Patents

Literature

44 results about "Saturation polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The saturation is shown to originate from an unusual and strong electron-ion correlation that leads to cancellation between electronic and ionic polarizations. Our results shed new insight on the polarization properties, and reveal the existence of a fundamental limit to the strain-induced polarization enhancement.

Method for preparing multi-ferroic material under intense magnetic field

The invention discloses a method for preparing and treating a multiferroics BiFeO3 in the intense magnetic field environment. The method is characterized in that a BiFeO3 sample is prepared and treated by utilizing the intense magnetic field, so as to improve the magnetoelectric coupling performance of BiFeO3. A Bi-Fe-O precursor and a thin film is prepared or the BiFeO3 sample is directly produced (including polycrystal, single crystal, nano-material or thin film) by adopting a chemical method or a physical method, then the prepared products are positioned in an intense magnetic field heating furnace in an atmosphere with air or other gases (such as oxygen) for sintering or annealing, and are cooled down to the room temperature by rapid quenching or adopting the cooling speed of 1 DEG C / min after the heat preservation for one to six hours at the magnetic field intensity of between 0 and 20-tesla and a temperature of between 400 and 880 DEG C. The method can effectively improve the macroscopic magnetic moment and saturation polarization intensity of BiFeO3 and enhance the magnetoelectric coupling effect.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

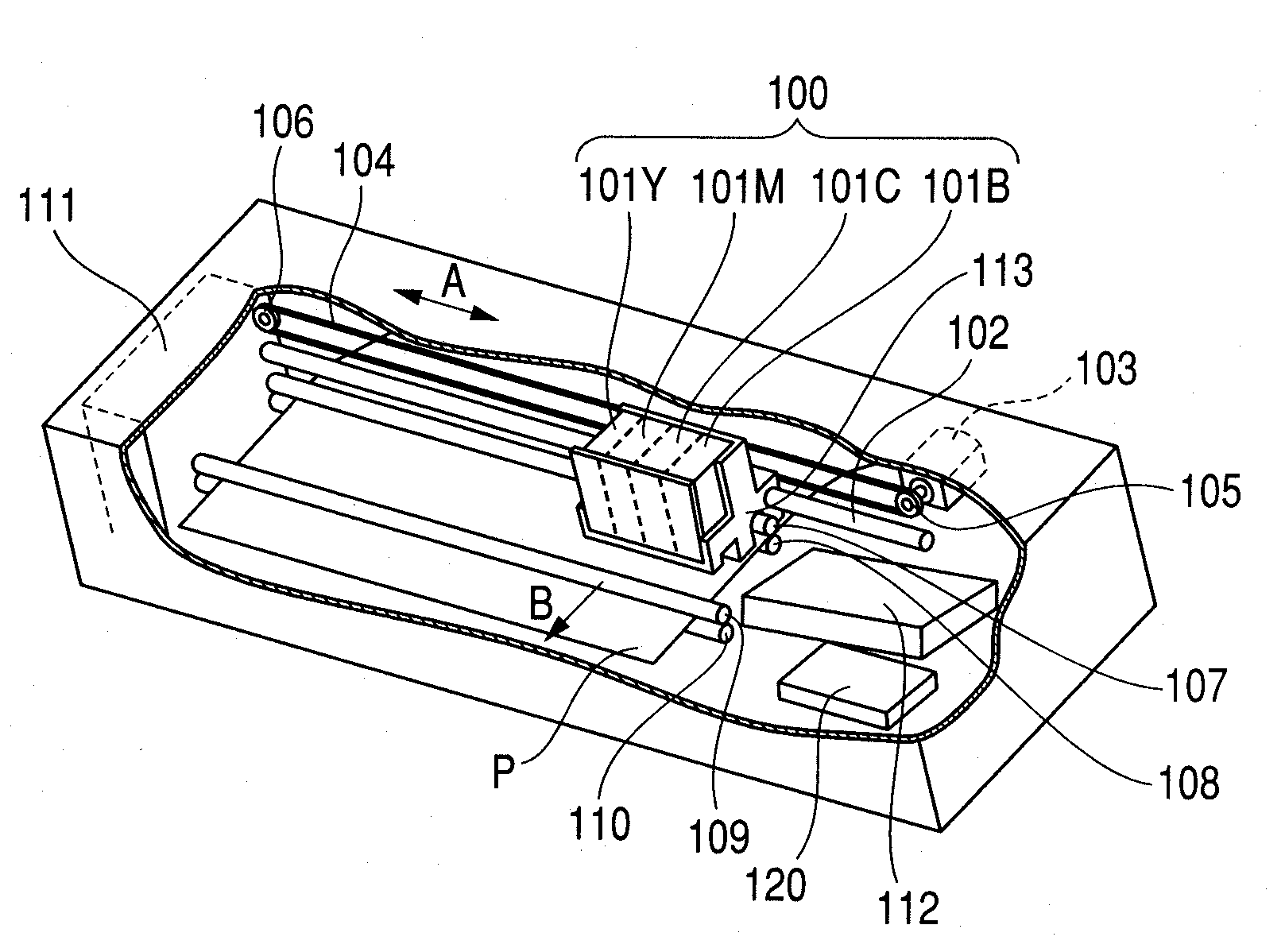

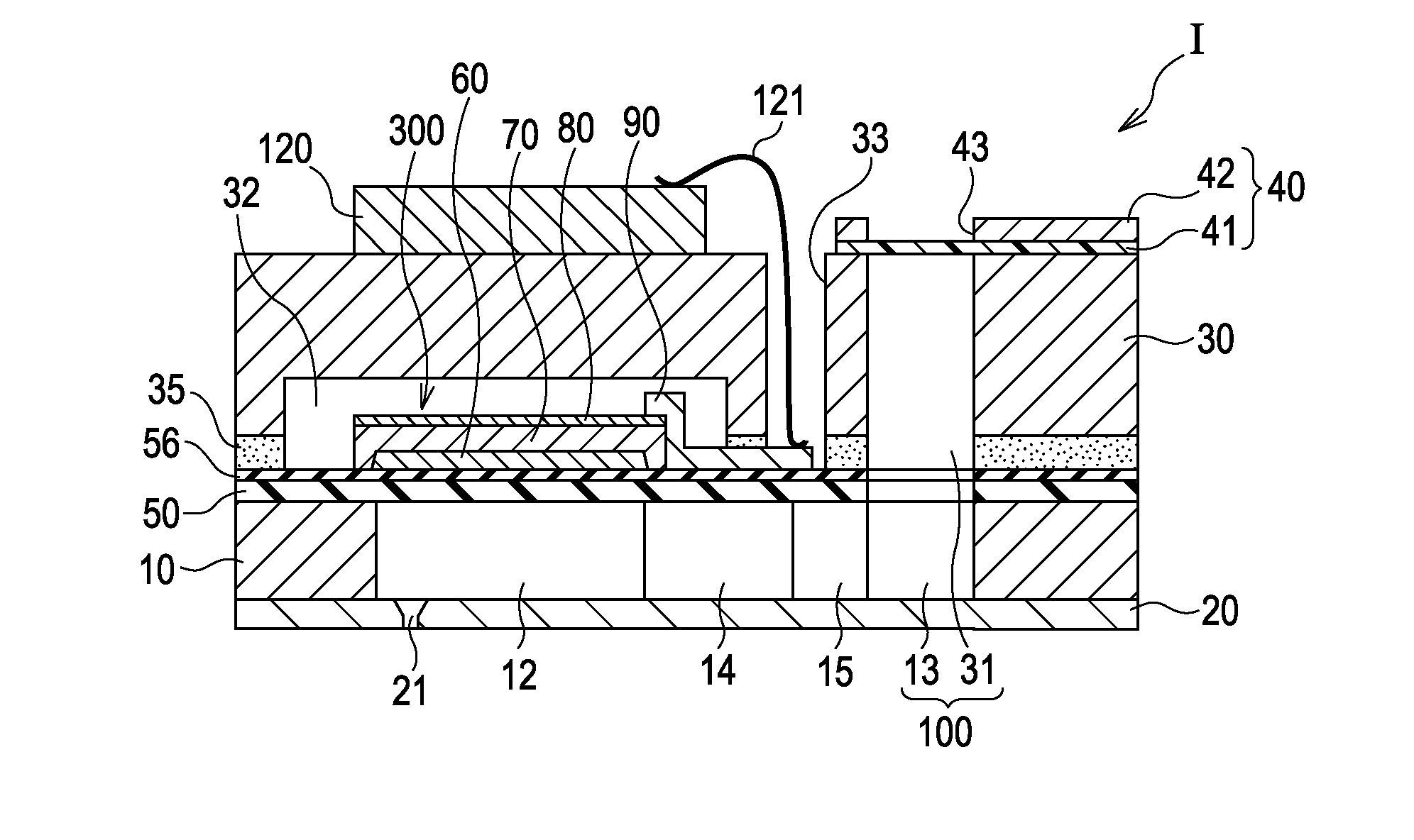

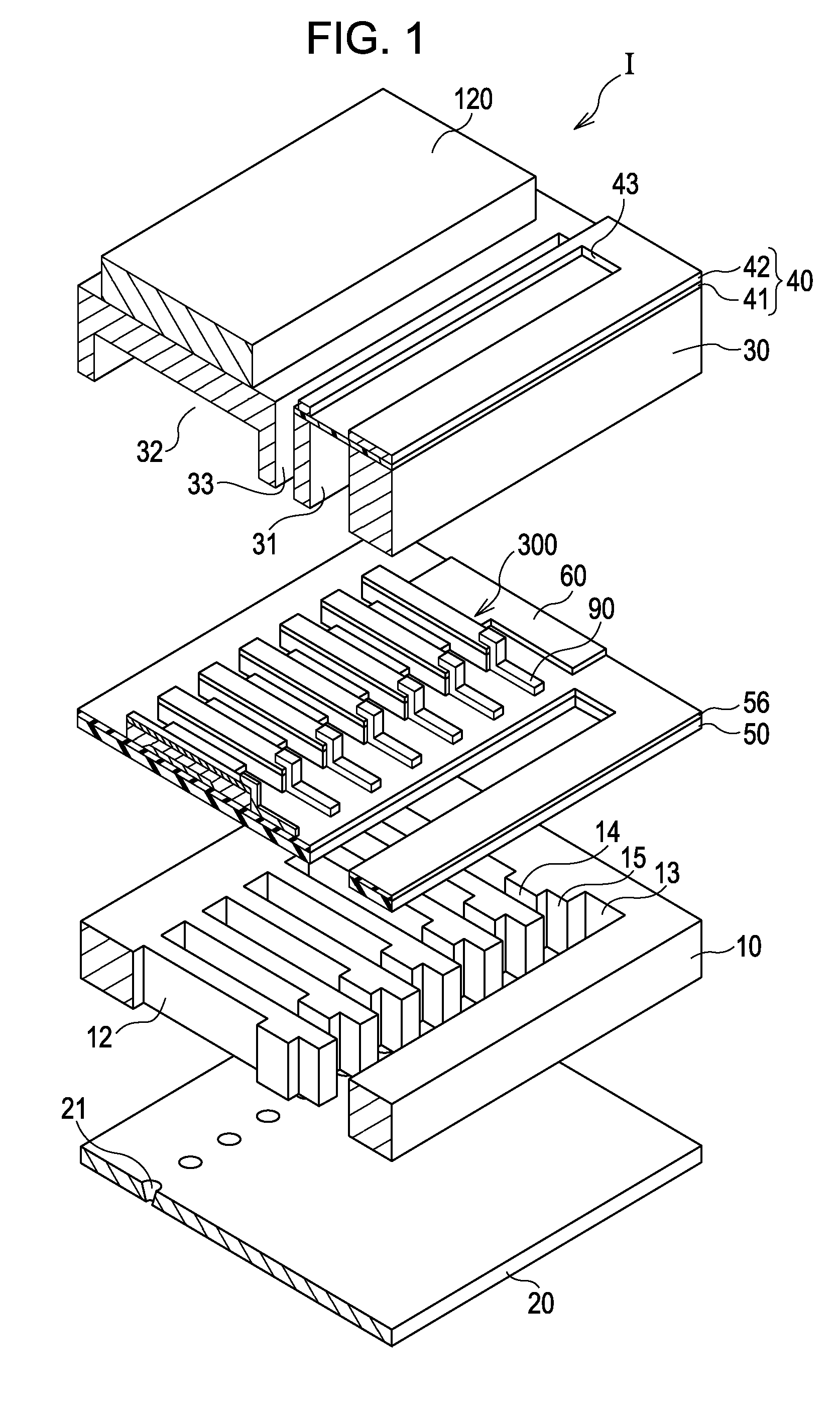

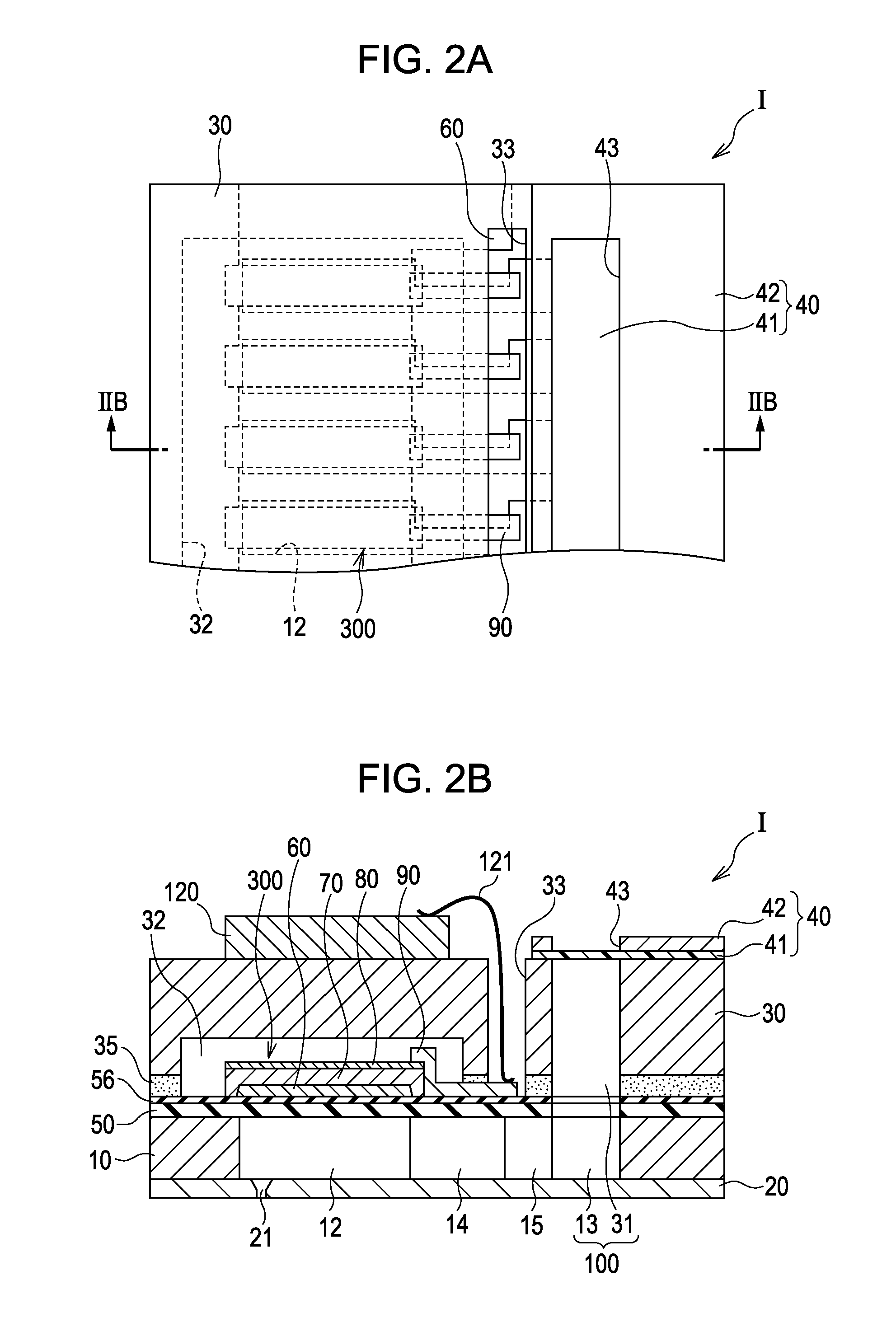

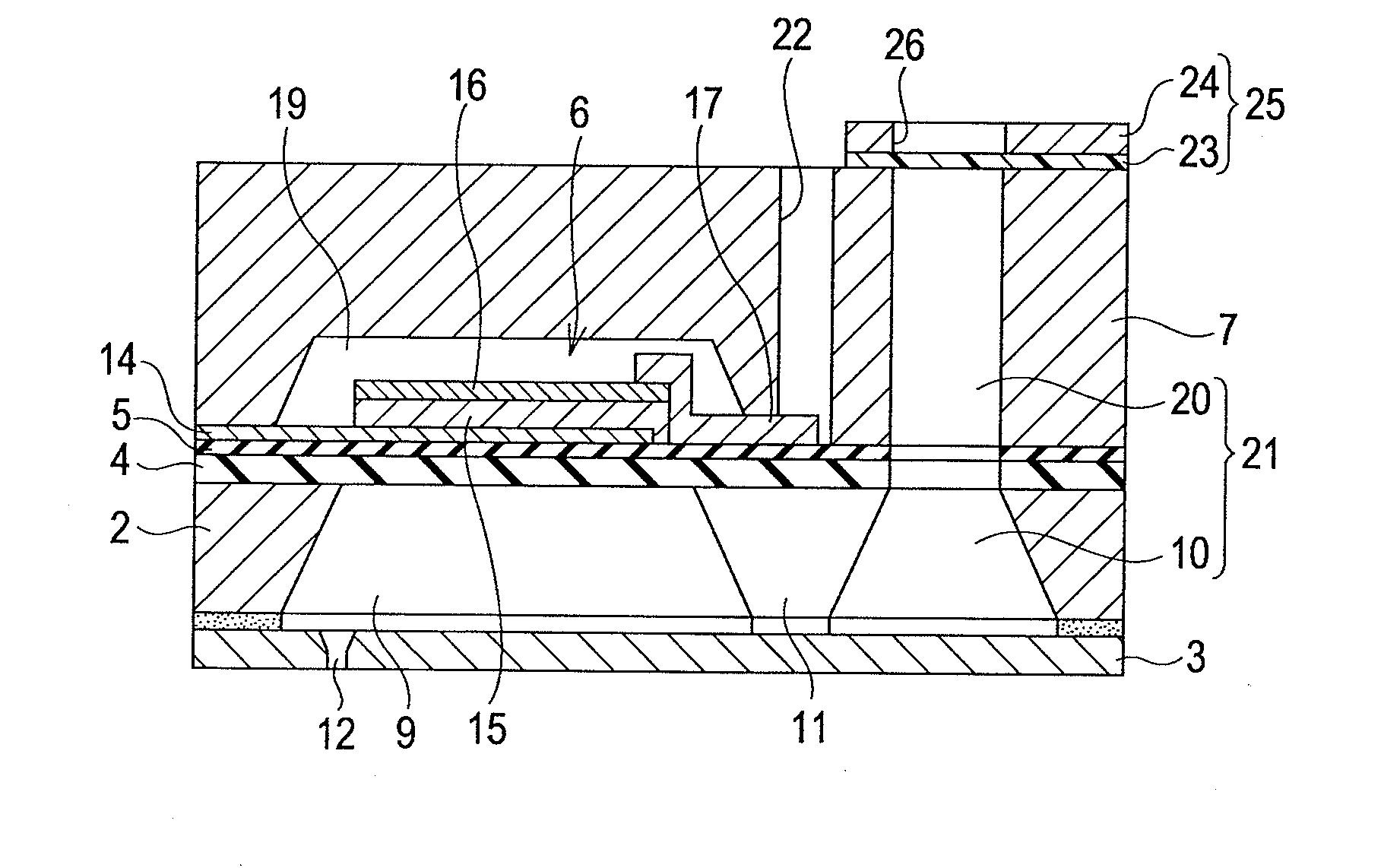

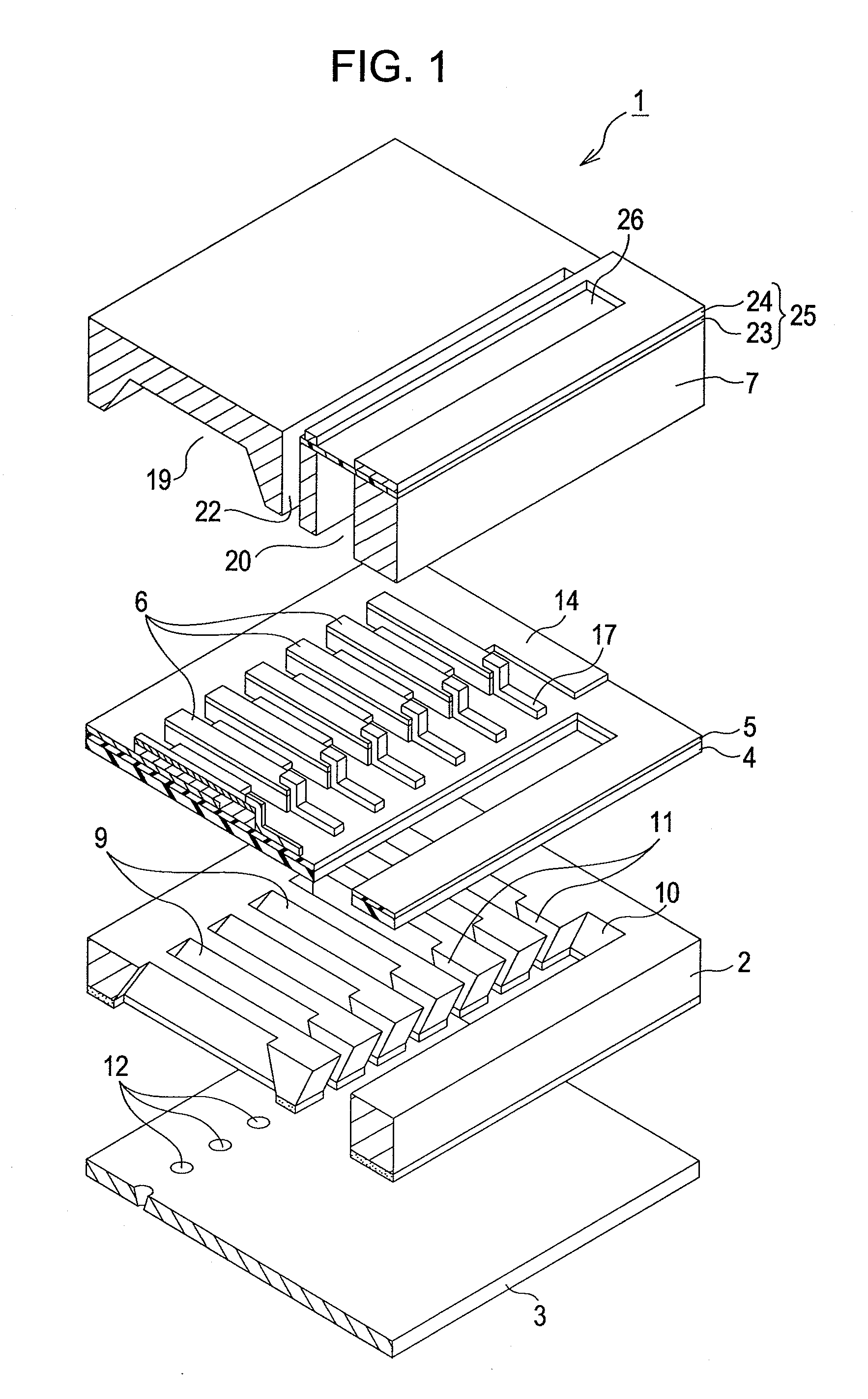

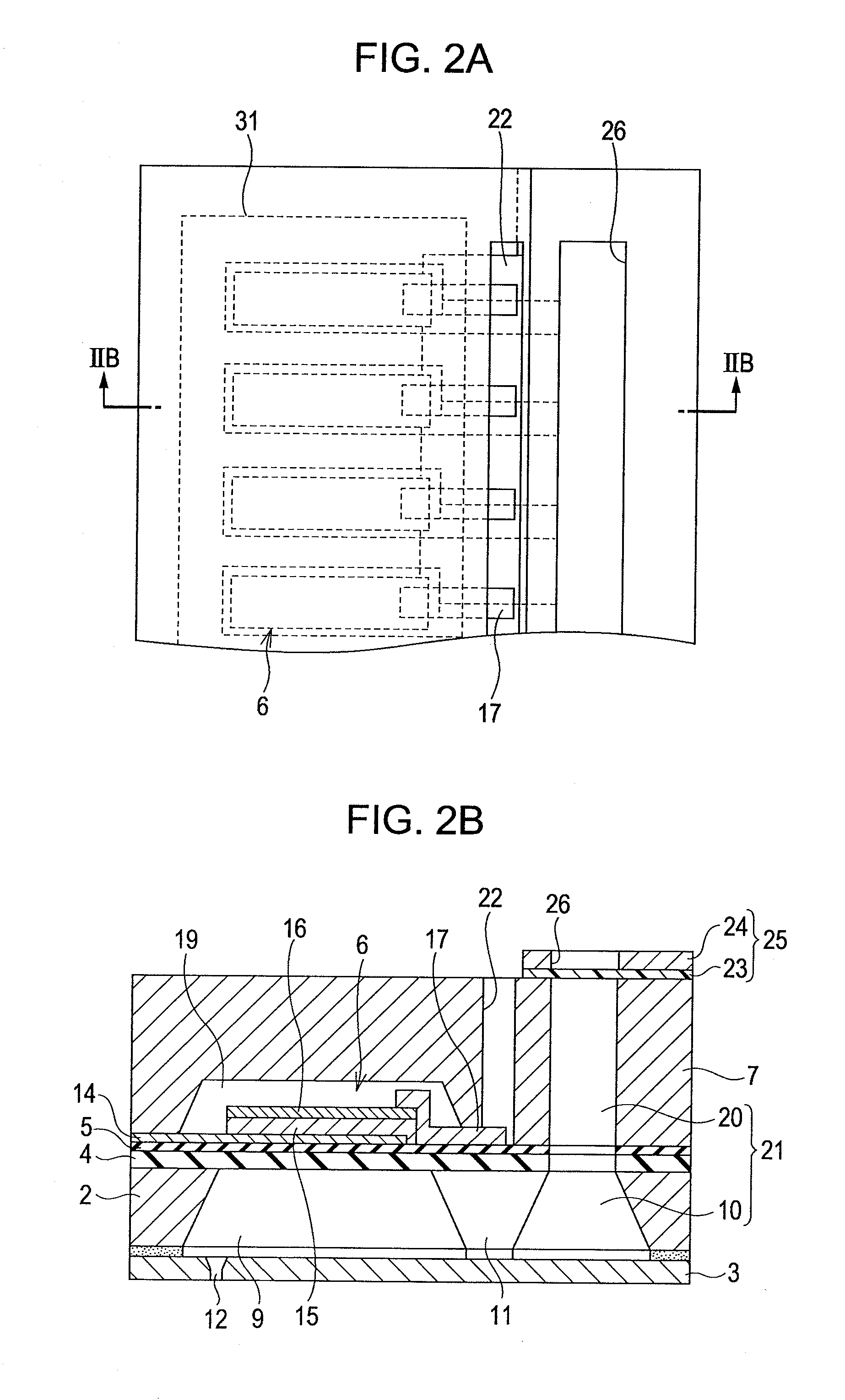

Liquid discharge head and liquid discharge apparatus

InactiveUS20080239016A1Piezoelectric/electrostrictive device manufacture/assemblyPrintingHysteresisElectricity

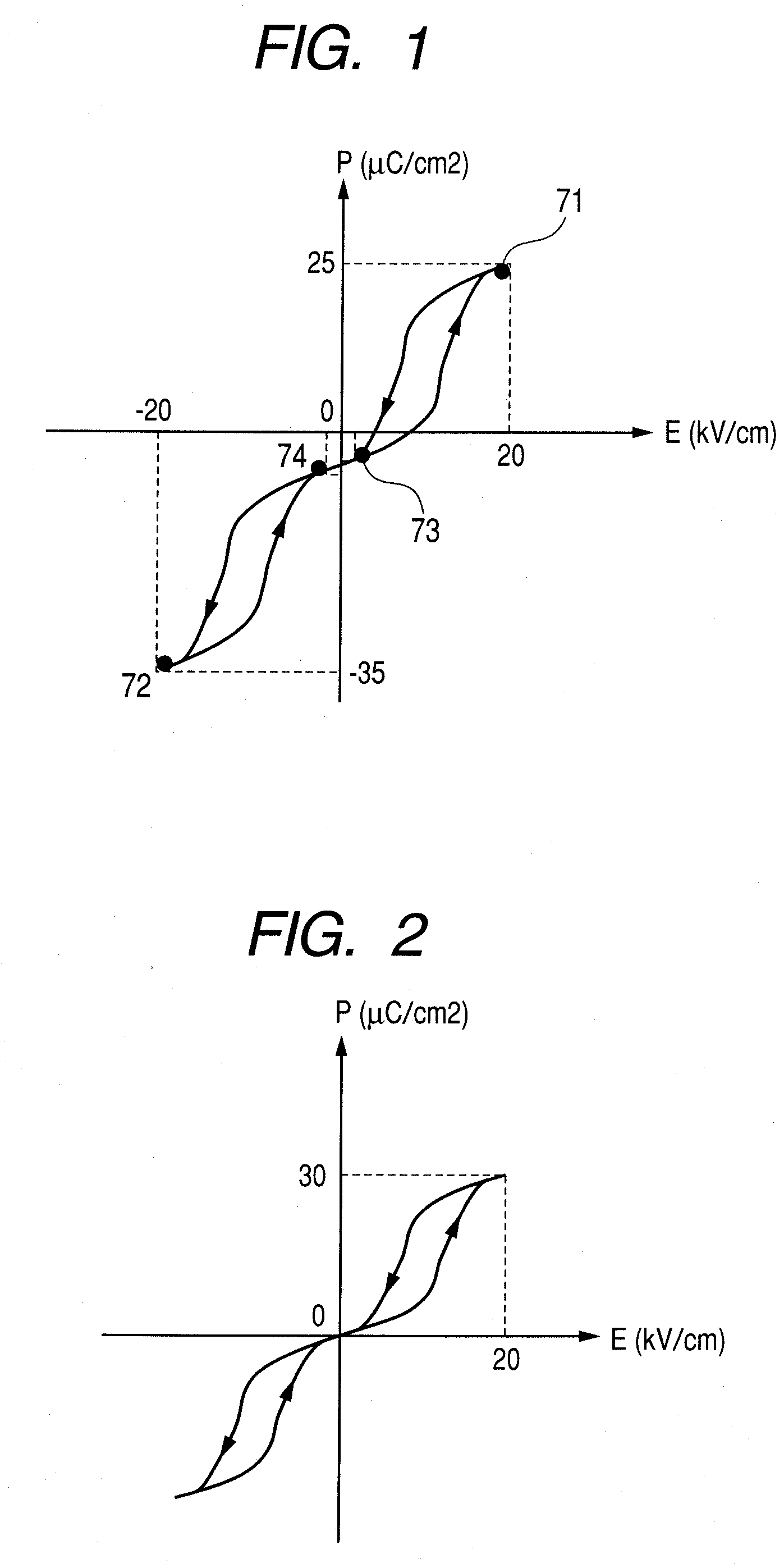

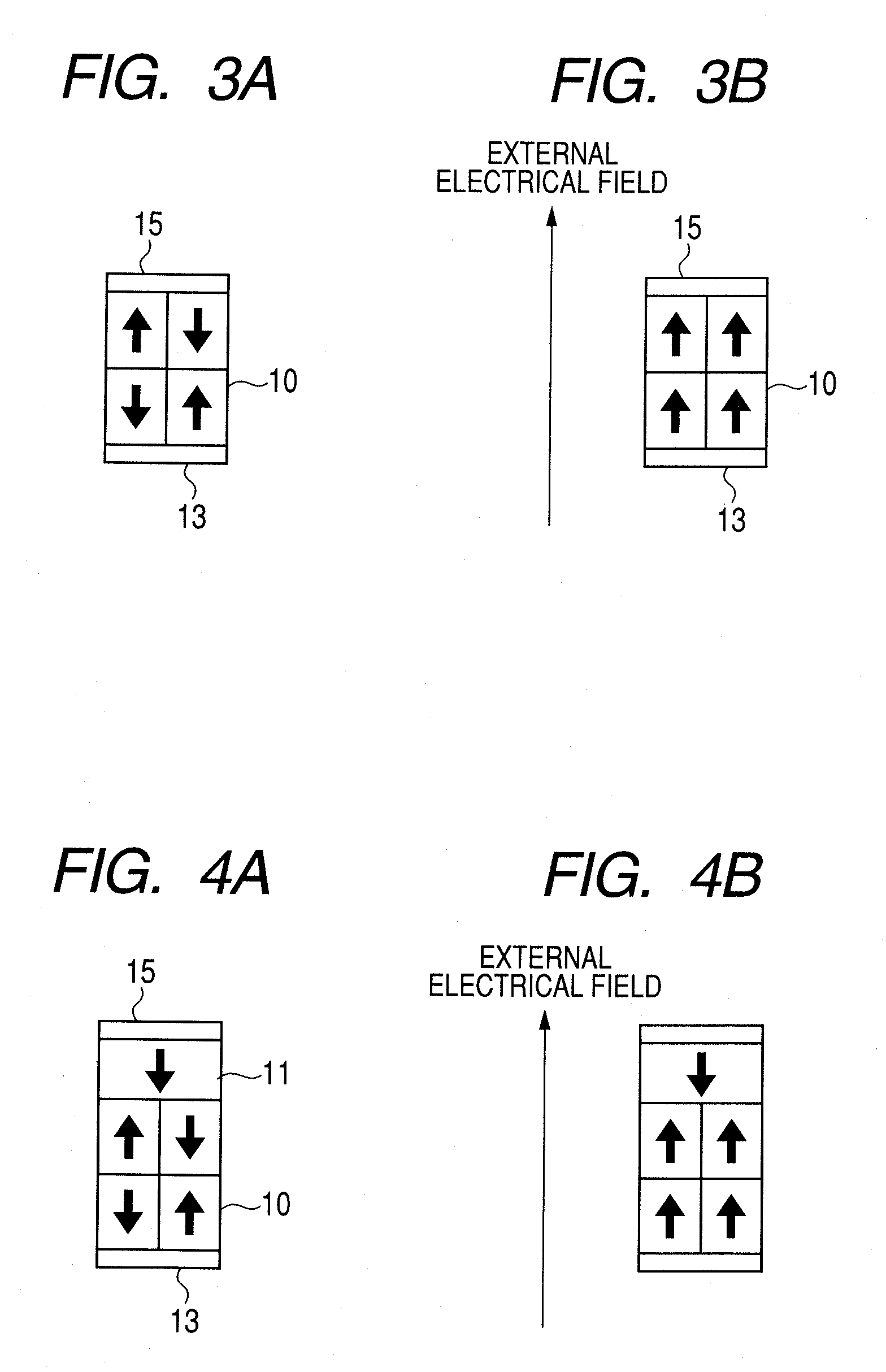

A liquid discharge head is provided, which includes a piezoelectric element for which the polarization characteristic can be recovered without having to apply an electrical field in a direction opposite to that in which an electrical field is to be applied during driving. A piezoelectric element provided for a liquid discharge head of the present invention includes a field-polarization hysteresis characteristic that has, at the least, one hysteresis loop. A saturation polarization point and a critical polarization point, on one hysteresis loop for the hysteresis characteristic, are positioned in the same field polarity, and different signs are provided for a polarization value at the saturation polarization point and for the polarization value at the critical polarization point.

