Patents

Literature

150 results about "Laser Nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

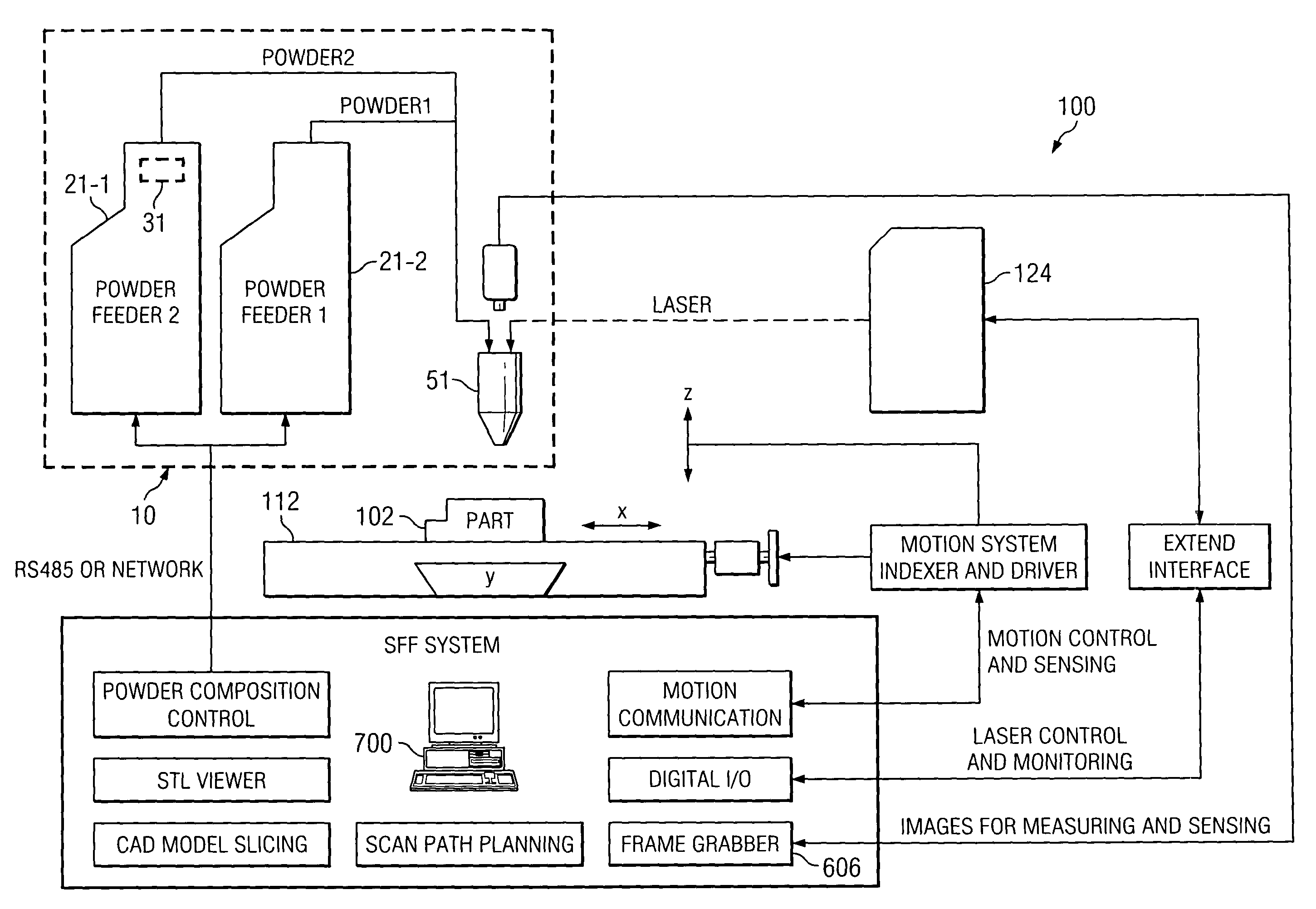

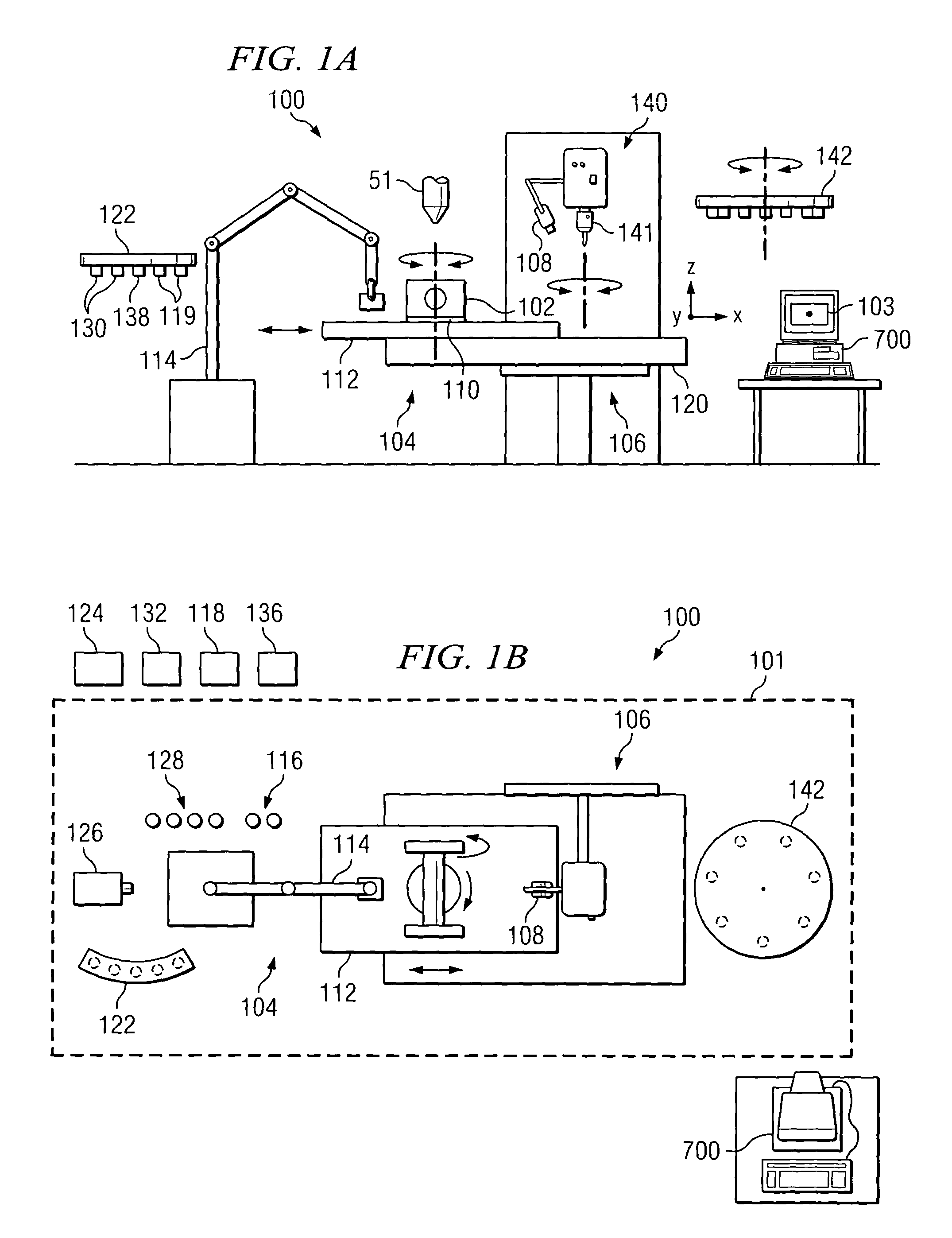

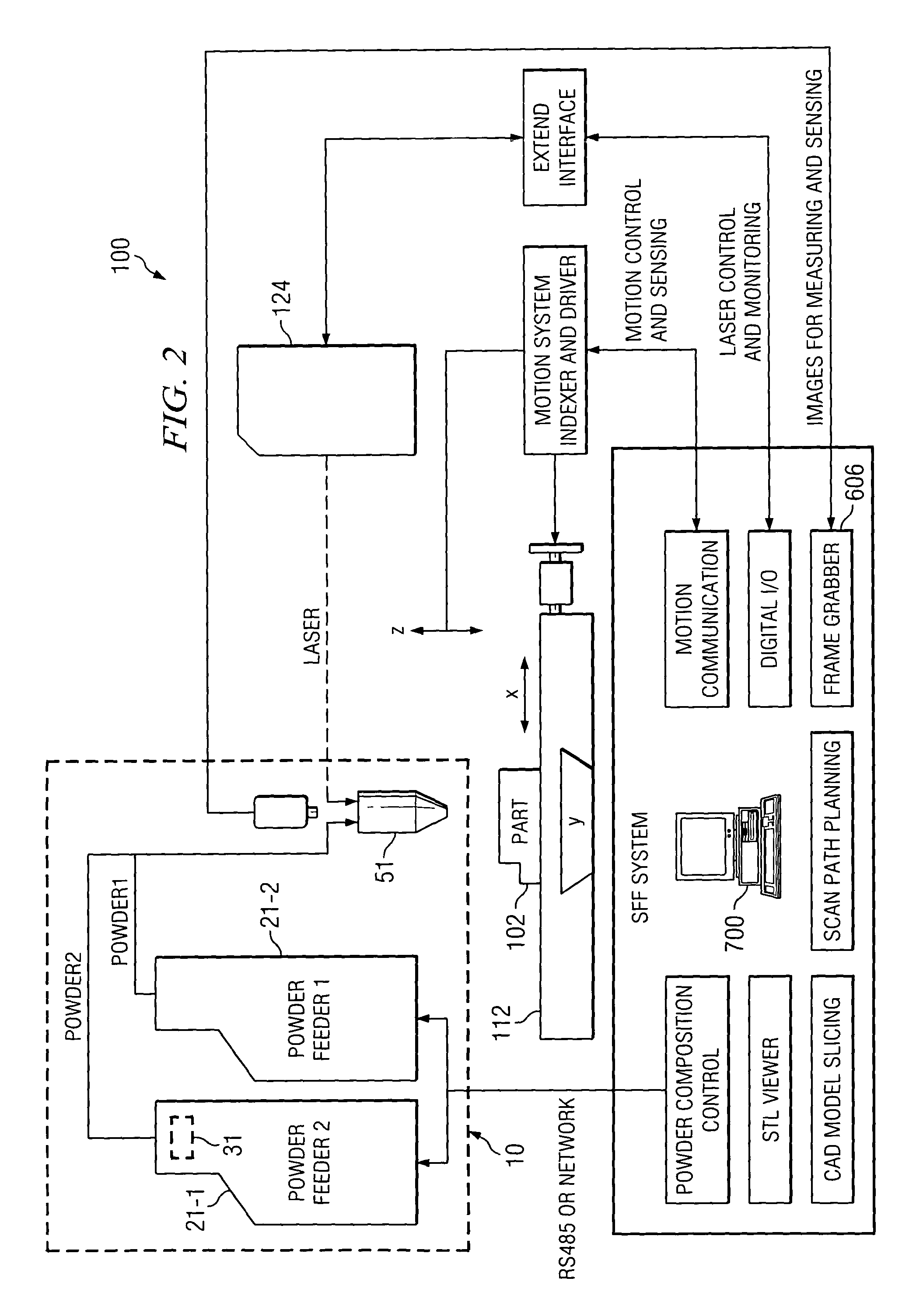

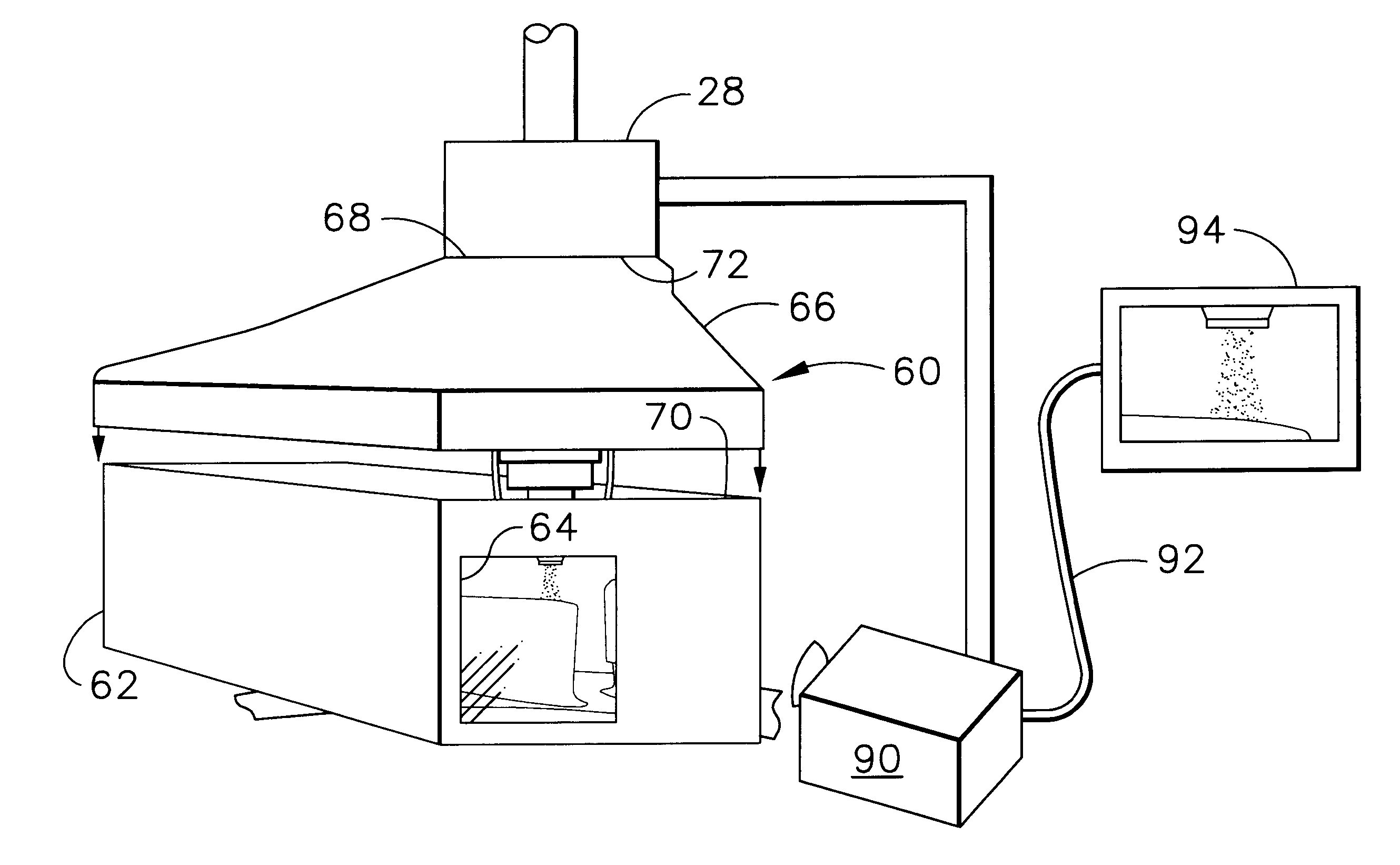

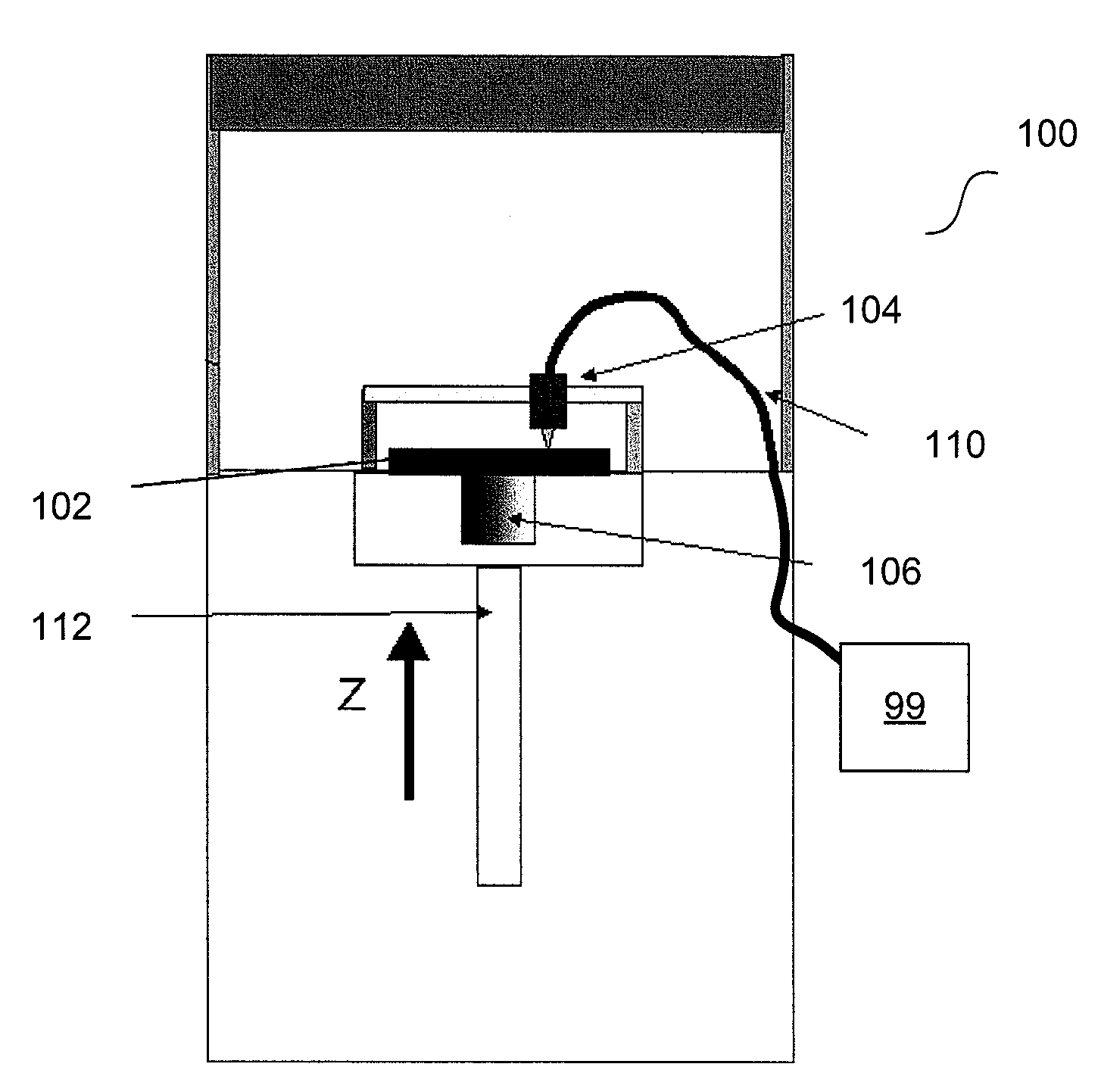

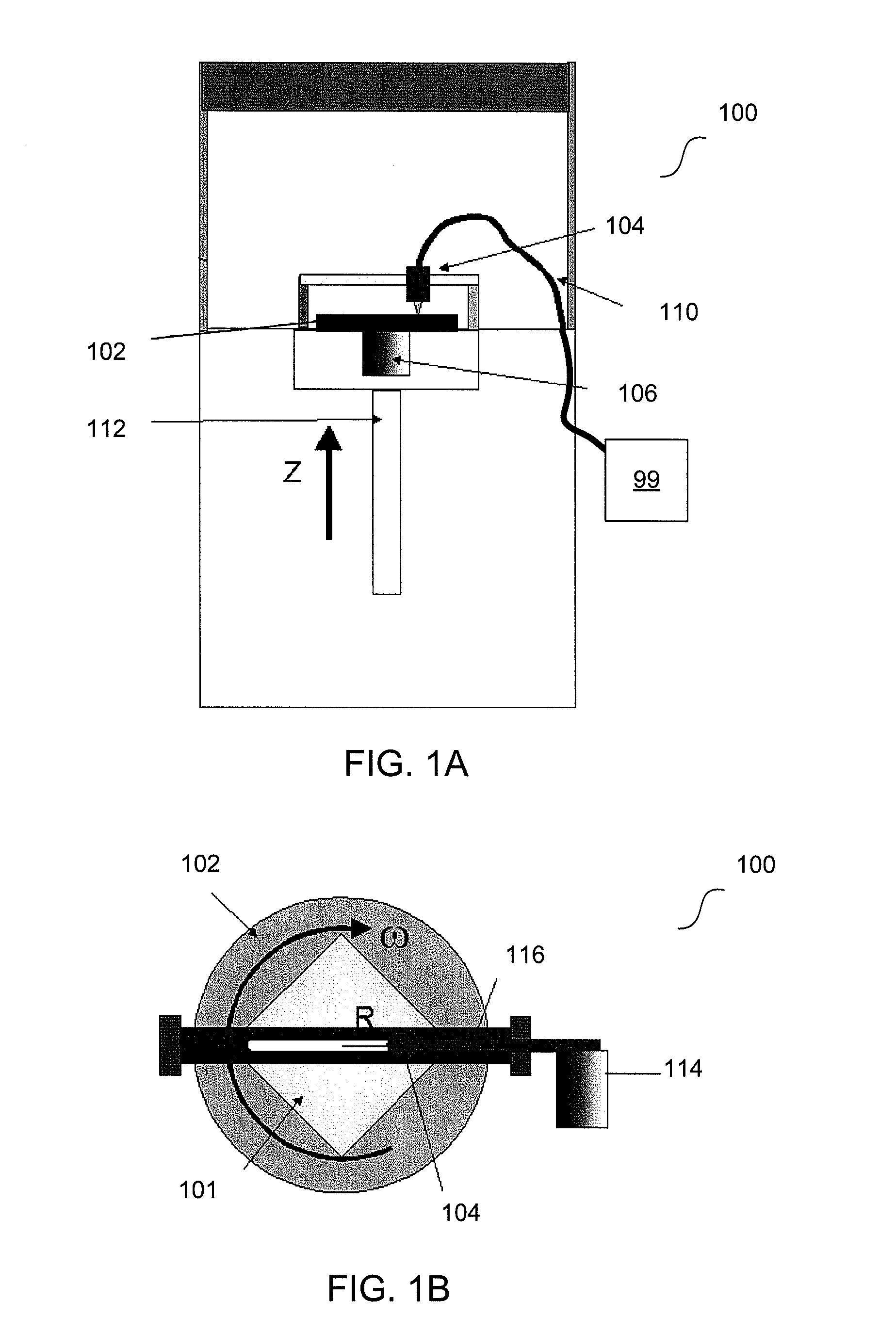

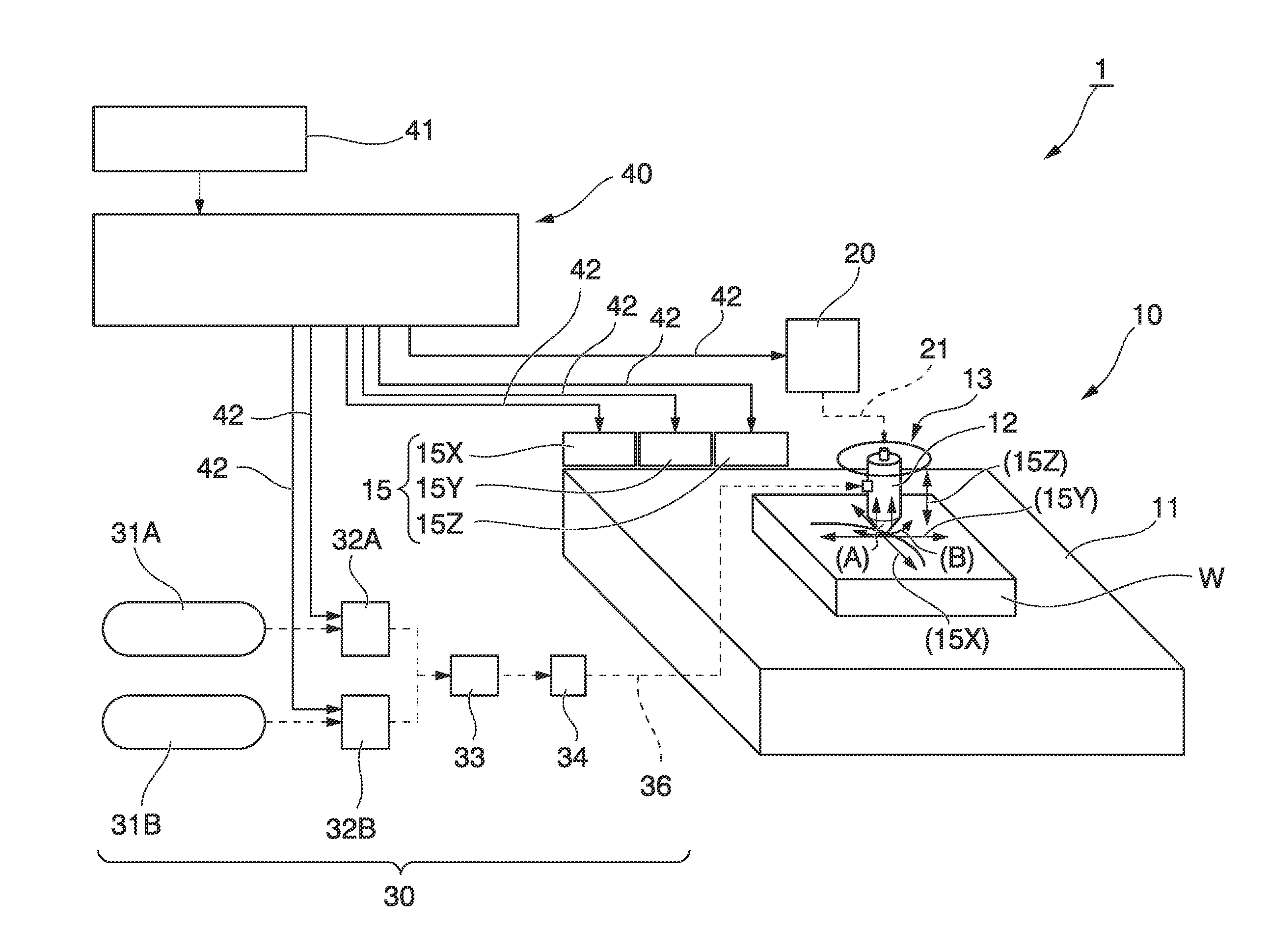

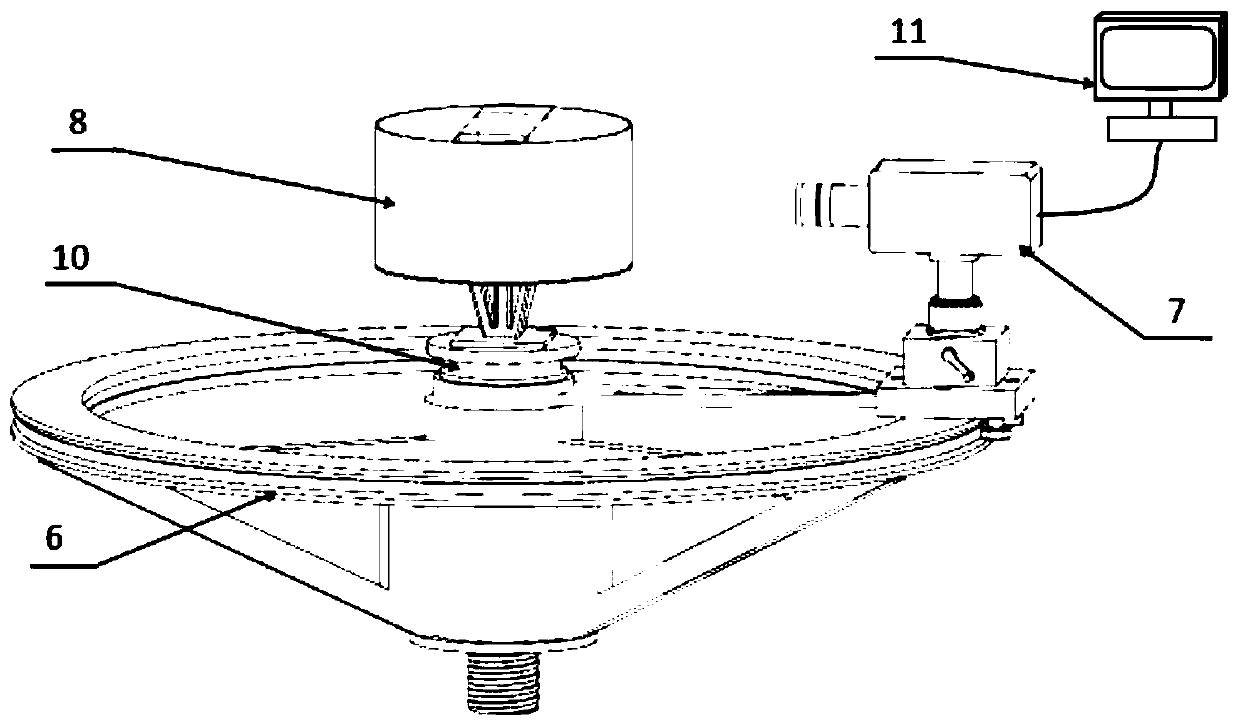

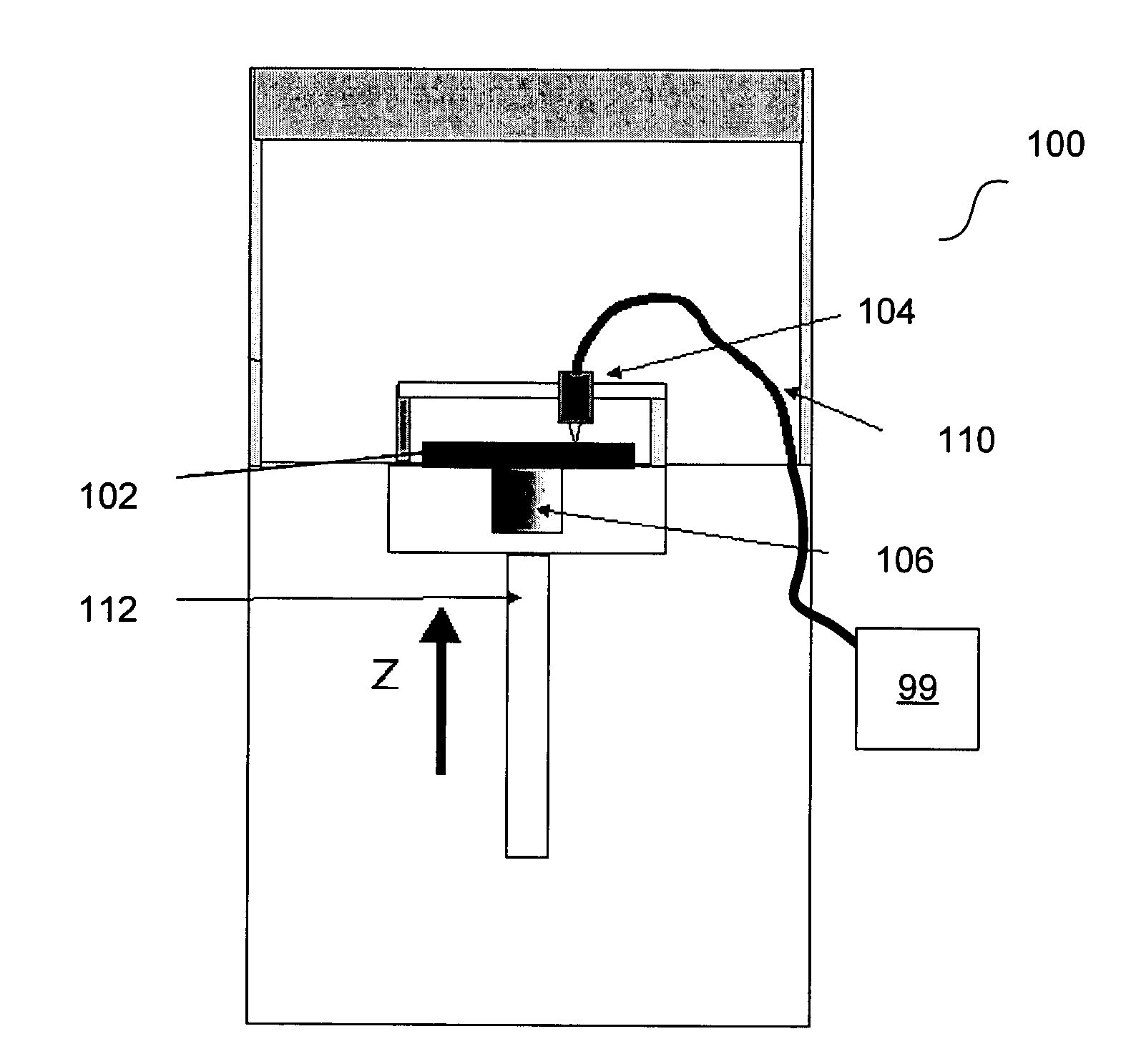

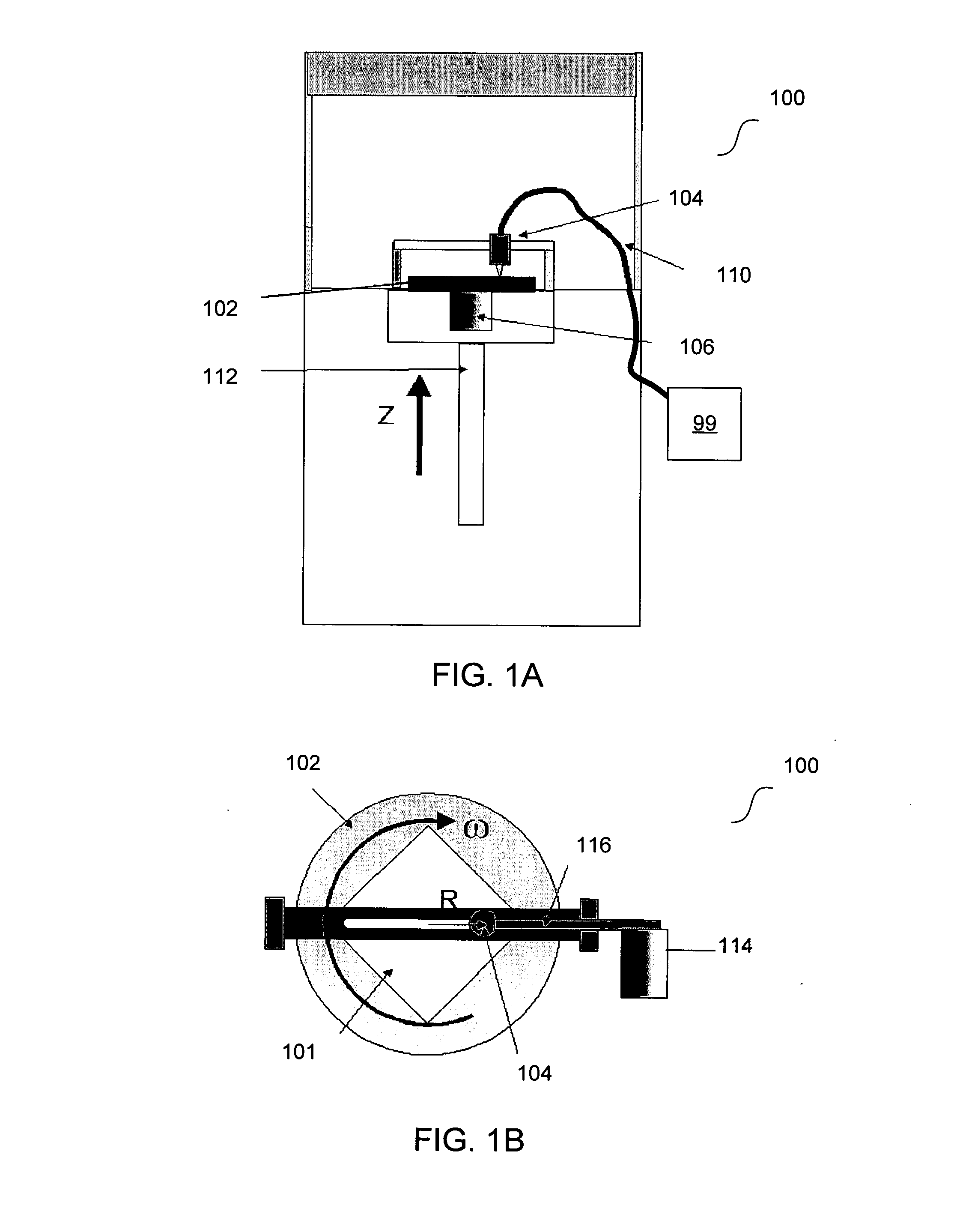

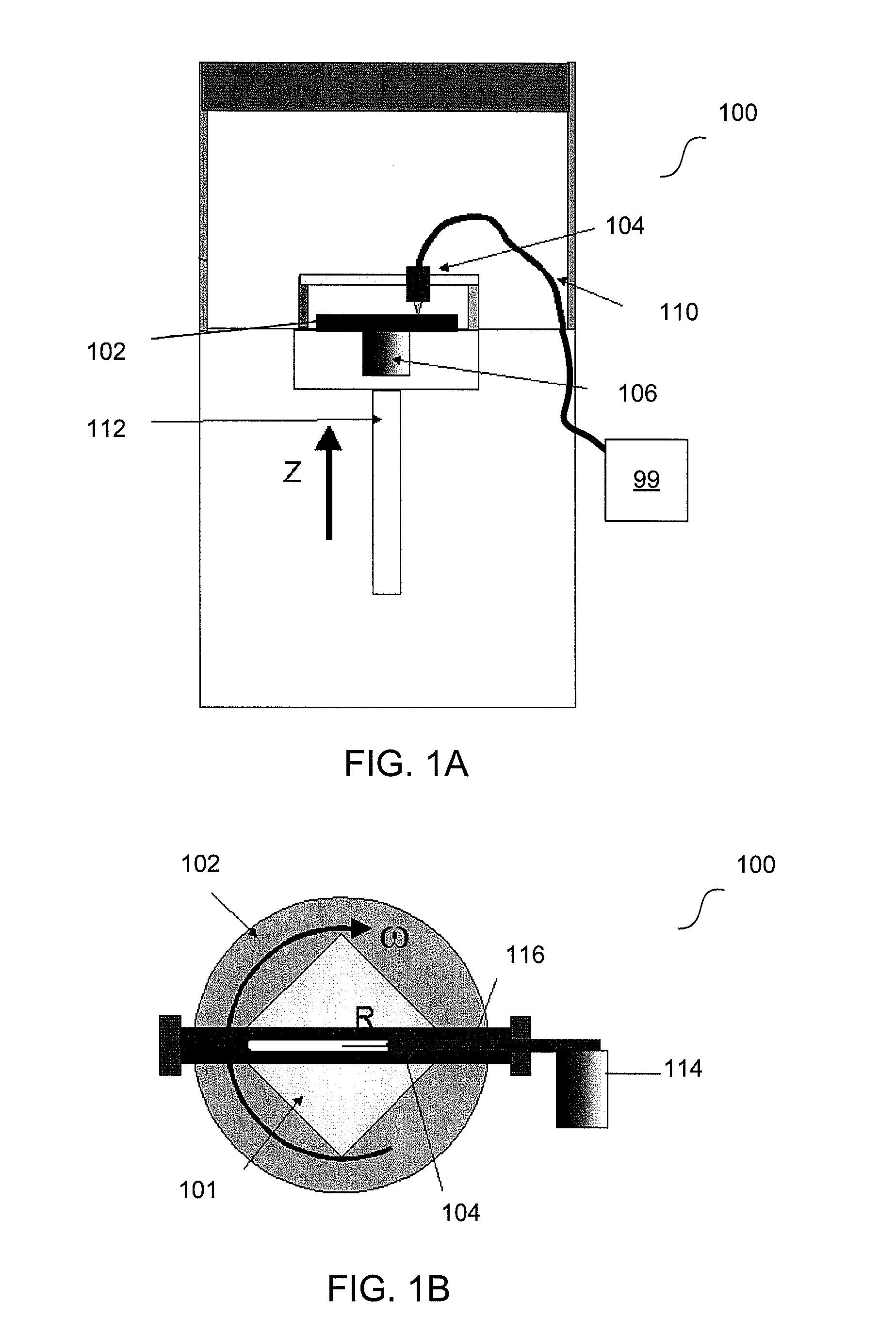

System and method for controlling the size of the molten pool in laser-based additive manufacturing

InactiveUS6995334B1High geometric accuracyEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankLaser Nozzle

According to one embodiment of the invention, a method for controlling the size of the molten pool in a laser based additive manufacturing process includes coaxially aligning an imaging device with a laser nozzle and imaging a molten pool, created by a laser, on a substrate with the imaging device. The method further includes comparing at least one characteristic of the molten pool with a respective characteristic of a target molten pool, and adjusting, in substantially real-time, a laser power of the laser based on the comparison in order to correlate the characteristic of the molten pool with the respective characteristic of the target molten pool.

