Patents

Literature

1608results about How to "Strong weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

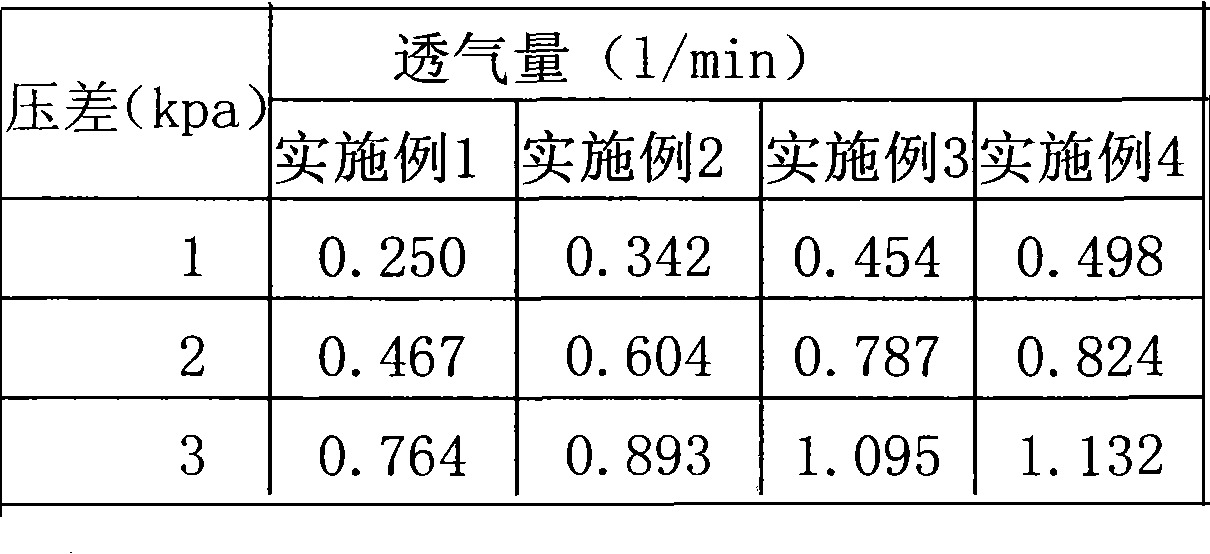

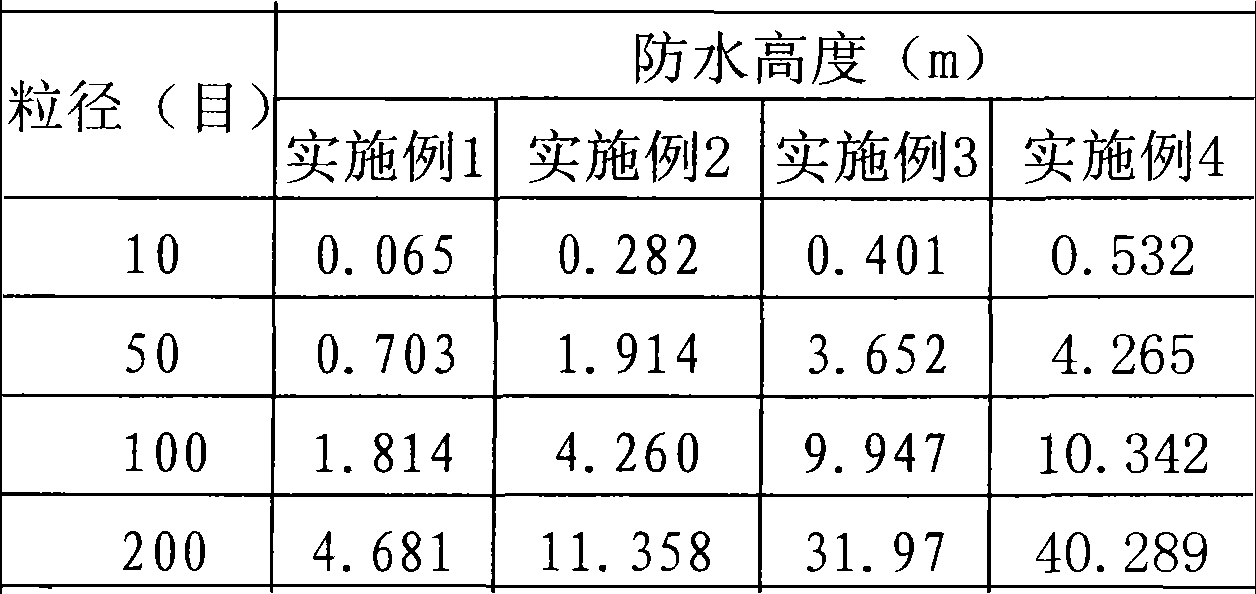

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

Fluororesin radiating paint and preparation method thereof

ActiveCN103131274AReduce thermal contact resistanceHigh thermal conductivityCoatingsCarbon nanotubeElectron transfer

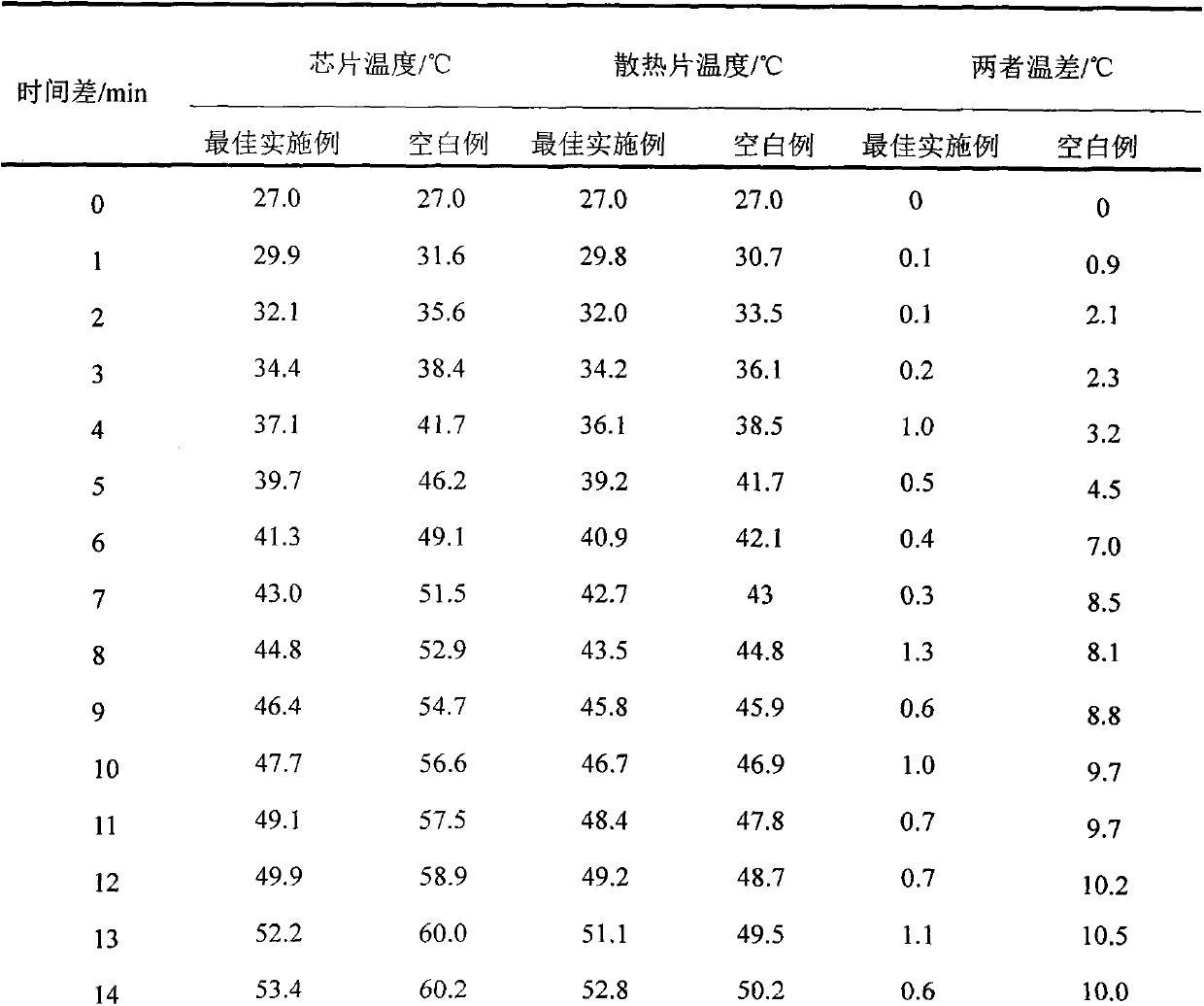

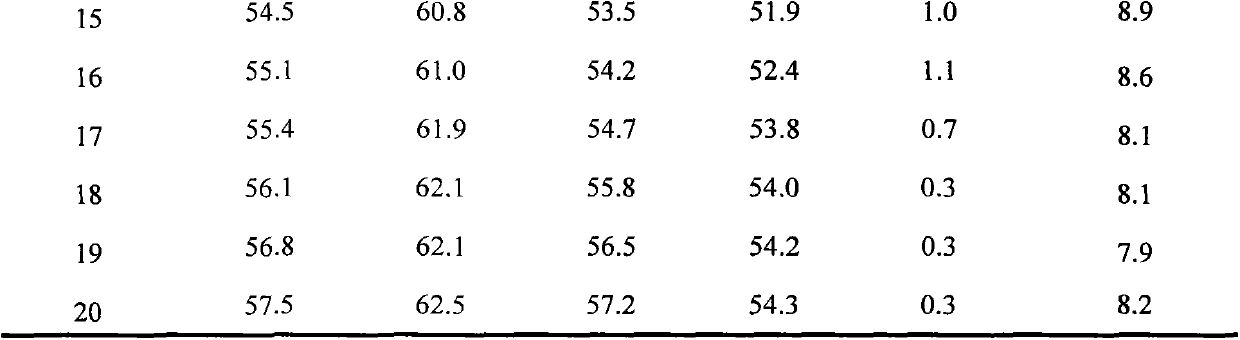

The invention discloses fluororesin radiating paint and a preparation method thereof. The paint mainly comprises an electron transfer type organic compound, graphene, a carbon nanotube, titanium white, other additives and fluororesin, wherein the fluororesin is a paint brand having the highest comprehensive property at present; the electron transfer type organic compound can greatly enhance the thermal radiation rate of the paint; the graphene and the carbon nanotube can further accelerate thermal conduction; and the electron transfer type organic compound, the carbon nanotube and the graphene finally form a full three-dimensional network distribution of granules (electron transfer type organic compound), wires (carbon nanotube) and planes (graphene) in a fluid. The fluororesin radiating paint disclosed by the invention has high thermal radiation rate, high thermal conductivity and low thermal resistance, can realize radiation cooling, and simultaneously has the effects of self cleaning, acid / alkali resistance and super high insulativity, thereby having high practical value.

