Special master batch for PC (Polycarbonate) sunlight board and application thereof

A solar panel and masterbatch technology, applied in fibrous fillers, dyeing physical treatment, dyed low molecular organic compound treatment, etc., can solve the problems of PC solar panel transparency reduction, pure PC resin poor fluidity, transparency decline, etc. Achieve the effects of good heat insulation effect, good dispersion and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

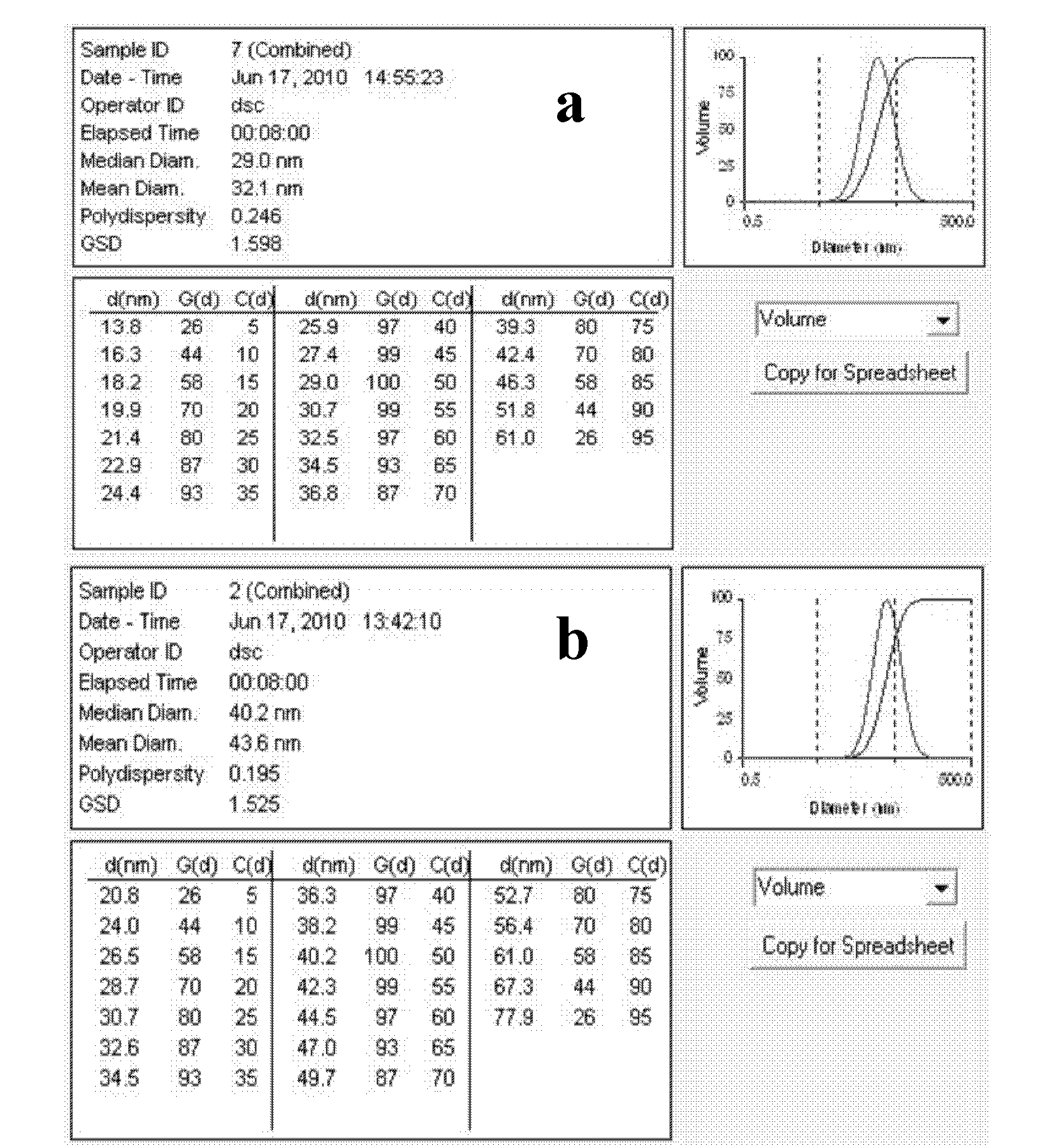

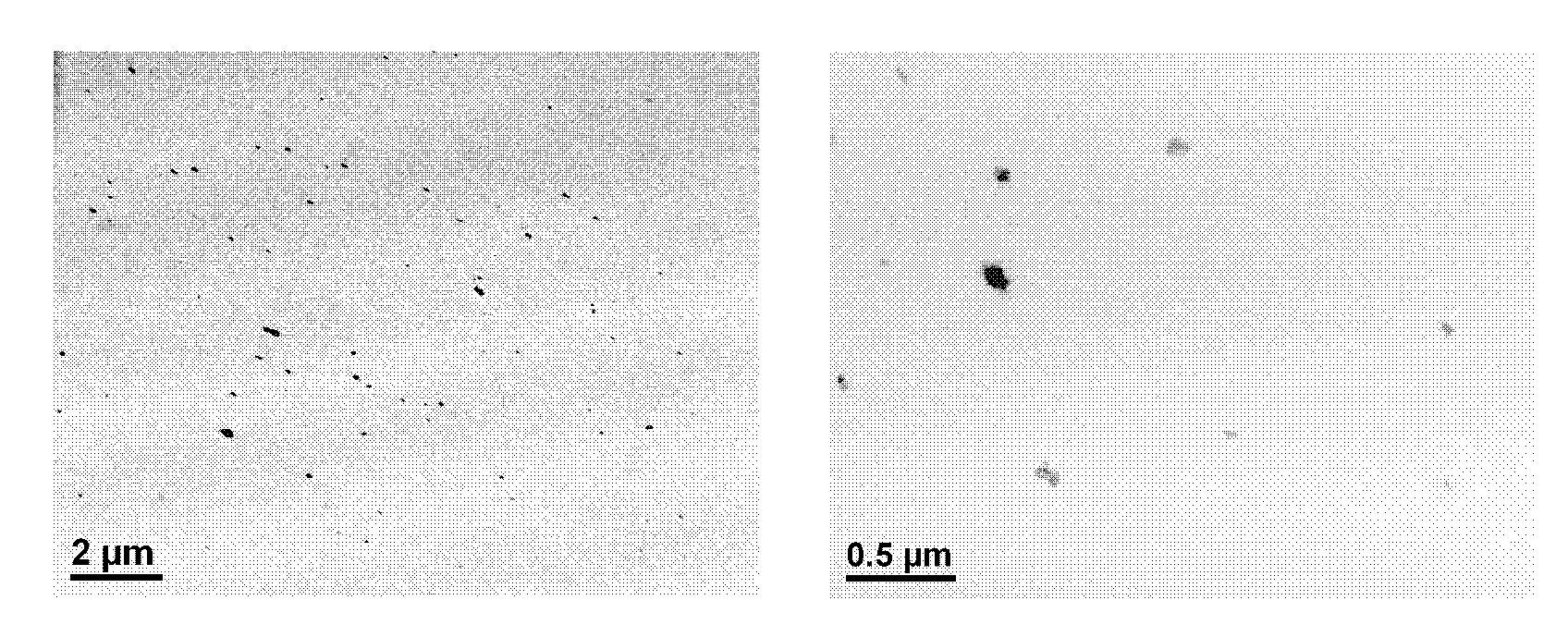

[0041] ATO modification: add dispersant KH570 (Sinopharm Chemical Reagent Co., Ltd.) accounting for about 1.0% of the mass of ATO (Shanghai Huzheng Nano Co., Ltd.) into distilled water and stir, then add ATO to form a suspension with a solid content of 30%. Liquid, adjust suspension pH to 10 with 1M NaOH solution, modify ATO with ball milling method (ball mill model QM-2SP12, ball milling beads are zirconium beads with a particle diameter of 1mm, ball mill rotating speed 380rpm, ball milling time 7.5h) to obtain slurry, adjust Adjust the pH to about 8.0 (see the particle diameter of ATO in the slurry figure 2 a). Then, the nano-dispersed ATO slurry was evaporated to dryness at about 45° C. in a rotary evaporator, and then ground to obtain ATO nanoparticles.

Embodiment 2

[0043] Dispersant KH570 is changed into KH560 (Sinopharm Group Chemical Reagent Co., Ltd.), and the usage amount is changed into 1.8% of the ATO quality simultaneously, and other is the same as embodiment 1, obtains slurry and adjusts pH to be adjusted to about 8.0 (the particle diameter of ATO in the slurry sees figure 2 b).

Embodiment 3

[0045] The dispersant stearic acid of 0.2g is added in 80g dehydrated alcohol and stir, then add the ATO of 20g (Shanghai Huzheng Nano Co., Ltd.), modify ATO with ball milling method (ball mill model QM-2SP12, ball milling beads are particle diameter 1mm zirconium beads, ball mill speed 380rpm, ball milling time 2.5h) to obtain the absolute ethanol slurry of ATO. Then, the nano-dispersed ATO slurry was evaporated to dryness in a rotary evaporator at about 30° C. and ground to obtain ATO nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com