS

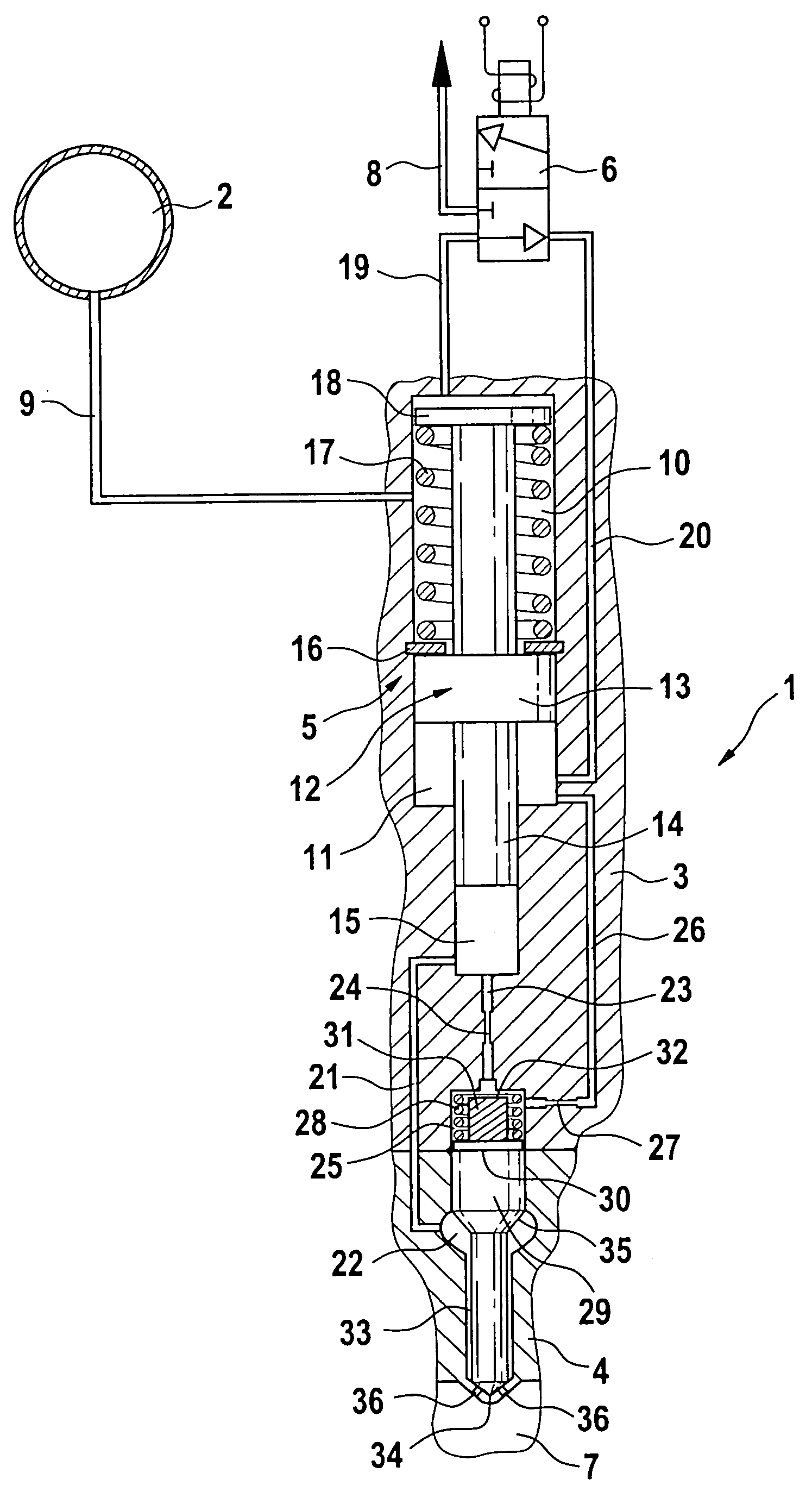

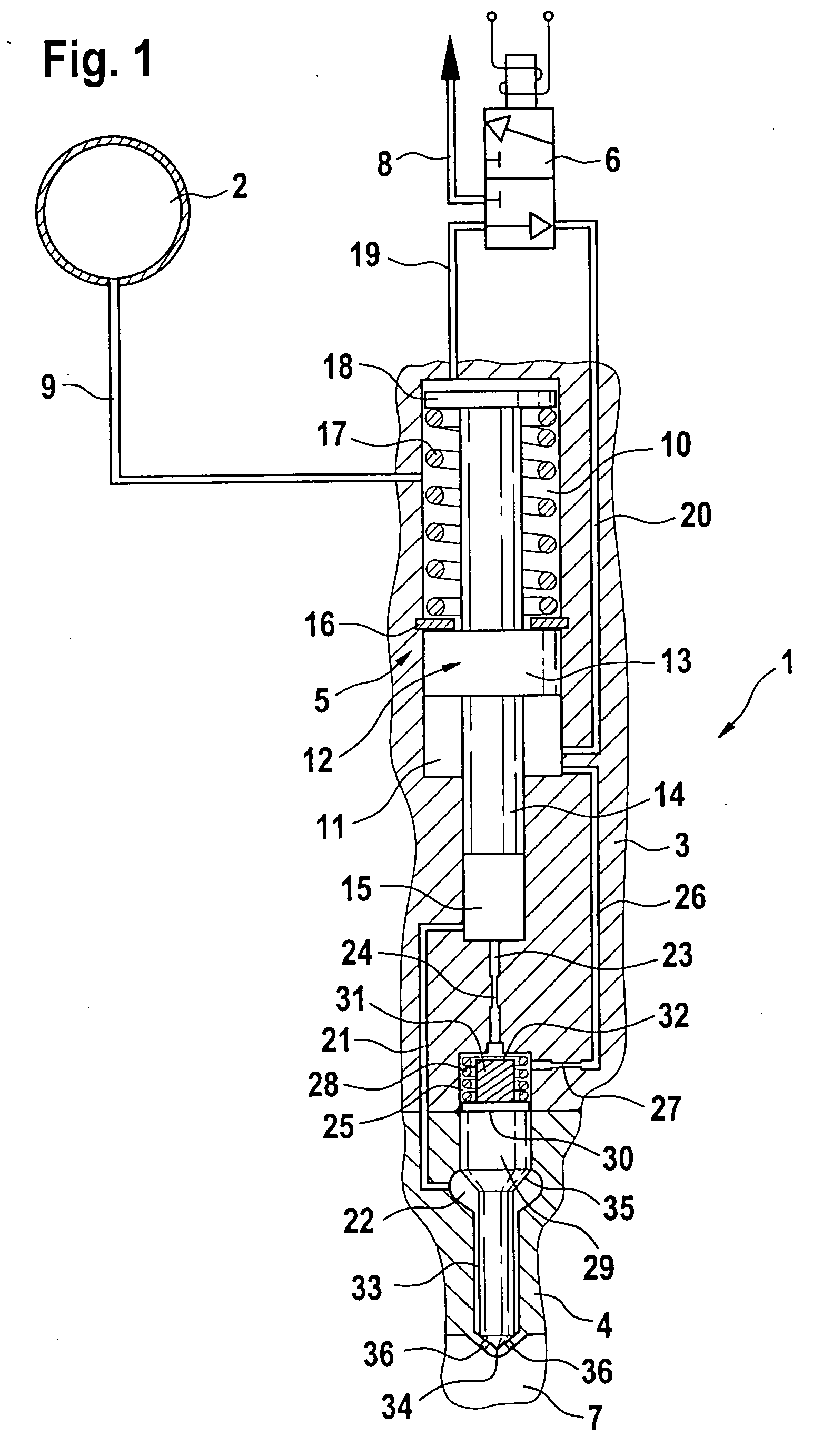

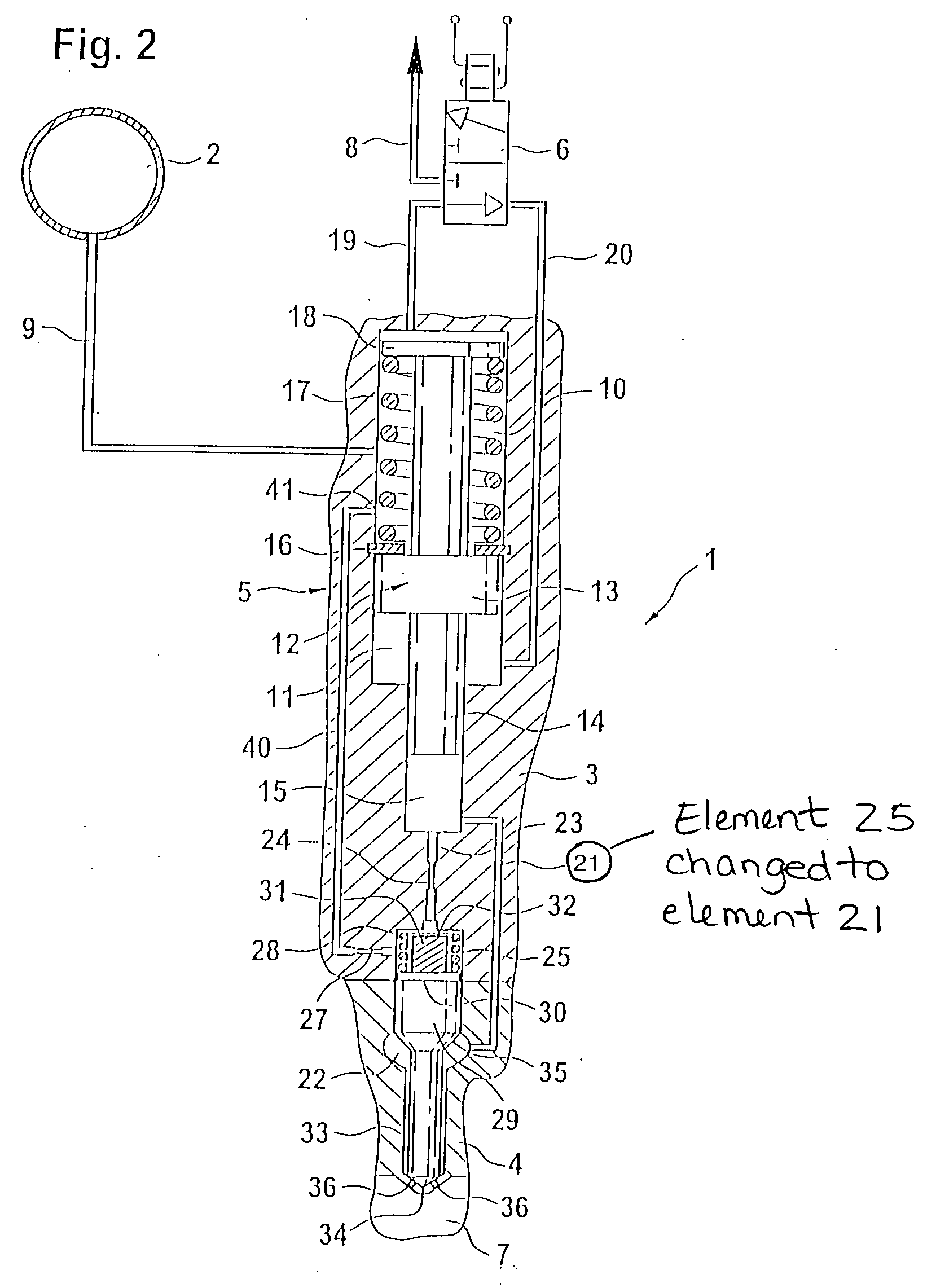

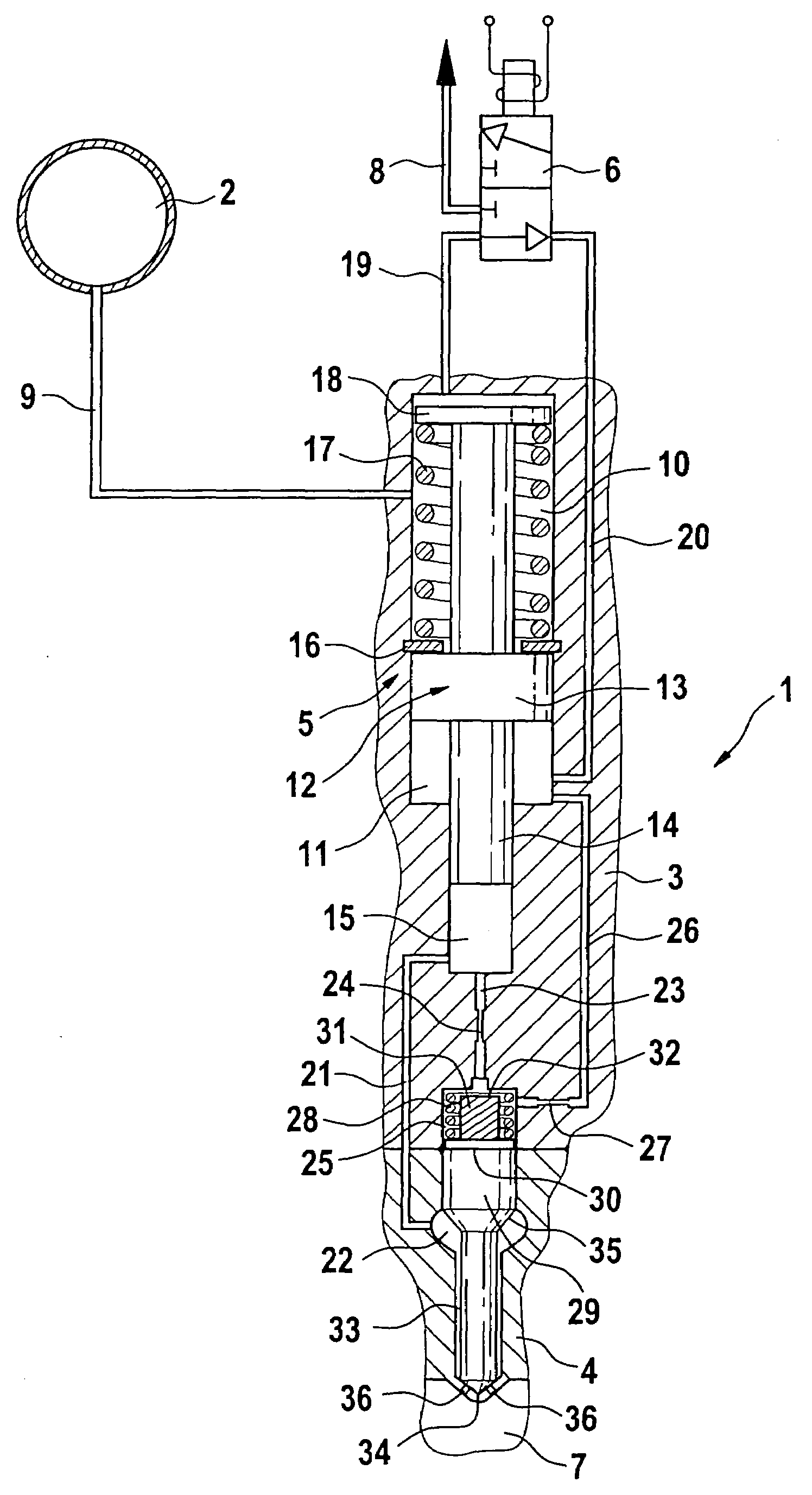

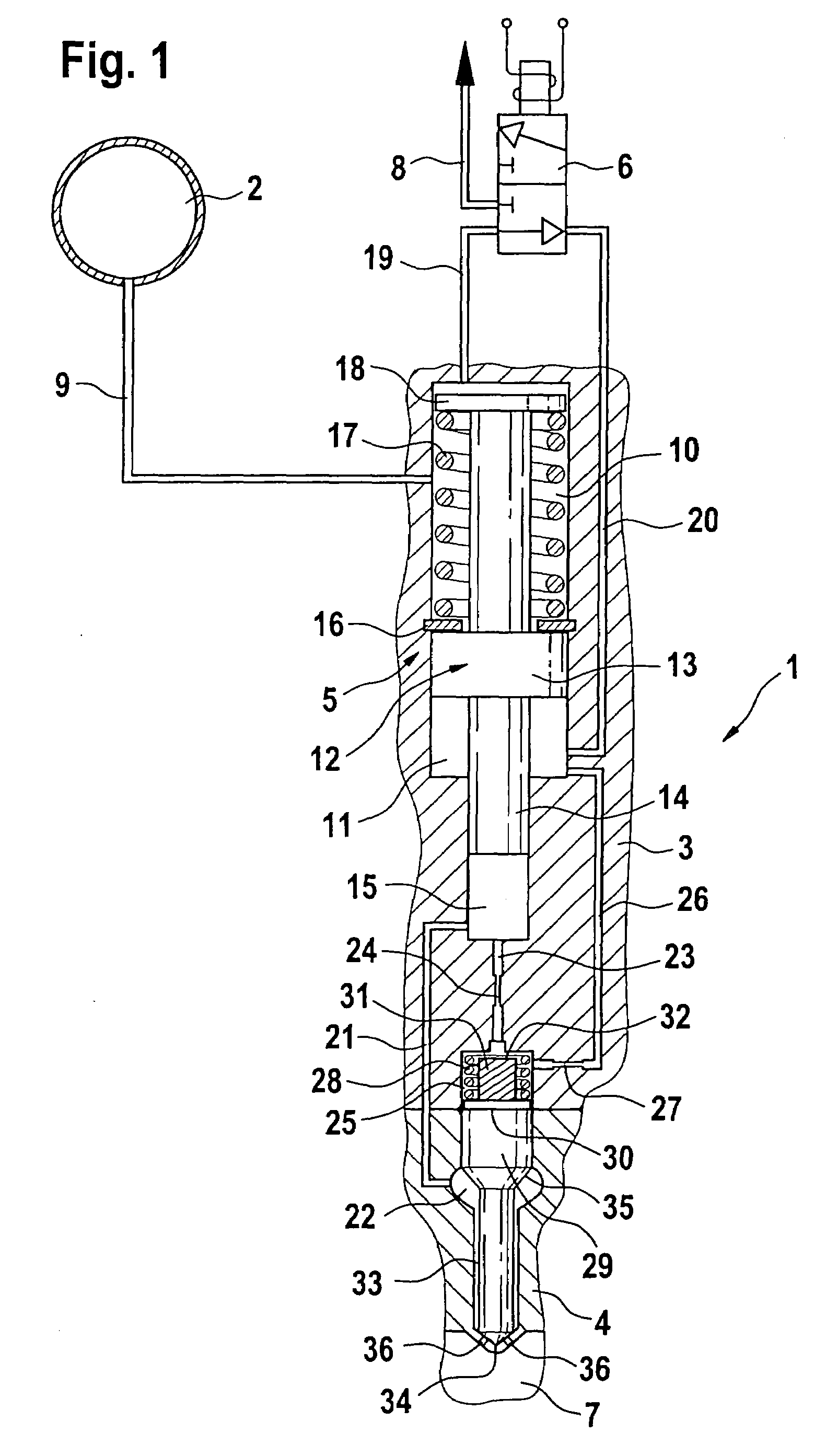

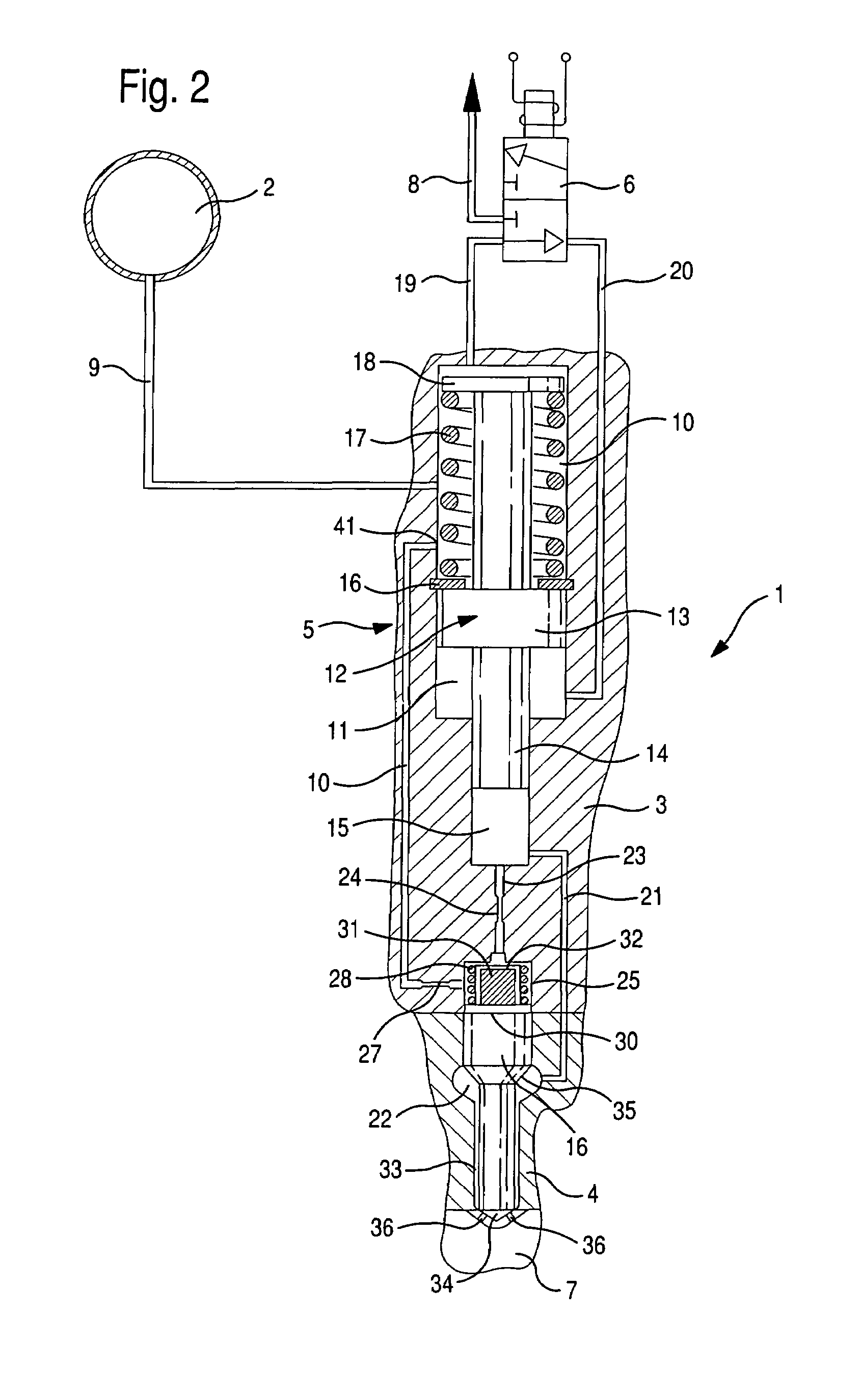

Device for damping the needle lift in fuel injectors

InactiveUS20050077378A1Quick closeRaise emission levelsMachines/enginesFuel injecting pumpsCombustion chamberPiston

A fuel injection apparatus for injecting fuel into the combustion chambers of an internal combustion engine includes a high pressure accumulator, a pressure booster, and a metering valve. The pressure booster includes a working chamber and a control chamber that are separated from each other by an axially movable piston. A pressure change in the control chamber produces a pressure change in a compression chamber that acts on a nozzle chamber via a fuel inlet. The nozzle chamber encampasses a nozzle needle. A nozzle spring chamber that acts on the injection valve element can be filled on the high-pressure side via a line that leads from the compression chamber and contains an inlet throttle restriction. On the outlet side, the nozzle spring chamber is connected to a chamber of the pressure booster via a line that contains an outlet throttle restriction.

Owner:ROBERT BOSCH GMBH

Device for damping the needle lift in fuel injectors

InactiveUS7083113B2Eliminate useImproves minimum quantity capacityMachines/enginesFuel injecting pumpsCombustion chamberControl room

A fuel injection apparatus for injecting fuel into the combustion chambers of an internal combustion engine. includes a high pressure accumulator, a pressure booster, and a metering valve. The pressure booster includes a working chamber and a control chamber that are separated from each other by an axially movable piston. A pressure change in the control chamber produces a pressure change in a compression chamber that acts on a nozzle chamber via a fuel inlet. The nozzle chamber encompasses a nozzle needle. A nozzle spring chamber that acts on the injection valve element can be filled on the high-pressure side via a line that leads from the compression chamber and contains an inlet throttle restriction. On the outlet side, the nozzle spring chamber is connected to a chamber of the pressure booster via a line that contains an outlet throttle restriction.

