Method for fabricating ferroelectric memory device

A ferroelectric memory, ferroelectric storage technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, capacitors, etc., can solve the problems of easy oxidation, insufficient titanium in PZT, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

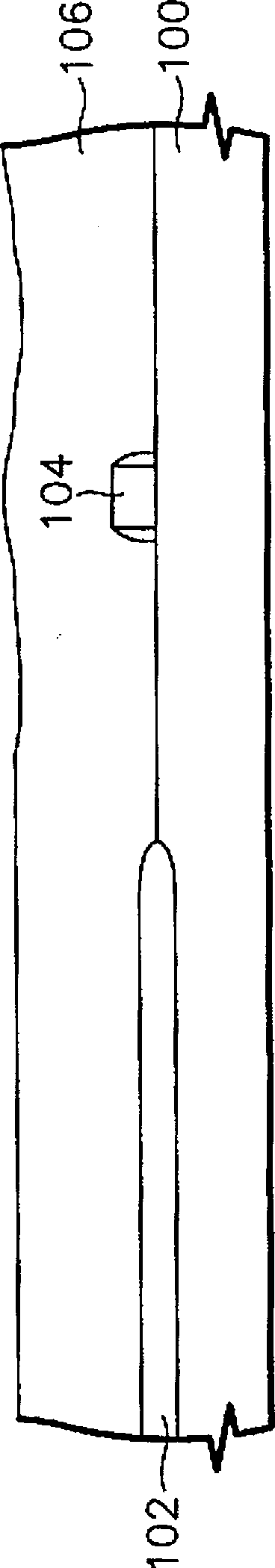

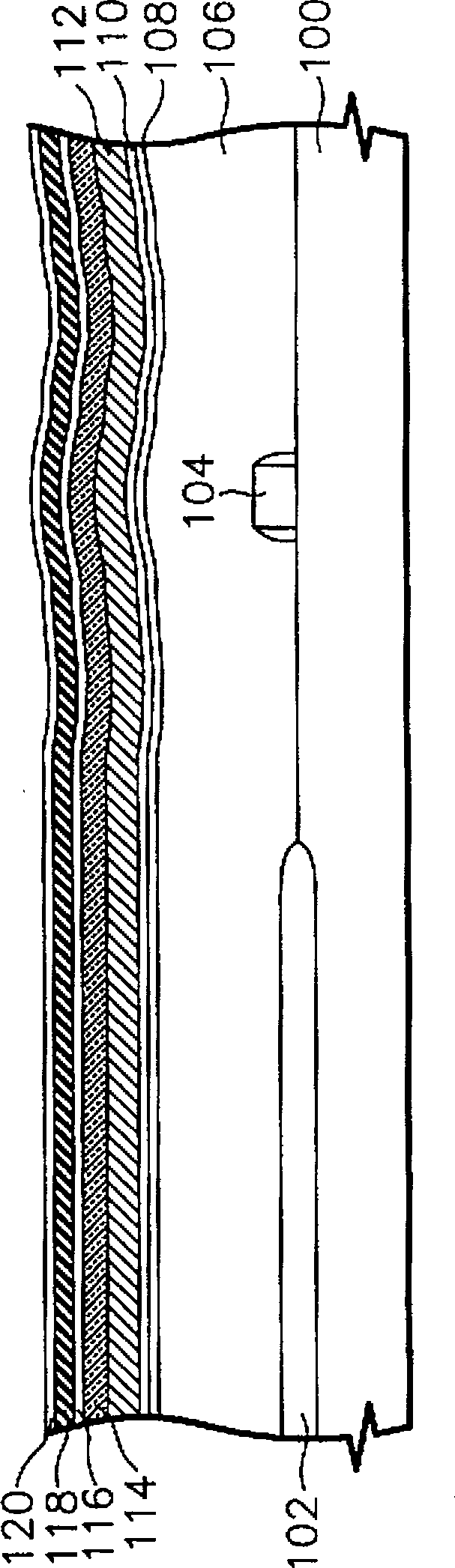

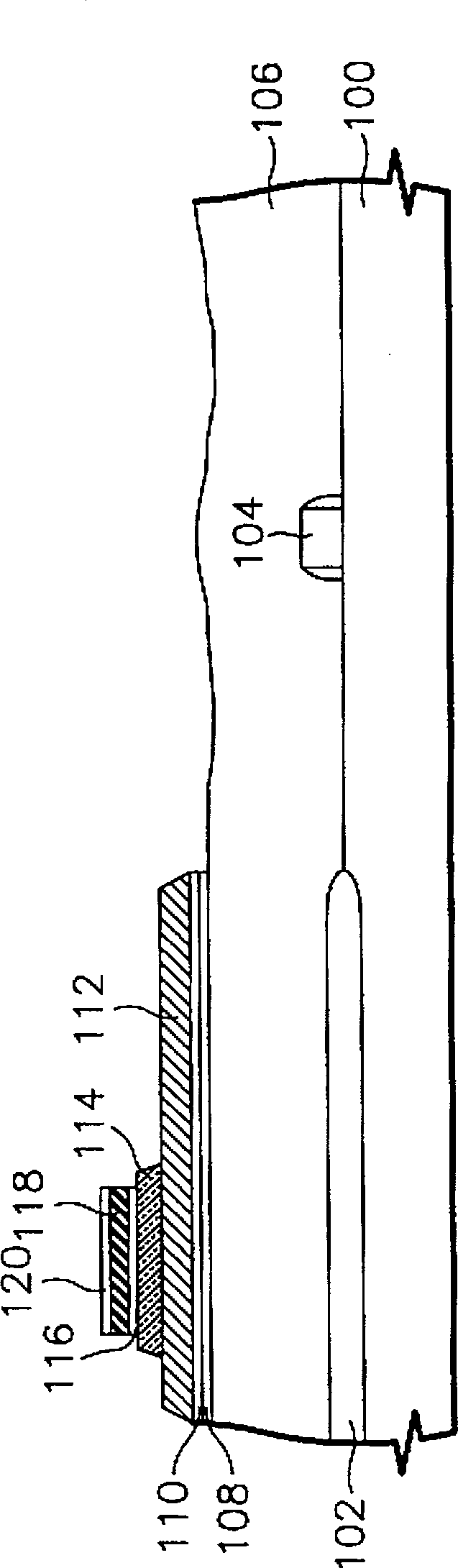

[0015] Consistent with the object of the present invention, a method of manufacturing a ferroelectric memory device will be specifically described below. Figures 1A-1J is a cross-sectional view of a semiconductor substrate at a select process stage for a ferroelectric capacitor. see Figure 1A , providing a semiconductor substrate 100 having a transistor 104 and a first insulating layer 106 on an active region thereof. The active region is surrounded by a device isolation region 102 having a predetermined pattern. Transistor 104 includes a gate with an insulating capping layer, and a pair of source / drain regions extending from lateral edges of the gate to a predetermined depth within the active region.

[0016] see Figure 1B , forming an adhesion / barrier layer 108 on the first insulating layer 106 . The adhesion / barrier layer 108 is used to enhance the adhesion between the bottom electrode of the subsequent ferroelectric capacitor and the first insulating layer 106 . Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com