Patents

Literature

280results about How to "Not easy to separate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient slow-release urea and preparation method thereof

ActiveCN102584496AIncrease profitEasy to separateAgriculture gas emission reductionFertilizer mixturesCoated ureaAdhesive

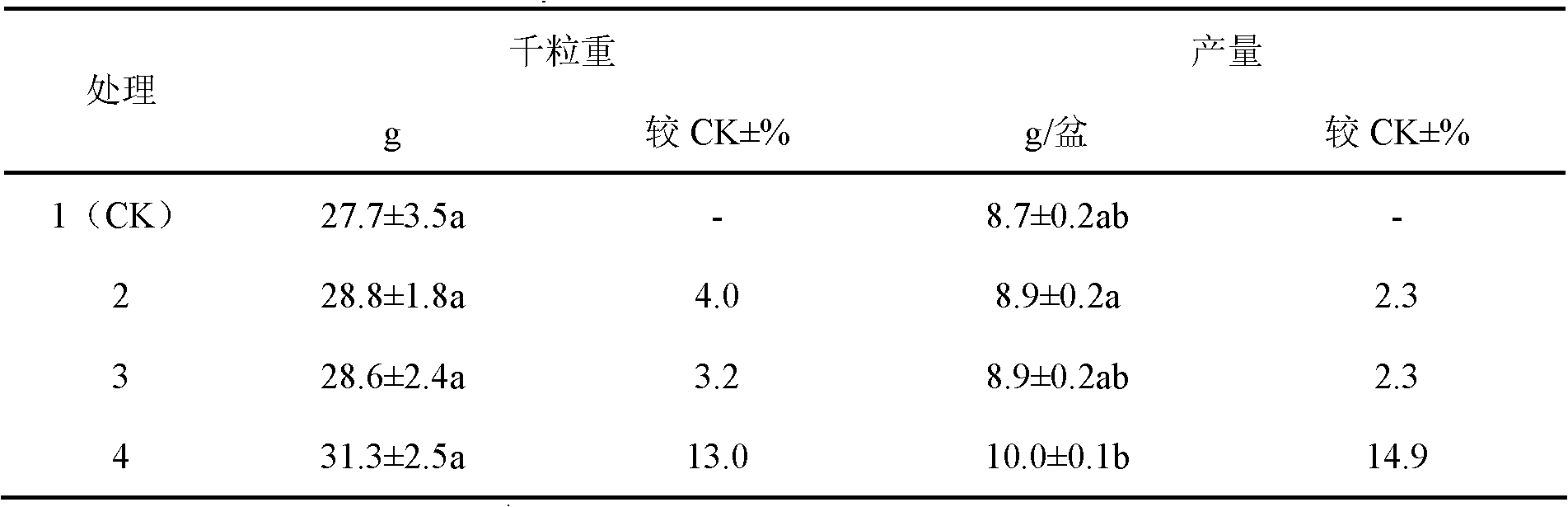

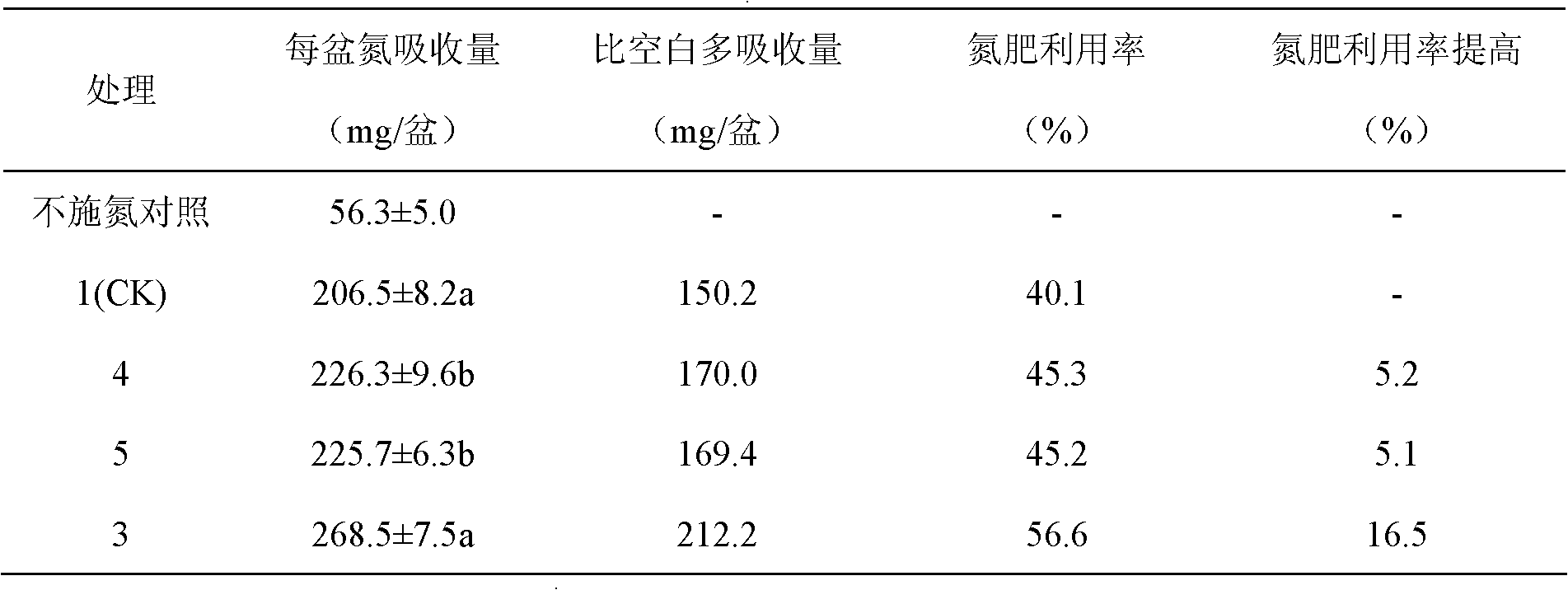

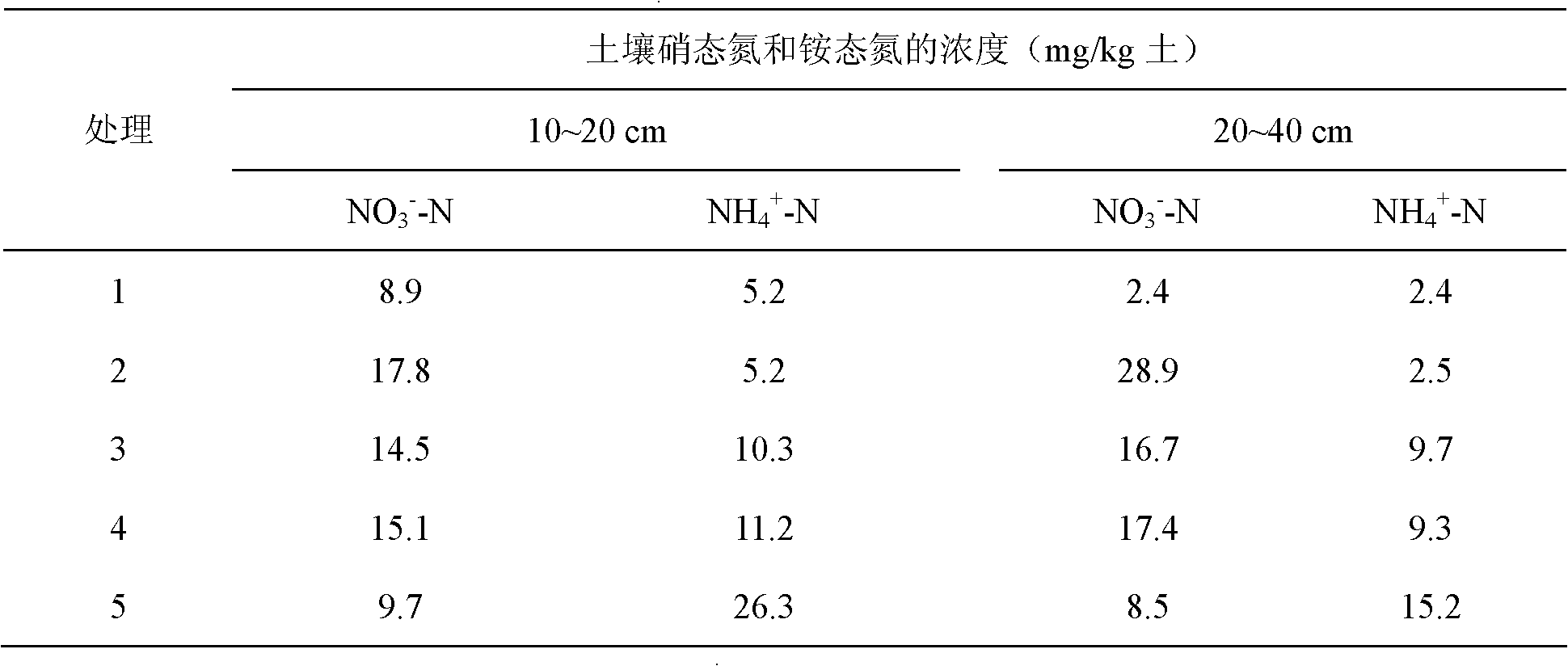

The invention discloses an efficient slow-release urea. The efficient slow-release urea is prepared by coating urea by utilizing a coating slow-release solution and drying and solidifying the coated urea, wherein the coating slow-release solution consists of the following components in percentage by mass: 1 to 5 percent of gamma-polyglutamic acid, 1 to 5 percent of nitration inhibitor, 0.5 to 5 percent of adhesive, 0.05 to 2 percent of surfactant and the balance of water; and the pH of the efficient slow-release urea is 5.5 to 6.5. The invention also discloses the preparation method of the efficient slow-release urea. The gamma-polyglutamic acid in the efficient slow-release urea has the effects of coating and chelating the urea and the nitration inhibitor, so that separation of the nitration inhibitor and a nitrogen fertilizer is reduced, leaching and runoff losses of nitrate nitrogen are reduced, one-time fertilization can be realized, top dressing is not required, the utilization rate of the fertilizer can be improved by over 15 percent, and the yield of the crops is increased by 10 to 30 percent.

Owner:NANJING UNIV OF TECH

Cake dough improver, mousse cake and method for preparing mousse cake

InactiveCN107156219ASoft and dense tasteStable tasteDough treatmentPre-baking dough treatmentBiotechnologyOrganic chemistry

The invention discloses a cake dough improver, a mousse cake and a method for preparing the mousse cake. The cake dough improver is prepared from raw materials in percentage by weight as follows: 2%-5% of an alkaline leavening agent, 2%-6% of an acidity regulator, 0.01%-30% of an emulsifier, 0.01%-0.1% of enzyme and the balance of a dispersant. The mousse cake comprises cake dough and a mousse layer, wherein the cake dough comprises the cake dough improver; and the mousse layer comprises a cream frothing stabilizer and a thickening and emulsifying stabilizer. The cake dough improver is added to the mousse cake, so that after the cake dough is frothed, coated and baked, the mousse cake tastes soft and creamy and can be continuously preserved for 9 months or longer under freezing and refrigeration conditions. The cream frothing stabilizer and the thickening and emulsifying stabilizer are added to the mousse layer of the mousse cake, the mousse cake is kept stable under long-term refrigeration and freezing conditions, water-oil separation cannot occur easily, and the cake is ensured to still taste fresh and moist under the long-term freezing condition and have a longer guarantee period.

Owner:广州市盛轩食品有限公司

Preparation method of copper red microcrystalline glass

ActiveCN102372438AReduce or eliminate adverse effectsIncrease added valueHigh-temperature corrosionPrinted circuit board

The invention provides a preparation method of copper red microcrystalline glass. The preparation method comprises the following steps of 1, carefully screening waste and old glass, cleaning, and crushing to obtain waste and old glass powder, 2, pretreating waste circuit boards, and carrying high temperature oxidation to obtain a metal oxide concentrate, 3, mixing the waste and old glass powder and the metal oxide concentrate, adding a nucleating agent and auxiliary agents, mixing well, and carrying out ball milling to obtain a mixed raw material, and 4, melting the mixed raw material at a high temperature into molten glass liquid, carrying out molding after clarification and homogenization, and carrying out nucleation and crystallization through heat treatment after annealing to obtain the copper red microcrystalline glass. The preparation method reduces or eliminates adverse influences from waste and old glass and waste circuit boards on the environment, changes waste into valuables, produces copper red microcrystalline glass having an extremely high artistic value, and has large economic and social benefits.

Owner:GEM CO LTD

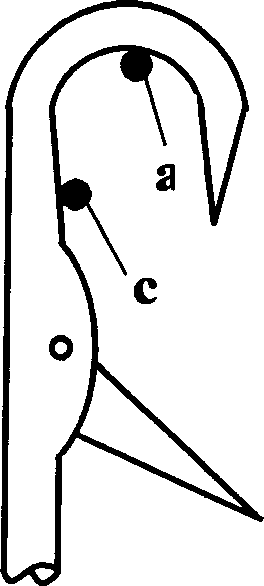

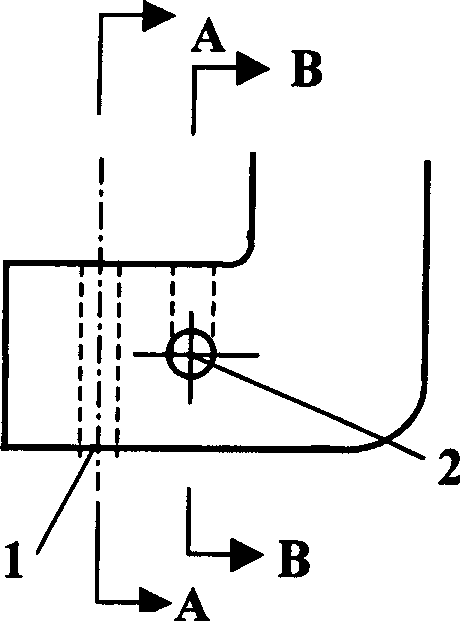

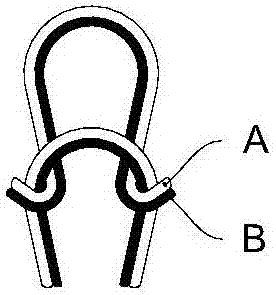

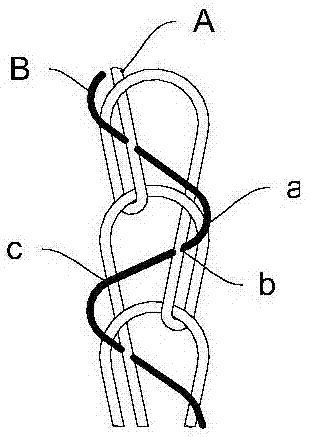

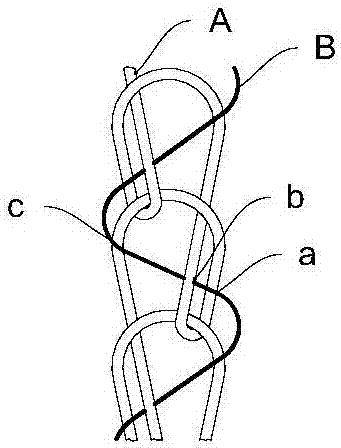

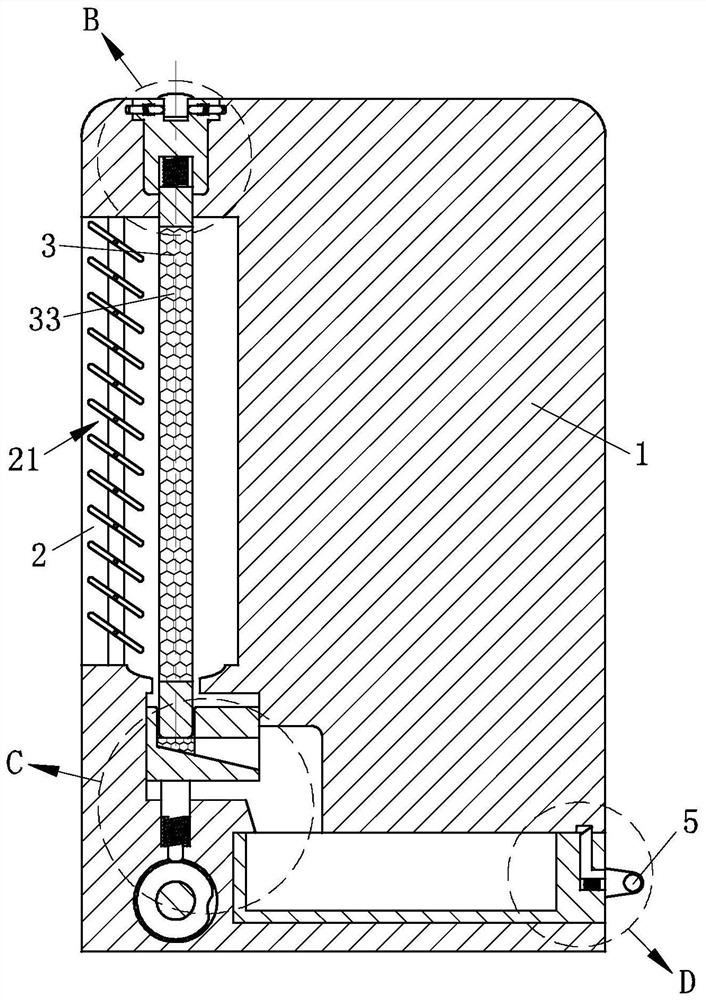

Large bobbin radius single side weft-knitting three-thread plating feeder

InactiveCN1821472AImprove wrinkle resistanceImprove wear resistanceCircular knitting machinesState of artYarn

The present invention relates to plating feeder, and is especially one kind of large bobbin diameter single side weft-knitting three-yarn plating feeder. The plating feeder includes one feeder body, three guiding elements on the body, possessing guiding holes, including the first guiding hole for ground yarn, the second guiding hole for the middle yarn and the third guiding hole for the facing yarn; and chutes on the body for the second guiding hole and the third guiding hole to slide up and down to realize altering yarn feeding angle. The present invention solves the technological problem of felter and makes it possible to weaving various kinds of three-yarn texture with high quality.