Owner:CANON KK

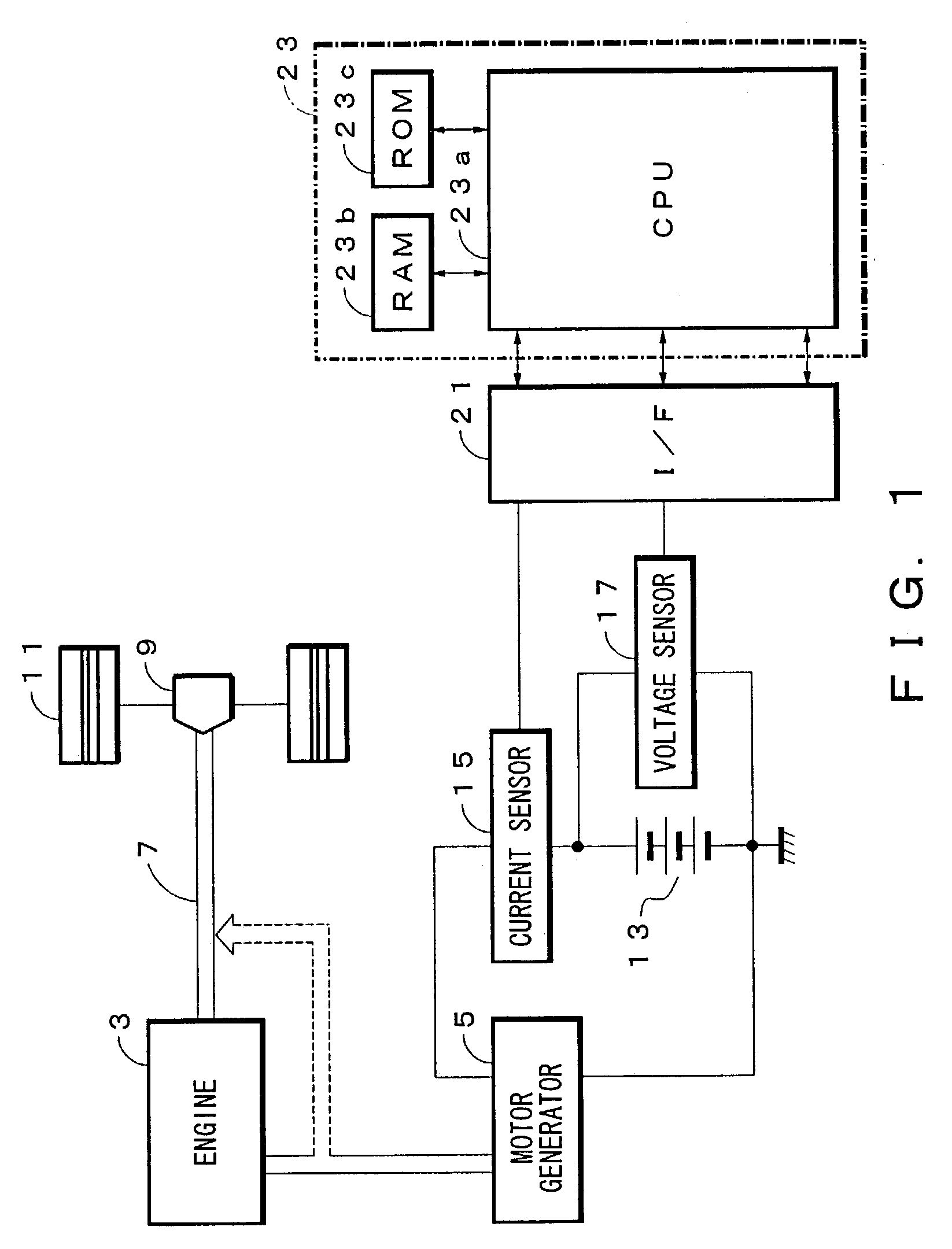

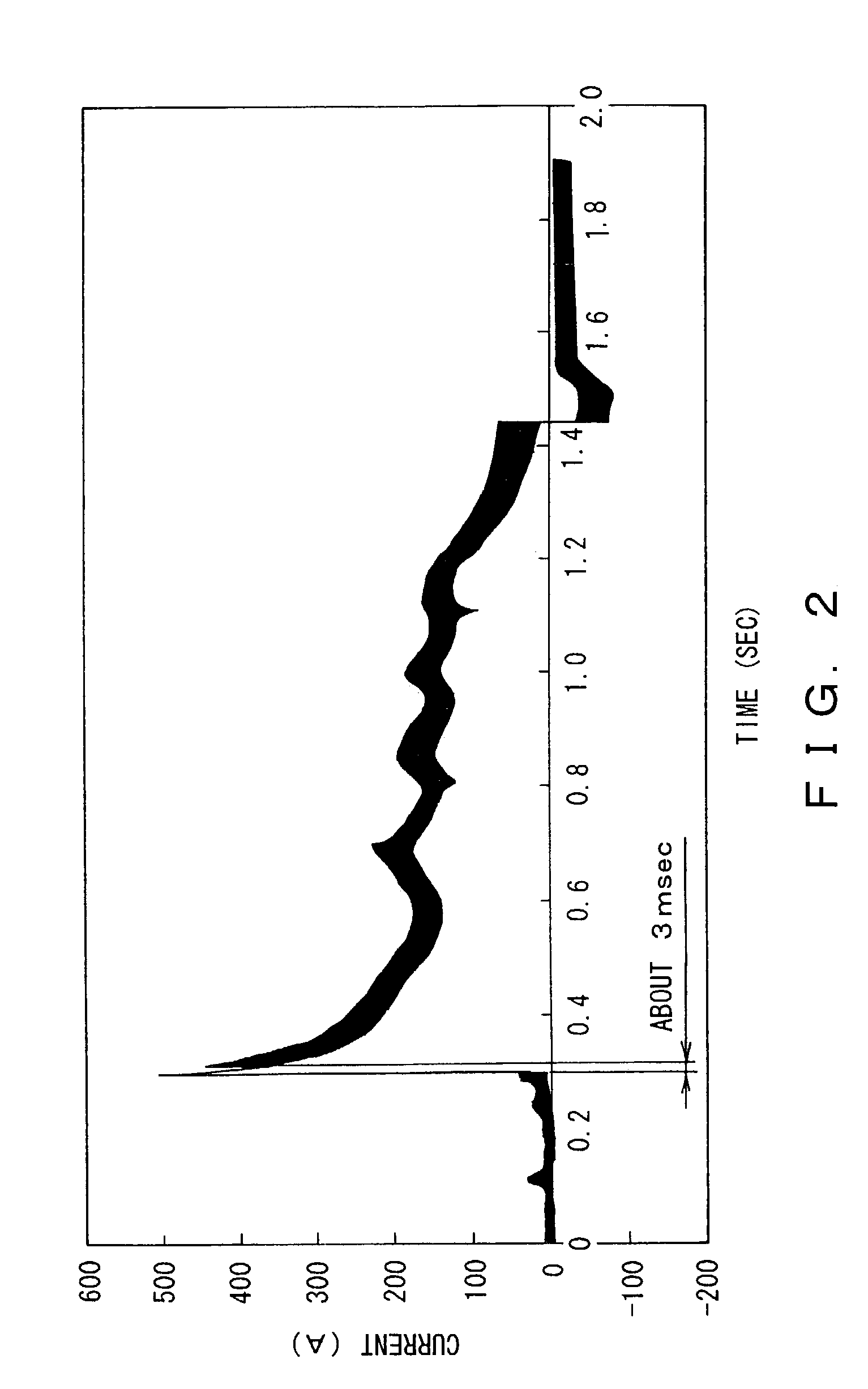

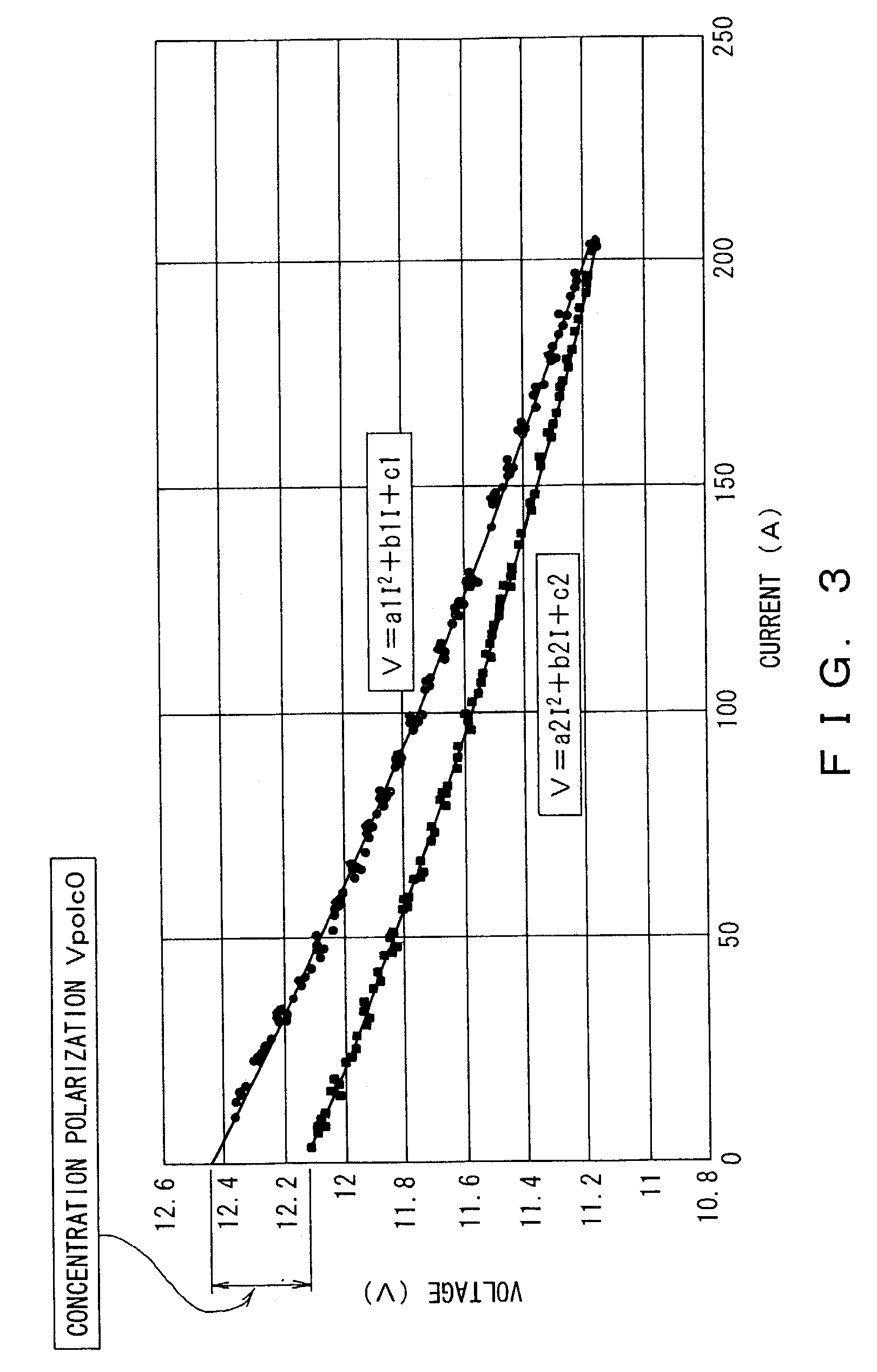

Battery status monitoring apparatus which monitors internal battery resistance, saturation polarization detecting method and dischargeable capacity detecting method

InactiveUS7034504B2Batteries circuit arrangementsMaterial analysis by electric/magnetic meansMicrocomputerElectrical resistance and conductance

Owner:YAZAKI CORP

Liquid-ejecting head and liquid-ejecting apparatus

InactiveUS20110216135A1Reduce contentLess negative impactPiezoelectric/electrostrictive/magnetostrictive devicesPrintingSaturation polarizationEngineering

A liquid-ejecting head includes a pressure-generating chamber communicating with a nozzle opening and includes a piezoelectric element including a piezoelectric layer and electrodes. The piezoelectric layer contains bismuth sodium potassium titanate and satisfies the inequality 0≦Pr / Pm≦0.25 at 25° C., where Pm and Pr are the saturation polarization and remanent polarization, respectively, of the piezoelectric layer.

Owner:SEIKO EPSON CORP

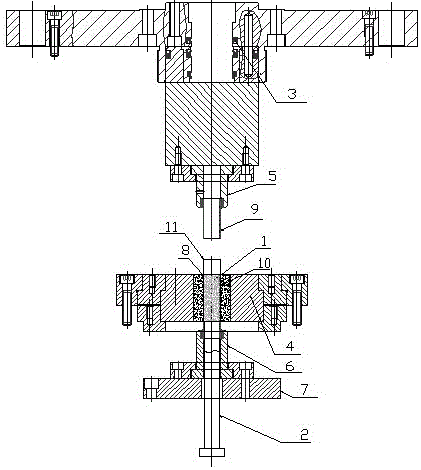

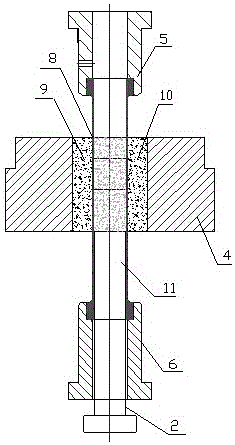

Magnetic material powder forming mold

ActiveCN102847938ADoes not affect suppressionUniform magnetic fieldShaping pressSaturation polarizationHomogeneous magnetic field

The invention discloses a magnetic material powder forming mold, which comprises a female die, wherein a female die cavity is arranged in the female die; and the saturation polarization strength of at least one side face of the female die cavity is consistent with the saturation polarization strength of magnetic material powder to be pressed. According to the magnetic material powder forming mold, the saturation polarization strength of the at least one side face of the female die cavity is consistent with the saturation polarization strength of the magnetic material powder, so that an edge distortion phenomenon of a magnetic field is transferred from the magnetic material powder to a side face of the female die cavity made of the material, the magnetic field of the magnetic material powder is guaranteed to be a uniform magnetic field, and the performance of a blank made through the mold is guaranteed. Because of an arrangement mode of an isolating plate, the material with the saturation polarization strength consistent with that of the magnetic material powder is arranged on different side faces according to different requirements, so that the application range is wide and the pressing of the magnetic powder is not affected.

