Patents

Literature

215 results about "Phase boundary" patented technology

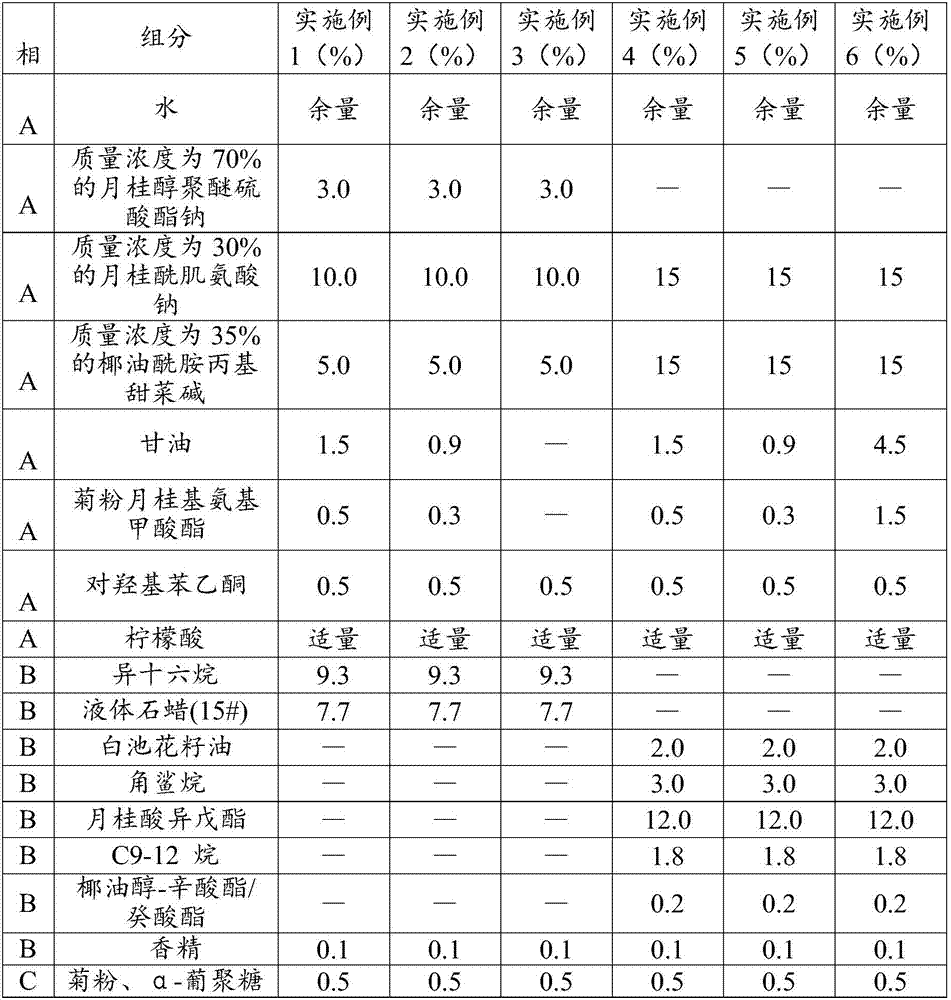

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In thermal equilibrium, each phase (i.e. liquid, solid etc.) of physical matter comes to an end at a transitional point, or spatial interface, called a phase boundary, due to the immiscibility of the matter with the matter on the other side of the boundary. This immiscibility is due to at least one difference between the two substances' corresponding physical properties. The behavior of phase boundaries has been a developing subject of interest and an active research field, called interface science, in physics and mathematics for almost two centuries, due partly to phase boundaries naturally arising in many physical processes, such as the capillarity effect, the growth of grain boundaries, the physics of binary alloys, and the formation of snow flakes.

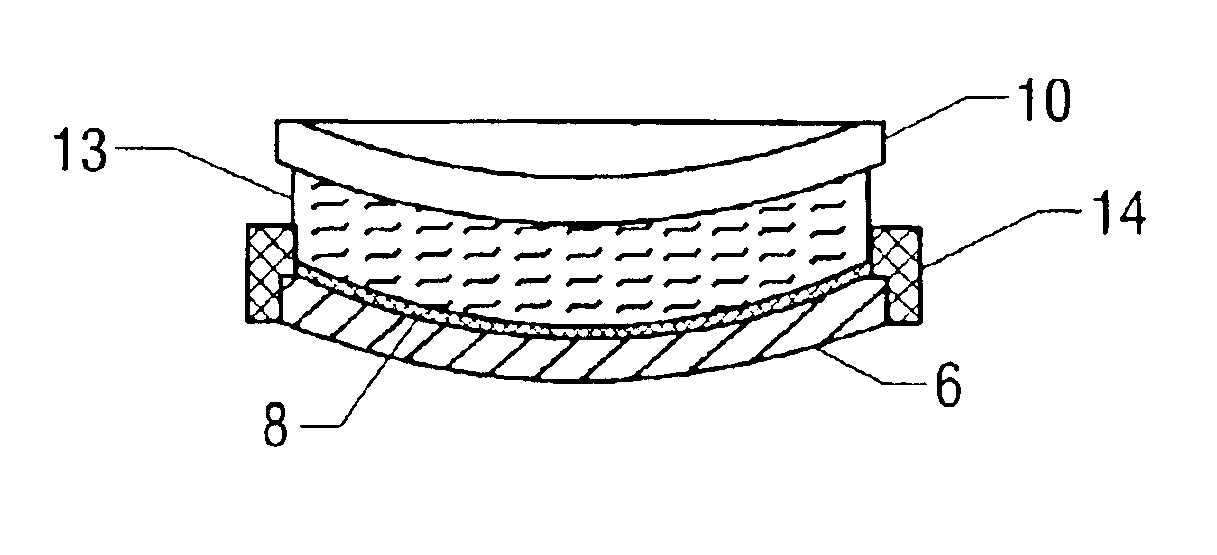

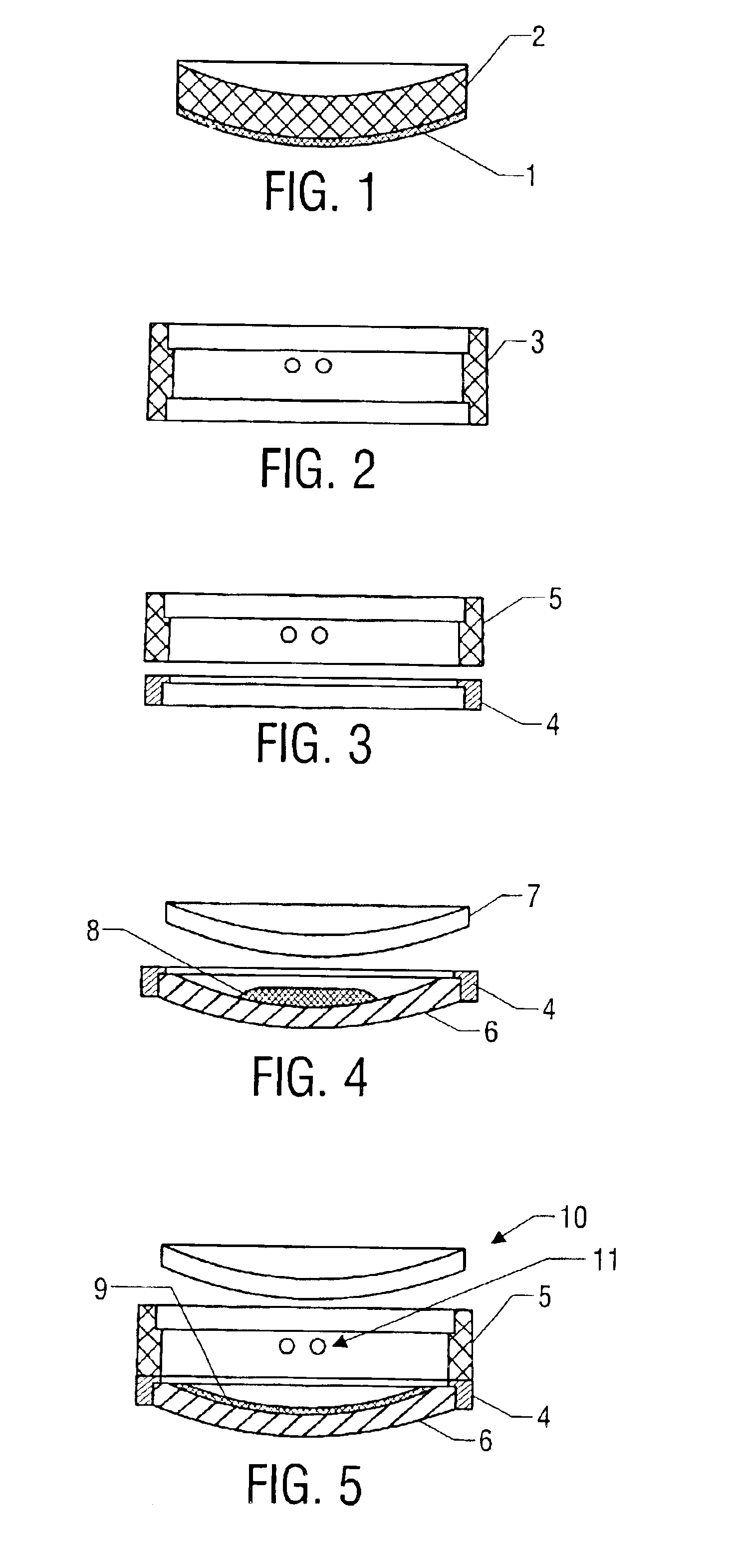

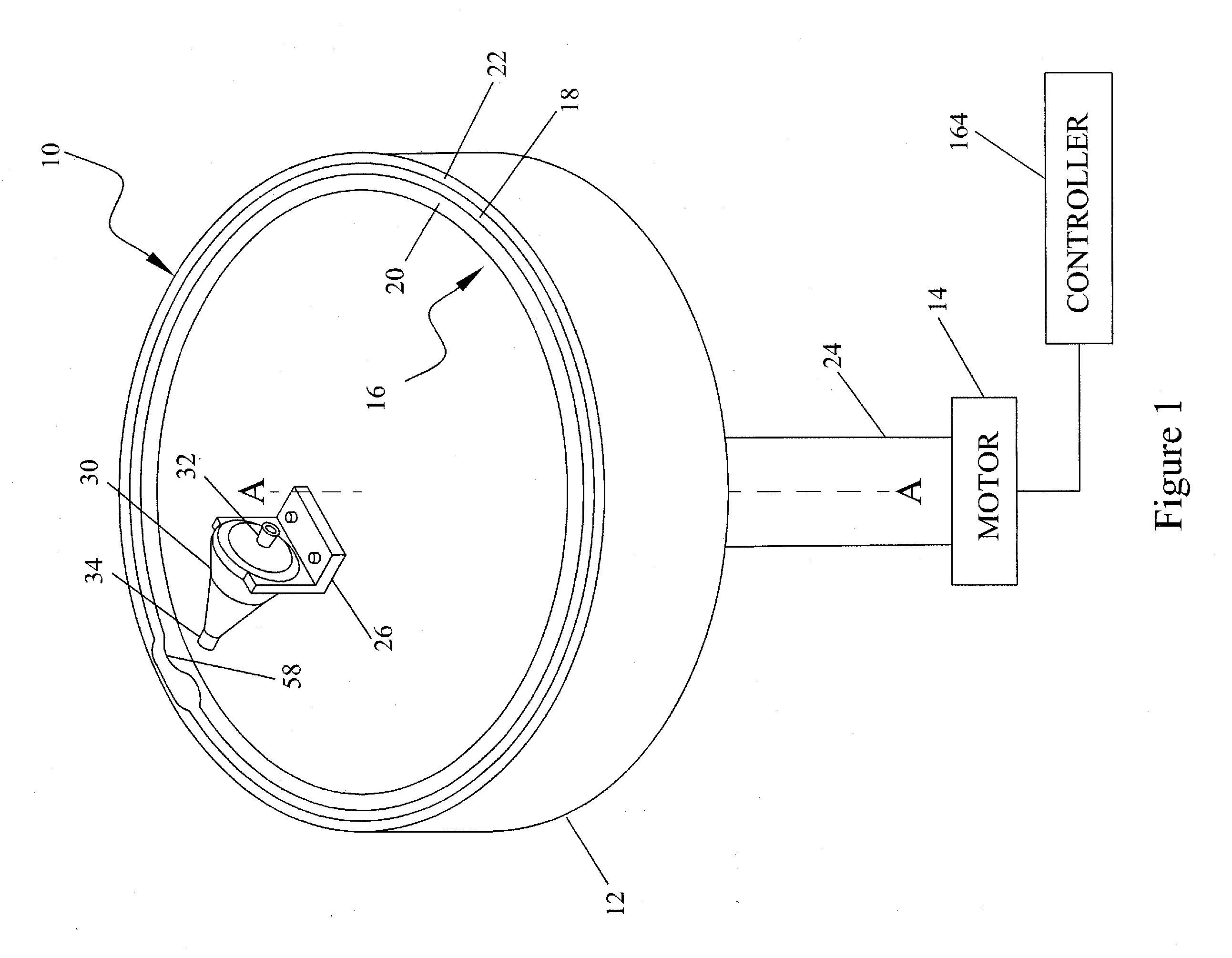

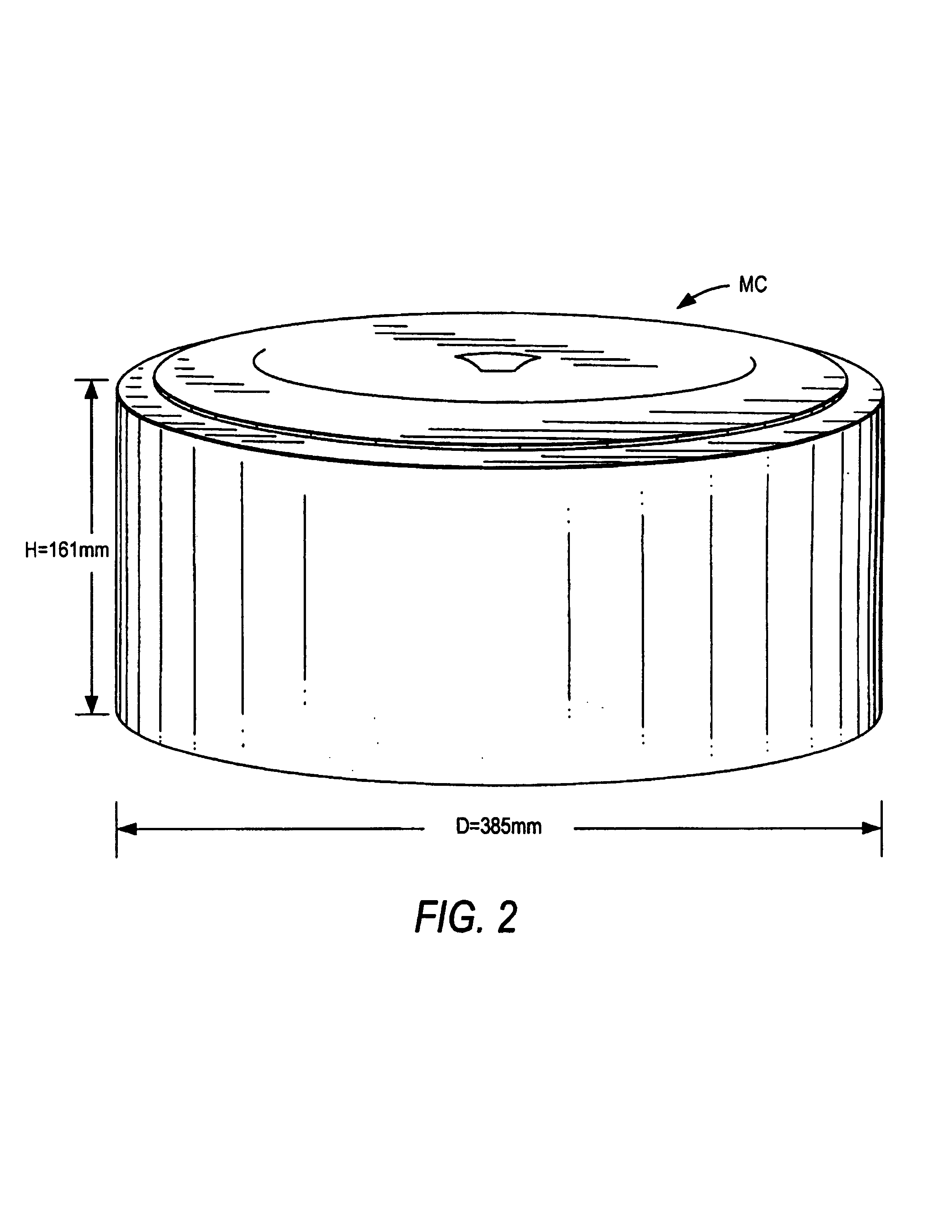

Methods for preparing composite photochromic ophthalmic lenses

A method of manufacturing a composite photochromic ophthalmic lens having an index of refraction of at least 1.49 is disclosed. The method comprises providing against a front portion of a mold, a first ophthalmic lens-forming composition including a polymerizable monomer, oligomer, or polymer and a photochromic compound; filling a rear portion of the mold with a second ophthalmic lens-forming composition, sufficiently different from the first ophthalmic lens-forming composition such that a distinct phase boundary results between the two compositions after complete curing of the two compositions, the second ophthalmic lens-forming composition including a polymerizable monomer, oligomer or polymer that is different from the monomer, oligomer or polymer of the first ophthalmic lens-forming composition, such that the second ophthalmic lens-forming composition is in contact with the first lens-forming composition, wherein either the first or second ophthalmic lens-forming composition is gelled before adding the other ophthalmic lens-forming composition, in an ungelled state, to the mold; and curing the first and second ophthalmic lens-forming compositions simultaneously, while the first and second ophthalmic lens-forming compositions are in intimate contact.