Owner:DONGHUA UNIV

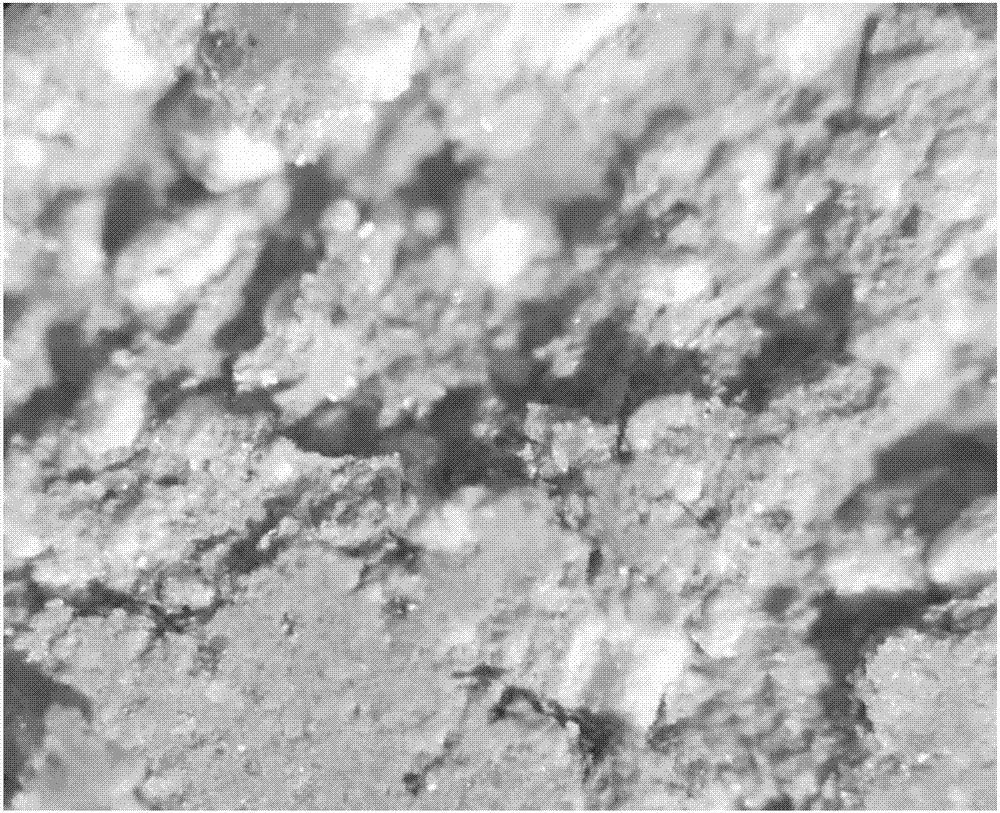

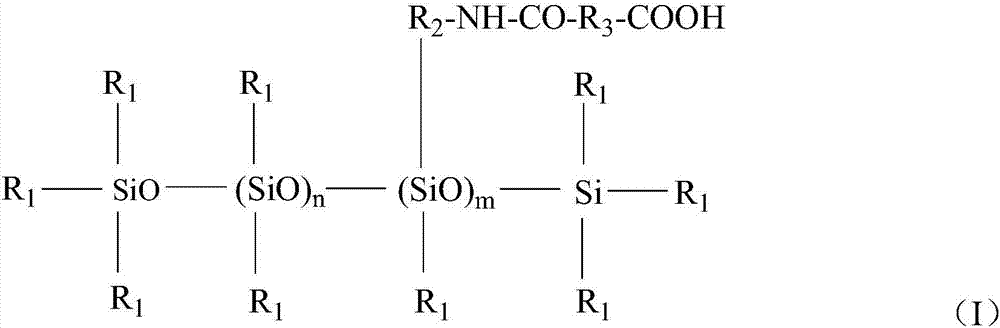

Heat conductive silicone grease containing liquid metal heat conductive filler

ActiveCN107501953ANot suitable for short circuitImprove thermal efficiencyHeat-exchange elementsHydrogenLiquid metal

The invention creatively provides heat conductive silicone grease containing liquid metal heat conductive filler. The silicone grease includes, by weight, 40-60 parts of organic silicon basic resin, 40-100 parts of the liquid metal heat conductive filler, and 0-10 parts of other additives. The organic silicon basic resin is composed of, by mass, 30-70% of vinyl-terminated dimethyl polysiloxane, of which the dynamic viscosity is lower than 2000 cst at 25 DEG C, 25-40% of vinyl-terminated dimethyl polysiloxane, of which the dynamic viscosity is higher than 10000 cst at 25 DEG C, 5-10% of vinyl cyclopolysiloxane, 2-10% of hydrogen-containing silicone oil, of which the dynamic viscosity is 50-2000 cst at 25 DEG C, and 5-20% of polyether-modified polysiloxane. The heat conductive silicone grease has high heat conductivity and matrix stability.

Owner:深圳沃尔提莫电子材料有限公司

Tagging method

InactiveCN101808531AGood miscibilityQuality improvementComponent separationBiological testingFood additiveVegetable oil

A method of identifying a product comprises forming a tagged product by adding to said product a tracer material comprising at least one tracer compound which is acceptable for use as an additive in food and subsequently analysing a sample of said product to determine the presence of said tracer compound thereby to determine whether said sample is a sample of the tagged product. The method is especially useful for the identification of vegetable oil products from sustainably managed sources. The use of permitted food additives as tracers enables the product to be identifiedin the supply chain whilst also allowing it to be used safely in foodstuffs if required.

Owner:JOHNSON MATTHEY PLC

Liquid metal heat-conduction filling material-containing polyethylene terephthalate heat-conduction film

ActiveCN107488416AShould not overflowImprove thermal efficiencyNon-macromolecular adhesive additivesFilm/foil adhesivesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a PET (polyethylene terephthalate) heat-conduction film, which comprises a PET bearing membrane and an adhesive material layer attached on the surface of the PET bearing membrane. The adhesive material layer comprises the following raw materials by weight: 10-50 parts of a liquid metal heat-conduction filling material, 2-10 parts of micro wax powder, 20-30 parts of spherical graphite, 1-10 parts of a membrane-forming auxiliary agent, 0.5-3 parts of a cosolvent, 0.5-3 parts of a dispersant, 0.1-0.5 parts of an antifoaming agent, 0.1-2 parts of a thickening agent, 0.1-2 parts of a levelling agent, 20-40 parts of a silicone acrylic emulsion, and 0-5 parts of other auxiliary agents. The heat-conduction film has high heat conduction coefficient, and the adhesive material has stable long-term coating and stripping effects on the PET membrane.

Owner:深圳沃尔提莫电子材料有限公司

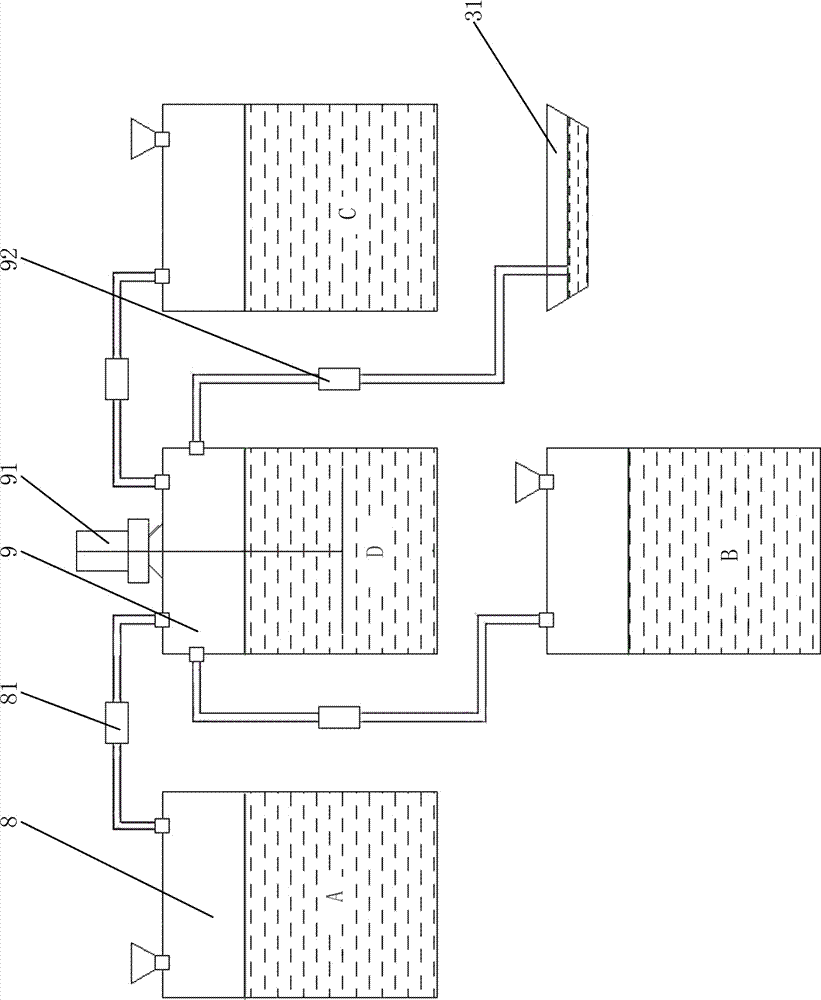

Method for 3D printing of bicomponent composite material with skin-core structure

InactiveCN109203473ARich varietyEasy to separate3D object support structuresApplying layer meansSkin corePolymer

The invention relates to a method for 3D printing of a bicomponent composite material with a skin-core structure. Skin layer polymers and core layer polymers are conveyed to an outer layer and a middle layer of the same nozzle of a 3D printer by different runners for extrusion to prepare the bicomponent composite material with the skin-core structure; the skin layer polymers and the core layer polymers are materials for forming a skin layer and a core layer of the bicomponent composite material with the skin-core structure; the 3D printer mainly consists of a bin I, a bin II, a screw extruderI, a screw extruder II, a metering pump I, a metering pump II, a distribution plate, a nozzle and multiple melt pipes; and the skin layer polymers and the core layer polymers are fed in the screw extruder I and the screw extruder II by the bin I and the bin II for melting, then, are conveyed into the metering pump I and the metering pump II by the melt pipes, are metered into the same distributionplate by the metering pumps, and are distributed into the nozzle by the distribution plate. Products printed by the method can integrate the characteristics of different materials to meet the demandsin different fields.