Owner:明朔(北京)电子科技有限公司

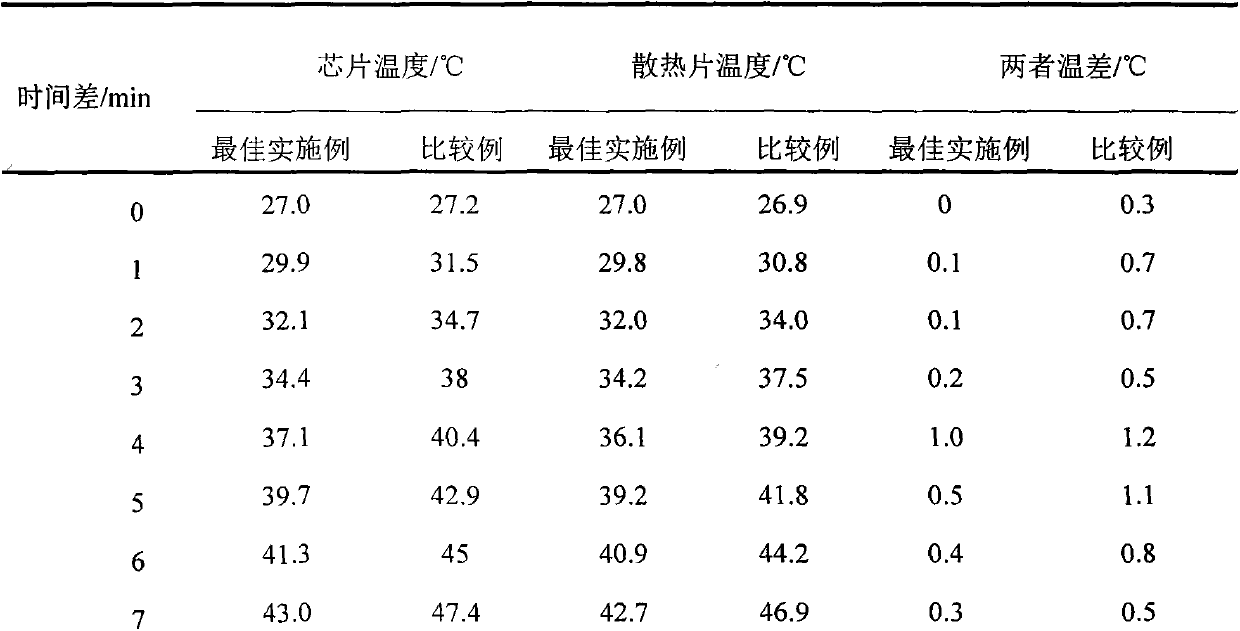

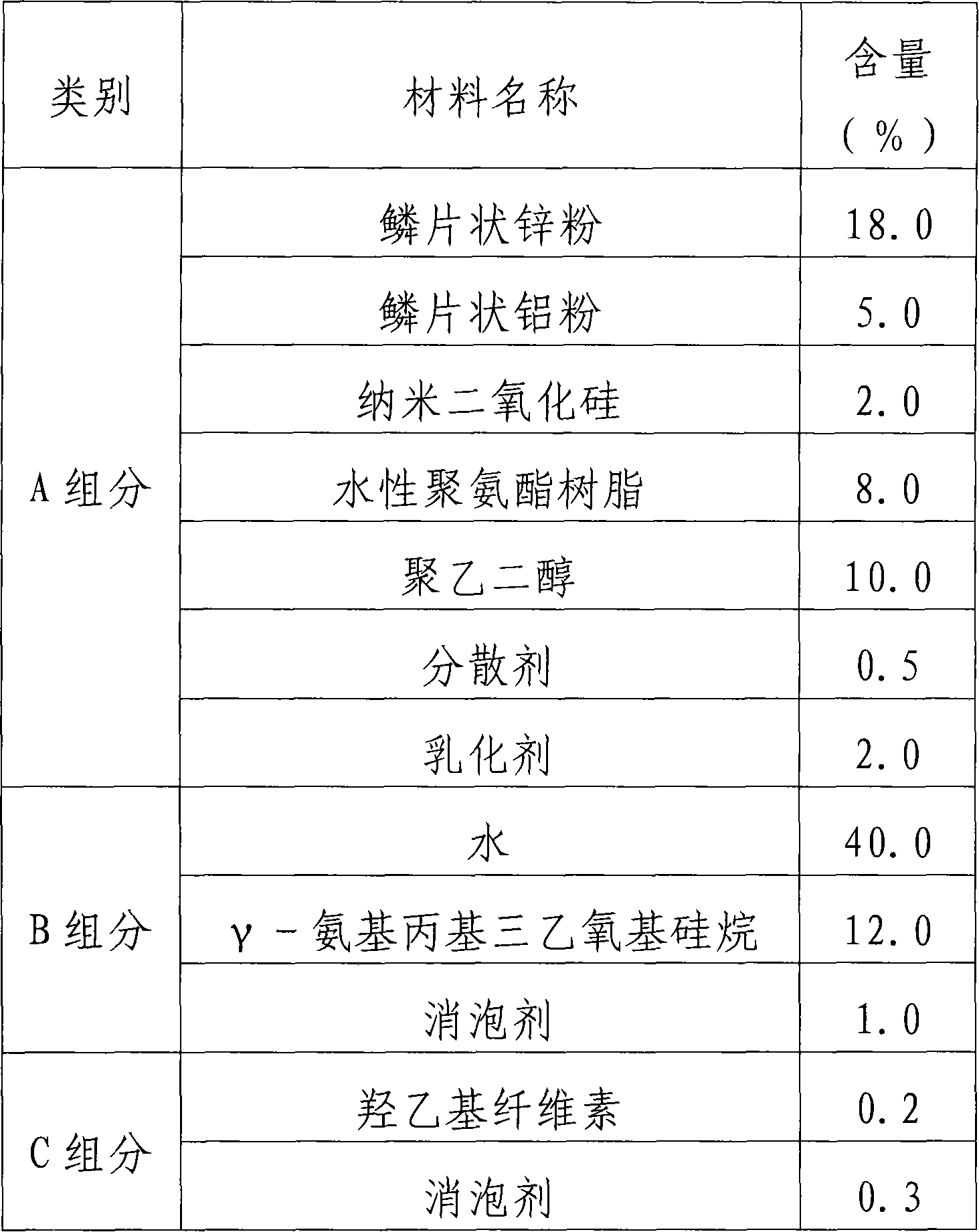

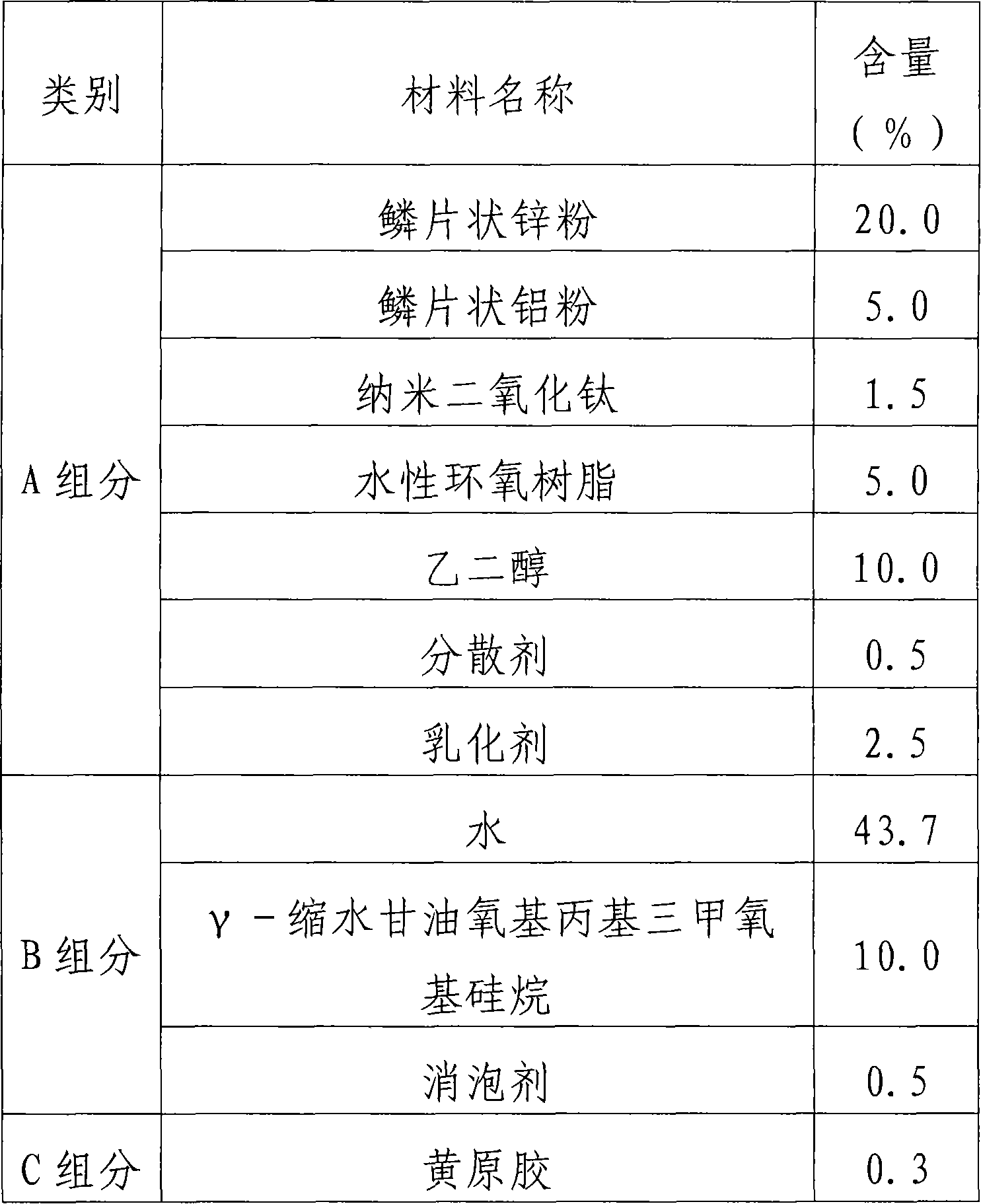

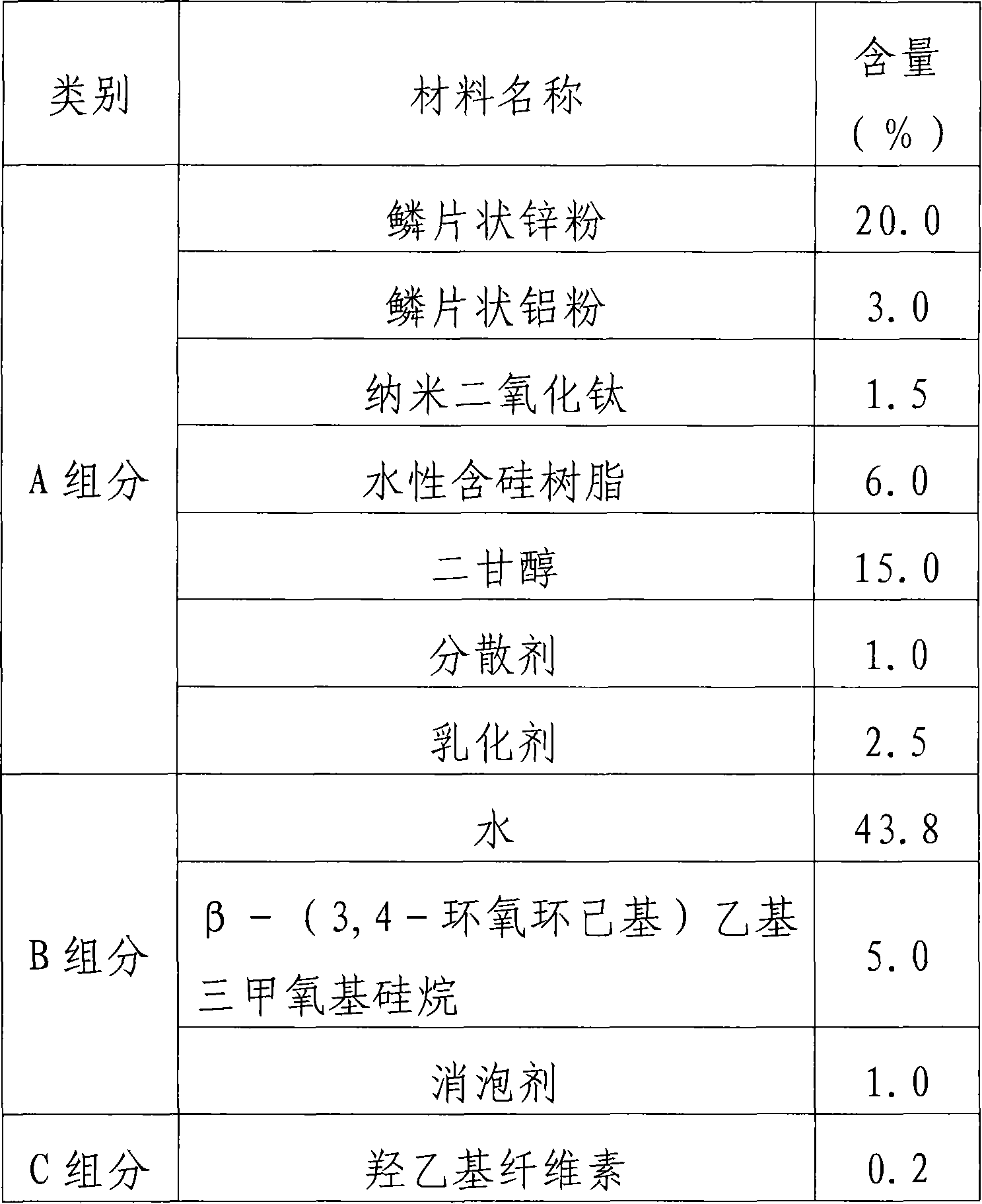

Hydrophilic nano zinc based composite coating

InactiveCN101613559AStrong weather resistanceNo pollution in the processAnti-corrosive paintsPolyurea/polyurethane coatingsSilanesSolvent

The invention belongs to the technical field of chemical engineering coatings and particularly relates to a hydrophilic nano zinc based composite coating used for preventing corrosion on the surfaces of the metal parts. The coating comprises an emulsifier, a dispersant, an antifoaming agent, scaly metallic powder, nano oxides, a silane coupler, an alcohol-type solvent, a high-molecule organic material, a thickener and 30.0 to 60.0 percent of water serving as a disperse medium. The coating can be coated by spraying, brushing, soaking and soaking-centrifugal coating and other methods, and the coating can be formed by being roasted at a temperature of about 200 DEG C for 20 minutes. Neutral salt spray corrosion resistant tests show that the neutral salt spray corrosion resistant time is more than 800h, the binding force is proved to be above level 4 (by an adhesive band test). The coating has the advantages of environmental pollution prevention, excellent metallic corrosion resistant property, economy and practicability and convenient use; and moreover, the coating can be widely used for the corrosion resistant treatment of the surface of metal parts made of iron, aluminum, copper and magnesium alloy and the like, particularly the corrosion resistant treatment of metal parts with complex geometric shapes.

Owner:YUNNAN GREAT IND DEV

Plant extract and microbe composite deodorant

ActiveCN105536509AReduce generationGrowth inhibitionGas treatmentDispersed particle separationMicroorganismDeodorant

The invention relates to the field of deodorization, and especially relates to a plant extract and microbe composite deodorant. According to the invention, a plant extract and a microbial fermentation broth are mixed according to a ratio of 1:3; the mixture is placed in plastic buckets; and sealed anaerobic fermentation is carried out for 5-9 days, such that the composite deodorant is obtained. The microbial fermentation broth is obtained through the following steps: saccharomycetes, lactobacillus, bacillus subtilis, acetobacter pasteurianus and photosynthetic bacteria are inoculated according to the ratio of 1-4:2-6:5-25:1-4:1-2, and mixed fermentation is carried out; and after 60-84h of aerobic fermentation, the microbial fermentation broth is obtained. The invention aims at providing the plant extract and microbe composite deodorant. Deodorizing is realized with the combination of the plant extract and microbes. With the deodorant, fast and continuous deodorization can be realized; production cost is reduced; and a deodorization effect is good. With the deodorant, deodorization can be achieved fundamentally.

