Manufacturing method of pnbzt ferroelectric thin film and composite electronic parts

一种铁电薄膜、制造方法的技术,应用在固定电容的零部件、电气元件、固定电容器电介质等方向,能够解决未公开铁电薄膜特性等问题,达到减少泄漏电流、电特性和寿命可靠性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

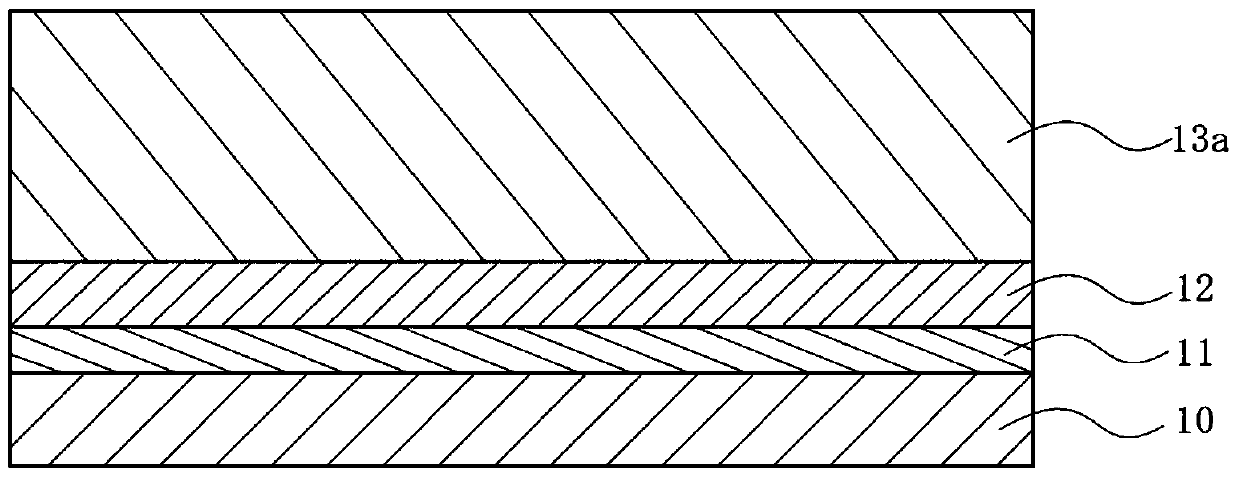

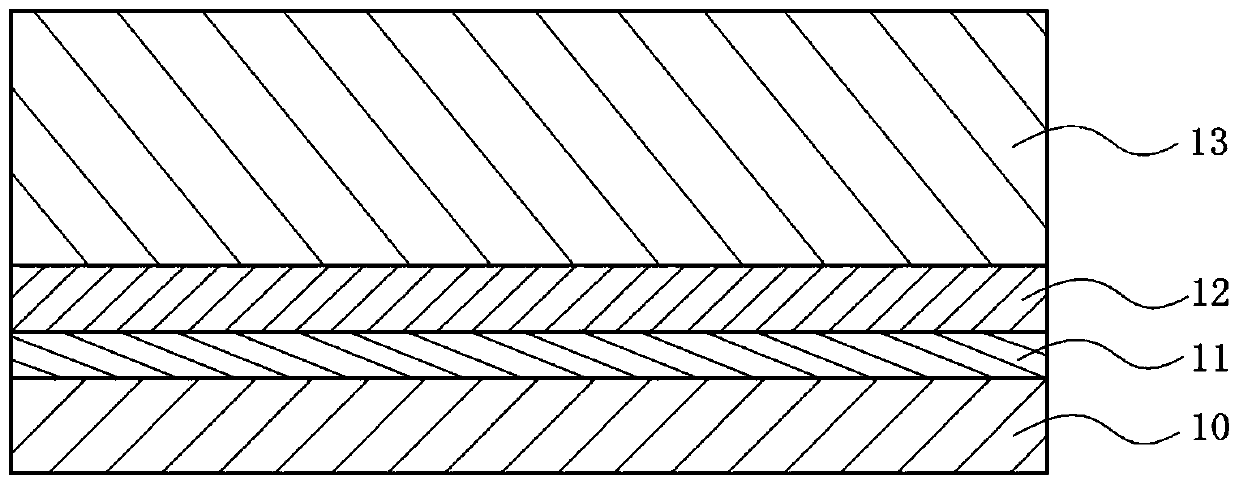

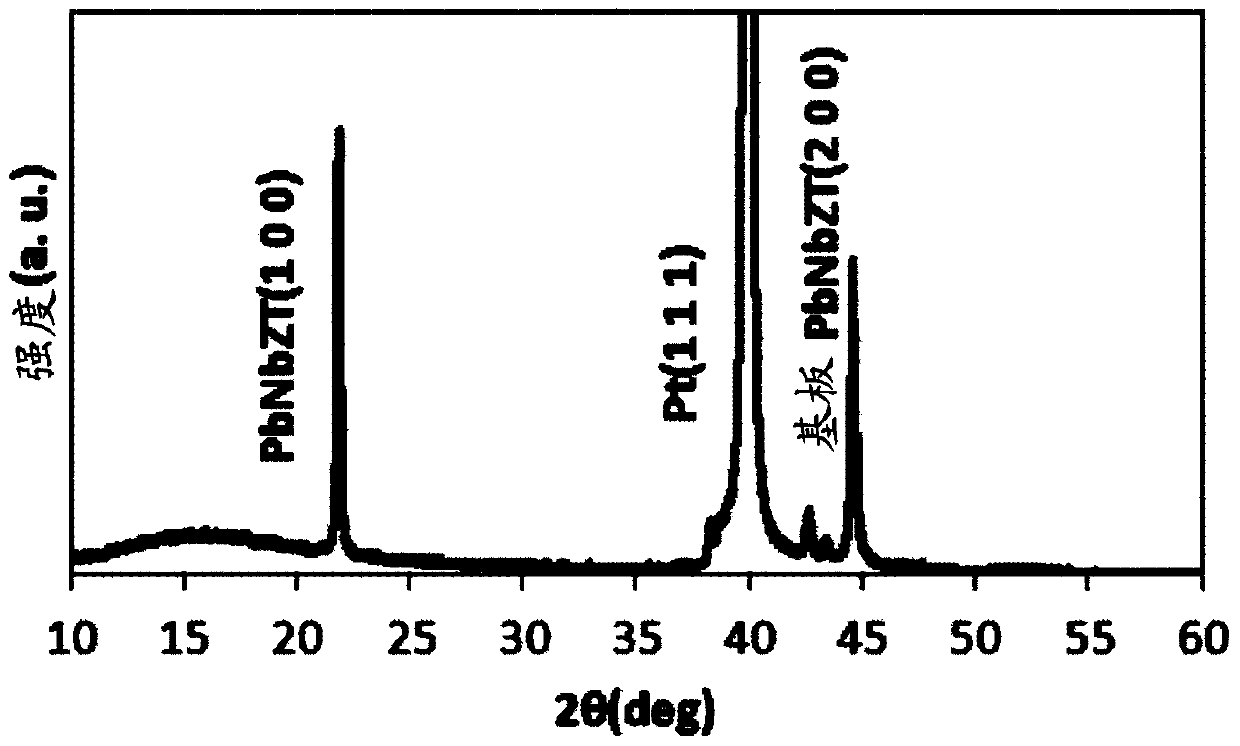

[0052] As a composition for forming a PZT ferroelectric thin film for forming a crystallization-promoting layer, a metal combination ratio of 115 / 53 / 47 (Pb / Zr / Ti) was prepared, and a precursor concentration was diluted with 1-butanol as a solvent ( The total of the Pb source, the Zr source, and the Ti source) was adjusted to a PZT sol-gel solution (manufactured by Mitsubishi Materials Corporation, product name: PZT-E1) of 12% by mass in terms of oxides. And, as a composition for forming a PNbZT ferroelectric thin film, prepare a metal combination ratio of 115 / 8 / 47.8 / 44.2 (Pb / Nb / Zr / Ti), and use 1-butanol as a solvent to dilute the precursor concentration ( The total of Pb source, Nb source, Zr source, and Ti source) was adjusted to a PNbZT sol-gel solution (manufactured by Mitsubishi Materials Corporation, product name: PNbZT-E1) at an oxide conversion rate of 15% by mass. That is, in this composition, 8 atomic % of Nb is contained in the total 100 atomic % of B site atoms (Zr,...

Embodiment 1-2、1-3 and comparative example 1-1~ comparative example 1-3