Owner:DONGHUA UNIV

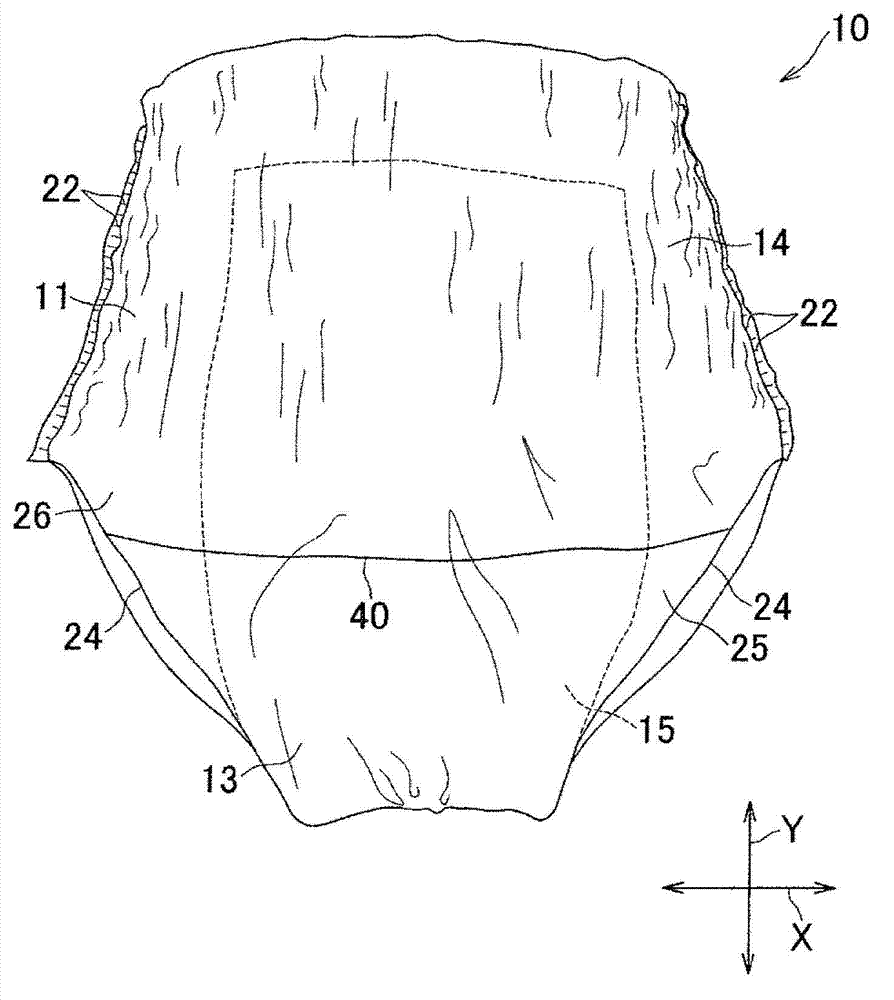

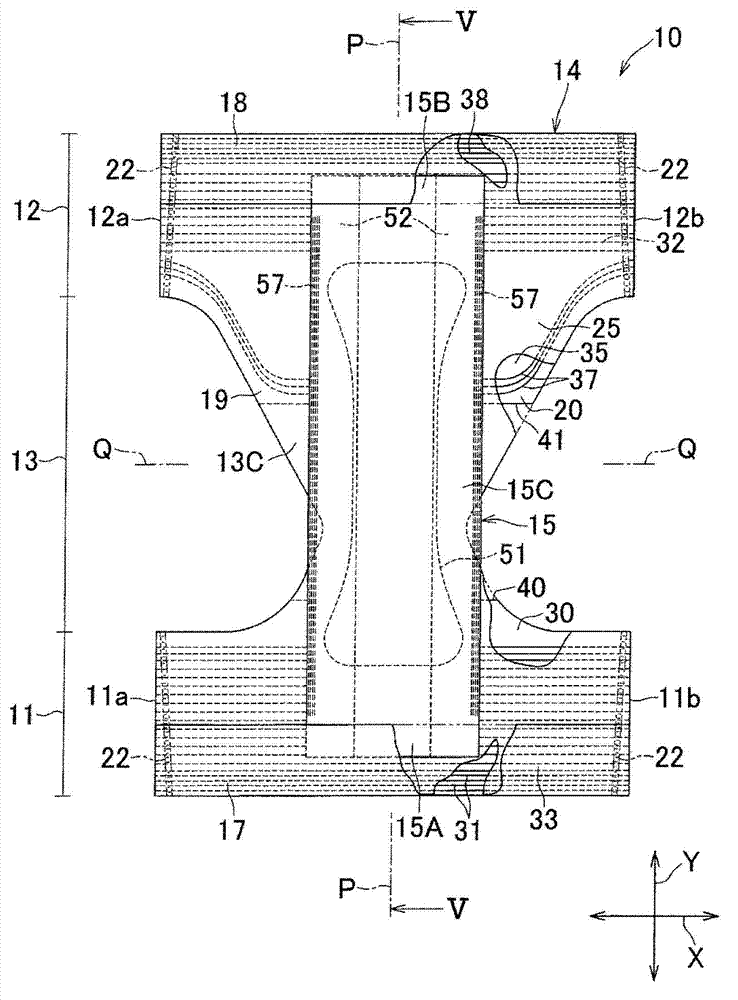

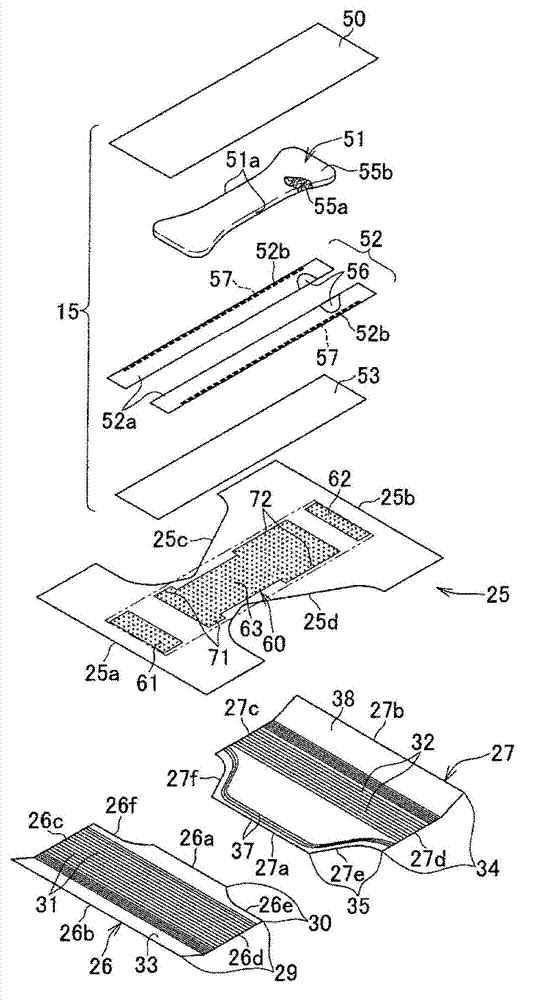

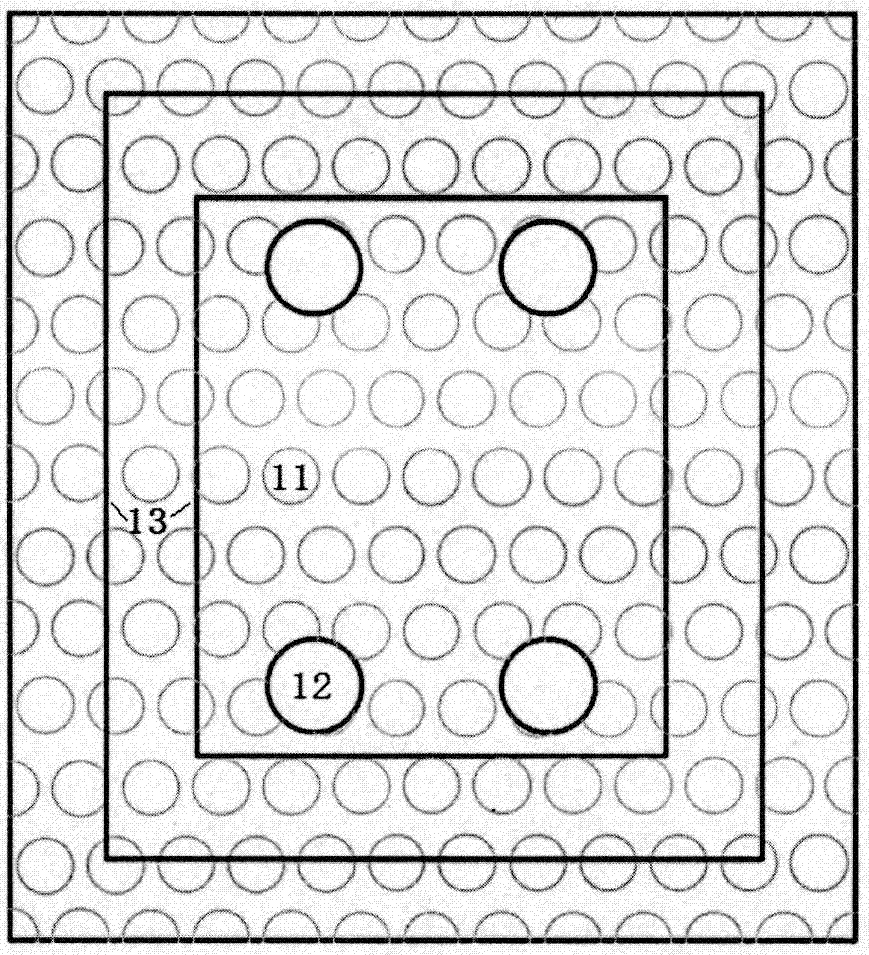

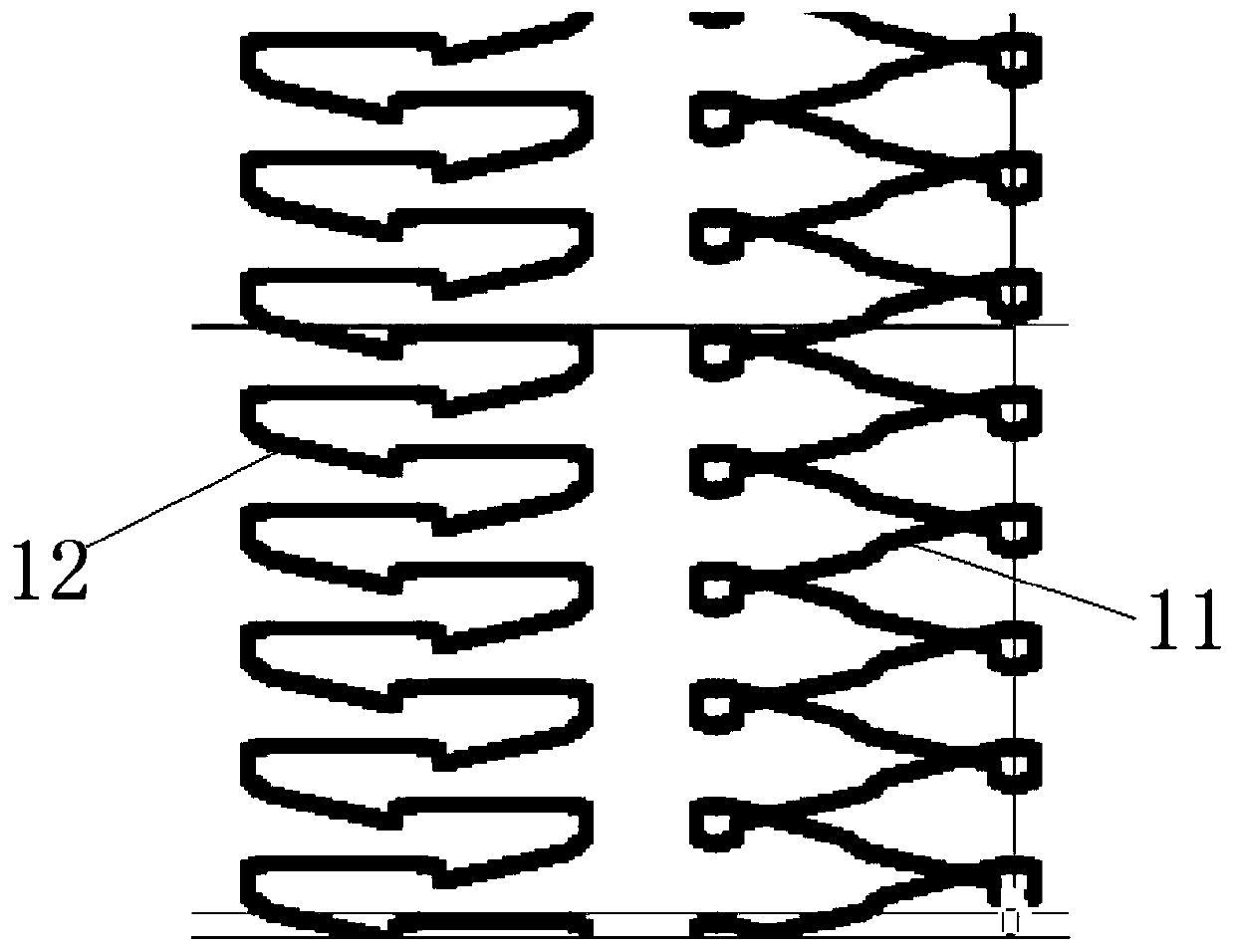

Pants-type apparel artical

The invention provides a pants-type apparel artical, at least a central part is soft, a front waist area side is provided with required tensile strength and at least part of the front waist area (11) side is a multi-layer area (44) passing by a laminated substrate part (25) and a front waist part (26). The central part (13c) of a crotch area (13) is a single-layer area (43) only formed by a substrate part (25); the multi-layer area (44) is provided with a corner part (73) surrounded by a boundary (40), an inner edge (11d) of the front waist area (11), a junction area (60) for connecting an absorption configuration body (15) and a bottom (14) and the above concave-curve shaped side edge (19c) of the crotch area (13); and the boundary (40) of the multi-layer area (44) and the single-layer area (43) passes across the junction area (60).

Owner:UNI CHARM CORP

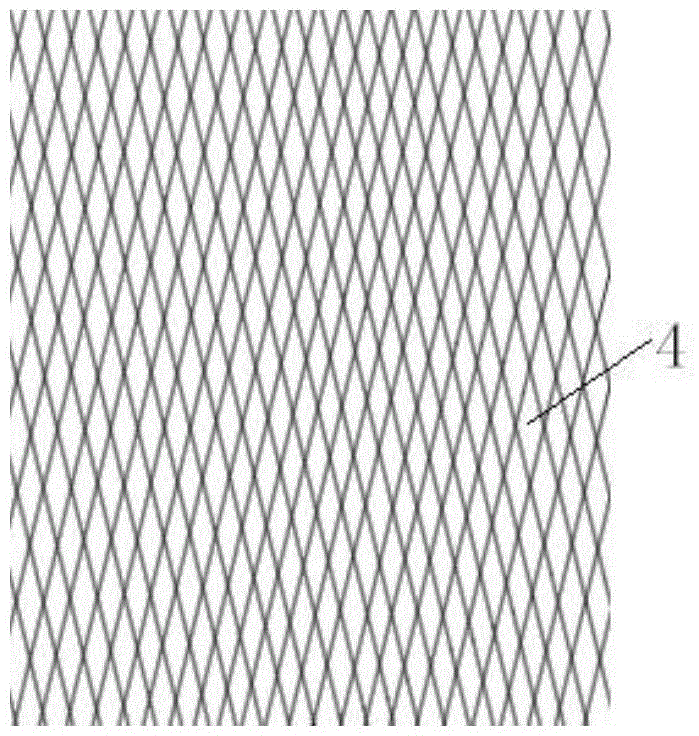

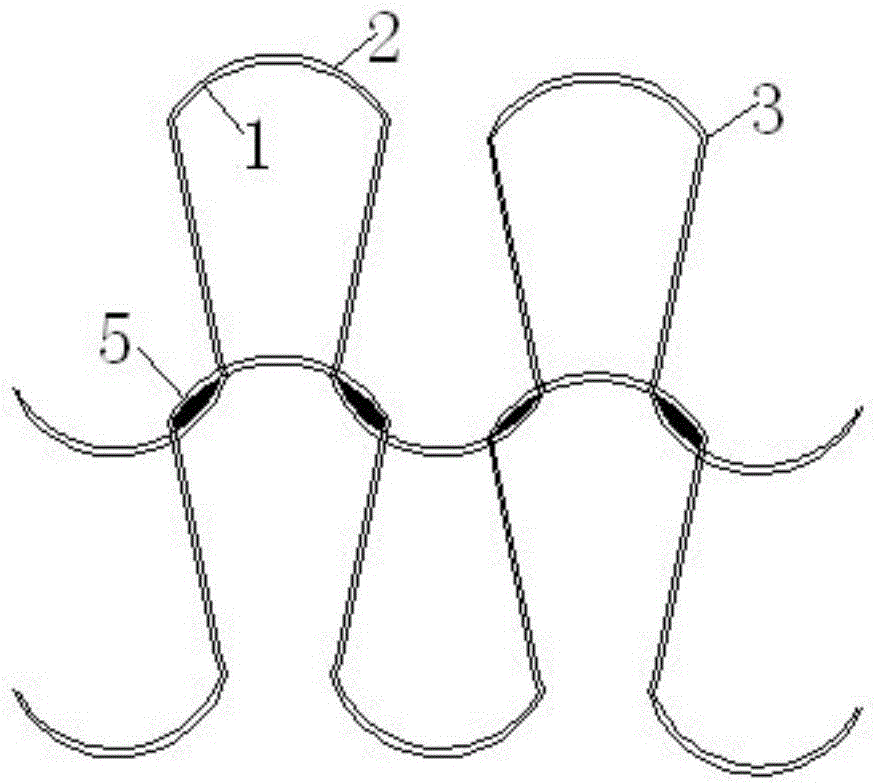

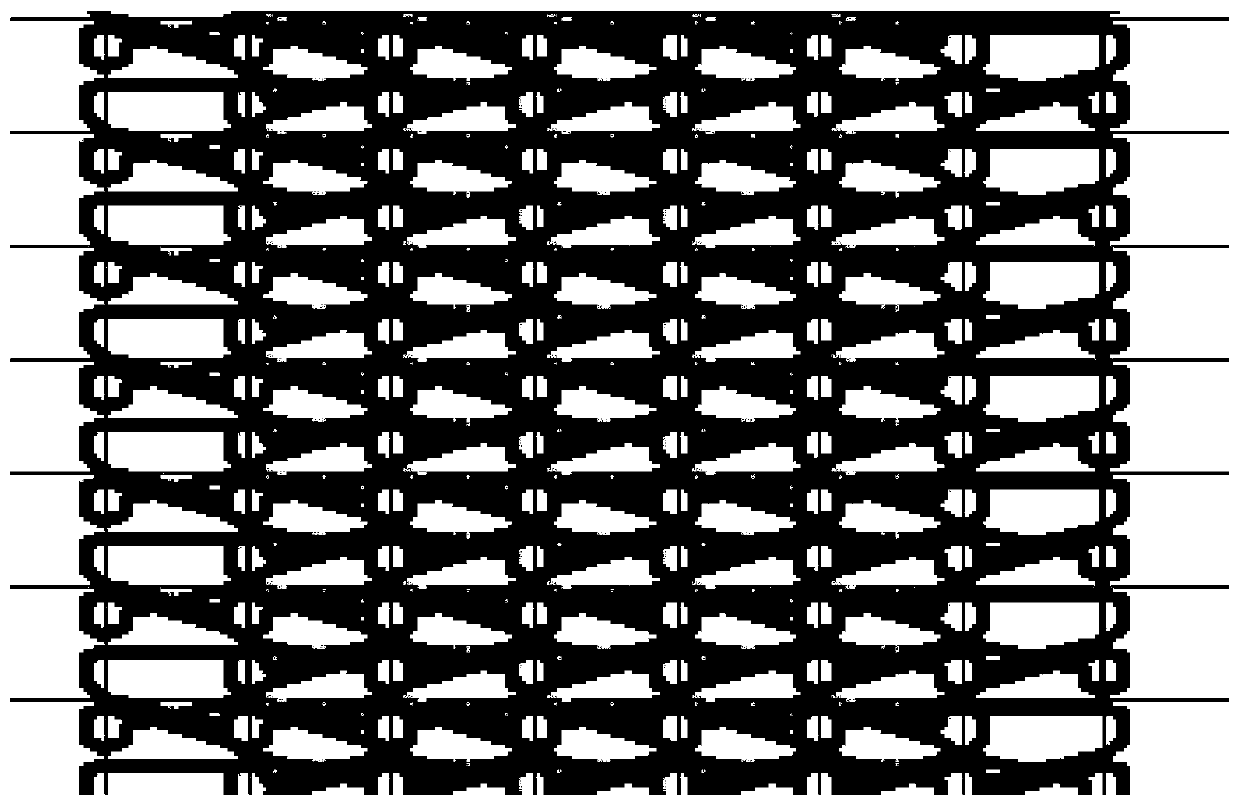

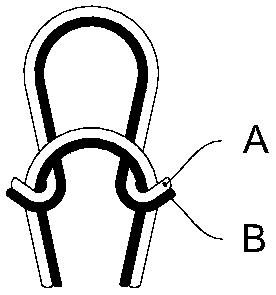

Rotator cuff patch

PendingCN107496052AGood biomechanical strengthAvoid Patch CreepLigamentsMusclesBiomechanical strengthSacroiliac joint

The invention relates to a patch for treating rotator cuff injuries, in particularly to a patch applicable to repairing huge rotator cuff tear. The patch is woven through the warping technology, is low in mass and not likely to be disengaged and has the good clipping performance; due to the special hole and boundary design, corresponding clipping and sewing fixation are easily perfrmed according to surgical needs. The rotator cuff patch is good in biomechanical intensity, can provide enough mechanical support for rotator cuff joints, avoids patch creep deformation and improves the surgical efficiency and the treatment effect.

Owner:BEIJING WANJIE MEDICAL DEVICE CO LTD

Method of preparing amphiphilic superbranched polyether nano-level self-assembly body

The invention relates to a producing method of amphiphilic hyperbranched polyaether nano self-assemblies. The invention includes following steps: (1) preparing monomer 3-eshyl-3-oxacyclobutane carbinol; (2) processing a ring opening polymerization reaction; (3) adding ethylene oxide again for reaction, getting product, depositing by sedimentation agent, drying in vacuum to a constant weight; (4) distributing it in the water solution under the magnetic stirring, then dripping into the water solution or organic solvent for dialysis, obtaining amphiphilic hyperbranched polyaether nano self-assemblies. The inventive self-assemblies has an adjustable size between 10-200nm and stabilize in nano level. The nano micelle has an even size which avoids the PEO phase separation on the micelle surface.