Owner:HUNAN PUTAIER ENVIRONMENTAL CO LTD

Clay-based compound sand consolidating material

ActiveCN102229804APermeableReduce evaporationOrganic fertilisersSoil conditioning compositionsSoil scienceEngineering

The invention discloses a clay-based compound sand consolidating material and belongs to the technical field of sand prevention and consolidation. The clay-based compound sand consolidating material is made of clay, sodium silicate, lewis acid, organic polymer and the like according to a certain ratio. The material is added with water to form solution at certain concentration by adding water, andthe solution is sprayed onto the surface of sand and naturally dries in an open environment to form a consolidated skin; or the clay and sand are uniformly mixed according to a certain ratio and pilled in grids, then solution prepared from the sodium silicate, lewis acid, organic polymer and water is sprayed onto the surface of the grids and naturally dries in an open environment to form consolidated skin, and thus, sand preventing and consolidating clay grids are formed. The consolidated skin of the sand consolidating material disclosed by the invention has high pressure strength, high waterpermeability, high weather resistance, and good sand consolidating effect; and the raw materials are readily available, the sand consolidation process is simple, the cost is low and the clay-based compound sand consolidating material is suitable to be promoted in a large area in desert regions.

Owner:NORTHWEST NORMAL UNIVERSITY

Water-based expandable fireproof steel structure coating and preparation method

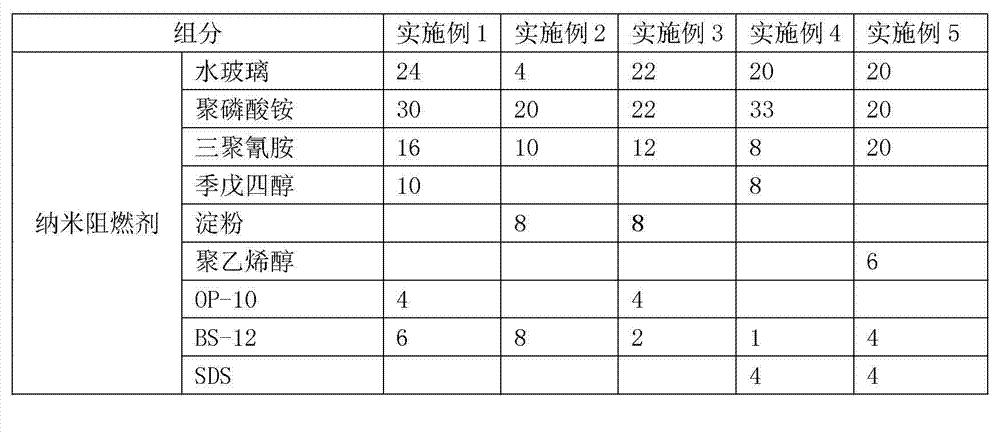

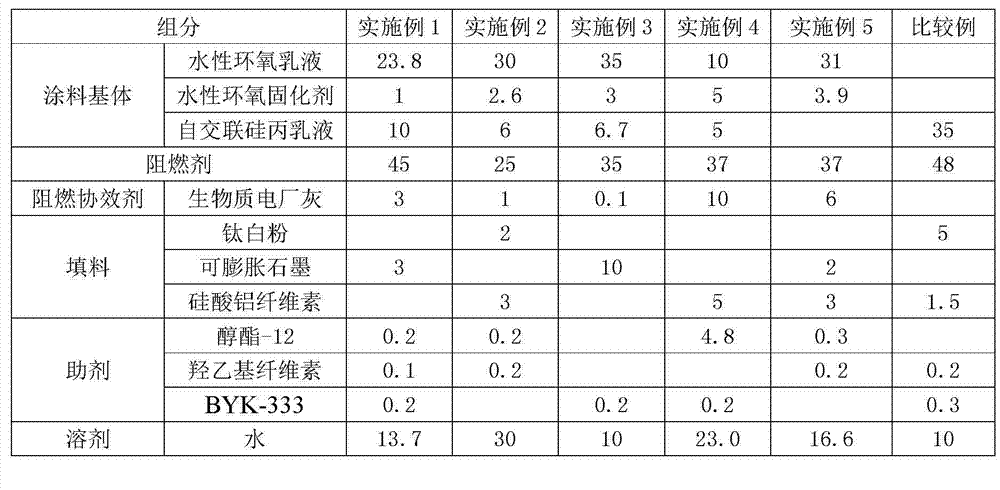

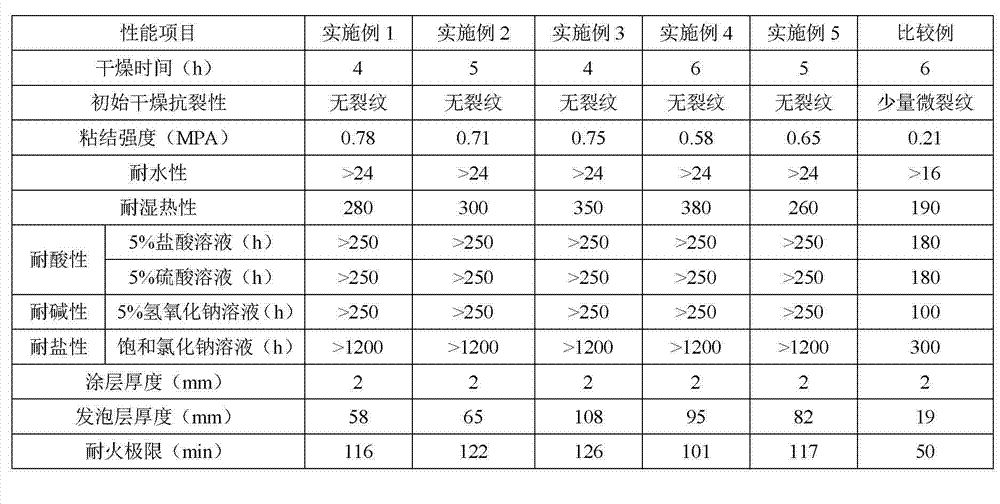

ActiveCN103045037AStrong weather resistanceImprove dispersion performanceFireproof paintsAcid polymer adhesivesEmulsionBiomass

The invention relates to a water-based expandable fireproof steel structure coating and a preparation method thereof. The water-based expandable fireproof steel structure coating comprises the following components in mass percentage: 20-45% of coating matrix, 25-45% of nano-flame retardant, 0.1-10% of flame-retardant synergist, 1-10% of filler, 0.2-5% of auxiliary agent and 5-30% of water. The preparation method of the water-based expandable fireproof steel structure coating comprises the following steps: firstly, preparing the nano-flame retardant; secondly, adding a water-based epoxy emulsion, a water-based epoxy curing agent and a self-crosslinking silicone acrylic emulsion in the coating matrix into a stirring barrel, and stirring uniformly; thirdly, adding the nano-flame retardant, the flame-retardant synergist, the filler, the auxiliary agent and water, stirring for 10-30 minutes, adding a mixture into a ball grinding mil, grinding, checking whether the fineness of the coating meets a requirement, and if so, stopping grinding; fourthly, filtering the mixture with a filter screen, and separating grinding balls from the coating; and finally, filling the coating into a specified jar, discharging and barreling. The water-based expandable fireproof steel structure coating has a high expansion rate, has the fire endurance as long as 120 minutes and the coating thickens of 2 mm; and the water-based expandable fireproof steel structure coating is simple in preparation method, disposes solid wastes in the field of biomass power generation, is low in cost and wide in application and has significant economic and social benefits.

Owner:ZHONGYING CHANGJIANG INTERNATIONAL NEW ENERGY INVESTMENT CO LTD

Water super-thin steel structure fire-proof paint and preparation method thereof

InactiveCN101125980AHigh strengthImprove fire performanceFireproof paintsPentaerythritolDiammonium phosphate

The invention relates to a waterborne super thin steel structure fireproof coating and a preparation method Which is evidently different from the solvent-typed expansion foam fireproof coating, the invention solves the problems of environmental pollution, resource waste and high cost in prior solvent-typed super thin steel structure fireproof coating. The invention takes water as solvent and comprises the components with certain weight portions: water of 5-25 weight portions, waterborne resin or mixed waterborne resin of 10-30 weight portions, waterborne expansion additive of 25-50 weight portions, pentaerythritol or dipentaerythritol or starch of 5-15 weight portions, one or two components among urea, melamine and dicyano diammonium with 6-15 weight portions, ammonium dihydrogen phosphate, ammonium polyphoste or diammonium phosphate of 15-30 weight portions, expansion regulator of 3-18 weight portions, titanium dioxide of 3-12 weight portions, dispersion agent of 0.1-1.0 weight portions.

Owner:应急管理部四川消防研究所

Sand texture type polyester/epoxy powder coating and preparation method thereof

InactiveCN103160192AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyPollution

The invention discloses a sand texture type polyester / epoxy powder coating and a preparation method thereof. The sand texture type polyester / epoxy powder coating comprises the following raw materials, by weight, 350-400 parts of polyester resin (P5040), 240-280 parts of epoxy resin (E-12), 100-150 parts of extinction barium sulfate, 40-60 parts of spherical silica powder, 8-12 parts of modified polyethylene wax powder, 10-15 parts of organic coated titanium dioxide, 5-10 parts of sand texture agent (SWMBX-30), 4-6 parts of benzoin, 5-8 parts of 2-phenyl imidazoline, 4-6 parts of 2-methylimidazole, 5-10 parts of ferrite yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The prepared powder coating has the advantages of being high in hardness, high in intensity, high in abrasion resistance, good in heat resistance, good in ageing resistance, short in solidifying time, environment-friendly, free of pollution and the like. The solidified coating produces a texture effect of the sand texture, the sand texture is meticulous and clear, distribution is even, visual comfort is provided for people, and combination properties of the coating are good.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Novel acrylic acid modified alkyd resin and method for preparing same

ActiveCN102993424AImprove drynessGood weather resistancePolyester coatingsLiquid mediumAging resistance

The invention aims to provide an acrylic acid modified alkyd resin which is improved in hardness, dryness, abrasion resistance and aging resistance and also maintains particular flexibility, pigment wettability and the like. Simultaneously, the acrylic acid modified alkyd resin provided by the invention solves the problem that the common acrylic acid modified alkyd resin in the market is poor in acid and alkali resistance. The acrylic acid modified alkyd resin provided by the invention is characterized that a paint film is free of bubbling, rusting, crazing and falling in 48 hours when being measured through a liquid medium resistance experiment according to GB / T 9274-1988; and the acrylic acid modified alkyd resin is obviously superior to the traditional soybean oil alkyd resin and the common acrylic acid modified alkyd resin.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

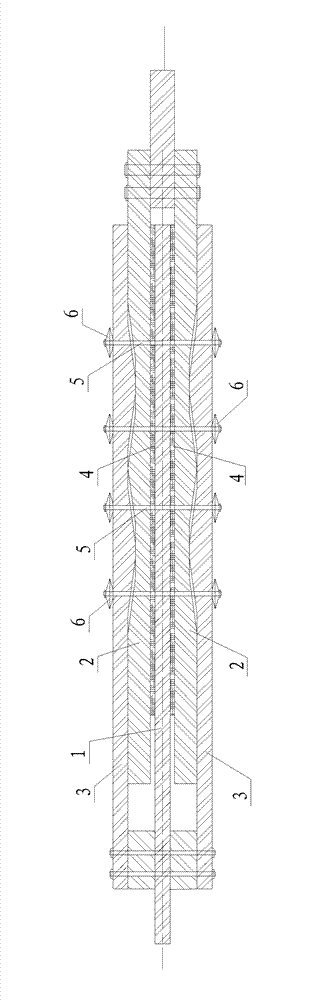

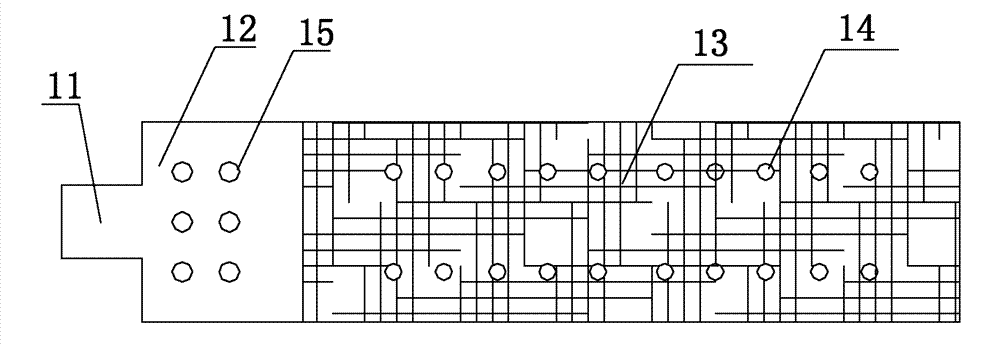

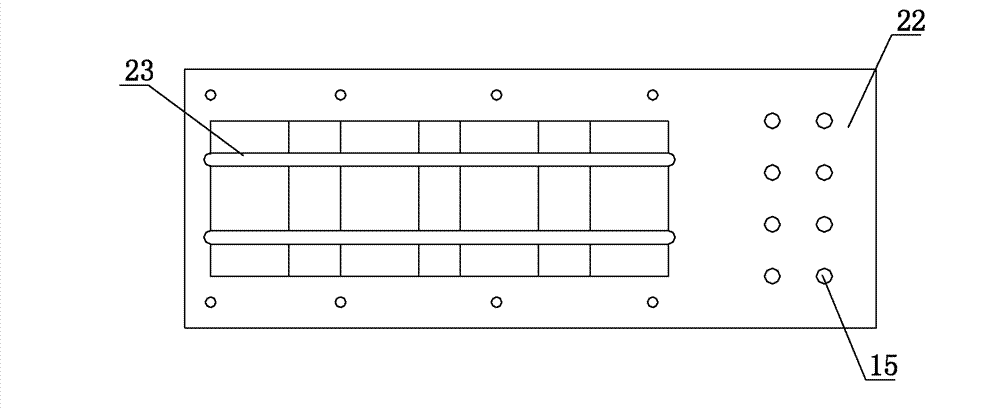

Variable-friction damper

The invention discloses a variable-friction damper which comprises a plurality of steel plates stacked or sleeved together. The middle portions of at least one pair of adjacent steel plates are in concave-convex surface contact, every two remaining adjacent steel plates are in plane contact, friction materials are adhered between other steel plates, the other surface of each steel plate with one surface being a concave surface or a convex surface is a plane, the steel plates arranged at intervals form a group of steel plate groups, a first steel plate group and the friction materials adhered to the first steel plate group are provided with at least one group of corresponding bolt holes, a second steel plate group and the friction materials adhered to the second steel plate group are provided with strip-shaped sliding grooves corresponding to the bolt holes along the steel plate length direction, and bolts enabling the steel plates and the friction materials to be connected together penetrate into each group of bolt holes respectively. Linear damping is provided in a friction mode by means of changes of positive pressure, and the variable-friction damper has good damping performance.

