Patents

Literature

93 results about "Film applicator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A film applicator is a device used to evenly spread a substance, such as paint, ink, or cosmetics, over a substrate such as a drawdown card. Applicators are usually metal bars that are manufactured to high tolerances to give consistent, repeatable results. Each bar will give a "theoretical wet film thickness" or, in other words, the thickness of the coating that should remain on the drawdown card after application. Even with high manufacturing tolerances, the actual wet film thickness can vary from 50% to 90% of the gap.

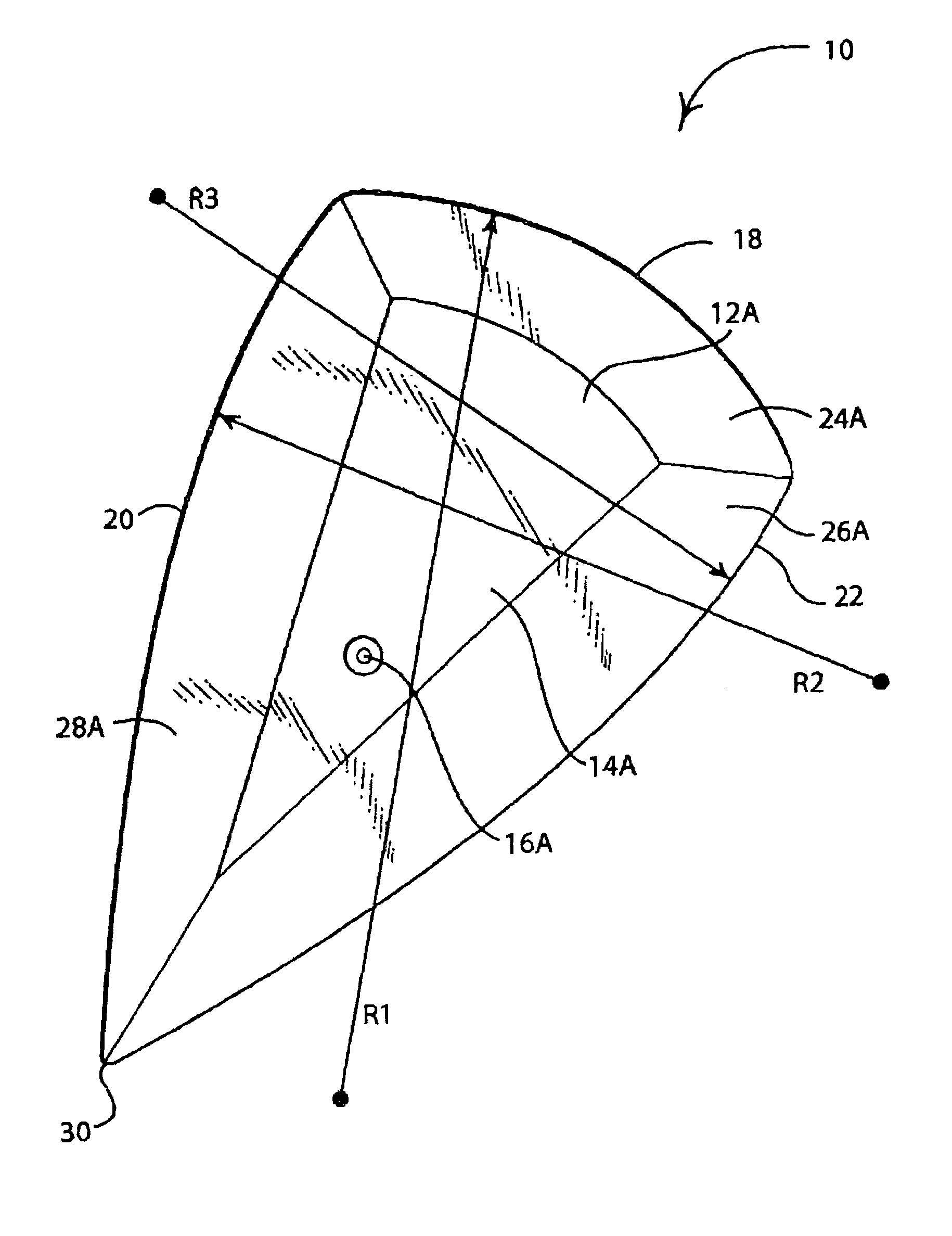

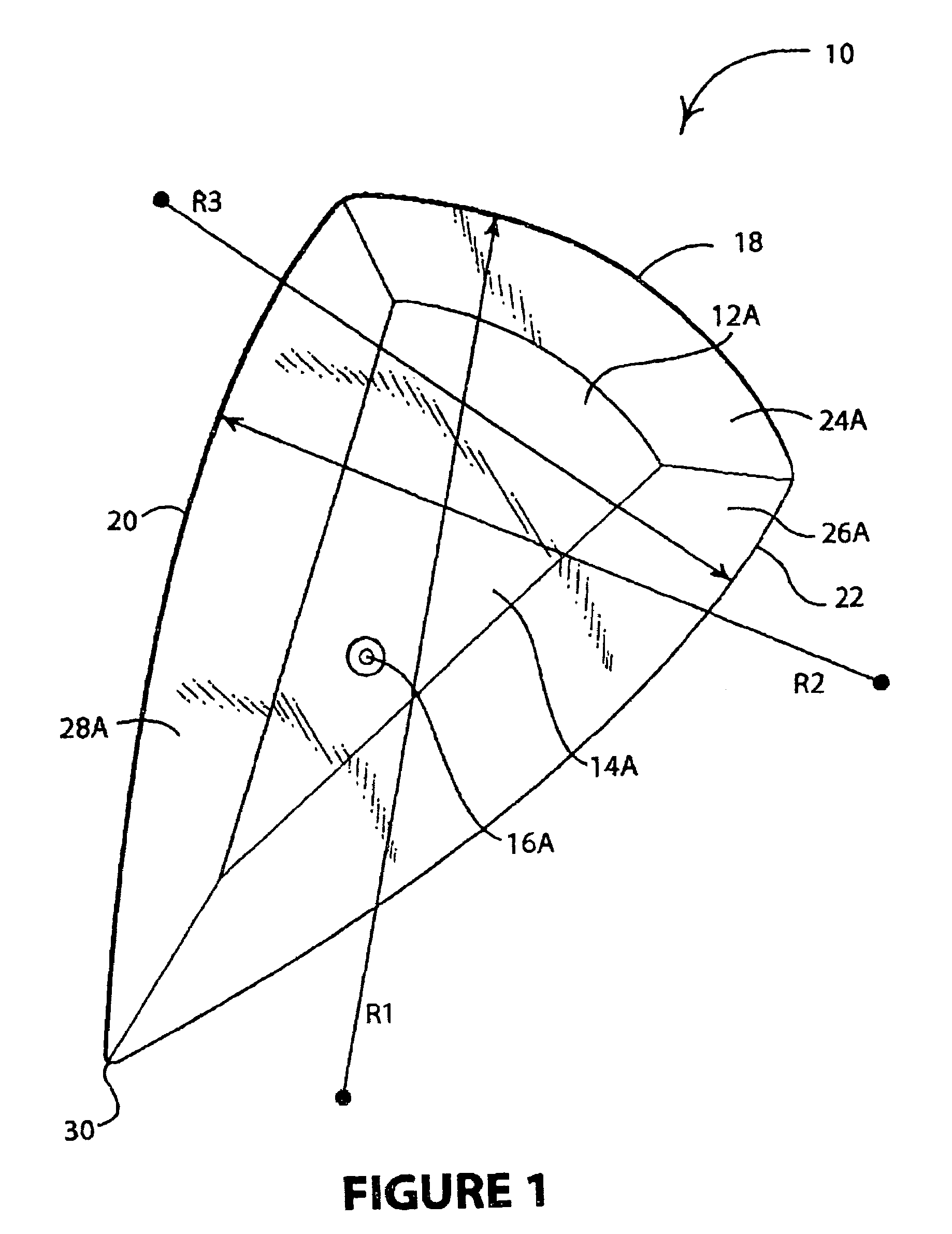

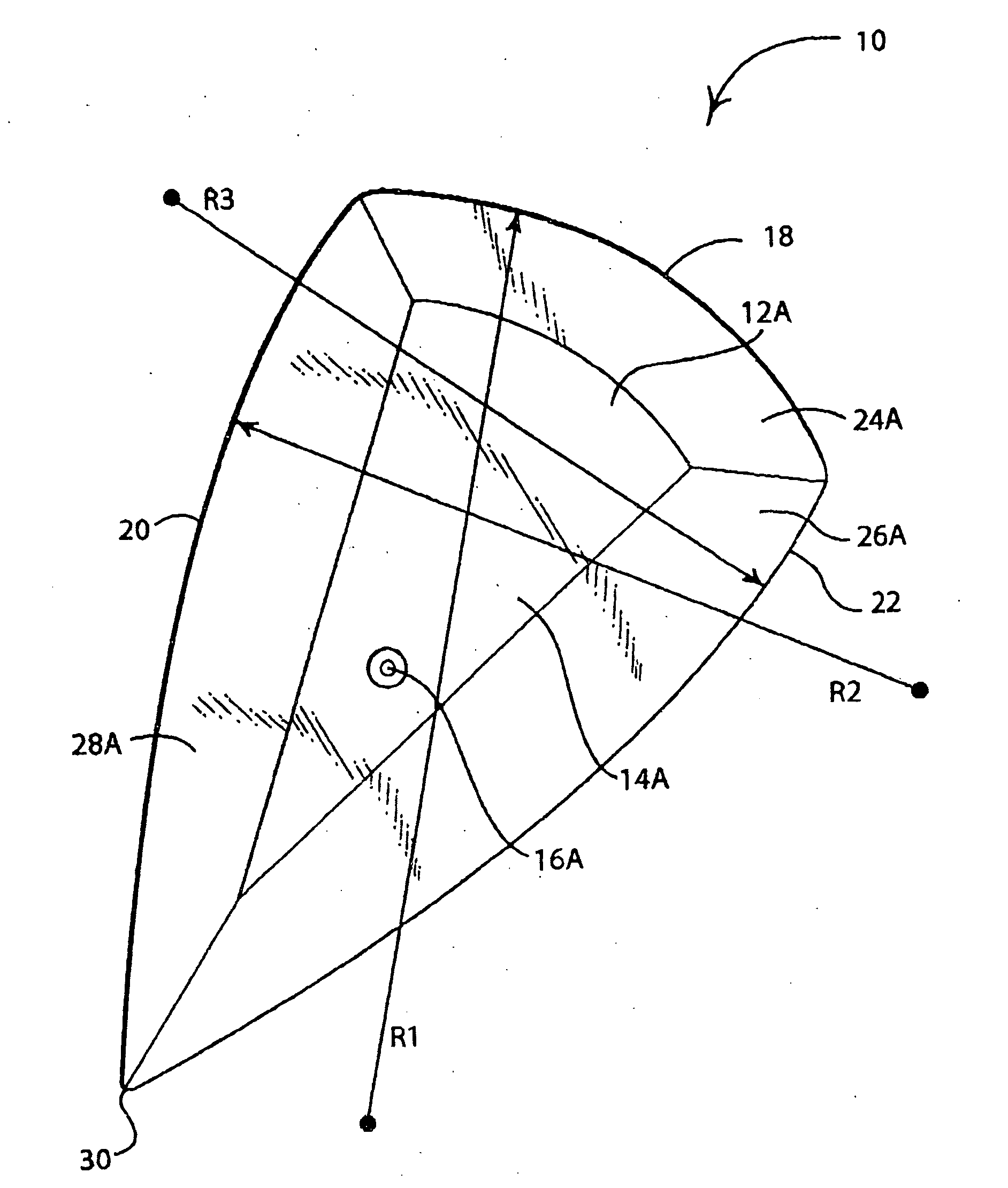

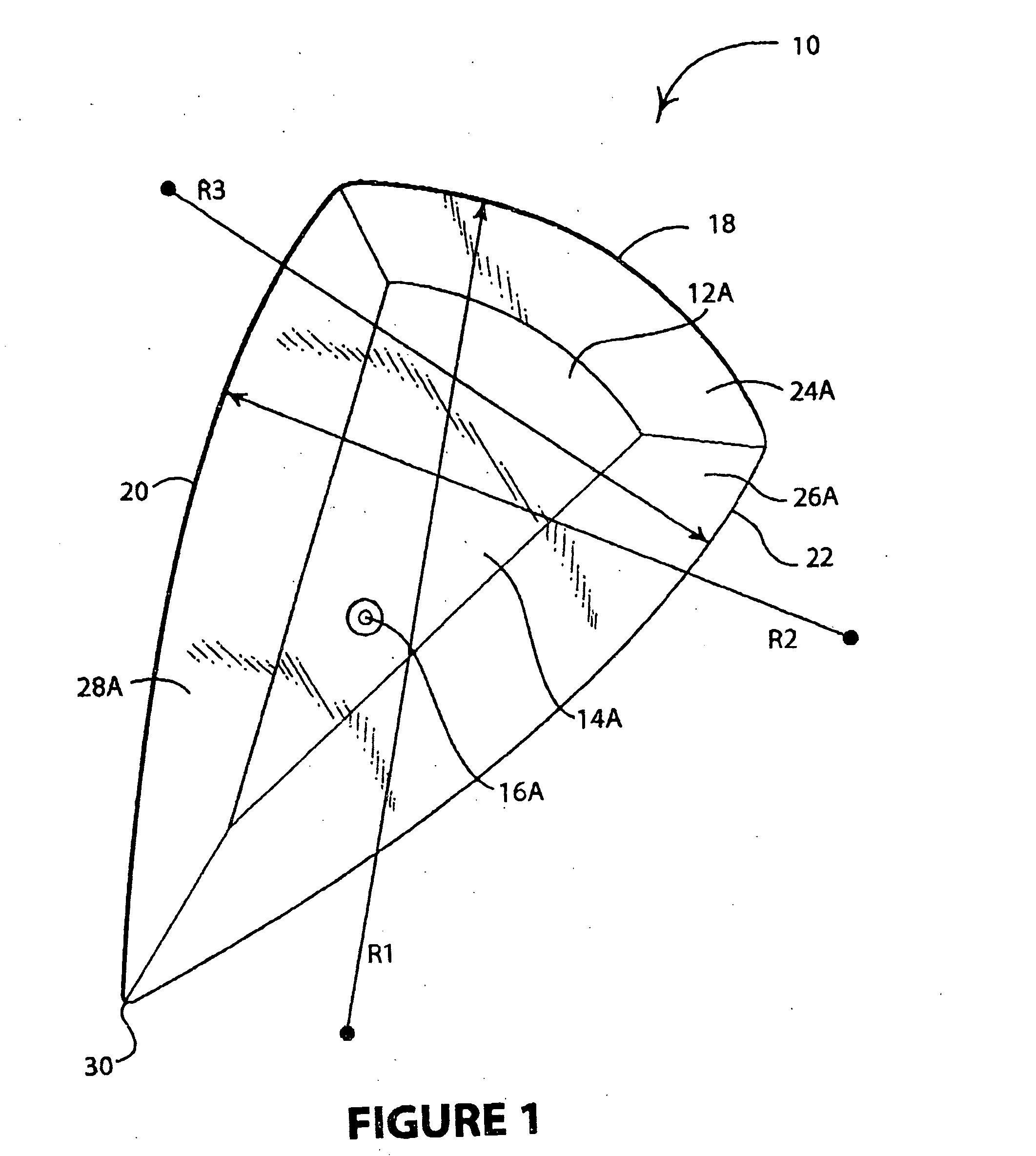

Film applicator tool with arcuate edges

InactiveUS7225848B2Sufficient flexibilityAvoid cutsLiquid surface applicatorsCovering/liningsHardnessEngineering

Film applicator tools are provided which have at least two arcuate edges which are sufficiently flexible and resilient to permit application of adhesive films to smooth surfaces without leaving air bubbles, creases or other defects. The tools are molded of polymeric materials which have hardness values effective to permit the application of smooth and uniform pressure without tearing or abrading the films.

Owner:WILLIAMS ROBERT D

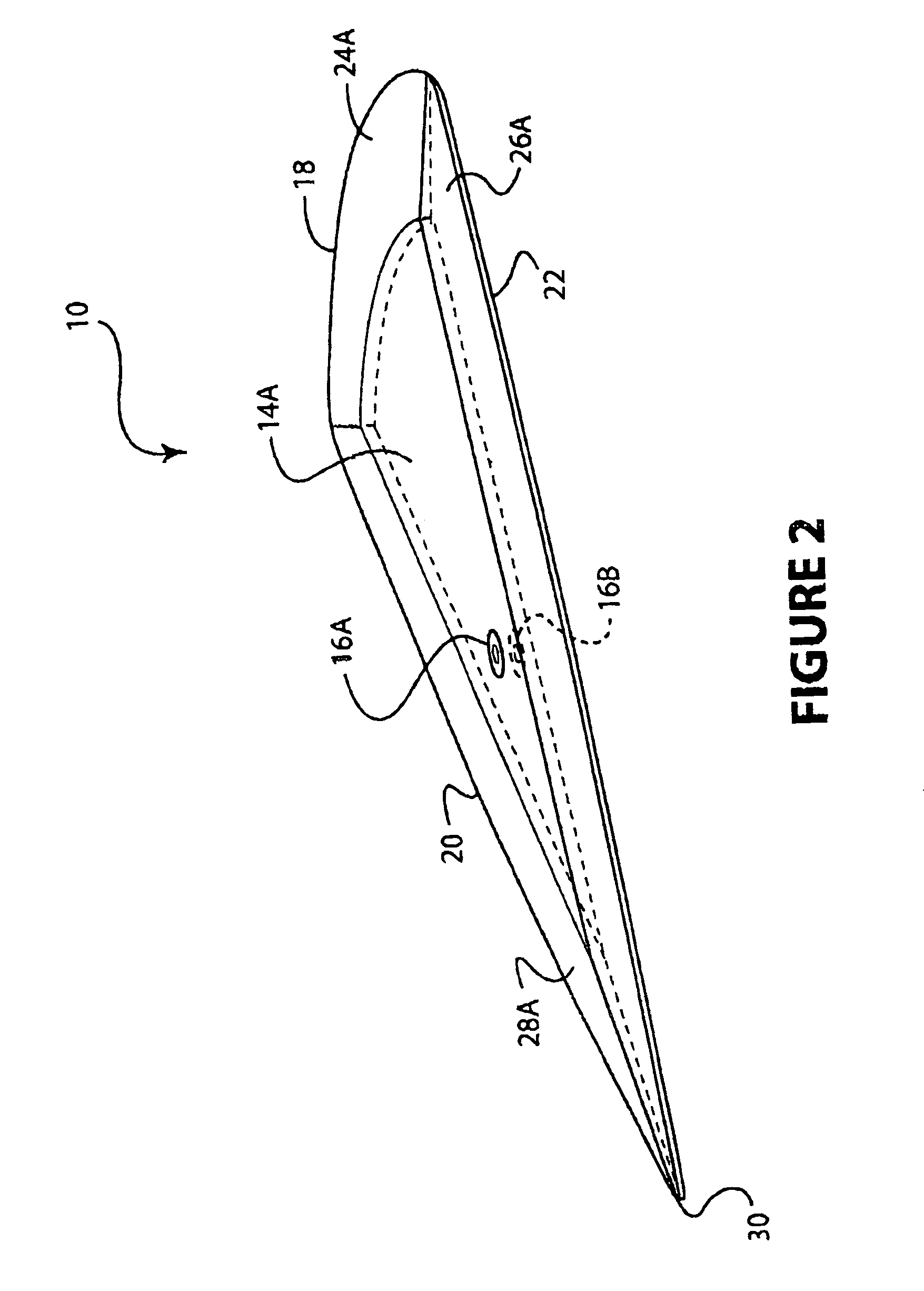

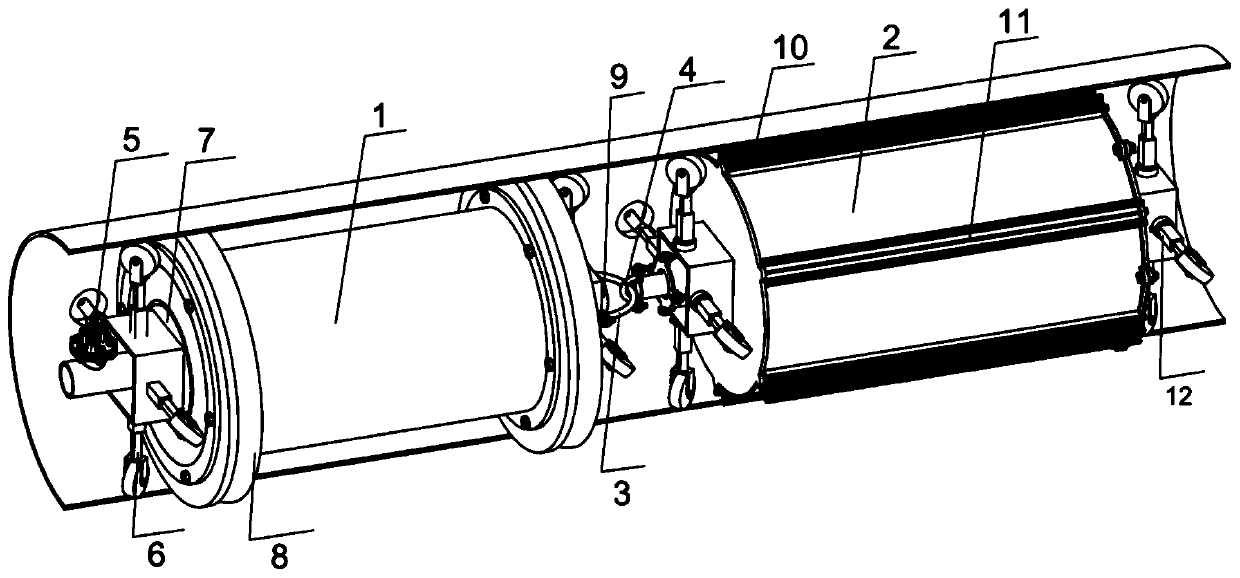

Corrosion inhibitor film applicator for gathering and transportation pipelines

ActiveCN102266838AAdjust speedReduce corrosion rateLiquid surface applicatorsPipe elementsEngineeringMoisture

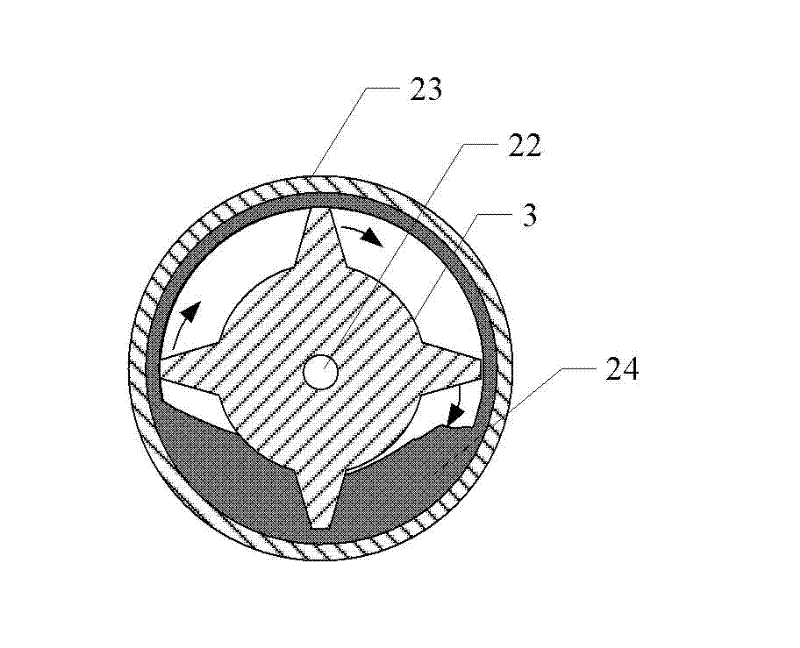

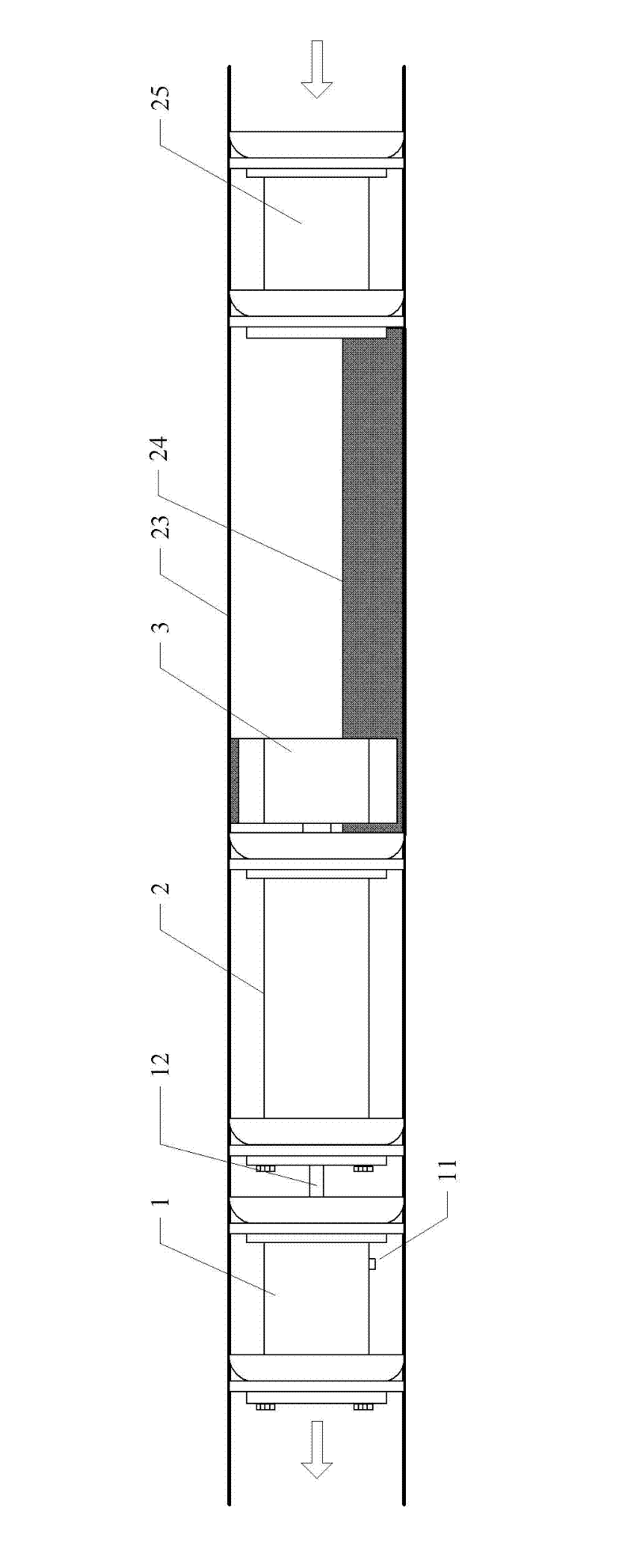

The invention discloses a slow-release agent film applicator for gathering and transportation pipelines, especially a corrosion inhibitor film applicator for gathering and transportation pipelines for high-sulfur-containing moisture, which is composed of a battery compartment, a motor compartment, and an impeller, and the battery compartment and the motor compartment It is a tubular body, with guide discs and sealing cups installed at both ends, fixed on the front and rear end plates by bolts, battery packs and governors are installed in the battery compartment, and the battery compartment and motor compartment are connected through universal joints; speed regulation The wires are arranged in the universal joint to connect the governor to the motor in the motor compartment, and the motor shaft is connected to the impeller. The impeller rotates under the drive of the motor, and the slow-release agent in the lower part of the pipeline is carried to the top of the pipeline through the blades, covering the entire pipeline. The inner wall, at the same time, can adjust the speed of the impeller according to the size of the air volume, which ensures the pre-film time and film quality, and effectively reduces the top corrosion rate.