Owner:ROBERT BOSCH GMBH

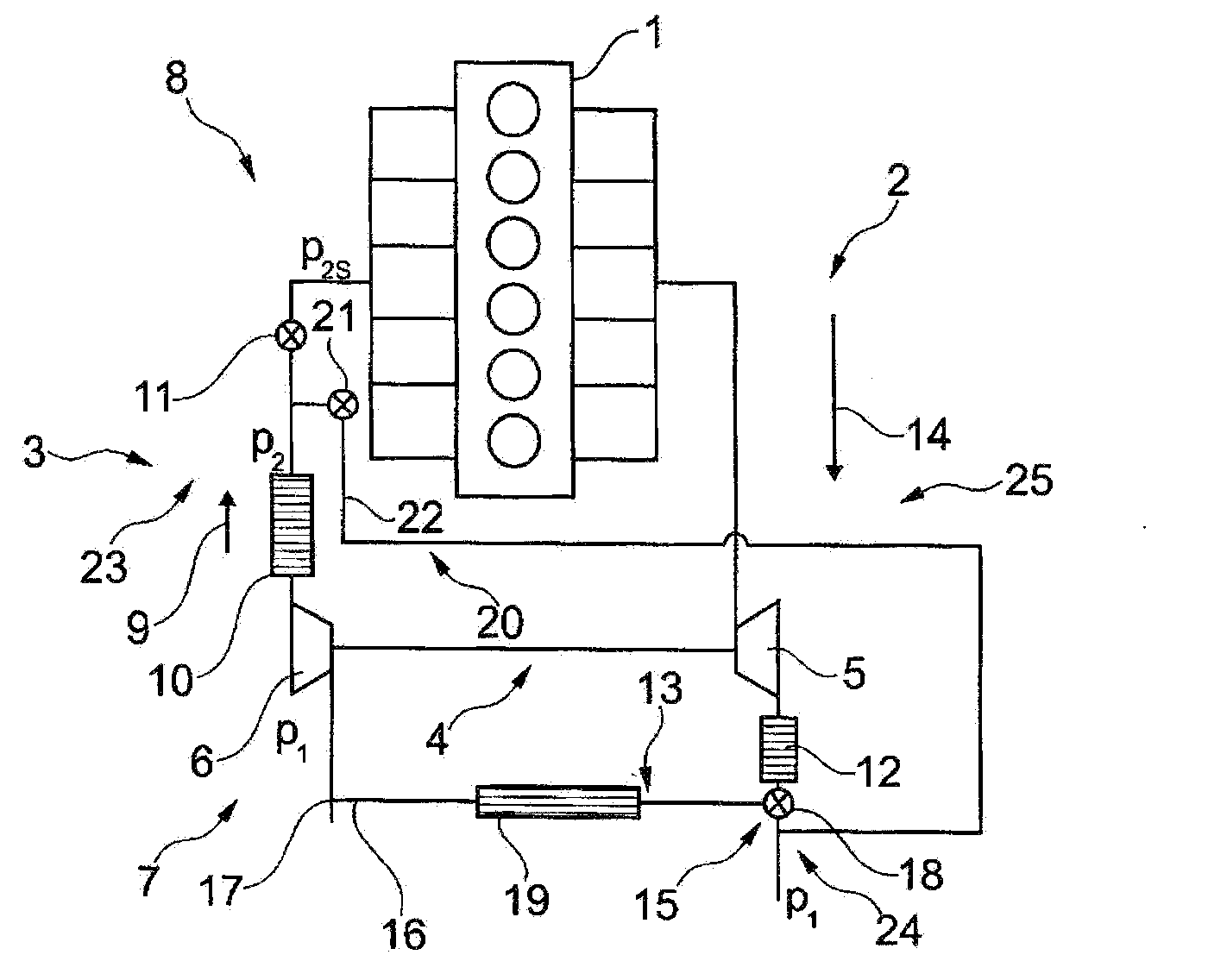

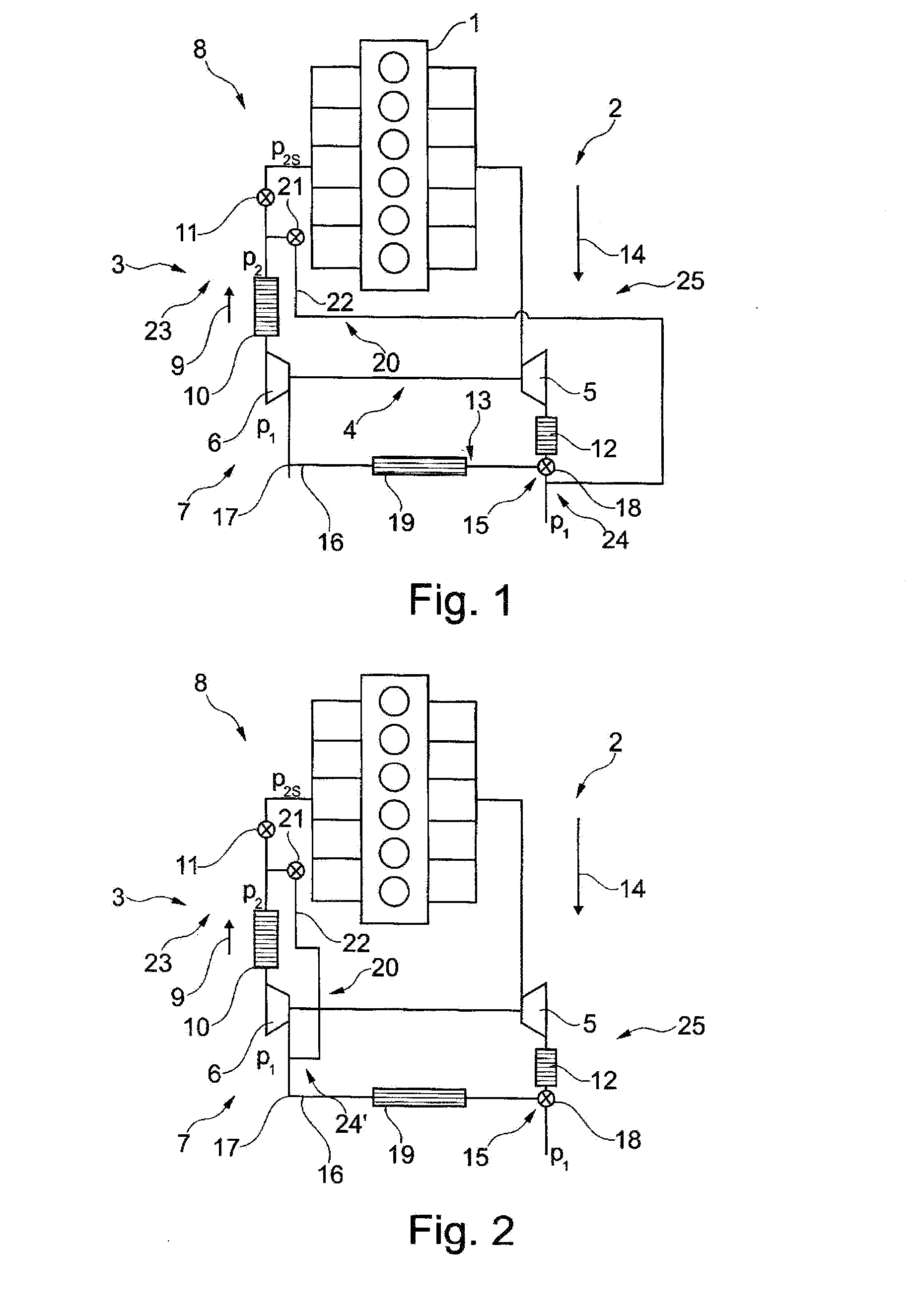

Exhaust gas recirculation arrangement with condensate discharge

InactiveUS20130219886A1Reduce environmental impactLess aggressiveInternal combustion piston enginesNon-fuel substance addition to fuelEnvironment effectExhaust fumes

In an exhaust gas recirculation arrangement in which condensate is discharged from an exhaust gas recirculation path of an internal combustion engine, in particular of a motor vehicle, wherein, due to a pressure difference between a condensate collection region arranged in the EGR path and a condensate discharge region, collected condensate is discharged at least partially from the condensate collection region into the condensate discharge region, when the pressure level prevalent in the condensate collection region is greater than in the condensate discharge region in a secure manner and with low environmental impact.

Owner:DAIMLER AG

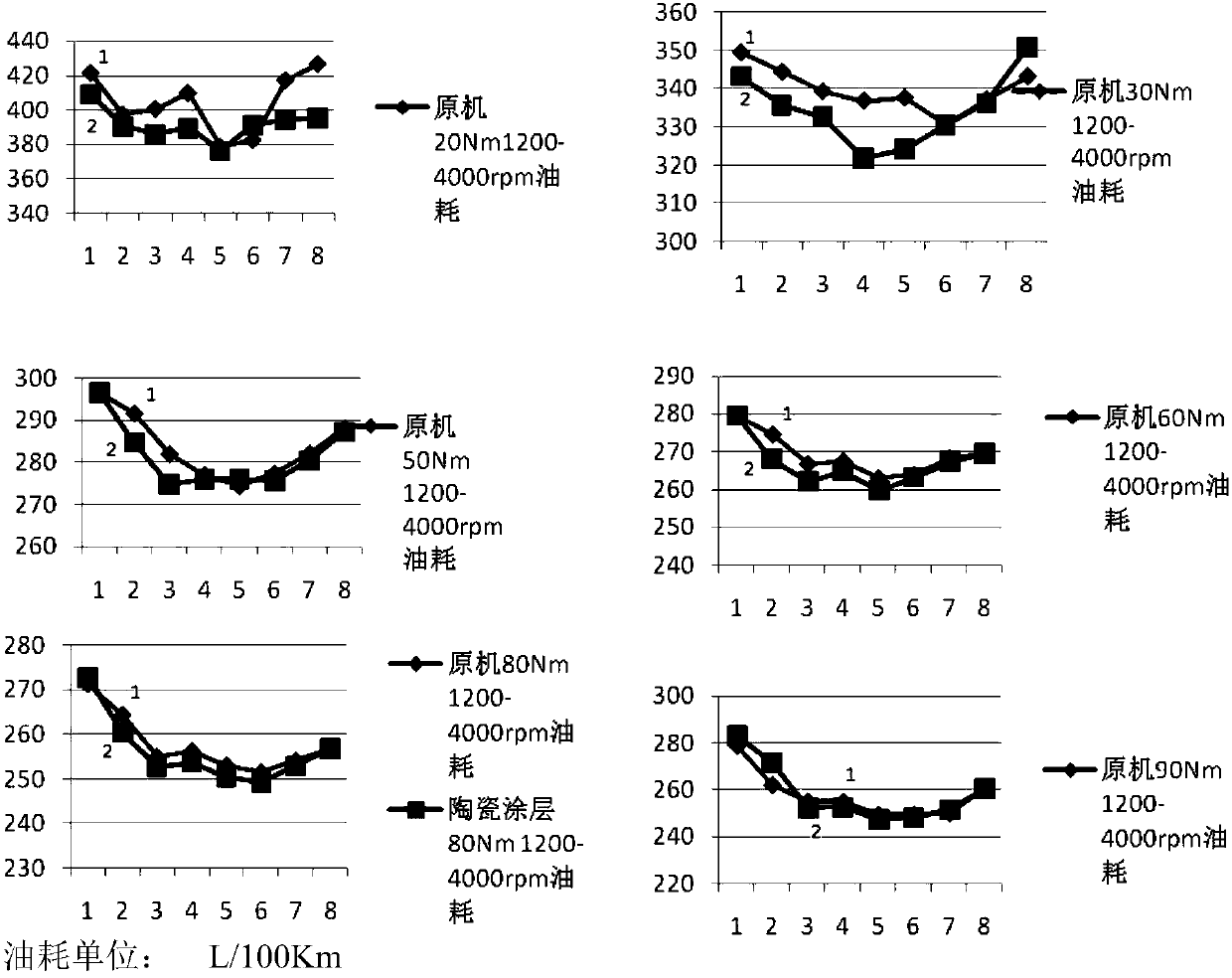

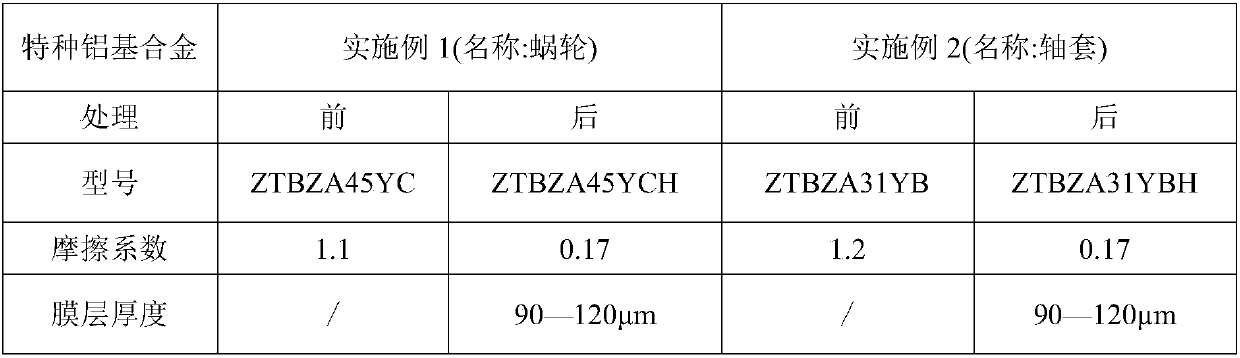

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

ActiveCN105951151AOutstanding heat insulationOutstanding FeaturesAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

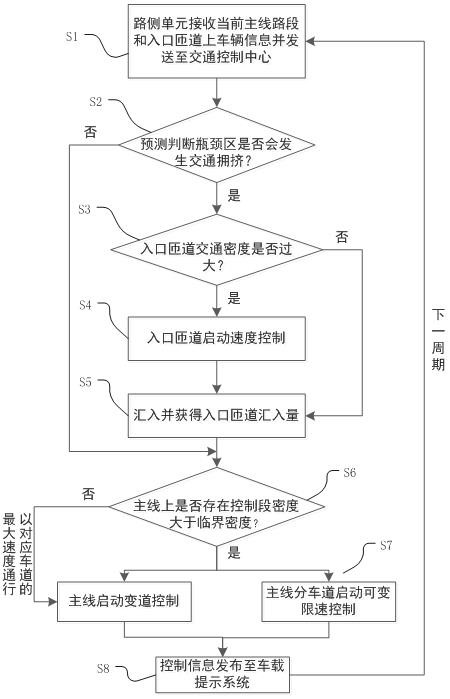

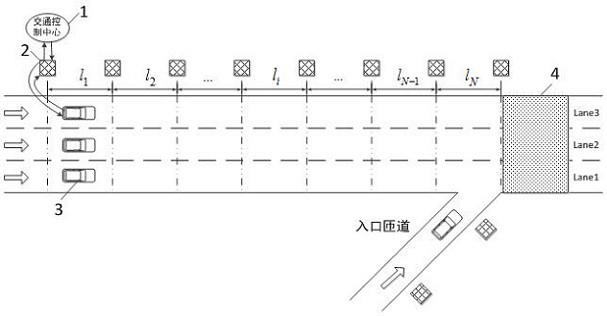

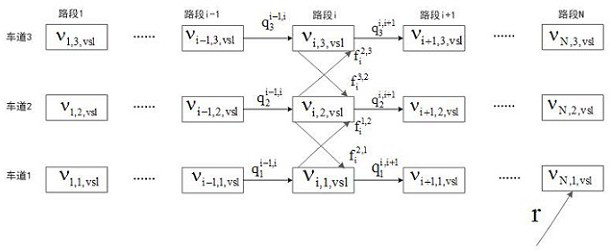

Highway variable speed limit and lane change cooperative control method under vehicle-road cooperation

ActiveCN113450583AImprove stabilityImprove robustnessControlling traffic signalsTime informationIn vehicle

The invention discloses an highway variable speed limit and lane change cooperative control method under vehicle-road cooperation, and the method specifically comprises the steps: laying a road side unit, and dividing a highway section containing an entrance ramp into a plurality of control sections; predicting that traffic congestion will occur in the next period in the highway bottleneck area; controlling the speed of the vehicle on the entrance ramp in the current period; determining the critical density of the main line lane allowing convergence after convergence; judging whether the traffic density of each control road section on the highway main line in the next period is greater than the critical density of the main line lane allowing convergence after convergence or not; carrying out the variable speed limiting control and lane changing control on each control road section on the highway main line; issuing the control information to the vehicle-mounted prompting system, and regulating and controlling the flow flowing into the downstream. According to the invention, on the basis of real-time information sharing of vehicle-road cooperation, through cooperation of variable speed limit control and lane change control, the passing efficiency of the highway is improved, a large number of centralized lane change behaviors are reduced, and the risk of rear-end collision is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