Owner:SOUTHERN METHODIST UNIVERSITY

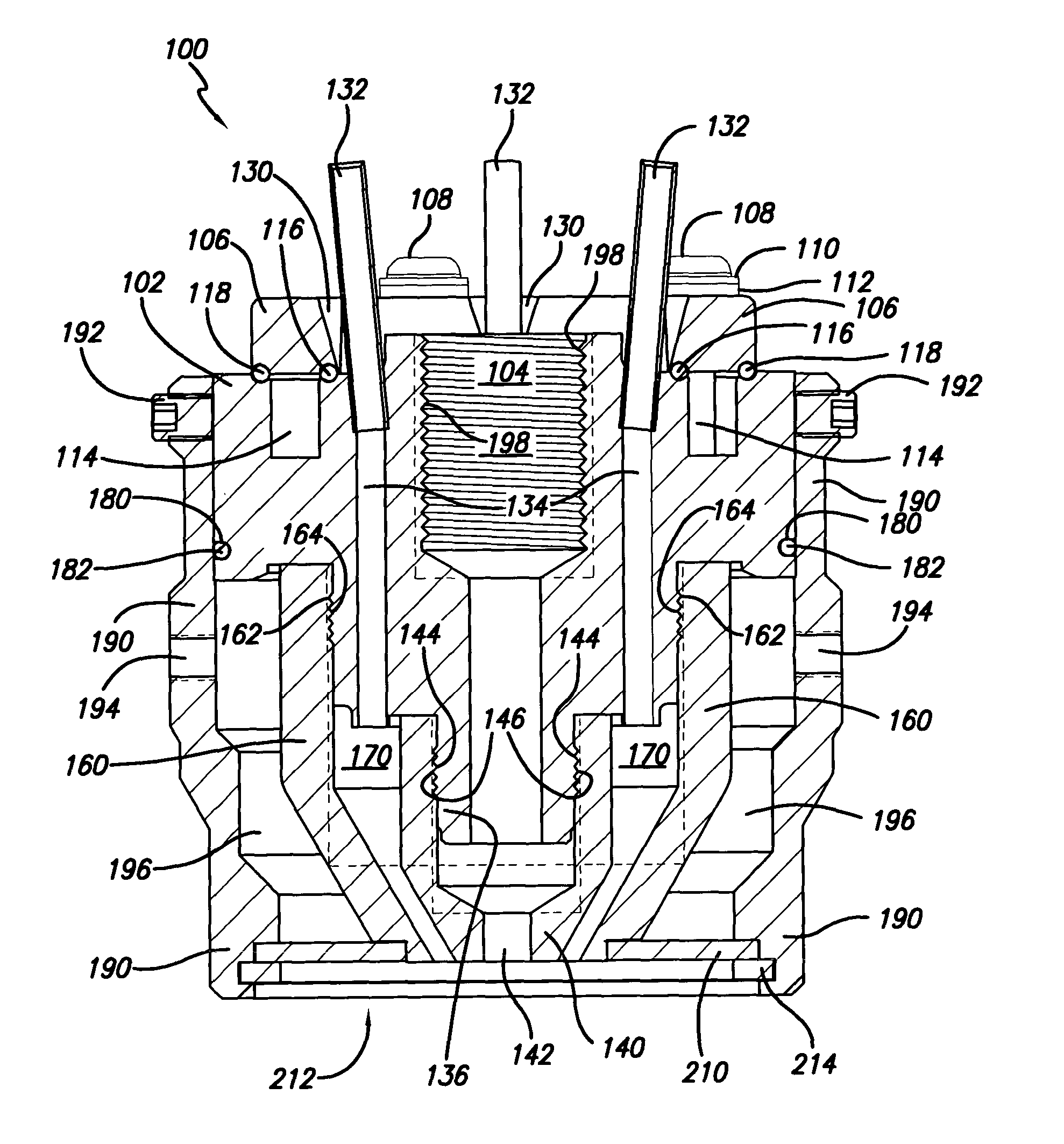

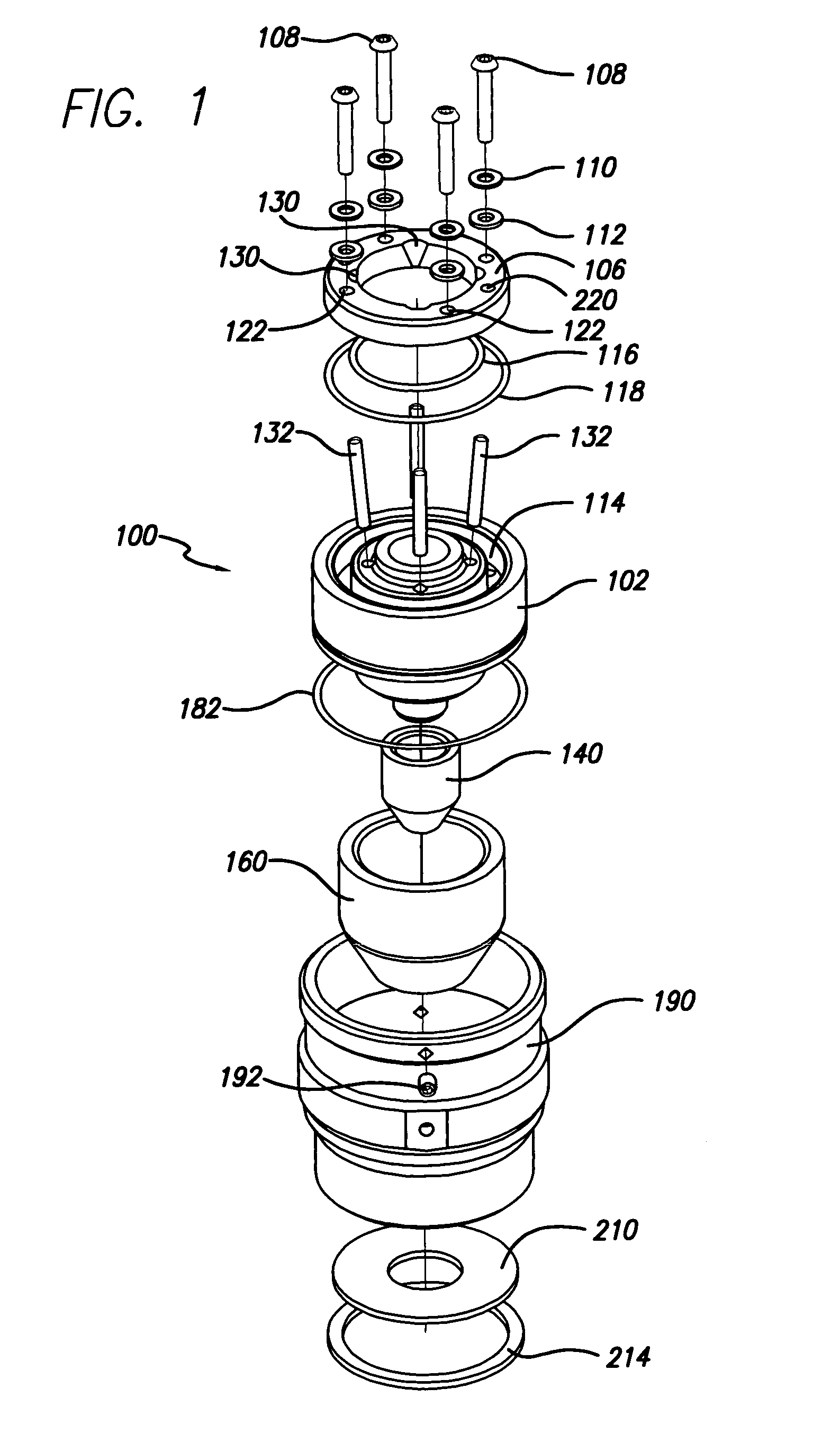

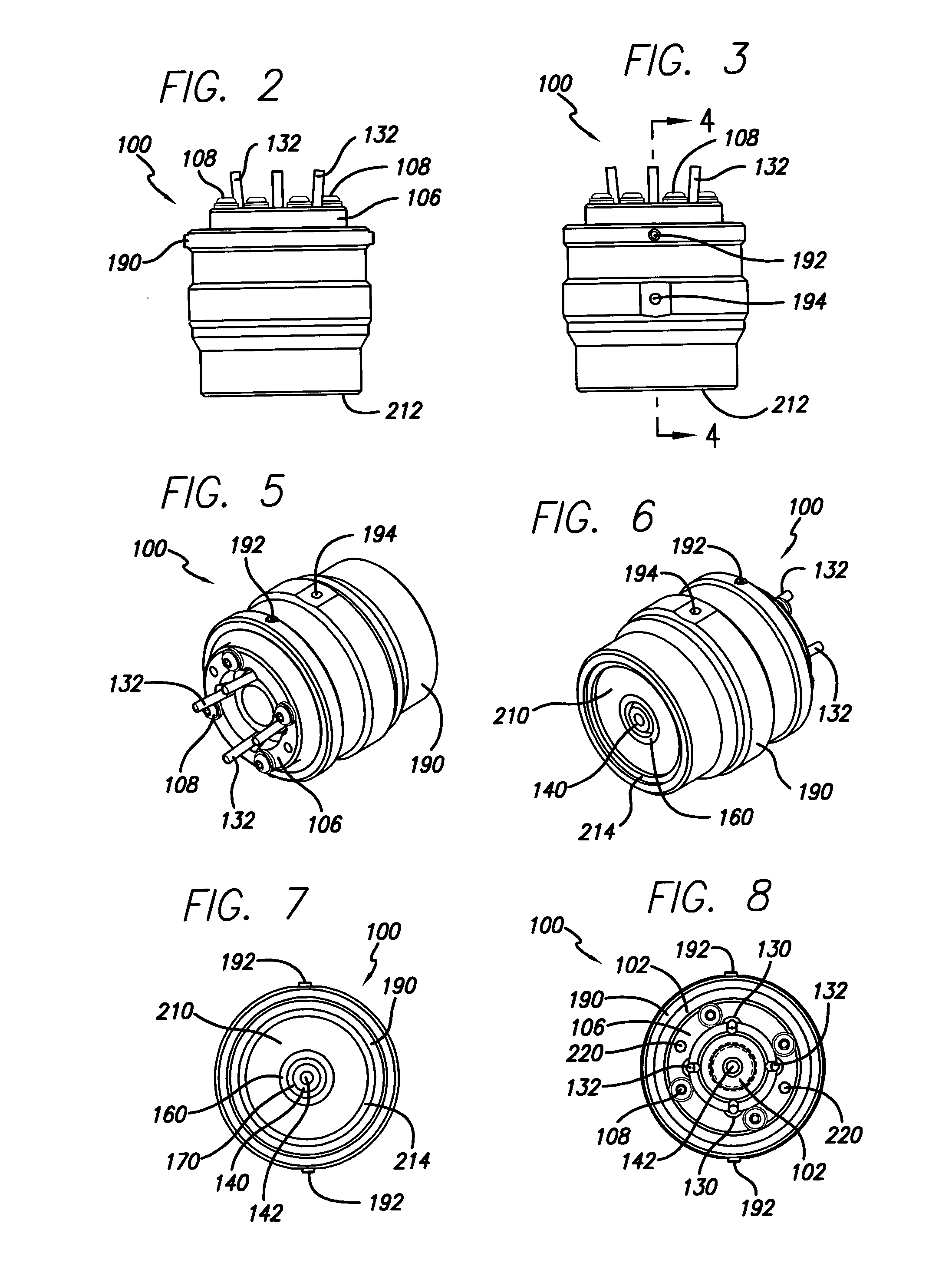

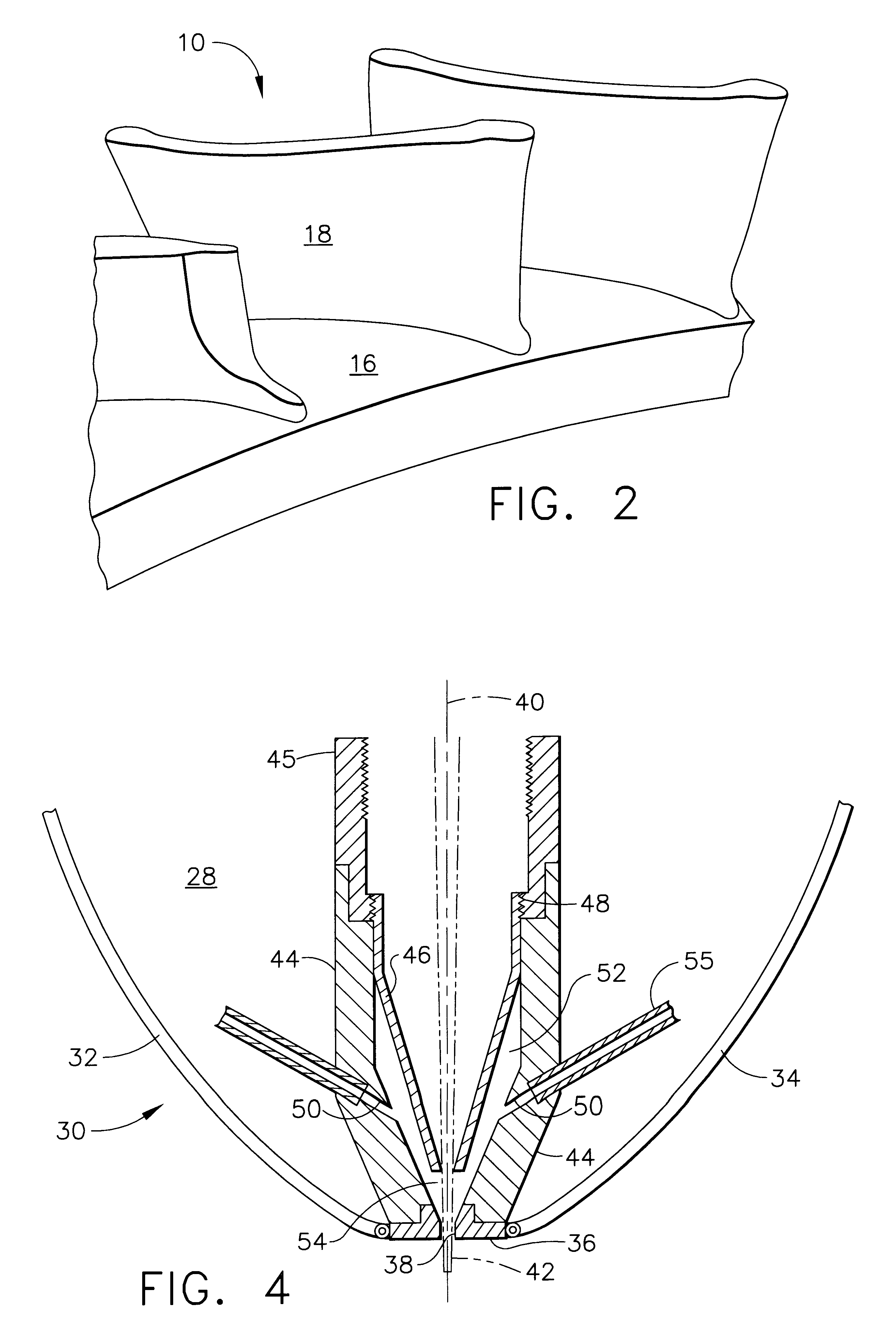

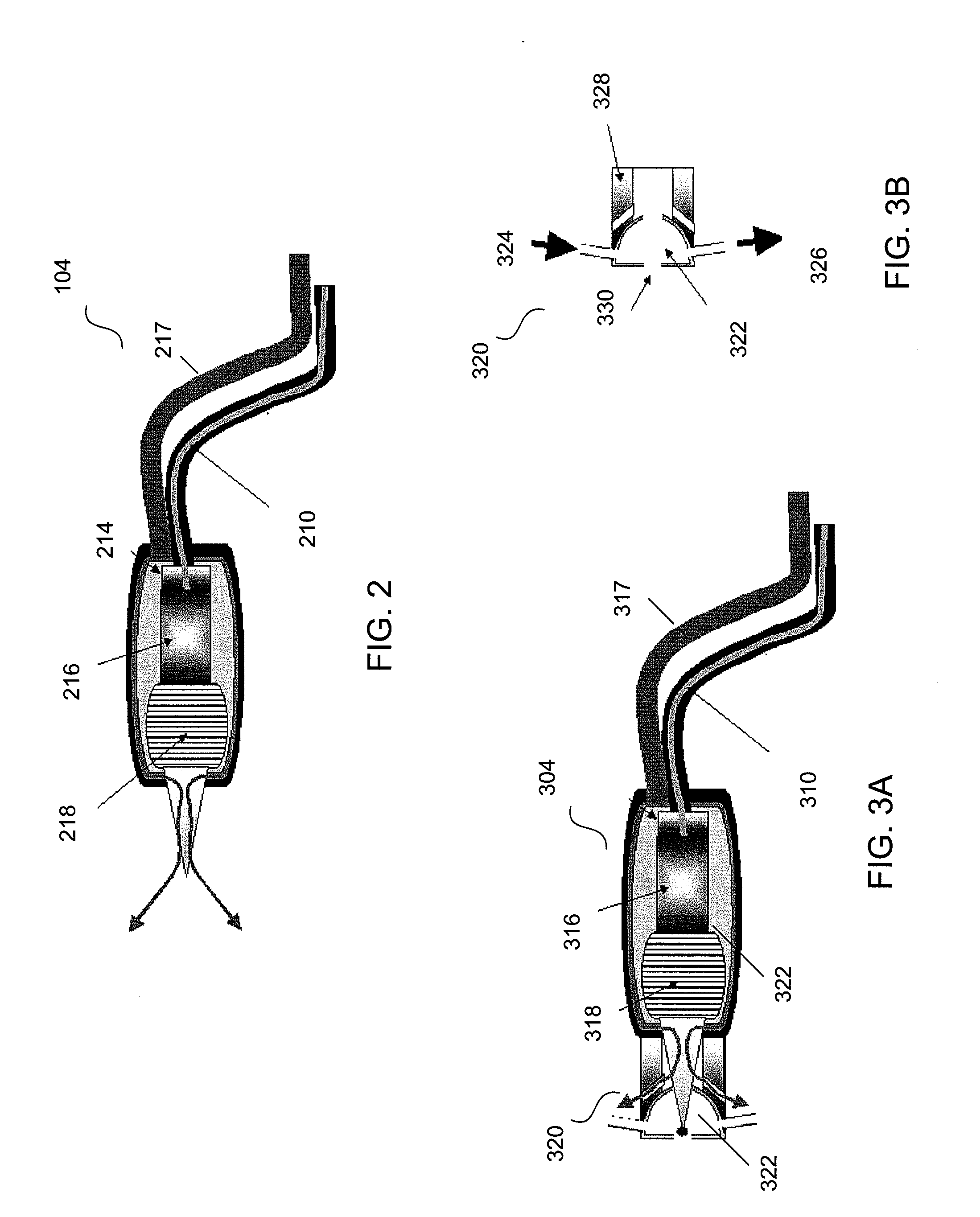

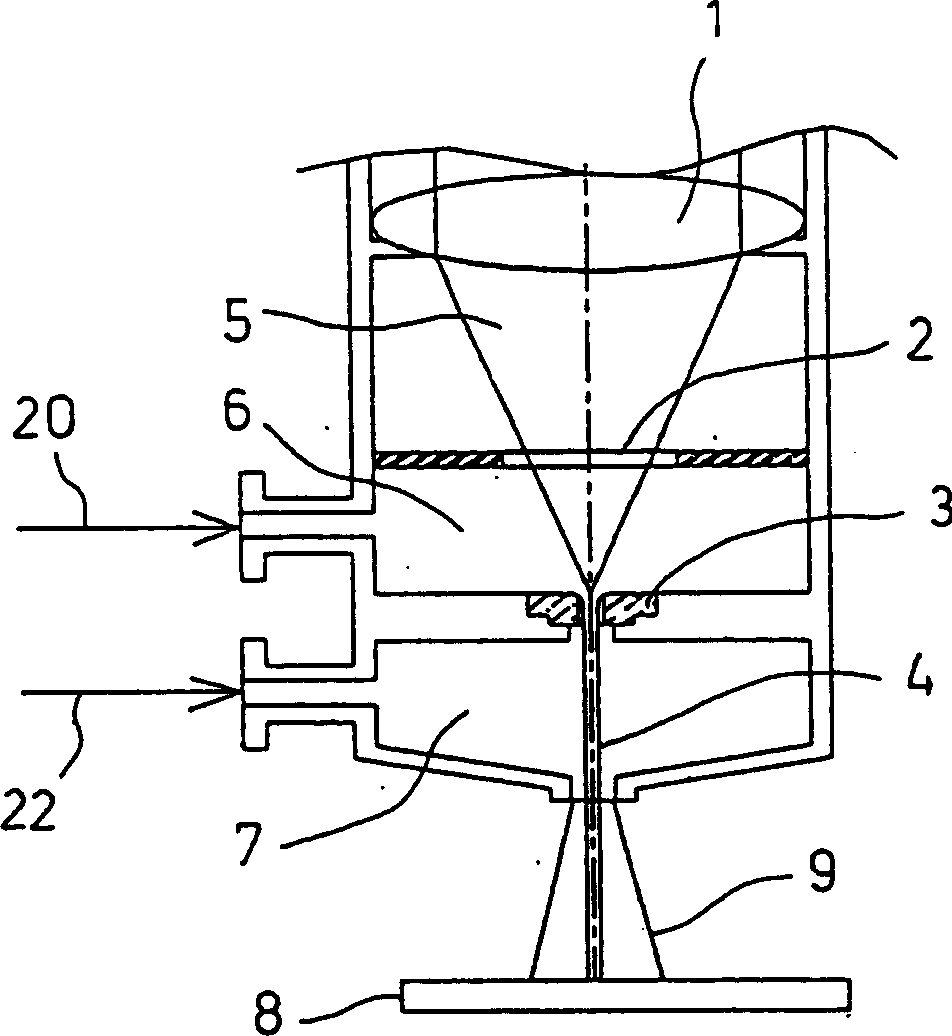

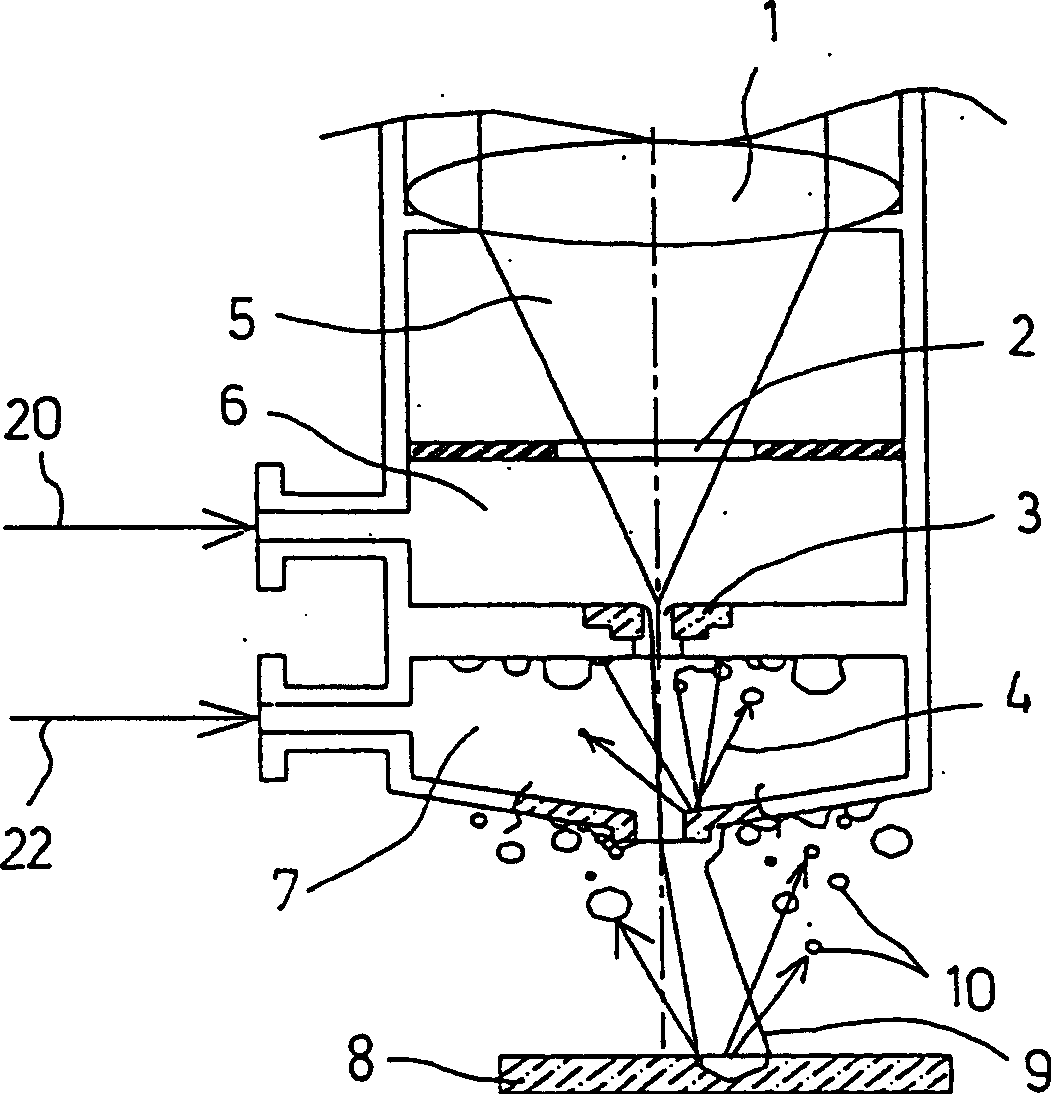

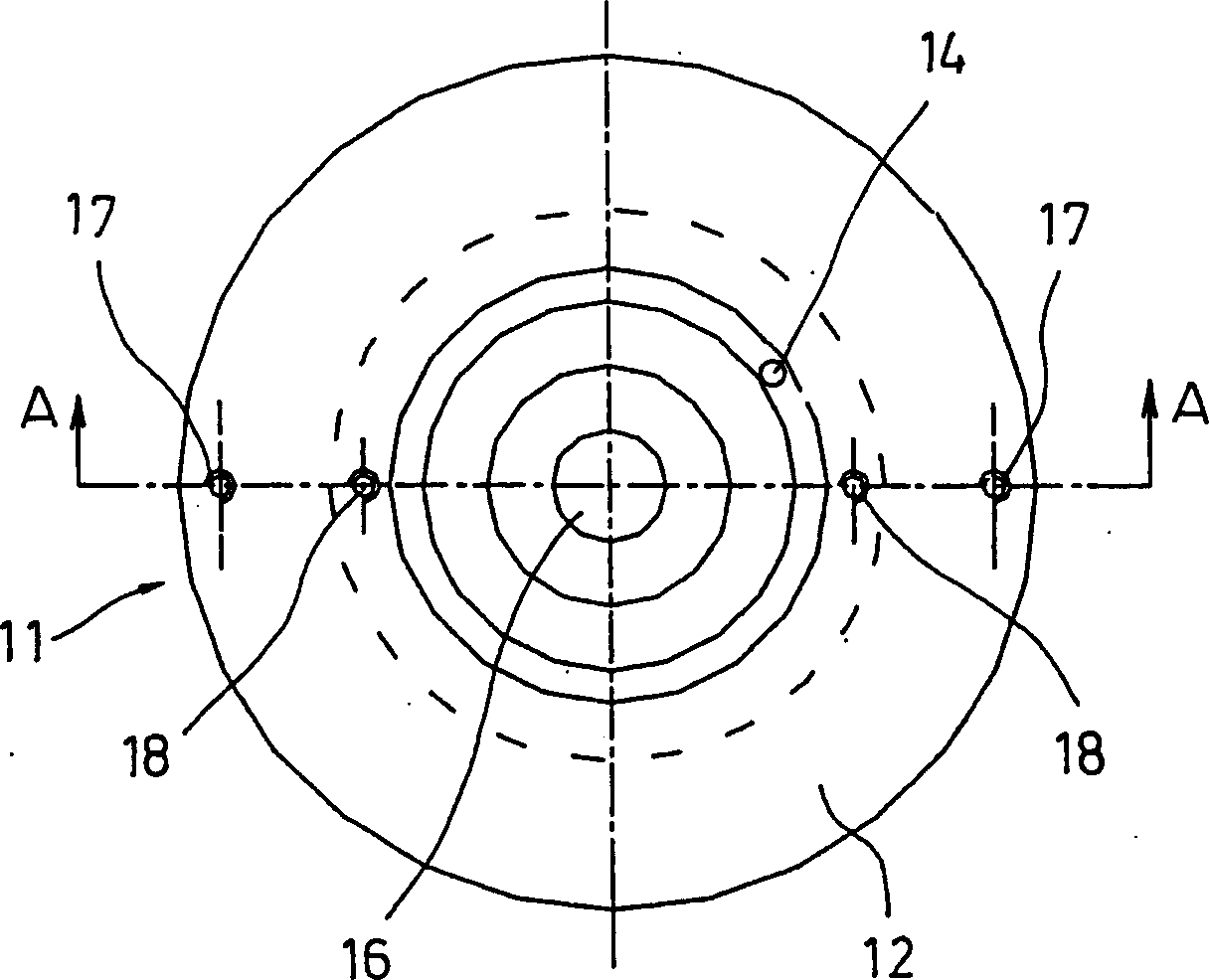

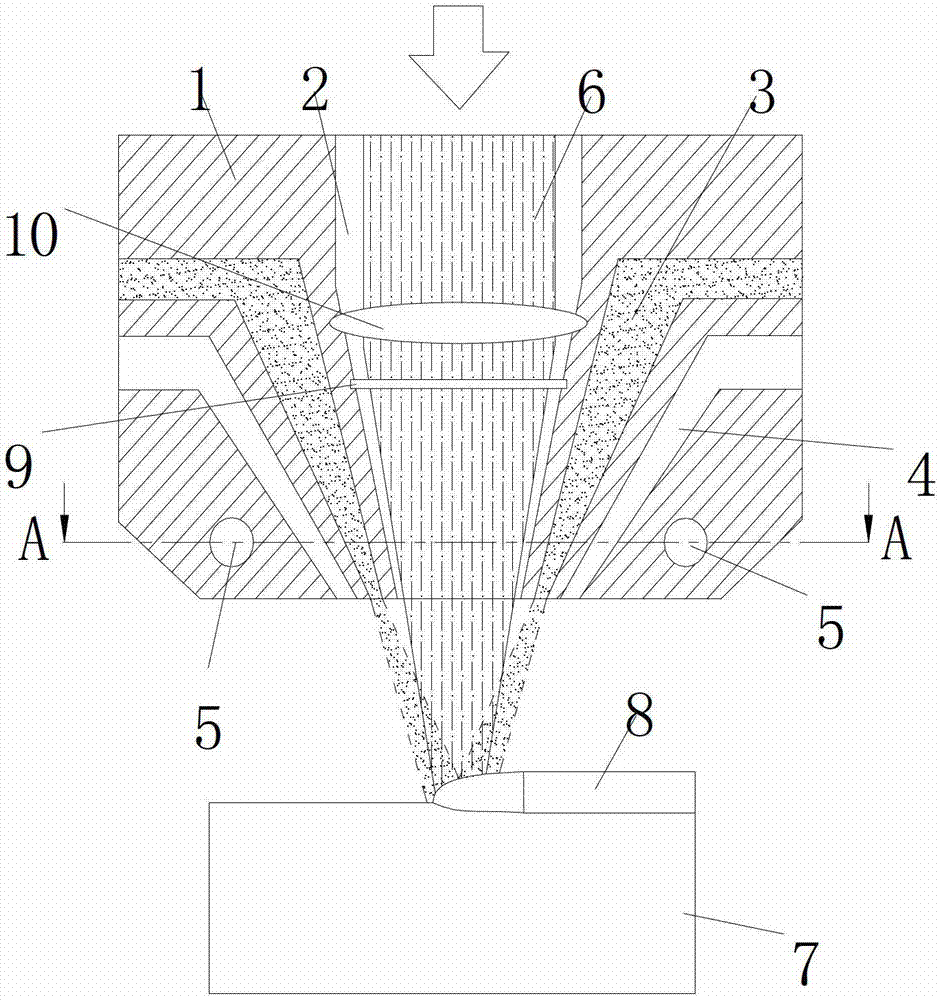

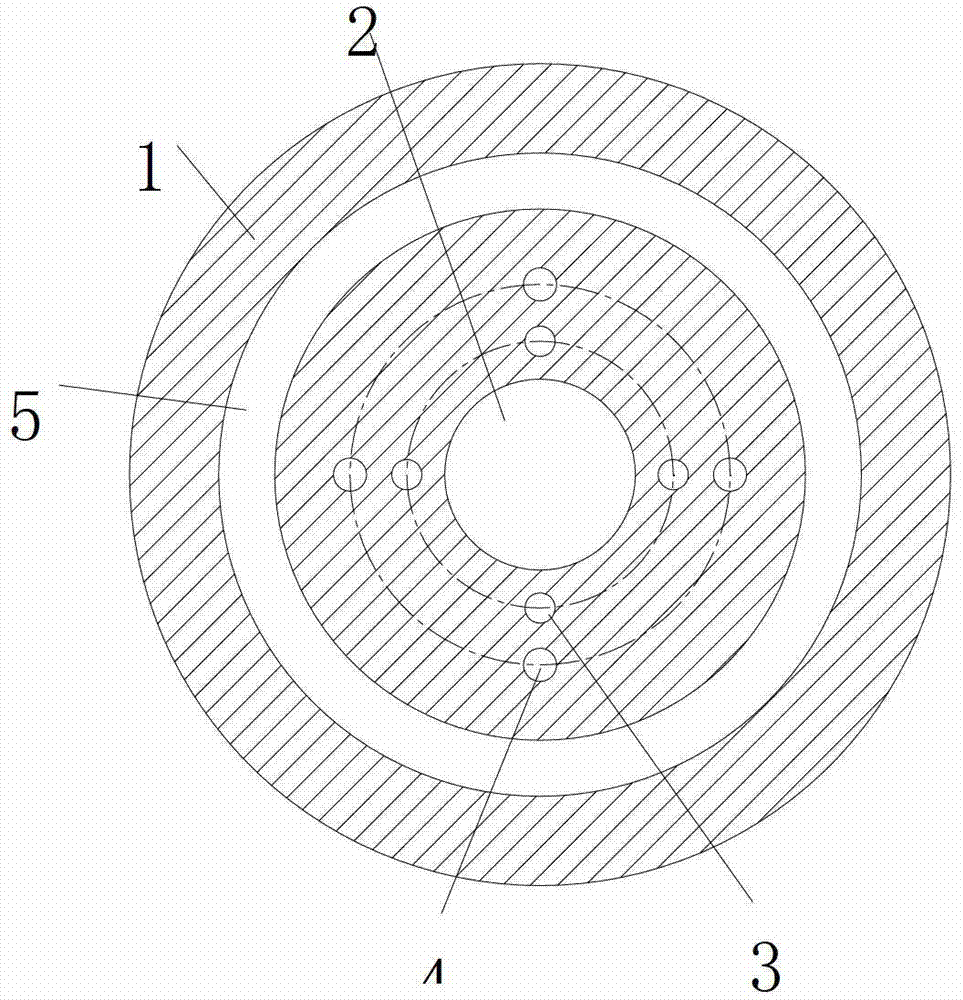

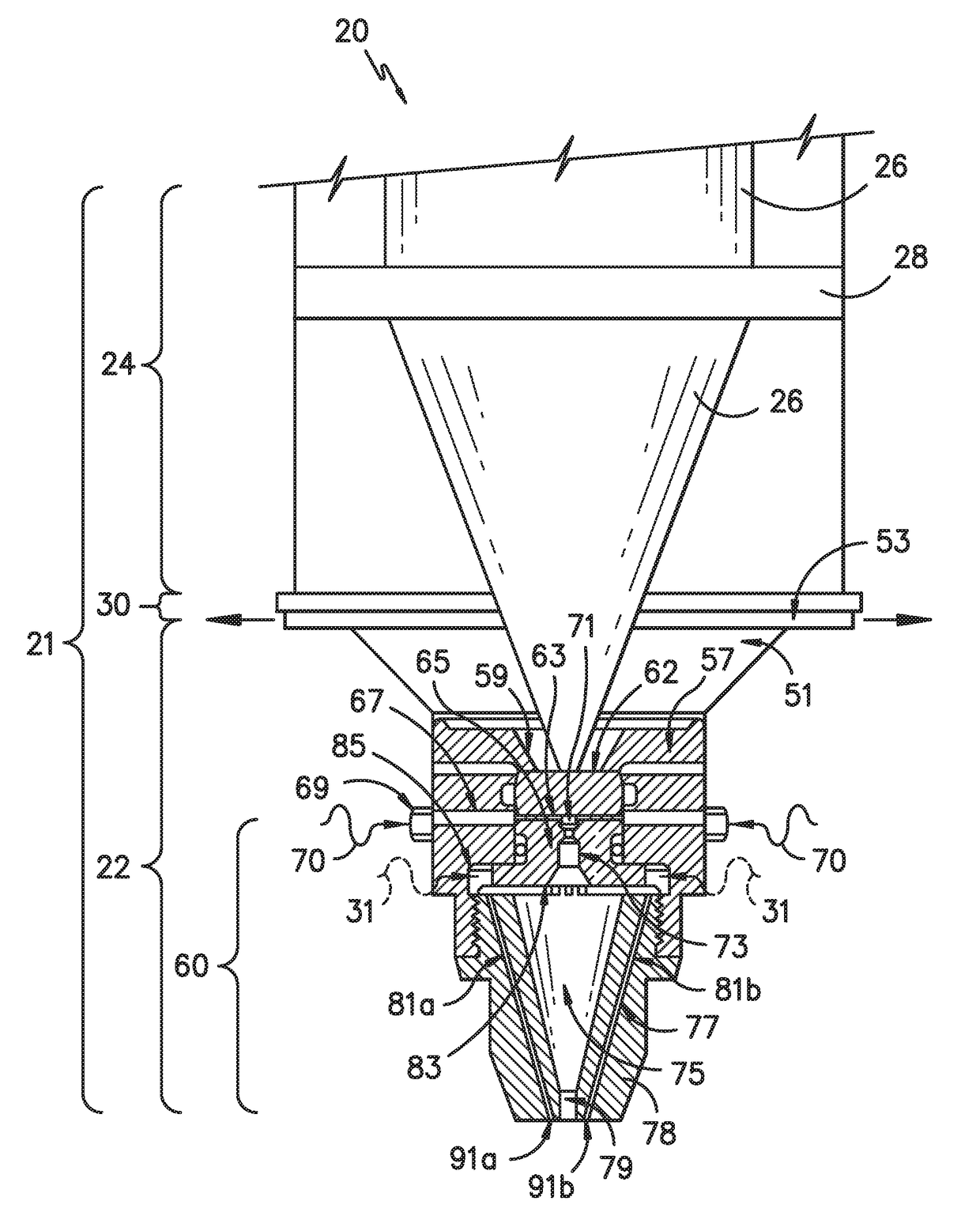

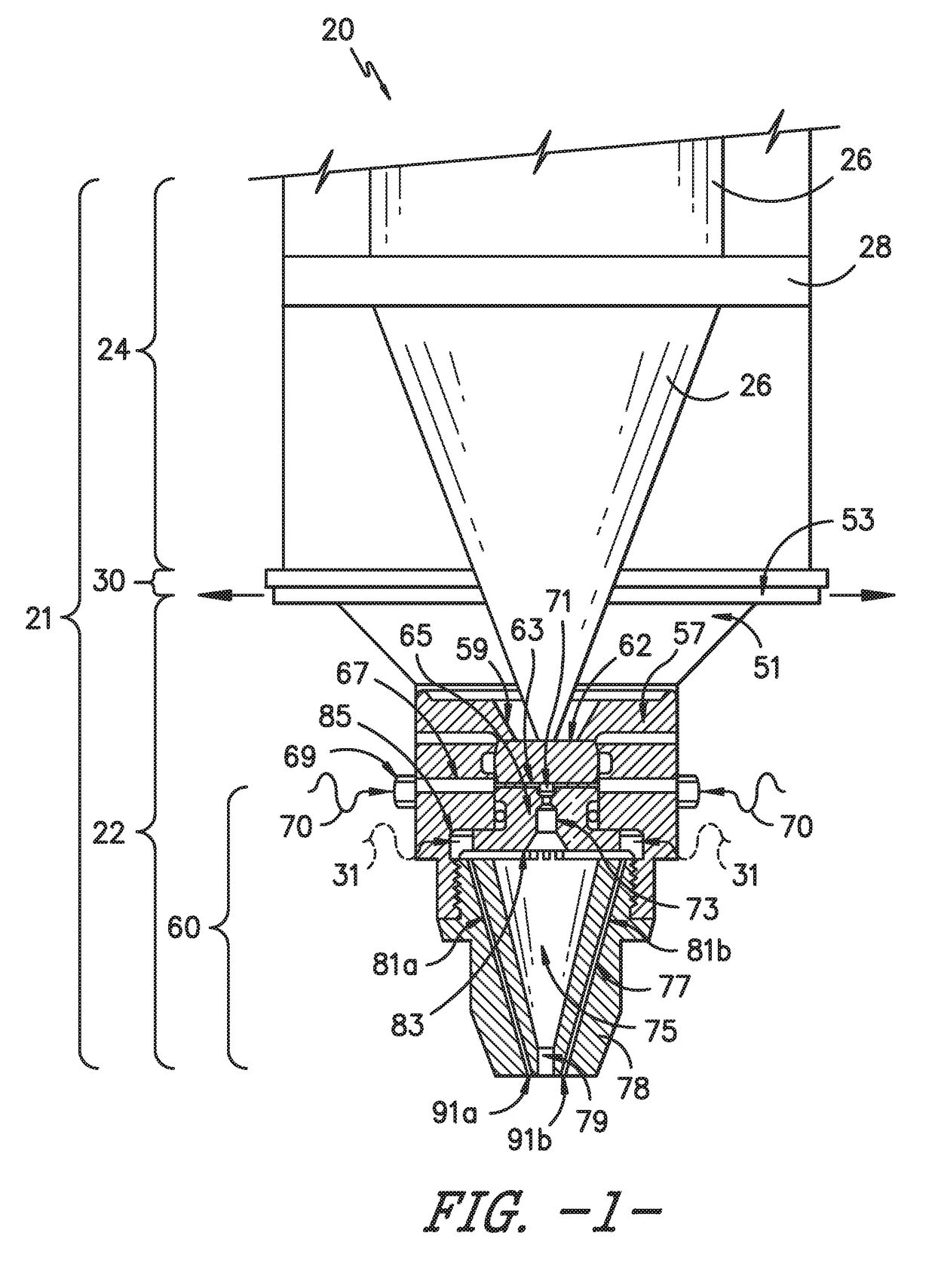

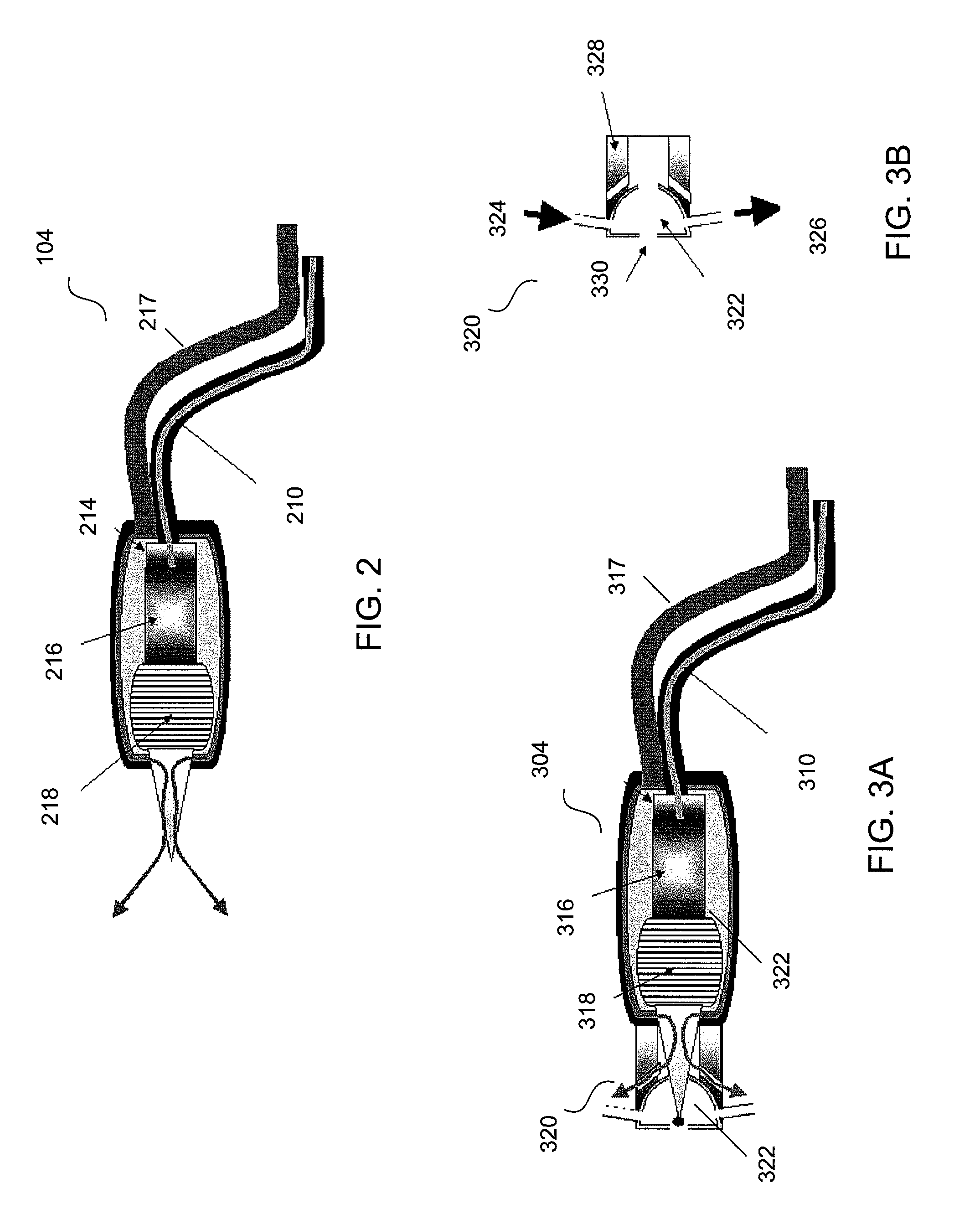

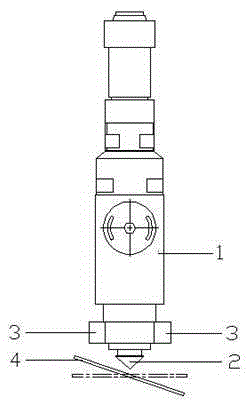

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

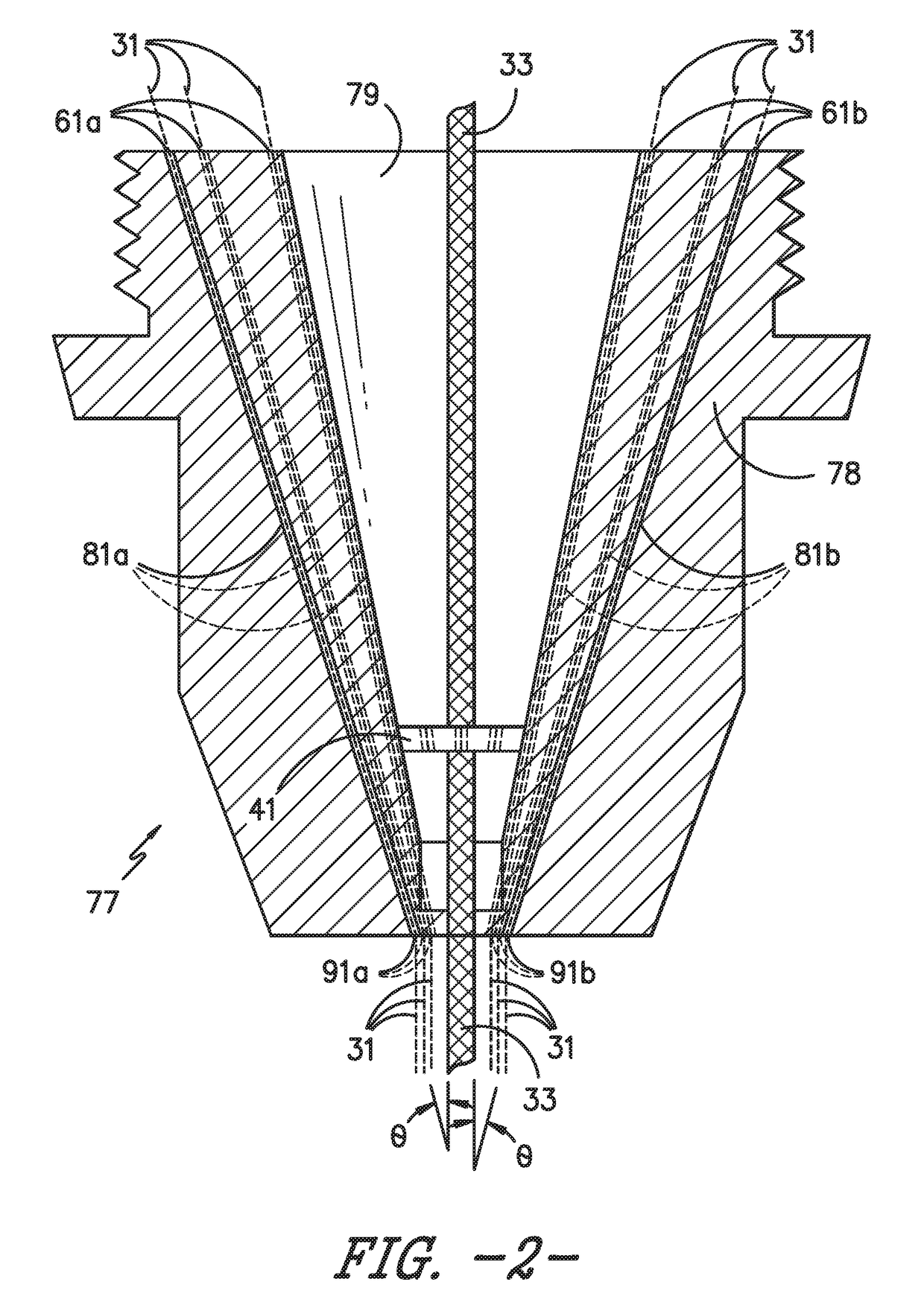

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