Owner:CABR TECH CO LTD

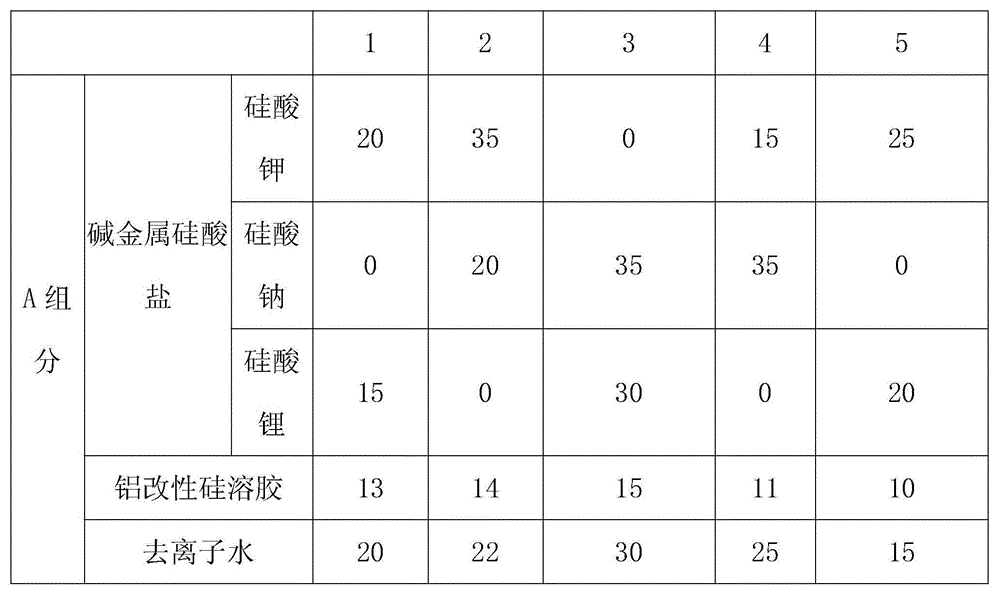

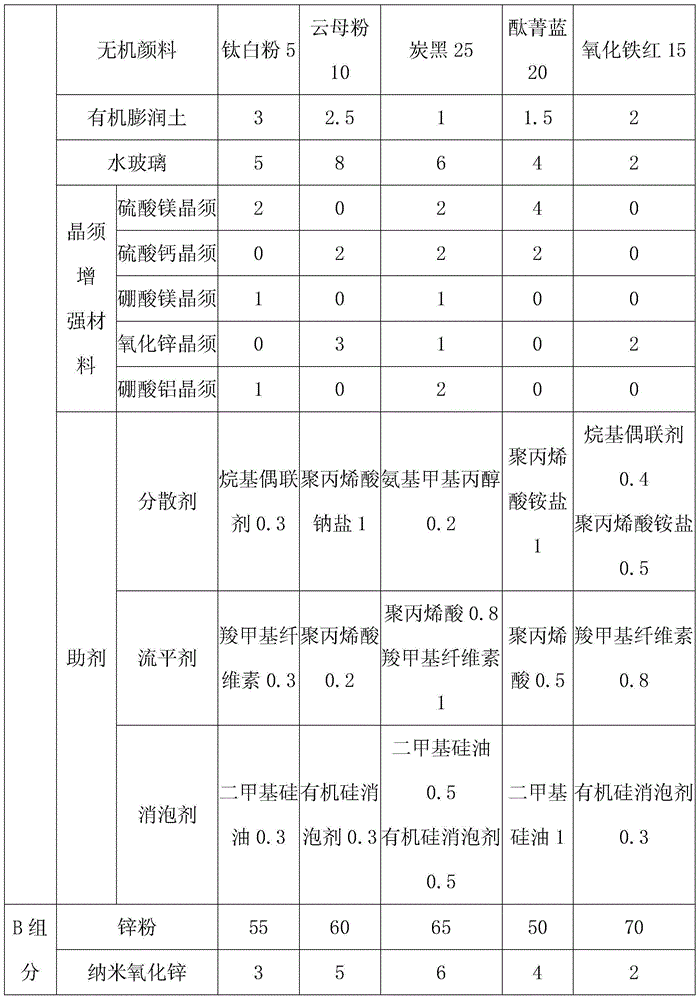

Aqueous inorganic zinc-rich prime coat and preparation method thereof

InactiveCN105131665AImprove anti-corrosion performanceStrong adhesionAlkali metal silicate coatingsAnti-corrosive paintsSodium BentoniteInorganic pigments

The present invention relates to an aqueous inorganic zinc-rich prime coat, which comprises a component A and a component B, wherein the component A comprises 35-65 parts of an alkali metal silicate, 10-15 parts of an aluminum modified silica sol, 15-30 parts of deionized water, 5-25 parts of an inorganic pigment, 1-3 parts of organic bentonite, 2-8 parts of water glass, 2-8 parts of a crystal whisker reinforced material and 1-3 parts of an auxiliary agent, and the component B comprises 50-70 parts of zinc powder, 2-6 parts of nanometer zinc oxide, 1-3 parts of nanometer titanium dioxide, 2-6 parts of composite iron-titanium powder and 2-7 parts of a curing agent. The aqueous inorganic zinc-rich prime coat of the present invention has characteristics of chemical corrosion resistance, high temperature resistance, low temperature resistance, strong adhesion and strong impact resistance.

Owner:YIXING JUREN PAINT

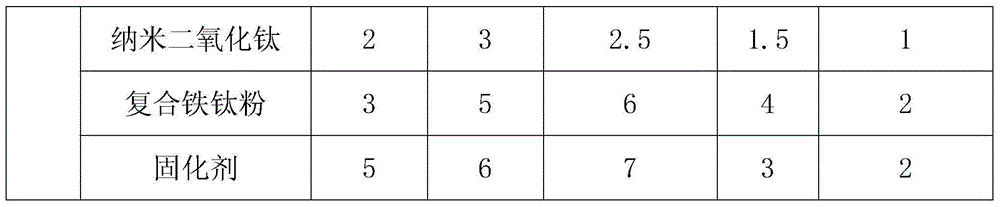

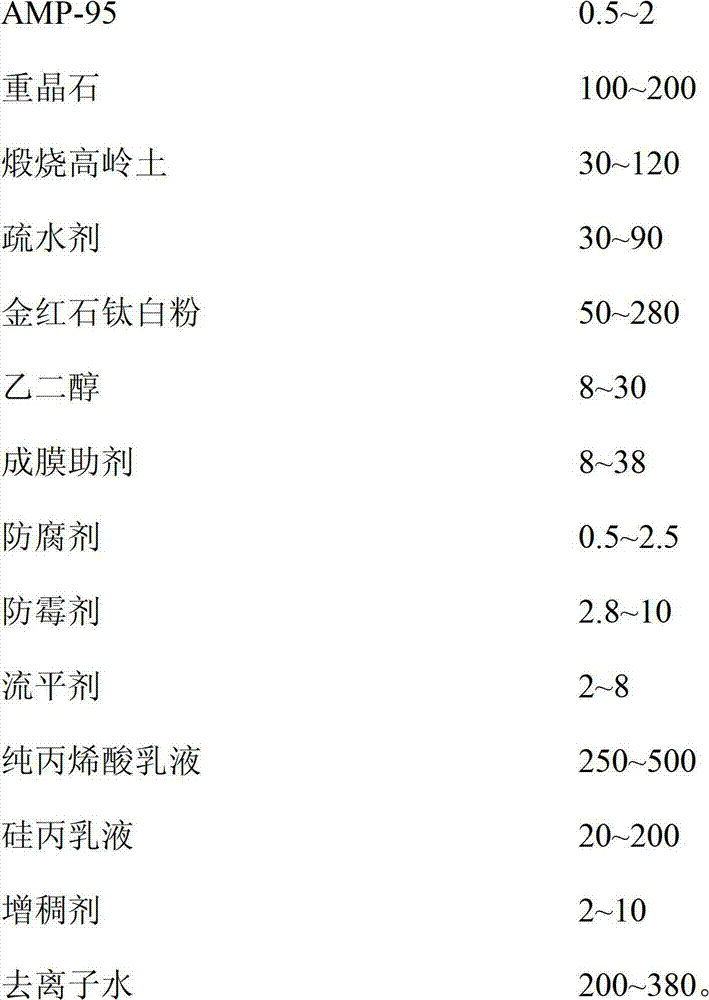

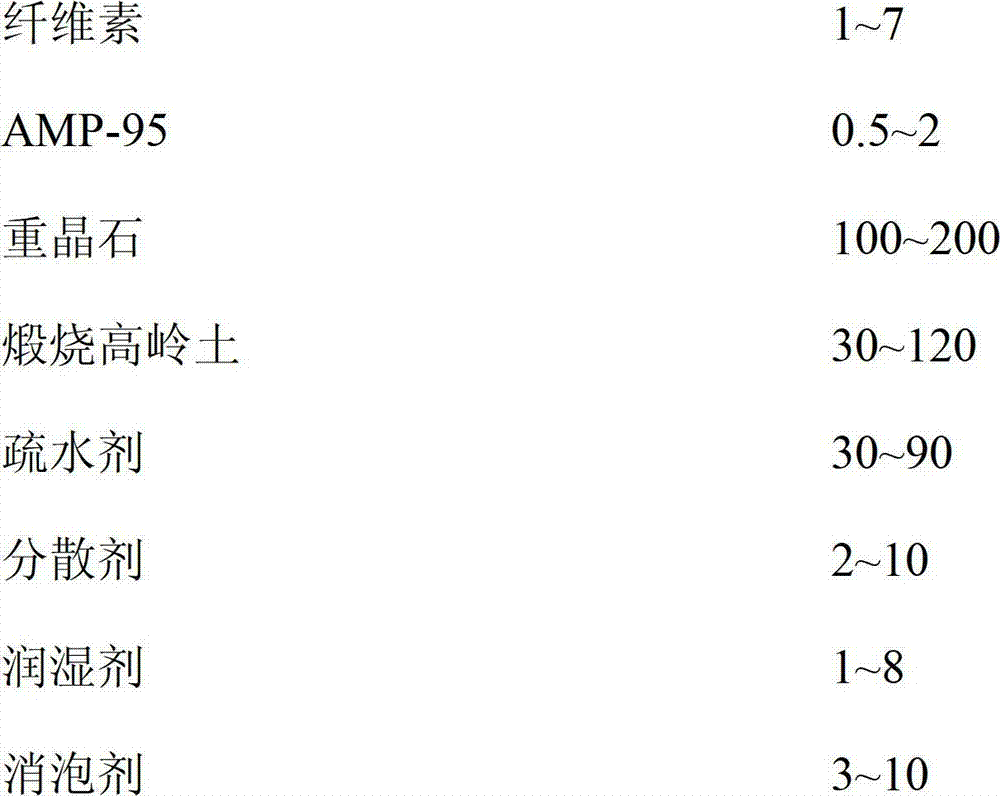

Weather-resistant exterior wall paint and preparation method thereof

InactiveCN102850878AImproves UV resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesCelluloseMoisture resistance

The invention relates to a weather-resistant exterior wall paint which comprises, by weight, 1 to 7 parts of cellulose, 0.5 to 2 parts of AMP-95, 100 to 200 parts of barite, 30 to 120 parts of calcined kaolin, 30 to 90 parts of a hydrophobic agent, 50 to 280 parts of rutile titanium dioxide, 8 to 30 parts of glycol, 8 to 38 parts of a film forming auxiliary agent, 0.5 to 2.5 parts of an antiseptic, 2.8 to 10 parts of a mildew inhibitor, 2 to 8 parts of a leveling agent, 250 to 500 parts of pure acrylic acid emulsion, 20 to 200 parts of silicone acrylic emulsion, 2 to 10 parts of a thickening agent and 200 to 380 parts of deionized water. The weather-resistant exterior wall paint provided by the invention can resist ultraviolet rays in the environment, overcomes the problems of fading and gloss loss of a coating, prolongs the service life of the coating and has good anti-fouling performance, rub resistance, chalking resistance, weather resistance, mildew resistance and moisture resistance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and preparation method for same

