Patents

Literature

178results about How to "Indicators are stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering indium and germanium from zinc leaching residue

The invention discloses a method for recovering indium and germanium from a zinc leaching residue. The method comprises the following steps of: leaching the zinc leaching residue containing the indium and the germanium by using a sulfuric acid, eliminating ferric iron and removing silicon, and then, adding a hydroximic acid and P204 kerosene to synergistically extract the indium and the germanium, extracting 99% of the germanium and the indium, and then carrying out back extraction on the germanium through an ammonium fluoride and precipitating the germanium by ammonia gas or ammonia water, carrying out the back extraction on the indium through concentration and a hydrochloric acid, replacing the indium with aluminum, and roasting a germanium precipitation residue to respectively obtain an indium ingot and a germanium concentrate. By using the method, the germanium and the indium can be extracted from slag with a lower grade; a procedure is simple; the operation is easy; and fewer pollutants are discharged.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

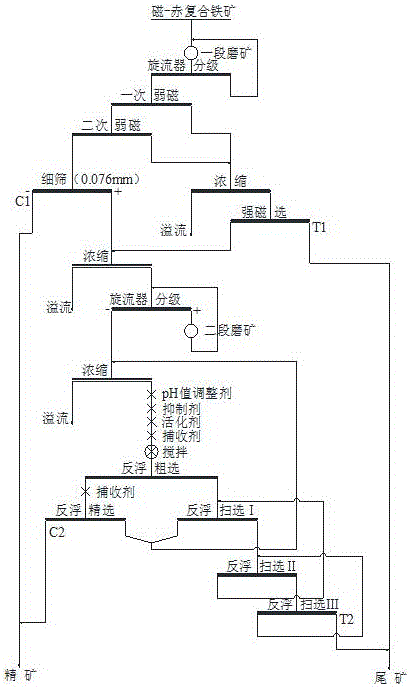

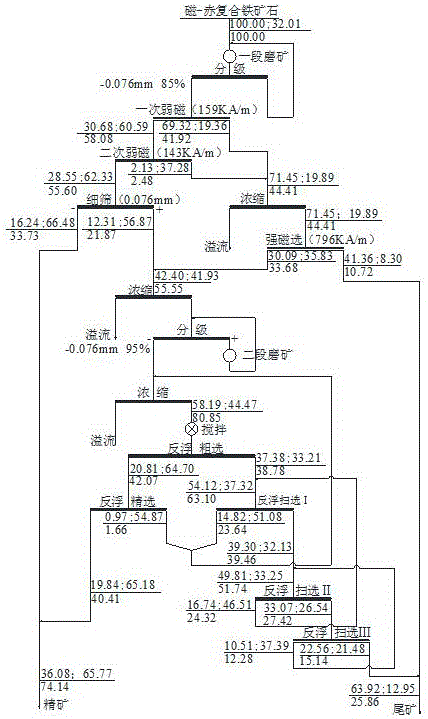

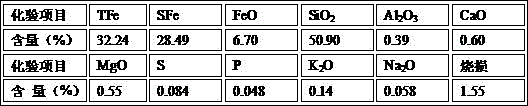

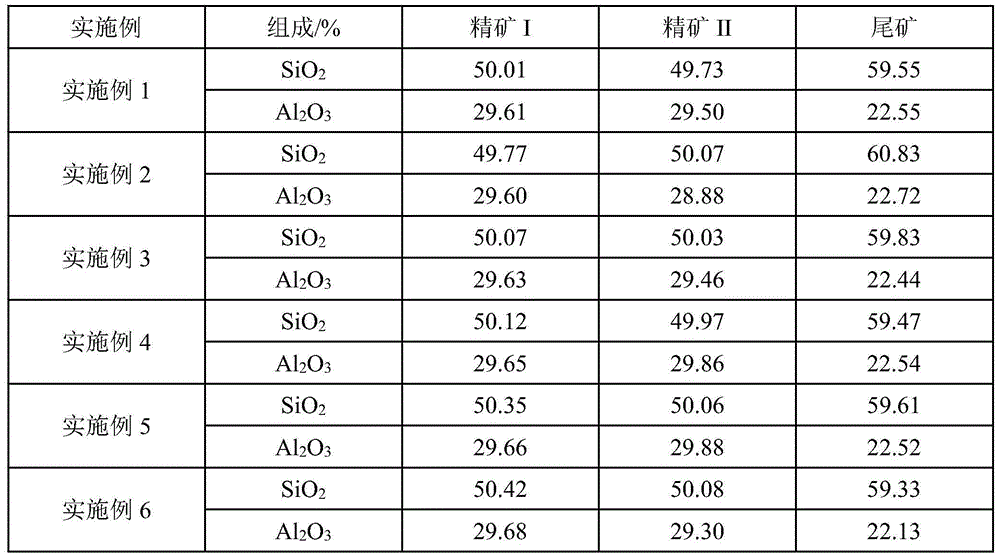

Compound maghemite ore dressing method

ActiveCN106076606AAdvantages of beneficiation methodIndicators are stableWet separationMaghemiteHigh intensity

The invention discloses a compound maghemite ore dressing method. The compound maghemite ore dressing method comprises the following steps: feeding compound maghemite ore into an ore grinding-grading-low-intensity magnetic separation operation segment to obtain low intensity magnetic separation concentrate and low-intensity magnetic separation tailings; feeding the low-intensity magnetic separation concentrate into a fine sieving operation segment to obtain finely-sieved concentrate C1; feeding the low-intensity magnetic separation tailings into a high-intensity magnetic separation operation segment, and throwing out high-intensity magnetic separation tailings T1 to obtain high-intensity magnetic separation concentrate; combining coarse fraction low-intensity magnetic separation concentrate with the high-intensity magnetic separation concentrate, and feeding the mixture into a pre-grading-two-stage ore grinding-reverse flotation operation segment to obtain reverse flotation concentrate C2, and throwing out reverse flotation concentrate T2. In the method, staged ore grinding and high-intensity tailing throwing are adopted, so that discarding as soon as possible is realized; the low-intensity magnetic separation concentrate is obtained by fine sieving, so that collection as soon as possible is realized; oversize finely-sieved and high-intensity coarse concentrate is ground, so that the amount of ore ground at a second segment is lowered greatly, and energy-saving and consumption lowering are facilitated; an oversize finely-sieved product is reground and floated, so that the flotation grade is raised, and the adaptability of negative ion reverse floatation to ore characteristic fluctuation is improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

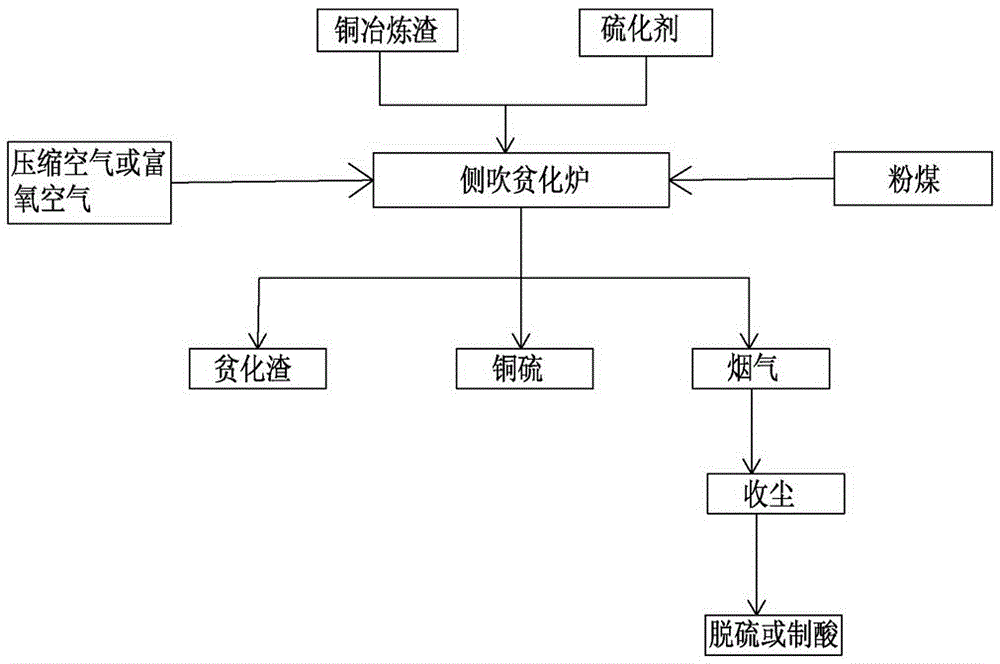

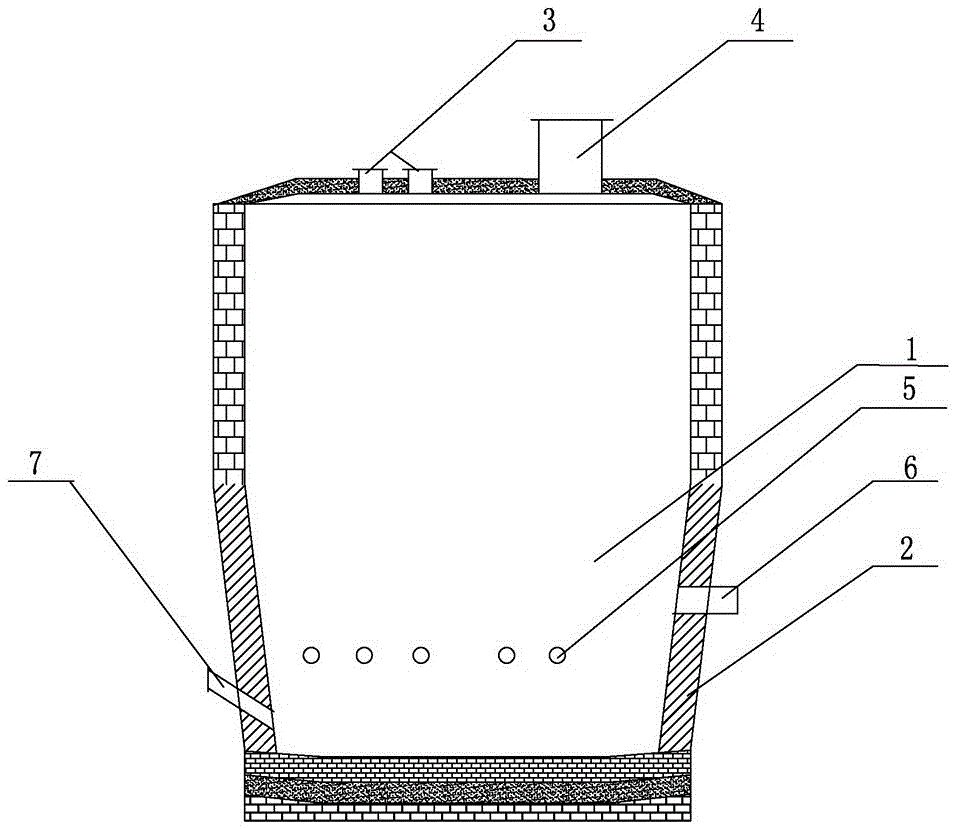

Side-blown depletion copper smelting slag production method

ActiveCN106367605ALow costImprove heat transfer performanceProcess efficiency improvementShaft furnaceMelting tankMass ratio

The invention belongs to the technical field of copper smelting, and particularly relates to a side-blown depletion copper smelting slag production method. The side-blown depletion copper smelting slag production method includes the following steps that a vulcanizing agent and copper smelting slag are added into a side-blown depletion furnace from a feeding opening, wherein the mass ratio of the copper smelting slag to the vulcanizing agent is 100:0-15, and the copper smelting slag is molten copper smelting slag or solid copper smelting slag; fuel is jetted into a molten pool through a spraying gun opening formed in the side portion of the depletion furnace, wherein the fuel is a mixture of pulverized coal and compressed air or a mixture of pulverized coal and oxygen-enriched air, the fuel is used for achieving stirring, heat transferring and medium transferring in the depletion furnace, the temperature in the furnace ranges from 1100 DEG C to 1300 DEG C, the pressure ranges from 0.1 Mpa to 0.4 Mpa, and the depth of the molten pool ranges from 800 mm to 2000 mm; copper matte is placed in through a copper matte opening, and depletion slag is discharged through a slag outlet; and smoke enters a gas desulfurization system after being subject to cooling and dust collection, is subject to desulfuration and is released after the standard is met. The process has the beneficial effects of saving investment, and being low in energy consumption, low in cost, high in automatic degree, environment-friendly and the like.

Owner:HENAN YUGUANG GOLD & LEAD

Method for vanadium leaching by sulfate-adding wet-pile oxidation conversion of stone coal under atmospheric temperature and atmosphere pressure

InactiveCN101082085AReduce energy consumptionShorten the leaching timeProcess efficiency improvementSulfateAtmospheric temperature

The normal temperature and normal pressure process of leaching vanadium from stone coal includes the following steps: 1. grinding stone coal to below 60 mesh; 2. adding 70-98 wt% concentration sulfuric acid solution in the material / acid weight ratio of 100 to 26-35 via stirring; 3. piling the mixture in the height greater than 0.5 m at normal temperature and normal pressure for 4-15 days; 4. exothermic reaction inside the pile to complete the oxidation of vanadium inside stone coal with oxygen in the air at temperature over 85 deg.c; and 5. adding water in 1-3 times the solid at normal temperature and normal pressure, and stirring for 3-8 hr to leach out vanadium in 65-97.7 %. The process of leaching out vanadium from stone coal is wide applicable for original stone coal ore and oxidized stone coal ore.

