Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1746results about How to "Reduce wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

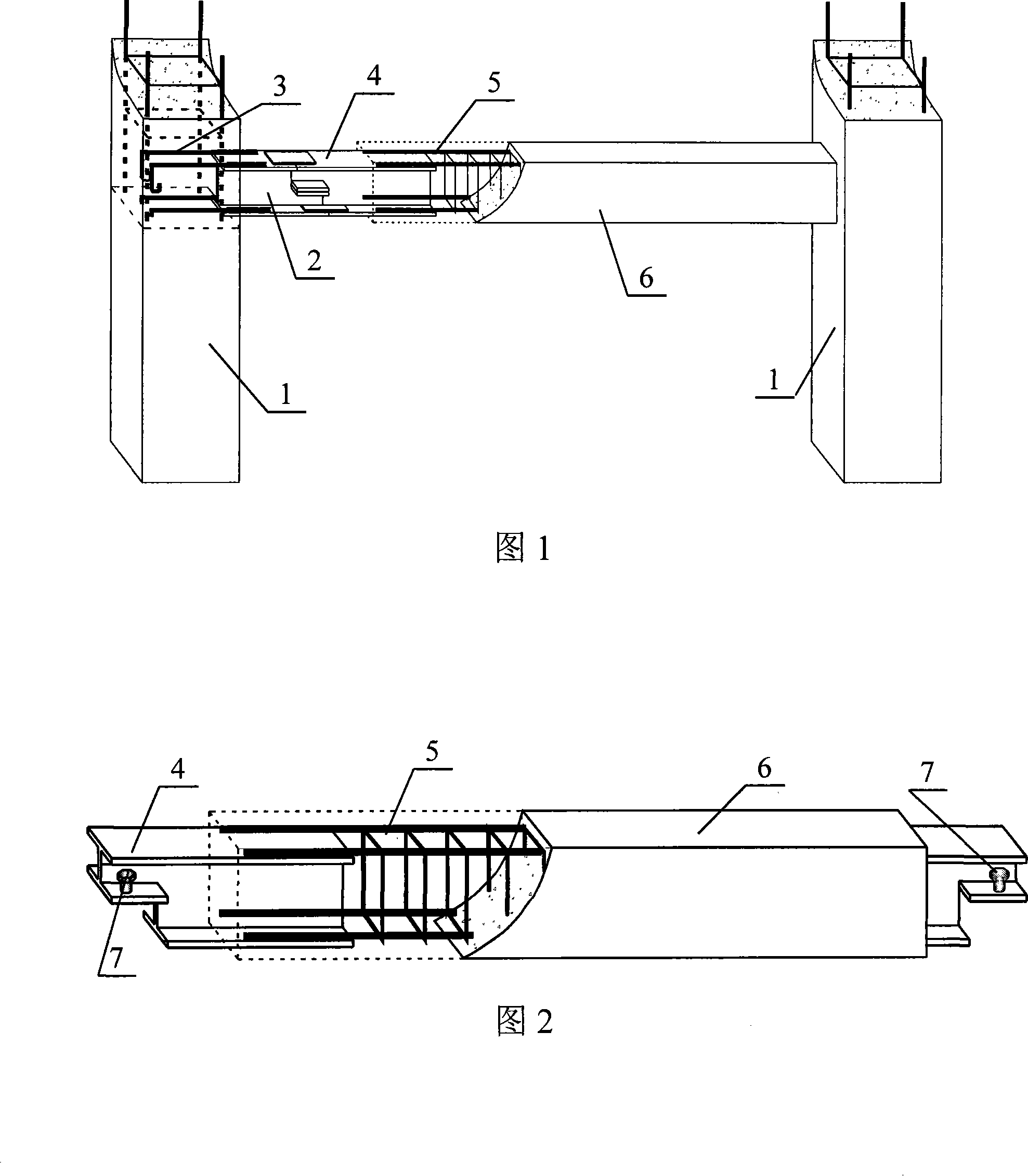

Combination beam

InactiveCN101215855AImprove integrityEasy to make nodesBuilding constructionsReinforced concreteMaterial consumption

The invention discloses a composite beam, which comprises reinforcement concrete prefab beam and section steel joints, wherein both ends of reinforcements of the reinforcement concrete prefab beam are connected with section steels, one end of section steel joint is pre-imbedded into the wall pier concrete and is connected to the reinforcement inside the wall pier, the other end of the section steel joint is remained outside the wall pier, both ends of section steel of the prefab beam and the section steel joints are connected to form the composite prefab beam. Due to the composite beam, the section steel joints and the wall piers are integrated with good connection integration property of the beams and simple process, wherein both ends of the section steel is connected with the section steel joints of the prefab beam to form composite beam, the connection between the prefab beam end and the section steel joints adopts welding, bolt connection type, and the like, the composite beam production can be industrialized, needs no framework, has small materials consumption and rapid construction progress.

Owner:吴方伯

Propagation method for using single-bud short tamarix to cut containerized seedlings

InactiveCN101611681AShort cultivation periodSolve the problem of low reproduction coefficientCultivating equipmentsHorticultureCamellia oleiferaTamarix

The invention relates to a propagation method for using a single-bud short tamarix to cut containerized seedlings. The propagation method comprises the main operating steps of: firstly establishing pergolas, preparing cutting containers, cutting matrixes and cutting beds of the containers, then carrying out cutting propagation operation, selecting the branches of the middle-upper part of the periphery of the middle-old age excellent clonal crown as cuttings, carrying out cutting in summer or autumn, doing well in work of weeding, fertilizing, moisturizing and prevention of pests. The propagation method has short culturing period, generally needs only 10 to 12 months, has simple operation, high propagation coefficients, fast propagation expansion and good transplanting effect, also can effectively reduce the loss of cutting propagation materials, and improve comprehensive benefit of industrial development of good seeds of the oil tea.

Owner:GUANGXI FORESTRY RES INST

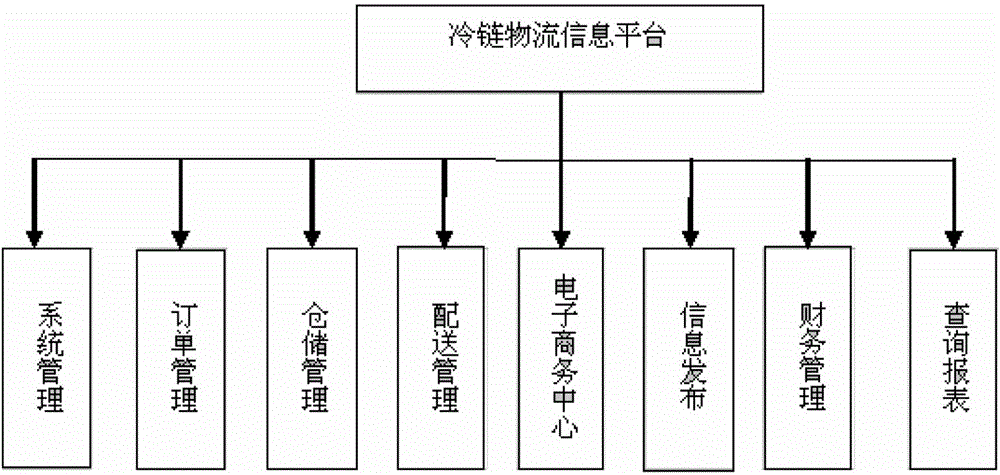

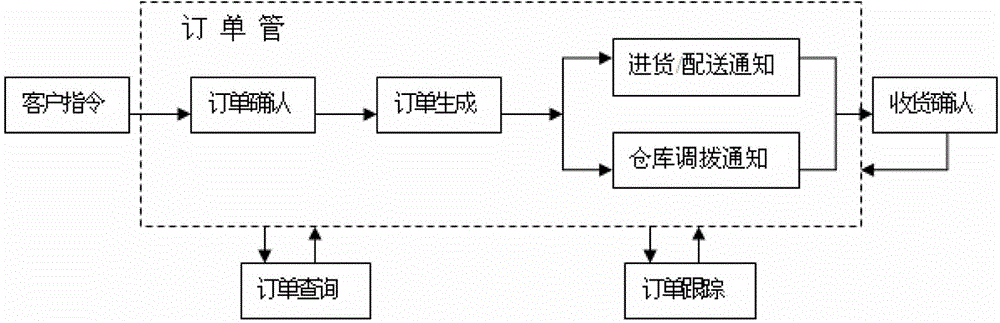

Cold-chain logistics information platform system

The invention discloses a cold-chain logistics information platform system. The cold-chain logistics information platform system is characterized by comprising a system management module, an order management module, a warehousing management module, a delivery control module, an e-commercial trade module, an information release platform, a financial management module and a report query module. The system management module is applicable to system-level operations such as maintenance of basic data, warehousing information and personnel information. The cold-chain logistics information platform system has the advantages that management efficiency is improved, information sharing is enhanced, and operating cost is lowered.

Owner:LIUZHOU TIANYU GERMANY REFRIGERATED TRANSPORT

Method for producing compound fertilizer by high tower granulating

ActiveCN1935748ALower melting temperatureAchieve low temperature meltingFertiliser formsUrea compound fertilisersMelting tankPhosphate

The invention discloses a method for producing urea-base grain compound fertilizer by high-tower prilling, comprising pulping and prilling, where the pulping adopts three-step series continuous gradual cooling pulping method, comprising the steps of: adding fluxing agent and urea in a melting tank, melting the urea at low temperature and making the urea melt flow into the first stage mixing tank; in the first stage mixing tank, adding unreactable raw materials into the urea melt, and making the mixed melt flow into the second stage mixing tank; in the second stage mixing tank, adding in ammium phosphate and mixing for less than 4 min, and obtaining mixed melted pulp; spraying the mixed melted pulp through the double-speed rotating prilling nozzle of the high tower into a prilling tower to complete prilling. And it has advantages of low temperature operation, low energy consumption, low loss, good pulp fluidity, good operating environment. And the produced compound fertilizer grains are round, less broken and uniform.