Owner:CHINA PETROCHEMICAL CORP +1

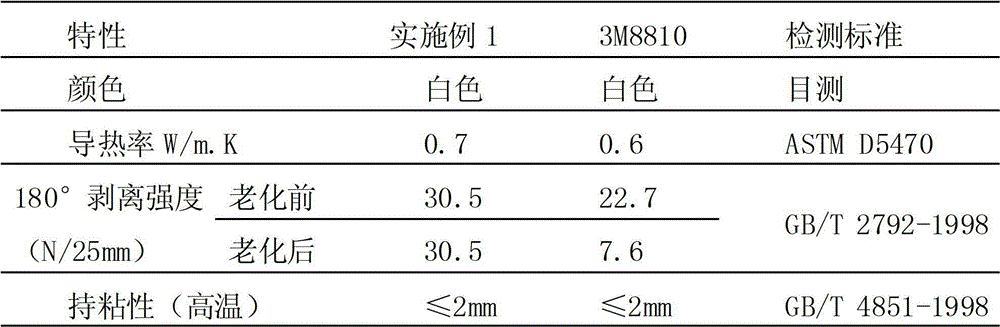

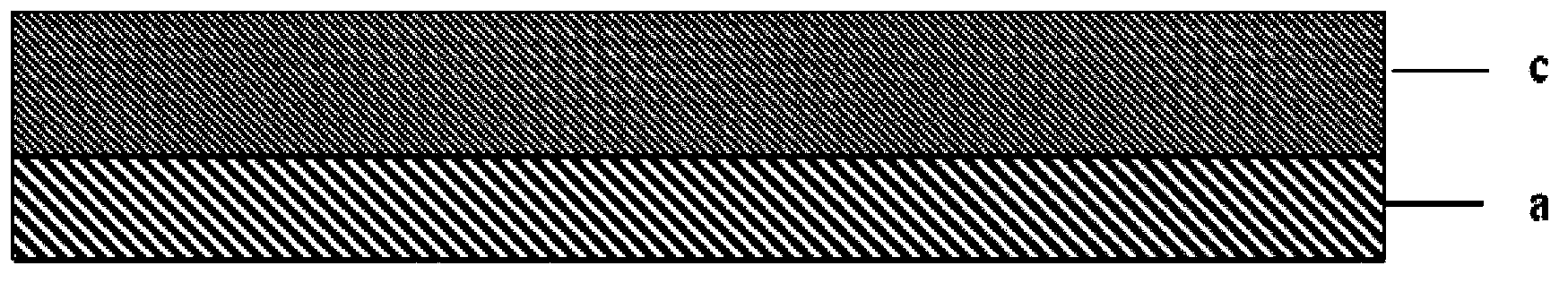

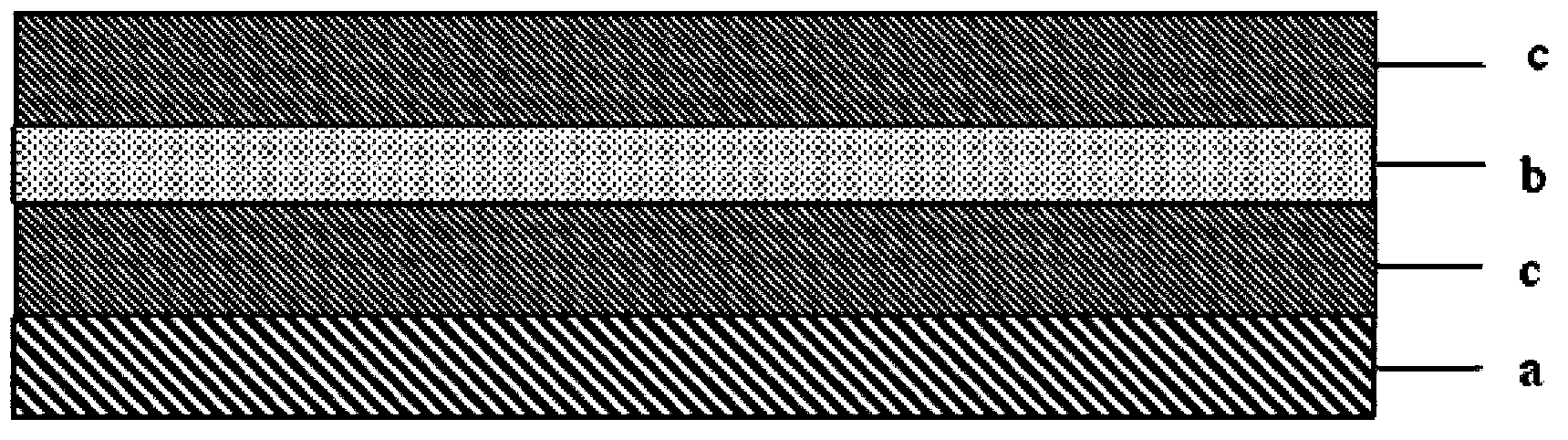

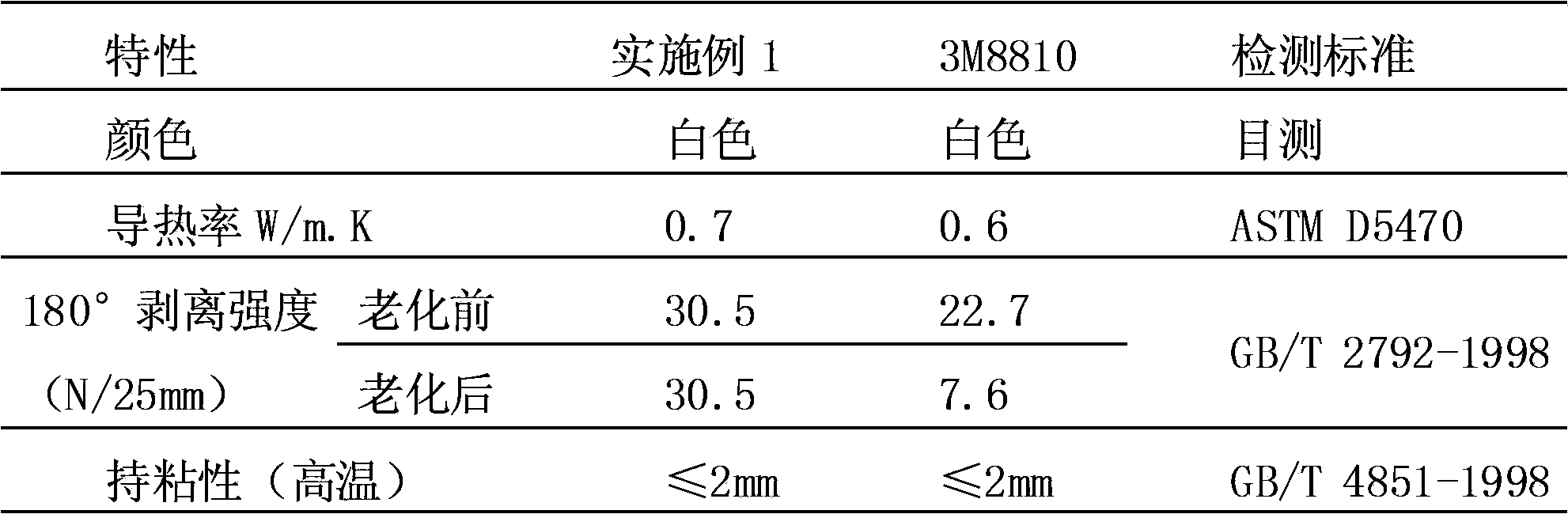

Heat-conducting insulated pressure sensitive tape and preparation method thereof

ActiveCN102746799AWith thermal insulationSensitive to pressureNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingHeat sink

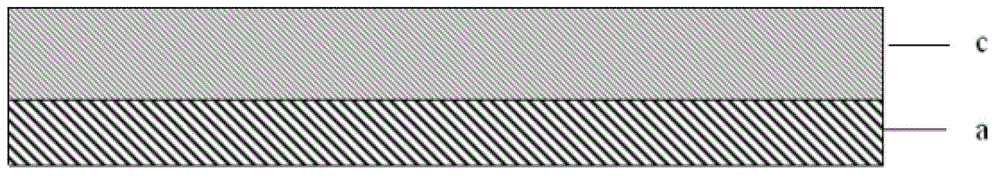

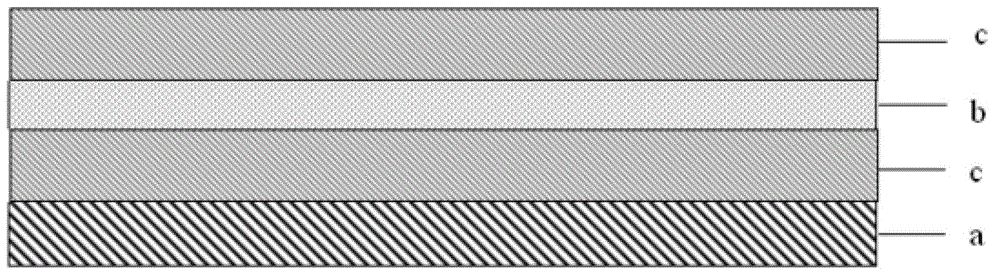

The invention relates to a heat-conducting insulated pressure sensitive tape and a preparation method of the tape. The principal technical features are as follows: the heat-conducting insulated pressure sensitive tape comprises a heat-conducting insulated pressure sensitive tape without a base material and a heat-conducting insulated pressure sensitive tape with the base material; and the preparation method comprises the following steps: (1) preparing a polyacrylate adhesive; (2) preparing modified heat-conducting filler dispersion liquid; and (3) mixing the polyacrylate adhesive prepared in the step (1) with the modified heat-conducting filler dispersion liquid prepared in the step (2), coating wet glues with different thicknesses onto a release protection layer by a film coater, and drying in a gradually heating way to prepare the heat-conducting insulated pressure sensitive tape without the base material; or bonding with the both faces of the base material to prepare the heat-conducting insulated pressure sensitive tape with the base material. The heat-conducting insulated pressure sensitive tape is high in heat conductivity, good in bonding performance and excellent in ageing resistance, has excellent die cutting processability, and can be widely applied to bonding of heat radiating fins and heating devices such as a CPU (central processing unit), a power tube, a module power supply and the like, as well as bonding of screens, frames and injection molded boards in electronic products such as a mobile phone, an LED (light emitting diode) device and the like.

Owner:TIANJIN BOYUAN NEW MATERIALS

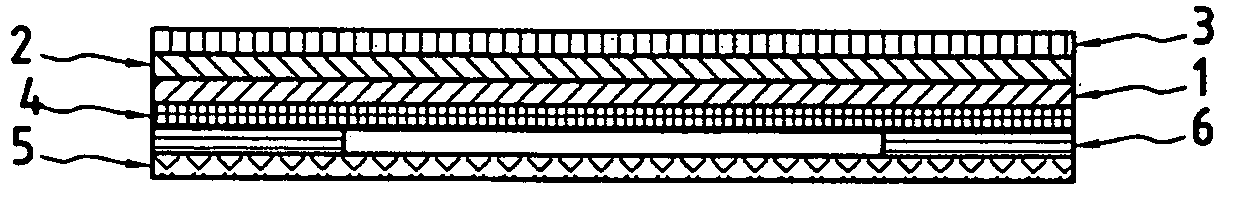

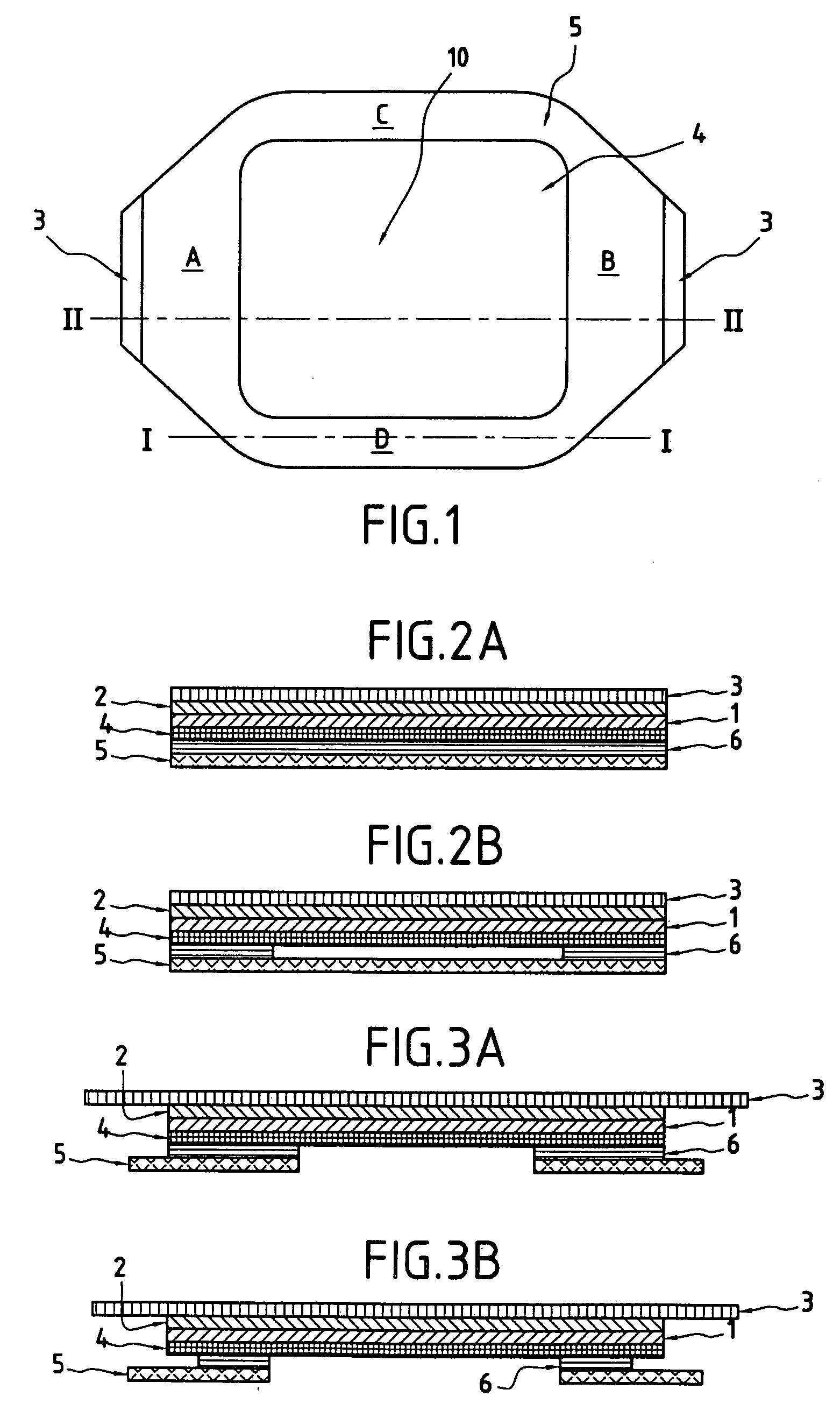

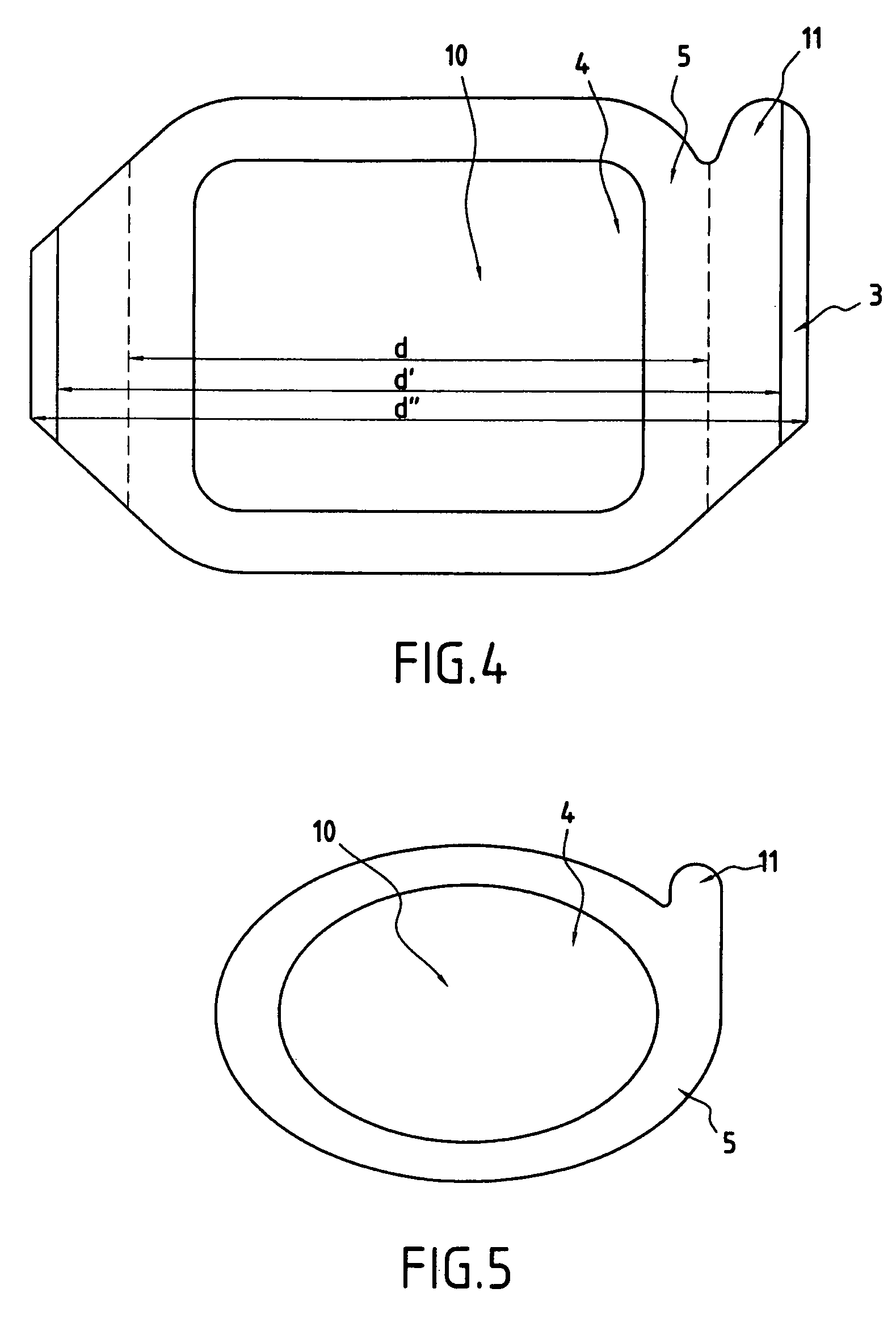

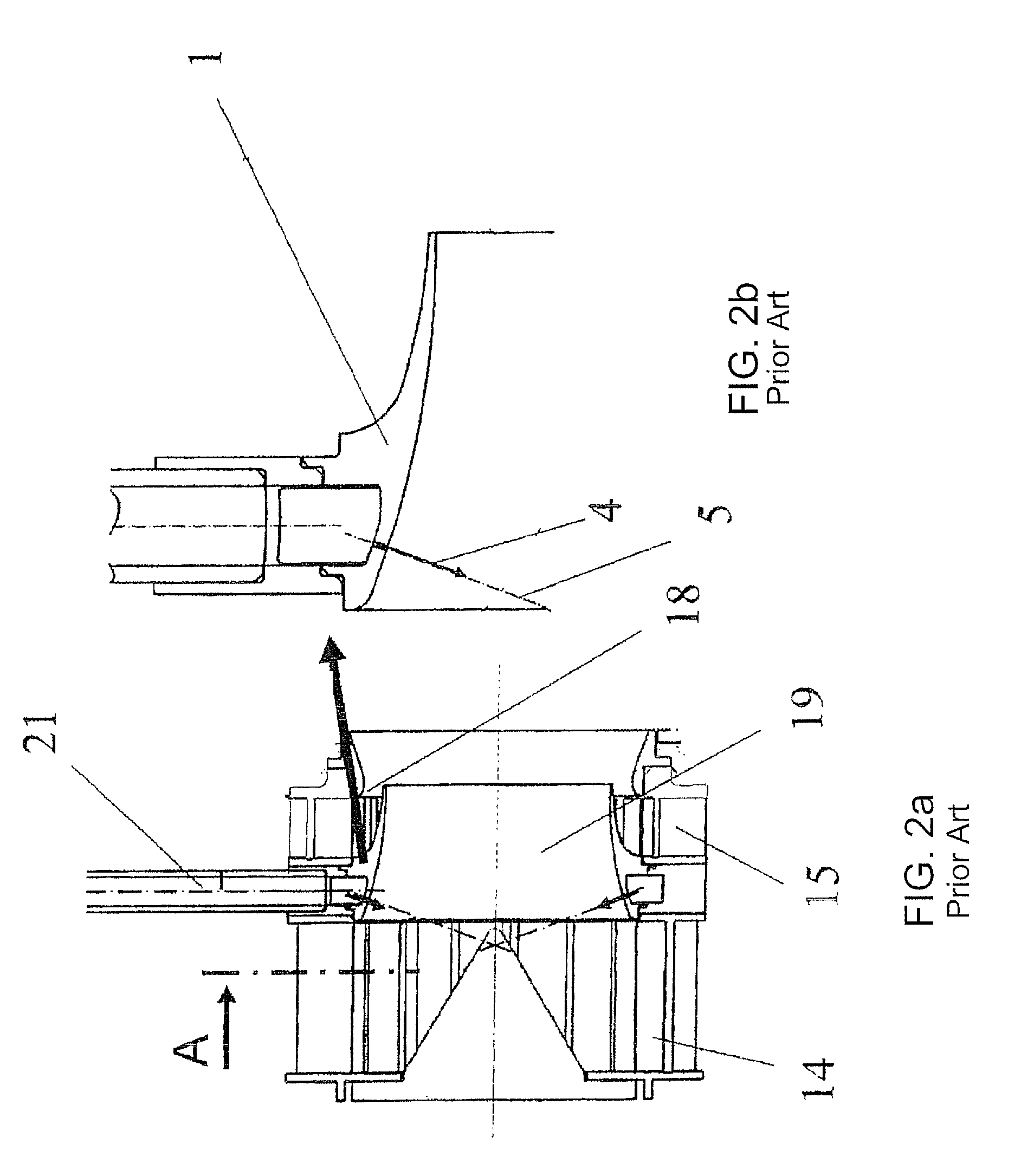

Dressing Provided With a Thin Film Applicator

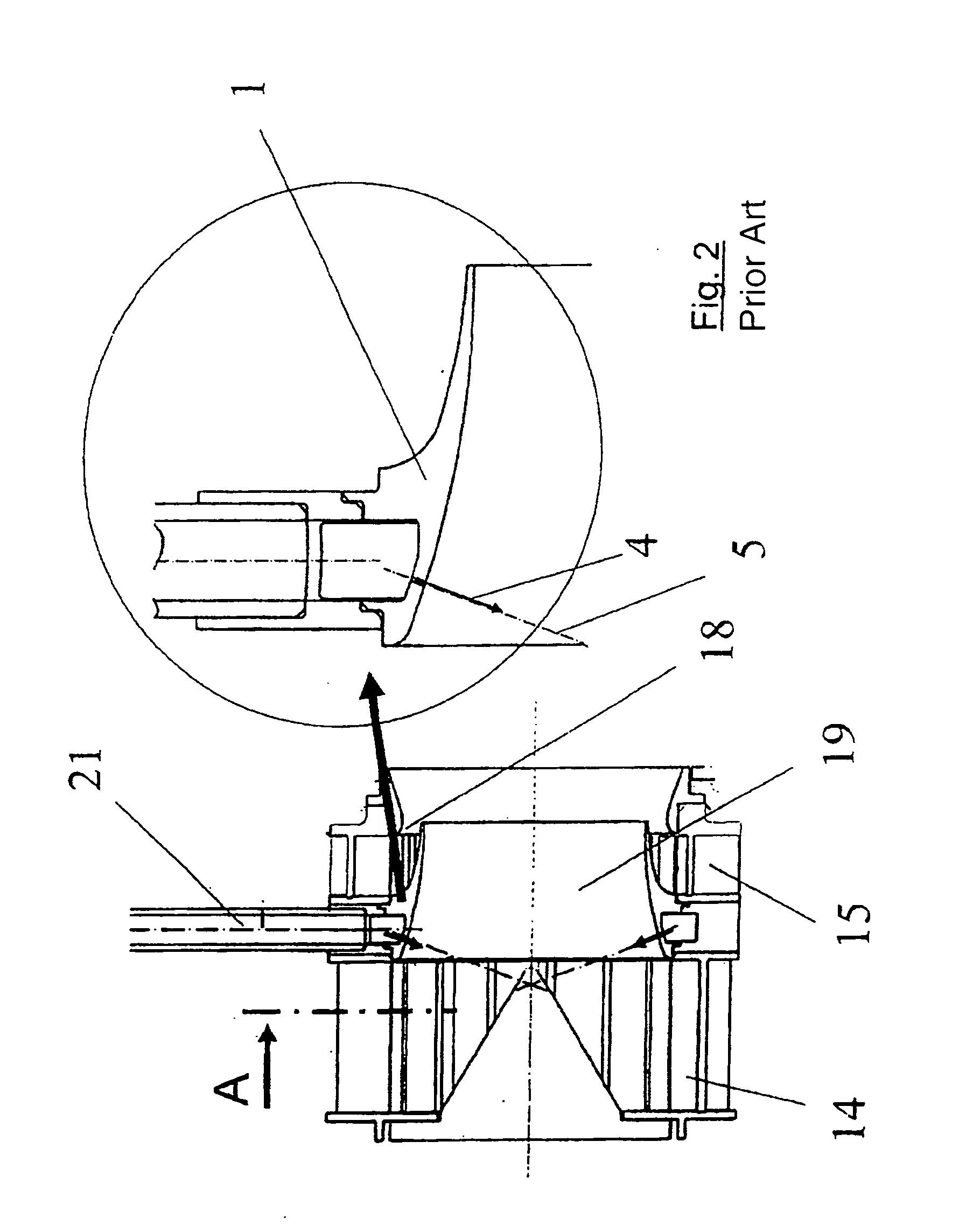

The present invention provides a novel system for applying dressings, said dressings comprising a thin film (1) coated on one face with a pressure-sensitive adhesive (2) and said application system being constituted by a detachable combination of another thin film (4) and a frame (5), thus avoiding problems with degradations to the adhesive bond between the skin and the dressing.

Owner:LABORATOIRE URGO

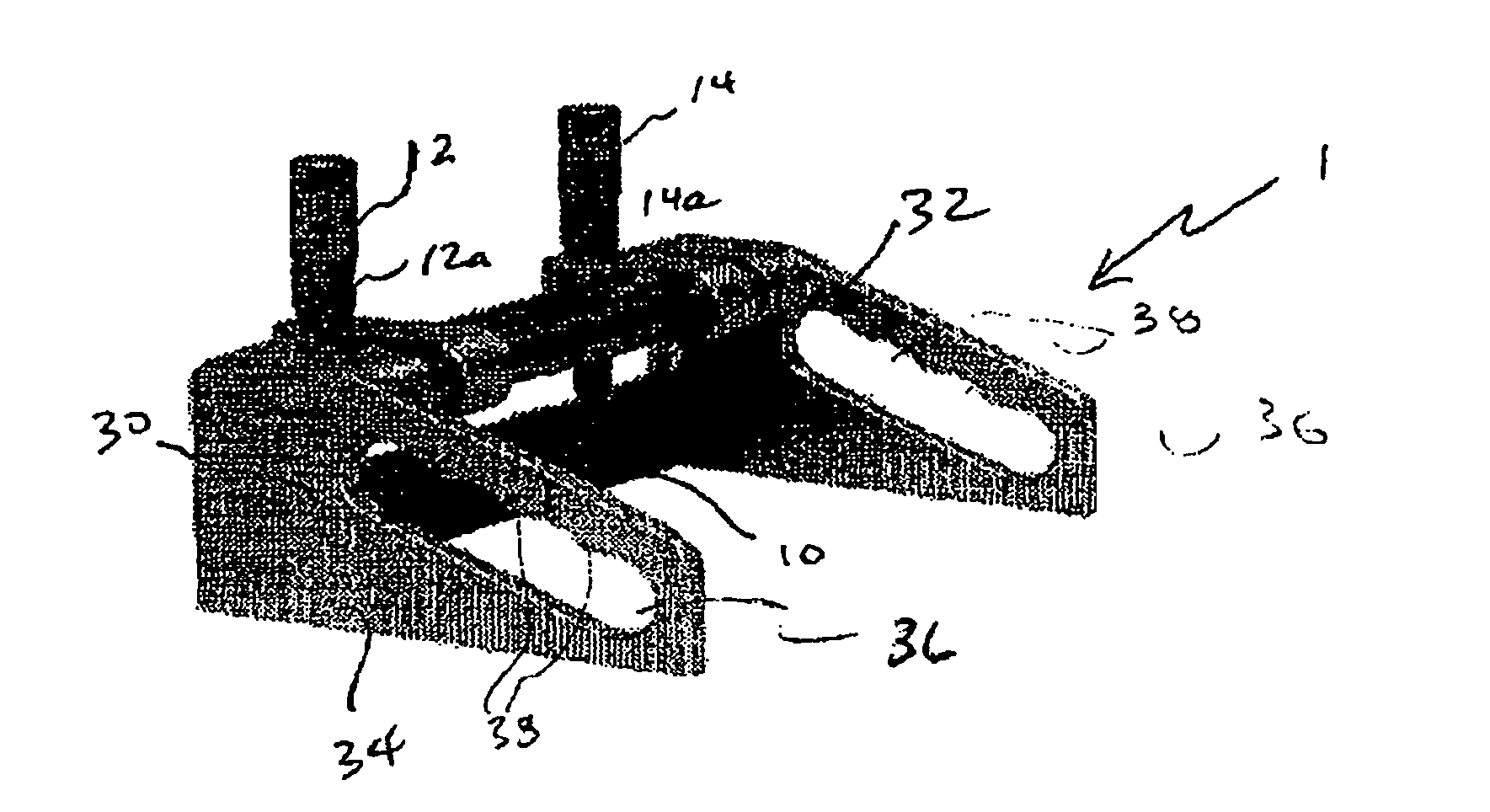

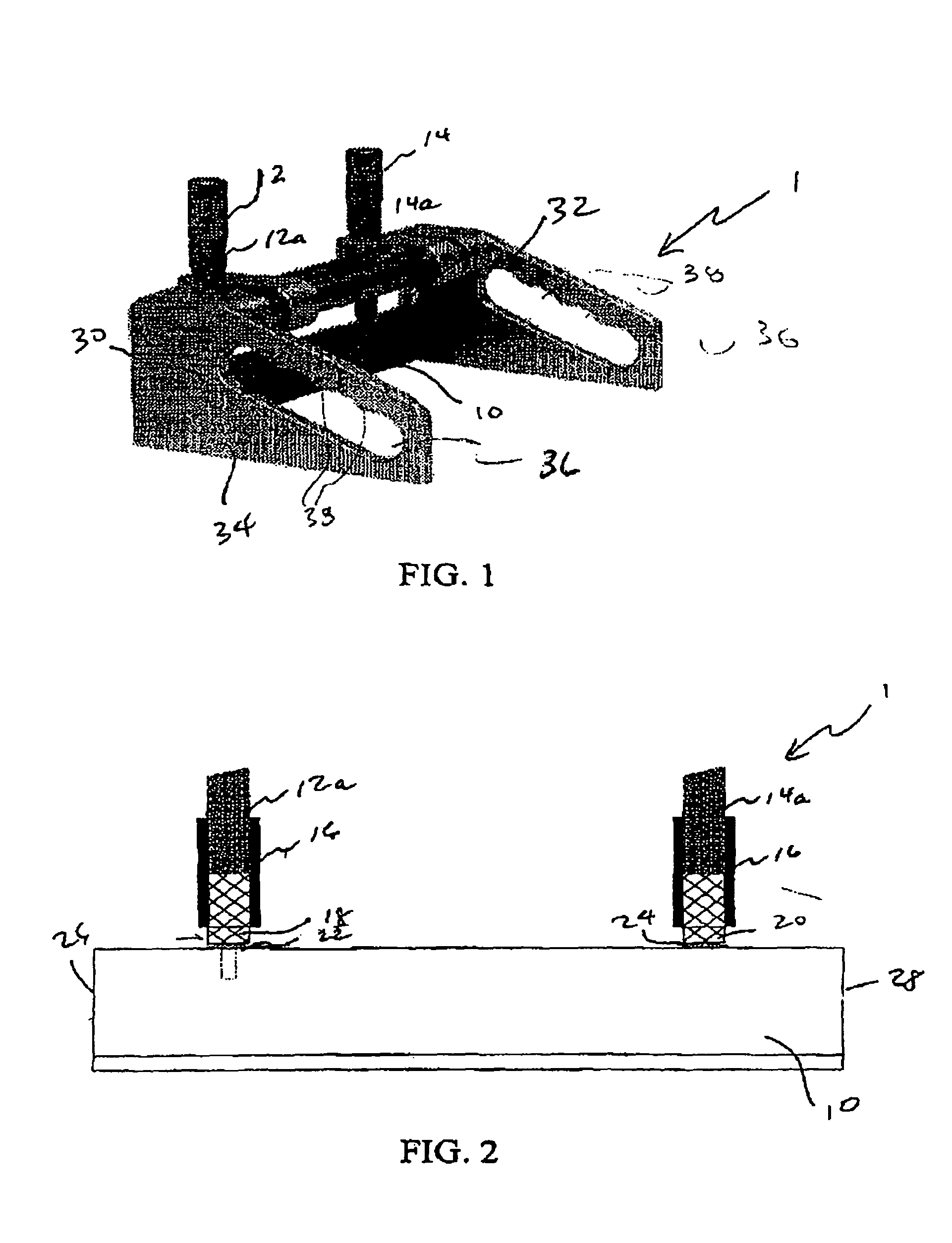

Film applicator tool with arcuate edges

InactiveUS20060118246A1Solve the lack of flexibilitySufficient resiliencyLiquid surface applicatorsCovering/liningsHardnessEngineering

Film applicator tools are provided which have at least two arcuate edges which are sufficiently flexible and resilient to permit application of adhesive films to smooth surfaces without leaving air bubbles, creases or other defects. The tools are molded of polymeric materials which have hardness values effective to permit the application of smooth and uniform pressure without tearing or abrading the films.

