Patents

Literature

98results about How to "Piezoelectric constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

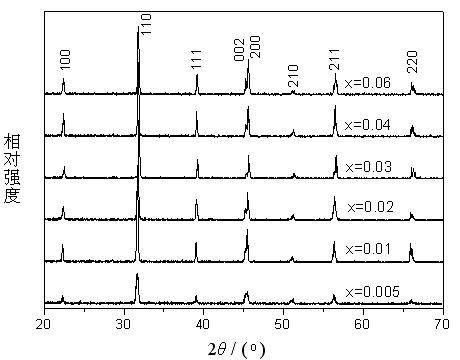

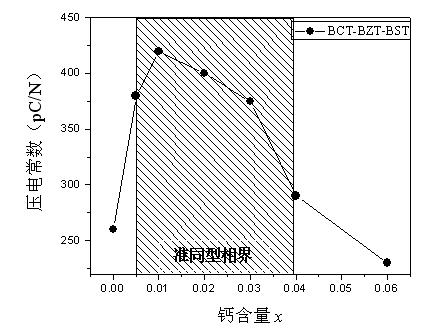

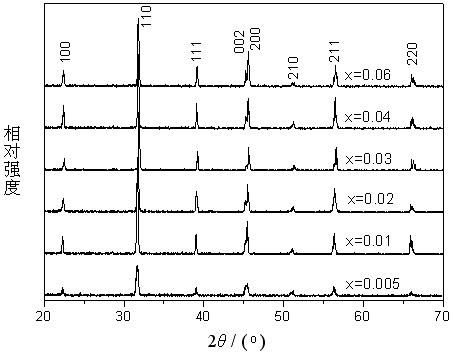

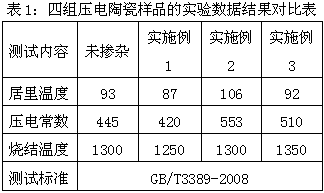

BCT-BZT-BST (Barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic

InactiveCN102531578AExcellent piezoelectric propertiesThe preparation process is stableBarium titanateElectromechanical coupling coefficient

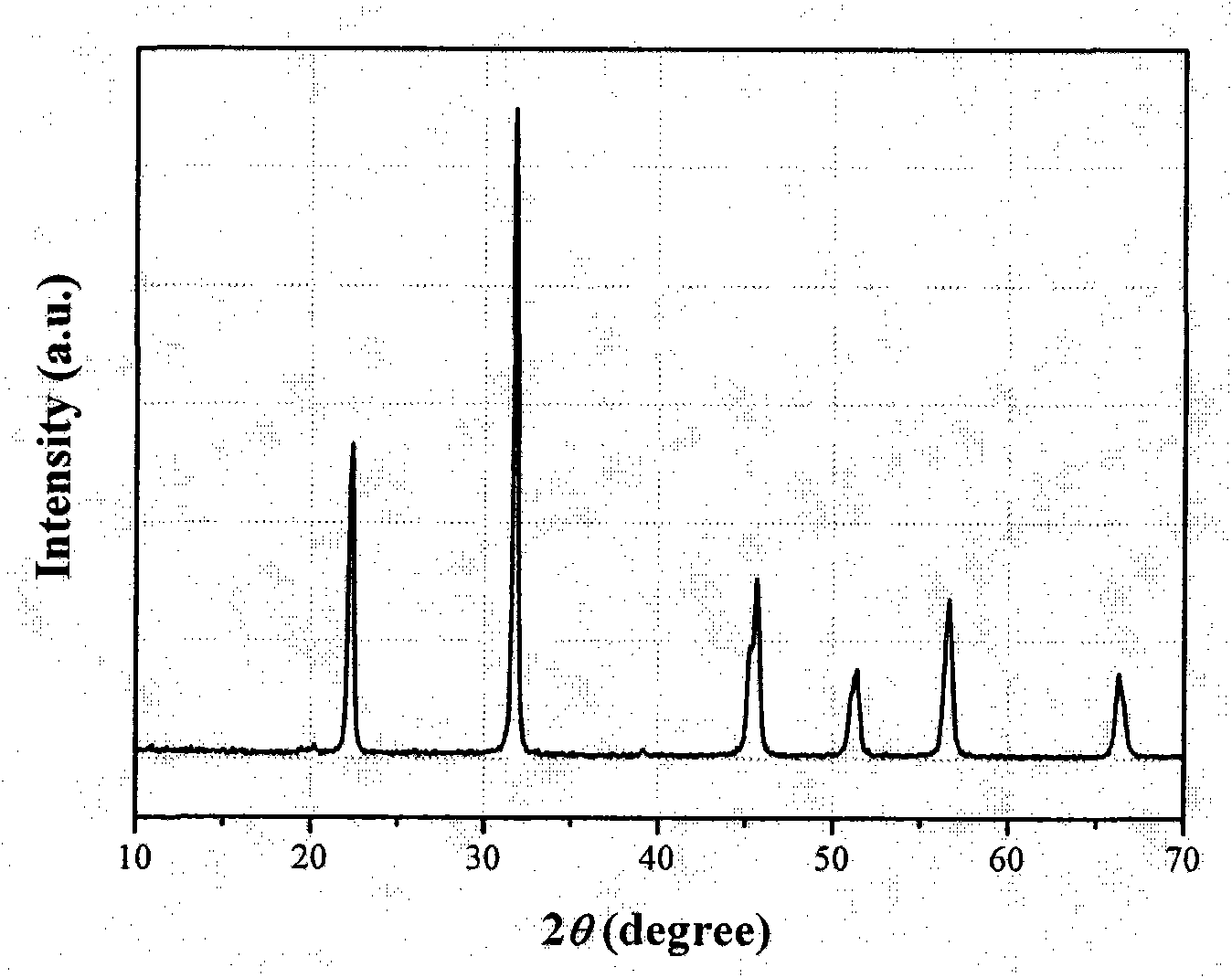

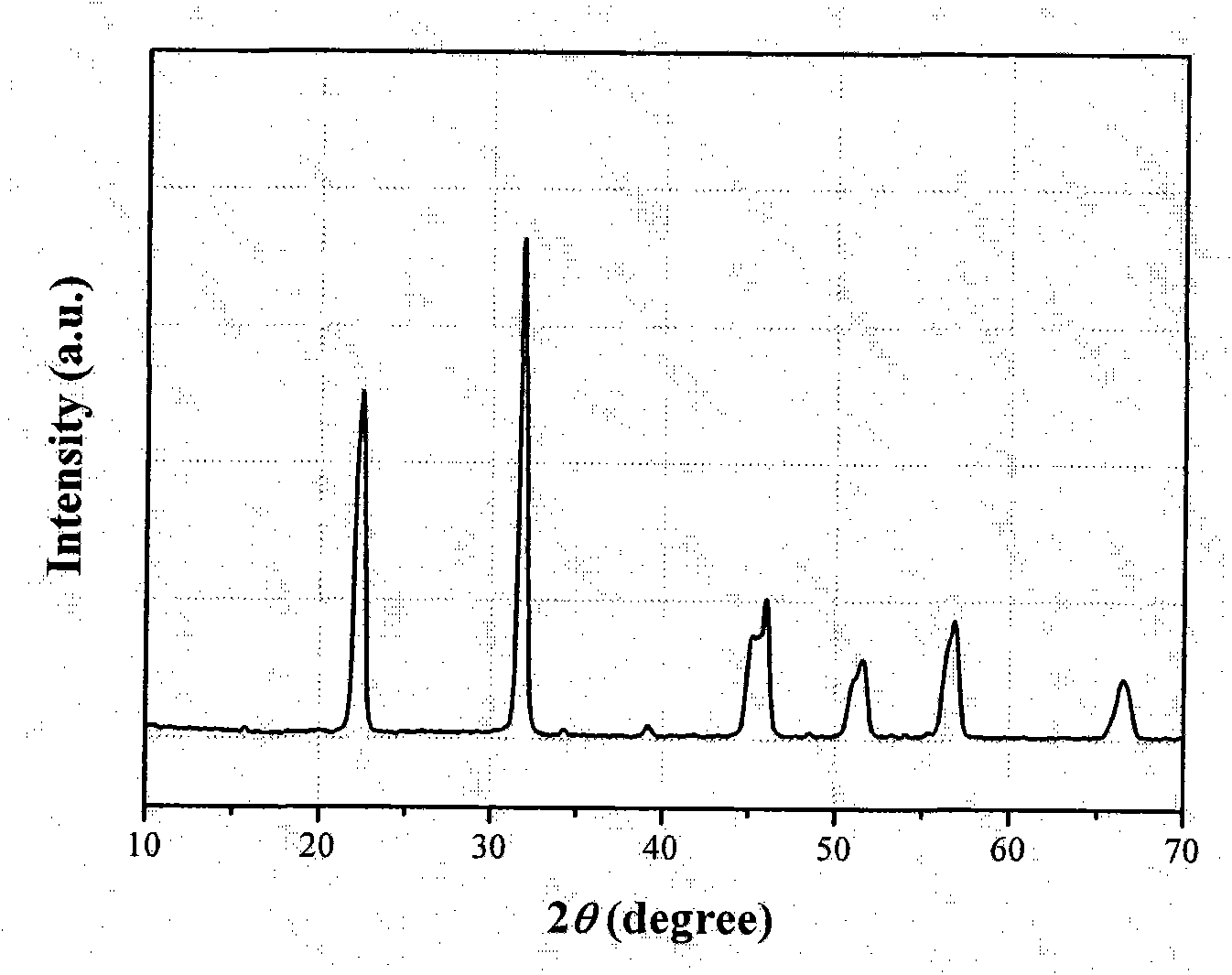

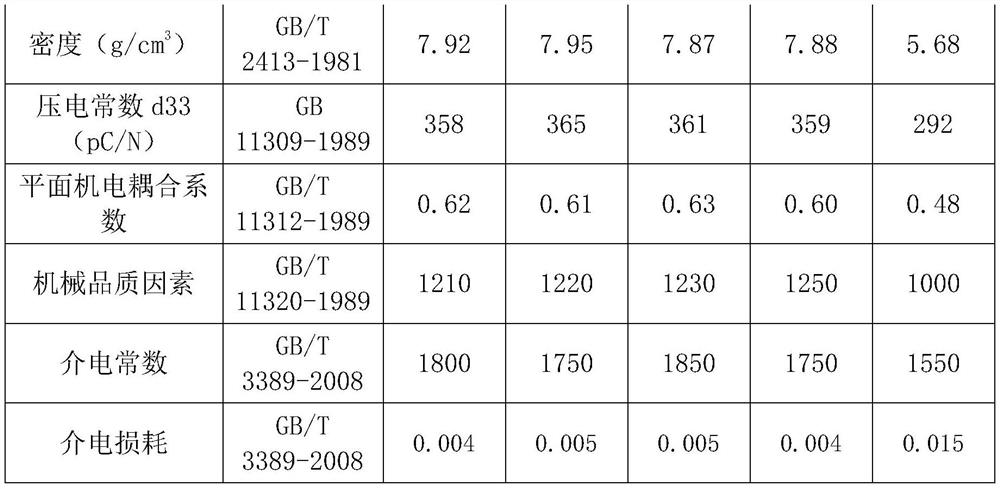

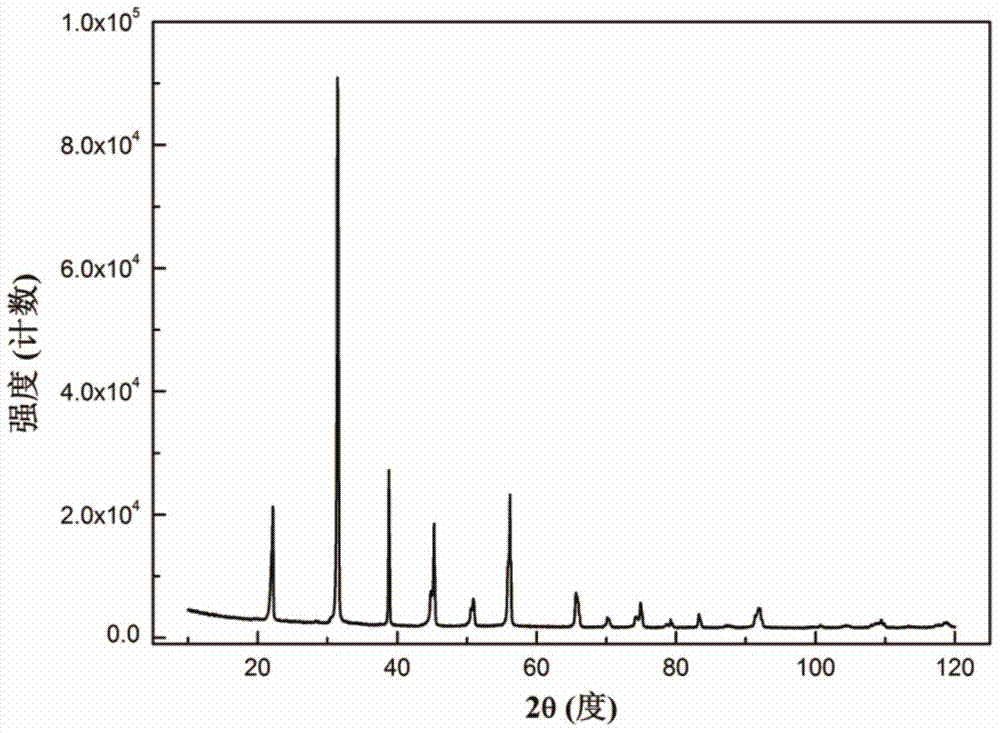

The invention belongs to the field of a lead-free piezoelectric material and discloses BCT-BZT-BST (barium calcium titanate-barium zirconate titanate-barium stannate titanate) ternary system lead-free piezoelectric ceramic. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is characterized by having the following material components: Ba0.8-xCaxTi0.8O3-0.1BaTi0.9Sn0.1O3-0.1BaTi0.8Zr0.2O3, wherein x is in the range of 0.005 to 0.06. The BCT-BZT-BST ternary system lead-free piezoelectric ceramic is prepared from industrial raw materials by adopting a conventional piezoelectric ceramic preparation technology. The system is a perovskite phase. When x is in the range of 0.005 to 0.04, the BCT-BZT-BST ternary system lead-free piezoelectric ceramic is in morphotropic phase boundary region, has excellent piezoelectric property, has a piezoelectric constant d33 value of 420pC / N and an electro-mechanical coupling coefficient of 44 percent, and has a stable preparation process and wide application prospect.

Owner:LIAOCHENG UNIV

Barium titanate based piezoelectric ceramic materials as well as preparation method and uses thereof

InactiveCN101182203AReduce manufacturing costLower sintering temperaturePiezoelectric/electrostrictive/magnetostrictive devicesUltrasonic sensorBarium titanate

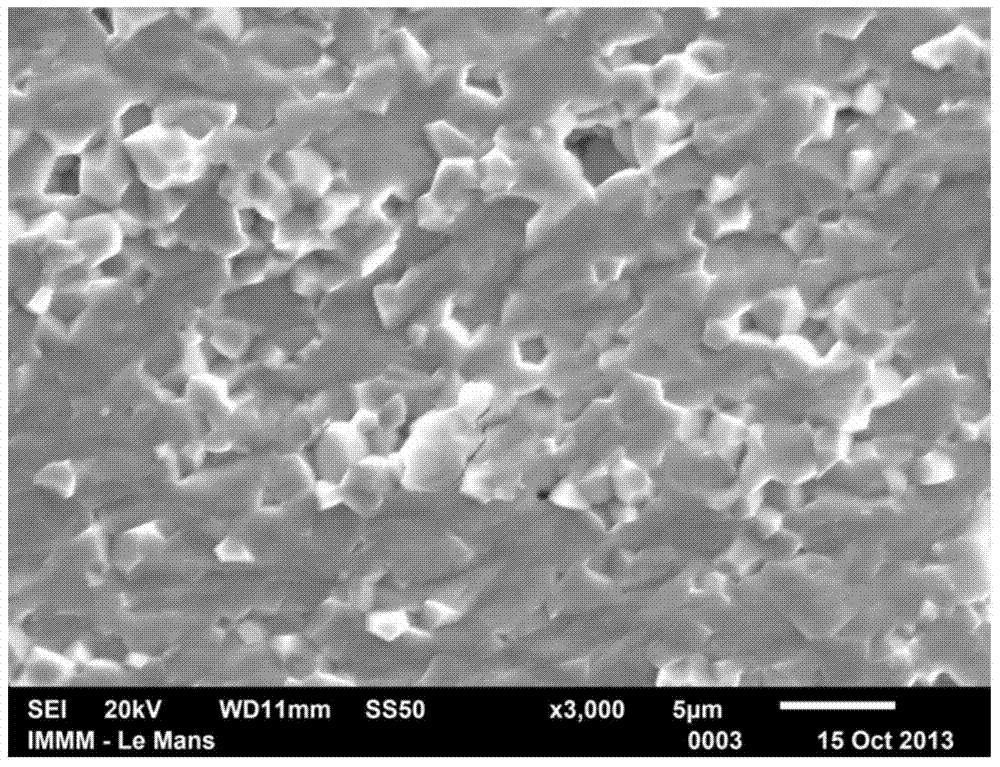

The invention relates to a titanium acid barium based piezoelectric ceramic material which uses titanium dioxide and barium carbonate as initial raw materials to produce tetragonal barium carbonate based powder through milling and pre-sintering solid phase reaction. The particle average size of the powder is at submicron grade, and the crystal structure of the powder is tetragonal. Then the titanium acid barium based piezoelectric ceramic material is produced, which is provided with a microstructure, the average size of the middle grain particle diameter of which is 0.2-7.5 Mu m, and the piezoelectric performance index d33 value of which is larger than 225pC / N. the barium titanate based piezoelectric ceramic material of the invention has the characteristics of low production cost, large piezoelectric constant d33 value and high planar electromechanical coupling factor kp value, can be applied to various electronic components and devices of sensors, drivers, ultrasonic transducers, resonators, filters, buzzers, electronic igniters, etc. and can be used as lead-free piezoelectric ceramic to substitute lead bearing PZT piezoelectric ceramic material which is widely applied currently.

Owner:SHANDONG UNIV

High-temperature-resistant piezoelectric ceramic and preparation method thereof

ActiveCN105622097AMeet needsLow voltage electric constantPiezoelectric/electrostrictive device manufacture/assemblyElectricityAlkaline earth metal

The invention relates to a high-temperature-resistant piezoelectric ceramic and a preparation method thereof. The structural general formula of the piezoelectric ceramic is Pb(Zr1 / 2Ti1 / 2)x(Ni1 / 3Nb2 / 3)y(Sb1 / 3Nb2 / 3)z(Mg1 / 3Nb2 / 3)1-x-y-zO3+wmo1%A, wherein x ranges from 0.85 to 0.97, y ranges from 0.01 to 0.10, z ranges from 0.01 to 0.05, w ranges from 0.05 to 2.0, and A is a modified element of alkali metal or alkaline-earth metal. The preparation method of the high-temperature-resistant piezoelectric ceramic comprises the following steps: pre-sintering; ball milling; drying; sieving; granulating, forming, punching, dumping and sintering; silver brushing, silver sintering and polarizing. The high-temperature-resistant piezoelectric ceramic provided by the invention solves the problems that existing piezoelectric ceramic is low in use temperature, and the electrical property cannot meet the requirements, can be used at the temperature of above 200 DEG C and has a high-voltage constant and a high-dielectric constant.

Owner:GUIZHOU ZHENHUA HONGYUN ELECTRONICS

Piezoelectric film and method for manufacturing same

InactiveUS20160020381A1Piezoelectric constantReduce power consumptionInking apparatusSynthetic resin layered productsPerovskite (structure)Engineering

Provided is a piezoelectric film having a perovskite type crystal structure represented by the following Formula (P), in which a piezoelectric constant d31 (pm / V), a relative dielectric constant ∈(−), and a dielectric loss tan δ(−) satisfy (d31)2 / (∈×tan δ×1000)>3. In addition, a method for manufacturing the above piezoelectric film is provided.Pbx[(ZraTi1−a)1−yNby]Oz (P)(in Formula (P), x represents a lead content, y represents a Nb content (B site doping amount), z represents an oxygen content, a represents a Zr / Ti ratio, and y>0.14, and although x=1.0 and z=3 is standard, numerical values of x and z may deviate from 1.0 and 3, respectively, within a range where a perovskite structure can be adopted.)

Owner:FUJIFILM CORP

Low-temperature cofiring multilayer piezoelectric ceramic and preparation method thereof

InactiveCN103641475APiezoelectric constantGood Electromechanical Coupling CoefficientMultilayer membraneDielectric

The invention relates to a low-temperature cofiring multilayer piezoelectric ceramic. The main material composition is as follows: yPb(ZrxTi(1-x))O3-(1-y-z)Pb(Mn1 / 3Sb2 / 3)O3-zPb(Zn1 / 3Nb2 / 3)O3, in addition, a proper amount of CuO is added as a fluxing agent to realize multilayer film low-temperature sintering, wherein the x value accounts for 0.40%-0.60%, the y value accounts for 0.60%-0.88%, the z value accounts for 0.02%-0.1%, and the weight percentage of CuO is 0%-0.05%. A multilayer film is prepared by adopting a tape casting method; the high-density multilayer piezoelectric ceramic is obtained by carrying out glue arrangement between 110 DEG C and 500 DEG C and carrying out low-temperature sintering at 830-850 DEG C; the appearance d33 of the piezoelectric multilayer film ceramic with a three-layer structure is more than or equal to 875 Pc / N by being tested through pressure point property and is far more than the d33 value (306 Pc / N) of a single-layer ceramic with same components. The low-temperature cofiring multilayer piezoelectric ceramic disclosed by the invention realizes the low-temperature sintering, prevents the problem of environment pollution caused by the high energy consumption, high cost, component deviation and PbO volatilization of high-temperature sintering, is excellent in piezoelectric property, achieves the d33 more than or equal to 875 Pc / N, the dielectric constant at 3000-6000 and the electromechanical coupling coefficient K31 more than or equal to 0.56 and meets the requirements of a multilayer piezoelectric ceramic device.

Owner:苏州衡业新材料科技有限公司

Bismuth ferrite-barium titanate lead-free piezoelectric ceramic as well as preparation method and application thereof

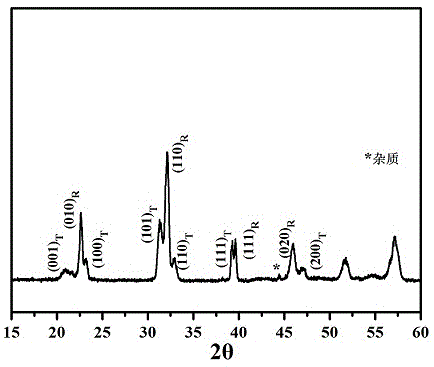

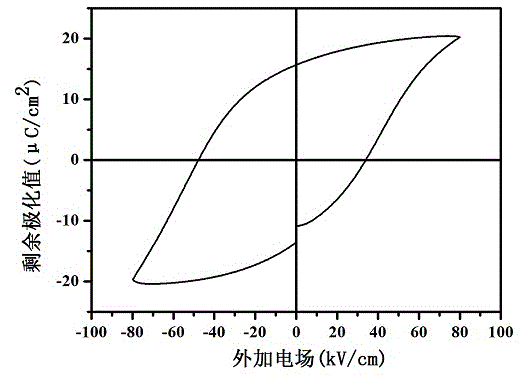

The invention relates to bismuth ferrite-barium titanate lead-free piezoelectric ceramic and an application thereof. The chemical formula of the bismuth ferrite-barium titanate is (1-x)BiyFeO3-xBaTiO3, x and y are mole fraction, x is 0.3-0.4, y is 0.6-1.2, the raw materials for preparing the bismuth ferrite-barium titanate comprise Bi2O3, Fe2O3, BaCO3 and TiO2, and the preparation method comprises the following steps: reacting Bi2O3, Fe2O3, BaCO3 and TiO2 at 780-850 DEG C to prepare a precursor; and performing granulation treatment, forming treatment, glue discharging treatment, sintering treatment, specific annealing treatment, silver firing treatment, quenching treatment and polarization treatment on the precursor. The microstructure, density and charge defect concentration of the ceramic are improved through annealing treatment, the ceramic generates lattice distortion in the high-temperature quenching process through quenching treatment after silver firing, and the piezoelectric property of the ceramic is cooperatively improved.

