Patents

Literature

40results about How to "Good ferroelectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

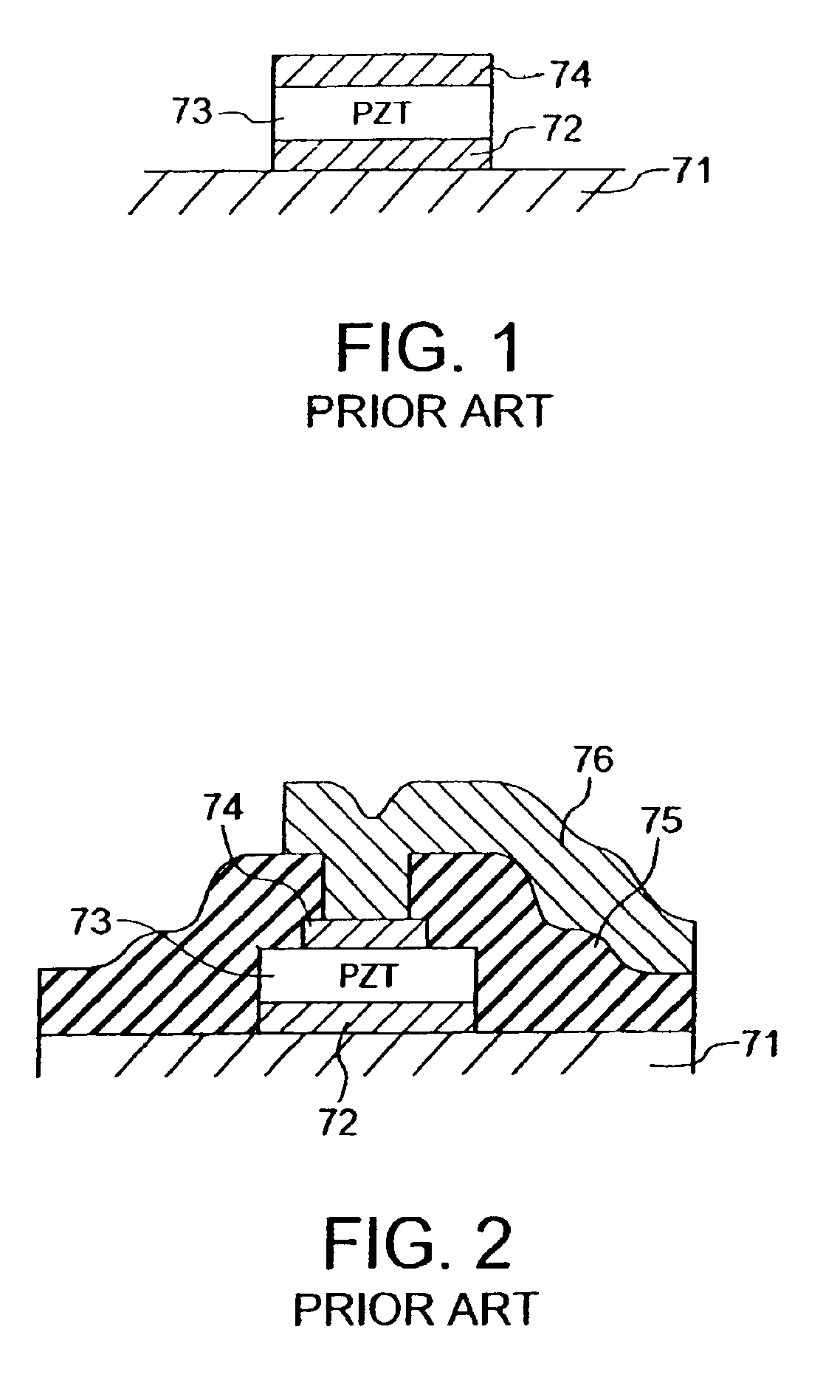

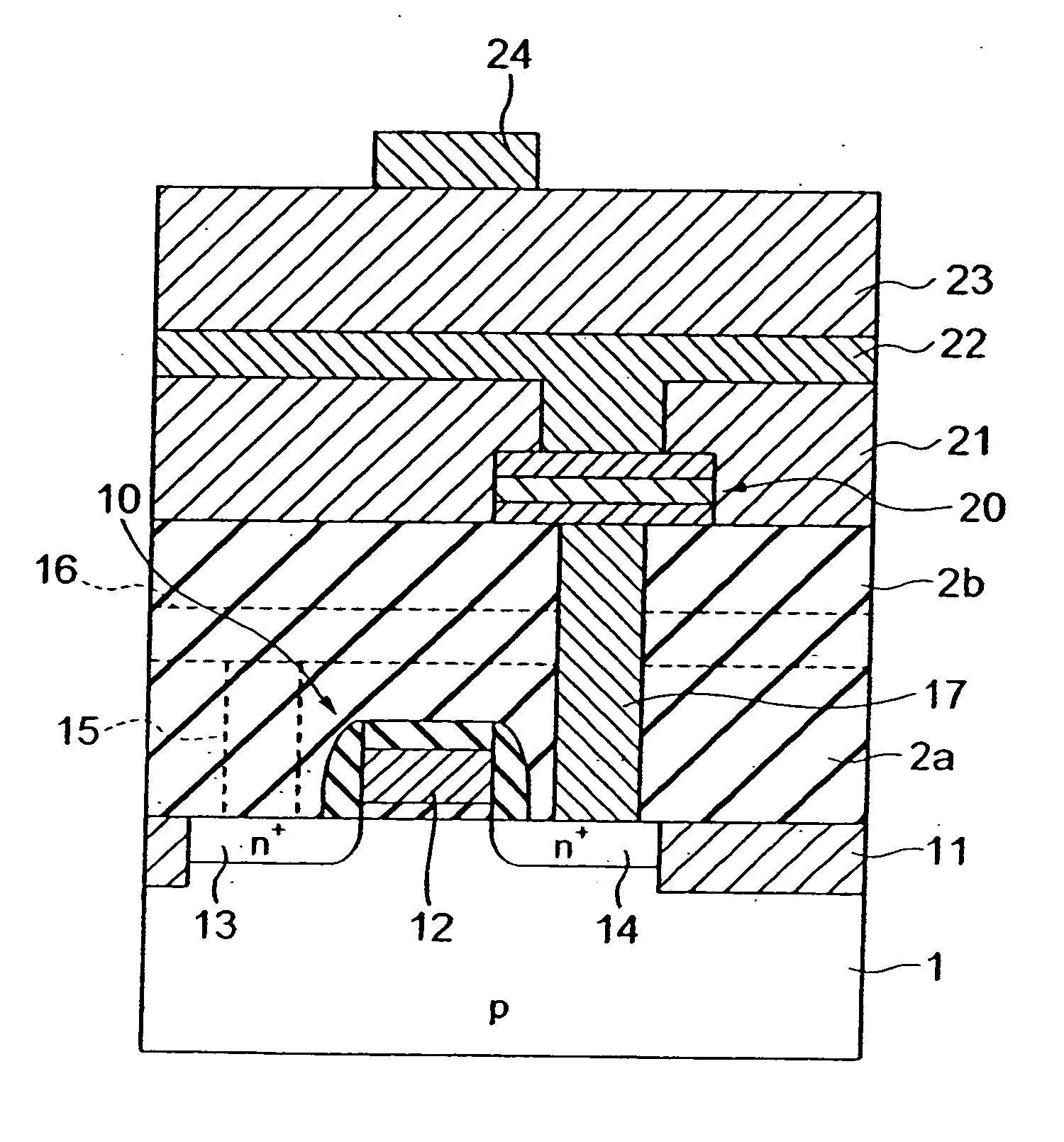

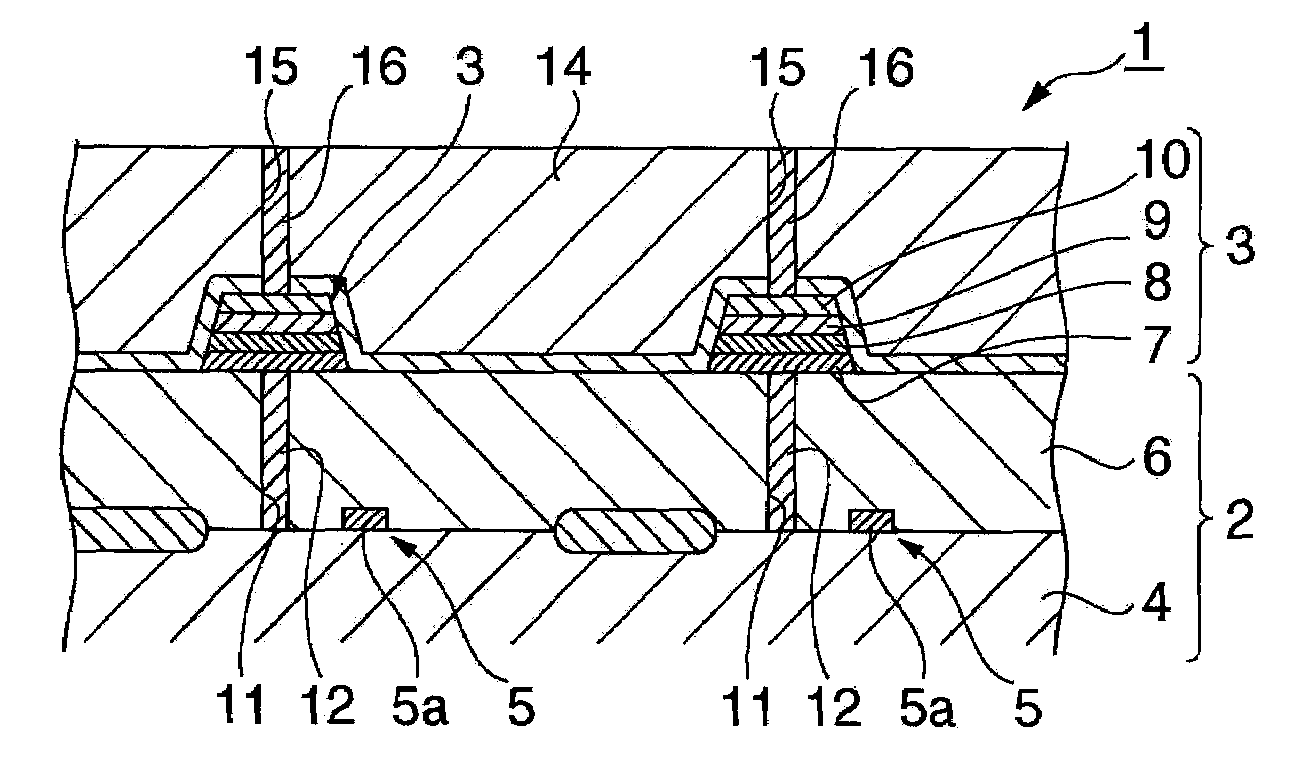

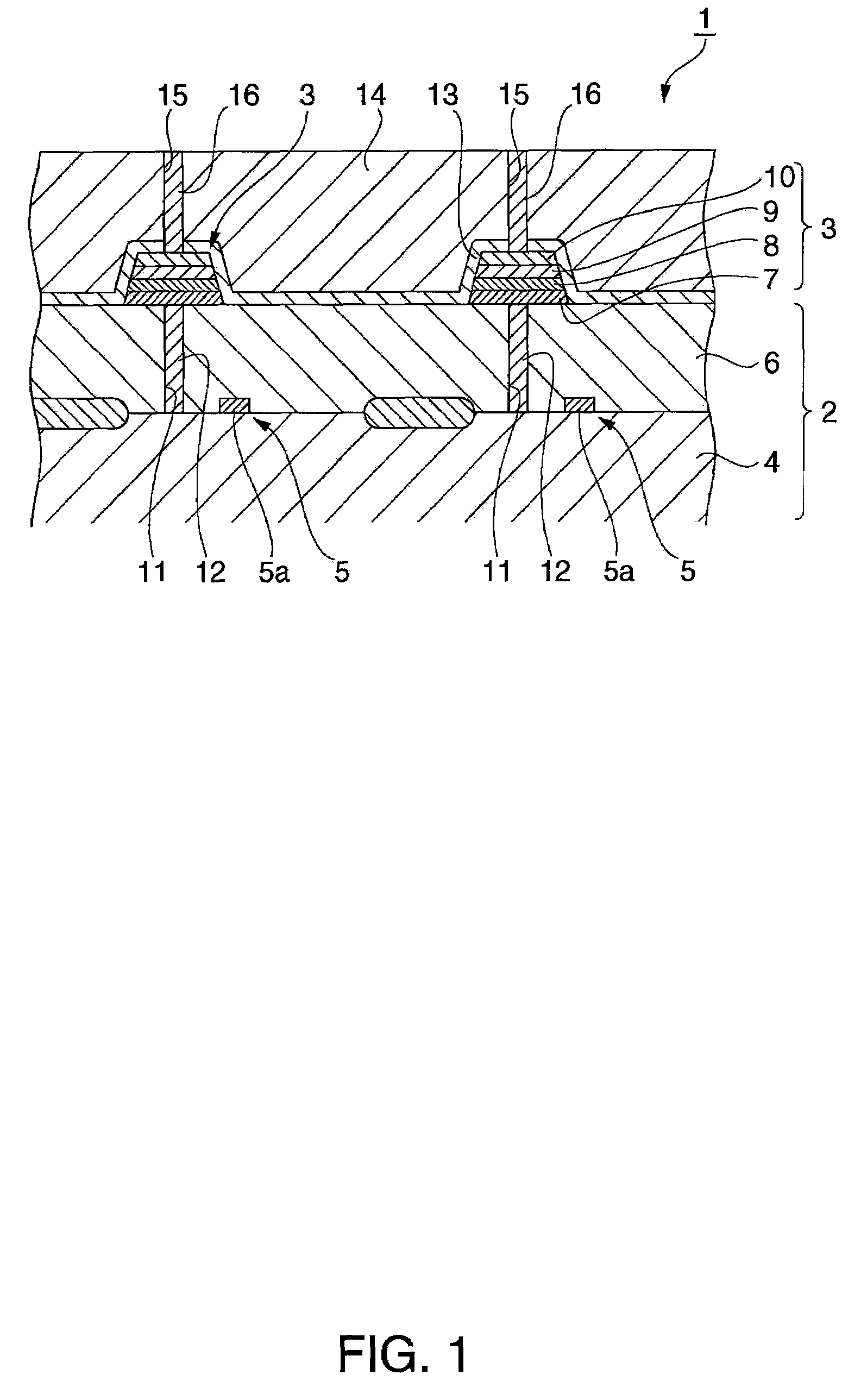

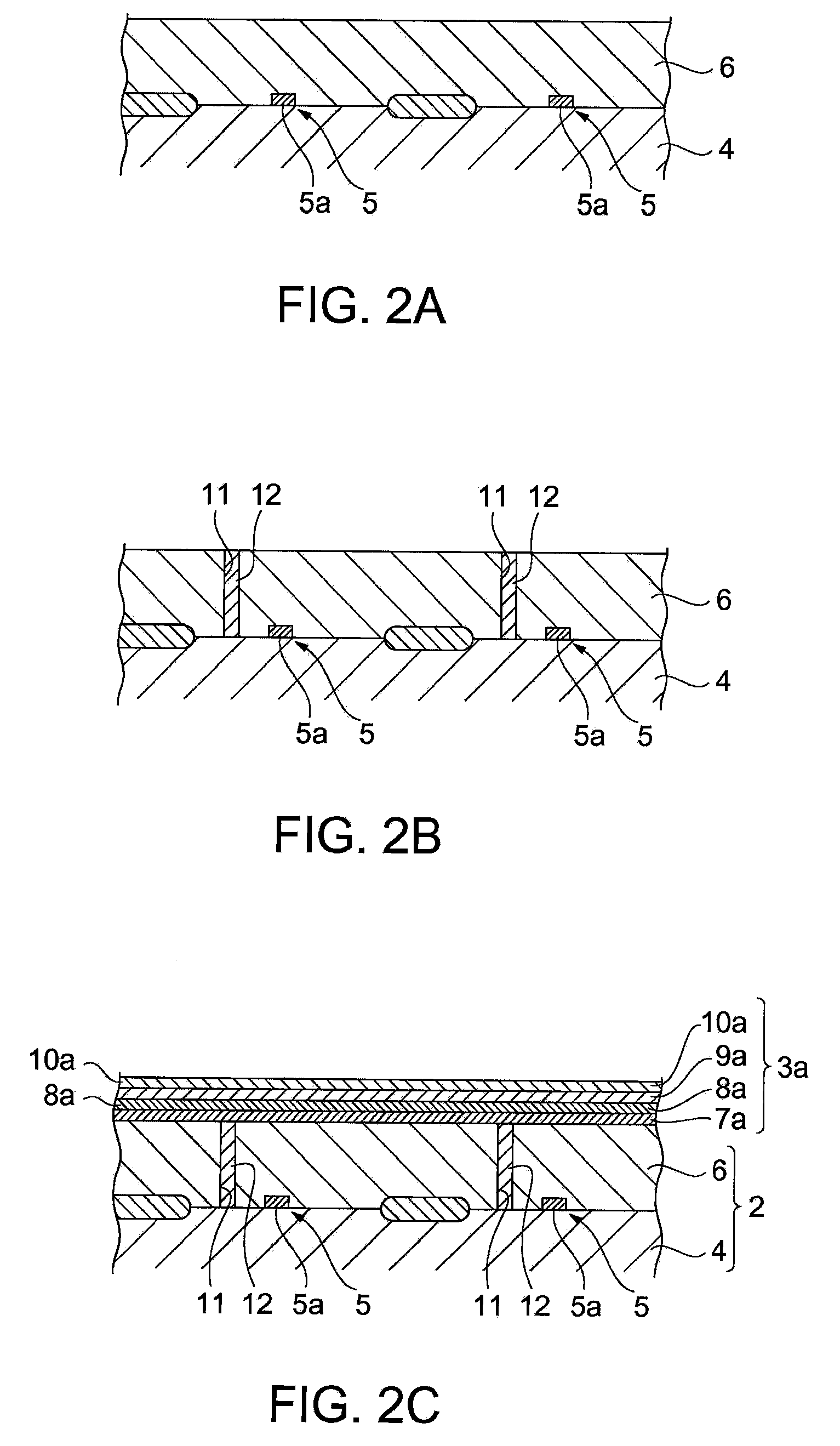

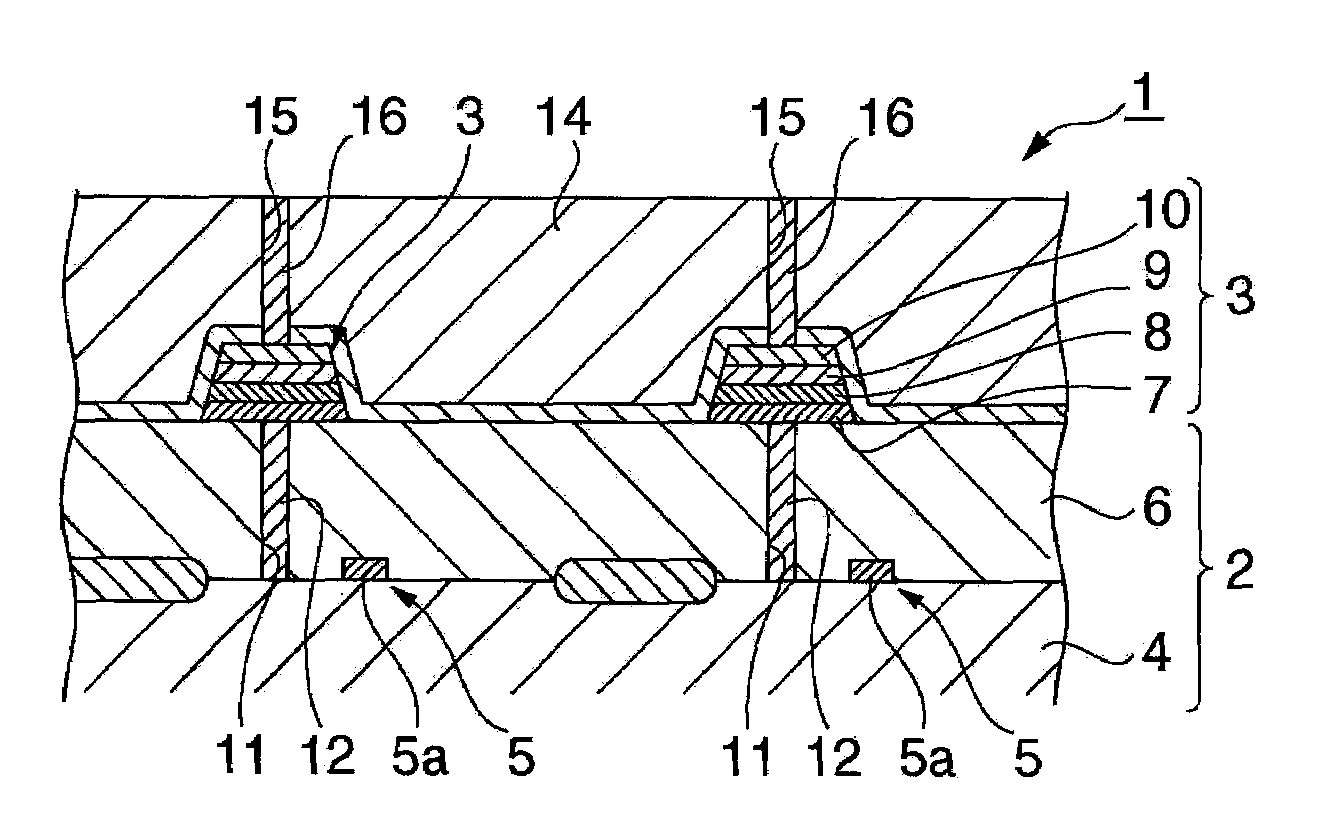

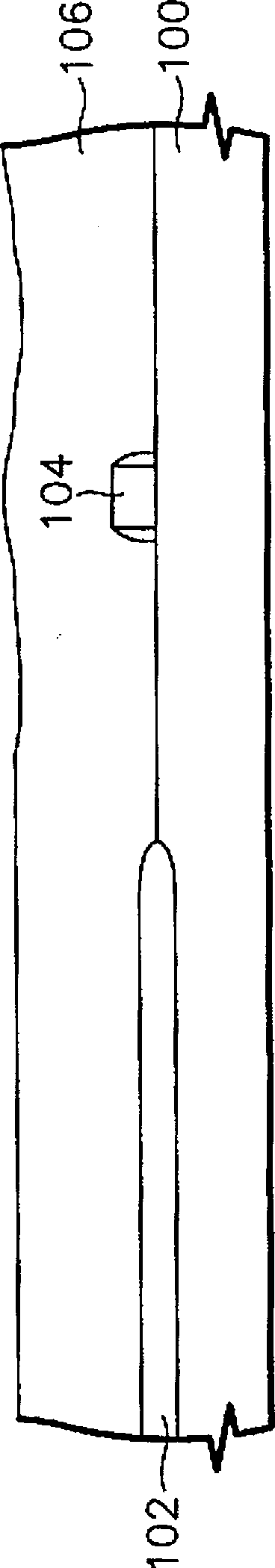

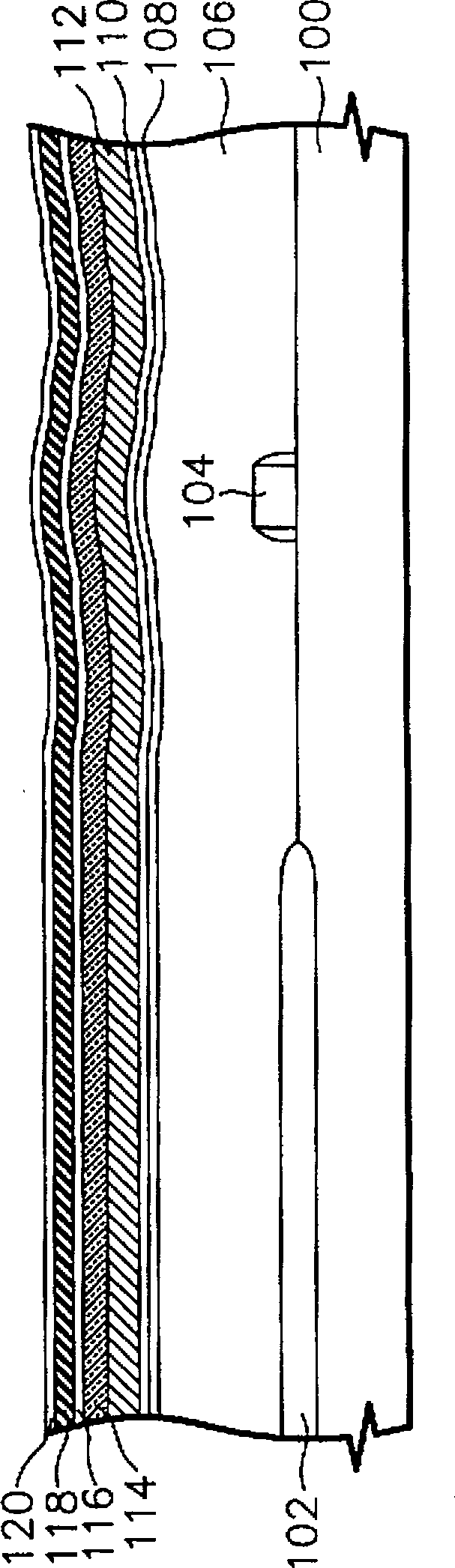

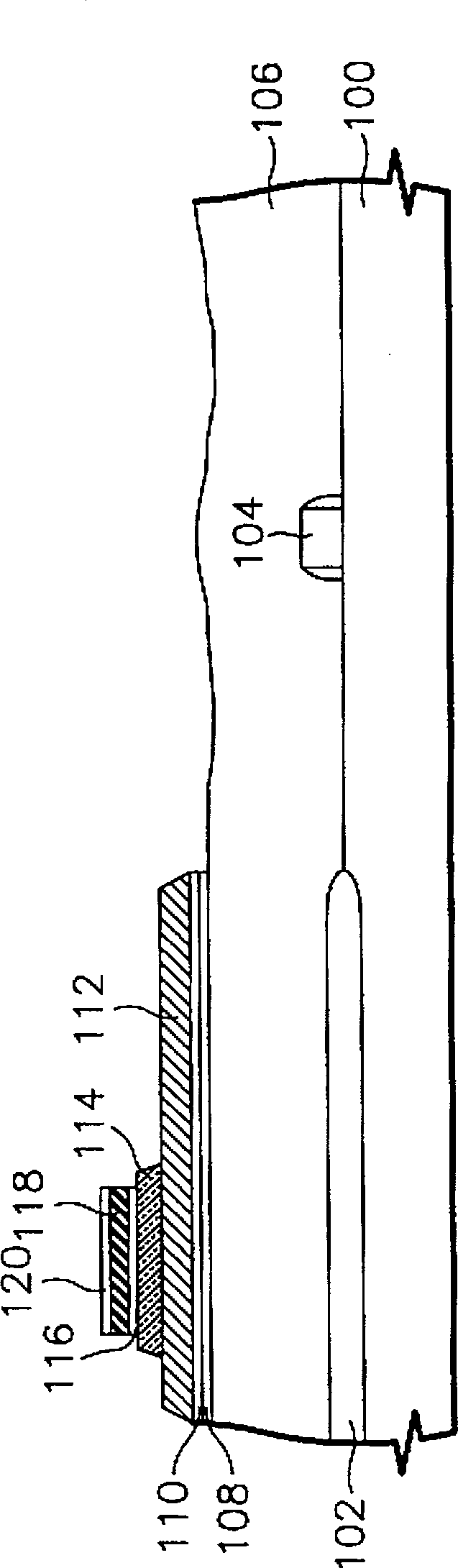

Semiconductor memory device and production method of the same

InactiveUS6313539B1Good ferroelectric propertiesHigh yieldTransistorSemiconductor/solid-state device detailsElectrical connectionEngineering