Owner:WILLIAMS ROBERT D

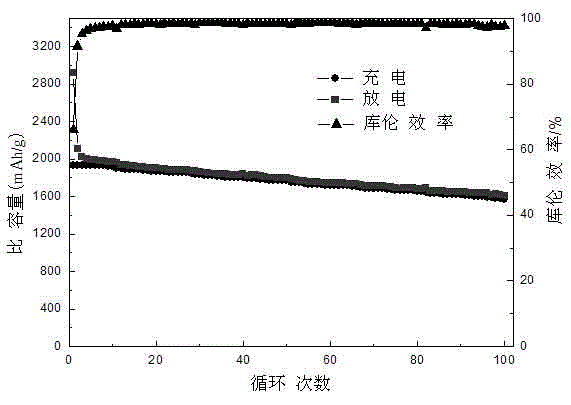

Adhesive-free graphene/silicon electrode for lithium ion battery and preparation method thereof

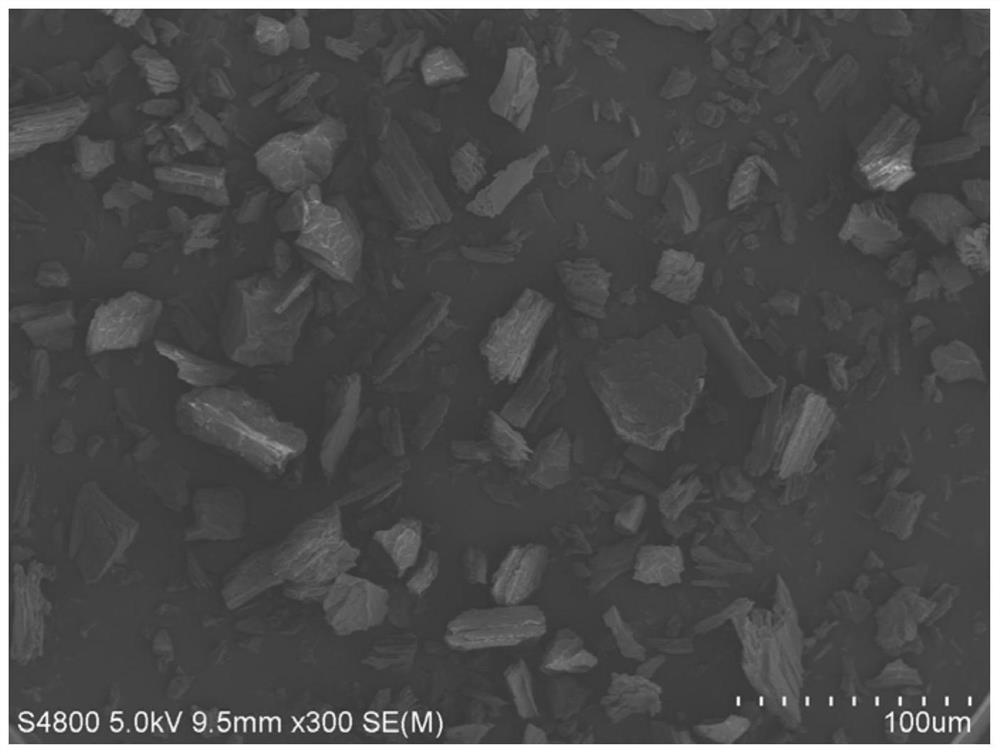

ActiveCN104617280AImprove bindingIncrease capacitySecondary cellsElectrode collector coatingActive agentCopper foil

Owner:HARBIN INST OF TECH

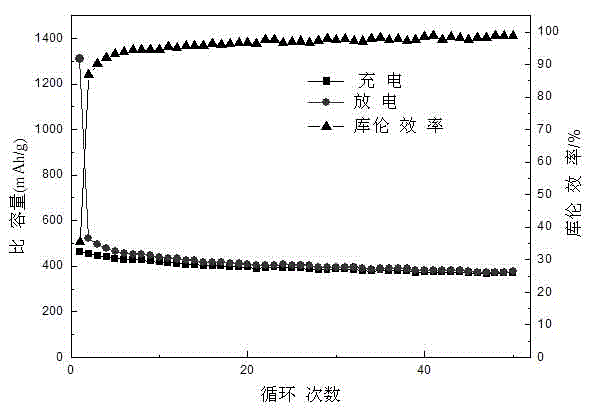

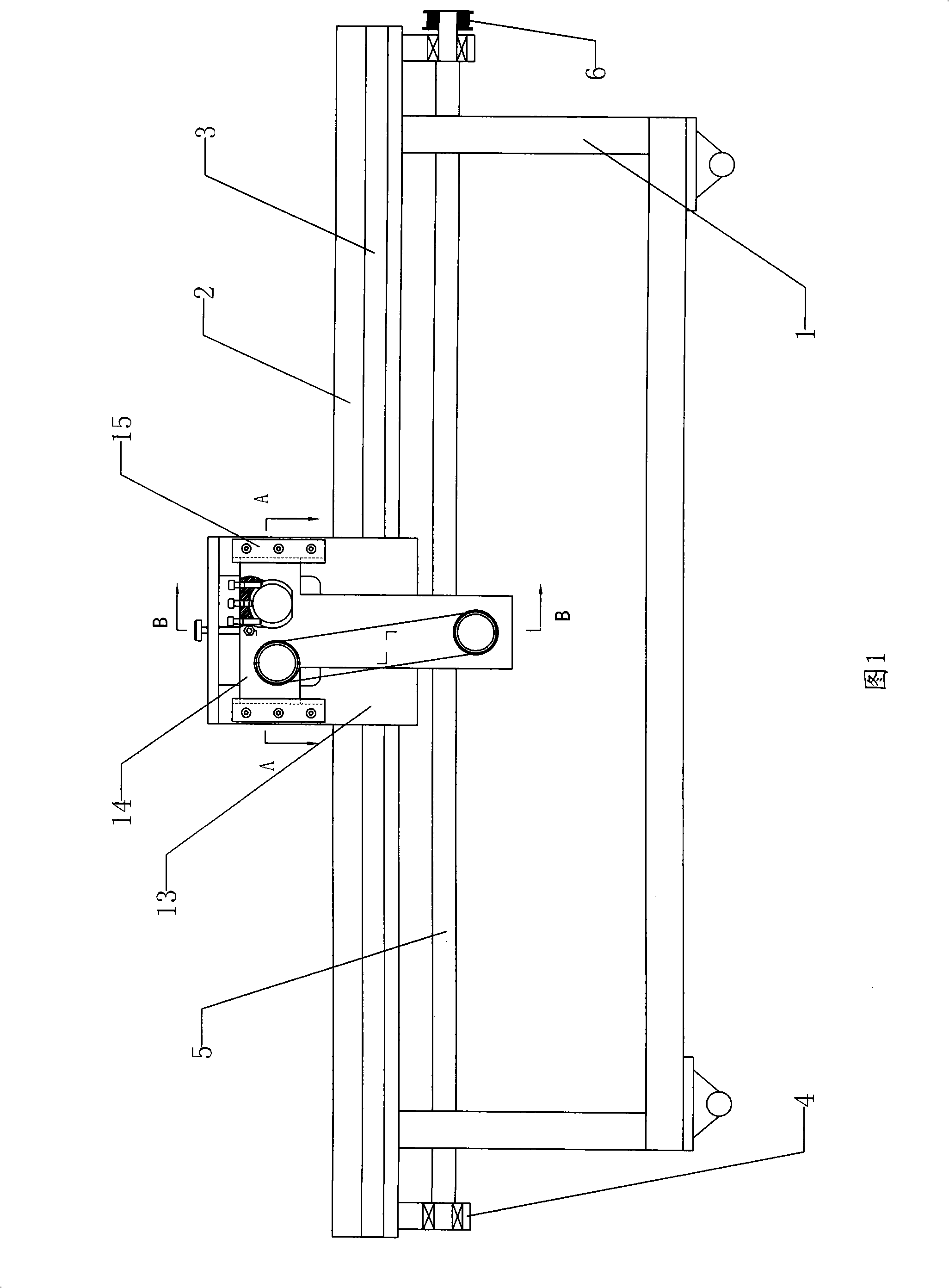

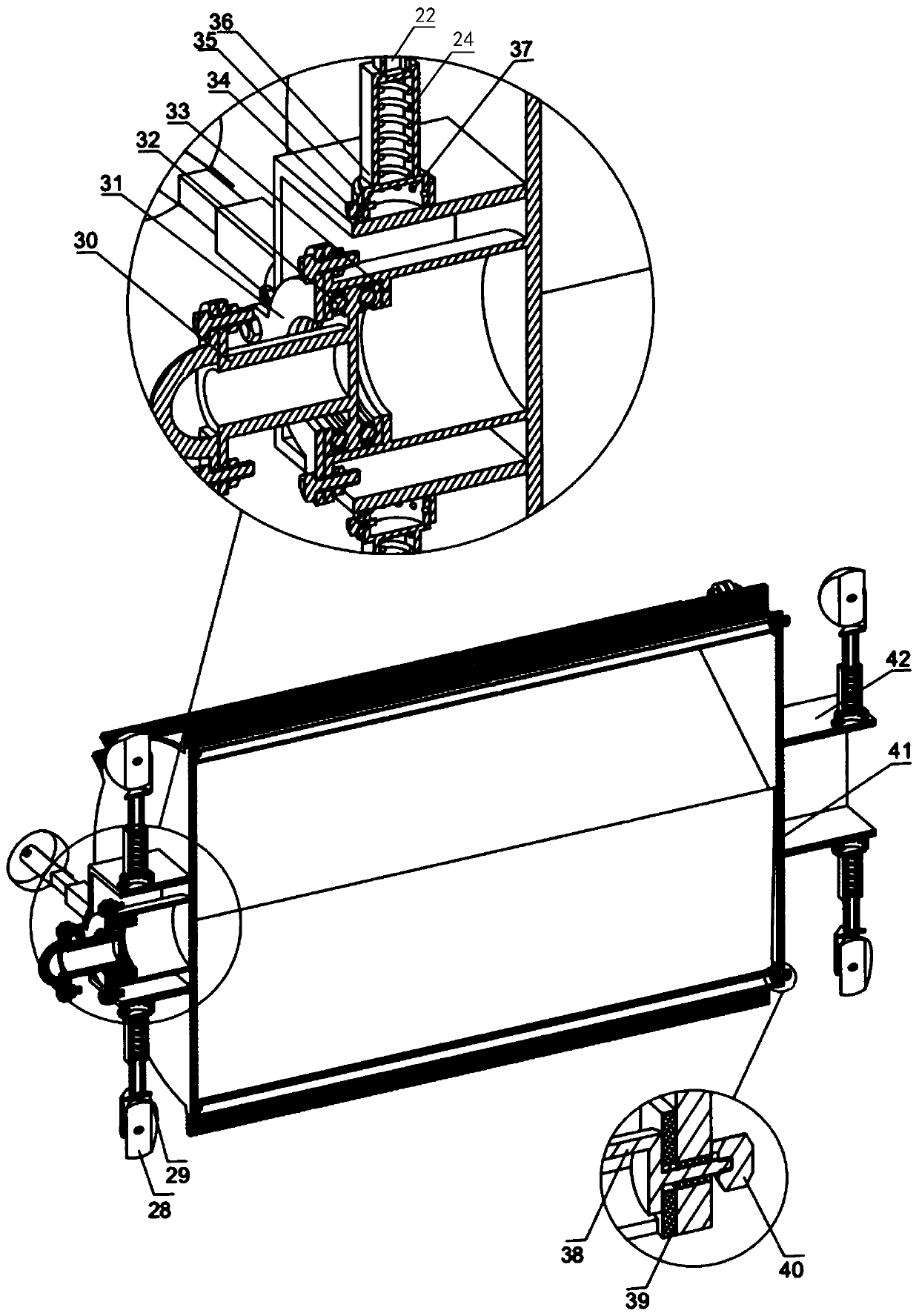

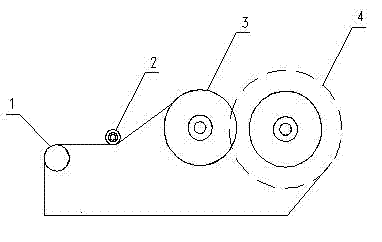

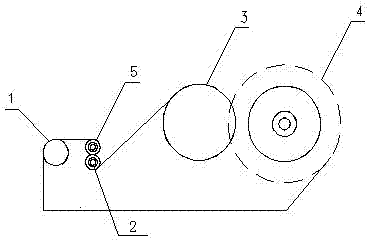

Novel film applicator

InactiveCN101342521AImprove stabilityImprove adhesionLiquid surface applicatorsCoatingsOptical axisEngineering

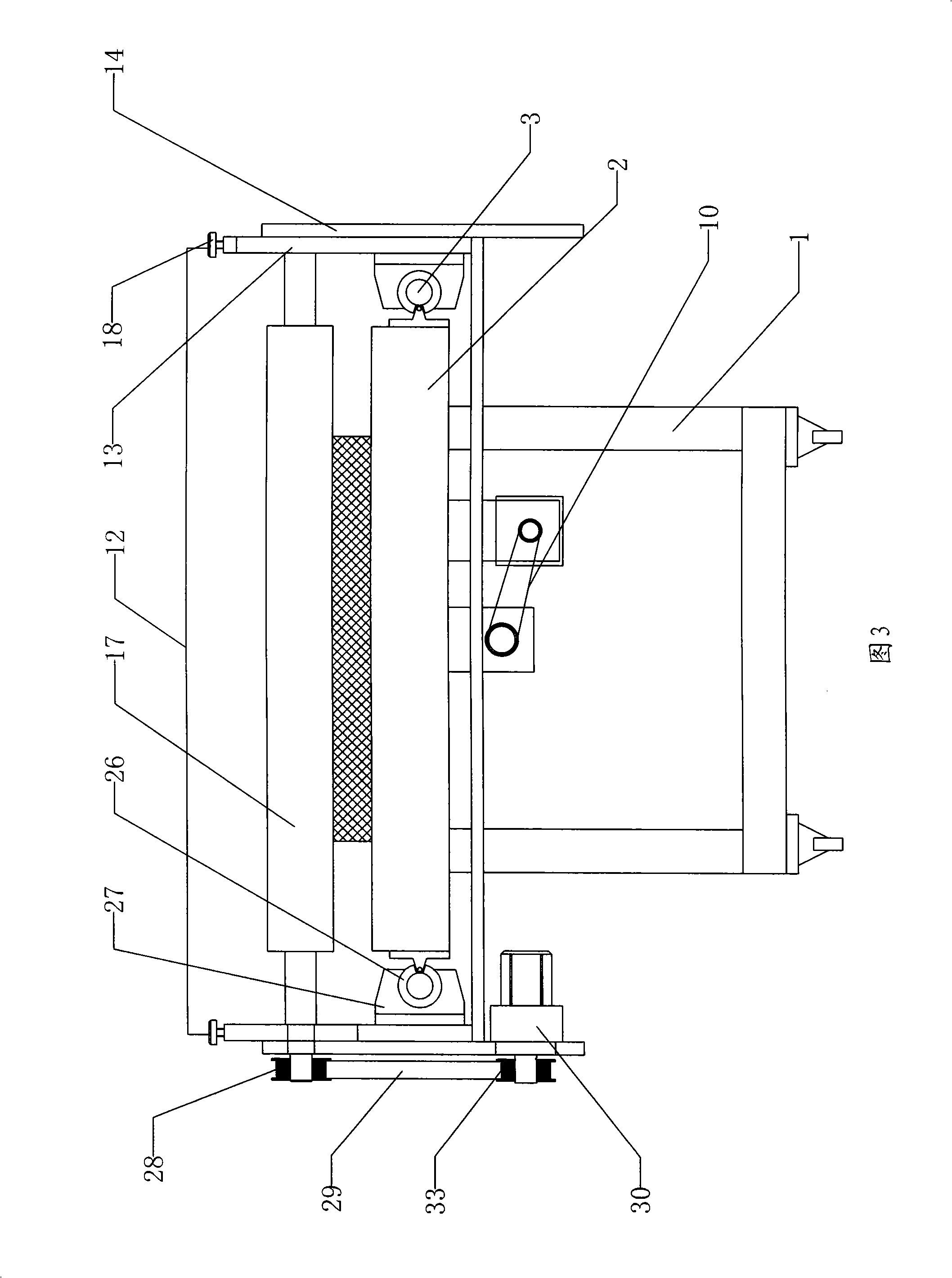

The invention relates to a novel film coating machine, comprising a machine frame, a work-table, two guide rails, two hanging plates, a lead screw and an electric motor. The work-table is fixed on the machine frame; the guide rails are respectively arranged on both sides of the work-table, and the hanging plates are arranged at both ends of the work-table; the two hanging plates are connected with the two ends of by a bearing; a bearing housing is coated on the bearing, and the right end of the lead screw is connected with a belt wheel; the electric motor is fixed on the lower part of the right hanging plate, the belt wheel on the electric motor is connected with the belt wheel arranged at the right end of the lead screw, and the lead screw is coated in the nut; the film costing device comprises a riser, a slider, a fixing guide rail, an optical axis, a rubber shaft, frame strips, a connect plate, a nut, a linear bearing and an electric motor. The invention has the advantages of that the picture is fixed, the method that the rubber shaft moves horizontally and rolls for film coating in the inverse direction is adopted; the stability of film costing is enhanced and the film coating quality is improved; the gap between the rubber shaft, the movement speed of the rubber shaft and the rolling speed is adjustable; the film coating quality is ensured and the thickness of the film coat is controlled.

Owner:常明旺

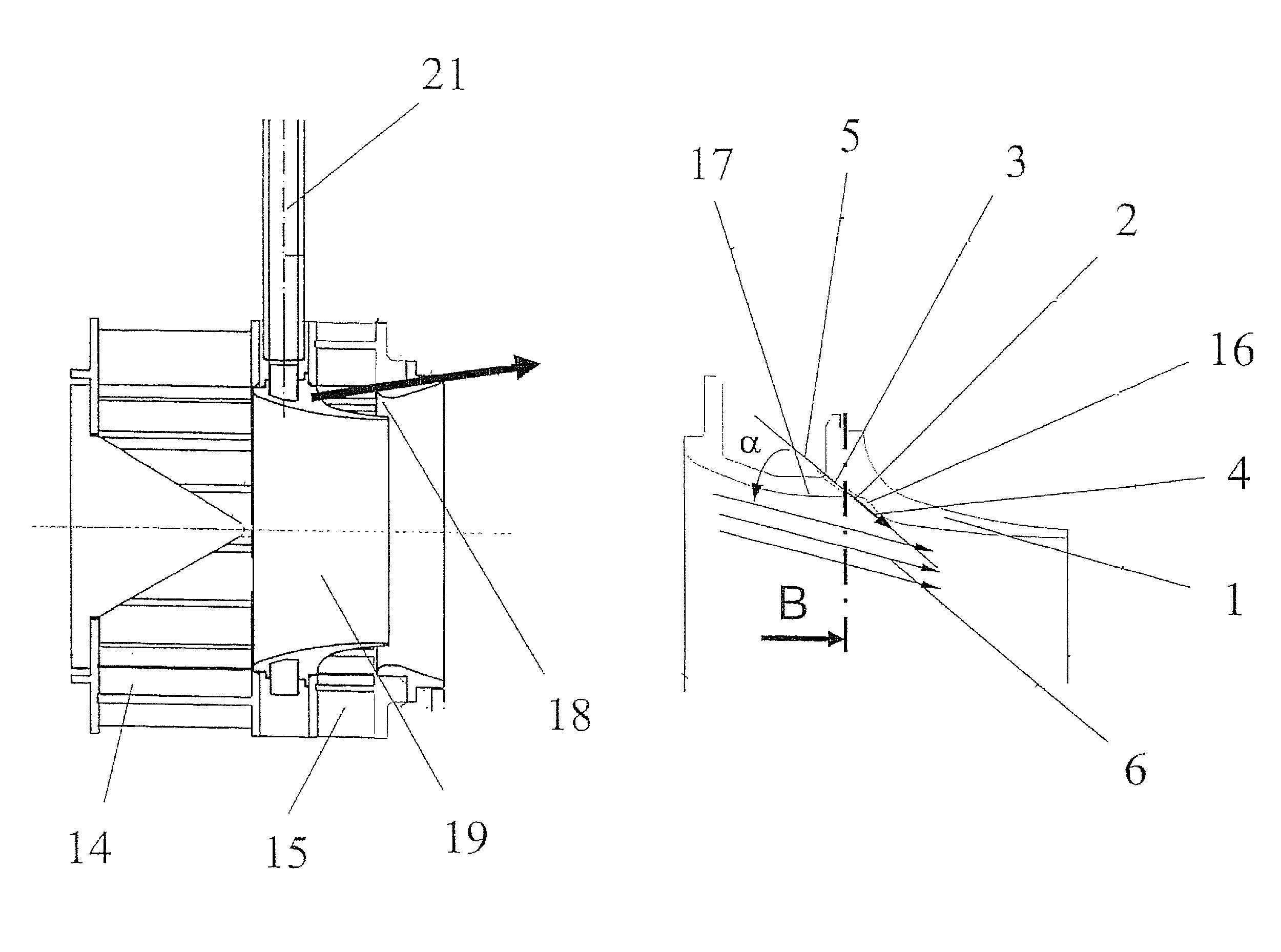

Fuel injection nozzle with film-type fuel application

InactiveUS20050133642A1Simple designBurnersContinuous combustion chamberCombustion chamberEngineering

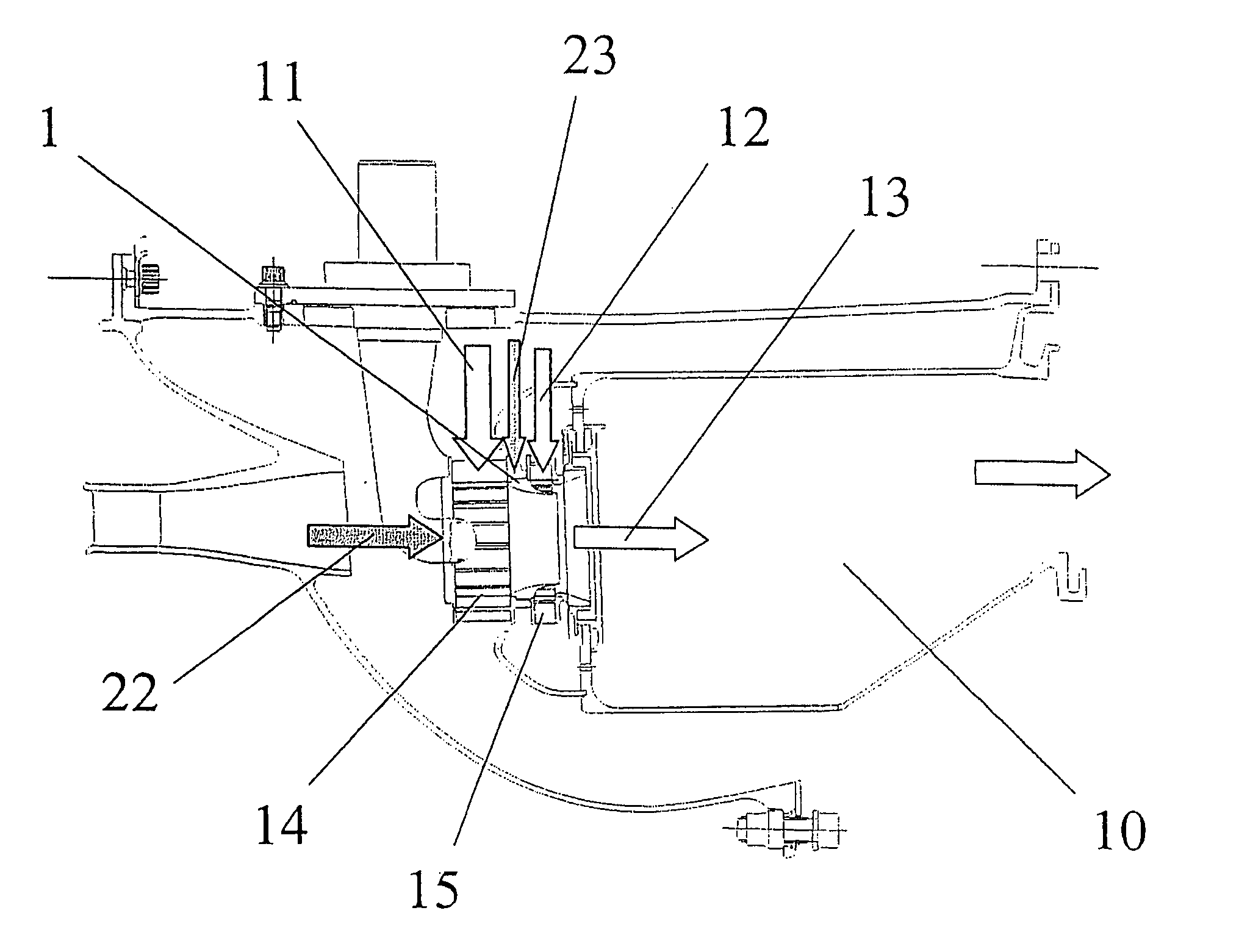

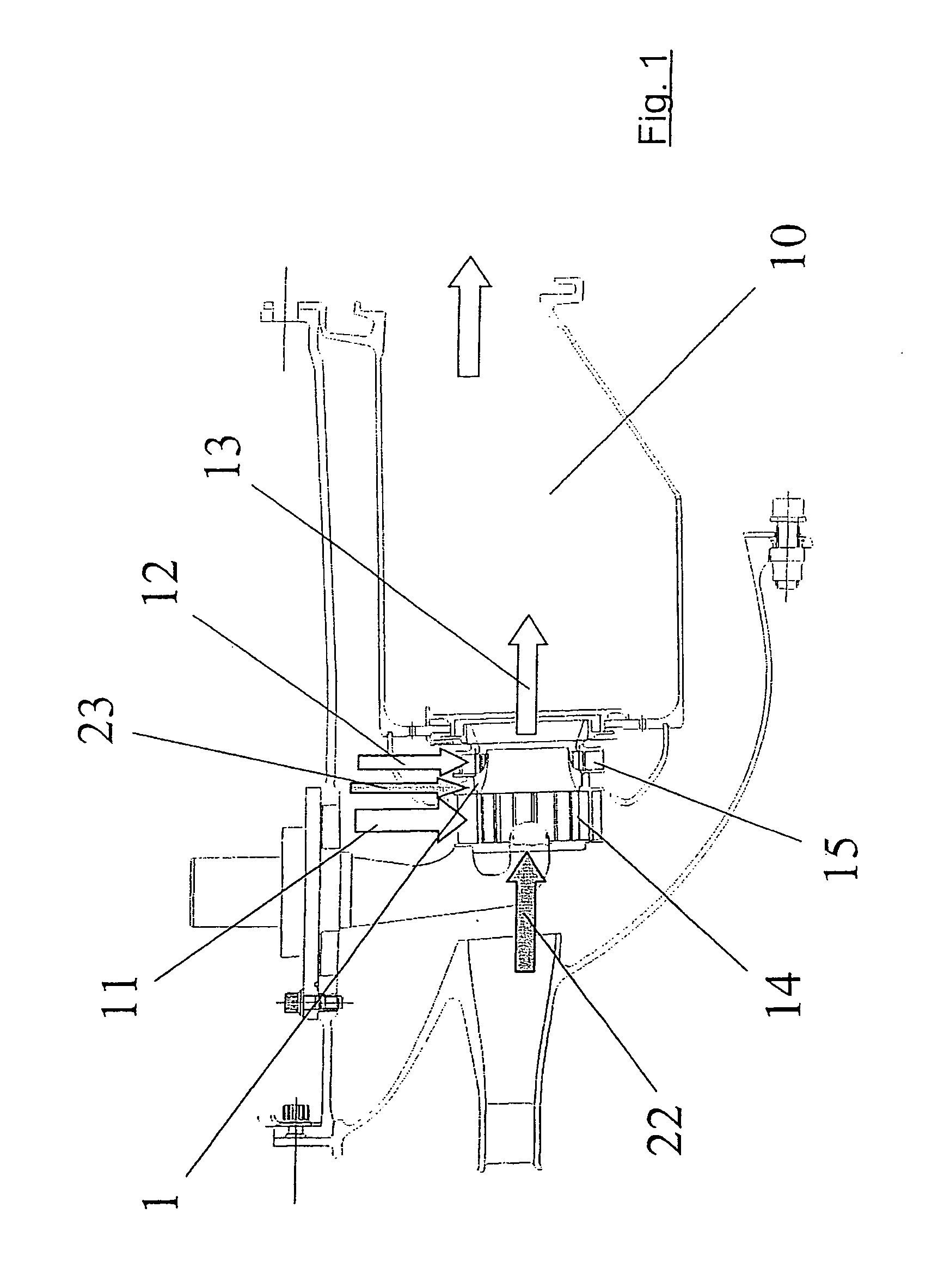

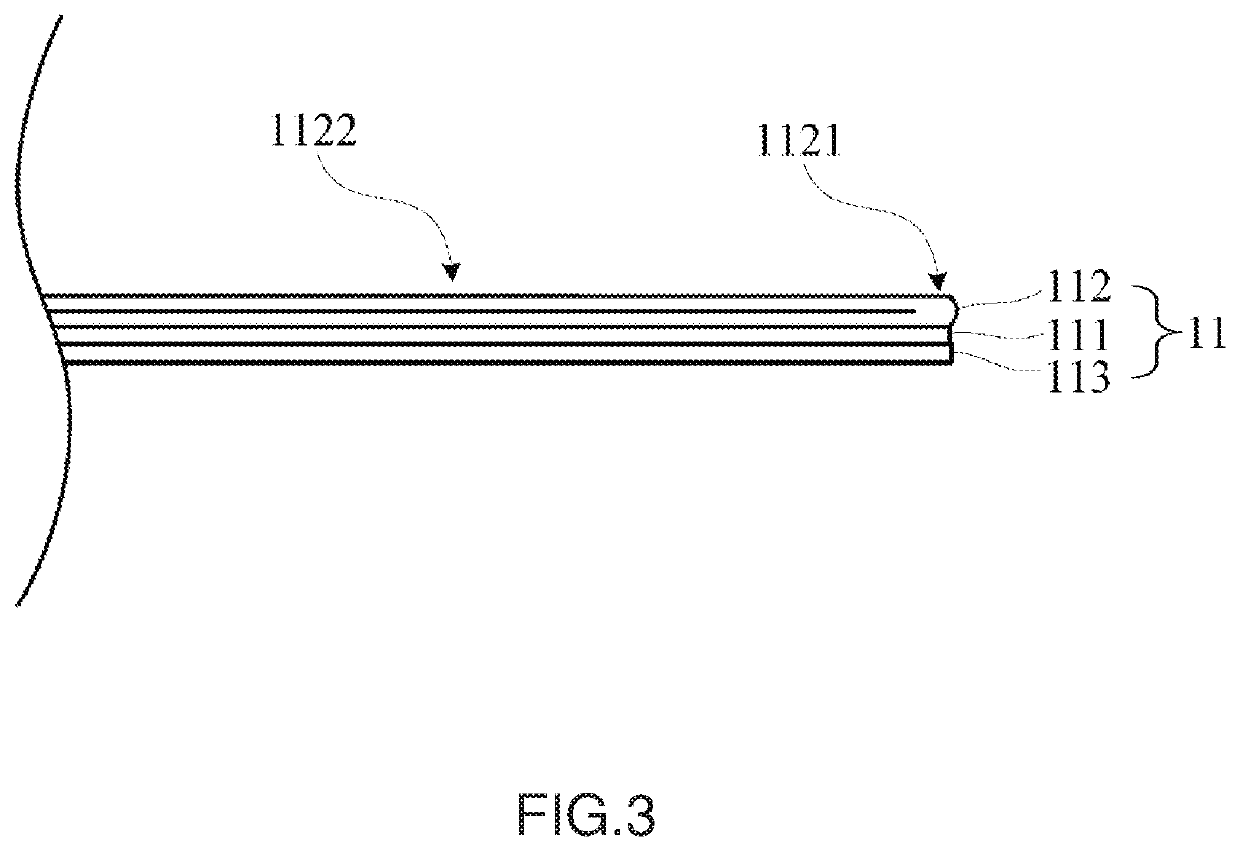

A fuel injection nozzle for a gas turbine combustion chamber with a film applicator (1) is provided with several fuel openings (2). Center axes (5) of the fuel openings (2) through the film applicator (1), with regard to their radial orientation, are essentially parallel to the main flow direction (6) of the air.

