Patents

Literature

258results about How to "Improve lamination quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

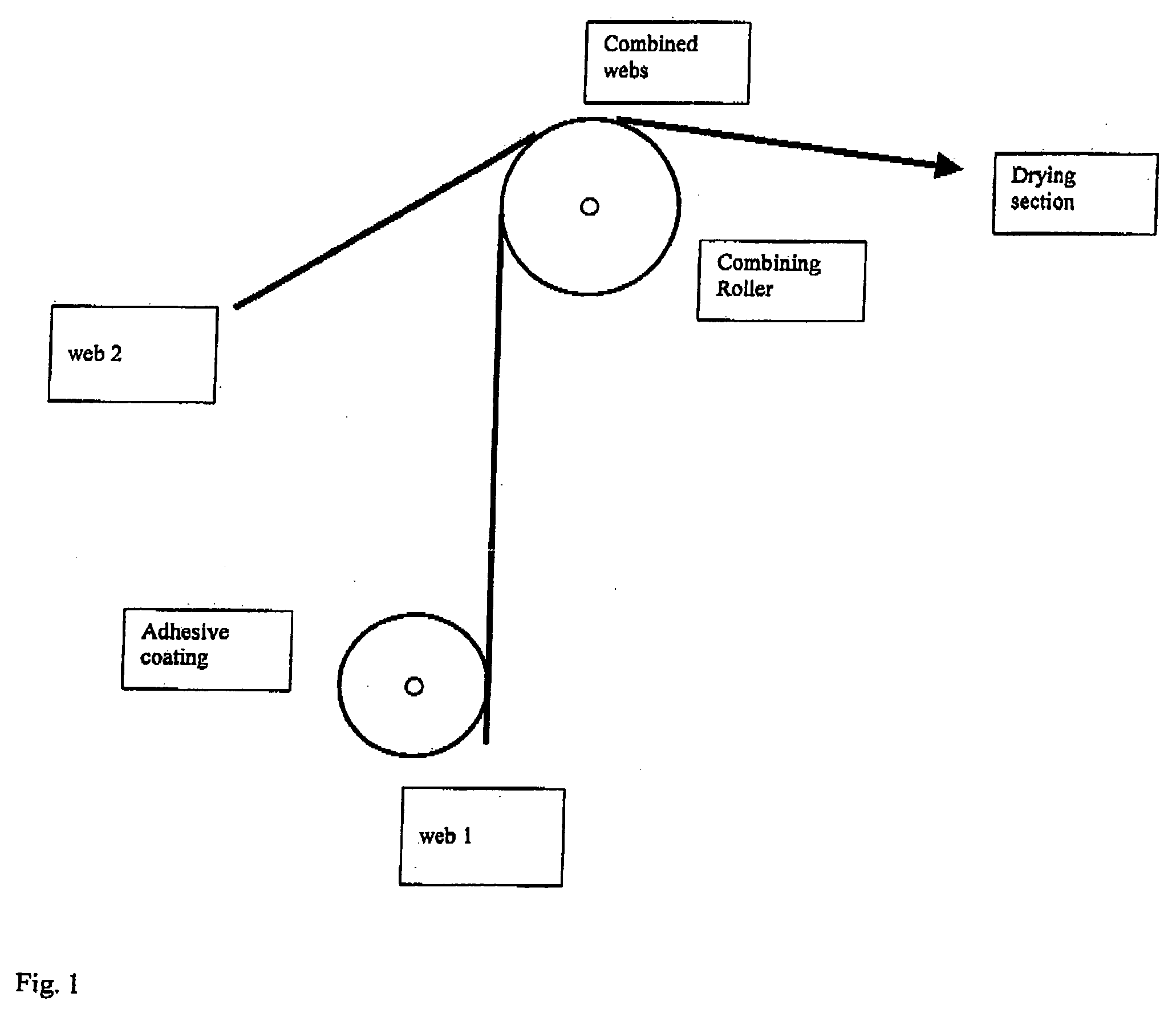

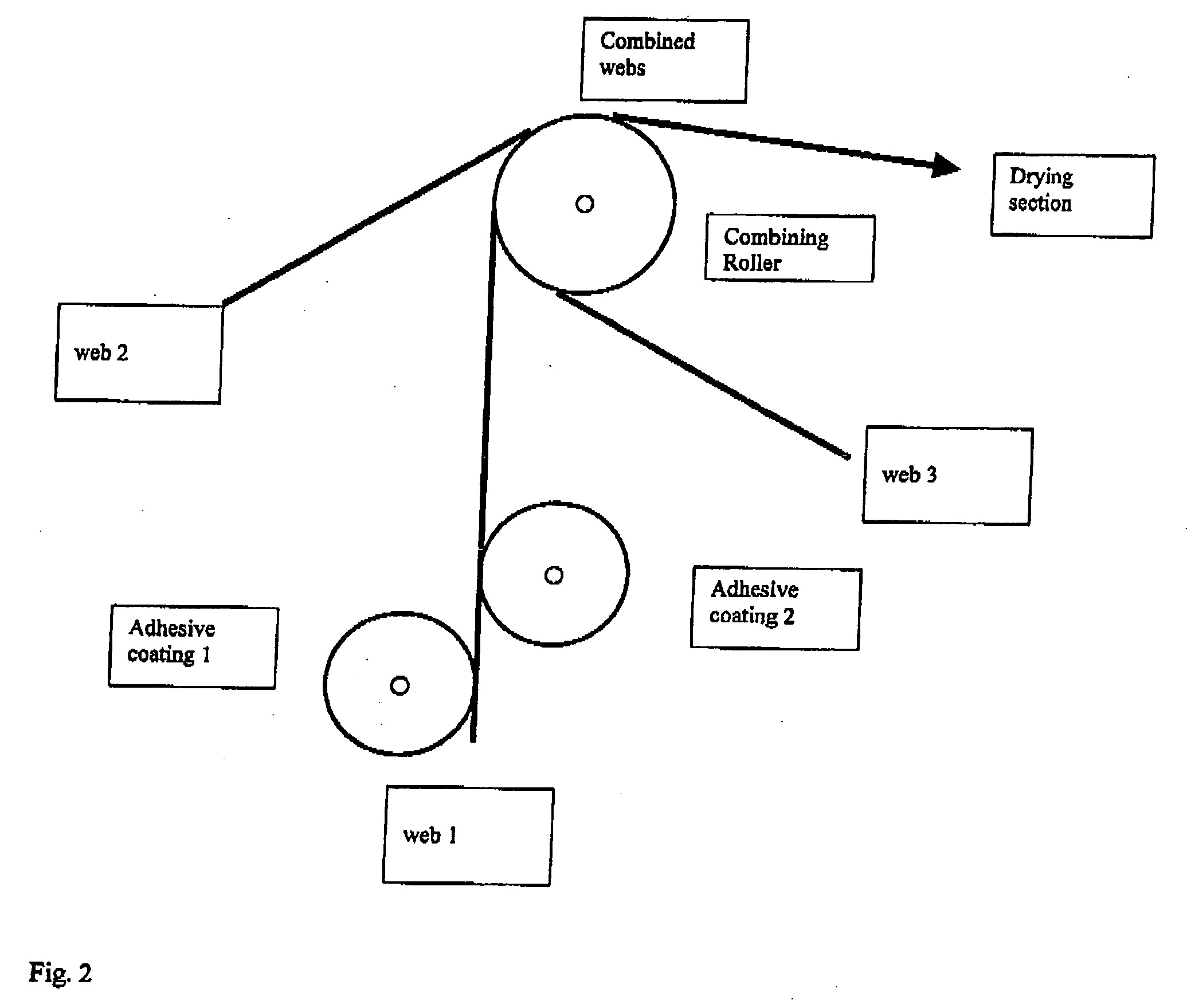

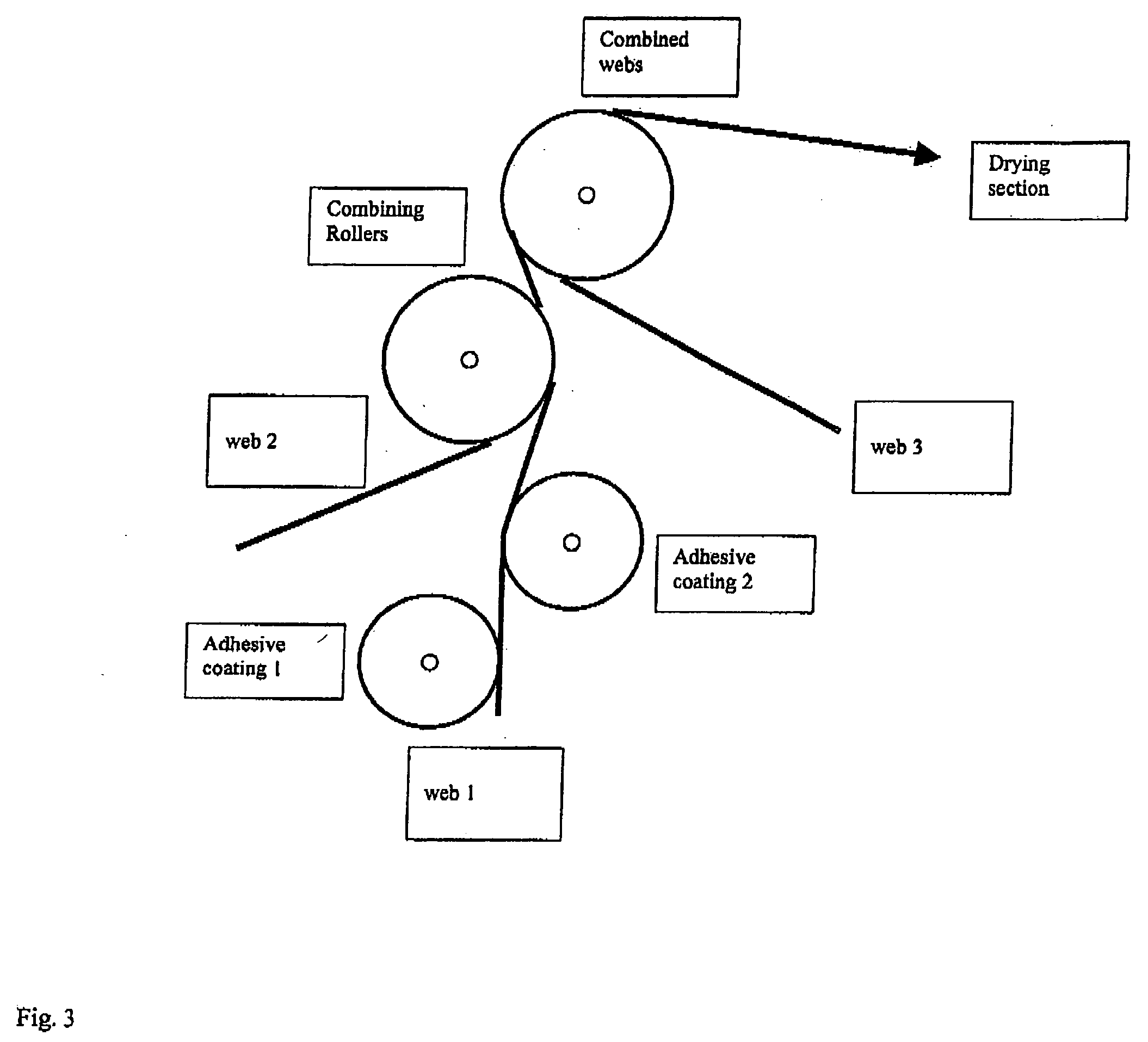

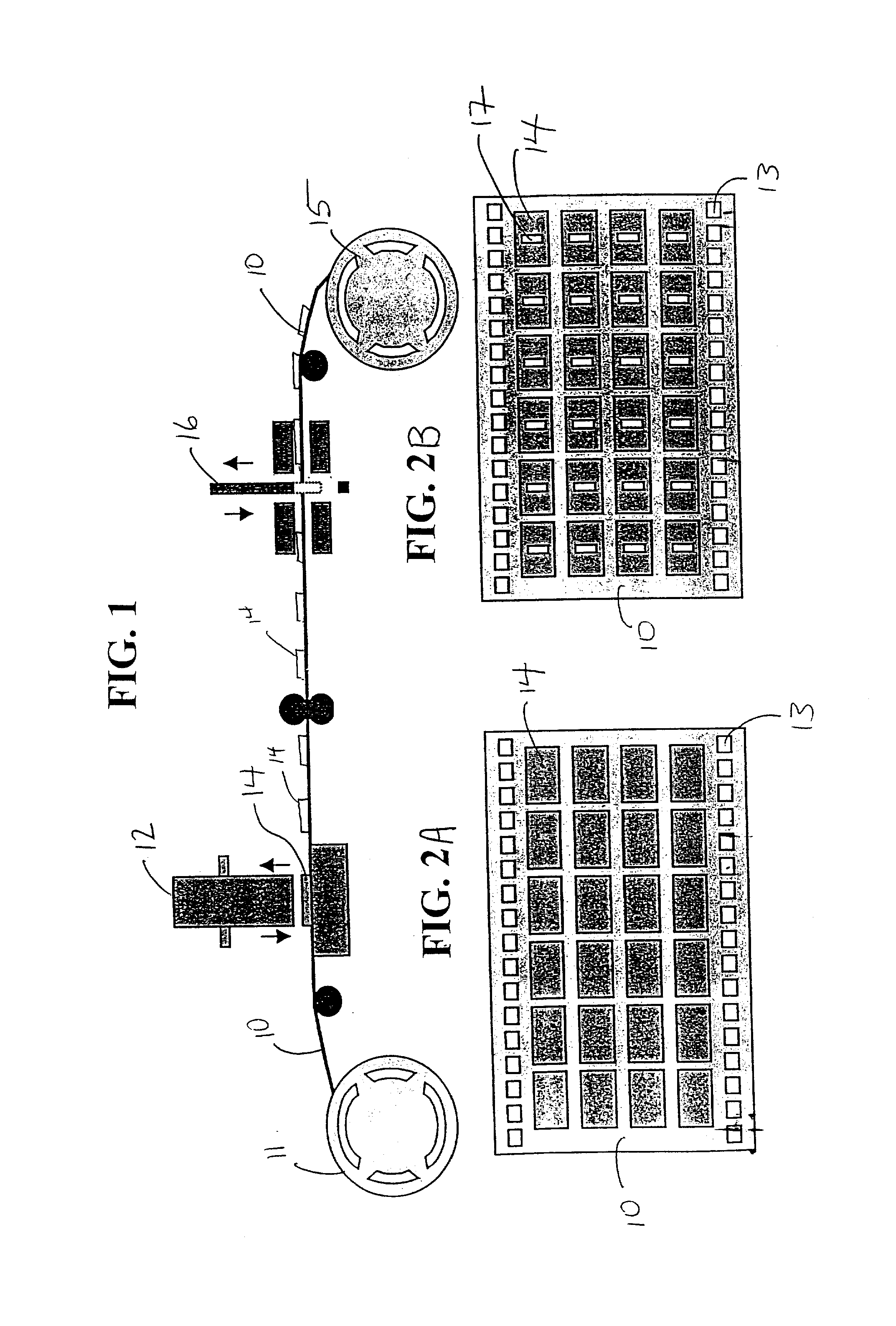

Laminating process and laminates resulting therefrom

InactiveUS20060194004A1Effective combinationIncrease speedAdhesive processesLamination ancillary operationsAdhesiveEngineering

A roll-to-roll lamination process for flexible webs including coating of at least one side of a first flexible web with a film forming adhesive and contacting the adhesive side(s) of the first flexible web to at least one of a second flexible web and a third flexible web on a transport roller while the combined webs are touching the transport roller from one side on a length of more than 5 mm without being further pressurized. Also, a 2 or more ply laminate of flexible webs comprising a first flexible web and a second flexible web, which are permanently attached by a film forming adhesive in a roll-to-roll lamination process, characterised in that the outer surface of the second flexible web has a heat sensitive recording layer and the first flexible web comprises fleece.

Owner:SIHL

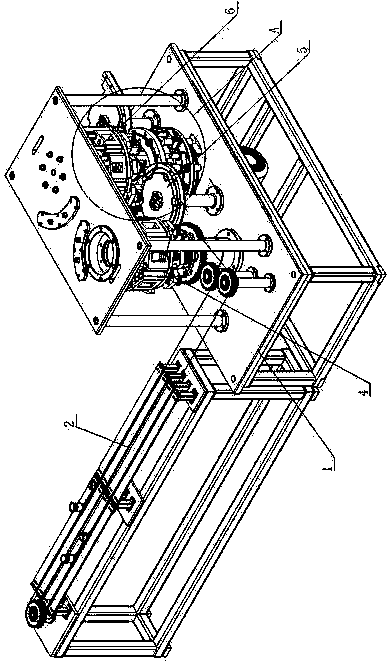

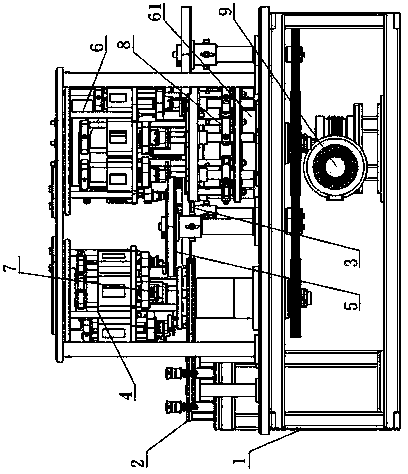

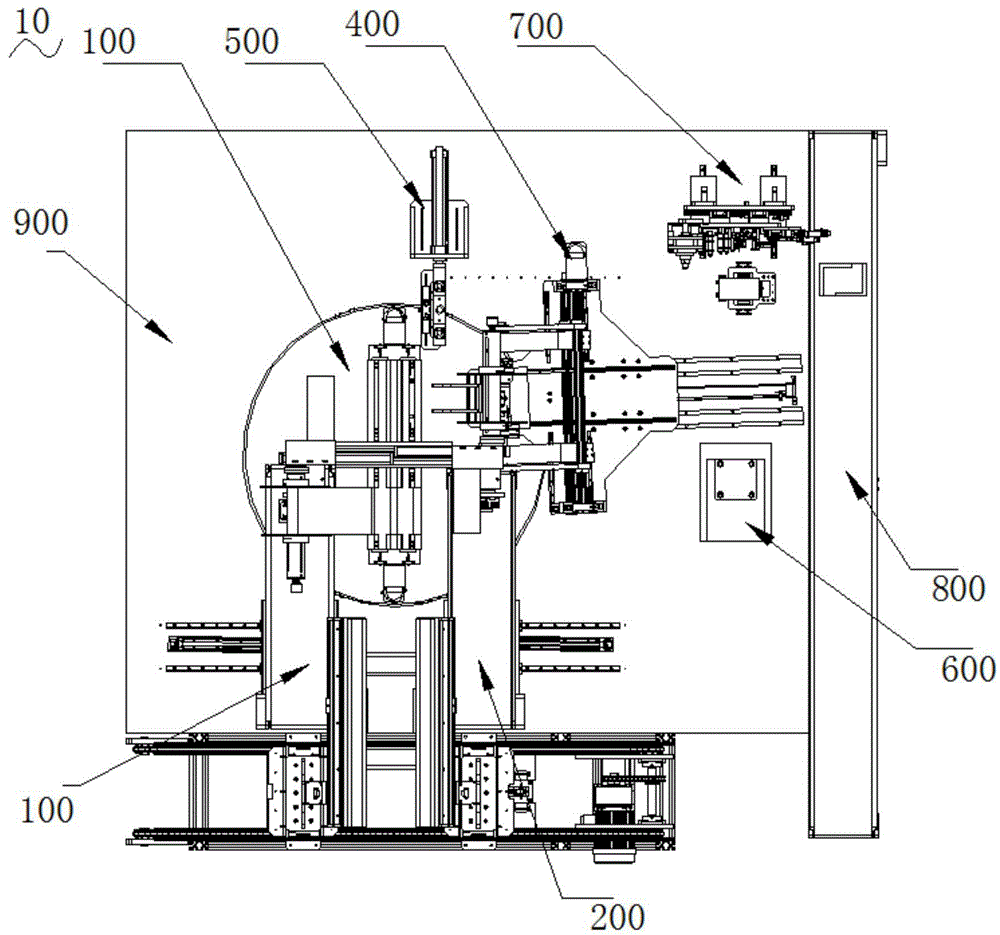

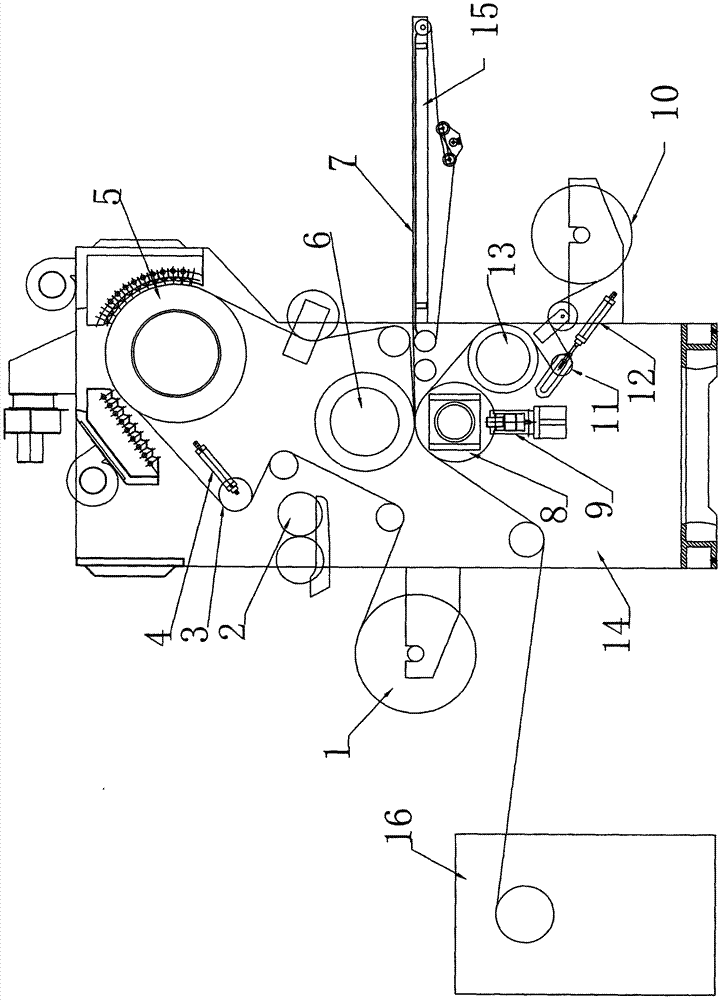

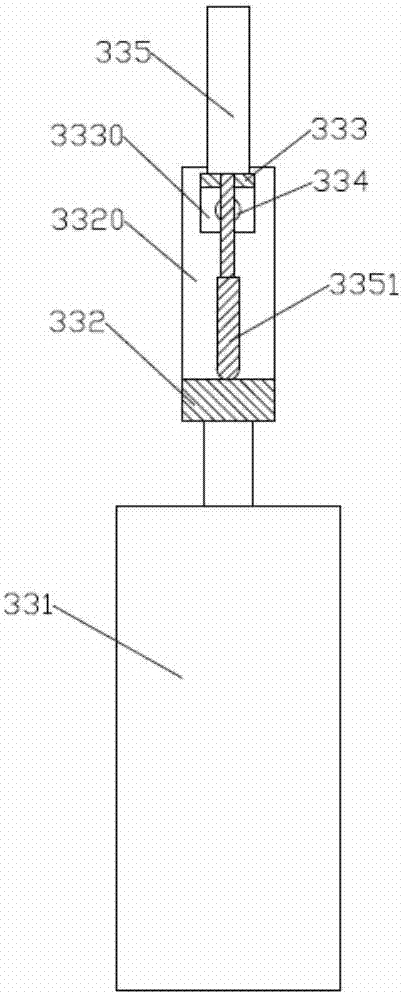

Bottle cap assembling device and assembling method

The invention discloses a bottle cap assembling device. The bottle cap assembling device comprises a rack, an outer cap feeding mechanism, an inner cap feeding mechanism, an auxiliary rotary tower, a transfer drive plate and a press fit rotary tower. The auxiliary rotary tower, the transfer drive plate and the press fit rotary tower are arranged on the rack in a rotating mode, a suction device is arranged on the auxiliary rotary tower, and a suction device and a jacking device are arranged on the press fit rotary tower, wherein the jacking device is located under the suction device. The outer cap feeding mechanism is arranged on the rack. The auxiliary rotary tower rotates to transport an outer cap sucked by the suction device to the transfer drive plate. The transfer drive plate is arranged between the auxiliary rotary tower and the press fit rotary tower. The inner cap feeding mechanism is arranged on the rack. The bottle cap assembling device has the advantages of being high in press fit quality, low in rejection rate, suitable for multiple outer caps of different shapes, and wide in application range. The invention further discloses a bottle cap assembling method.