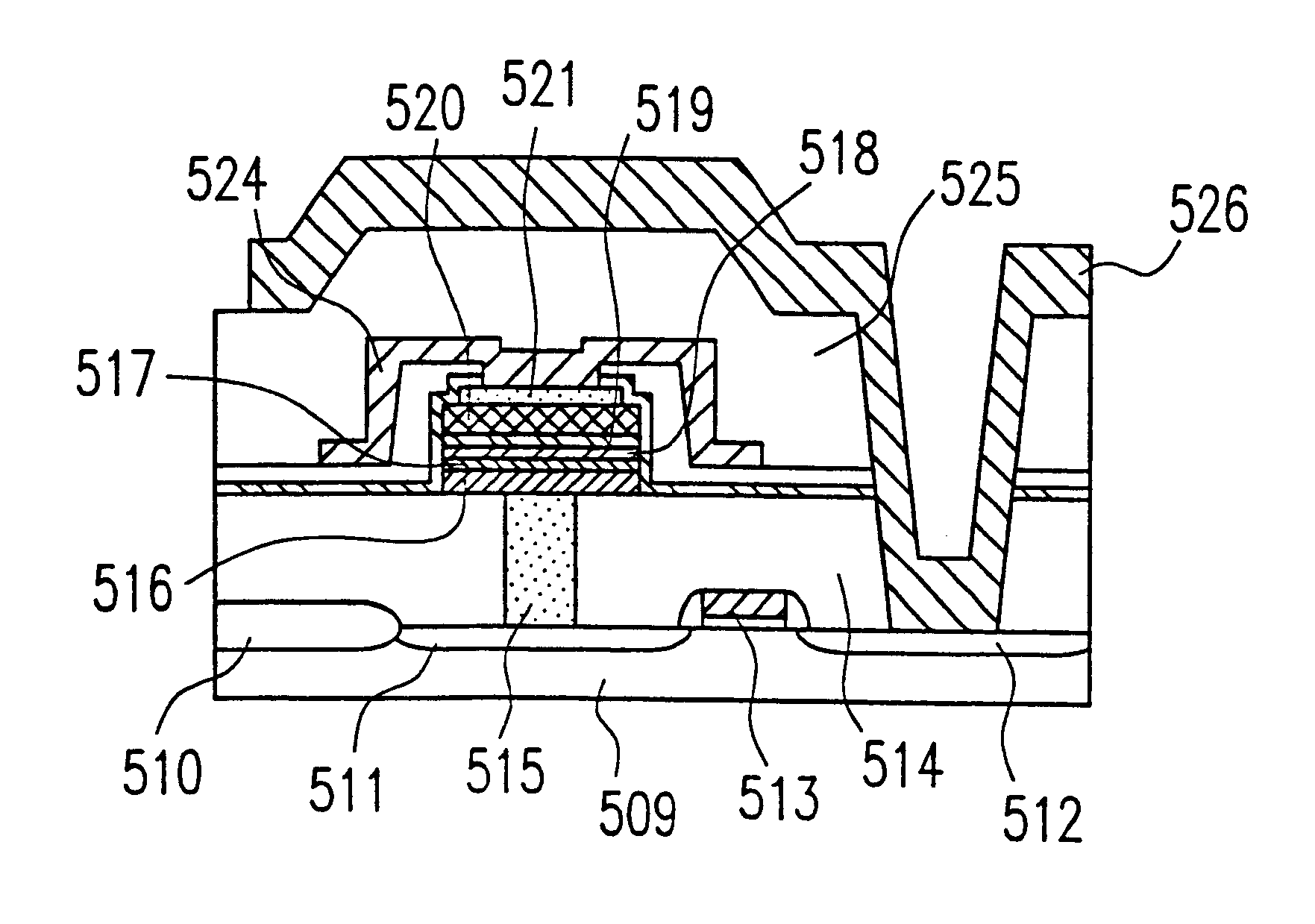

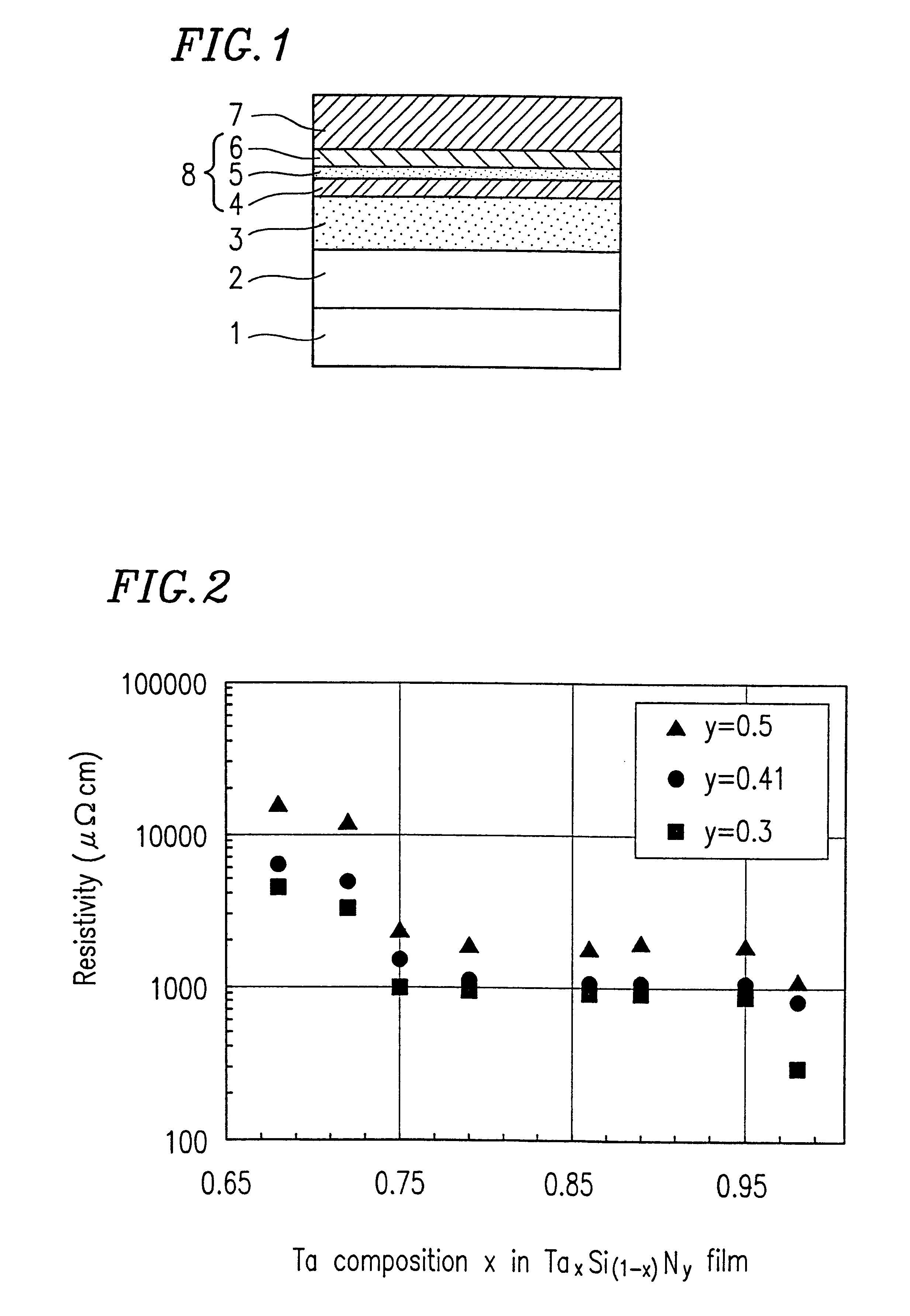

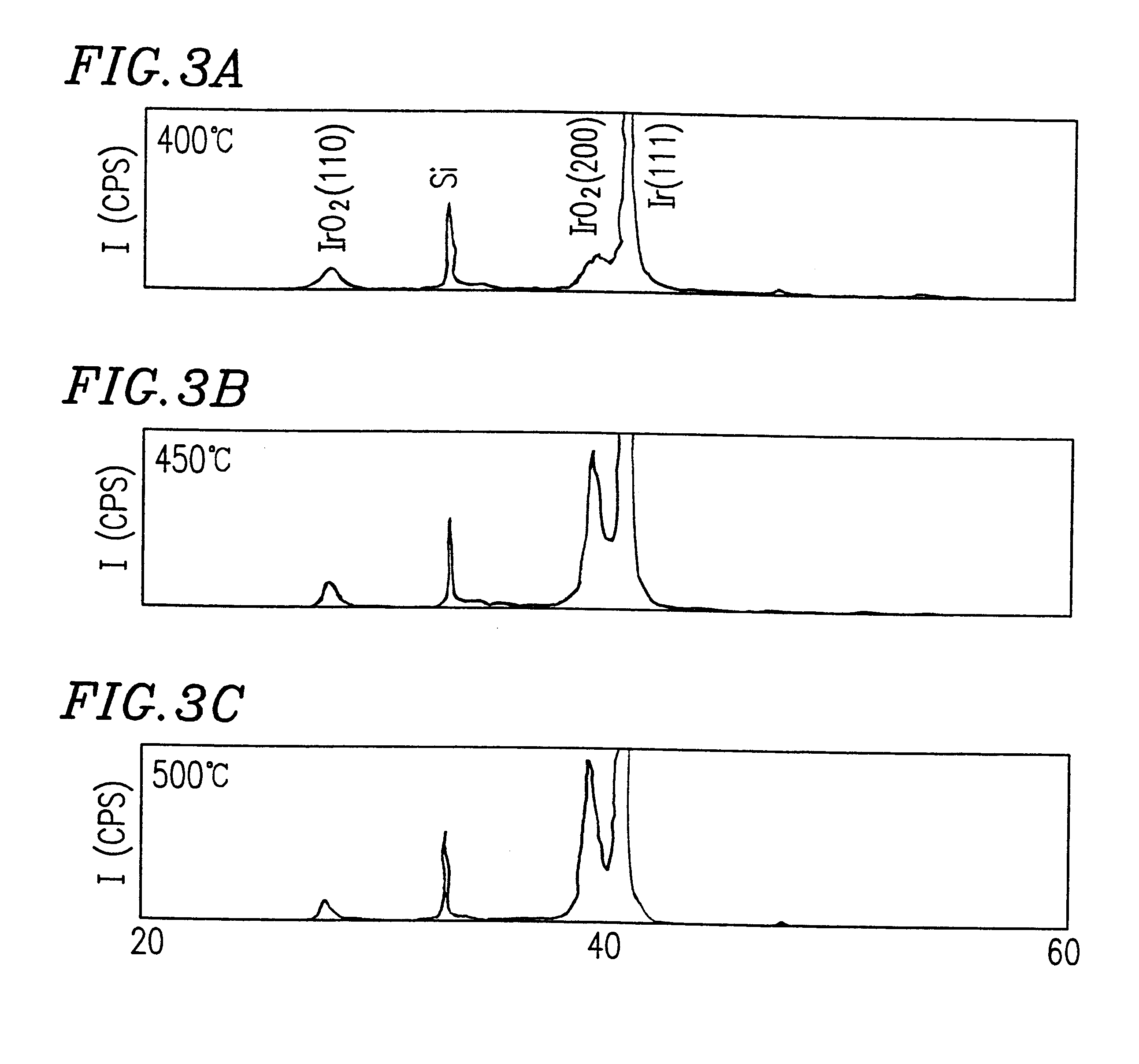

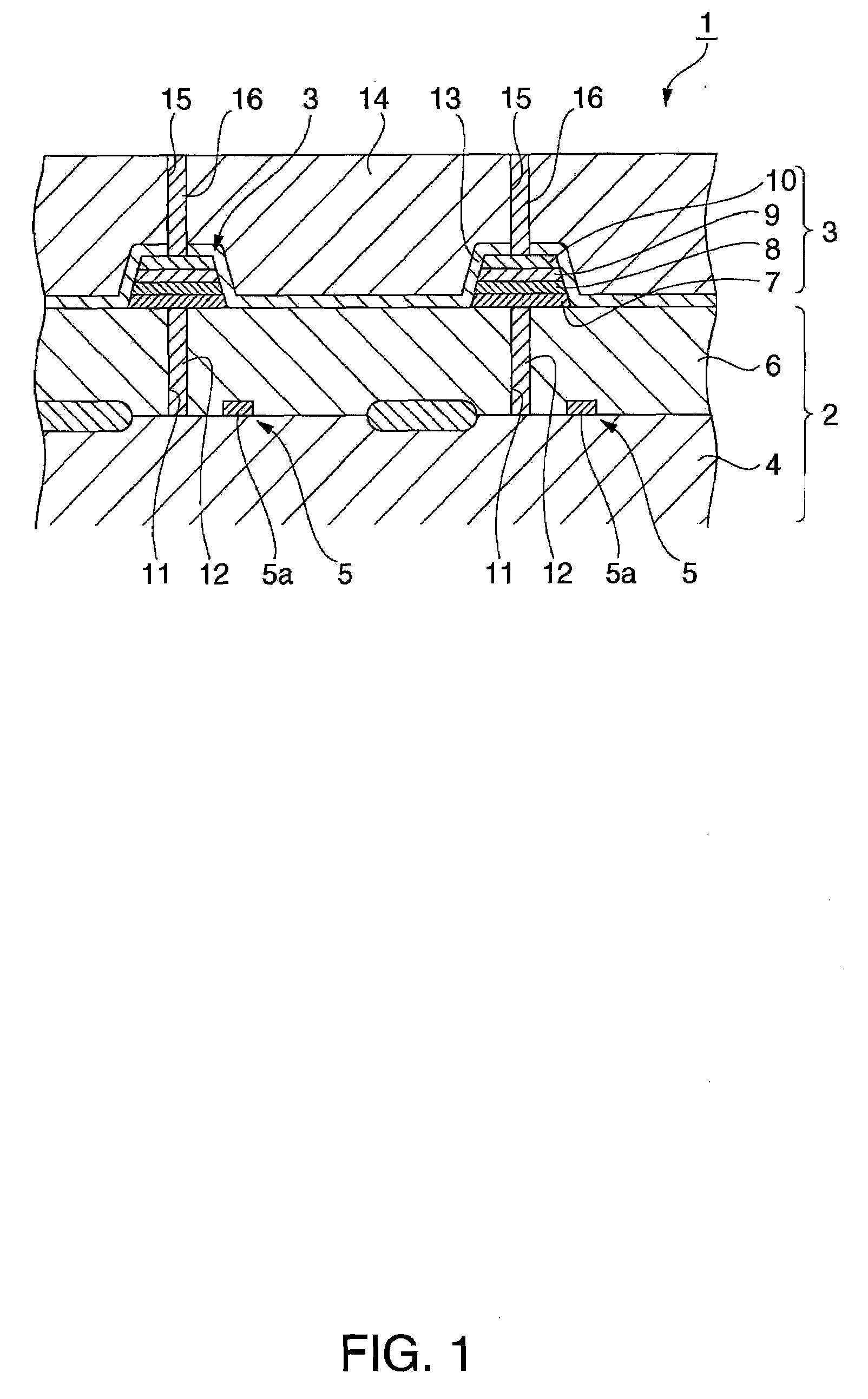

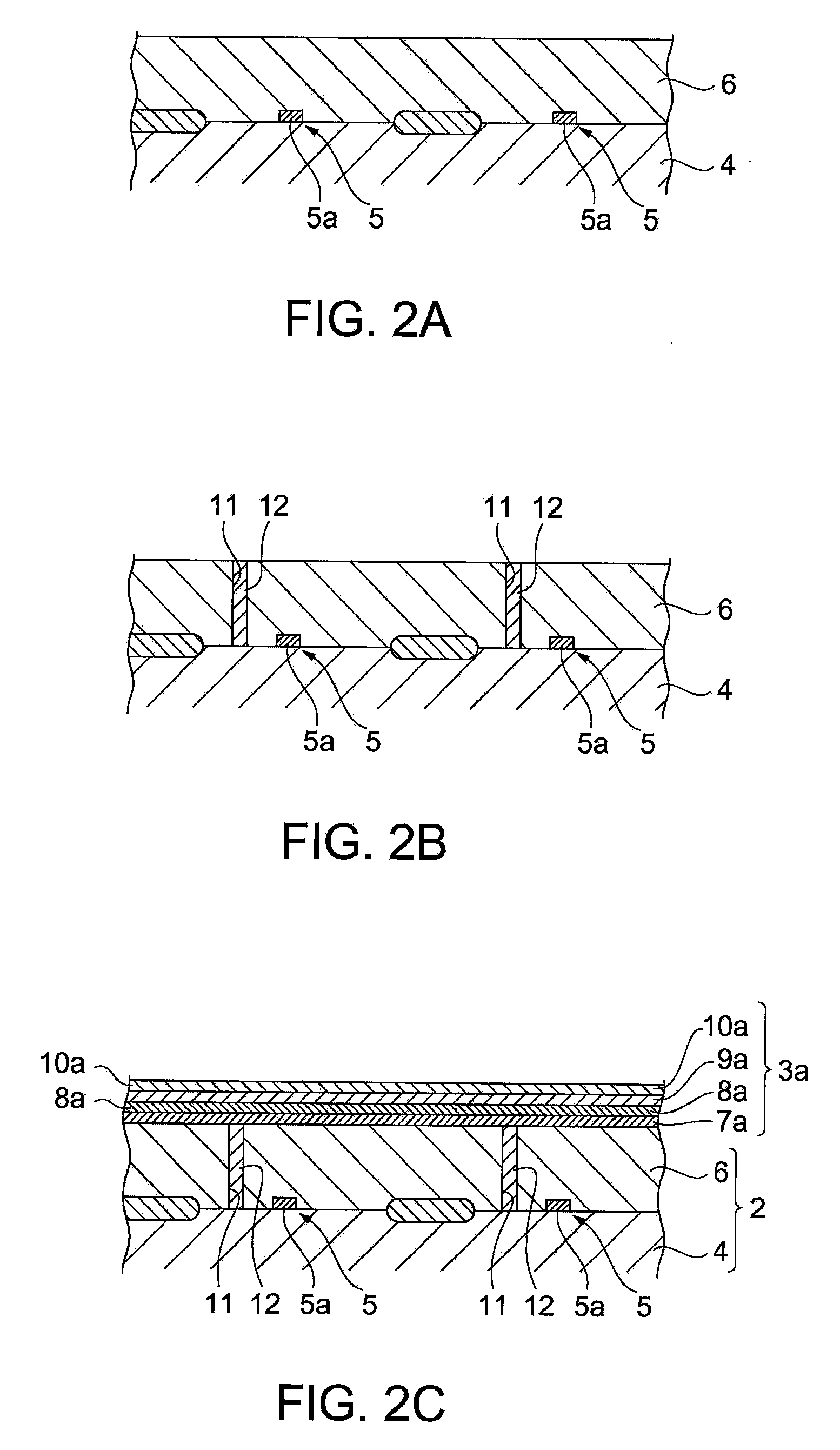

A semiconductor memory device includes: a capacitor formed on a substrate and including a lower electrode, a dielectric film and an upper electrode; a selection transistor formed at the substrate; an electrically conductive plug for providing electrical connection between the selection transistor and the capacitor; and a diffusion barrier film provided between the electrically conductive plug and the lower electrode of the capacitor. The diffusion barrier film is a TaxSi1-xNy film or a HfxSi1-xNy film (where 0.2<x<1 and 0<y<1). The lower electrode includes an Ir film and an IrO2 film which are sequentially formed.