Owner:SHANGHAI JIAO TONG UNIV

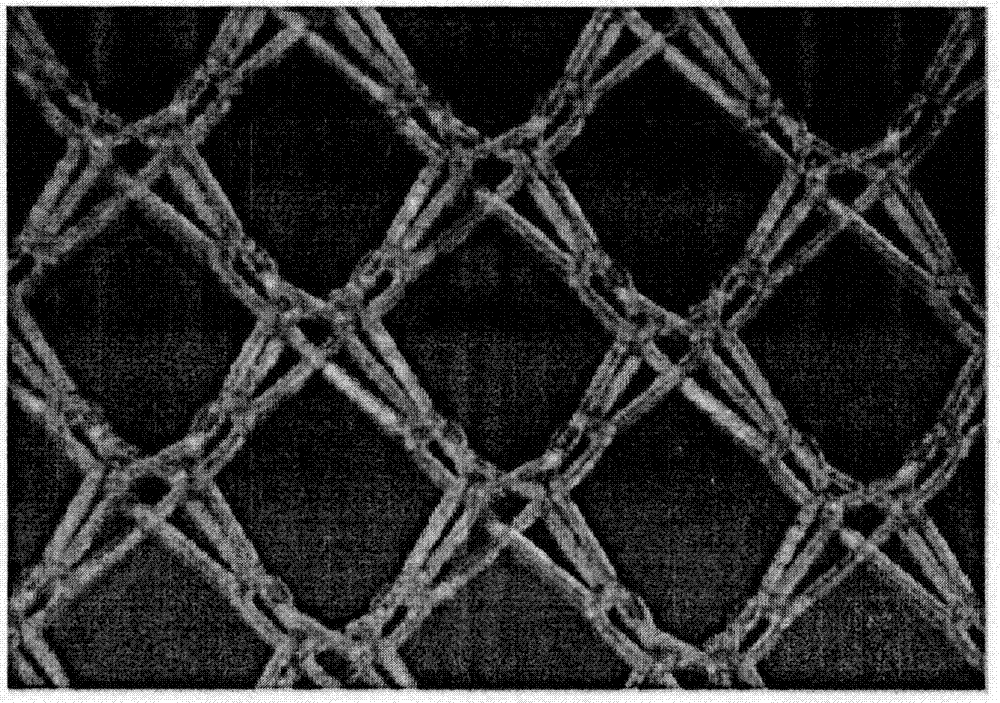

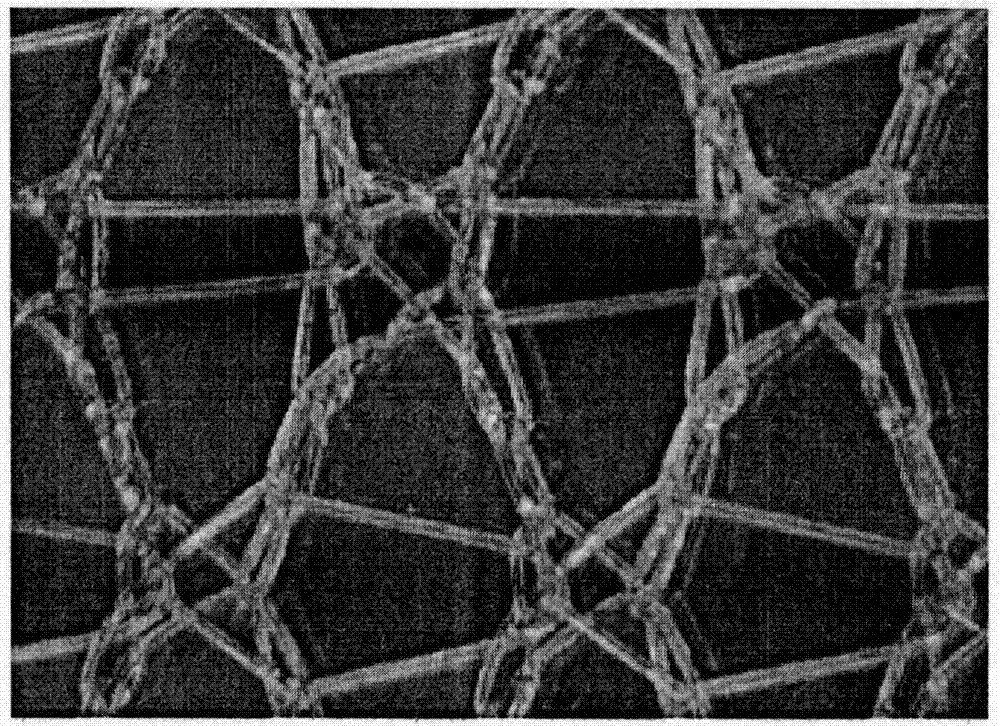

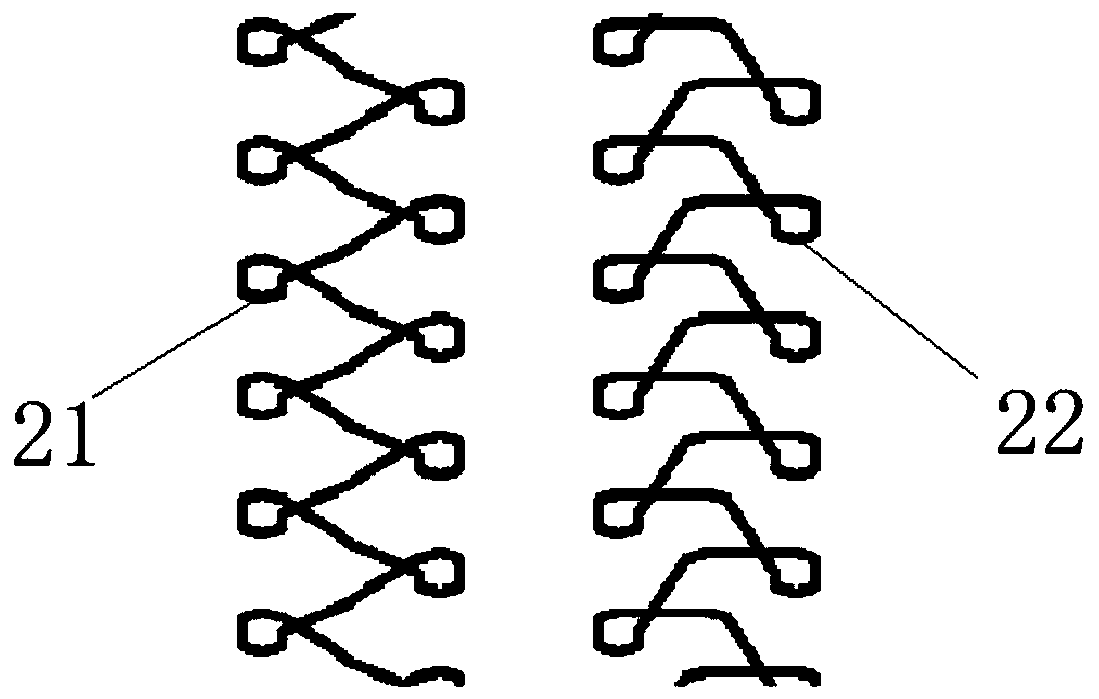

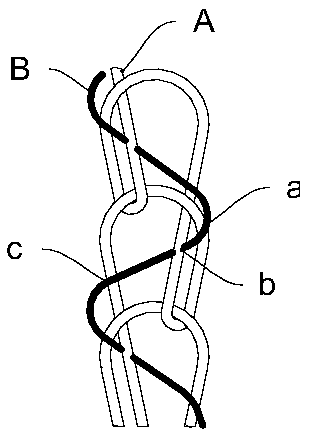

Knitting method of multi-bar warp-knitting machine

The invention provides a knitting method of a multi-bar warp-knitting machine. The method includes the following steps of firstly, preparing a raw material wire; secondly, feeding the raw material wire into a looping ground bar; thirdly, making the looping ground bar start knitting, wherein the raw material wire is composed of N yarns, N is larger than or equal to 1, and at least one of the N yarns is a raveling-resistant yarn. Raveling-resistant yarn loops are added on the basis of existing loops, the tightness of the existing loops is increased, joints of all the loops are staggered or overlapped, ground net yarn loops are made to have quite strong cohesive force and more closely cohered to fancy yarns forming a pattern, and even no chain stitch transfer transverse yarn or thermofuse yarn is added, the ground yarn loops and the fancy yarns are not prone to raveling after damage.

Owner:TIANHAI LACE CO LTD

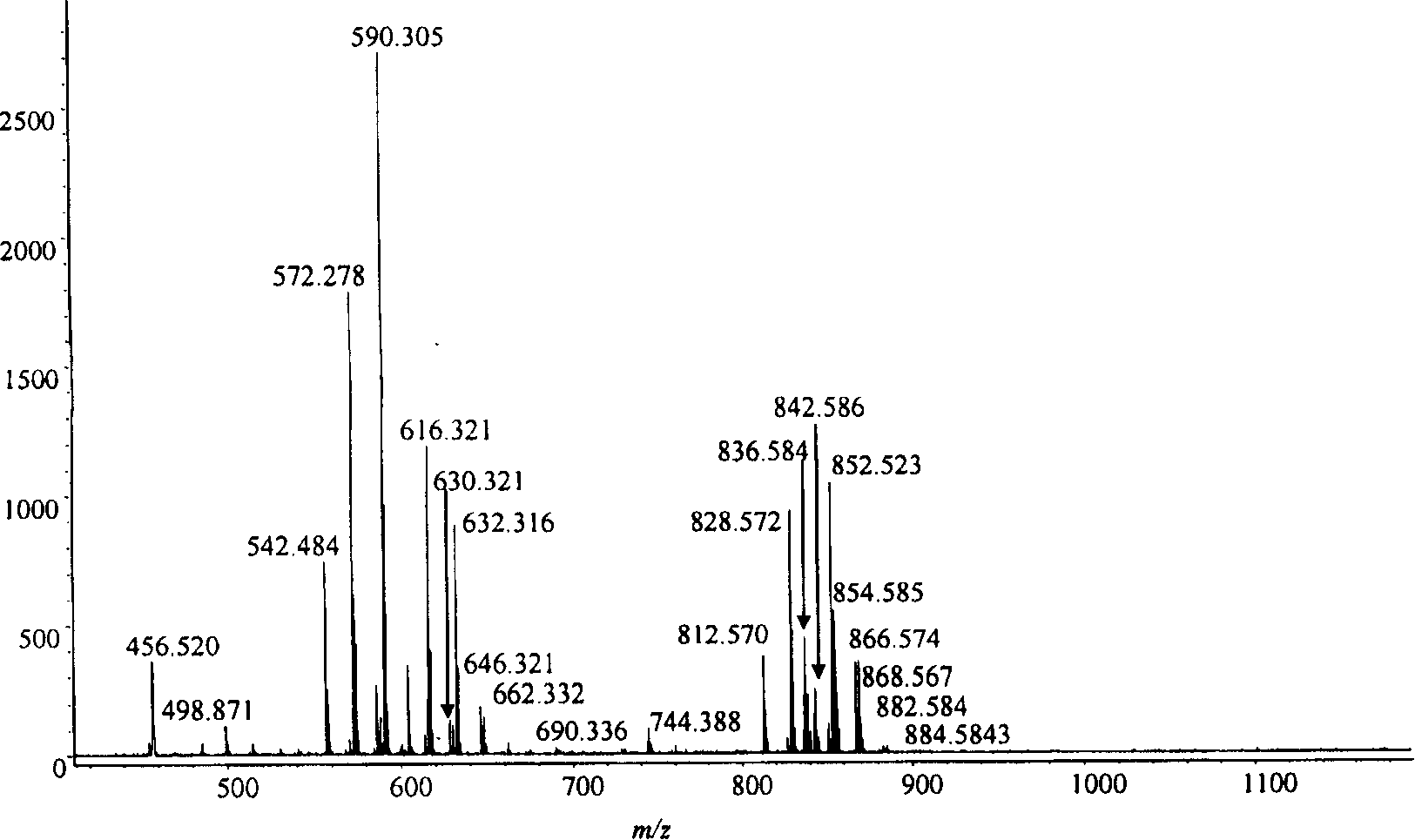

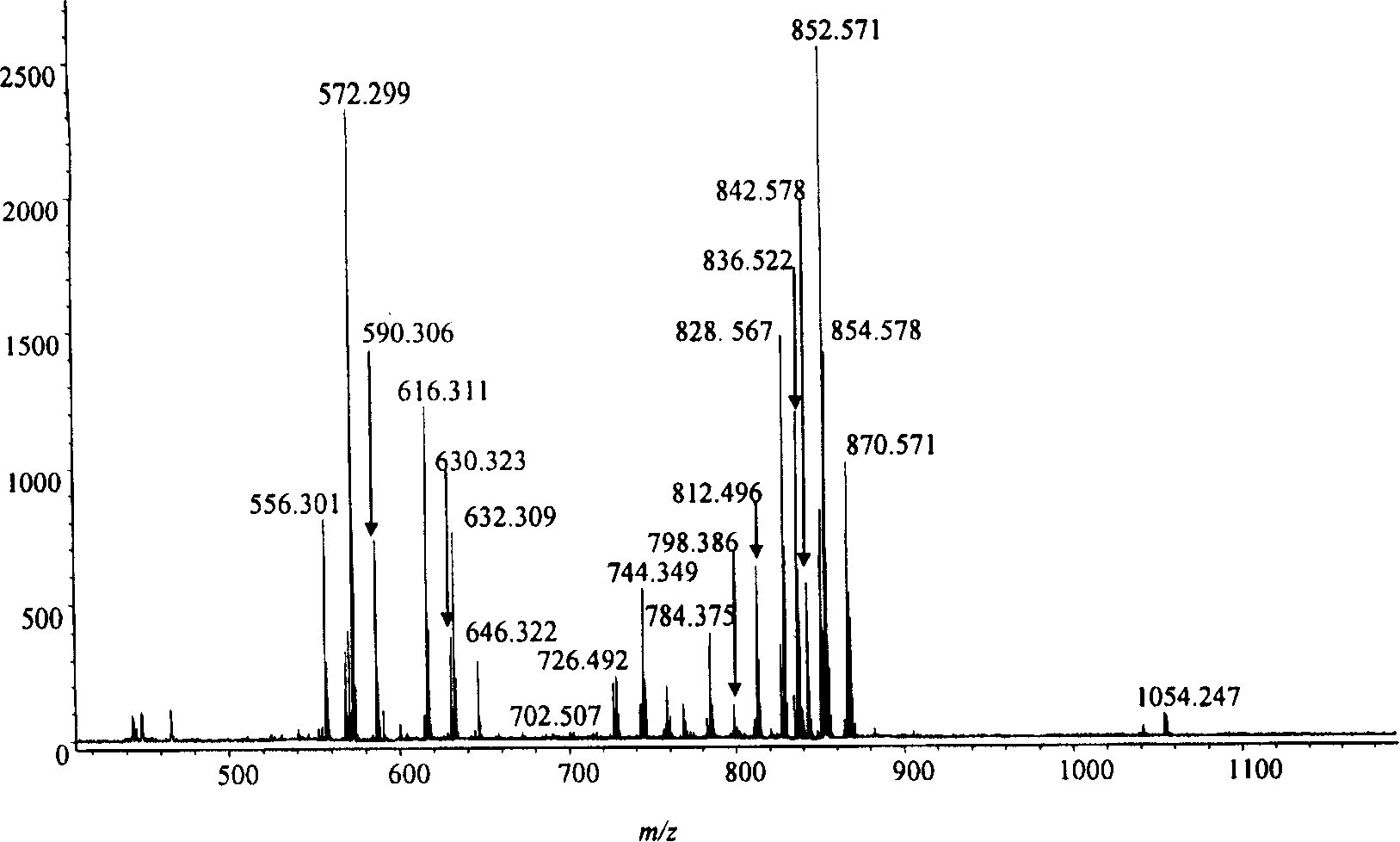

Method for directly analyzing chemical composition of plant tissue slice

InactiveCN101196491AReduce or eliminate lossesEasy to analyzeComponent separationMaterial analysis by electric/magnetic meansChemical treatmentMatrix solution

The invention is a method of directly analyzing the chemical composition of plant tissue slice, which relates to the chemical composition analyzing technology and comprises the following procedures: S1. Cutting the plant for testing into the slice of 10-20 Mu m thickness, and taking a piece of slice to lay on the target of stroma auxiliary laser analyzing flying time mass spectrograph; S2. Preparing stroma solution; S3. Using liquid displacing machine to add the stroma solution on the plant tissue slice; S4. Laying the target and the tissue slice dotted with stroma solution in vacuum dryer to dry; S5. Directly putting the target and the plant tissue slice for testing after drying into the stroma auxiliary laser analyzing flying time mass spectrograph to conduct analyzing, and finally achieving the information of the chemical composition contained by the plant slice. The analyzing method of the invention is convenient, quick and high-efficient, which doesn't need sample chemical processing, thus avoiding the defects that the traditional sample processing and analyzing method wastes long time, and the microcomposition is difficult to analyze and is possible to damage the chemical composition.

Owner:蔡宗苇

Low-temperature Lycra free-cut double-sided knitting fabric

The invention relates to a low-temperature Lycra free-cut double-sided knitting fabric which is made of blended yarns formed by interweaving low-temperature Lycra yarns and spinning fiber yarns. The fabric is formed by interweaving the blended yarn. The blended yarn is of a rib or double-rib woven structure. The fabric is a double-faced weft-knitting knitted structure, and joints between the blended yarns are mutually soluble bonding points. The low-temperature Lycra free-cut double-sided knitting fabric is advantageous in that the yarn is bonded solidly in a mutually soluble mode, the fabric can be cut freely, edges will not ravel, the manufacturing cost is low, and the overall fabric is flat and beautiful.

