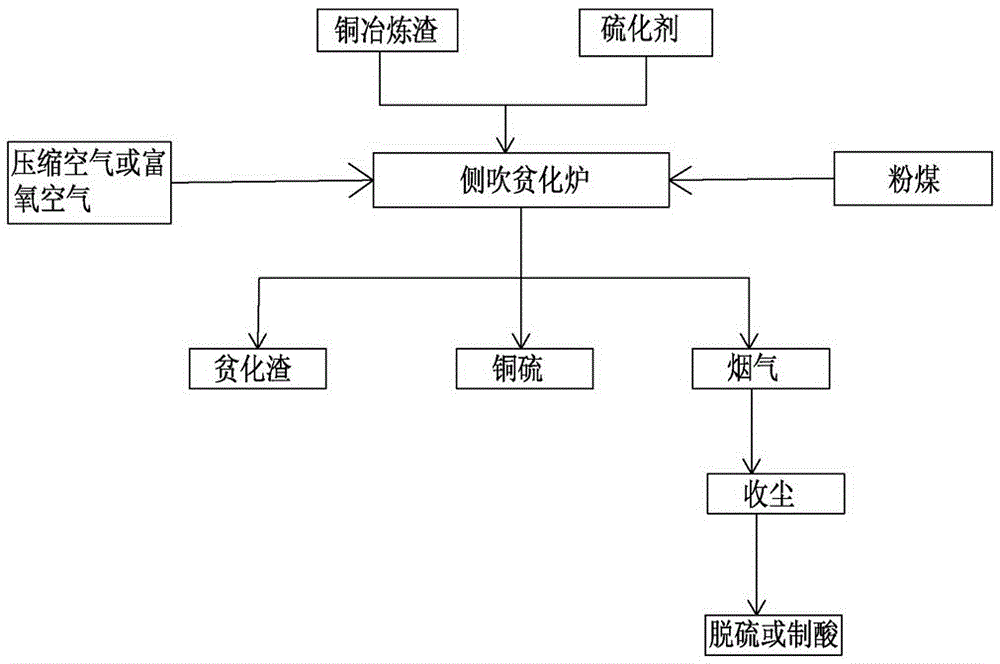

Side-blown depletion copper smelting slag production method

A production method and technology for copper smelting slag, which are applied in the production field of side-blown depleted copper smelting slag, can solve the problems of complex process flow and low recovery efficiency, and achieve the effects of speeding up the reaction, saving energy and ensuring the effect of depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

