Battery electrode structure and method for manufacture thereof

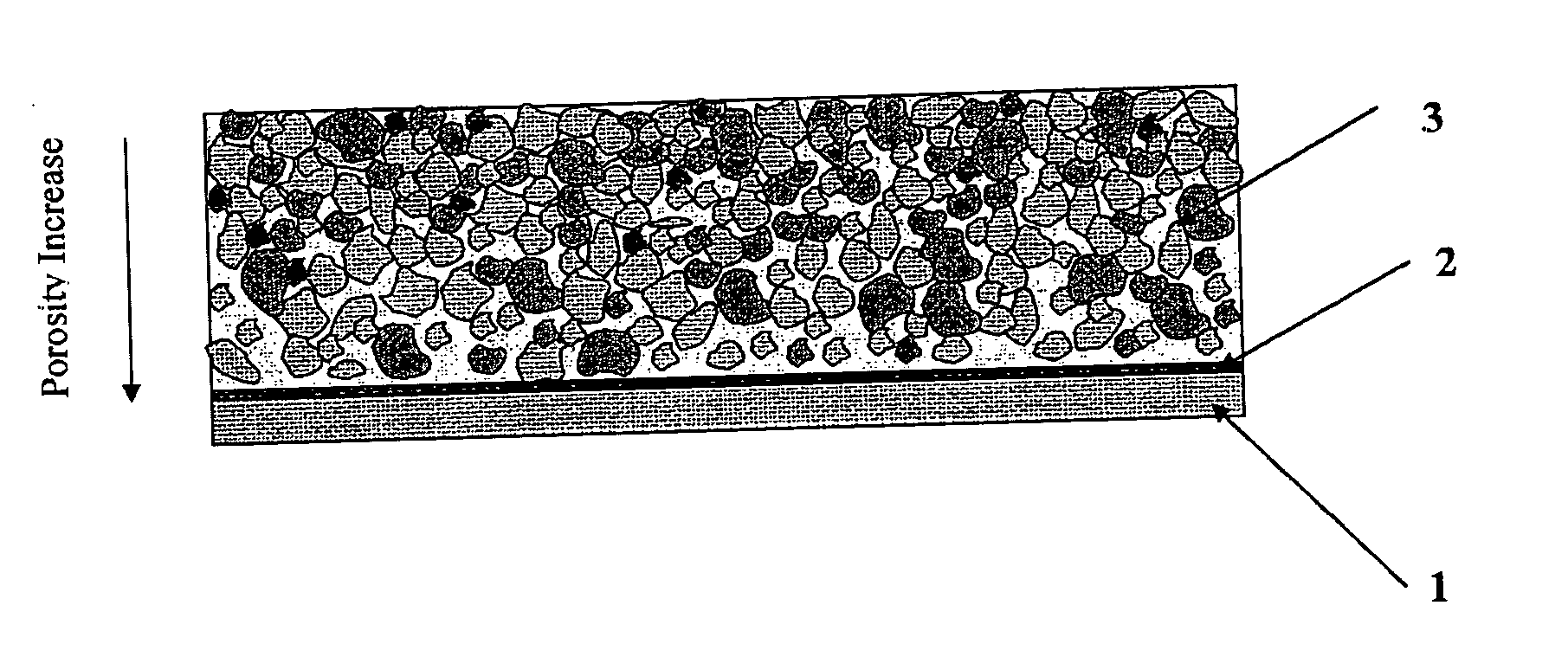

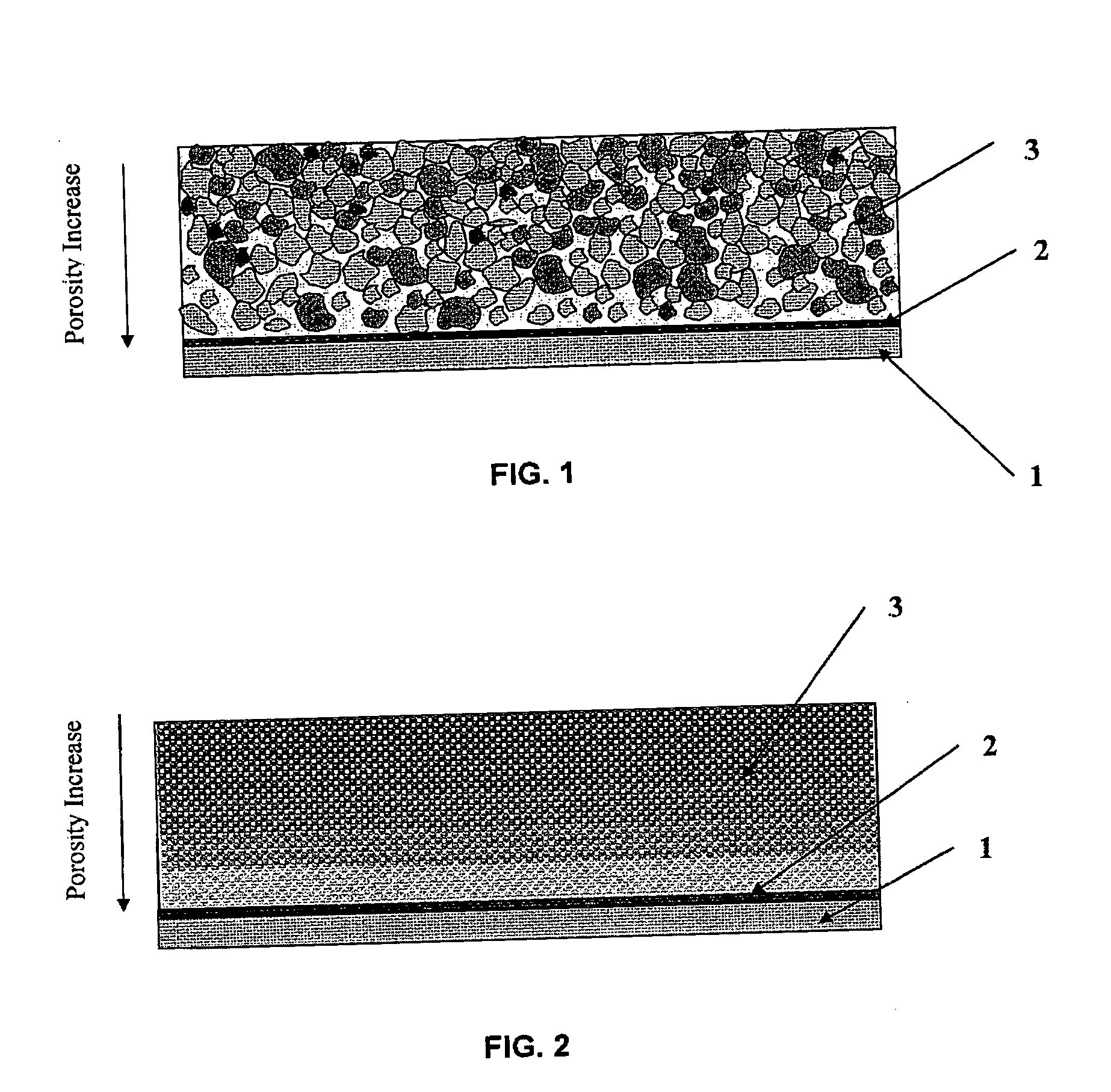

a battery electrode and electrode structure technology, applied in primary cell electrodes, non-aqueous electrolyte accumulator electrodes, coatings, etc., can solve the problems of reducing the electrode capacity and non-uniform consumption of the depolarizer, and achieve the effects of increasing the energy density of chemical sources, reducing porosity, and increasing electrode density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0077] Cathode active layers with a composition by weight of 70% elemental sulphur (available from Fisher Scientific, Loughborough, UK), 10% conductive carbon black (Ketjenblack® EC-600JD, available from Akzo Nobel Polymer Chemicals BV, Netherlands) and 20% polyethylene oxide (PEO, 4,000,000 molecular weight, available from Sigma-Aldrich Company Ltd, Gillingham, UK) were prepared by the following method. A mixture of dry components was ground in a homogenising system Microtron® MB550 for 10-15 minutes. Acetonitrile was added as a solvent to the obtained mixture. The resulting liquid suspension or slurry was mixed for 15-20 hours with a laboratory stirrer DLH. The solids content of the slurry was 10-15 weight percent. The resulting mixture was cast by an automatic film applicator Elcometer® SPRL with a doctor blade onto one side of an 18 micrometre thick conductive carbon coated aluminium foil (available from InteliCoat®, South Hadley, Mass.) as a current collector and substrate. The...

example 2

[0079] The slurry from Example 1 was cast by an automatic film applicator Elcometer® SPRL with onto one side of an 18 micrometre thick conductive carbon coated aluminium foil (available from InteliCoat®, South Hadley, Mass.) as a current collector and substrate. The doctor blade gap was different from that used in Example 1. The coating was dried under ambient conditions for 20 hours and then dried under vacuum at 50° C. for five hours.

[0080] The resulting dry cathode active layer had a thickness of about 21 micrometres with a loading of the cathode composition of 1.35 mg / cm2. The volumetric density of the electroactive coating was about 636 mg / cm3. The porosity of the cathode active layer was 65%.

example 3

[0081] A second layer of the slurry was cast by an automatic film applicator Elcometer® SPRL on top of the solid composite cathode from Example 1. The new coating was dried under ambient conditions for 20 hours and then dried under vacuum at 50° C. for five hours.

[0082] The resulting overall thickness of the dry cathode active layer was 25 micrometres with a loading of the cathode composition of 2.23 mg / cm2. The volumetric density of two layers of the electroactive coating was about 890 mg / cm3. The porosity of the cathode active layer was 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com