Owner:拉多美科技集团股份有限公司

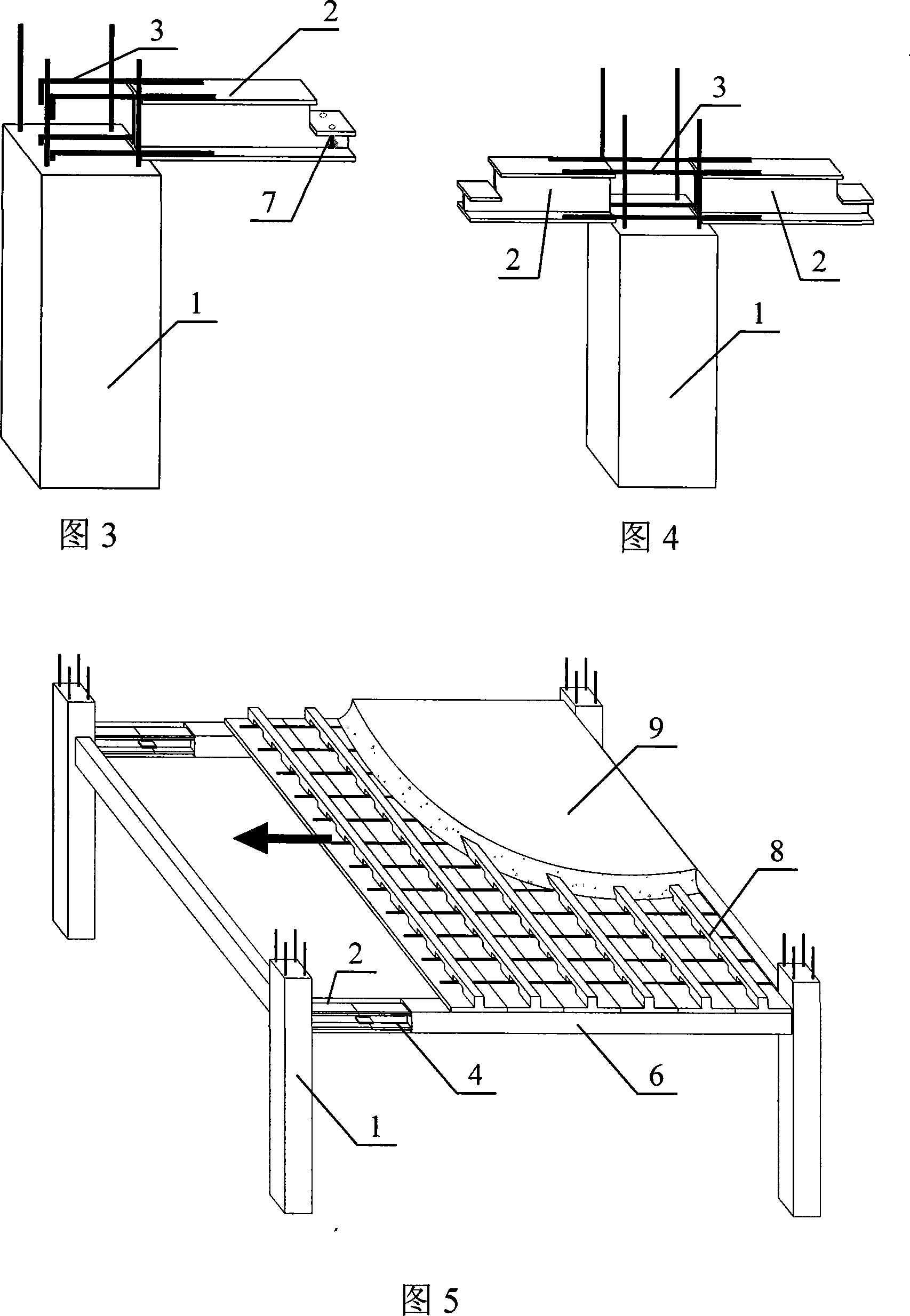

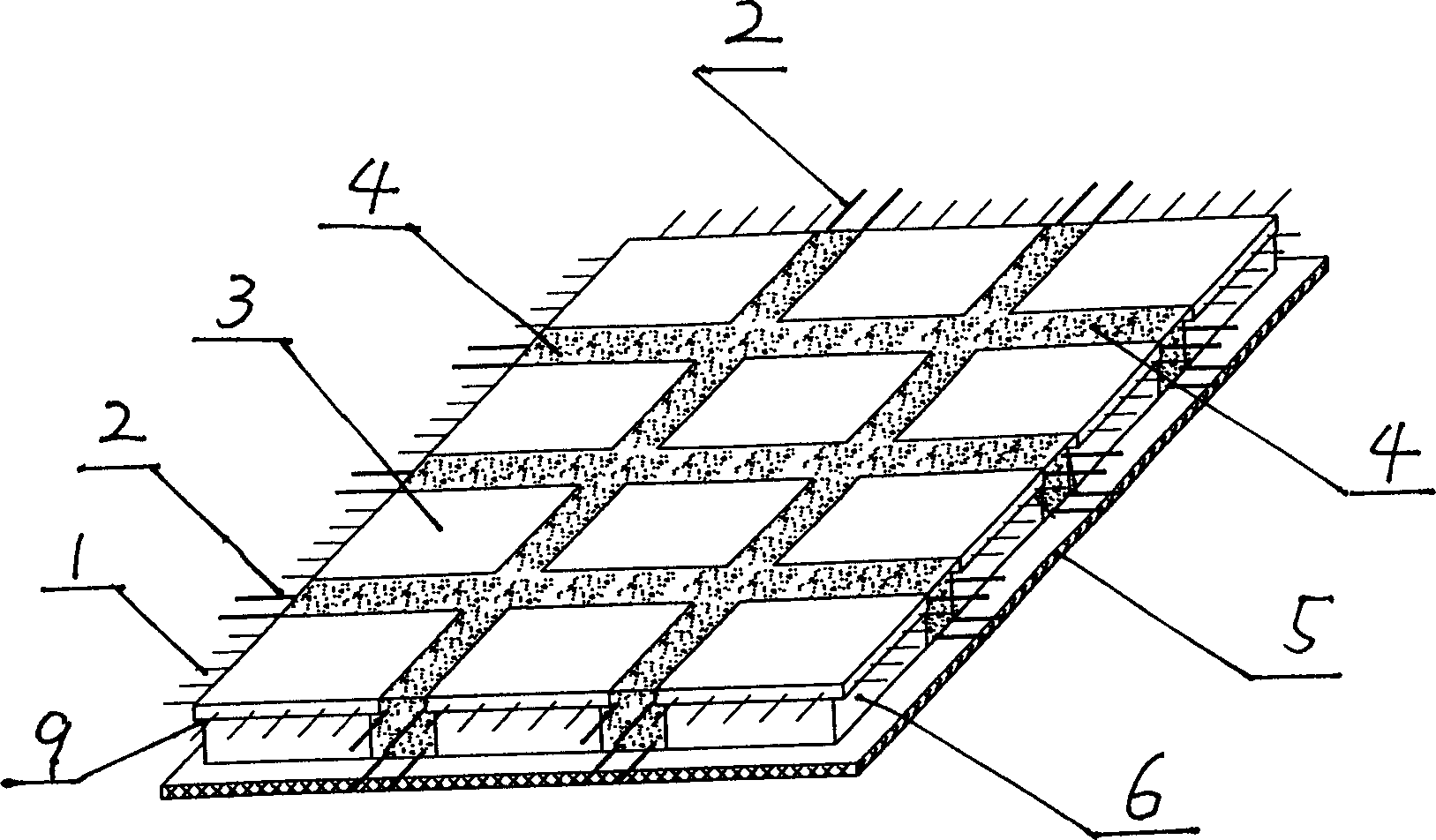

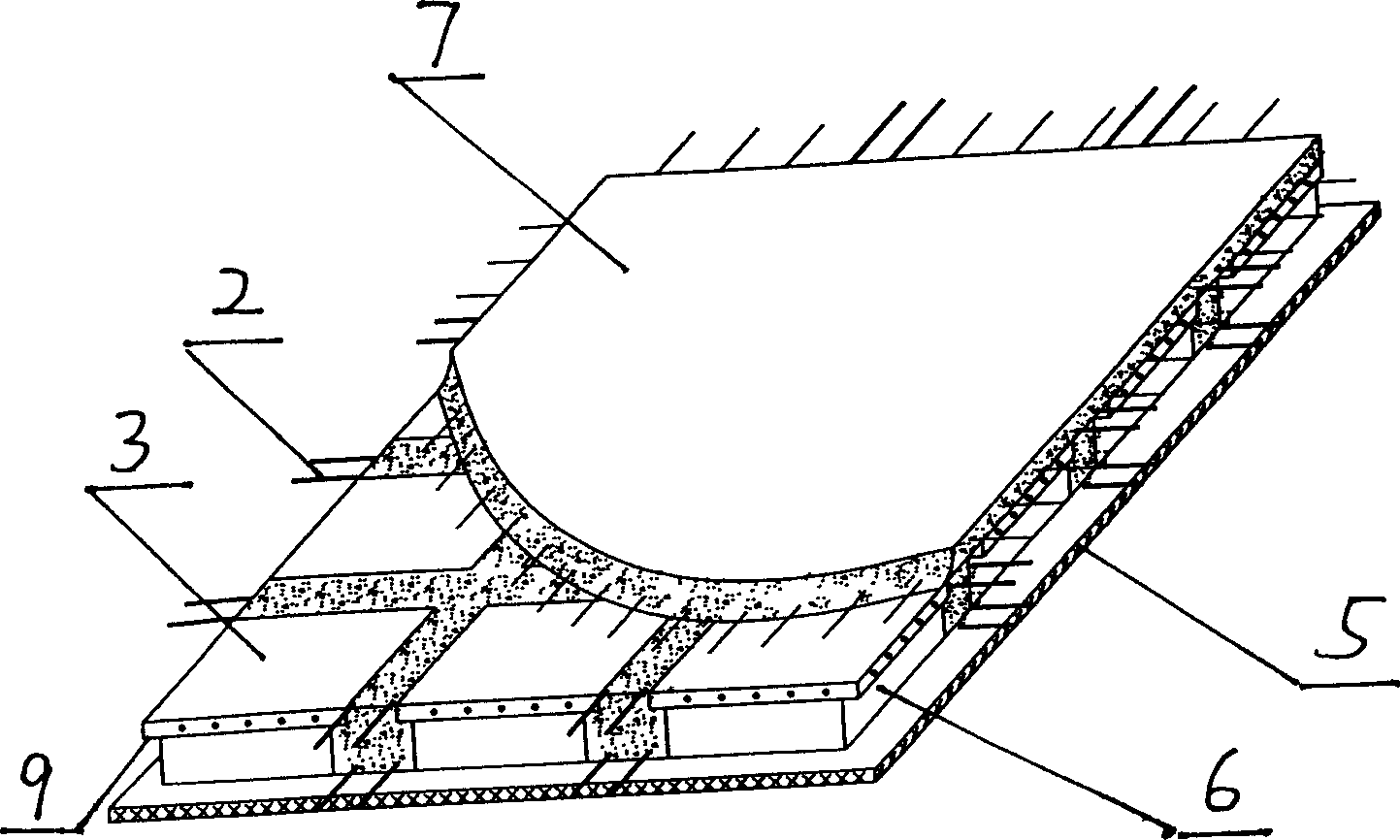

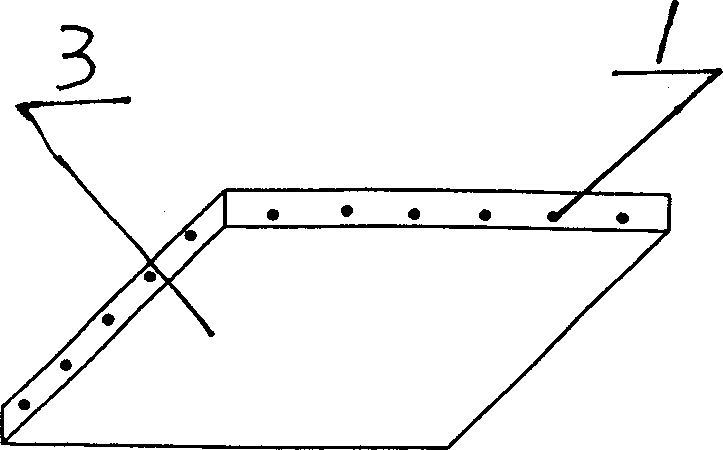

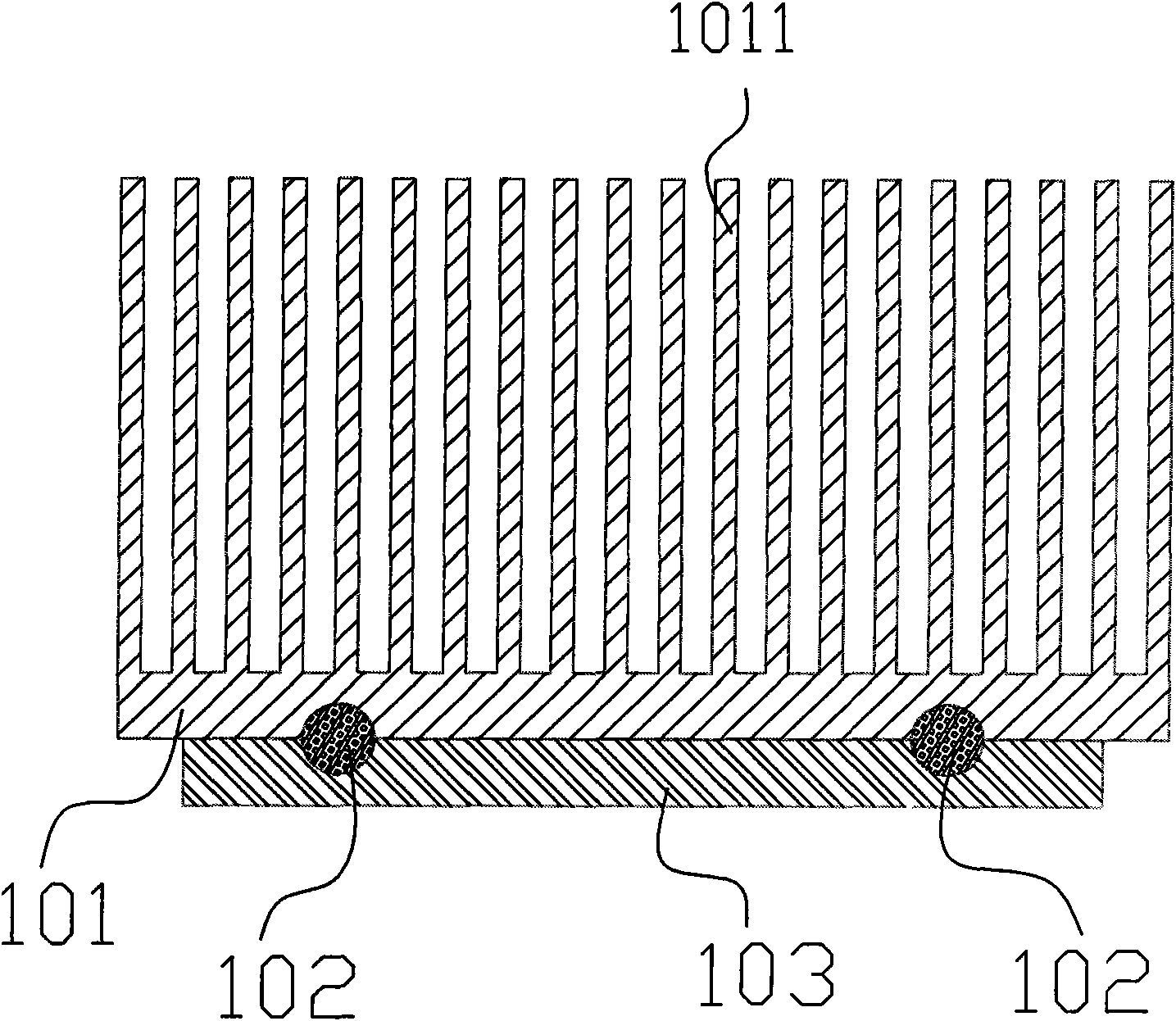

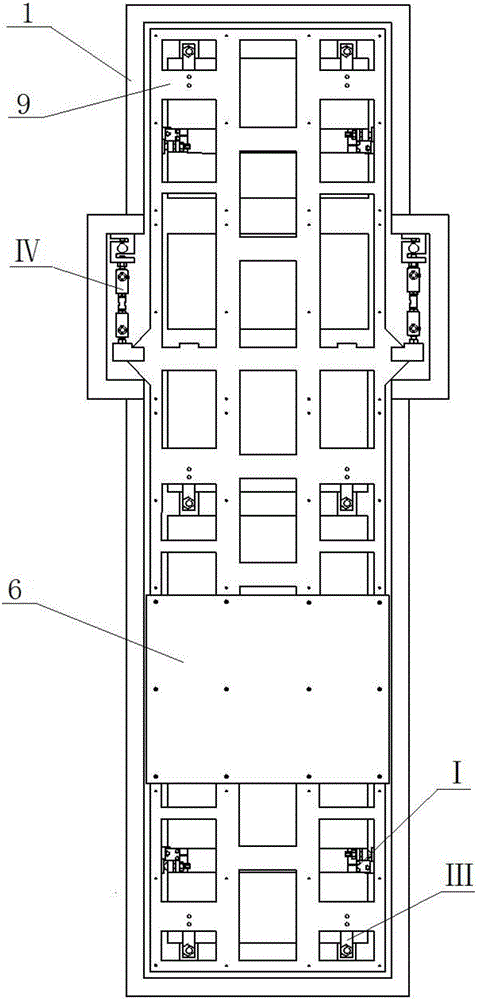

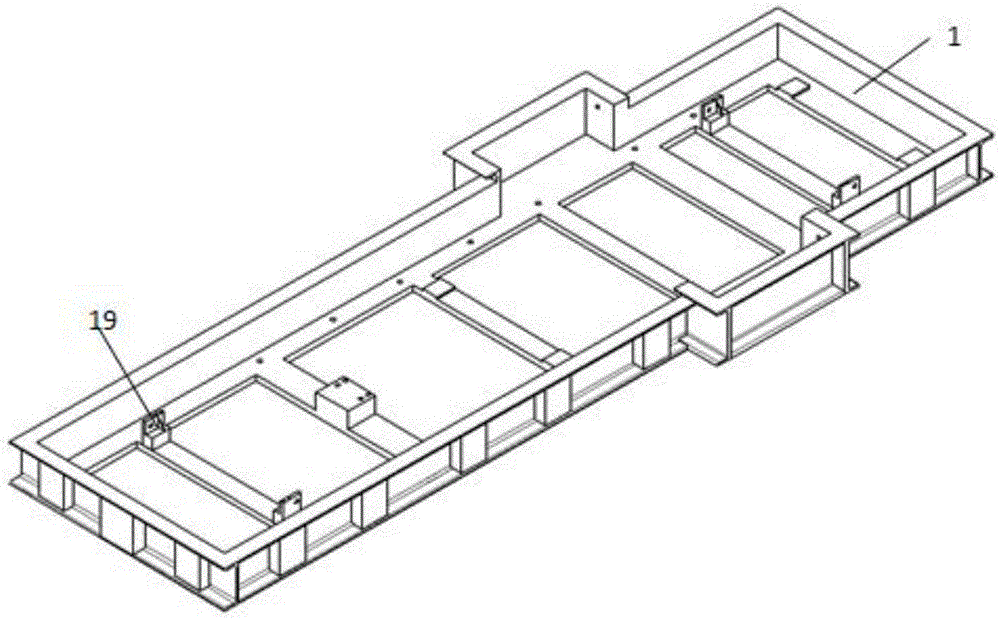

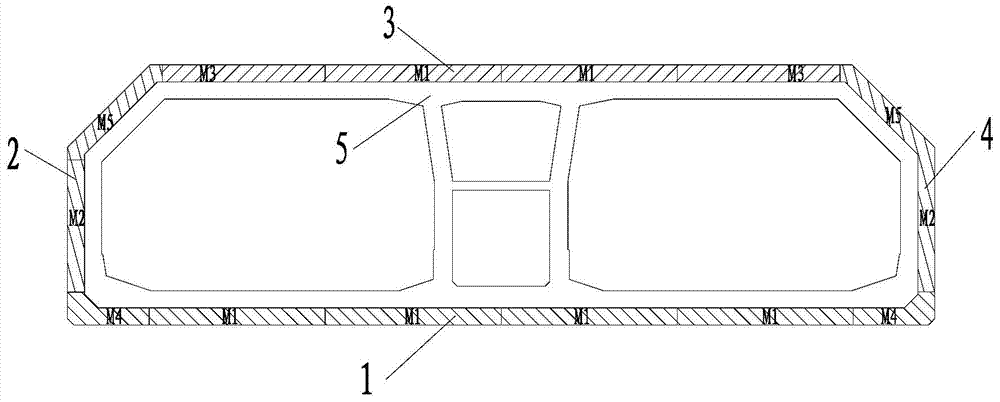

Steel bar concrete dense rib floor

InactiveCN1900449AReduce wear and tearImprove construction progressFloorsReinforced concreteFloor slab

The disclosed floor slab includes prefabricated unit, dense ribs. The floor slab is composed of multiple prefabricated units assembled on the dense ribs. The prefabricated component includes frame of hollow unit, and cover for prefabricated unit made from reinforced concrete. The frame and the cover constitute assembled unit. Assembling multiple blocks of assembled unit arranged in length and breadth forms the floor slab of dense rib. Multiple frames of hollow unit arranged in length and breadth are placed on template. The template can be in bar shape. Being built on stilts, multiple frames of hollow unit are supported on templates, which also can be as a full template. Thus, it is does not need template to support girder side of dense rib or under plate between dense ribs. Advantages are: small quantity of templates, simple working procedure, saving time and labor, less consumption, and quickening construction progress.

Owner:吴方伯

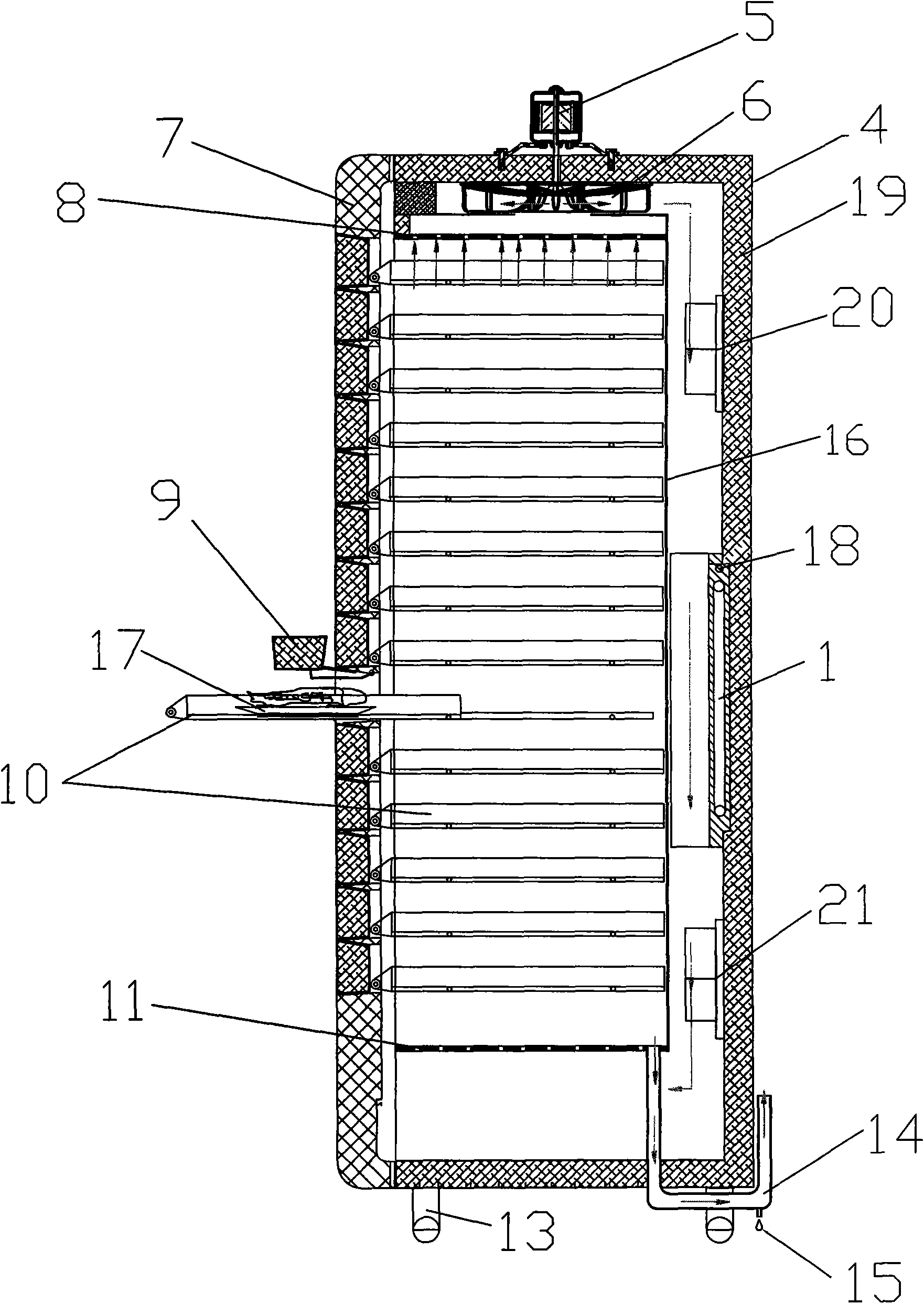

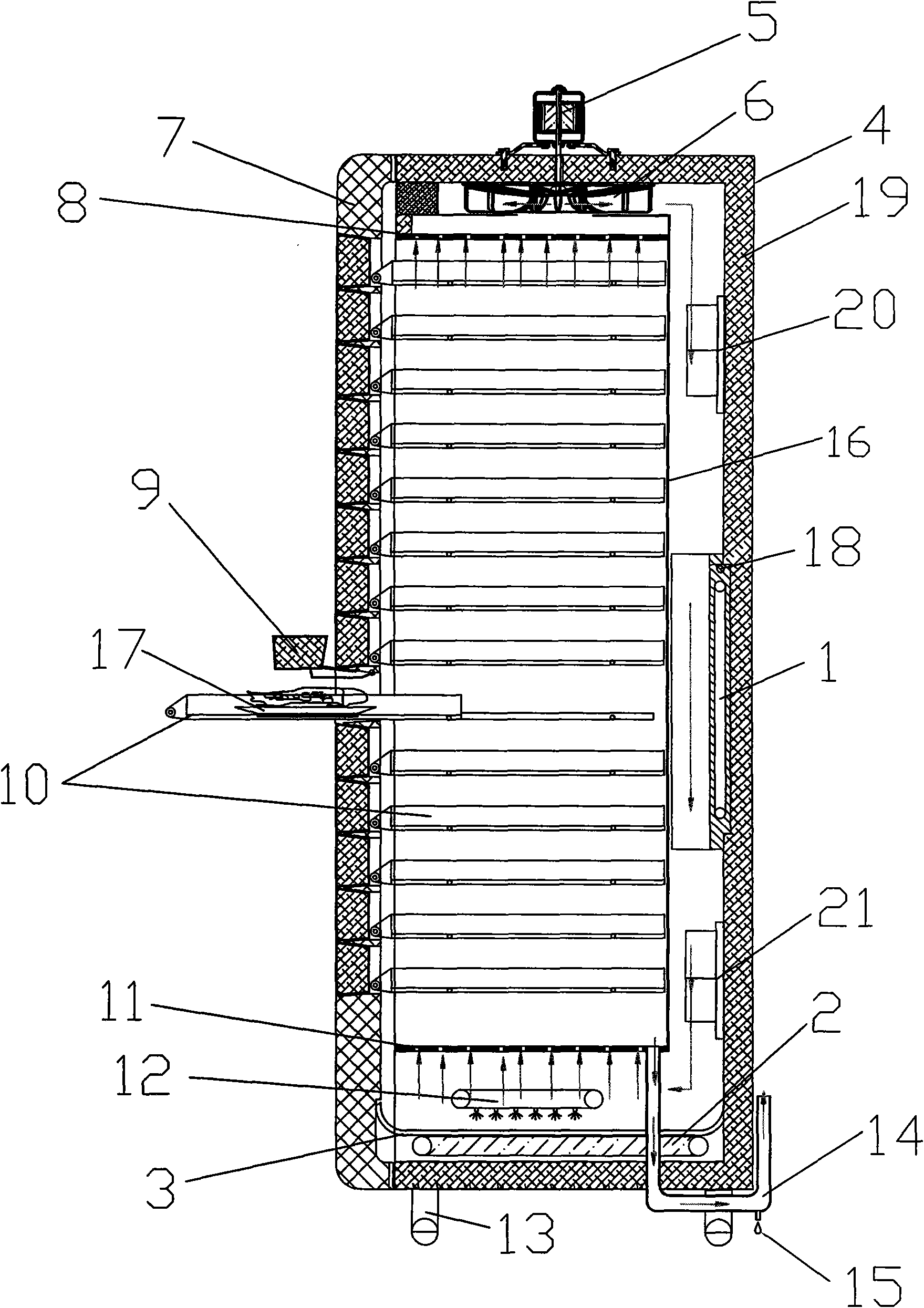

Hot air circulating heating insulation device and method for using same

InactiveCN101658385AReduce wear and tearQuick conversionSteam cooking vesselsWarming devicesAir heaterProduct gas

The invention discloses a hot air circulating heating insulation device and a method for using the same, which aim to solve the problems of energy waste and inconvenient operation of the prior device.The insulation device comprises a box body with an insulating layer, a box door and an electric heater, and is characterized in that: the inside of the box body is also provided with an inner box, acirculating fan, two temperature and humidity sensors and an exhaust pipe, wherein the inner box has a proper gap with a top plate, a bottom plate and a back wall of the box body respectively, a plurality of layers of withdrawable cage lattices mutually parallel to each other are arranged in the inner box, the top plate and the bottom plate are an air balancing baffle plate respectively, and unitdoors mutually corresponding to the cage lattices are arranged in the box door; the circulating fan is arranged in the gap between the inner box and the top plate of the box body; the electric heateris an air heater, and is arranged in the gap between the inner box and the back wall of the box body; one temperature and humidity sensor is arranged at the upper part of the back wall in the box body, and the other one is arranged at the lower part of the back wall in the box body; and the exhaust pipe is U-shaped, and one end of the exhaust pipe is communicated with the bottom of the inner box,while the other end penetrates out of the bottom plate of the box body to be communicated with the atmosphere.

Owner:倪军

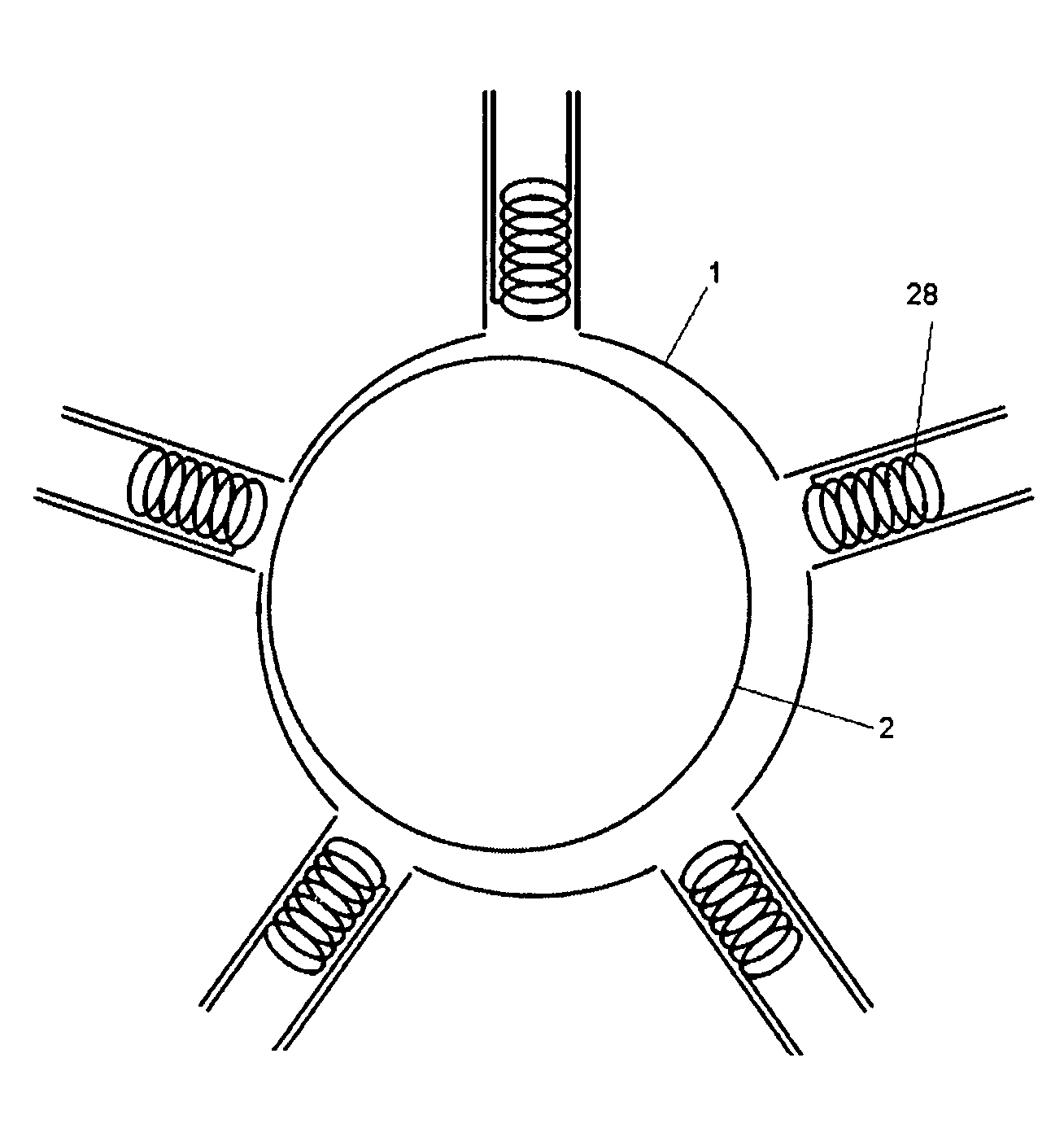

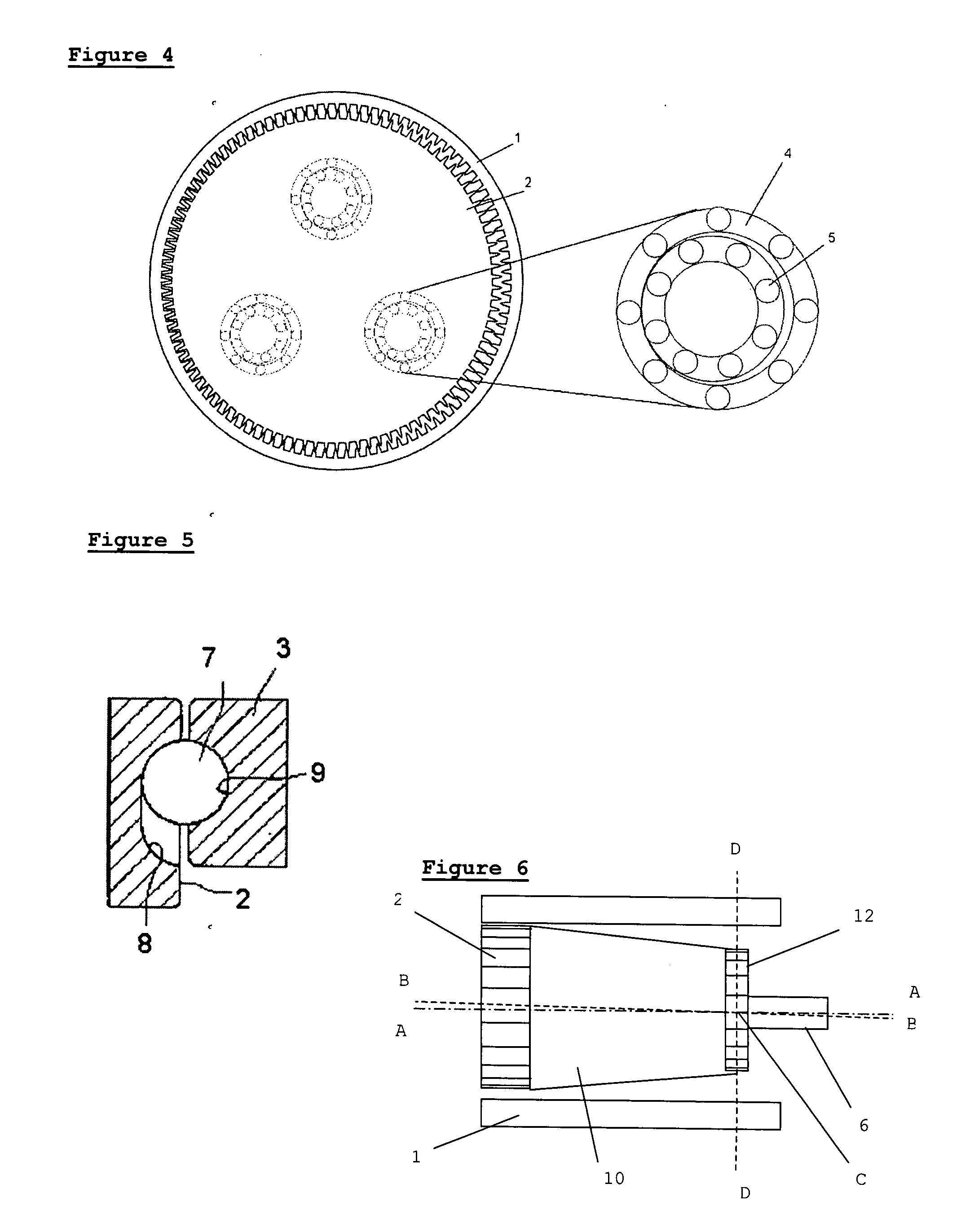

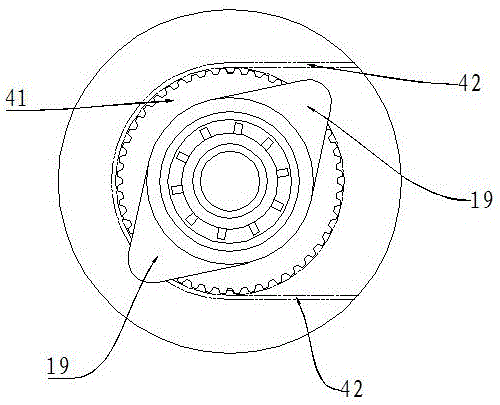

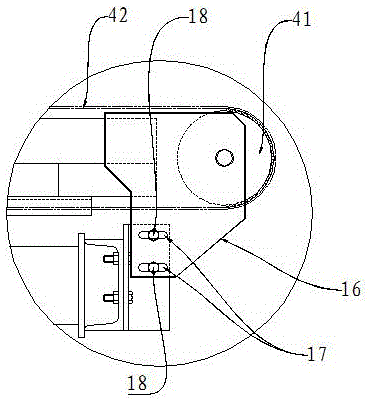

Motor using magnetic normal force

InactiveUS20080007130A1Reduce wear and tearIncreased torque densityGearingMechanical energy handlingInternal cavityEngineering

A motor is disclosed, comprising at least one fixed member comprising at least one magnetic winding, having an internal cavity; at least one driven member inside said fixed member, comprising magnetically conductive materials; constraining means for constraining said driven member to a path of movement with respect to said fixed member, said driven member being able to move within said fixed member, wherein magnetic normal force is induced in said fixed member periodically, whereby said driven member is periodically moved around said path by magnetic force, whereby rotary motion is produced.