Owner:刘健 +1

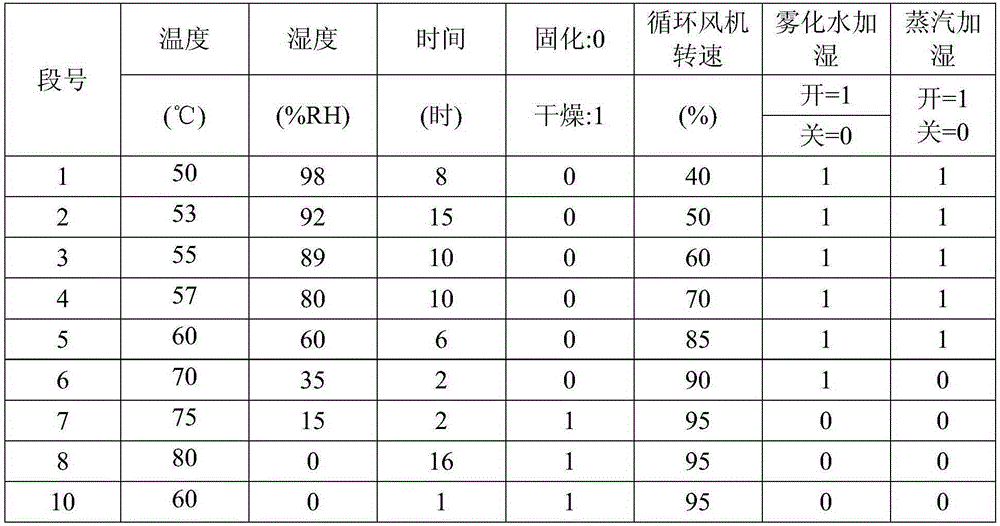

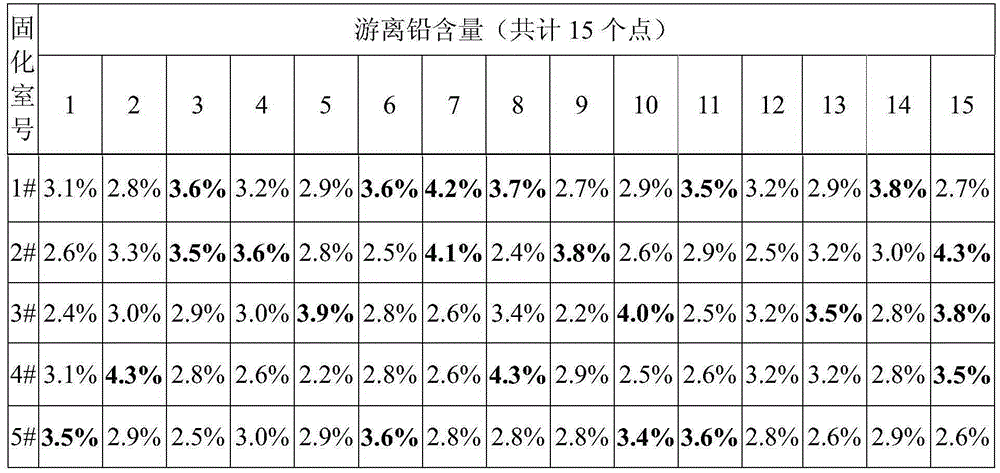

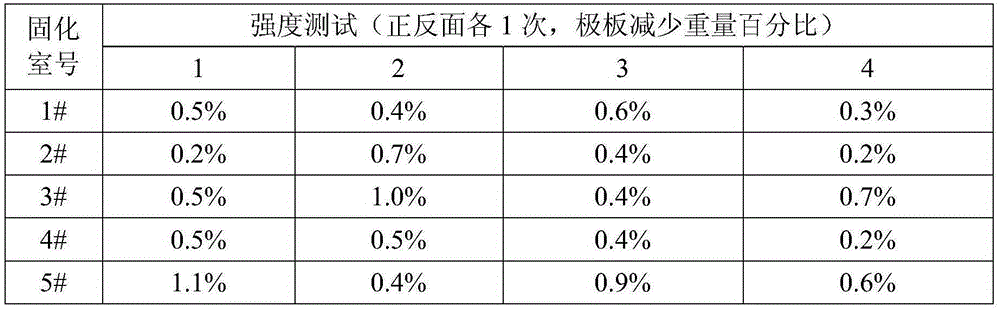

Curing process for negative plate of lead acid battery

ActiveCN105428603AIncrease spacingIndicators are stableLead-acid accumulator electrodesRejection rateRelative humidity

The present invention discloses a curing process for a negative plate of a lead acid battery. The curing process comprises an oxidation stage and a drying stage, wherein the oxidation stage comprises the following steps: an initial step: maintaining a temperature of 50 DEG C, a relative humidity of not less than 98%, and time of 3-5 hours; a temperature raising and humidity decreasing step: raising the temperature for 3-5 DEG C each time, decreasing the relative humidity by 2%-4%, maintaining for 3-5 hours after temperature raising and humidity decreasing, and finally, raising the temperature to 60 DEG C; and a temperature raising and cooling step: firstly, raising the temperature for 5-10 DEG C each time, maintaining for 4-8 hours after temperature raising, raising to a highest temperature of 75 DEG C, then cooling for 3-5 DEG C each time, maintaining for 3-5 hours after cooling, cooling to the lowest temperature of 65 DEG C, and maintaining the humidity to be not less than 95% in the step. According to the curing process disclosed by the present invention, by optimizing process parameters, an electrode plate is guaranteed to be oxidized in the shortest time, the crystallization effect of active substances of the electrode plate is guaranteed to be the best, the strength of the electrode plate is obviously improved, the fragmentation rejection rate is reduced by nearly 1%, and the time of the curing process is shortened to two days.

Owner:ZHEJIANG TIANNENG POWER ENERGY

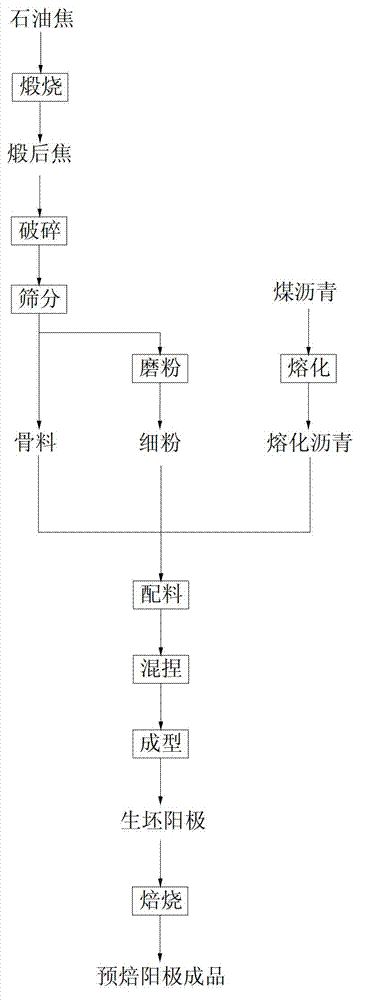

Production method of low-air-permeability prebaked anode

The invention discloses a production method of a low-air-permeability prebaked anode. The production process mainly comprises the processes of petroleum calcining, crushing, screening, grinding, mixing, coal tar pitch melting, kneading, forming, roasting and the like. A prebaked anode produced by the production method has the advantages that the air permeability is 1.2+ / -0.4 npm, the index is stable, and the current situations that the air permeability is commonly higher and the index fluctuation is great are changed.

Owner:山东平阴丰源炭素有限责任公司

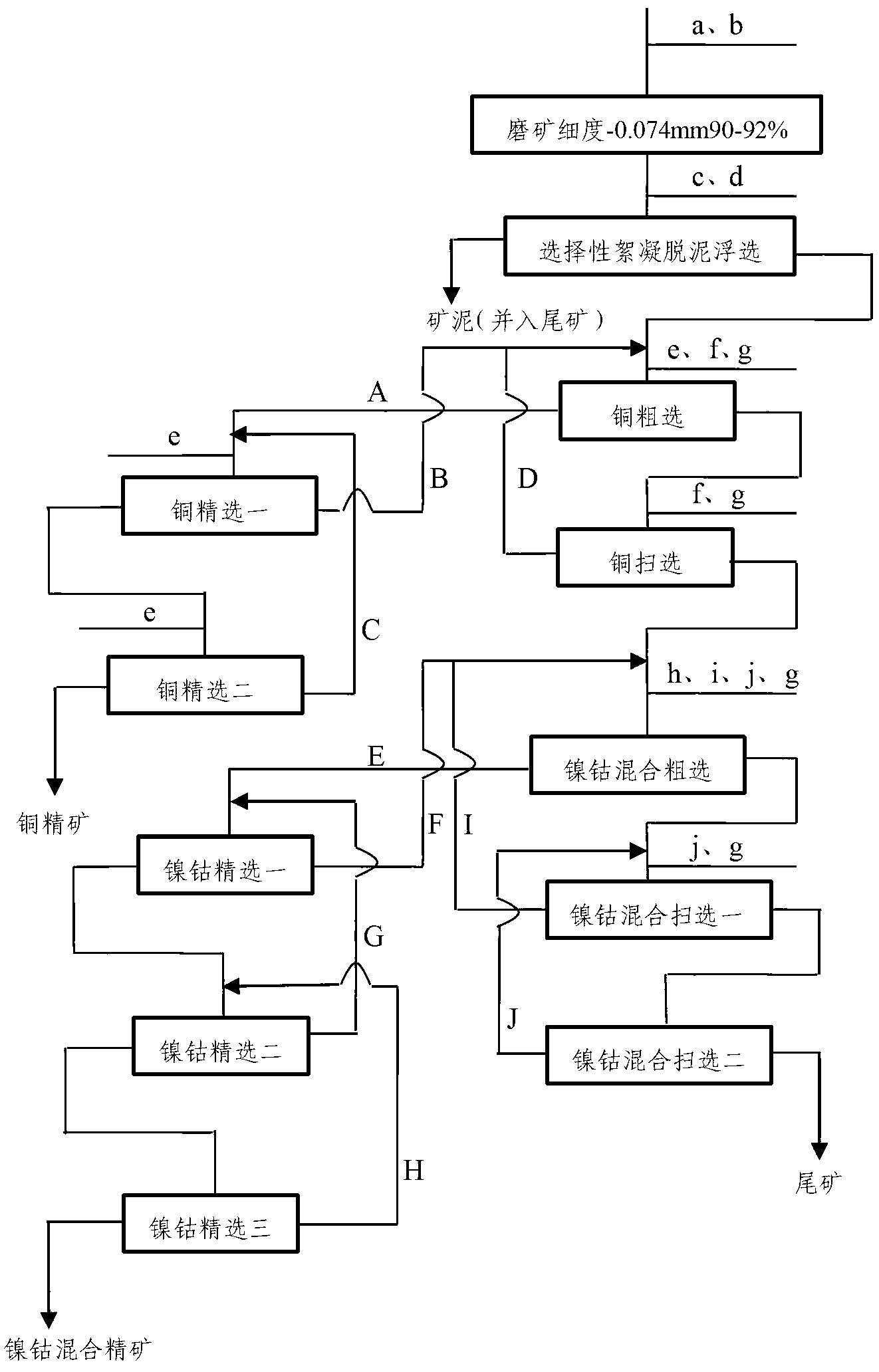

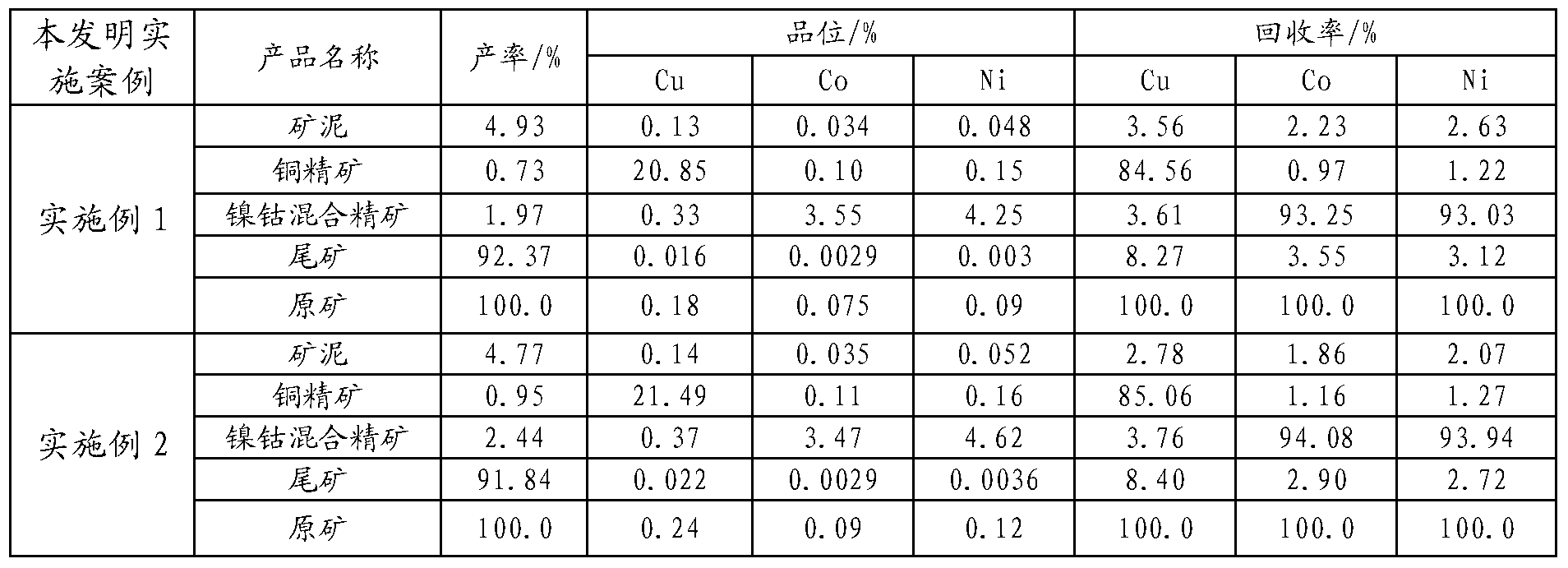

Beneficiation method of low-grade copper, cobalt and nickel sulphide ore

ActiveCN103301956AImprove sorting effectIndicators are stableDifferential sedimentationFlocculationLower grade

The invention relates to a beneficiation method of low-grade copper, cobalt and nickel sulphide ore. The technical scheme is adopted as follows: according to the property and characteristics of ore, a selective flocculation desliming-flotation technology is adopted, and technological advantages of differential flotation and bulk flotation are absorbed. The method is good in separation effect and stable in index, accords with property and characteristics of the ore, can effectively eliminate influences of slurry on flotation, and can recycle metal of copper, cobalt and nickel to the greatest extent.

Owner:厦门紫金矿冶技术有限公司

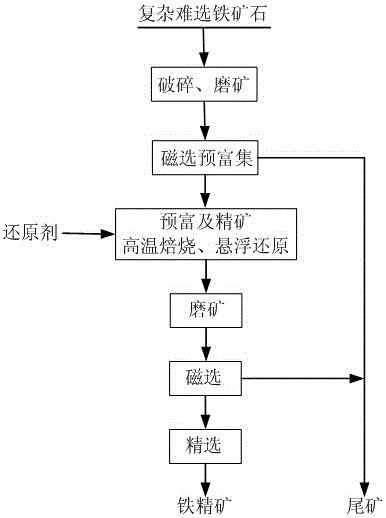

Novel method for producing iron concentrates through complex refractory iron ore

The invention belongs to the technical field of mineral machining and particularly relates to a novel method for producing iron concentrates through complex refractory iron ore. The novel method includes the steps that firstly, the complex refractory iron ore is subjected to ore grinding classifying treatment; classified overflow products are subjected to magnetic separation preconcentration, and powdery preconcentrated concentrates are obtained; the powdery preconcentrated concentrates are fed into a suspension roaster to obtain suspension roasted ore; water is added to the suspension roasted ore, and ore pulp is manufactured, preconcentration is conducted, and obtained magnetic concentrates serve as rough concentrates; and an electromagnetic separator is used for conducting concentration on the rough concentrates, the obtained concentrated concentrates are filtered, moisture is removed, concentrate products with the iron grade ranging from 60% to 68% are obtained, the recovery rate of iron ranges from 80%-90%, the concentrate products with the iron grade ranging from 60%-68% are subjected to reverse floatation desilicication, and concentrate products with the iron grade ranging from 61% to 69% are further obtained. The iron concentrate products with the iron grade larger than 60% are obtained, the recovery rate of iron is larger than 80%, product indexes are stable, the economical efficiency is good, and complex refractory iron ore resources can be efficiently utilized.