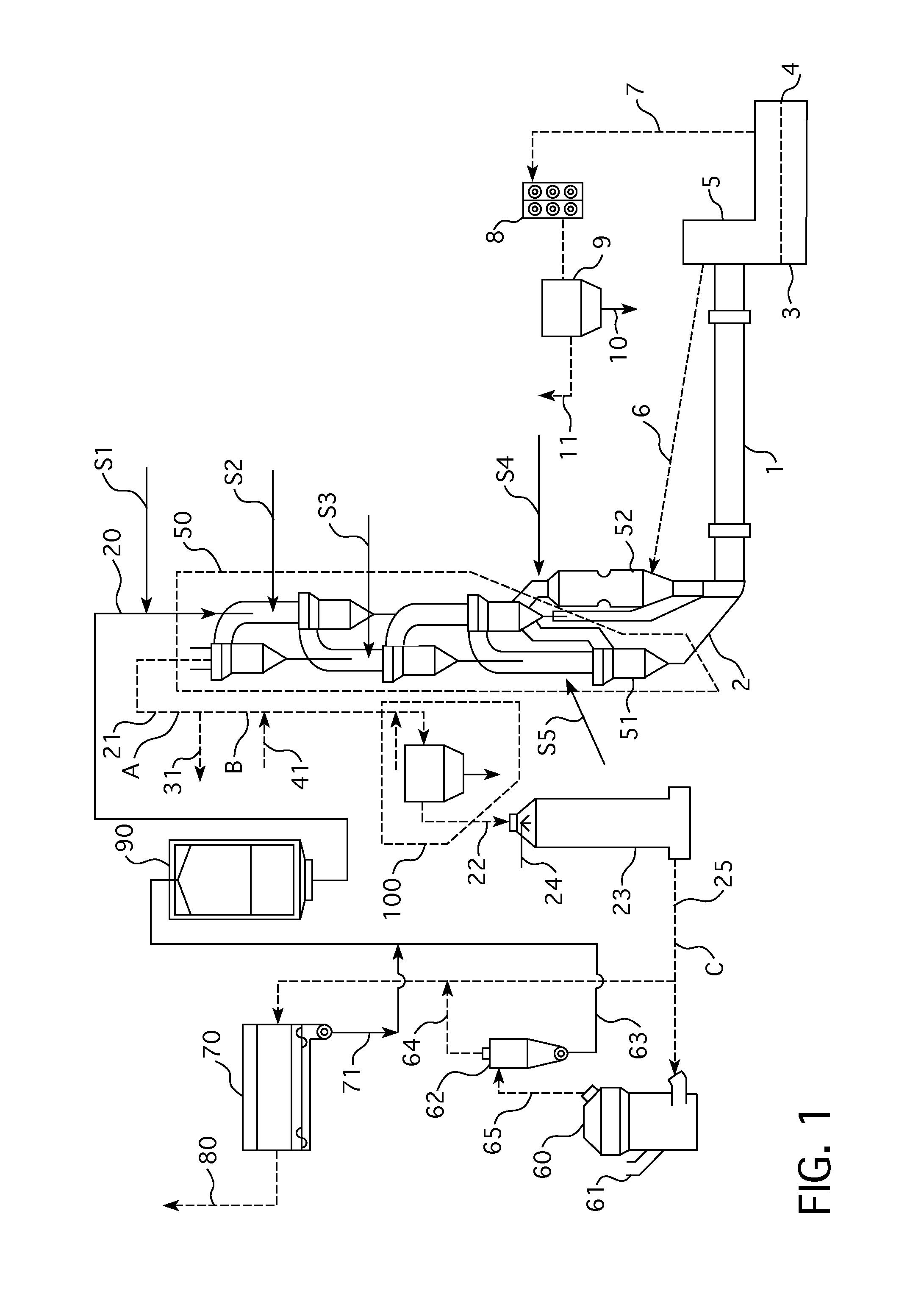

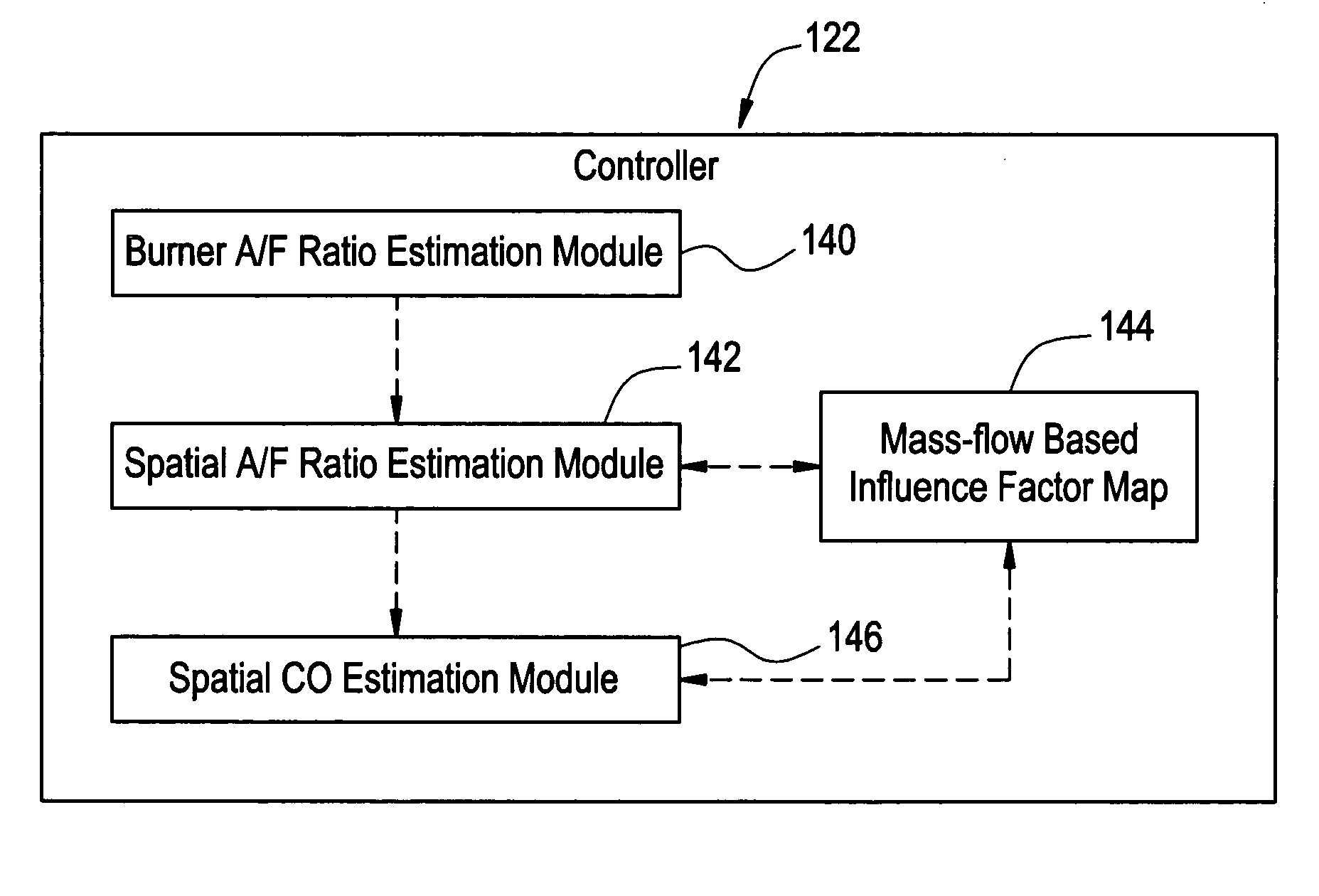

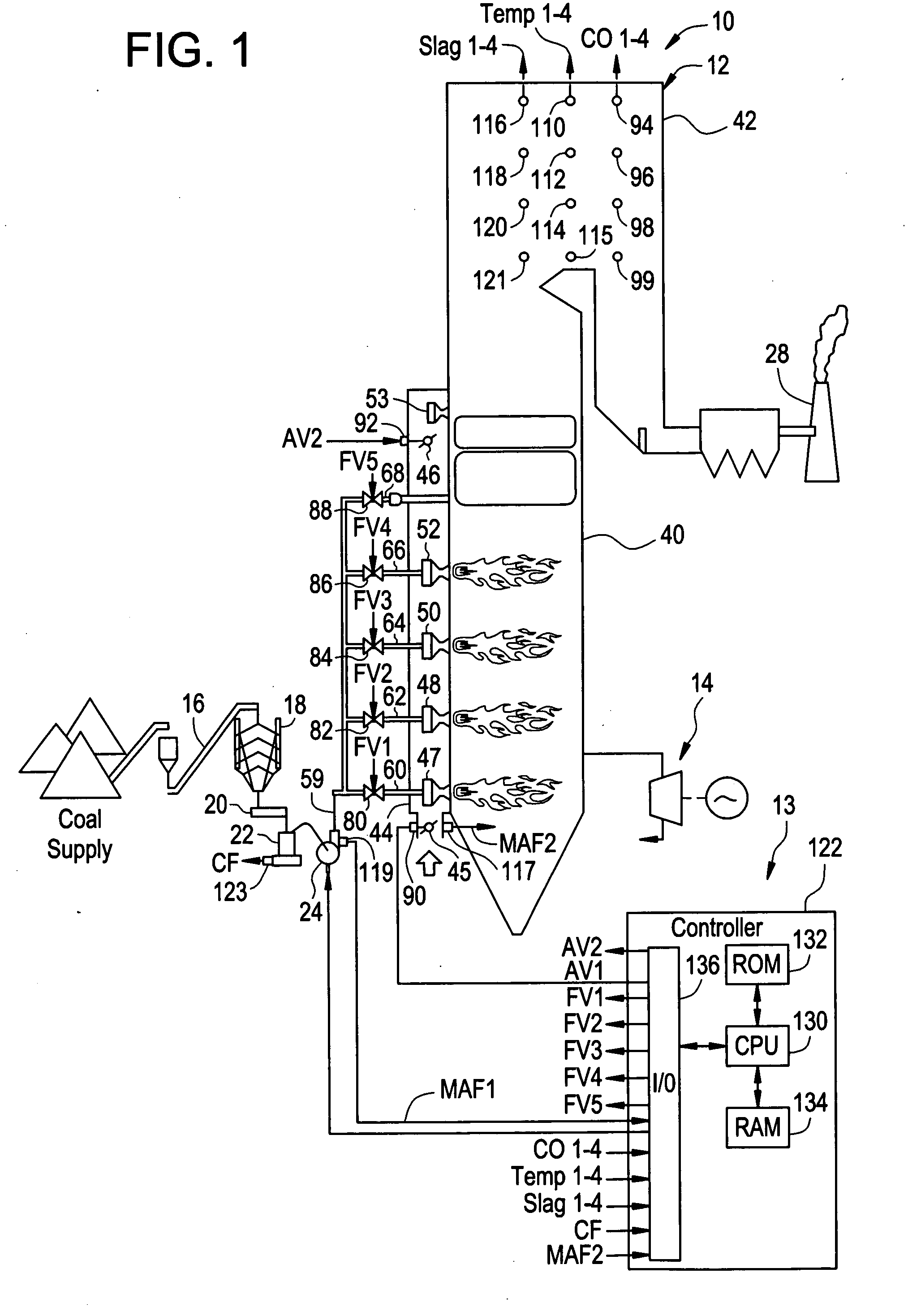

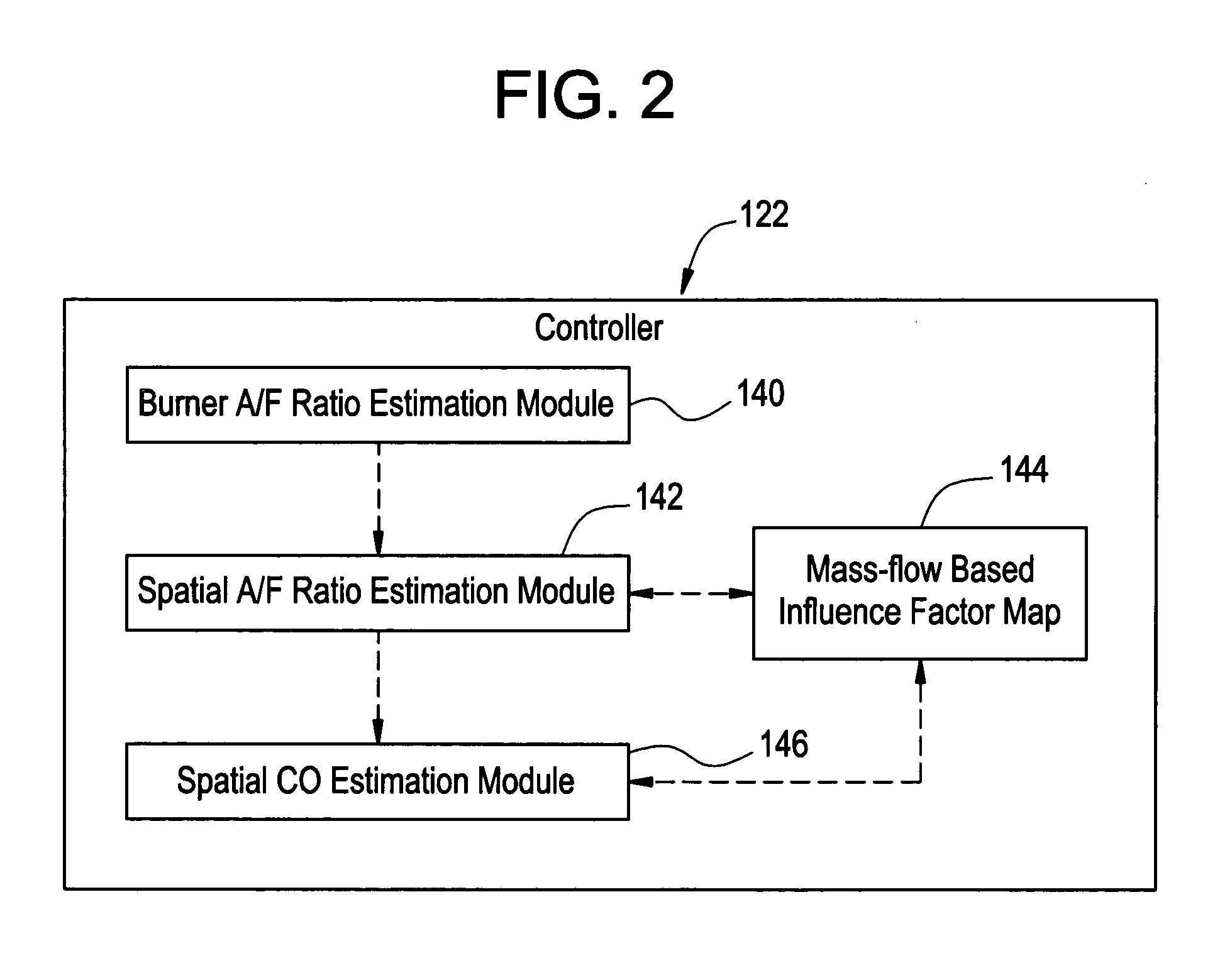

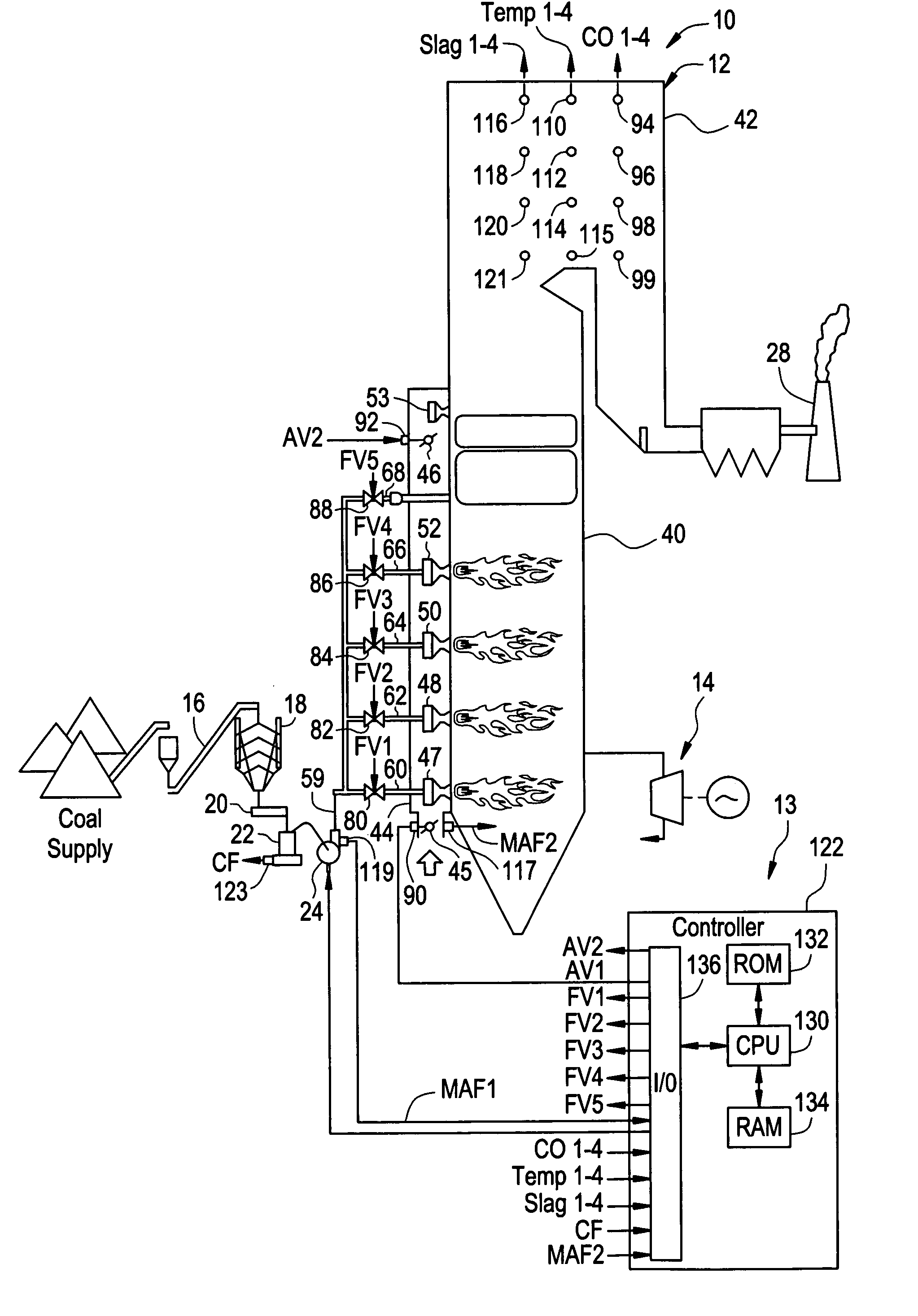

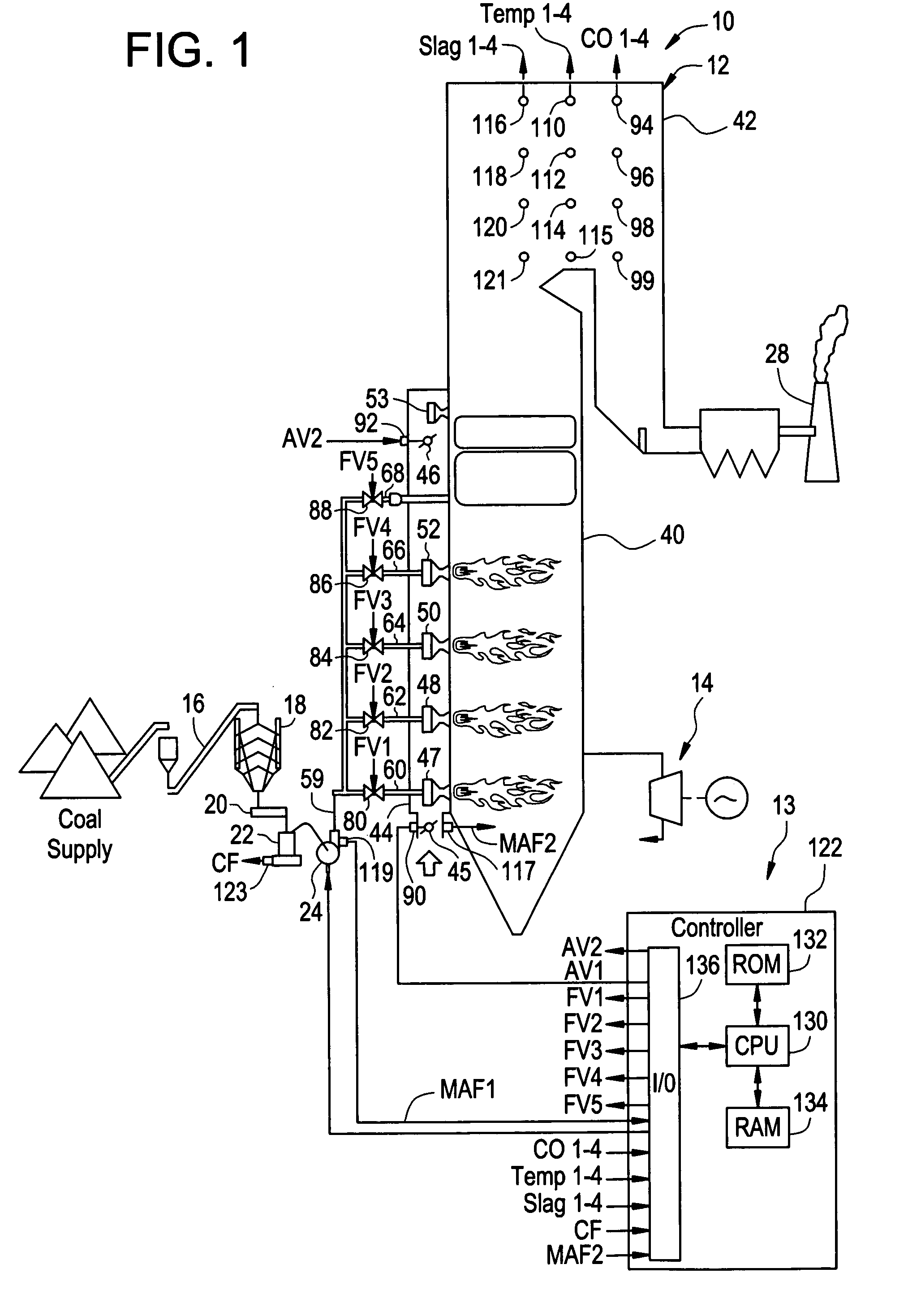

System, method, and article of manufacture for adjusting CO emission levels at predetermined locations in a boiler system

InactiveUS20070122757A1Decrease CO levelImprove the level ofBurnersPilot flame ignitersCombustorSystems approaches

A system, a method, and an article of manufacture for adjusting CO emission levels in predetermined locations in a boiler system are provided. The boiler system has a plurality of burners and a plurality of CO sensors disposed therein. The system determines locations within the boiler system that have relatively high CO levels utilizing the plurality of CO sensors and then adjusts A / F ratios of burners affecting those locations to decrease the CO levels at the locations.

Owner:GENERAL ELECTRIC CO

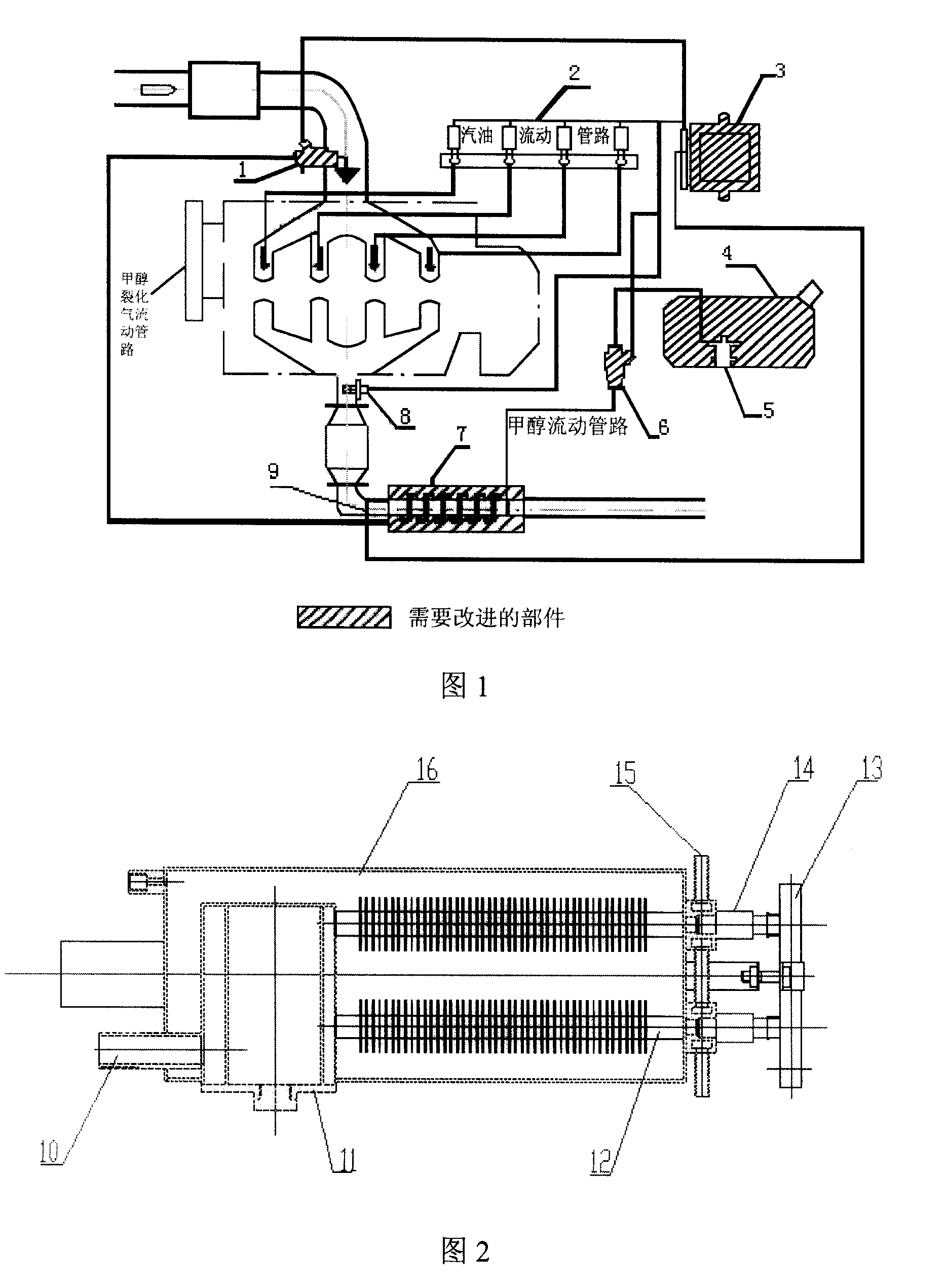

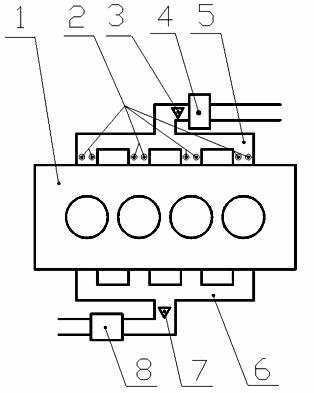

Apparatus for petrol engine combustion methanol cracking gas

InactiveCN101251044ABurn quicklyImprove efficiencyInternal combustion piston enginesGaseous engine fuelsProcess engineeringMethanol

The invention provides a device for cracking the burnt methane of a gasoline engine. The invention is provided with a methane cracking air injection valve, a methane providing system, a methane cracking device and a fuel switching system mainly on the basis of the prior gasoline motor injection control system. The methane is cracked into carbon monoxide and hydrogen under the action of a catalyst by heating the methane cracking device and the carbon monoxide and the hydrogen are used for the engine. The device can realize the quick combustion and solve the problem that cold starting is difficult to carry out by burning methane; moreover, the device has simple structure and convenient use, thereby easing the energy shortage situation of a country; in addition, the burning of the cracked methane can greatly improve the vehicle discharge level and the fuel economical efficiency.

Owner:CHERY AUTOMOBILE CO LTD

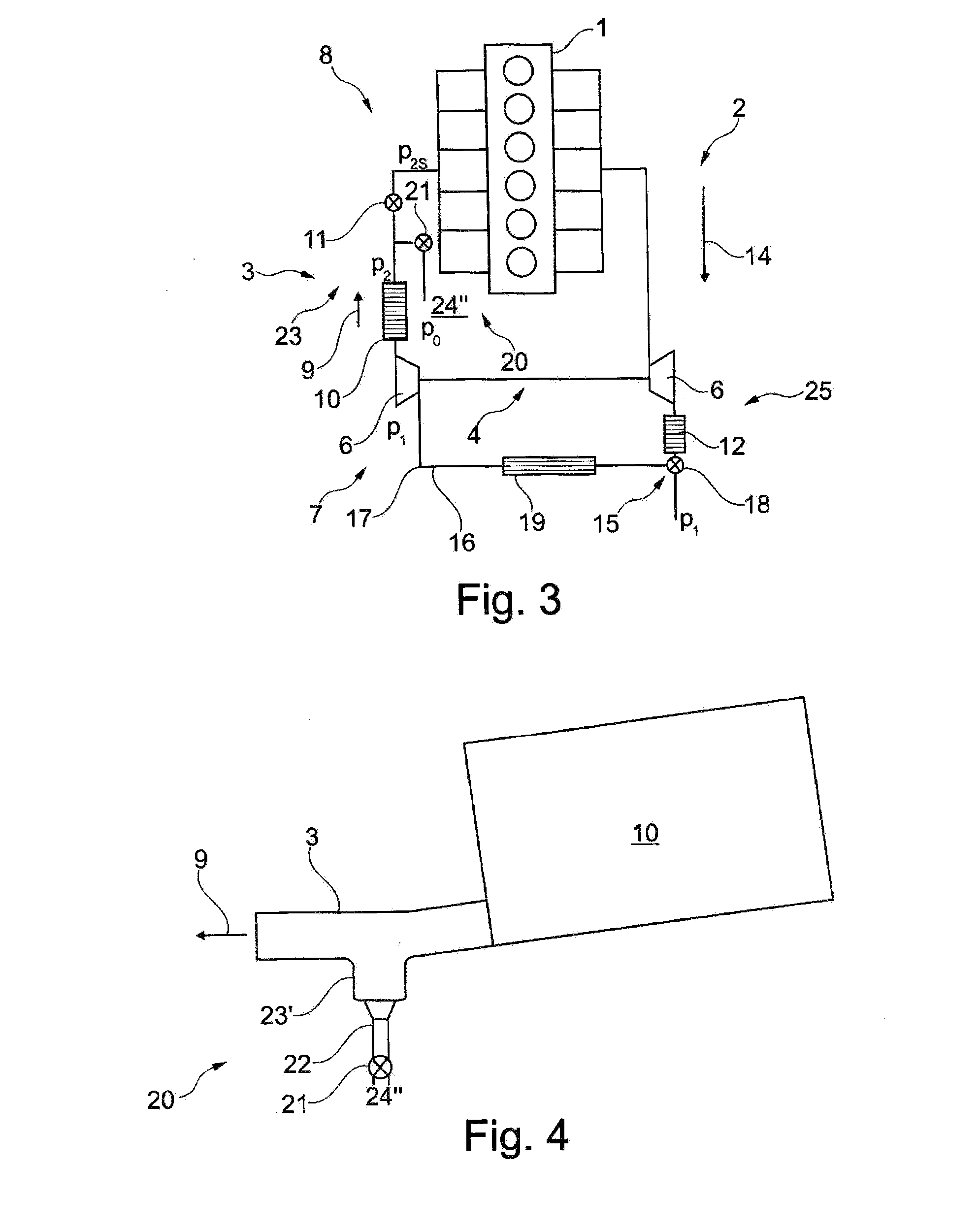

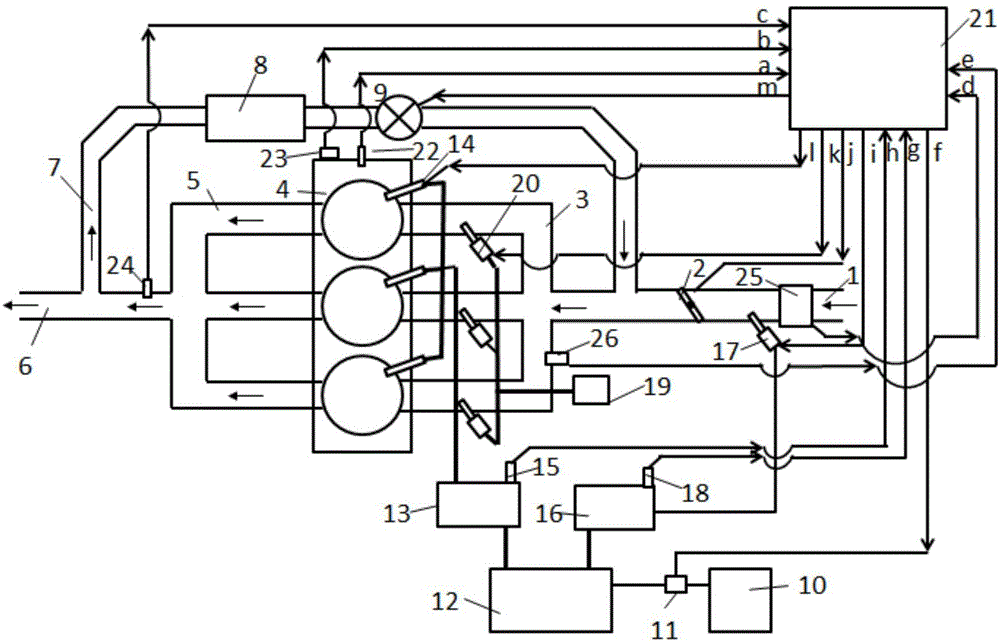

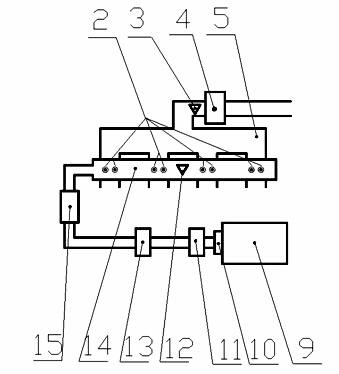

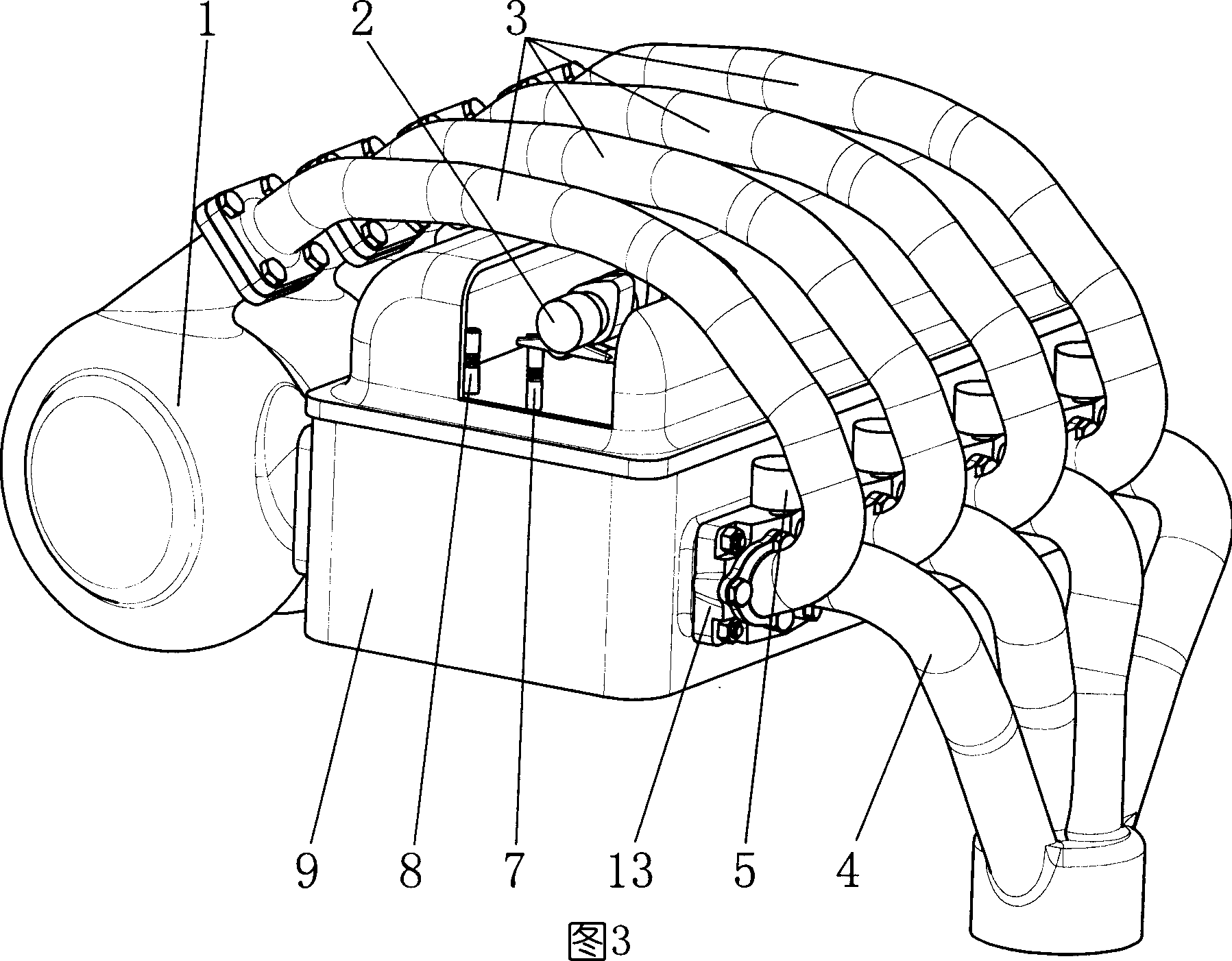

Hydrogen-doped inlet air and oxygen-enriched gasoline engine with EGR and combustion control method

ActiveCN105673199AEmission reductionEasy dischargeElectrical controlNon-fuel substance addition to fuelElectrolysisExhaust gas recirculation

The invention relates to a hydrogen-doped inlet air and oxygen-enriched gasoline engine with EGR and a combustion control method. The device mainly comprises a gasoline engine, an EGR cooler, an EGR valve, a water electrolysis device, a hydrogen storage, an oxygen storage, a pressure control device, a hydrogen injection device and an oxygen injection device. According to the hydrogen-doped inlet air and oxygen-enriched gasoline engine, in-cylinder combustion modes of four air inlet modes including inlet air doped with hydrogen and oxygen, small-scale exhaust gas recirculation and hydrogen doping, large-scale exhaust gas recirculation and hydrogen doping and oxygen enrichment are respectively adopted in a cold start and idling condition, a medium or small load condition, a large load condition and a full load condition of the engine, so that the effects that the thermal efficiency is obviously improved and the HC and CO discharge is reduced at the cold start and idling stage of the gasoline engine can be achieved; the pumping loss of the engine is greatly reduced in the medium or small load condition, and the oil consumption and NOx discharge are greatly reduced; the engine power is obviously increased within short time when a throttle valve is fully opened. The hydrogen-doped inlet air and oxygen-enriched gasoline engine has excellent overall properties such as low emission, low oil consumption and instantaneous high power output.