Owner:SIGNET ARMORLITE INC

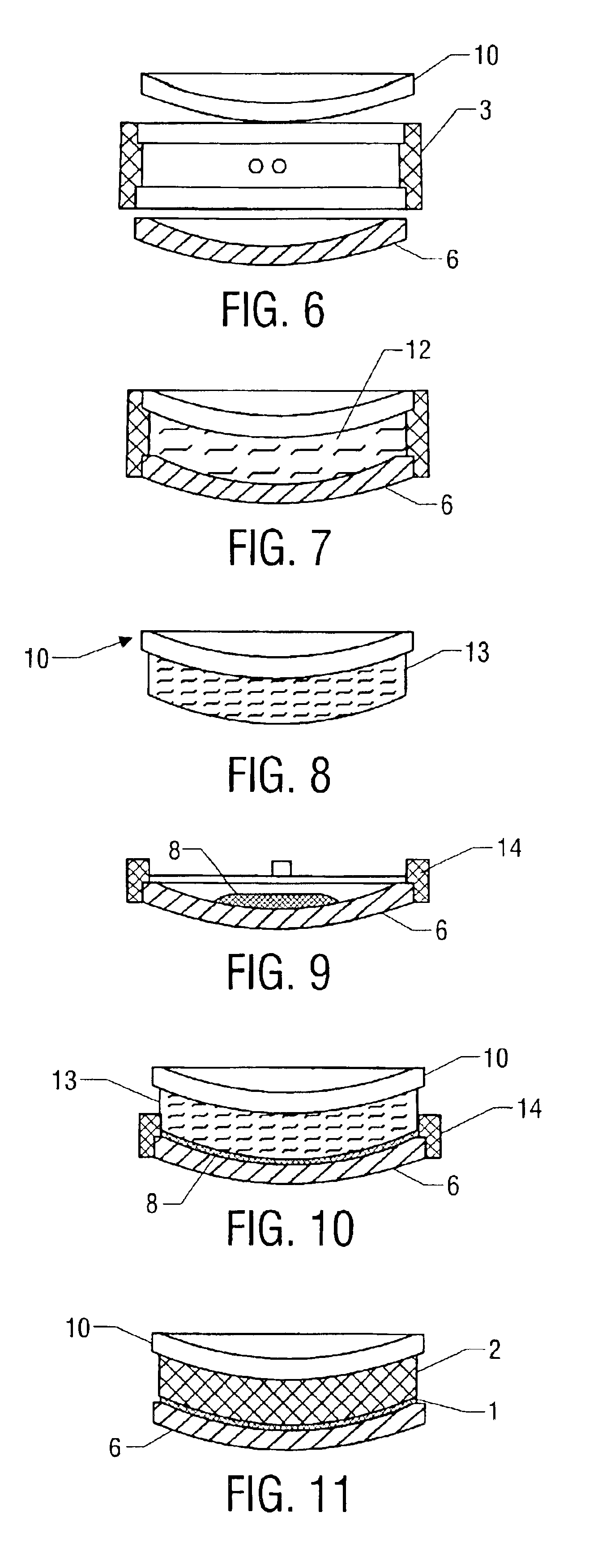

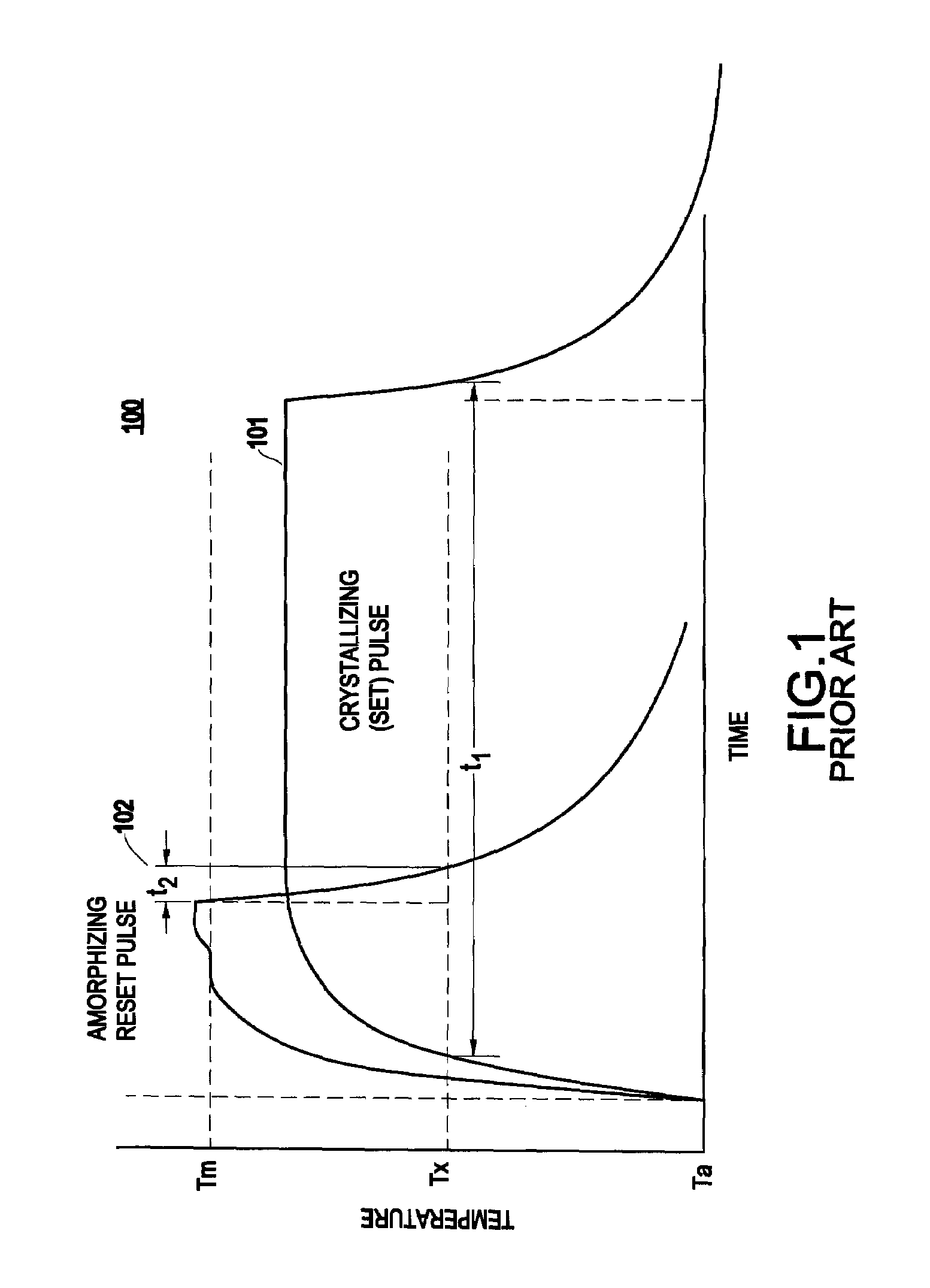

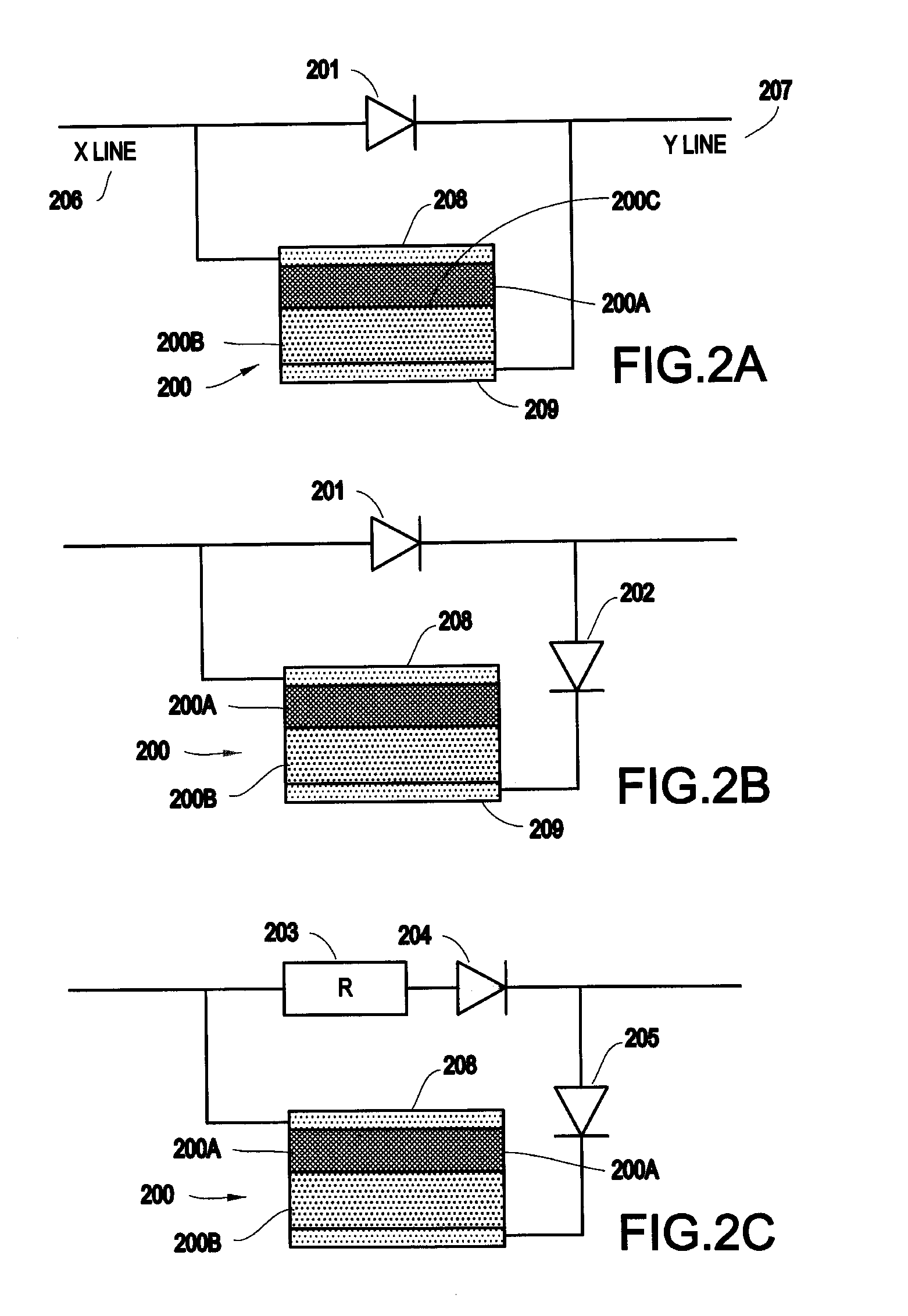

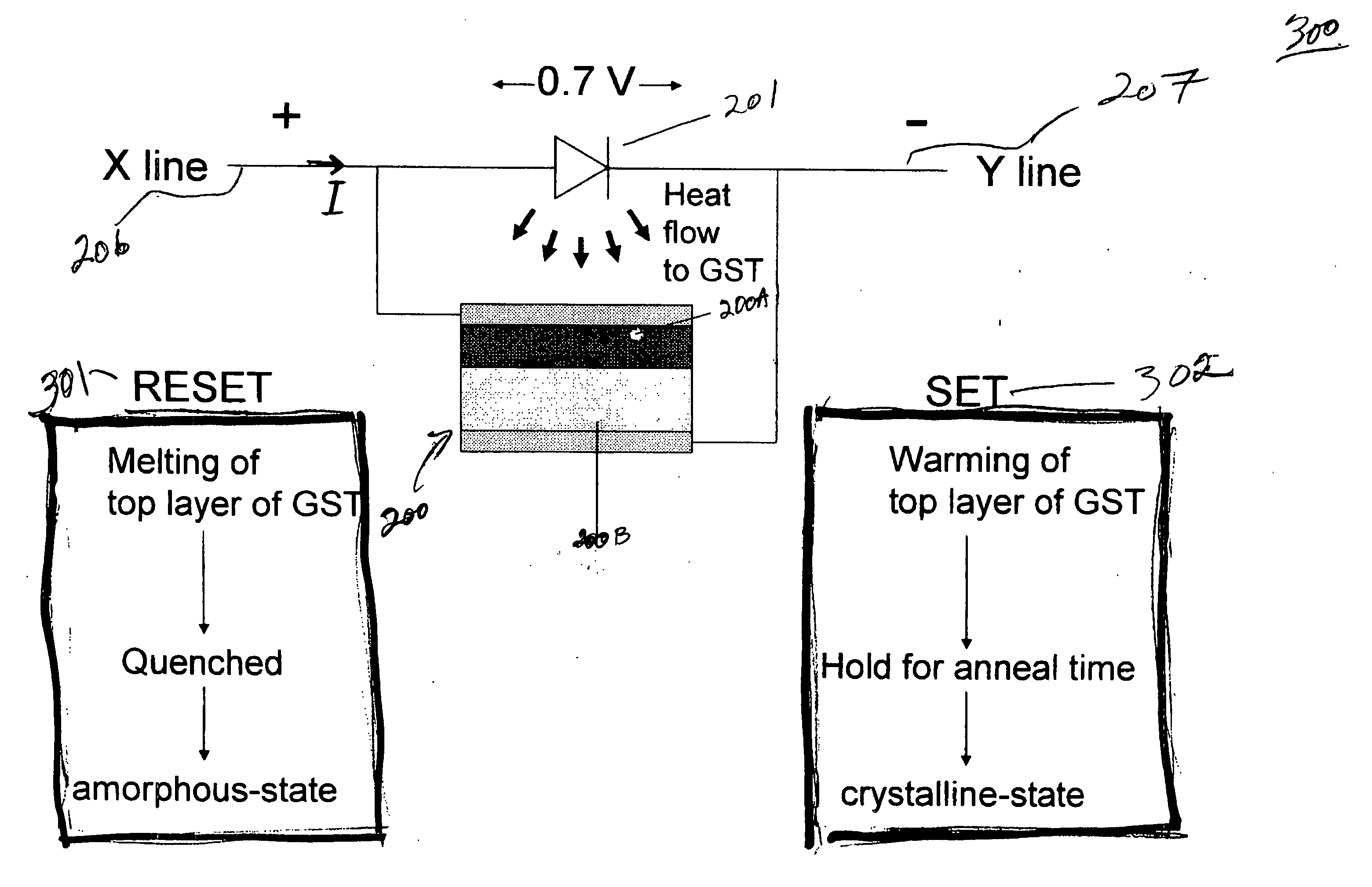

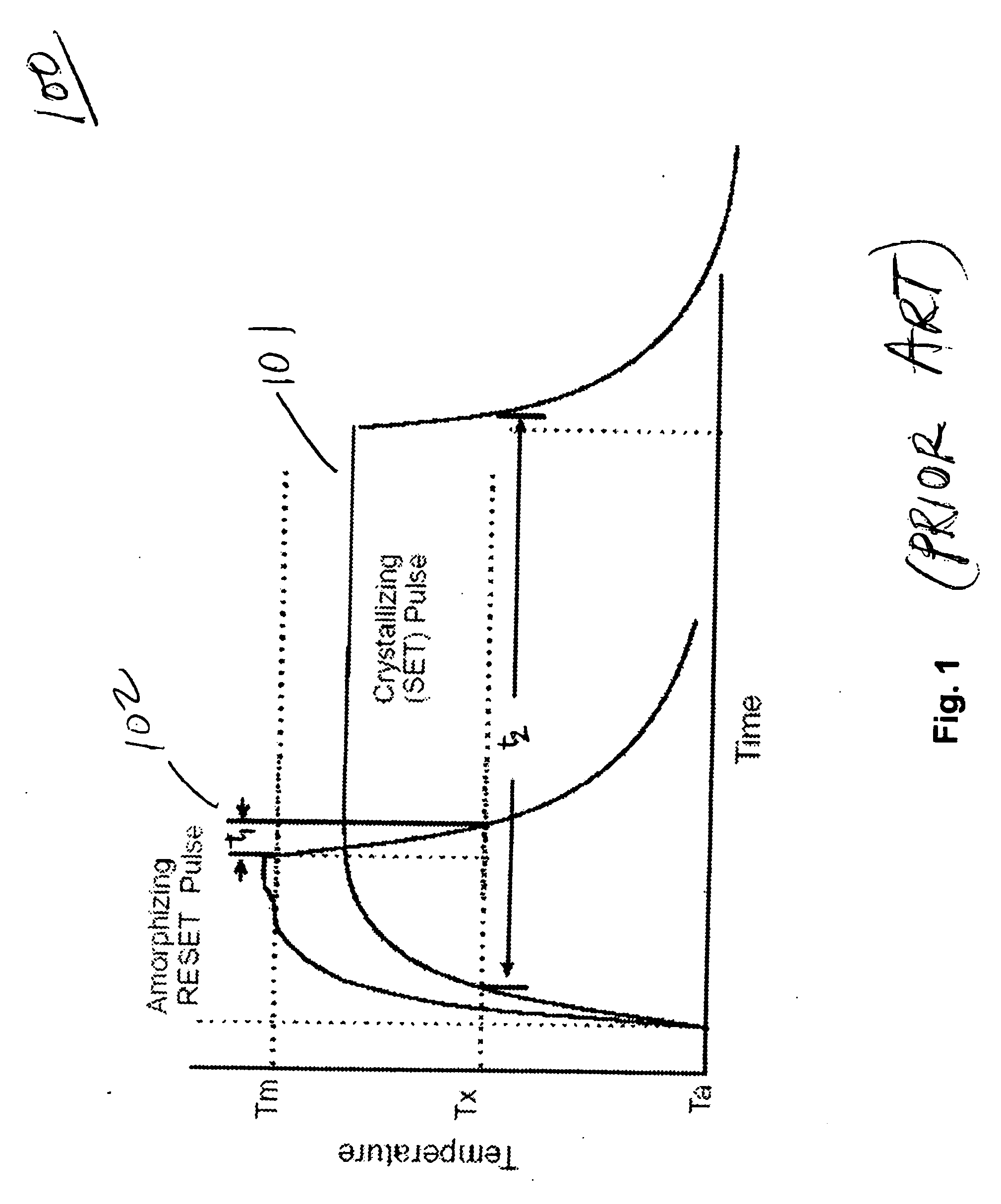

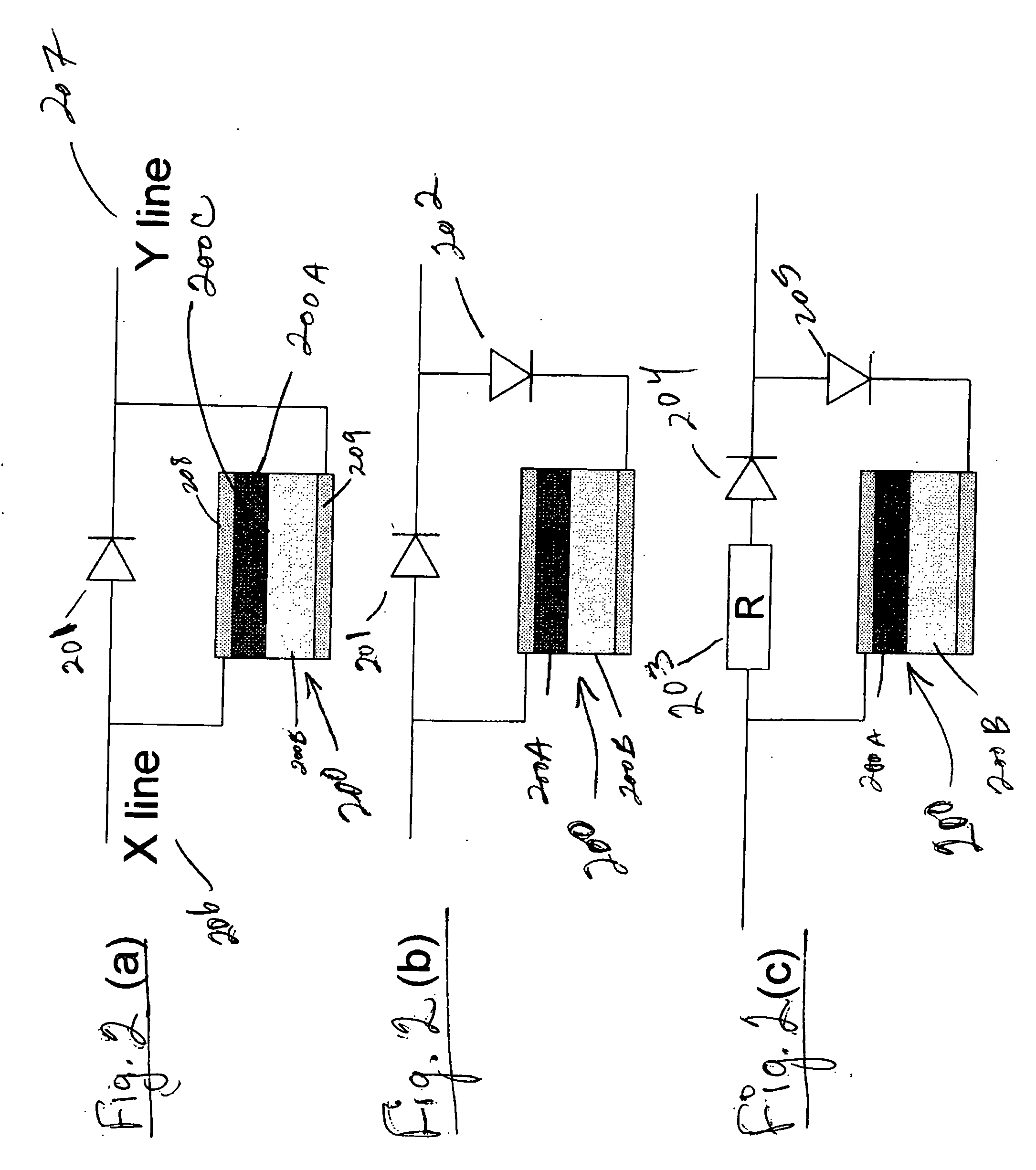

Method and structure for high performance phase change memory

ActiveUS7221579B2Faster and efficient and scalable PRAMImprove performanceSolid-state devicesDigital storagePhase-change memoryEngineering

A method (and structure) for a memory cell having a phase change material (PCM) element and a heating element external to the PCM element. The heating element causes one of a presence of and an absence of a phase boundary within the PCM element for storing information in the PCM element.

Owner:GLOBALFOUNDRIES US INC

Method and structure for high performance phase change memory

ActiveUS20060279978A1Improve performanceIncrease speedSolid-state devicesDigital storagePhase-change memoryPhase-change material

A method (and structure) for a memory cell having a phase change material (PCM) element and a heating element external to the PCM element. The heating element causes one of a presence of and an absence of a phase boundary within the PCM element for storing information in the PCM element.

Owner:GLOBALFOUNDRIES US INC

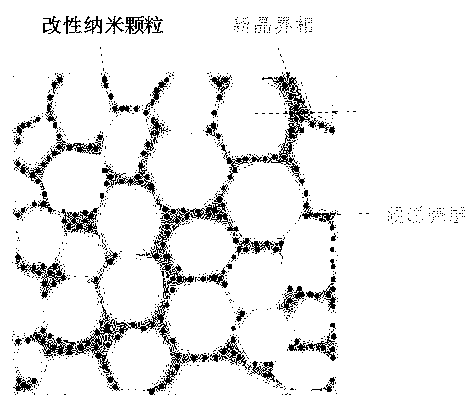

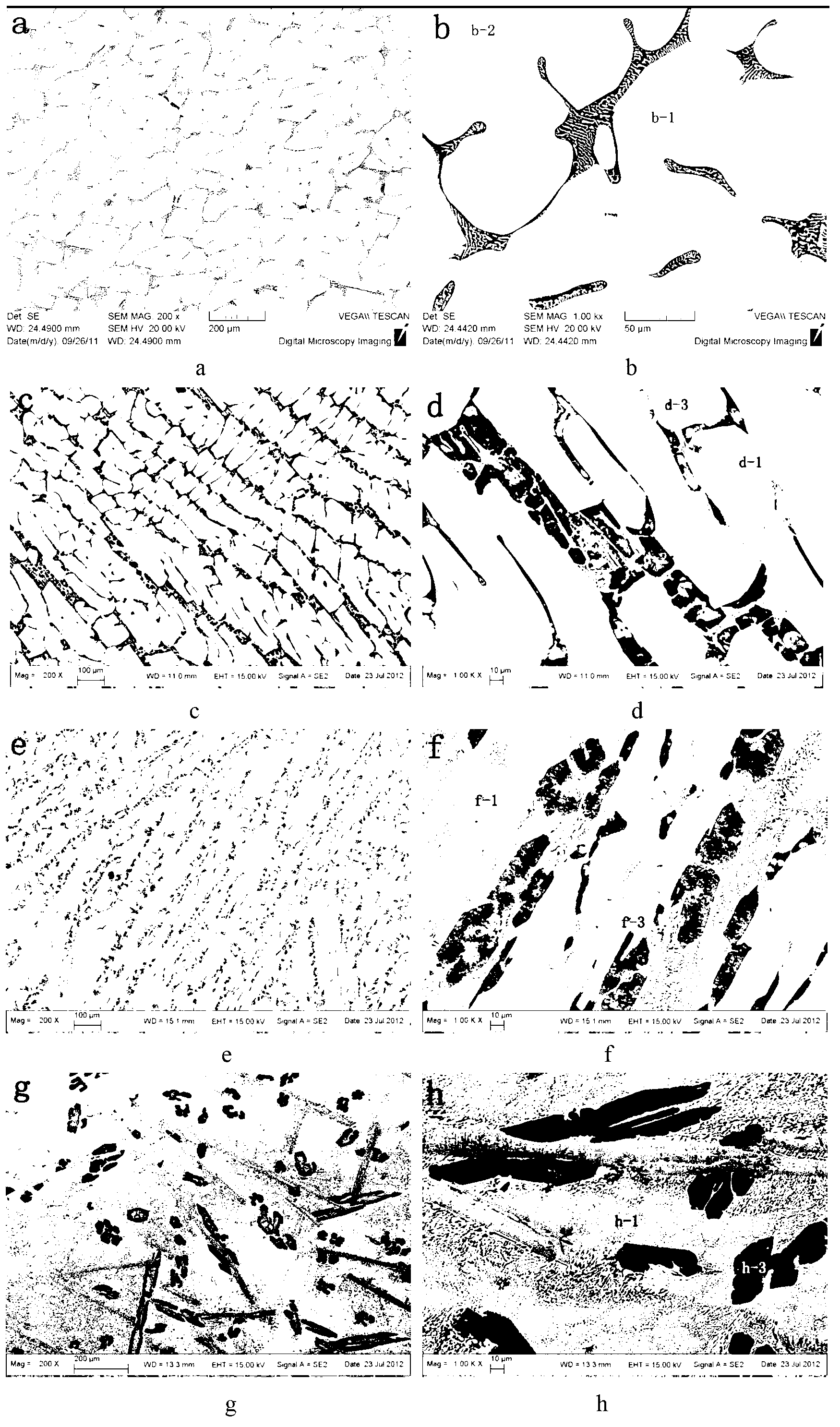

Rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and preparation method thereof

ActiveCN103123839AReduce production and sales balancePromote the balance of production and salesInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementCost Controls

The invention discloses a rare earth permanent magnet produced by applying abundant rare earth cerium (Ce) and a preparation method of the rare earth permanent magnet produced by applying abundant rare earth Ce. Based on a double-alloy process, main phase alloy formula uses Ce to partly replace neodymium (Nd), an optimized composition design enables a main alloy to form Ce2Fe14B phase and Nd2Fe14B phase to a greatest extent, and therefore high intrinsic magnetic property is guaranteed. A brand new crystal boundary phase is prepared by a crystal boundary reconstitution technology, and high integral magnetic property and corrosion resistant property are guaranteed, and meanwhile a nanometer powder crystal modification method is supplemented, a micro organization structure of a magnet is optimized, crystal boundary distribution is improved, and the magnetic property and the corrosion resistant property are further improved. By applying abundant rare earth cerium, cost is effectively reduced, and meanwhile balance between production and marketing is promoted. Praseodymium (Pr), Nd, and the like are chosen to form a hard magnetic shell layer of a main phase boundary in a composition design of crystal phase auxiliary alloy at the same time, compared high price heavy rare earth elements of dysprosium (Dy) and terbium (Tb) with the elements, and cost control can be further achieved.

Owner:ZHEJIANG UNIV +1

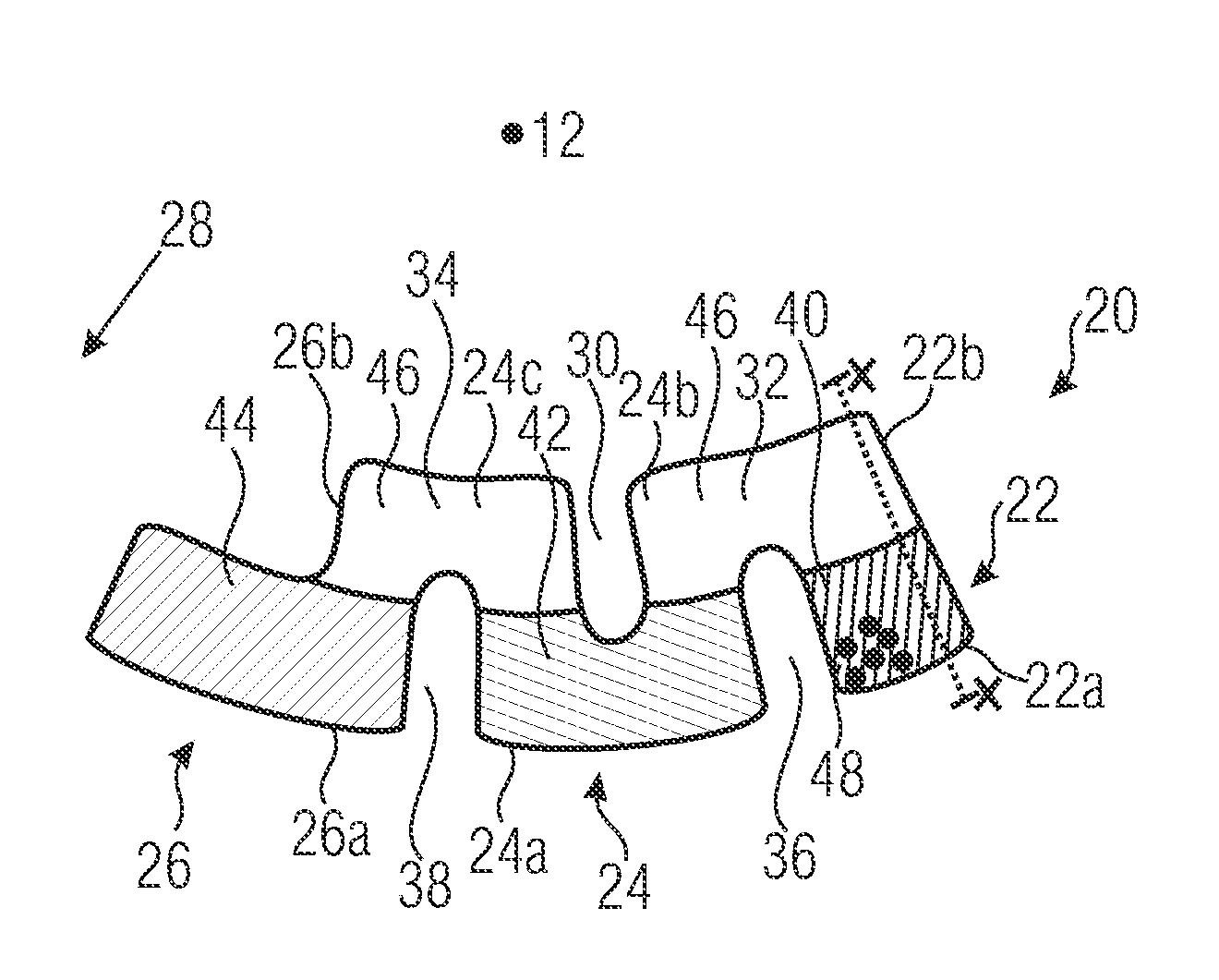

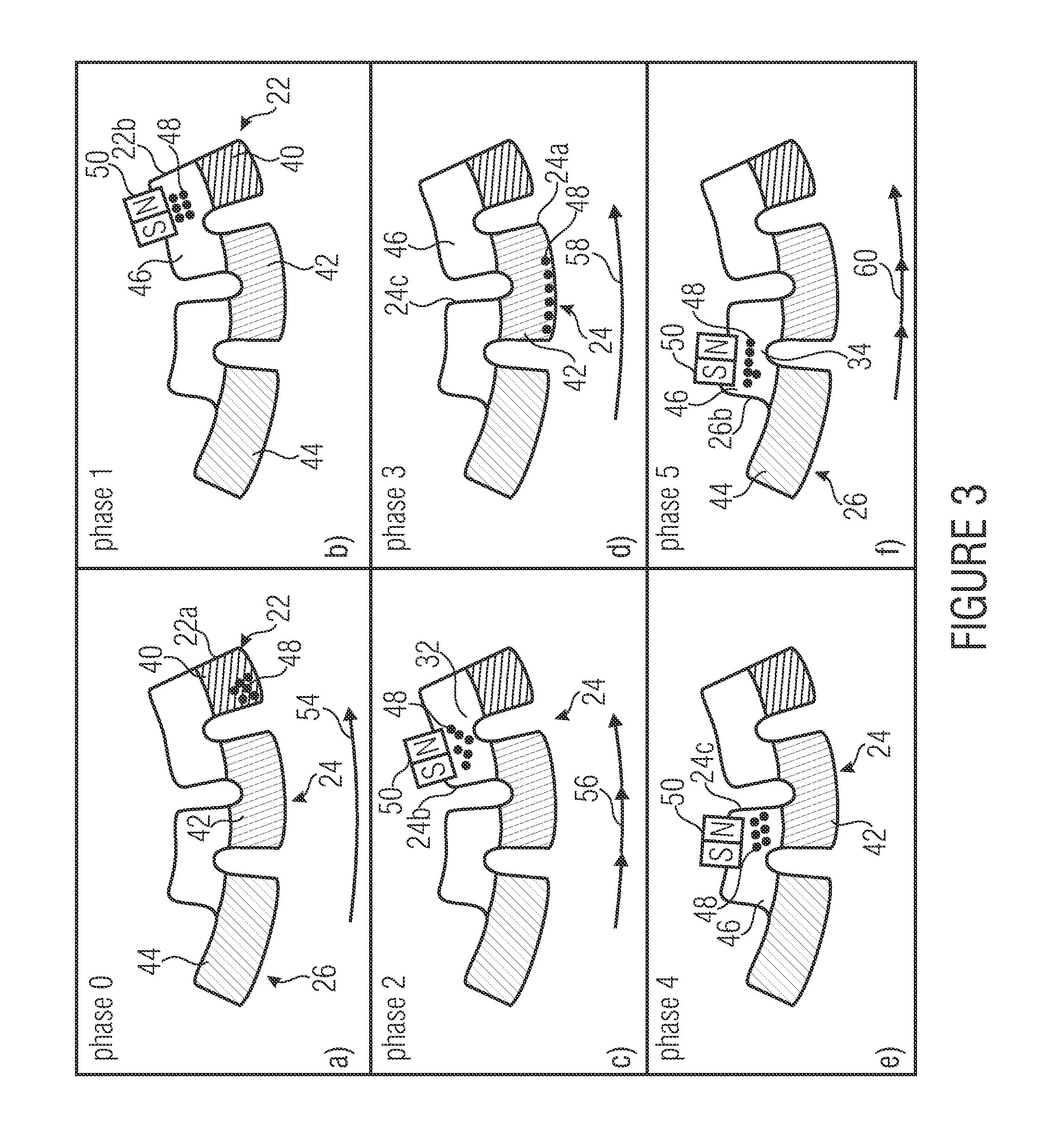

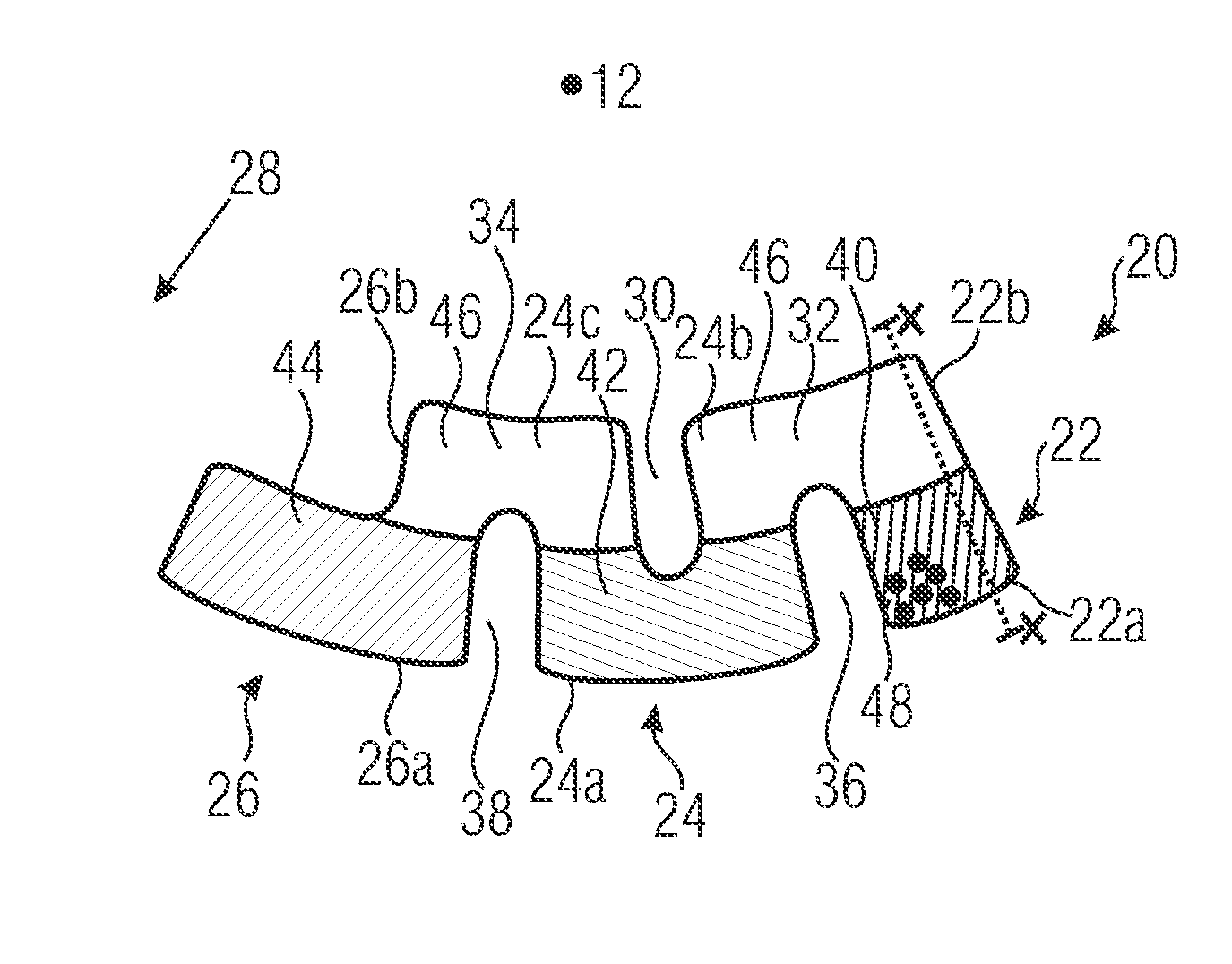

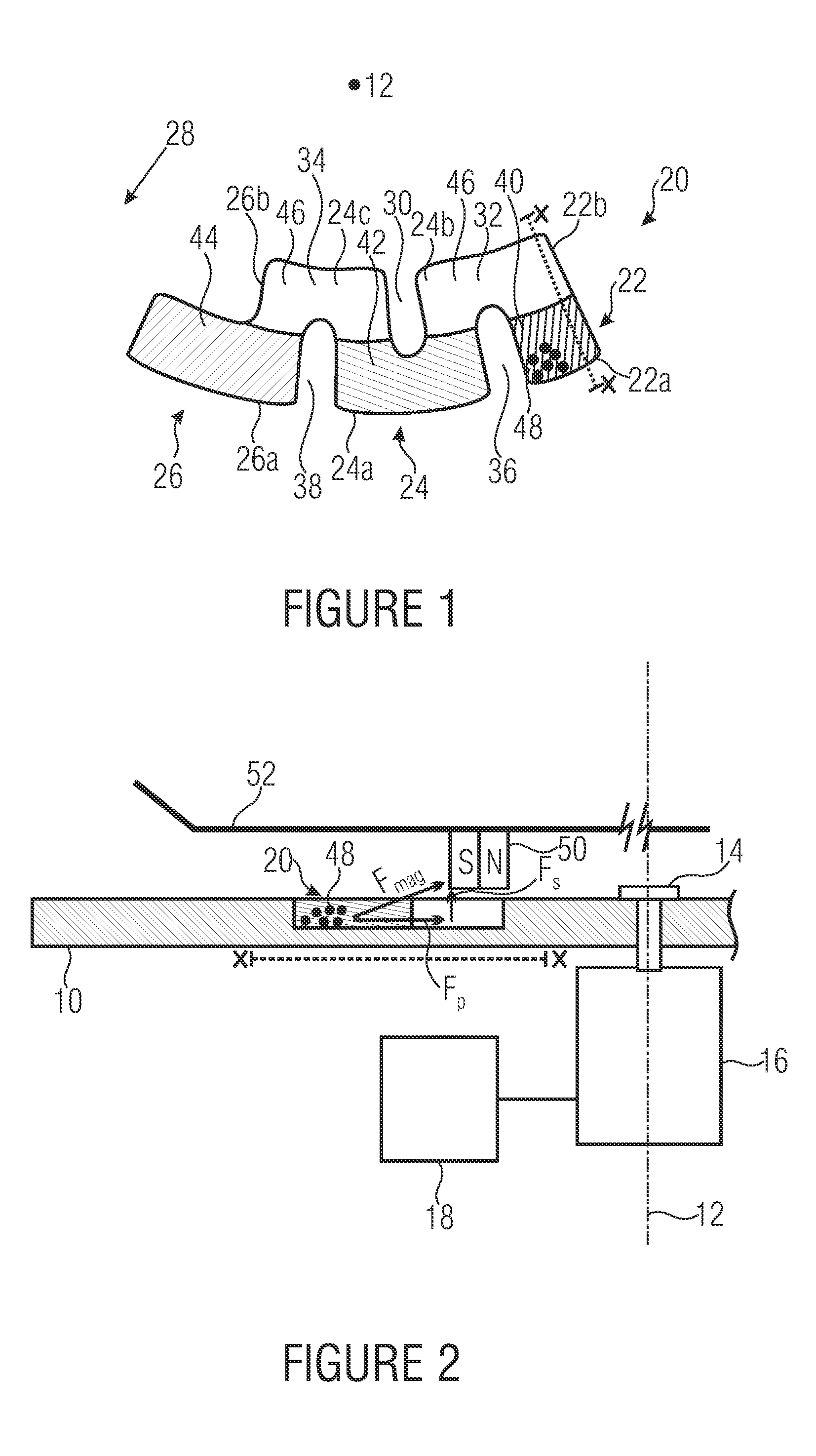

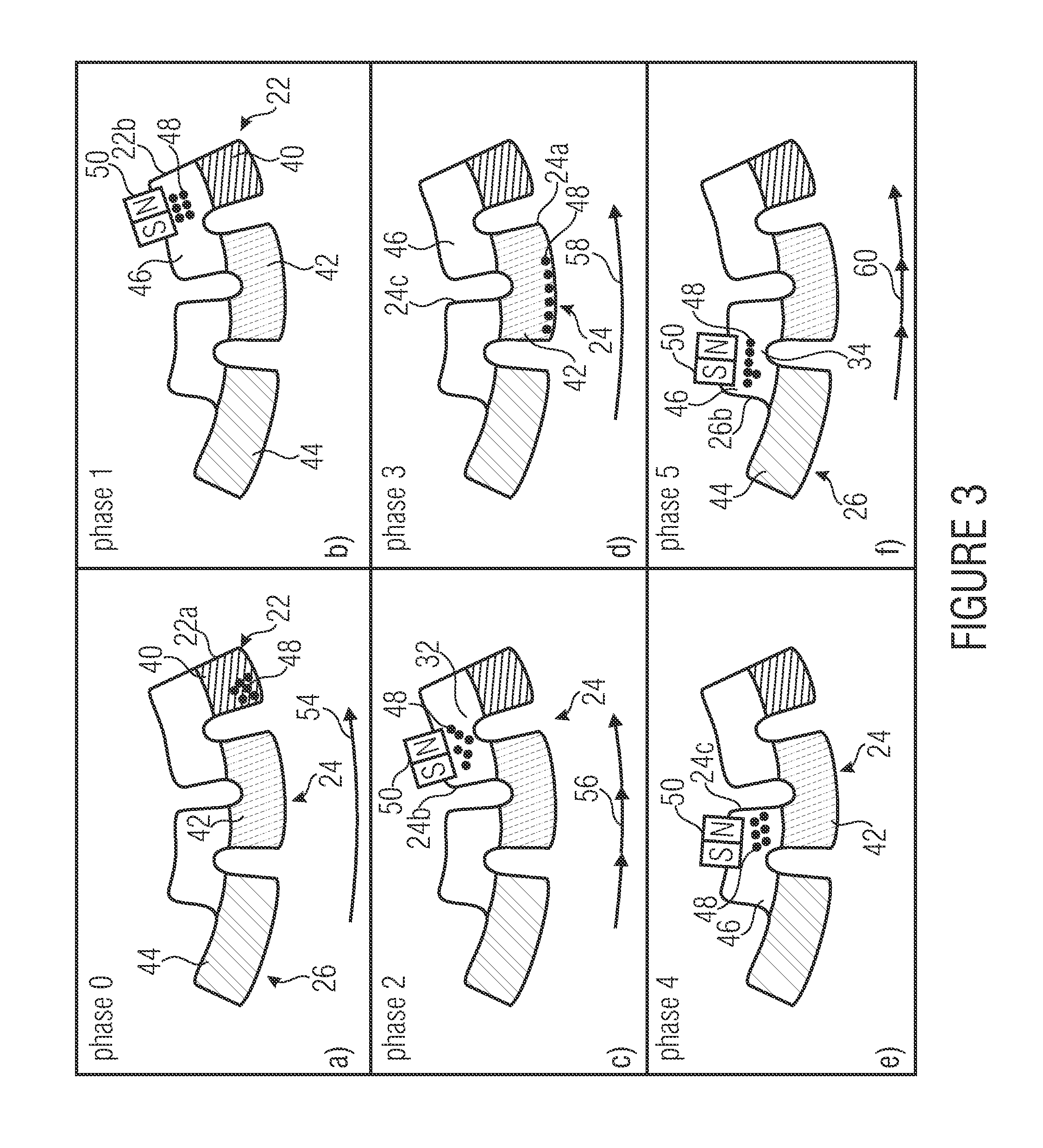

Method of transporting magnetic particles

ActiveUS20130206701A1Low costIncrease spaceSemi-permeable membranesFixed microstructural devicesMagnetic tension forceEngineering