Owner:NORTHEASTERN UNIV +1

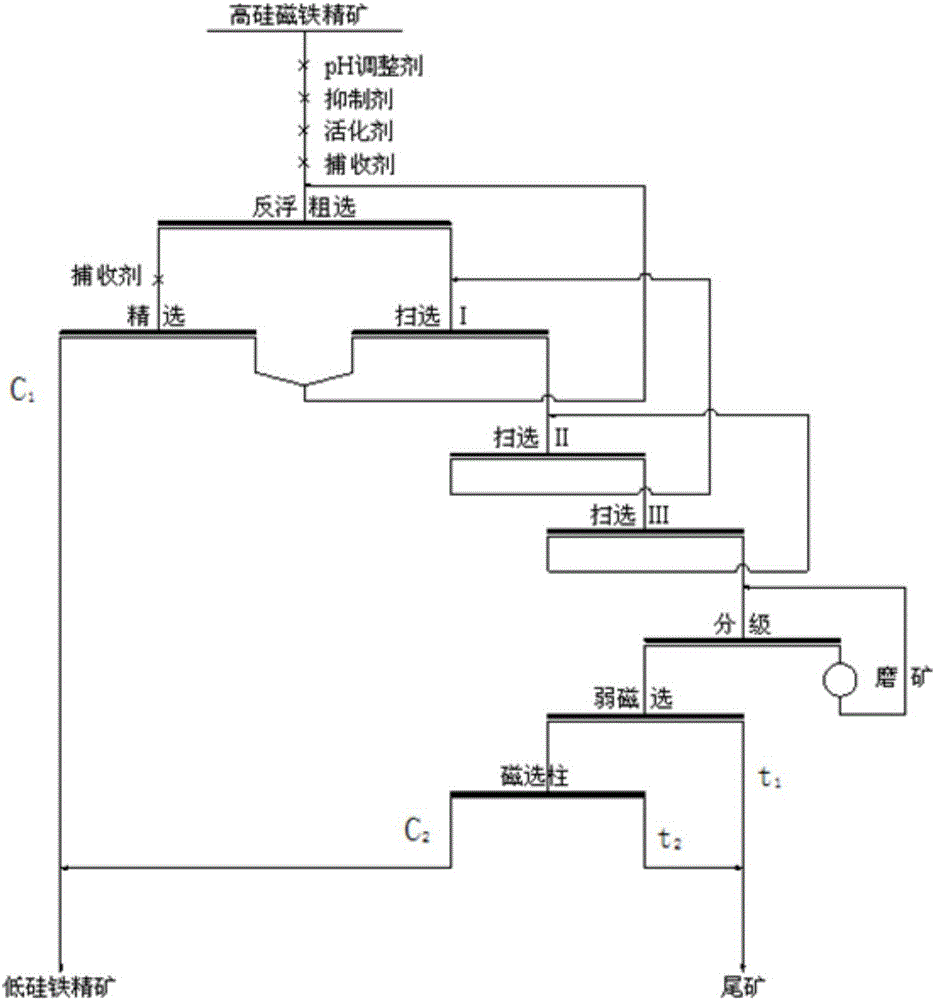

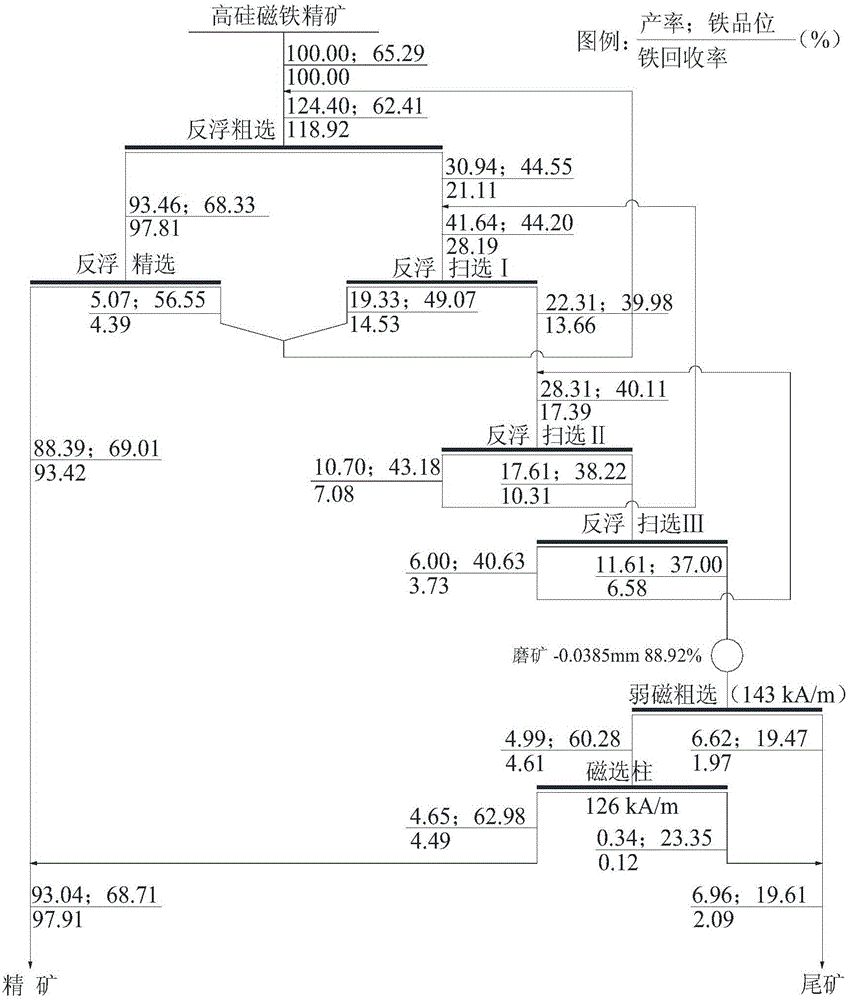

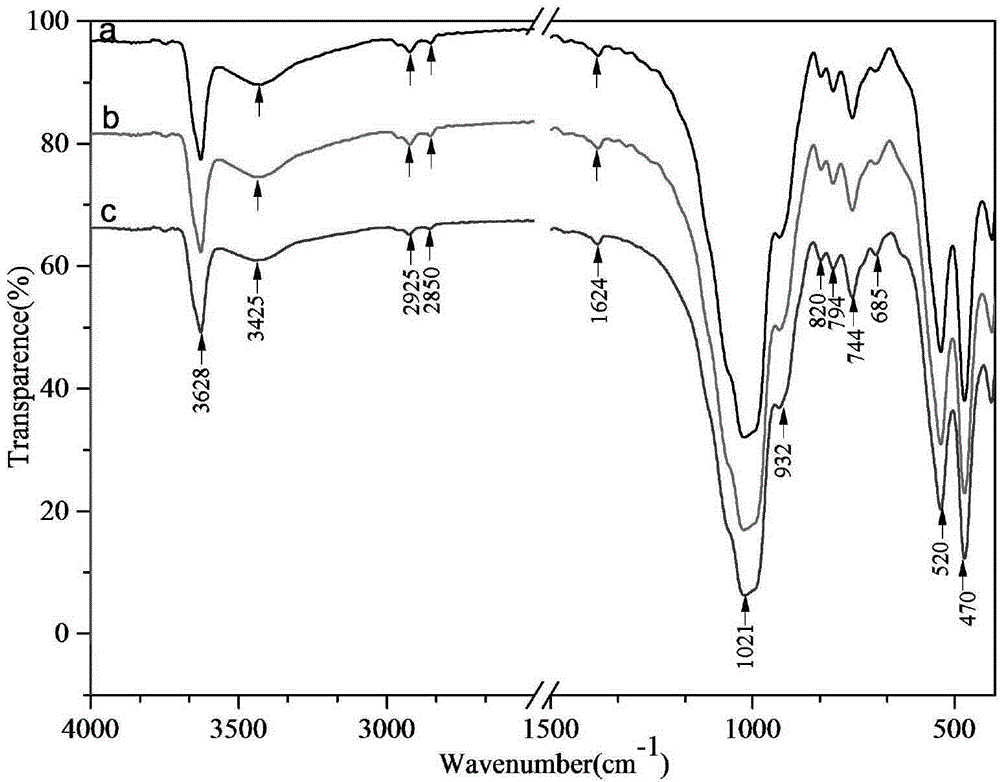

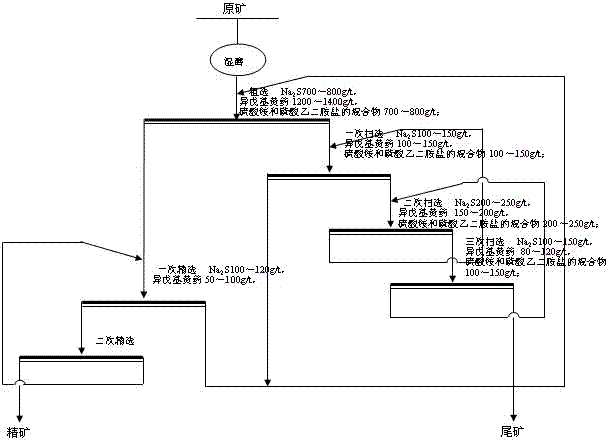

Beneficiation method for reducing content of SiO2 in magnetite concentrate

InactiveCN105728176AReduce SiO <sub>2</sub> contentSiO <sub>2</sub> Low contentDifferential sedimentationFlotationMagnetiteReverse flotation

The invention discloses a method for reducing SiO in magnetite concentrate 2 The beneficiation method adopts the following process: 1) Anion reverse flotation of high-silicon magnetite concentrate to obtain TFe≥68.75%, SiO 2 High-quality low-silicon ferrosilicon concentrate C with content <3.0% 1 , and discharge anion reverse flotation tailings; 2) anion reverse flotation tailings pre-classification-regrinding-weak magnetic separation to obtain weak magnetic separation concentrates; 3) weak magnetic separation magnetic re-separation concentrates to further obtain TFe≥ 62.5%% Magnetic Gravity Separation Iron Concentrate C 2 . The invention has the advantages of high grade iron concentrate, SiO 2 It has the advantages of low content, high iron recovery rate, small loss of fine-grained iron minerals, low energy consumption for beneficiation, stable indicators, and easy operation and management on site.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

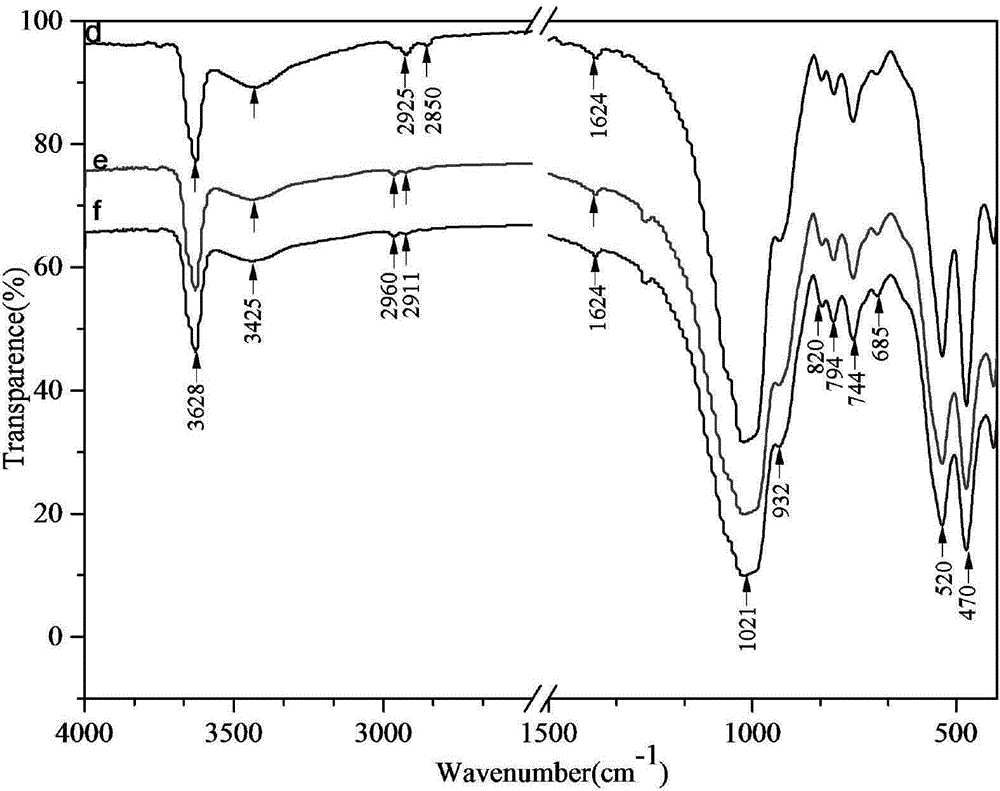

Method used for preparing sericite powder used for cosmetics

InactiveCN104909380AUniversally applicableHigh selectivityCosmetic preparationsToilet preparationsDispersityFlocculation

The invention discloses a method used for preparing sericite powder used for cosmetics. The method comprises following steps: shear flocculation, wherein a sericite quartz powder ore pulp with a mass concentration of 10 to 60% is delivered into a stirring sanding dispersing multifunction machine for shearing and stirring, and an inhibitor, a pH value regulating agent, a surface conditioning agent, and a cation collector are added successively so as to complete preliminary modification of sericite and formation of hydrophobic flocculation; flotation and purification, wherein after shear flocculation, the sericite quartz powder ore pulp is delivered into a flotation machine so as to obtain ore concentrate via floatation, wherein floatation concentration is controlled to be 3 to 20%, ore pulp pH value is controlled to be 2 to 3; and aging and modification, wherein obtained ore concentration I and II are subjected to dewatering and drying, and aging at high temperature so as to obtain the modified sericite powder used for cosmetics. The technological process of the method is coherent; operation is simple; the prepared cosmetic pigment is high in purity, excellent in dispersity, glossiness, malleability, and skin paste performance; skin feeling is fresh; the performance of the sericite powder is capable of satisfying quality requirements of extender pigments used for cosmetics; and the method can be used for matured industrialized large-scaled production.