Owner:SICHUAN XINGDA PACKAGING EQUIP MFG

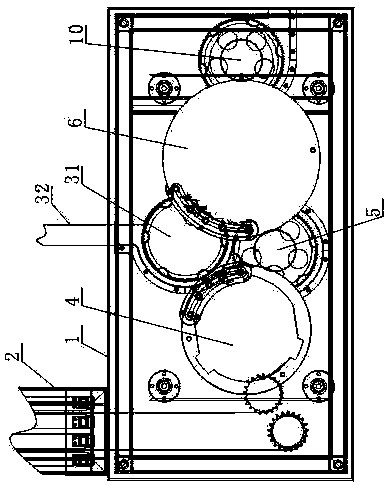

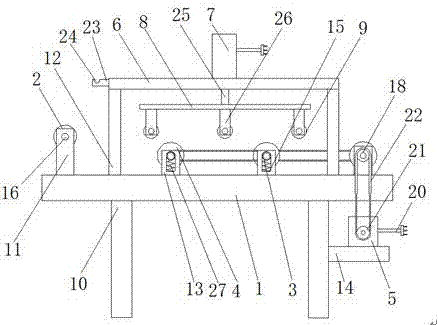

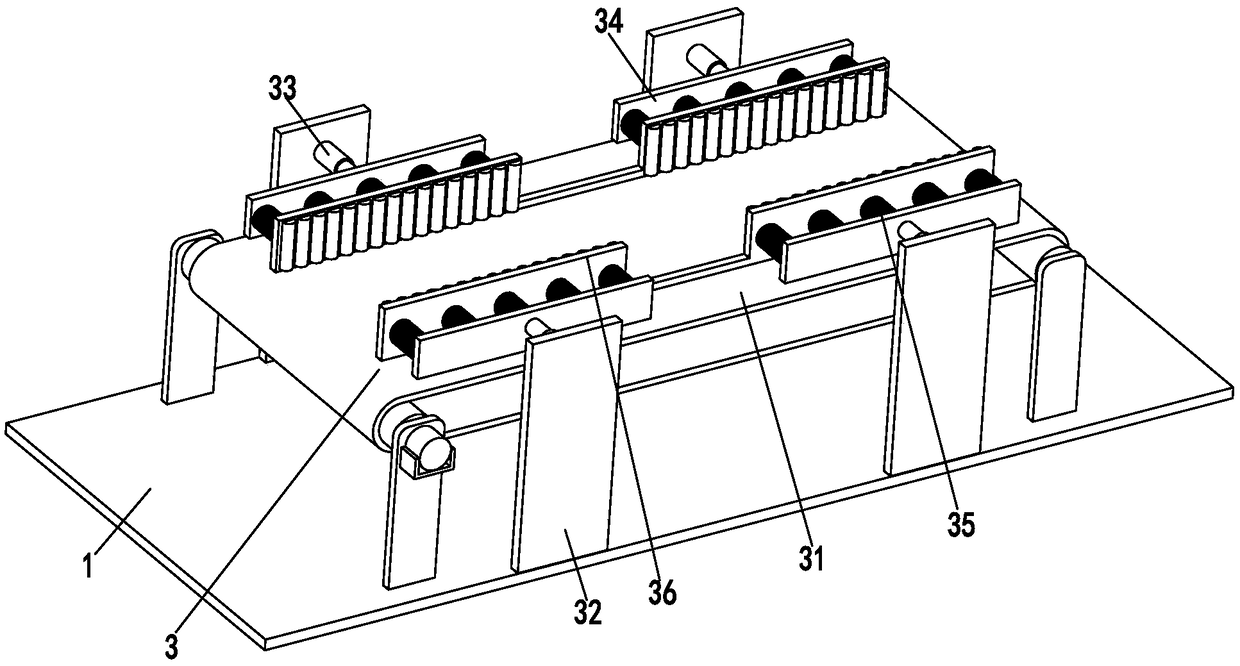

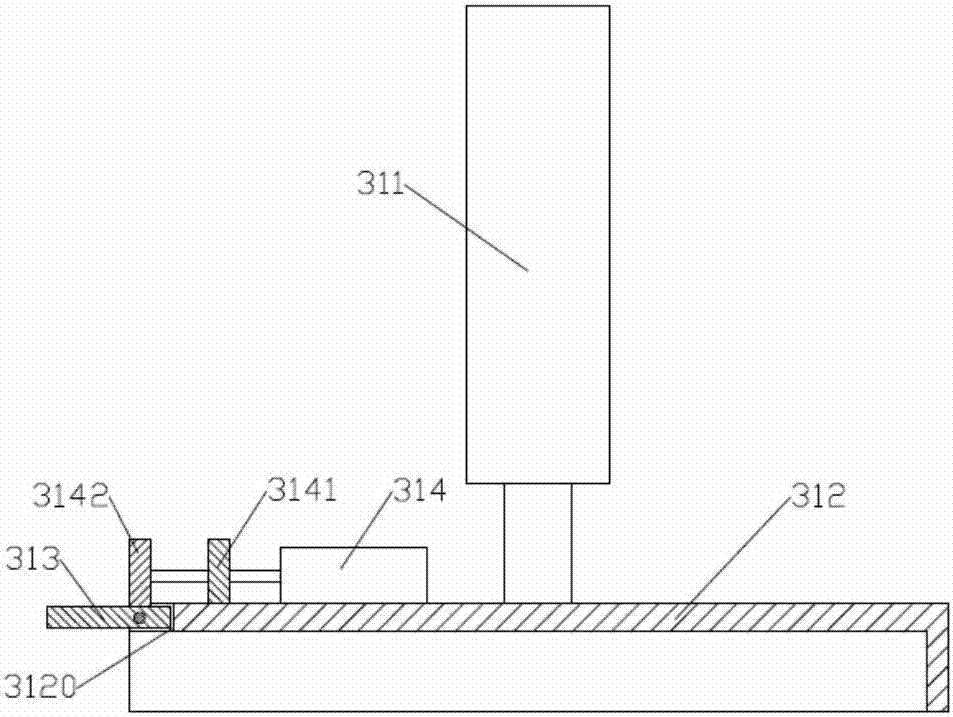

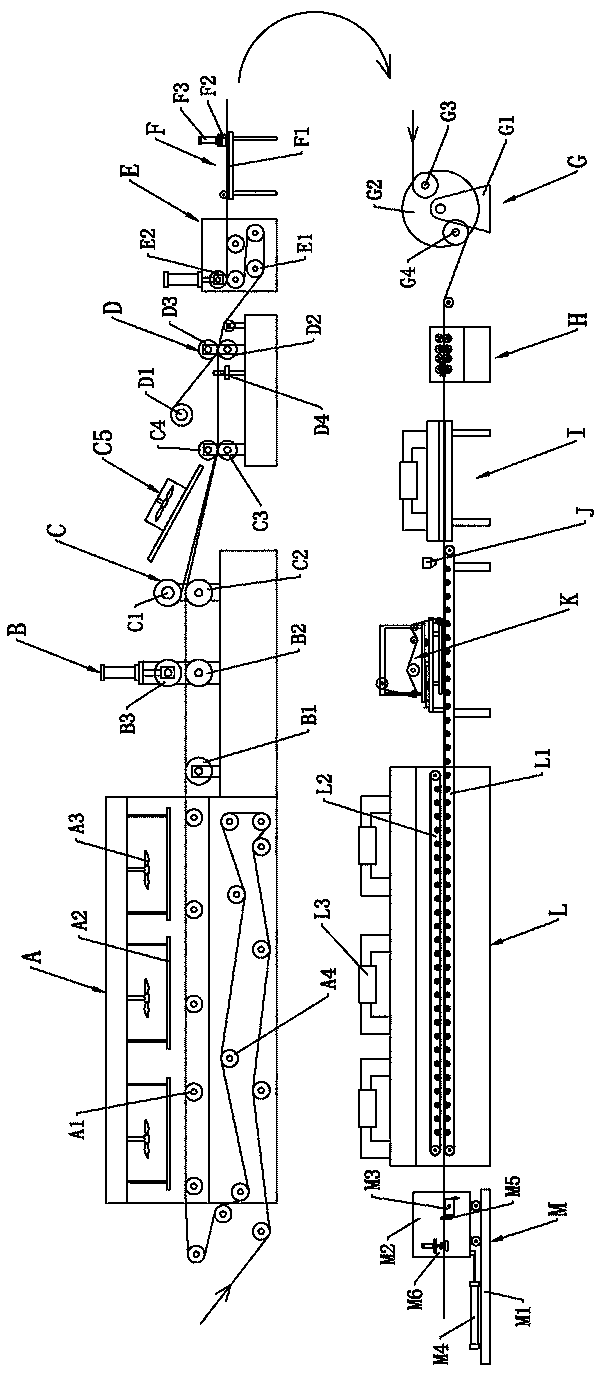

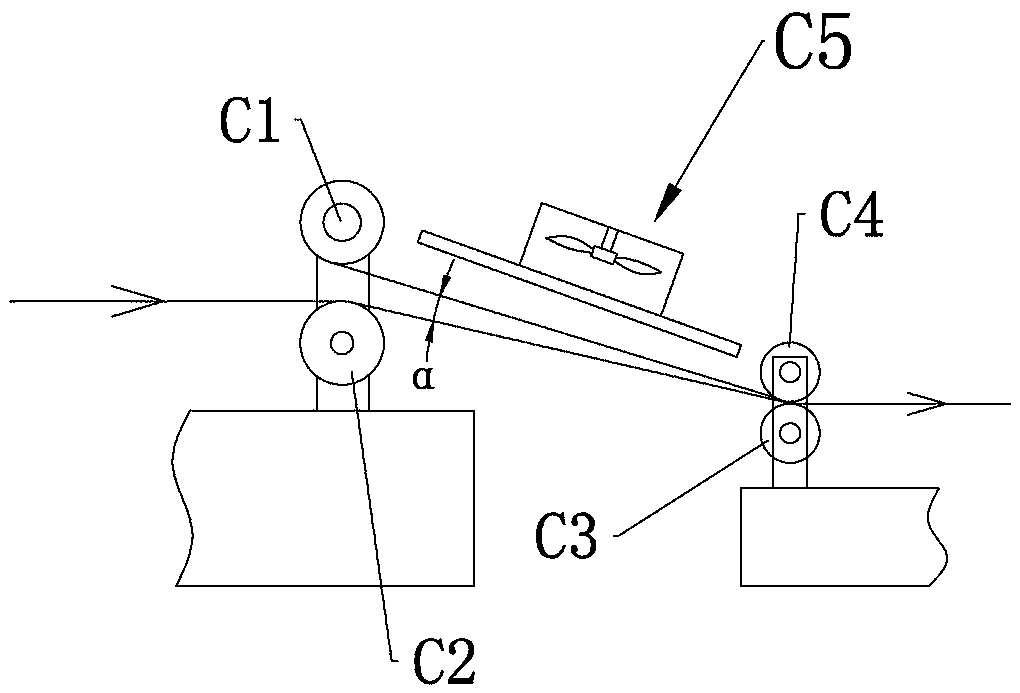

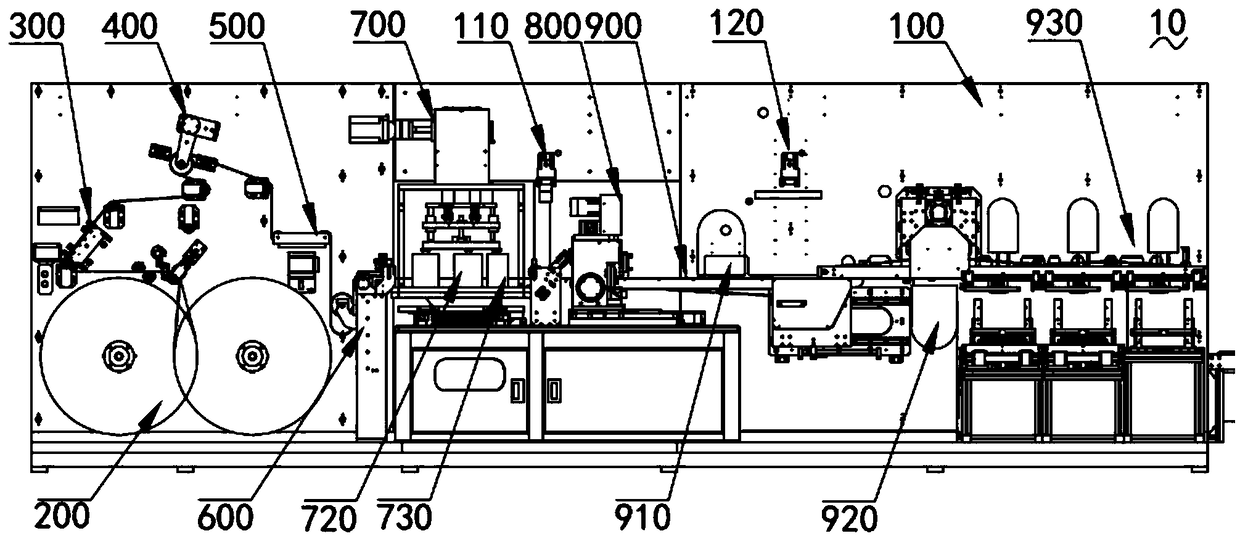

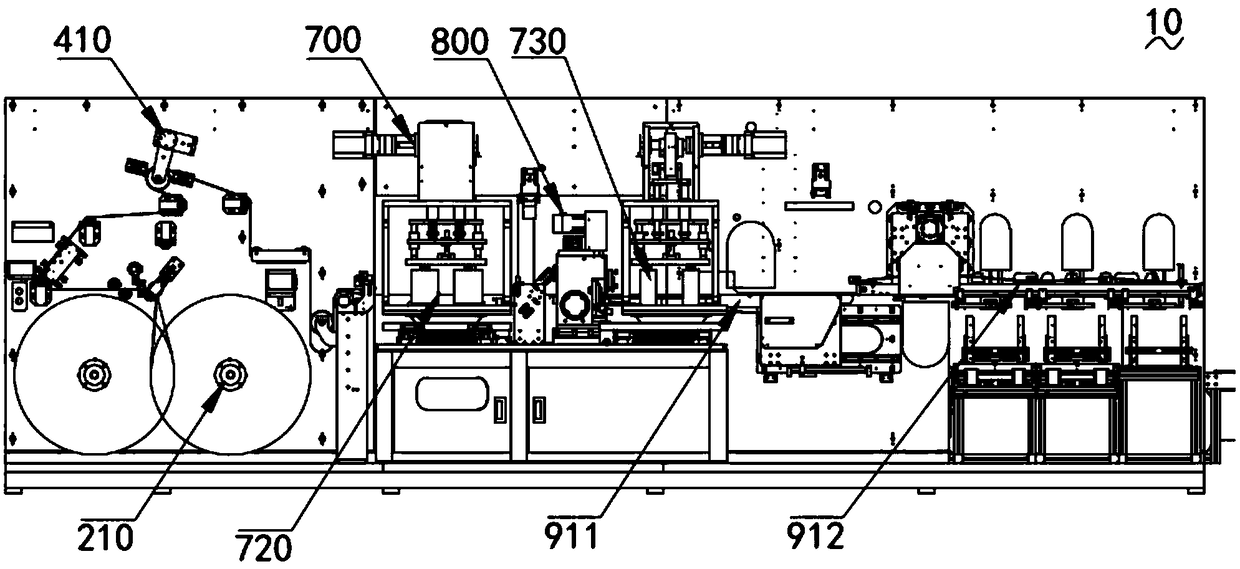

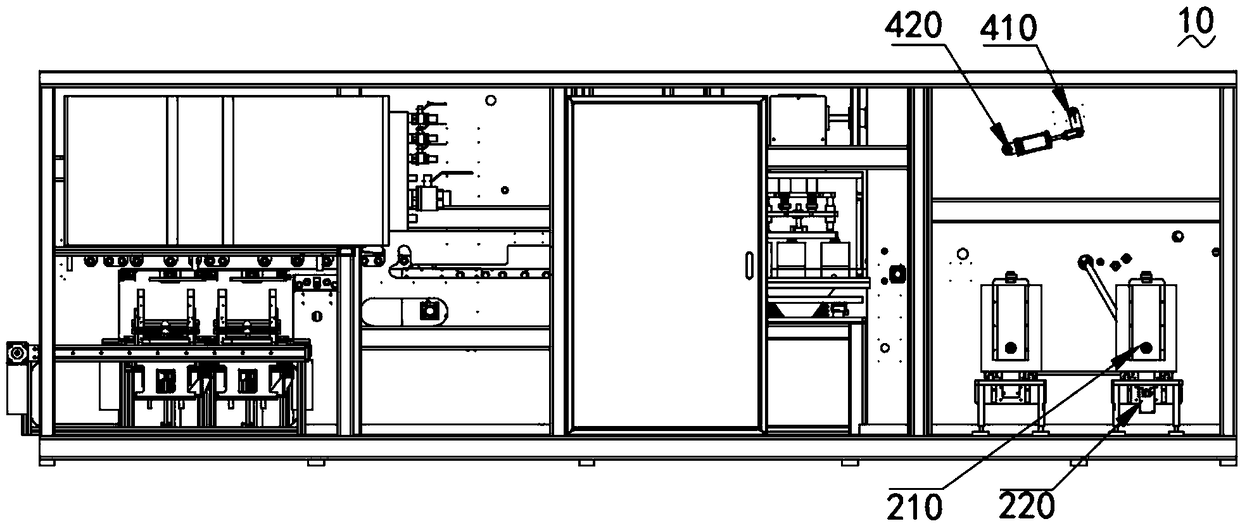

Integrated cell laminating machine and cell laminating method

ActiveCN106374144AHigh precisionImprove lamination qualityAssembling battery machinesFinal product manufactureVertical planeEngineering

The invention relates to the technical field of battery lamination, particularly to an integrated cell laminating machine and a cell laminating method. The integrated cell laminating machine comprises a laminating station, wherein the laminating station comprises a rotary plate, a rotary plate rotating apparatus arranged below the rotary plate for driving the rotary plate to rotate, and multiple laminating apparatuses uniformly arranged on the rotary plate for performing lamination; each laminating apparatus comprises a laminating rotary platform, a laminating power mechanism for driving the laminating rotary platform to swing in a vertical plane, and a first attraction mechanism and a second attraction mechanism which are symmetrically arranged on the two sides of the laminating rotary platform for attracting and driving a positive plate and a negative plate to swing in a vertical plane, and a diaphragm material-releasing mechanism mounted above the laminating rotary platform for supplying diaphragms, wherein each laminating power mechanism is positioned at the bottom of the corresponding laminating rotary platform; and the swinging track of the laminating rotary platform is externally tangent with the swinging track of the corresponding first attraction mechanism and second attraction mechanism. The integrated cell laminating machine has high laminating efficiency, high laminating precision and good laminating quality.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

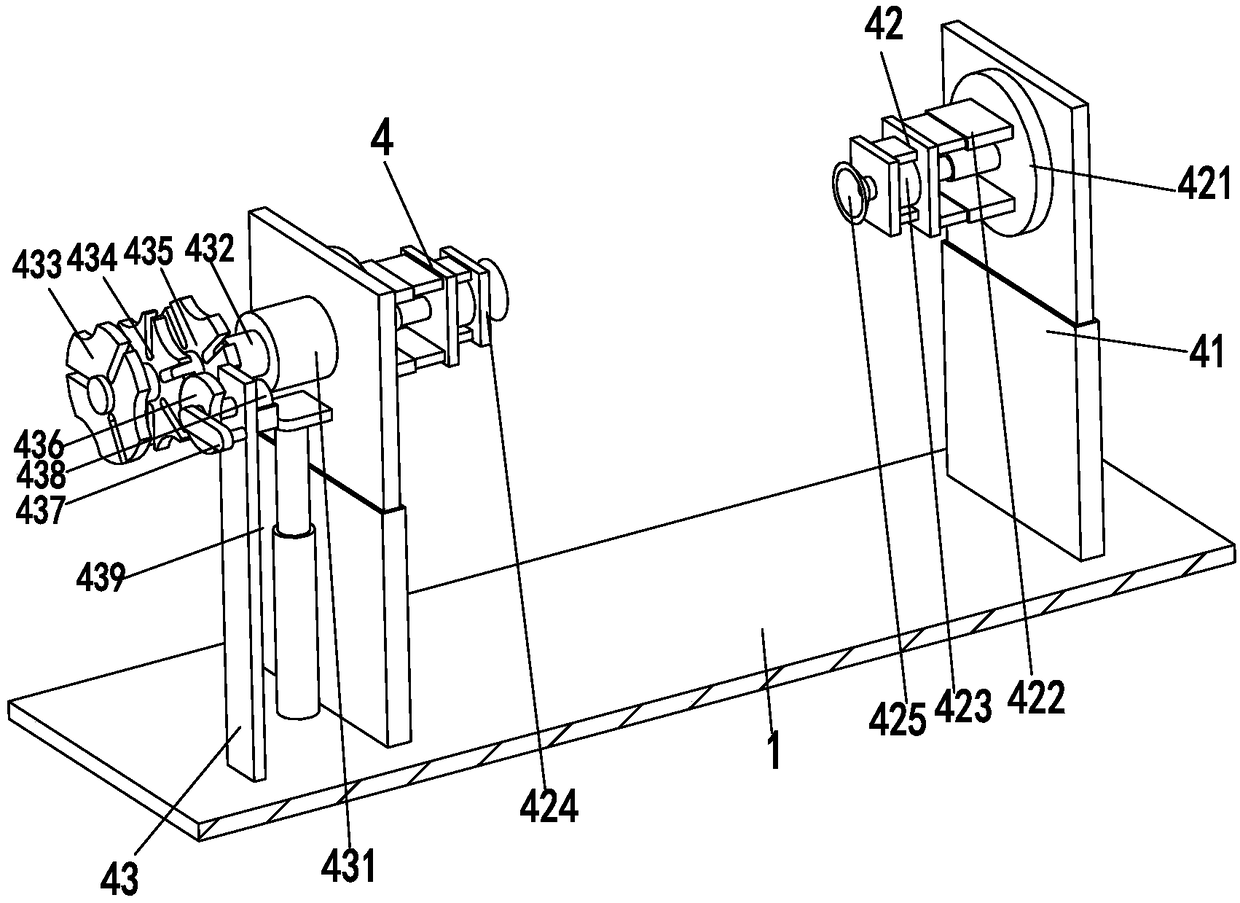

Robot device for automatically shimming transformer

ActiveCN103559999AReduce labor intensityMeet automation requirementsInductances/transformers/magnets manufactureConveyor partsTransformerEngineering

The invention discloses a robot device for automatically shimming a transformer, belonging to the technical field of a large transformer. The robot device comprises a strip carrying robot, wherein the strip carrying robot is installed on the ground; strip positioning devices are installed on the tail end of the strip carrying robot; shimming robots are installed on the tail ends of the strip positioning devices. The robot device is reliable in structure and high in automation.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