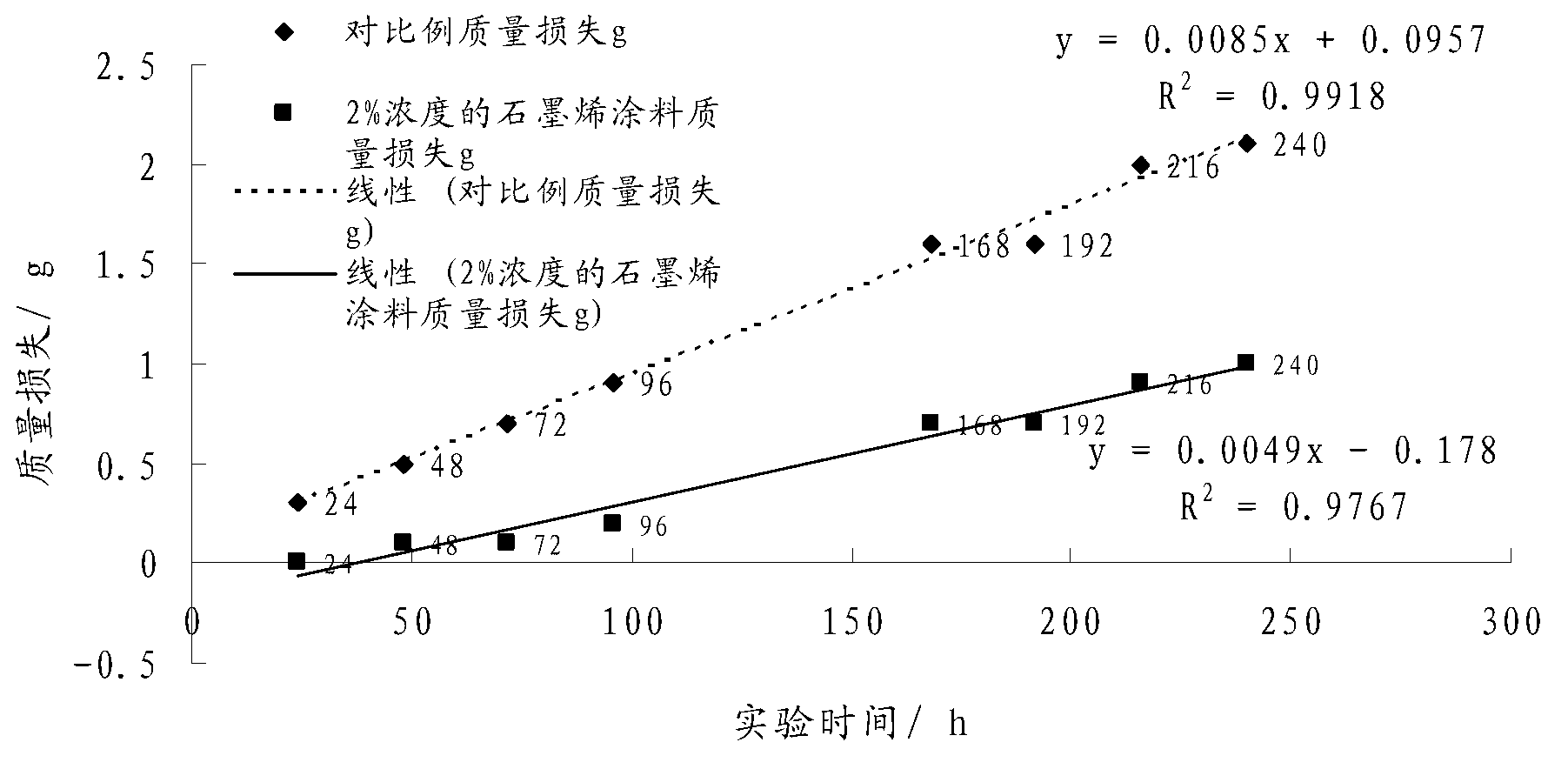

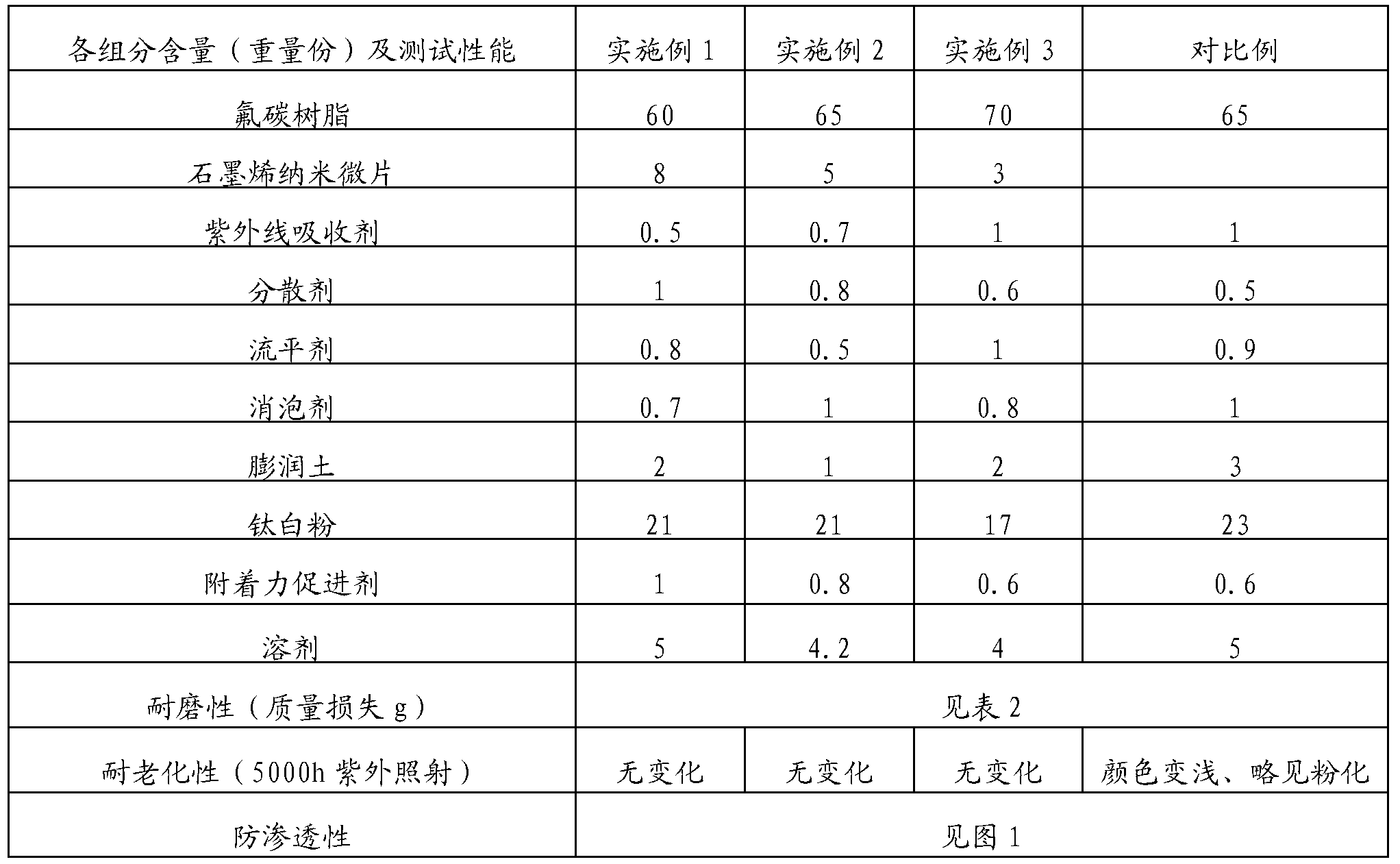

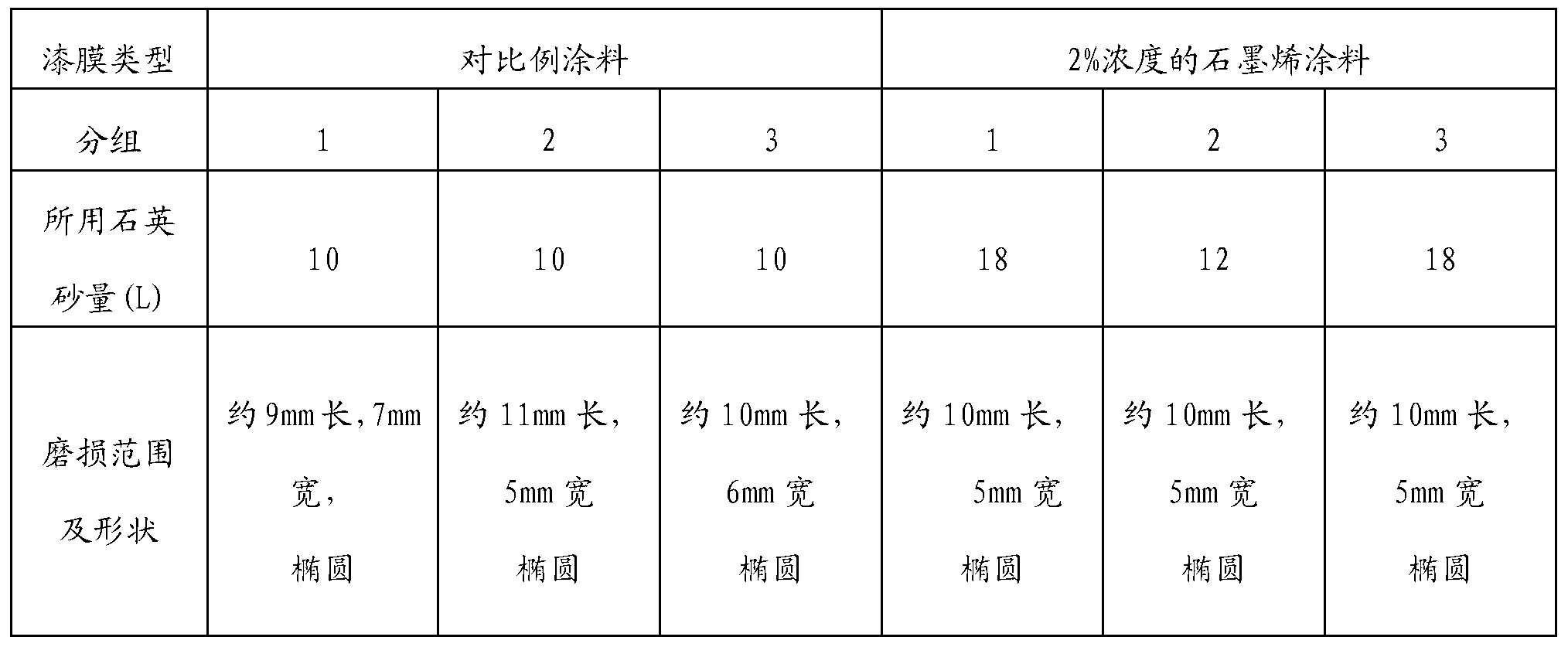

The invention provides a novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and a preparation method for the same. The novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint is composed of an agent A and an agent B, wherein the agent A is composed of the following components in percentage by weight: 60-70% of fluorocarbon resin, 1-8% of graphene nanometre micro-sheets, 0-2% of an ultraviolet absorber, 0.5-1% of a dispersing agent, 0.5-1% of a levelling agent, 0.5-1% of a defoaming agent, 1-3% of bentonite, 20-25% of titanium dioxide, 0.5-1% of an adhesion promoter and 2-5% of a solvent; and the agent B is a curing agent used with the agent A. The preparation method provided by the invention is simple in operation and preparation processes; the prepared graphene anti-corrosion paint is excellent in wear-resistant, ageing-resistant, anti-bacteria and anti-corrosion performances; and moreover, graphene has no toxic and side effects, as well as is efficient and environment-friendly.

Owner:青岛科孚纳米技术有限公司

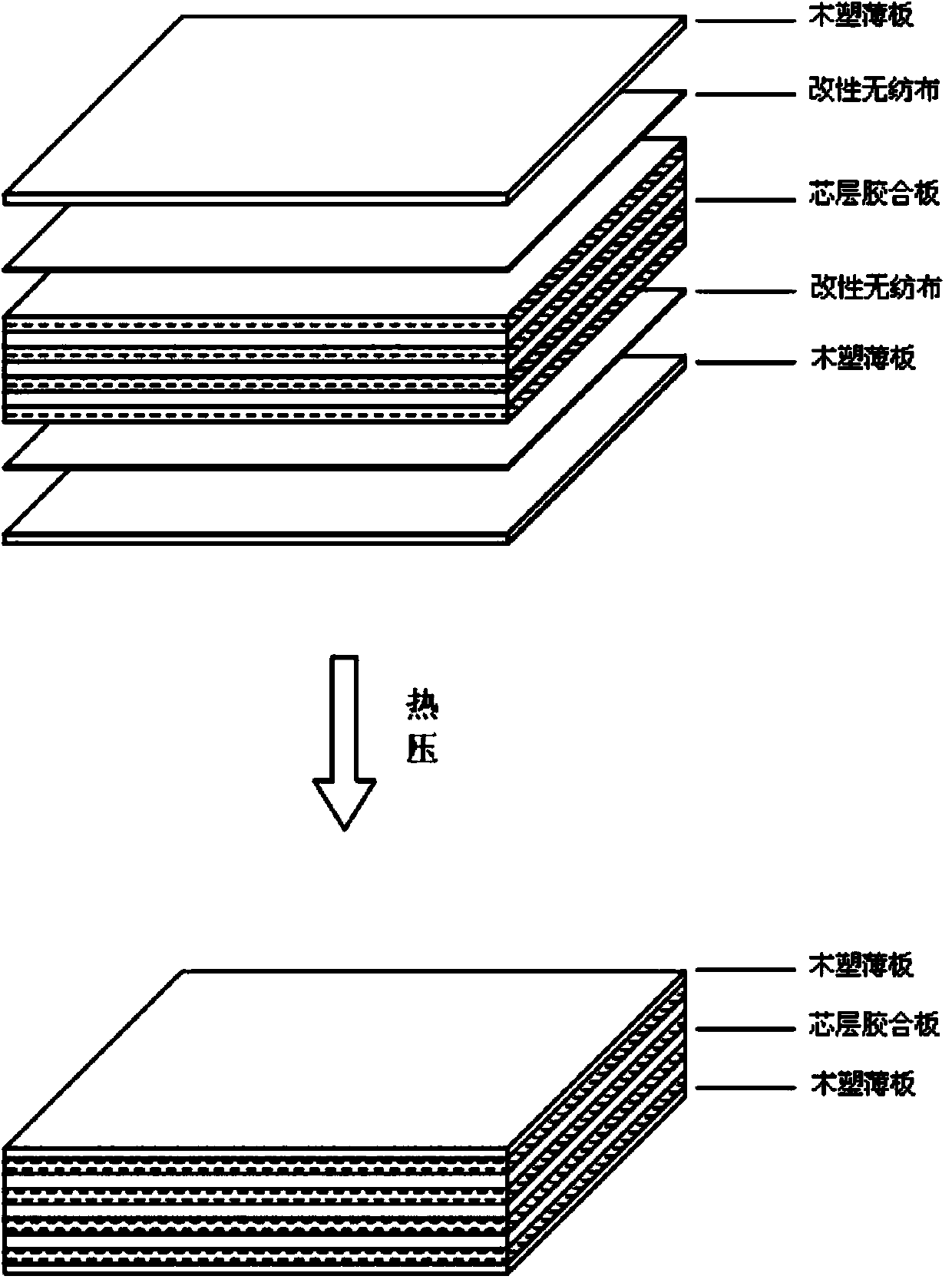

Wood plastic composite material cladding plywood formwork and manufacturing method thereof