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV

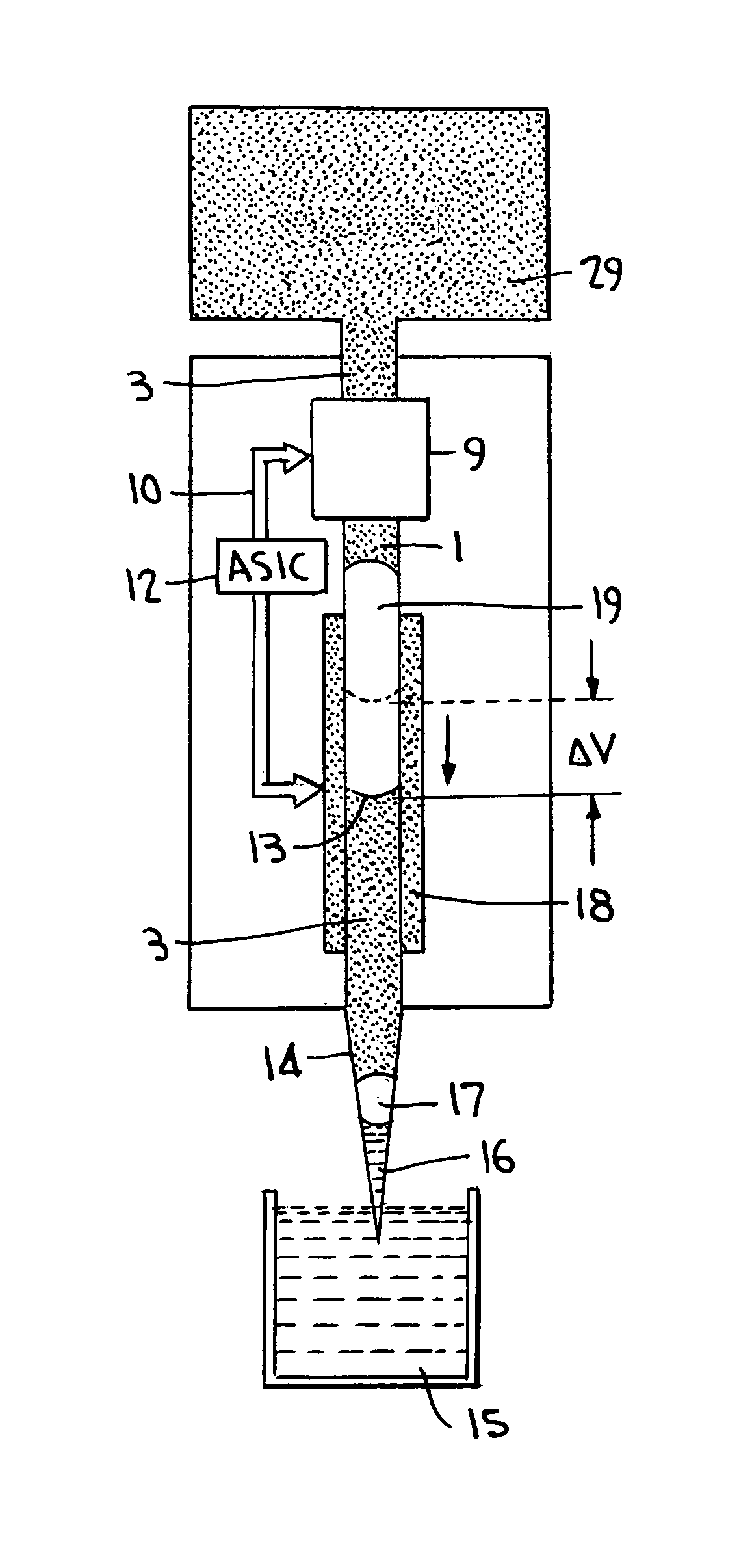

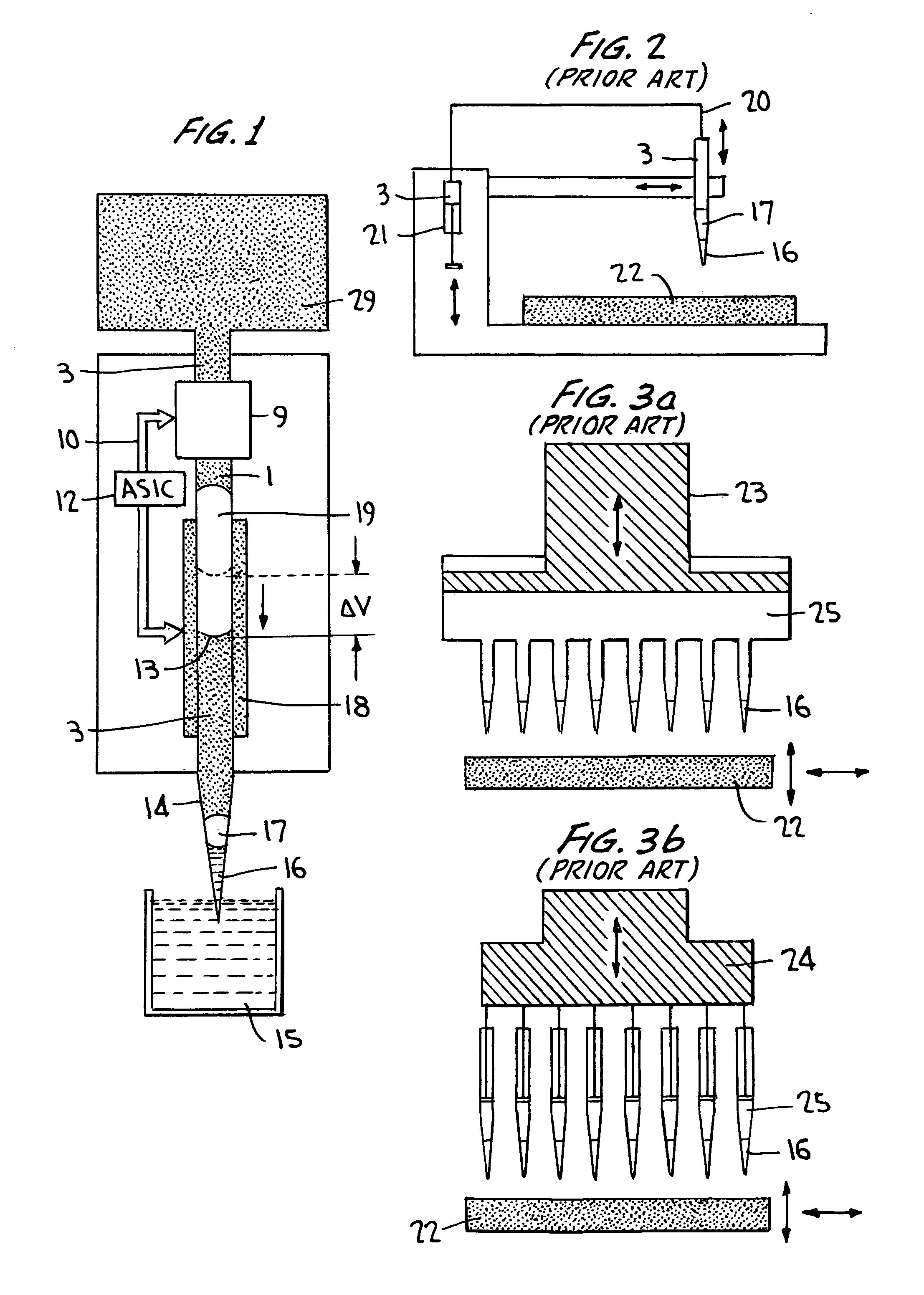

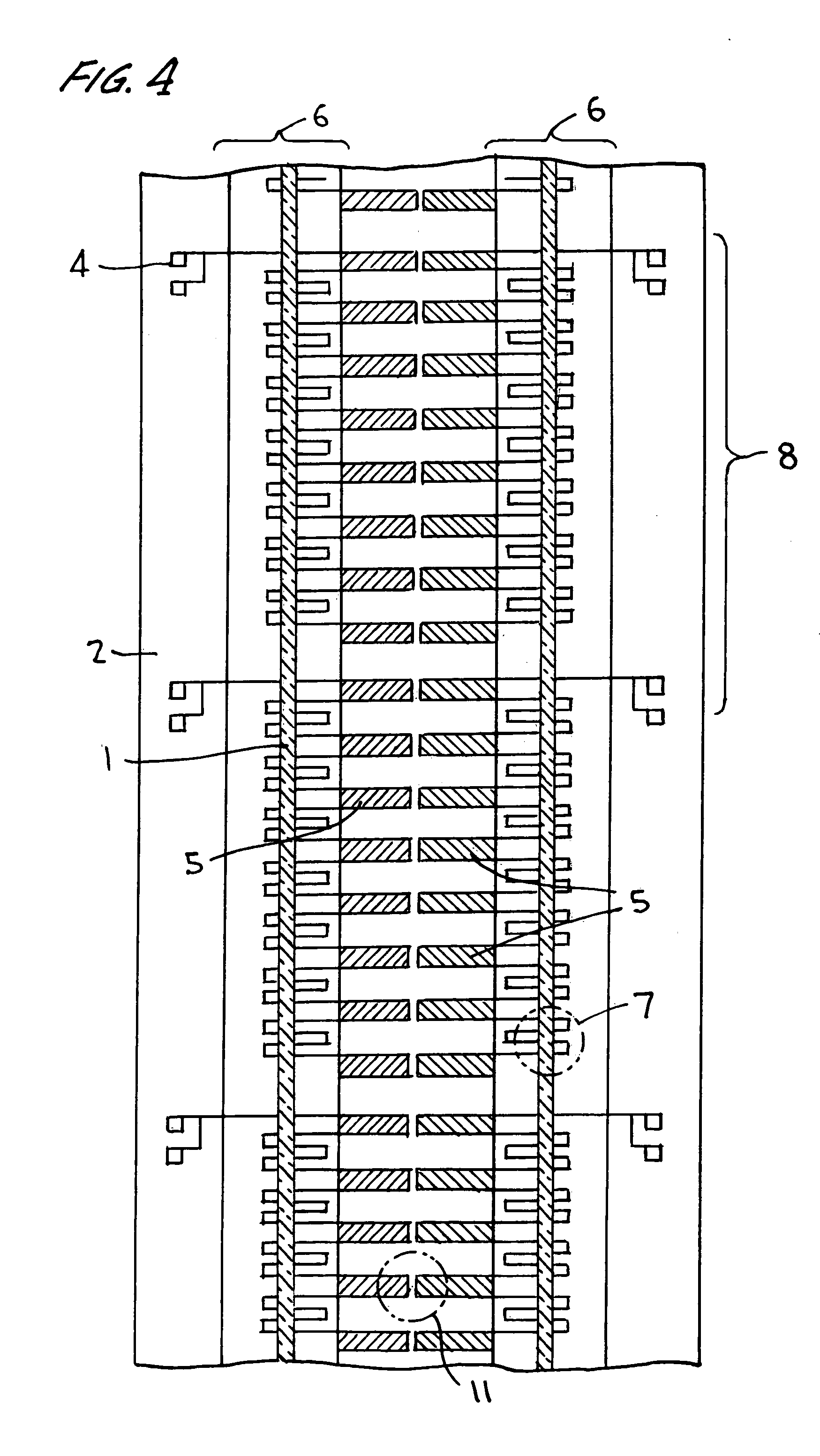

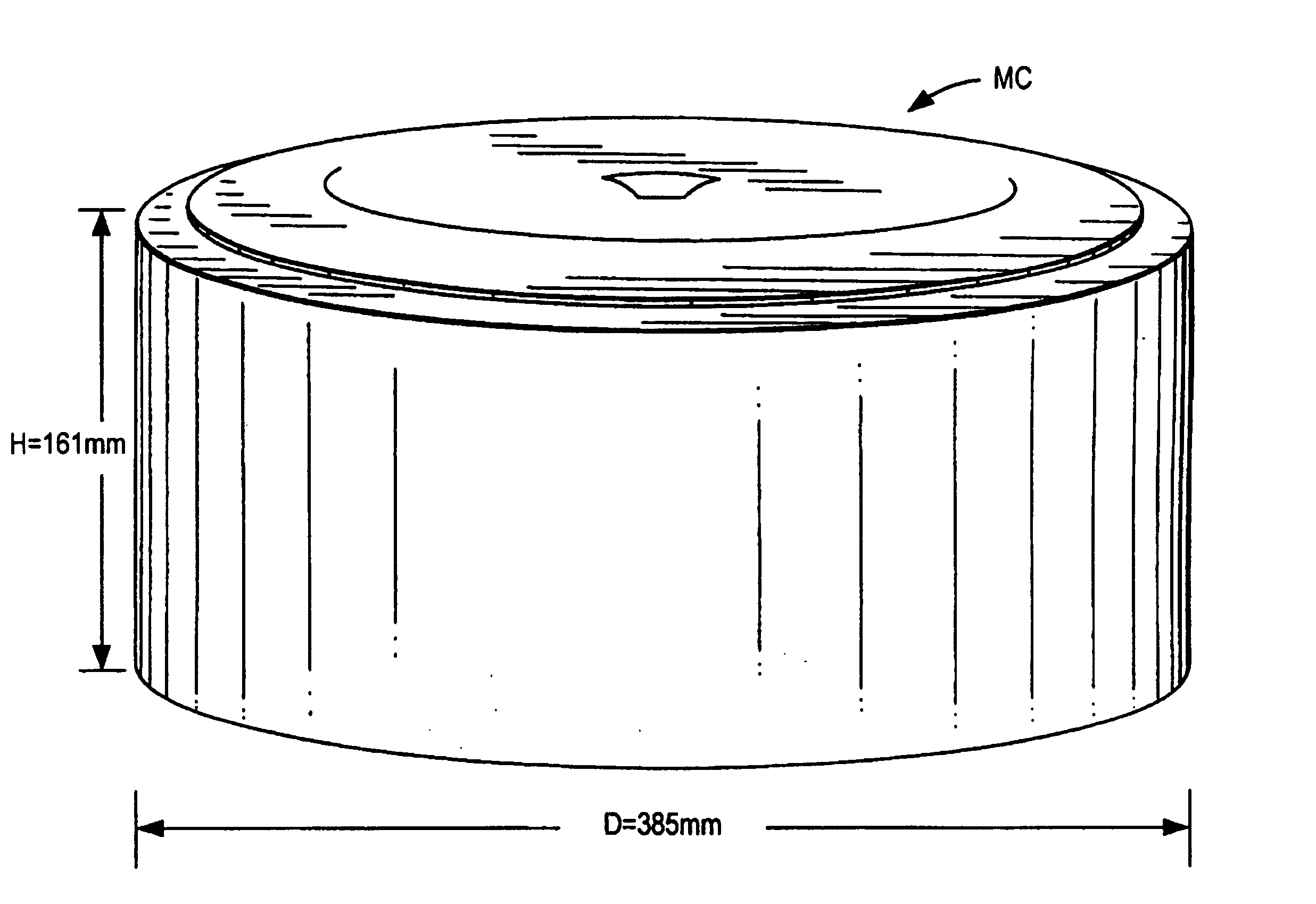

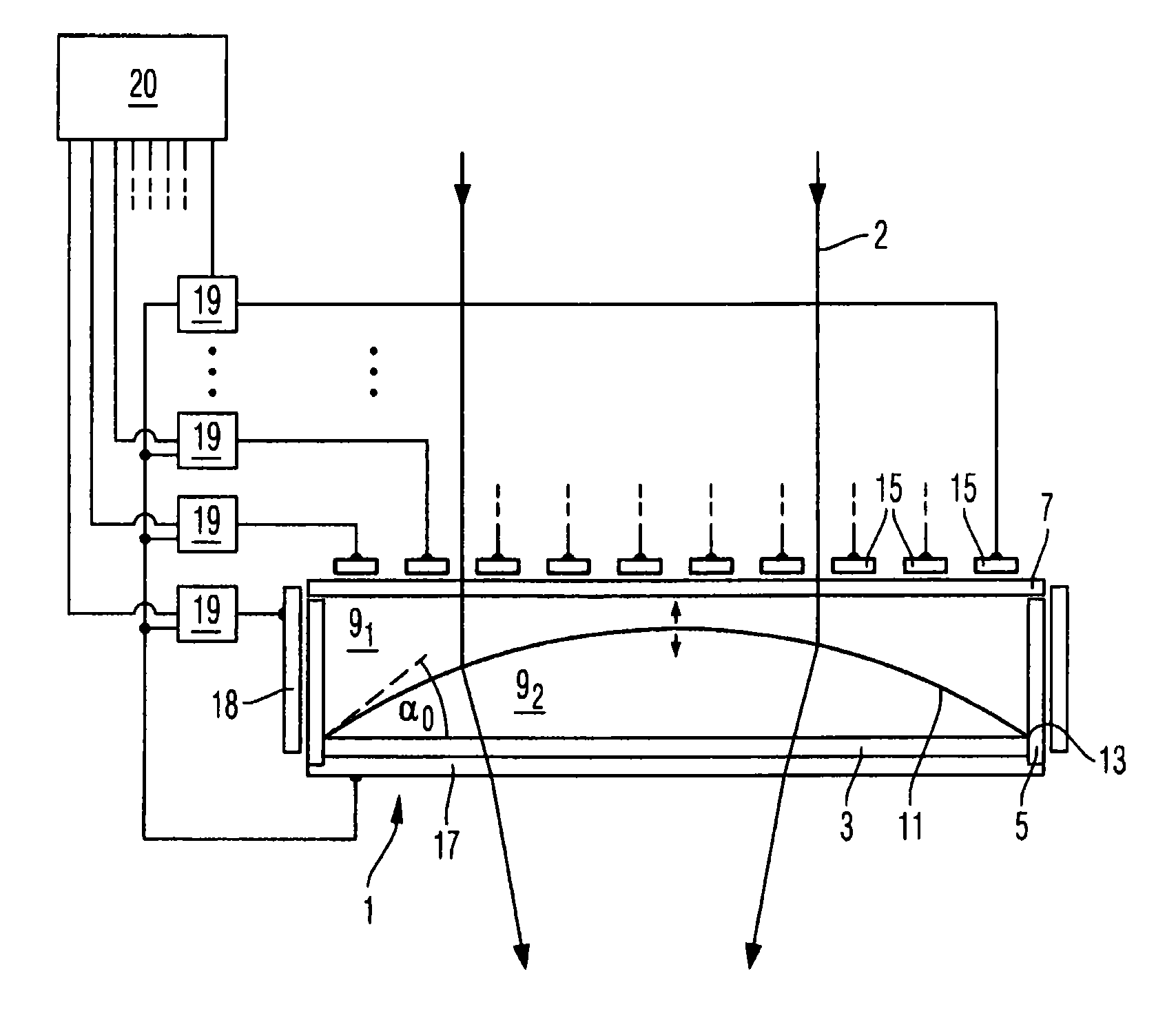

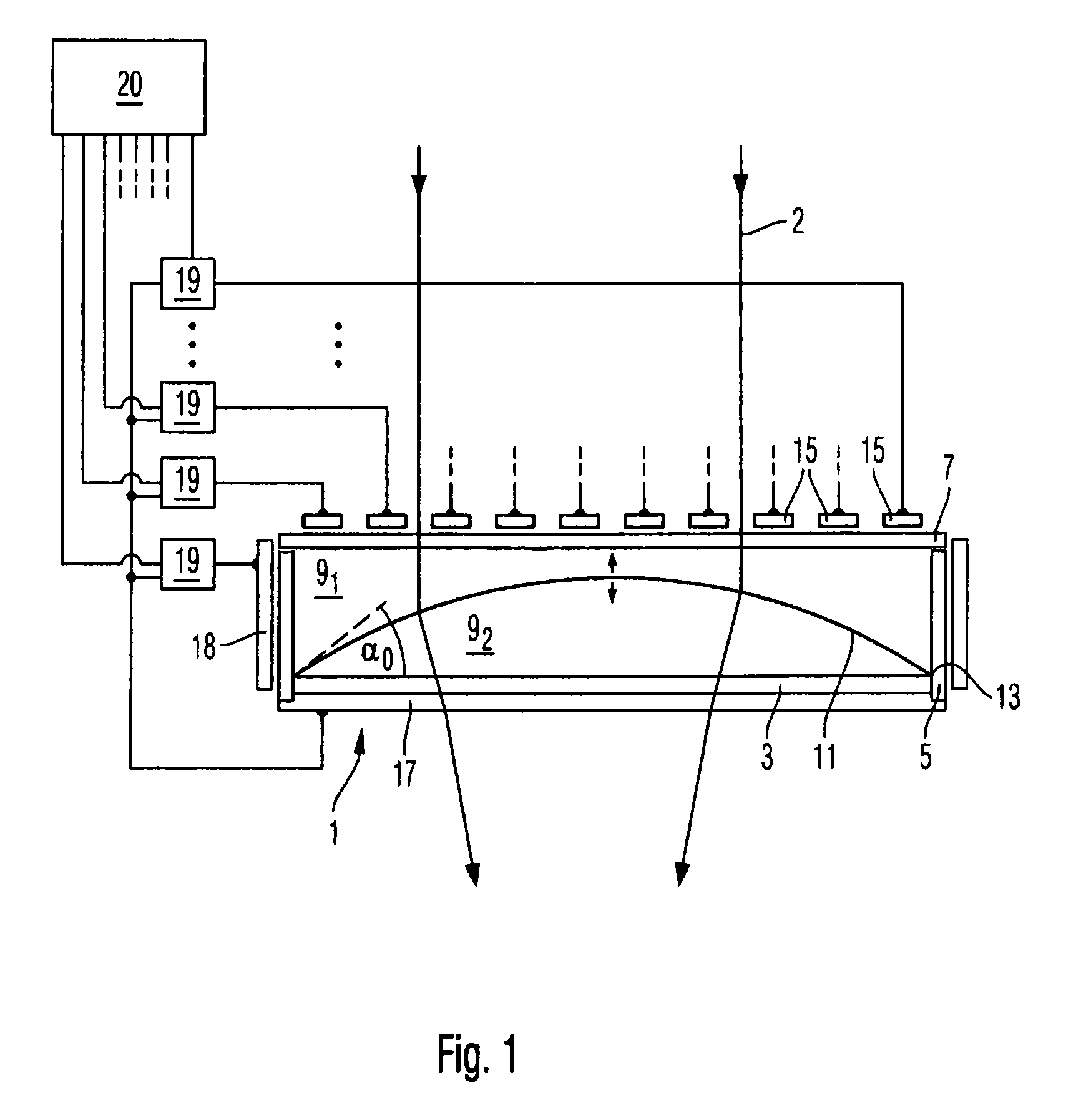

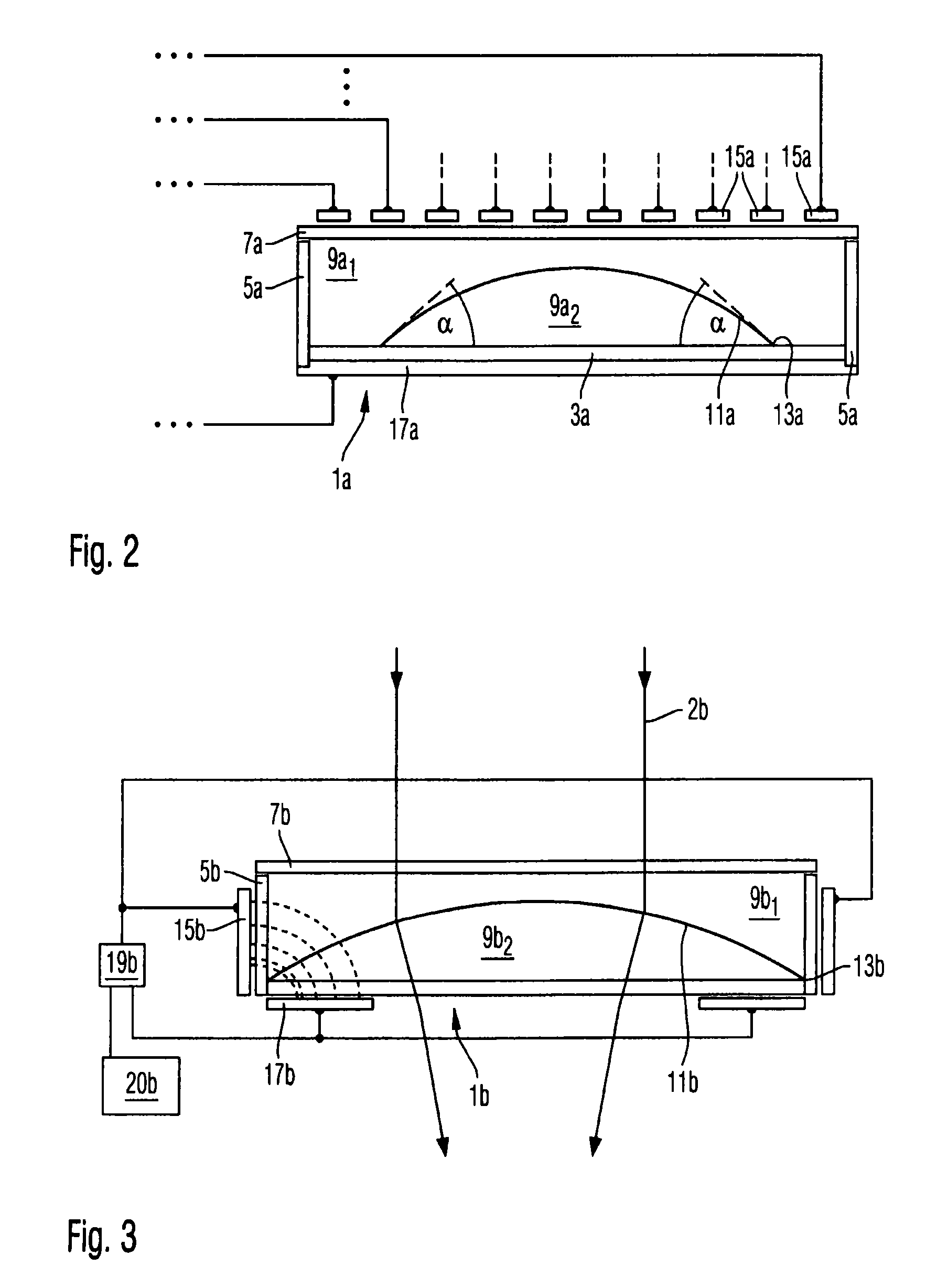

Pipette system and pipette array

InactiveUS7413710B2Avoid disadvantagesEasy to controlLarge containersAnalysis by subjecting material to chemical reactionPipetteActuator

A pipette system including a pipette capillary tube and an actuator, with the actuator serving to set the position of a phase boundary between a system medium and a second medium in the pipette capillary is described. A sensor element is also provided for measuring the position of the phase boundary, in such a way that the actuator is controlled by a regulating element in response to an output signal from the sensor element.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

