Patents

Literature

45 results about "Texture type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are 4 types of texture in art actual texture, simulated texture, abstract texture and invented texture. Texture creates the feeling of an object as this is known. This is the actual texture of how the work of art looks and feels to the touch. [www.stateoftheart-gallery.com/glossary/t] ~[⇑] s can be felt with the fingers,...

EXIF-based imaged feature set for content engine

InactiveUS20050163378A1Faster photo/image search algorithmDigital data information retrievalImage analysisPattern recognitionColor image

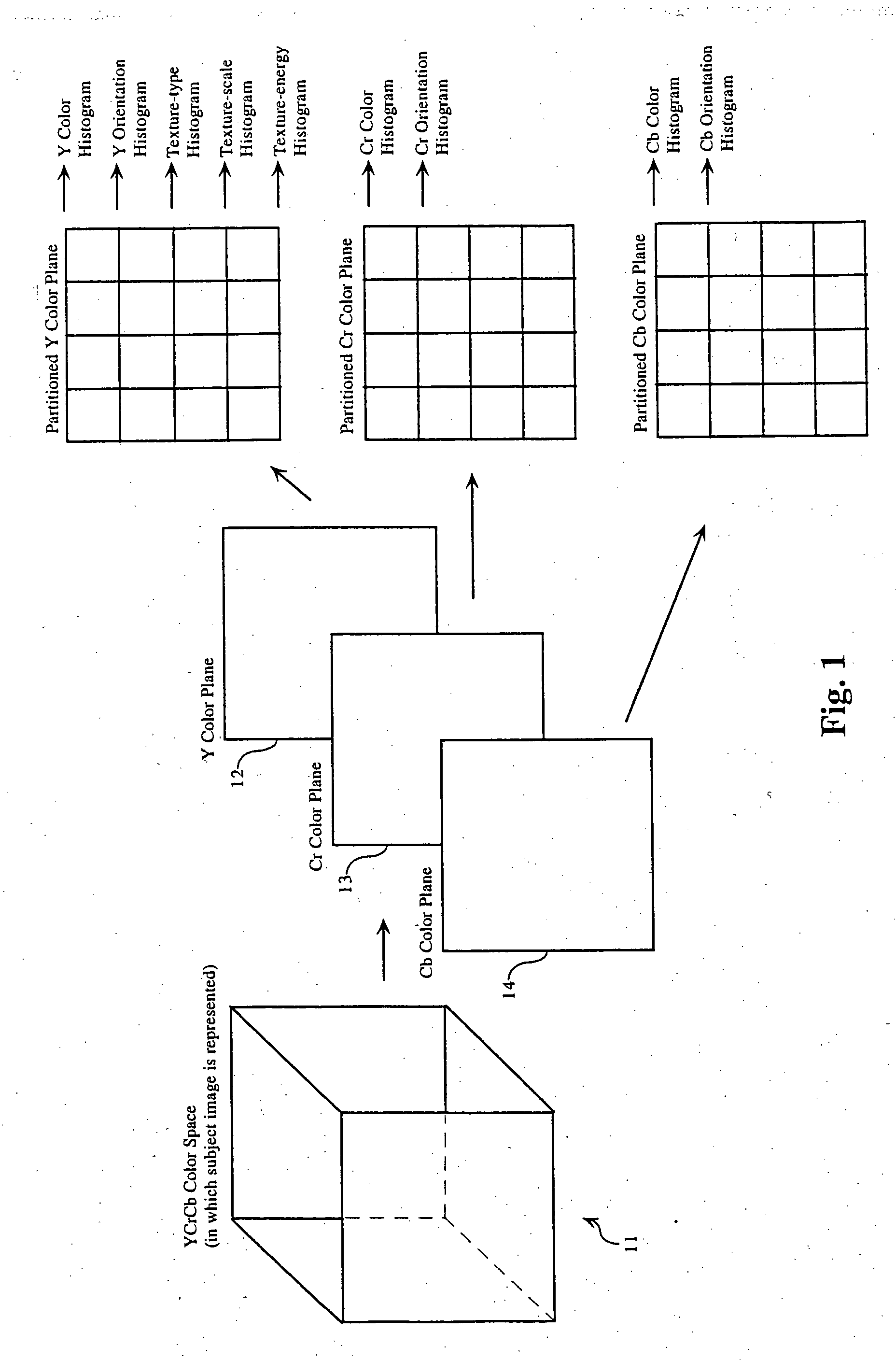

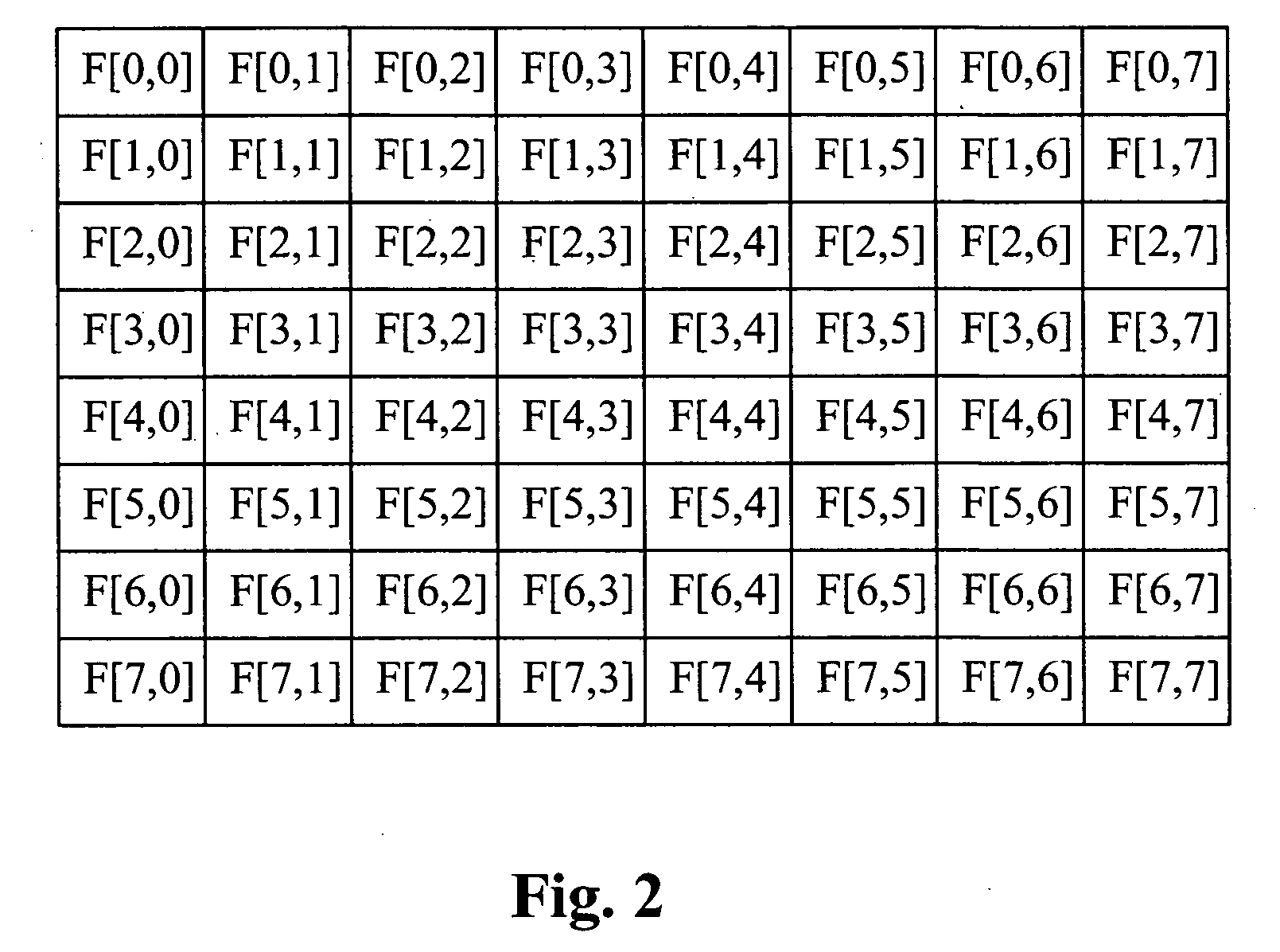

An improved feature set and accompanying image-content-based management / search method / algorithm enable fast and effective searching of a collection of digital color images to identify a particular image or group of images. The feature set, which is designed for EXIF formatted thumbnail color images, is derived from select transform (e.g., DCT) coefficients of the individual color components of the searched images. The feature set comprises color features, edge features, and texture features including texture-type, texture-scale and texture-energy. The feature set of a query image is compared to the feature sets of images in the relevant search range to identify all similar images.

Owner:SEIKO EPSON CORP

High efficiency video coding (HEVC) intraframe coding method, device and system based on texture direction

InactiveCN103297781AReduce complexityGood for real-time coding applicationsTelevision systemsPattern recognitionCoding block

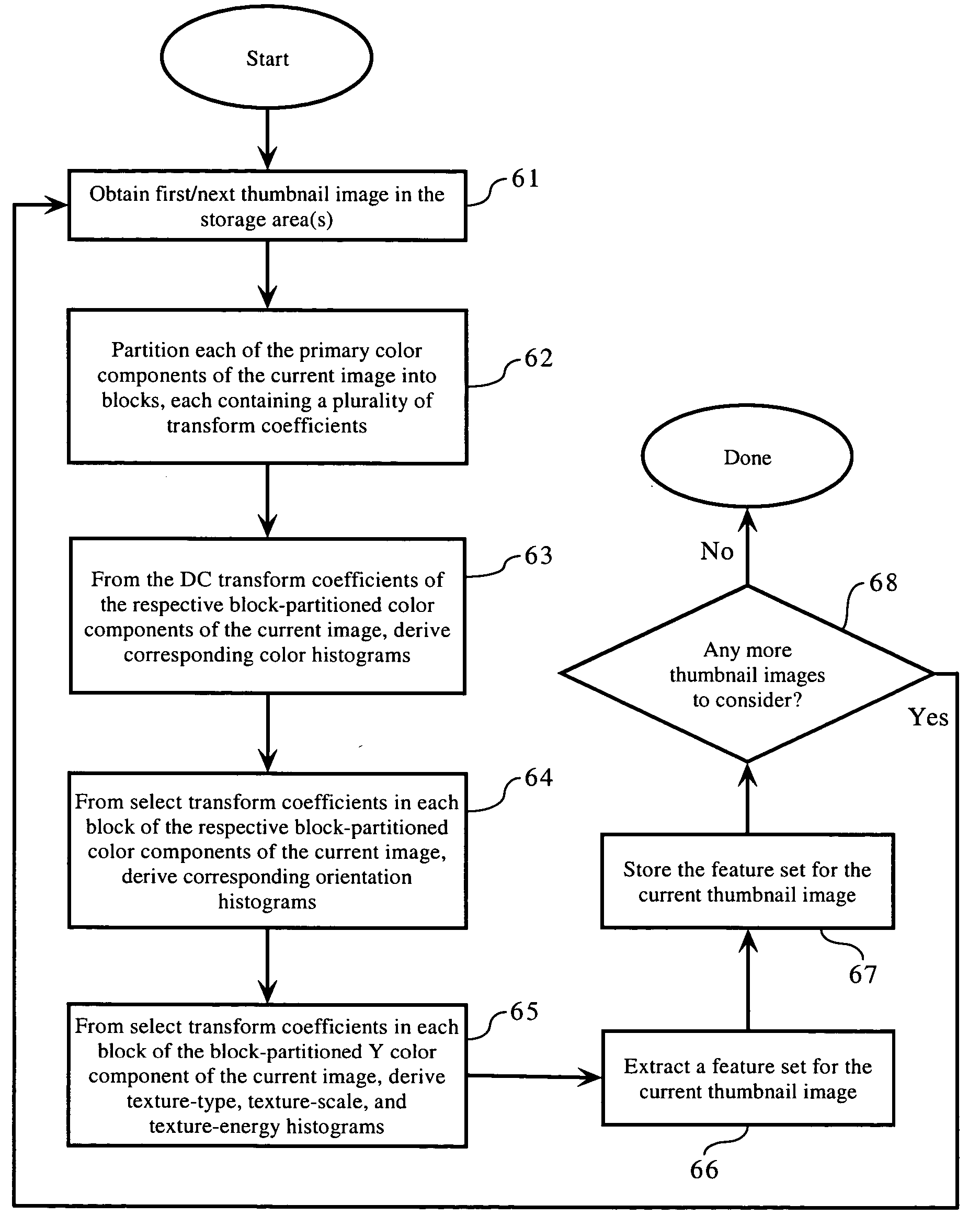

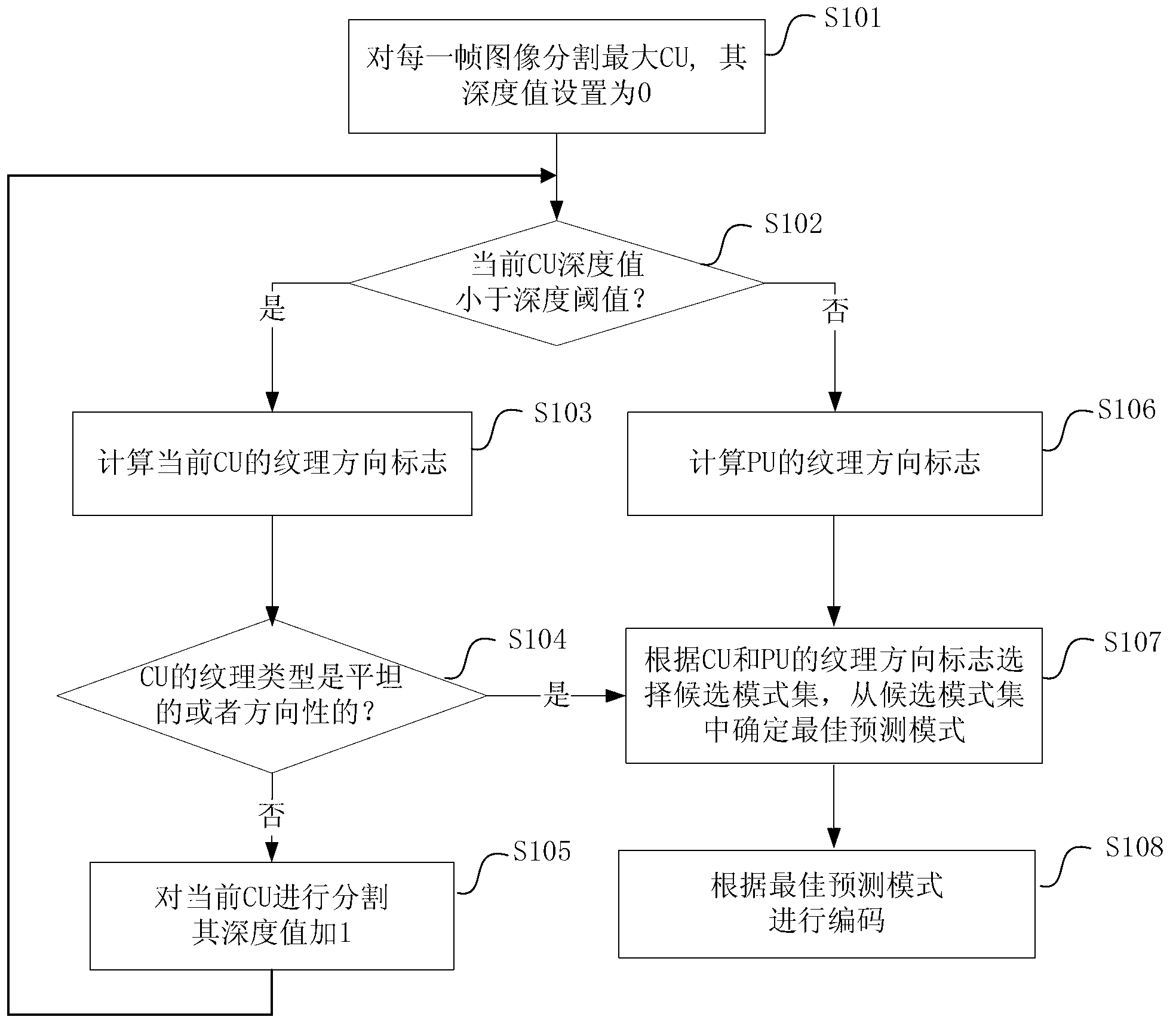

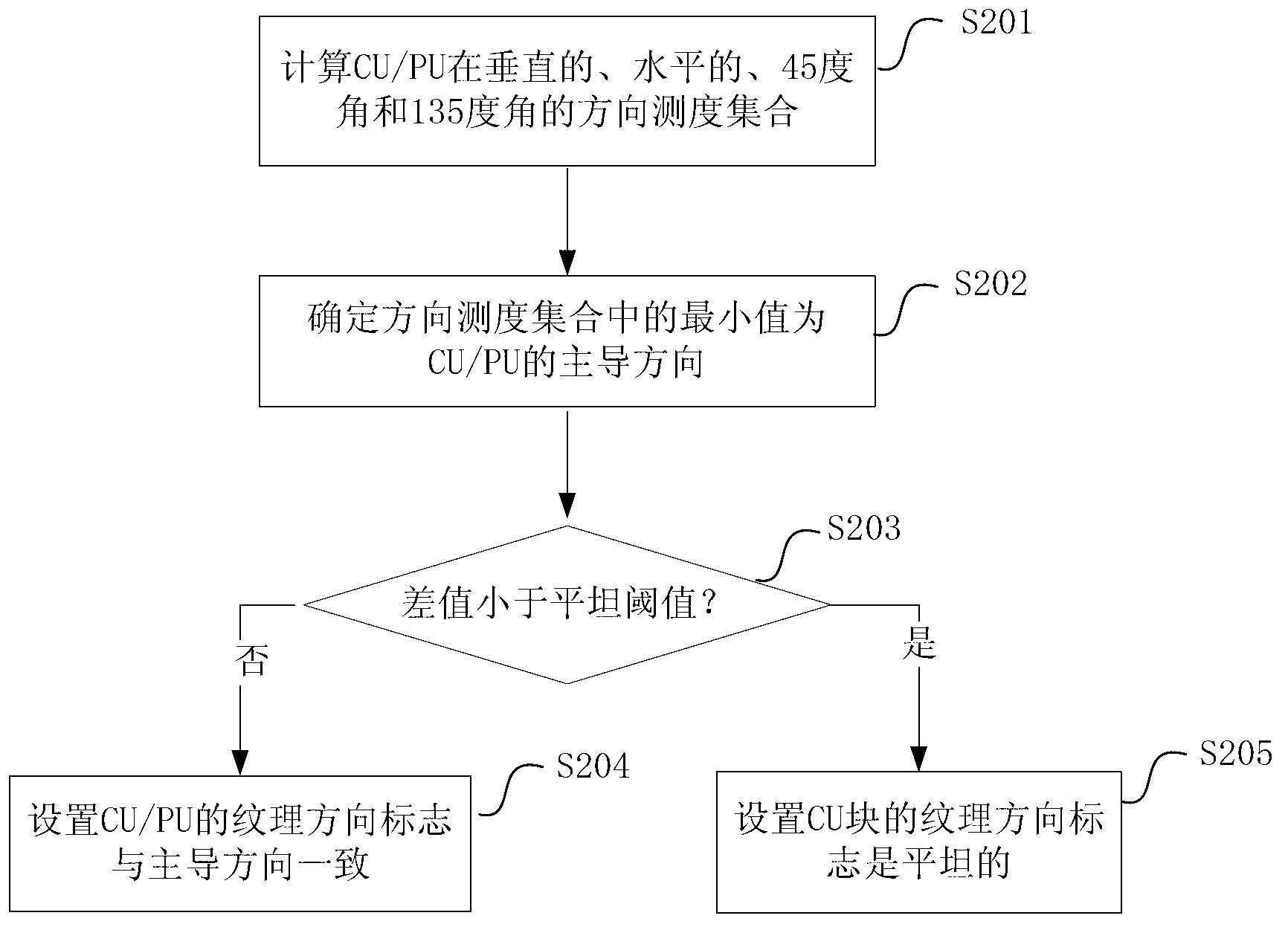

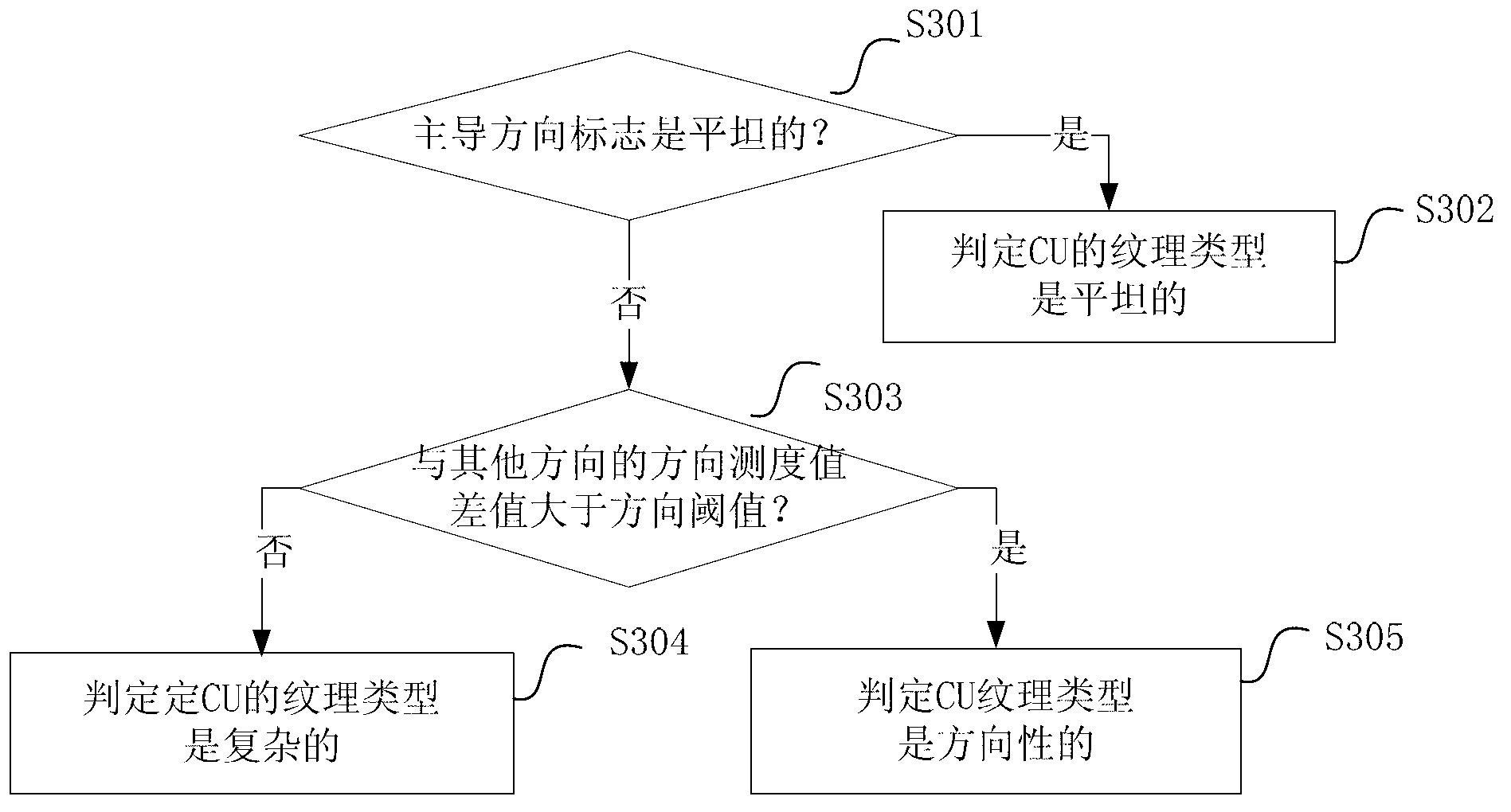

The invention discloses a high efficiency video coding (HEVC) intraframe coding method, device and system based on a texture direction. The method comprises the steps of segmenting every frame of image into maximum coding units (CUs), enabling depth values of the maximum CUs to be set as 0; obtaining a depth value of a current CU; when the depth value is smaller than a depth threshold, calculating texture direction signs of the current CU, judging whether a texture type of the current CU is flat or directional, and if the texture type of the current CU is not flat or directional, segmenting the current CU, and adding 1 to the depth value of the current CU; when the depth value reaches the depth threshold, calculating texture direction signs of a prediction unit (PU); selecting a candidate mode set of prediction modes according to the texture direction signs of the CU and / or the PU, and determining an optimum prediction mode from the candidate mode set to perform coding. According to the HEVC intraframe coding method, device and system based on the texture direction, CU layer block segmentation optimization and PU layer prediction mode optimization are performed through texture direction signs of coding blocks, and accordingly coding complexity and coding time are greatly reduced.