Owner:JIANGSU NEW XUEZHU INT FASHION

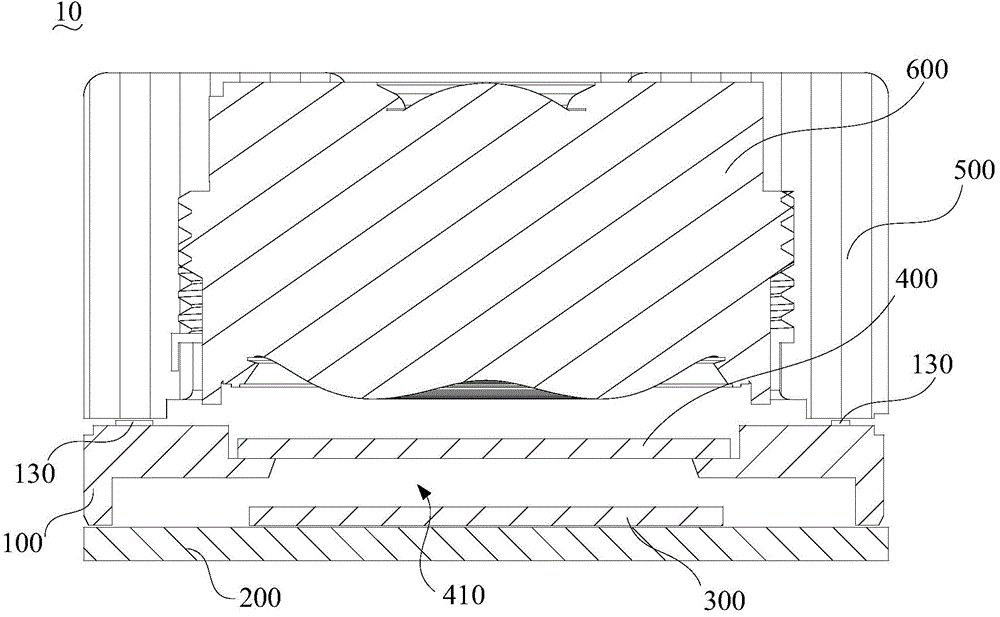

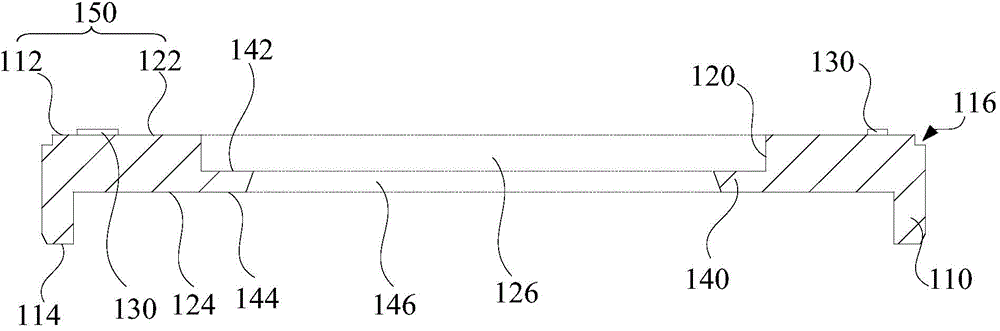

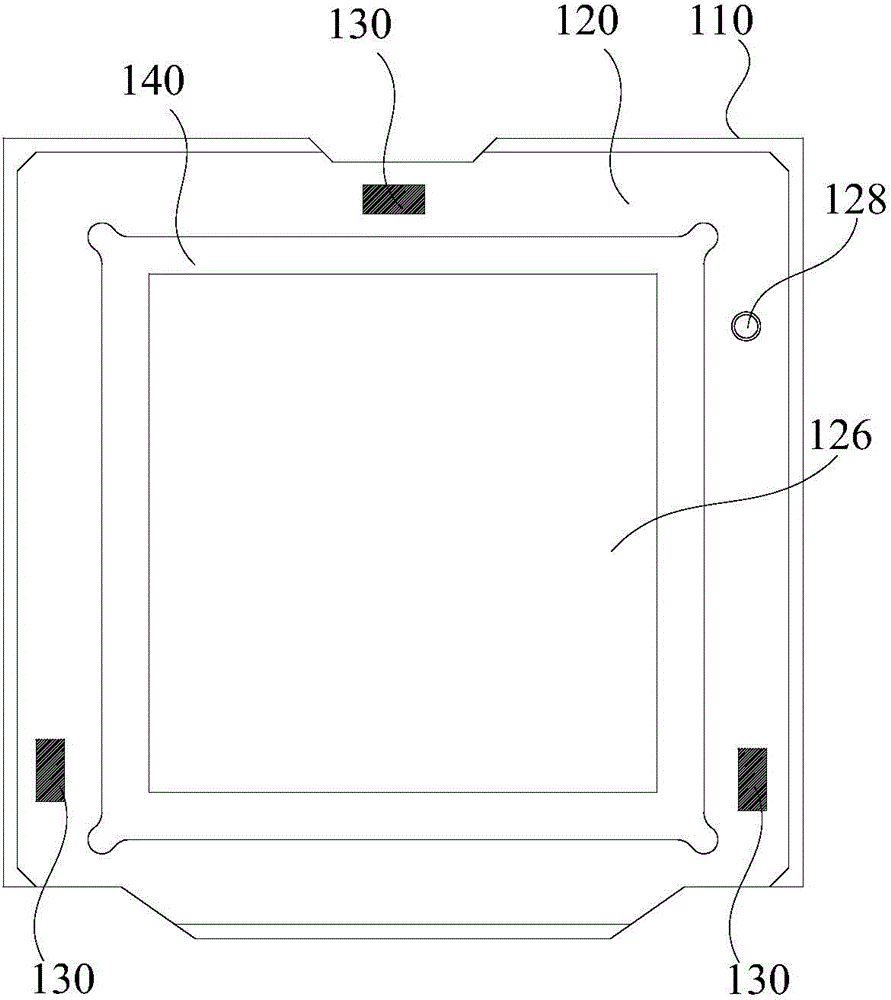

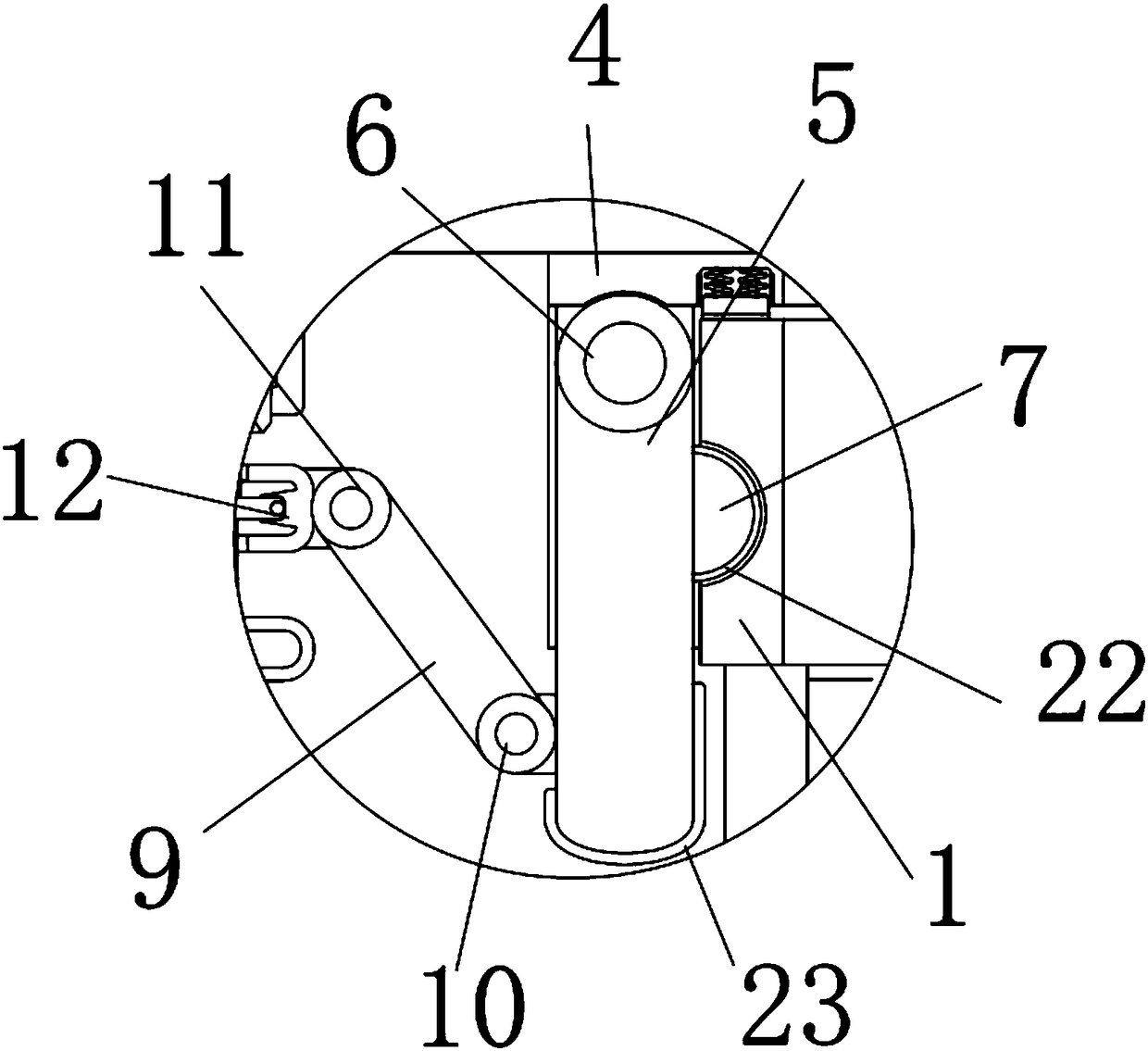

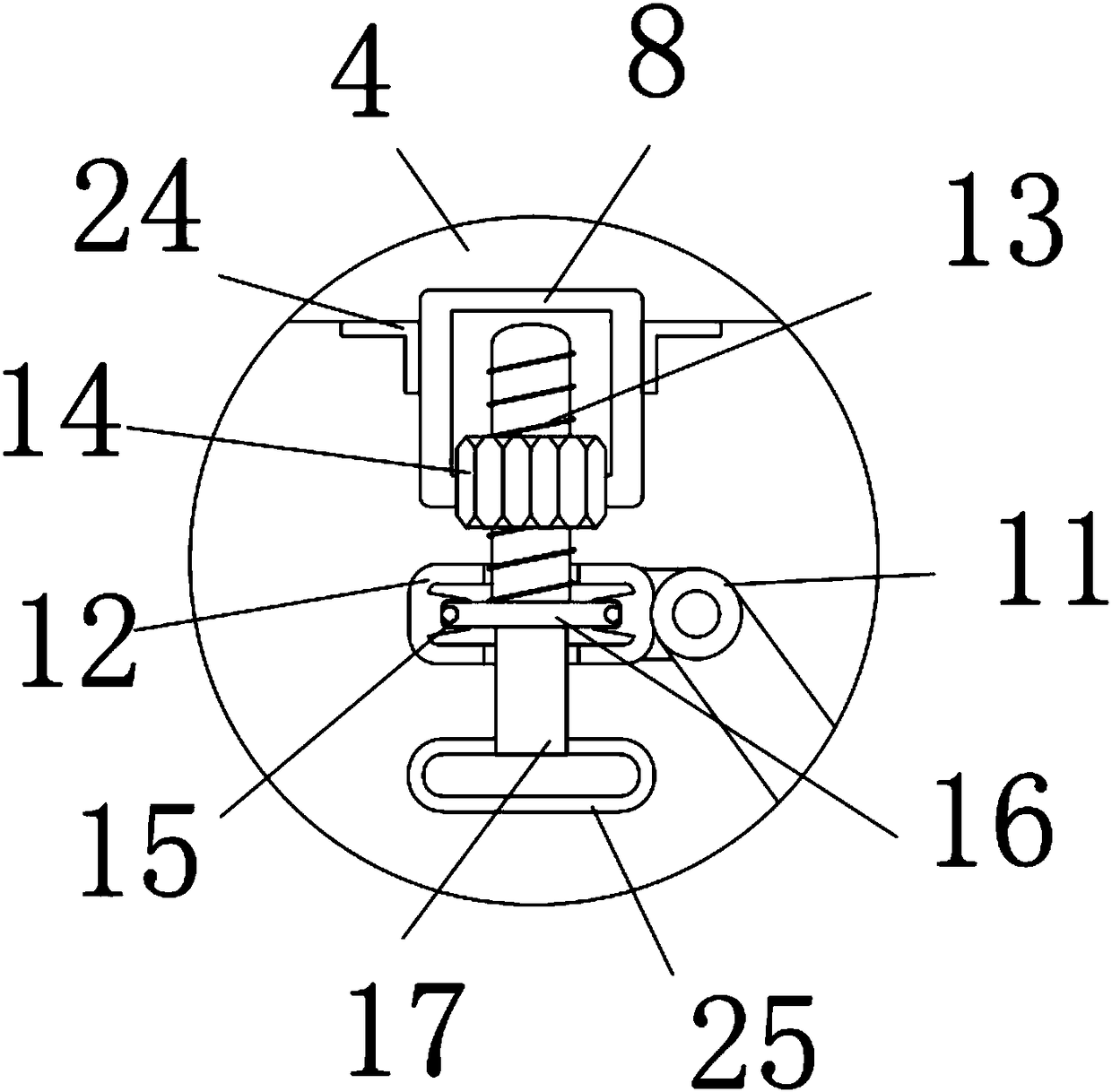

Camera module and bracket thereof

ActiveCN104902156AAvoid flowing toNot easy to separateTelevision system detailsColor television detailsEngineeringInfrared cut-off filter

The invention relates to a camera module and a bracket thereof. The bracket comprises a barrel, a mounting plate and lugs, wherein the barrel has a first end face and a second end face which are opposite to each other; the mounting plate has a first surface and a second surface which are opposite to each other; the mounting plate is arranged in the barrel; the first surface and the first end face are flush with each other and constructed a mounting surface; the mounting plate is provided with a light hole passing through the first surface and the second surface; the light hole is used for accommodating an infrared cut-off filter of the camera module; the lugs are arranged on the mounting plate; one side of each lug far away from the mounting plate is used for carrying a voice coil motor of the camera module; a plurality of lugs are distributed in such a way that the voice coil motor of the camera module can be erected on the lugs under the condition of no external force; a space between the mounting surface and the lugs far away from the mounting surface is taken as a glue accommodating area; and the second end face is used for connecting a circuit board of the camera module. During assembly of the bracket, the overall dimension of the camera module can be ensured, and the voice coil motor can be prevented from being separated from the bracket in the case of falling.

Owner:O FILM IMAGE TECH (GUANGZHOU) CO LTD +4

Free cut fabric not prone to hemming

PendingCN110042551AIncrease elasticityModerate elasticityWarp knittingResilient fabricsEngineeringSurface structure

Owner:梁源

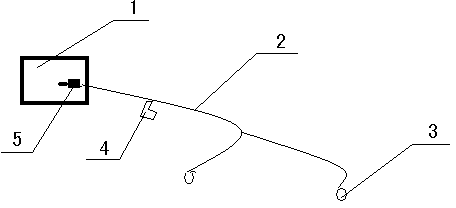

Mobile phone earphone with antitheft function

InactiveCN103347227AReduce the chance of lossFirmly connectedEarpiece/earphone attachmentsEngineeringMobile phone

The invention discloses a mobile phone earphone with an antitheft function. The mobile phone earphone comprises an earphone line (2), earphone bodies (3), a fixing clamp (4) and an earphone plug (5). The two ends of the earphone line (2) are connected with the earphone bodies (3) and the earphone plug (5) respectively. The fixing clamp (4) is located on the earphone line (2). The mobile phone earphone with the antitheft function further comprises a mobile phone placing bag (1). The front end of the mobile phone placing bag (1) and the earphone line (2) are integrally formed. The earphone plug (5) is placed inside a cavity of the mobile phone placing bag (1). The rear end of the mobile phone placing bag (1) is designed to be capable of being opened and closed. According to the mobile phone earphone with the antitheft function, due to the fact that the connection between the earphone and the mobile phone is strengthened, the mobile phone and the earphone can not be easily separated, and the probability that the mobile phone is lost under the alert-free condition is reduced.