Owner:LANZHOU UNIVERSITY +1

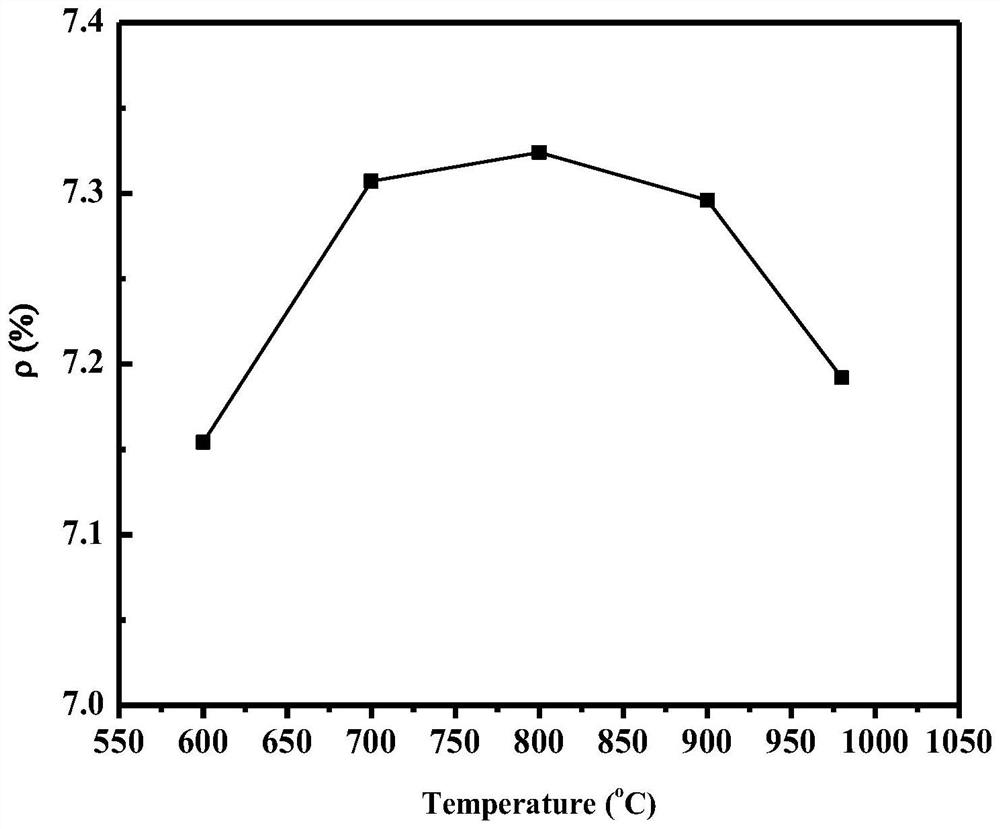

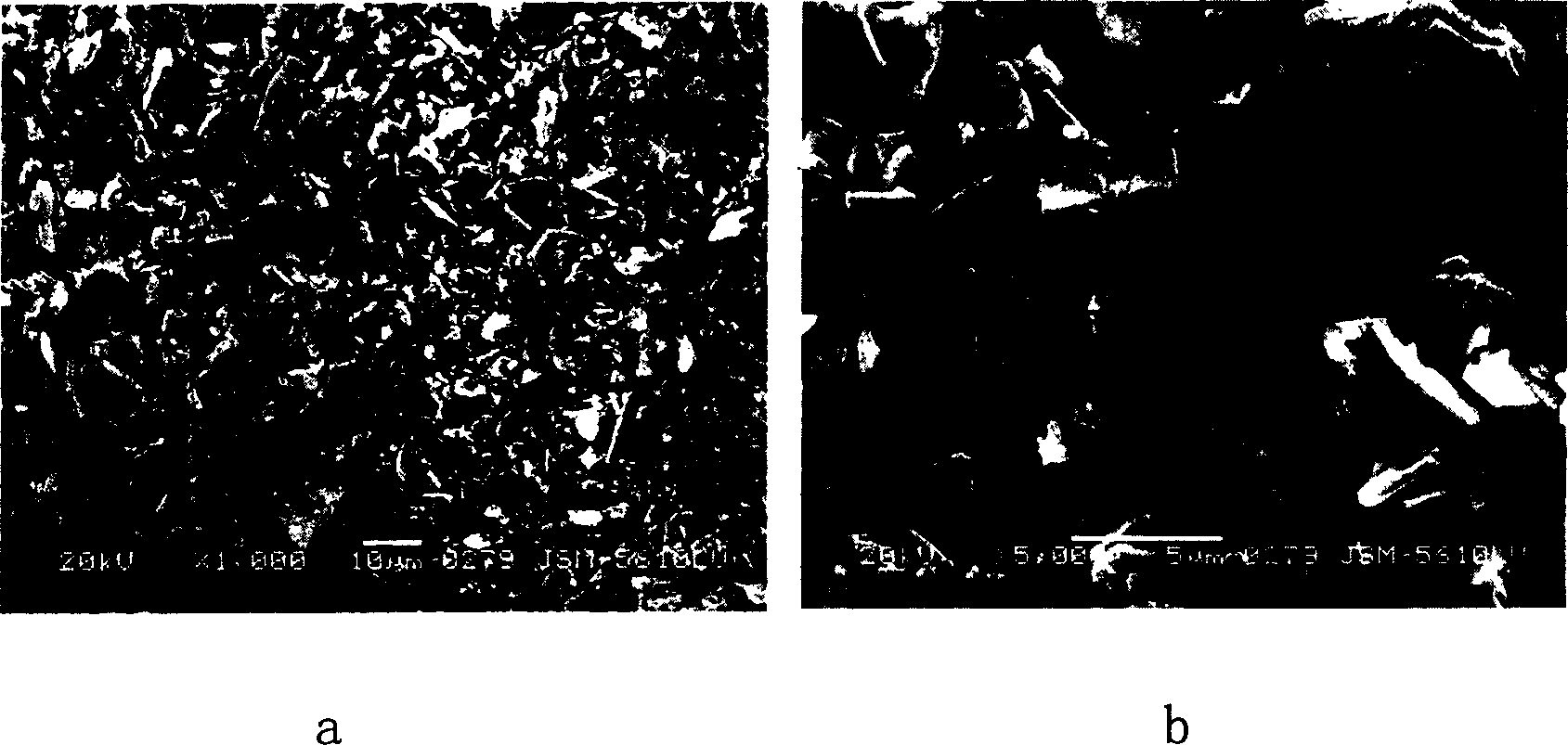

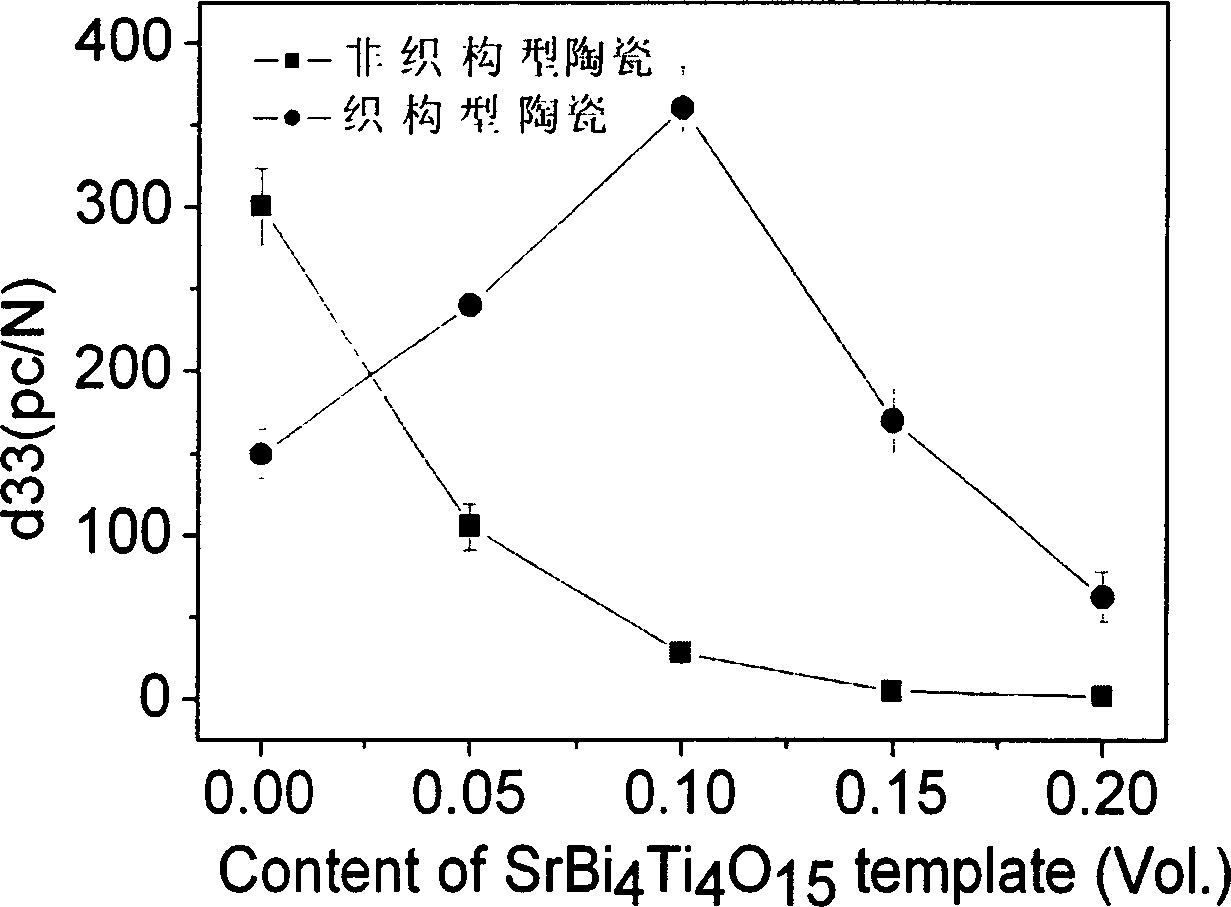

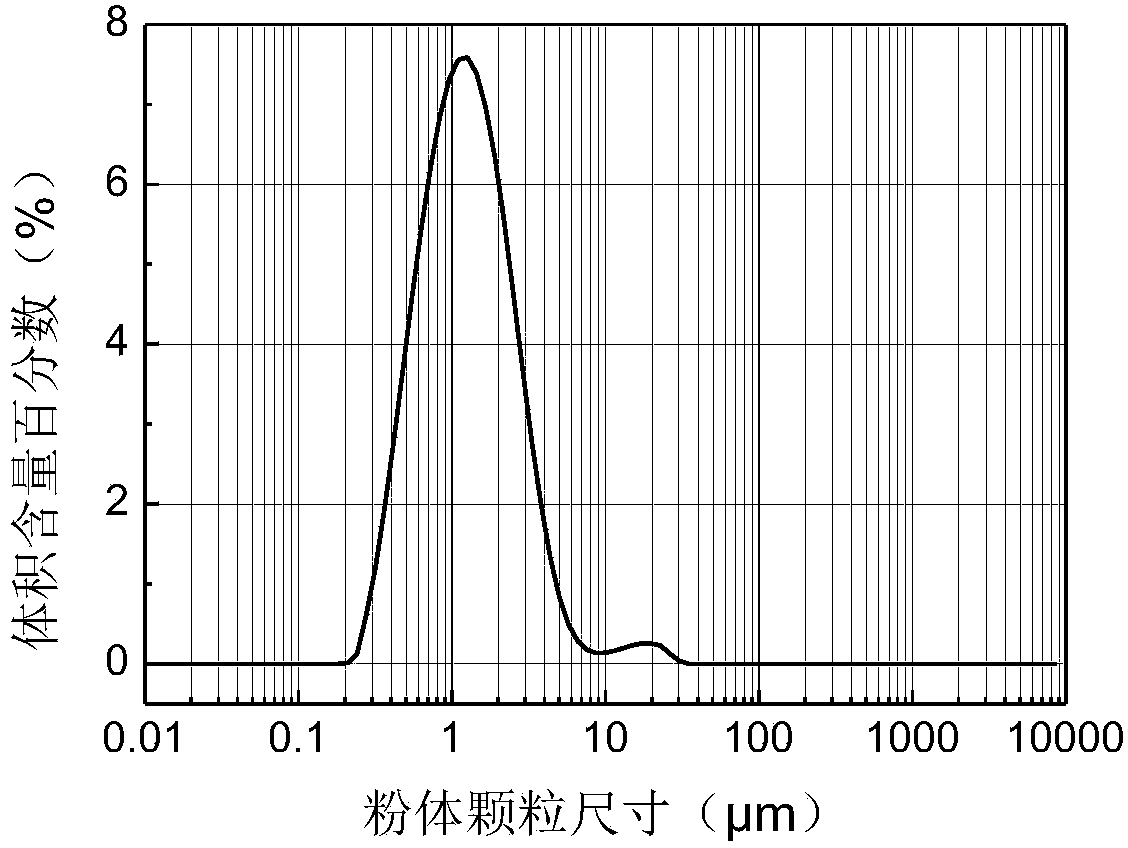

Preparation of textured piezoelectric ceramic using (001) oriented sheet-like SrBi4Ti4O15 as template material

InactiveCN1669984AGood orientationPiezoelectric constantPiezoelectric/electrostrictive/magnetostrictive devicesAir atmosphereChemical composition

Disclosed is a method for preparing texture piezoelectric ceramic film wherein the major chemical composition of the ceramics is Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3, x=0.429-0.538, containing 3-20 wt% (001) oriented sheet-like SrBi4Ti4O15 formwork material, and having the shape of (001) oriented sheet-like SrBi4Ti4O15. The preparation process comprises charging Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3 powder into the mixed solvent of anhydrous alcohol and methyl ethyl ketone, charging dispersing agent simultaneously, mixing and ball milling, then charging SrBi4Ti4O15 formwork material, charging binding agent and plasticizing agent simultaneously, mixing and ball milling again, de-soaking the obtained slurry and doctor-blade casting, drying, laminating and press forming, subjecting the samples to isostatic cool pressing and plastic-discharging at elevated temperature, immersing in polyvinyl alcohol aqueous solution and pressurizing again, thermally pressing and sintering at the presence of argon atmosphere, and sintering in the atmosphere of air atmosphere, the prepared textured piezo-electric ceramics has higher piezoelectric constant.

Owner:WUHAN UNIV OF TECH

Potassium niobate sodium-based multi-layer piezoelectric ceramic element and preparing method thereof

ActiveCN104051606AImprove piezoelectric performanceGuaranteed performanceMagnetostrictive device manufacture/assemblyElectromechanical coupling coefficientDielectric permittivity

The invention provides a potassium niobate sodium-based multi-layer piezoelectric ceramic element. A chemometry general form of a formula of potassium niobate sodium-based leadless piezoelectric ceramics is that [(Na0.52K0.44)1-xLix] (Nb0.93-ySb0.07Tay)O3, wherein 0.02<=x<=0.06, 0.02<=y<=0.06, a piezoelectric constant ranges from 300 pC / N to 350 pC / N and even higher, a dielectric constant ranges from 1700 to 2000, and an electromechanical coupling coefficient ranges from 0.40 to 0.45.

Owner:PAIHE SCI & TECH HLDG CO LTD BEIJING +1

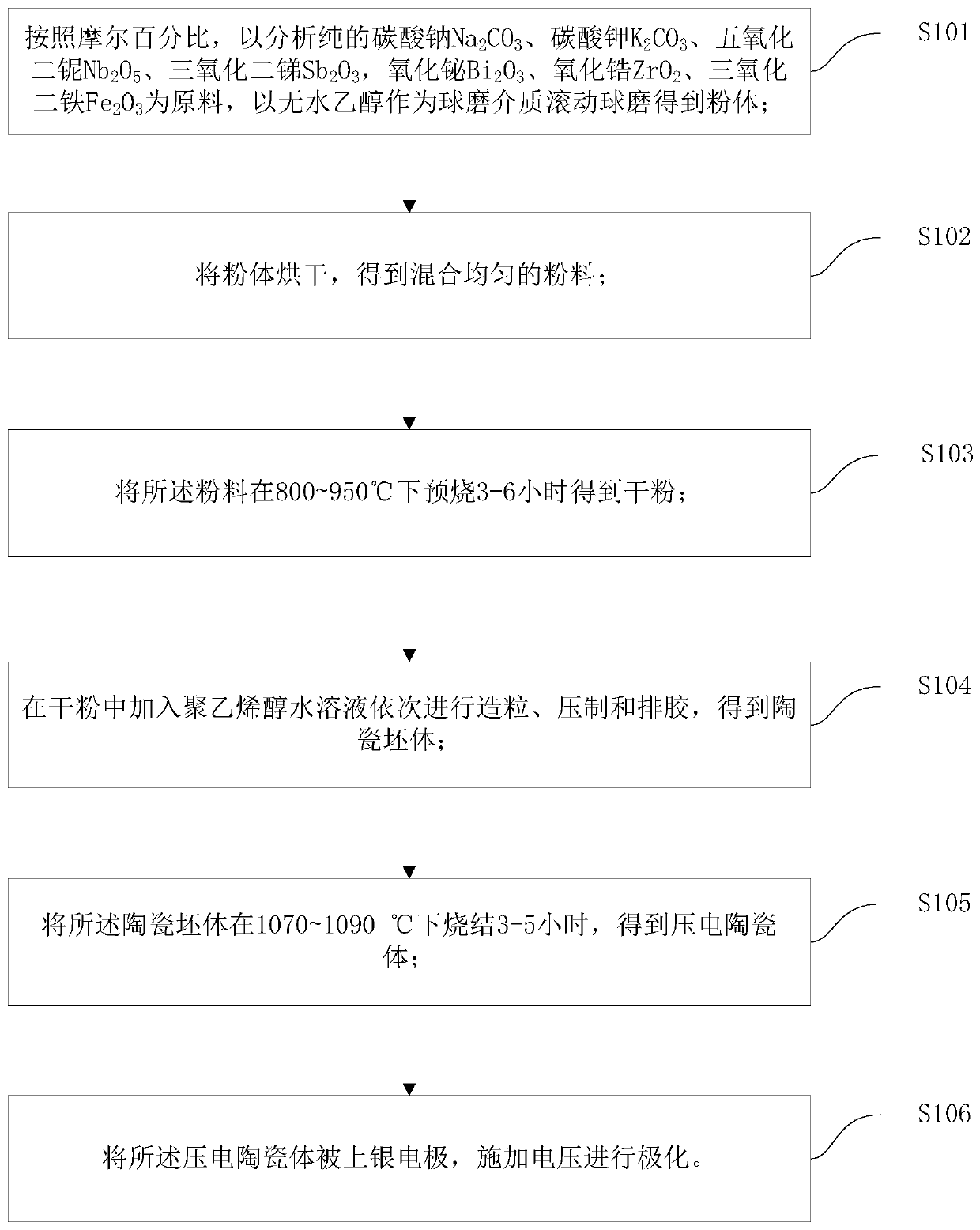

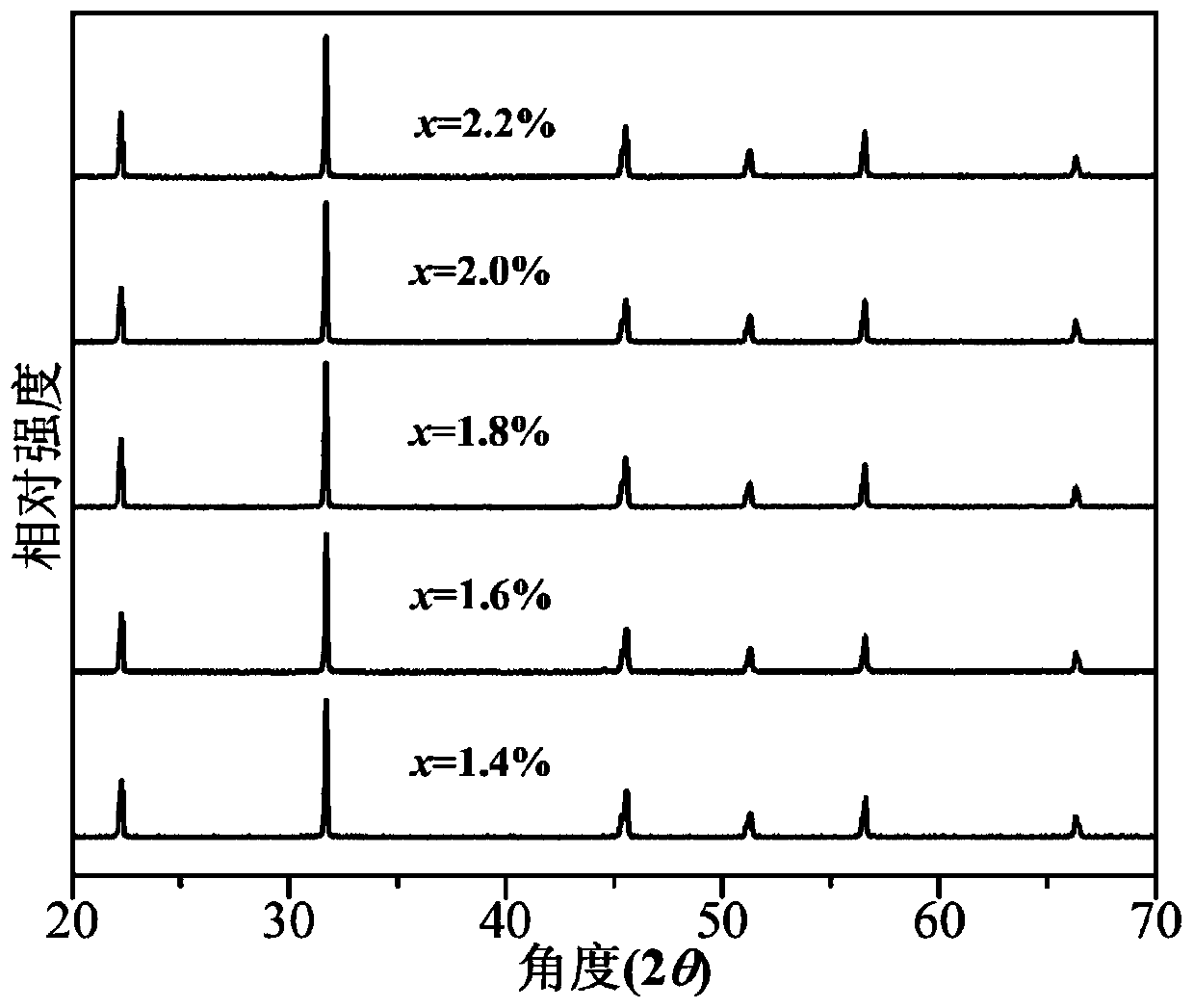

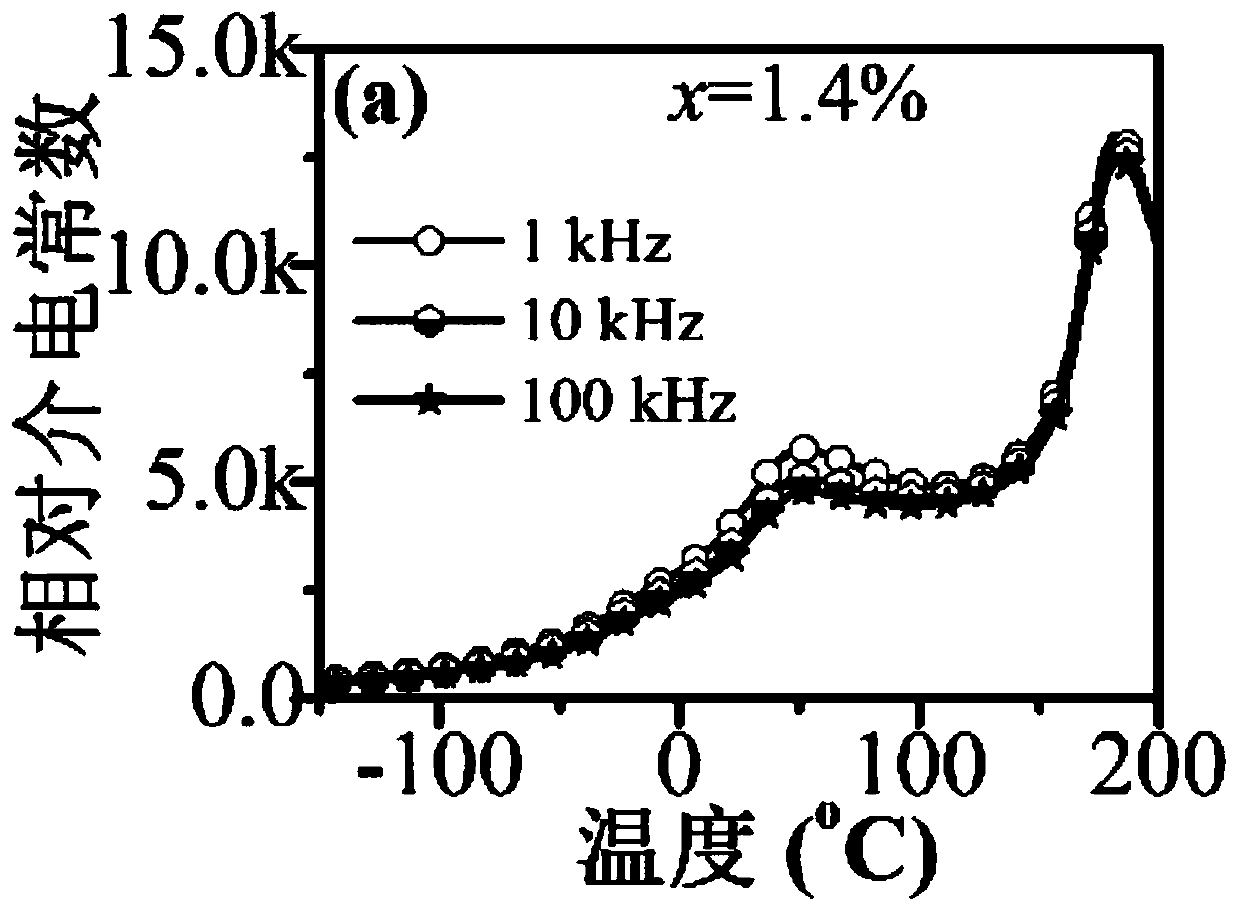

Piezoelectric ceramic material and preparation method

The invention discloses a piezoelectric ceramic material and a preparation method thereof. The general chemical formula of the piezoelectric ceramic material is shown in the specification, (0.96-X)K<0.48>Na<0.52>Nb<0.95>Sb<0.05>O<3>-0.04Bi<0.5>(Na<0.82>K<0.18>)<0.5>ZrO<3>-0.4%Fe2O3-xRSbO3, wherein the R is an alkali metal element, the x is the molar percentage of antimonate RSbO3, and the x is greater than or equal to 1.4% and less than or equal to 2.5%. The piezoelectric ceramic material provided by the embodiment of the invention has a relatively high piezoelectric constant and a relativelyhigh planar electromechanical coupling coefficient, and has a wide application range. In addition, the piezoelectric ceramic material provided by the embodiment of the invention does not contain a lead element, belongs to an environment-friendly material, conforms to the sustainable development strategy in the current international social development, and is beneficial to environmental protection.