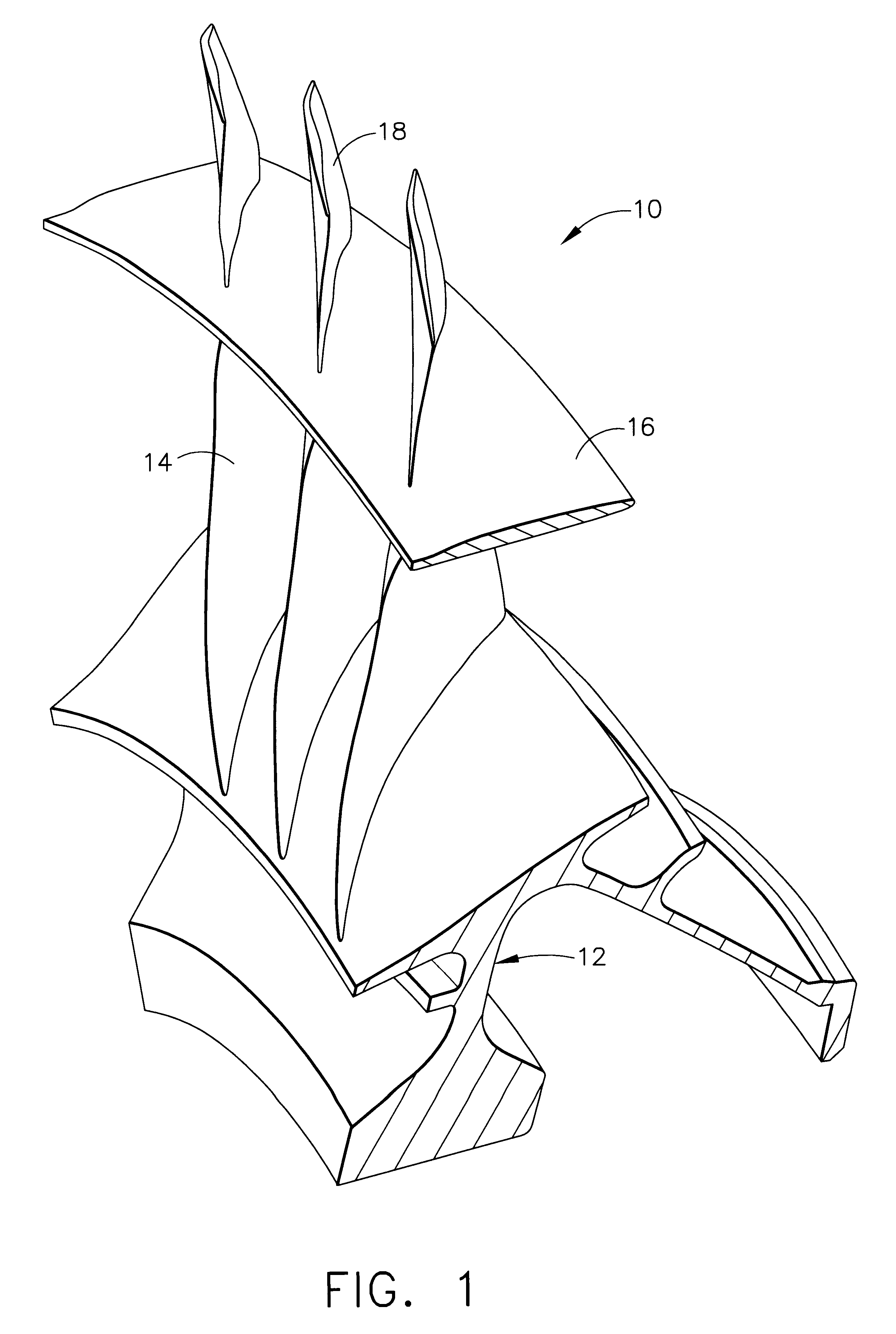

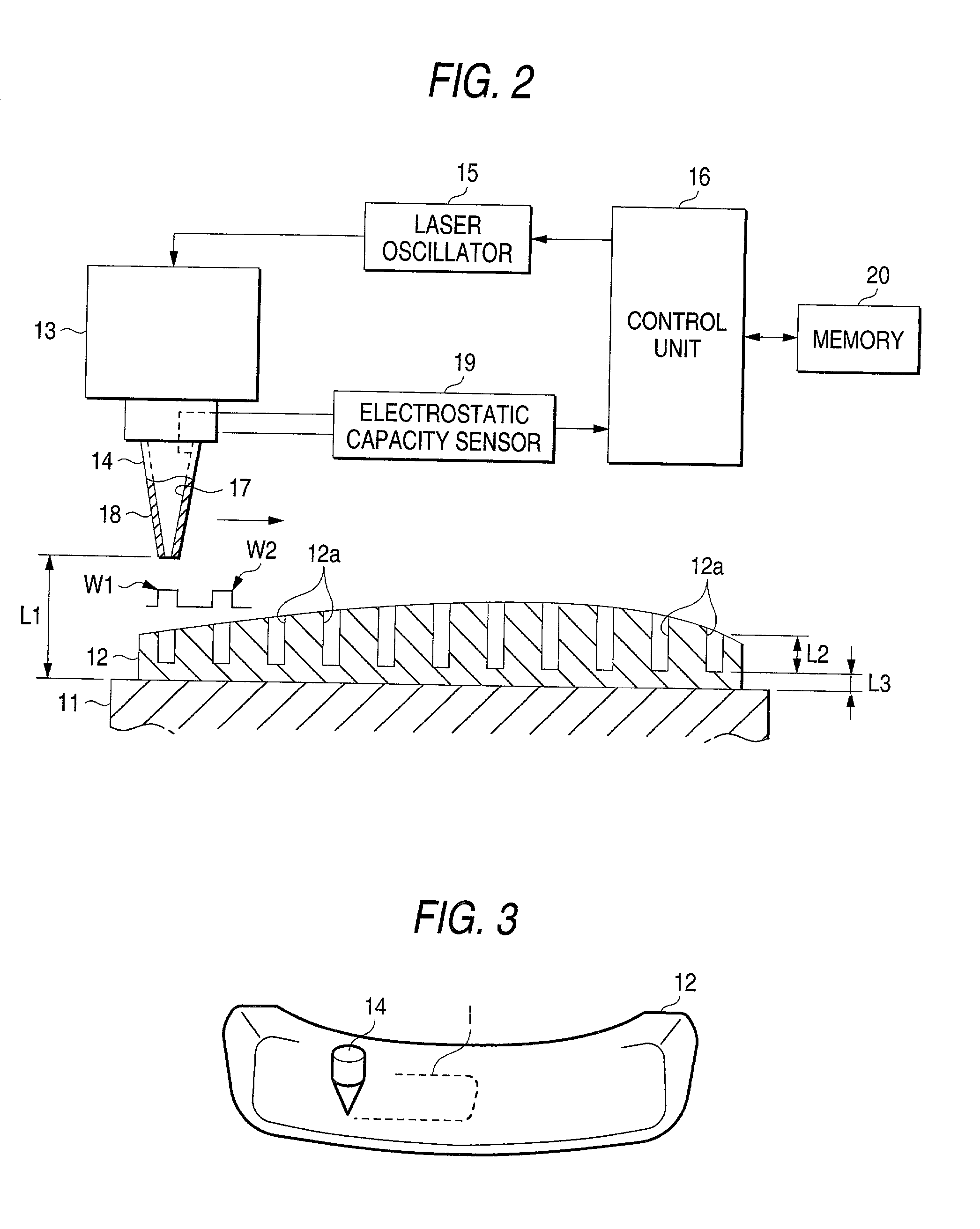

Method for laser twist welding of compressor blisk airfoils

A method for repair welding a titanium compressor blisk using laser twist welding. A blisk assembly has damaged portions removed. The surface to be repaired is provided with a predetermined geometry. The portions to be repaired are surrounded by a fixture which contains a laser nozzle. The fixture can provide a protective atmosphere to the area under repair while also shielding adjacent areas from damage resulting form welding. The welding is accomplished using preprogrammed patterns. The welding within the fixture is monitored remotely and is adjusted when stand-off between the weld nozzle and the molten metal are not within a predetermined range.

