Stable nanometer silver colloidal sol and preparation method thereof

A nano-silver sol and nano-silver technology, which is applied in the field of stable nano-silver sol and preparation, can solve the problems of average particle size and particle size distribution difference, uneven particle size distribution of nano-silver particles, and limit the use of nano-silver. Fewer, suitable for large-scale production, the effect of novel ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

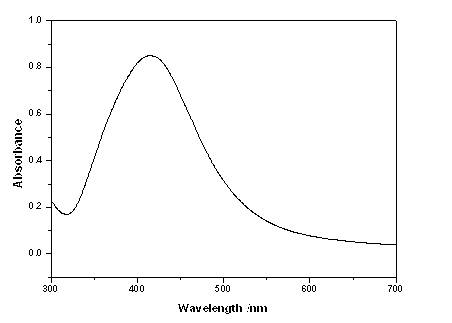

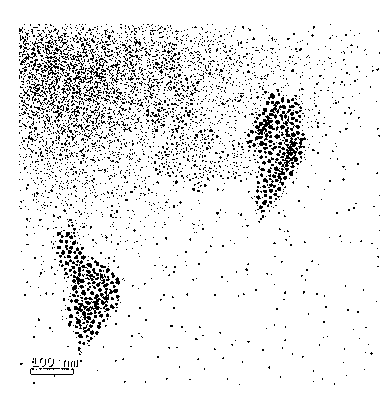

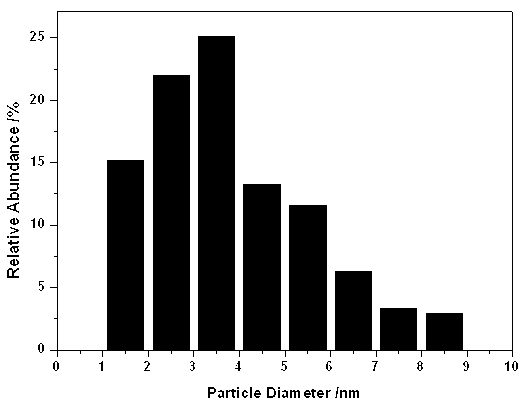

[0032] Using silver-containing compound and protective agent as raw materials, using water as solvent, mixing silver-containing compound, protective agent and water to form a mixed solution, the silver content in the solution is 200ppm, and the protective agent content in the solution is 0.02%-1%. The rest is water content; the ratio of the above raw materials is by weight percentage; the silver-containing compound, protective agent and water are mixed to form a mixed solution, and the sol containing nano-silver particles is obtained by illuminating with a light source containing ultraviolet light. The silver-containing compound adopts silver salt── Silver nitrate, the protective agent adopts polyvinylpyrrolidone (Polyvinylpyrrolidone, PVP), and the light source containing ultraviolet rays adopts a high-pressure mercury lamp, and the specific preparation steps are as follows:

[0033] Preparation nano-silver content is the stable nano-silver sol of 200ppm, is raw material with si...

Embodiment 2

[0039] A stable nano-silver sol with a nano-silver content of 10000ppm was prepared.

[0040] Using silver-containing compound and protective agent as raw materials, using water as solvent, mixing silver-containing compound, protective agent and water to form a mixed solution, the silver content in the solution is 10000ppm, and the protective agent content in the solution is 0.02%-1%. The rest is water content; the ratio of the above raw materials is by weight percentage; the silver-containing compound, protective agent and water are mixed to form a mixed solution, and the sol containing nano-silver particles is obtained by illuminating with a light source containing ultraviolet light. The silver-containing compound adopts silver salt── Silver nitrate, the protective agent adopts polyvinylpyrrolidone (Polyvinylpyrrolidone, PVP), and the light source containing ultraviolet rays adopts a high-pressure mercury lamp, and the specific preparation steps are as follows:

[0041] Prep...

Embodiment 3

[0048] A stable nano-silver sol with a nano-silver content of 1000ppm was prepared.

[0049] Using silver-containing compounds and protective agents as raw materials, using water as a solvent, mixing silver-containing compounds, protective agents and water to form a mixed solution, the silver content in the solution is 1000ppm, and the protective agent content in the solution is 0.02%-1%. The rest is water content; the ratio of the above raw materials is by weight percentage; the silver-containing compound, protective agent and water are mixed to form a mixed solution, and the sol containing nano-silver particles is obtained by illuminating with a light source containing ultraviolet light. The silver-containing compound adopts silver salt── Silver nitrate, the protective agent adopts polyvinylpyrrolidone (Polyvinylpyrrolidone, PVP), and the light source containing ultraviolet rays adopts a high-pressure mercury lamp, and the specific preparation steps are as follows:

[0050]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com