ActiveCN103758340AReduced flatness errorGood dimensional stabilityFibre treatmentSynthetic resin layered productsPlastic filmToughness

The invention relates to a plywood formwork and a manufacturing method of the plywood formwork, in particular to a wood plastic composite material cladding plywood formwork and a manufacturing method of the wood plastic composite material cladding plywood formwork. The wood plastic composite material cladding plywood formwork aims to solves the problems that a wood plywood formwork manufactured in the prior art is low in intensity and poor in durability. The wood plastic composite material cladding plywood formwork is formed by a wood plastic sheet, an improved non-woven fabric and core-layer plywood in a manufactured mode. The manufacturing method comprises the steps that the wood plastic sheet is manufactured; the non-woven fabric is improved; the core-layer plywood is manufactured; pavement is carried out; the formwork is formed. The wood plastic composite material cladding plywood formwork is low in manufacturing cost, high in intensity, good in toughness, long in service life, resistant to moisture and corrosion, stainless, bright, clean and flat in surface, light in weight, and convenient to transport and construct, a die does not swell easily, and the die is released easily. The wood plastic composite material cladding plywood formwork is used as a building formwork.

Owner:NORTHEAST FORESTRY UNIVERSITY

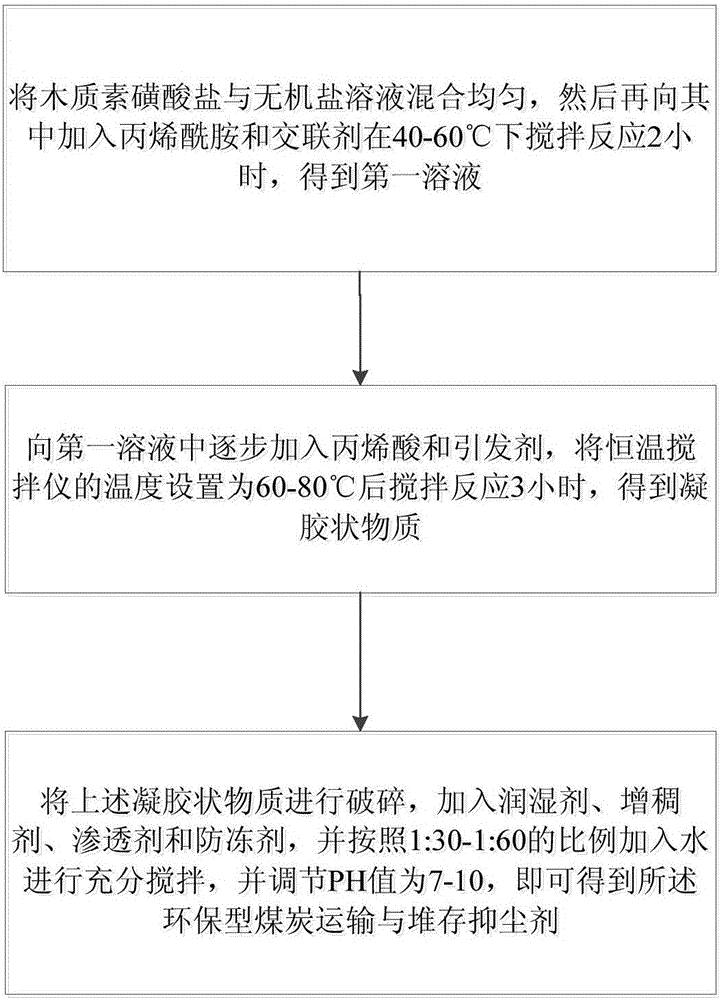

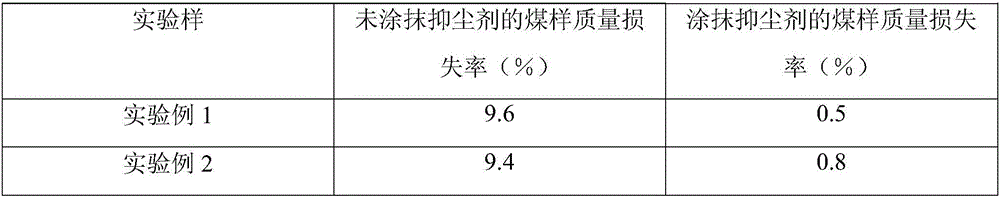

Environmentally-friendly coal transporting and stockpiling dust inhibitor and preparation method thereof

ActiveCN105950116ASuppress flyingImprove wettabilityOther chemical processesInorganic saltsLignosulfonates

The invention discloses an environmentally-friendly coal transporting and stockpiling dust inhibitor and a preparation method thereof. The dust inhibitor comprises, by mass, 5-10% of lignosulfonate, 5-10% of acrylamide, 10-15% of acrylic acid, 0.5-1.4% of a wetting agent, 0.4-0.9% of a thickener, 0.3-0.5% of an osmotic agent, 0.2-0.5% of an antifreeze agent, 0.05-0.1% of an initiator, 0.5-0.8% of a cross-linking agent, 0.2-0.5% of an inorganic salt, and the balance of water. A finally generated gel state substance has an obviously better coal wrapping effect than spraying, and can form a stable protection layer after the gel state substance is sprayed on the surface of coal. The dust inhibitor has the advantages of good wetting effect, fast solidification speed, and large hardness and obvious dust inhibiting effect of the formed protection layer.

Owner:SHANDONG UNIV OF SCI & TECH

Iron rust conversion agent and preparation method thereof

InactiveCN103173757AStrong weather resistanceImprove mechanical propertiesMetallic material coating processesAtmospheric airSolvent

The invention relates to an iron rust conversion agent for removing and preventing rust on the surface of steel. The iron rust conversion agent can be coated on a rusty surface of the steel, the iron rust is conversed into a layer of a protective film, the complicated components of the rust layer are converted into stable products, and the stable products show no rust in the relatively long time in the atmosphere, therefore, the rusty surface of the steel can be directly coated and constructed without removing the rust. A synthetic resin emulsion is used as a main film-forming agent, pyrogallic acid and tannic acid are used as main conversion agents, citric acid is used as an auxiliary conversion agent, and a film-forming auxiliary agent is adopted to realize the curing film-forming at room temperature, thus the compactness and water resistance of the film are improved; and moreover, isopropyl alcohol is used as a solvent and penetrating agent, so as to stabilize the rusty layer. The iron rust conversion agent is sprayed to the rusty surface of the steel, thus a compact and uniform black film is formed on the surface of the steel in short time. In addition, the iron rust conversion agent has advantages of simple preparation process, low cost, stable performance, economy and practicality, safety and environmental friendliness, not containing of toxic and harmful ingredients such as formaldehyde, benzene and nitrite, and no simulation on operating personnel and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High strength energy saving heat insulation material for use outside external wall

InactiveCN1458112AImprove workabilityAvoid chalkingConstruction materialSolid waste managementFoaming agentPolystyrene

The heat insulation material consists of cement 50-55 wt%, granular polystyrene 10-15 wt%, flyash 20-25 wt%, light calcium carbonate 1-5 wt%, heavy calcium carbonate 5-10 wt%, flyash 10-20 wt%, cellulose fiber 0.1-0.5 wt%, methyl cellkulose 0.1-0.3 wt%, amylase 0.1-0.2 wt%, foaming agent 0.1-0.2 wt% and air entraining agent 0-0.2 wt%. The present invention is a kind of green furnishing and decorating material and is suitable for use as heat insulating material outside the outer wall and roof.

Owner:王胜怀

Synthesis method for resin with high water absorbability

ActiveCN102617781AImprove performanceFix security issuesAbsorbent padsOrganic fertilisersPotassium hydroxideCross linker

The invention discloses a method for preparing resin with high water absorbability. The method comprises the following steps of: neutralizing polymerized monomer crylic acid by use of a sodium hydroxide (or potassium hydroxide) solution until the neutralization degree is 70-85 percent, thus obtaining a polymerized monomer solution; sequentially adding a secondary monomer and a cross-linking agent, uniformly mixing, obtaining water absorption resin gel under sunshine radiation for 1 to 6 hours, and cutting and drying the gel to obtain the resin with high water absorbability. According to the method, any chemical initiator, comprising a light initiator, is not added, so that polymerization reaction is not controlled by the concentration of the initiator; and the method has the advantages of easiness for control, environmental friendliness, energy conservation and the like. Furthermore, the obtained resin with high water absorbability is subjected to surface cross-linking treatment and surface compound treatment, so that water absorption resin for a sanitary material and a soil water-retaining agent are obtained and have high water absorbability.

Owner:珠海农神生物科技有限公司

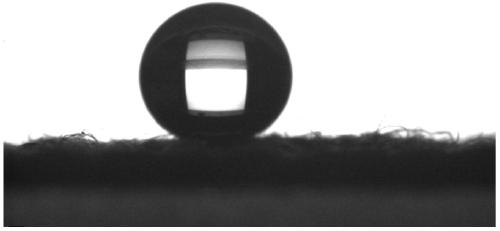

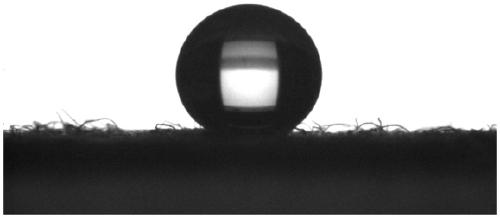

Hydrophilic and oleophobic easy-to-clean organic coating and preparation method thereof

ActiveCN102585664AImprove wettabilityEasy to replaceEpoxy resin coatingsOrganic solventFluorine containing

The invention discloses a hydrophilic and oleophobic easy-to-clean organic coating and a preparation method thereof. The organic coating is obtained by curing an organic solution by a curing agent, the organic solution is a fluorine-containing polyurethane modified epoxy resin solution formed by carrying out a reaction on fluorine-containing polyurethane and an epoxy resin in an organic solvent, and the fluorine-containing polyurethane and the epoxy resin form a semi-interpenetrating network structure formed through the bonding of chemical bonds. A micro area with uniformly distributed hydrophilicity and oleophobicity is constructed on the surface of an object to be coated through the semi-interpenetrating structure and low surface performances of fluorine, so the hydrophilic and oleophobic easy-to-clean organic coating is formed. Experiments prove that the lowest contact angle between the organic coating and water can reach 15DEG, and the highest contact angle between the organic coating and oil can reach 90DEG, so water can thoroughly displace oil stains on the surface of an original solid, and an easy-to-clean effect is reached.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

