Coaxial type nozzle used for laser micro machining of thin-walled tube

A thin-walled tube, coaxial technology, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of complex water guiding mechanism and large wear of laser nozzles, reducing light intensity, good technical effect, The effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

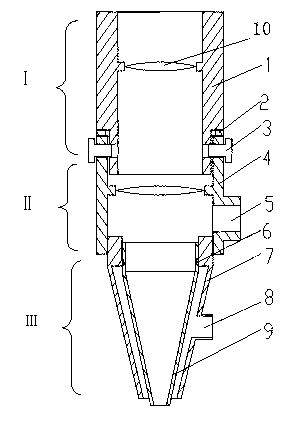

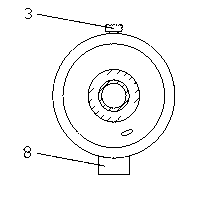

[0029] This embodiment provides a coaxial nozzle suitable for laser micromachining of thin-walled pipes, such as figure 1 As shown, it includes three parts: the upper part is the connection module I connected with the laser generator, the middle part is the transition module II, the lower part is the nozzle module III, the upper connection seat 1 is equipped with a focusing lens 10, and the connection module I is equipped The upper connection seat 1, the upper end of the upper connection seat 1 has an external thread to connect with the laser generator, the lower end of the thread is connected to the filter connection sleeve 4, and a silicone pad 2 and a knurled adjustment screw 3 are installed at the joint; the transition module II is equipped with The transition connection sleeve 4 is provided with an auxiliary gas inlet 5; the nozzle module III is composed of a nozzle inner core 9 and a nozzle outer core 7, and there are threads on the nozzle inner core 9 and nozzle outer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com