Patents

Literature

109 results about "Antimonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, antimonite refers to a salt of antimony(III), such as NaSb(OH)₄ and NaSbO₂ (meta-antimonite), which can be prepared by reacting alkali with antimony trioxide, Sb₂O₃. These are formally salts of antimonous acid, hc(OH)₃, whose existence in solution is dubious. Attempts to isolate it generally form Sb₂O₃·xH₂O, antimony(III) oxide hydrate, which slowly transforms into Sb₂O₃.

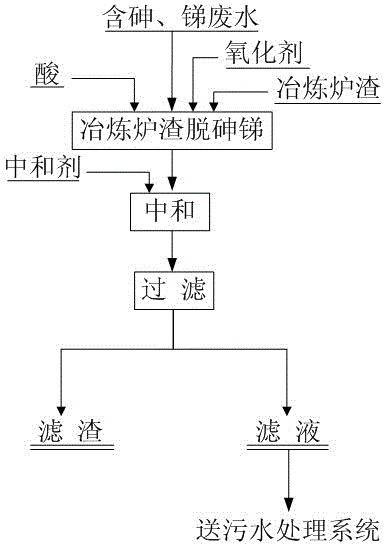

Method for removing arsenic and antimony in industrial wastewater by using smelting furnace slag

InactiveCN103553197AShort reaction timeSave precipitantSolid waste disposalWaste water treatment from metallurgical processArsenateMagnesium

The invention relates to a method for removing arsenic and antimony in industrial wastewater by using smelting furnace slag. The method comprises the following steps: adding acid to the industrial wastewater containing more than 10mg / L of As and more than 10mg / L of Sb so as to adjust the acidity, and controlling the pH to 0.5-4; adding the smelting furnace slag and an oxidizing agent, enabling the smelting furnace slag to chemically react with or physically adsorb As<3+> and Sb<3+> in the wastewater under acidity and oxidation atmospheres, controlling the temperature at 40-100 DEG C, and carrying out heat preservation reaction for 1-3 hours; adding a neutralizing agent for neutralization, and controlling the pH to 6-9; filtering a solution so as to obtain filtrate and filter residues, if the As contained in the filtrate is less than 0.3mg / L and Sb contained in the filtrate is less than 0.5mg / L, meeting the residue removal standards, feeding the filtrate to a wastewater treatment system for further purifying other impurities, if the As contained in the filtrate is more than 0.3mg / L and the Sb contained in the filtrate is more than 0.5mg / L, repeating the steps till meeting the residue removal standards, and sending the filtrate residues to a filter residue yard for storage. The method has the advantages that the smelting furnace slag is used for replacing a precipitant so as to remove impurities, the arsenic and the antimony in the wastewater are rapidly and efficiently removed within 1 to 3 hours, the removal rate is close to 100%, the method is high in efficiency and low in cost, and the filter residues have good crystal structures, are easy to clarify and filter and contain arsenate and antimonite formed by iron, calcium, magnesium, aluminium, pentavalent arsenic and pentavalent antimony and have stable chemical property.

Owner:HONGHE COLLEGE

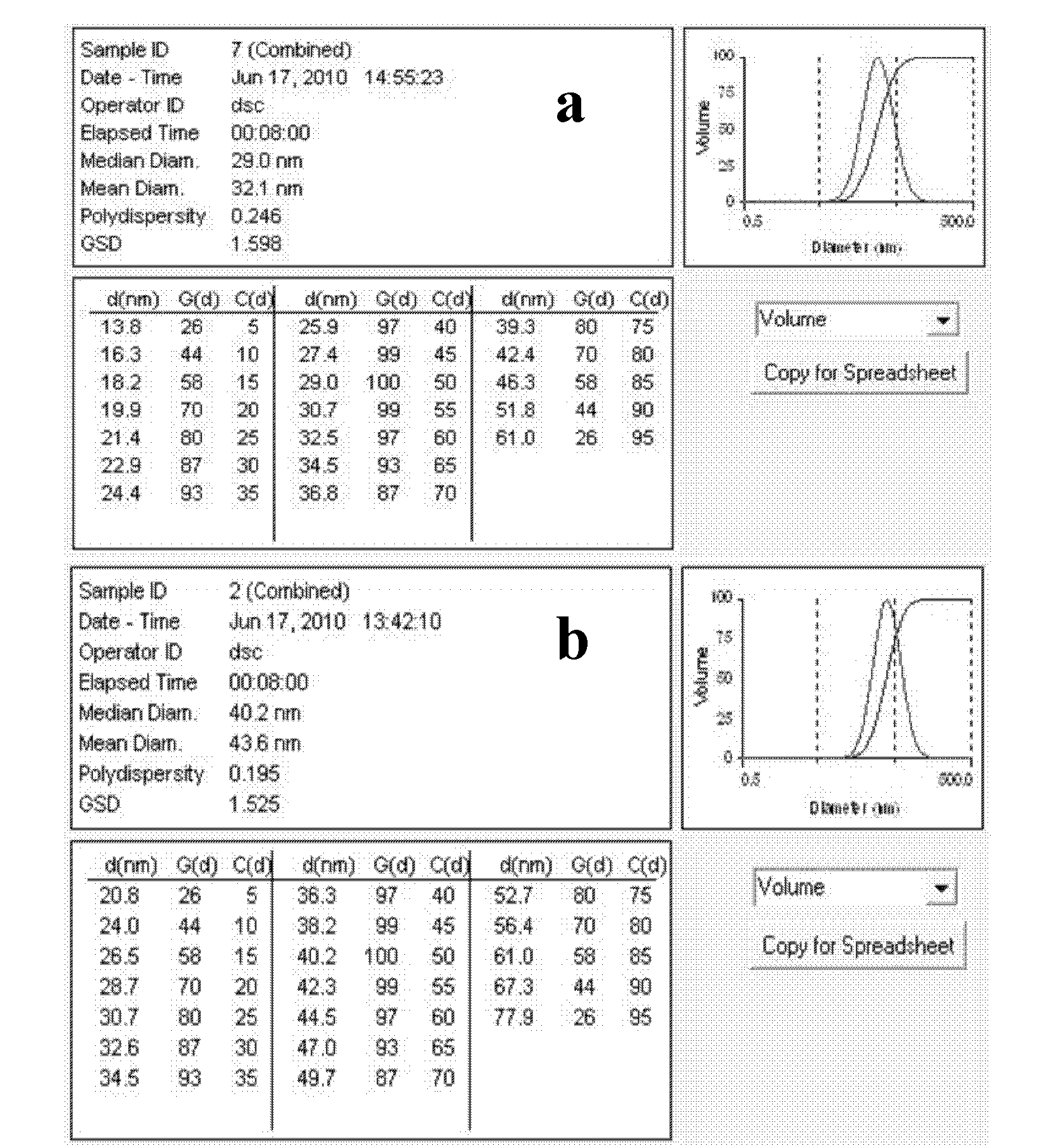

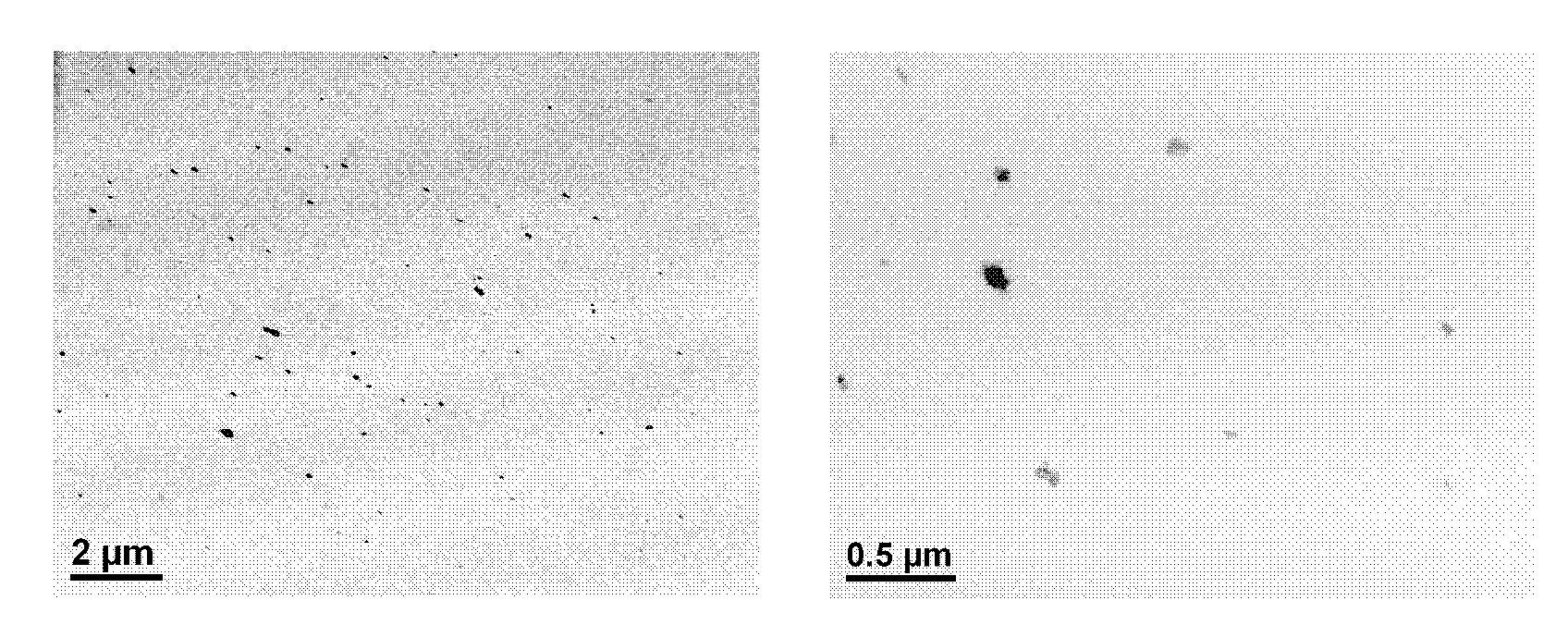

Special master batch for PC (Polycarbonate) sunlight board and application thereof

InactiveCN101921470AHigh ATO contentImprove liquidityPigment treatment with organosilicon compoundsPigment physical treatmentNanoparticleStearic acid

The invention discloses a special master batch for a PC (Polycarbonate) sunlight board and application thereof. The preparation method of the special master batch for PC sunlight board comprises the following steps of: (1) carrying out nano dispersion and modification to dispersing agent, the ATO (Arsenic Trioxide) content of which accounts for 0.1%-10% of the mass of the ATO to obtain ATO nanoparticles, wherein the dispersing agent is a silane coupling agent or stearic acid, and the ATO is stibium-doped stannic oxide; and (2) fusing and mixing the ATO nanoparticles in PC resins to prepare the special master batch for PC sunlight board, wherein the mass fraction of the ATO is 1%-50%. The master batch has high processing fluidity and is suitable for preparing the PC sunlight board with higher transparence and good heat-insulation effect.

Owner:ZHEJIANG UNIV OF TECH +1

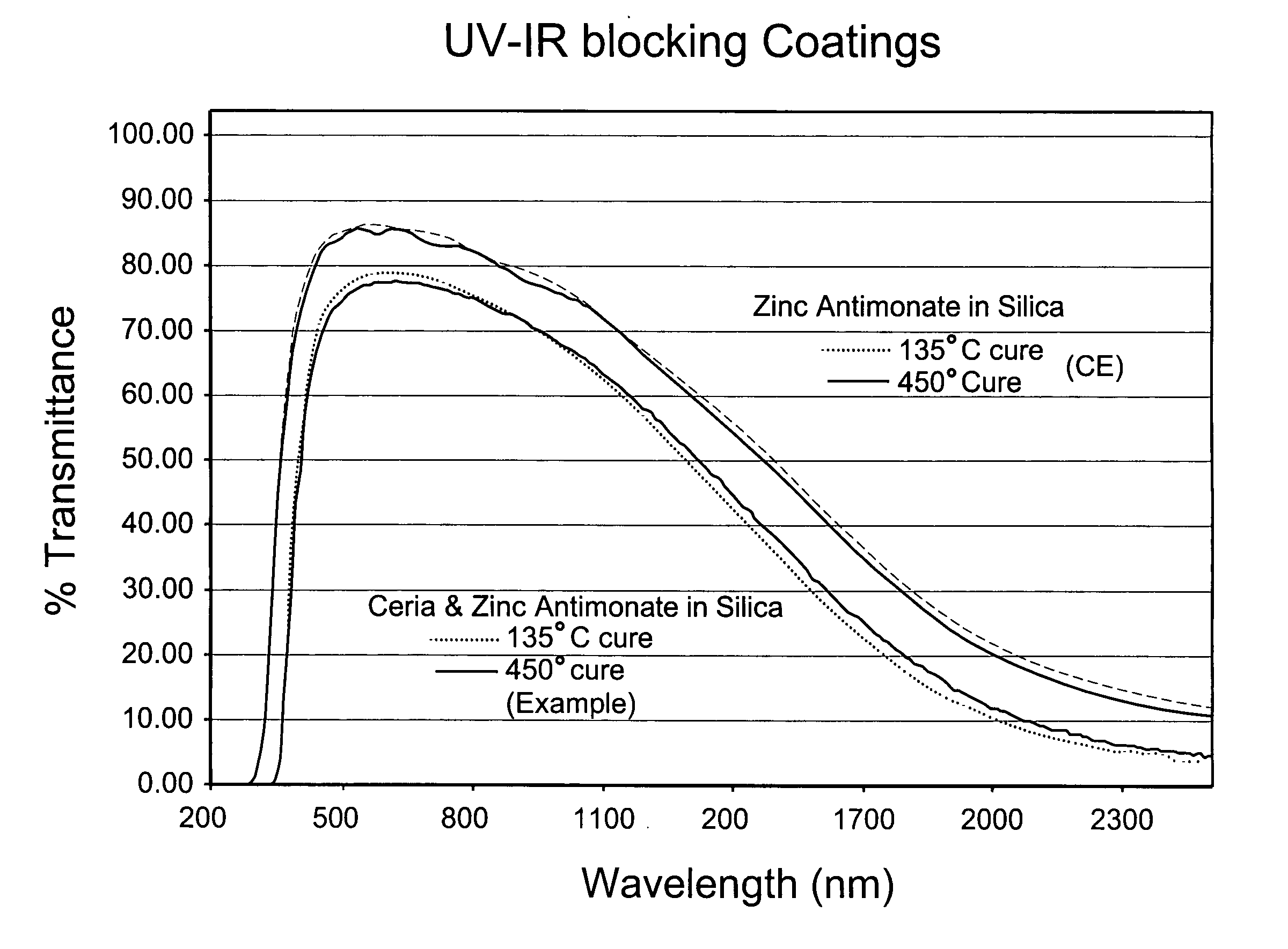

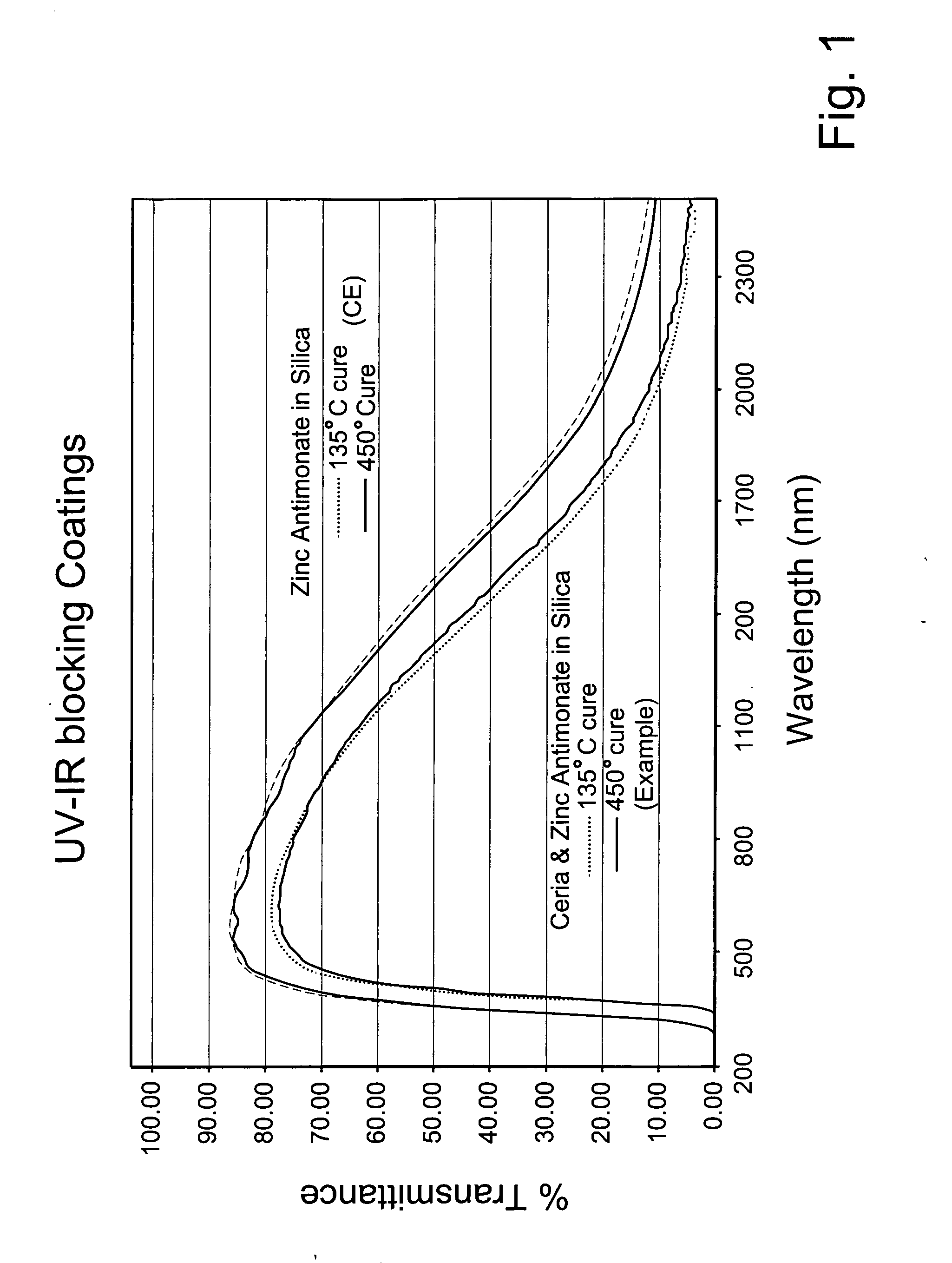

Coating with infrared and ultraviolet blocking characterstics

InactiveUS20070065670A1Resistant to high-temperaturesEffective blockingPretreated surfacesGlass/slag layered productsUltravioletSilica matrix

A composite oxide coating is provided that efficiently blocks both ultraviolet (UV) and infrared (IR) radiation. Certain embodiments of this invention relate to a coating having IR and UV blocking characteristics. In certain example embodiments, the coating includes a silica matrix, zinc antimonite, and a UV blocking material such as cerium oxide, thereby permitting the coating after application to block significant amounts of both IR and UV radiation.