Owner:JIANGXI JLMAG RARE EARTH

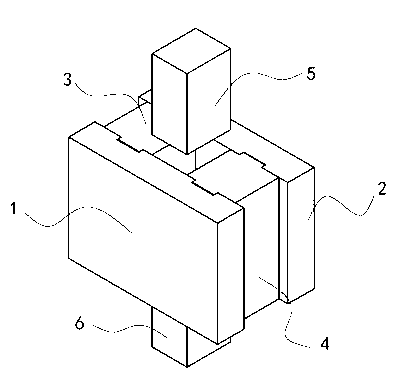

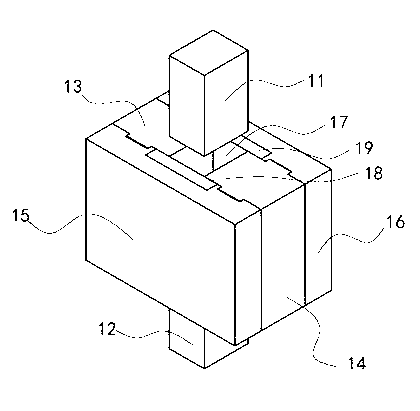

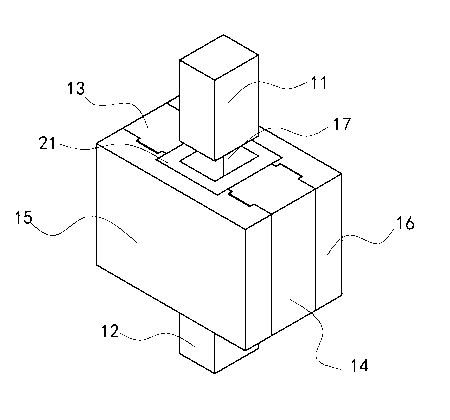

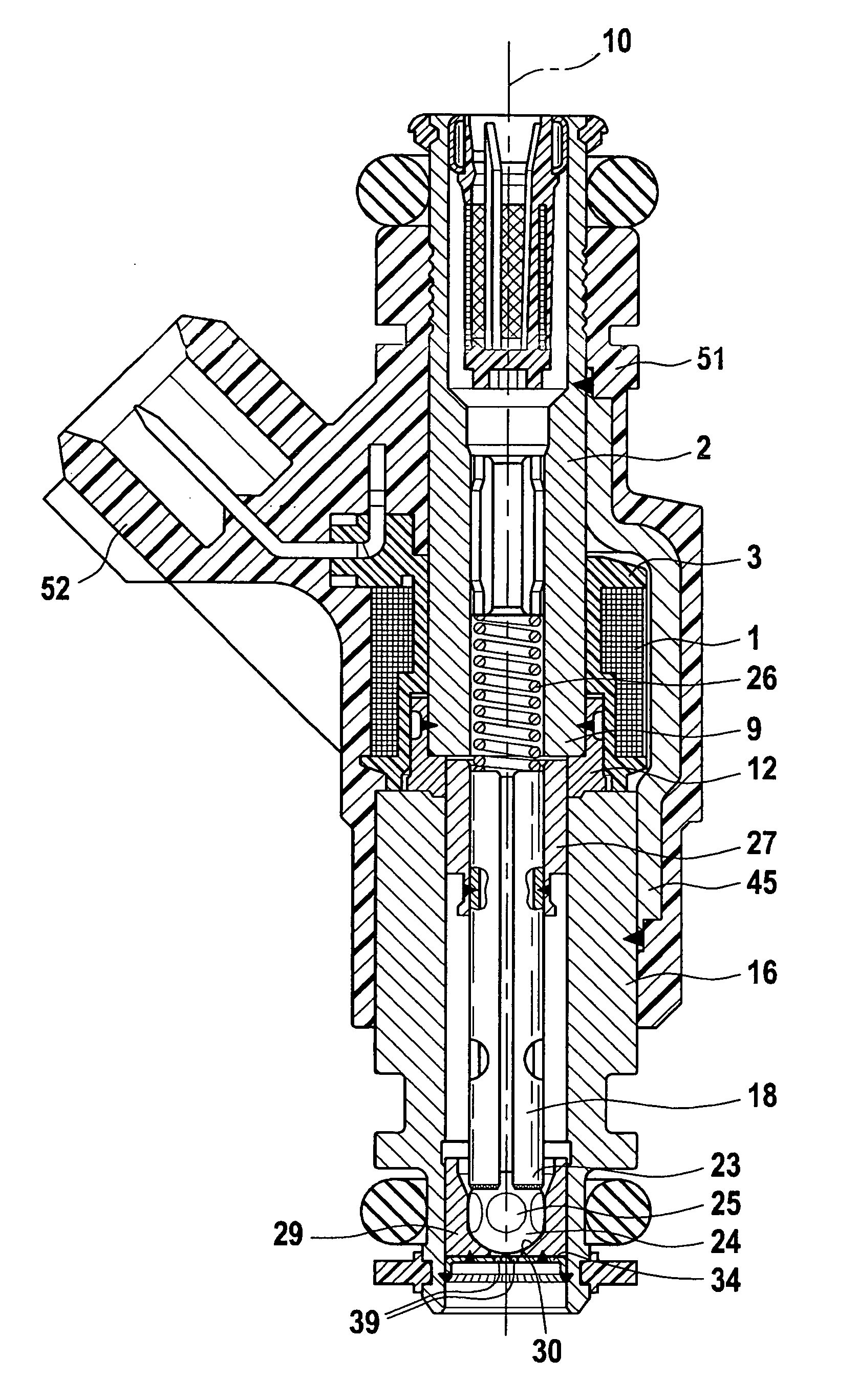

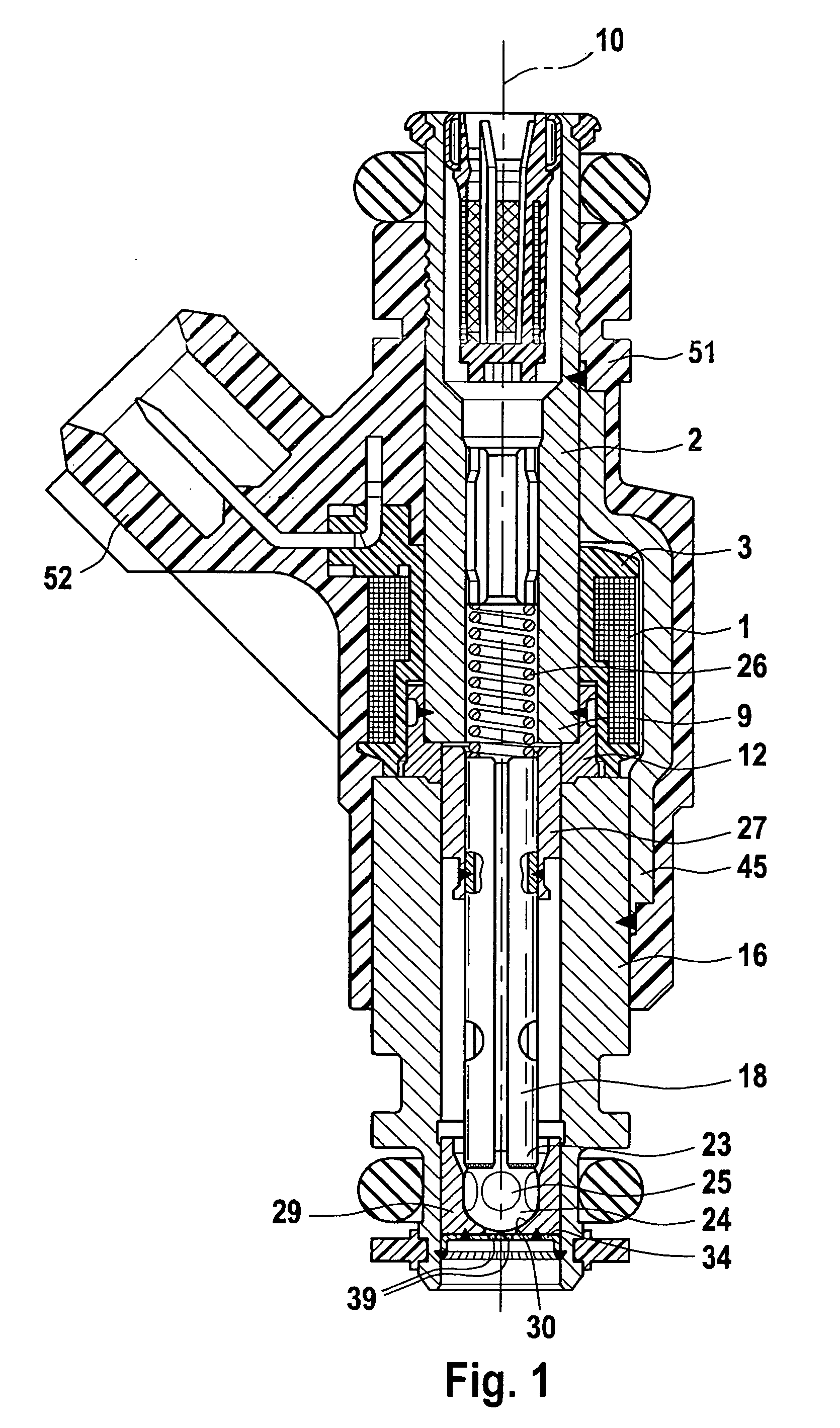

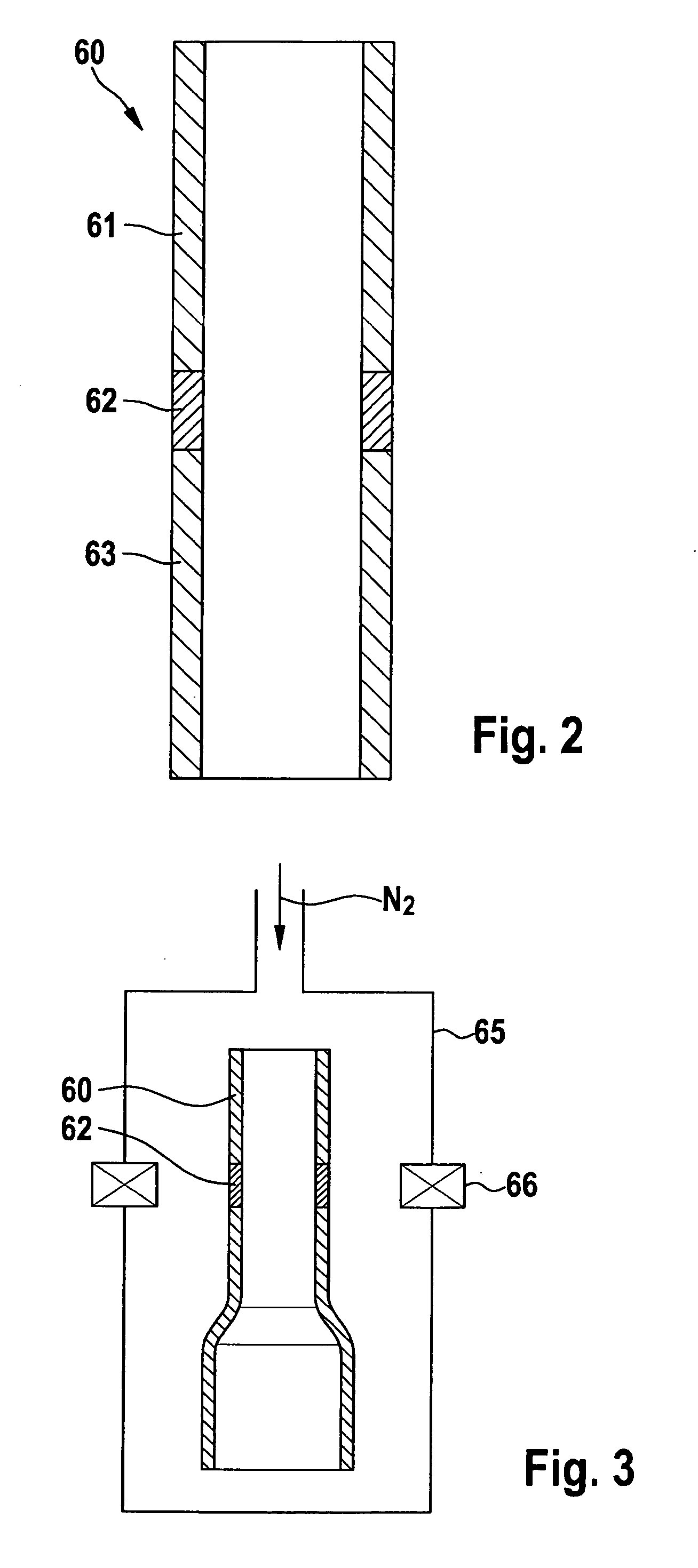

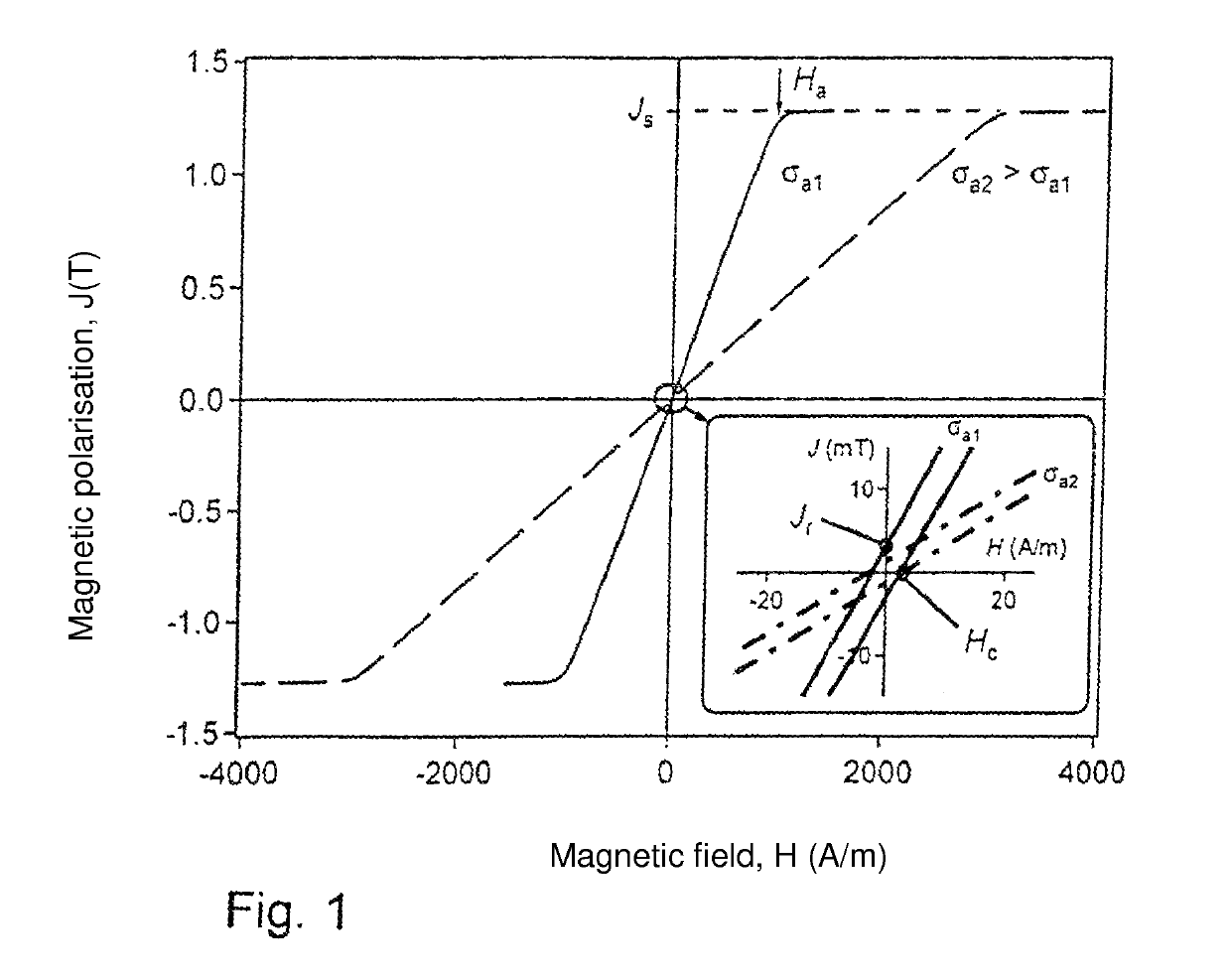

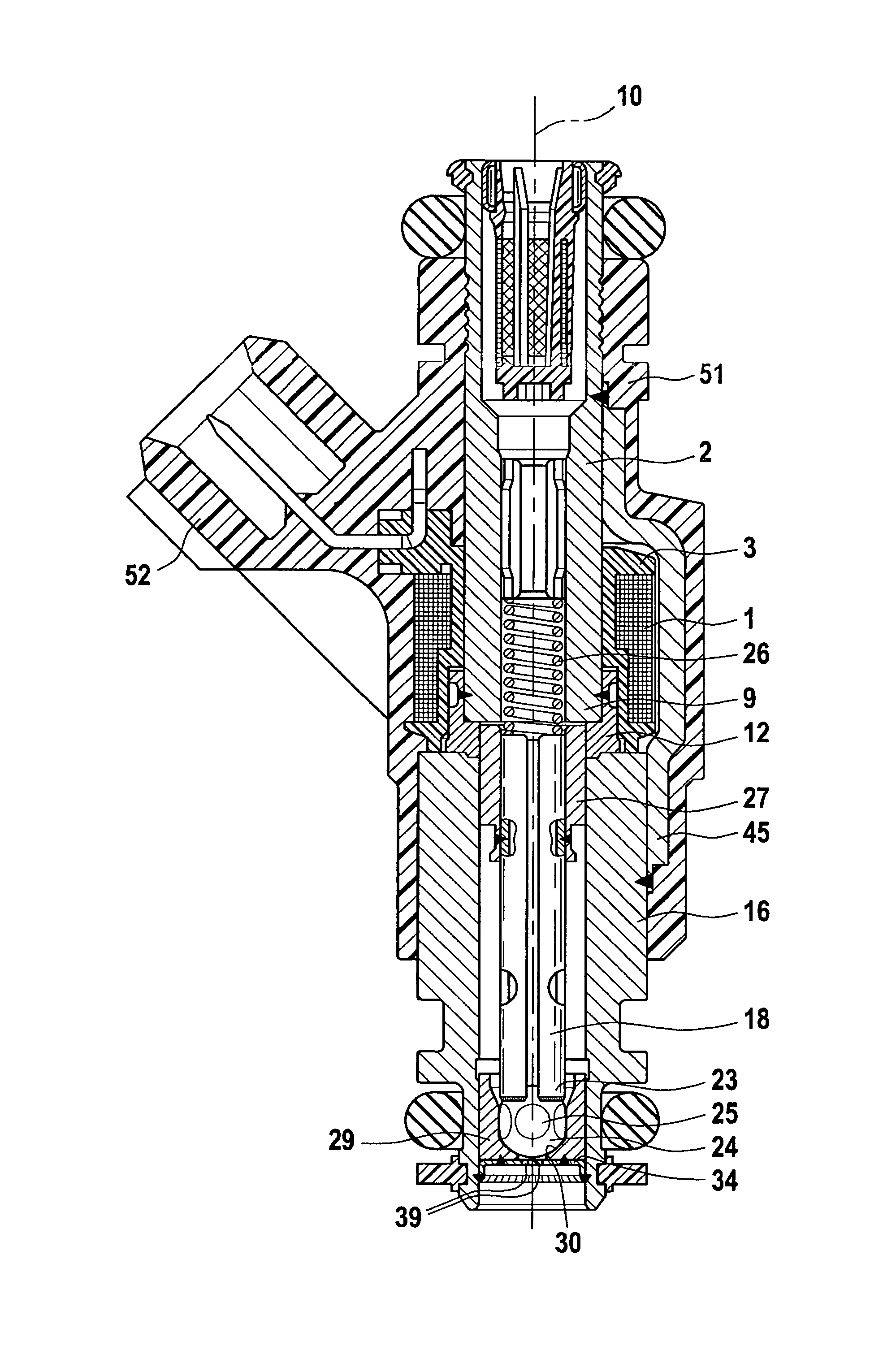

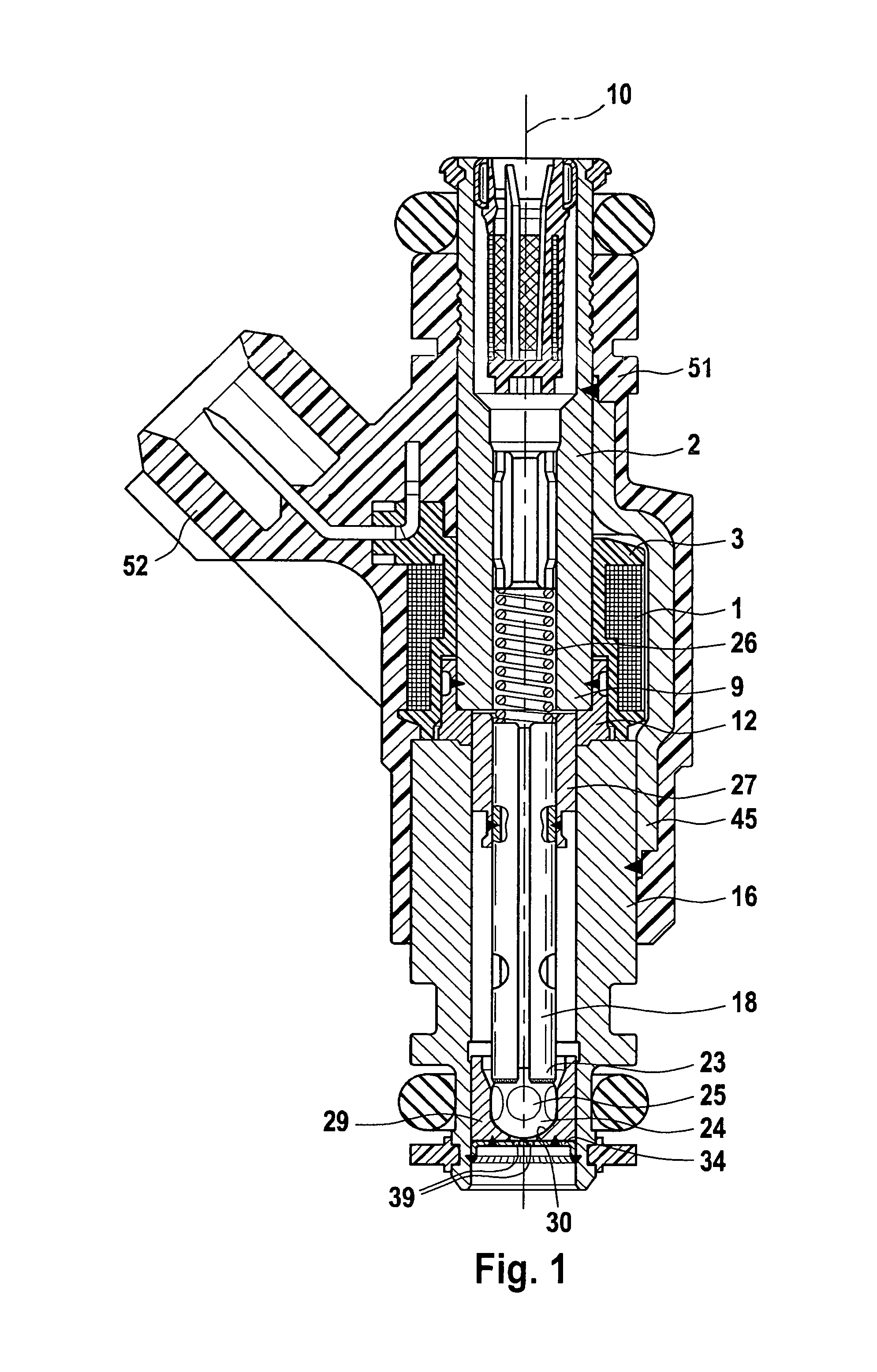

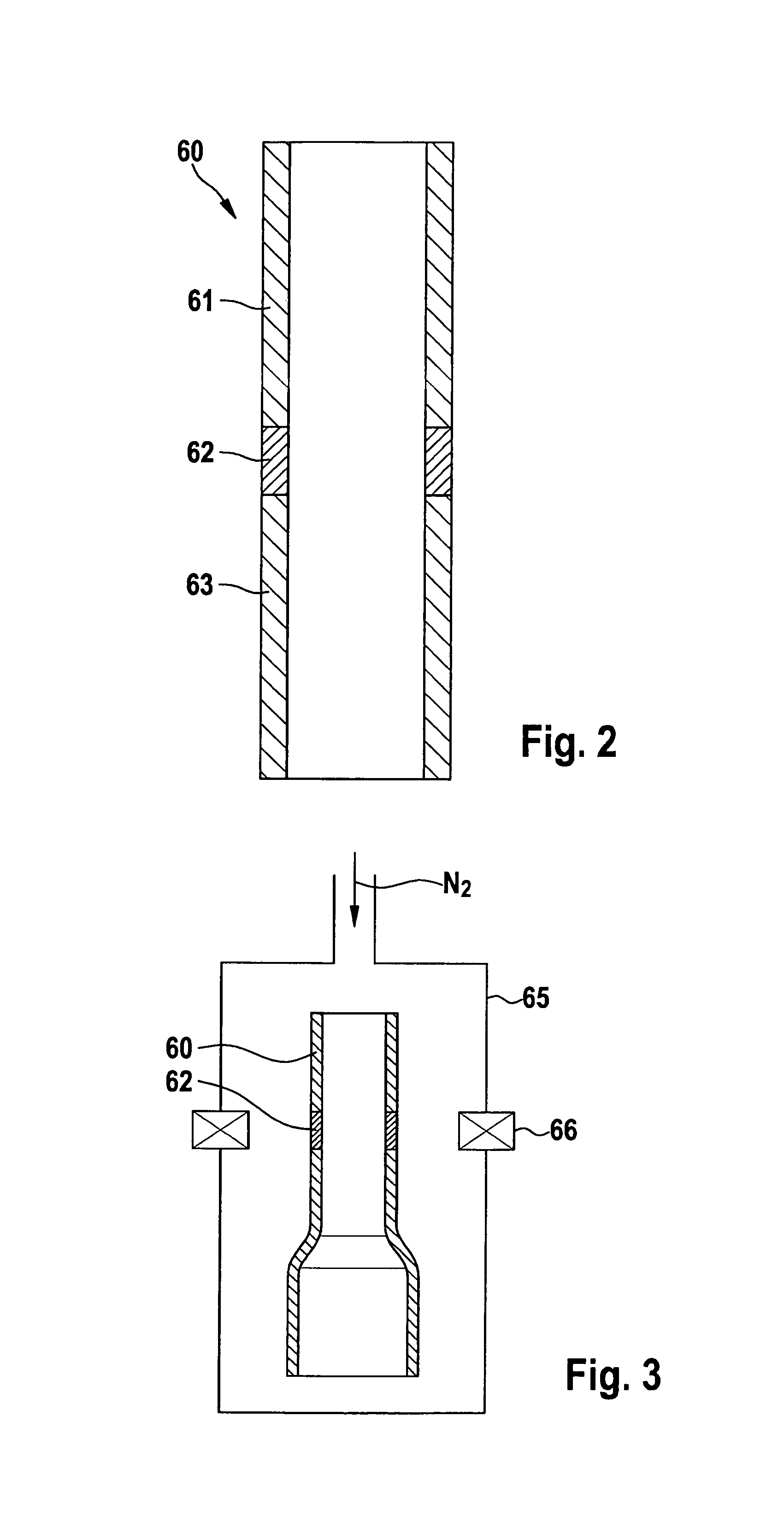

Method for manufacturing a metal composite component, in particular for an electromagnetic valve

InactiveUS20110163256A1Simple and inexpensive mannerReduced saturation polarizationMagnetsInorganic material magnetismCombustionSaturation polarization

A method for manufacturing a metal composite component is characterized in that the composite component (60) is provided with at least two sections (61, 62, 63) of different magnetization, at least two sections (61, 62, 63) being situated on the one-piece component (60) in direct succession. The starting material for manufacturing the composite material (60) is a semi-austenitic steel, which is provided as a cylindrical blank. The blank is subsequently shaped into an intended shape of the composite component (60) and rendered magnetizable in a multistage forming and / or heat treatment process, the heat treatment being performed in such a way that the component has a saturation polarization Js=0.9-1.5 T. This is followed by a local heat treatment in a partial area under simultaneous cooling of the areas of the composite component (60) where the magnetic properties are not to be changed, in order to define strictly delimited transitional areas between the different areas of magnetization (61, 62, 63). The composite component (60) is suitable in particular for use in electromagnetic valves, for example, including in fuel injectors of internal combustion engines.

Owner:ROBERT BOSCH GMBH

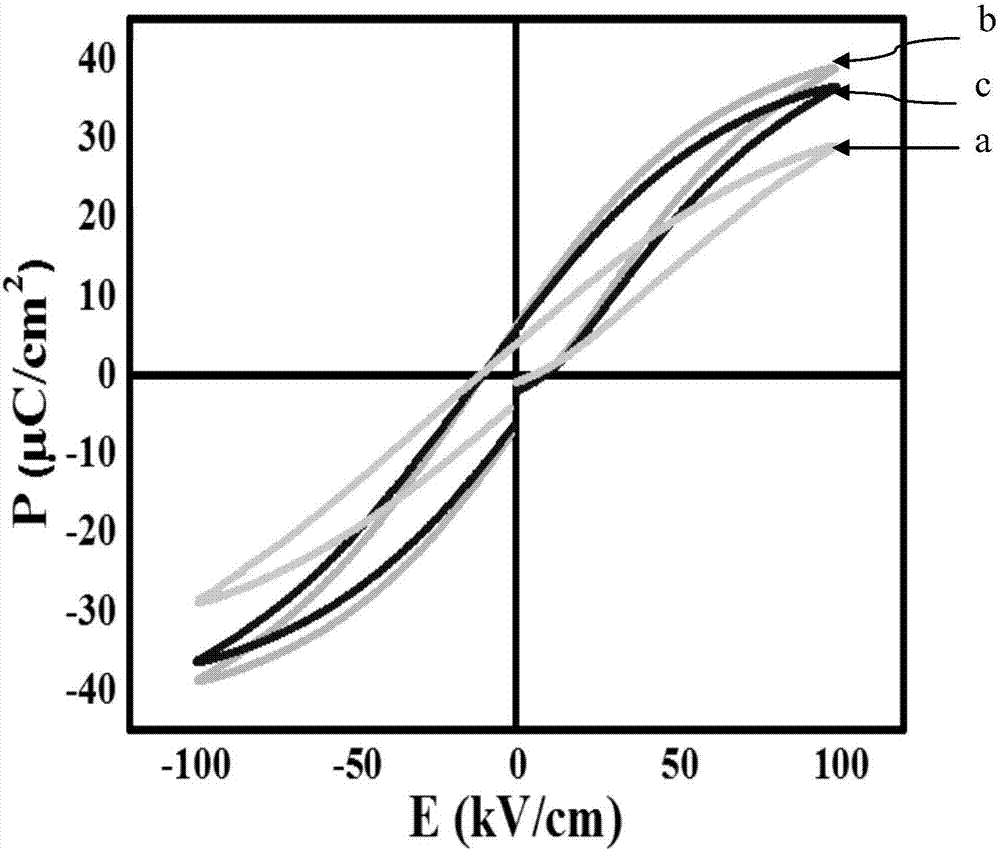

Sodium bismuth titanate-based ferroelectric ceramic as well as preparation method and application thereof

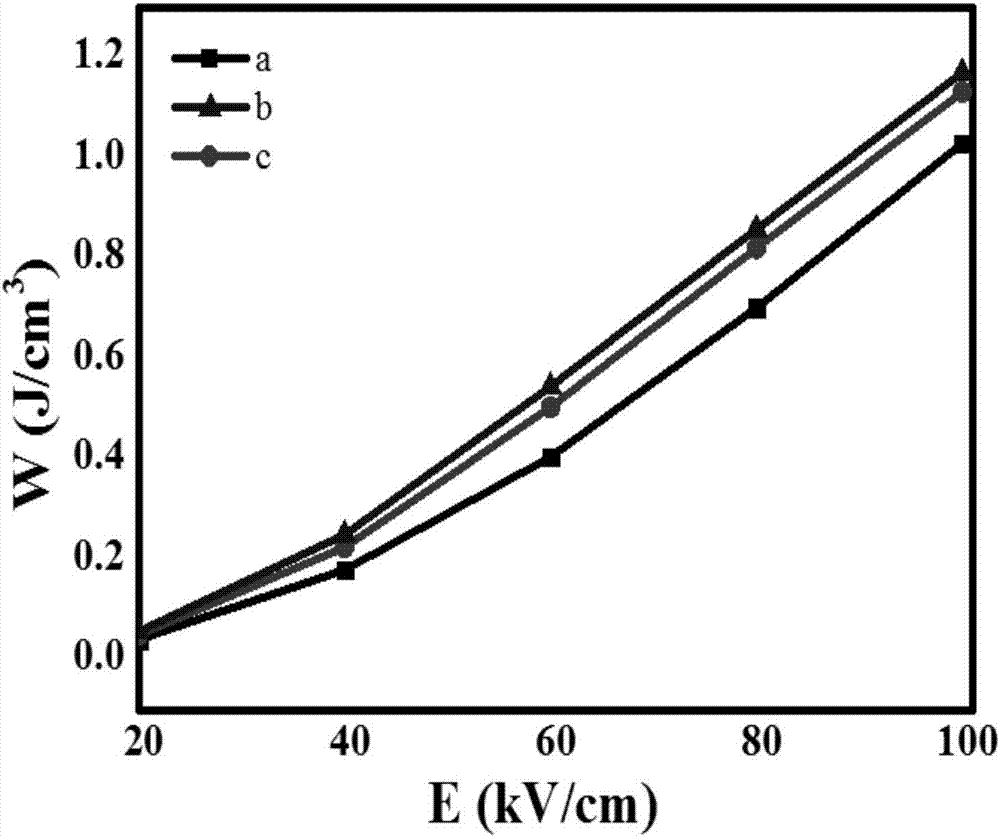

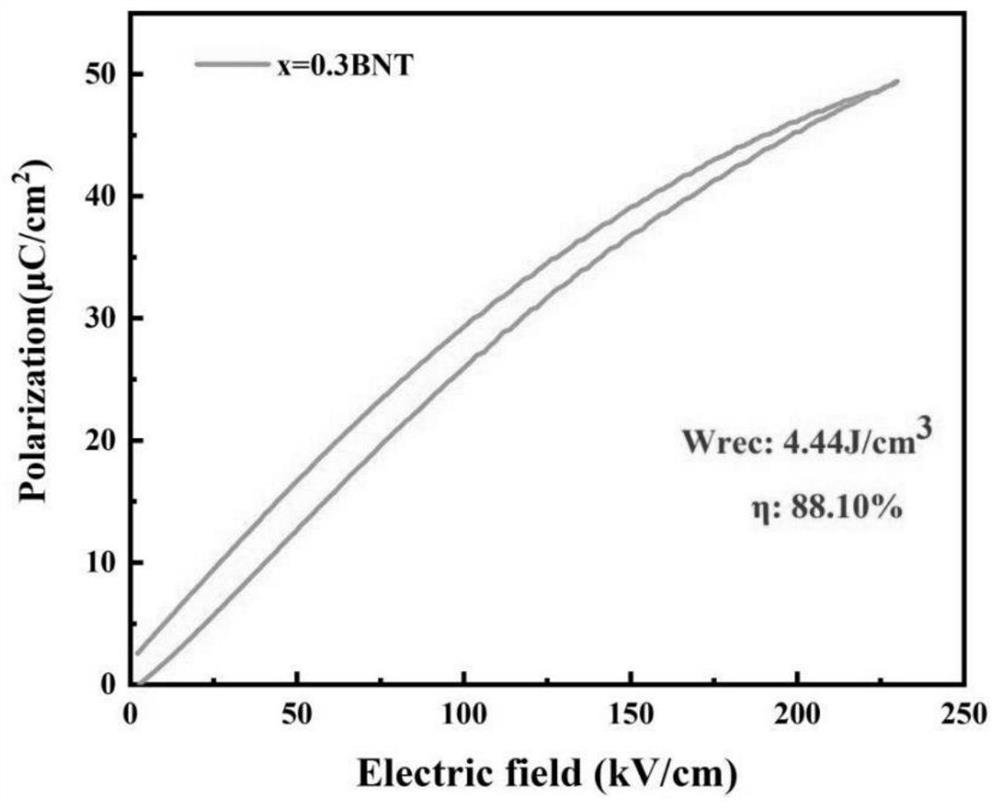

InactiveCN107140975AImprove stabilityRaise the saturation polarization valueFixed capacitor dielectricCeramic shaping apparatusBreakdown strengthSodium bismuth titanate

The invention relates to a sodium bismuth titanate-based ferroelectric ceramic as well as a preparation method and the application thereof. A general chemical formula of the sodium bismuth titanate-based ferroelectric ceramic is (1-x)[0.9(0.94Na0.5Bi0.5TiO3-0.06BaTiO3)-0.1NaNbO3]-xZn, wherein x in the formula is greater than or equal to 0 and less than or equal to 0.01. The preparation method comprises the following steps: firstly, preparing all raw material components according to the stoichiometric ratio, then uniformly mixing all the raw material components and carrying out pre-sintering and grinding in sequence to obtain a ground powder body; secondly, carrying out granulating to obtain a granulated powder body; thirdly, carrying out dry pressing and cold isostatic pressing to obtain a densified ceramic green body, carrying out adhesive removal on the densified ceramic green body, and then sintering to obtain the sodium bismuth titanate-based ferroelectric ceramic. According to the preparation method disclosed by the invention, by doping zinc in the sodium bismuth titanate-based ferroelectric ceramic, the breakdown strength and a saturation polarization value of the sodium bismuth titanate-based ferroelectric ceramic are improved, the energy storage density and the stability are improved, leakage current is reduced, growth orientation of crystals is benefited as well as development and application of high-power and high-capacity storage capacitors are facilitated.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