Owner:ROLLS ROYCE DEUT LTD & CO KG

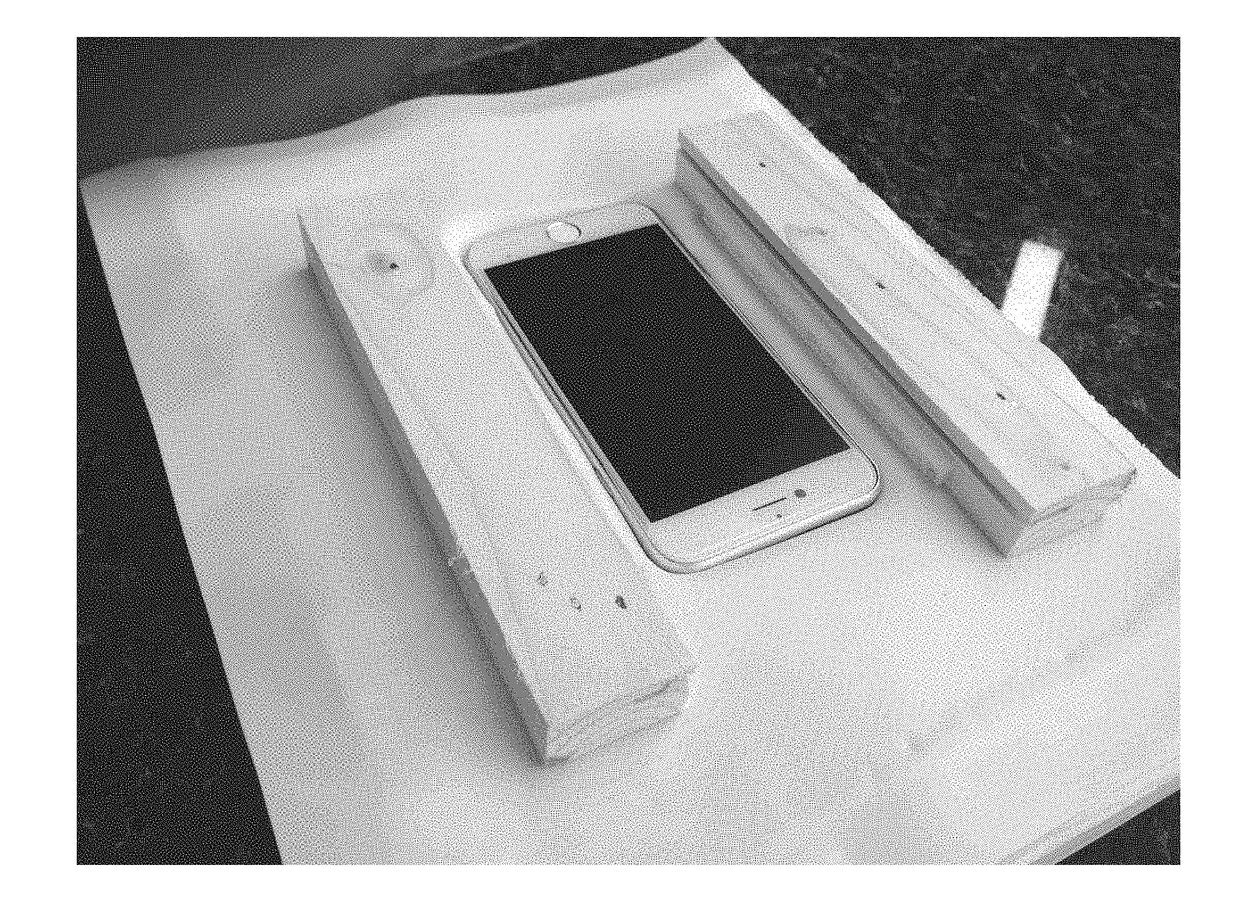

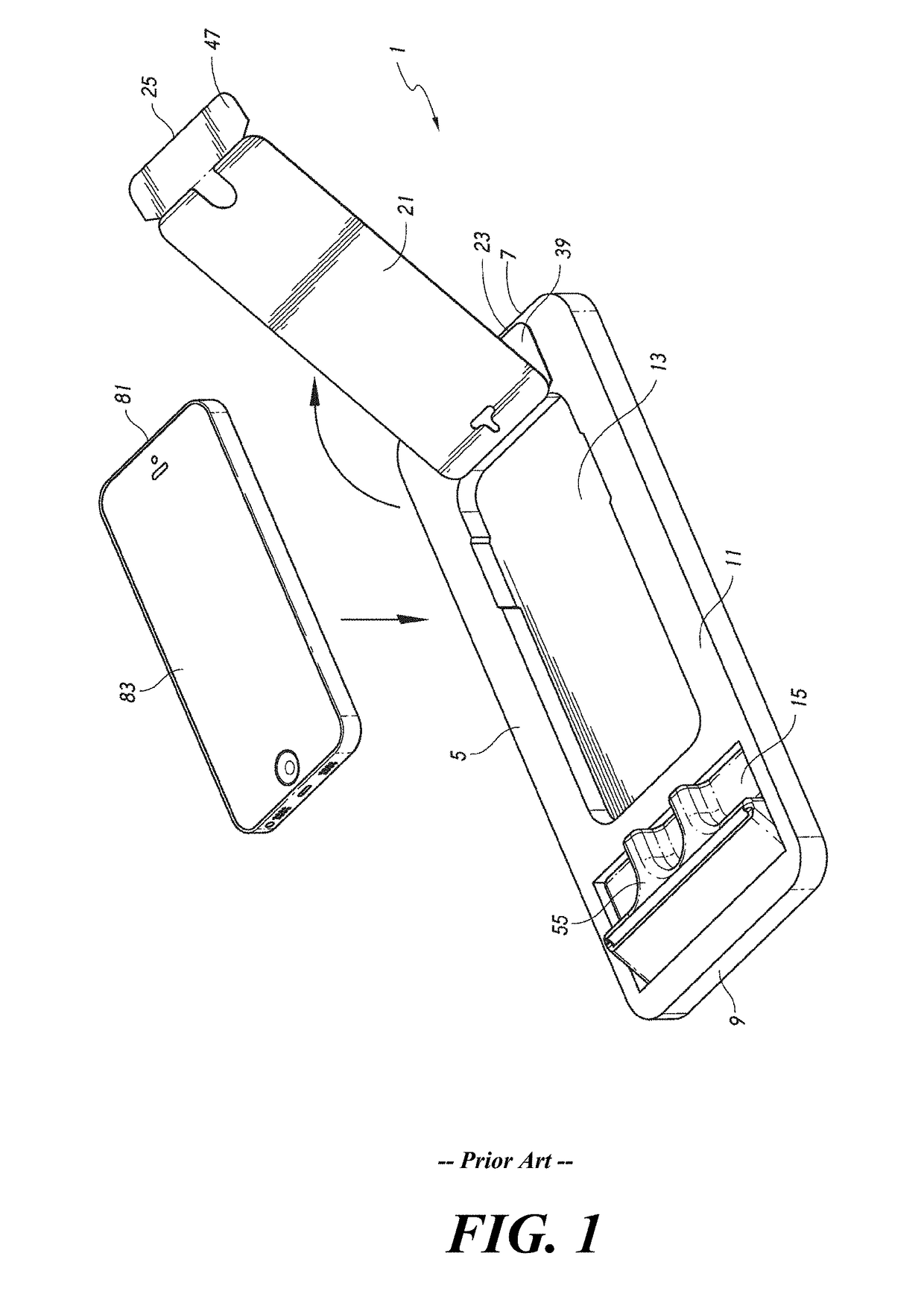

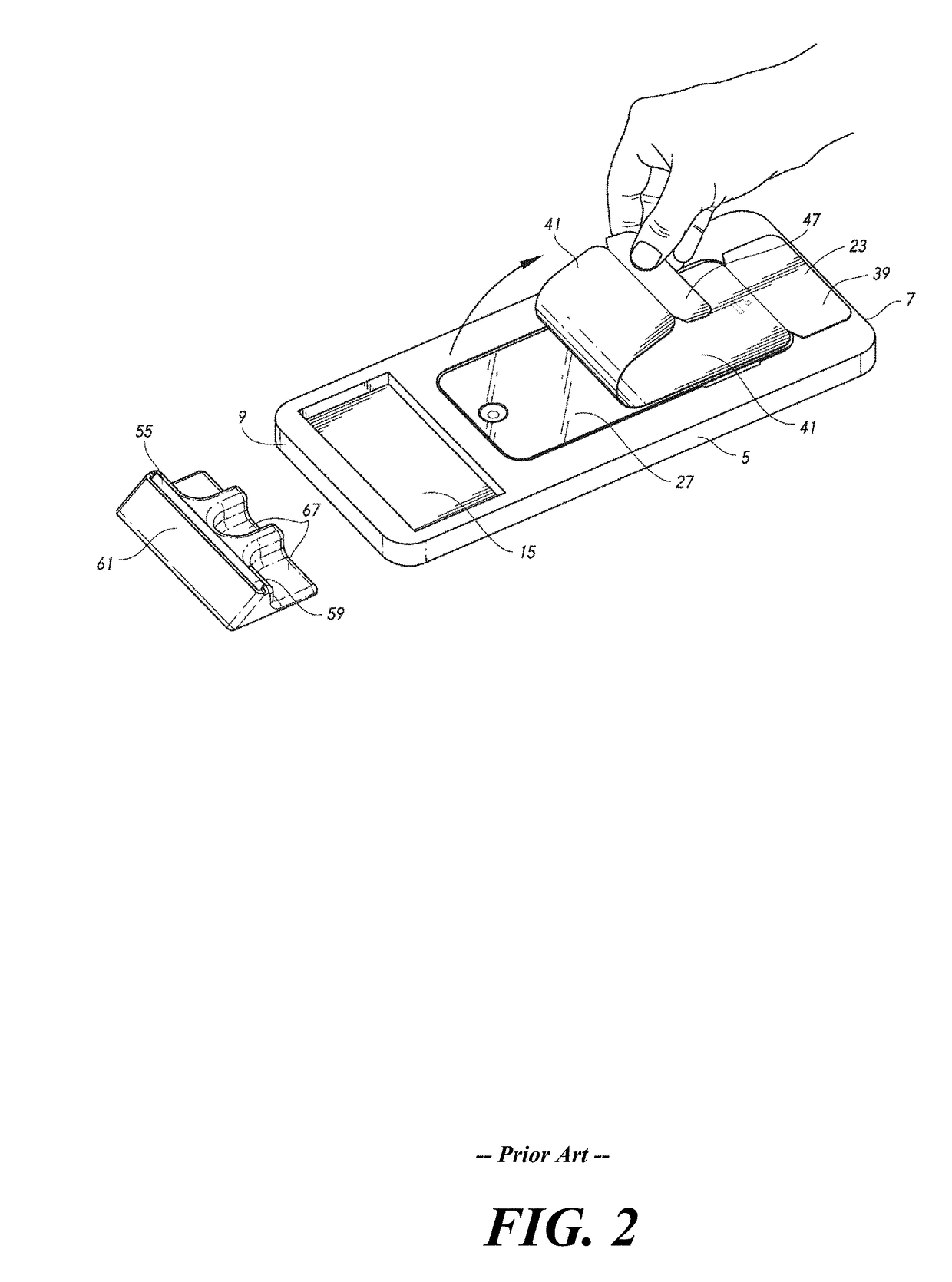

Tool for applying protective films to mobile communications devices

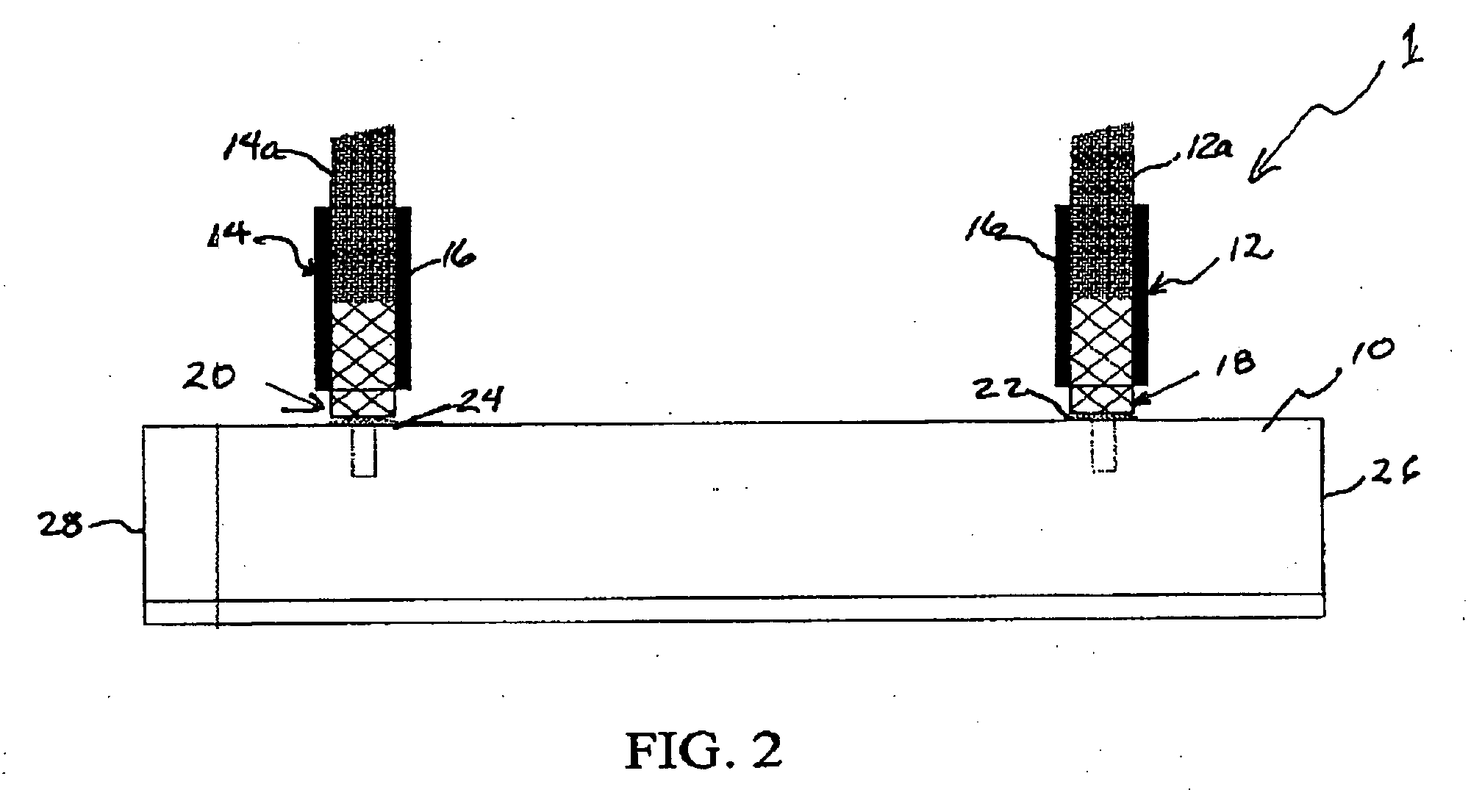

In combination with a mobile communications device equipped with a display, and a film equipped with an adhesive backing and a release liner, a tool is provided for applying the film to the display. The tool includes a substrate having a depression therein in which the mobile communications device is seated; first and second opposing rails disposed on opposing sides of the depression; and a film applicator which travels along the first and second rails. The film applicator is equipped with first and second wheels which engage the first and second rails, respectively, and is further equipped with a blade which pressingly engages the film as the film applicator which travels along the first and second rails.

Owner:MICROSTRATE INC

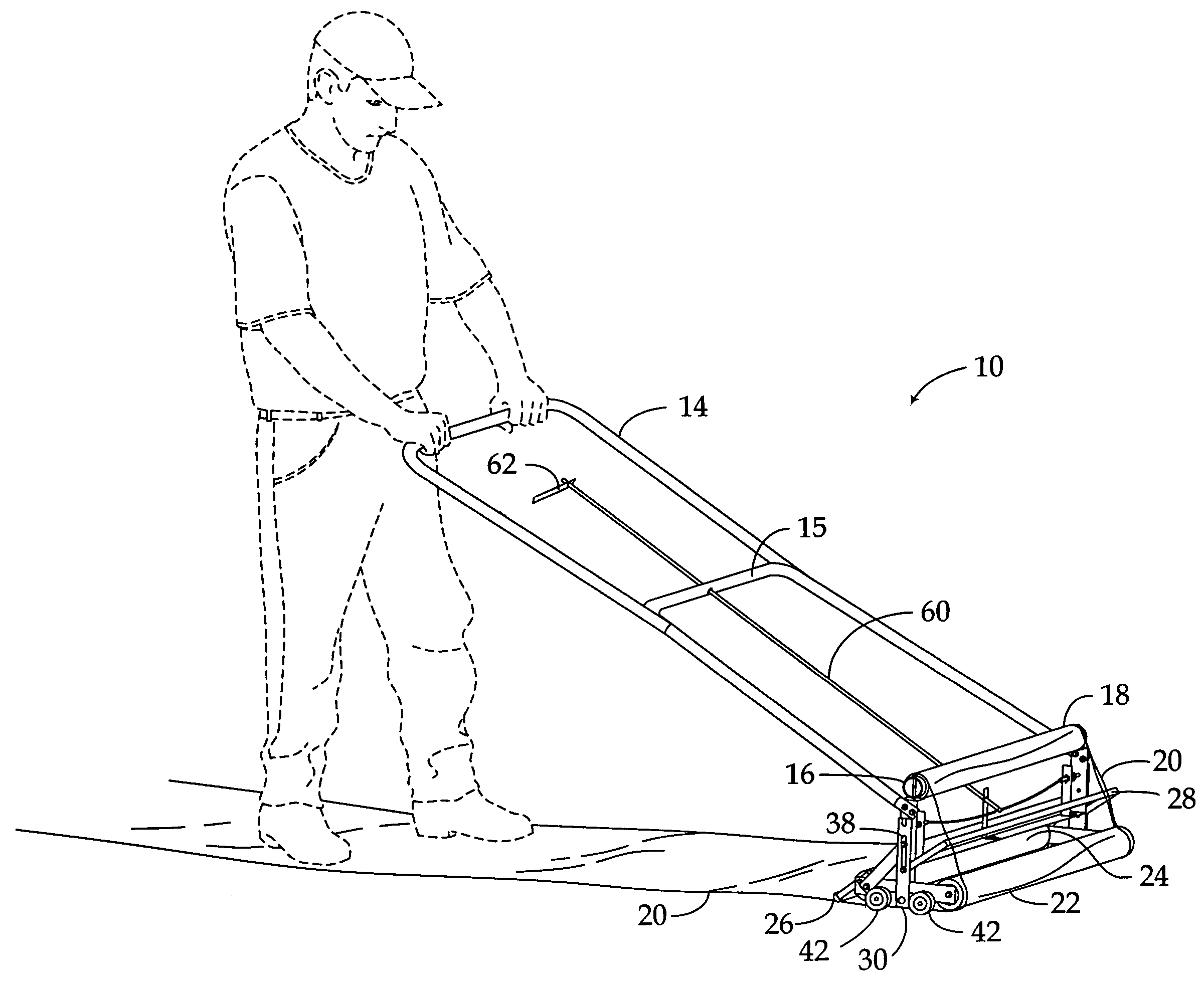

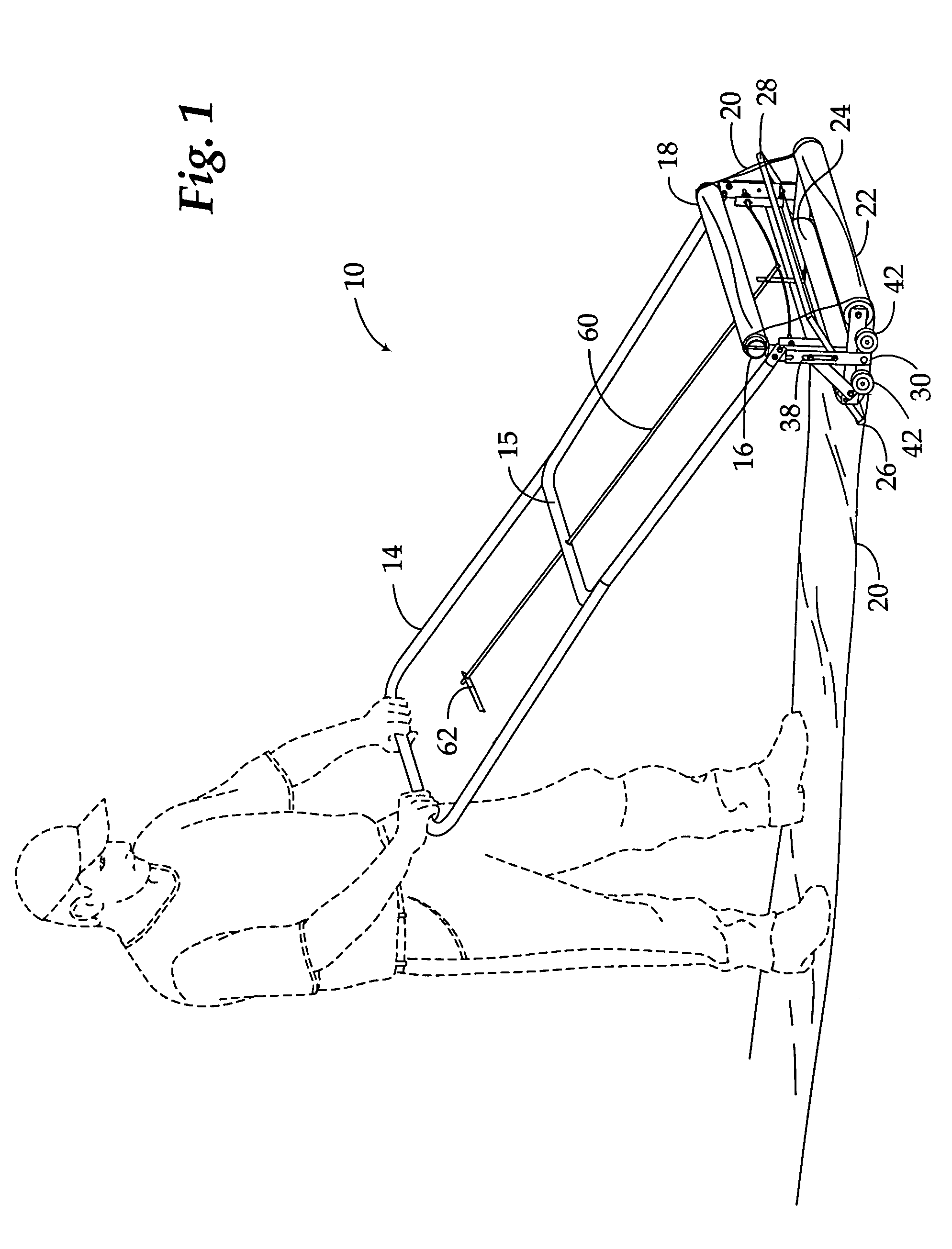

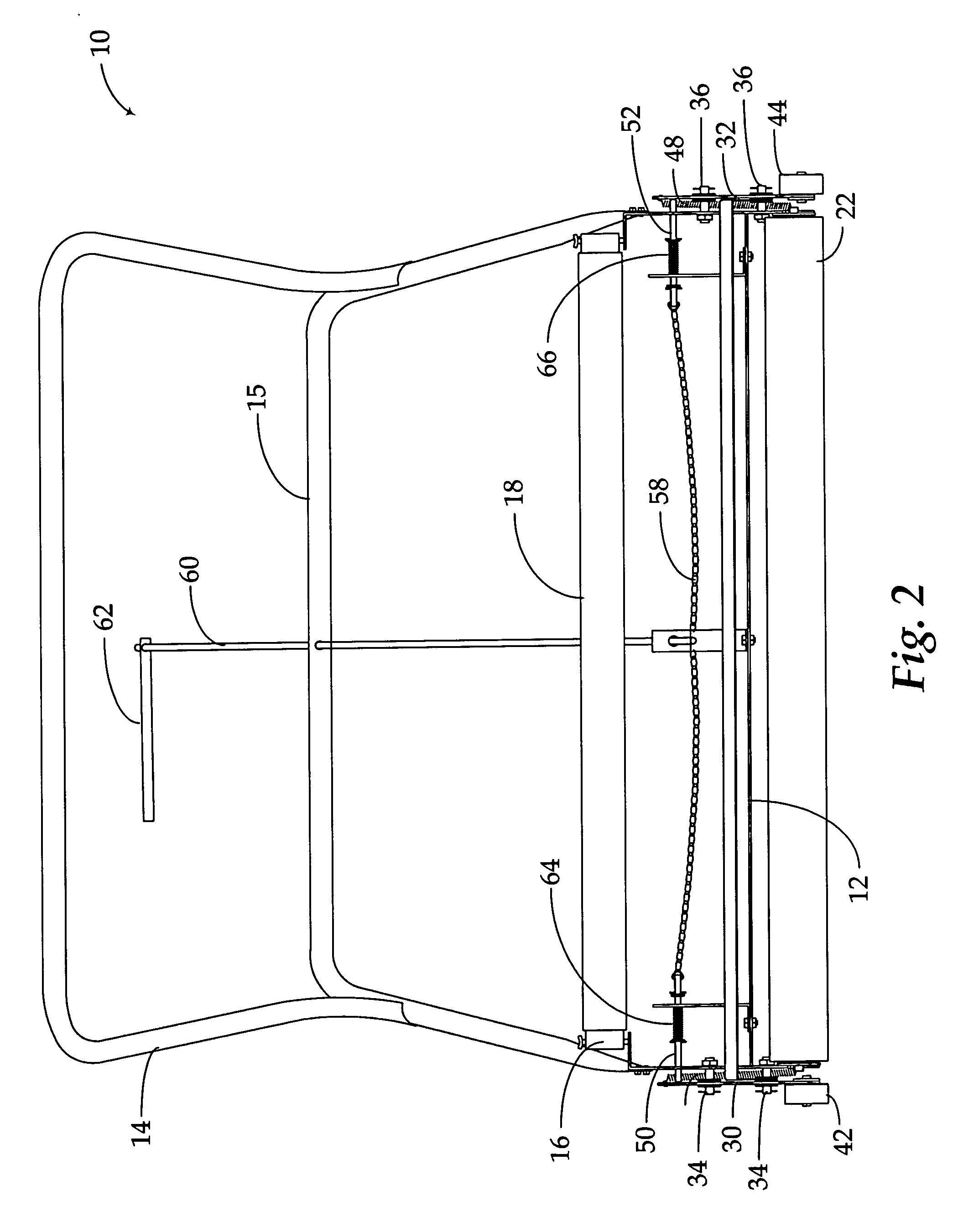

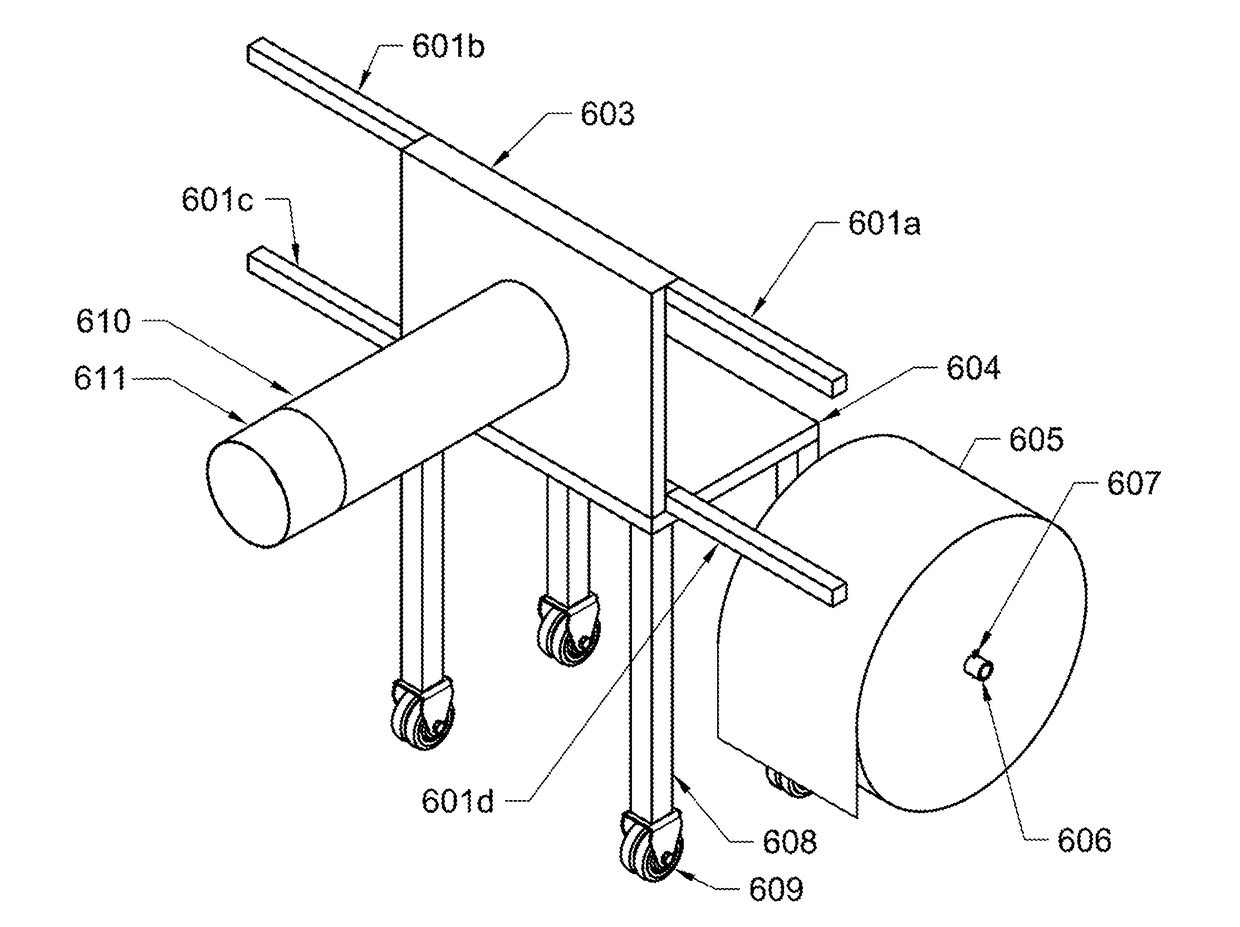

Carpet film applicator

An apparatus for applying a plastic film to a surface such as a carpet is provided which includes a handle, frame, film roll dispenser, guide bar, at least one roller and a trailing roller. The trailing roller supports the apparatus off of the roller to allow the apparatus to be pulled back against the stair to smooth the film against the front of the stair.