Owner:SHARP KK

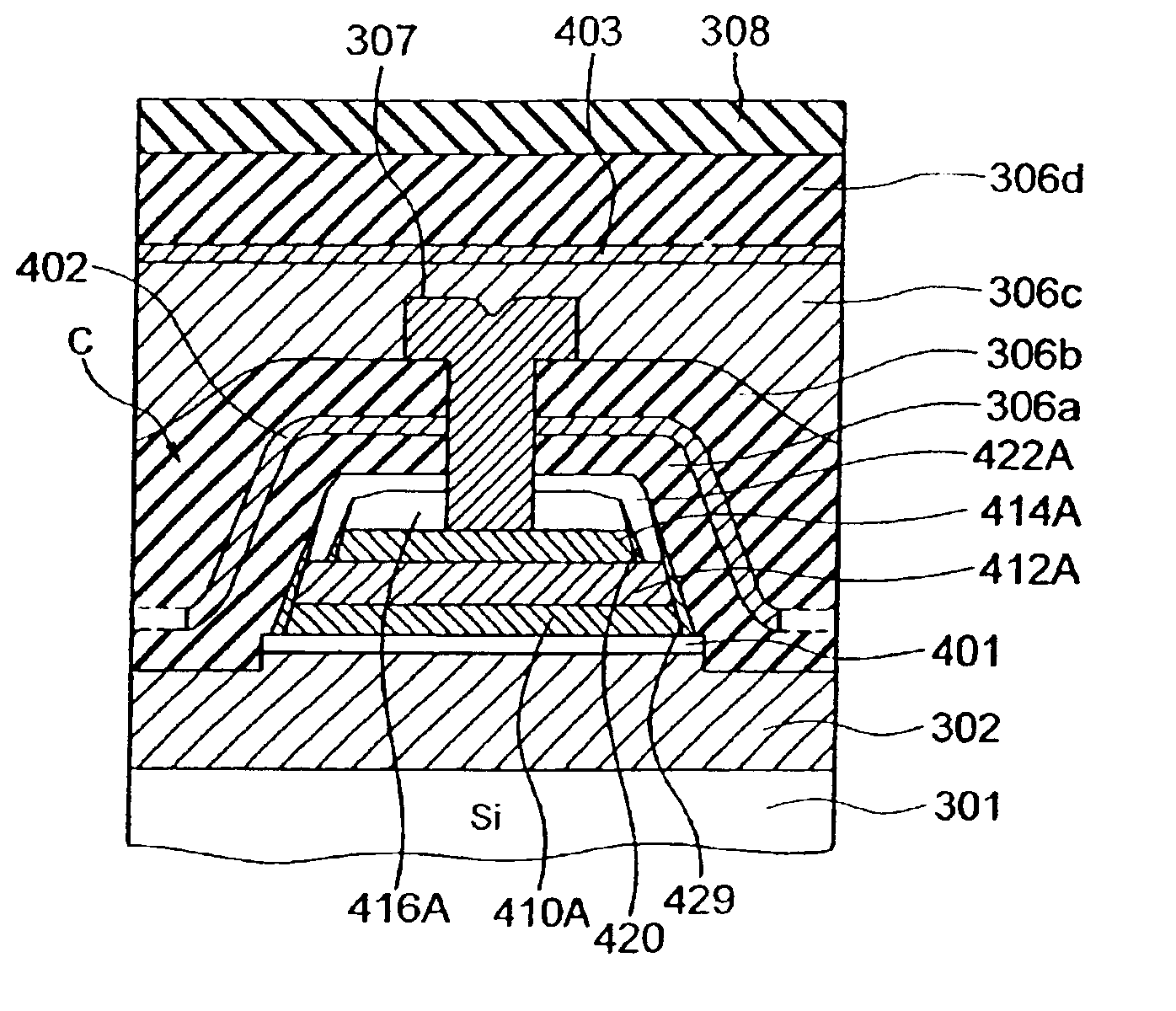

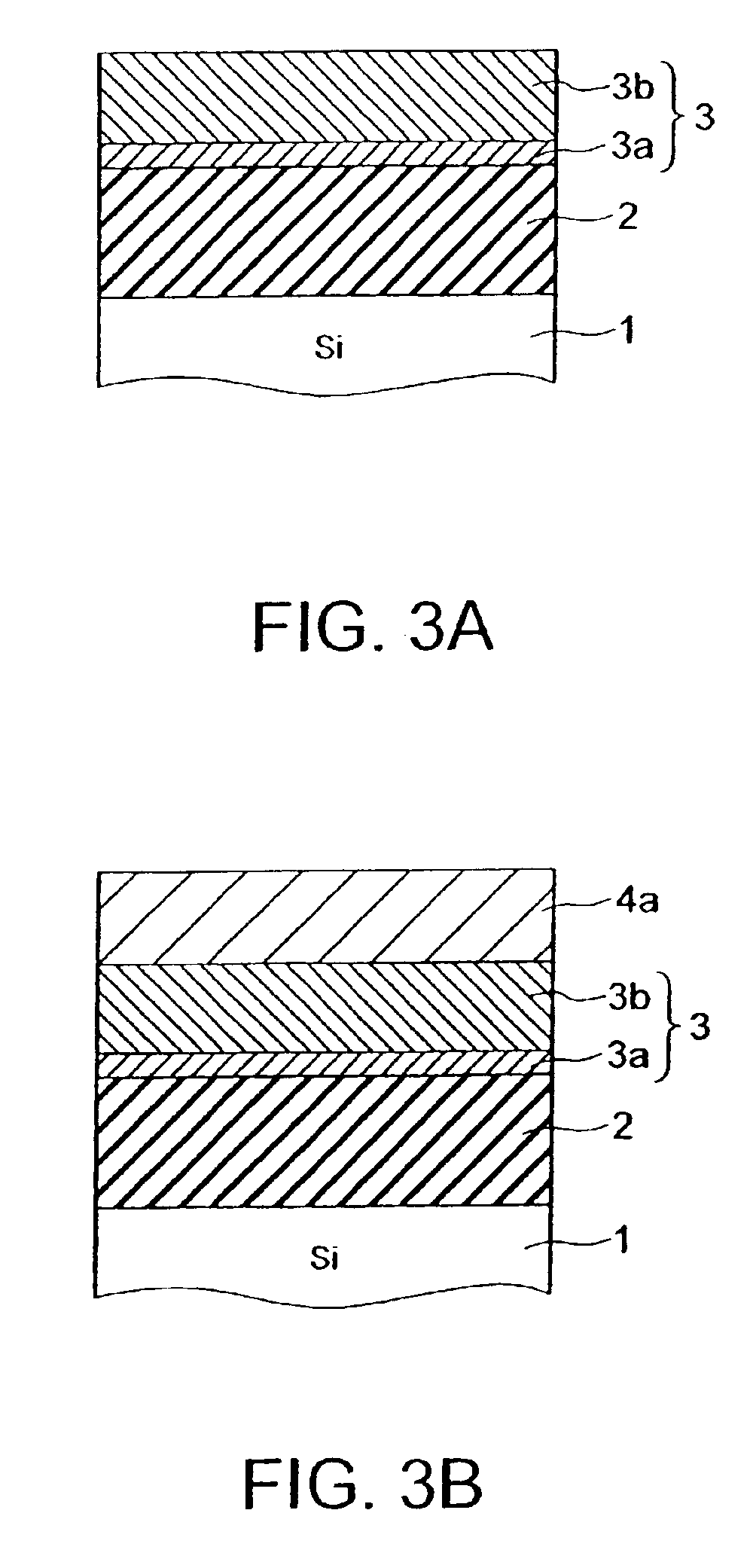

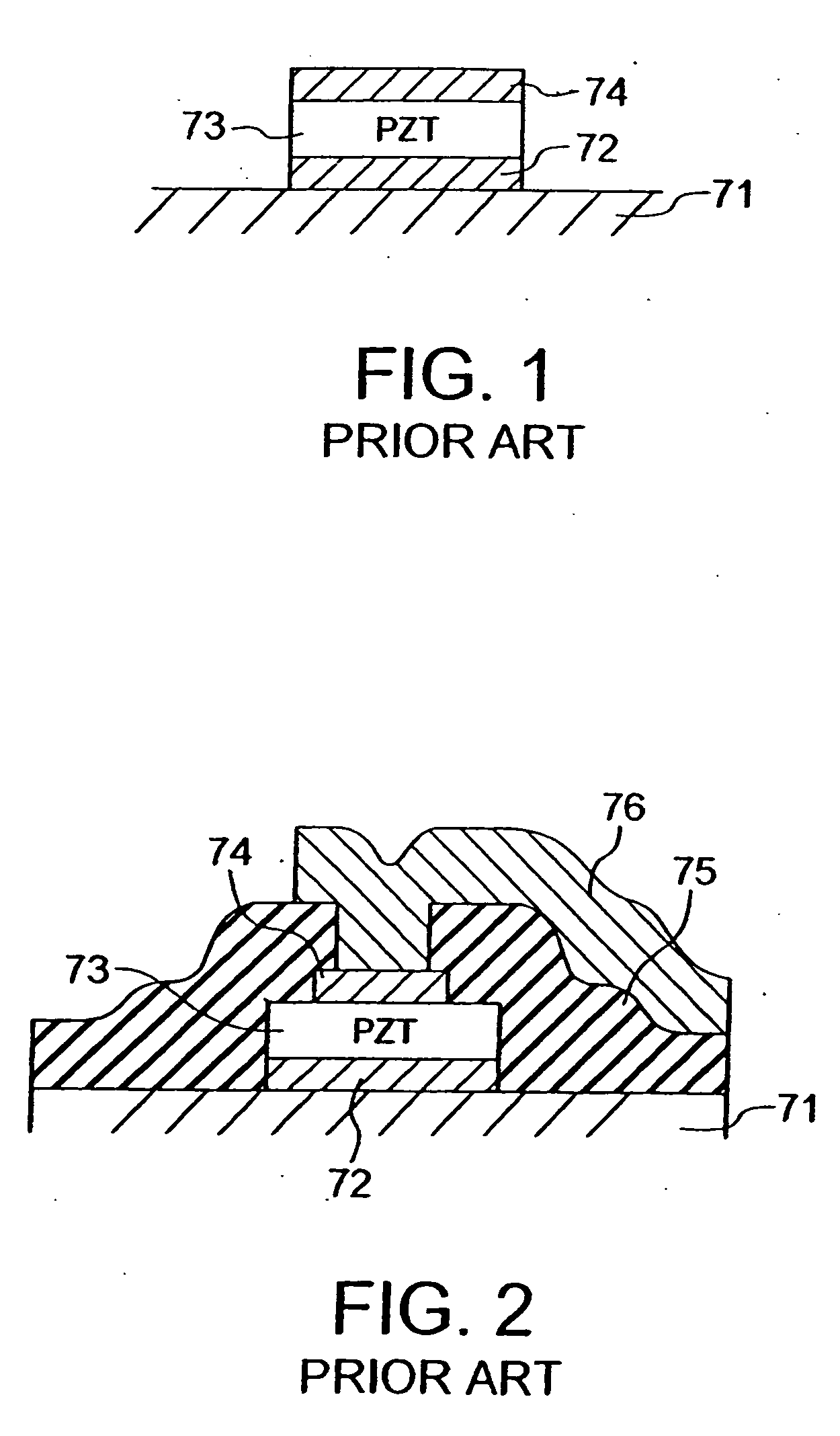

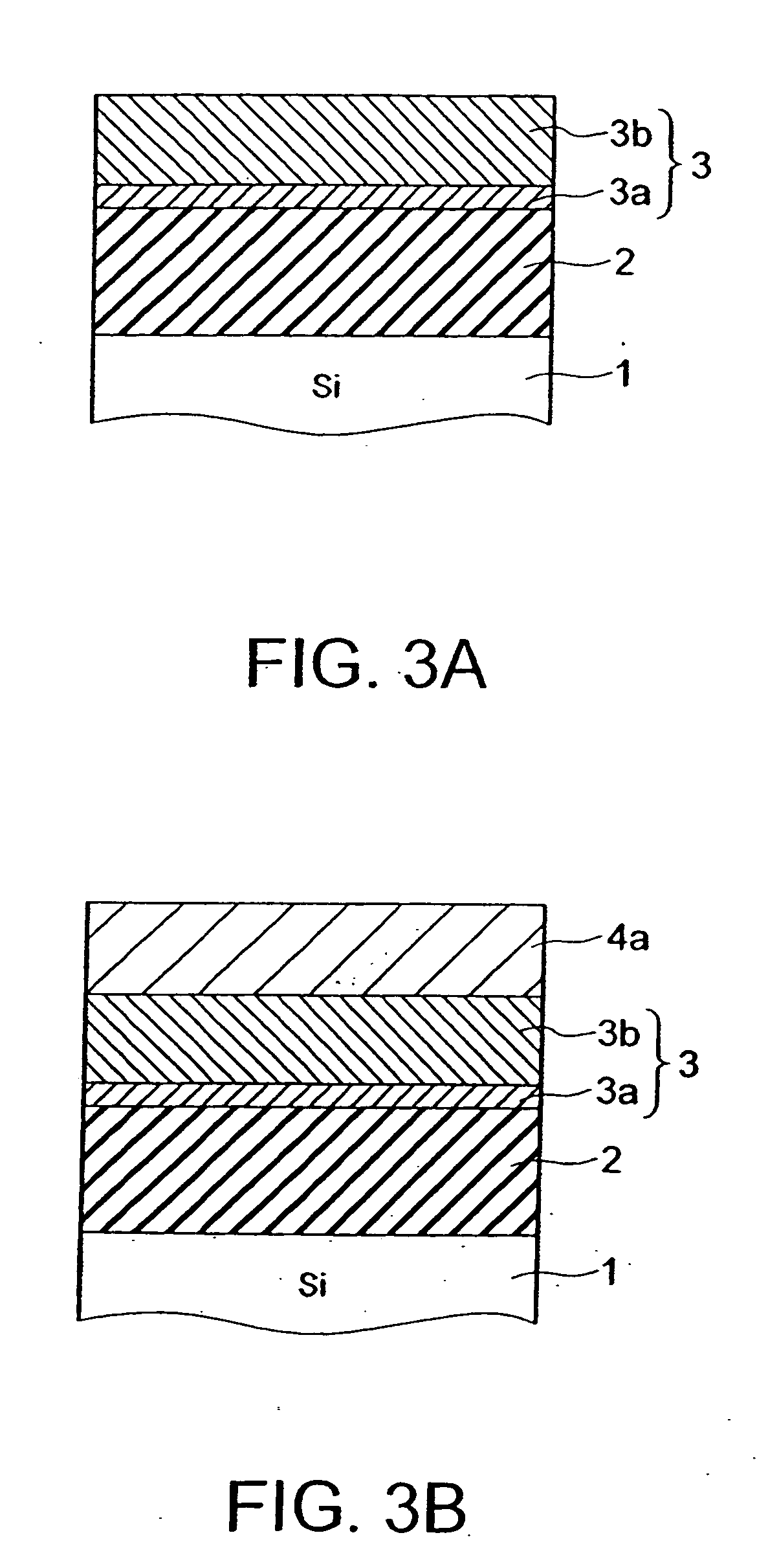

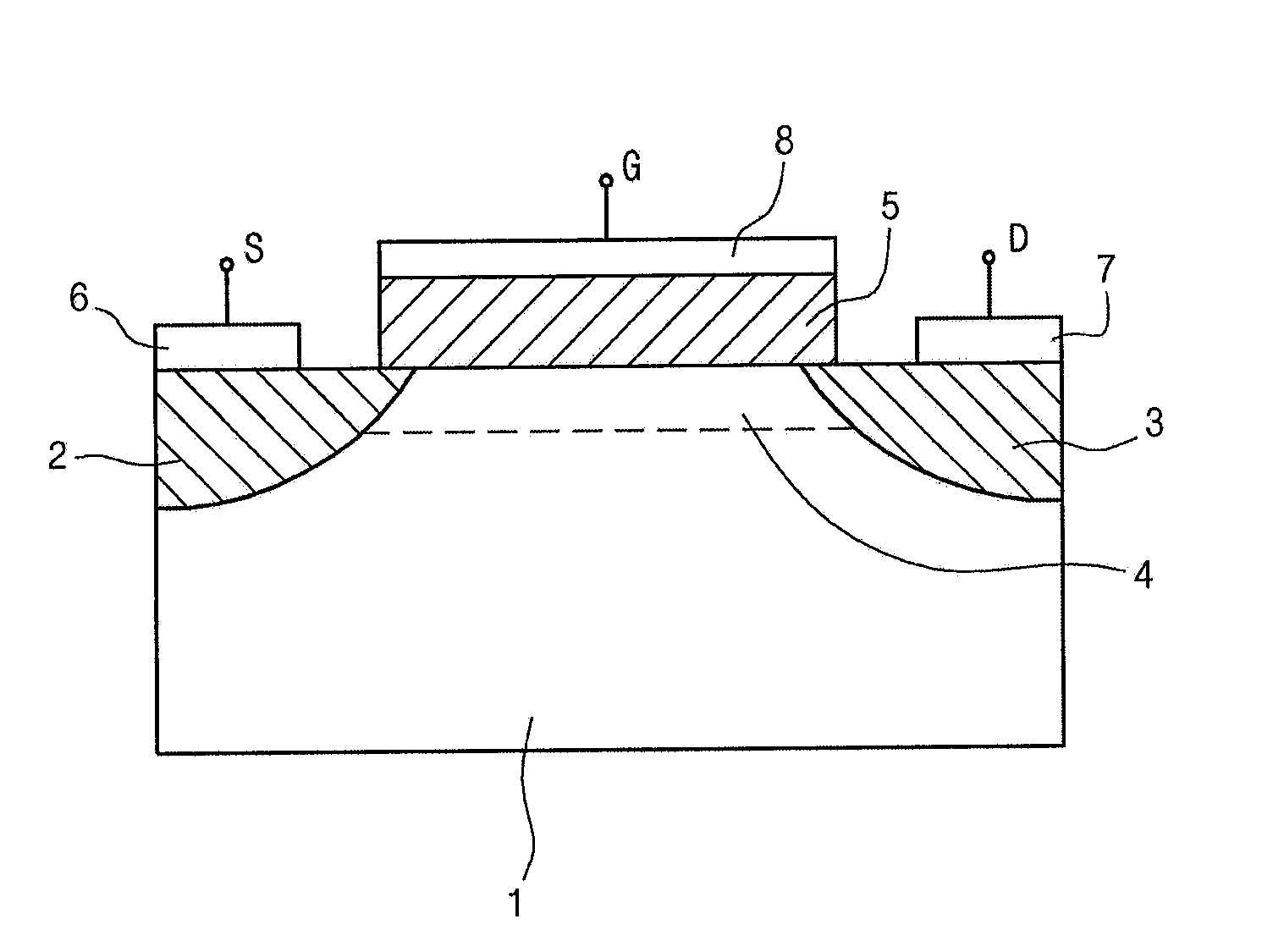

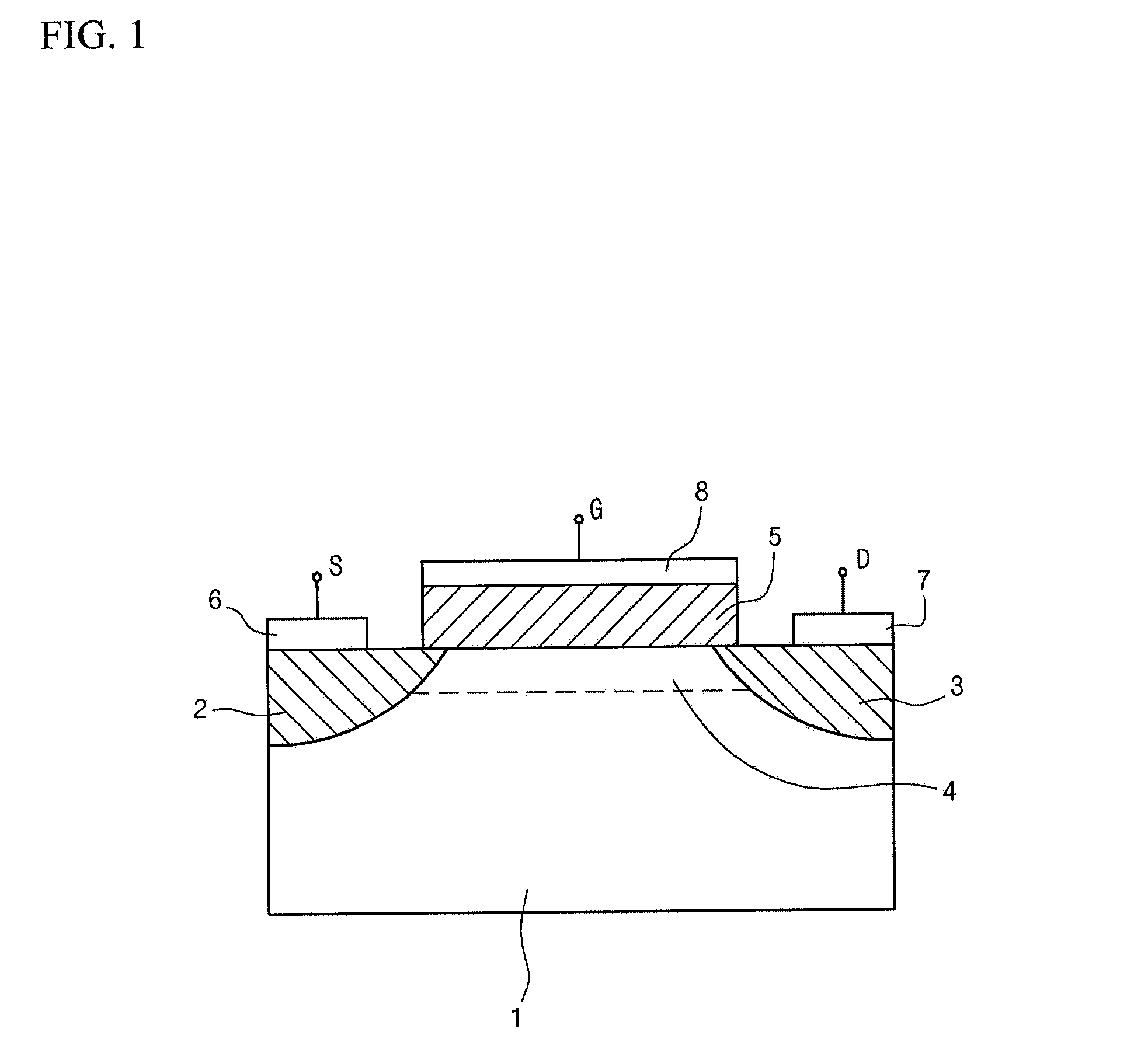

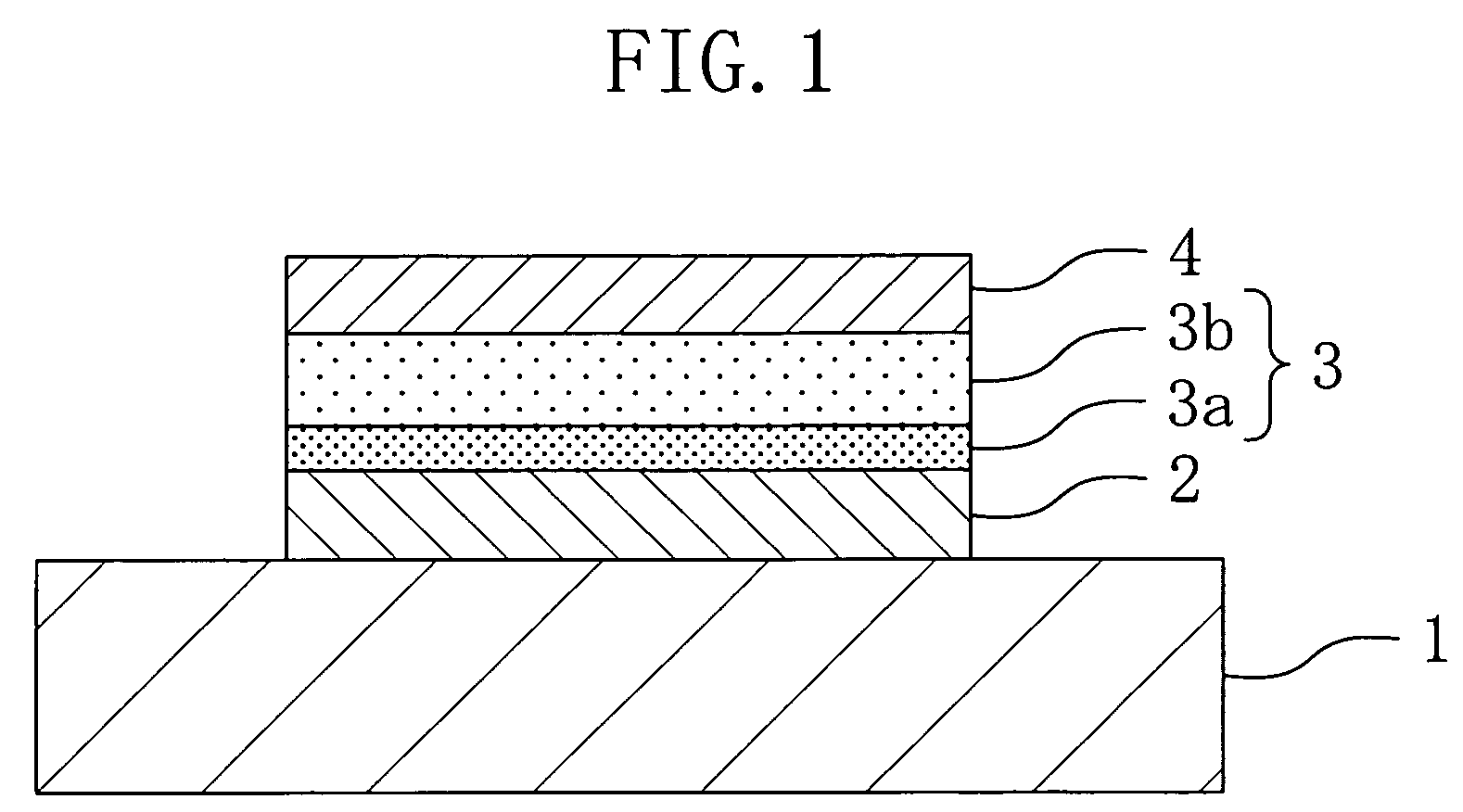

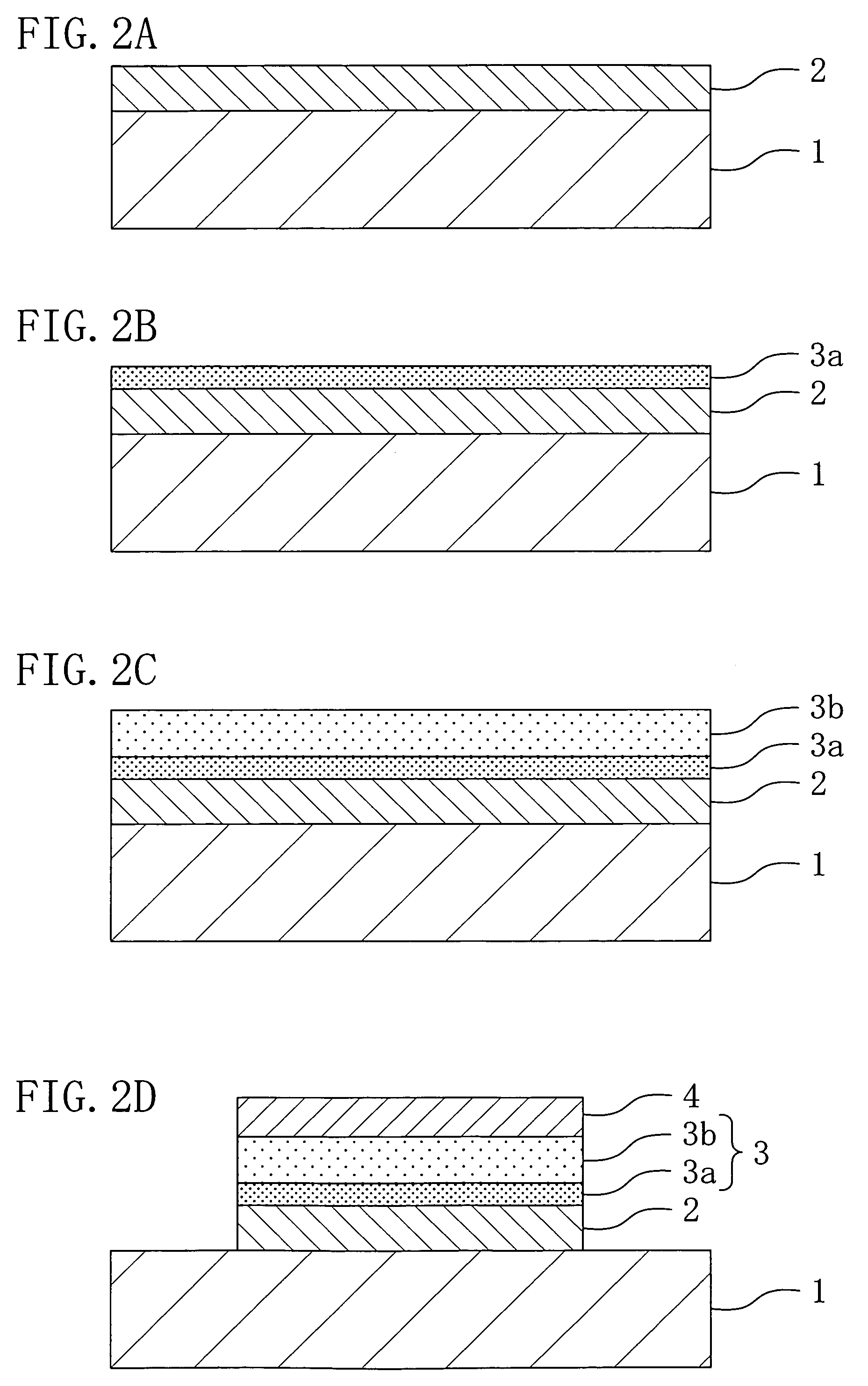

Ferroelectric memory device having a hydrogen barrier film

InactiveUS6982444B2Small degradation in characteristicGood ferroelectric propertiesTransistorSolid-state devicesHydrogenFerroelectric thin films

There is provided a semiconductor device having a ferroelectric capacitor formed on a semiconductor substrate covered with an insulator film, wherein the ferroelectric capacitor comprises: a bottom electrode formed on the insulator film; a ferroelectric film formed on the bottom electrode; and a top electrode formed on the ferroelectric film. The ferroelectric film has a stacked structure of either of two-layer-ferroelectric film or three-layer-ferroelectric film. The upper ferroelectric film is metallized and prevents hydrogen from diffusing in lower ferroelectric layer. Crystal grains of the stacked ferroelectric films are preferably different.

Owner:KK TOSHIBA

Semiconductor device and method for manufacturing the same

InactiveUS20060017086A1Small degradation in characteristicGood ferroelectric propertiesTransistorSolid-state devicesDevice materialEngineering

Owner:KK TOSHIBA

Liquid composition for forming ferroelectric thin film and process for producing ferroelectric thin film

InactiveUS20060046320A1Good ferroelectric propertiesReduce the temperatureAlkaline earth titanatesMaterial nanotechnologyLiquid mediumFerroelectric thin films

It is an object to provide a liquid composition for forming a thin film, with which a ferroelectric thin film having excellent characteristics can be prepared even by baking at a low temperature, and a process for producing a ferroelectric thin film using it. The above object is achieved by use of a liquid composition for forming a ferroelectric thin film, characterized in that in a liquid medium, ferroelectric oxide particles being plate or needle crystals, which are represented by the formula ABO3 (wherein A is at least one member selected from the group consisting of Ba2+, Sr2+, Ca2+, Pb2+, La2+, K+ and Na+, and B is at least one member selected from the group consisting of Ti4+, Zr4+, Nb5+, Ta5+ and Fe3+) and have a Perovskite structure and which have an average primary particle size of at most 100 nm and an aspect ratio of at least 2, are dispersed, and a soluble metal compound which forms a ferroelectric oxide by heating, is dissolved.

Owner:ASAHI GLASS CO LTD

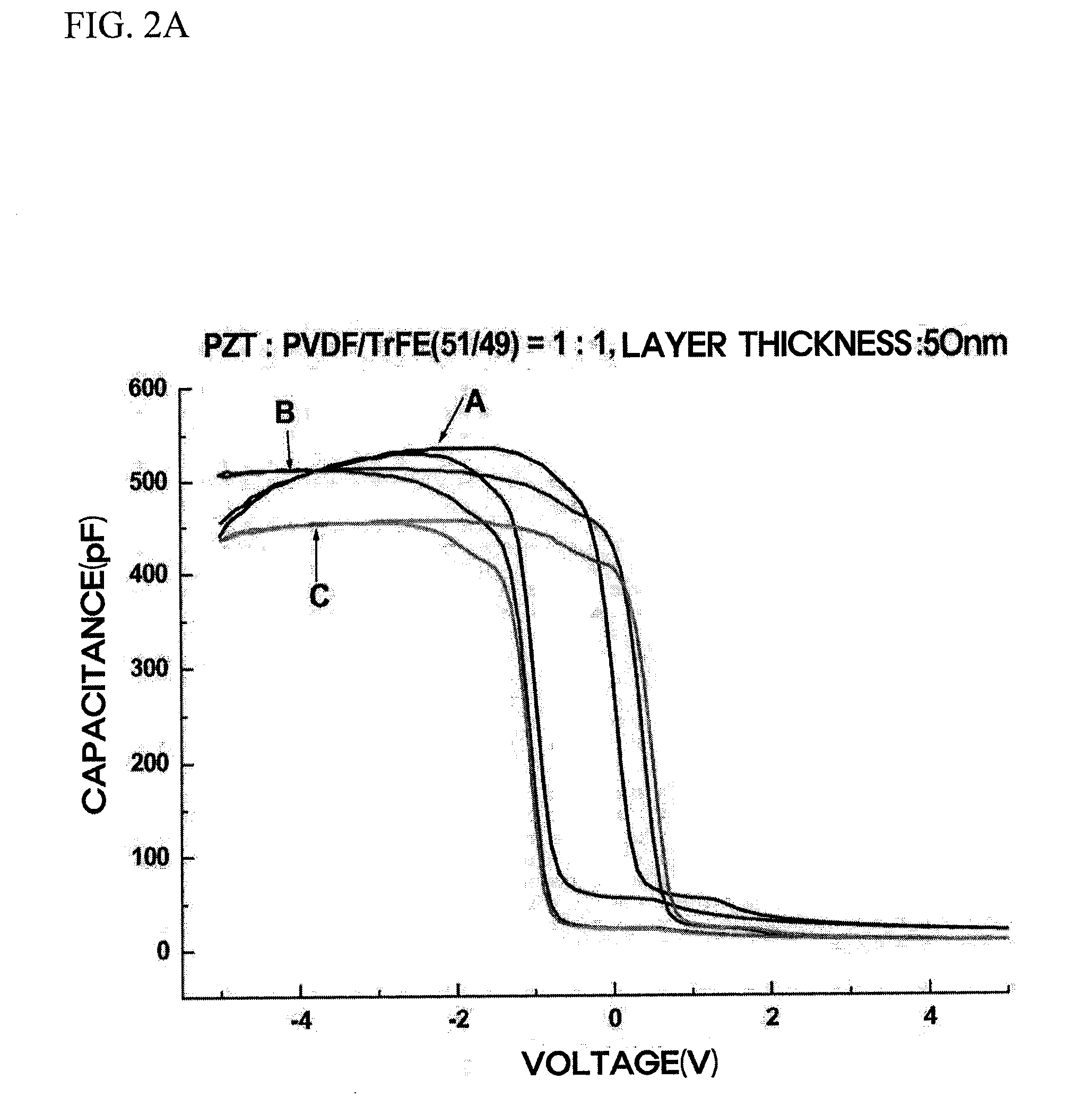

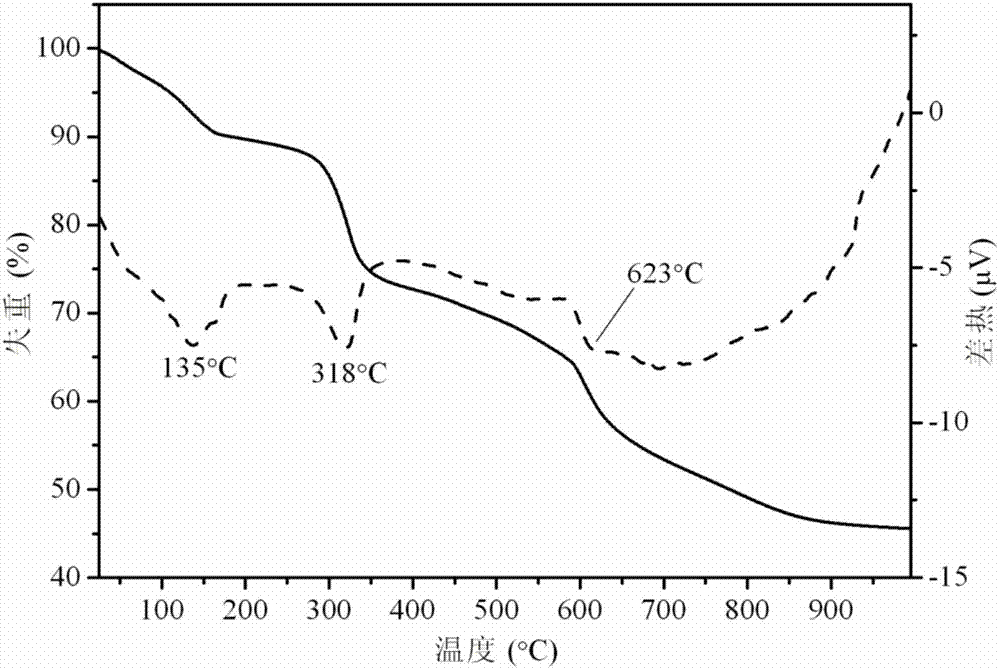

Ferroelectric material and method of forming ferroelectric layer using the same

InactiveUS20100215836A1Good ferroelectric propertiesConductive materialSolid-state devicesMaterials scienceFerric

Disclosed herein are a ferroelectric material that can be effectively used in manufacturing various electric and electronic elements, and a method of forming a ferroelectric layer using the ferroelectric material. The ferroelectric material in accordance with the present invention is composed of a mixture of an inorganic ferroelectric material and an organic ferroelectric material. The method of forming a ferroelectric layer includes: preparing a mixed solution of an inorganic ferroelectric material and an organic material; forming a ferroelectric film by applying the mixed solution onto a substrate; and forming a ferroelectric layer by annealing the ferroelectric film.

Owner:UNIV OF SEOUL IND COOPERATION FOUND

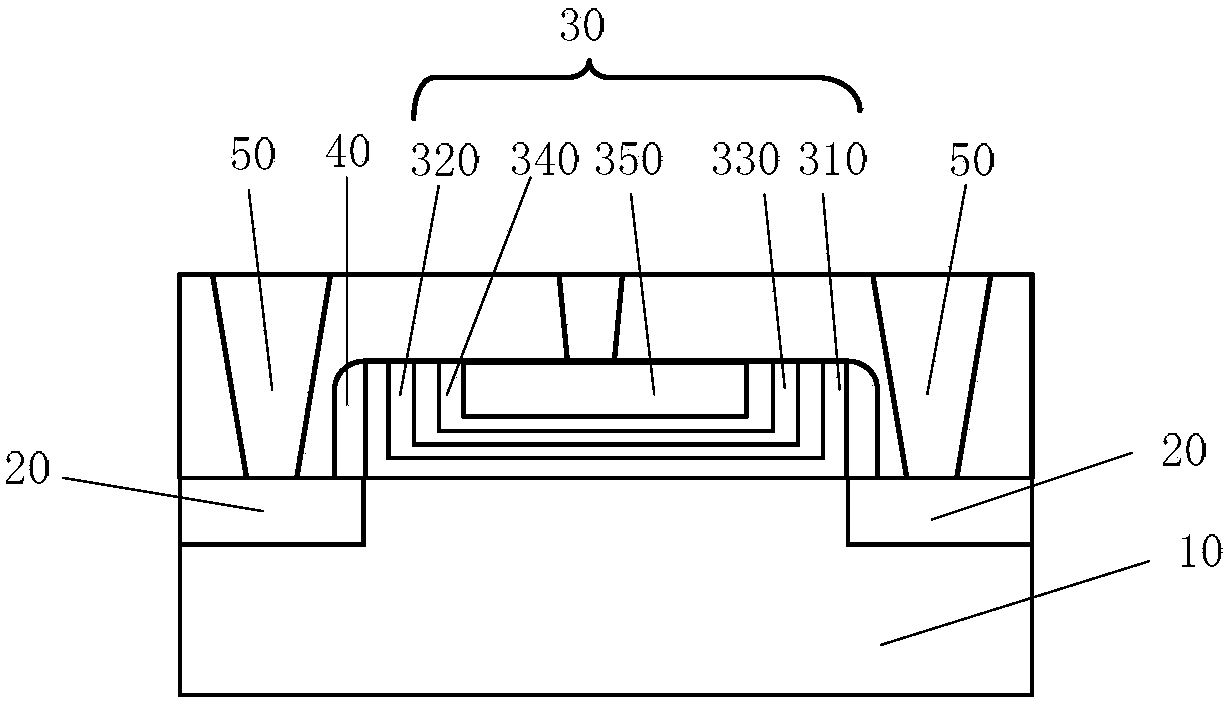

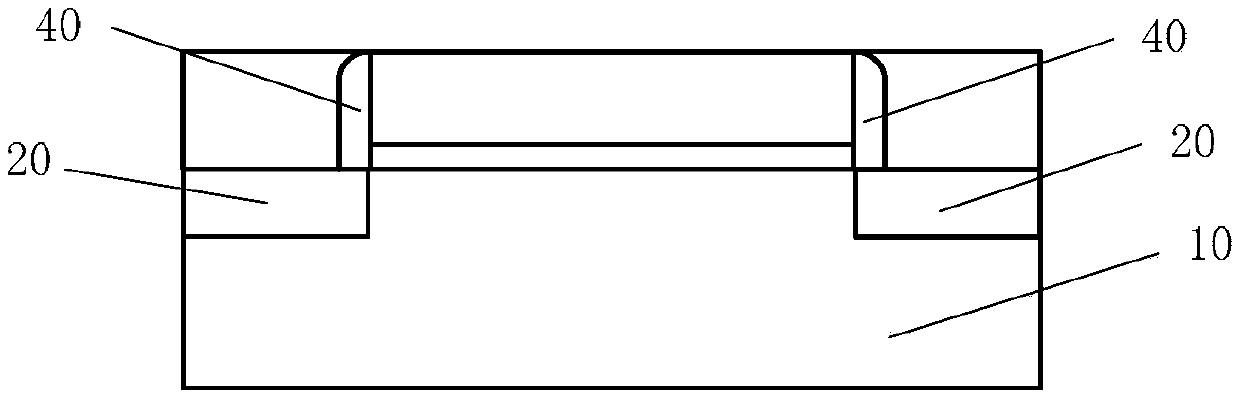

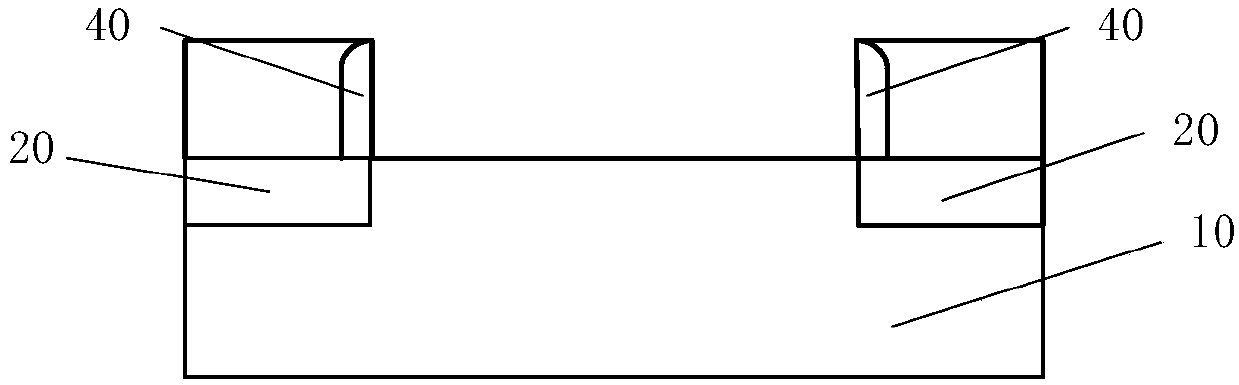

Ferroelectric field effect transistor and preparation method thereof

ActiveCN108091693AGuaranteed to workGood ferroelectric propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricGate stack

The invention provides a ferroelectric field effect transistor and a preparation method thereof. The ferroelectric field effect transistor includes a substrate, a source / drain, a gate stack, and sidewalls. The gate stack is composed of a gate dielectric layer, a lower electrode layer, a ferroelectric layer, an insulating dielectric layer, and a gate electrode stacked sequentially in a direction away from the substrate. Since the lower electrode and the ferroelectric layer of the ferroelectric field effect transistor are separated from the gate electrode through the insulating dielectric layer,the purpose of improving the ferroelectric characteristics of the ferroelectric layer and reducing the leakage between the lower electrode and the gate electrode can be achieved. The device operatingcharacteristics are improved and the proper operation of the ferroelectric field effect transistor can be ensured.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

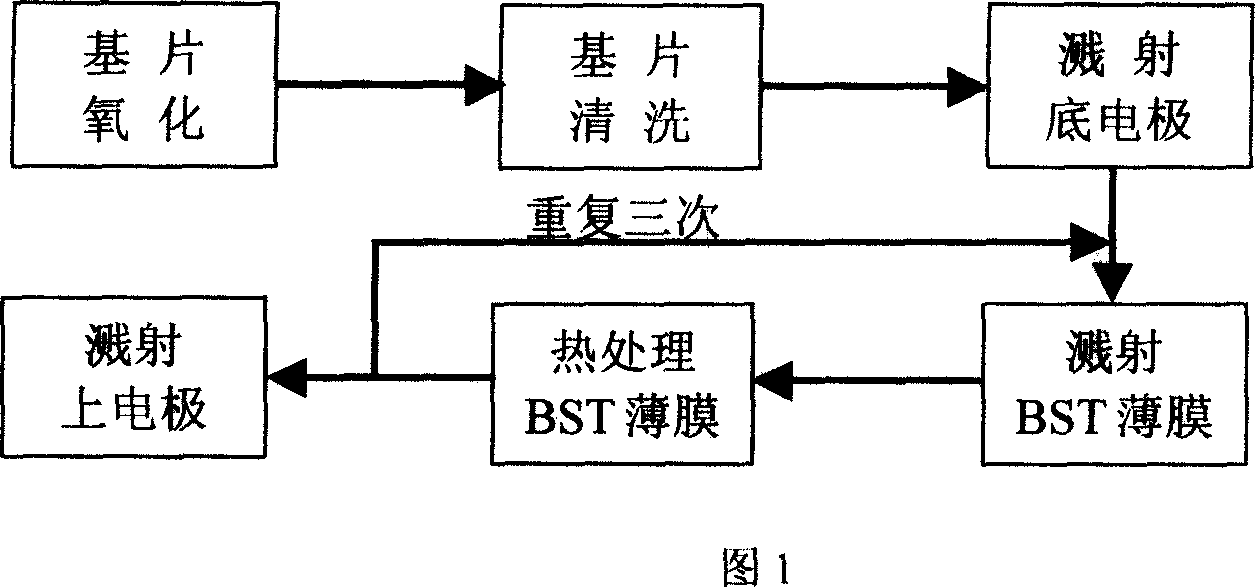

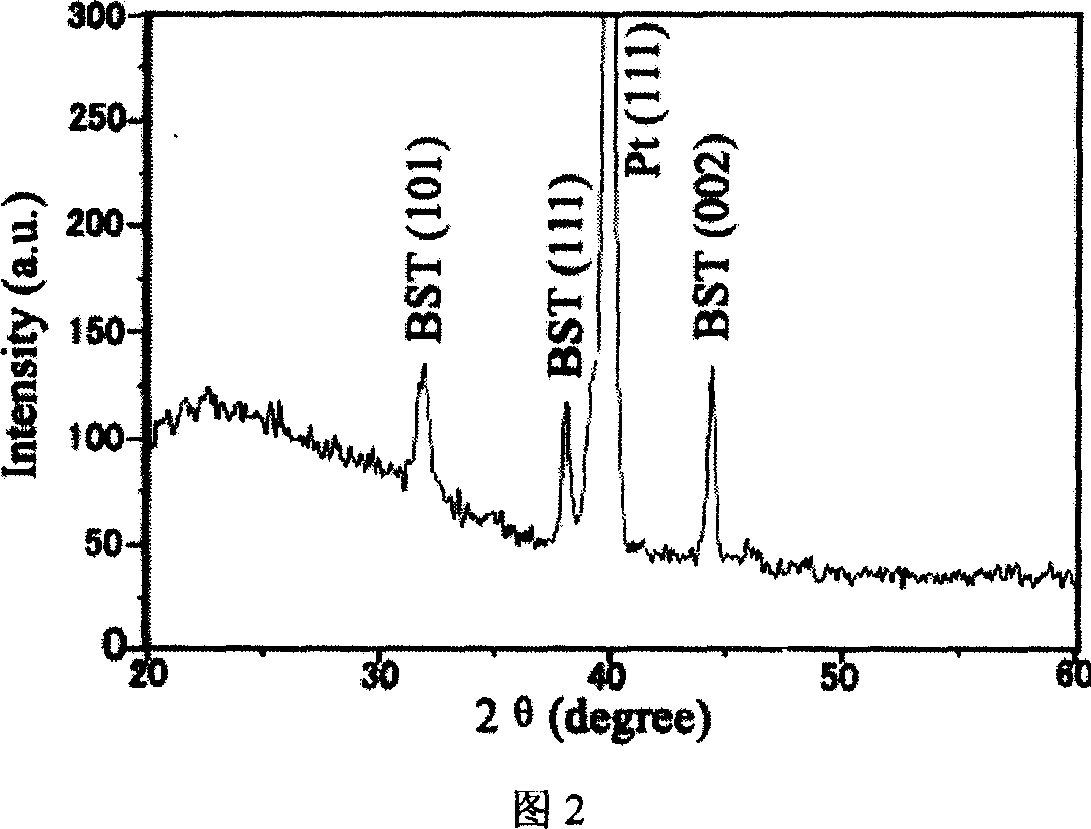

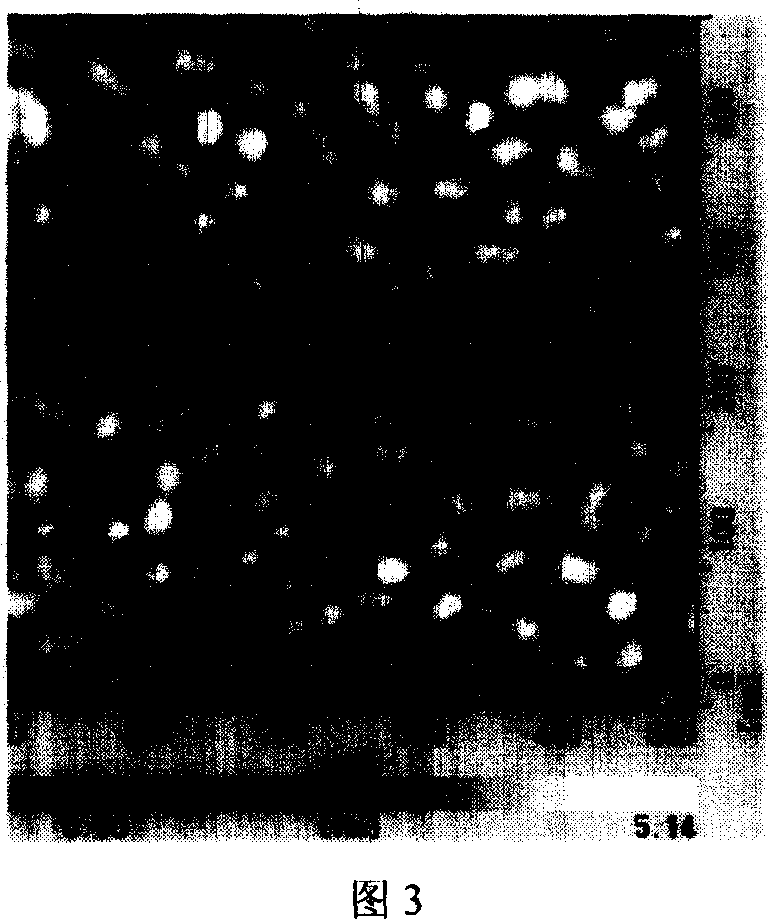

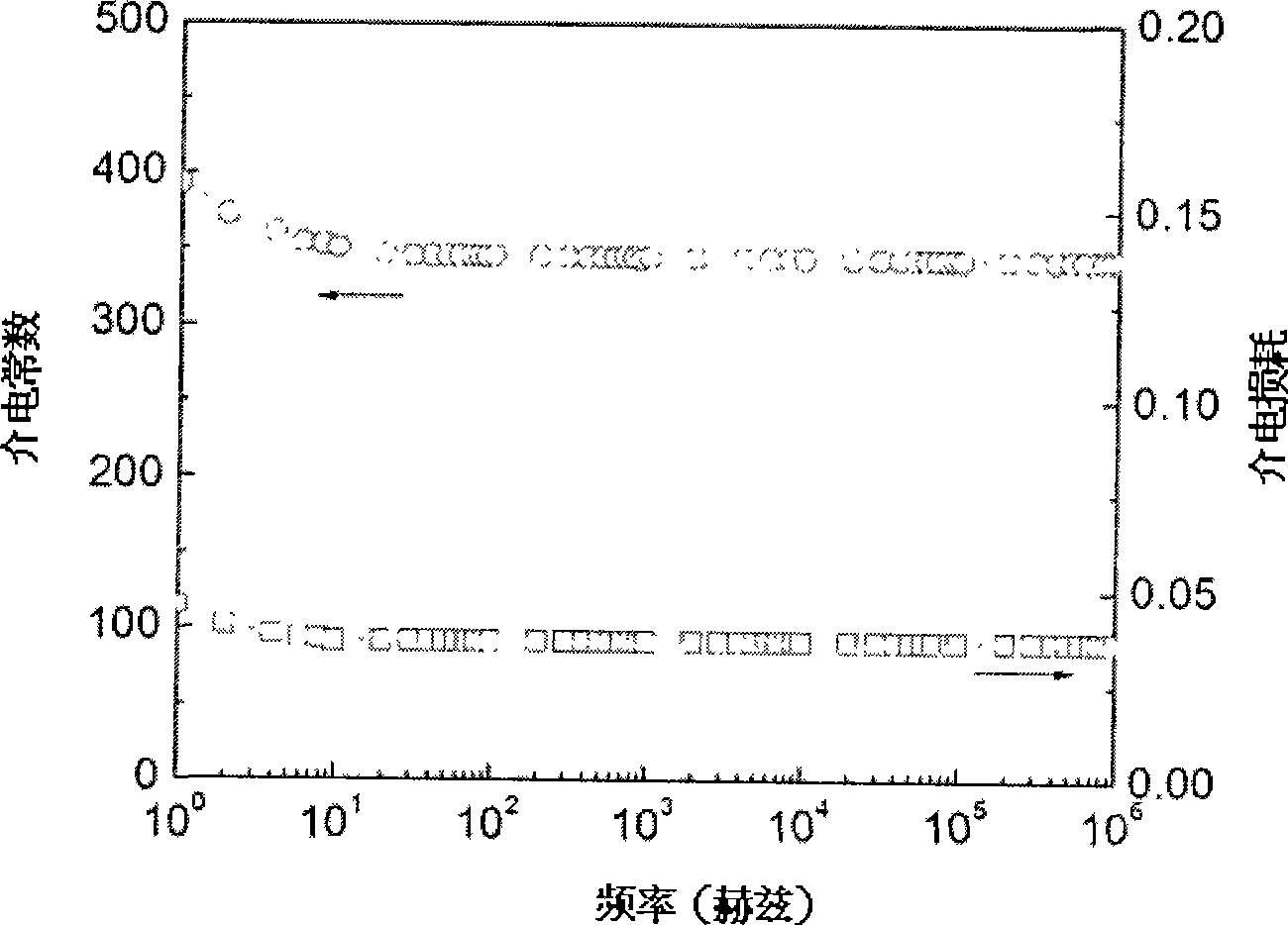

Prepn process of boron strontium titanate film material

InactiveCN1932080AUniform grain sizeGood ferroelectric propertiesVacuum evaporation coatingSputtering coatingIr detectorDirect current magnetron sputtering