Owner:SICHUAN UNIV

Composite piezoelectric film and preparation method thereof

PendingCN110828654AStrong piezoelectricityHigh sensitivityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionCellulose fiberNanocellulose

The invention discloses a composite piezoelectric film and a preparation method thereof. The pure natural plant nano cellulose fiber, Mxene and polyvinylidene fluoride are used as raw materials, and anano cellulose / PVDF composite film with stronger piezoelectric property is prepared by the processes of mechanical mixing, drying film formation, high-voltage polarization and the like. The production cost is low, and the process is simple; the product is good in flexibility, high in sensitivity, suitable for batch production and continuous production, high in piezoelectric constant and high in environmental adaptability, and has great application potential in the fields of medical care, sports and leisure, human-computer interaction, transportation and the like.

Owner:QILU UNIV OF TECH

Lead-free piezoceramic-polyvinyl alcohol (PVA) piezoelectric composite material and preparation method thereof

InactiveCN101661991ASimple processProcess stabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionPolyvinyl alcoholMetal electrodes

The invention relates to a potassium-sodium niobate based lead-free piezoceramic-polyvinyl alcohol (PVA) piezoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: mixing materials according to a formula (1-x)(LiaNabK1-a-b)(Nb1-cSbc)O3-xABO3-yM, adopting analytical pure anhydrous carbonate or oxide as the raw material, and using the traditional ceramic preparation technique to prepare ceramic powder; mixing the ceramic powder and polyvinyl alcohol into mixed powder according to a volume ratio of 5 / 90 to 95 / 5, adding deionized waterto the mixed powder and heating to dissolve the PVA; and then carrying out ultrasonic dispersion, drying the mixed powder, then conducting cold-pressing and forming by a sheet-pressing machine, then using a muffle furnace for heating treatment, finally sputtering metal electrodes on the surface thereof, carrying out silicon oil bath for polarization, finally obtaining the potassium-sodium niobatebased lead-free piezoceramic-polyvinyl alcohol piezoelectric composite material. The piezoelectric composite material is pure perovskite crystal phase, has no mixed phase and has good piezoelectric performance and dielectric property.

Owner:SICHUAN UNIV

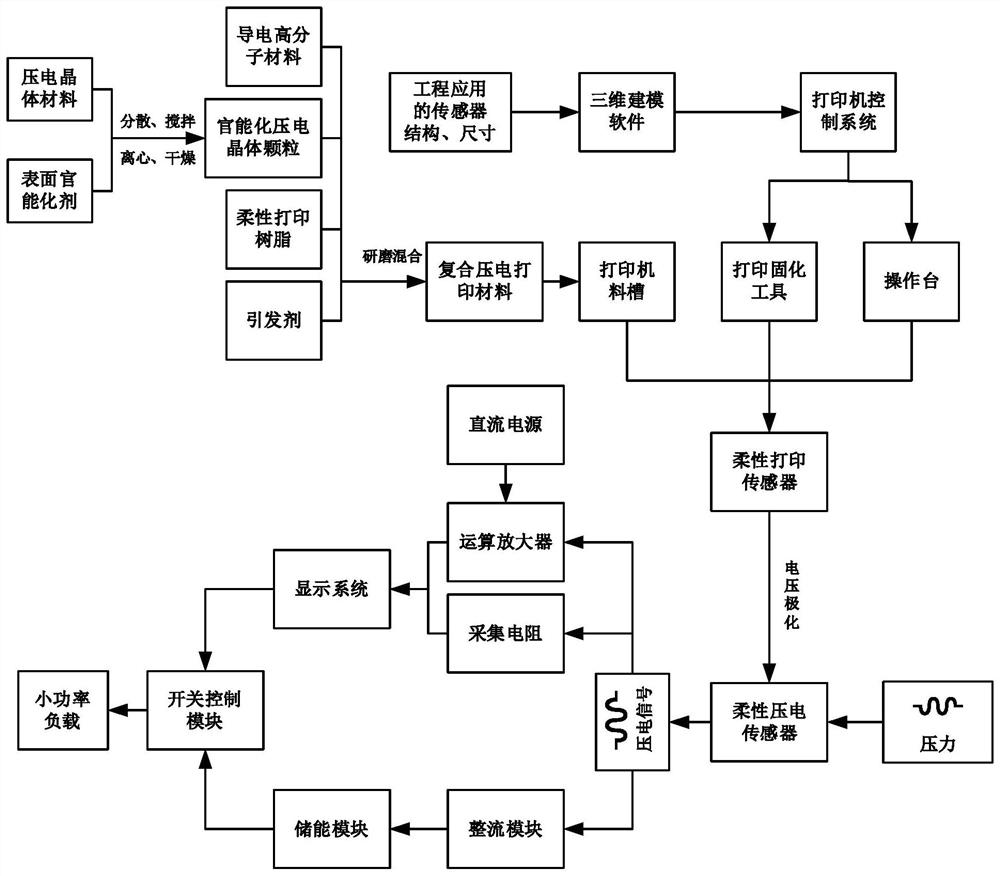

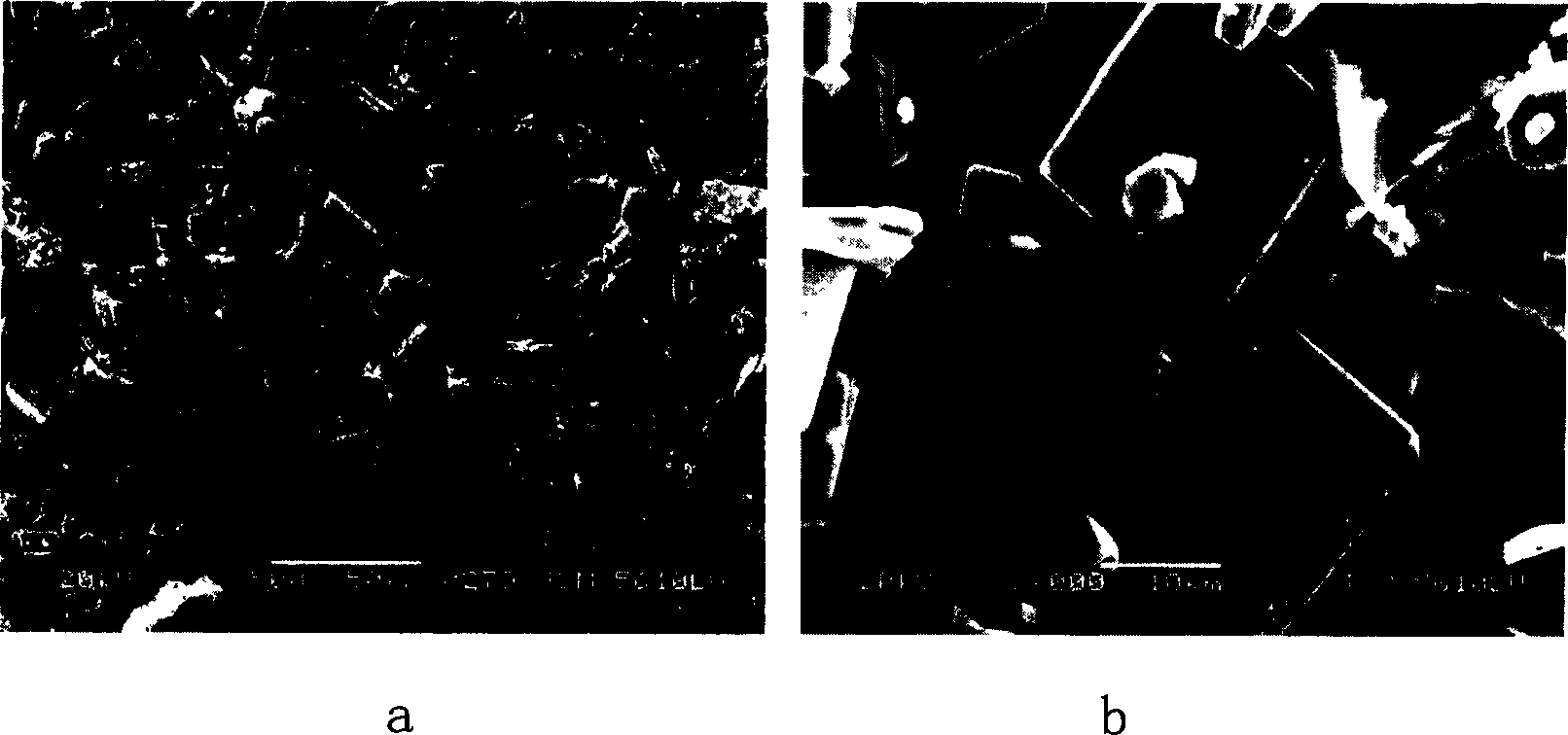

Flexible sensor device based on 3D printing and manufacturing method thereof

ActiveCN112895433APiezoelectric constantImprove toughnessPiezoelectric/electrostrictive device manufacture/assemblyAdditive manufacturing apparatusComputer printing3d printer

The invention provides a manufacturing method of a flexible self-energy-taking piezoelectric sensor device based on 3D printing. The manufacturing method comprises the following steps of S1, manufacturing a composite piezoelectric printing material which meets the performance requirements; S2, modeling a flexible piezoelectric sensor through three-dimensional drawing software to obtain a printing model of the flexible piezoelectric sensor; S3, curing and manufacturing the composite piezoelectric printing material through a 3D printer to obtain a flexible printing sensor; S4, conducting voltage polarization treatment on the flexible printing sensor to obtain the flexible piezoelectric sensor; and S5, enabling the flexible piezoelectric sensor to be externally connected with a self-energy-taking circuit to obtain the flexible self-energy-taking piezoelectric sensor device. According to the manufacturing method of the flexible self-energy-taking piezoelectric sensor device based on 3D printing, the printed sensor is subjected to voltage polarization treatment to obtain piezoelectric characteristics, the flexible piezoelectric sensor can obtain sensitive piezoelectric measurement characteristics, and finally the flexible piezoelectric sensor which can meet the comprehensive requirements for any shape structure, flexibility, sensitivity and the like is obtained.

Owner:HEBEI UNIV OF TECH

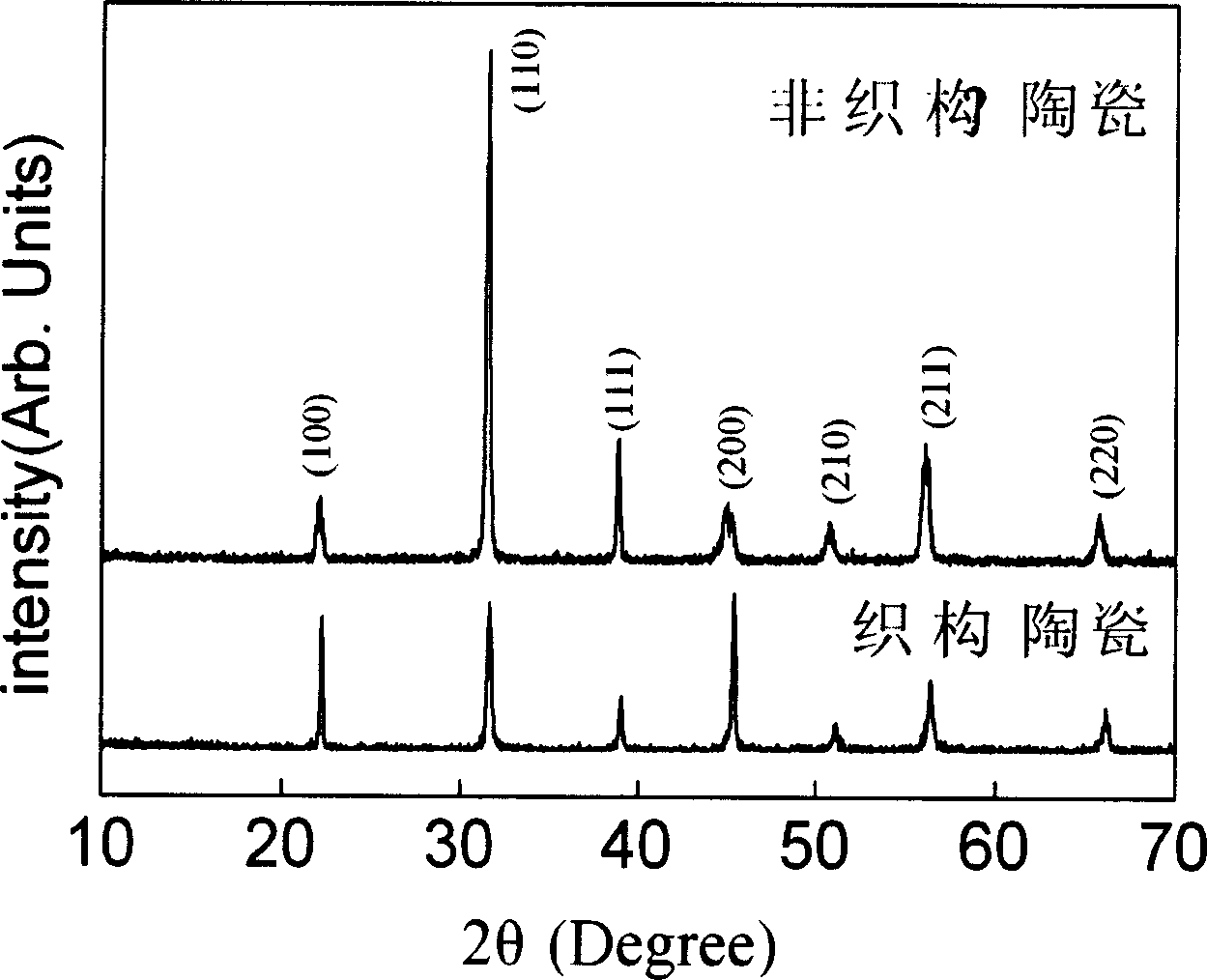

Preparation of textured piezoelectric ceramic using (001) oriented sheet-like SrTiO3 as template material

InactiveCN1669985AGood orientationPiezoelectric constantPiezoelectric/electrostrictive/magnetostrictive devicesAir atmospherePolymer science

Disclosed is a method for preparing texture piezoelectric ceramic film wherein the major chemical composition of the ceramics is Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3, x=0.429-0.538, containing 3-20 wt% (001) oriented sheet-like SrTiO3 formwork material, and having the shape of (001) oriented sheet-like SrTiO3. The preparation process comprises charging Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3 powder into the mixed solvent of anhydrous alcohol and methyl ethyl ketone, charging dispersing agent simultaneously, mixing and ball milling, then charging SrTiO3 formwork material, charging binding agent and plasticizing agent simultaneously, mixing and ball milling again, de-soaking the obtained slurry and doctor-blade casting, drying, laminating and press forming, subjecting the samples to isostatic cool pressing and plastic-discharging at elevated temperature, immersing in polyvinyl alcohol aqueous solution and pressurizing again, thermally pressing and sintering at the presence of argon atmosphere, and sintering in the atmosphere of air atmosphere, The prepared textured piezo-electric ceramics has higher degree of orientation and higher piezoelectric constant.

Owner:WUHAN UNIV OF TECH

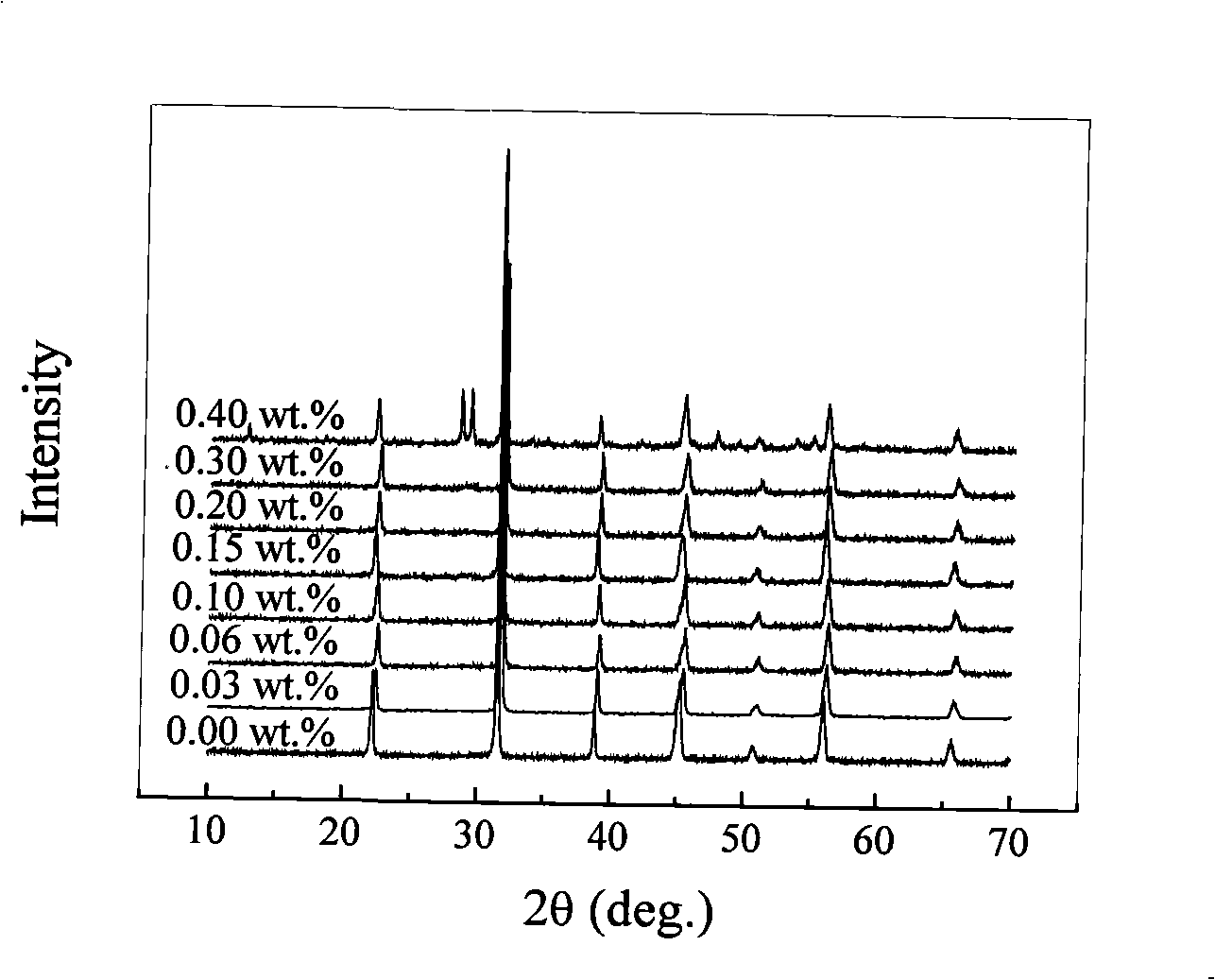

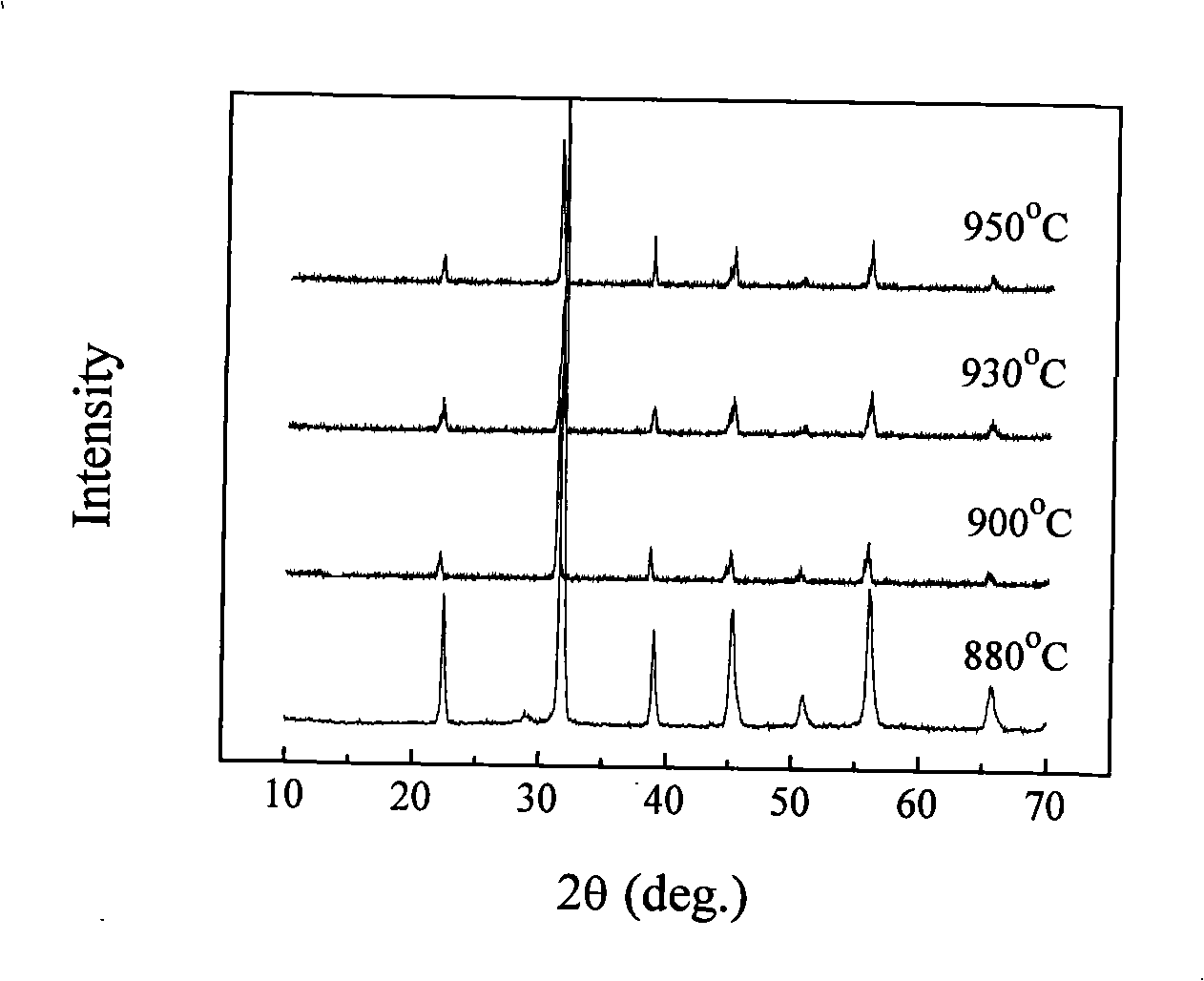

Low temperature sintering lithium antimonite doped quinary system piezoelectric ceramics material and method for preparing same

InactiveCN101337814APiezoelectric constantHigh Electrical Coupling CoefficientPiezoelectric/electrostrictive/magnetostrictive devicesLithiumDielectric loss

The invention provides low-temperature sintering lithium antimoniate mixed quinary system piezoelectric ceramics, which consists of the materials expressed with the following general expression: 0.02Pb(Mg1 / 2W1 / 2)O3-yPb(Sb1 / 2Nb1 / 2)O3-(0.39-y)Pb(Ni1 / 3Nb2 / 3)O3-Pb0.59(Zr0.38Ti0.21)O3+xLiSbO3. In the general expression, x is more than 0 percent by weight, but less than 0.40 percent by weight; y is more than or equal to 0 percent by weight, but less than or equal to 0.030mol. The preparation method of the lower-pressure sintering lithium antimoniate mixed quinary system peizoelectric ceramics comprises the processing steps of preparing lithium antimoniate, synthesizing ingredients, pre-burning, granulation, tabletting, batching-out, sintering, burning silver and polarization. According to the laboratory investigation result, the piezoelectric constant and the planar electromechanical coupling factor of the quinary system piezoelectric ceramics prepared are high; the low-temperature sintering performance is good. By comparing the low-temperature sintering antimoniate mixed quinary system with similar piezoelectric ceramics reported in literatures, the mechanical quality factor Qm and the dielectric loss tan Delta are significantly reduced; the piezoelectric constant d33 and the planar electromechanical coupling factor Kp are significantly improved; the sintering temperature is significantly reduced from 1200 DEG C to 900 DEG C; and the preparation process is simple with high repetitiveness, yield and low cost.