Owner:ANKE SMART CITY TECH PRC +2

Sand texture type polyester/epoxy powder coating and preparation method thereof

InactiveCN103160192AImprove thermal stabilityImprove scratch resistance and anti-agingPowdery paintsEpoxy resin coatingsEpoxyPollution

The invention discloses a sand texture type polyester / epoxy powder coating and a preparation method thereof. The sand texture type polyester / epoxy powder coating comprises the following raw materials, by weight, 350-400 parts of polyester resin (P5040), 240-280 parts of epoxy resin (E-12), 100-150 parts of extinction barium sulfate, 40-60 parts of spherical silica powder, 8-12 parts of modified polyethylene wax powder, 10-15 parts of organic coated titanium dioxide, 5-10 parts of sand texture agent (SWMBX-30), 4-6 parts of benzoin, 5-8 parts of 2-phenyl imidazoline, 4-6 parts of 2-methylimidazole, 5-10 parts of ferrite yellow, 5-10 parts of iron oxide red and 10-15 parts of carbon black. The prepared powder coating has the advantages of being high in hardness, high in intensity, high in abrasion resistance, good in heat resistance, good in ageing resistance, short in solidifying time, environment-friendly, free of pollution and the like. The solidified coating produces a texture effect of the sand texture, the sand texture is meticulous and clear, distribution is even, visual comfort is provided for people, and combination properties of the coating are good.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Garment texture recognition and classification method based on LBP and GLCM

PendingCN109934287ATo achieve the purpose of automatic classificationLess boringImage enhancementImage analysisFeature vectorFeature extraction

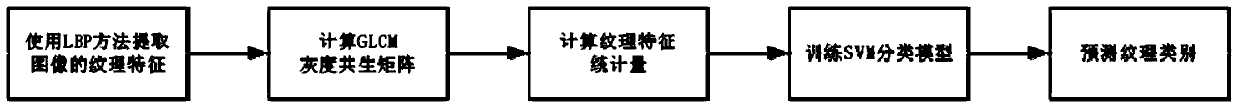

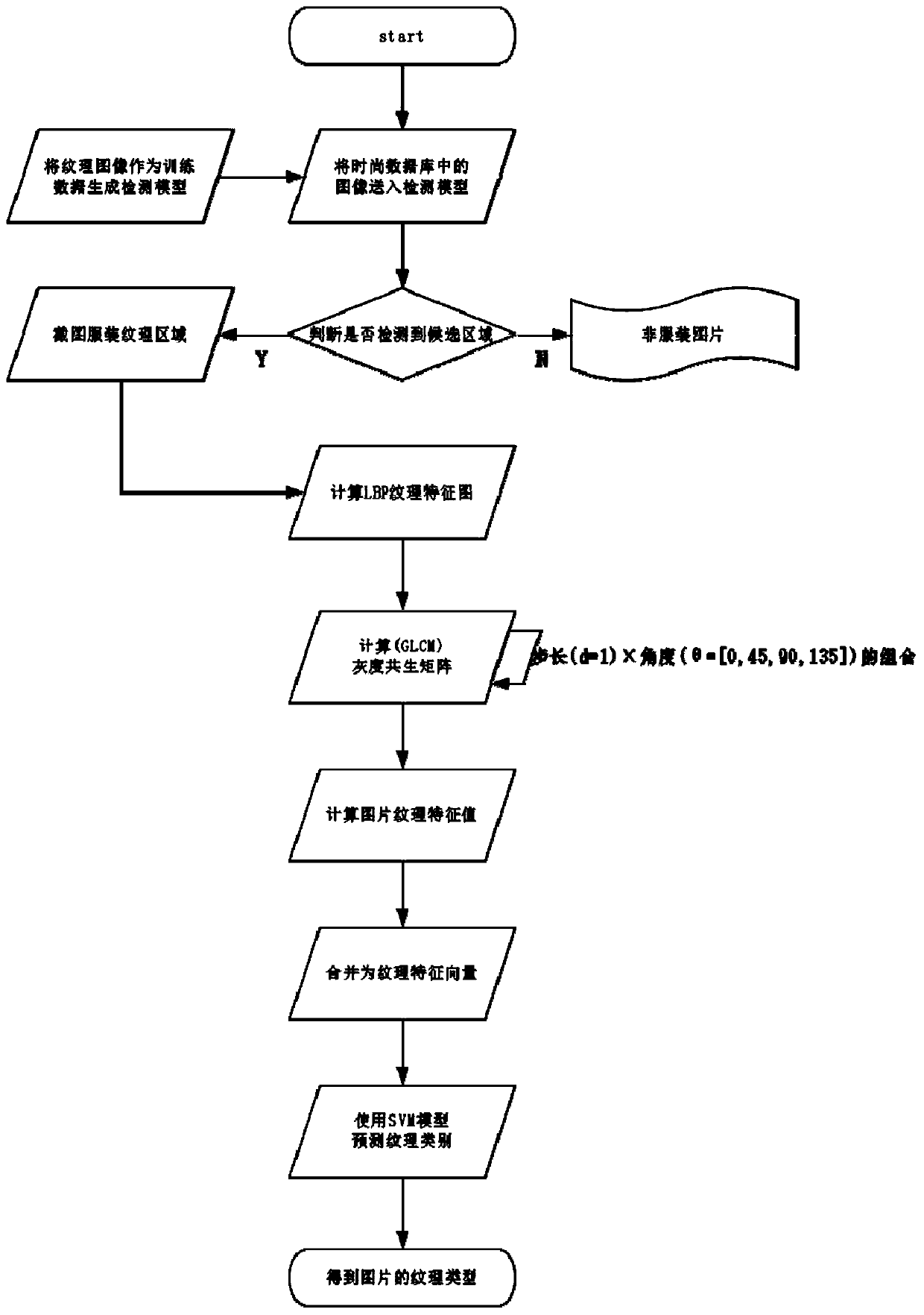

The invention relates to a garment texture recognition and classification method based on LBP and GLCM. The classification method for the texture types in fashionable garment images comprises the following steps: S1, extracting LBP texture features; S2, designing a GLCM texture image feature statistic extraction function; S3, calculating a texture feature value; and S4, training the feature vectors by using an SVM algorithm, and classifying the texture pictures. The method has the advantages that the challenge of texture recognition in fashionable clothes is well solved in the actual production process, the constraint of manual recognition is liberated, convenience is brought to later data analysis and algorithm development optimization, and the method has important practical significance.

Owner:上海宝尊电子商务有限公司

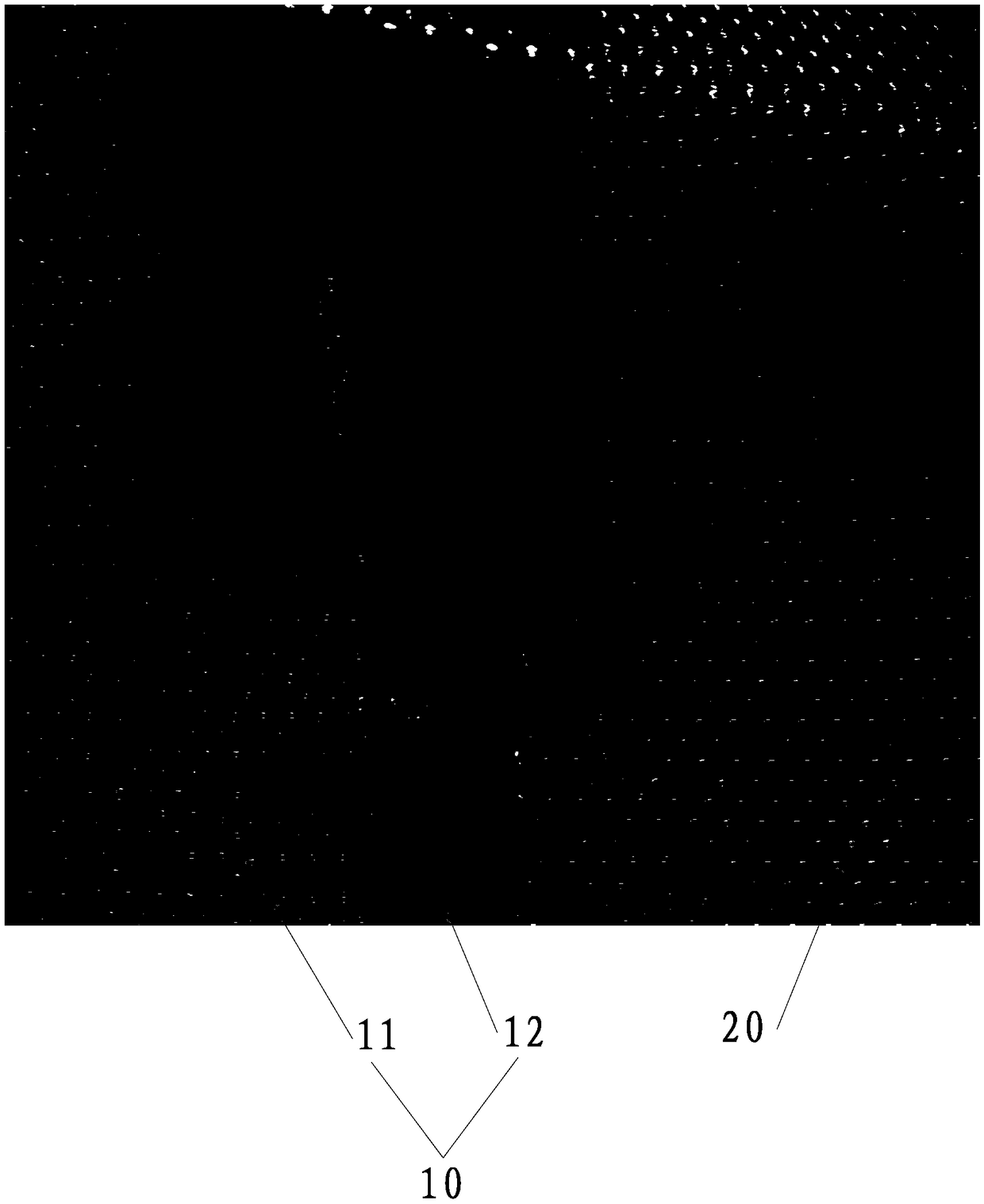

Yarn dyed fabric texture type recognition method

InactiveCN105787562AEasy to identifyImprove classification effectImage enhancementImage analysisYarnPattern recognition

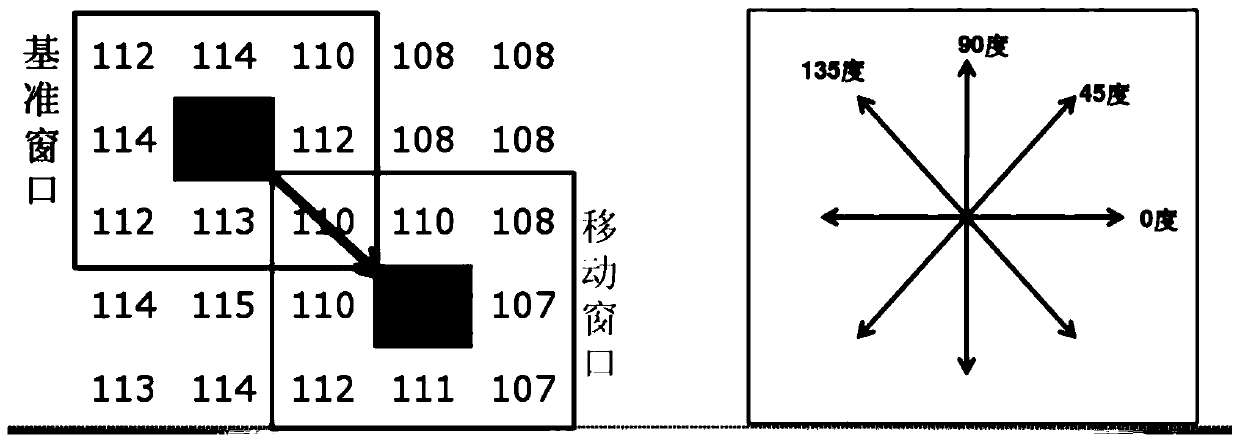

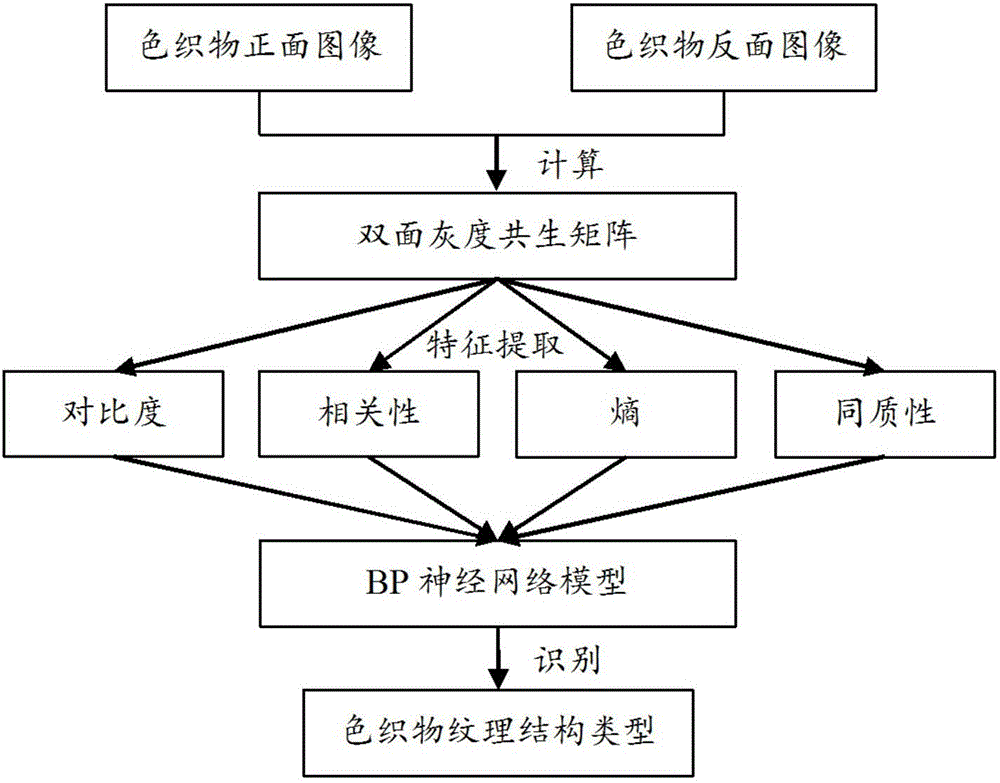

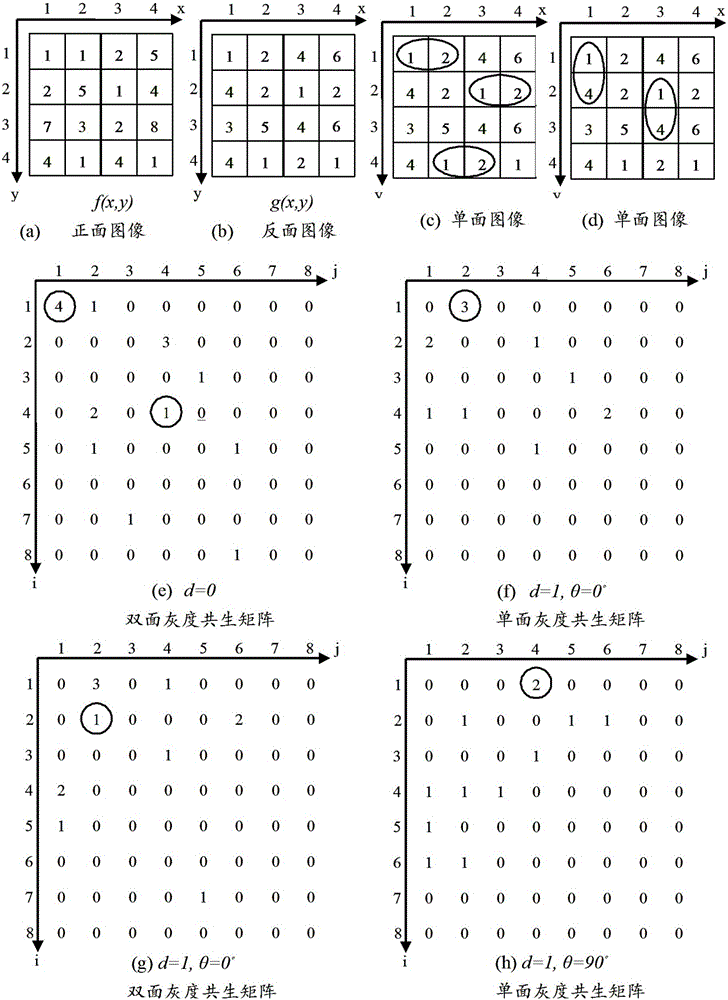

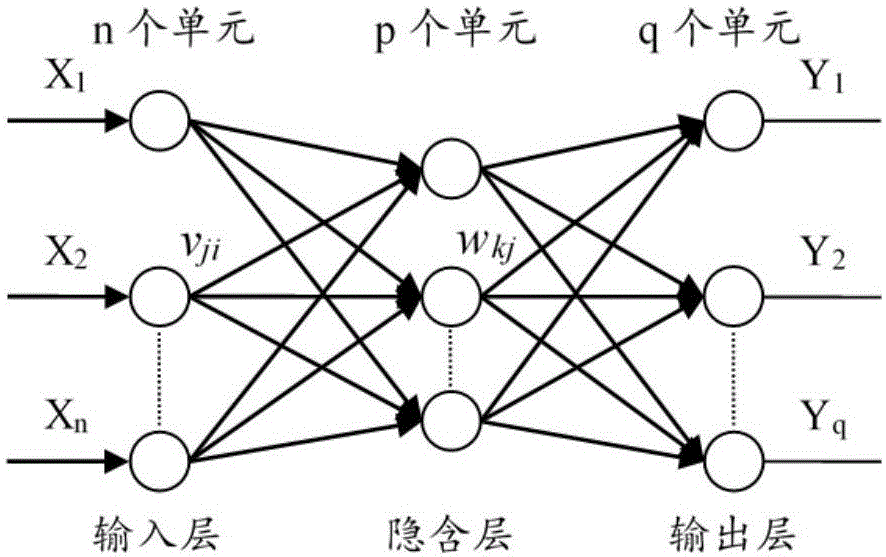

The invention provides a yarn dyed fabric texture type recognition method, which comprises three steps of building of a double-sided gray level co-occurrence matrix, extraction of texture feature parameters and building of a BP neural network model. Through the above three steps, the front image and the back image of the yarn dyed fabric are converted into gray level images, and in a condition with a certain direction and distance apart, the joint probability for appearing of pixel pairs formed by pixel points on the front image and pixel points on the back image is calculated; later, contrast, correlation, entropy and homogeneity are selected as parameters for describing the image textures, and numerical values are calculated; and the extracted four texture feature parameters serve as input vectors, a texture structure type serves as an output vector, and a three-layer BP neural network is built for recognizing the texture structure type of the yarn dyed fabric. Through training of a certain amount of samples, the yarn dyed fabric texture structure type recognition accuracy is thus enhanced.