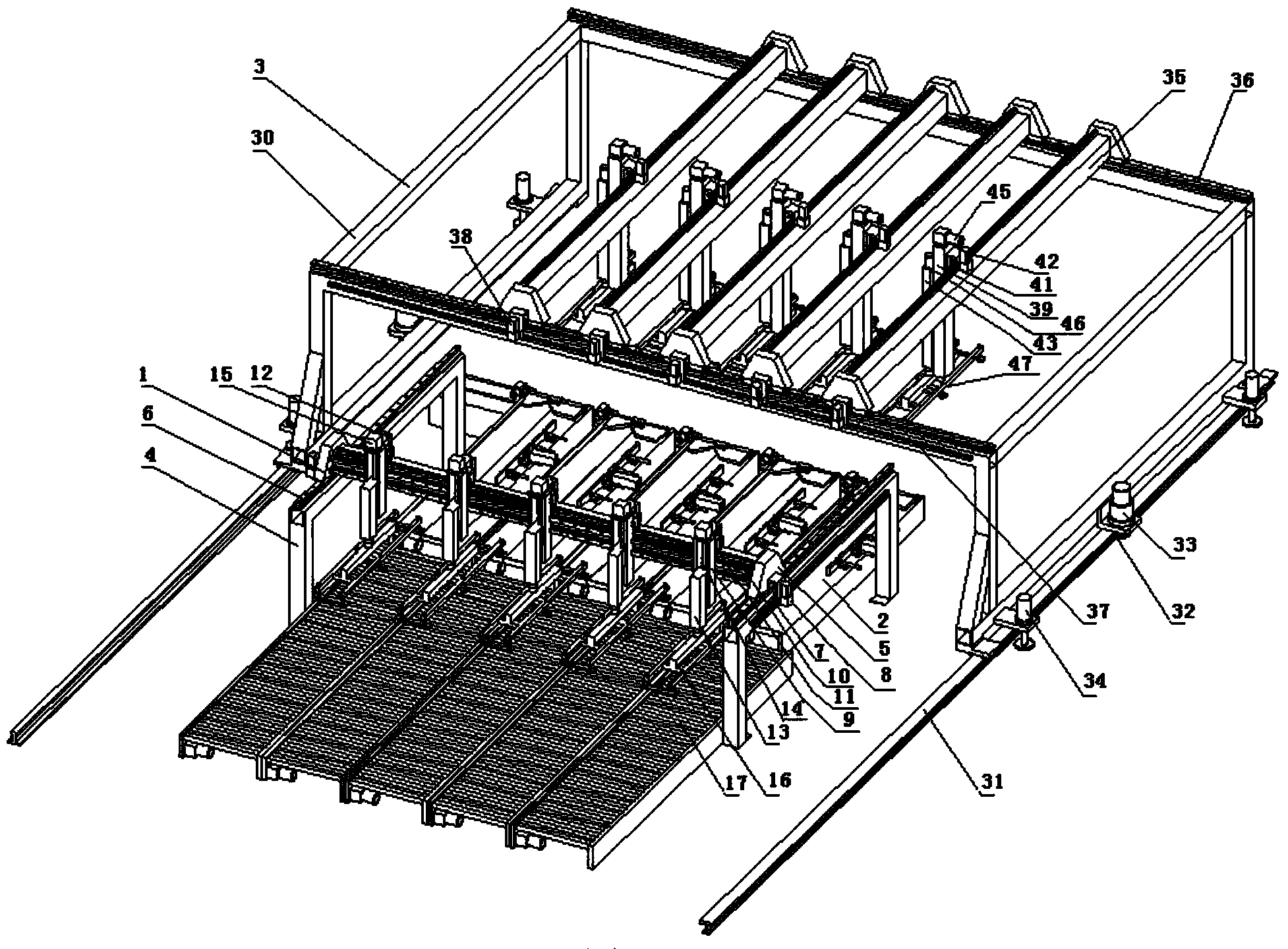

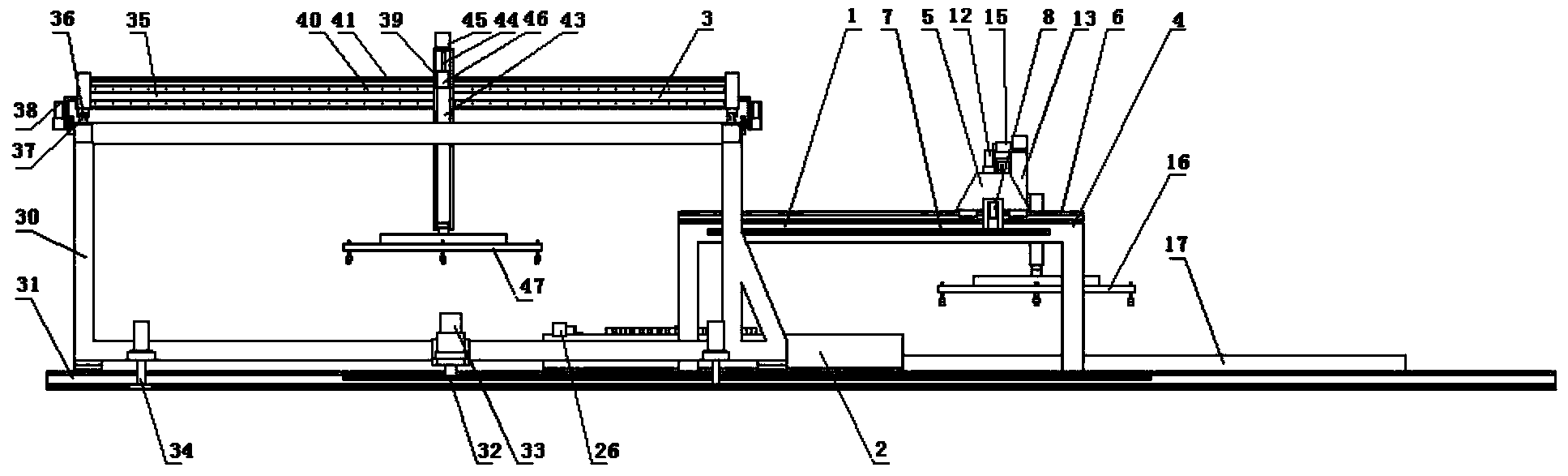

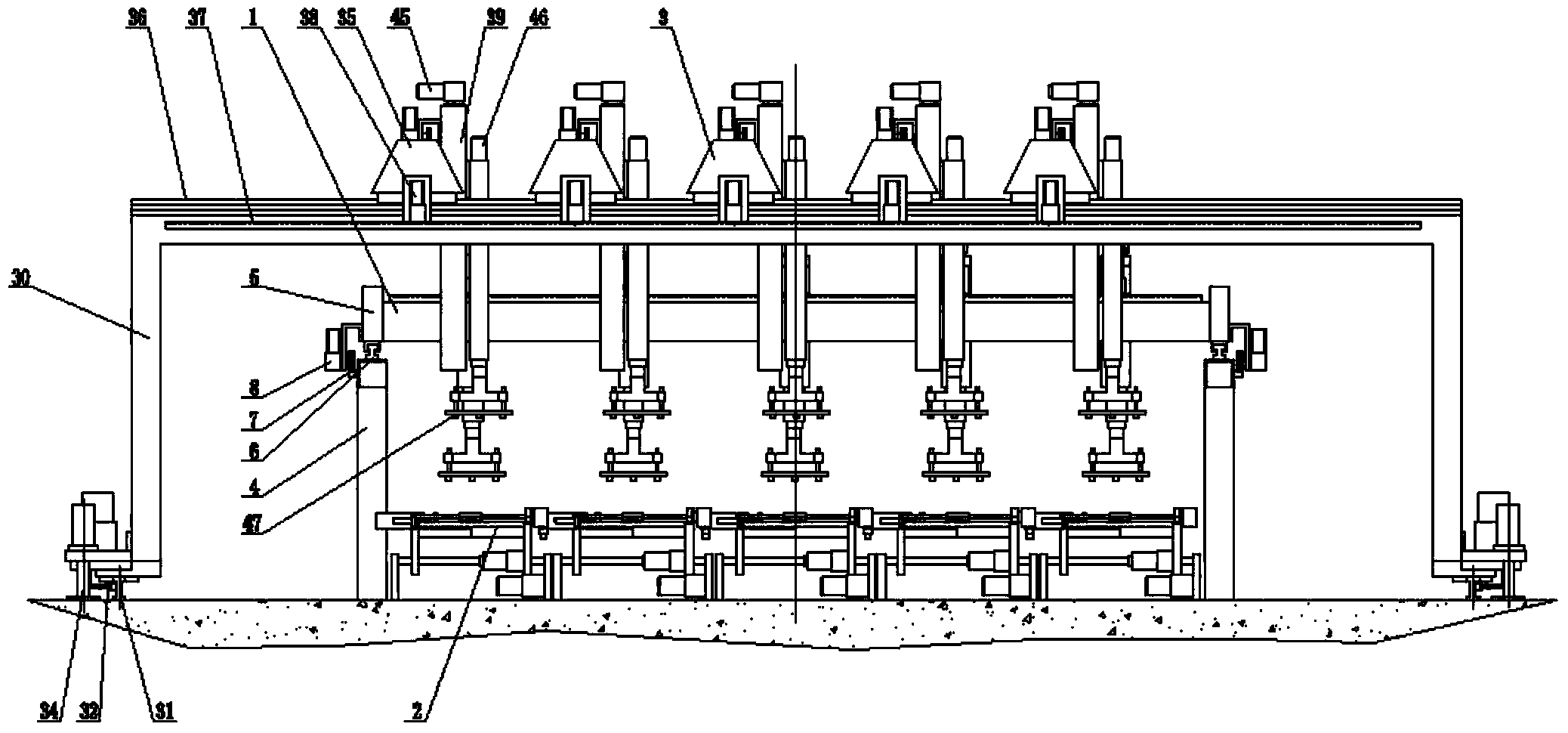

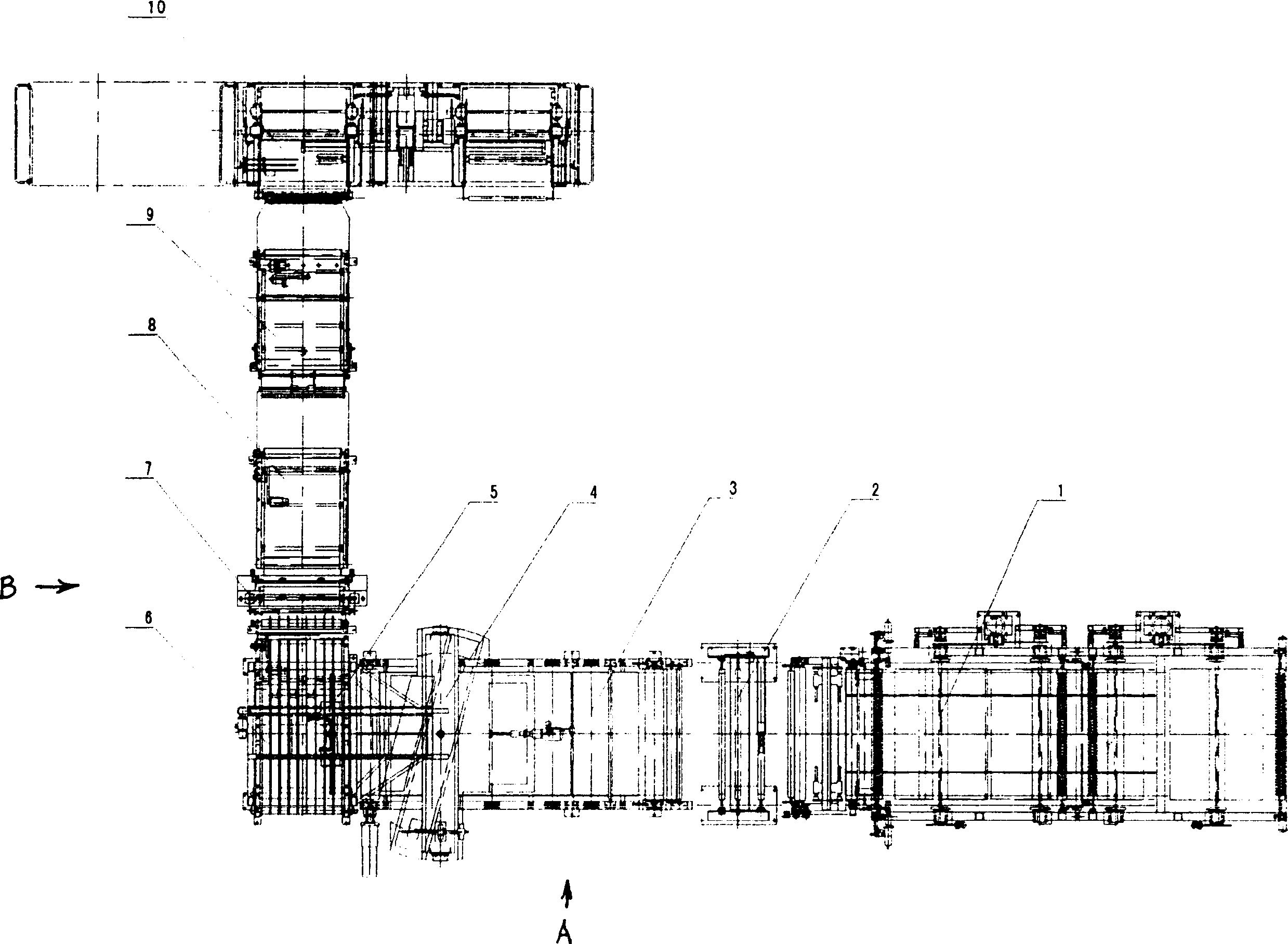

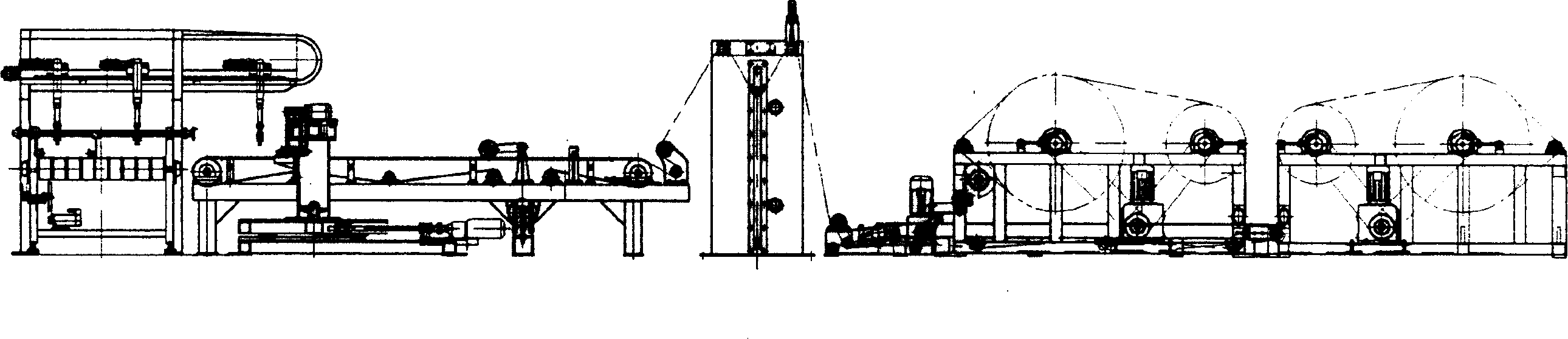

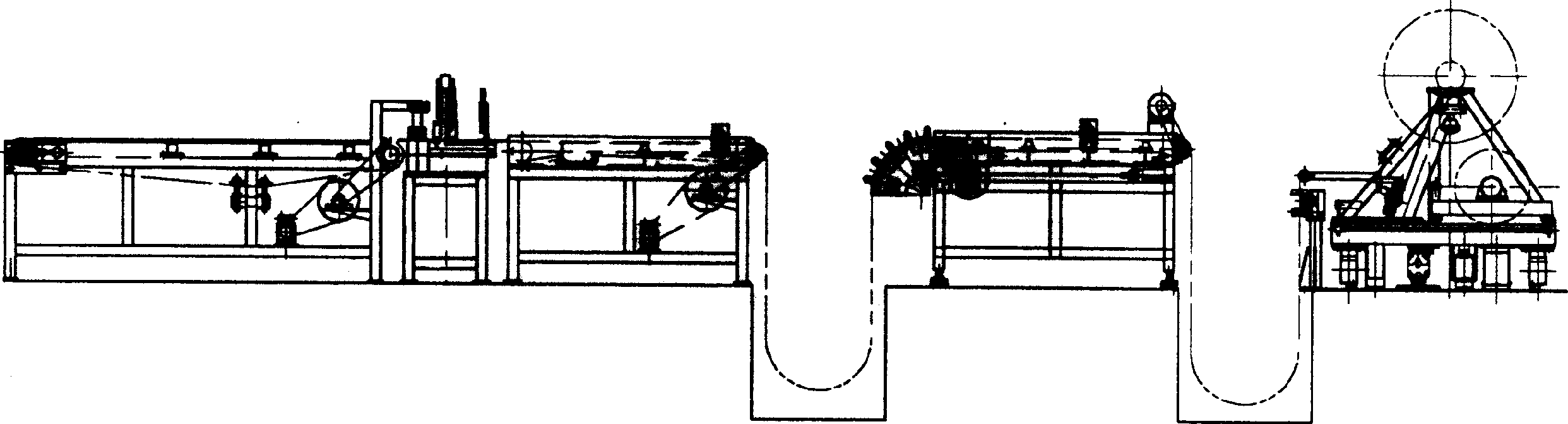

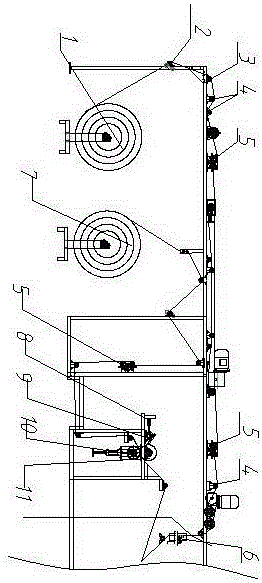

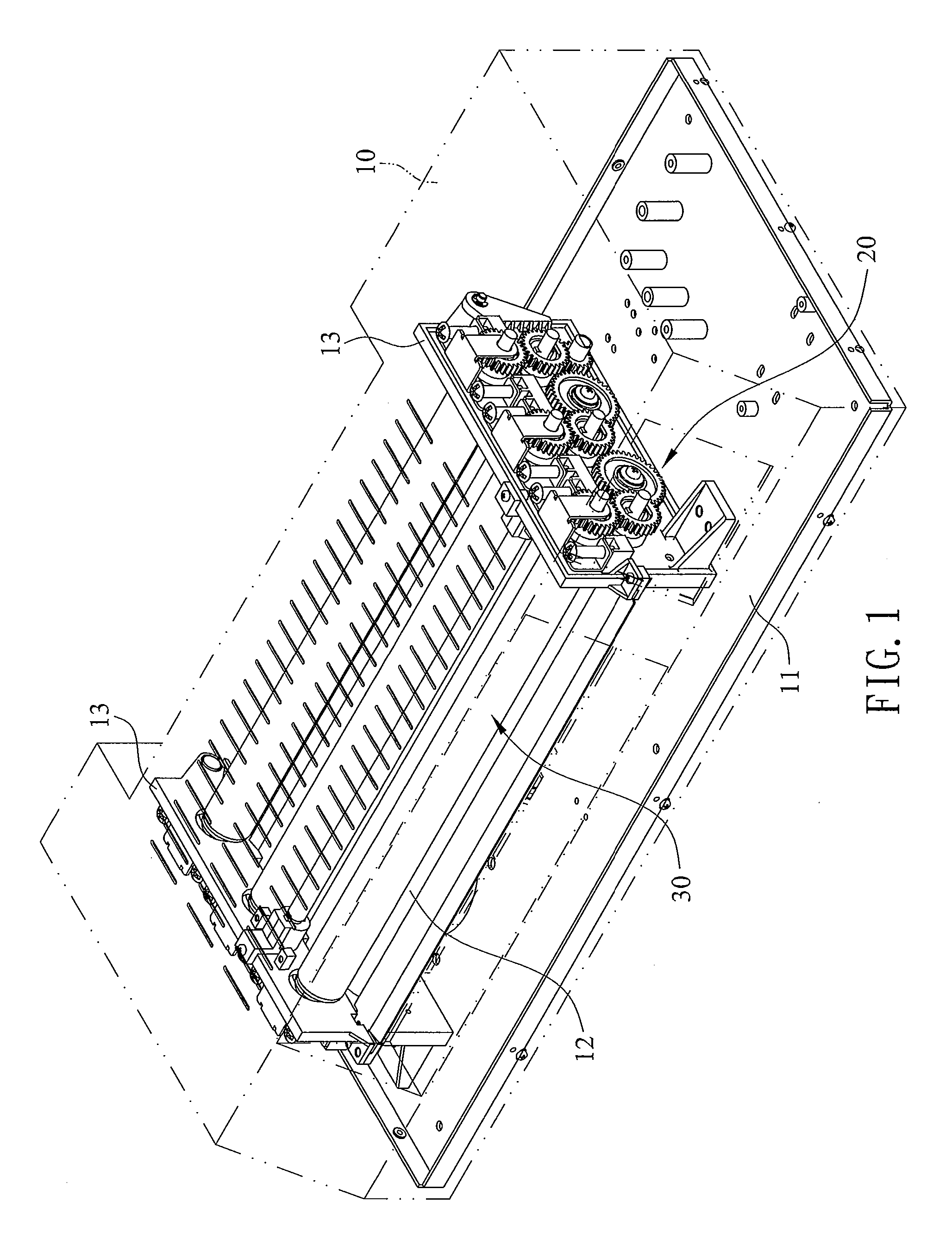

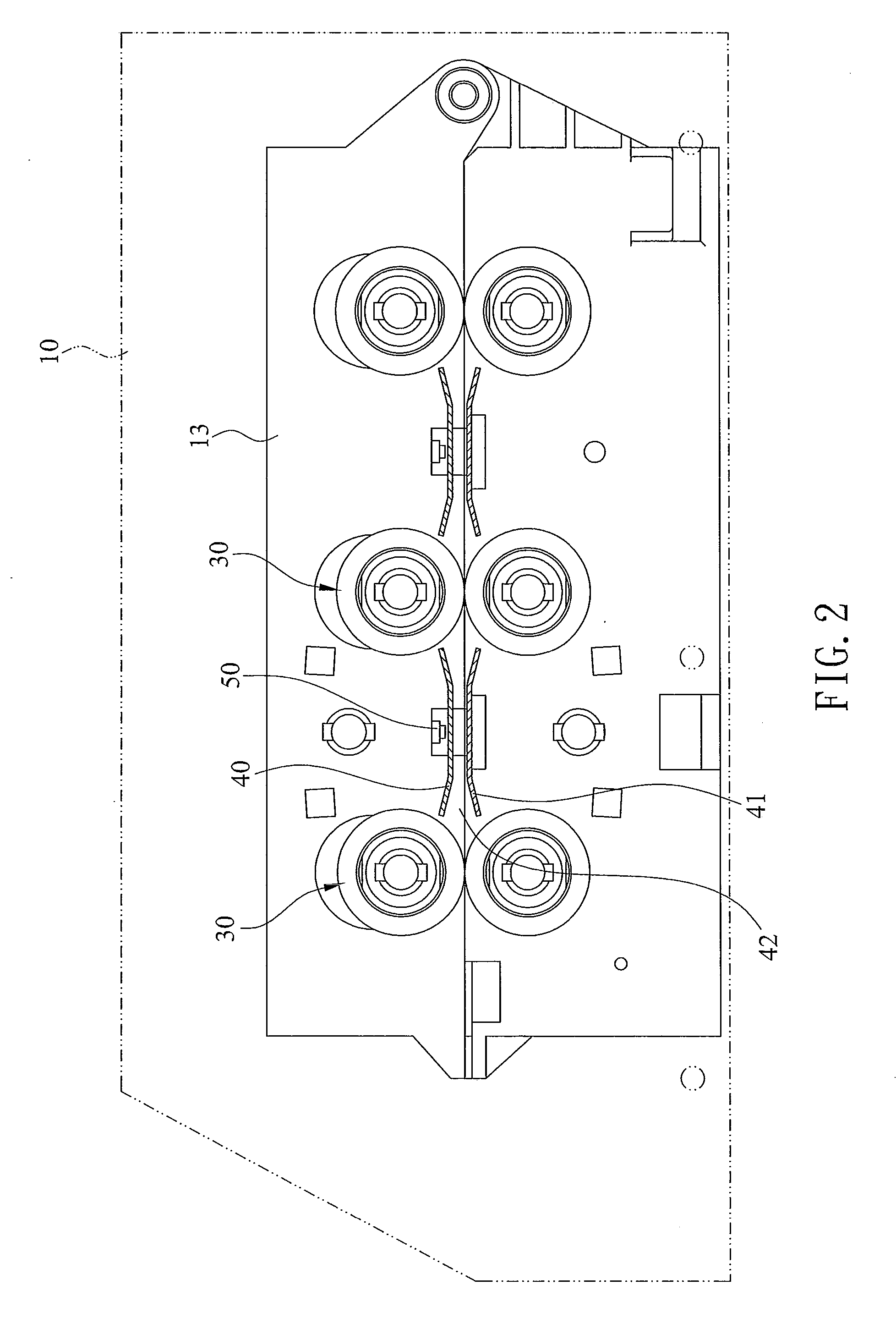

Automatic machine for cutting and jointing cord fabric of radial plytyre

InactiveCN1526545AImprove lap joint dimensional accuracyImprove the intrinsic quality of the structureSevering textilesTyresConductor CoilMechanical engineering

The automatic machine for cutting and jointing cord fabric of radial plytyre features that it consists of two work sites, each of which consists of unwinding unit, fabric storing unit, conveying belt A, cutter, automatic fabric feeder, conveying belt B, jointing unit, conveying belt C, aligning unit and winding unit connected successively, with the cutter, the automatic fabric feeder and the jointing unit being not in the same plane as other units. The present invention has the advantages of automatic operation.

Owner:TIANJIN PLASTIC RUBBER MACHINERY INST

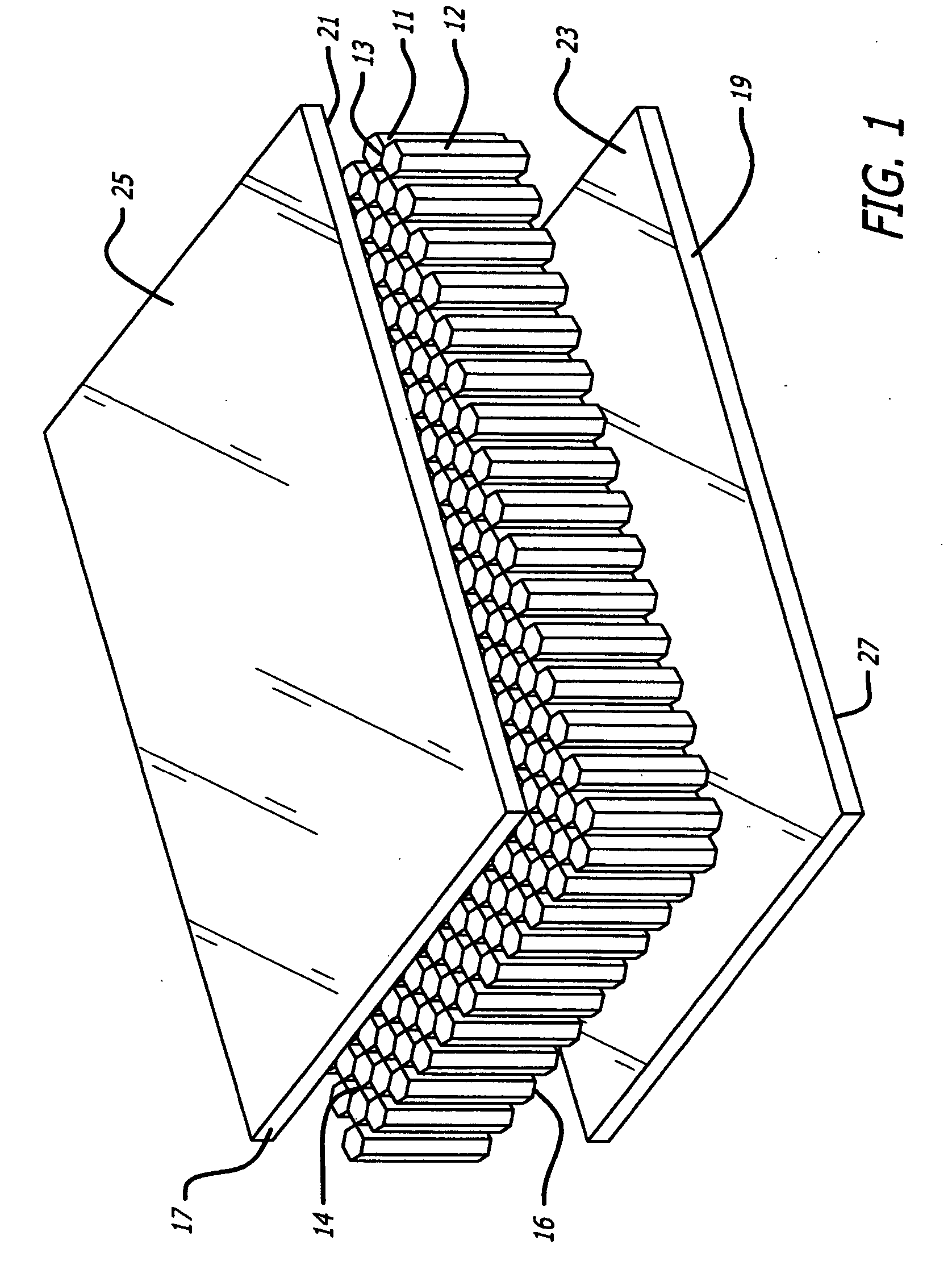

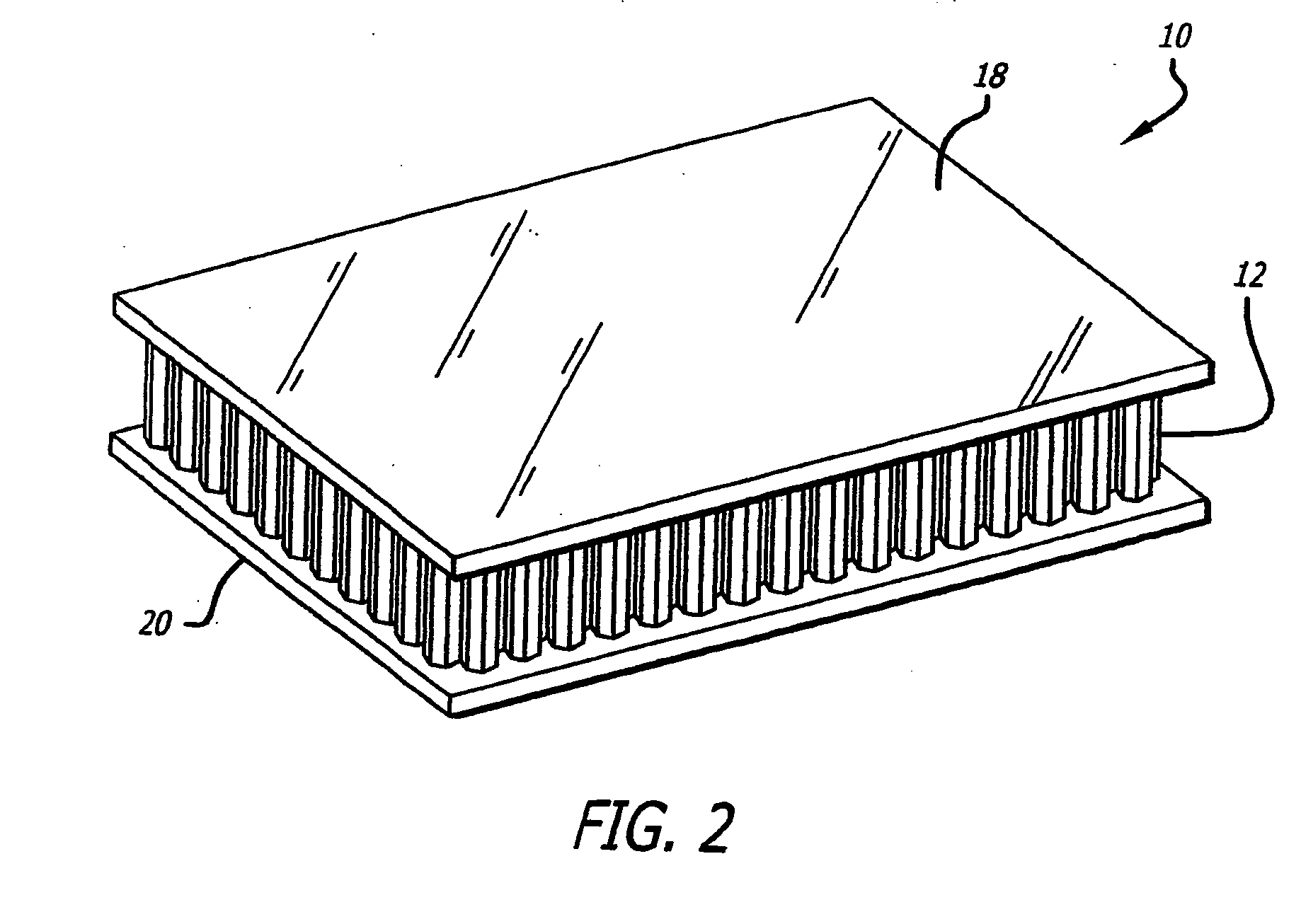

Bismaleimide prepreg systems

ActiveUS20070134480A1Excellent characteristicsIncrease flexibilitySynthetic resin layered productsRecord information storageHoneycombMonomer

Prepreg composite materials that include a fiber layer and a prepreg resin composed of a bismaleimide resin component, a thermoplastic toughening agent and a resin distribution stabilizer. The bismaleimide component is an amorphous mixture of at least three different bismaleimide monomers and a co-curing agent. The prepreg is useful in panel construction where a honeycomb core is sandwiched between two sheets of composite material.

Owner:HEXCEL

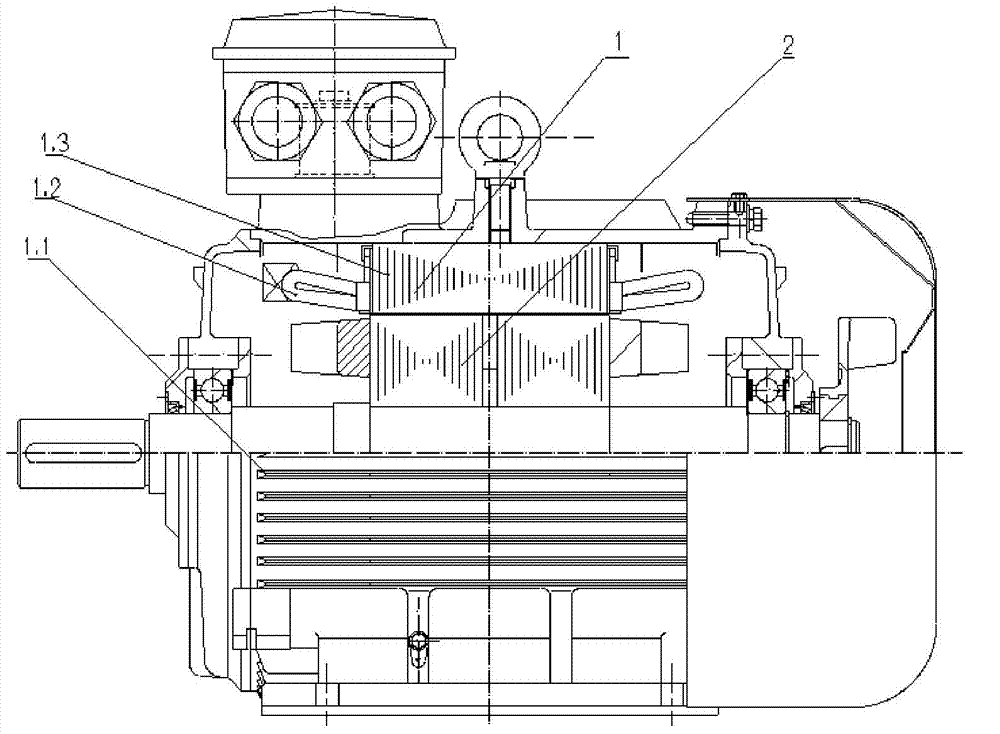

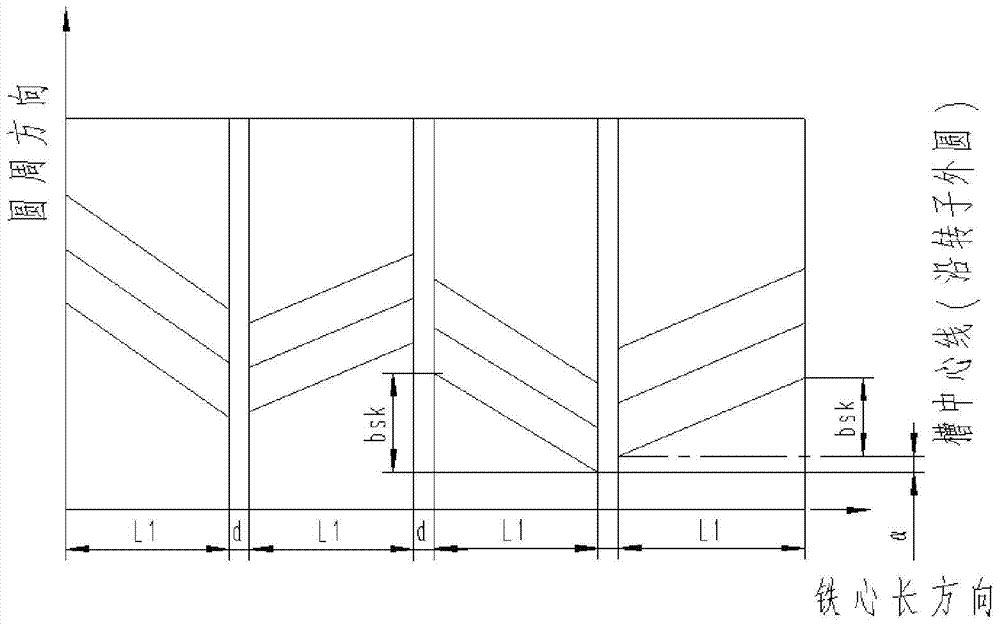

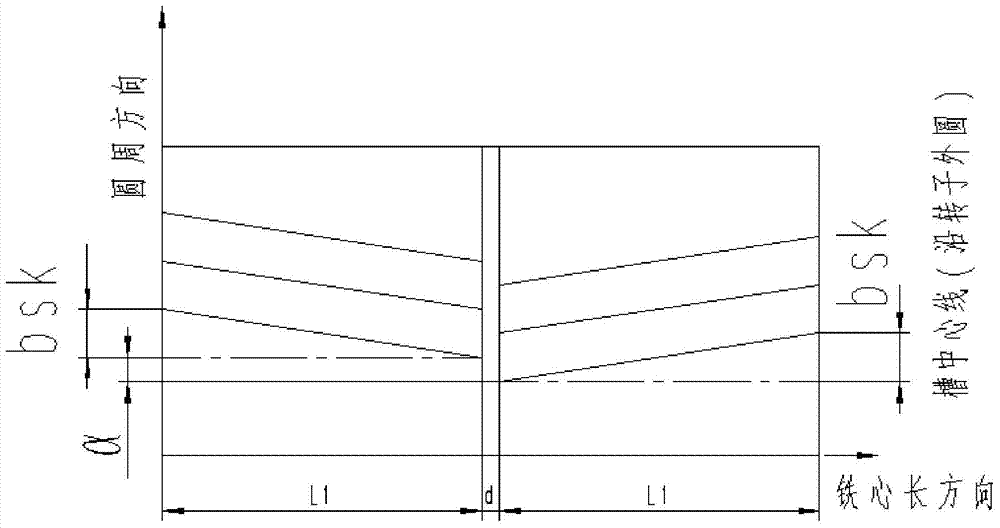

Chute low-noise motor

ActiveCN103501065AEliminate axialEliminate torsional vibrationMagnetic circuit rotating partsLow noiseElectric machine

The invention relates to a motor, in particular to a chute low-noise motor, which comprises a machine seat, a stator, a rotor and a rotating shaft, wherein the stator, the rotor and the rotating shaft are arranged on the machine seat, the rotor comprises at least two sections of rotor iron cores, the rotor iron cores are punched and laminated by a false axis inclination angle taper key method to form chute iron cores; chutes of the adjacent chute iron cores are in opposite directions and are in arrangement in a way of staggering for an angle alpha. Therefore, the chute low-noise motor has the following advantages that 1, great-degree optimization is respectively realized in aspects of vibration, noise, iron core laminating quality, cast aluminum quality and chute cast aluminum rotor structure adopted by a high-power motor, and the chute low-noise motor is suitable for small and medium-sized cast aluminum rotor structure alternating current motors with higher vibration and noise requirements; 2, the stress uniformity and the rigidity of iron core laminating punching are fundamentally ensured, the iron core laminating quality is improved, the influence of deformation on vibration noise is reduced, the aluminum overflowing and bubble problems are solved, and the quality of the cast aluminum rotor and the motor performance reliability are improved.

