Thermoformed sheet and printed film lamination device and production method

A printing film and thermoforming technology, which is applied in the field of mechanical processing, can solve the problems of insufficient aesthetics and achieve the effects of enhancing aesthetics, various colors, and improving the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

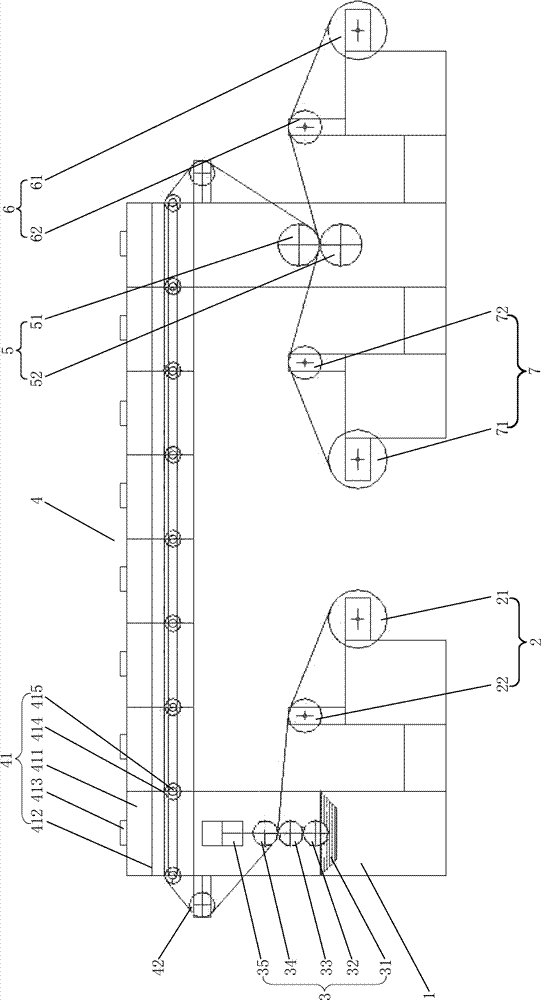

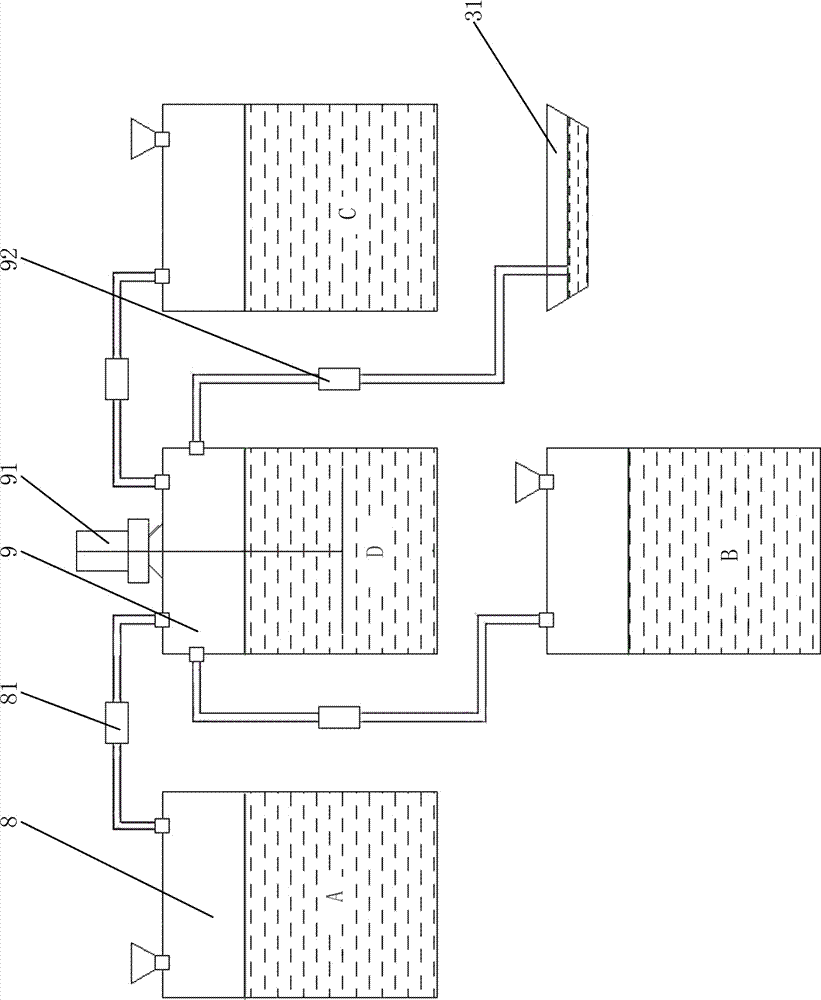

[0033] Such as figure 1 As shown, a thermoforming sheet and printing film lamination device in this embodiment includes a supporting wallboard 1, a printing film unwinding mechanism 2, a glue coating mechanism 3, a drying mechanism 4, a laminating mechanism 5, a sheet Material unwinding mechanism 6 and rewinding mechanism 7, printing film unwinding mechanism 2, gluing mechanism 3, drying mechanism 4, laminating mechanism 5, sheet material unwinding mechanism 6 and rewinding mechanism 7 are respectively installed on the supporting wallboard 1, according to the printing film processing sequence, there are printing film unwinding mechanism 2, gluing mechanism 3, drying mechanism 4, laminating mechanism 5, sheet unwinding mechanism 6 and winding mechanism 7, printing film unwinding mechanism 2 Including the first winding mandrel 21 and the first supporting guide roller 22, the printing film is wound on the first winding core 21 and transported to the gluing mechanism 3 through the...

Embodiment 2

[0047] The difference between the thermoforming sheet and printed film lamination device and production method in this embodiment and embodiment 1 is:

[0048] In this embodiment, a glue formula for laminating the thermoforming sheet and the printed film is provided. The glue formula includes the following parts by weight: 50 parts of ethyl acetate solution, 50 parts of polyurethane adhesive A, and 25 parts of polyurethane adhesive B ; wherein the ethyl acetate solution includes the following parts by weight: 23 parts of ethyl acetate, 128 parts of water; polyurethane adhesive A includes the following parts by weight: 3 parts of terephthalic acid, 3 parts of isophthalic acid, hexane 2 parts of diacid, 3 parts of trimethylolpropane, 3 parts of diethylene glycol, 3 parts of 2,4-diisocyanate, 75 parts of ethyl acetate; Polyurethane adhesive B includes the following parts by weight: 2,4-diisocyanate 6 parts of isocyanate, 5 parts of trimethylolpropane, 85 parts of ethyl acetate. ...

Embodiment 3

[0050] The difference between the thermoforming sheet and printed film lamination device and production method in this embodiment and embodiment 1 is:

[0051] This embodiment provides a glue formula for laminating the above-mentioned thermoformed sheet with the printed film. The glue formula includes the following parts by weight: 60 parts of ethyl acetate solution, 60 parts of polyurethane adhesive A, and 30 parts of polyurethane adhesive B ; wherein the ethyl acetate solution includes the following parts by weight: 30 parts of ethyl acetate, 170 parts of water; polyurethane adhesive A includes the following parts by weight: 5 parts of terephthalic acid, 4 parts of isophthalic acid, hexane 3 parts of diacid, 4 parts of trimethylolpropane, 5 parts of diethylene glycol, 5 parts of 2,4-diisocyanate, 80 parts of ethyl acetate; Polyurethane adhesive B includes the following parts by weight: 2,4-diisocyanate 8 parts of isocyanate, 8 parts of trimethylolpropane, 90 parts of ethyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com