Method for making non-conducting hole in inner layer of multilayer PCB board

A technology of PCB board and manufacturing method, which is applied in the direction of printed circuit manufacturing, electrical components, printed circuit, etc., can solve the problems of insufficient support force at the position of large NP holes, unqualified PCB boards, and easy formation of hole halos, etc., to achieve internal support The effect of strengthening force, improving reliability, and improving lamination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

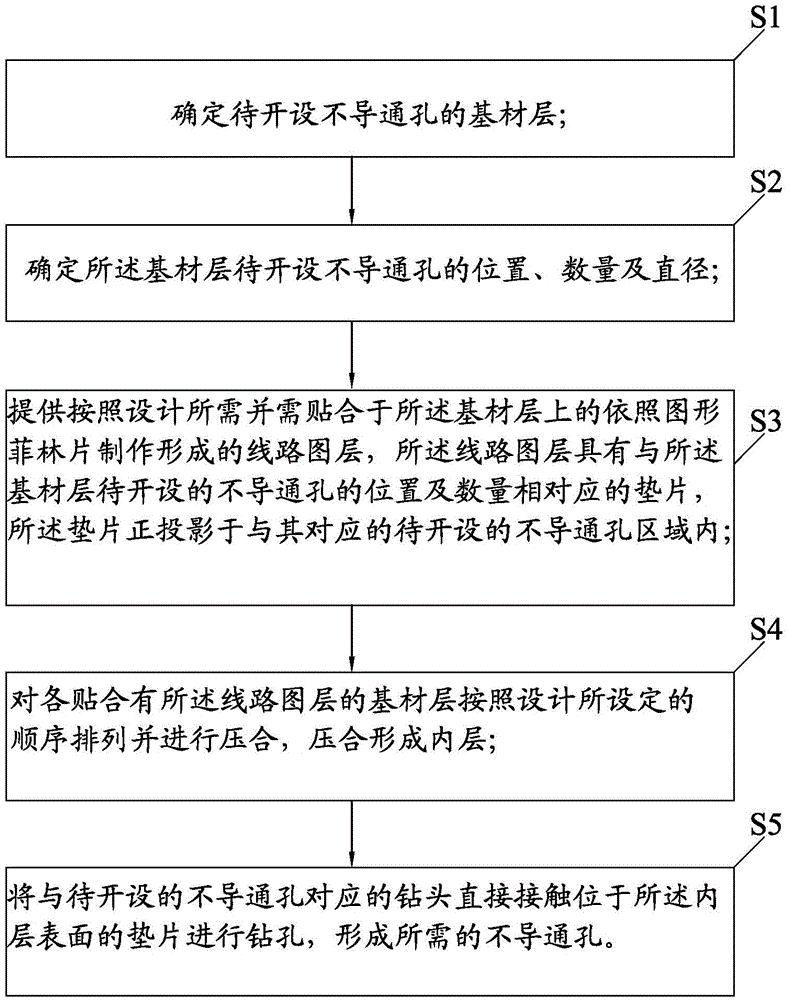

[0021] Such as figure 1 As shown, the method for making the non-conducting hole in the inner layer of the multilayer PCB of the present invention comprises the following steps:

[0022] (S1) Determine the substrate layer to be opened with non-conducting holes;

[0023] (S2) determining the position, quantity and diameter of the non-conducting holes to be opened in the substrate layer;

[0024] (S3) Provide a circuit layer formed according to the graphic film sheet that needs to be attached to the substrate layer according to the design, and the circuit layer has a non-conductive hole to be opened with the substrate layer The pads corresponding to the position and quantity of the pads, the pads are orthographically projected in the area of the corresponding non-conducting hole to be opened; (S4) for each substrate laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com