Owner:SHANGHAI UNIV OF ENG SCI

Textured columbate leadless piezoelectric materials and method for making same

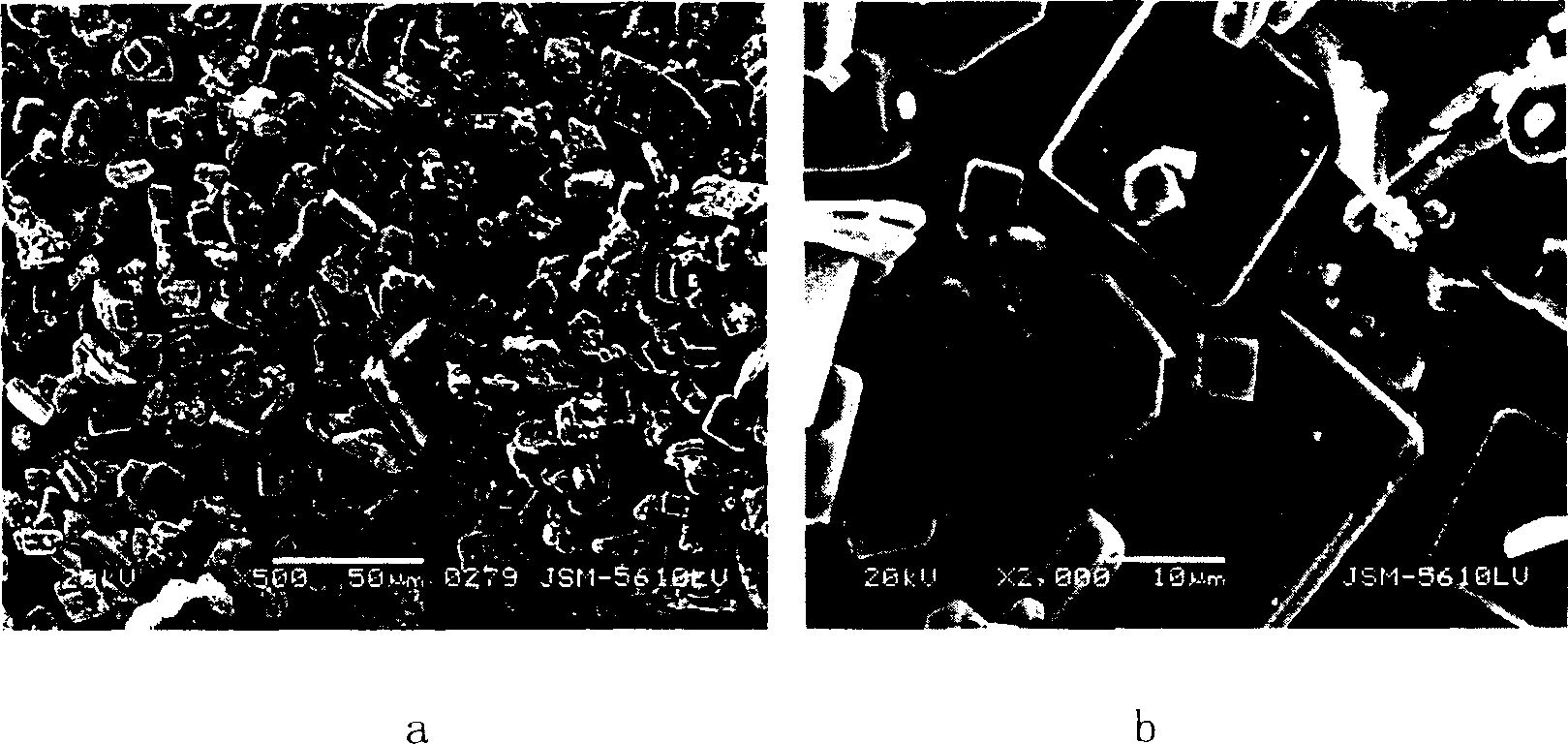

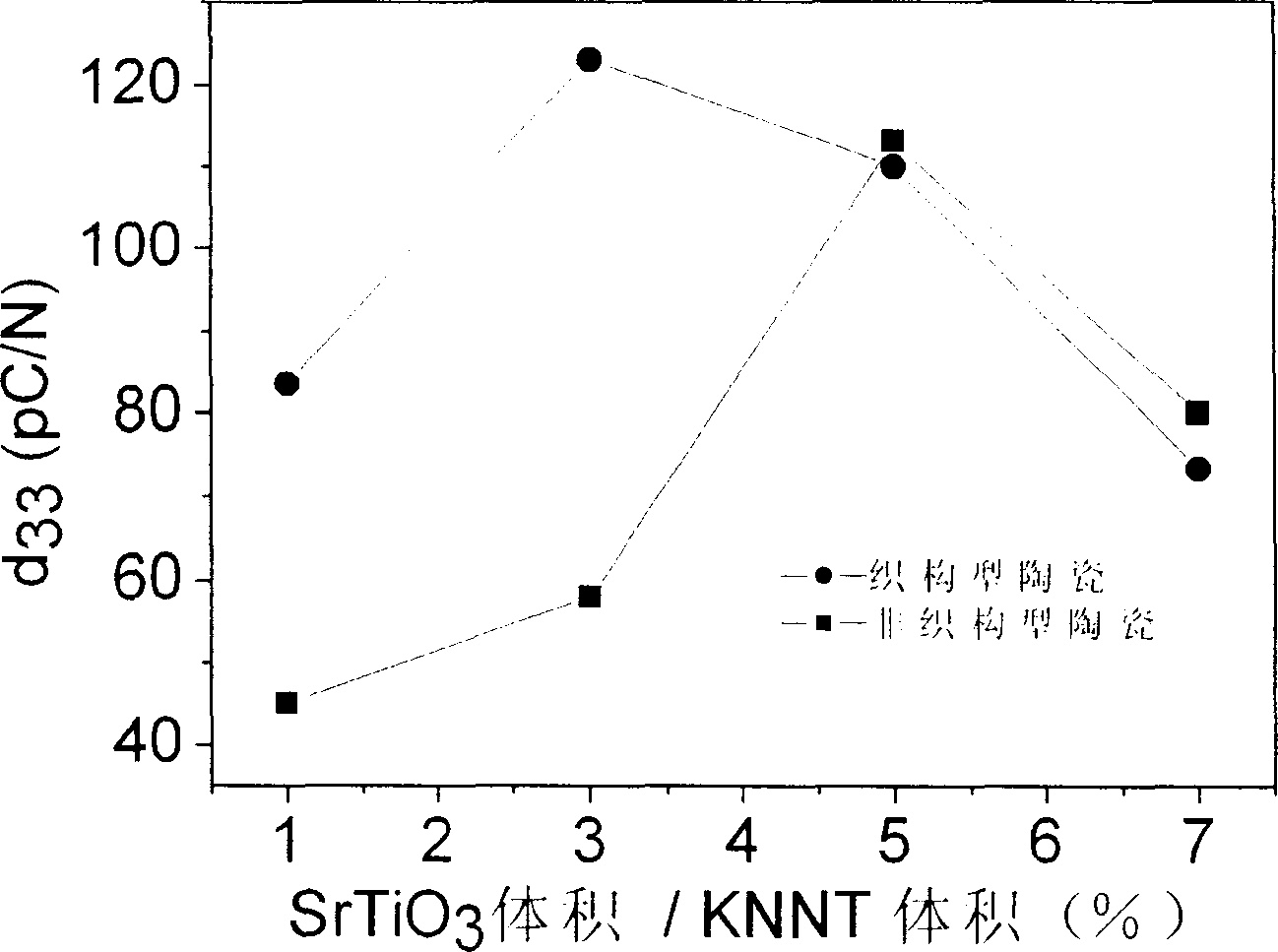

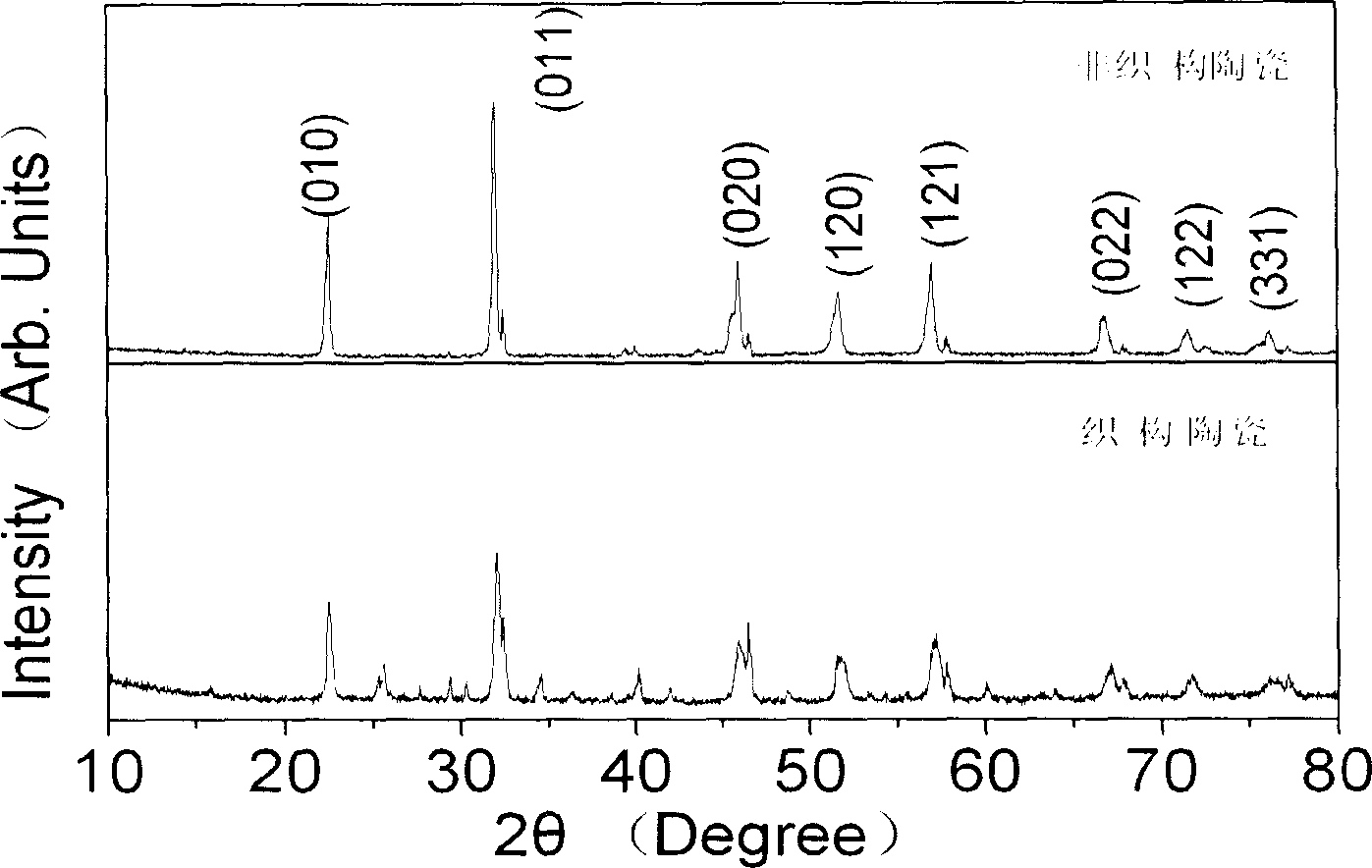

The invention relates a texture-type niobate leadless piezoelectric ceramic material and its preparation method. Said ceramic material, which is mixed with 1-30mol% of surface orientation sheet-like formwork material, mainly contains (K0.44Na0.52Li0.04)(Nb0.84Ta0.10Sb0.06)O3. The method for making comprises the following steps: according to stoichiometric ratio mixing powders of KHCO3, NaHCO3, Li2CO3, Nb2O5, Ta2O5 and Sb2O5; adding alcohol to mixture to be processed in ball mill; drying it and adding adhesive to it; pressing it to block and presintering; comminuting and grinding; and so on. The invention can increase piezoelectric performance greatly.

Owner:WUHAN UNIV OF TECH

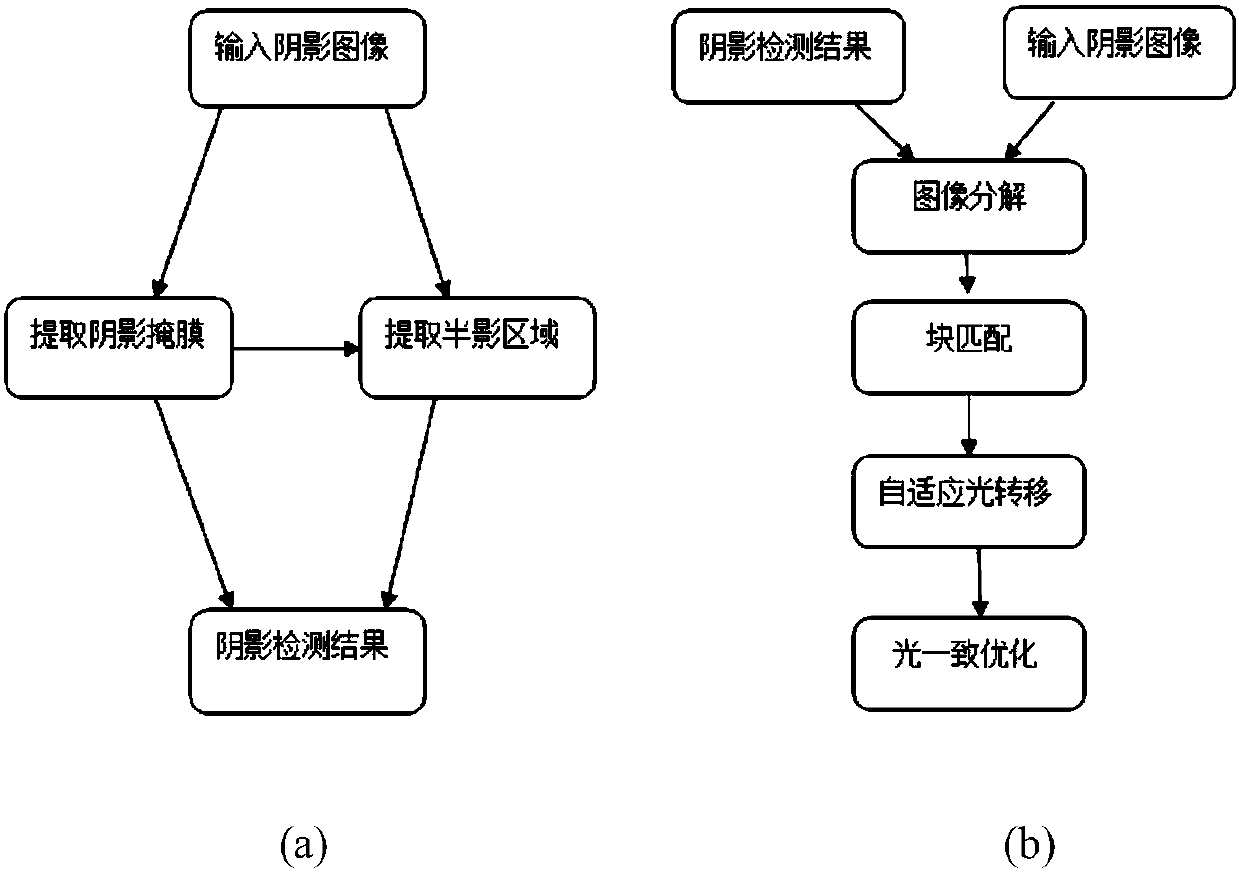

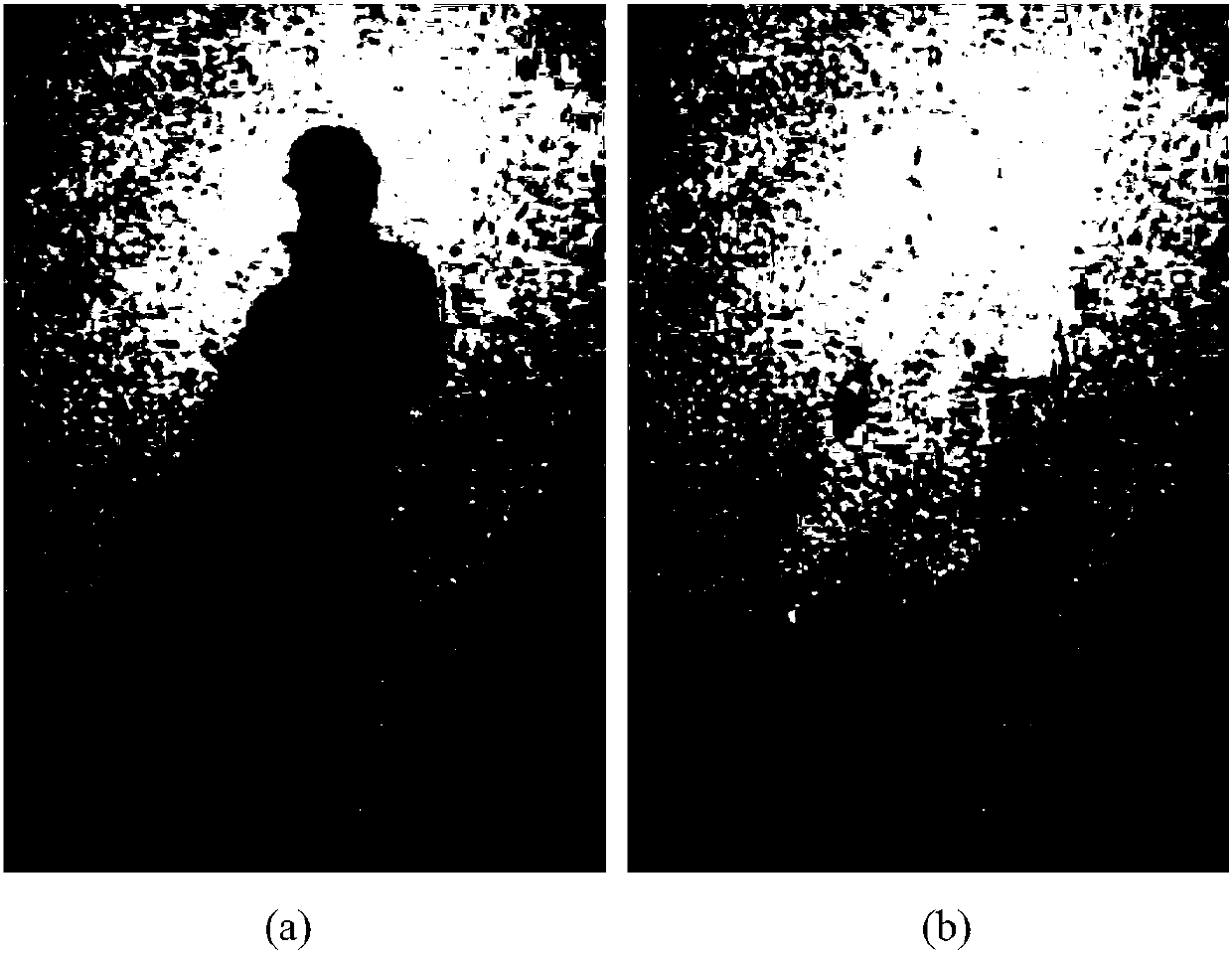

Self-adaptive light-transfer single-shadow removal method based on block matching

InactiveCN107808366AImprove protectionProtect texture informationImage enhancementImage analysisDecompositionAlgorithm

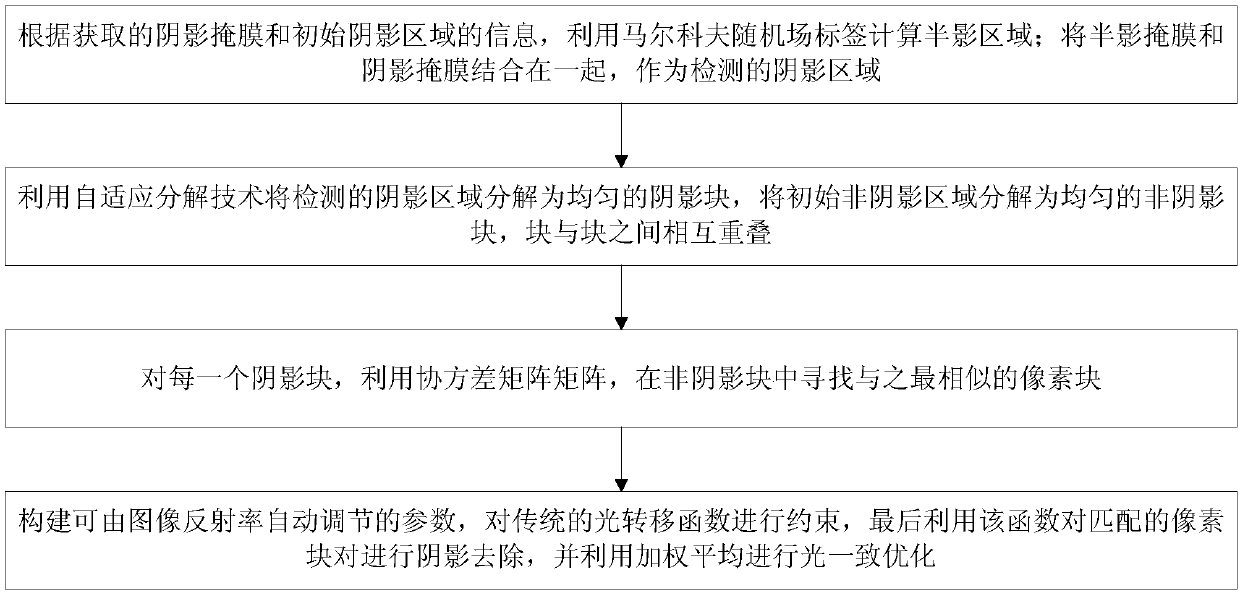

The invention discloses a self-adaptive light-transfer single-shadow removal method based on block matching. The method includes the following steps: utilizing Markov random field (MRF) labels to calculate a penumbra area according to information of an acquired shadow mask and an initial shadow area; combining a penumbra mask and the shadow mask together to use the same as a detected shadow area;utilizing self-adaptive decomposition technology to decompose the detected shadow area into uniform shadow blocks, and decomposing an initial non-shadow area into uniform non-shadow blocks, wherein the blocks mutually overlap; for each shadow block, utilizing a covariance matrix to find a pixel block, which is most similar to the same, in the non-shadow blocks; and constructing parameters, which can be automatically adjusted by image reflectivity, to constrain a conventional light-transfer function, finally utilizing the function to carry out shadow removal on matched pixel block pairs, and utilizing weighted averaging for light consistency optimization. The method can obtain high-quality shadow removal effects for all of non-uniform shadows, shadows of curved surfaces and shadows of multiple texture types.