Owner:FLOWERS BOBBY N

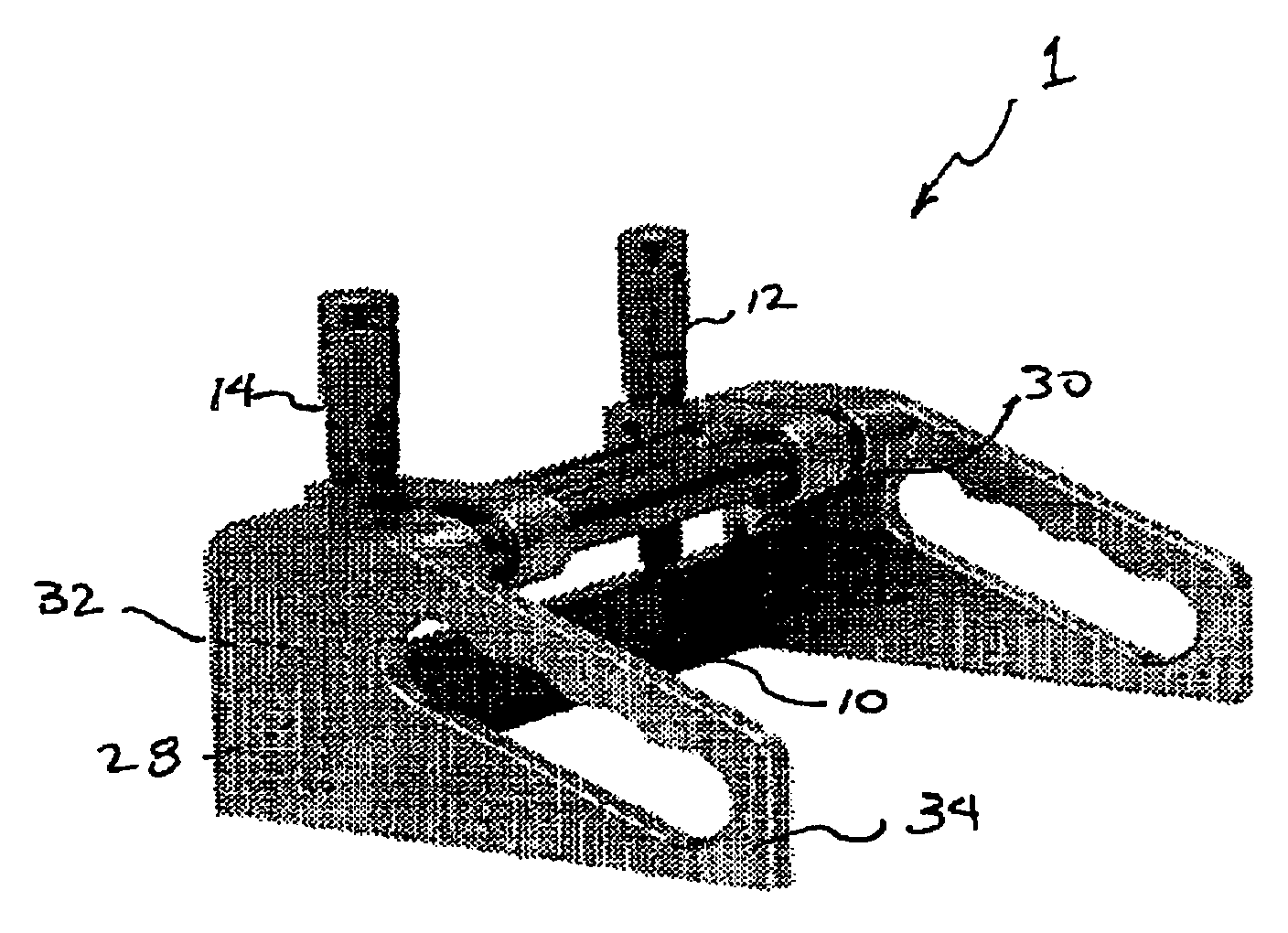

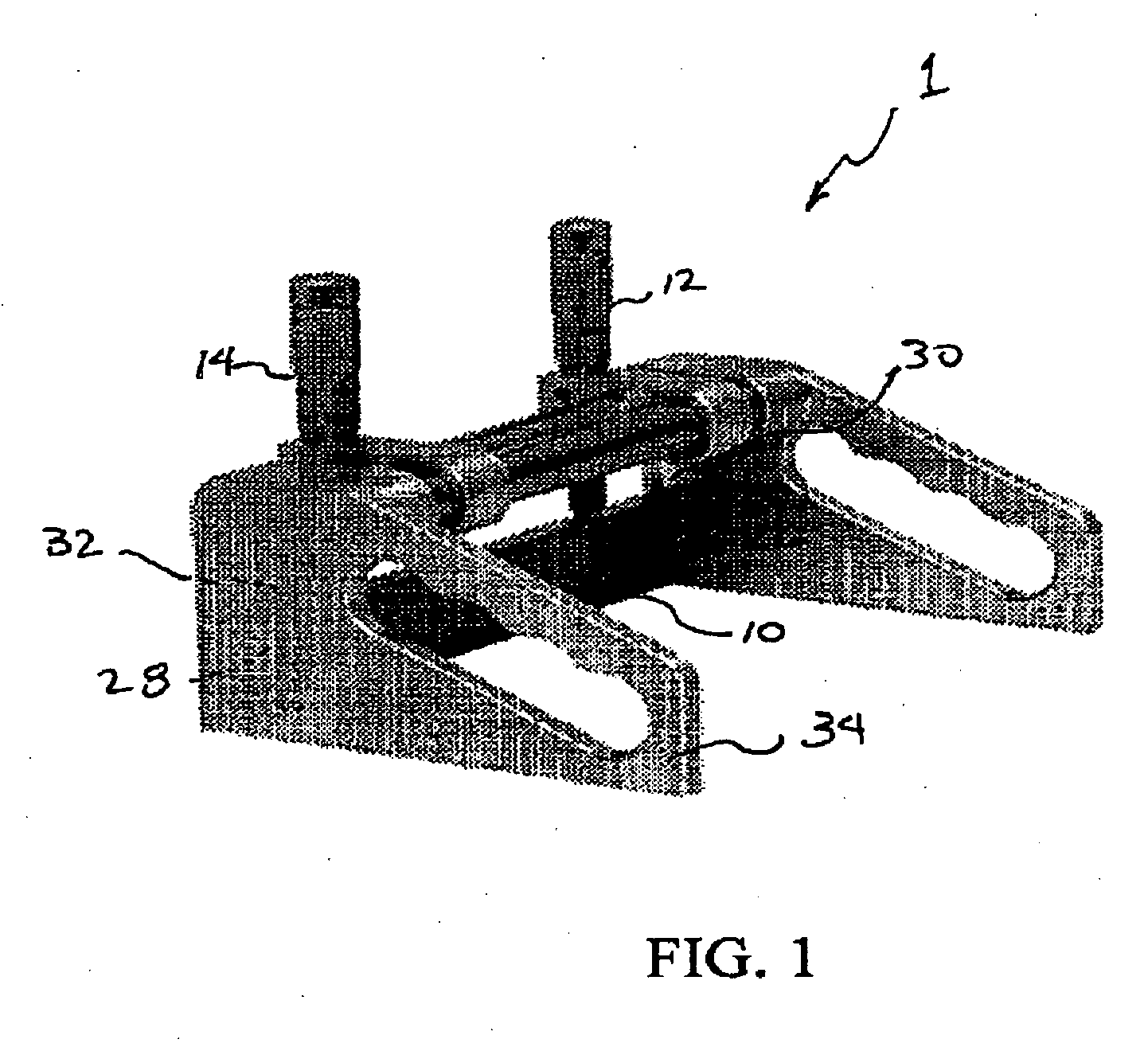

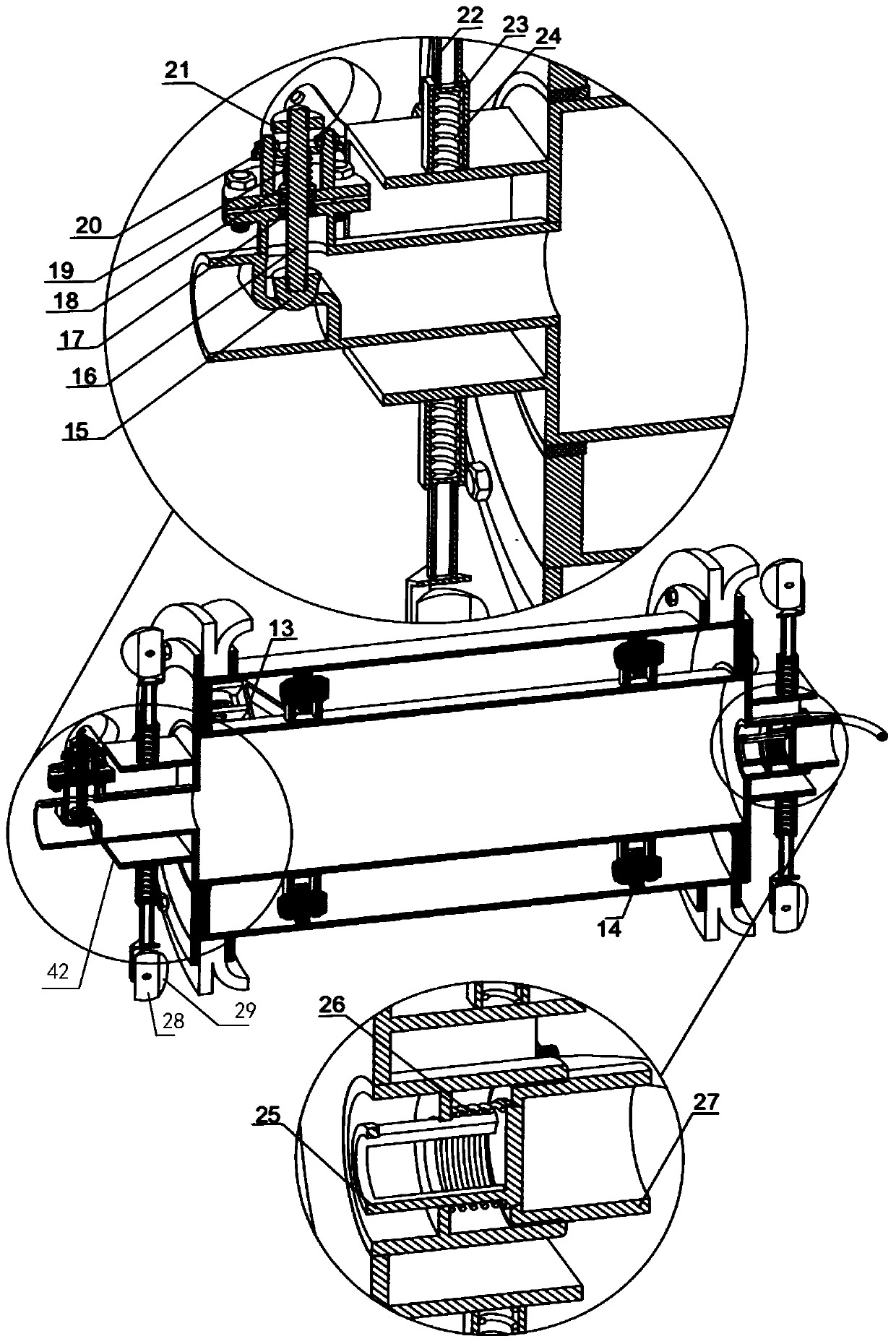

Adjustable film applicator

InactiveUS20070151511A1Reduced tendency to clogLess-expensive to manufactureLiquid surface applicatorsRoads maintainenceMicrometerFilm applicator

A film applicator which includes an applicator housing, an applicator blade positioned within the housing, a micrometer secured to the applicator housing and having a plurality of shafts and a plurality of magnets each having one end secured to a respective micrometer shaft and another end in releasable magnetic engagement with the applicator blade.

Owner:BYK USA INC

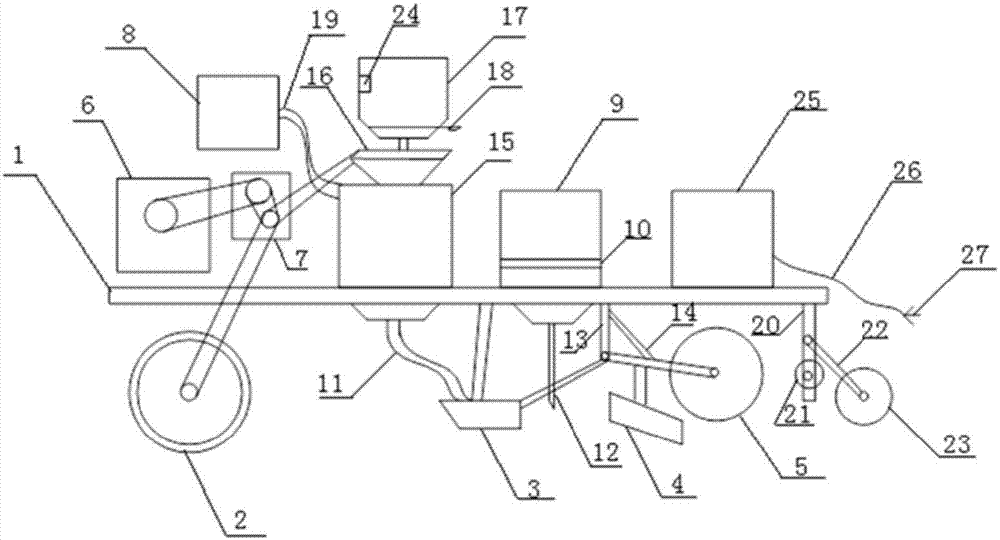

Fertilizer application-sowing-chemical spraying integrated machine

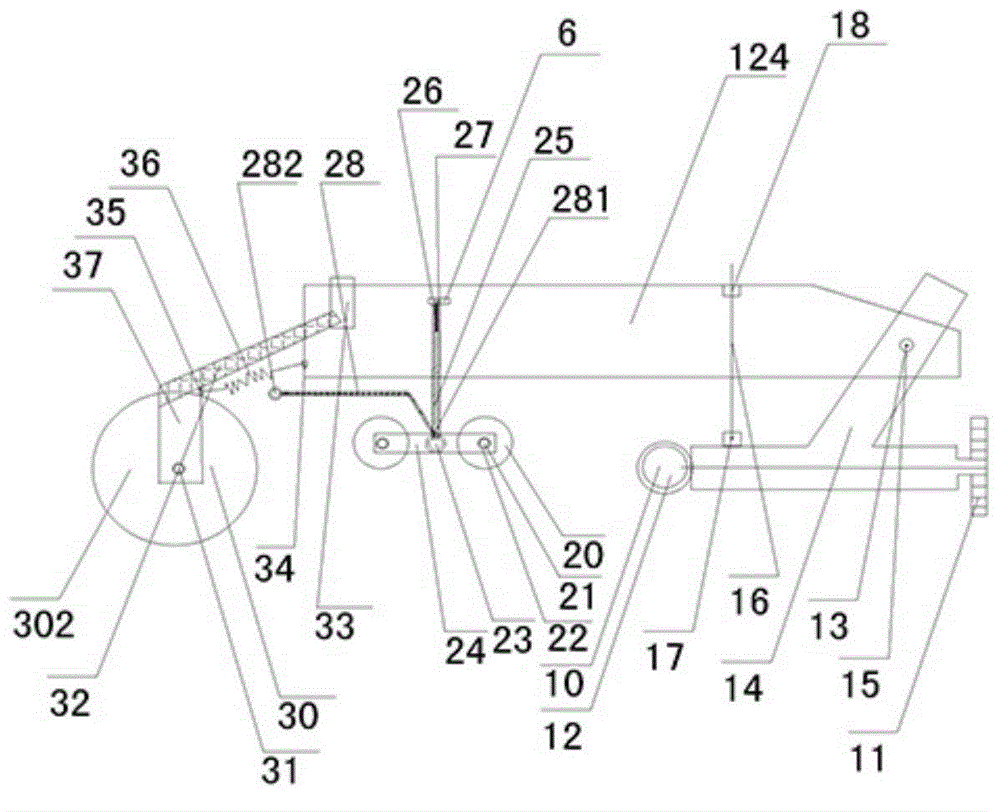

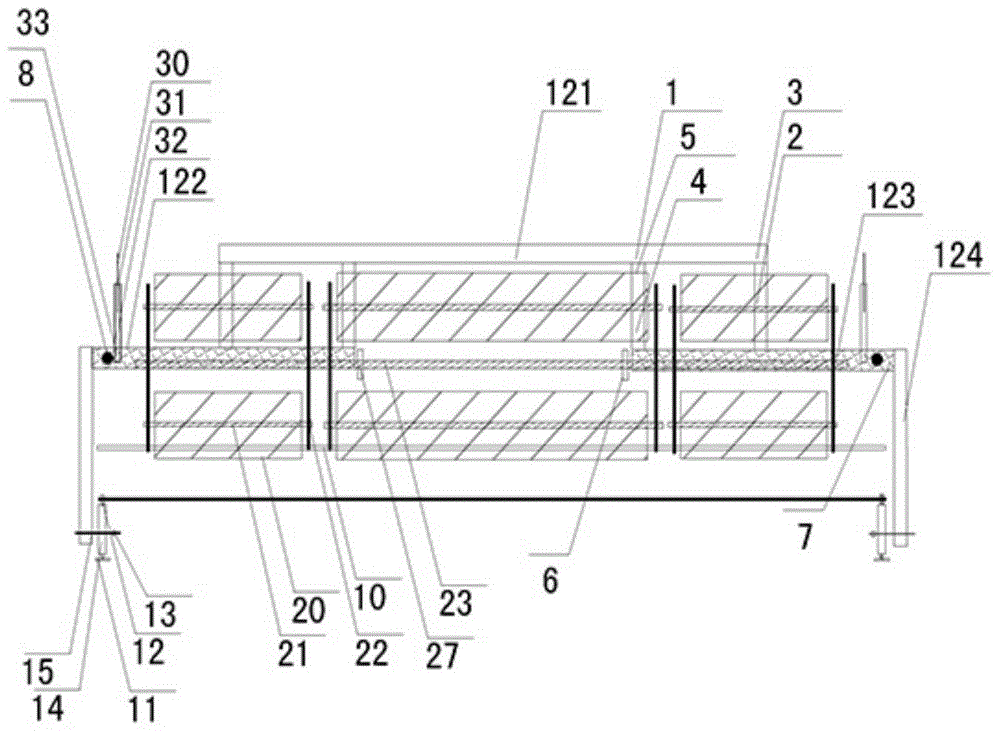

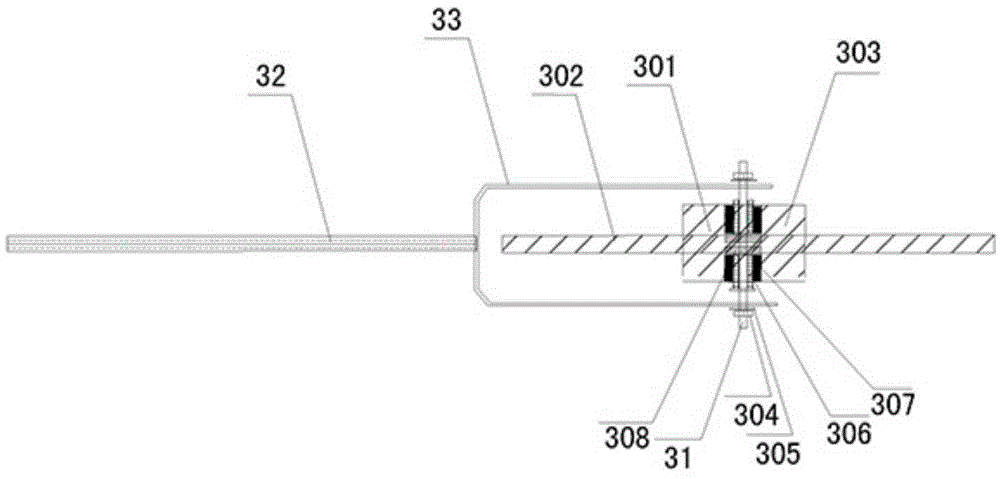

InactiveCN107241942AReasonable designEasy to usePlantingLiquid fertiliser regulation systemsSprayerAgricultural engineering

The invention relates to a fertilizer application-sowing-chemical spraying integrated machine, belonging to the technical field of agricultural machinery and equipment. The integrated machine comprises a machine frame, wherein the bottom of the machine frame is sequentially provided with road wheels, a furrowing machine, a furrow coverer, press wheels and a film applicator from front to back; a drive unit, a gear box, a fertilizer applicator, a sowing box and a chemical sprayer are sequentially arranged on the machine frame from front to back; a fertilizer application pipe is connected with the furrowing machine; the outlet of a sowing pipe is positioned below the machine frame, and positioned between the furrowing machine and the furrow coverer; the furrow coverer and packing wheels are respectively connected with the machine frame through a first connecting rod; and the film applicator is connected with the machine frame through a hydraulic transmission gear. The integrated machine is convenient to use, implements ditching, fertilizer application, sowing, furrow covering, press, film application, chemical spraying and many other operations at one time, has higher automation degree, is simple to operate, reduces the operation frequency, enhances the operating efficiency, and lowers the labor force.

Owner:高连平

Fuel injection nozzle with film-type fuel application

A fuel injection nozzle for a gas turbine combustion chamber with a film applicator (1) is provided with several fuel openings (2). Center axes (5) of the fuel openings (2) through the film applicator (1), with regard to their radial orientation, are essentially parallel to the main flow direction (6) of the air.