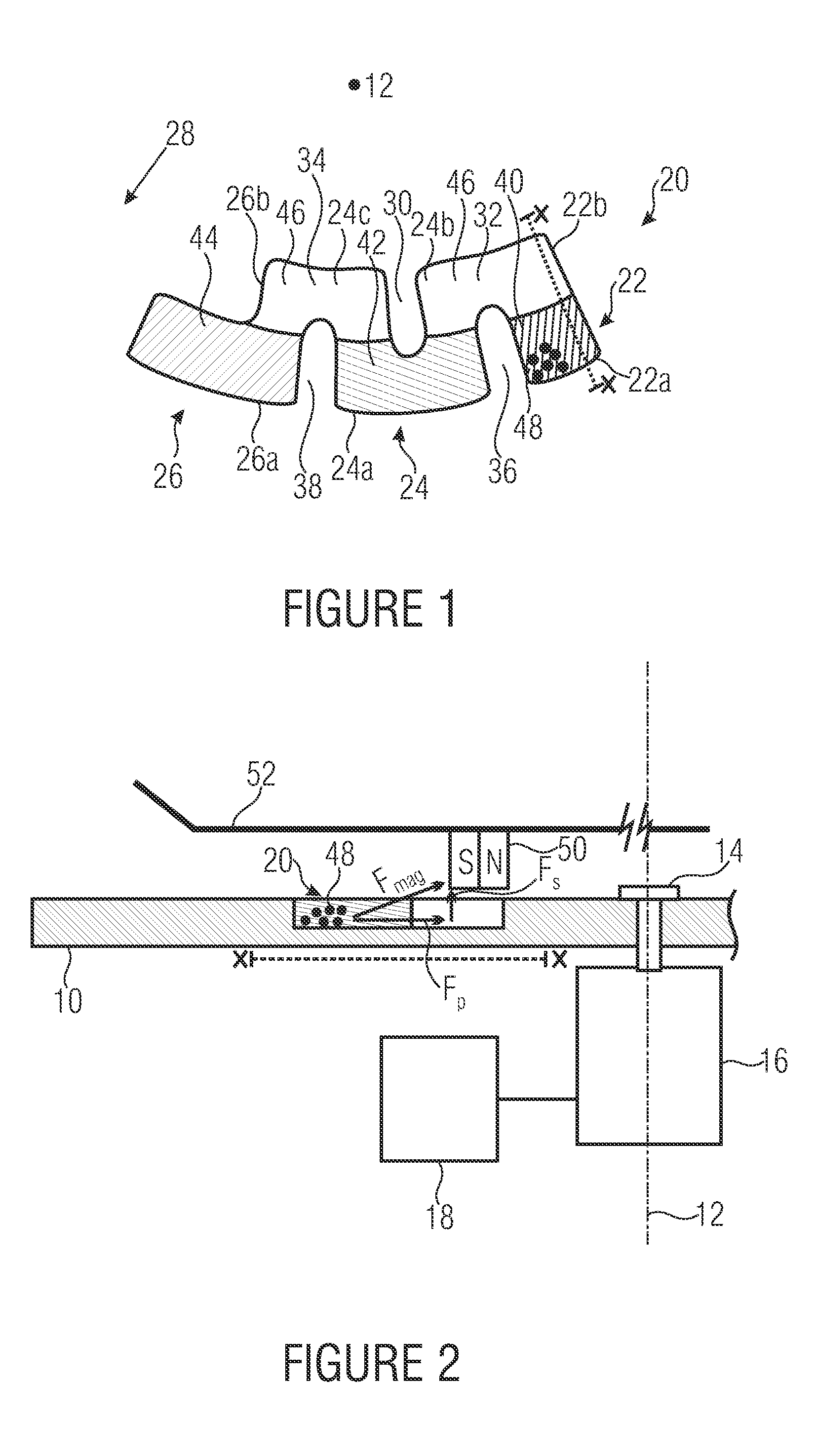

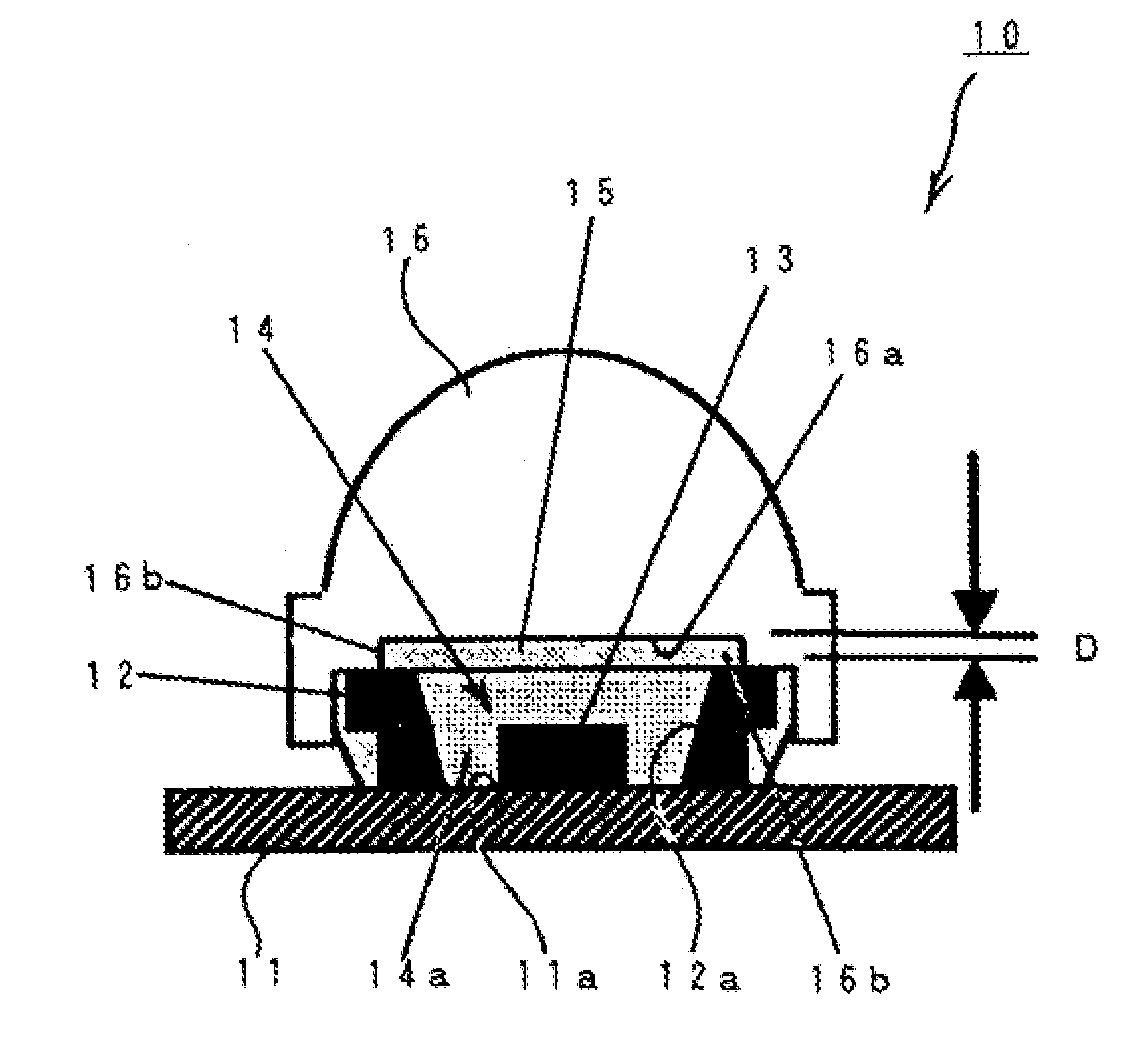

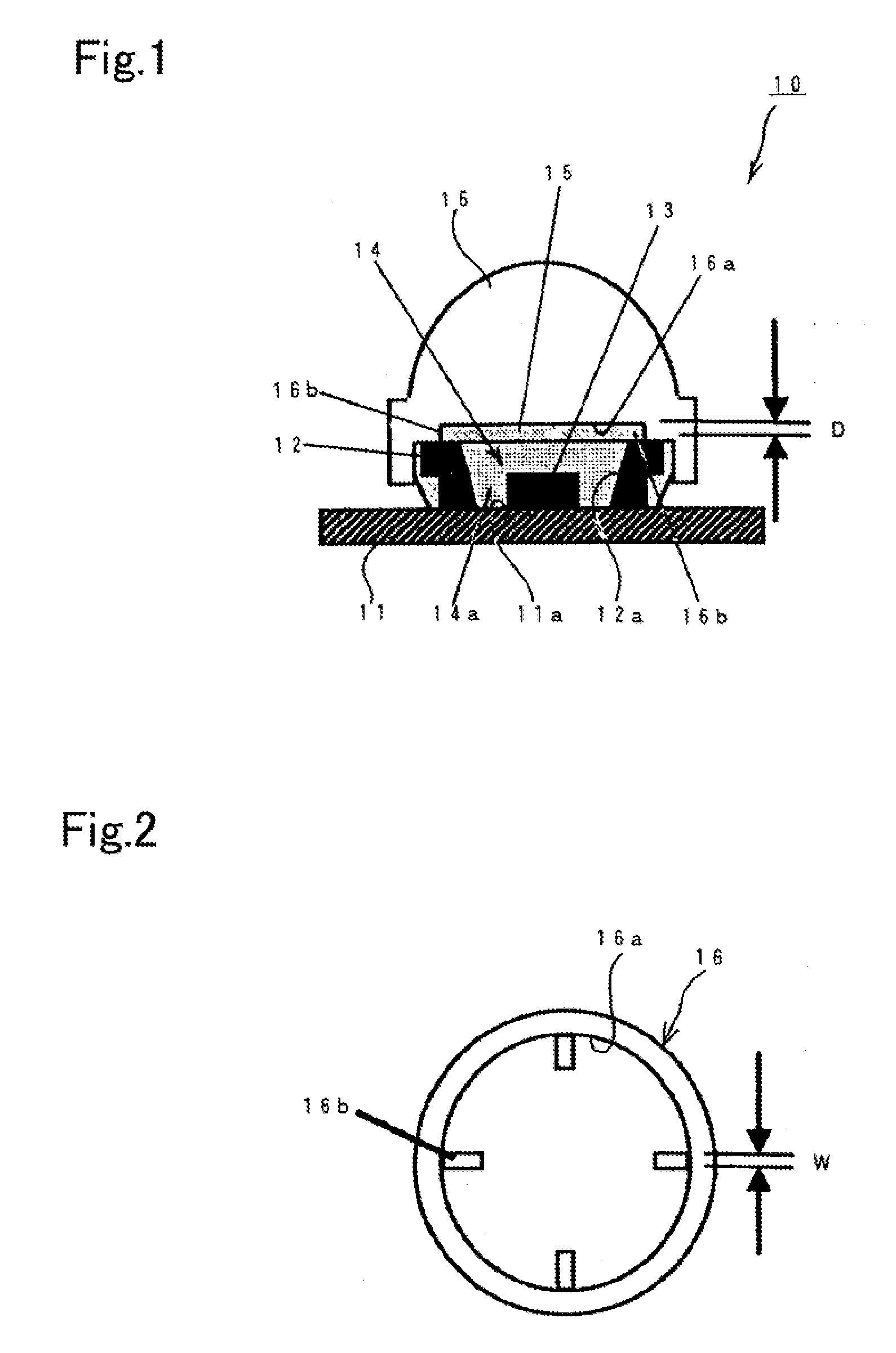

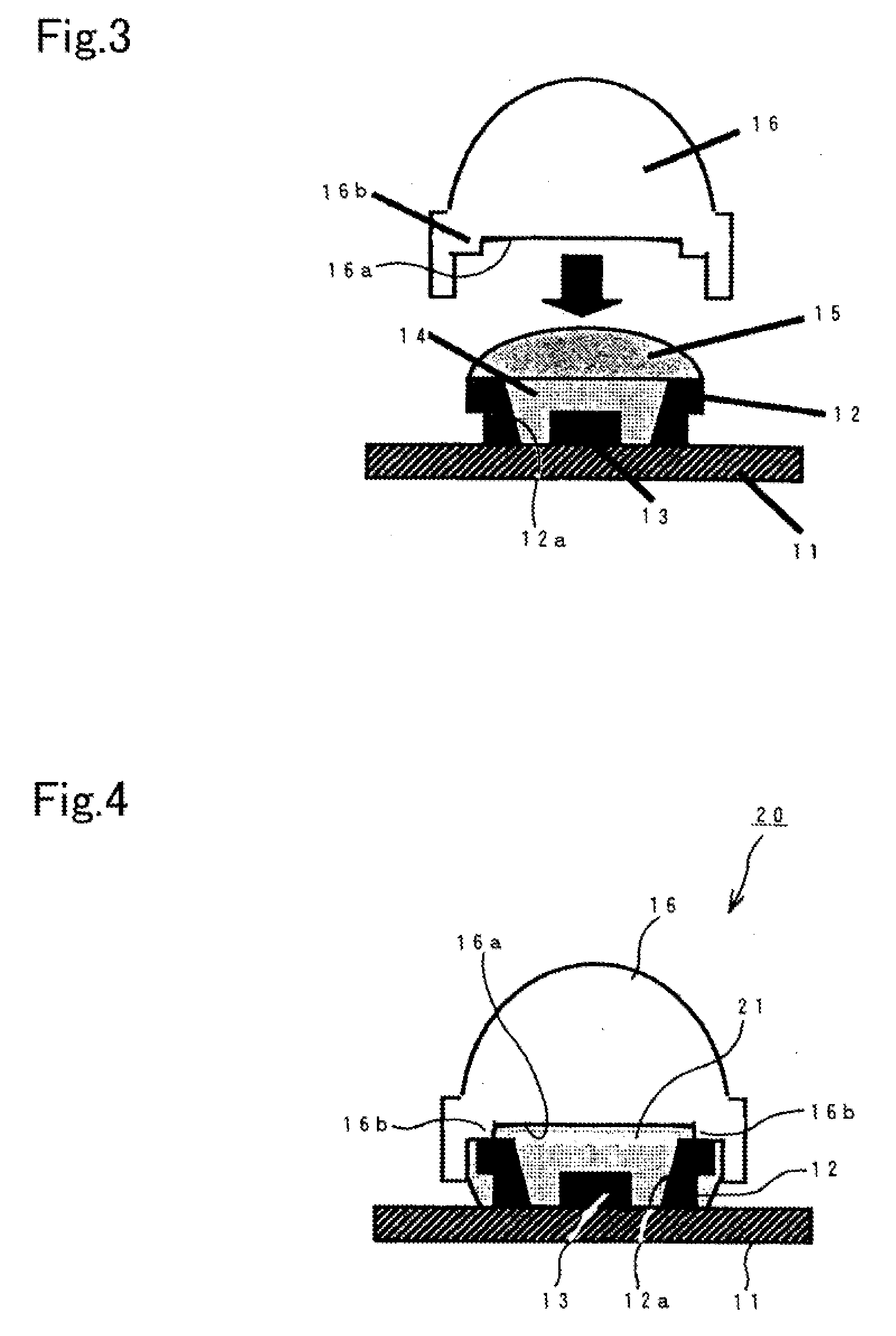

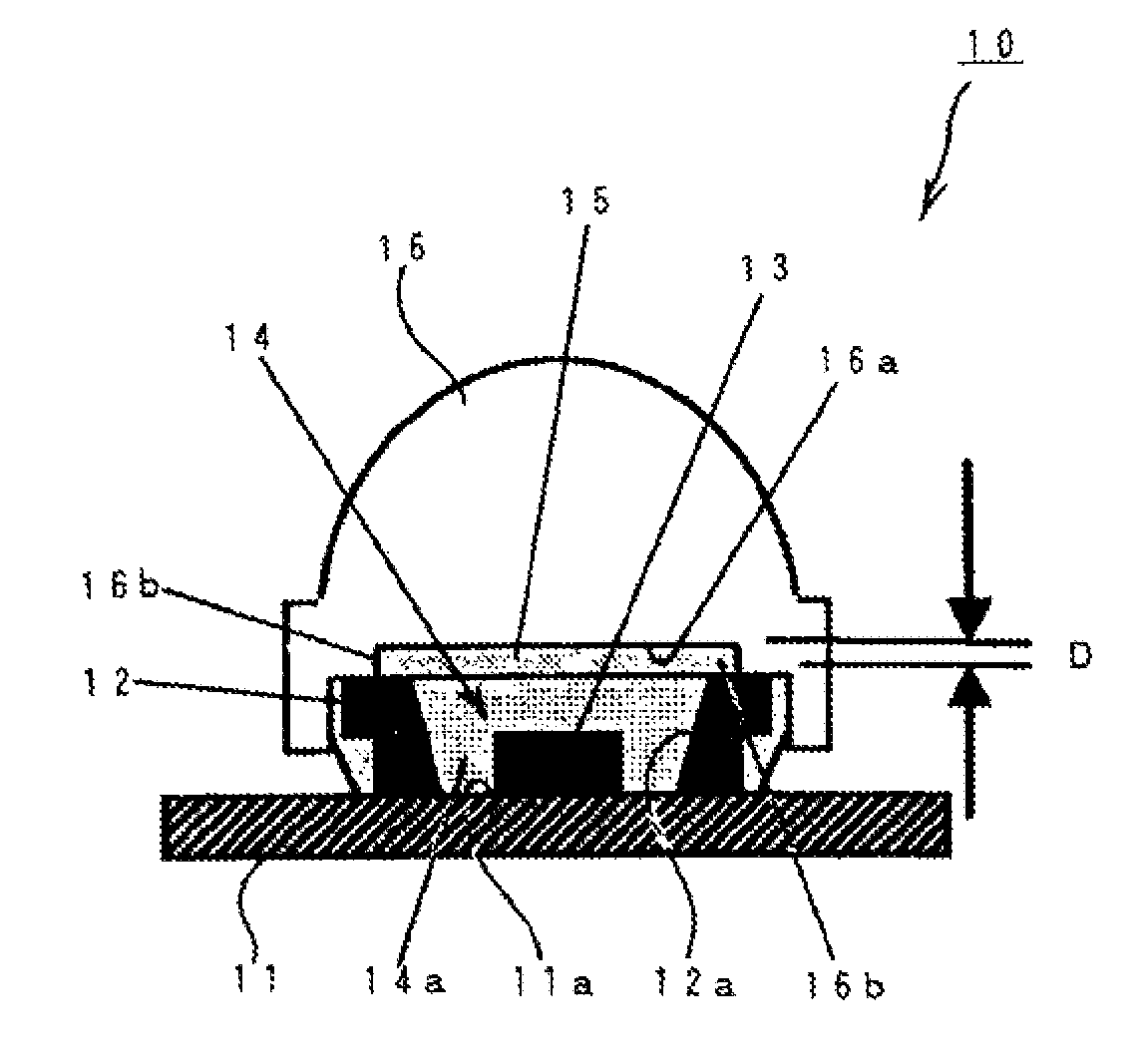

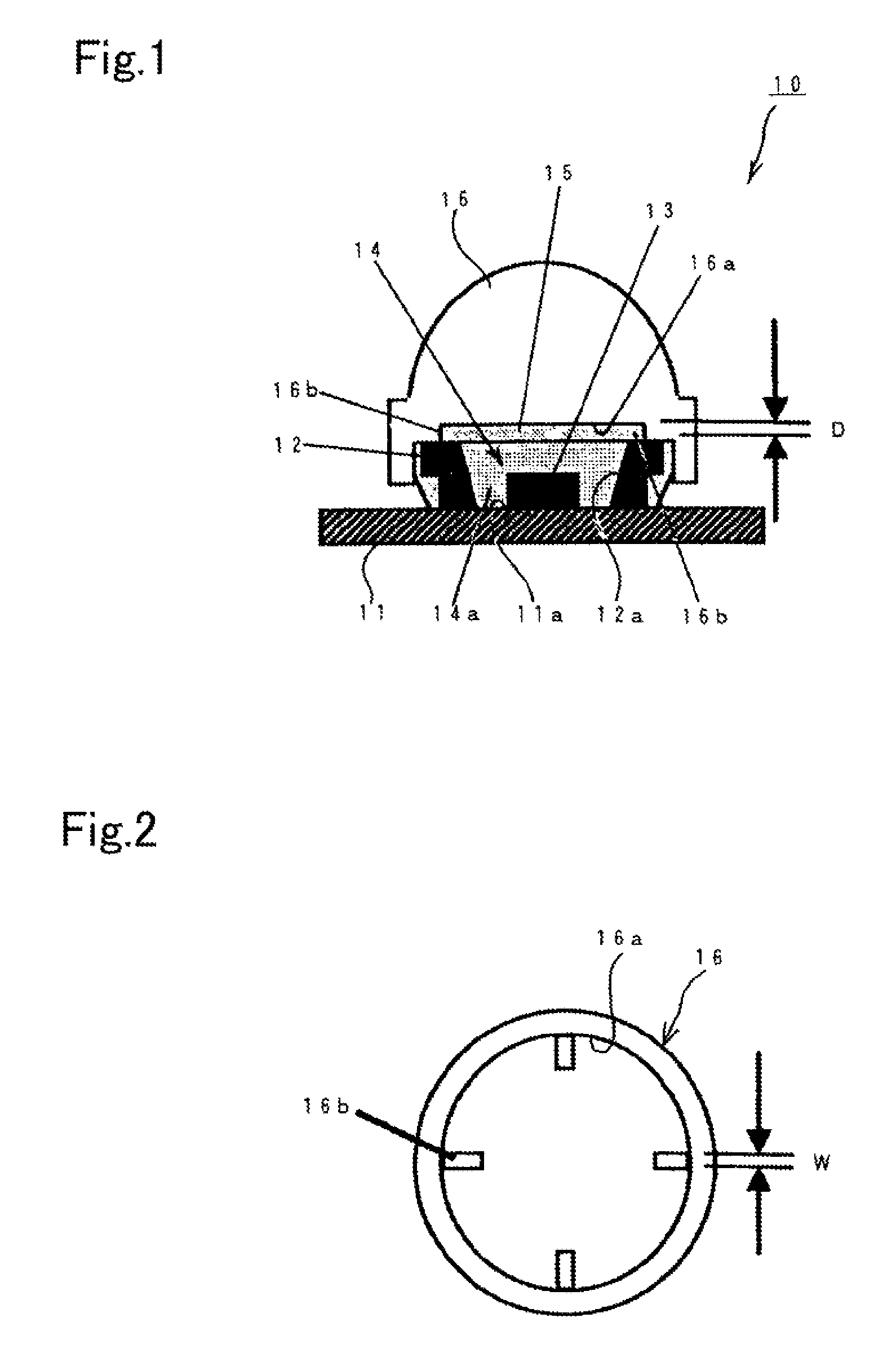

Semiconductor light emitting device and method for manufacturing the same

ActiveUS20070267643A1Improve reliabilitySolid-state devicesSemiconductor devicesOptical axisEngineering

Owner:STANLEY ELECTRIC CO LTD

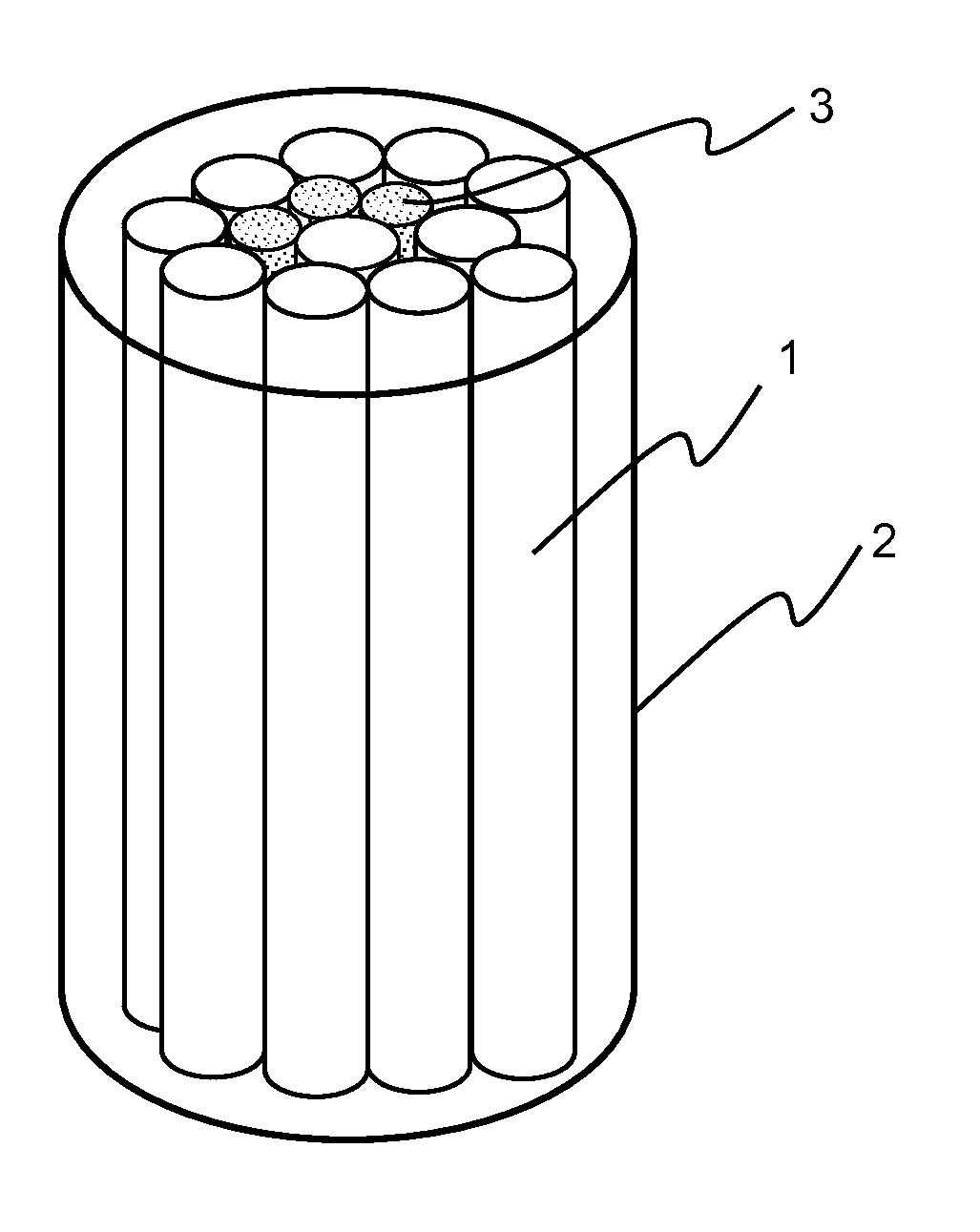

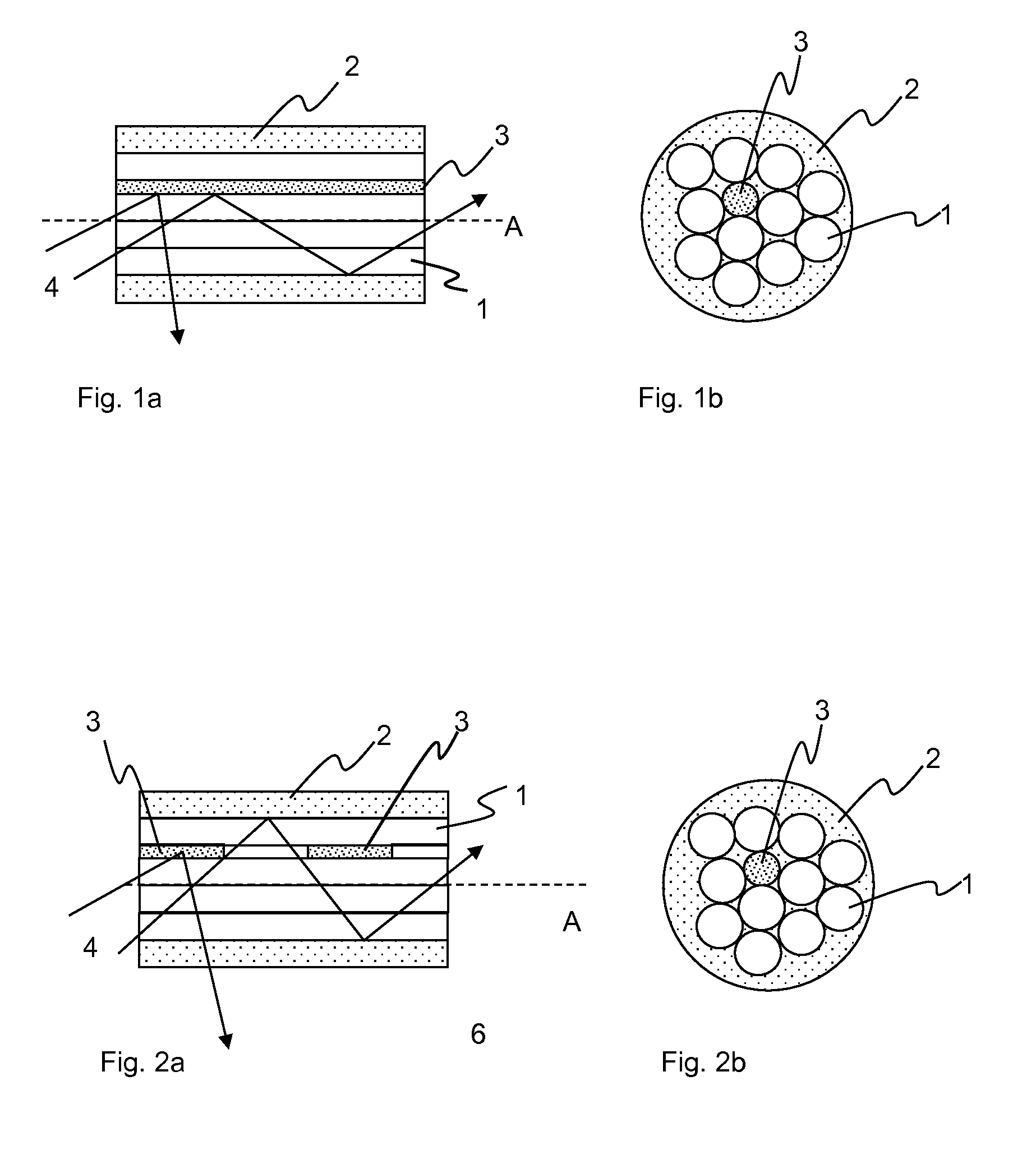

Side emitting glass element

ActiveUS20130314940A1Realize the shapeSuitable for useMechanical apparatusLight guidesLight guideRefractive index

Side emitting glass elements are provided that include a plurality of light guiding elements, which are inseparably connected to one another at their outer circumferential surfaces, and at least one scattering element. The scattering element is inseparably connected to the outer circumferential surface of at least one light guiding element. The light guiding elements have at least one glass with a refractive index n1, wherein the individual light guiding elements are not enclosed by a cladding. A phase boundary is present between the light guiding elements through which the guided light can pass and to reach the scattering element.

Owner:SCHOTT AG

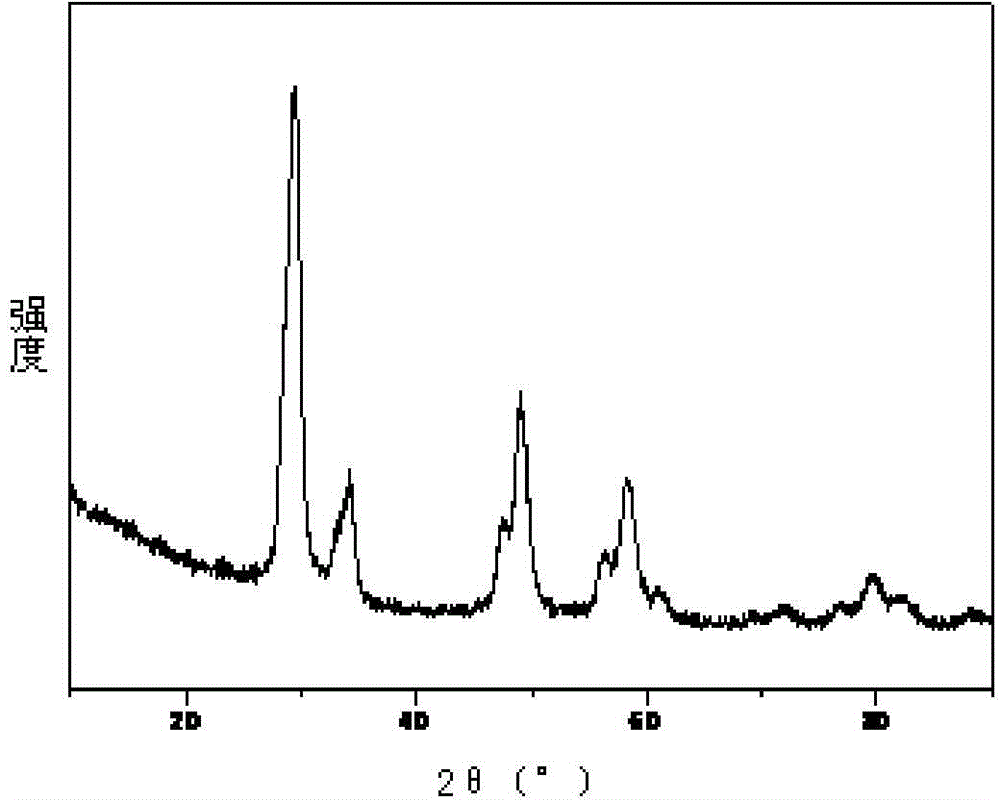

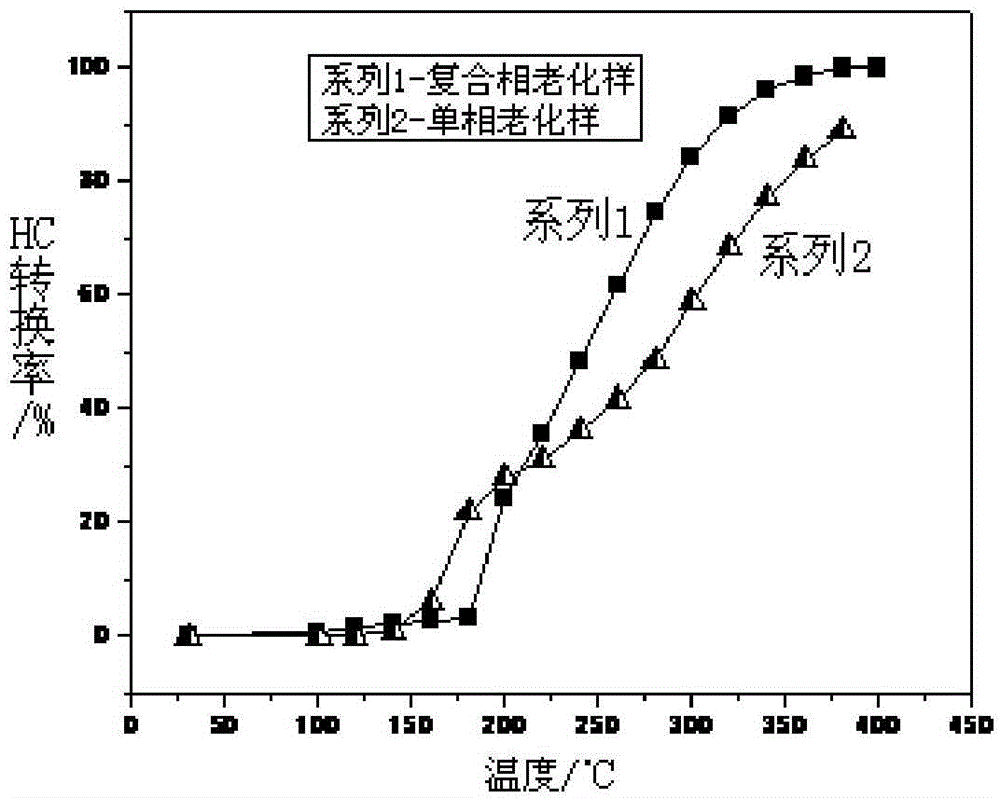

Cerium-zirconium composite oxide, preparation method of cerium-zirconium composite oxide and use of catalyst

ActiveCN105983403AImprove anti-sintering performanceImprove high temperature stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementAlkaline earth metal

The invention provides a cerium-zirconium composite oxide, a preparation method of the cerium-zirconium composite oxide and a use of the catalyst. The cerium-zirconium composite oxide has a composite phase structure and comprises a cerium oxide phase and a cerium-zirconium solid solution. The cerium-zirconium solid solution has a chemical formula of CexZr1-x-yMyO2, wherein M represents one or more of rare earth elements but cerium, transition metal elements and alkali earth metals, x is in a range of 15-85mol% and y is in a range of 0-20mol%. The cerium oxide phase and the cerium-zirconium solid solution have different cell parameters so that the cerium oxide phase and the cerium-zirconium solid solution have different phase boundaries and a contact area of a sintering neck is reduced. Under action of cooperation or coupling of the cerium oxide phase and the cerium-zirconium solid solution, the cerium-zirconium composite oxide has high anti-sintering performances so that high temperature stability of the cerium-zirconium composite oxide is improved.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method of transporting magnetic particles

ActiveUS8951417B2Low costIncrease spaceFixed microstructural devicesVolume/mass flow measurementEngineeringCentrifugal force

Owner:HAHN SCHICKARD GESELLSCHAFT FUER ANGEWANDTE FORSCHUNG EV

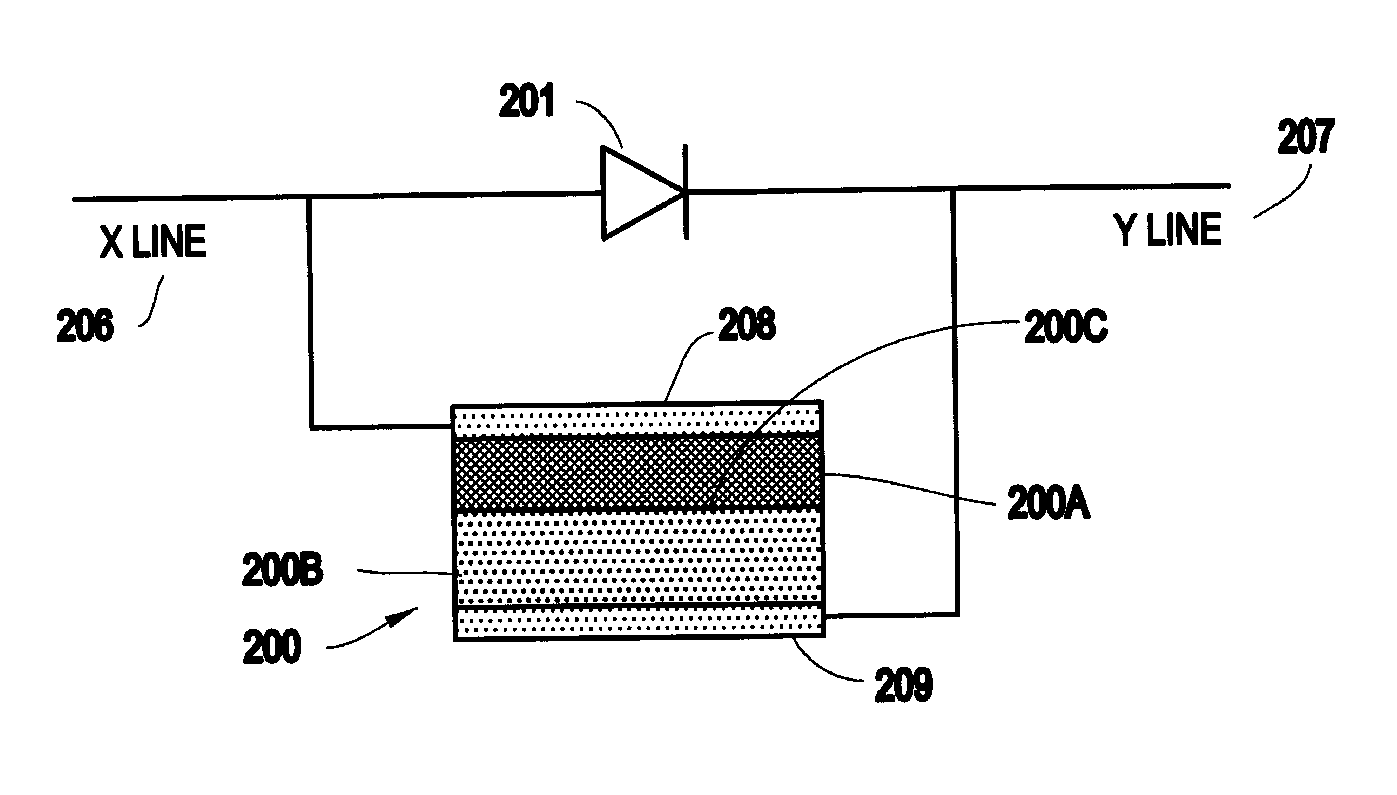

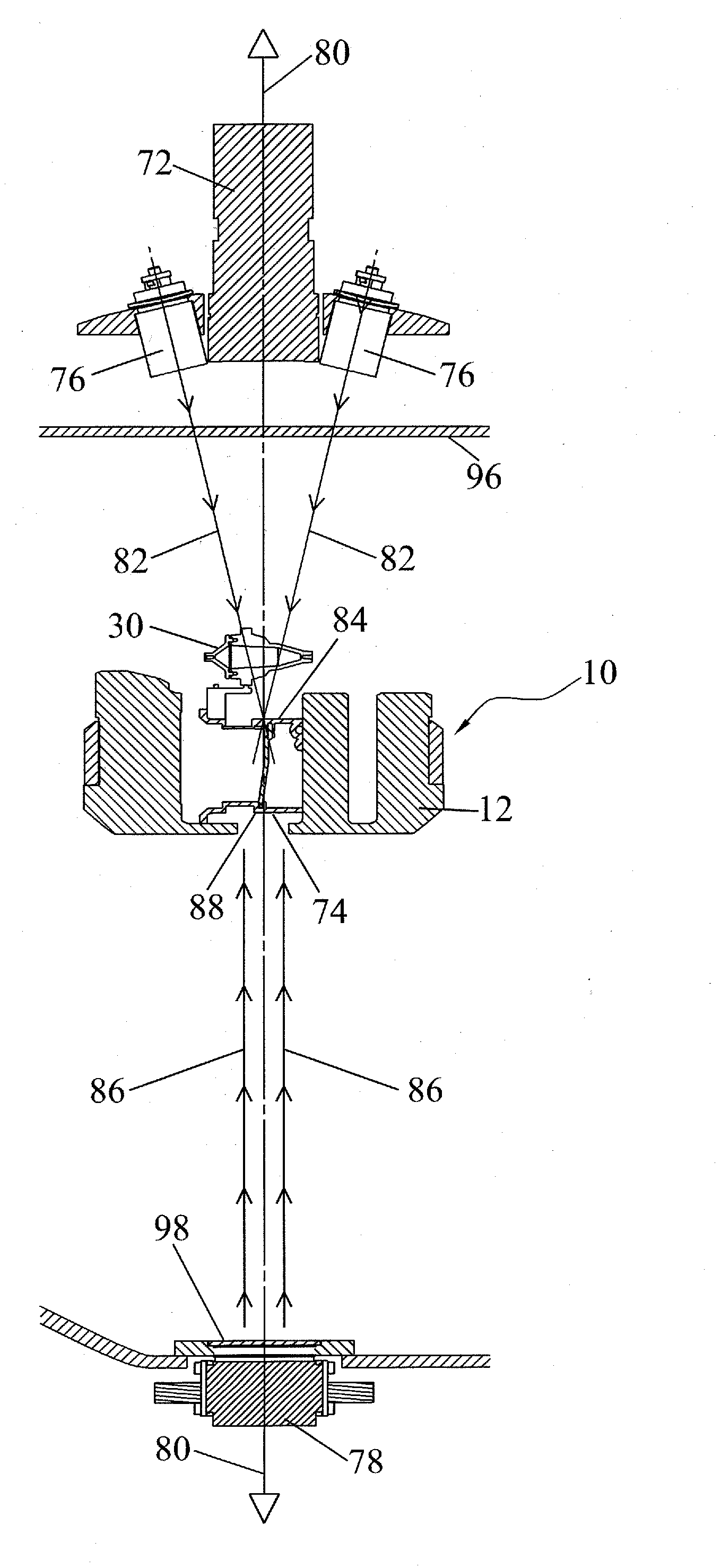

Semiconductor light-emitting device and method for manufacturing the same

A reliable semiconductor light-emitting device and a method for manufacturing the same can be provided in which peeling can be prevented in a phase boundary, and optical axis positional errors between the optical lens and a semiconductor light-emitting chip can be reduced or prevented. The semiconductor light-emitting device can include a base board having at least one chip, a reflector fixed on the base board so as to enclose the chip, and an encapsulating resin disposed in the reflector. An optical lens can include a concave-shaped cavity that has an inner corner surface having a plurality of convex portions thereon. The optical lens can be located adjacent the reflector by contacting the lens with a top surface of the reflector so as to enclose the reflector. A spacer that is disposed between the concave-shaped cavity and the reflector can ease a stress that is generated due to temperature changes.

