Method for machining through hole in highlighted side of mobile phone shell and mobile phone

A mobile phone shell, high-gloss technology, applied in the direction of telephone communication, telephone structure, electrical components, etc., can solve the problems of affecting the smoothness of the outer tube of the shell, increasing the defect rate of the finished shell, affecting the appearance of the shell, etc. The effect of promotion, reduction of wear and tear, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

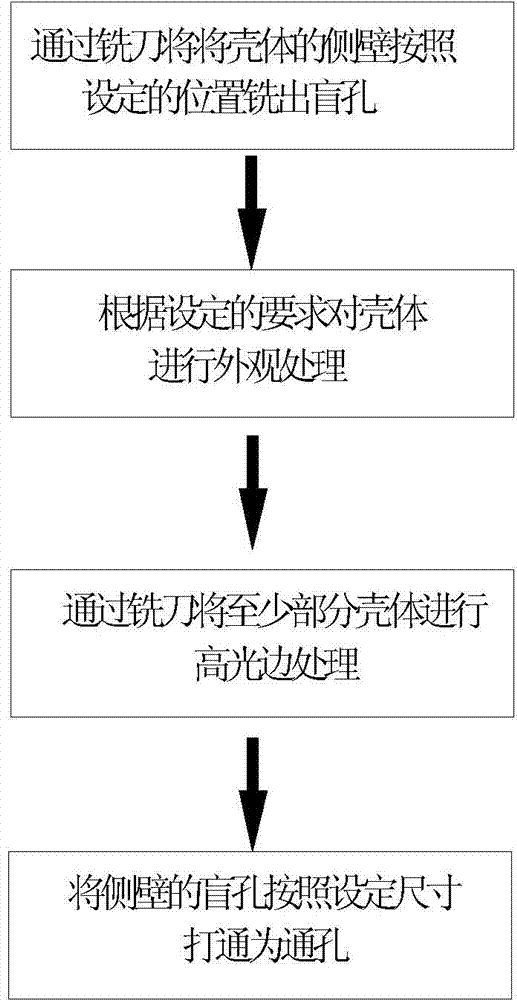

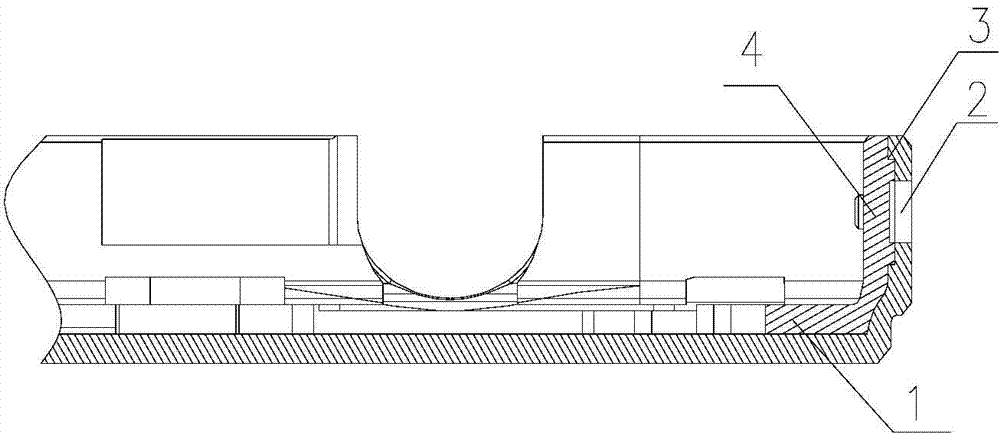

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

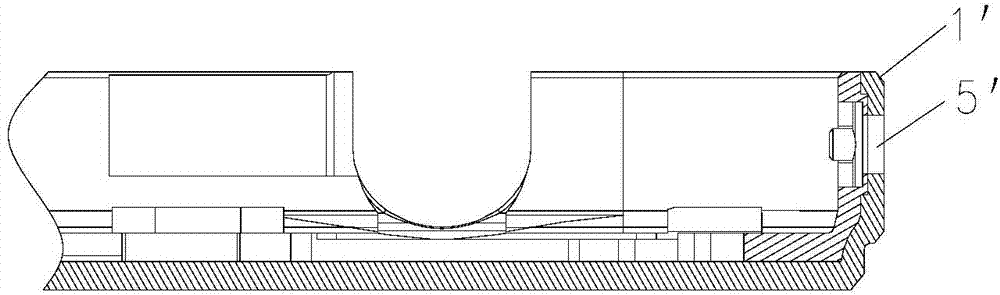

[0031] In the prior art, the casing of the mobile phone needs to pre-process the set through hole 5' for wiring or placing parts before the appearance treatment during production. ’ is treated with high-gloss edges, because the existence of the through hole 5’ forms a structure of cantilevered beams, so that when the high-gloss edge is processed, the pressure is uneven and the knife is easy to vibrate, which leads to poor high-gloss edge vibration of the shell and affects the The smoothness of the outer tube of the shell is improved.

[0032] In view of the above situation, in the prior art, clamps are often erected near the through hole 5' during highlight edge processing to strengthen the internal support force of the suspension beam structure and solve the problem of uneven pressure bearing. Howe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com