The present invention discloses preparation process of boron strontium titanate (BST) film material. The preparation process includes the first magnetically controlled DC sputtering to prepare Pt / Ti bottom electrode, pre-sputtering BaxSr1-xTiO3 ceramic target material with magnetically controlled RF sputtering apparatus to form BST film, slow heat treatment in O2 atmosphere and repeating the foregoing steps for three times; and final magnetically controlled DC sputtering to prepare upper electrode on the BST film so as to obtain sandwiched material. The said process can obtain ferroelectric BST film with high ferroelectric performance in perovskite structure and homogeneous crystal particle size. The ferroelectric BST film may be used in DRAM, dielectric phase shifter, voltage controlled filter, pyroelectric IR detector and other fields.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

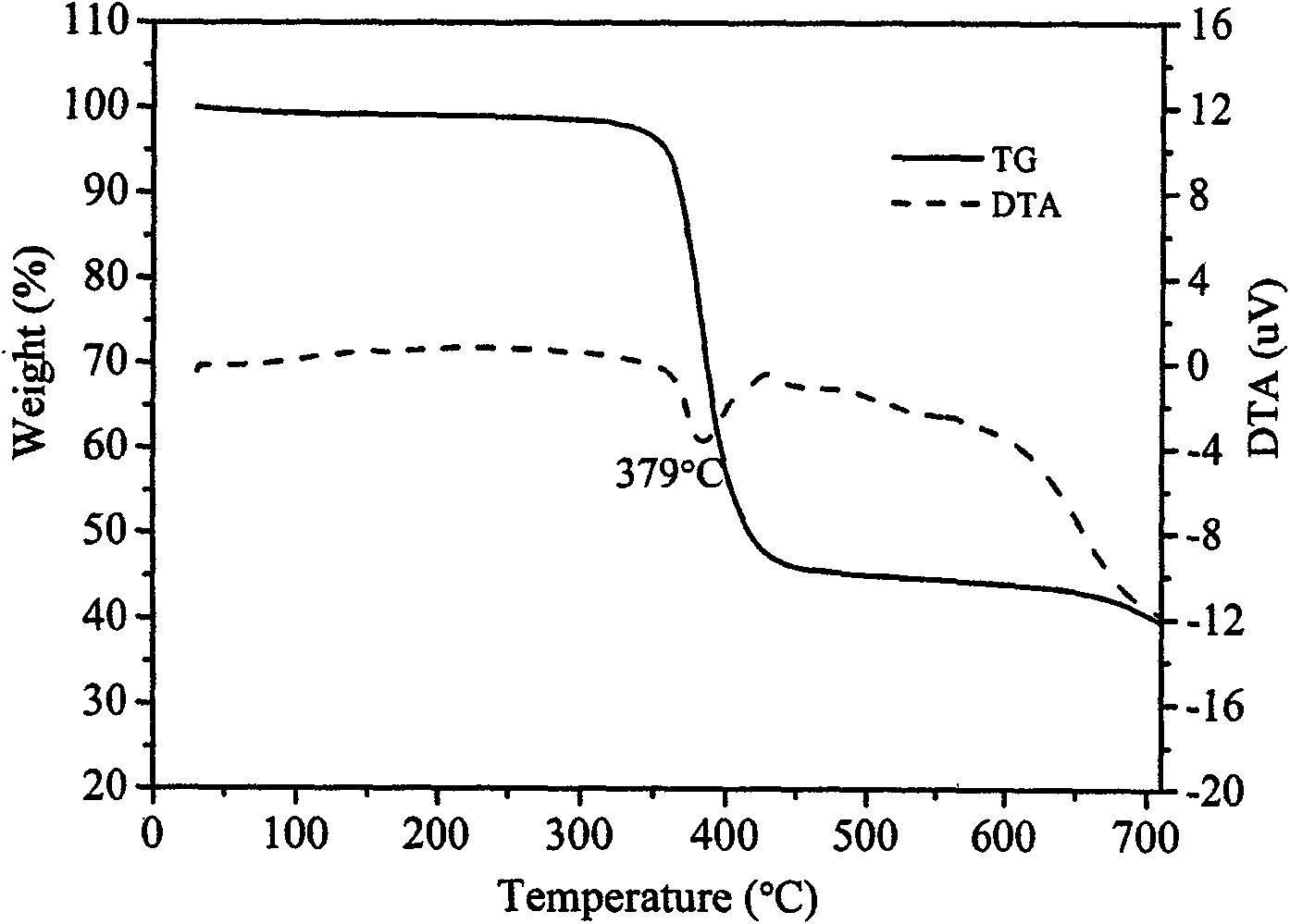

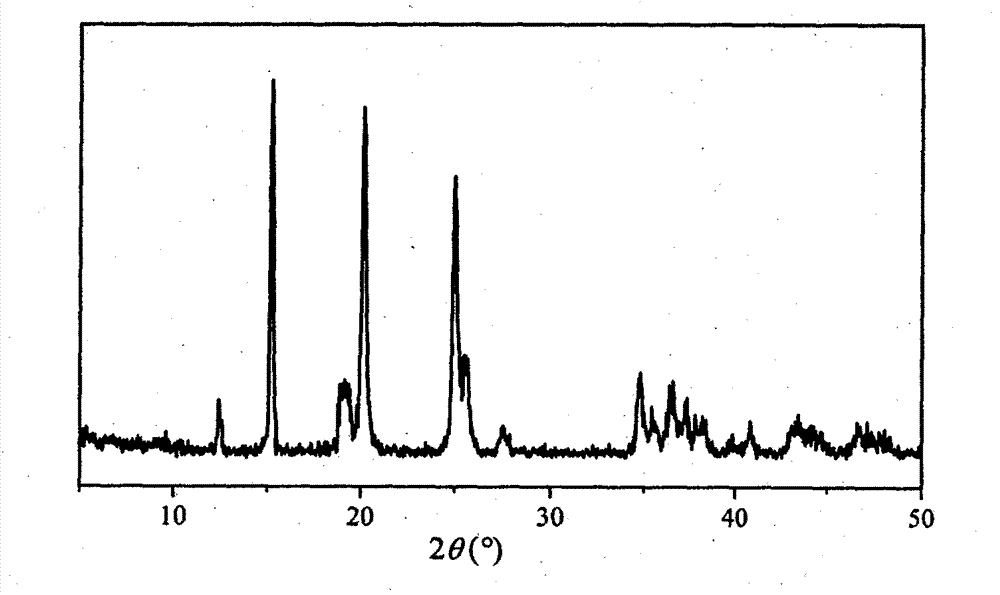

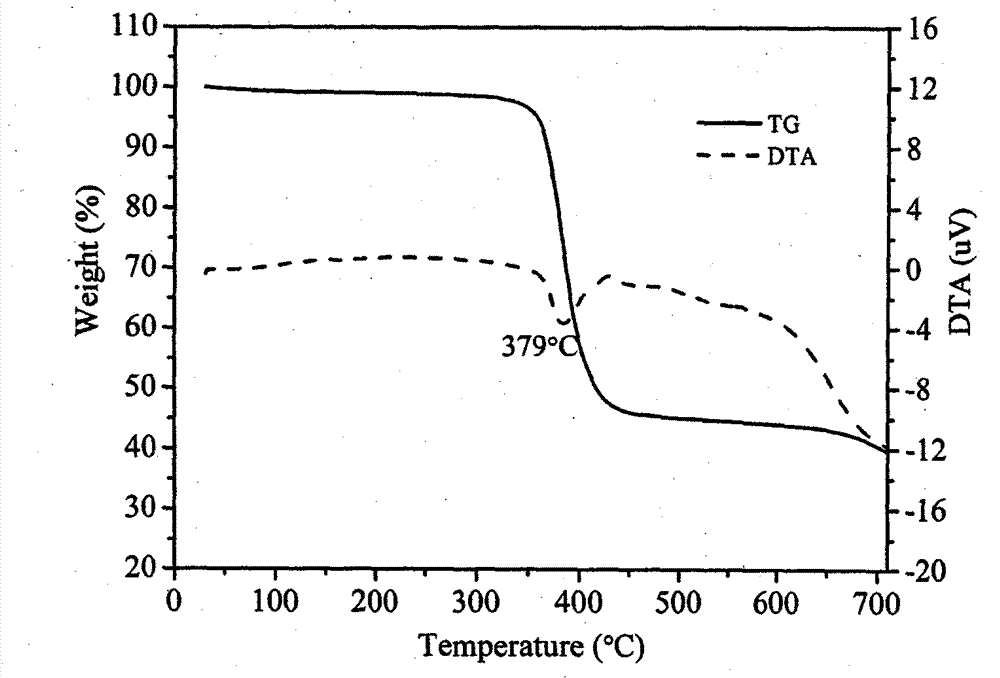

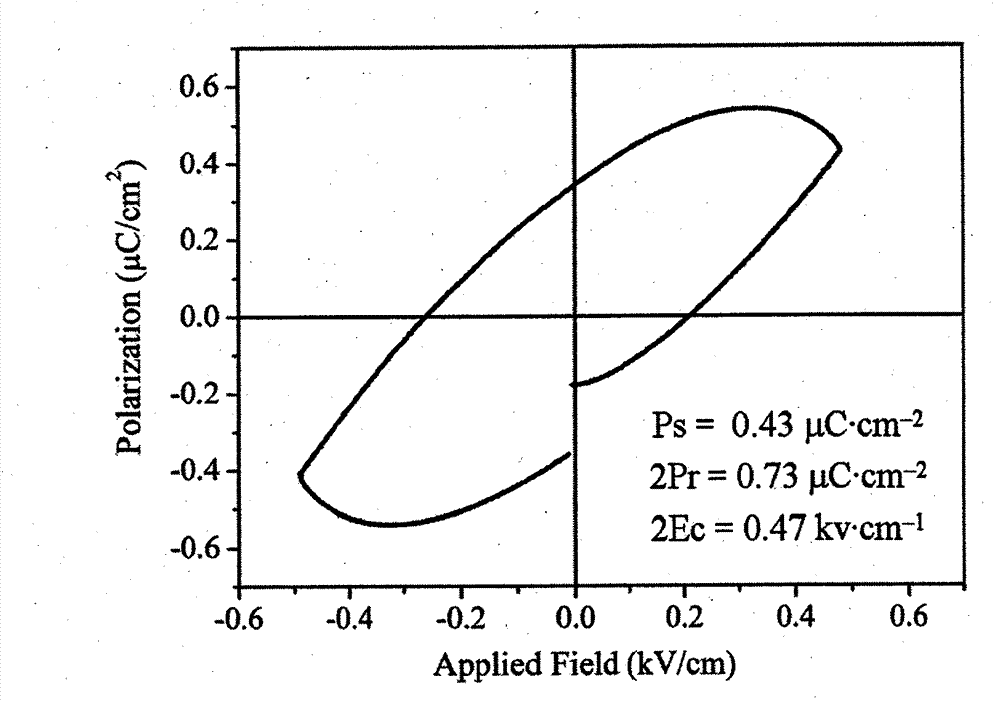

Anhydrous zinc tartrate ferroelectric function material and preparation method thereof

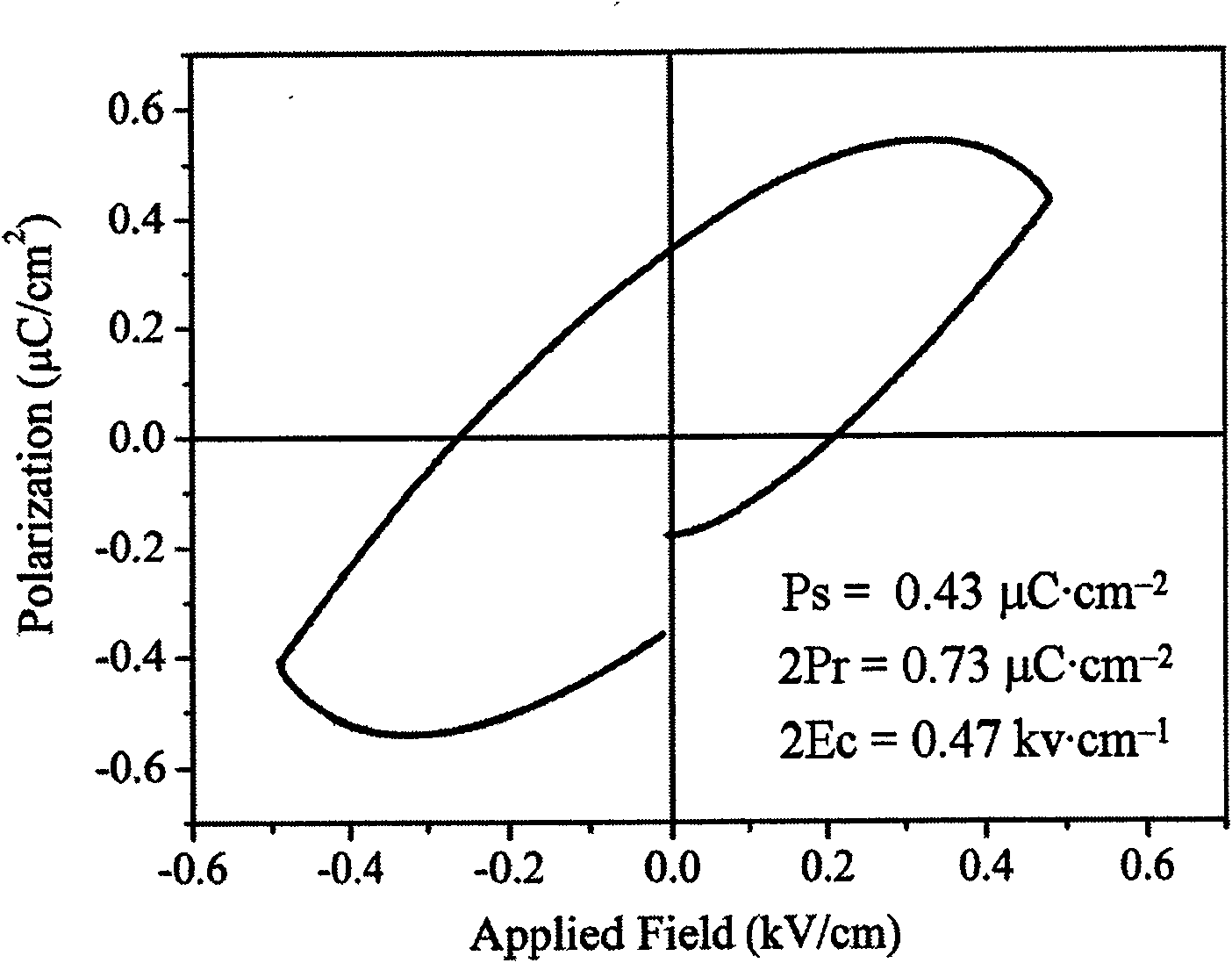

InactiveCN101654408AGood ferroelectric propertiesEfficient use ofCarboxylic acid salt preparationPh controlWhite powder

The invention discloses an anhydrous zinc tartrate ferroelectric function material, the molecular formula of which is Zn(C4H4O6), and the ferroelectric function material can pass through white powderwith purity of no less than 99 percent of 100 meshes, the heat quantitative temperature of the white powder is 350 DEG C, parameters of the ferroelectric properties of the ferroelectric function material is respectively as follows: Ps=0.43 mu C.cm<-2>, 2Pr=0.73 mu C.cm<-2>, 2Ec=0.47 kV.cm<-1>; thereby, the anhydrous zinc tartrate ferroelectric function material has better ferroelectric propertiesand thermalstability; the invention also discloses a preparation method of the ferroelectric function material, which can realize the nucleus formation and growth processes of the prophase product ofthe anhydrous zinc tartrate through controlling the concentration and proportion of the materials, the adding speed of the reactants, the stirring time, the temperature of the reaction system, pH control of the solution and the like, in addition, dehydration treatment is then carried out, and anhydrous zinc tartrate ferroelectric power with higher purity and good performance can be obtained.

Owner:NINGBO UNIV

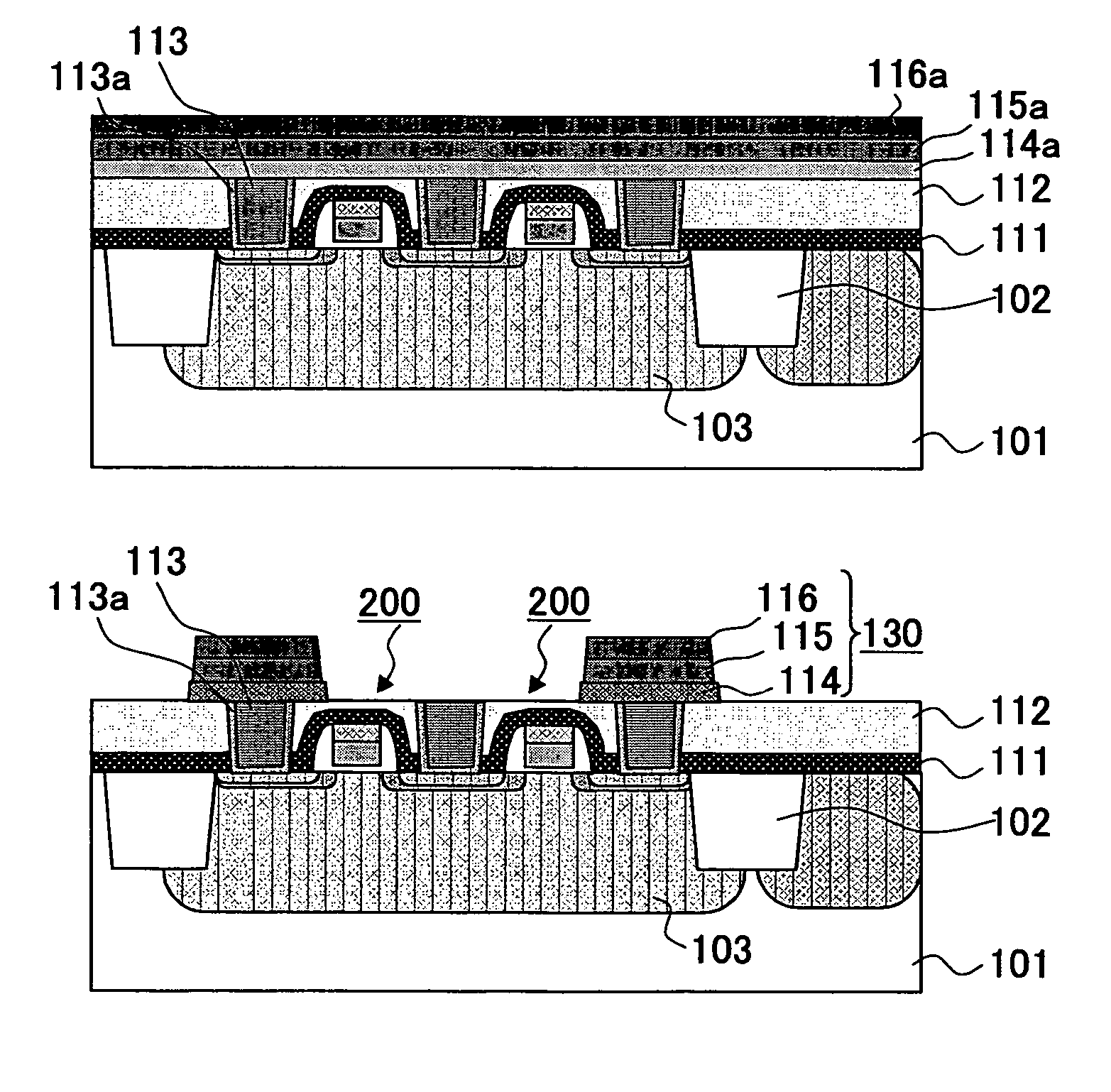

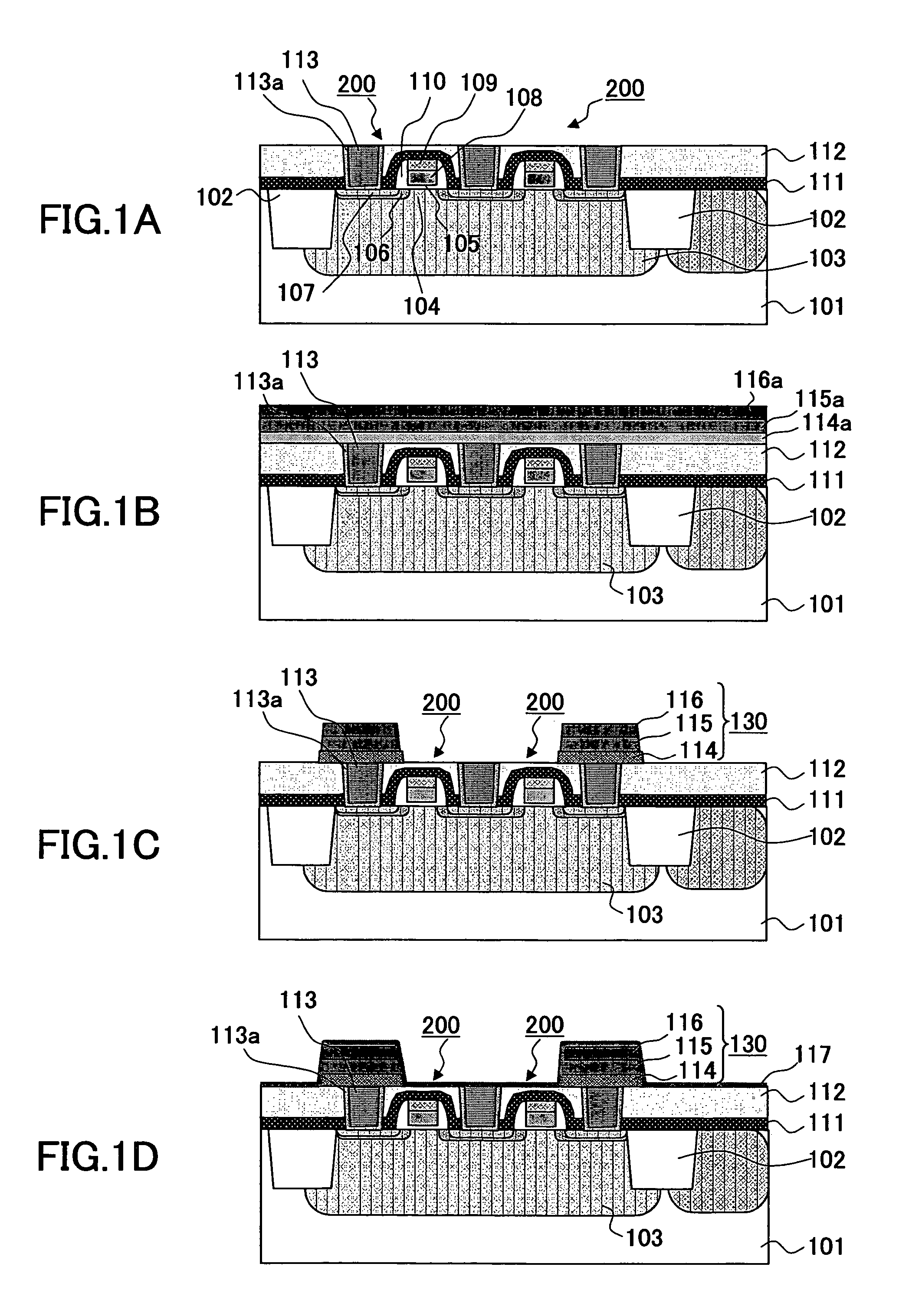

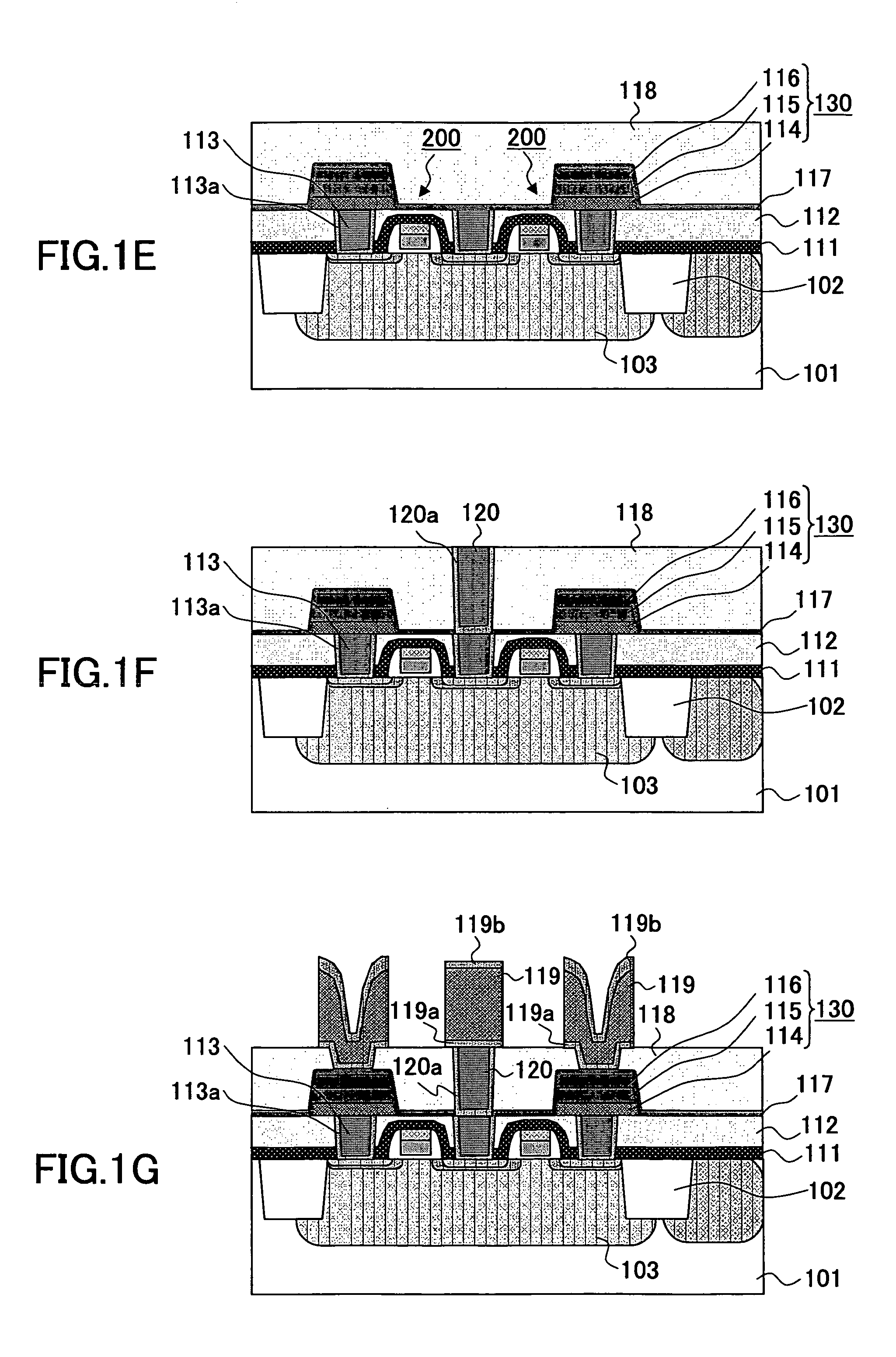

Method for fabricating semiconductor device

InactiveUS7029984B2Good ferroelectric propertiesReducing impurity and crystal defectSolid-state devicesSemiconductor/solid-state device manufacturingDeposition temperatureDeposition process