Owner:中国船舶重工集团公司第七一二研究所

Photovoltaic cell packaging technology for double-sided glass curtain

InactiveCN101587921AStable positionEasy laminationWallsSemiconductor devicesElectrical batteryEngineering

The invention discloses a photovoltaic cell packaging technology for a double-sided glass curtain, which comprises the following steps: front side welding, back side serial connection, laminated laying, component lamination and battery trimming. The photovoltaic cell packaging technology can vacuumize and remove air bubbles by lamination with good lamination effect; the lamination is performed by several times to ensure that the relative position of a component string and glass and the like, and the lamination quality is high; and the curing time is short and the production efficiency is high.

Owner:HUAIAN WEIHAO NEW ENERGY TECH

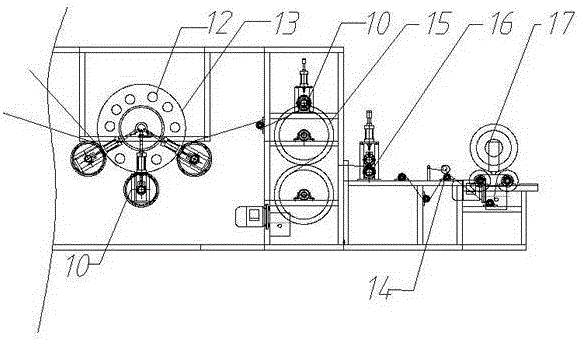

Multi-purpose type double-sided film laminating system

InactiveCN107160852AAvoid wrinklesFully warmed upLamination ancillary operationsLaminationMechanical engineeringEnergy conservation

The invention discloses a multi-purpose type double-sided film laminating system applied to a film laminating machine. The multi-purpose type double-sided film laminating system comprises a rack (14), an upper film roller (1) and a hot-pressing mechanism, wherein a gluing mechanism and a drying mechanism (5) are installed in sequence on the rack and above the hot-pressing mechanism, and a preheating roller (13) and a lower film roller (10) are installed in sequence on the rack and below the hot-pressing mechanism. An extension roller (11) is installed on the rack and between the preheating roller and the lower film roller, and the extension roller is connected with an extension power source (12).According to the multi-purpose type double-sided film laminating system, instant coating or precoating can be flexibly selected, so that the convenience is provided for the next processing procedure after a film is laminated on paper, the film can be effectively prevented from generating wrinkles during operation, a big enough wrap angle between the film and the preheating roller is guaranteed so as to be fully preheated, and the film laminating quality is high. The multi-purpose type double-sided film laminating system has the advantages of reasonable structure, simplicity in operation, energy conservation, environmental friendliness and high heat utilization rate, multiple purposes of one machine are realized, and the multi-purpose type double-sided film laminating system can be widely used for various paper materials.

Owner:RUIAN GREAT PRINTING & PACKAGING MACHINERY

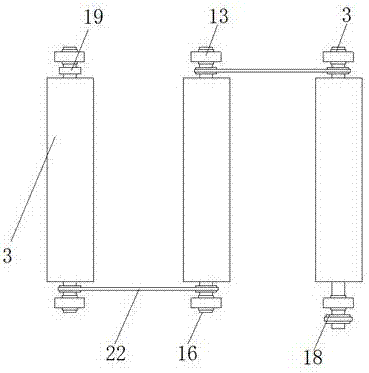

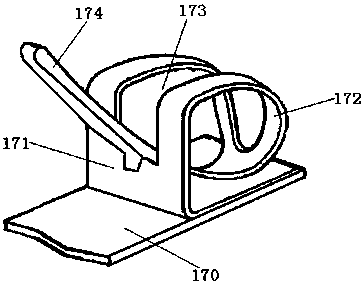

Laminating device used for identifying labels and operation method of laminating device

The invention discloses a laminating device used for identifying labels. The laminating device comprises a control console, a guide roller, bushings, transmission rollers, a motor, a top plate, an adjusting plate and a press roller and is characterized in that the operating console is arranged on a support, a bearing plate is arranged on the support, limit slots are arranged in vertical plates, the guide roller is arranged between fixing plates through a connecting shaft, the bushings are arranged in the corresponding limit slots, the connecting shafts are arranged at two ends of the transmission rollers, the motor is arranged on the bearing plate, the top plate is arranged on uprights, an air cylinder is arranged on the top plate, the adjusting plate is arranged on a piston rod, a positioning plate is arranged on the adjusting plate, and the press roller is arranged between positioning plates through the connecting shafts. The guide roller is arranged between the fixing plates, partition plates are arranged on the guide roller and can prevent a thin film skewing on the guide roller, and laminating quality in identifying the labels is improved.

Owner:ANHUI STARLIGHT LOGO SYST CO LTD

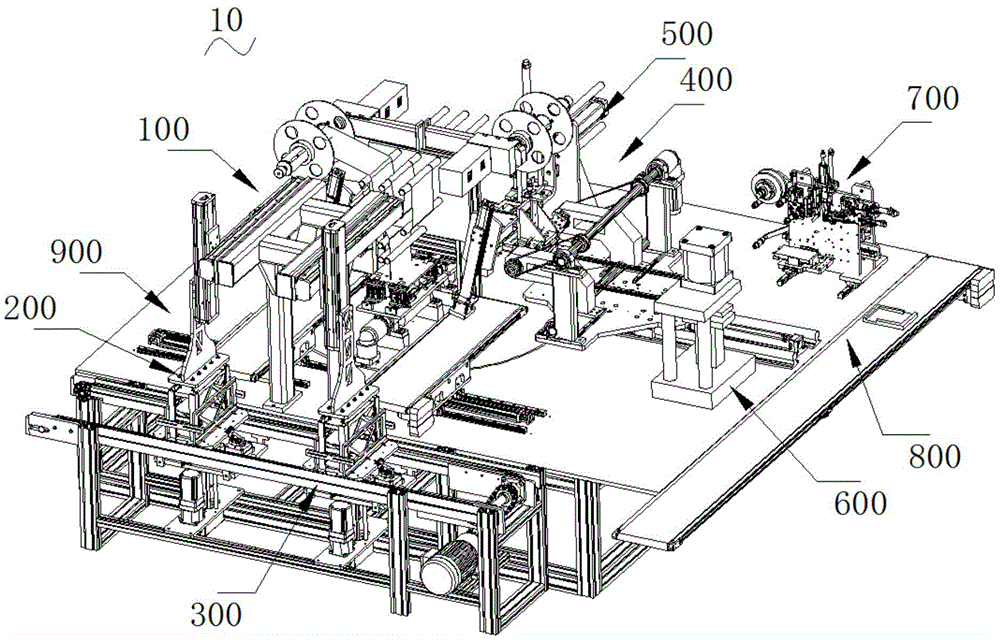

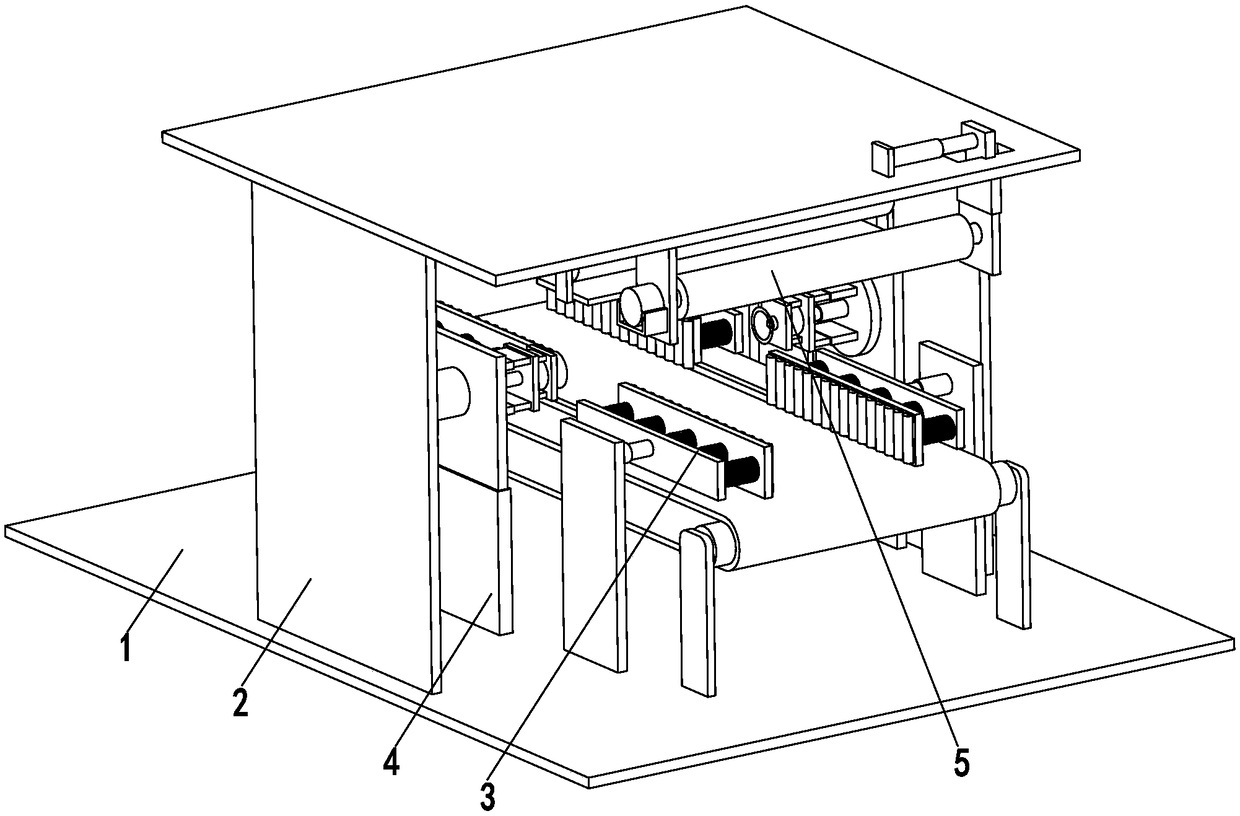

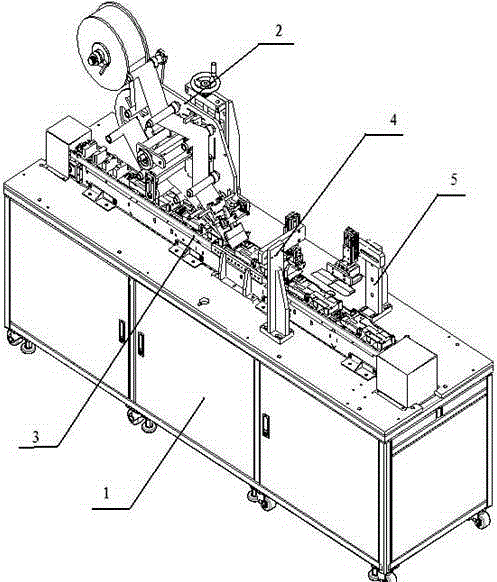

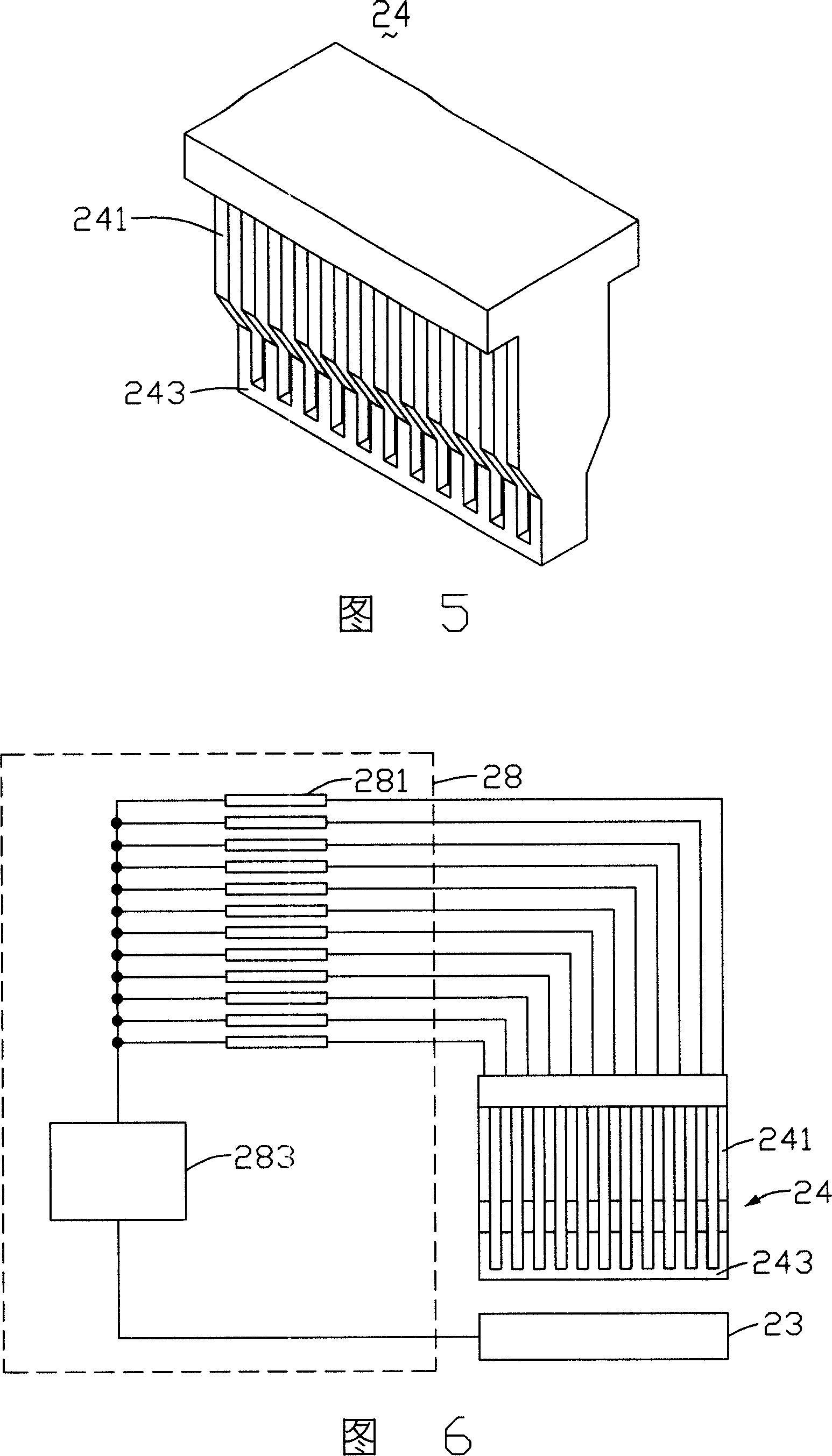

Printed matter surface automatic laminating robot

ActiveCN109016830ARealize automatic laminationLaminating difficulty is smallPrinting press partsEngineeringMechanical engineering

The invention relates to a printed matter surface automatic laminating robot. The printed matter surface automatic laminating robot comprises a bottom plate, a mounting frame, a conveying device, a fixing device and a laminating device. The conveying device is mounted on the bottom plate, the fixing device is arranged on the front side of the conveying device, the mounting frame is arranged on theupper side of the conveying device, an auxiliary sliding groove is formed in the mounting frame, both the fixing device and the mounting frame are mounted on the bottom plate, and the laminating device is mounted at the lower end of the mounting frame. The conveying device comprises a conveyor, a fixing plate, a positioning air cylinder, a positioning plate, a spring and an auxiliary frame. The fixing device comprises a telescopic lifting plate, a fixing mechanism and a rotating mechanism. The problems that in the existing prismatic product laminating process, the laminating difficulty is high, the laminating effect is not ideal, and the working stability and the adjustability are poor can be solved, the function of automatic laminating of prismatic products can be achieved, and the printed matter surface automatic laminating robot has the beneficial effects that the laminating difficulty is low, the laminating effect can be improved, and the stability and the adjustability are good.

