Engine ignition control and fuel injection control methods based on engine cycles

A technology of ignition control and control method, applied in the direction of engine control, automatic control, automatic control, etc., can solve the problems of inability to accurately control engine combustion, poor combustion, unstable operation, etc., to ensure accuracy, improve power performance, injection Oil Phase Precise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

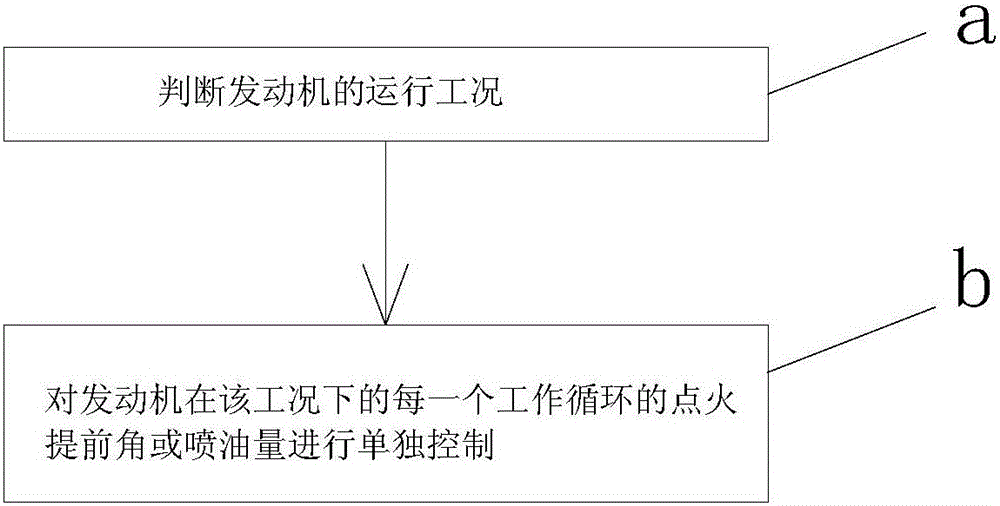

[0025] Embodiment one: figure 1 It is a control logic schematic diagram of the present invention; as shown in the figure: the engine ignition control method based on the engine cycle of the present embodiment includes the following steps:

[0026] a. Judging the operating conditions of the engine; wherein, the method for judging the working conditions can adopt the existing working condition judging method, for example, to judge the working conditions according to parameters such as the throttle opening of the engine and the variation of the throttle opening per unit time ; b. Independently control the ignition advance angle of each working cycle of the engine under this working condition;

[0027]Independent control of the ignition advance angle of each working cycle of the engine under a certain working condition can refine the ignition control of the engine to each working cycle of the engine, thereby making the control parameters of each working cycle of the engine more ac...

Embodiment 2

[0034] Embodiment two: a kind of engine injection control method based on the engine cycle of the present embodiment comprises the following steps: a. judge the operating condition of the engine; wherein, the method for judging the working condition can adopt the existing working condition judging method, For example, according to the parameters such as engine throttle opening and throttle opening variation per unit time, the working condition is judged; b. The fuel injection quantity of each working cycle of the engine under this working condition is individually controlled; The independent control of the fuel injection quantity of each working cycle under a certain working condition can refine the fuel injection control of the engine to each working cycle of the engine, thereby making the control parameters of each working cycle of the engine more accurate and ensuring these control The accuracy of parameters in transitional conditions will ultimately greatly improve the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com