Owner:SHAANXI NORMAL UNIV

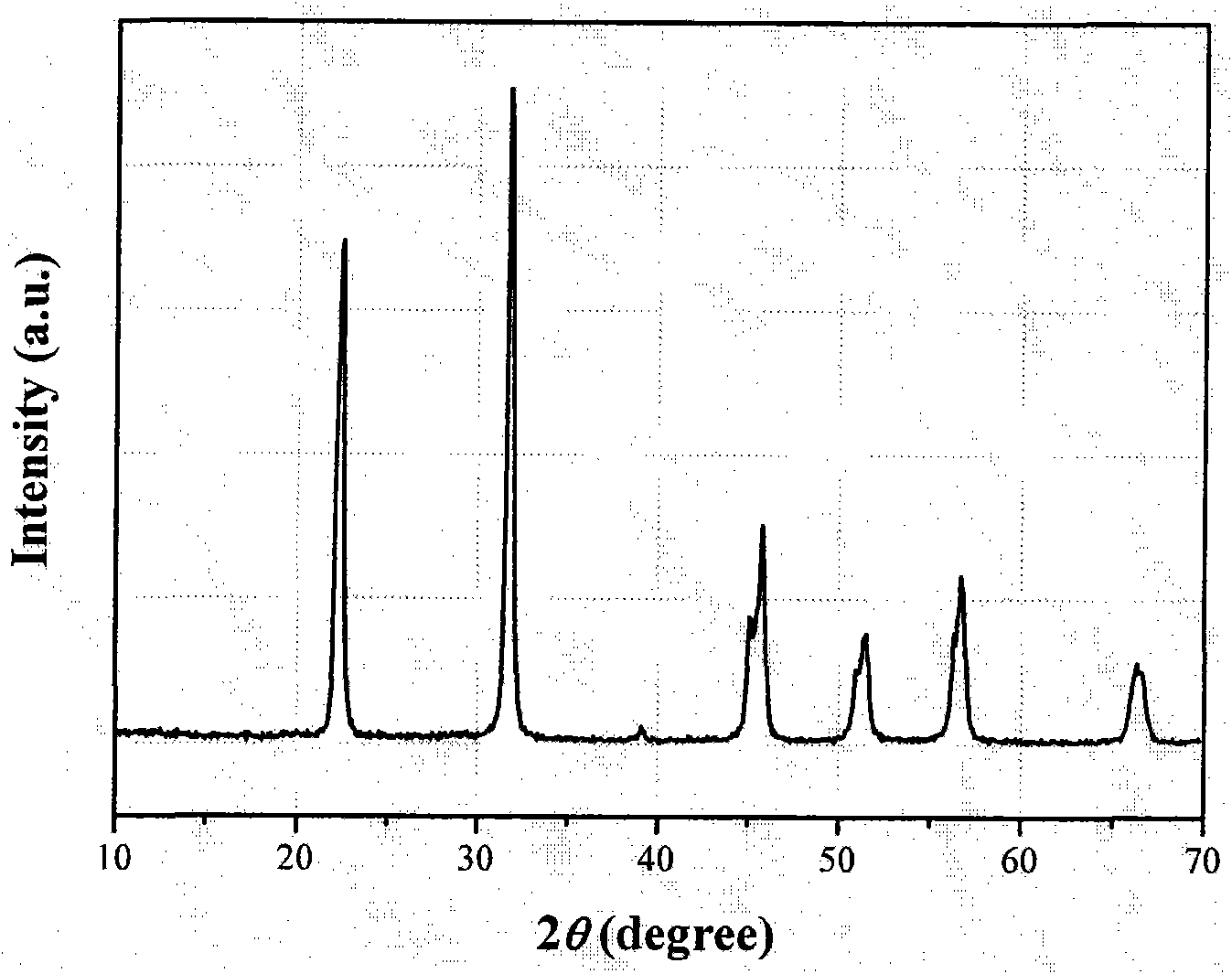

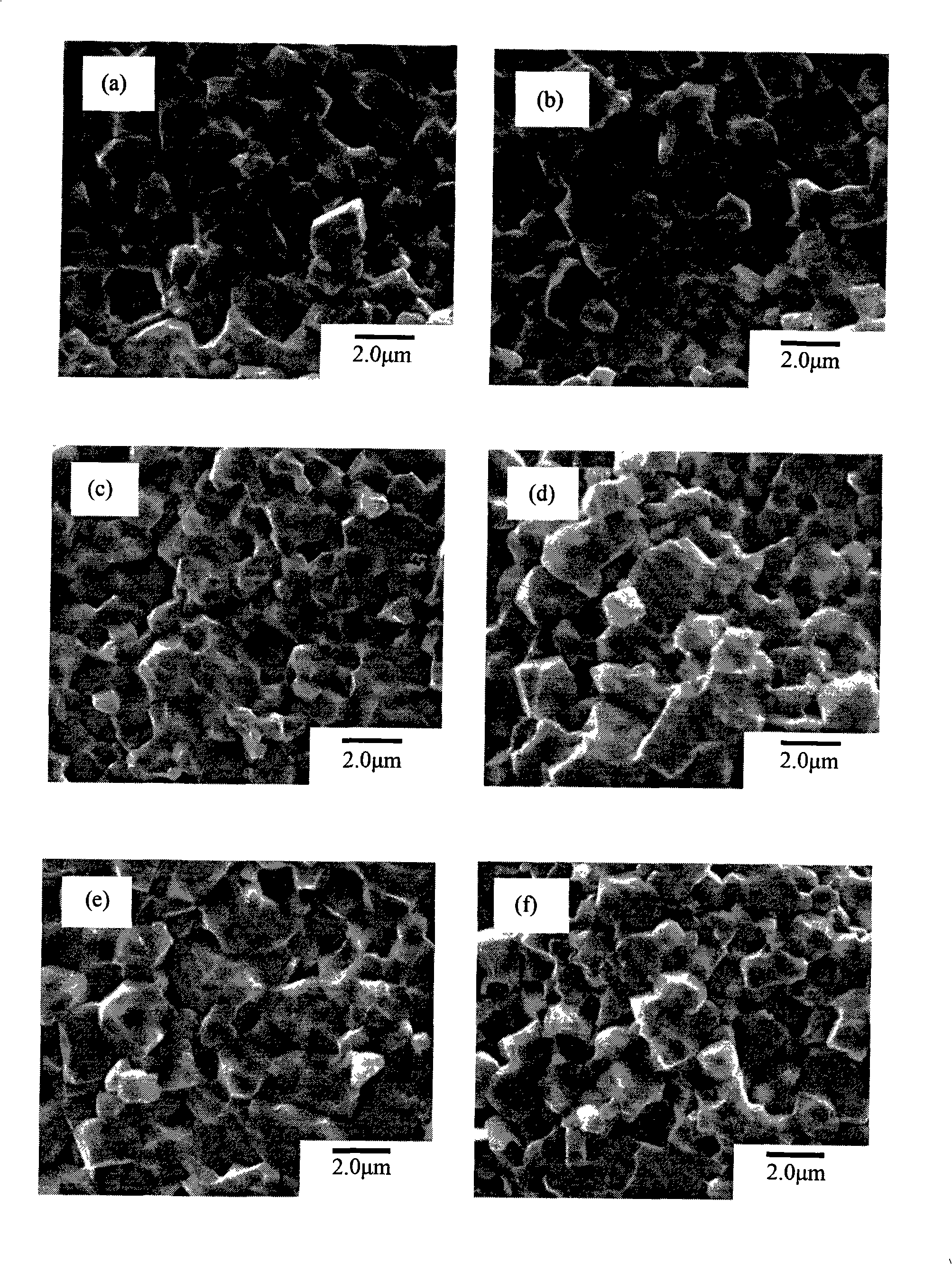

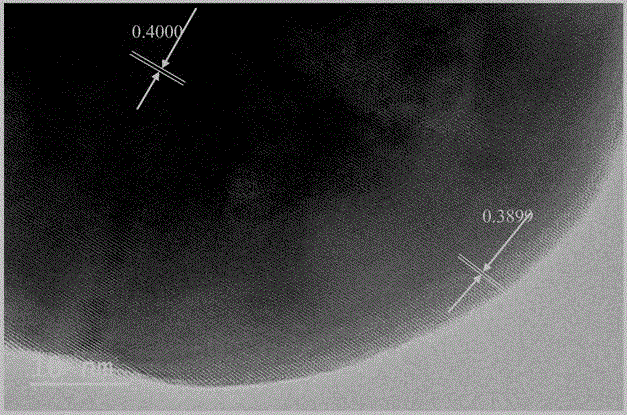

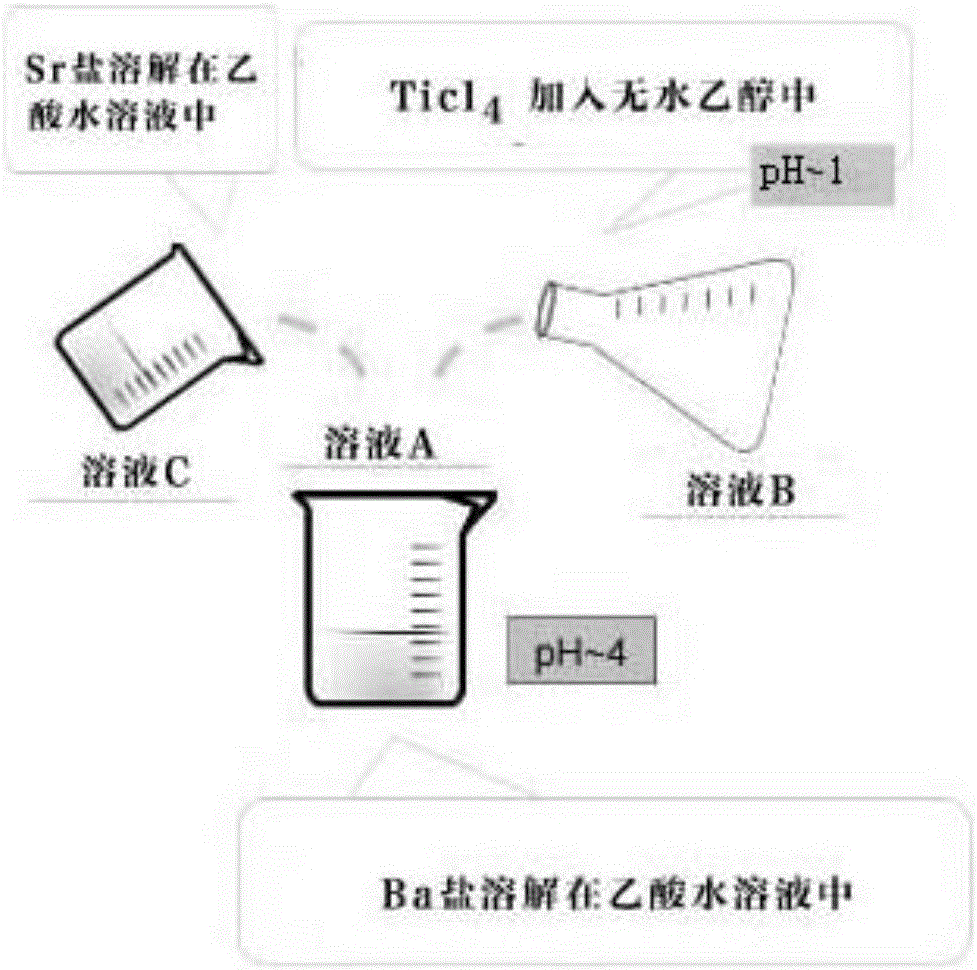

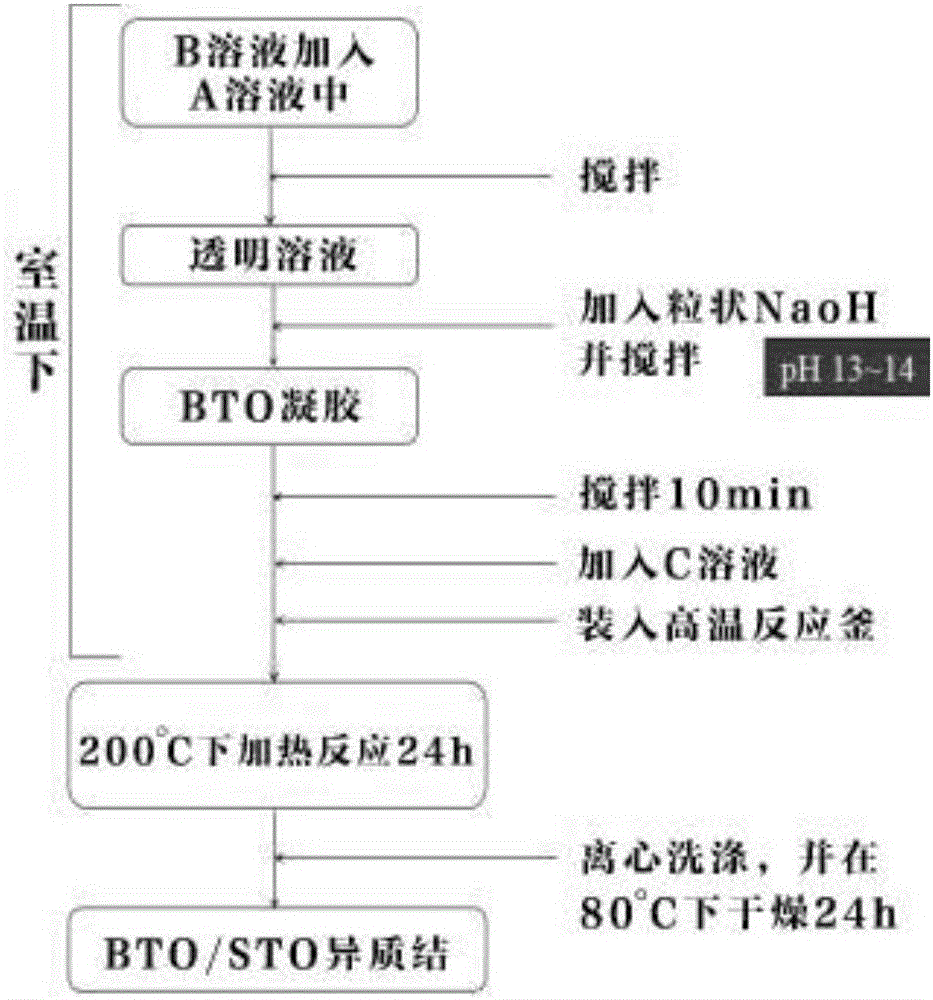

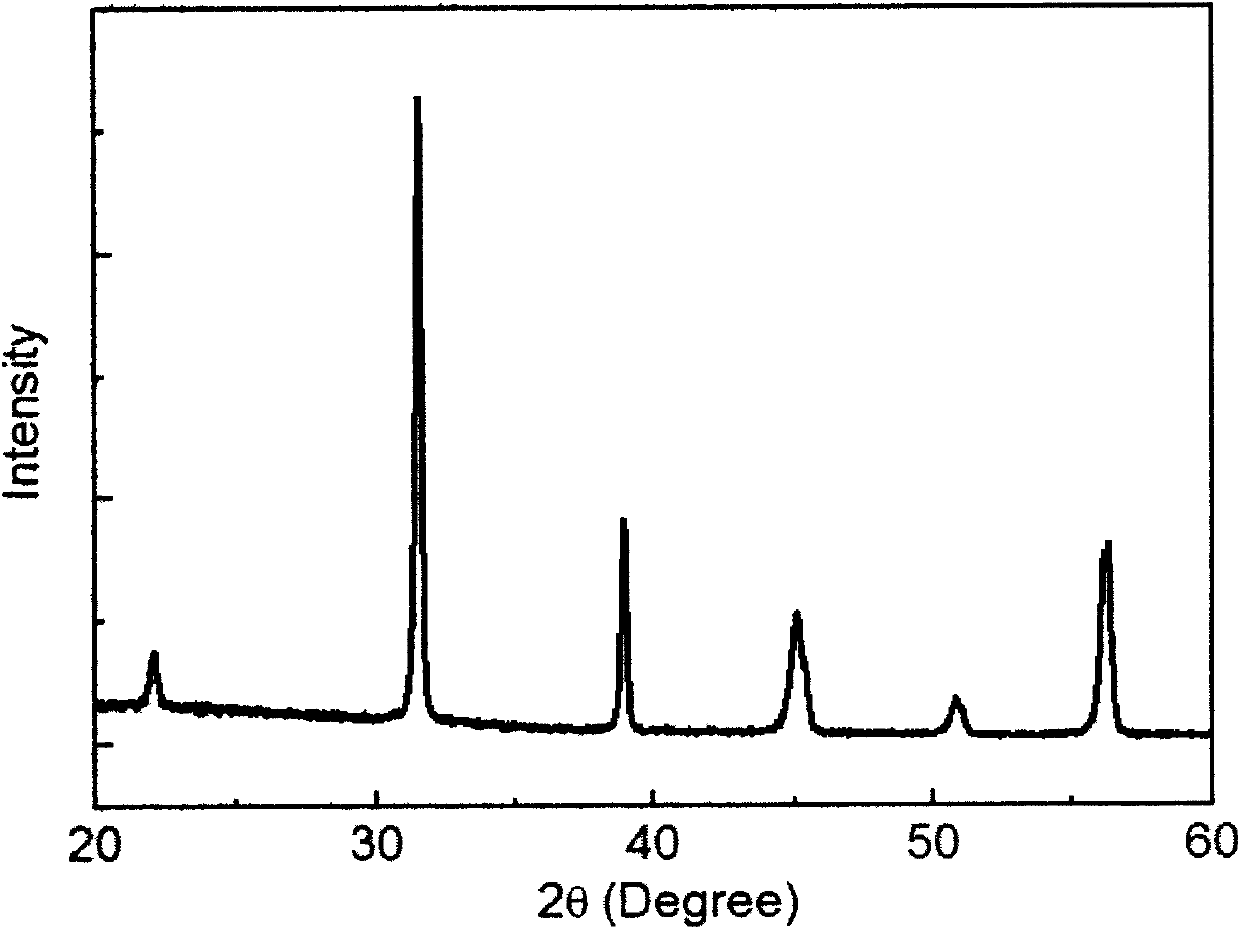

Synthesis method of SrTiO3 heterogeneously coated BaTiO3 ultrafine nano-powder

ActiveCN105948735AEffective dopingHigh dielectric constantMaterial nanotechnologyHeterojunctionSynthesis methods

The invention discloses a synthesis method of SrTiO3 heterogeneously coated BaTiO3 ultrafine nano-powder. According to the invention, BaTiO3 nano-particles are synthesized with a sol precipitation method; SrTiO3 is subjected to secondary nucleation with a hydrothermal method, such that a coating layer is formed; and the SrTiO3 heterogeneously coated BaTiO3 ultrafine nano-powder is synthesized. With the method provided by the invention, the synthesized nano-particles have small particle size, good dispersion and a significant core-shell structure. Also, because BaTiO3 and SrTiO3 have different interplanar spacings, the two are subjected to lattice distortion at contact interface layers, such that the dielectric constant and piezoelectric constant of BaTiO3 are improved. With the change of the doping amount of Sr, the interplanar spacings of heterojunction show a regular change.