Owner:STANLEY ELECTRIC CO LTD

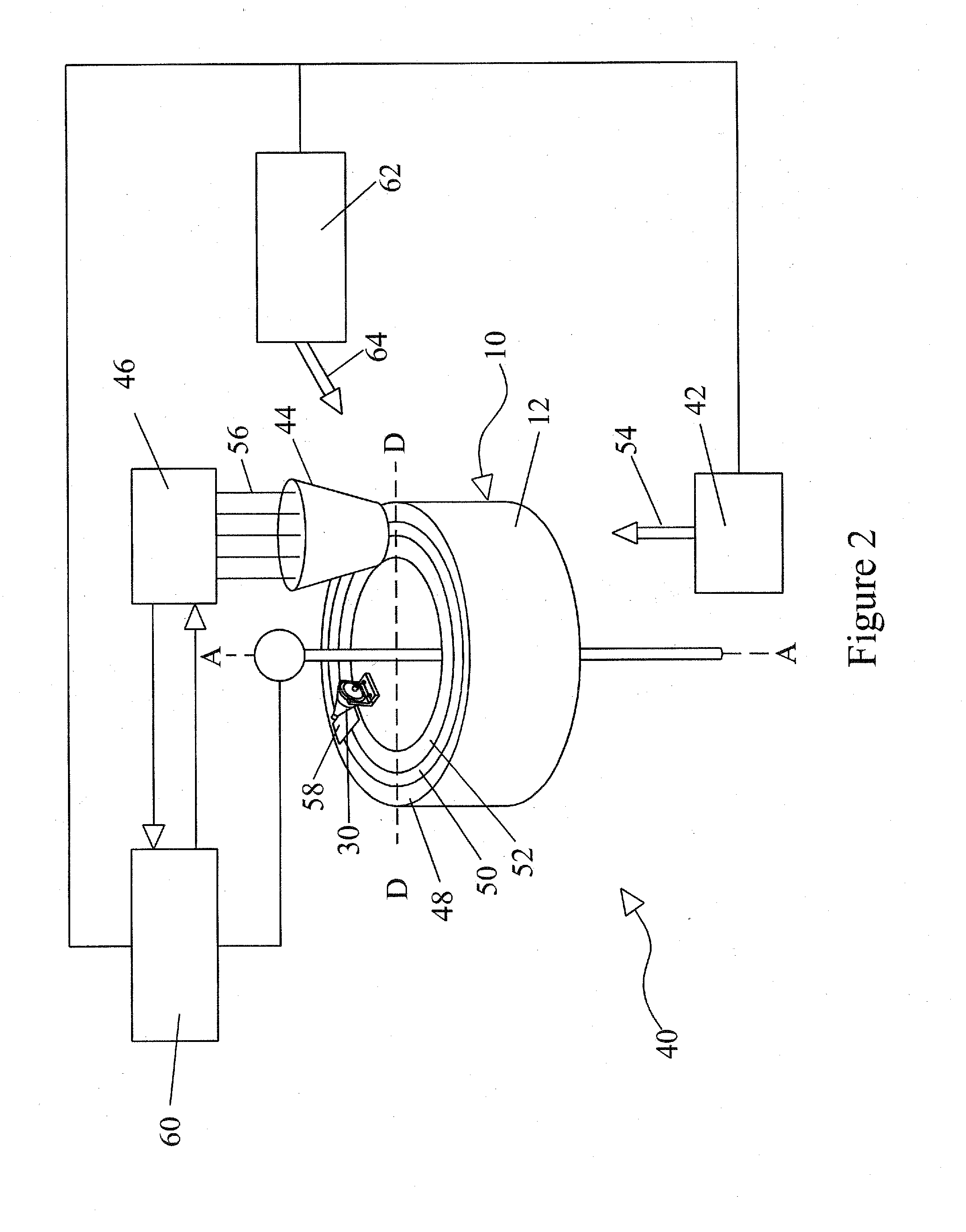

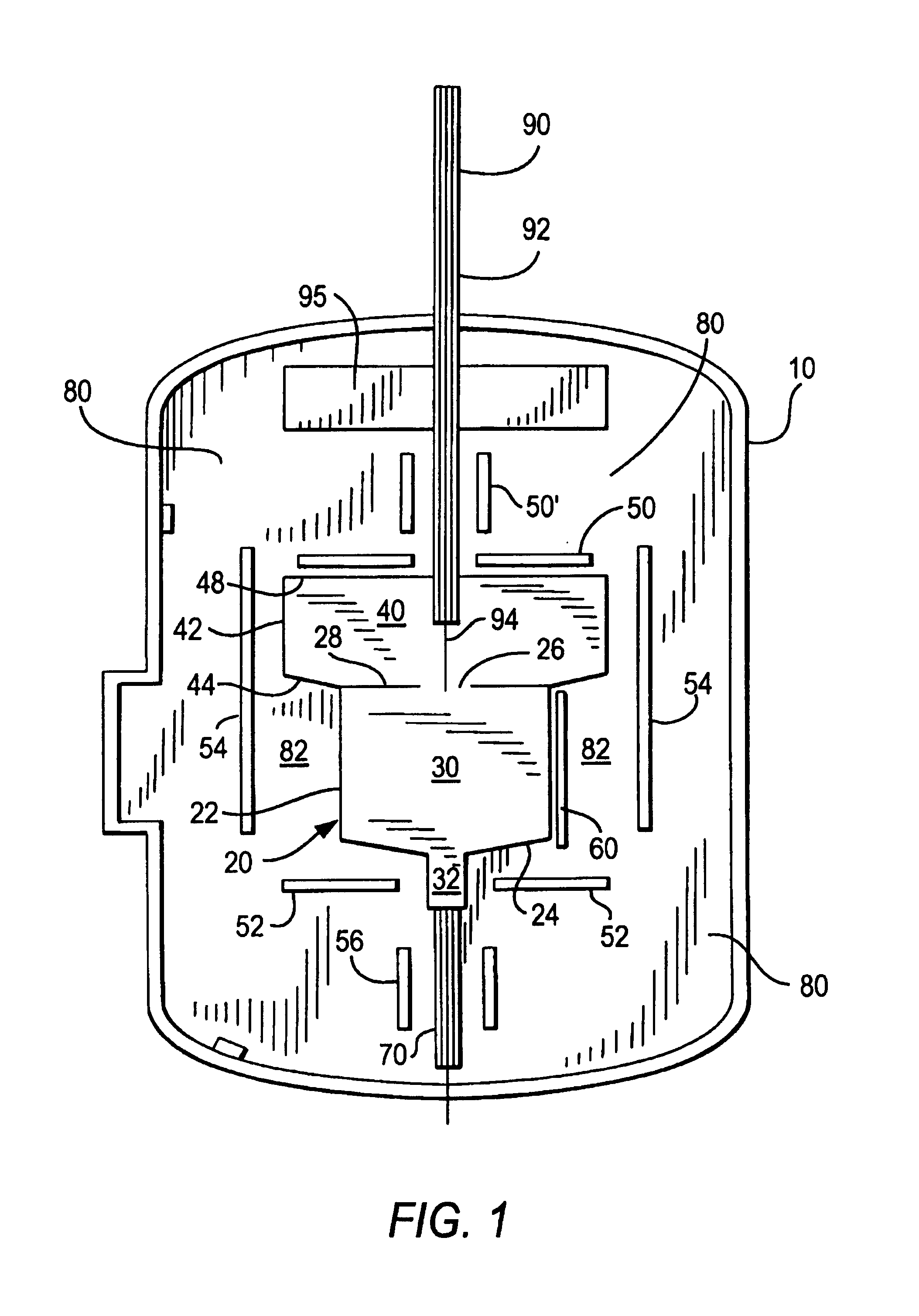

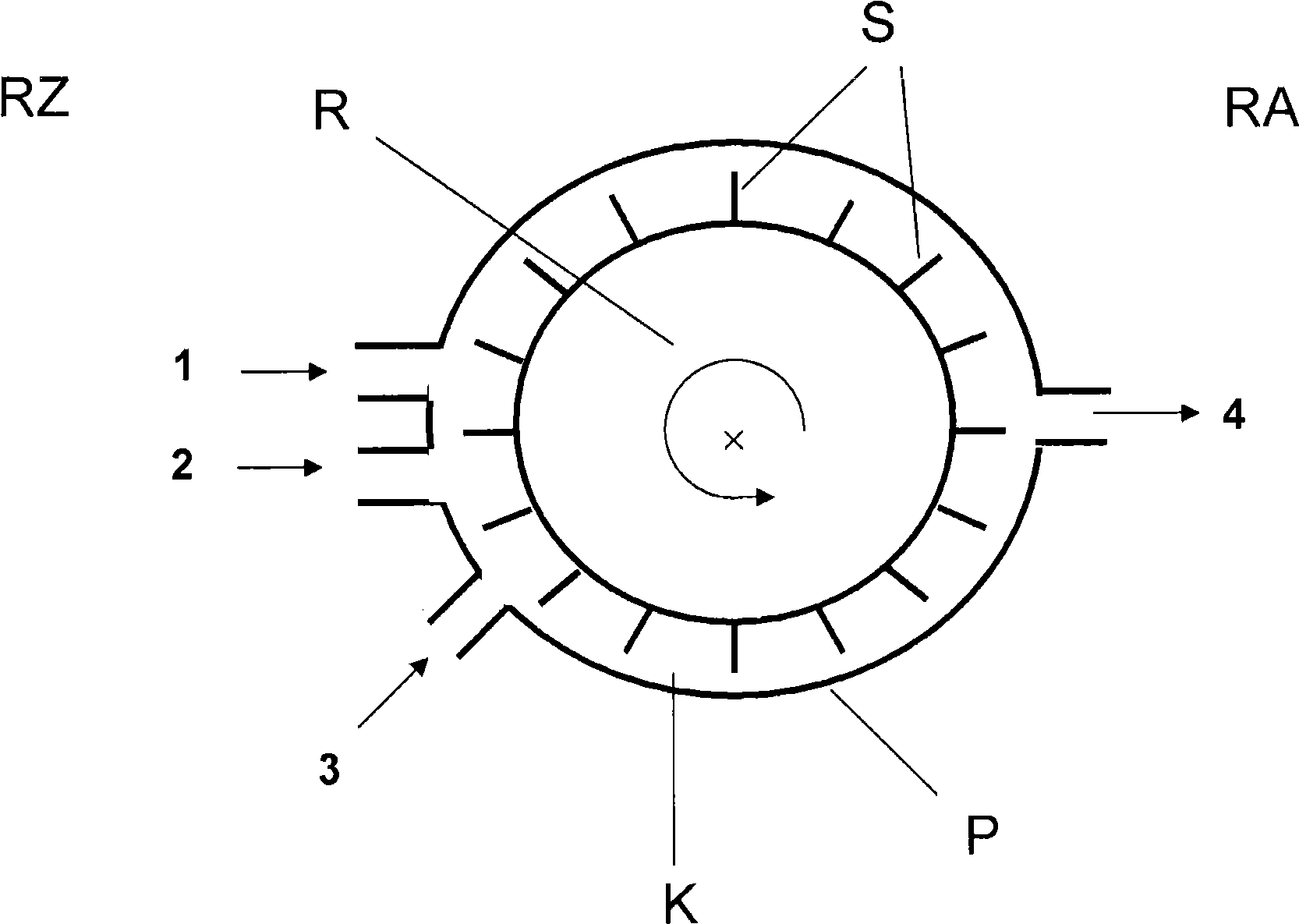

Blood Processing Apparatus with Robust Automated Process Control

ActiveUS20080045394A1Accurate collectionReduce detectionImage enhancementWater/sewage treatment by centrifugal separationImaging processingAutomatic process control

A centrifuge for separating blood having a camera observing fluid flow, and a controller controlling the flow. The location of an interface is detected by image processing steps, which may comprise the steps of “spoiling” the image, “diffusing” the image, “edge detection”, “edge linking”, “region-based confirmation”, and “interface calculation”. “Spoiling” reduces the number of pixels to be examined preferentially on orthogonal axis oriented with respect to the expected location of the interface or phase boundary. “Diffusing” smoothes out small oscillations in the interface boundary, making the location of the interface more distinct. “Edge detection” computes the rate of change in pixel intensity, or. “Edge linking” connects adjacent maxima. “Region-based confirmation” creates a pseudo image of the regions that qualify as distinct. “Final edge calculation” uses the points where the shade changes in the pseudo image, averages the radial displacement of these points for the interface position.

Owner:CARIDIANBCT

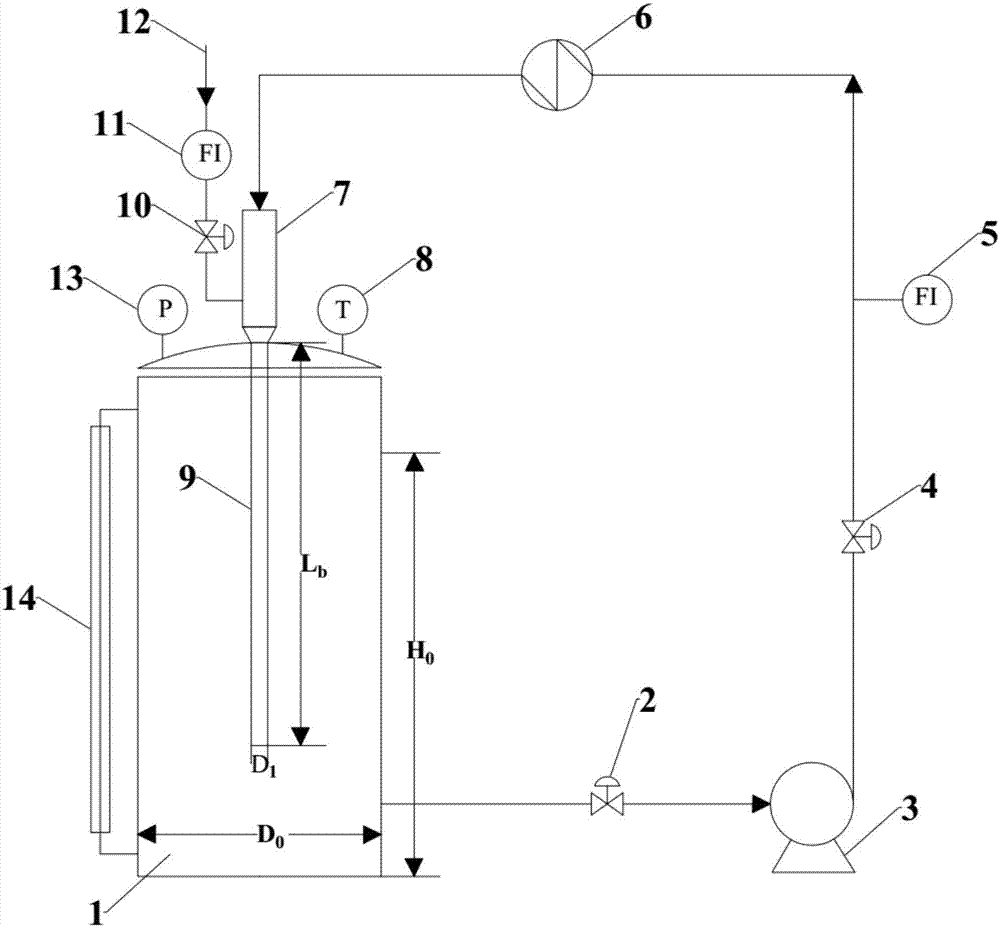

Modelling method for phase contact area structure-activity adjusting and controlling model for micro-interface enhanced reactor

ActiveCN107335390AEffective structureReduce mistakesLiquid-gas reaction as foam/aerosol/bubblesDesign optimisation/simulationModel methodReaction system

The invention relates to a modelling method for a phase contact area structure-activity adjusting and controlling model for a micro-interface enhanced reactor. A general expression of a gas-liquid interface area of a micro-interface enhanced reactor, a general expression of the gas content of the micro-interface enhanced reactor and an expression of the rising speed of air bubbles in a gas-liquid system of the micro-interface enhanced reactor are established in sequence; a structure-activity adjusting and controlling model of the phase contact area of the micro-interface enhanced reactor is acquired; the blank of prior art is filled up. According to the method provided by the invention, the reaction efficiency (energy efficiency and physical efficiency) of an ultrafine gas-liquid particle reaction system, physical and chemical characteristics of the system, micro-interface characteristics, mass transfer characteristics and a reactor structure are associated according to a mathematical method, so that the maximization target of the energy efficiency and the physical efficiency in a reacting process can be achieved by adjusting structural parameters and operation parameters; or under a specified reaction target (task) and energy consumption and physical consumption, a high-efficiency reactor structure is designed.

Owner:NANJING UNIV

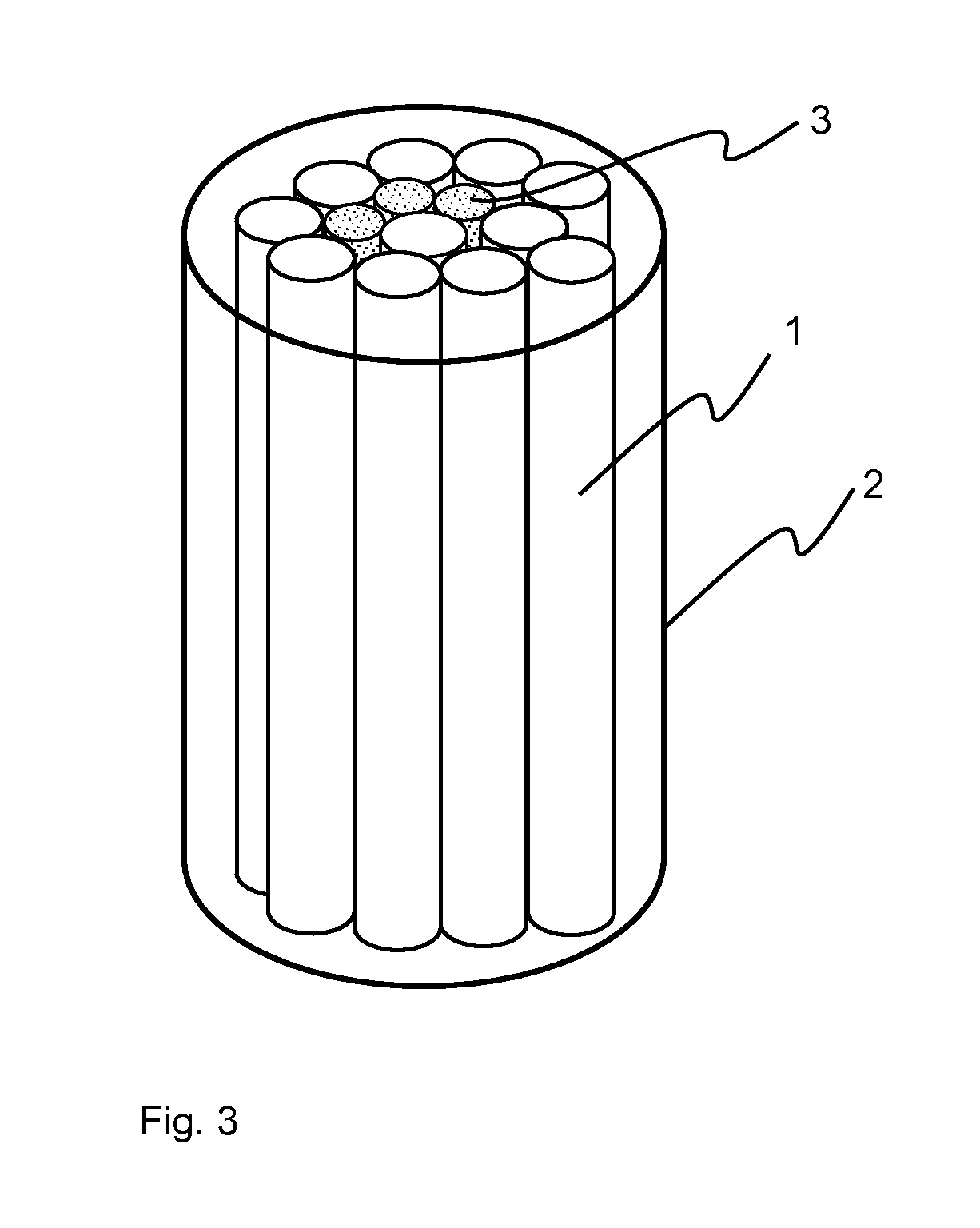

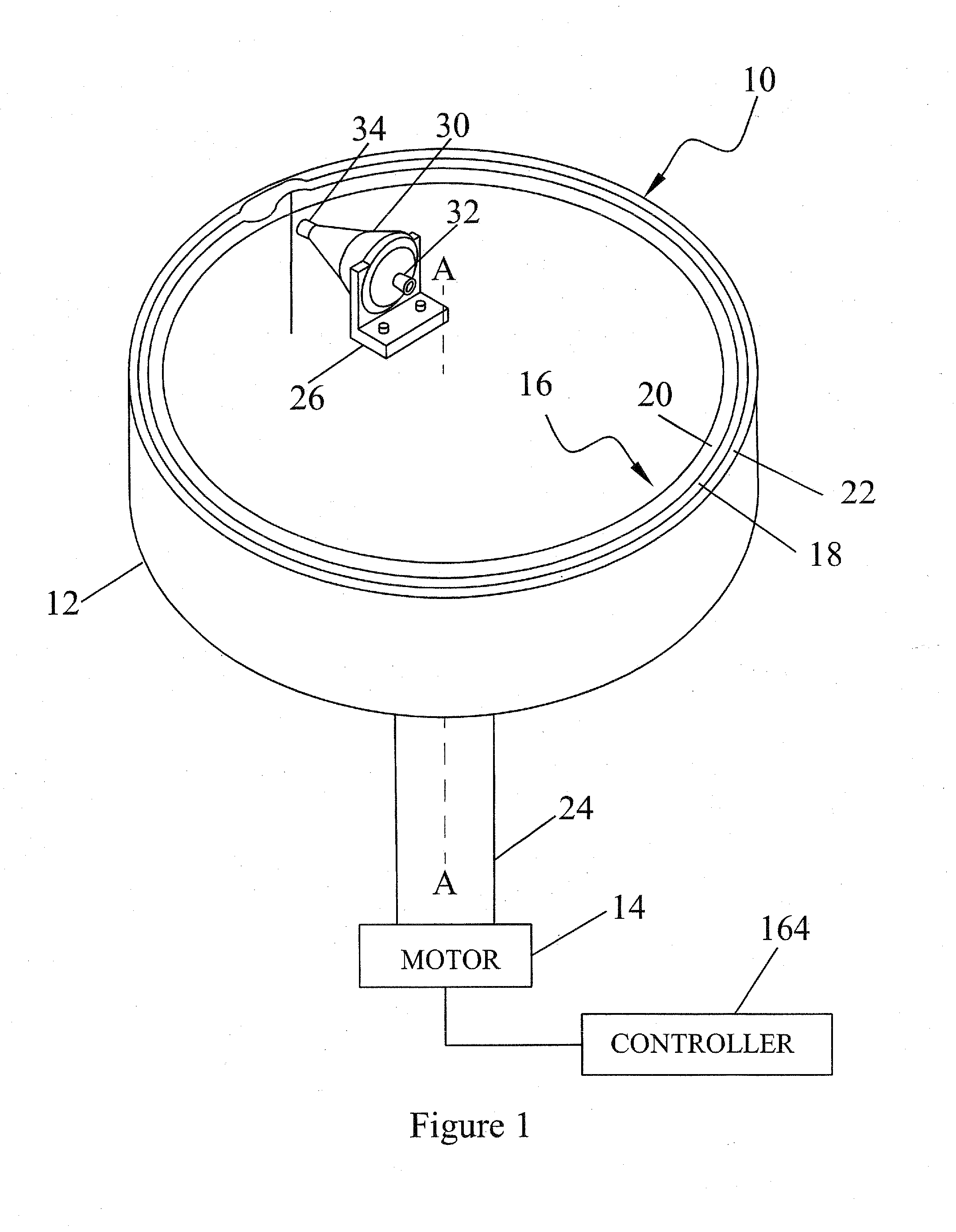

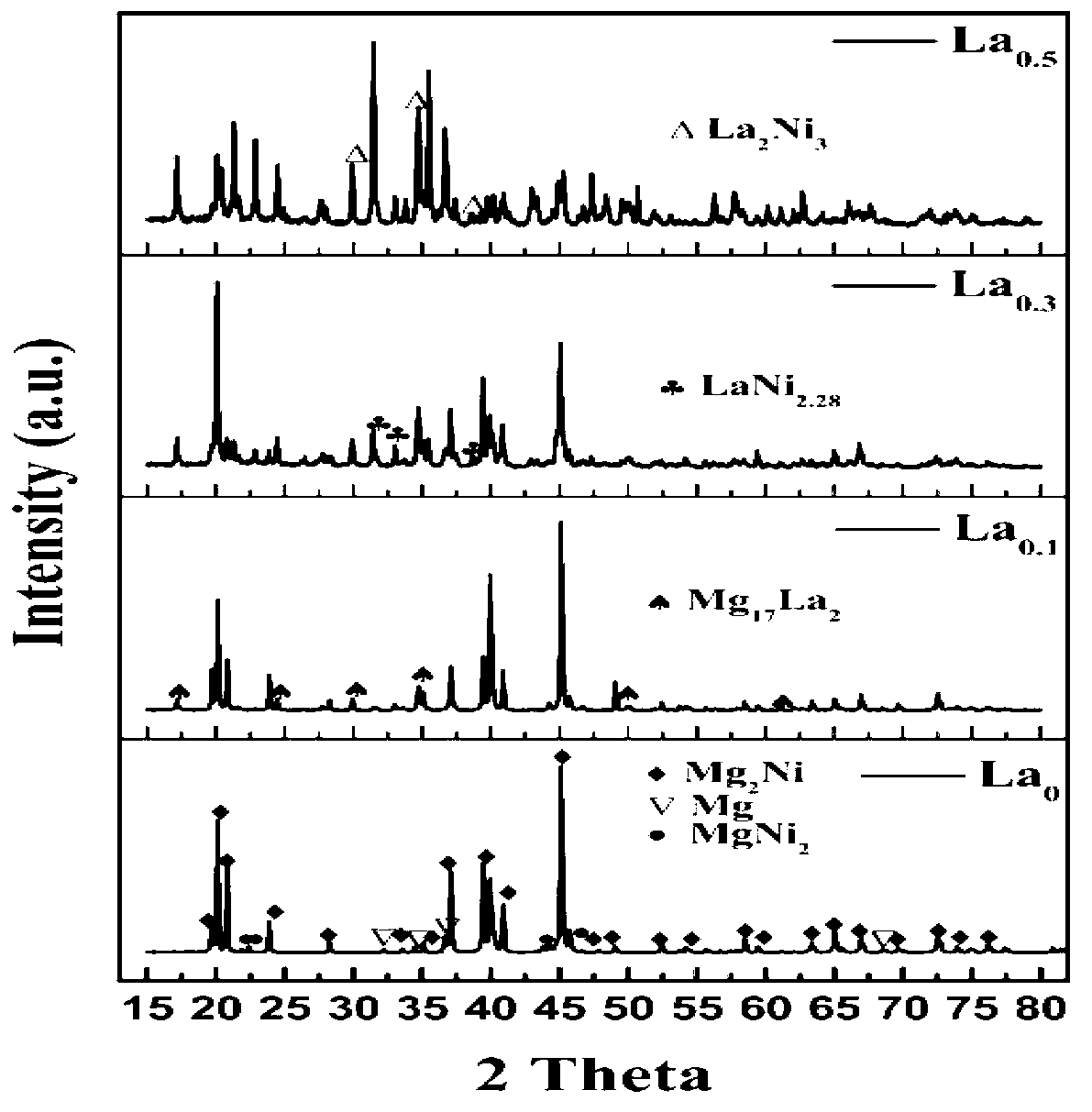

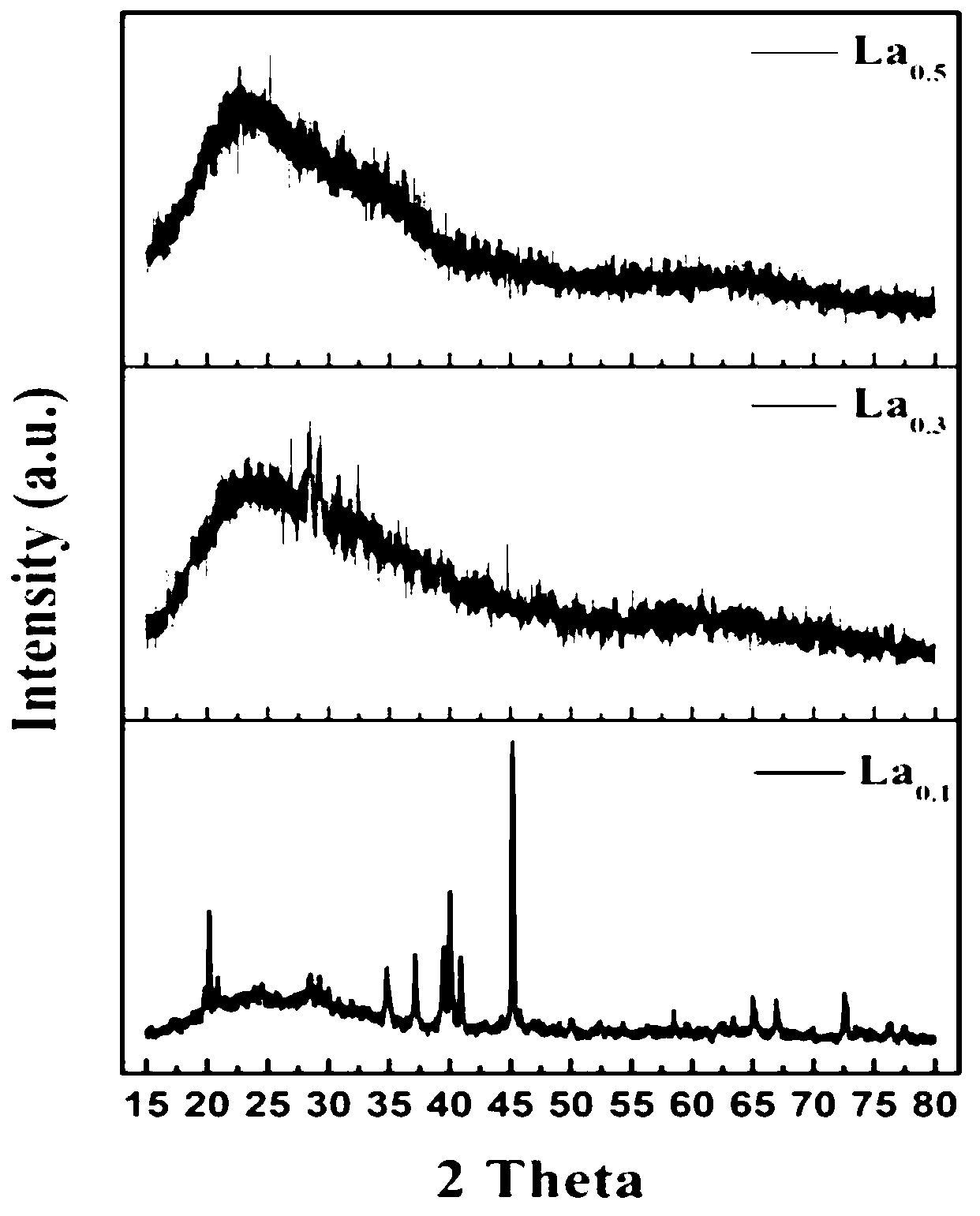

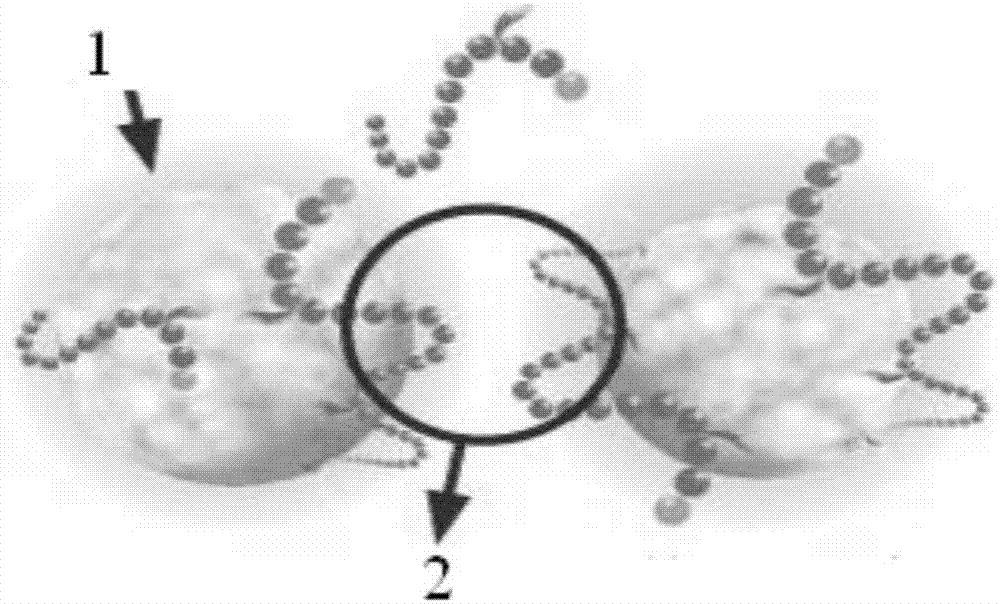

Mg-Ni-La based composite hydrogen-storage alloy powder and preparation process thereof

The invention discloses Mg-Ni-La based composite hydrogen-storage alloy powder and a preparation process thereof. The Mg-Ni-La based composite hydrogen-storage alloy powder is composed of Mg-Ni-La alloy strips and multi-walled carbon nanotubes (MWCNTs) and TiF3 catalysts. According to the Mg-Ni-La based composite hydrogen-storage alloy powder and the preparation process thereof, a melt rapid-quenching technology is used, a melt is ejected by the aid of the argon gas pressure and sprayed on surfaces of rotating smooth copper rods, by the aid of the quenching effect produced by the rotating copper rods, alloy structures are refined, and channels such as grain boundaries / phase boundaries, which are beneficial to diffusion of H atoms, are increased, so that amorphous / nano crystalline alloys are prepared. According to the Mg-Ni-La based composite hydrogen-storage alloy powder, the MWCNTs and the TiF3 catalysts are added simultaneously, rare earth La is added to improve the phase composition of Mg-Ni alloys, the formation of a new phase is beneficial to decomposition of H2 molecules on material surfaces and diffusion of the H atoms in materials, and the hydrogen absorption and desorption dynamic performance of Mg2Ni alloys is greatly improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Double-layer cleansing milk and preparation method thereof

ActiveCN107997996APrevent re-aggregationImprove stabilityCosmetic preparationsMake-upStable stateCarbamate

The invention discloses double-layer cleansing milk. The double-layer cleansing milk is prepared from, by weight, 5-30% of oil phases, 5-40% of surfactant, 0.1-6% of emulsifier, 0-10% of moisturizer,0-10% of skin conditioner and 0.06-1% of preservative; the emulsifier comprises inulin lauryl carbamate; the weight percentage of inulin lauryl carbamate in the double-layer cleansing milk is 0.1-1.5%. The double-layer cleansing milk is layered more stably in a surfactant system with high oil content, the two-phase boundary line is obvious, lower-layer liquid is clear and transparent, and the composition problem is solved that high-content oil and abundant and stable foam cannot coexist. The two phases can be rapidly separated and restored to a stable state after mixing and standing under external force, and the layering speed and time are optimized. Since the content of the oil in the composition is high, the double-layer cleansing milk has a certain makeup removing capability at the sametime.

Owner:仙婷(广州)科技研发有限公司

Erosion resistant coating

A platinum plus chromium coating applied to the roots and firtrees of turbine blades where the inclusion of chromium creates a single phase outer zone which minimizes diffusion paths for sulphur which can preferentially diffuse down phase boundaries and enables a chromium rich outer oxide scale to form on top of the coating.