Owner:徐州宏光电子有限公司

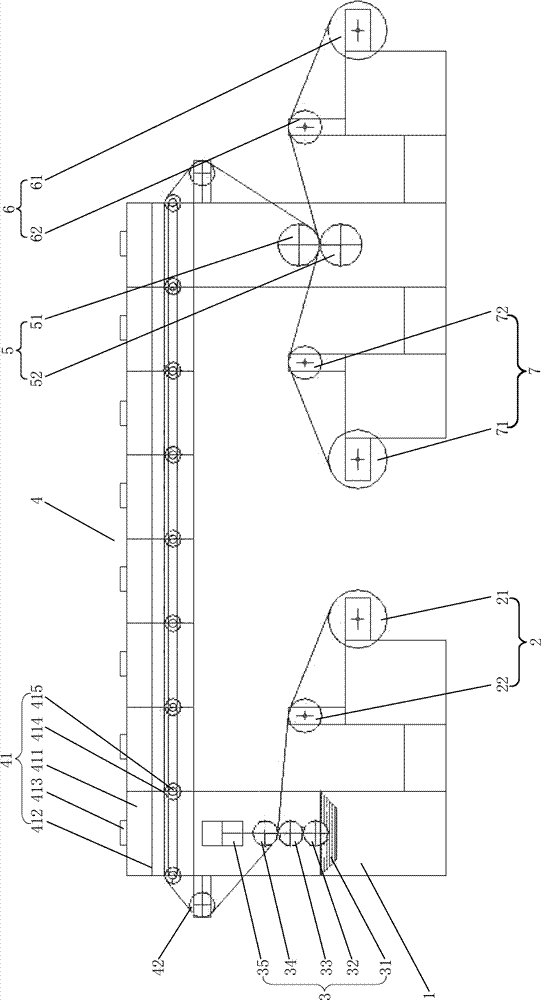

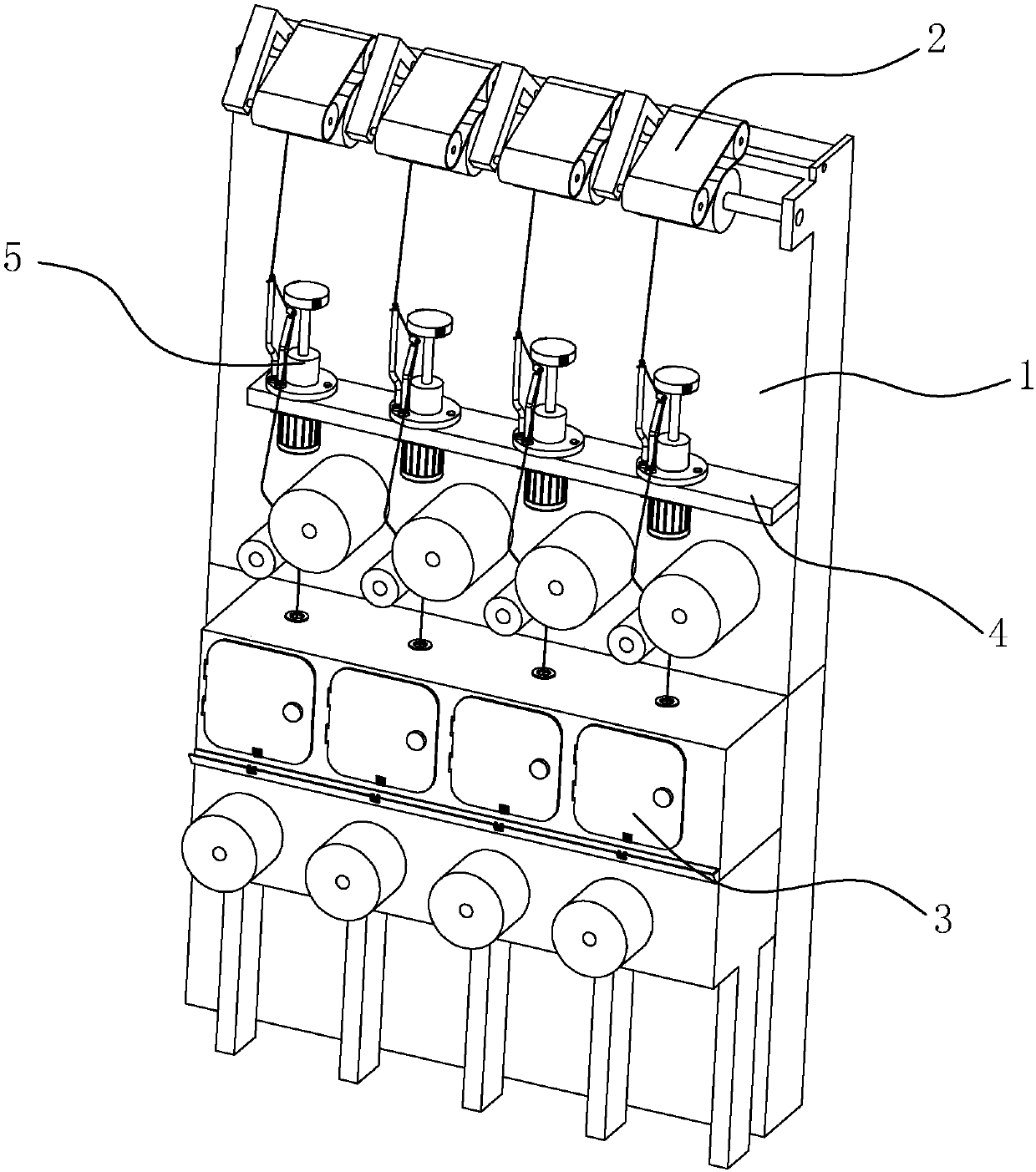

Thermoformed sheet and printed film lamination device and production method

PendingCN107160819AVariety of surface tonesImprove aestheticsLamination ancillary operationsPolyureas/polyurethane adhesivesThermoformingAdhesive glue

The invention relates to a thermoformed sheet and printed film lamination device and a production method. The lamination device comprises supporting wall plates, a printed film unwinding mechanism, a gluing mechanism, a drying mechanism, a laminating mechanism, a sheet unwinding mechanism and a winding mechanism, wherein the printed film unwinding mechanism, the gluing mechanism, the drying mechanism, the laminating mechanism, the sheet unwinding mechanism and the winding mechanism are respectively mounted on the supporting wall plates, and the printed film unwinding mechanism, the gluing mechanism, the drying mechanism, the laminating mechanism, the sheet unwinding mechanism and the winding mechanism are arranged in sequence according to a printed film processing sequence. The thermoformed sheet and printed film lamination device is characterized in that the gluing mechanism comprises a glue tank, a glue smooth roll, a glue transitional roll, a glue press roll and a pneumatic cylinder, the glue smooth roll is immersed in the glue tank, the glue smooth roll, the glue transitional roll, the glue press roll and the pneumatic cylinder are sequentially connected from bottom to top, and a piston rod of the pneumatic cylinder is connected to the glue press roller. The lamination device can be used for realizing the diversity of surface hues of a thermoformed sheet, increasing the attractiveness of the thermoformed sheet and improving the quality of film lamination.

Owner:SHANTOU SAMMA PLASTIC IND CO LTD

The knitting method of multi-bar warp knitting machine

Owner:TIANHAI LACE CO LTD

Synthesis process of p-tert-butyl phenol formaldehyde resin

The invention belongs to the technical field of synthesis of p-tert-butylphenol formaldehyde resin, and discloses a synthesis process of p-tert-butylphenol formaldehyde resin. The synthesis process comprises the following steps: adding a formaldehyde solution and ammonia water into a reaction kettle; uniformly adding p-tert-butylphenol, then heating to boiling, and maintaining for 150-180 minutes;cooling, adding acetic acid, neutralizing and stirring, and adding toluene for extraction; after standing for layering, draining wastewater; adding oxalic acid and tap water, stirring, standing for layering, and then draining wastewater; detecting pH which approximates 7-7.5, desolventizing the toluene under normal pressure, vacuumizing, and discharging under vacuum to obtain tert-butyl phenol formaldehyde resin. According to the process, the ammonia water is alkalescent, so that reaction is relatively mild, and the p-tert-butyl phenol formaldehyde resin prepared by the method is stable in product index and stable in use performance.

Owner:河北泽田化工有限公司

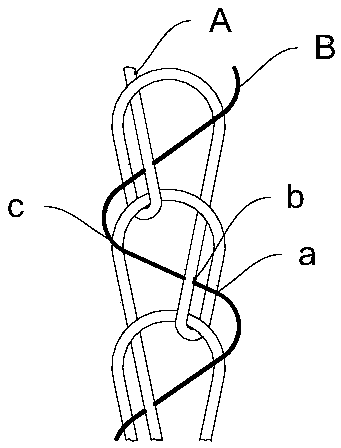

Method for knitting warp-knitted biaxial reinforced fabric

InactiveCN103481555AImprove structural stabilityImprove product qualityLayered productsFiberEngineering

The invention belongs to the field of methods for knitting warp-knitted fabrics and in particular relates to a method for knitting a warp-knitted biaxial reinforced fabric. The method comprises the following steps: laying reinforced fibers in directions of 0 degree and 90 degrees, feeding the reinforced fibers in the directions of 0 degree and 90 degrees into a knitting mechanism of a biaxial warp-knitting machine, binding, and knitting the reinforced fibers into the biaxial reinforced fabric. The method has the advantages that the biaxial reinforced fabric produced by the method is not easily ravelled in a warp direction when being cut, the structural stability of a uniaxial reinforced fabric is improved, the requirements of customers on avoidance of the ravelling of the warp yarns of the biaxial fabric in a cutting process are met, the product quality of the biaxial reinforced fabric is greatly improved, and the fabric has the characteristics of low elongation rate, high strength, good toughness and the like.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

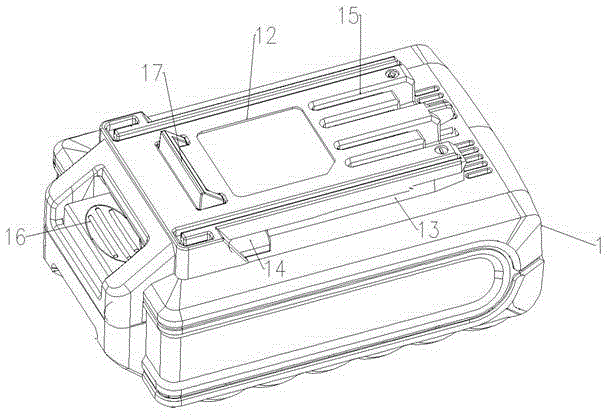

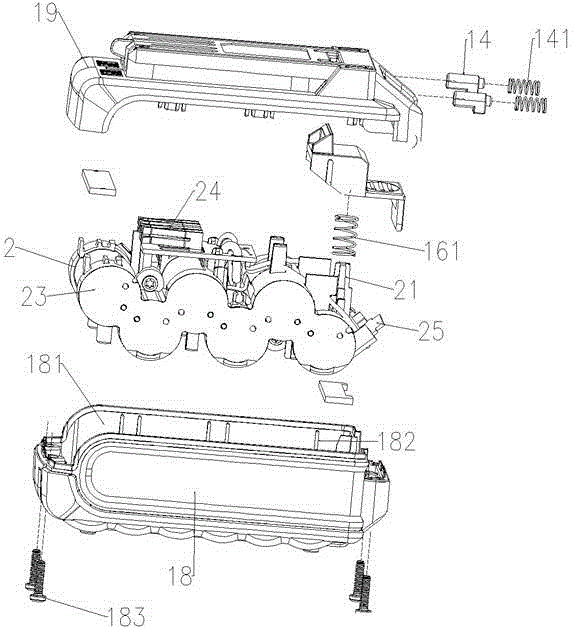

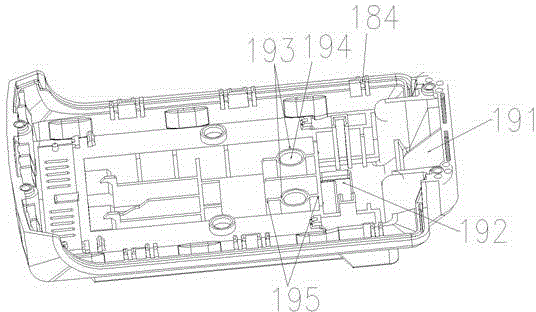

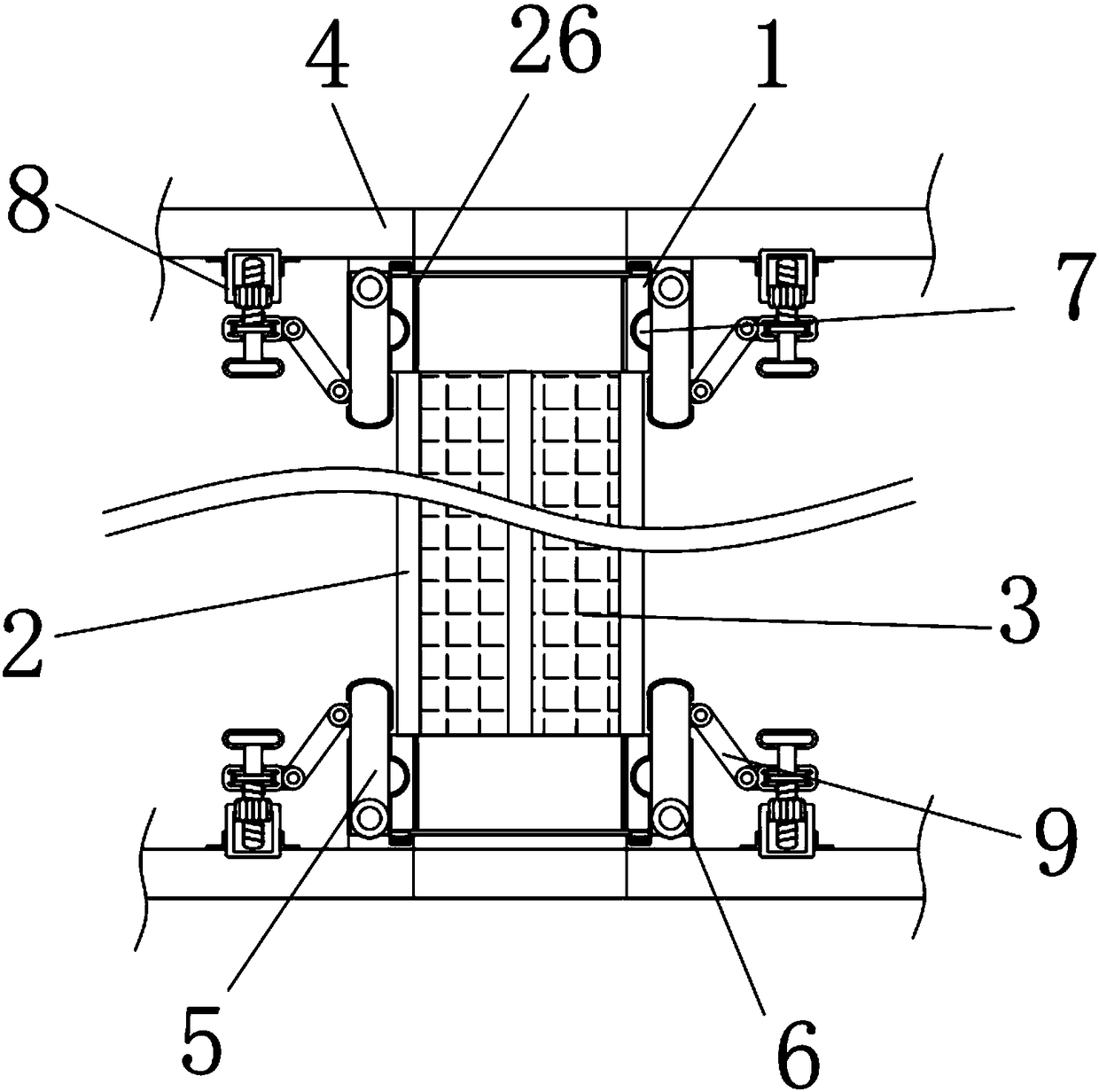

Battery pack

ActiveCN104979501AOverall goodReduce shockCell component detailsBattery packElectrical and Electronics engineering

The invention relates to a battery pack which comprises a shell, a battery core assembly and electrodes, wherein the shell is formed by combining an upper cover and a lower cover; the battery core assembly comprises at least one battery unit and a bracket which is used for containing the at least one battery unit. The battery pack is characterized in that a columnar opposite-inserting structure is arranged among the bracket, the upper cover and the lower cover; the columnar opposite-inserting structure comprises limiting columns and limiting holes; during assembling, the limiting columns are inserted into the limiting holes. As the limiting columns of the opposite-inserting structure on the at least one battery unit are combined with the limiting holes of the upper cover and the lower cover of the battery pack, the battery core assembly and the shell are kept in a good integrality; the inserted limiting columns on the battery unit bracket can deform at the moment that the battery pack falls down, and the impact of the battery core assembly on the shell can be buffered during falling down, so that the connection malposition of the upper cover and the lower cover of the shell can be prevented during falling down and further the shell can not be separated.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

Manufacturing method of spaced chain stitch type heavy elastic bonding liner

ActiveCN102599662AIncrease elasticityStrong and goodFilm/foil adhesivesFibre typesPolyesterPolyresin

The invention discloses a manufacturing method of spaced chain stitch type heavy elastic bonding liner. The method comprises (1) preparing a whole-width fabric base formed of plural pieces of fabric bases by sewing on a double thread chain stitch sewing machine, wherein warp yarns of the fabric base adopt polyester filaments of 75-100D and spandex filaments, and weft yarns adopt polyester filaments of 300-350D; (2) refining; (3) subjecting to water-proof finishing in a finishing machine; and (4) adhering resin to the surface of the fabric base, infrared-heating the fabric base with dot-like resin adhered at 250-270 DEG C to dry and fix the resin onto the surface of the fabric base, and subjecting the infrared-heated fabric base to tentering setting in a tentering machine. The product obtained by the inventive method has good stiffness and resilience, can fully satisfy use requirements of general waist liners, has good ductility to improve the stretching effects of the product under force, and improves waist liner quality.

Owner:NITTOBO CHINA CO LTD

Household air filter element placement structure

PendingCN108114544AWon't fall apartGuaranteed to proceed normallyGas treatmentDispersed particle filtrationAir filterEngineering

The invention discloses a household air filter element placement structure. The household air filter element placement structure comprises a connecting pipe and connecting rods, wherein the connectingrods are mounted on four corners of the bottom of the connecting pipe, a bolt sequentially penetrates through a second channel steel and a nut, and a first channel steel is mounted on the outer wallof the nut and is connected with a base. According to the household air filter element placement structure, the connecting rods, the connecting pipe and a filter net are combined into a filter element, so that the filter net can be used for filtering and is not scattered; the filter element can be placed on the base and can be clamped on the base through a baffle; the baffle and the connecting pipe can be mutually clamped through a clamping block and cannot be easily separated, and the connecting pipe is fixed on the baffle; and the baffle is stabilized and unlikely to shake by virtue of the connecting rods, so that the filter element is fixed on the base, and the filter element can be taken down from the base by wrenching the baffle and can be conveniently cleaned.