Owner:镇江恒华彩印包装有限责任公司

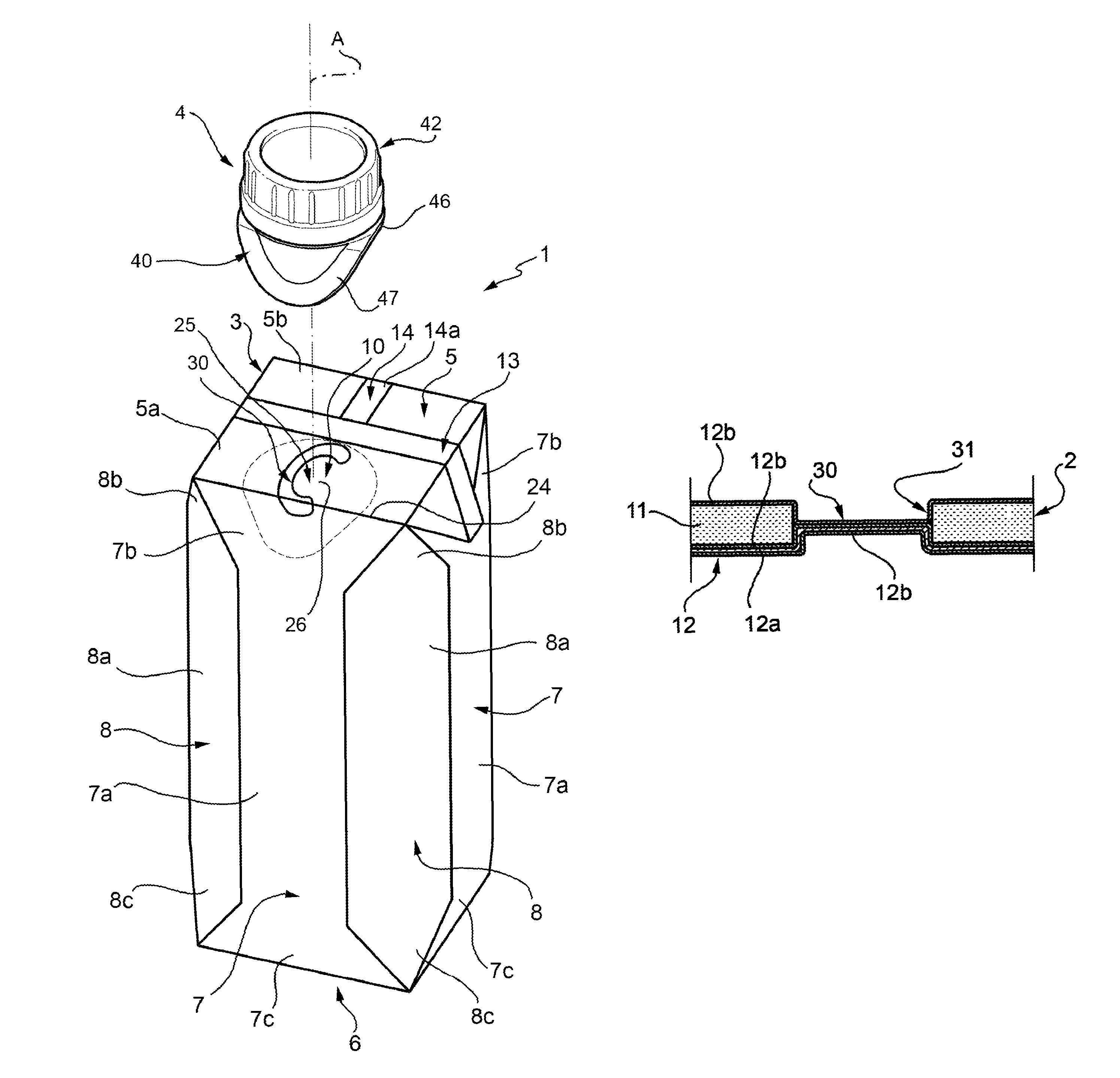

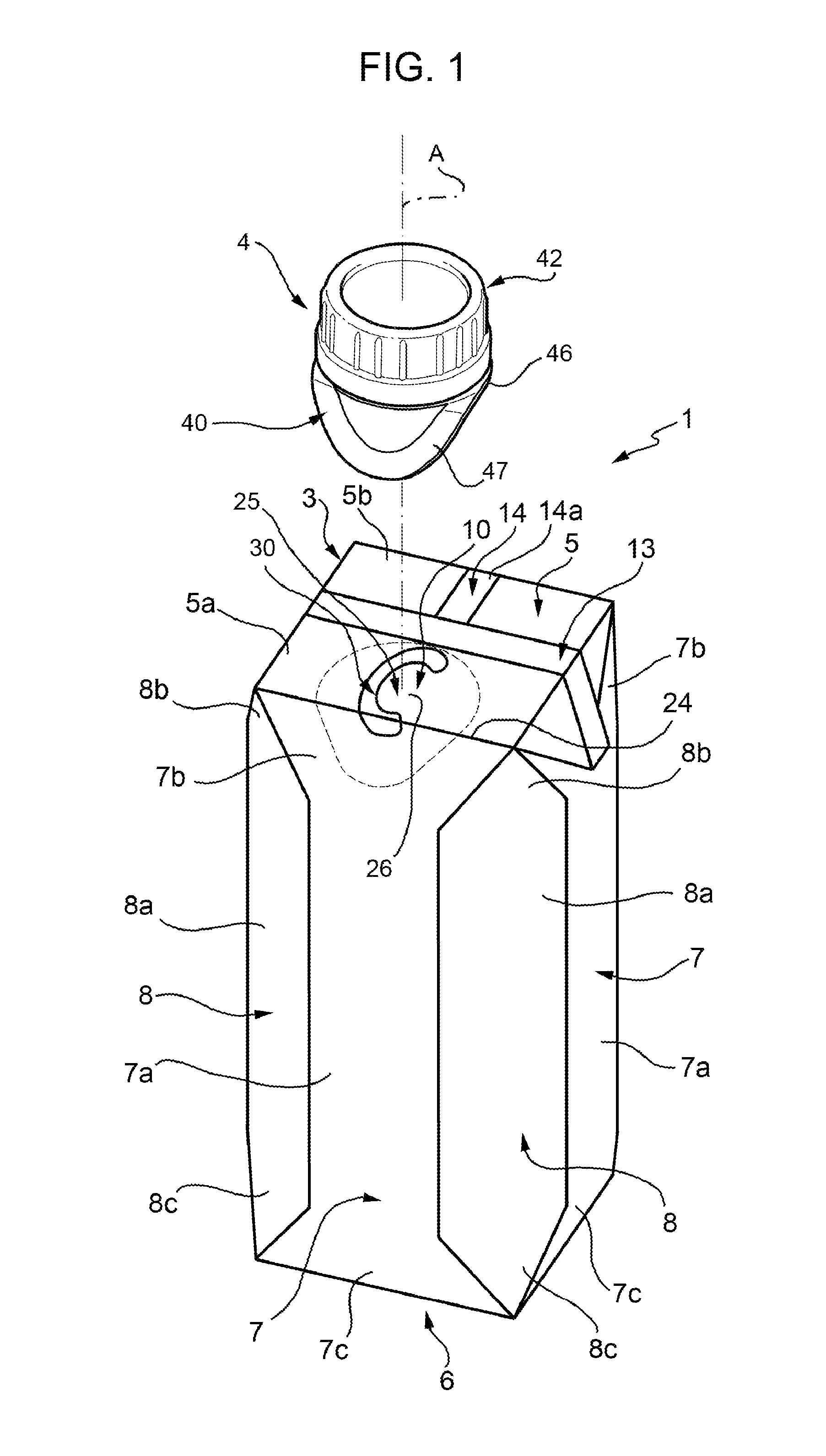

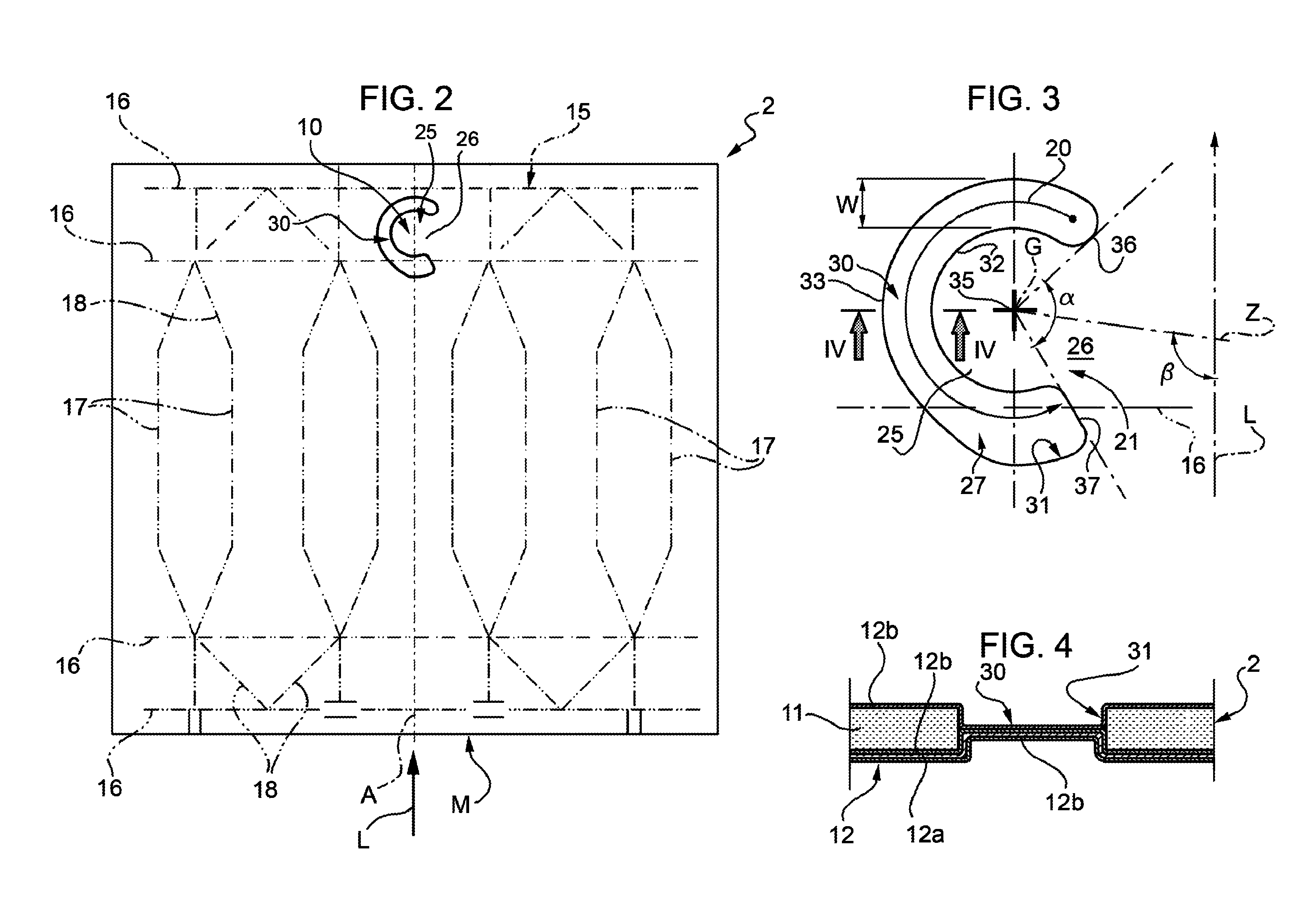

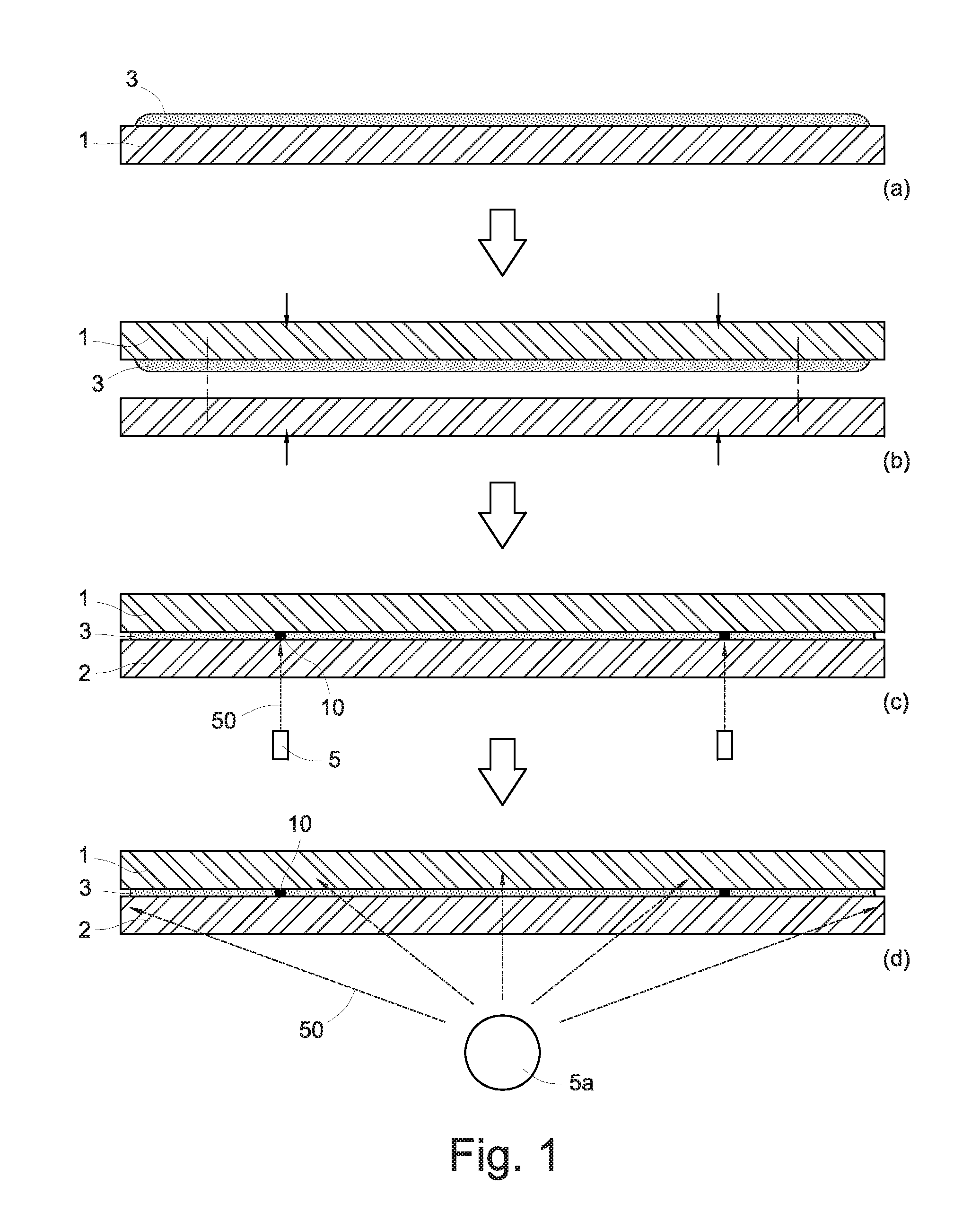

Sheet packaging material for producing sealed packages of pourable food products

InactiveUS9487324B2Improve lamination qualityIncrease speedPackaging milkThin material handlingEngineeringBiomedical engineering

A sheet packaging material for producing a sealed package of a pourable food product comprises one base layer, a number of lamination layers covering both sides of the base layer, and a removable portion which, in use, can be detached partly from the rest of the packaging material along at least one arc-shaped cutting line and folded at a folding zone extending between opposite ends of the cutting line to free a pour opening; the removable portion comprises a central area made of whole packaging material and which, in use, remains attached to the rest of the packaging material through a permanent bridge defined by the folding zone, and a peripheral area for cutting interaction, extending around part of the central area, containing the cutting line and including at least one pre-laminated opening formed by a through slot at least in the base layer and covered by one or more of the lamination layers.

Owner:TETRA LAVAL HLDG & FINANCE SA

Non-setting adhesive laminator device for uniform gluing and cutting

ActiveCN110667227AApply evenlyReduce lossLamination ancillary operationsLaminationIndustrial engineeringFully automated

The invention relates to the technical field of machinery, and concretely relates to a non-setting adhesive laminator device for uniform gluing and cutting. The device comprises a supporting frame, afeeding mechanism, a non-setting adhesive recovery mechanism, a rolling mechanism and a cutting mechanism, the feeding mechanism is fixedly arranged above one end of the supporting frame, the non-setting adhesive recovery mechanism is fixedly arranged above one end of the feeding mechanism, a first raw material frame is arranged below the side of the feeding mechanism, the first raw material frameis fixedly arranged at one end of the supporting frame, second raw material frame is arranged above the side of the feeding mechanism, the rolling mechanism is fixedly arranged at the middle of thesupporting frame, the cutting mechanism is fixedly arranged at the other end of the supporting frame, and the rolling mechanism is fixedly arranged at one side, away from the rolling mechanism, of thecutting mechanism. The non-setting adhesive laminator device for uniform gluing and cutting raw materials has the advantages of realization of fully-automatic production processing of raw materials,great reduction of the loss of human resources, high film laminating quality, easiness and convenience in operation, and according with the market requirements.

Owner:青岛宏特服饰有限公司

Heat element for maintaining laminator at predetermined working temperature

InactiveUS20090039075A1Improve lamination qualityOhmic-resistance heating detailsHeating element materialsThermodynamicsWorking temperature

A heating element that can maintain a laminator at a predetermined working temperature is disclosed. A low-power heating filaments and a high-power heating filaments are sandwiched between insulators. The high-power heating filaments are shut down once it is heated to a predetermined temperature. The low-power heating filaments are then turned on to maintain a constant temperature. When the temperature drops below a predetermined temperature, the low-power heating filaments are shut down and the high-power heating filaments are turned on to heat up the laminator. The temperature is thus maintained within a predetermined range through such cycles.

Owner:MICHILIN PROSPERITY

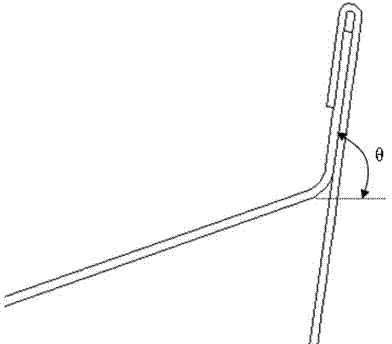

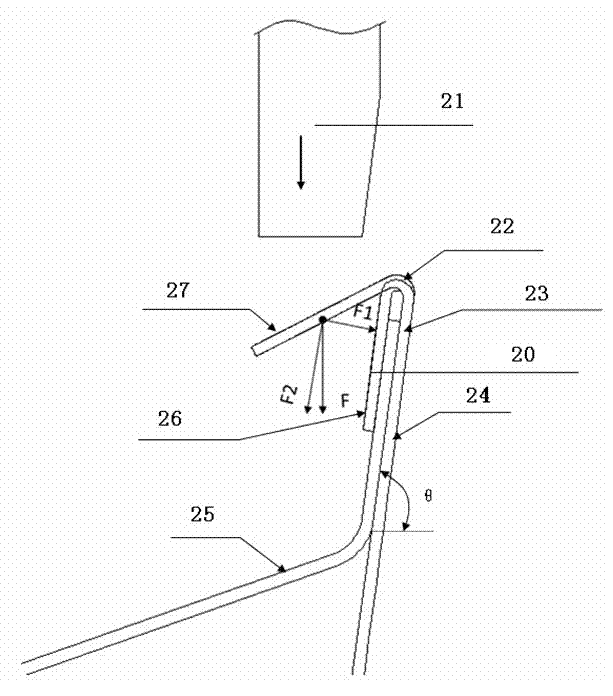

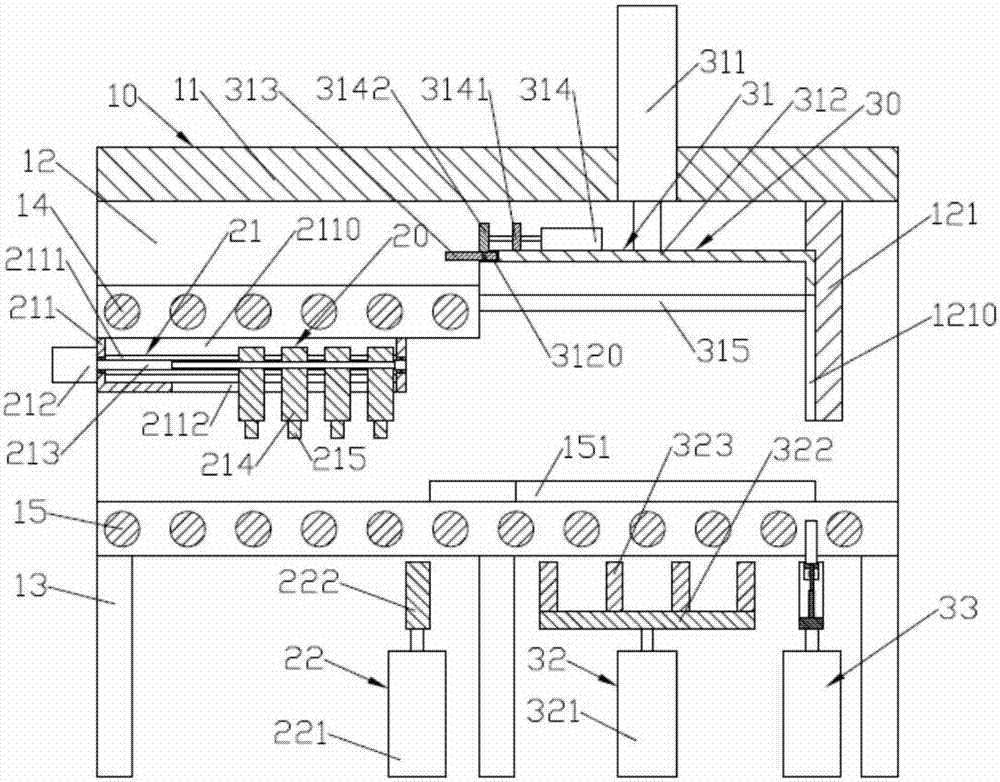

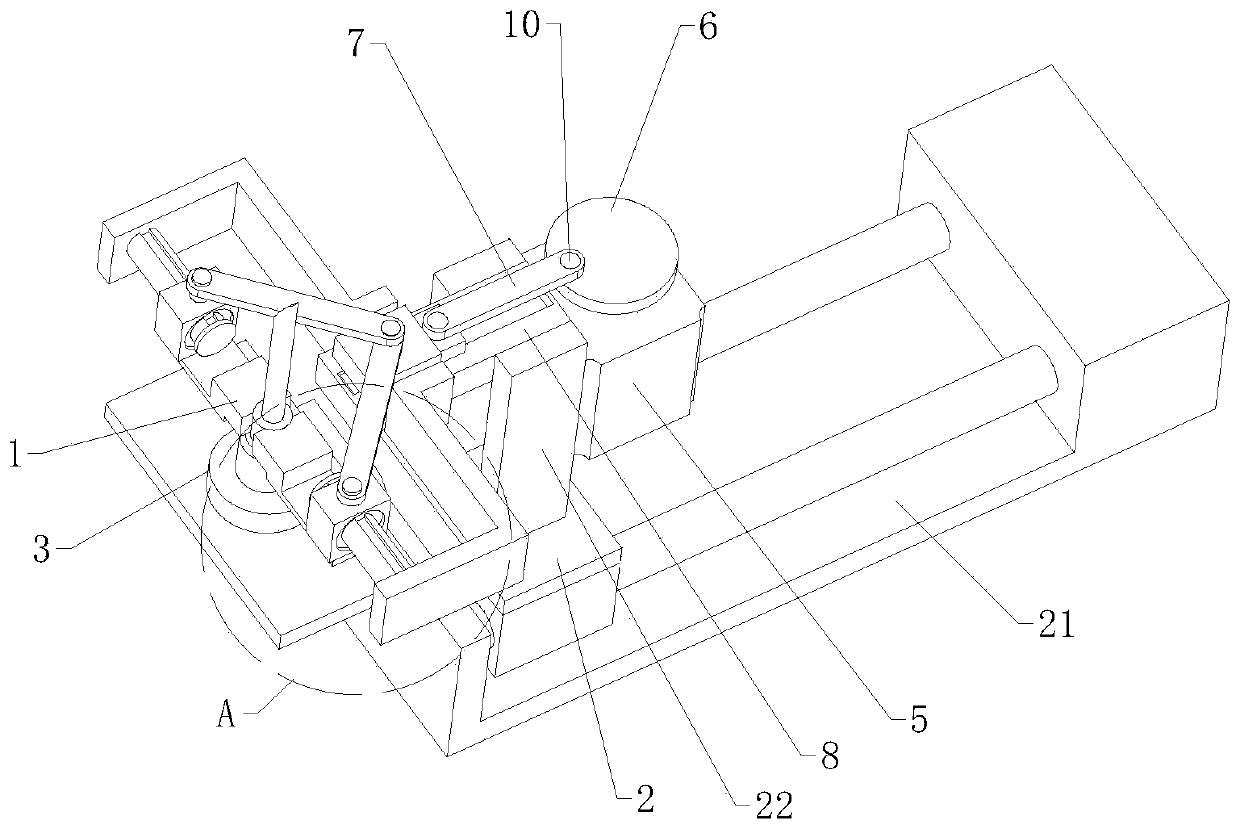

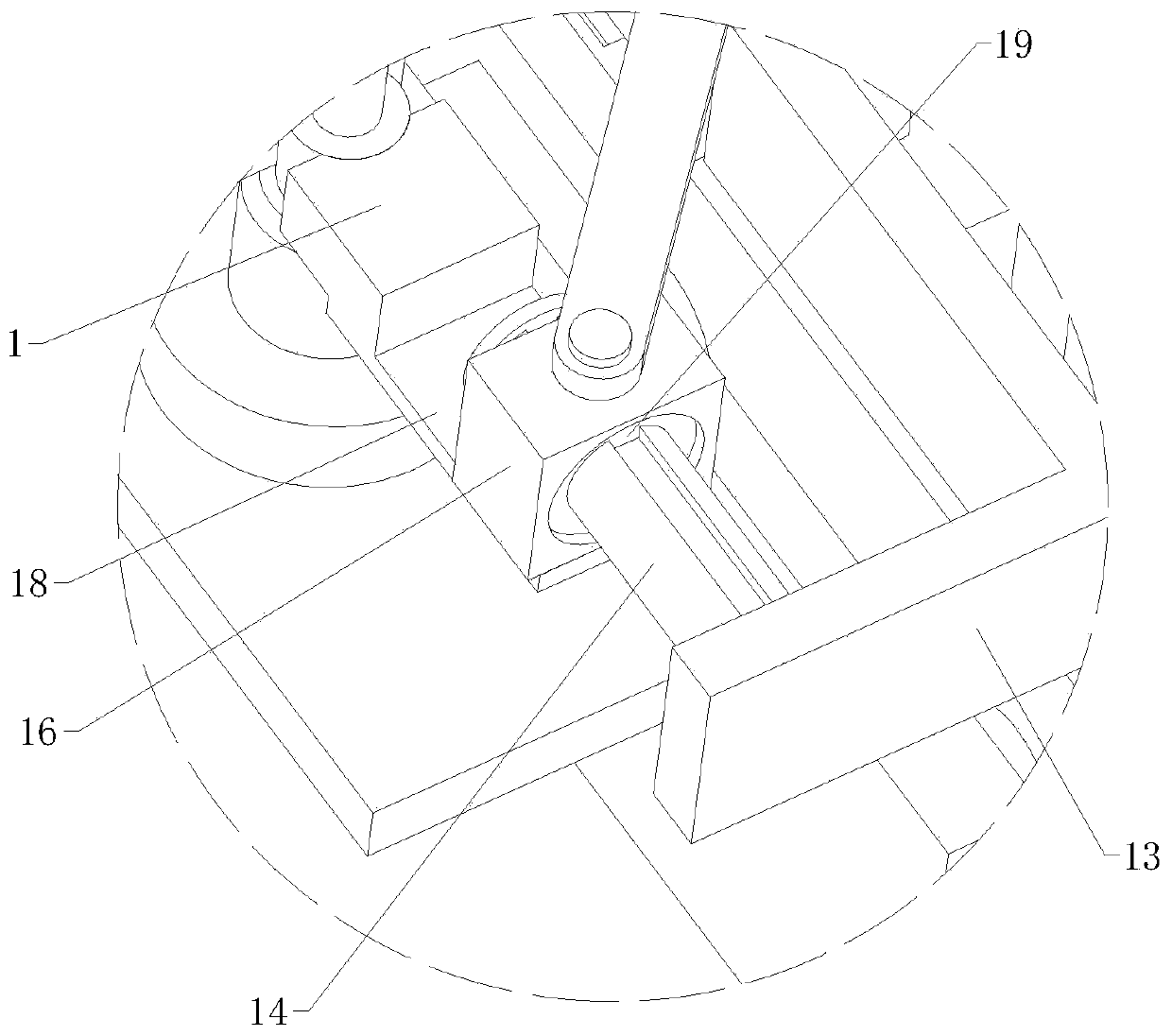

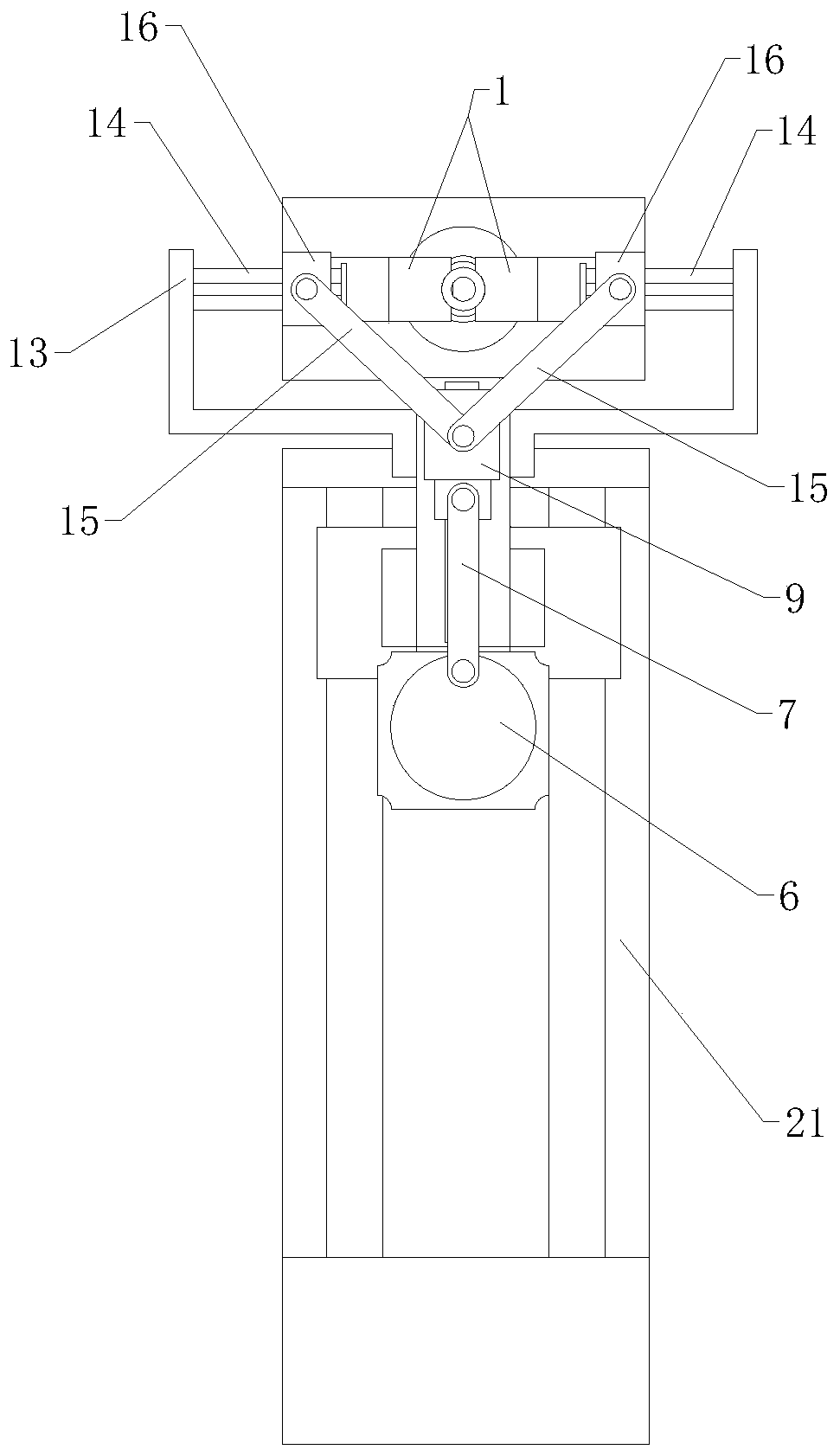

Edge covering mold structure with rotating press fit wedge

The invention relates to an edge covering mold structure with a rotating press fit wedge. The edge covering mold structure comprises an upper mold body (1) and a lower mold body (4), a lower mold insert (3), a pre-bending wedge (5) and a press fit driving block (6) are arranged on the lower mold body (4), a pre-bending drive block (8) and the rotating press fit wedge (9) are arranged on the upper mold body (1), a pre-bending insert (2) is fixedly arranged on the pre-bending wedge (5), a press fit insert (10) is arranged on the rotating press fit wedge (9), a plate is arranged on the lower mold insert (3) and is composed of an inner plate (25) and an outer plate (24), and the edge covering mold structure is characterized in that the moving direction of the press fit insert (10) is changed through the rotating press fit wedge (9), the press fit insert (10) conducts press fit edge coverage in the normal direction of the press fit edge coverage face, and the phenomenon that in the press fit process of an existing press fit edge coverage mold structure, component force parallel to the press fit edge coverage face is generated, an appearance ridge and the outer surface of a press fit edge coverage association part are stretched, and the plate is deformed is avoided.

Owner:CHERY AUTOMOBILE CO LTD

Automatic board laminating device

ActiveCN107139570ASpray evenlyReduce labor intensityLaminationLamination apparatusEngineeringMechanical engineering

Owner:唐山光跃商贸有限公司

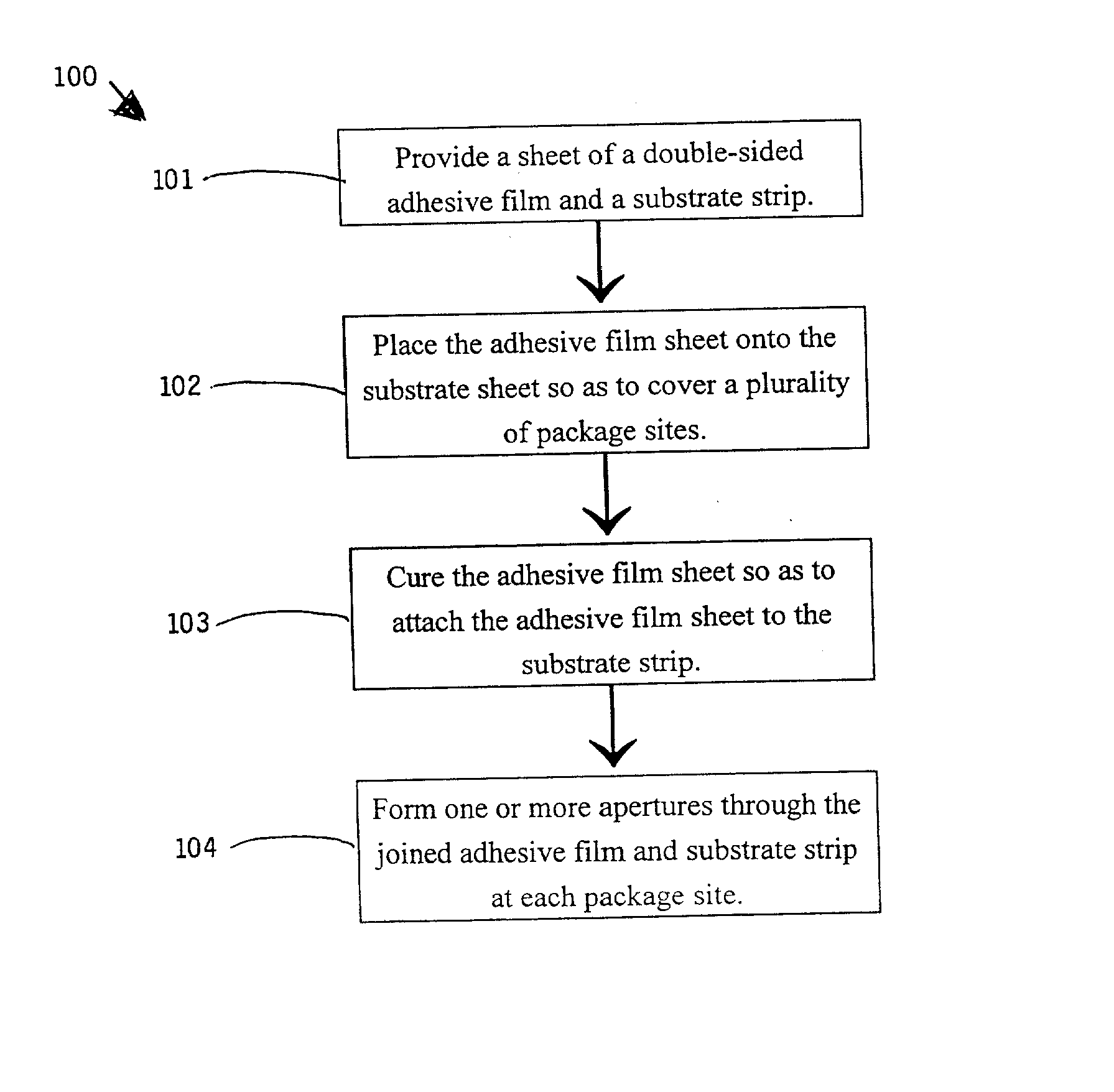

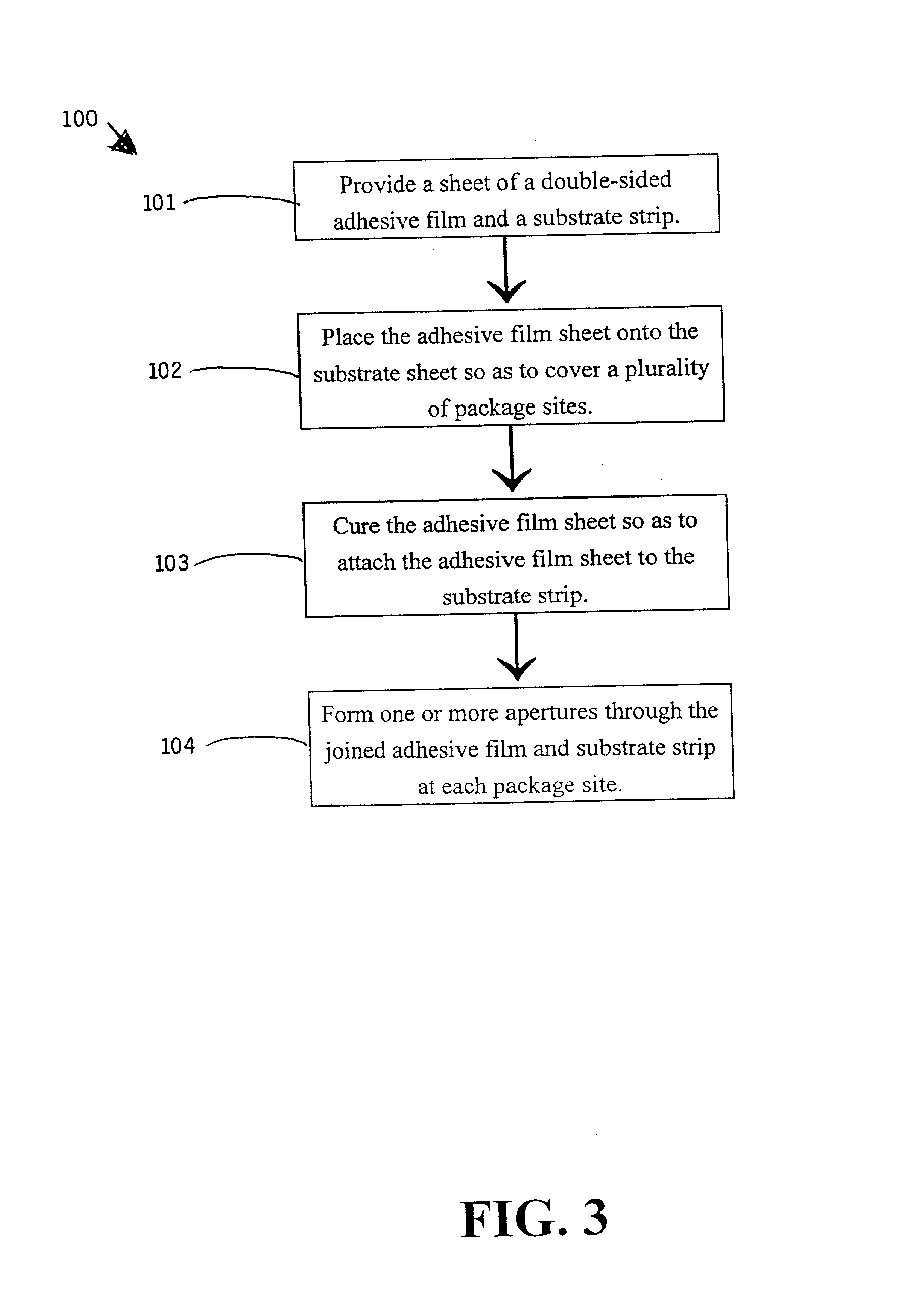

Methods Of Attaching A Sheet Of An Adhesive Film To A Substrate In The Course Of Making Integrated Circuit Packages

InactiveUS20020096253A1Improve efficiencyReduce inventoryCovering/liningsSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

<heading lvl="0">Abstract< / heading> Methods of making packages for integrated circuit devices are described. An exemplary method includes providing a substrate sheet having an array of package sites at which individual integrated circuit packages will be assembled. A continuous sheet of an adhesive film is placed on the substrate strip so as to cover the plurality of package sites. The adhesive film sheet is then cured by applying heat or pressure or heat and pressure to the substrate strip and the sheet of adhesive film. The pressure and / or heat cause the sheet of adhesive film to be permanently attached to the substrate strip. A subsequent step forms one or more apertures though the joined substrate strip and adhesive film at each package site. An integrated circuit die is mounted on the adhesive film at each package site, and bond wires are attached through the aperture between metallizations of the substrate and the integrated circuit device. After the one or more apertures at each site are filled with an insulative material, the adjacent package sites are separated, forming individual packages each having an integrated circuit device.