Owner:ROLLS ROYCE PLC

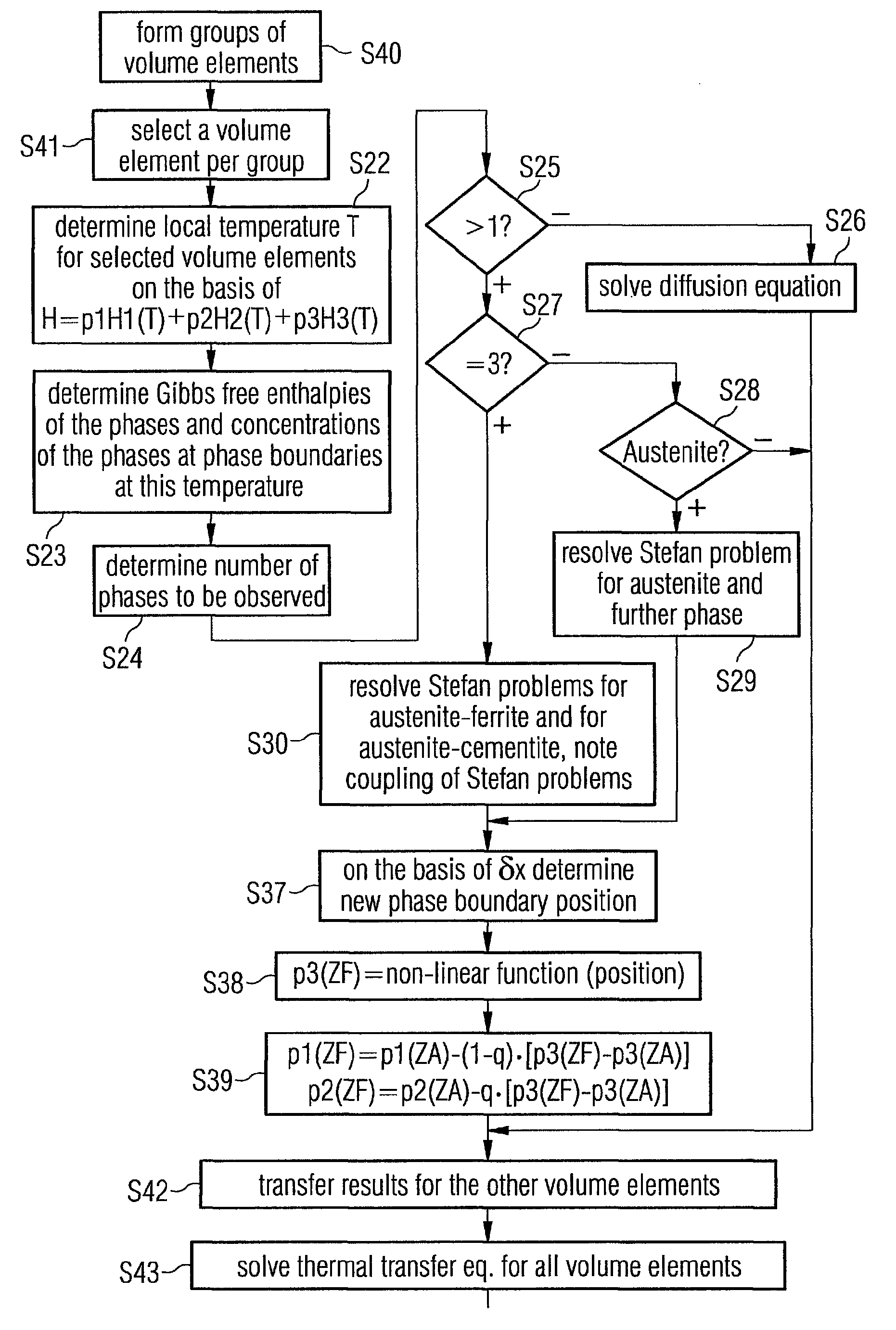

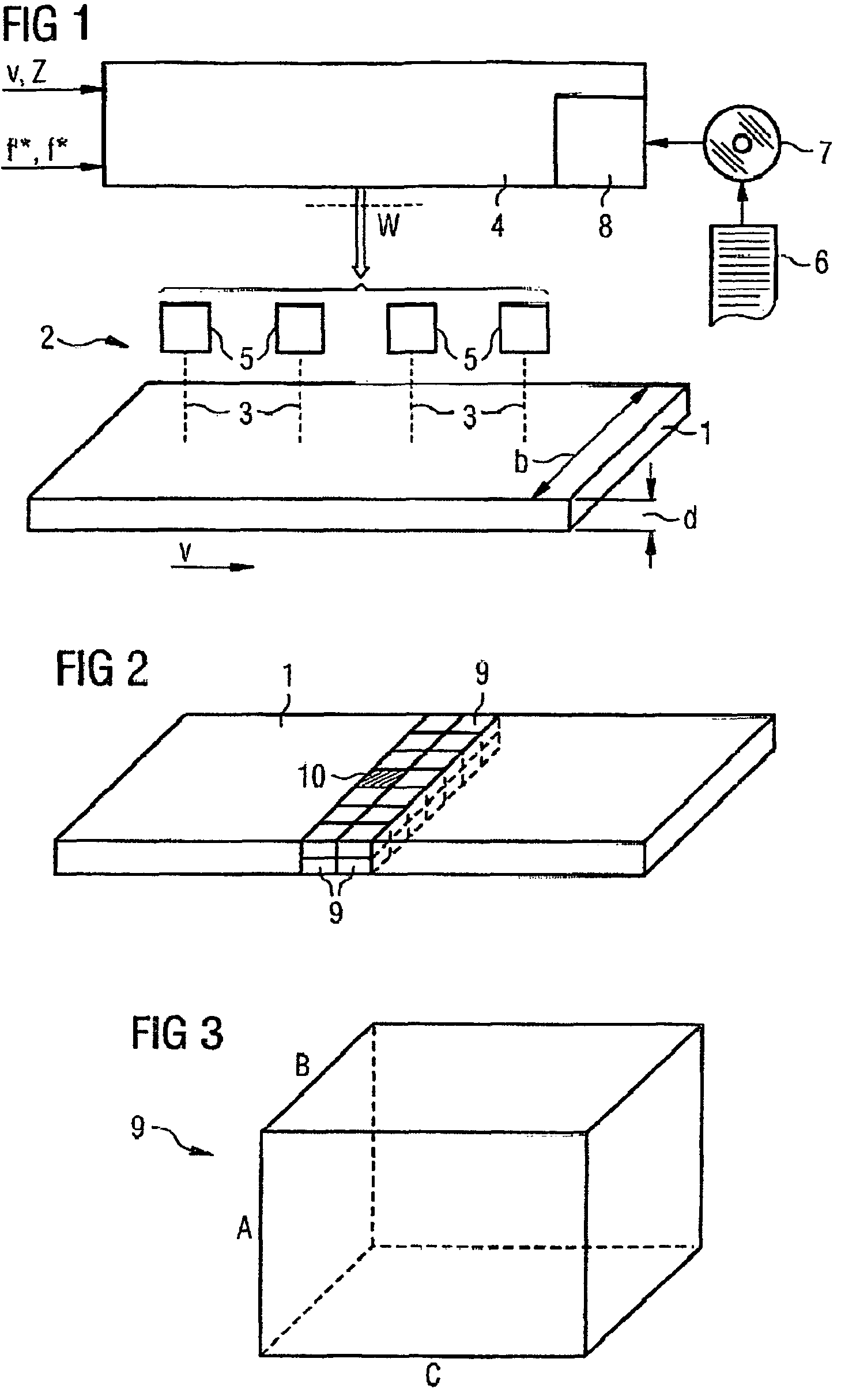

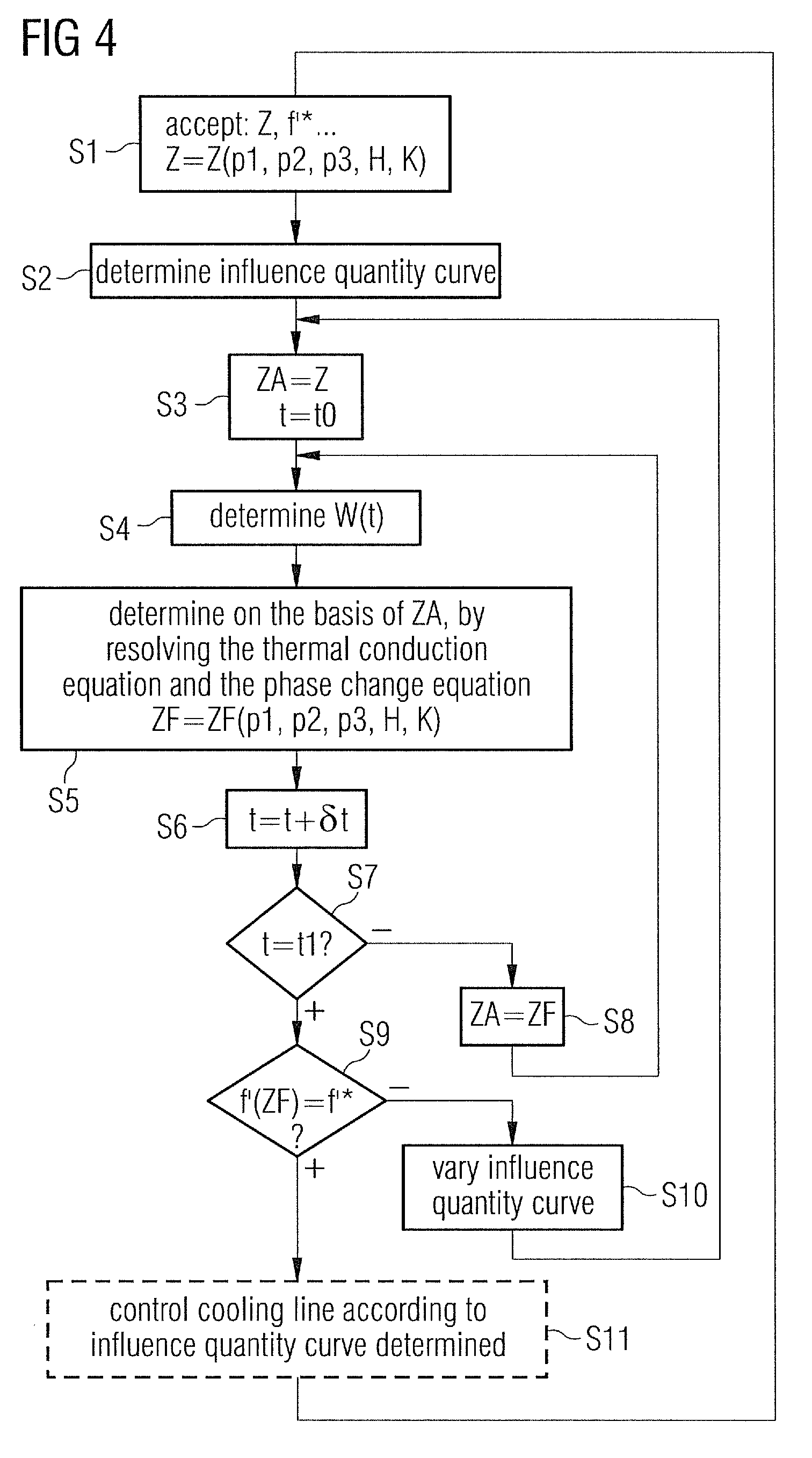

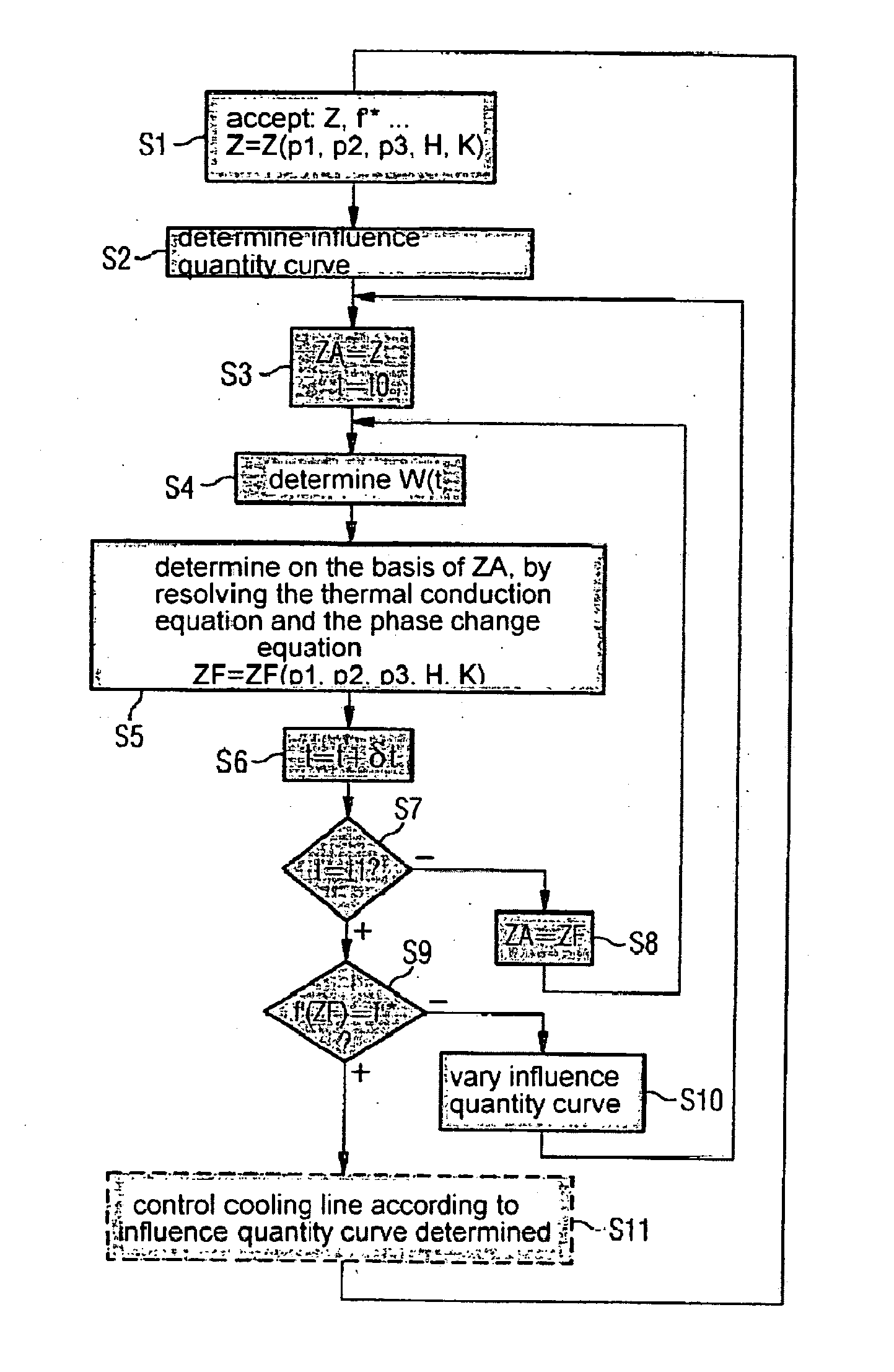

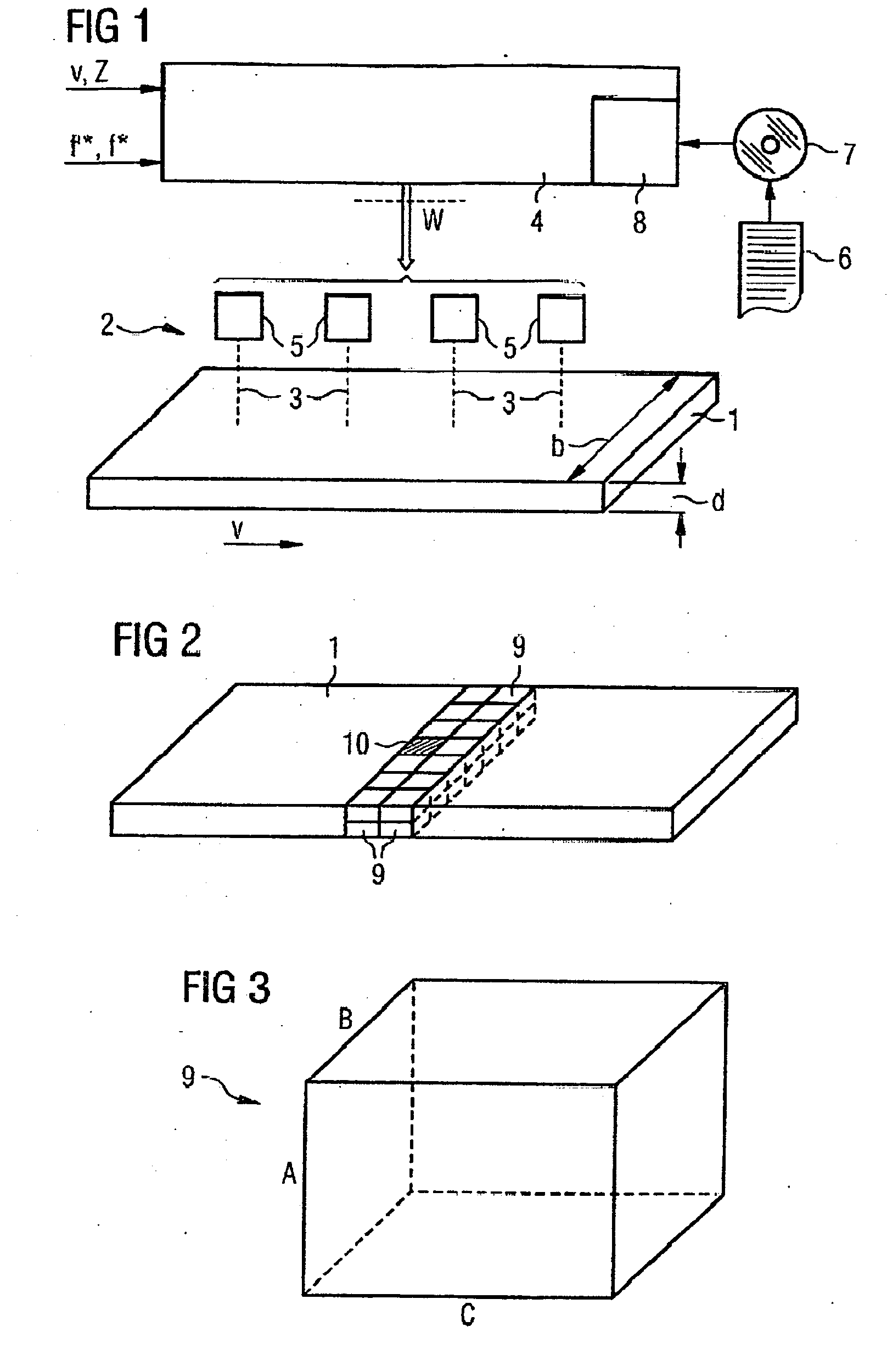

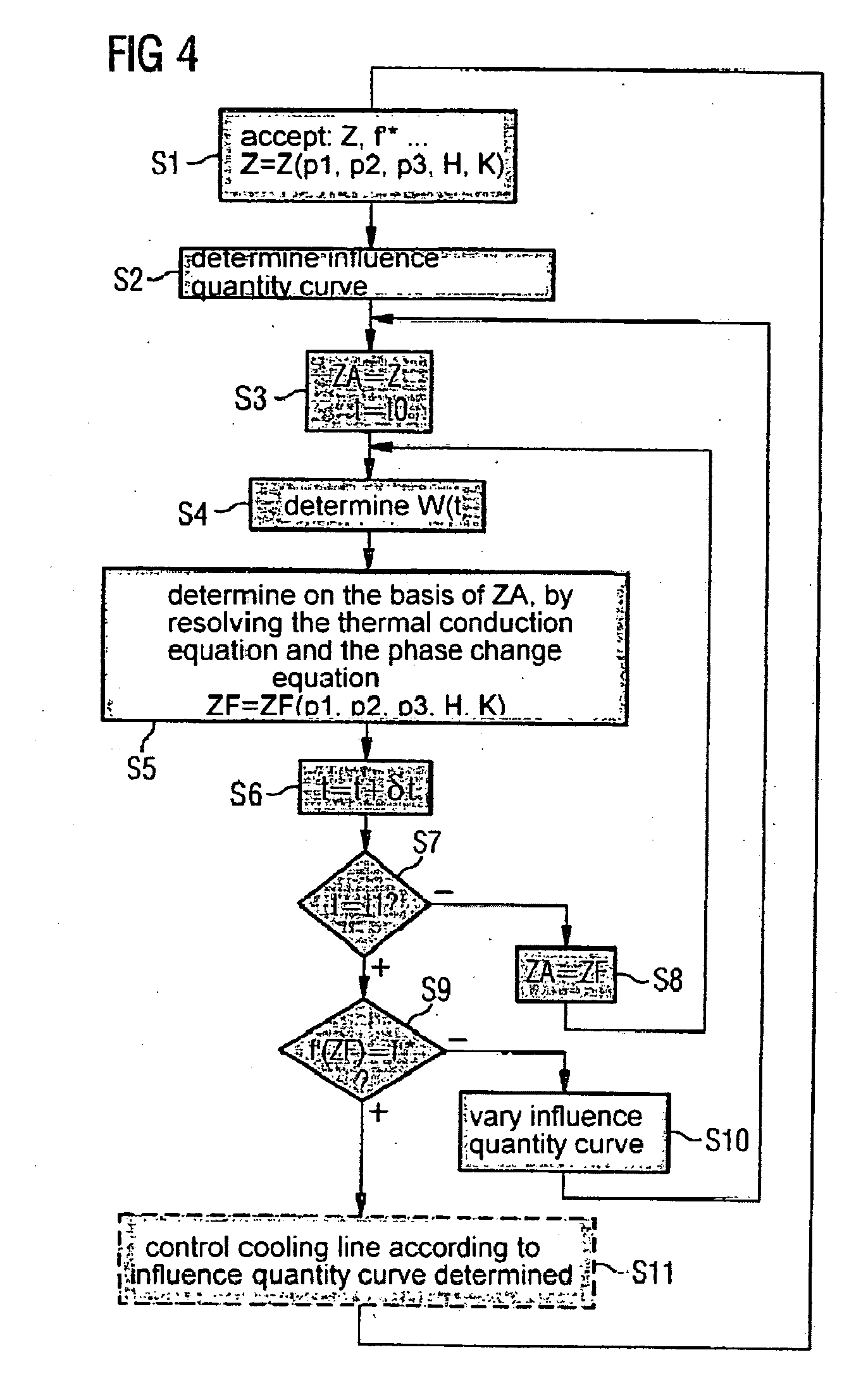

Computer-assisted modelling method for the behavior of a steel volume having a volumetric surface

InactiveUS7865341B2Modelling resultAccurate descriptionTemperature control deviceSimulator controlImage resolutionPhase change

A computer determines a subsequent state of a steel volume, based on an instantaneous initial state of said steel volume and at least one volumetric surface, the temporary influence quantities acting on said steel volume, by resolution of an equation of thermal condition and phase change. The states include for at least one volumetric element of the steel volume, a local distribution in concentration of a alloy element mobile in the steel, the local proportions of the modeled phases of the steel and a quantity describing a local energy content of the steel. The phases include austenite and another phase, generally, ferrite or cementite. In the context of the change equation, the concentration levels of the mobile alloy element, which are located on either side of the phase boundary, between the austenite and the other phase are determined by resolution of a Stephan problem.

Owner:SIEMENS AG

Computer-Assisted Modelling Method for the Behavior of a Steel Volume Having a Volumetric Surface

InactiveUS20070276638A1Modelling resultAccurate descriptionTemperature control deviceSimulator controlPhase changePhase boundary

The present invention concerns a computer which determines a subsequent state of a steel volume, based on an instantaneous initial state of said steel volume and at least one volumetric surface, the temporary influence quantities acting on said steel volume, by resolution of an equation of thermal condition and phase change. The states include for at least one volumetric element of the steel volume, a local distribution in concentration of a alloy element mobile in the steel, the local proportions of the modeled phases of the steel and a quantity describing a local energy content of the steel. The phases comprise austenite and another phase, generally, ferrite or cementite. In the context of the change equation, the concentration levels of the mobile alloy element, which are located on either side of the phase boundary, between the austenite and the other phase are determined by resolution of the Stephan problem.