Owner:BOREALIS TECH LTD

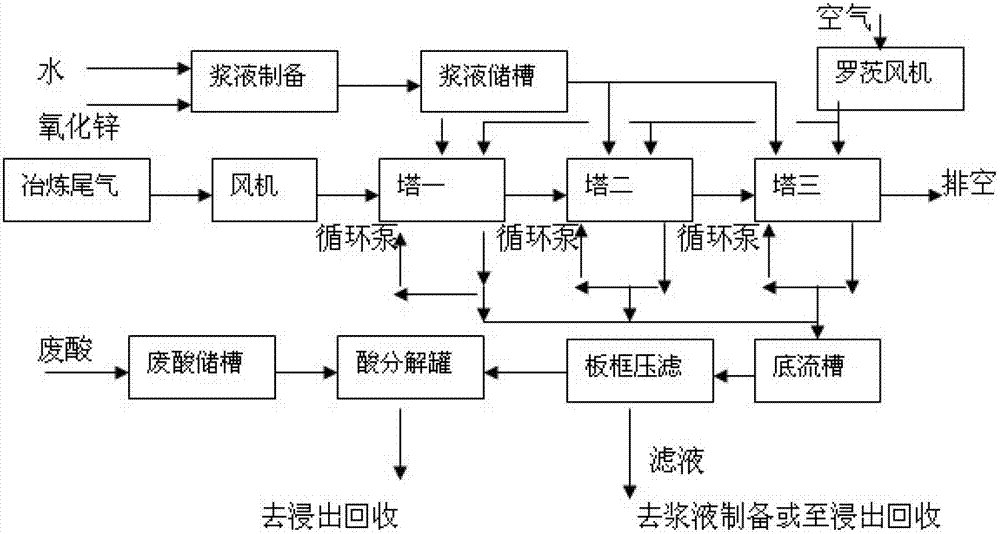

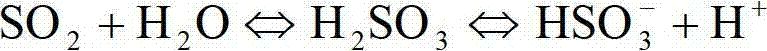

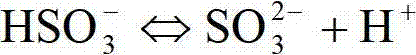

Tail gas desulfuration adopting zinc oxide method in smelting industry

ActiveCN102755826AReduce in quantityReduce wear and tearDispersed particle separationLiquid wasteDecomposition

The invention belongs to the technical filed of environmental protection, and particularly relates to tail gas desulfuration adopting a zinc oxide method in smelting industry. The tail gas desulfuration adopting a zinc oxide method in smelting industry comprises the following steps of: preparing a serous fluid-increasing smelting tail gas pressure-absorbing procedure-oxygenation procedure-plate frame pressure filtration procedure-acid decomposition procedure; the quantity of absorbing towers can be determined according to the temperature of tail gas to be processed and sulfur dioxide content, and a primary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 0-6000 mg / Nm3; and a secondary-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 6000-12000 mg / Nm3, and a third-level absorbing tower is used when the sulfur dioxide content of the tail gas is in the range of 12000-24000 mg / Nm3. The air oxidation is realized in the absorbing tower, ZnSO3.5H2O which is easy to crystallize is oxidized to be ZnSO4, the quantity of the crystals is greatly reduced, the phenomena of sedimentation and choking are greatly relieved, and the abrasion to the circulating pump and a pipeline is relieved; and the waste acid generated by a smelting industry is utilized, part of waste fluid or waste acid is reused, and the clean production and work is promoted.

Owner:江苏恒丰伟业科技工程有限公司

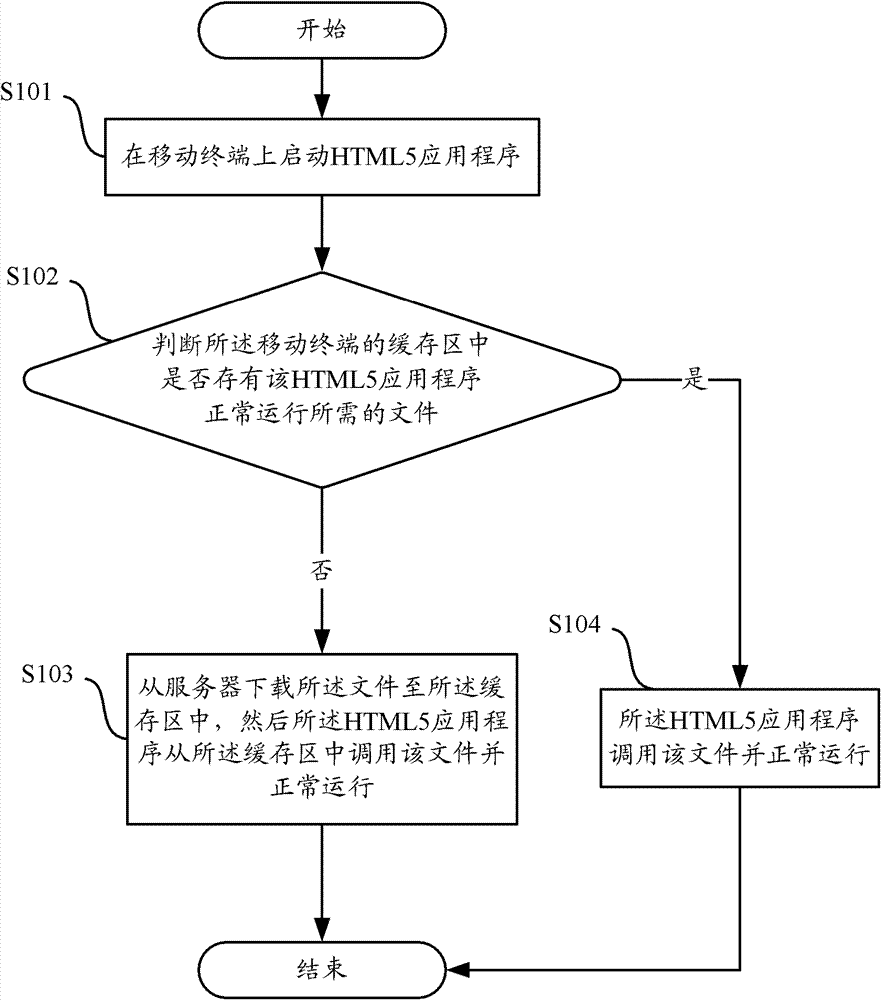

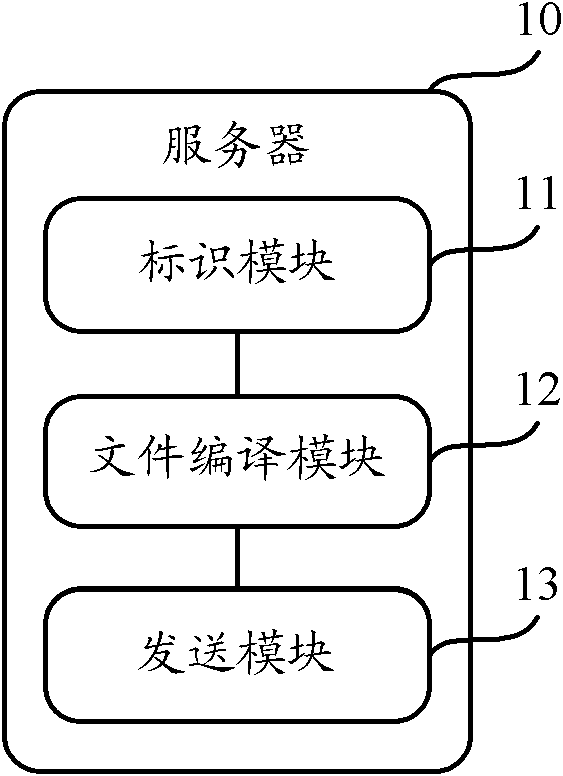

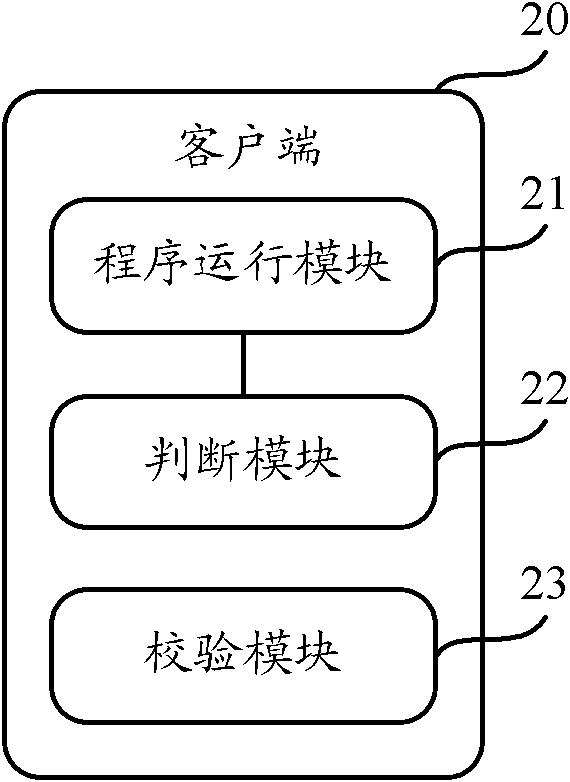

Method and device for offline running of HTML5 (hypertext markup language 5) application program in mobile terminal

InactiveCN102779128AOffline apps start quicklyImprove operational efficiencySpecial data processing applicationsTraffic capacityHTML5

The invention provides a method for offline running of an HTML5 (hypertext markup language 5) application program in a mobile terminal, which comprises the steps of: starting the HTML5 application program on the mobile terminal, judging whether a file for normal running of the HTML5 application program exists in a cache region of the mobile terminal or not; if the file exists in the cache region, calling the file by the HTML5 application program for normal running of the HTML5 application program; and if the file does not exist in the cache region, downloading a file from a server into the cache region, and calling the file from the cache region by the HTML5 application program for normal running of the HTML5 application program. Correspondingly, the invention also provides the server and a client side. By implementing the method and the device provided by the invention, the frequency of repeated downloading of the file can be reduced, traffic losses can be reduced for the mobile terminal, the startup of offline application of the HTML5 program can be quickened, the waiting time of a user can be decreased, and the running efficiency of the HTML5 program can be increased.

Owner:北京磊友信息科技有限公司

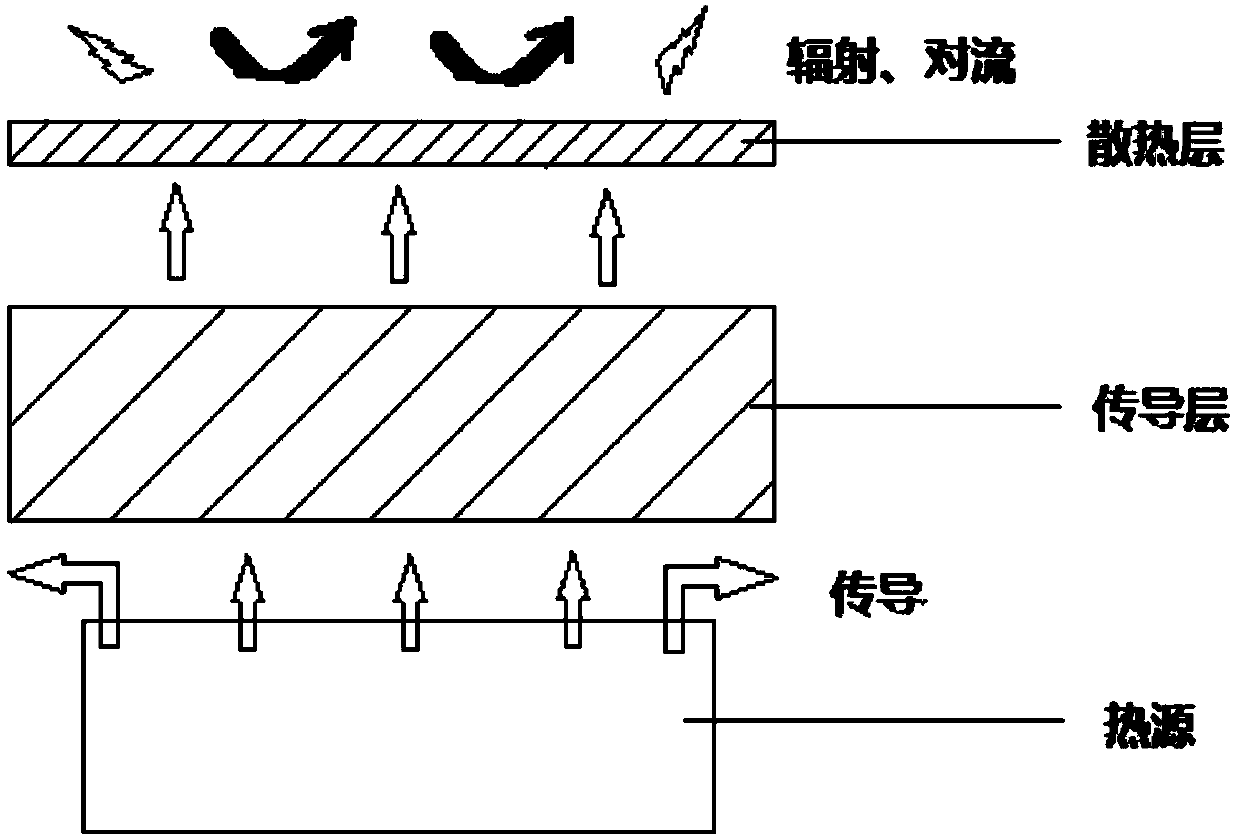

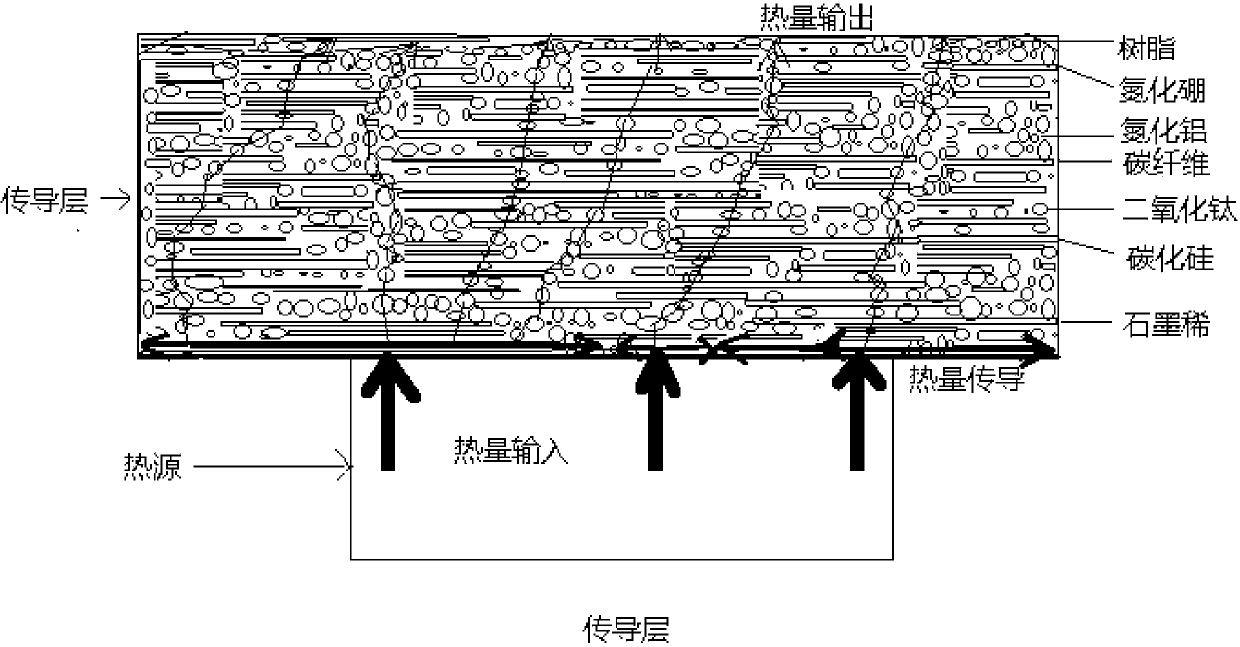

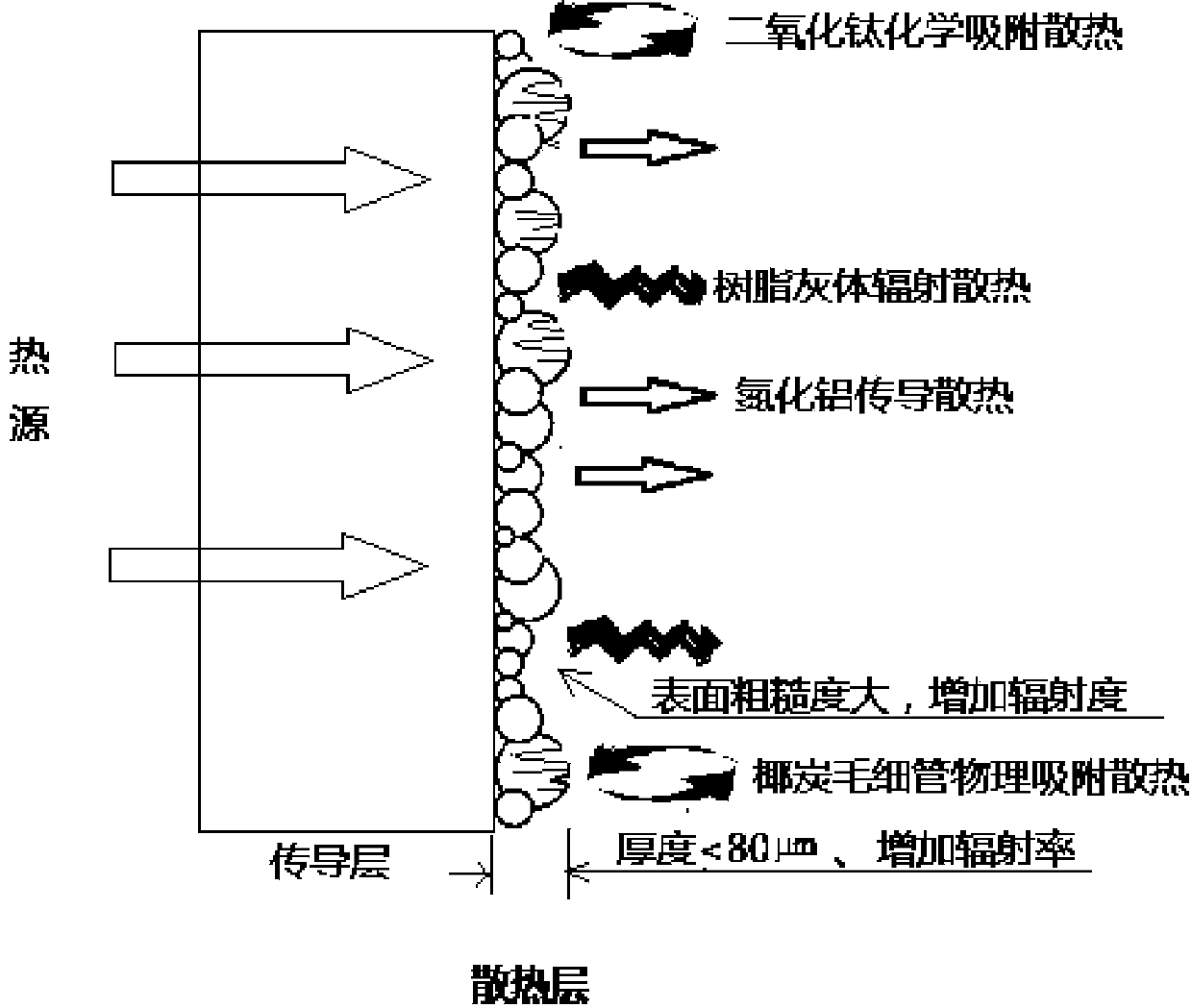

Heat-conducting insulating composite material and preparation method thereof

ActiveCN103738022AHigh densityReduce weightSynthetic resin layered productsRough surfaceHeat conducting

The invention provides a heat-conducting insulating composite material and a preparation method of the heat-conducting insulating composite material. The composite material sequentially comprises a conduction layer and a heat dissipation layer according to the distance between the layers and a heat source from the near to the distant, wherein one side of the heat-conducting insulating composite material is a smooth surface, and the other side of the heat-conducting insulating composite material is a rough surface; the smooth surface is used for receiving a heat source, the thermal contact resistance can be greatly reduced through the smooth surface, and the heat energy can be well and rapidly absorbed; the rough surface is a heat dissipation surface and has a honeycomb porous structure, a far infrared radiation coefficient can be improved, convection is accelerated, and the heat dissipation capacity of the material is improved. The heat conductivity coefficient of the composite material can be 8-20W / m.k, the far infrared radiation coefficient can be over 0.9, the composite material has high heat-conducting performance, and the inherent good processability and insulating property are kept.