Owner:TIANJIN UNIV

Waterborne exterior-wall paint and its preparation method

InactiveCN103360874ANo pollution in the processConstruction safety and non-toxicCoatingsEmulsionHardness

The invention relates to a waterborne exterior-wall paint and its preparation method. The paint comprises the following components: by weight, 20-50% of water, 15-45% of a nano-modified fluoropropionate emulsion, 1-20% of nano-modified polymer, 2-20% of rutile titanium dioxide, 1-10% of wollastonite powder, 1-10% of meerschaum powder, 0.2-10% of mica powder, 1-6% of glycol and a conventional auxiliary agent. The paint provided by the invention can be made into texture-type exterior-wall paint of different types and different colors. The paint film has characteristics of high weatherability, scrub resistance, stain resistance, high hardness, strong adhesion, good hydrophobicity, excellent ageing resistance and the like.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

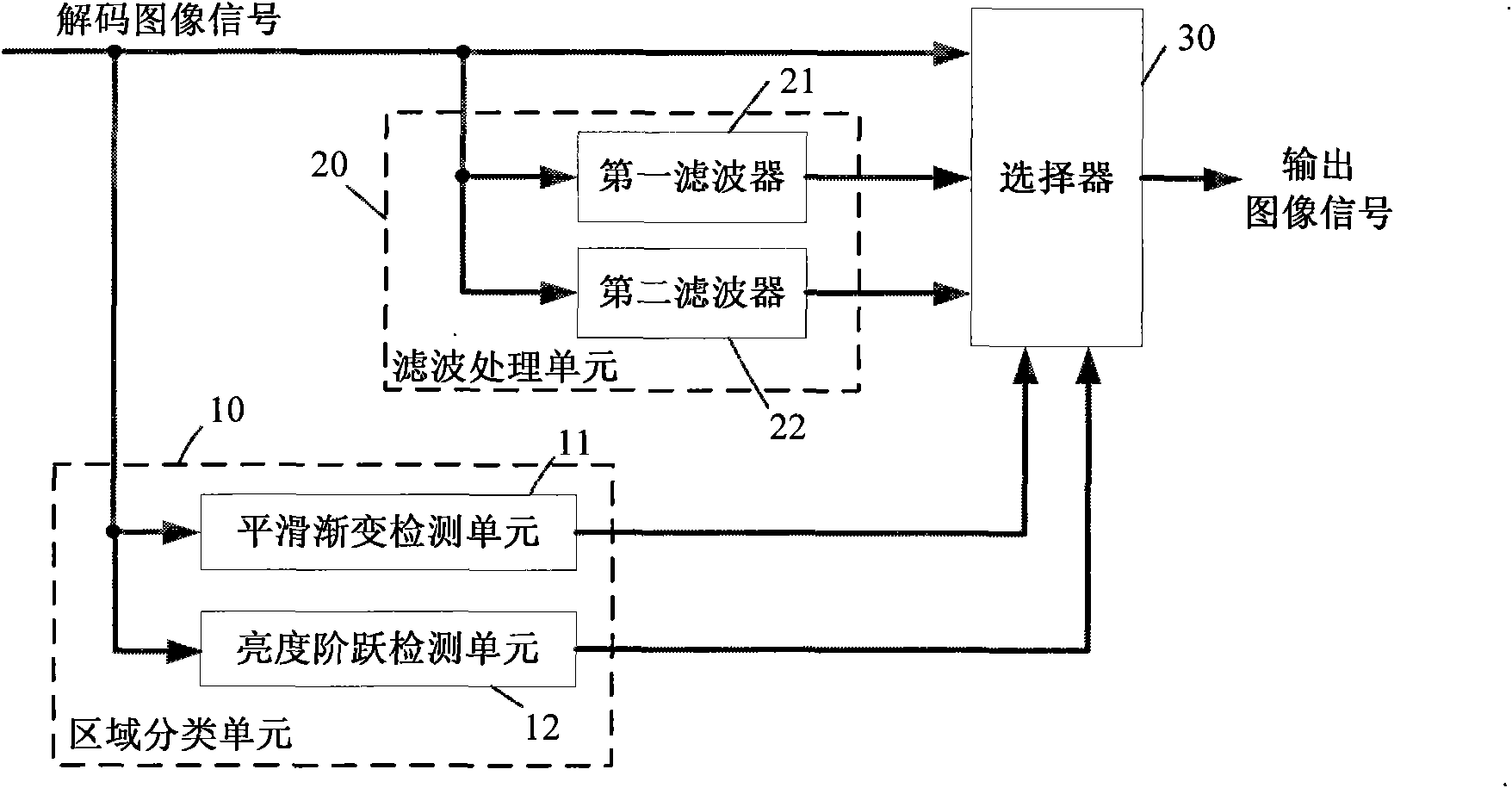

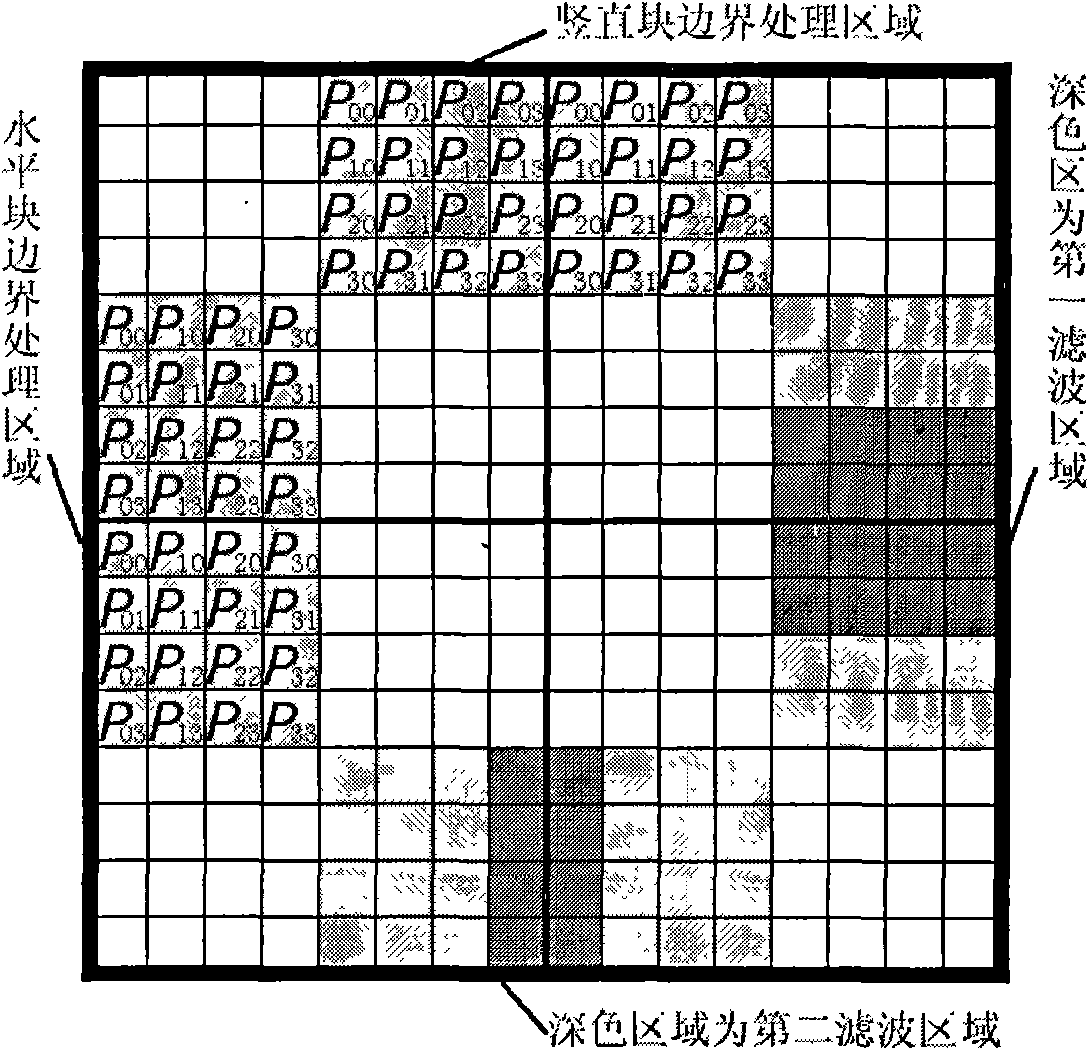

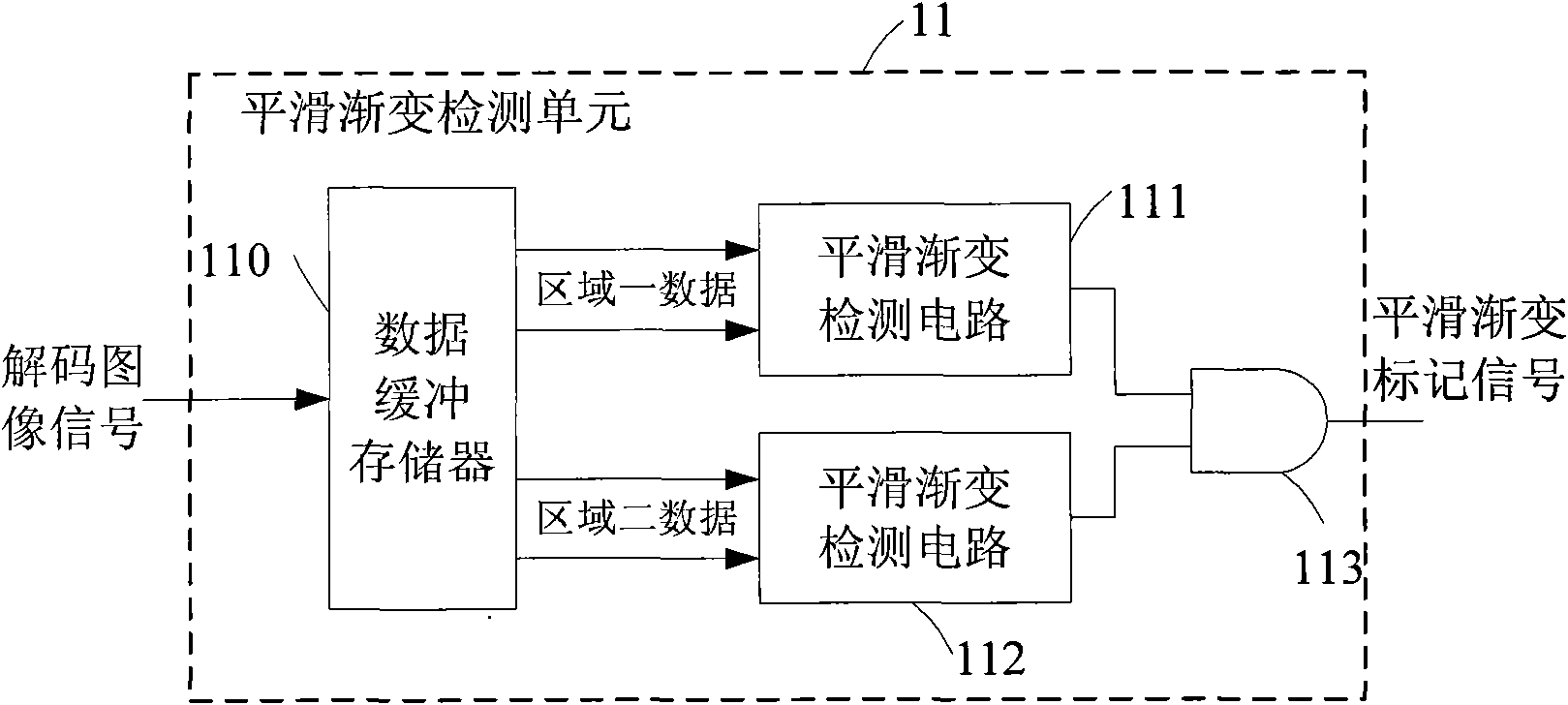

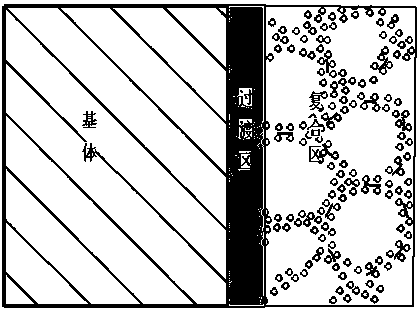

Blocky effect removal device for compression coded image

InactiveCN101616324AEfficient removalGood effectTelevision systemsDigital video signal modificationImage compressionBoundary region

The invention discloses a device for removing blocky effect possible to be produced at boundary of image after decoding as DCT coefficient is lost caused by quantification in image compression process. The device comprises a region classification unit, a filtering processing unit and a selector; firstly the region classification unit is used to detect block boundary region and mark the block boundary region as smooth gradient type, brightness phase step type and complex texture type, and then the selector selects a filter with corresponding smooth strength according to the output signal of the region classification unit to output or directly outputs the decoded image signal. The invention filters boundary regions in different types in different strength in a smoothing way, can effectively remove the blocky effect in the image and meanwhile detail section or high frequency components can be retained; in addition, the invention is non-iterative operation, the whole processing procedure can be completed by integer arithmetic and shift operation, the blocky effect can be removed in real time, and complexity of hardware realization is low while removal efficiency is higher and effect is better.

Owner:广州市花都区中山大学国光电子与通信研究院

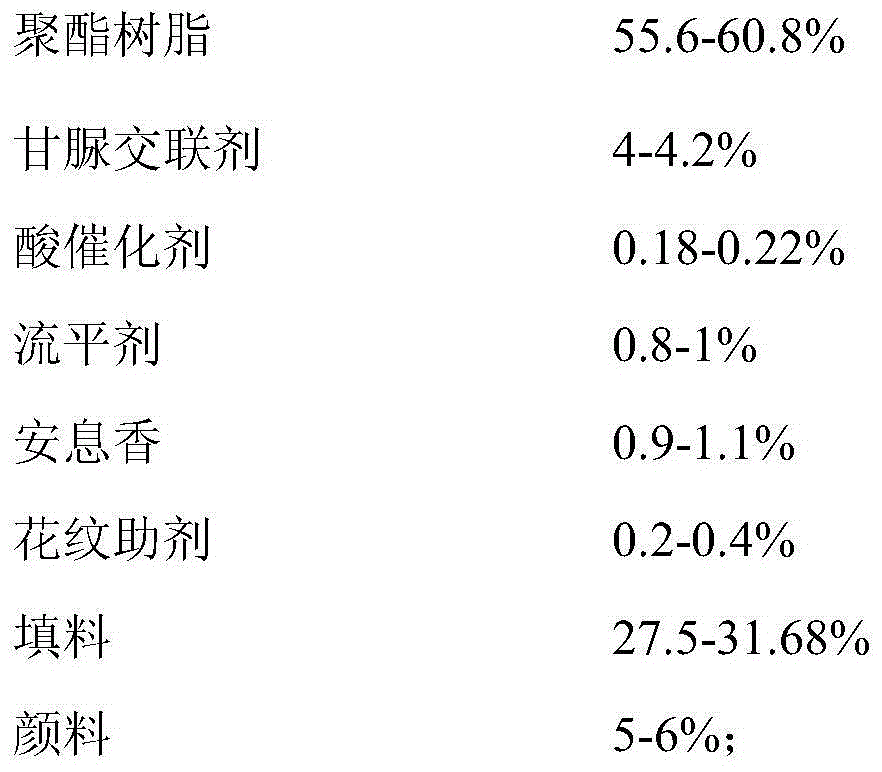

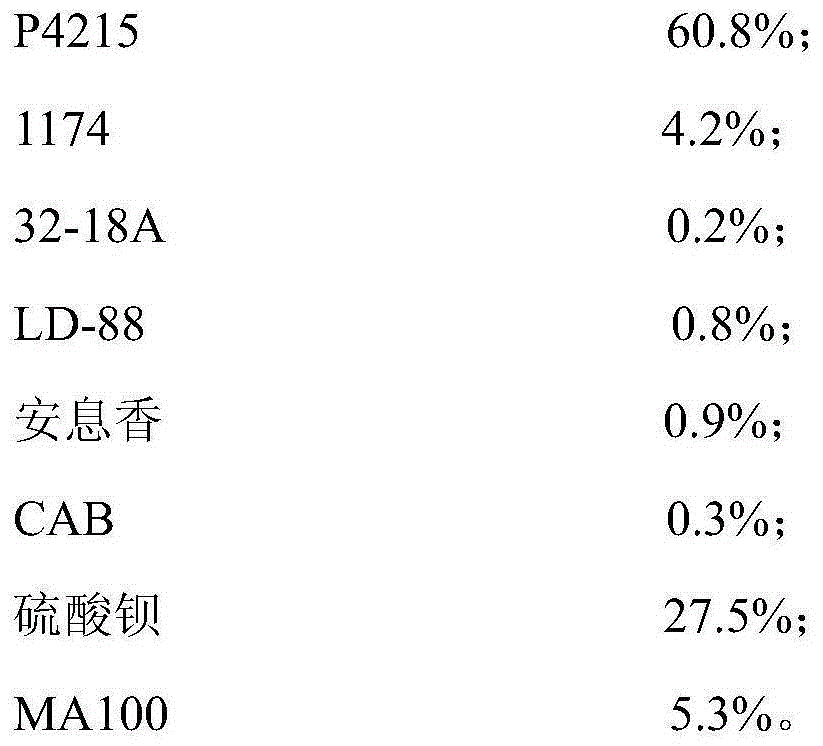

Continuous pattern type powder coating with flashing effect as well as preparation method and application thereof

PendingCN104877527AAchieve hiding powerImprove the decorative effectLuminescent paintsPowdery paintsGlycolurilAluminium powder

The invention belongs to the field of powder coating and particularly relates to a continuous pattern type powder coating with a flashing effect as well as a preparation method and application thereof. The powder coating is prepared by binding base powder and aluminum powder, wherein the base powder is prepared from the following raw materials in percentage by weight: 55.6 to 60.8 percent of polyester resin, 4 to 4.2 percent of glycoluril crosslinking agent, 0.18 to 0.22 percent of acid catalyst, 0.8 to 1 percent of leveling agent, 0.9 to 1.1 percent of benzoin, 0.2 to 0.4 percent of pattern assistant, 27.5 to 31.68 percent of filler and 5 to 6 percent of pigment. The preparation method of the continuous pattern type powder coating comprises the following steps of uniformly mixing raw materials, performing melt extrusion by an extruder, and performing tabletting, air cooling, grinding and sieving to obtain the base powder; binding the aluminum powder and the base powder to obtain the power coating; the prepared continuous pattern type powder coating with the flashing effect is cured to obtain a coating film product; according to the powder coating disclosed by the invention, the functions of covering power, color and metal flashing effect of a flash coating and an angle-dependent optical effect are achieved, effective combination of the aluminum powder and an art texture type powder coating with good decorative effect is realized, and a good development prospect is produced.