Owner:ROLLS ROYCE DEUT LTD & CO KG

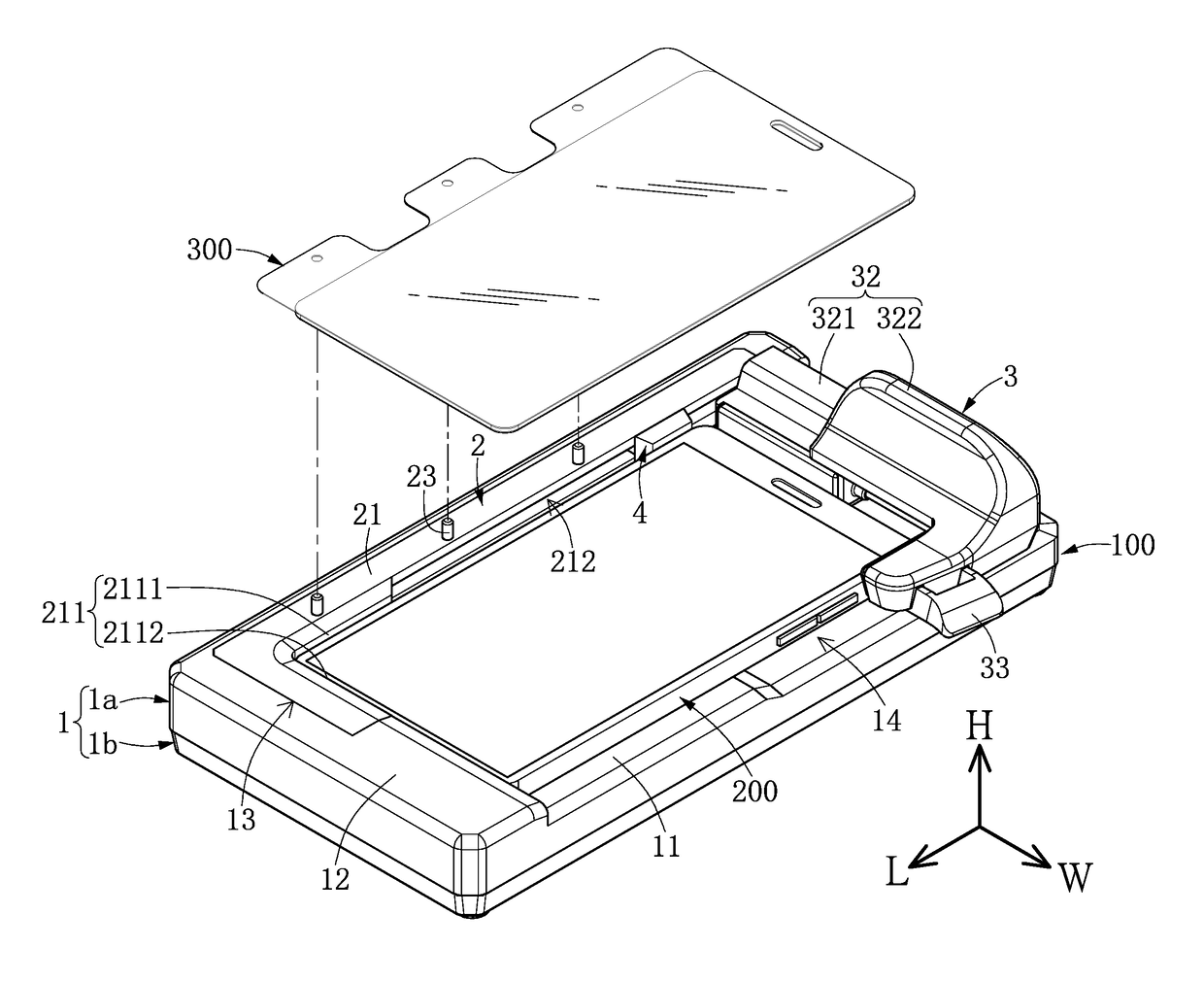

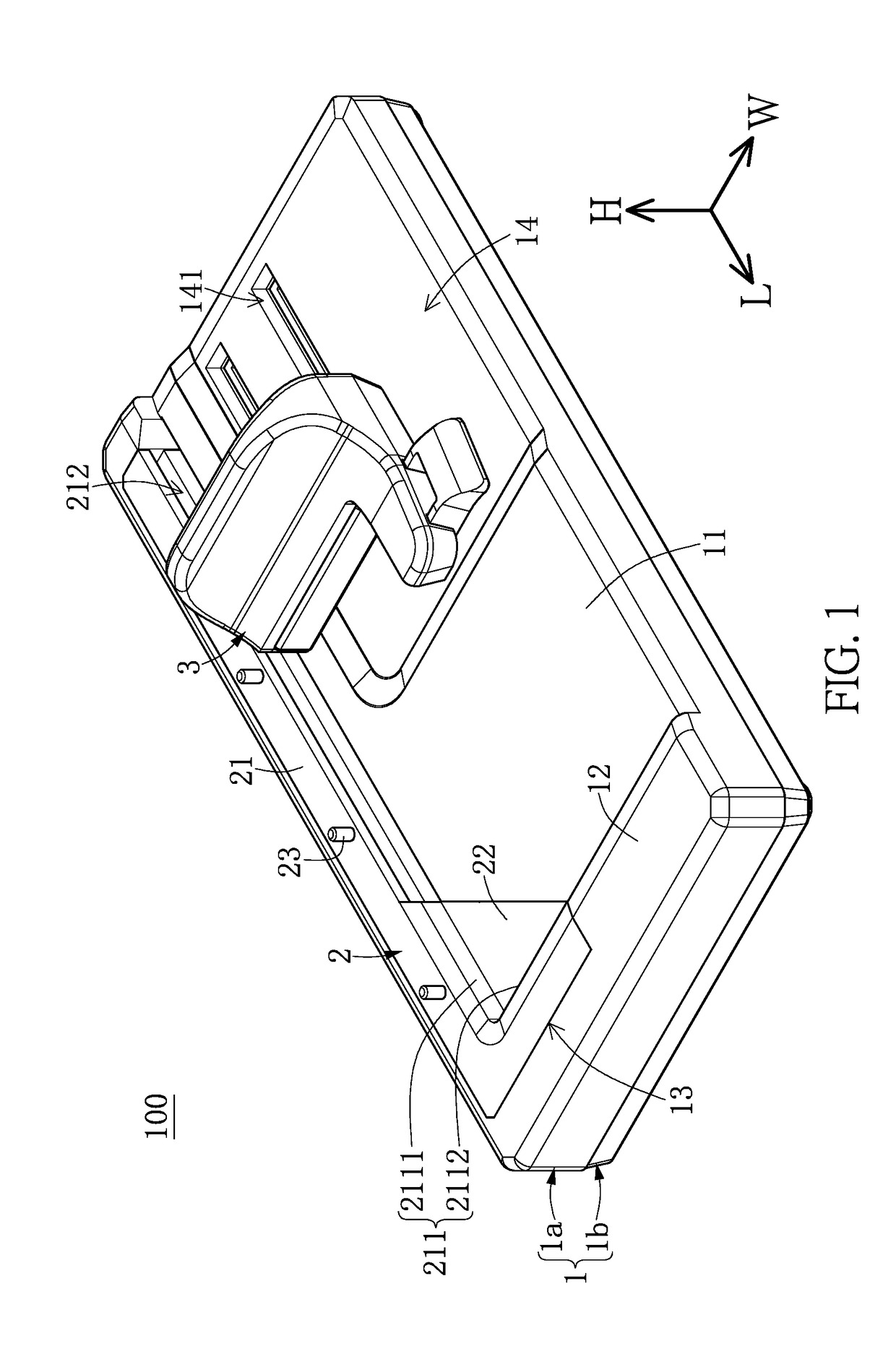

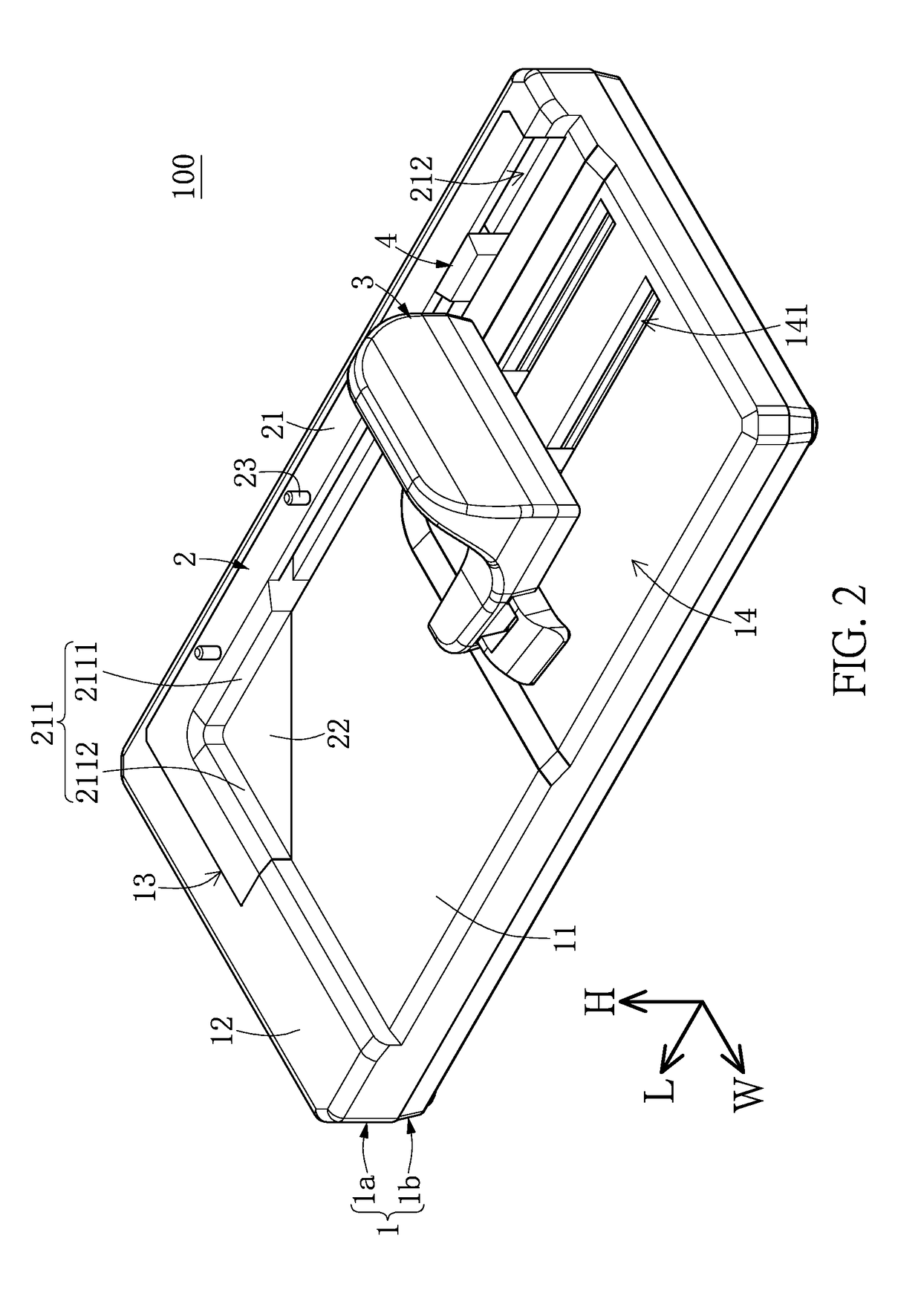

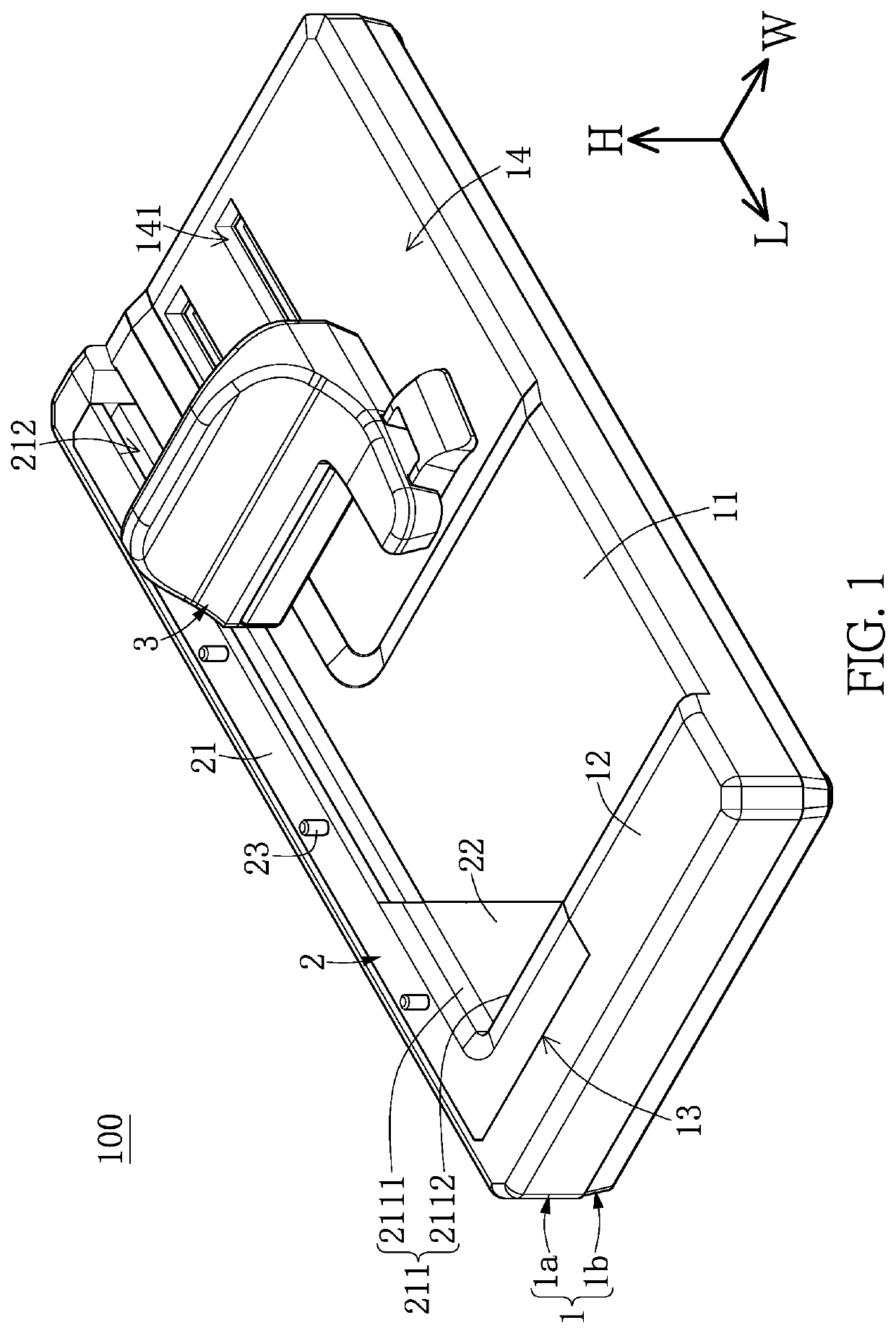

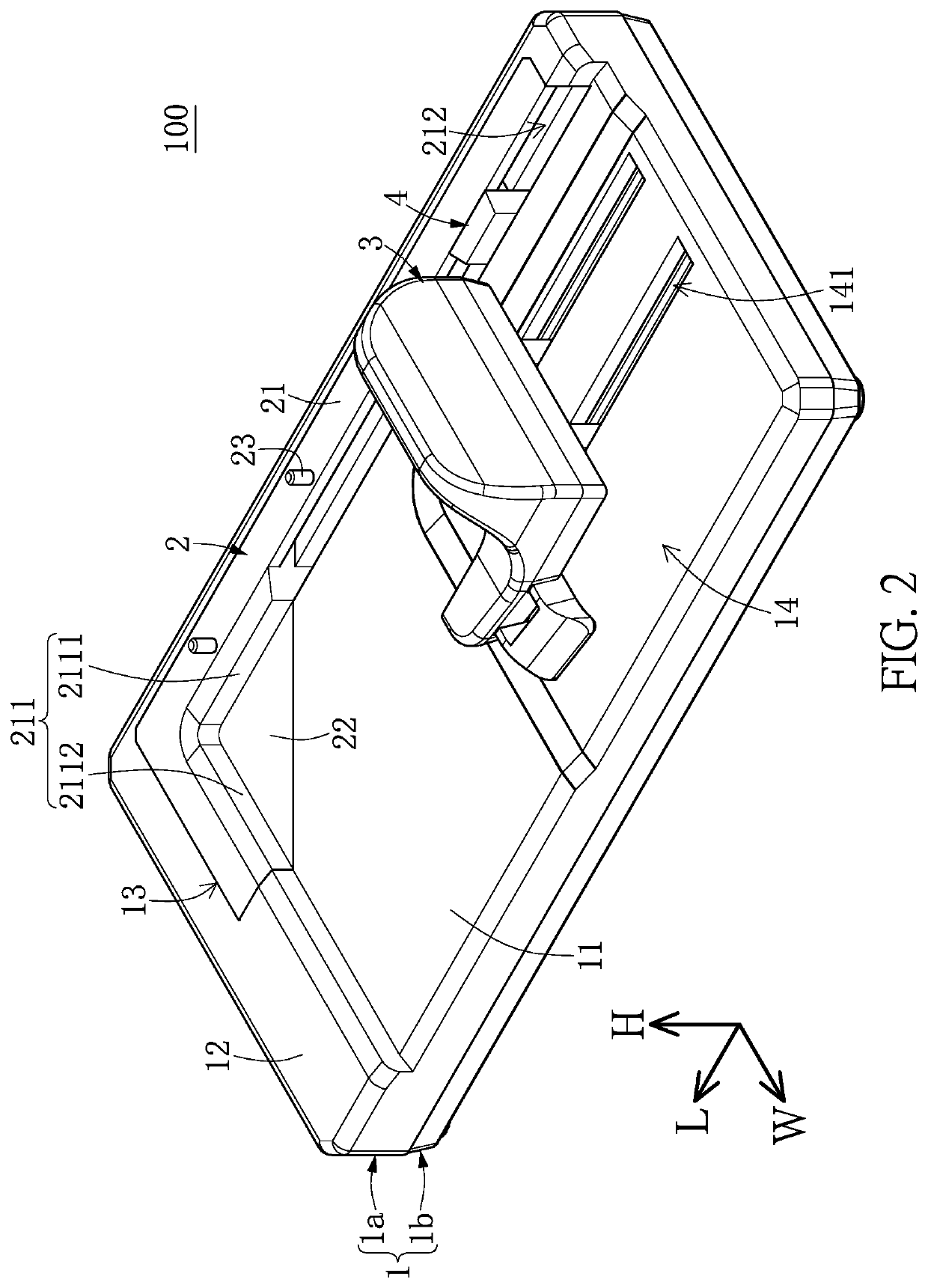

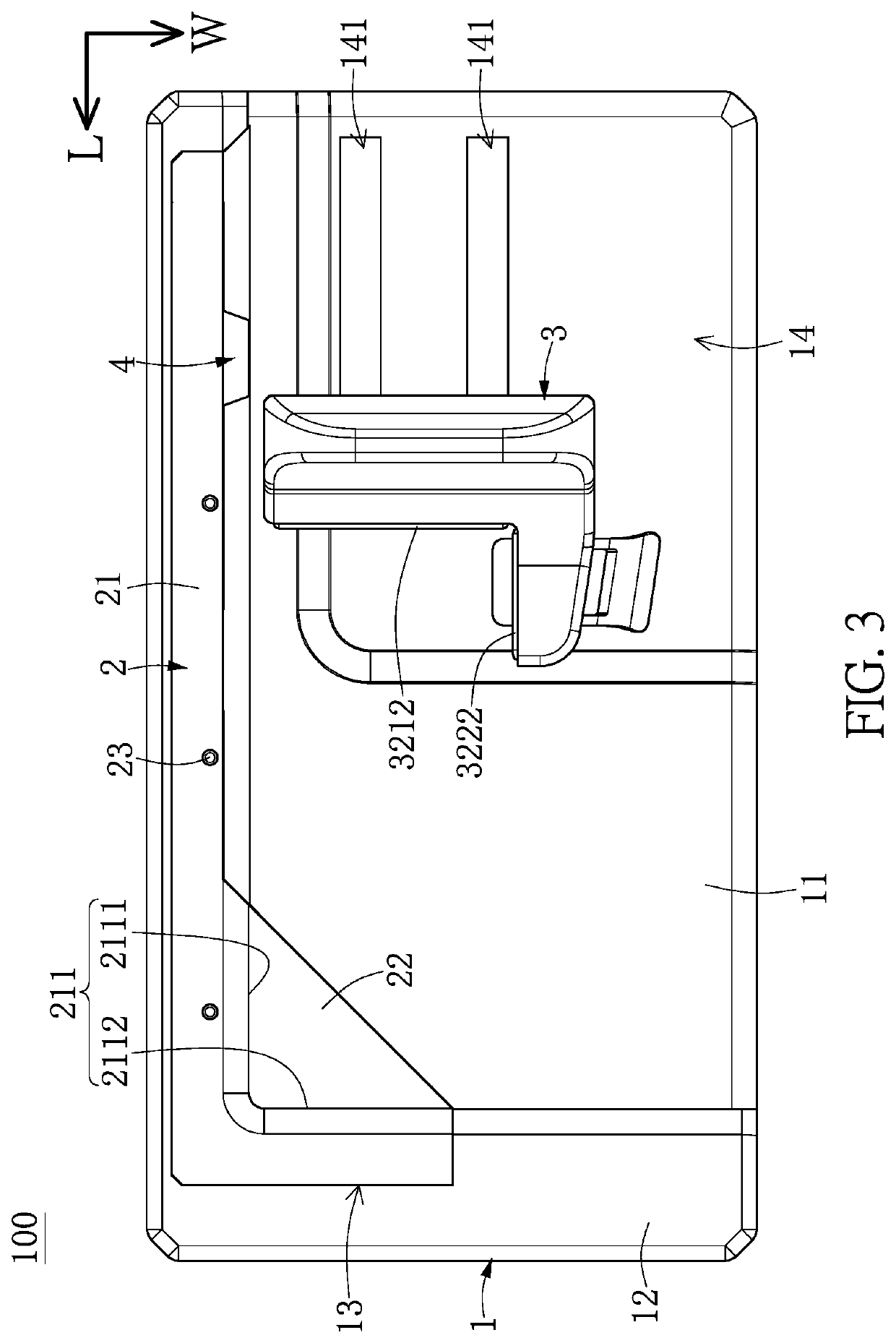

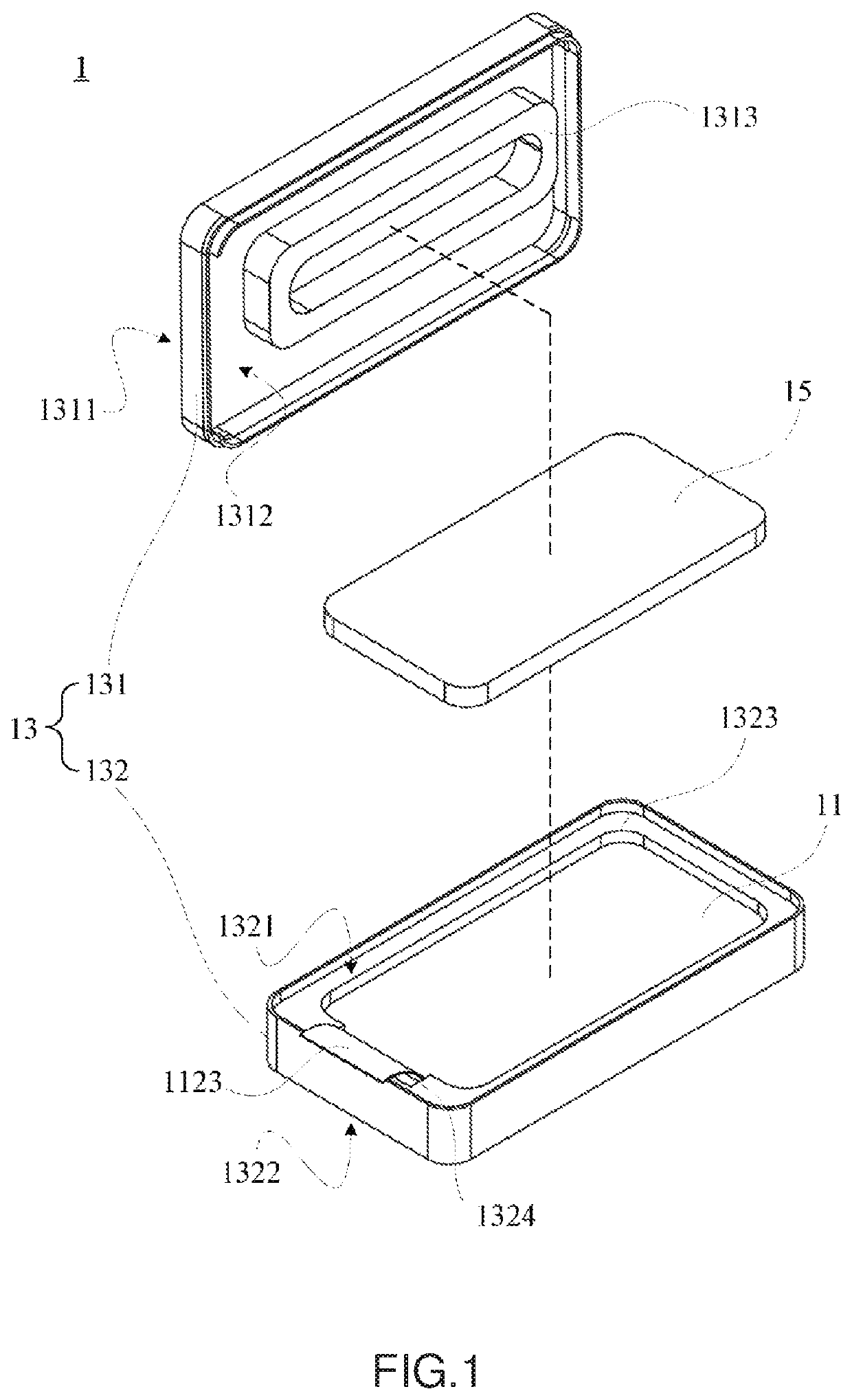

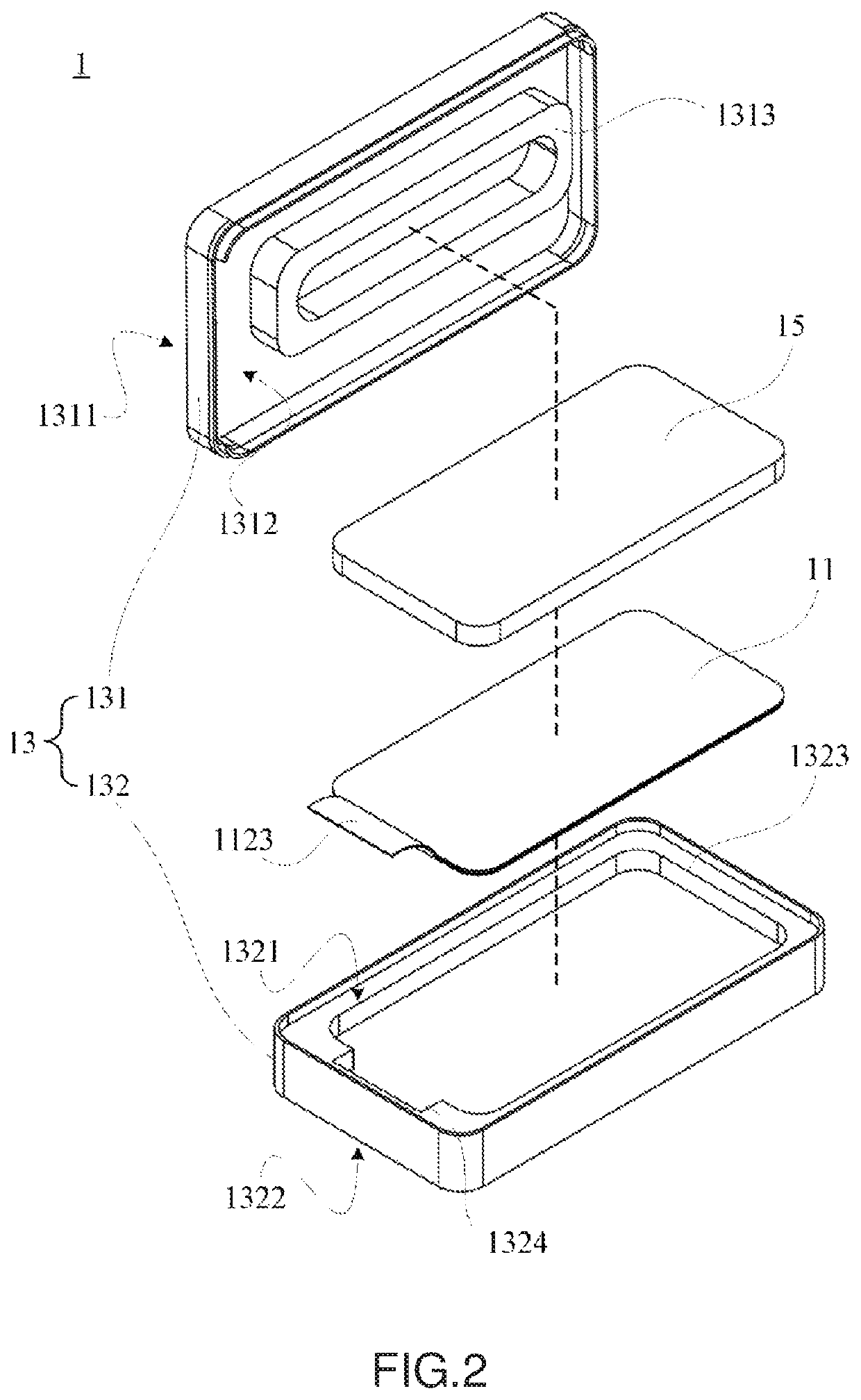

Glass screen film applicator and carrier module thereof

A glass screen film applicator includes a carrier, a positioning member integrally formed as a one-piece structure, and a clamping mechanism fastened to the carrier. The carrier includes a mounting slot and an accommodating trough, and the accommodating trough includes a rail hole recessed in a bottom thereof. The positioning member includes an L-shaped structure and a plurality of positioning pillars extending from the L-shaped structure, and the L-shaped structure has a positioning corner arranged on an inner side thereof. The clamping mechanism includes a holder and a moving unit. The holder and the positioning corner respectively clamp two diagonal corners of a mobile device by the moving unit, and the positioning pillars allow the glass screen film structure to be disposed on and aligned with the mobile device.

Owner:LIN CHIA CHING

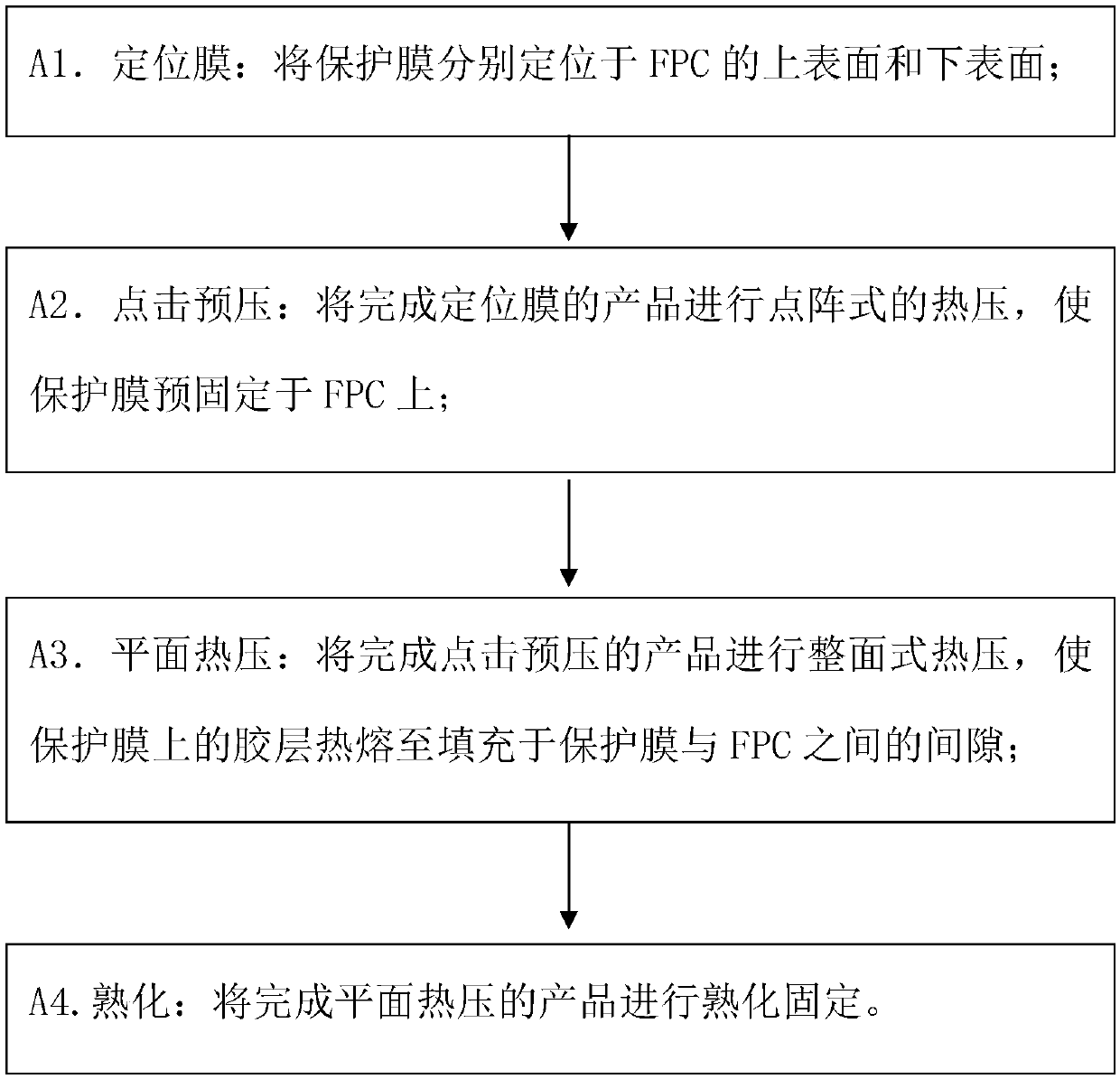

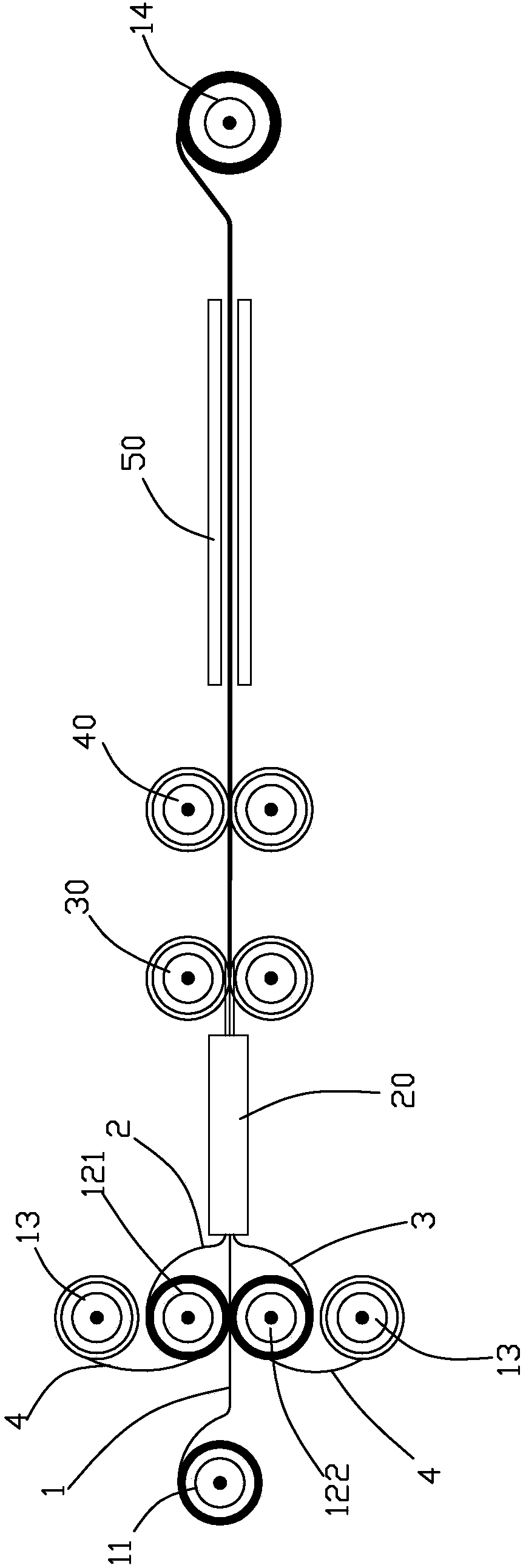

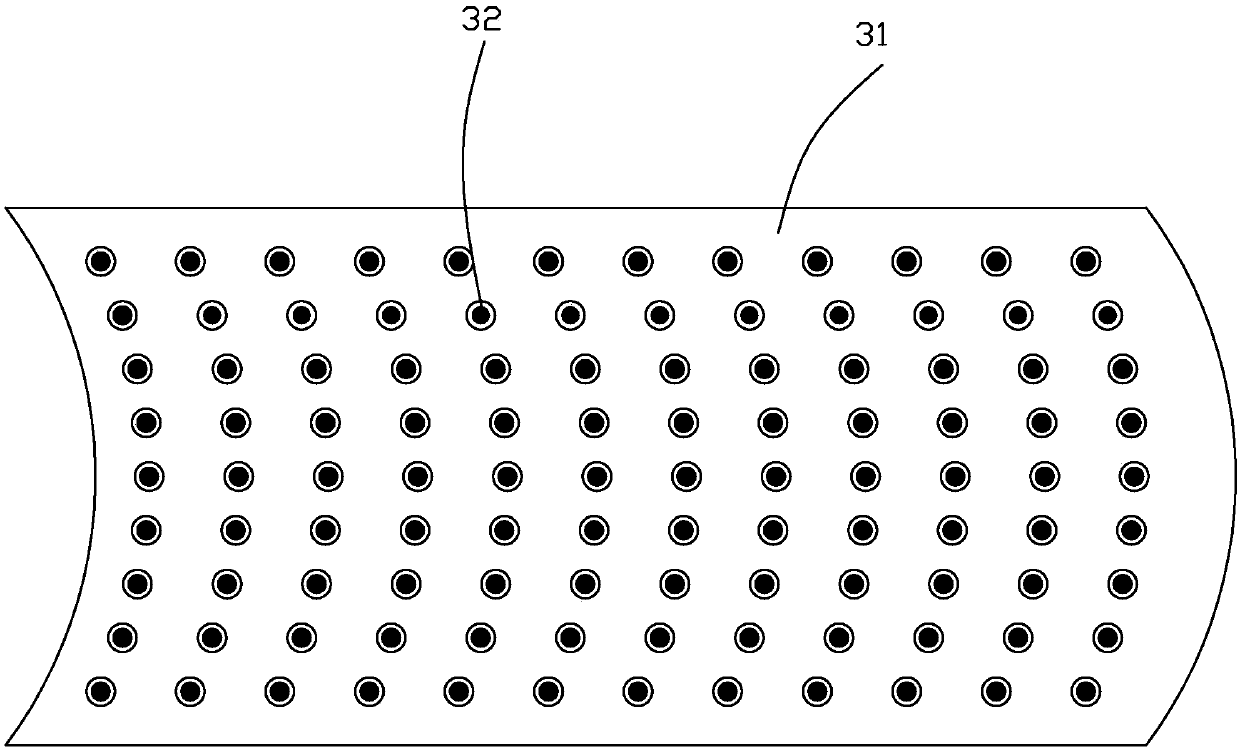

Method and device for covering FPC with film

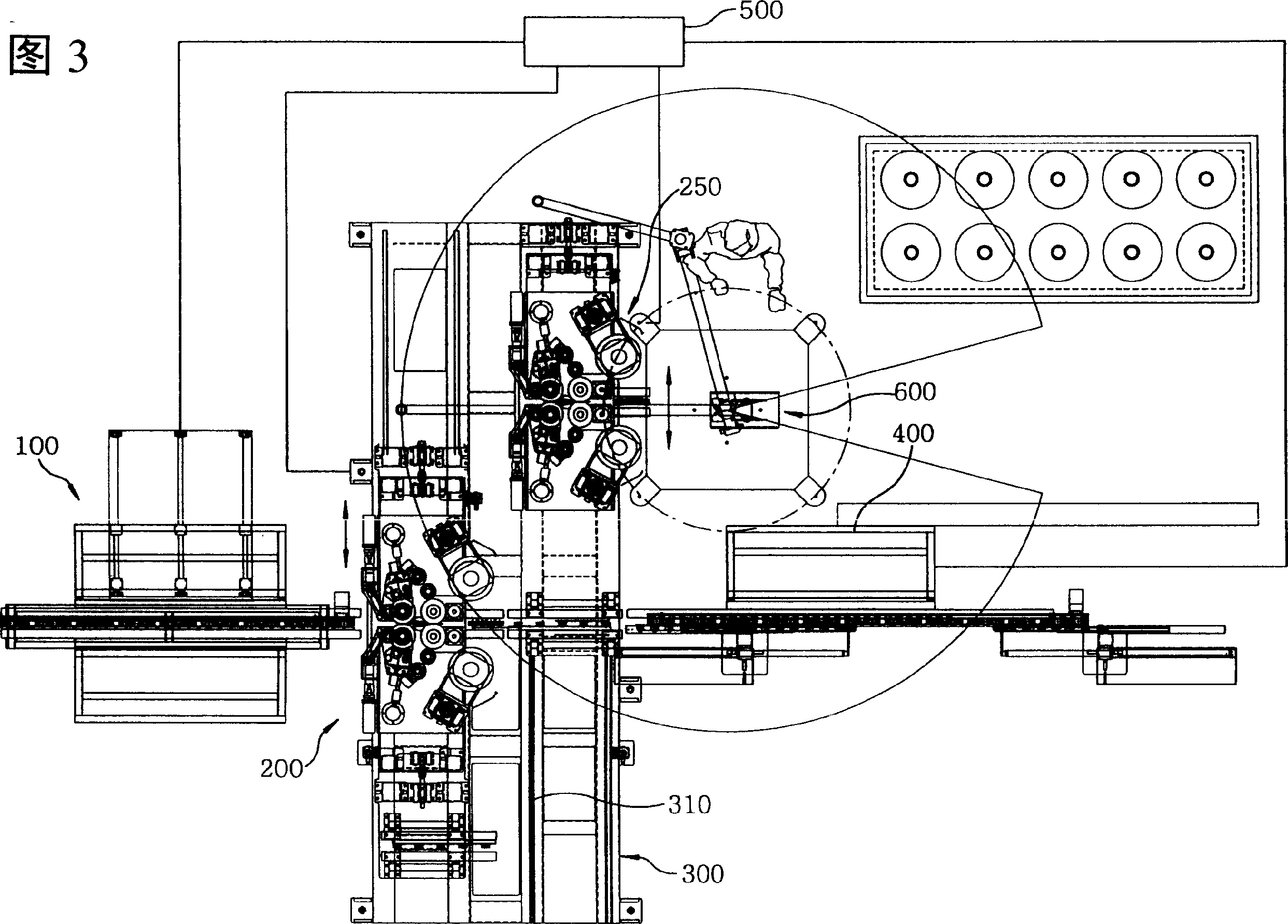

ActiveCN107949180AUniform coverageImprove yieldNon-metallic protective coating applicationTectorial membraneDot matrix