Owner:GUARDIAN GLASS LLC

Ultrahigh heat-resistant polyester alloy for vehicle lamp and preparation method thereof

InactiveCN101724229AEasy to processImprove low temperature resistancePolyesterPolytetramethylene terephthalate

The invention provides an ultrahigh heat-resistant polyester alloy for a vehicle lamp, which comprises the following components in part by weight: 30 to 40 parts of PET nucleating agent blend, 30 to 50 parts of PBT, 0.5 to 0.8 parts of antioxidant, 0.6 to 1.2 parts of chain extender, 1 to 1.5 parts of dispersing aid, 10 to 20 parts of montmorillonoid, 0.5 to 0.9 part of silicone powder, 10 to 15 parts of talcpowder treated by coupling agent, 0.8 to 2 parts of antimonite and 0.8 to 2 parts of sodium dihydrogen phosphate. The polyester alloy of the invention keeps good workability, low temperature resistance, weather resistance and chemical resistance of thermoplastic polyester, improves the crystallinity and shaping workability of PET, has excellent heat resistance (the thermal deformation temperature under 0.46MPa reaches 222 DEG C) and good size stability, can replace the traditional BMC manufactured reflection component, and realizes integration of a reflector of a head lamp and a lamp body.

Owner:上海红京印实业有限公司

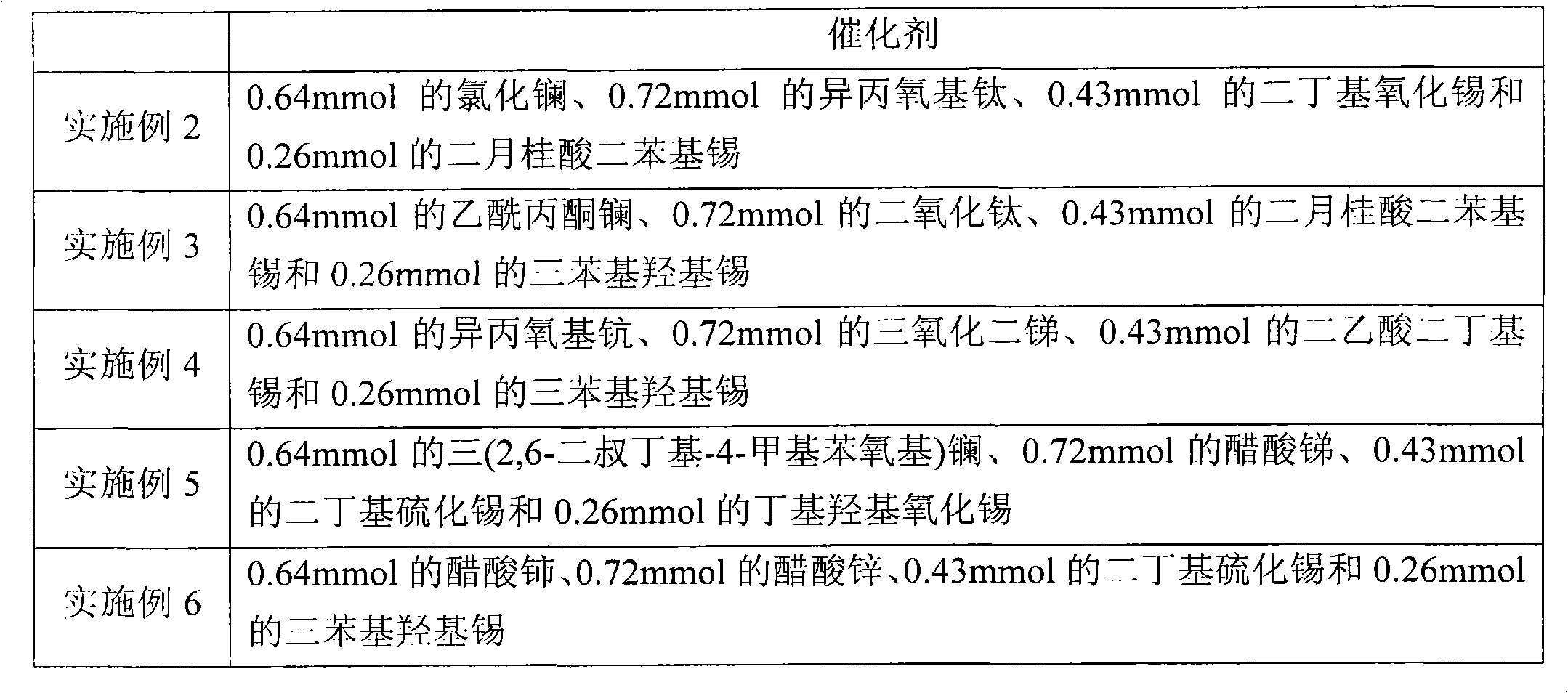

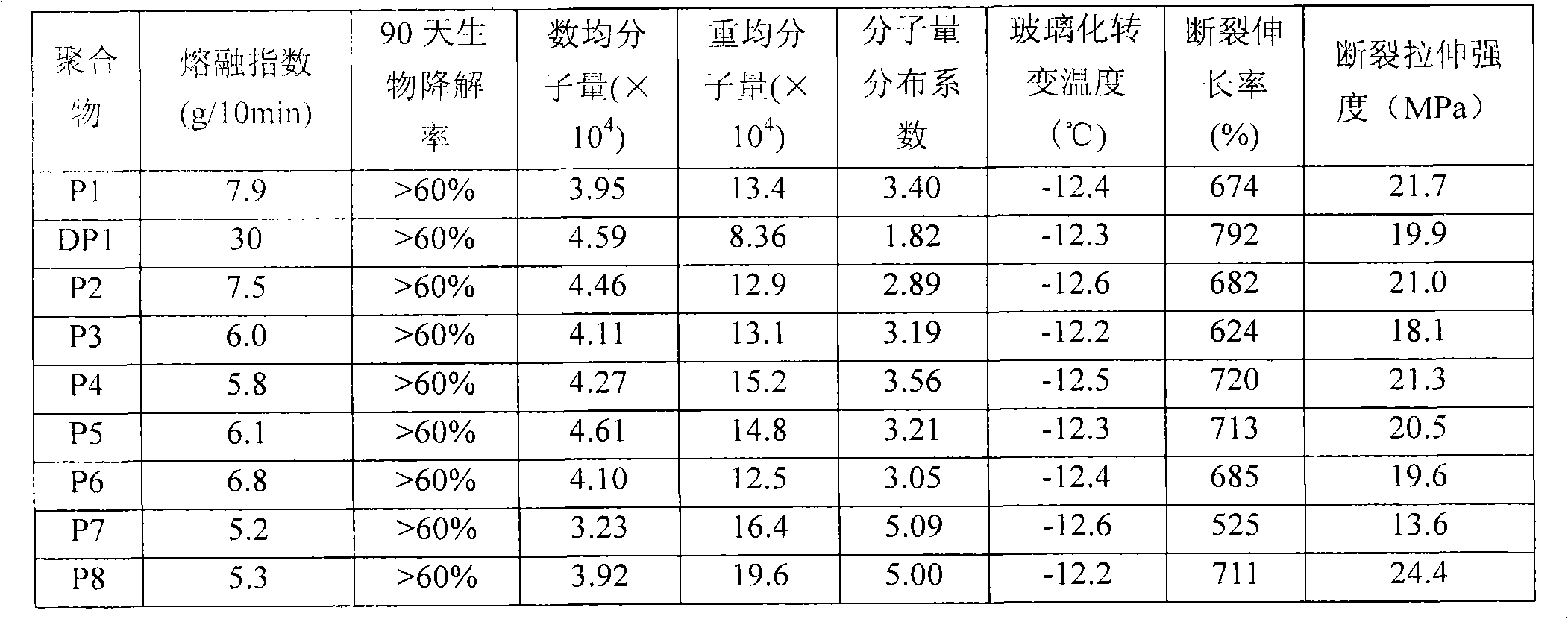

Aliphatic-aromatic copolyester and preparation method thereof

The invention relates to aliphatic-aromatic copolyester and a preparation method of the aliphatic-aromatic copolyester. The method comprises the steps of allowing an ingredient a to react with an ingredient b with the existence of a first catalyst, a second catalyst and a third catalyst, allowing an obtained reaction mixture, an ingredient c, an ingredient d and the selectively added ingredient b to react with the existence of the catalysts, and allowing an obtained reaction mixture to be subjected to condensation reaction. The first catalyst is a titanic oxide, an antimony oxide, a zinc oxide, M(OR1)n or M(-OOCR2)m; the second catalyst is a chemical compound with the chemical formula of RE(R3)3; the third catalyst is an organo-tin compound; the ingredient a contains aromatic dibasic acid and / or dibasic anhydride; the ingredient b is aliphatic dibasic alcohol; the ingredient c is aliphatic dibasic acid and / or dibasic anhydride; and the ingredient d is polyhydric alcohol, polybasic carboxylic acid or polybasic carboxylic anhydride with the degree of functionality greater than 2. The aliphatic-aromatic copolyester prepared according to the method is lower in melt index, and better in biodegradability and tensile mechanical property.

Owner:CHINA PETROLEUM & CHEM CORP +1

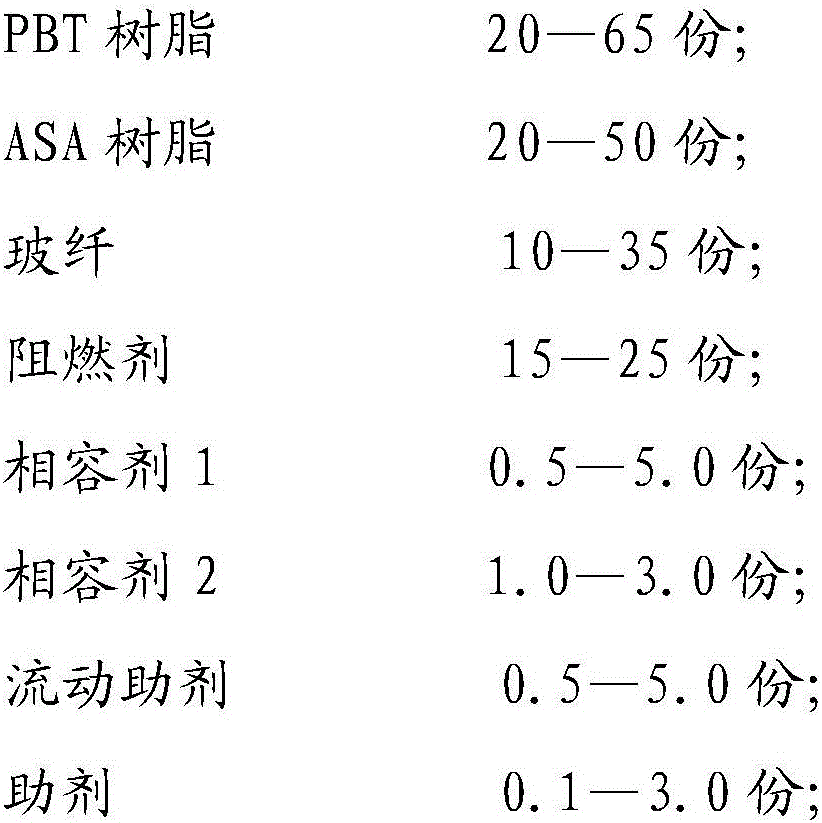

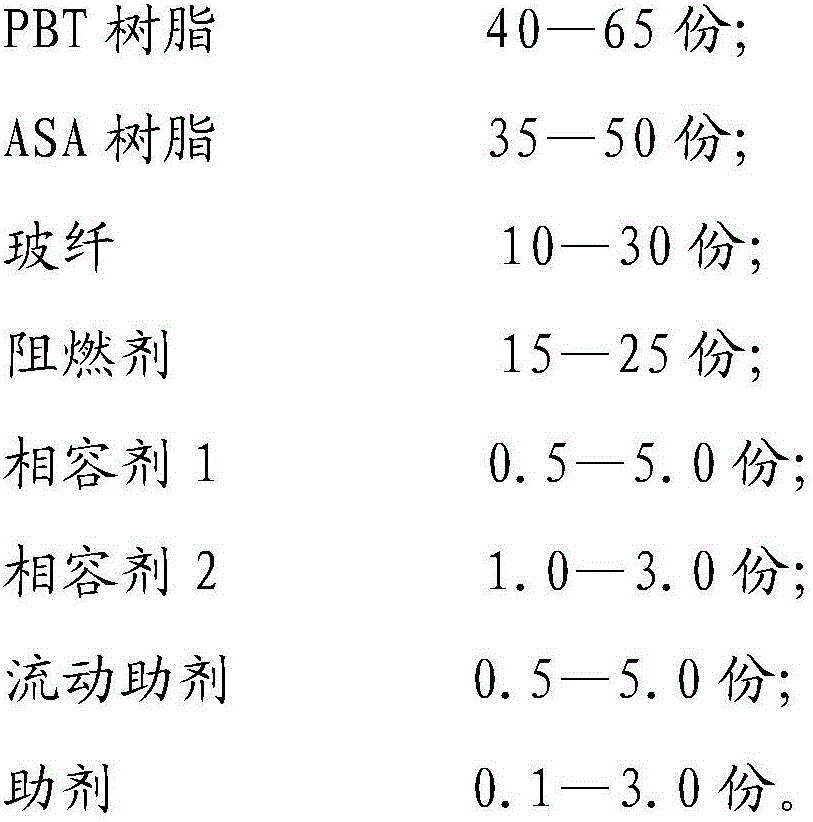

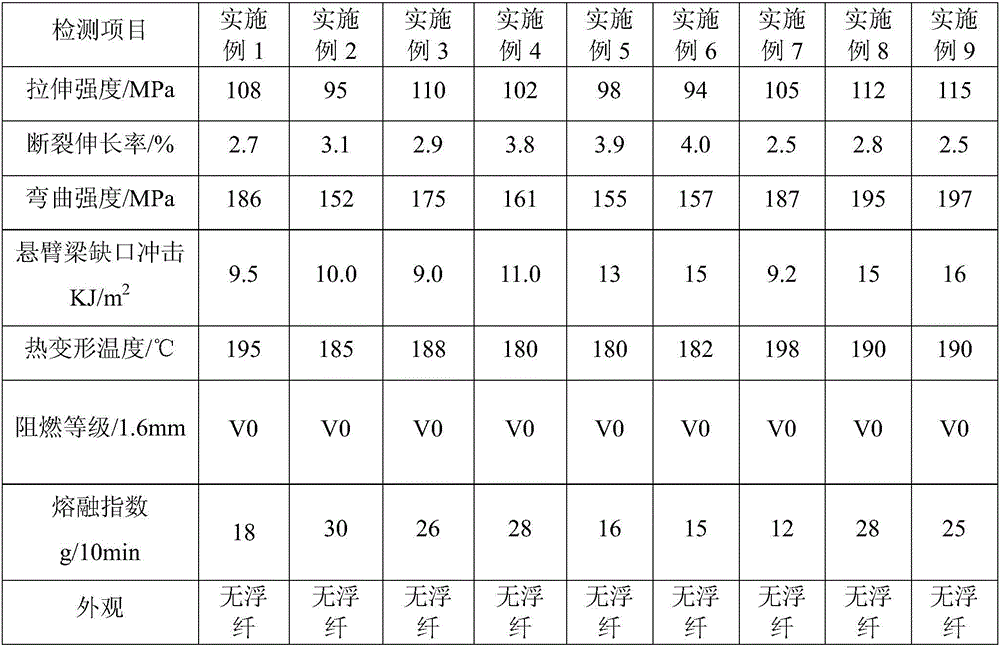

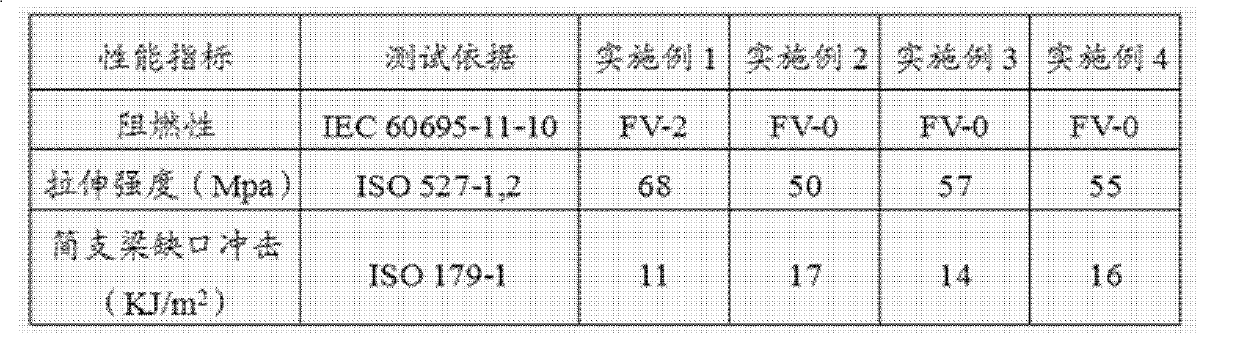

PBT/ASA alloy material and preparing method thereof

ActiveCN106589844AImprove flame retardant performanceImprove impact resistanceGlass fiberPolystyrene

The invention discloses a PBT / ASA alloy material and a preparing method thereof. The alloy material is prepared from, by weight, 20-65 parts of PBT resin, 20-50 parts of ASA resin, 10-35 parts of glass fiber, 15-25 parts of fire retardant, 0.5-5.0 parts of first compatilizer, 1.0-3.0 parts of second compatilizer, 0.5-5.0 parts of a flow promoting agent and 0.1-3.0 parts of auxiliary, wherein the fire retardant is compounded by main fire retardant brominated polystyrene and fire retardant synergist sodium antimonite according to a mass ratio of (10-20):(4-5), the first compatilizer is a styrene copolymer, and the second compatilizer is bisphenol A type epoxy resin with an epoxy value of 0.5-1.5. The prepared PBT / ASA alloy material has the functions of both flame retardancy and resistance to shocks at the same time, and the material is not prone to warpage and good in comprehensive mechanical performance.