Owner:FUJITSU SEMICON LTD

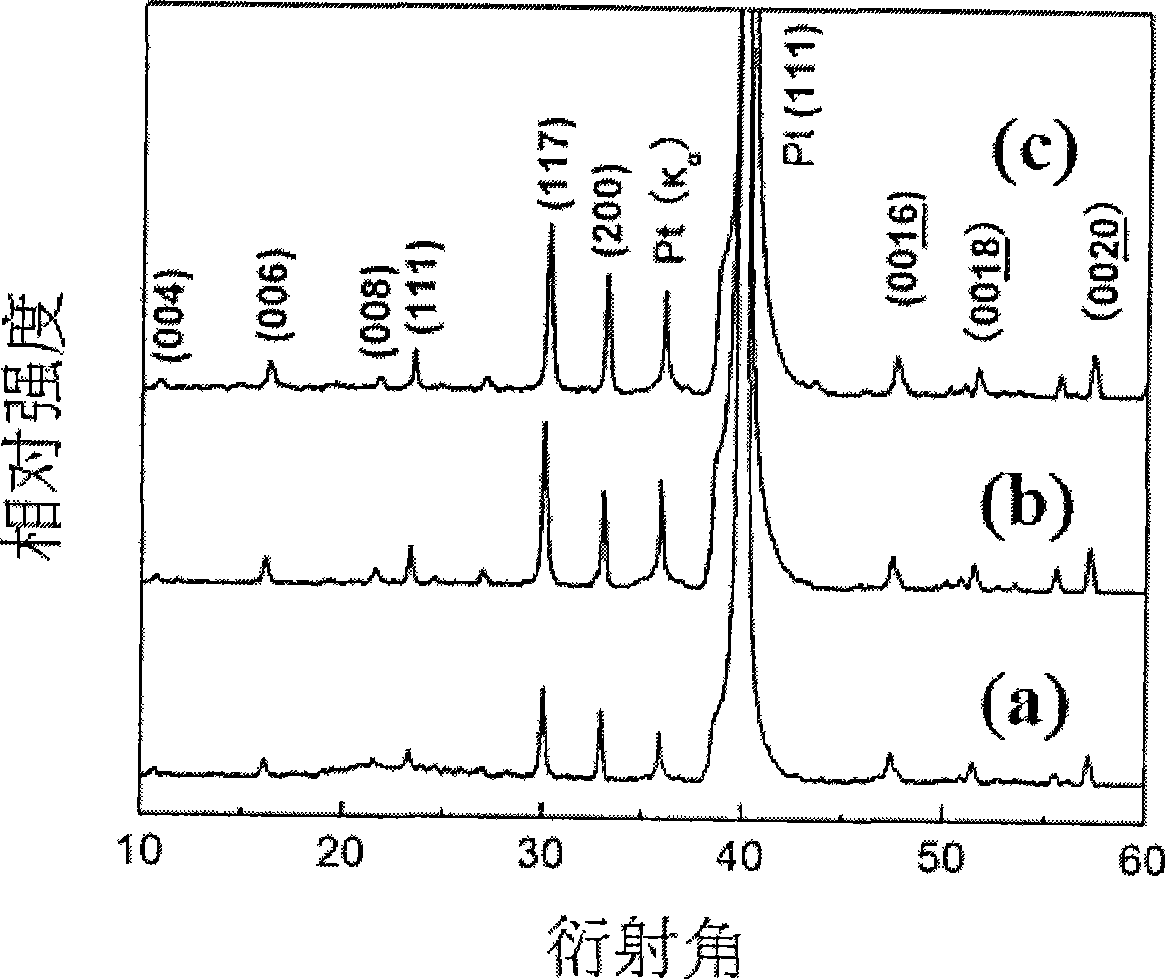

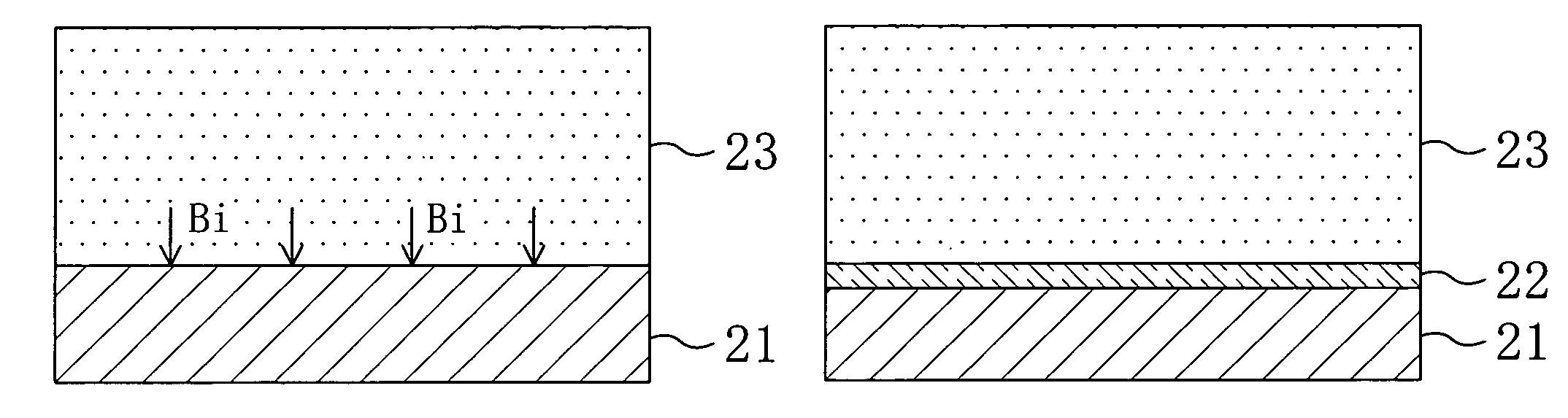

Liquid composition for forming ferroelectric thin film and process for producing ferroelectric thin film

InactiveUS20060124890A1Good ferroelectric propertiesReduce the temperatureMaterial nanotechnologyCeramicsLiquid mediumFerroelectric thin films

The present invention provides a liquid composition for forming a thin film, with which a ferroelectric thin film having excellent characteristics can be prepared even by baking at a low temperature, and a process for producing a ferroelectric thin film using it. A liquid composition for forming a ferroelectric thin film is used, which is characterized by comprising a liquid medium, crystalline ferroelectric oxide particles represented by the formula (Bi2O2)2+(Bim-1TimO3.5m-0.5)2− (wherein m is an integer of from 1 to 5) or (Bi2O2)2+(Am-1TimO3.5m-0.5)2− (wherein A is Bi3+ or La3+, the La3+ / Bi3+ ratio is from 0.05 to 0.5, and m is an integer of from 1 to 5) and having an average primary particle diameter of at most 100 nm, dispersed in the liquid medium, and a soluble metal compound capable of forming a ferroelectric oxide by heating, dissolved in the liquid medium.

Owner:ASAHI GLASS CO LTD

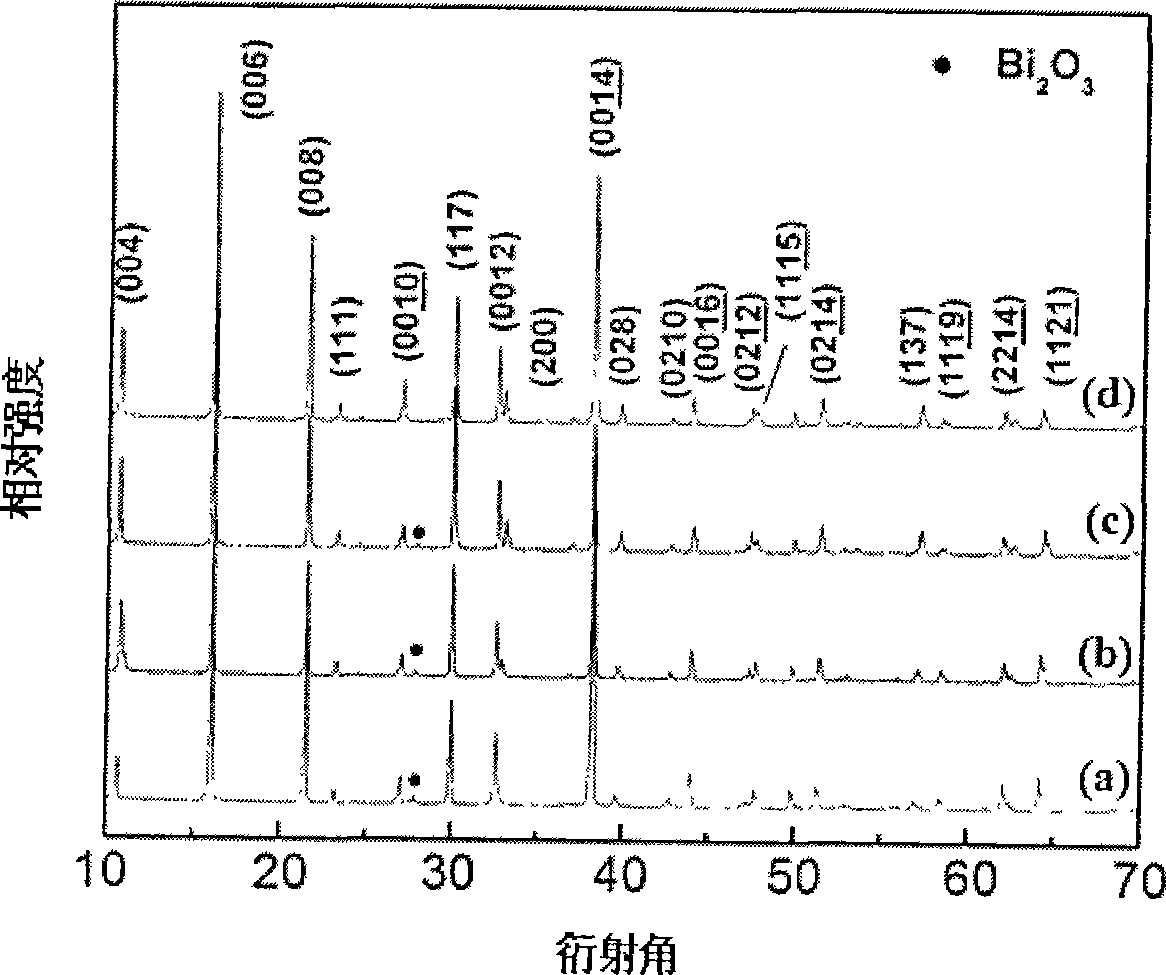

A-site Pr doping BTO film material and preparation thereof

InactiveCN101434408AMake up for volatile lossInhibit component segregationVacuum evaporation coatingFerroelectric carrier recordingRadio frequency magnetron sputteringOxygen ions

The invention relates to the field of information storage thin-film material, disclosing an A-bit Pr doped BTO thin-film material which consists of praseodymium, bismuth, titanium and oxygen ions. The composition molecular formula of the material is Bi(4-11x / 9)Pr<x>Ti3O12, and x is 0.3-0.9. The thin-film material is prepared by an RF magnetron sputtering method, which specifically comprises the following steps: depositing Bi(4-11x / 9)Pr<x>Ti3O12 target on a Pt / TiO2 / SiO2 / p-Si substrate, pumping the target to microvacuum, carrying out pre-sputtering, inletting oxygen and argon to regulate working air pressure, re-sputtering, and finally annealing rapidly to obtain the thin film. The thin film prepared by the invention is the polycrystal thin film with random orientation, which has smooth surface, even grain size, low drain current and better ferroelectric hysteresis, thus being compatible with the existing CMOS process.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for fabricating ferroelectric capacitive element and ferroelectric capacitive element

InactiveUS7338814B2Occurrence of a defect in refinement processing is suppressedSufficient ferroelectric characteristicSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceFerroelectric thin films

A method for fabricating a ferroelectric capacitive element of this invention includes the steps of forming a lower electrode made of a first conductive film on a substrate; forming a first ferroelectric film including bismuth in a first concentration on the lower electrode; forming a second ferroelectric film including bismuth in a second concentration on the first ferroelectric film; performing annealing after forming the first ferroelectric film and the second ferroelectric film; and forming an upper electrode made of a second conductive film on the second ferroelectric film after the annealing. The first conductive film is a metal film more easily etched than a platinum film, and the second ferroelectric film is formed in such a manner that the second concentration is lower than the first concentration before the annealing.

Owner:PANASONIC CORP

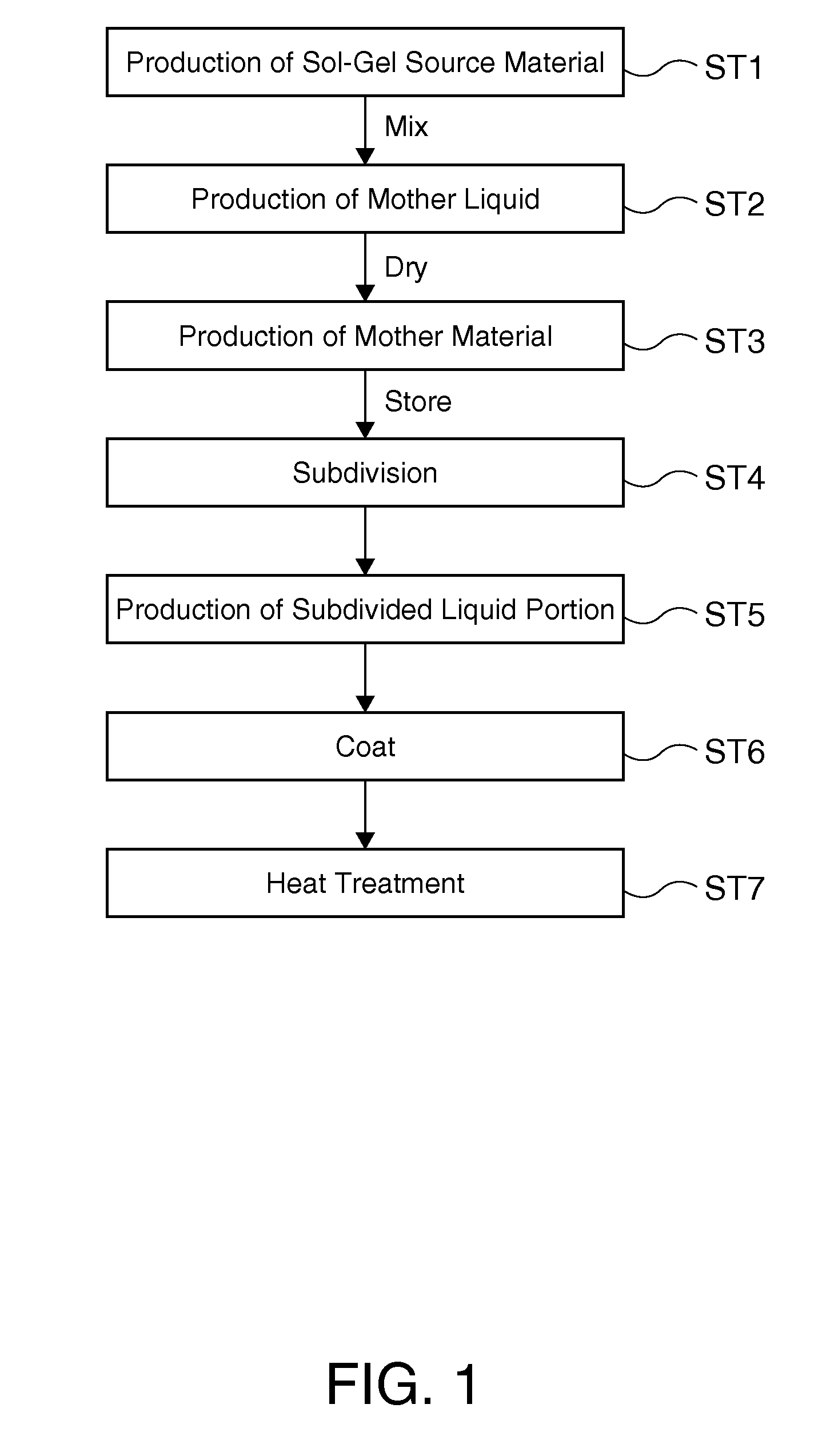

Method for manufacturing ferroelectric memory

InactiveUS20090186150A1Avoid disagreementGood ferroelectric propertiesSolid-state devicesSemiconductor/solid-state device manufacturingSolventHeat treated

A method for manufacturing a ferroelectric memory includes the steps of: preparing a sol-gel solution; removing solvent from the sol-gel solution to obtain powder; dividing the powder into at least first powder and second powder; obtaining solution with the first powder; coating the solution on a first conductive film; and applying heat treatment to the solution on the first conductive film to form a ferroelectric film.

Owner:SEIKO EPSON CORP

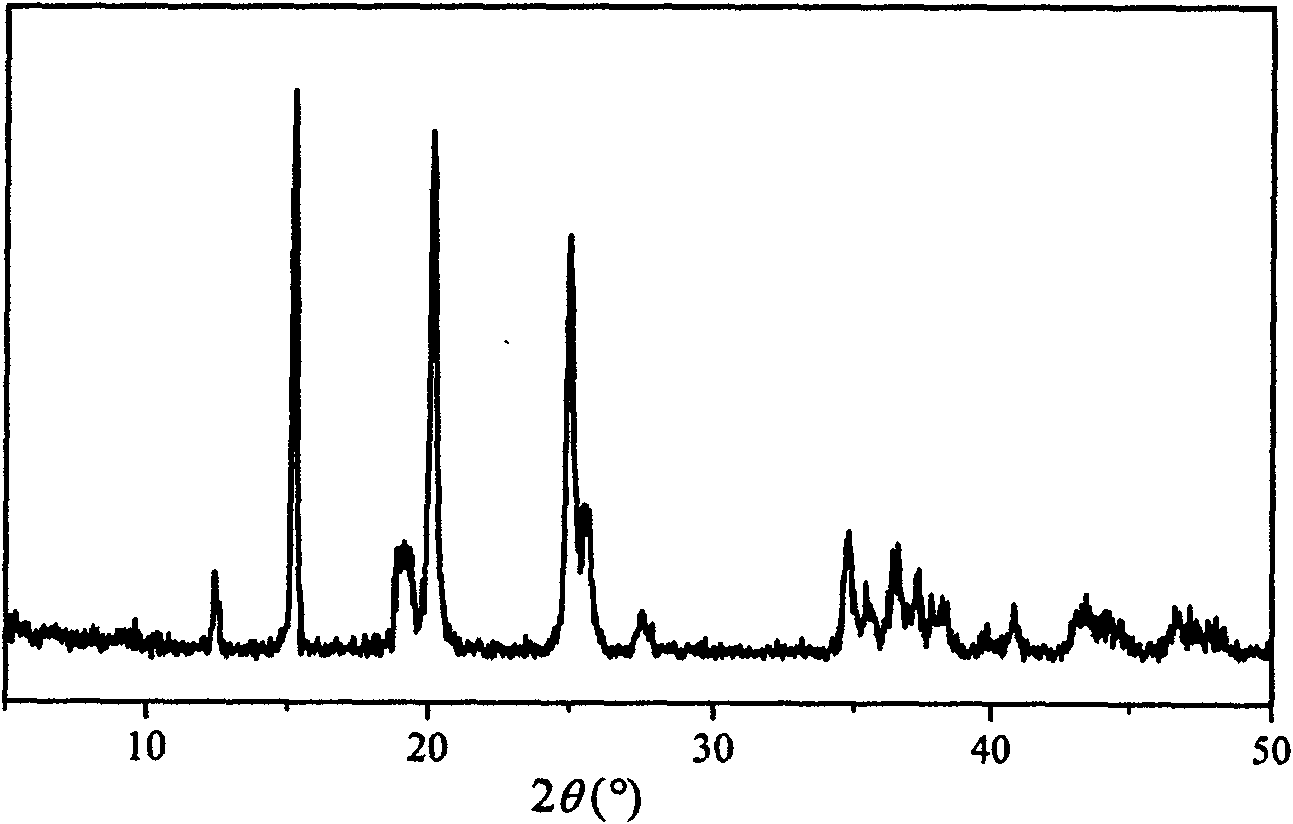

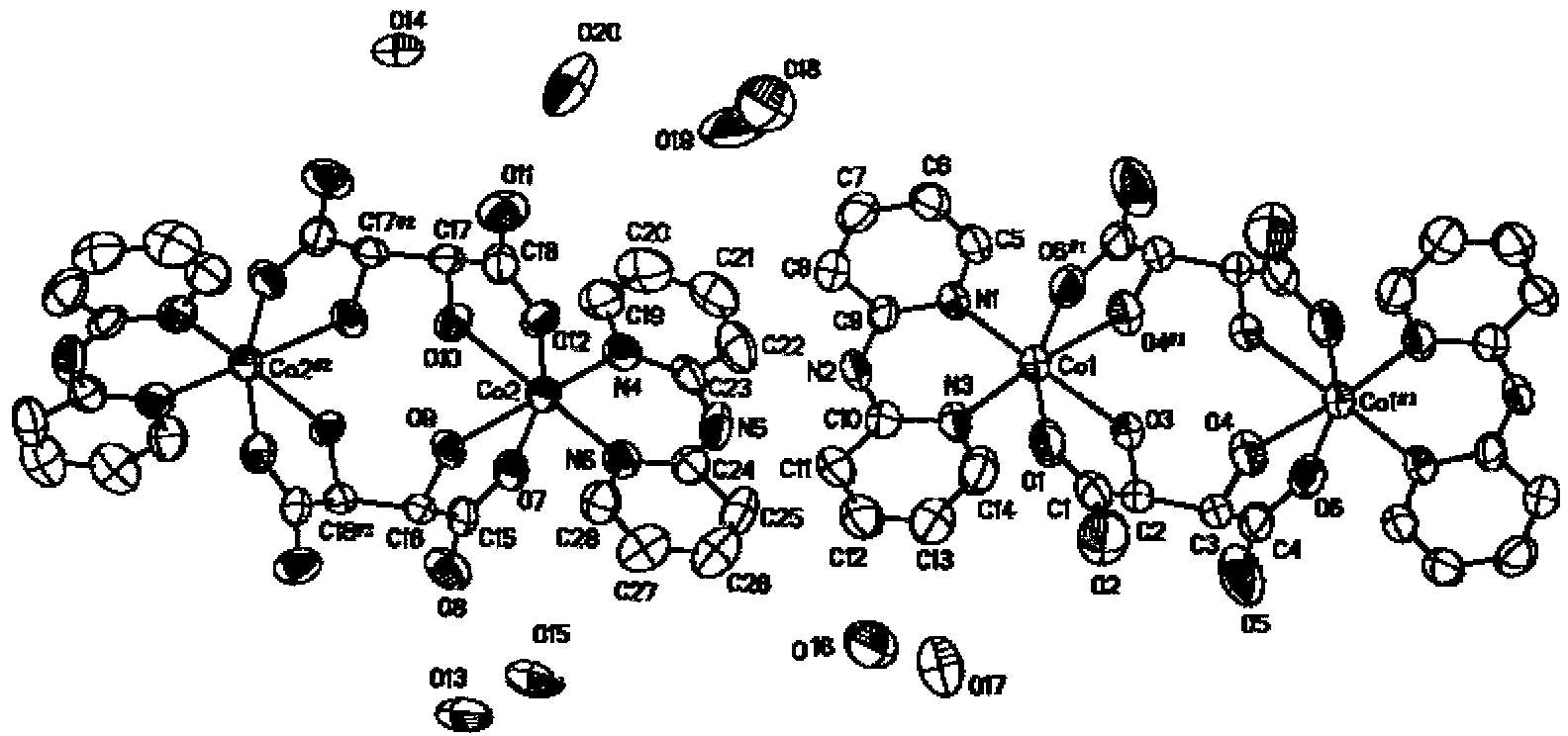

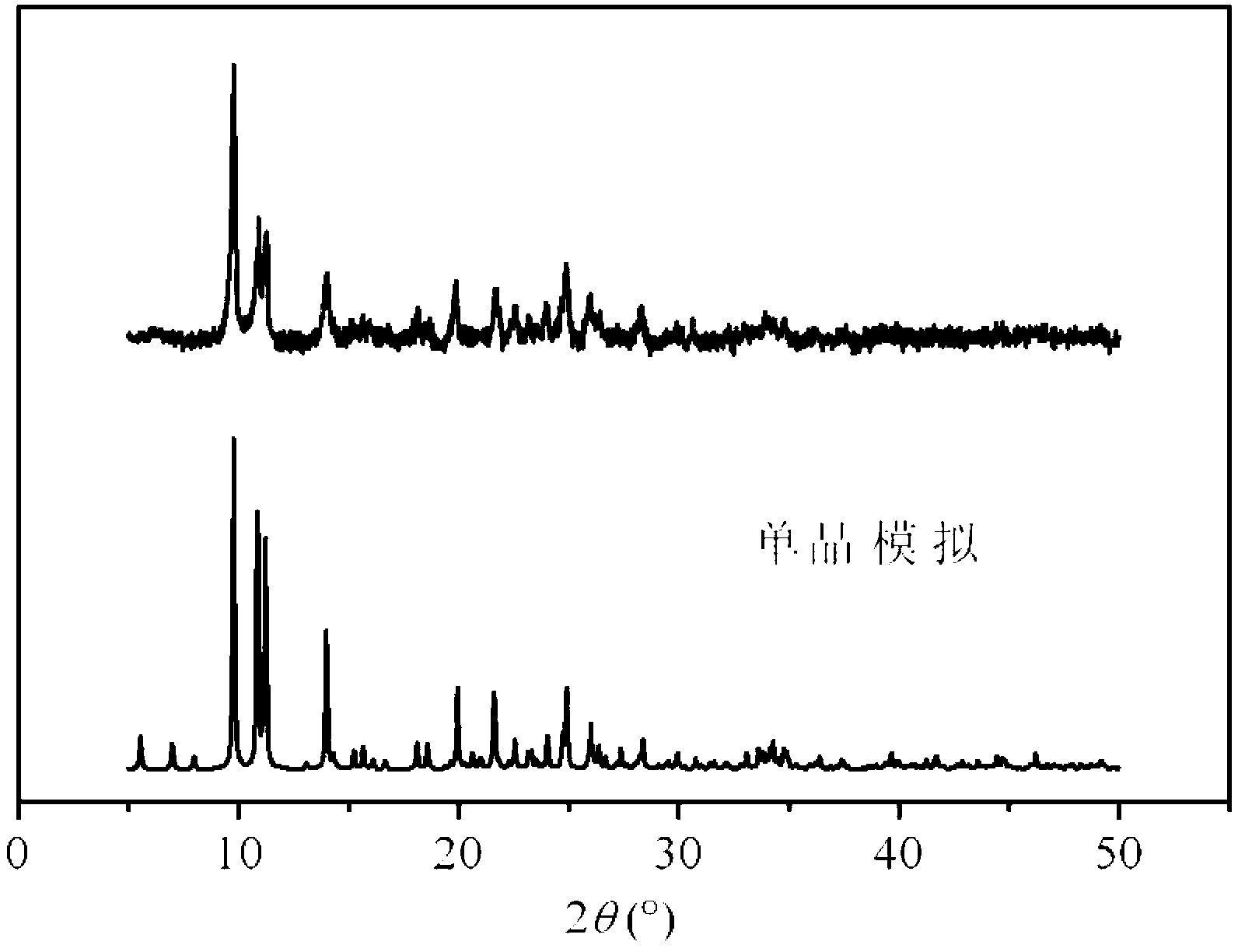

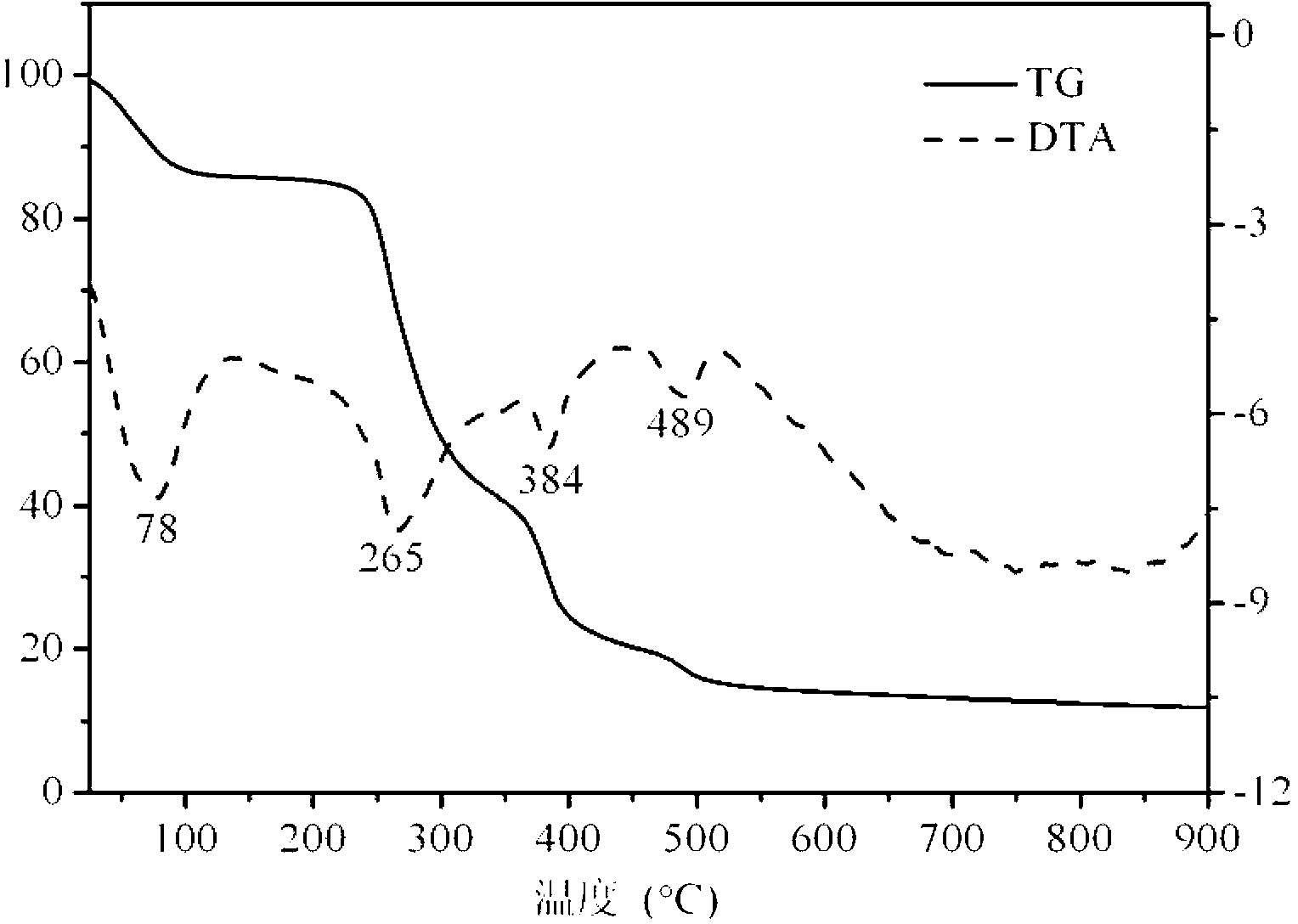

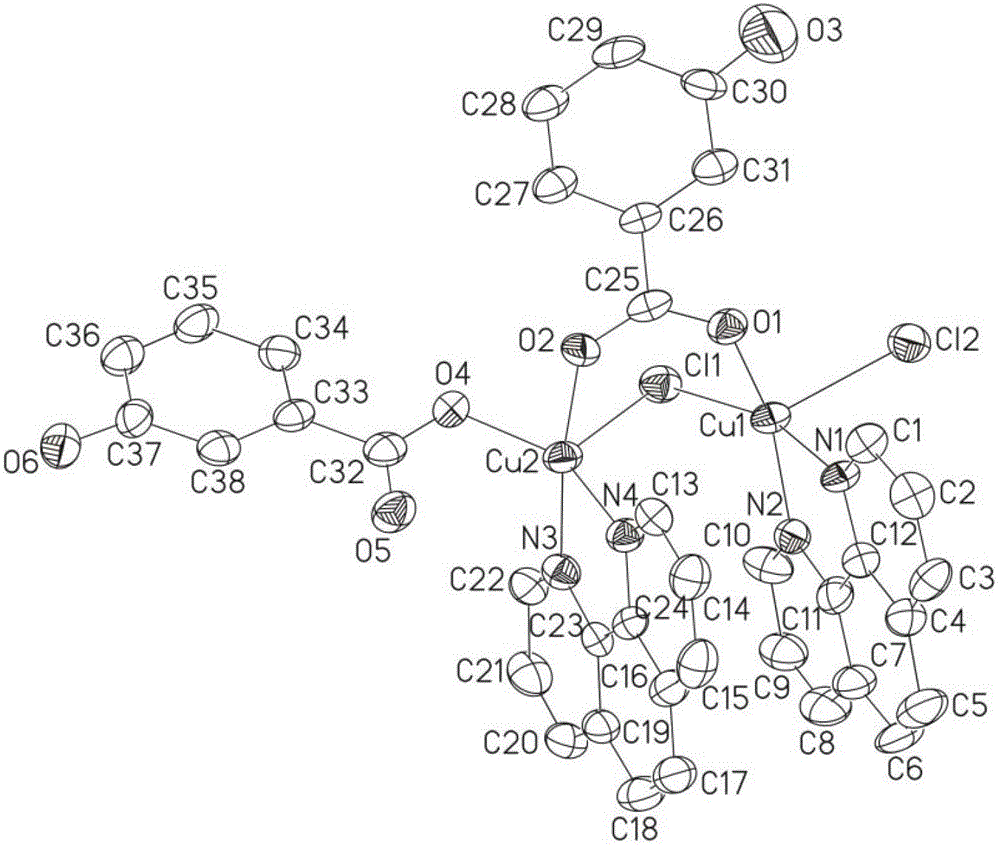

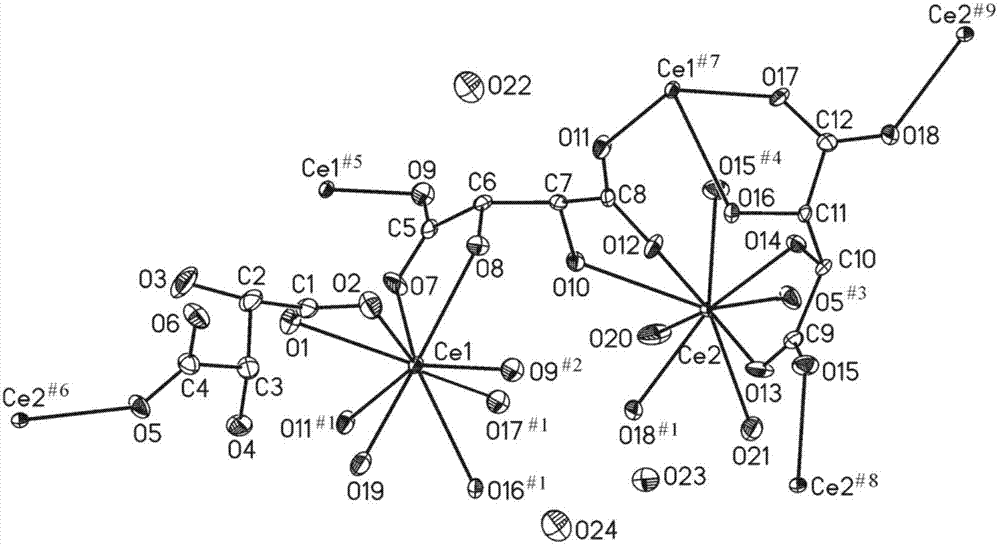

D-tartaric acid 2,2-dipyridylamine cobalt ferroelectric function material and preparation method

InactiveCN103012495AGood ferroelectric propertiesShort processPolycrystalline material growthFrom normal temperature solutionsSpace groupCobalt salt

The invention discloses a D-tartaric acid 2,2-dipyridylamine cobalt ferroelectric function material and a preparation method. The molecular formula is [Co(dpa)(D-C4H4O6)]2.8H2O, wherein dpa is 2,2-dipyridylamine; the ferroelectric function material is monoclinic system powder of which the purity is not lower than 99%; the structure of space group is C2; the ferroelectric characteristic parameters are as follows: the remanent polarization strength 2Pr=0.05(mu)C.cm<-2>, coercive electric field 2Ec=15.2kv.cm<-1>, and saturization polarization strength Ps=0.249(mu)c.cm<-2>; and the ferroelectric function material has relatively good ferroelectric characteristics. The preparation method of the ferroelectric function material comprises the following steps of: enabling the newly prepared cobalt carbonate to react with the mixed solution of D-tartaric acid 2,2-dipyridylamine to obtain a D-tartaric acid 2,2-dipyridylamine cobalt solution; devitrifying; and grinding to obtain ferroelectric function material powder passing through a 100-mesh sieve. The method has the advantages of few processes, simple technology, low requirements on equipment, cheap materials of cobalt salt and tartaric acid, no pollution, low cost and easiness in realizing industrialization.