Owner:SHANDONG UNIV

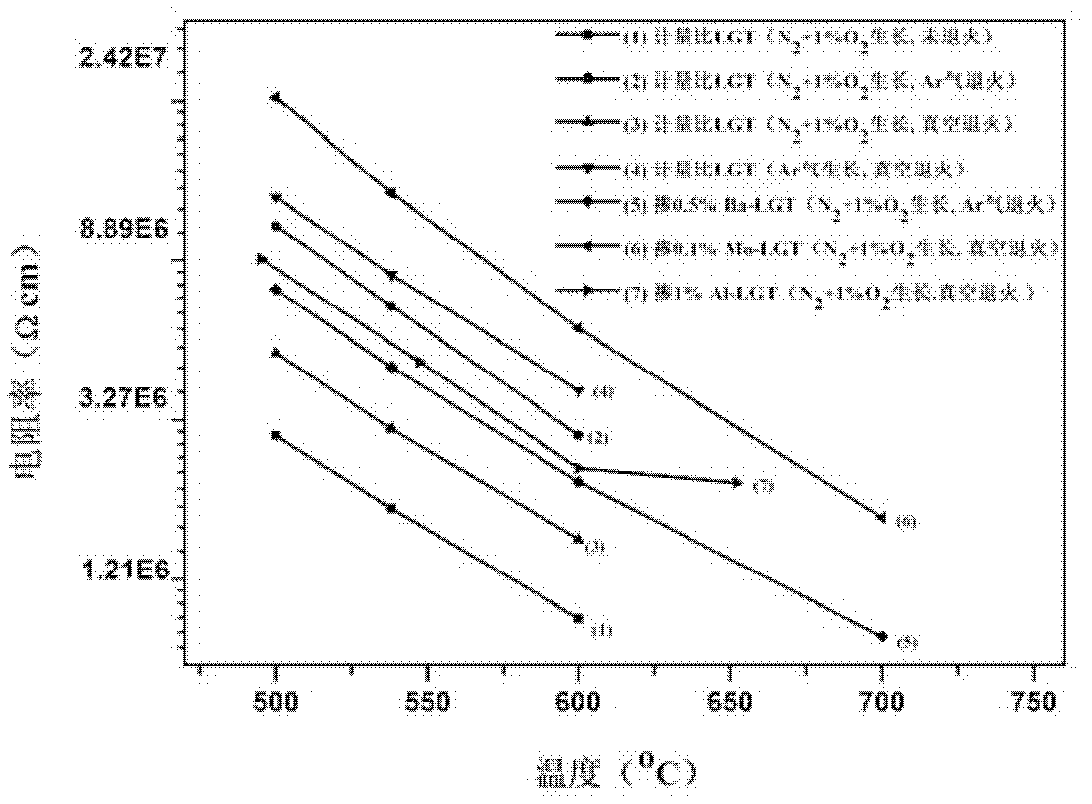

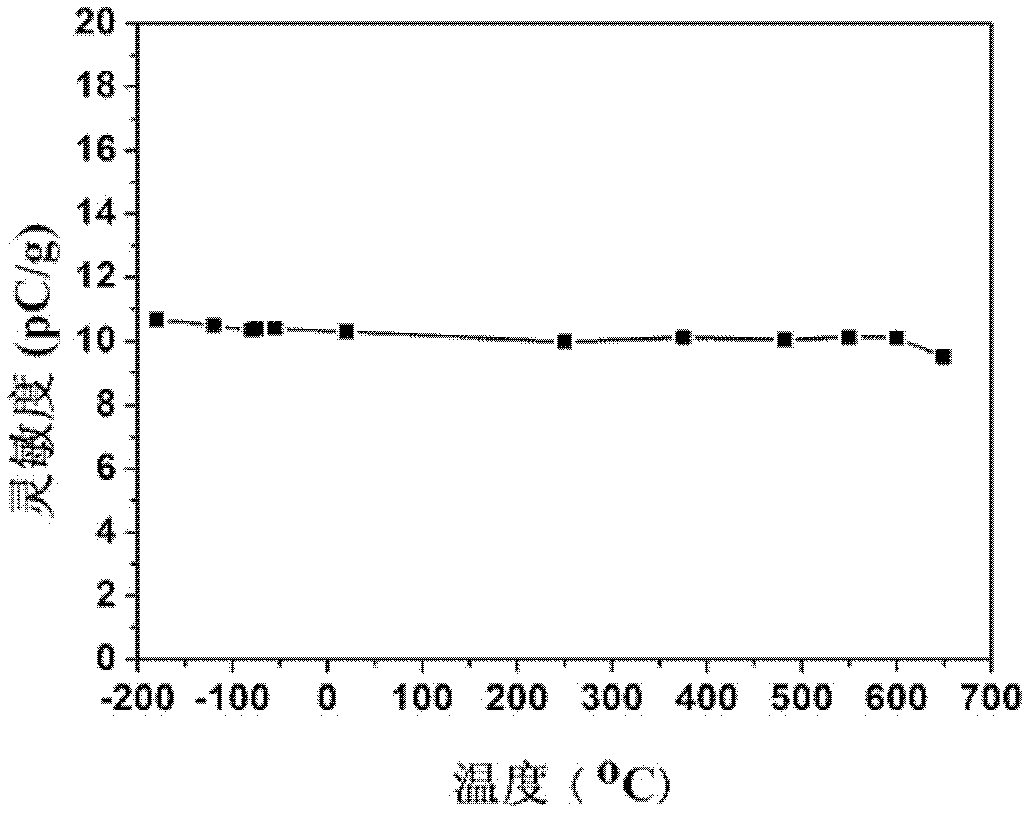

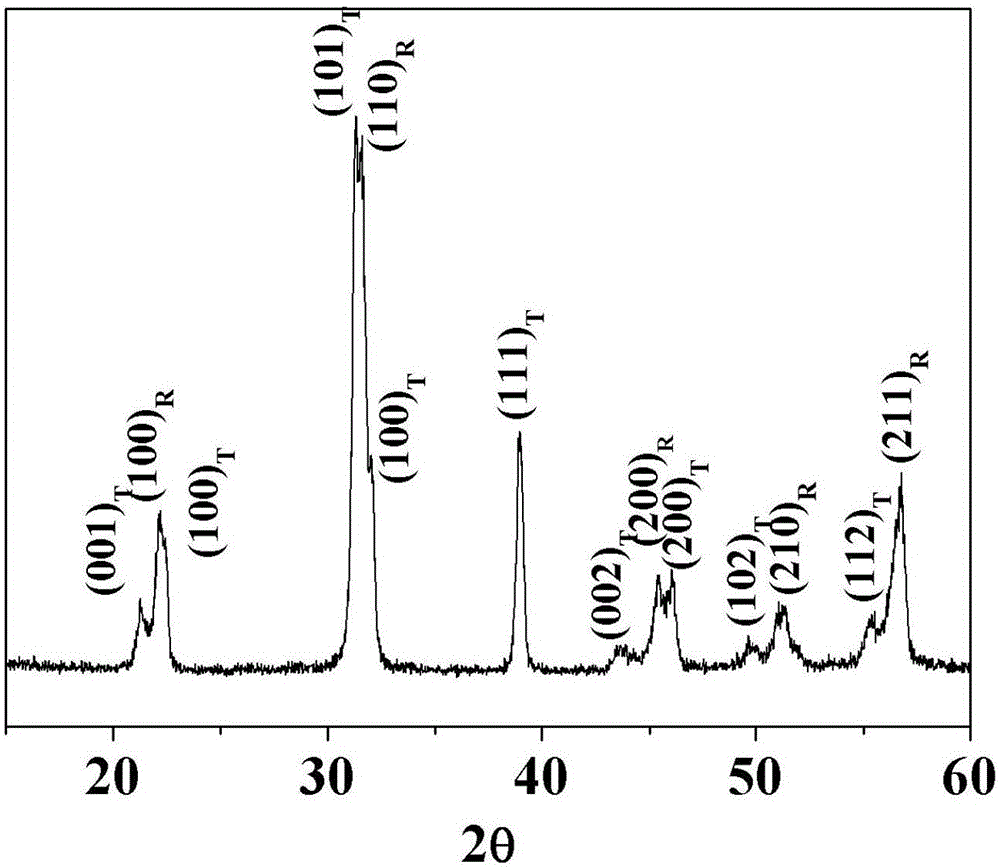

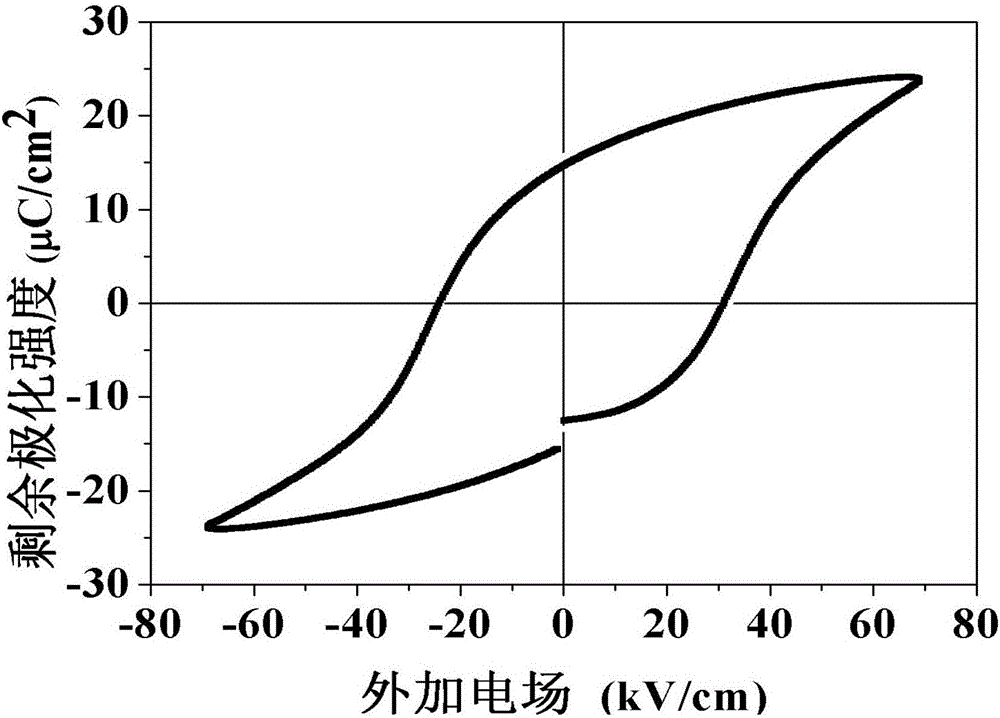

Doping type tantalic acid gallium-lanthanum crystal for high-temperature piezoelectric devices and preparation method thereof

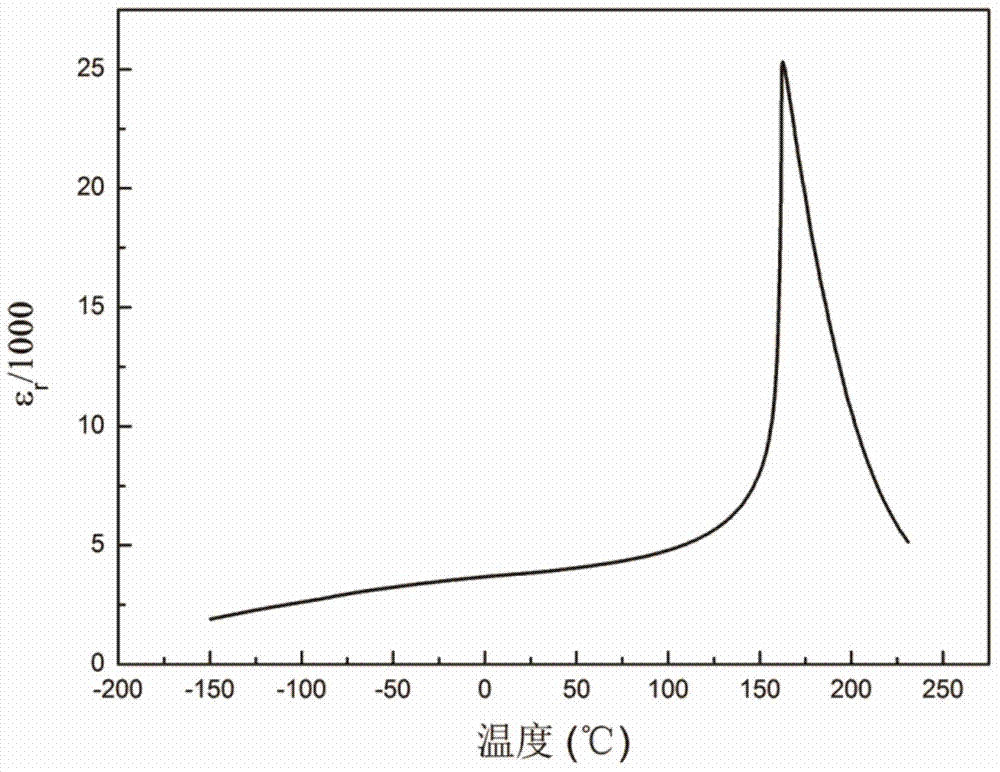

ActiveCN103173861ASmall sizeQuality improvementPolycrystalline material growthAfter-treatment detailsCzochralski methodLanthanum

The invention relates to a doping type tantalic acid gallium-lanthanum crystal for high-temperature piezoelectric devices and a preparation method of the doping type tantalic acid gallium-lanthanum crystal. The general formula of the doping type tantalic acid gallium-lanthanum (M-LGT) crystal is y%M: La3Ta0.5+xGa5.5-xO14, wherein x is larger than or equal to -0.3 and smaller than or equal to 0.3, y is larger than or equal to 3.0 and smaller than or equal to 2, and a doping element M is at least selected from one of Ba, Mo and Al. The crystal can be prepared through adopting crystal growing methods such as a czochralski method and a bridgeman-stockbarger method, and the electrical resistivity of the crystal at high temperature can be obviously increased through optimizing growing atmosphere, doping elements and post treating. A piezoelectric element which is produced by the crystal is firstly and successfully applied to a high-temperature piezoelectricity acceleration sensor of -200 DEG C-649DEG C, and the doping type high-electrical resistivity LGT crystal material has a bright application prospect in future piezoelectric devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

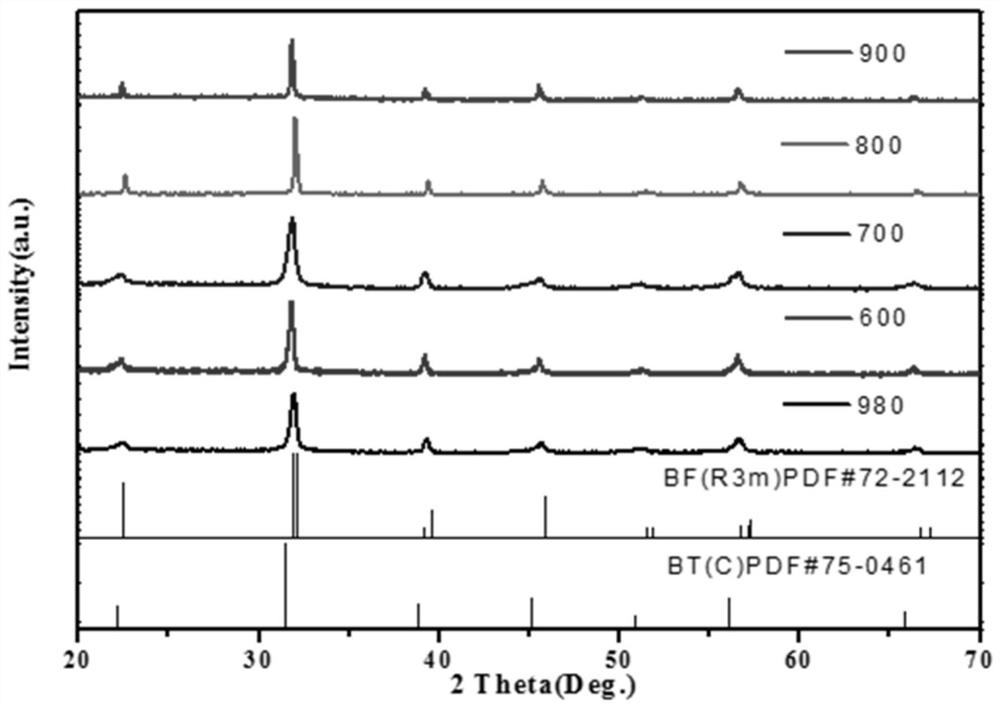

Bismuth ferrite-lead titanate-barium titanate ternary-system high-temperature piezoelectric ceramics and preparation method thereof

InactiveCN106810235AHigh curie temperatureImprove piezoelectric performanceBarium titanateSolid reaction

The invention discloses bismuth ferrite-lead titanate-barium titanate ternary-system high-temperature piezoelectric ceramics and a preparation method thereof. The BF-PT-BT high-temperature piezoelectric ceramics have the advantages that the BF-PT-BT high-temperature piezoelectric ceramics are prepared through a solid reaction process, so that insulation performance of a BF-PT material is improved remarkably through introduction of a third component BT into a BF-PT solid solution; a piezoelectric constant of the BF-PT-BT high-temperature piezoelectric ceramics is as high as 195 pC / N, the Curie temperature thereof is as high as 547 DEG C, and the piezoelectric performance thereof can be kept sable relatively at the temperature lower than 490 DEG C; the BF-PT-BT high-temperature piezoelectric ceramics are approximate to a piezoelectric material of a commercial bismuth layer structure in Curie temperature but are 4 times greater than that in piezoelectric coefficient.

Owner:SHANGHAI UNIV

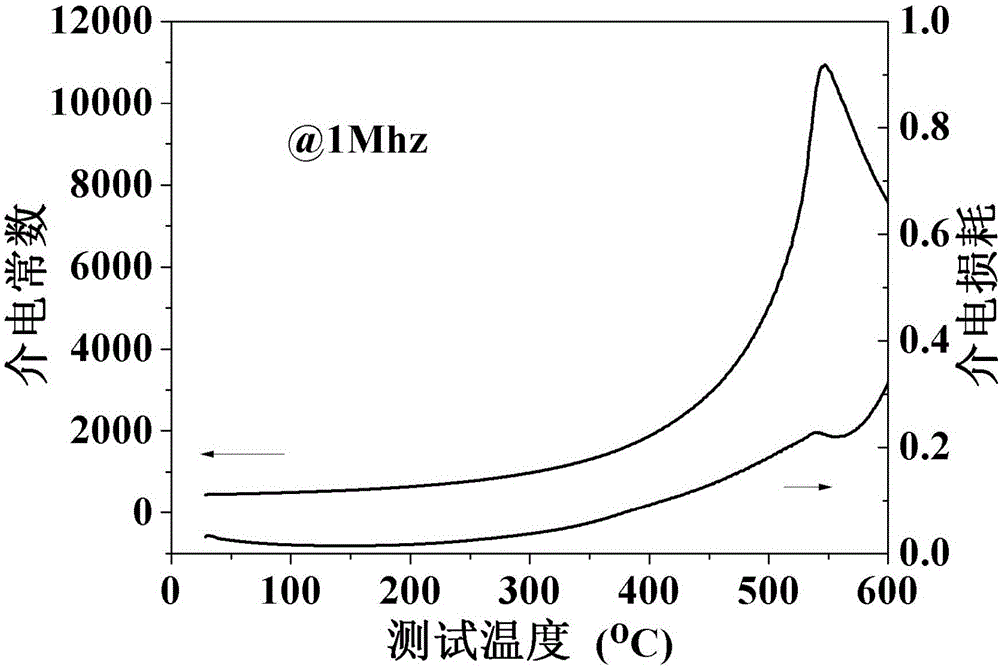

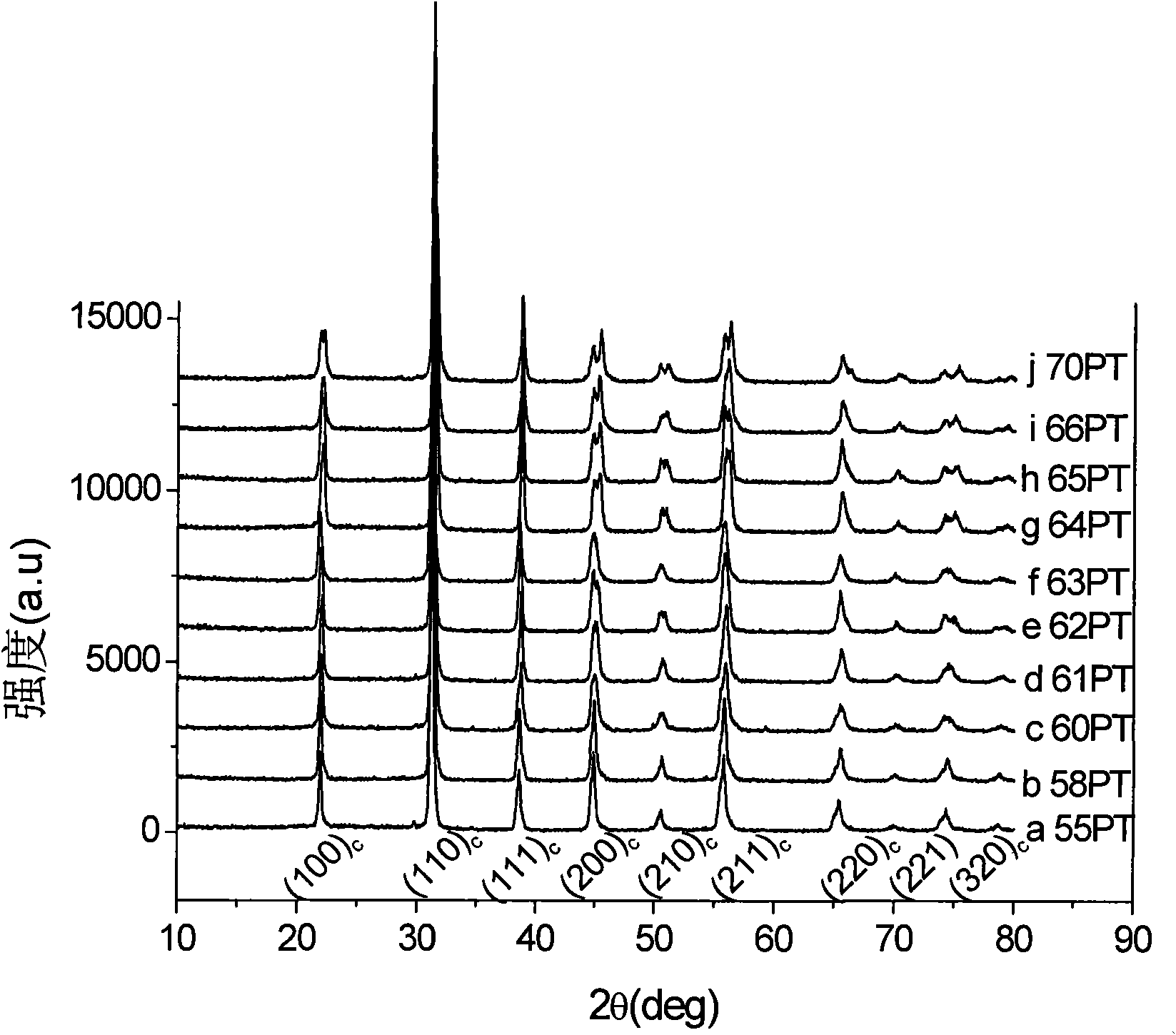

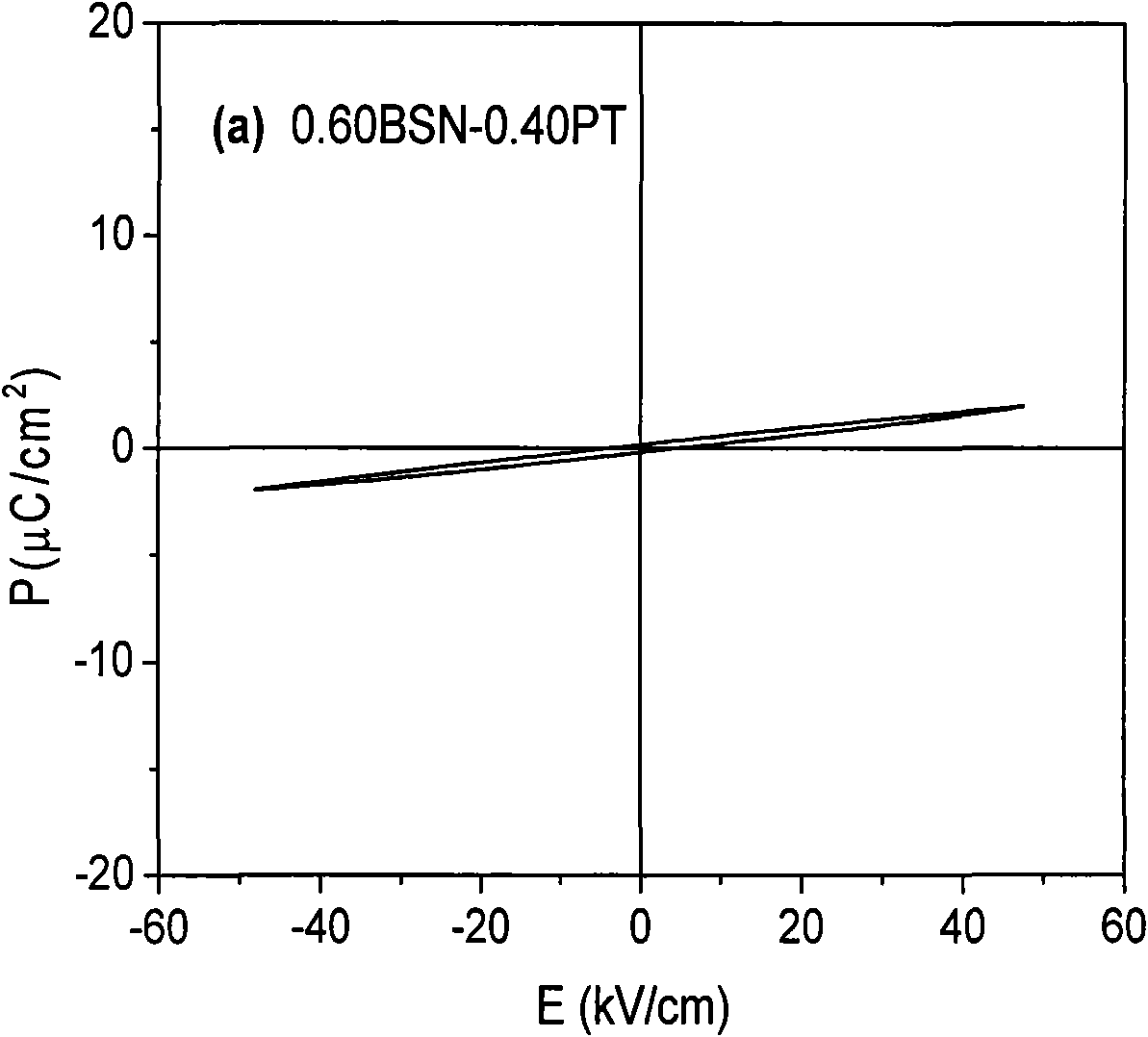

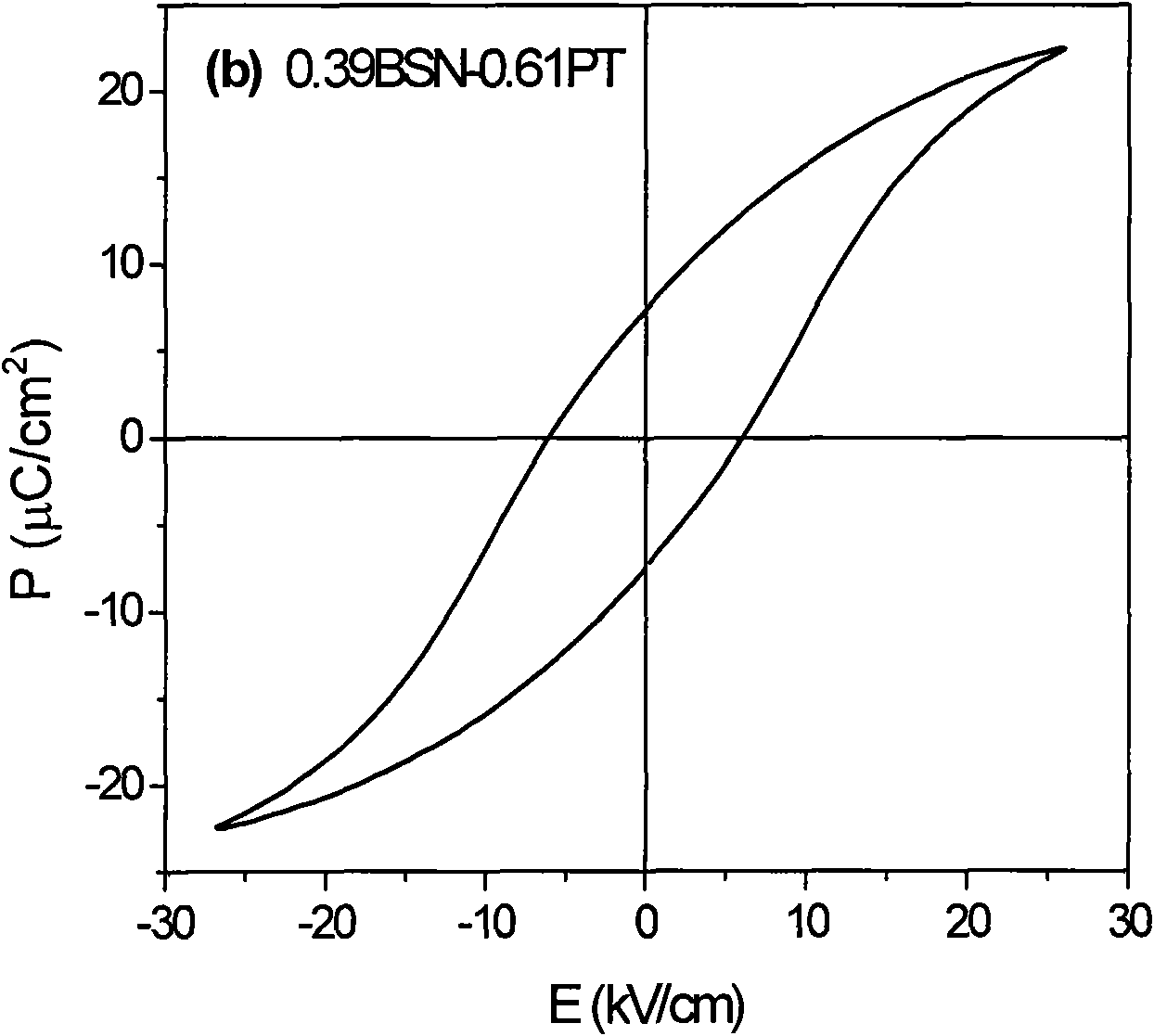

Novel ferroelectric ceramic barium niobate scandate -lead titanate, preparation method and application thereof