Owner:山东朗法博粉末涂装科技有限公司

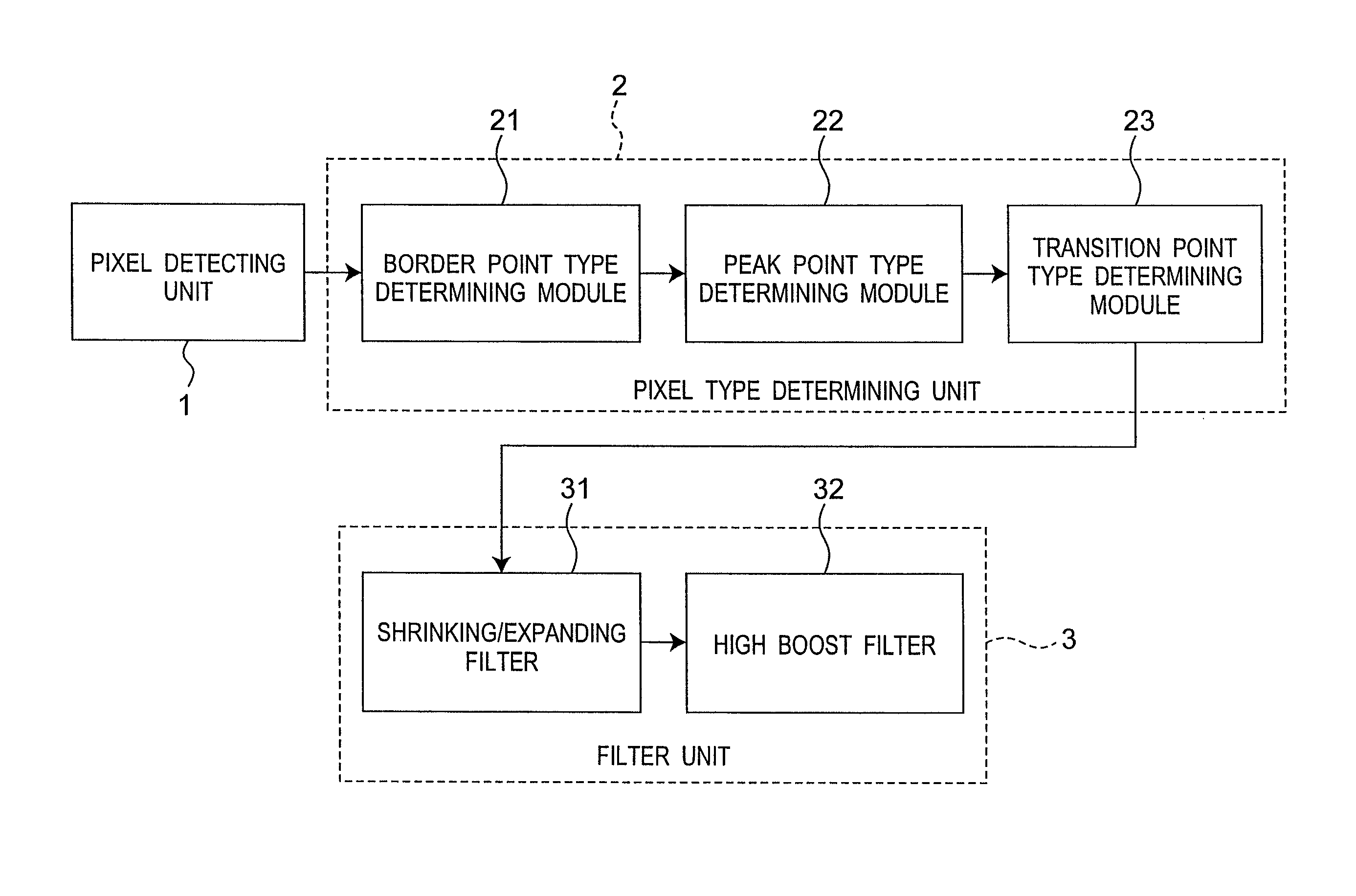

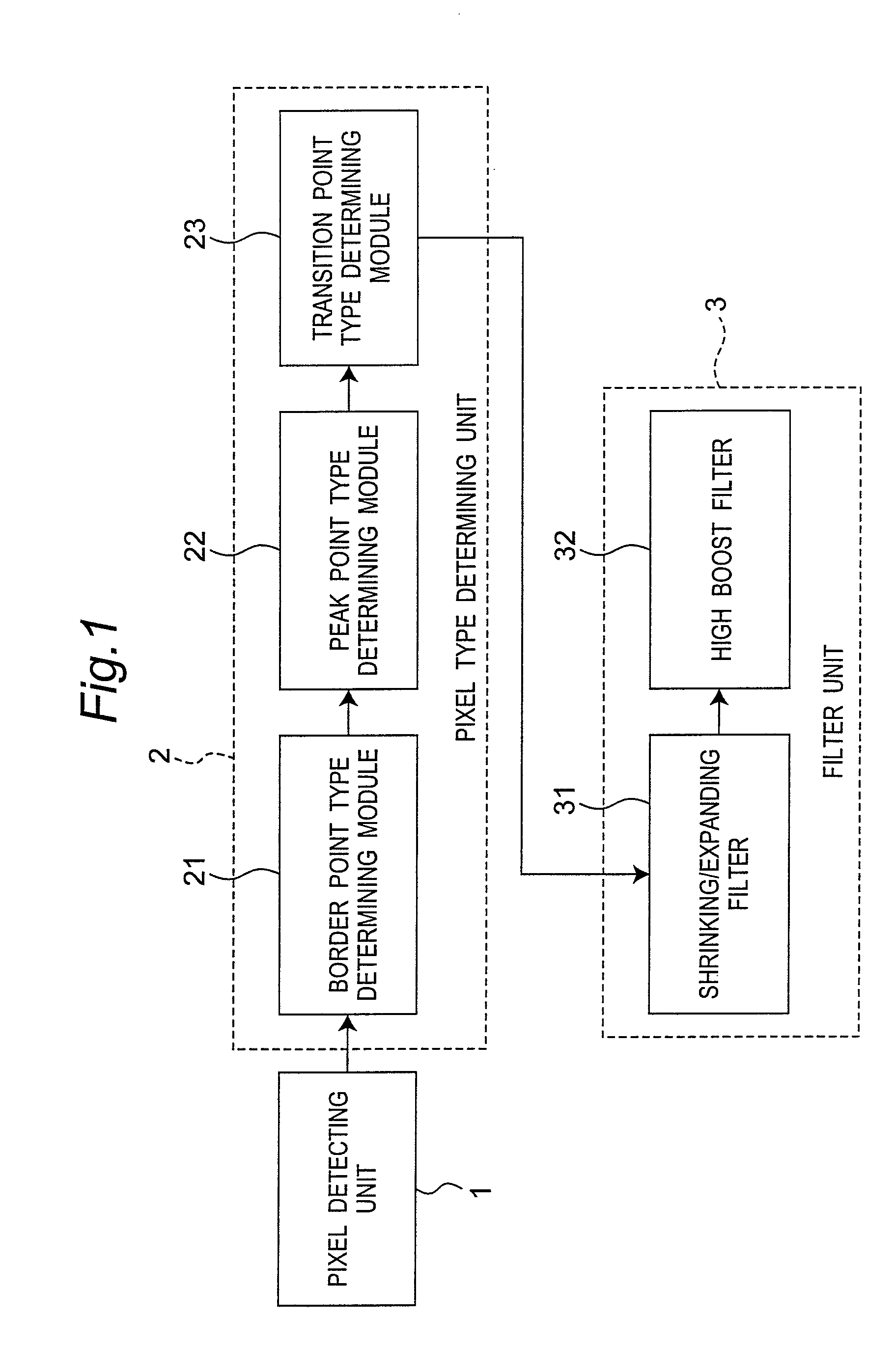

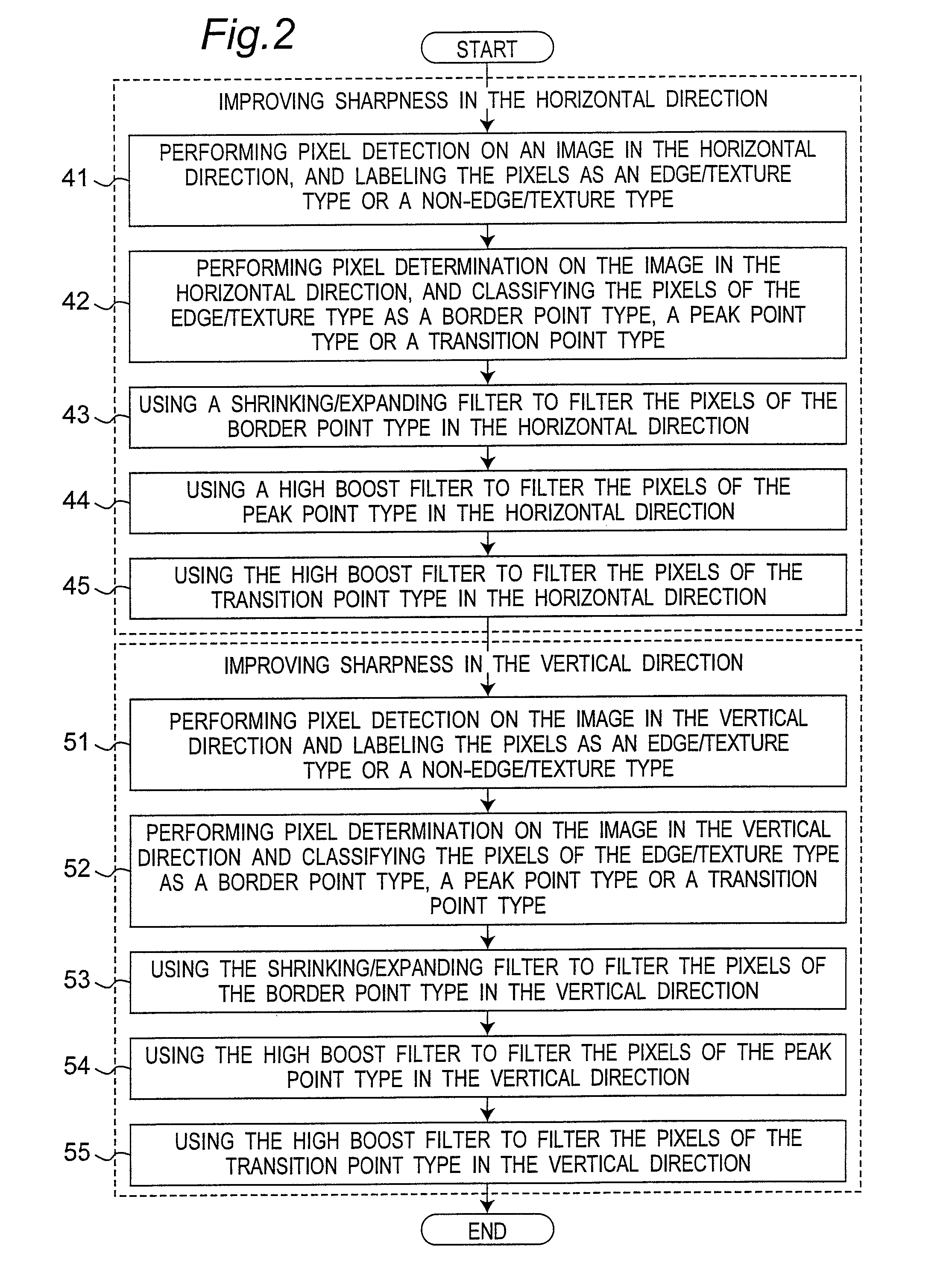

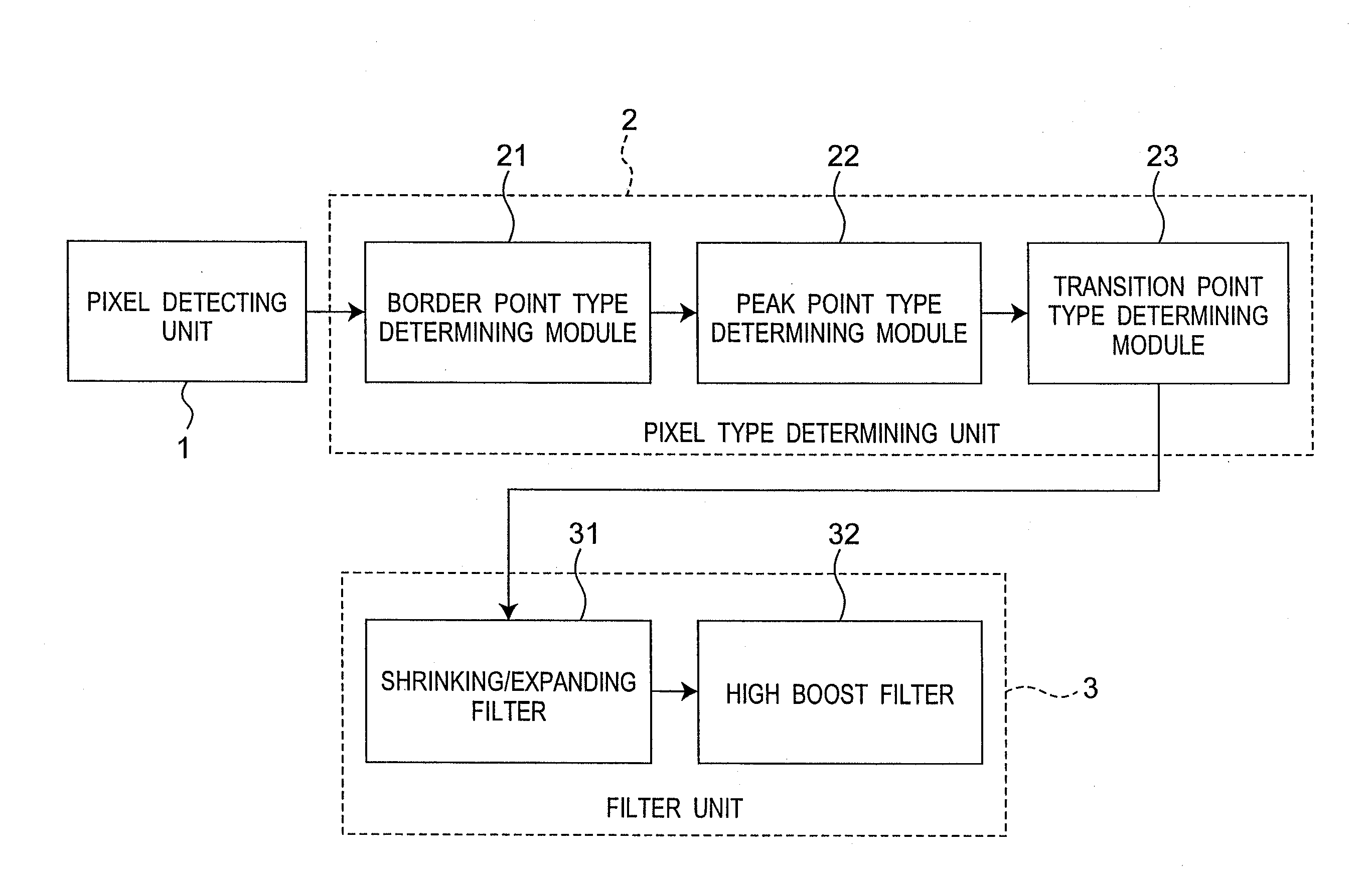

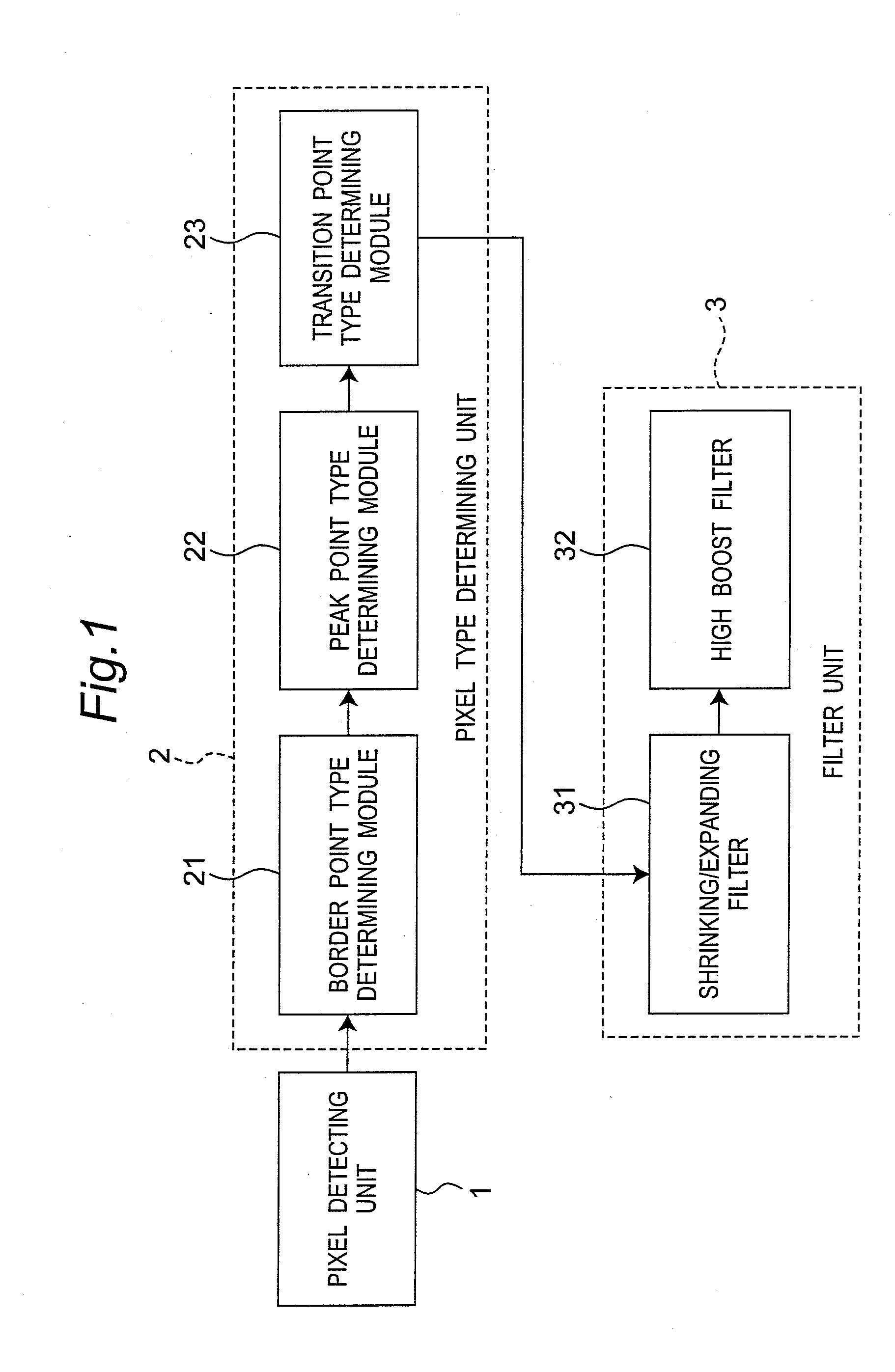

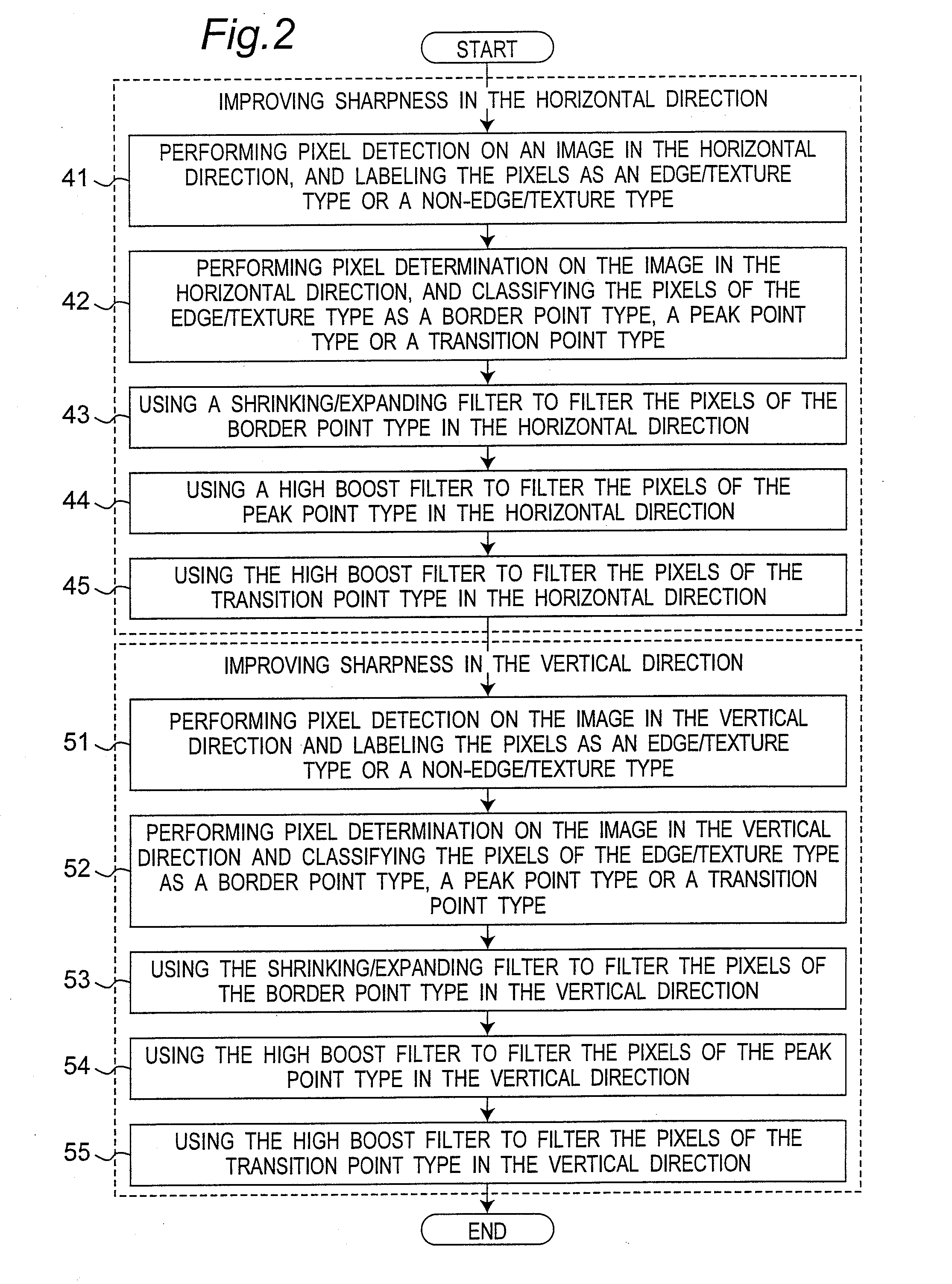

Method, apparatus and integrated circuit for improving image sharpness

InactiveUS8265416B2Improve imaging claritySharpen imageTelevision system detailsImage enhancementPeak valueComputer vision

In a method, apparatus and integrated circuit for improving image sharpness, the method includes the following steps: (a) labeling each of pixels in an image as one of an edge / texture type and a non-edge / texture type; (b) classifying each of the pixels that are labeled as the edge / texture type into one of a border point type, a transition point type, and a peak point type; and (c) using a shrinking / expanding filter to filter the pixels of the border point type, and subsequently using a high boost filter to first filter the pixels of the peak point type and then filter the pixels of the transition point type to sharpen the image.

Owner:PANASONIC CORP

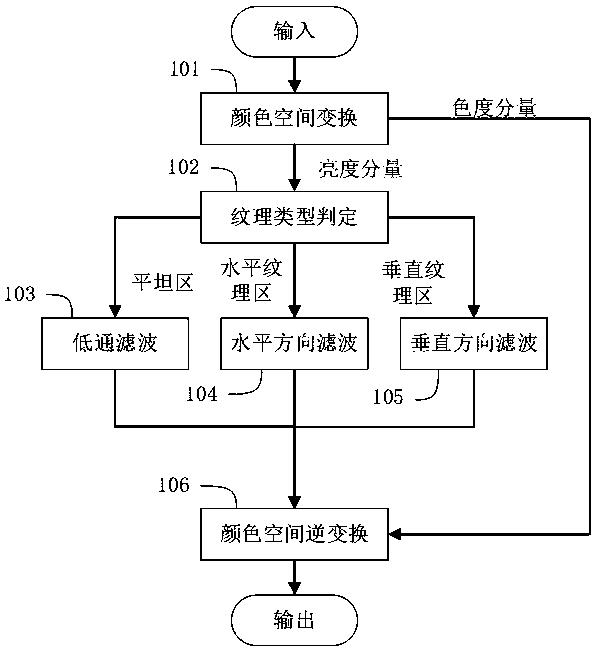

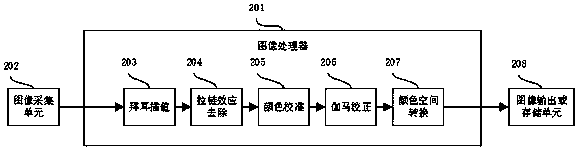

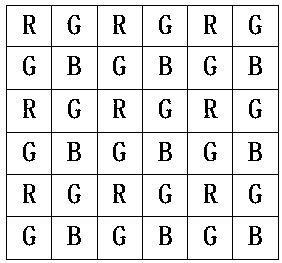

Removal method of zipper effect of bayer interpolation

The invention discloses a removal method of a zipper effect of bayer interpolation. The bayer interpolation is a device of interpolating missing color components of pixel points of a color filter array; and the zipper effect is an image error appearing most easily in the bayer interpolation. According to the characteristics that the zipper effect mutational in a brightness domain and even in a chroma domain, the method comprises the steps of converting RGB (red, green and blue) image data after the bayer interpolation to a brightness-chroma color space (such as YUV and Lab) via color space transformation, determining texture types of regions where pixel points of an image brightness component are located one by one, performing low-pass filtration in case of an even region, performing horizontal and vertical filtration in case of a horizontal or vertical marginal region, constituting a new image with the filtered image brightness component and the original chroma component, and performing color space inverse transformation to form a final RGB image. The method can effectively eliminate the zipper effect generated by the bayer interpolation and significantly improves image quality.

Owner:珠海亿智电子科技有限公司

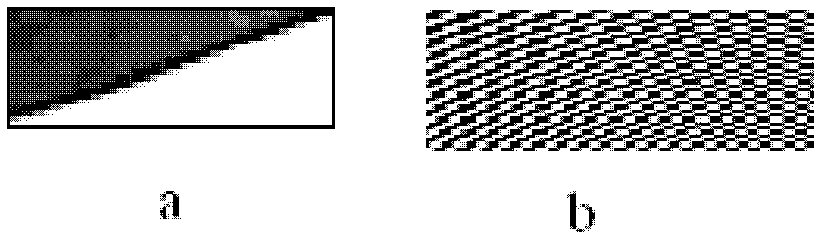

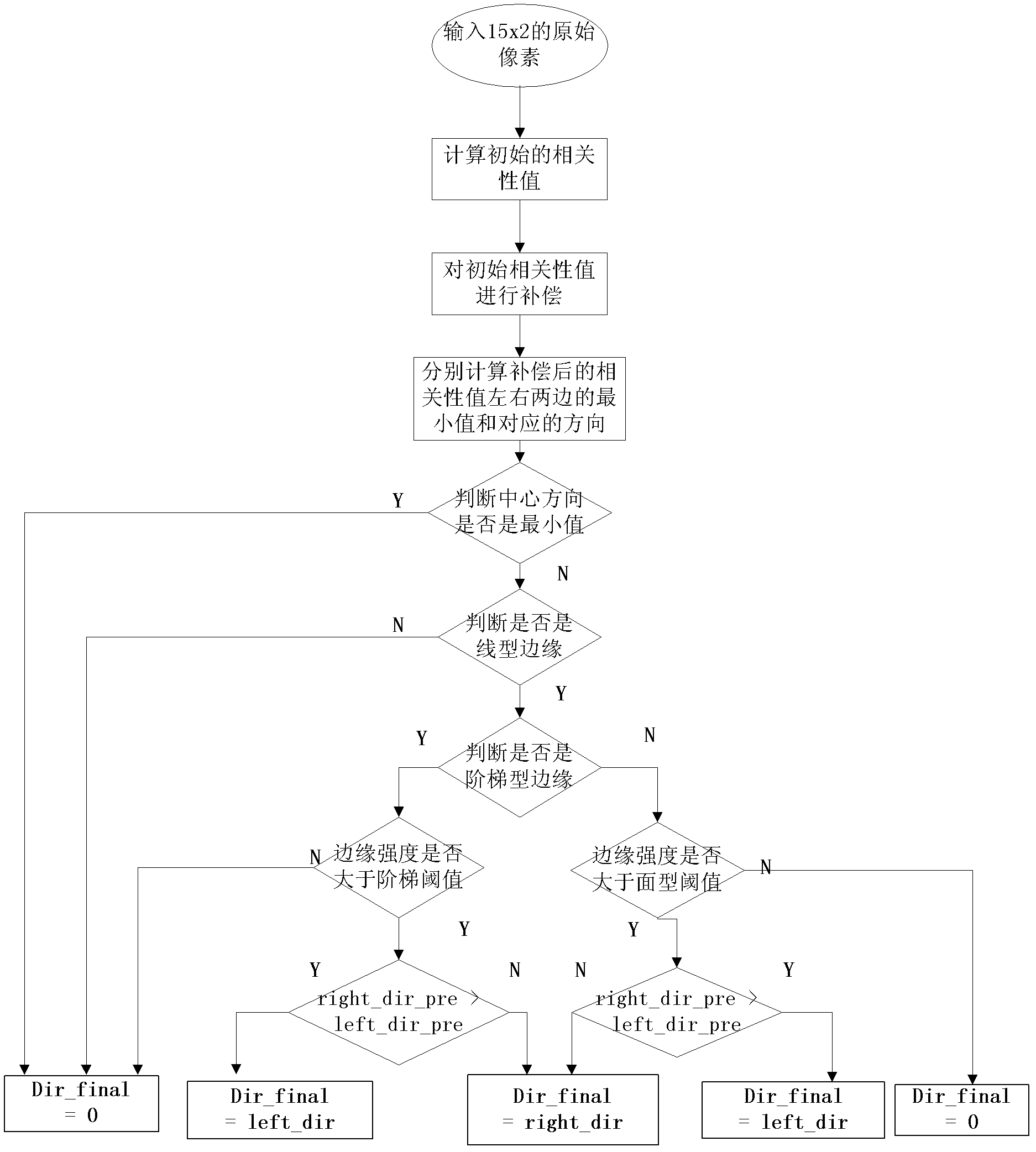

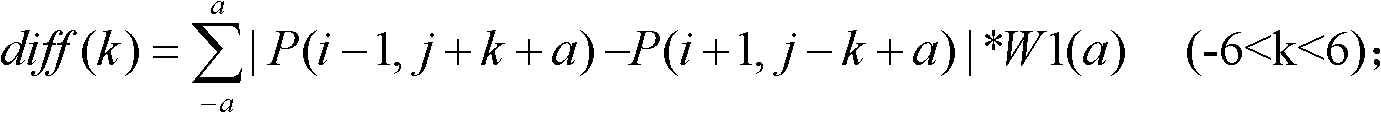

Edge adaptive de-interlacing interpolation method

ActiveCN102497524AGood edge protectionTelevision system detailsColor television detailsPattern recognitionEdge strength

The invention relates to an edge adaptive de-interlacing interpolation method. The method comprises the following steps of: a, calculating the sum of the difference value of each direction pixel pair to obtain a primary correlation value; b, correcting and compensating the correlation value; c, preferentially selecting a central direction; d, according to the texture type of an area in which a present pixel point is, comparing the edge strength of the present pixel point with a set threshold to obtain the final interpolation direction; e, obtaining a candidate pixel value of a present interpolation point according to the interpolation direction; and f, performing median filtering on an upper point and a lower point of the present interpolation point pixel, and the candidate pixel value obtained in the step e to obtain the final interpolation pixel. By the edge adaptive de-interlacing interpolation method, high edge protection ability is endowed to an image pixel, and a de-interlacing image with a smooth edge and no flash of details can be obtained.