Owner:NINGBO UNIV

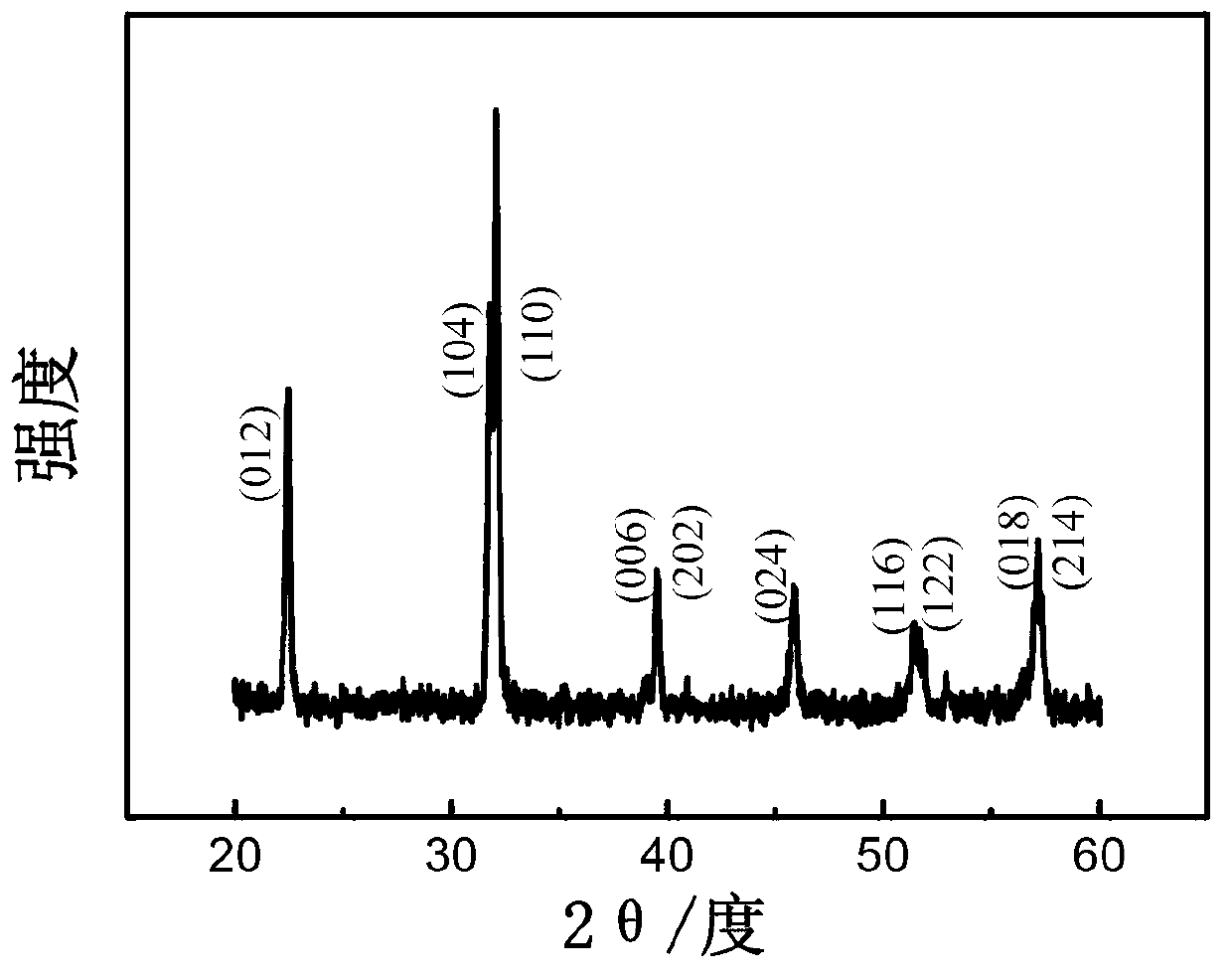

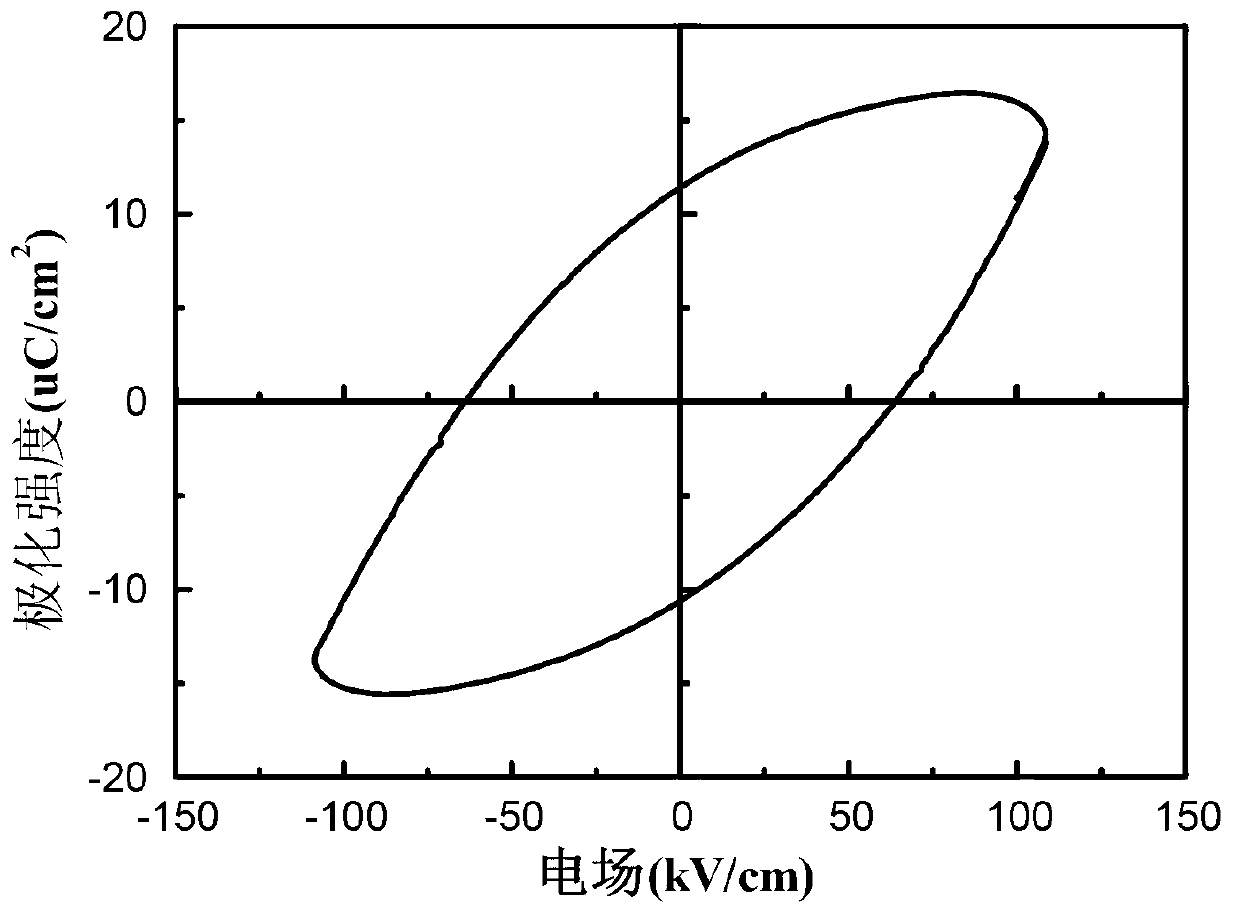

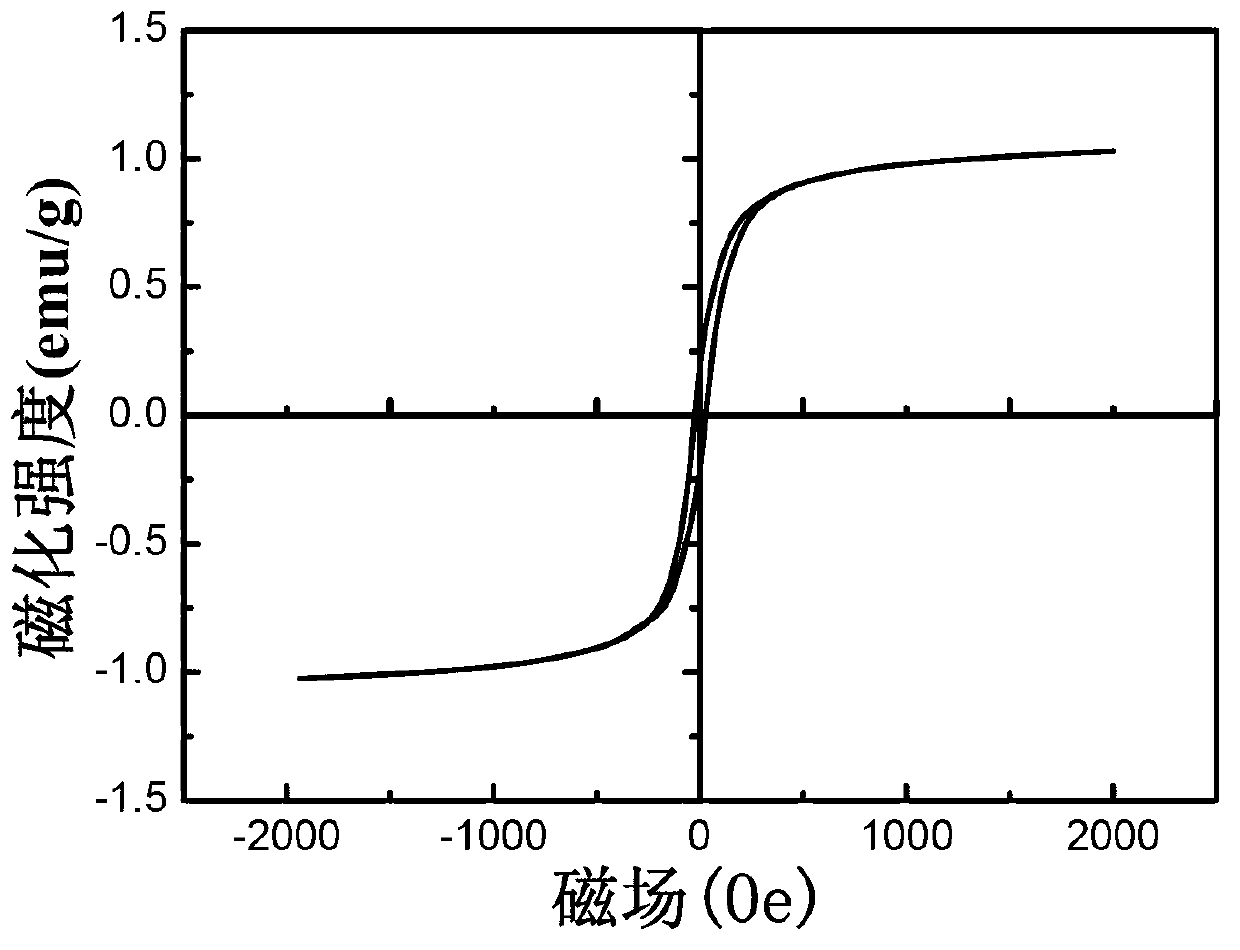

Acid bismuth ceramic with multiferroic holmium and chrome codoping iron at room temperature and preparation method of acid bismuth ceramic

The invention relates to acid bismuth ceramic with multiferroic holmium and chrome codoping iron at room temperature and a preparation method of the acid bismuth ceramic, and belongs to the field of electronic ceramic materials. The ceramic has the chemical formula as follows: Bi1 - xHoxFe1- yCryO3, wherein x is greater than 0 and is less than or equal to 0.15, and y is greater than 0 and is less than or equal to 0.1. The method comprises the following steps: carrying out the treatments of mixing and ball-milling on raw materials including Ho2O3, Bi2O3, Cr2O3 and Fe2O3 by weight to obtain a slurry material; calcining for 2 hours at the temperature of 750 to 830 DEG C after the slurry material is dried; carrying out the ball-milling treatment on the powder again; adding a polyvinyl alcohol aqueous solution to the powder after the powder is dried; pressing the mixture into a tablet shape by using a tablet press under the pressure of 100 to 150 MPa; extracting colloid from a tablet-shaped material for 4 hours at the temperature of 550 DEG C; and finally, sintering the tablet-shaped material into the ceramic at the temperature of 800 to 870 DEG C. The multiferroic ceramic provided by the invention has excellent ferroelectric and ferromagnetic properties at the room temperature.

Owner:BEIJING UNIV OF TECH

Method for preparing BTS film by virtue of radio frequency magnetron sputtering

InactiveCN104532186AReduce manufacturing costLow ferroelectric propertiesVacuum evaporation coatingSputtering coatingSputteringHeat conducting

The invention relates to a method for preparing a BTS film by virtue of radio frequency magnetron sputtering. The method comprises the following steps: (1) firstly injecting ITO powder into a mold, rolling out, sealing the mold, and carrying out compression shaping; (2) putting target materials prepared in the step (1) and a substrate with a heat-conducting property into a vacuum sputtering cavity; (3) supplying oxygen and argon into the vacuum sputtering cavity, regulating the flow ratio of the oxygen and the argon to (12-18) to (2-8), regulating the intervals of the target materials to 8mm, setting the film plating power to 150w-175w, setting the film plating time to 3-4 hours, setting the sputtering pressure to 1.0Pa-1.5Pa, and setting the heating temperature of substrate to 200-400 DEG C; and (4) after the sputtering is finished, annealing the film-plated substrate, so as to obtain the film. According to the method, the film is prepared from powder target materials, so that the preparation cost of the BTS film is greatly lowered, and a sample prepared based on the process foundation has good structural performance and visible light permeability and excellent electrical performance.

Owner:庞凤梅 +2

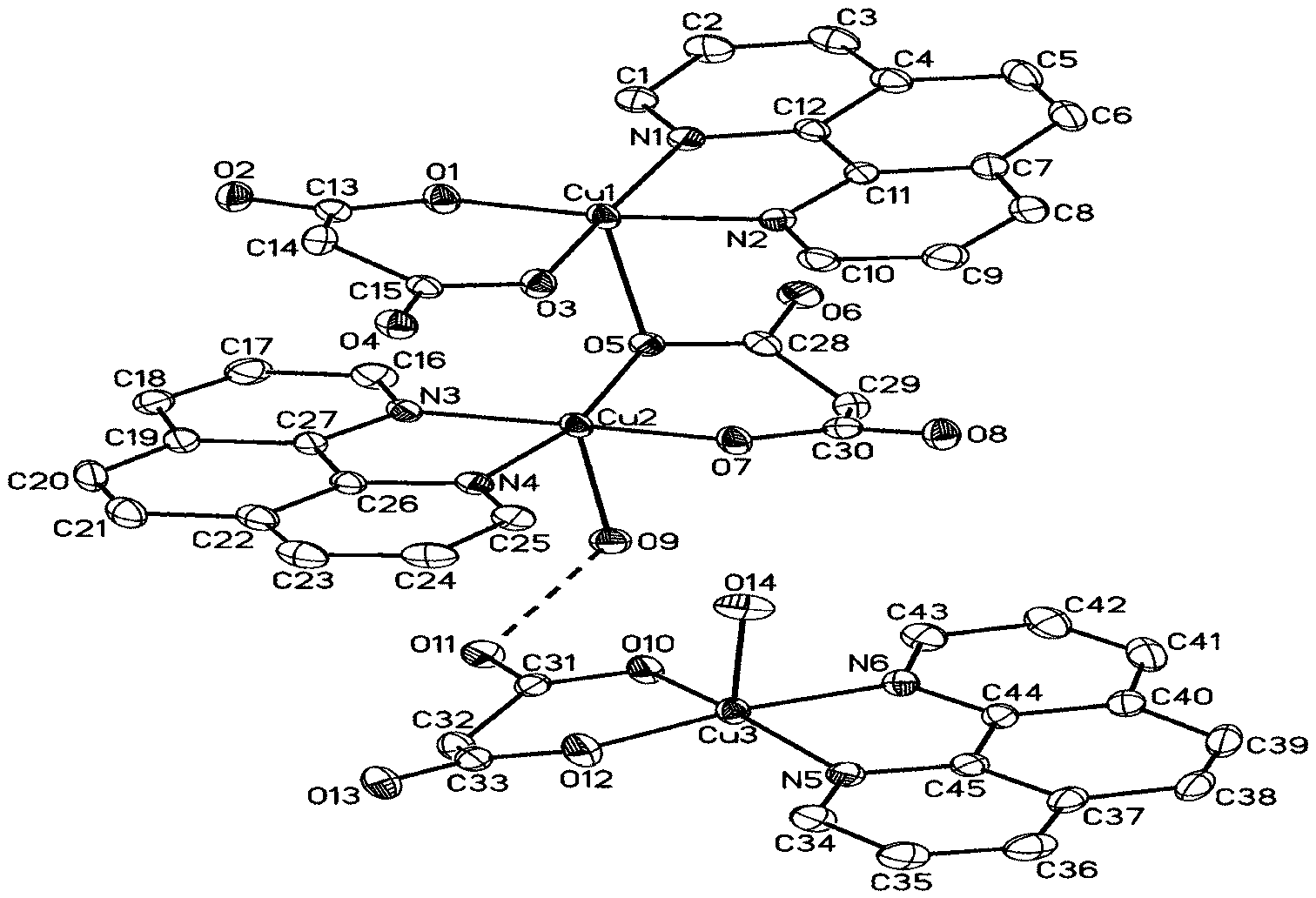

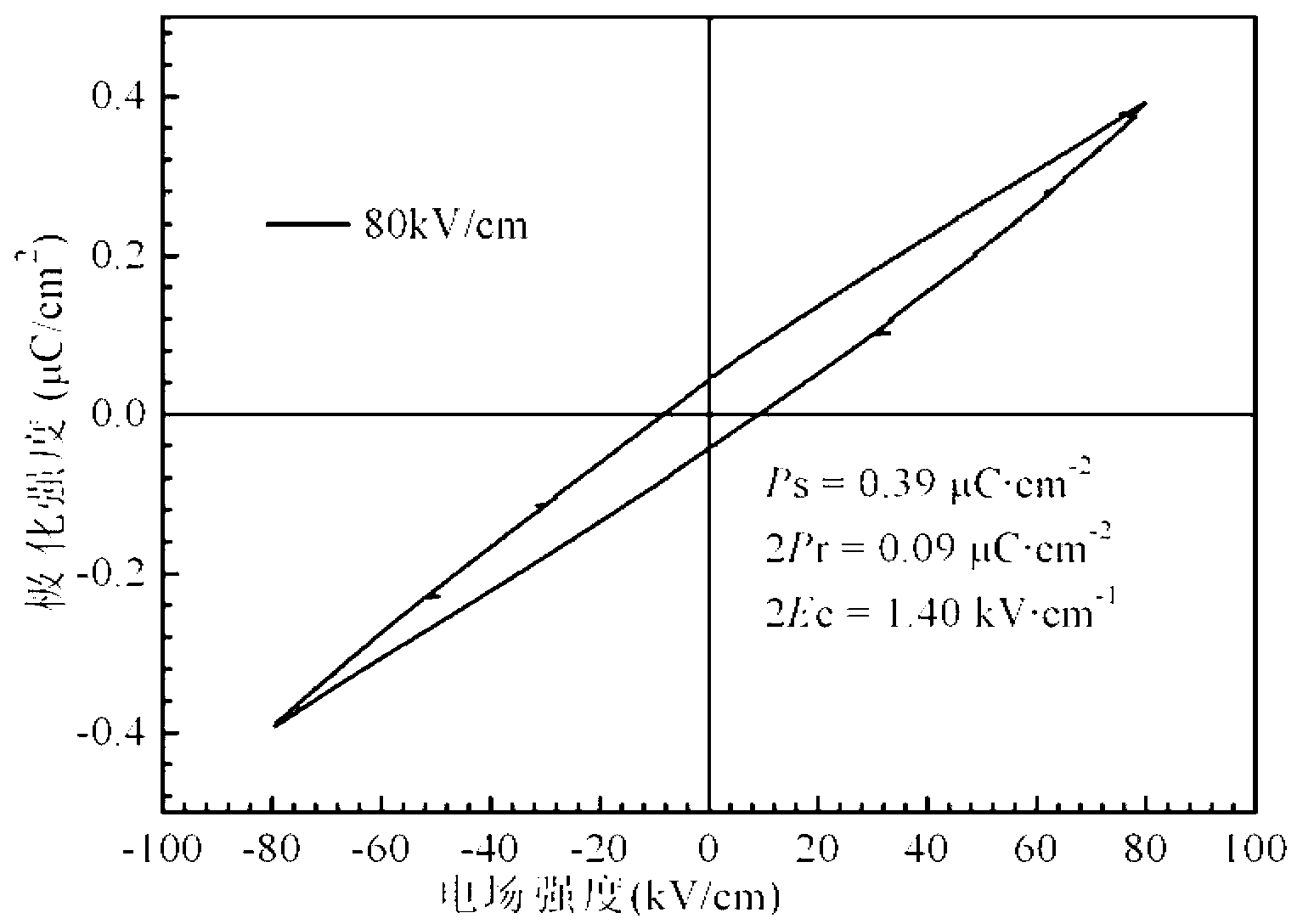

Phenanthroline copper malonate ferroelectric electric functional material and preparation method thereof

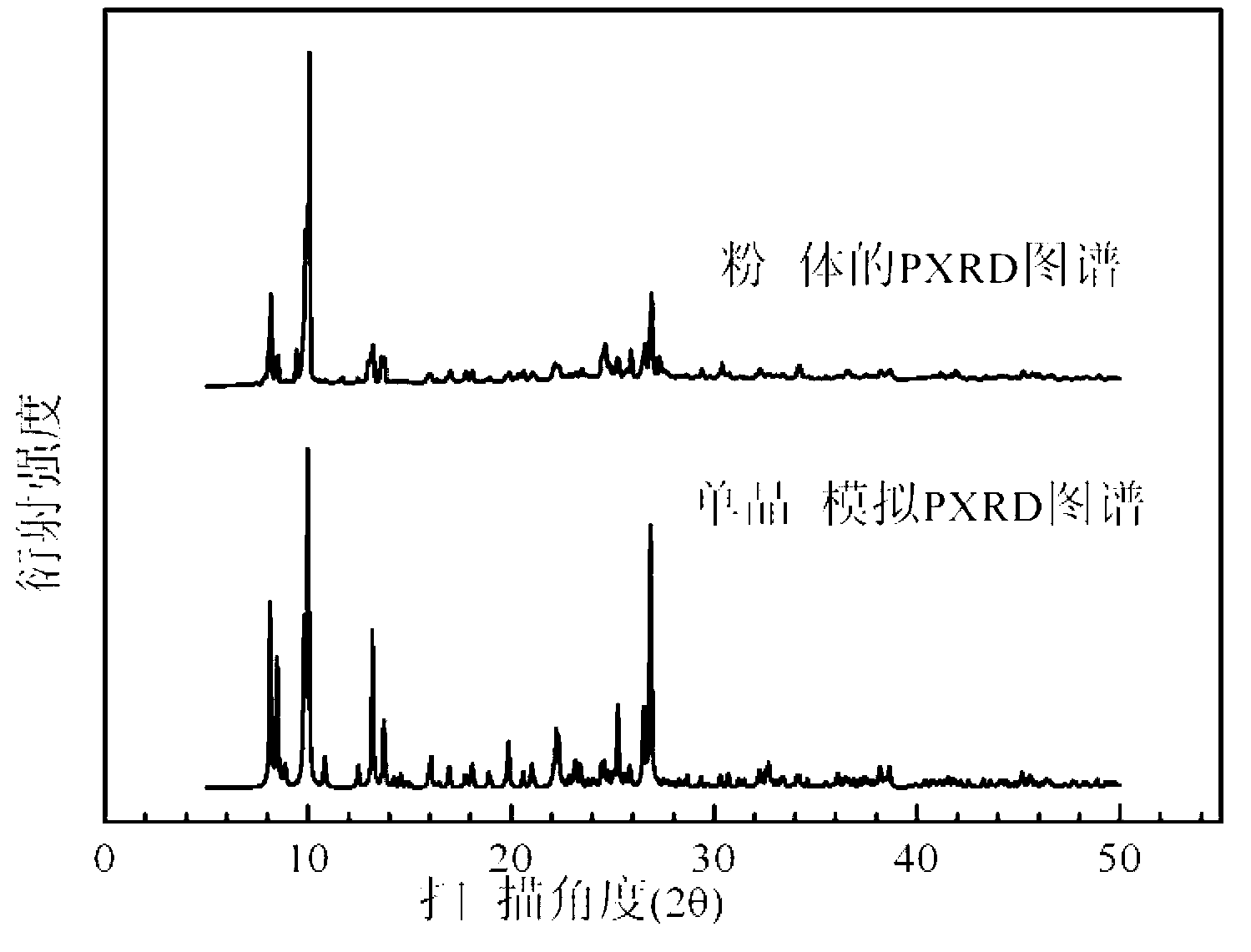

InactiveCN103232479AGood ferroelectric propertiesShort processCopper organic compoundsSaturation polarizationPhenanthroline

The invention discloses a phenanthroline copper malonate ferroelectric functional material and a preparation method thereof. The ferroelectric functional material has a molecular formula of [Cu3(C12H8N2)3(H2O)2(C3H2O4)3].11H2O, is blue powder of which the purity is not lower than 99%, and has a C2 polarity point group structure. The ferroelectric characteristic parameters of the ferroelectric functional material are as follows: the remanent polarization strength 2Pr is equal to 0.09 muC.cm<-2>, the coercive electric field 2Ec is equal to 1.40kv.cm<-1>, and the saturation polarization strength Ps is equal to 0.39 muC.cm<-2>; and the cell parameter of the powder of the ferroelectric functional material is as follows: the saturation polarization strength of the ferroelectric functional material is 1.56 times that of Rochelle salt, so that the ferroelectric functional material is a new ferroelectric with excellent ferroelectric performance. The ferroelectric functional material is prepared by reacting a cupric salt solution with a methane dicarboxylic acid solution at first, then reacting with a phenanthroline solution and carrying out crystallization under the condition that the pH value is 3.0-5.0, has the advantages of less flow, simple process, low requirements for equipment, no pollution and low cost, and is easy to realize industrialization.

Owner:NINGBO UNIV

Method for manufacturing ferroelectric memory device

InactiveUS7390679B2Good ferroelectric propertiesImprove workabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsTitanium oxide

A method for manufacturing a ferroelectric capacitor, includes the steps of: forming a ferroelectric capacitor layer having a lower electrode layer, a ferroelectric layer and an upper electrode layer on a base substrate; forming a titanium oxide layer on the ferroelectric capacitor layer; patterning the titanium oxide layer by high-temperature etching between 200° C. and 500° C. to thereby form a mask pattern; and etching the ferroelectric capacitor layer by using the mask pattern as a mask, to thereby form a ferroelectric capacitor having a lower electrode, a ferroelectric film and an upper electrode.

Owner:SEIKO EPSON CORP

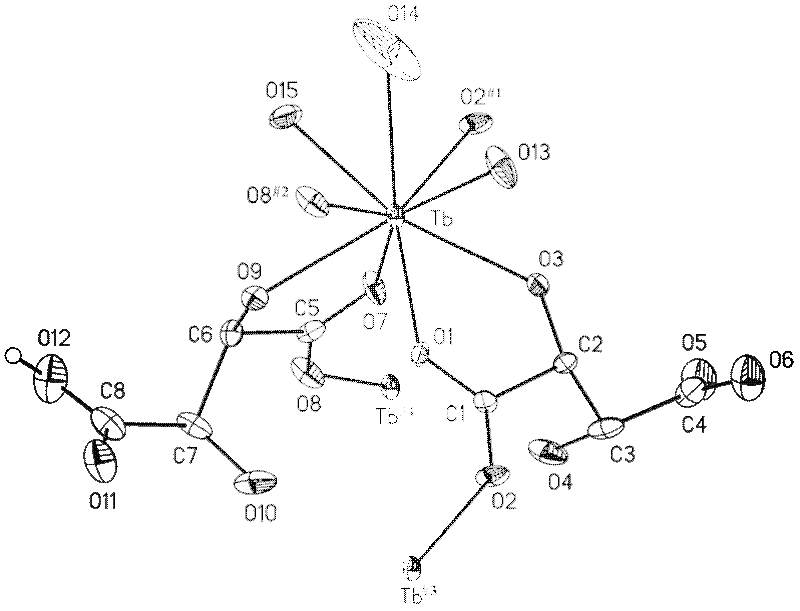

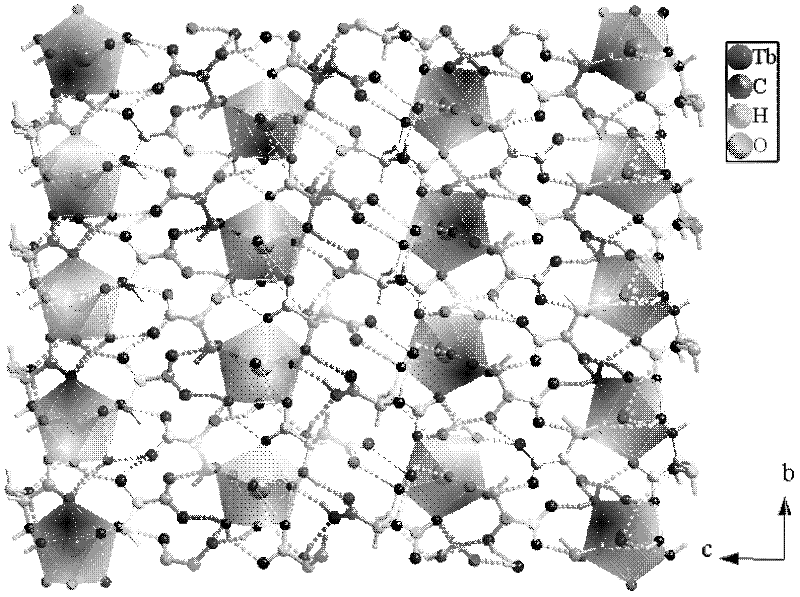

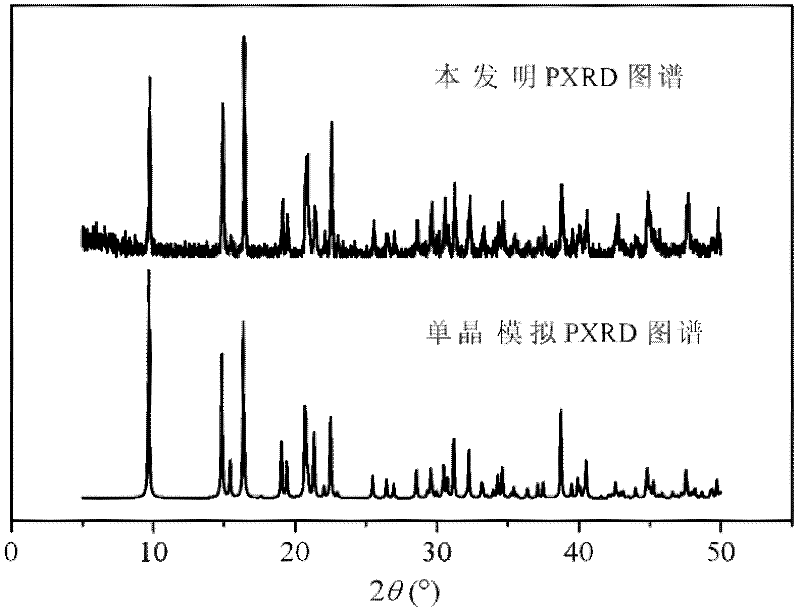

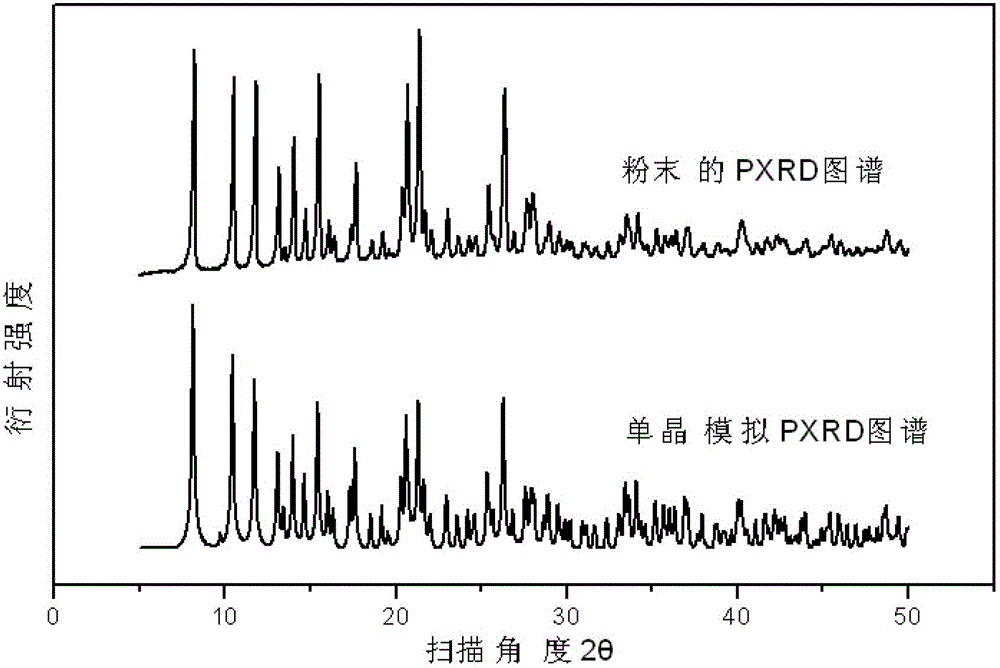

Tartaric acid terbium ferroelectric functional material and preparation method thereof

InactiveCN102516276AGood ferroelectric propertiesPromote nucleationGroup 3/13 element organic compoundsTerbiumTetragonal crystal system

The invention discloses a tartaric acid terbium ferroelectric functional material, which is 100-mesh white tetragonal crystal system powder, and has a molecular formula of [Tb(H2O)3(C4H5O6) (C4H4O6)], a P41 space group structure, an electric hysteresis 2Ec value of 44.3kV . cm-1, 2, a Pr value of 1.60muC . cm-2, a Ps value of 0.176muC . cm-2, and better ferroelectric properties. A preparation method of the ferroelectric functional material is characterized in that: a terbium salt and a tartaric acid are synthesized into the high-purity tartaric acid terbium ferroelectric functional material by a soft synthesis method in coordination chemistry, and the better nucleation and growth of tartaric acid terbium crystals can be realized by controlling the concentration and ratio of the material, the pH value of a solution to 2 to 5, and the temperature of nucleation and growth of the crystal to 30-60 DEG C and the like. The method provided by the invention has the advantages of few flow, simple process, low equipment requirements, cheap terbium salt and tartaric acid as raw materials, no pollution, low cost, and easiness in industrialization.

