End steel shell mounting and positioning device and operation method

A technology of position adjustment device and end steel shell, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of low installation accuracy, complex process, large steel consumption, etc., to simplify construction links and avoid resources. The effect of waste and reduction of steel wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

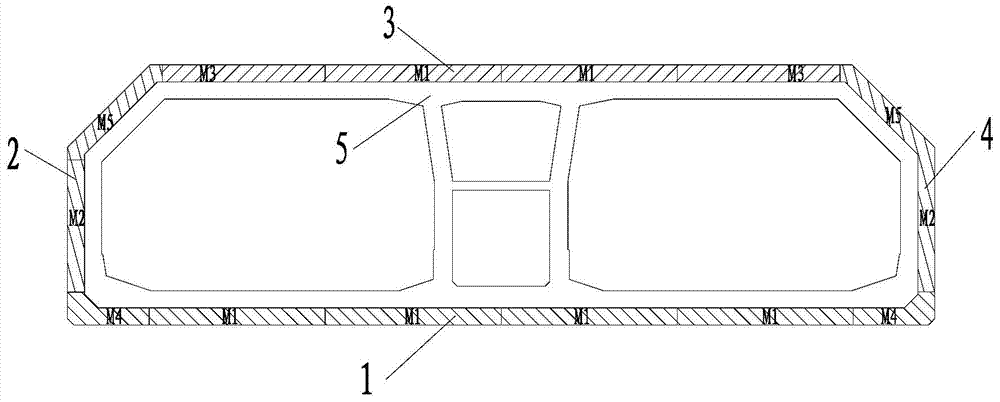

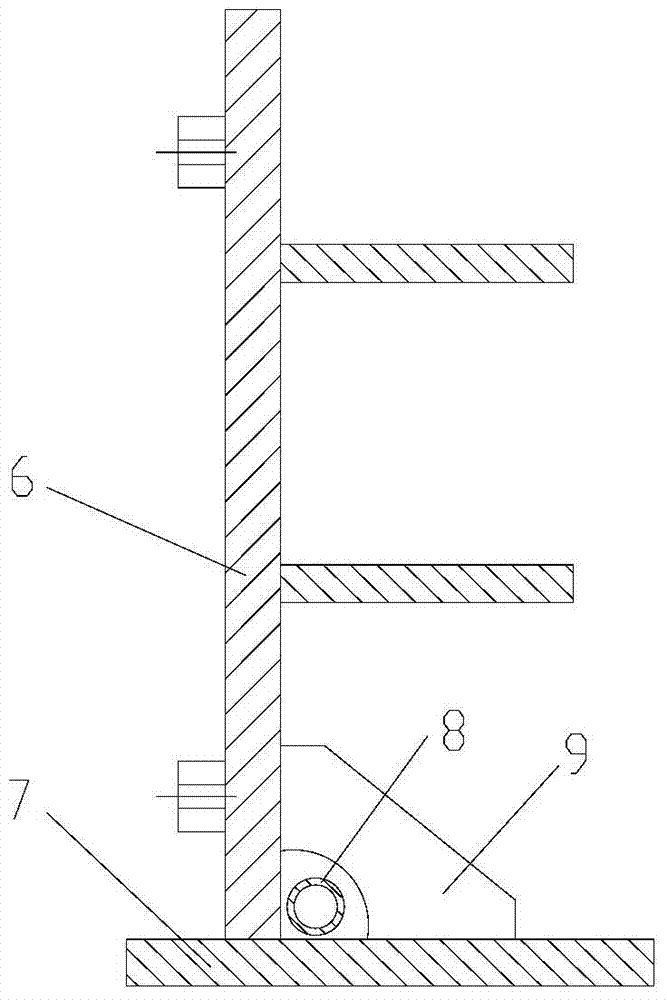

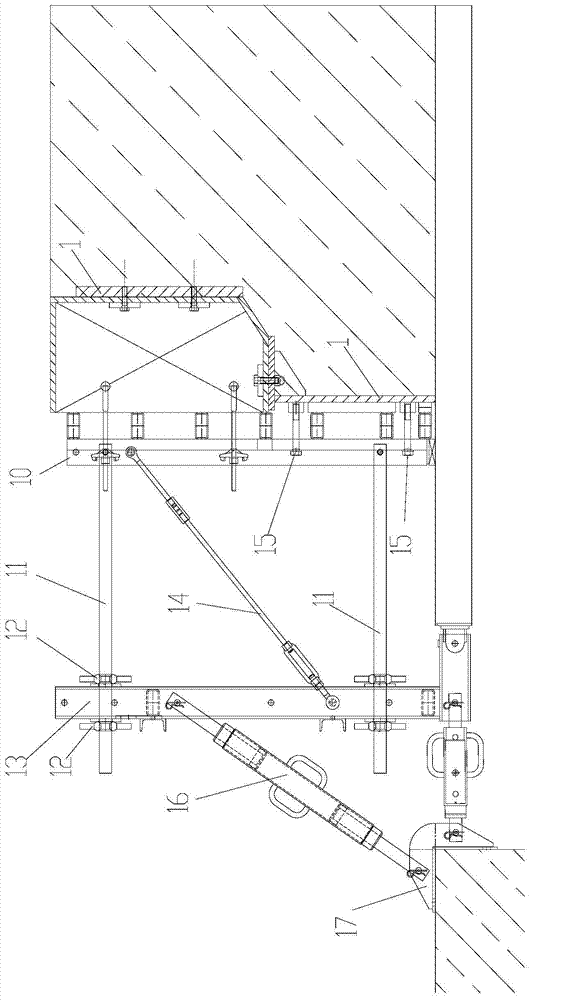

[0032] Such as figure 1 and image 3 As shown, a device for installing and adjusting the steel shell at the end of an immersed tube includes an end steel shell and an end mold unit. The end steel shell includes a bottom plate segment 1, a left wall segment 2, and a right wall formed by splicing segmented steel shells. Section 4 and roof section 3, the end mold unit includes formwork back frame 10, adjusting screw rod 11, stand 13, telescoping rod 16 and fixed seat 17, adjusting screw rod 11 connects stand 13 and formwork back frame 10, formwork back frame 10 and The steel shell at the end of the bottom plate 1 is closely connected, the adjusting screw 11 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com