Owner:SICHUAN PANOVASIC TECH

Method of preparing mesophase pitch by means of naphthene-based vacuum gas oil co-carbonization

InactiveCN104498072ARealize cross-linking modificationHigh softening pointWorking-up pitch/asphalt/bitumen by chemical meansHydrogen atmosphereCarbonization

The invention provides a method of preparing mesophase pitch. The method comprises the following steps: with the furfural extract oil of naphthene-based crude oil vacuum gas oil as raw material, carrying out oxidative cross-linking modification on the raw material by air to obtain an intermediate product; carrying out a co-carbonization treatment on the intermediate product under the synergetic hydrogen supply action of a hydrogen atmosphere and a hydrogen supply solvent to obtain the mesophase pitch, wherein the hydrogen supply solvent is 1,2,3,4-tetrahydroquinoline, and the adding amount is 5-20wt% of the amount of the raw material. According to the method provided by the invention, the cross-linking modification of the raw material is realized by means of air oxidation, thus the softening point and the carbonization yield of the raw material are increased, and moreover, lots of oxygen atoms are not introduced in the molecules of the modified raw material, thus the carbonization action thereof is not influenced; under the hydrogen atmosphere, an appropriate amount of the hydrogen supply solvent is added to carry out synergetic hydrogen supply co-carbonization with the cross-linked raw material, thus the carbonization reaction action of the raw material can be further improved. The mesophase pitch prepared by the method provided by the invention presents a flow state or a large texture-type state.

Owner:CHINA NAT OFFSHORE OIL CORP +2

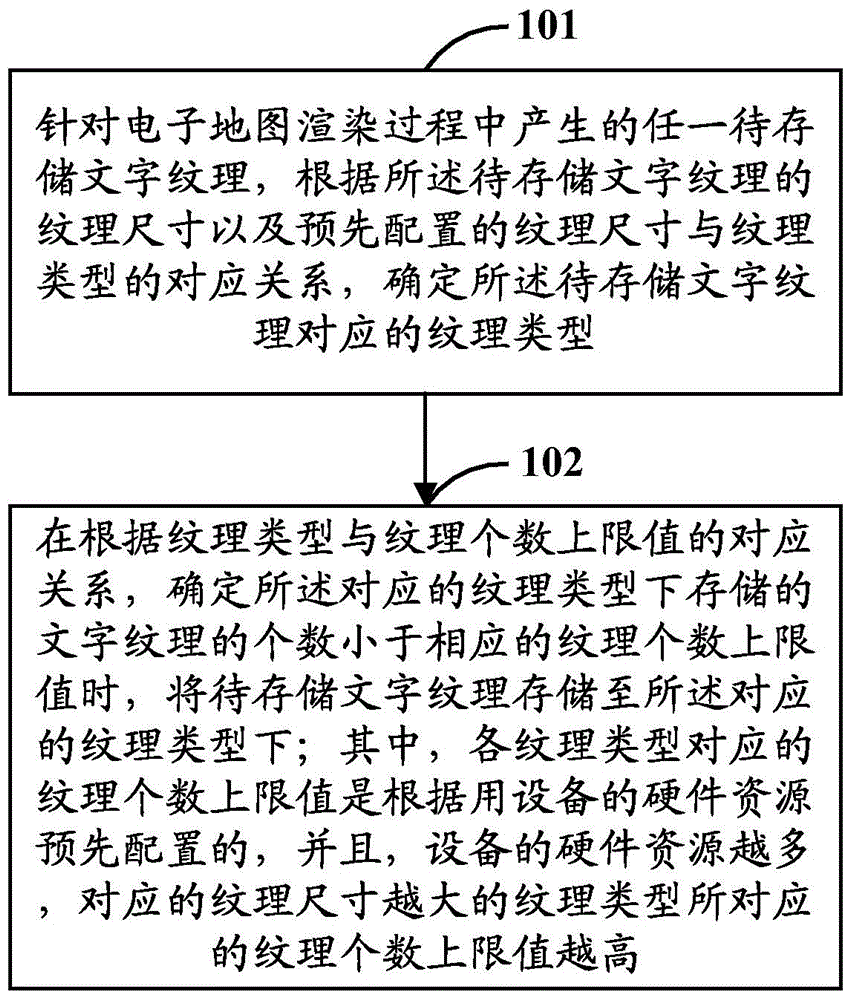

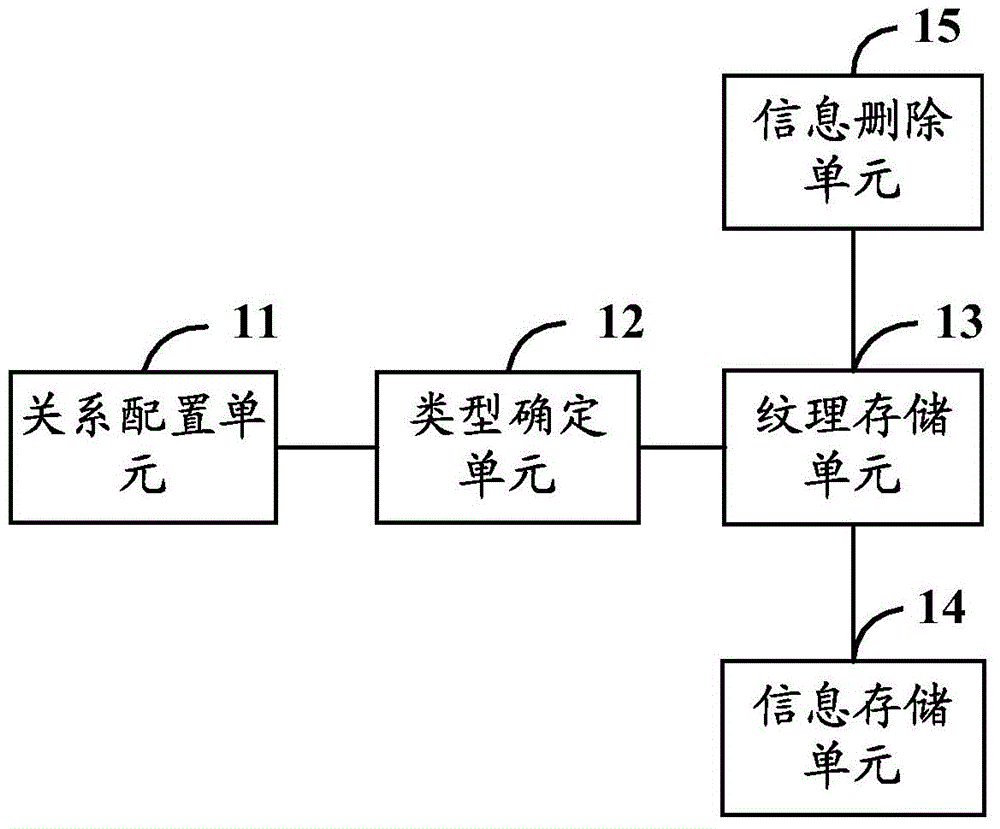

Character texture management method and device

ActiveCN105022758AMany additions and deletionsSpecial data processing applications3D-image renderingComputer graphics (images)Texture type

Disclosed are a method and device for managing a character texture. The method comprises: determining a texture type corresponding to any character texture to be stored according to a preset correspondence between texture sizes and texture types, and when it is determined that the number of textures stored under the corresponding texture type is smaller than a corresponding upper limit, storing the character texture to be stored under the corresponding texture type, wherein the upper limit of the number of textures under each texture type is configured according to hardware resources of a device, and the more the hardware resources of the device are, the higher the upper limit of the number of textures under a texture type having a correspondingly larger texture size is. In this scheme, the textures can be classified according to the texture sizes and the textures can be stored according to the texture types, and the more the hardware resources of the device are, the higher the upper limit of the number of textures under a texture type having a correspondingly larger texture size is. Therefore, the textures are prevented from being added or deleted too frequently in the current texture management, and thus the storage space of the device can be reasonably utilized.

Owner:ALIBABA (CHINA) CO LTD

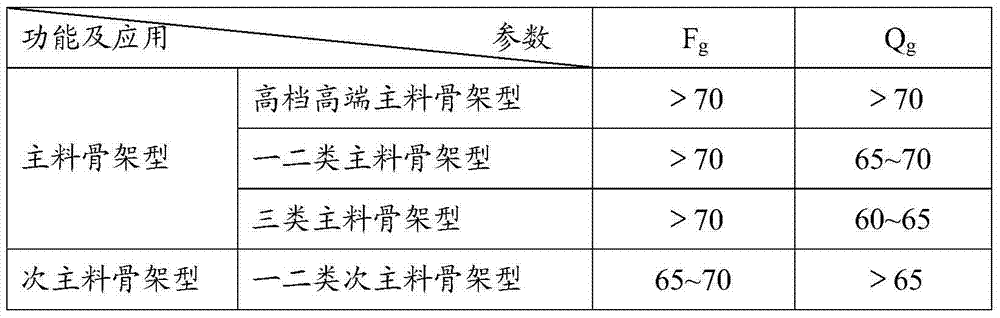

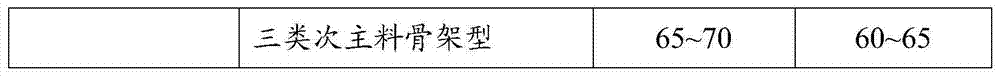

Building and application method for functional tobacco module

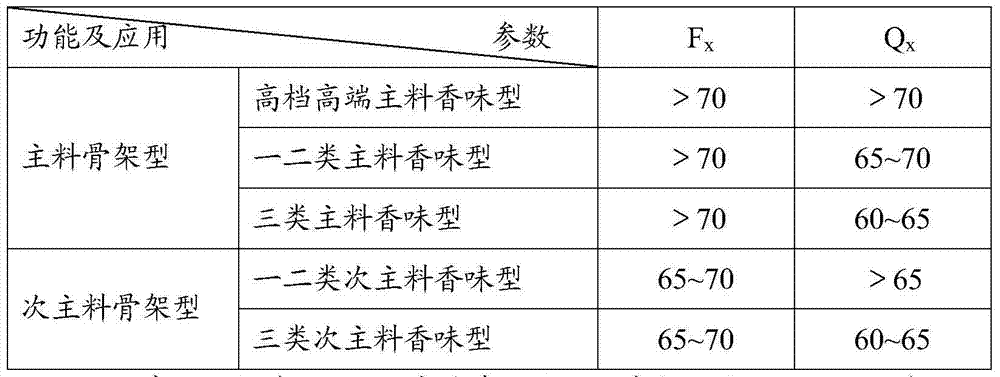

InactiveCN104323412AImprove objectivityImprove stabilityTobacco preparationChemical compositionComputer science

The invention relates to a building and application method for a functional tobacco module. The method comprises the following steps of dividing tobaccos into skeleton type tobaccos, fragrance type tobaccos and texture type tobaccos by a judgment model based on sensory evaluation; detecting the content of chemical components in the tobaccos, and performing stepwise regression analysis on the detected content of chemical components in the detected tobaccos, so as to obtain the skeleton type tobacco function parameter Fg and skeleton type tobacco quality parameter Qg of the skeleton type tobaccos, the fragrance type tobacco function parameter Fx and fragrance type tobacco quality parameter Qx of the fragrance type tobaccos, and the texture type tobacco function parameter Fz and texture type tobacco quality parameter Qz of the texture type tobaccos. The method has the advantages that the parameters of the applicable function tobacco module can be predicted by the built different function tobacco function parameter and quality parameter prediction models, the objectiveness and stability of evaluation on functions and application of the tobacco module are improved, and the effective and reasonable utilization of tobacco resources is guaranteed.

Owner:CHINA TOBACCO YUNNAN IND

Leather texture detection device

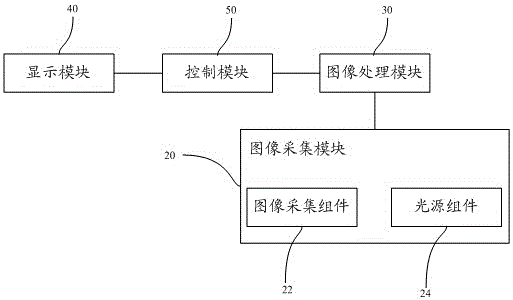

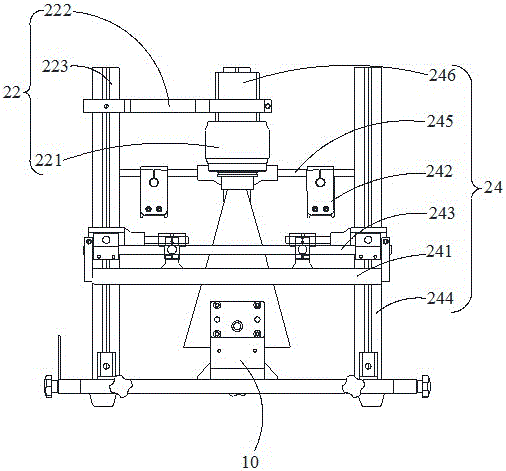

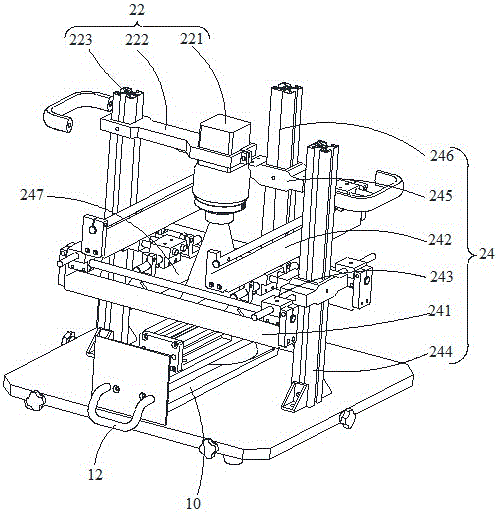

InactiveCN105021618AEasy to detectObjective detectionMaterial analysis by optical meansPattern recognitionImaging processing

The present invention is applicable to the technical field of leather detection, provides a leather texture detection device, and aims to solve the problem of leather texture objective classification detection in the prior art. The leather texture detection device includes a support bracket, an image collection module for texture image collection, and an image processing module, leather texture type can be obtained by calculation of leather texture features of obtained texture image by the image processing module, the image collection module comprises a light source component for irradiating light on to-be-detected leather surface and an image collection component. The leather texture detection device utilizes the light emitted from the light source component to irradiate on the to-be-detected leather surface, and uses the image collection component to collect the texture feature image of the to-be-detected leather surface, and the image processing module acquires the leather texture feature image for calculation and comparison to obtain the to-be-detected leather texture type, the detection is convenient and objective, and automated detection is facilitated.

Owner:深圳爱橙子科技有限公司

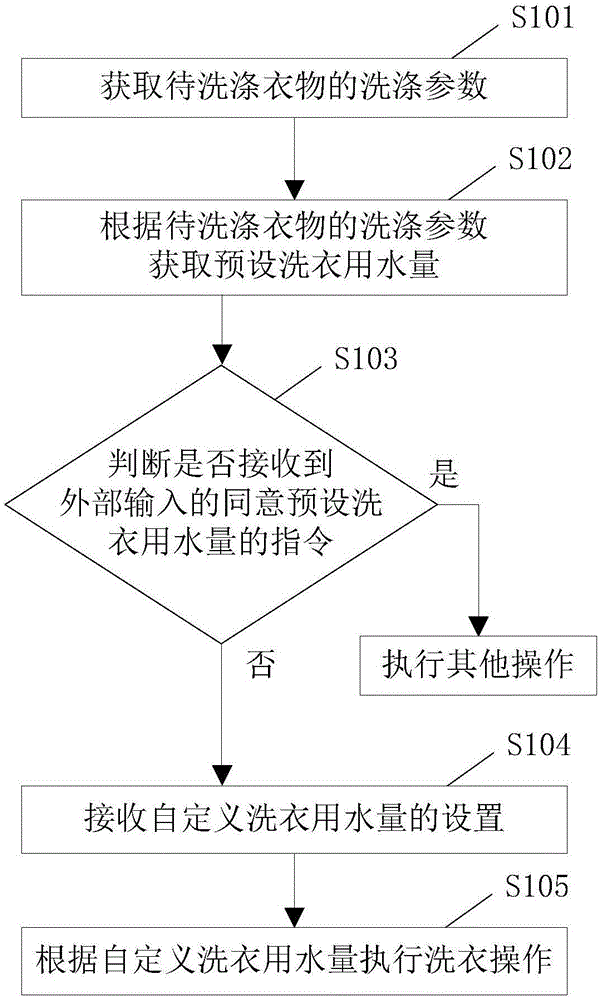

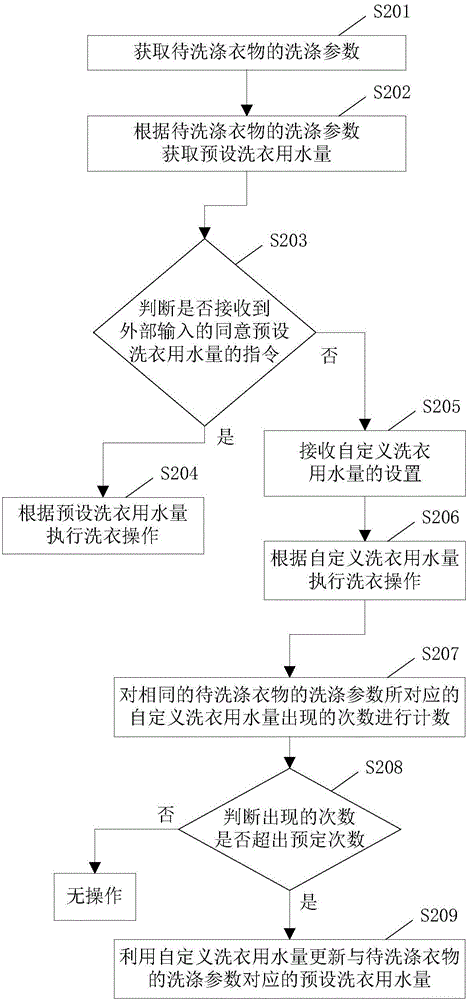

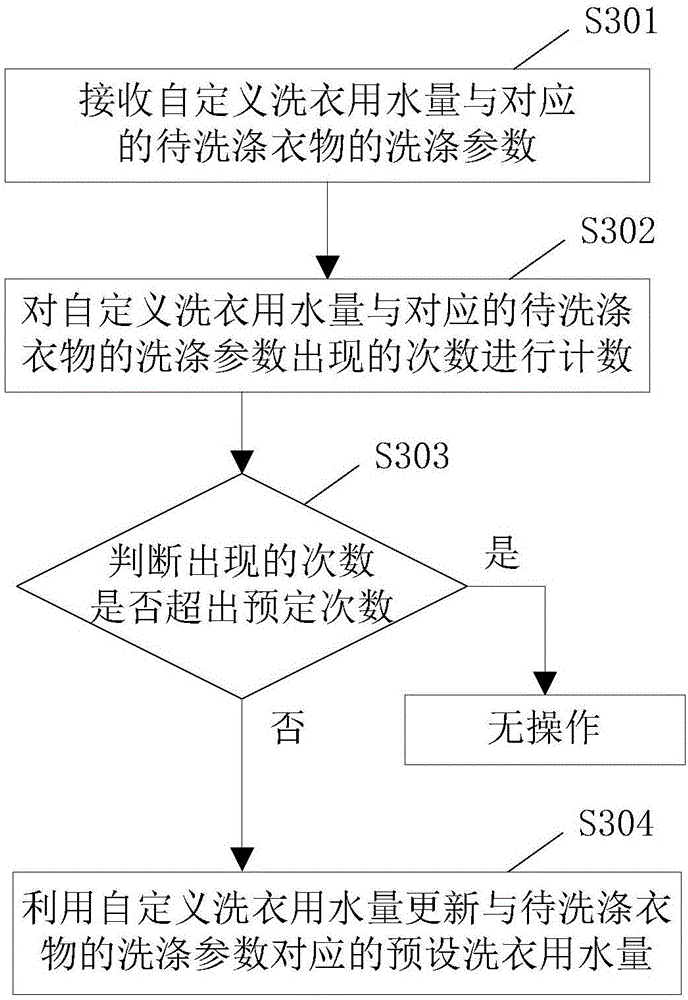

Control method and device of washing machine, and water use quantity updating method and device

ActiveCN106567221AFlexible settingsConserve waterControl devices for washing apparatusTextiles and paperWater useEngineering

The invention discloses a control method and a device of a washing machine, and a water use quantity updating method and a device. The control method comprises steps of acquiring washing parameters of to-be-washed clothes, wherein the washing parameters comprise initial weight and / or texture types of the to-be-washed clothes; according to the washing parameters of to-be-washed clothes, acquiring preset water use quantity for washing; judging whether an externally input instruction agreeing with the preset water use quantity is received or not; when an instruction denying the preset water use quantity is received, receiving setting of customized water use quantity; and according to the customized water use quantity, executing washing operation. According to the invention, the water use quantity can be flexibly set by a user according to specific conditions of the to-be-washed clothes, so water is saved.