Owner:GUANGZHOU KEYUAN INNOVATIVE MATERIALS

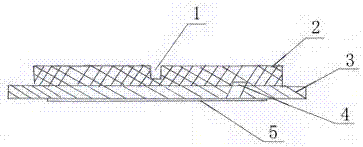

Lead niobium antimonite-containing five-element piezoelectric ceramics material for driver and preparation thereof

InactiveCN101302105AThe process steps are simpleGood repeatabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive/magnetostrictive devicesElectromechanical coupling coefficientNiobium

The invention discloses a pentabasic piezoelectric ceramic material containing antimonite lead for a drive, consisting of a material expressed by a general formula of xPb ( Mg1 / 2W1 / 2)O3-yPb (Sb1 / 2Nb1 / 2)O3- ( 0.41-x-y)Pb ( Ni1 / 3 Nb2 / 3) O3-Pb0.59 (Zr z Ti 0.59-x )O3, in the formula, the x is more than or equal to 0.05 and less than or equal to 0.07, the y is more than 0 or equal to o and less than or equal to 0.04, and the z is more than or equal to 0.30 and less than or equal to 0.50. A preparing method comprises the processing steps of ingredient synthesis, precalcination, granulation, pressing, evacuation, sintering, silver calcination and polarization, and the processing steps are simple, the repeatability is good and the rate of finished products is high. Piezoelectric ceramic made by the invention passes the test, the tested result shows that the dielectric coefficient is between 600 and 850 pc / N, the electromechanical coupling factor is between 0.55 and 0.75, and the relative dielectric constant in room temperature is between 3500 and 5000. The pentabasic piezoelectric ceramic material can be used for preparing a vibration transducer, a controller shell, a dynamic fuel injected nozzle, a high-power ultrasonic device, a high-temperature and high-frequency vibrometer, a high-temperature flowmeter, a high-temperature resistant swarming buzzer, a high-temperature sensor, a drive and so on arranged in an automobile.

Owner:SHAANXI NORMAL UNIV

Basic aqueous easily-soluble modified polyesters and preparation method

The present invention discloses alkali soluble modified polyester and the preparation method. The production method includes esterification and condensation reactions and is characterized in that in the reaction, terephthalic acid dimethyl ester or terephthalic acid and ethylene alcohol are first component and second component, and m-phthalic acid ester with metallic sulphonate respectively is thirdcomponent; metatitanic acid ester is catalyst, phosphorus compound is stabilizer and alkali metal compound is assistant additive. The polyester copolymer provided by the present invention is characterized in that the viscosity is 0.40 to 0.65dl / g (including 0.40dl / g, 0.55dl / g, 0.65dl / g); wherein, the content of stibium compound is less than or equal to 100ppm in the unit of stibium atom relatively to polyester. The polyester copolymer produced by the present invention has excellent heat resistance, full alkali solubility and good spinning performance.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Polybutylece terephthalate (PBT) engineering plastics as well as preparation method and application thereof

InactiveCN102040810AGlow wire test value increasedImproved tracking indexPlastic/resin/waxes insulatorsTetrabromobisphenol AAntioxidant

The invention is suitable for the technical field of high polymer materials and provides polybutylece terephthalate (PBT) engineering plastics as well as a preparation method and an application thereof. The PBT engineering plastics comprise the following components in parts by weight: 45-75 parts of PBT resins, 15-30 parts of fire retardants, 4-10 parts of flame retardant synergist, 0.8-1.2 parts of lubricating agents, 28-33 parts of glass fibers, 3-5 parts of flexibilizer, and 0.2-0.5 part of antioxidant, wherein the fire retardants are two or more of decabromdiphenylethane (DBDPE), brominated triazine, phosphorus-nitrogen based flame retardant and tetrabromobisphenol A; and the flame retardant synergist is antimonous oxide or sodium antimonite. The glowing filament test value, the proof tracking index (PTI) and the like of the PBT engineering plastics can be greatly improved by the modification effect of the flame retardants and the flame retardant synergist. In the preparation method of the PBT engineering plastics, sources of the raw materials are wide, the cost is low, the preparation process is simple, the production process is smooth and controllable, and the productivity effect is high; and the preparation method of the PBT engineering plastics is suitable for industrial production.

Owner:SHENZHEN KEJU NEW MATERIAL

Batch composition for producing low air bubble content, high permeability glass

The invention discloses a fitting material composition to manufacture low-foam content and high transmission rate glass, which consists of necessary antimonite and selectable sulfate, wherein the antimonite can be antimony oxide, sodium antimonite or sodium pyroantimoniate; the sulfate is sodium sulfate, calcium sulfate and potassium sulfate. The weight percentage of antimonite corresponding to Sb2O3 is not less than 0.05% and weight percentage of sulfate corresponding to SO3 is not over 0.8%. The invention is fit for non-floating manufacturing pattern of glass.

Owner:江苏华东耀皮玻璃有限公司

Catalyst system and process for preparing of polyester resins, fibre, filaments and yarn using said catalyst system

InactiveUS20130184414A1Reduce polymerization timeReduce generationMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsYarnPolyester resin

The present invention relates to a process for preparation of polyester resin in the presence of a novel catalyst system comprising an antimony compound and inorganic tin compound. The present invention also relates to a catalyst system for the preparation of polyester comprising an antimony compound and inorganic tin compound which reduces the polymerization time at all stages of polyester synthesis and reduces the generation of degradation product. This invention further relates to polyester resin with improved L color having significant importance in end-use applications.

Owner:RELIANCE INDUSTRIES LIMITED

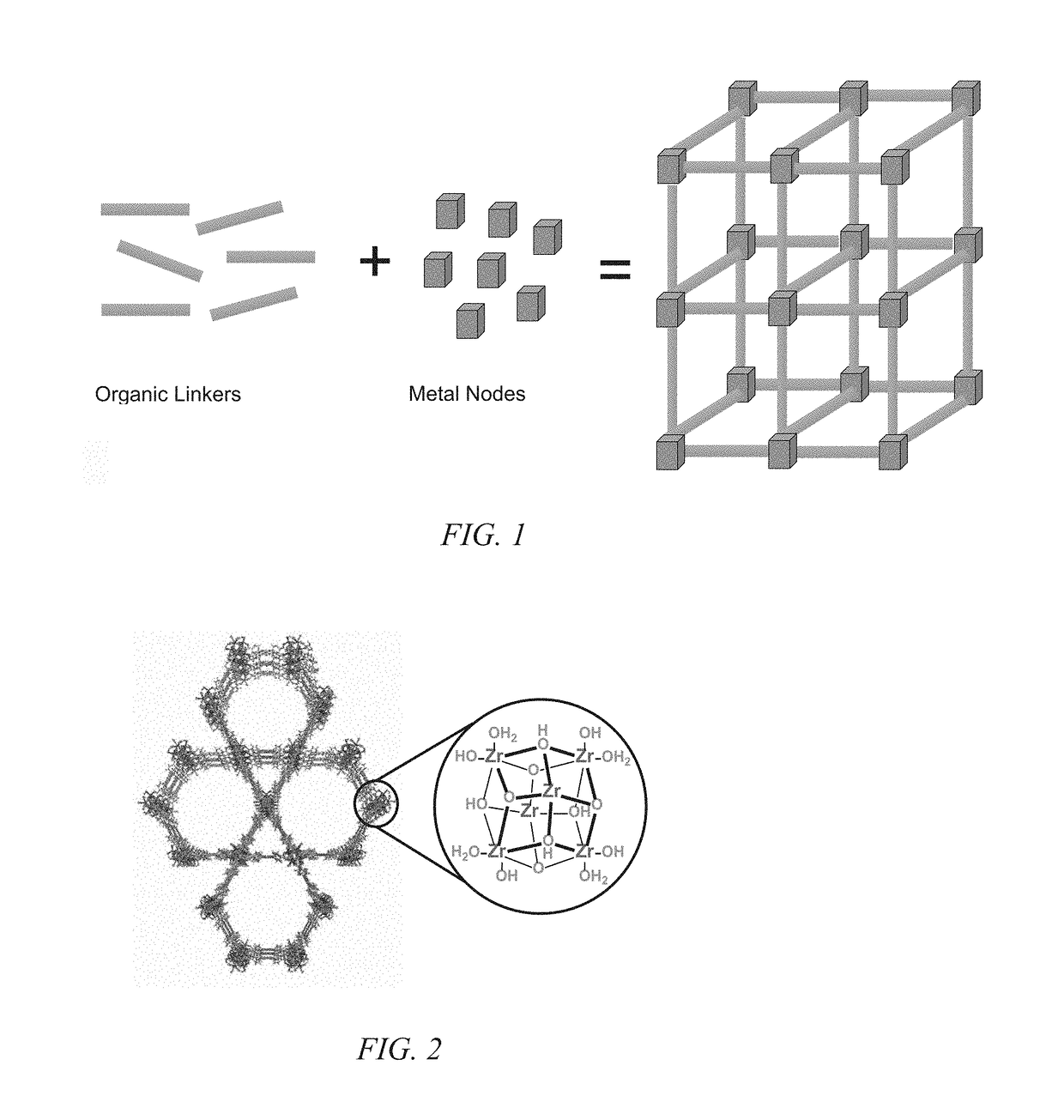

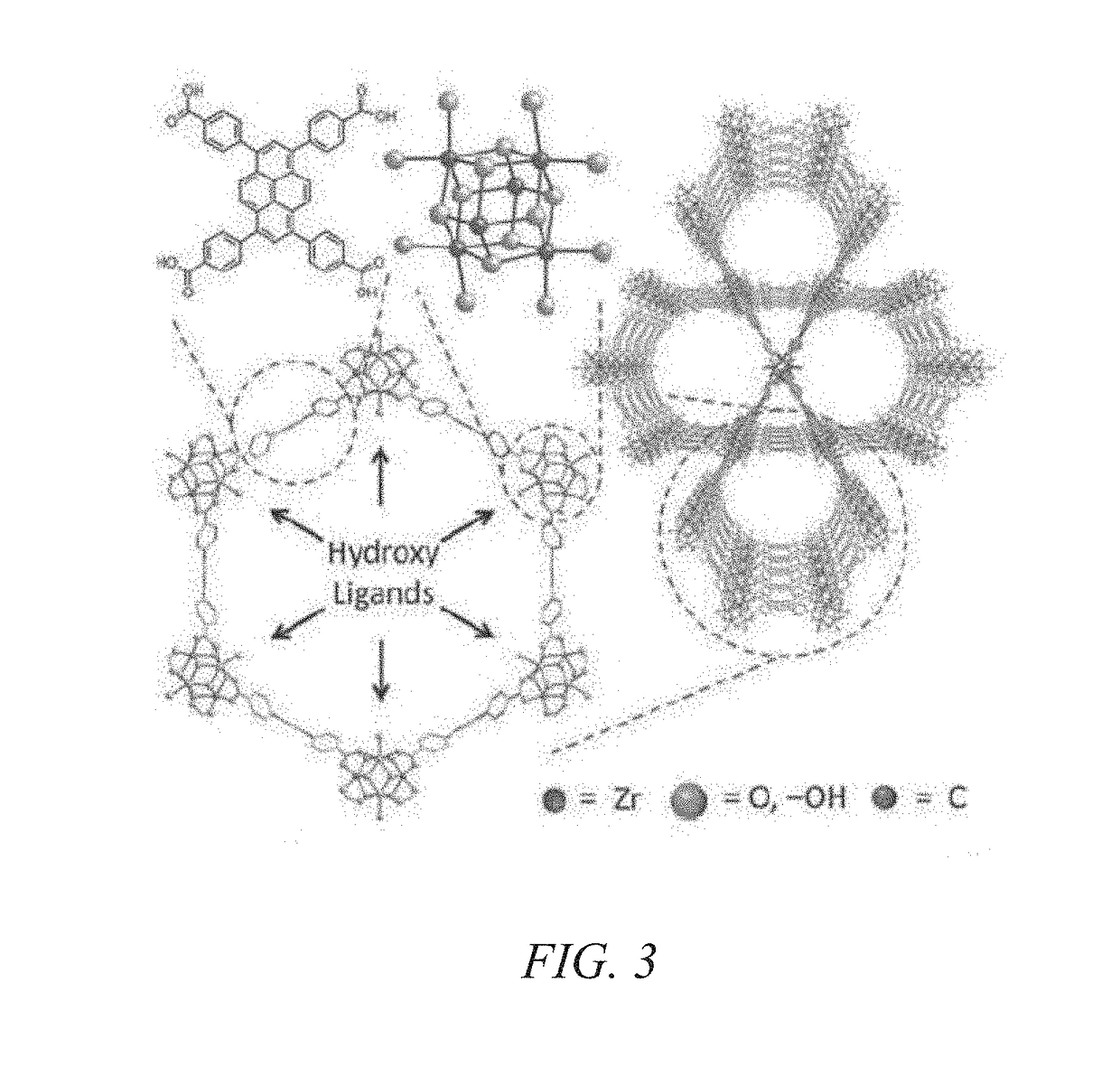

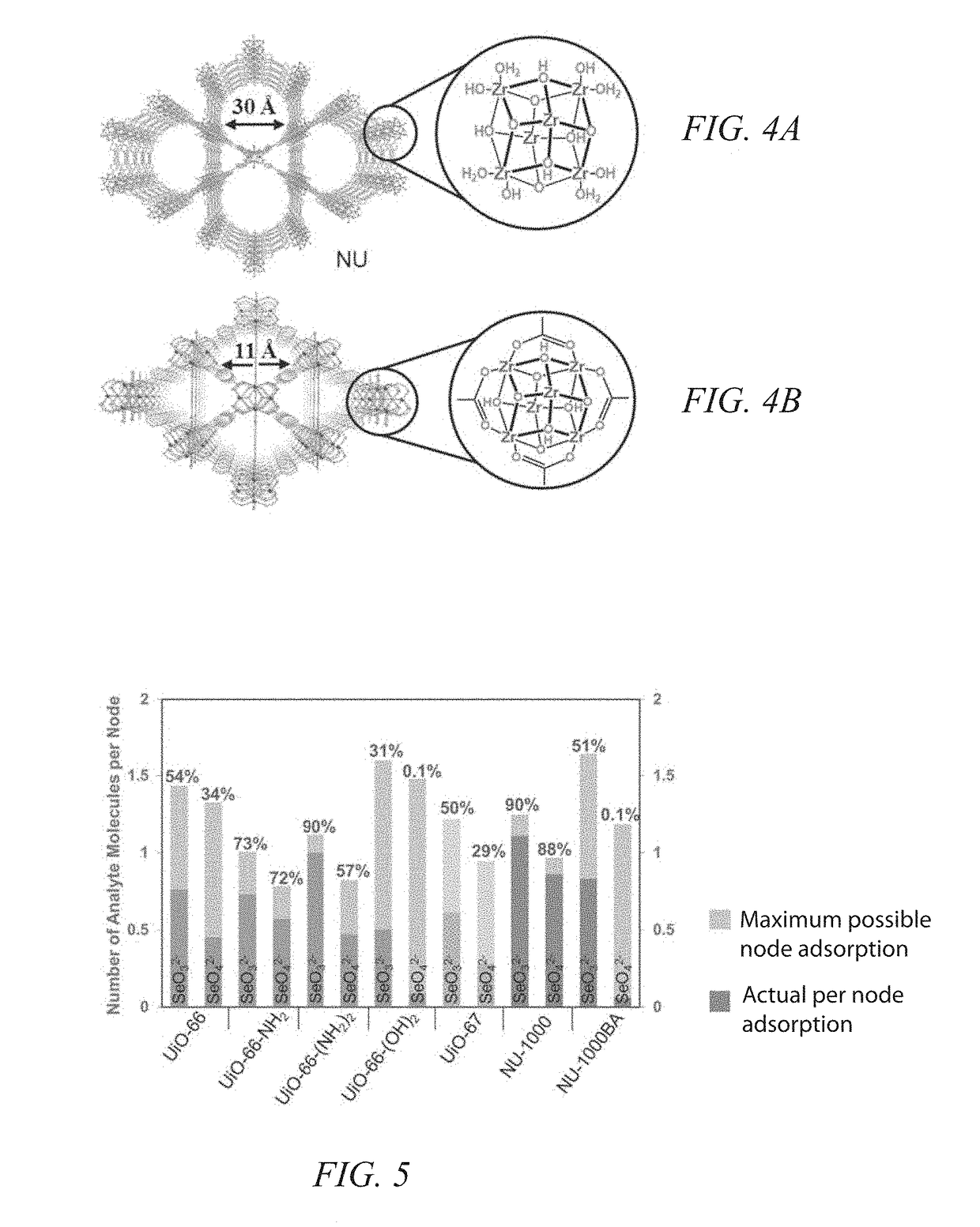

Metal-Organic Frameworks for Adsorption of Liquid Phase Compounds

ActiveUS20180134581A1Reduce concentrationReducing oxy-anion concentrationWater/sewage treatment by ion-exchangeWaste water treatment from gaseous effluentsChemical speciesMetal-organic framework

The present invention provides for the use of a metal-organic framework (MOF) in removing particular chemical species or compounds, in particular oxy-anions, from a liquid or liquid stream. In some embodiments, the MOF is a Zr-based MOF, such as NU-1000, and the oxy-anions that are removed include, include, for example, oxy-anions of selenium, including selenite (SeO32−) and selenate (SeO42−); oxy-anions of antimony, including oxy-anions in either the Sb[III] (antimonite) or the Sb[V] (antimonate) redox state; and oxy-anions of lead, including oxy-anions in either the Pb[II] or the Pb[IV] redox state, such as Pb(OH)62−, Pb(OH)64−, PbO32−, and PbO22−. The Zr-based MOF, including NU-1000 can be used to remove these oxy-anions from various liquid streams in industrial processes such as a nuclear and fossil fuel power plants, including the latter's flue gas desulfurization system.