Owner:湖州南浔兴科纺织品原料厂

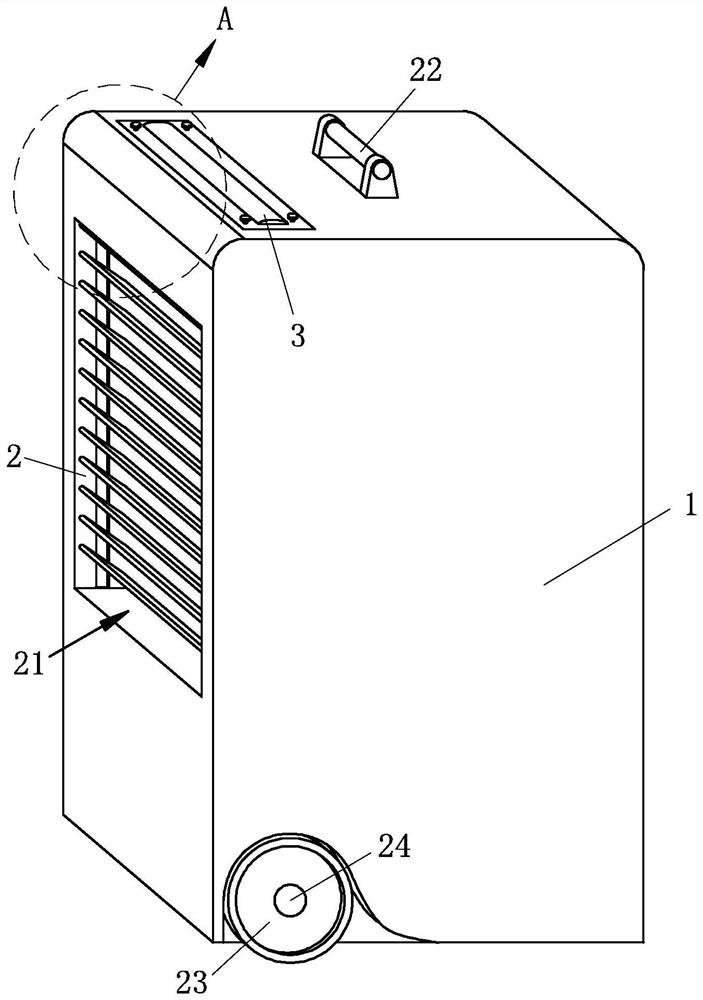

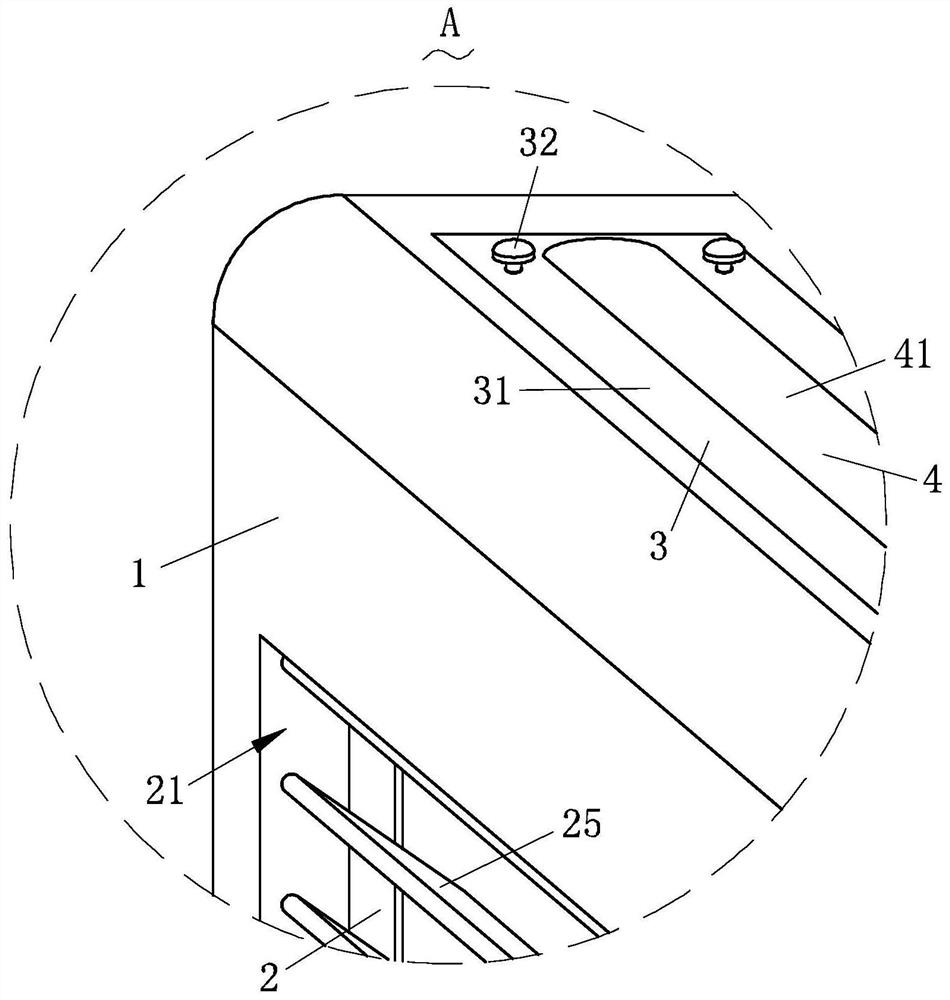

Intelligent exhaust device with dust removal assembly

ActiveCN111765571AEasy to moveEasy to take and moveGas treatmentDispersed particle filtrationThermodynamicsDust control

The invention relates to the field of air conditioner fans, in particular to an intelligent exhaust device with a dust removal assembly. The device comprises an air conditioner fan body, an exhaust mechanism, a filter mechanism, a lockout mechanism, a collecting mechanism, a dust removal mechanism and a shaking mechanism, under the effect of the exhaust mechanism, the wind direction can be changed, the air conditioner fan body is moved and taken, under the effect of the filter mechanism, the exhaust mechanism can be subjected to filter and dust removal, meanwhile, under the effect of the lockout mechanism, the position between the filter mechanism and the air conditioner fan body is subjected to limit lockout, under the effect of the dust removal mechanism, the dust falling off from the filter mechanism can be exhausted, meanwhile, through the shaking assembly, the dust attached to the filter mechanism falls off, secondary pollution is reduced, the falling dust can fall in the collecting mechanism through the dust removal mechanism to be stored, meanwhile, through pulling out of the collecting mechanism, the dust in the collecting mechanism is cleaned, and the interior of the air conditioner fan body is more clean and sanitary.

Owner:江苏博朗智能装备有限公司

Composition contg. azacyclic compound and glycol for grain decoration of resin material, removal of stain and removal of resin material

InactiveCN1386818ANot easy to separateInsulating substrate metal adhesion improvementInsulating layers/substrates workingNitrogenDiol

The present invention relates to a swelling agent composition comprising a nitrogen heterocyclic compound and a diol and methods of using the composition. The swelling agent composition may also contain a high flash point solvent and water. The swelling agent composition is used to condition the resin material to etch a porous textured surface on the resin material. Porous texturing deposits metal on the resin material to form a high affinity bond between the textured resin material and the deposited metal. This bonding between metal and resin materials prevents delamination between metal and resin. The swelling agent combination of nitrogen heterocyclic compound and diol also removes resinous material stains from the substrate. Swelling agent compositions of azacycles and diols can be used to treat resinous materials used in the fabrication of printed wiring boards. Metal can be deposited on the textured resinous material by suitable plating methods.

Owner:SHIPLEY CO INC

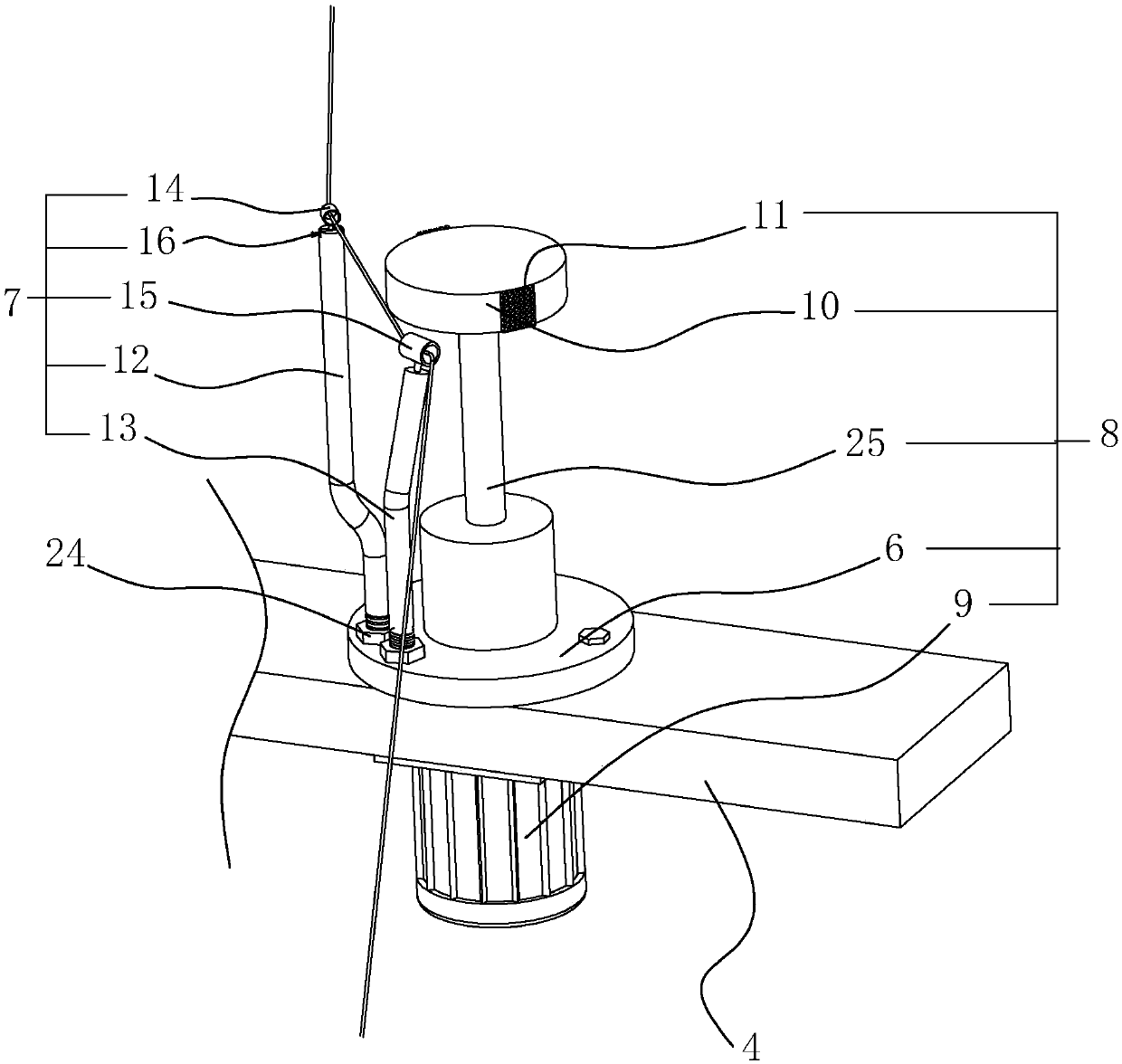

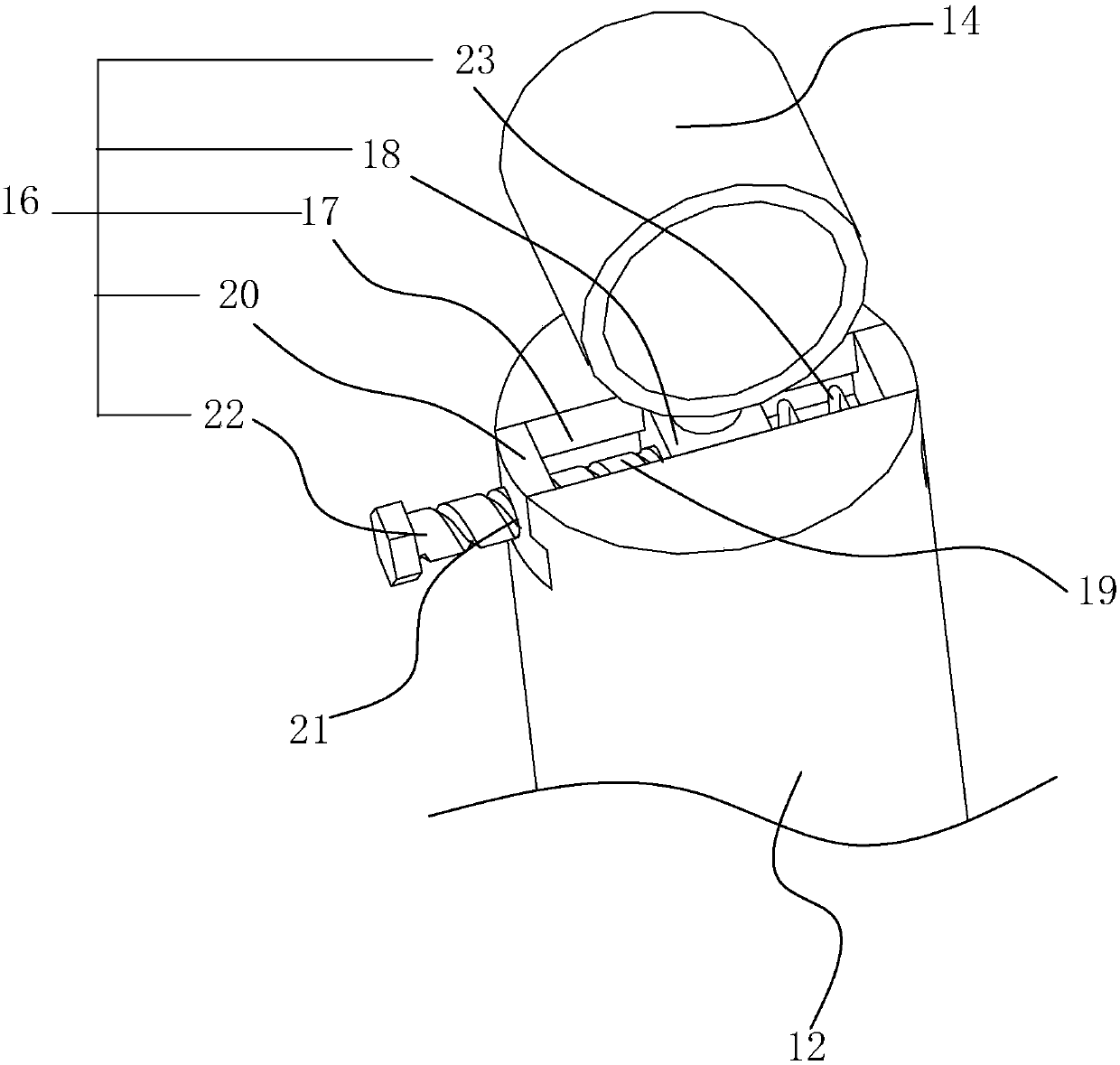

Fluffing device of spinning frame

The invention discloses a fluffing device of a spinning frame. The problem is solved that for a traditional spinning frame, when two pieces of roving are combined into one piece of yarn, the yarn is not easily bonded and is easily separated in the later period. According to the technical scheme, the fluffing device of the spinning frame is characterized by comprising a mounting rack fixedly arranged on a device body, the mounting rack is located between a drawing mechanism and a twisting mechanism and provided with a fluffing mechanism, and the fluffing mechanism comprises a base fixedly arranged on the mounting rack, a guide assembly fixedly arranged on the base and a fluffing assembly arranged on the base; the roving penetrates through the guide assembly, and the fluffing assembly abutsagainst the roving through intermittent friction. According to the fluffing device of the spinning frame, the roving is subjected to friction fluffing before twisting of the roving, so that the surface of the roving is rough, the roving and other yarn are conveniently combined for winding, and the roving and the yarn are not easily separated in the later period.