Owner:深圳市上欧新材料有限公司

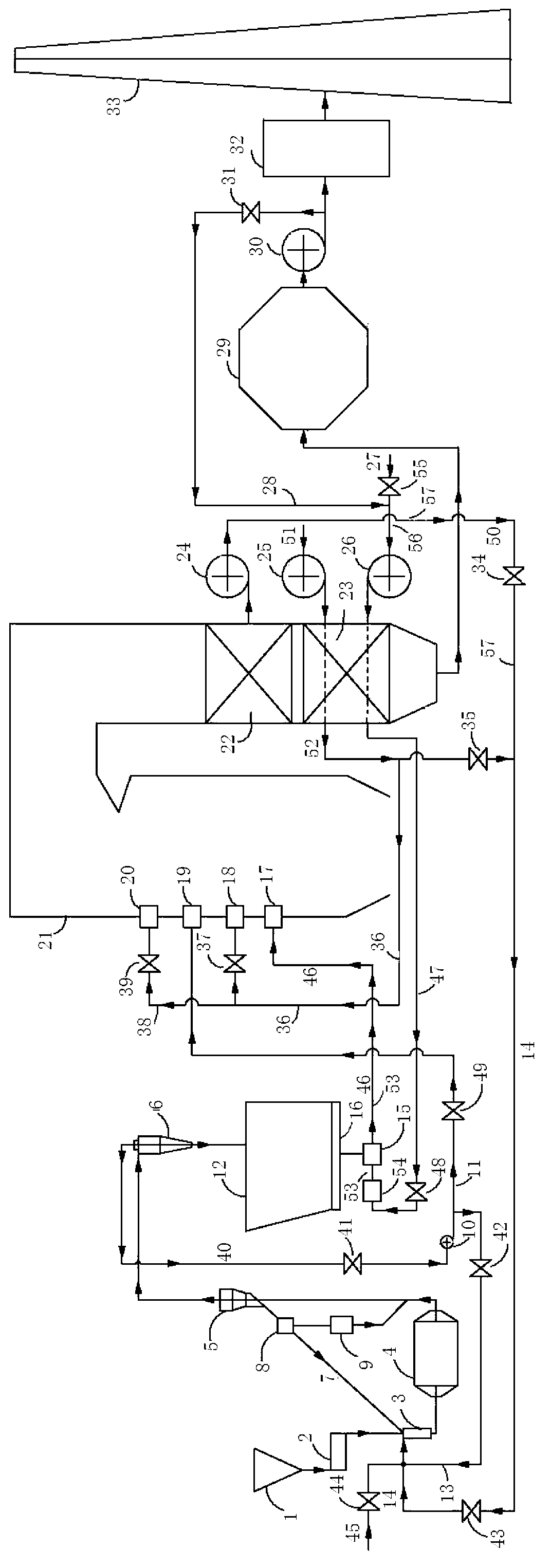

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

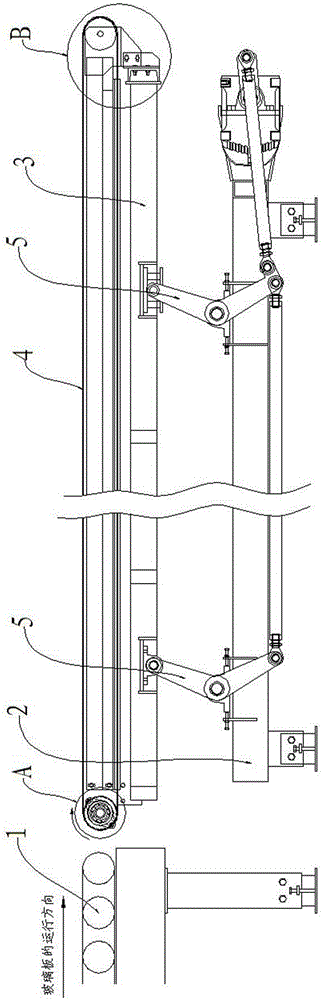

Lifting type belt plate fetching machine

ActiveCN105059896ASmooth entryEntry does not produceConveyorsConveyor partsRelative motionManufacturing line

The invention discloses a lifting type belt plate fetching machine. The lifting type belt plate fetching machine is correspondingly arranged at the tail end of a roller way used for conveying glass plates in a glass production line. The lifting type belt plate fetching machine comprises a base, a belt conveying rack, a lifting mechanism and a belt conveying mechanism horizontally mounted on the belt conveying rack. A belt conveying motor used for driving the belt conveying mechanism to operate is arranged at one end of the belt conveying rack. The belt conveying rack is horizontally mounted on the lifting mechanism. The lifting mechanism is fixed to a base. A lifting mechanism transmission station in transmission connection with the lifting mechanism is arranged on one side of the base. The lifting mechanism transmission station drives the belt conveying rack to act through the lifting mechanism so that the belt conveying mechanism can have certain displacement in the horizontal direction while the vertical height of the belt conveying mechanism is changed, and accordingly the glass plate at the tail end of the roller way is transferred onto the belt conveying mechanism. According to the lifting type belt plate fetching machine, the conveying speed of the belt conveying mechanism is the same as that of the roller way, in this way, it is guaranteed that the glass plate enters a belt of the belt conveying mechanism smoothly, relative movement is avoided, the quality of glass is improved, and the rate of finished products is increased.

Owner:HENAN HAICHUAN ELECTRONICS GLASS CO LTD

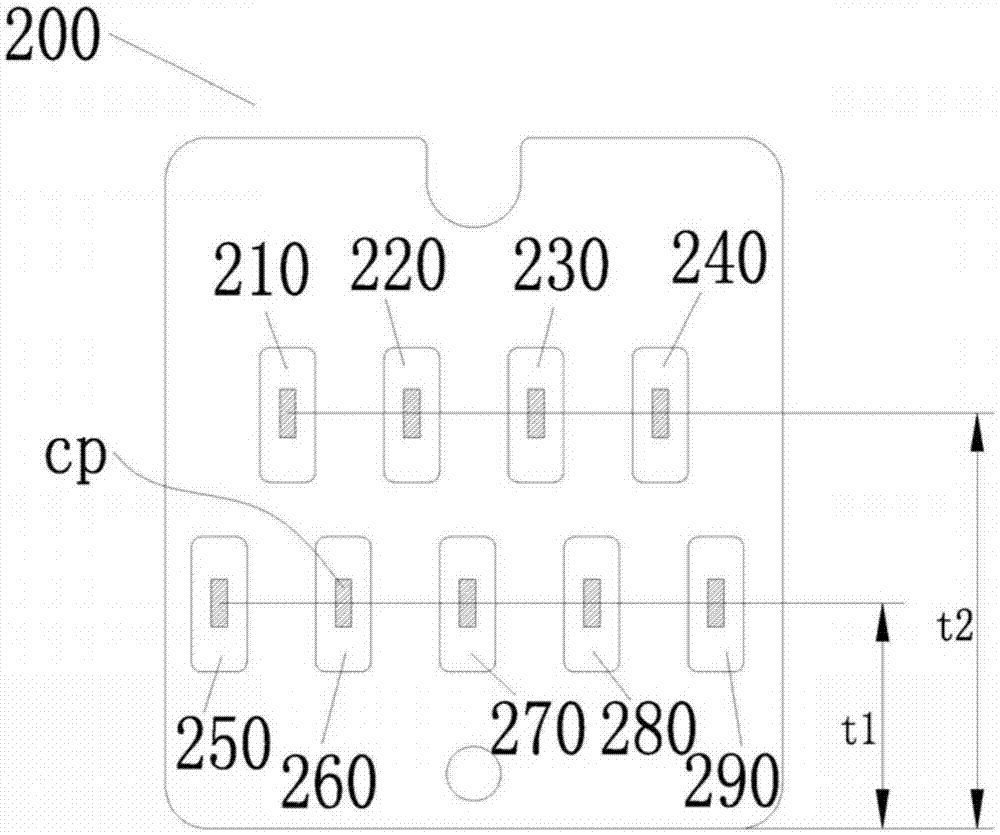

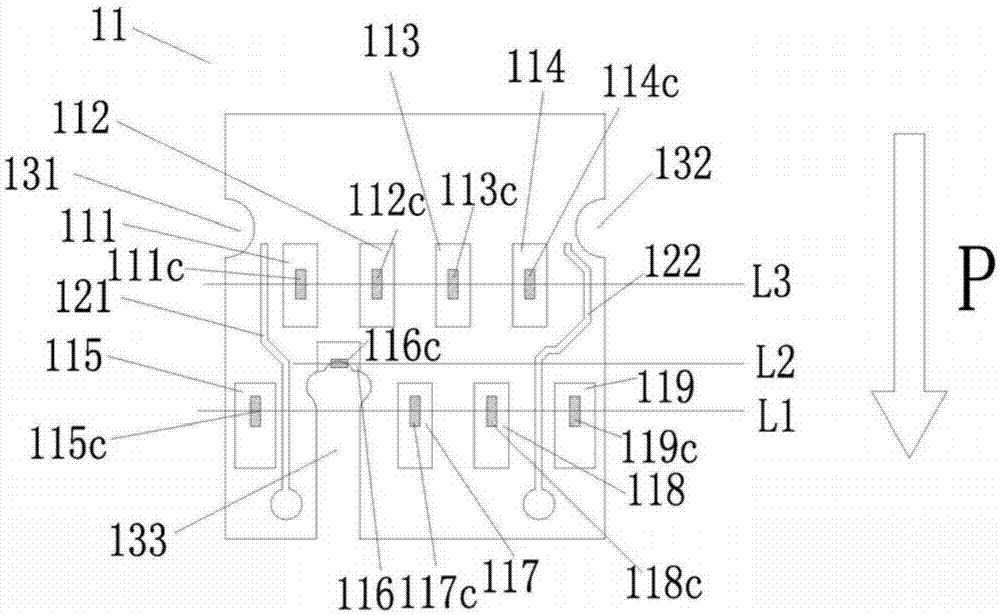

Chip for ink-jet printer and ink-jet printer

ActiveCN106864040AGuaranteed stability and reliabilityImprove stability and reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectricityEngineering

The present invention provides a chip for an ink-jet printer and an ink-jet printer. The chip for an ink-jet printer comprises a hollow portion, a memory, two installation and detection terminals and a power terminal connected with the memory. Each installation and detection terminal is provided with an installation and detection contact portion being in electrical contact with a printer contact probe, the power terminal is provided with a power contact portion being electrical contact with the printer contact probe, the power terminal is arranged at the end surface of the hollow portion, the two installation and detection contact portions are arranged at two sides of the hollow portion and installed at the installation direction of a printer along the chip, and the distances between the two installation and detection contact portions and the front end of the chip are smaller than the distance between the power contact portion and the front end of the chip. The chip for ink-jet printer and the ink-jet printer overcome the defects in the prior art and effectively ensure the stable reliability of the usage of the chip.

Owner:ZHUHAI NINESTAR MANAGEMENT CO LTD

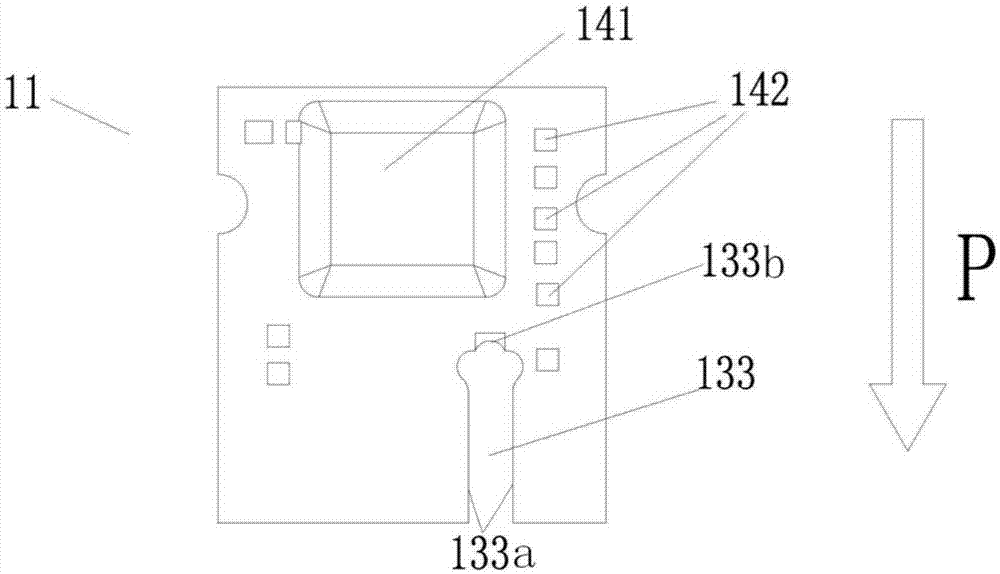

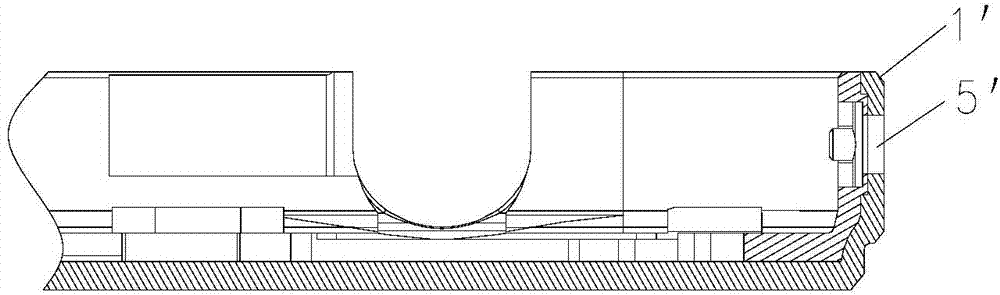

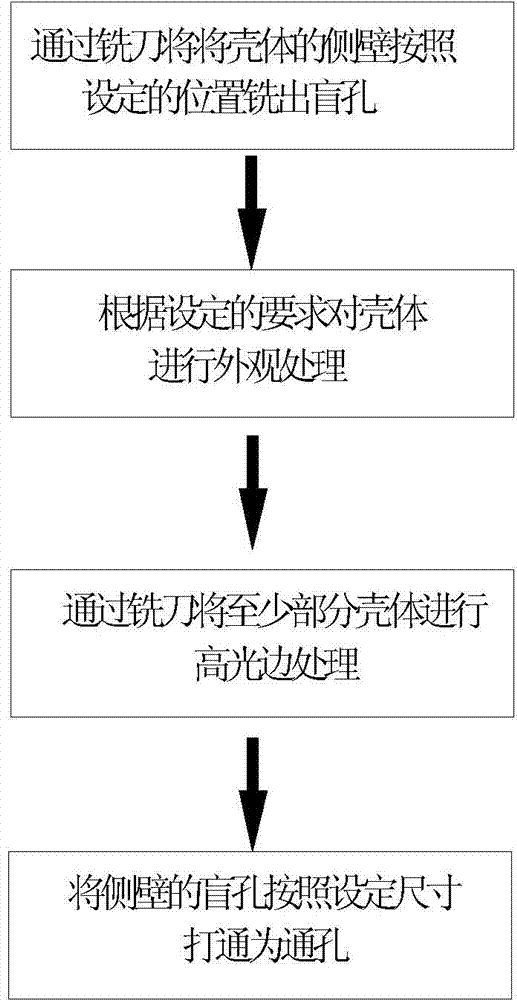

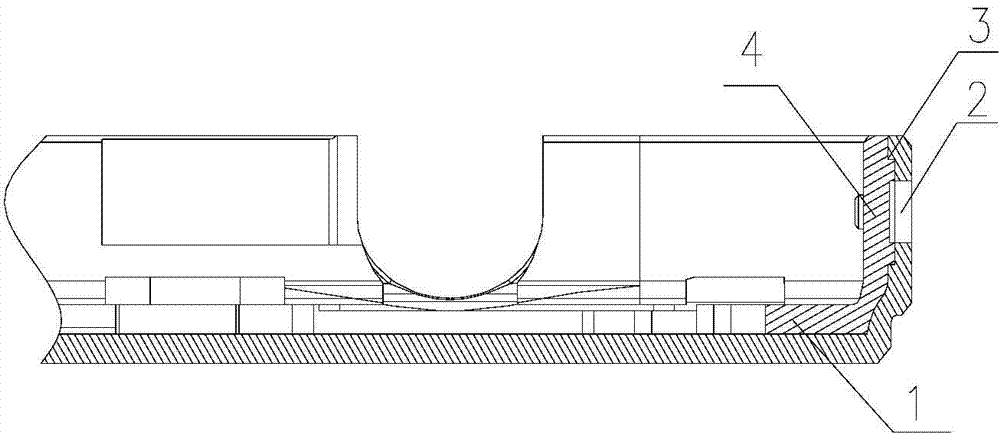

Method for machining through hole in highlighted side of mobile phone shell and mobile phone

ActiveCN104493443AEnhance internal supportReduce wear and tearTelephone set constructionsEngineeringMobile phone

The invention relates to the technical field of electronic equipment, in particular to a method for machining a through hole in a highlighted side of a mobile phone shell. The method comprises the following steps: when the highlighted side is milled around the through hole, forming a blind hole at a position where the through hole is required to be formed, and after the highlighted side is milled, machining the blind hole into the through hole according to a set size, wherein the blind hole is a part of the through hole required to be formed. The invention further provides a mobile phone. A shell of the mobile phone is manufactured by the method. Before the highlighted side is milled, the blind hole is preformed at the position where the through hole is required to be formed so as to improve an internal supporting force of the shell when the highlighted side is milled; by the method, the production efficiency and the product quality are improved; the method is simple and convenient to operate; in the method, a fixture is not used, so that a knife shaking problem is solved, wear and pressure damage of the fixture to a side hole of a product are reduced and the production yield is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