Owner:SHANGHAI JIAO TONG UNIV

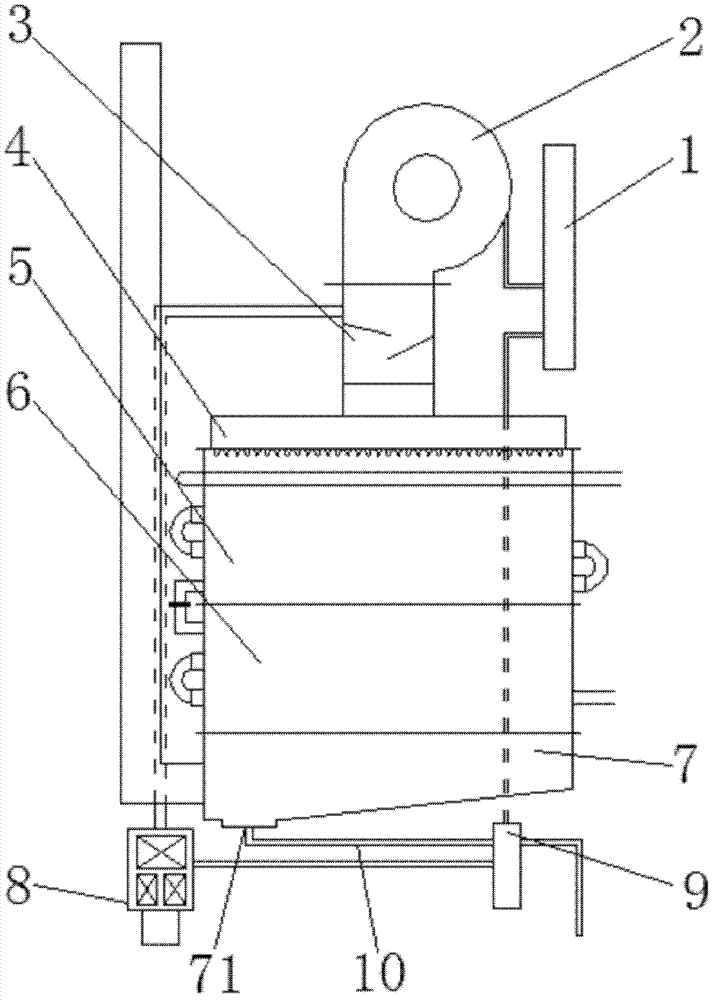

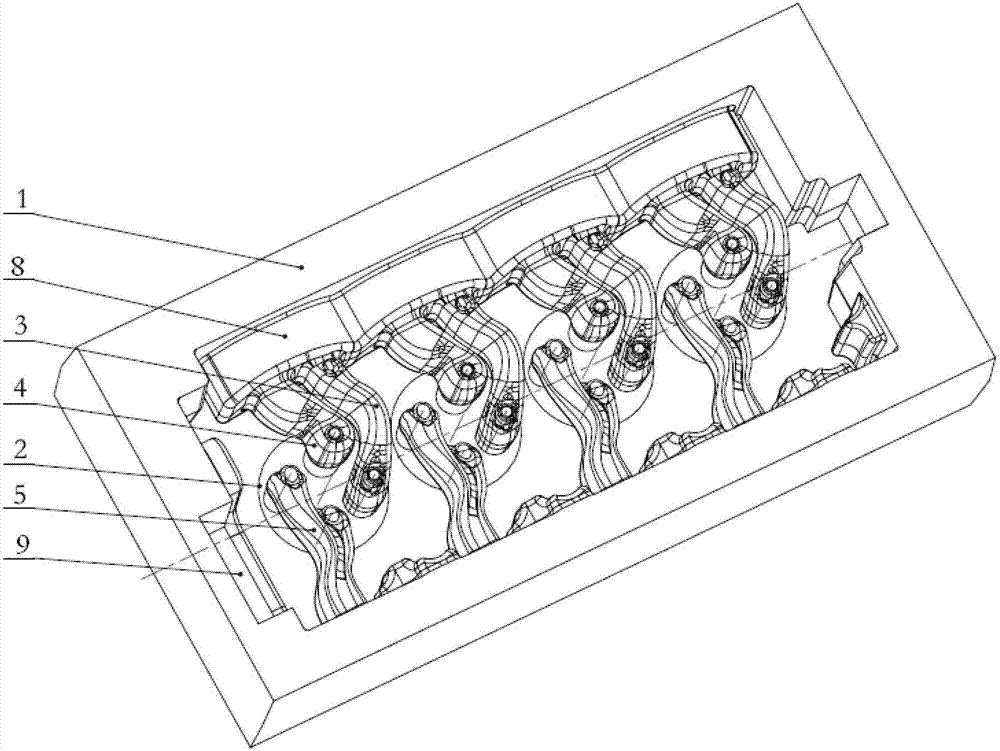

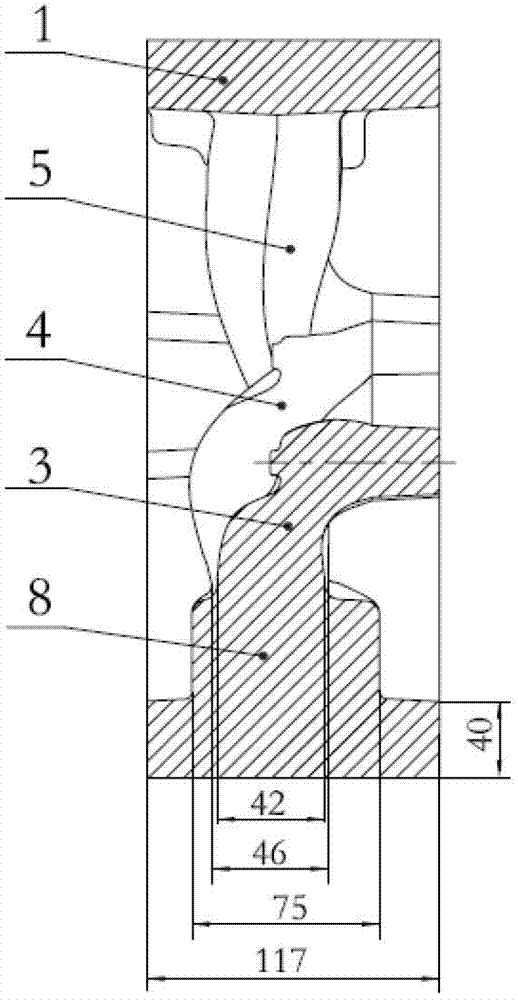

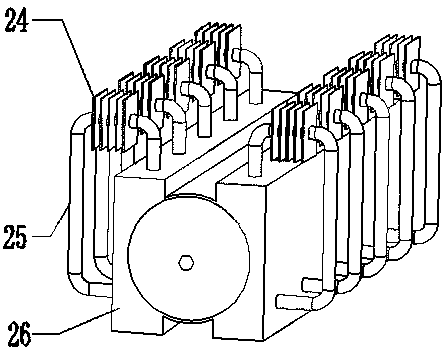

Inverted full-premix condensing gas water heater

ActiveCN103090541AWell mixedRaise emission levelsEnergy efficient heating/coolingAir heatersCombustorMaster controller

The invention discloses an inverted full-premix condensing gas water heater. An inverted metal fiber burner is used. A primary heat exchanger and a secondary heat exchanger are both inverted. Reasonable proportion of gas valve assemblies to fans is controlled via a master controller. Mixed gases enter a gas mixer and are mixed well by the gas mixer prior to entering a burner assembly, and uniformity of the gas mixture is guaranteed when the gas mixture enters the burner. Burning in the full-premix way need not air supply any more, the ratio of actual air to theoretical air is 1.3:1, burning efficiency is high, flames are short, temperature is low, and emission level is high. The metal fiber burner with wide regulating ratio range is used, and accordingly all fire power requirements can be met with no need of subsection control. In addition, the burner and the heat exchangers are inverted for the problem of proneness to blockage of the metal fiber burner, so that the problem that residue of the heat exchangers falls on the burner in long-term use is solved; condensate is discharged through a liquid sealing device, and smoke leakage is effectively prevented.

Owner:SAKURA BATH & KITCHEN PRODS CHINA

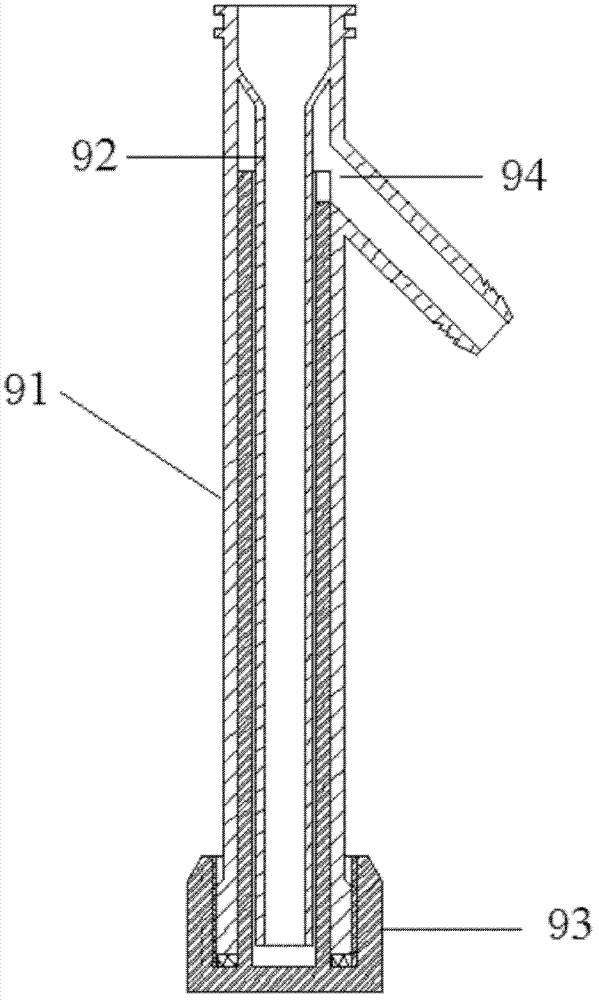

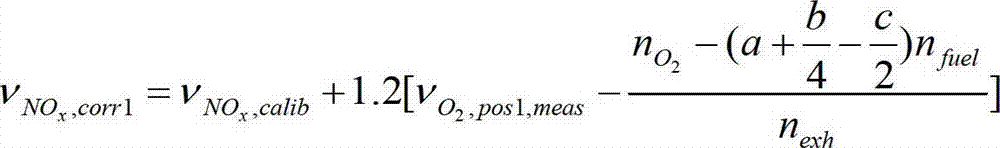

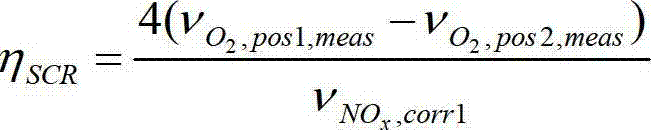

Oxygen sensor-based urea jet control device for diesel and control method for jet control device

ActiveCN102900502ASolve the problem of insufficient reaction efficiencyLow costInternal combustion piston enginesExhaust apparatusOxygen sensorClosed loop

The invention discloses an oxygen sensor-based urea jet control device for a diesel and a control method for urea jet control device, and relates to a post-treatment selective catalytic reduction (SCR) control technology of the diesel. The jet control device comprises an electric control unit (ECU), a urea box, a urea pump, a urea nozzle, an SCR box, an SCR box front air exhaust pipe, an SCR box rear air exhaust pipe, an SCR box front oxygen sensor and an SCR box rear oxygen sensor, wherein the SCR box front oxygen sensor and the SCR box rear oxygen sensor are respectively arranged on the SCR box front air exhaust pipe and the SCR box rear air exhaust pipe; closed-loop control of jet volume of urea, namely NH3 is realized through signals of the SCR box front oxygen concentration sensor and the SCR box rear oxygen concentration sensor; a calibration value of NOx discharged from tail gas is corrected and compensated through the signals of the SCR box front oxygen sensor and the SCR box rear oxygen sensor; and the reaction efficiency of the SCR box is judged through the signals of the SCR box front oxygen sensor and the SCR box rear oxygen sensor, and the jet volume of the NH3 is accurately controlled; and the price of the oxygen sensor is far lower than that of a NOx sensor. By the urea jet control device, urea jet is controlled through the signals of the SCR box front oxygen sensor and the SCR box rear oxygen sensor, so that the cost of post-treatment systems is greatly reduced.

Owner:河北索奇汽车电子科技有限公司

Field emission display having emitter arrangement structure capable of enhancing electron emission characteristics

InactiveUS7301268B2Raise emission levelsIncrease the number ofDischarge tube luminescnet screensLamp detailsInsulation layerField emission display

Owner:SAMSUNG SDI CO LTD

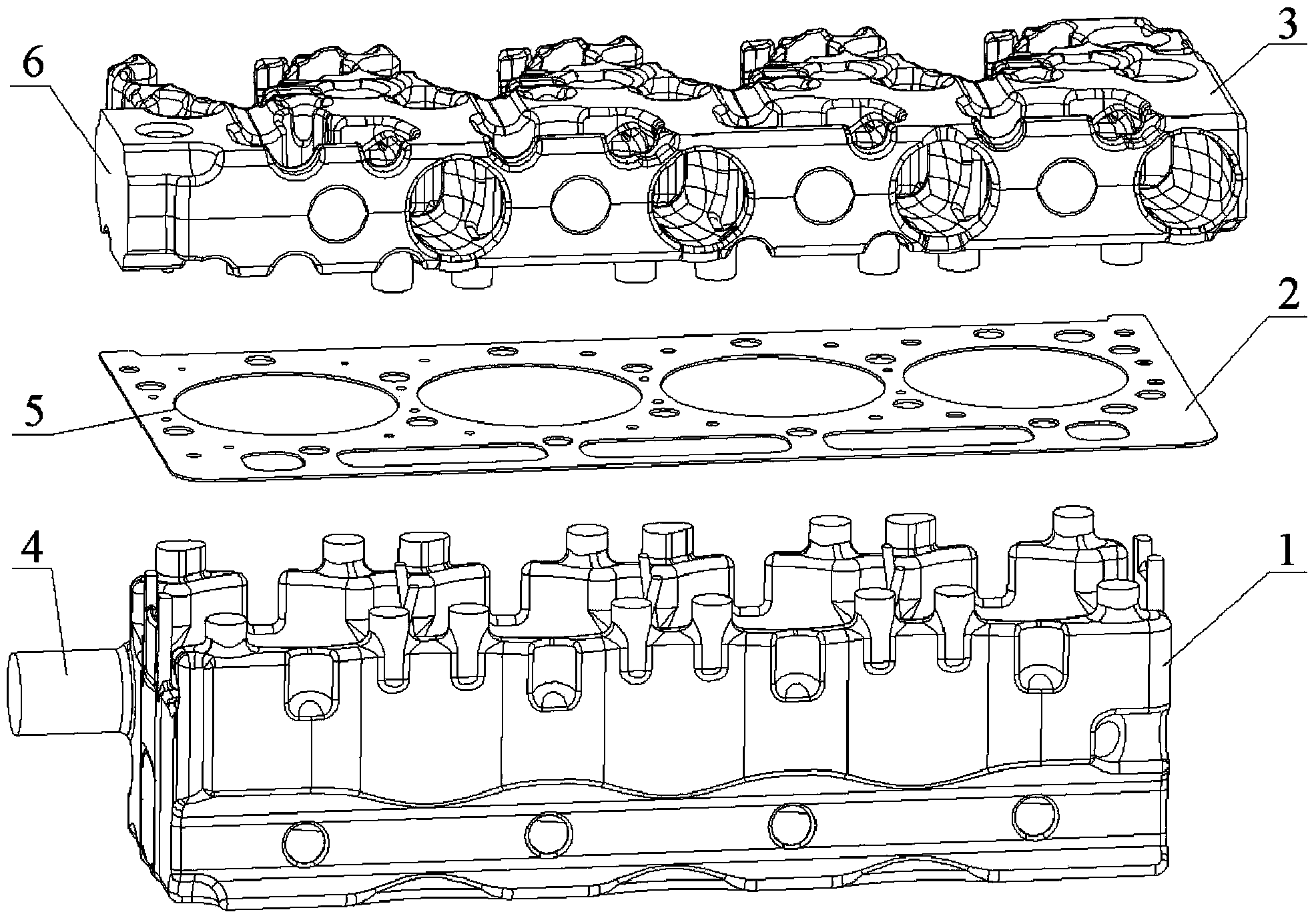

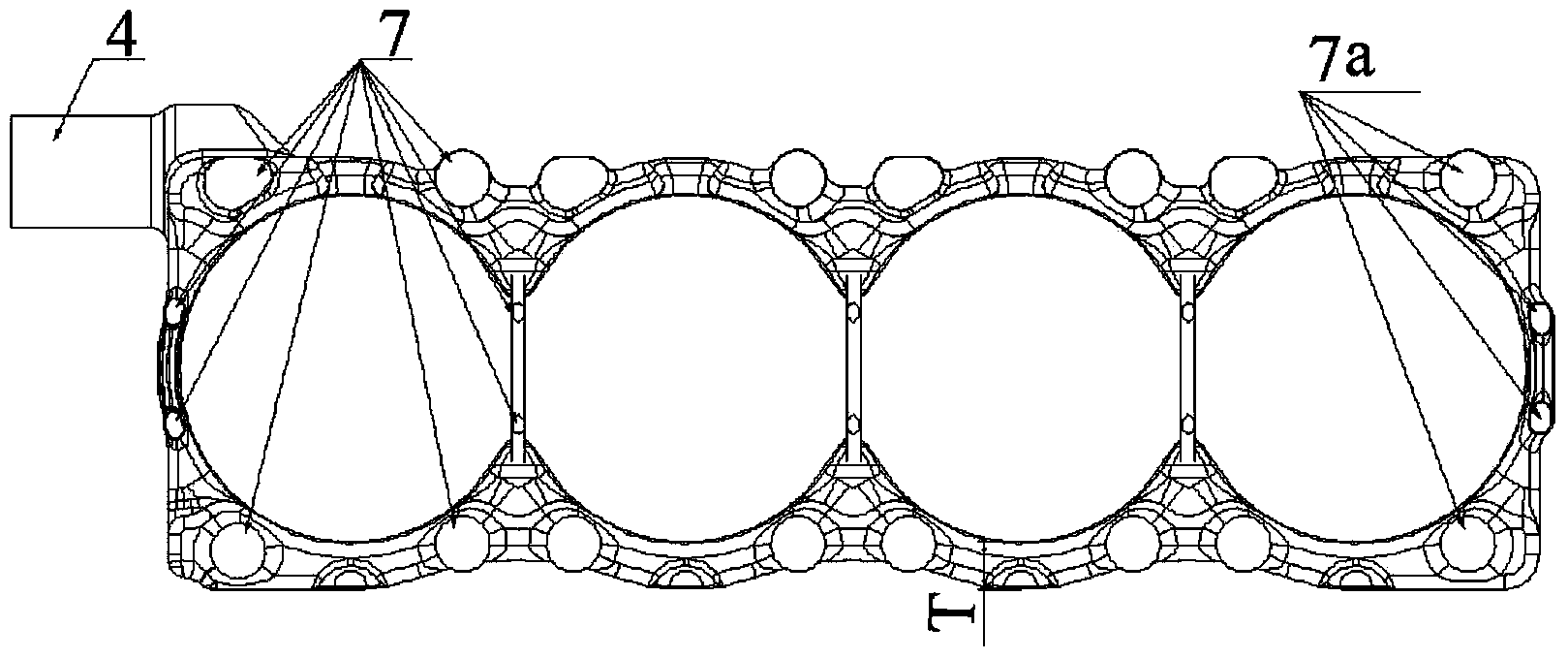

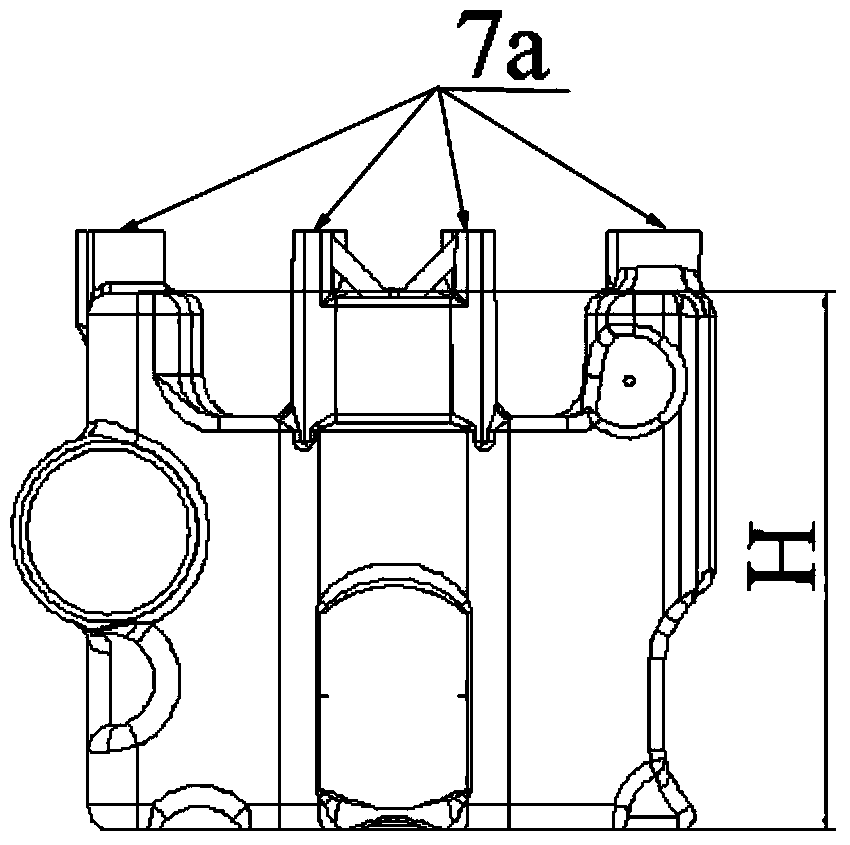

Engine cooling water jacket

InactiveCN104295392ARaise emission levelsEasy to moveCylinder headsCylindersCylinder headEngineering

The invention discloses an engine cooling water jacket. The engine cooling water jacket comprises a cylinder block water jacket body, a cylinder head gasket and a cylinder head water jacket body, wherein a water inlet is formed in the front end of the cylinder block water jacket body, water feeding holes are formed around each cylinder, the water feeding hole located at the rearmost end of each cylinder is a main water feeding hole, the cylinder head water jacket body corresponds to the cylinder block water jacket body, a water outlet is formed in the front end of the cylinder head water jacket body, water inlets corresponding to the water feeding holes in position are formed in the cylinder head water jacket body, and the water inlet located at the rearmost end of each cylinder is a main water inlet; the cylinder head gasket is arranged between the cylinder block water jacket body and the cylinder head water jacket body, a plurality of round holes are formed in the length direction of the cylinder head gasket, water passing holes are formed around each round hole, and each water passing hole located at the rearmost end is a main water passing hole; the water passing holes become larger gradually and sequentially from the front end to the rear end, and the size of each main water feeding hole is identical with that of the corresponding main water passing hole and that of the corresponding main water inlet. By the adoption of the engine cooling water jacket, the flowing speed of cooling liquid in the cylinder block water jacket body can be effectively increased, the temperatures of different parts of the cylinder block tend to be consistent, and the service life of an engine is prolonged.