Owner:WUHAN UNIV OF TECH +1

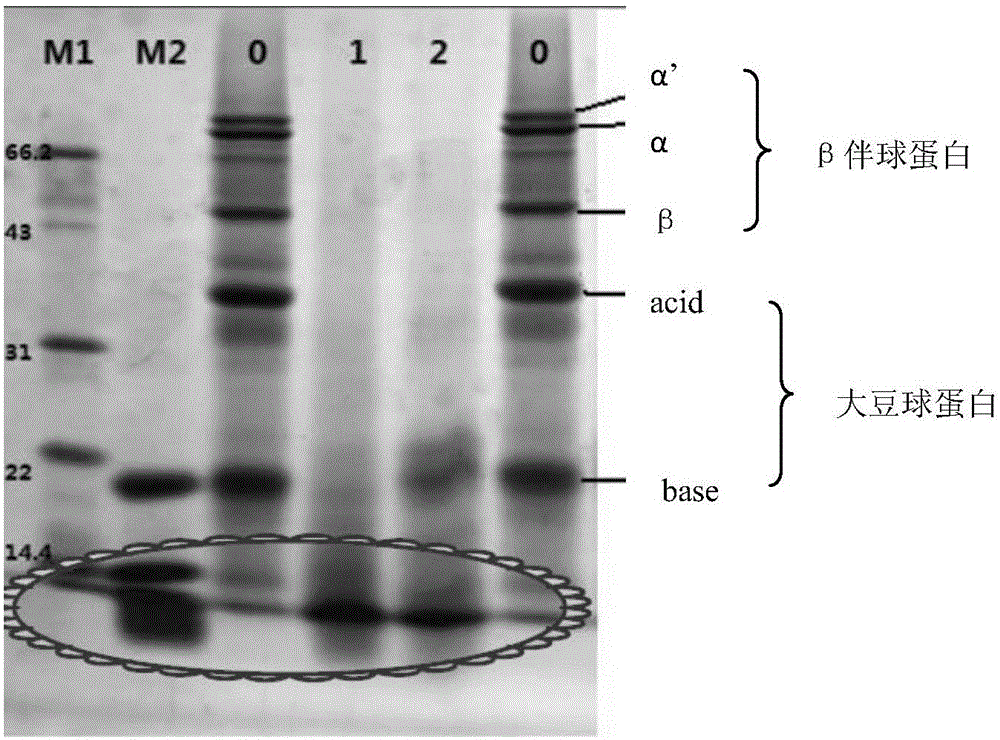

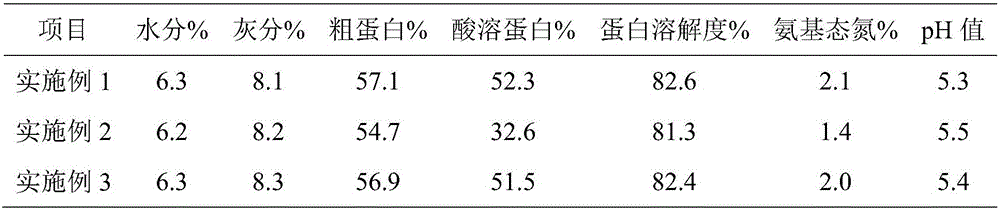

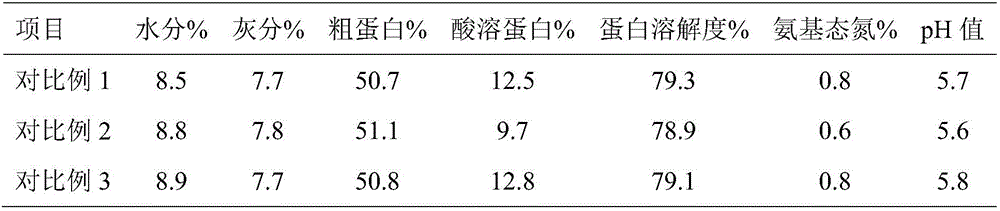

High-quality enzymolysis-fermented bean pulp as well as preparation method and application thereof

ActiveCN106615672AImprove digestibilityImprove palatabilityFood processingAnimal feeding stuffAntigenMetabolite

The invention relates to a high-quality enzymolysis-fermented bean pulp as well as a preparation method and application thereof. The preparation method comprises the steps of crushing peeled bean pulp, sieving by virtue of an 80-mesh sieve, carrying out primary enzymolysis by virtue of alpha-galactosidase and glucoamylase, carrying out secondary enzymolysis by virtue of papain, carrying out enzyme deactivation, inoculating a compound strain of saccharomycetes, bacillus and lactic acid bacteria, sequentially carrying out aerobic fermentation and anaerobic fermentation to obtain a finished product, and carrying out spray drying on the finished product, so as to preserve active components to the greatest extent. The prepared enzymolysis-fermented bean pulp has the special fermentation flavor, the protein content is about 55%, the acid soluble protein content is more than 50%, antinutritional factors such as antigens are fundamentally eliminated, the components are stable, and the enzymolysis-fermented bean pulp has the characteristics of strong hydrophily, high water holding ratio and strong palatability and has an obviously food calling effect on aquatic animals; and the enzymolysis-fermented bean pulp is rich in functional small peptides, probiotics and metabolite of the probiotics, beneficial to the nutrient balance of intestinal tract of bred animals and is suitable for being added into feeds of piglets, poultries, pets, aquatic products and the like, the problem of trophic diarherra of the animals is solved, and the suggested use ratio is 2%-5%.

Owner:岳阳市展翔生物科技有限公司

Medicine for treating chronic pharyngitis and its preparing method

InactiveCN101152504AImprove ICAM-1 elevationQuite effectiveAnthropod material medical ingredientsRespiratory disorderAdditive ingredientChronic pharyngitis

The present invention discloses a medicine for curing chronic pharyngitis and the preparation method; the present invention belongs to an improved dose type of pharyngitis tablet. The medicine for curing chronic pharygitis comprises tablets made of the raw materials of medicinal ingredient tablets with corresponding weigh portions which are wrapped by film coating made of film coating materials: 120 portion of figwort roots, 150 portion of dyers woad roots, 90 portion of asparagus roots, 90 portion of winter wheat, 90 portion of moutan bark, 90 portion of stemona roots, 90 portion of Chinese white olive, 90 portion of coltsfoot flowers, 90 portion of rehmannia roots, 30 portion of Indian trumpet flowers, 30 portion of cicada slough and 0.3 portion of mint oil. In this way, the sugar coat can be prevented from changing color and being made tainted caused by the nature of cane sugar that attracting dampness and the product stability is increased and the application population is enlarged. The new process is stable and simple and the quality can be controlled; the repeatability is good and the present invention is fit for large-scale production.

Owner:晁岱勇

No-sugar health wine and its making process

The making process of no-sugar health wine includes dissolving mangosteen triterpene glycoside extracted form alcoholized mangosteen into edible alcohol to obtain mangosteen triterpene glycoside solution; regulating the temperature of completely fermented grape juice as base wine to 18-28 deg.c; mixing the mangosteen triterpene glycoside solution and the fermented grape juice; and maintaining the mixture at 18-28 deg.c for over 2 hr to obtain the no-sugar health wine. The no-sugar health wine contains no monosaccharide, disaccharide and polysaccharide and is suitable for all people. It has the health functions similar to various grape wine as well as the health functions of clearing away heat of pharynx and larynx, moistening lung and relieving cough, like mangosteen.

Owner:张雨生

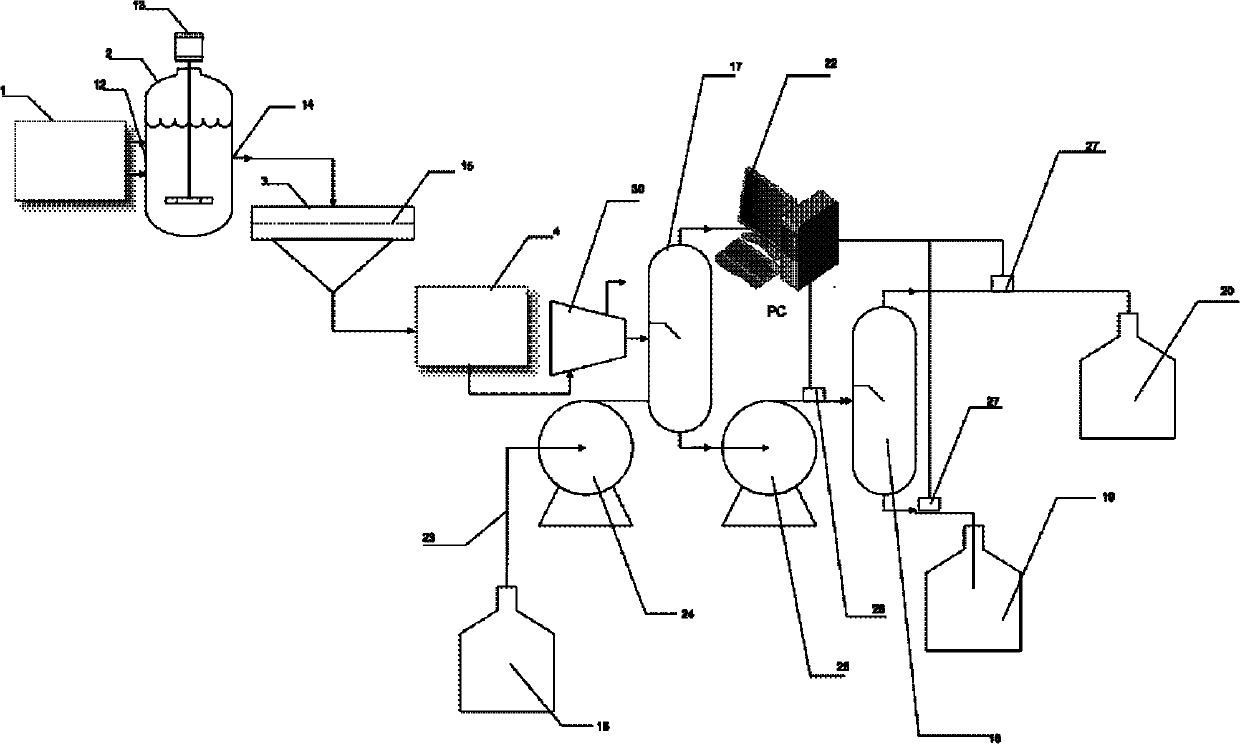

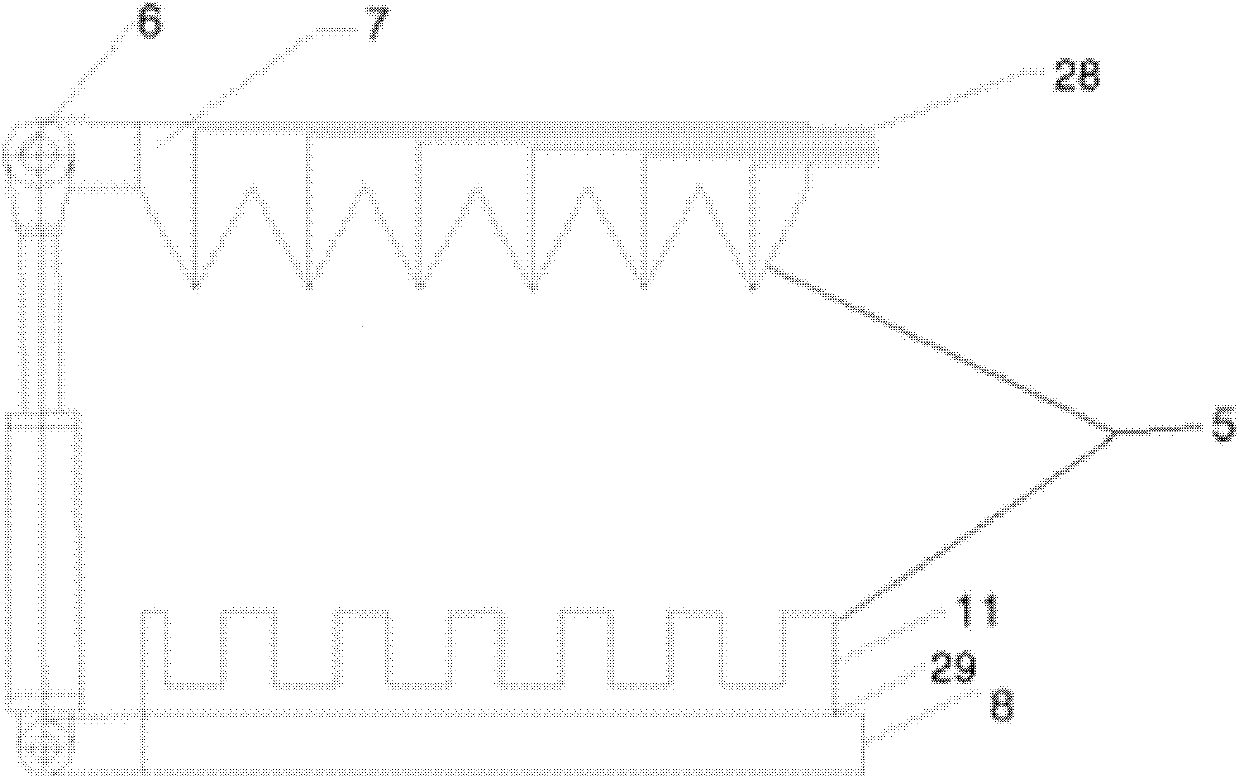

Extraction and perfusion culture system for MSCs (Mesenchymal Stem Cells)

InactiveCN103305419AKeep aliveReduce pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion CultureLiquid waste

The invention discloses an extraction and perfusion culture system for MSCs (Mesenchymal Stem Cells), belongs to a field of medical instruments, and more specifically, provides a set of continuous and completed system design for obtaining high-purity stem cell products from a placenta organ. The device provided by the invention comprises an extraction device and a perfusion culture system, and the extraction device and the perfusion culture system are connected hermetically and aseptically, wherein the extraction device comprises a placenta cutting device, a reaction tank, a filter device, a filtrate collection device and a density gradient centrifugation device; and the perfusion culture system comprises a culture solution storer, a monitoring reactor, a cell culture bottle, a liquid waste bottle, a bottle for obtaining liquid, a biochemical criterion detection head group, an online monitoring system, a speed control fluid propeller and a pipeline device capable of controlling speed. The extraction and perfusion culture system for the MSCs (Mesenchymal Stem Cells) has benefits that the cutting efficiency is high; the operation is convenient and effective; the production efficiency can be greatly improved; the preparation technology is simple; and the quality control is simple and convenient, so as to efficiently obtain uniform and good stem cell products within a short time.