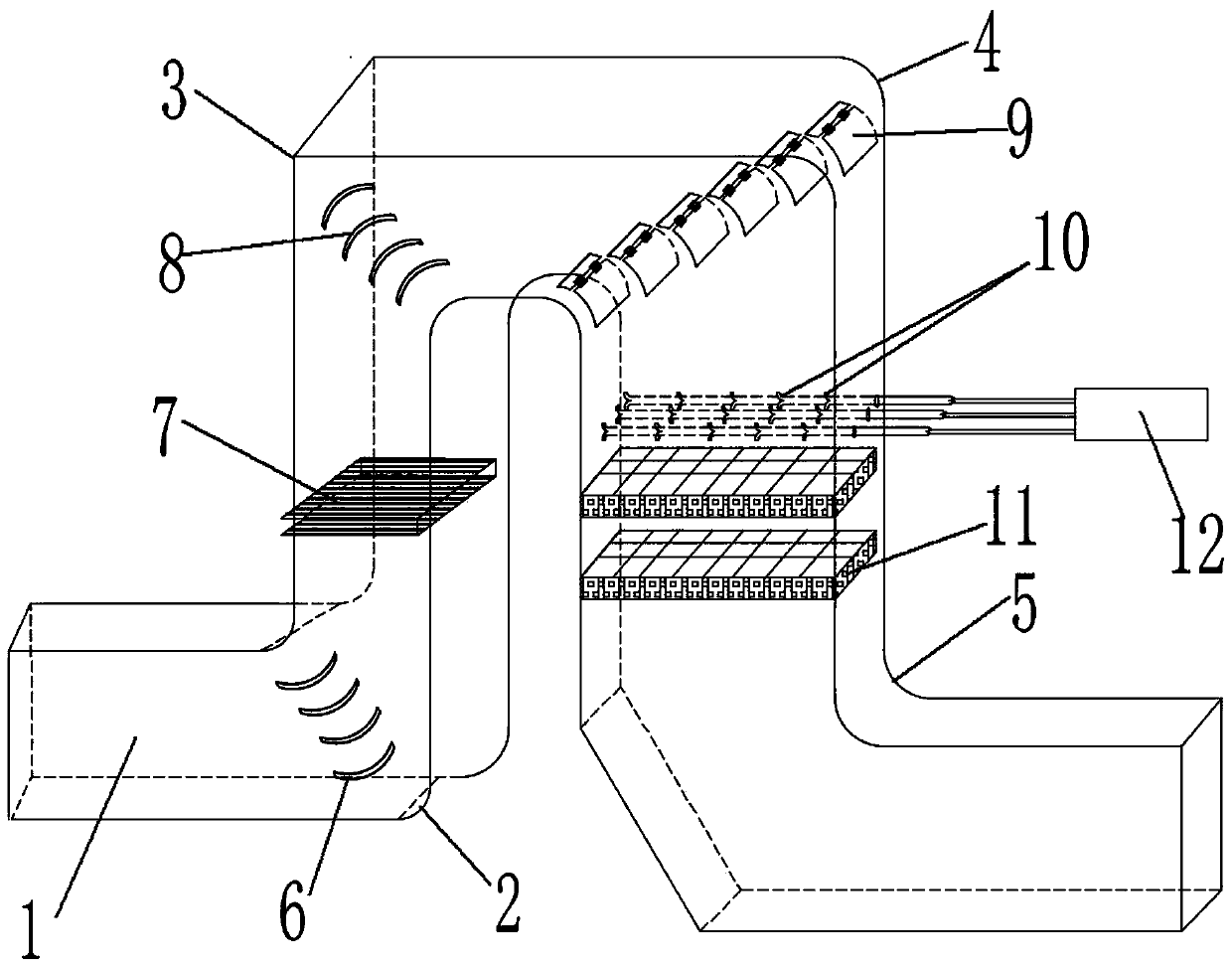

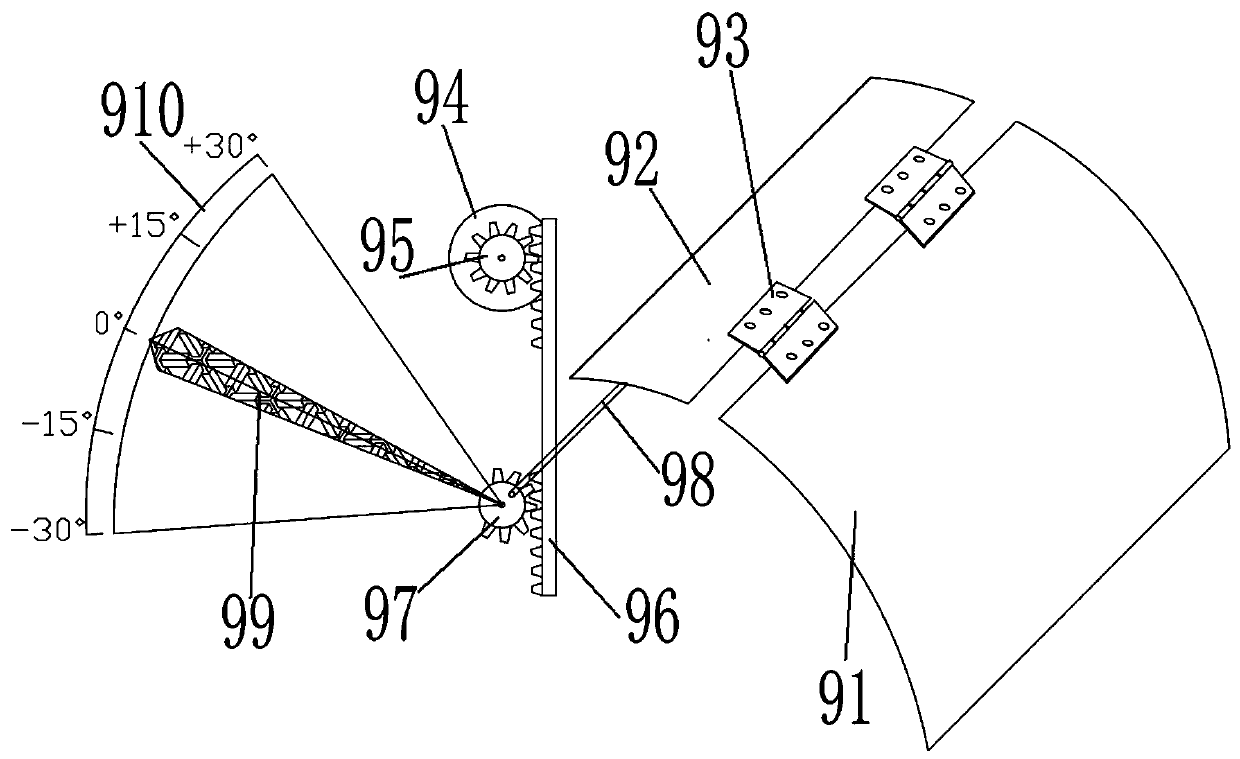

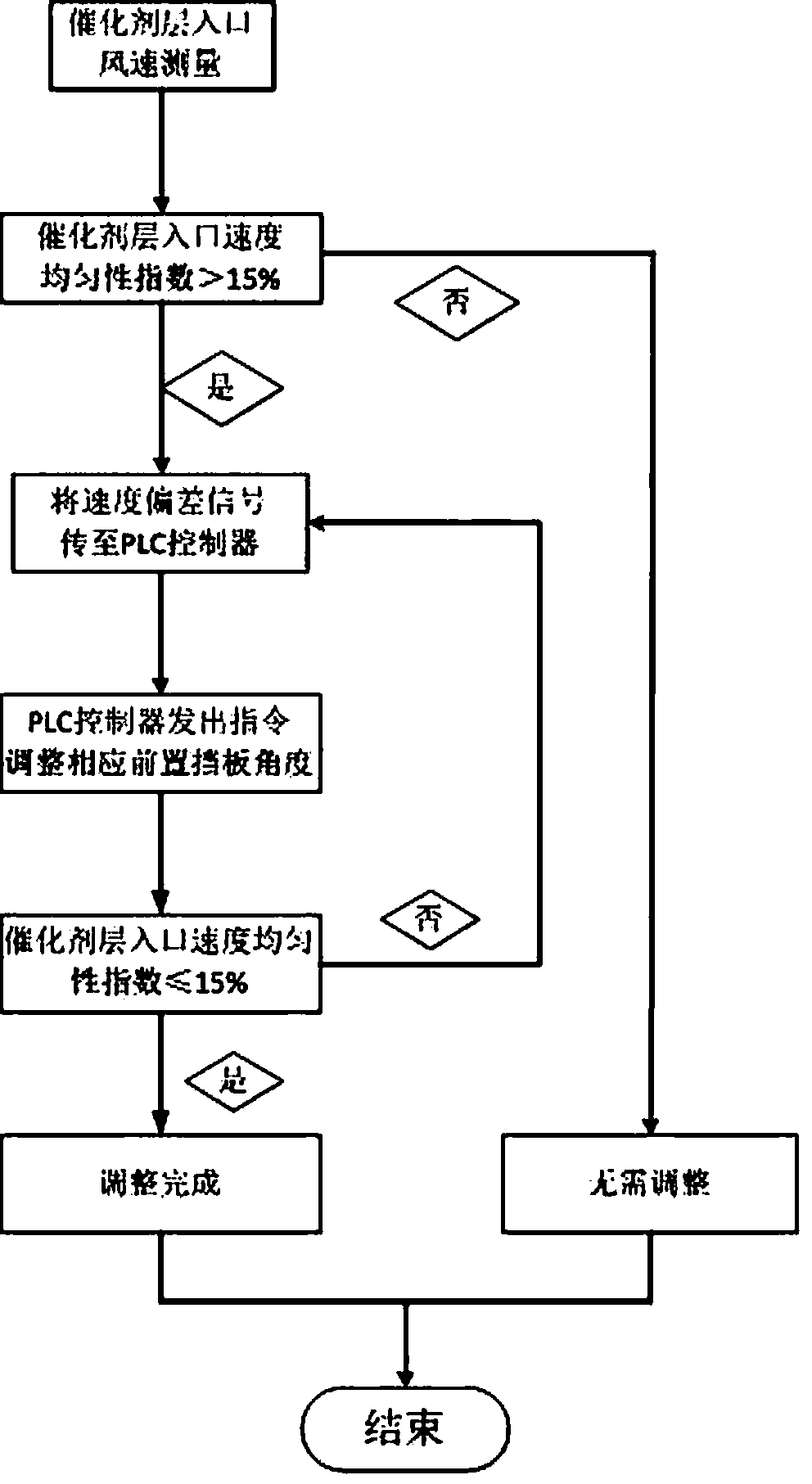

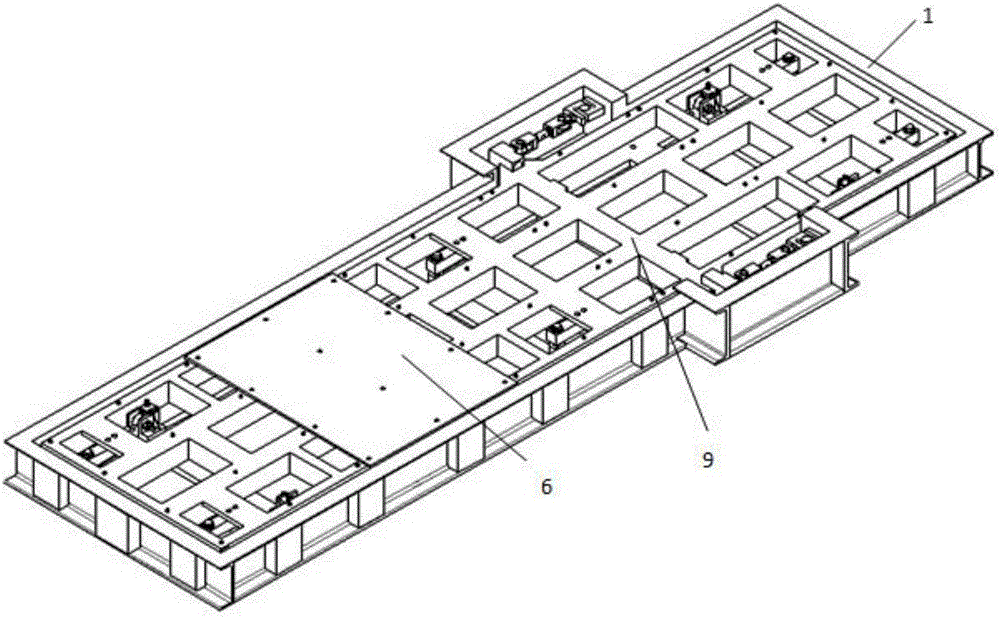

System and method for improving uniformity of selective catalytic reduction (SCR) flow field

ActiveCN107198964AIncrease the circulation areaReduce cloggingGas treatmentDispersed particle separationFlue gasDifferential pressure

The invention relates to a system and a method for improving the uniformity of a selective catalytic reduction (SCR) flow field. The system comprises a flue, a plurality of circular arc-shaped primary guide plates, a plurality of circular arc-shaped secondary guide plates, an ammonia injection grid, N tertiary guide plates, a plurality of catalyst layers, and M sets of differential pressure measurement components which are horizontally arranged along the width direction of the flue and are positioned between the catalyst layers and the tertiary guide plates, wherein each set of differential pressure measurement component is evenly provided with N differential pressure detection devices arranged at intervals along the depth direction of the flue. The system and the method can improve the flue gas flow field in front of the catalyst layers, guarantees the speed uniformity of an SCR system, and effectively reduces the phenomenon that the catalyst layers are blocked or worn.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

High-precision flat plate-type brake test bench

InactiveCN106053097AImprove test accuracyThe test result is accurateVehicle testingChinese charactersEngineering

The invention provides a high-precision flat plate-type brake test bench, which is composed of a supporting frame, a brake soleplate, a bearing frame, brake force detection mechanisms, a wheel weight detection mechanism and a guide limiting mechanism, wherein two sides of the supporting frame are symmetrically provided with two grooves, the notch of each groove faces inwardly, and thus, the supporting frame presents a symmetrical structure in a shape like a Chinese character zhong; the bearing frame is arranged at the inner side of the supporting frame; the brake soleplate is fixedly arranged above the bearing frame; two groups of brake force detection mechanisms are symmetrically arranged in the grooves at two sides of the supporting frame; the wheel weight detection mechanism is located between the bearing frame and the bottom plate of the supporting frame; and the guide limiting mechanism is connected with the bearing frame and the supporting frame. The technical scheme of the invention can effectively improve defects existing in aspects such as the overall frame structure of the traditional flat plate-type brake test bench and the wheel brake equivalent transfer and brake force acquisition, and the brake force detection precision of the flat plate-type brake test bench is improved.

Owner:JILIN UNIV

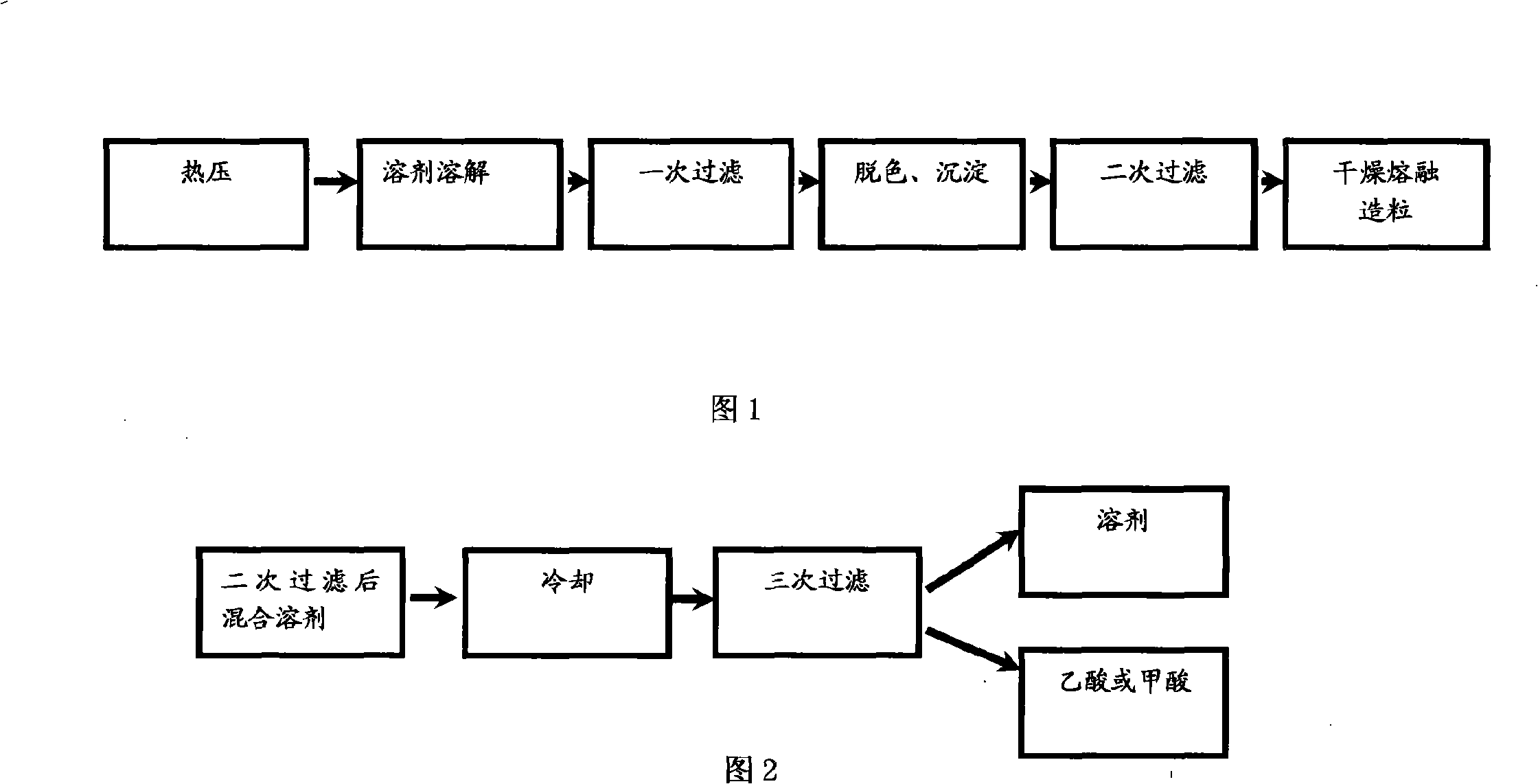

Novel method for recovering waste and old polystyrol

The invention discloses a novel technology for recycling waste polystyrene with low cost. The technology is as follows: low-temperature hot pressing is performed on the waste polystyrene; the waste polystyrene is dissolved in good solvent of polystyrene; insoluble impurities are primarily filtered and removed; decolorization is performed; precipitator is added for precipitation; secondary filtration is performed and other technological processes; the waste polystyrene is reclaimed and polystyrene granules are regenerated; simultaneously, micro nucleating agent is added by the means of low-temperature cooling to realize high-efficiency separation of the solvent and the polystyrene precipitator, and the polystyrene granules are reclaimed; and the reclaimed granules can be used for continuous production of polystyrene downstream products. The technology can highly efficiently realize effective separation of the solvent and the precipitator, thereby greatly improving the quality of polystyrene reclaimed by adoption of the technology and the solvent recovery rate, and greatly reducing the polystyrene cost of recovering the polystyrene. The technology has the advantages of short technological flow, high production efficiency, low solvent consumption, high product quality, low energy consumption, no secondary pollution caused, environmental protection and so on, and has important industrial application value.

Owner:KUNMING UNIV OF SCI & TECH

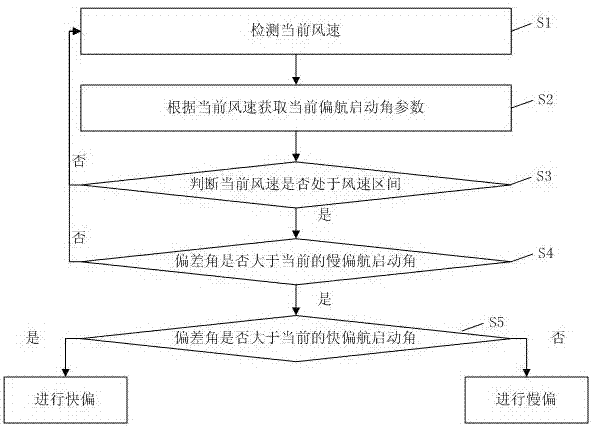

Wind alignment method and wind alignment system of wind generator yaw system

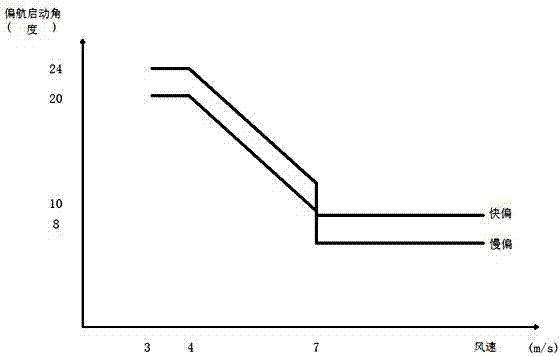

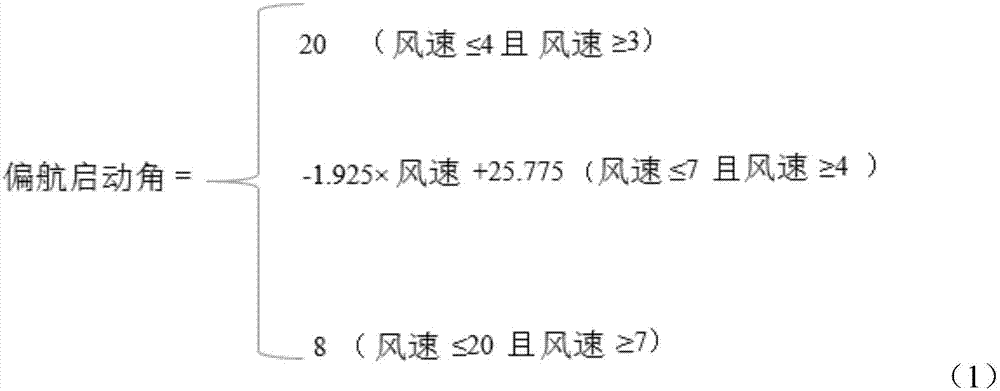

InactiveCN107061161AIncrease power generationReduce the frequency of movementsWind motor controlMachines/enginesAir velocityGear wheel

The invention discloses a wind alignment method of a wind generator yaw system. The method comprises the steps that a current yaw starting angle parameter is obtained through current wind speed according to the functional relationship between the wind speed and a yaw starting angle by a yaw system; and when a deviation angle between a wind generator bin and the wind direction is judged to be larger than the current yaw starting angle by the yaw system, the yaw system controls the wind generator bin to yaw. According to the wind alignment method, the yaw starting angle is set according to the current wind speed, so that yaw starting control is more precise; the action frequency of the yaw system is effectively lowered; abrasion of yaw gears is reduced; yaw fatigue is alleviated; and the generation capacity of the wind generator is improved.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

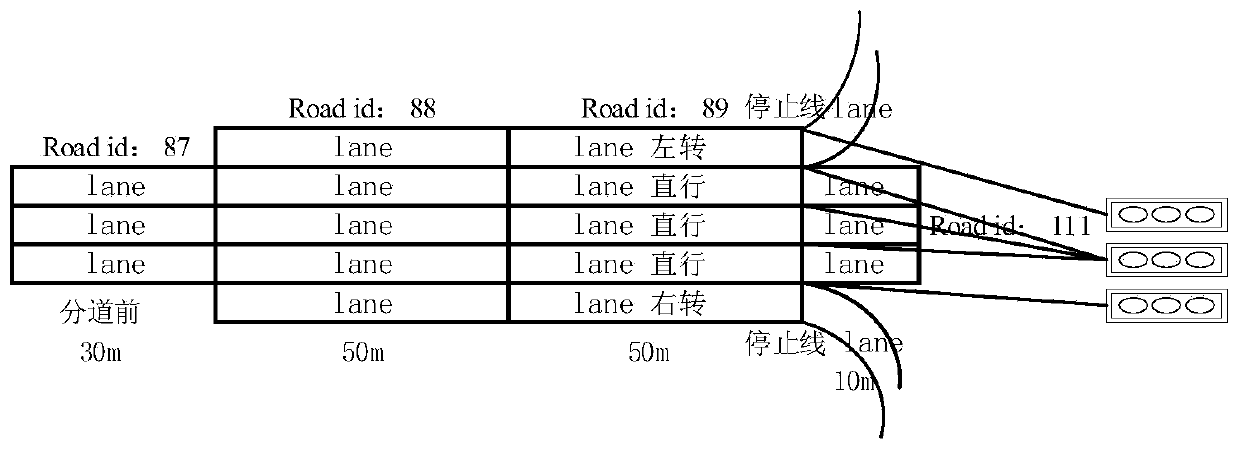

Real-time traffic light identification method

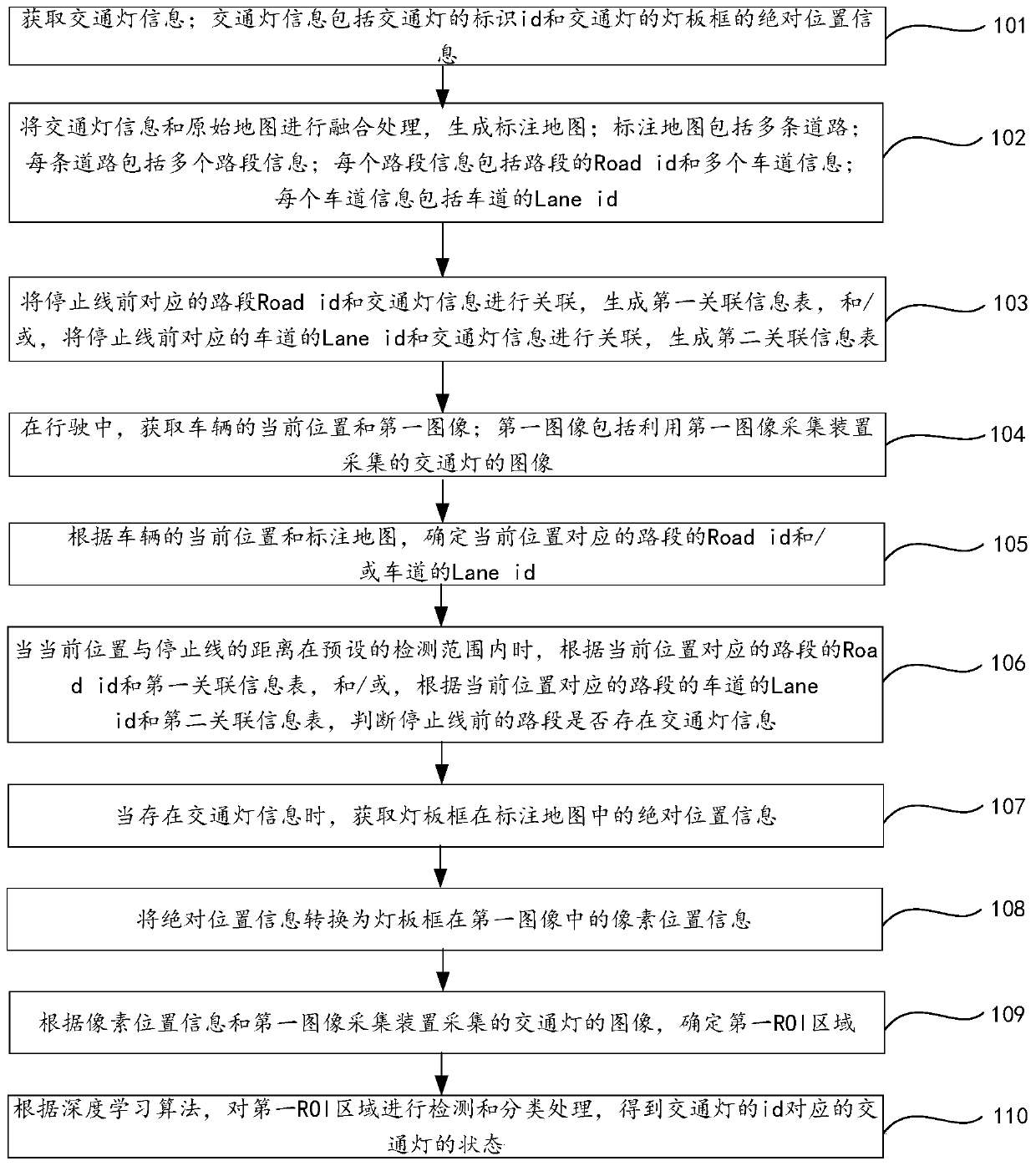

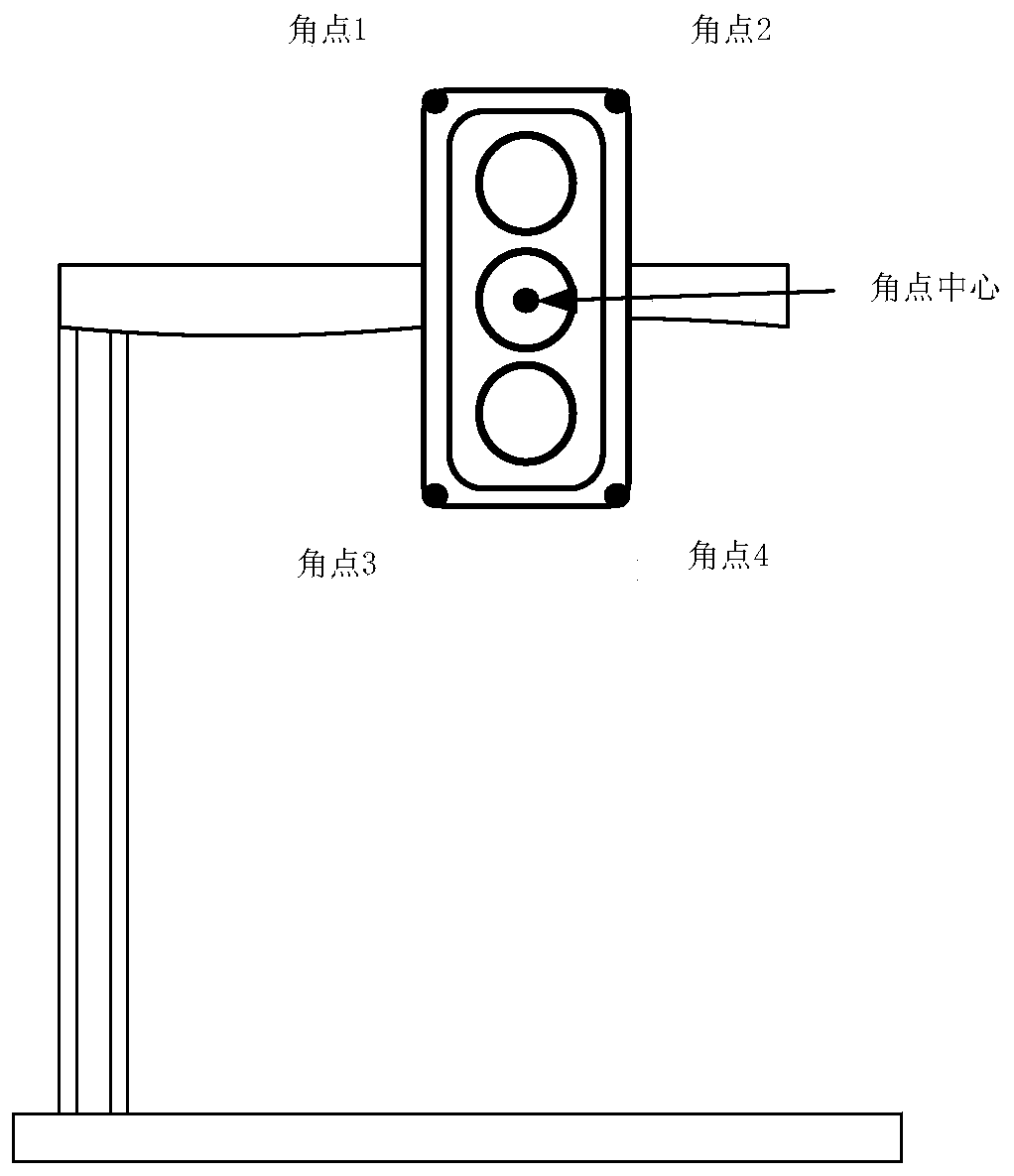

ActiveCN109949594AMeet detectionMeet the distanceRoad vehicles traffic controlCharacter and pattern recognitionVisual perceptionVisual identification

The invention provides a real-time traffic light identification method. The method comprises following steps: acquiring traffic light information, and performing fusion processing on the traffic lightinformation and an original map to generate a marked map; associating the traffic light information with Road id of a corresponding road section and Lane id of a lane in front of a stop line respectively, and generating a first associated information table and / or a second associated information table; determining Road id of the road section and / or Lane id of the lane according to the current position of a vehicle and the marked map; judging whether the traffic light information exists in the road section in front of the stop line when distance between the vehicle and the stop line is in a preset range according to Road id of the road section and the first associated information table and / or Lane id of the lane and the second associated information table, and acquiring absolute position information of a light plate frame in the marked map and converting the absolute position information into pixel position information in a first image when the traffic light information exists; detecting and classifying a first ROI (region of interest) with a deep learning algorithm to obtain a traffic light state corresponding to id of a traffic light. Therefore, precision and speed of visual identification are increased.