Owner:SIEMENS AG

Blood Processing Apparatus with Robust Outflow Process Control

Owner:TERUMO BCT

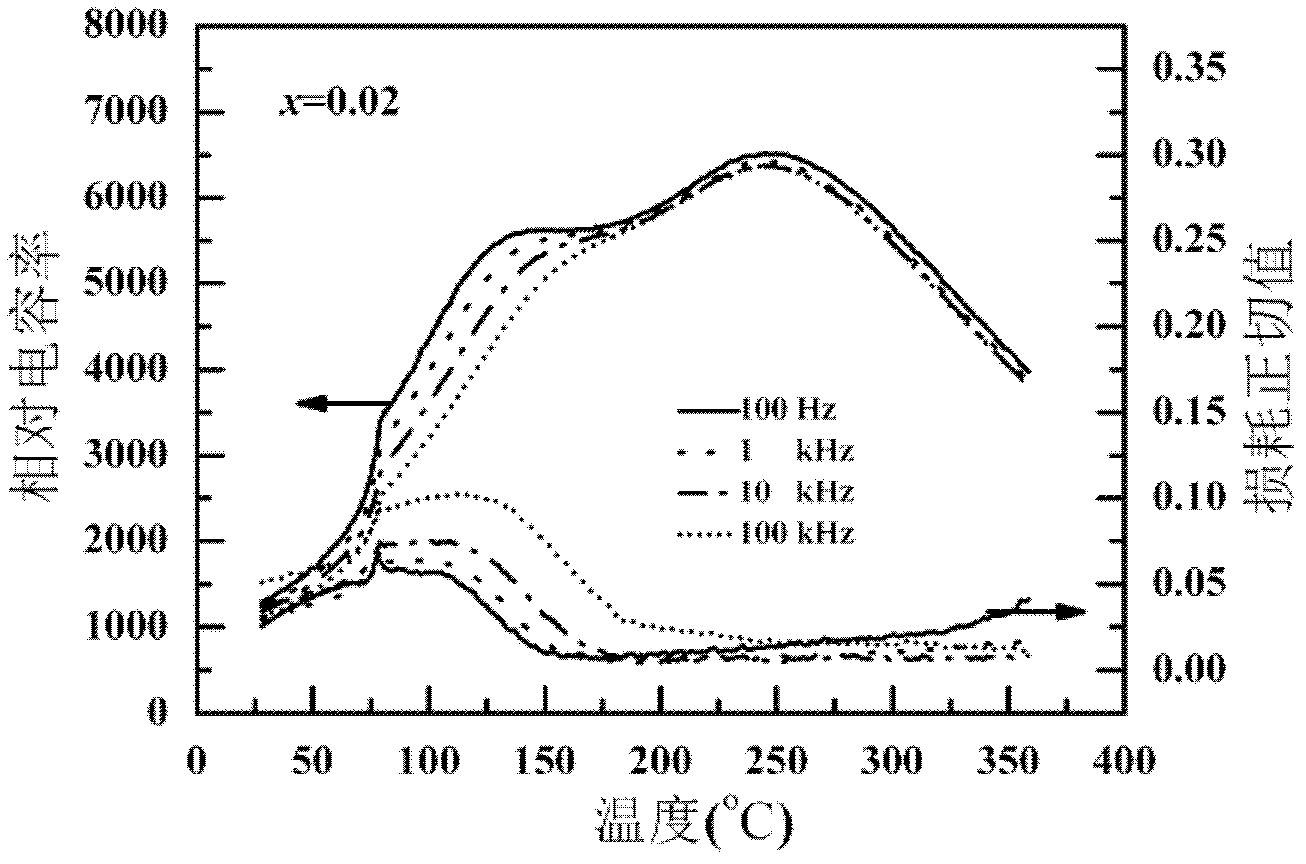

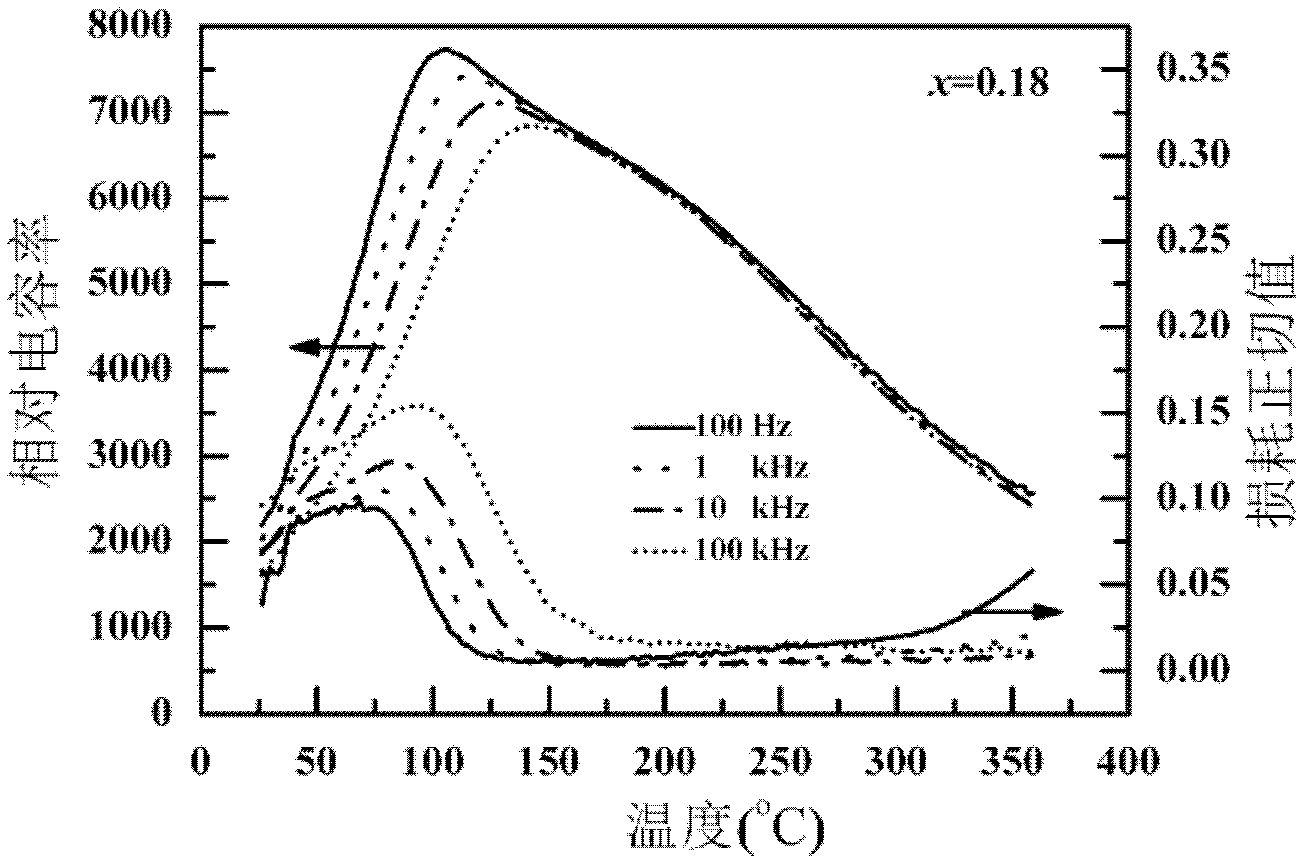

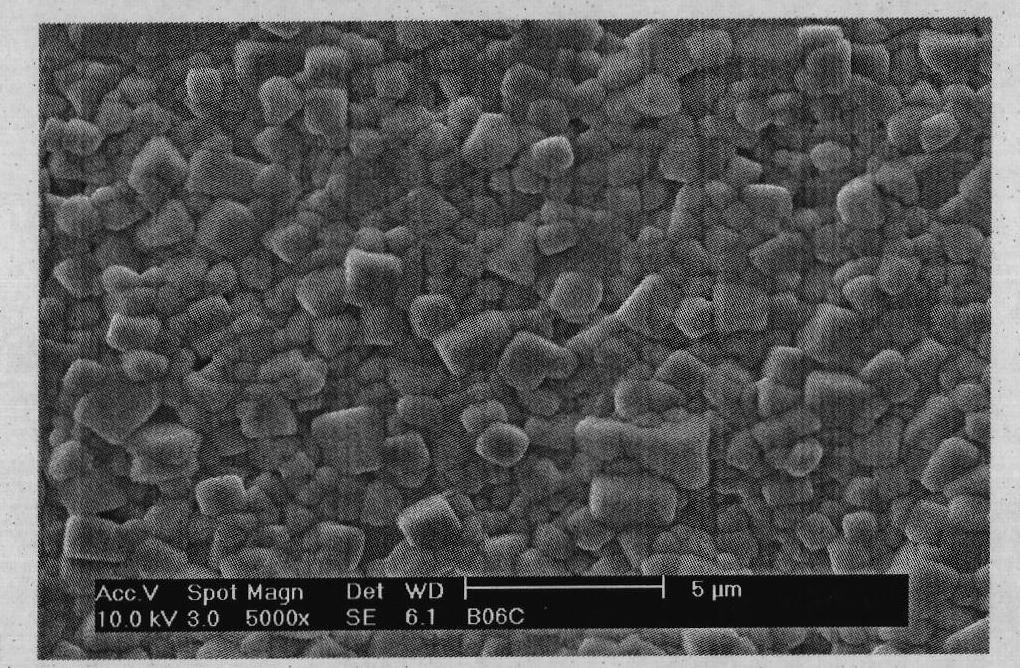

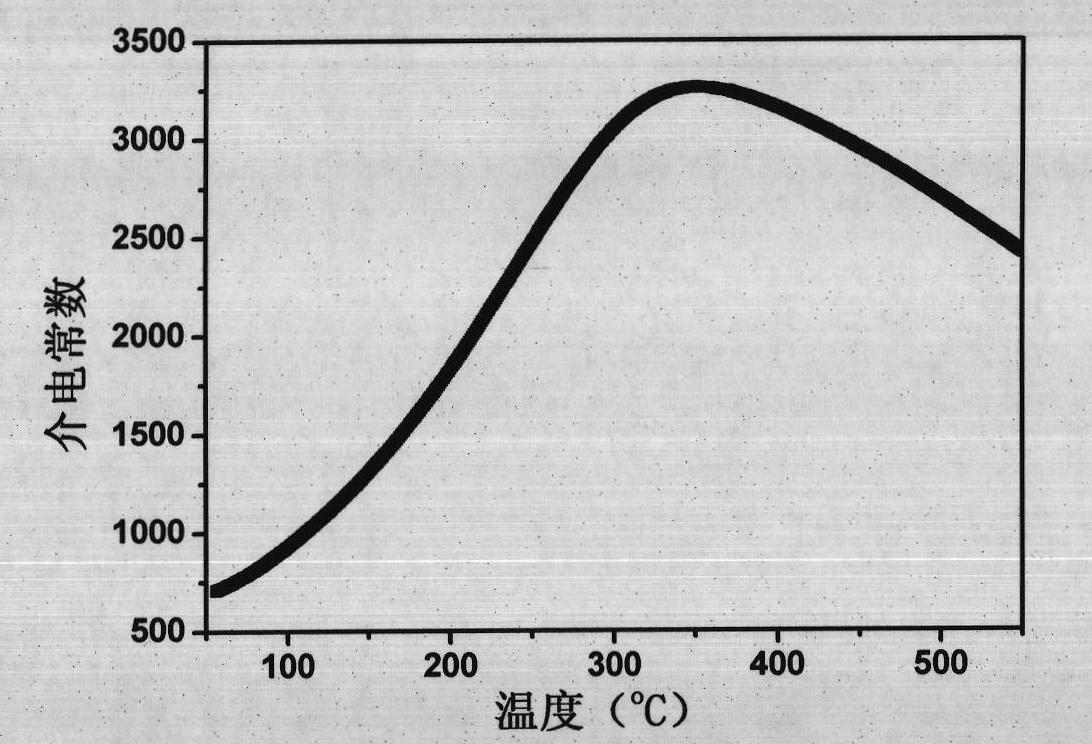

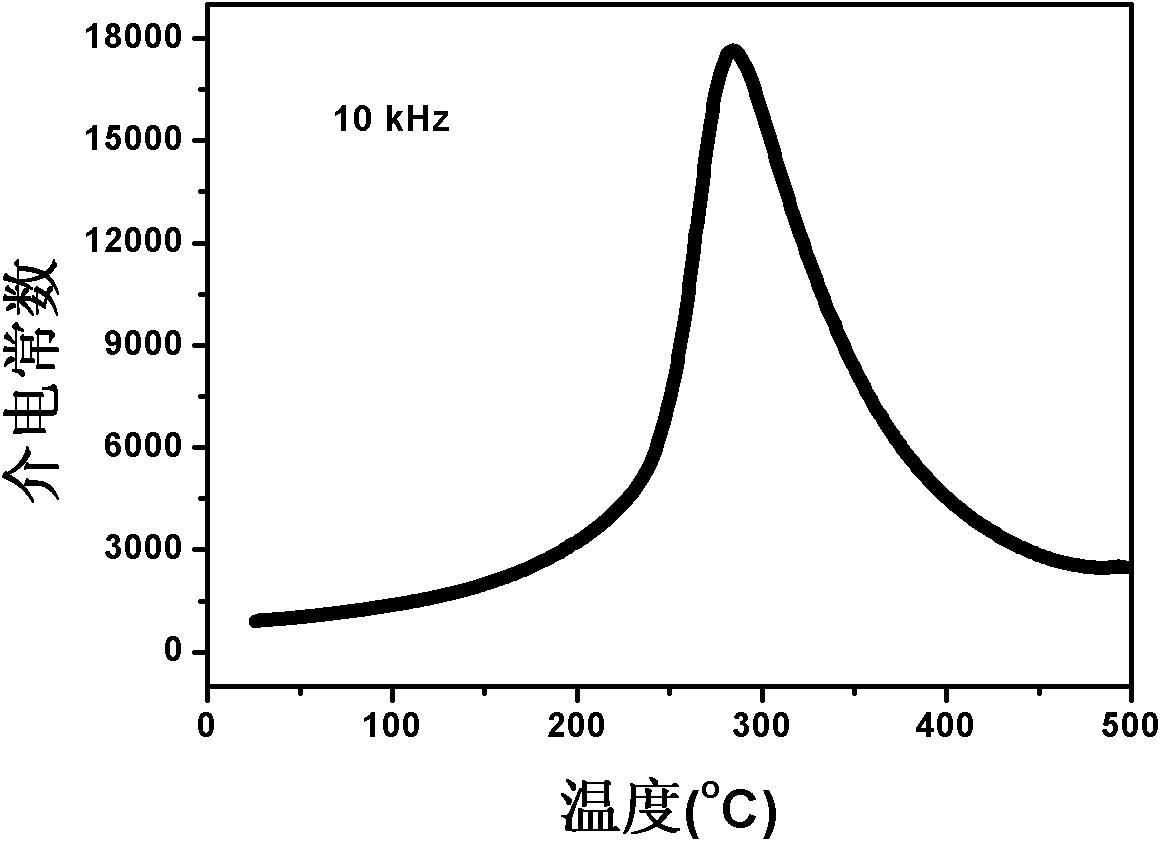

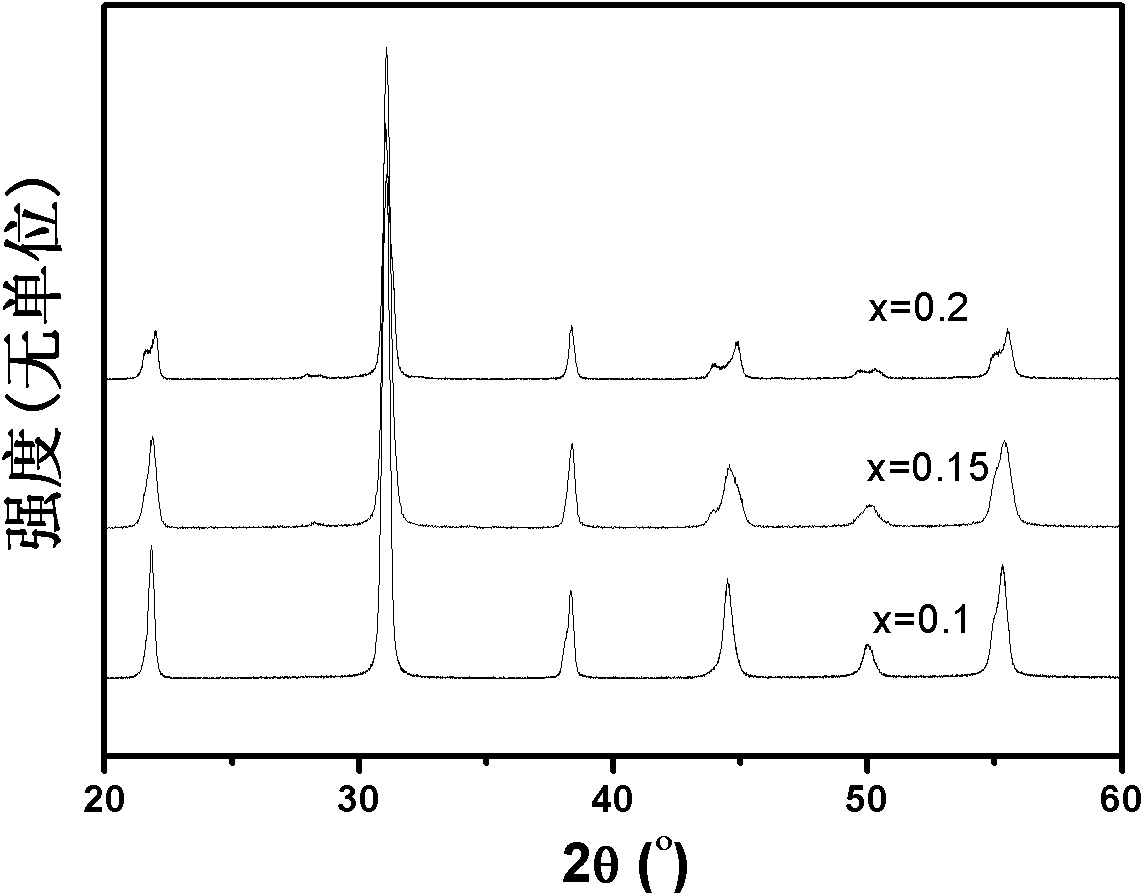

High-electrostriction sodium-bismuth-titanate-base lead-free piezoelectric material and preparation method thereof

InactiveCN102633503AHigh electrostrainApplicable displacement controlChemical compositionSolid-state drive

The invention discloses a high-electrostriction sodium-bismuth-titanate-base lead-free piezoelectric material. The invention is characterized in that the chemical composition is (0.935-x)Bi0.5Na0.5TiO3-0.065BaTiO3-xSrTiO3, wherein 0<=x<=0.30. On the basis of a binary morphotropic phase boundary (MPB) component solid solution 0.935Bi0.5Na0.5TiO3-0.065BaTiO3, SrTiO3 is introduced to prepare a ternary system solid solution, thereby preparing a high-electromechanical-responsiveness lead-free system. Compared with the existing lead-free system, the invention can disclose the MPB component of the ternary solid solution, obtain the high-electrostriction system, can acquire high strain capacity in a small electric field, and is prospected to be applied to novel environment-friendly solid state drives.

Owner:SHANGHAI NORMAL UNIVERSITY

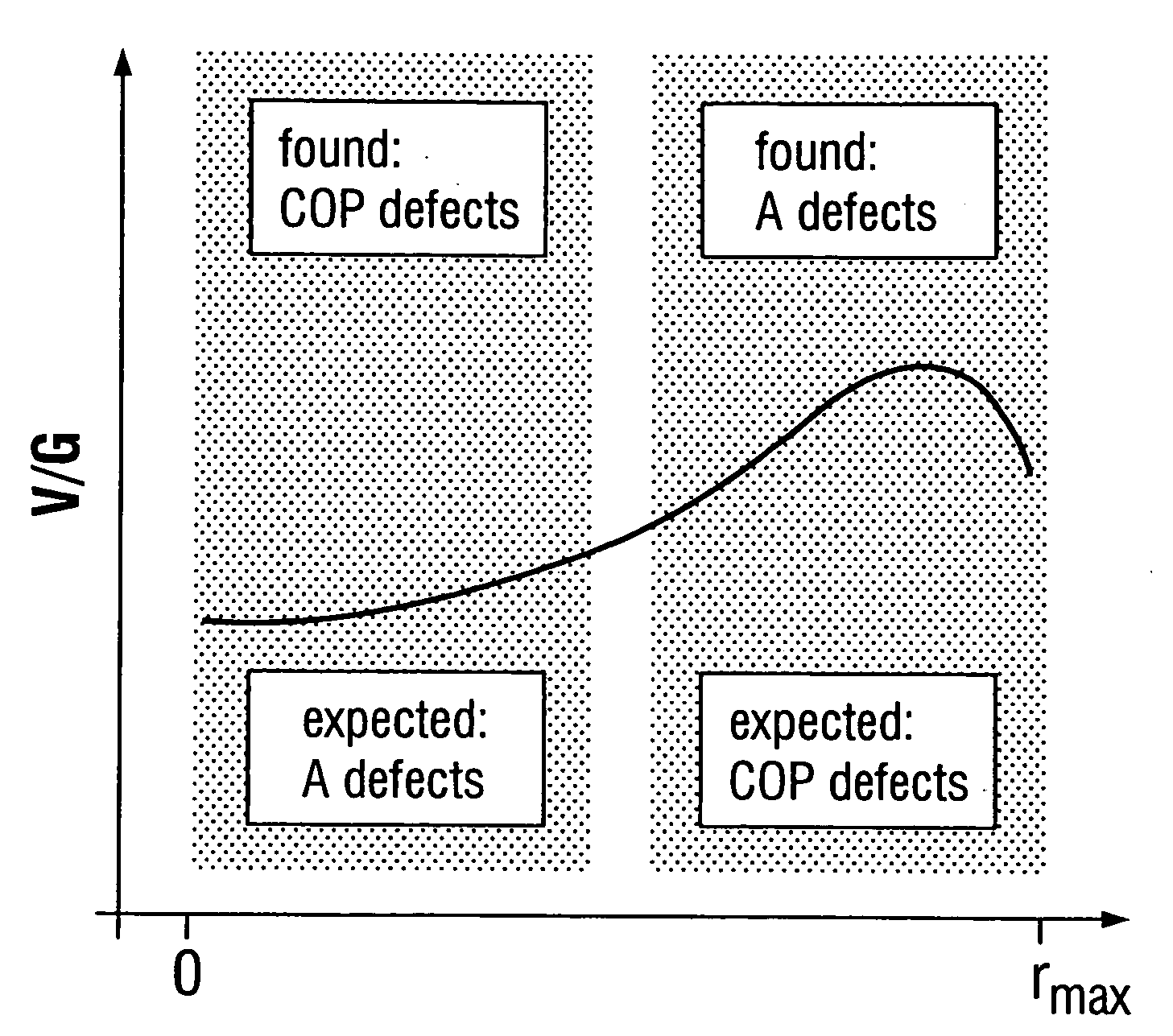

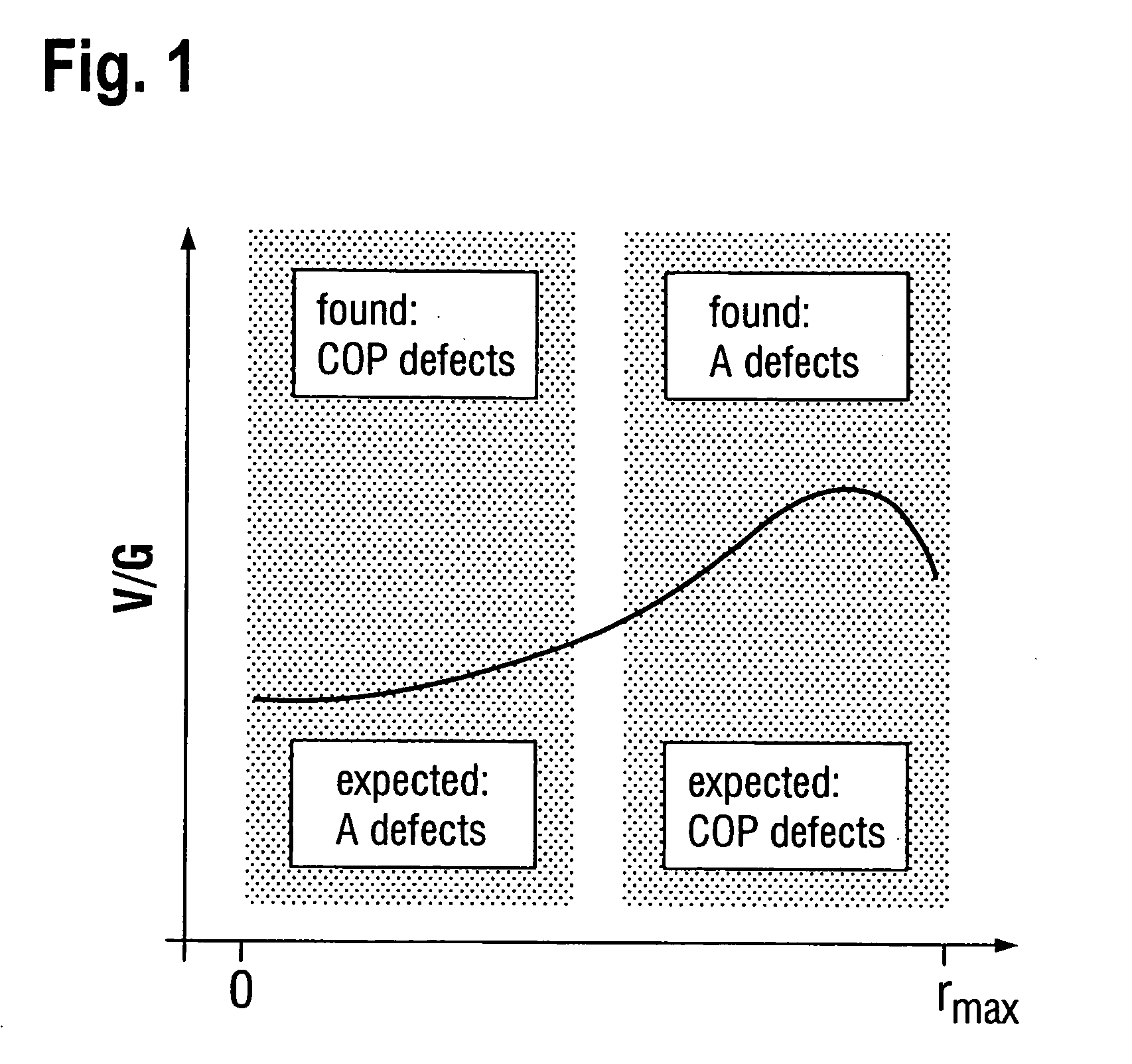

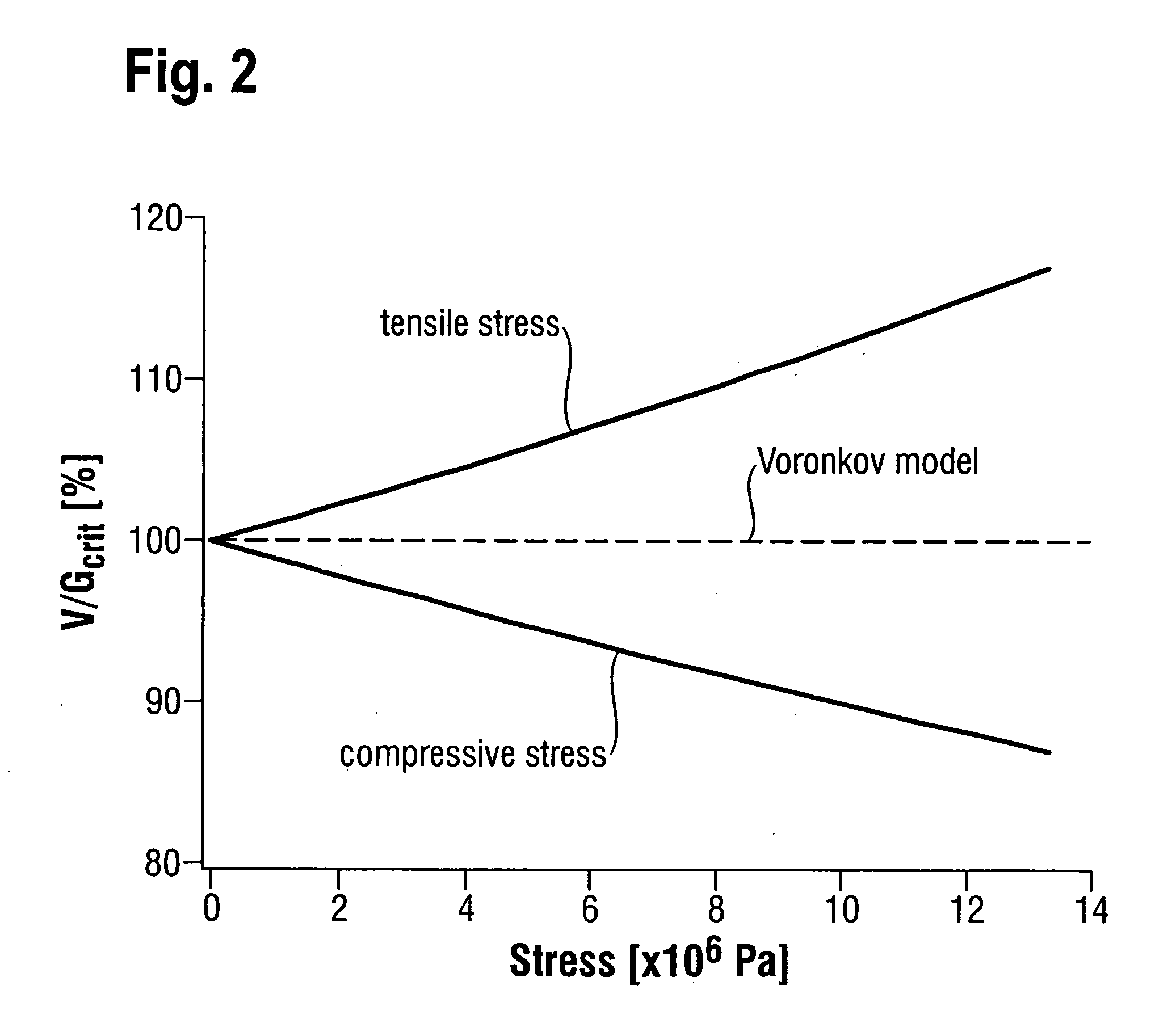

Semiconductor wafers of silicon and method for their production

ActiveUS20080187736A1Polycrystalline material growthSynthetic resin layered productsCrucibleSingle crystal

Semiconductor wafers of silicon are produced by pulling a single crystal growing on a phase boundary from a melt contained in a crucible and cutting of semiconductor wafers therefrom, wherein during pulling of the single crystal, heat is delivered to a center of the phase boundary and a radial profile of a ratio V / G from the center to an edge of the phase boundary is controlled, G being the temperature gradient perpendicular to the phase boundary and V being the pull rate. The radial profile of the ratio V / G is controlled so that the effect of thermomechanical stress in the single crystal adjoining the phase boundary, is compensated with respect to creation of intrinsic point defects. The invention also relates to defect-free semiconductor wafers of silicon, which can be produced economically by this method.

Owner:SILTRONIC AG

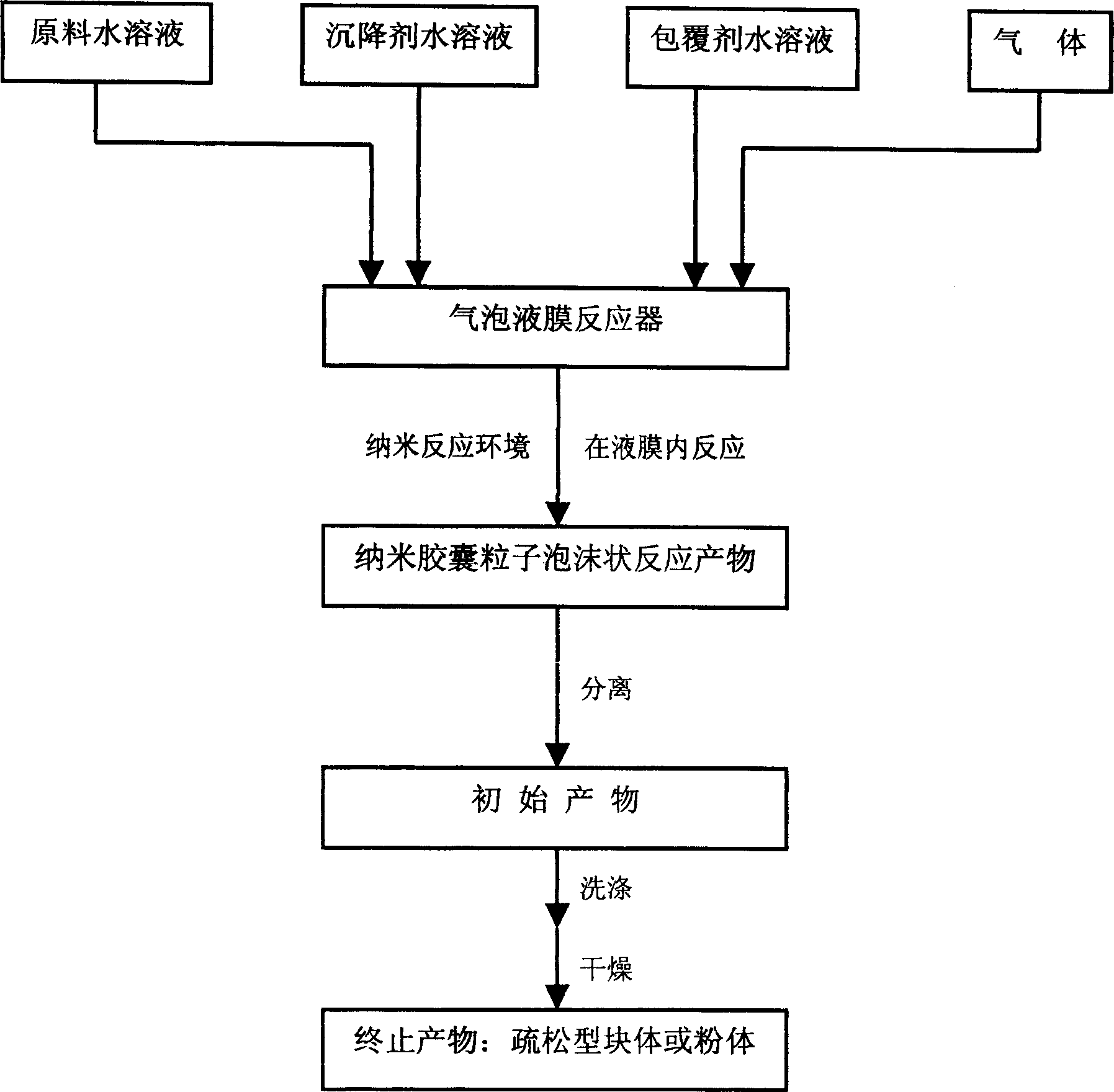

Air bubble liquid membrane method for producing nanometer granule material

ActiveCN1803272AReduce pollutionEasy to separateChemical/physical/physico-chemical processesLiquid-liquid reaction processesForming gasGas phase

Owner:LANZHOU LANSHI ZHONGKE NANOTECHNOLOGY CO LTD

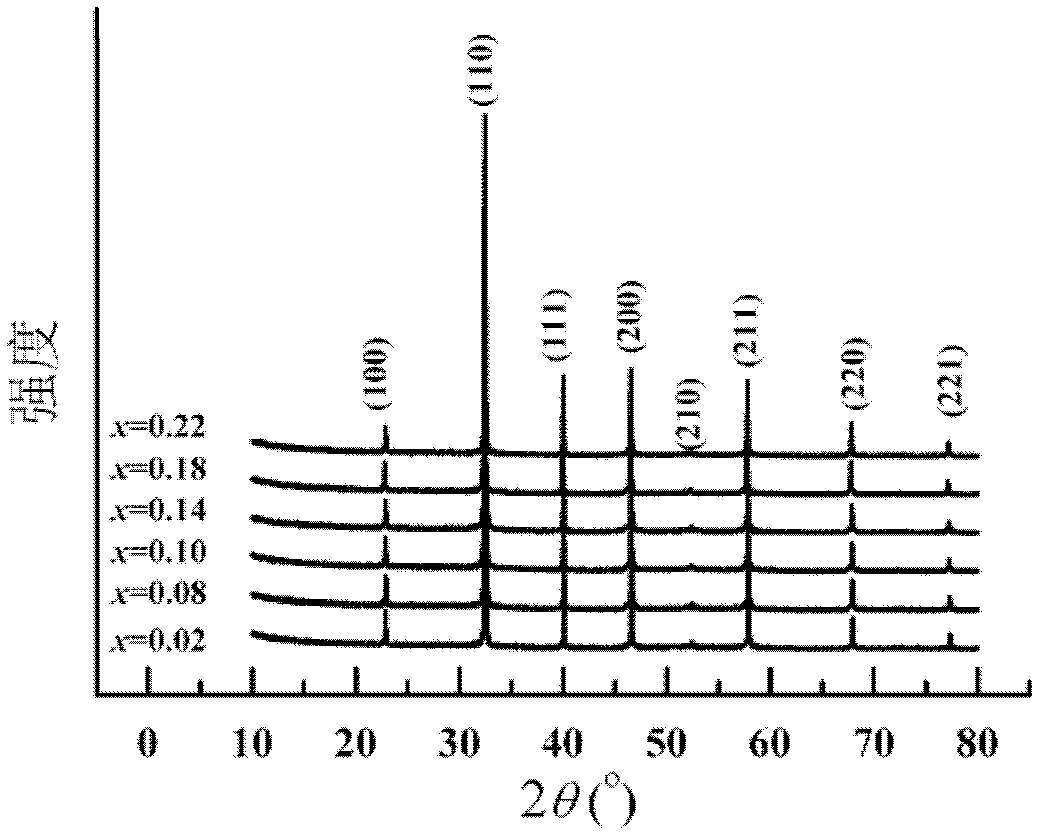

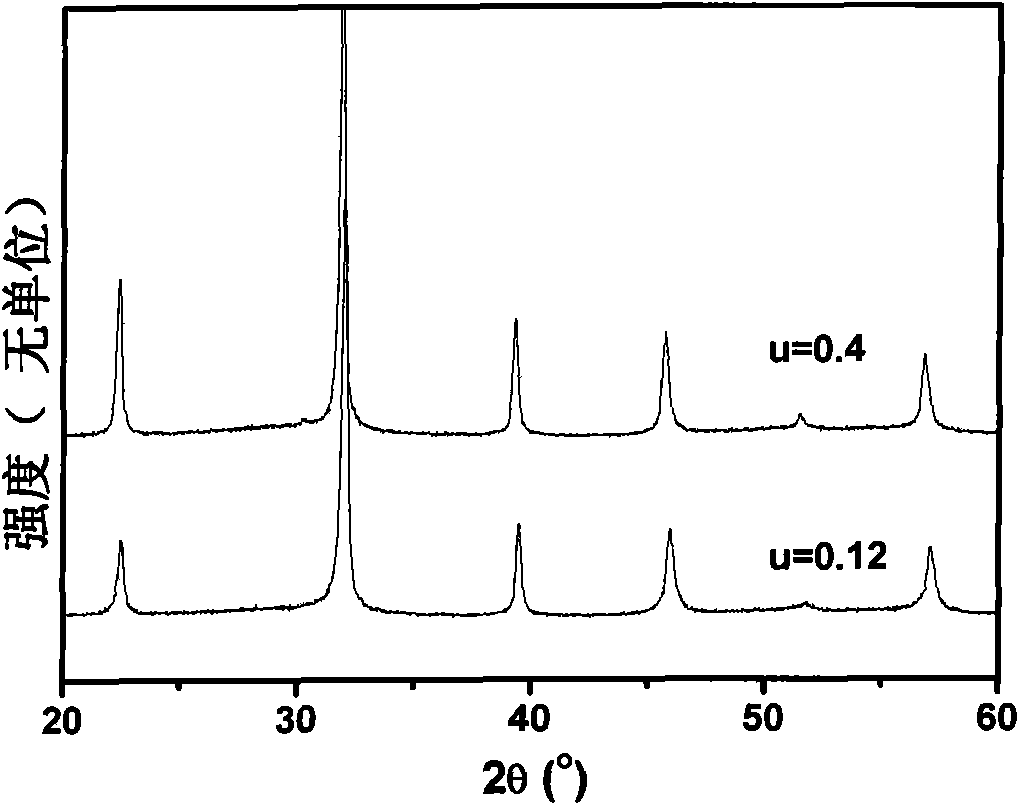

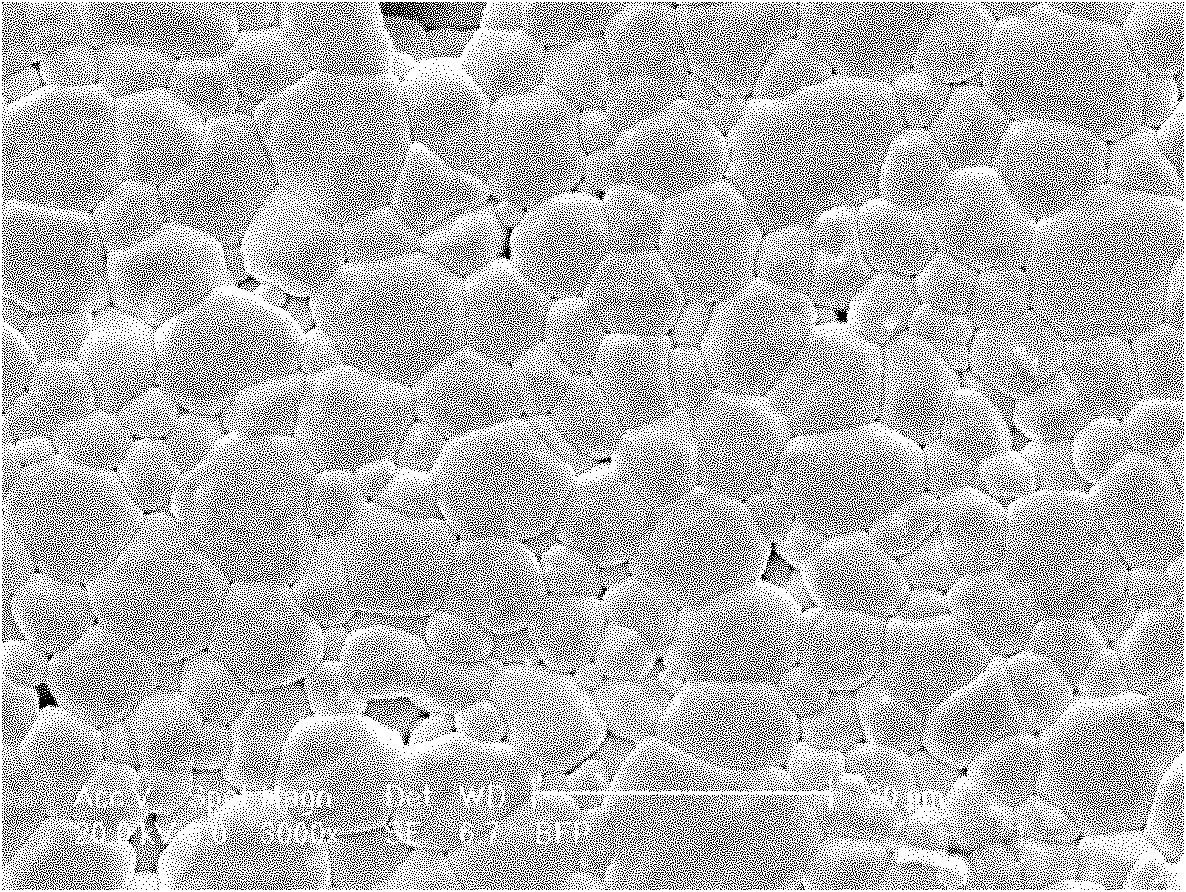

Potassium-bismuth titanate-based solid solution lead-free piezoelectric ceramic and manufacturing method thereof

InactiveCN101973763AImprove performanceGood environmental coordinationPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPotassium

The invention discloses a potassium-bismuth titanate-based solid solution lead-free piezoelectric ceramic and a manufacturing method thereof. The components are represented by the general formula of (1-n){(1-u)(Bi0.5K0.5)TiO3+u[(1-z)Bi(CxDy)O3+zBiEO3]}+nM. The ceramic components of the invention have a morphotropic phase boundary of the rhombic ferroelectric phase and the cubic ferroelectric phase, good piezoelectric performance and higher Curie temperature. The ceramic components have the characteristic of environmental protection, can realize the replacement of a part of the traditional lead-containing piezoelectric ceramics, and can be manufactured by using the manufacturing method of the traditional piezoelectric ceramic and the industrial materials, thereby having practical application.