Owner:AMKOR TECH INC

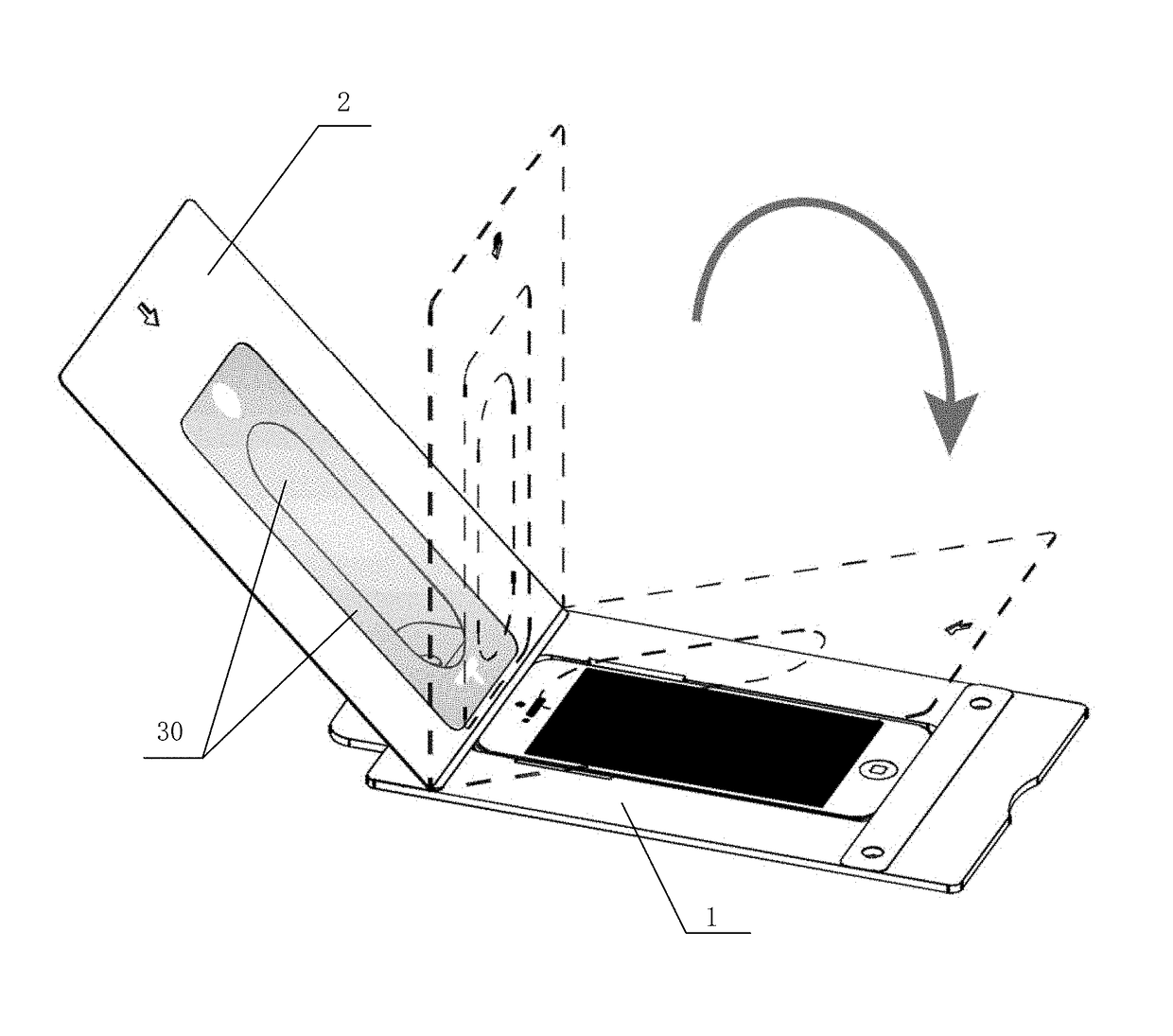

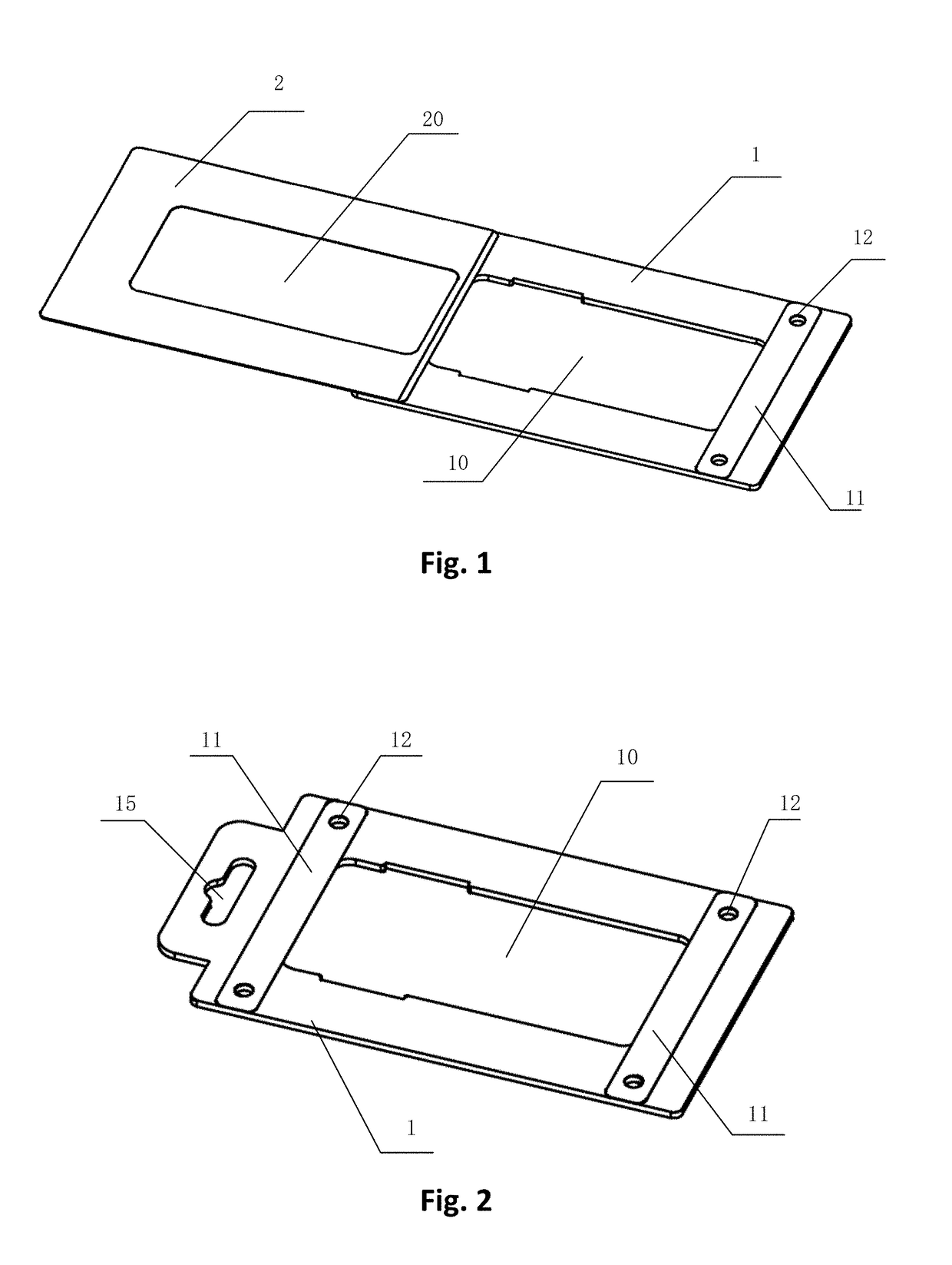

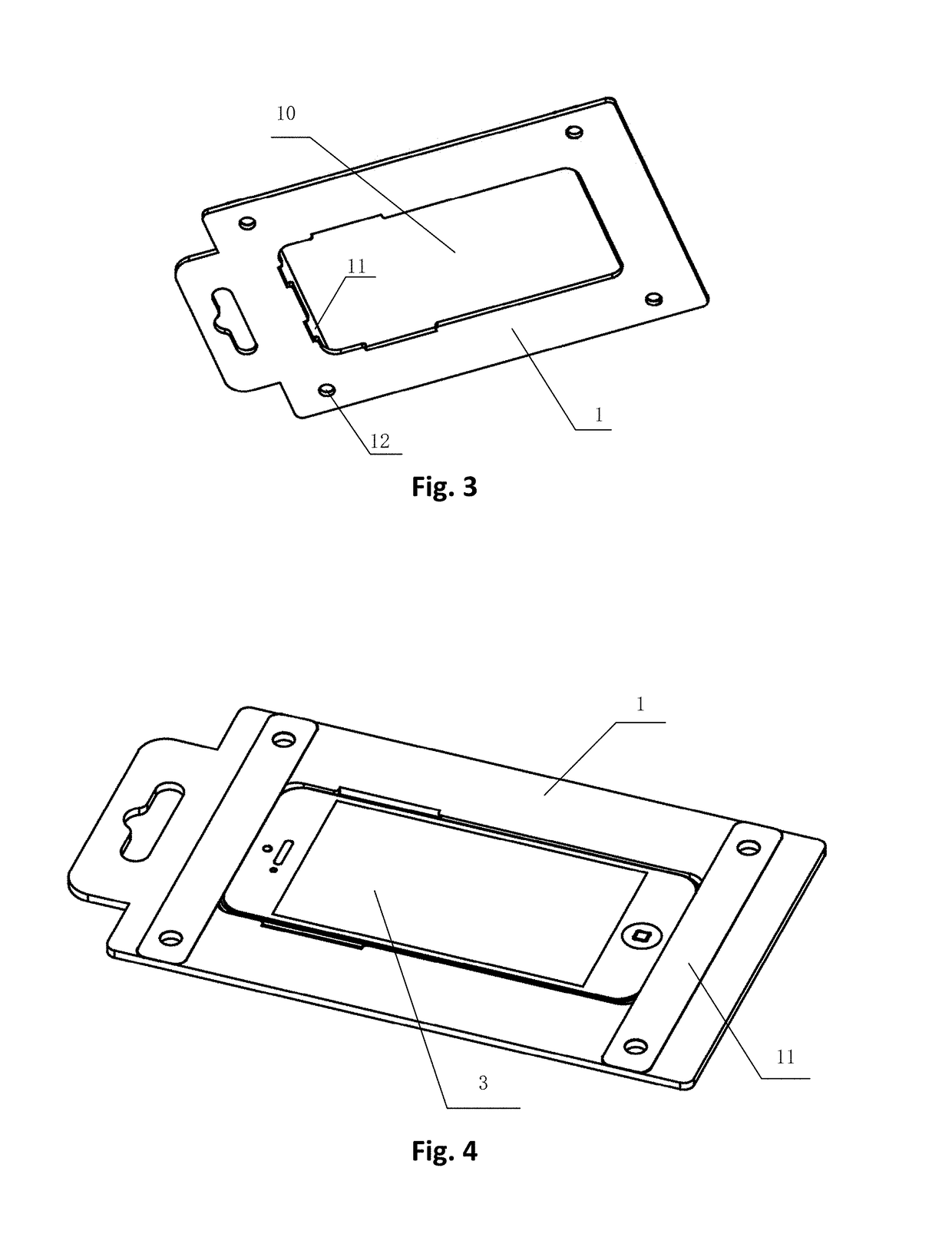

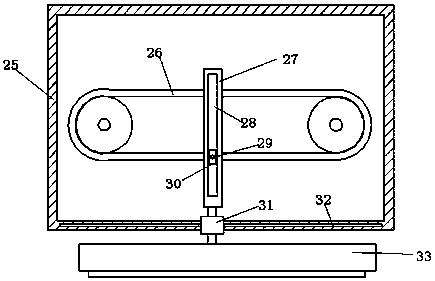

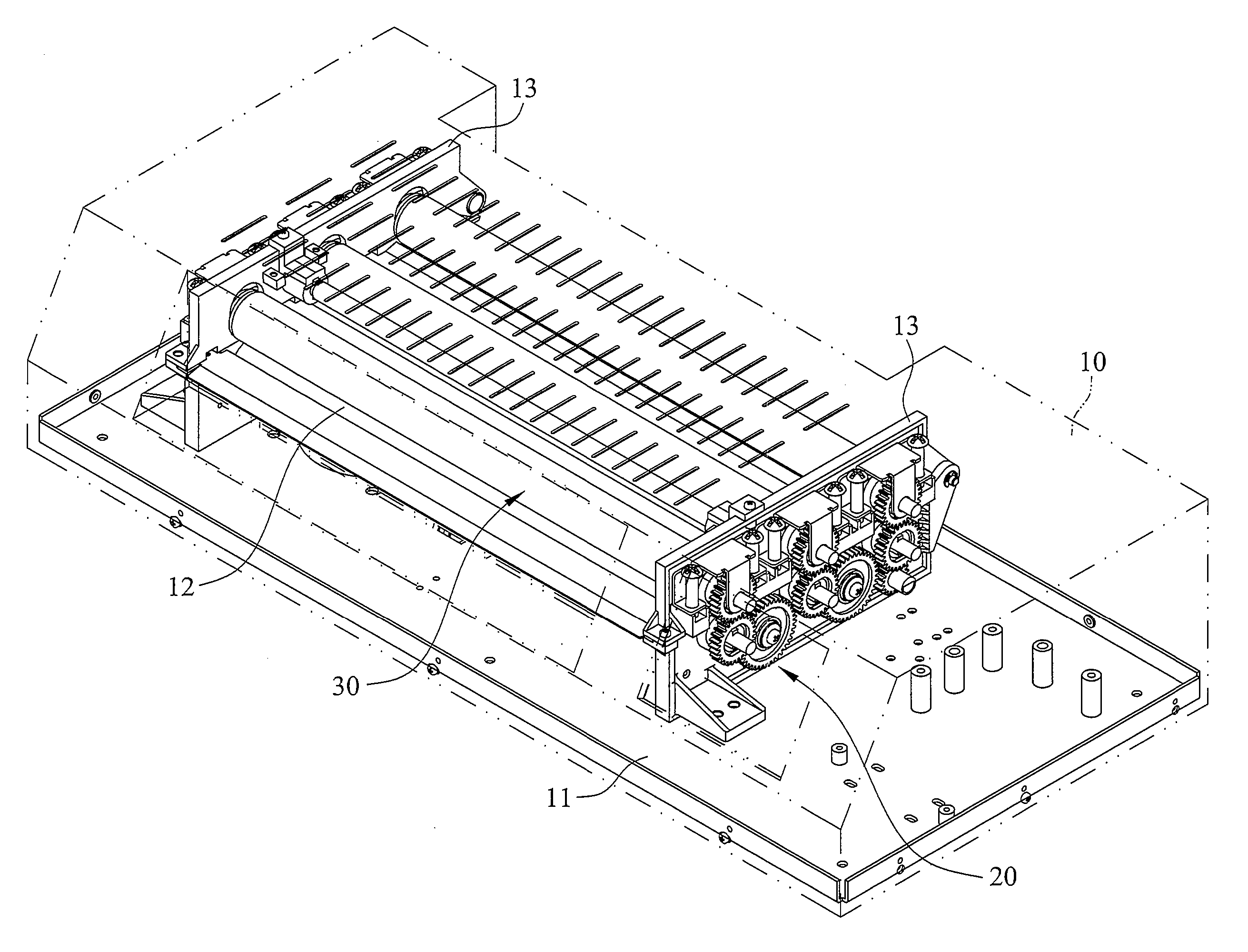

Film laminator for cell phones

ActiveUS10076894B2Low costImprove lamination qualityLamination ancillary operationsLaminationEngineering

Provided is a film laminator for cell phones, useful for film lamination on a surface of a cell phone, including: a cell phone fixing plate, on which a through hole for receiving the cell phone is established, and a top surface of which is a horizontal face; with at least one position limiting plate for abutting the cell phone within the through hole being also fixed on the top surface. The film laminator for cell phones further includes: a film laminating plate for fixing a cell phone film; one end of which is hinged to the cell phone fixing plate, and the other end of which is movable freely so that the film laminating plate is bonded with the top surface of the cell phone fixing plate.