Owner:BEIJING ZHIXINGZHE TECH CO LTD

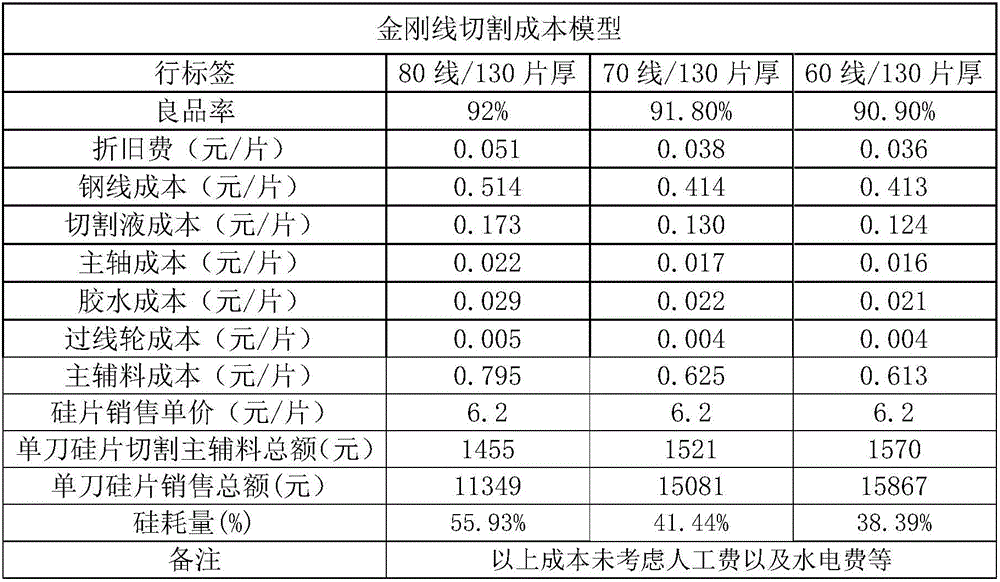

Method for cutting ultra-thin silicon wafer by superfine steel wire

The invention relates to a method for cutting ultra-thin silicon wafer by a superfine steel wire. The method comprises the following steps of: (1) forming slots in a man shaft; (2) sticking bars; (3) preparing a cooling liquid; (4) cutting; (5) unloading; (6) degumming and cleaning; and (7) detecting; the cooling liquid prepared in the step (3) is pure water and a water-based cutting fluid with concentration being 0.6%-2.0%; and during cutting in the step (4), cutting steel wires are 60 [mu]m diamond wires, diamond particles are particles with diameter being 6-8 [mu]m, tension is set to be 7-9 N, and slot pitch of the main shaft is 0.19-0.210 mm. According to the method, single crystal slicing yield is further reduced, slicing thickness is reduced, silicon loss is reduced and processing cost is reduced; and meanwhile, a wire braking rate can be reduced, yield is increased, and wire doubling is avoided.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD

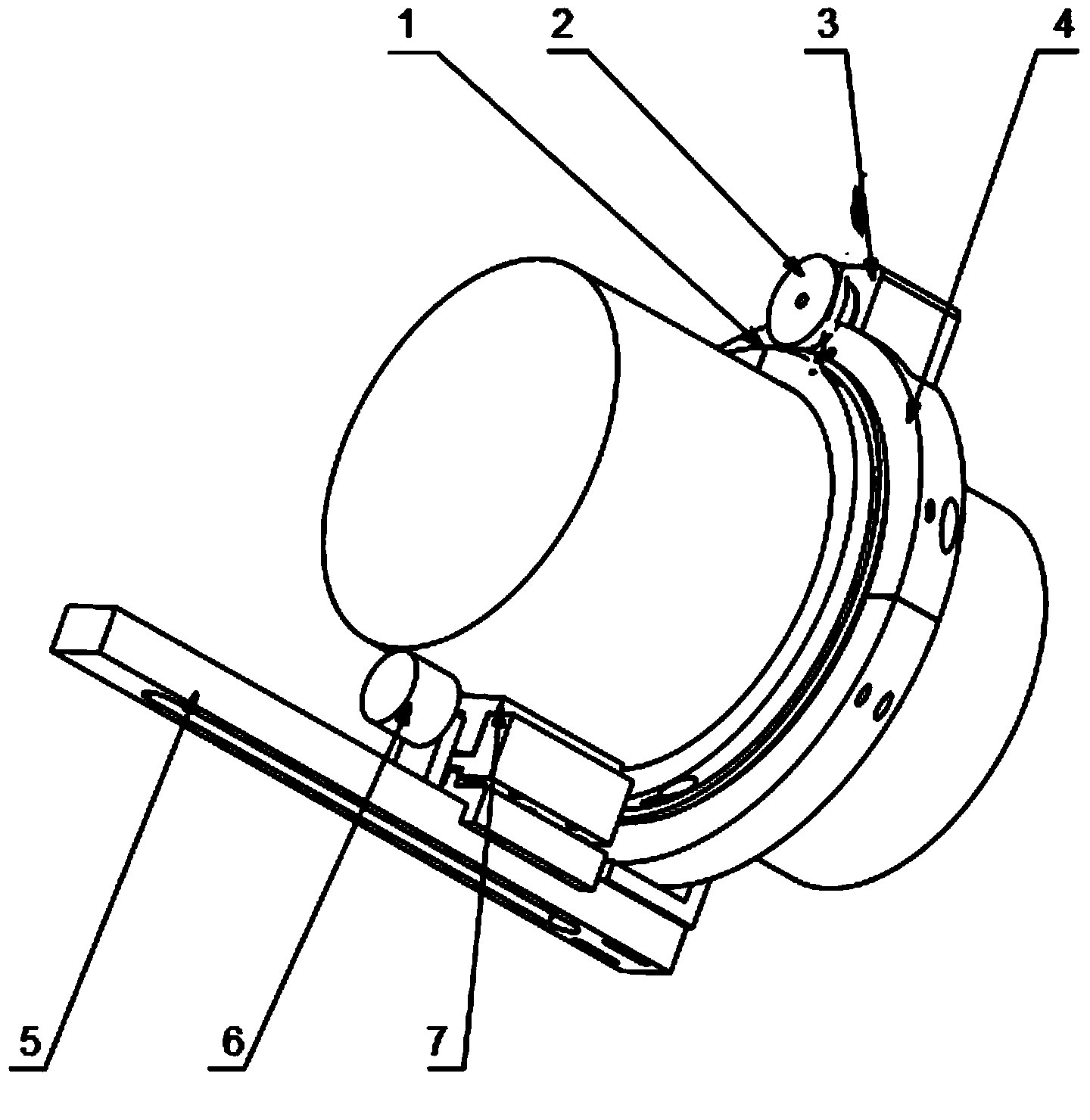

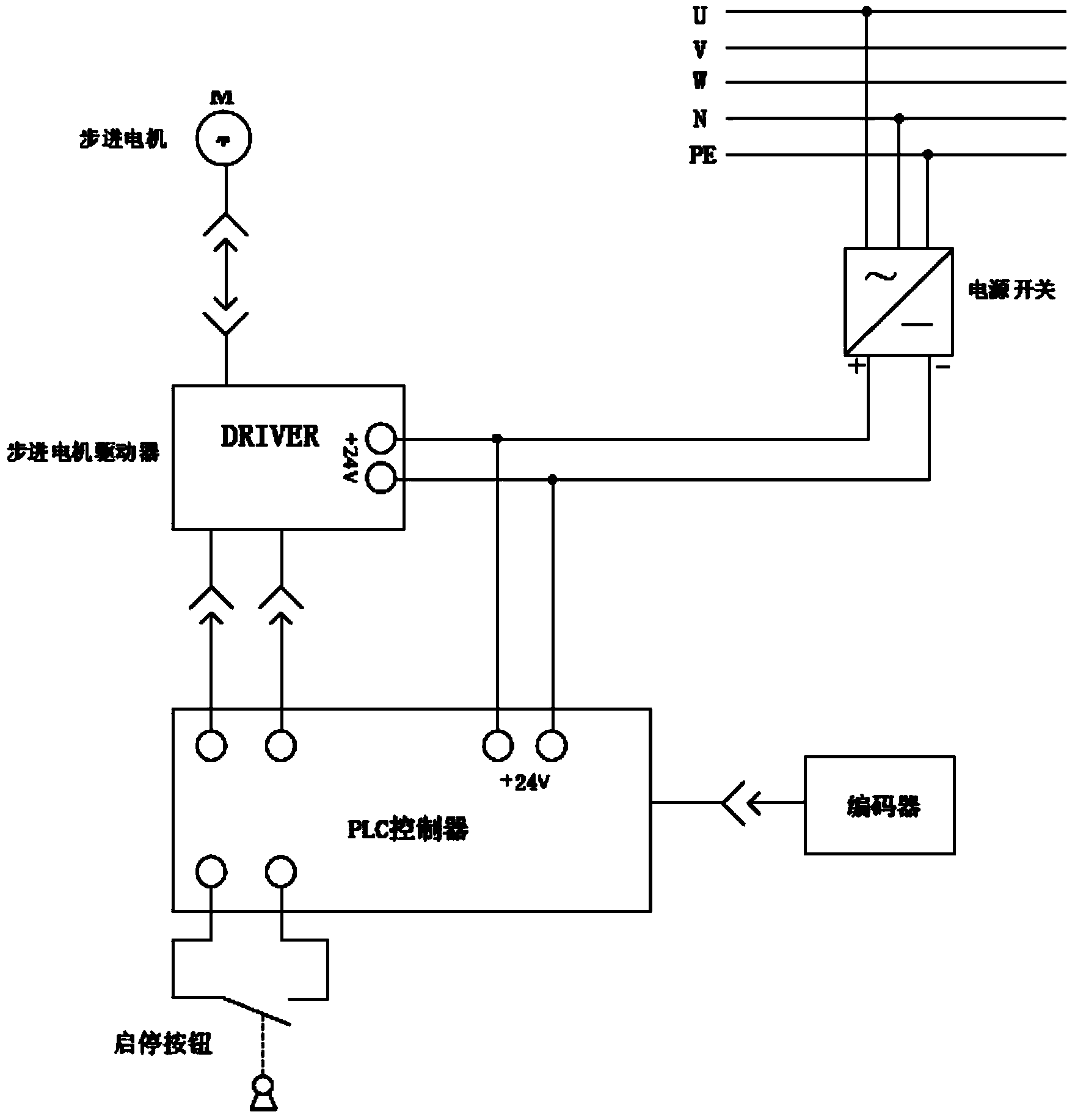

Device and method for automatic circumferential ultrasonic detection of joint of polyolefin composite tube

ActiveCN103512954ASolve the problem of too weak echoReduce wear and tearAnalysing solids using sonic/ultrasonic/infrasonic wavesPolyolefinEngineering

The invention relates to the field of ultrasonic detection of an electric welded joint and aims at providing a device and a method for automatic circumferential ultrasonic detection of a joint of a polyolefin composite tube. The automatic circumferential ultrasonic detection device comprises an ultrasonic detection instrument, a probe, a probe clamping device, an encoder, an inner clamp, an outer clamp, a small gear, a stepping motor and a control module; the method is used for detecting the joint of the to-be-detected tube, and finally a C-scanning image is formed through the ultrasonic detection instrument and displayed. According to the invention, a phased array focusing technology is adopted to solve the problem of too weak echo caused by excessive acoustic attenuation; a special coupling agent is chosen, so that the loss of interface sound transmission is minimized or even no loss is produced during the detection conducted with a contact method, and a special scanning device is developed to form the real-time C-scanning image.

Owner:ZHEJIANG UNIV

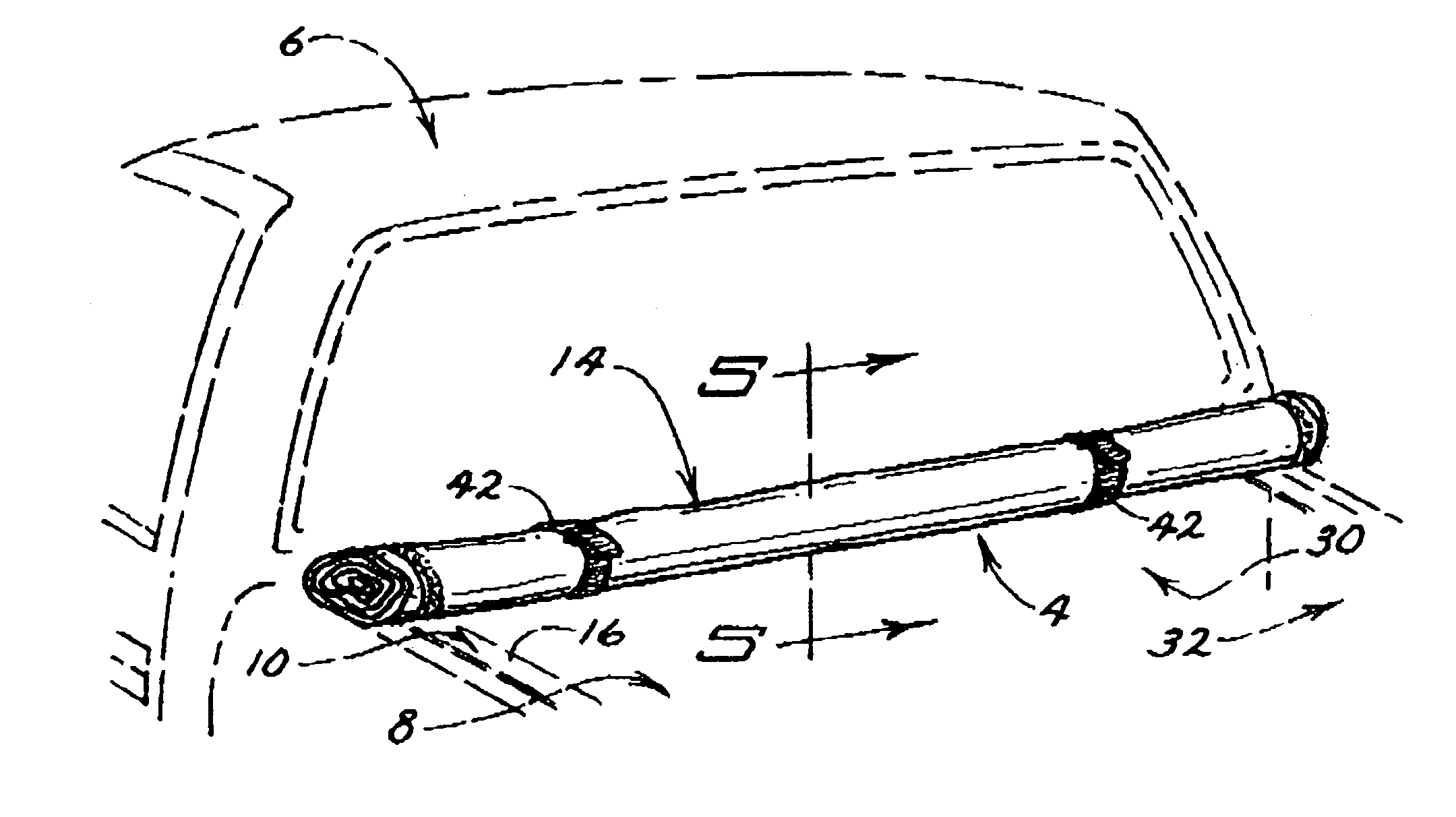

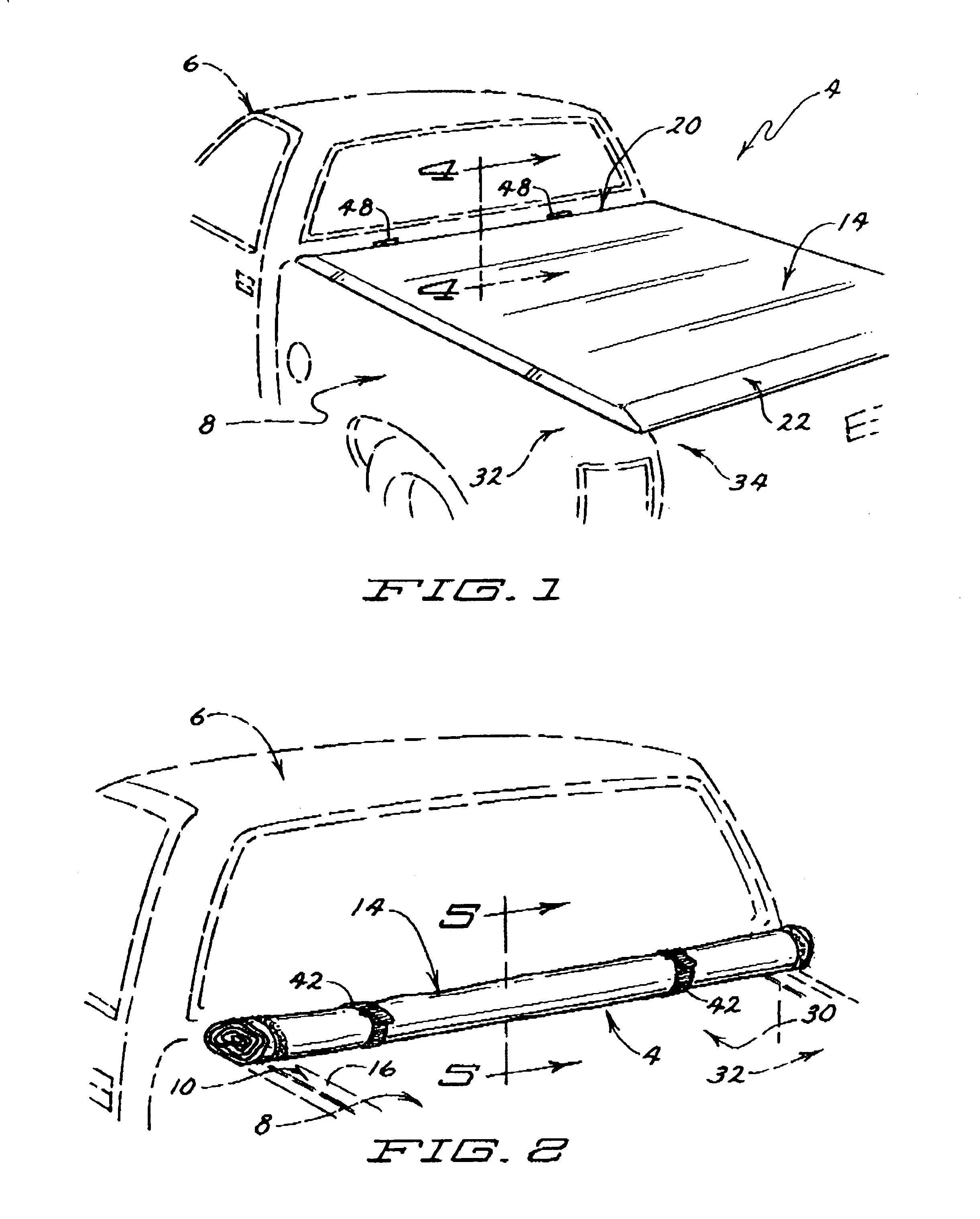

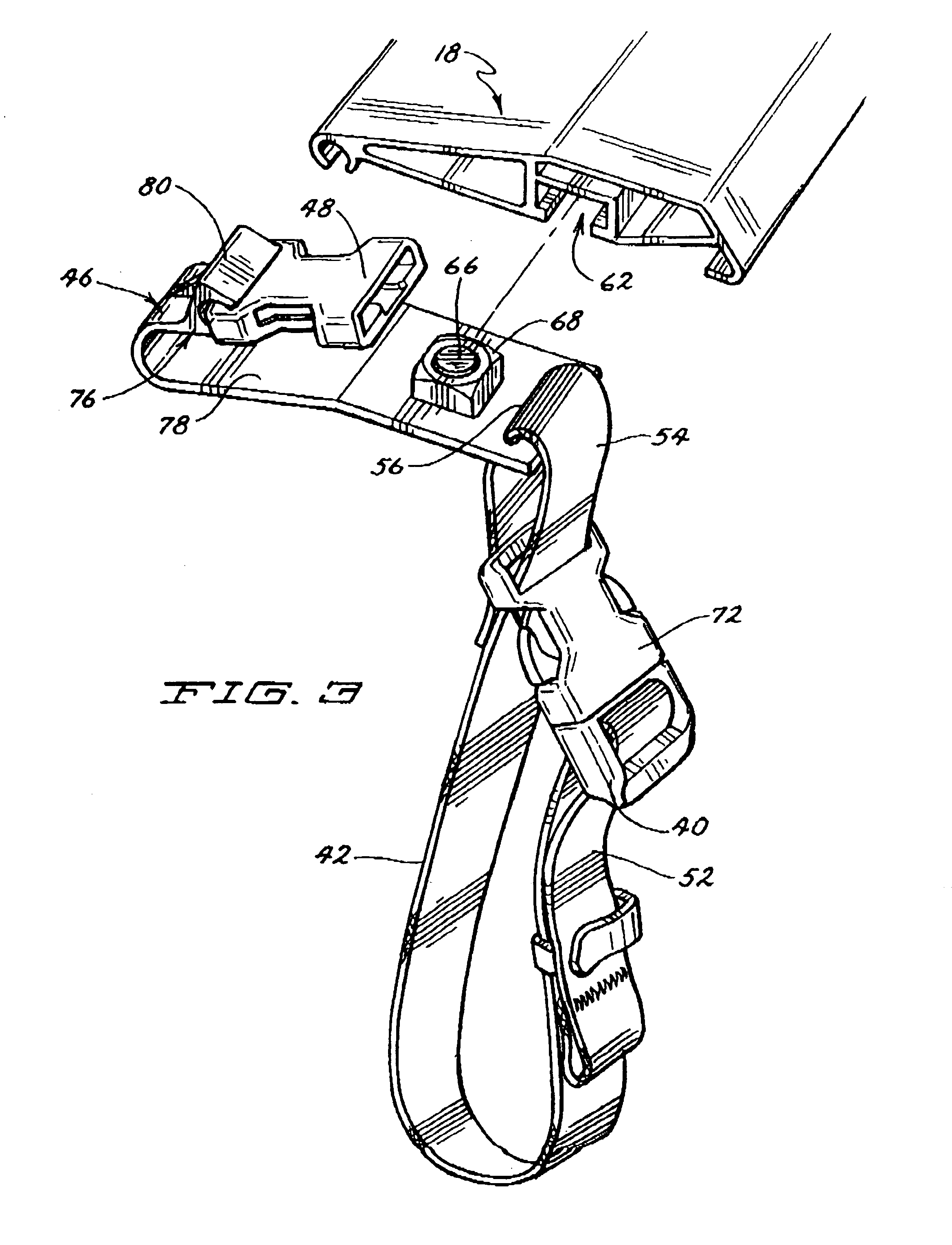

Strap bracket for soft roll-up covers

A Strap Assembly for a tonneau cover and a tonneau cover apparatus including a strap assembly. The apparatus preferably includes, a flexible cover, the flexible cover having first and second ends; a support frame for attachment to a cargo box of a pick-up truck; the support frame having a front bar to which the first end of the flexible cover is secured. The strap assembly includes a strap bracket; and a buckle insertion member; a strap to secure the flexible cover in a rolled up configuration proximate the front bar when the flexible cover is not in use to cover an opening defined by the perimeter of the cargo box. The strap has first and second ends; the buckle insertion member being secured to the first end of the strap; and a strap bracket attached to the front bar. The strap bracket includes a buckle insertion receiving member and a strap receiving opening. The buckle insertion receiving member resists movement forward of the front bar of a rolled up segment of the flexible cover, when the rolled up segment is secured to the front bar by the strap when the buckle insertion member is secured to the buckle insertion receiving member and support frame is secured to the cargo box.