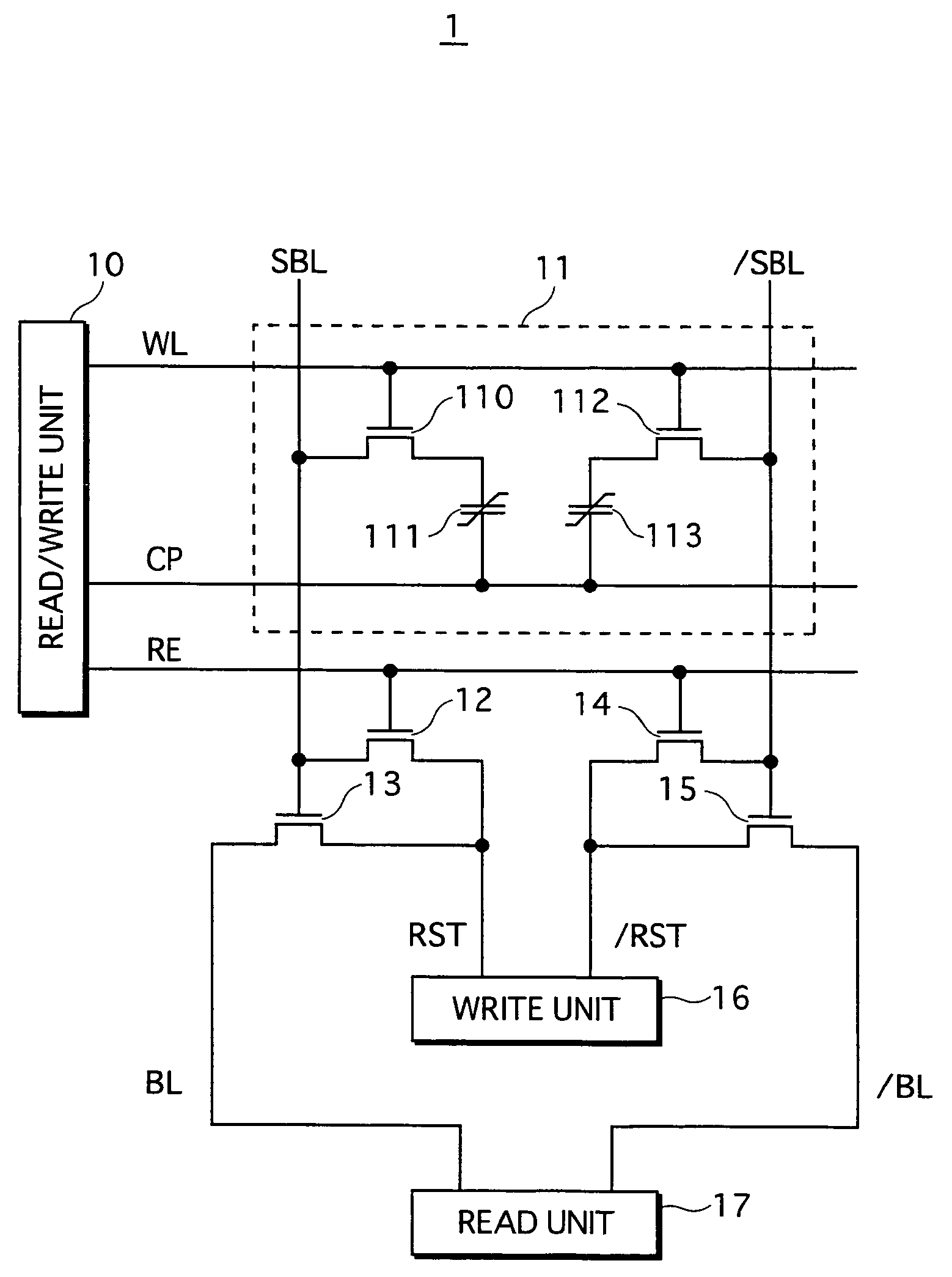

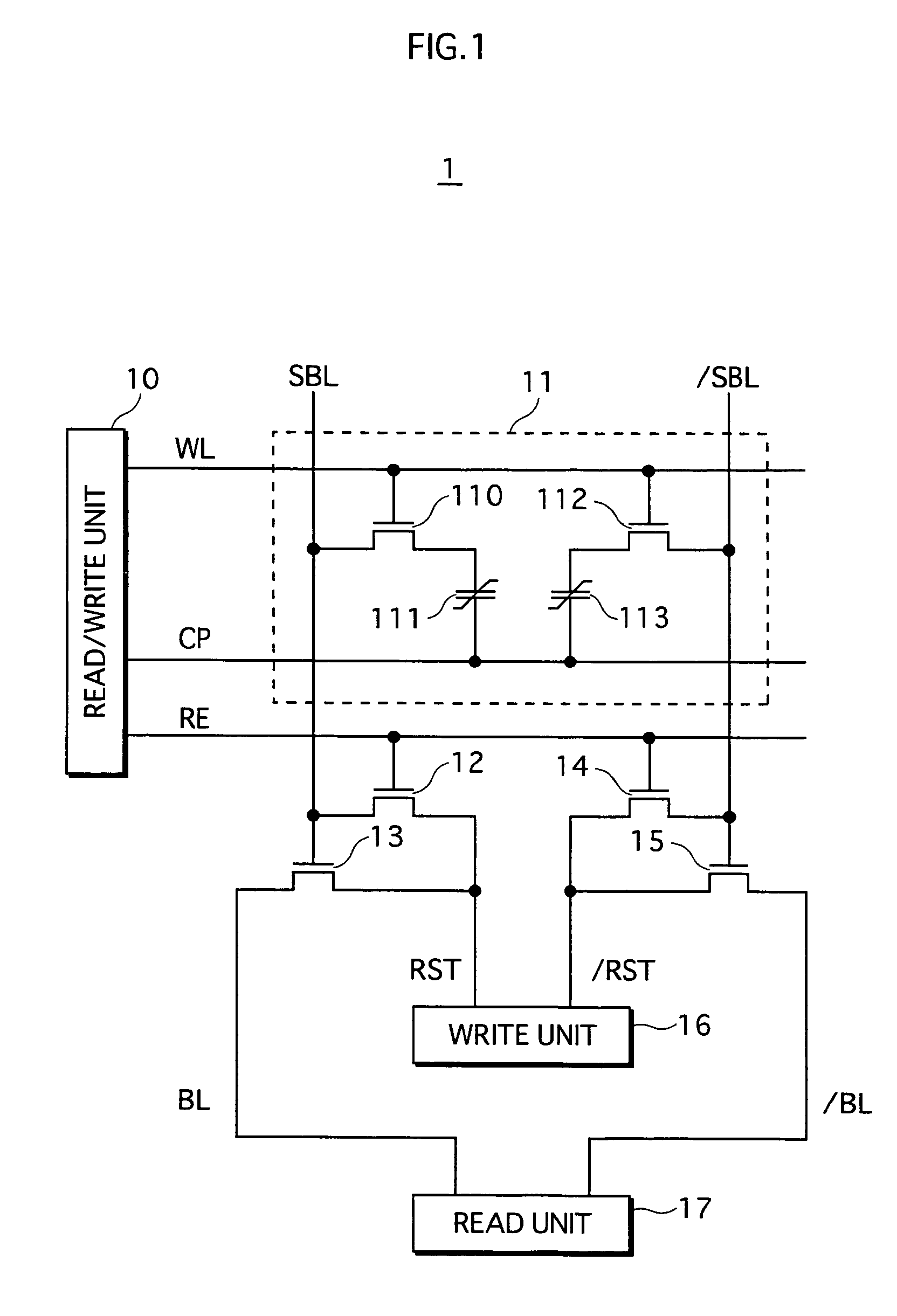

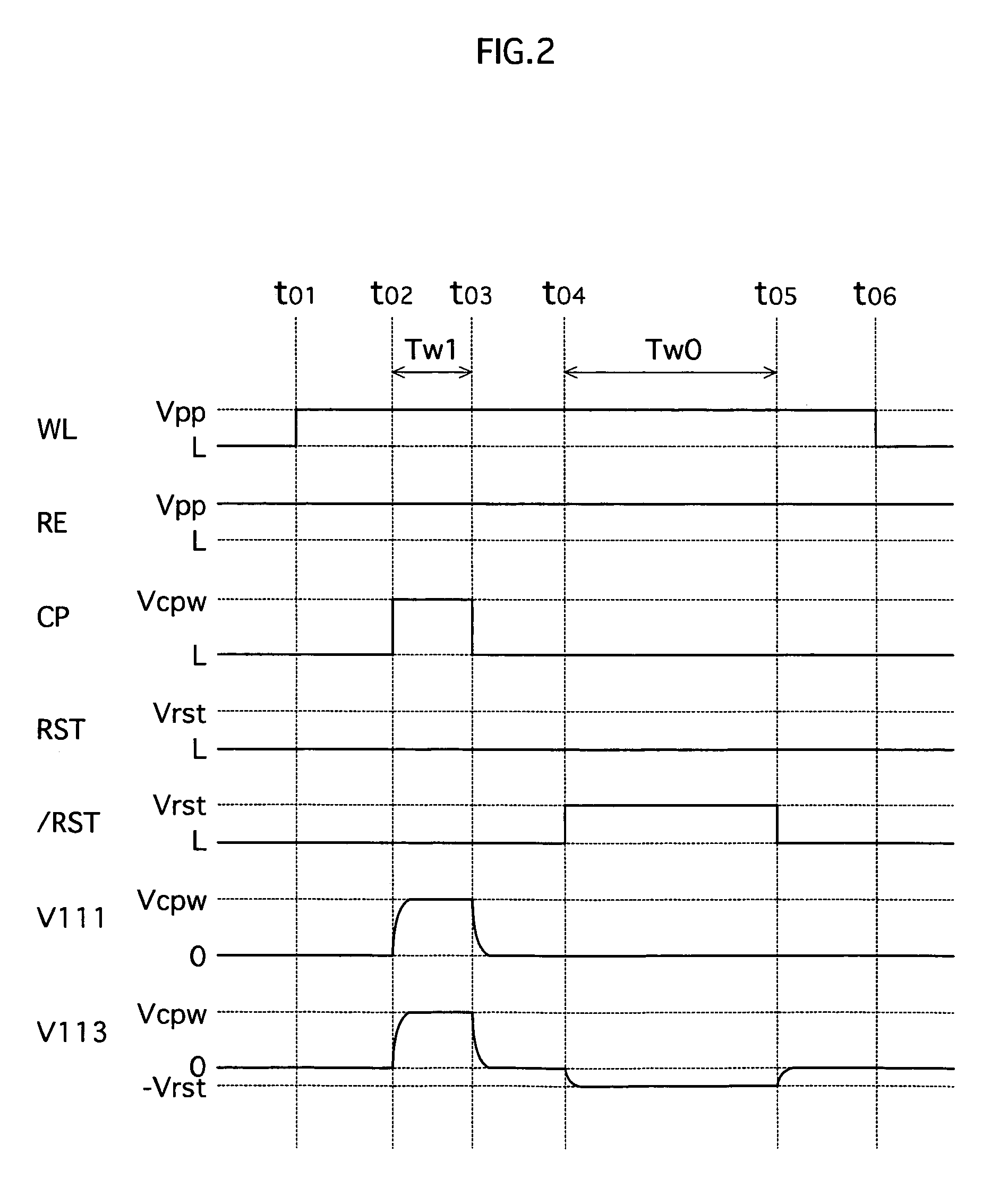

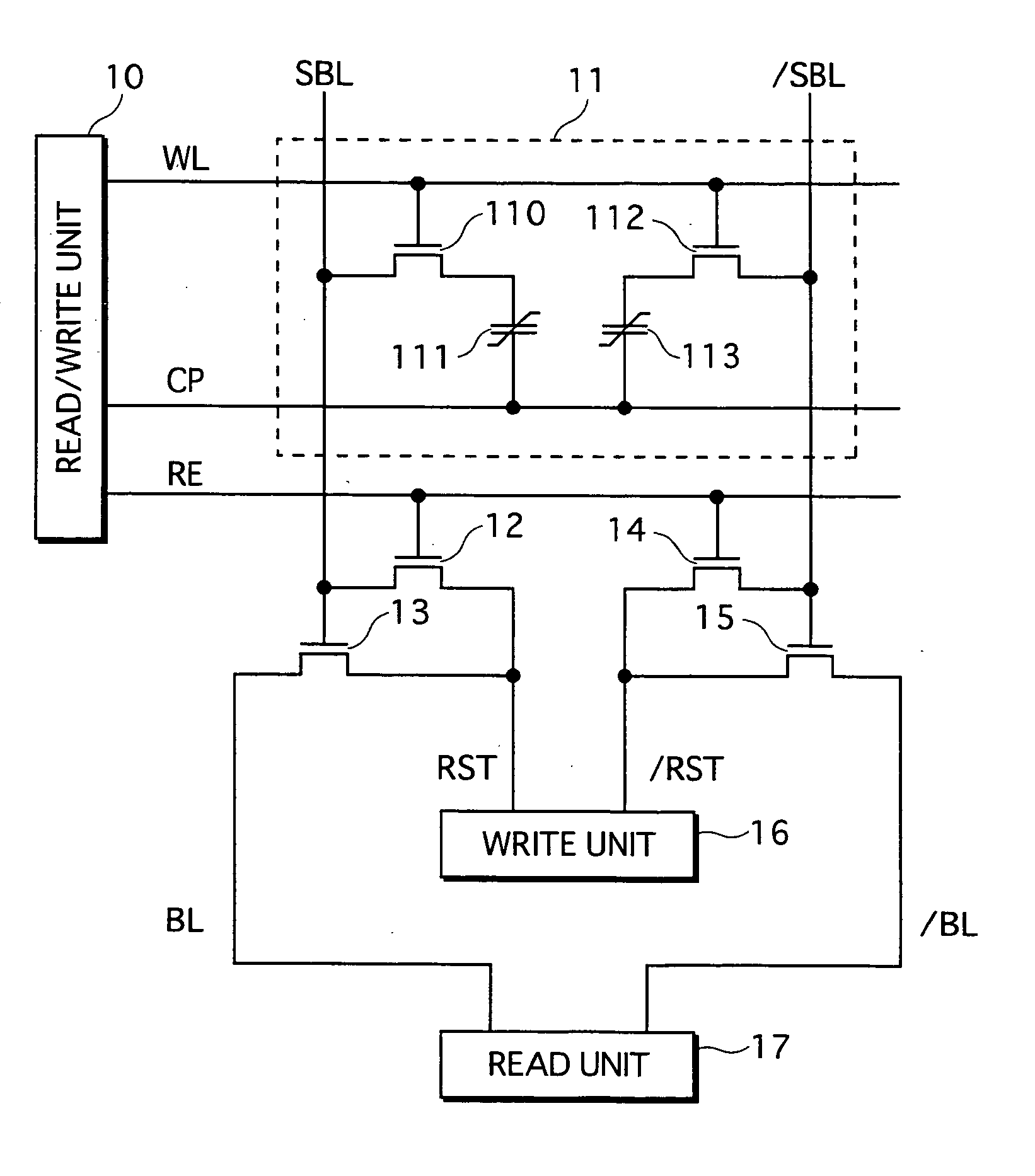

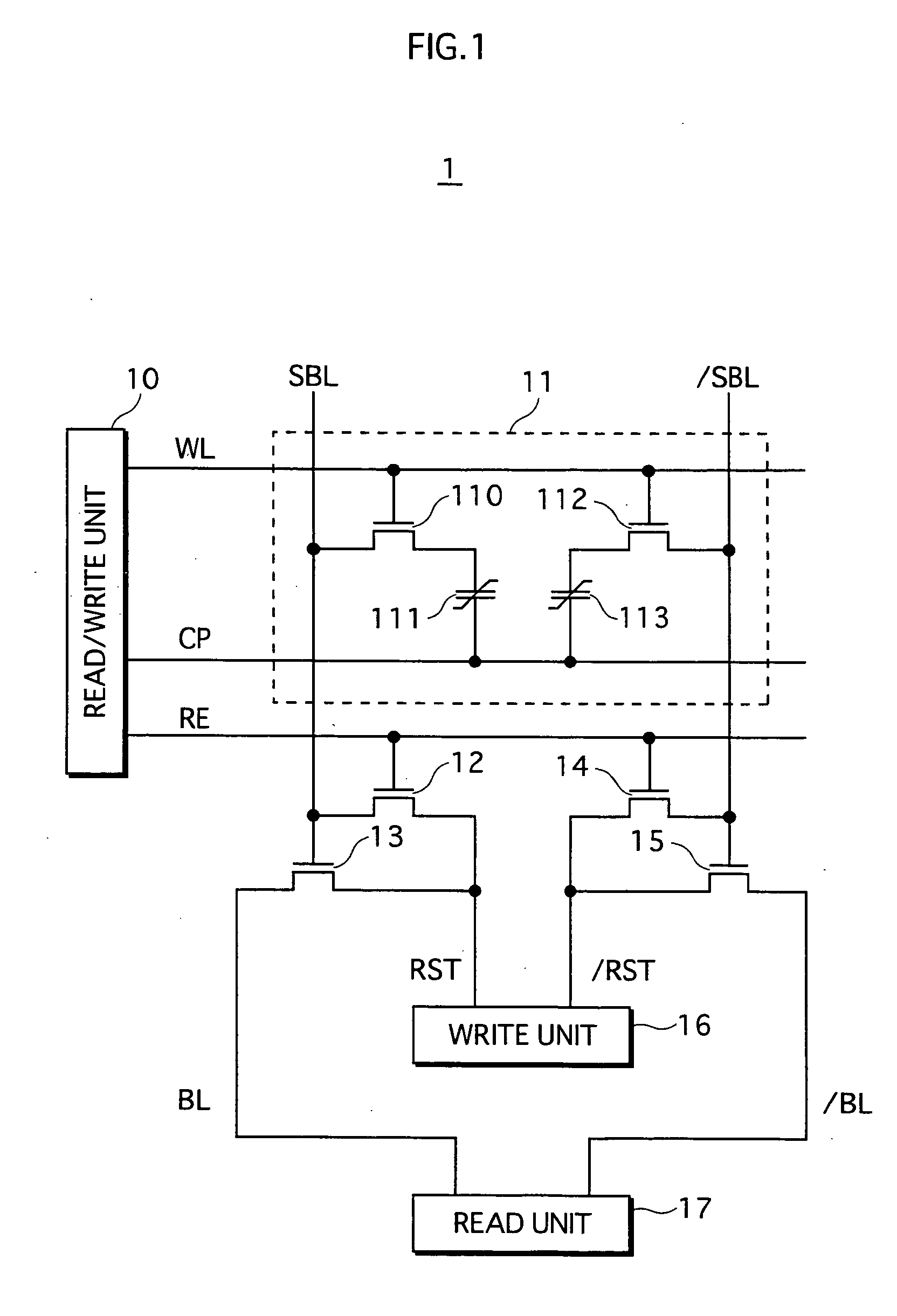

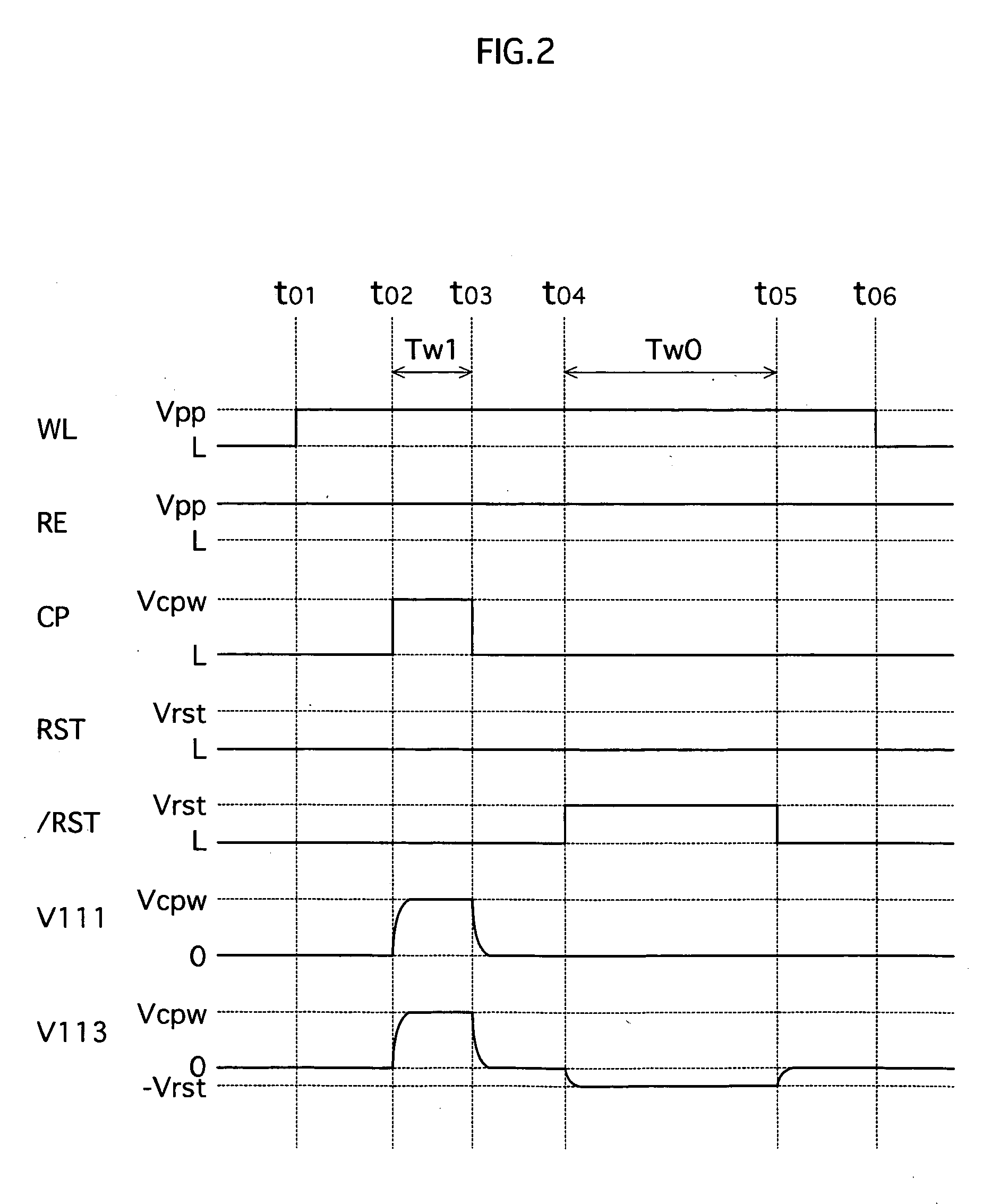

Ferroelectric storage device

InactiveUS6992913B2Shorten the timeImprove reliabilityDigital storageSaturation polarizationEngineering

In the present invention, a polarization having a lower polarization level than a saturation polarization is caused in a ferroelectric capacitor by applying a voltage that is lower than a saturation voltage to the ferroelectric capacitor. This allows a storage device to store many values by changing a length of a write-time during which the voltage is applied to the capacitor.

Owner:PANASONIC CORP

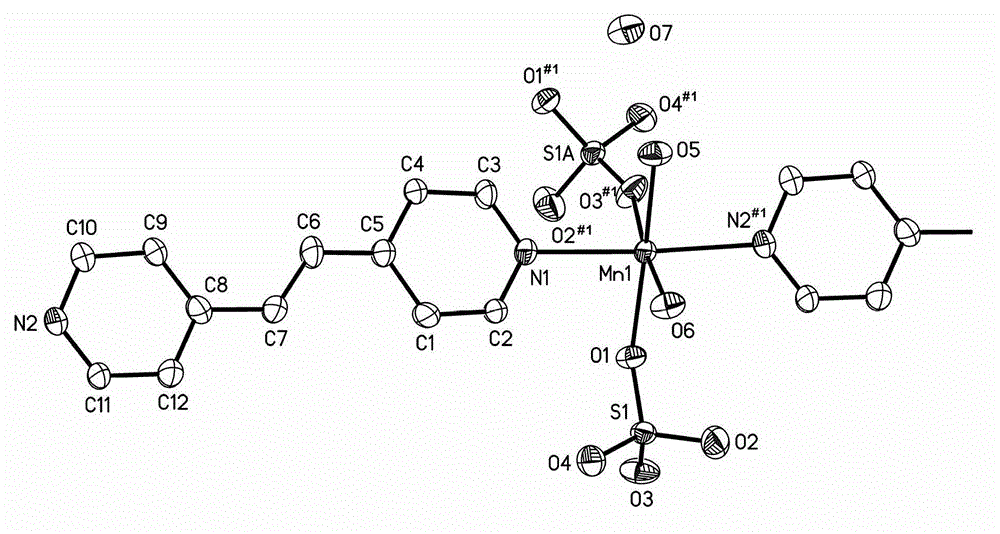

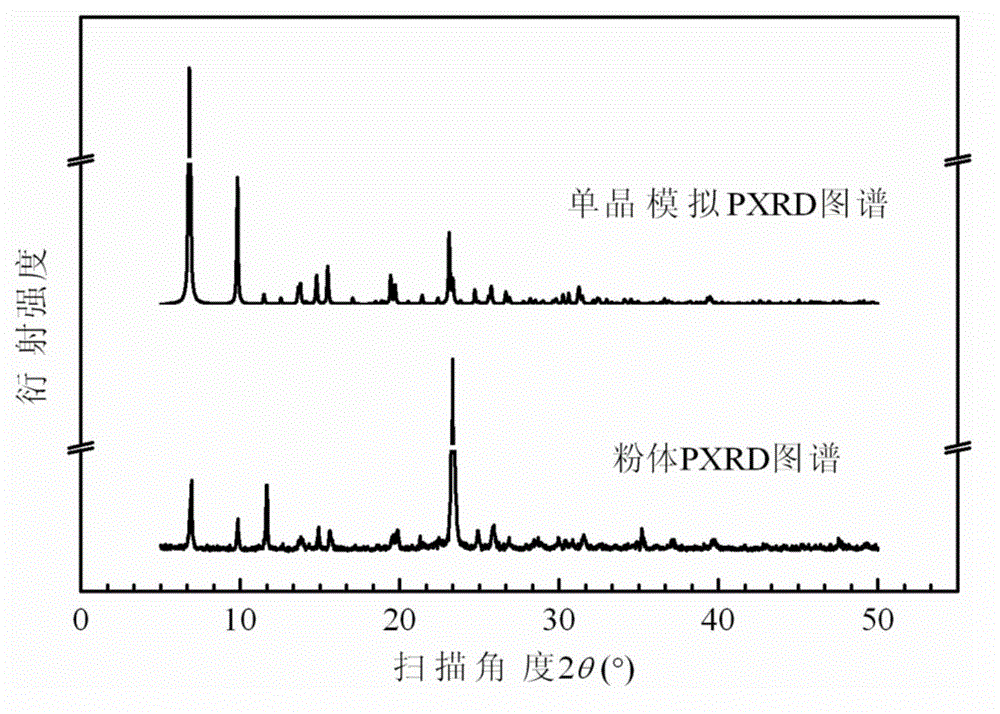

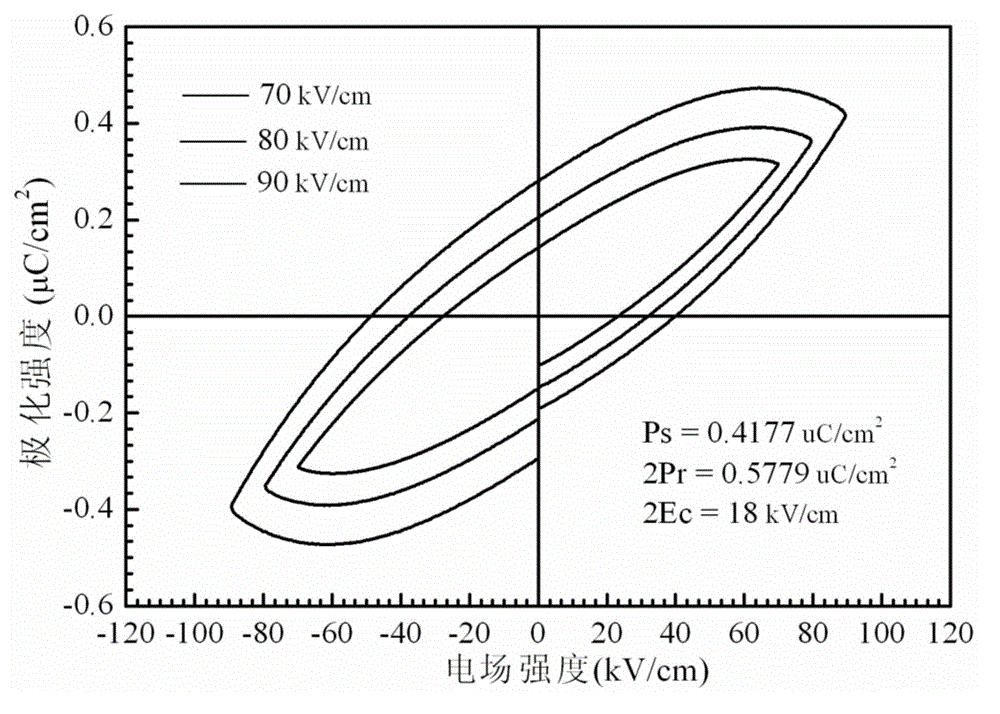

Hydrated 1,2-bis(4-pyridyl) ethylene manganese sulfate ferroelectric functional material and method for preparing same

InactiveCN102977148ALow costGood ferroelectric propertiesGroup 7/17 element organic compoundsSpace groupSaturation polarization

Owner:NINGBO UNIV

Alloy, magnet core and method for producing a strip from an alloy

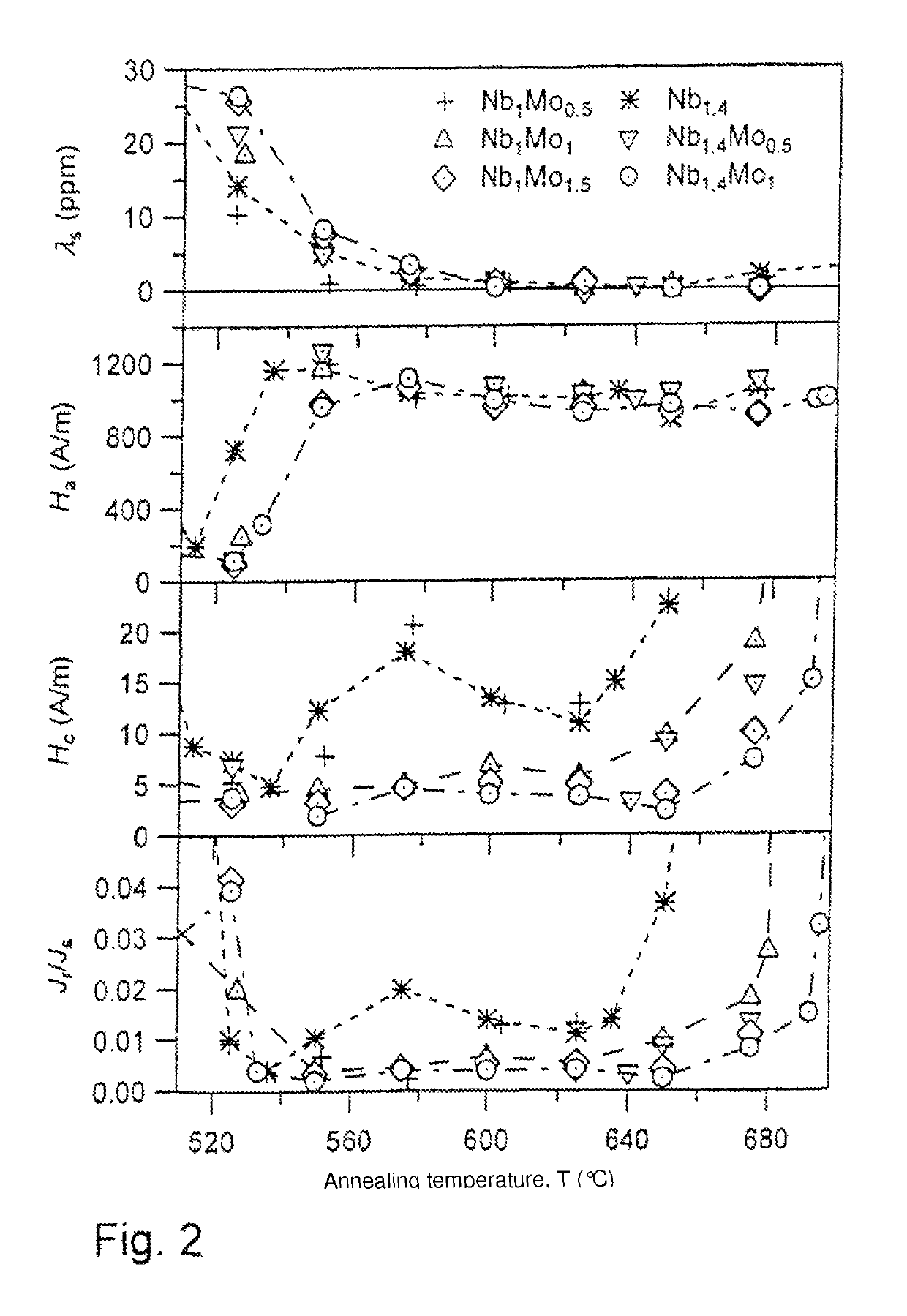

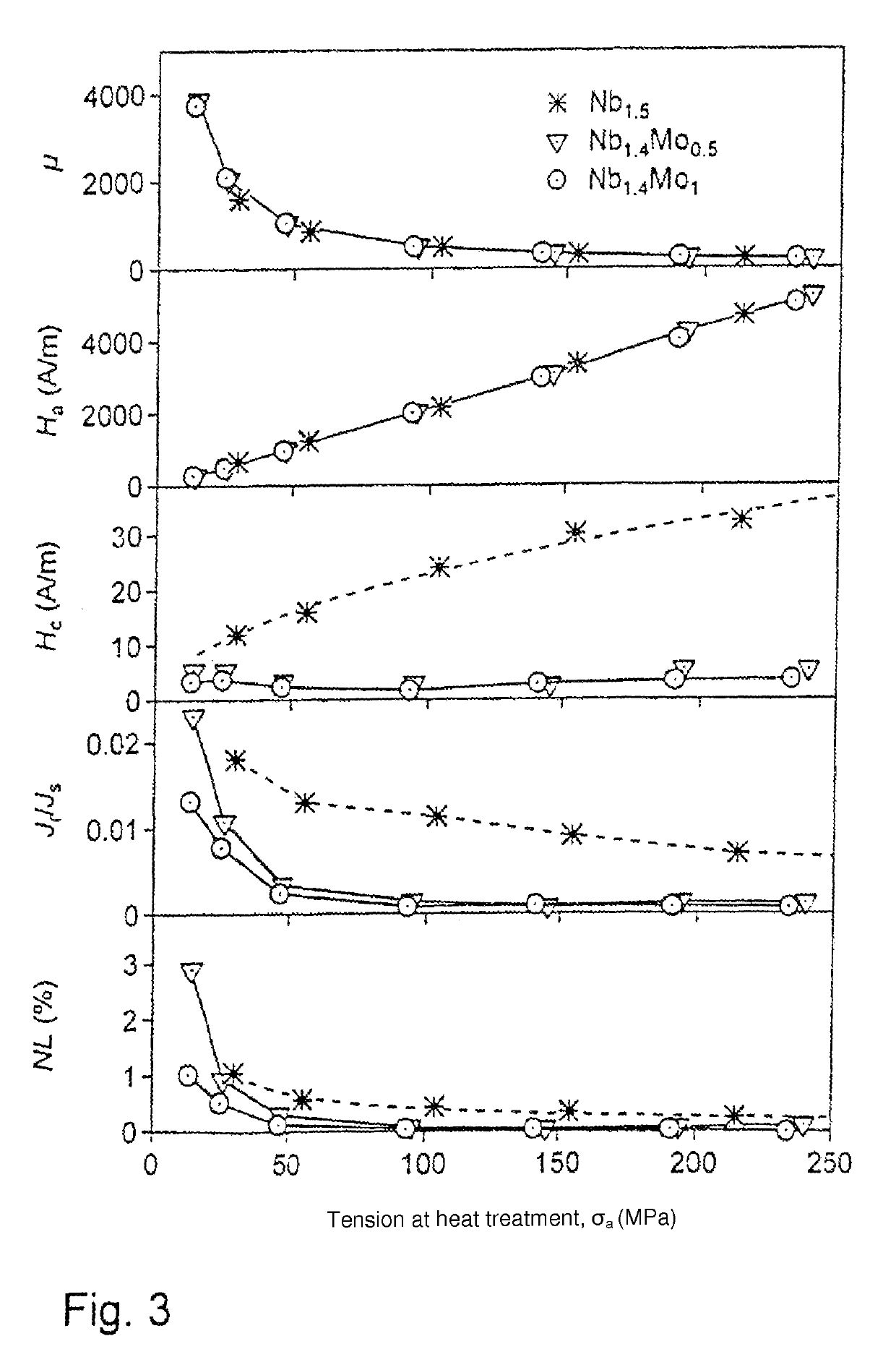

ActiveUS10347405B2Produced cost-effectivelyInductances/transformers/magnets manufactureMagnetic materialsSaturation polarizationAlloy