Owner:SHANGHAI ANGECON BIOTECH

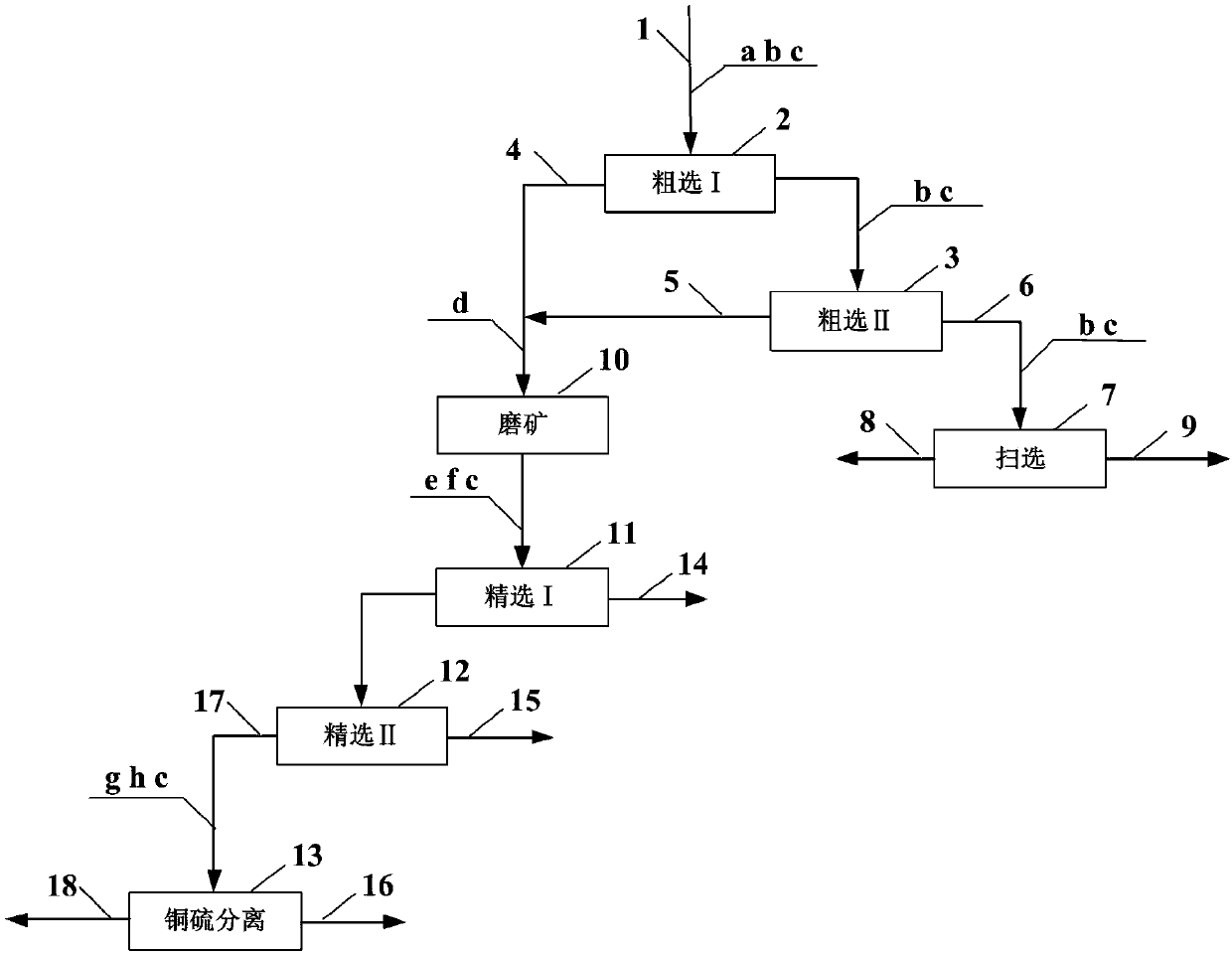

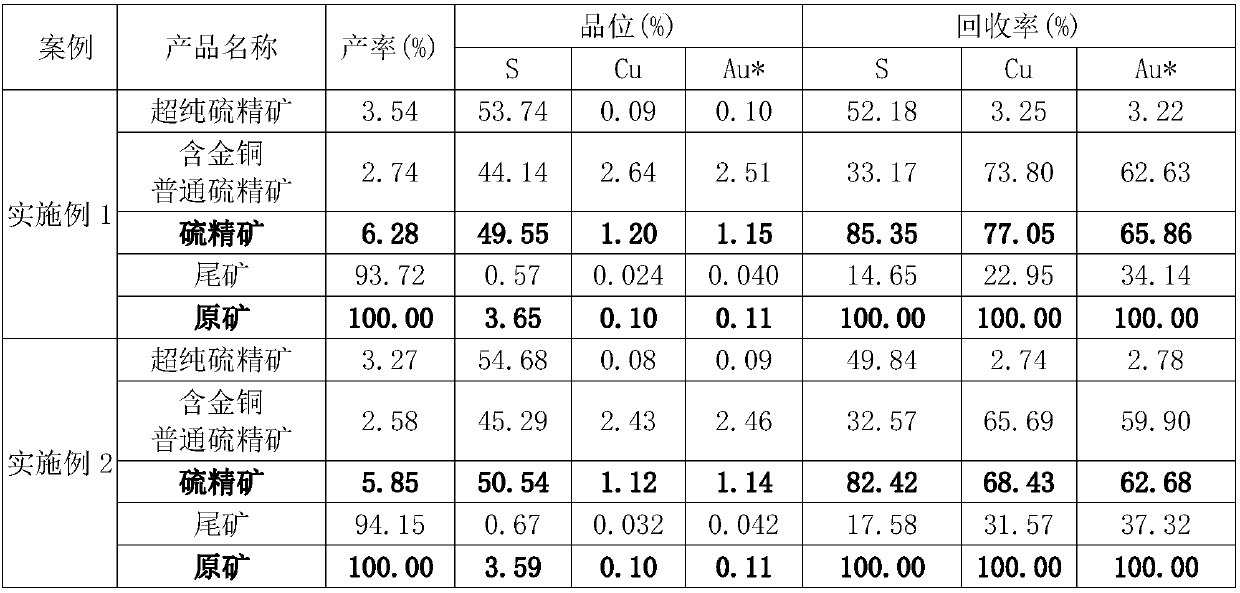

Flotation process for comprehensively recovering gold and sulfur from copper tailings

The invention relates to a flotation process for comprehensively recovering gold and sulfur from copper tailings. According to the floatation process, cave acid waste water, a capture agent and an alcohol foaming agent are added to the tailings from copper processing, recovery of objective minerals, copper and associated gold and silver is intensified, regrinding is conducted after ammonium sulfate is added, the objective minerals are cleaned and dissociated, sulfur concentrates are obtained through two-time concentration and serial return of middling products, the sulfur concentrates are subjected to size mixing through sulfuric acid and then subjected to flotation, and super-pure sulfur concentrates (sulfuric acid residues can be directly used as raw materials for iron-making) and gold-copper containing common sulfur concentrates (the sulfuric acid residues can comprehensively recover gold-copper). The flotation process has the advantages that the concentration effect is good, recovery of subsequent operation is facilitated, the sulfur concentrates are high in grade and good in purity, and the resource additive value of the sulfur concentrates can be improved, and the flotation process is suitable for being applied to copper mineral dressing plants for obtaining the super-pure sulfur concentrates with sulfur-copper tailings as raw materials and comprehensively recovering associated gold elements.

Owner:ZIJIN MINING GROUP +1

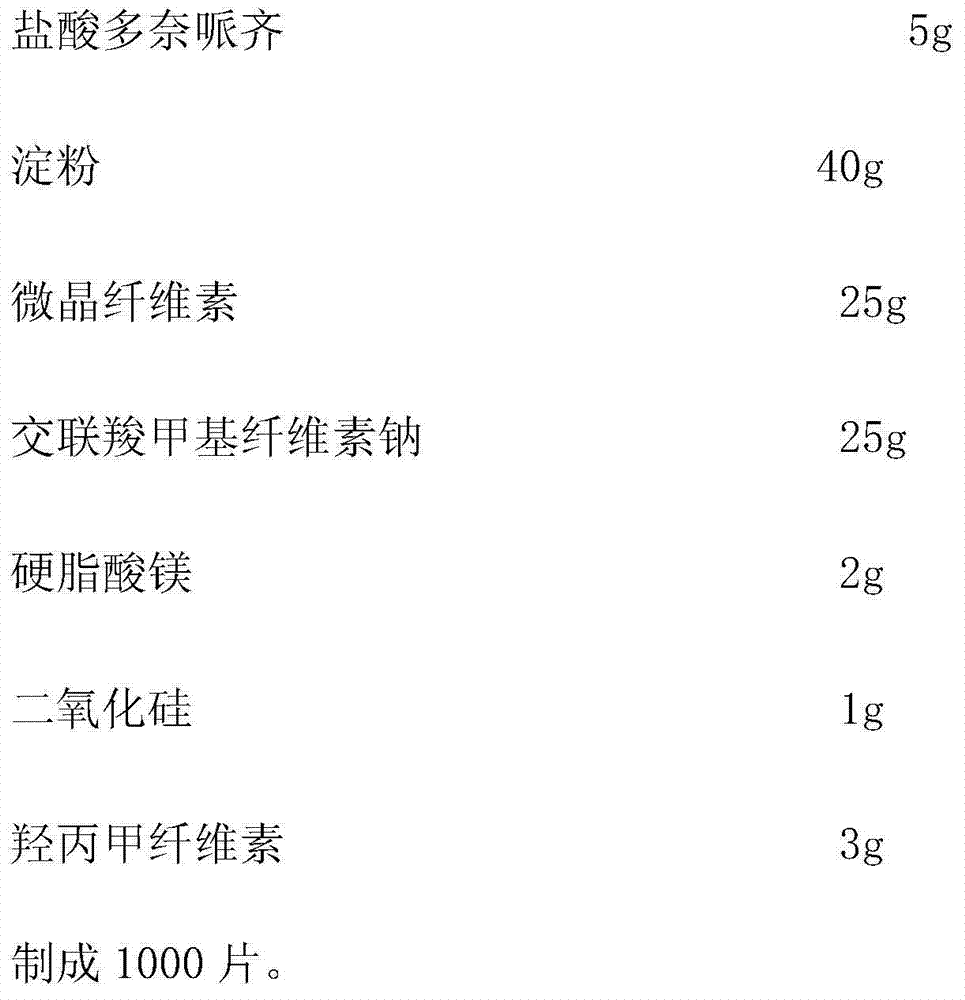

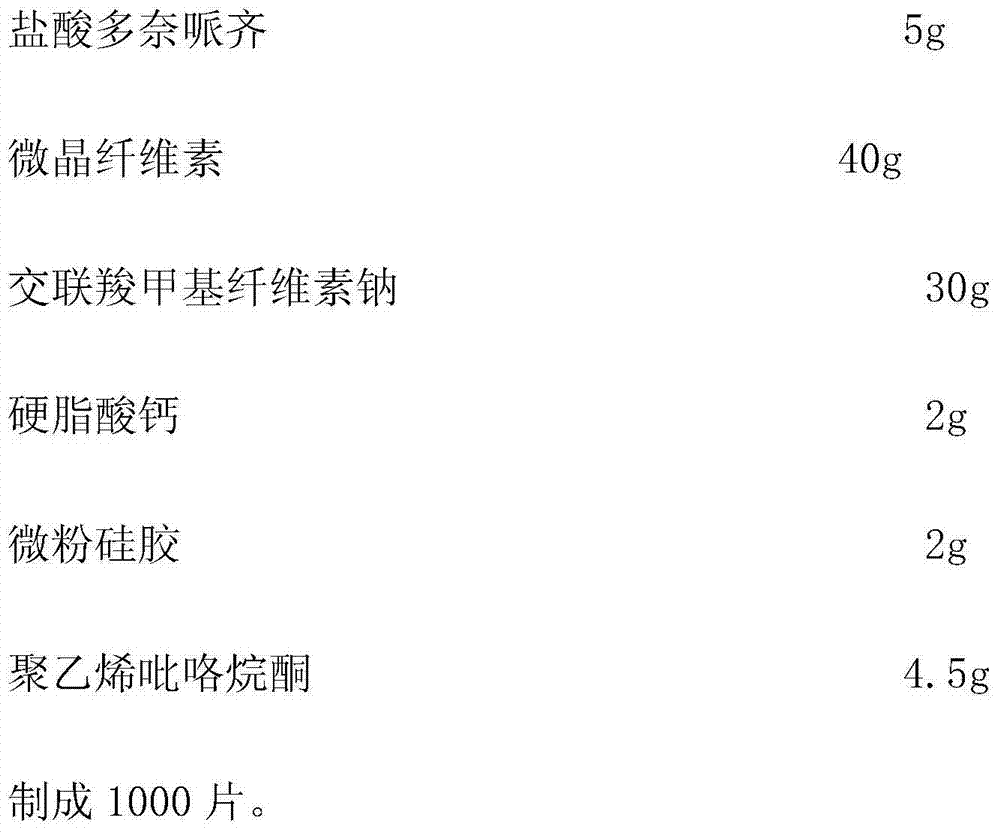

Donepezil hydrochloride dispersible tablet and preparation method thereof

InactiveCN103877046AGood effectPromote dissolution and absorptionNervous disorderPill deliveryDiseaseAdhesive

The invention relates to a donepezil hydrochloride dispersible tablet and a preparation method thereof, and belongs to the technical field of medicines. The donepezil hydrochloride dispersible tablet comprises the following components in percentage by weight: 1-5 percent of donepezil hydrochloride, 40-90 percent of disintegrating agent, 1-15 percent of lubricant and glidant and 1-15 percent of adhesive. The preparation method comprises the following steps: screening the components; uniformly mixing the donepezil hydrochloride and the disintegrating agent; adding the adhesive to prepare a soft material; granulating, baking and straightening granulating; adding the disintegrating agent, the lubricant and the glidant, and uniformly mixing; determining tablet weight, and tabletting to obtain the oxycodone hydrochloride dispersible tablet. The medicine is mainly used for treating senile dementia, especially mild or moderate alzheimer disease in clinical application, has stable quality, is beneficial to drug dissolution and absorption, is quick in response and convenient to take, can be taken orally after being dispersed with water, and also can be sucked in the mouth or swallowed.

Owner:张绪伟

Chinese medicament additive for improving liver function of Clarias lazera

InactiveCN101822313AIndicators are stablePlay a relieving effectAnimal feeding stuffMixed feedingLiver function

The invention discloses a Chinese medicament additive for improving the liver function of a Clarias lazera. The additive comprises the following Chinese medicaments in percentage by weight: 15 percent of astragalus, 25 percent of white paeony root, 20 percent of rhubarb, 15 percent of liquoric root, 15 percent of Himalayan teasel root and 10 percent of gardenia. The Chinese medicaments are dried crude medicaments and are mixed together and crushed into particles having a particle size by which the particles can pass through a 30-mesh standard screen. A method for using the Chinese medicament additive for improving the liver function of the Clarias lazera comprises the following steps of: mixing the prepared Chinese herbal medicament powder into a compound feed in a proportion of 5 percent; preparing the mixture into a granulated feed; and performing mixed feeding in a weight ratio of the compound feed to fresh chicken and duck internal organs of 1:5. The Chinese medicament additive has the following advantages that: the average value of glutamic alanine amino transferase of 5 percent of feed-fed experimental groups using the Chinese medicament additive for improving the liver function of the Clarias lazera has a stationary trend, while the glutamic alanine amino transferase of the groups which do not use the medicament additive increases exponentially, so the Chinese herbal medicament additive has certain repairing function to liver injuries.