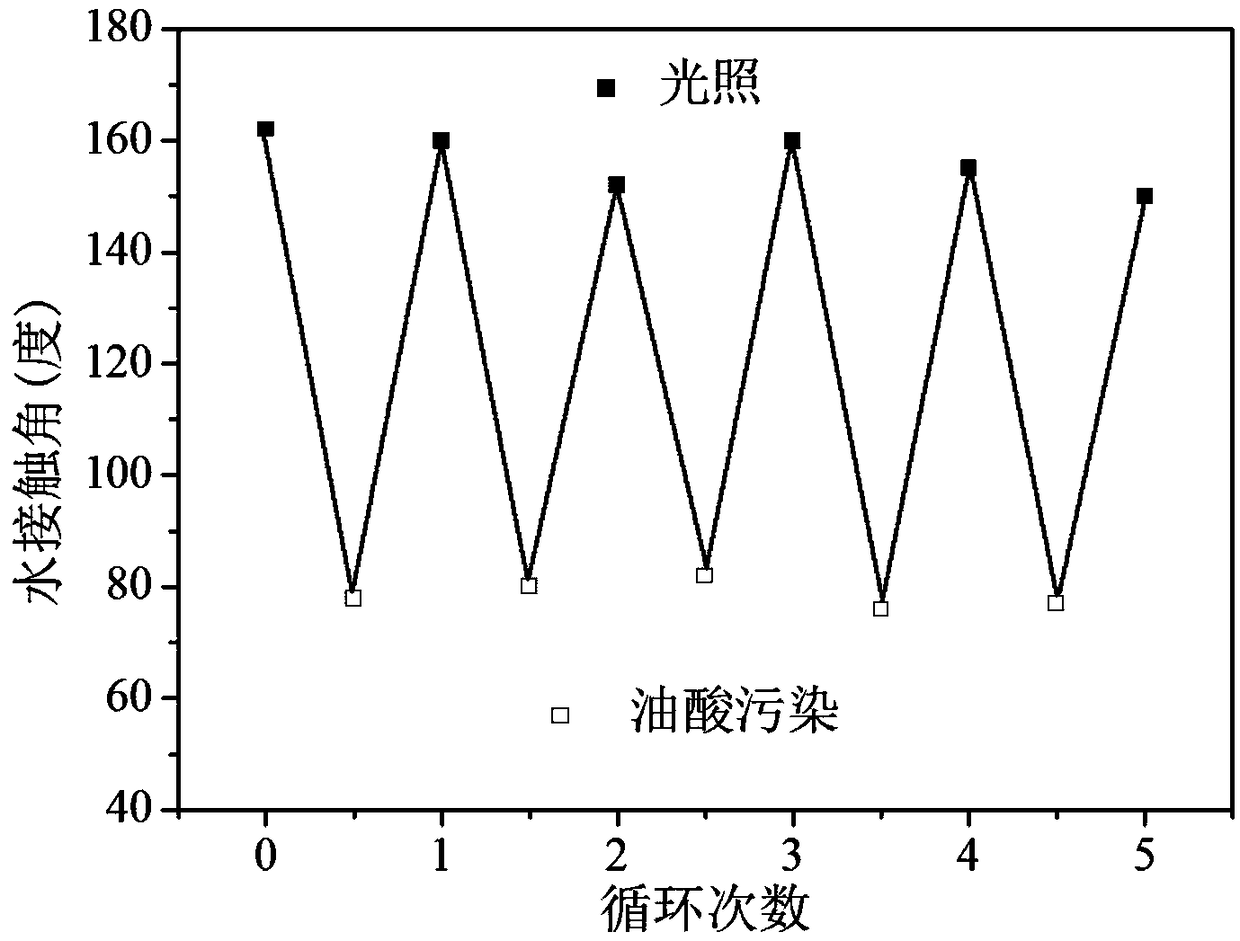

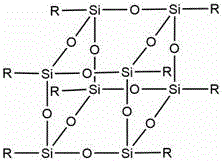

Self-healing type super-amphiphobic and photocatalytic double self-cleaning coating and method for preparing same

ActiveCN109082230AExcellent super oleophobic propertiesAvoid pollutionAntifouling/underwater paintsPaints with biocidesSelf-healingRoom temperature

The invention discloses a self-healing type super-amphiphobic and photocatalytic double self-cleaning coating and a method for preparing the same. Mixed solution with fluorine-polyhedral oligomeric silsesquioxane (F-POSS) and photocatalysis particles is coated on the surfaces of base materials to form the self-healing type super-amphiphobic and photocatalytic double self-cleaning coating. The self-healing type super-amphiphobic and photocatalytic double self-cleaning coating and the method have the advantages that the self-healing type super-amphiphobic and photocatalytic double self-cleaningcoating has super-hydrophobic and super-oleophobic super-amphiphobic performance, is capable of photocatalytically degrading organic pollutants adhered on the surfaces of the self-healing type super-amphiphobic and photocatalytic double self-cleaning coating, can be self-healed and can be placed at the room temperature or can be appropriately heated, and accordingly degradation of the super-amphiphobic performance due to long-time illumination can be repaired; the self-healing type super-amphiphobic and photocatalytic double self-cleaning coating is applicable to the surfaces of the base materials for glass, wood, building external walls, diversified textiles and the like with the requirements on self-cleaning functions.

Owner:SUZHOU UNIV

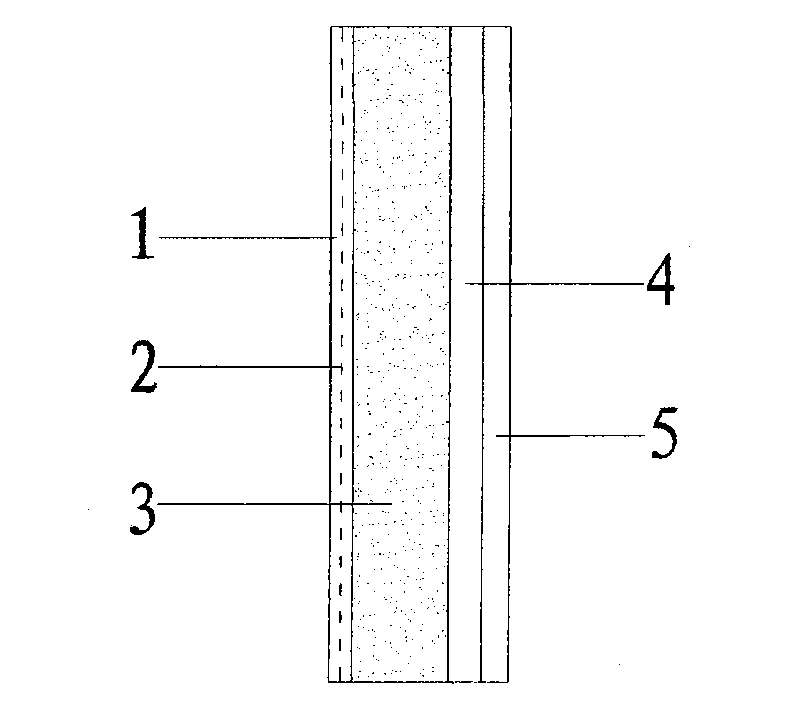

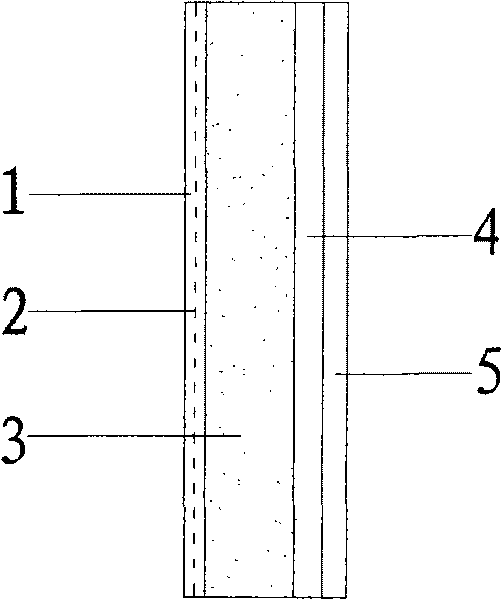

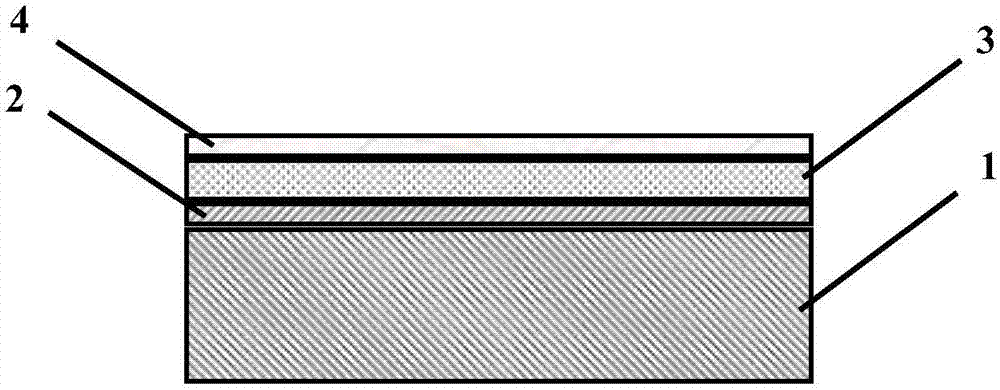

Flexible decorative facing brick and production process thereof

The invention provides a flexible decorative facing brick. By adopting a sheet as a basic-layer matrix body 1, polymer color-sand glue material on the matrix body as a brick body 2 and transparent paint as a brick-surface protection layer 3, the flexible decorative facing brick is produced through the processes of scraping, coating, baking, spraying and cutting. A production process comprises: manufacturing a sheet matrix body in advance for later use; washing, screening and drying natural color sand; weighing 55 to 65 percent of natural color sand and 35 to 45 percent of polymer latex in a weight ratio, putting the two into a kettle for preparing the polymer color-sand glue material, stirring uniformly and producing the polymer color-sand glue material for later use; introducing the sheet matrix body onto a gathering platform of a production line for the flexible decorative facing brick, adding the polymer color-sand glue material, performing scraping-coating, pressing, knurling and block division, sending the obtained product into the production line for dewatering and drying; spraying the transparent paint serving as the brick-surface protection layer; and cutting and packaging the obtained product according to size. The decorative facing brick manufactured by the method has the advantages of good elasticity and flexibility, and the production process is high in manufacturing efficiency and saves energy.

Owner:烟台同化防水保温工程有限公司

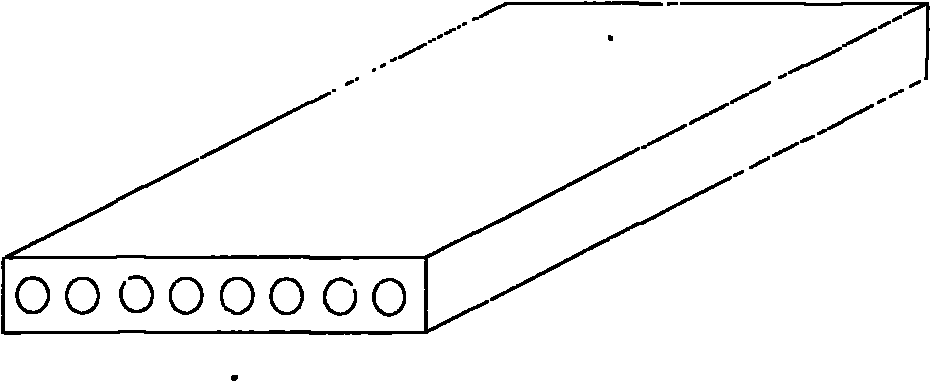

Hollow ceramic insulation board for coal gangues and construction wastes and manufacturing method thereof

InactiveCN101973756AEasy to useLow water absorptionSolid waste managementThermal insulationCalcination

The invention relates to a hollow ceramic insulation board for coal gangues and construction wastes and a manufacturing method thereof. In the invention, a large amount of coal gangues and construction wastes are taken as raw materials, and 50-70% of coal gangues, 10-30% of construction wastes, 5-15% of shale and 5-10% tailing residues are mixed in accordance with a formula. The manufacturing method thereof comprises the following steps: mixing the materials in the formula, grinding the materials to 40-80 meshes, adding 15-20% of water to stirring, aging the mixture for 24-72h, extruding laminas with mesopores by an extruder, drying the laminas, and performing calcination on the dried laminas in a kiln at the temperature of 1100-1200 DEG C to obtain the hollow ceramic insulation board for coal gangues and construction wastes. The invention is characterized in that a large amount of the coal gangues and the construction wastes are taken as the raw materials for the products, and usage amount of the coal gangues and the construction wastes reaches above 70%; the products are ceramic laminas with the mesopores; the water absorption of the products is lower than 3.5%, the strength is high and the weather fastness is strong; and the coefficient of heat conductivity of the products is lower than 0.45w / (m.K) and the thermal insulation property is good.

