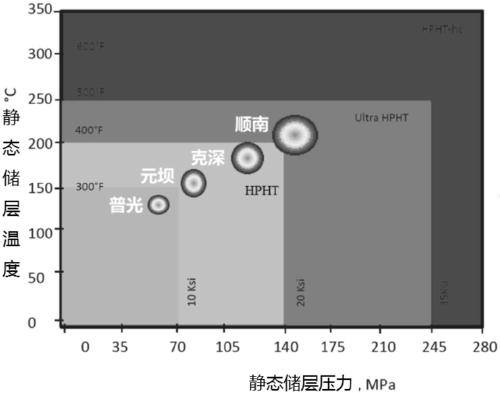

Nano-material mixed modified superhigh-temperature high-performance well cementing slurry system and preparation method thereof

A technology of cementing slurry and nanomaterials, which is applied in the field of oil and gas well cementing, can solve the problems of being unable to meet the needs of ultra-high temperature cementing, unfavorable development of cement stone strength, and limited high-temperature resistance, so as to reduce porosity and promote water retention. The effect of speed of conversion and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

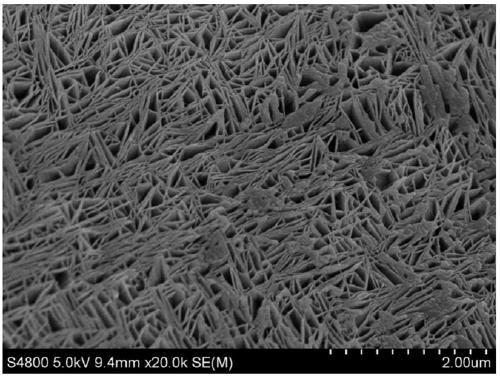

Method used

Image

Examples

preparation example Construction

[0057] The preparation process of coarse silica sand and fine silica sand is as follows: (1) Pulverization: Preliminarily pulverize vein quartz block into 50-80 mesh quartz particles with a compound crusher; (2) Acid leaching: use 37wt% concentrated hydrochloric acid, 10wt% hydrofluoric acid The volume ratio of acid and water is 10:1:10 to prepare an acid solution, acid leaching at room temperature for 12 hours, and stirring at a speed of 100r / min; (3) Washing and filtering: remove impurities mixed with coarse ore particles by washing with water (4) Grinding: using a ball mill, the ratio of material to ball is 1:2, the ratio of adding water is 50%, and the ball milling time is 30 minutes for grinding, and then the silica sand with different particle sizes is screened out.

[0058] Defoamer: purchased from Chengdu Oumericke Petroleum Technology Co., Ltd., DF-A grade.

[0059] High temperature fluid loss reducer: purchased from Chengdu Oumericke Petroleum Technology Co., Ltd., H...

Embodiment 1

[0067] Example 1: Taking G-grade oil well cement as an example, design the formula of ultra-high-temperature high-performance cementing slurry system modified by nanomaterials

[0068]A method for designing ultra-high-temperature high-performance cementing slurry system modified by mixing nanomaterials, comprising the following steps:

[0069] (1) According to the Hudson model, determine the particle size of the silica sand used to minimize the porosity of the cement slurry system; determine the mass ratio of silica sand with different particle sizes in the cement slurry system according to the Andreason equation.

[0070] (2) Determine the composition and content of the main minerals according to the type of oil well cement used, and calculate the calcium-silicon ratio of the cement used; according to the type of hydration products generated by the cement hydration reaction at different temperatures, determine the amount of silica sand to be added. Adjust the calcium-silicon ...