Owner:GUANGXI YUCHAI MASCH CO LTD

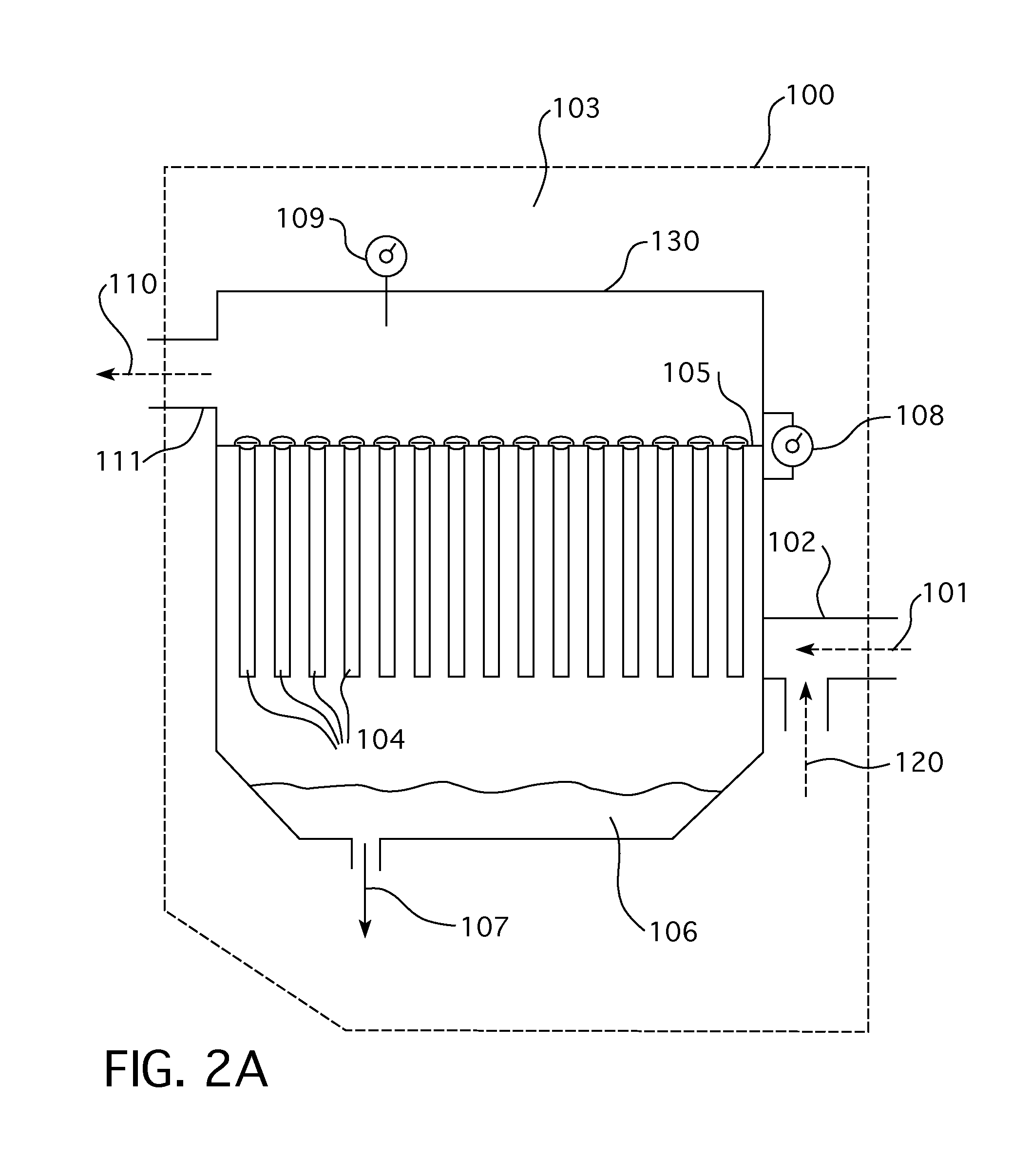

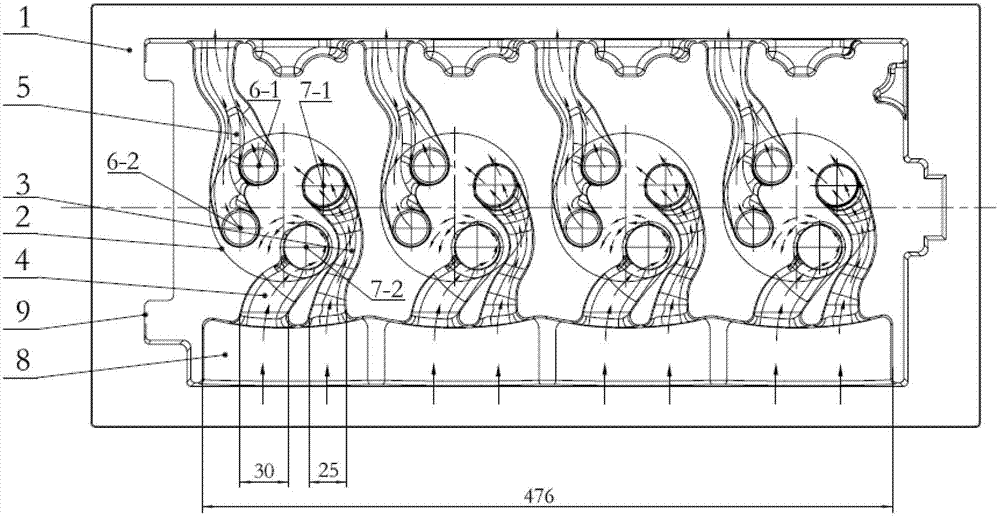

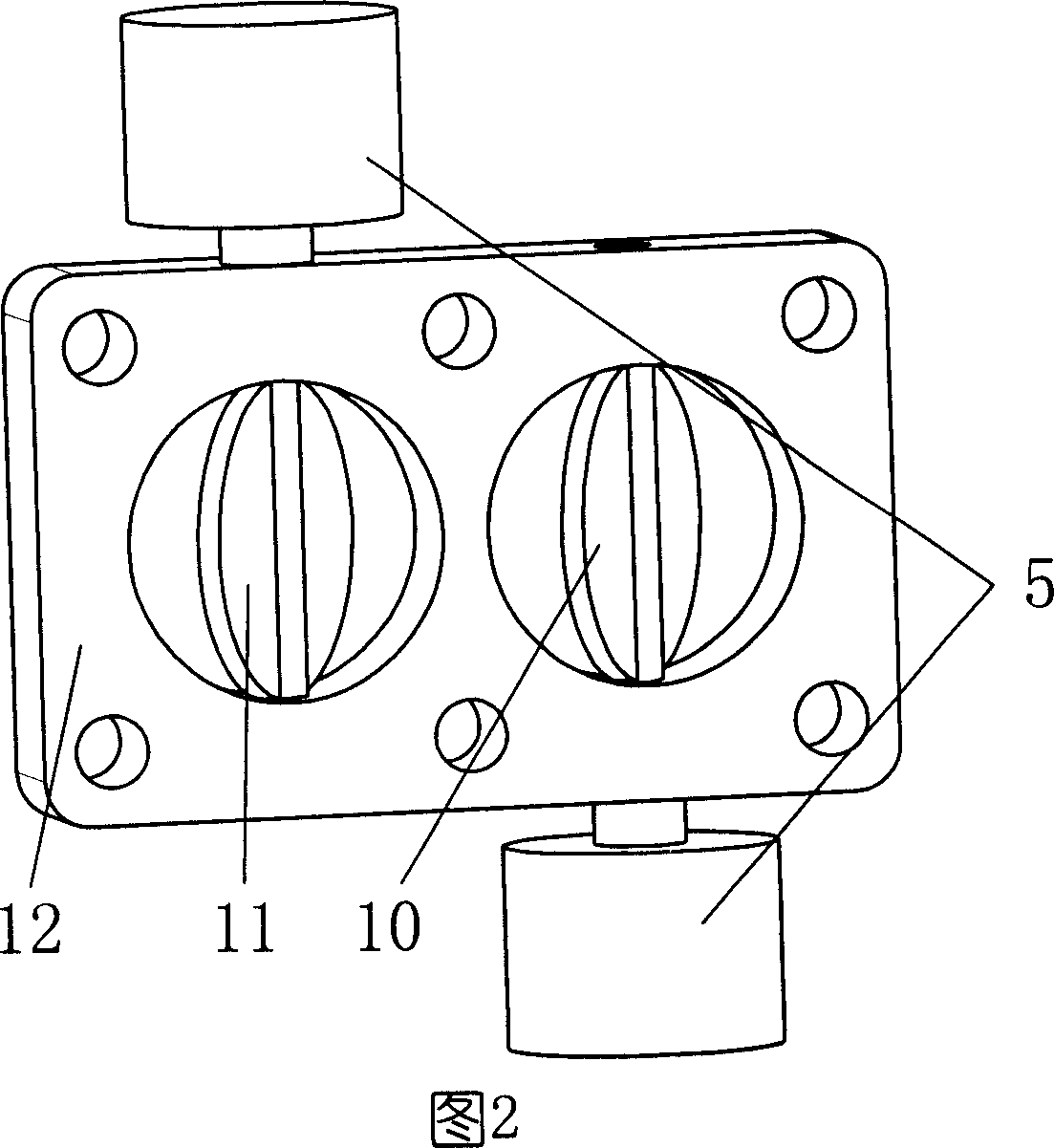

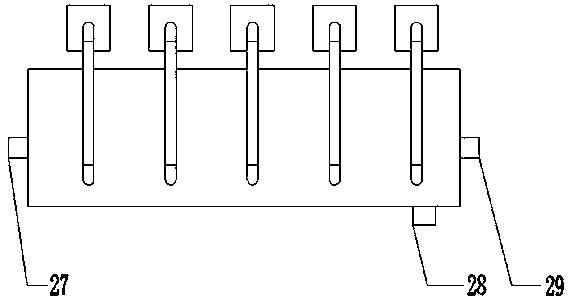

Frame structure integral air flue for multi-valve diesel engine

InactiveCN102733984AAssembly positioning is accurateReduce assembly errorsCylinder headsFoundry mouldsFlueEngineering

The invention discloses a frame structure integral air flue for a multi-valve diesel engine. An air flue outer frame is provided with 4-6 cylinders; each cylinder is provided with a tangential air inlet channel and a spiral air inlet channel and a parallel air exhaust channel; the air inlet channels and the parallel air exhaust channels are uniformly distributed on the peripheries of the corresponding cylinders ; two branches of each parallel air exhaust channel are communicated with a first air exhaust valve and a second air exhaust valve respectively; the tangential and spiral air inlet channels are communicated with a first air inlet valve and a second inlet valve respectively; the air inlet cavity of each pair of tangential and spiral air inlet channels is provided with an inwardly-concave integral sand core; one end of the inwardly-concave integral sand core is connected with the outer frame, and the other end of the inwardly-concave integral sand core is connected with the tangential and spiral air inlet channels; the air flue outer frame is provided with a cooling water jacket positioning groove; and the central line of each cylinder is coincided with the central line of the positioning groove. Due to the adoption of the frame structure integral air flue, the swirl rate of each cylinder air flue can be kept uniform and consistent, each air flue core is assembled and positioned accurately, the assembling error is effectively lowered, the problem of non-uniform burning of each cylinder caused by inconsistent swirl rates is effectively improved, and the economic efficiency and discharging level of the diesel engine are improved.

Owner:东风朝阳朝柴动力有限公司

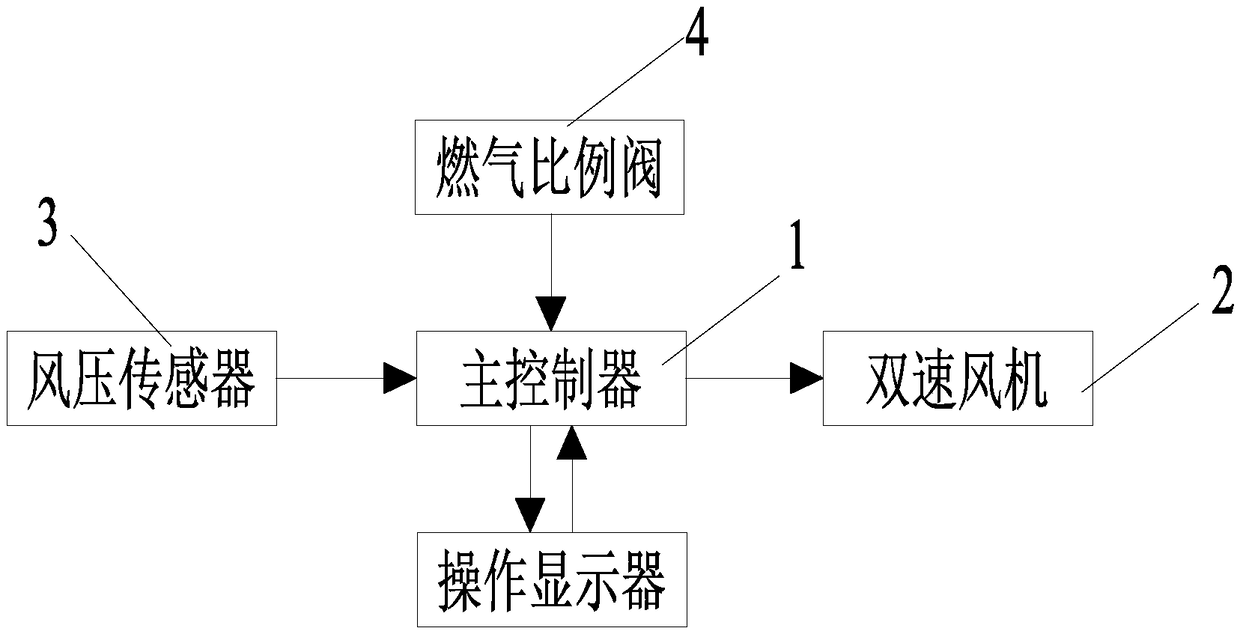

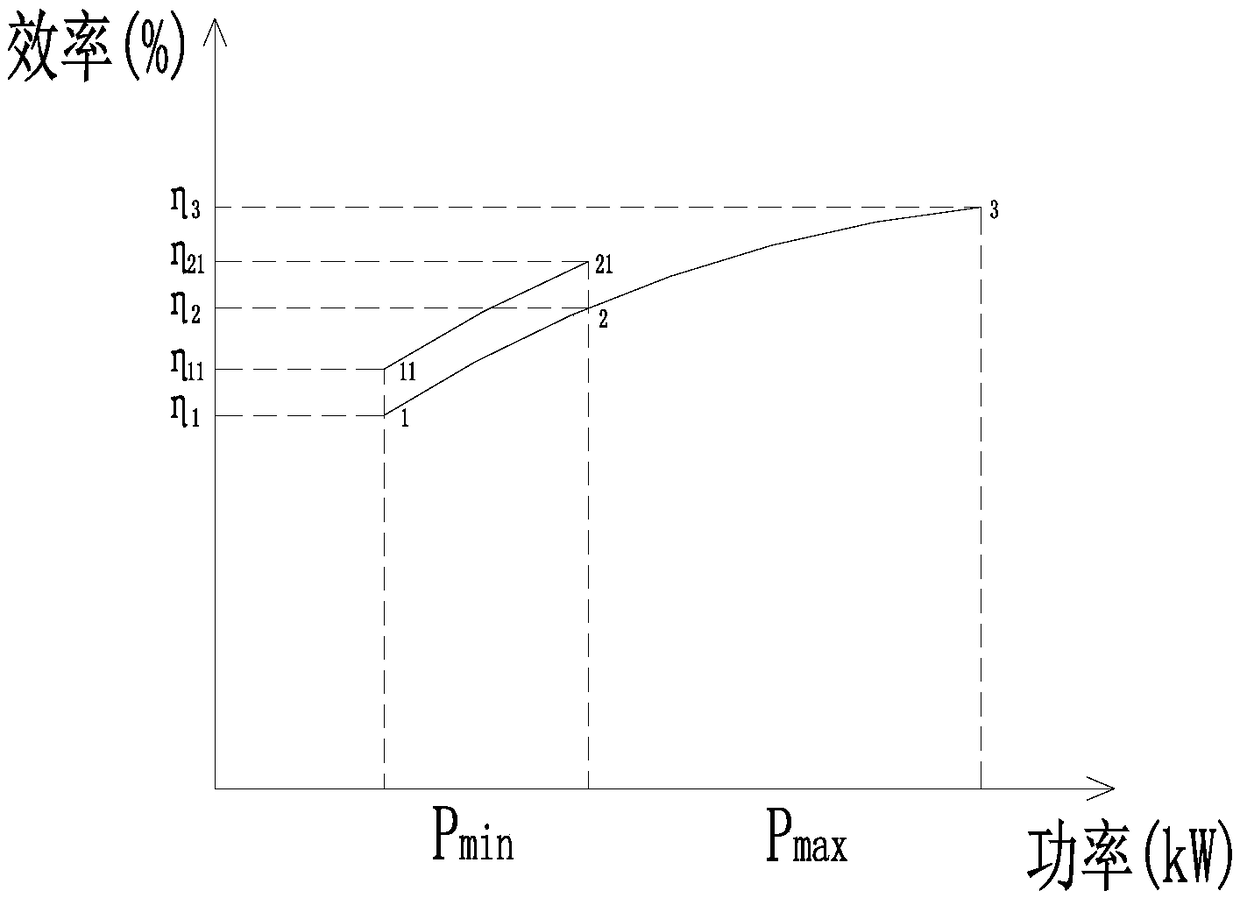

High-power fuel gas heating water heater control system and control method

PendingCN108626781AImprove comprehensive operation heat exchange efficiencyEnhance long-term use safety and stabilityLighting and heating apparatusSpace heating and ventilation detailsFailure rateControl system

The invention discloses a high-power fuel gas heating water heater control system which comprises a main controller, and a fuel gas proportion valve and a fan connected with the main controller. The high-power fuel gas heating water heater control system is characterized in that the fan is the double-speed fan with a high grade and a low grade; and the main controller controls the double-speed fanto work on the high grade or the low grade according to the opening degree of the fuel gas proportion valve. According to the high-power fuel gas heating water heater control system provided by the invention, the air speed of the fan with the high grade and the low grade is used for adapting to the combustion loads of a fuel gas heating water heater, so that when the fuel gas heating water heaterruns at a small-power load section, the fuel gas heating water heater can have higher combustion heat exchange efficiency, the comprehensive running heat exchange efficiency of the fuel gas heating water heater is improved, the effects on energy conservation and emission reduction are achieved, and meanwhile, the long-time use safety stability of the fuel gas heating water heater is improved. Meanwhile, the high-power fuel gas heating water heater control system is low in failure rate, reliable to run, and highly valuable in industrial application. The invention further provides a high-powerfuel gas heating water heater control method.

Owner:MACRO THERMAL ENERGY TECH

New energy cylinder sleeve and production method thereof

InactiveCN106523171AAccelerate emissionsReduce fuel consumptionCylinder headsCylindersDetonationNew energy

The invention aims at providing a new energy cylinder sleeve and a production method thereof. The cylinder sleeve comprises the chemical components in percentage by weight: 2.70-3.20% of C, 1.60-2.10% of Si, 0.50-0.90% of Mn, 0.20-0.50% of P, less than or equal to 0.10% of S, 0.20-0.50% of Cr, 0.50-0.90% of Cu and Ni, 0.20-0.60% of Mo and the balance Fe. The new energy cylinder sleeve provided by the invention meets the requirements of high detonation pressure, high emission and low fuel consumption so as to be suitable for new energy.