Owner:ALPHA COMM ENTERPRISES LLC

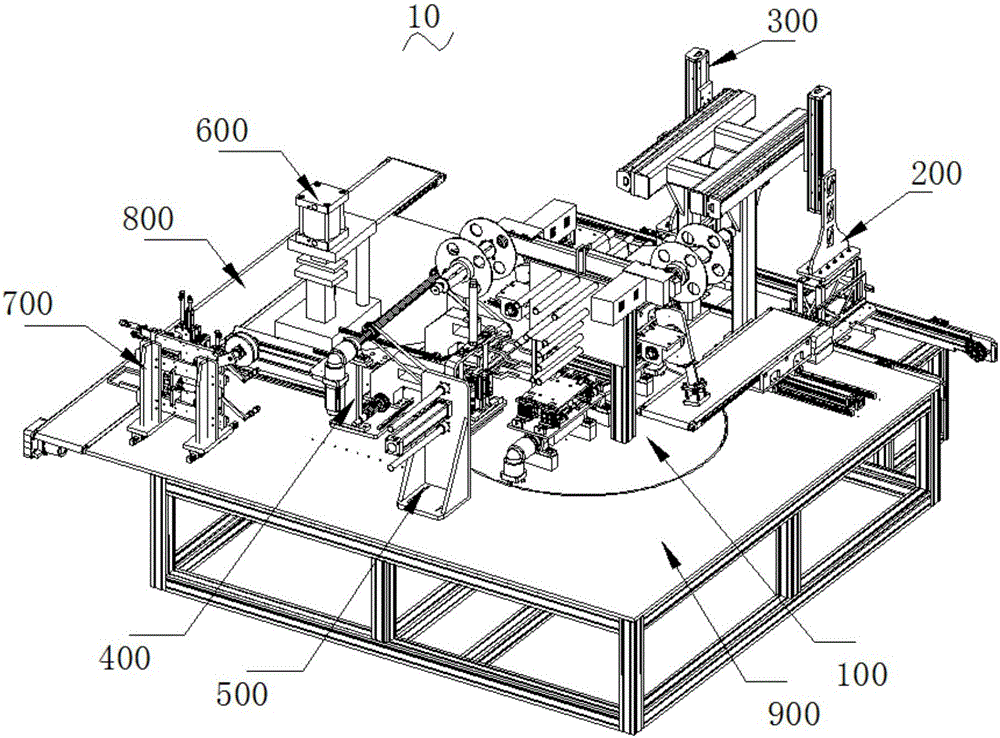

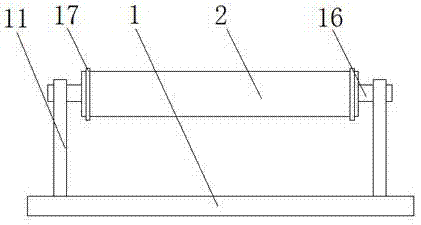

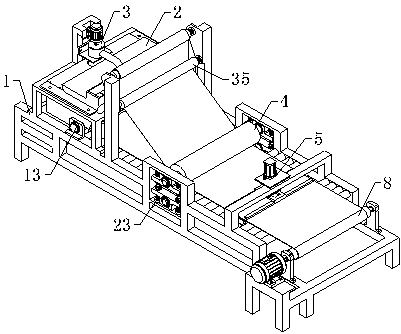

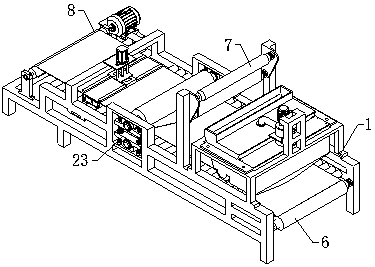

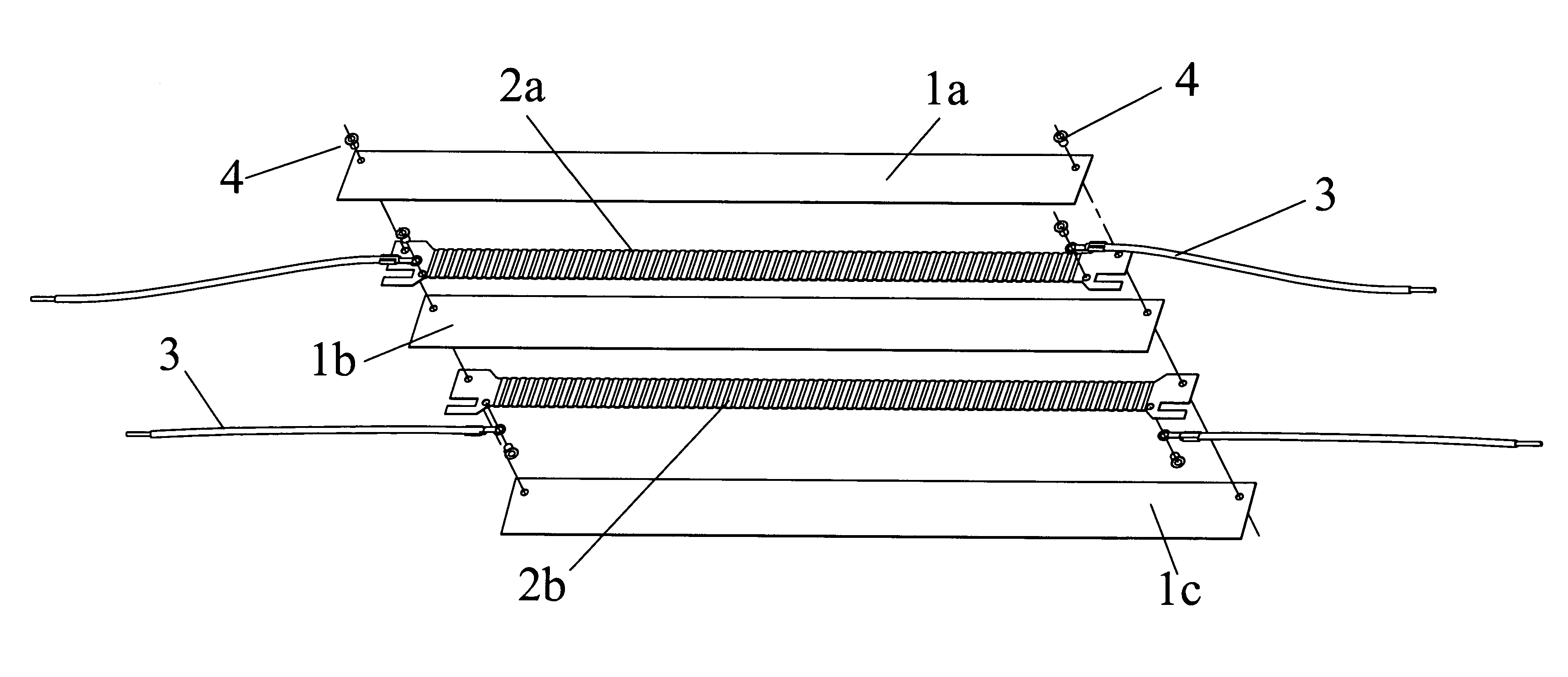

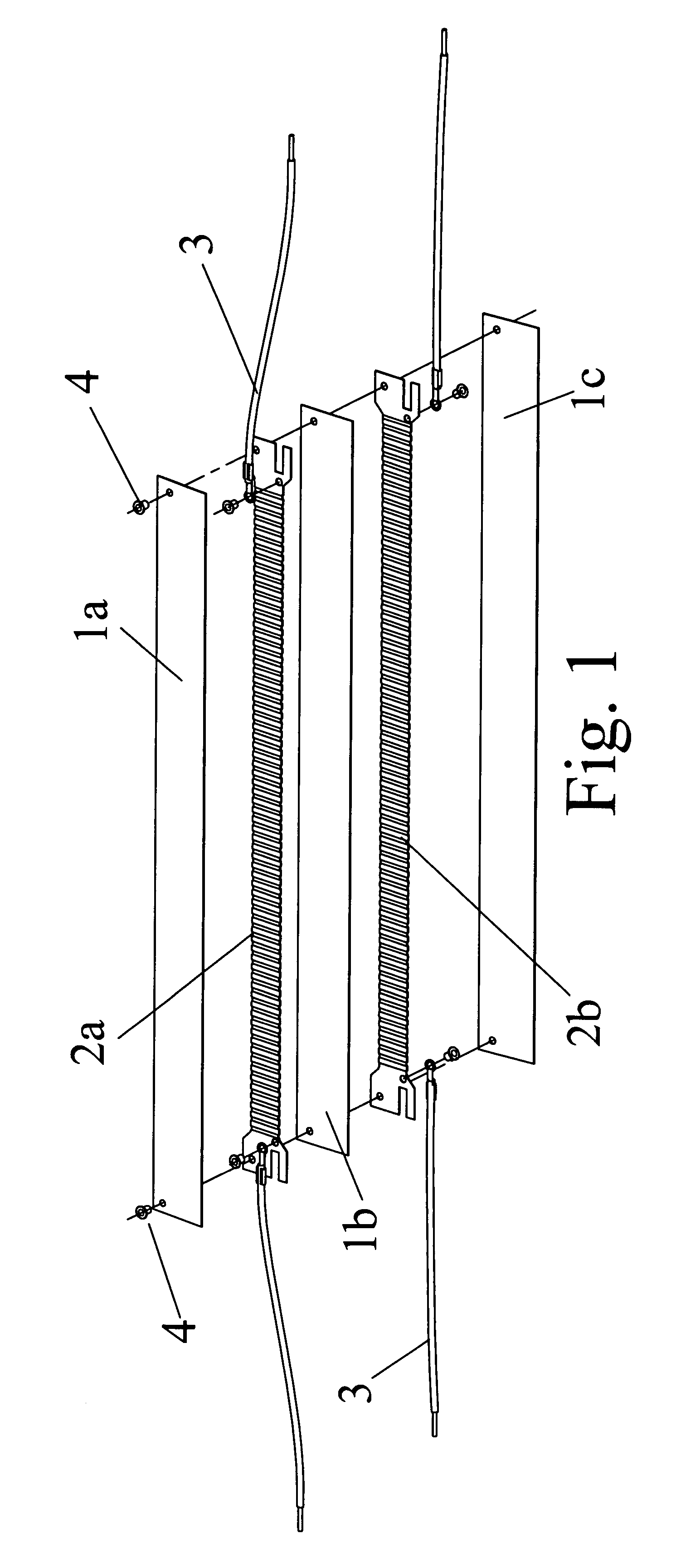

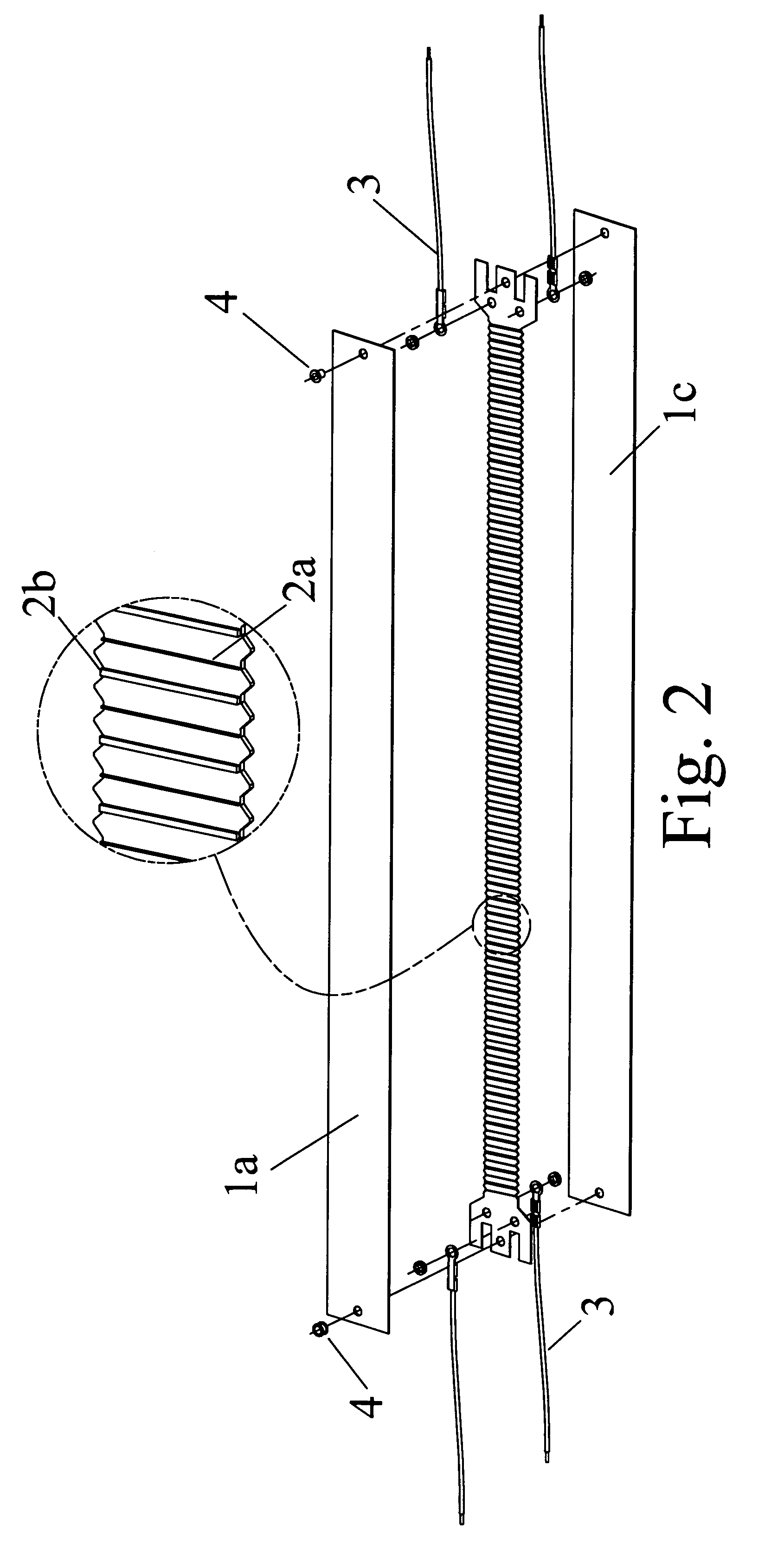

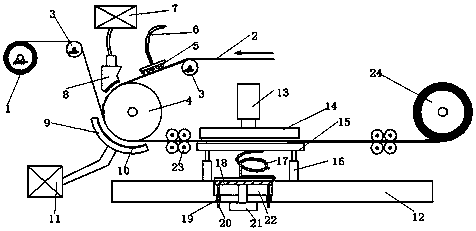

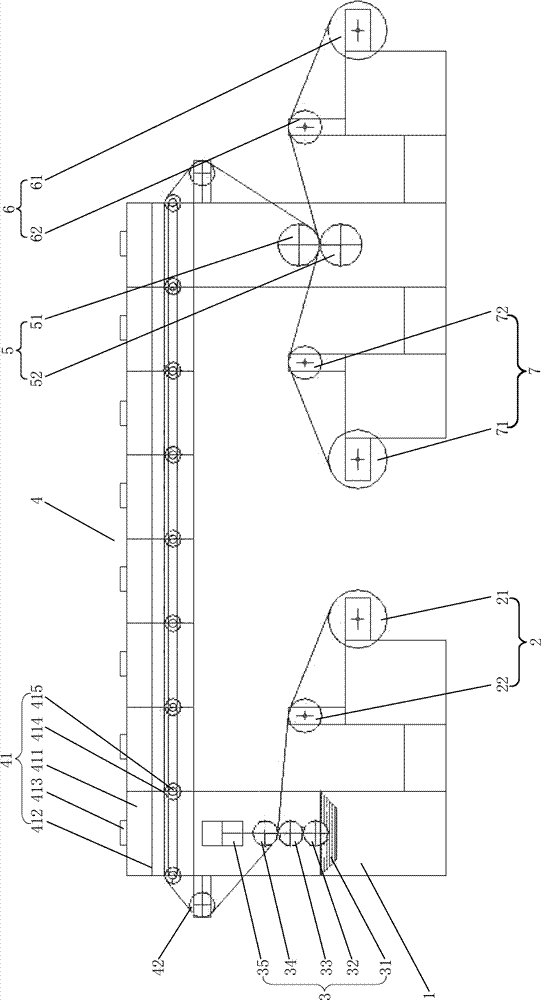

Fabric laminating machine using PU glue

InactiveCN106364125AImprove flatnessImprove lamination qualityLamination ancillary operationsLaminationPre treatmentEngineering

The invention discloses a fabric laminating machine using PU glue. The fabric laminating machine using the PU glue comprises a machine frame, wherein a top fabric uncoiling mechanism, a bottom fabric uncoiling mechanism, a gluing mechanism, a hot pressing mechanism, a dragging mechanism and a coiling mechanism are arranged on the machine frame; the hot pressing mechanism comprises a hot pressing roll and press rolls adhered to the hot pressing roll; oil guiding slots are formed in the hot pressing roll; an oil inlet and an oil returning port are formed in the end surfaces of the two sides of the hot pressing roll respectively; the oil inlet and the oil returning port are connected with oil pipes through rotating connectors; top fabric and bottom fabric are laminated by the hot pressing mechanism, cooled by a cooling device, dragged by the dragging mechanism, counted by a counter, sent into the coiling device and coiled. Through arrangement of winding and scutching rolls, pneumatic deviation-correcting rolls, selvedge uncurlers and the like, the fabric laminating machine corrects deviation, removes creases and performs other pretreatments, so that the levelness of the fabric is improved; the hot pressing roll is filled with heat-conducting oil, and is connected with the oil pipes through the rotating connectors, so that the hot pressing roll is uniformly heated and the laminating quality of the top fabric and the bottom fabric can be improved.

Owner:JIANGSU YUANHUA LIGHT CHEM EQUIP

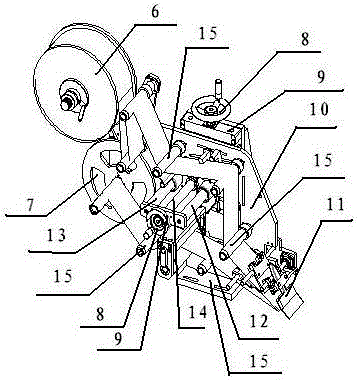

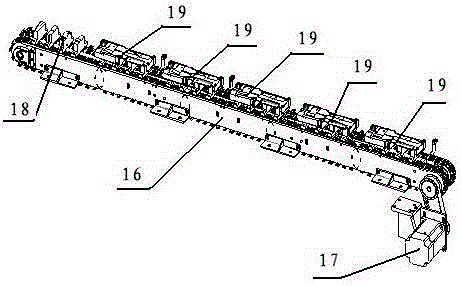

Chain transmission type automatic film sticking machine and film sticking process thereof

A chain transmission type film sticking machine comprises a support, a protective film clamping mechanism, a chain transmission mechanism, a front side face and rear side face film sticking mechanism and a left side face and right side face film sticking mechanism; the chain transmission mechanism is installed on the support; the protective film clamping mechanism is installed on the support and located on the side face of the chain transmission mechanisms; the front side face and rear side face film sticking mechanism and the left side face and right side face film sticking mechanism are installed on the support and located at the two sides of the chain transmission mechanism respectively. According to the technical scheme, the chain transmission type film sticking machine has the beneficial effects that a hinge type conveying belt is adopted to drive all working stations, and an assembly line type film sticking process is achieved; compared with the prior art, manual surface film sticking operation with the efficiency being 100 products per hour is changed into mechanical surface film sticking operation with the efficiency being 400 products per hour, the efficiency is greatly improved, the production cost is reduced, and meanwhile the film sticking quality is improved.

Owner:HOWWEIH ELECTRONIC TECH (HUIZHOU) CO LTD

Aerogel material surface laminating equipment

The invention discloses aerogel material surface laminating equipment. The aerogel material surface laminating equipment is simple in structure and convenient to use; during laminating pressing, a pressing force can be adjusted; meanwhile, the pressing force can be automatically adjusted so as to prevent an overlarge pressing force from exerting negative influence on the quality of an aerogel rollmaterial; meanwhile, during lamination, glue can be uniformly treated, the treatment speed is high, the movement is smooth and the vibration is small, so that the laminating quality can be improved and the aerogel laminating efficiency is enhanced; meanwhile, an elastic frame assembly is used for pressing, the pressing force is moderate, and compared with a spring design, the elastic frame assembly design has the advantages as follows: the service life is longer and the laminating quality is higher.

Owner:汉信天诚(江苏)科技有限公司

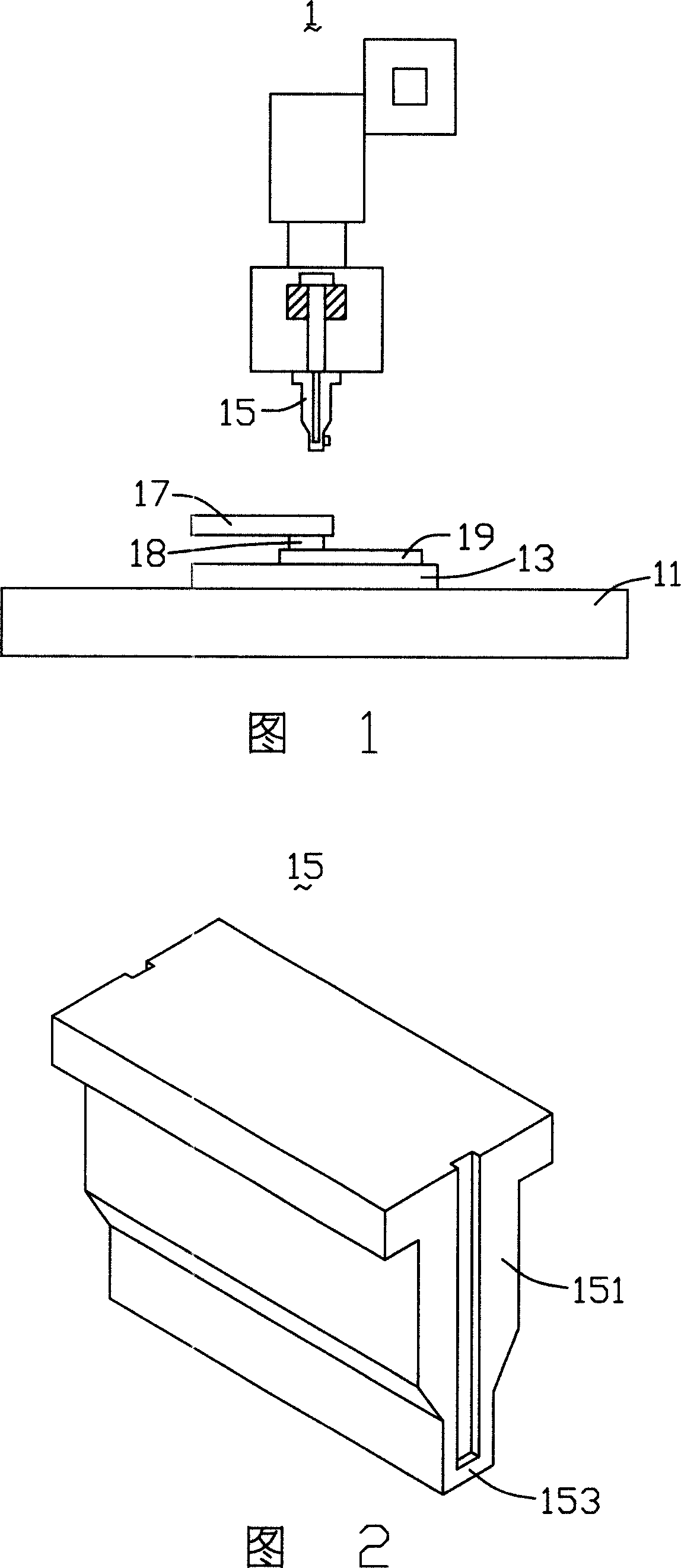

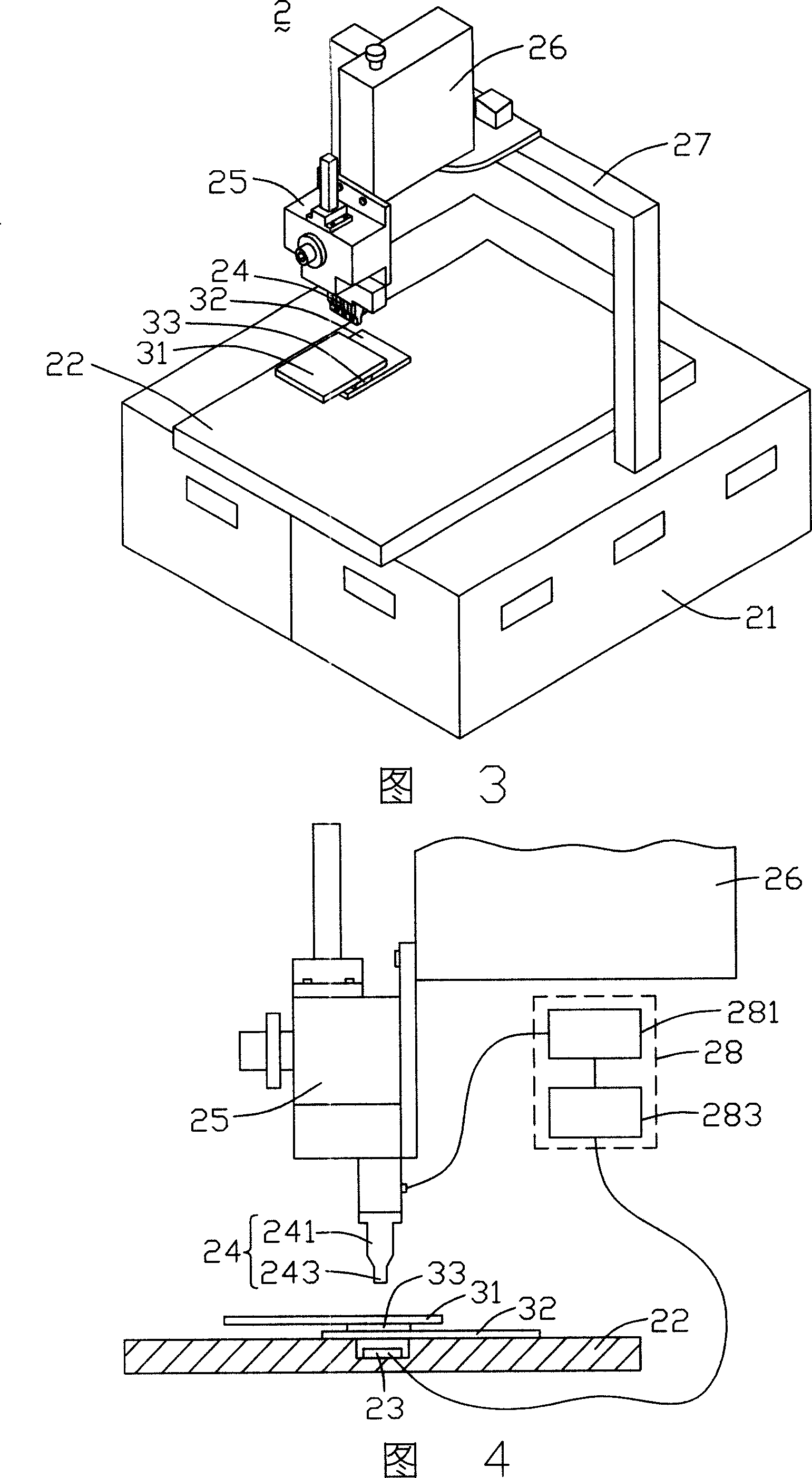

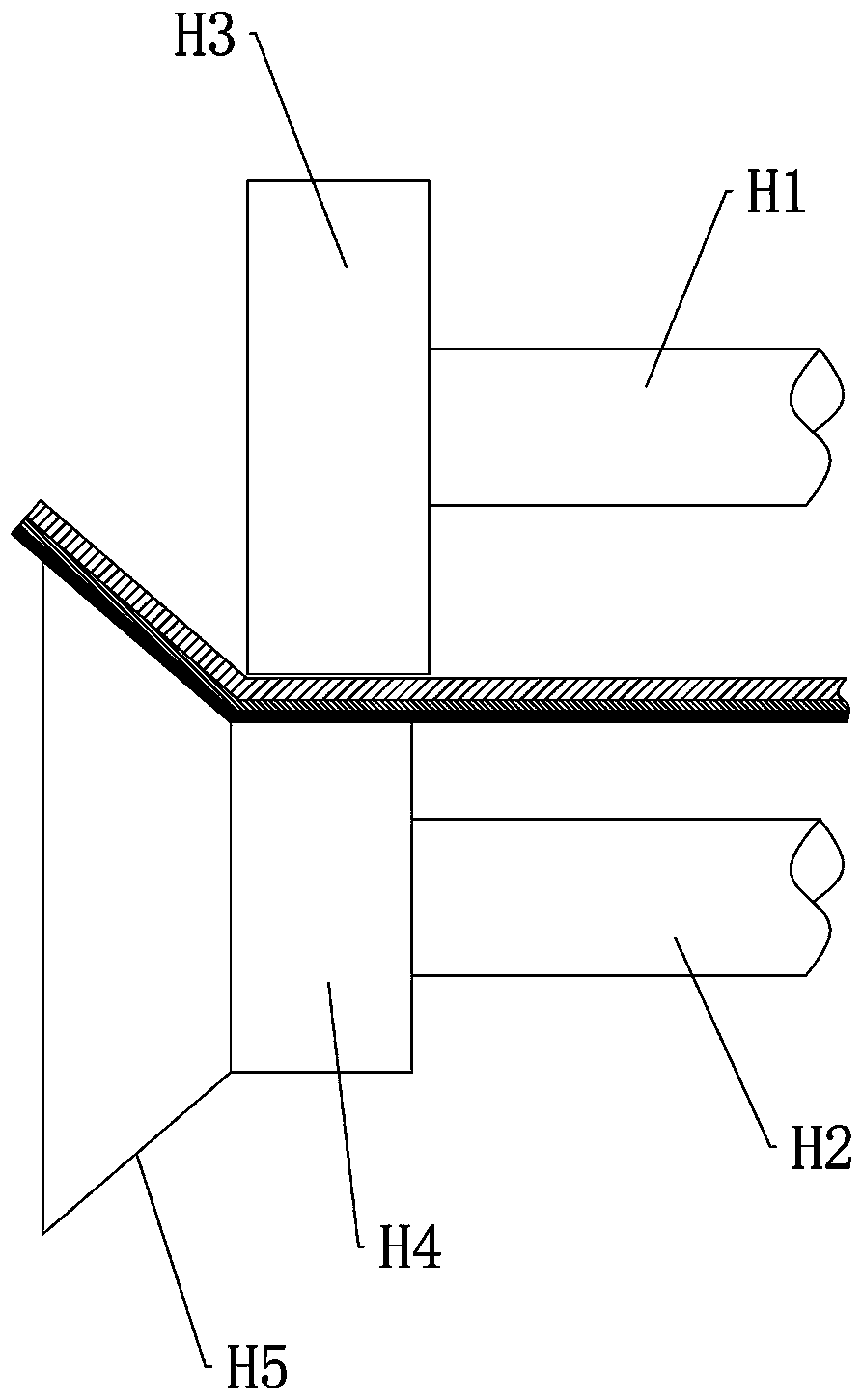

Hot press device and hot press method using the same

InactiveCN101125386AAvoid uneven temperatureImprove lamination qualityPrinted circuit assemblingHeating appliancesElectricityHot press

The present invention relates to a hot-pressing device used for electrically and mechanically connecting for the two electronic components waiting for pressing and a hot-pressing method by adopting the hot-pressing device. The hot-pressing device comprises a control unit and a hot-pressing contract electrically connected with thereof, wherein, the hot-pressing contract comprises a plurality of heating noumena, and the control unit respectively controls each heating noumenon to work. The hot-pressing device ensures the even temperature on the surface of the pressing position of the electronic components waiting for pressing by controlling the working of a plurality of heating noumena by the control unit, and avoids that: the disproportionation of heat transmission and releasing causes the temperature uneven in the pressing position, thereby causing the impact to pressing quality.

Owner:INNOCOM TECH SHENZHEN +1

Laminating machine

InactiveUS20100307690A1Protection wearImprove lamination qualityMechanical working/deformationControlling laminationCounter rotationEngineering

A laminating machine is provided therein with an upper guide plate and a lower guide plate that disposed opposite each other. A workpiece to be laminated passes through a guide slot formed between the upper and lower guide plates, wherein the upper guide plate can be pushed upward, and a micro switch is provided above the upper guide plate for controlling the rotation of roller sets. If the workpiece is too thick or is somehow impeded such that the workpiece creases, the upper guide plate will be pushed upward by the workpiece and therefore touches the micro switch. As a result, another circuit is activated to rotate the roller sets reversely and thereby eject the workpiece. Hence, not only is the laminating machine protected and saved from a lot of maintenance work, but also precious paper documents, such as photos, in the workpiece are well preserved.