Owner:GREE ELECTRIC APPLIANCES INC

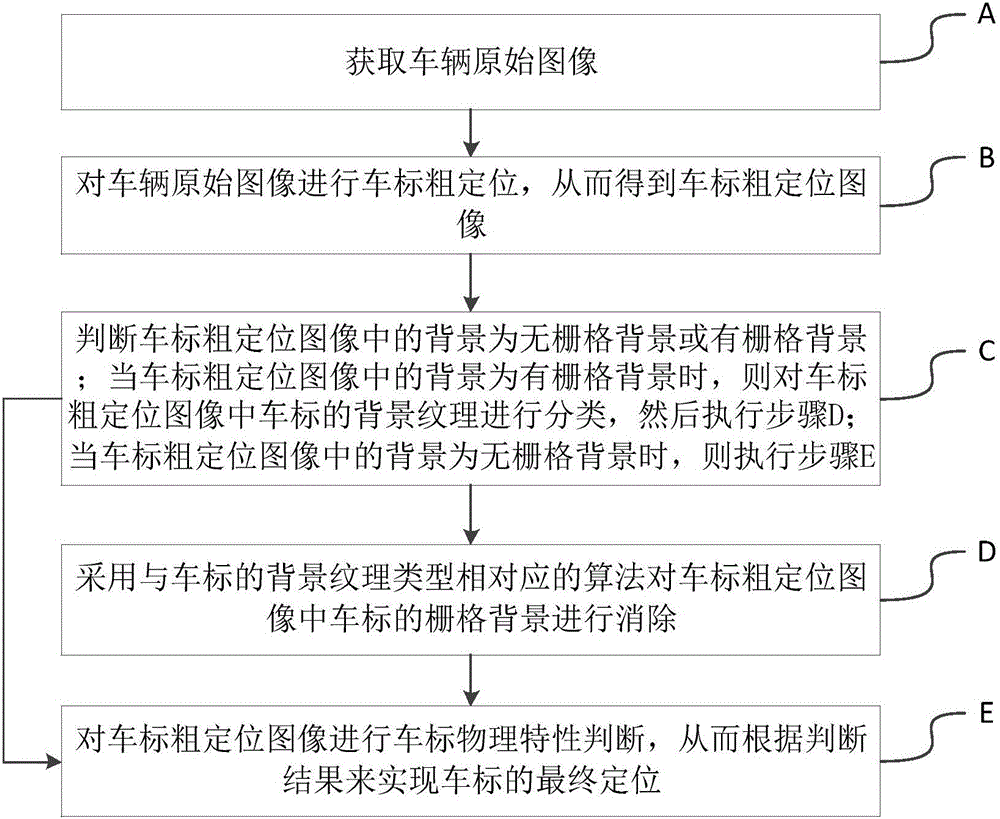

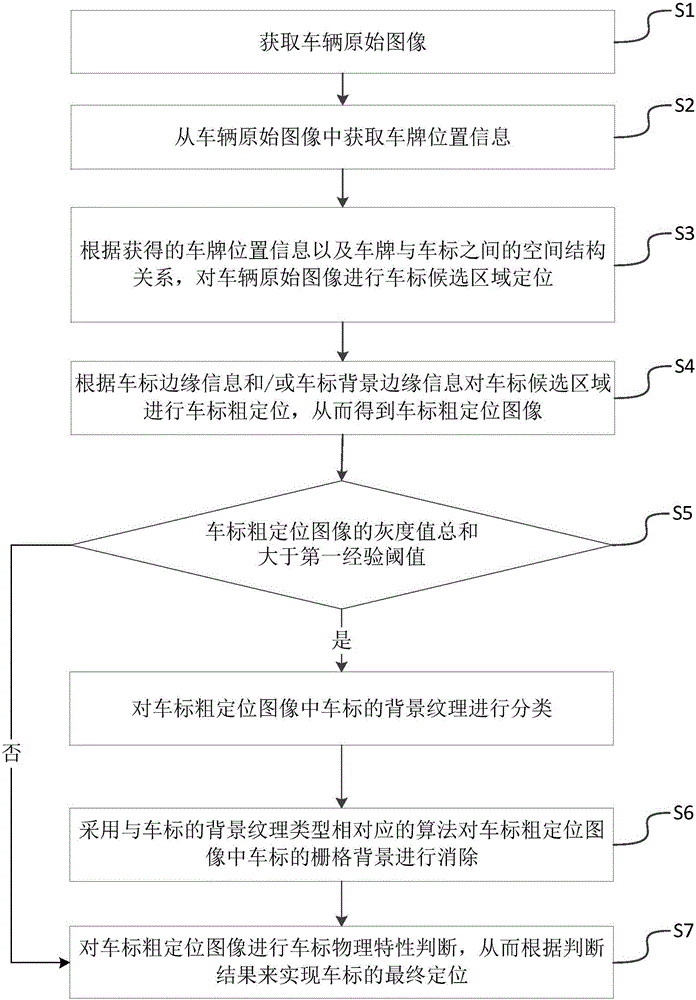

Vehicle logo location method based on radiator grid background ablation

ActiveCN105760876AImprove accuracyProcessing speedCharacter and pattern recognitionComputer visionComputer science

The invention discloses a vehicle logo location method based on radiator grid background ablation, comprising performing vehicle logo coarse location on a vehicle original image; determining the background in a vehicle logo coarse location image is a no-grid background or a grid background; if a grid background, classifying vehicle logo background textures in the vehicle logo coarse location image, employing an algorithm corresponding to a vehicle logo background texture type to eliminate the vehicle logo grid background in the vehicle logo coarse location image, determining vehicle logo physical characteristics of the vehicle logo coarse location image, and realizing final location of a vehicle logo according to a determination result; and if a no-grid background, determining vehicle logo physical characteristics of the vehicle logo coarse location image, and realizing final location of a vehicle logo according to a determination result. The vehicle logo location method possesses the advantages of low complexity, fast processing speed, high location accuracy, etc., and can be widely applied to the vehicle logo location field.

Owner:SUN YAT SEN UNIV

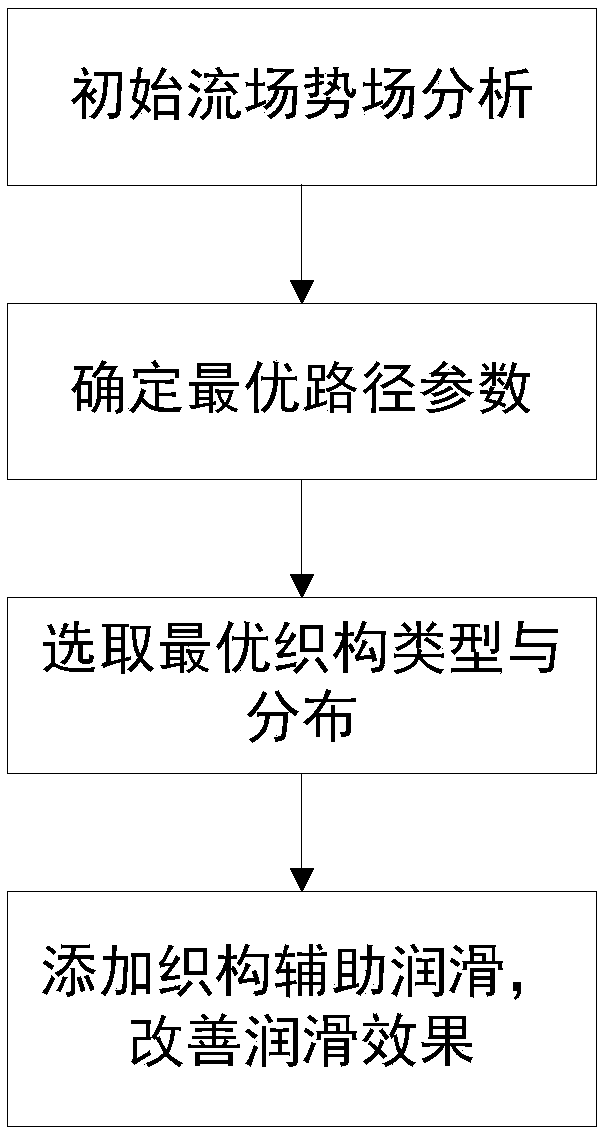

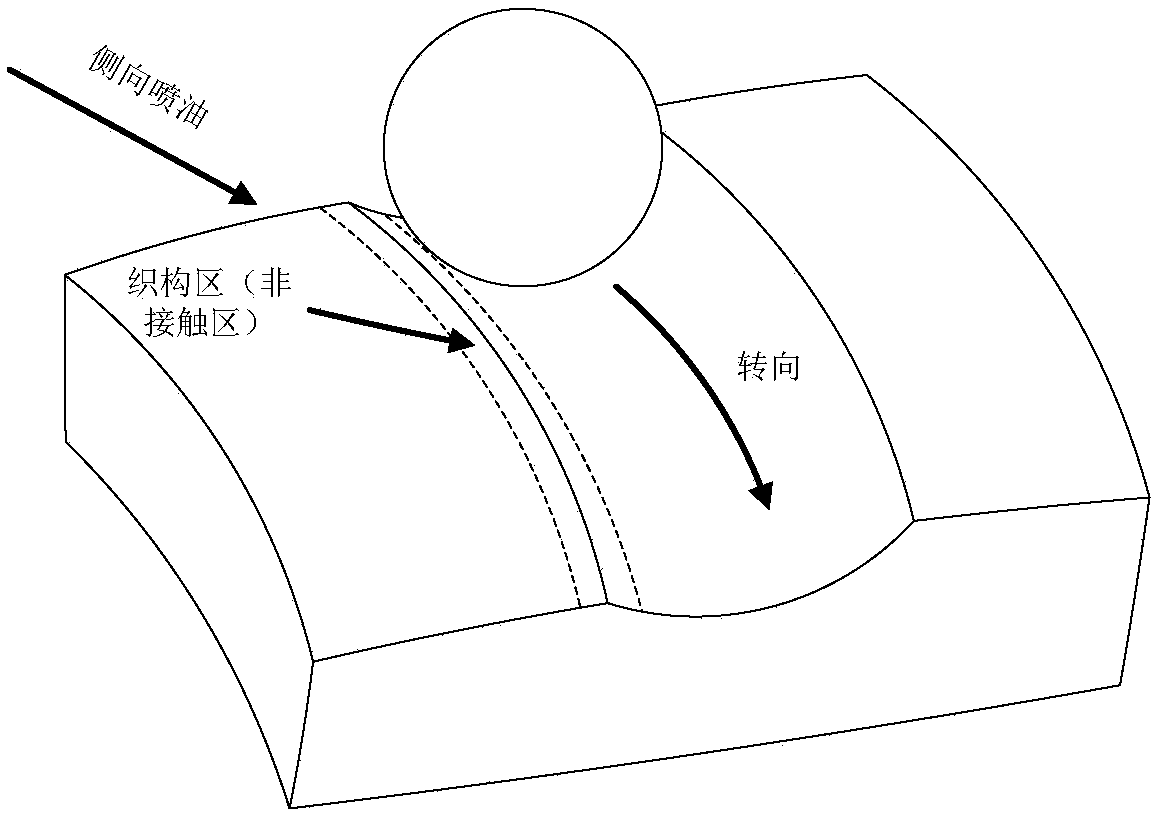

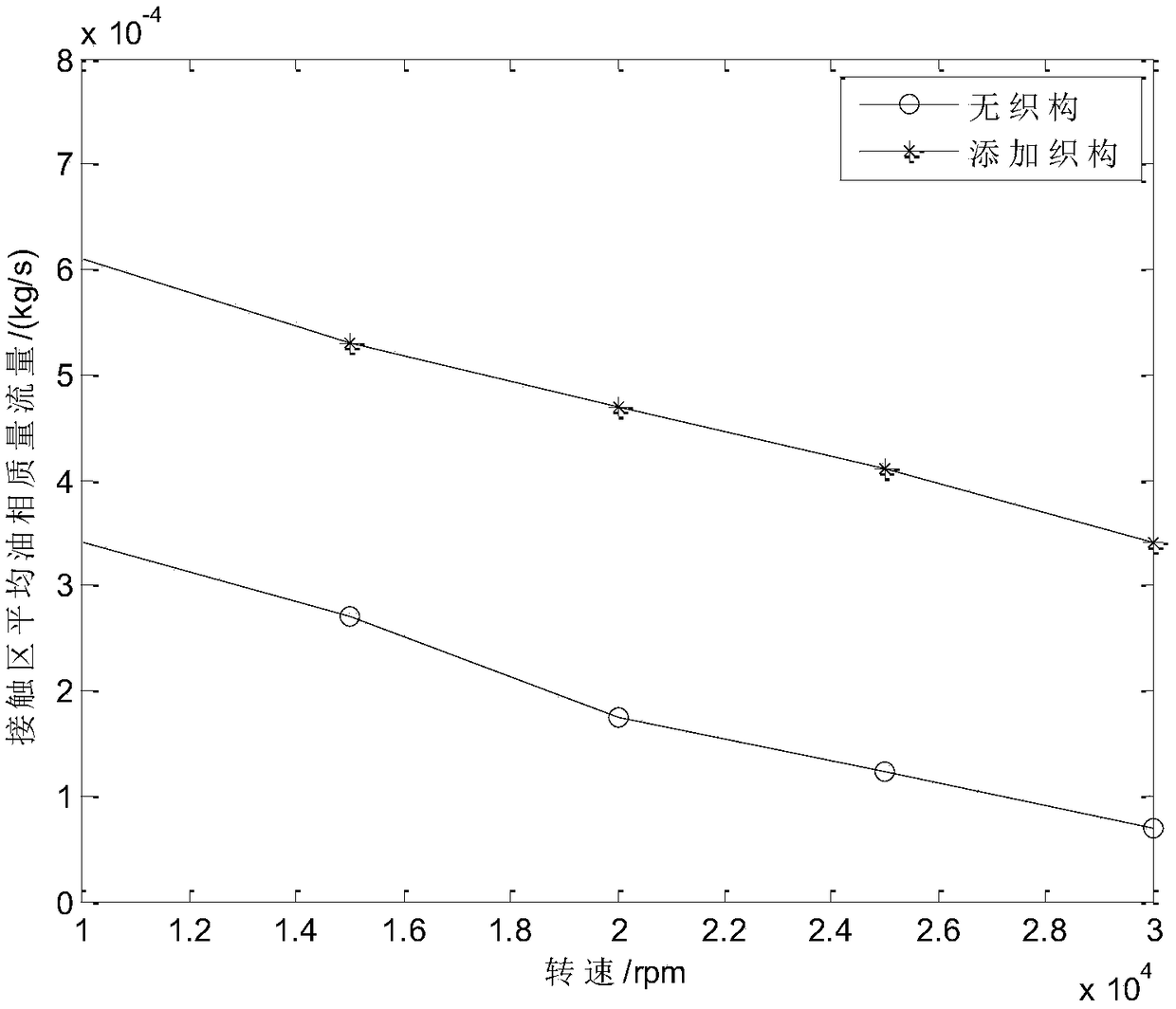

Surface texture assisted lubrication method of rolling bearing

ActiveCN109488694ADoes not affect life strengthImprove the lubrication effectBearing componentsPotential fieldRolling-element bearing

The invention relates to a surface texture assisted lubrication method of a rolling bearing. The method comprises the steps of analyzing flow field and potential field distribution on the surface of aroller path under a given operating condition, determining an optimal flow path, selecting an optimal texture type capable of guiding a lubrication medium to flow according to the optimal path as perthe analyzed optimal path, at last, treating a non-contact area on the surface of the roller path according to the selected optimal texture type and the distribution, wherein the texture type includes a poriform texture and a linear texture; and the poriform texture comprises a triangular repetition texture, a quadrilateral repetition texture, a pentagonal repetition texture and a circular repetition texture. According to the method, lubrication is improved by adding the texture on the surface of the roller path; the method has the advantages of effectively guiding the lubrication medium to accumulate in a ball-roller path contact area and form an oil film, and having small influence on the life and strength of the rolling bearing; and the method is a brand-new rolling bearing lubricationmode.

Owner:XI AN JIAOTONG UNIV

Wood texture type UV offset printing technology

InactiveCN109278431AAccurate overprintImprove printing efficiencyPattern printingOther printing apparatusScreen printingPulp and paper industry

The invention discloses a wood texture type UV offset printing technology. The technology comprises the following steps: 1, drawing patterns of shadow and line of a wood texture effect, and printing down; 2, printing bottom gloss oil on the pattern with the wood texture effect; and 3, printing top gloss oil on the basis of the printed bottom gloss oil, wherein the dyne after bottom gloss oil printing is 24-28; and the dyne after top gloss oil printing is not less than 38. With the adoption of the technology, the wood texture effect can be printed at one time; and moreover, the chromatography is accurate; the matte effect is realized; the sense of concavo-convex is achieved; a traditional silk-screen printing technology can be replaced; and the printing efficiency is improved.

Owner:广东启晨数字科技有限公司

Similar coating shell texture type anti-corrosion wear-resistant composite coating and preparation method thereof

ActiveCN108118339AImprove corrosion resistanceImprove wear resistanceTransportation and packagingMetal-working apparatusWear resistantRoom temperature

The invention relates to a similar coating shell texture type anti-corrosion wear-resistant composite coating and a preparation method thereof. The coating consists of a similar coating shell texturecompounding region, a metallurgy fusion transition region and a diffusion influence region; the thickness is adjustable in a range being 2 to 5mm; the similar coating shell texture compounding regionis uniformly distributed between a spherical alloy region by fine and uniform hard phase particles; alloy is positioned among hard particles; almost continuous and irregularly distributed GO thin sheets also exist for forming a coating shell surrounding an alloy region. The preparation method comprises the following steps of (1) substrate pretreatment; (2) composite powder mixing: putting GO, hardparticles and nickel-based alloy powder into distilled water; performing stirring and uniform mixing to obtain the coating composite powder; (3) coating layer coating: before the coating of the mixedpowder, coating the nickel-based alloy powder on the surface of the metal substrate to be used as a transition layer; (4) similar coating shell texture type coating layer sintering: putting a pre-firing element into a vacuum sintering furnace; raising the temperature; performing heat insulation for 5 to 45 minutes; performing cooling from the furnace to 150 DEG C, discharging; performing air cooling to room temperature to obtain the coating.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method, apparatus and integrated circuit for improving image sharpness

InactiveUS20100021076A1Improve imaging clarityAvoid it happening againTelevision system detailsImage enhancementPeak valueComputer vision

In a method, apparatus and integrated circuit for improving image sharpness, the method includes the following steps: (a) labeling each of pixels in an image as one of an edge / texture type and a non-edge / texture type; (b) classifying each of the pixels that are labeled as the edge / texture type into one of a border point type, a transition point type, and a peak point type; and (c) using a shrinking / expanding filter to filter the pixels of the border point type, and subsequently using a high boost filter to first filter the pixels of the peak point type and then filter the pixels of the transition point type to sharpen the image.

Owner:PANASONIC CORP

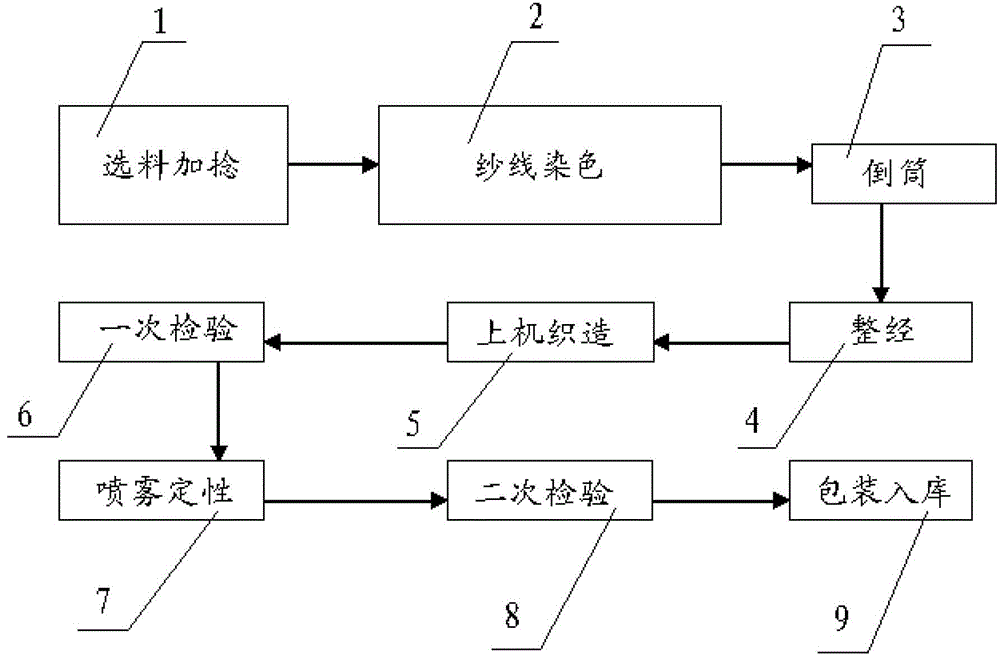

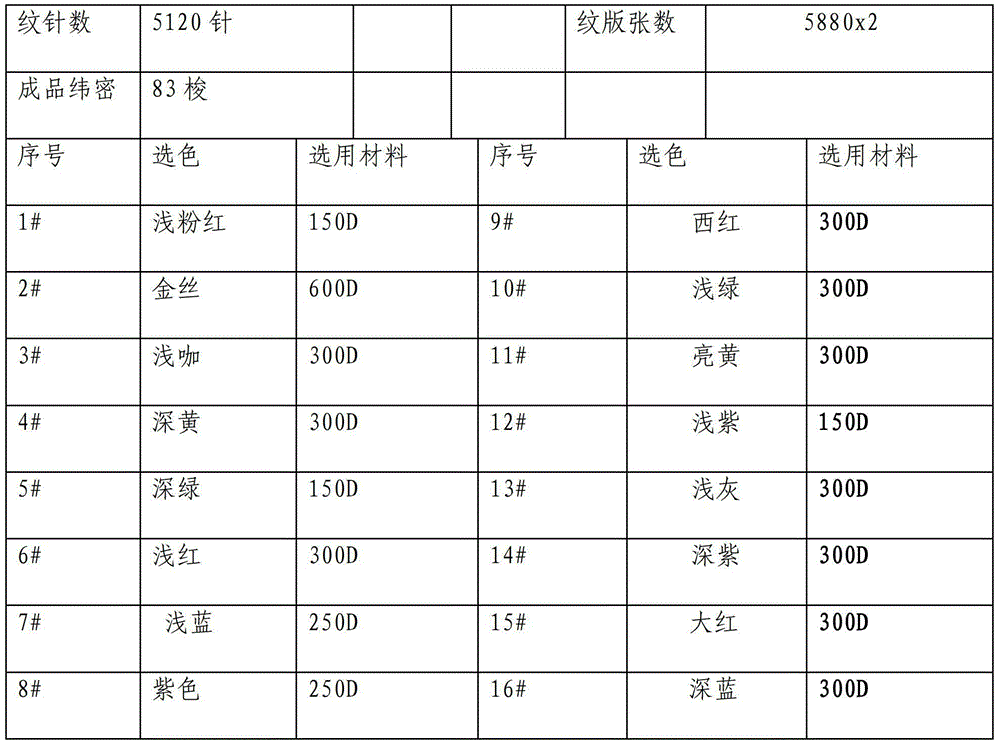

Weaving technology of sixteen-color-weft numerical code brocade

The invention discloses a weaving technology of sixteen-color-weft numerical code brocade. The weaving technology of the sixteen-color-weft numerical code brocade includes the following steps of material selecting, twisting, yarn dyeing, rewinding, beam warping, on-machine weaving, first-time inspecting, atomizing attribute determining, second-time inspecting, packaging and warehousing. Due to the fact that an electronic jacquard machine is improved to make 16 colors capable of being selected, the situation that for a current device, only 14 colors can be selected is improved. The sixteen-color-weft weaving technology is adopted, an organization structure changes, a two-color overlapping technology, a multi-color overlapping technology and other technologies are continually used to perform weaving, and weft colors of fabric can reach16 kinds unprecedentedly. In comparison with the prior art, brocade fabric woven with the technology is diversified in color, rich in texture type and strong in three-dimensional sense, overcomes the defects that traditional brocade is few in color, monotonous in design color, prone to draping and silk snagging and the like, can be widely applied to the fields of high-grade home textiles, high-grade clothes and the like, and fills a domestic vacancy.