Owner:TIANJIN AGRICULTURE COLLEGE

Method for coating titanium dioxide Zr-Al based on sulfate method

InactiveCN104356693ALower free energyHigh chemical inertnessInorganic pigment treatmentWeather resistanceChemistry

The invention belongs to the technical field of sulfate method titanium dioxide production process, and in particular relates to a method for coating titanium dioxide Zr-Al based on a sulfate method. The method is characterized in that the method is a new method of adding zircon salt three times, regulating a pH value and sufficiently dispersing; the aluminum oxide film uniformly wraps the surface of the titanium dioxide through precise control, the aluminum oxide film is uniformly covered, the surface free energy of titanium dioxide is lowered, the chemical inertness is increased, the surface character is changed due to compact film, and the application range is greatly improved; and each process in the enveloping process is seriously controlled, the product stability is improved, the wrapped oxide film is compact and uniform, the lustrousness, covering power and weather resistance of titanium dioxide is improved, the product index is stable, and the percent of pass is high.

Owner:SHANDONG DAWN TITANIUM IND

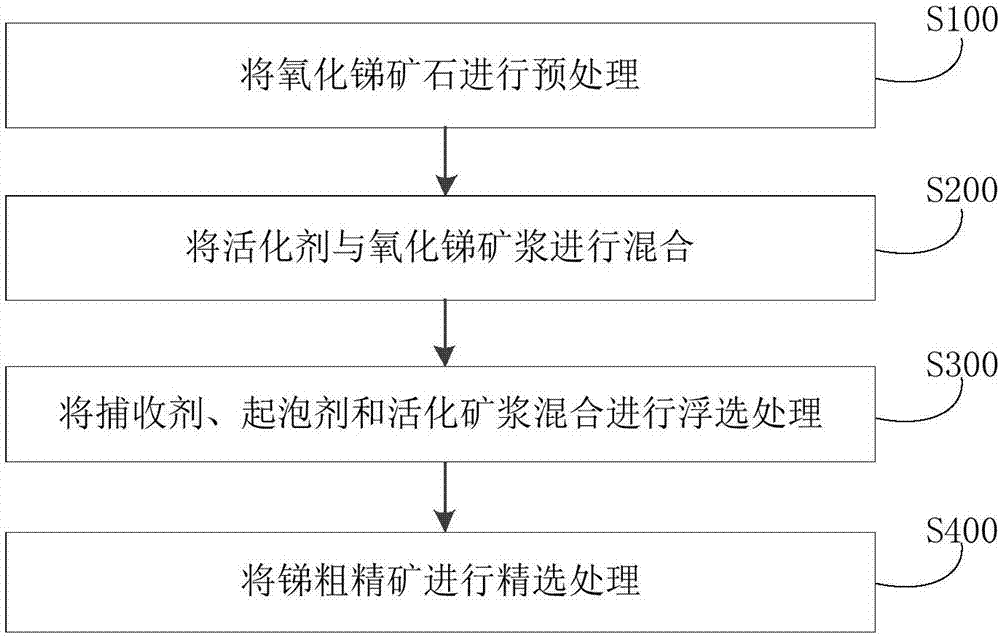

Method for treating antimony oxide ore

InactiveCN107243415AImprove adsorption capacitySolve the problem of poor floatabilityFlotationFoaming agentPre treatment

The invention discloses a method for treating antimony oxide ore. The method comprises the steps that (1), the antimony oxide ore is pretreated, so that antimony oxide ore pulp and fine mud are obtained; (2), an activator is mixed with the antimony oxide ore pulp, and activated ore pulp is obtained; (3), a collecting agent, a foaming agent and the activated ore pulp are mixed, and the flotation treatment is conducted, so that antimony rough concentrate and tailings are obtained; and (4), concentration treatment is conducted on the antimony rough concentrate, and antimony concentrate is obtained. According to the method, a beneficiation reagent is low in cost, the regime of the agent is simple, the index is stable, meanwhile the recovery rate of the antimony concentrate is increased by over 42%, and the economical benefits are remarkable.

Owner:CHINA ENFI ENGINEERING CORPORATION

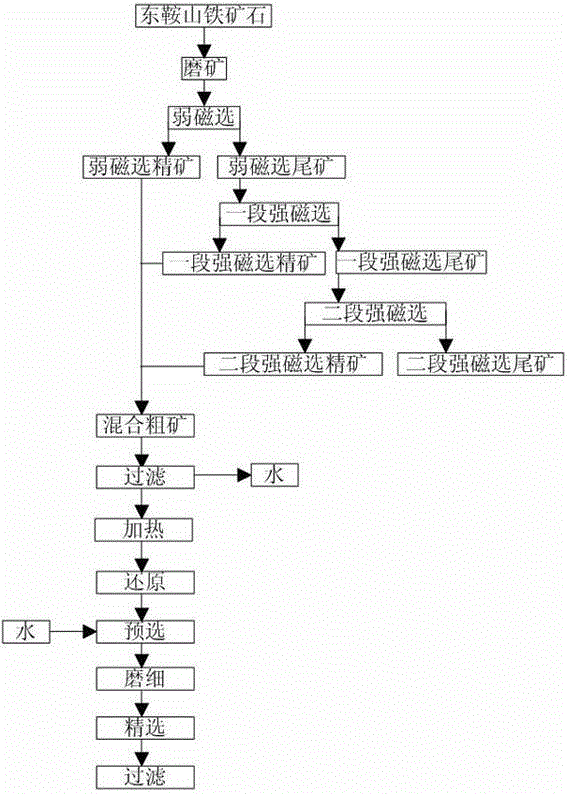

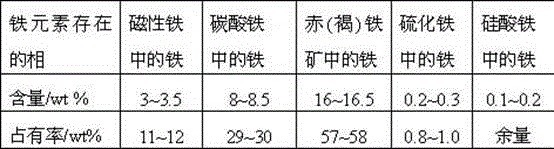

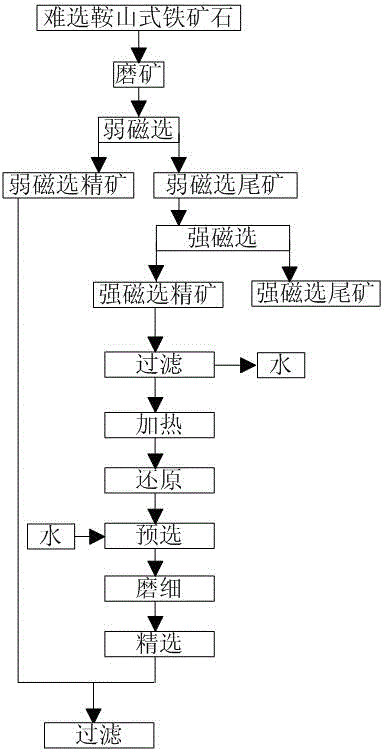

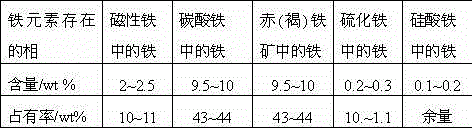

Ore dressing method of iron ore

InactiveCN104607311AProduct indicators are stableEconomicalMagnetic separationGrain treatmentsMagnetic separatorHigh intensity

The invention relates to an ore dressing method of an iron ore, and belongs to the technical field of minerals processing. The ore dressing method comprises the following steps: (1) carrying out the ore grinding treatment after the iron ore is broken; (2) carrying out the low intensity magnetic separation, primary-section high intensity magnetic separation and secondary-section high intensity magnetic separation on classified overflow products by virtue of a low intensity magnetic separation machine, mixing the primary-section high intensity magnetic separated ore concentrate, the secondary-section high intensity magnetic separated ore concentrate and the low intensity magnetic separated ore concentrate to be used as mixed coarse ore; (3) filtering the mixed coarse ore, heating and dehydrating the mixed coarse ore, then thermally preserving the mixed coarse ore for 5 to 60 minutes under a reduction atmosphere condition, and cooling the ore in the air to obtain magnet coarse ore; (4) mixing the magnet coarse ore with water to form ore pulp, stirring the ore pulp, and then pre-selecting the ore pulp by utilizing a barrel-type magnetic separator; (5) grinding the coarse concentrate, then finely selecting the ground coarse concentrate by utilizing an electromagnetic fine selecting machine, filtering and dehydrating the obtained finely-selected concentrate, and thus obtaining the concentrate product with iron grade of 63 to 68 percent. By adopting the method, a product with the iron grade more than 60 percent can be obtained, the product index is stable, the economic efficiency is good, and the resource can be efficiently utilized.

Owner:ANSTEEL GRP MINING CO LTD

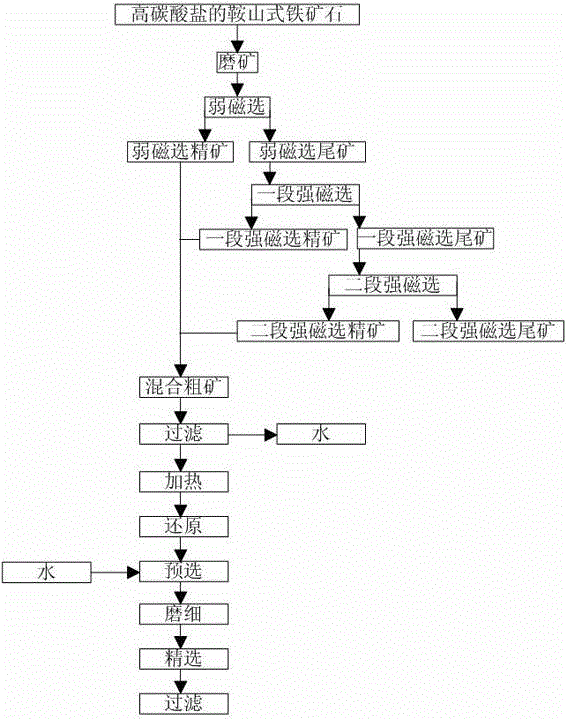

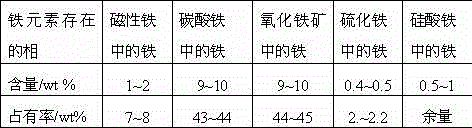

Beneficiation method for high carbonate iron ore

Provided is a beneficiation method for high carbonate iron ore, and belongs to the technical field of the mineral processing. The method comprises the following steps: firstly, ore grinding processing is carried out on the high carbonate iron ore after the carbonate iron ore is crushed; secondly, weak magnetic separation, first-stage strong magnetic separation and second-stage strong magnetic separation are carried out on hierarchic flooding products to separate tailings, and concentrates are merged to be used as mixed roughs; thirdly, filtration is carried out on the mixed roughs, heating is carried out to eliminate water, heat preservation is carried out on the mixed roughs for three min to sixty min under a reducing atmosphere condition, and air cooling is carried out on the mixed roughs; fourthly, ore pulp is prepared by adding water, and pre-selection is carried out after stirring; fifthly, fine selection is carried out by an electromagnetic fine selecting machine after fine grinding is carried out, and water is eliminated by filtration. According to the method, the strong magnetic separation and the weak magnetic separation are adopted, baking and reducing are carried out, pre-selection, namely, ore grinding and fine selecting, is carried out, and the products with iron grade larger than sixty percent are obtained. The method has the advantages that the product index is stable, the economical efficiency is good, and resources can be efficiently utilized.