Owner:VACUUMSCHMELZE GMBH & CO KG

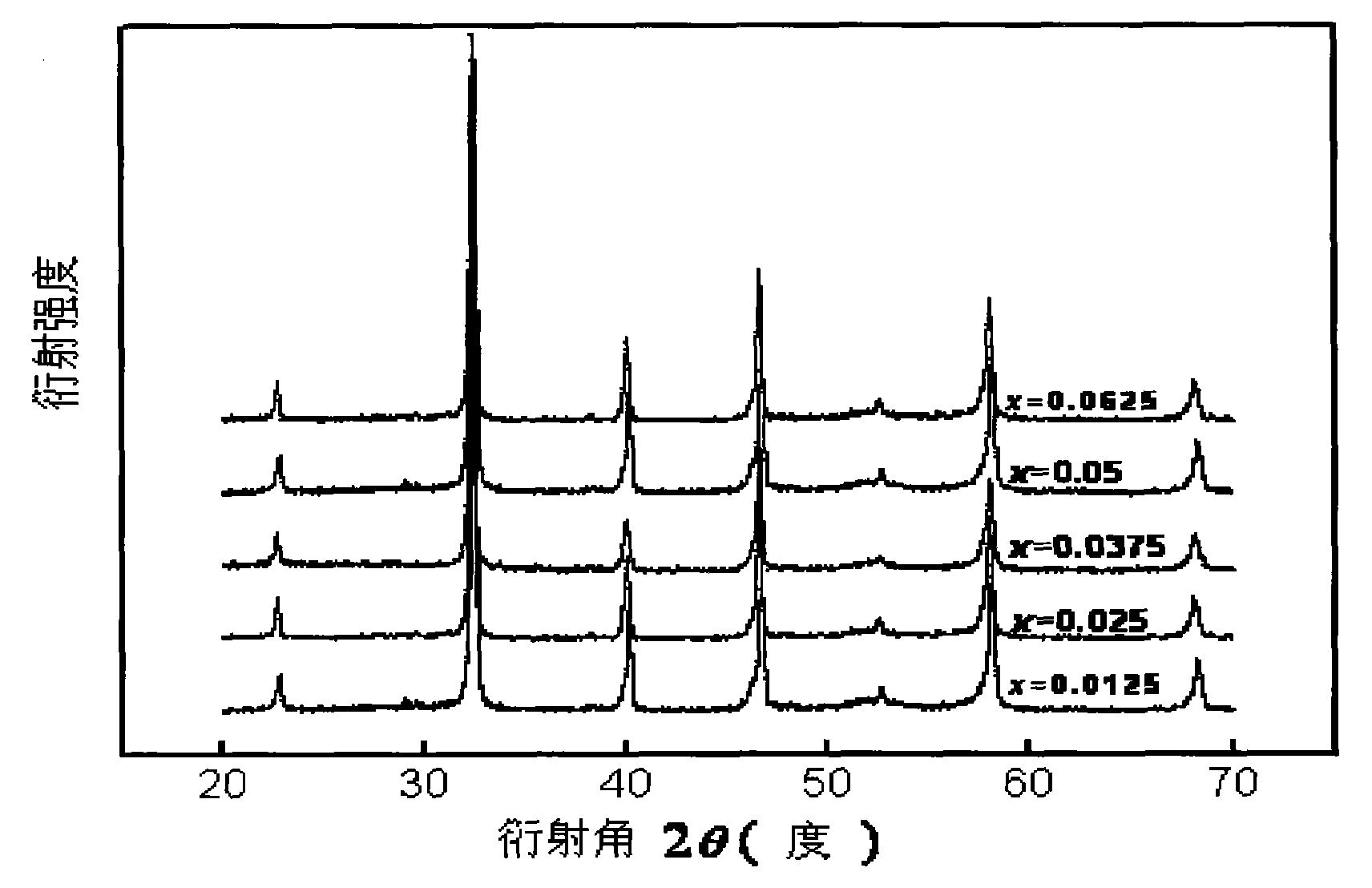

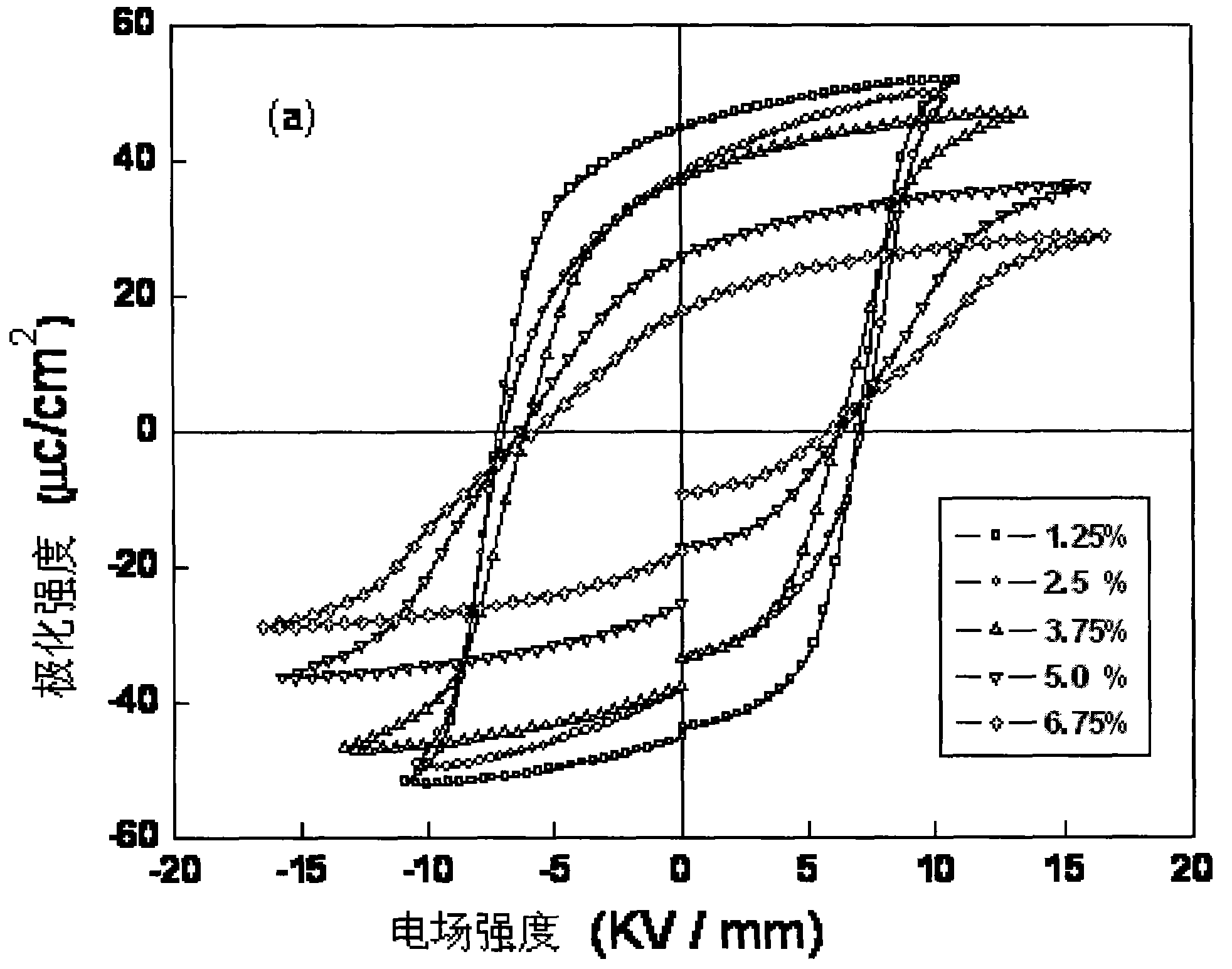

Leadless piezoelectric ceramics

InactiveCN101560093AGood high temperature ferroelectricExcellent piezoelectric propertiesPiezoelectric/electrostrictive/magnetostrictive devicesSaturation polarizationElectromechanical coupling coefficient

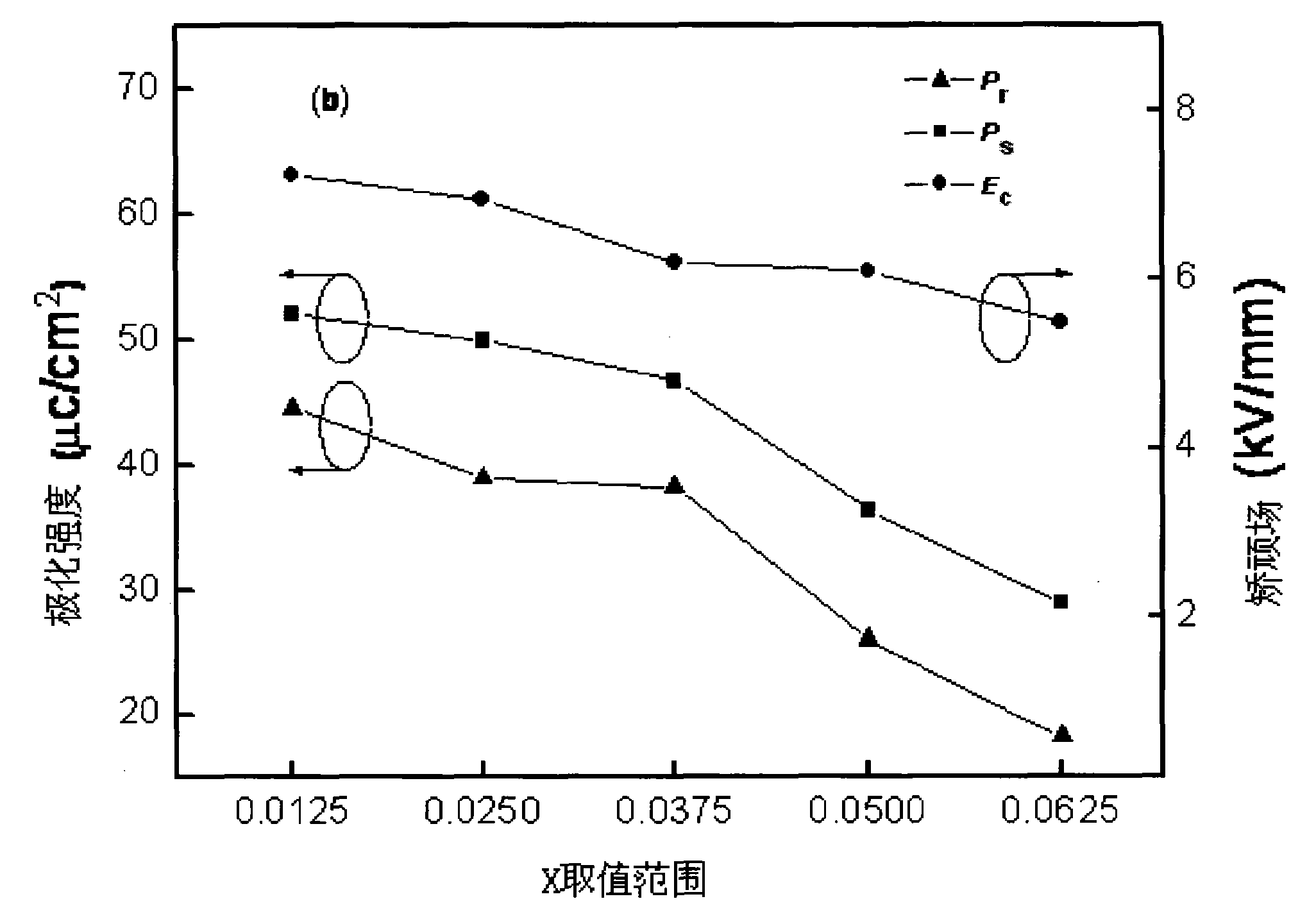

The invention discloses leadless piezoelectric ceramics, the chemical formula thereof is (1-x)Bi0.5Na0.5TiO3-xBi0.8La0.2FeO3, wherein x is more than or equal to 0.0125 and is less than or equal to 0.0625; the invention replaces Bi0.5Na0.5TiO3 with introduced Bi0.8La0.2FeO3 so as to form tripartite-orthogonal morphotropic phase boundary structure which has leadless piezoelectric ceramics composition point with excellent high temperature ferroelectric and piezoelectric property, thereby increasing the depolarization temperature of the ceramics to a certain degree; the piezoelectric modulus d33 and the electromechanical coupling factor kp decrease with increasing parameter x, d33 varies from 20pC / N to 128pC / N, and kp varies from 0.27 to 0.30; the saturation polarization, residual polarization and coercive field of the ceramics decrease with increasing parameter x; in particular, the depolarization temperature of the ceramics (Td) increases between 163 DEG C and 171 DEG C with increasing x.

Owner:NANJING UNIV

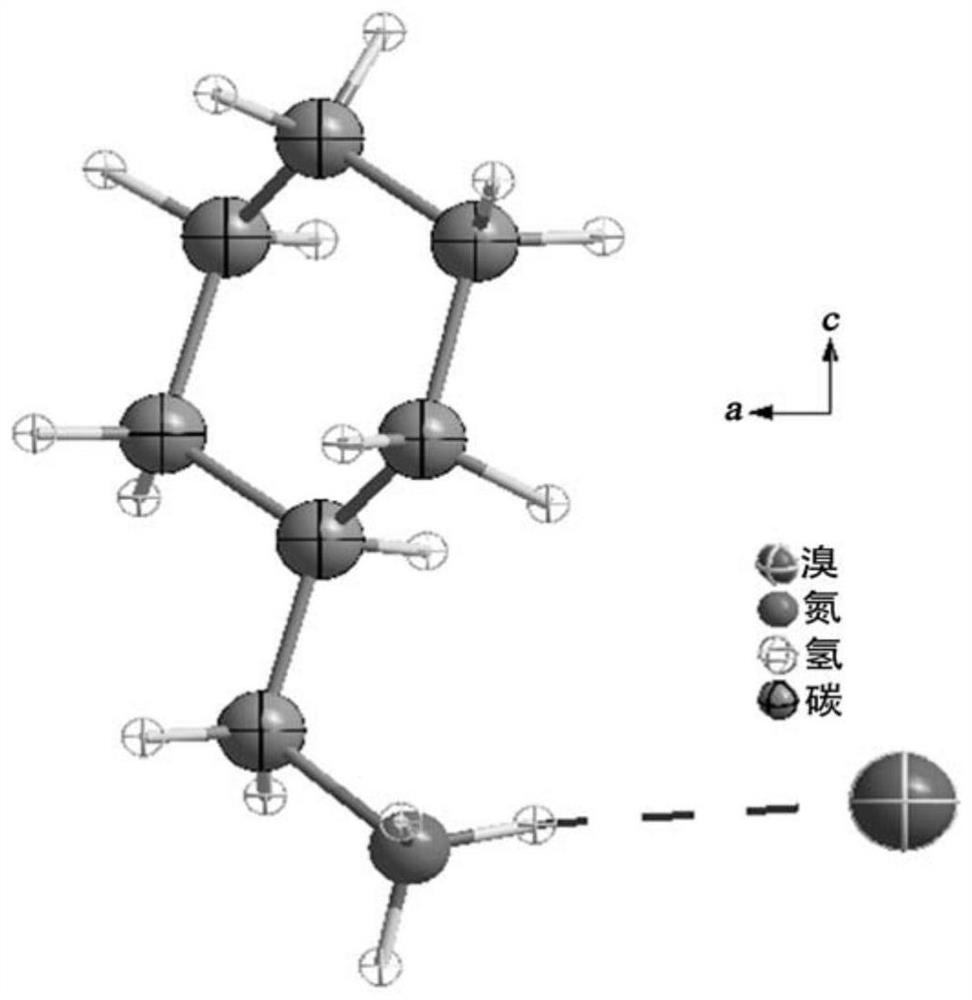

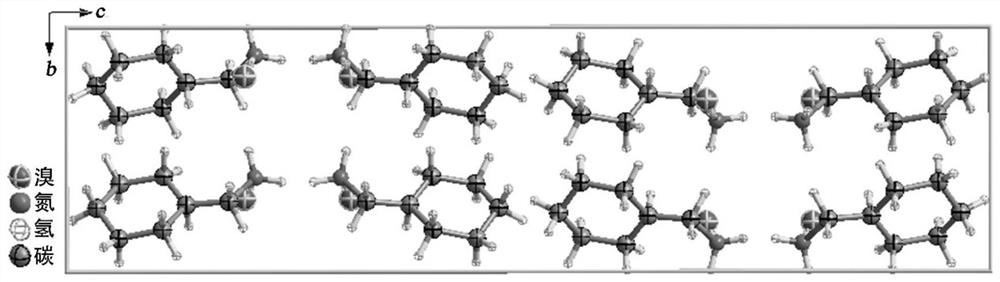

Organic molecular ferroelectric crystal di-n-butylamine difluoromonochloroacetate, preparation method therefor and use of organic molecular ferroelectric crystal di-n-butylamine difluoromonochloroacetate

ActiveCN106480506AImprove stabilitySaturation polarization is highPolycrystalline material growthFrom normal temperature solutionsHysteresisSaturation polarization

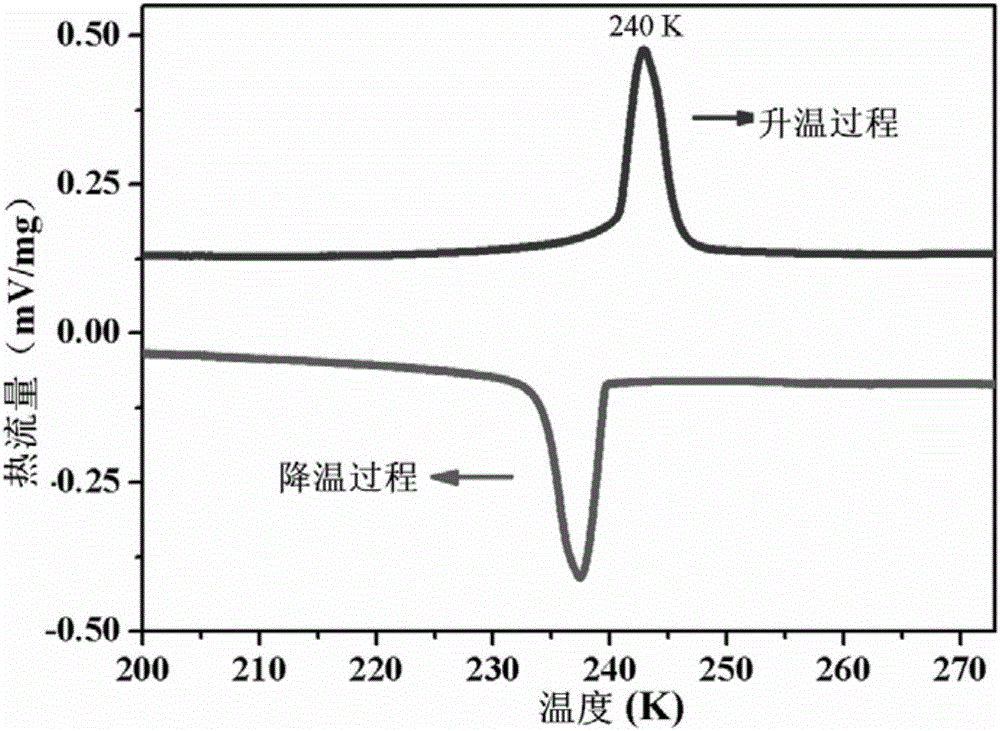

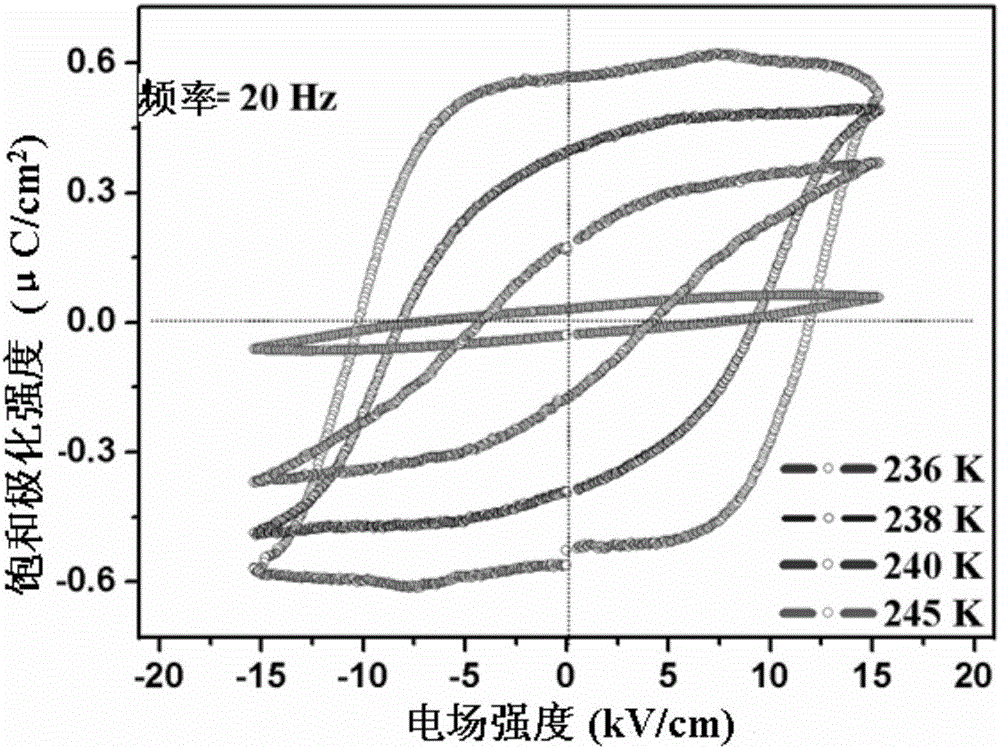

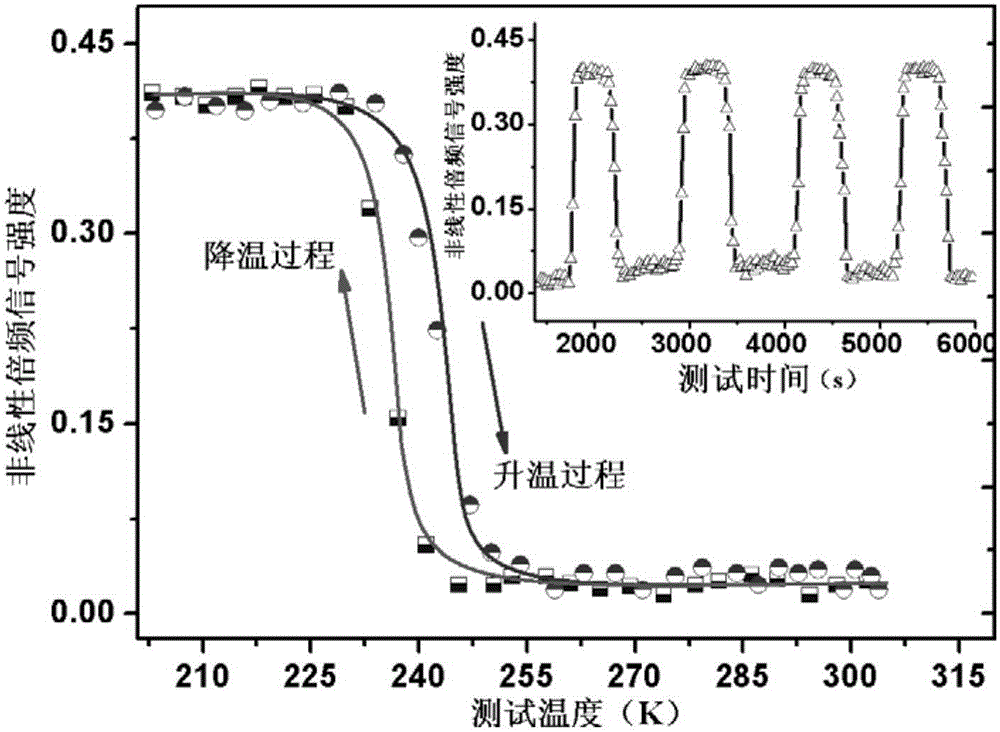

The invention relates to an organic molecular ferroelectric crystal di-n-butylamine difluoromonochloroacetate, a preparation method therefor and use of the organic molecular ferroelectric crystal di-n-butylamine difluoromonochloroacetate. Proven by tests on electric hysteresis loop of the organic molecular ferroelectric crystal material, i.e., di-n-butylamine difluoromonochloroacetate through a Sawyer-Tower circuit, the material shows good ferroelectric properties in a ferroelectric phase and has relatively high saturation polarization strength reaching 3.9[mu]c / cm<2> and moderate coercive field about 12.4kV / cm. Proven by variable temperature nonlinear tests, the material does not have obvious second-order nonlinear frequency-doubled signals in a paraelectric phase, obvious second-order nonlinear frequency-doubled signals appear when the temperature is cooled to Curie temperature (243K), the strength value of the nonlinear signals is saturated along with decrease of temperature, excellent nonlinear on / off performance is shown in an entire test temperature range, the on / off ratio reaches 28, and the repeatability is relatively good. The reaction is simple, and the conditions are moderate.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

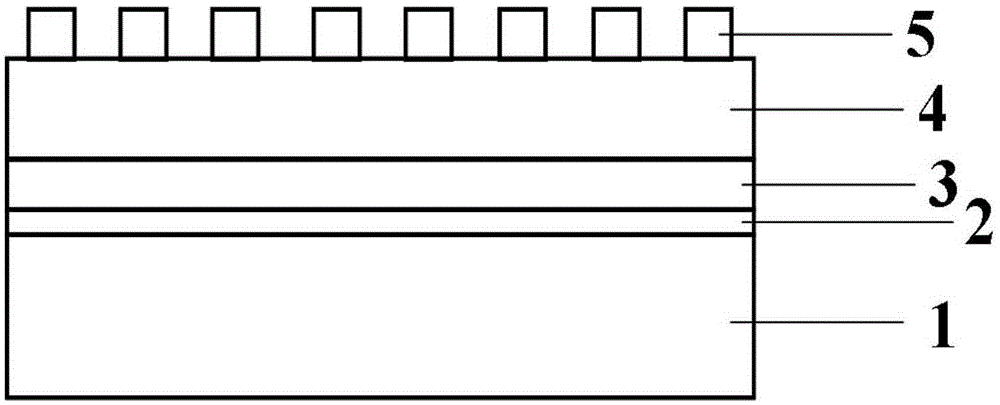

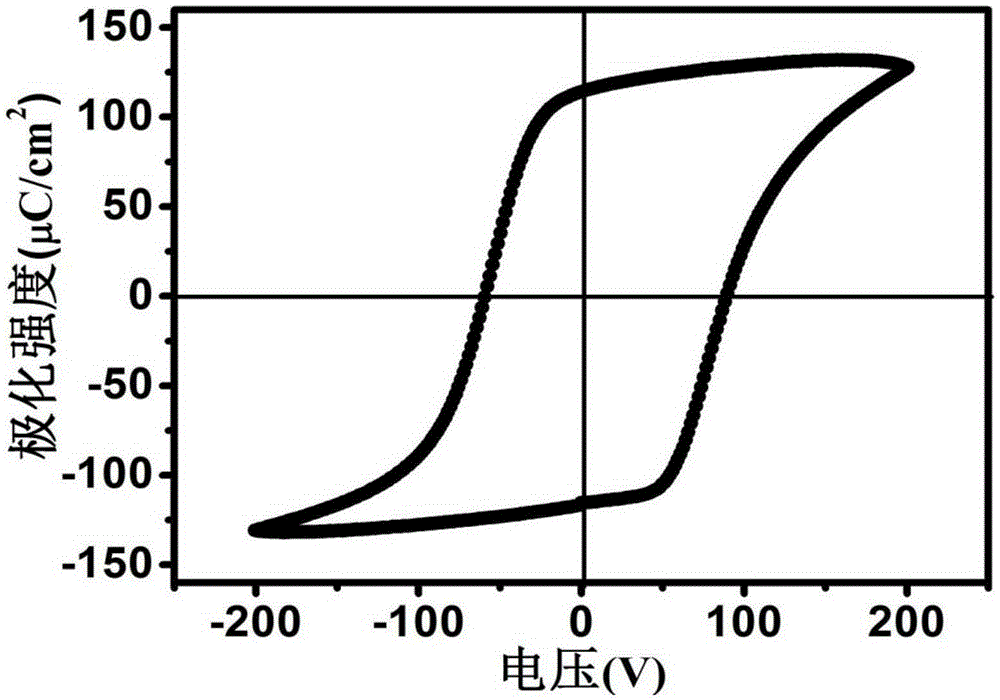

High-polarization-intensity bismuth ferrite thick film material system and medium and low temperature preparation method

ActiveCN105336845AImprove pressure resistanceHigh polarization retentionPiezoelectric/electrostrictive device manufacture/assemblySemiconductor devicesOxygen vacancySingle crystal

The invention provides a high-polarization-intensity bismuth ferrite thick film material system and a medium and low temperature preparation method. The high-polarization-intensity bismuth ferrite thick film material system comprises a base body, a buffer layer, a bottom electrode, a bismuth ferrite dielectric layer and a top electrode. Semiconductor monocrystalline acts as the base body, the buffer layer acts as a metal or metal oxide thin layer, and the bottom electrode acts as an inert metal thin layer. According to the preparation technology, crystallization temperature of the material system is relatively low (<=500 DEG C) so that application of a large-area silicon integrated circuit is facilitated; and volatilization of elements in the material system is greatly reduced by low crystallization temperature so that generation of the defect of oxygen vacancy of the material can be avoided and film material with excellent performance can be acquired, saturation polarization intensity can be 130muC / cm2, and external voltage which can be withstood is not less than 200V. The technological process and equipment operation are easy, the used raw material is sold on the market, cost is relatively low and device integration is easy so that the method is suitable for industrial popularization and production.

Owner:欧阳俊

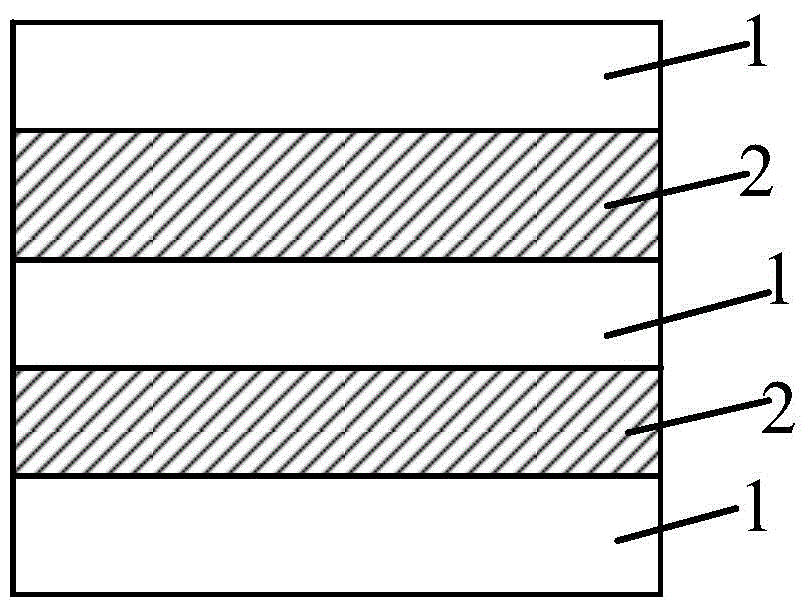

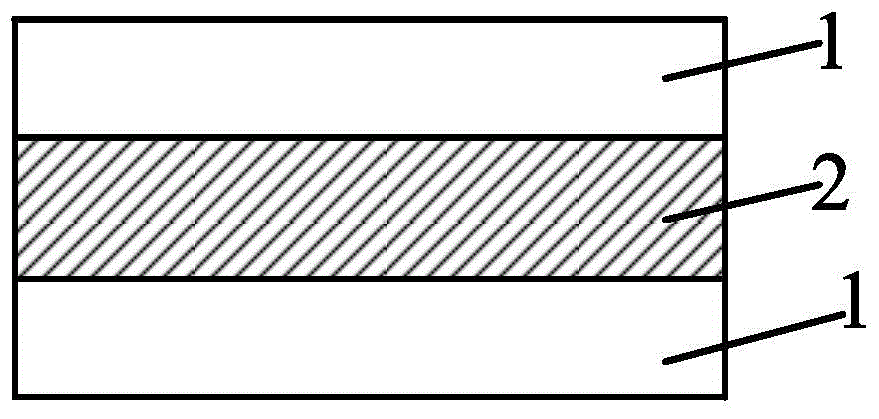

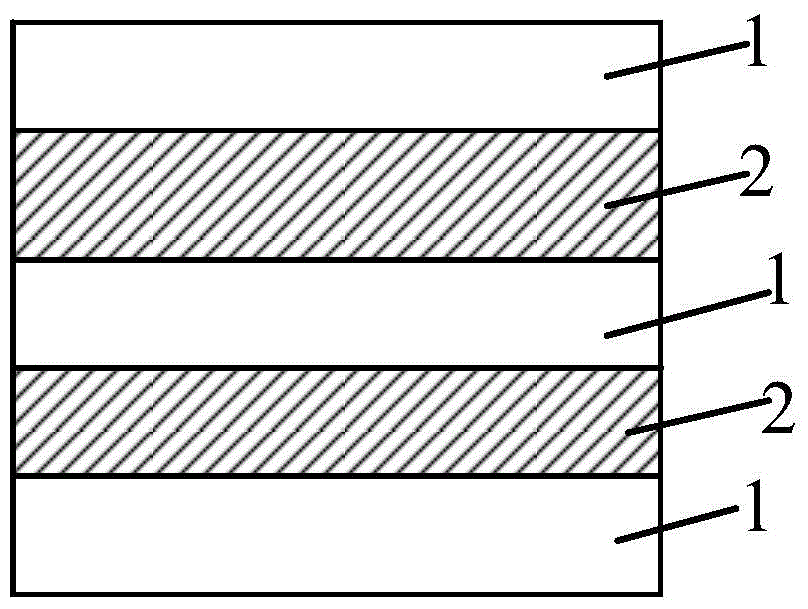

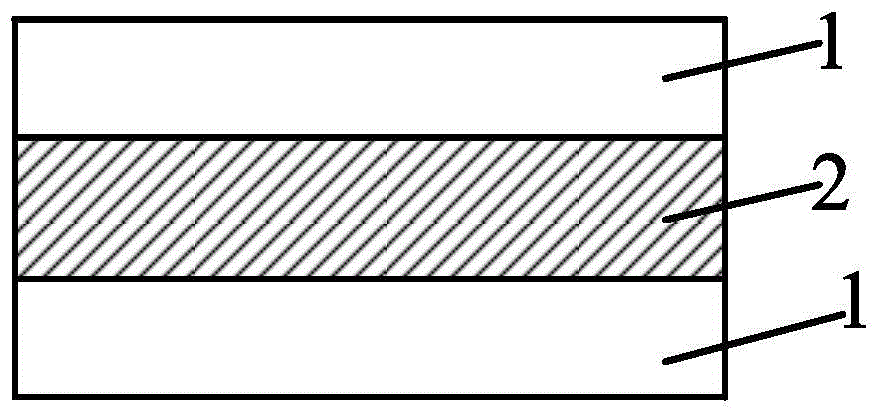

CoFe2O4/BaTiO3 layered magnetoelectric composite material and preparation method thereof

ActiveCN104557027AImprove ferroelectric propertiesImprove ferromagnetic propertiesDielectric lossMagnetization

The invention discloses a CoFe2O4 / BaTiO3 layered magnetoelectric composite material and a preparation method thereof. The preparation method comprises the following steps: sintering BaTiO3 powder and CoFe2O4 powder at the temperature of 1000 to 1050 DEG C in a 2-2 composite base superposition arrangement mode, thereby obtaining the CoFe2O4 / BaTiO3 layered magnetoelectric composite material. With the adoption of the 2-2 composite base superposition arrangement mode, mutual reaction between two phases can be effectively inhibited so as to maintain the respective characteristics, so that the prepared composite material has high ferroelectricity and high ferromagnetic property. The electric constant reaches 1900-4500, and the dielectric loss is 0.19-1.50. The saturated polarization Ps is 14.8-18.7mu C / cm<2>, the coercive field Ec is 8.6-14.6kV / cm, and the saturation magnetization Ms is 3.4-20.9emu / g.