Owner:GENERAL ELECTRIC CO

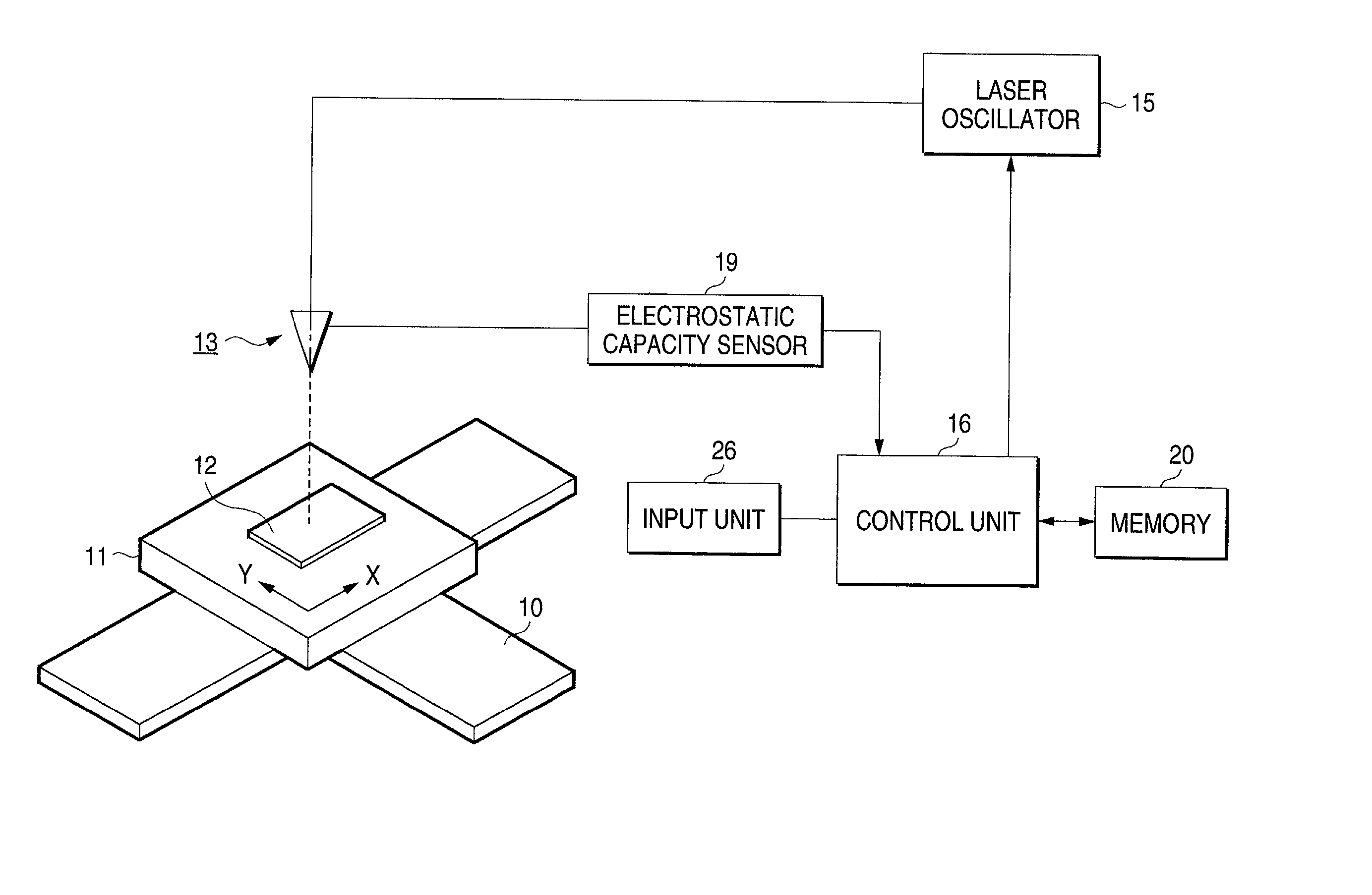

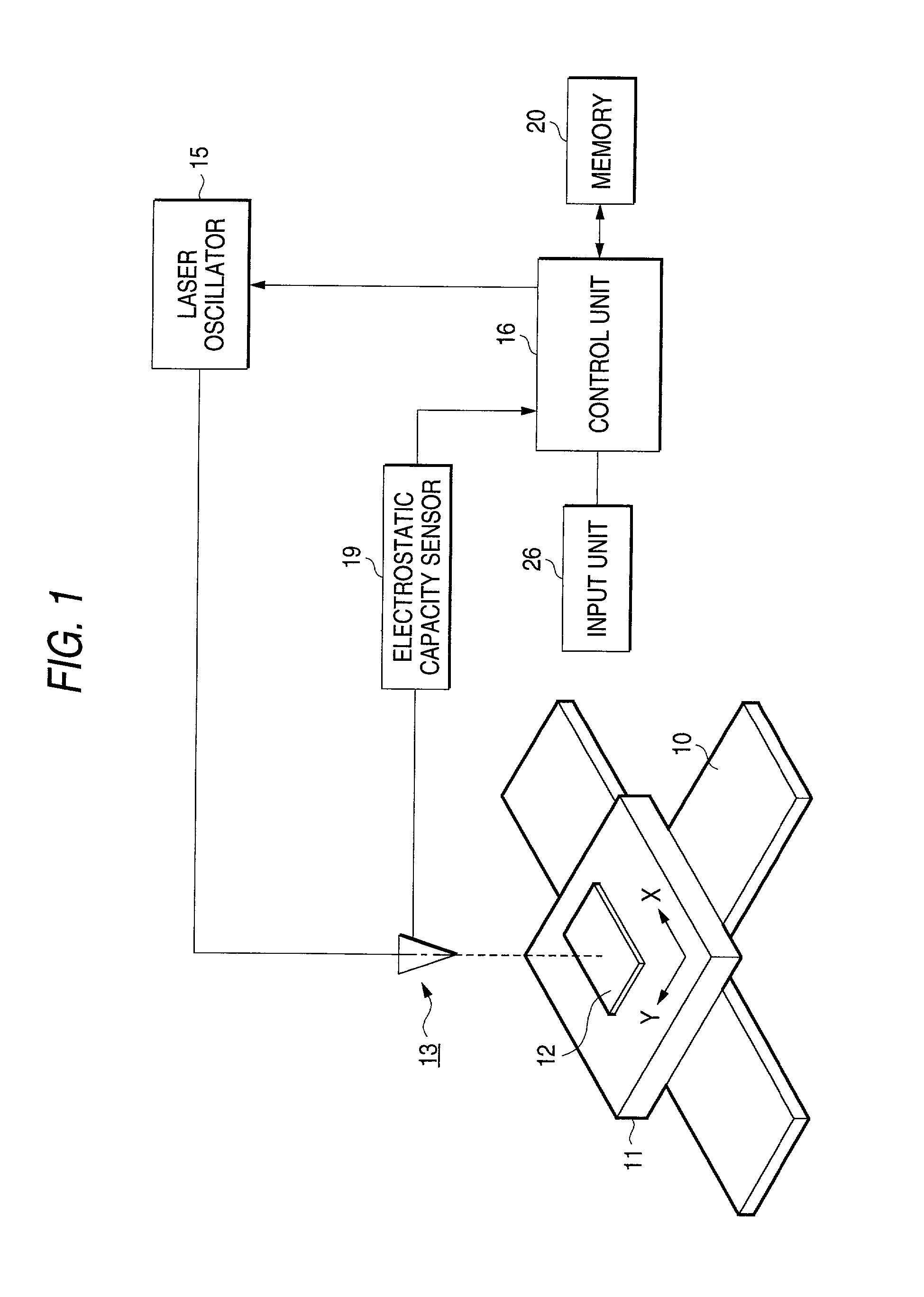

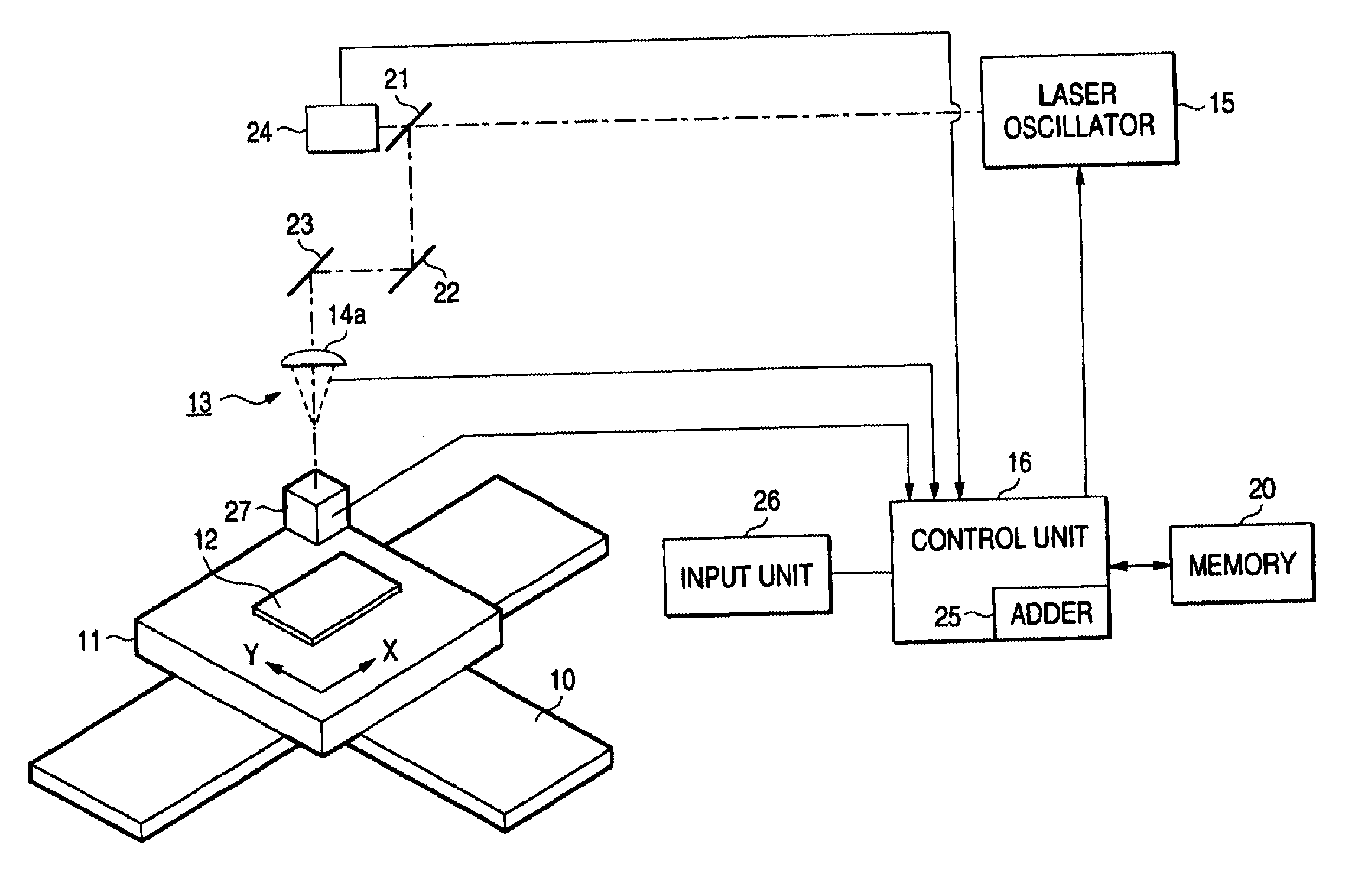

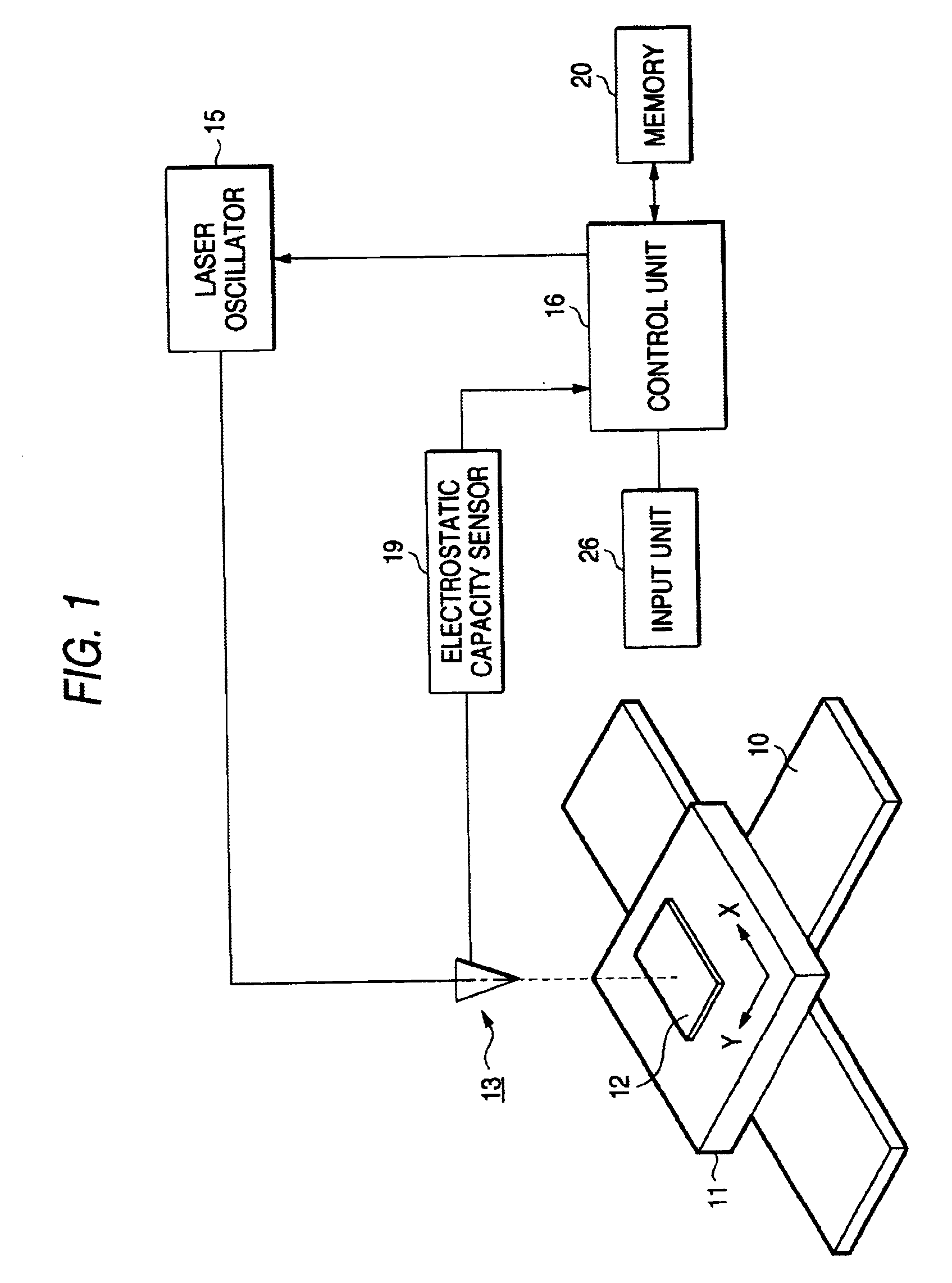

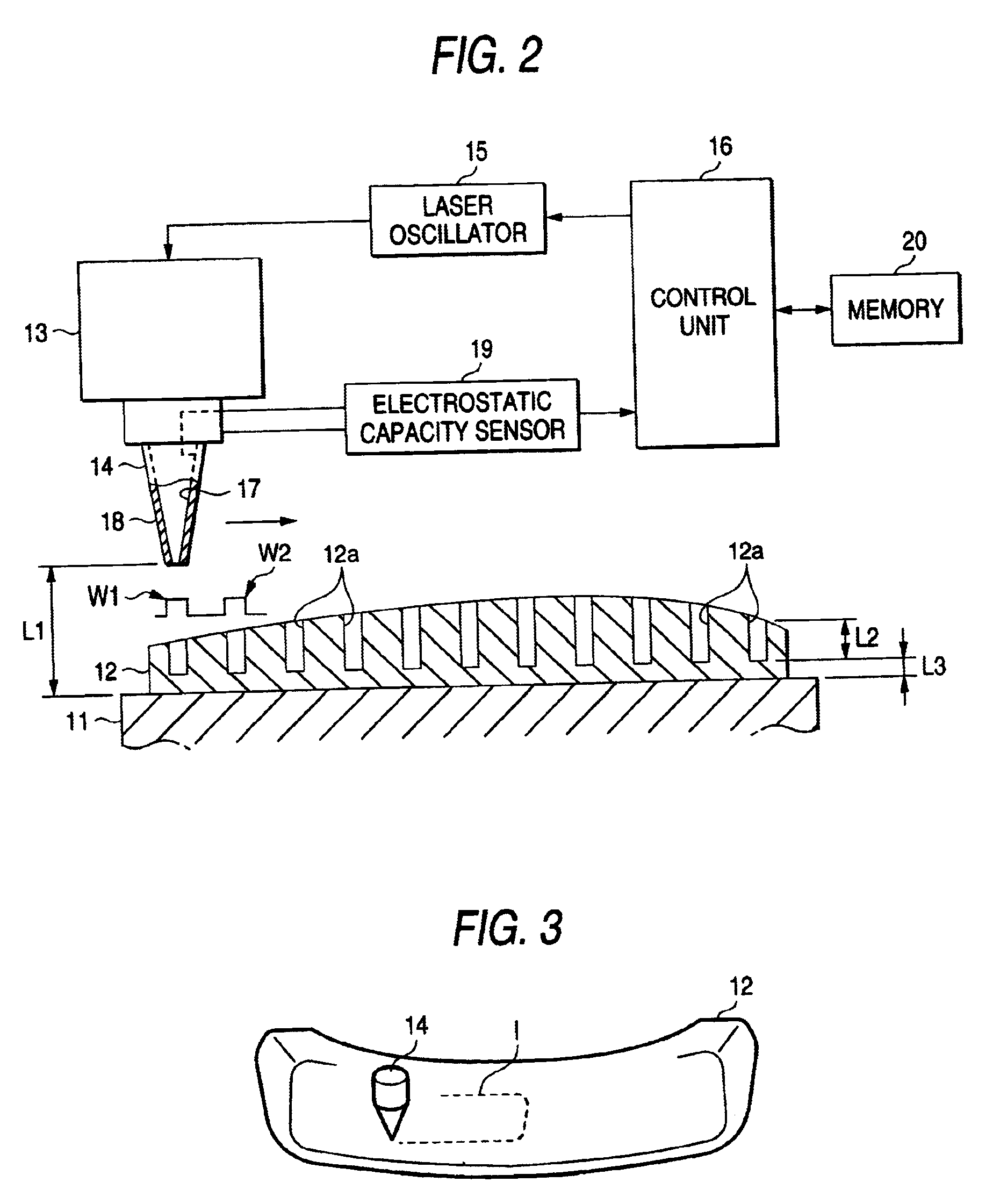

Laser beam machining apparatus and laser beam machining method

InactiveUS20030000927A1Pedestrian/occupant safety arrangementLaser beam welding apparatusLaser NozzleSpray nozzle

A laser beam machining apparatus forms blind holes at predetermined intervals in a workpiece by intermittently irradiating a laser beam from a laser nozzle to the workpiece while the laser nozzle and the workpiece being moved relatively. During the time the workpiece is subjected to machining, the electrostatic capacity between the support member and the laser nozzle is detected by an electrostatic capacity sensor while the workpiece made of conductive material is supported on the support member. The irradiation output power is controlled by a control unit which operates to vary the number of output pulses from the laser nozzle each time one hole is formed according to the result detected in response to variation in the thickness of the workpiece.

Owner:KOMATSU IND CORP

Laser beam machining apparatus and laser beam machining method

InactiveUS6680459B2Pedestrian/occupant safety arrangementLaser beam welding apparatusLaser NozzleSpray nozzle

A laser beam machining apparatus forms blind holes at predetermined intervals in a workpiece by intermittently irradiating a laser beam from a laser nozzle to the workpiece while the laser nozzle and the workpiece being moved relatively. During the time the workpiece is subjected to machining, the electrostatic capacity between the support member and the laser nozzle is detected by an electrostatic capacity sensor while the workpiece made of conductive material is supported on the support member. The irradiation output power is controlled by a control unit which operates to vary the number of output pulses from the laser nozzle each time one hole is formed according to the result detected in response to variation in the thickness of the workpiece.

Owner:KOMATSU IND CORP

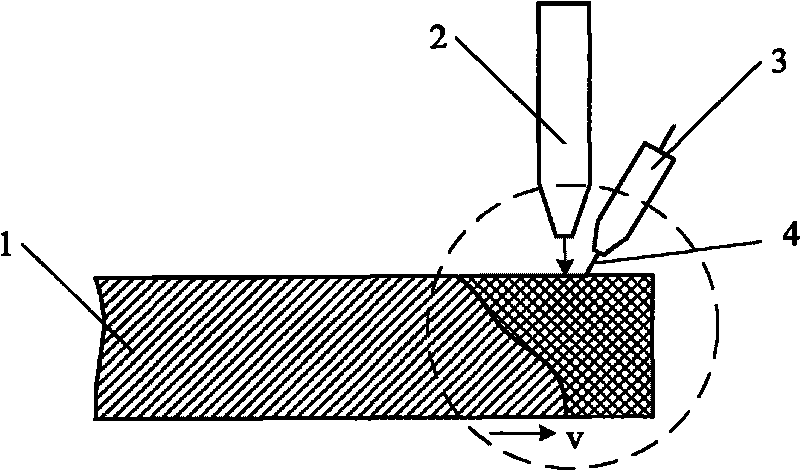

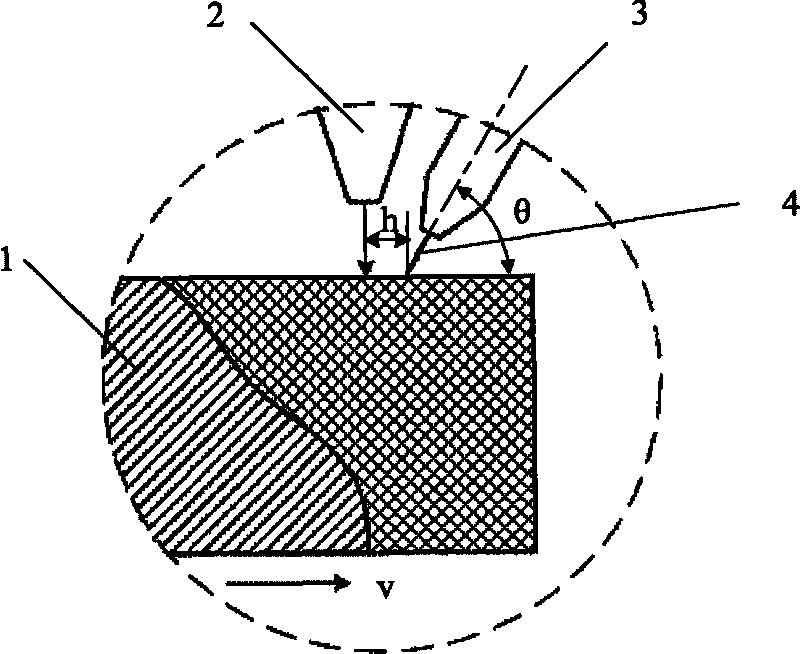

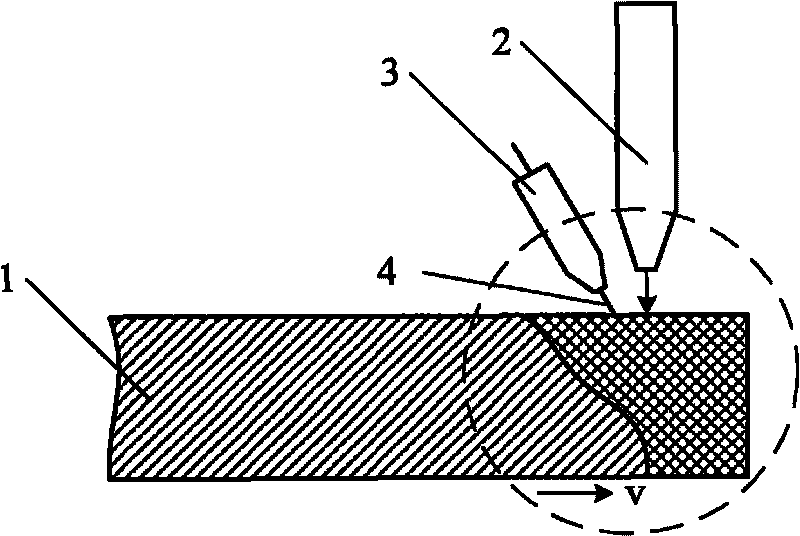

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

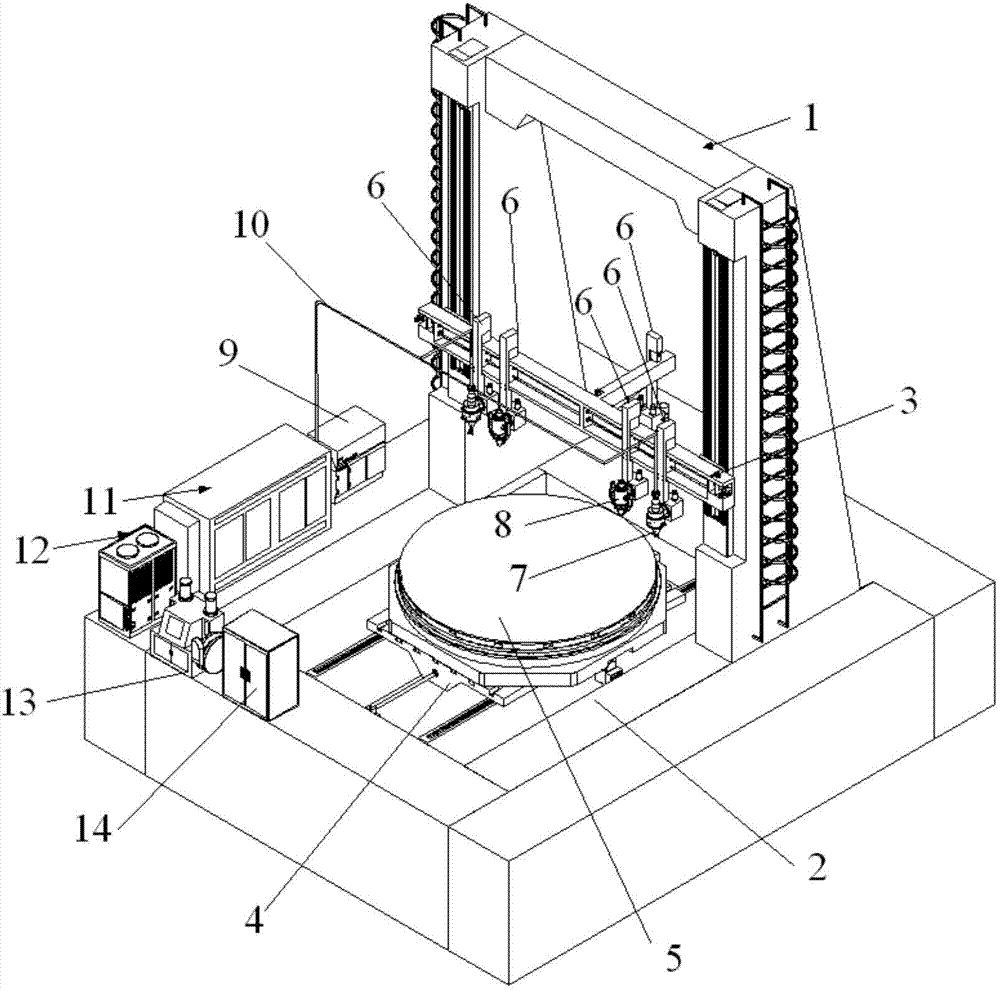

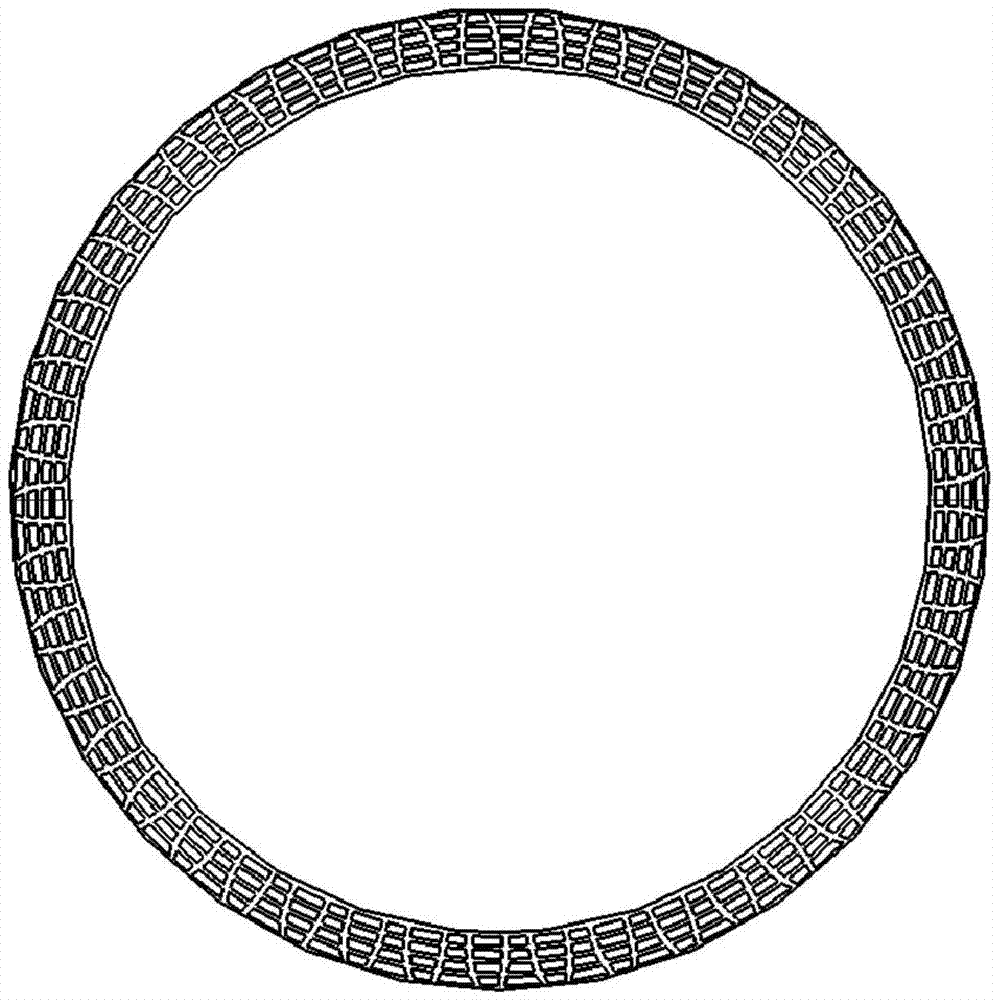

Nuclear heavy blank molding process and LCD-EBAM integrated printing equipment

ActiveCN104498943AHigh speed machiningGuaranteed molding accuracyIncreasing energy efficiencyMetallic material coating processesLaser NozzleEngineering

The invention discloses a nuclear heavy blank molding process and LCD-EBAM integrated printing equipment. The process sequentially comprises the following steps: establishing a model in a three-dimensional way, and guiding into a molding software program for data processing; running a laser nozzle and an electron beam gun to the origin of coordinates; molding an annular support; molding a cylinder body; molding a top cover and a top spherical shell wall of a deep end socket; molding a cylindrical boss in a pipe connecting section; separating an auxiliary support from a molded part. According to the equipment, a rack is fixed on a bottom beam; a movable cross beam can longitudinally lift and be positioned on the rack; a multi-shaft robot is arranged on the movable cross beam; the laser nozzle and the electron beam gun are respectively arranged on arms of the multi-shaft robot, a laser and a powder feeder are used for respectively providing laser and metal powder to the laser nozzle, and a thread feeder and a power supply are used for providing metal threads and electric power to the electron beam gun; the laser nozzle and the electron beam gun can respectively reach random positions on a workbench; and a controller is used for controlling work of each part. The equipment can be used for realizing high-speed processing of high-precision products and saving energy.

Owner:JIANGSU YONGNIAN LASER FORMING TECH

Laser Nozzle Methods And Apparatus For Surface Cleaning

InactiveUS20070163715A1Semiconductor/solid-state device manufacturingElectrostatic cleaningSurface cleaningLaser Nozzle

Apparatuses and methods for cleaning a surface comprising contaminate particles are provided. In one respect, plasma and / or a shockwave may be created in a fluid flowing through a nozzle. The nozzle, coupled to a laser source and a fluid feed may be configured to deliver the generated plasma and / or shockwave to the surface.

Owner:SEMATECH

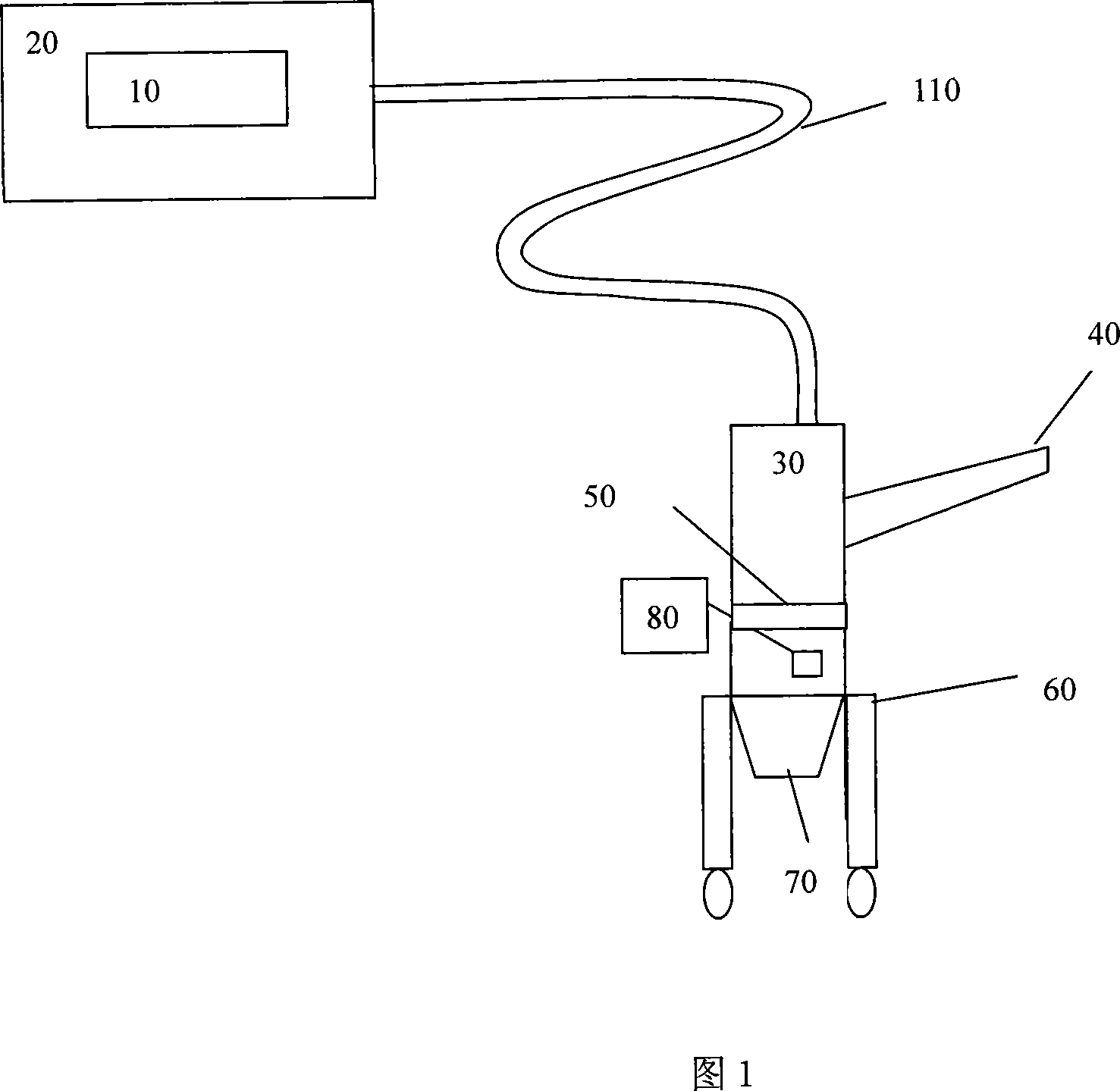

Hand-hold laser processing spear system

InactiveCN101176949ASimple structureReduce volumeLaser beam welding apparatusLaser processingLaser Nozzle

The invention discloses a hand-held laser processing gun system, comprising a fiber laser (10), a control system (20), a body of a laser gun (30), a focusing system (50), a laser nozzle (70), a focus-controlling and rotating wheel for the processing gun (60), and an optical fiber. The invention is characterized in that: the fiber laser (10) is connected with the control system (20); the laser is also connected with a laser head integrated in the body of the laser gun (30) through the optical fiber; the focus-controlling and rotating wheel (60) is fixed at the bottom of the body for the laser gun; laser beam from the laser (10) is output by the laser head, and focuses and works on a workpiece through the focusing system (50) and the laser nozzle (70). The invention has the advantages of convenience in portability due to compact size, light weight and good light speed quality of the fiber laser and the characteristics of hand-held laser processing gun, and avoidance of inconvenient manufacturing due to the position, cost and other reasons in the past.

