Special processing device for ultraviolet laser texture cylinder liner inner wall

An ultraviolet laser and processing device technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of increasing processing preparation time, failing to meet requirements, and unfavorable production efficiency, so as to save adjustment time and facilitate debugging , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

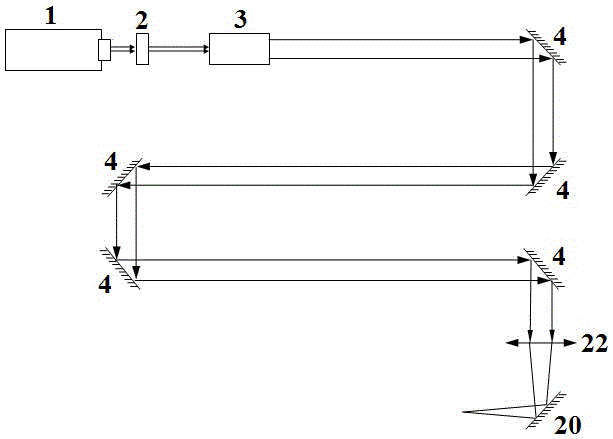

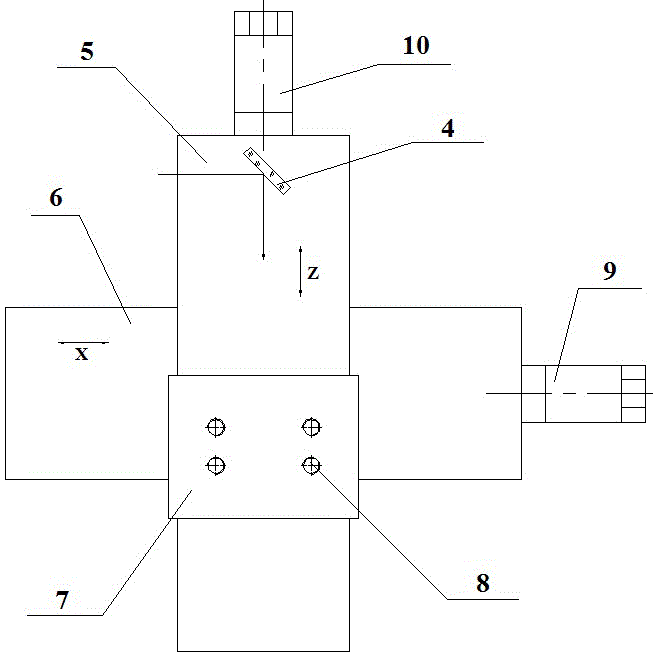

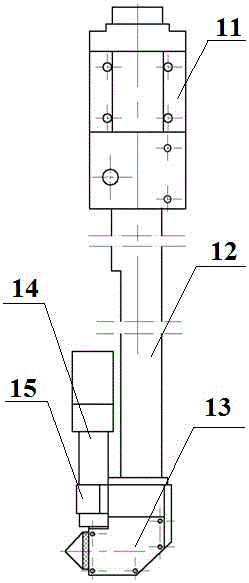

[0026] like Figure 1-8As shown, the processing device includes a laser 1, an optical path collimator 3, several optical path adjustment mirrors 4, a laser head movement platform, a laser head and a cylinder liner rotary movement platform; Straightener 3, optical path collimator 3 rear positions are installed several adjustment reflectors 4 according to the optical path adjustment circuit, and the laser head is fixedly installed on the laser head motion platform; the laser head motion platform includes a motion base 7, a horizontal motion guide rail 6, Vertical motion guide rail 5, horizontal motion motor 9 and vertical motion motor 10, horizontal motion guide rail 6, vertical motion guide rail 5 are installed on the motion base 7, and horizontal motion motor 9 is installed on the right side of horizontal motion guide rail 6, passes horizontal The screw rod connection in the motion guide rail 6 controls the vertical motion guide rail 5 and the motion base 7 to move in the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com