Owner:SHAANXI UNIV OF SCI & TECH

Ferroelectric storage device

InactiveUS20050162890A1Improve accuracyShorten the timeDigital storageSaturation polarizationEngineering

In the present invention, a polarization having a lower polarization level than a saturation polarization is caused in a ferroelectric capacitor by applying a voltage that is lower than a saturation voltage to the ferroelectric capacitor. This allows a storage device to store many values by changing a length of a write-time during which the voltage is applied to the capacitor.

Owner:PANASONIC CORP

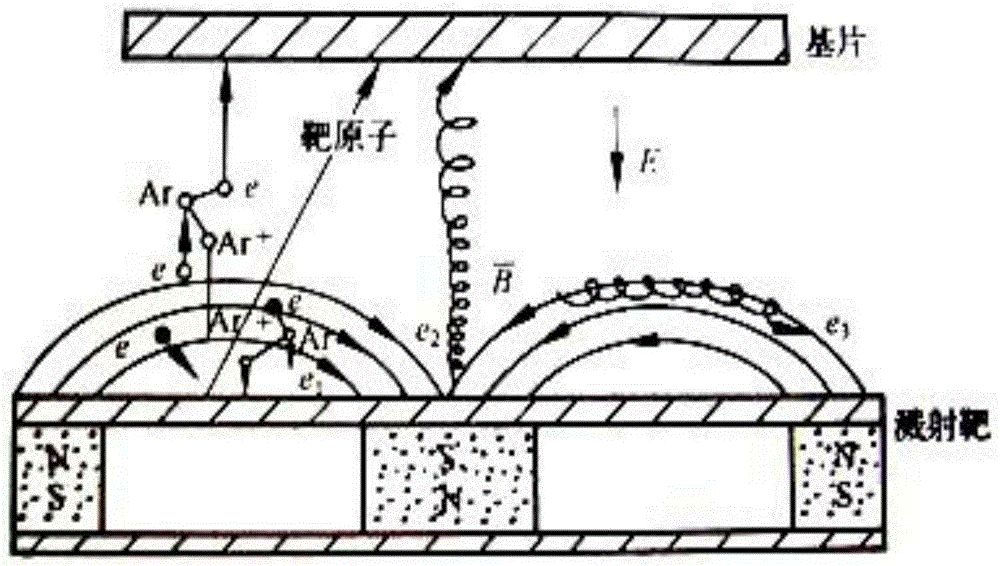

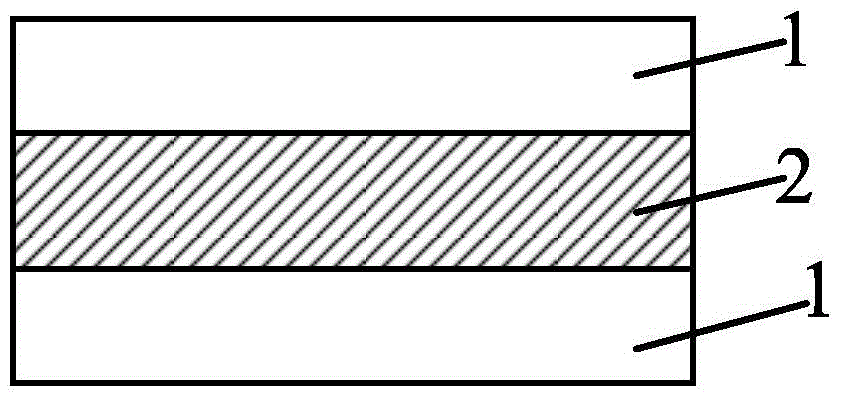

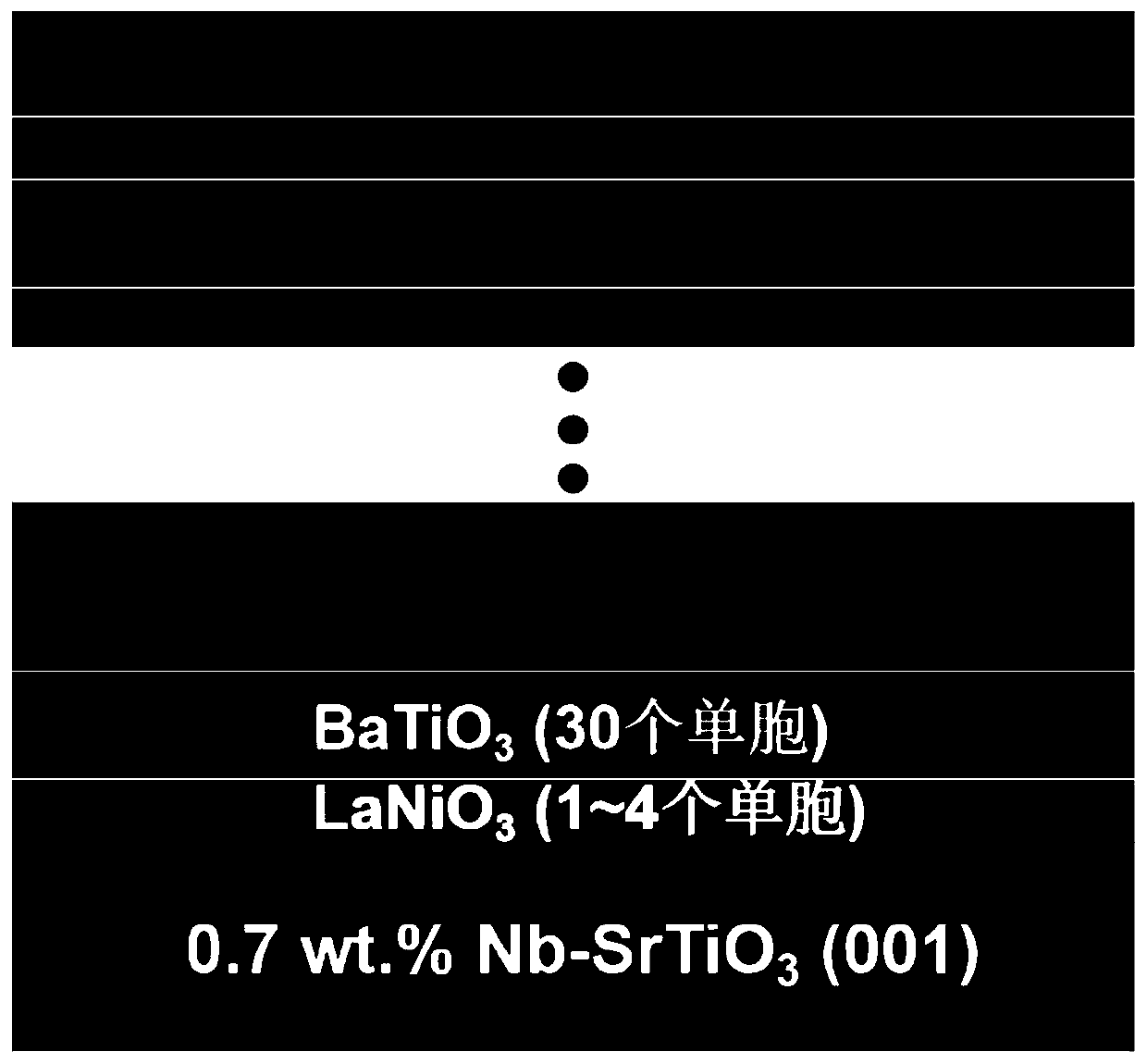

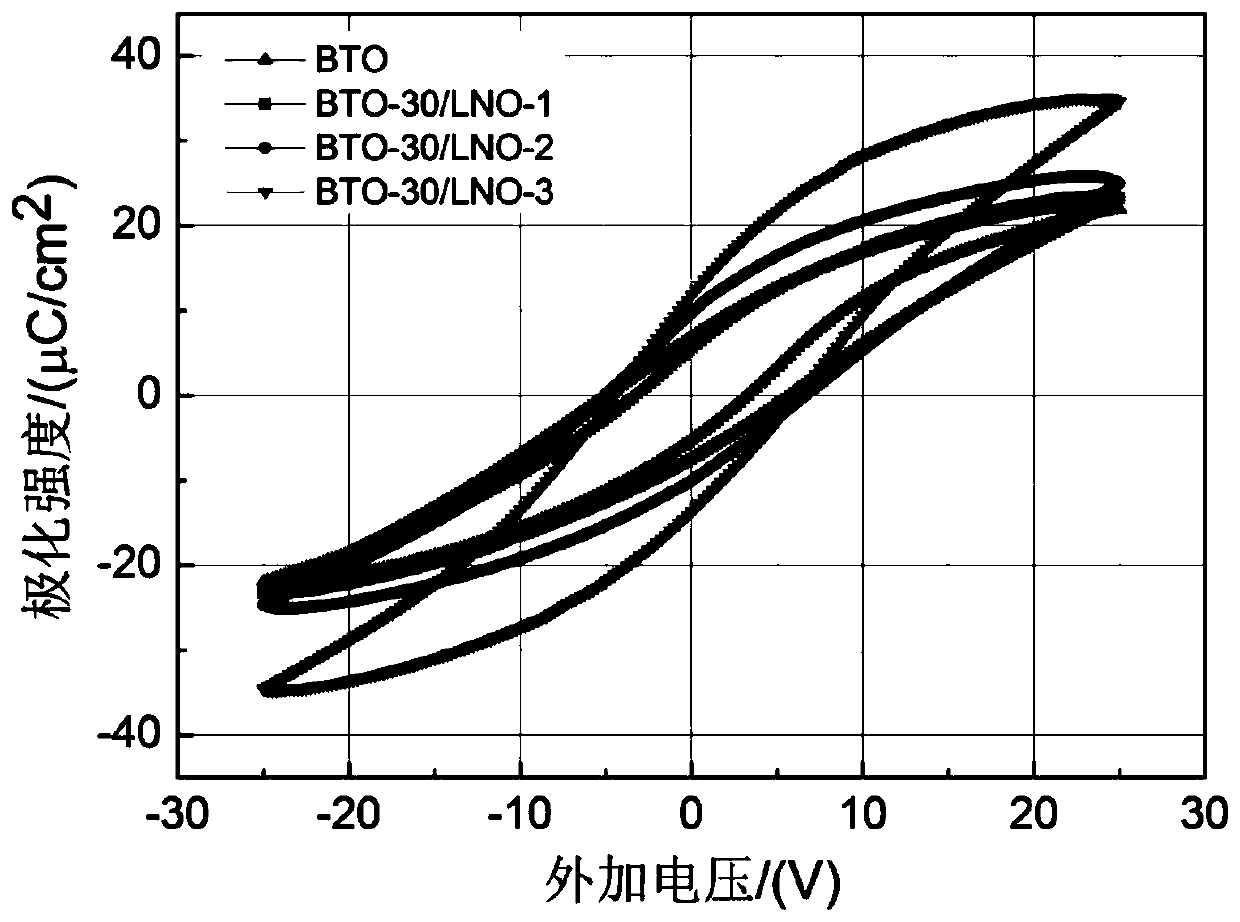

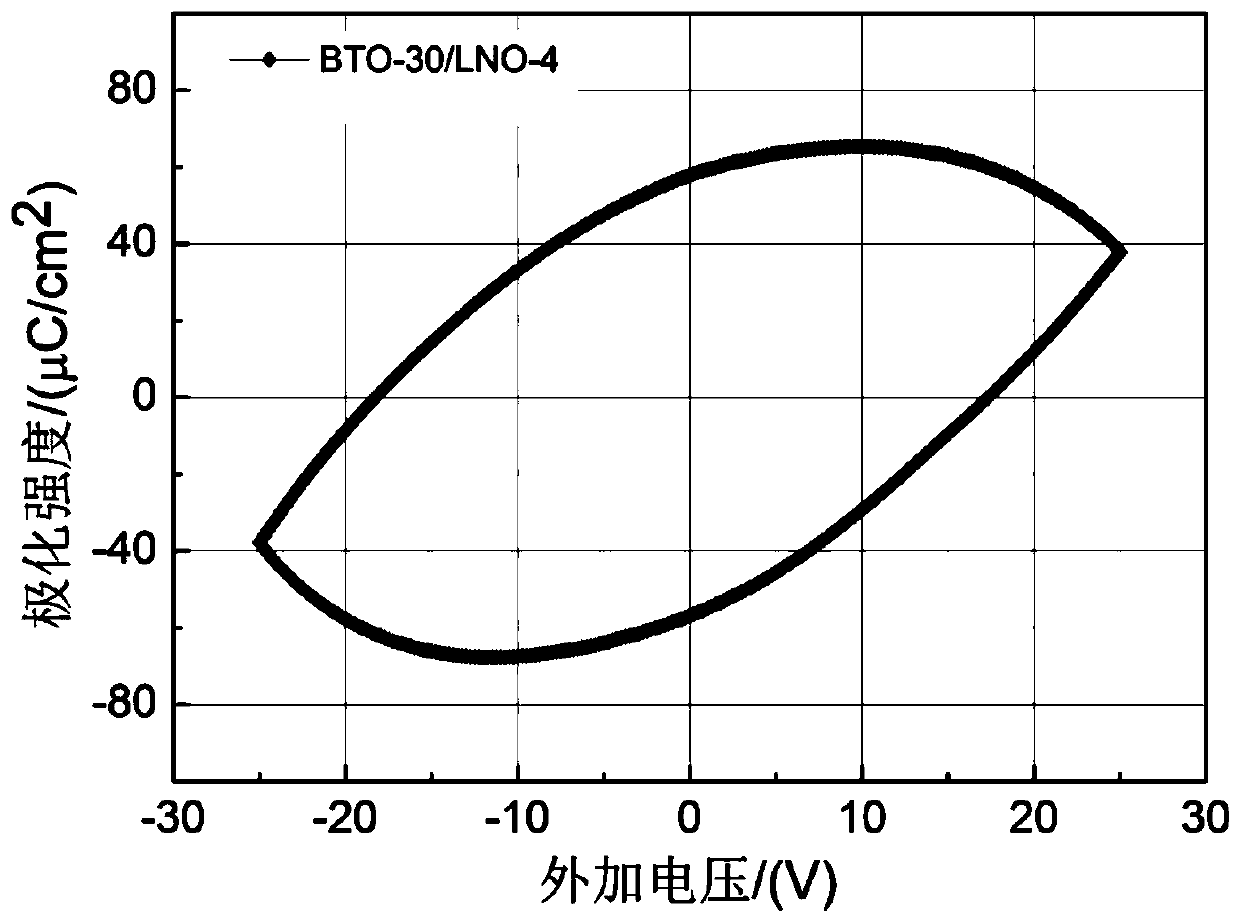

Barium titanate/lanthanum nickelate ferroelectric superlattice film material and preparation method thereof

InactiveCN110527952APrecise thickness controlEnhanced ferroelectricityVacuum evaporation coatingSputtering coatingBarium titanateMetallic conductivity

The invention aims to provide a barium titanate / lanthanum nickelate ferroelectric superlattice film material and a preparation method thereof. The material is composed of a ferroelectric oxide material barium titanate and a metal conductive oxide material lanthanum nickelate which grow periodically. The barium titanate / lanthanum nickelate ferroelectric superlattice film material has the advantagesthat the dielectric constant is increased by 11-90% compared with that of a pure barium titanate film; the barium titanate film has good ferroelectric polarization performance, the remnant polarization intensity of the barium titanate film reaches 13.1 mu C / cm<2>, the saturation polarization intensity of the barium titanate film reaches 34.6 mu C / cm<2>, and compared with a pure barium titanate film, the remnant polarization intensity of the barium titanate film is improved by 140%, and the saturation polarization intensity of the barium titanate film is improved by 58%. According to the preparation method of the material, lanthanum nickelate and barium titanate are alternately grown on a single crystal substrate by using a pulse laser deposition method, and the period thickness of superlattices is accurately regulated and controlled by controlling the time of laser bombarding different target materials. The ferroelectric superlattice material has wide application prospects in ferroelectric memories, sensors, actuators and other integrated ferroelectric devices.

Owner:SHENYANG POLYTECHNIC UNIV

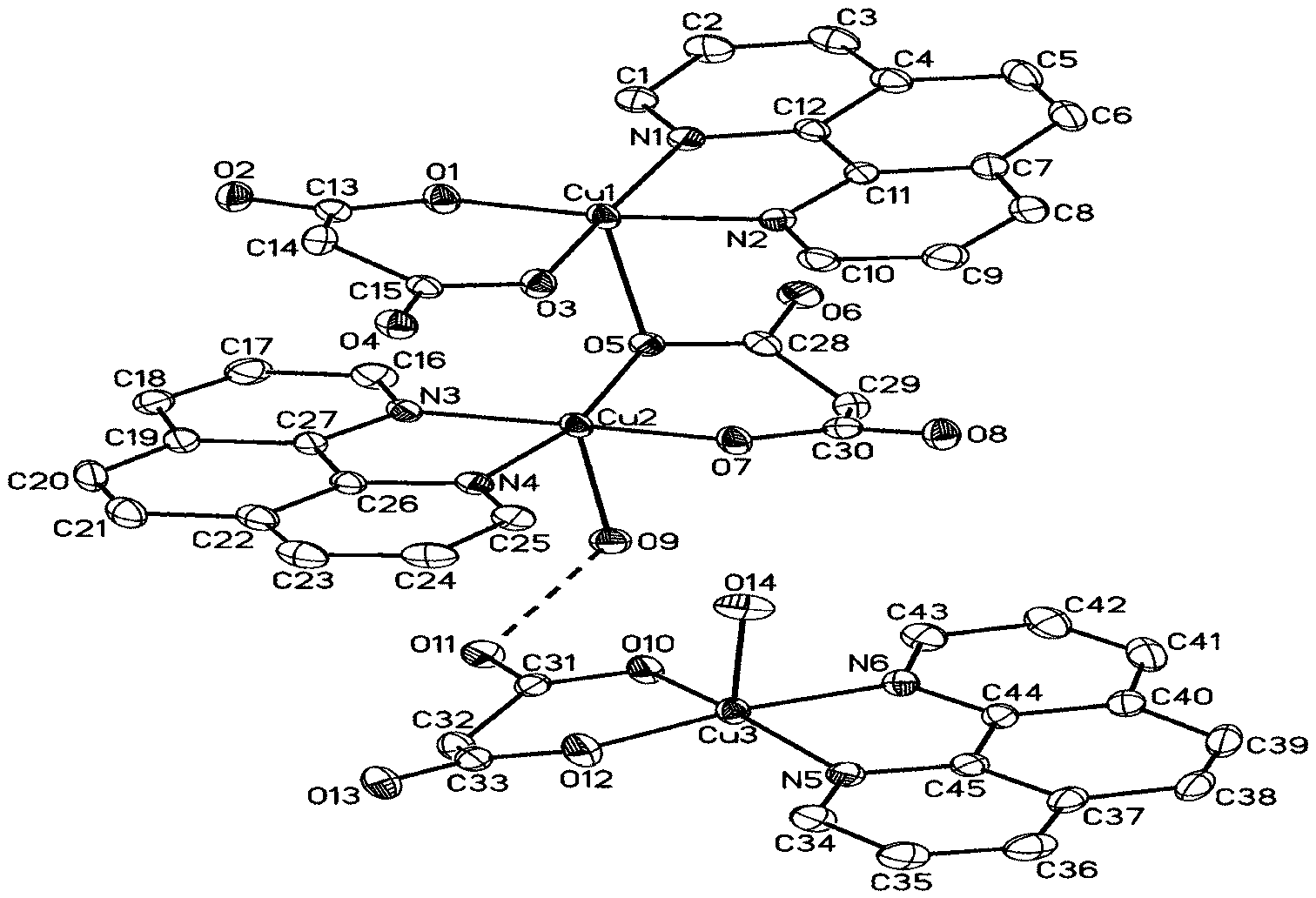

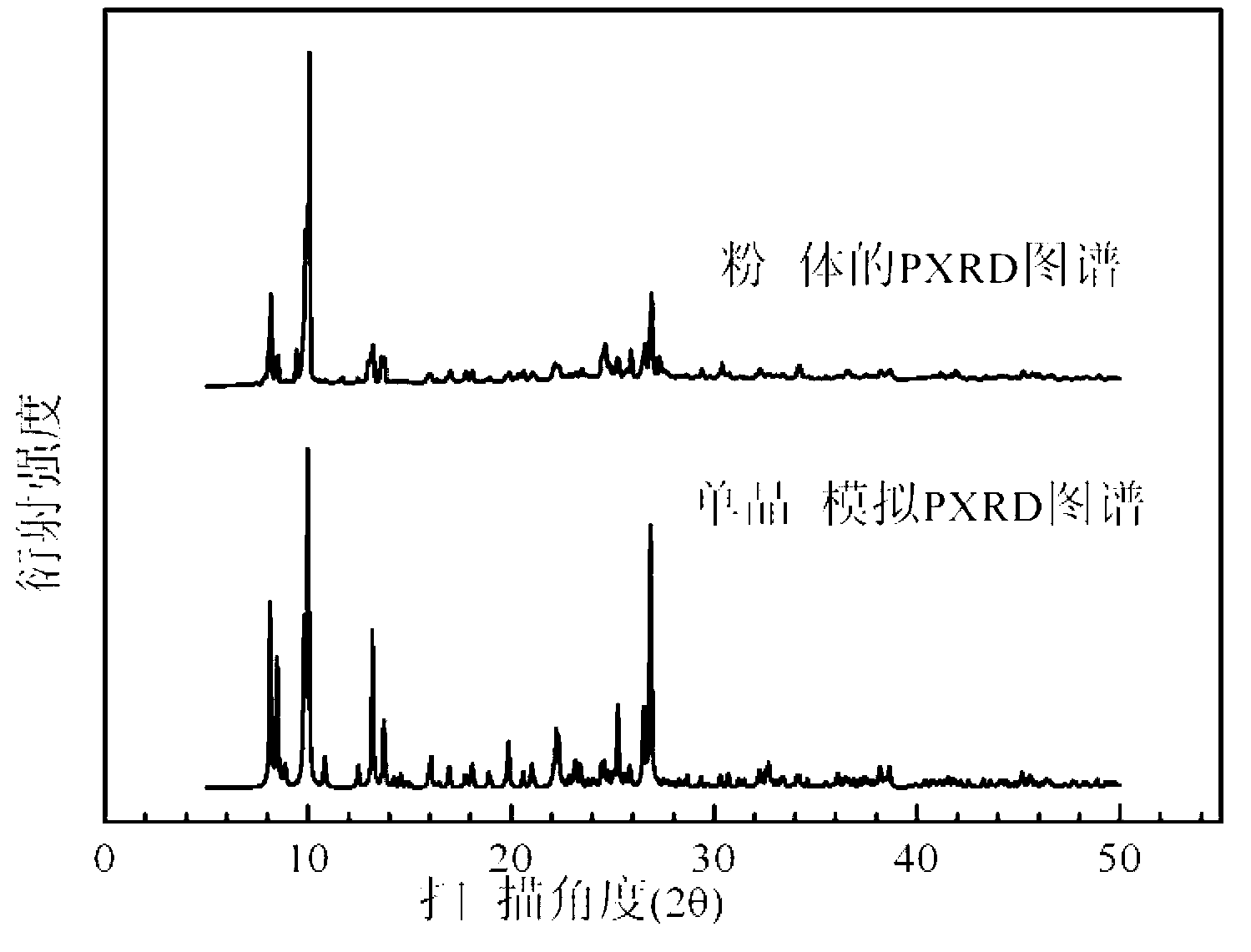

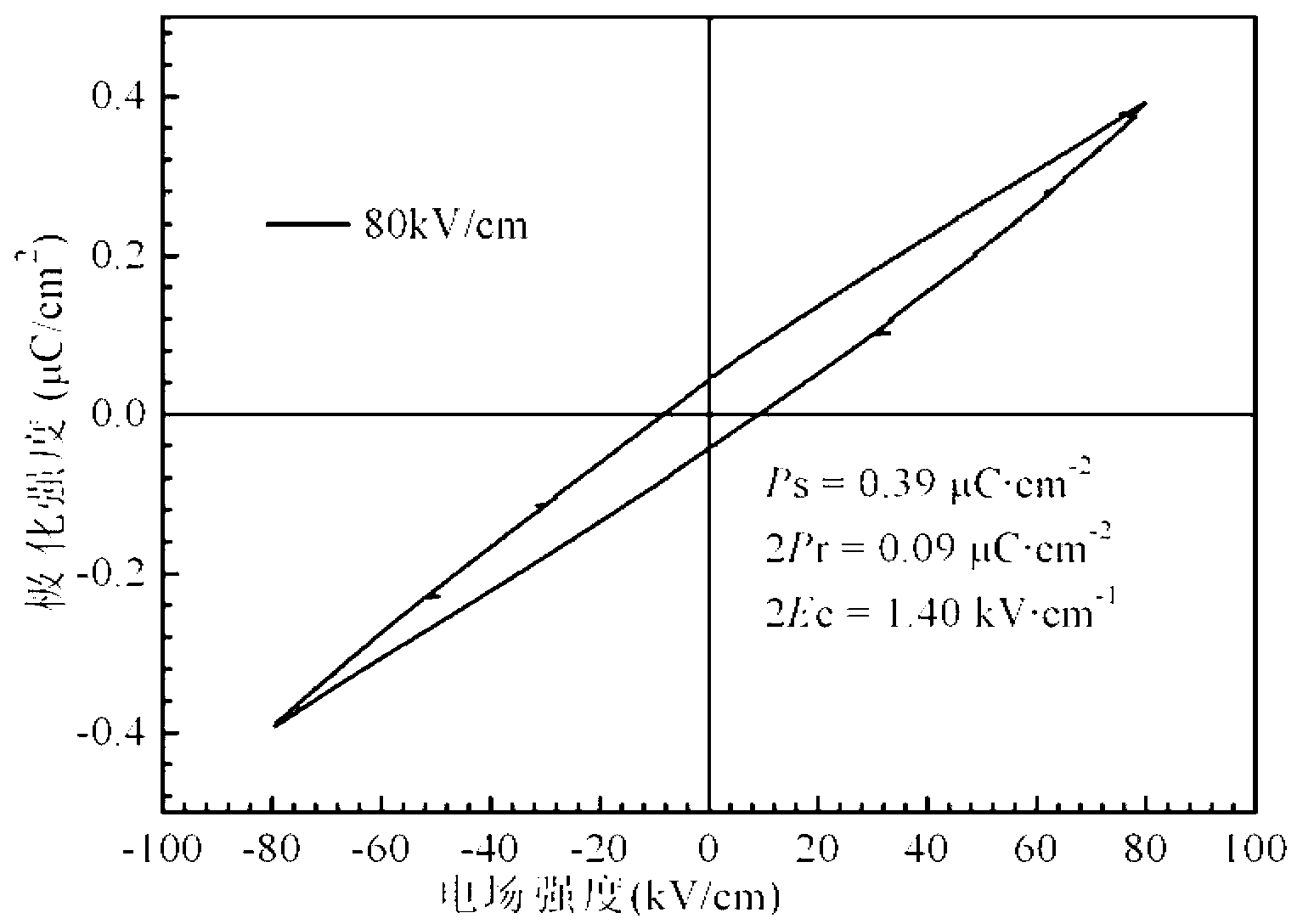

Phenanthroline copper malonate ferroelectric electric functional material and preparation method thereof

InactiveCN103232479AGood ferroelectric propertiesShort processCopper organic compoundsSaturation polarizationPhenanthroline

The invention discloses a phenanthroline copper malonate ferroelectric functional material and a preparation method thereof. The ferroelectric functional material has a molecular formula of [Cu3(C12H8N2)3(H2O)2(C3H2O4)3].11H2O, is blue powder of which the purity is not lower than 99%, and has a C2 polarity point group structure. The ferroelectric characteristic parameters of the ferroelectric functional material are as follows: the remanent polarization strength 2Pr is equal to 0.09 muC.cm<-2>, the coercive electric field 2Ec is equal to 1.40kv.cm<-1>, and the saturation polarization strength Ps is equal to 0.39 muC.cm<-2>; and the cell parameter of the powder of the ferroelectric functional material is as follows: the saturation polarization strength of the ferroelectric functional material is 1.56 times that of Rochelle salt, so that the ferroelectric functional material is a new ferroelectric with excellent ferroelectric performance. The ferroelectric functional material is prepared by reacting a cupric salt solution with a methane dicarboxylic acid solution at first, then reacting with a phenanthroline solution and carrying out crystallization under the condition that the pH value is 3.0-5.0, has the advantages of less flow, simple process, low requirements for equipment, no pollution and low cost, and is easy to realize industrialization.