Owner:HAINING TIANYI TEXTILE

Standard normalized preparation method of experimental soil sample

InactiveCN104764644AFast preparationEfficient preparationPreparing sample for investigationHigh densityPore diameter

The invention discloses a standard normalized preparation method of an experimental soil sample. Before preparation of the soil sample, natural soil is smashed and is screen by sieves with different pore diameters respectively, and fine soil without impurities is obtained finally and is used pure soil; deionized water is added into the fine soil proportionally according to the characters of the required soil sample, and a culture dish is used as a soil preparation tool; generally, when the amount of the fine soil is fixed, the more the deionized water is added, the thinner the mushy soil is, and the prepared soil sample is hard, has high density, low porosity and low moisture content finally. The standard procedure can provide basic reference for preparing the soil samples with different texture types rapidly.

Owner:秦始皇帝陵博物院

Production process of vamp screen cloth

The invention provides a production process of vamp screen cloth. The production process comprises the steps of knitting preparation, combing arrangement, machine knitting, dyeing, finishing, shapingand the like; when a non-vamp area is woven, Jacquard embroidery yarn traverses through meshes of a mesh base layer to form a thin structure, when a vamp area is woven, the Jacquard embroidery yarn traverses through the meshes of the mesh base layer to form a thick structure or the Jacquard embroidery yarn does not traverse through the meshes of the mesh base layer to form a hollowed-out structure, and the boundary between the thin structure and the thick structure or the hollowed-out structure is utilized to form a contour shape after the vamp is unfolded. Because the Jacquard embroidery yarnis woven by a Jacquard comb, the texture type of fabric does not need to be changed, the process is relatively simple, and compared with a traditional technical scheme that the vamp is obtained by adopting a mode of firstly cutting and then sewing, the cost is relatively low.

Owner:SINCETECH FUJIAN TECH CO LTD

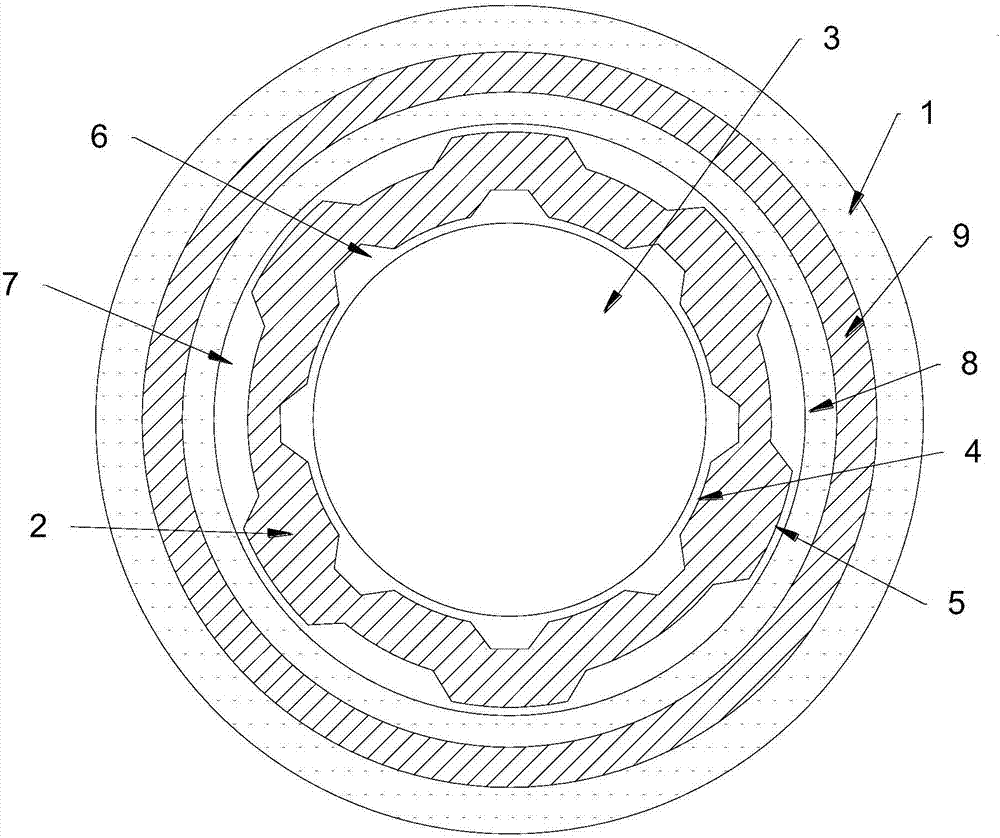

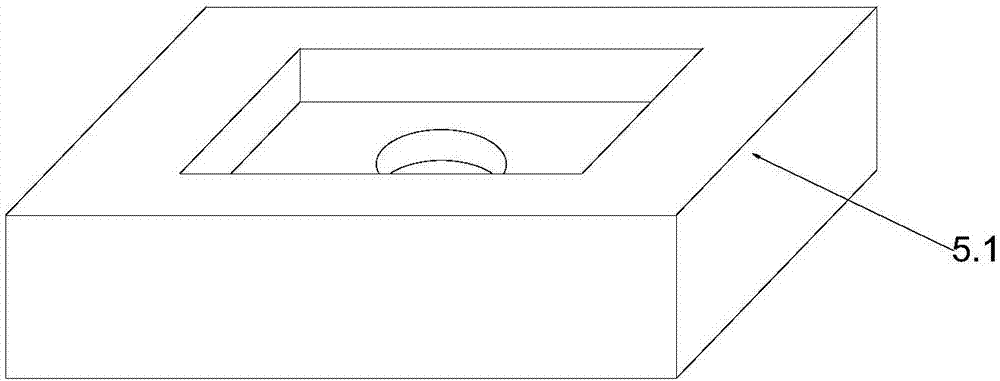

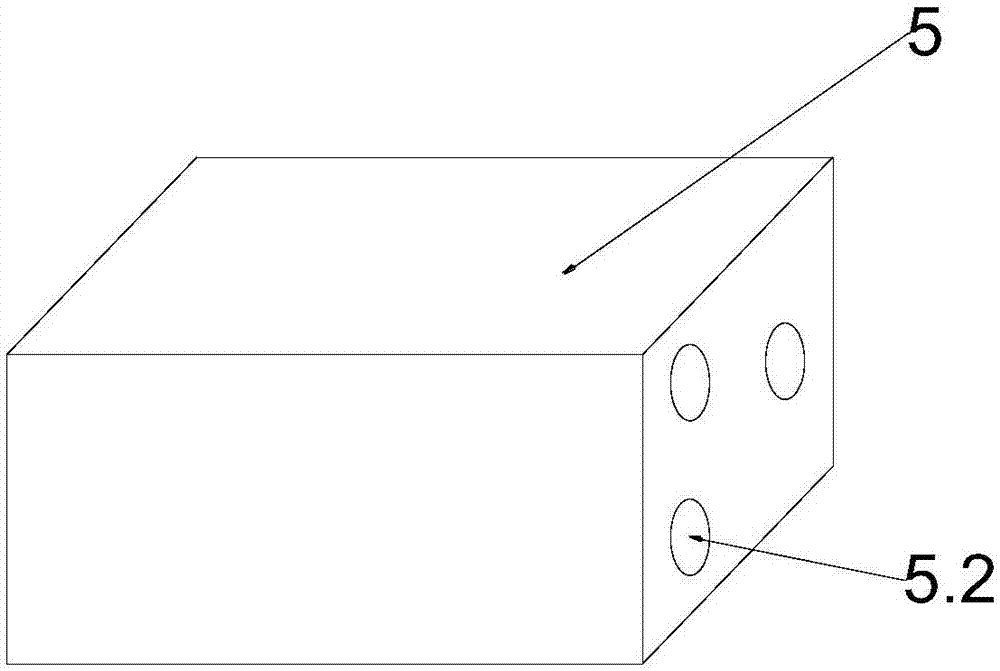

Mesh fluid texture type damping bearing

InactiveCN107461405AReduce frictionImprove comfortWaterborne vesselsSliding contact bearingsEngineeringBatten

The invention discloses a mesh fluid textured damping bearing, comprising a metal outer ring, a rubber body and a main shaft, the rubber body is sleeved in the metal outer ring, the main shaft is sleeved in the rubber body, and the rubber body is sleeved The inner and outer layers are arranged with axially distributed inner rubber slats and outer rubber slats, the adjacent slats of the inner rubber slats are provided with inner water grooves, and the adjacent slats of the outer rubber slats are provided with outer water grooves, The inner water tank and the outer water tank are respectively connected with the external hydraulic system. The invention has the advantages that it can reduce the relative friction between the friction pairs, reduce vibration and noise, and can improve the comfort of civil ships and the concealment of underwater vehicles.

Owner:WUHAN UNIV OF TECH

Preparation method for ceramic board painting

InactiveCN105667191AImprove yieldImprove plasticityDecorative surface effectsOrnamental structuresSTEP-NCCeramic

A method for preparing calligraphy and painting on a ceramic plate, comprising the following steps: A, preparing a clay plate; B, painting and infiltrating: placing a permeable layer on the plate surface of the clay plate, and painting patterns or characters on the permeable layer, statically Remove the permeable layer after setting to obtain a clay tablet with permeable patterns or calligraphy characters; C, hollow out and shape: hollow out the clay tablet obtained in step B to make the pattern or characters appear in the form of protruding textures; D, dry Firing: After drying the clay board obtained in step C, it is fired in a kiln to obtain ceramic board calligraphy and painting with protruding patterns or characters. The invention proposes a method for preparing calligraphy and painting on ceramic boards. The mud boards are hollowed out and shaped before being dried and fired. The plasticity is greatly improved, and the phenomenon of stretched angles is not easy to occur, which greatly improves the quality of the embossed ceramic boards. Painting yield.

Owner:夏树丽

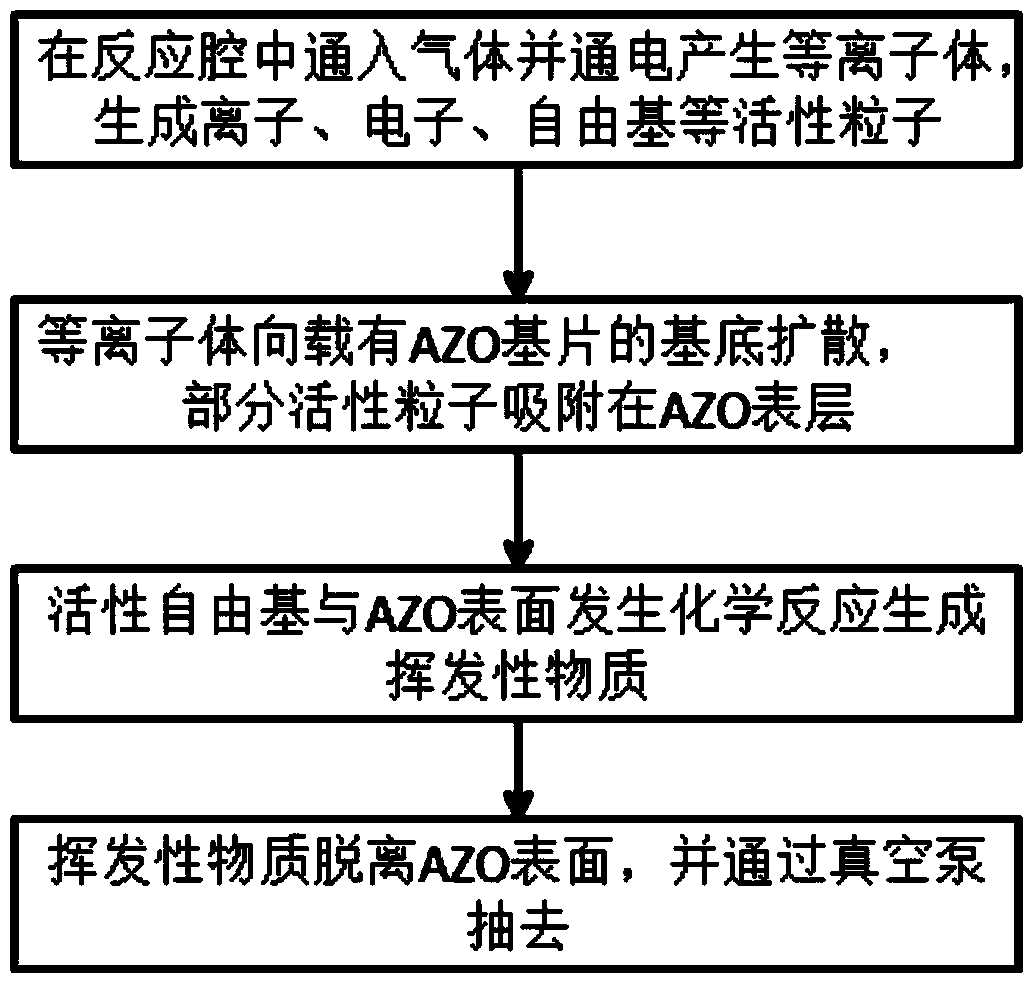

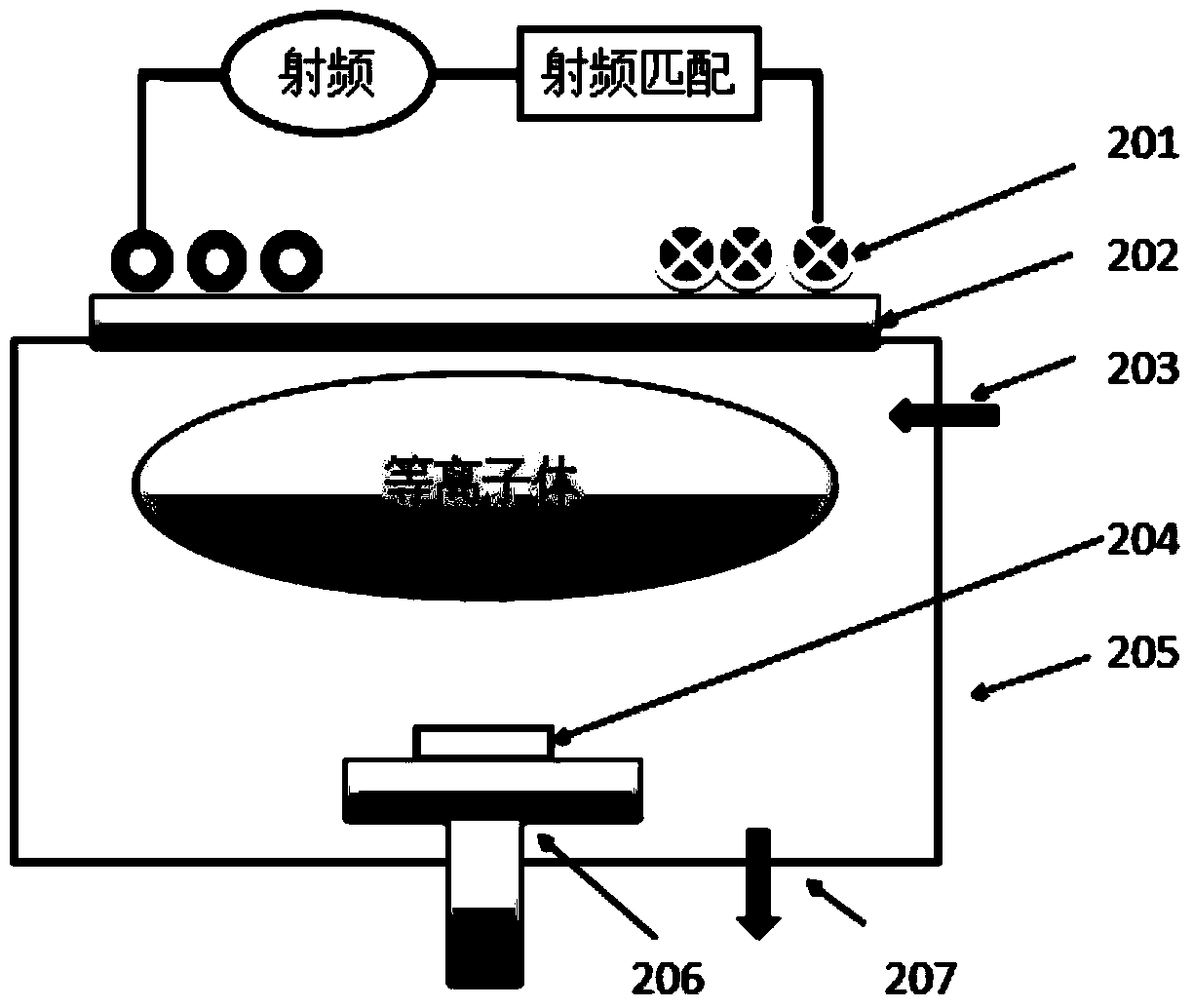

Plasma texturing method of AZO film of film solar cell

InactiveCN104201235ATo achieve the effect of etchingAvoid pollutionFinal product manufacturePhotovoltaic energy generationTrappingSolar cell

The invention relates to the field of semiconductor industry, and in particular relates to a plasma texturing method of an AZO film of a film solar cell. The method is characterized in that the advantages of physical etching and chemical etching of the plasma etching method and high regulation performance of the etching degree and other advantages are utilized to etch the AZO film of the film solar cell. With the adoption of the method, the effect of wet etching can be reached; meanwhile, any corrosive solution is not used, so that the environmental pollution caused by improper handling of reaction solution can be avoided; the heating temperature, flow rate of inlet air, power and frequency of a radio source, and etching time of a substrate rack are controlled to improve the etching controllability; compared with the sputtering-depositing texturing type AZO film of which the particle energy is limited and obvious texturing effect is not reached, the AZO film has the advantage that a good etching effect can be reached; the texturing method of the AZO film of the film solar cell has the advantages of being high in light trapping structure effect, high in etching controllability and free of pollution; therefore, the method can be applied to the technology for improving the converting efficiency of a solar cell.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

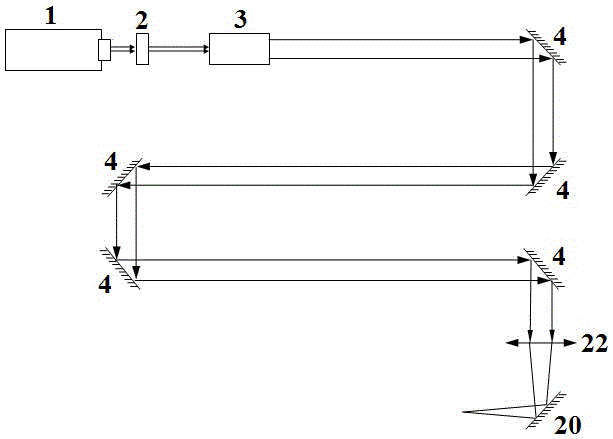

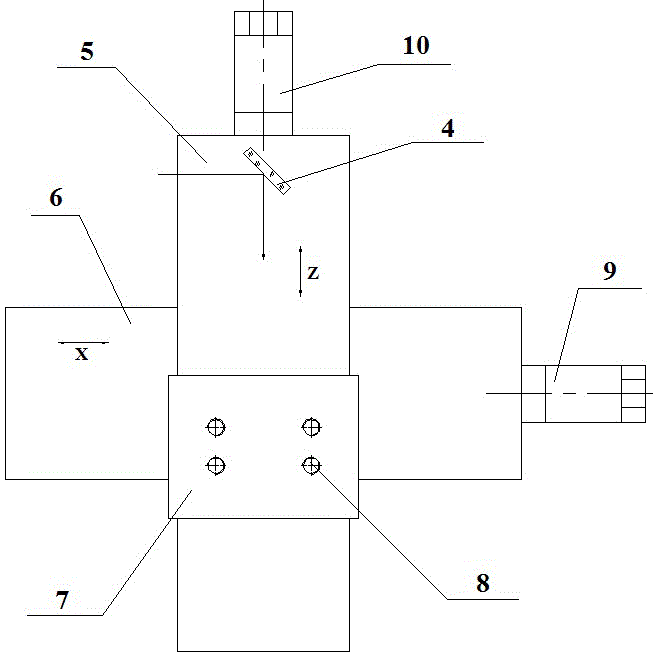

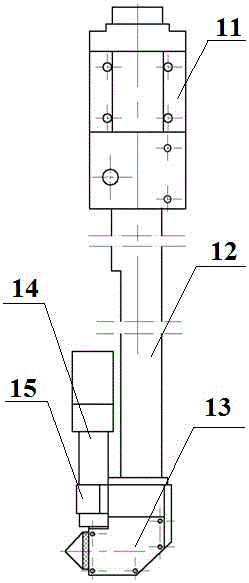

Special processing device for ultraviolet laser texture cylinder liner inner wall

InactiveCN104874912BShort wavelengthHigh energyLaser beam welding apparatusUv laserHeat-affected zone

The invention discloses a special ultraviolet laser texturing type processing device for an inner wall of a cylinder sleeve. The device is that a light path collimator (3) is mounted at the back of a laser (1) through a pneumatic gate (2); a plurality of adjusting reflectors (4) are mounted at the back of the light path collimator (3) according to a light path adjusting line; a straight barrel (12) is mounted on a worktable; the top end of the straight barrel (12) is aligned to the light path of one adjusting reflector, and while the bottom end of the straight barrel (12) is connected to one angle of a rectangular cavity body (13); a focusing lens (22) is mounted in the rectangular cavity body (13); a light hole (23) is formed below the focusing lens (22) above the rectangular cavity (13); a reflector (20) is mounted on the laterally inclined inner wall of the rectangular cavity (13); a laser nozzle (17) is arranged at the other angle of the rectangular cavity (13). The device is simple in structure, short in ultraviolet laser wavelength, and small in thermal influencing area while interacting with the materials, and can perform cold light processing during processing the material.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com