[0056] A PNbZT ferroelectric thin film was formed on the lower electrode in the same manner as in Example 1-1, except that the coating amount of the PZT sol-gel liquid was adjusted so that the thickness of the crystallization promoting layer was as shown in Table 1 below. In addition, in Comparative Example 1-1, the coating amount of the PZT sol-gel solution was set to 0, that is, the crystallization-promoting layer was not formed, but the PNbZT sol-gel solution was directly coated on the lower electrode, and in the same manner as in Example 1-1 The same conditions for pre-sintering, firing, etc., in order to form PNbZT ferroelectric thin film.

Embodiment 2-1、2-2 and comparative example 2-1、 comparative example 2-2

[0058] In addition to changing the addition amount of Nb in the crystallization promotion layer to the ratio shown in Table 1 below by changing the addition composition when manufacturing the above-mentioned PNbZT sol-gel liquid, the same method as in Example 1-1 was formed on the lower electrode. PNbZT ferroelectric thin film.

[0059]

[0060] Regarding the PNbZT ferroelectric thin films formed in Examples 1-1 to 2-2 and Comparative Examples 1-1 to 2-2, the thickness of the crystallization promoting layer and the PNbZT ferroelectric thin film, the crystallization of the lower electrode and the crystallization promoting layer Orientation, film structure of PNbZT ferroelectric thin film (with or without cracks), electrical characteristics (relative permittivity), and leakage current density were evaluated. These results are shown in Table 1 below.

[0061] (1) Thickness: The cross-sectional thickness (total thickness) of the crystallization-promoting layer before forming th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com