InactiveCN101618964AHigh dielectric permittivityPiezoelectric constantSynthesis methodsLead titanate

The invention relates to performances, preparation method and application of novel ferroelectric ceramic barium niobate scandate -lead titanate. The ceramic has a perovskite type structure and comprises the chemical formula of (1-x)Ba(Sc1 / 2Nb1 / 2)O3-xPbTO3, wherein 0 is more than or equal to 0 and less than or equal to 1. The ceramic system has a morphotropic phase boundary (MPB) with the range of more than 0.61 and less than 0.65. The ceramic can be prepared by a Columbite synthesis method or the conventional solid phase synthesis method and belongs to environment-friendly piezoelectric ceramics containing little lead.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Preparation method of macromolecule piezoelectric material

ActiveCN106380756AHigh dielectric constantPiezoelectric constantPulping with acid salts/anhydridesRaw material divisionCelluloseFiber

The invention discloses a preparation method of a macromolecule piezoelectric material, and belongs to the technical field of an electric material. The preparation method comprises the steps that firstly, biogas and bamboo splits are mixed and fermented, so that fiber is activated; then, steam explosion treatment is performed, so that the bamboo fiber is subjected to fiber separation; primary degradation is performed; after freezing, ice crystals are generated inside the fiber; the ice crystals crack under the grinding pressure, so that the bamboo fiber is refined; then, the fiber and phosphoric acid are subjected to mixed ball milling to prepare cellulose whiskers; the polyhydroxy characteristics of the cellulose whiskers are used for adsorbing precipitates; through calcination, the fiber is carbonized, and magnetic ferroferric oxide is adsorbed; finally, obtained black powder and polyvinylidene fluoride particles are mixed and are subjected to ball milling; after hot pressing sheet forming, polarization treatment is performed to obtain the macromolecule piezoelectric material. The preparation method has the advantages that the strength of a material film is enhanced by the carbonized fiber; the magnetic ferroferric oxide adsorbed by the fiber can be uniformly dispersed in a thin film; the repeatability of the film is improved, so that the structure is controllable; the service life is greatly prolonged; wide market prospects are realized.

Owner:TIANCHANG CHENGTAI MEDICINAL MACHINERY EQUIP CO LTD

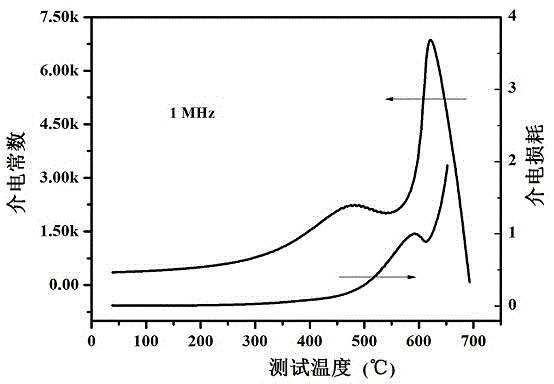

Ternary piezoceramic material with high Curie temperature and preparation method thereof

InactiveCN103951405AImproved high conductivity characteristicsImprove insulation performanceManganeseCurie temperature

The invention discloses a ternary piezoceramic material with high Curie temperature and a preparation method thereof. The piezoceramic material has a chemical formula of (1-y)((1-x)BF-xPT)-yPMN, wherein 0<y<0.1 and 0.2<x<0.4. A third component of plumbum manganese niobate (PMN) is introduced into a bismuth ferrite-plumbum titanate (BF-PT) system for the first time to form a ternary solid solution system. The characteristic of high Curie temperature of the BF-PT material itself is effectively used, and the introduction of the third component of PMN significantly improves the insulating property of the BF-PT material, which enables the BF-PT-PMN material of the invention to be easily polarized to obtain a high piezoelectric constant. The novel ternary piezoceramic material with high Curie temperature of the invention can prepare high temperature piezoelectric ceramics with a Curie temperature of up to 620 DEG C and a piezoelectric constant of up to 90 pC / N, and when compared with high temperature piezoelectric ceramics prepared in an US patent of Xiaoli Tan in 2013, the prepared high temperature piezoelectric ceramics have more excellent performance with not only a Curie temperature increased by nearly 50 DEG C, but also a piezoelectric constant increased by 26 pC / N. With the material and the method of the invention, application of BF-PT based materials in the high temperature piezoelectric field takes a big step forward.

Owner:SHANGHAI UNIV

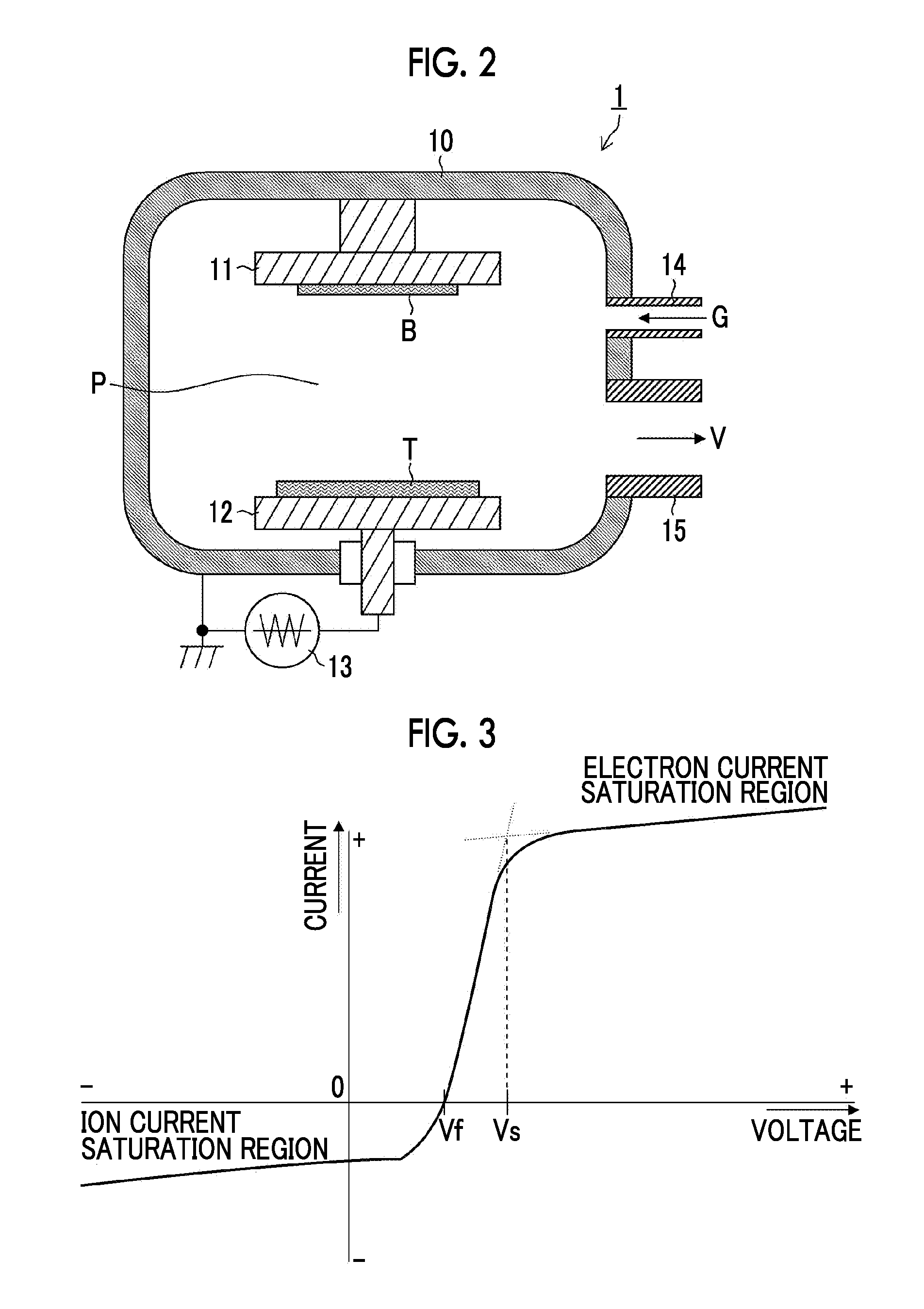

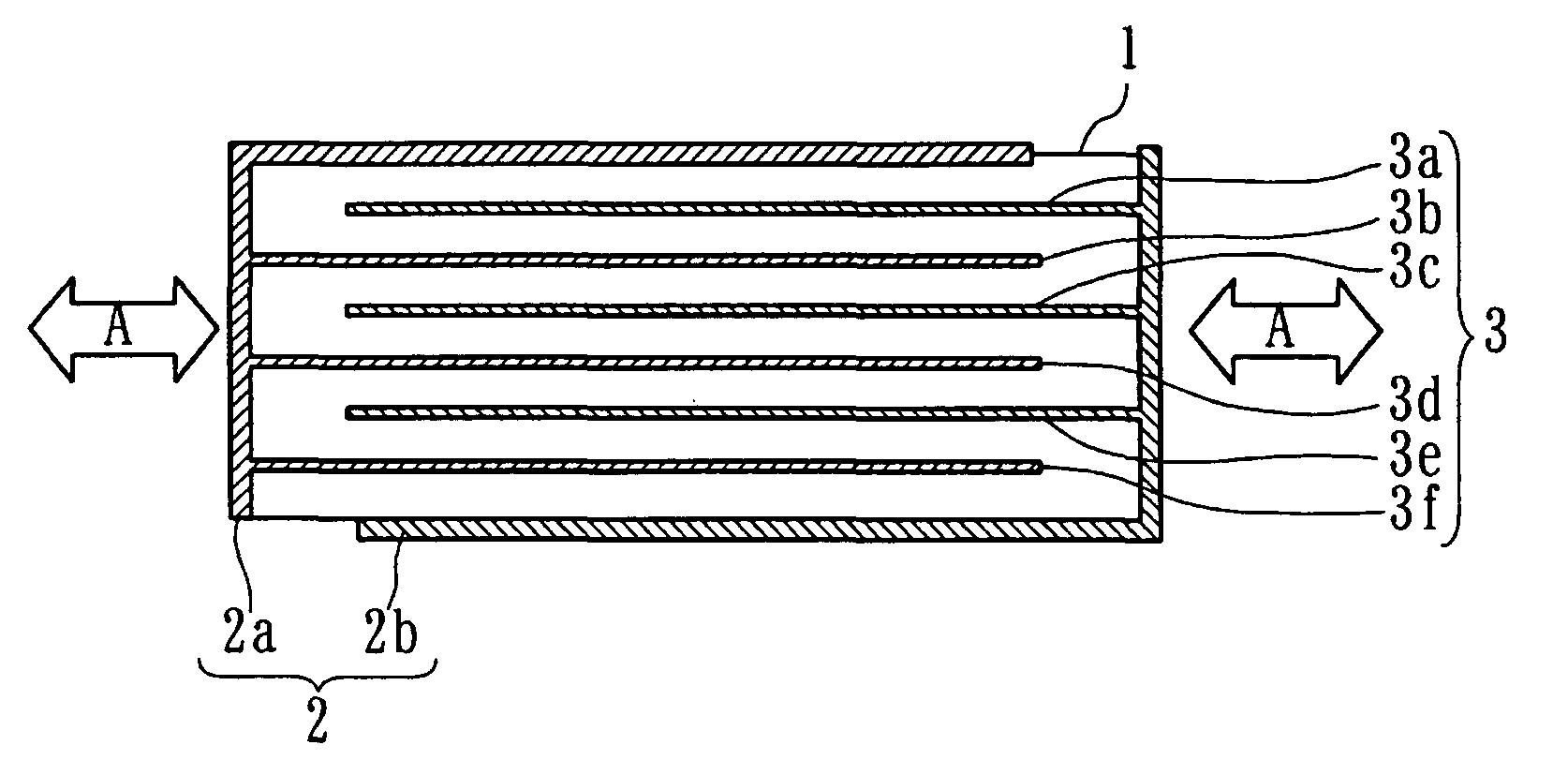

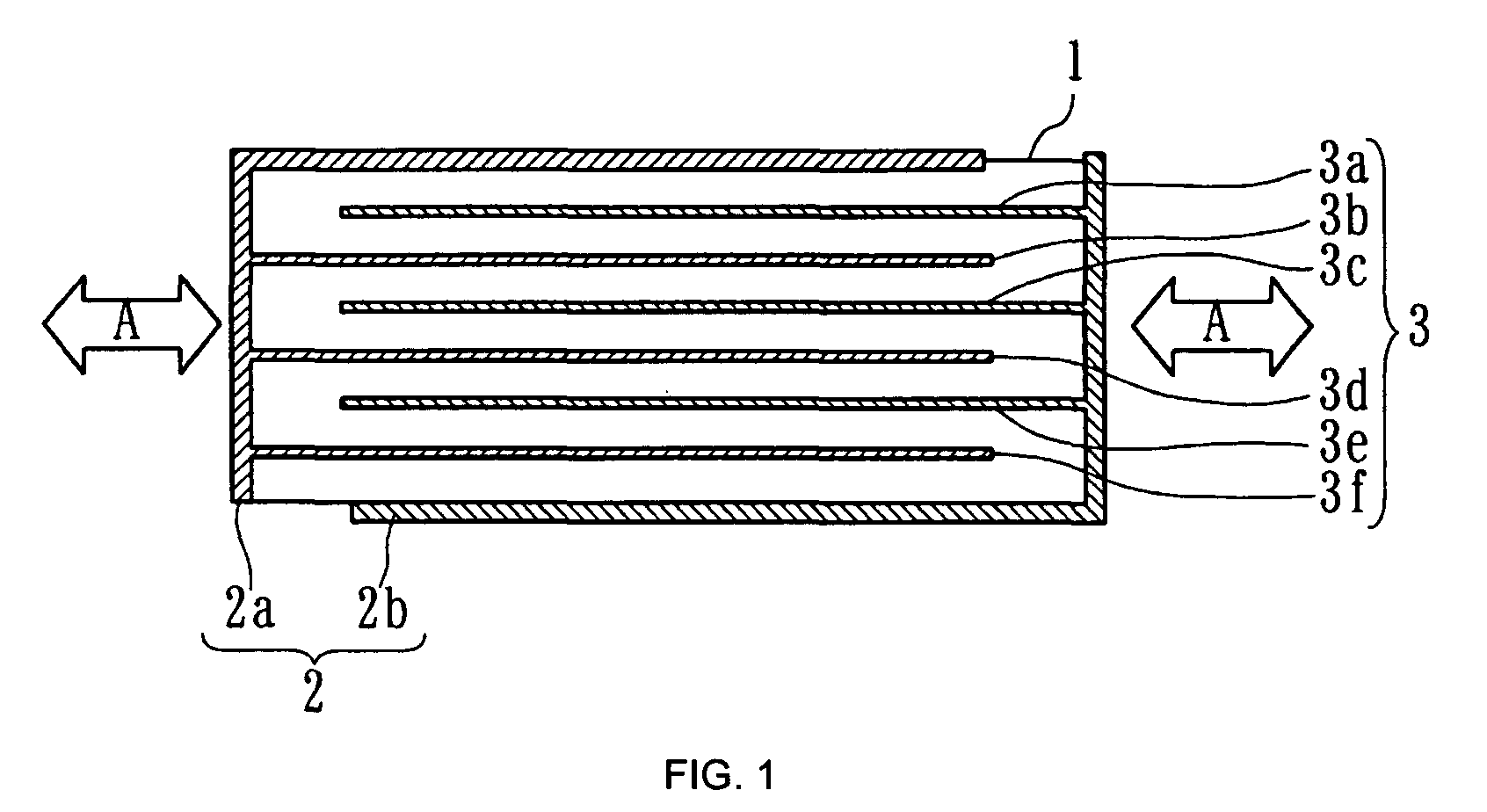

Manufacturing method for monolithic piezoelectric part, and monolithic piezoelectric part

ActiveUS7431785B2High piezoelectricExcellent insulation resistancePiezoelectric/electrostrictive device manufacture/assemblyLaminationInsulation resistanceOxide

A monolithic piezoelectric part capable of yielding a high piezoelectric d constant and suppressing reduction in reliability such as deterioration in insulation resistance can be obtained by a method for manufacturing a monolithic piezoelectric part wherein a piezoelectric ceramic body is formed of a perovskite compound oxide expressed by the general formula of ABO3, and the molar quantity of the A site component, Pb, is reduced by about 0.5 mol % to 5.0 mol % from that of the stoichiometric composition, ceramic raw materials are combined so that the average valence of the B site component is greater than quadrivalent, which is the same as the stoichiometric composition, to synthesize the ceramic powdered raw material, which is processed subsequently to fabricate a layered article, and the layered article is subjected to sintering processing within an atmosphere wherein the oxygen concentration is about 5% or less but more than 0% by volume.

Owner:MURATA MFG CO LTD

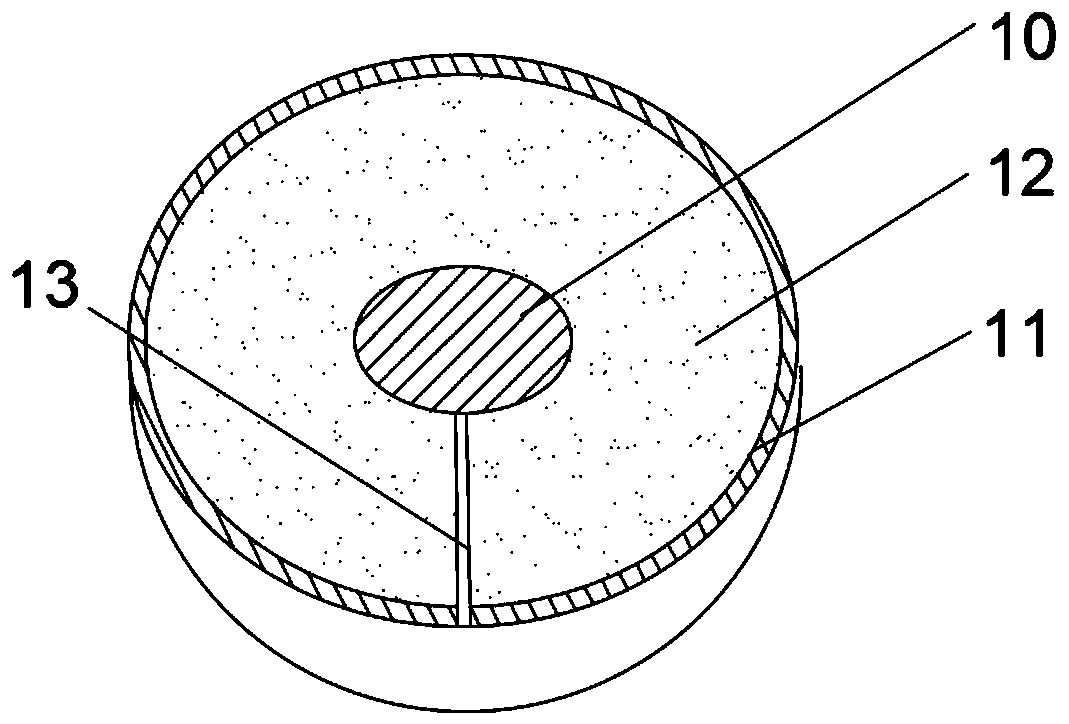

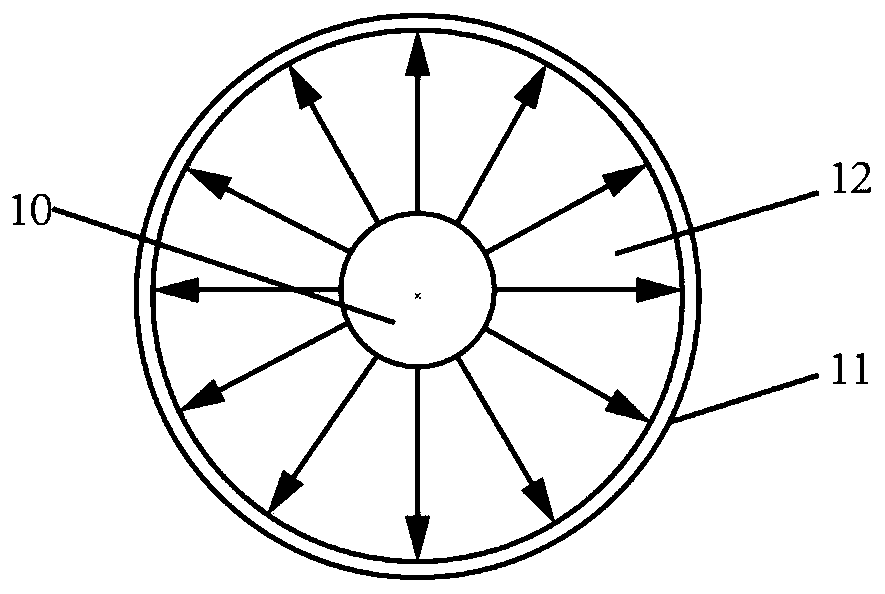

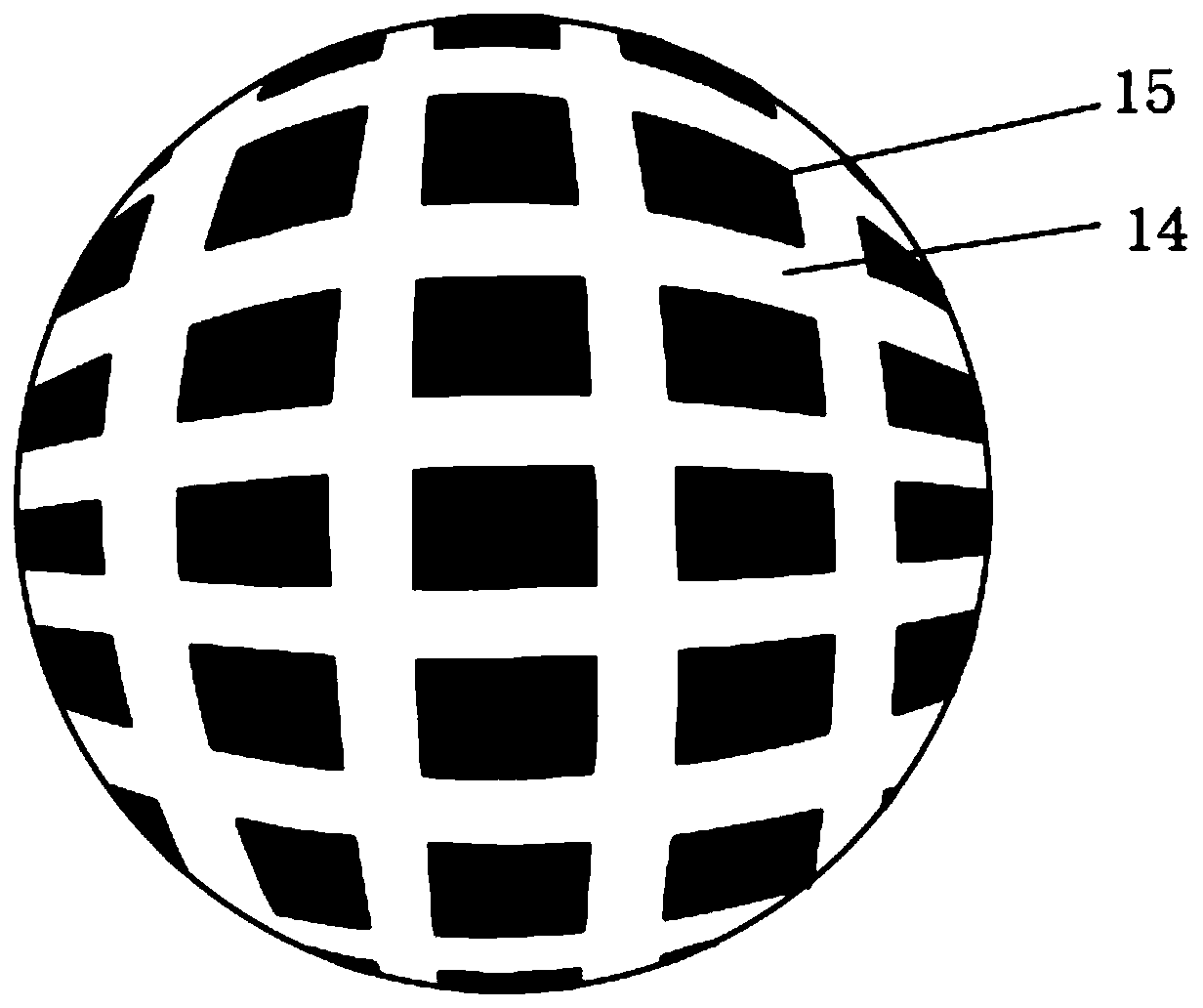

Piezoelectric ceramic intelligent structure and method for embedding piezoelectric ceramic intelligent structure into metal matrix