Owner:BEIJING UNIV OF TECH

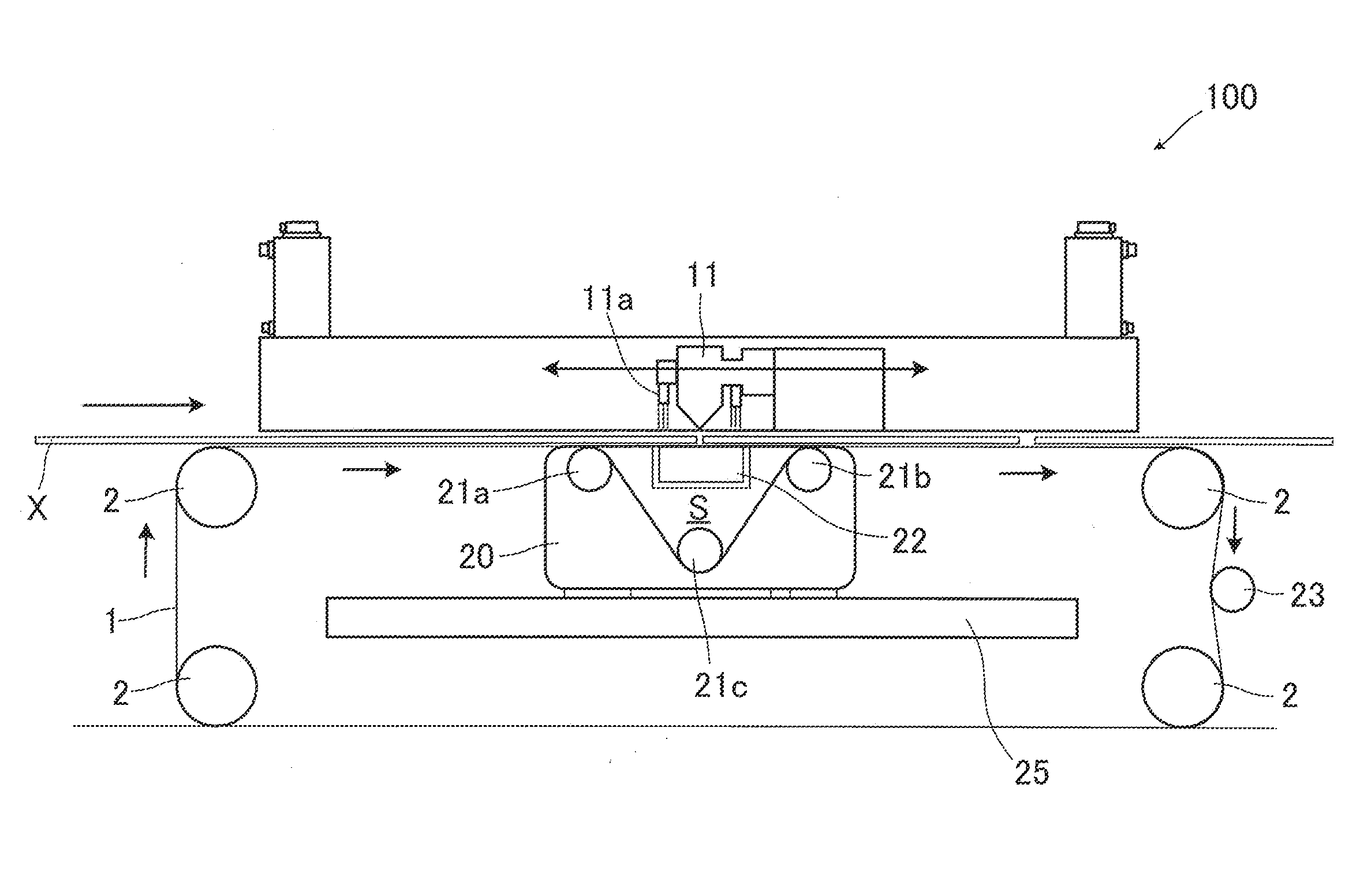

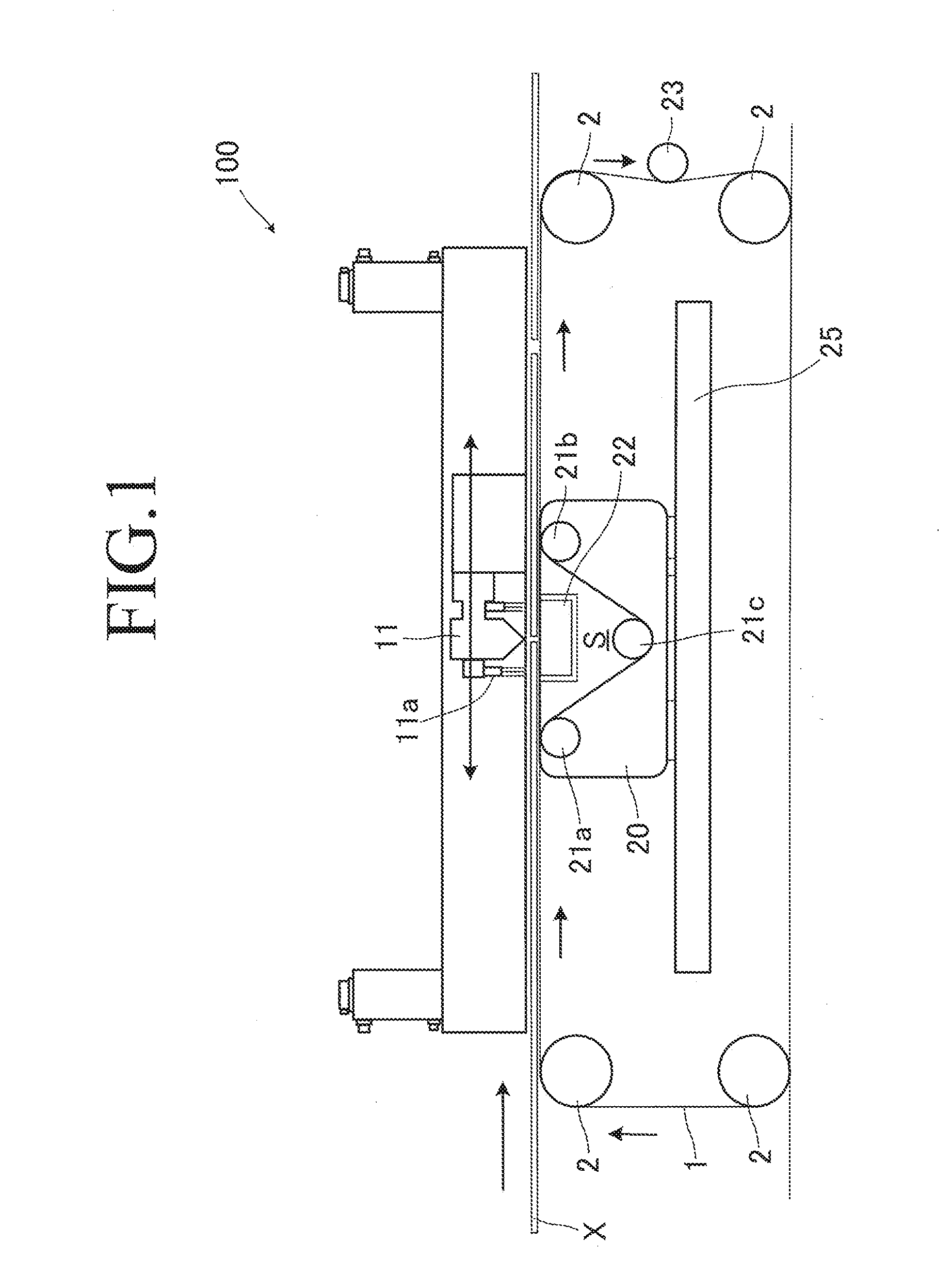

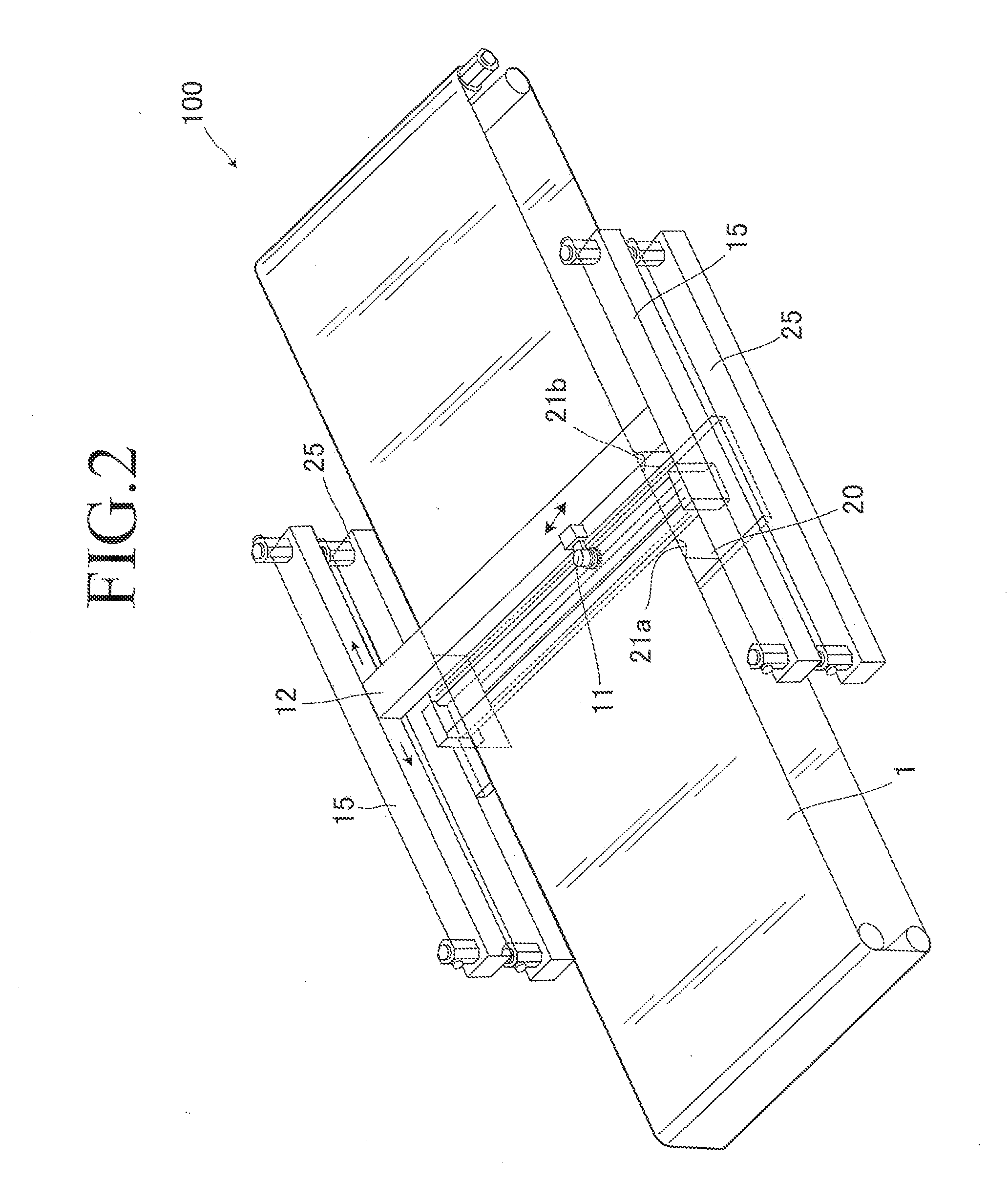

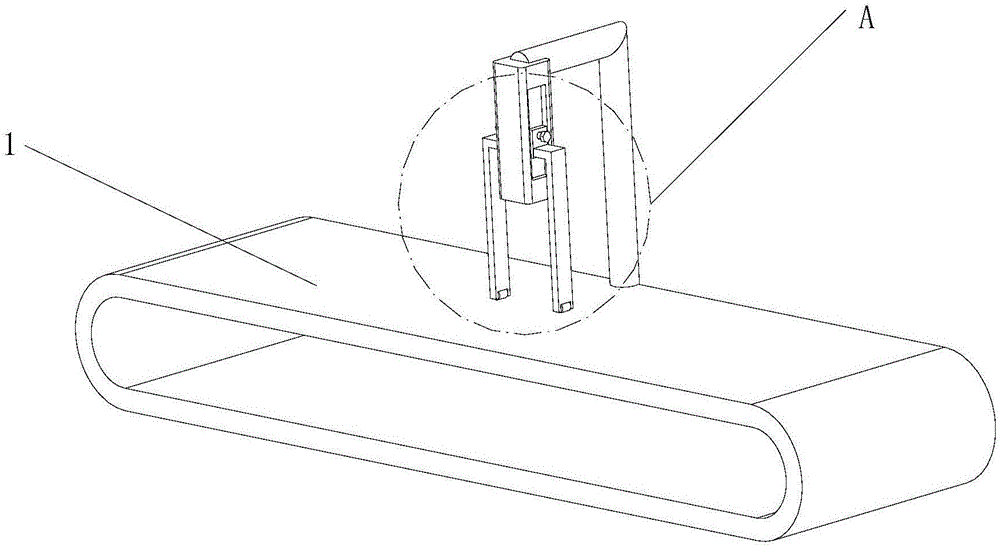

Laser blanking apparatus and processing method using same

ActiveUS20160214207A1Save spaceEasy to installLaser beam welding apparatusLaser processingLaser Nozzle

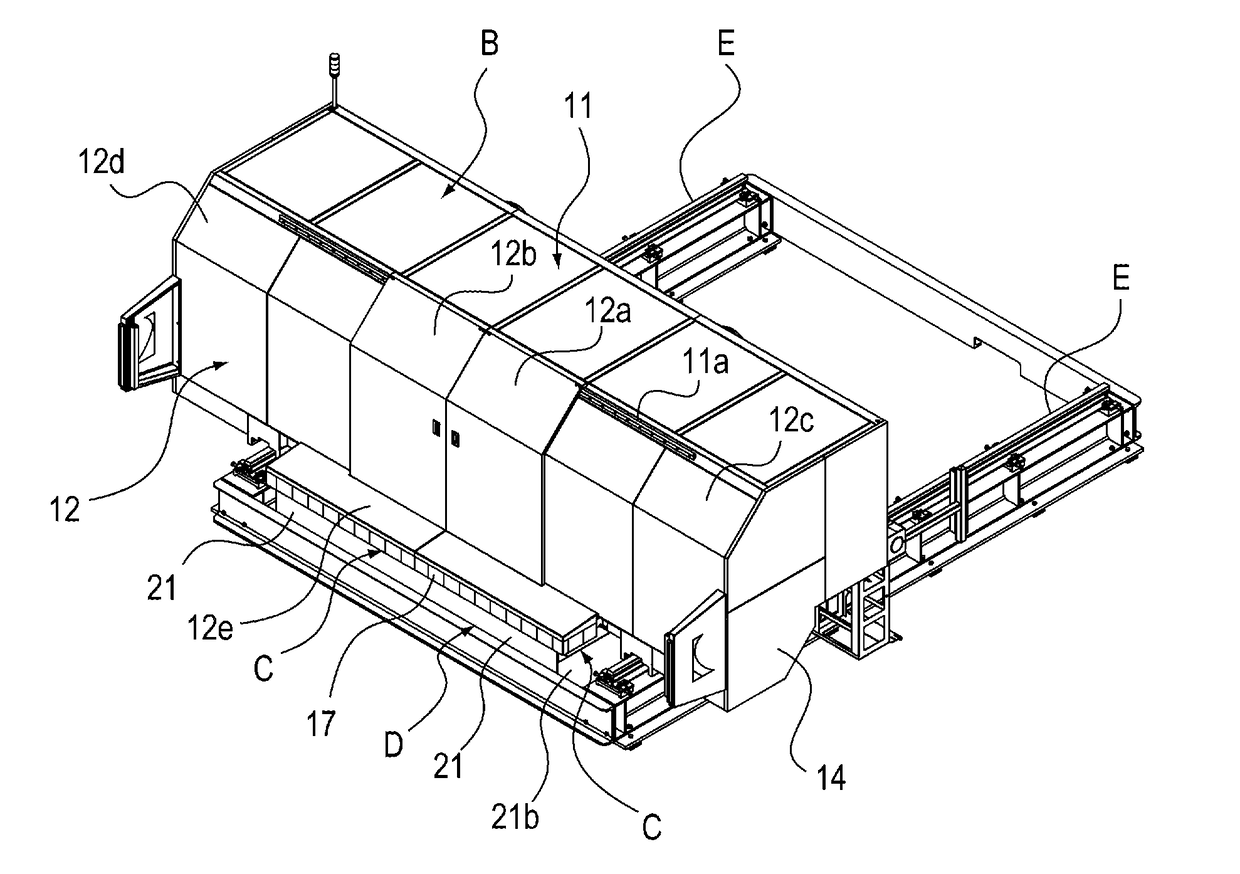

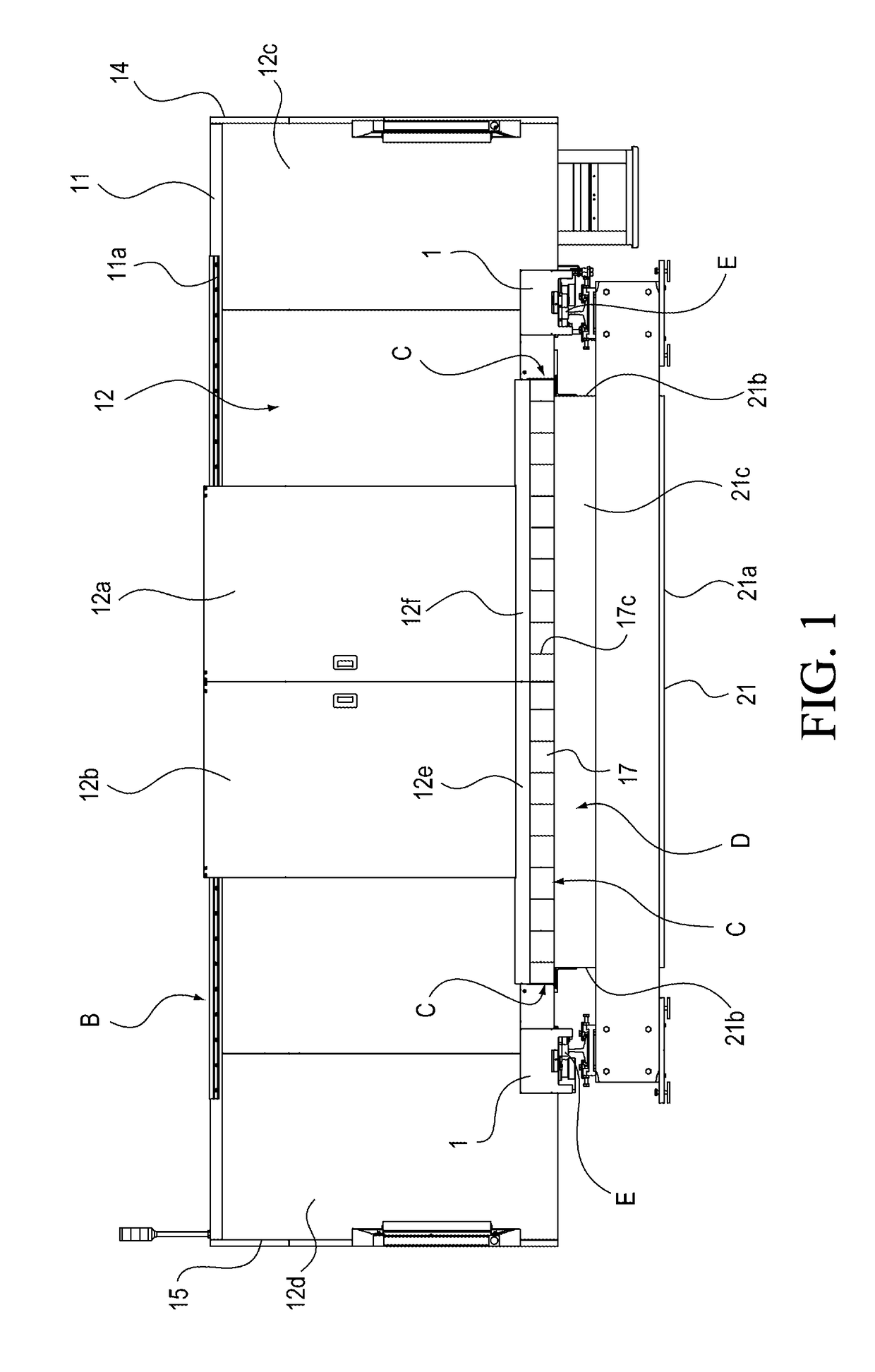

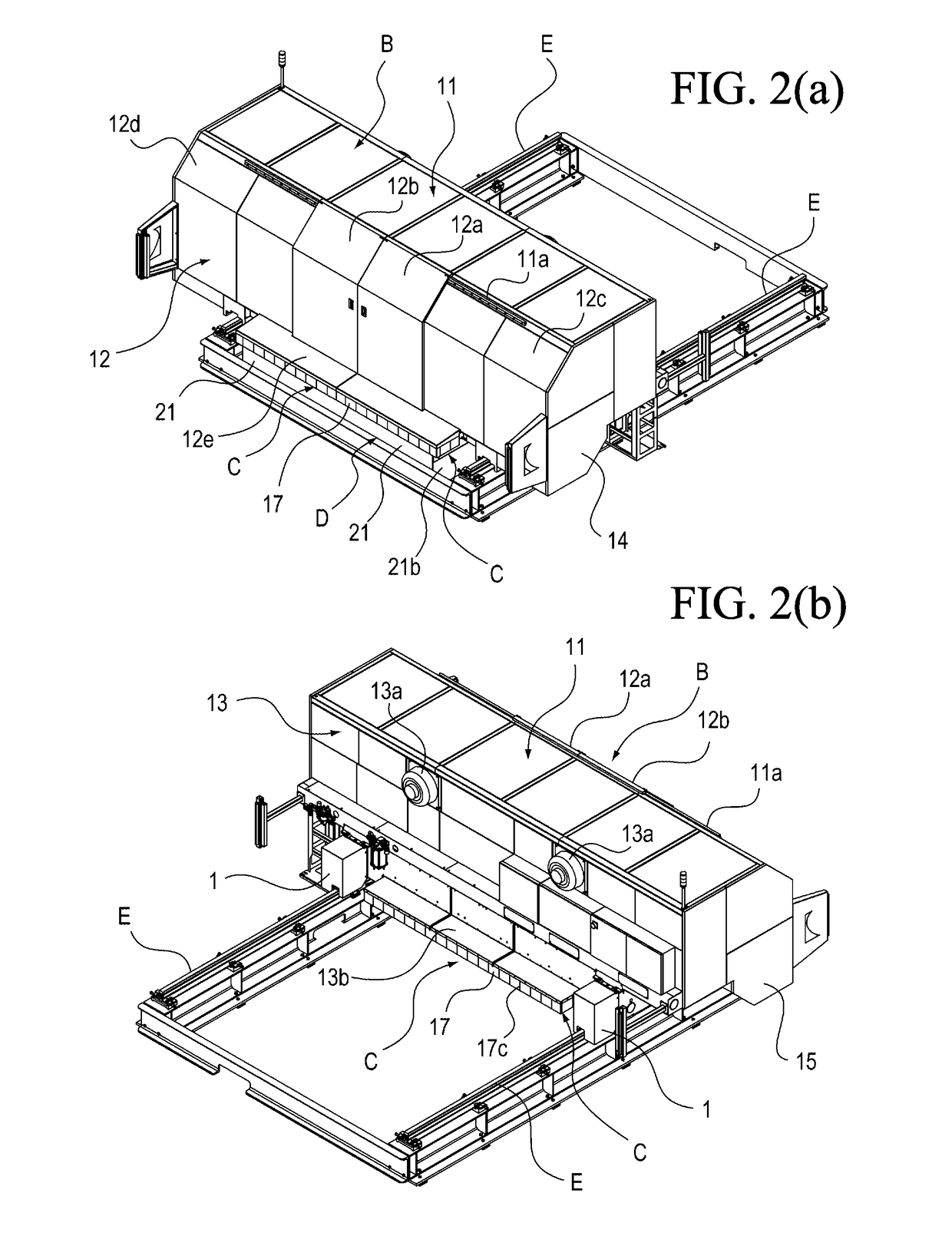

[Object] To provide a laser blanking apparatus that saves space, is easy to install, and yet is capable of laser-processing a plate material into a desired shape without causing misalignment while conveying the plate material and a processing method using the same.[Solution] The present invention is directed to a laser blanking apparatus 100 that, while conveying a flat plate material X, cuts the plate material X into a blank material with laser light emitted from a laser nozzle 11, including: an endless conveyor 1 for feeding the plate material X; a pair of upstream and downstream support rollers 21a and 21b provided below the laser nozzle 11; and a drawing roller 21c provided below the upstream and downstream support rollers 21a and 21b, wherein the upstream and downstream support rollers 21a and 21b and the drawing roller 21c guide the endless conveyor 1.

Owner:HITACHI ZOSEN FUKUI CORP

Water induced laser nozzle anti-sputtering protector

An anti-splash protector for the water-guided laser nozzle in order to prevent said nozzle from being burnt out has a base plate fixed to the bottom of water-guided laser nozzle module and a central plate surrounded by said base plate and with a central hole for allowing the micro water column for water-guided laser to pass throught. At slot is between said both plates for preventing water drips from flowing from base plate to central plate.