Owner:咸阳陶瓷研究设计院有限公司

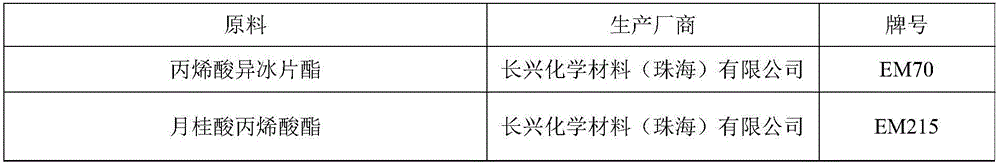

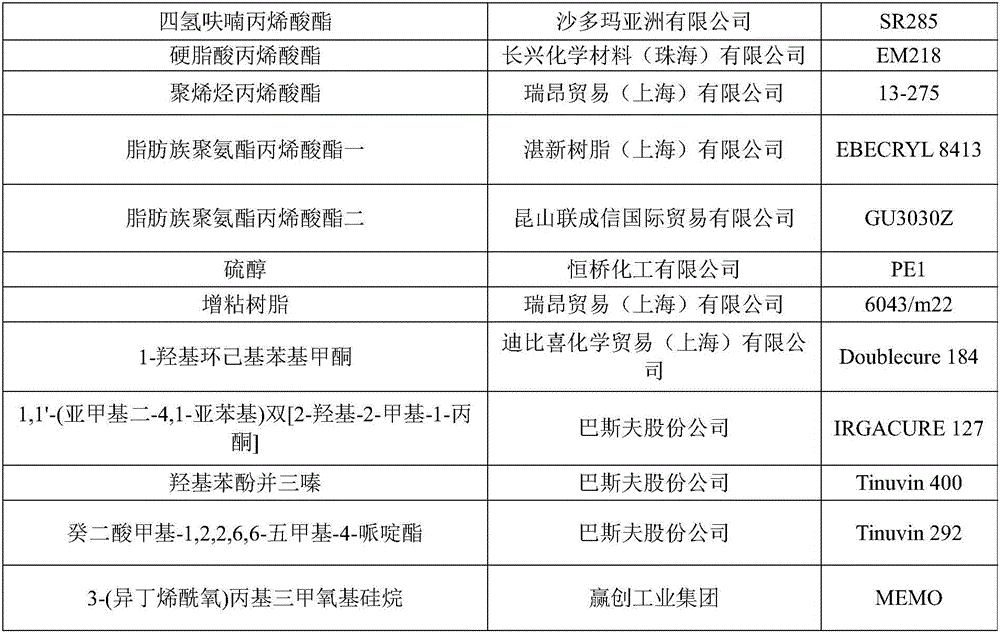

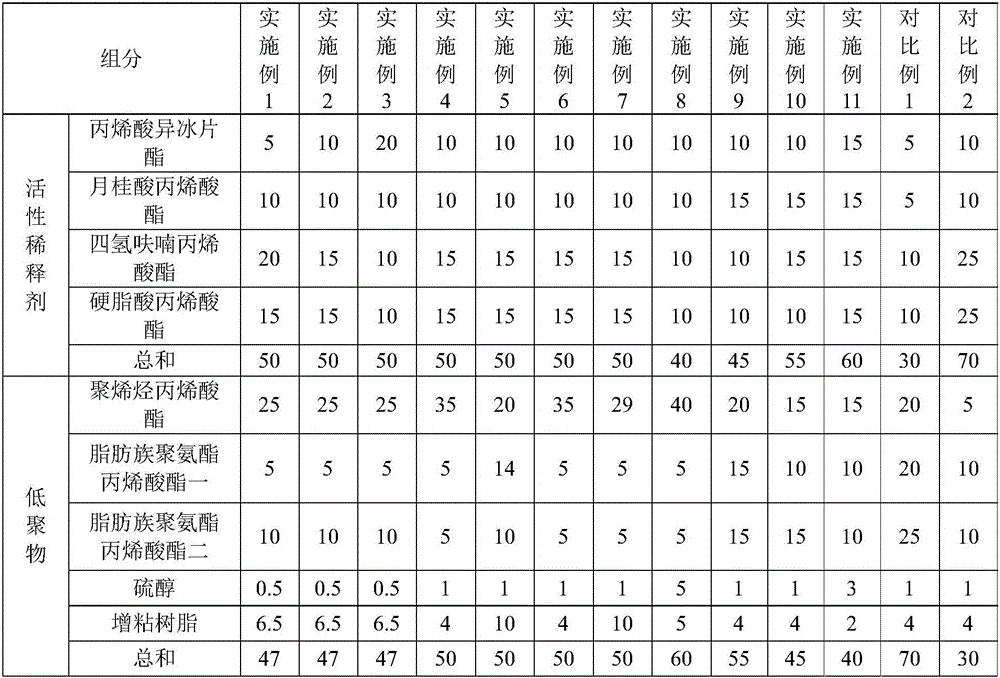

Ultraviolet-curing pressure-sensitive composition and pressure-sensitive adhesive

ActiveCN105969253AStrong weather resistanceNot easy to yellowPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesPolyolefinWeather resistance

The invention provides an ultraviolet-curing pressure-sensitive composition and a pressure-sensitive adhesive. The ultraviolet-curing pressure-sensitive composition comprises low polymers, a reactive diluent and a photoinitiator, wherein the weight ratio of the reactive diluent to the low polymers is 40:60-60:40, and the weight content of the photoinitiator in the composition is 1-5%. The low polymers comprise the following components in parts by weight: 20-40 parts of polyolefin acrylate and 4-30 parts of polyurethane acrylate. The ultraviolet-curing pressure-sensitive composition can not result in pollution caused by solvent volatilization in the use process. The weight ratio of the monomer reactive diluent to the low polymers is controlled at 40:60-60:40, so that the bonding property of the pressure-sensitive adhesive is greatly enhanced. Furthermore, by using the polyolefin acrylate as the component of the low polymer, the olefin functional group can enable the pressure-sensitive adhesive formed by the ultraviolet-curing pressure-sensitive composition to have higher weather resistance and further have higher light transmission rate.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Formula and preparation method for ground slipping preventing liquor

ActiveCN104531071AEffective penetrationImprove permeabilityOther chemical processesAcetic acidPotassium carbonate

The invention discloses a formula and preparation method for a ground slipping preventing liquor. The ground slipping preventing liquor is prepared from the following components in percentage by weight: 28% of tartaric acid, 2% of acetic acid, 12% of a surfactant, 0.5% of a defoamer, 9% of sodium chloride, 5% of potassium carbonate, 2% of an emulsifier, 41% of purified water and 0.5% of a corrosion inhibitor. The ground slipping preventing liquor disclosed by the invention is environment-friendly and has a long-time slipping preventing effect.

Owner:SHANGHAI JIADELI NON SLIP PROTECTION TECH

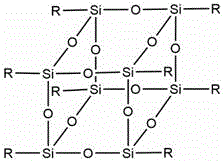

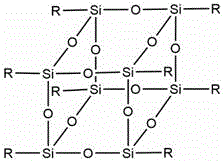

POSS and silicone oil modified fluorinated acrylate building waterproof paint

InactiveCN106752628AImprove permeabilityImprove mechanical propertiesCoatingsWeather resistanceSilsesquioxane

The invention belongs to the technical field of polymer fine chemicals, and discloses a POSS and silicone oil modified fluorinated acrylate building waterproof paint and a preparation method thereof. The preparation method comprises adopting POSS, silicone oil and fluorinated methacrylate to perform the copolymerization to obtain POSS-containing silicone oil modified fluorinated methacrylate polymer, wherein the selected alkenyl-containing POSS is polyhedral polysilsesquioxane containing alkenyl. The polymer disclosed by the invention has good weather resistance, has good adhesive force and permeation to concrete and other building materials, has a good waterproof effect, and is suitable for the waterproof work of various concrete constructions.

Owner:UNIT 61489 OF PLA

Multifunctional putty for building external walls

The invention discloses multifunctional putty for building external walls, consisting of the following components in percentage by weight: 30% of white cement, 16% of sericite, 20% of talcum powder, 30% of quartz sand, 3.5% of re-dispersible polymer powder, 0.1% of defoaming agent, 0.1% of naphthalene-series water reducer, 0.1% of methylcellulose, 0.1% of waterproof agent and 0.1% of wood fiber. According to the invention, the sericite is used as functional padding so that the putty disclosed by the invention has strong weather ability because the sericite has a trough for absorbing ultraviolet lights as high as 85% and has a strong function for shielding ultraviolet lights. Moreover, through the sheet overlapping and blocking function of the sericite because of high radius-thickness ratio, the reflection and thermal-insulation capability can be effectively improved and the heat-insulating performance of the putty is enhanced. The sericite has active hydroxyl groups and is easy to combine and wrap with molecular chains in the re-dispersible polymer powder so that the comprehensive mechanical property and the penetration resistance of the putty are greatly improved.

Owner:武汉市丰达建筑节能材料有限公司

Artificial colored sand

The invention provides an artificial colored sand which is manufactured by composite color paste and gravel, wherein the composite color paste includes acrylic ester emulsion, toner, auxiliaries and water. According to the technical scheme, the produced artificial colored sand is rich in color, has bright and uniform color and luster, and has little limitation from the ore source; and meanwhile, the artificial colored sand has the cost lower than that of the natural colored sand, and the demand of a customer on personalized color can be met; and the economy and environmental protection can be achieved; and moreover, the composite color paste and the gravel have high attaching force during being sintered, so that the flexibility of the colored sand is improved. Compared with currently used natural colored sand, the artificial colored sand provided by the invention has uniform color, excellent film forming property, high attaching force, high resistance to water and alkali, relatively high pollution resistance, and super wear resistance, is economic and environment-friendly, and solves the problems of the natural colored sand that the ore sources are gradually reduced, the demands on production cannot be met, products in different batches have color difference, and the timeliness of the production cannot be met.

Owner:ASIA PAINT SHANGHAI

Macromolecular adhesive cement

The invention relates to a cement-based self-leveling mortar, and more particularly relates to a macromolecular adhesive cement. The macromolecular adhesive cement comprises the components in parts by weight: 80-100 parts of water-borne epoxy resin, 16-20 parts of water-borne epoxy curing agent, 120-150 parts of complex portland cement, 30-50 parts of quartz silt powder, 10-15 parts of water, 35-50 parts of pigments and fillers, 0.3-0.5 parts of wetting dispersant, 2-6 parts of self-leveling additives, and 2-5 parts of water-borne color paste. The macromolecular adhesive cement disclosed by the invention is a single-component, dry-powder-shaped and water-borne self-leveling cement-based hard / soft type waterproof adhesion-blocking and leveling material which is processed via scientific proportioning, integrates the functions of water prevention, adhesion, blockage and leveling, as well as is non-toxic and odorless, and belongs to cement-based macromolecular polymer water-borne dry-powder waterproof mortars.

Owner:浙江西塘实业有限公司

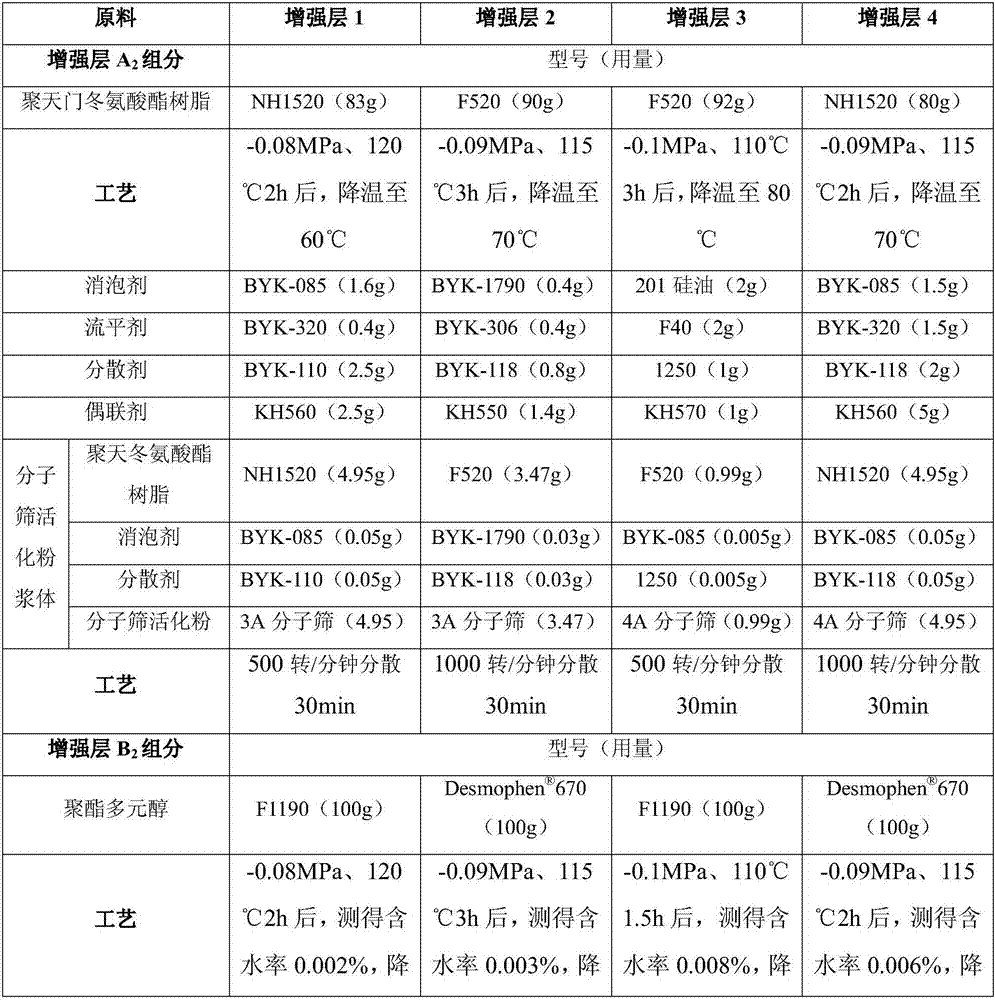

High-durability concrete shield system capable of rapid construction and preparation method thereof

ActiveCN107337993AFast curing rateImprove adaptabilityPolyurea/polyurethane coatingsLow temperature curingEngineering

The invention discloses a high-durability concrete shield system capable of rapid construction and a preparation method thereof. The concrete shield system comprises a concrete base layer, a polyaspartate permeation primer layer, a polyaspartate elasticity enhancement layer and a fluorine-silicon-modified polyaspartate high-weather-resistance finish paint layer from bottom to top. Compared with the prior art, the system has the advantages of short construction cycle, high weather resistance and the like, can be constructed on a wet basal plane, can implement construction within one day and low-temperature curing, has the multiple functions of high mechanical strength, fatigue resistance, aging resistance, high elasticity, corrosion resistance and the like, and has the characteristics of simple construction, high safety and environment friendliness.

Owner:辽宁苏博特船牌制漆有限公司 +2

Heat insulation super-weather-proof powder coating and preparation method and application thereof

ActiveCN103131294AHigh infrared reflectivityReduce heat transfer ratePowdery paintsEpoxy resin coatingsEpoxyFluorocarbon

The invention relates to a heat insulation super-weather-proof powder coating which comprises an epoxy resin particle system and a fluorocarbon resin particle system, wherein the epoxy resin particle system contains epoxy resin and a curing agent A, the fluorocarbon resin particle system contains fluorocarbon resin, a curing agent B and a heat insulation material. The ratio of parts by weight for the epoxy resin particle system and the fluorocarbon resin particle system is 6-4:4-6. The heat insulation super-weather-proof powder coating not only has good heat insulation, weather-proof and corrosion-resistant performance, but also can achieve self-layering after one-time coating, and is simple to construct.

Owner:NINGBO SOUTH SEA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com