Owner:NORTHWESTERN UNIV

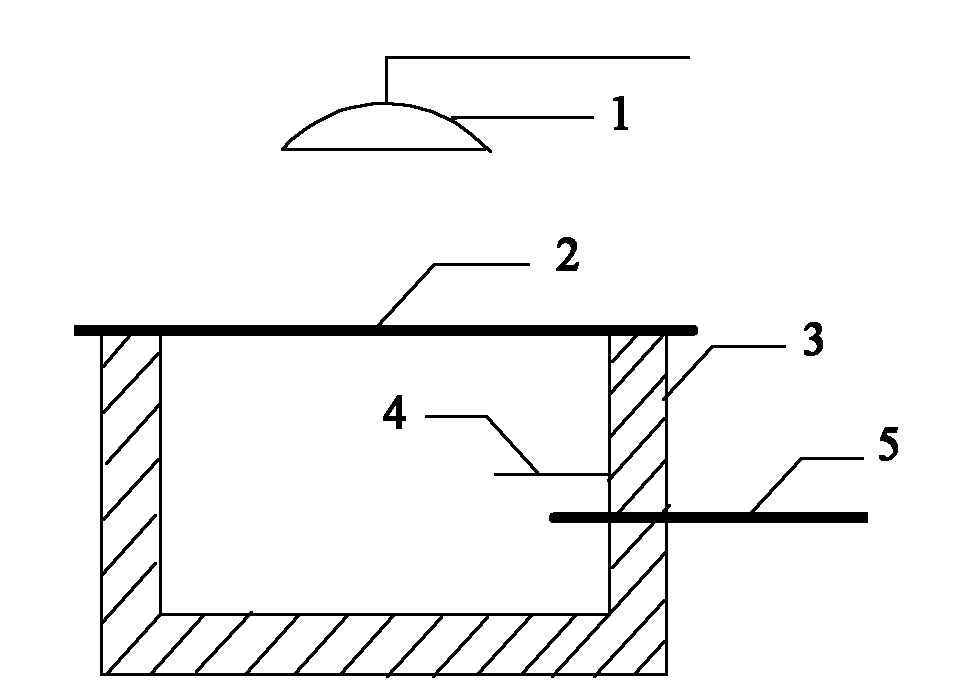

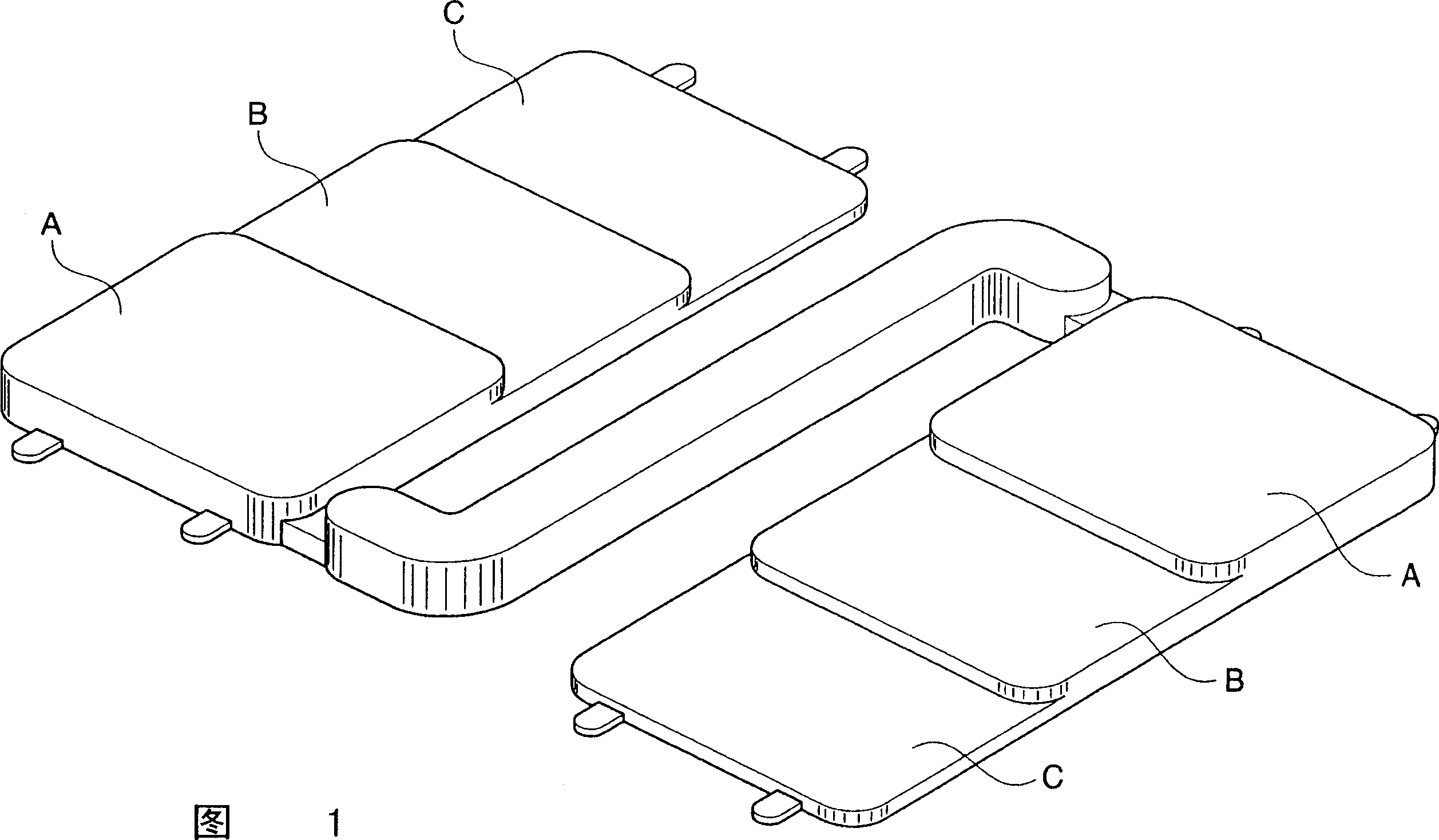

Environment-friendly high-efficiency automobile ceramic brake pad and production method thereof

InactiveCN108006120AImprove braking effectGuaranteed uptimeOther chemical processesFriction liningCarbon graphiteSulfide

The invention discloses an environment-friendly high-efficiency automobile ceramic brake pad and a production method thereof. The automobile ceramic brake pad comprises a friction layer (2), a steel backing (3), a silencing sheet (5), an alarm card (4) and a notch (1), and is characterized in that the friction layer comprises, by weight, 7-8 parts of aramid fiber, 5-8 parts of ceramic fiber, 5-6 parts of 98% copper fiber, 1-2 parts of potassium titanate whisker, 23.2-33.5 parts of calcium carbonate whisker, 5-7 parts of aluminum oxide, 1-1.9 parts of antimony sulfide, 1.5-1.7 parts of 40-meshhigh-carbon graphite, 7.3-21.3 parts of calcined petroleum coke, 2-2.8 parts of acrylonitrile butadiene rubber powder, 1.6-3 parts of vermiculite, 5.7-15.7 parts of frictional powder, 4.2-4.75 parts of barite powder, 22.2-37.5 parts of light calcium, and 5 parts of phenolic resin. The environment-friendly high-efficiency automobile ceramic brake pad has the stable friction coefficient, good thermal stability, low thermal conductivity and low thermal attenuation properties and has the advantages of high temperature resistance, abrasion resistance, braking stability, no damage to a brake disk, environmental protection, no noise, long service life and the like.

