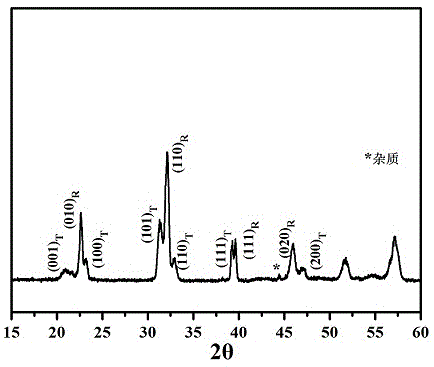

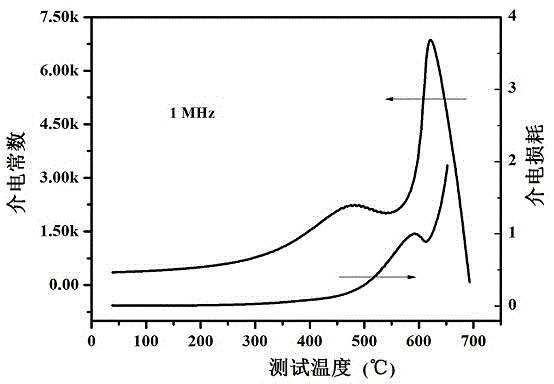

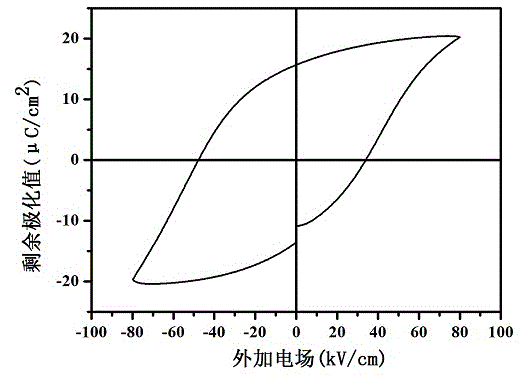

Ternary piezoceramic material with high Curie temperature and preparation method thereof

A technology of piezoelectric ceramics and temperature range, applied in the field of ternary high Curie temperature piezoelectric ceramic materials and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Component selection: (1-y)((1-x)BF-xPT)-yPMN, y=0.04, x=0.3. The content of lead niobium manganate in the third component is 4%, and the ratio of bismuth ferrite and lead titanate is 7:3.

[0017] A. Preparation of 0.96(0.7BF-0.3PT)-0.04PMN green body

[0018] (1) Preparation of powder

[0019] With analytically pure Bi 2 o 3 , Fe 2 o 3 , PbO, TiO 2 , MnCO 3 and Nb 2 o 5 As a raw material, weigh the above-mentioned raw materials according to the stoichiometric ratio required for the preparation of 50 g 0.96(0.7BF-0.3PT)-0.04PMN and put them into a ball mill jar, then add 24 ml of deionized water and 1.5 ml of ammonia water as a solvent and weight as a raw material Zirconia beads with a weight of 0.8 to 1.5 times were used as a ball milling medium, and rolled for 24 hours. After ball milling, pour the ball mill slurry into a clean porcelain bowl, put it in a constant temperature oven at 120 ℃ and dry it, then grind the powder finely, put it in a crucible for ca...

Embodiment 2

[0028] Component selection: (1-y)((1-x)BF-xPT)-yPMN, y=0.08, x=0.35. The content of lead niobium manganate in the third component is 8%, and the ratio of bismuth ferrite and lead titanate is 13:7.

[0029] A. Preparation of 0.92(0.65BF-0.35PT)-0.08PMN green body

[0030] (1) Preparation of powder

[0031] With analytically pure Bi 2 o 3 , Fe 2 o 3 , PbO, TiO 2 , MnCO 3 and Nb 2 o 5 As a raw material, weigh the above raw materials according to the stoichiometric ratio required for the preparation of 50 g 0.92(0.65BF-0.35PT)-0.08PMN and put them into a ball mill jar, then add 24 ml of deionized water and 1.5 ml of ammonia water as a solvent and weight as a raw material Zirconia beads with a weight of 0.8 to 1.5 times were used as a ball milling medium, and rolled for 24 hours. After ball milling, pour the ball mill slurry into a clean porcelain bowl, put it in a constant temperature oven at 120 ℃ and dry it, then grind the powder finely, put it in a crucible for calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com