Owner:HEFEI UNIV OF TECH

Bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic and preparation method thereof

The invention discloses a bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic and a preparation method thereof. The bismuth-containing complex perovskite-lead zirconate titanate quasi-ternary system piezoelectric ceramic has a general formula: (1-n)[(1-u-v)Pb(Zr1-zTiz)O3+uBi(CxDy)O3+v(Bi0.5E0.5)TiO3]+nM. The ceramic has a morphotropic phase boundary of a rhombic ferroelectricity phase and a tetragonal ferroelectricity phase, has the advantages of excellent piezoelectric constants, higher Curie temperature, lowered lead content and practicability, can replace parts of traditional lead-containing piezoelectric ceramic and can be prepared from industrial raw materials by adopting the traditional preparation technology of the piezoelectric ceramic.

Owner:HEFEI UNIV OF TECH

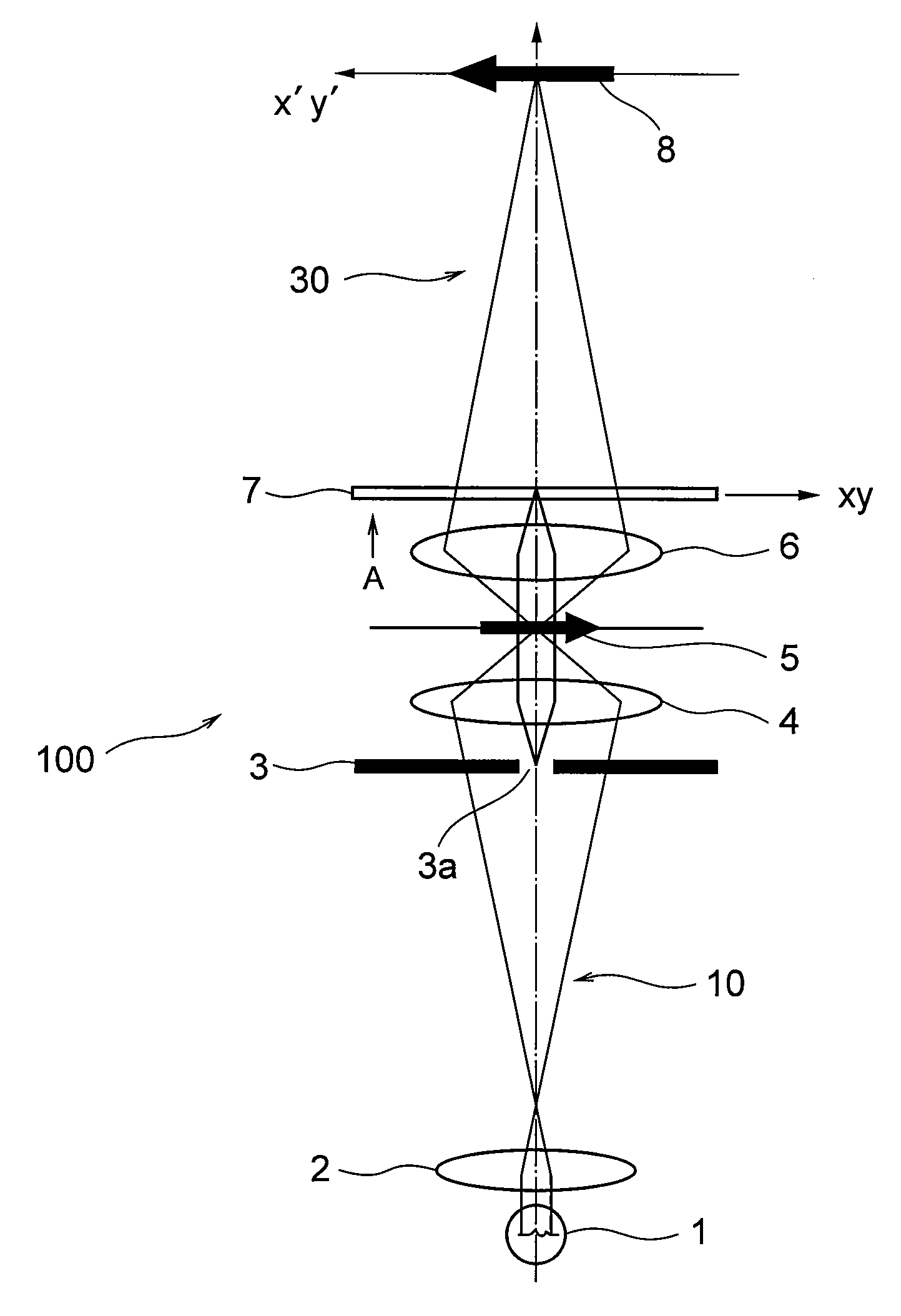

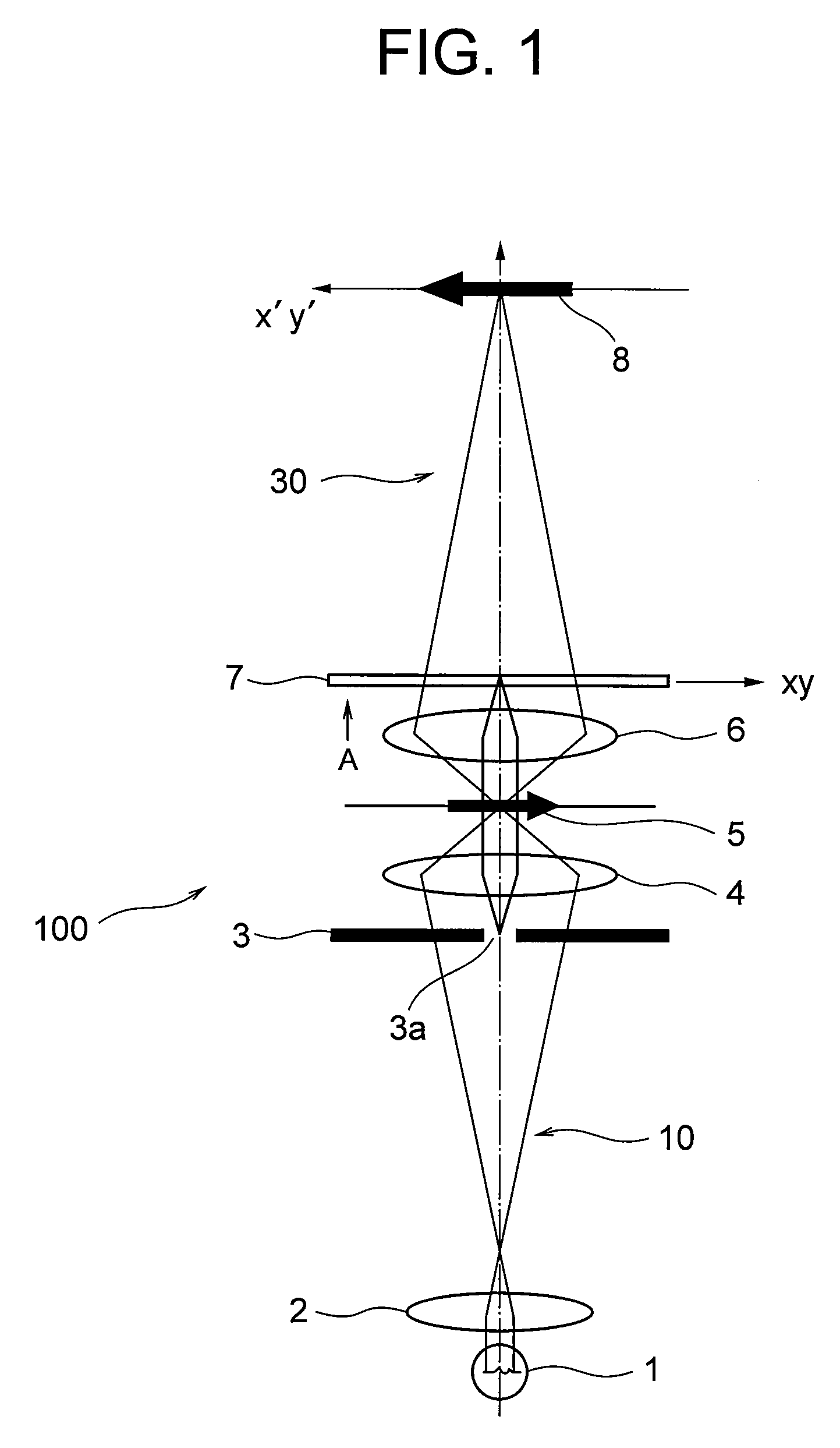

Microscope apparatus

Providing a microscope apparatus capable of observing phase variation of a phase object with sufficient contrast with a white light source having an area such as a halogen lamp and a mercury lamp commonly used in a microscope. A microscope apparatus 100 comprising: an illumination optical system 10 that illuminates a sample 5 with illumination light emitted from a light source 1; an imaging optical system 30 that converges light emitted from the sample to form a sample image by an objective lens 6; an aperture member 3 that is disposed in the illumination optical system in the vicinity of a conjugate plane of a rear focal plane of the objective lens and has an aperture for limiting the illumination light; and a filter member that includes a phase plate 7 that is disposed in the imaging optical system in the vicinity of the rear focal plane of the objective lens or in the vicinity of the conjugate plane of the rear focal plane of the objective lens and has a first phase area introducing phase difference of 180 degrees into the light from the sample and a second phase area; a phase boundary portion between the first phase area and the second phase area being disposed in a conjugate aperture of the aperture.

Owner:NIKON CORP

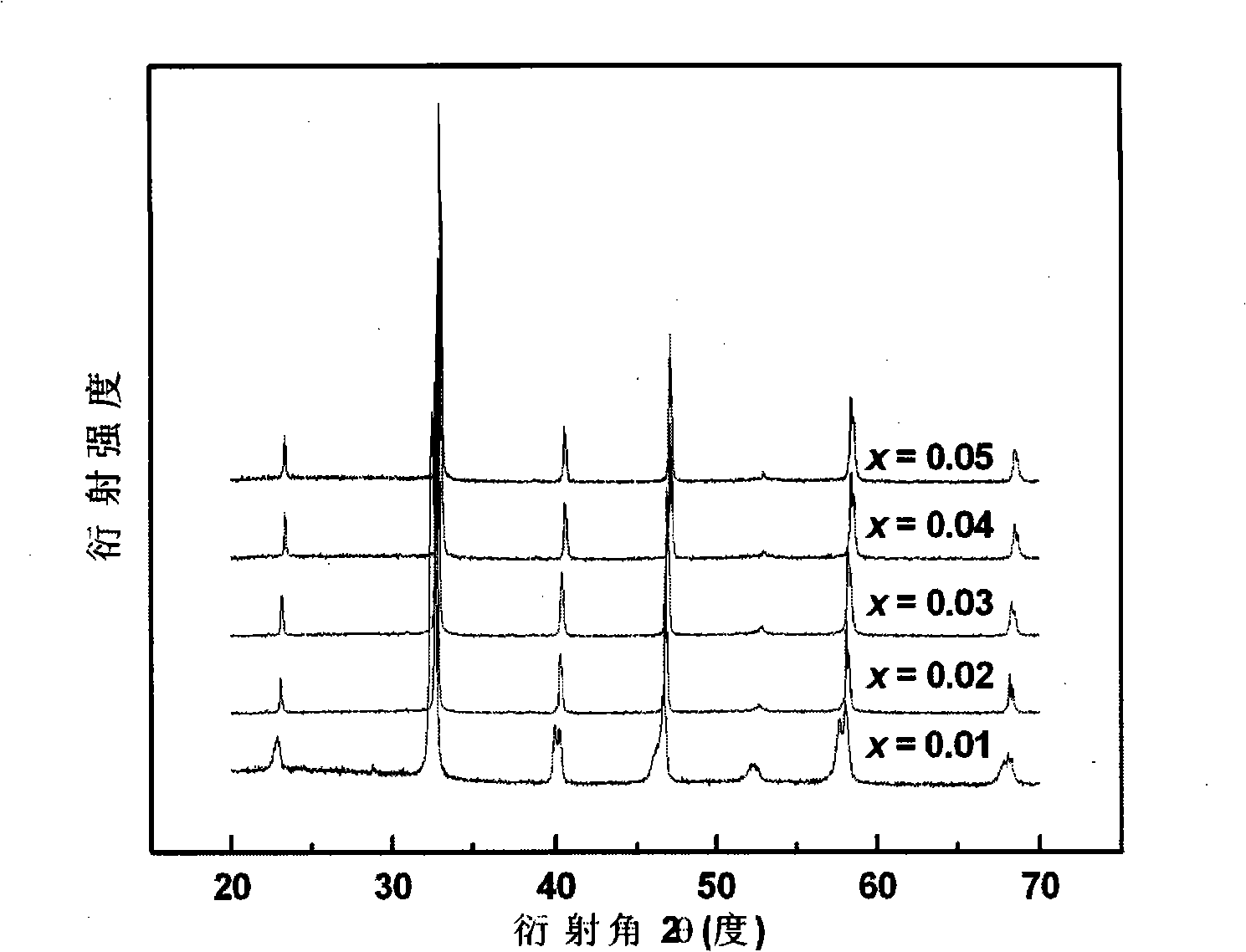

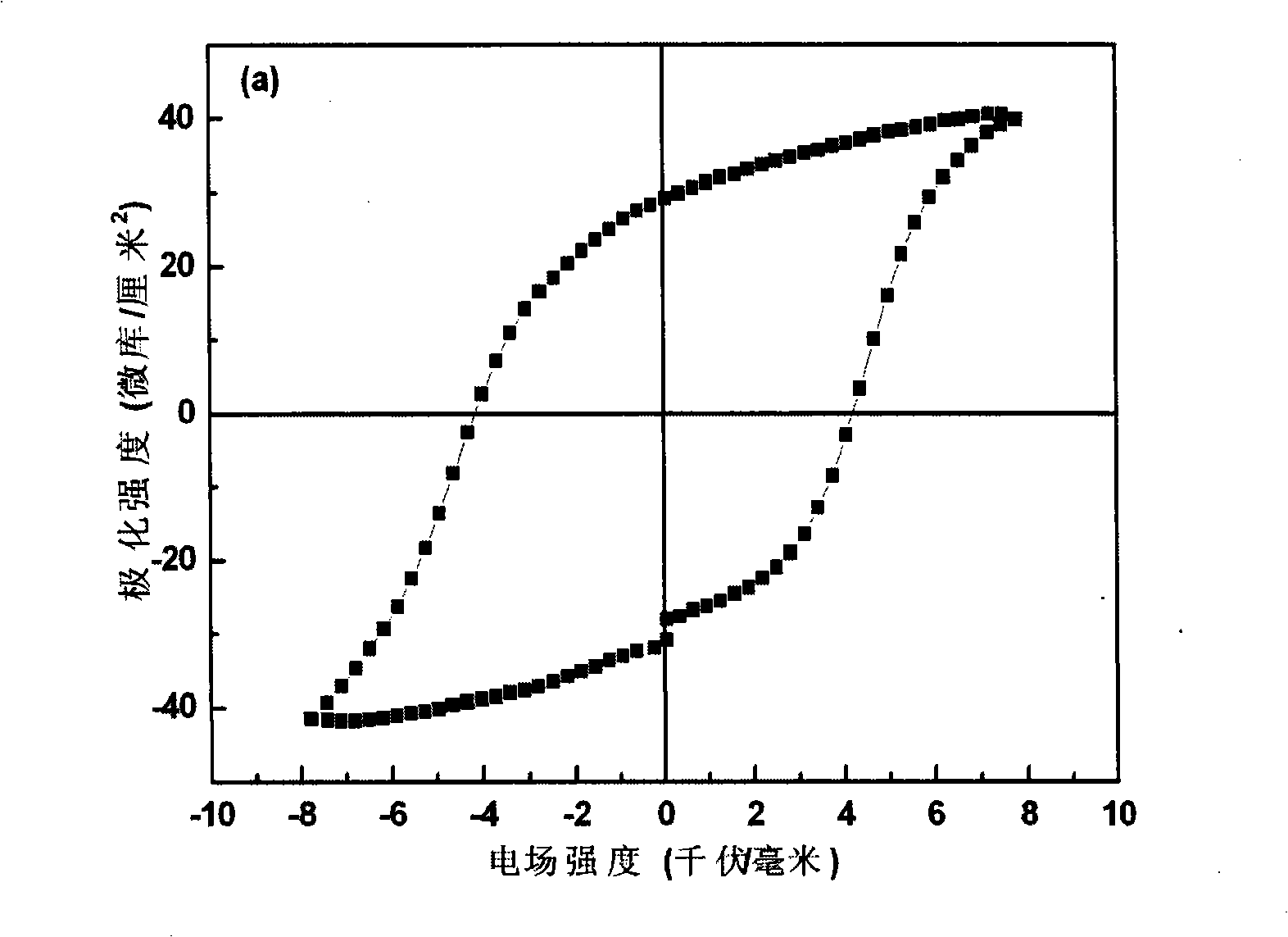

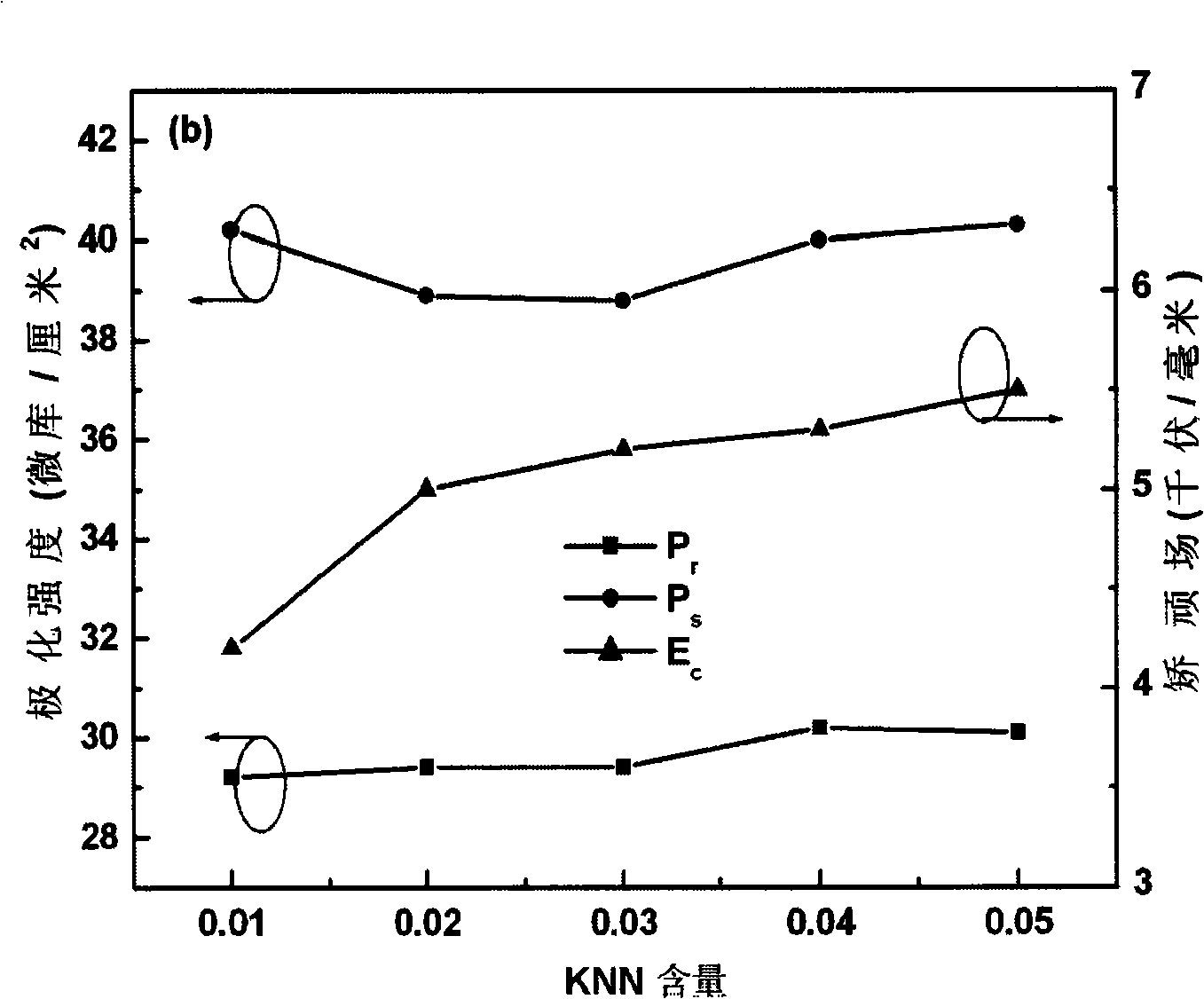

Leadless piezoelectric ceramics and method for preparing the same

InactiveCN101323522ARaise the depolarization temperatureLow costPiezoelectric/electrostrictive/magnetostrictive devicesPhase boundarySolid state reaction method

The invention discloses a leadless piezoelectric ceramics and a corresponding preparation method. The chemical formula of the leadless piezoelectric ceramics is as follows: 0.94Bi0.5Na0.5TiO3-(0.06-x)BaTiO3-xK0.5Na0.5NbO3, wherein, x is larger than 0 and less than 0.06. The leadless piezoelectric ceramics is manufactured through a solid state reaction method, and the structure of the ceramics is similar to a tripartite-orthogonal morphotropic phase boundary and has better ferroelectric and piezoelectric capability, and a residual polarization is about 30 Mu C / cm<2> and a saturation polarization is about 40 Mu C / cm<2> without depending on the contents, and the coercive field alters from 4.2 to 5.5kV / mm and increases as the increase of parameter x; and a piezoelectric coefficient d33 and an electro-mechanical coupling factor Kp decrease as the increase of parameter x, d33 alters from 86 to 118pC / N and kp alters from 0.26 to 0.29. A depolarization temperature (T<d>) increases from 108 to 146 DEG C as the increase of KNN.

Owner:NANJING UNIV

Lithium ion battery anode material adopting in-situ developed heterogeneous core-shell structure and preparation method of material

ActiveCN105514362AImprove first-time efficiencyImprove cycle stabilityMaterial nanotechnologyCell electrodesElectrochemistryCarbonate

The invention provides a lithium ion battery anode material adopting an in-situ developed heterogeneous core-shell structure and a preparation method of the material. The lithium ion battery anode material is a composite with a lithium-rich lamellar phase material as a core layer and a heterogeneous spinel phase generated on the surface of the core layer in an in-situ manner. The lithium ion battery anode material is prepared in the steps as follows the lithium-rich lamellar phase material containing Ni, Mn and M is prepared from carbonate or hydroxides with a coprecipitation method and then dispersed in a mixed salt solution of Ni, Mn and M, the amount-of-substance ratio of Ni to Mn to M in the solution is the same with that in the lithium-rich lamellar phase material, the coprecipitation reaction is performed again, and the mixed metal carbonate (or metal hydroxide) coated lithium-rich lamellar phase material is obtained, the lithium-rich lamellar phase material is sintered at the high temperature in the absence of a Li source, and the lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure can be obtained. The lithium ion battery anode material adopting the in-situ developed heterogeneous core-shell structure has the advantages as follows the shell layer coats the core layer in a uniform, complete and thickness-controllable manner, no obvious phase boundaries exist between the core layer and the shell layer, and the electrochemical performance of the material is improved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

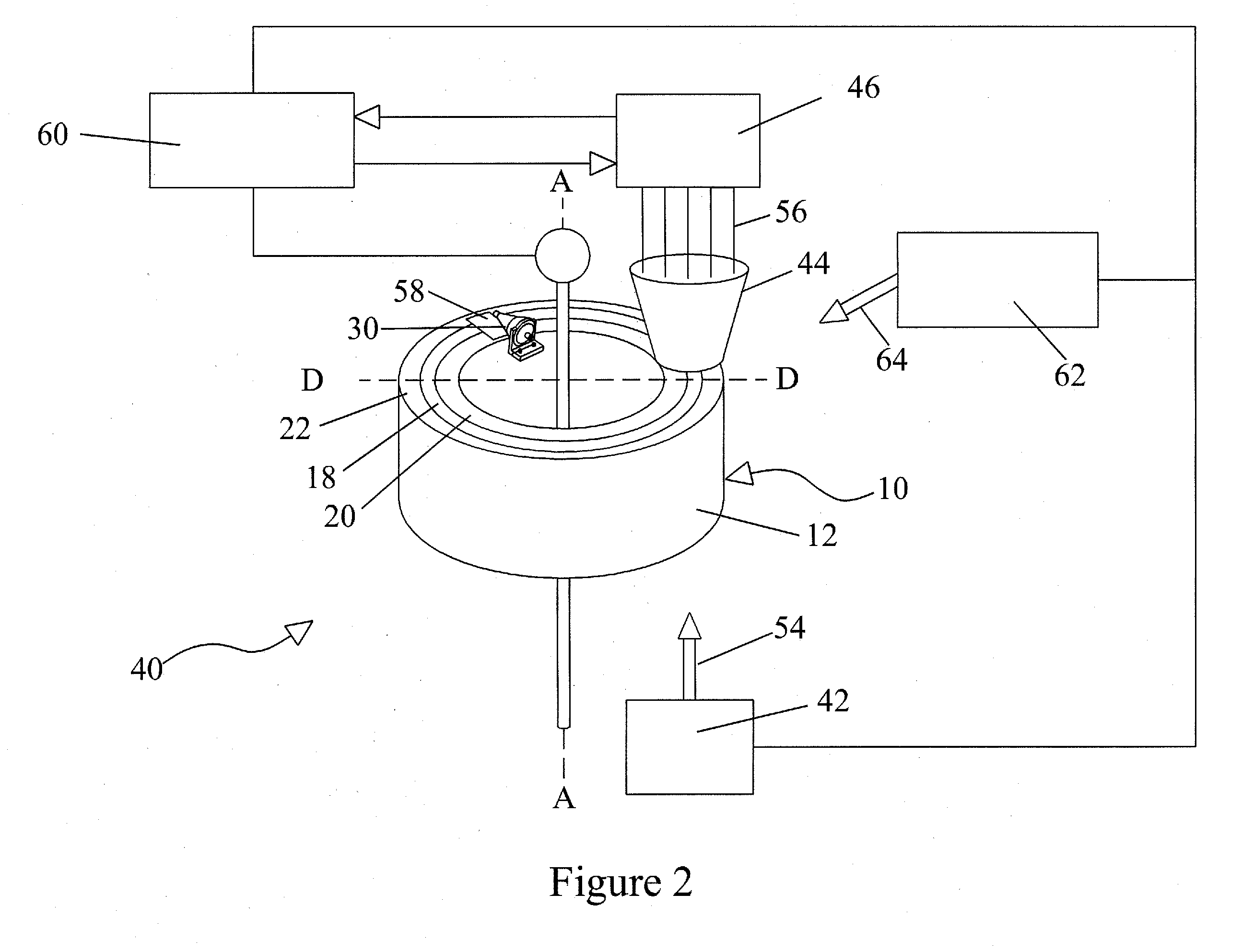

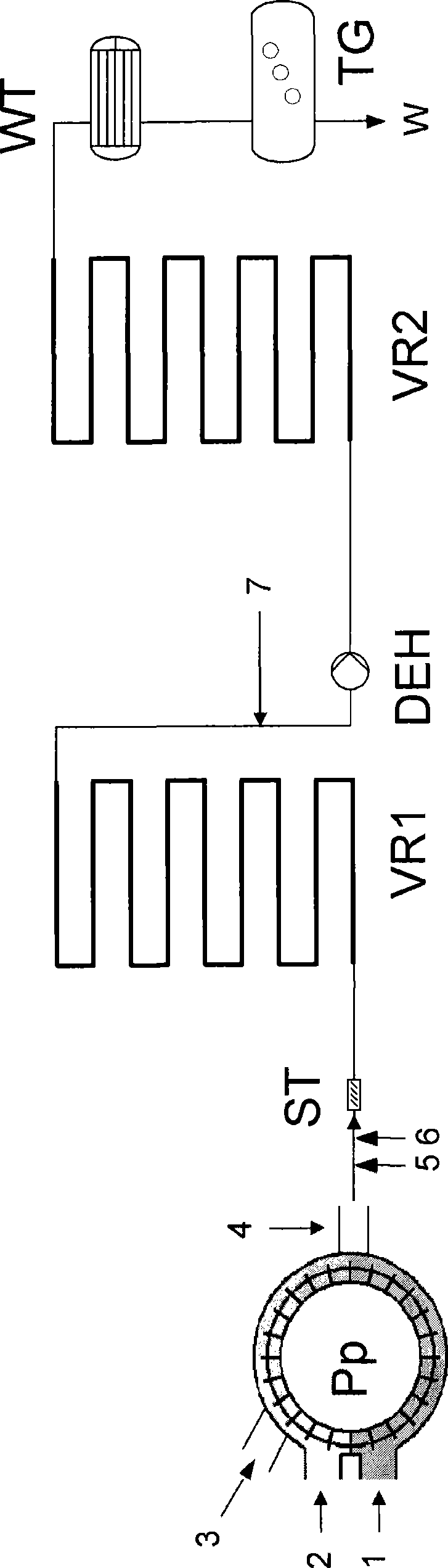

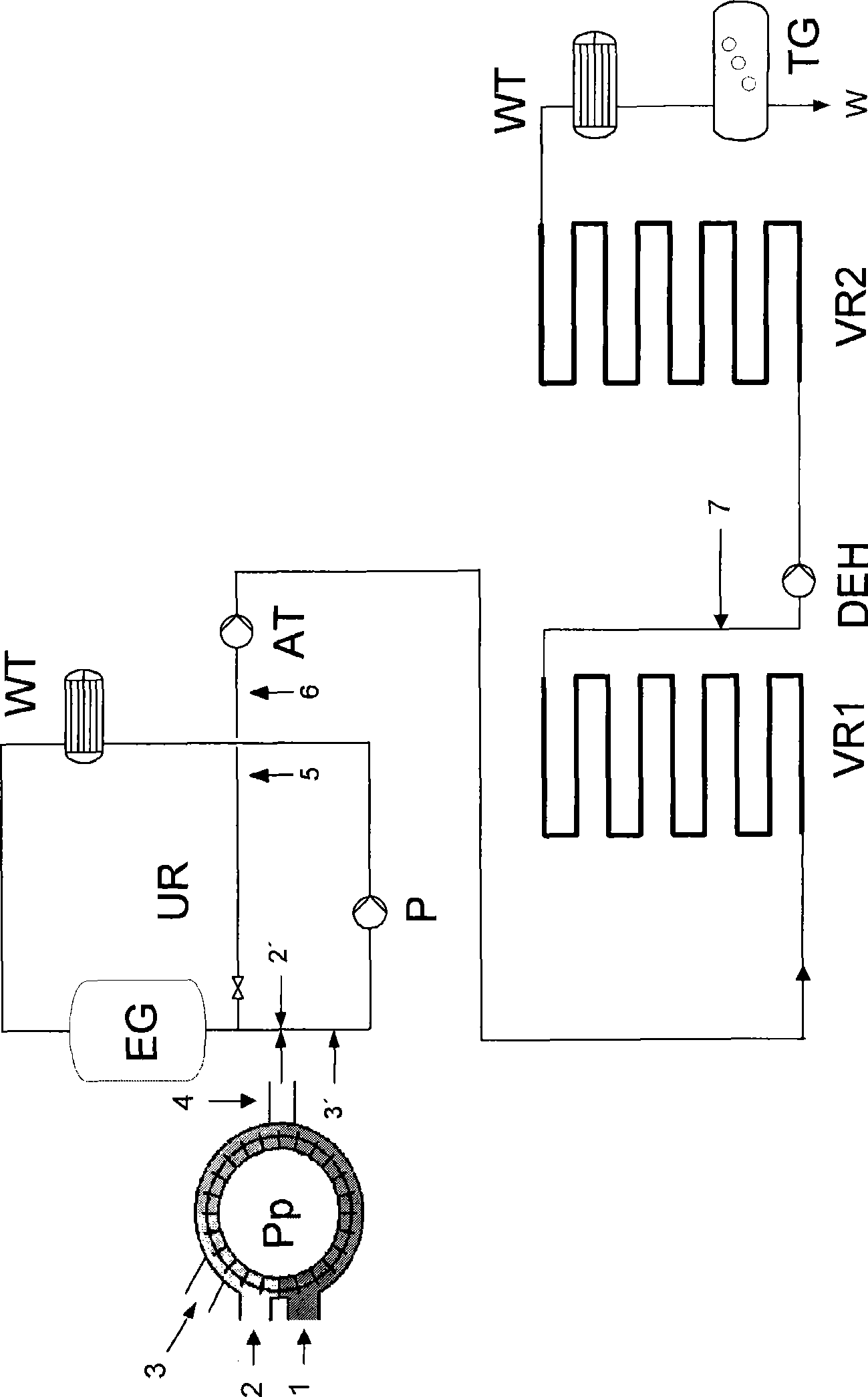

Method and device for growing large-volume oriented monocrystals

InactiveUS6969502B2Unusual sensitivityPrevent undesirable premature meltingAluminium silicatesBy zone-melting liquidsHeat flowMetallurgy

In the method for growing large-volume monocrystals crystal raw material is heated in a melting vessel with heating elements to a temperature above its melting point until a melt is formed. A monocrystal is then formed on the bottom of the melting vessel by lowering the temperature at least to the crystallization point. A solid / liquid phase boundary is formed between the monocrystal and the melt. The monocrystal grows towards the melt surface in a direction that is perpendicular to the phase boundary. A vertical axial temperature gradient is produced and maintained between the bottom of the melting vessel and its upper opening and heat inflow and / or heat outflow through side walls of the melting vessel is prevented, so that the solid / liquid phase boundary has a curvature radius of at least one meter. A crystal-growing device for performing this process is also described.

Owner:HELLMA MATERIALS

Variable lens

InactiveUS7929218B2Reduce accelerationReduce positional influenceSpectrum generationLensDielectricPower flow

The invention relates to a variable lens for controlling electromagnetic radiation that interacts with said lens in a controlled manner. The lens includes a container; a first dielectric fluid that is held in the container; a second dielectric fluid that is held in the container, a phase boundary layer between the first and the second fluid. The relative dielectric constant of the first fluid is different from a relative dielectric constant of the second fluid. At least one first electrode; and at least one second electrode is positioned in relation to the first electrode in such a way that an electric current that is applied between the first and the second electrode generates an electric field, which infiltrates the phase boundary layer.

Owner:CARL ZEISS MEDITEC AG

Process for the preparation of polycarbonates and diaryl carbonate

The present invention relates to a process for the continuous preparation of polycarbonates or diaryl carbonates by the method of the phase boundary process, in which both the mixing of the organic and aqueous phase and the upstream oligomerization step or aryl chloroformate and / or diaryl carbonate preparation step are effected in a special pump.

Owner:BAYER MATERIALSCIENCE AG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com