Owner:SICHUAN PROVINCE NANBU JIALING POWDER METALLURGY

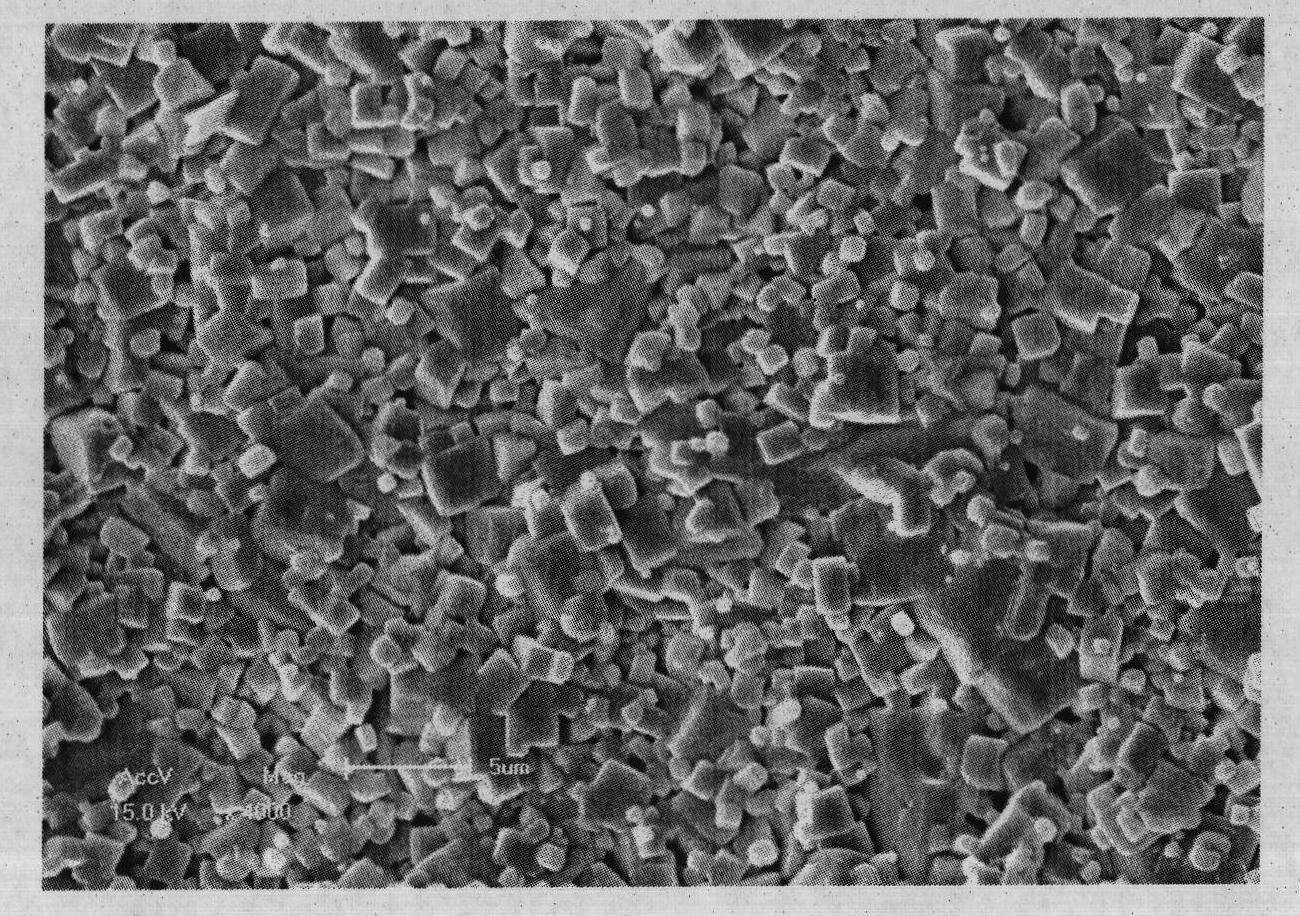

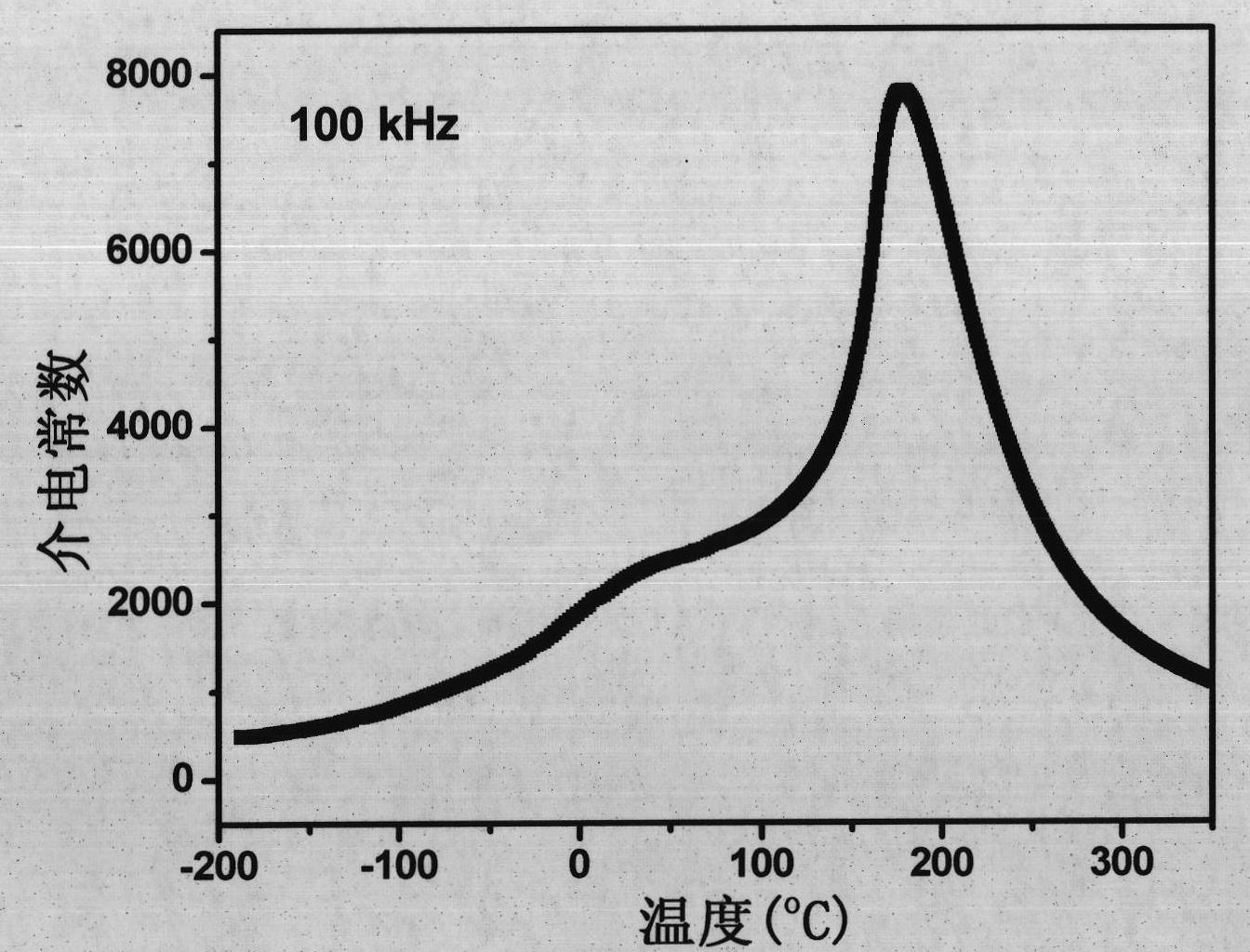

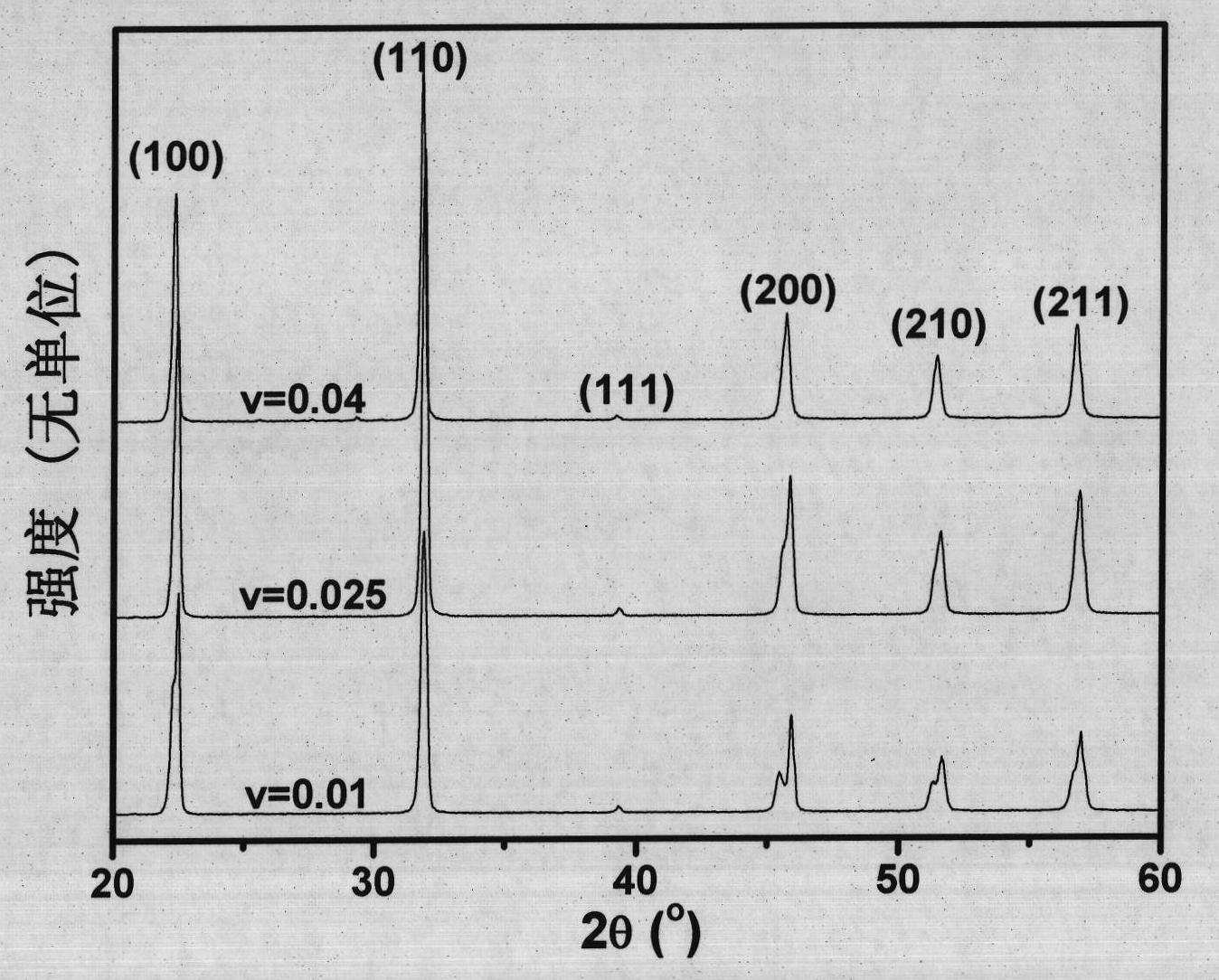

Alkali metal niobium-tantalum antimonite-based leadless piezoelectric ceramic and preparation method thereof

InactiveCN101962292AImprove performanceLead-free system with good performance has good environmental compatibilityNiobiumCeramic

The invention discloses alkali metal niobium-tantalum antimonite-based leadless piezoelectric ceramic modified by barium-based cubic perovskite and a preparation method thereof. The alkali metal niobium-tantalum antimonite-based leadless piezoelectric ceramic is indicated by a general formula of (1-u) [(NaxKy) (Nbx+y-zSbz)O3+(1-x-y-v)LiTaO3+vBaMeO3]+uM. The alkali metal niobium-tantalum antimonite-based leadless piezoelectric ceramic has a morphotropic phase boundary of a rhombic ferroelectric phase and a square ferroelectric phase as well as good sintering property and piezoelectric property, is good-performance leadless series environmental harmony piezoelectric ceramic, can replace the traditional partial leady piezoelectric ceramic and can be obtained by adopting the traditional piezoelectric ceramic preparation technology and industrial materials and has practicability.

Owner:HEFEI UNIV OF TECH

Foaming agent for preparation of hollow glass beads and application of foaming agent

ActiveCN102849947AImprove yieldHigh yieldGlass shaping apparatusGlass productionPotassium nitrateFoaming agent

The invention discloses a foaming agent for preparation of hollow glass beads. The foaming agent which serves as a component of a glass mixed batch is a mixture of sodium antimonite NaSb(OH)6 with sodium nitrate NaNO3 or potassium nitrate KNO3, wherein the mass ratio of the sodium antimonite NaSb(OH)6 to the sodium nitrate NaNO3 or potassium nitrate KNO3 is 1: (4-8). The foaming agent is used for preparation of high-performance hollow glass beads by means of the glass powder method, and usage of the foaming agent accounts for 0.1-1.5% of the total mass of the glass mixed batch. The prepared hollow glass beads is 0.15-0.7g / cm<3> in density, 3-150MPa in compressive strength, equal to or smaller than 80 micrometers in particle diameter, equal to or larger than 95% in floating rate and larger than 50% in yield weight. By means of the foaming agent for preparation of hollow glass beads, product performance of the hollow glass beads can be precisely controlled, the rate of finished products and yield of the hollow glass beads are greatly increased, cost is reduced, and consequently, the high-performance hollow glass beads can be applied to more fields of military and civilian products to promote mass production of the high-performance hollow glass beads.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

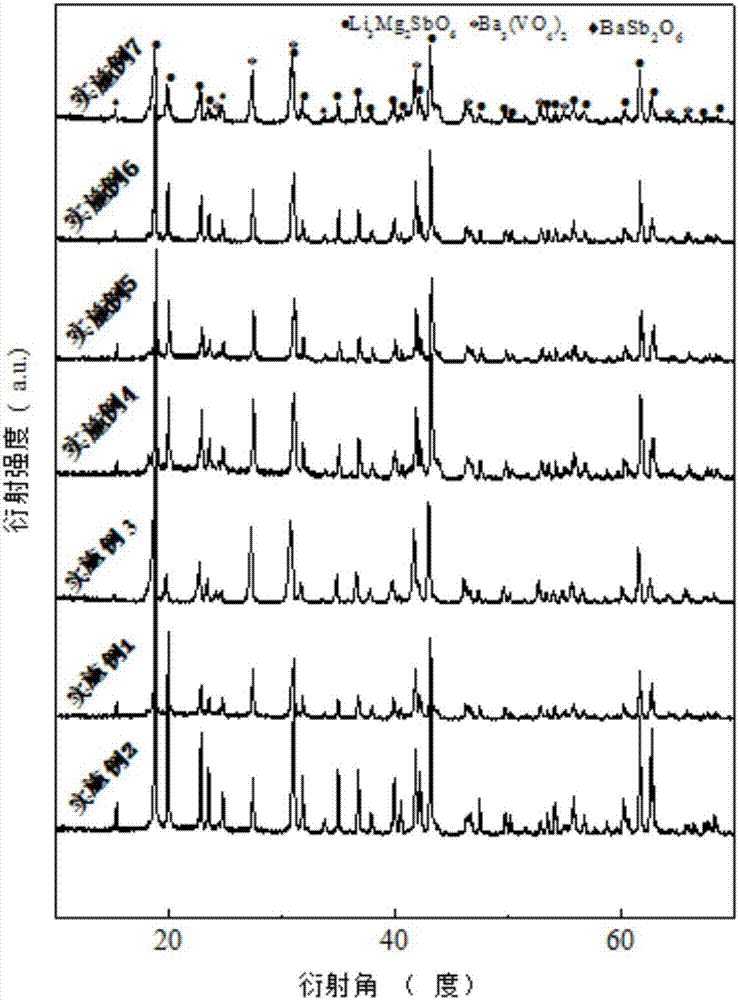

Temperature stable type magnesium antimonite lithium base medium microwave composite ceramic and its preparation method

ActiveCN107235711AImprove temperature stabilityExcellent microwave dielectric propertiesElectricityLithium

The invention discloses a temperature stable type magnesium antimonite lithium base medium microwave composite ceramic and its preparation method. A phase of a composite ceramic comprises Li3Mg2SbO6 phase in a rock salt structure, Ba3 (VO4)2 phase in an orthorhombic structure and a BaSb2O6 in a trilateral structure, wherein Li3Mg2SbO6 content is 54wt%-78wt%, Ba3 (VO4)2 content is 13wt%-38wt%, and the rest is BaSb2O6. Through adding Ba3 (VO4)2 presintering powder in the Li3Mg2SbO6 main powder body, the composite ceramic inhibits the rupturing of Li3Mg2SbO6, improves its temperature stability, and acquires a new material with good microwave dielectric property; the dielectric constant is 9.0-12.1, the quality factor is 18400-45100 GHz, and the resonate frequency temperature coefficient is -9.0 to +7.0 ppm / DEG C. The preparation method is rich in raw materials, simple in technique, and good for industrial production.

Owner:XIAN UNIV OF POSTS & TELECOMM +1

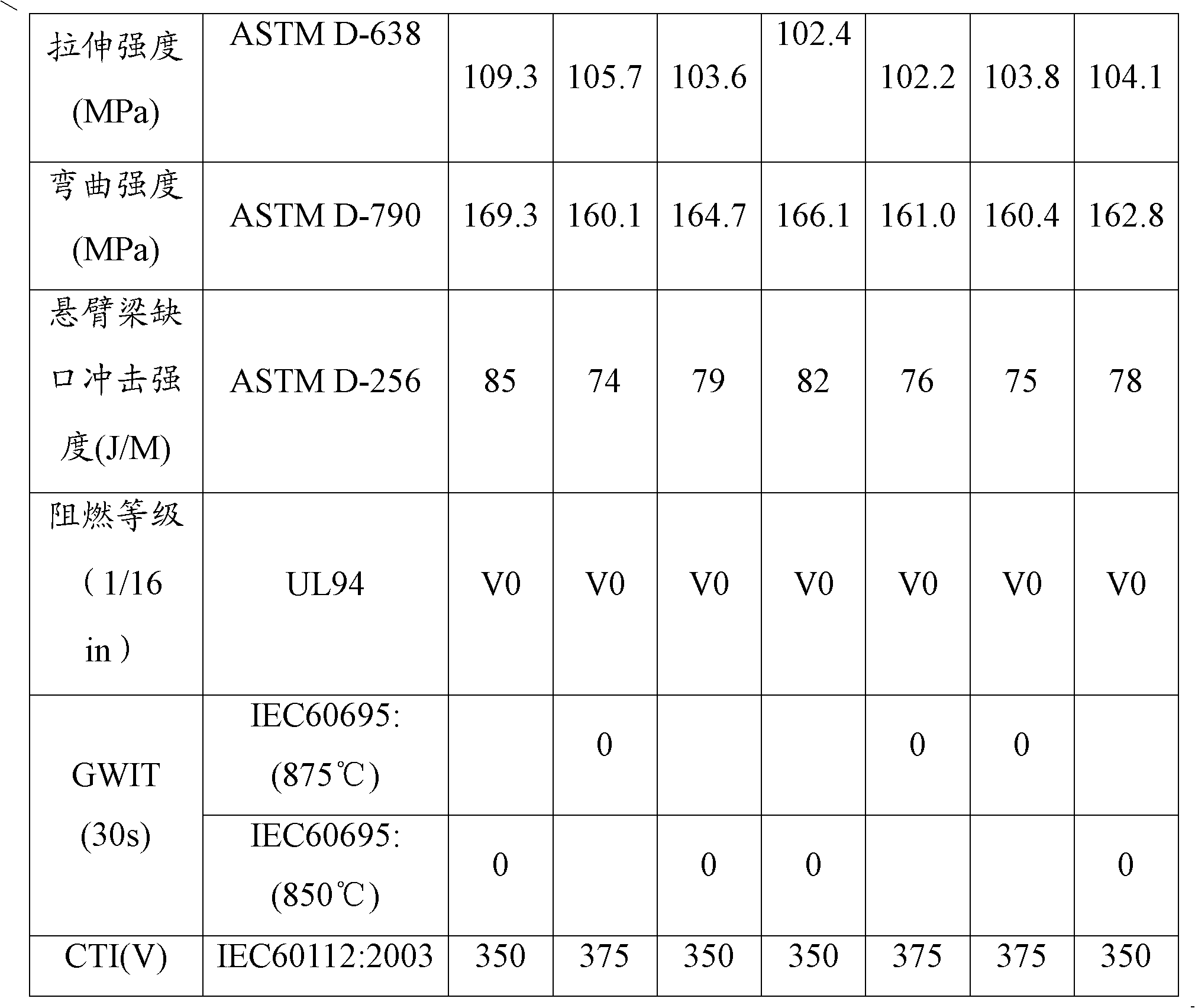

Flame-retardant reinforced PBT (polybutylene terephthalate) plastic meeting requirement for incombustibility of glow wire at temperature of 850 DEG C and preparation method thereof

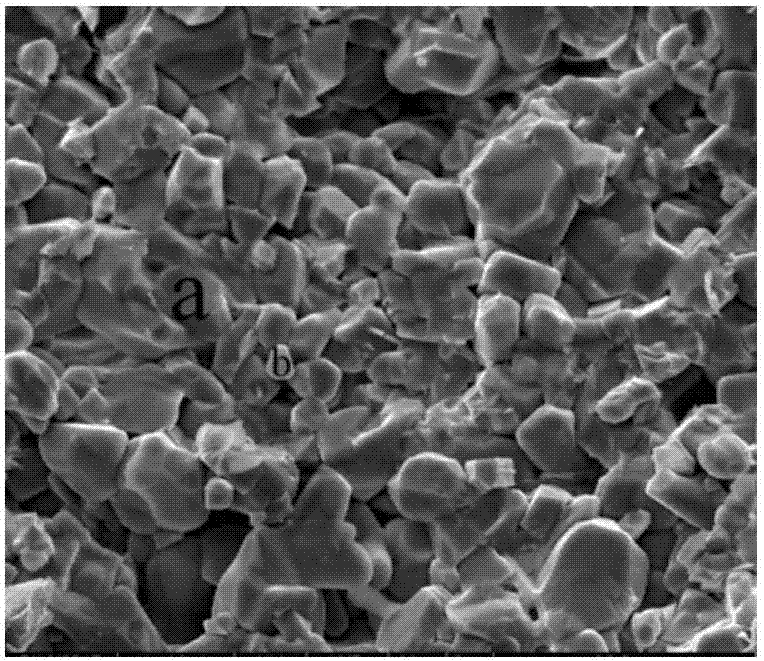

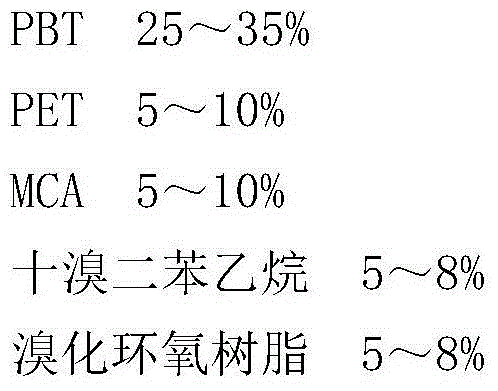

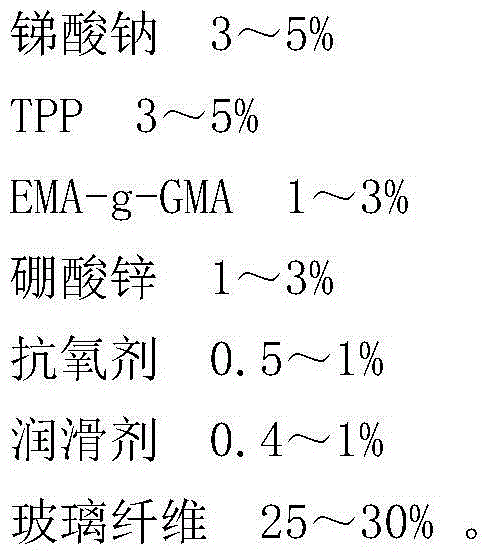

The invention discloses flame-retardant reinforced PBT (polybutylene terephthalate) plastic meeting the requirement for incombustibility of a glow wire at the temperature of 850 DEG C. The plastic comprises the following components in percentage by weight: 25-35% of PBT, 5-10% of PET (polyethylene terephthalate), 5-10% of MCA (methyl cyanoacrylate), 5-8% of decabromodiphenyl ethane, 5-8% of brominated epoxy resin, 3-5% of sodium antimonite, 3-5% of TPP (triphenyl phosphate), 1-3% of EMA-g-GMA, 1-3% of zinc borate, 0.5-1% of antioxidants, 0.4-1% of lubricants and 25-30% of glass fiber. The PBT plastic is prepared from multiple flame retardants in a compounding mode, the flame-retardant efficiency is improved, the use quantity of the flame retardants is reduced, the flame retardance and the mechanical performance are both considered, the requirement that the glow wire does not combust at the temperature of 850 DEG C can be met, the requirement for the mechanical performance is also met and the PBT plastic is suitable for practical use.