The invention provides a method for covering an FPC with a film and a device for realizing the method. The method comprises steps of adopting a film positioning step to position an FPC and a protective film, performing click prepressing and dot matrix pre-hot pressing to achieve dot matrix pre-fixing and minimize the gap between the protective film and the FPC, and finally performing the entire surface hot pressing. The dot matrix fixed point has a guiding role, and the hot-melt glue can be quickly and evenly applied after the entire surface hot pressing and is not easy to generate bubbles, sothat the protective film covers uniformly and the yield rate is high. A full-automatic film applicator for realizing the above method not only achieves the above high-yield operation, but also realizes full-automatic production, so that the production efficiency is remarkably improved, and at the same time the continuity of the Roll TO Roll process is satisfied, and the FPC is not required to becut before film covering operation.

Owner:XIAMEN BOLION CIRCUIT

Preparing process of sclareol

InactiveCN101323559ANo pollution in the processSuitable for large-scale productionHydroxy compound separation/purificationDistillationSolvent

The invention discloses a preparation technology of sclareol, which adopts a molecular still with a distance of 2cm to 5cm between an evaporating surface and a condensing surface. The technology of the invention is characterized in the operation under the following technological conditions is carried out and comprises the following steps of: operating pressure for the still is 1Pa to 150Pa, distilling temperature is 100 DEG C to 400 DEG C, cooling temperature is minus 8 DEC G to minus 15 DEG C, rotating speed of a film applicator is 10rpm to 300rpm, remains of the first-step distillation are deemed as raw materials for a next distillation and are taken 2 times to 3 times of distillation, temperature contrast between the evaporating surface and the condensing surface is kept as 175 DEG C to 275 DEG C for each time of distillation, so as to completely separate and extract sclareol from clary sage concrete and to ensure the yield of sclareol to reach 98 percent. The technology of the invention has advantages of simple technology, short operating time, nonuse of solvent, nonproduction of other high boiling materials and pollution-free. The technology of the invention has high efficiency on extracting the sclareol, high product yield and high benefit, and is applicable to large-scale production of the sclareol.

Owner:延安汇丰工贸有限公司 +1

Glass screen film applicator and carrier module thereof

A glass screen film applicator includes a carrier, a positioning member integrally formed as a one-piece structure, and a clamping mechanism fastened to the carrier. The carrier includes a mounting slot and an accommodating trough, and the accommodating trough includes a rail hole recessed in a bottom thereof. The positioning member includes an L-shaped structure and a plurality of positioning pillars extending from the L-shaped structure, and the L-shaped structure has a positioning corner arranged on an inner side thereof. The clamping mechanism includes a holder and a moving unit. The holder and the positioning corner respectively clamp two diagonal corners of a mobile device by the moving unit, and the positioning pillars allow the glass screen film structure to be disposed on and aligned with the mobile device.

Owner:LIN CHIA CHING

Adjustable film applicator

InactiveUS7930991B2Easy to useReduced tendency to clogLiquid surface applicatorsRoads maintainenceMicrometerEngineering

Owner:BYK USA INC

Corrosion inhibitor coating device with controllable speed of gathering and transportation pipeline

ActiveCN110860434AUniform coatingAchieve the purpose of slowing downLiquid surface applicatorsCoatingsControl valvesFilm applicator

The invention discloses a corrosion inhibitor coating device with controllable speed of a gathering and transportation pipeline. The corrosion inhibitor coating device comprises a controllable speed part and a film coating device; the inner part of the controllable speed part is a high-pressure air storage cylinder, and the outer periphery of the controllable speed part is sleeved with at least one sealing rubber cup; the front end of the high-pressure air storage cylinder is provided with a speed control valve and a first group of rotating mechanisms, the rear end of the high-pressure air storage cylinder is provided with a second group of rotating mechanisms and a first connecting ring, a plurality of circumferential rotating bearings and two groups of axial rotating bearings are uniformly mounted on the outer wall of the high-pressure air storage cylinder in the circumferential direction; the inside of a cylinder body of the film coating device is hollow and is used for storing a corrosion inhibitor, a liquid outlet groove and a film coating brush are arranged on the periphery of the cylinder body, a second connecting ring is arranged at the front end of the cylinder body, the first connecting ring is connected with the second connecting ring, and when the film coating device exceeds a preset speed, the speed control valve is opened. According to the corrosion inhibitor coating device, gas emitted by the high-pressure air storage cylinder of the controllable speed part can slow down the device, the running speed is controlled to be lower than a specific value, and the film coating device is uniformly coated on the inner wall of the pipeline by the film coating brush carrying the corrosion inhibitor, and therefore, the situation that the speed is controllable, the coating film is automatic and the coating film are uniform can be achieved.

Owner:SOUTHWEST PETROLEUM UNIV +1

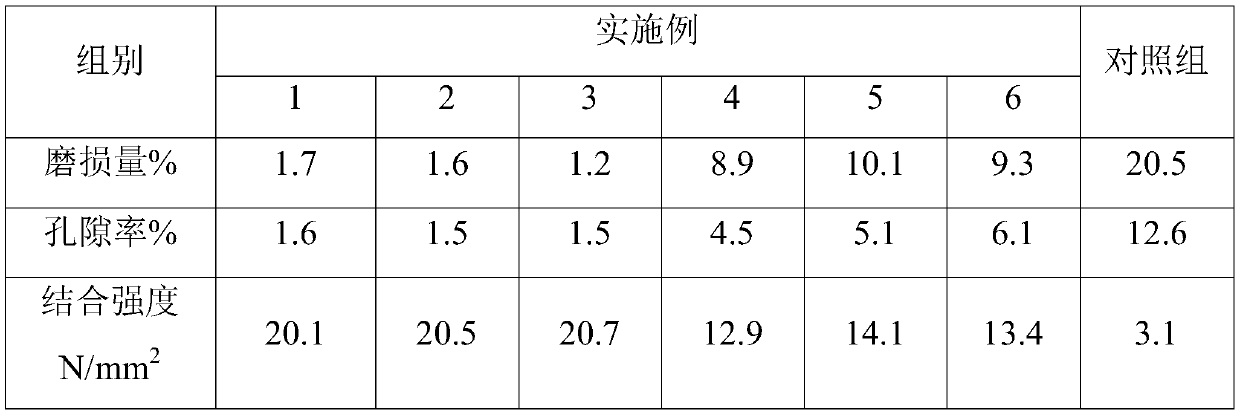

Wear-resistant carbon fiber coating and coating method thereof

InactiveCN109957306ALess prone to delaminationReduce entryPretreated surfacesAnti-corrosive paintsCarbon fibersWear resistant

The invention provides a wear-resistant carbon fiber coating and a coating method thereof. Resin in a carbon fiber coating material is mixed and melted with a solvent, clay, a binder and a filler; under the action of a ball mill, a coating material which has uniform particle size and is less than 1000 meshes is obtained; with the combination of dispersion effect of a dispersion machine, the coating material can be better combined with the surface of carbon fiber. The coating material is coated in three layers during coating: the first layer and the second layer are coated under the ultravioletirradiation such that silicon dioxide ultrafine particles of the polymerization reactive functional group are dispersed therein to form a more stable coating; and the third layer of the coating material is uniformly scraped and synchronously solidified on a frame-type film applicator to strengthen the adhesion between the coating materials, and then the coating is less prone to delamination and the speed of corrosive particles entering the coating is effectively delayed. Thereby, the coating shows good chemical corrosion resistance and remarkable wear resistance.

Owner:佛山市石金科技有限公司

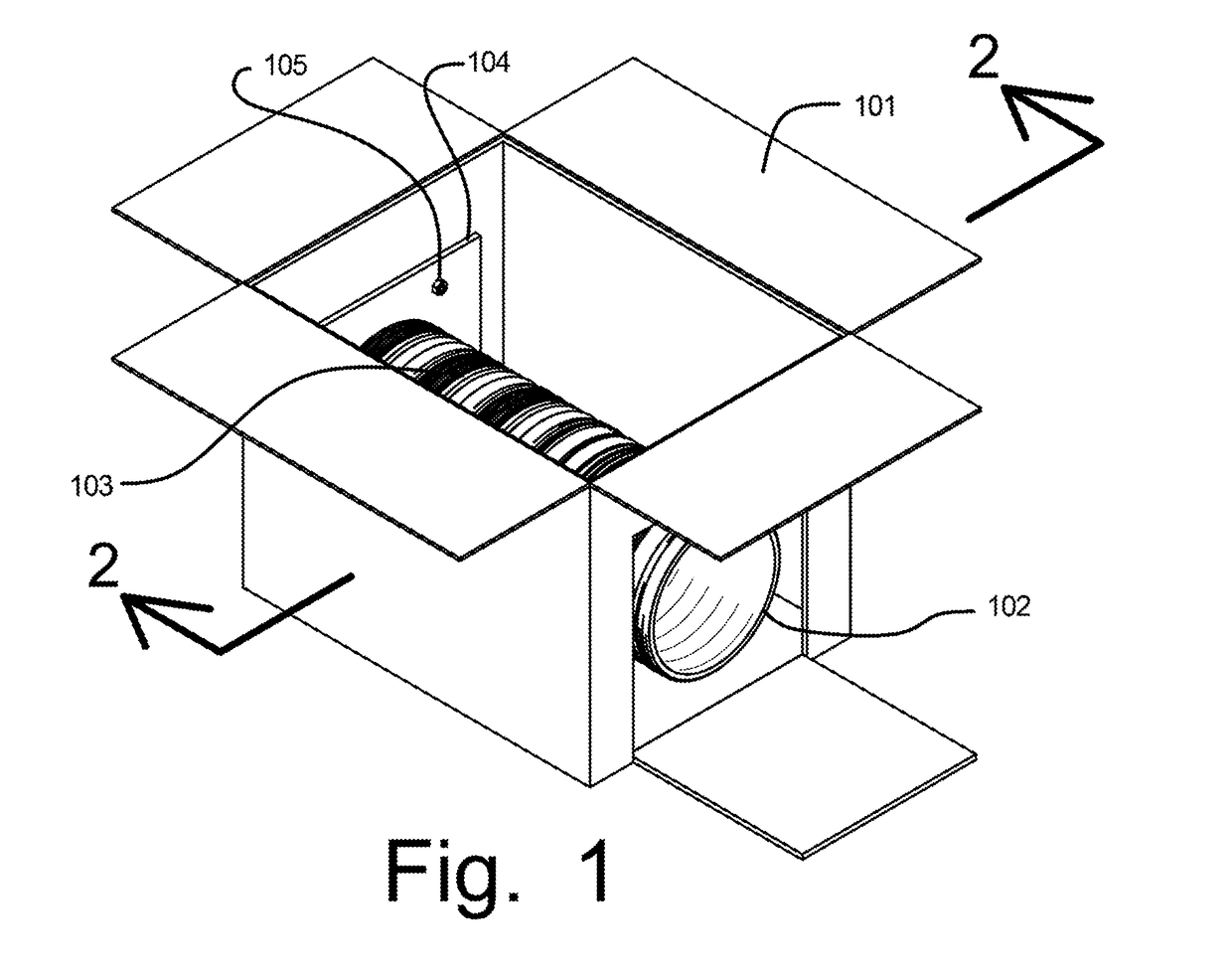

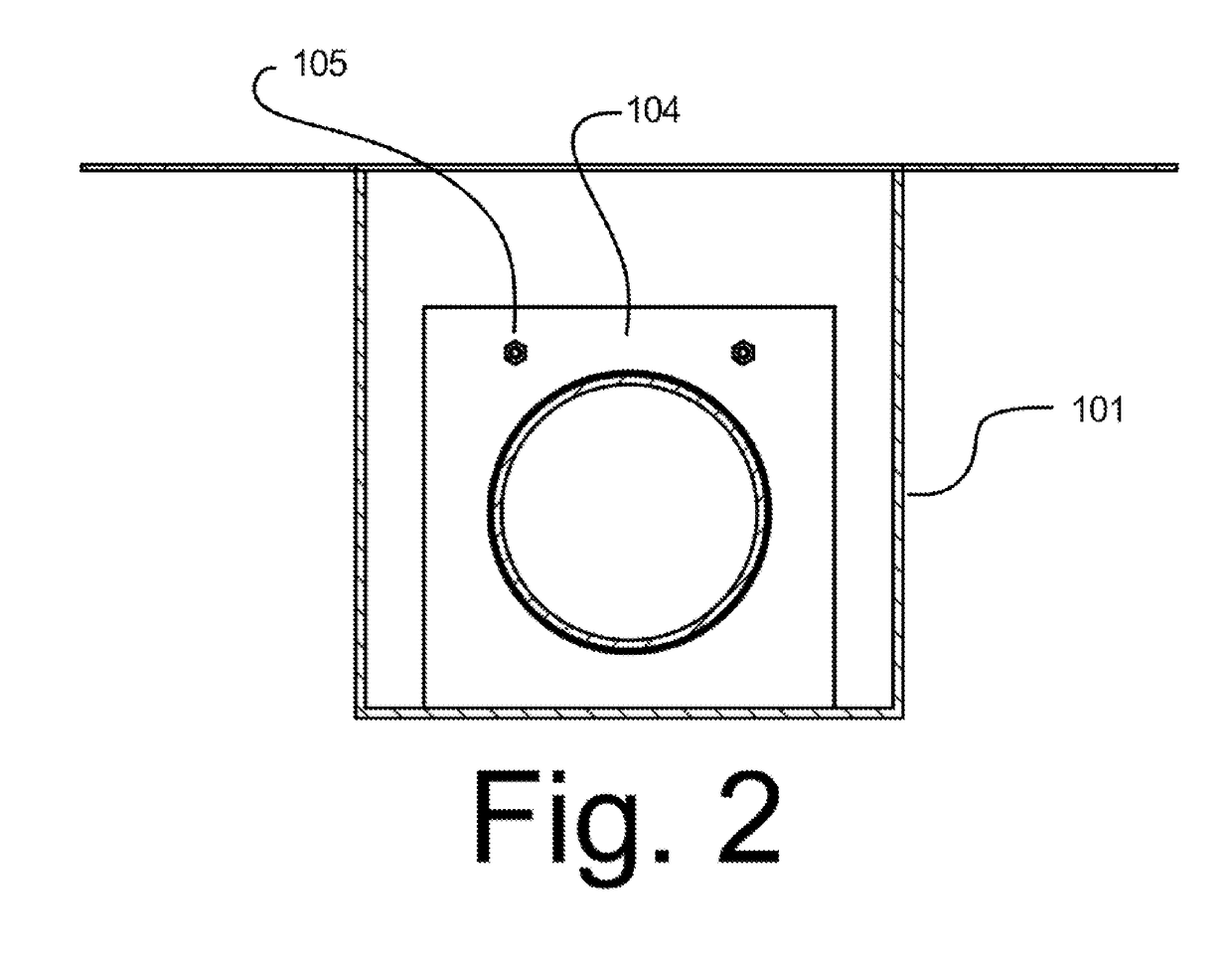

Packaging box of covering film and film applicator

ActiveUS10751931B1The process is simple and convenientImprove coating efficiencyPackaging vehiclesContainers for machinesThin membraneEngineering

The present invention discloses a packaging box of a covering film and a film applicator. By structural designs of the packaging box and the covering film, the packaging box is provided with an internal cavity matching an outer shape of an electronic device and the covering film includes a release film having an extension portion, enabling the packaging box to provide the covering film with storage, dustproof and shock-absorbing functions and to further serve as a film application auxiliary tool when a film application process is performed. Thus, a user is allowed to accurately, quickly and efficiently form a layer providing protection on a surface of the electronic device directly by using the packaging box.

Owner:HSU HSIANG PIN

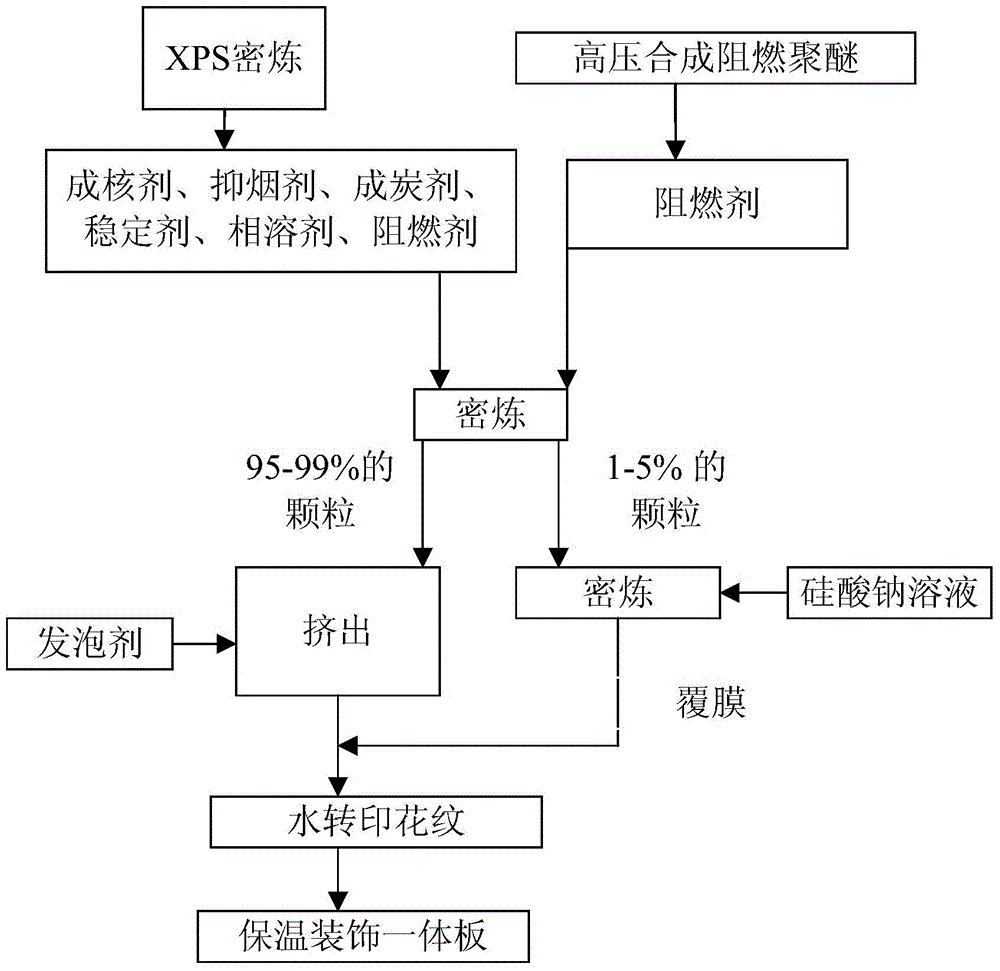

Manufacturing method for polystyrene A-level non-ignitable building outer wall heat-preservation decorative plate

ActiveCN104631737AStrong weather resistanceBreak the flammable ideaCovering/liningsSynthetic resin layered productsBrickWeather resistance

The invention provides a manufacturing method for a polystyrene A-level non-ignitable building outer wall heat-preservation decorative plate. The manufacturing method includes the steps that (1) banburying is carried out on 100 mass parts of XPS for 20-30 minutes, nucleating agents, smoke suppression agents, charring agents, stabilizer, solvents and fire retardants are added and mixed, then banburying continues, and particles are obtained to be used; (2) 95-99 mass parts of particles are put into a foam extruder to manufacture plates; (3) sodium silicate is added into the other particles, banburying is carried out for 25 minutes, then the particles are put into a film applicator, the plates obtained in the second step are put into the film applicator, 15 kilos of pressure heat coating films are added, and film-coated plates are obtained. Organic XPS materials are manufactured through the method, are not ignitable when being fired, non-toxic, odourless, safe, environmentally friendly and high in weather resistance, have heat insulation and heat preservation performance, are as bright and smooth as ceramic tiles, and are free of decoration integration. The manufactured outer wall heat-preservation decorative plate extends the application field of outer wall heat-preservation decorative materials.

Owner:江西合盛安泰新材料有限公司

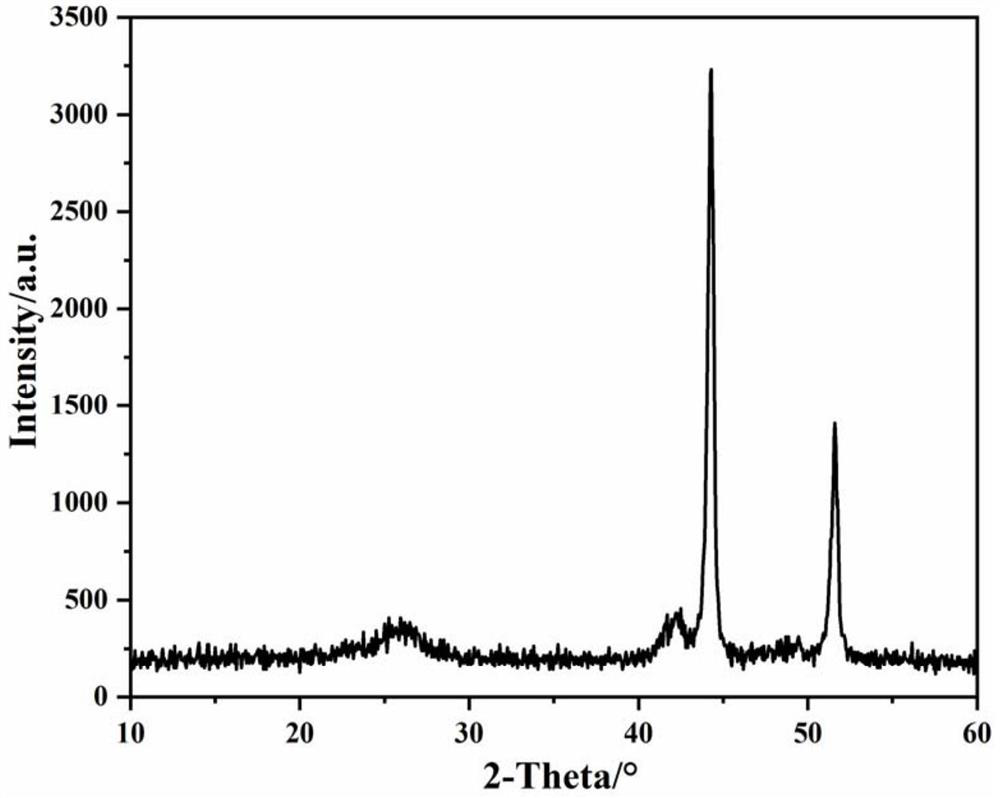

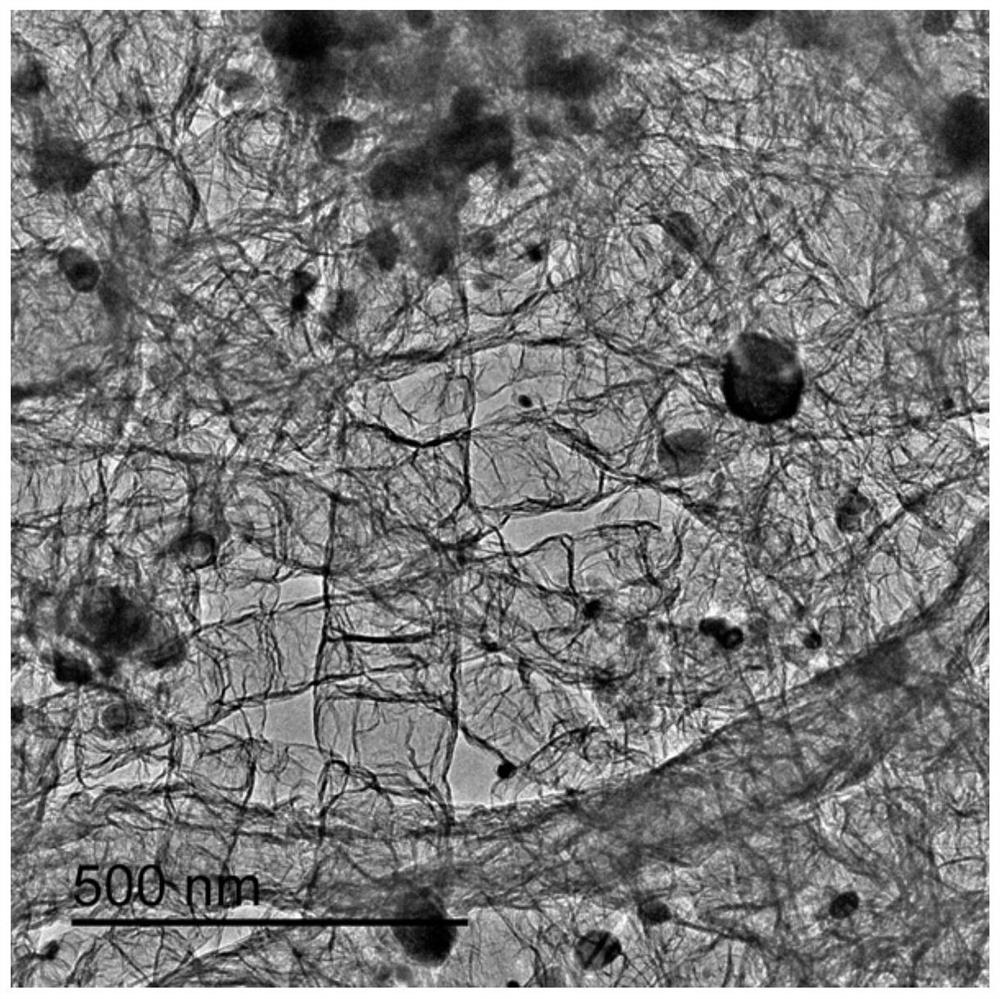

High-entropy alloy/carbon nanotube modified lithium carbon fluoride battery positive plate, preparation method thereof and lithium carbon fluoride battery

PendingCN113964291AImproved magnification performanceHigh voltage platformNon-aqueous electrolyte accumulator electrodesElectrical batteryPhysical chemistry

The invention discloses a high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery positive plate and a preparation method thereof. The preparation method comprises the following steps: step 1, preparing a high-entropy alloy / carbon nanotube composite material; step 2, weighing 70%-90% of carbon fluoride, 5%-20% of the high-entropy alloy / carbon nanotube composite material and 5%-10% of a binder in percentage by mass, grinding and uniformly mixing, then adding a solvent, and uniformly stirring to obtain positive electrode slurry with flowability; and step 3, uniformly coating an aluminum foil or a carbon-coated aluminum foil with the positive electrode slurry by using a film coating device, and carrying out vacuum drying to remove the solvent to obtain the high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery positive electrode plate. The invention also provides a lithium carbon fluoride battery. The lithium carbon fluoride battery comprises an electrolyte, a diaphragm, a negative plate and the high-entropy alloy / carbon nanotube modified lithium carbon fluoride battery positive plate. The prepared positive plate can improve the conductivity and rate capability of the lithium carbon fluoride battery, and improve the specific energy and storage performance of the battery.