Owner:AGRI COVER

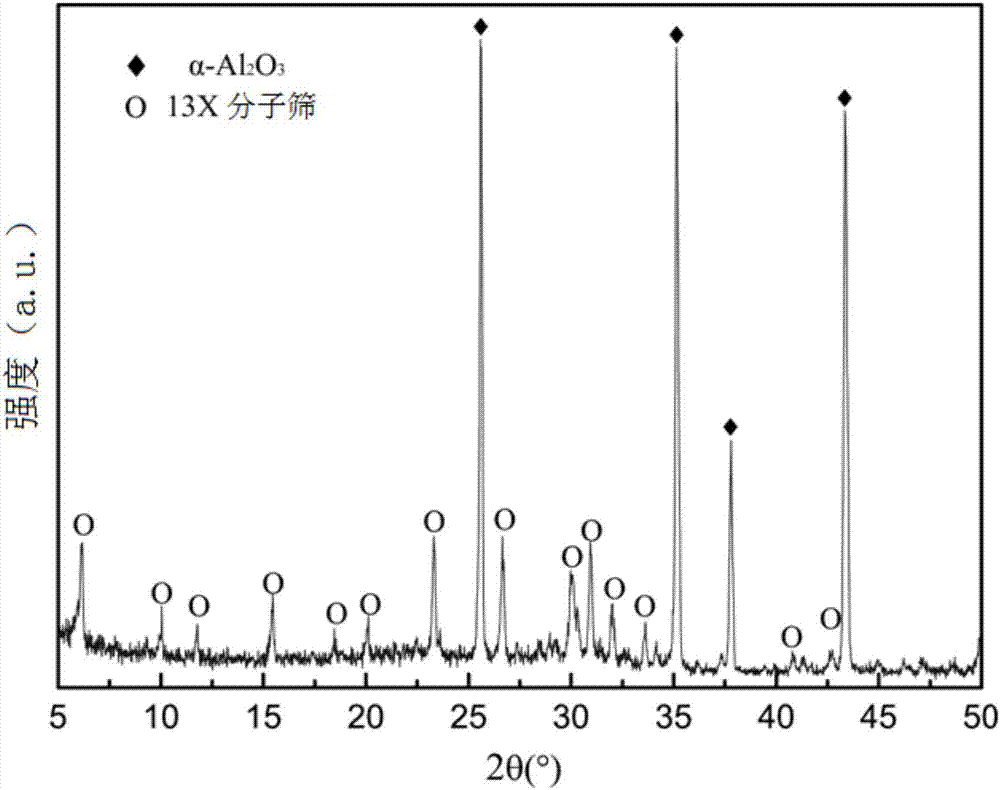

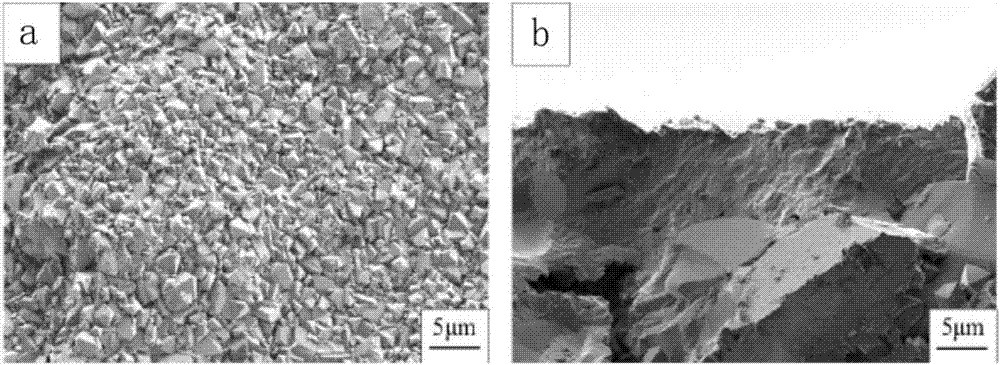

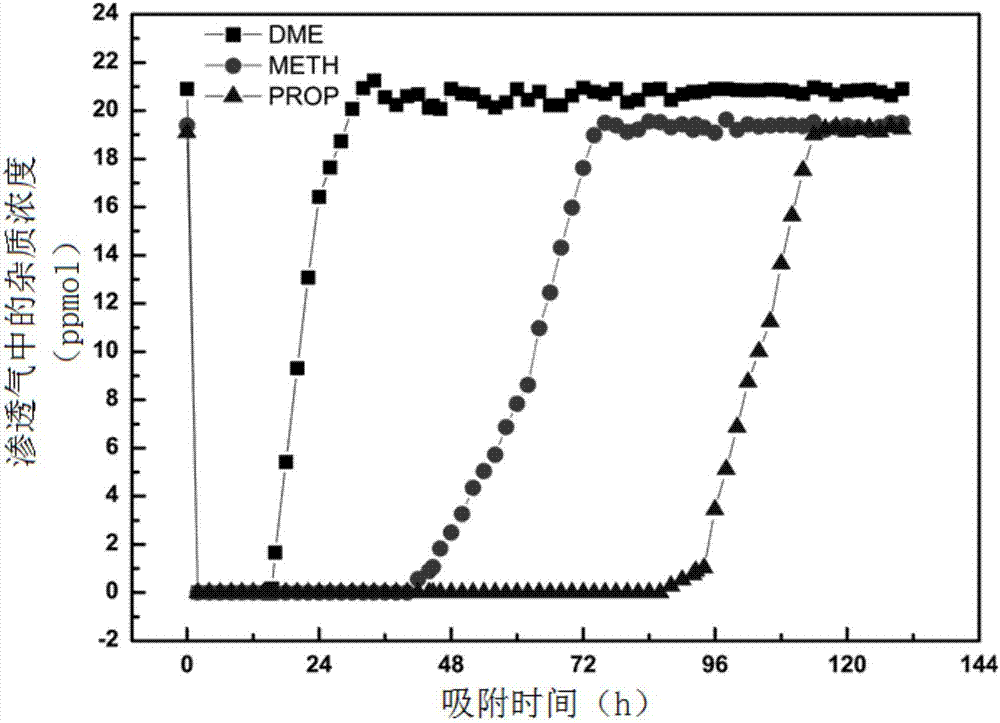

Molecular sieve ceramic membrane material for olefin purification as well as preparation method and application of molecular sieve ceramic membrane material

ActiveCN107970781AReduce mass transfer resistanceReduce energy consumptionSemi-permeable membranesOther chemical processesMolecular sieveBonding strength

The invention relates to a molecular sieve ceramic membrane material for olefin purification as well as a preparation method and application of the molecular sieve ceramic membrane material. In the molecular sieve ceramic membrane material, the particle sizes of molecular sieve particles supported on the surface of the ceramic material are 0.1-3 [mu]m, and the thickness of a molecular sieve layeris 3-5 [mu]m; during preparation, ceramic material pretreatment, molecular sieve seed crystal pre-coating and sealed crystallization are sequentially carried out; and the molecular sieve ceramic membrane material is used for removing a polar oxygenated compound in a gaseous olefin flow to be 1ppm or below. Compared with the prior art, the molecular sieve ceramic membrane material prepared by the preparation method of the invention has the molecular sieve layer with higher mechanical strength, larger specific surface area and uniform thickness, in addition, the molecular sieve layer has no longitudinal or horizontal cracks, has no air pores in the surface and is high in bonding strength and not easy to fall off; and when the polar oxygenated compound in the olefin flow is adsorbed, the purification depth is 1ppm or smaller, so that not only is the mass transfer resistance lower, but also the energy consumption is lower, and the regeneration capacity is high.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

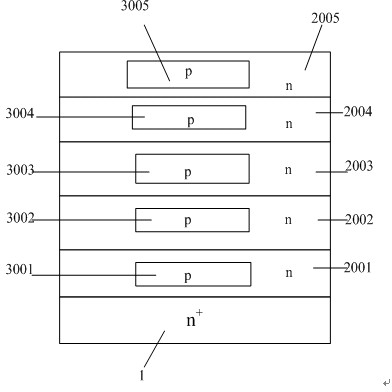

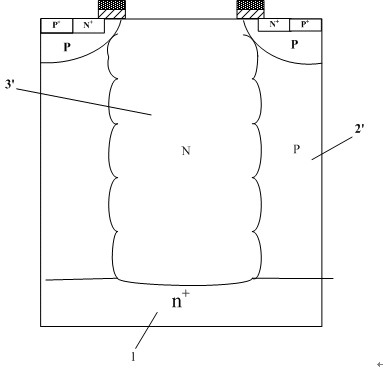

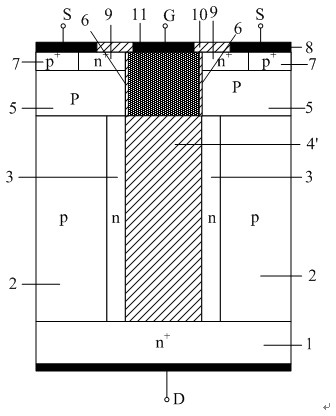

Methods for manufacturing superjunction structure and superjunction semiconductor device

InactiveCN102148163AImprove pressure resistanceImprove performanceSemiconductor/solid-state device manufacturingDielectricCapacitance

The invention discloses methods for manufacturing a superjunction structure and a superjunction semiconductor device. A novel semiconductor superjunction and a superjunction device are formed by the key process steps of etching a trench, performing ion implantation at a small inclination angle, filling an insulating dielectric and planarizing, forming an active layer and an electrode and the like. Compared with the prior art, the methods have the advantages that: firstly, a method of forming the superjunction by using a plurality of epitaxy processes and a plurality of implantation processes is prevented from being used; secondly, the bottom of a trench gate can be guaranteed to be flush with or slightly lower than the lower boundary of a body region, so that withstand voltage of the device is improved, and gate-source capacitance and gate-drain capacitance are reduced; thirdly, since the depth of the trench is reduced, the process difficulty of the small-angle implantation is reduced, the process tolerance is increased, and the dielectric in the extended trench is easier to fill and planarize; fourthly, a complex mask is not required, so that the influence of small-angle implantation on a trench region is avoided; and fifthly, the adverse effects of the filling and the planarizing of the extended trench and the manufacturing and the planarizing of the trench gate on the formed body region, body contact region and source region are avoided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

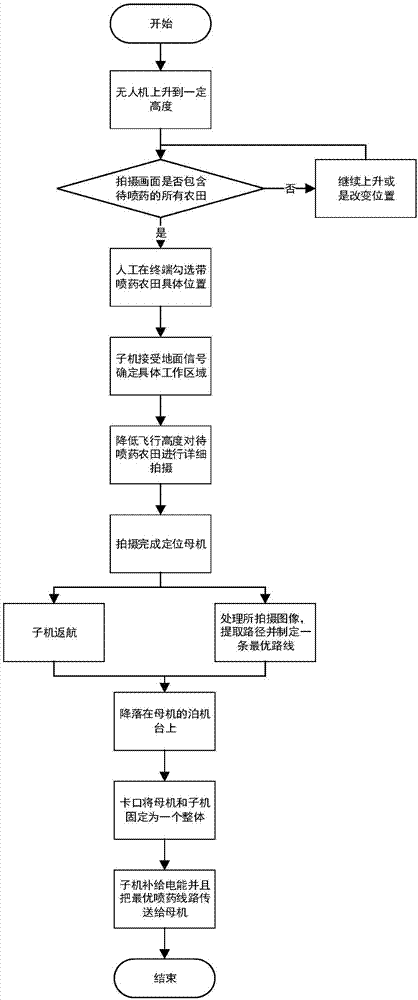

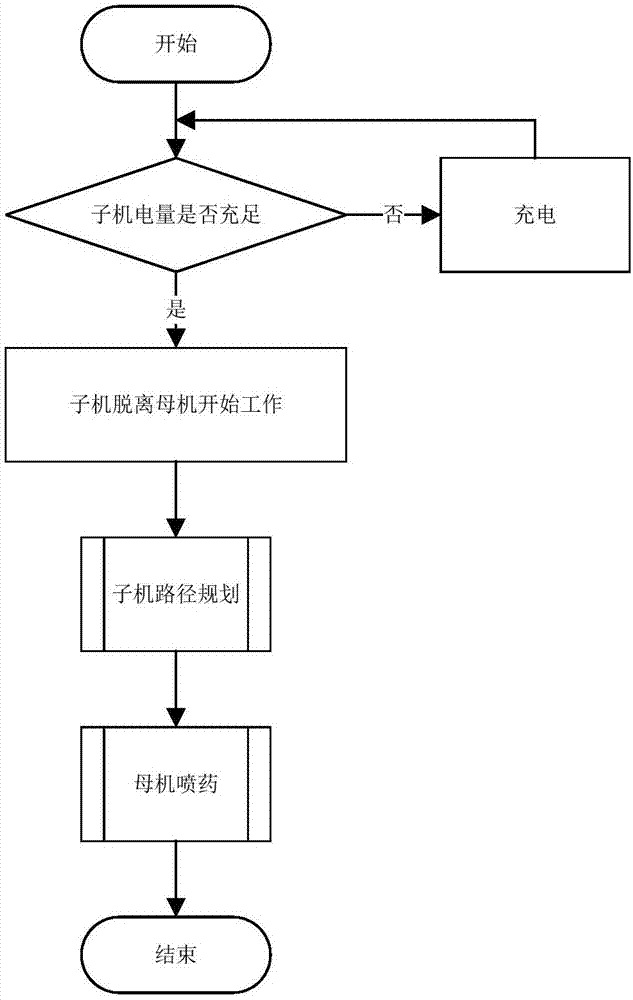

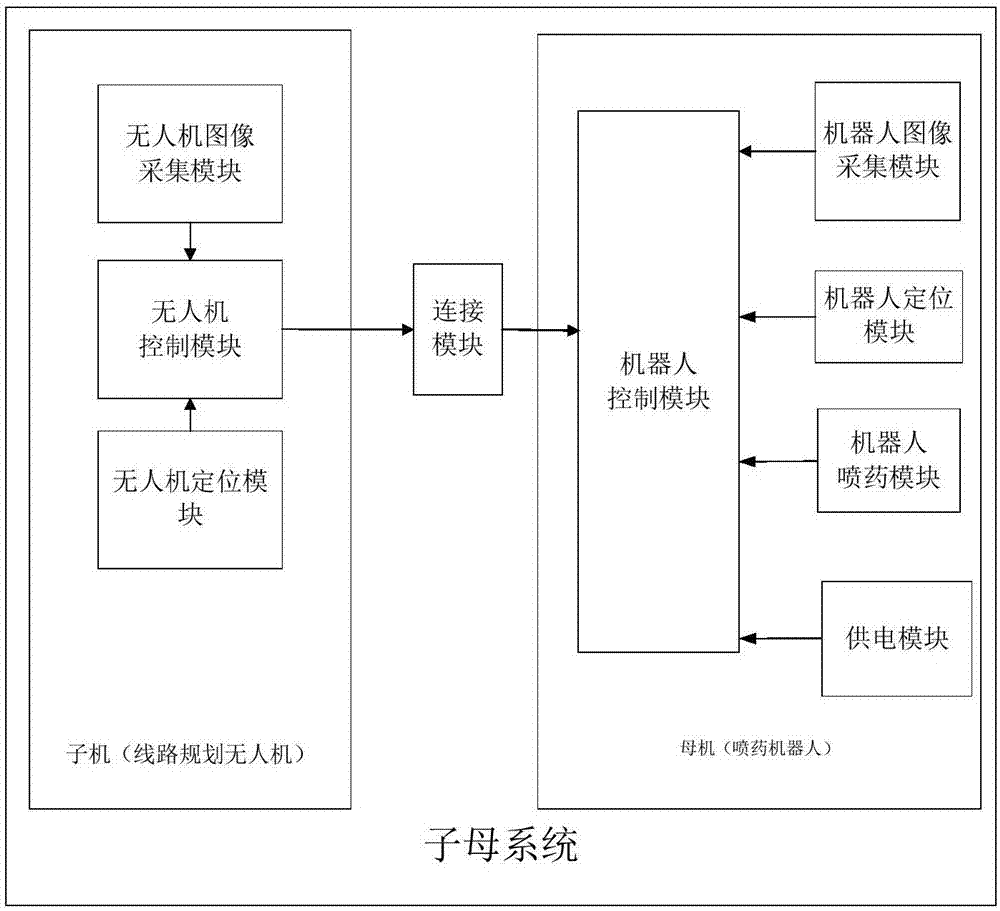

Pesticide spraying system and method based on child-mother system

ActiveCN107272739AReduce wear and tearPrecision SprayingPosition/course control in three dimensionsRobot controlCrop protection

The invention discloses a pesticide spraying system and a method based on a child-mother system. Crop protection is implemented by a child-mother system composed of a pesticide spraying robot and a route planning unmanned aerial vehicle (UAV). A UAV image acquisition module acquires a farmland image, and sends the farmland image to a UAV control module. The UAV control module generates an optimal pesticide spraying route according to the farmland image, and sends the optimal pesticide spraying route to a robot control module. After the robot control module makes the robot move to near a farmland area needing pesticide spraying according to the optimal pesticide spraying route, a robot image acquisition module acquires an image of crops around, identifies a part of crops needing pesticide spraying, and sends the part to the robot control module. The robot control module makes a mechanical arm move to the part of crops needing pesticide spraying, makes the nozzle aligned with the part of crops needing pesticide spraying and starts spraying pesticide. Through intelligent route planning by the UAV, the consumption of pesticide, power and the like in the working process of the robot is minimized.

Owner:XIANGTAN UNIV

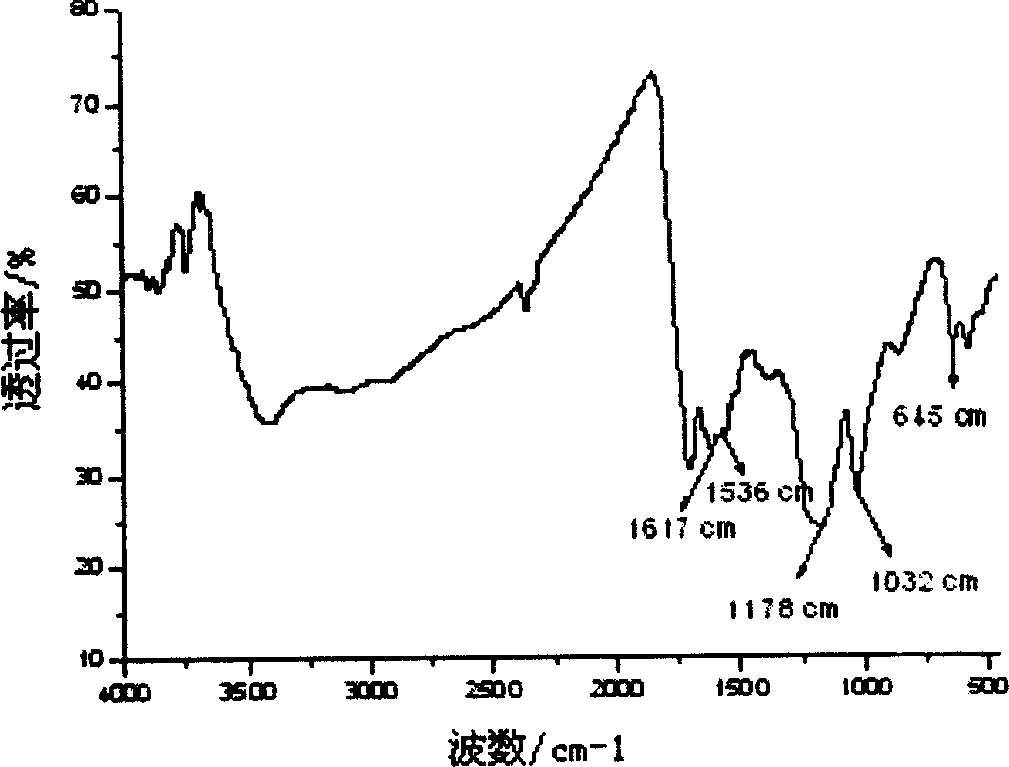

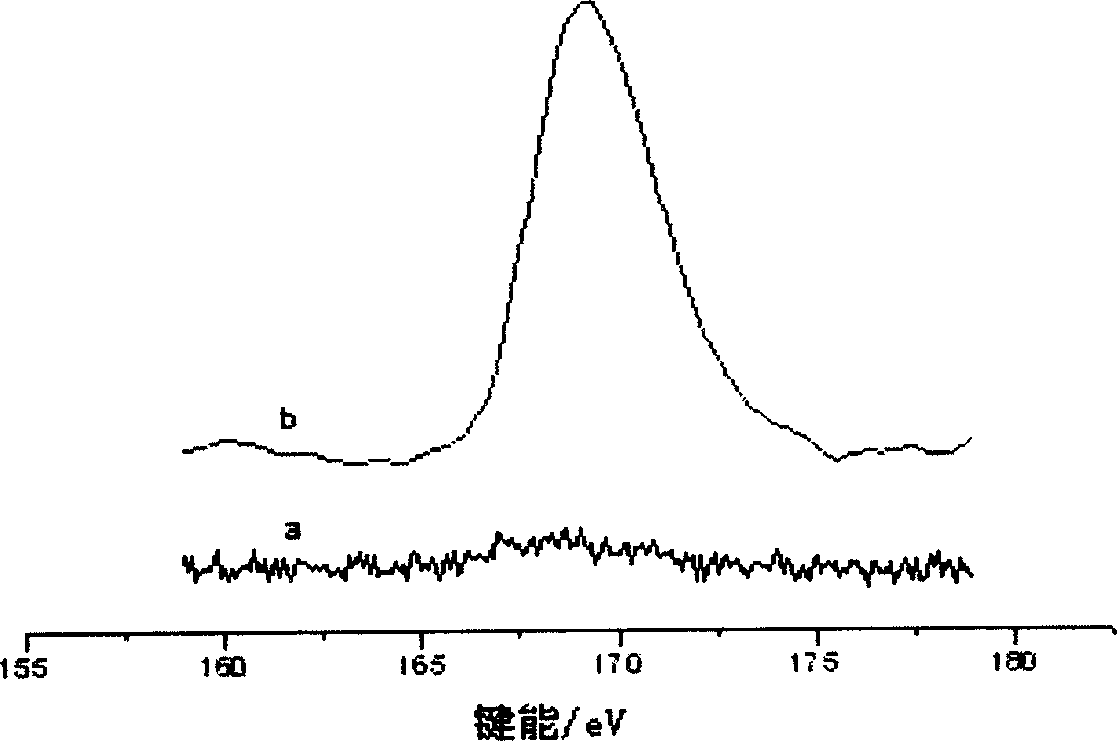

Method for preparing solid sulfonic acid from reproducible vegetable material

InactiveCN1915507AReduce wear and tearReduce energy consumptionPhysical/chemical process catalystsCelluloseResource utilization

A process for preparing solid sulfonic acid from the regeneratable vegetative raw material, such as wood bits and bamboobits, includes such steps as drying the vegetative raw material containing cellulose and lignin, breaking, proportionally mixing it with sulfuric acid, stirring at 40-200 deg.C for 1-20 hr, cooling, washing with deionized water until it becomes neutral, baking, proportionally adding sulfonating agent, sulfonating at 30-150 deg.C for 1-20 hr, cooling, washing with deionized water until it becomes neutral, testing no deposition in BaCl2 solution, and baking.