Owner:GUANGDONG SHUNDE SHUNYAN NEW MATERIALS

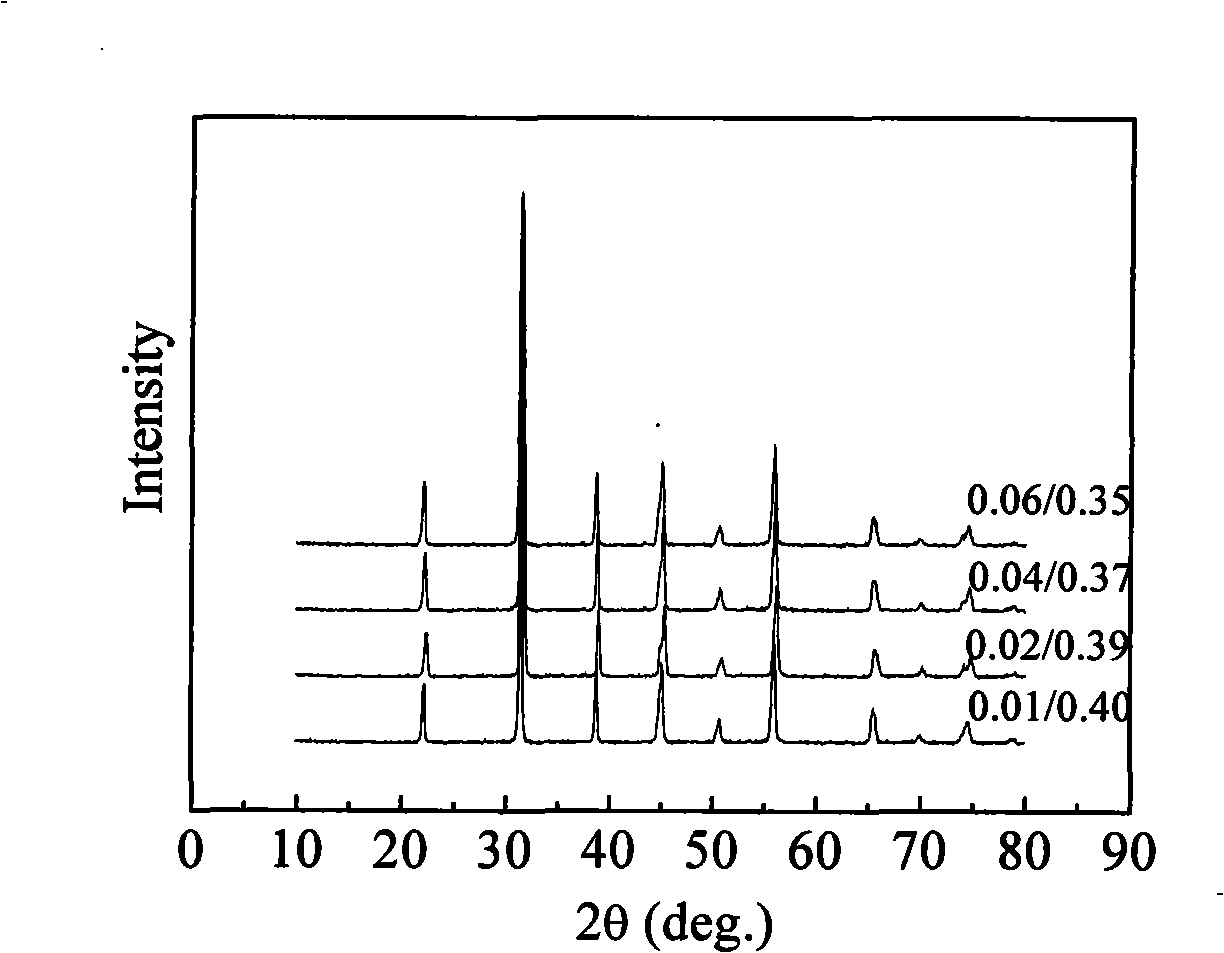

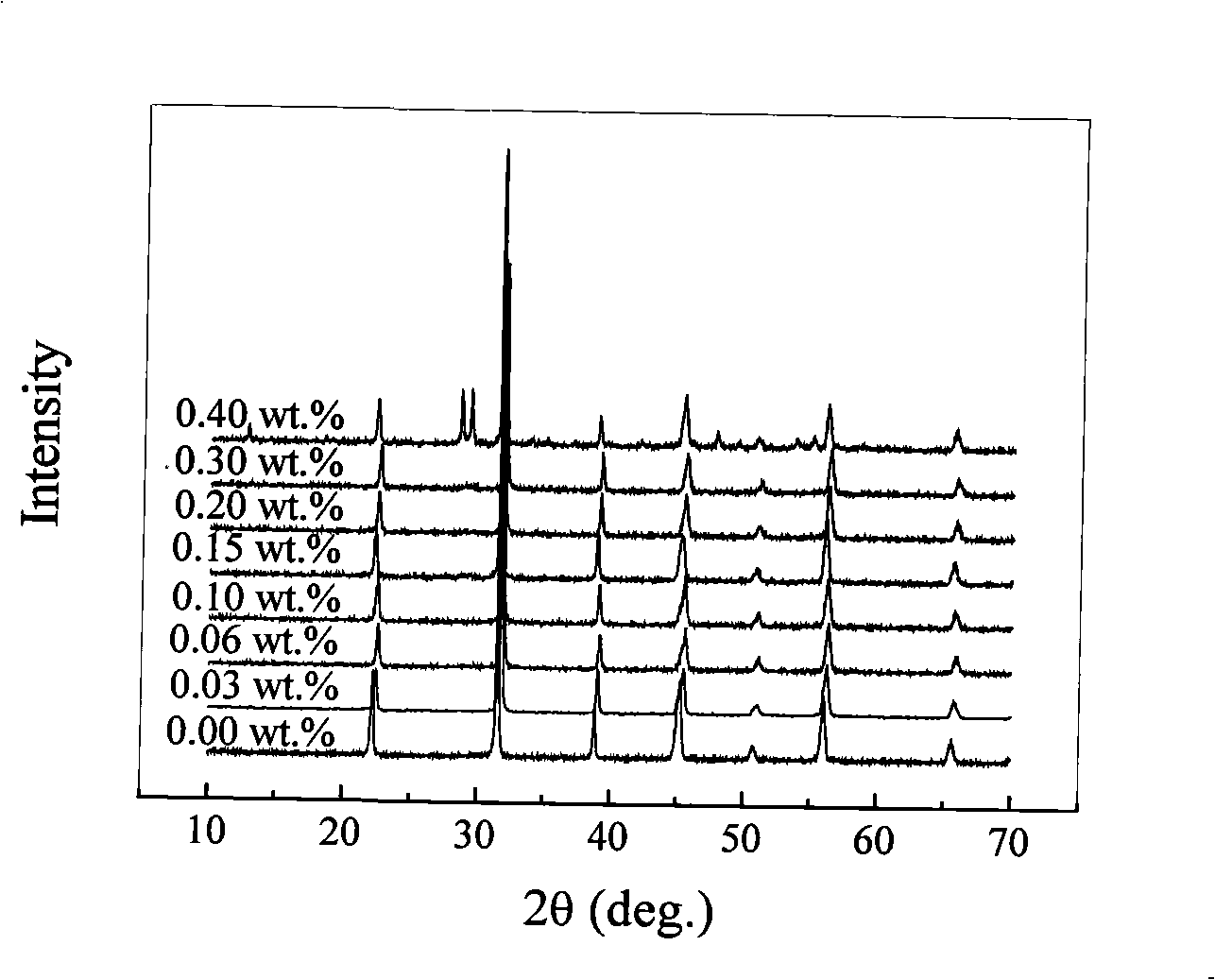

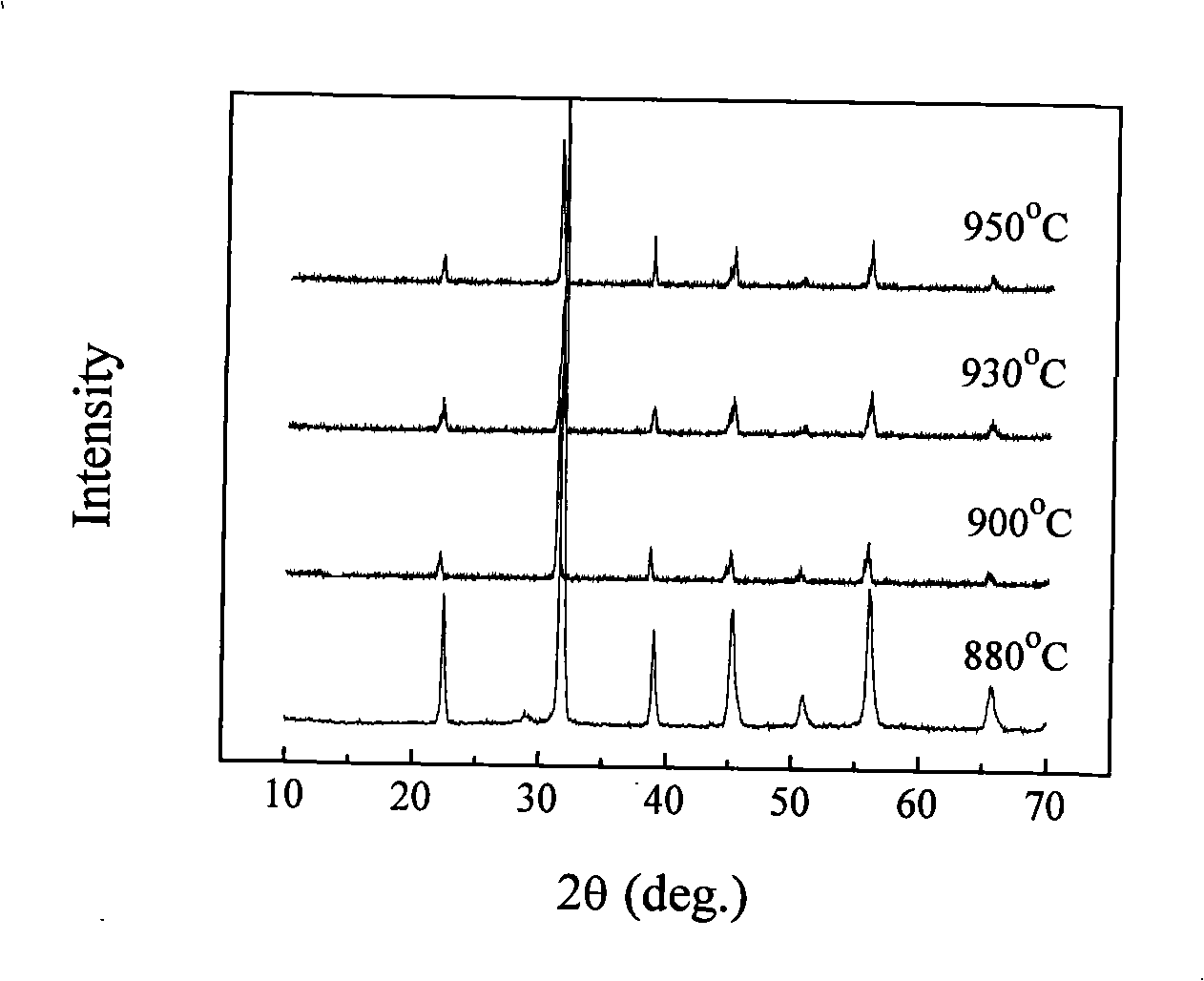

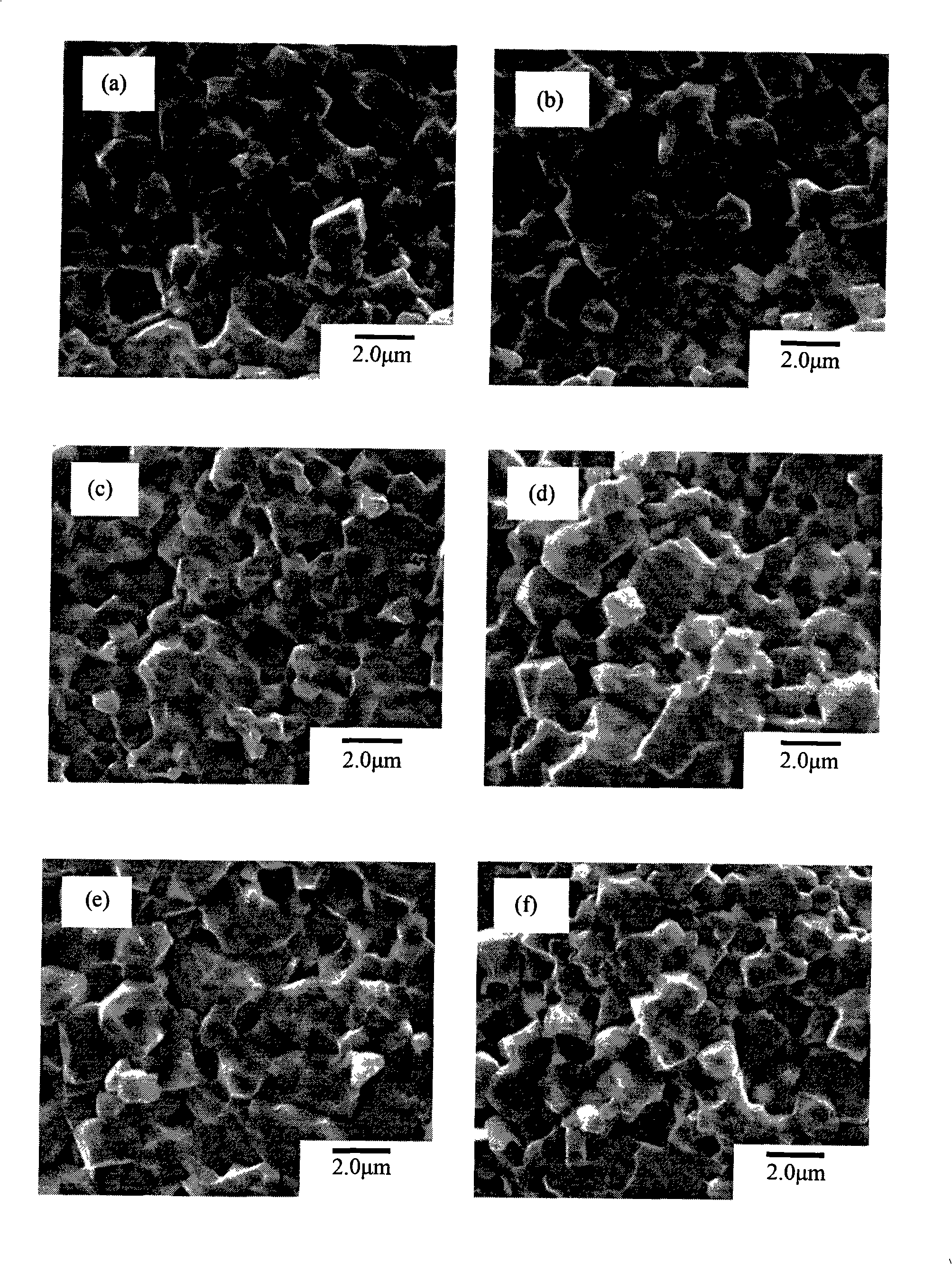

Low temperature sintering lithium antimonite doped quinary system piezoelectric ceramics material and method for preparing same

InactiveCN101337814APiezoelectric constantHigh Electrical Coupling CoefficientPiezoelectric/electrostrictive/magnetostrictive devicesLithiumDielectric loss

The invention provides low-temperature sintering lithium antimoniate mixed quinary system piezoelectric ceramics, which consists of the materials expressed with the following general expression: 0.02Pb(Mg1 / 2W1 / 2)O3-yPb(Sb1 / 2Nb1 / 2)O3-(0.39-y)Pb(Ni1 / 3Nb2 / 3)O3-Pb0.59(Zr0.38Ti0.21)O3+xLiSbO3. In the general expression, x is more than 0 percent by weight, but less than 0.40 percent by weight; y is more than or equal to 0 percent by weight, but less than or equal to 0.030mol. The preparation method of the lower-pressure sintering lithium antimoniate mixed quinary system peizoelectric ceramics comprises the processing steps of preparing lithium antimoniate, synthesizing ingredients, pre-burning, granulation, tabletting, batching-out, sintering, burning silver and polarization. According to the laboratory investigation result, the piezoelectric constant and the planar electromechanical coupling factor of the quinary system piezoelectric ceramics prepared are high; the low-temperature sintering performance is good. By comparing the low-temperature sintering antimoniate mixed quinary system with similar piezoelectric ceramics reported in literatures, the mechanical quality factor Qm and the dielectric loss tan Delta are significantly reduced; the piezoelectric constant d33 and the planar electromechanical coupling factor Kp are significantly improved; the sintering temperature is significantly reduced from 1200 DEG C to 900 DEG C; and the preparation process is simple with high repetitiveness, yield and low cost.

Owner:SHAANXI NORMAL UNIV

Sesame sauce residue/coal gangue compounded alcohol group casting paint and preparation method thereof

InactiveCN104439043AImprove performanceLow costFoundry mouldsFoundry coresPolyvinyl alcoholCordierite

The invention discloses sesame sauce residue / coal gangue compounded alcohol group casting paint and a preparation method thereof. The sesame sauce residue / coal gangue compounded alcohol group casting paint is characterized by being prepared from the following raw materials in parts by weight: 70-95 parts of corundum powder, 1.1-2.3 parts of titanium oxide, 2-3 parts of chromium oxide, 20-30 parts of cordierite, 25-35 parts of coal gangues, 0.4-0.6 part of sodium antimonite, 1-4 parts of graphene, 13-17 parts of sesame sauce residues, 1-2 parts of bentonite, 5-8 parts of polyvinyl alcohol carboxyl butyraldehyde, 45-60 parts of alcohol and 3-6 parts of auxiliaries. According to the sesame sauce residue / coal gangue compounded alcohol group casting paint disclosed by the invention, the sesame sauce residues and the coal gangues are modified and compounded and then are added into raw materials, so that not only can various comprehensive performances of the paint be strengthened, but also the environment is protected and the cost is lowered, and therefore, the paint has extremely high economic benefits and social benefits. The paint prepared by adopting the preparation method disclosed by the invention can reach the effects of the casting paint, and can realize the comprehensive utilization and cyclic utilization.

