Foaming agent for preparation of hollow glass beads and application of foaming agent

A hollow glass microsphere and foaming agent technology, which is applied in glass production, glass forming, glass manufacturing equipment and other directions, can solve the problems of increased cost, high price of high-performance hollow glass microspheres, easy to break through the glass wall, etc. The effect of improving yield and productivity, promoting large-scale production, and broadening application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

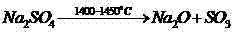

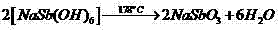

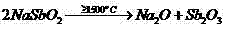

Method used

Image

Examples

Embodiment 1

[0021] Calculated by weight, quartz sand 56.4kg, feldspar 2.1kg, calcium carbonate 9kg, boric acid 8.5kg, soda ash 20.5kg, lithium carbonate 2.00kg, sodium antimonate 0.25kg, NaNO 3 1.25kg, of which foaming agent accounts for 1.5% of the whole batch, NaNO 3 With sodium antimonate NaSb(OH) 6 The mass ratio is 5:1. Put the mixed glass raw materials into an electric melting crucible and melt at 1450°C for 5 hours, then quench the melted glass in water, dry it at 200°C to 300°C for 5 hours, and grind the dried cullet into Particles of about 1mm, and then the glass particles are crushed and classified in the jet mill classifier, and the particle size of the crushed and classified particles is D 10 =5.99μm, D 50 =23μm, D 90 =45μm, the maximum particle size does not exceed 60μm, the classified glass powder is fed into the spheroidizing furnace with a feeder at a rate of 20kg / h, the spheroidizing temperature is controlled between 1450°C and 1500°C, and the spheroidizing time is 0....

Embodiment 2

[0023] Quartz sand 56.4kg, feldspar 3.5kg, calcium carbonate 9kg, boric acid 8.5kg, soda ash 20.5kg, lithium carbonate 2.00kg, sodium antimonate 0.01kg, NaNO 3 0.09kg, of which the blowing agent accounts for 0.1% of the whole batch, NaNO 3 With sodium antimonate NaSb(OH) 6 The mass ratio is 8:1. Put the mixed glass raw materials into an electric melting crucible and melt at 1450°C for 5 hours, then quench the melted glass in water, dry it at 200°C to 300°C for 5 hours, and grind the dried cullet into Particles of about 1mm, and then the glass particles are crushed and classified in the jet mill classifier, and the particle size of the crushed and classified particles is D 10 =5.99μm, D 50 =23μm, D 90 =45μm, the maximum particle size does not exceed 60μm, the classified glass powder is fed into the spheroidizing furnace with a feeder at a rate of 20kg / h, the spheroidizing temperature is controlled between 1450°C and 1500°C, and the spheroidizing time is 0.5 Seconds, after...

Embodiment 3

[0026] Calculated by weight, quartz sand 60.474kg, feldspar 1.74kg, calcium carbonate 7.40kg, alumina 8.046kg, soda ash 20.56kg, lithium carbonate 0.98kg, sodium antimonate 0.15kg, KNO 3 0.65kg. Among them, the foaming agent accounts for 0.8% of the whole batch, NaNO 3 With sodium antimonate NaSb(OH) 6 The ratio is 4:1. Put the mixed glass raw materials into an electric melting crucible and melt at 1500°C for 5 hours, then quench the melted glass liquid in water, dry at 200°C-300°C for 5 hours, and grind the dried cullet into Particles of about 1mm, and then the glass particles are crushed and classified in the jet mill classifier, and the particle size of the crushed and classified particles is D 10 =3.99μm, D 50 =15.38μm, D 90=30.4μm, the maximum particle size does not exceed 38μm, the graded glass powder is fed into the spheroidizing furnace with a feeder at a rate of 20kg / h, the spheroidizing temperature is controlled between 1350°C and 1450°C, and the spheroidizing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com