Owner:NINGBO UNIV

Anhydrous zinc tartrate ferroelectric function material and preparation method thereof

InactiveCN101654408BGood ferroelectric propertiesEfficient use ofCarboxylic acid salt preparationWhite powderHeat stability

The invention discloses an anhydrous zinc tartrate ferroelectric function material, the molecular formula of which is Zn(C4H4O6), and the ferroelectric function material can pass through white powder with purity of no less than 99 percent of 100 meshes, the heat quantitative temperature of the white powder is 350 DEG C, parameters of the ferroelectric properties of the ferroelectric function material is respectively as follows: Ps=0.43 mu C.cm<-2>, 2Pr=0.73 mu C.cm<-2>, 2Ec=0.47 kV.cm<-1>; thereby, the anhydrous zinc tartrate ferroelectric function material has better ferroelectric properties and thermal stability; the invention also discloses a preparation method of the ferroelectric function material, which can realize the nucleus formation and growth processes of the prophase product of the anhydrous zinc tartrate through controlling the concentration and proportion of the materials, the adding speed of the reactants, the stirring time, the temperature of the reaction system, pH control of the solution and the like, in addition, dehydration treatment is then carried out, and anhydrous zinc tartrate ferroelectric power with higher purity and good performance can be obtained.

Owner:NINGBO UNIV

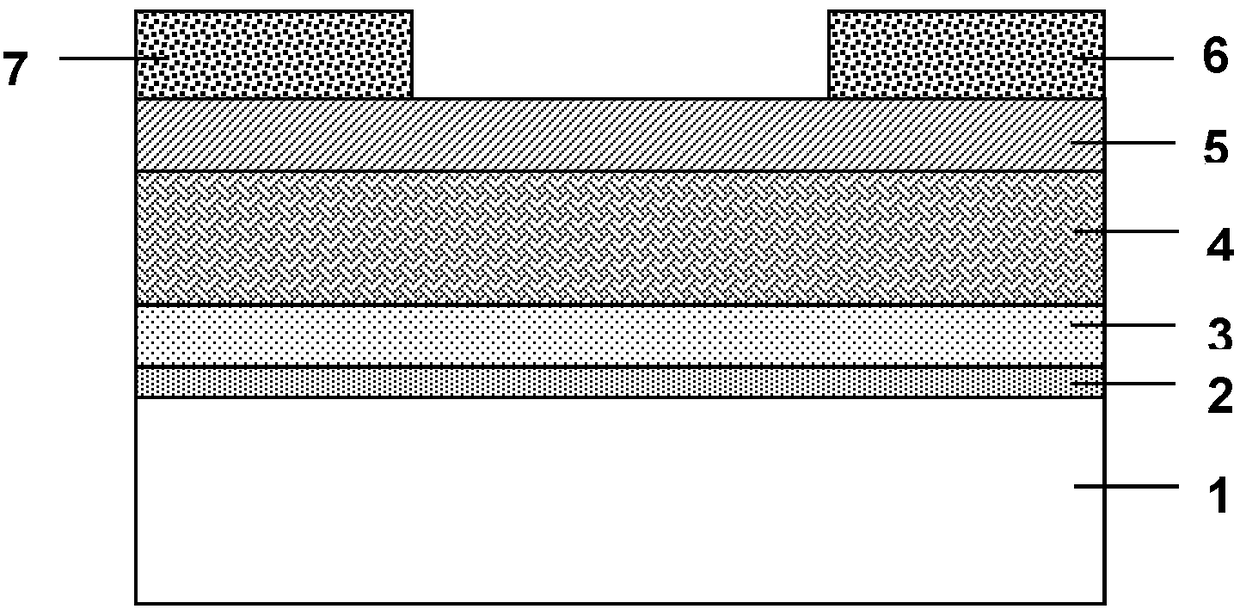

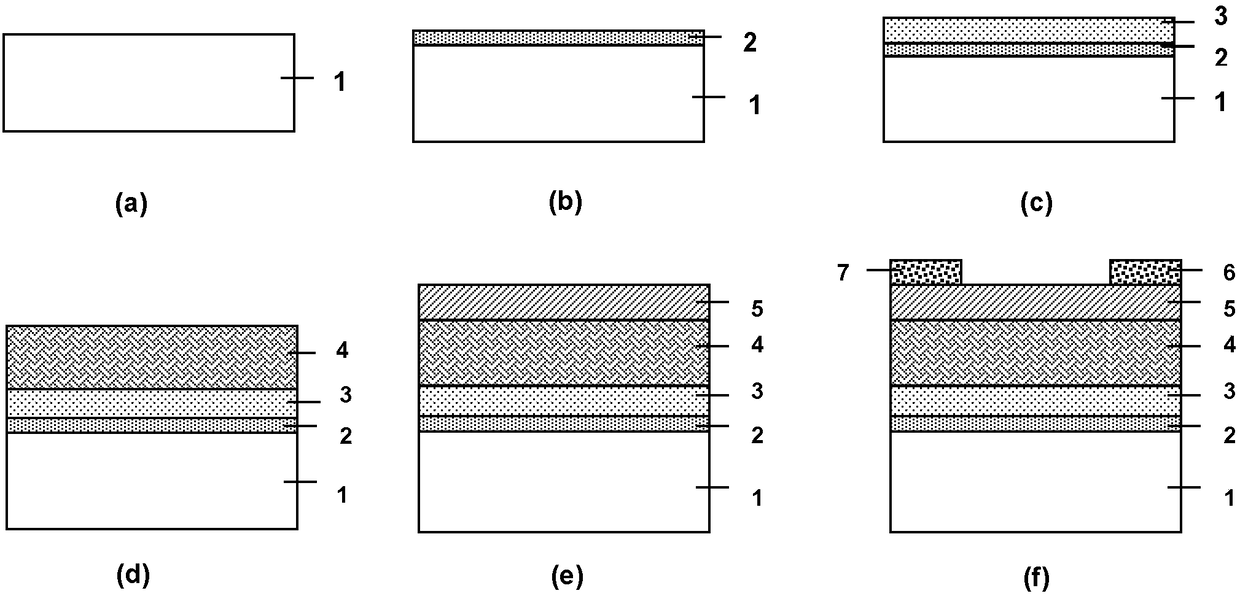

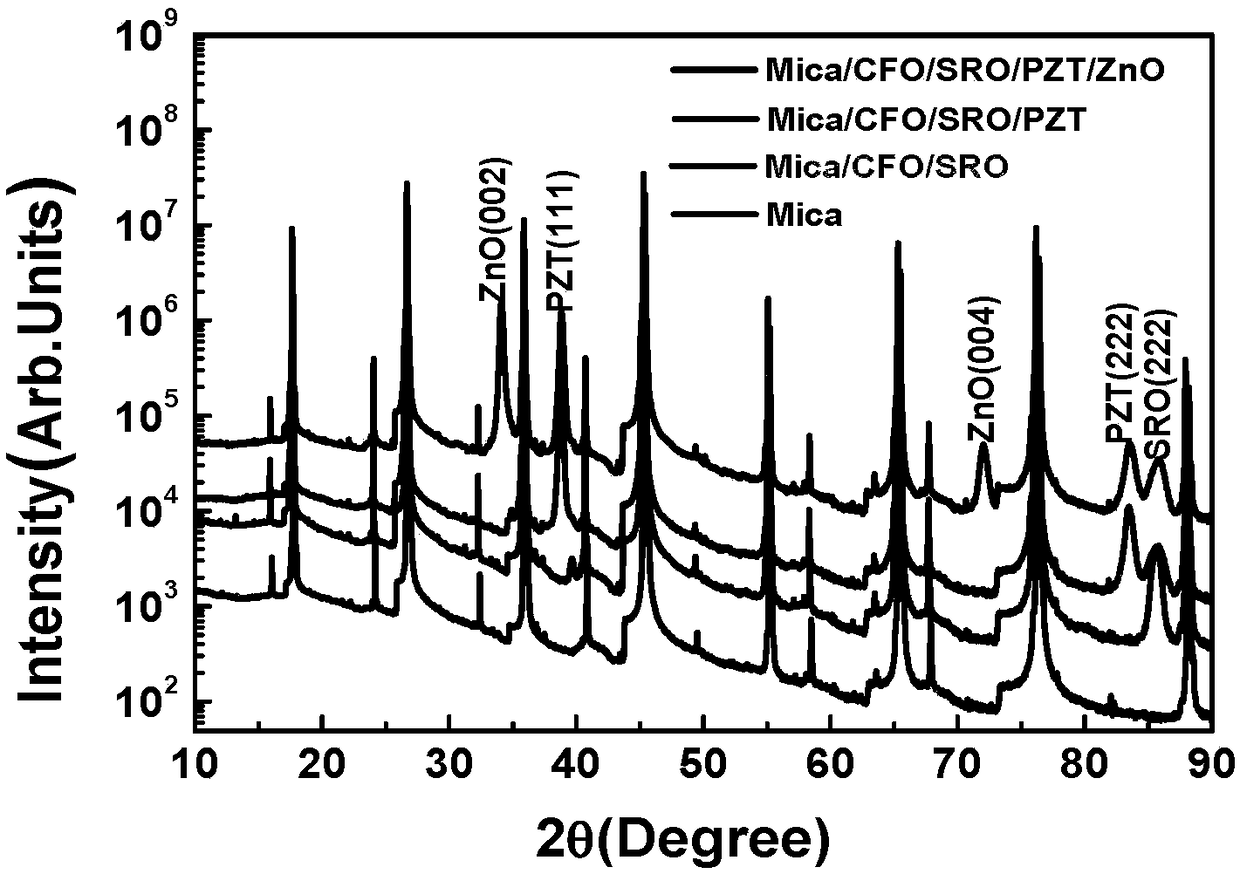

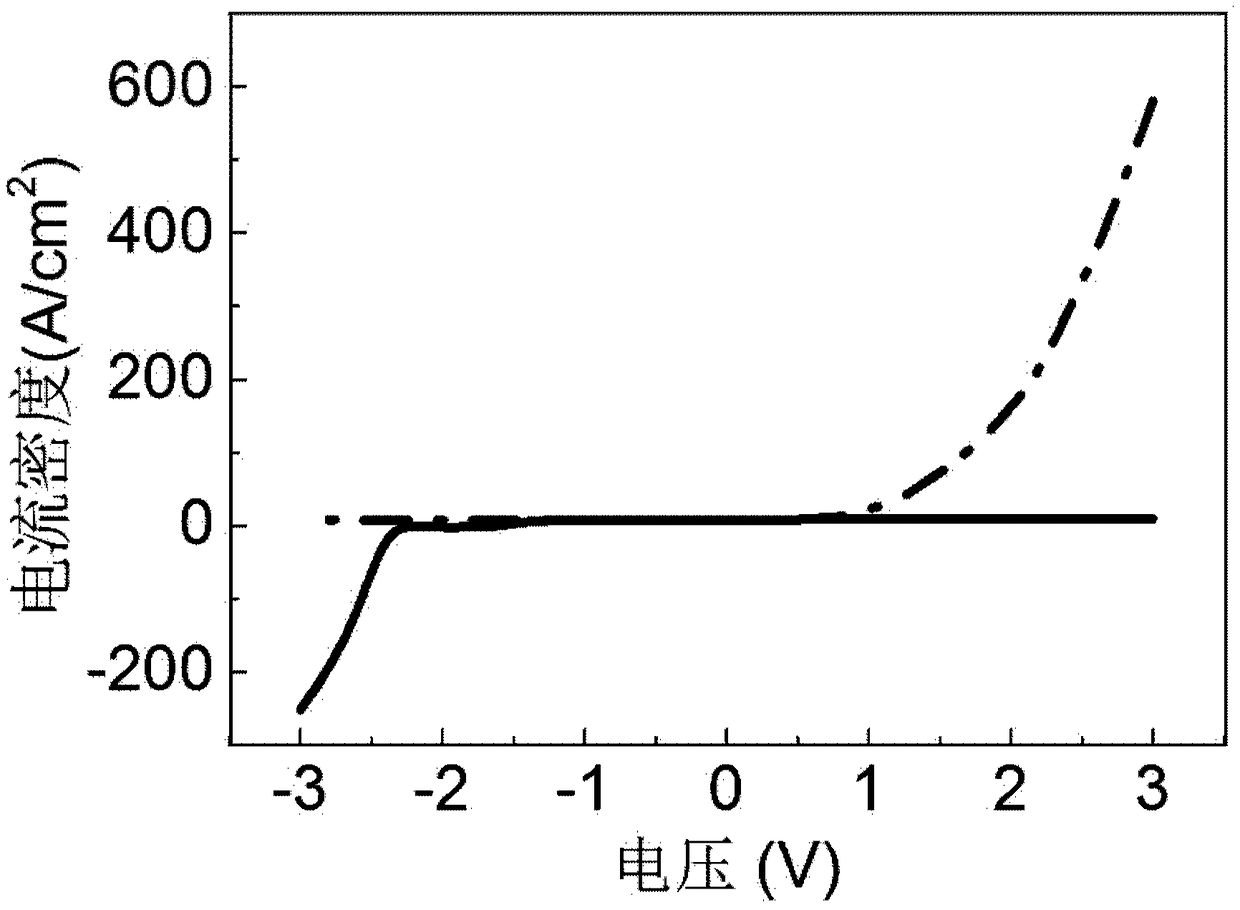

Flexible epitaxial ferroelectric-gate thin-film transistor and preparation method thereof

InactiveCN108550627AGood ferroelectric propertiesHigh remanent polarizationTransistorSemiconductor/solid-state device manufacturingGate dielectricFerroelectric thin films

The invention discloses a flexible epitaxial ferroelectric-gate thin-film transistor and a preparation method thereof. The transistor is composed of a flexible mica substrate, a buffer layer formed onthe substrate, a bottom gate electrode formed on the buffer layer, an epitaxial ferroelectric thin film layer formed on the bottom gate electrode, a channel layer formed on the epitaxial ferroelectric thin film layer, a source electrode formed on the channel layer, and a drain electrode being formed on the channel layer and being separated from the source electrode. According to the invention, the perovskite oxide SrRuO3 epitaxial film with metal conductivity is used as the bottom gate electrode and the perovskite oxide epitaxial ferroelectric film is used as a gate dielectric layer. The transistor has the excellent mechanical bending property and is resistant to bending with the 2-mm bending radius for repeated 1000 times; and the electrical property of the ferroelectric gate thin-film transistor is kept to be unchanged basically. The reading and writing speed is fast; and the high temperature-resistant performance is excellent; and after annealing at a temperature of 400 DEG C, theelectrical property of the transistor does not change obviously. Moreover, the preparation process is simple; the process is stable; and the manufacturing cycle is short.

Owner:XIANGTAN UNIV

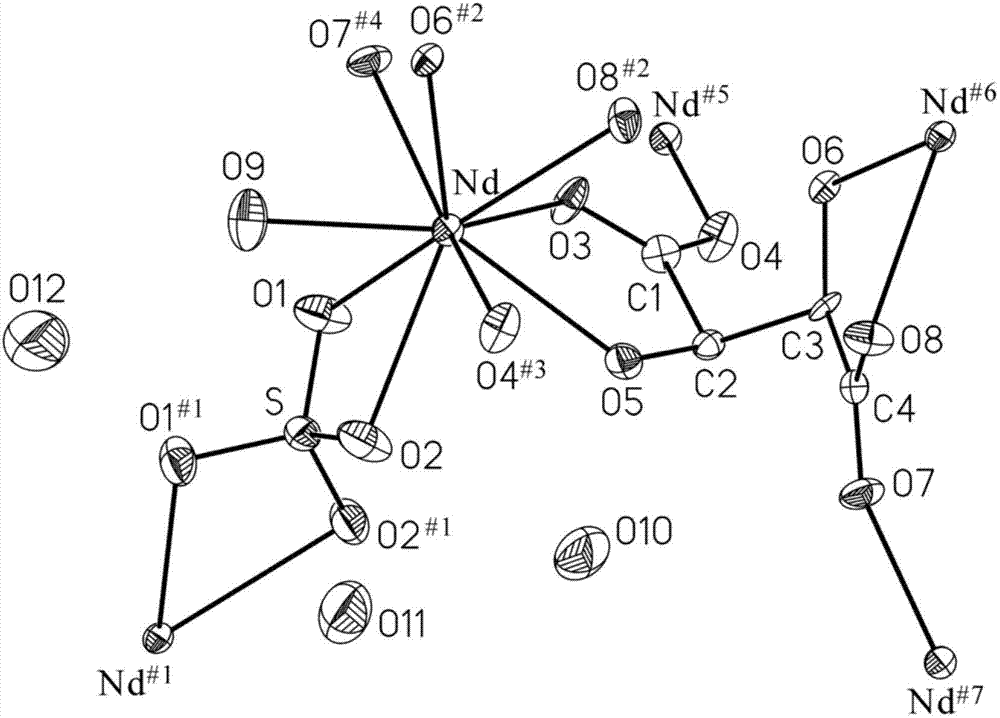

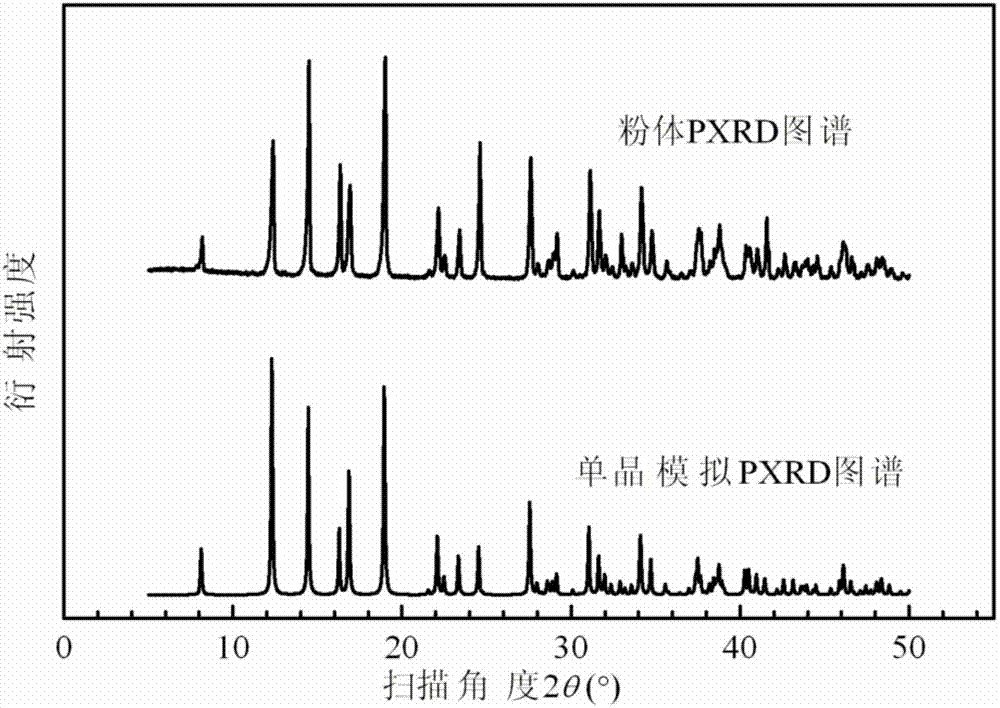

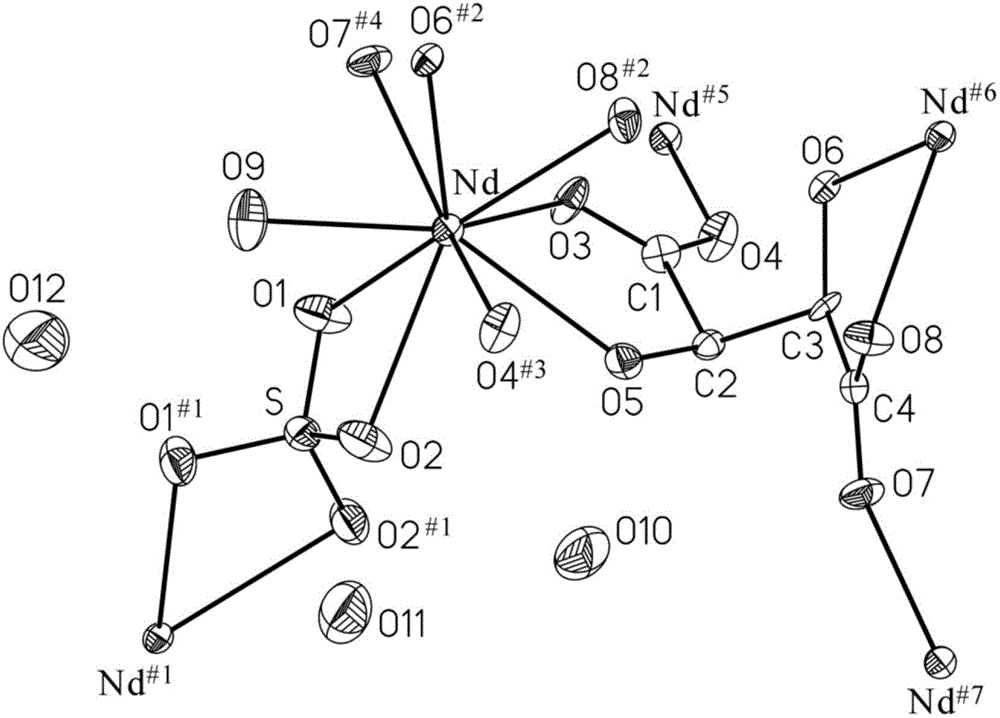

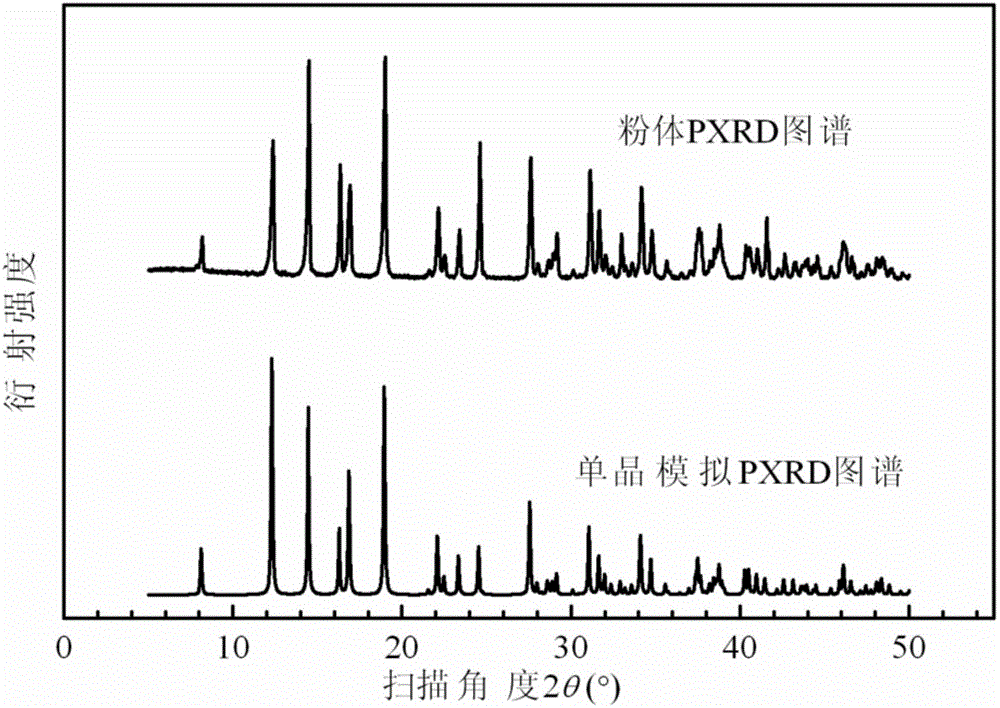

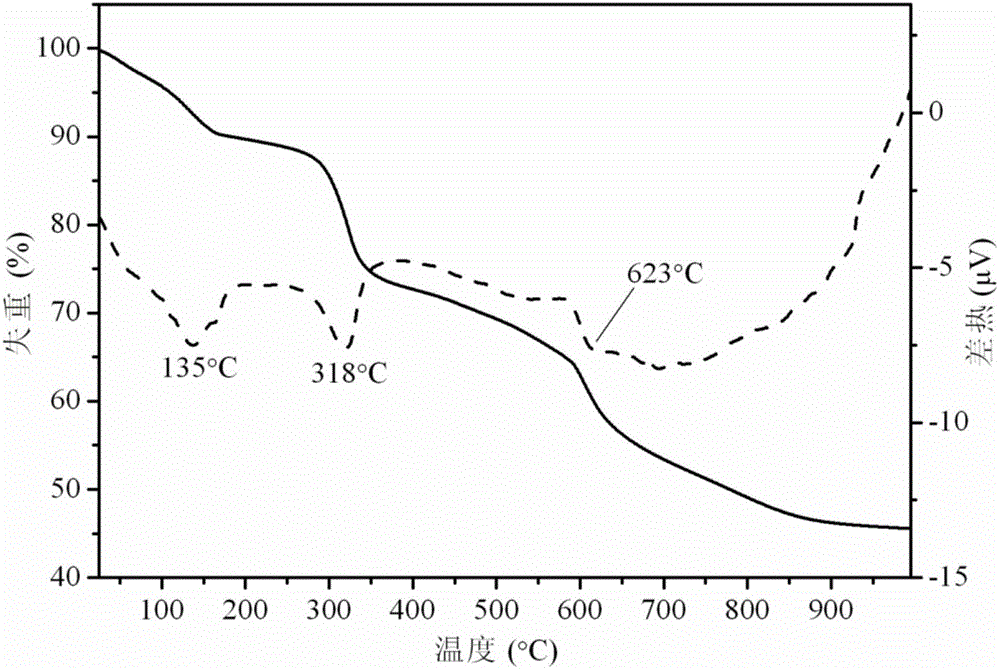

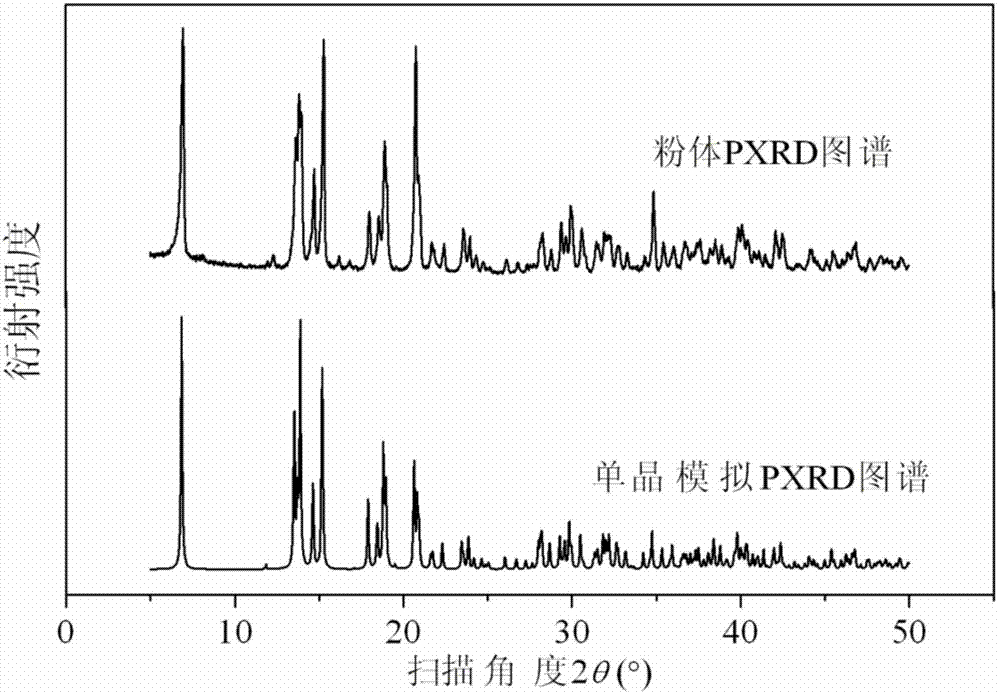

Hydrated L-tartaric acid neodymium sulfate ferroelectric functional material and preparation method thereof

InactiveCN103113394AShort processSimple processGroup 3/13 element organic compoundsSolventSolvothermal reaction

The invention discloses a hydrated L-tartaric acid neodymium sulfate ferroelectric functional material and a preparation method thereof. The ferroelectric functional material has a molecular formula of {Nd2(H2O)2(L-C4H4O6)2(SO4)}.4H2O. The ferroelectric functional material has the following ferroelectric characteristic parameters: the remanent polarization 2Pr is 0.390 mu C / cm<2>; the coercive electric field 2Ec is 74.7 kv / cm; and the saturation polarization Ps is 0.307 mu C / cm<2>. The saturation polarization of the ferroelectric functional material is 1.23 times that of seignette salt, so that the ferroelectric functional material disclosed by the invention is a novel ferroelectric body with excellent ferroelectric performance. The preparation method comprises the following steps: carrying out a solvothermal reaction between neodymium oxide and L-tartaric acid by using an ethanol solvent; and adding a sulfuric acid solution into the mixture and nucleating in a reaction kettle so as to grow into the hydrated L-tartaric acid neodymium sulfate. The preparation method has the advantages of short flow, simple process, low equipment requirement, no pollution and low cost and can be easily industrialized.