Owner:WUHU HONGKUN AUTO PARTS

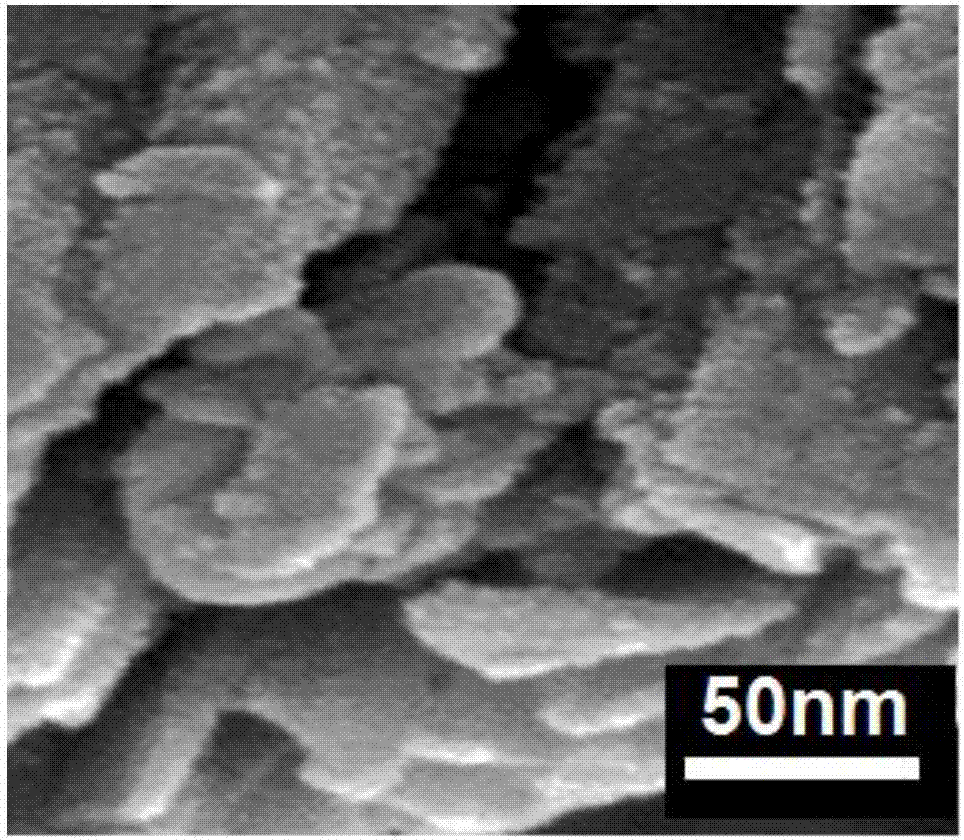

Preparation method of solid-state sodium-ion battery electrolyte

InactiveCN107482249ALarge specific surface areaImproved magnification performanceSecondary cellsElectrolytesWater bathsNano structuring

The invention discloses a preparation method of solid-state sodium-ion battery electrolyte. The preparation method comprises the following steps: dissolving sodium sulfide into 1L of deionized water; heating the mixed solution in a thermostat water bath to 80-90 DEG C; adding sodium antimonite and NH4F into the mixed solution, wherein the mass ratio of sodium sulfide, sodium antimonite and NH4F is 3.5-1.5:1:0.5-2.5; slowing stirring the mixed solution for 3-4h, naturally cooling to room temperature and filtering; drying at the temperature of 70-80 DEG C in a drying box and then heating up to 300-400 DEG C for a reaction in a furnace tube. The chemical formula of the prepared solid-state sodium-ion battery electrolyte is Na3-xSbS4-xFx, the electrolyte contains F ions, is in a nano-structure and is formed by stacked nanosheets; a lot of gaps are contained between every two adjacent nanosheets. The doped F ions provide an efficient channel for conductive ions. When the electrolyte is applied in a sodium-ion battery, the rate capability and the cycling stability of the battery can be enhanced.

Owner:卢荣红

Flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

ActiveCN103374191ADilution concentrationFlame retardantChlorinated polyvinyl chlorideCombustible gas

The invention discloses a flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material which is prepared from the components in parts by weight: 40-80 parts of CPVC, 10-50 parts of ABS, 1-10 parts of a flame retardant and 1-8 parts of a processing agent. The invention further discloses a preparation method of the flame retardant CPVC-ABS alloy material. Compared with the prior art, CPVC in the alloy material disclosed by the invention combusts to generate HCl which can shield and dilute combustible gases. Antimonous oxide or (and) sodium antimonite in the initial combustion period is fused on the surface of the material to form a protective film to isolate air. In a high temperature state, antimonous oxide or (and) sodium antimonite is gasified to dilute oxygen concentration in air and is commonly used with CPVC to generate SbOCl and SbCl3, so as to have the flame retardant effect. The alloy material is less in use level and good in flame retardant effect.

Owner:滁州格美特科技有限公司

Anti-aging and wear-resistant rubber material for tire

The invention discloses an anti-aging and wear-resistant rubber material for a tire. The anti-aging and wear-resistant rubber material for the tire is prepared from, by weight, 15-35 parts of natural rubber, 25-35 parts of 320 type chloroprene rubber, 25-35 parts of neoprene, 20-50 parts of modified kaolinite, 0.5-1.5 parts of 616 antiager, 0.2-0.8 part of phosphite, 0.5-1.2 parts of tetramethyl thiuram disulfide, 0.5-1.5 parts of zinc oxide, 1-3 parts of magnesium oxide, 5-15 parts of pumice, 10-18 parts of zinc borate, 1-2 parts of aluminum borate whiskers, 12-18 parts of sodium antimonite, 5-15 parts of aluminum phosphate, 10-20 parts of carbon black, 0.2-0.8 part of polyepoxy soybean oil, 0.1-0.9 part of hydroxyl silicone oil, 1-2 parts of white oil, 1-3 parts of pine tar, 0.2-0.8 part of fatty acid, 0.5-1.5 part of stearic acid and 1-2 parts of 3-aminopropyltrimethoxysilane. The anti-aging and wear-resistant rubber material for the tire is good in wear-resistant and anti-tear performance and excellent in anti-aging performance.

Owner:DELUN RUBBER

Process for producing olefin oligomer

InactiveUS7550639B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionOxygenSulfur containing

Owner:SUMITOMO CHEM CO LTD

Method of making 1,1,1-trifluoroethane

Owner:HONEYWELL INT INC

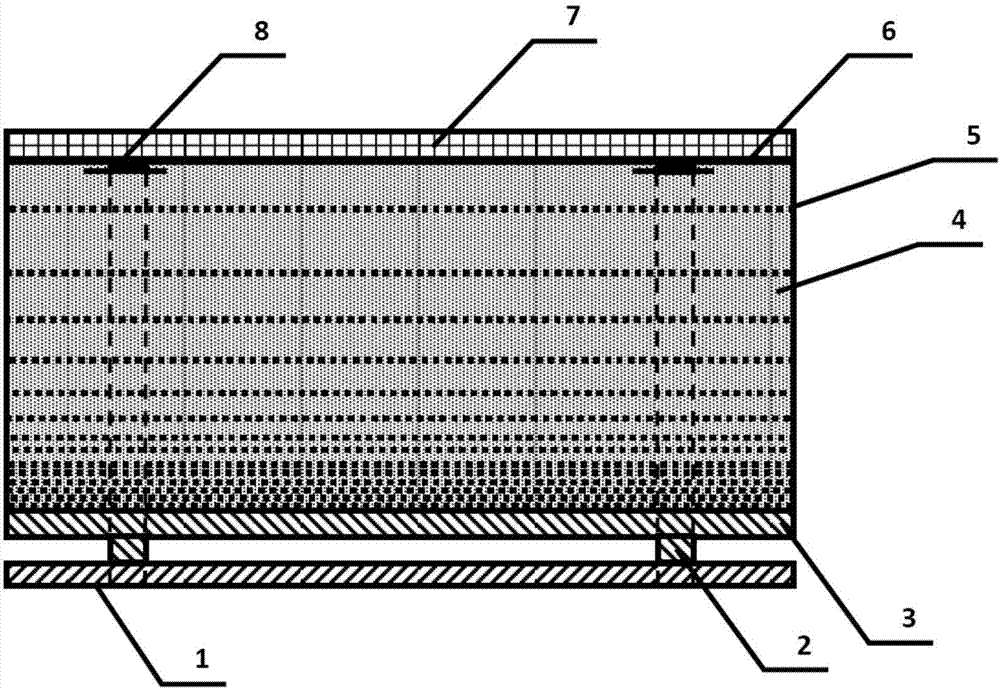

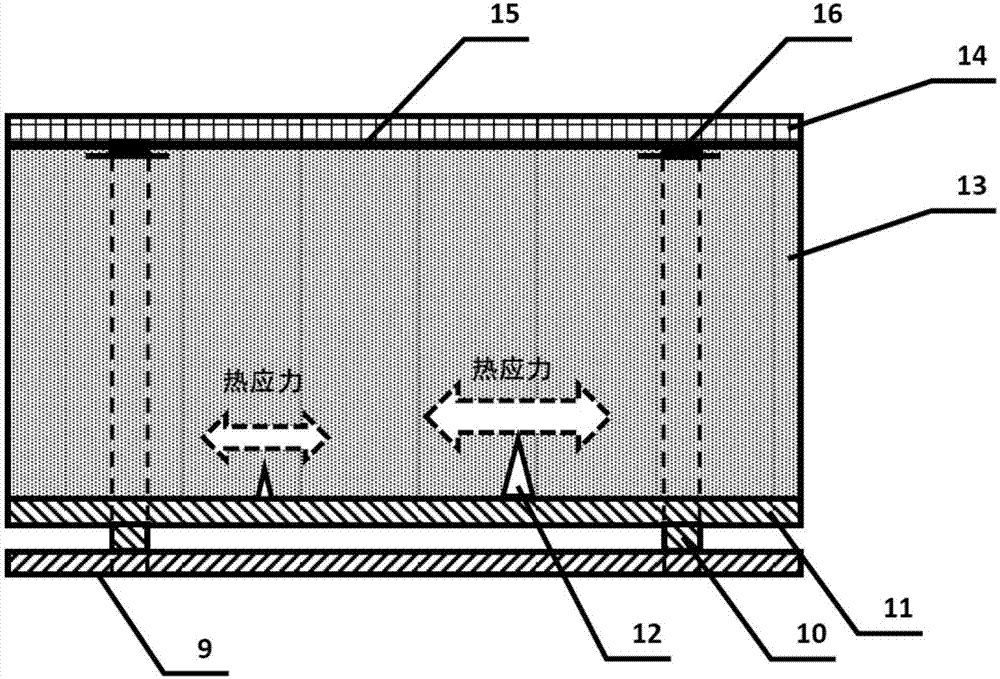

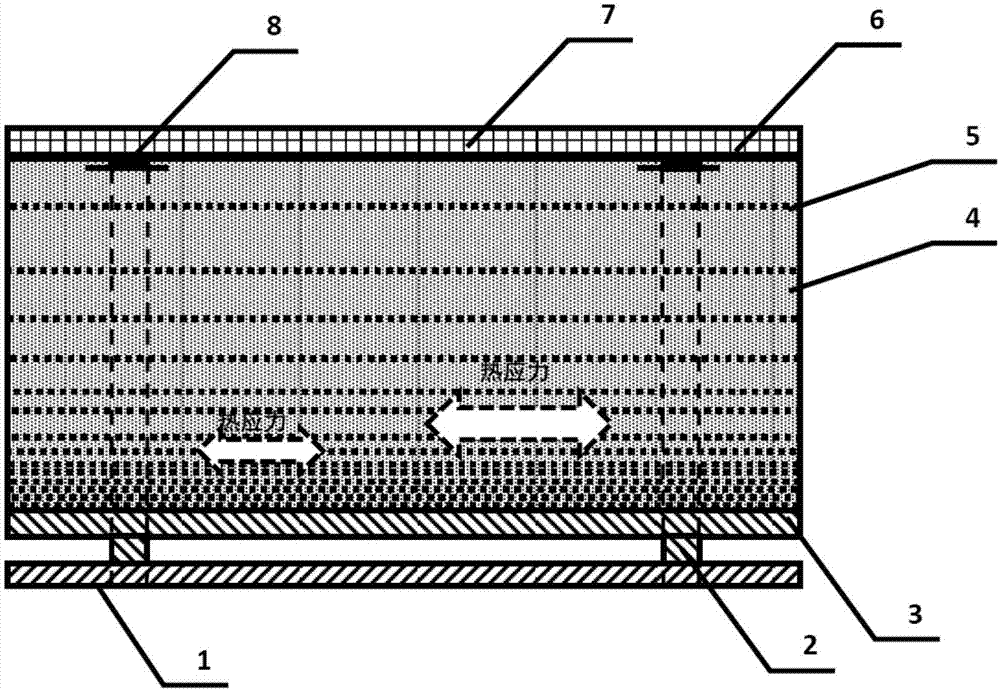

LNG (liquefied natural gas) carrier gradient enhancement heat-insulating material and short-process preparation method thereof

The invention discloses an LNG carrier gradient enhancement heat-insulating material and a short-process preparation method thereof. The LNG carrier gradient enhancement heat-insulating material is composed of polyether polyol, polyisocyanates, foaming agent, foam stabilizer, tertiary amine catalysts, organic tin catalysts, brominated flame retardants, antimonic flame retardants and continuous glass fiber mats at a weight ratio of 100:140-160:25-50:1.5-2:0.2:0.9-1:80-85:20-25:10-40; the density of the LNG carrier gradient enhancement heat-insulating material is 70-130 kg / m3, and the limit oxygen index of the LNG carrier gradient enhancement heat-insulating material is higher than 30%. The preparation method of the LNG carrier gradient enhancement heat-insulating material comprises the processes of drying, moulding, mould foaming, curing, demoulding, surface cutting and the like. The preparation method of the LNG carrier gradient enhancement heat-insulating material solves the problem that heat-insulating materials prepared in the prior art are easy to fall off from the surface of the metal wall of a subpanel due to expansion difference, and are high in contraction stress when close to low temperature to result in cracks and heat-insulating plates are high in thermal stress to result in damage to the structure of heat-insulating layers due to high temperature difference between two surfaces. The preparation method of the LNG carrier gradient enhancement heat-insulating material is a near-set-shape production process and has the advantages of being short in process, capable of saving glass fiber, low in cost, simple in production, integrative in formation and good in product comprehensive performance.

