Heat-conducting insulating composite material and preparation method thereof

A composite material, heat conduction and insulation technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of prolonging the production cycle, reducing thermal conductivity, high electrical conductivity, etc., to improve heat dissipation performance, improve Processability, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

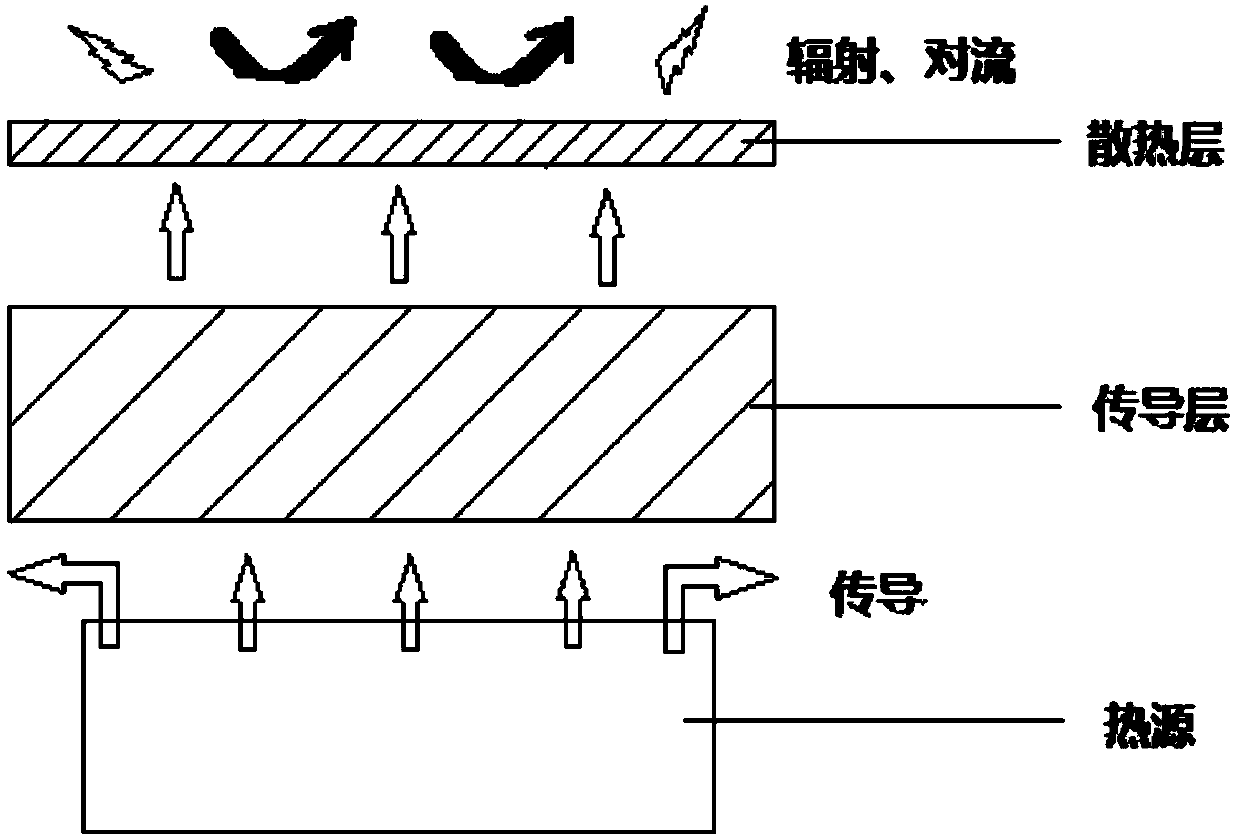

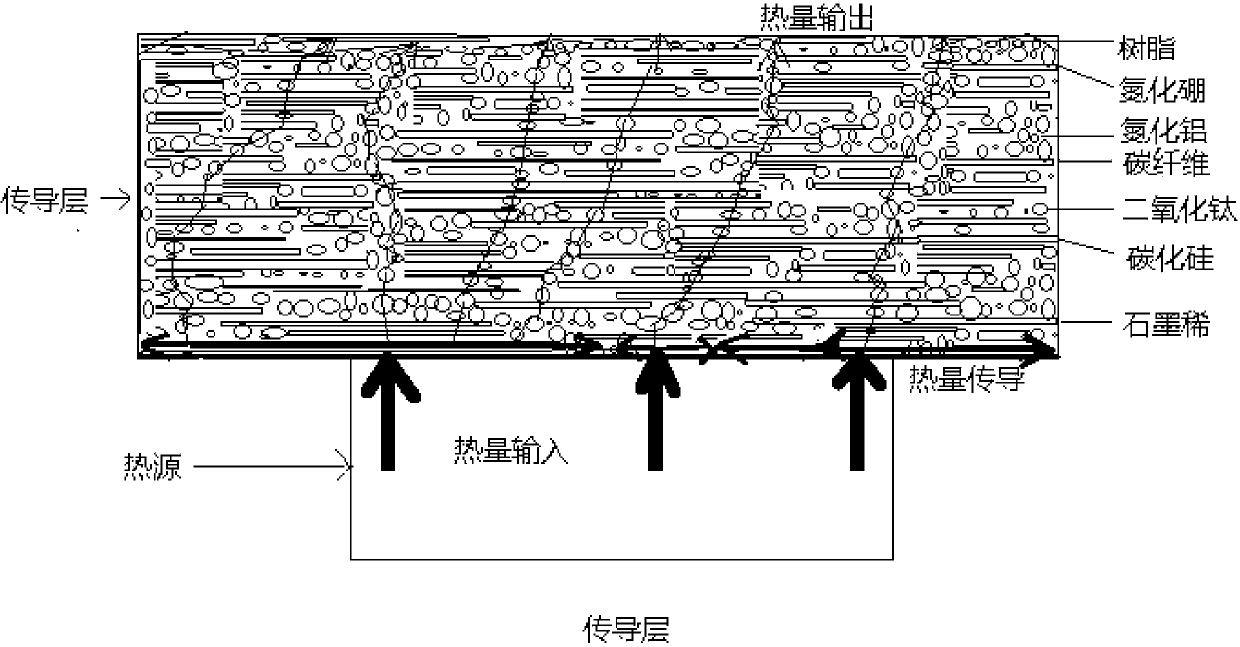

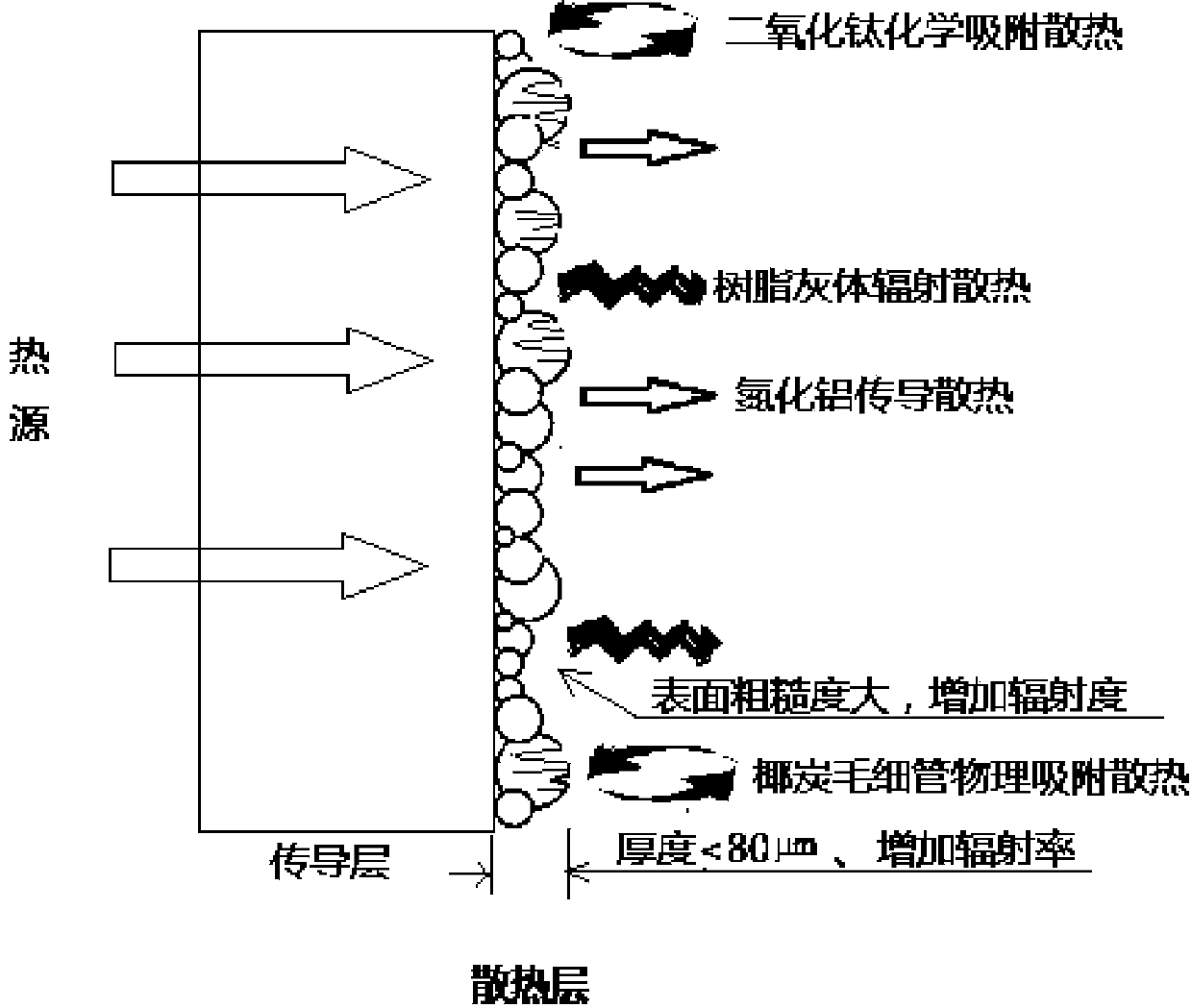

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Mother particle formula 1:

[0061]

[0062]

[0063] Component Four Formula One

[0064]

[0065] The preparation method of described composite material is as follows:

[0066] One, the preparation method of mother particle:

[0067]1) Pretreatment of raw materials: including drying treatment and surface pretreatment, first add inorganic fillers (silicon carbide, boron nitride, aluminum nitride and titanium dioxide) in batches (that is, each inorganic filler is pretreated separately) In the mixer, the mixing temperature is 20°C, add the coupling agent (according to the ratio of 100:0.5) in the low-speed stirring of 50 rpm, mix well and gradually raise the temperature to 120°C, and then stir at 400-800 rpm Stir at high speed for 2 minutes, so that the surface of the filler particles is specially treated to facilitate the combination with the resin. At the same time, the polycarbonate and saturated polyester are blown and dried at 110°C for 3 hours to make the...

Embodiment 2

[0081] Master Particle Formula 2:

[0082]

[0083]

[0084] Component four formula two

[0085] filler

particle size

Weight%

Length 20-80μm, pore size <50nm

1

aluminum nitride

<50nm

5

Titanium dioxide

6.8-15nm

5

89

[0086] The preparation method of described composite material is as follows:

[0087] One, the preparation method of mother particle:

[0088] 1) Pretreatment of raw materials: including drying treatment and surface pretreatment, first add inorganic fillers (silicon carbide, boron nitride, aluminum nitride and titanium dioxide) in batches (that is, each inorganic filler is pretreated separately) In the mixer, the mixing temperature is 50°C. Add the coupling agent (according to the ratio of 100:0.5) while stirring at a low speed of 100 rpm. After mixing evenly, gradually raise the temperature to 120°C, and then stir at a high speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com