Owner:崇电雷射科技股份有限公司

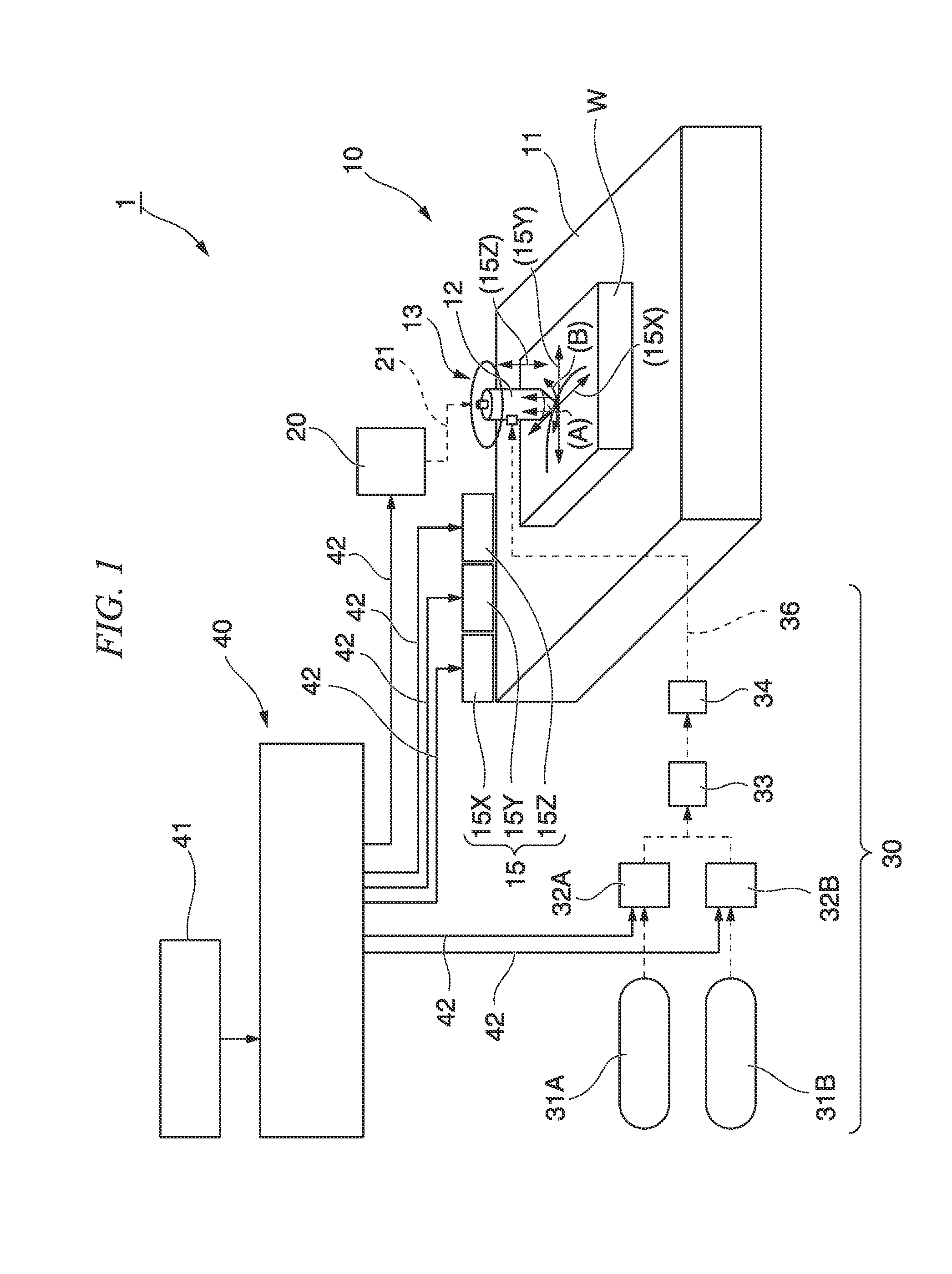

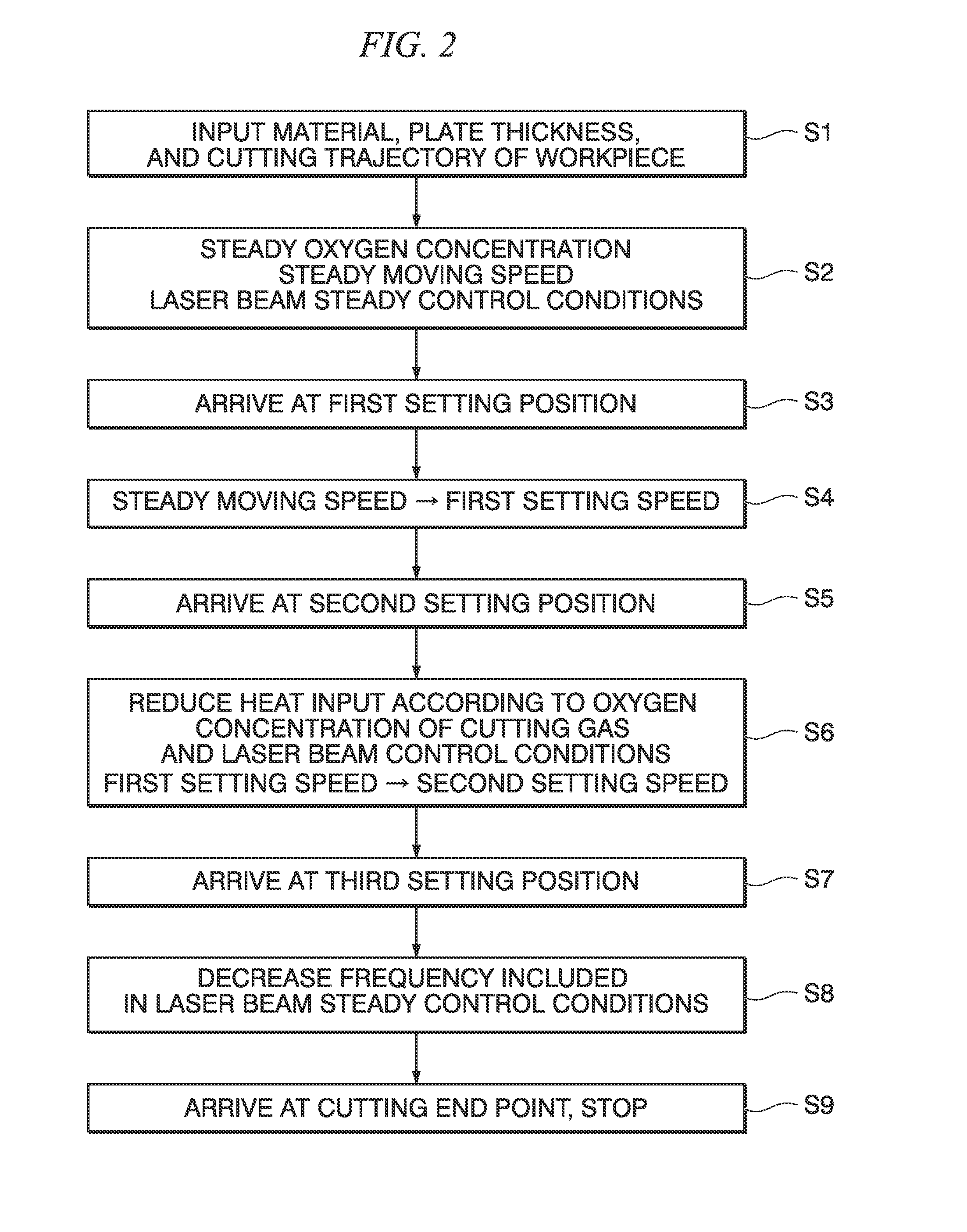

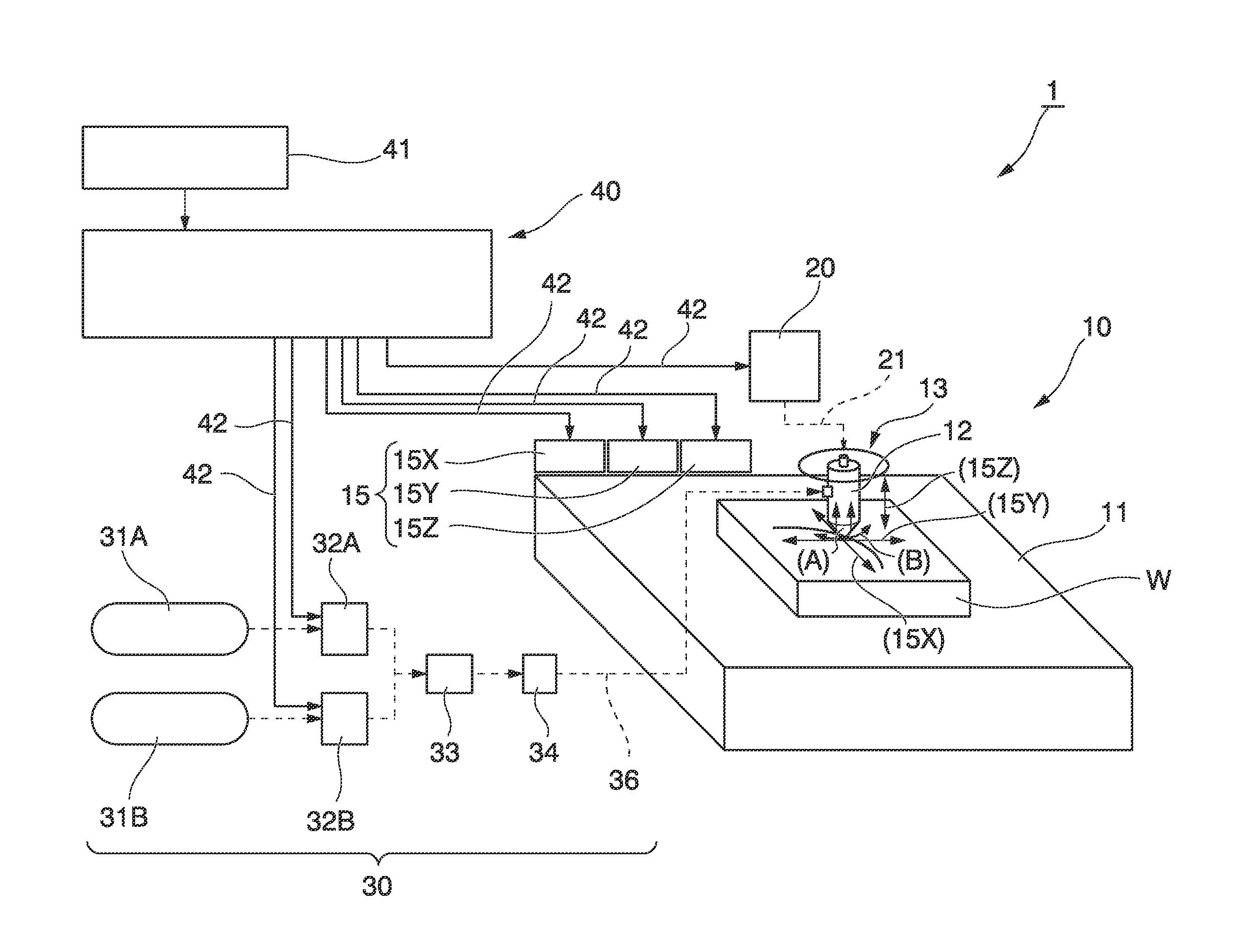

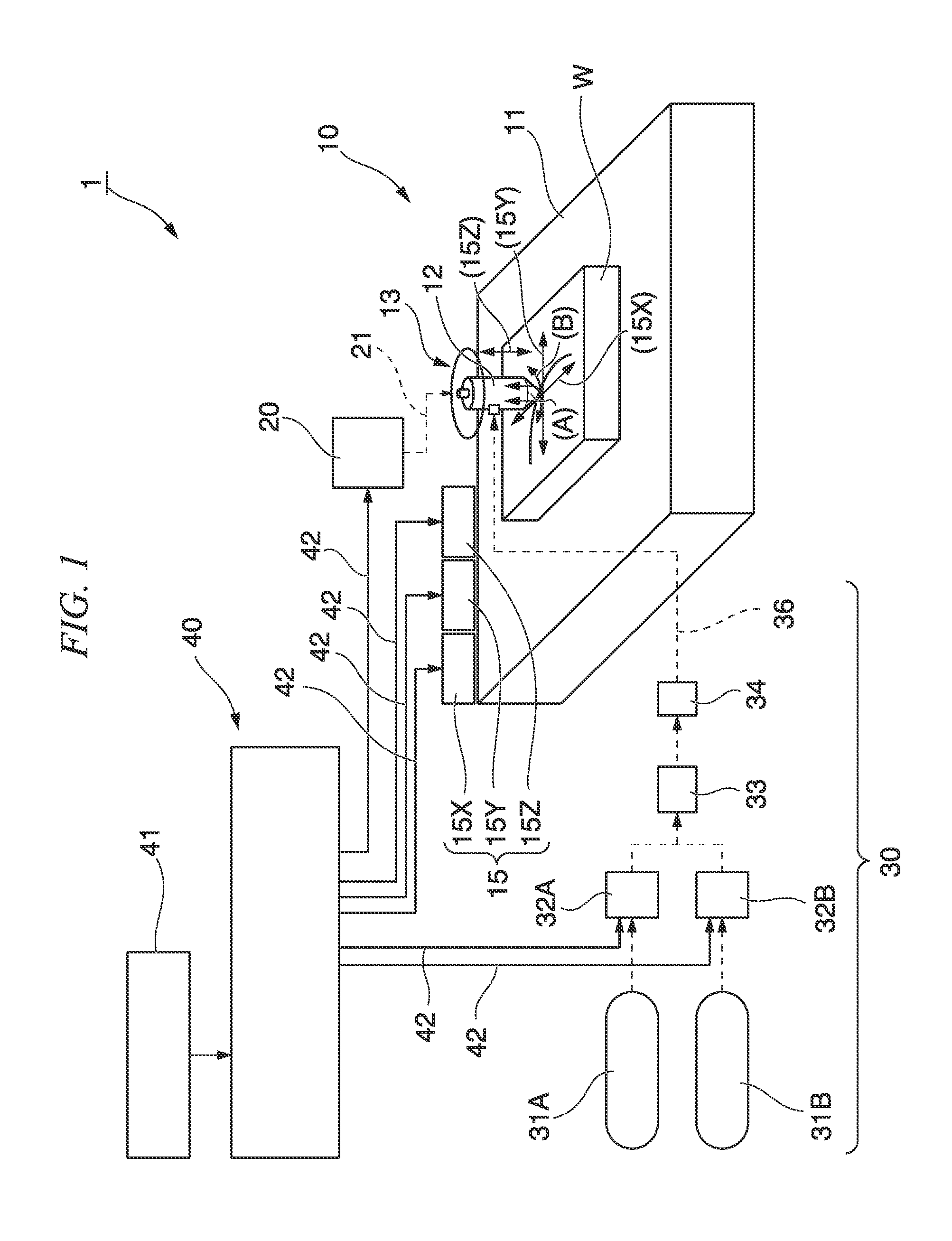

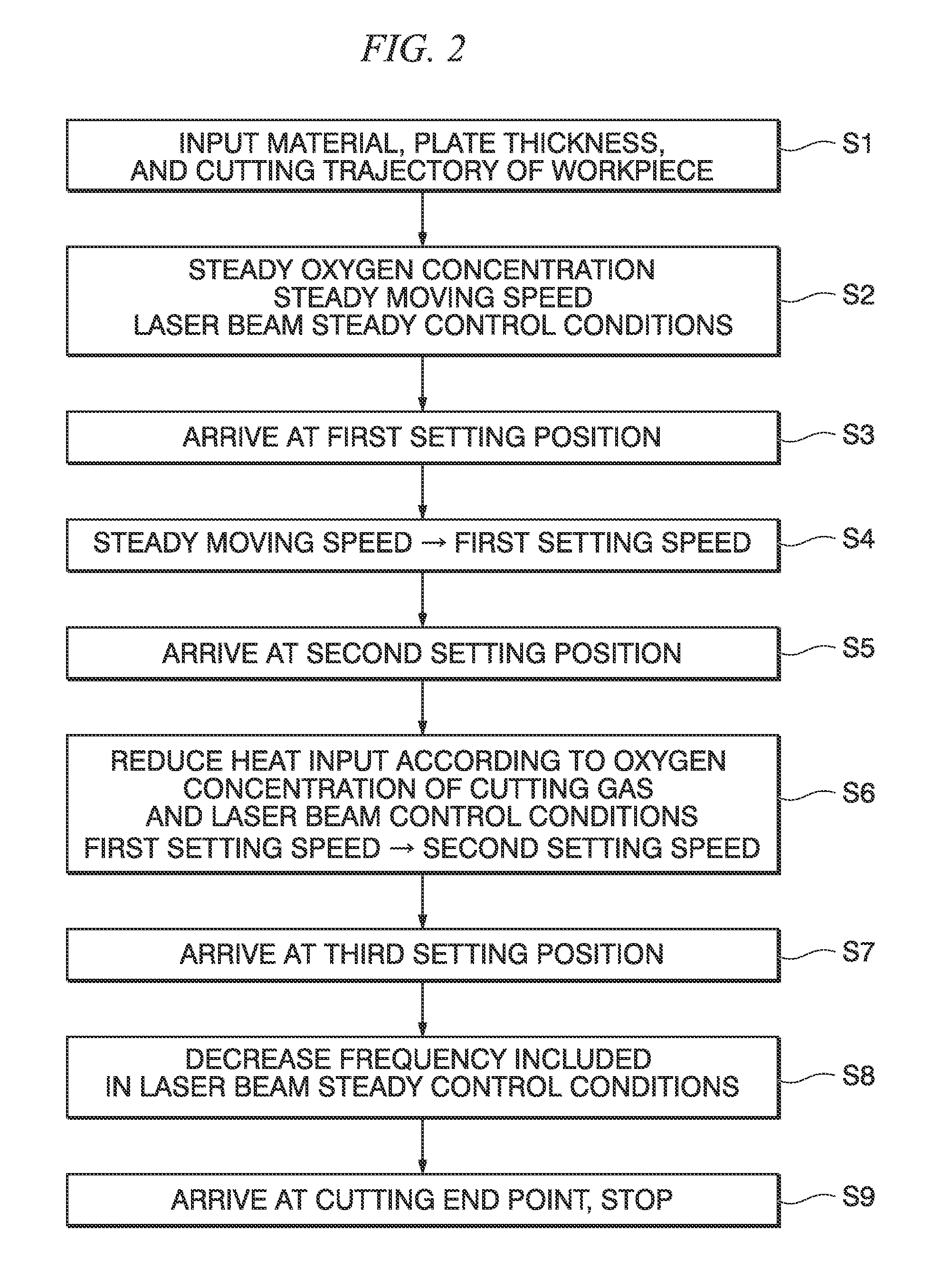

Laser cutting method and laser cutting device

InactiveUS20140246405A1InhibitionSuppress the occurrence of scratching in the workpieceArc welding apparatusWelding/cutting media/materialsLaser NozzleEngineering

A laser cutting device includes a control unit which sets a steady oxygen concentration, a moving speed of a laser nozzle and laser beam steady control conditions based on a material and a plate thickness of the workpiece, decreases the moving speed of the laser nozzle to a first setting speed when the laser nozzle arrives a first setting position in front of an end point of a cutting trajectory, and decreases a relative moving speed of the laser nozzle to a second setting speed by varying the oxygen concentration of the cutting gas and the control condition of the laser beam when the laser nozzle arrives at a second setting position.

Owner:NISSAN TANAKA

Laser cutting method and laser cutting device

InactiveUS9434024B2InhibitionSuppress the occurrence of scratching in the workpieceLaser beam welding apparatusLaser NozzleLight beam

A laser cutting device includes a control unit which sets a steady oxygen concentration, a moving speed of a laser nozzle and laser beam steady control conditions based on a material and a plate thickness of the workpiece, decreases the moving speed of the laser nozzle to a first setting speed when the laser nozzle arrives a first setting position in front of an end point of a cutting trajectory, and decreases a relative moving speed of the laser nozzle to a second setting speed by varying the oxygen concentration of the cutting gas and the control condition of the laser beam when the laser nozzle arrives at a second setting position.

Owner:NISSAN TANAKA CORP

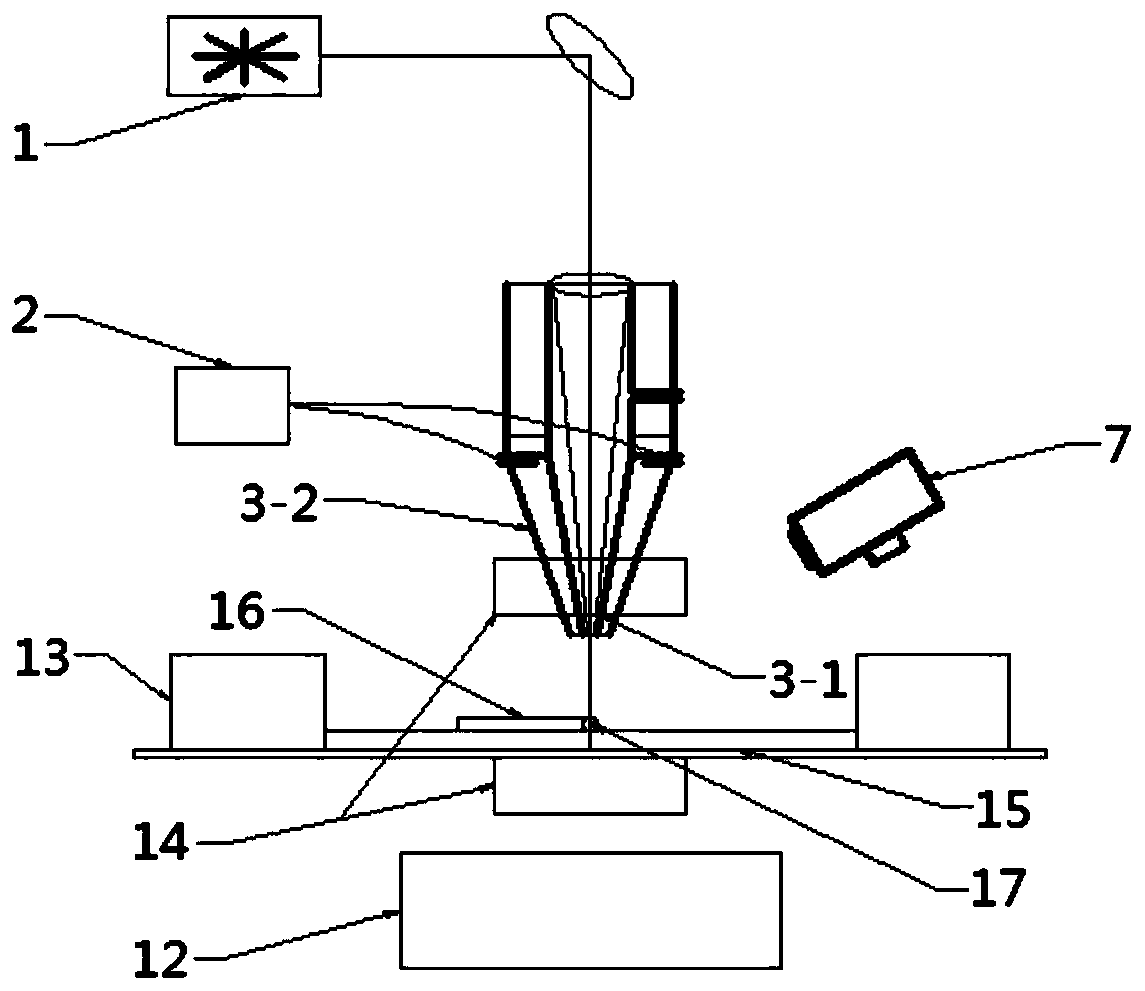

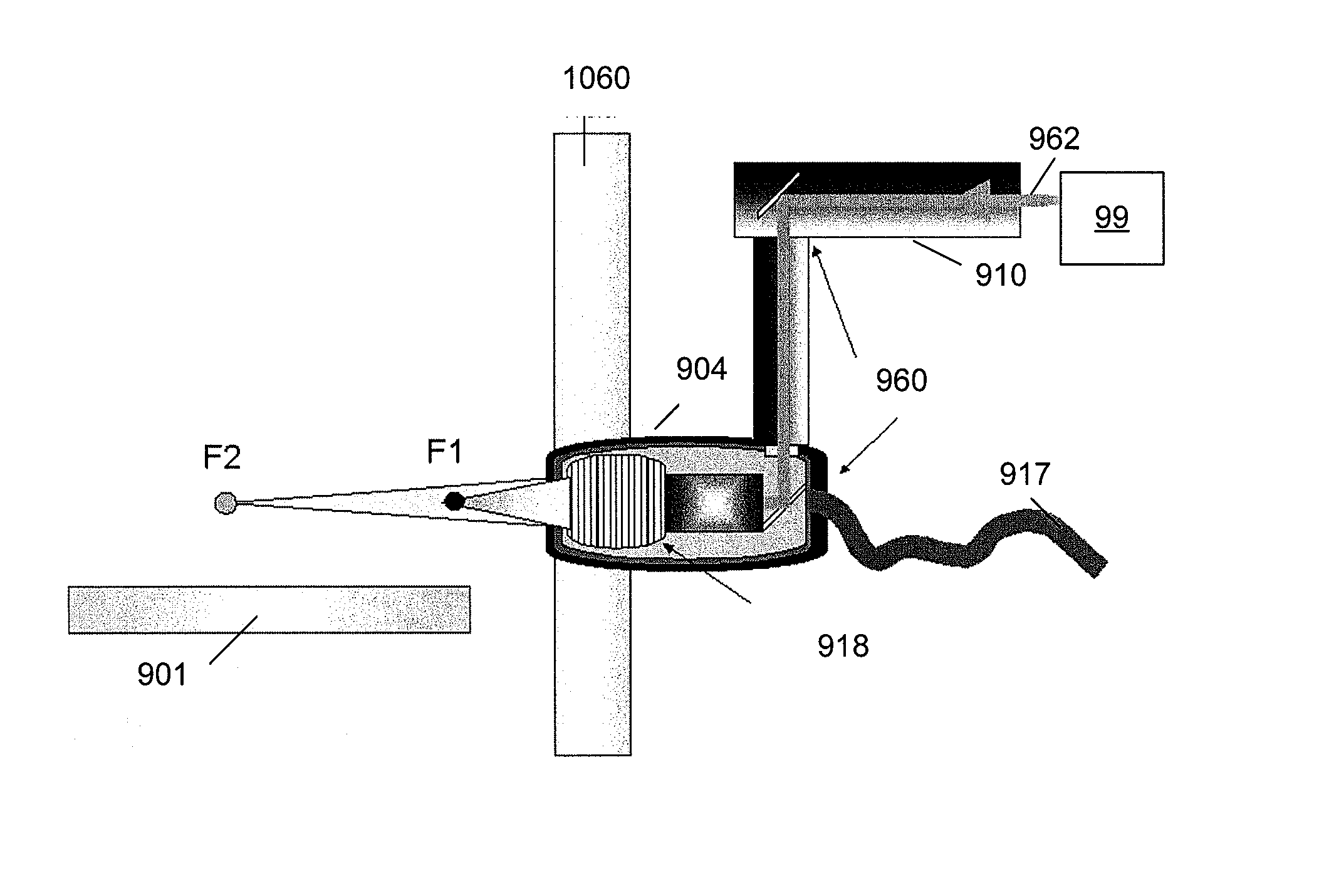

Adjustable magnetic field coupling and ultrasonic-assisted laser additive manufacturing and monitoring device

InactiveCN110280904AWide range motion captureComprehensive perspectiveLaser beam welding apparatusUltrasonic assistedLaser Nozzle

Owner:JIANGSU UNIV

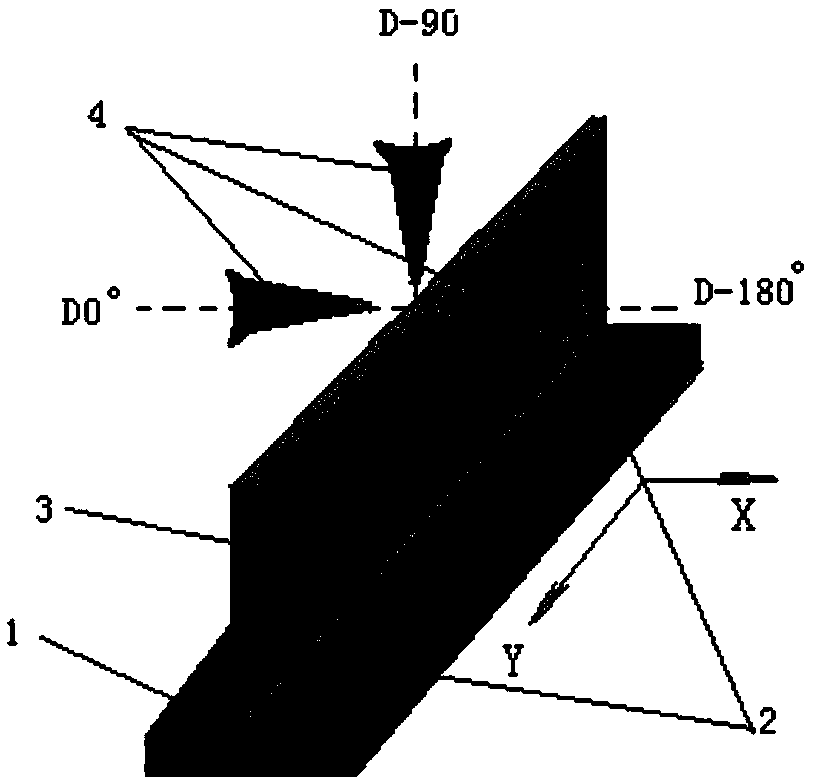

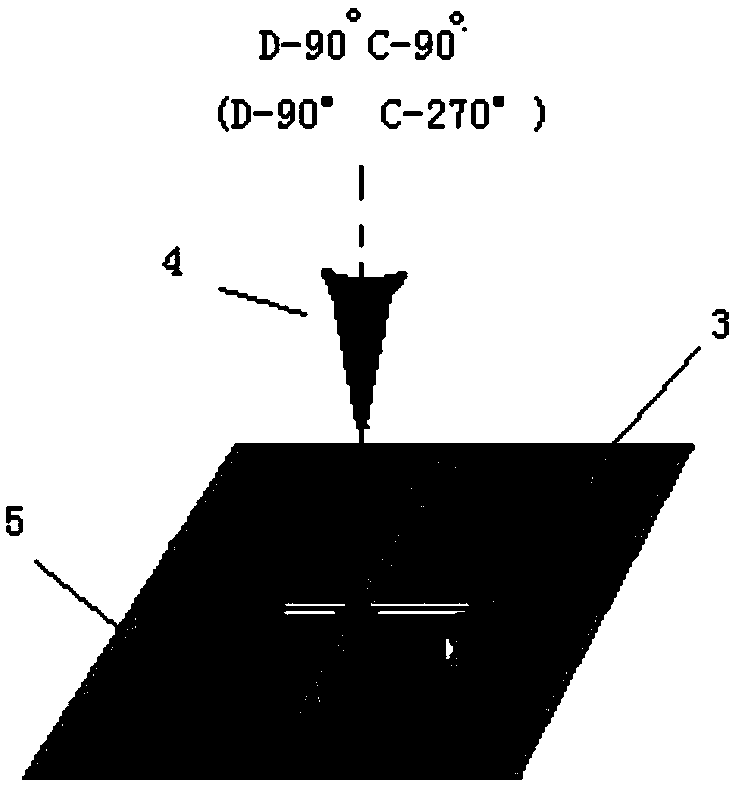

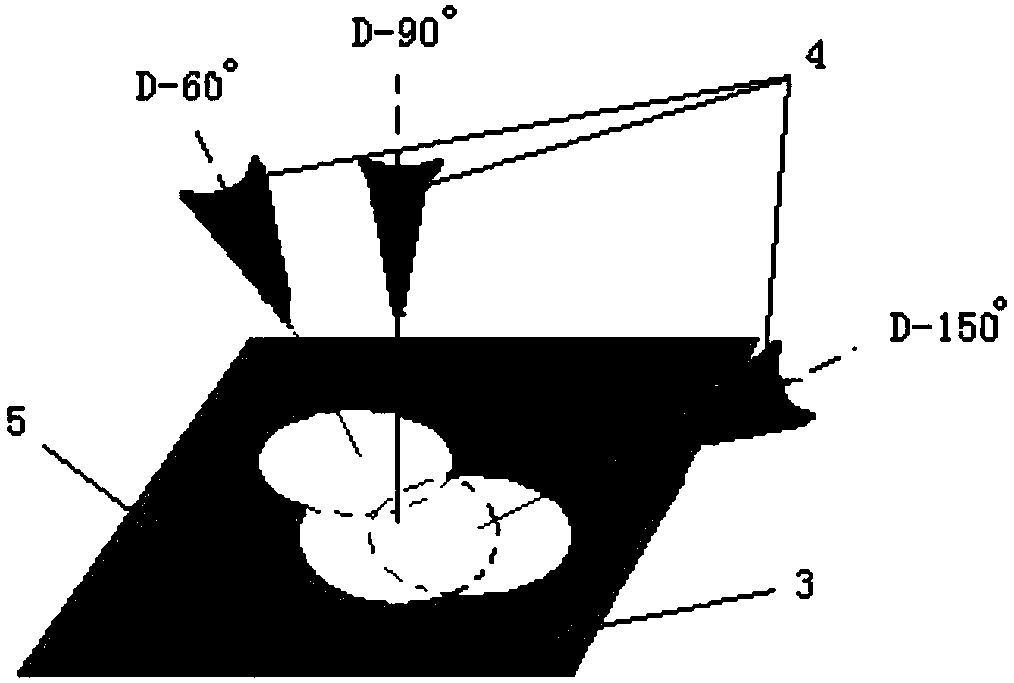

5-shaft linkage calibrating method of laser drilling machine

ActiveCN109454338AAchieve radiusRealize zero offset compensationLaser beam welding apparatusLaser NozzleSpray nozzle

The invention discloses a 5-shaft linkage calibrating method of a laser drilling machine. A base is fixed on a worktable surface of a machine tool; in a 5-shaft linkage function state, a system controls a laser nozzle to drill a special stainless steel sample plate by different angles to realize the offset compensation of the radius of a D shaft and the zero point. Then, a magnet is adopted to firmly and horizontally absorb the special stainless steel sample plate on the worktable surface; according to the calibrating flow of a C shaft, the system controls the laser nozzle to drill a plane ofthe special stainless steel sample plate by different angles; and the hole deviation of holes is measured to realize the offset compensation of the radius of the C shaft and the zero point. The calibrating method adopts simple laser drilling tests, and can observes approaching or overlapping of the circle point centers of round small holes machined by different angles to conveniently detect the 5-shaft calibrating effect, so that the 5-shaft linkage deviation problem can be timely discovered and rectified, hidden troubles are removed in a bud state, and the laser drilling and cutting quality is effectively guaranteed.

Owner:AECC AVIATION POWER CO LTD

Laser cutting head follow-up device

InactiveCN103071934AGood anti-loose effectConsistent cuttingLaser beam welding apparatusLaser processingBall screw

The present invention belongs to the technical field of laser machining equipment, and particularly relates to a laser cutting head follow-up device. The laser cutting head follow-up device comprises a stepping motor, a coupling, a bearing seat I, a shaft end support I, a rolling bearing I, a nut seat, a ball screw nut, a ball screw, a rolling bearing II, a shaft end support II, a bearing seat II, a sleeve and a nozzle. The laser cutting head follow-up device has the advantages that a guide rail is reduced, the ball screw simultaneously has the effects of transmission and guiding, a half-arc groove milled on the excircle of the nut is matched with a cylindrical pin and has good anti-loose effect, capacitive sensing is adopted, the rotation of the stepping motor is controlled through electric signals, the distance between the laser nozzle and the surface of a cut work piece can be automatically adjusted, automatic focusing is always performed, work pieces are artistic, uniformly cut and formed, and have no burrs, and the cutting quality and the cutting efficiency are greatly improved.

Owner:浪潮数字(山东)科技有限公司

Laser nozzle cleaning tool

InactiveUS20060213615A1Semiconductor/solid-state device manufacturingCleaning processes and apparatusShock waveEnergy transfer

An apparatus including a laser operating in different cleaning techniques is provided. In one embodiment, the laser interacts with the particle to remove the particle by expansion. In another embodiment, a liquid-assisted laser cleaning technique evaporates a liquid layer on the surface by laser pulses and subsequently removing the particles from the surface. Further, the present disclosure provides parameters to control the energy transfer to the particle. For example, for a shock wave generation parameters, the droplets size and concentration (e.g., pressure), substrate surface temperature, chemical composition of the droplets may be controlled.

Owner:SEMATECH

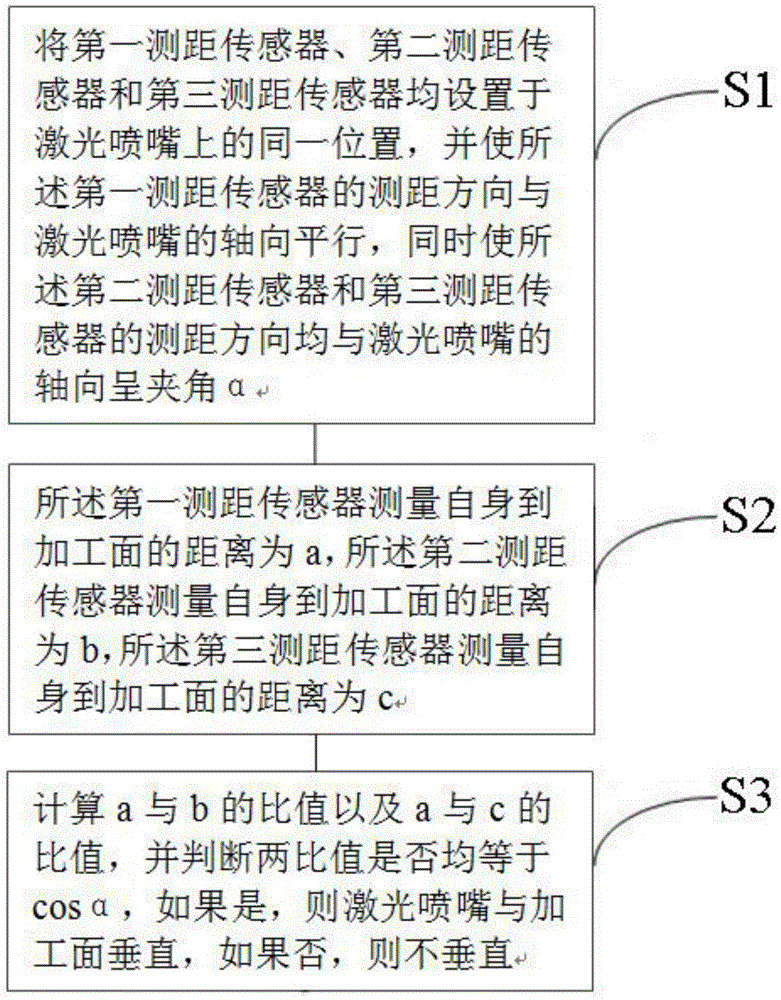

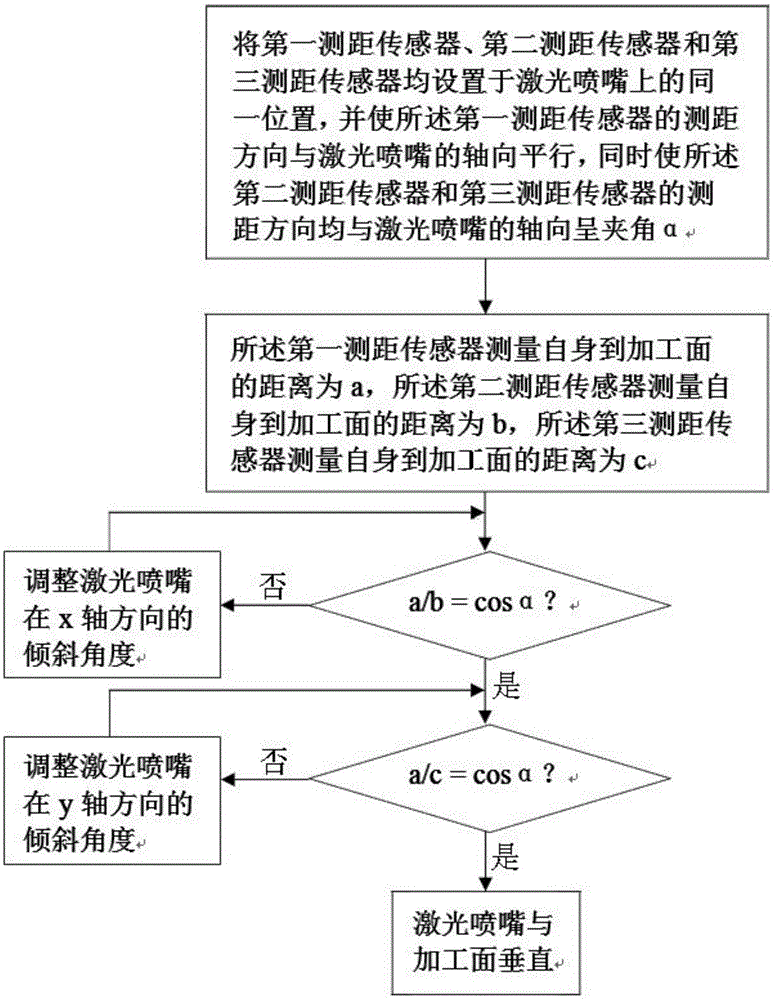

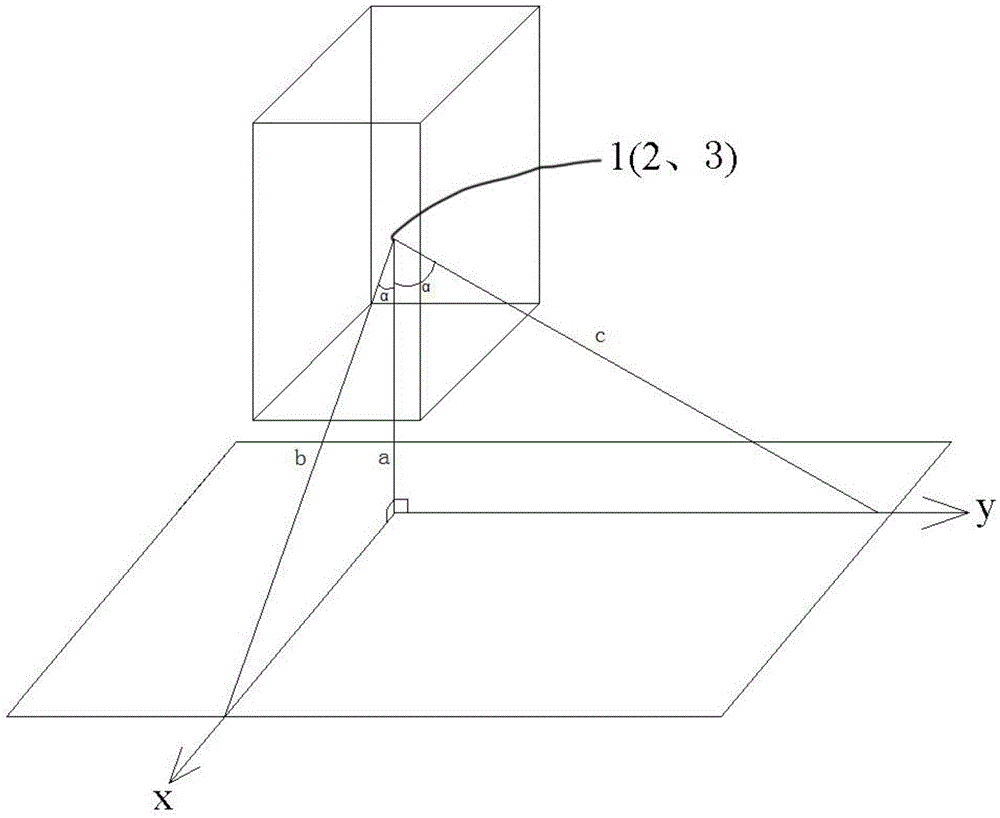

Method and system for checking perpendicularity between laser nozzle and machining surface

InactiveCN105598595AFast and precise identificationAvoid naked eye observationLaser beam welding apparatusLaser NozzleSpray nozzle

The invention discloses a method for checking the perpendicularity between a laser nozzle and a machining surface. The method comprises the steps of: arranging three distance measuring sensors at the same position of the laser nozzle and making the distance measuring direction of a first distance measuring sensor be parallel to the axial direction of the laser nozzle, and making a second distance measuring sensor and a third distance measuring sensor form in an included angle alpha with the axial direction of the laser nozzle; measuring a distance a from the first distance measuring sensor to the machining surface, a distance b from the second distance measuring sensor to the machining surface, and a distance c from the third distance measuring sensor to the machining surface; and calculating the ratios of a and b and a and c, judging whether the two ratios are both equal to cosine alpha, if yes, judging that the laser nozzle is perpendicular to the machining surface, and if not, judging that the laser nozzle is not perpendicular to the machining surface. According to the method, three distance measuring sensors are adopted such that the observation by naked eye and the contact type ruler measurement method in the prior art are replaced, and the relation between the laser nozzle and the machining surface can be rapidly and accurately recognized. The invention also discloses a system for checking the perpendicularity between the laser nozzle and the machining surface, and the system has the beneficial effects as recited above.