Owner:ZYNP GRP

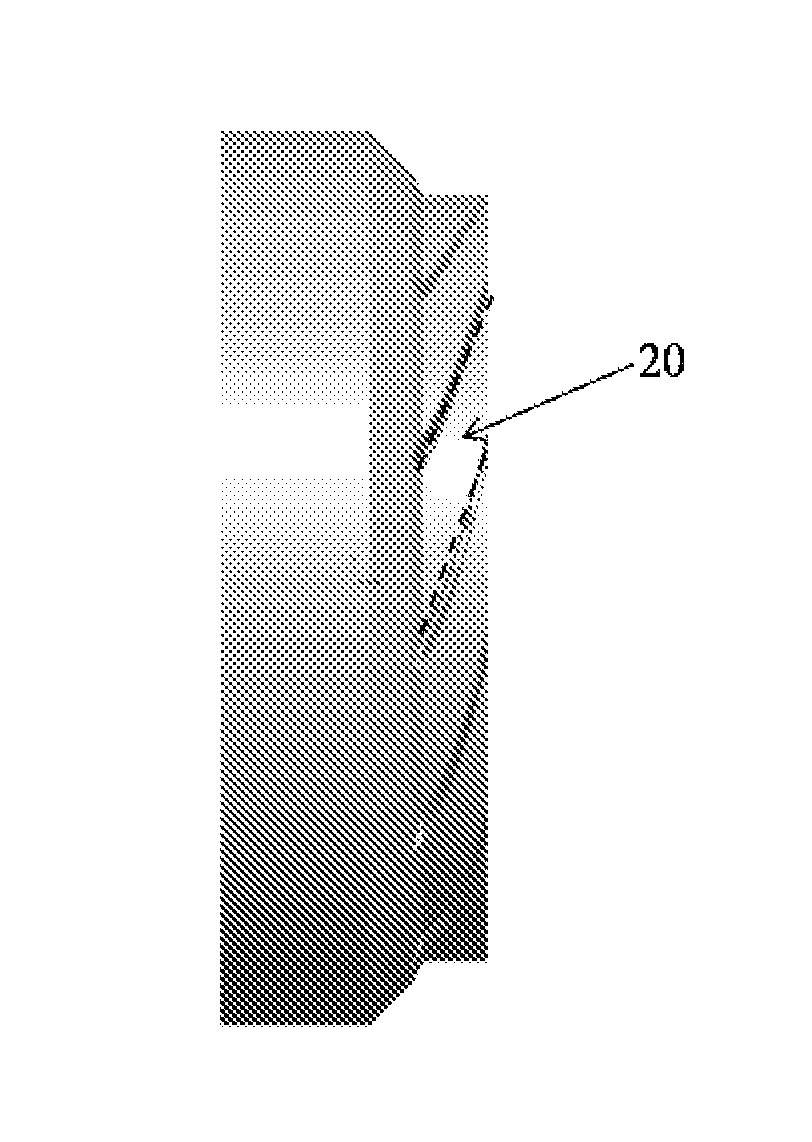

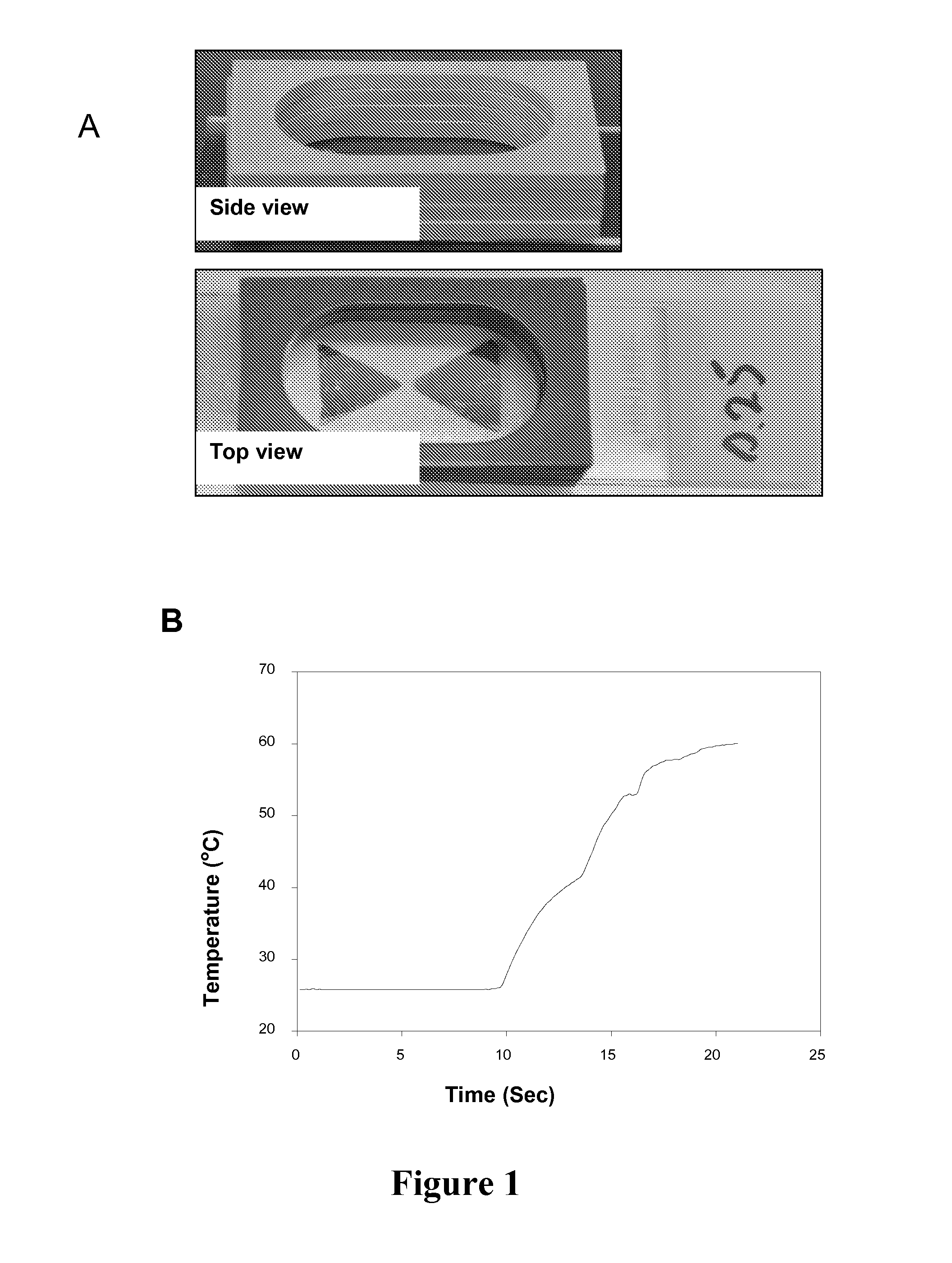

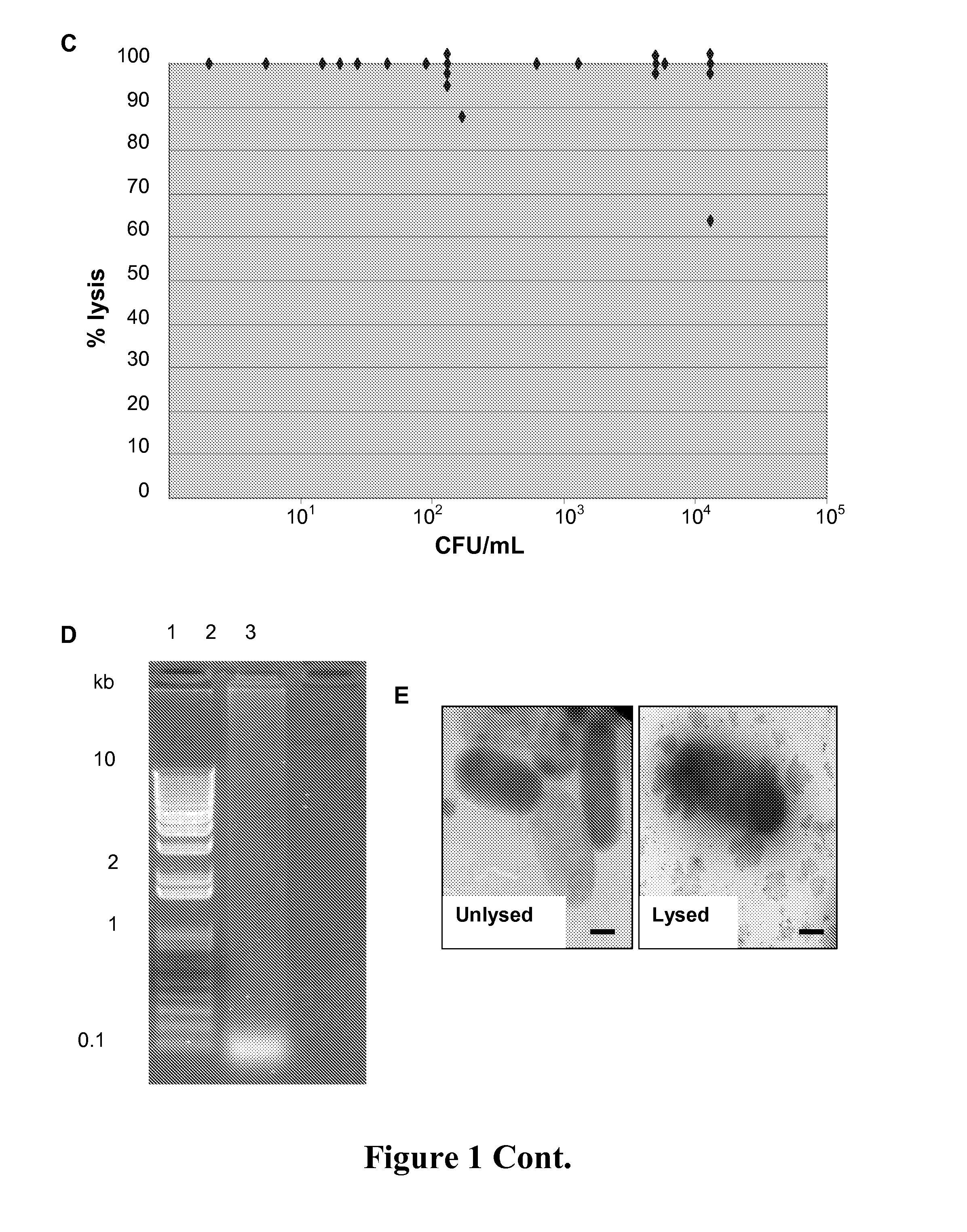

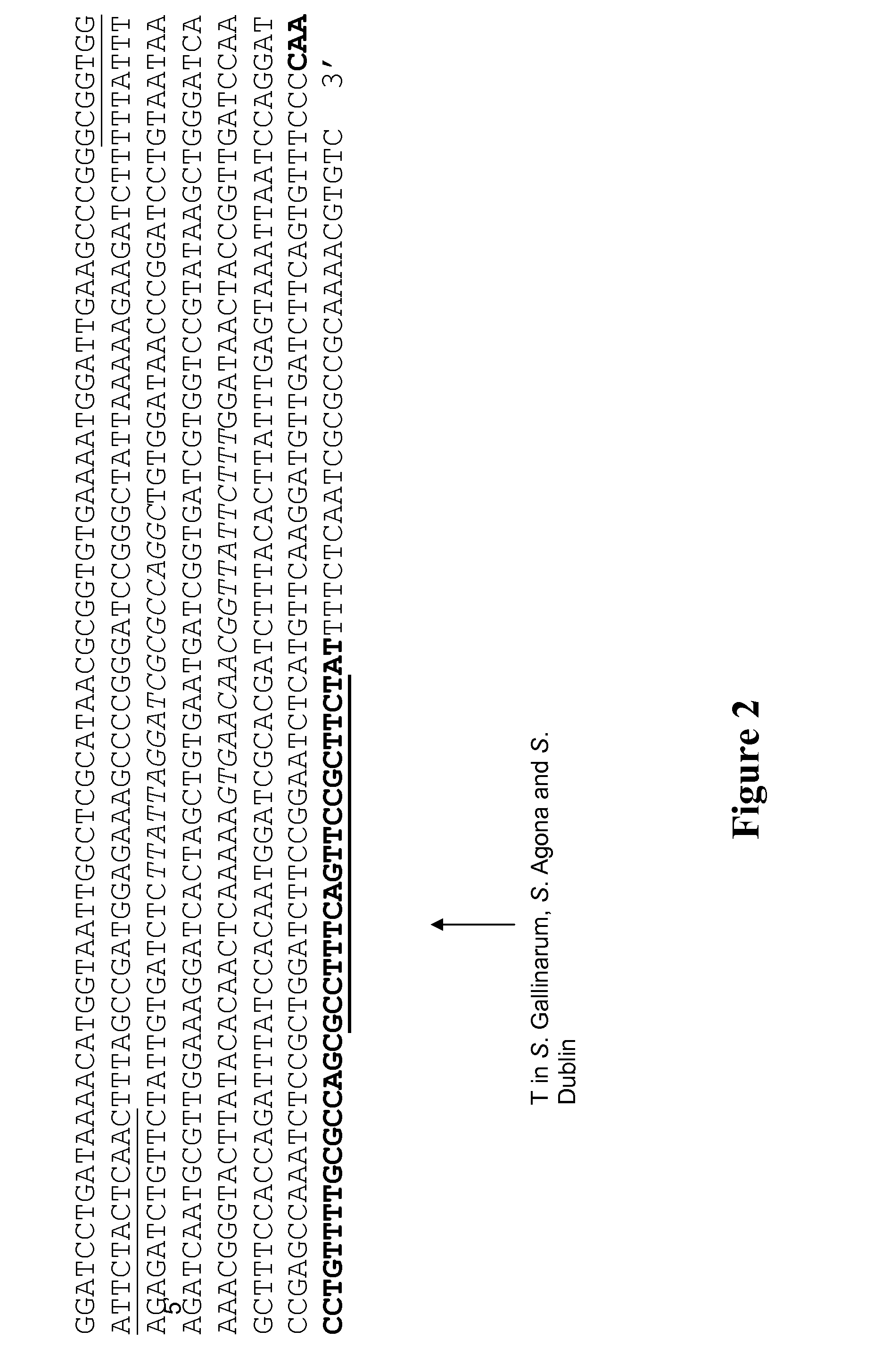

Assays for pathogen detection using microwaves for lysing and accelerating metal-enhanced fluorescence

ActiveUS20140030700A1High sensitivityLow powerBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismAssay

The present invention relates to an assay for the determination of a microorganism including a lysing chamber having triangular shaped metallic structures wherein the apexes of two triangles are arranged in alignment and forming a reactive zone for placement of the microorganism and lysing by microwave energy for exposing and isolating a target polynucleotide sequence. The isolated target polynucleotide sequence is introduced to an assay system for contact with polynucleotides which are complimentary to the isolated target polynucleotide sequence. Fluorophore-labeled capture polynucleotides are added for hybridizing to any bound target polynucleotide. Bound target polynucleotides are detected by metal enhanced fluorescence.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

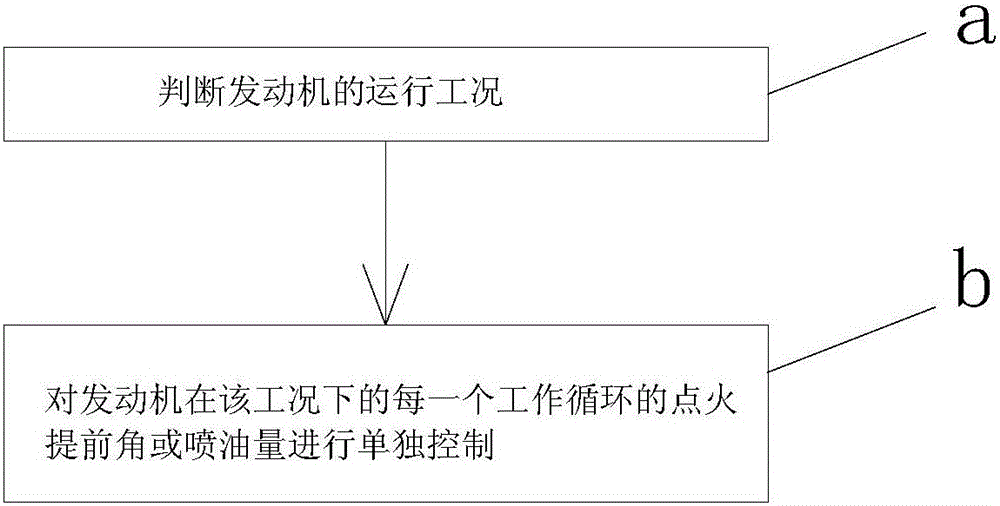

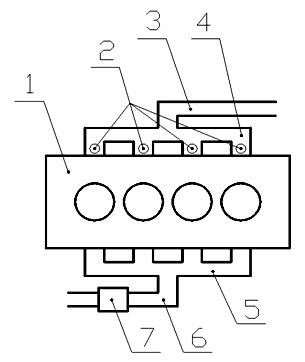

Engine ignition control and fuel injection control methods based on engine cycles

ActiveCN106246437AImprove powerImprove economyElectrical controlInternal combustion piston enginesWork cycleControl parameters

The invention discloses engine ignition control and fuel injection control methods based on engine cycles. The engine ignition control method comprises the steps of a, judging the operation condition of an engine; and b, and independently controlling the ignition angle of advance and fuel injection quantity of the engine in each working cycle under the condition. According to the engine ignition control and fuel injection control methods, control for ignition and fuel injection of the engine is refined in each working cycle of the engine, control parameters (ignition time, fuel injection pulse width and fuel injection phase position) of all the working cycles of the engine are more accurate, the accuracy of the control parameters under the transition working condition is guaranteed, and finally, the dynamic property, economy and emission level of the engine are improved to the greatest extent.

Owner:CHONGQING LONCIN MOTOR

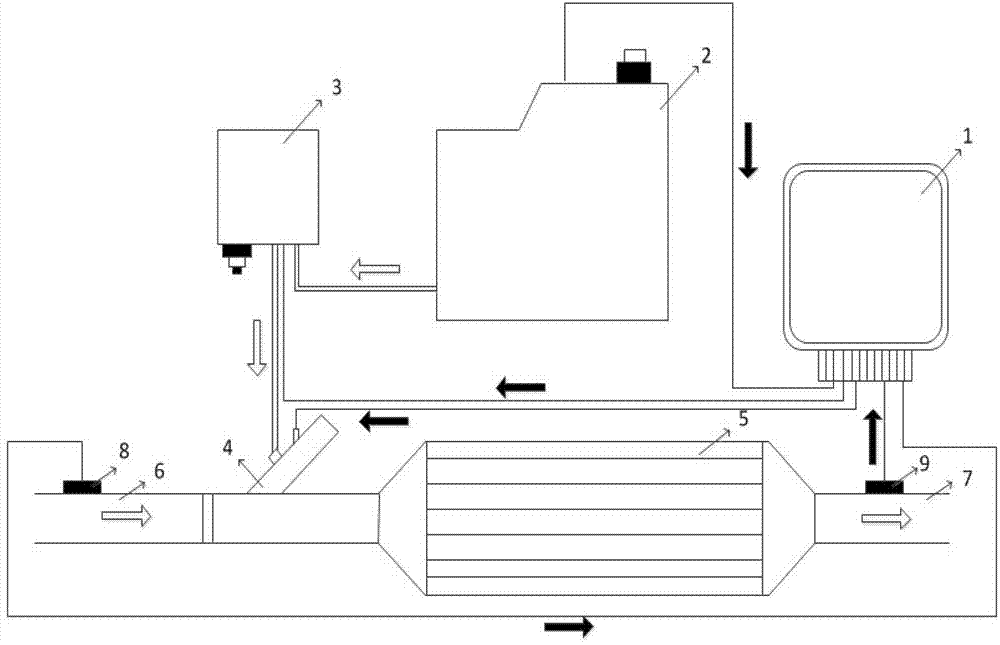

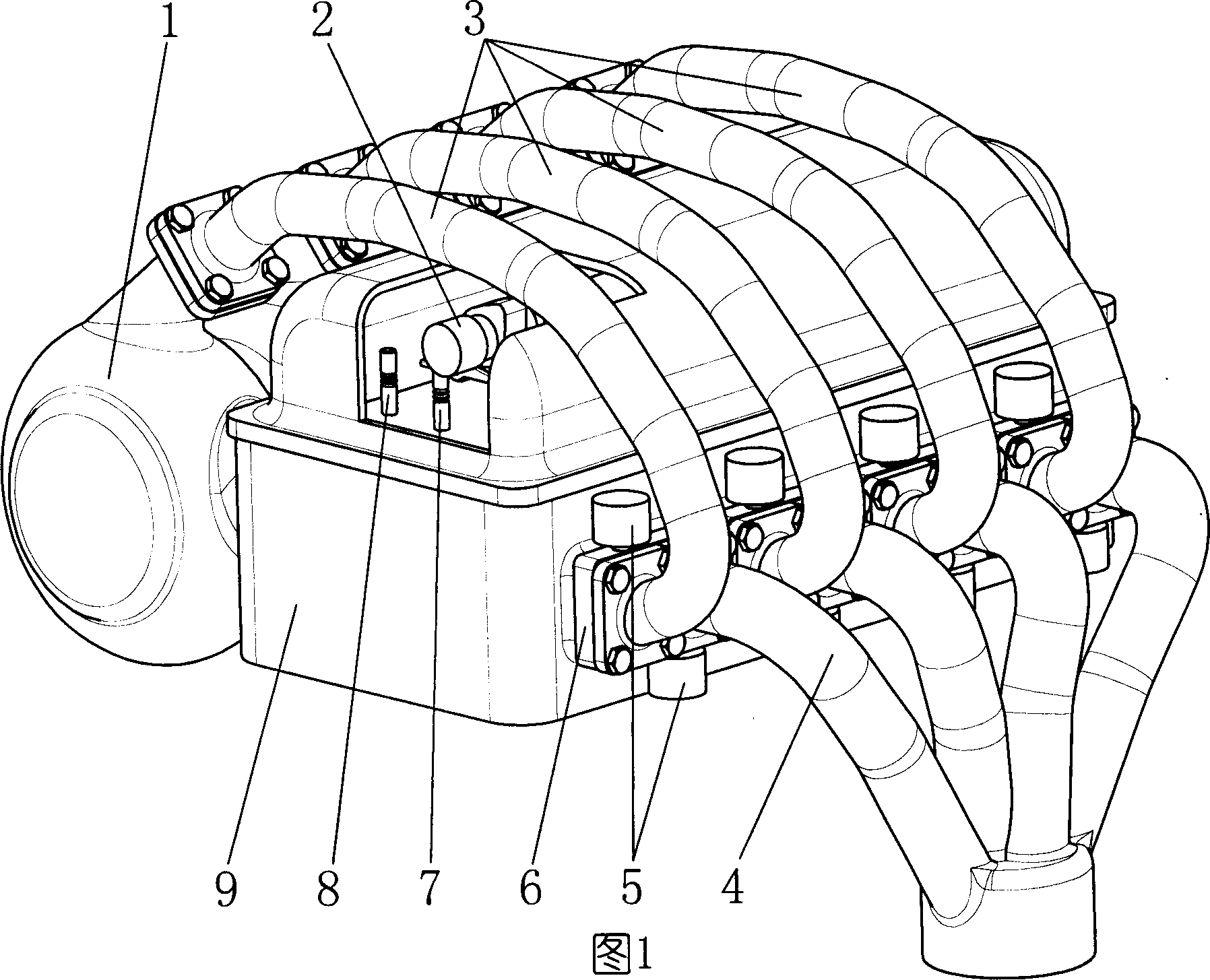

Hydrogen engine

InactiveCN102155291ALow costRaise emission levelsElectrical controlInternal combustion piston enginesPressure stabilizationSolenoid valve

The invention relates to a hydrogen engine comprising a hydrogen supplying system, an air intake system, an engine body and an exhaust system, wherein the hydrogen supplying system comprises a high pressure hydrogen bottle, a solenoid valve, a first-grade reducing valve, a second-grade reducing valve, a flame arrestor and a connecting pipeline. A hydrogen pressure temperature sensor is arranged in a hydrogen air-rail, an air intake pressure temperature sensor is arranged at the front end of a pressure stabilization cavity of an air intake manifold, and a wide scope oxygen sensor is arranged on an exhaust manifold of the exhaust system, an electronic throttle is arranged at the front end of the air intake manifold, the hydrogen pressure temperature sensor, the air intake pressure temperature sensor and the wide scope oxygen sensor transmit signals to an ECU (electronic control unit). In the hydrogen engine, gasoline is replaced by hydrogen to be used as engine fuel, and CO2 emission is reduced to the maximum extent on the basis of not changing the engine body and not increasing the engine cost, so as to improve the emission level of the engine.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Composite gas inlet system for engine

InactiveCN1924323ALower working temperatureIncreased cross-sectional area of air intakeEngine controllersMachines/enginesGas cylinderEngineering

This invention relates to motor compound gas-in system, wherein, the gas cylinder channel is fixed with gas-in tube and control valve bus connected with discharge tube and with discharge channel; the control valve bus gas-in channel is connected to gas-in tube; the control valve bus discharge channel is fixed with one gas control valve and discharge control valve through screw tube to control switch between discharge tube and channel; at end of motor discharge, discharge door and control valve closes and the gas-in door opens.

Owner:姬腾飞

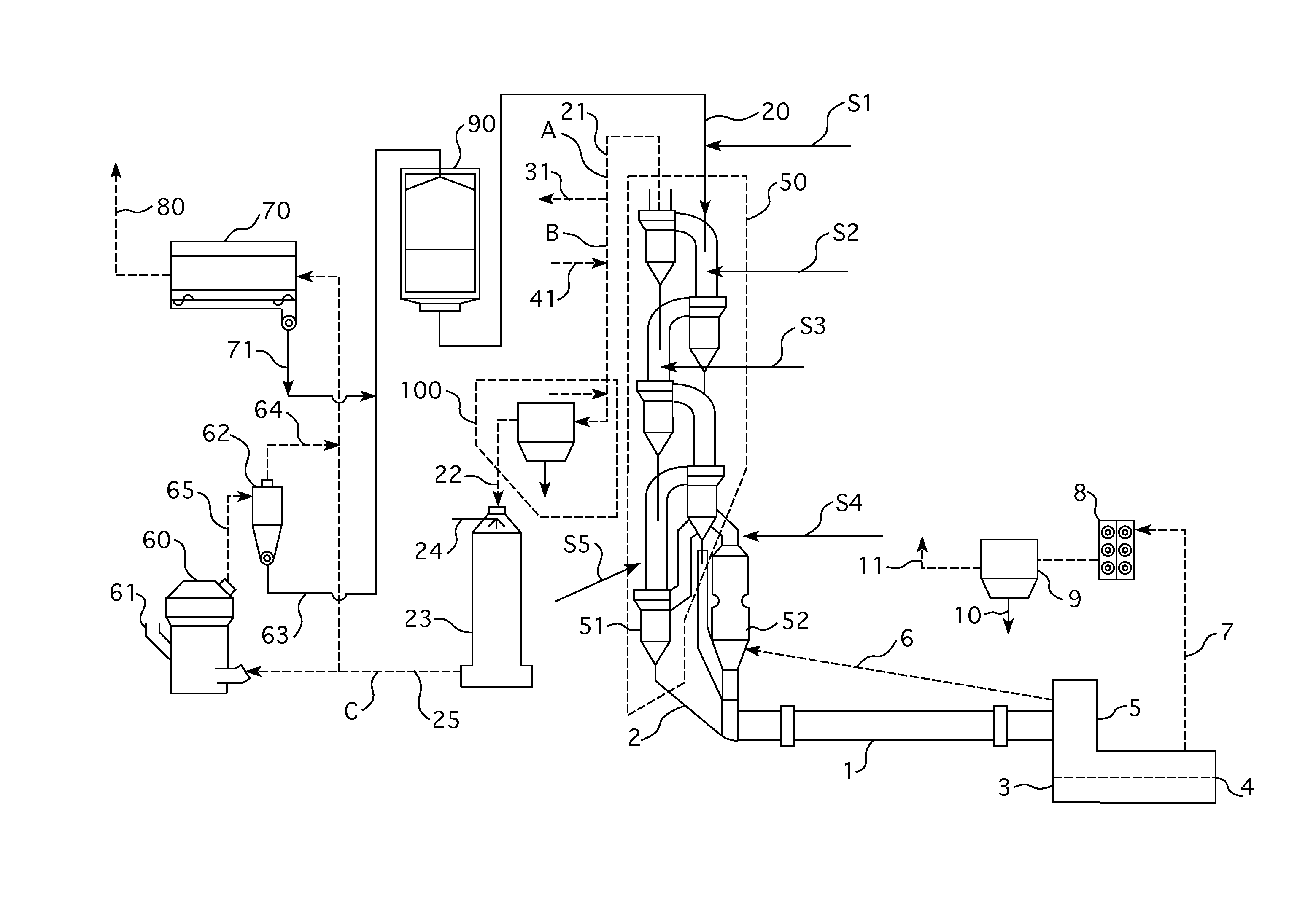

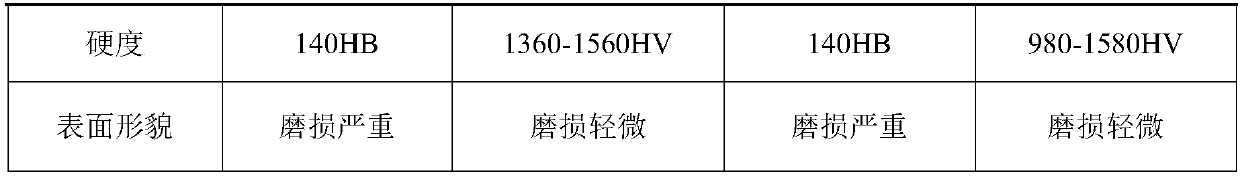

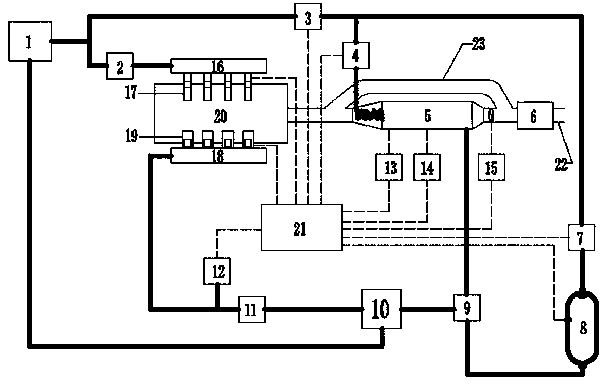

Methanol and hydrogen dual-fuel power system

PendingCN111305947AHigh thermal efficiencyImprove combustion performanceHydrogenInternal combustion piston enginesGasolineProcess engineering

The invention discloses a methanol and hydrogen dual-fuel power system. The thermal efficiency of gasoline and diesel engines is only 20-45%, and waste heat of tail gas is discharged into the atmosphere and is not effectively utilized, so that energy waste is caused. The methanol and hydrogen dual-fuel power system comprises an engine (20), a hydrogen production device (5), a methanol box (1) anda cold start electric heating hydrogen production device (8), and the methanol box communicates with a methanol injection rail (16) on an engine intake manifold, a methanol inlet of the cold start electric heating hydrogen production device and a methanol inlet pipe of the hydrogen production device through pipelines; and the methanol inlet pipe of the hydrogen production device is connected to the hydrogen production device of an engine exhaust pipe (22), one end of a gas outlet pipeline of the cold start electric heating hydrogen production device communicates with a gas inlet of the hydrogen production device through an electromagnetic three-way one-way valve (9), the other end of the gas outlet pipeline communicates with a gas cooling and gas-liquid separating device (10), and a methanol outlet of the gas cooling and gas-liquid separating device communicates with the methanol box through a pipeline. The invention is used for the methanol and hydrogen dual-fuel power system.