Owner:NINGBO UNIV

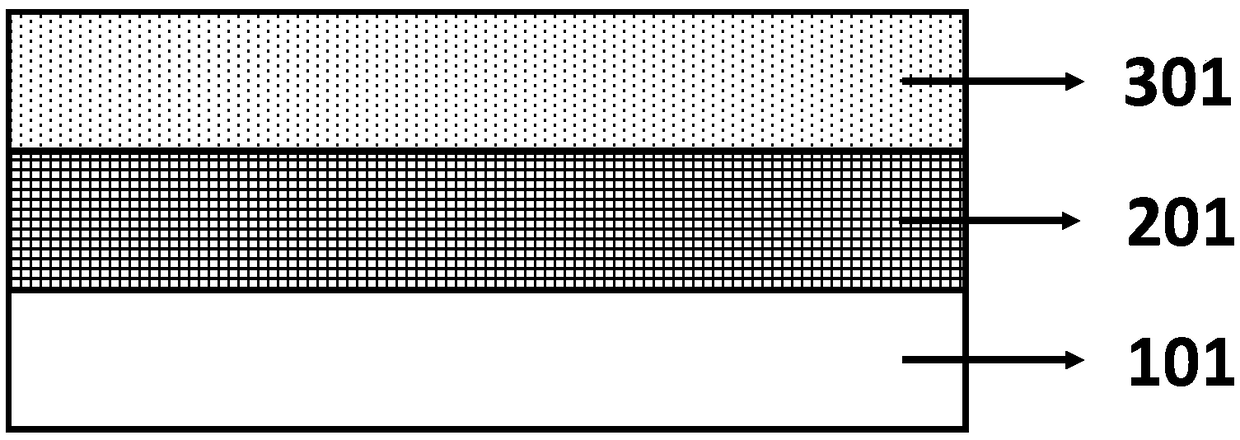

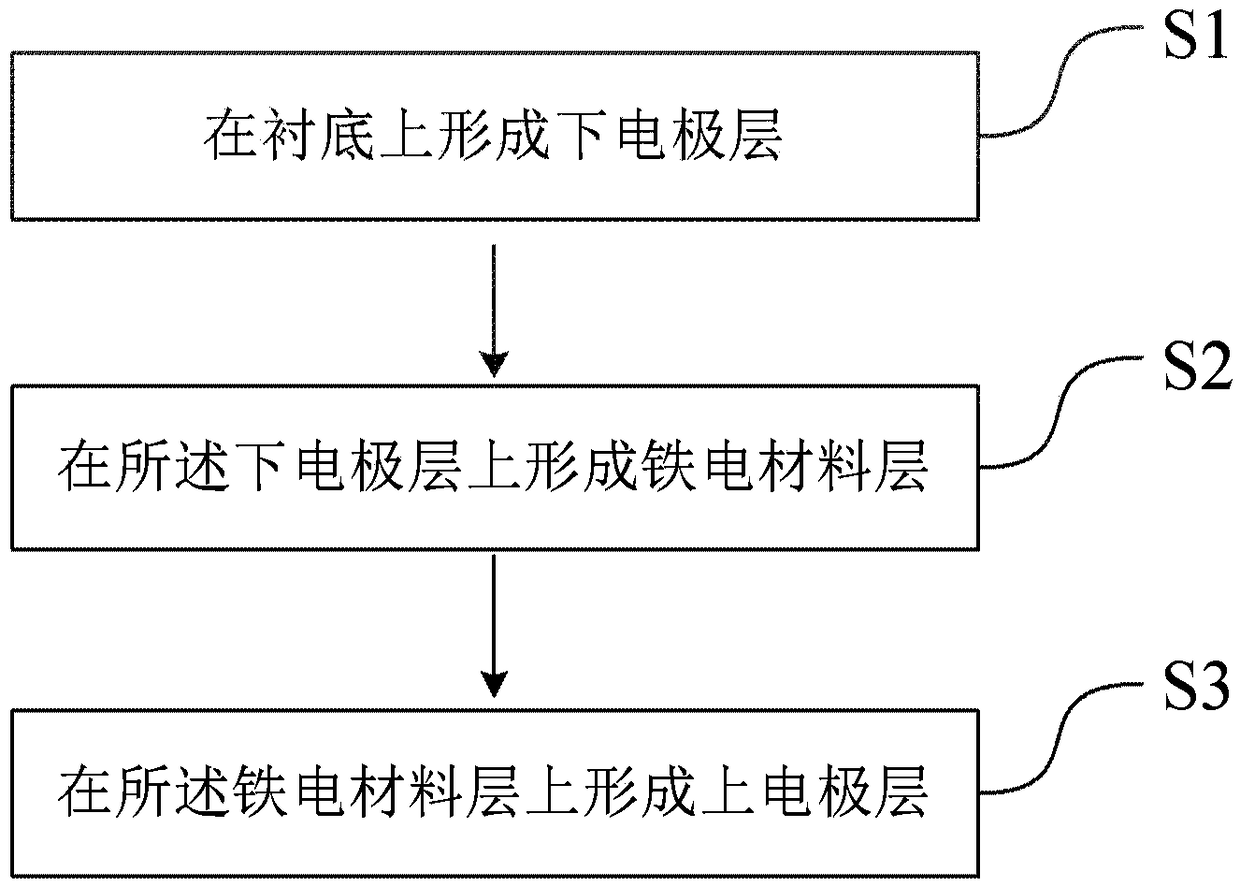

Resistive random access memory and preparation method thereof

InactiveCN109065712AImprove toleranceMiniaturizationElectrical apparatusStatic random-access memoryRandom access memory

The invention discloses a resistive memory, which is characterized in that the resistive memory comprises a lower electrode layer, a ferroelectric material layer and an upper electrode layer in orderfrom bottom to top, wherein the ferroelectric material layer comprises a doped HfO2 ferroelectric thin film.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

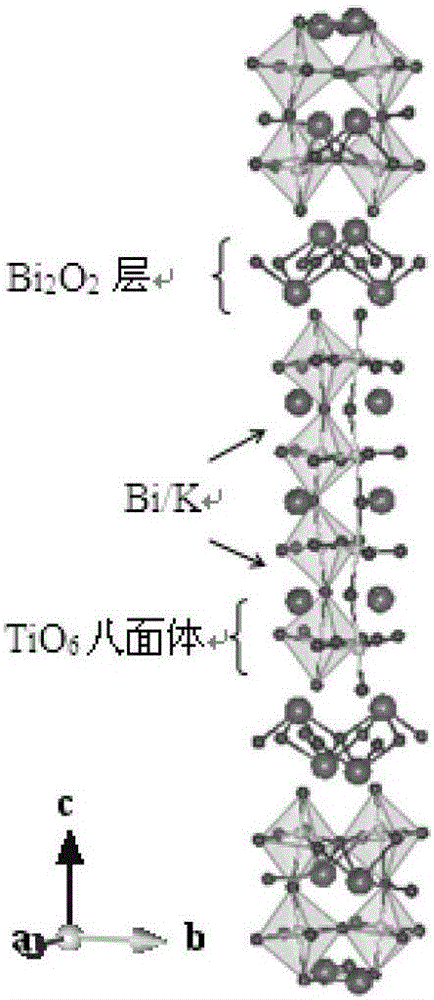

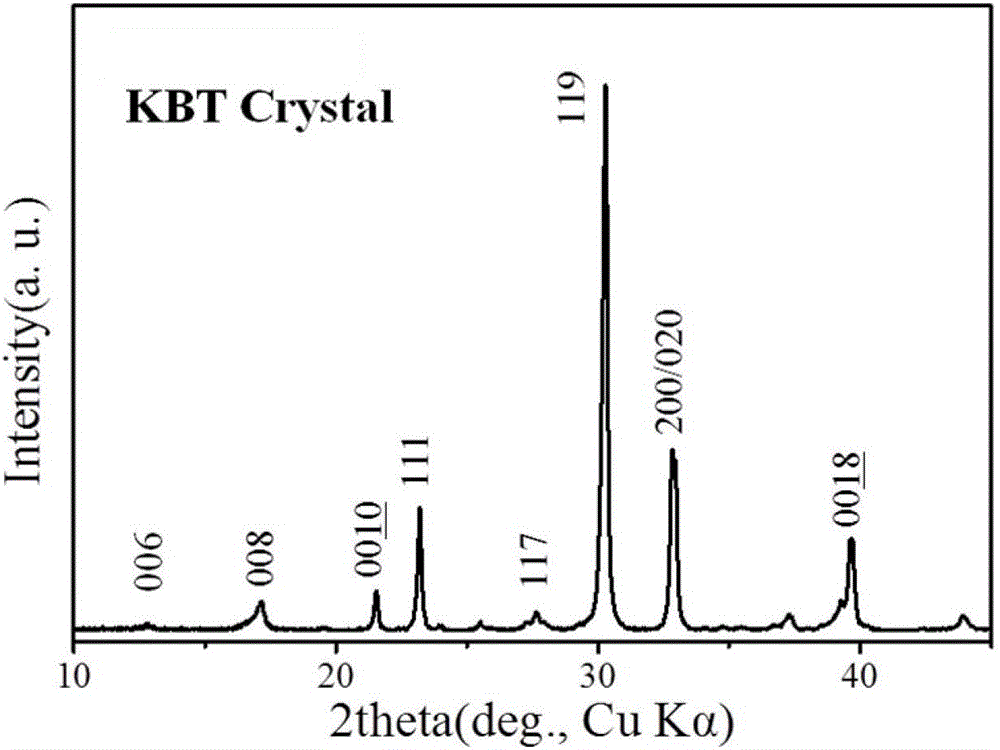

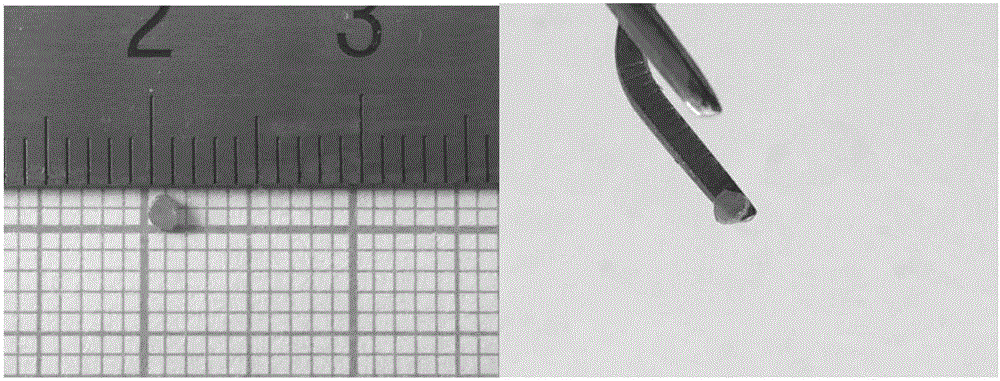

Preparing technology of bismuth-layer-structure K0.5Bi4.5Ti4O15 crystal

InactiveCN106087059AAdjustable growth parametersShorten the growth cyclePolycrystalline material growthAfter-treatment detailsPlatinumArgon atmosphere

The invention belongs to the field of ferroelectric function crystal materials, and particularly relates to a preparing technology of a bismuth-layer-structure K0.5Bi4.5Ti4O15 crystal. The preparing technology includes the steps that a polycrystal material is prepared; the polycrystal material is pulverized to be pressed a solid block again, the solid block is subjected to secondary sintering, polished and cut, and a polycrystal raw material rod is obtained; the polycrystal raw material rod is put at the lower portion of a hollow platinum tube, then put into a crystal growing furnace, heated in the argon atmosphere and melted, a platinum wire is led, and nucleation and growth of the crystal are carried out; the crystal completely grows to be slowly moved away fusion intervals, the platinum wire is taken out after stabilization is carried out for 1 h to 2 h, and bismuth-layer-structure K0.5Bi4.5Ti4O15 crystal is obtained; the bismuth-layer-structure K0.5Bi4.5Ti4O15 crystal is annealed at the high temperature. The K0.5Bi4.5Ti4O15 crystal prepared with the technology is good in evenness, and has the good ferroelectric characteristics.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Method for manufacturing ferroelectric memory device

InactiveUS20070218568A1Improve the immunityElectrical conductivitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsTitanium oxide

A method for manufacturing a ferroelectric capacitor, includes the steps of: forming a ferroelectric capacitor layer having a lower electrode layer, a ferroelectric layer and an upper electrode layer on a base substrate; forming a titanium oxide layer on the ferroelectric capacitor layer; patterning the titanium oxide layer by high-temperature etching between 200° C. and 500° C. to thereby form a mask pattern; and etching the ferroelectric capacitor layer by using the mask pattern as a mask, to thereby form a ferroelectric capacitor having a lower electrode, a ferroelectric film and an upper electrode.

Owner:SEIKO EPSON CORP

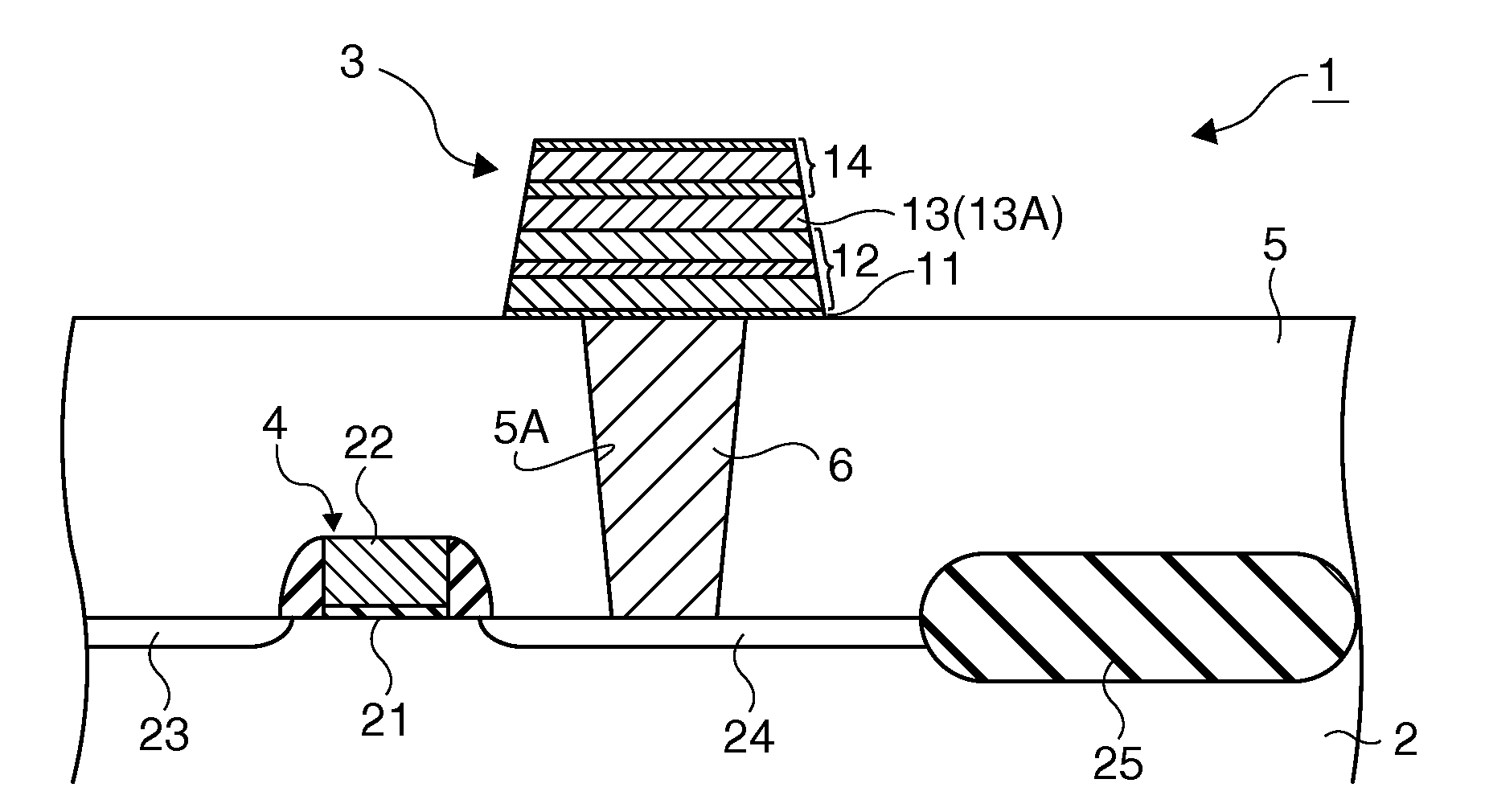

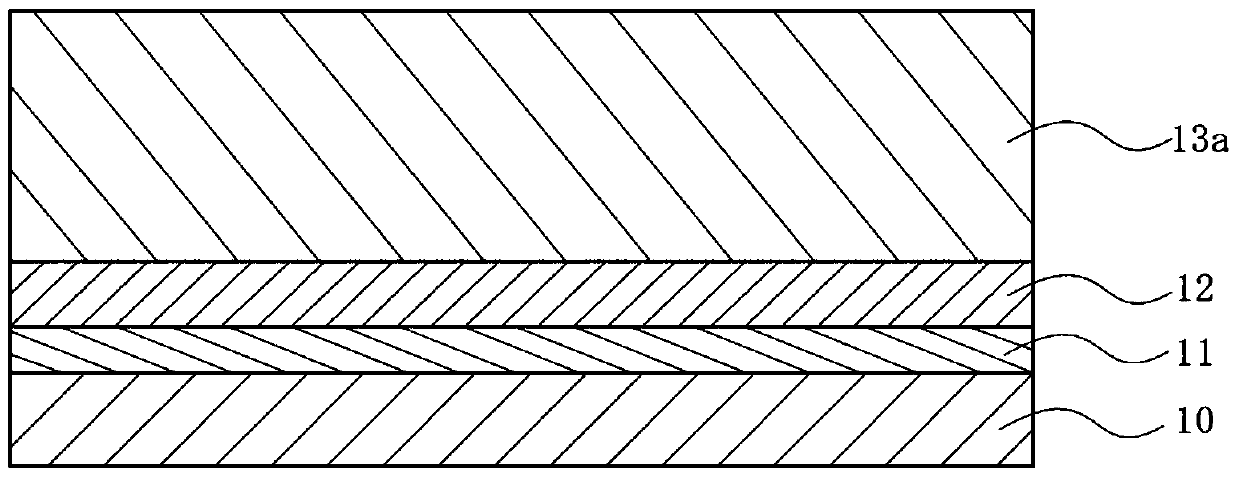

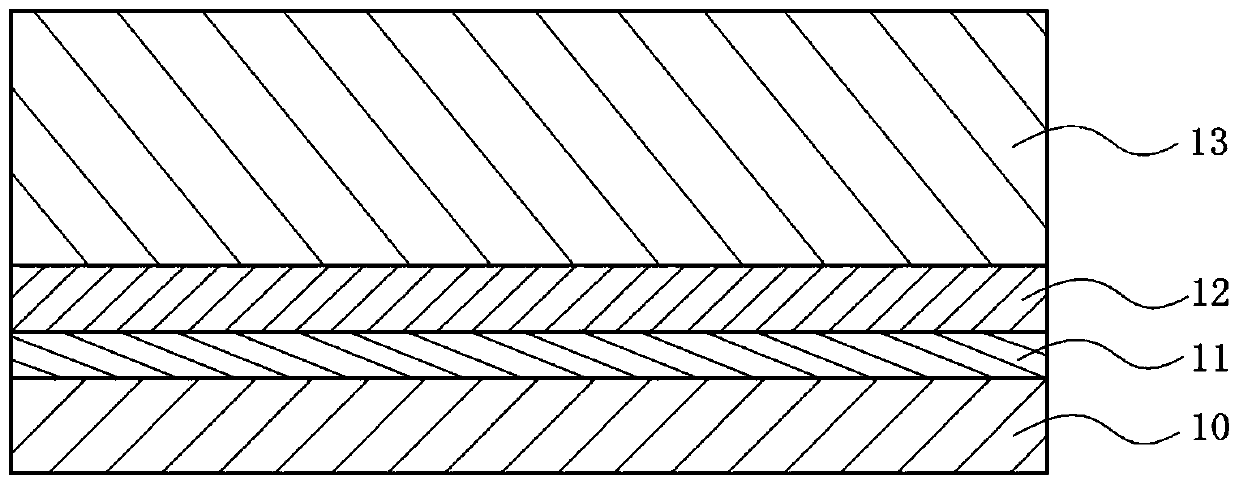

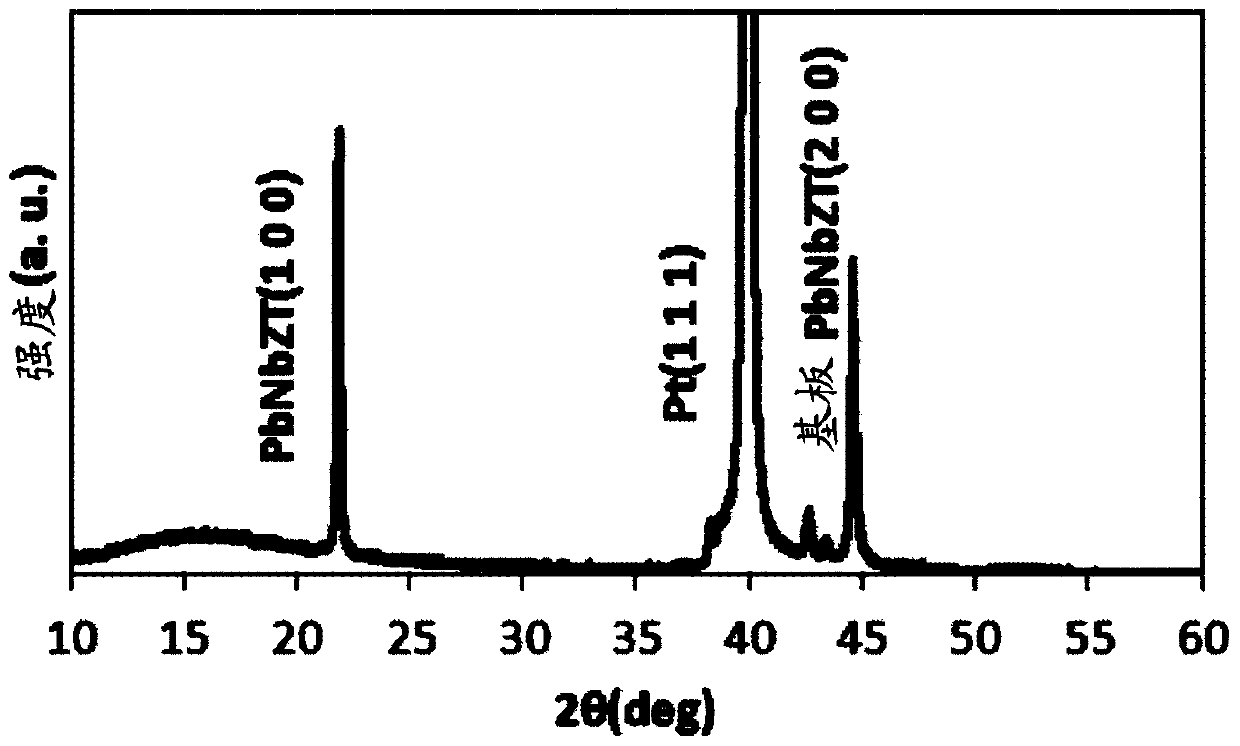

Manufacturing method of pnbzt ferroelectric thin film and composite electronic parts

ActiveCN104072135BHigh relative permittivityReduce leakage currentFixed capacitor dielectricVacuum evaporation coatingFerroelectric thin filmsThin membrane

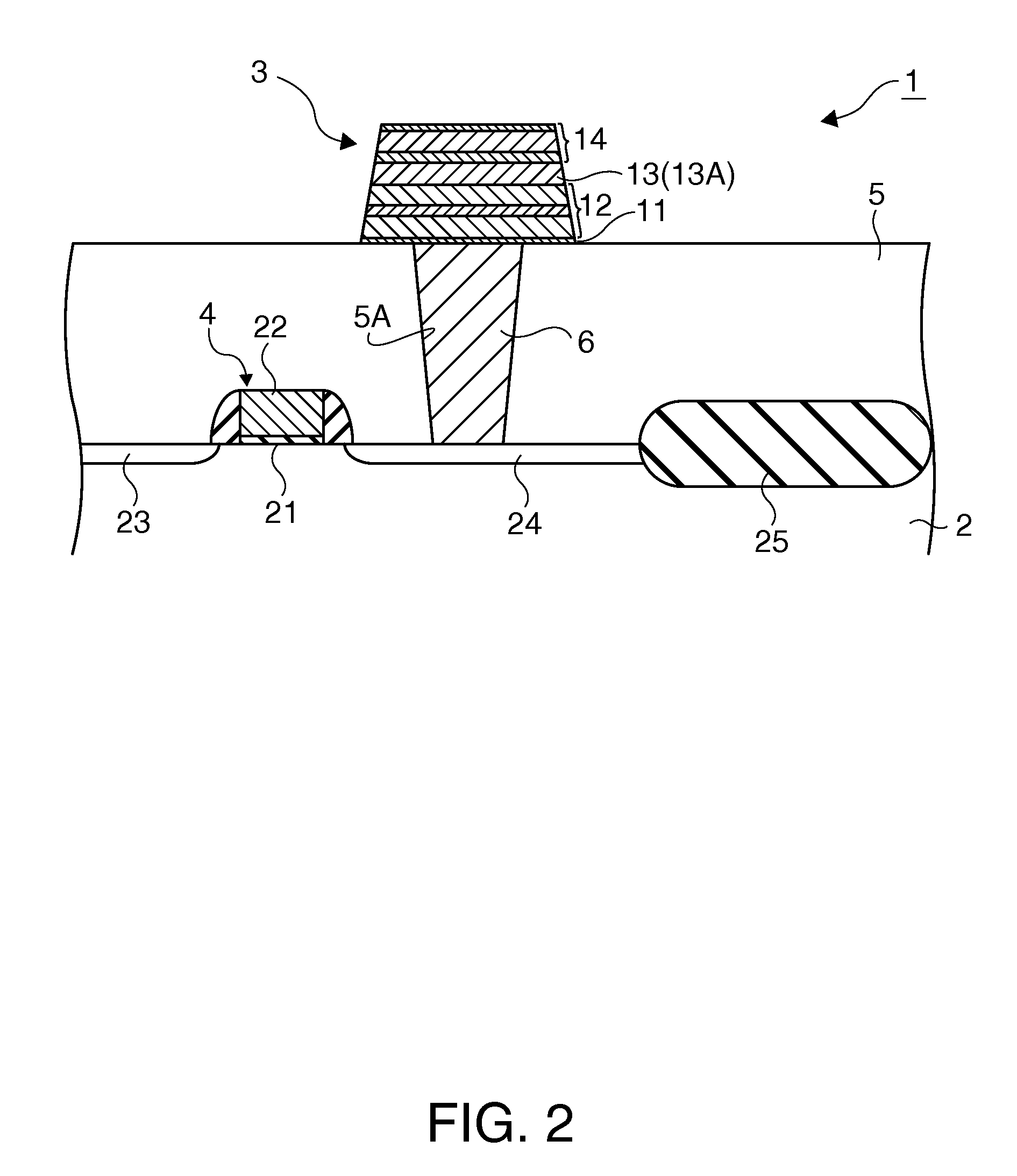

The invention provides a method for manufacturing a PNbZT ferroelectric thin film and a composite electronic component. In this method, a composition for forming a Nb-free PZT ferroelectric thin film is coated on a lower electrode (11) formed on a substrate (10), pre-sintered, and fired to crystallize it, thereby A crystallization promoting layer (12) with a thickness of 45 to 90 nm is formed, and a composition for forming a PNbZT ferroelectric thin film is coated on the crystallization promoting layer (12) formed above to form a coating film (13a) of PNbZT. After the coating film (13a) is pre-sintered, it is fired to crystallize it, thereby forming a PNbZT ferroelectric thin film on the above-mentioned lower electrode (11), wherein, in the PNbZT ferroelectric thin film, the 4-10 atomic % of Nb is contained in the total 100 atomic % of Zr and Ti contained perovskite B-site atoms.

Owner:MITSUBISHI MATERIALS CORP

Hydrated L-tartrate neodymium sulfate ferroelectric functional material and preparation method

InactiveCN103113394BGood ferroelectric propertiesLess ferroelectric propertiesGroup 3/13 element organic compoundsSeignette saltSolvent

The invention discloses a hydrated L-tartaric acid neodymium sulfate ferroelectric functional material and a preparation method thereof. The ferroelectric functional material has a molecular formula of {Nd2(H2O)2(L-C4H4O6)2(SO4)}.4H2O. The ferroelectric functional material has the following ferroelectric characteristic parameters: the remanent polarization 2Pr is 0.390 mu C / cm<2>; the coercive electric field 2Ec is 74.7 kv / cm; and the saturation polarization Ps is 0.307 mu C / cm<2>. The saturation polarization of the ferroelectric functional material is 1.23 times that of seignette salt, so that the ferroelectric functional material disclosed by the invention is a novel ferroelectric body with excellent ferroelectric performance. The preparation method comprises the following steps: carrying out a solvothermal reaction between neodymium oxide and L-tartaric acid by using an ethanol solvent; and adding a sulfuric acid solution into the mixture and nucleating in a reaction kettle so as to grow into the hydrated L-tartaric acid neodymium sulfate. The preparation method has the advantages of short flow, simple process, low equipment requirement, no pollution and low cost and can be easily industrialized.

Owner:NINGBO UNIV

Method for fabricating ferroelectric memory device

InactiveCN100539013CGood ferroelectric propertiesHigh read/write durabilityTransistorSolid-state devicesZirconateTitanium

A ferroelectric capacitor with a ferroelectric film having a relatively larger amount of titanium constituent than zirconate constituent improves ferroelectric characteristics. The method for fabricating the ferroelectric capacitor includes the step of performing a heat treatment in an oxygen atmosphere after forming a contact opening in an insulating layer which covers an already formed ferroelectric capacitor. This heat treatment in an oxygen atmosphere can minimize undesirable side effects resulting from a platinum electrode oxidizing the ferroelectric film components.

Owner:SAMSUNG ELECTRONICS CO LTD

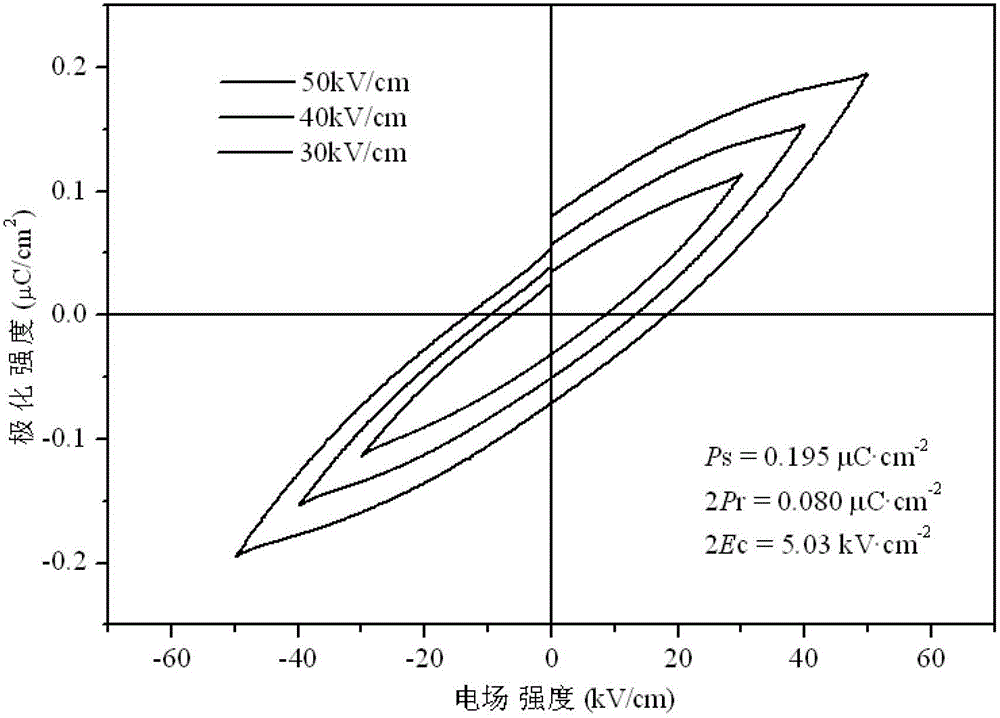

Copper o-phenanthroline m-hydroxybenzoate ferroelectric functional material and preparation method thereof

InactiveCN103254218BGood ferroelectric propertiesAchieve growthCopper organic compoundsBenzoic acidPhenanthroline

The invention discloses an o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material and a preparation method thereof. The molecular formula of the o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material is Cu2(C12H8N2)2Cl2(C7H5O3)2. The ferroelectric function material is dark blue powder with the purity being not less than 99% and has a C2v point group structure. The ferroelectric characteristic parameters are respectively as follows: the remanent polarization 2Pr equals to 0.08muC*cm<-2>, the coercive electric field 2Ec equals to 5.03kv*cm<-1>; and the saturated polarization Ps equals to 0.195muC*cm<-2>. The ferroelectric function material has good ferroelectric characteristics. According to the ferroelectric function material, m-hydroxybenzoic acid solution and copper chloride solution are stirred for reacting, and then o-phenanthroline solution is added to realize nucleation and growth of o-phenanthroline m-hydroxybenzoic acid copper. The o-phenanthroline m-hydroxybenzoic acid copper ferroelectric function material is simple and practicable in process, low in facility request, low in raw material cost, high in productivity, less in pollution and the like.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com