Owner:海宁市晶成纺织有限公司

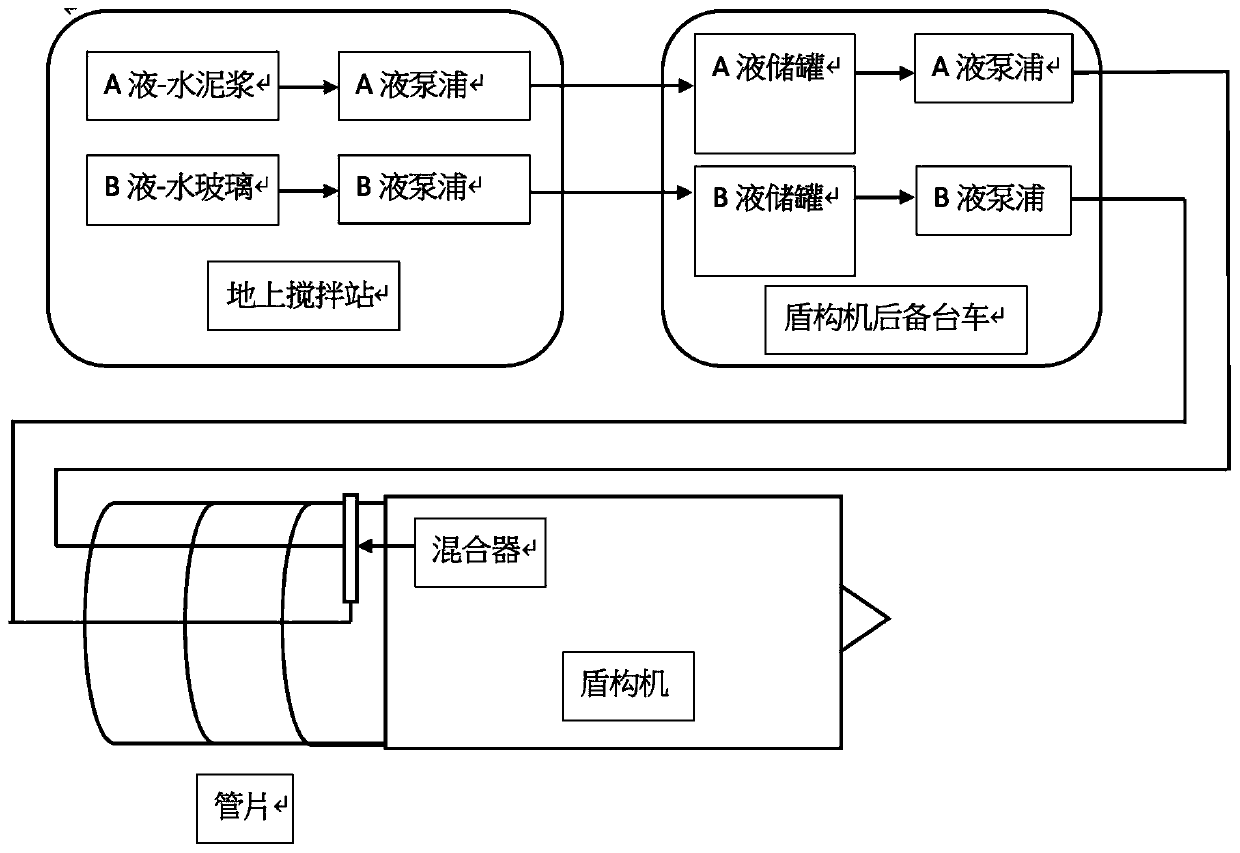

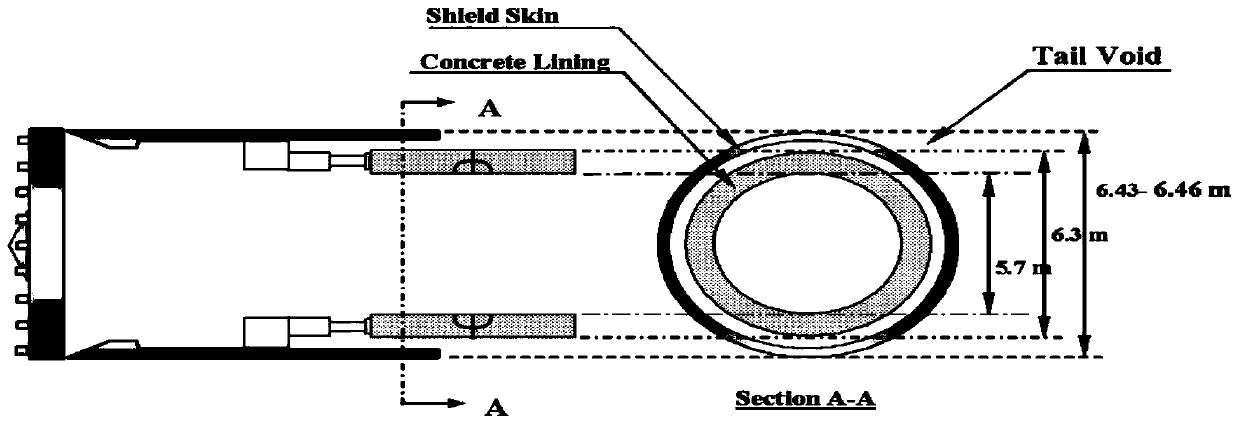

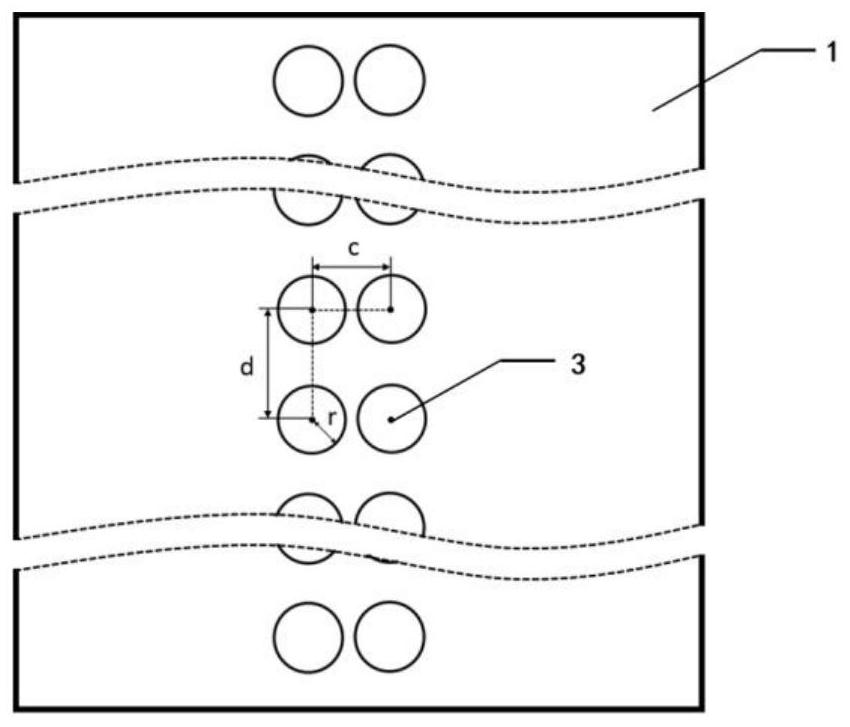

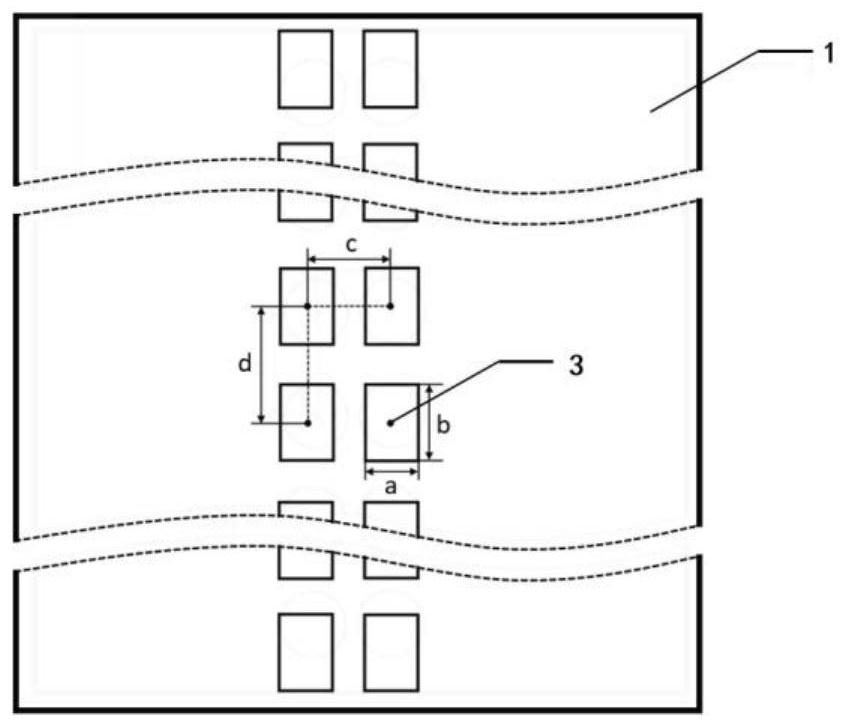

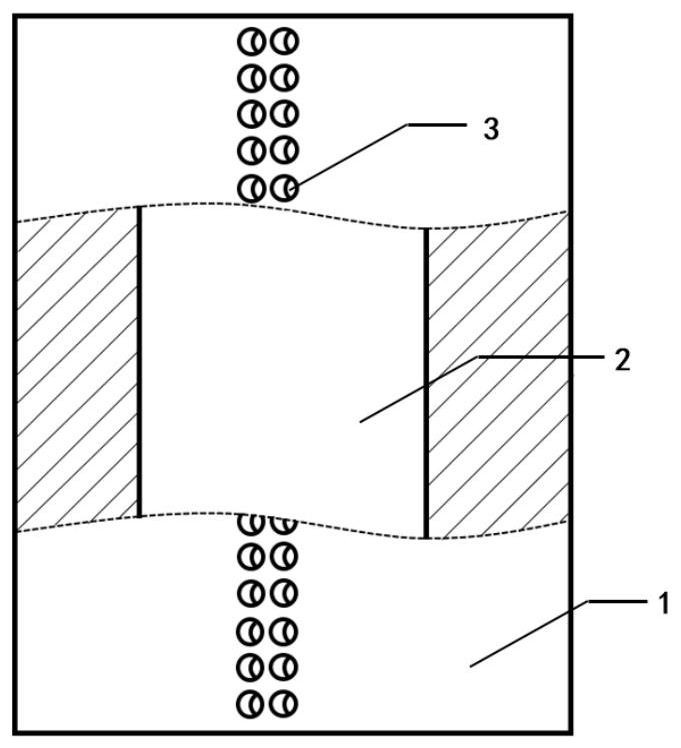

Backfill grouting double liquid and backfill grouting method

InactiveCN110630293AFast cementationProvides early strength quicklyUnderground chambersTunnel liningCompressive strengthUltimate tensile strength

The invention belongs to the technical field of grouting in shield machines and in particular relates to a backfill grouting double liquid and a backfill grouting method. The cementing speed of the backfill grouting double liquid is high, and the backfill grouting double liquid can rapidly provide early strength (the compressive strength reaches 0.5 kgf / cm2 within 1 h, and the compressive strengthreaches 8 kgf / cm2 within 24 h). The the compressive strength of the backfill grouting double liquid can reach 0.6-1.1 kgf / cm2 within 1 h and can reach 9-13 kgf / cm2 within 24 h. The cementing time ofthe backfill grouting double liquid after being mixed is 8-15 s and is obviously less than the cementing time (3 min-3h) of an existing double liquid. Compared with single liquid synchronous grouting,the grouting of the cemented backfill grouting double liquid is harder to generate material separation.

Owner:YANGTIE MACHINERY HANGZHOU CO LTD

Porous-based ultrasonic-speed adsorption type compressor blade

ActiveCN113153815AFlow separation controlAvoid easy separationSupersonic fluid pumpsPump componentsShock waveEngineering

The invention discloses a porous-based ultrasonic-speed adsorption type compressor blade. A suction chamber which is through in a blade extending direction is arranged between a suction surface and a pressure surface of the ultrasonic-speed adsorption type compressor blade. A plurality of suction holes which communicate with the suction chamber are distributed in the suction surface of the ultrasonic-speed adsorption type compressor blade. Each suction hole is a circular hole or a rectangular hole with the same cross section area. Blade spacing on a gate plate, of the ultrasonic-speed adsorption type compressor blade is 30.55 mm, and a mounting angle is 47 degrees; during numerical simulation under a designed working condition, an inlet gas flow angle is 61 degrees, and an inlet Mach number is 1.5. The porous-based ultrasonic-speed adsorption type compressor blade avoids reflection, on the suction force, of shock waves, reduces loss of passing shock waves; and meanwhile, shock wave impact points are in the suction holes, so that mutual interference between the shock waves and the attaching layer of the suction force are effectively weakened, an attaching layer separation phenomenon after shock waves is effectively inhibited, too great Mach after before shock waves due to continuous acceleration, on the suction force, of the gas flow is avoided, and Mach number before waves and shock wave loss are reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

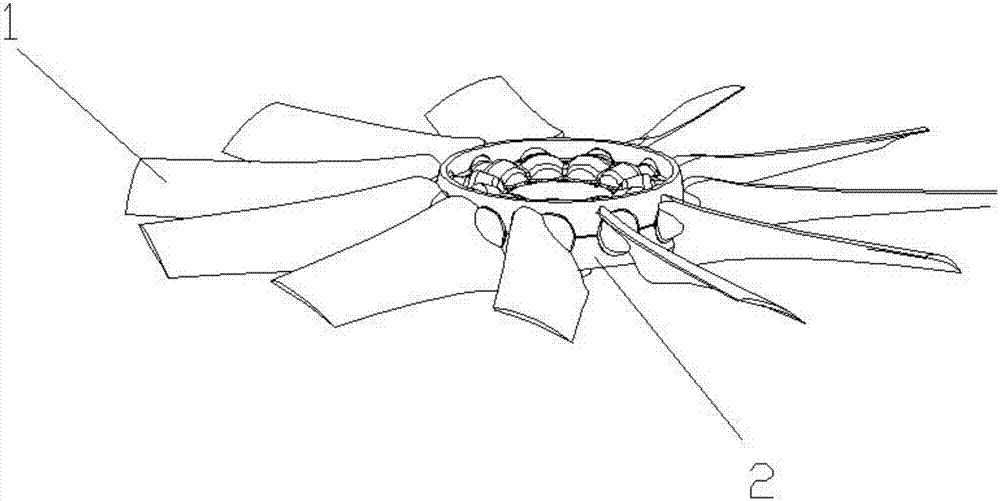

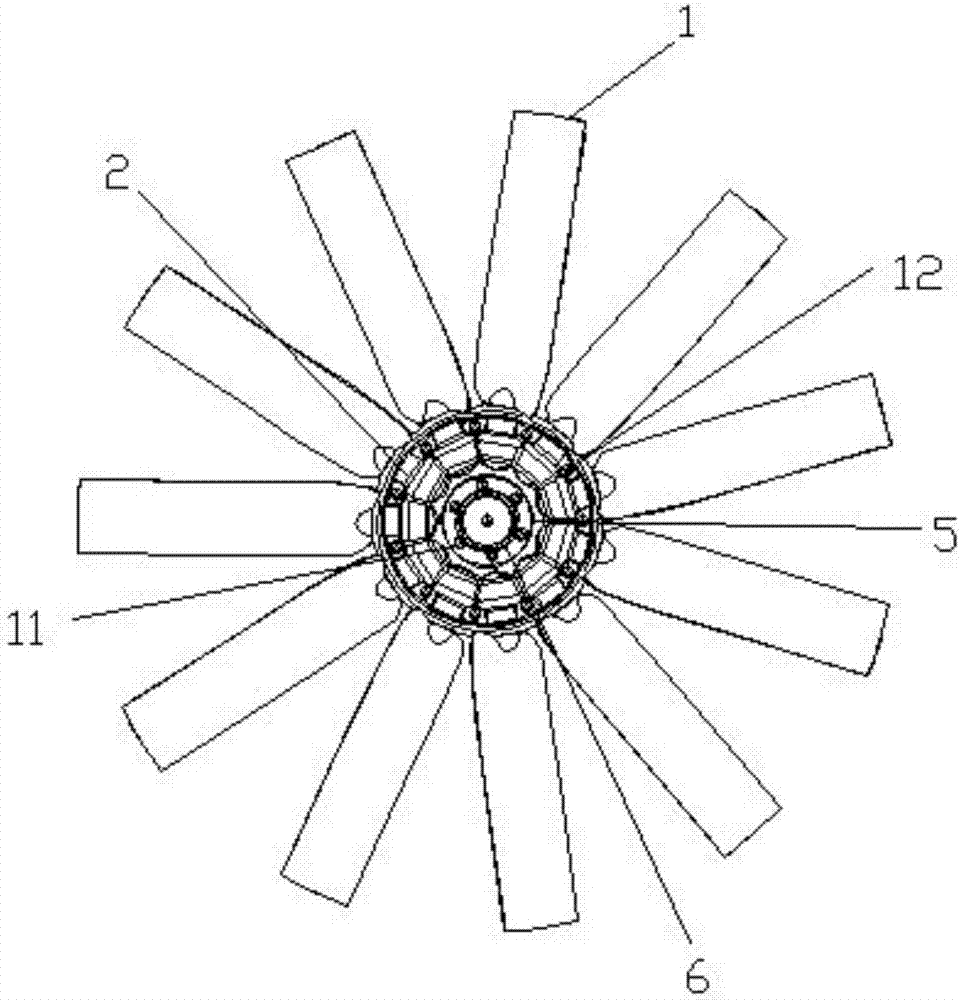

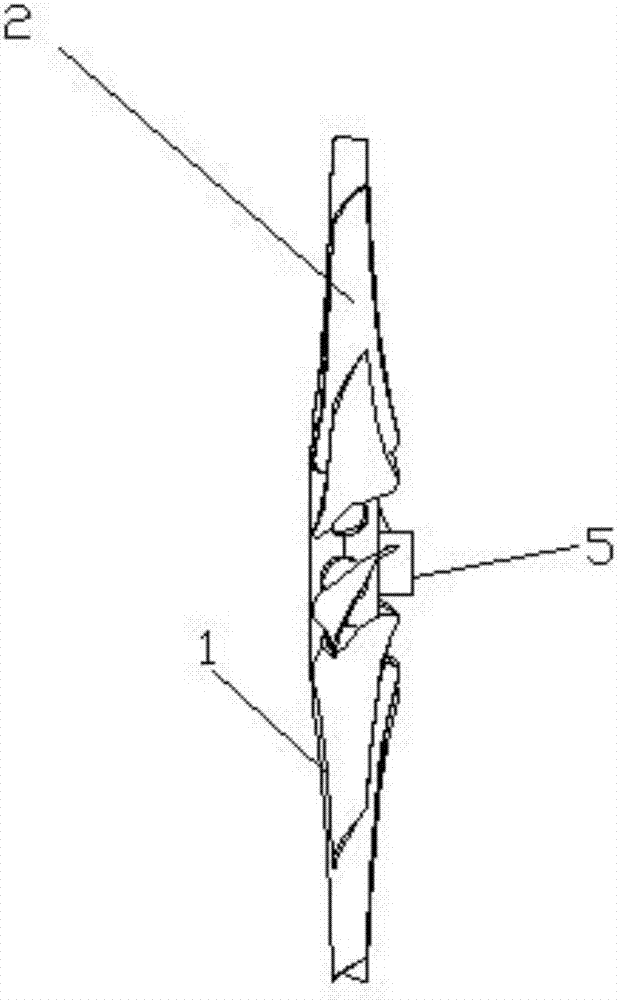

Novel vane wheel and installing method thereof

The invention discloses a novel vane wheel and an installing method thereof. The vane wheel comprises a hub and multiple blades, and the multiple blades are evenly installed on the hub; each blade comprises a blade surface and a blade handle, and each blade handle is provided with a circular truncated cone structure; and the hub is provided with installing slots matched with the blade handles, and the blades are installed on the hub through the installing slots. The novel vane wheel has the advantages that installation is convenient to achieve, angle adjustment is convenient to achieve, and the service life of the vane wheel is long.

Owner:SHAANXI JINYI VENTILATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com