Owner:SHAANXI UNIV OF SCI & TECH

Mulching film applicator

InactiveCN104686262AComplete efficientlyImprove reliabilityPlant protective coveringsOrganic farmingAgricultural engineering

The invention discloses a mulching film applicator, which is used for the organic agricultural production and planting link, and is a major breakthrough in the agricultural planting field. The mulching film applicator produced according to the technology can quickly finish the film mulching for a paddy field; a film mulching and rice transplanting integrated machine can be produced according to the technology, so as to finish the film mulching and the rice seedling transplantation at a time; in the organic rice production process, herbicides, insecticides and chemical fertilizers cannot be used, weed control is the most important problem for the organic rice production, and the film mulching technology for the rice can thoroughly solve the problem; the existing film mulching technology for the rice is troublesome, wastes labor and low in efficiency, and seriously influences the industrialized planting of the organic rice as the the manner that a film is mulched manually or mechanically at first and then the rice seedlings are transplanted manually is adopted; the mulching film applicator provided by the invention solves the problem that the production efficiency is low in the prior art.

Owner:王威

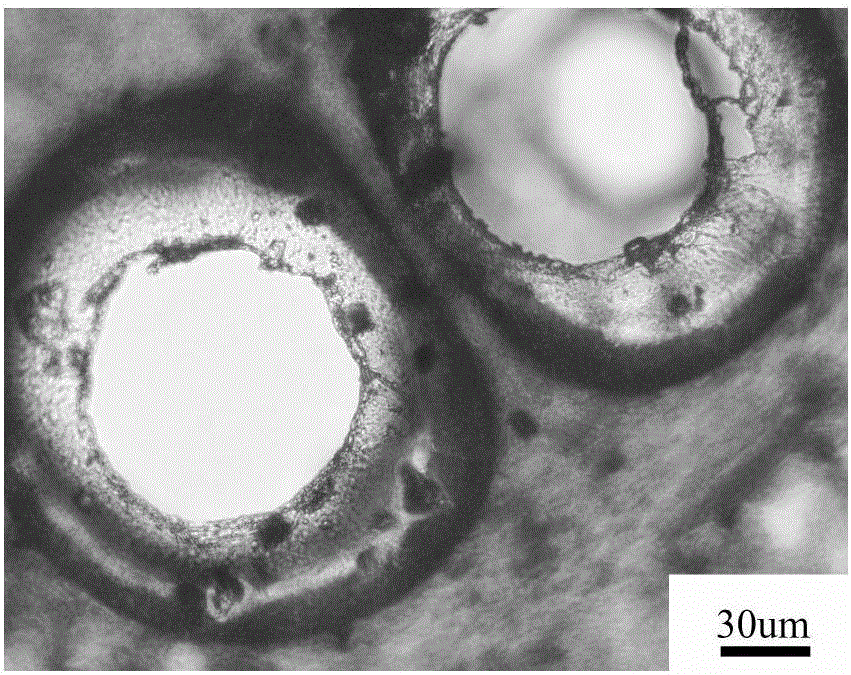

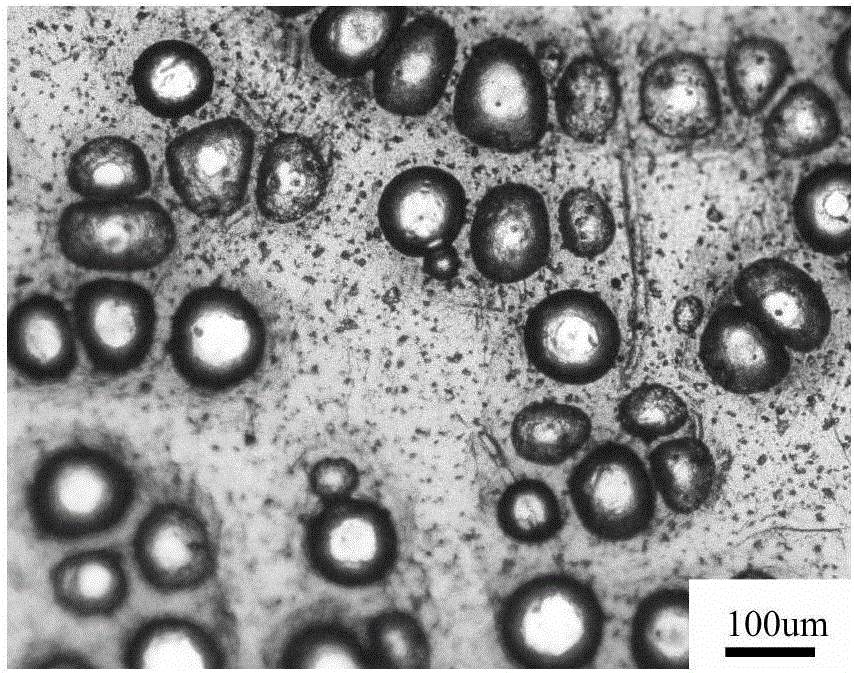

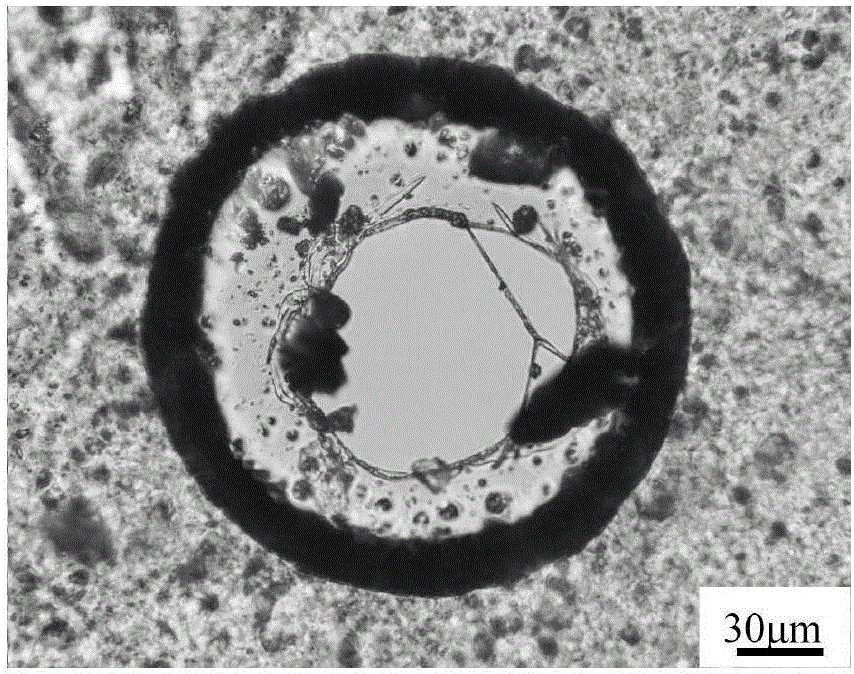

Dry-method preparing method for polyurethane micro-porous film

InactiveCN106823862ASimple processEasy to operateMembranesSemi-permeable membranesFoaming agentFilm applicator

The invention discloses a dry-method preparing method for a polyurethane micro-porous film. The dry-method preparing method includes the following steps that a resin solution and a pore-foaming agent solution are stirred and mixed, and a glue solution is obtained; then release paper is coated with the glue solution with a filming device, drying is carried out for 8 min to 10 min, then the film is peeled, and the polyurethane micro-porous film is obtained. The resin solution is a polyether urethane resin solution; a pore-foaming agent is an AC foaming agent and a catalytic promoter ZnO. The dry-method preparing method is short in technology period, easy to operate and low in production cost, the ventilation performance, the moisture permeable performance and the waterproof performance of the polyurethane micro-porous film are effectively improved, and large-scale production can be achieved.

Owner:HEBEI UNIV OF TECH

Sanitary Sleeve Applicator for Hoses

ActiveUS20180134513A1Reduce the possibilitySuitable protectionFouling preventionFilament handlingFilm applicatorBiomedical engineering

The conceived invention provides both a film applicator and a method for placing a continuous film sleeve around a hose, or a grouping of a plurality of hoses. The sleeve thickness is approximately ½ mil to 20 mils thick, which is suitable for cleanliness protection and reducing the possibility of ripping when the hoses are dragged across a floor.The embodied invention includes a plastic sleeve payout tube, that surrounds and encompasses the hose / hoses. The hoses are routed through the sleeve payout tube when they are hauled into a building to be cleaned. The payout tube stores a compacted length of an enclosing plastic sleeve, and the sleeve pays off as the hoses are dragged into the facility to be cleaned. The initial attachment of the plastic sleeve and hoses is by use of an adhesive tape or an outer clamping strap.

Owner:GORDON GARRETT M

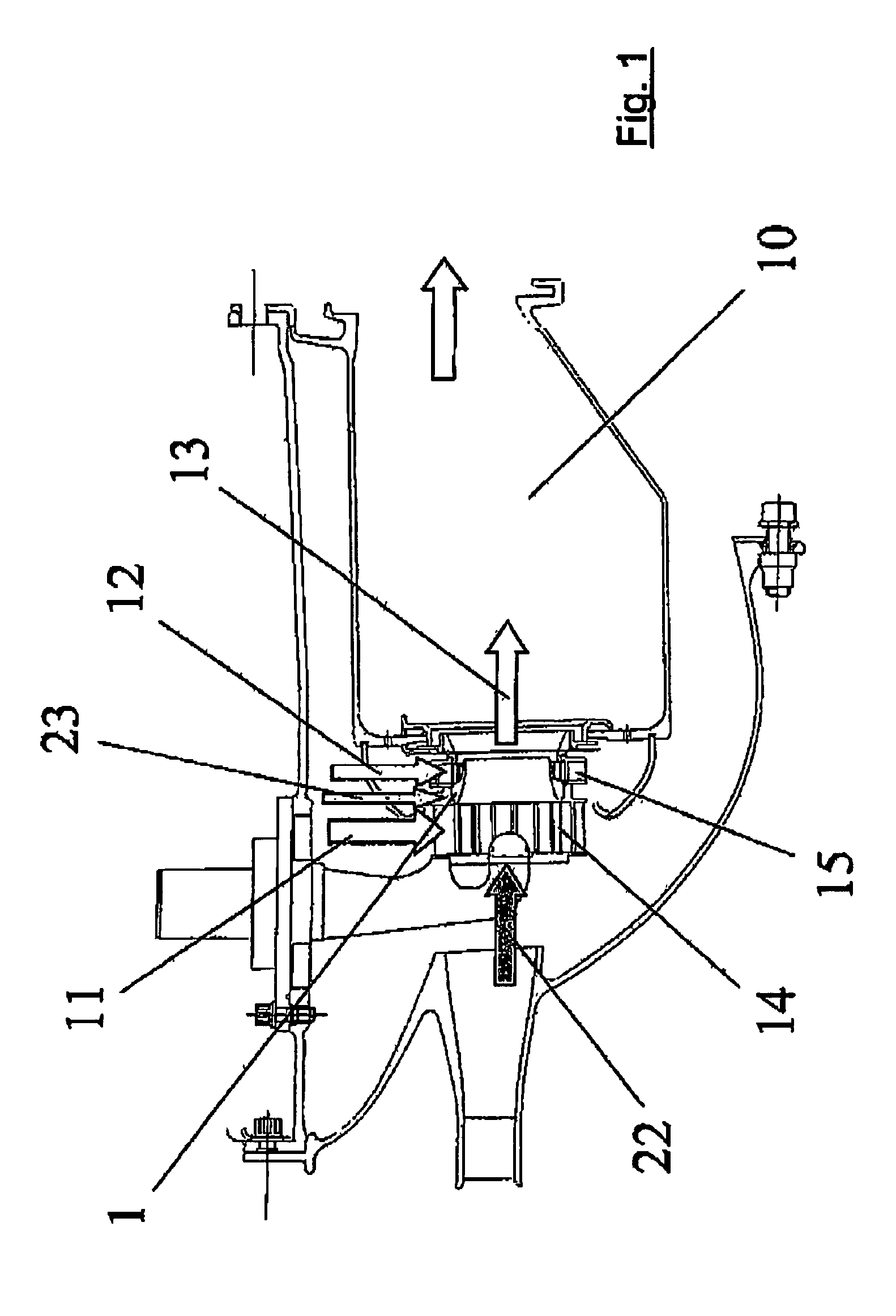

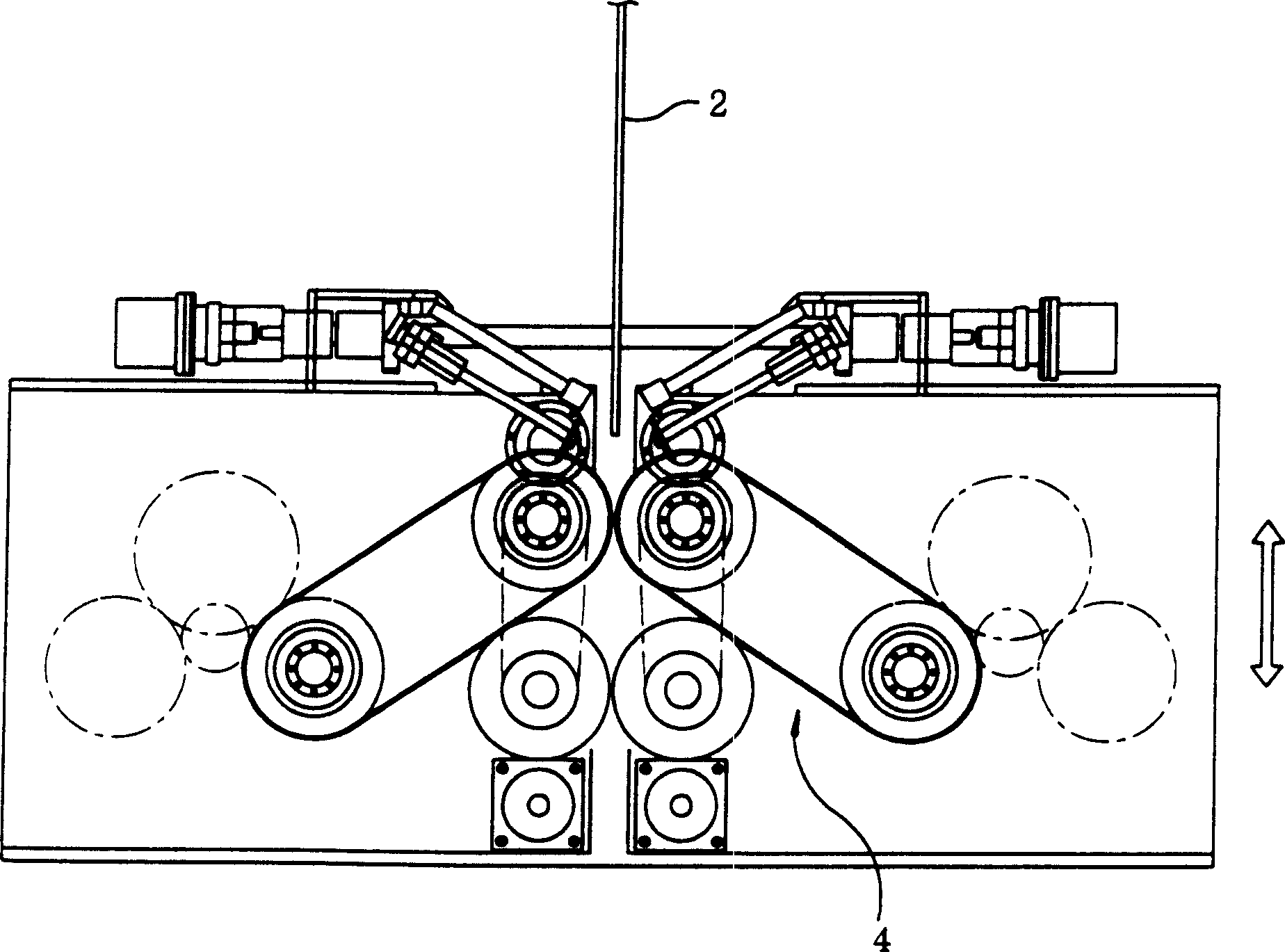

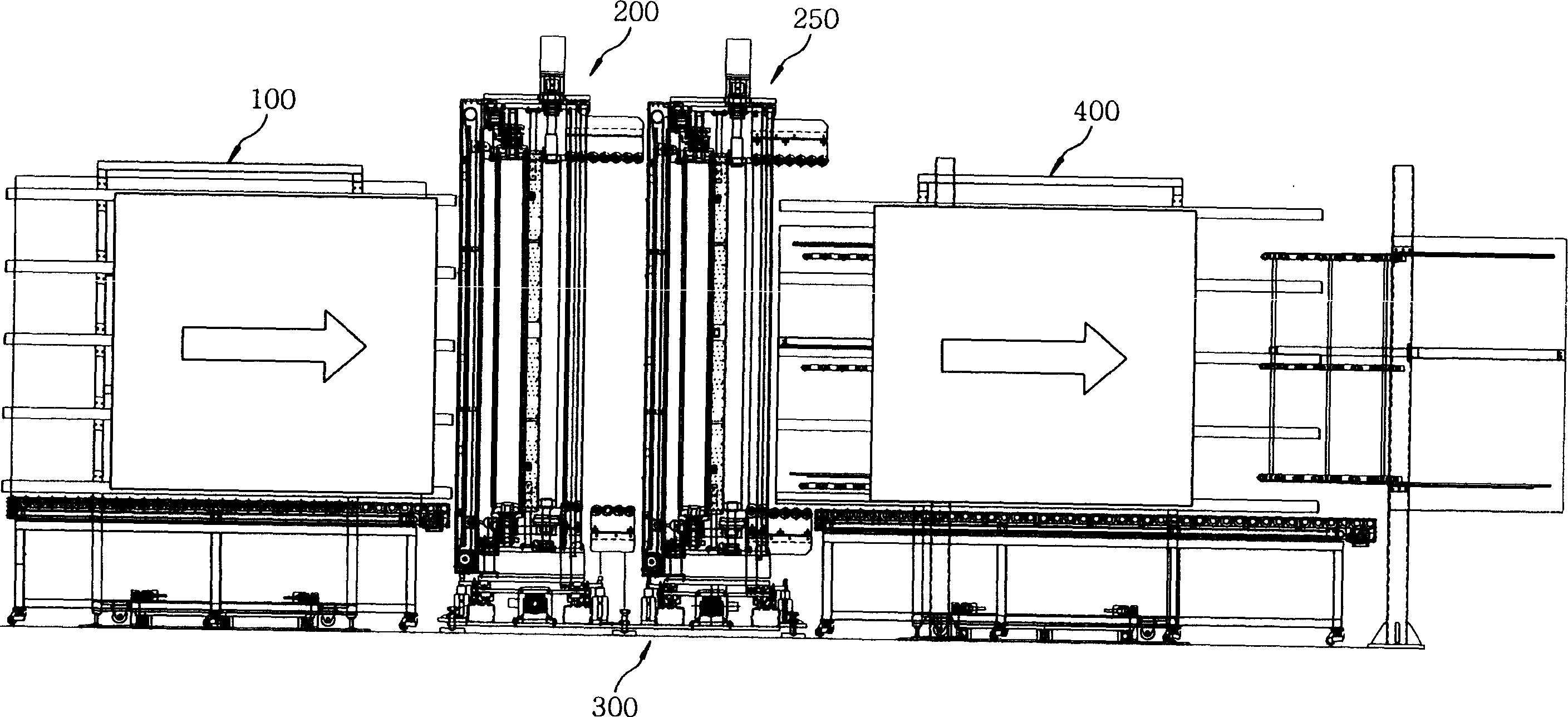

Filming device and method of glass substrate

The invention provides a film coating device and method for a glass substrate. It applies thin films to large glass substrates while effectively utilizing the clean room, minimizing downtime, vibration of the glass substrate, adhesion of foreign matter, etc. Contains: a loading conveyor that floats the glass substrate in a vertical state on both sides without contact; first and second film applicators that are installed vertically to apply a film to both sides of the glass substrate discharged from the above loading conveyor ; The applicator conveying equipment is used to move the first and second film applicators respectively between the coating position and the supply position; the unloading conveyor transports the glass substrate coated with the film on both sides to one direction; and The control mechanism controls the operation of the loading / unloading conveyor, the first and second film applicators, and the applicator conveying equipment.

Owner:SAMSUNG CORNING CO LTD

Production method of high-strength glass for mobile phone screen

InactiveCN108658455AHigh strengthImprove uniformityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsThermal insulationHigh pressure

The invention discloses a production method of high-strength glass for a mobile phone screen, and relates to the technical field of production of outer mobile phone screens. The production method comprises the following steps of: (1) uniformly mixing, heating and melting raw materials for production, calendering a molten solution to a glass plate by a calendering method, (2) cutting the glass plate into a required size, and chamfering the edges, (3) putting the chamfered glass in a cleaning liquid for ultrasonic cleaning, (4) heating the cleaned glass to 400-500 DEG C, performing thermal insulation for 2-3h and then carrying out furnace cooling to a room temperature, (5) heating the annealed glass to 700-720 DEG C again, performing thermal insulation for 160-180s, blowing high-pressure cold air to the glass quickly to cool the glass to the room temperature for 120-130s, and (6) performing filming and package on the glass treated in step (5) through a film applicator, and testing the glass. The production method is simple in technology, and good in operating condition controllability, and the prepared glass is high in strength and rigidity, lower in brittleness, and good in light transmittance and corrosion resistance.

Owner:安徽智胜光学科技有限公司

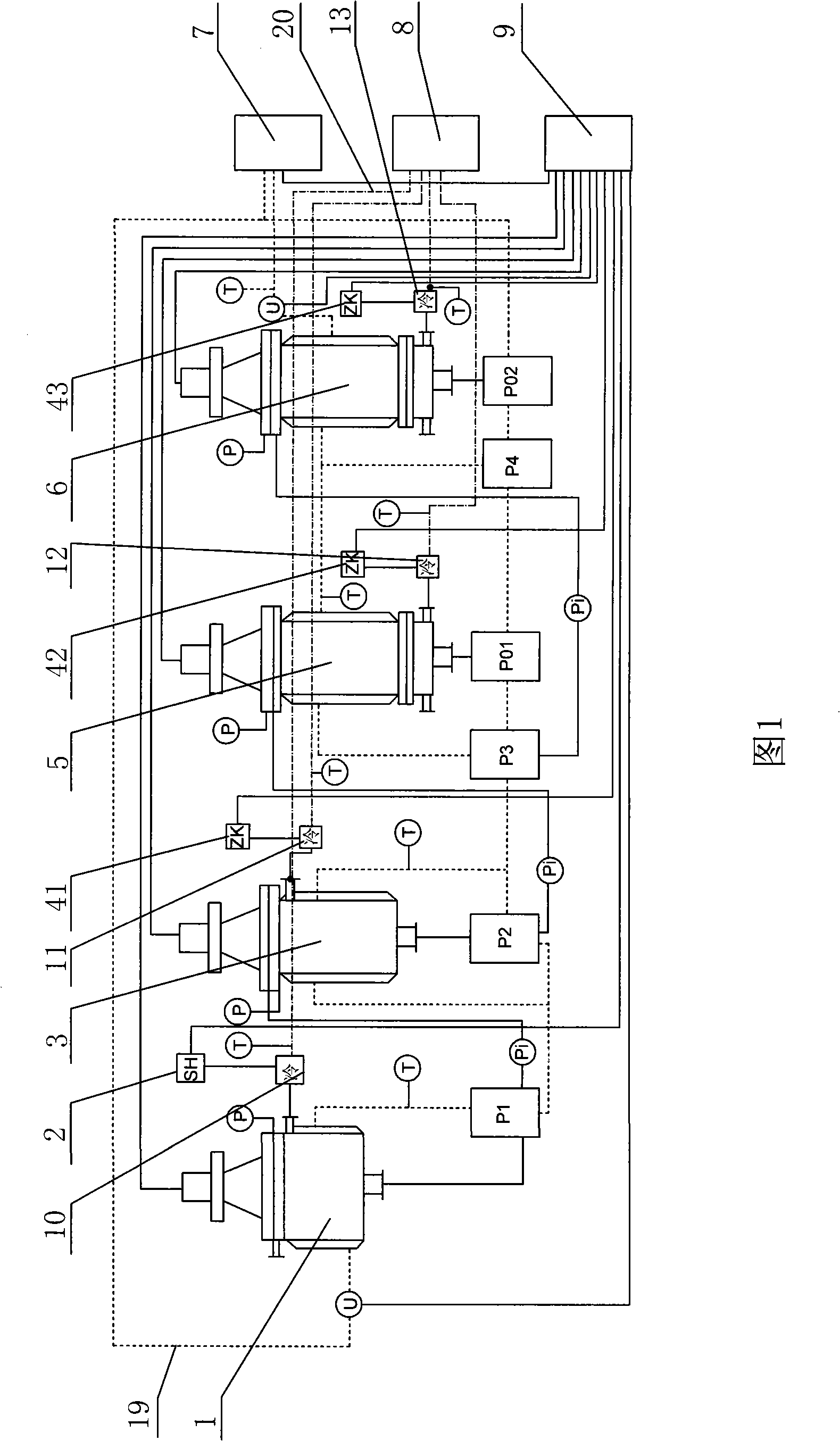

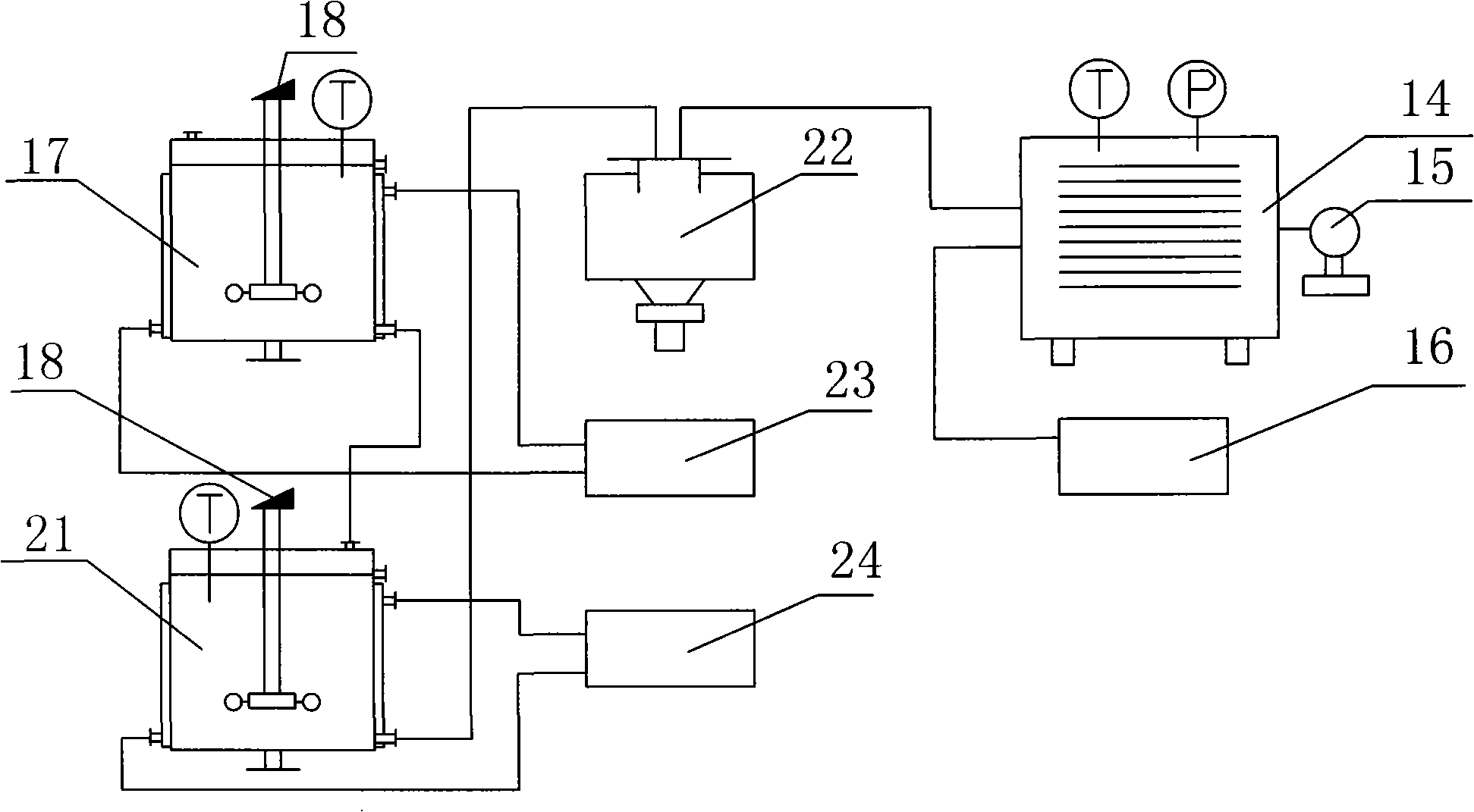

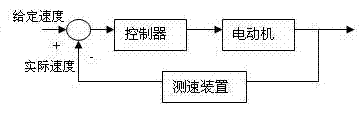

Automatic constant-linear-speed control system of film applicator

InactiveCN102560936AUniform longitudinal thicknessReduce labor intensityTextile treatment machine partsNumerical controlFrequency changerWire speed

Disclosed is an automatic constant-linear-speed control system of a film applicator. A motor is connected with a scroll of a cloth reeling roll, a cloth unreeling roll is mounted in front of the cloth reeling roll, an auxiliary roll is mounted between the cloth unreeling roll and a film applicator roll, a speed detection roll is mounted above the auxiliary roll, a speed detecting device is mounted on the speed detecting roll, and the speed detecting device is connected with the motor to form closed-loop control through a frequency converter after the speed detected by the speed detecting device is compared to a given speed. The motor connected with the scroll is controlled in a frequency-variable speed regulation manner, , a closed-loop control system for film applying speed is realized under PI (proportional integral) control by comparing measuring signals to set signals, speed accuracy is controlled within + / -0.5%, the longitudinal thickness of the film is more uniform, and labor intensity of operators is alleviated.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Heat-conducting insulated pressure sensitive tape and preparation method thereof

ActiveCN102746799BWith thermal insulationSensitive to pressureNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingAging resistance

The invention relates to a heat-conducting insulated pressure sensitive tape and a preparation method of the tape. The principal technical features are as follows: the heat-conducting insulated pressure sensitive tape comprises a heat-conducting insulated pressure sensitive tape without a base material and a heat-conducting insulated pressure sensitive tape with the base material; and the preparation method comprises the following steps: (1) preparing a polyacrylate adhesive; (2) preparing modified heat-conducting filler dispersion liquid; and (3) mixing the polyacrylate adhesive prepared in the step (1) with the modified heat-conducting filler dispersion liquid prepared in the step (2), coating wet glues with different thicknesses onto a release protection layer by a film coater, and drying in a gradually heating way to prepare the heat-conducting insulated pressure sensitive tape without the base material; or bonding with the both faces of the base material to prepare the heat-conducting insulated pressure sensitive tape with the base material. The heat-conducting insulated pressure sensitive tape is high in heat conductivity, good in bonding performance and excellent in ageing resistance, has excellent die cutting processability, and can be widely applied to bonding of heat radiating fins and heating devices such as a CPU (central processing unit), a power tube, a module power supply and the like, as well as bonding of screens, frames and injection molded boards in electronic products such as a mobile phone, an LED (light emitting diode) device and the like.

Owner:TIANJIN BOYUAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com