Owner:鞍钢集团矿业公司有限公司

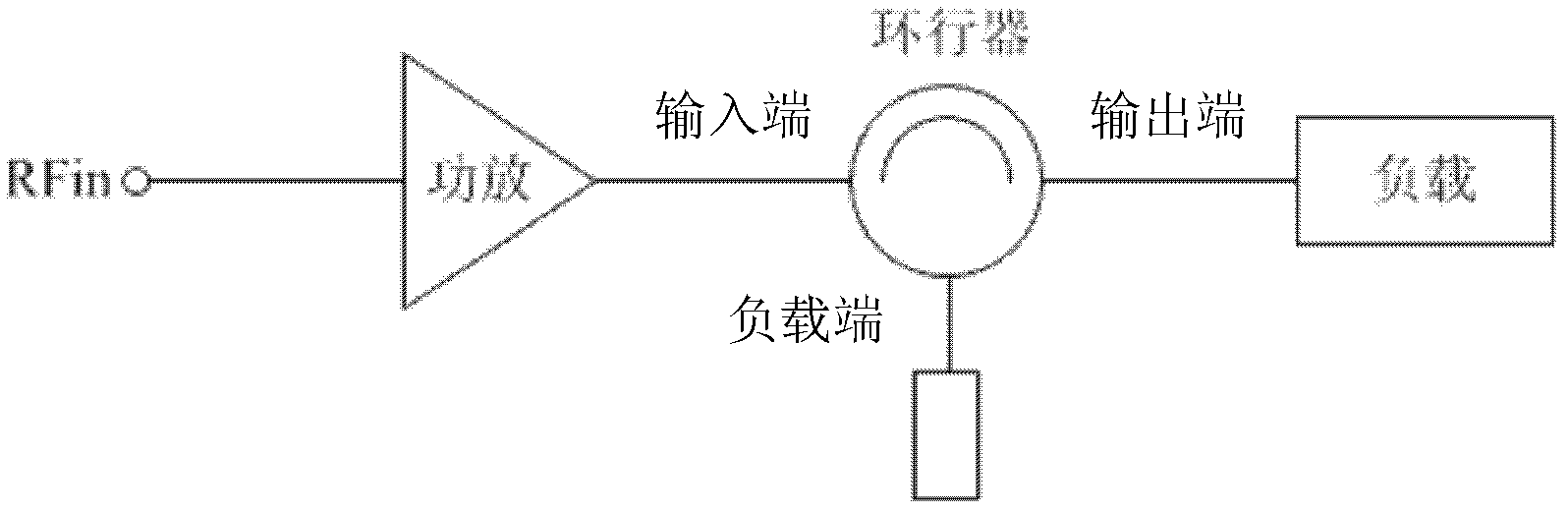

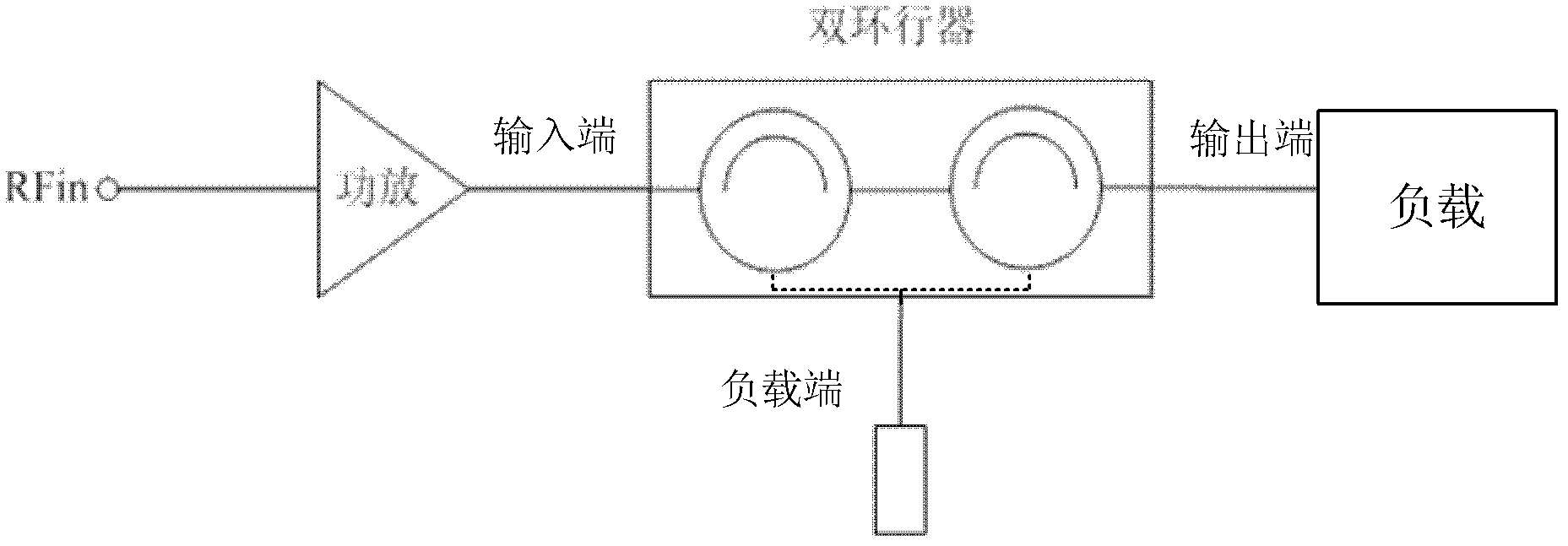

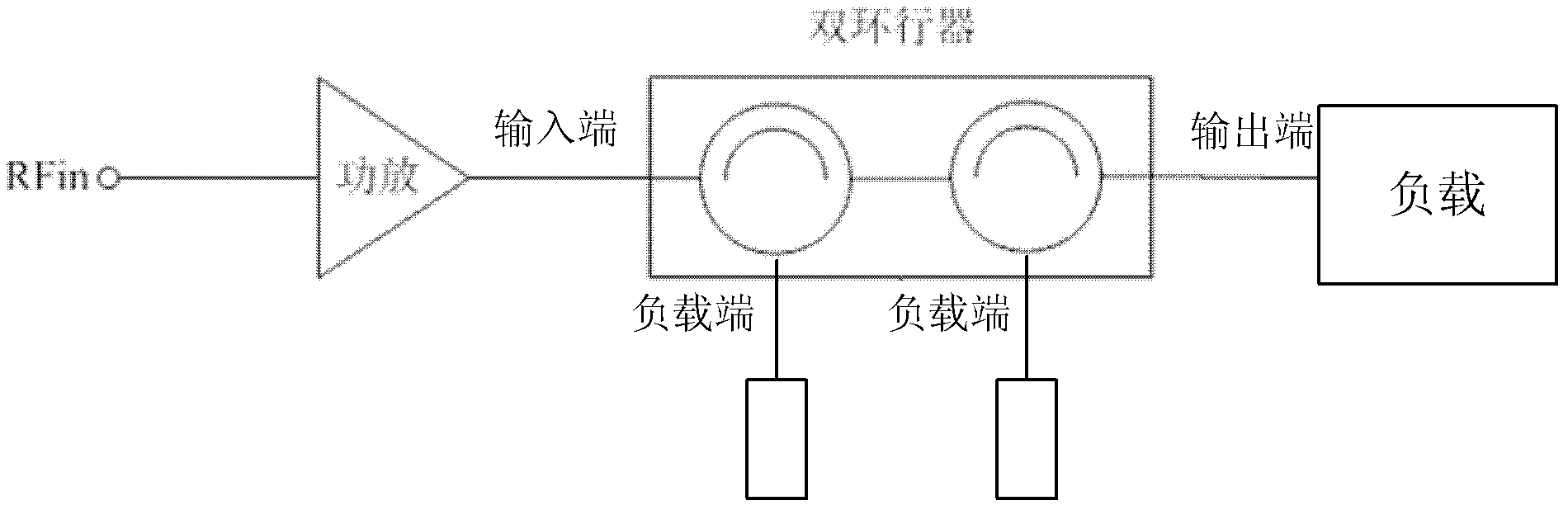

Circulator power amplifier circuit and design method thereof

InactiveCN103187935AImprove isolationImprove amplifier reliabilityHigh frequency amplifiersPower amplifiersDesign methodsCircuit design

The invention provides a circulator power amplifier circuit and a design method thereof, wherein the circulator power amplifier circuit comprises a power amplifier, a circulator, a power load and a load, wherein the output end of the power amplifier is connected with the input end of the circulator, the load is connected with the output end of the circulator, the power load is connected with the load end of the circulator, the circulator is an N-level circulator or M-level circulator, and N and M are integers of more than 1. The circulator power amplifier circuit designed by adopting the circulator power amplifier circuit is improved in isolation degree of the circulator, and has great importance of improving the standing wave of the power amplifier, ensuring that indexes are stable, avoiding the mismatch and damage of the power amplifier and improving the reliability of the power amplifier.

Owner:ZTE CORP

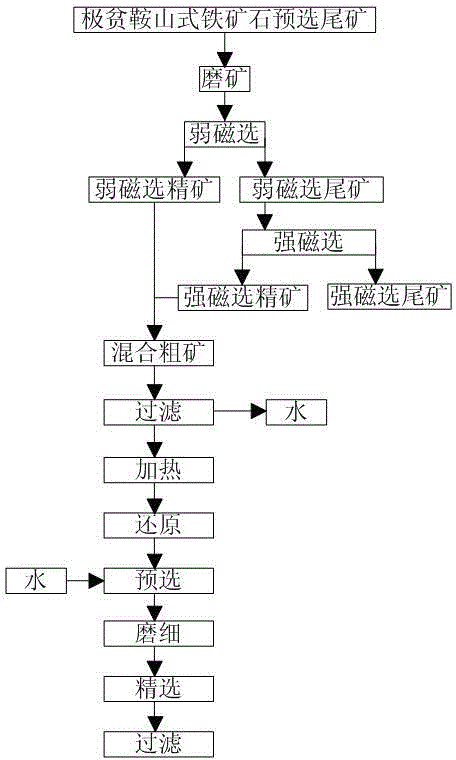

Beneficiation method for extremely lean iron ore pre-separation tailings

InactiveCN104588202AEfficient use ofIndicators are stableMagnetic separationWet separationIronstoneCalcination

The invention discloses a beneficiation method for extremely lean iron ore pre-separation tailings, and belongs to the technical field of mineral processing. The method comprises the following step: (1) smashing extremely lean iron ore pre-separation tailings, and grinding; (2) performing low intensity magnetic separation and high intensity magnetic separation, and combining strong magnetic concentrate and weak magnetic concentrate into mixed coarse ore; (3) filtering the mixed coarse ore, heating the mixed coarse ore to 580-700 DEG C, preserving heat for 20-120 seconds, putting the mixed coarse ore under a reducing atmosphere condition for preserving heat for 3-60 minutes, and cooling in the air to a temperature below 50 DEG C; (4) adding water to prepare ore pulp, stirring and performing pre-separation; (5) finely grinding, performing concentration, and filtering water from concentrate. According to the method, the high intensity magnetic separation and low intensity magnetic separation, calcination and reduction, and pre-separation-grinding and concentration are performed to obtain a product of which the iron grade is larger than 60 percent. The product has a stable index and high economical performance, and resources can be effectively utilized.

Owner:鞍钢集团矿业公司有限公司

Flotation method of highly argillaceous alkaline gangue copper oxide ore

The invention provides a flotation method of highly argillaceous alkaline gangue copper oxide ore. loatability of the highly argillaceous alkaline gangue copper oxide ore is utilized to improve a conventional sulfating flotation technique, and a flotation process of foaming agent absence-powerful activation-mud dispersion-powerful collection to efficiently recycle the copper oxide ore. The method provided by the invention comprises the following steps: firstly grinding the highly argillaceous alkaline gangue copper oxide ore, then performing size mixing on the grinded ore, and finally carrying out flotation to produce copper concentrate, wherein no foaming agent is added in the whole flotation process. Compared with the conventional sulfating flotation technique, with the adoption of the method, the recycling rate of copper is improved by more than 15% based on accordant concentrate grade, not only the influence of ore mud on the flotation process is eliminated, the efficient recovery of the copper oxide ore is guaranteed, but also the convenient flotation operation and stable index are achieved; and the method is suitable for realizing further industrial and large-scale production.

Owner:KUNMING UNIV OF SCI & TECH

Beneficiation method for refractory iron ores

InactiveCN104588203AEfficient use ofIndicators are stableHigh gradient magnetic separatorsWet separationIronstoneMoisture

The invention discloses a beneficiation method for refractory iron ores, belonging to the technical field of mineral processing and comprising the following steps: (1) crushing the refractory iron ores and grinding; (2) carrying out low-intensity magnetic separation and high-intensity magnetic separation; (3) filtering concentrates obtained from the high-intensity magnetic separation to obtain filter cakes, heating the filter cakes to remove moisture, preserving the heat of the cakes in a reducing atmosphere, and performing air cooling; (4) adding water to prepare ore pulp, stirring and beneficiating preliminarily; (5) levigating and beneficiating finely, mixing the obtained finely beneficiated concentrates with concentrates obtained from the low-intensity magnetic separation, and filtering to remove the moisture. According to the method disclosed by the invention, through the high-intensity magnetic separation, low-intensity magnetic separation, roasting, reducing, preliminarily beneficiating, grinding and finely beneficiating, products with iron grade greater than 60% can be obtained; meanwhile, product indexes are stable, the economy is good, and resources can be utilized efficiently.

Owner:鞍钢集团矿业公司有限公司

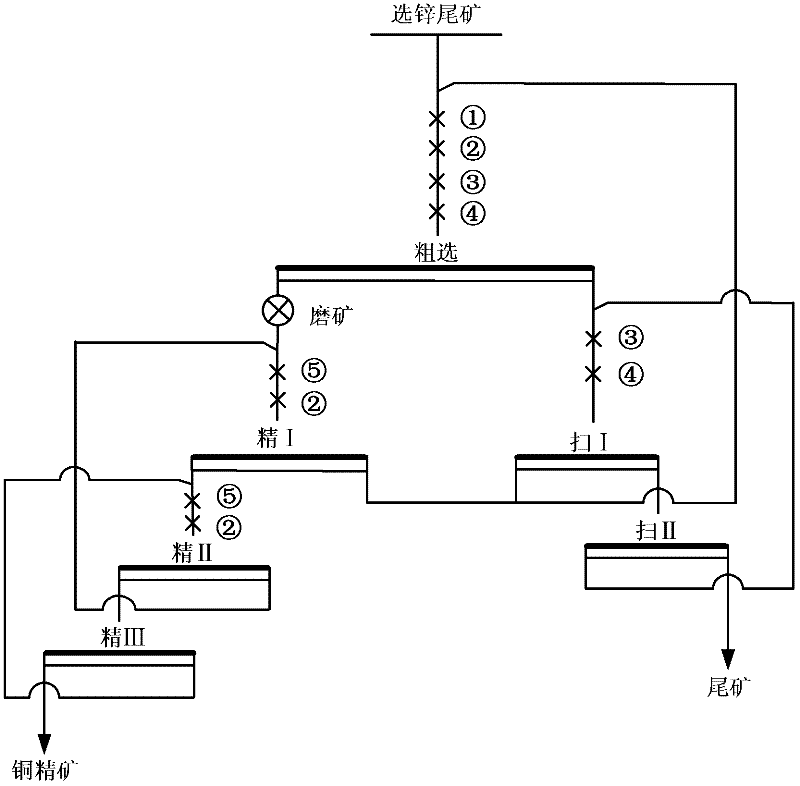

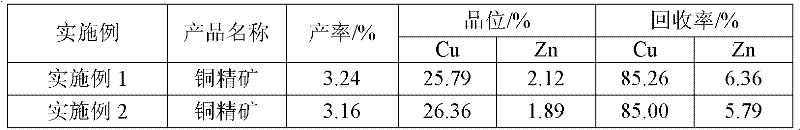

Process for separating copper from waste micro/fine-particle zinc tailing

The invention discloses a process for separating copper from waste micro / fine-particle zinc tailing and adopts a technical scheme based on the flotation rate characteristics of micro / fine-particle copper minerals. The process comprises the following steps: firstly separating effectively-activated micro / fine-particle copper minerals by using a high-efficiency floatation agent in the floatation rough-separation stage, and enhancing recovery of liberated copper minerals and copper mineral combinations; and then grinding the crude concentrate until the content of 0.02 mm particles is 80 to 90% todestroy the copper mineral combinations and increase the degree of liberation of the copper mineral monomers; and finally removing impurities and recovering copper minerals by concentration for 2 to 3 times under the conditions of low concentration, high inhibitor consumption and high dispersant, to obtain qualified copper concentrate.

Owner:ZIJIN MINING GROUP

Injectio Natarii Norcantharidatis freeze-drying powder injection and its preparation method

InactiveCN1557298AGood effectInstant in waterOrganic active ingredientsPowder deliveryFreeze-dryingCantharidin

The present invention is freeze dried demethyl sodium cantharidinate powder for injection and its preparation process, and belongs to the field of medicine technology. The freeze dried demethyl sodium cantharidinate powder for injection contains demethyl cantharidin 0.25-70 wt%, sodium hydroxide 0.1-35 wt% and excipient 0-99 wt%. The preparation process includes compounding demethyl cantharidin and sodium hydroxide in liquid compounding tank, adding injection water and heating to dissolve, adding excipient, dissolving and regulating pH value; adding proper amount of carbon for injection, stirring for 30 min for adsorption, filtering to eliminate carbon and sterilize, packing in Schering bottle, and freeze drying to obtain the freeze dried demethyl sodium cantharidinate powder for injection. The medicine is clinically used in treating liver cancer, esophagus cancer, hepatitis, etc.