Owner:HUNAN NORMAL UNIVERSITY

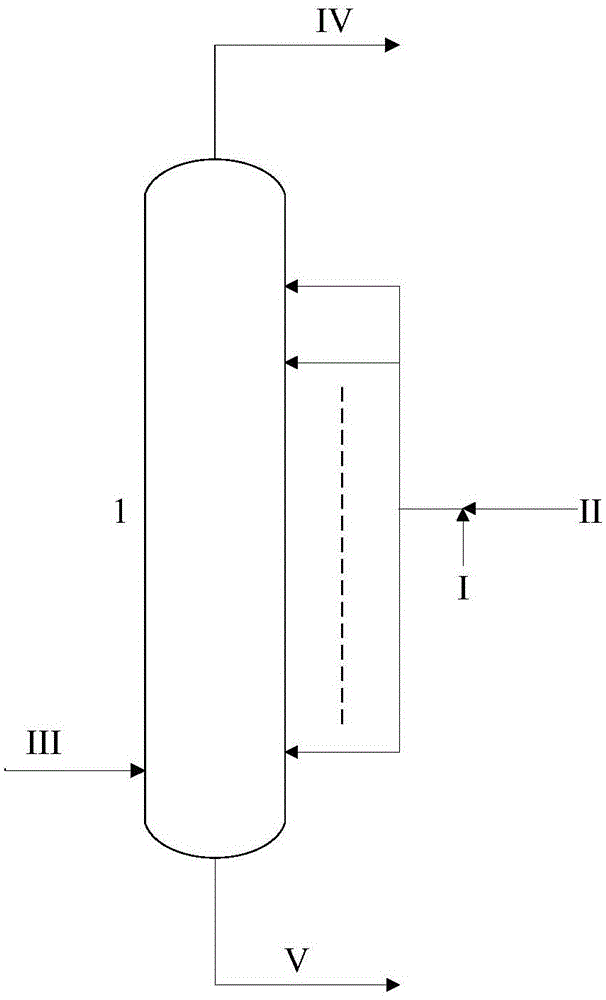

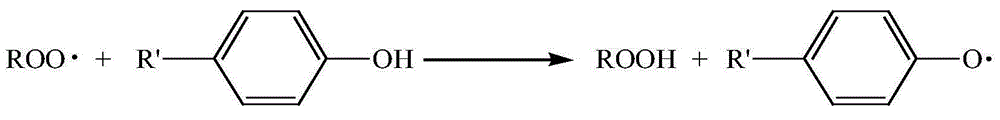

Method of inhibiting olefin polymerization in alkaline washing column of methanol-to-olefin (MTO) device

InactiveCN106467447AReduce pollutionInhibit aggregationHydrocarbon purification/separationHydrocarbonsOrganic chemistryPoor control

The invention relates to a method of inhibiting olefin polymerization in an alkaline washing column of a methanol-to-olefin device and mainly solves the technical problems of poor control effect on olefin polymerization, poor targeted applications, instability, complex operations, high toxicity and high cost in an alkaline wash column of an MTO apparatus in the prior art. In the technical scheme, a) an olefin polymerization inhibitor (I) is employed and includes, by weight, 0-20 parts of an amine compound and 0-10 parts of an alcohol compound; and b) the olefin polymerization inhibitor (I) is injected to the alkaline wash column (1) along with an alkaline solution (II) in an online continuous injection manner through an alkaline solution injection line on the alkaline wash column. The method solves the technical difficult problems and can be used for controlling and preventing the olefin polymerization in the MTO apparatus.

Owner:CHINA PETROLEUM & CHEM CORP +1

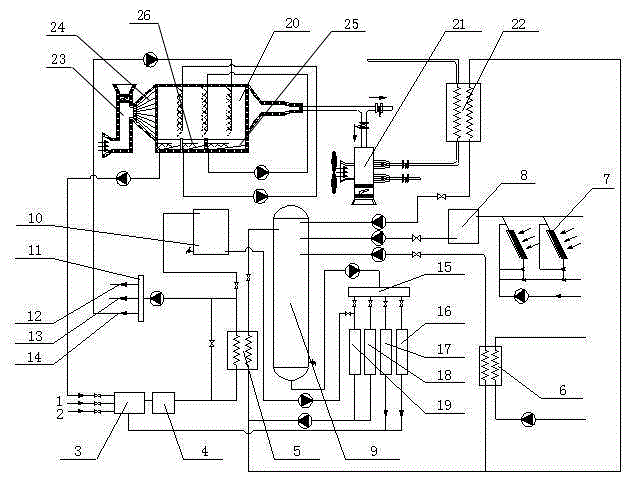

Multi-resource low-temperature waste heat comprehensive utilization system

InactiveCN103604244AGuaranteed heat supply in winterGuaranteed cooling effectHeat pumpsClimate change adaptationIndustrial waste waterWater source

The invention discloses a multi-resource low-temperature waste heat comprehensive utilization system. The multi-resource low-temperature waste heat comprehensive utilization system comprises a sewage treatment device, a water storage tank, a low-temperature water source heat pump, a heat storage water tank, a cold storage water tank, a first branched water collector, a second branched water collector, an air-compressor cooling water source heat pump, a solar heat collecting device, an air heat source pump, an air mixing device and a multi-stage spraying chamber. The multi-resource low-temperature waste heat comprehensive utilization system disclosed by the invention has the advantages that recovery of waste heat resources such as industrial waste gas, industrial waste water and domestic waste water and utilization of solar energy and air energy are integrated, so that the heating in winter and cooling in summer are realized; multiple waste heat resources and other energies in a mining area are fully utilized, the energy-saving effect is obvious, the dust removing effect is good and the economic and social benefits are obvious.

Owner:TAIYUAN UNIV OF TECH +1

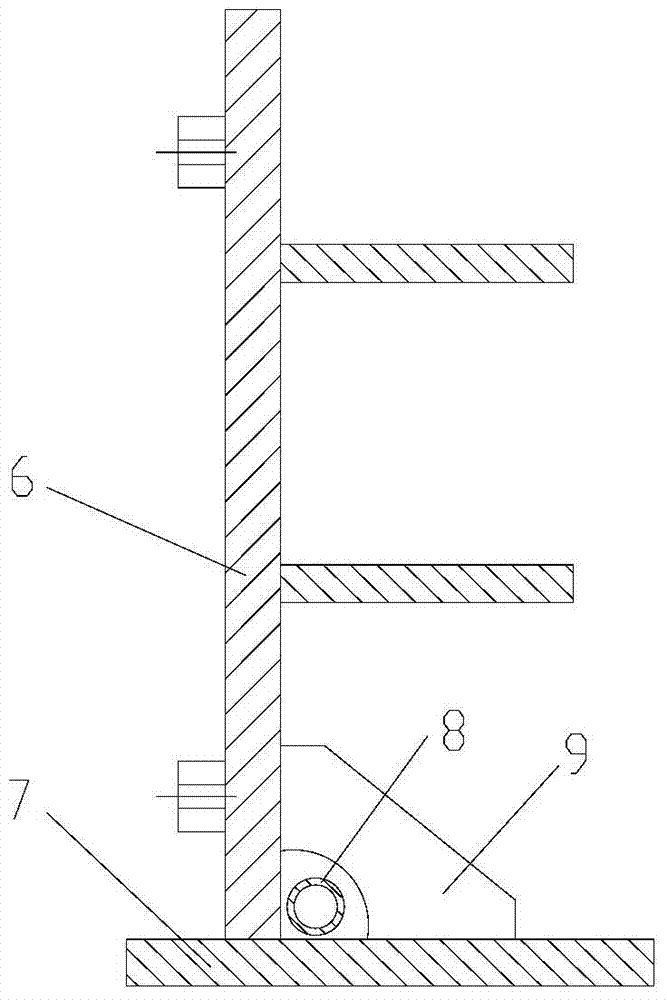

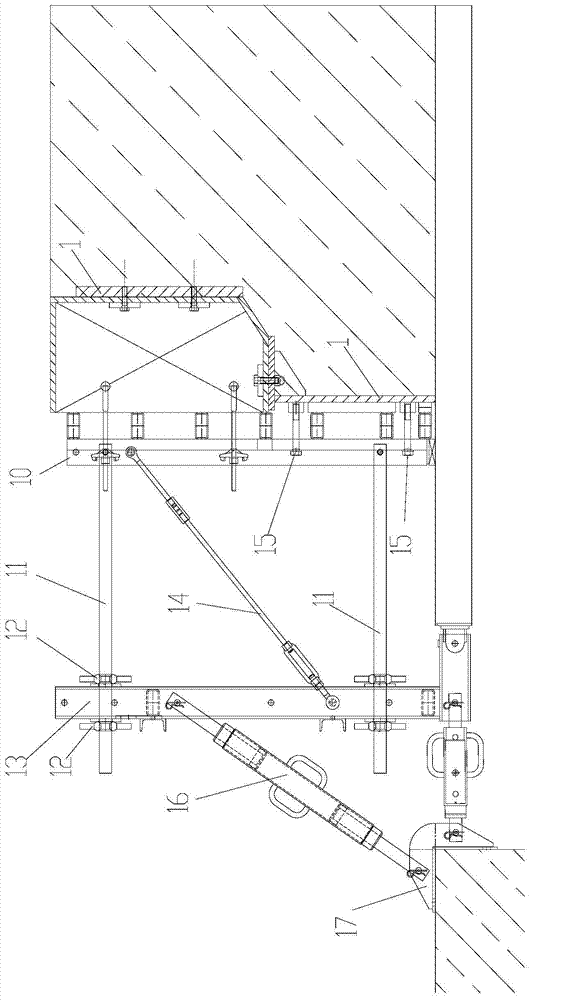

End steel shell mounting and positioning device and operation method

ActiveCN104711996AGuaranteed accuracyReduce wear and tearArtificial islandsUnderwater structuresRebarSoldering

The invention relates to the manufacturing field of subsea tunnel immersed tubes, in particular to an immersed tube end steel shell mounting and positioning device and an operating method. The end steel shell mounting and positioning device comprises an end steel shell and an end formwork unit. The end steel shell comprises a bottom plate segment, a left wall segment, a right wall segment and a top plate segment which are each formed by splicing segmented steel shell parts. The end formwork unit comprises a formwork back rack, adjusting threaded rods, a vertical frame, a telescopic rod and a fixing base, wherein the adjusting threaded rods are connected with the vertical frame and the formwork back rack; the formwork back rack is closely connected with the end steel shell; the adjusting threaded rods are provided with nuts; the telescopic rod is connected with the vertical frame and the fixing base; the end steel shell is provided with reflective pasters. Firstly, the spliced end steel shell large-segments are sequentially and initially located at the end of a bundled overall reinforcement cage, and then joint soldering is conducted; secondly, the reinforcement cage and the end steel shell are pushed into a pouring region, the end formwork unit and the end steel shell are connected and then accurately positioned and fixed; finally, the end steel shell and immersed tube sections are formed through one-time pouring, and then real-time positioning is conducted. The device is high in mounting accuracy, small in steel consumption, simple in process, high in working efficiency and low in cost.

Owner:THE SECOND ENG COMPANY OF CCCC FOURTH HARBOR ENG +3

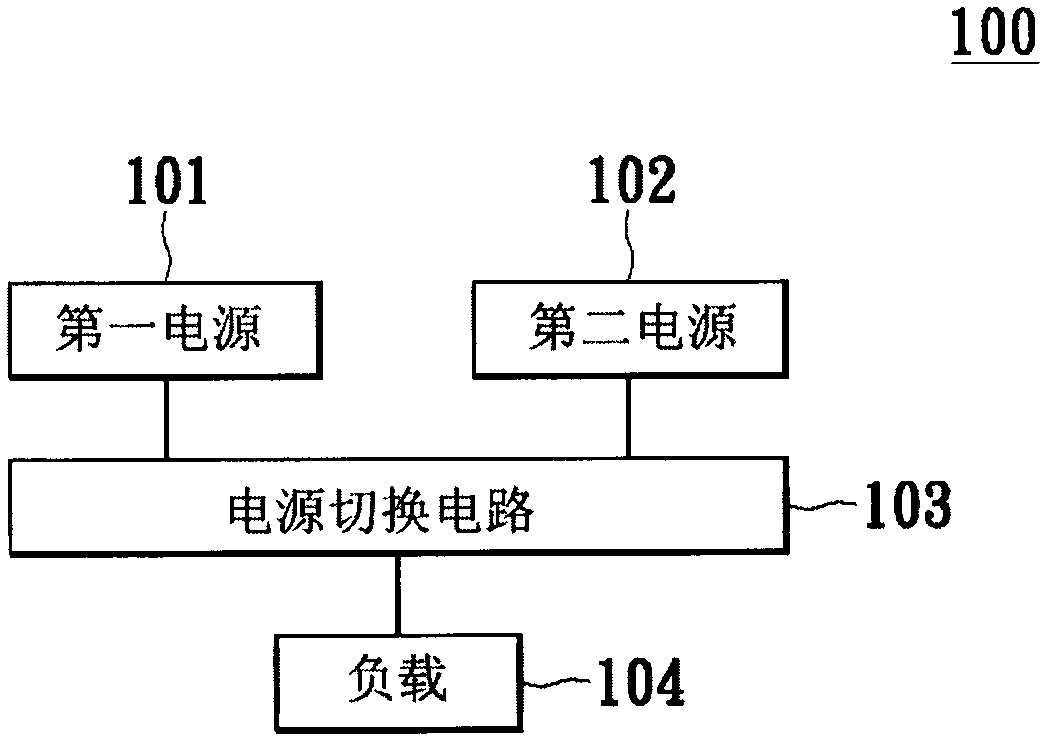

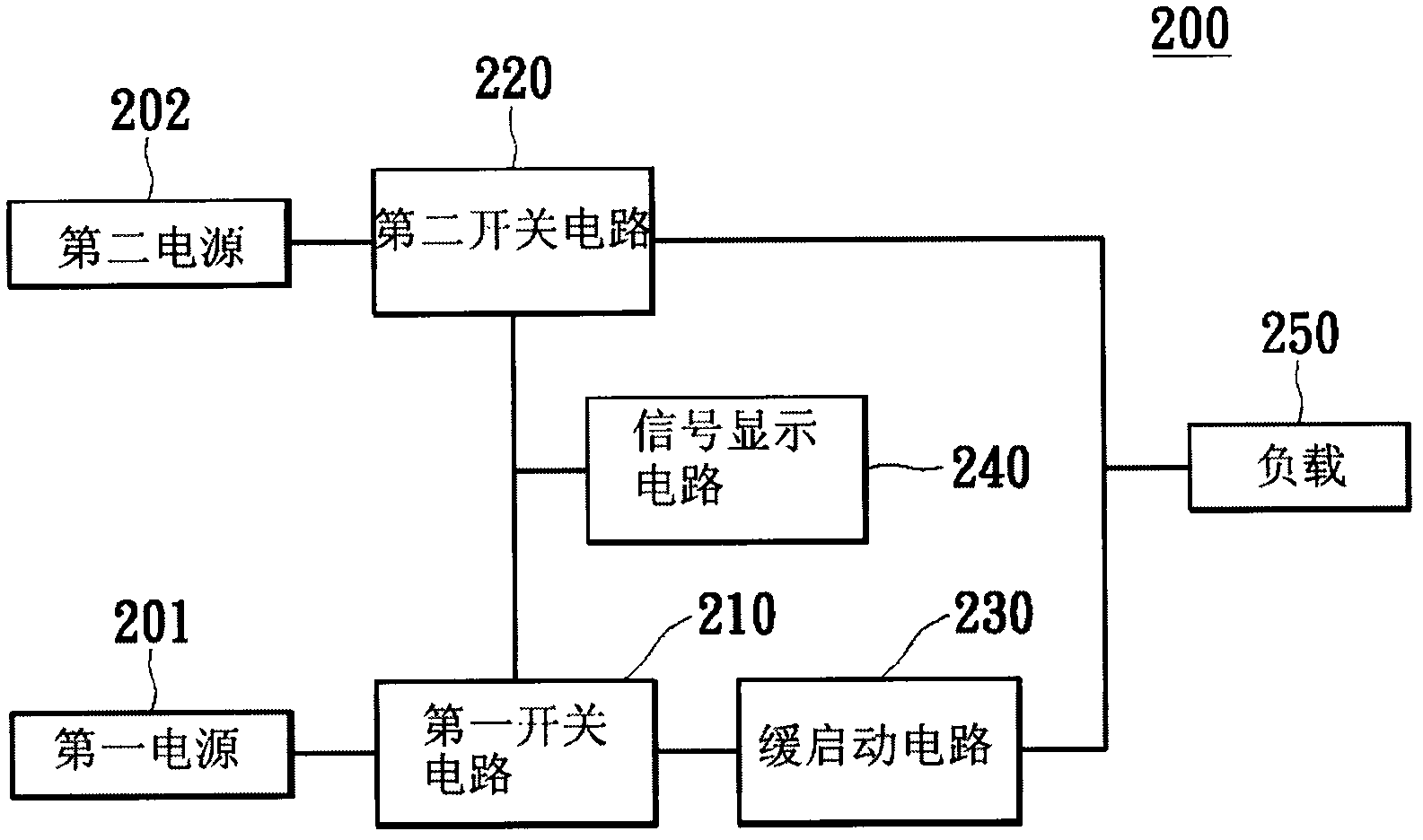

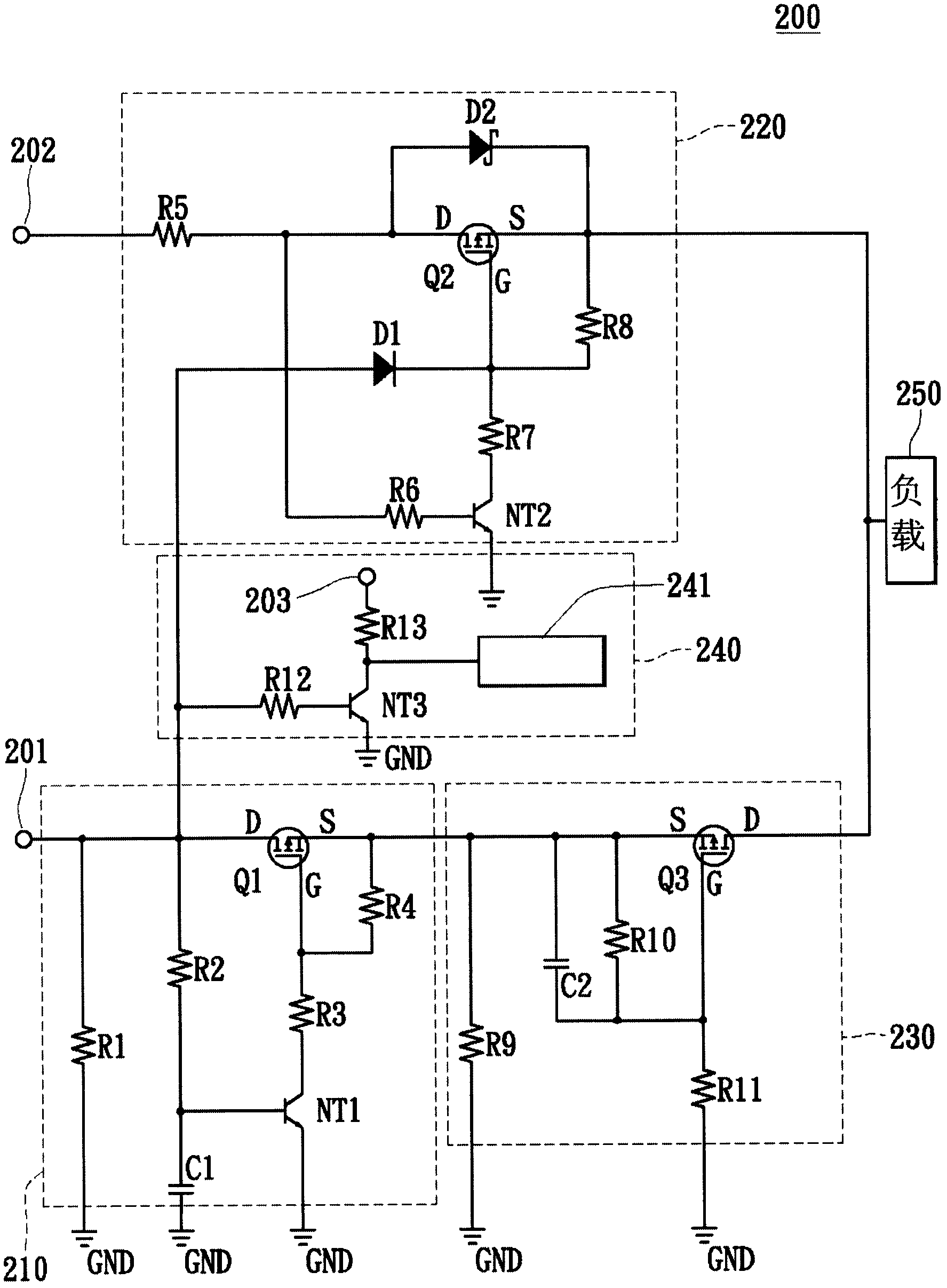

Power switching circuit and power switching method thereof

ActiveCN103138376AReduce wear and tearImprove performanceEmergency power supply arrangementsSupply managementPower switching

The invention discloses a power switching circuit and a power switching method thereof. The power switching circuit comprises a first switching circuit, a second switching circuit and a slow starting circuit. The first switching circuit is coupled with a first power supply end, and breakover or turnoff is determined according to the voltage level of the first power supply end. The second switching circuit is coupled among the first switching circuit, a second power supply end and load, and breakover or turnoff is determined according to the voltage level of a power supply and a second power supply. The slow starting circuit is coupled between the first switching circuit and the load. When the voltage level of the first power supply end is larger than a preset value, breakover of the first switching circuit and turnoff of the second switching circuit are achieved. When the voltage level of the first power supply end is lower than the preset value, turnoff of the first switching circuit and breakover of the second switching circuit are achieved, and breakover of the slow starting circuit is achieved after the breakover of the first switching circuit lasts for a preset time. According to the power switching circuit and the power switching method, power supply management is achieved through a hardware circuit design mode, and resource consumption is further reduced.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com