Owner:SHANGHAI JIAO TONG UNIV

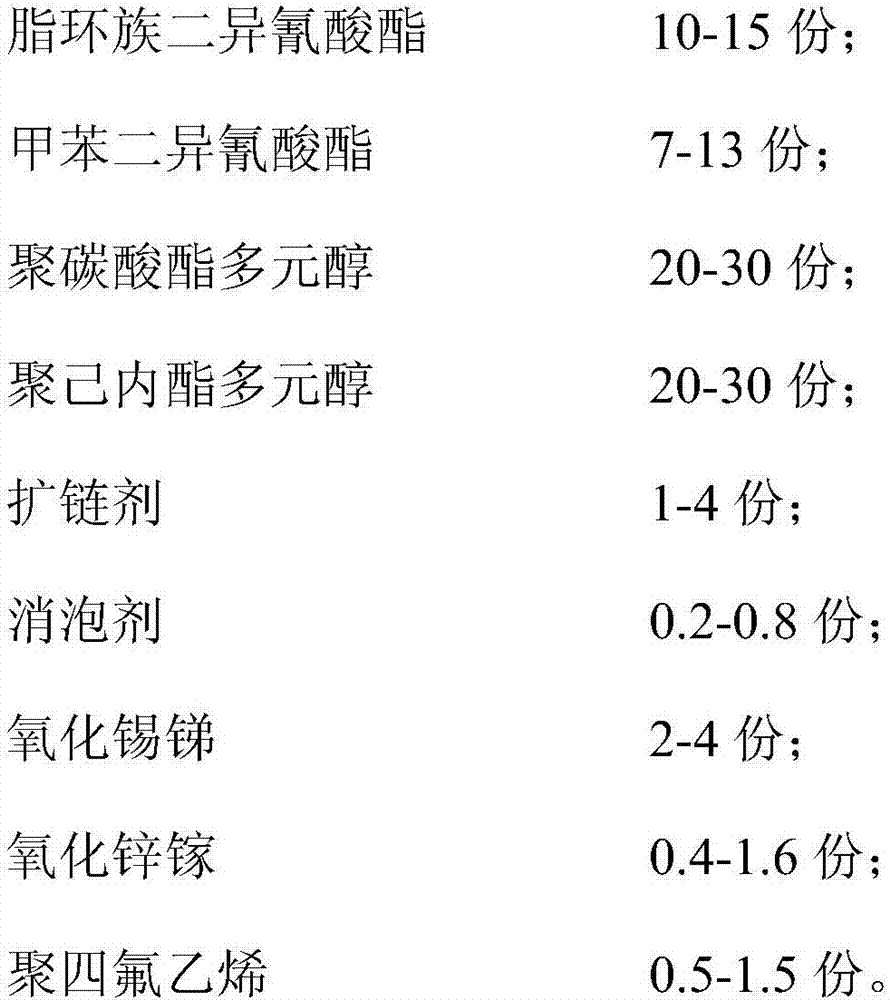

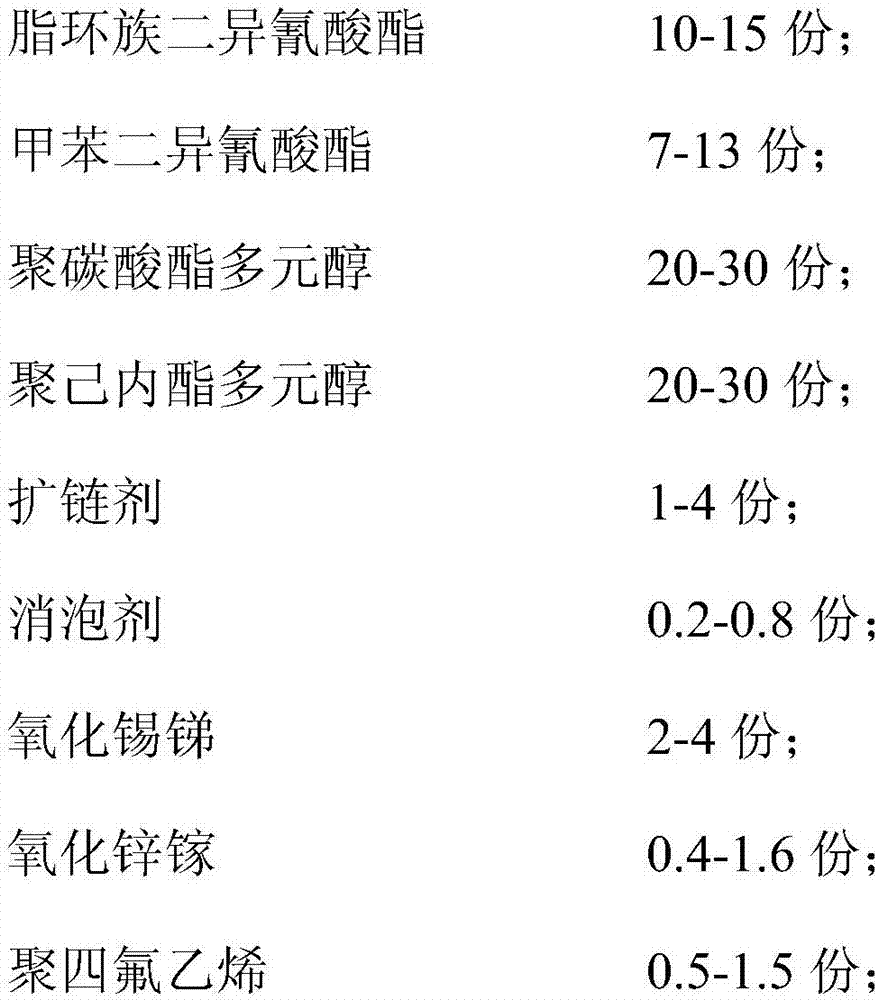

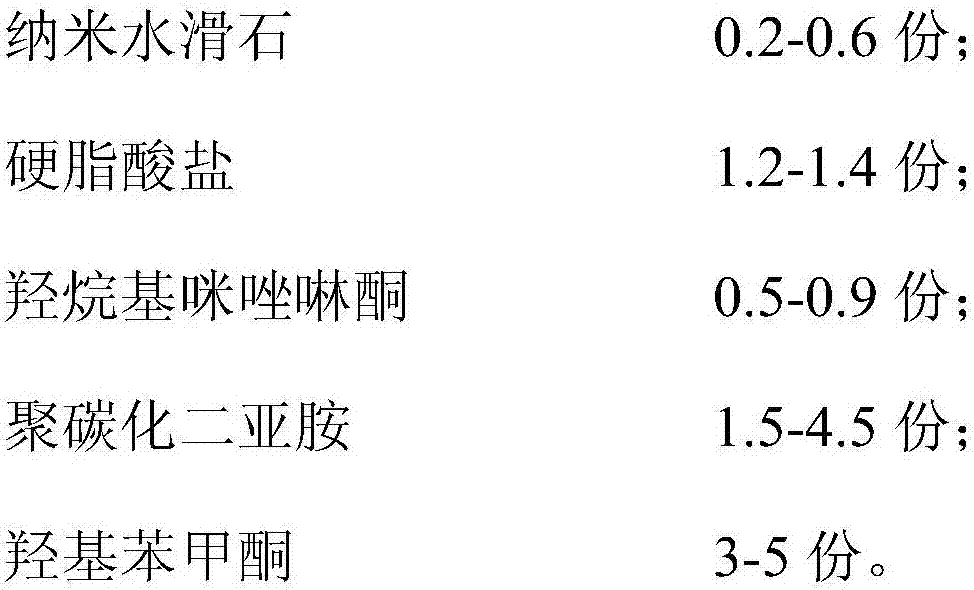

High-transparency TPU (Thermoplastic Polyurethane) film for high-speed rail laminating film and preparation method of TPU film

The invention relates to a high-transparency TPU (Thermoplastic Polyurethane) film for a high-speed rail laminating film and a preparation method of the TPU film. The TPU film comprises the following raw materials in parts by weight: 10-15 parts of alicyclic diisocyanate, 7-13 parts of toluene diisocynate, 20-30 parts of polycarbonate polyol, 20-30 parts of polycaprolactone polyol, 1-4 parts of a chain extender, 0.2-0.8 part of an antifoaming agent, 2-4 parts of tin antimony oxide, 0.4-1.6 parts of gallium zinc oxide and 0.5-1.5 parts of polytetrafluoroethylene. The TPU film disclosed by the invention has the light transmittance of 98% or higher, the glare index of lower than 10 and the Shore hardness of 80-100A and can achieve the effects of effectively reinforcing the train window, optimizing riding experience and improving the safety.

Owner:SUZHOU XIONGLIN NEW MATERIAL SCI & TECH CO LTD

PC/ABS waste recovering formula

A formula of PC / ABS waste materials recycle essentially comprises the ingredient components in mass fraction ratio: 80 to 90 PC / ABS waste materials, 1 to 3 for compatilizer, 1 to 3 plasticizer, 3 to 8 for bromide fire retardant, 1 to 3 for stibium fire retardant, 4 to 8 for acrylic acid impact resistance modifier, 0.2 to 0.5 oxidation inhibitor, 0.1 to 0.3 for ultraviolet absorber. By adding auxiliary agent such as compatilizer, plasticizer, fire retardant and antiaging dope, etc., the formula of PC / ABS waste materials recycle of the invention reproduces and reuses the PC / ABS waste materials based on environmental protective, and achieves the PC / ABS raw material standard of various properties of PC / ABS waste materials; so that the invention reduces the production cost, avoids the environmental pollution and has favorable social benefits and economic benefits.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Catalysts for polyester production, process for producing polyester, and polyester

A catalyst for polyester production which comprises a solid titanium compound comprising titanium, oxygen, carbon, and hydrogen and having a Ti-O bond and which, when dissolved in ethylene glycol with heating at 150 DEG C, has a solubility in the ethylene glycol of at least 3,000 ppm in terms of titanium atom amount; a catalyst for polyester production which comprises a titanium-containing solution obtained by dissolving a product obtained by contacting a polyhydric alcohol with a hydrolyzate of a titanium halide or titanium alkoxide, in ethylene glycol in an amount of 3,000 to 100,000 ppm in terms of titanium atom amount; a process for producing a polyester with any of these catalysts; and a polyester produced by this process. According to the present invention, a polyester can be prepared with a higher catalytic activity as compared with a case of using a conventional catalyst, and a polyester having better transparency, better hue and lower acetaldehyde content can be obtained as compared with a process using an antimony compound as a polycondensation catalyst.

Owner:MITSUI CHEM INC

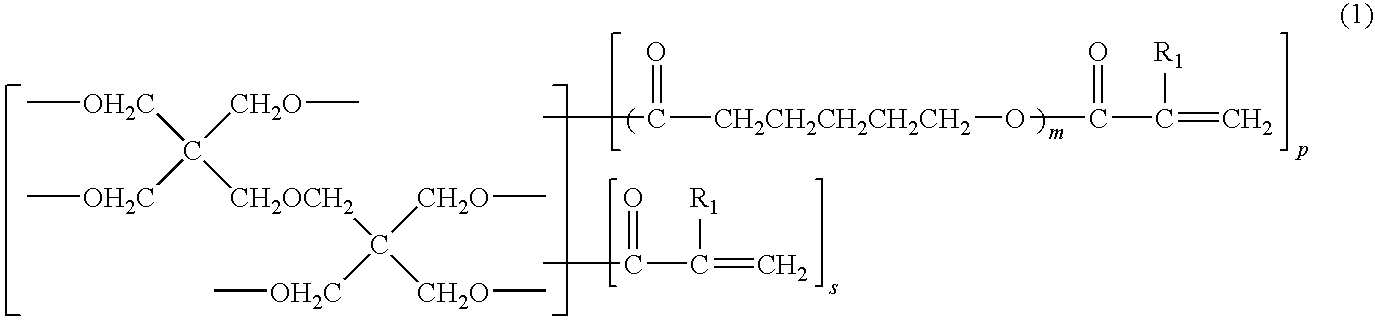

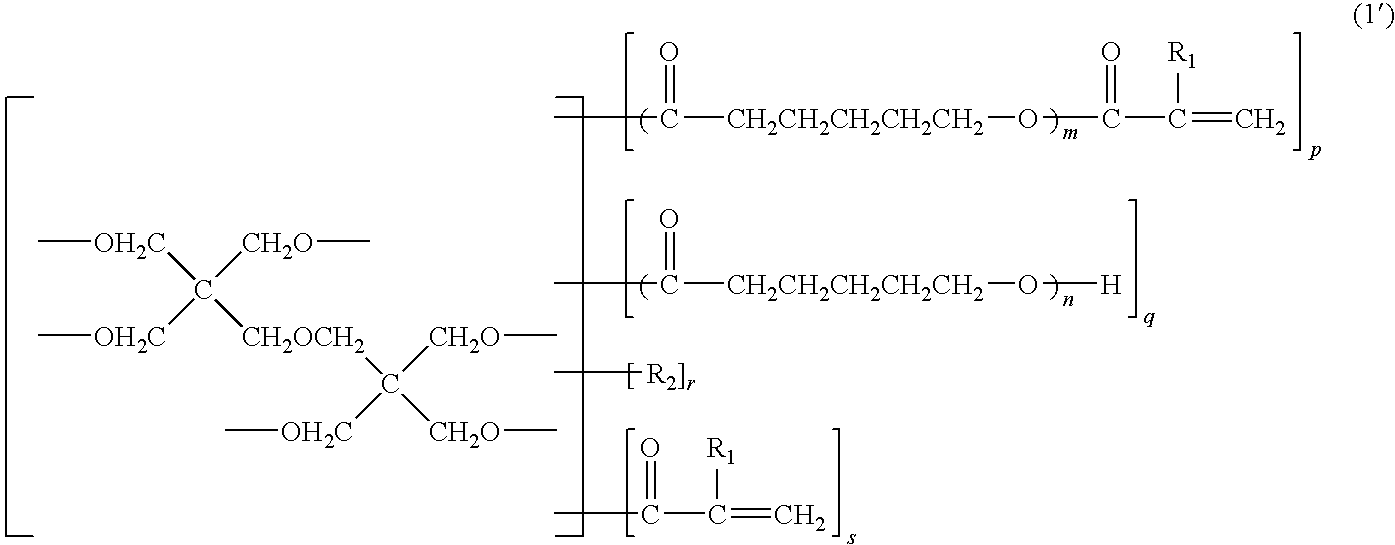

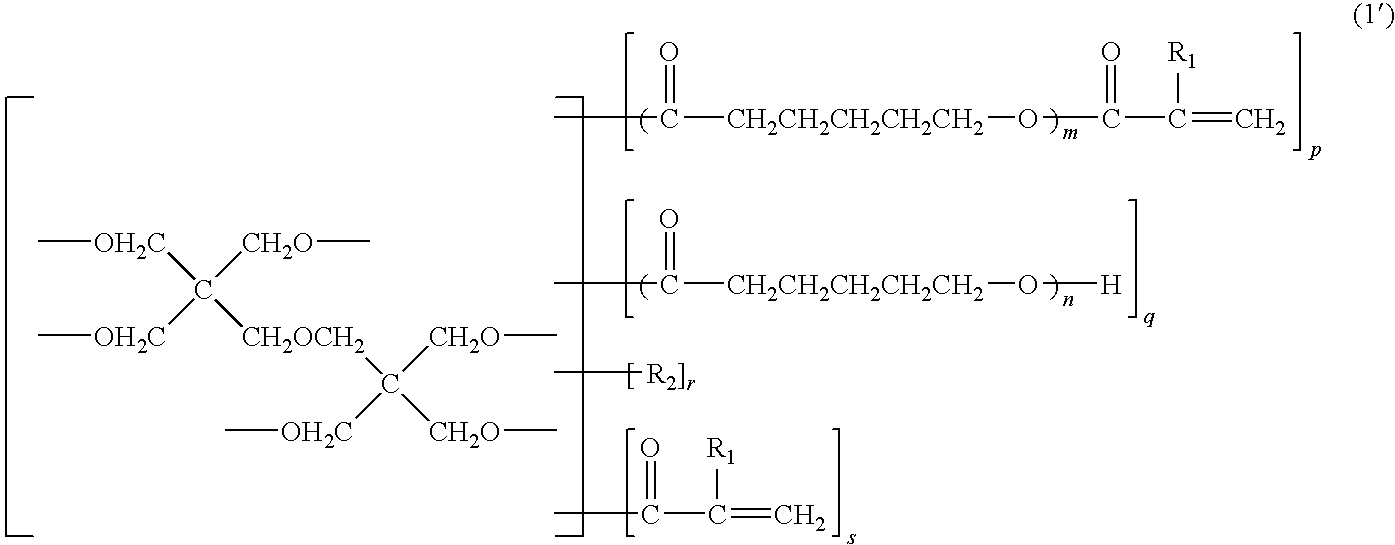

Photosensitive resin composition, dry film, and processed product made using the same

InactiveUS20100084172A1Improve flame retardant performanceHigh riskOrganic chemistryPhotosensitive materialsHydrogen atomMeth-

Disclosed is a photosensitive resin composition which does not contain any halogenated compound or any antimony compound that has a high risk of putting a load on the environment, which exerts good flame retardancy after being cured, and which particularly meets the recent exacting requirements with respect to bending resistance and insulation reliability. Specifically disclosed is a photosensitive resin composition comprising: (A) a (meth)acrylate compound represented by the general formula (1); (B) a polyimide precursor; and (C) a photopolymerization initiator [in the formula, R1 represents a hydrogen atom or a methyl group; R2 represents a hydrogen atom or a univalent organic group; n and m independently represent an integer of 1 to 5; p represents an integer of 0 to 6; q and r independently represent an integer of 0 to 4; and s represent an integer of 0 to 6, provided that the sum of p, q, r and s is 6, and the sum total of p and s may range from 3 to 6 and is preferably 6].

Owner:PRINTEC CORP

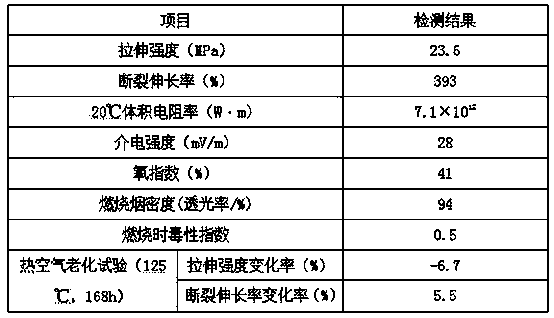

Low-smoke halogen-free flame-retardant polyethylene cable material and preparation method thereof

InactiveCN104356476AImprove flame retardant performanceWon't releasePlastic/resin/waxes insulatorsPhosphoric Acid EstersPolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyethylene cable material and a preparation method thereof. The low-smoke halogen-free flame-retardant polyethylene cable material is prepared from the following raw materials in parts by weight: 34-48 parts of medium-density polyethylene, 22-36 parts of polyamide-imide, 5-10 parts of diacetyl epoxy soybean oleic acid glyceride, 4-8 parts of sodium antimonite, 16-28 parts of bisphenol A polycarbonate, 3-4 parts of calcium stearate, 5-10 parts of ammonium metatungstate, 10-15 parts of methyl benzoate, 2-3 parts of zinc ricinoleate, 15-20 parts of StronWiTM powder, 10-15 parts of diphenyl benzyl phosphate, 3-6 parts of magnesium stannate, 1-2 parts of 2,5-di-tert-amyl hydroquinone, 8-12 parts of tris [2-[2-(2-methoxyethoxy)ethoxy]ethyl] orthoborate, 10-15 parts of a flame retardant, 2-3 parts of bi-(2,4-di-t-butylphenyl) pentaerythritol diphosphite and 1.5-2.5 parts of drometrizole trisiloxane. The low-smoke halogen-free flame-retardant polyethylene cable material and the preparation method thereof have the benefits that the cable material has good flame-retardant property, the flame-retardant grade reaches UL94V0, and the cable material is low-smoke halogen-free, cannot release toxic and harmful gas, is safe and environment-friendly and has excellent thermal aging resistance, oil resistance, wear resistance, fatigue resistance and corrosion resistance, thereby having a wide application prospect.

Owner:安徽电信器材贸易工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com