ActiveCN111129282APiezoelectric constantHigh Young's modulusPiezoelectric/electrostrictive device manufacture/assemblyCeramic materials productionMetal coatingSensor array

The invention provides a piezoelectric ceramic intelligent structure and a method for embedding the piezoelectric ceramic intelligent structure into a metal matrix. The piezoelectric ceramic intelligent structure provided by the invention comprises a piezoelectric ceramic spherical shell, wherein the middle of the piezoelectric ceramic spherical shell is provided with a spherical metal inner coreserving as an internal electrode, the outer surface of the piezoelectric ceramic spherical shell is provided with a metal coating serving as an external electrode, the outer surface of the piezoelectric ceramic spherical shell is subjected to electrode segmentation to form pressure sensor arrays arranged at equal intervals, and the piezoelectric ceramic spherical shell is internally provided witha lead channel used for leading out the internal electrode. According to the piezoelectric ceramic spherical array structure with the spherical metal inner core, piezoelectric ceramic has a high piezoelectric constant and Young modulus compared with piezoelectric fibers, and the reaction speed is high. The structure is uniform in spatial directivity, can focus and sense signals by 360 degrees, andcan be used as a signal receiver and a signal generator at the same time.

Owner:HANGZHOU DIANZI UNIV

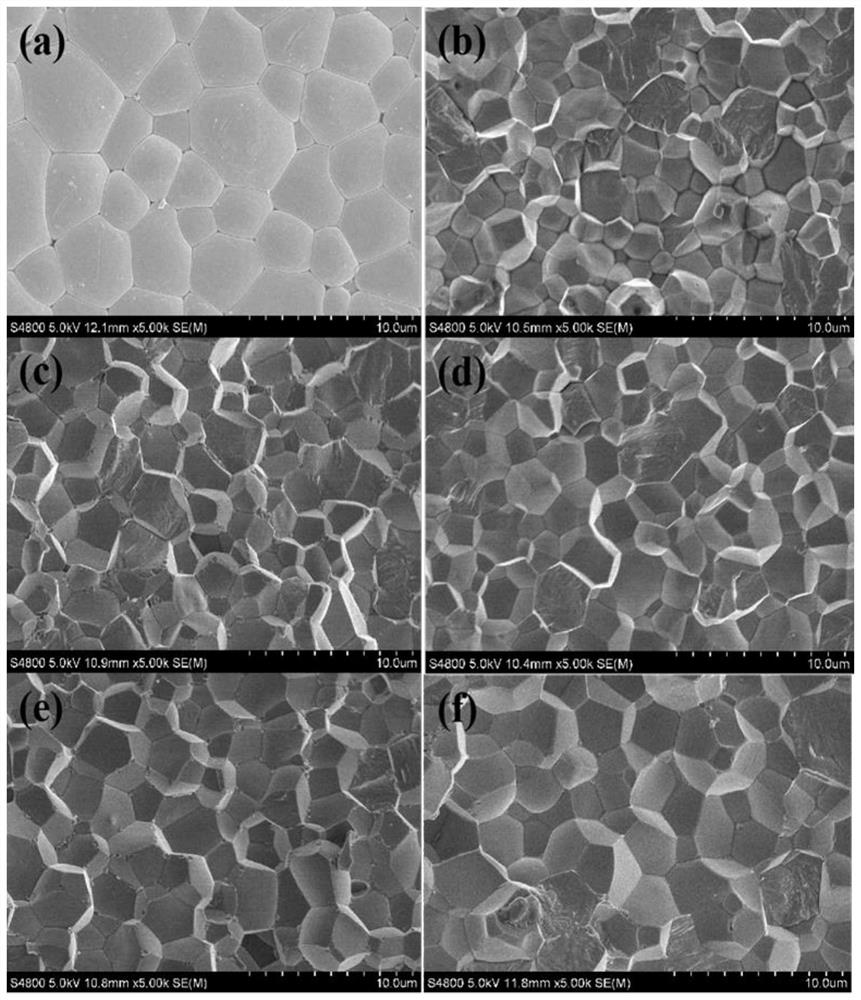

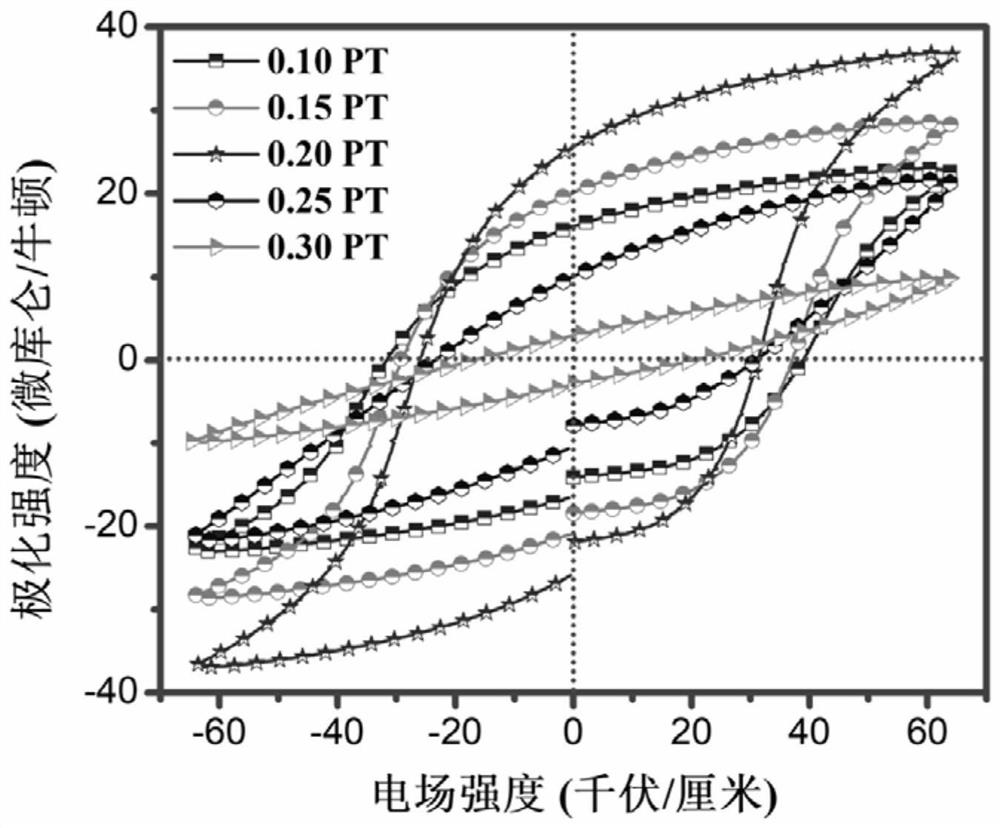

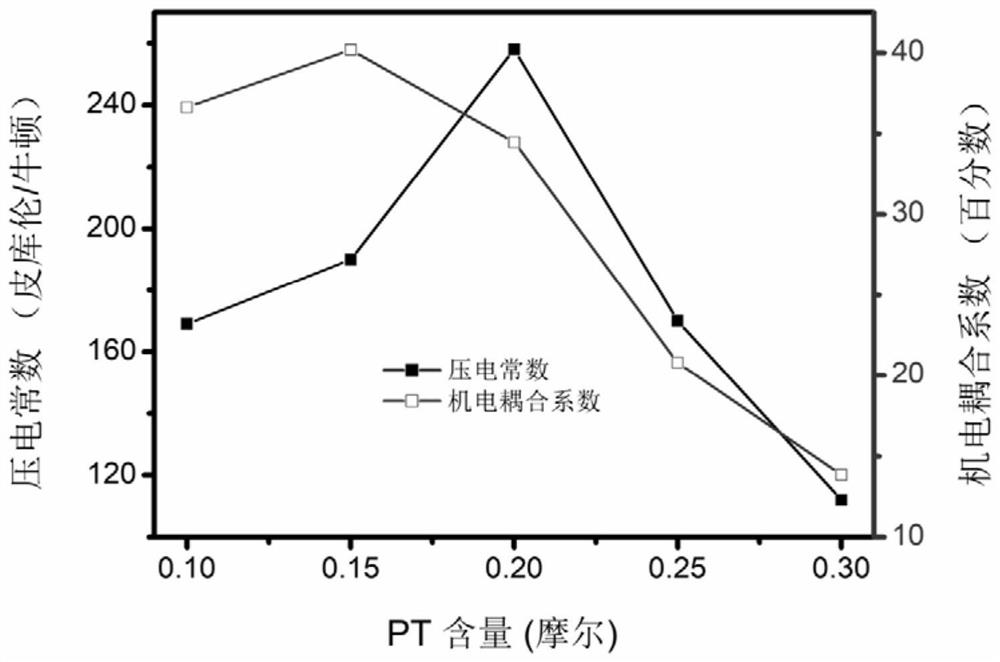

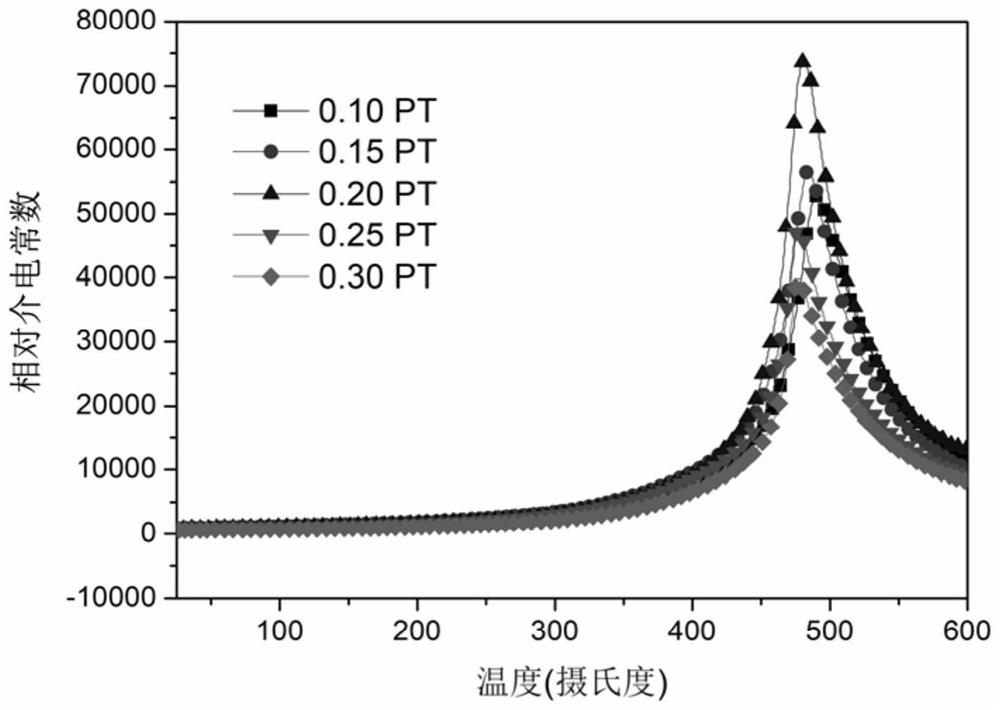

Bismuth ferrite-based piezoelectric ceramic material with high depolarization temperature and high piezoelectric property, and preparation method thereof

InactiveCN112062551AHigh curie temperatureHigh depolarization temperatureCompression moldingBarium titanate

The invention relates to a bismuth ferrite-based piezoelectric ceramic material with high depolarization temperature and high piezoelectric property, and a preparation method thereof, wherein the general chemical formula of the bismuth ferrite-based piezoelectric ceramic material is (1-x)(0.725BiFeO3-0.275BaTiO3)-xPbTiO3+0.8 mol% MnO2, and x is greater than or equal to 0.1 and less than or equal to 0.3. The preparation method comprises the following steps: mixing all metal oxide raw materials, sequentially carrying out ball milling, drying and presintering, mixing with a manganese source, carrying out secondary ball milling and drying, mixing with PVA, granulating, and carrying out compression molding to obtain a ceramic green body; and finally carrying out rubber discharging and sinteringon the ceramic green body to obtain the bismuth ferrite-based piezoelectric ceramic material. Compared with the prior art, the bismuth ferrite-based piezoelectric ceramic material disclosed by the invention has the advantages that the preparation method is simple, economic, practical and the like, and the prepared bismuth ferrite barium titanate-based piezoelectric ceramic has high Curie temperature, excellent temperature stability and relatively high piezoelectric constant, and shows a wide industrial application prospect.

Owner:TONGJI UNIV

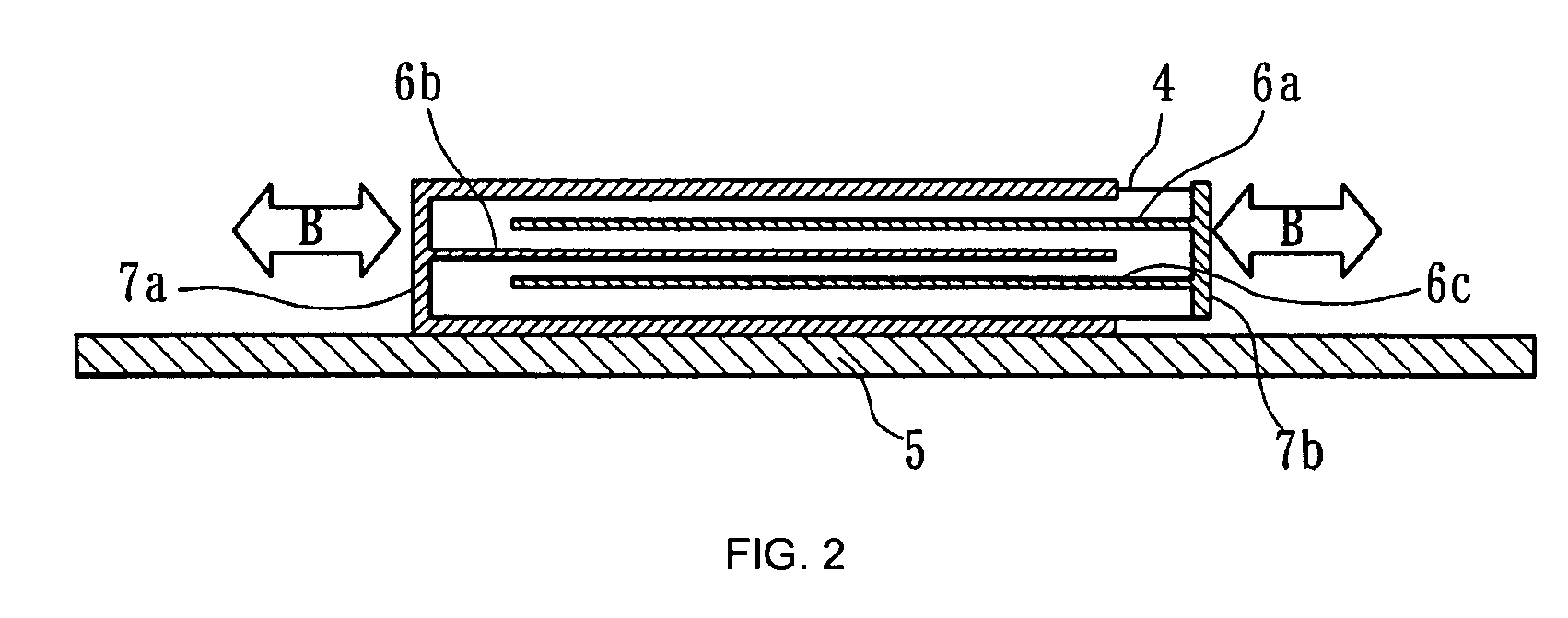

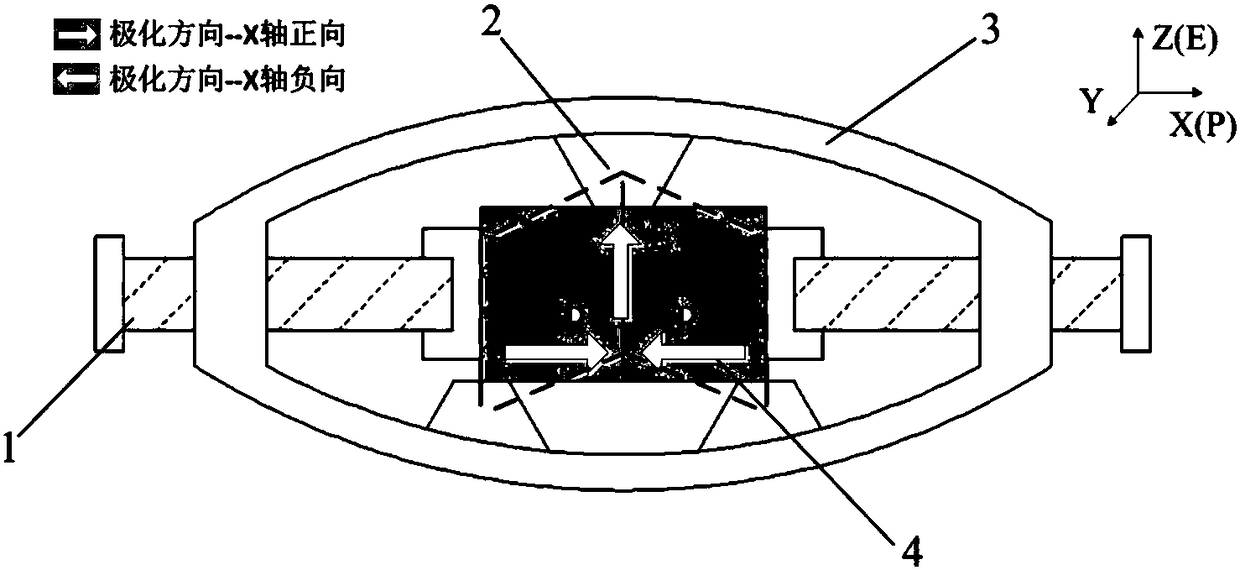

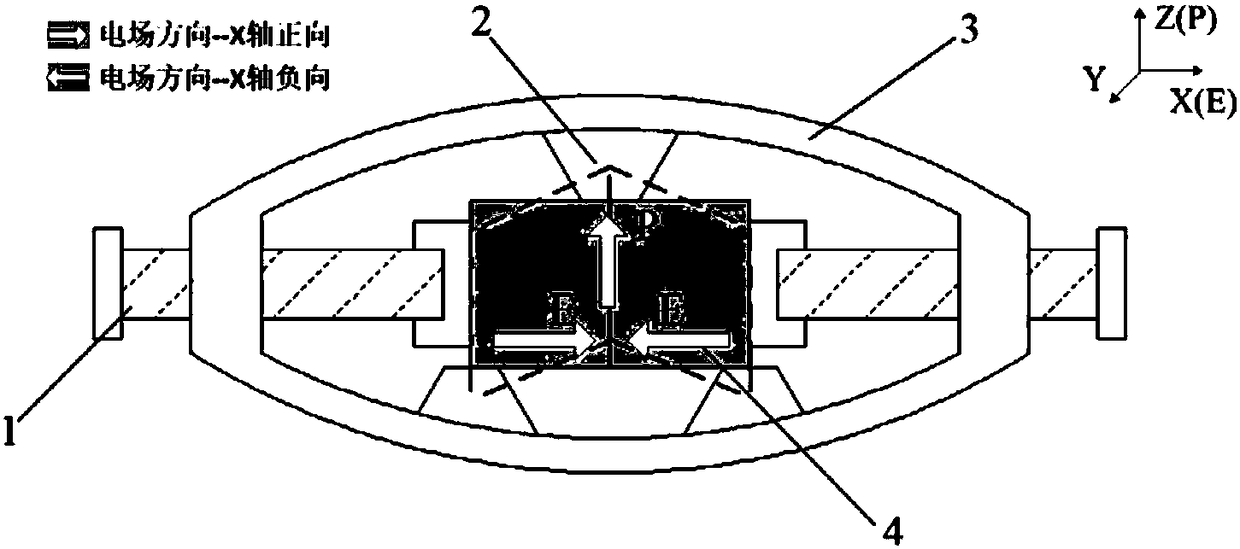

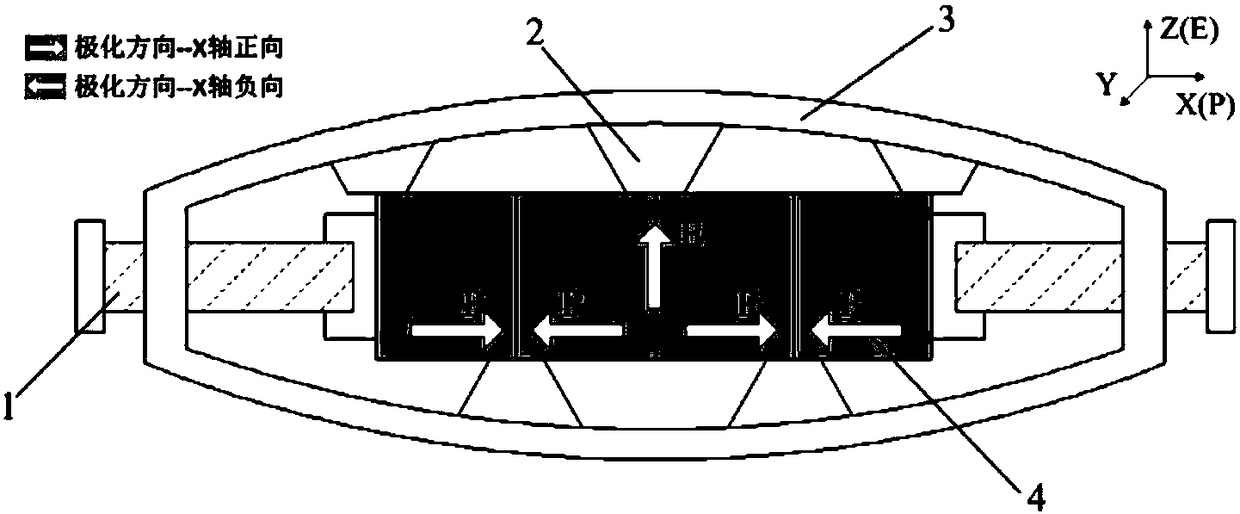

Piezoelectric vibrator based on shear vibration and flexural vibration, flexural transducer and manufacturing method of flexural transducer

ActiveCN108493328AImprove performanceImprove distance accuracyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device detailsElectromechanical coupling coefficientTransducer

The invention relates to a piezoelectric vibrator based on shear vibration and flexural vibration, a flexural transducer and a manufacturing method of the flexural transducer. According to the piezoelectric vibrator based on shear vibration and flexural vibration, the flexural transducer and the manufacturing method of the flexural transducer, with the limitations of the application of a d33 modeby a conventional 1-3 piezoelectric composite transducer eliminated, a d15 mode with a higher piezoelectric constant and an electromechanical coupling coefficient is selected to act as a vibration element; in order to avoid the defect of the shear vibration generation of the d15 mode, the shear vibration of the d15 mode is transformed to the flexural vibration of the upper surface and lower surface of a flexural shell through a special structural design, so that the shear vibration mode can be adopted to generate transverse waves; a low-frequency, high-power and small-sized transducer which ismanufactured on the basis of the d15 mode meets requirements such as underwater long-distance communication and detection. In the underwater sound field, the piezoelectric vibrator based on shear vibration and flexural vibration can improve the working distance and detection accuracy of a sonar system, and provide effective help for military detection, early warning, civil navigation, fishing andthe like.