Owner:TEX YEAR INDS

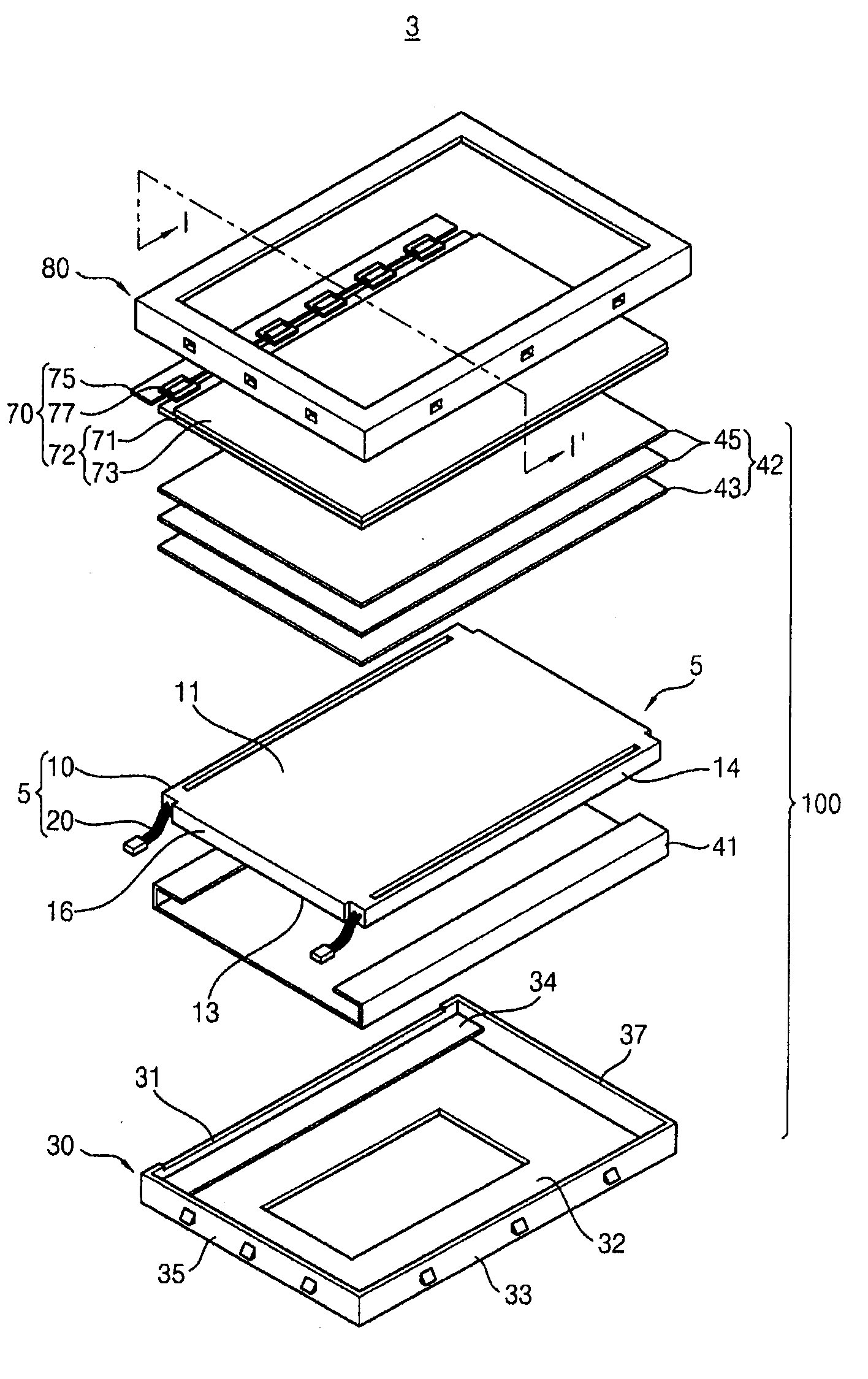

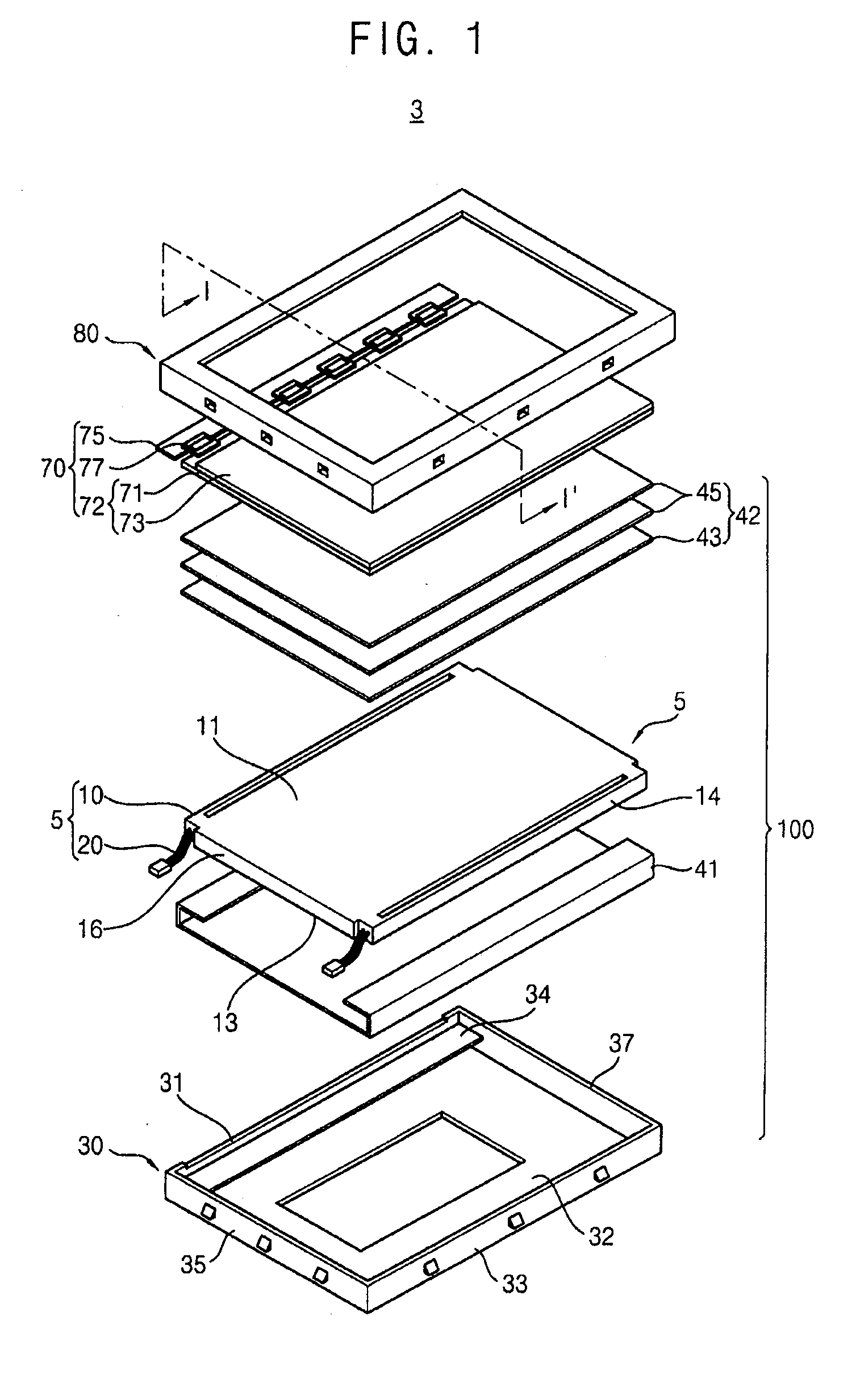

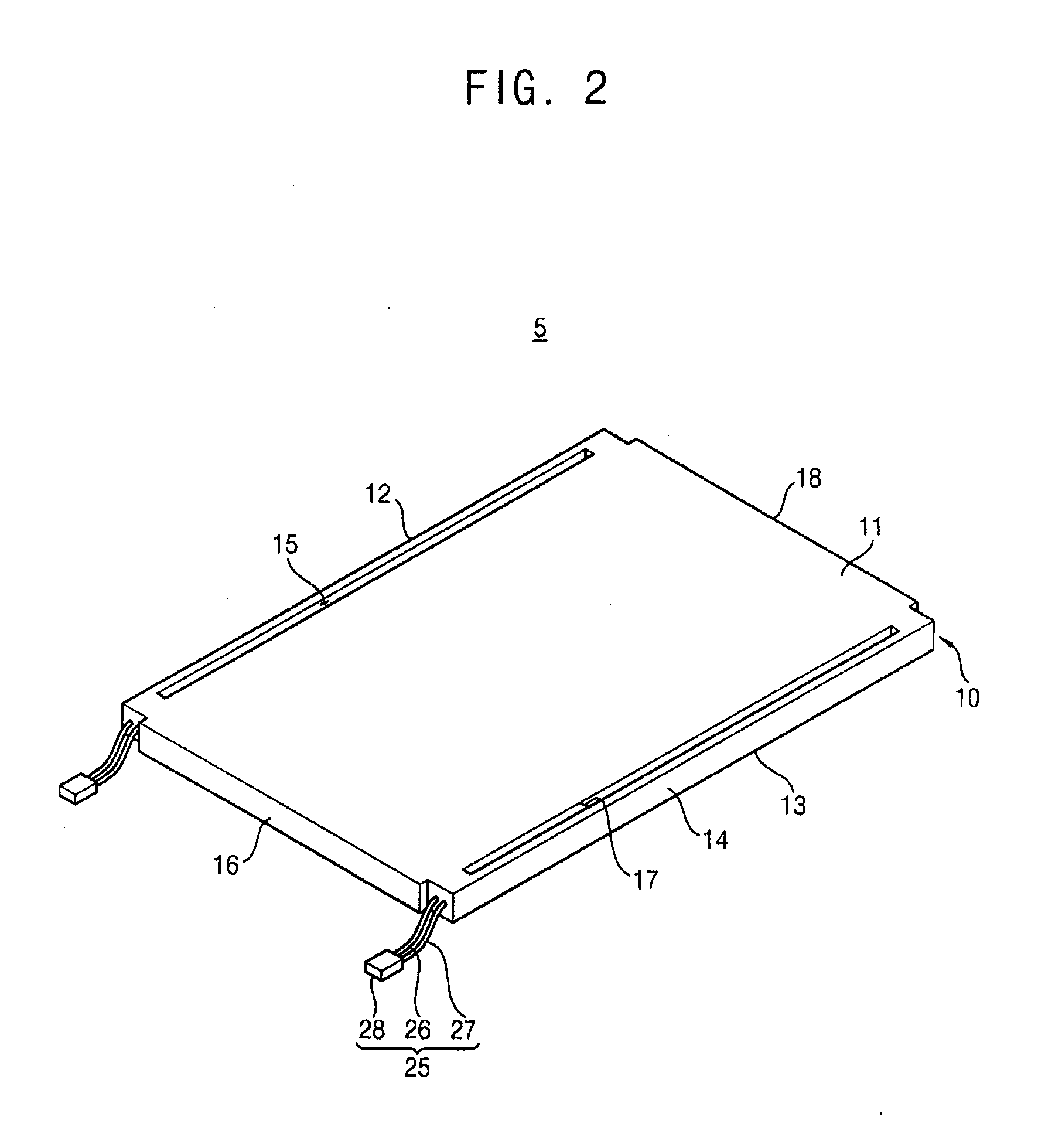

Light source apparatus, method of manufacturing the light source apparatus and backlight assembly having the same

InactiveUS20090323371A1Reduce the size of the moduleReduce the number of partsVessels or leading-in conductors manufacturePlanar/plate-like light guidesLight guideInjection molding process

In a light source apparatus, a method of manufacturing the light source and a backlight assembly having the same, a light guide plate (LGP) includes an upper surface and a lower surface facing each other and a first side surface and a second side surface. The light source is placed in the LGP adjacent to the first side surface and emits light toward the second side surface. The power supply unit is electrically connected to the light source and partially placed in the LGP. The light source may include a lamp or a light-emitting diode (LED). The power supply unit may include a wire or a power supply substrate. The light source apparatus may be formed by an injection molding process using lower and upper mold frames. Therefore, backlight assembly size, the number of parts and manufacturing steps may be decreased, and the illumination quality may be improved.

Owner:SAMSUNG DISPLAY CO LTD

Integrated production system for integrated wall panel

InactiveCN109648898AWarm up evenlySmall surface temperature differenceBuilding componentsFlat articlesTectorial membraneFoaming agent

The invention relates to an integrated production system for an integrated wall panel. The integrated production system comprises a drying oven, a PVC coating mechanism, a protective film coating mechanism, a composite pressing mechanism, a clamping mechanism, a temporary storage mechanism, a mortise forming mechanism, a foaming agent filling mechanism, an aluminum foil overlying mechanism and a tunnel foaming box. The integrated production system provided by the invention can realize continuous automatic production of coating, mortise formation and foaming, and realizes good quality of the panel. Before a coating process, a base belt is heated by virtue of the drying oven so as to be uniformly preheated, the temperature difference of the surface of the base belt is reduced, and the coating quality if improved; the base belt in a hot state can realize proper heat transfer to a film so that the overall film can be slightly softened, therefore the film firmly coats the surface of the metal base belt; a conveying belt and a shaping conveying belt which are arranged inside the funnel foaming box can be used for clamping and conveying a base material continuously and also provide pressure application and pressure bearing effects, and thus a closed space is formed after the base material is fed, and foaming can be conveniently implemented.

Owner:RONGDE ANJIA NEW MATERIALS FUZHOU CO LTD

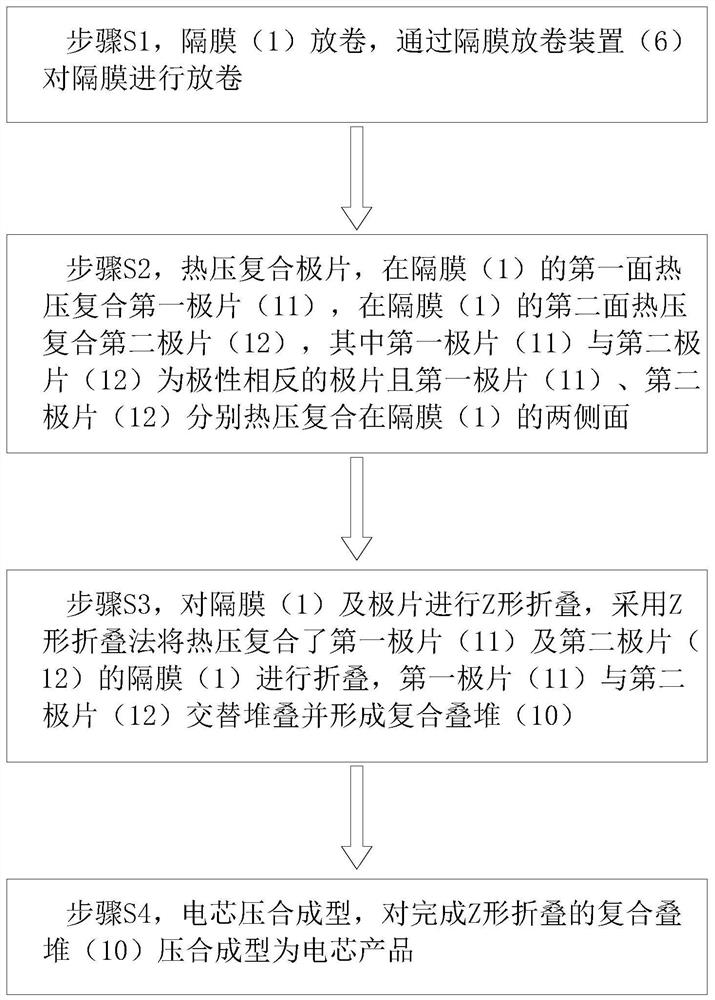

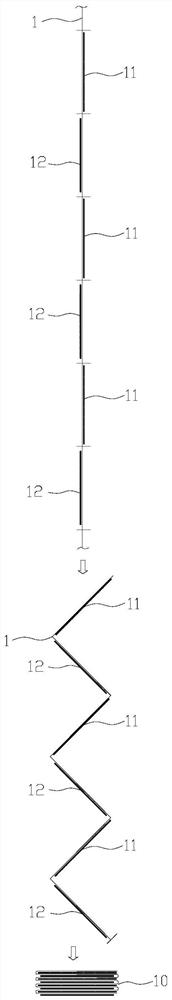

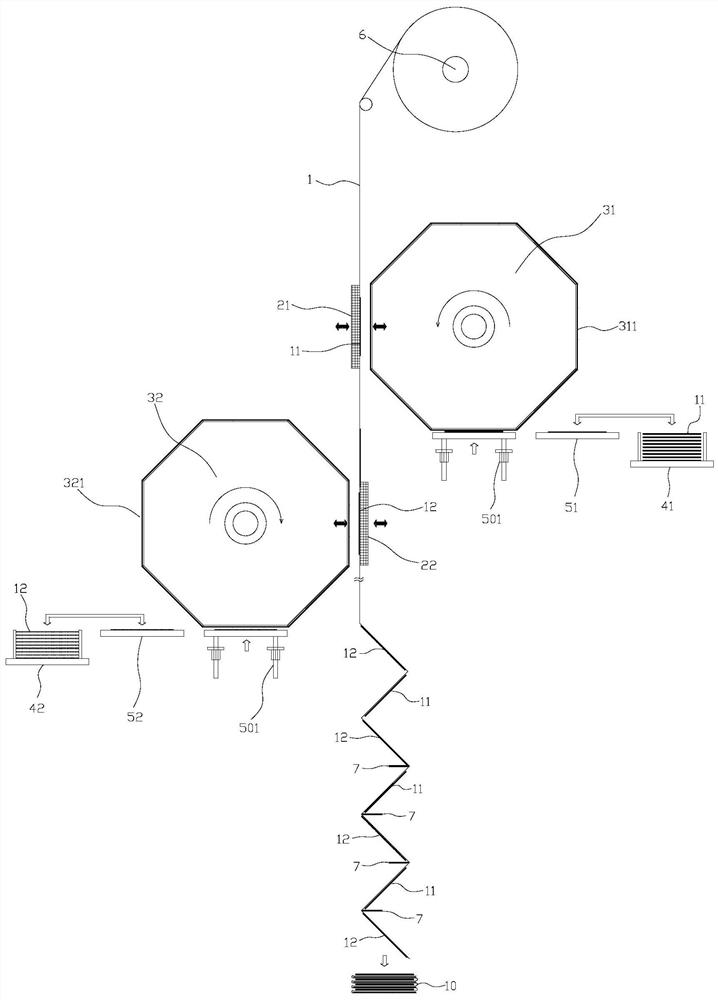

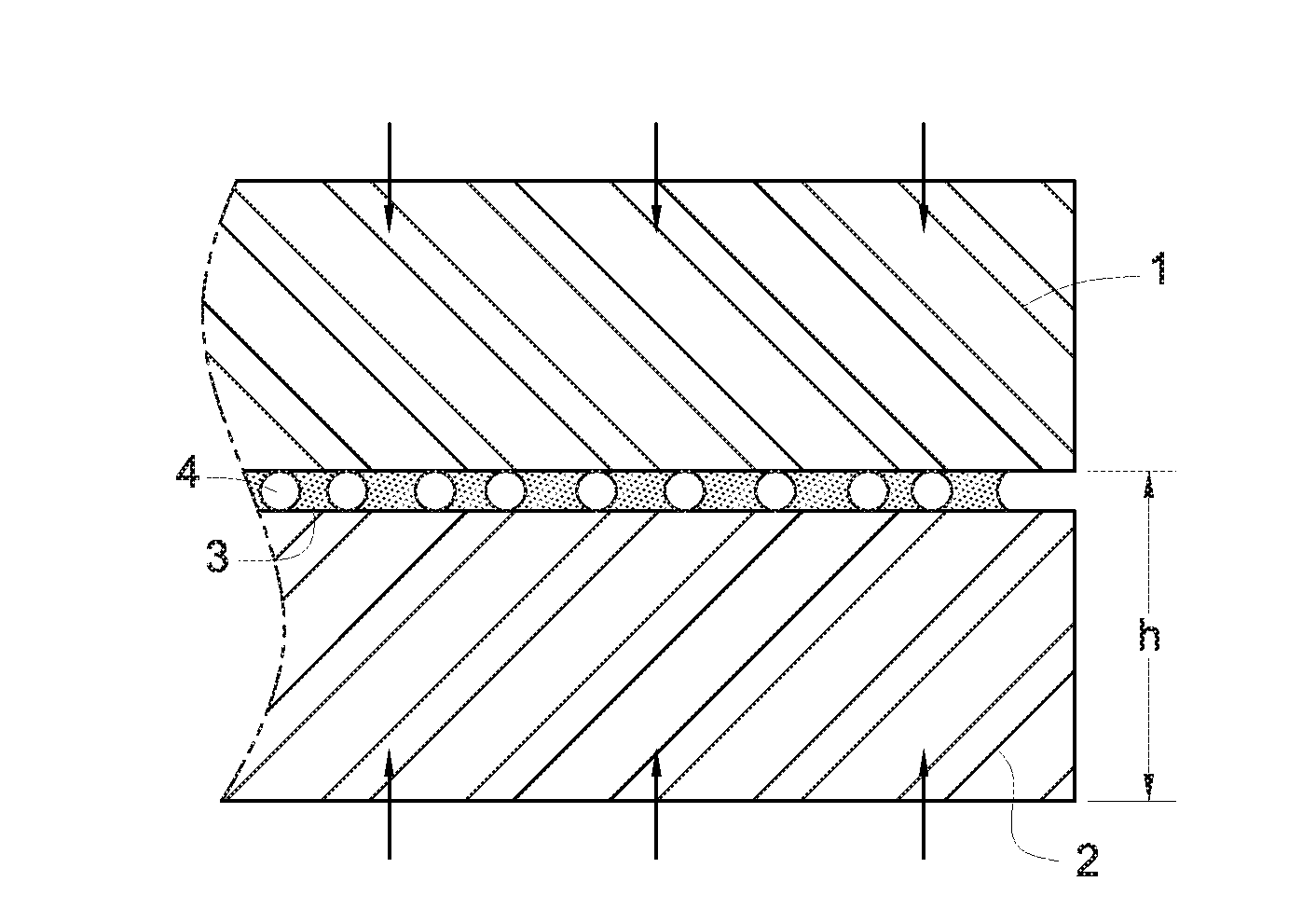

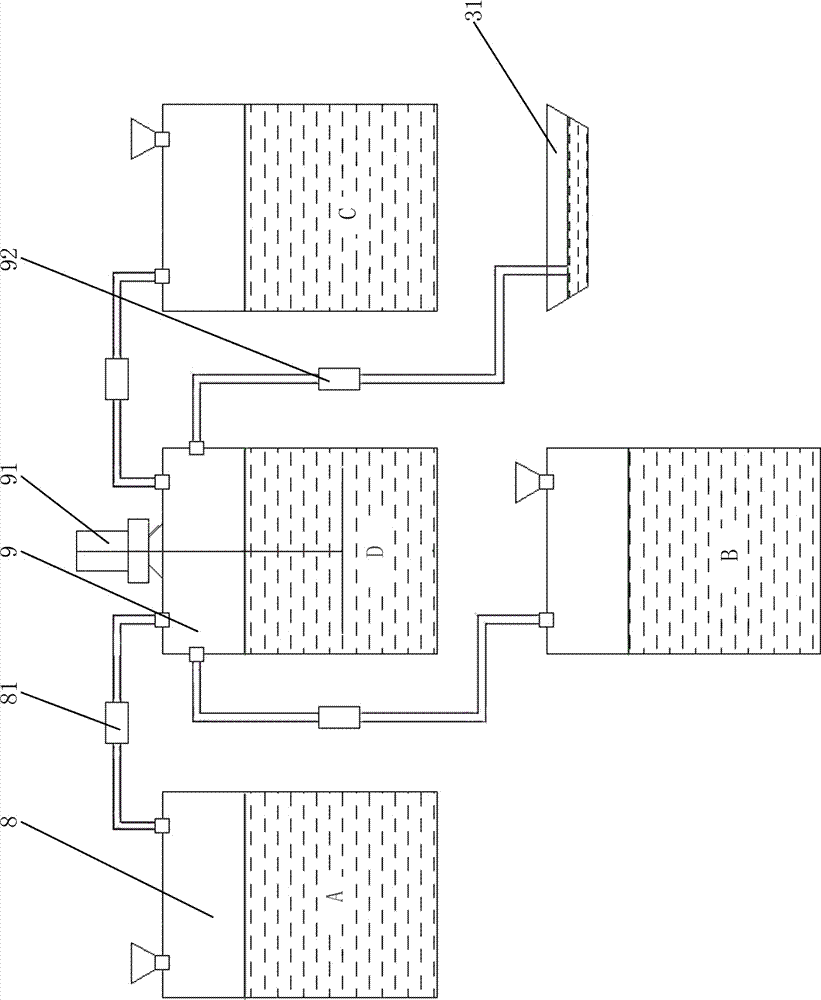

Thermal composite cell preparation method and system

PendingCN112234257AImprove securityHigh coincidencePrimary cell manufactureAssembling battery machinesEngineeringPole piece

The invention discloses a thermal composite cell preparation method and system. The thermal composite cell preparation method comprises the following steps of diaphragm unwinding, unwinding a diaphragm through a diaphragm unwinding device; hot-pressing and compounding a pole piece, hot-pressing and compounding a first pole piece on the first surface of the diaphragm 1, and hot-pressing and compounding a second pole piece on the second surface of the diaphragm; carrying out Z-shaped folding on the diaphragm and the pole piece; pressing and forming the battery cell; the thermal compounding battery cell preparation system comprises a diaphragm unwinding device, a pole piece conveying device, a hot-pressing compounding device, a folding thimble and a pressing device. The thermal composite cellpreparation method and system have the advantages of simple structure and low implementation cost, can effectively improve the lamination precision and lamination quality in the practical applicationprocess, greatly improve the lamination efficiency, and have better product safety.

Owner:JIANGSU KATOP AUTOMATION CO LTD

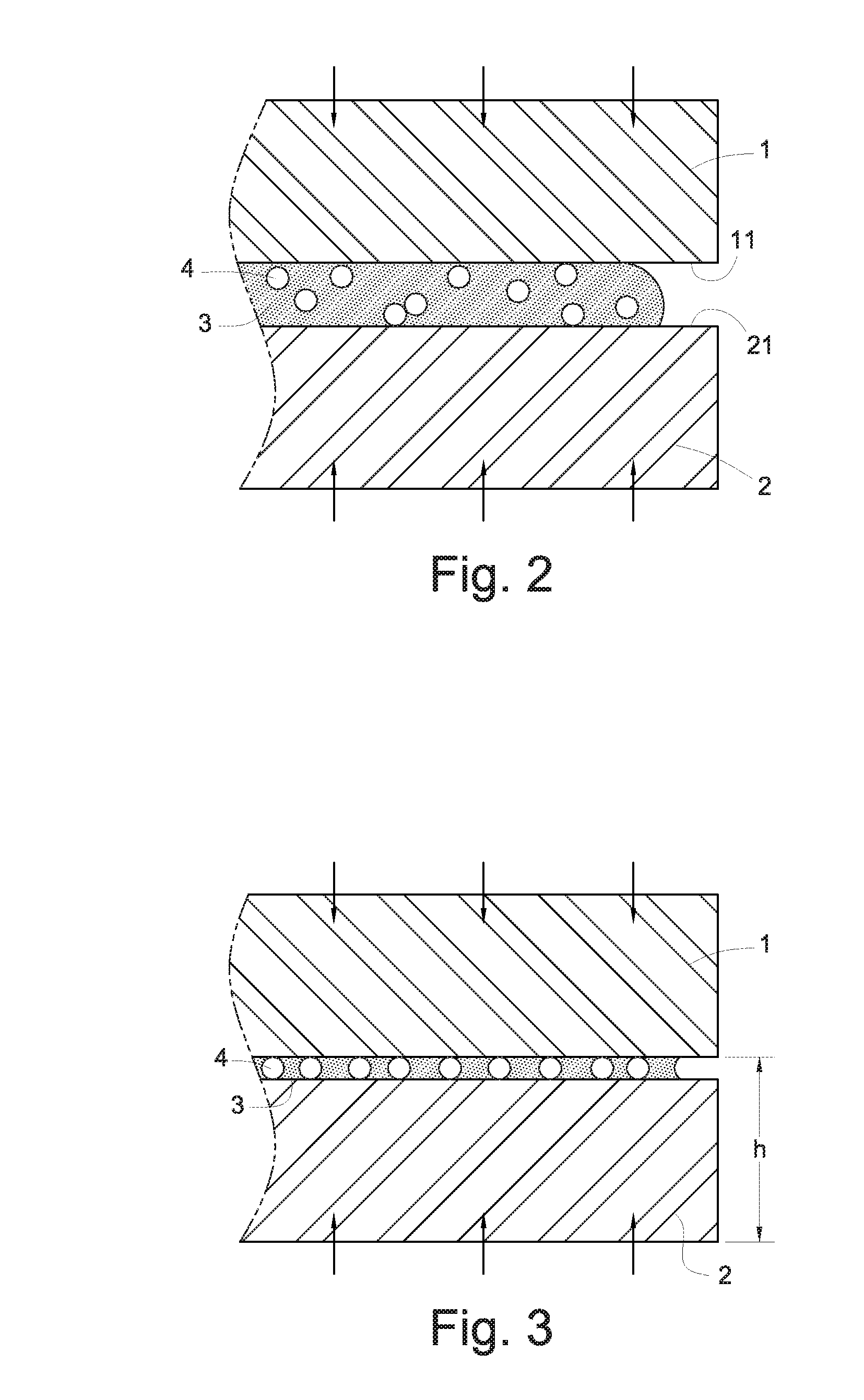

Optical curable resin composite for laminating optical substrates and method thereof

InactiveUS20130101827A1Avoid residual stressAvoid defectsAdhesive processesLamination ancillary operationsElastomerBead shape

In an optical curable resin (OCR) composite for laminating optical substrates and a method of using the OCR composite to laminating two optical substrates, the OCR composite is formed by projecting an ultraviolet light to cure a liquid adhesive containing a plurality of bead-shaped elastic particles, and the method includes the steps of coating the liquid adhesive onto a first optical substrate, stacking the first optical substrate to a second optical substrate, such that each particle is separated between the first and second optical substrates, and projecting the ultraviolet light onto the first and second optical substrate again to cure the liquid adhesive, so that the particles are separated to form a gap with equal heights between the first and second optical substrates to enhance the lamination efficiency and quality of the optical substrates.

Owner:CHEN CHIN YU

Thermoformed sheet and printed film lamination device and production method

PendingCN107160819AVariety of surface tonesImprove aestheticsLamination ancillary operationsPolyureas/polyurethane adhesivesThermoformingAdhesive glue

The invention relates to a thermoformed sheet and printed film lamination device and a production method. The lamination device comprises supporting wall plates, a printed film unwinding mechanism, a gluing mechanism, a drying mechanism, a laminating mechanism, a sheet unwinding mechanism and a winding mechanism, wherein the printed film unwinding mechanism, the gluing mechanism, the drying mechanism, the laminating mechanism, the sheet unwinding mechanism and the winding mechanism are respectively mounted on the supporting wall plates, and the printed film unwinding mechanism, the gluing mechanism, the drying mechanism, the laminating mechanism, the sheet unwinding mechanism and the winding mechanism are arranged in sequence according to a printed film processing sequence. The thermoformed sheet and printed film lamination device is characterized in that the gluing mechanism comprises a glue tank, a glue smooth roll, a glue transitional roll, a glue press roll and a pneumatic cylinder, the glue smooth roll is immersed in the glue tank, the glue smooth roll, the glue transitional roll, the glue press roll and the pneumatic cylinder are sequentially connected from bottom to top, and a piston rod of the pneumatic cylinder is connected to the glue press roller. The lamination device can be used for realizing the diversity of surface hues of a thermoformed sheet, increasing the attractiveness of the thermoformed sheet and improving the quality of film lamination.

Owner:SHANTOU SAMMA PLASTIC IND CO LTD

Automatic pressing mechanism for syringe needle assembly

InactiveCN110919326AAct as a guide to movePlay the role of limit movementMetal working apparatusPhysicsSyringe

The invention relates to the technical field of syringe needle processing, in particular to an automatic pressing mechanism for syringe needle assembly. The automatic pressing mechanism comprises an accommodating jig for placing workpieces and a bidirectional pressing and riveting mechanism, the bidirectional pressing and riveting mechanism comprises a horizontal moving assembly, a rotary drivingassembly and two end pressing and riveting assemblies, the two end pressing and riveting assemblies are arranged on the two sides of the accommodating jig correspondingly, the two end pressing and riveting assemblies are symmetrically arranged, each end pressing and riveting assembly is respectively provided with a pressing and riveting block, the rotary driving assembly is located on one side between the two end pressing and riveting assemblies, the output end of the rotary driving assembly is in transmission connection with the interior of each end pressing and riveting assembly, the horizontal moving assembly is horizontal and is located below the rotary driving assembly, the horizontal moving assembly comprises a moving plate, and the interior of the rotary driving assembly is fixedlyconnected with the top of the moving plate. By means of the equipment, the two pressing and riveting blocks can be pressed at the same time in a connecting rod way, pressing quality is improved, and the cost is reduced.

Owner:利辛县众善医药科技有限公司

Die cutting mechanism with pole piece corner cutting, system comprising die cutting mechanism and method

The invention relates to the technical field of pole piece die cutting, in particular to a die cutting mechanism with pole piece corner cutting, a system comprising the die cutting mechanism and a method. The die cutting mechanism comprises a tab cutting mould, a regulating mechanism and a corner cutting mould, wherein the tab cutting mould is used for cutting out a tab for a pole piece; the regulating mechanism is used for regulating the tab cutting mould to adapt different sizes of pole pieces to cut out the tabs; and the corner cutting mould is arranged on one side of the tab cutting mouldand is used for cutting the corner of the pole piece with the tab. The regulating mechanism comprises at least one groups of X regulating modules and Y regulating modules regulated and transmitted tothe X regulating modules. The tab cutting mould is connected with a driving component and a support used for fixedly installing the driving component, and the support is arranged at the Y regulating modules. The moulds of the die cutting mechanism have certain universality, the die cutting mechanism can die-cut out different sizes of pole pieces by only needing to store the same two kinds of moulds, and the storage amount and the cost of the moulds are reduced. The mould becomes smaller after being separated, the difficulty in mould processing is reduced, and the service life of the mould is long.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com