Chain transmission type automatic film sticking machine and film sticking process thereof

A chain transmission mechanism and chain transmission technology, applied in packaging and other directions, can solve the problems of increased film lamination cost, uneven film lamination, and large product size, and achieve the effects of reducing production costs, improving lamination quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical solution of the present invention in more detail, it is further described in conjunction with the accompanying drawings as follows:

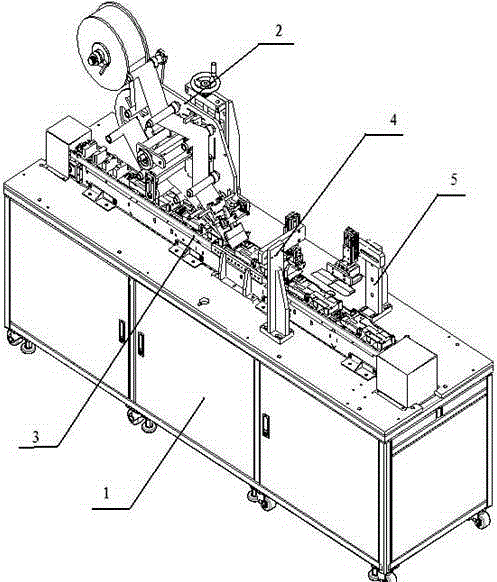

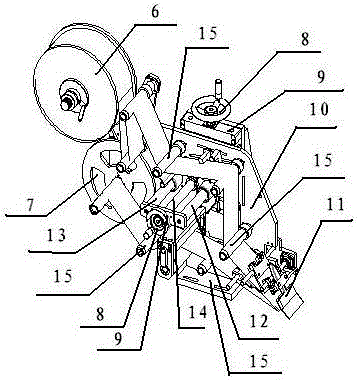

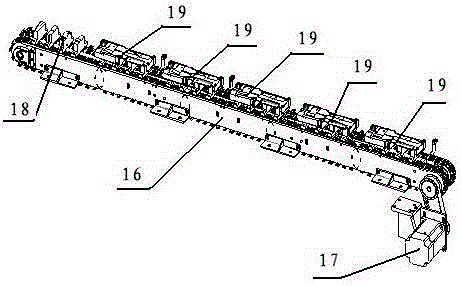

[0023] Such as figure 1 As shown, a chain-driven automatic film lamination machine according to the present invention includes five parts: a support frame 1, a protective film clamping mechanism 2, a chain transmission mechanism 3, a front and rear side film lamination mechanism 4, and a left and right side film laminating structure 5. The chain transmission mechanism 3 is installed on the support frame 1, the protective film clamping mechanism 2 is installed on the support frame 1 and is located on the side of the chain transmission mechanism 3, the front and rear side film sticking mechanism 4 and the left and right side film covering structures 5 Installed on the support frame 1 and located on both sides of the chain transmission mechanism 3 respectively.

[0024] The main function of the protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com