Owner:GUANGDONG ZHENGYE TECH

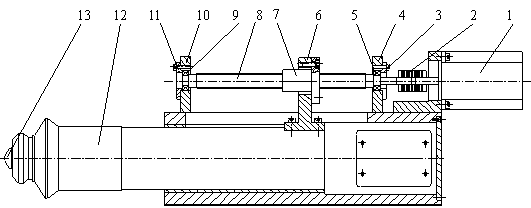

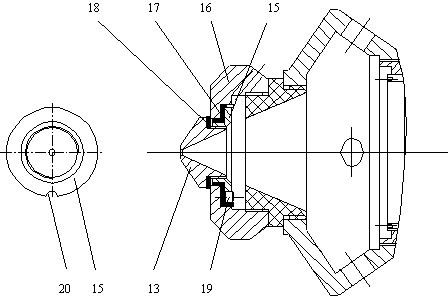

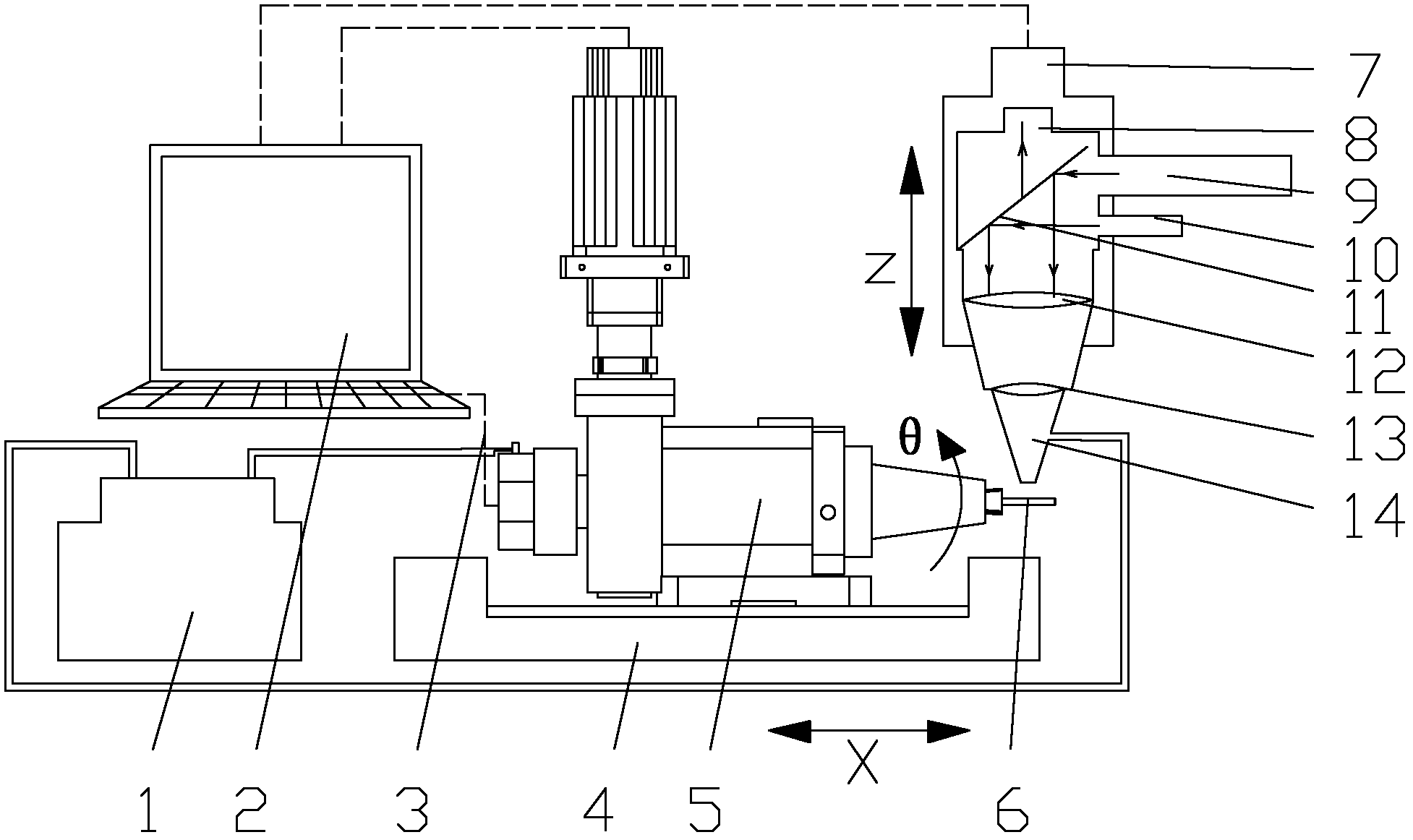

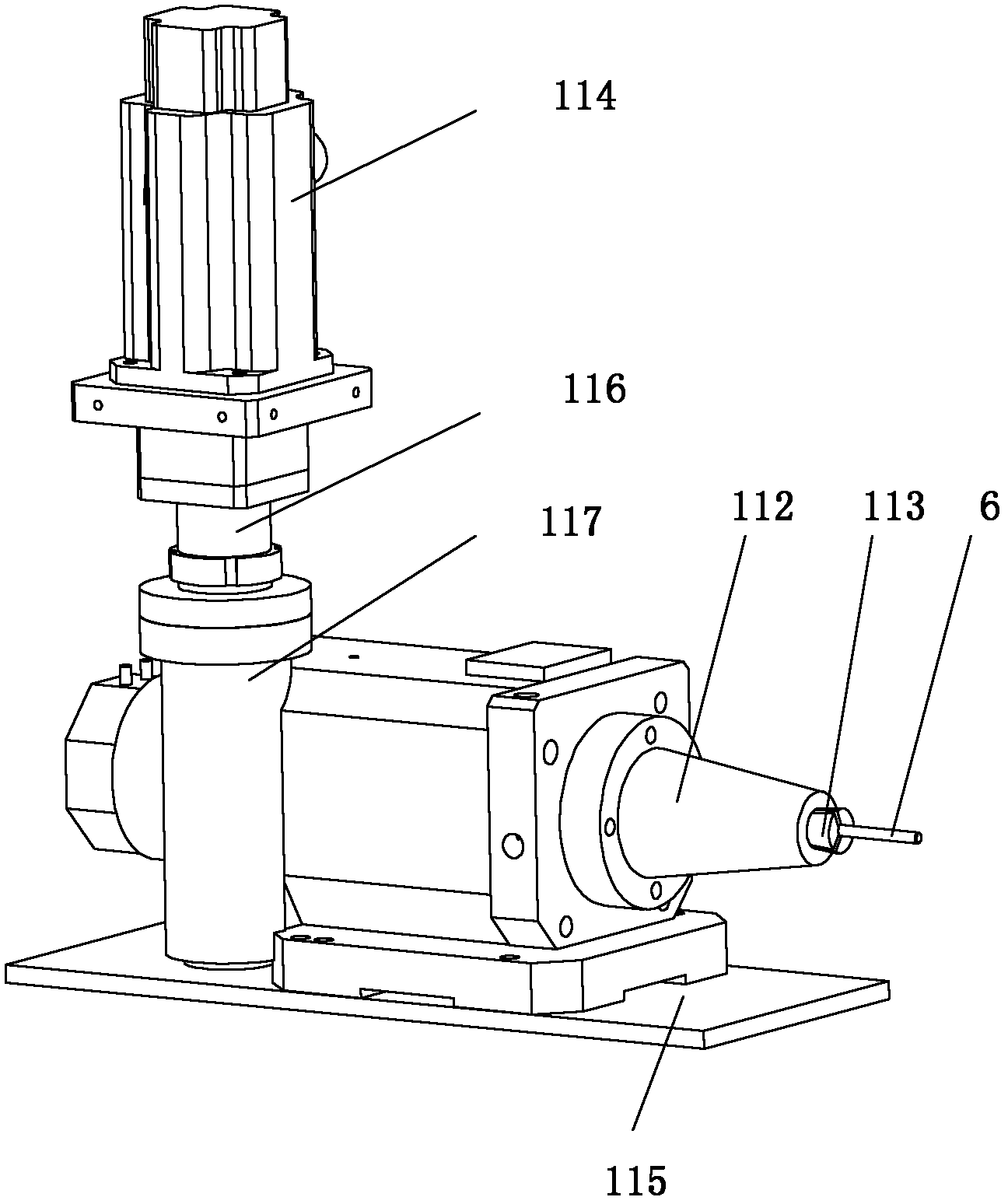

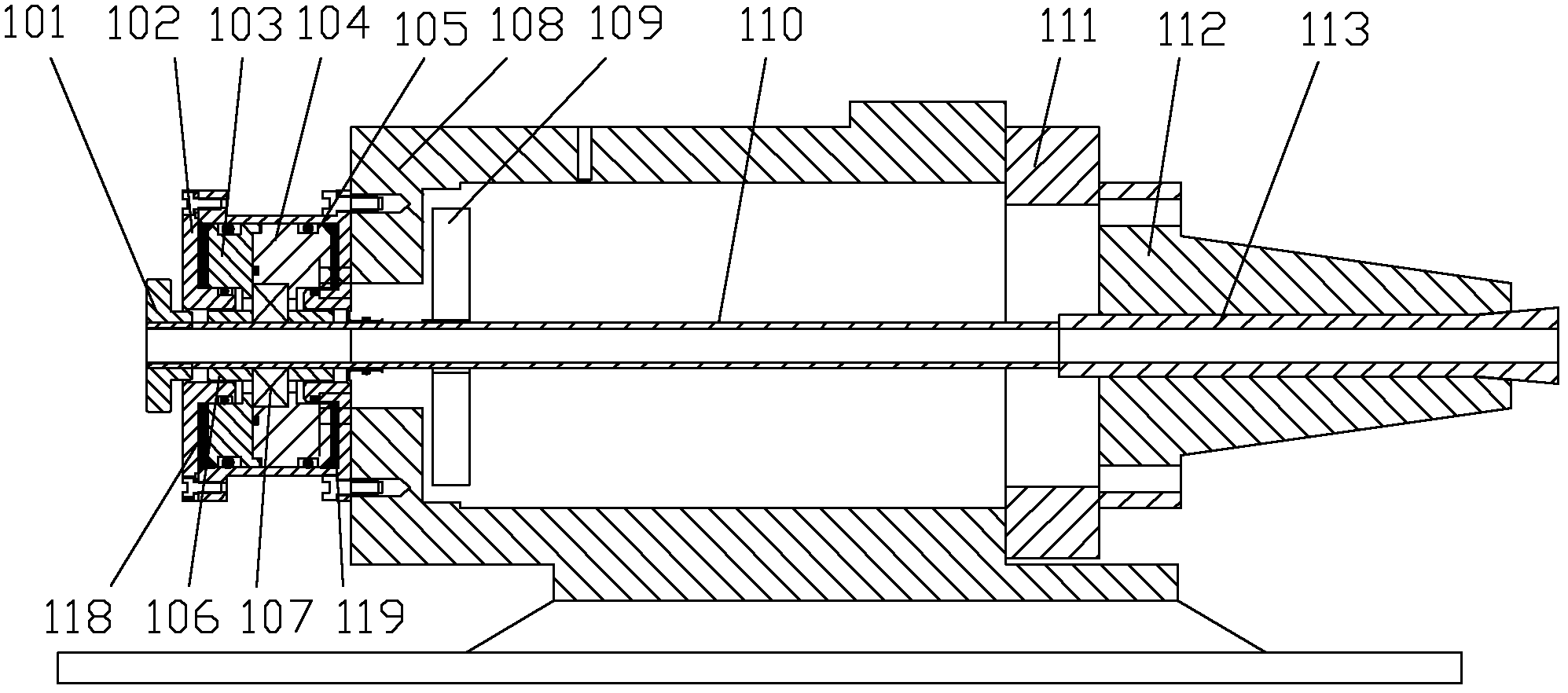

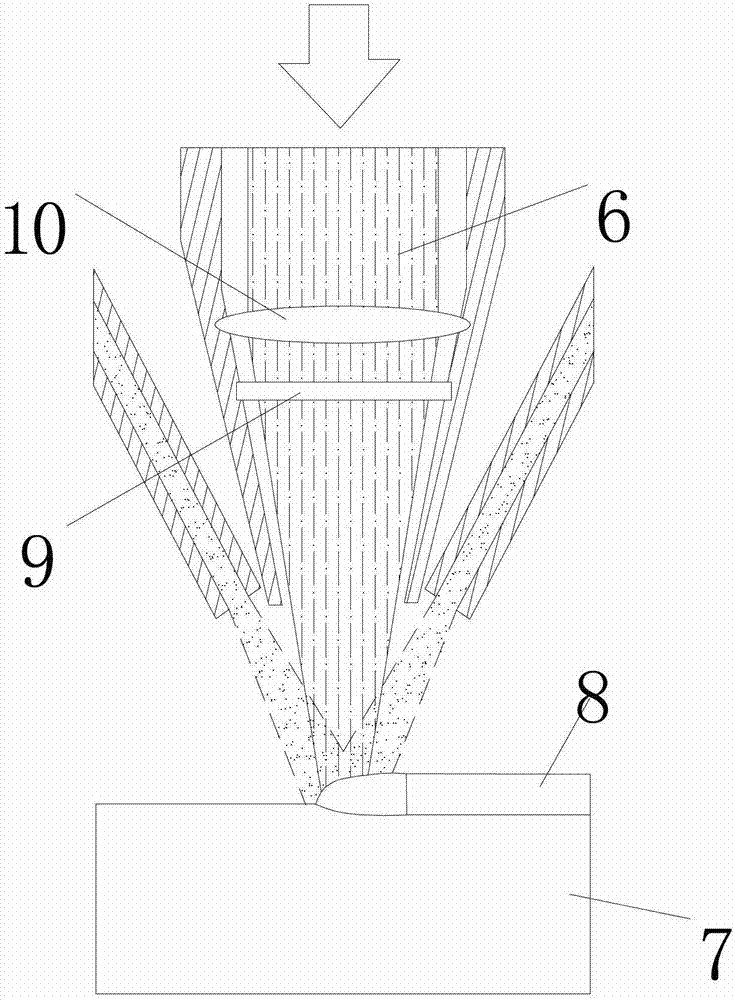

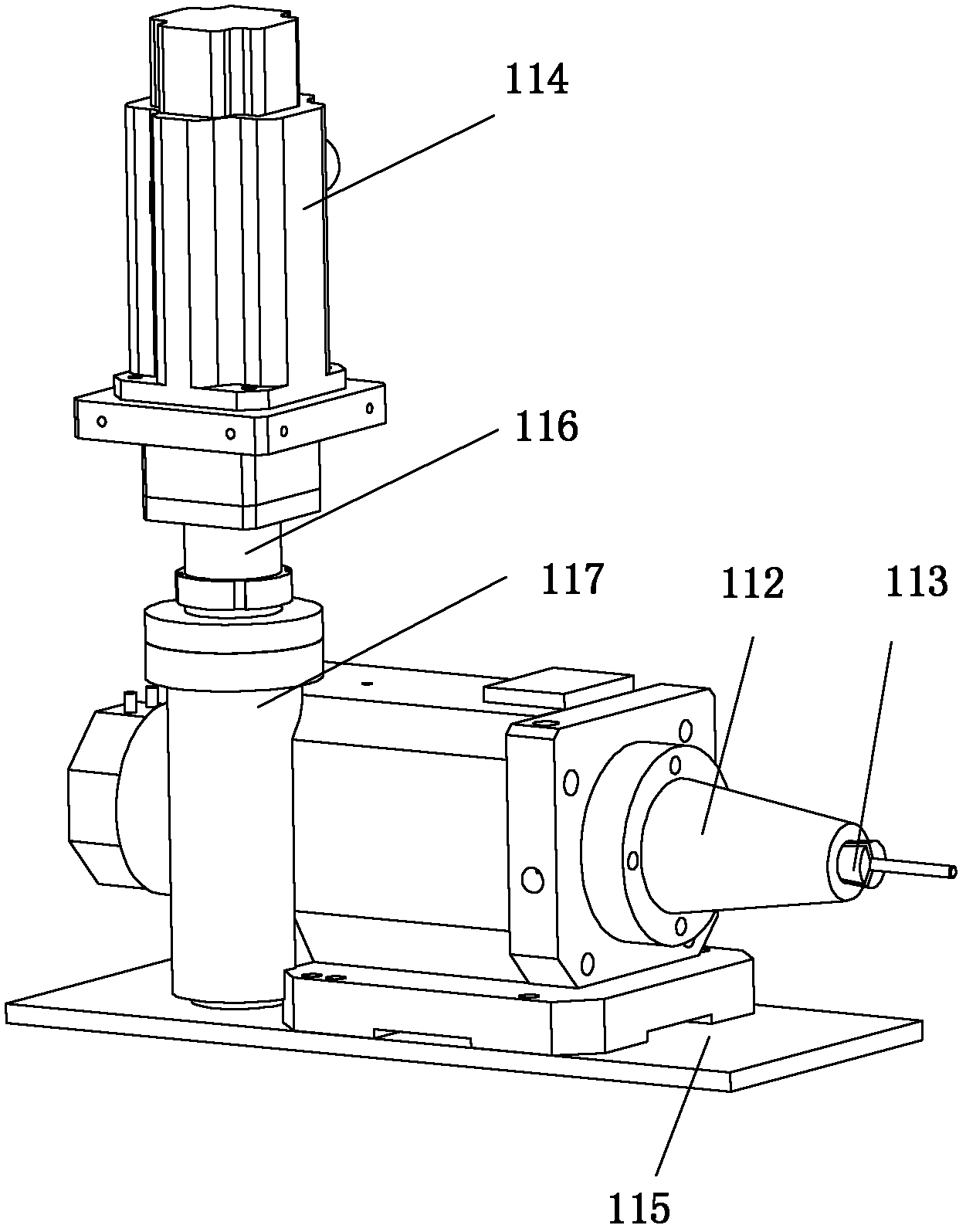

Laser processing equipment for thin-wall pipes

ActiveCN103212863AFast processingImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesRotational axisLaser processing

The invention provides laser processing equipment for thin-wall pipes, which comprises a rotary shaft, a linear shaft, a laser cutting head, an auxiliary high-pressure air-supplying unit, a Z axis module, a laser generator, a collimation and beam expanding lens, a lighting source, a 45-degree reflector, a CCD (Charge Coupled Device) and a control system. The laser cutting head comprises a laser nozzle, a protection lens and a focusing lens. The rotary shaft comprises a motor, a coupler, a worm, a worm gear, a pull-rod module, a shell, an end cover and a clamp head. The pull-rod module comprises a pull-rod cover, a piston, a pull-rod seat, a rolling bearing, a shaft sleeve and a hollow pull rod. The CCD is used for observing the focusing condition of optical spots during position adjusting of the laser optical spots, checking the processing condition anytime during the machining process, and videoing the whole machining process. The control system comprises a moving control unit fro controlling the linear shaft, the rotary shaft and the Z axis module, and a laser control unit for controlling the laser generator. The laser processing equipment for the thin-wall pipes disclosed by the invention is quick in processing speed and high in processing accuracy.

Owner:KUNSHAN THETA MICRO

Inner-cooling nozzle for laser cladding

InactiveCN102828179AGood cladding effectImprove efficiencyMetallic material coating processesLaser NozzleEngineering

The invention discloses an inner-cooling nozzle for laser cladding, which comprises a laser channel disposed at the center of the nozzle, a powder channel disposed at the periphery of the laser channel, and an annular cooling channel disposed on the nozzle for high-pressure air or liquid injection; a center axis of the annular cooling channel superposes a center axis of the laser channel. Another technical scheme provided by the invention is that: an inner-cooling nozzle for laser cladding comprises a laser channel disposed at the center of the nozzle, a powder channel disposed at the periphery of the laser channel, and a spiral cooling channel disposed on the nozzle for high-pressure air or liquid injection; a center axis of the spiral cooling channel superposes a center axis of the laser channel. Three coaxial schemes of coaxial powder injection, coaxial protective gas, and coaxial cooling are designed in one laser nozzle, which provides good cladding effect, high efficiency, and more safety and reliability.

Owner:张家港市和昊激光科技有限公司

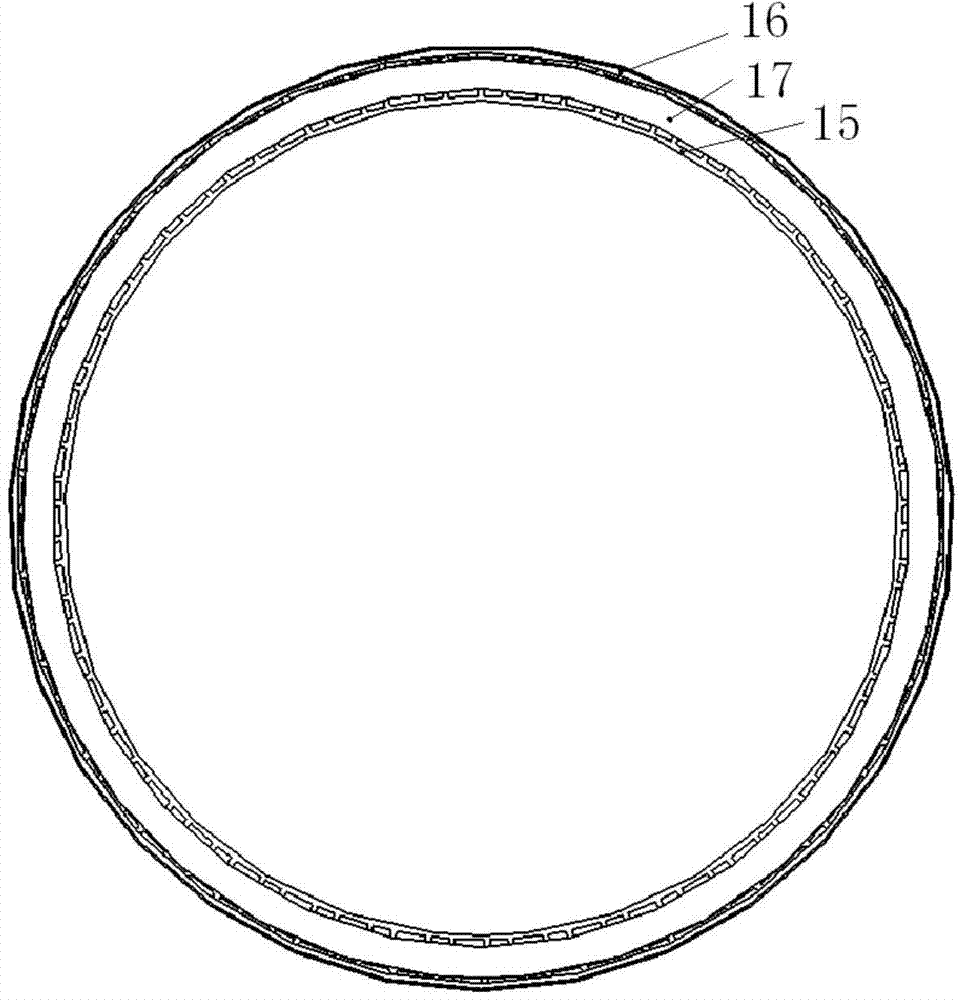

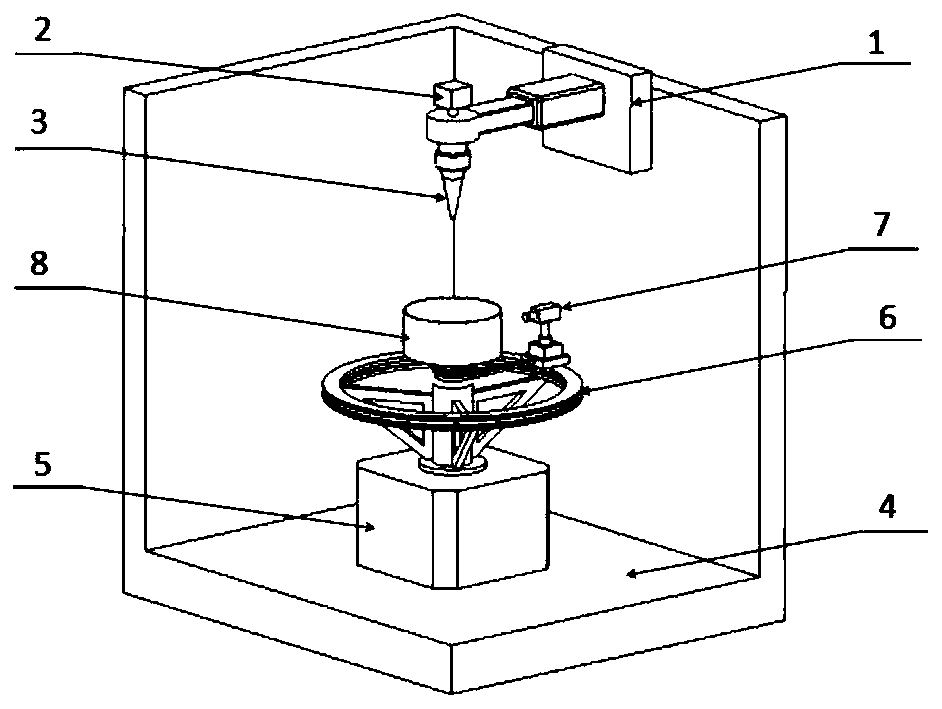

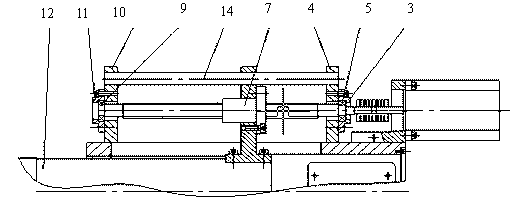

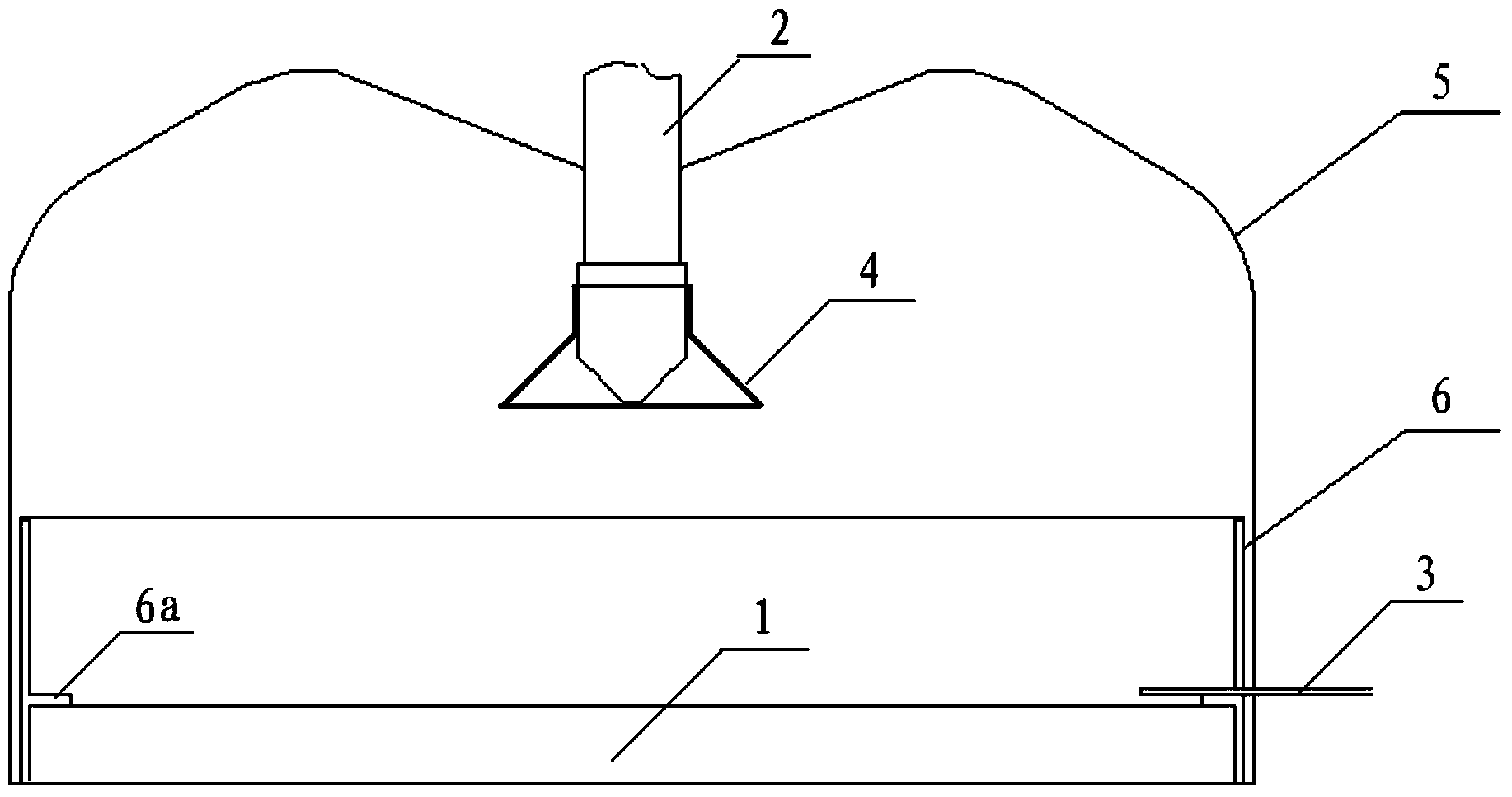

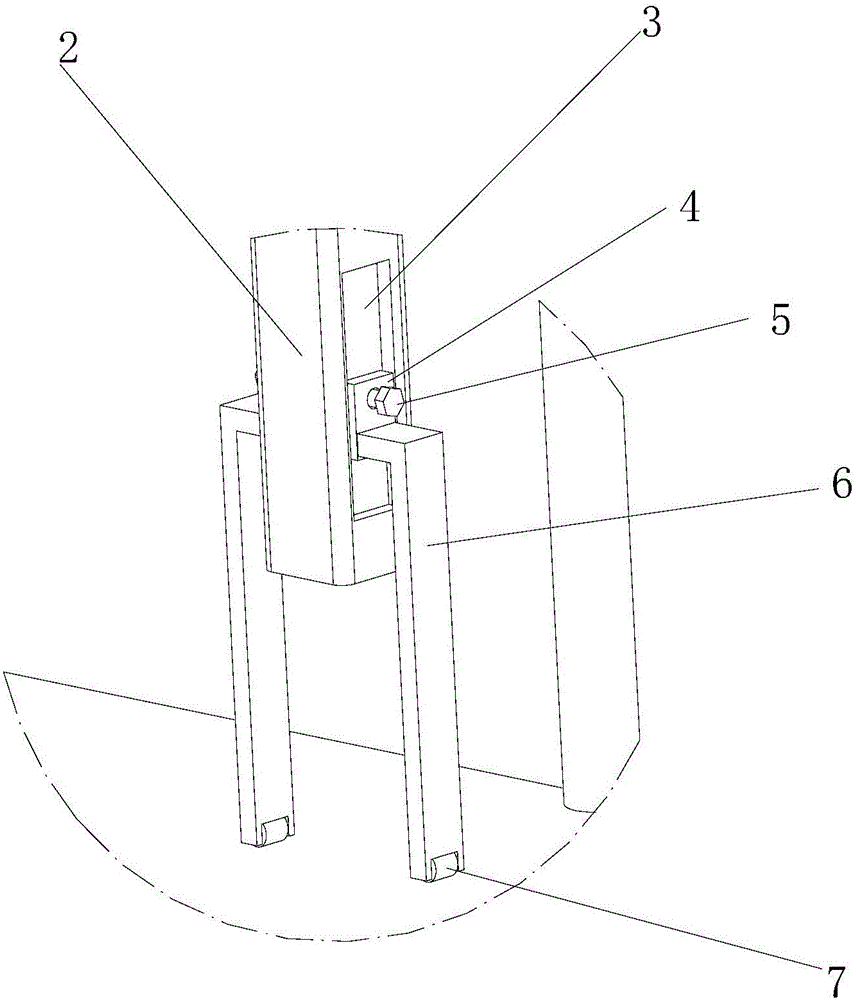

Inert atmosphere protecting chamber of laser solid forming equipment

ActiveCN103894609ALow gas consumptionReduce preparation timeIncreasing energy efficiencyLaser NozzleSpray nozzle

The invention belongs to the laser forming and recovering technology, and relates to an inert atmosphere protecting chamber of laser solid forming equipment. The inert atmosphere protecting chamber comprises a rotary workbench (1), a laser nozzle (2) and a gas inlet pipe (3). The inert atmosphere protecting chamber is characterized in that a soft protecting mechanism comprising a shading cover (4), a plastic bag (5) and a shading cylinder (6) is provided. The inert atmosphere protecting chamber of the laser solid forming equipment is adaptive to meeting the processing requirements of small-size parts, preparing time is shortened greatly, working efficiency is improved, usage of inert is saved, processing cost is reduced, and operating processes are simplified.