Owner:NINGBO UNIV

Piezoelectric element and method for manufacturing the same, liquid-ejecting head and method for manufacturing the same, and liquid-ejecting apparatus

ActiveUS20100110148A1Large deformationOperation can be performedPiezoelectric/electrostrictive device manufacture/assemblyInking apparatusHysteresisSaturation polarization

A piezoelectric element includes a piezoelectric film containing lead (Pb), zirconium (Zr), and titanium (Ti). The piezoelectric film has a composition satisfying the relationship of Zr / (Ti+Zr)>Ti / (Ti+Zr) and has a polarization-electric field hysteresis loop having a Pm / 2Pr of 1.95 or more and a Vc(−) of −1.75 V or more, wherein Pm denotes saturation polarization, Pr denotes remanent polarization, and Vc(−) denotes a negative coercive electric field intensity.

Owner:SEIKO EPSON CORP

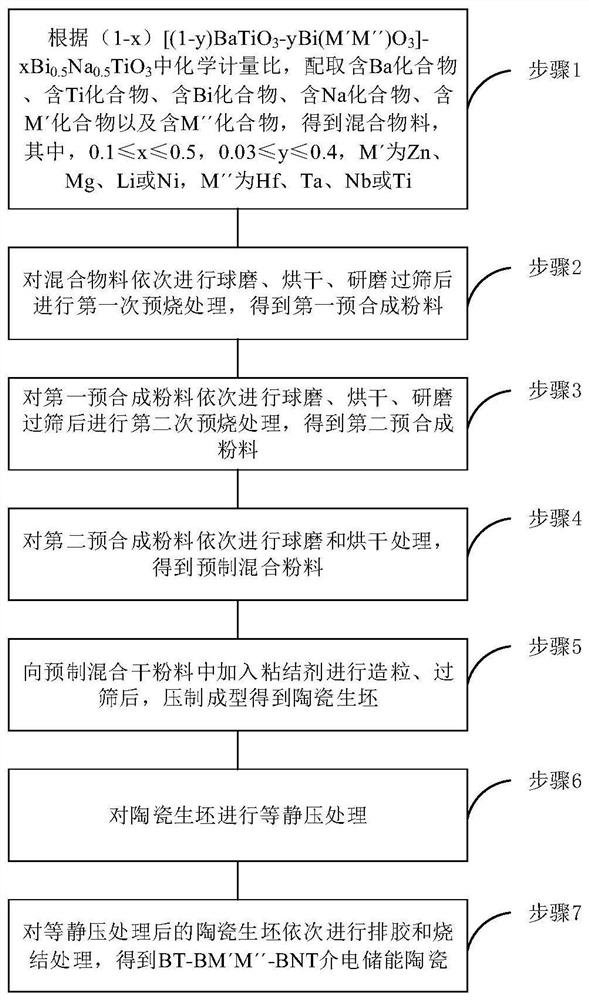

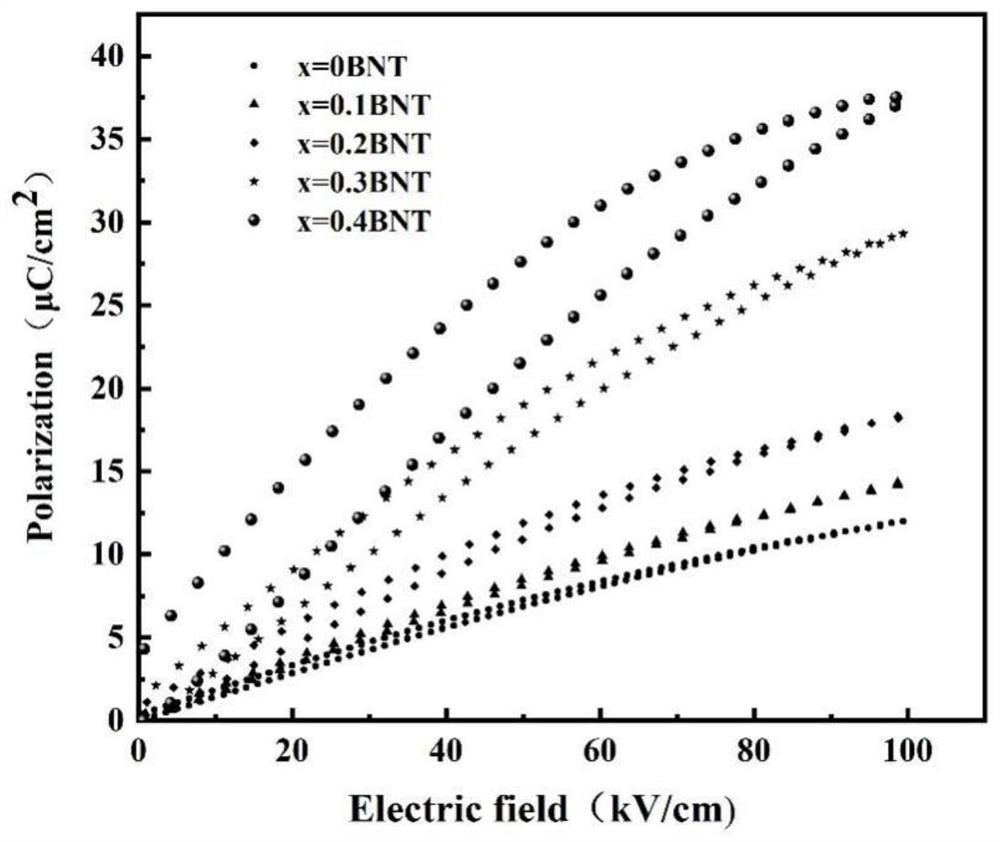

Lead-free high-energy-density ceramic material and preparation method thereof

ActiveCN113999004ALarge saturation polarizationIncreased saturation polarizationSaturation polarizationUltimate tensile strength

The invention relates to a lead-free high-energy-density ceramic material and a preparation method thereof, the chemical formula of the lead-free high-energy-density ceramic material is (1-x) [(1-y) BaTiO3-yBi (M'M'') O3]-xBi0. 5Na0. 5TiO3, 0.1 < = x < = 0.5, 0.03 < = y < = 0.4, M' is Zn, Mg, Li or Ni, and M'' is Hf, Ta, Nb or Ti. According to the lead-free high-energy-density ceramic material, BNT with large saturation polarization intensity serves as a third component, solid solution is conducted on the BNT and the relaxor ferroelectric BaTiO3-Bi (M'M'') O3, a BT-BM'M''-BNT system is obtained, the saturation polarization intensity of the lead-free high-energy-density ceramic material is remarkably improved, and the lead-free high-energy-density ceramic material still keeps extremely low remanent polarization intensity, and great energy storage density can be obtained under extremely low field intensity.

Owner:XIDIAN UNIV

Preparation method of A-site ion-doped sodium bismuth titanate based lead-free piezoelectric ceramic and product obtained by method

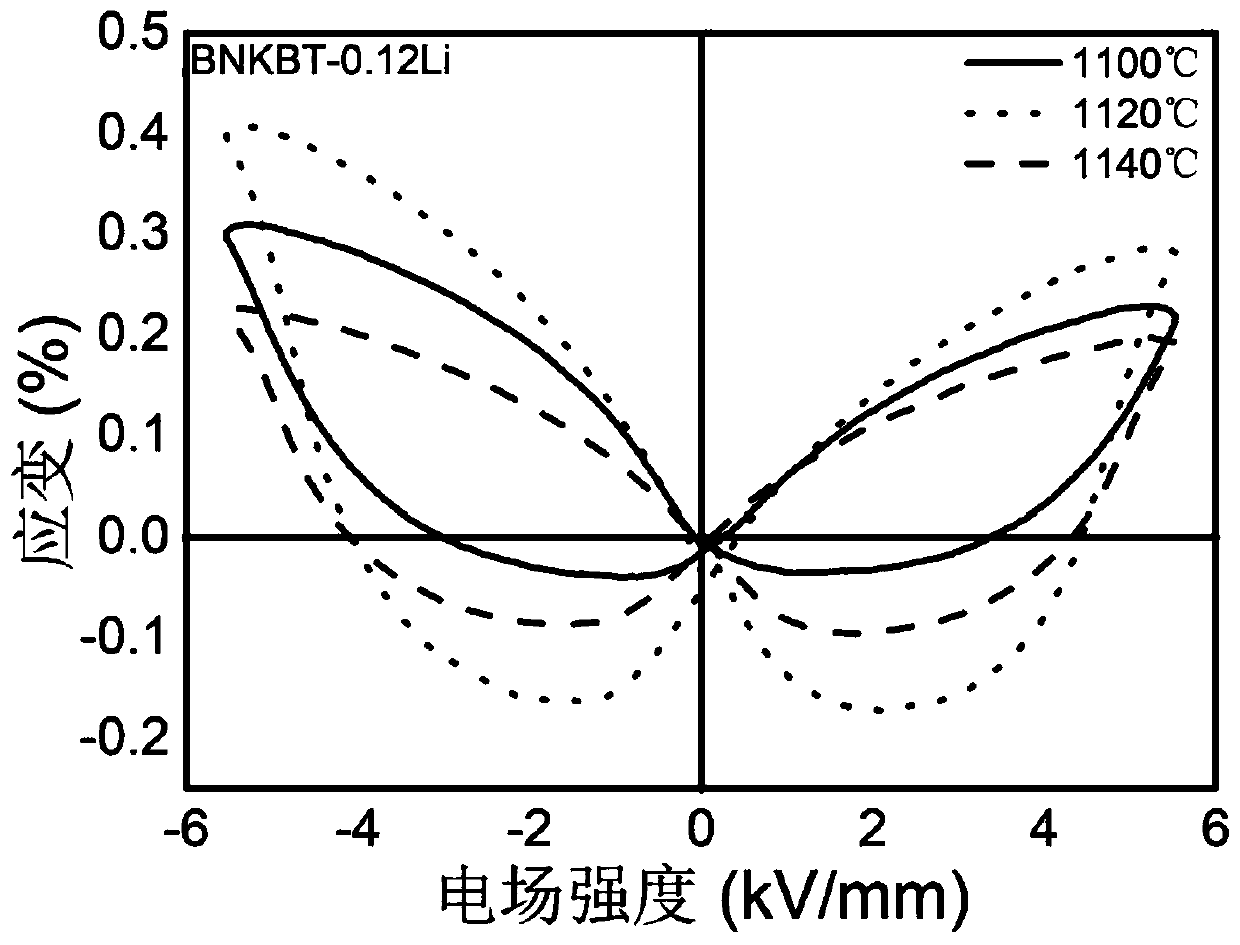

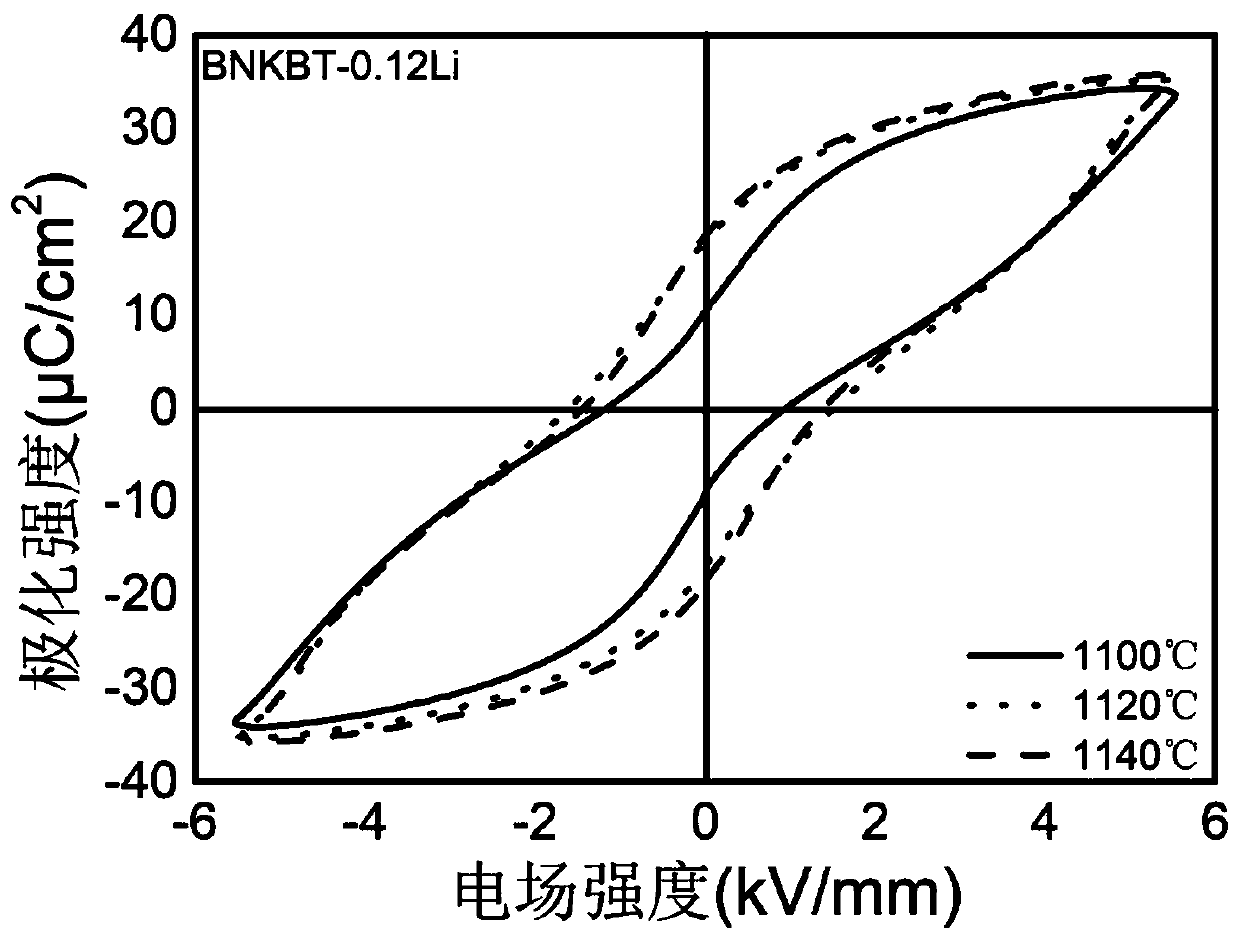

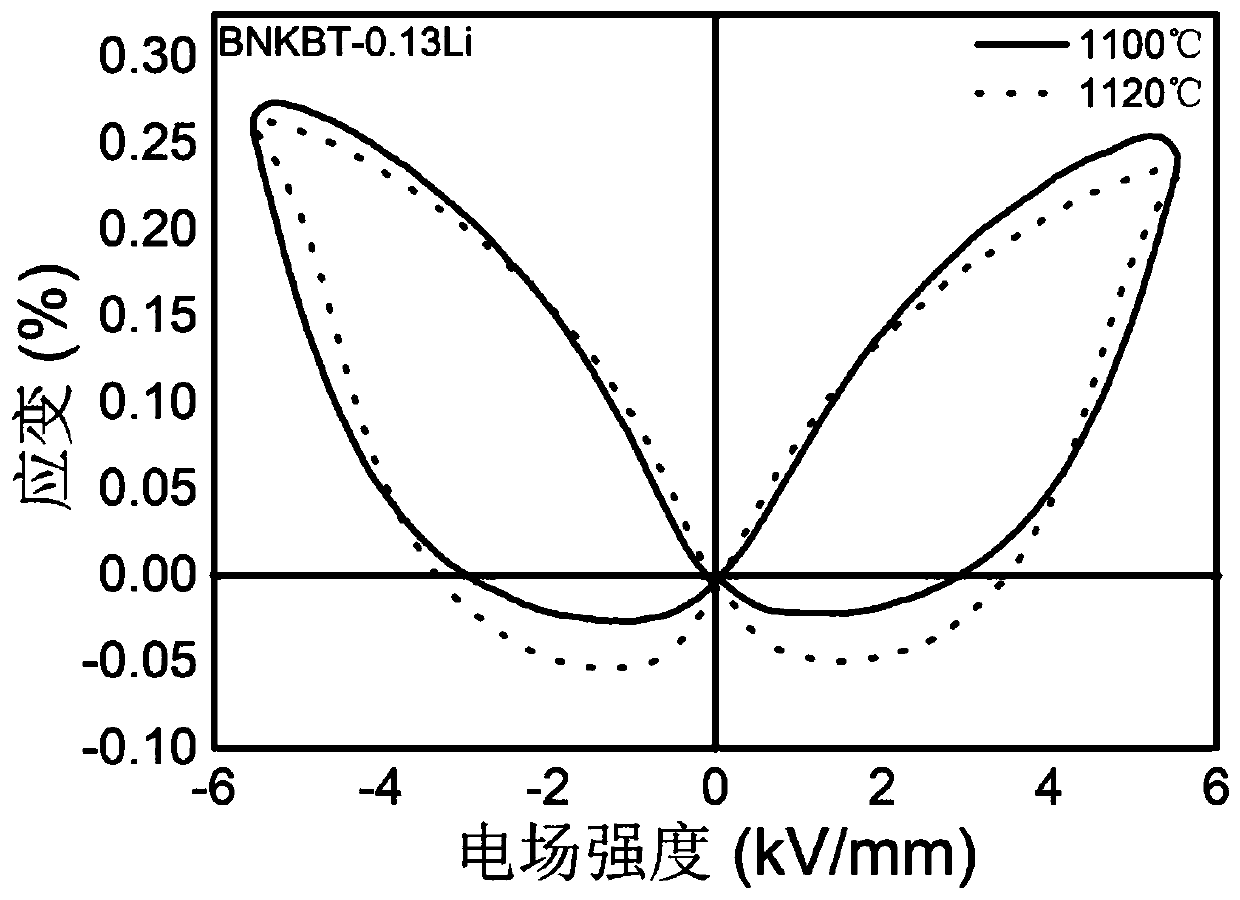

InactiveCN109851354AOptimizing Sintering TemperatureEnhance resilienceSodium bismuth titanatePotassium carbonate

The invention discloses an A-site ion-doped sodium bismuth titanate based lead-free piezoelectric ceramic and a preparation method thereof. The sodium bismuth titanate based lead-free piezoelectric ceramic has the following chemical formula: 0.852{Bi<0.5>[Na<1-x>Li<x>]<0.5>}TiO<3>-0.110(Bi<0.5>K<0.5>)TiO<3>-0.038BaTiO<3>, and the chemical formula is denoted as BNKBT-xLi, wherein 0.12<=x<=0.13. Thepreparation method comprises the following steps: respectively preparing sodium carbonate, potassium carbonate, bismuth trioxide, titanium dioxide, lithium carbonate and barium carbonate according tothe chemical formula, performing ball milling, performing drying, performing pre-synthesis on the mixed raw materials at 800-900 DEG C, performing granulation, performing molding, performing debinding, and performing sintering at 1100-1140 DEG C to obtain the high-performance A-site ion-doped modified sodium bismuth titanate based lead-free piezoelectric ceramic. The method provided by the invention not only optimizes sintering temperature, reduces volatilization of an alkali metal, but also improves strain performance, wherein the maximum strain S is 0.42%, the inverse piezoelectric coefficient d33* is 760 pm / V, and the saturation polarization intensity Ps is 34-38 [mu]C / cm<2>.

Owner:TIANJIN UNIV

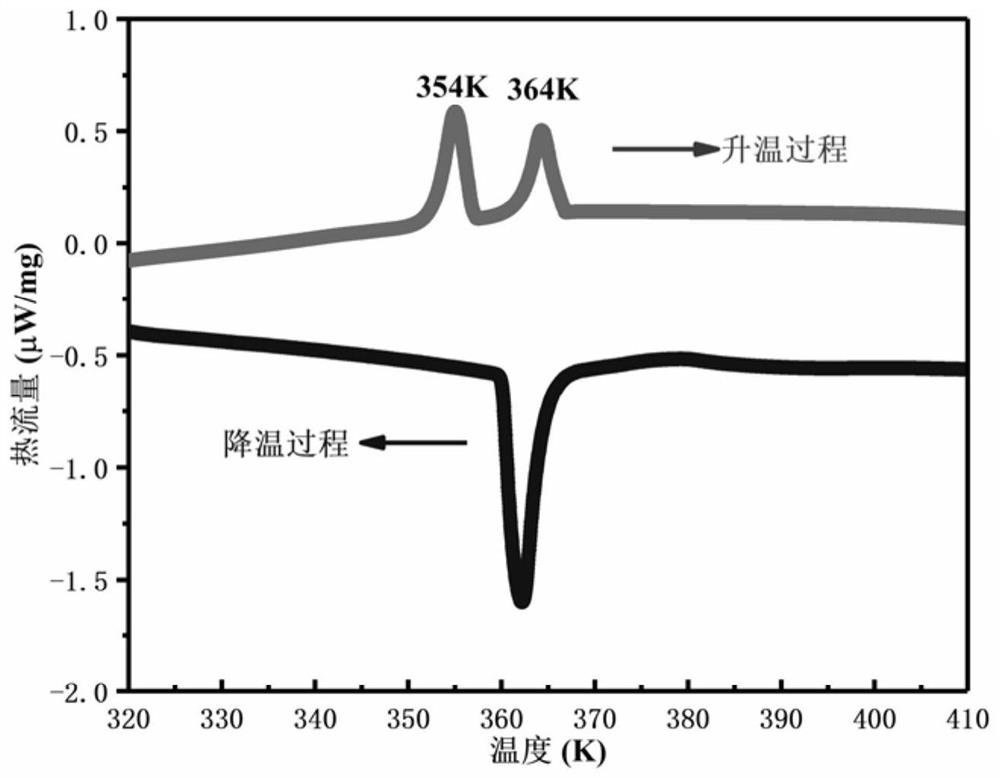

Organic molecule-based antiferroelectric material, preparation method and application thereof

ActiveCN112812021AThe synthesis method is simpleLow costOrganic compound preparationHybrid capacitor electrodesSaturation polarizationPolymer chemistry

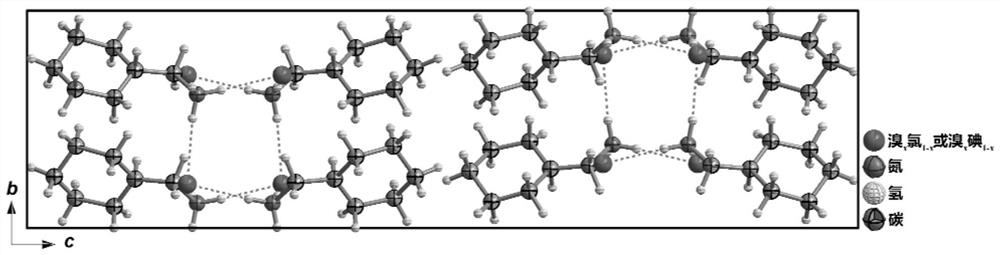

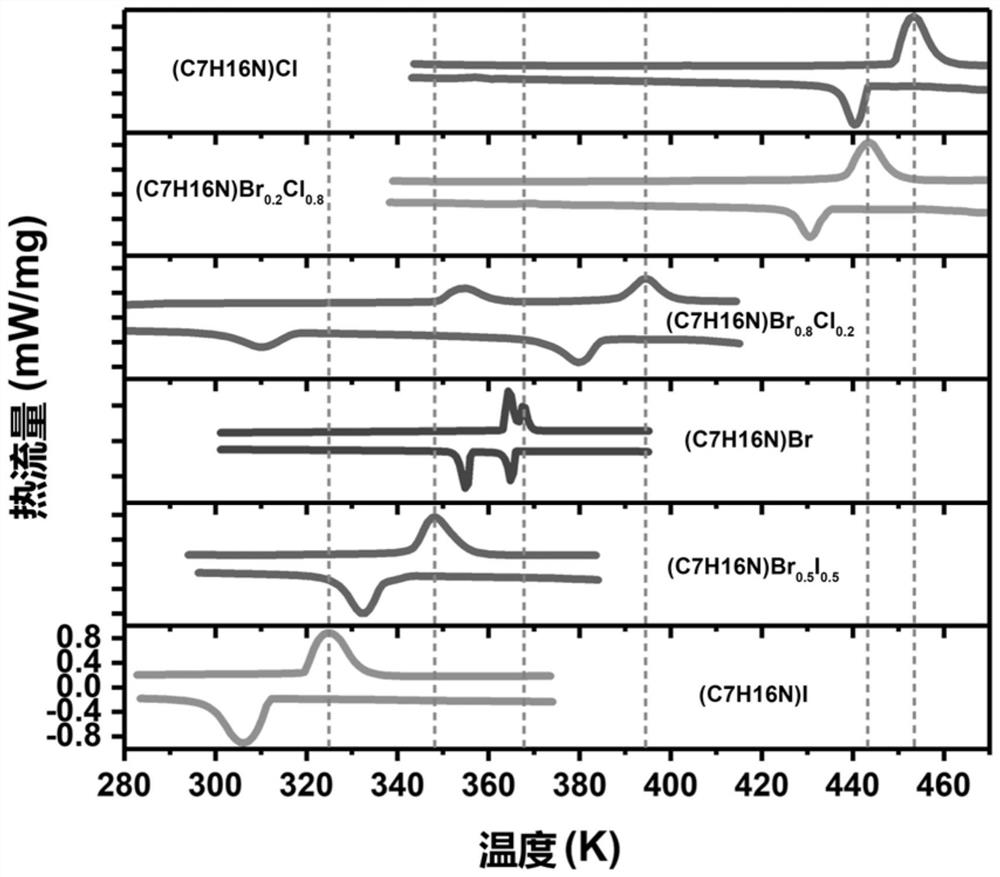

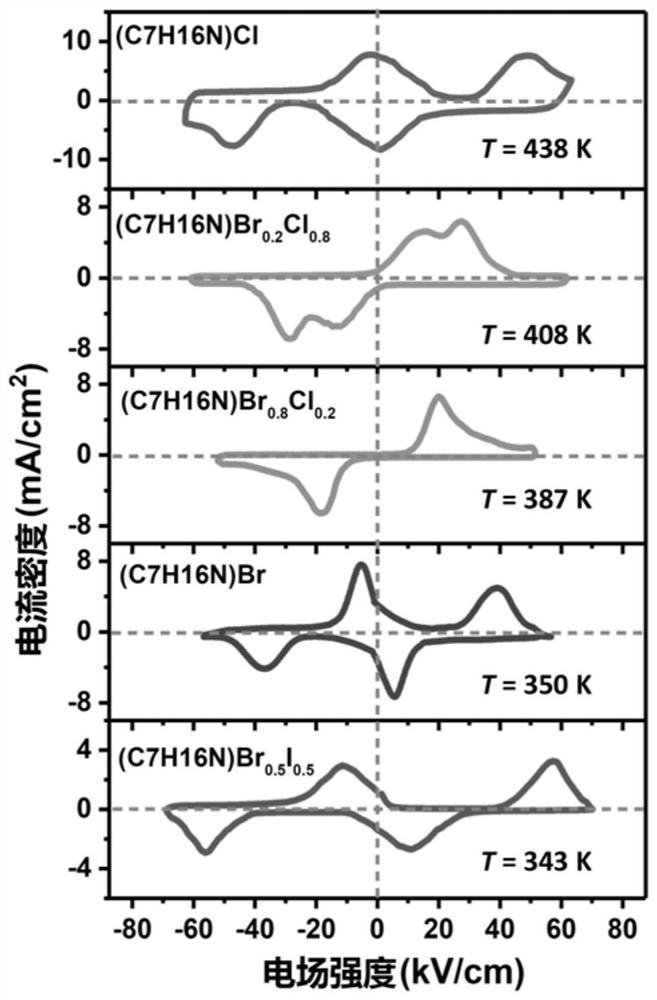

The invention relates to an organic molecule-based antiferroelectric material, a preparation method and application thereof, wherein the chemical formula of the organic molecule-based antiferroelectric material is C7H16NBr, the organic molecule-based antiferroelectric material is an orthorhombic system Pbca space group at room temperature, the cell parameters are as follows: a is 8.1818 (2), b is 7.9363 (3) and Z is 8, the temperature rises to 354K, the organic molecule-based antiferroelectric material is converted into a ferroelectric phase, and when the temperature rises to be higher than 364K, the organic molecule-based antiferroelectric material is converted into a paraelectric phase. The organic molecule-based antiferroelectric material disclosed by the invention is simple in synthesis method, low in cost, mild in reaction condition and relatively high in stability, and is an organic molecule antiferroelectric compound with relatively high saturation polarization intensity.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