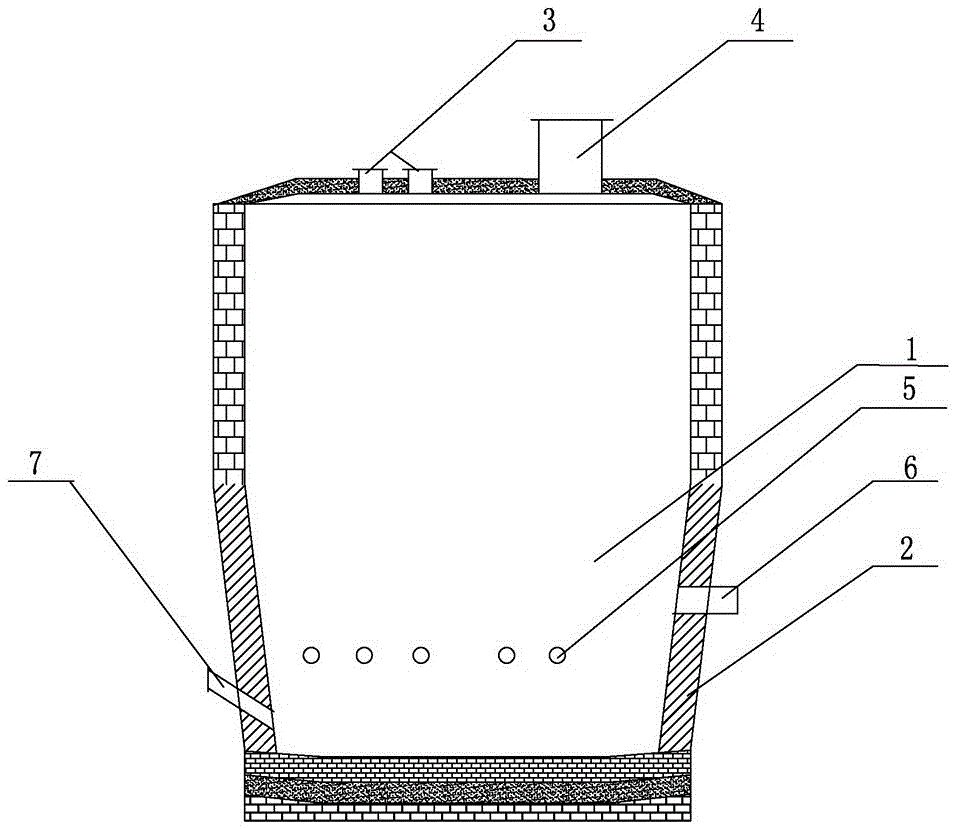

Embodiment 1

[0028] Example 1 This example is the case where only molten copper smelting slag is used without vulcanizing agent. 40t / h molten copper smelting slag is added to the side blowing depletion furnace from the feed port 3, wherein the copper smelting The slag can be fed intermittently or continuously, and the fuel is sprayed into the molten pool through the lance port 5 arranged on the side of the lean furnace, wherein the fuel is a mixture of pulverized coal and compressed air or pulverized coal and enriched The mixture of oxygen and air is used to stir, transfer heat and mass transfer to the lean furnace through the injected fuel. The temperature in the furnace is controlled at 1100~1300℃, the injection pressure is 0.1~0.4 Mpa, and the depth of the molten pool is 800~2000mm. Put a pack of 6m through copper matte port 7 every 18h 3 copper matte, put a pack of 12m through the slag outlet every 45 minutes 3 The depleted slag, the flue gas is sent to the acid system for acid produc...

Embodiment 2

[0029] Example 2 This example is the case where only molten copper smelting slag is used, and the ratio of copper smelting slag and vulcanizing agent is 50:1. 40t / h of molten copper smelting slag is used, wherein the ratio of smelting slag to blowing slag is The ratio is 4:1, and it is fed into the side-blown depletion furnace from the feed port 3, and the vulcanizing agent is measured by a belt scale at a mass ratio of 0.8t / h and continuously fed into the side-blown depleted furnace through the feed port 3, wherein the copper smelting The slag can be fed intermittently or continuously, and the fuel is sprayed into the molten pool through the lance port 5 arranged on the side of the lean furnace, wherein the fuel is a mixture of pulverized coal and compressed air or pulverized coal and enriched The mixture of oxygen and air is used to stir, transfer heat and mass transfer to the lean furnace through the injected fuel. The temperature in the furnace is controlled at 1100~1300℃, ...

Embodiment 3

[0030]Example 3 In this example, only solid copper smelting slag is used, and the vulcanizing agent is used at 100:15. 40t / h solid copper smelting slag is used, wherein the copper smelting slag is mainly refining slag or blowing slag from the feed port 3 is added to the side-blown depletion furnace, and the vulcanizing agent is measured by a belt scale at a mass ratio of 6 / h and continuously fed into the side-blown depletion furnace through the feed port 3, wherein the copper smelting slag is continuously fed, and is set in the lean The nozzle 5 on the side of the furnace sprays the fuel into the molten pool through the spray gun, wherein the fuel is a mixture of pulverized coal and compressed air or a mixture of pulverized coal and oxygen-enriched air, and the fuel injected into the lean furnace is Stirring, heat transfer, and mass transfer, control the temperature in the furnace at 1100~1300°C, the injection pressure at 0.1~0.4 Mpa, the depth of the molten pool at 800~2000mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com