Owner:肖广常 +1

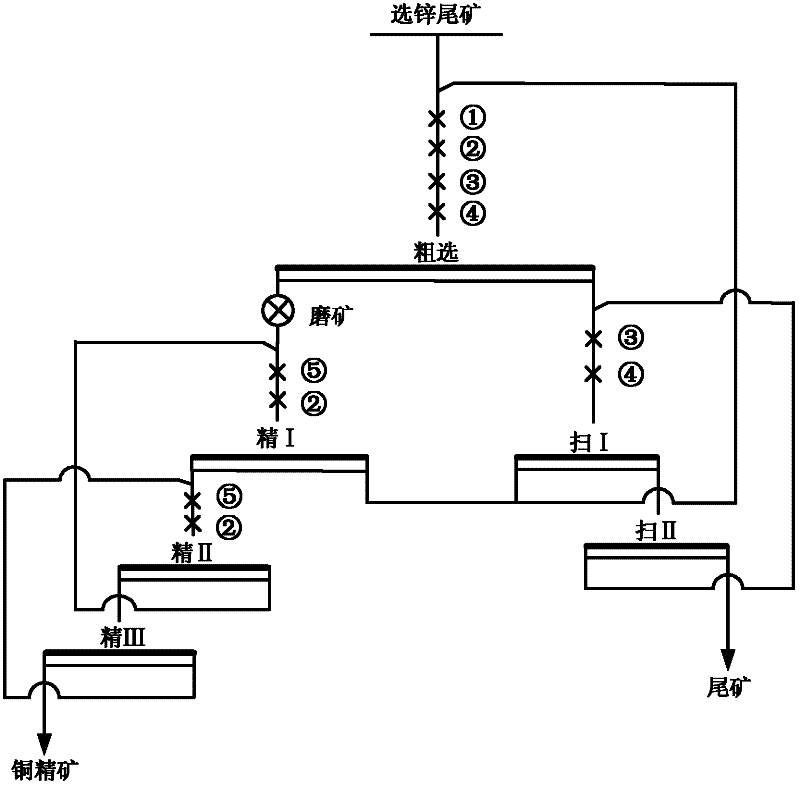

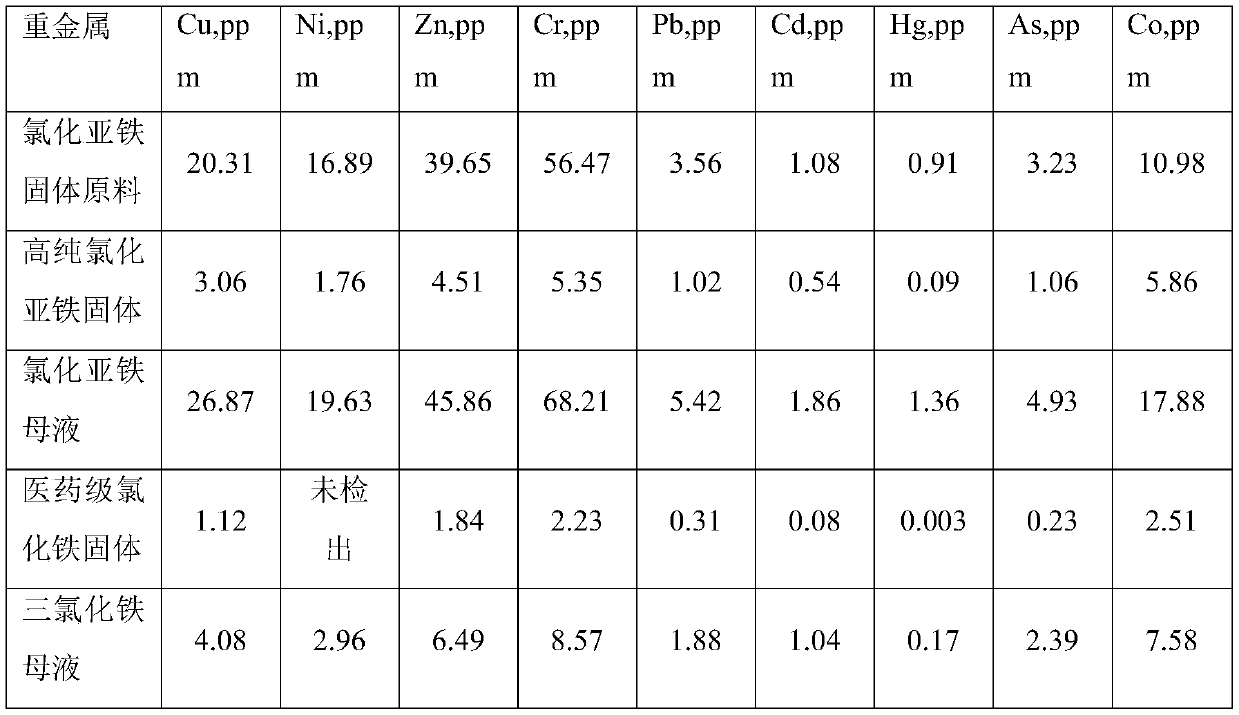

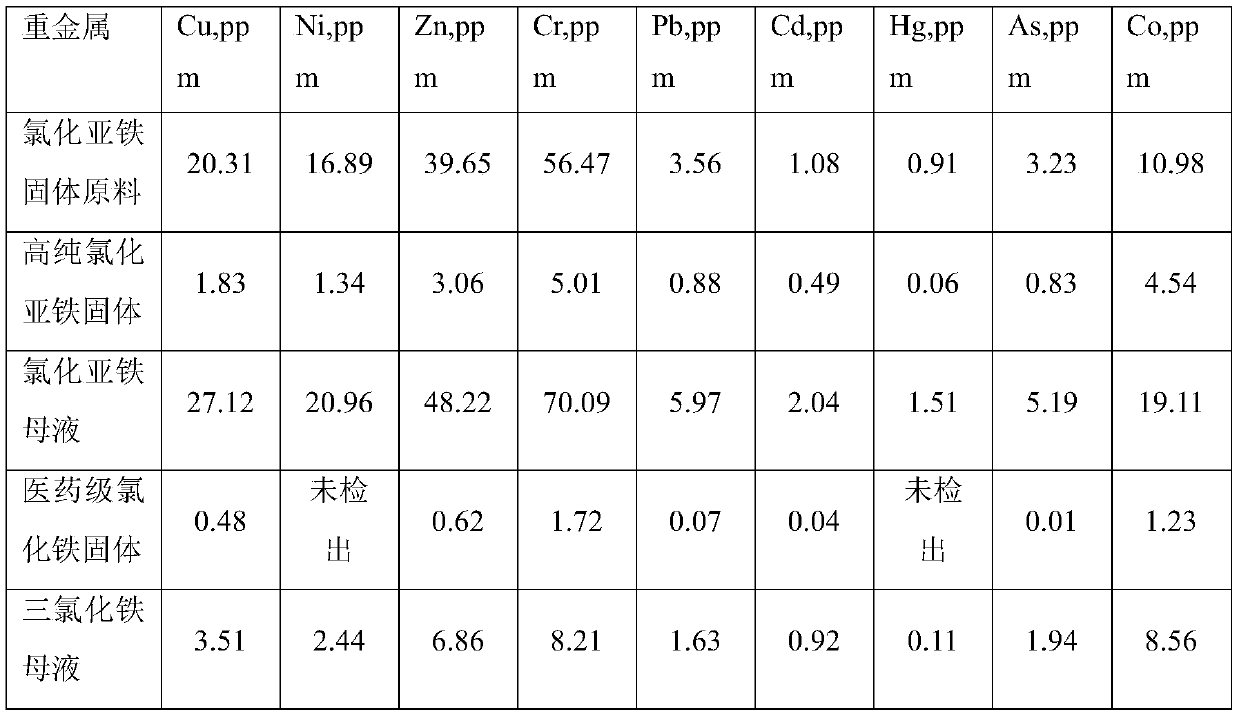

Preparation method of pharmaceutical grade ferric trichloride product

ActiveCN110902727AEfficient removalMeet the indicator requirementsIron halidesSodium chlorateProcess engineering

The invention discloses a preparation method of a pharmaceutical grade ferric trichloride product, and the method comprises the following steps: dissolving a raw material ferrous chloride solid in water, adding hydrochloric acid to obtain a ferrous chloride solution, filtering, and removing insoluble substances in the solution; evaporating and concentrating the obtained filtrate until the mass fraction is 38-45%; naturally cooling, standing, extracting upper-layer mother liquor, and centrifuging lower-layer crystals through a centrifugal machine until no mother liquor is left, so as to obtaina ferrous chloride solid; dissolving the ferrous chloride solid in a hydrochloric acid solution to obtain a ferrous chloride liquid; oxidizing the ferrous chloride liquid with chlorine, adding a smallamount of sodium chlorate for many times to oxidize until ferrous chloride reaches the standard of pharmaceutical grade ferric trichloride, evaporating and concentrating until the content of ferric trichloride is 58-63%, cooling, adding seed crystals, slowly stirring, transferring into the centrifugal machine, and centrifuging until no mother liquor is left. The method is simple to operate and stable in quality, and can effectively remove various impurities in the raw materials, so that various indexes of the product can stably meet the index requirements of the pharmaceutical grade ferric trichloride.

Owner:3R ENVIRONMENTAL TECH CO LTD +1

Synthesis process of p-tert-butyl phenol formaldehyde resin

The invention belongs to the technical field of synthesis of p-tert-butylphenol formaldehyde resin, and discloses a synthesis process of p-tert-butylphenol formaldehyde resin. The synthesis process comprises the following steps: adding a formaldehyde solution and ammonia water into a reaction kettle; uniformly adding p-tert-butylphenol, then heating to boiling, and maintaining for 150-180 minutes;cooling, adding acetic acid, neutralizing and stirring, and adding toluene for extraction; after standing for layering, draining wastewater; adding oxalic acid and tap water, stirring, standing for layering, and then draining wastewater; detecting pH which approximates 7-7.5, desolventizing the toluene under normal pressure, vacuumizing, and discharging under vacuum to obtain tert-butyl phenol formaldehyde resin. According to the process, the ammonia water is alkalescent, so that reaction is relatively mild, and the p-tert-butyl phenol formaldehyde resin prepared by the method is stable in product index and stable in use performance.

Owner:河北泽田化工有限公司

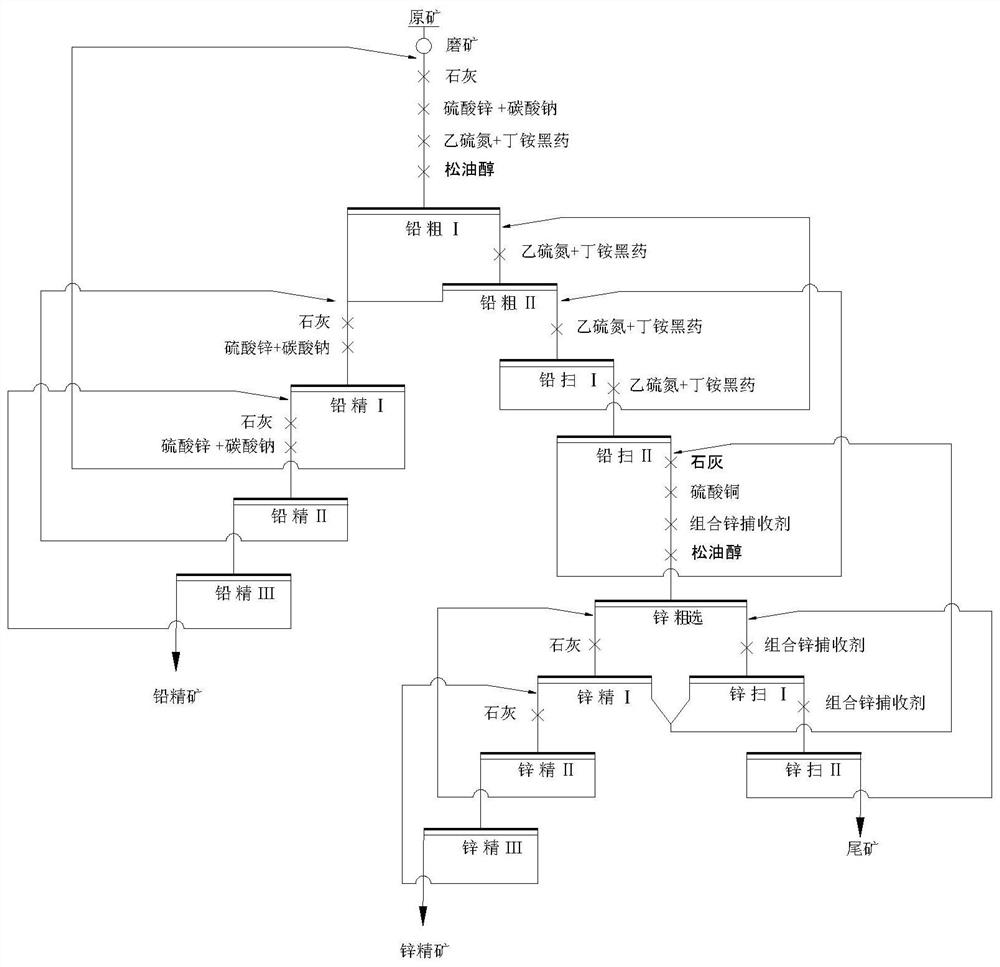

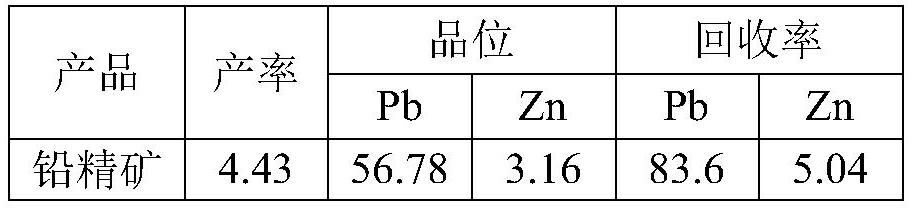

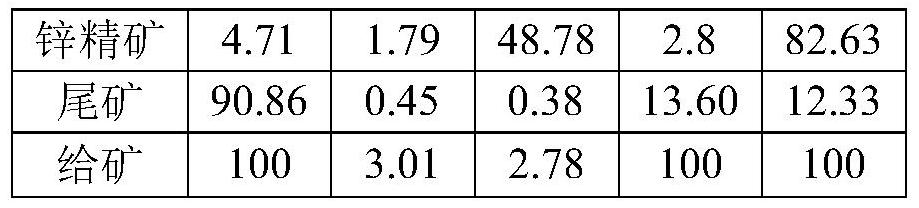

Combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof

The invention discloses a combined zinc collecting agent for flotation of lead-zinc sulfide ore and application thereof. The combined zinc collecting agent comprises the following active components inparts by weight: 10-30 parts of ammonium dibutyl dithiophosphate, 30-50 parts of ethyl thiocarbamate and 30-50 parts of 2-aminothiophenol. According to the efficient combined collecting agent for sphalerite flotation, the combined collecting agent is composed of ammonium dibutyl dithiophosphate, ethyl thiocarbamate and 2-aminothiophenol and is easy to obtain, low in price, small in dosage and free of pollution. The ammonium dibutyl dithiophosphate is weak in collecting capacity, but has foamability, high sulfur and nitrogen collecting capacity and certain lead sulfide ore and zinc sulfide orecollecting capacity; compared with a conventional collecting agent butyl xanthate, 2-aminothiophenol has good flotation effect of on marmatite even under the condition that copper ion activation is not used, and has poor lead sulfide ore flotation effect; however, 2-aminothiophenol is a weakly acidic compound, and cannot fully react with zinc sulfide ore when a pH value is relatively low; and therefore, the components of the combined collecting agent can supplement each other.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com