Owner:BEIJING INFORMATION SCI & TECH UNIV

High-performance piezoelectric ceramic and preparation method thereof

The invention discloses a high-performance piezoelectric ceramic and a preparation method thereof. The chemical general formula is Pb<n>Sr<m>(Mg<1 / 3>Nb<2 / 3>) Zr<y>Ti<x>O<3>+g%CeO<2>+h%PbO+b%CuO+d%Nb<2>O<5>, in the formula, 0.927 < = n < = 0.976, 0.024 < = m < = 0.073, 0.25 < = z < = 0.25, 0.35 < = y < = 0.35, 0.50 < = x < = 0.60, 0.4<=g<=0.7, 0.1<=h<=0.3, 0.1<=b<=0.3, 0.1<=d<=0.3. According to thepreparation method, Pb(Mg<1 / 3>Nb<2 / 3>)O<3> is synthesized, and adding into a PZT system is adopted to realize high intensity. The prepared product is high in density, high in power, high in efficiency, and high in quality. The piezoelectric ceramic is a modified hard PZT system piezoelectric ceramic, has high power bearing capacity and high comprehensive performance, can meet the requirements ofpeople, is extremely suitable for power type transducers with extremely high power and high driving requirements, and can be widely applied to sensors with extremely high power requirements such as high-power sound wave welding and fishery group detection.

Owner:李茂洪

Piezoelectric optoelectronic material for degradation of organic pollutants and degradation method thereof

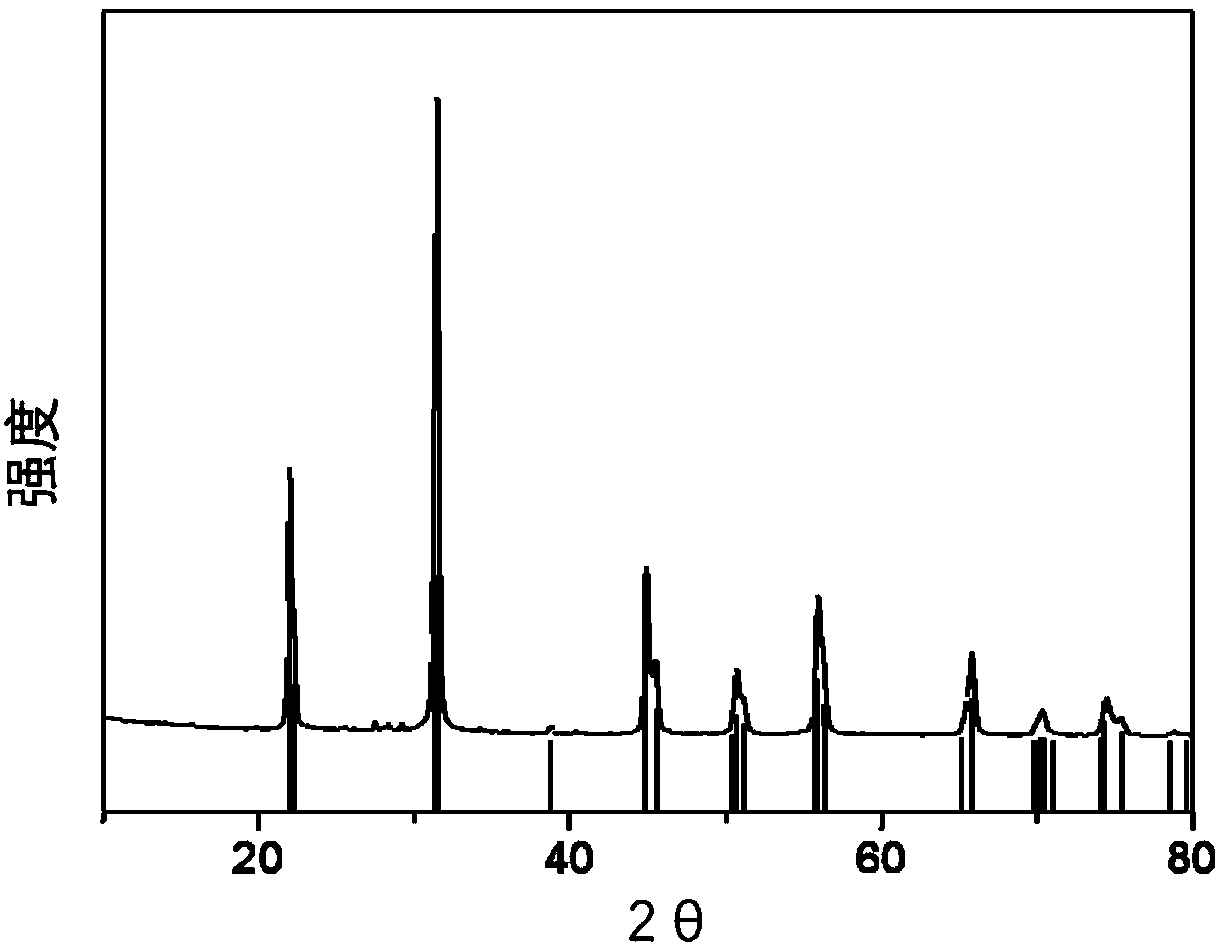

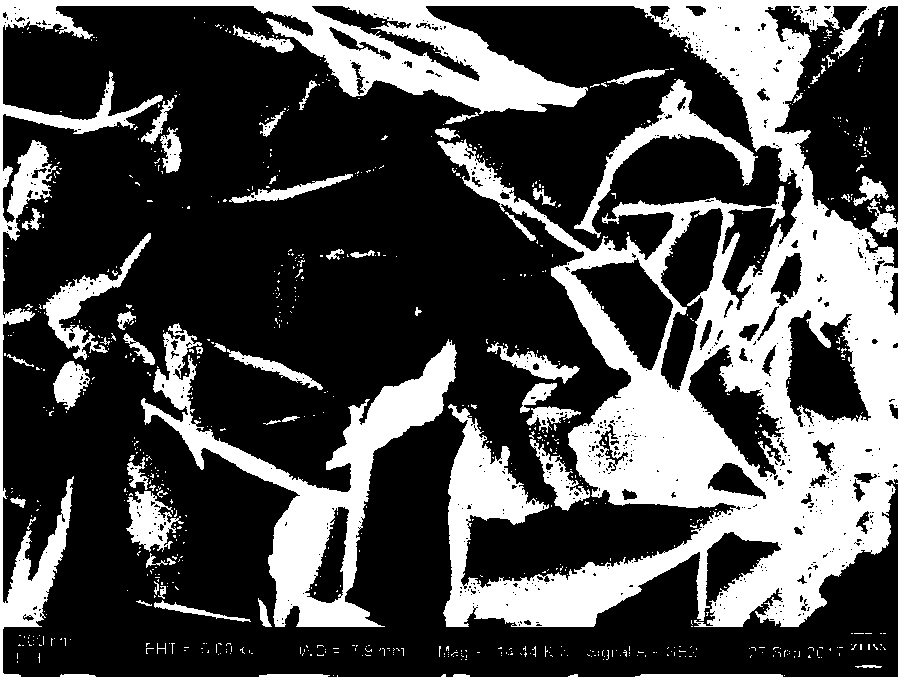

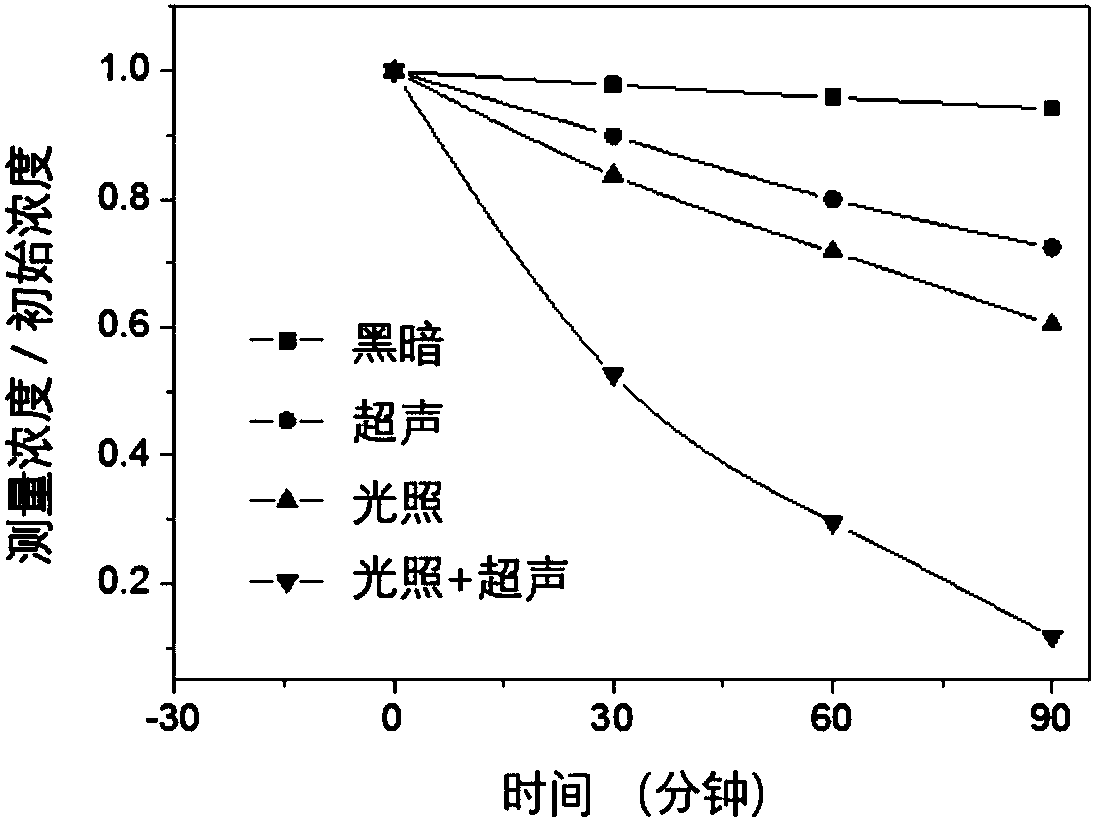

InactiveCN108479748ALarge specific surface areaStrong adsorption capacityWater/sewage treatment by irradiationWater treatment compoundsChemistryOptoelectronic materials

The invention discloses a piezoelectric optoelectronic material for the degradation of organic pollutants. The piezoelectric optoelectronic material utilizes two-dimensional KNbO3 nanosheets. A preparation method of the two-dimensional KNbO3 nanosheet comprises orderly adding KOH and Nb2O5 into a container with ethylene glycol according to the ratio, carrying out full dispersion, transferring themixed solution into a high pressure reactor, carrying out heating for some time, carrying out cooling to the room temperature, carrying out cleaning and drying to obtain a white product, grinding thewhite product into powder, and carrying out calcination at a high temperature to obtain the two-dimensional KNbO3 nanosheet. The invention also provides an organic pollutant degradation method. The method utilizes the piezoelectric optoelectronic material as a catalyst, and ultrasonic wave or combination of illumination and ultrasonic waves to assist in the degradation of organic pollutants. The piezoelectric optoelectronic material fully utilizes the two-dimensional KNbO3 nanosheet advantages of a large ratio of the active exposed surface, a strong adsorption capacity, easy deformation and high piezoelectric constant, can be used as a photocatalyst to be excited by ultraviolet light, can excite more electron hole pairs under ultrasonic conditions through the piezoelectric effects and realizes the efficient removal of organic pollutants.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

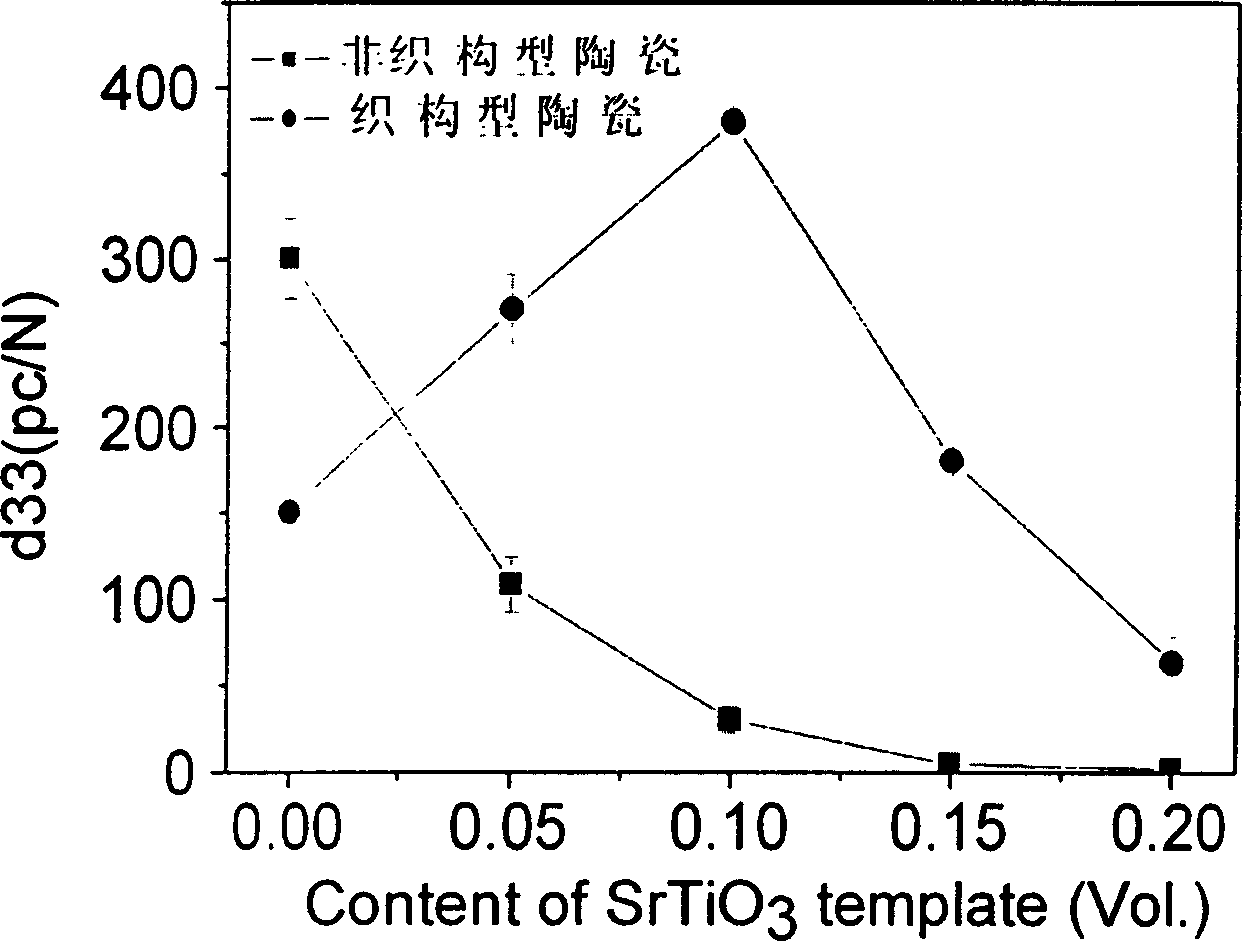

Barium calcium zirconate titanate BCZT piezoelectric ceramic and textural preparation method thereof

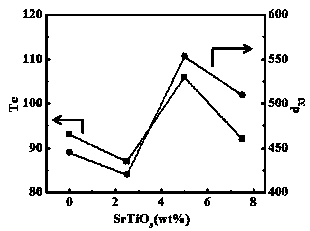

ActiveCN107602114AHigh curie temperaturePiezoelectric constantPiezoelectric/electrostrictive/magnetostrictive devicesZirconateCurie temperature

The invention discloses a barium calcium zirconate titanate BCZT piezoelectric ceramic and a textural preparation method thereof. The barium calcium zirconate titanate BCZT piezoelectric ceramic is prepared from BaCO3 and TiO2 as main raw materials, CaCO3 and ZrO2 as doping agents and SrTiO3 as seed grain, wherein the mole ratio of BaCO3 to TiO2 to CaCO3 to ZrO2 is 2.5-10% of the mass percent of (Ba0.85Ca0.15) (Zr0.1Ti0.9)O3 and SrTiO3. The piezoelectric ceramic disclosed by the invention has the characteristics of excellent piezoelectric property, high Curie temperature and high piezoelectricconstant. The method disclosed by the invention is characterized by low sintering temperature.

Owner:GUIZHOU UNIV +1

Barium-based magnesium zirconate-titanate lead-free piezoelectric ceramic with high piezoelectric constant

InactiveCN101767993AExcellent dielectric propertiesPiezoelectric constantChemical solutionBarium titanate

The invention discloses barium-based magnesium zirconate-titanate lead-free piezoelectric ceramic with high piezoelectric constant. The piezoelectric ceramic has a component of (Ba1-xMgx) (Ti1-yZry)O3, wherein x is more than 0 and less than 0.20, and y is more than 0 and less than 0.20; and the synthesized piezoelectric ceramic is prepared by adopting a sol-gel method, a solid-phase reaction method, a wet chemical solution method, a template grain growth technology, a reactive template grain growth technology or other methods. The prepared barium-based magnesium zirconate-titanate lead-free piezoelectric ceramic has very favorable dielectric property and high piezoelectric constant; compared with the pure barium titanate ceramic, the piezoelectric constant of the piezoelectric ceramic is improved by 2 to 3 times; and the barium-based magnesium zirconate-titanate lead-free piezoelectric ceramic has remarkable advantages compared with the traditional lead-based piezoelectric ceramics, is free of lead and suitable for environment protection requirements and especially suitable for being applied in middle and low temperature piezoelectric components.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Composite piezoelectric film and preparation method and application thereof

PendingCN111063794AUniform distribution of piezoelectric effectLarge output piezo voltagePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionFiberSpinning

The invention belongs to the technical field of piezoelectric materials, and particularly relates to a composite piezoelectric film and a preparation method and application thereof. The preparation method comprises the following steps: adding inorganic piezoelectric powder into a polymer solution to obtain a precursor solution; and carrying out electrostatic spinning on the precursor solution andperforming collection in a water medium to obtain the composite piezoelectric film. The composite piezoelectric film is a porous structure fiber film and is filled with inorganic piezoelectric powder,and a polymer piezoelectric material and a rigid piezoelectric material are well compounded. Moreover, the composite piezoelectric film is a beta-phase enhanced flexible composite film, can generatea relatively large output piezoelectric voltage, has a relatively high piezoelectric constant, is uniform in piezoelectric effect distribution, and can solve the problem that an existing polymer piezoelectric film cannot be effectively combined with an inorganic piezoelectric material to form a flexible device with high piezoelectric performance. In addition, the preparation method is simple in preparation process and beneficial to large-scale production.

Owner:GUANGDONG UNIV OF TECH

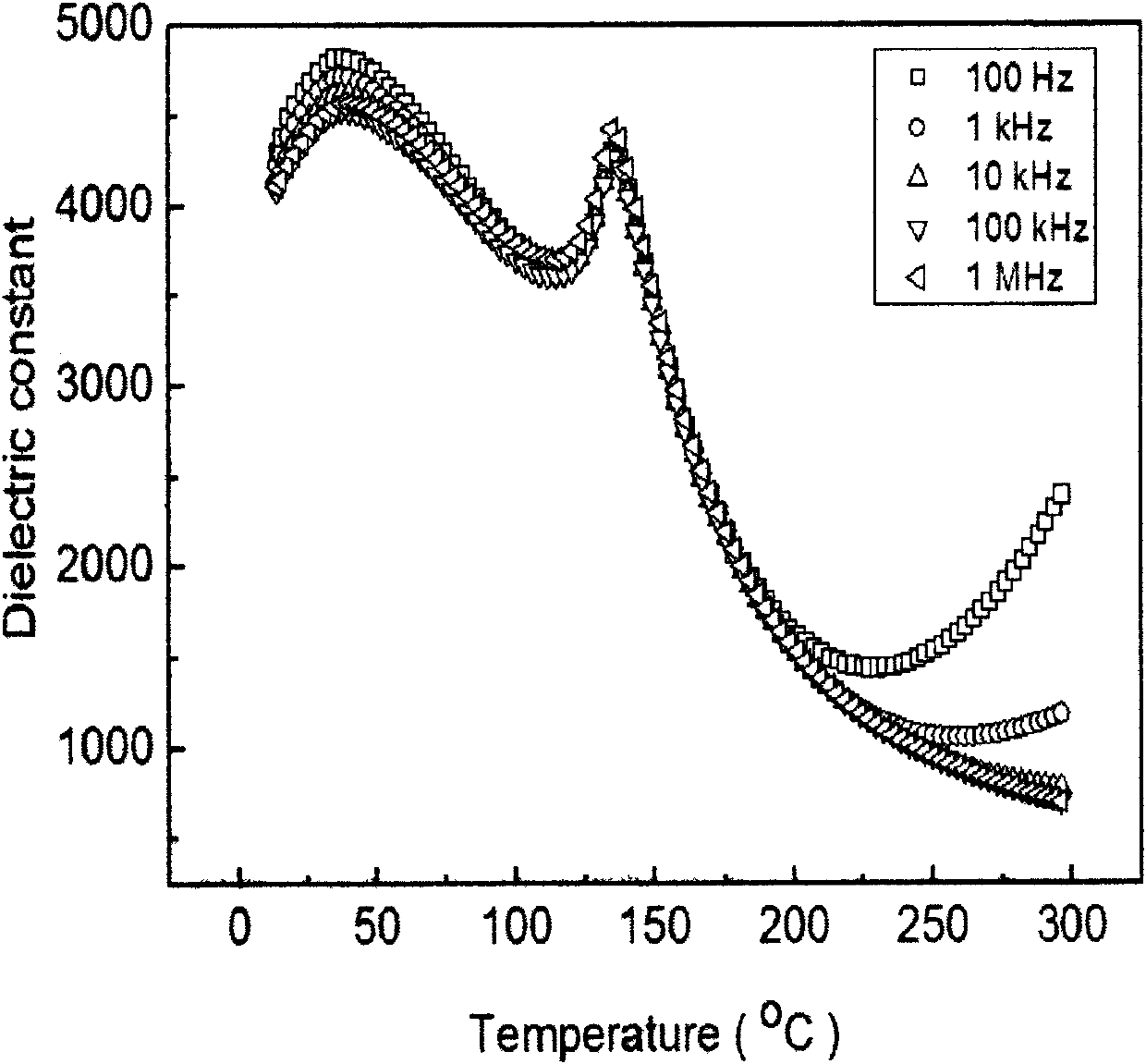

Piezoelectric material having high piezoelectricity performance and temperature stability in wide temperature range and application thereof

The invention discloses a piezoelectric material having high piezoelectricity performance and temperature stability in a wide temperature range and an application thereof. The piezoelectric material has a pure ABO3 type perovskite structure without a pyrochlore phase, has the following composition formula of (1-x-y)Pb(Mg1 / 3Nb2 / 3)O3-xPbTiO3-yXTiO3+zM, in the formula, X is at least one of Ca, Ba and Sr, M is at least one of MnO2, ZnO and MgO, 0.29<x<=0.38, 0<y<=0.1, and 0<z<=0.1. A PMN-PT material simultaneously has high piezoelectric constants and near zero temperature coefficient in the wide temperature range, can meet application requirements of the actuator and sensor fields, and has outstanding application values.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com