Ga-modified (Bi0.8Gd0.2) FeO3-PbTiO3 piezoelectric ceramic and preparation method thereof

A BGGF-PT, feo3-pbtio3 technology, applied in the field of piezoelectric devices, can solve the problems of low breakdown voltage of BF-PT materials, unsatisfactory insulation, unfavorable application of process materials, etc., to improve high conductivity characteristics , low insulation and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

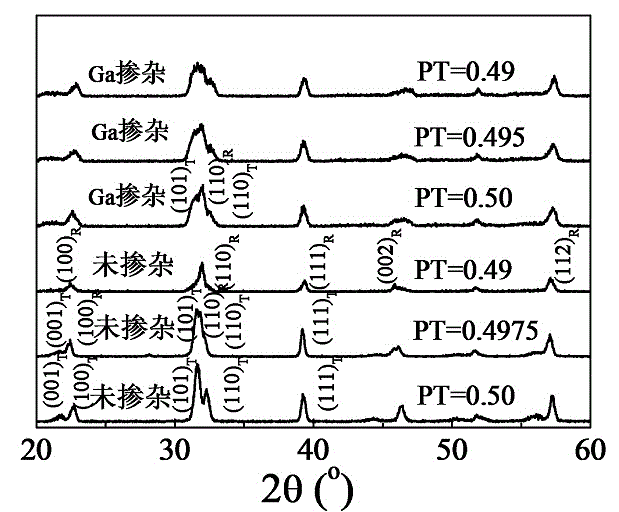

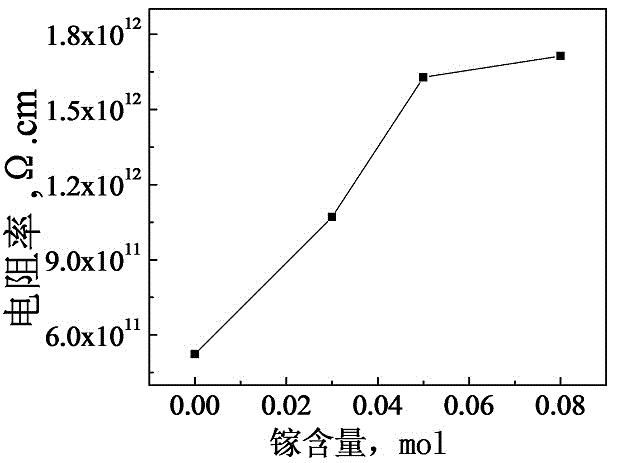

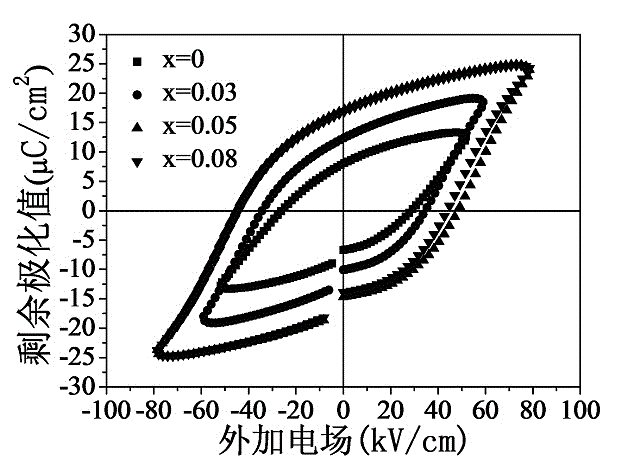

[0022] In this example, Ga modified (Bi 0.8 Gd 0.2 )FeO 3 -PbTiO 3 Piezoelectric ceramics, its chemical formula is: (Bi 0.8 Gd 0.2 ) (Fe 1-x Ga x )O 3 -PbTiO 3 , where x=0.03, 0.05 and 0.08. That is (Bi 0.8 Gd 0.2 )FeO 3 -PbTiO 3 The Ga element is introduced into the system to form a BGGF-PT piezoelectric ceramic solid solution system, and the chemical formula is (Bi 0.8 Gd 0.2 ) (Fe 0.97 Ga 0.03 )O 3 -PbTiO 3 , (Bi 0.8 Gd 0.2 ) (Fe 0.95 Ga 0.05 )O 3 -PbTiO 3 and (Bi 0.8 Gd 0.2 ) (Fe 0.92 Ga 0.08 )O 3 -PbTiO 3 The BGGF-PT piezoelectric ceramic material.

[0023] In this example, Ga modified (Bi 0.8 Gd 0.2 )FeO 3 -PbTiO 3 A method for preparing piezoelectric ceramics, comprising the steps of:

[0024] ① Preparation of BGGF-PT piezoelectric ceramic powder: Doping Ga element into (Bi 0.8 Gd 0.2 )FeO 3 -PbTiO 3 In the piezoelectric ceramic material system, a BGGF-PT piezoelectric ceramic solid solution system is formed, that is, the high-puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com