Film capacitor element, film capacitor, and method of producing the film capacitor element

A technology for thin film capacitors and a manufacturing method, which is applied in the directions of thin film/thick film capacitors, fixed capacitor dielectrics, capacitors, etc., can solve the problems of slow deposition rate of vapor-deposited polymer films, difficulty in meeting the requirements of thin film capacitors, and reduced productivity. Effects of improving relative dielectric constant, high withstand voltage, and excellent productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the present invention, specific embodiments of the present invention will be described with reference to the accompanying drawings.

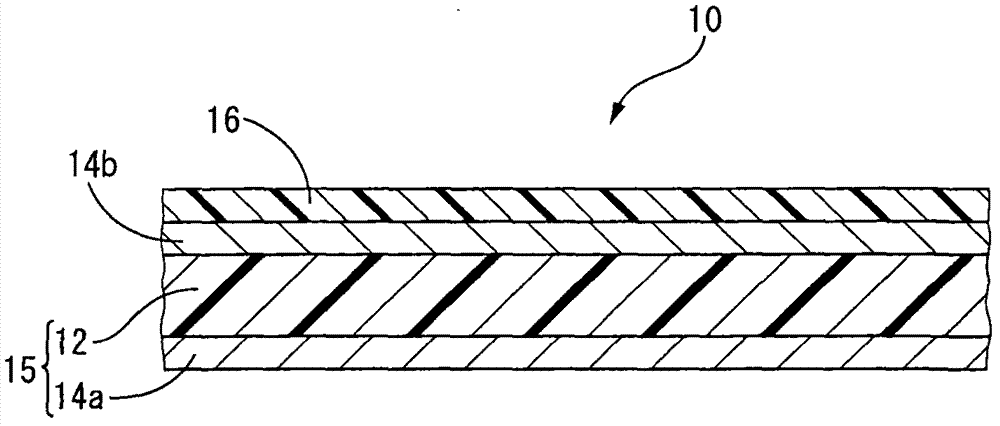

[0030] first, figure 1 One embodiment of a film capacitor element according to the invention is shown in vertical section. like figure 1 As shown, the thin film capacitor element 10 of this embodiment includes a metallized film 15 including a metal vapor-deposited film 14a and a resin film 12 serving as a dielectric film on the surface of the metal vapor-deposited film 14a. Film capacitor element 10 further includes, on metallized film 15 , metal vapor-deposition film 14 b on the side opposite to metal vapor-deposition film 14 a (the other surface of resin film 12 ) and vapor-deposited polymer film 16 on metal vapor-deposition film 14 b. That is, in the present embodiment, thin film capacitor element 10 is a laminate including metal vapor-deposition film 14a, resin film 12, metal vapor-deposition film 14b,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com