Owner:营口福泰科技有限责任公司

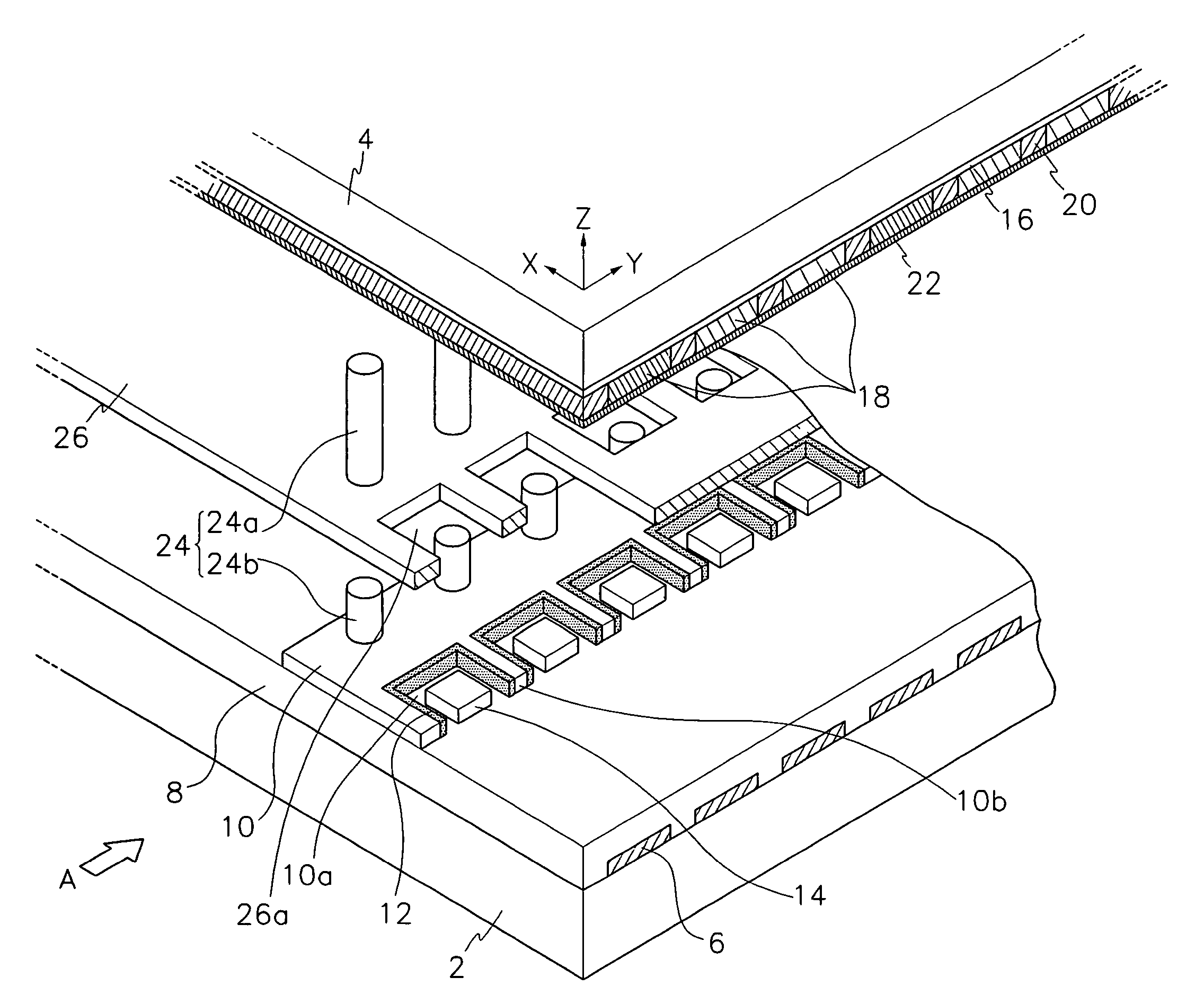

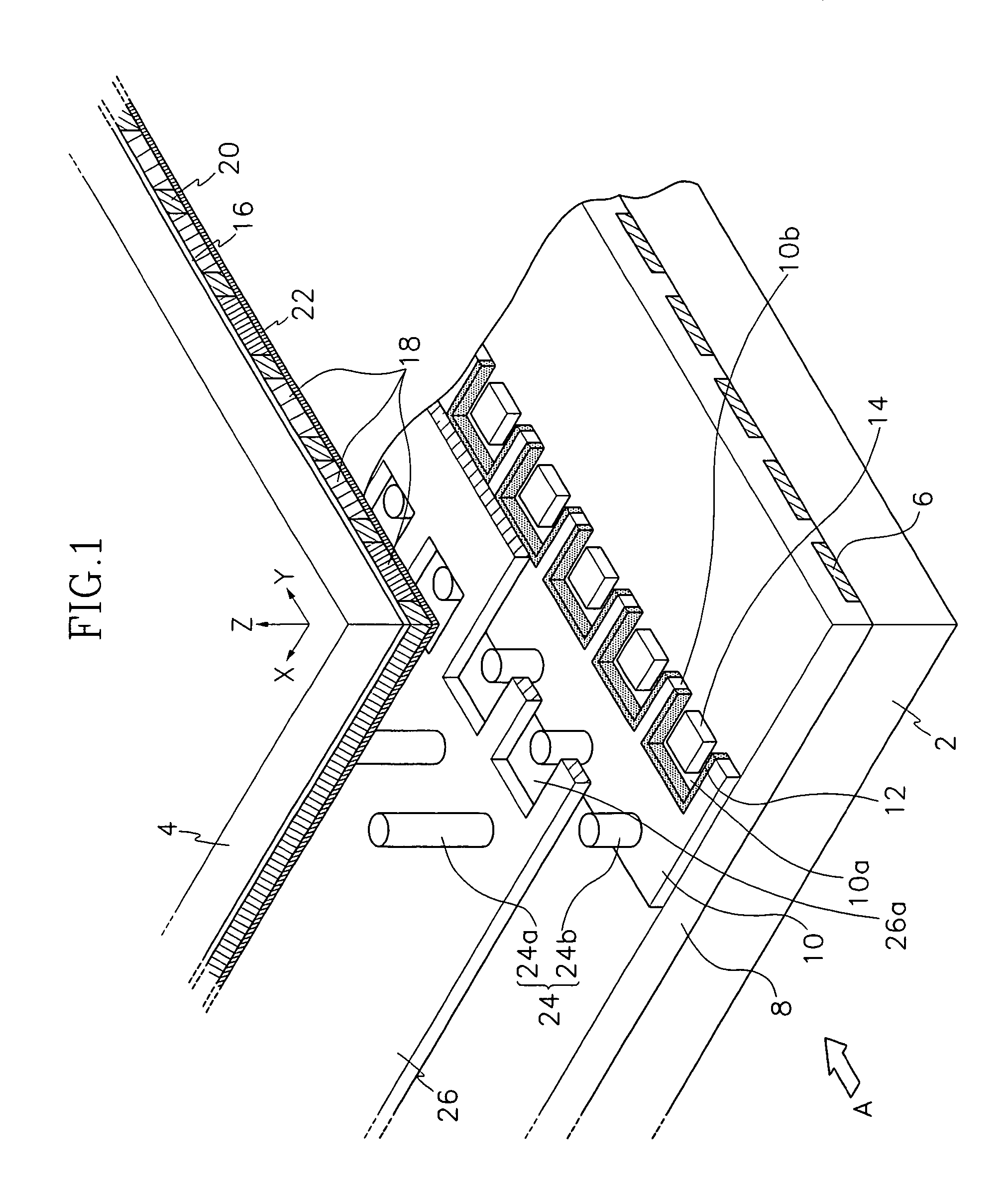

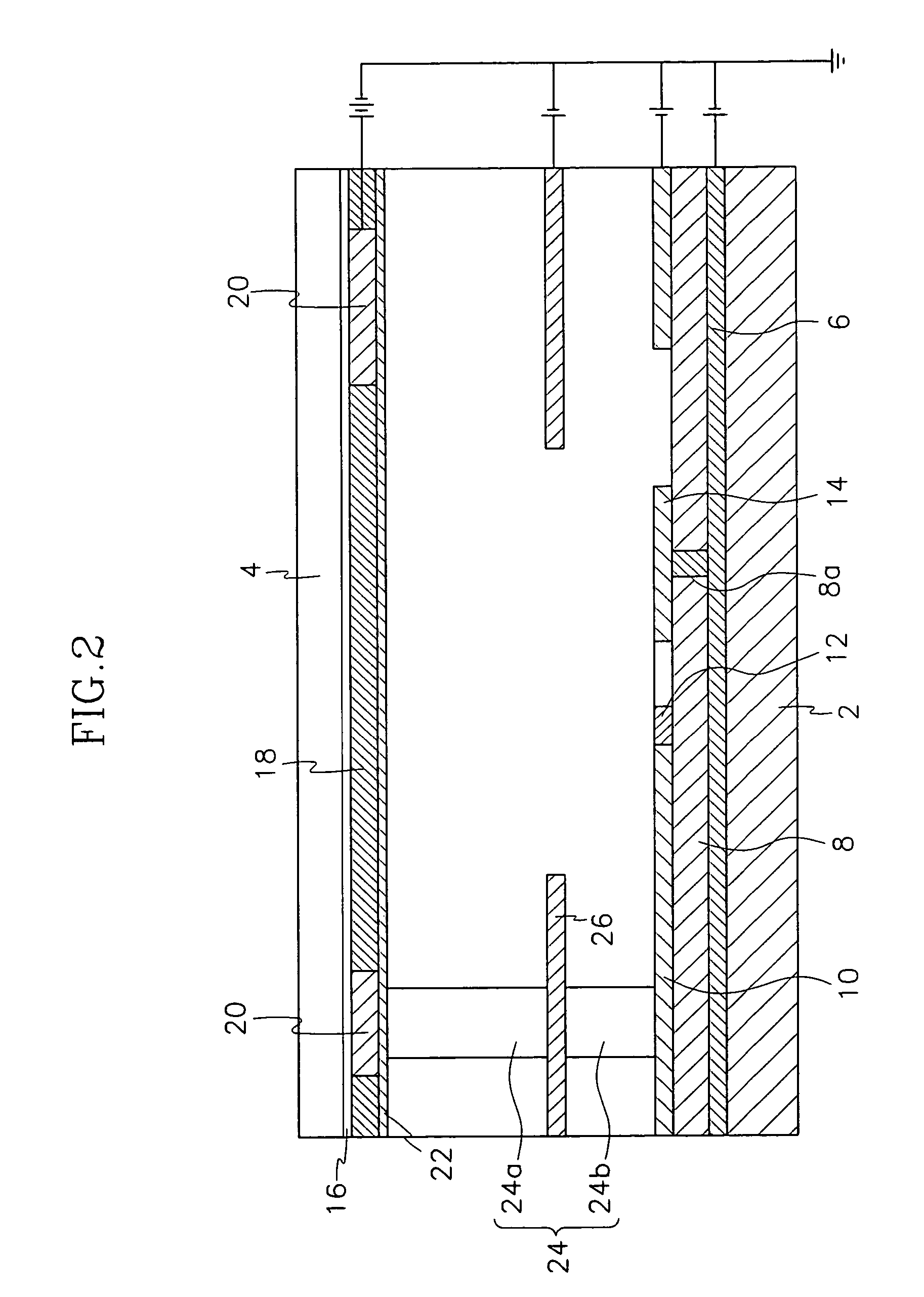

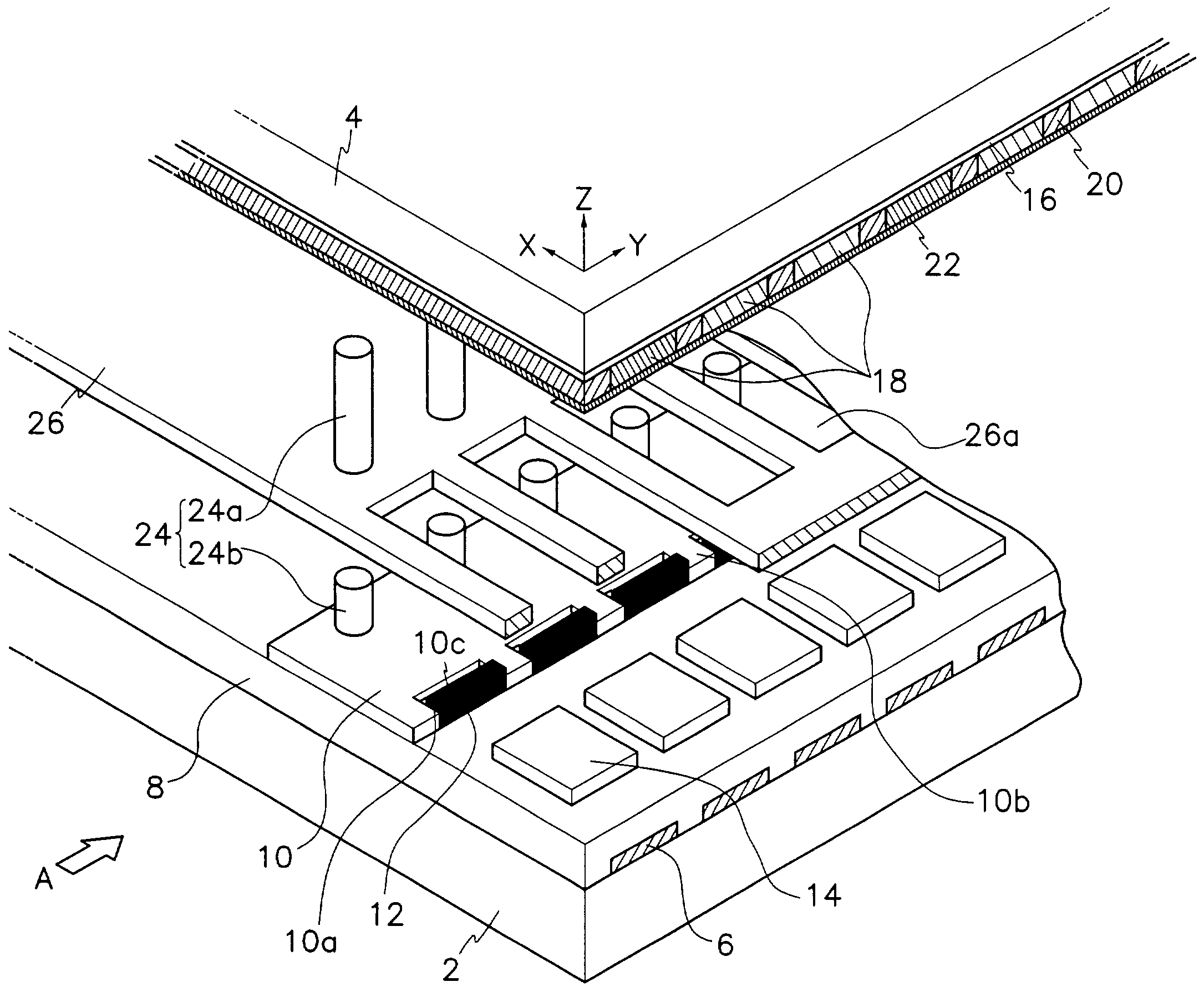

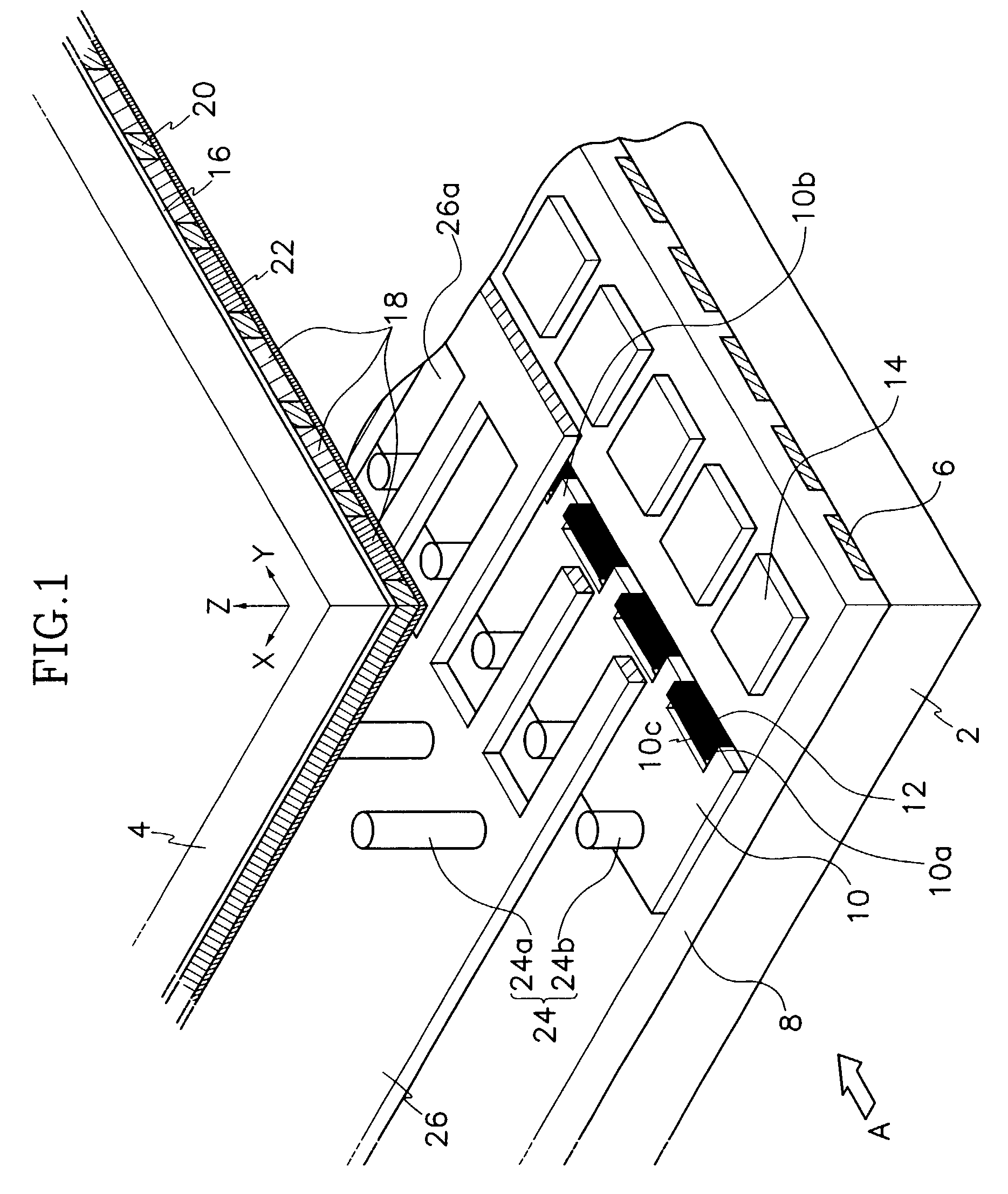

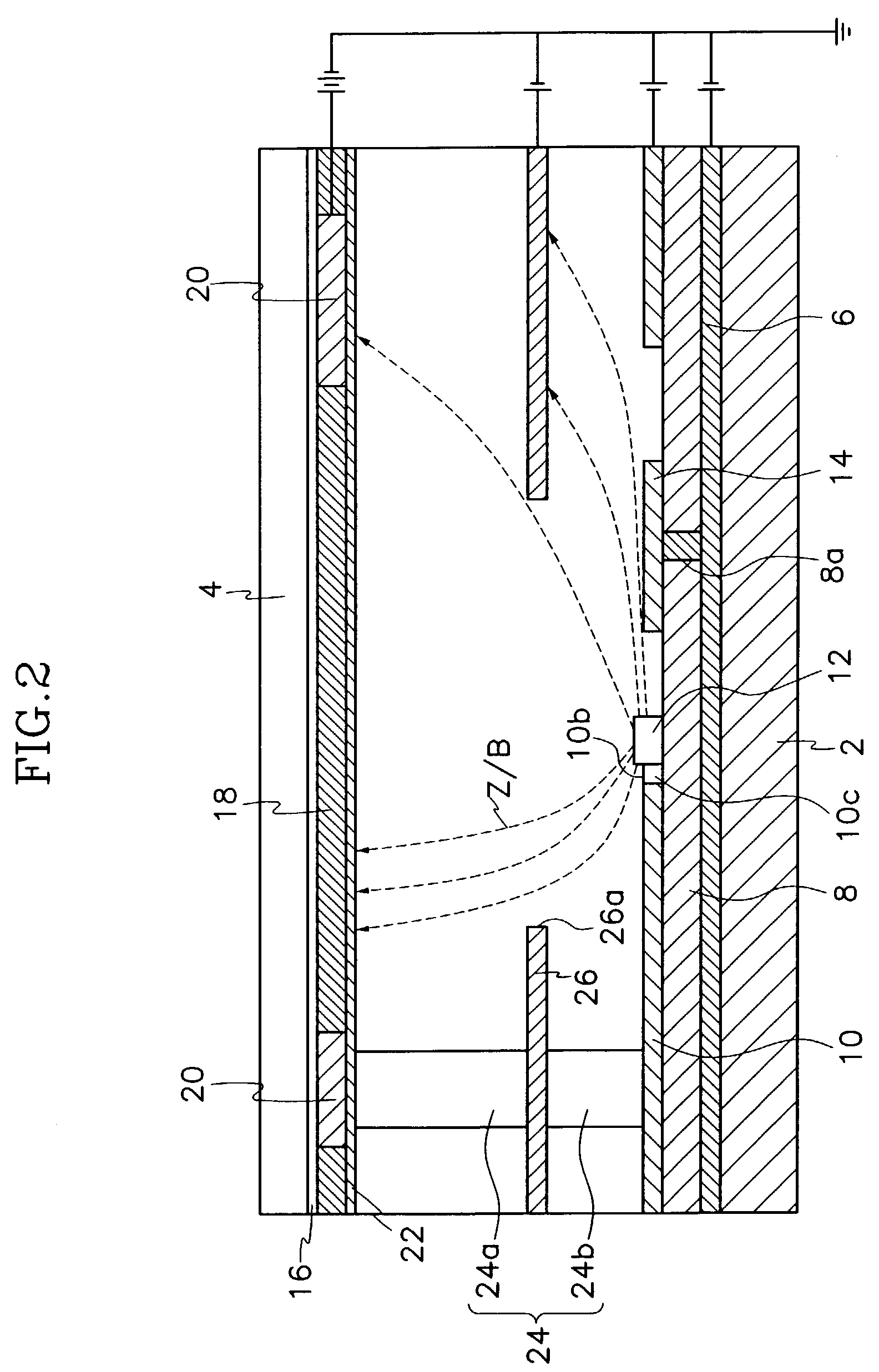

Field emission display having emitter arrangement structure capable of enhancing electron emission characteristics

InactiveUS7173365B2Width of can varyRaise emission levelsDischarge tube luminescnet screensLamp detailsInsulation layerCathode electrode

A field emission display. Gate electrodes are formed in a predetermined pattern on a first substrate. An insulation layer is formed on the first substrate covering the gate electrodes. Cathode electrodes are formed in a predetermined pattern on the insulation layer. Emitters are provided electrically contacting the cathode electrodes. A second substrate is provided opposing the first substrate with a predetermined gap therebetween. The first substrate and the second substrate form a vacuum container. An anode electrode is formed on a surface of the second substrate opposing the first substrate. Phosphor layers are formed in a predetermined pattern on the anode electrode. Portions of the cathode electrodes are removed to form emitter-receiving sections. Fences are formed between the emitter-receiving sections, one of the emitters being provided in each of the emitter-receiving sections electrically contacting the cathode electrodes.

Owner:SAMSUNG SDI CO LTD

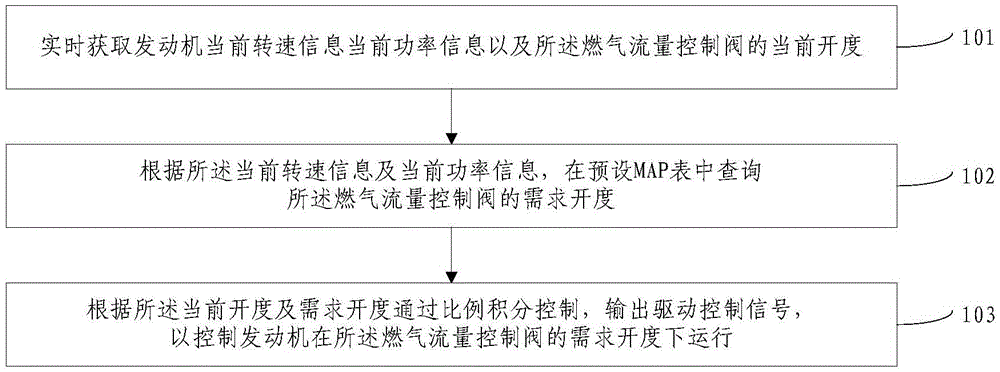

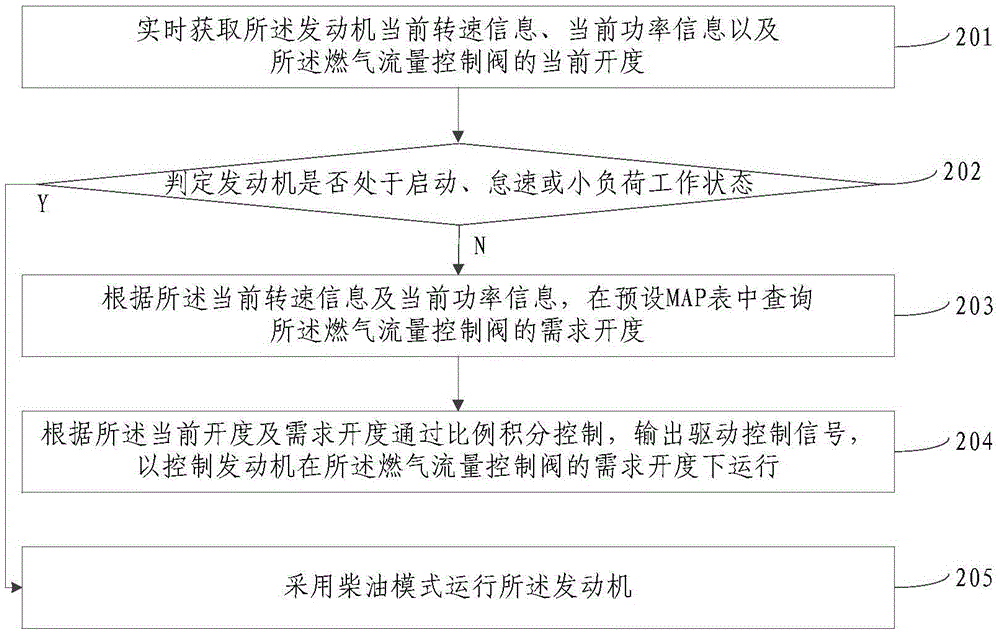

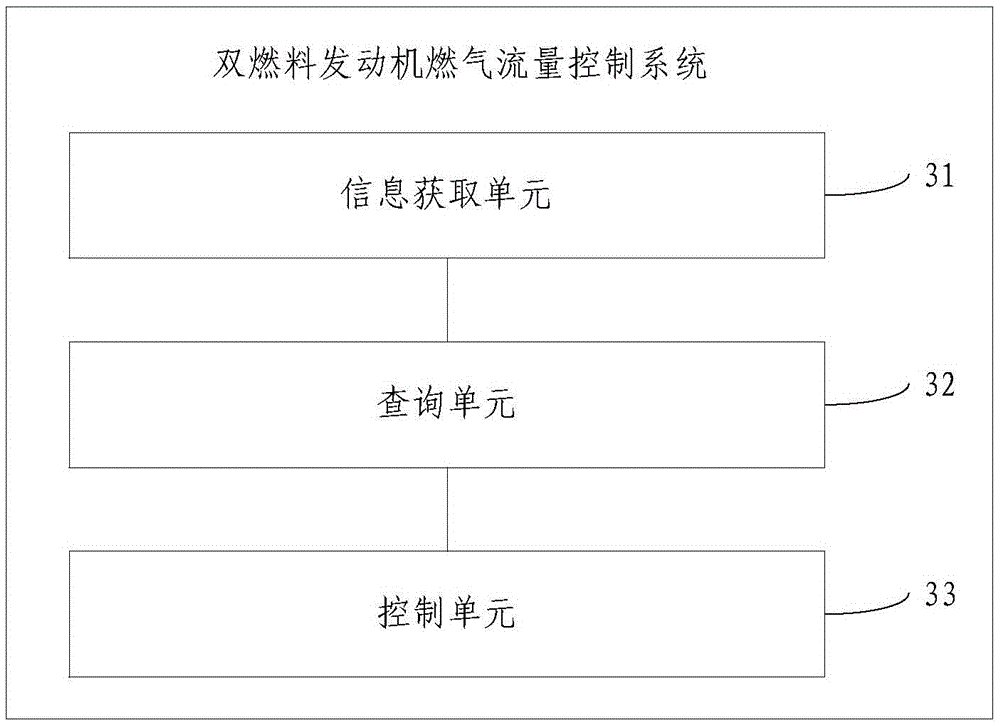

Gas flow control method and device of dual-fuel engine

InactiveCN105626284ARaise emission levelsLow application costElectrical controlInternal combustion piston enginesControl signalEngineering

The invention provides a gas flow control method and device of dual-fuel engine. The method comprises the following steps: acquiring current revolving speed information and current power information of the engine and current open degree of a gas flow control valve; inquiring required open degree of the gas flow control valve in an MAP chart according to the current revolving speed information and the current power information; controlling through proportional integral according to the current open degree and the required open degree, and outputting a driving control signal so as to control the engine to run under the required open degree of the gas flow control valve, wherein the MAP chart is a relation chart of the revolving speed of the engine and the required open degree of the gas flow control valve. The method can effectively improve emission level of the engine on the premise of relatively low modification, application and maintenance costs.

