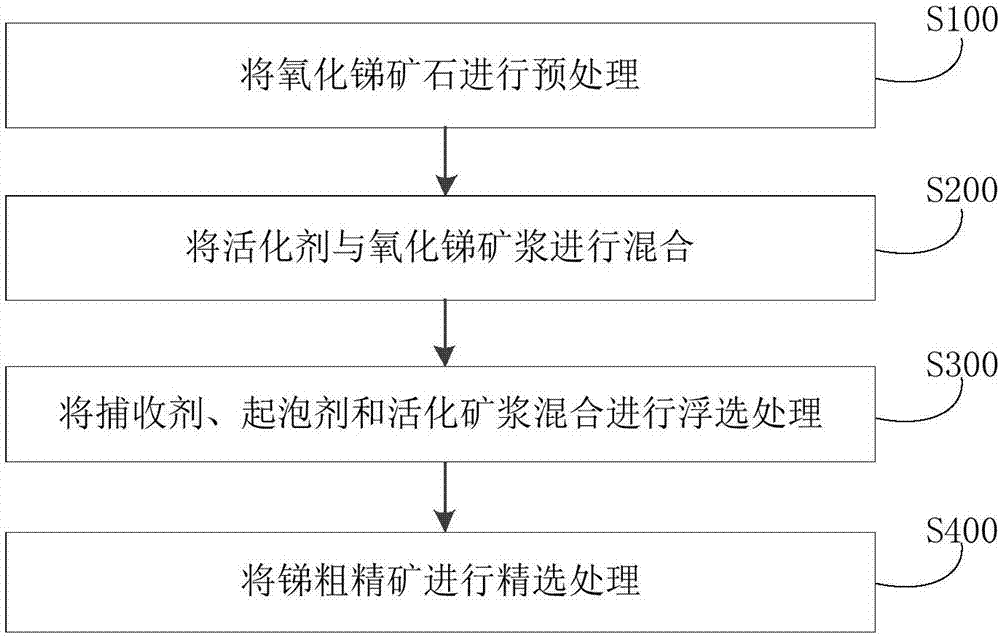

Method for treating antimony oxide ore

A technology for antimony oxide and ore, applied in solid separation, flotation and other directions, can solve the problems of difficult recovery of antimony oxide ore, large number of equipment, waste of resources, etc., to solve the problem of poor floatability, simple pharmaceutical system, and improved recovery rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In a certain antimony mine in Hunan, the antimony oxide ore contains 1.10wt% Sb (mainly yellow antimony ore and antimonite). First, the antimony oxide ore is mixed with water, and then the mixed material is sent to a ball mill for ball milling. The ore washing machine washes the materials after ball milling to obtain antimony oxide slurry with a particle size of no more than 0.074 mm and a mass concentration of 20-70 wt %, and antimony oxide slurry with a particle size of no more than 10 microns. Then mix the lead nitrate and antimony oxide pulp according to the mass ratio of 4:10000 in the state of stirring, and stir for 2-6min to obtain the activated pulp; then combine the collector RCOOM, the foaming agent methyl isobutyl carbinol and the activated The ore pulp is mixed and stirred according to the mass ratio of 40:5:100000, and stirred for 2-6 minutes to obtain a mixed liquid with a pH value of 6.0-10.0, and then the mixed liquid is subjected to flotation for 3-10 mi...

Embodiment 2

[0050] In a certain antimony mine in Guangxi, the antimony oxide ore contains 1.30wt% Sb (mainly yellow antimonite and antimonite). The antimony oxide ore is mixed with water first, and then the mixed material is sent to a ball mill for ball milling, and finally the antimony oxide ore is mixed with water. The ore washing machine washes the materials after ball milling to obtain antimony oxide slurry with a particle size of no more than 0.074 mm and a mass concentration of 20-70 wt %, and antimony oxide slurry with a particle size of no more than 10 microns. Then mix the lead nitrate and antimony oxide pulp according to the mass ratio of 3:10000 in the state of stirring, and stir for 2-6min to obtain the activated pulp; then combine the collector RCOOM, the foaming agent methyl isobutyl carbinol and the activated The pulp is mixed and stirred according to the mass ratio of 60:4:100000, and stirred for 2-6 minutes to obtain a mixed liquid with a pH value of 6.0-10.0, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com