Owner:AECC AVIATION POWER CO LTD

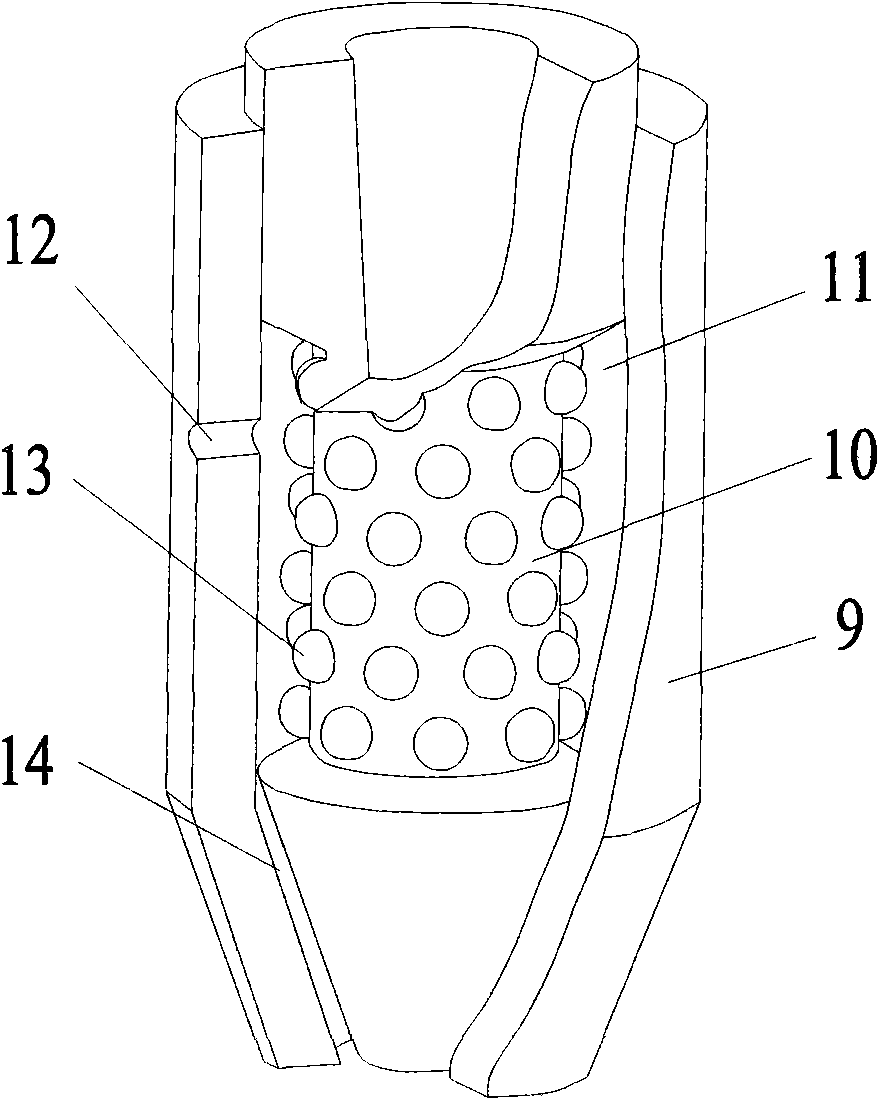

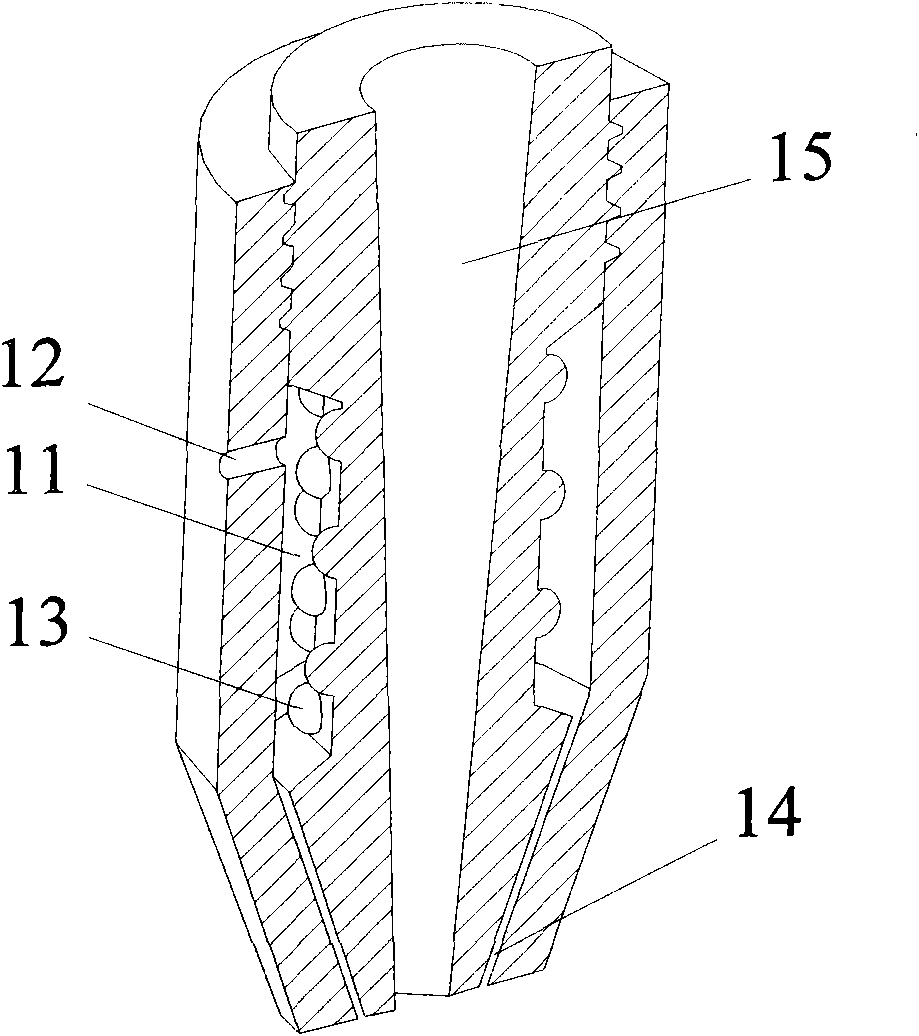

Laser nozzle device and method for uniformly distributing powder

ActiveCN101942656AChange trajectoryEvenly distributedMetallic material coating processesLaser beam welding apparatusLaser NozzleSteel ball

The invention discloses a laser nozzle device. The device comprises an outer sleeve and a nozzle core arranged in the outer sleeve, wherein the side wall at the upper end of the outer sleeve is provided with a powder inlet externally connected with a powder inlet pipe; a powder outlet is arranged between the lower end of the outer sleeve and the lower end of the nozzle core; a powder channel is arranged between the inner side of the outer sleeve and the outer side of the nozzle core and extended to the powder outlet, and the powder inlet, powder channel and powder outlet are intercommunicated; the outer side wall of the nozzle core is embedded with a plurality of steel balls, and a laser channel is arranged in the nozzle core; and the upper of the outer sleeve is muff-coupled with the upper end of the nozzle core. The invention also provides a method for uniformly distributing powder by the device. Because the device uses the steel balls, the uniform conveying of powder is realized without needing a longer power-conveying channel, so that the overall size of the nozzle is reduced, the complexity of a powder-conveying system matched with the device is greatly lowered, and the operability of the nozzle device is improved.

Owner:SOUTH CHINA UNIV OF TECH

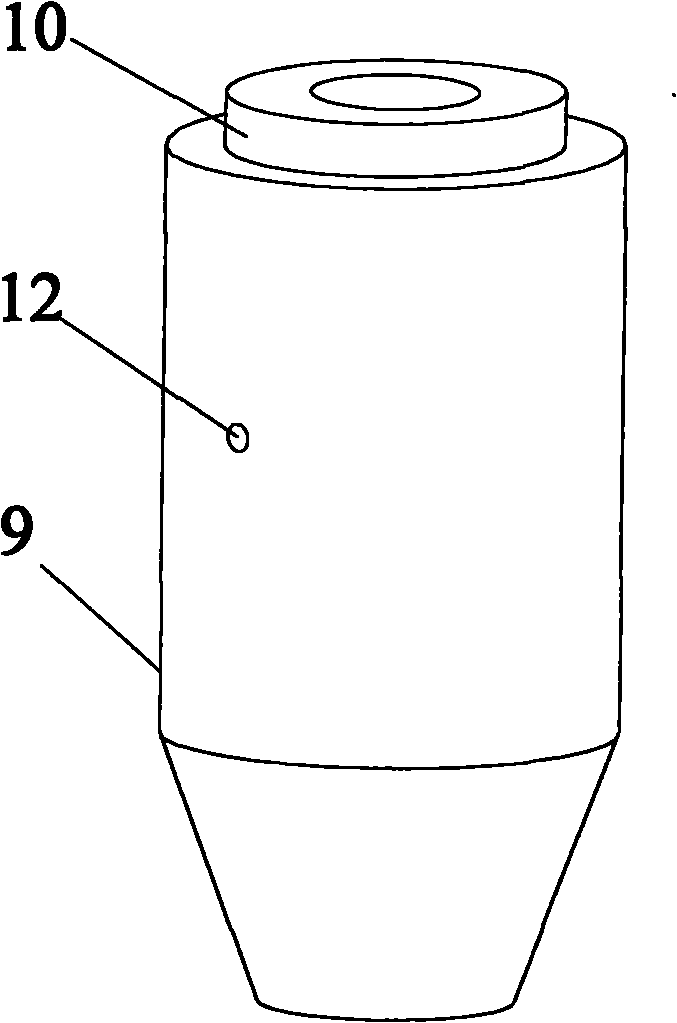

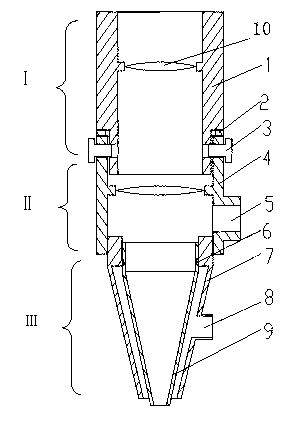

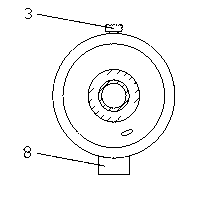

Coaxial type nozzle used for laser micro machining of thin-walled tube

InactiveCN103212802AReduce wear and tearReduce the temperatureLaser beam welding apparatusLaser NozzleHigh pressure water

The invention relates to a coaxial type nozzle used for laser micro machining of a thin-walled tube, which mainly solves the problems in the prior art that in the laser machining process of a small-diameter tube, the loss of a laser nozzle is larger and a water guiding mechanism is complex. The technical scheme adopted by the invention is as follows: the coaxial type nozzle comprises three parts: an upper part which is a connecting module I connected with a laser generator, a middle part which is a transitional module II, and a lower part which is a nozzle module III, wherein the nozzle module III consists of a nozzle inner core (9) and a nozzle outer core (7), the nozzle inner core (9) and the nozzle outer core (7) are provided with threads and are connected through threaded fit, and a joint of the nozzle inner core (9) and the nozzle outer core (7) is sealed by an O-shaped sealing ring (6); and a high pressure water inlet (8) is arranged on a side wall of the nozzle outer core (7), and the opening direction of the high pressure water inlet (8) is perpendicular to the direction of the nozzle, so that the problems are better solved. The coaxial type nozzle can be used in the industrial production of laser wet cutting machining.

Owner:KUNSHAN THETA MICRO

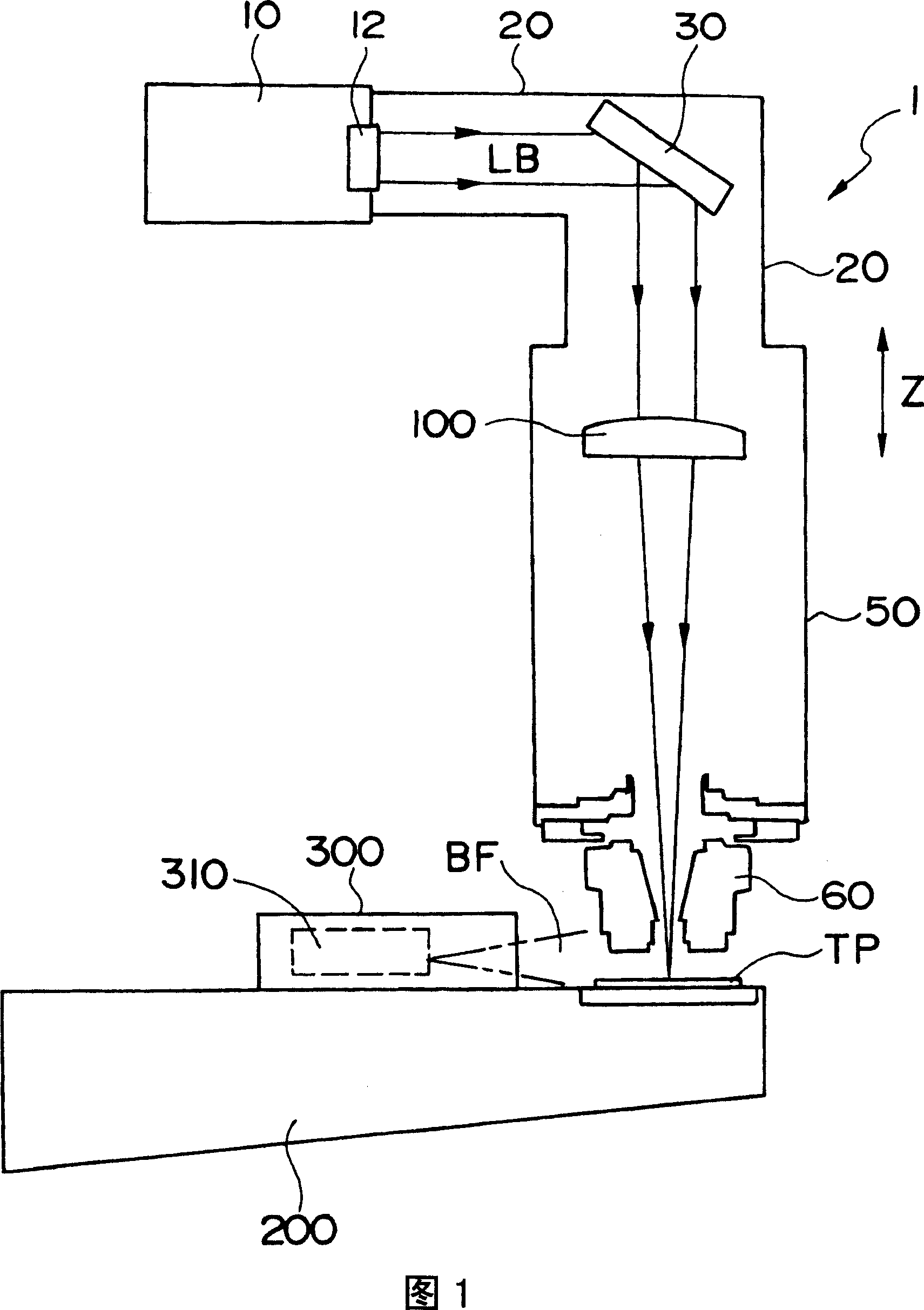

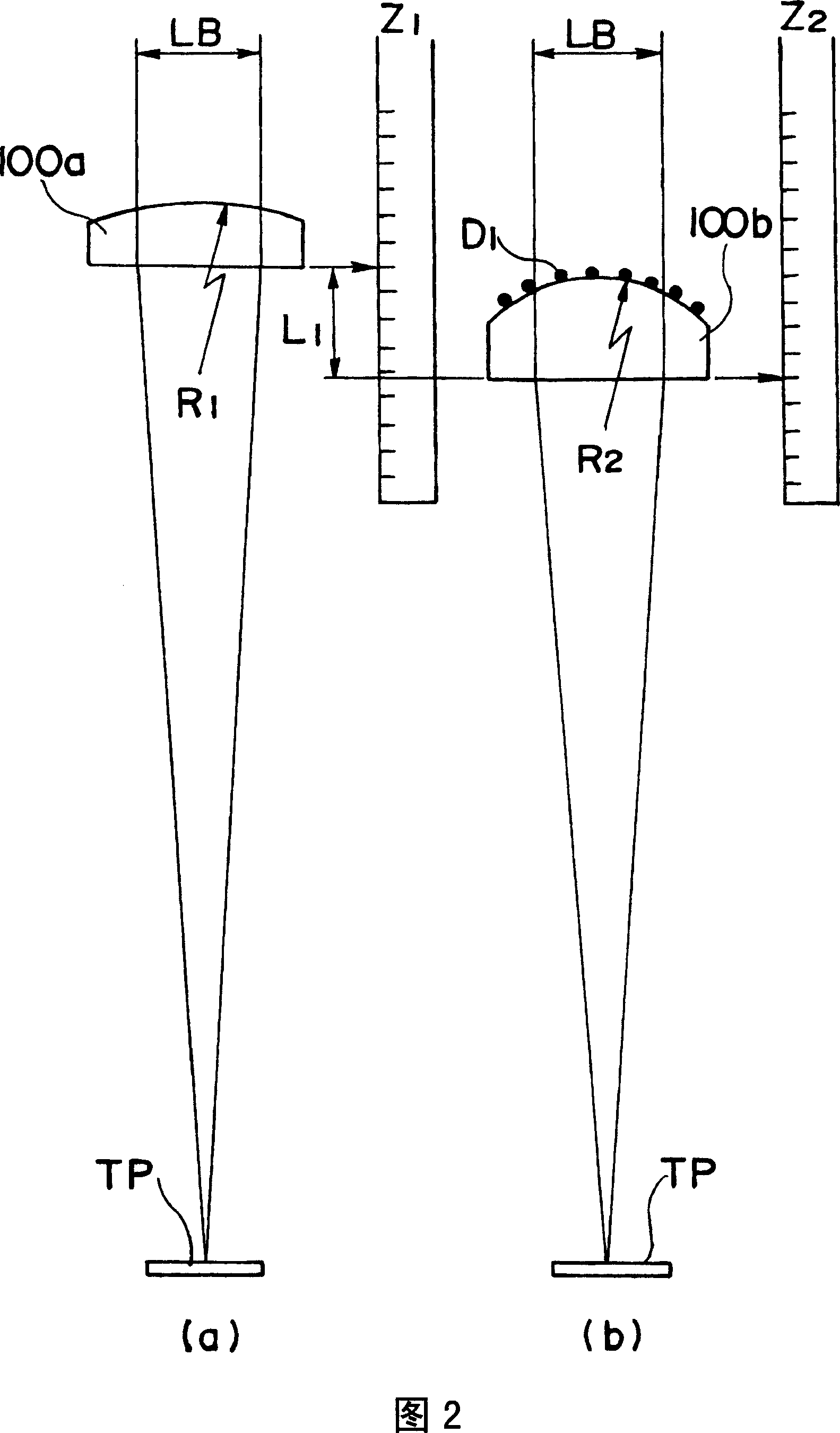

Laser processing machine condensing lens dirt detecting method and device

InactiveCN101078691AEasy to detectMaterial analysis by optical meansLaser beam welding apparatusMachine controlLaser processing

The invention provides a technology that fouling on condensing lens of laser processing machine is inspected according to the change of focal distance. Condensing lens (100) in machining head (50) is used to condense laser beam (LB) outputted by laser resonator (10). The laser beam irradiates testing part (TP) from laser nozzle (60). The control device of laser processing machine controls processing head (50) to move to Z direction and stores coordinates. If the focus is the same on test part (TP) blue flame (BF) happens. Lighted device (300) receives blue flame and sends signal to the control device. If fouling clings to the condensing lens (100), because heat is stored lens expands and focal distance is shortened. According to the change fouls on condensing lens can be inspected.

Owner:YAMAZAKI MAZAK KK

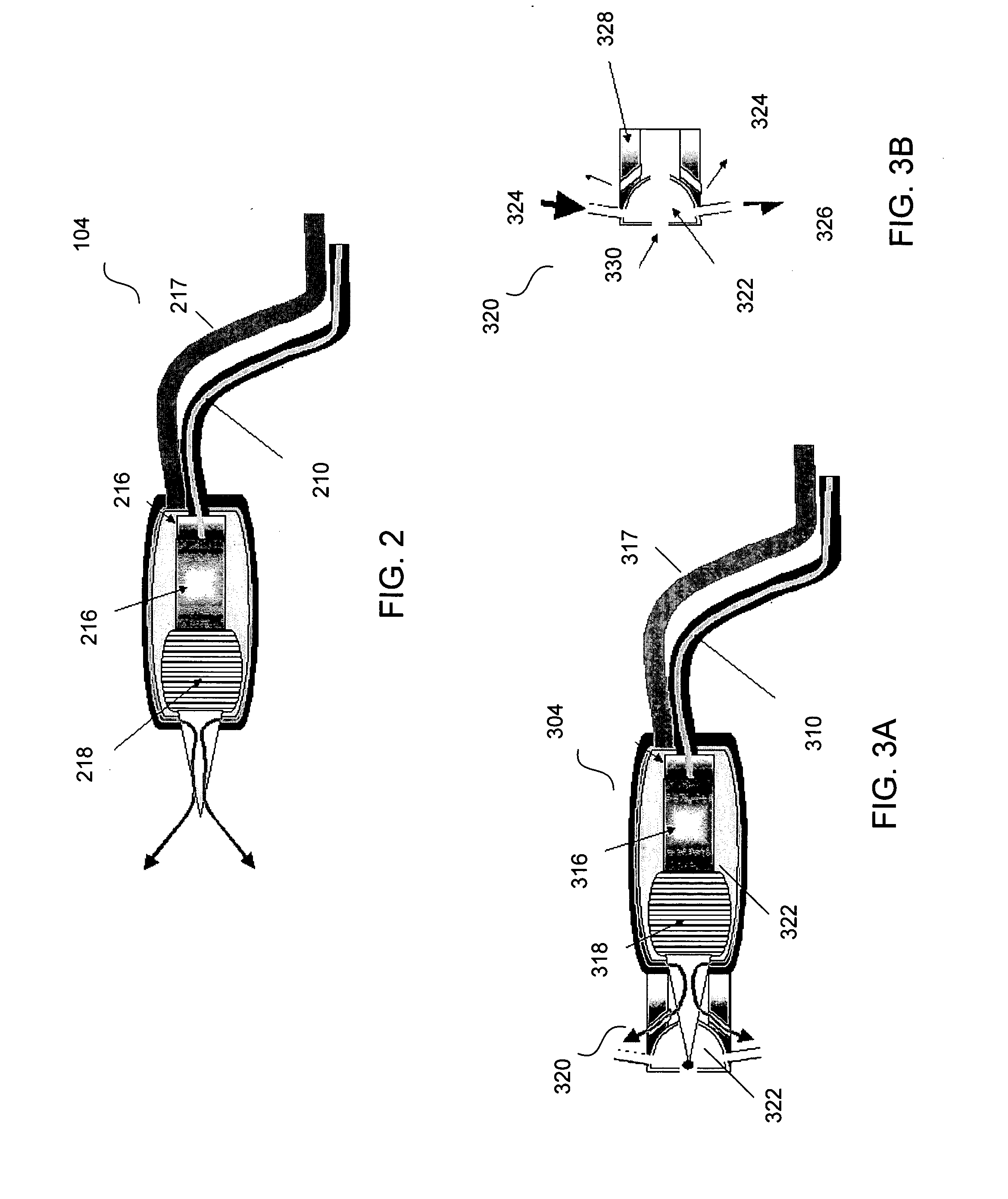

Decoupled Liquid-Jet Guided Laser Nozzle Cap

ActiveUS20170252865A1Liquid laser constructional detailsLaser beam welding apparatusLiquid jetLaser Nozzle

A head assembly for a liquid jet guided laser system is disclosed having a coupling unit removably disposed to a laser focus optic module of the laser system. The coupling unit has a nozzle assembly removably connected to the coupling unit. The nozzle assembly has a liquid jet nozzle and a nozzle cap. The nozzle cap has a plurality of axial assist gas conduits and static assist gas conduits in fluid communication with an assist gas source extending through the nozzle cap body to individually transport assist gas to axial exit ports and static exit ports positioned to exhaust assist gas proximate the liquid jet. At least a portion of the plurality of axial assist gas conduits are partitioned from fluid communication with the liquid jet hole. A lateral movement assembly can be configured between the laser focus optic module and coupling unit.

Owner:SYNOVA SA

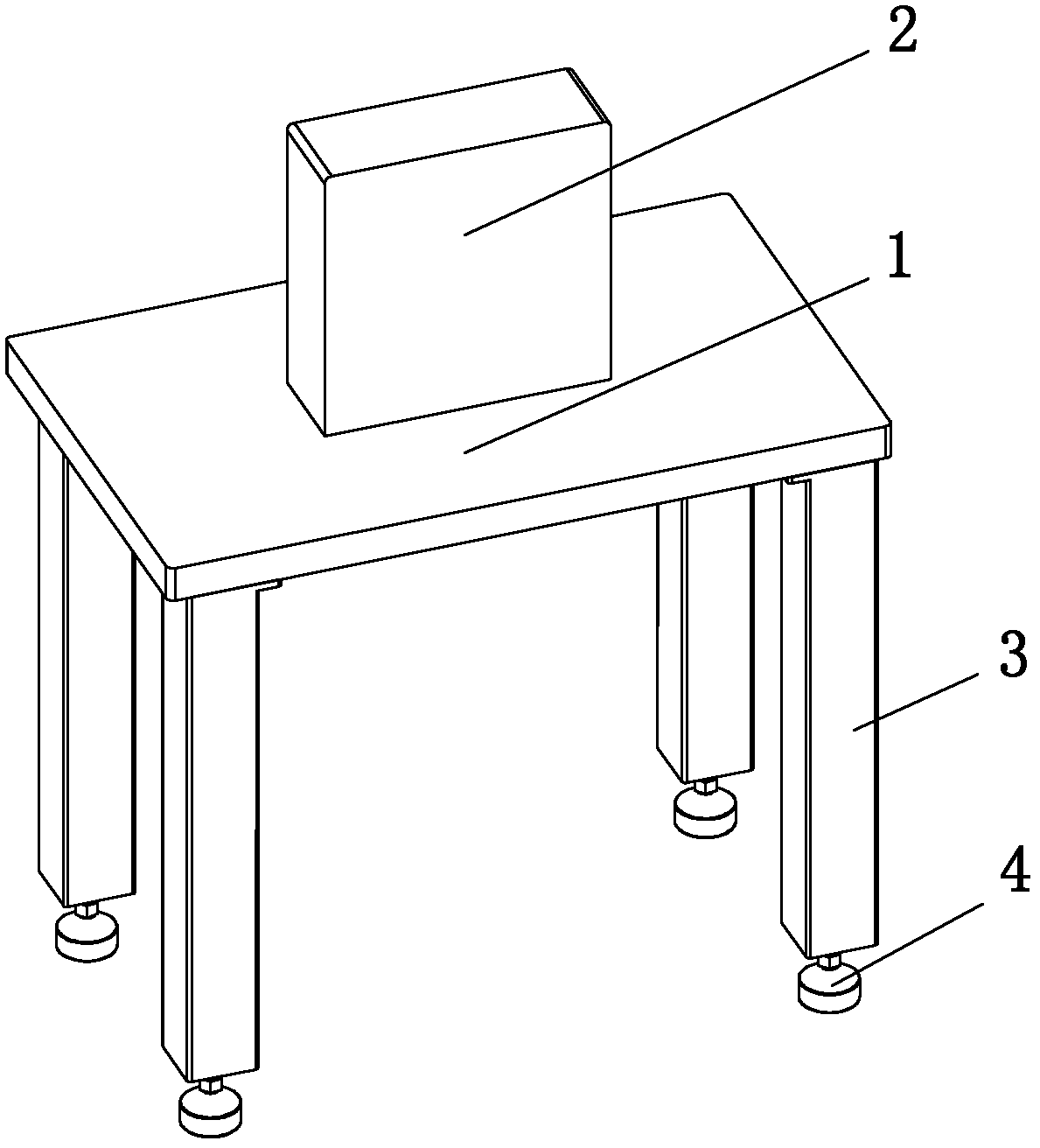

Laser machining device

ActiveUS20170165788A1Prevent leakageAvoid reflectionsWelding/cutting auxillary devicesAuxillary welding devicesLaser NozzleSpray nozzle

A laser machining device having a surface plate upon which a material to be machined is placed, a rail, a saddle, a garter, a horizontal carriage, and a laser nozzle. On it is attached: a machining trolley that causes the saddle to travel along rail, causes the horizontal carriage to travel horizontally along garter, irradiates laser light from laser nozzle towards a material to be machined, and cuts or welds the material. A cover is provided that covers substantially the entire surface of machining trolley and has an upper surface cover, a laser nozzle-side cover, a garter-side cover, and a side surface body. On a lower end side of the laser nozzle-side cover and the garter-side cover, there is a flexible light-blocking member for preventing laser light from leaking from a gap between the lower end section and the upper surface of the surface plate.

Owner:KOIKE SANSO KOGYO CO LTD

Laser nozzle methods and apparatus for surface cleaning

InactiveUS7629556B2Semiconductor/solid-state device manufacturingElectrostatic cleaningLaser NozzleSurface cleaning

Owner:SEMATECH

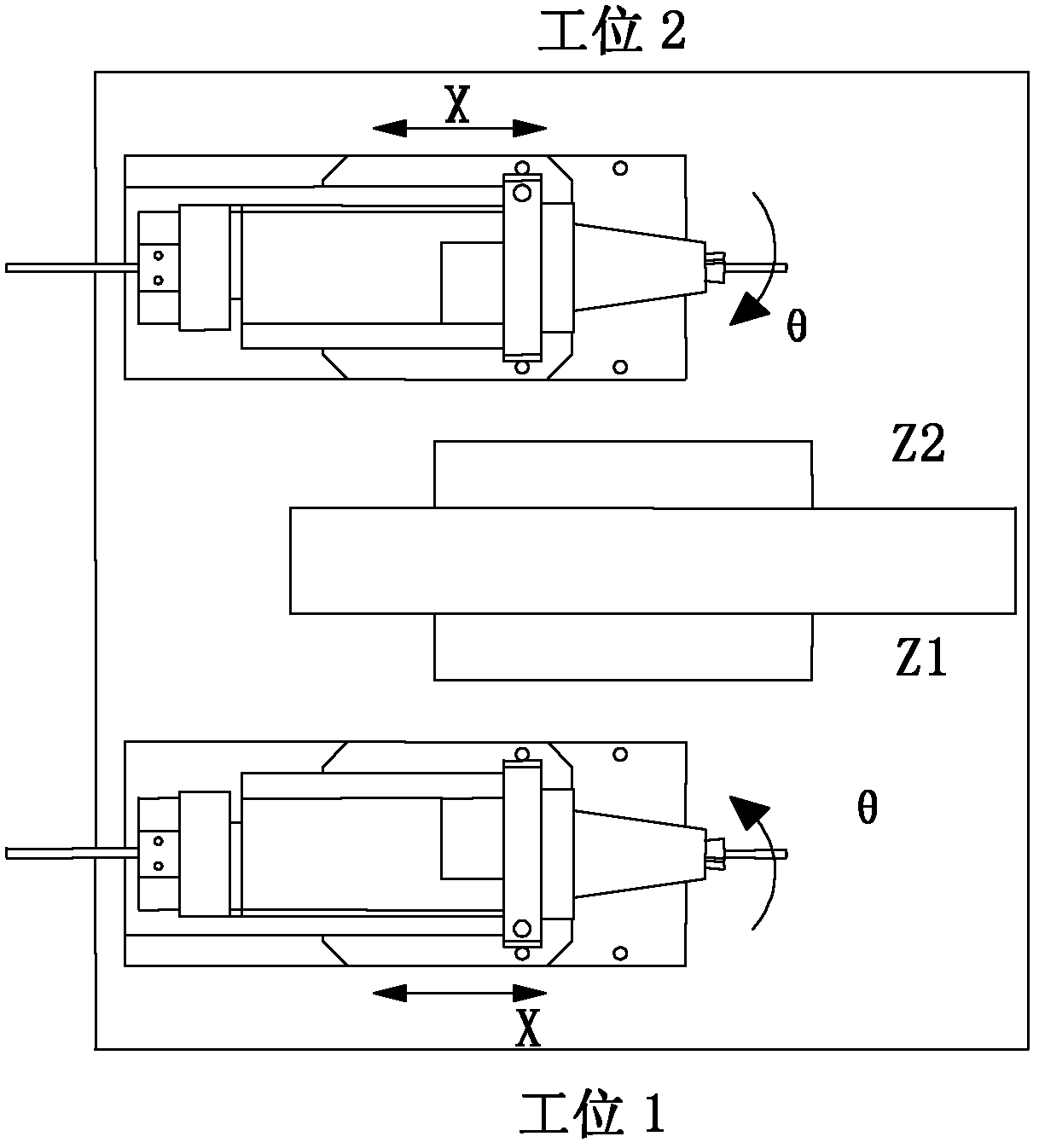

Laser micro processing equipment for double-station thin-walled tubes

ActiveCN103212861ACompact structureReduce manufacturing costLaser beam welding apparatusRotational axisLaser Nozzle

The invention provides laser micro processing equipment for double-station thin-walled tubes. The laser micro processing equipment comprises two processing stations, wherein each processing station is used for independently processing different workpieces; each processing station is provided with a rotating shaft, a linear shaft, a laser cutting head, an auxiliary high pressure gas supply unit, a Z-axis module, a laser generator, a collimation and beam expanding mirror, a lighting source, a 45-degree reflector and a CCD (Charge Coupled Device); each laser cutting head comprises a laser nozzle, a protective glass and a focus lens; each rotating shaft comprises a motor, a coupler, a worm, a worm gear, a draw bar module, a shell, an end cover and a chuck; and each draw bar module comprises a draw bar cover, a piston, a draw bar seat, an antifriction bearing, a shaft sleeve and a draw bar; and the draw bar is of a hollow structure. According to the laser micro processing equipment for the double-station thin-walled tubes, one equipment is provided with the two stations, so that two workers are allowed to operate on the equipment simultaneously, the equipment has a compact structure, and the production cost is greatly reduced.

Owner:KUNSHAN THETA MICRO

Preparation method of food packaging bag code spraying device facilitating positioning

InactiveCN106004084AEliminate static electricityAvoid displacementTypewritersPackagingPlastic packagingLaser Nozzle

The invention provides a method for preparing a food packaging bag coding device that is convenient for positioning, which includes a transmission unit, a bracket, a coder body and two sets of auxiliary positioning units located on both sides of the coder unit, and the coder body is fixed on the bracket Above, the laser nozzle on the inkjet printer body is facing the conveying surface of the conveying unit; the auxiliary positioning unit includes a boom and an iron roller, the upper end of the hook is connected to the side of the printer body, and the iron roller is located at the lower end of the boom; There is a gap between the roller and the conveying surface of the conveying unit, allowing food packaging bags to pass through. The beneficial effect of the invention is that it can effectively remove the static electricity of the plastic packaging bag, avoid the displacement of the packaging bag on the conveyor belt, facilitate the positioning of the food packaging bag, and facilitate the coding.

Owner:TIANJIN HONGLU FOODS

Anti-collision laser head and laser cutting machine and laser head anti-collision method

InactiveCN105382427AWelding/cutting auxillary devicesAuxillary welding devicesLaser NozzleDistance sensors

The invention provides an anti-collision laser head which comprises a laser head body. A laser nozzle is arranged below the laser head body. The laser head body is provided with distance sensors. The distance sensors measure the distance between the highest point of a cut workpiece and the lowest point of the laser nozzle. The position of the highest point of the machined workpiece is measured through the distance sensors, and whether the turned workpiece collides with the laser head or not is judged through the position of the highest point.

Owner:WUHAN GOLDEN LASER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com