Owner:WEICHAI POWER CO LTD

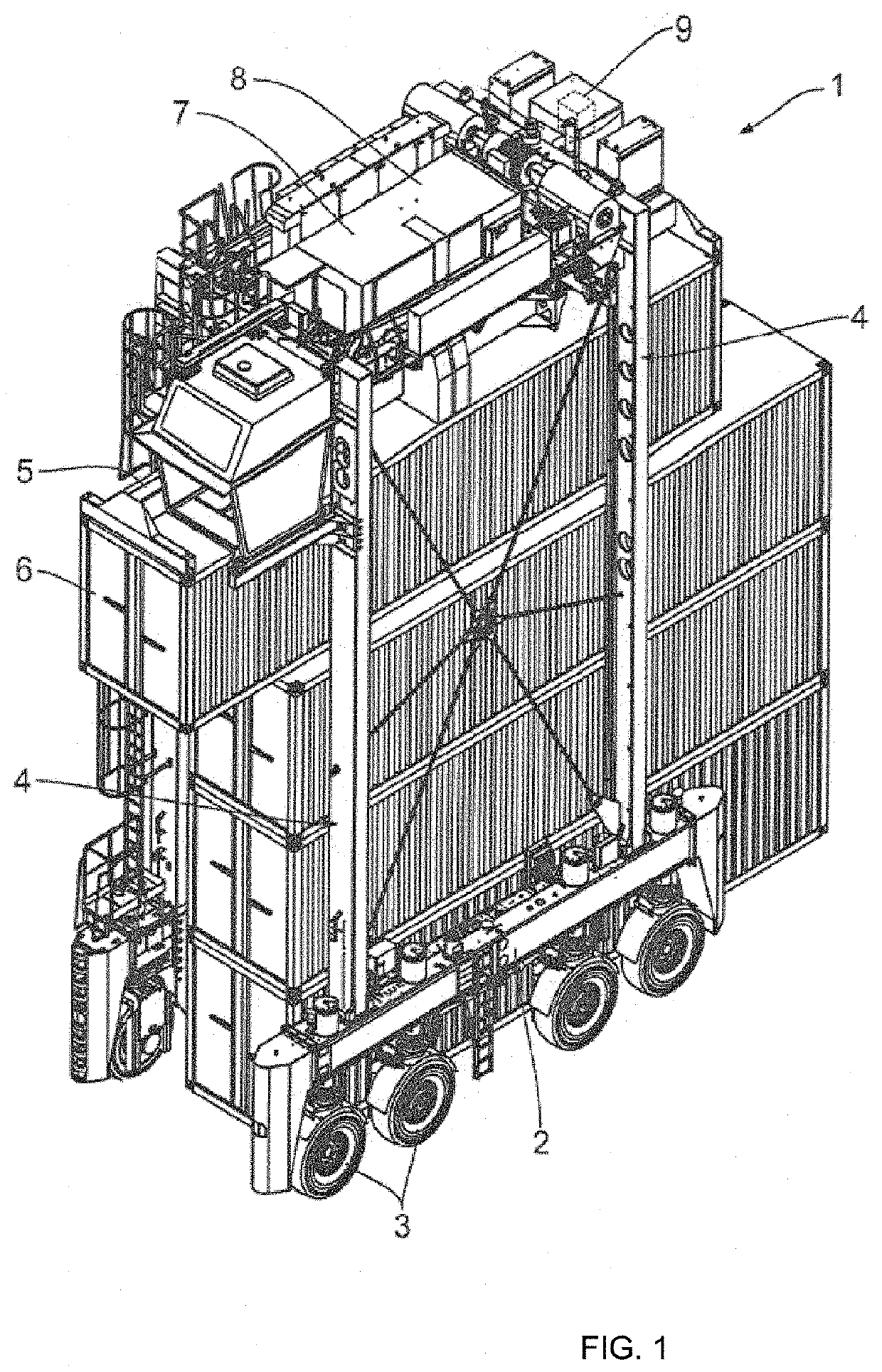

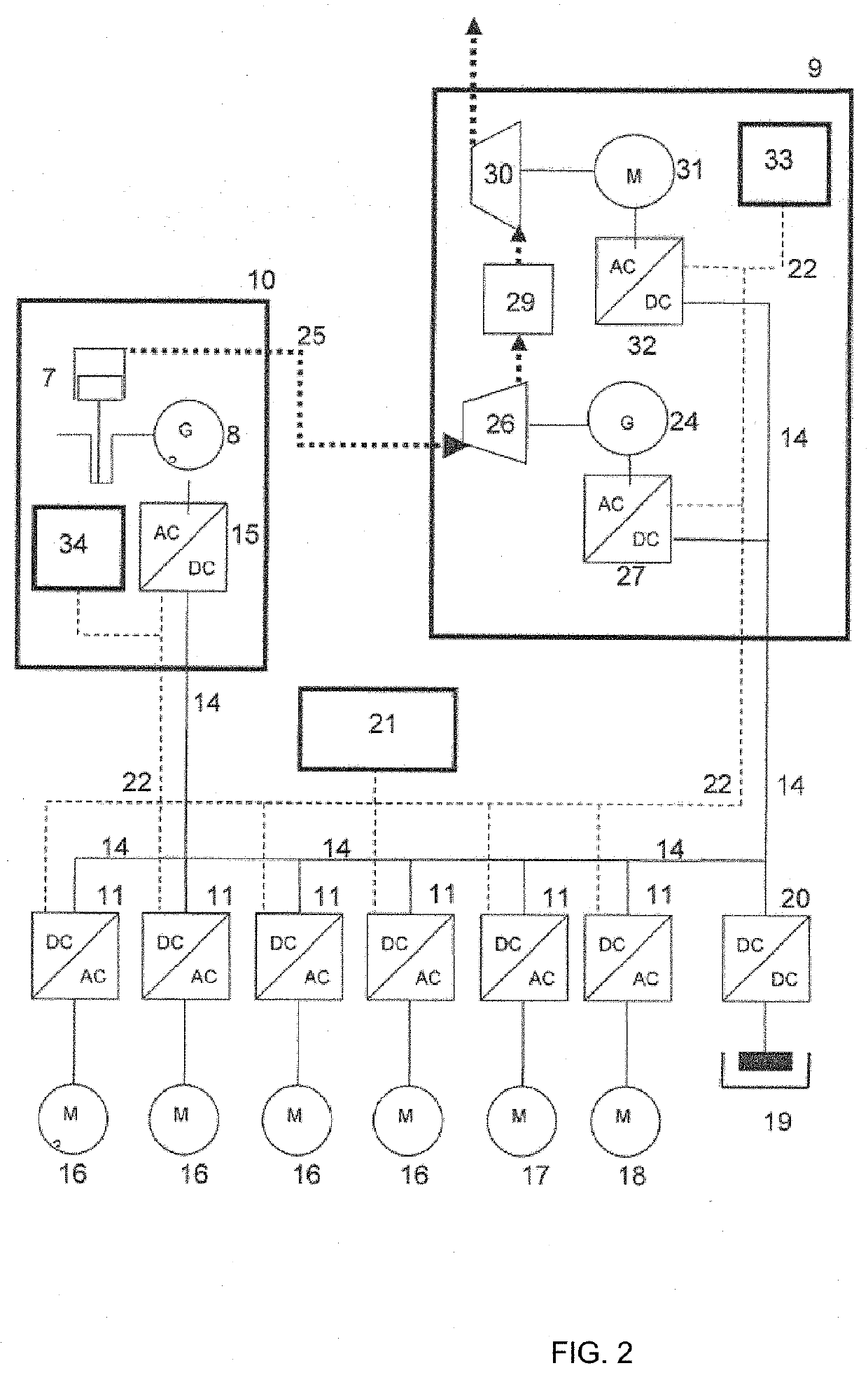

System having a secondary current generating assembly for the secondary conversion into electricity of exhaust gas heat from a primary current generating assembly

ActiveUS20200056564A1Improve efficiencyReduce fuel consumptionInternal combustion piston enginesExhaust apparatusControl systemExhaust fumes

A system having a primary current generating assembly includes a primary thermal engine and a secondary current generating assembly, in particular an electric turbo compound installation, for the secondary conversion into electricity of exhaust gas heat from the primary current generating assembly. The secondary current generating assembly includes an exhaust gas turbine arranged in an exhaust gas stream of the primary thermal engine, and the exhaust gas turbine drives an electric secondary generator. In order to improve efficiency, and in particular to reduce fuel consumption, it is proposed that an exhaust gas cooler followed by a compressor are arranged in the exhaust gas stream downstream of the exhaust gas turbine, the compressor being driven by an electric motor and the rotational speeds of the compressor and the exhaust gas turbine are controlled by a process control system. The disclosed invention also relates to a vehicle equipped therewith.

Owner:KONECRANES GLOBAL

System, method, and article of manufacture for adjusting CO emission levels at predetermined locations in a boiler system

InactiveUS7581945B2Raise emission levelsBig advantageBurnersPilot flame ignitersCombustorManufacturing engineering

A system, a method, and an article of manufacture for adjusting CO emission levels in predetermined locations in a boiler system are provided. The boiler system has a plurality of burners and a plurality of CO sensors disposed therein. The system determines locations within the boiler system that have relatively high CO levels utilizing the plurality of CO sensors and then adjusts A / F ratios of burners affecting those locations to decrease the CO levels at the locations.

Owner:GENERAL ELECTRIC CO

Tangential combustor with vaneless turbine for use on gas turbine engines

ActiveUS8904799B2Shorten the lengthSmall sizeContinuous combustion chamberEfficient propulsion technologiesTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

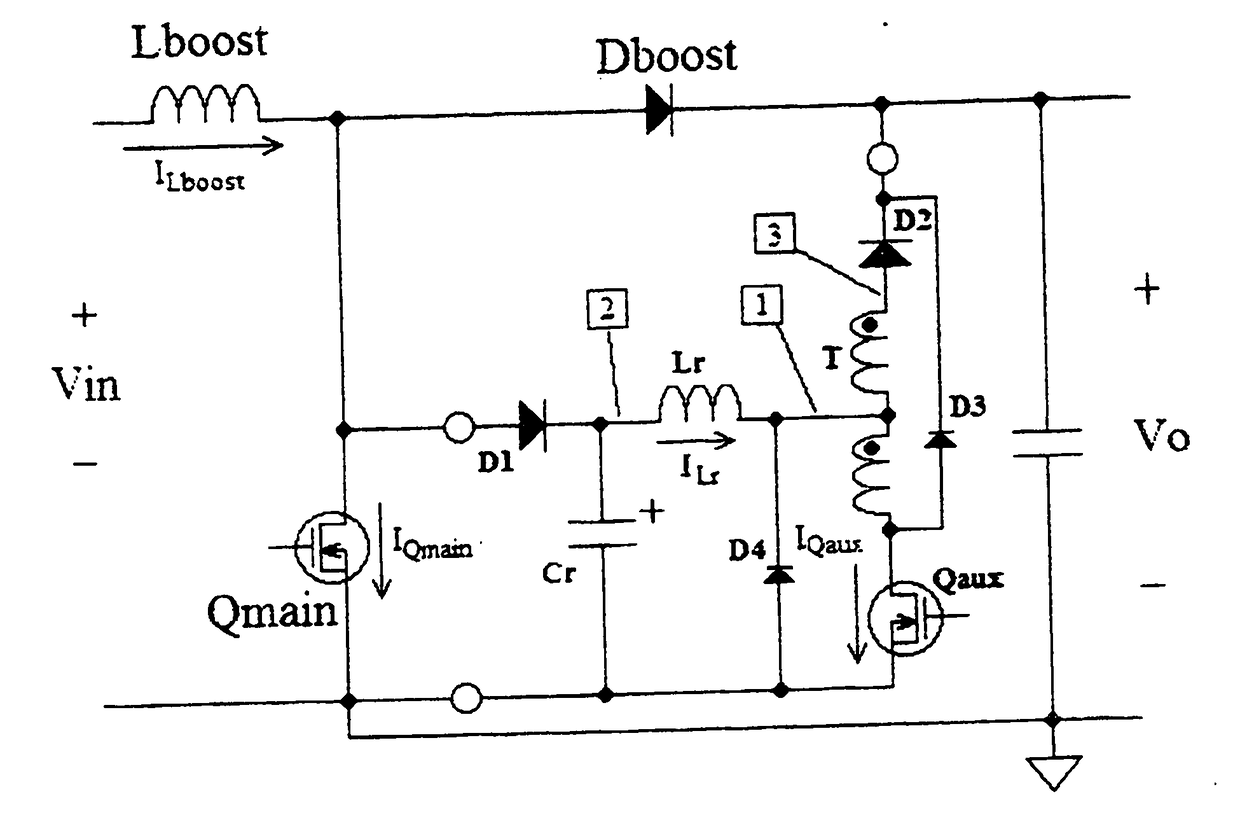

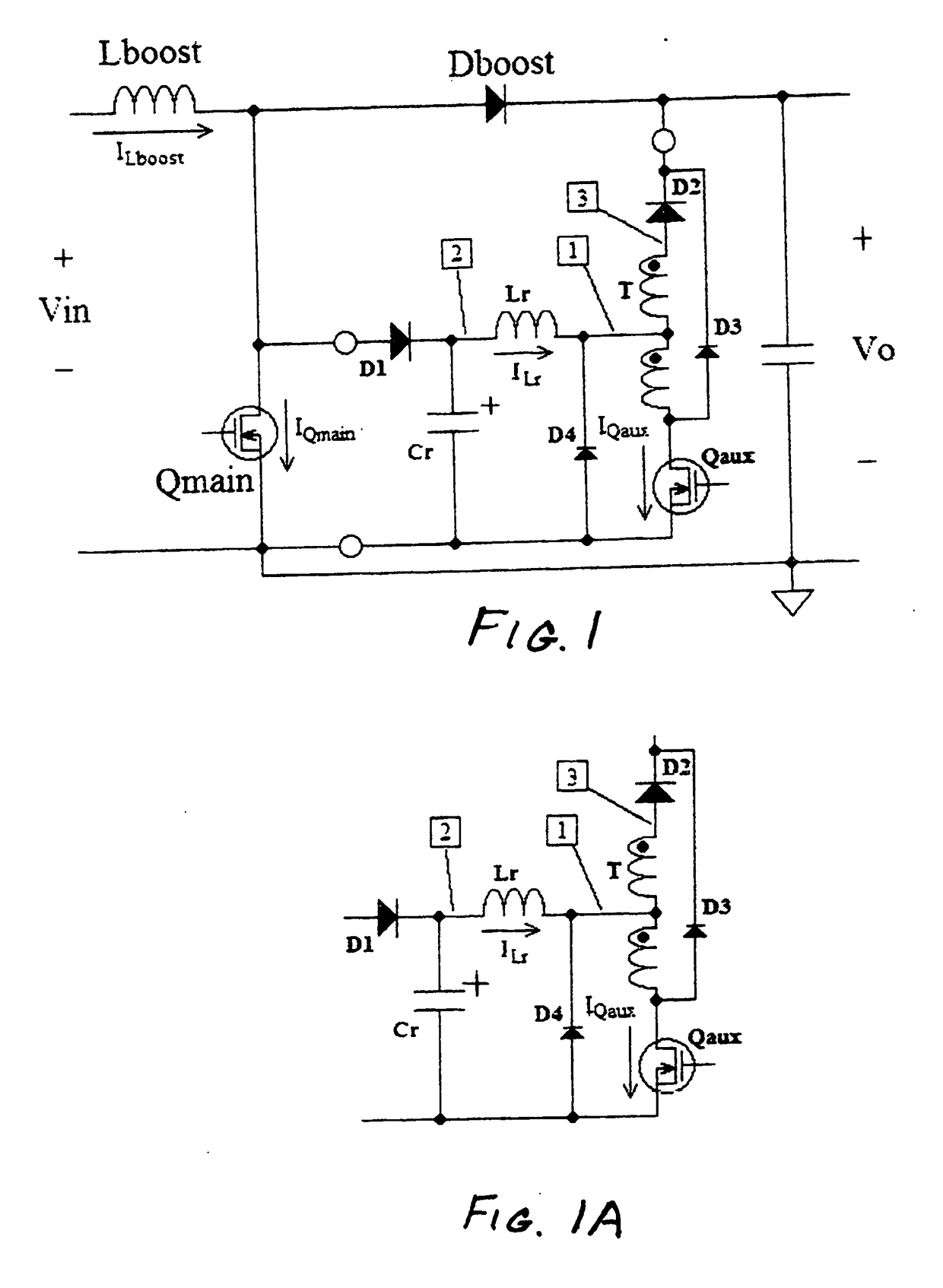

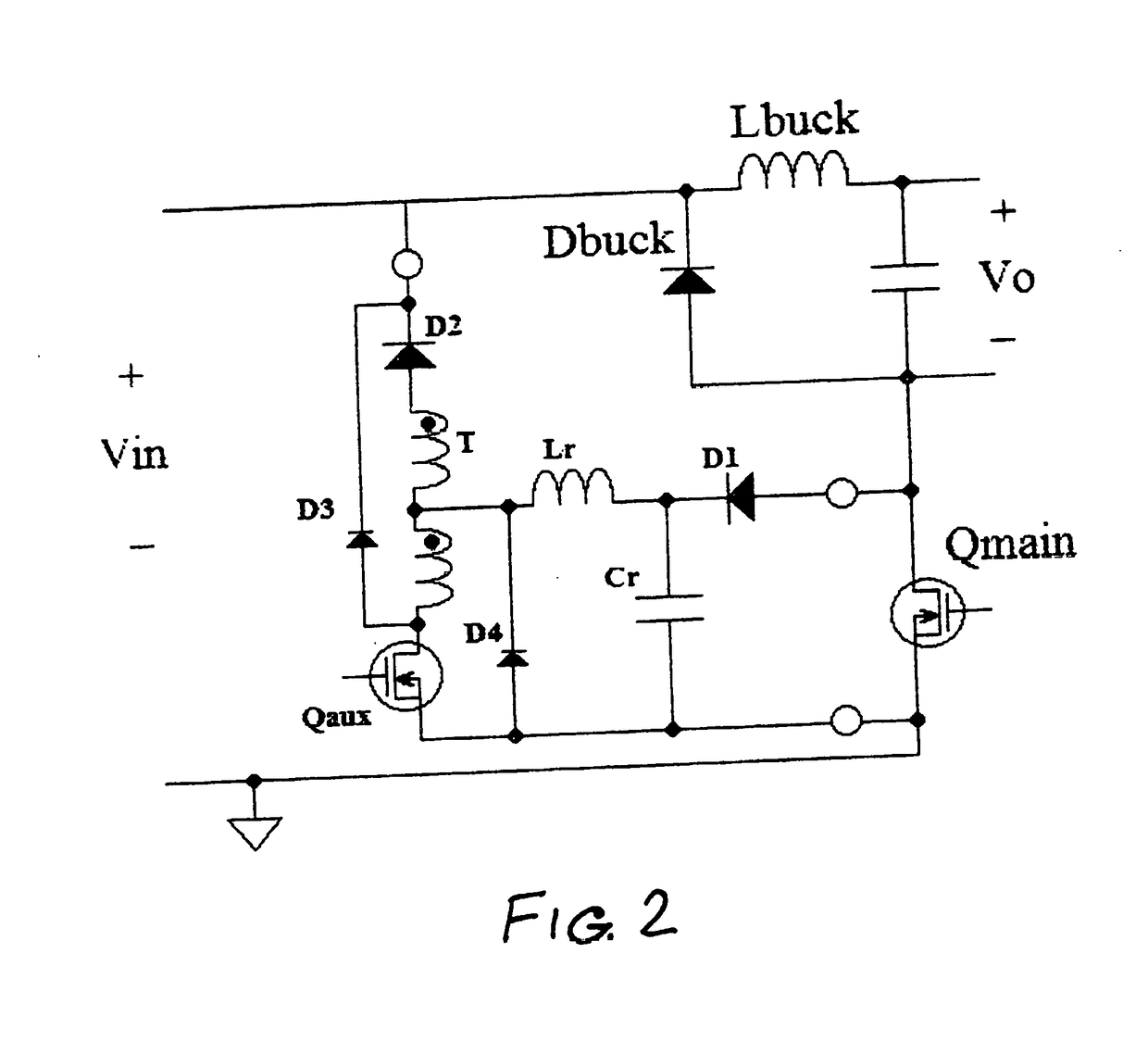

Soft-switching for high-frequency power conversion

InactiveUS20180323713A1Improves EMI emission levelLessens turn-off lossEfficient power electronics conversionConversion using Cuk convertorsSoft switchingHigh frequency power

A power converter designed for operation at high frequencies includes a soft-switching cell comprising a split inductor, a resonant inductor, a resonant capacitor, two diodes and a controlled semiconductor. Alternatively, the power converter includes a soft-switching cell comprising a transformer having isolated windings, a resonant inductor, a resonant capacitor, two diodes and a controlled semiconductor.

Owner:EMD TECH

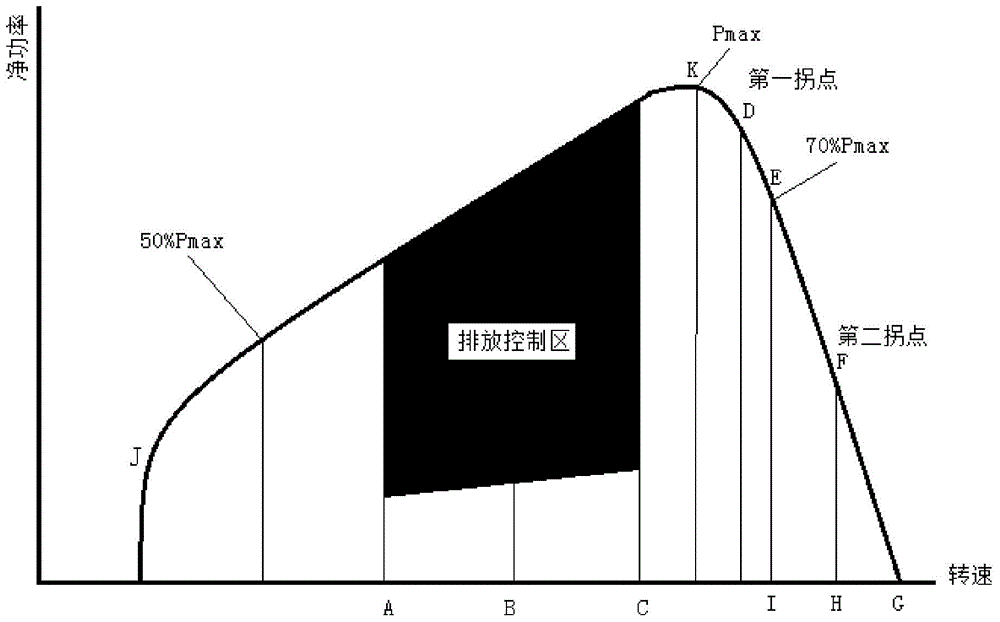

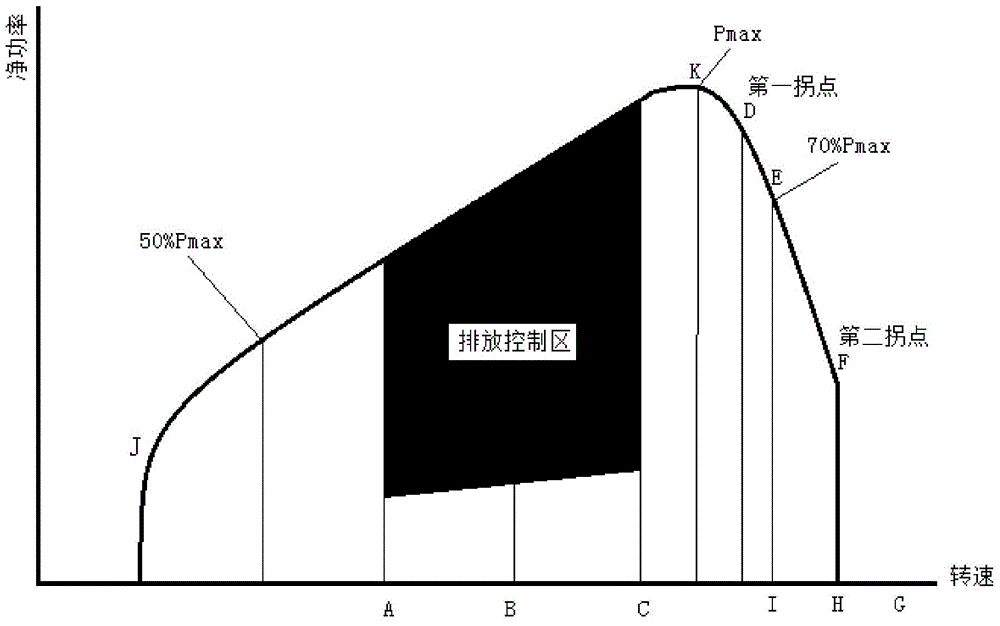

Electric control engine speed adjustment characteristic curve design method

ActiveCN104832294AIncrease fuel consumptionRaise emission levelsEngine controllersMachines/enginesEngineeringElectric control

The invention relates to an electric control engine speed adjustment characteristic curve design method. According to the electric control engine speed adjustment characteristic curve design method, a curve of which speed adjustment rate is zero is adopted to replace a curve in an original speed adjustment characteristic curve, wherein the load rate of the curve in the original speed adjustment characteristic curve is low, and an obtained curve is a new speed adjustment characteristic curve; and the curve in the original speed adjustment characteristic curve, of which the load rate is low, is a curve of which the rotation speed is higher than that of a curve corresponding to a second inflection point, wherein the second inflection point is a point located between a point where the power value of the original speed adjustment characteristic curve is 70% of the power value of a rated power point, and a G point. With the electric control engine speed adjustment characteristic curve designed by the method of the invention adopted, an engine will not enter a high-rotation speed and low-torque area below the original speed adjustment characteristic curve under control, and therefore, oil consumption and emission level of the engine can be improved, and the service life of the engine can be prolonged, and dynamic and driving performance of the engine will not be affected.

Owner:DONGFENG CUMMINS ENGINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com