Embodiment 2

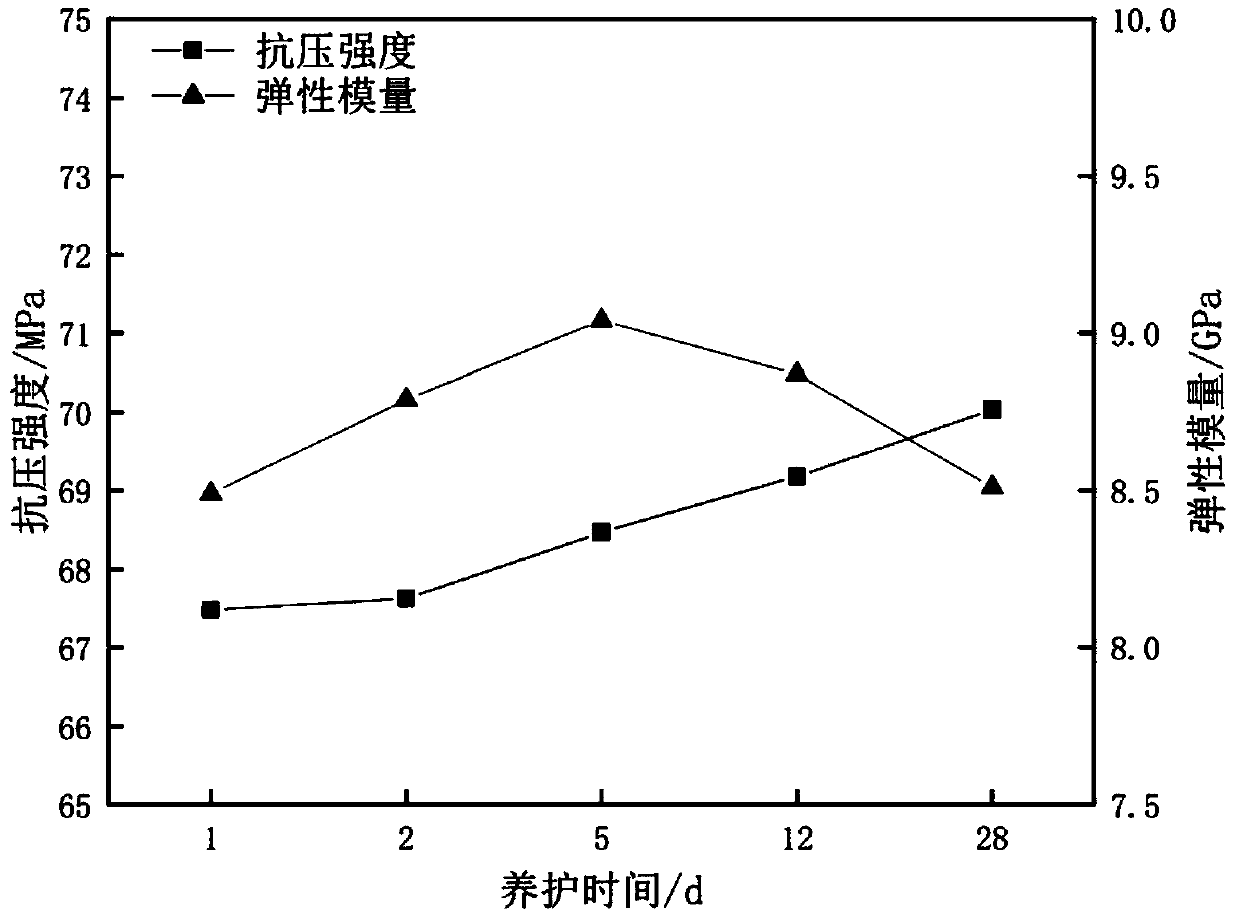

[0100] A nano-material mixed modified ultra-high temperature high-performance cement slurry system, including the following components by mass:

[0101] Oil well G-grade cement 100 parts, coarse silica sand 20 parts, fine silica sand 20 parts, chemical vapor deposition method nano-silica powder 6 parts, carbonization method nano-calcium carbonate powder 3 parts, defoamer 0.2 parts, drag reducer 2.5 parts, 10 parts of fluid loss reducer, 2 parts of retarder, 53.2 parts of water;

[0102] The preparation method comprises the following steps:

[0103] Mix oil well G-grade cement, coarse silica sand, fine silica sand, nano-silicon dioxide and nano-calcium carbonate evenly, then add water, defoamer, drag reducer, fluid loss reducer and retarder and stir evenly to obtain nano-material mixture Modified ultra-high temperature and high performance cementing cement slurry system.

[0104] The development curve of the compressive strength of the ultra-high-temperature high-performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com