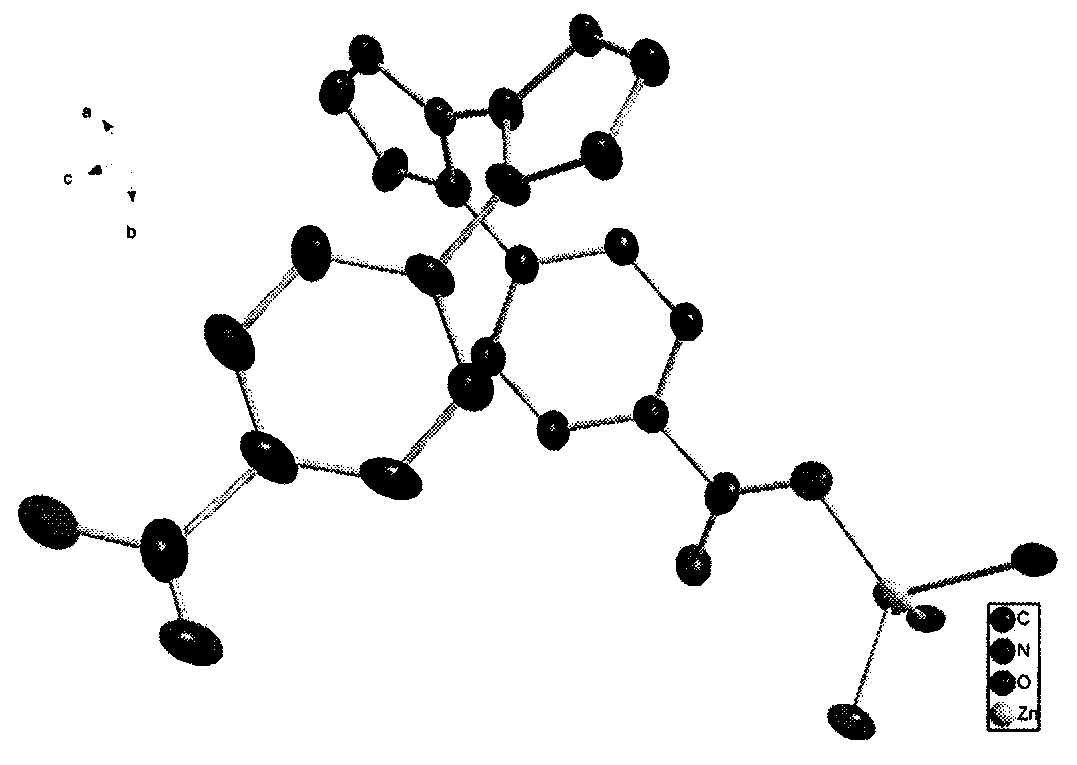

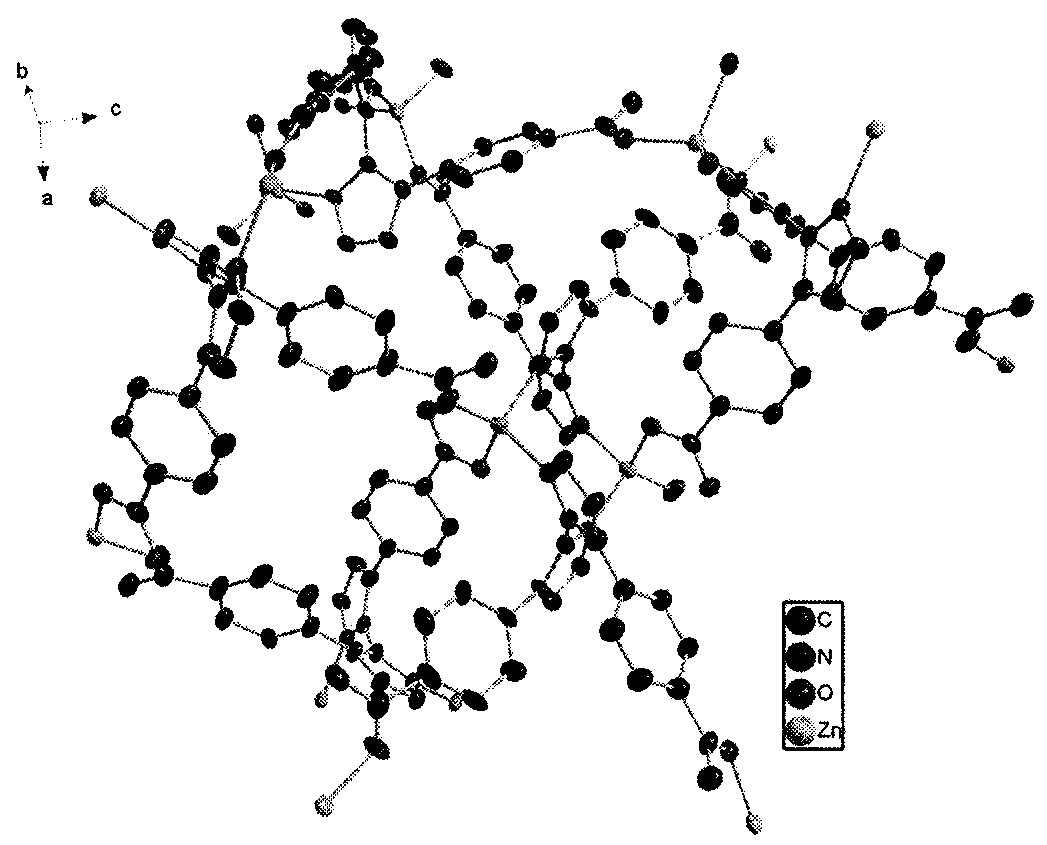

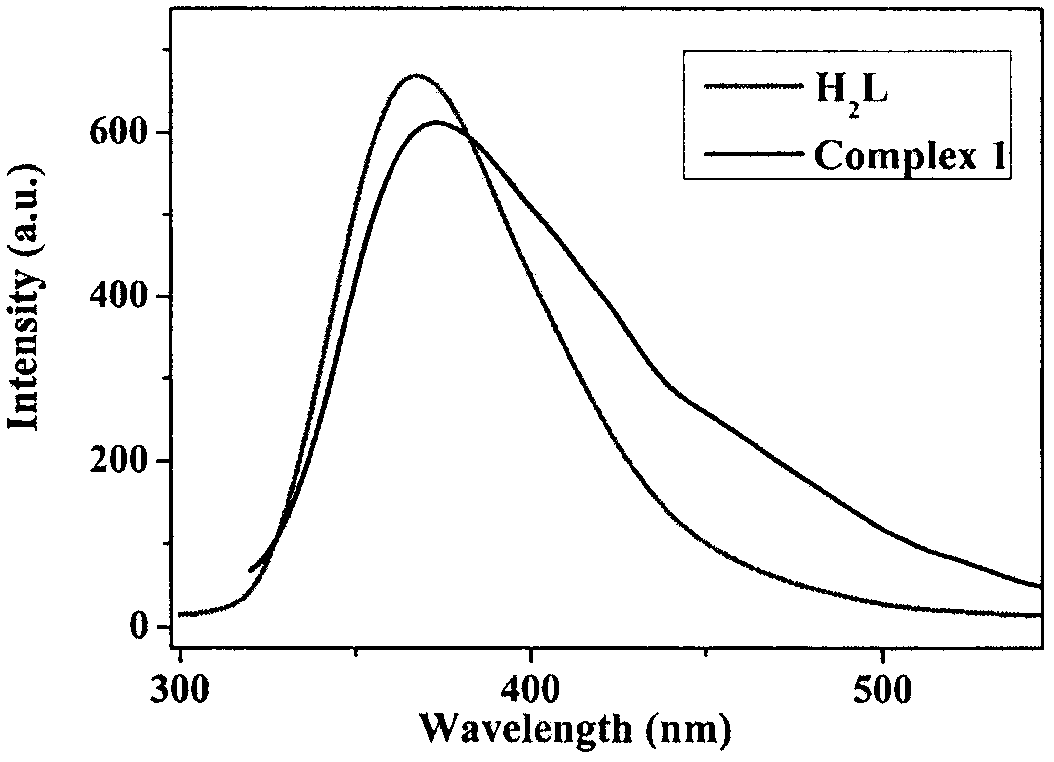

Synthesis method of zinc complex, and applications of zinc complex as fluorescent probe and ferroelectric material

InactiveCN110885339AHigh puritySimple processFluorescence/phosphorescenceLuminescent compositionsNitrofuralFluoProbes

The invention provides a preparation method of a zinc metal complex, and applications of the zinc metal complex as a fluorescent probe and a ferroelectric material. The chemical formula of the complexis [Zn(L).H2O] n, wherein H2L is 1,1'-(4-carboxyl phenyl)-2,2'-biimidazole. The zinc metal complex is of a three-dimensional structure formed by self-assembling zinc ions with an L<2-> ligand. The zinc complex shows an obvious fluorescence quenching effect on ferric ions, dichromate ions, antibiotics furacilin and nitrofurantoin, can be used as the fluorescent probe, and has potential applicationvalues in the fields of environmental monitoring and life science. In addition, the zinc complex has excellent ferroelectric properties: when an external electric field is 1200 V, the remnant polarization is 1.84 [mu]C / cm<2>, the coercive field is 714 V / cm, and the saturation polarization is 2.15 [mu]C / cm<2>, so that the zinc complex is expected to become the novel ferroelectric material, and hasa wide application prospect in the field of information storage.

Owner:YANCHENG TEACHERS UNIV

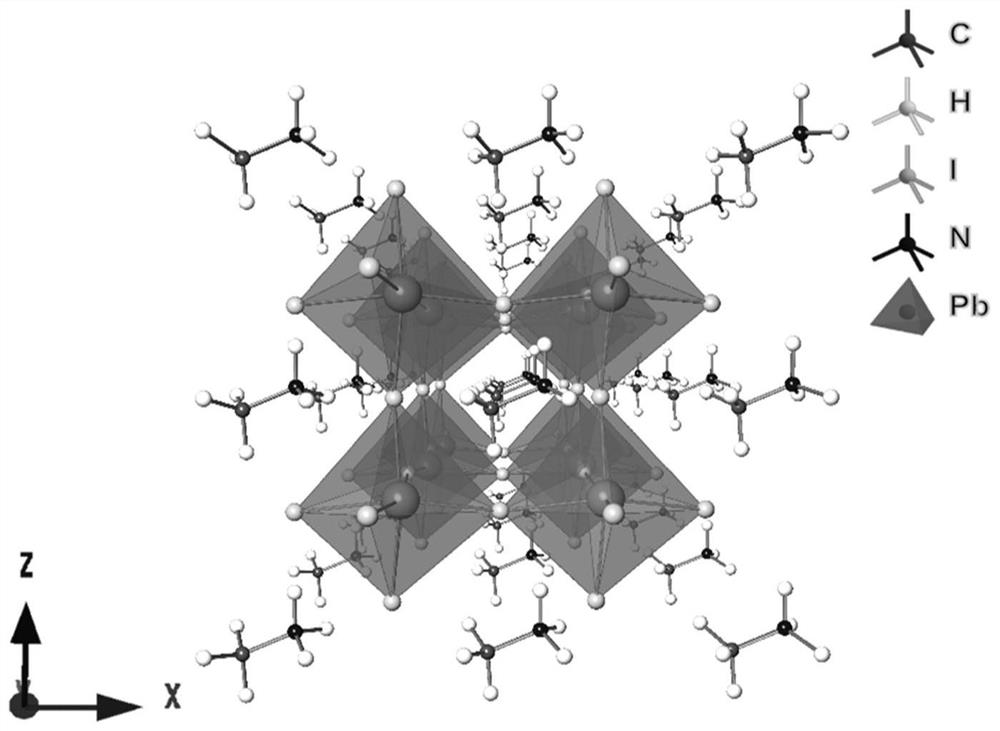

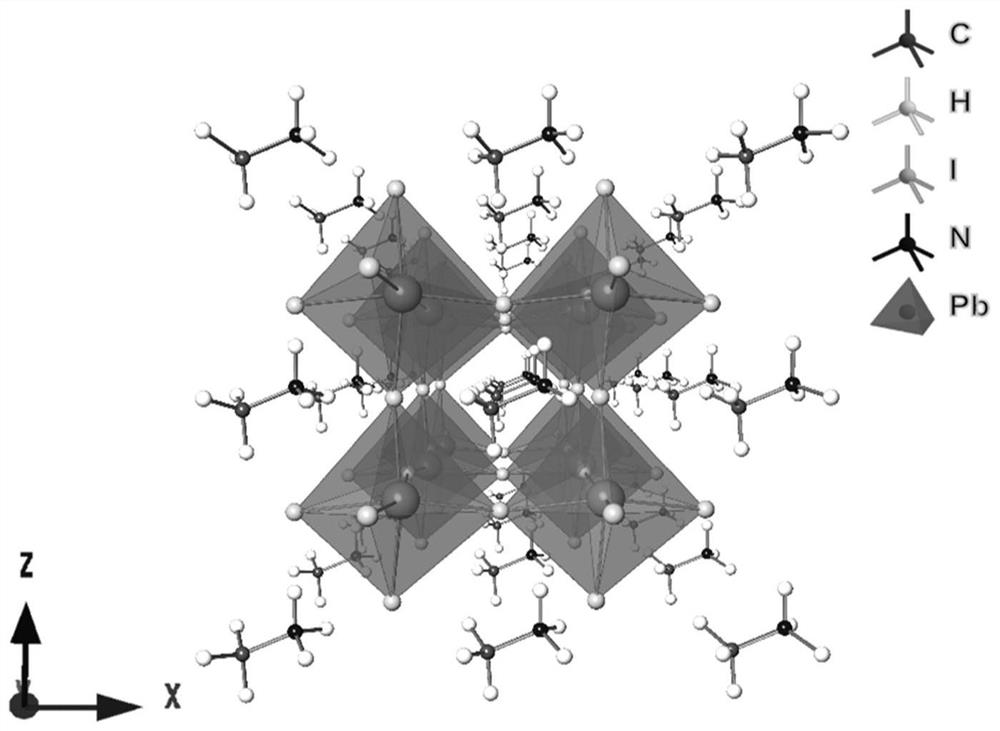

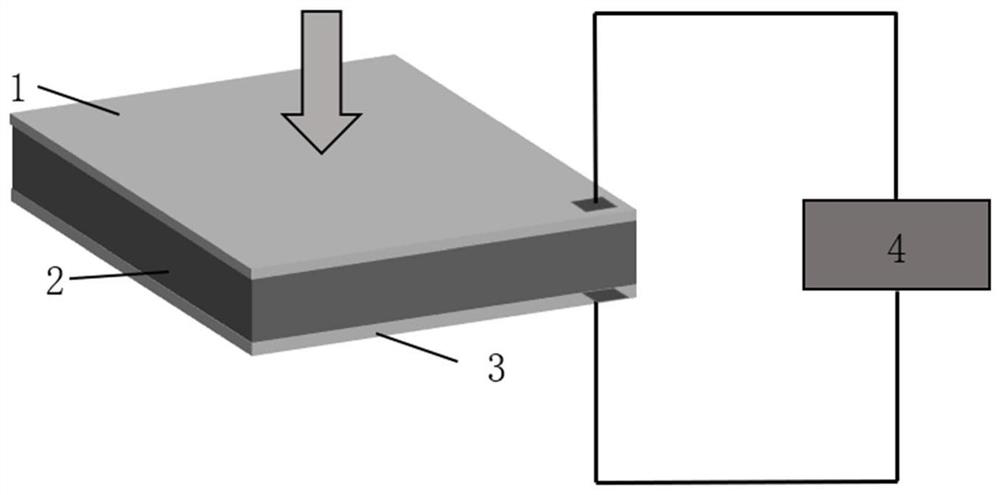

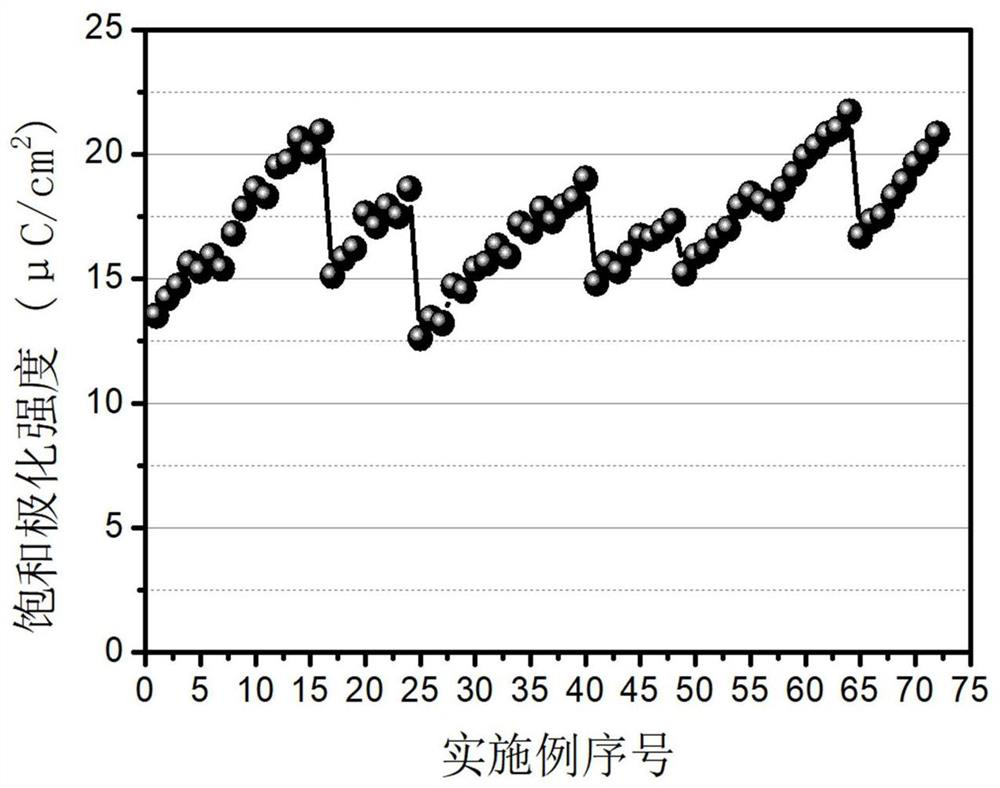

A kind of lead position doping methylamine lead iodine single crystal thin film and preparation method thereof

ActiveCN113584594BQuality improvementLow toxicityPolycrystalline material growthLiquid-phase epitaxial-layer growthSaturation polarizationPhysical chemistry

The invention discloses a lead-site-doped methylamine-lead-iodine single crystal thin film and a preparation method thereof. The single crystal thin film is made of CH 3 NH 3 PB 3 As the parent body, La is doped at the lead site, and the molecular formula is CH 3 NH 3 Pb 1‑x La 2x / 3 I 3 ( x =0.005‑0.19) single crystal thin film, doped with Sm at the lead site, the molecular formula is CH 3 NH 3 Pb 1‑y SM 2y / 3 I 3 ( x =0.005‑0.19) single crystal film, doped with Pr at the lead site, the molecular formula is CH 3 NH 3 Pb 1‑z PR z I 3 ( z =0.005‑0.27) single crystal film. The present invention effectively improves the saturation polarization intensity, remnant polarization intensity, piezoelectric coefficient and mobility of carriers through the doping of La, Sm, and Pr elements, and the substitution of lead greatly improves its photoelectric performance and reduces The toxicity brought by the heavy metal lead is eliminated, the process is simple, the preparation process is easy to control, and the repeatability is high.

Owner:NANJING UNIV OF SCI & TECH

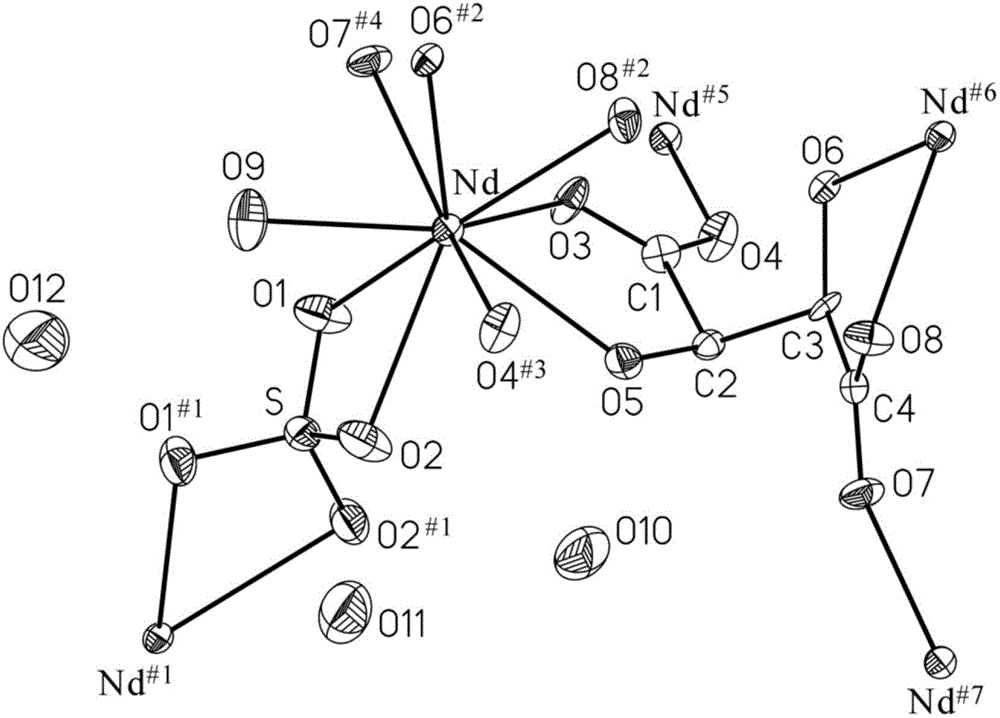

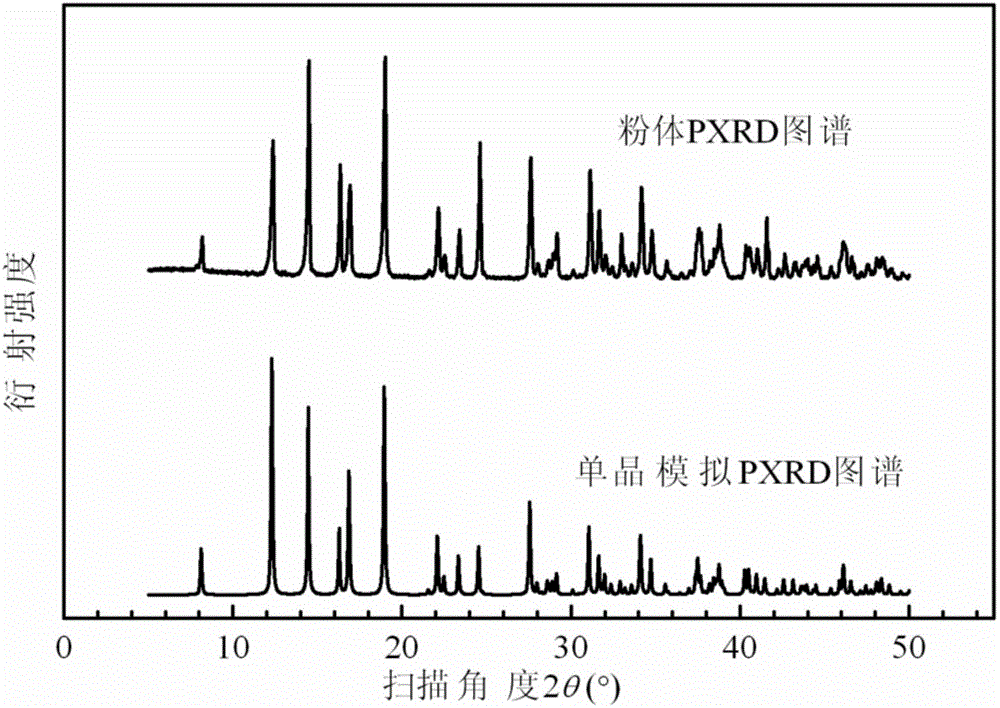

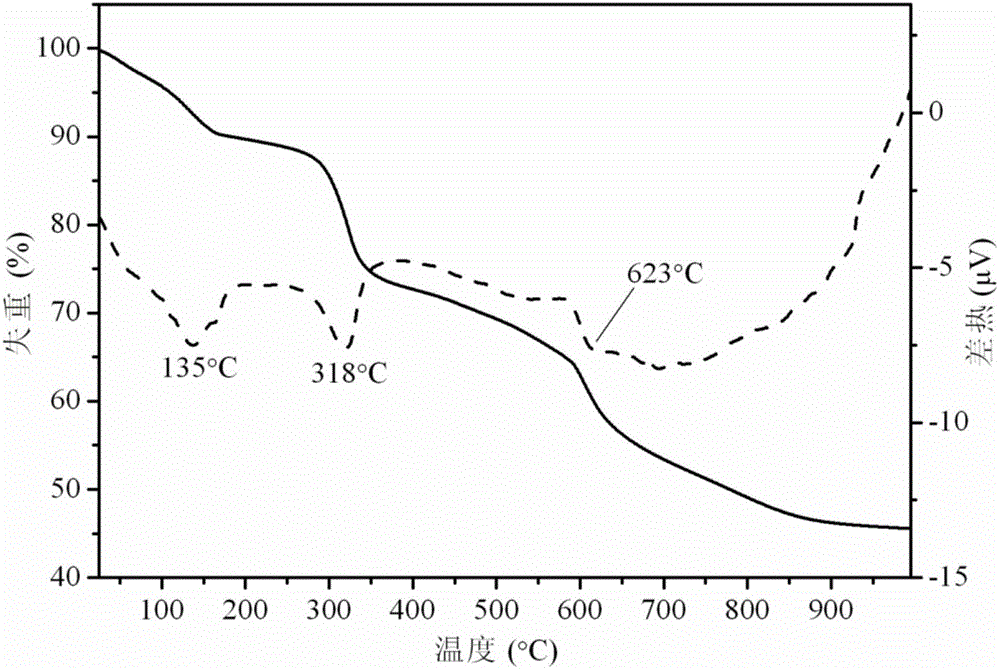

Hydrated L-tartrate neodymium sulfate ferroelectric functional material and preparation method

InactiveCN103113394BGood ferroelectric propertiesLess ferroelectric propertiesGroup 3/13 element organic compoundsSeignette saltSolvent

The invention discloses a hydrated L-tartaric acid neodymium sulfate ferroelectric functional material and a preparation method thereof. The ferroelectric functional material has a molecular formula of {Nd2(H2O)2(L-C4H4O6)2(SO4)}.4H2O. The ferroelectric functional material has the following ferroelectric characteristic parameters: the remanent polarization 2Pr is 0.390 mu C / cm<2>; the coercive electric field 2Ec is 74.7 kv / cm; and the saturation polarization Ps is 0.307 mu C / cm<2>. The saturation polarization of the ferroelectric functional material is 1.23 times that of seignette salt, so that the ferroelectric functional material disclosed by the invention is a novel ferroelectric body with excellent ferroelectric performance. The preparation method comprises the following steps: carrying out a solvothermal reaction between neodymium oxide and L-tartaric acid by using an ethanol solvent; and adding a sulfuric acid solution into the mixture and nucleating in a reaction kettle so as to grow into the hydrated L-tartaric acid neodymium sulfate. The preparation method has the advantages of short flow, simple process, low equipment requirement, no pollution and low cost and can be easily industrialized.

Owner:NINGBO UNIV

Metal-molecule-free antiferroelectric solid solution as well as preparation method and application thereof

PendingCN114702392AExcellent antiferroelectric propertiesImprove responseAmino preparation from aminesOrganic chemistry methodsCrystallographySaturation polarization

The invention relates to a metal-molecule-free antiferroelectric solid solution as well as a preparation method and application thereof. The general formula of the solid solution is (C7H16N) BrxI1-x and (C7H16N) BrxCl1-x (0 < = xlt; 1) the material is an antiferroelectric phase at room temperature and belongs to an orthorhombic system; the solid solution shows excellent antiferroelectric properties at the Curie temperature or below, wherein the saturation polarization of the cyclohexyl methylamine chloride can reach 11.4 [mu] C / cm < 2 >. In addition, the solid solution also has near-zero remanent polarization, large coercive field and high breakdown voltage resistance, and can be used as a candidate material of an energy storage dielectric.

Owner:MINDU INNOVATION LAB

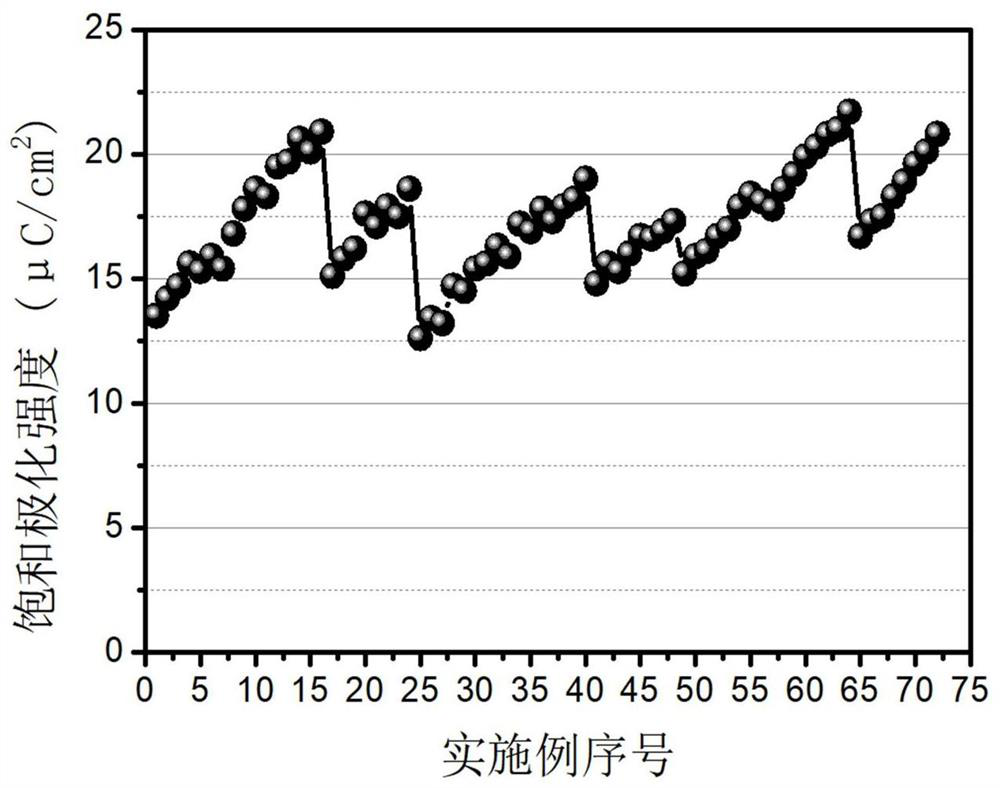

A CoFe 2 o 4 /BaTiO 3 Layered magnetoelectric composite material and its preparation method

ActiveCN104557027BImprove ferroelectric propertiesImprove ferromagnetic propertiesPiezoelectric/electrostrictive/magnetostrictive devicesDielectric lossMagnetization

A CoFe2O4 / BaTiO3 layered magnetoelectric composite material and its preparation method. BaTiO3 powder and CoFe2O4 powder are sintered at 1000-1050°C in a 2-2 composite barrier layer stacking arrangement to prepare CoFe2O4 / BaTiO3 layered magnetoelectric composite material. Composite materials, due to the 2-2 composite barrier layer stacking arrangement, can effectively suppress the mutual reaction between the two phases and maintain their respective characteristics, so that the prepared composite materials have both good ferroelectricity and Better ferromagnetism. The electrical constant reaches 1900~4500, and the dielectric loss is 0.19~1.50. The saturation polarization intensity Ps is 14.8~18.7μC / cm2, the coercive field Ec is 8.6~14.6kV / cm, and the saturation magnetization Ms is 3.4~20.9emu / g.

Owner:SHAANXI UNIV OF SCI & TECH

A forming device and method for a thin-walled sleeve-like magnetic material

The invention provides a forming device and a forming method for thin-wall sleeve magnetic materials, and relates to the field of powder metallurgy forming. The device comprises a powder forming machine and a pressing die; the fit clearance between a lower punch of the die and the inner wall of a punching hole is 5-8mum, and the fit clearance between an upper punch of the die and the punching hole is 5-8mum; the strength of a material adopted by effective working parts of a rod core, the upper punch and the lower punch, and a female die are respectively higher than the saturation polarization strength of soft magnetic material powder which needs to be pressed; tungsten steel of which the compressive strength is more than HRA89 degrees is adopted by the effective working parts of inner walls of the upper punch and the lower punch and the rod core; high-speed steel is adopted by the female die and a substrate of the pressing die, i.e. the upper punch and the lower punch are both of welding structures of the tungsten steel and the high-speed steel. According to the forming device and the forming method provided by the invention, the pressing effect of the soft magnetic powder is enhanced, so that the density of all parts of a formed thin-wall sleeve is uniform, and the thin-wall sleeve has higher dimensional accuracy.

Owner:PINGHU GEOR CHI ELECTRONICS CO LTD

Single crystal film doped with methylamine lead iodine at lead position, and preparation method thereof

ActiveCN113584594AQuality improvementLow toxicityPolycrystalline material growthLiquid-phase epitaxial-layer growthSaturation polarizationPhysical chemistry

The invention discloses a single crystal film doped with methylamine lead iodine at the lead position, and a preparation method thereof. The single crystal film takes CH3NH3PbI3 as a matrix, La is doped at the lead position to obtain the single crystal film with the molecular formula of CH3NH3Pb1-xLa2x / 3I3 (x = 0.005-0.19), Sm is doped at the lead position to obtain the single crystal film with the molecular formula of CH3NH3Pb1-ySm2y / 3I3 (x = 0.005-0.19), and Pr is doped at the lead position to obtain the single crystal film with the molecular formula of CH3NH3Pb1-zPrzI3 (z = 0.005-0.27). By doping La, Sm and Pr elements, the saturation polarization intensity, remanent polarization intensity, piezoelectric coefficient and mobility of carriers are effectively improved, the photoelectric property is greatly improved through lead site substitution, the toxicity caused by heavy metal lead is reduced, the process is simple, the preparation process is easy to control, and repeatability is high.

Owner:NANJING UNIV OF SCI & TECH

Liquid-ejecting head and liquid-ejecting apparatus

InactiveUS8746852B2Avoid excessive impactReduce voltagePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesSaturation polarizationEngineering

Owner:SEIKO EPSON CORP

Method for manufacturing a metal composite component, in particular for an electromagnetic valve

InactiveUS9196408B2Simple and inexpensive mannerReduce polarizationInorganic material magnetismMetal layered productsSaturation polarizationCombustion

A method for manufacturing a metal composite component is characterized in that the composite component (60) is provided with at least two sections (61, 62, 63) of different magnetization, at least two sections (61, 62, 63) being situated on the one-piece component (60) in direct succession. The starting material for manufacturing the composite material (60) is a semi-austenitic steel, which is provided as a cylindrical blank. The blank is subsequently shaped into an intended shape of the composite component (60) and rendered magnetizable in a multistage forming and / or heat treatment process, the heat treatment being performed in such a way that the component has a saturation polarization Js=0.9-1.5 T. This is followed by a local heat treatment in a partial area under simultaneous cooling of the areas of the composite component (60) where the magnetic properties are not to be changed, in order to define strictly delimited transitional areas between the different areas of magnetization (61, 62, 63). The composite component (60) is suitable in particular for use in electromagnetic valves, for example, including in fuel injectors of internal combustion engines.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com